Rough Country 242N2 User Manual

921242N200

Thank you for choosing Rough Country for all your suspension needs.

Rough Country recommends a certified technician install this system. In addition to these instructions, professional

knowledge of disassemble/reassembly procedures as well as post installation checks must be known. Attempts to install

this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read instructions before beginning installation. Check the kit hardware against the product layout and kit contents

information on these instructions. Be sure you have all needed parts and know where they go. Also please review tools

needed list and make sure you have needed tools.

As a general rule, the taller a vehicle is, the easier it will roll. Seat belts and shoulder harnesses should be worn at all

times. Avoid situations where a side rollover may occur. Generally, braking performance and capability are decreased

when larger/heavier tires and wheels are used. Take this into consideration while driving. Do not add, alter, or fabricate

any factory or after-market parts to increase vehicle height over the intended height of the Rough Country product purchased. Mixing component brands is not recommended.

Rough Country makes no claims regarding lifting devices and excludes any and all implied claims. We will not be responsible for any product that is altered. If question exist we will be happy to answer any questions concerning the design, function, and correct use of our products.

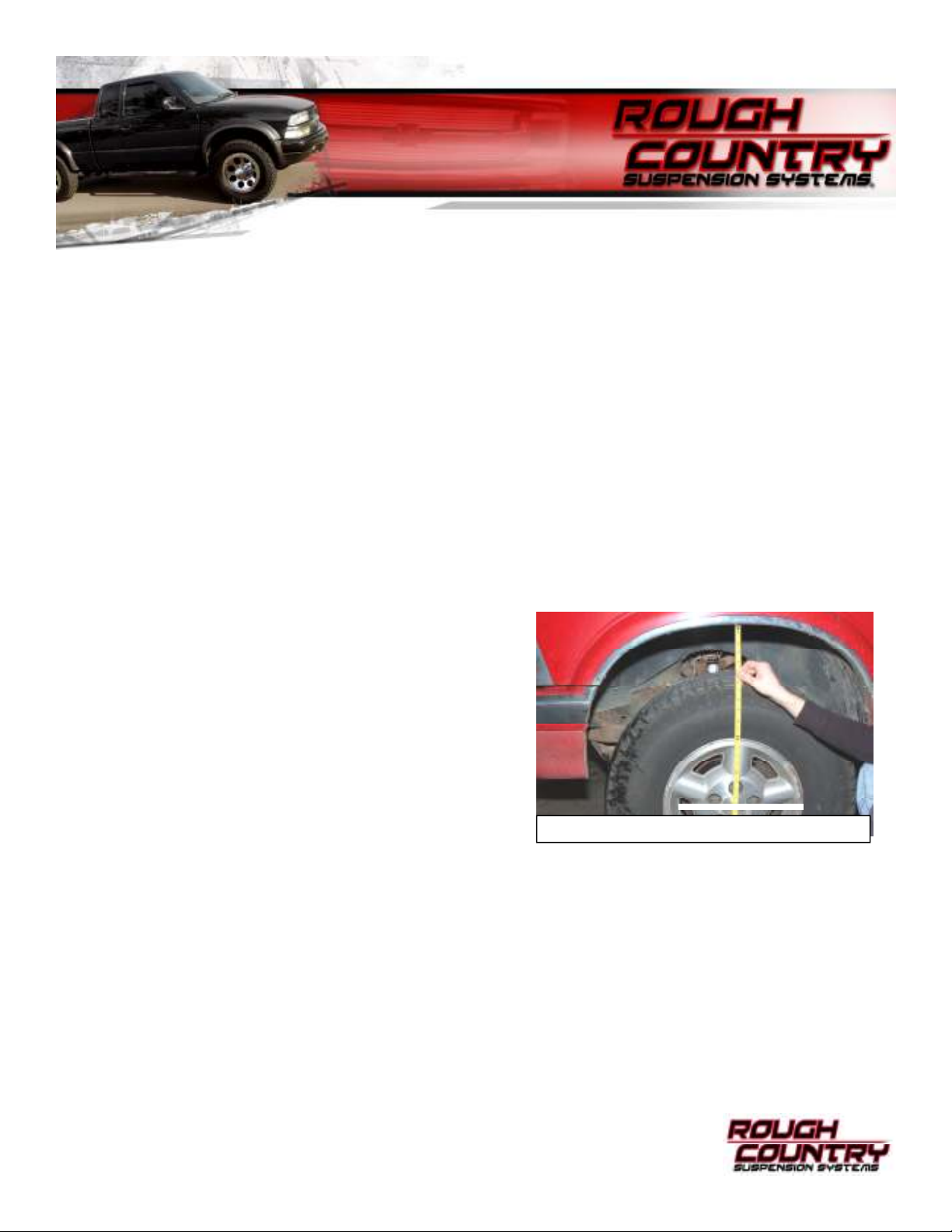

This suspension system was developed using a 31x10.5x15,

tire with factory wheels. If wider tires are used, offset wheels

and trimming will be required. This kit was developed to obtain

