Rough Country 244.20 User Manual

92124400

6” S-10 Pickup Ext. Cab Only NTD Kit

Thank you for choosing Rough Country for all your suspension needs.

Rough Country recommends a certified technician install this system. In addition to these instructions, professional

knowledge of disassemble/reassembly procedures as well as post installation checks must be known. Attempts to install

this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read instructions before beginning installation. Check the kit hardware against the product layout and kit contents

information on these instructions. Be sure you have all needed parts and know where they go. Also please review tools

needed list and make sure you have needed tools.

As a general rule, the taller a vehicle is, the easier it will roll. Seat belts and shoulder harnesses should be worn at all

times. Avoid situations where a side rollover may occur. Generally, braking performance and capability are decreased

when larger/heavier tires and wheels are used. Take this into consideration while driving. Do not add, alter, or fabricate

any factory or after-market parts to increase vehicle height over the intended height of the Rough Country product purchased. Mixing component brands is not recommended.

Rough Country makes no claims regarding lifting devices and excludes any and all implied claims. We will not be responsible for any product that is altered. If question exist we will be happy to answer any questions concerning the design, function, and correct use of our products.

**Note this kit will only fit a S-10 pickup ext. cab.**

This suspension system was developed using a 265/75-16, tire with 16” x 8” wide wheel with a 4.5” to 5” backspacing with minor trimming. If wider tires are used, offset wheels and trimming will be required. This kit was

developed to obtain a front ride height of 25” on newer body style and 26” older body style as measured from

the center of the front wheel to the bottom of the fender well.

NOTICE TO DEALER AND VEHICLE OWNER

Any vehicle equipped with any Rough Country product should have a “Warning to Driver” decal installed on the inside of

the windshield or on the vehicle’s dash. The decal should act as a constant reminder for whoever is operating the vehicle of its unique handling characteristics.

INSTALLING DEALER - it is your responsibility to install the warning decal and forward these installation instructions on

to the vehicle owner for review.

PRODUCT USE INFORMATION

Tools Needed

7mm Socket

8mm Socket/Wrench

10mm Socket/Wrench

11mm Socket

13mm Socket/Wrench

14mm Socket/Wrench

15mm Socket/Wrench

16mm Socket/Wrench

17mm Socket/Wrench

18mm Socket/Wrench

19mm Socket/Wrench

21mm Socket/Wrench

22mm Socket/Wrench

24mm Socket

35mm Socket

9/16” Line Wrench

5/8” Wrench

3/4” Wrench

Sawzall

Needle Nose Plyers

Flat Head Screwdriver

Jack

Jack Stands

Hammer

11/32” Drill Bit

7/16” Drill Bit

Torque Specs:

Size Grade 5 Grade 8

5/16” 15 ft/lbs 20 ft/lbs

3/8” 30 ft/lbs 35 ft/lbs

7/16” 45 ft/lbs 60 ft/lbs

1/2” 65 ft/lbs 90 ft/lbs

9/16” 95 ft/lbs 130 ft/lbs

Class 8.8 Class 10.9

6MM 5 ft/lbs 9 ft/lbs

8MM 18ft/lbs 23 ft/lbs

10MM 32ft/lbs 45ft/lbs

12MM 55ft/lbs 75ft/lbs

14MM 85ft/lbs 120ft/lbs

Kit Picture

M

N

O

P

E

W

DD

AA

Y V

X

A

S

B

C

I

H

T

X

BB

AA Z

W

Y

V

EE FF

CC

O

N

P

M

D

K

R

G

L

F

U

L

G

Q

J

Kit Boxes

1243BOX1 1-Front Cross Member (A)

1-Rear Cross Member (B)

1-Lower Skid Plate (C)

1-1243BAG3

1243BOX2 1-Driver Side Upper Control Arm Drop (D)

1-Passenger Side Upper Control Arm Drop (E)

1-Upper Control Arm Brace (F)

2-Control Arm Brace Shims (G)

1-Diver Diff Drop (H)

1-Passenger Diff Drop (I)

1-Driver Front Shock Mount (J)

1-Passenger Front Shock Mount (K)

2-Sway Bar Drop Brackets (L)

2-Front Brake Line Brackets (M)

2-Upper Control Arm Flag Nuts (N)

4-Cam Block Off Plates (O)

2-Upper Control Arm Crush Sleeves (P)

2-Brake Line Ext. 84-97 Models (Q)

