Page 1

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

1 of 165

Document title

HW4 Software version 2

General instructions and functions common to all devices

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 2

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

2 of 165

Document title

Table of contents

1 ORGANIZATION OF THE HW4 MANUALS ........................................................................ 5

2 OVERVIEW ........................................................................................................................... 6

2.1 HW4 Standard Edition ................................................................................................................. 6

2.2 HW4 Professional Edition ............................................................................................................ 6

2.3 HW4 Lite ...................................................................................................................................... 7

2.4 HW4 Professional with OPC Server ............................................................................................. 7

2.5 HW4 Professional with AwQuick .................................................................................................. 7

2.6 HW4 Professional Trial Version ................................................................................................... 7

2.7 HW4 Validated ............................................................................................................................. 7

3 NEW IN VERSION 2.1.0 OR HIGHER ................................................................................. 8

3.1 HW4 v 2.1.0 ................................................................................................................................. 8

3.2 HW4 v 2.1.1 ................................................................................................................................. 9

3.3 HW4 v 2.2.0 ................................................................................................................................. 9

3.4 HW4 v 2.3.0 ................................................................................................................................10

4 INSTALLATION .................................................................................................................. 12

4.1 Software Licensing Agreement ...................................................................................................12

4.2 HW4 requirements ......................................................................................................................12

4.3 Installing HW4 .............................................................................................................................14

4.4 Updating HW4 to a newer version ..............................................................................................18

4.5 Uninstalling HW4 (full uninstall) ..................................................................................................18

5 CONNECTING DEVICES TO THE HW4 PC ...................................................................... 19

5.1 Definition: masters and slaves (HW4 Professional) ....................................................................19

5.2 Connection methods for master devices .....................................................................................19

5.3 Devices used as RS-485 slaves (HW4 Professional) .................................................................19

6 PREPARING FOR DEVICE CONNECTION ...................................................................... 21

6.1 Physical serial port ......................................................................................................................21

6.2 Bluetooth virtual serial port .........................................................................................................21

6.3 USB port .....................................................................................................................................21

6.4 Ethernet (TCP/IP) connection .....................................................................................................24

6.5 RS-485 slaves: address and Baud rate requirements .................................................................29

7 INITIAL START-UP ............................................................................................................ 31

7.1 Language selection .....................................................................................................................31

7.2 Product key and registration .......................................................................................................32

7.3 Automatic device discovery during initial start-up .......................................................................34

7.4 Creating the first user (HW4 Professional) ..................................................................................35

7.5 Access to functions and screens (HW4 Professional) .................................................................35

8 SEARCHING FOR DEVICES WITH HW4 .......................................................................... 36

8.1 Searching for master devices......................................................................................................36

8.2 Searching for RS-485 slaves (HW4 Professional) ......................................................................36

9 HW4 MAIN SCREEN .......................................................................................................... 37

9.1 Device Tree (left pane) ...............................................................................................................38

9.2 Right pane in Device View mode ................................................................................................41

9.3 Right pane in Group View mode .................................................................................................49

10 HW4 MAIN MENU BAR ...................................................................................................... 53

10.1 File ..............................................................................................................................................53

10.2 Devices and Groups ...................................................................................................................54

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 3

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

3 of 165

Document title

10.3 View ............................................................................................................................................58

10.4 Settings and Tools ......................................................................................................................59

10.5 Help ............................................................................................................................................60

10.6 Shortcut buttons ..........................................................................................................................60

11 ETHERNET CONFIGURATION TOOL .............................................................................. 61

12 USERS AND PASSWORDS (HW4 Professional) ............................................................ 62

12.1 Minimum user rights ....................................................................................................................62

12.2 Additional user rights ..................................................................................................................63

12.3 Creating and logging-on the first user .........................................................................................64

12.4 User table form ...........................................................................................................................67

12.5 Menu bar .....................................................................................................................................67

12.6 User login security ......................................................................................................................69

13 COLUMN HEADERS .......................................................................................................... 69

14 HW4 GLOBAL SETTINGS ................................................................................................. 72

14.1 View Tab .....................................................................................................................................72

14.2 General Tab ................................................................................................................................74

14.3 Language/Unit System Tab ........................................................................................................77

14.4 File Locations Tab .......................................................................................................................79

14.5 Graph Settings Tab .....................................................................................................................81

14.6 Alarm Settings Tab (HW4 Professional) .....................................................................................84

14.7 Events Tab (HW4 Professional) ..................................................................................................86

15 USER EVENTS (HW4 Professional) ................................................................................. 87

15.1 Menu bar .....................................................................................................................................88

16 ALARM TABLE (HW4 Professional) ................................................................................ 89

16.1 Alarm acknowledgement .............................................................................................................90

16.2 Alarm table menu bar and buttons ..............................................................................................91

17 PSYCHROMETRIC CONVERSIONS ................................................................................. 93

18 DEVICE PROTECTION ...................................................................................................... 94

19 DATA LOGGING - directly on the PC .............................................................................. 96

19.1 Start logging data to the PC ........................................................................................................96

19.2 Stop logging data to the PC ........................................................................................................98

20 ACCESSING LOG FILES, PROTOCOLS AND EVENT FILES ......................................... 99

21 VIEW / SIGN A PROTOCOL ............................................................................................ 101

21.1 Protocol viewer menu bar .........................................................................................................103

22 VIEW / SIGN A LOG FILE ................................................................................................ 104

22.1 Opening a log file in HW4 View Data ........................................................................................104

22.2 View Data menu bar .................................................................................................................108

22.3 View Data Toolbar ....................................................................................................................116

22.4 Graph Tab .................................................................................................................................117

22.5 Data Table / File Name Tab ......................................................................................................121

22.6 Working with log files and graphs (How To) ..............................................................................121

23 ALARM INDICATION & REPORTING - Overview .......................................................... 122

23.1 Standard alarm notification (all HW4 versions) .........................................................................122

23.2 Optional alarm notification (HW4 Professional).........................................................................123

23.3 Alarm Reporting (HW4 Professional) ........................................................................................124

23.4 Additional alarm data ................................................................................................................124

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 4

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

4 of 165

Document title

24 ERES REGULATORY COMPLIANCE (HW4 Professional) ........................................... 128

24.1 Required settings and selections ..............................................................................................128

24.2 Electronic records .....................................................................................................................128

24.3 Log File Format .........................................................................................................................128

25 RECORD KEEPING - Overview (HW4 Professional) .................................................... 129

25.1 Event Files ................................................................................................................................129

25.2 Protocols ...................................................................................................................................133

25.3 Cross referencing protocols and event files ..............................................................................135

26 FILE PROTECTION .......................................................................................................... 136

26.1 Authentication stamp ................................................................................................................136

26.2 Overview ...................................................................................................................................137

27 RELOCATING THE HW4 USER FOLDER ...................................................................... 137

27.1 Method 1 (using Windows Explorer) .........................................................................................138

27.2 Method 2 (after the initial HW4 start-up) ...................................................................................141

27.3 Retrieving your previous settings and other data ......................................................................145

28 CHANGING THE BAUD RATE OF AN ETHERNET DEVICE ......................................... 147

29 CONCURRENT HW4 SESSIONS ON DIFFERENT WORKSTATIONS.......................... 150

29.1 Polling synchronization .............................................................................................................151

30 MULIPLE HW4 SESSIONS ON THE SAME PC .............................................................. 154

31 STARTING HW4 AUTOMATICALLY with Windows ...................................................... 154

32 BASIC ETHERNET CONCEPTS...................................................................................... 156

32.1 Compatibility requirements .......................................................................................................156

32.2 DHCP ........................................................................................................................................157

32.3 MAC Address ............................................................................................................................157

33 WATER ACTIVITY MEASUREMENT WITH HW4 ........................................................... 157

33.1 Water Activity: definition and applications ................................ ................................................. 157

33.2 Instruments and probes for measuring water activity ................................................................159

33.3 Water activity measurement modes in HW4 .............................................................................159

33.4 Mode selection and settings .....................................................................................................160

33.5 Using the AwE mode ................................................................................................................161

33.6 Using the AwQuick mode ..........................................................................................................162

33.7 Water activity measurement report ...........................................................................................163

34 DOCUMENT RELEASES ................................................................................................. 165

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 5

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

5 of 165

Document title

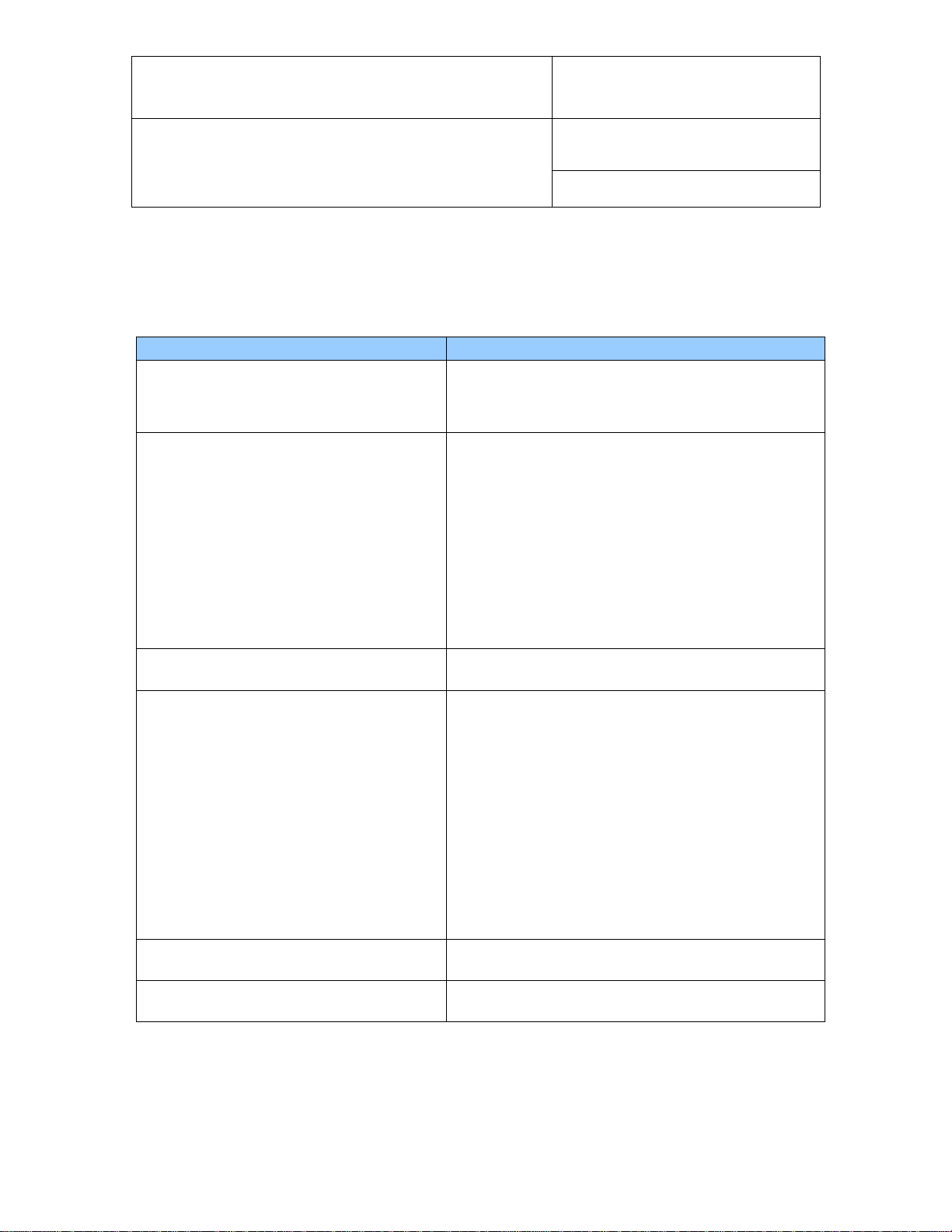

HW4 Manuals

Contents

HW4 Main Book

General software description

Installation, start-up and settings

Device connection methods

Functions common to all devices used with HW4

Device Specific Functions 1

(separate book for each device type or model)

Legacy devices (original HygroClip technology):

o HygroLog NT data logger

o HygroFlex 2, HygroFlex 3 and M3 transmitters (same

icon in device tree)

o HygroLab 2 and HygroLab 3 bench indicators

o HygroPalm 2 and HygroPalm 3 portable indicators

o HygroClip DI digital interface

o HygroClip Alarm programmable logic

o HygroStat MB

Device Manager (device configuration) and other device

specific functions

Probe Adjustment 1

Humidity and temperature adjustment function common to

all legacy devices (original HygroClip technology)

Device Specific Functions 2

(separate book for each device type or model)

Devices based on the AirChip 3000 technology such as:

o HygroClip 2 (HC2) probes

o HF3 transmitters and thermo-hygrostats

o HF4 transmitters

o HF5 transmitters

o HF6 transmitters

o HF7 transmitters

o HF8 transmitters

o HL20 and HL21 data loggers

o HP21, HP22 and HP23 hand-held indicators

o Custom designed OEM products

Device Manager (device configuration, AirChip 3000

functions)

Probe Adjustment 2

Humidity and temperature adjustment function common to

all devices based on the AirChip 3000 technology

Data Recording Function

Data recording function common to all devices based on the

AirChip 3000 technology

1 ORGANIZATION OF THE HW4 MANUALS

The HW4 manuals are organized in separate books so as to limit the size of the individual documents. A list

of the HW4 manuals is provided in document E-M-HW4v2-DIR

Both the HW4 manuals (software) and device specific manuals (hardware) are available on the HW4 CD.