a front ride height of 21” on newer body style and 22” older

body style as measured from the center of the front wheel to

the bottom of the fender well. See Photo. It was also intended

to be a leveling kit—taking out the stock factory rake by raising

the rear only 1’ and raising the front 2-3”. If additional rear lift

is desired please contact your Rough Country Distributor.

NOTICE TO DEALER AND VEHICLE OWNER

Any vehicle equipped with any Rough Country product should have

a “Warning to Driver” decal installed on the inside of the windshield

or on the vehicle’s dash. The decal should act as a constant reminder for whoever is operating the vehicle of its unique

handling characteristics.

INSTALLING DEALER - it is your responsibility to install the warning decal and forward these installation instructions on

to the vehicle owner for review. These instructions should be kept in the vehicle for its service life.

82-04 S10 PICKUP / BLAZER & ZR2 MODELS 2.5”LIFT

PRODUCT USE INFORMATION

MEASURING RIDE HEIGHT

TOOLS NEEDED:

Torsion Bar Tool

Hammer

Jack Stands

Floor Jack

Wheel Chocks

Reciprocating Saw

7mm Socket / Wrench

10mm Socket / Wrench

11mm Socket / Wrench

13mm Socket / Wrench

15mm Socket / Wrench

18mm Socket / Wrench

19mm Socket / Wrench

21mm Socket / Wrench

35mm Socket

1-1/16” Socket

9/16” Socket / Wrench

Pliers

INSTALLATION INSTRUCTIONS

1. Chock rear wheels where the truck will not roll. Place vehicle in neutral.

2. Raise the front with a floor jack, positioned underneath the front axle cross member. Place jack stands under the

frame rails, behind the front wheel wells and lower frame onto jack stands. Remove the front tires.

