Rough Country 282 User Manual

92128100

07-UP TAHOE/YUKON/SUB 5” KIT

Thank you for choosing Rough Country for your suspension needs. We appreciate your business!!

This kit will not fit vehicles equipped with electric steering or trucks with factory auto leveling or auto ride systems.

Important note: Please refer to the instructions on the last page for trimming the tie rods. For alignment purposes,

it will be necessary to trim/shorten the tie rod end to allow the front end alignment to be set properly.

Rough Country recommends a certified technician install this system. In addition to these instructions, professional knowledge of disassemble/reassembly procedures as well as post installation checks must be known. Attempts to install this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read instructions before beginning installation. Check the kit hardware. Be sure you have all needed parts and know

where they go.

As a general rule, the taller a vehicle is, the easier it will roll. Seat belts and shoulder harnesses should be worn at all times.

Avoid situations where a side rollover may occur. Generally, braking performance and capability are decreased when larger/

heavier tires and wheels are used. Take this into consideration while driving. Do not add, alter, or fabricate any factory or

after-market parts to increase vehicle height over the intended height of the Rough Country product purchased. Mixing component brands is not recommended.

Rough Country makes no claims regarding lifting devices and excludes any and all implied claims. We will not be responsible for any product that is altered. We will be happy to answer any questions concerning the design, function, and correct

use of our products.

This kit is packaged as a leveling kit—raising the front 5” and the rear 4.5”.

Due to differences in manufacturing, dimension and inflated measurements, tire and wheel combinations should be test fit

prior to installation. For this application we recommend a 18” or larger wheel not to exceed 9” in width. When using a 18”

wheel backspacing should be maximum of 5.5” and a minimum 5.0” . With a 20” or larger wheel backspacing should be a

maximum of 6.0” and a min of 5.5”. Additionally a quality tire of radial design is recommended, not exceeding 33” tall and

12.5” wide. Please note that use of a 33” x 12.5” tire may require modification to the front valance.

Optional kicker Bars Part #1262 are available for this kit. Please contact you local Rough Country Dealer for information.

Any vehicle equipped with any Rough Country product should have a “Warning to Driver” decal installed on the inside of the

windshield or on the vehicle’s dash. The decal should act as a constant reminder for whoever is operating the vehicle of its

unique handling characteristics.

INSTALLING DEALER - it is your responsibility to install the

warning decal and forward these installation instructions on to

the vehicle owner for review. These instructions should be kept

in the vehicle for its service life.

We hope installing your Rough Country lift kit is a positive

experience. Please note that variations in construction and

assembly in the vehicle manufacturing process will virtually

ensure that some parts may seem difficult to install. Additionally, the current trend in manufacturing of vehicles results in a frame that is highly flexible and may shift slightly

on disassembly prior to installation. The use of pry bars and

tapered punches for alignment is considered normal and

usually does not indicate a faulty product. However, if you

are uncertain about some aspect of the installation process,

please feel free to call our tech support department at 800222-7023. We do not recommend that you modify the Rough

Country parts in any way as this will void any warranty expressed or implied.

PRODUCT USE INFORMATION

NOTICE TO DEALER AND VEHICLE OWNER

KIT COMPONENTS

This kit is packaged in 4 boxes. Please confirm that you have all the needed parts and know where they go prior to beginning installation.

1264Box1

Front Cross Member

Rear Cross Member

1264Box3

Driver Knuckle

Pass Knuckle

1208Box1

Front Strut Spacers

Driver Diff Bracket

Pass Diff Bracket

Skid Plate

Sway Bar Drop Bracket

CV Spacers

Front Brake Line Brackets

3/8 Stud Bag

1264Bag1

1264Bag2

1209Box2

Rear Coil Spring

Bump Stops

Driver Rear Shock Bracket

Pass Rear Shock Bracket

Sway Bar Links

Track Bar Bracket

Brake Line Bracket

1280Bag1

Front Cross Member

5/8” X 4 1/2” Bolt (2)

5/8” Nuts (2)

5/8” Flat Washers (4)

Rear Cross Member

5/8” x 5 1/2”Bolt (2)

5/8” Lock Nuts (2)

5/8” Flat Washers (4)

Front CV Axle Spacers

10mm x 65mm SHCS Bolt (12)

Driver Side Diff. Drop Bracket

12mm x 35mm Bolt (2)

12mm Flange Nut (2)