The manuals can also be downloaded from several of the ROTRONIC web sites.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 6

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

6 of 165

Document title

2 OVERVIEW

The HW4 software was developed by ROTRONIC AG for use with the ROTRONIC line of digital instruments

and devices. HW4 is available in the following versions:

2.1 HW4 Standard Edition

o Unlimited number of instruments (depends on capabilities of PC and available ports)

o On-line display of the measured and calculated values (dew point or other), limited to one instrument at

a time.

o Automatic retention of the most recent data in a temporary on-line buffer (multiple instruments).

o Logging of measured and calculated values to the PC (multiple instruments).

o Easy-to-read graphs and data tables.

o Statistical data tools: mean, standard deviation, minimum and maximum of the recorded data (off line

only).

o Data print-out (table or graph)

o Automatic device/instrument recognition and identification

o Device/instrument configuration

o Access to the data recorded by a data logger and data transfer to the PC

o Adjustment (calibration) of the HygroClip digital probes

o Psychrometric Conversion Tool

o Built-in security to protect against data manipulation

2.2 HW4 Professional Edition

HW4 Professional edition complies with ERES regulations. This version of HW4 allows multiple users, with

either administrator or standard rights and password protection.

o All the functionality of HW4 Standard Edition

o RS-485 multi-dropped sub-networks of up to 64 instruments per sub-network

o On-line display of the data from multiple instruments and probes

o Possibility to overlay and synchronize data from several log files into a single graph

o User Event Logging: automatically records user main operations.

o Multiple users distributed into two groups: administrator and standard, each with different rights

o Self Event Logging: automatically records any software problem to facilitate troubleshooting

o Logger Event Logging: automatically records the data logger internal events and configuration changes.

o Automatic creation of protocols detailing instrument configuration and programming changes as well as

and probe adjustments.

o Optical or acoustical indication of an alarm condition, tracking of alarm conditions in a table, and

possibility of printing a report, sending an e-mail, etc.

o Visual Indication an alarm conditions when viewing log file data

o Password protected log-in

o Meets the requirements of FDA 21CFR Part II for electronic records and electronic signatures

o Meets the EU GMP requirements regarding pharmaceuticals.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 7

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

7 of 165

Document title

2.3 HW4 Lite

HW4 Lite is a special version of HW4 Professional which includes all features of HW4 Professional while

being restricted to devices of the HygroWin type.

2.4 HW4 Professional with OPC Server

HW4 Professional with OPC server is a special version of HW4 Professional which includes all features of

HW4 Professional while also providing OPC tags that can be enabled for each individual device

communicating with HW4. This allows transferring data with practically any OPC client (requires

configuration / programming of the OPC client by the user).

2.5 HW4 Professional with AwQuick

HW4 Professional with AwQuick is a special version of HW4 Professional designed to facilitate

measurement of the water activity (Aw) of foods, pharmaceuticals, etc. This version includes all the features

of the regular HW4 Professional Edition. Two modes are available for measuring water activity: AwE and

AwQuick. Both modes can be used with any of our instruments. In the AwE mode, HW4 monitors the natural

equilibration of the product being measured and automatically stops the measurement process when

equilibrium is reached. With most products, natural equilibrium requires from 45 to 90 minutes. The AwQuick

mode reduces the time required to measure water activity to a few minutes, usually with almost the same

accuracy as the AwE mode.

2.6 HW4 Professional Trial Version

HW4 Trial is a fully functional version of HW4 Professional, including the OPC server and water activity

measurement functionality. A compressed installation file (zip) can be downloaded free of charge from the

ROTRONIC website at:

http://www.rotronic-humidity.com/software/humidity_software_download.php

Note: this web page is subject to change

Activation requires an HW4 product key which can be requested by filling a form on the ROTRONIC web

site. A trial product key will be sent to your e-mail address. This must be entered in the registration form

which appears when starting HW4 for the first time. After 30 days, the trial product key expires and HW4 can

no longer be started.

2.7 HW4 Validated

HW4 Validated offers the same functionality as HW4 Professional with OPC server. Additionally, the “HW4

e-compliance Package” is available. This extensive collection of documents (including template of

qualification documents) is designed to support the “regulated user” by qualifying/validating HW4-based

solutions.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 8

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

8 of 165

Document title

3 NEW IN VERSION 2.1.0 OR HIGHER

3.1 HW4 v 2.1.0

HW4 version 2.1.0 or higher includes all the functions and features of HW4 version 2.0.1 (last validated

version) with the following modifications and additions:

● Organization of the HW4 manuals

Starting with HW4 version 2.1.0, the HW4 manuals are organized in separate books so as to limit the size of

the individual documents:

● Alarm-Test scheduling

HW4 features a simulated alarm test that is used to automatically verify at regular intervals of time that the

HW4 measurement system is currently operating and that an alarm notification will be issued whenever

necessary.

Starting with version 2.1.0, HW4 adds the following options when scheduling the automatic simulated alarm

test:

o Each hour

o Each 4 hours

o Each 8 hours

o Each 12 hours

The scheduling options offered by HW4 2.0.1 are still available.

● Polling Synchronization (concurrent HW4 sessions on different workstations)

Stating with version 2.1.0, HW4 includes a polling synchronization function designed to avoid conflicts when

devices are being simultaneously polled by several workstations.

● Probe Adjustment (AirChip 3000 devices)

Starting with version 2.1.0, introduction of products based on the AirChip 3000 has made it necessary to add

a new probe adjustment function.

Note: HW4 version 2 can also be used to adjust devices based on the original HygroClip technology (prior to

the AirChip 3000).

● Devices compatible with HW4

a) Legacy devices – original HygroClip technology

o HygroLog NT data logger

o HygroFlex 2, HygroFlex 3 and M3 transmitters (same icon in device tree)

o HygroLab 2 and HygroLab 3 bench indicators

o HygroPalm 2 and HygroPalm 3 portable indicators

o HygroClip DI digital interface

o HygroClip Alarm programmable logic

o HygroStat MB

Note: HW4 version 2 can also be used to configure the HygroFlex 1, HygroLab 1, HygroPalm 1 and

HygroPalm 0. These instruments are not designed to be used with HW4 for any other purpose.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 9

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

9 of 165

Document title

Recommended minimum firmware version for legacy devices:

HygroLog NT : v 1.2 (v.1.3b or higher: HW4 2.2.0 is required)

Docking station for HygroLog NT : v 1.4

HygroPalm, HygroLab, HygroFlex and M3 : v 4.1

HygroClip DI : v 1.0

HygroClip Alarm : v 2.1

HygroStat MB : v 1.0

b) Devices based on the AirChip 3000 technology (HW4 2.1.0 or higher):

o HygroClip 2 (HC2) probes

o HF3 transmitters and thermo-hygrostats

o HF4 transmitters

o HF5 transmitters

o HF6 transmitters

o HP21, HP22 hand-held indicators

o Custom designed OEM products

3.2 HW4 v 2.1.1

● Communication protocol options

Starting with firmware version 1.3, a number of devices based on the AirChip 3000 offer several

communication protocol options that can be used when the device is not communicating with HW4. For

more details see document E-M-AC3000-CP

HW4 version 2.1.1, Device Manager supports the selection and configuration of the optional communication

protocols.

3.3 HW4 v 2.2.0

● Devices compatible with HW4

HW4 v 2.2.0 adds support for the following devices:

a) Legacy devices – original HygroClip technology

HygroLog NT with firmware v.1.3b (backlit LC display)

b) Devices based on the AirChip 3000 technology (HW4 2.1.0 or higher):

o HF7 transmitter

o XB OEM transmitter

o XA OEM probes

o MP102H and MP402H meteorological probes

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 10

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

10 of 165

Document title

3.4 HW4 v 2.3.0

● Alarm Table (HW4 Professional)

The alarm table View menu now includes two additional items:

o All Alarms: displays the entire contents of the alarm file

o Navigation: duplicates the function of the arrow buttons (go to the beginning of the alarm file, go to

the end of the alarm file, etc.)

● HW4 main menu bar > Devices and Groups

The structure of the Devices and Groups menu (HW4 Main Menu Bar) has been modified as follows:

1) Search for Master Devices: this submenu now includes the new function Refresh Master Devices:

This function interrogates all PC connections (COM, USB and Ethernet) that are used by the master devices

currently in HW4. When communication has been lost with any master device the function re-establishes the

communication. Refresh Master Devices does not add any new device to the device tree and does not look

for slave devices that may be connected to any of the master devices. Refresh Master Devices does not

work with the AC3010 adapter and this adapter has its own refresh function (see below).

2) Search for RS-485 Slave Devices: this submenu is available with all versions of HW4 Professional and

now offers the following options:

o Search for slaves connected to any master present in the device tree

o Search for slaves connected only to the master currently highlighted (selected) in the device tree

o Refresh all RS-485 networks

o Refresh RS-485 network attached to selected master

o Search for devices connected via AC3010 adapter

o Refresh devices connected via AC3010 adapter

When communication has been lost with a slave device already present in the device tree, the “Refresh”

function re-establishes the communication. Refresh does not add any new device to the device tree.

Note: explanations about the AC3010 adapter are provided under “Devices compatible with HW4”

● Device tree > Device menu box

The device menu box can be opened by right clicking on any device present in the device tree. In the case

of a master device the menu box now includes two new items:

o Search for RS-485 slave devices

o Refresh the RS-485 slave devices

These two items operate in the same manner as the equivalent items in the Search for RS-485 Slave

devices submenu and are not available when a slave device has been selected.

● HW4 status line (bottom of the HW4 main screen)

The HW4 version and build number now appear at the bottom right corner of the HW4 main screen

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 11

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

11 of 165

Document title

● Current Values Tab > Column Headers

The serial number of a probe or instrument based on the AirChip 3000 technology can be displayed as one

of the columns in the Current Values tab, both in device or group view.

o The serial number of legacy instruments and probes cannot be displayed

o In the case of instruments such as the HP22, HP23 and HF5, the HC2 probe serial number is

displayed but not the instrument serial number

● HW4 Main Menu Bar > Shortcut Buttons

The HW4 main menu bar now features a new button that is used to globally erase the contents of both the

online buffer and online chart.

● Log-to-PC files > File Header

The header of the files generated with the Log-to-PC function now includes the HW4 version and build

number.

● RH sensor test (AirChip 3000 devices)

The configuration and settings of the RH sensor test function have been modified and the function itself can

be turned on or off. The RH sensor test function is not described in this document. For a description see the

HW4 Device Manager manual available for each individual type of device.

● Devices compatible with HW4

HW4 v 2.3.0 adds support for the following devices:

o HP23 indicator

o AC3010 USB / RS-485 converter cable

Note: the AC3010 converter allows connecting one or several probes and instruments with a RS-485 port to

the USB port of a PC, without requiring a master device.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 12

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

12 of 165

Document title

4 INSTALLATION

4.1 Software Licensing Agreement

1) Rights to software, know-how and process

Without any specific agreement, the customer may make use of the available software HW4, the know-how,

the data carriers and the documentation to the extent provided for, but must not pass it on to third parties.

Any improvement, amendment or copying of the software by the customer requires permission in writing

from ROTRONIC. The customer must include the same property rights notations on all modifications and

copies as there are on the original.

