Page 1

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

1 of 36

Document title

HygroFlex HF5

Humidity Temperature Transmitters

User Guide

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 2

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

2 of 36

Document title

Table of contents

1 Overview .............................................................................................................................................. 3

2 Mechanical configurations and dimensions ..................................................................................... 4

2.1 Supply voltage up to 40 VDC / 28 VAC ............................................................................................ 4

2.2 Supply voltage 85…240 VAC ........................................................................................................... 5

2.3 Models with USB or Ethernet interface ............................................................................................. 5

3 General description ............................................................................................................................. 6

3.1 Power supply options ....................................................................................................................... 6

3.2 Measured parameters ...................................................................................................................... 6

3.3 Calculated parameters ..................................................................................................................... 6

3.4 Analog output signals ....................................................................................................................... 7

3.5 Digital outputs ................................................................................................................................... 7

3.6 Service connector ............................................................................................................................. 8

3.7 Probe ................................................................................................................................................ 8

3.8 HW4 software version compatibility .................................................................................................. 8

4 User configurable settings and functions ......................................................................................... 8

4.1 Function overview ............................................................................................................................. 8

4.2 Interaction between the HF5 and probe functions .......................................................................... 10

4.3 Analog output signal type (except HF52) ........................................................................................ 11

5 Mechanical installation ..................................................................................................................... 11

5.1 General guidelines .......................................................................................................................... 11

5.2 HF5 enclosure ................................................................................................................................ 12

5.3 Installation of the HF5 type D (through wall mount) ........................................................................ 12

5.4 Installation of the HF5 type W (surface mount)............................................................................... 12

6 Electrical installation ........................................................................................................................ 13

6.1 General wiring guidelines ............................................................................................................... 13

6.2 Guidelines for RS-485 wiring .......................................................................................................... 14

6.3 Cable grip and cable specifications ................................................................................................ 14

6.4 Wiring ............................................................................................................................................. 15

7 Operation ........................................................................................................................................... 27

7.1 HF5 analog outputs ................................................................ ........................................................ 27

7.2 HF5 digital outputs .......................................................................................................................... 27

7.3 Display and keypad option ............................................................................................................. 28

7.4 Internal menu (optional keypad and display) .................................................................................. 28

7.5 Displayed parameters (optional keypad and display) ..................................................................... 30

8 Maintenance....................................................................................................................................... 30

8.1 Service cable .................................................................................................................................. 30

8.2 Location of the service connector (mini USB type) ......................................................................... 30

8.3 Periodic calibration check of the probe ........................................................................................... 31

8.4 Cleaning or replacing the probe dust filter ...................................................................................... 32

8.5 Validation of the output signals transmission .................................................................................. 32

9 Firmware updates .............................................................................................................................. 32

10 Technical data ................................................................................................................................... 33

10.1 Specifications ................................................................................................................................. 33

10.2 Dew point accuracy ........................................................................................................................ 35

11 Accessories ....................................................................................................................................... 35

12 Supporting documents ..................................................................................................................... 35

13 Document releases ........................................................................................................................... 36

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 3

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

3 of 36

Document title

Applicability:

This manual applies to the following HF5 series transmitters:

2-wire loop powered models (HF52) with firmware version 1.6

All other models with firmware version 2.x, where 2.x can be 2.0, 2.1, etc.

Changes to the last digit of the version number reflect minor firmware changes that do not affect the manner in

which the instrument should be operated.

1 Overview

The HygroFlex HF5 transmitter series is designed for fixed installation in applications where high

measurement accuracy is required and can be used with any of the HygroClip 2 plug-in probes.

The wide assortment of HygroClip 2 humidity-temperature probes can meet almost any application

requirement. The HygroClip 2 probes feature well proven, durable sensors. Digital signal processing within the

probe ensures consistent product performance and also facilitates the task of field maintenance with features

such as potentiometer-free calibration, hot-swapping of the probe, etc.

Main features of the HF5 series:

Interchangeable, plug-in HygroClip 2 probe (sold separately)

Probe separation: up to 5 m / 16.4 ft (100 m / 330 ft with a digital signal booster)

Relative humidity, temperature, dew point or other psychrometric parameter

0...100%RH and -100 to 200°C (-148 to 392°F) - depending on probe model

Accuracy: ± 0.8%RH and 0.1ºC / 0.2ºF

Analog outputs only, analog and digital outputs combined or digital outputs only

User configurable settings

Calculation of psychrometric parameters such as the dew or frost point

Humidity temperature calibration and adjustment

Simulator mode

Automatic humidity sensor test and drift compensation

Sensor failure mode

Data recording

1) Except model HF52 (2-wire circuit type)

The ability for the user to easily update both the HF5 and HygroClip 2 probe firmware means that instruments

of the HF5 series can be kept up-to-date regarding any future functionality improvement.

1)

1)

1)

1)