12mm Washer (2)

Pas Side Differential Brkt

12mm x 45mm Bolt (2)

12mm Flange Nut (2)

12mm Washer (2)

Lower Strut to Ctrl Arm Mt

10mm x 55mm Bolt (4)

10mm Lock Nuts (4)

10mm Washers (8)

Sway Bar Bracket

10mm x 35mm Bolt (4)

10mm Lock Nuts (4)

10mm Lock Washer (4)

10mm Washers (8)

Frt & Rr Brake Line Brackets

5/16” x 3/4” Bolt (4)

5/16” Nylon Lock Nut (4)

5/16” Washer (8)

Skid Plate Installation

3/8” x 1” Bolt (4)

3/8” Lock Washer (4)

3/8” Flat Washer (4)

Rear Spring Spacer

3/8” x 3 3/4” Bolt (2)

3/8” Flangelock

Spring Spacer Washers

Rear Shock Brackets

5/8” x 1.5” Bolt (2)

5/8” Lock Nut (2)

5/8” Washers(4)

14mm x 75mm Bolts (2)

14mm Nylocks (2)

14mm Washers (4)

Rear Sway Bar Links

12mm x 65mm Bolts (2)

12mm Flangelocks (2)

12mm Washers (2)

Sleeves (4)

Brake Line Bracket

5/16” x 1 1/4” Bolt

5/16” Flange Lock Nut

Track Bar Bracket

Sleeve .562 x .750 x 1.75

9/16” x 3 1/2” Bolt

9/16” Lock Nut

9/16” Washer (2)

7/16” x 1” Bolt (2)

7/16” Nylock (2)

7/16” Washers (4)

Rear Bump Stops

3/8” x 1” Self Tapping Bolt (4)

