IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

HygroLog HL-NT Data Logger

Instruction Manual

Instruction Manual

Document Type

Page

1 of 74

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

2 of 74

Table of contents:

Overview.................................................................................................................................. 4

1.

1.1 General ................................................................................................................................ 4

1.2 Compatibility with previous models of probes and docking stations ................................... 6

2. General description of the HygroLog HL-NT ....................................................................... 7

2.1 Models ................................................................................................................................. 7

2.2 Required accessories .......................................................................................................... 8

2.3 HygroLog HL-NT inputs ....................................................................................................... 9

2.4 Power supply ..................................................................................................................... 12

2.5 Memory card ...................................................................................................................... 14

2.6 LED Indicators ................................................................................................................... 15

2.7 Beeper ............................................................................................................................... 15

2.8 HygroLog HL-NT functions ................................................................................................ 16

2.9 HygroClip 2 probe functions .............................................................................................. 21

2.10 Event tracking .................................................................................................................... 21

2.11 Operating limits (electronics only) ..................................................................................... 25

3. Docking stations for the HygroLog HL-NT ........................................................................ 26

3.1 Models ............................................................................................................................... 27

3.2 Installation .......................................................................................................................... 32

3.3 Relay contacts ................................................................................................................... 39

4. Pin-out diagrams .................................................................................................................. 40

5. HW4 software ........................................................................................................................ 43

5.1 Computer/Operating System Requirements ..................................................................... 43

5.2 Operating System Compatibility ........................................................................................ 44

5.3 Settings and functions acces sible only with HW4 ............................................................. 45

6. ERES regulatory compliance .............................................................................................. 47

7. Getting started ...................................................................................................................... 48

8. Stand-alone operation ......................................................................................................... 48

8.1 Operating modes ............................................................................................................... 48

8.2 Display and keypad ........................................................................................................... 49

8.3 Display modes ................................................................................................................... 51

8.4 Settings and functions accessible from the Keypad .......................................................... 52

8.5 Internal function menu (models with display and keypad)................................................. 53

9. Operation on a network ....................................................................................................... 59

9.1 Baud rate and communications protocol compatibility requirements ................................ 59

9.2 Ethernet local area network ............................................................................................... 60

9.3 RS-485 multi-drop network ................................................................................................ 61

9.4 General wiring guidelines .................................................................................................. 63

9.5 Guidelines for RS-4 85 w ir in g ............................................................................................. 64

10. HygroClip probe adjustment procedures ..................................................................... 65

10.1 Single Point adjustment ..................................................................................................... 65

10.2 Multi-Point adjustment ....................................................................................................... 67

11. Warnings and useful tips ................................................................................................ 67

12. Communications protocol .............................................................................................. 68

13. Firmware updates ............................................................................................................ 68

14. Specifications .................................................................................................................. 69

15. Accessories ...................................................................................................................... 72

16. Supporting documents ................................................................................................... 73

17. Document releases .......................................................................................................... 74

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

3 of 74

Applicability:

This manual is va lid for inst rum ents with firm ware version 2.0x (see MENU - Instrument or check

using the ROTRONIC HW4 software, Device Manager). Examples: 2.0a, 2.0b. Changes in the last

character of the ver sion number reflec t minor changes in the intern al software of the instr ument

that do not affect the manner in which the instrument should be operated.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

4 of 74

1. Overview

1.1 General

HygroLog HL-NT is a series of networkable data loggers primarily designed for use with the

HygroClip 2 digital humidity-temperature probes.

Depending on the model and options, the HygroLog HL-NT main features are as follows:

o Internal probe input: allows installing a HC2-S humidity-temperature probe internally to

prevent unauthori zed removal. T his input can also be c onnected to an external pr obe by

means of an extension cable.

o Inputs for up to 6 a dditional exter nal probes , including analog probes and 4-wire pass ive

RTD probes.

o Monitoring of up to two external contacts (relay output, door, etc.).

o Large recording capacity with removable flash memory card. Up to 750,000 values can be

recorded with the standard 64 MB card. Cards with a capacity of up to 1 GB are available.

o Display with backlight and keypad. This allows the HygroLog HL-NT to operate as a stand-

alone unit after initial configuration with the HW4 software.

o Compliance with F DA 21 CF R Part II and G AMP r egulat ions r egardin g elec tronic rec ords

and electronic signatures (ERES).

o Compatible with Ethernet networks (TCP / IP protocol – LAN or WLAN).

o Dedicated RS-485 network of up to 64 HygroLog HL-NT per communication port

o Simultaneous data recording and data display either locally or on a PC.

Internal power for both the HygroLog HL-NT and probes is provided by a 9V battery (factory

standard) or by a 9V rechargeable battery (user supplied).

The HygroLog HL-NT requires a docking station to (a) to power the HygroLog HL-NT with an

external AC adapter, (b) to configure the HygroLog HL-NT and comm unicate with a PC, (c) to

connect the HygroLo g HL-NT to a network and (d) to m ount the HygroLog H L-NT to a wall or to

place the HygroLog HL-NT on the optional desk-top stand.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

5 of 74

The most basic m odel of doc k ing station s im ply pro vides a m eans of m ountin g the HygroLog HLNT to a wal l and of poweri ng the H ygroLog HL-NT with an ext ernal AC adapter. All o ther m odels

offer the same f unctionality as the basic model and also pro vide a communicatio n port (RS232,

USB or RJ45 / Eth ernet) as well as addi tional inputs for probes and external contacts . Docking

stations with an RS232 or USB port are used to connect the H ygroLog HL-NT directl y to a PC.

Docking stations with an RJ45 connector are used to connect the HygroLog HL-NT to an Ethernet

LAN. In both cases, the docking station features an RS485 port that can be us e d to c onnect up to

64 HygroLog HL-NT i n a multi-dropped ar rangement (ded icated RS-485 net work). This is usef ul

when the PC does not have a n Ethernet ne twork inter face card or when the number of a vailable

Ethernet ports is lim ited. Direct connection to an Ethernet LAN allows, in pr inciple, an unlimited

number of HygroLog HL-NT to be put on a ne twork monitored b y the HW 4 software. HW 4 allo ws

any combination of RS-232, USB, Ethernet and RS-485 connections.

When equipped with a docking station, the HygroLog HL-NT can be used together with the

ROTRONIC HW4 software for Windows based PCs (version 2.3.0 or higher). In addition to

providing for the net working of large quantities of dat a loggers and other instrum ents, the main

functions of HW4 include:

o Configuration of the HygroLog HL-NT and docking station

o Programming of the HygroLog HL-NT logging function

o Manual or automatic downloading of the data recorded by the HygroLog HL-NT

o On-line data monitoring and direct data recording by the PC

o Automatic generation of graphs and data tables

o Monitoring of the networked instruments and data for alarm conditions

o Alarm reporting

o Maintenance of audit trails

o Calibration and adjustment of the HygroClip 2 probes

o Generation of protocols, electronic signatures, etc.

A high level of protectio n agai nst net work failures c an be ac hieved by log ging dat a direc tl y on the

PC while also recording t he data locally on the H ygroLog HL-NT with automat ic download to the

PC at regular interval of times.

Note: Instructions for using the HW 4 software are not included in this m anual. These ins tructions

are shipped separately on the software CD ROM.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

6 of 74

1.2 Compatibility with pr e vi ous m ode ls of probes and docking stations

o The HygroLog HL-NT is designed for use with the H ygroClip 2 probes (UART interface)

and is not compatible with the previous generation of HygroClip probes (DIO interface).

o Docking stations designed f or the previous ge neration of HygroClip pro bes (such as DS-

U1, DS-U4, etc.) are not compatible with the HygroLog HL-NT.

o RS-485 drop-down networks: the HygroLog HL-NT is compatible with previous versions of

the HygroLog NT and with other legacy products. The HygroLog HL-NT cannot be used in

the same RS-485 drop-down as a HF4 or HF5 transmitters or any product that rely on the

RO-ASCII communications protocol.

o Unlike previous versions, The HygroLog HL-NT does not have a remote mode

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

7 of 74

2. General description of the HygroLog HL-NT

2.1 Models

Basic models without display and keypad

o HygroLog HL-NT2: lo gger for plug-in HygroClip 2 pr obe (probe is not included and must

be ordered separat ely). Probe model HC2-S can be m ounted either internally or in the

extended position. Other probe models are external and require an extension cable.

o HygroLog HL-NT3: same as HL-NT2 with 2 additional connectors suitable for a HygroClip2

digital probe.

