Rough Country 256.20 User Manual

92114500 REV

73-87 CHEVY P/U, 73-91 BLAZER, SUBURBAN, 1 ton 4”-6” SUSPENSION KITS

Rough Country recommends this system be installed by a certified technician. In addition to these instructions,

professional knowledge of disassemble/reassembly procedures as well as post installation checks must be known.

Attempts to install this system without this knowledge and expertise may jeopardize the integrity and/or operating

safety of the vehicle.

Please read instructions before beginning installation. Be sure you have all needed parts and know where they go.

With the installation of all lift kits and larger tires it is important to check the condition of your steering stabilizer. If

the stabilizer is worn or leaking it should be replaced. Steering stabilizers are designed to restrain “bump steering”

and front end vibration, giving added life to tires, ball joints, and other steering components. A dual stabilizer kit is

recommended for vehicles equipped with a snow plow, winch, or larger tires

PRODUCT USE INFORMATION

As a general rule, the taller a vehicle is, the easier it will roll. Offset, as much as possible, what is lost in rollover

resistance by increasing tire track width. In other words, go "wide" as you go "tall". Many sportsmen remove their

mud tires after hunting season and install ones more appropriate for street driving; always use as wide a tire and

wheel combination as possible to enhance vehicle stability.

We strongly recommend, because of rollover possibility, that the vehicle be equipped with a functional roll-bar and

cage system. Seat belts and shoulder harnesses should be worn at all times. Avoid situations where a side rollover

may occur

Generally, braking performance and capability are decreased when significantly larger/heavier tires and wheels are

used. Take this into consideration while driving.

Do not add, alter, or fabricate any factory or after-market parts to increase vehicle height over the intended height

of the Rough Country product purchased. Mixing component brands is not recommended.

Rough Country makes no claims regarding lifting devices and excludes any and all implied claims. We will not be

responsible for any product that is altered.

If question exist we will be happy to answer any questions concerning the design, function, and correct use of our

products.

NOTICE TO DEALER AND VEHICLE OWNER

Any vehicle equipped with any Rough Country product should have a “Warning to Driver” decal installed on the

inside of the windshield or on the vehicle’s dash. The decal should act as a constant reminder for whoever is

operating the vehicle of its unique handling characteristics.

INSTALLING DEALER - it is your responsibility to install the warning decal and forward these installation

instructions on to the vehicle owner for review. These instructions should be kept in the vehicle for its service.

INSTALLATION INSTRUCTIONS

1. Put the vehicle on a level surface and chock the rear wheels.

2. Jack up the vehicle and place jack stands on the frame rail to support the vehicle.

3. Remove the shock absorbers from the front axle and discard. New Heckethorn shocks will be installed in a

later step.

4. Support the axle with a floor jack. On ½ & 3/4T, remove the u-bolts. On 1 ton, remove the u-bolts and studs

from the axle.

5. Lower axle down, away from the spring, using the floor jack. Note: use caution when lowering the axle not

to overextend the brake lines.

6. After the spring is free from the axle, remove the spring eye bolts and remove the spring.

7. Install the new Rough Country springs in the spring mounts using the stock hardware. Torque to 100-120ft/lbs.

8. Jack axle up to meet the new Rough Country spring. On the ½ & ¾ t, install the new u-bolts and torque to 8090ft/lbs. On 1 Ton models, install the u-bolts and studs. Note: Make sure the axle seats properly on the

springs and the center pin is in the axle housing.

Page 1

INSTRUCTION SHEET

9. Install new shock absorbers. 4” lift kits use 650329. 6” lift kits use 650341. Front upper uses spacer bushings /

sleever. The ½”sleeve will be installed on the bottom eye ring.

10. Install the wheels and tires on the front end.

11. Proceed to the rear installation instructions

REAR BLOCK INSTALLATION

1. Jack up the rear of the vehicle and remove the wheels and tires. Place the vehicle on jack stands. Position the

jack stands directly in front of the spring hanger on the frame.

2. Place a floor jack under the center of the axle and remove the stock u-bolts. Also remove the stock shock

absorbers. Lower the axle away from the leaf springs to allow for installation of lift blocks.

3. Install the blocks with the flat part of the block on the leaf springs and the narrow part of the block toward the

center of the vehicle Do not forget to install the block pin in the block for proper positioning

4. Install the new u-bolts and tighten to 80-100 ft/lbs.

5. Install the new shock absorbers Part# 650341. The 9/16” sleeve will be installed on the bottom of the shock

with the bushing and the pin will be installed on the top of the shock.

REAR LIFT SPRING INSTALLATION

1. Jack up the rear of the vehicle and remove the wheels and tires. Place the vehicle on jack stands. Position the

jack stands directly in front of the spring hanger on the frame.

2. Place a floor jack under the center of the axle and remove the stock u-bolts. Also remove the stock shock

absorbers. Lower the axle away from the leaf springs. Remove the stock leaf springs.

3. Install the new springs in the same manner as the stock springs were removed. Tighten the spring bolts and

jack up the axle to meet the leaf spring, paying close attention to the spring pin. Spring shim should be

positioned with the narrow part toward the center.

4. Install the u-bolts and torque to 80-100 ft/lbs.

5. Install the new shock absorbers. Part # 650341. The 9/16” sleeve will be installed on the bottom of the shock

with the bushing and the pin will be installed on the top of the shock.