In all cases, ROTRONIC or its licensers retain the ownership of the software and the know-how and also

retain the right to continued utilization, even if ROTRONIC supplies the source codes or if the customer

subsequently makes amendments to the software programs or know-how recordings.

2) Warranty against defects

The customer's warranty rights presume that he or she has fulfilled his or her legal obligation to examine and

make a complaint in respect of a defect immediately on receipt of the goods as is required.

ROTRONIC shall be released from all obligations under all warranties either expressed or implied, if the

software covered hereby is modified by persons other than its own authorized personnel, unless such

modification by others is made with the written consent of ROTRONIC or unless such modification in the

sole opinion of ROTRONIC is minor or unless such modification is merely the installation of a new

ROTRONIC update or patch for the software. ROTRONIC makes no warranties which extend beyond the

description of the software covered hereby other than as expressly stated herein, ROTRONIC expressly and

specifically disclaims the implied warranty of merchantability and makes no warranty with respect to the

fitness of the software covered hereby for any particular purpose or use unless such a warranty is expressly

set forth.

The buyer or anyone claiming under any warranty relating to the software sold hereunder agrees that if

ROTRONIC breached any such warranty, or any warranty implied either in fact or by operation of law, or if

the software warranted hereunder proves defective in any manner whatsoever, ROTRONIC sole liability

hereunder is limited to either replacement of the defective software or at the option of ROTRONIC, refunding

to the buyer the purchase price paid for such defective software. The buyer and anyone else claiming under

any warranty relating to the software sold hereunder expressly and specifically agree that ROTRONIC is not

responsible for, and the buyer or such other claimant or claimants shall assume, any liability for property

damage, prospective profits, special, indirect, or consequential damage, or other commercial or economic

loss arising out of use or possession of the software sold hereunder. ROTRONIC shall not be liable for, and

a buyer or anyone else claiming under any warranty relating to the software sold hereunder further agrees,

and shall assume, any liability for personal injury arising out of use or possession of the software sold

hereunder. Representations and warranties made by any person, including dealers and representatives of

ROTRONIC which are inconsistent or in conflict with the terms of this warranty (including but not limited to

the limitations of the liability of ROTRONIC as set forth above), shall not be binding upon ROTRONIC unless

given in writing and approved by an expressly authorized representative of ROTRONIC.

4.2 HW4 requirements

4.2.1 Computer/Operating System Requirements

The following are the minimum values required to install and run HW4 on a computer. It is highly

recommended to exceed these values.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 13

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

13 of 165

Document title

o Processor: Pentium II, 450 MHz

o RAM: 128 MB

o Available hard disk space: 50 MB

o Monitor: SVGA, 1024 x 768, 256 colors

o Ports: one free serial (COM) port or one free USB port or Network Interface Card / Ethernet LAN with

one free port (RJ45 connector)

4.2.2 Operating System Compatibility

o Windows XP, NT4 with SP 6a or higher, Vista

o Windows 2000 with SP 2 or higher

o Windows Server 2003

HW4 was written for the Microsoft .NET framework (version 2.0) and requires this framework to be installed

on the computer.

The .NET framework offers significant improvements in the areas of networking and user security. When

new software is being installed, the .NET framework also eliminates the potential problem of conflicting

dynamic library files (DLL). According to Microsoft, the .NET framework will be used by all future Microsoft

operating systems.

4.2.3 Important information to review prior to installing HW4

Microsoft .NET framework

Prior to installing HW4 you should verify that the Microsoft .NET framework (version 2.0) is installed on the

PC. To do this, open Control Panel in Windows and select Add or Remove Programs. Windows displays an

alphabetical list of installed programs. If Microsoft .NET framework is not listed it is not installed on the PC.

Microsoft .NET framework v. 2.0 is included in the HW4 CD-ROM and can be installed as part of the HW4

installation procedure.

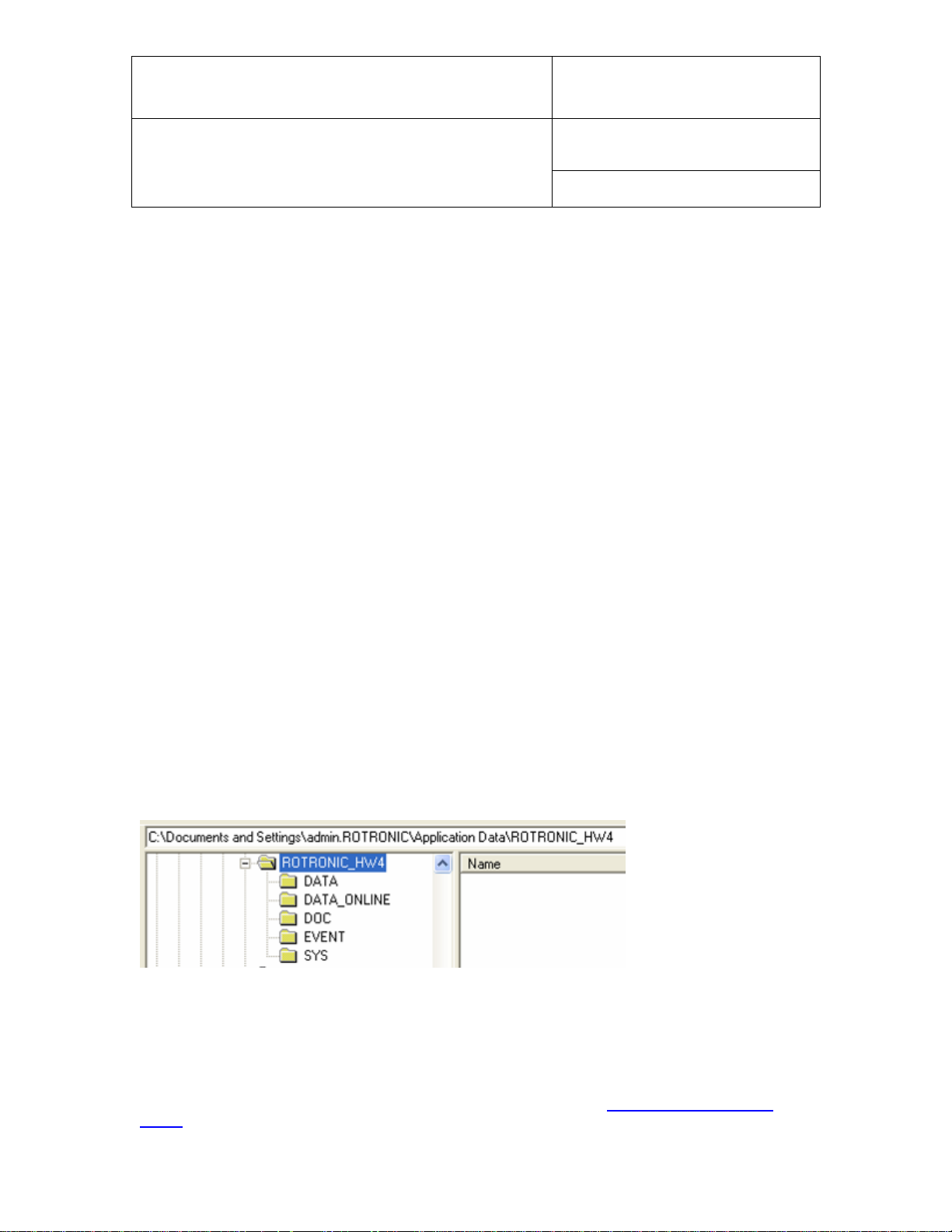

Location of the HW4 User Folder

During the initial startup, HW4 creates a User Folder named ROTRONIC_HW4. By default, this folder is

created in C:\Documents and Settings\Windows User\Application Data, where Windows User is the name

that was used to log into the current Windows session.

This folder is used to hold the HW4 configuration file as well as the different data, event and protocol files

created by HW4.

Windows automatically gives Windows User exclusive access to the directory C:\Documents and

Settings\Windows User and subfolders. For this reason, the default path for the HW4 user folder may not be

suitable for the intended use of HW4.

For instructions about changing the path of the HW4 User Folder, see Relocating the HW4 User

Folder before installing HW4.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 14

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

14 of 165

Document title

Running HW4 from several workstations with a Windows 2003 server

Generally, we do not recommend installing HW4 directly on a Windows 2003 file server. When you wish to

run HW4 on multiple workstations viewing and sharing the same data, you should proceed as follows:

Log in on one of the workstations as an administrator of the Windows 2003 server.

Install HW4 on the workstation following the procedure described under Installing HW4

After installing HW4 and prior to starting HW4, go to the HW4 installation directory on the workstation

and change the path used by HW4 to locate the HW4 User Folder to the root directory of a file

server drive that is mapped on each workstation (see Relocating the HW4 User Folder).

Start HW4 following the procedures described in this manual under Initial Startup

Close HW4 before installing HW4 on the next workstation

Repeat this procedure for each workstation

Note: It is important to distinguish between a Windows workstation user and a HW4 user. It is equally

important to distinguish between the Windows permissions to a folder and HW4 rights. When the HW4 User

Folder is located on the File server and is shared by all workstations, you should give all Windows users

sufficient permissions to the HW4 User Folder and subfolders (Folder Properties - Security).

4.3 Installing HW4

Insert the HW4 CD-ROM into the CD drive or your PC. The installation program should start automatically. If

the installation program does not start, use My Computer in Windows to open the CD drive and double click

on the file start.exe located in the root directory of the CD.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 15

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

15 of 165

Document title

IMPORTANT: HW4 requires a PC with the Microsoft .NET Framework version 2.0 or higher installed. If the

Microsoft .NET Framework is not already installed on your PC, please click with the mouse on step 1 to

install the framework.

Note: save your work and close all open files because the computer will have to restart to complete the

installation process.

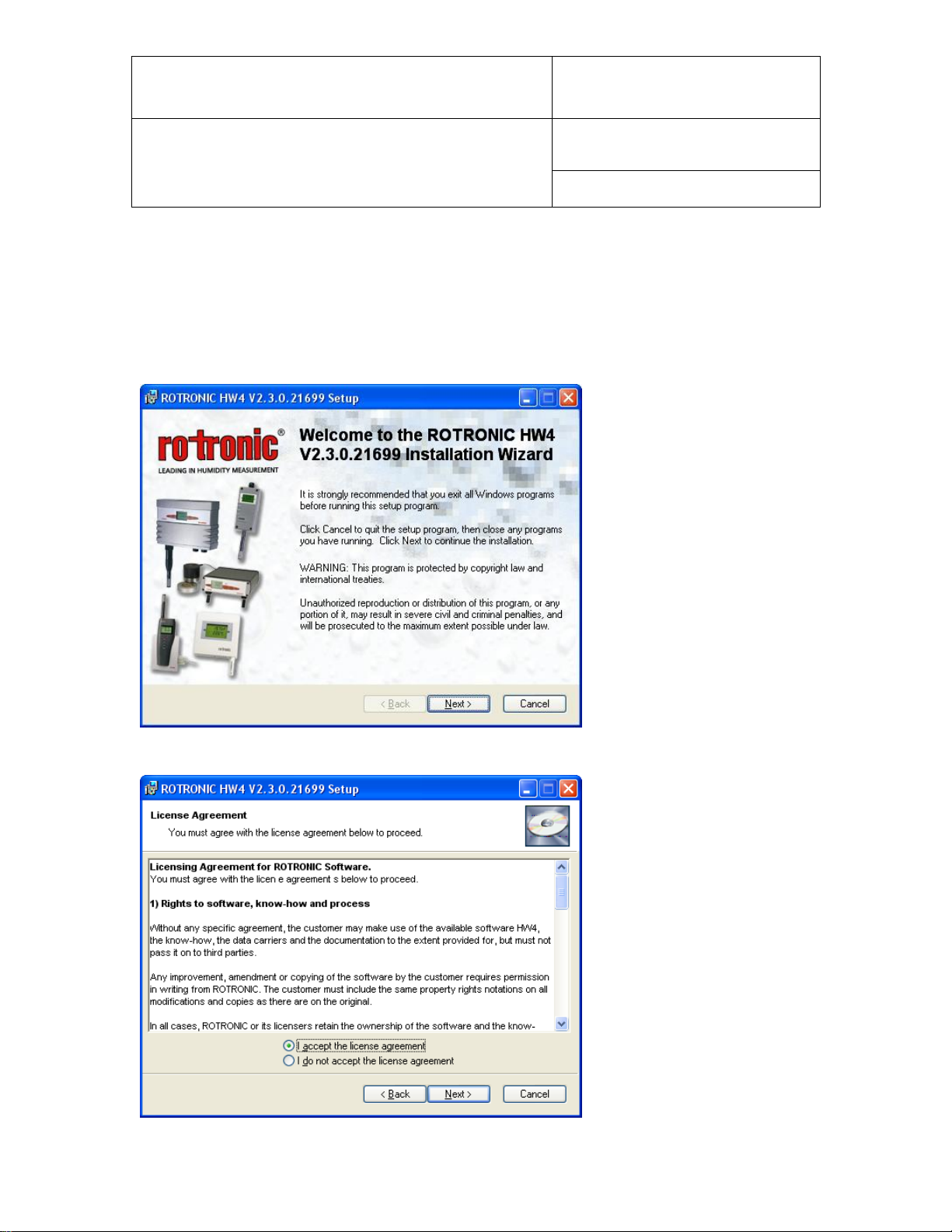

After installing the Microsoft .NET Framework, click on step 2 with the mouse to install HW4. Installation

begins with the following form:

Click on the NEXT button:

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 16

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

16 of 165

Document title

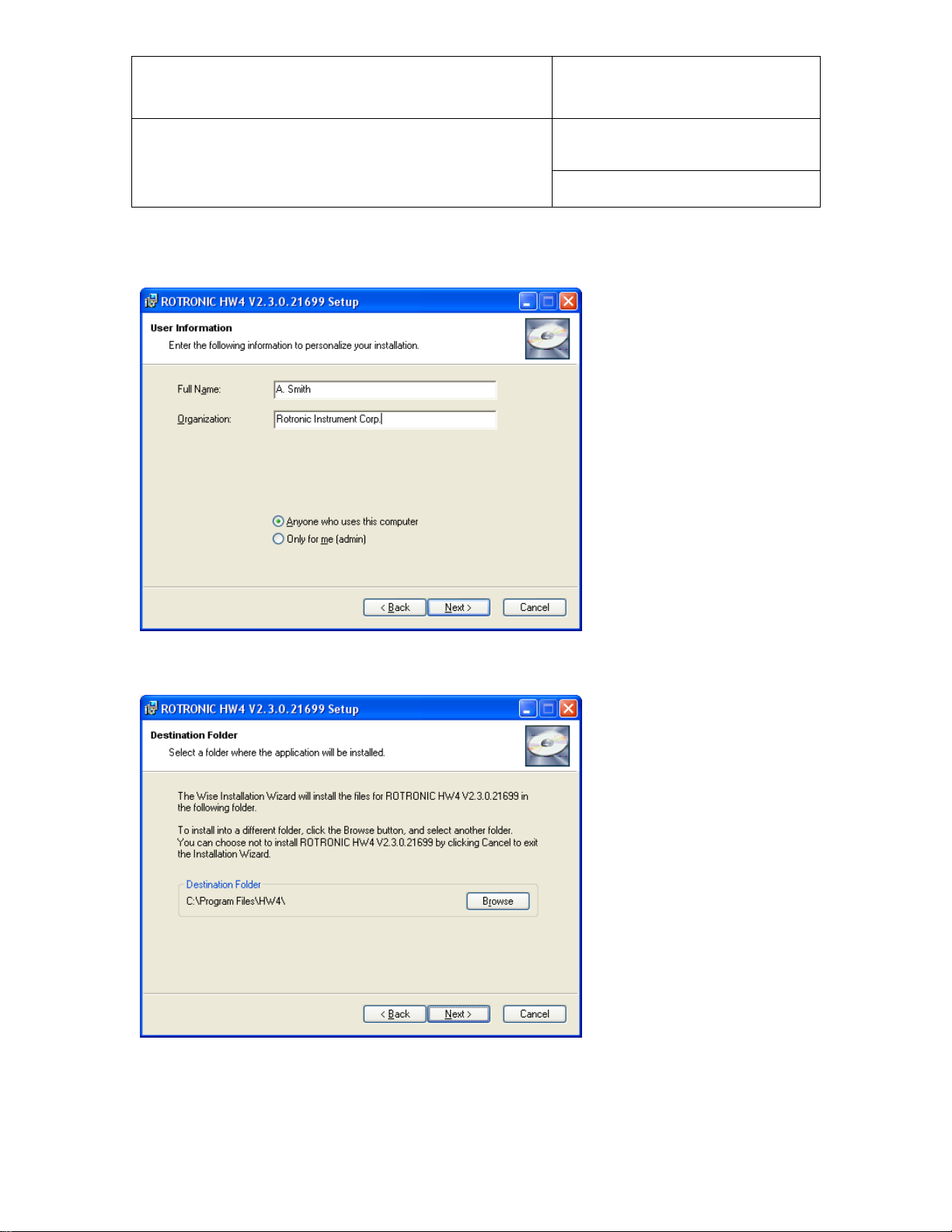

Click on the NEXT button to move through the different installation steps and follow the instructions provided

on the screen.

The choice made above determines how the HW4 install program will make entries in the Windows registry

(entries for all users or for the current user only).

The default installation directory is C:\Program Files\HW4 and can be changed during installation.

The shortcut HW4 is automatically created on the desktop during installation:

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 17

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

17 of 165

Document title

Note: Upon starting HW4 for the first time, the folder ROTRONIC_HW4 will be automatically created in

C:\Documents and Settings\Windows User\Application Data, where Windows User is the name that was

used to log into the current Windows session.

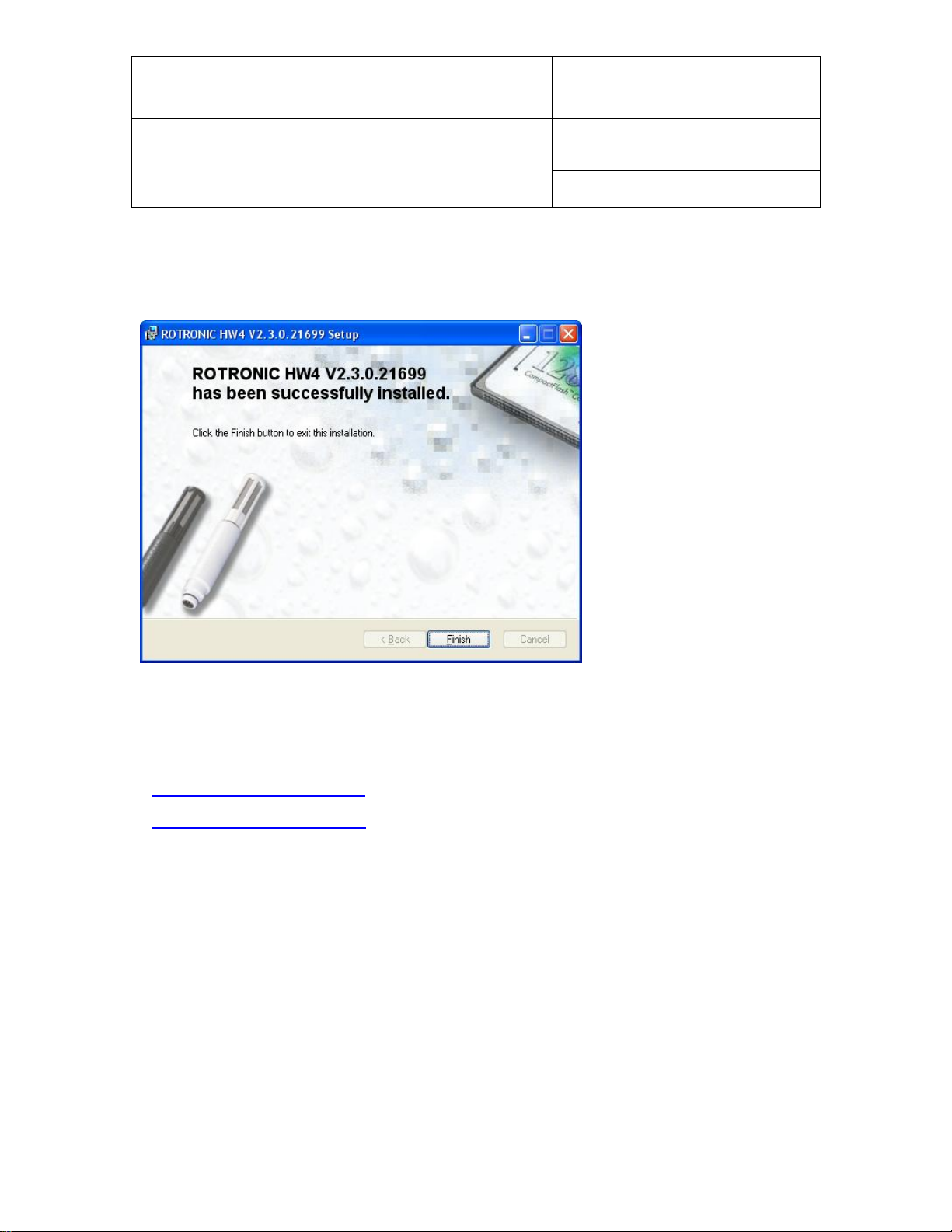

When installation is complete, the following screen should appear:

STOP HERE!

Do not start using HW4 without reading the following:

● Relocating the HW4 User Folder

● Preparing for device connection

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 18

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

18 of 165

Document title

4.4 Updating HW4 to a newer version

When updating HW4 to a newer version, two distinct situations may present themselves. In both cases, it is

advisable to make a note of your old HW4 product key prior to updating, even if in principle re-entering this

information and registering the new version of HW4 are not required.

4.4.1 Partial update: HW4.exe

In the case of a partial update, simply copy the new HW4.exe file over the old file, normally located in the

directory C:\Program Files\HW4.

4.4.2 Full update: Install_HW4.exe

In the case of a full update, you should first uninstall the old version of HW4. To do this properly, click on

Start in Windows and open the Control Panel. Select Add or Remove Programs. ROTRONIC HW4 should

be listed as one of the installed programs. Select ROTRONIC HW4 and click on the Remove button.

Note: uninstalling HW4 from the Windows Control Panel does not delete the HW4 User Folder.

IMPORTANT: do not delete the HW4 User Folder (ROTRONIC_HW4) created by the old HW4 version.

Unless otherwise mentioned, this folder can be used with the updated HW4.

The default path of the HW4 User Folder is C:\Documents and Settings\XXXX\Application Data, where

XXXX is the Windows user who initially installed HW4.

Deleting the HW4 User Folder would erase all users, all configuration and measurement data as well as all

event tracking and protocols. It is advisable to make a temporary back-up copy of this folder.

4.5 Uninstalling HW4 (full uninstall)

IMPORTANT: Not following this procedure may result in problems if HW4 is installed again.

To properly uninstall HW4 and remove its main components, you should click on Start in Windows and open

the Control Panel. Select Add or Remove Programs. ROTRONIC HW4 should be listed as one of the

installed programs. Select ROTRONIC HW4 and click on the Remove button.

To complete a full uninstall you should manually delete the HW4 User Folder (ROTRONIC_HW4). The

default path of the HW4 User Folder is C:\Documents and Settings\XXXX\Application Data, where XXXX is

the Windows user who initially installed HW4.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 19

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

19 of 165

Document title

5 CONNECTING DEVICES TO THE HW4 PC

5.1 Definition: masters and slaves (HW4 Professional)

HW4 Professional makes use of the following definitions:

Master: any device / docking station that is directly connected either to a physical or to a virtual port of the

PC or that is directly connected to an Ethernet port (TCP/IP) either by cable or by wireless.

Slave: any device / docking station that is connected to a master by means of an RS-485 multi-drop. Slaves

cannot be used in conjunction with HW4 Standard Edition.

5.2 Connection methods for master devices

All versions of HW4 are compatible with the following methods for connecting devices to the HW4 PC:

● Physical serial port

● Bluetooth serial port (virtual COM port)

● USB port

● LAN (TCP/IP) - cable or wireless connection

5.3 Devices used as RS-485 slaves (HW4 Professional)

HW4 Professional allows the use of one RS-485 multi-drop with each master device. Any RS-485 multi-drop

is limited to a maximum of 64 devices (1 master and up to 63 slaves). Any device with a RS-485 port can be

used either as a master or a slave, without special configuration.

IMPORTANT:

o RS-485 compatibility: the communications protocol used by the products based on the AirChip 3000

technology is not compatible with the protocol used by the previous generation of ROTRONIC products.

Do not connect legacy products and AirChip 3000 products to the same RS-485 multi-drop network.