2-Brake Line Ext. 98-up Models (R)

1-1243BAG1

1-1243BAG4

1-1243BAG5

1-1243BAG6

1243BOX3 1-Steering Link (S)

1-1243BAG2

1-Stabilizer Bracket (T)

1-Stabilizer Cylinder

1-87334BAG1

1243BOX4 1-Front Skid Plate (U)

1243BOX5 2-Rear Axle Perches (V)

2-Lower U-bolt Plates (W)

2-Upper U-bolt Plates (X)

2-Rear Shock Brackets (Y)

1-Rear Brake Line Bracket (Z)

2-Rear Disk Brake Brackets (AA)

1243BAG8

1-Emergency Brake Bracket (BB)

1-9/16BAG

4-9/16” Square U-bolts

2-N2.0 Front Shocks

2-N2.0 Rear Shocks

1244BOX1 1-Driver NTD Bracket (CC)

1-Passenger NTD Bracket (DD)

2-NTD Flag Nuts

1-Driver Side Torsion Bar Relocation

Bracket (EE)

1-Passenger Torsion Bar Relocation

Bracket (FF)

1-1244BAG1

1-1244BAG2

1244BAG1 1-Instructio Sheet

1-Warning to Driver

5-N2.0 Stickers

1243BAG2 4-3/8” x 1” Bolt

4-3/8” Washers

4-3/8” Nylocks

2-1/2” x 2.5” Bolts

4-1/2” Washers

4-1/2” Top Locks

2-1/2” x 1.75” Bolts

2-1/2” Hiems Joint

2-1/2” Jam Nuts

1-Threaded Steering Link

1-1.38” Long Sleeve

1243BAG3 4-9/16” x 4” Bolts

8-9/16” x 8” Washers

4-9/16” Nylocks

1243BAG4 2-Diff Bushings

1-1/2” x 3/4” x 1.90” Sleeve

1-1/2” x 3.5” Bolt

2-1/2” Washers

1-1/2” Nylock

2-7/16” x 1.25” Bolts

4-7/16” Washers

2-7/16” Nylocks

1-5/16” x 7” Vent Hose

1-5/16” Vent Hose Coupler

2-5/16” x 1” Self Tapping Bolts

1243BAG5 4-7/16” x 4” Bolts

4-7/16” Washers

4-7/16” Nylocks

8-3/8” x 1.25” Bolts

16-3/8” Washers

8-3/8” Nylocks

6-5/16” x 1” Bolts

6-5/16” Washers

6-5/16” Flange Locks

1243BAG6 8-3/8” x 1.25” Bolts

12-3/8” Washers

2-3/8” x 1” Self Tapping Bolts

4-3/8” Nylocks

2-5/16” x 1” Bolts

2-5/16” Washers

2-5/16” Flange Locks

Kit Bags

1243BAG8 4-3/8” x 1.25” Bolts

4-3/8” Washers

4-3/8” Nylocks

2-5/16” x 1” Self Tapping

2-1/2” x 2.5” Bolts

2-1/2” Washers

2-1/2” Nylocks

2-5/16” x 1” Bolts

2-5/16” Washers

2-5/16” Flange Locks

9/16BAG 8-9/16” Nylocks

8-9/16” Washers

87334BAG1 2-Stem Bushings

2-Cup Washers

1-3/8” Nut

1244BAG2 4-7/16” x 1.25” Bolts

10-7/16” Washers

4-7/16” Nylocks

2-9/16” Nylocks

1. Jack the front of the truck up and place jack stands under the frame rail. Lower truck on stand and remove front tires.