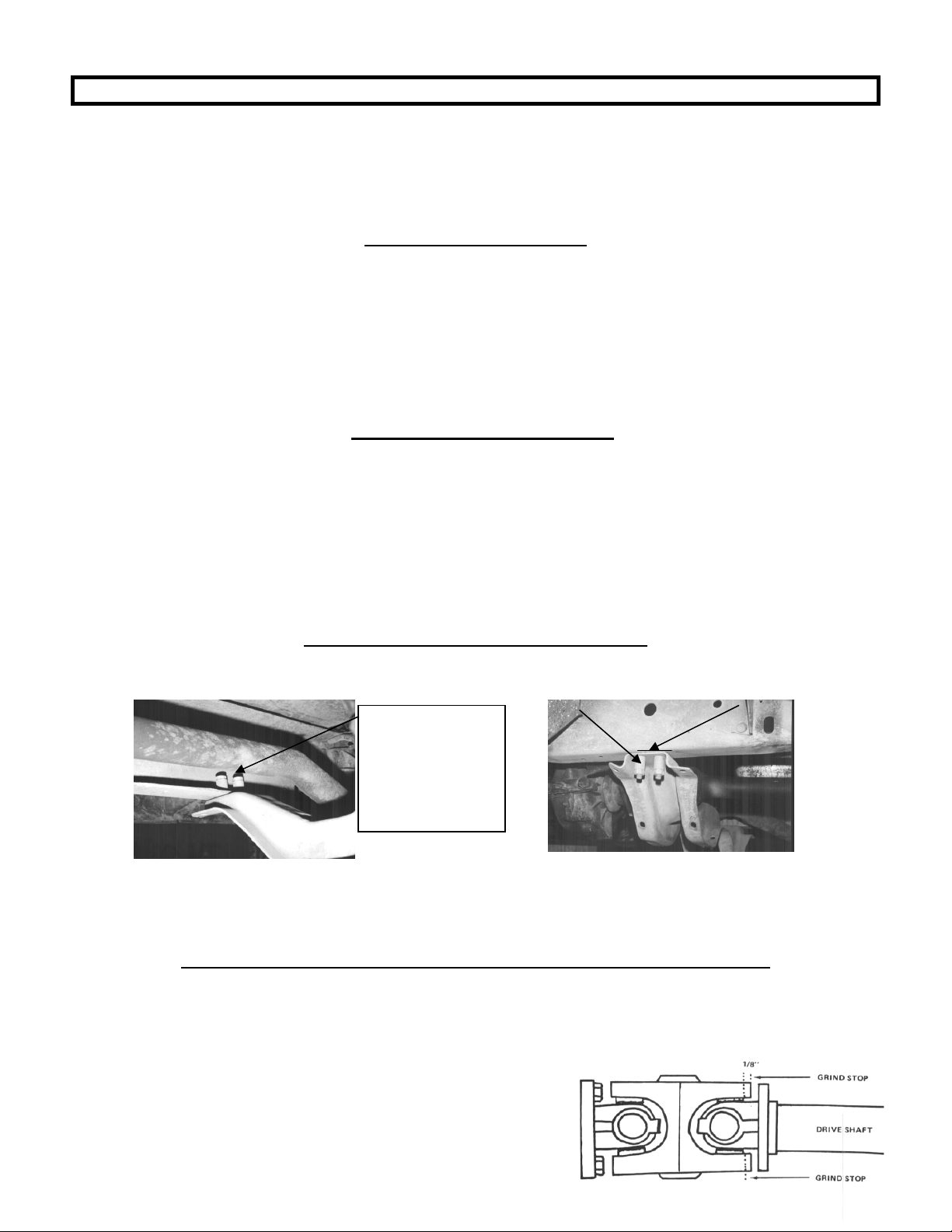

TRANSFER CASE LOWERING INSTRUCTIONS

For ½ & ¾T 1980 and later model years on 4” and 6” lifts, the transfer case is lowered by using stock

mounting hardware on the transfer case cross-member.

The sleeves may

be either on top

of the frame rail

or on the bottom

from the factory

as shown here.

1. Place floor jack under transfer case cross-member, raise jack until it applies pressure to the cross-member.

Remove stock mounting hardware.

2. Lower floor jack until there is enough space between the cross-member and the frame to install stock spacer

and mounting hardware per the picture. Tighten all hardware.

FRONT CONSTANT VELOCITY U-JOINT STOPS MODIFICATION INSTRUCTIONS

The stops on the front cv u-joint and the stops on the front drive shaft must be modified to obtain maximum

suspension travel on all 4” and 6” lift systems (see diagram below). These stops are designed to prevent the

drive shaft from contacting the road surface in the event of a u-joint failure at the front-end housing.

1. Remove the front drive shaft assembly from the vehicle.

Use a grinder or other suitable tool and remove the

amount of material needed to gain ample u-joint clearance

at the drive shaft stop. (Remove as little material as

possible). About 1/8” of material.

2. With the grinding completed, reinstall the drive shaft and

check the stop clearance by turning the drive shaft

Technical Assistance - (731) 285-9000 Page 2

Place sleeves here, between the frame and cross-member.

Loading...

Loading...