Models with display and keypad

o HygroLog HL-NT2-D: same probe as HygroLog HL-NT2

o HygroLog HL-NT3-D: same probe / probe inputs as HygroLog HL-NT3

Models with internal HC2-S probe pre-installed

o Models HL-NT2-P, HL-NT2-DP, HL-NT3-P and HL-NT3-DP are supplied with an internal

HC2-S probe pre-installed.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

8 of 74

2.2 Required accessories

● Models without display/keypad:

The following accessories are required in order to be able to use the logger:

- Any model of docking station (except model DS-NT1)

- Connecting cable docking station to PC

- PC with the ROTRONIC HW4 software installed (version 2.3.0 or higher)

● Models with display/keypad:

In principle, these models can be used without any accessory. However, accessing all of the

product functions and cha nging some important s ettings such as the date and tim e requires the

same accessories as for the models without display.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

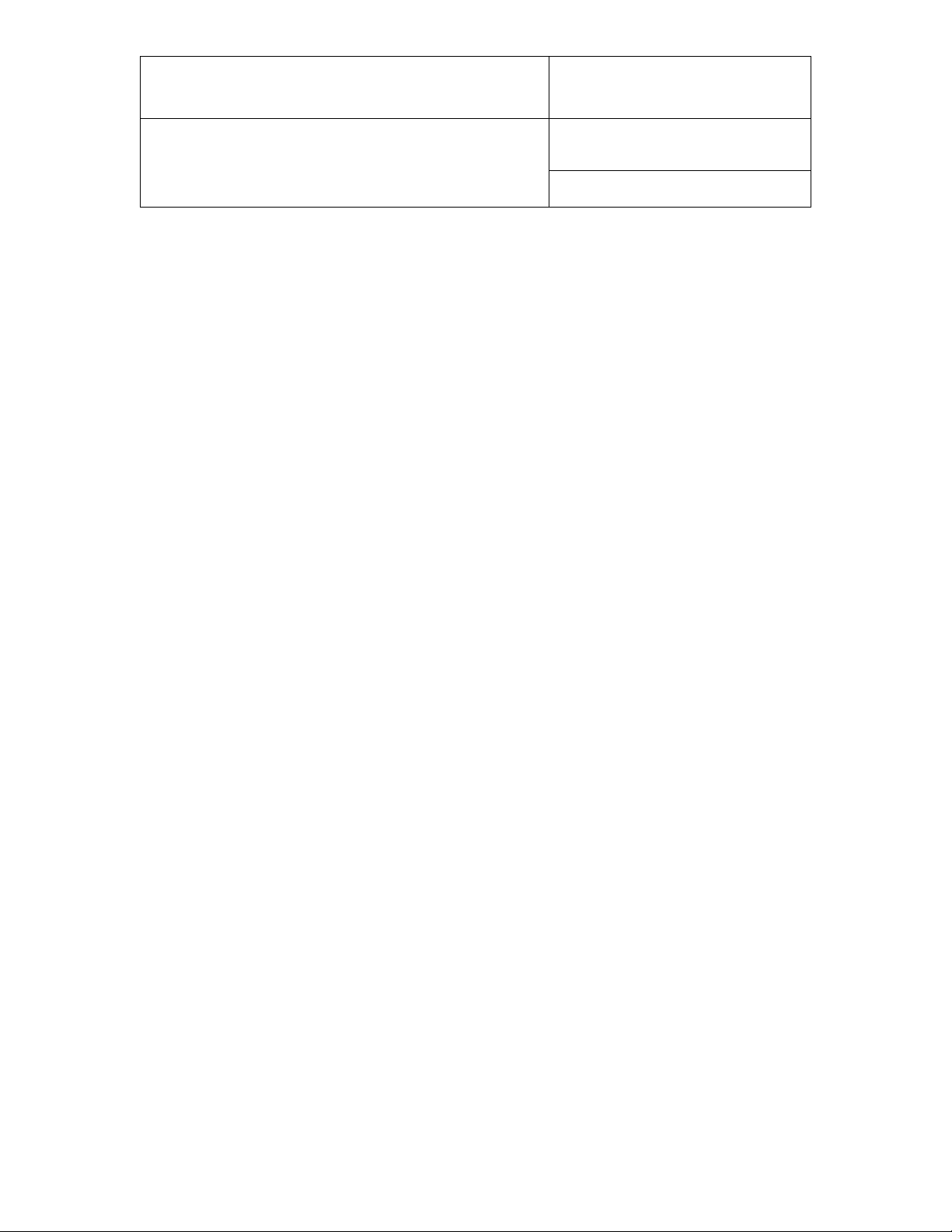

To open the housing of the

HygroLog, remove the

screws

arrows.

The

drawing shows

the HygroClip S probe in the

retracted position. The base

o

a connector that is

separated from the main

board by a length of wire.

Probe

connector

The shorter screw

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

9 of 74

2.3 HygroLog HL-NT inputs

2.3.1 Probe input 1

HygroLog HL-NT2-P, HL-NT2-DP, HL-NT3-P and HL-NT3-DP: these models are supplied with

an internal HC2-S plug-in probe. T his probe can be either retracted or extended. T he probe can

also be separated from t he logger with an ex te ns io n cable, a nd i n this case the HC2-S pr ob e may

be replaced with another model of HygroClip 2 probe so as to meet specific application

requirements (see document E-M-HC2 Probes-V1). Open the housing of the HygroLog to change

the position of the probe or to install a probe extension cable.

five

, as indicated by the

far right

f the probe is plugged into

To extend the pro be, lif t the H ygroClip S probe f rom its position a nd rem ove the slotted cap from

the HygroLog. To extend the probe, place on the probe the ring supplied with the HygroLog. Insert

the ring into the s lot in the instrument housing wher e the slotted cap was. Reloc ate the probe

connector up b y one or two ribs. Close the instrument housing. Proceed in a sim ilar manner to

install a probe extension cable.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

goes here

IN-E-HL-NT-V2_15

HygroClip S

Extension cable used to

Ring

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

extended position

(replaces the slotted cap)