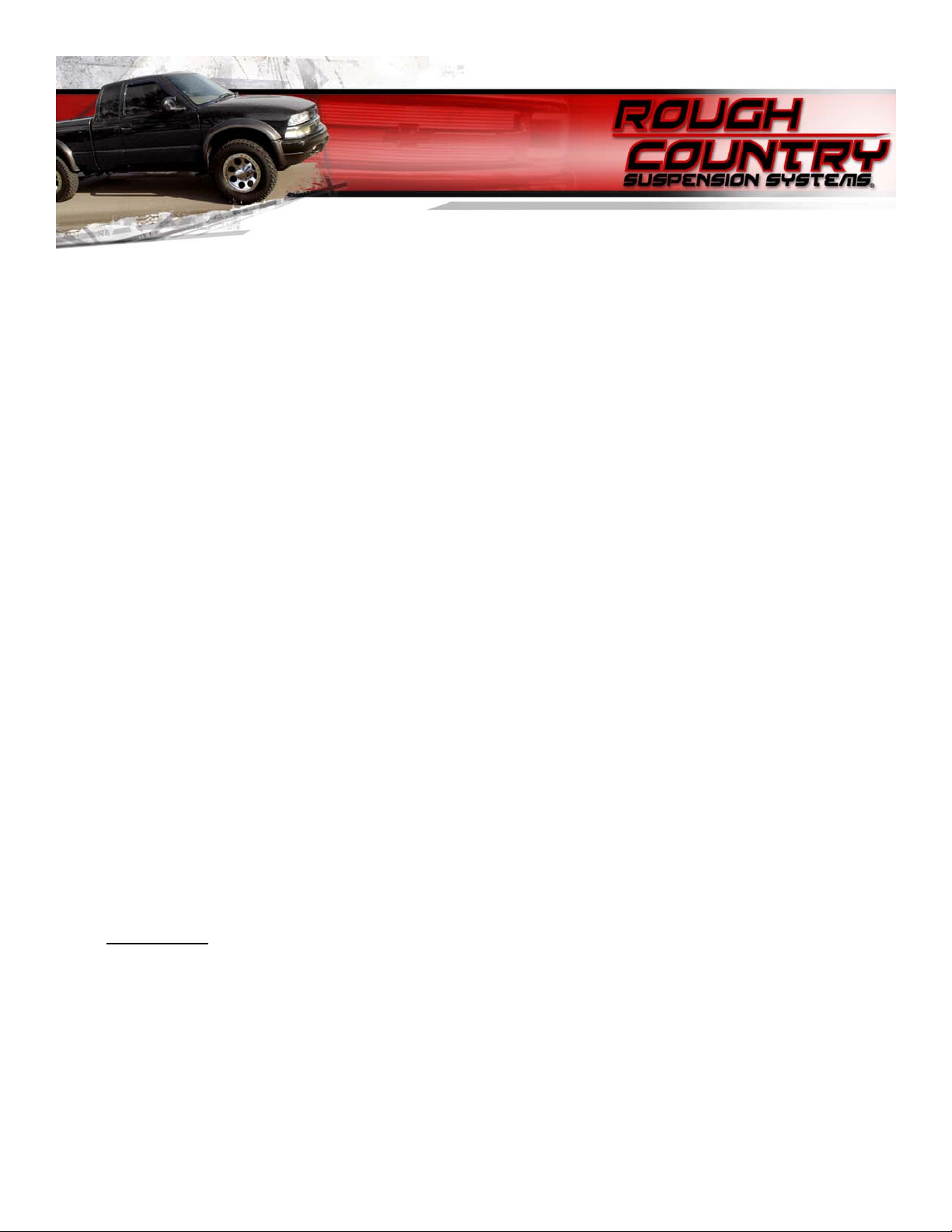

2. Using a 8mm or 5/16 wrench remove battery cables. Using a 13mm remove bolt from battery holder. Remove battery. Remove the two bolt from battery tray using a 13mm socket. Note on some earlier models you may have to

remove the grill to gain access to one of the bolts just under headlight. See Photo 1 & 2.

Photo 1

3. Find the two bolts holding the 4x4 actuator that are on the inner fender well. Using a 13mm socket remove the bolts.

Then turn the metal clip to release cable from actuator and use a pair of needle nose to release the plastic clip to

remove cable from bracket. Remove actuator. See Photo 3 & 4.