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 4

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

4 of 36

Document title

Probe

connector

Probe

connector

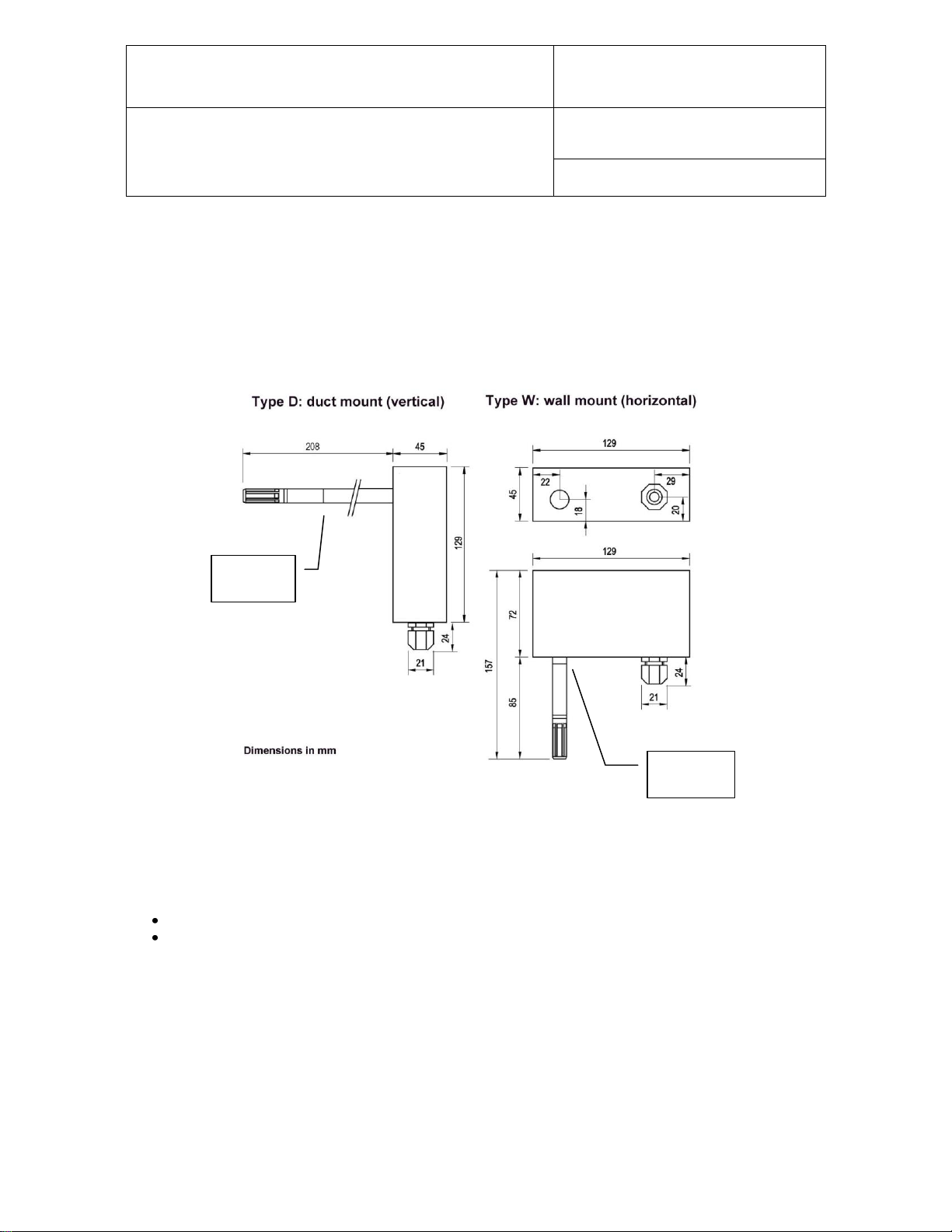

NOTE:

Vertical mounting applies only to:

HF52 type D without keypad and display

HF53 and HF54 type D without keypad and

display or without digital option

All other models are mounted horizontally

2 Mechanical configurations and dimensions

Depending on the supply voltage, the HF5 uses two different sizes of enclosure

2.1 Supply voltage up to 40 VDC / 28 VAC

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 5

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

5 of 36

Document title

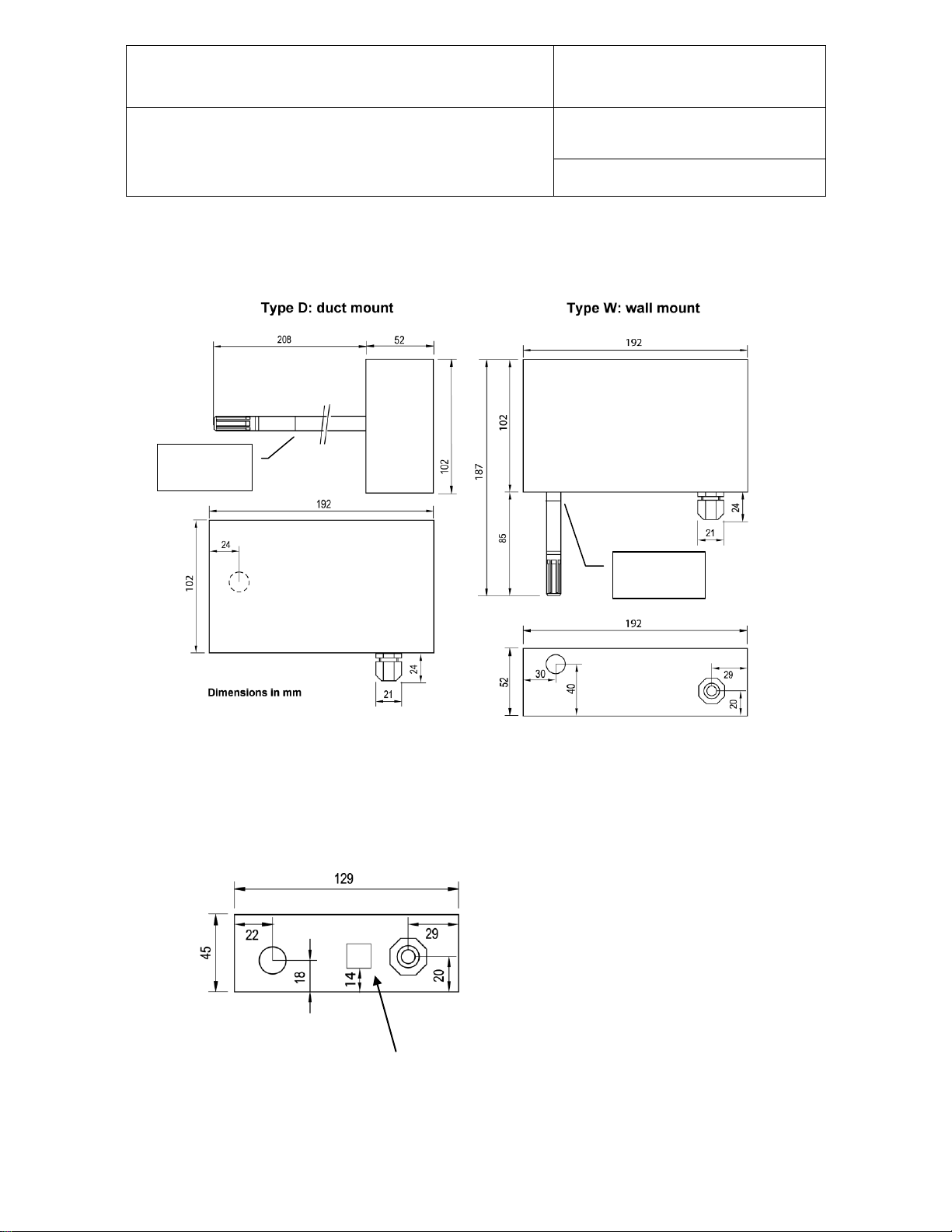

Probe

connector

Probe

connector

USB or Ethernet interface

2.2 Supply voltage 85…240 VAC

2.3 Models with USB or Ethernet interface

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 6

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

6 of 36

Document title

3 General description

3.1 Power supply options

Depending on the circuit type, the HF5 requires the following power supply:

a) HF52 (2-wire loop powered, analog outputs): 10…28 VDC - depending on the load connected to the

output(s). The minimum supply voltage can be determined as follows:

V min = 10 V + (0.02 x Load*) *Load resistance in ohms.

For the maximum load of 500 , the minimum supply voltage is 10 + (0.02 x 500) = 20 VDC. With both

output circuits closed, the maximum current consumption is 40 mA.

b) HF53, HF54 and HF56 (3-wire, analog outputs optionally combined with a digital output):

- HF53: 15 to 40 VDC or 12 to 28 VAC

- HF54: 9 to 36 VDC or 7 to 24 VAC, galvanic isolation of the analog outputs and power supply

- HF56: 85…240 VAC, galvanic isolation of the analog outputs and power supply

HF53 and HF54: with both output circuits closed, the typical current consumption is 100 mA.

HF56: typical current consumption <50 mA at 85 VAC and <35 mA at 240 VAC

Please verify the product identification label to determine which power supply option is installed on your

transmitter.

c) HF556, HF557 and HF566 (digital output only):

- HF556: 5 to 40 VDC or 12 to 28 VAC

- HF557: PoE (power over Ethernet).The HF557 is not available with a RS-485 interface and can be

powered only via a LAN.

- HF566: 85…240 VAC

Typical current consumption

HF556 with USB interface : 100 mA

HF556 with Ethernet (TCP/IP) interface and HF557 : 300 mA

HF566 USB interface : <50 mA at 85 VAC and <35 mA at 240 VAC

HF566 with Ethernet (TCP/IP) interface : <50 mA at 85 VAC and <35 mA at 240 VAC

3.2 Measured parameters

The HygroClip 2 probe used with the HF5 transmitter measures relative humidity with a ROTRONIC

Hygromer® IN1 capacitive sensor and temperature with a Pt100 RTD.

3.3 Calculated parameters

Using the ROTRONIC HW4 software, the HF5 can be configured by the user to calculate one of the following

parameters:

o Dew point (Dp) above and below freezing

o Frost point (Fp) below freezing and dew point above freezing

o Wet bulb temperature (Tw)

o Enthalpy (H)

o Vapor concentration (Dv)

o Specific humidity (Q)

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 7

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

7 of 36

Document title

o Mixing ratio by weight (R)

o Vapor concentration at saturation (Dvs)

o Vapor partial pressure (E)

o Vapor saturation pressure (Ew)

Note: some of the above parameters depend on the value of the barometric pressure. Using the ROTRONIC

HW4 software, a fixed barometric pressure value can be specified. For instructions see the following HW4

manual: E-M-HW4v3-F2-005

3.4 Analog output signals

Parameter:

With the ROTRONIC HW4 software any of the two analog output signals can be made to correspond to one of

the following:

Relative humidity

Temperature

Calculated parameter

Any output can also be disabled.

Output Scale:

The scale of each analog output can be set within the numerical limits of -999.99 and 9999.99. The D/A

converters used to generate the analog output signals feature a 16-bit resolution.

Signal Type:

Both analog outputs provide the same type of signal. With the exception of the HF52 (always 4…20 mA), the

type of signal can be selected with the ROTRONIC HW4 software to any of the following:

0…20 mA, 4…20 mA, 0…1V, 0…5V or 0…10V (see 4.3).

3.5 Digital outputs

Models with a digital output can simultaneously transmit 3 parameters: relative humidity, temperature and

calculated parameter

a) RS-485 serial interface

Some models of the HF5 are equipped with a RS-485 serial interface. This can be used to connect together

up to 64 devices in a multi-dropped arrangement. In principle, an unlimited number of such networks can be

monitored with the HW4 software, but each RS-485 multi-drop network is limited to 64 devices. The HF5 can

be used either as a slave or a master, without special configuration. The master is automatically the device

that is directly connected to a PC by means of a USB port or Ethernet (TCP/IP) port.

RS-485 Compatibility: The communication protocol used by the HF5 and other AirChip 3000 products is not

compatible with the protocol used by the previous generation of ROTRONIC instruments. Do not connect

legacy products and AirChip 3000 products to the same RS-485 multi-drop network.

b) USB or Ethernet interface

Some models of the HF5 are available with a USB or Ethernet interface in addition to the RS-485 interface. In

this case the protection grade of the HF5 enclosure is no longer IP65 / NEMA 4 rated.