Instruction Manual

Document Type

Page

10 of 74

separate the probe from

the HygroLog.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

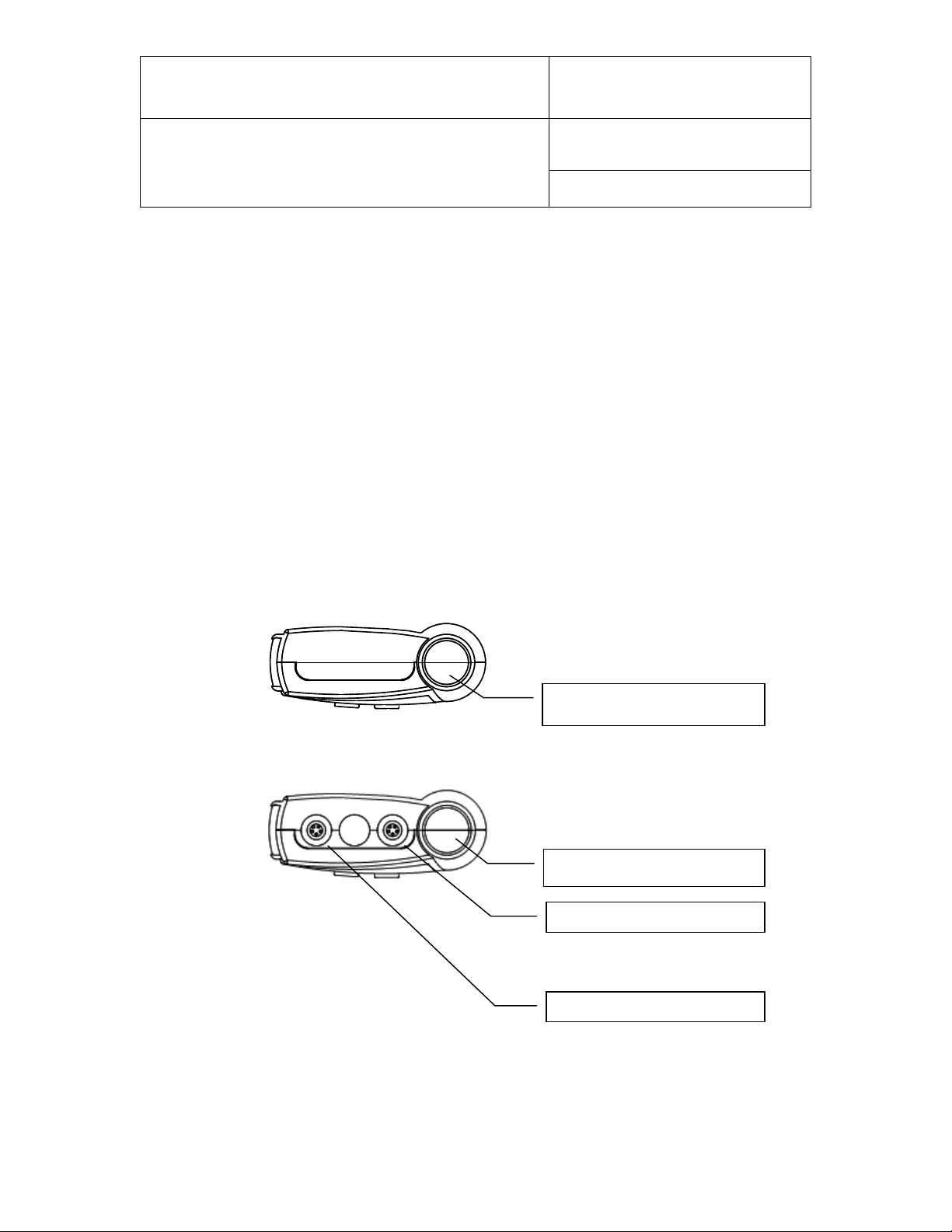

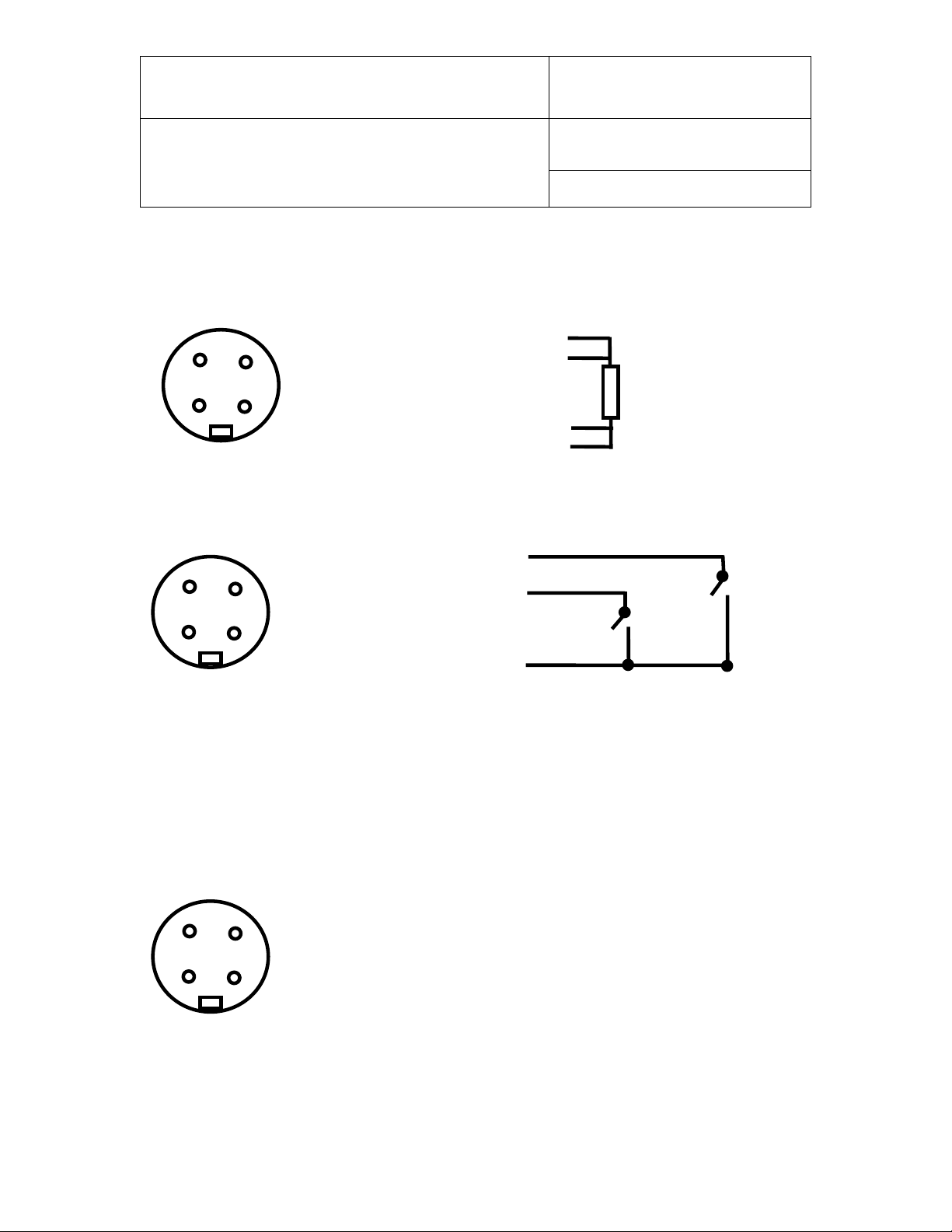

Input 1 (HygroClip 2 probe)

Input 2 (HygroClip 2 probe)

Input 3 (HygroClip 2 probe)

Input 1 (HygroClip 2 probe)

HL-NT2

HL-NT3

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Notes:

o For maximum protection against vandalism, use the HC2-S probe in the retracted position.

For a faster response, use the probe in the extended position.

o For additional information on the HygroClip 2 probes see document

E-M-HC2 Probes-V1.

Instruction Manual

Document Type

Page

11 of 74

2.3.2 Probe inputs 2 and 3 (HygroLog HL-NT3)

The HygroLog HL-NT3 can be used with up to 2 additional HygroClip 2 probes. For further

information on the HygroClip 2 probes, see document E-M-HC2 Probes-V1.

2.3.3 Connector identification

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

12 of 74

2.4 Power supply

The HygroLog HL-NT ships with a r egular 9V battery which must be inser ted first (see battery

replacement).

To conserve battery po wer, models wit h the LC displa y and keypad are s hipped with the D isplay

Sleep function enabled (s ee Software Fu nctions). W hen the keypad has n ot been used for some

time, this function au tomatic ally turns of f the disp lay off . The displa y can be tem poraril y activ ated

by pressing on any key of the keypad.

When connected to a dock ing station, the H ygroLog HL-NT can be po wered with an external AC

adapter.

Note: most models of docking station require the use of an external AC adapter due to the current

consumption of the docking station internal electronics.

After reconfiguring the HygroLog HL-NT with the ROTRONIC HW4.software, a rechargeable

battery (accumulator ) can be used instead of a regu lar battery. Rechargi ng the battery require a

docking station and an external AC adapter.

WARNING: Trying to recharge a regular battery is potentially danger ous. Whenever a regular

battery is being used, the logger should be configured with the internal battery charge

function disabled.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Rechargeable