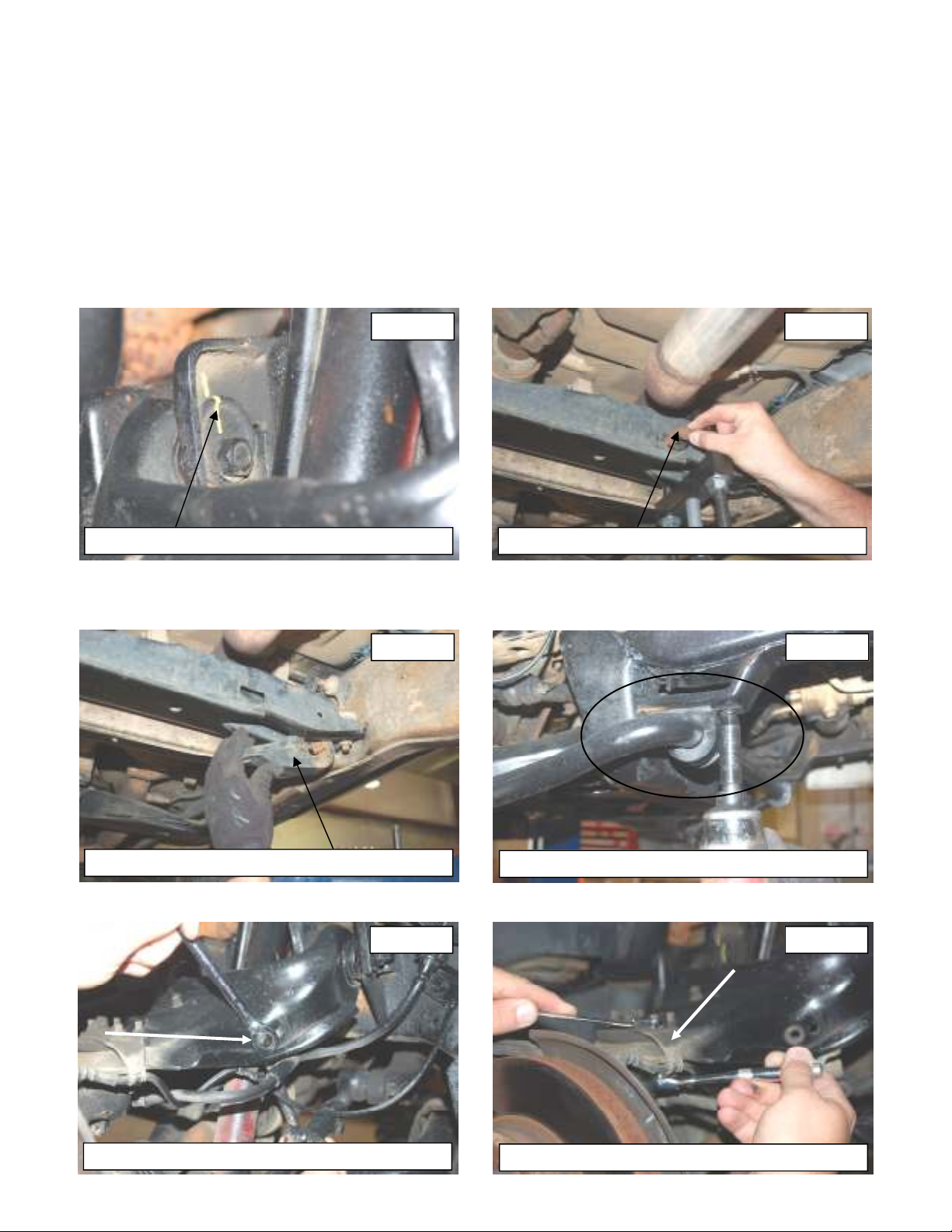

3. Mark cam bolts. See Photo 1.

4. The torsion bar keys are removed next and requires the use of a torsion bar tool. Torsion bar tool Part #1067 is

available from Rough Country.

5. Place the torsion bar tool on the cross member and tighten using a 1 1/16 socket until the stock torsion bar threaded

block is free. Make sure the torsion bar tool is properly placed on the torsion bar key to prevent the tool from slipping

and causing possible damage. Be extremely careful when loading or unloading the torsion bars: there is a tremendous amount of stored energy in the bars. Be sure to keep your hands and body clear of the adjuster arm assembly

and puller tool in case anything slips or breaks.

6. Remove the stock torsion bar bolt using a 18mm socket and remove the threaded bock. See Photo 2.

PHOTO 1 PHOTO 2

REMOVE THE ADJUSTER BOLT AND BLOCK MARK CAM BOLTS

7. Slide the torsion bar forward and remove the torsion bar key from the torsion bar cross-member. See Photo 3.

8. Remove the sway bar from the frame using a 10mm socket and 15mm wrench. Retain the stock hardware for reuse.

See Photo 4.