HW4 is compatible with both AirChip 3000 products and legacy products as long as these products are

connected to separate RS-485 multi-drop network.

o Baud rate: unlike legacy products, the 19200 Baud rate used by all products based on the AirChip

3000 cannot be changed

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 20

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

20 of 165

Document title

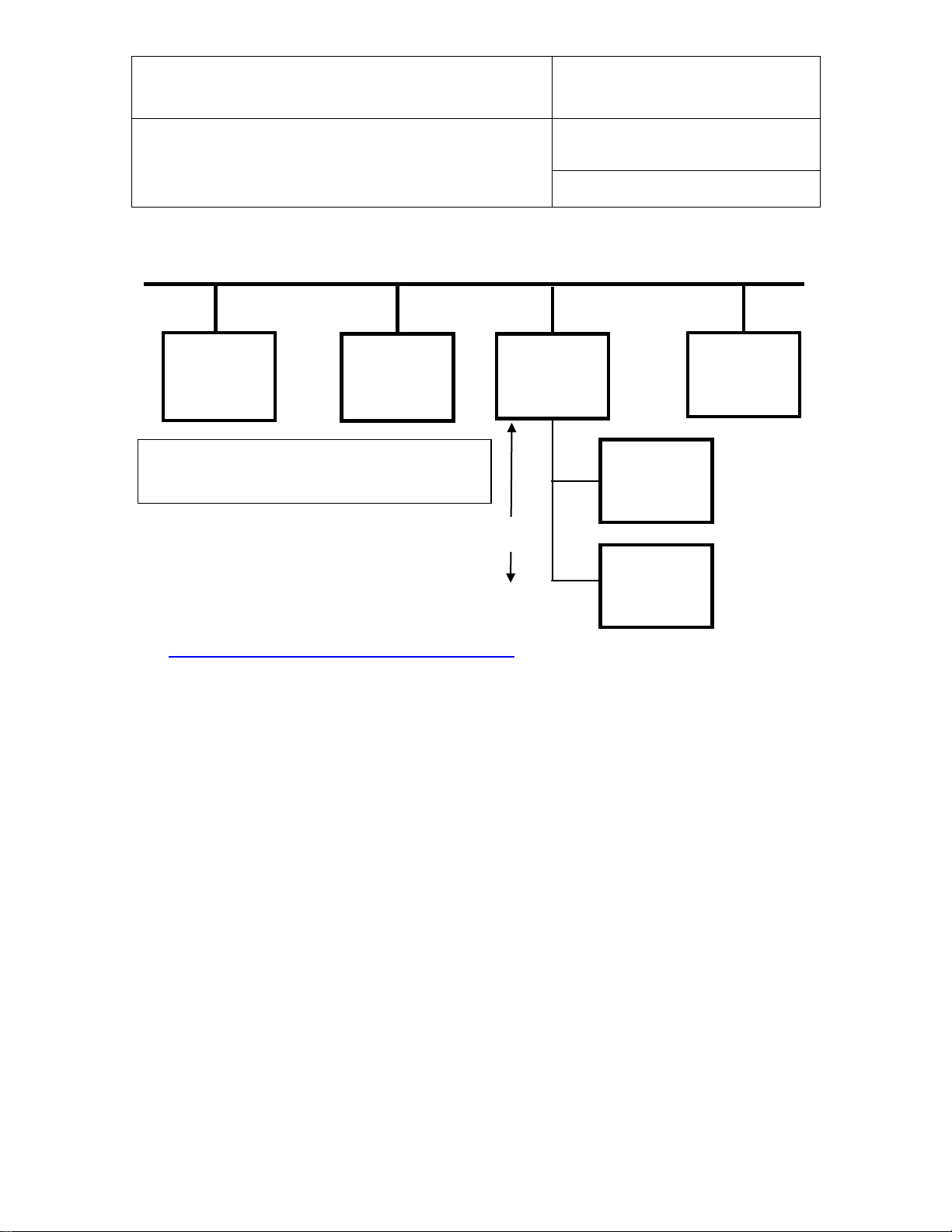

RS485: 2 wires

PC (HW4)

Network

Interface

Card

RS Addr. 1

RS Addr. 1

RS485

RS485

IP Addr.1

RS Addr. 1

RS485

IP Addr. 2

IP Addr. n

LAN (TCP/IP)

RS-485 multi-drop: up to 1000m (3300 ft)

Note: each device directly connected to the LAN

should have a unique IP address and must meet the

compatibility requirements of the LAN.

RS Addr. 2

RS485

Slave

RS Addr. 64

RS485

Slave

Example: slaves connected to an Ethernet master

See RS-485 slaves: address and Baud rate requirements.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 21

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

21 of 165

Document title

6 PREPARING FOR DEVICE CONNECTION

NOTE:

o The HygroLog NT requires a docking station to provide an interface with the PC.

o If you want to run HW4 on multiple workstations connected to a Windows 2003 file server, use only

devices connected by Ethernet (wired or wireless) because this is the only type of connection that can be

shared by all workstations. Devices connected by RS-485 to an Ethernet device can also be shared.

6.1 Physical serial port

Connecting an instrument or device to a physical COM port of the HW4 PC does not require any

preparation. Simply connect the device to any available serial (COM) port on the PC.

6.2 Bluetooth virtual serial port

Note: This connection method is available only with some HygroLog NT models. Check the local menu of

the HygroLog NT - Settings, and make sure that Bluetooth is on.

Communication via Bluetooth requires the HW4 PC to be equipped with an internal or external Bluetooth

transceiver. Connect your Bluetooth transceiver to the HW4 PC and install the driver supplied with the

transceiver as per the instructions of the transceiver manufacturer.

Typically, the Bluetooth driver has provisions for defining one or several Bluetooth serial ports (look for Local

Services and / or Bluetooth Client Applications). Bluetooth serial ports are virtual COM ports and should be

given a number that is distinct from the physical COM ports already present on the PC. Both the transceiver

attached to the PC and the HygroLog NT should be given a unique COM port number.

In addition, it is usually necessary to “pair” the transceiver with the Bluetooth enabled HygroLog NT. For

security reasons, the process of “pairing” requires a password to be entered. By default, all ROTRONIC

Bluetooth devices are identified as HygroBlue and use 1234 as the pairing password.

In order to allow detection by HW4, any Bluetooth serial port must be manually declared in HW4 Global

Settings – General Tab in the text box labeled Bluetooth serial ports, and then discovered manually using

Search for RS-232 masters under Devices and Groups in the HW4 main menu bar.

HW4 detects and displays a Bluetooth device in the same manner as any device connected to the PC by

way of a physical serial port.

6.3 USB port

Prior to connecting any ROTRONIC device to a USB port you should install the ROTRONIC USB driver on

the HW4 PC.

IMPORTANT: do not run HW4 while installing the USB driver on the PC.

The ROTRONIC USB driver (ROTRONIC USB Option) can be installed before or after installing HW4.

The following example shows how to install the driver with Windows XP.

1. Prior to connecting the device to the PC, insert the HW4 CD-ROM in any available PC drive. The HW4

installation screen starts automatically. Exit this screen.

2. Connect the instrument or docking station to any available USB port. Upon detecting the presence of a

device connected to the USB port, Windows XP automatically starts the following wizard:

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 22

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

22 of 165

Document title

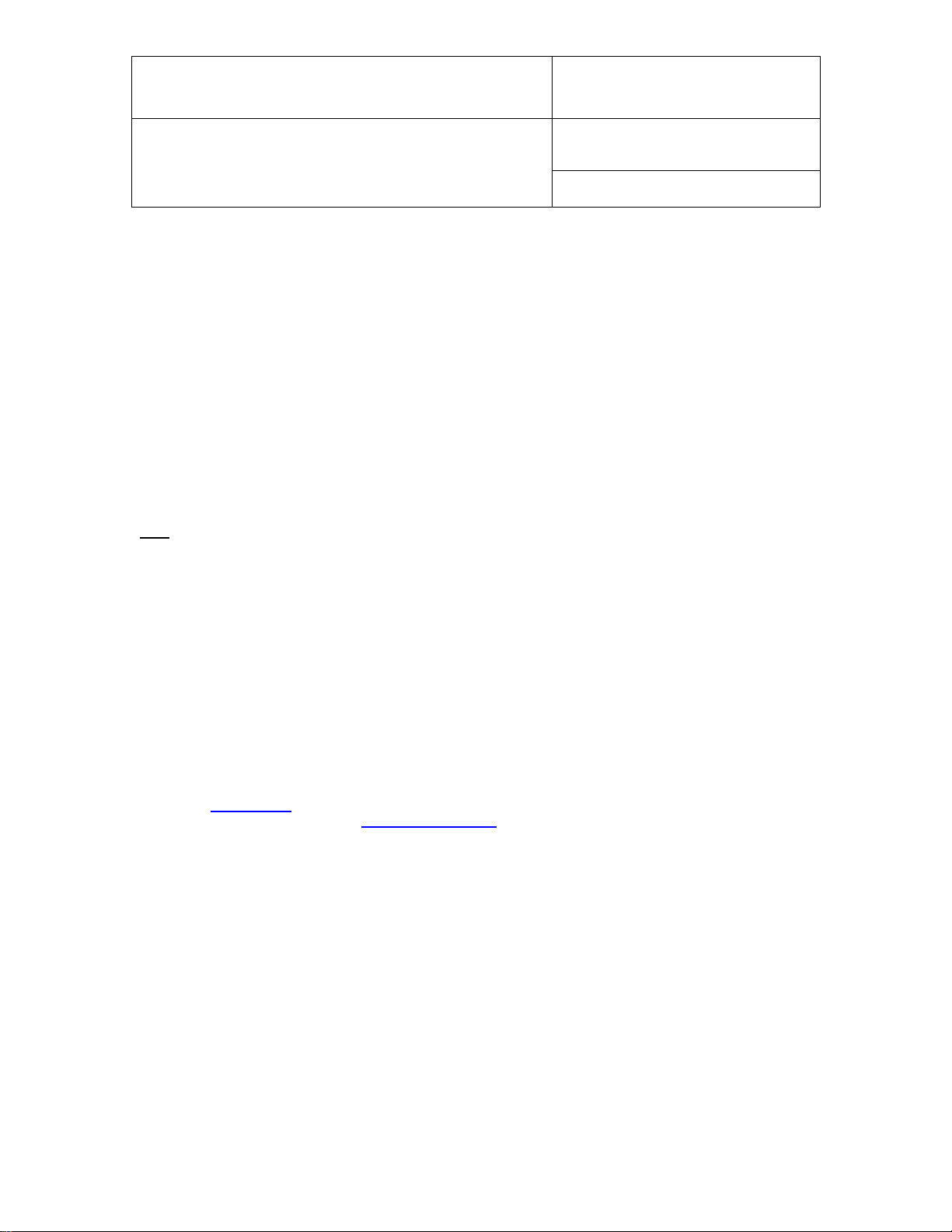

If you are using Windows XP Professional SP2, the following screen appears. Select “No, not this time” and

click on Next. This screen does not appear if you have not installed SP2.