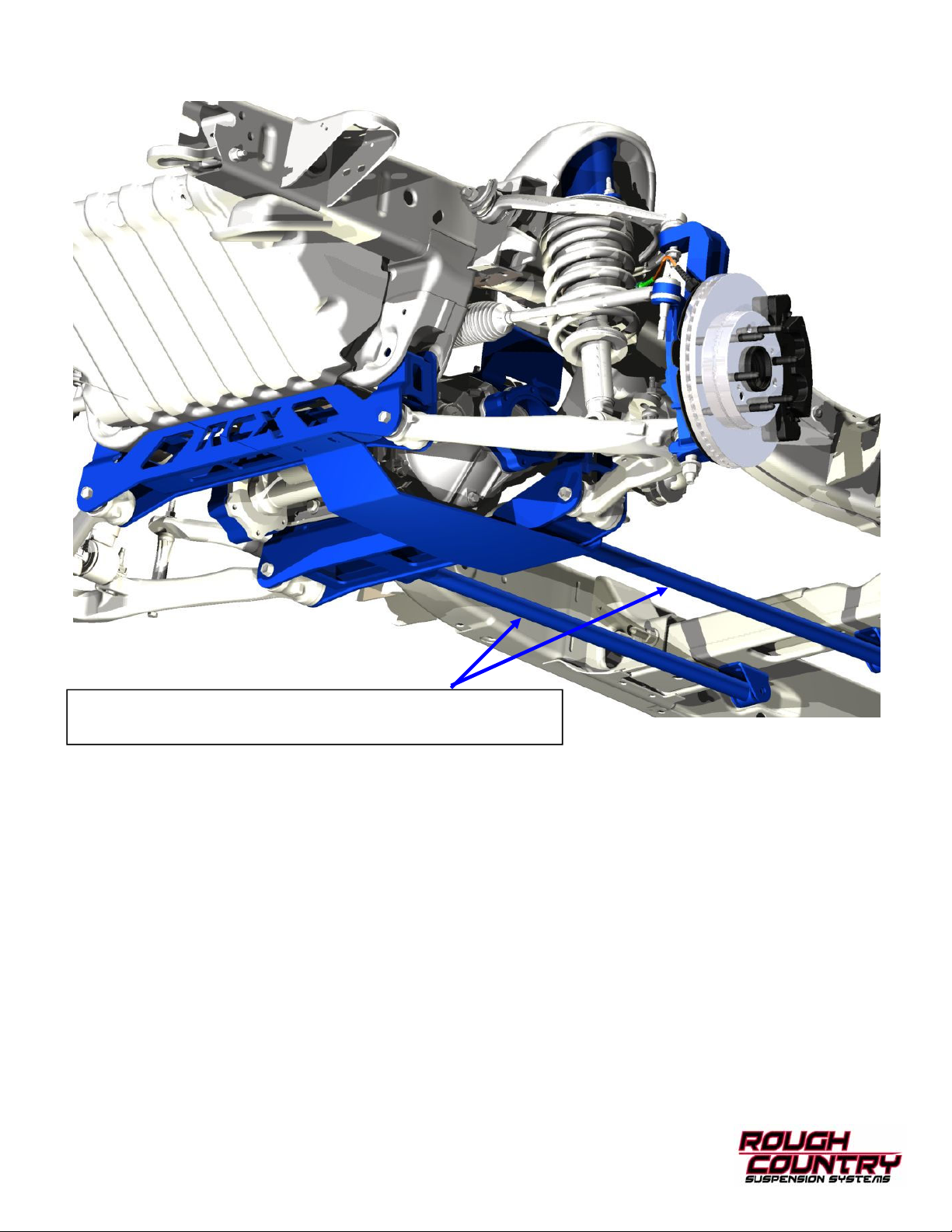

CAD DRAWING SHOWING KIT COMPONENTS AND INSTALLED LOCATIONS

DIAGRAM SHOWN WITH OPTIONAL KICKER BARS PART #1262

INSTALLED

Torque Specs:

Size Grade 5 Grade 8

5/16” 15 ft/lbs 20 ft/lbs

3/8” 30 ft/lbs 35 ft/lbs

7/16” 45 ft/lbs 60 ft/lbs

1/2” 65 ft/lbs 90 ft/lbs

9/16” 95 ft/lbs 130 ft/lbs

5/8” 135 ft/lbs 175 ft/lbs

3/4” 185 ft/lbs 280 ft/lbs

Class 8.8 Class 10.9

6MM 5 ft/lbs 9 ft/lbs

8MM 18ft/lbs 23 ft/lbs

10MM 32ft/lbs 45ft/lbs

12MM 55ft/lbs 75ft/lbs

14MM 85ft/lbs 120ft/lbs

16MM 130ft/lbs 165ft/lbs

18MM 170ft/lbs 240ft/lbs

Tools Needed:

Floor Jack /Jack Stands

8mm Allen Socket

10mm socket /wrench

11mm socket /wrench

13 mm socket/wrench

15mm socket / wrench

17mm socket/wrench

18mm socket /wrench

21mm socket /wrench

22mm socket /wrench

24mm socket /wrench

19mm socket /wrench

35mm socket

9/16 socket /wrench

Torsion bar Tool

Reciprocating Saw

Drill

11/16” Drill Bit

Hand Grinder

Thread Locker

FRONT INSTALLATION

1. Park the vehicle on a level surface and chock the rear wheels.

2. Jack up the front of the vehicle. Place jack stands under the frame rails and lower onto jack stands letting the front suspension hang.

3. Remove the tires and wheels. Remove the upper and lower factory skid plates using a 15mm wrench. Retain factory

hardware and front skid plate for reuse.

