Page 1

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

1 of 48

Document title

HygroLog HL-NT Data Logger

Instruction Manual

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 2

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

2 of 48

Document title

Table of contents:

1. Overview.................................................................................................................................. 3

1.1 General ................................................................................................................................ 3

1.2 Compatibility with previous models of probes and docking stations ................................... 4

2. General description of the HygroLog HL-NT ....................................................................... 5

2.1 Models ................................................................................................................................. 5

2.2 Required accessories .......................................................................................................... 5

2.3 HygroLog HL-NT inputs ....................................................................................................... 5

2.4 Power supply ....................................................................................................................... 8

2.5 Memory card ........................................................................................................................ 9

2.6 LED Indicators ................................................................................................................... 10

2.7 Beeper ............................................................................................................................... 10

2.8 HygroLog HL-NT functions ................................................................................................ 10

2.9 HygroClip 2 probe functions .............................................................................................. 13

2.10 Event tracking .................................................................................................................... 14

2.11 Operating limits (electronics only) ..................................................................................... 16

3. Docking stations for the HygroLog HL-NT ........................................................................ 17

3.1 Models ............................................................................................................................... 17

3.2 Installation .......................................................................................................................... 20

3.3 Docking station inputs........................................................................................................ 25

3.4 Relay contacts ................................................................................................................... 26

4. Pin-out diagrams .................................................................................................................. 26

5. HW4 software ........................................................................................................................ 28

5.1 Computer/Operating System Requirements ..................................................................... 28

5.2 Operating System Compatibility ........................................................................................ 29

5.3 Settings and functions accessible only with HW4 ............................................................. 29

6. ERES regulatory compliance .............................................................................................. 30

7. Getting started ...................................................................................................................... 31

8. Stand-alone operation ......................................................................................................... 31

8.1 Operating modes ............................................................................................................... 31

8.2 Display and keypad ........................................................................................................... 31

8.3 Display modes ................................................................................................................... 33

8.4 Settings and functions accessible from the Keypad .......................................................... 33

8.5 Internal function menu (models with display and keypad)................................................. 34

9. Operation on a network ....................................................................................................... 37

9.1 Baud rate and communications protocol compatibility requirements ................................ 37

9.2 Ethernet local area network ............................................................................................... 37

9.3 RS-485 multi-drop network ................................................................................................ 38

9.4 General wiring guidelines .................................................................................................. 39

9.5 Guidelines for RS-485 wiring ............................................................................................. 40

10. HygroClip probe adjustment procedures ..................................................................... 41

10.1 Single Point adjustment ..................................................................................................... 41

10.2 Multi-Point adjustment ....................................................................................................... 42

11. Warnings and useful tips ................................................................................................ 42

12. Communications protocol .............................................................................................. 43

13. Firmware updates ............................................................................................................ 43

14. Specifications .................................................................................................................. 44

15. Accessories ...................................................................................................................... 47

16. Supporting documents ................................................................................................... 47

17. Document releases .......................................................................................................... 48

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 3

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

3 of 48

Document title

Applicability:

This manual is valid for instruments with firmware version 2.0x (see MENU - Instrument or check

using the ROTRONIC HW4 software, Device Manager). Examples: 2.0a, 2.0b. Changes in the

last character of the version number reflect minor changes in the internal software of the

instrument that do not affect the manner in which the instrument should be operated.

1. Overview

1.1 General

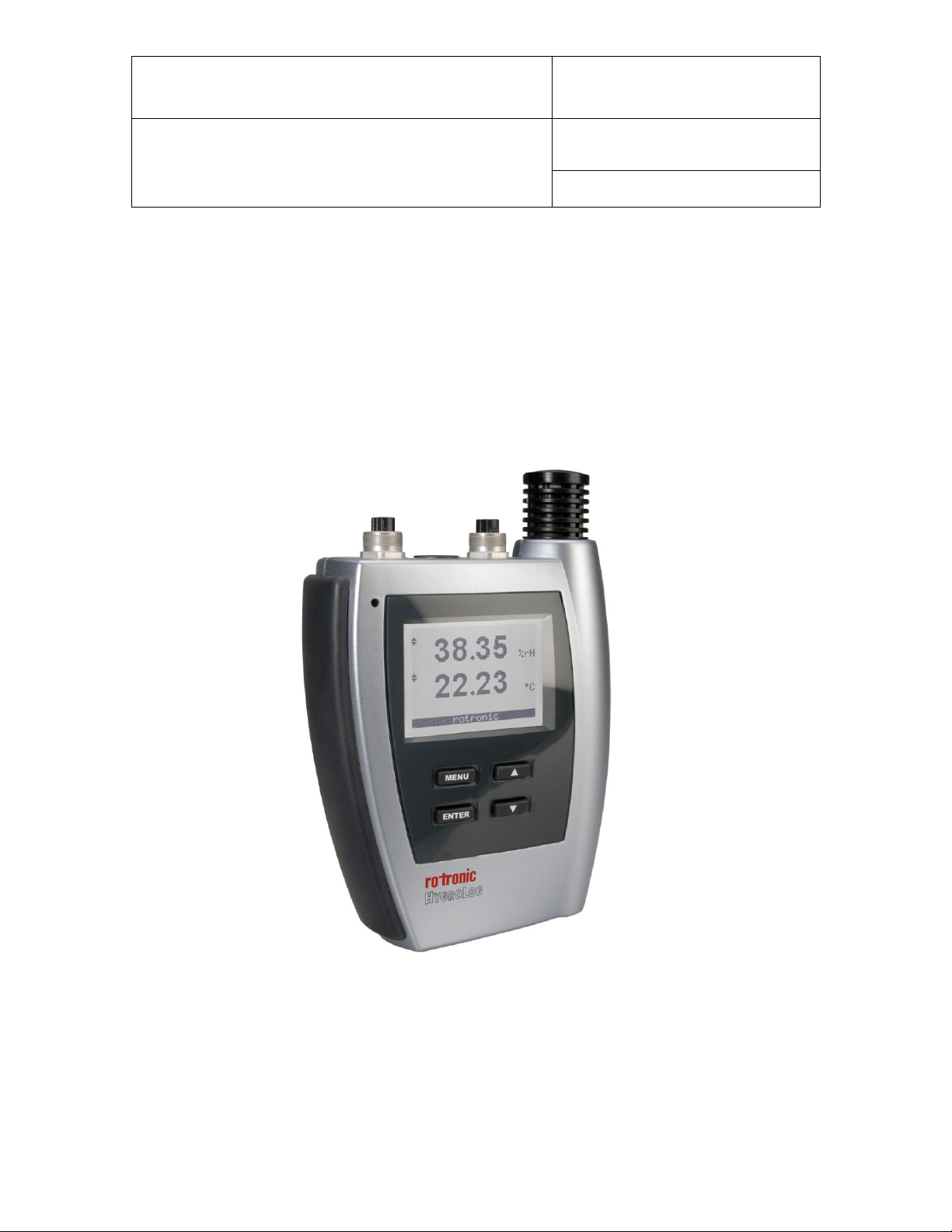

HygroLog HL-NT is a series of networkable data loggers primarily designed for use with the

HygroClip 2 digital humidity-temperature probes.

Depending on the model and options, the HygroLog HL-NT main features are as follows:

o Internal probe input: allows installing a HC2-S humidity-temperature probe internally to

prevent unauthorized removal. This input can also be connected to an external probe by

means of an extension cable.

o Inputs for up to 6 additional external probes, including analog probes and 4-wire passive

RTD probes.

o Monitoring of up to two external contacts (relay output, door, etc.).

o Large recording capacity with removable flash memory card. Up to 750,000 values can

be recorded with the standard 16 MB card. Cards with a capacity of up to 1 GB are

available.

o Display with backlight and keypad. This allows the HygroLog HL-NT to operate as a

stand-alone unit after initial configuration with the HW4 software.

o Compliance with FDA 21 CFR Part II and GAMP regulations regarding electronic records

and electronic signatures (ERES).

o Compatible with Ethernet networks (TCP / IP protocol – LAN or WLAN).

o Dedicated RS-485 network of up to 64 HygroLog HL-NT per communication port

o Simultaneous data recording and data display either locally or on a PC.

Internal power for both the HygroLog HL-NT and probes is provided by a 9V battery (factory

standard) or by a 9V rechargeable battery (user supplied).

The HygroLog HL-NT requires a docking station to (a) to power the HygroLog HL-NT with an

external AC adapter, (b) to configure the HygroLog HL-NT and communicate with a PC, (c) to

connect the HygroLog HL-NT to a network and (d) to mount the HygroLog HL-NT to a wall or to

place the HygroLog HL-NT on the optional desk-top stand.

The most basic model of docking station simply provides a means of mounting the HygroLog HLNT to a wall and of powering the HygroLog HL-NT with an external AC adapter. All other models

offer the same functionality as the basic model and also provide a communication port (RS232,

USB or RJ45 / Ethernet) as well as additional inputs for probes and external contacts. Docking

stations with an RS232 or USB port are used to connect the HygroLog HL-NT directly to a PC.

Docking stations with an RJ45 connector are used to connect the HygroLog HL-NT to an Ethernet

LAN. In both cases, the docking station features an RS485 port that can be used to connect up to

64 HygroLog HL-NT in a multi-dropped arrangement (dedicated RS-485 network). This is useful

when the PC does not have an Ethernet network interface card or when the number of available

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 4

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

4 of 48

Document title

Ethernet ports is limited. Direct connection to an Ethernet LAN allows, in principle, an unlimited

number of HygroLog HL-NT to be put on a network monitored by the HW4 software. HW4 allows

any combination of RS-232, USB, Ethernet and RS-485 connections.

When equipped with a docking station, the HygroLog HL-NT can be used together with the

ROTRONIC HW4 software for Windows based PCs (version 2.3.0 or higher). In addition to

providing for the networking of large quantities of data loggers and other instruments, the main

functions of HW4 include:

o Configuration of the HygroLog HL-NT and docking station

o Programming of the HygroLog HL-NT logging function

o Manual or automatic downloading of the data recorded by the HygroLog HL-NT

o On-line data monitoring and direct data recording by the PC

o Automatic generation of graphs and data tables

o Monitoring of the networked instruments and data for alarm conditions

o Alarm reporting

o Maintenance of audit trails

o Calibration and adjustment of the HygroClip 2 probes

o Generation of protocols, electronic signatures, etc.

A high level of protection against network failures can be achieved by logging data directly on the

PC while also recording the data locally on the HygroLog HL-NT with automatic download to the

PC at regular interval of times.

Note: Instructions for using the HW4 software are not included in this manual. These instructions

are shipped separately on the software CD ROM.