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 8

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

8 of 36

Document title

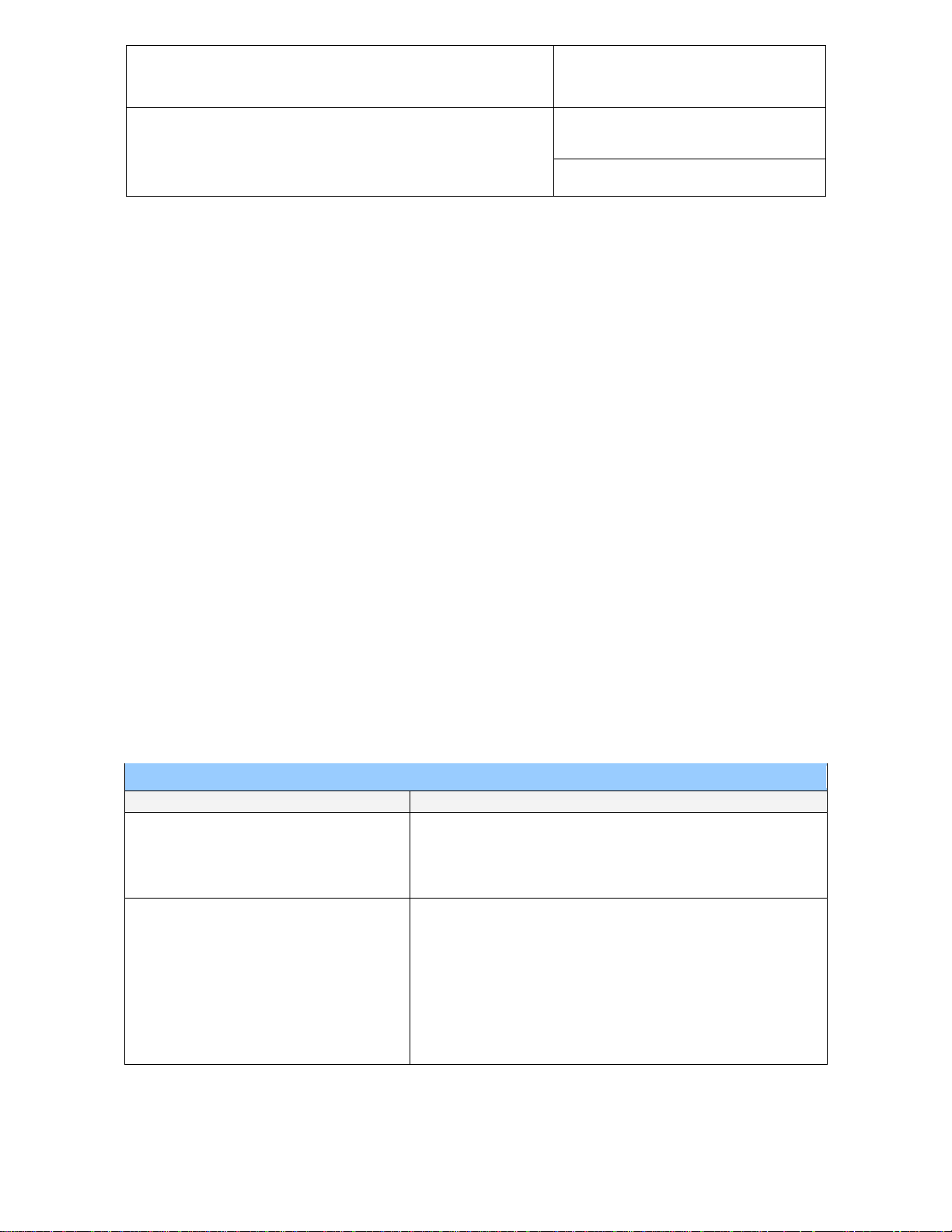

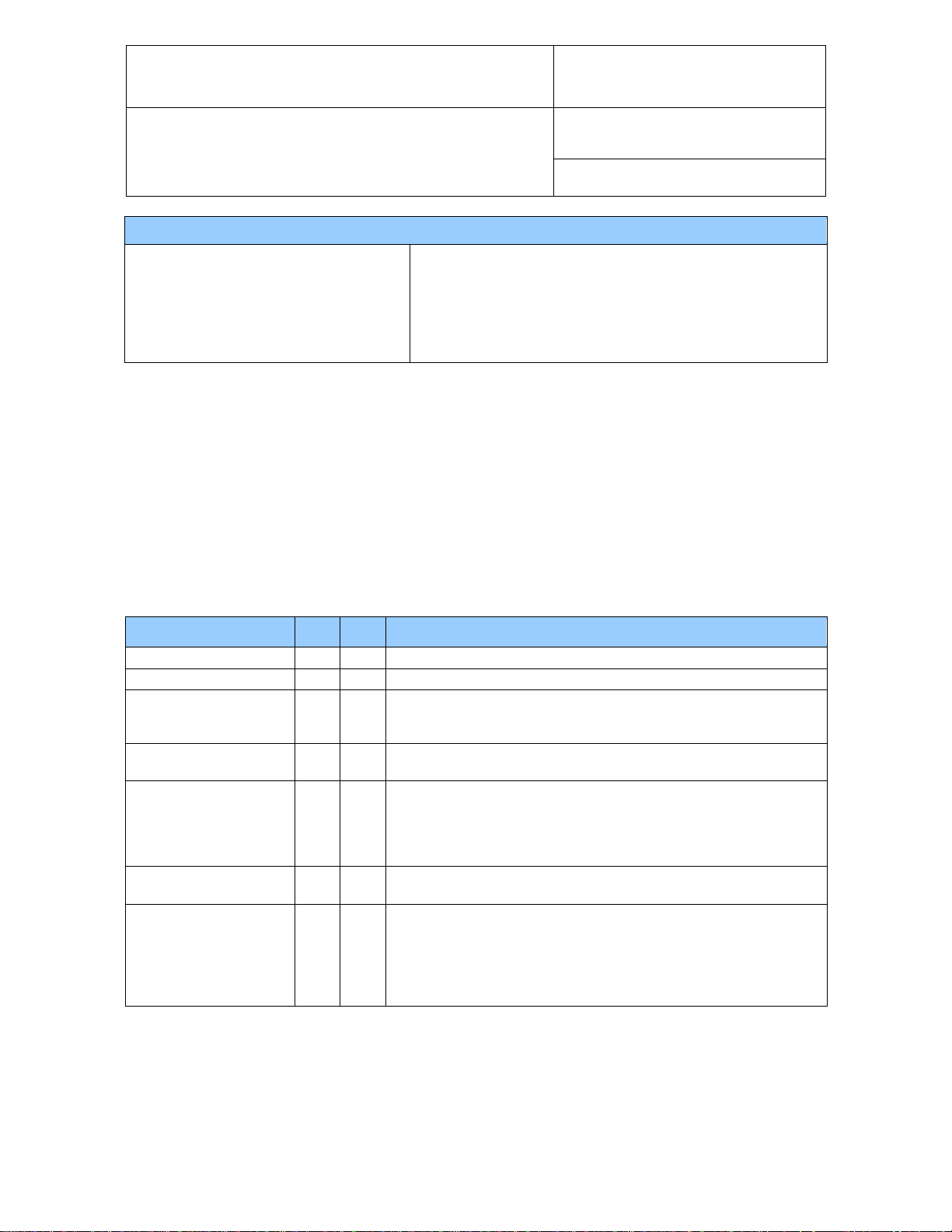

MEASUREMENT ACCURACY AND RELIABILITY (PROBE FUNCTIONS)