Rechargeable

Regular

Regular

1 Probe / 5s Interval

2.7

3.4

11

22

1 Probe / 5s Interval / LCD

2.1

2.6

8.9

17

1 Probe / 1min Interval

14

17

59

118

1 Probe / 1min Interval / LCD

5.8

7.3

24

48

1 Probe / 15min Interval

89

111

372

744

1 Probe / 15min Interval / LCD

8.9

11

37

74

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

13 of 74

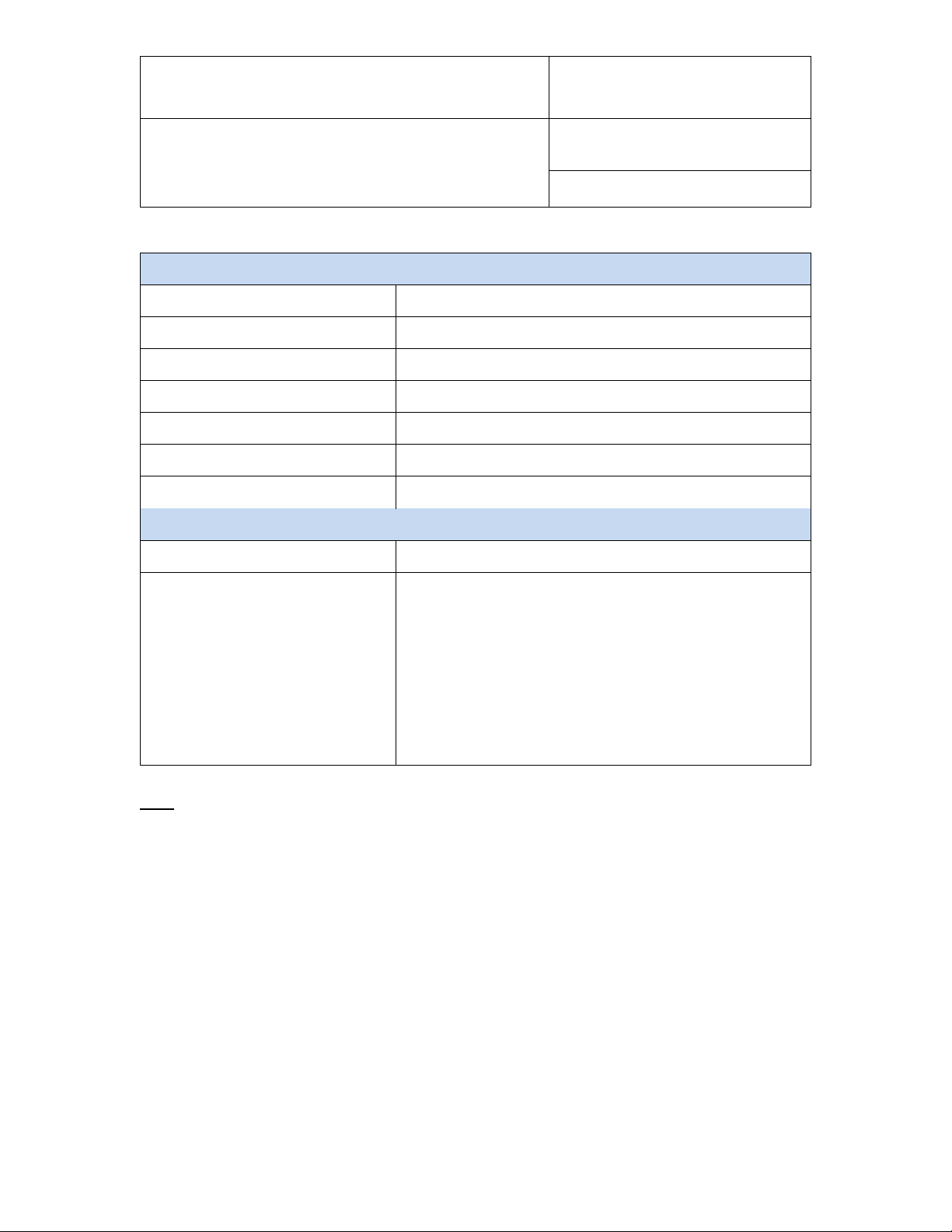

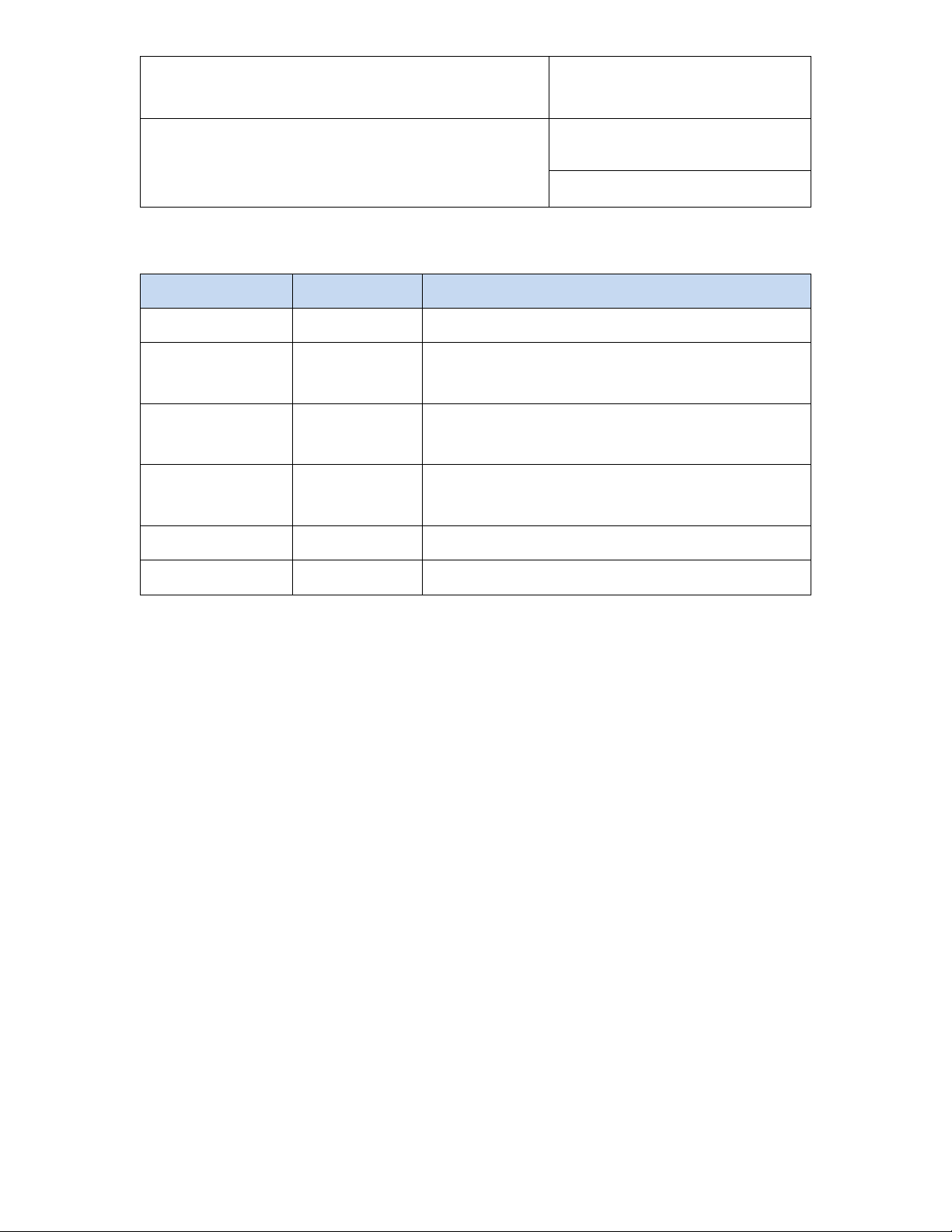

2.4.1 Battery lifetime

The battery lifetim e depends on the manner in which th e HygroLog HL-NT is being used. The

HygroLog HL-NT has a battery lifetim e of one year wh en just one HygroC lip probe is be ing used

(standard 500 mAh alkaline battery), when no docking station with internal electronics is connected

to the HygroLog HL-NT and when the logger is configured / programmed as follows:

• Display Sleep function enabled (models with display)

• No docking station with internal electronics

• LED and beeper functions disabled

• Log interval set to 15 minutes

Additional examples of battery lifetime (LED turned off, Logging active): in the following table, LCD

means that the LC display is permanently on (Display Sleep function disabled). No docking station

with internal electronics is connected to the HygroLog HL-NT.

Lifetime in days

Note: the consumption of the display is negligible when the Display Sleep function is enabled. With

the display always on, power consumption is at its highest when the display refresh rate is set with

HW4 to the minimum of 5 sec.

Because of the requirement to keep track of the date and time, the HygroLog HL-NT does not have

Battery

120mAh

Battery

150mAh

Battery

500mAh

Battery

1000mAh

a power on/off switch. Every minute, both the date and time are recorded to the internal EEPROM.

Seconds are not rec orded. In the event of a relatively brief interruption of po wer (such as when

replacing the battery), t im e may fall behin d in incr em ents of one minute. Rem oving the batt ery for

an extended period of time will cause the logger to completely lose track of the date and time.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

cover

To access the

remove the screw shown

to the right and open

rubber cover.

The

the bottom

instrument

battery

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

2.4.2 Battery replacement

battery,

the

battery is located at

of the

.

2.5 Memory card

Instruction Manual

Document Type

Page

14 of 74

The HygroLog HL-NT has a non-volatil e 64 kb EEPROM internal memory that is used to s av e the

logger configuration data, the logger events and to temporarily hold measurement data.

The main memor y is a plug-in f lash m em ory card. As a standard, the H ygroLo g HL-NT ships with

a 64 MB card. This card allows the recording of up to 400,000 values in text file format (unprotected)

or up to 750,000 values in bin ary file f ormat ( protected) . Mem ory cards with a c apacit y of up to 1

GB can be purchased f rom third parties. Regardless of its size, the flash memory card ho lds a

maximum of 512 files and directories, including one logger-configuration and one logger-event file.

The measurem ent data c an be s av ed ei ther to a file with exte ns ion X L S or to a file with extension

LOG. Files with XLS exten sion can be read with Note pad or imported into Micro soft Excel. Files

with extension LOG are encoded in binary format so as to prevent data manipulation and can only

be read with the RO TRO NIC HW4 software. Both t ypes of f iles can c o-exis t on t he m em or y card.

The memory card ca n be rem oved from the logger an d transf erred to a car d reader, a PDA, etc .

The flash memory card can also be read without being removed from the logger.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

cover

memory

Memory Card:

To access the memory

card,

shown to the right and pull

out the rubber cover.

The plug

card is located

the main board.

screw

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

card

remove the screw

-in flash memory

on top of

Instruction Manual

Document Type

Page

15 of 74

2.6 LED Indicators

The HygroLog HL-NT is equipped with a green and red LED. The logger can be conf igured with

HW4 to have the green side of the LE D f las h when lo ggi ng is act ive. The red side of t he LE D c a n

be made to flash when there is an a larm condition (see note below) and / or when the logger

requires attention (low battery, flash memory card full, etc.)

In the transient alarm mode, the red LED flashes for only as long as the data from a probe

corresponds to an alarm condition. In the durable alarm mode, the red LED stays on even after the

alarm condition has dis appeared. When the LED is set to prov ide a dura ble al arm, it c an be rese t

from the keypad or with HW4.

2.7 Beeper

The HygroLog HL-NT is equipped with an internal beeper and can be configured with HW4 to make

a clicking so und when an y key is being pres sed. The beep er can also be c onfigured to em it a 5second non-repeating s ound when ther e is an alarm cond ition and / or when t he logger requires

attention.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

16 of 74

2.8 HygroLog HL-NT functions

2.8.1 Calculated parameter

Using the HW 4 software, the HygroLog HL-NT can be set t o compute for eac h HygroClip probe

one of the following psychrometric parameters.

o Dew point (Dp)

o Frost point (Fp)

o Wet bulb temperature (Tw)

o Enthalpy (H)

o Vapor concentration (Dv)

o Specific humidity (Q)

o Mixing ratio by weight (R)

o Vapor concentration at saturation (Dvs)

o Vapor partial pressure (E)

o Vapor saturation pressure (Ew)

Each individual probe input can be associated with a different parameter.

Note: depending on whether dew point or f ros t po int w as s elec t ed, bot h t he HygroLog HL-NT and

HW4 will displa y either t he symbol Dp or the s ymbol Fp for values belo w freezing. The s ymbol Fp

indicates that the va lue is a frost point as op posed to being a de w point. Regardless of the dew

point / frost point selection, the symbol Dp is always displayed for values above freezing.

Some of the above parameters require barometric pressure as an input. When an analog pressure

probe is connected to one of the HygroLog HL-NT inputs, the logger can be set to use the

measurement fr om this pro be. When no pressure prob e is b ein g used, a fixed press ure val ue c a n

be used. This value can be specified as part of the HygroLog HL-NT settings.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

17 of 74

2.8.2 Data logging

Data logging requires that a flash memory card be inserted inside the logger. Using the HW4

software, log files can be set to one of the following formats:

• H W4 binary format [LOG]: files in this format are encoded and can be opened only with the

ROTRONIC HW 4 software. HW 4 does not al low an y manipulat ion / alter ation of the data

and requires a pass word to log in. Should the file be som ehow modif ied, HW 4 will give a

warning that the file is not an original.

• Text file format [XLS]: in principle, files in th is format can be opened with an y text editor

and / or imported into Microsoft Excel.

The log fil e form at is a glob al setting of the f lash memor y card (cha nging th is setting r equires the

HW4 software). At any gi ven time, the card records data f r om all inputs i n eit her o ne f ormat or the

other. Files of diff erent f orm ats can co-exist in the flash m emor y card. Binar y files (protec ted) us e

substantially less memory space than text files (unprotected).

The logging func tion is independently activated for each individual input. The HygroLog HL-NT

creates a separate fil e for e ach in put that is to be recor ded. Mu ltiple in puts can not be recorde d to

the same file. The H ygroLo g HL-NT automatical l y generates each f ile nam e. A f ile nam e c onsists

of 8 digits followed by the extension LOG or XLS. The first 4 digits are the same as the last 4 digits

th

of the logger serial number, the 5

digit is the same as the input number and the last 3 digits are a

number between 000 and 999 used to dif ferentiate log files created for the sam e input. The last

number that was created is retained in the non-vo lat il e EEPRO M an d is u pda ted when ev er a n e w

file is created for the input. When the number reaches 999, the next update will reset it to 000.