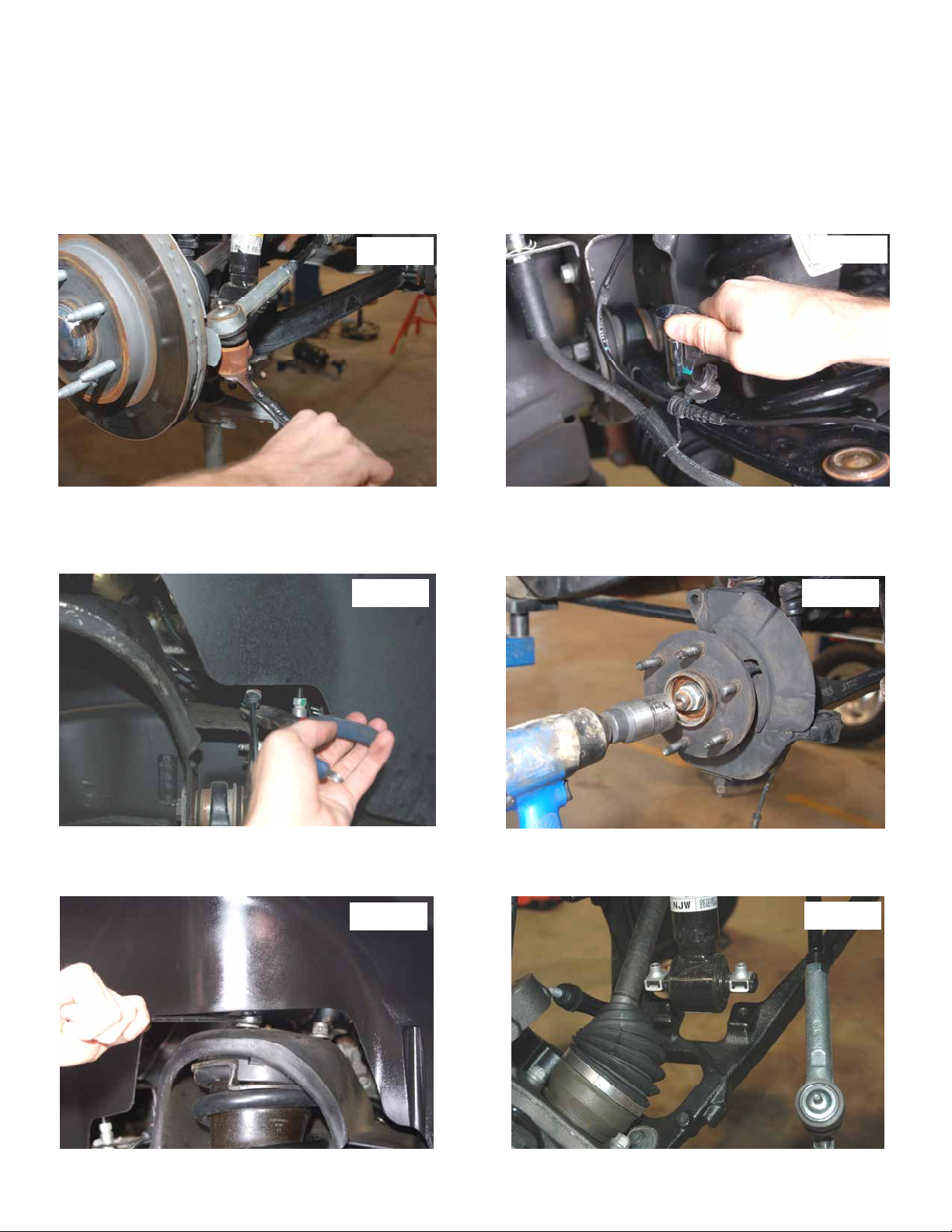

4. Using a 21mm wrench, remove the tie-rod nut as shown in Photo 1. Strike the side of the mount to dislodge the tie rod

end. Remove from the knuckle.

5. Remove the sensor wire from the plastic clip. Remove the bracket from the control arm using a 10mm wrench. See

Photo 2.

Photo 1

6. Remove and unplug the ABS sensor wire from the frame as shown in Photo 3 and remove the two bolts holding brake

caliper to the factory knuckle using a 18mm wrench. Remove the caliper assembly from the knuckle and hang securely

out of the way. Do not hang the caliper by the brake hose.