AirChip 3000 Functions

Description

► Humidity / temperature adjustment

o 1-point or multi-point humidity calibration or adjustment

o 1-point or 2-point temperature calibration or adjustment

o Generate a time stamp for calibrations and adjustments

o Retain and view last adjustment date and adjustment values

o Generate calibration and adjustment protocols

► Automatic humidity sensor test

and optional drift compensation

Tests the humidity sensor for drift caused by contaminants and

can be used to automatically apply a correction. The test is

automatically carried out at regular intervals of time. Can be

configured, enabled, or disabled

The humidity sensor status can be verified either with the HW4

software or with the instrument display (if available) and is

shown as Good, SQ-tuned (corrected for drift) or Bad (defective)

Not available when the probe is connected to a HF52

3.6 Service connector

The service connector is a UART digital interface (Universal Asynchronous Receiver Transmitter) with a miniUSB type connector. This allows connecting the HF5 with a service cable to a PC running the ROTRONIC

HW4 software. See “Maintenance” for the location of the service connector and for the type of service cable to

be used. The service connector is used to configure the HF5 and to and update its firmware with the HW4

software.

Note: any digital output (USB, Ethernet and RS-485) offers the same functionality as the service connector.

3.7 Probe

The HF5 is compatible with all available models of HygroClip 2 probes. For detailed information on the probes

see document E-M-HC2 Probes-V1.

3.8 HW4 software version compatibility

The HF5 version 2 requires HW4 version 3.0.0 or higher for full functionality of the Device Manager function.

4 User configurable settings and functions

The HF5 ships configured as specified on the customer order. Models with analog outputs only can be

installed and used just as any conventional humidity and temperature transmitter and most users will never

need to use the HF5 configurable settings and functions. Models with a digital output generally require some

configuration by the user.

Making use of the HF5 and probe configurable settings and functions is entirely up to the user and the

appropriate settings depend on the user application. We have provided below a short description of the HF5

and probe functions and also indicated the factory default settings.

4.1 Function overview

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 9

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

9 of 36

Document title

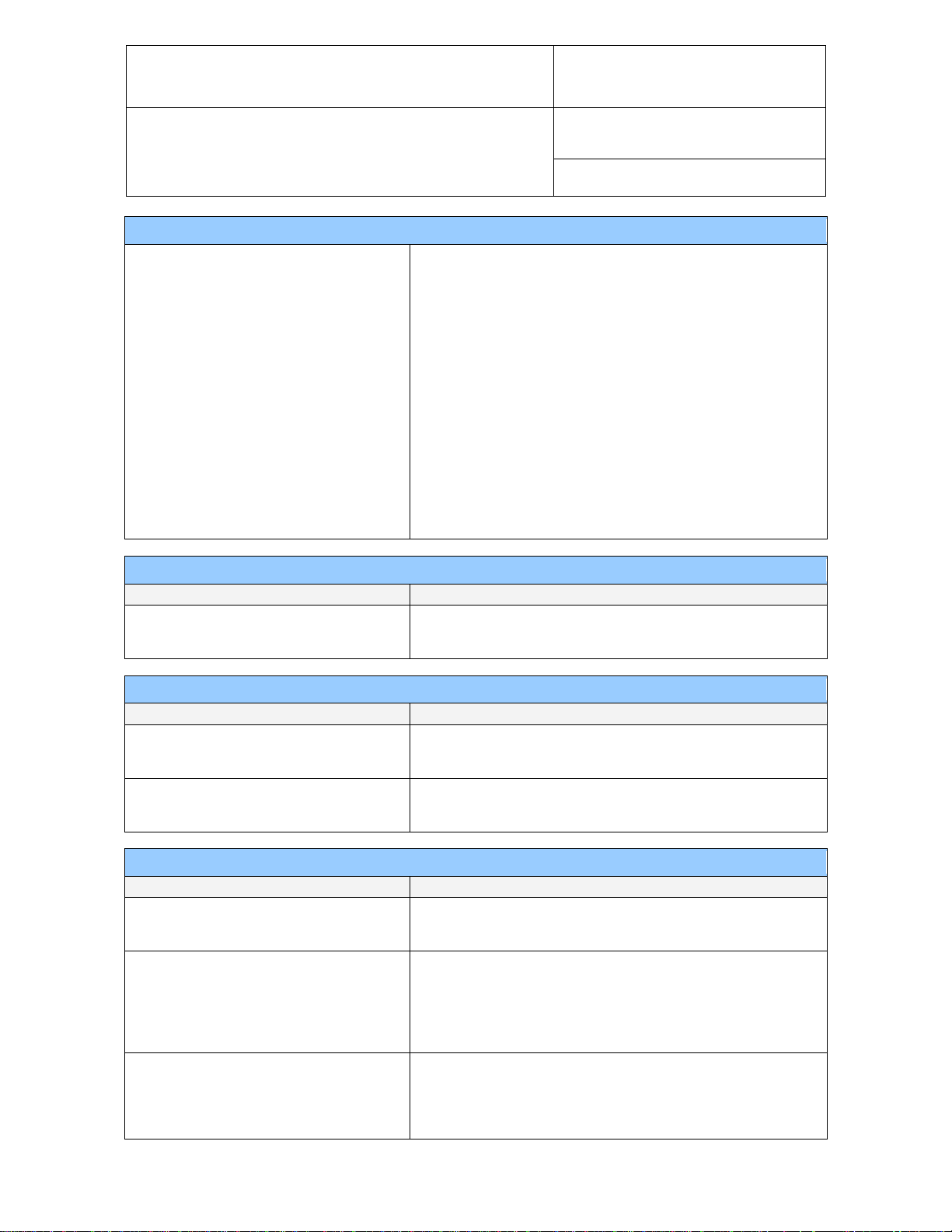

MEASUREMENT ACCURACY AND RELIABILITY (PROBE FUNCTIONS)