All files are located in the r oot directory of the f lash memory card, includ ing the logger event f ile

and the logger conf iguration file. R egardless of the memor y card capacit y, the root directory is

limited to a maxim um of 250 files. T his m eans that the m emor y card can hold a m aximum of 248

log files, and that a card with this amount of files is considered to be full, even if all the memory has

not been used.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Using HW4, the following log settings can be defined individually for each input:

• Start date and time

• Stop date and time

• Log interval (minimum 5 seconds)

• Measured values and computed parameter, or any parameter combination

• User custom text (used for the log file header)

• User name, HW4-ID, HW4 Serial Number

• Automatic creation of a new file after 200,0 00 d ata p o ints or at th e end of each day, week

or month

Note: unlimited logging (loop mode logging) is not possible. Logging stops automatically when the

flash memory card is full. Prior to logging, th e user may use HW 4 to check the amount of fr ee

Instruction Manual

Document Type

Page

18 of 74

memory, and verify that there is enough room available.

If the flash memor y card is removed when logging is ac tive, the HygroLog HL-NT will stop logging

until a new card is inserted. Un less the stop date and time hav e been reached, logging will s tart

again under the next available file name when a new card is inserted.

Warning: removing the m emory card while lo gging is active m ay result in a corrupted log f ile and

in loss of data.

Logging can be started im mediatel y for any individua l input fr om the ke ypad of the HygroLo g HLNT. A deferred start can only be programmed with the HW4 software. The green LED of the

HygroLog HL-NT can be set to f lash when the i nstrument is recording data. T o conserve batter y

power, you may want to do this only when an external power source is being used.

Logging can be imm ediately stopped f or any indi vidual inpu t directl y from the keypad. W ith HW4,

logging can be stopped either imm ediately or at a fut ure date and tim e for any individua l input or

for all inputs.

When logging is ended, the HygroLog HL-NT returns to the measuring mode.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

19 of 74

2.8.3 Trend indicators

See also: Main operating modes and measurement interval

When the trend indic ator f u nction is ena bled, a s ymbol app ears o n th e left side of the LC d ispla y,

on the line corresponding to each measured or calculated value. An up arrow denotes a rising value

and a down arrow denotes a decreasing value. Both arrows denote a stable value.

The trend of a parameter is evaluated by comparing successive averages made of 6 values each.

With the shortest possible measurement interval of 5 seconds, each average covers a time period

of 30 seconds and th e first indication of a trend is availab le after one m inute. Subsequently, th e

trend is evaluated and updated every 30 seconds. With a longer measurement interval, each

average is computed over a longer p eriod of time (alwa ys using 6 values) and the trend is also

updated over longer intervals of time.

For any measured or c a lc ul ated par ameter, the trend i ndicat or s ho ws a s tab le co ndit io n w hen th e

absolute value of the difference between two successive averages is < 0.02.

2.8.4 Alarm function

Using the HW4 sof tware, both a high an d a low a larm value ca n be associ ated with the humidit y,

temperature and calculated parameter of each probe input, A hysteresis value can also be entered

for each parameter. This value is used for both the low and the high alarm conditions.

The HygroLog HL-NT has a red LED which ca n be set with HW 4 to flash when ever the value of

any parameter corresponds to an alarm condition. The LED can be set to flash only as long as the

alarm condition exits or it can be s et to provide a durable alarm and, in this case, it will to keep

flashing until the alarm is reset.

The HygroLog HL-NT can also be se t with HW4 to beep for 5 seconds when there is an alarm

condition. The HygroLog HL-NT will beep only once, when the condition occurs.

Log files do not recor d the exis tence of an a larm cond ition. However, when the c ontents of a log

file are viewed as a data table with the HW4 software, values that correspond to an alarm condition

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

20 of 74

are printed over a red bac kground, based on the a larm settings that HW 4 downloaded from the

logger.

2.8.5 Display-Sleep function

This function can be enabled and configured only with the HW4 software.

Using the Display Sleep f unction can substantially extend the lif etime of the battery. When the

Display Sleep f unction is ac tive, the LC display of the HygroLog H L-NT stays blank . The Display

Sleep function is effective both in the measure and in the record mode.

The display of the HygroLog HL-NT can be set to be always on. It can also be set to automatically

go blank af ter 30 seconds , 1, 5, 1 0 or 20 minutes when no k ey is bein g pressed or when there is

no communication with a P C. If t he H ygroCli p NT was in the function menu at the time the display

goes blank, it automatically exits the menu.

The HygroLog suspends the Display Sleep function whenever a key is pressed. The f unction is

also suspended when ext ernal power is available or when the logger receives a communication

1

request (for exam ple from a PC

). When the displ ay comes up again, it shows by defau lt the

measurements from the probe that was selected last.

1

When the HygroLog HL-NT is connected by means of a docking station to a PC and HW4

is running, you should use an external AC adapter to power both the HygroLog HL-NT and

docking station. HW4 can be set to use a polling i nte r val as s hort as 5 s econds to interrogate al l

instruments connected to the PC and this could cause the battery life time to be sharply reduced.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

21 of 74

2.9 HygroClip 2 probe functions

2.9.1 Simulator function (validation of the signal transmission):

If so desired, transm ission of the HC2 pr obe output signals c an be validated b y using the probe

simulator function. T he HW4 s oftwar e is r equir ed to en able and conf igur e this f unc tion. When the

function is enabled the probe generates digital and analog signals corresponding to values

specified by the user.

2.9.2 Sensor failure detection and fail safe mode:

The HygroClip 2 probe aut omatically detects a sensor failure such as a shorted or open sensor.

This information is passed to both the HygroLog HL-NT and HW4 software. The optional display of

the HygroLog H L-NT will show an alar m message. The H ygroC lip 2 pr o be c an al s o be configured

with the HW4 software to generate a "safe or readily identifiable" fixed value for humidity and

temperature in the event of a shorted or open sensor.

Note: the sensor diagnostics and drift compensation function of the HygroClip 2 probe is not

available with the HygroLog HL-NT due t o the fact that the probe is powered on ly briefly during

each log or measurement interval.

2.10 Event tracking

The HygroLog HL-NT maintains an internal event file with the extension EVT. This function is

always enabled.

Part of the procedure to ensure conformity to the FDA requirements is to use the HW4 software to

disable the MENU key on the HygroLog HL-NT keypad. The MENU key is the only key that can be

used to make c hanges to t he Hygr oLog HL-NT. When this proce dure is implem ented, th e events

recorded by the HygroLog HL-NT are the result of an interaction with the HW4 software. When the

MENU ke y i s not disable d, a l imited number of events ar e rec orded in the logger eve nt file. In this

case no entries are made in the logger event file header. The two tables below provide a list of the

events tracked by the HygroLog HL-NT.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

The battery was inserted or the instrument powered down and up

Writing device

While recording data, the logger could not find the memory card. The

The memory card was replaced while data was being logged. The

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

22 of 74

The logger event file is spli t bet ween the internal memory of the logger ( up to 1 70 even ts ) and the

flash memory card (practically unlimited number of events). HW4 offers the possibility of

downloading, open ing and print ing the ent ire file conte nts. All pas t logger eve nts are ava ilable to

HW4 as long as t he flas h m emory card is not rem oved f rom the lo gger. T he serial number of the

logger is used as the file name.

Example: 1111111111.EVT

The logger event file consists of a file header and a file body. The file header provides the following

information:

o Most recent programming of the log function: programming date and time, user and HW4

product ID

o Most recent device configuration: date and time, user and HW4 product ID

o Most recent adjustment to the PC date and time: date and time, user and HW4 product ID

An individual record with date and time is enter ed in the e vent file bod y for each indi vidual event

listed in the two tables below:

Interaction with the HW4 software:

Event Description

Power up

after an internal problem

Watchdog overflow Internal instrument error (normally should not occur)

New or existing configuration written to logger

configuration

Memory card removed

data was written to the EEPROM and are not yet lost

Memory card full No free memory space on the memory card

New memory card

data will be split between two different memory cards. Possibly,

inserted

some data has been lost.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Logging stopped

Logging ended

Out-of-limits value

The battery is empty and the logger has powered itself off (keeping

Beginning accumulator

Accumulator charge

Lost data, memory

While recording data, the logger could not find the memory card. The

HygroClip probe

HygroClip probe

A HygroClip probe was removed from input # or the input can no

External power

External power

The A/C adapter was disconnected, or failed, or is not being

Device time changed /

Device date and time prior and after adjustment (up to firmware

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

Instruction Manual

instruction manual

Document title

Page

Event Description

Humidity adjusted Humidity adjustment of the probe connected to input #

Temperature adjusted Temperature adjustment of the probe connected to input #

Logging started Start recording data from input #

Data recording of input # ended before the programmed stop time

manually

Data recording of input # ended at the programmed stop time

automatically

An out-of-limits value was newly detected on input #

detected

Battery almost empty Battery voltage dropped below 6.5V

23 of 74

Document Type

Battery empty

charge

ended

MFG command

card not ready

connected 1

disconnected 1

connected

removed or faulty

power up could result in erroneous data or loss of data)

Starting to charge the rechargeable battery

Rechargeable battery full

Reserved for the factory

data could not be written to the EEPROM, and was lost

A HygroClip probe was connected to input #

longer communicate with the probe

The A/C adapter was connected and is being powered

powered

adjusted

v1.1d only)

Prior device time Device date and time prior to change (firmware v1.2a and up)

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

RS-485 address

Docking station

The docking station was disconnected or there is no longer any

Docking station

A docking station was connected and communication was

Logger language file

A different internal language file was loaded or the same file was

Log function

Logging stopped

Log function

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

Instruction Manual

instruction manual

Document title

Page

Event Description

New device time Device date and time after change (firmware v1.2a and up)

The RS-485 address was changed

changed

EEPROM erased

disconnected 2

connected 2

downloaded

Reserved for the factory

communication with it

established

loaded again

The log function has been programmed for input #

programmed

24 of 74

Document Type

Event file deleted

1

connection / removal of analog probes is not recorded

2

only when the docking station has internal electronics

Reserved for the factory

Events triggered from the keypad:

Event Description

Humidity adjusted Humidity adjustment of the probe connected to input #

Temperature adjusted Temperature adjustment of the probe connected to input #

Logging started Start recording data from input #

Data recording of input # ended before the programmed stop time

manually

Prior device time Device date and time prior to change (firmware v1.2a and up)

New device time Device date and time after change (firmware v1.2a and up)

programmed

The log function has been programmed for input #

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

25 of 74

2.11 Operating limits (ele c tr onics only)

Models without display:

● -10…50°C with the factory supplied alkaline battery

● -30…70°C with a lithium battery or an external AC adapter

Models with display:

● -10…50°C with the factory supplied alkaline battery

● -10…60°C with a lithium battery or an external AC adapter

The HygroClip probes have generally wider operating limits (see individual probe specifications).