1.2 Compatibility with previous models of probes and docking

stations

o The HygroLog HL-NT is designed for use with the HygroClip 2 probes (UART interface)

and is not compatible with the previous generation of HygroClip probes (DIO interface).

o Docking stations designed for the previous generation of HygroClip probes (such as DS-

U1, DS-U4, etc.) are not compatible with the HygroLog HL-NT.

o RS-485 drop-down networks: the HygroLog HL-NT is compatible with previous versions

of the HygroLog NT and with other legacy products. The HygroLog HL-NT cannot be

used in the same RS-485 drop-down as a HF4 or HF5 transmitters or any product that

rely on the RO-ASCII communications protocol.

o Unlike previous versions, The HygroLog HL-NT does not have a remote mode

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 5

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

5 of 48

Document title

2. General description of the HygroLog HL-NT

2.1 Models

Basic models without display and keypad

o HygroLog HL-NT2: logger for plug-in HygroClip 2 probe (probe is not included and must

be ordered separately). Probe model HC2-S can be mounted either internally or in the

extended position. Other probe models are external and require an extension cable.

o HygroLog HL-NT3: same as HL-NT2 with 2 additional connectors suitable for a

HygroClip 2 digital probe.

Models with display and keypad

o HygroLog HL-NT2-D: same probe as HygroLog HL-NT2

o HygroLog HL-NT3-D: same probe / probe inputs as HygroLog HL-NT3

Models with internal HC2-S probe pre-installed

o Models HL-NT2-P, HL-NT2-DP, HL-NT3-P and HL-NT3-DP are supplied with an internal

HC2-S probe pre-installed.

2.2 Required accessories

● Models without display/keypad:

The following accessories are required in order to be able to use the logger:

- Any model of docking station (except model DS-NT1)

- Connecting cable docking station to PC

- PC with the ROTRONIC HW4 software installed (version 2.3.0 or higher)

● Models with display/keypad:

In principle, these models can be used without any accessory. However, accessing all of the

product functions and changing some important settings such as the date and time requires the

same accessories as for the models without display.

2.3 HygroLog HL-NT inputs

2.3.1 Probe input 1

HygroLog HL-NT2-P, HL-NT2-DP, HL-NT3-P and HL-NT3-DP: these models are supplied with

an internal HC2-S plug-in probe. This probe can be either retracted or extended. The probe can

also be separated from the logger with an extension cable, and in this case the HC2-S probe may

be replaced with another model of HygroClip 2 probe so as to meet specific application

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 6

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

6 of 48

Document title

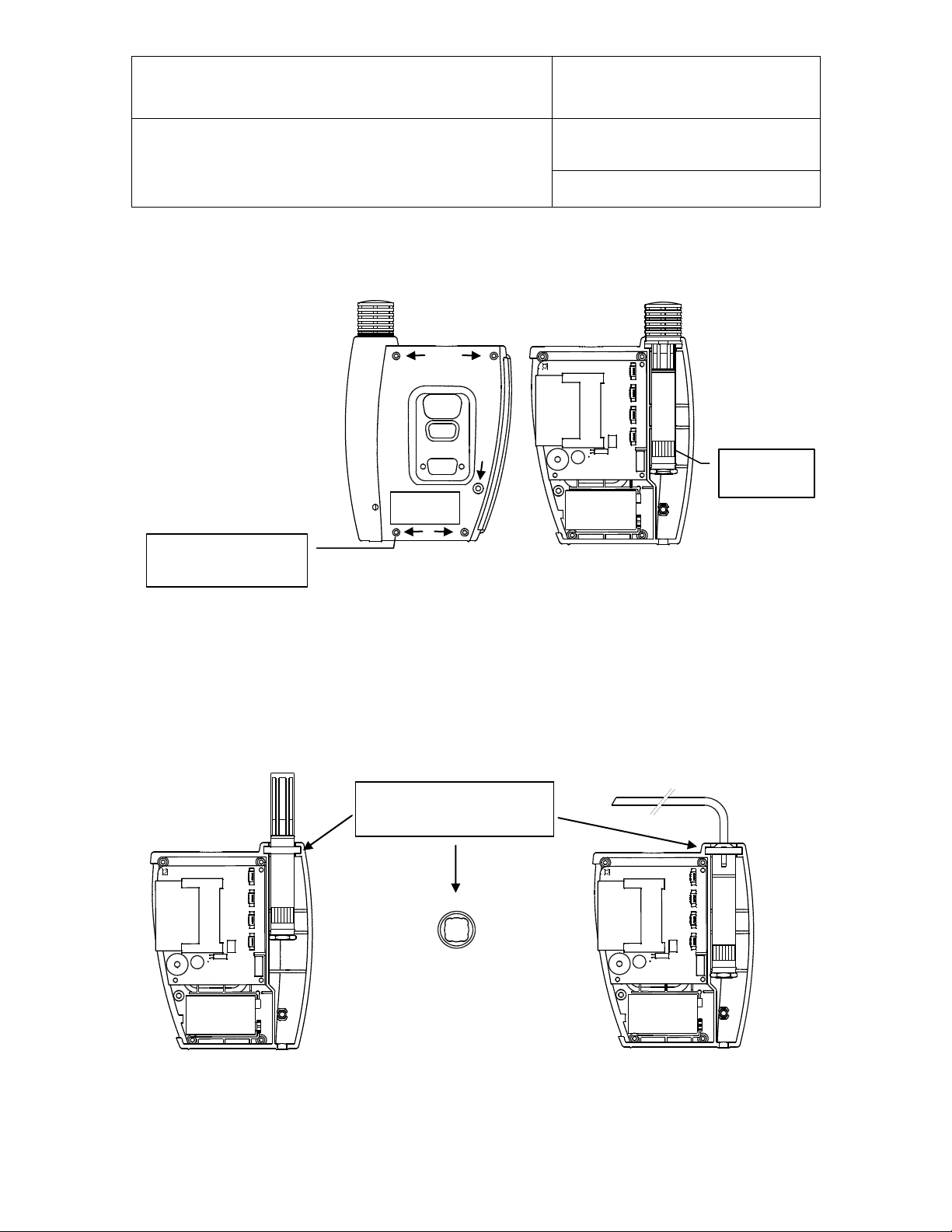

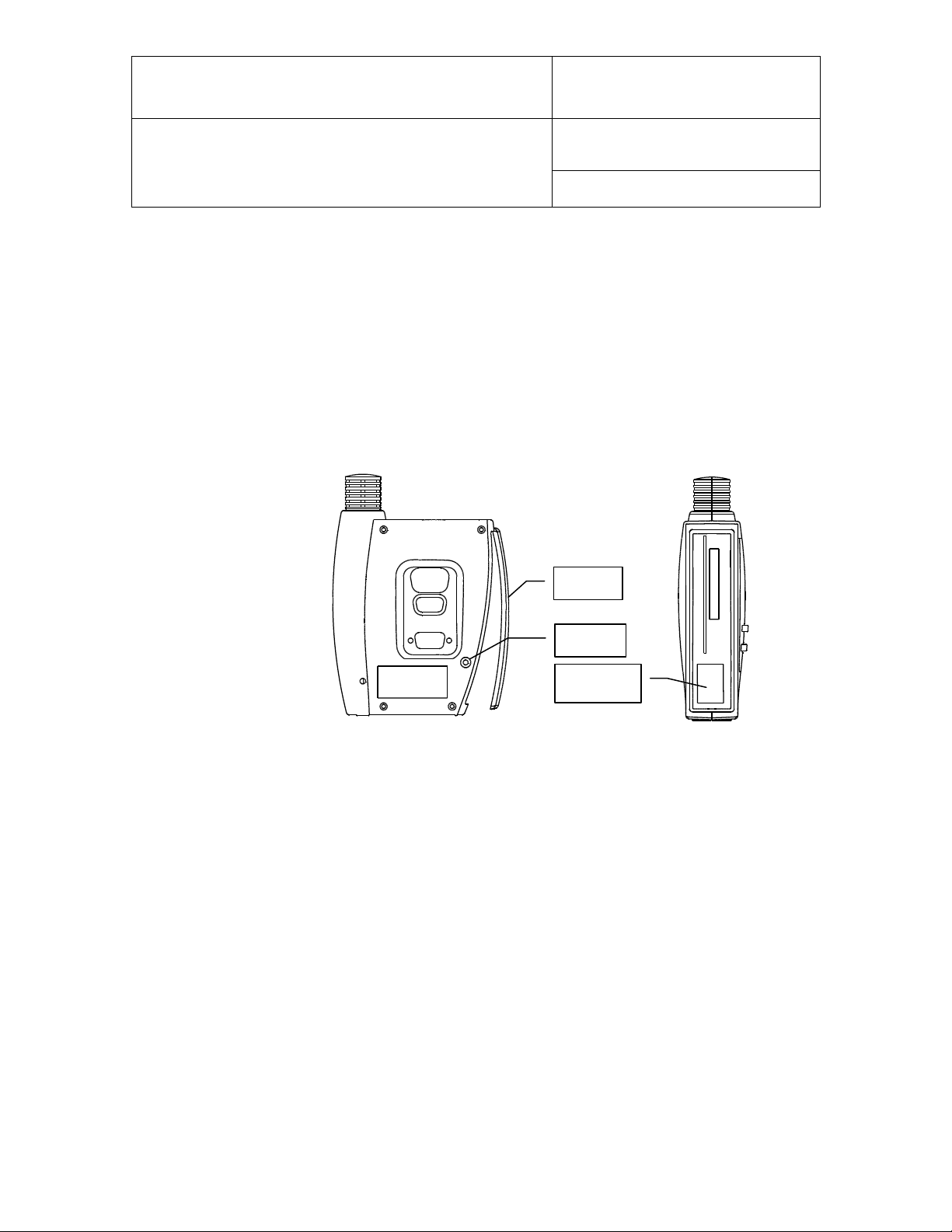

HygroClip S

extended position

Extension cable used to

separate the probe from

the HygroLog.

Ring

(replaces the slotted cap)

To open the housing of the

HygroLog, remove the five

screws, as indicated by the

arrows.

The far right drawing shows

the HygroClip S probe in the

retracted position. The base

of the probe is plugged into

a connector that is

separated from the main

board by a length of wire.

Probe

connector

The shorter screw

goes here

requirements (see document E-M-HC2 Probes-V1). Open the housing of the HygroLog to

change the position of the probe or to install a probe extension cable.

To extend the probe, lift the HygroClip S probe from its position and remove the slotted cap from

the HygroLog. To extend the probe, place on the probe the ring supplied with the HygroLog.

Insert the ring into the slot in the instrument housing where the slotted cap was. Relocate the

probe connector up by one or two ribs. Close the instrument housing. Proceed in a similar

manner to install a probe extension cable.