► Data recording

The data recording function differs from a true data logging

function in the sense that the AirChip 3000 does not time stamp

the data. The data recording function can be use to investigate

events such as a sensor malfunction as well as to retrieve data

that would otherwise be lost

o Start or stop data recording - up to 2000 value pairs (%RH

and temperature). Starting a recording session erases all

previously recorded data

o The recording mode and log interval can be specified

o When the device is powered off, the recording session is

paused but not ended As long as the recording session has

not been ended, the device automatically resumes recording

data when powered up again

o The recorded data can be downloaded to a PC with the

HW4 software, time stamped and viewed

Not available when the probe is connected to a HF52

MEASUREMENT LOOP VALIDATION

Functions

Description

► Simulator mode

Used to make the HF5 generate fixed values for the humidity,

temperature and calculated parameter. Can be configured,

enabled or disabled

DEVICE SAFEGUARDS

Functions

Description

► Device write protection

Used to protect the HF5 with a password to prevent

unauthorized digital access by a digital user. Can be configured,

enabled or disabled

► Internal menu access from keypad

Used to prevent accidental changes to the HF5 settings and

temperature-humidity adjustment by disabling the MENU key on

the optional keypad. Can be enabled or disabled

PROCESS PROTECTION AND PROTECTION OF OTHER DEVICES

AirChip 3000 Functions

Description

► Limit humidity output to 100 %RH

This probe function is used to prevent the humidity signal from

exceeding 100 %RH when condensation forms on the sensor.

Can be enabled or disabled

► Out-of-limit value alarm

Used to specify the normal range for humidity, temperature and

the calculated parameter depending on the user application.

Can be configured, enabled or disabled

Out-of-limit values trigger a digital alarm which can be also be

seen on the optional display

► Bad sensor alarm

This is a built-in probe function. Cannot be disabled

A bad humidity or temperature sensor triggers a digital alarm

which can be also be seen on the optional HF5 display provided

that the HF5 is set to monitor probe alarms

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 10

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

10 of 36

Document title

PROCESS PROTECTION AND PROTECTION OF OTHER DEVICES

► Fail safe mode

Used to specify a "safe" fixed value for humidity and for

temperature (HF5 or probe) in the event of:

o Loss of communication with the probe (HF5 function)

o Sensor failure (probe function)