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

26 of 74

3. Docking stations for the HygroLog HL -NT

The HygroLog HL-NT requires a docking station with the appropriate interface to be able to

communicate with a PC with the RO TRONIC HW4 software inst alled. The connector located on

the back of the HygroLog HL-NT is meant to be used with one of the available docking stations

(UART interface). When installed on a PC, the ROTRONIC HW4 software is used to configure the

HygroLog HL-NT, to program its logging function, to download the recorded data and to adjust the

probes connected to the logger against a reference environment.

A docking station is required for any of the following:

o Mount the HygroLog HL-NT to a wall

o Place the HygroLog on the optional desk-top stand

o Use an external AC adapter to power the HygroLog HL-NT

o Connect the HygroLog HL-NT to a PC: RS232 or USB port, Ethernet (TCP/IP) LAN

or WLAN

o Connect up to 64 H ygroLog HL-NT or other devices together in a m ulti-dropped network

(RS-485)

Depending on the model, using a docking station also adds functionality to the HygroLog HL-NT:

o Up to 4 additional probes, including analog probes and direct 4-wire RTDs

o Logical inputs (external contacts)

o Relay outputs

Note: docking stations with internal electronics and PC interf ace should b e ge ner a l ly use d with an

external AC adapter.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

27 of 74

3.1 Models

All models of docking st ation have the same physical dimensions an d can be used either as a

mechanical adapter to plac e the HygroLog HL-NT on t he option al desk -top stand or as a bracket

to mount the HygroLog HL-NT to a wall. Docking stations are available in the following

configurations:

3.1.1 Basic docking stations (no digital interface)

o HL-DS-NT0: basic docking station without internal electronics. This model simply provides

a means of mounting the HygroLog HL-NT to a wall

o HL-DS-NT1: basic dock ing station without internal electronic s (similar to m odel HL-DS-

NT0). This model simply provides a receptacle for an AC adapter used to power the

HygroLog HL-NT

3.1.2 Docking stations with RS-232 serial interface

o HL-DS-NT2: receptacle for AC adapter, one serial port (RS232) and one RS485 port (multi-

drop).

o HL-DS-U1: receptacle f or AC adapter, one serial (R S232) port, one RS485 port (m ulti-

drop), four probe inputs (HygroClip 2 or analog probe with 0…2.5 V signal), one connector

for up to two logical input signals.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

28 of 74

3.1.3 Docking stations with USB interface

o HL-DS-NT3: receptacle for AC adapter, one USB port and one RS485 port (multi-drop).

o HL-DS-U2: receptacle f or AC adapter, one USB port, one RS485 port (m ulti-drop), four

probe inputs (HygroClip or analog probe with 0…2.5 V signal), one connector for up to two

logical input signals.

o HL-DS-U2-420: same as HL-DS-U2 but designed for analog probes with a 4…20 mA

output signal. Each probe input uses an internal 150 Ohm resistor to convert 4…20 mA to

600…3000 mV (nominal).

o HL-DS-PT2: receptacle for AC adapter, one USB port, one RS485 port (multi-drop

networking), four con nectors f or RTD probe (dir ect 4-wire con nection), one c onnector f or

up to two logical input signals.

o HL-DS-R1: receptacle for AC adapter, one USB port, one RS485 port (multi-drop

networking), one conn ector for up to two logical inp ut signals and t wo independent r elay

output connectors.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

29 of 74

3.1.4 Docking stations with wired Ethernet interface

Note: with an y of the follow ing models, use an exte nsion cable to s eparate all probes from either

the HygroLog HL-NT or docking station s o as to av oid m easur ement err ors due to s elf -heating b y

the docking station.

o HL-DS-NT4: receptacle for AC a dapter, one RJ 45 connector (Ethernet) , one RS 485 port

(multi-drop) and one connector for up to two logical input signals.

o HL-DS-NT4-WEB: same as HL-DS-NT4 but with an internal web server that can be

accessed with a web browser.

Note: Probe adjustment is not possible with WEB docking stations.

o HL-DS-U4: receptacle f or AC adapter, one RJ45 connector (Ethernet), one RS485 port

(multi-drop), four probe inputs (HygroClip or analog probe with 0…2.5 V signal), one

connector for up to two logical input signals.

o HL-DS-U4-WEB: same as HL-DS-U4 but with an internal web server that can be accessed

with a web browser.

Note: Probe adjustment is not possible with WEB docking stations.

o HL-DS-U4-420: same as HL-DS-U4 but designed for analog probes with a 4-20 mA output

signal. Each probe input uses an internal 150 Ohm resistor to convert 4…20 mA to

600…3000 mV (nominal).

o HL-DS-U4-420-WEB: same as HL-DS-U4-420 but with an internal web server that can be

accessed with a web browser.

Note: Probe adjustment is not possible with WEB docking stations.

o HL-DS-PT4: receptac le for AC adapter, on e RJ45 connector (Et hernet), one RS485 p ort

(multi-drop networking), two connectors for RTD probe (direct 4-wire connection), one

connector for up to two logical input signals.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

30 of 74

3.1.5 Docking stations with wireless Ethernet interface

Note: with any of the follow ing models, use an exte nsion cable to s eparate all probes from either

the HygroLog HL-NT or docking station s o as to av oid m easur ement err ors due to s elf -heating b y

the docking station.

o HL-DS-NT4-WL: receptacle f or AC adapter, WLAN trans ceiver, one RS485 port (m ulti-

drop) and one connector for up to two logical input signals.

o HL-DS-U4-WL: receptacle for AC adapter, WLAN transceiver, one RS485 port (multi-

drop), two probe inputs (HygroClip 2 or analog probe with 0…2.5 V signal), one connector

for up to two logical input signals.

o HL-DS-U4-WEB-WL: same as HL-DS-U4-WL but with an interna l web s erver that c an be

accessed with a web browser.

Note: Probe adjustment is not possible with WEB docking stations.

o HL-DS-PT4-WL: receptacl e for AC adapter, WLAN transceiver, on e RS485 port (multi-

drop networking), two connectors for RTD probe (direct 4-wire connection), one connector

for up to two logical input signals.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Network Interface – Wireless LAN

Standard

IEEE 802.11b

Frequency

2.4 GHz

Data Rate

Up to 11 Mbps with automatic fallback

Modulation

CCK (11/5.5 Mbps), DQPSK (2 Mbps), DBPSK (1 Mbps)

Typical Transmit Power

16 dBm

Receive Sensitivity

-52 dBm @ 11 Mbps

Connector

1 x RP-5MA

WLAN Security

WEP (Wired Equivalent Privacy)

64 / 128-bit encryption (RCA)

WPA / WPA2 / 802.11i

128-bit TKIP/CCMPA (AES) encryption

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

o

Instruction Manual

Document Type

Page

31 of 74

Note: The WLAN security of docking station HL-DS-U4-WEB-WL (with internal web browser) is

limited to WEP with 64-bit encryption (no WPA).

Enterprise mode (802.1X); LEAP (WEP only), PEAP,

TTLS, TLS; EAP-FAST, GTC, MD5, OTP, PAP, CHAP,

MSCHAP, MSCHAP

, TTLS-MSCHAPV2

V2

Pre-shared key mode (PSK/Personal)