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 7

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

7 of 48

Document title

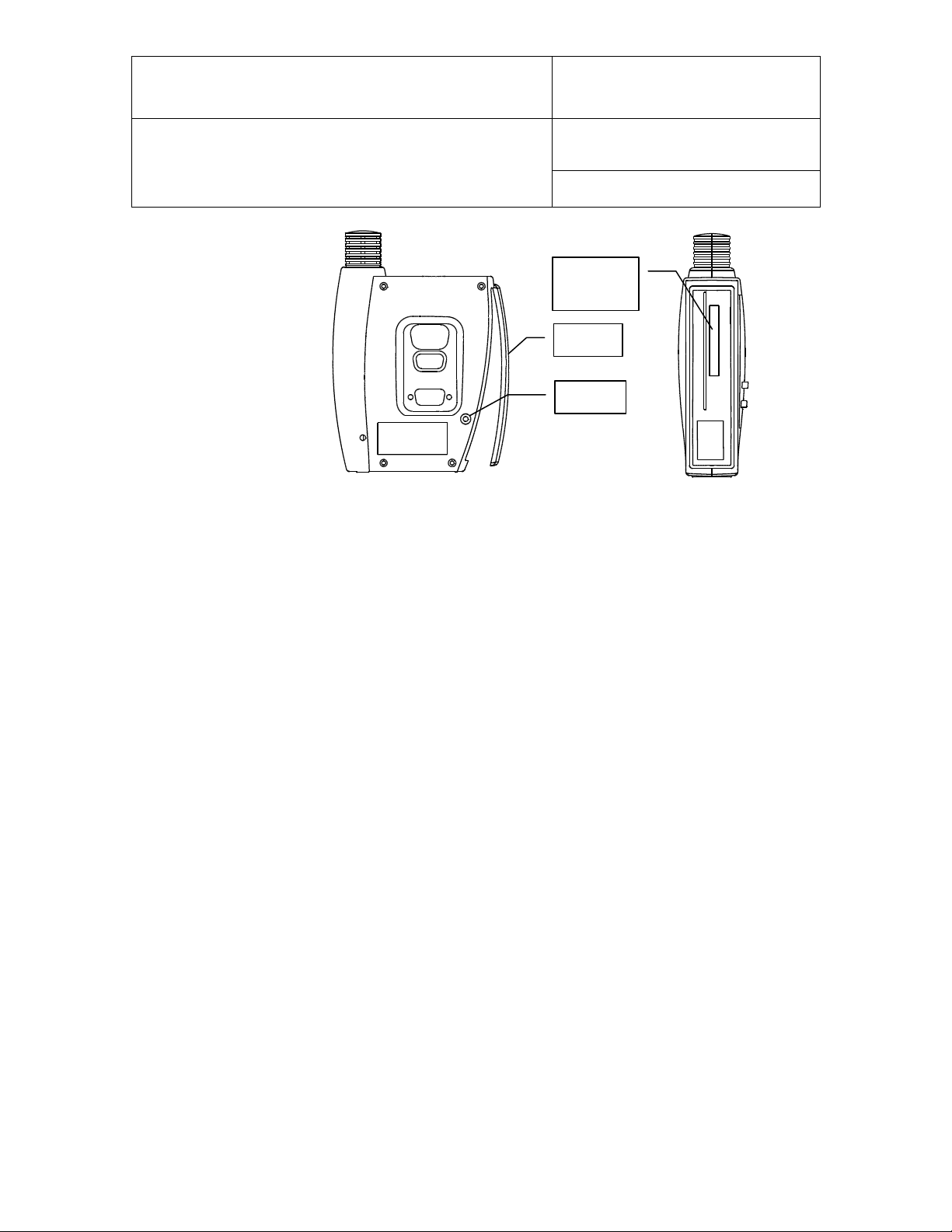

Input 1 (HygroClip 2 probe)

Input 2 (HygroClip 2 probe)

Input 3 (HygroClip 2 probe)

Input 1 (HygroClip 2 probe)

HL-NT2

HL-NT3

Notes:

o For maximum protection against vandalism, use the HC2-S probe in the retracted

position. For a faster response, use the probe in the extended position.

o For additional information on the HygroClip 2 probes see document

E-M-HC2 Probes-V1.

2.3.2 Probe inputs 2 and 3 (HygroLog HL-NT3)

The HygroLog HL-NT3 can be used with up to 2 additional HygroClip 2 probes. For further

information on the HygroClip 2 probes, see document E-M-HC2 Probes-V1.

2.3.3 Connector identification

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 8

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

8 of 48

Document title

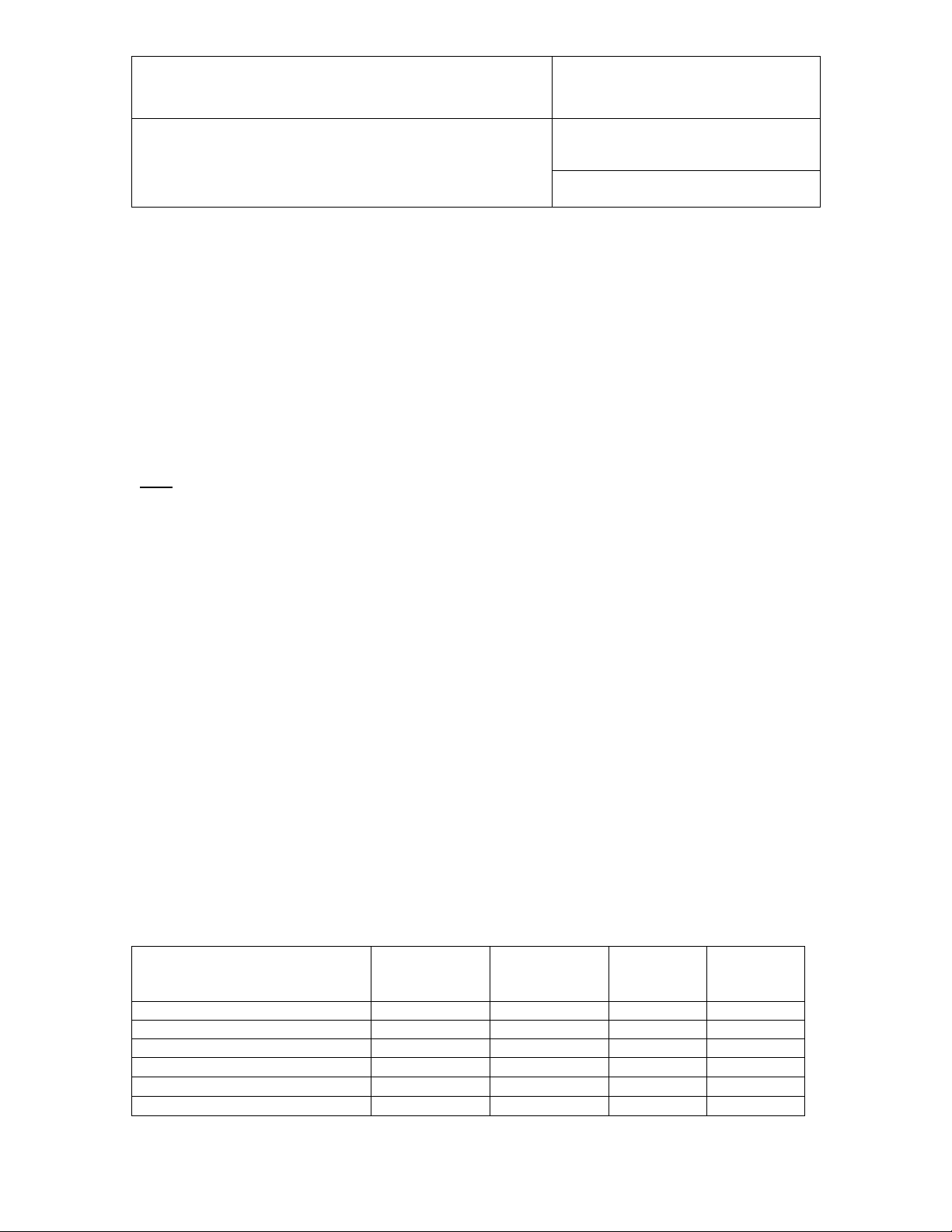

Lifetime in days

Rechargeable

Battery

120mAh

Rechargeable

Battery

150mAh

Regular

Battery

500mAh

Regular

Battery

1000mAh

1 Probe / 5s Interval

2.7

3.4

11

22

1 Probe / 5s Interval / LCD

2.1

2.6

8.9

17

1 Probe / 1min Interval

14

17

59

118

1 Probe / 1min Interval / LCD

5.8

7.3

24

48

1 Probe / 15min Interval

89

111

372

744

1 Probe / 15min Interval / LCD

8.9

11

37

74

2.4 Power supply

The HygroLog HL-NT ships with a regular 9V battery which must be inserted first (see battery

replacement).

To conserve battery power, models with the LC display and keypad are shipped with the Display

Sleep function enabled (see Software Functions). When the keypad has not been used for some

time, this function automatically turns off the display off. The display can be temporarily activated

by pressing on any key of the keypad.

When connected to a docking station, the HygroLog HL-NT can be powered with an external AC

adapter.

Note: most models of docking station require the use of an external AC adapter due to the current

consumption of the docking station internal electronics.

After reconfiguring the HygroLog HL-NT with the ROTRONIC HW4.software, a rechargeable

battery (accumulator) can be used instead of a regular battery. Recharging the battery require a

docking station and an external AC adapter.

WARNING: Trying to recharge a regular battery is potentially dangerous. Whenever a

regular battery is being used, the logger should be configured with the internal battery

charge function disabled.