7. Remove the axle nut from the knuckle as shown in Photo 4 using a 35mm socket. Retain the hardware for reuse.

Photo 3

Photo 2

Photo 4

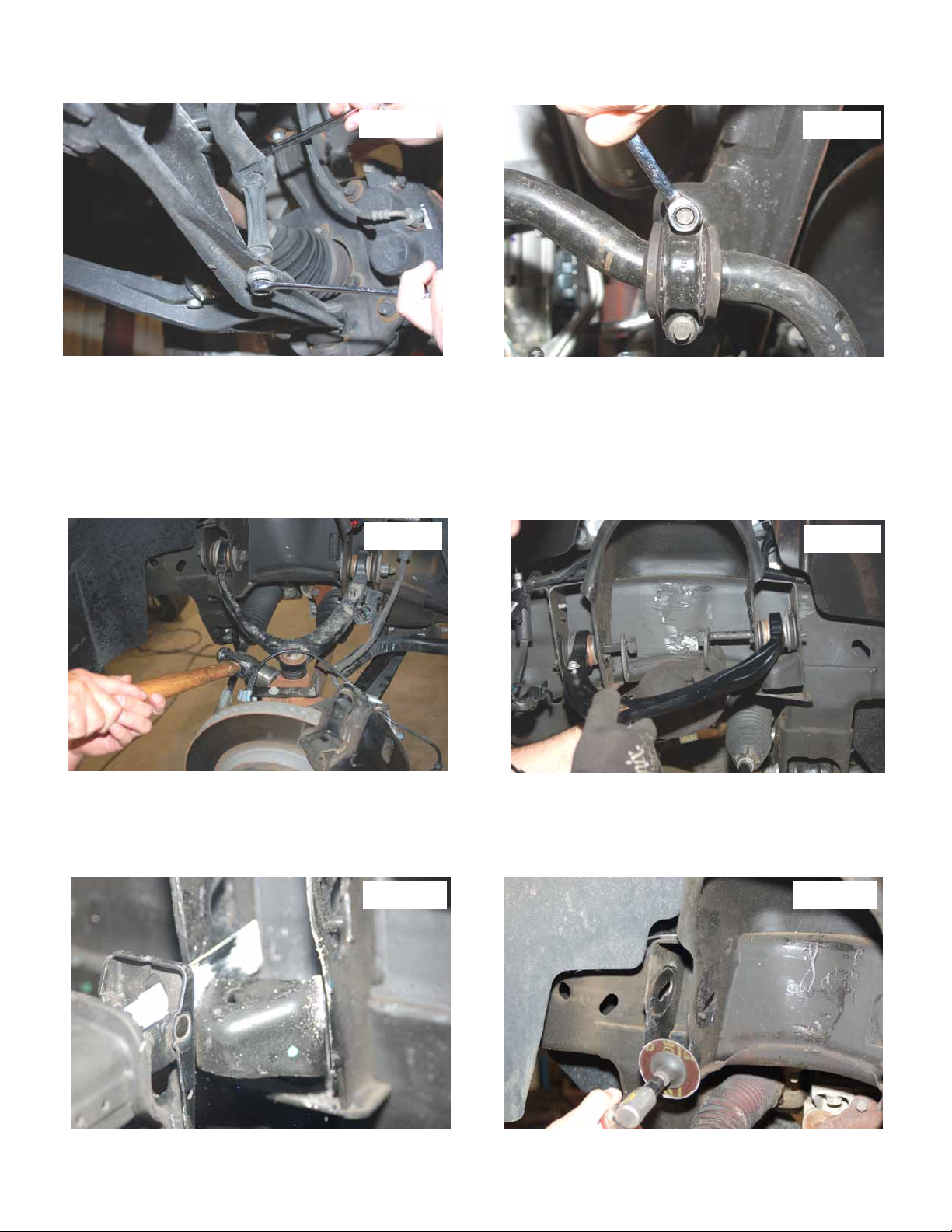

8. Using a 18mm wrench, remove the upper strut nuts as shown in Photo 5. Retain factory hardware for reuse.

9. Using a 15mm wrench, remove the 2 bolts securing the lower strut as shown in Photo 6, to the lower control arm and

remove the strut from the vehicle. Remove and discard the factory lower retainer clips. New hardware will be used.

Photo 5

Photo 6

10. Remove the sway bar & end links from the lower control arm as shown in Photo 7 using a 15mm wrench.

11. Remove the sway bar from the frame as shown in Photo 8 using a 10mm wrench. Retain all hardware for reuse.

Photo 7

12. Using a 15mm wrench, remove the 6 axle shaft bolts from the differential and remove from the knuckle. Repeat on op-

posite side.

13. Remove the upper and lower ball joint from knuckle using a 18mm wrench and 24mm on the lower. Upper shown in

Photo 9. Strike the knuckle as shown to dislodge the ball joint. Separate the upper control and lower control arm from

the knuckle and remove the knuckle and the lower control arms from the vehicle.

14. Mark location of alignment cams on upper control arms to allow reinstallation of stock arm to the same position. Using

a 21mm wrench and 21mm socket, remove the upper control arms from the vehicle. See Photo 10. Retain the hardware for reuse.

Photo 9

Photo 8

Photo 10

15. Cut the bump stop from the upper control arm mount on the passenger and driver side as shown in Photo 11 using a

reciprocating saw. Passenger side shown.

16. After the bump stop has been cut from the control arm mount, grind and apply paint to the cut surface to prevent rust-

ing. See Photo 12. Reinstall the factory control arm in the factory location using the factory hardware. Tighten using a

21mm Socket / wrench. Be sure to use the marks made earlier for alignment reference.

Photo 11 Photo 12

Loading...

Loading...