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

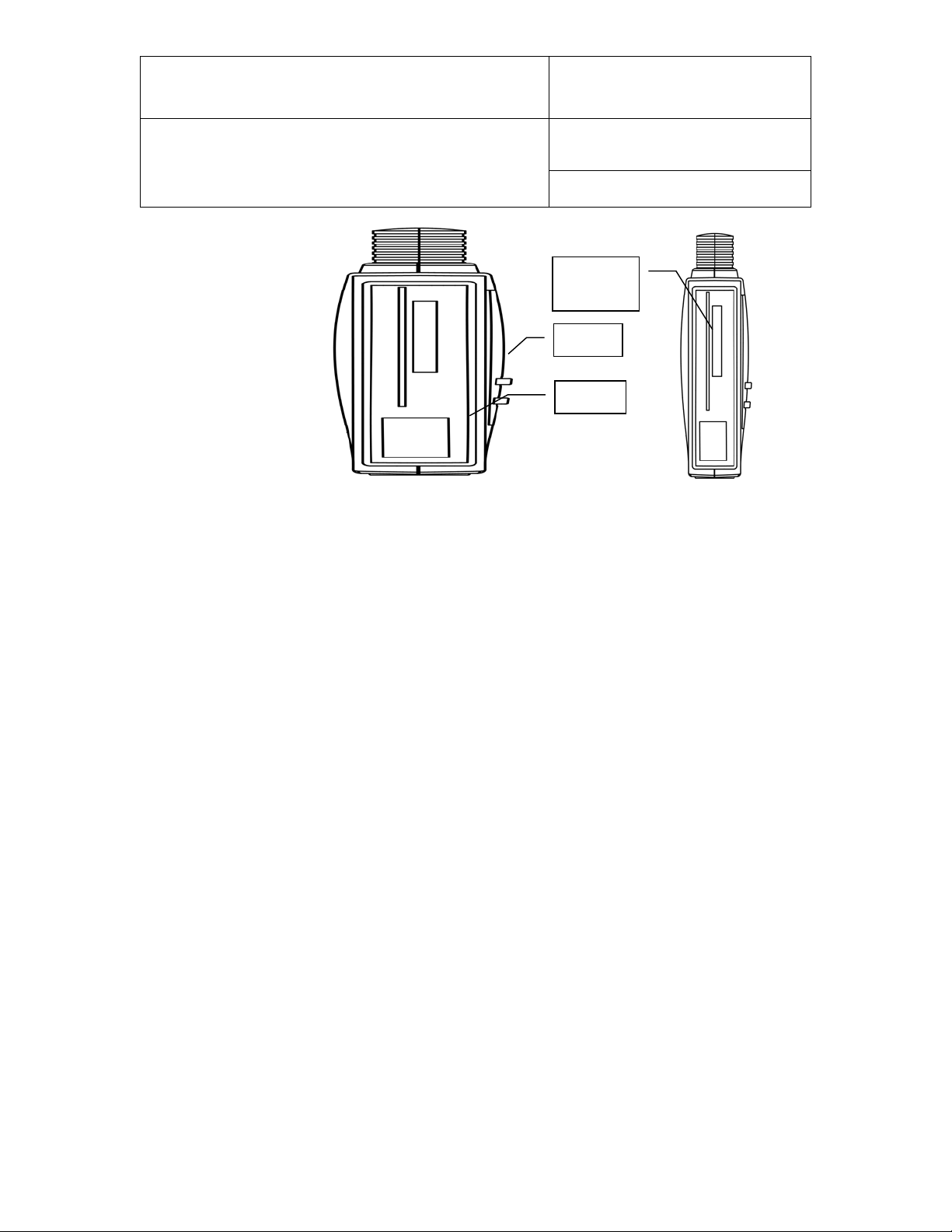

To mount the docking station to a wall, use

the two holes shown on the right

HygroLog

docking station

To attach the HygroLog NT to the

so as to match the

to prevent removal

[B]

[B]

[A]

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

3.2 Installation

Installation is the same for all models of docking station.

. The

NT can then be attached to the

as explained below.

Instruction Manual

Document Type

Page

32 of 74

docking station:

Place the HygroLog NT on the

docking station

two areas [A]. Press lightly one

against the other and secure the

assembly with threaded pin [B].

When the docking station is

mounted on a wall, a small

padlock (not shown) may be put

through pin [B]

of the HygroLog NT from the

docking station.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Probe input 4

Probe input 5

Logical inputs

Probe input 6

Probe input 7

RS-485

12VDC Power

RS-232

Probe input 4

Probe input 5

Probe input 6

Probe input 7

RS-485

12VDC Power

(+) center

USB

Logical inputs

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

3.2.1 Connector identification

HL-DS-U1

(HC2 / 0…2.5 V)

(HC2 / 0…2.5 V)

Instruction Manual

Document Type

Page

(HC2 / 0…2.5 V)

(HC2 / 0…2.5 V)

33 of 74

(+) center

HL-DS-U2

(HC2 / 0…2.5 V)

(HC2 / 0…2.5 V)

(HC2 / 0…2.5 V)

(HC2 / 0…2.5 V)

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Probe input 4

Probe input 5

Logical inputs

Probe input 6

RJ45

RS-485

12VDC Power

Probe input 7

Probe input 4

Probe input 5

Probe input 6

Probe input 7

RS-485

12VDC Power

USB

Logical inputs

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

HL-DS-U2-420

(HC2 / 0(4)…20 mA)

(HC2 / 0(4)…20 mA)

(+) center

Instruction Manual

Document Type

Page

34 of 74

(HC2 / 0(4)…20 mA)

(HC2 / 0(4)…20 mA)

HL-DS-U4

(HC2 / 0…2.5 V)

(+) center

(HC2 / 0…2.5 V )

(HC2 / 0…2.5 V )

(HC2 / 0…2.5 V )

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Probe input 4

Logical inputs

Probe input 6

Antenna

RS-485

12VDC Power

Probe input 4

Probe input 5

Logical inputs

Probe input 6

RJ45

RS-485

12VDC Power

Probe input 7

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

HL-DS-U4-420

(HC2 / 0(4)…20 mA)

Instruction Manual

Document Type

Page

(HC2 / 0(4)…20 mA)

(HC2 / 0(4)…20 mA)

35 of 74

(+) center

HL-DS-U4-WL

(HC2 / 0…2.5 V )

(HC2 / 0(4)…20 mA)

(HC2 / 0…2.5 V )

(+) center

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Input 4: RTD

Binder ET-409

Input 5: RTD

Binder ET-409

Logical inputs

Input 6: RTD

Input 7: RTD

RS-485

12VDC Power

USB

Input 4: RTD

Logical inputs

Input 6: RTD

RJ45

RS-485

12VDC Power

(+) center

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

HL-DS-PT2

Connector type:

Binder ET-409

Connector type:

Binder ET-409

Instruction Manual

Document Type

Page

Connector type:

Connector type:

36 of 74

(+) center

HL-DS-PT4 / HL-DS-PT4-WL

Connector type:

Binder ET-409

or WLAN

Connector type:

Binder ET-409

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Contact material

Silver alloy

Initial contact resistance

100 mΩ

Initial insulation resistance

Min. 1,000 MΩ at 500V DC

Nominal switching capacity 1)

2 A 250 VAC

Minimum switching power 1)

1,500 VA

Maximum switching voltage 1)

250 V AC

Maximum switching current 1)

2 A AC

Minimum switching capacity 1)

100 mA, 5 V DC

Expected life (min. operations)

Mechanical: 5 x 106

Relay 1

Not used

Logical Inputs

Relay 2

Not used

RS-485

12VDC Power

(+) center

USB

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

HL-DS-R1

Instruction Manual

Document Type

Page

37 of 74

The relay contacts are specified as follows:

Electrical: N.O. 5 x 104

4

N.C. 3 x 10

1) Resistive

The DS-R-1 docking stat ion is provided with two matching 4-pin connectors. The pins of thes e

connectors are numbered on the connector solder side (see pin-out diagrams).

Docking station inputs:

Depending on the m odel of docking station, the signals from up to 4 additional probes can be

processed by the HygroLog HL-NT.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

38 of 74

3.2.2 HygroClip 2 probes

By default inputs 4, 5, 7 and 7 of d ocking stat ions HL-DS-U1, HL-DS-U2, HL-DS-U4 and HL-DSU4-WL are c onfigured by the factory to accept a HygroClip 2 probe. An y model of HygroClip 2

probe can be connected these using one of the available extension cables. See document

E-M-HC2-accessories.

3.2.3 1-channel analog probes with voltage output

Inputs 4, 5, 7 and 7 of docking stations HL-DS-U1, HL-DS-U2, HL-U4 and HL-DS-U4-WL can also be

configured to accept one of the following:

o 1-channel analog probe: To be compatible with the docking station the analog probe must meet

the following requirem ents: s upply volta ge: 5 VDC , curr ent consum ption: max . 10 m A, output

signal: 0 to max. 3.3 VDC. The docking station uses a 12-bit A/D converter to digitize the probe

analog signal and can be configured to measure practically any parameter.

o Analog pressure probe: this is a special case of analog probe and is subject to the same

compatibility requirements. When analog pressure probe is selected, any input of the HygroLog

HL-NT and doc king station can be configured to use the signal f rom the pressure probe to

calculate any humidity parameter that requires barometric pressure as an input value (example:

mixing ratio).

3.2.4 1-channel analog probes with current output

Docking station HL-DS-U4-420 is similar to doc king station HL-DS-U4 with the difference that it

accepts up to four 3-wire single channel analog probes with a 4-20 mA current output signal. Each

probe input uses an in ternal 150 O hm resis tor to convert 4… 20 mA to 600… 3000 m V (nominal).

The HW4 software allows a 2-point adjustment of the mA to mV conversion to compensate for the

tolerance on the 150 Ohm resistor (use Device Manager in HW4). The probes are powered by the

docking station (supply voltage: 5 VDC, maximum current draw: 10 mA / probe).

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

39 of 74

3.2.5 Pt100 RTD 4-wire probes

Docking stations HL-DS-PT2, HL-DS-PT4 and HL-DS-PT4-WL are designed for 4-wire RTD

probes. These docking stations allow the measurement of temperature conditions within the range

of -100 to 600°C. Accuracy depends on the class of the Pt100 RTD. Adjustment of the RTD inputs

against a reference temperature is limited to a 1-point adjustment (global offset).

3.2.6 Logical inputs (on / off)

Several models of doc king station allow the H ygroLog HL-NT to proces s up to 2 logical inp uts.

Typically this is used to monitor a relay contact, a door contact, etc.

3.3 Relay contacts

Docking station model HL-DS-R1 features two independent relays, each with 3 contacts: normally

closed, normally open a nd common. When conf iguring the HygroLog HL-NT and doc king station

with the HW4 software, a number of conditions can be defined that will cause the relay to be either

energized or de-energized.