3. The following screen appears:

Select “Install from a list or specific location” and click on Next.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 23

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

23 of 165

Document title

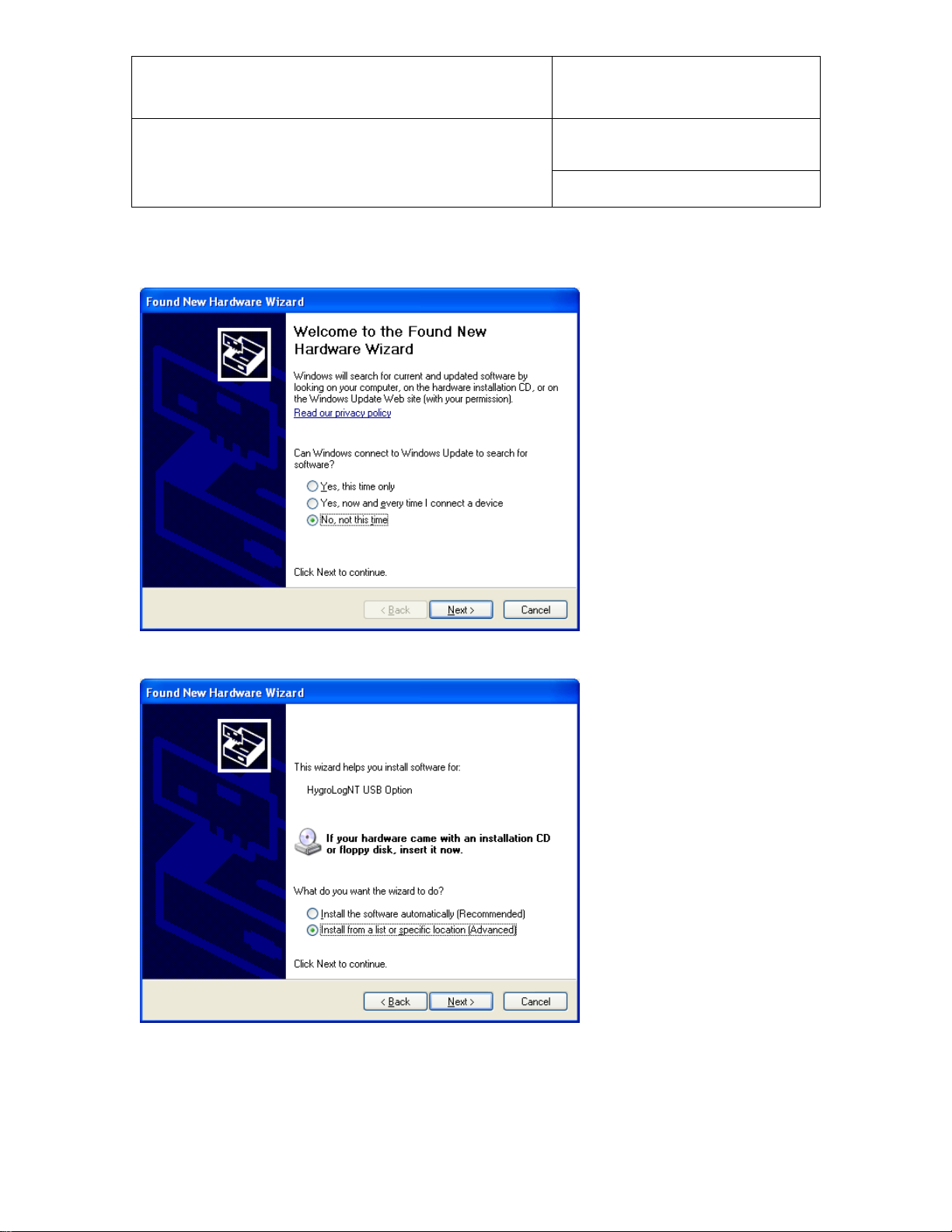

4. Select “Search for the best driver in these locations”. Note that at this time the HW4 CD_ROM should

have been already inserted in the PC.

Click on Next

5. You will receive the following warning. Disregard this warning and click on “Continue anyway”.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 24

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

24 of 165

Document title

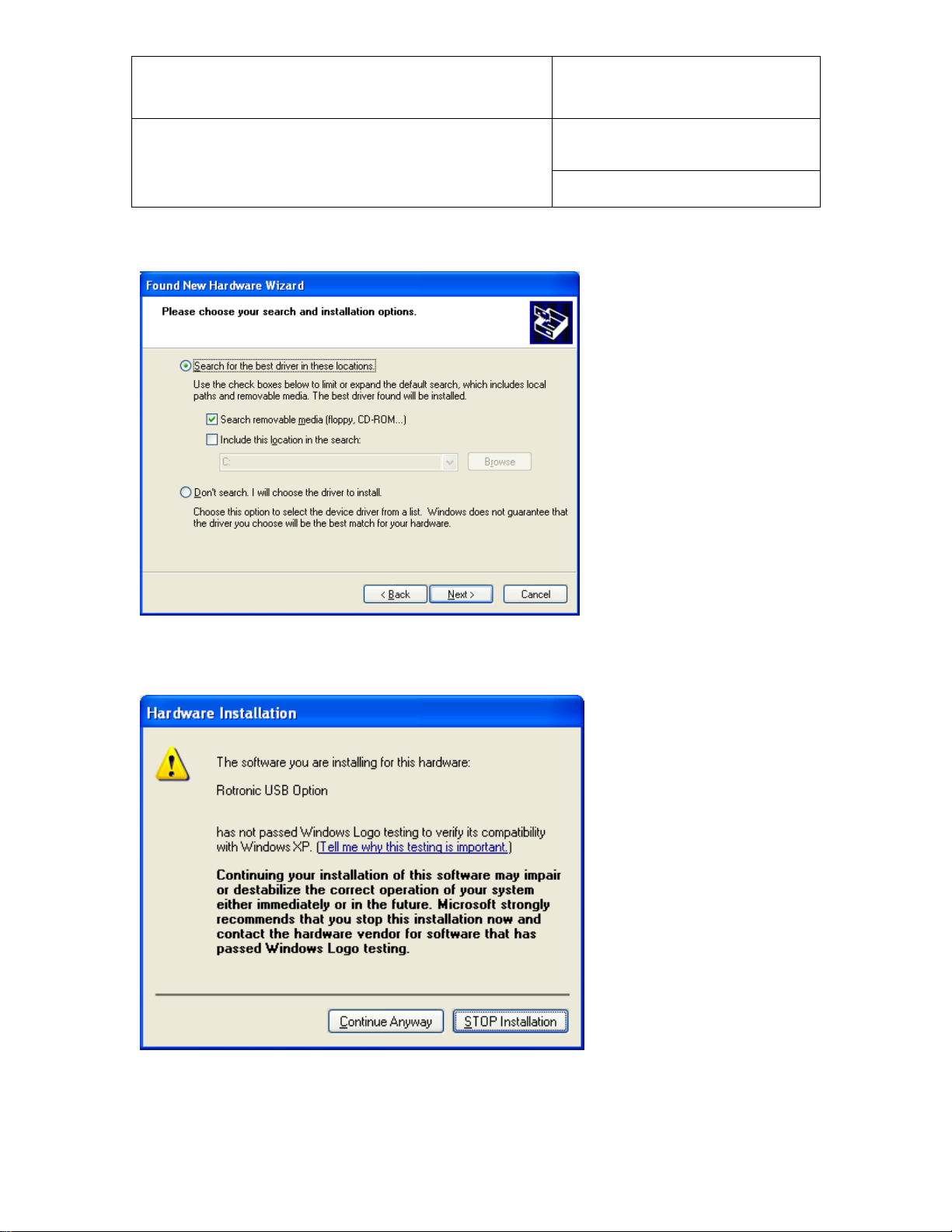

6. Windows copies the USB driver located on the HW4 CD-ROM and displays the following message when

done:

Click on “Finish” to complete the process.

Note: If your device has only a serial port and the PC has a USB port but no COM port, you can install a

USB Serial Adapter on one of the PC USB ports. In this situation, install the driver supplied with the USB

serial adapter (not the driver supplied with HW4) and connect the device to this adapter. HW4 will assume

that the device is connected to a serial (COM) port.

6.4 Ethernet (TCP/IP) connection

NOTES:

ROTRONIC devices with an Ethernet interface require configuration of the TCP/IP settings to ensure

compatibility with the LAN to which the HW4 PC is connected (IP address, sub-net mask, gateway,

etc.). Detailed instructions for configuring a ROTRONIC device with Ethernet (TCP/IP) interface are

provided separately in document IN-E-TCPIP-Conf_11. A PDF version of this document can be

downloaded from our web site. You may also want to read “Basic TCP/IP concepts” in this manual

or consult with your network administrator prior to connecting any device to your local area network.

ROTRONIC devices with an Ethernet interface (both wired and wireless) are shipped with a Device

Configuration Certificate that provides information about the factory configuration settings of both the

Ethernet module and device.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 25

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

25 of 165

Document title

Before configuring the device TCP/IP settings, you should make sure that the following is available to you:

o An unused static IP address that is compatible with your network

o The subnet mask of your network

o The local IP address of the router used on the same LAN as the HW4 PC, the default gateway used by

all devices on the LAN

In addition, the following information is required for a wireless connection:

o The wireless network name (SSID)

o The security mode (WAP, WEP or other) used by the HW4 network and the key or keys used by the

security mode.

6.4.1 Wired TCP/IP connection

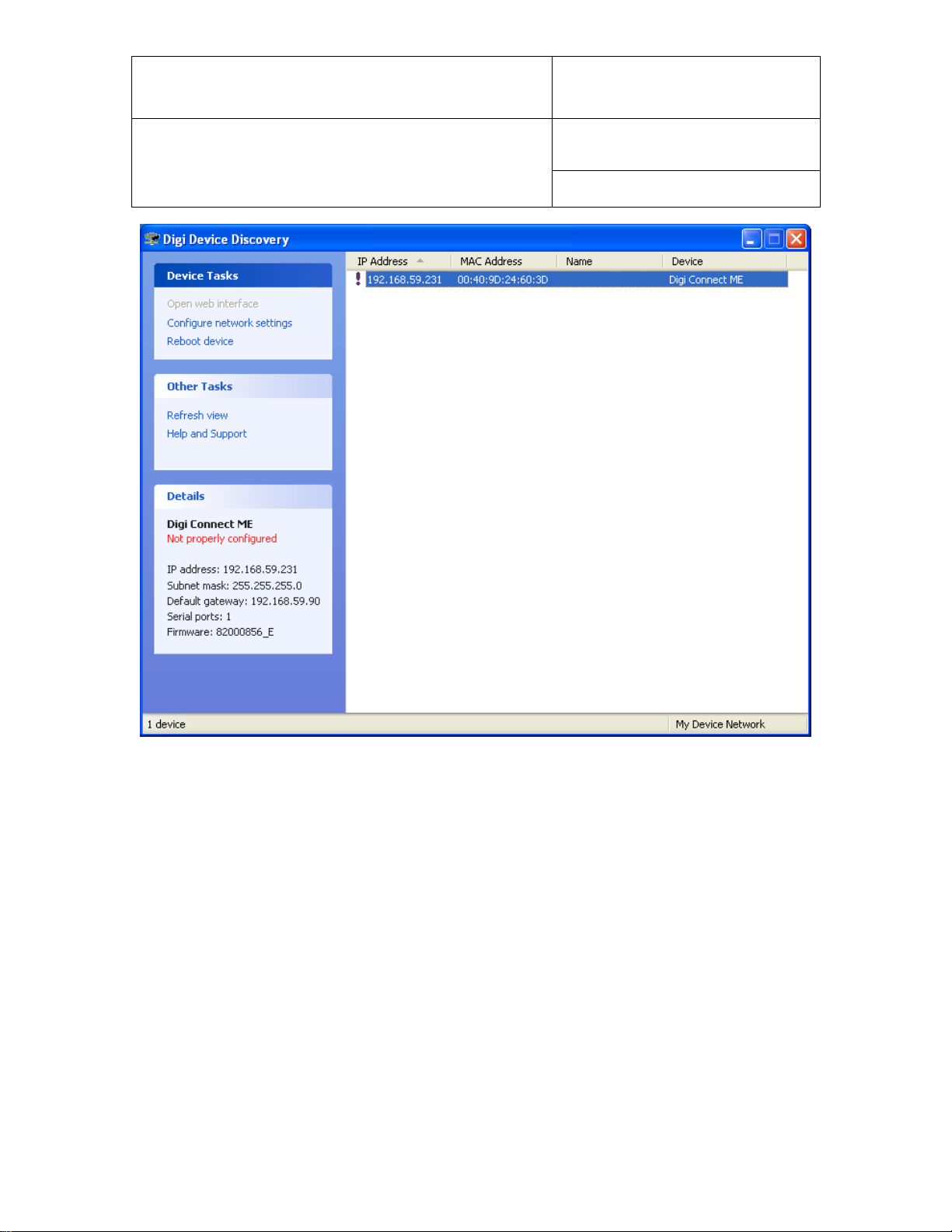

A device discovery utility (Digi Device Discovery) is provided in the HW4 installation directory (usually,

C:\Program Files\HW4). The name of the corresponding file is dgdiscvr.exe. The Digi Device Discovery

utility can be started by double clicking with the mouse on the file.

Digi Device Discovery detects only products from Digi International such as the internal Ethernet module

currently used by ROTRONIC for devices with an Ethernet interface.

Connect the device to be configured to your LAN and double click with the mouse on dgdiscvr.exe to start

Digi Device Discovery.

When activated, Digi Device Discovery automatically detects any ROTRONIC device present on the LAN

and provides a list of all such devices.

The following example shows the initial screen for a device with TCP/IP settings that are not compatible with

the LAN. Note the red warning that appears on the left side of the screen when the device is selected

(highlighted).