Photo 3

Photo 2

Photo 4

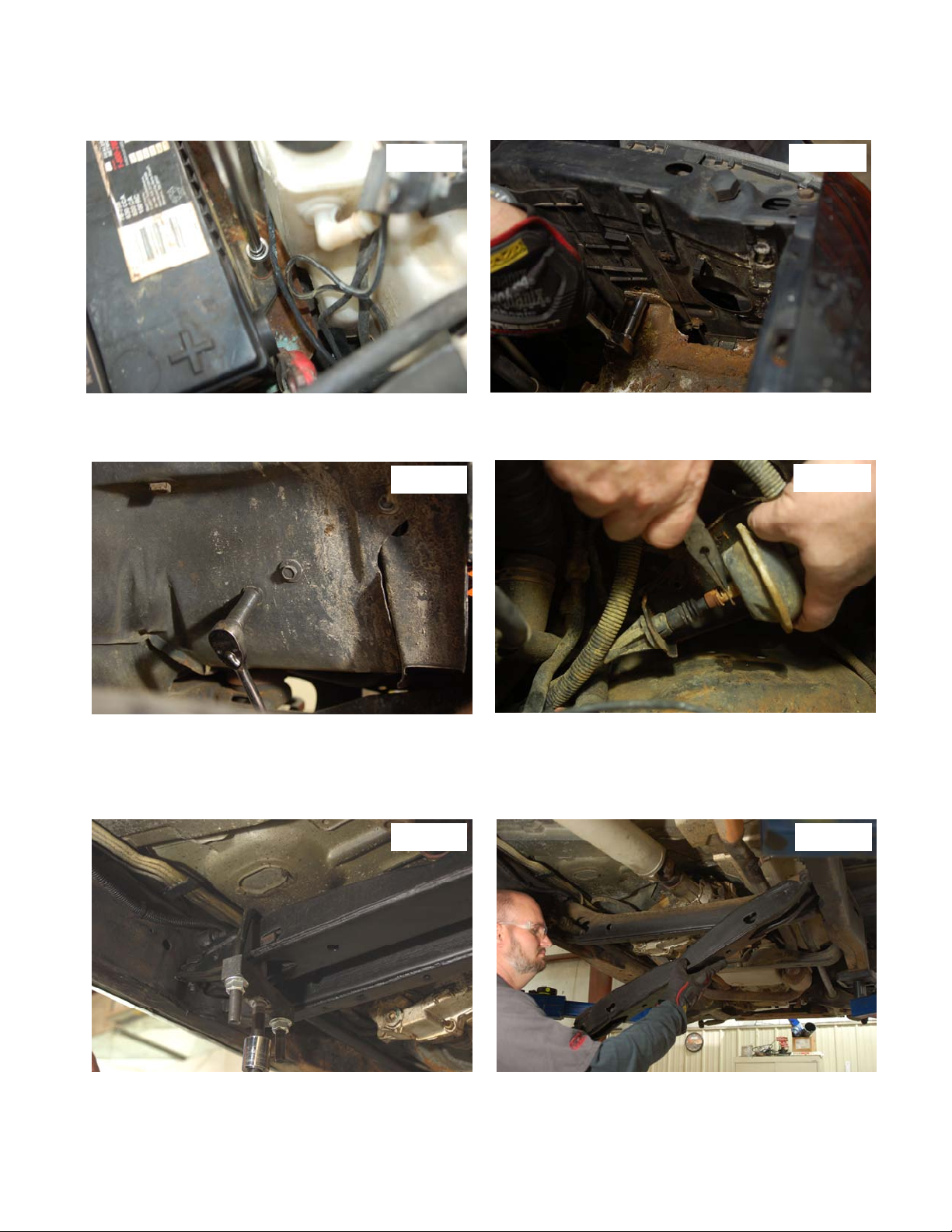

4. Using a 15mm and a 13mm socket remove all 3 skid plates from truck

5. With the truck on jack stands measure the torsion bar adjusting bolts and write it down for later. Unload torsions bar

using a 18mm socket and a torsion bar tool. See Photo 5. After torsion bars are unloaded remove the torsion bar

cross-member using a 18mm socket one side at a time while removing the torsion key. Remove torsion bars. Remove the torsion bar hangers using a 15mm wrench and socket. See Photo 6.

Photo 5 Photo 6

6. Remove the sway-bar using a 13mm socket a pair vise grips on the lower control arm. A 10mm socket and 15mm

wrench on the frame. See Photo 7 & 8.