The relays of the HL-DS-R1 docking station can be used to provide a local indication of the

following:

o Out of limit values for probe inputs 1 to 3 of the HygroLog HL-NT

o Status of the two logical inputs of the DS-R-1 docking station

o Memory card error

o External power failure

o Low battery charge

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

HygroClip 2 probe

7: TXD (UART)

Analog 1-channel probe

7: not used

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

40 of 74

4. Pin-out diagrams

Note: all pin-out diagrams are shown from the solder side of the matching connector

• HygroLog HL-NT2 and HL-NT3: the probe inputs are always configured for a HygroClip2

probe

• Dock ing s tati ons HL-DS-U1, HLDS--U2, HL-DS-U4, HL-DS-U4-420 and HL-DS-U4-WL: the

probe inputs can be configured for either a HygroClip 2 probe or for a 1-chann el ana log prob e

1: RXD (UART)

2: GND (digital and power)

3: V+ (nominal 3.3 VDC)

4: not used

5: not used

6: not used

1: not used

2: GND (analog and power)

3: V+ (nominal 5 VDC, maximum 10 mA)

4: not used

5: not used

6: analog signal (0.0…3.3 VDC or 4…20 mA

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

1: DC (+)

1 2 3

4

4-wire RTD

4

3

2

1 4 3

2

1

1: + 3.5 VDC

1

2

GND: not used (eventually use for a shield)

+3.5 V

Note: an internal pull-down resistor sets

3

4 1 2

1: Normally closed (relay de-energized)

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

• Docking stations HL-DS-PT2, HL-DS-PT4 and HL-DS-PT4-WL:

direct Pt100 RTD (Bi nder ET-409 connector)

2: measurement (+)

3: measurement (-)

4: DC (-)

• Docking stations with logical inputs (Binder ET-409 connector)

Instruction Manual

Document Type

Page

41 of 74

2: Input 1

3: Input 2

4: GND

each input to 0 when the contact is open.

Logical Thresholds: logical 1: ≥ 2.8 VDC, logica l 0: ≤ 0.7 VDC

• Docking station HL-DS-R1 with relay outputs (Binder ET-409 connector)

2: Common

3: Normally open

4: Not used

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

1: 485 (-)

4

3 2 1

Note: use pins 3 and 4 to power multi-dropped instruments with a single external 12 VDC

Pin #

RS-232

2

TX 3 RX 5 GND

1 5 6

9

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

Instruction Manual

instruction manual

Document title

• Docking stations with RS-485 port (Binder ET-409 connecotr)

2: 485 (+)

3: GND (see note)

4: DC + (see note)

power supply with adequate mA rating. Pin 4 and the 12VDC power jack of the docking

station are not connected.

• Docking stations with RS-232 port

Page

42 of 74

Document Type

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

43 of 74

5. HW4 software

The HygroLog HL-NT requires a docking station with the appropriate interface to be able to

communicate with a PC with the ROTRONIC HW4 software installed (version 2.3.0 or higher).

Detailed instructions are prov ided in the HW 4 manual s (see Suppor ting docum ents at the e nd of

this manual).

The HW4 instruction manuals are available on the HW4 installation CD and can also be

downloaded from our web site.

5.1 Computer/Operating Sy s t e m Requirements

The following are the m inimum values require d to install a nd run HW 4 on a c omputer . It is highl y

recommended to exceed these values.

o Processor: Pentium II, 450 MHz

o RAM: 128 MB

o Available hard disk space: 50 MB

o Monitor: SVGA, 1024 x 768, 256 colors

o Ports: one free serial (COM) port or one free USB port or Network Interface Card / Ethernet LAN

with one free port (RJ45 connector)

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

44 of 74

5.2 Operating System Compat ibility

o Windows XP, NT4 with SP 6a or higher, Vista

o Windows 2000 with SP 2 or higher

o Windows Server 2003

HW4 was written for the Microsoft .NET framework (version 2.0) and requires this framework to be

installed on the computer.

The .NET framework offers significant improvements in the areas of networking and user security.

When new software is being installed, the .NET framework also eliminates the potential problem of

conflicting dynamic library files (DLL). Acc ordi ng to Microsoft, the .NET f r am ework will b e us e d by

all future Microsoft operating systems.

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

Instruction Manual

instruction manual

Document title

Page

45 of 74

5.3 Settings and functions acc e s sible only with HW4

Device configuration settings

• User specific information (retained in the logger)

• Custom text associated with the logger (30-character descr ipti on)

• Network address of the logger

• Language used in the logger menu

• Date and time format / separators

• Decimal symbol

• Pressure unit (English) and mixed unit systems

• Individual input settings:

o Probe type (HygroClip 2 or analog) – docking station only

o Probe / input description (maximum 12 characters)

o Parameter to be calculated for an individual input

Document Type

o Barometric pressure: fixed value or read from an input

o Value to be used as fixed barometric pressure

o Alarm settings for humidity, temperature and calculated parameter

• ● Display settings:

o Display refresh rate

o Turn display off after xx minutes (display sleep function)

• Backlight operation

• Alternate the display - automatically show all inputs one after the other

• Keypad disable functions:

o Disable entire keypad

o Disable only the MENU key

• Type of internal power source: standard battery or rechargeable battery

• LED and Sound settings

• Cancel a latching alarm (LED on logger and/or de-energizing optional docking station

relays)

• Memory card settings: log file format and memory management

• Programming of the optional inputs (docking station)

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Data recording functions

• Logging functions (set individually for each input, can be scheduled for a future date / time):

o Start date and time

o Stop date and time

o Log measured values and computed parameter, or any combination

o Custom text (used for the log file header - up to 43 characters)

o User name, HW4-ID, HW4-serial number (used for the log file header)

o Automatic creation of a new file after 200,000 data points or at the end of each

day, week or month

• Global programming of the log function of all inputs

• Data downloading (from the logger) and associated functions

HygroClip 2 probe functions

Instruction Manual

Document Type

Page

46 of 74

• Device Manager (probe configuration settings, simulator function, fail safe mode)

• Data recording (at the probe level)

• Probe calibration and adjustment (full functionality)

For detailed instructions, see the following HW4 software manuals:

o E-M-HW4v3-F2-013: Device Manager – HygroLog HL-NT data logger

o E-M-HW4v3-F2-001: Device Manager – HC2 probe series

o E-M-HW4v3-A2-001: Probe Adjustment function AirChip 3000 devices

o E-M-HW4v3-DR-001: Data Recording Function AirChip 3000 Devices

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

47 of 74

6. ERES regulatory compliance

In order to comply with ERES regulatory requirements (Electronic Records and Electronic

Signatures), the H ygroLog HL-NT should be used together with th e ROTRON IC HW4 software –

Professional Edition (version 2.3.0 or higher). HW4 is designed to keep track of logger configuration

changes, programming changes and of any probe adjustment. HW4 also keeps track of user events

(main operations performed by each user) and self-events (software problems). The records

generated by HW4 are protected with an electronic authentication stamp, can be cross referenced

and can be electronically signed.

IMPORTANT: In order to comply with ERES regulatory requirements, be sure to configure both the

HygroLog HL-NT and the HW4 software as follows:

o In HW4, create a user with full r ights (adm inistrator ) and a p assword ( see HW 4 m anual -

Users and Passwords). After creating the first user, be sure to log in as this user (see HW4

manual - Users and Passwords - Change Us er). This enab les both the H ygroLog HL-NT

and the HW4 software to maintain a record of events and to associate these with a specific

user. Create additional users with or without limited rights, as per your requirements.

o Enable HW4 t o m onitor ele ctronic signat ures and user events ( se e HW 4 m anual - Global

Settings - Events)

o Enable HW4 to monitor system events (see HW4 manual - Global Settings - General)

o Enable protocols in HW4 (see HW4 manual - Device Manager - Device Manager Settings)

If the HygroLog HL-NT has a display and keypad, disable the MENU key (see HW4 manual - Device

Manager - HygroLog HL-NT - Keypad).

© 2009-2015; Rotronic AG IN-E-HL-NT-V2_15

IN-E-HL-NT-V2_15

Document code Unit

Rotronic AG

Bassersdorf, Switzerland

HygroLog HL-NT data logger:

instruction manual

Document title

Instruction Manual

Document Type

Page

48 of 74

7. Getting started

Insert a 9V alk aline battery in the HygroLog HL-NT as explained under Hardware Description Power. To conserve battery power, models with a display are shipped with the Display Sleep

function enabled. With this function enabled and when logging is not active, the logger just keeps

track of the date and time and uses very little batter y power. Press any key on the keypad to

temporarily suspend the Display Sleep function. The HW4 software is required to either disable the

Display Sleep function or to reconfigure this function. See Displ ay Sleep function under S oftware

Functions

8. Stand-alone operation

8.1 Operating modes

The HygroLog HL-NT has two main operating modes: measure and record.

• Measure mode: the H ygroLog HL-NT defaults to this mode when it is not recor ding any

data. What happens in this mode depends on whether or not the HygroLog HL-NT is

communicating with a PC.

When there is no communication with a PC, th e model with out display is in a low power

consumption mode and just keeps track of the date and time. The model with display

behaves differentl y, depending on whether or not the Displa y Sleep function is enabled

(see Software Func tions). If the functi on is disabled (displ ay always on), m easurements

take place at intervals of time corresponding to the display refresh interval that was

specified with HW4 when configuring the data logger. When the display goes blank

because the Display Sleep function is enabled, the model with display behaves in the same

manner as the model without display.

• Record mode: the model without display measures data according to the log interval that

was specified for eac h individual input. The shortest l og interval is 5 seconds. The log