Can be configured, enabled or disabled

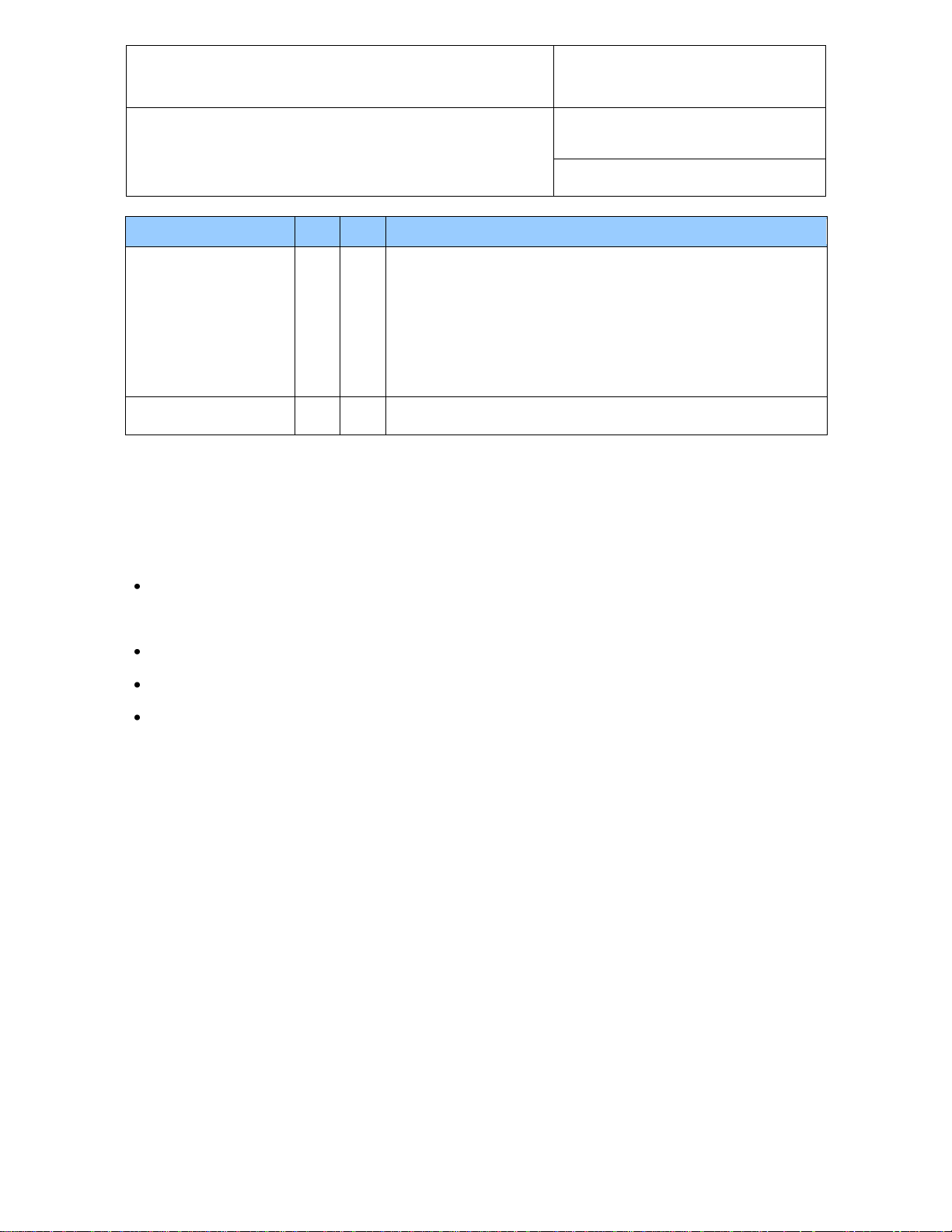

Function / Setting

HF5

HC2

Notes

Device protection

X

X

Individual to the HF5 and HC2 probe

RS-485 address

X

X

Individual to the HF5 and HC2 probe

Device Name

X

X

User defined description

The device name of the HC2 probe is not displayed by HW4 and is

replaced with the HF5 Input Name

Calculation

X

X

Psychrometric calculation

HF5 setting overrides HC2 probe setting

Data refresh rate

X

This setting has no effect on the HF5 and probe. Depending on the

model, the data refresh rate is as follows:

HF52: typically 5 s

Other models: typically 1 s

Simulator function

X

X

Generates fixed humidity and / or temperature value

When enabled, the HF5 settings override the HC2 probe settings

Unit system

X

X

The HF5 setting overrides HC2 probe setting regarding the HF5

signals. The HC2 probe settings still apply when the probe is used

alone

Make sure to use the same humidity symbol and the same

temperature unit for both the HF5 and probe.

4.2 Interaction between the HF5 and probe functions

It is important to note that when used together, the HF5 transmitter and HC2 probe (HygroClip 2) constitute a

2-component system. Each system component has its own microprocessor, firmware and functions. Some of

these functions are unique to each system component. Other functions are found in both components.

HF52 (2-wire, loop powered transmitter): due to the necessity of limiting the current consumption of the

combination of HF52 and HC2 probe to less than 4 mA, several probe functions such as RH sensor test, data

recording and probe adjustment are not available with the HF52.

The functions and settings of the HF5 transmitter and HygroClip 2 probe (HC2) operate together as indicated

below:

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 11

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

11 of 36

Document title

Function / Setting

HF5

HC2

Notes

Out-of-limits value alarm

X

X

The HF5 settings are independent from the HC2 probe settings.

The HC2 probe settings have an effect only when the HF5 is

enabled to monitor alarms generated by the probe

When out-of-limit values have been defined for the same parameter

for both the HF5 and probe, any alarm is triggered based on the

narrowest set of limits (assuming that the HF5 has been set to

monitor probe alarms).

Analog outputs

X

X

Parameter and scale

The HC2 probe settings have no effect on the HF5

4.3 Analog output signal type (except HF52)

Both analog outputs of the HF5 provide the same type of signal. With the exception of the HF52 (always

4…20 mA), the type of signal can be selected with the ROTRONIC HW4 software to any of the following:

0…20 mA, 4…20 mA, 0…1V, 0…5V or 0…10V. To select the analog signal type proceed as follows:

Use the appropriate model of service cable (see Maintenance > Service Cable) to connect the

service connector of the HF5 to a USB port of a PC with the HW4 software installed (HW4 3.0.0 or

higher). Note that the ROTRONIC USB driver must be installed on the PC as explained in the HW4

manual E-M-HW4v3-Main

Start HW4 on the PC and search for the HF5 (HW4 Main Menu Bar > Devices and Groups > Search

for USB Masters).

After finding the HF5 with HW4, expand the device tree to see the HF5 functions. Select Device

Manager.

For further instructions see HW4 manual E-M-HW4v3-F2-005

No adjustment is required after changing the type of output signal.

5 Mechanical installation

5.1 General guidelines

Relative humidity is extremely dependent on temperature. Proper measurement of relative humidity requires

that the probe and its sensors be at exactly the temperature of the environment to be measured. Because of

this, the location where you choose to install the probe can have a significant effect on the performance of the

instrument. The following guidelines should guarantee good instrument performance:

a) Select a representative location: install the probe where humidity, temperature and pressure

conditions are representative of the environment to be measured.

b) Provide good air movement at the probe: air velocity of at least 200 ft/ minute (1 meter/second)

facilitates adaptation of the probe to changing temperature.

c) Avoid the following: (1) Close proximity of the probe to a heating element, a cooling coil, a cold or

hot wall, direct exposure to sun rays, etc. (2) Close proximity of the probe to a steam injector,

© 2009-2013; Rotronic AG E-M-HF5-V2_12

humidifier, direct exposure to precipitation, etc. (3) Unstable pressure conditions resulting from

excessive air turbulence.

d) Immerse as much of the probe as possible in the environment to be measured.

Page 12

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

12 of 36

Document title

Vertical:

HF52 type D without

keypad and display

HF53 and HF54 type D

without keypad and

display, and without

digital option

Horizontal:

HF52 type D with

keypad and display

HF53, HF54 type D with

keypad and display or

with digital option

All other type D models

Horizontal:

HF52, HF53, HF54, HF55 and HF56 type W

e) Prevent the accumulation of condensation water at the level of the sensor leads. Install the

probe so that the probe tip is looking downward. If this is not possible, install the probe horizontally.

5.2 HF5 enclosure

The HF5 enclosure consists of a base and a cover held together with 4 screws. To open the enclosure, use a

metric 2.5 mm or 3 mm hex key. Prior to re-assembling the enclosure, verify that the red seal is sitting properly

in its groove on the base.

5.3 Installation of the HF5 type D (through wall mount)

Mounting position of the enclosure

Mounting hardware

The QMA-15 consists of a flange and compression fitting and is designed to

hold the probe of the HF5 type D when mounted through a wall (see

Accessories). The HF5 does not require any additional support.