2.4.1 Battery lifetime

The battery lifetime depends on the manner in which the HygroLog HL-NT is being used. The

HygroLog HL-NT has a battery lifetime of one year when just one HygroClip probe is being used

(standard 500 mAh alkaline battery), when no docking station with internal electronics is

connected to the HygroLog HL-NT and when the logger is configured / programmed as follows:

● Display Sleep function enabled (models with display)

● No docking station with internal electronics

● LED and beeper functions disabled

● Log interval set to 15 minutes

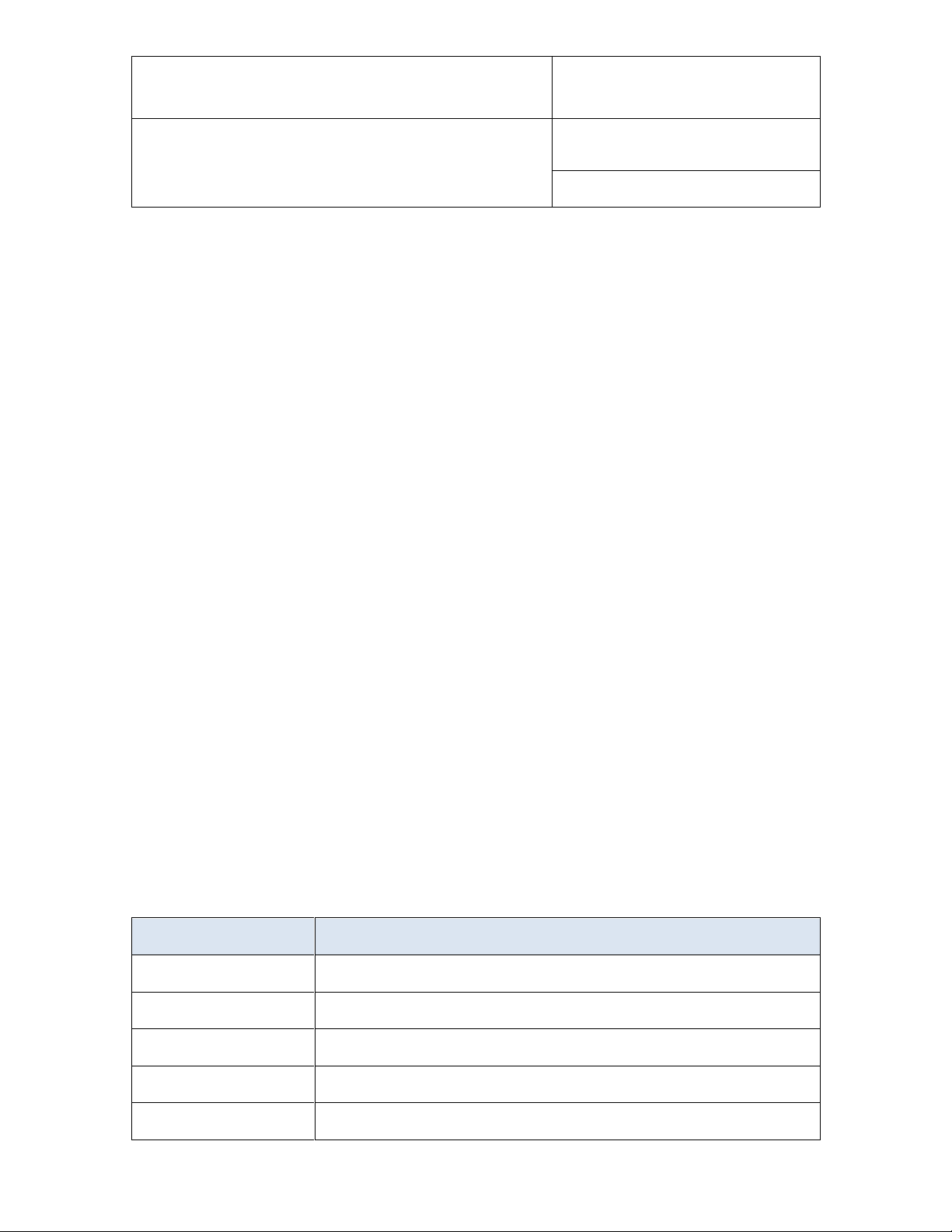

Additional examples of battery lifetime (LED turned off, Logging active): in the following table,

LCD means that the LC display is permanently on (Display Sleep function disabled). No docking

station with internal electronics is connected to the HygroLog HL-NT.

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 9

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

9 of 48

Document title

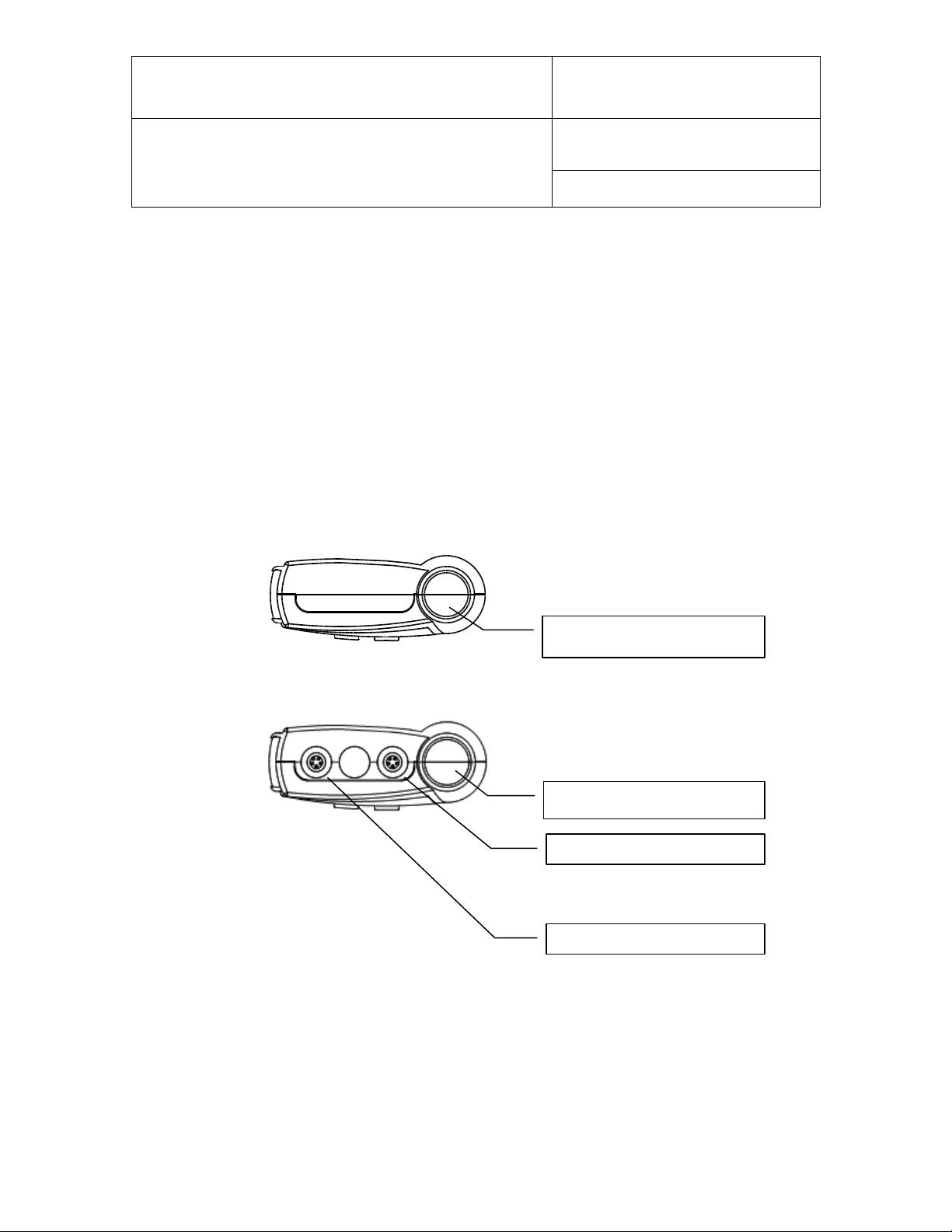

cover

To access the battery,

remove the screw shown

to the right and open the

rubber cover.

The battery is located at

the bottom of the

instrument.

Probe input 5

battery

Note: the consumption of the display is negligible when the Display Sleep function is enabled.

With the display always on, power consumption is at its highest when the display refresh rate is

set with HW4 to the minimum of 5 sec.

Because of the requirement to keep track of the date and time, the HygroLog HL-NT does not

have a power on/off switch. Every minute, both the date and time are recorded to the internal

EEPROM. Seconds are not recorded. In the event of a relatively brief interruption of power (such

as when replacing the battery), time may fall behind in increments of one minute. Removing the

battery for an extended period of time will cause the logger to completely lose track of the date

and time.

2.4.2 Battery replacement

2.5 Memory card

The HygroLog HL-NT has a non-volatile 64 kb EEPROM internal memory that is used to save the

logger configuration data, the logger events and to temporarily hold measurement data.

The main memory is a plug-in flash memory card. As a standard, the HygroLog HL-NT ships with

a 16 MB card. This card allows the recording of up to 400,000 values in text file format

(unprotected) or up to 750,000 values in binary file format (protected). Memory cards with a

capacity of up to 1 GB can be purchased from third parties. Regardless of its size, the flash

memory card holds a maximum of 512 files and directories, including one logger-configuration

and one logger-event file.

The measurement data can be saved either to a file with extension XLS or to a file with extension

LOG. Files with XLS extension can be read with Notepad or imported into Microsoft Excel. Files

with extension LOG are encoded in binary format so as to prevent data manipulation and can

only be read with the ROTRONIC HW4 software. Both types of files can co-exist on the memory

card. The memory card can be removed from the logger and transferred to a card reader, a PDA,

etc. The flash memory card can also be read without being removed from the logger.

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 10

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

10 of 48

Document title

cover

memory

card

Memory Card:

To access the memory

card, remove the screw

shown to the right and pull

out the rubber cover.

The plug-in flash memory

card is located on top of

the main board.

screw

2.6 LED Indicators

The HygroLog HL-NT is equipped with a green and red LED. The logger can be configured with

HW4 to have the green side of the LED flash when logging is active. The red side of the LED can

be made to flash when there is an alarm condition (see note below) and / or when the logger

requires attention (low battery, flash memory card full, etc.)

In the transient alarm mode, the red LED flashes for only as long as the data from a probe

corresponds to an alarm condition. In the durable alarm mode, the red LED stays on even after

the alarm condition has disappeared. When the LED is set to provide a durable alarm, it can be

reset from the keypad or with HW4.

2.7 Beeper

The HygroLog HL-NT is equipped with an internal beeper and can be configured with HW4 to

make a clicking sound when any key is being pressed. The beeper can also be configured to emit

a 5-second non-repeating sound when there is an alarm condition and / or when the logger

requires attention.

2.8 HygroLog HL-NT functions

2.8.1 Calculated parameter

Using the HW4 software, the HygroLog HL-NT can be set to compute for each HygroClip probe

one of the following psychrometric parameters.

o Dew point (Dp)

o Frost point (Fp)

o Wet bulb temperature (Tw)

o Enthalpy (H)

o Vapor concentration (Dv)

o Specific humidity (Q)

o Mixing ratio by weight (R)

o Vapor concentration at saturation (Dvs)

o Vapor partial pressure (E)

o Vapor saturation pressure (Ew)

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 11

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

11 of 48

Document title

Each individual probe input can be associated with a different parameter.

Note: depending on whether dew point or frost point was selected, both the HygroLog HL-NT and

HW4 will display either the symbol Dp or the symbol Fp for values below freezing. The symbol Fp

indicates that the value is a frost point as opposed to being a dew point. Regardless of the dew

point / frost point selection, the symbol Dp is always displayed for values above freezing.

Some of the above parameters require barometric pressure as an input. When an analog

pressure probe is connected to one of the HygroLog HL-NT inputs, the logger can be set to use

the measurement from this probe. When no pressure probe is being used, a fixed pressure value

can be used. This value can be specified as part of the HygroLog HL-NT settings.

2.8.2 Data logging

Data logging requires that a flash memory card be inserted inside the logger. Using the HW4

software, log files can be set to one of the following formats:

● HW4 binary format [LOG]: files in this format are encoded and can be opened only with the

ROTRONIC HW4 software. HW4 does not allow any manipulation / alteration of the data and

requires a password to log in. Should the file be somehow modified, HW4 will give a warning

that the file is not an original.