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 26

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

26 of 165

Document title

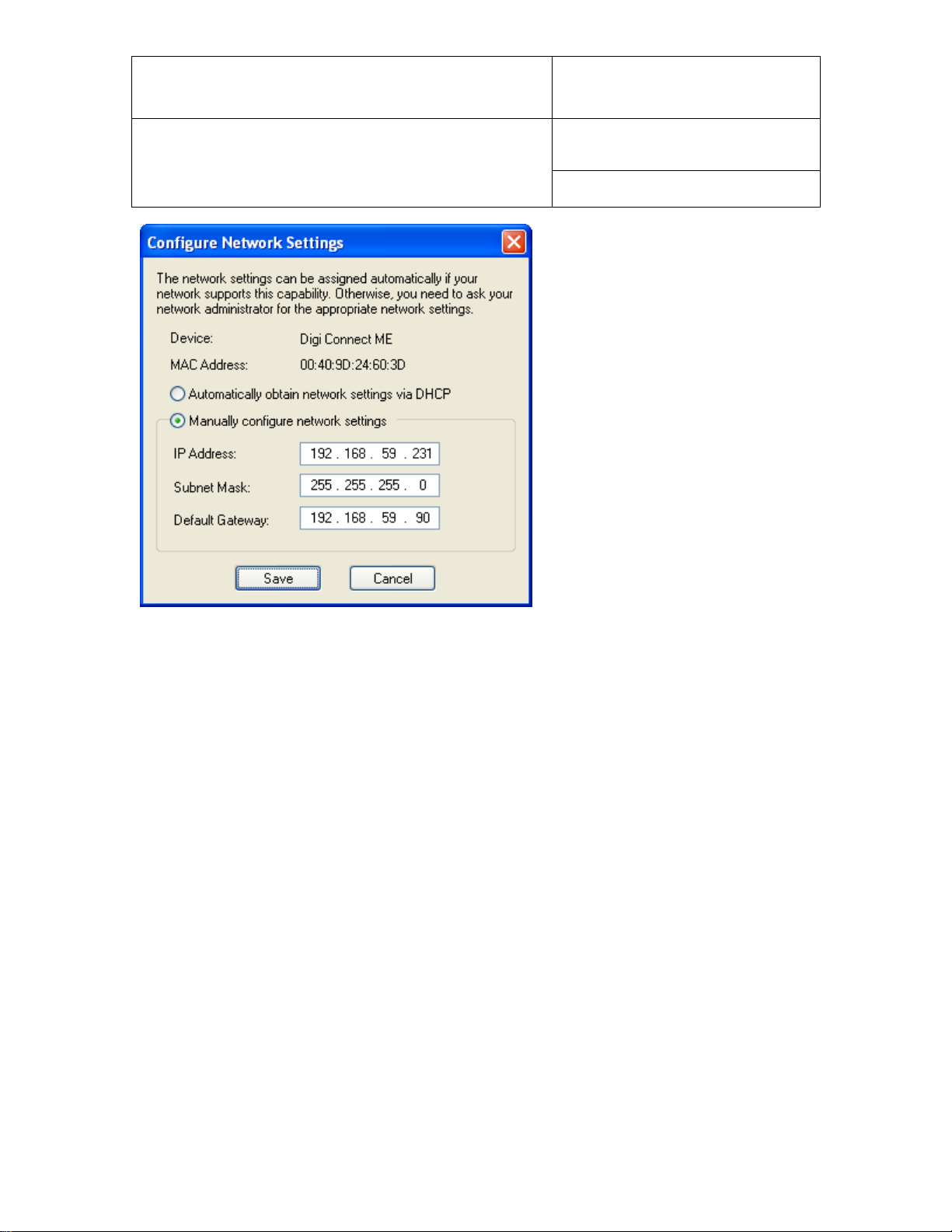

With the device highlighted, click on “Configure network settings” to open the dialog box shown below.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 27

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

27 of 165

Document title

When in doubt as to which setting to enter manually, select “automatically obtain network settings via

DHCP” (requires a LAN with DHCP server such as a router). Using DHCP ensures that the device settings

that are compatible with the LAN (subnet mask and default gateway) and that the IP address does not

generate any conflict.

Click on Save, Reboot the device and click on Refresh View.

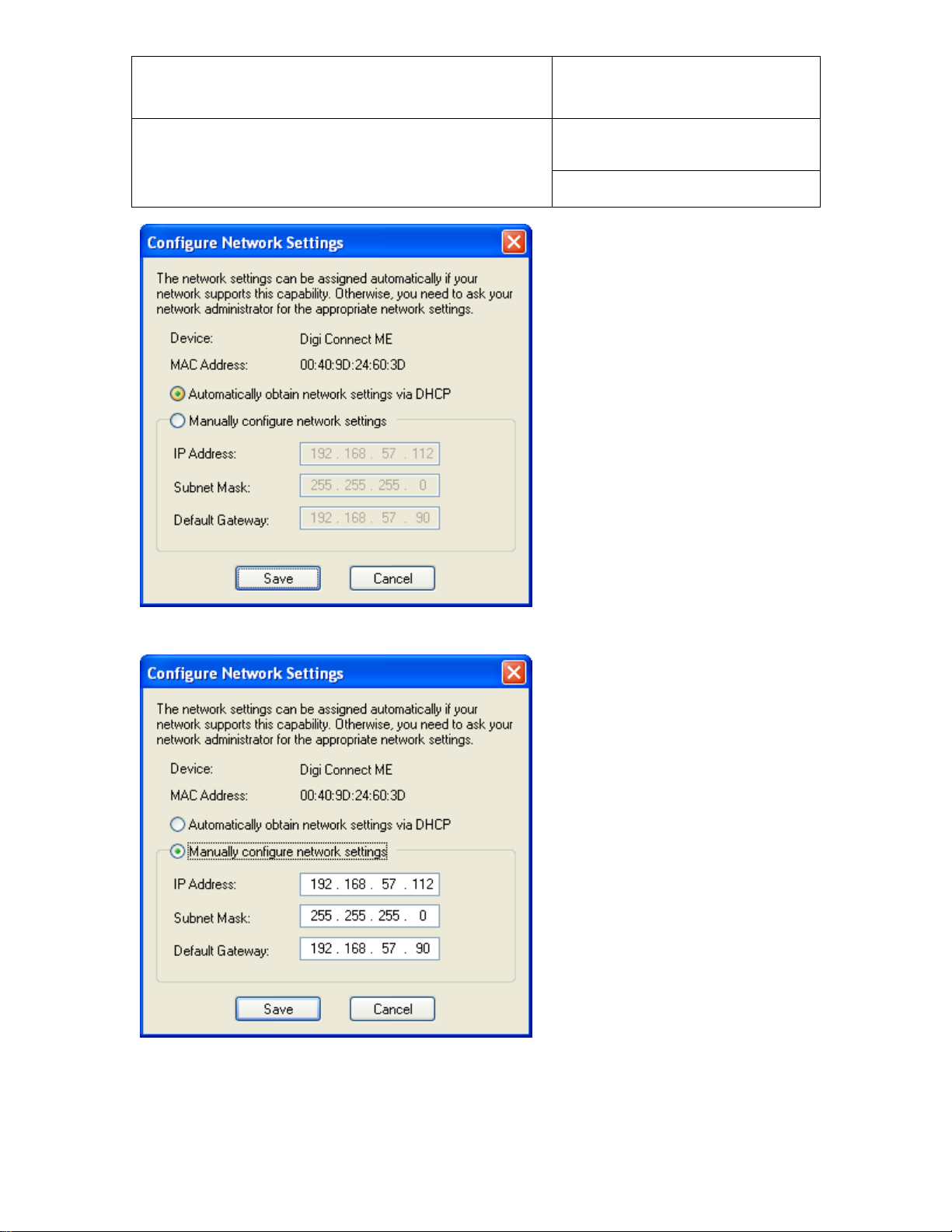

A dynamic IP address is subject to change whenever the device is powered down and then powered up. For

this reason, you should now change the device configuration from dynamic IP address (DHCP) to static IP

address. To do this, click again on “Configure network settings”. The current settings of the device (IP

address, subnet mask, etc.) appear in light gray.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 28

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

28 of 165

Document title

Click on “Manually configure network settings”.

Change the device IP address to an address that is both currently unused on the LAN and outside of the

range of dynamic IP addresses used by the DHCP server. To select a proper address, you may want to

consult your network administrator.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 29

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

29 of 165

Document title

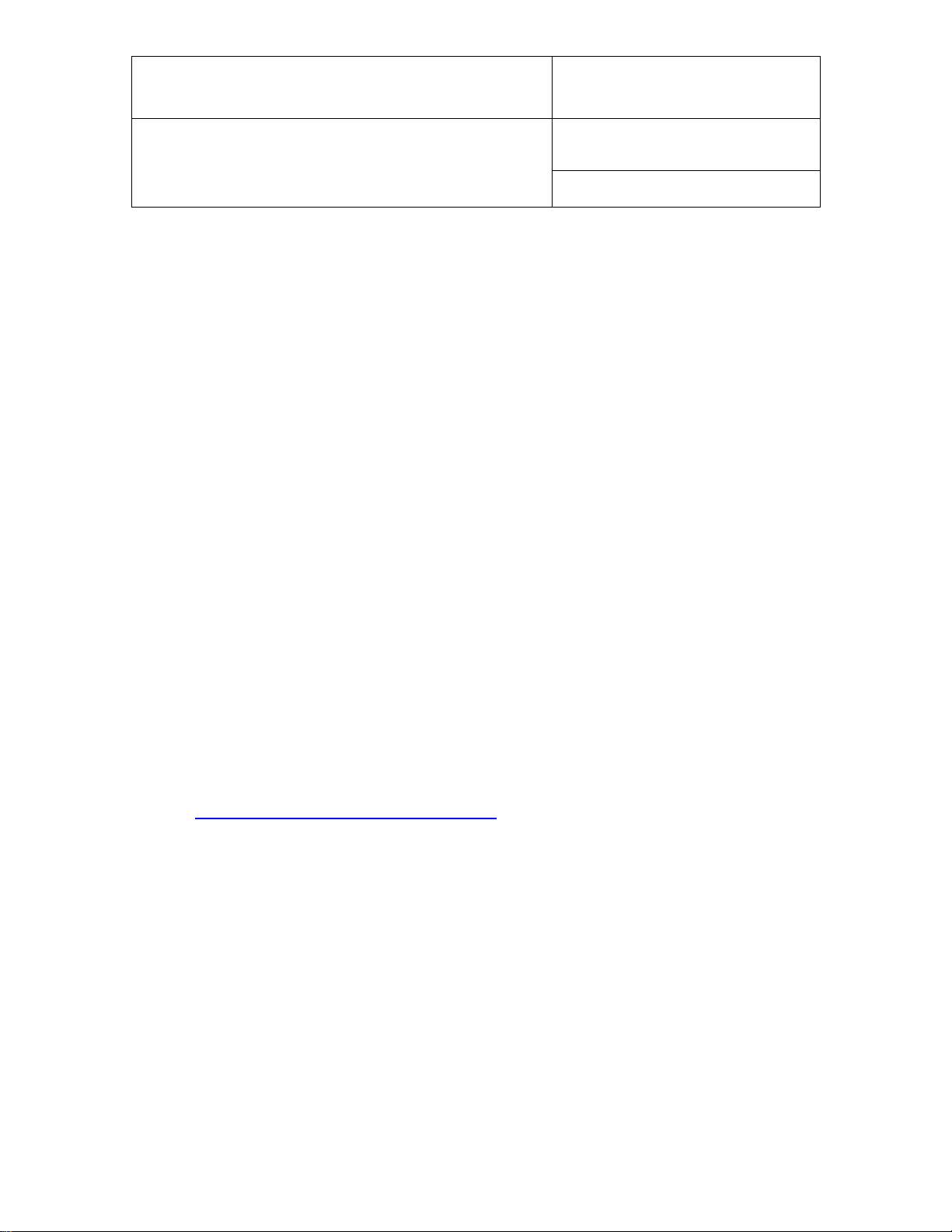

RS232: 3 wires (including ground wire)

RS485: 2 wires

PC (HW4)

COM Port

or

USB port

Address 1

Address 2

Address 64

RS232 or

USB

RS485

RS485

RS485

up to 150m (490 ft)

Slave

Slave

RS-485 multi-drop: up to 1000m (3300 ft)

HW4 Professional only

6.4.2 Wireless TCP/IP connection

The internal Digi module WI-ME used by wireless ROTRONIC devices does not allow a wired connection to

a LAN and must be configured using a wireless connection.