Photo 7

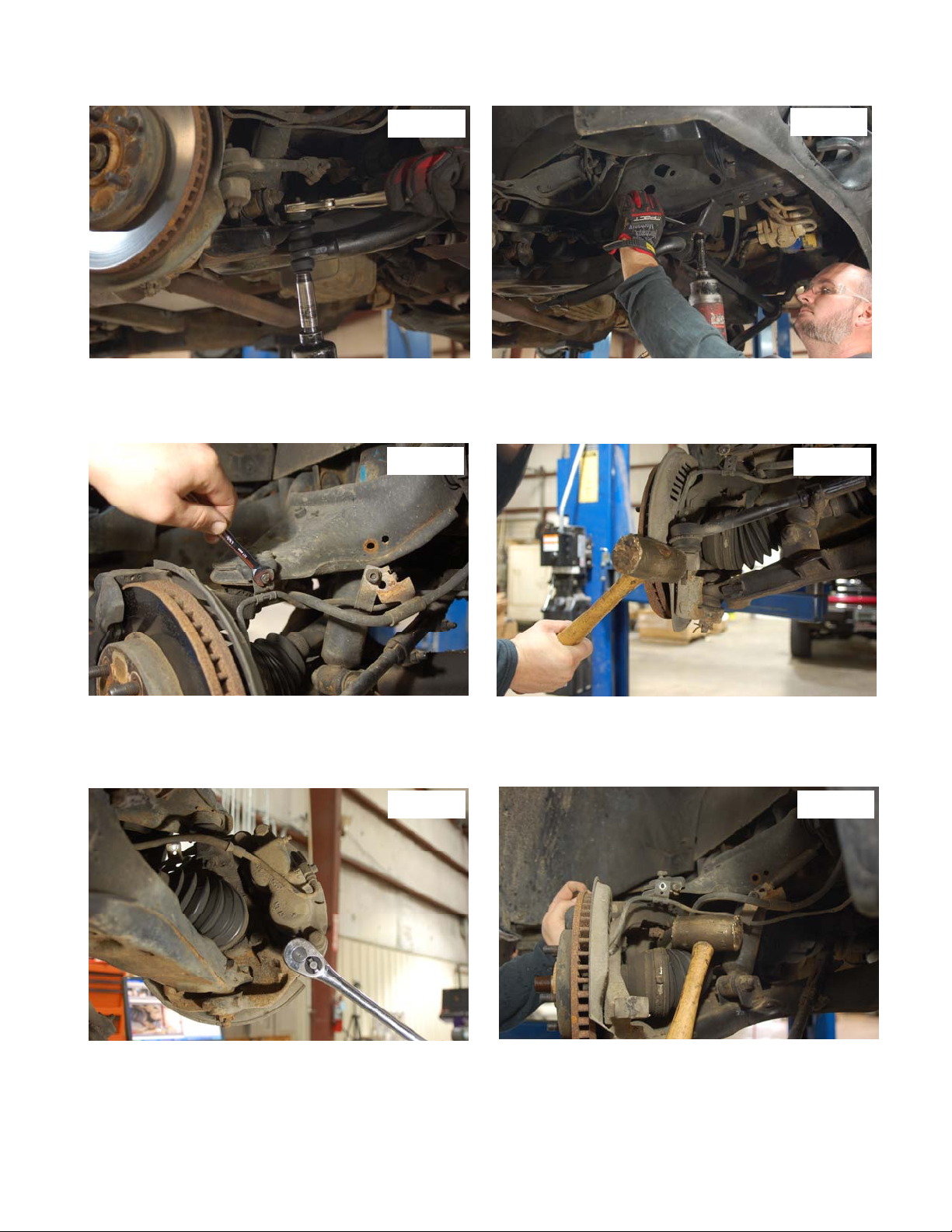

7. Remove the abs and brake line from upper control arm using two 13mm wrenches

8. Using a 10mm wrench remove the abs line from the ball joint mount. See Photo 9.

9. Remove tie rod using a 19mm wrench and use a hammer to strike the side of the knuckle to dislodge the taper on

the tie rod. See Photo 10.

Photo 9

Photo 8

Photo 10

10. Remove brake caliper bolts using a 18mm socket. See Photo 11.

11. Remove the brake line bracket using a 13mm wrench on the frame

12. Remove the cotter pin and then the nut on the upper ball joint using a 22mm wrench. Use a hammer to strike the

side of the knuckle to dislodge the taper on the upper ball joint. See Photo 12.