● Text file format [XLS]: in principle, files in this format can be opened with any text editor and / or

imported into Microsoft Excel.

The log file format is a global setting of the flash memory card (changing this setting requires the

HW4 software). At any given time, the card records data from all inputs in either one format or the

other. Files of different formats can co-exist in the flash memory card. Binary files (protected) use

substantially less memory space than text files (unprotected).

The logging function is independently activated for each individual input. The HygroLog HL-NT

creates a separate file for each input that is to be recorded. Multiple inputs cannot be recorded to

the same file. The HygroLog HL-NT automatically generates each file name. A file name consists

of 8 digits followed by the extension LOG or XLS. The first 4 digits are the same as the last 4

digits of the logger serial number, the 5th digit is the same as the input number and the last 3

digits are a number between 000 and 999 used to differentiate log files created for the same

input. The last number that was created is retained in the non-volatile EEPROM and is updated

whenever a new file is created for the input. When the number reaches 999, the next update will

reset it to 000.

All files are located in the root directory of the flash memory card, including the logger event file

and the logger configuration file. Regardless of the memory card capacity, the root directory is

limited to a maximum of 250 files. This means that the memory card can hold a maximum of 248

log files, and that a card with this amount of files is considered to be full, even if all the memory

has not been used.

Using HW4, the following log settings can be defined individually for each input:

● Start date and time

● Stop date and time

● Log interval (minimum 5 seconds)

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 12

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

12 of 48

Document title

● Measured values and computed parameter, or any parameter combination

● User custom text (used for the log file header)

● User name, HW4-ID, HW4 Serial Number

● Automatic creation of a new file after 200,000 data points or at the end of each day, week or

month

Note: unlimited logging (loop mode logging) is not possible. Logging stops automatically when the

flash memory card is full. Prior to logging, the user may use HW4 to check the amount of free

memory, and verify that there is enough room available.

If the flash memory card is removed when logging is active, the HygroLog HL-NT will stop logging

until a new card is inserted. Unless the stop date and time have been reached, logging will start

again under the next available file name when a new card is inserted.

Warning: removing the memory card while logging is active may result in a corrupted log file and

in loss of data.

Logging can be started immediately for any individual input from the keypad of the HygroLog HLNT. A deferred start can only be programmed with the HW4 software. The green LED of the

HygroLog HL-NT can be set to flash when the instrument is recording data. To conserve battery

power, you may want to do this only when an external power source is being used.

Logging can be immediately stopped for any individual input directly from the keypad. With HW4,

logging can be stopped either immediately or at a future date and time for any individual input or

for all inputs.

When logging is ended, the HygroLog HL-NT returns to the measuring mode.

2.8.3 Trend indicators

See also: Main operating modes and measurement interval

When the trend indicator function is enabled, a symbol appears on the left side of the LC display,

on the line corresponding to each measured or calculated value. An up arrow denotes a rising

value and a down arrow denotes a decreasing value. Both arrows denote a stable value.

The trend of a parameter is evaluated by comparing successive averages made of 6 values each.

With the shortest possible measurement interval of 5 seconds, each average covers a time period

of 30 seconds and the first indication of a trend is available after one minute. Subsequently, the

trend is evaluated and updated every 30 seconds. With a longer measurement interval, each

average is computed over a longer period of time (always using 6 values) and the trend is also

updated over longer intervals of time.

For any measured or calculated parameter, the trend indicator shows a stable condition when the

absolute value of the difference between two successive averages is < 0.02.

2.8.4 Alarm function

Using the HW4 software, both a high and a low alarm value can be associated with the humidity,

temperature and calculated parameter of each probe input, A hysteresis value can also be

entered for each parameter. This value is used for both the low and the high alarm conditions.

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 13

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

13 of 48

Document title

The HygroLog HL-NT has a red LED which can be set with HW4 to flash whenever the value of

any parameter corresponds to an alarm condition. The LED can be set to flash only as long as

the alarm condition exits or it can be set to provide a durable alarm and, in this case, it will to

keep flashing until the alarm is reset.

The HygroLog HL-NT can also be set with HW4 to beep for 5 seconds when there is an alarm

condition. The HygroLog HL-NT will beep only once, when the condition occurs.

Log files do not record the existence of an alarm condition. However, when the contents of a log

file are viewed as a data table with the HW4 software, values that correspond to an alarm

condition are printed over a red background, based on the alarm settings that HW4 downloaded

from the logger.

2.8.5 Display-Sleep function

This function can be enabled and configured only with the HW4 software.

Using the Display Sleep function can substantially extend the lifetime of the battery. When the

Display Sleep function is active, the LC display of the HygroLog HL-NT stays blank. The Display

Sleep function is effective both in the measure and in the record mode.

The display of the HygroLog HL-NT can be set to be always on. It can also be set to automatically

go blank after 30 seconds, 1, 5, 10 or 20 minutes when no key is being pressed or when there is

no communication with a PC. If the HygroClip NT was in the function menu at the time the display

goes blank, it automatically exits the menu.

The HygroLog suspends the Display Sleep function whenever a key is pressed. The function is

also suspended when external power is available or when the logger receives a communication

request (for example from a PC 1). When the display comes up again, it shows by default the

measurements from the probe that was selected last.

1

When the HygroLog HL-NT is connected by means of a docking station to a PC and HW4

is running, you should use an external AC adapter to power both the HygroLog HL-NT and

docking station. HW4 can be set to use a polling interval as short as 5 seconds to interrogate all

instruments connected to the PC and this could cause the battery life time to be sharply reduced.

2.9 HygroClip 2 probe functions

2.9.1 Simulator function (validation of the signal transmission):

If so desired, transmission of the HC2 probe output signals can be validated by using the probe

simulator function. The HW4 software is required to enable and configure this function. When the

function is enabled the probe generates digital and analog signals corresponding to values

specified by the user.

2.9.2 Sensor failure detection and fail safe mode:

The HygroClip 2 probe automatically detects a sensor failure such as a shorted or open sensor.

This information is passed to both the HygroLog HL-NT and HW4 software. The optional display

of the HygroLog HL-NT will show an alarm message. The HygroClip 2 probe can also be

configured with the HW4 software to generate a "safe or readily identifiable" fixed value for

humidity and temperature in the event of a shorted or open sensor.

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 14

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

14 of 48

Document title

Event

Description

Power up

The battery was inserted or the instrument powered down and up after

an internal problem

Watchdog overflow

Internal instrument error (normally should not occur)

Writing device

configuration

New or existing configuration written to logger

Memory card removed

While recording data, the logger could not find the memory card. The

data was written to the EEPROM and are not yet lost

Memory card full

No free memory space on the memory card

Note: the sensor diagnostics and drift compensation function of the HygroClip 2 probe is not

available with the HygroLog HL-NT due to the fact that the probe is powered only briefly during

each log or measurement interval.

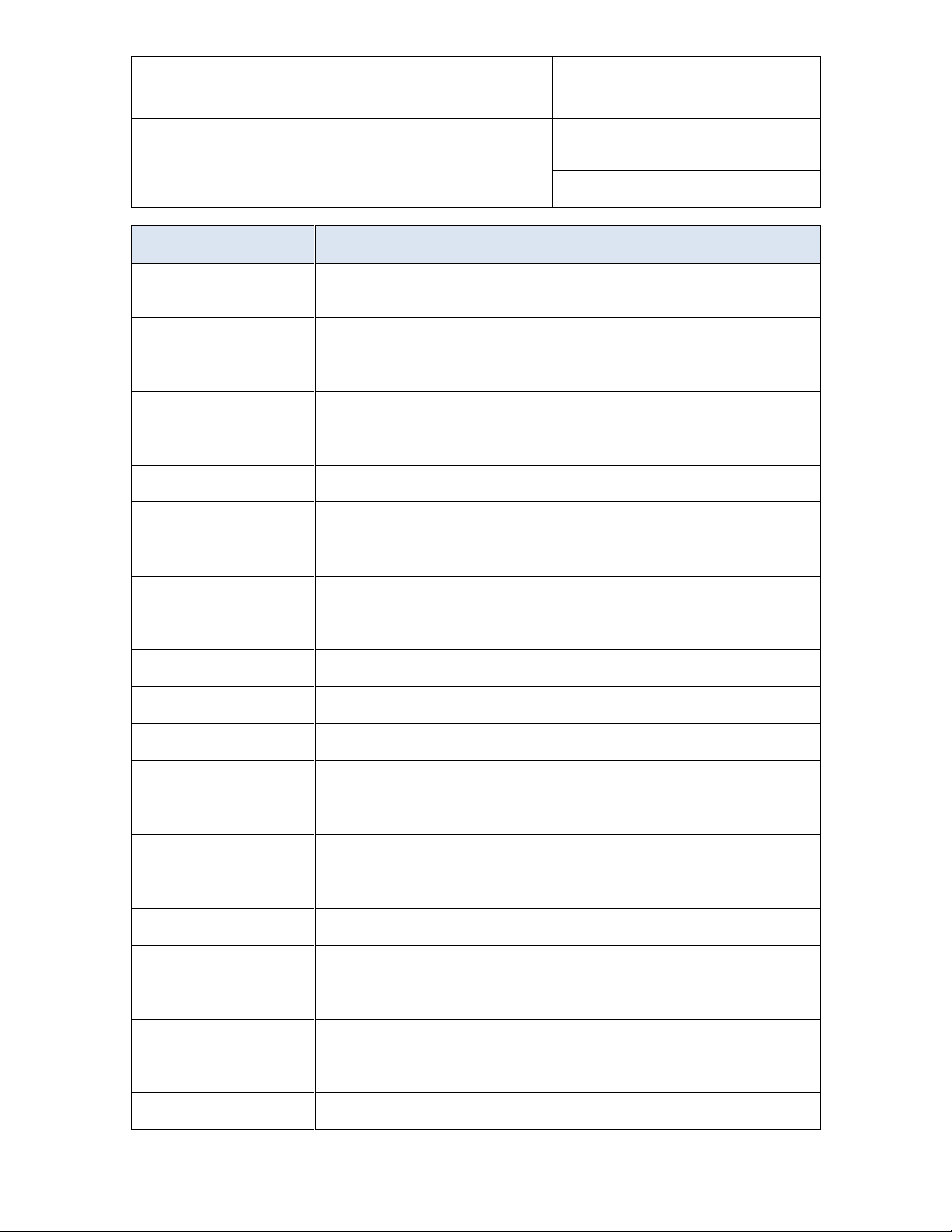

2.10 Event tracking

The HygroLog HL-NT maintains an internal event file with the extension EVT. This function is

always enabled.

Part of the procedure to ensure conformity to the FDA requirements is to use the HW4 software

to disable the MENU key on the HygroLog HL-NT keypad. The MENU key is the only key that can

be used to make changes to the HygroLog HL-NT. When this procedure is implemented, the

events recorded by the HygroLog HL-NT are the result of an interaction with the HW4 software.