PHOTO 3 PHOTO 4

REMOVE THE TORSION BAR KEY

REMOVE SWAY BAR HARDWARE

9. Remove the brake line and ABS line from control arm using a 13mm wrench. See Photo 5 & 6.

PHOTO 5 PHOTO 6

REMOVE THE BRAKE LINE FROM ARM

REMOVE THE ABS CLIP FROM BALL JOINT

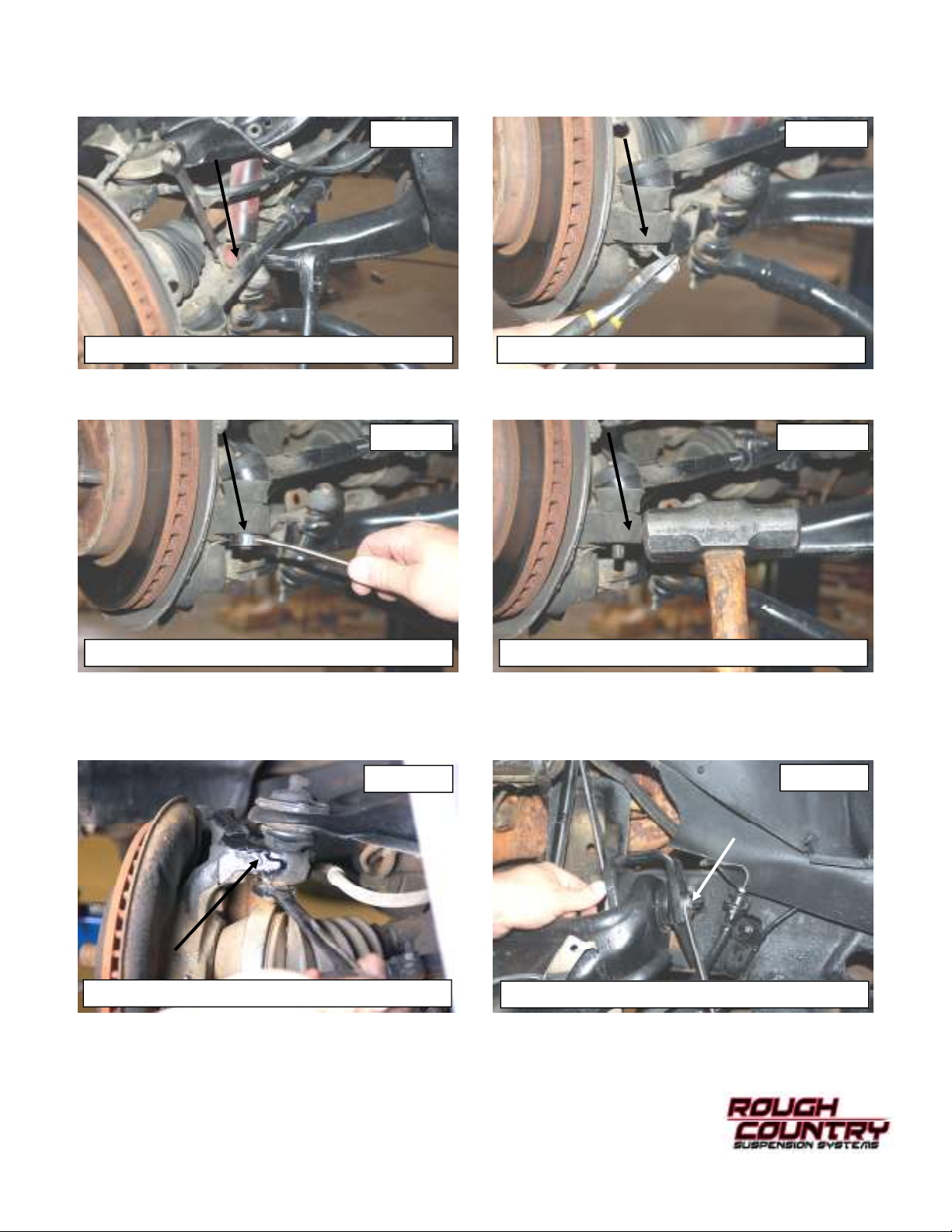

10. Remove the shock from the upper and lower shock mount using a 18mm wrench / socket. See Photo 7. Retain the

stock hardware for reuse. Remove the shock from the vehicle.

11. Remove the cotter pin from the tie rod end. Retain the stock hardware. See Photo 8.

PHOTO 8 PHOTO 7

REMOVE THE ABS CLIP FROM BALL JOINT REMOVE THE SHOCK

12. Remove the nut from the tie rod end using a 18mm wrench. Retain the factory hardware. See Photo 9.

13. Strike the knuckle as shown to dis-lodge the tie rod end. See Photo 10.

PHOTO 9 PHOTO 10

REMOVE THE TIE ROD NUT STRIKE TO DISLODGE TIE ROD

14. Remove the cotter pin on the upper ball joint and remove the nut using a 18mm wrench. Strike the knuckle near the

ball joint to dis-lodge the ball joint. See Photo 11.

15. Remove the upper control arm hardware using a 18mm socket / wrench. Retain the hardware for reuse. See Photo

12.