Photo 11 Photo 12

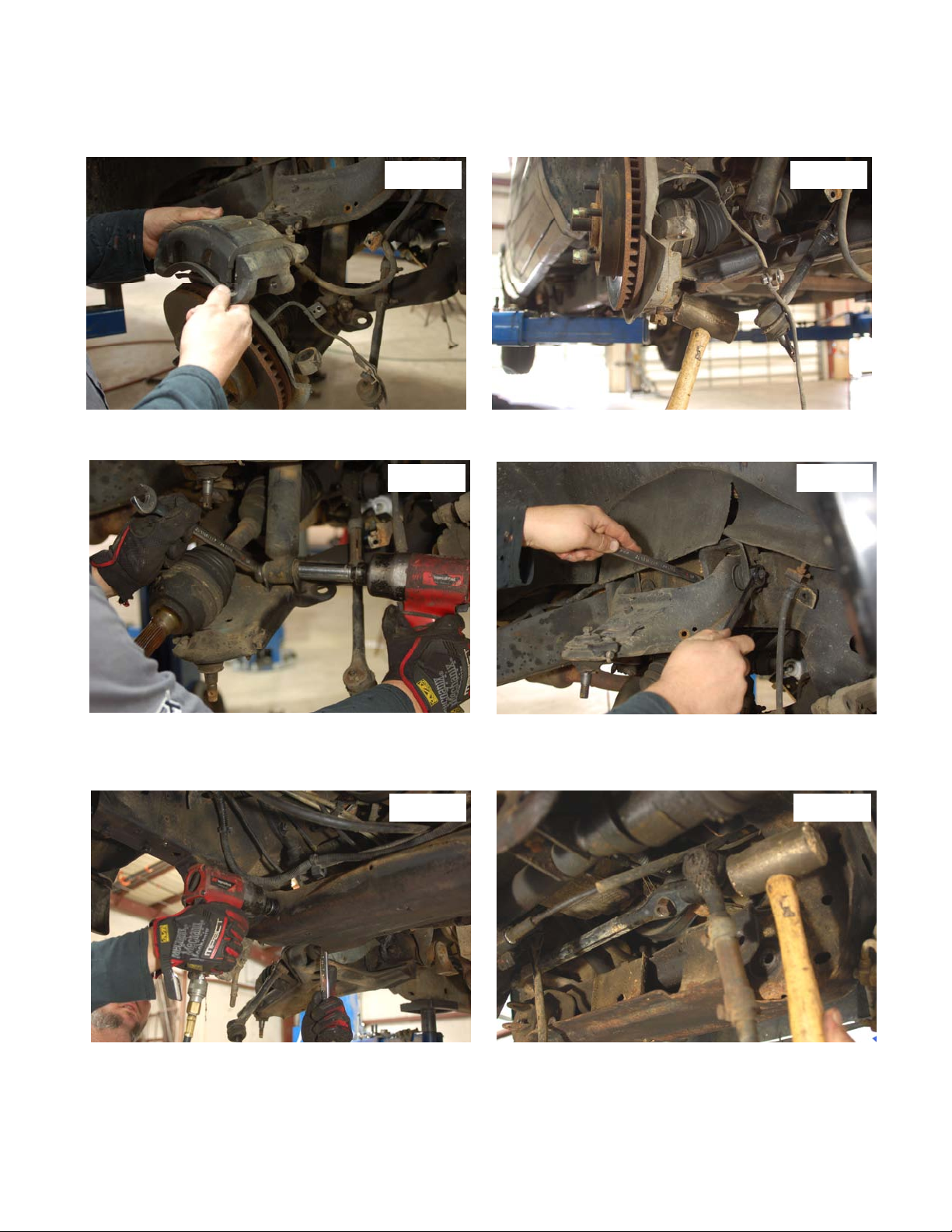

13. Now remove the brake caliper, swing the caliper and line to front of truck and hang safely. Remove axle nut using a

35mm socket. See Photo 13.

14. Remove the lower ball joint cotter pin and with a 24mm socket loosen the nut. Using a hammer strike the side of the

knuckle to brake the taper loose. See Photo 14.