When the MENU key is not disabled, a limited number of events are recorded in the logger event

file. In this case no entries are made in the logger event file header. The two tables below provide

a list of the events tracked by the HygroLog HL-NT.

The logger event file is split between the internal memory of the logger (up to 170 events) and the

flash memory card (practically unlimited number of events). HW4 offers the possibility of

downloading, opening and printing the entire file contents. All past logger events are available to

HW4 as long as the flash memory card is not removed from the logger. The serial number of the

logger is used as the file name.

Example: 1111111111.EVT

The logger event file consists of a file header and a file body. The file header provides the

following information:

o Most recent programming of the log function: programming date and time, user and HW4

product ID

o Most recent device configuration: date and time, user and HW4 product ID

o Most recent adjustment to the PC date and time: date and time, user and HW4 product ID

An individual record with date and time is entered in the event file body for each individual event

listed in the two tables below:

Interaction with the HW4 software:

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 15

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

15 of 48

Document title

Event

Description

New memory card

inserted

The memory card was replaced while data was being logged. The data

will be split between two different memory cards. Possibly, some data

has been lost.

Humidity adjusted

Humidity adjustment of the probe connected to input #

Temperature adjusted

Temperature adjustment of the probe connected to input #

Logging started

Start recording data from input #

Logging stopped

manually

Data recording of input # ended before the programmed stop time

Logging ended

automatically

Data recording of input # ended at the programmed stop time

Out-of-limits value

detected

An out-of-limits value was newly detected on input #

Battery almost empty

Battery voltage dropped below 6.5V

Battery empty

The battery is empty and the logger has powered itself off (keeping

power up could result in erroneous data or loss of data)

Beginning accumulator

charge

Starting to charge the rechargeable battery

Accumulator charge

ended

Rechargeable battery full

MFG command

Reserved for the factory

Lost data, memory card

not ready

While recording data, the logger could not find the memory card. The

data could not be written to the EEPROM, and was lost

HygroClip probe

connected 1

A HygroClip probe was connected to input #

HygroClip probe

disconnected 1

A HygroClip probe was removed from input # or the input can no

longer communicate with the probe

External power

connected

The A/C adapter was connected and is being powered

External power

removed or faulty

The A/C adapter was disconnected, or failed, or is not being powered

Device time changed /

adjusted

Device date and time prior and after adjustment (up to firmware v1.1d

only)

Prior device time

Device date and time prior to change (firmware v1.2a and up)

New device time

Device date and time after change (firmware v1.2a and up)

RS-485 address

changed

The RS-485 address was changed

EEPROM erased

Reserved for the factory

Docking station

disconnected 2

The docking station was disconnected or there is no longer any

communication with it

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 16

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

16 of 48

Document title

Event

Description

Docking station

connected 2

A docking station was connected and communication was established

Logger language file

downloaded

A different internal language file was loaded or the same file was

loaded again

Log function

programmed

The log function has been programmed for input #

Event file deleted

Reserved for the factory

Event

Description

Humidity adjusted

Humidity adjustment of the probe connected to input #

Temperature adjusted

Temperature adjustment of the probe connected to input #

Logging started

Start recording data from input #

Logging stopped

manually

Data recording of input # ended before the programmed stop time

Prior device time

Device date and time prior to change (firmware v1.2a and up)

New device time

Device date and time after change (firmware v1.2a and up)

Log function

programmed

The log function has been programmed for input #

1

connection / removal of analog probes is not recorded

2

only when the docking station has internal electronics

Events triggered from the keypad:

2.11 Operating limits (electronics only)

Models without display:

● -10…50°C with the factory supplied alkaline battery

● -30…70°C with a lithium battery or an external AC adapter

Models with display:

● -10…50°C with the factory supplied alkaline battery

● -10…60°C with a lithium battery or an external AC adapter

The HygroClip probes have generally wider operating limits (see individual probe specifications).

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 17

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

17 of 48

Document title

3. Docking stations for the HygroLog HL-NT

The HygroLog HL-NT requires a docking station with the appropriate interface to be able to

communicate with a PC with the ROTRONIC HW4 software installed. The connector located on

the back of the HygroLog HL-NT is meant to be used with one of the available docking stations

(UART interface). When installed on a PC, the ROTRONIC HW4 software is used to configure

the HygroLog HL-NT, to program its logging function, to download the recorded data and to

adjust the probes connected to the logger against a reference environment.

A docking station is required for any of the following:

o Mount the HygroLog HL-NT to a wall

o Place the HygroLog on the optional desk-top stand

o Use an external AC adapter to power the HygroLog HL-NT

o Connect the HygroLog HL-NT to a PC: RS232 or USB port, Ethernet (TCP/IP) LAN

or WLAN

o Connect up to 64 HygroLog HL-NT or other devices together in a multi-dropped network

(RS-485)

Depending on the model, using a docking station also adds functionality to the HygroLog HL-NT:

o Up to 4 additional probes, including analog probes and direct 4-wire RTDs

o Logical inputs (external contacts)

o Relay outputs

Note: docking stations with internal electronics and PC interface should be generally used with an

external AC adapter.

3.1 Models

All models of docking station have the same physical dimensions and can be used either as a

mechanical adapter to place the HygroLog HL-NT on the optional desk-top stand or as a bracket

to mount the HygroLog HL-NT to a wall. Docking stations are available in the following

configurations:

3.1.1 Basic docking stations (no digital interface)

o HL-DS-NT0: basic docking station without internal electronics. This model simply

provides a means of mounting the HygroLog HL-NT to a wall

o HL-DS-NT1: basic docking station without internal electronics (similar to model HL-DS-

NT0). This model simply provides a receptacle for an AC adapter used to power the

HygroLog HL-NT

3.1.2 Docking stations with RS-232 serial interface

o HL-DS-NT2: receptacle for AC adapter, one serial port (RS232) and one RS485 port

(multi-drop).

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 18

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

18 of 48

Document title

o HL-DS-U1: receptacle for AC adapter, one serial (RS232) port, one RS485 port (multi-

drop), four probe inputs (HygroClip 2 or analog probe with voltage output signal), one

connector for up to two logical input signals.

3.1.3 Docking stations with USB interface

o HL-DS-NT3: receptacle for AC adapter, one USB port and one RS485 port (multi-drop).

o HL-DS-U2: receptacle for AC adapter, one USB port, one RS485 port (multi-drop), four

probe inputs (HygroClip or analog probe with voltage output signal), one connector for up

to two logical input signals.

o HL-DS-U2-420: same as HL-DS-U2 but designed for analog probes with a 4-20 mA

output signal. Each probe input uses an internal 150 Ohm resistor to convert 4…20 mA to

600…3000 mV (nominal).

o HL-DS-PT2: receptacle for AC adapter, one USB port, one RS485 port (multi-drop

networking), four connectors for RTD probe (direct 4-wire connection), one connector for

up to two logical input signals.

o HL-DS-R1: receptacle for AC adapter, one USB port, one RS485 port (multi-drop

networking), one connector for up to two logical input signals and two independent relay

output connectors.

3.1.4 Docking stations with wired Ethernet interface

Note: with any of the following models, use an extension cable to separate all probes from either

the HygroLog HL-NT or docking station so as to avoid measurement errors due to self-heating by

the docking station.

o HL-DS-NT4: receptacle for AC adapter, one RJ45 connector (Ethernet), one RS485 port

(multi-drop) and one connector for up to two logical input signals.

o HL-DS-NT4-WEB: same as HL-DS-NT4 but with an internal web server that can be

accessed with a web browser.

o HL-DS-U4: receptacle for AC adapter, one RJ45 connector (Ethernet), one RS485 port

(multi-drop), four probe inputs (HygroClip or analog probe with voltage output signal), one

connector for up to two logical input signals.

o HL-DS-U4-WEB: same as HL-DS-U4 but with an internal web server that can be

accessed with a web browser.

o HL-DS-U4-420: same as HL-DS-U4 but designed for analog probes with a 4-20 mA

output signal. Each probe input uses an internal 150 Ohm resistor to convert 4…20 mA to

600…3000 mV (nominal).

o HL-DS-U4-420-WEB: same as HL-DS-U4-420 but with an internal web server that can

be accessed with a web browser.

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 19

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

19 of 48

Document title

o HL-DS-PT4: receptacle for AC adapter, one RJ45 connector (Ethernet), one RS485 port

(multi-drop networking), two connectors for RTD probe (direct 4-wire connection), one

connector for up to two logical input signals.

3.1.5 Docking stations with wireless Ethernet interface

Note: with any of the following models, use an extension cable to separate all probes from either

the HygroLog HL-NT or docking station so as to avoid measurement errors due to self-heating by

the docking station.

o HL-DS-NT4-WL: receptacle for AC adapter, WLAN transceiver, one RS485 port (multi-

drop) and one connector for up to two logical input signals.

o HL-DS-U4-WL: receptacle for AC adapter, WLAN transceiver, one RS485 port (multi-

drop), two probe inputs (HygroClip 2 or analog probe with voltage output signal), one

connector for up to two logical input signals.

o HL-DS-U4-WEB-WL: same as HL-DS-U4-WL but with an internal web server that can be

accessed with a web browser.

o HL-DS-PT4-WL: receptacle for AC adapter, WLAN transceiver, one RS485 port (multi-

drop networking), two connectors for RTD probe (direct 4-wire connection), one

connector for up to two logical input signals.

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 20

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

20 of 48

Document title

To mount the docking station to a wall, use

the two holes shown on the right. The

HygroLog NT can then be attached to the

docking station as explained below.

To attach the HygroLog NT to the

docking station:

Place the HygroLog NT on the

docking station so as to match the

two areas [A]. Press lightly one

against the other and secure the

assembly with threaded pin [B].

When the docking station is

mounted on a wall, a small

padlock (not shown) may be put

through pin [B] to prevent removal

of the HygroLog NT from the

docking station.

[B]

[B]

[A]

3.2 Installation

Installation is the same for all models of docking station.