PHOTO 11

REMOVE THE UPPER BALL JOINT NUT

REMOVE THE UPPER ARMS

PHOTO 12

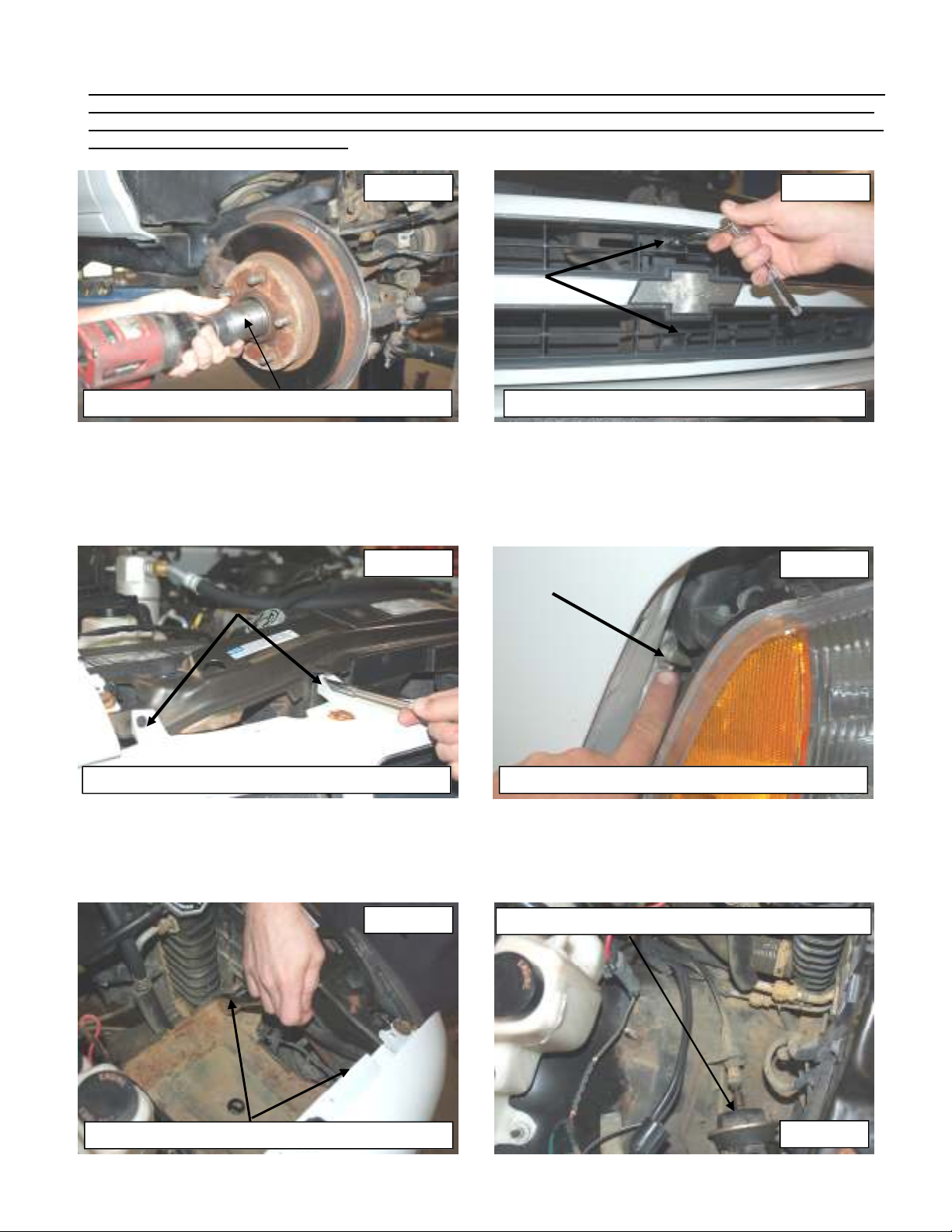

16. Remove the axle nut using a 35mm socket. Retain the hardware for reuse. See Photo 13.

17. On pickups / Blazers equipped with a cable floor shifter the following steps will be performed to disconnect the cable

shifter. Additionally the mounting hardware may vary and additional steps may need to be performed to access the

shifter cable. If the vehicle is equipped with an electronic push button 4WD selector these steps will NOT need to be

performed and will resume at Step 27. Please read the next steps before initiating.

18. Remove the two bolts as shown on the grill using a 7mm socket. Retain hardware for reuse. See Photo 14.

PHOTO 13 PHOTO 14

REMOVE THE AXLE NUT REMOVE THE GRILL (CABLE SHIFT)

19. Remove the 4 other screws securing the grill to the support. Retain hardware for reuse. See Photo 15.

20. Remove the grill and place away from harm.

21. Photo 16 shows the bolt that is to be accessed. If the bolt on the vehicle resembles the pictured bolt, then the grill

will not need to be removed. On other applications this bolt can be accessed beside the headlight with a 13mm

socket and the grill will not need to be removed. All other variations, the grill will need to be removed. This bolt secures the battery box to the body and is removed to access the shifter linkage.

PHOTO 15

GRILL HARDWARE SHOWN (CABLE SHIFT) NUT SHOWN THAT SECURES BATTERY TRAY

22. Remove the battery retaining hardware using a 13mm socket. Retain hardware for reuse.

23. Remove the battery tray by removing the two bolts using a 13mm socket. The two bolts will be accessible on some

models in the engine compartment. On other applications this bolt was removed in Step 21 from out side the vehicle

by the headlight. Retain the hardware for reuse. See Photo 17.

24. Photo 18 shows the area exposed under the battery tray.

PHOTO 17

VACUUM SHIFT ASSIST SHOWN (CABLE SHIFT)

PHOTO 16

REMOVE THE BATTERY TRAY (CABLE SHIFT)

PHOTO 18

Loading...

Loading...