To allow a new wireless device to connect, the HW4 network wireless router has to be temporarily

reconfigured and the wireless network security disabled. This is clearly not practical for most users and we

recommend using a dedicated wireless router for the purpose of configuring a wireless ROTRONIC device.

Detailed instructions for configuring a wireless Ethernet ROTRONIC device are provided separately in

document IN-E-TCPIP-Conf_11. A PDF version of this document can be downloaded from our web site.

6.5 RS-485 slaves: address and Baud rate requirements

IMPORTANT:

o RS-485 compatibility: The communications protocol used by the products based on the AirChip 3000

technology is not compatible with the protocol used by the previous generation of ROTRONIC products.

Do not connect legacy products and AirChip 3000 products to the same RS-485 multi-drop network.

o Baud rate: the 19200 Baud rate used by all products based on the AirChip 3000 cannot be changed

All devices that are compatible with HW4 have an internal RS-485 address ranging from 0 to 64. The factory

default for the RS-485 address is 0. Similarly, devices are configured at the factory to use a specific Baud

rate for all serial communications. In the case of devices with an internal Ethernet (TCP/IP) module, serial

communication includes communication between the device proper and it internal Ethernet module.

The RS-485 address is part of the communications protocol used by HW4 and is always included in the

command sent to a device and in the device response. In the case of an RS-485 multi-drop, this address is

used to identify each device and should be unique within the same multi-drop.

Example: slaves connected to a COM or USB master

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 30

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

30 of 165

Document title

When searching for RS-485 slaves, HW4 automatically changes the factory default RS-address of both

masters and slaves as explained below:

o Masters: HW4 automatically changes the RS-485 address of any new device that is directly connected

to the PC (master) from 0 to 1. As a result, all masters discovered by HW4 end up having the same RS485 network address (1).

o Slaves: in the situation where an RS-485 multi-drop is detected during a search, HW4 automatically

changes the address of each slave with address 0 to a unique address ranging from 2 to 64. The same

address range (2 to 64) is used again when there is more than one RS-485 multi-drop.

IMPORTANT:

o Avoid changing manually the factory default RS address (0) of new devices. Allow HW4 to change this

address automatically.

o Change manually the RS address to 0 in the following situations:

- A master will now be used as a slave

- A slave is being moved from one multi-drop to another.

The change of address should be done prior to changing the physical connection (use HW4 Device

Manager). If you forgot to do this, temporarily connect the device as a master to do the address change.

o Duplicate RS addresses are not permitted within the same RS-485 multi-drop (with the exception of

temporary address 0). Duplicate addresses may prevent communication with the devices or give

unpredictable results. It is OK to use the same RS address in different multi-drops.

o All devices within a multi-drop must use the same baud rate. Different Baud rates will prevent

communication between the devices and the HW4 PC.

Master with Ethernet (TCP/IP) interface: any change to Baud rate of the device done with HW4 Device

Manager should also be reflected in the configuration of the internal Digi International module used by

the device to connect to the LAN.

See: Changing the baud rate of an Ethernet device

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 31

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

31 of 165

Document title

7 INITIAL START-UP

Click on the HW4 shortcut created on your desktop by the installation program.

7.1 Language selection

The first form to open lists the different language files available within HW4:

Use the mouse to highlight the desired language and click on Open.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 32

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

32 of 165

Document title

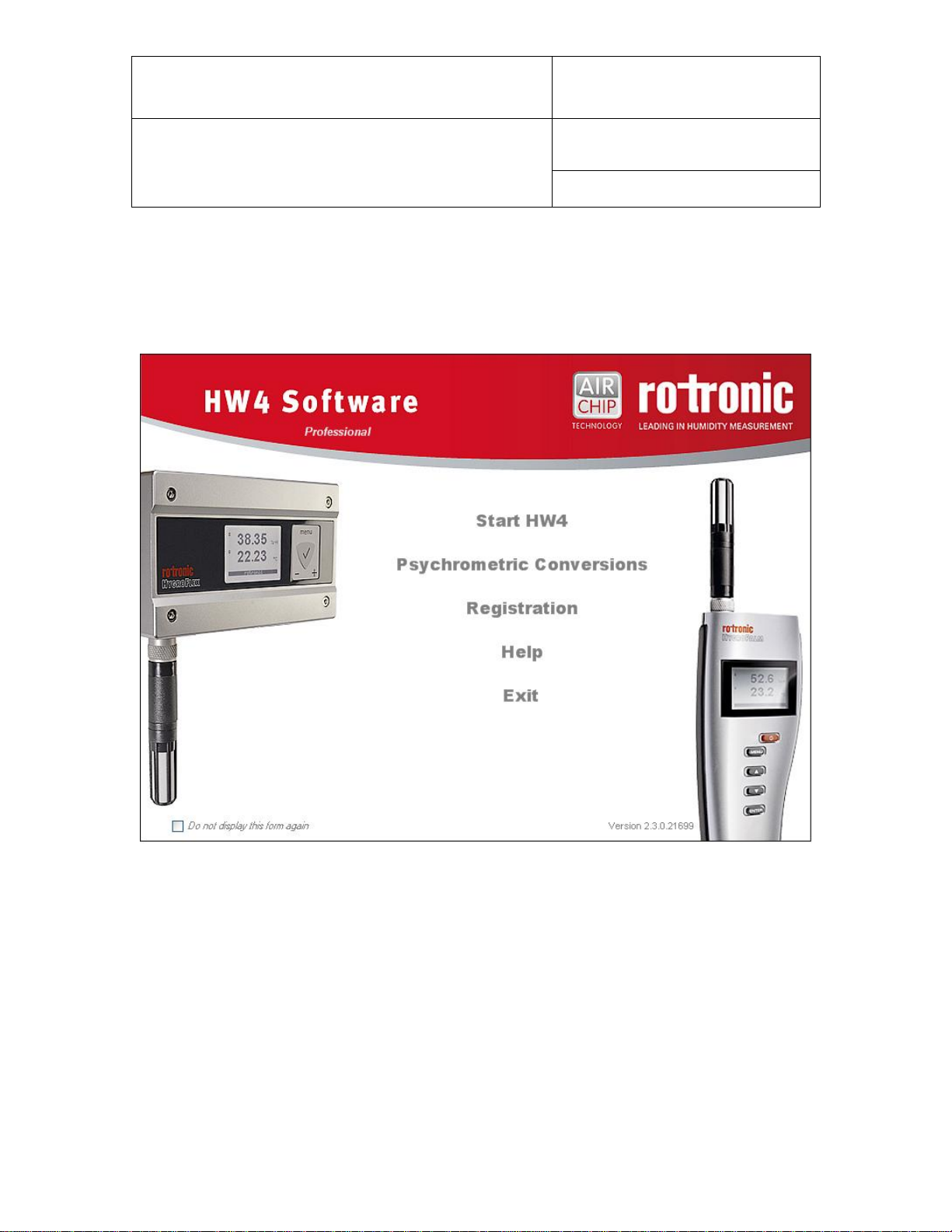

7.2 Product key and registration

The next form is the HW4 start-up form:

First Time Users: HW4 requires you to register and you should now click with the mouse on the underlined

Registration link. This opens the following form:

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 33

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

33 of 165

Document title

Enter the HW4 product key, which is printed on a sticker affixed to the protective cover of the HW4 CD. Fill

in the required information. If the box Register on-line is checked, clicking on Continue will connect you to

the ROTRONIC web site, where your registration data will be automatically entered. If you do not have an

internet connection or if you have already registered your copy of HW4, uncheck the Register on-line box

and click on Continue.

Registering on-line offers benefits such as free updates / patches and product information.

Upon completing the registration, HW4 returns to the Start-up Screen. Depending on the HW4 product key

entered in the previous form, the edition of HW4 that you are using is shown on the screen (in the example

below: the validated edition of HW4 Professional).

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 34

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

34 of 165

Document title

To open the HW4 main screen, click with the mouse on the blue link labeled Start HW4.

7.3 Automatic device discovery during initial start-up

During the initial start-up, HW4 automatically searches for any device that is connected either to a COM port

or to a USB port of the PC. HW4 stops searching after finding one such device. Devices connected by any

other method must be searched manually.

IMPORTANT: see also the following

Preparing for device connection

Searching for devices with HW4

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 35

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

35 of 165

Document title

When there is no device connected to the PC either by a COM port or by a USB port, HW4 stops searching

after a single pass. In that situation, HW4 creates a fictitious HygroLog NT in the device tree (see “HW4

main screen overview”). This instrument is named “Offline” and should be deleted after manually

discovering the actual devices connected to the PC. The red cross on top of the device icon indicates that

there is no communication with the device.

Note: whenever the device tree is empty HW4 automatically does the same search as during the initial startup.

7.4 Creating the first user (HW4 Professional)

If you are using HW4 Professional, you should create at least one user with administrator rights and a

password in order to comply with ERES regulatory requirements.

See: Users and passwords.

Once the first user has been created, you will need to log in each time that you open HW4.

7.5 Access to functions and screens (HW4 Professional)

In all versions of HW4 Professional, access to most functions and screen views requires the current user to

have sufficient rights. Whenever a function is not accessible or a screen view is not available, please verify

that you have been granted the necessary rights.

For an overview of user rights, including details for each individual right, please refer to the chapter Users

and Passwords.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 36

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

36 of 165

Document title

8 SEARCHING FOR DEVICES WITH HW4

IMPORTANT:

The following instructions assume that all necessary preparations have been made prior to connecting the

different devices to the HW4 PC. See Preparing for device connection.

8.1 Searching for master devices

Depending on the connection method used for the master, use the following commands available in the

HW4 main menu bar under Devices and Groups:

o Physical COM (serial) port : Search for RS-232 masters

o Bluetooth virtual COM port : Search for RS-232 masters

o USB port : Search for USB masters

o Ethernet (TCP/IP) - cable or wireless connection : Search for Ethernet masters

: Search for Specific IP Address

Search for Ethernet masters: this command searches only for devices that are directly connected to the

same local area network as the HW4 PC (both cable and wireless connection). The IP address of the

device(s) does not have to be specified by the user.

When the TCP/IP settings of a device are not compatible with the local area network, HW4 displays the

following message box:

Search for Specific IP Address: use this command to search for Ethernet devices that are connected to a

different network (eventually via Internet). The IP address of the device must be specified by the user.

8.2 Searching for RS-485 slaves (HW4 Professional)

Use the Search for RS-485 slave devices command located in the HW4 main menu bar under Devices

and Groups.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 37

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

37 of 165

Document title

Left

Pane

Right

Pane

9 HW4 MAIN SCREEN

The HW4 main screen varies slightly depending on which edition of HW4 is running. The following

description applies to the Professional edition which has more menu items and screens than the standard

edition.

The HW4 main screen is subdivided into a left pane and a right pane. The width of each pane can be

adjusted with the mouse. The height of the two sub-panes located in the right pane (table and graph) can

also be adjusted with the mouse. To change the size of a pane, go over the separation line with the mouse

cursor. When the cursor changes, click and hold with the mouse. Drag the separation line where you want it

to be.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 38

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

38 of 165

Document title

Each individual device is displayed in the left

pane (for example: Master HCA, HCA Test,

etc.). This is the default view for all versions of

HW4 and the only view available with HW4

Standard edition

Functions available for each device can be seen

when the tree is expanded. These functions are

specific of each type of device.

To select a device or a function, click on it with

the left mouse button.

9.1 Device Tree (left pane)

9.1.1 Tree populated with individual devices

All versions of HW4 display on the left pane of the screen a tree listing the devices that have been

discovered by HW4.

Right clicking with the mouse on a device opens the following menu:

Most items present in this menu are

described in chapter 10: HW4 Main Menu

Bar, under Device and Groups and under

View.

The following menu items are present only in

the case of a master device:

o Search for RS-485 Slave Devices

o Refresh the RS-485 Slave Devices

Search adds to the device tree any device

connected to the RS-485 interface of the

master

Refresh does not add nay new devices and

is used to re-establish a lost connection with

slave devices already present in the tree.

© 2008; Rotronic AG E-M-HW4v2-Main_13

Page 39

E-M-HW4v2-Main_13

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HW4 software v.2 General instructions and functions

common to all devices

Instruction Manual

Document Type

Page

39 of 165

Document title