15. Hold the knuckle and finish removing the lower ball joint nut.

Photo 13 Photo 14

16. Remove the bolts from the upper and lower shock mounts with a 18mm wrench and socket. See Photo 15.

17. Remove the upper control arm using a two 18mm wrenches. See Photo 16.

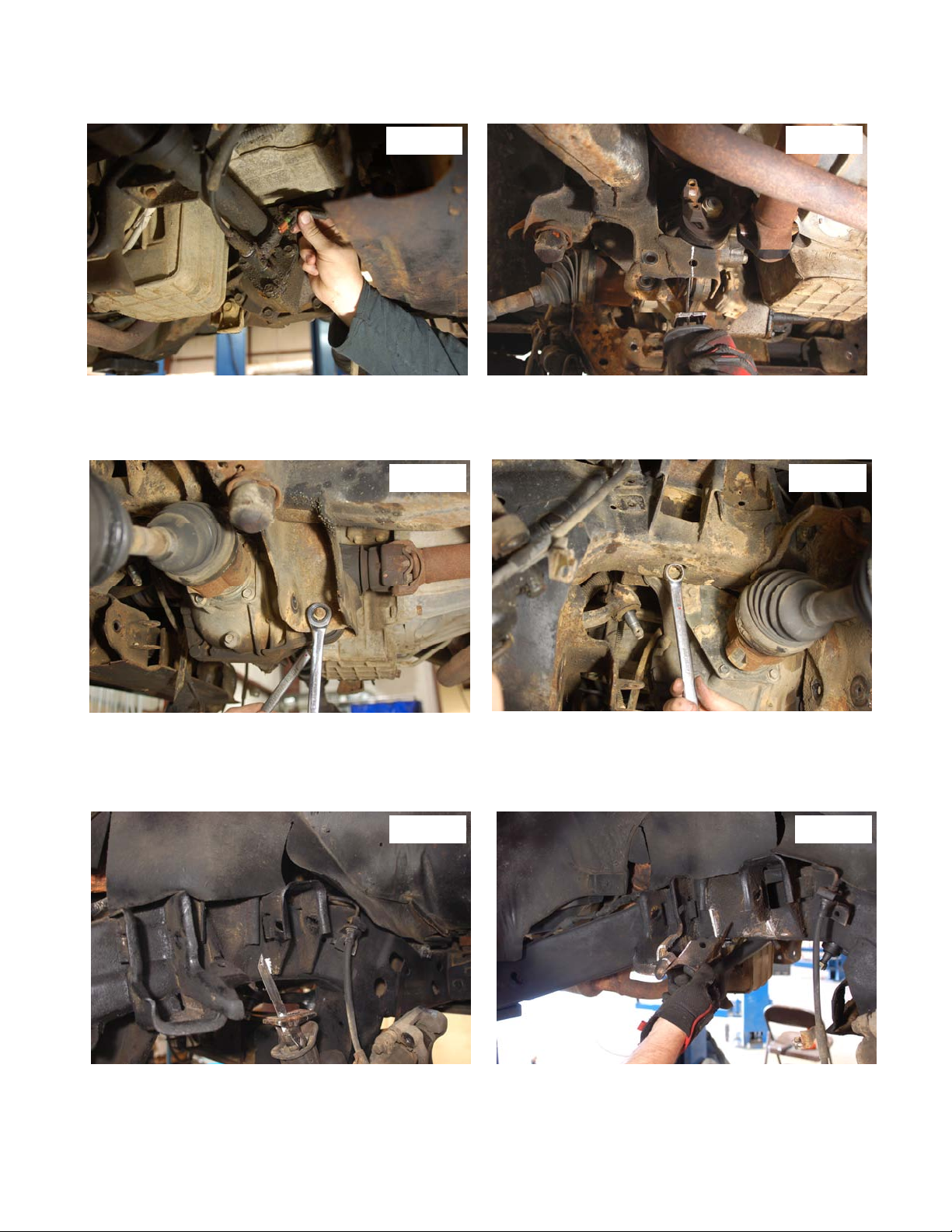

Photo 15 Photo 16

18. Removing the lower control arm using a 21 mm socket and wrench. See Photo 17.

19. Remove the center link using a 21mm socket and a hammer to strike the end of the steering link to dislodge the taper of the inner tie rod end. See Photo 18.

Photo 17 Photo 18

20. Repeat steps 6-19 on opposite side.

21. Now is a good time to inspect and replace any worn tie rods, ball joint, pitman arm, or cv shafts.

21. To remove the diff use a 7mm socket remove bolt from bracket holding the 4x4 light wire to diff. Unplug 4x4 light

wire from diff. remove driveshaft using 11mm socket. See Photo 19.

22. Cut the rear lower dif mount out using a sawzall. See Photo 20.

Photo 19

23. Remove the two passenger side nuts from diff using a 18mm socket. Remove the lower diff bole using 18mm

wrench and socket. See Photo 21.

24. There's a hole in the frame to access the nut for the upper diff mount. Support diff and use a 18mm wrench and

socket to remove upper diff bolt. Then remove the diff. See Photo 22.

Photo 21 Photo 22

Photo 20

25. Remove both bumper stops from frame using 13mm socket

26. Using a sawzall cut the upper control arm pocket one inch up from bottom on the rear of the front control arm pocket

a shown. See Photo 23.

27. Cut the upper control arm bump stop bracket off of rear control arm pocket. See Photo 24.

Photo 23 Photo 24

Loading...

Loading...