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 21

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

21 of 48

Document title

Probe input 4

Probe input 5

Logical inputs

Probe input 6

Probe input 7

RS-485

12VDC Power

(+) center

RS-232

Probe input 4

Probe input 5

Probe input 6

Probe input 7

RS-485

12VDC Power

(+) center

USB

Logical inputs

3.2.1 Connector identification

HL-DS-U1

HL-DS-U2

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 22

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

22 of 48

Document title

Probe input 4

Probe input 5

Logical inputs

Probe input 6

RJ45

RS-485

12VDC Power

(+) center

Probe input 7

Probe input 4

Logical inputs

Probe input 6

Antenna

RS-485

12VDC Power

(+) center

HL-DS-U4 / HL-DS-U4-420

HL-DS-U4-WL

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 23

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

23 of 48

Document title

Input 4: RTD

Input 5: RTD

Logical inputs

Input 6: RTD

Input 7: RTD

RS-485

12VDC Power

(+) center

USB

Input 4: RTD

Logical inputs

Input 6: RTD

RJ45

or WLAN

RS-485

12VDC Power

(+) center

HL-DS-PT2

HL-DS-PT4 / HL-DS-PT4-WL

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 24

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

24 of 48

Document title

Contact material

Silver alloy

Initial contact resistance

100 mΩ

Initial insulation resistance

Min. 1,000 MΩ at 500V DC

Nominal switching capacity 1)

2 A 250 VAC

Minimum switching power 1)

1,500 VA

Maximum switching voltage 1)

250 V AC

Maximum switching current 1)

2 A AC

Minimum switching capacity 1)

100 mA, 5 V DC

Expected life (min. operations)

Mechanical: 5 x 106

Electrical: N.O. 5 x 104

N.C. 3 x 104

Relay 1

Not used

Logical Inputs

Relay 2

Not used

RS-485

12VDC Power

(+) center

USB

HL-DS-R1

The relay contacts are specified as follows:

1) Resistive

The DS-R-1 docking station is provided with two matching 4-pin connectors. The pins of these

connectors are numbered on the connector solder side (see pin-out diagrams).

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 25

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

25 of 48

Document title

3.3 Docking station inputs

Depending on the model of docking station, the signals from up to 4 additional probes can be

processed by the HygroLog HL-NT.

3.3.1 HygroClip 2 probes

By default inputs 4, 5, 7 and 7 of docking stations HL-DS-U1, HL-DS-U2, HL-DS-U4 and HL-DSU4-WL are configured by the factory to accept a HygroClip 2 probe. Any model of HygroClip 2

probe can be connected these using one of the available extension cables.

See document E-M-HC2-accessories.

3.3.2 1-channel analog probes with voltage output

Inputs 4, 5, 7 and 7 of docking stations HL-DS-U1, HL-DS-U2, HL-U4 and HL-DS-U4-WL can also be

configured to accept one of the following:

o 1-channel analog probe: To be compatible with the docking station the analog probe must

meet the following requirements: supply voltage: 5 VDC, current consumption: max. 10 mA,

output signal: 0 to max. 3.3 VDC. The docking station uses a 12-bit A/D converter to digitize

the probe analog signal and can be configured to measure practically any parameter.

o Analog pressure probe: this is a special case of analog probe and is subject to the same

compatibility requirements. When analog pressure probe is selected, any input of the

HygroLog HL-NT and docking station can be configured to use the signal from the pressure

probe to calculate any humidity parameter that requires barometric pressure as an input

value (example: mixing ratio).

3.3.3 1-channel analog probes with current output

Docking station HL-DS-U4-420 is similar to docking station HL-DS-U4 with the difference that it

accepts up to four 3-wire single channel analog probes with a 4-20 mA current output signal.

Each probe input uses an internal 150 Ohm resistor to convert 4…20 mA to 600…3000 mV

(nominal). The HW4 software allows a 2-point adjustment of the mA to mV conversion to

compensate for the tolerance on the 150 Ohm resistor (use Device Manager in HW4). The

probes are powered by the docking station (supply voltage: 5 VDC, maximum current draw: 10

mA / probe).

3.3.4 Pt100 RTD 4-wire probes

Docking stations HL-DS-PT2, HL-DS-PT4 and HL-DS-PT4-WL are designed for 4-wire RTD

probes. These docking stations allow the measurement of temperature conditions within the

range of -100 to 600°C. Accuracy depends on the class of the Pt100 RTD. Adjustment of the

RTD inputs against a reference temperature is limited to a 1-point adjustment (global offset).

3.3.5 Logical inputs (on / off)

Several models of docking station allow the HygroLog HL-NT to process up to 2 logical inputs.

Typically this is used to monitor a relay contact, a door contact, etc.

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 26

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

26 of 48

Document title

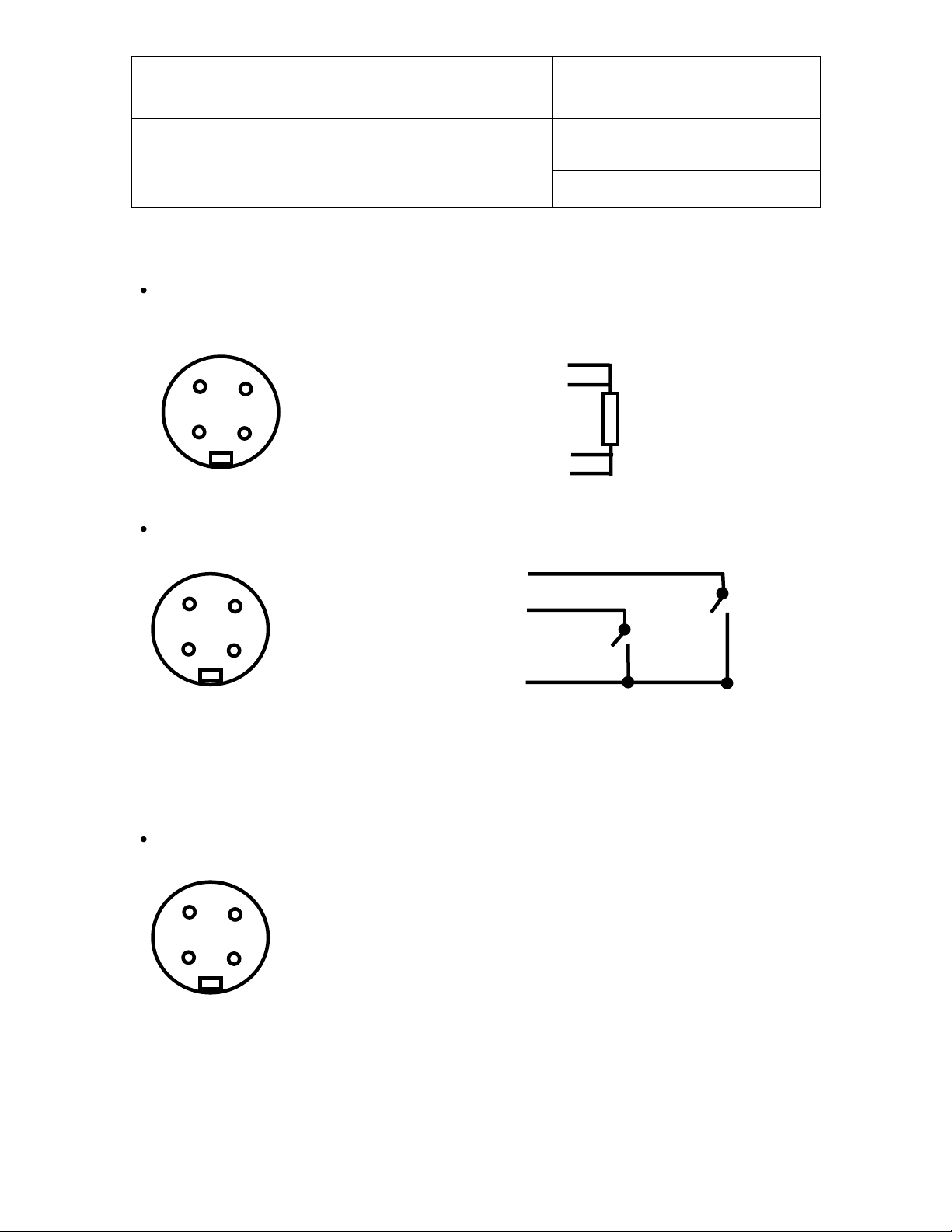

HygroClip 2 probe

1: RXD (UART)

2: GND (digital and power)

3: V+ (nominal 3.3 VDC)

4: not used

5: not used

6: not used

7: TXD (UART)

Analog 1-channel probe

1: not used

2: GND (power)

3: V+ (nominal 5 VDC, maximum 10 mA)

4: AGND (analog ground)

5: not used

6: analog signal (0.0…3.3 VDC or 4…20 mA

7: not used

3.4 Relay contacts

Docking station model HL-DS-R1 features two independent relays, each with 3 contacts: normally

closed, normally open and common. When configuring the HygroLog HL-NT and docking station

with the HW4 software, a number of conditions can be defined that will cause the relay to be

either energized or de-energized.

The relays of the HL-DS-R1 docking station can be used to provide a local indication of the

following:

o Out of limit values for probe inputs 1 to 3 of the HygroLog HL-NT

o Status of the two logical inputs of the DS-R-1 docking station

o Memory card error

o External power failure

o Low battery charge

4. Pin-out diagrams

Note: all pin-out diagrams are shown from the solder side of the matching connector

HygroLog HL-NT2 and HL-NT3: the probe inputs are always configured for a HygroClip 2

probe

Docking stations HL-DS-U1, HLDS--U2, HL-DS-U4, HL-DS-U4-420 and HL-DS-U4-WL:

the probe inputs can be configured for either a HygroClip 2 probe or for a 1-channel analog

probe

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 27

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

27 of 48

Document title

3

4

1

2

1: Normally closed (relay de-energized)

2: Common

3: Normally open

4: Not used

4

3

2

1

1: + 3.5 VDC

2: Input 1

3: Input 2

4: GND

1

2

GND: not used (eventually use for a shield)

+3.5 V

Note: an internal pull-down resistor sets

each input to 0 when the contact is open.

1: DC (+)

2: measurement (+)

3: measurement (-)

4: DC (-)

1 2 3

4

4-wire RTD

4

3 2 1

Docking stations HL-DS-PT2, HL-DS-PT4 and HL-DS-PT4-WL: direct Pt100 RTD

Docking stations with logical inputs

Logical Thresholds: logical 1: ≥ 2.8 VDC, logical 0: ≤ 0.7 VDC

Docking station HL-DS-R1 with relay outputs

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 28

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

28 of 48

Document title

Pin #

RS-232

2

TX 3 RX 5 GND

1 5 6

9

1: 485 (-)

2: 485 (+)

3: GND (see note)

4: DC + (see note)

4

3

2

1

Note: use pins 3 and 4 to power multi-dropped instruments with a single external 12 VDC

power supply with adequate mA rating. Pin 4 and the 12VDC power jack of the docking

station are not connected.

Docking stations with RS-485 port

Docking stations with RS-232 port

5. HW4 software

The HygroLog HL-NT requires a docking station with the appropriate interface to be able to

communicate with a PC with the ROTRONIC HW4 software installed (version 2.3.0 or higher).

Detailed instructions are provided in the HW4 manuals (see Supporting documents at the end of

this manual).

The HW4 instruction manuals are available on the HW4 installation CD and can also be

downloaded from our web site.

5.1 Computer/Operating System Requirements

The following are the minimum values required to install and run HW4 on a computer. It is highly

recommended to exceed these values.

o Processor: Pentium II, 450 MHz

o RAM: 128 MB

o Available hard disk space: 50 MB

o Monitor: SVGA, 1024 x 768, 256 colors

o Ports: one free serial (COM) port or one free USB port or Network Interface Card / Ethernet

LAN with one free port (RJ45 connector)

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 29

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

29 of 48

Document title

5.2 Operating System Compatibility

o Windows XP, NT4 with SP 6a or higher, Vista

o Windows 2000 with SP 2 or higher

o Windows Server 2003

HW4 was written for the Microsoft .NET framework (version 2.0) and requires this framework to

be installed on the computer.

The .NET framework offers significant improvements in the areas of networking and user security.

When new software is being installed, the .NET framework also eliminates the potential problem

of conflicting dynamic library files (DLL). According to Microsoft, the .NET framework will be used

by all future Microsoft operating systems.

5.3 Settings and functions accessible only with HW4

Device configuration settings

● User specific information (retained in the logger)

● Custom text associated with the logger (30-character description)

● Network address of the logger

● Language used in the logger menu

● Date and time format / separators

● Decimal symbol

● Pressure unit (English) and mixed unit systems

● Individual input settings:

- Probe type (HygroClip 2 or analog) – docking station only

- Probe / input description (maximum 12 characters)

- Parameter to be calculated for an individual input

- Barometric pressure: fixed value or read from an input

- Value to be used as fixed barometric pressure

- Alarm settings for humidity, temperature and calculated parameter

● Display settings:

- Display refresh rate

- Turn display off after xx minutes (display sleep function)

- Backlight operation

- Alternate the display - automatically show all inputs one after the other

● Keypad disable functions:

- Disable entire keypad

- Disable only the MENU key

● Type of internal power source: standard battery or rechargeable battery

● LED and Sound settings

● Cancel a latching alarm (LED on logger and/or de-energizing optional docking station relays)

● Memory card settings: log file format and memory management

● Programming of the optional inputs (docking station)

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 30

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

30 of 48

Document title

Data recording functions

● Logging functions (set individually for each input, can be scheduled for a future date / time):

- Start date and time

- Stop date and time

- Log measured values and computed parameter, or any combination

- Custom text (used for the log file header - up to 43 characters)

- User name, HW4-ID, HW4-serial number (used for the log file header)

- Automatic creation of a new file after 200,000 data points or at the end of each day, week

or month

● Global programming of the log function of all inputs

● Data downloading (from the logger) and associated functions

HygroClip 2 probe functions

● Device Manager (probe configuration settings, simulator function, fail safe mode)

● Data recording (at the probe level)

● Probe calibration and adjustment (full functionality)

For detailed instructions, see the following HW4 software manuals:

o E-M-HW4v2-F2-013: Device Manager – HygroLog HL-NT data logger

o E-M-HW4v2-F2-001: Device Manager – HYGROLOG HL-NT2 probe series

o E-M-HW4v2-A2-001: Probe Adjustment function AirChip 3000 devices

o E-M-HW4v2-DR-001: Data Recording Function AirChip 3000 Devices

6. ERES regulatory compliance

In order to comply with ERES regulatory requirements (Electronic Records and Electronic

Signatures), the HygroLog HL-NT should be used together with the ROTRONIC HW4 software –

Professional Edition (version 2.3.0 or higher). HW4 is designed to keep track of logger

configuration changes, programming changes and of any probe adjustment. HW4 also keeps

track of user events (main operations performed by each user) and self-events (software

problems). The records generated by HW4 are protected with an electronic authentication stamp,

can be cross referenced and can be electronically signed.

IMPORTANT: In order to comply with ERES regulatory requirements, be sure to configure both

the HygroLog HL-NT and the HW4 software as follows:

o In HW4, create a user with full rights (administrator) and a password (see HW4 manual -

Users and Passwords). After creating the first user, be sure to log in as this user (see

HW4 manual - Users and Passwords - Change User). This enables both the HygroLog

HL-NT and the HW4 software to maintain a record of events and to associate these with

a specific user. Create additional users with or without limited rights, as per your

requirements.

o Enable HW4 to monitor electronic signatures and user events (see HW4 manual - Global

Settings - Events)

o Enable HW4 to monitor system events (see HW4 manual - Global Settings - General)

o Enable protocols in HW4 (see HW4 manual - Device Manager - Device Manager

Settings)

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 31

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

31 of 48

Document title

If the HygroLog HL-NT has a display and keypad, disable the MENU key (see HW4 manual Device Manager - HygroLog HL-NT - Keypad).

7. Getting started

Insert a 9V alkaline battery in the HygroLog HL-NT as explained under Hardware Description Power. To conserve battery power, models with a display are shipped with the Display

Sleep function enabled. With this function enabled and when logging is not active, the logger

just keeps track of the date and time and uses very little battery power. Press any key on the

keypad to temporarily suspend the Display Sleep function. The HW4 software is required to either

disable the Display Sleep function or to reconfigure this function. See Display Sleep function

under Software Functions

8. Stand-alone operation

8.1 Operating modes

The HygroLog HL-NT has two main operating modes: measure and record.

● Measure mode: the HygroLog HL-NT defaults to this mode when it is not recording any data.

What happens in this mode depends on whether or not the HygroLog HL-NT is communicating

with a PC.

When there is no communication with a PC, the model without display is in a low power

consumption mode and just keeps track of the date and time. The model with display behaves

differently, depending on whether or not the Display Sleep function is enabled (see Software

Functions). If the function is disabled (display always on), measurements take place at

intervals of time corresponding to the display refresh interval that was specified with HW4

when configuring the data logger. When the display goes blank because the Display Sleep

function is enabled, the model with display behaves in the same manner as the model without

display.

● Record mode: the model without display measures data according to the log interval that was

specified for each individual input. The shortest log interval is 5 seconds. The log interval and

the measurement interval are the same. In the case of the model with display, the

measurement interval is the shortest of the log interval and display refresh interval. If the

Display Sleep function is active, the measurement interval is by default the same as the log

interval.

8.2 Display and keypad

Depending on the model, the HygroLog HL-NT is equipped with a display and a keypad.

Display

The HygroLog HL-NT uses a monochrome graphic LC display with backlight. The backlight works

only when the HygroLog HL-NT is powered via a docking station. The normal function of the

display is to show the most recent measured values, one at a time. The display is also used to

navigate the Function Menu of the HygroLog HL-NT.

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 32

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

32 of 48

Document title

IMPORTANT: Using the HW4 software, the display can be set to automatically go blank after a

specific time interval when there is no keypad activity and when there is no communication over

the UART interface. This serves the purpose of conserving battery power. The display comes up

again when any key is pressed or when a communication is initiated. See Software Functions,

Display Sleep function. HW4 is also required to configure the operation of the display backlight:

always off, always on, on key press (default setting).

Keypad

The keypad of the HygroLog HL-NT is comprised of the following keys:

● MENU: press this key to open the function menu, to go back one menu level or to exit the

menu.

● ENTER: this key has two functions:

If the function menu is not open, press this key to switch the display between showing the

measured values, date, time and probe number and showing the measured values and

calculated parameter (if HW4 was used to associate a calculated parameter with the probe).

If the function menu is open, press this key to select a menu item and/or to confirm a value or

setting.

● UP: the up-arrow key has two functions:

If the function menu is not open, the up-arrow key is used to switch the display between the

different probe inputs.

If the function menu is open, the up-arrow key is used to navigate the function menu and/or to

change the setting or value of a menu function.

● DOWN: the down-arrow key has a similar functionality as the up-arrow key:

IMPORTANT: the HW4 software can be used to disable either the MENU key or the entire

keypad. If the keypad does not work, you should check the configuration of the HygroLog HL-NT

with HW4. Disabling the MENU key prevents unauthorized changes to the configuration of the

HygroLog HL-NT and also prevents any probe adjustment. Compliance with FDA / GAMP

requires the MENU key to be disabled.

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 33

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

33 of 48

Document title

8.3 Display modes

The display shows the measurement data for one input at a time. Values shown on the display

are updated according a refresh interval that can be set with the HW4 software. Use the UP or

the DOWN arrow key to switch between inputs. Two different modes are available to display the

measurement data. Use the ENTER key to toggle between the two modes:

● Display Mode 1:

Measured value 1 (usually relative humidity

Measured value 2 (usually temperature)

Date and time

Probe / input description (as entered with HW4 when configuring the HygroLog HL-NT)

Note: the bottom line of the display remains empty if no description was entered for the probe

input.

● Display Mode 2:

Measured value 1 (usually relative humidity)

Measured value 2 (usually temperature)

Calculated parameter (as selected with HW4 when configuring the HygroLog HL-NT)

Note: in this mode, the last line of the display shows the symbols --.- when no calculated

parameter was selected with HW4.

In both modes, a trend indicator appears to the left of each measured value when the trend

function is enabled. See Software Functions, Trend Indicators.

8.4 Settings and functions accessible from the Keypad

Note: access to the following functions can be prevented by disabling the MENU key when

configuring the HygroLog HL-NT with the HW4 software.

The following settings can be entered / programmed from either the Keypad or with the HW4

software:

● Display mode: measured and calculated values or measured values, date, time and probe /

input description

● Unit System (metric or English) - configuring some English units such as pressure requires

HW4

● Trend indicators on / off

● Symbol used for humidity

● Contrast of the LC display

● Decimal resolution of the display

● Date

● Time

● Enable / disable optional Bluetooth transceiver

● Cancel alarm (works only when the latching mode is enabled)

© 2009; Rotronic AG IN-E-HL-NT-V2_10

Page 34

IN-E-HL-NT-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroLog HL-NT data logger:

instruction manual

Instruction Manual

Document Type

Page

34 of 48

Document title

● Logging functions (set individually for each input, cannot be scheduled for a future date / time):

- Start logging

- Stop logging

- Log Interval

● View recorded data (in table form only)

● Probe adjustment function, limited to a 1-point adjustment of humidity and temperature one

probe at a time (HygroClip 2 probes only)

8.5 Internal function menu (models with display and keypad)

8.5.1 Log data

This menu item is used to immediately start or stop recording data from each individual input. Log

operations that are set in the future and / or settings that apply globally to all probe inputs cannot

be programmed from here. When data logging is not active, selecting this menu item displays the

following:

● Probe: probe name (custom name specified by user)

To change the probe, use the up or down arrow key to highlight probe and press ENTER. Use

the arrow keys to change the probe and press ENTER to confirm the selection.

● Interval: log interval in HH:mm:ss

● START LOGGING: record data immediately

● EXIT: exit the log data function

When data logging is either in progress or has been scheduled at a future time, the third menu

item (START LOGGING) changes to:

● STOP LOGGING: stop recording data immediately

8.5.2 View data

This menu item is used to view on the LC display data from the most recent log file for the

selected probe (older log files cannot be opened with this menu item).

● Probe: probe name (custom name specified by user)

To change the probe, use the up or down arrow key to highlight probe and press ENTER. Use