5.4 Installation of the HF5 type W (surface mount)

Mounting position of the enclosure

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 13

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

13 of 36

Document title

Mounting hardware

Method 1: The HF5 is supplied with 2 screws, 2 drywall anchors and two

rubber washers. The base of the enclosure has 2 screw-wells (see drawing)

that are normally closed at the bottom. Use the template provided with the HF5

to drill mounting holes in the wall and insert the drywall anchors. Place a

rubber washer on each screw. Insert a screw in each well and push to open

the bottom of the well.

Method 2: When a DIN-rail (35 mm / 1 3/8 “) is available use part AC5002 (not

included). This is a DIN-rail mounting kit consisting of 2 clamps that attach to

the back of the enclosure with the screws provided.

6 Electrical installation

6.1 General wiring guidelines

Power supply wiring

Heavy machinery and instrumentation should not share the same power supply wiring. If this cannot be

avoided, noise filters and surge protectors should be used. Most UPS devices have those features already

integrated.

General guidelines for signal cables

The following guidelines are derived from European Standard EN 50170 for the transmission of signals by

copper wires. When planning an installation, the rules provided by EN 50170 should be followed under

consideration of local circumstances to determine the position of machines and equipment.

All ROTRONIC products are tested for Electromagnetic Compatibility according to EMC Directive

2004/106/EG and following European standards:

- EN 61000-6-1: 2001, EN 61000-6-2: 2005

- EN 61000-6-3: 2005, EN 61000-6-4: 2001 + A11

Whenever the level of electromagnetic interference is expected to be high, both the instruments and signal

cables should be placed as far away as possible from the source of interference.

In general, signal cables should be installed in bundles or channels / conduits, separate from other cables as

indicated in the table below:

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 14

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

14 of 36

Document title

Bus signals such as RS485

Data signals for PCs, printers etc.

shielded analog inputs

unshielded direct current (<= 60V)

shielded process signals (<= 25 V)

unshielded alternate current (<= 25V)

coaxial cables for CRT monitors

in common bundles or channels / conduits

direct current from 60 V to 400 V

(unshielded)

alternate current from 25V to 400 V

(unshielded)

in separated bundles or channels /

conduits, without minimum distance

direct and alternate current > 400 V

(unshielded)

Telephone lines

lines leading into EX-rated areas

in separated bundles or channels /

conduits, without minimum distance

Lightning protection

Cabling in areas with a risk of lightning requires a lightning protection. For cabling underground in between

buildings, we recommend the use of special fiber optic cables. If this is not possible, use copper cables that

are suitable for underground installation.

6.2 Guidelines for RS-485 wiring

See document E-DV04-RS485.01: RS485 Network Installation and Start-up Guidelines

6.3 Cable grip and cable specifications

Depending on the model, the HF5 is supplied either with one or two M16 sealing cable grips or with one or two

½” conduit adapters. The M16 cable grip provides effective sealing only with cables having the proper outside

diameter. Preferably, use a cable with an outside diameter of 6 to 7 mm (0.236 to 0.275 inch) with 18 AWG

wires.

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 15

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

15 of 36

Document title

Terminals

Description

K2-2: T-OUT

Temperature output (+)

OUT-2

K2-1: V+

Power supply: 10…28 VDC (+)

Terminals

Description

K1-2: H-OUT

Relative humidity or dew point (+)

OUT-1

K1-1: V+

Power supply: 10…28 VDC (+)

6.4 Wiring

6.4.1 HF52: 2-wire, loop powered transmitter

Electrical diagram

The maximum permissible cable length connecting

the HF52 to other devices is determined by the total

resistance resulting from the addition of the cable

resistance and that of the devices connected in series

with the unit. This resistance should not exceed 500

ohms.

Terminal block diagram

Note: connect the + of the power supply to only one of the V+ terminals. The two terminals marked V+ are

internally connected.

Measuring humidity or temperature only

Operation of the HF52 does not require both current loops to be closed. When using the HF52 to measure

either humidity only or temperature only, close only the loop that is being used.

Using the ROTRONIC HW4 software, any unused output of the HF52 can be disabled.

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 16

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

16 of 36

Document title

Terminals

Description

K1-1: GND

Power supply (-) or neutral

(tied with other GND)

K1-2: V+

Power supply: 15…40 VDC (+)

or 12…28 VAC (Phase)

K1-3: -►

Protective ground (see note below)

Terminals

Description

K2-4: GND

Ground (tied with other GND)

K2-3: GND

Ground (tied with other GND)

K2-2: OUT2

Temperature output (+)

K2-1: OUT1

Relative humidity or dew point (+)

V+

GND

OUT2

OUT1

GND

B2

U

B

V+

GND

B2

U

B

OUT2

OUT1

GND

6.4.2 HF53: 3-wire transmitter

Electrical diagram for voltage outputs

Electrical diagram for current outputs

Type D and W (horizontal mount)

The maximum permissible cable length can be

determined under consideration of the voltage drop

caused by the current flowing to the devices

connected to the unit. The voltage drop in the cable

depends both on cable resistance and on the

equivalent resistance of the devices connected in

parallel to the unit. The total resistance connected to

each unit output should be at least 1000 ohms. Cable

resistance should not be more than 1/1000 of the

load resistance.

The maximum permissible cable length, connecting

the unit to other devices, is determined by the total

resistance resulting from the addition of the cable

resistance and that of the devices connected in

series with the unit. This resistance should not

exceed 500 ohms.

Terminal block diagram (analog outputs only)

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 17

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

17 of 36

Document title

Terminals

Description

K2-4: GND

Ground (tied with other GND)

K2-3: GND

Ground (tied with other GND)

K2-2: OUT2

Temperature output (+)

K2-1: OUT1

Relative humidity or dew point (+)

Terminals

Description

K6-1: GND

Power supply (-) or neutral

(tied with other GND)

K6-1: V+

Power supply: 15…40 VDC (+)

or 12…28 VAC (Phase)

K6-3: -►

Protective ground (see note below)

Type D (vertical mount)

Note: Terminals K1-3 or K6-3 (protective or earth ground) are not tied with GND. If so desired, K1-3 or K6-3

can be tied with GND by closing a solder pad on the PCB

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 18

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

18 of 36

Document title

Terminals

Description

K1-1: GND

Power supply (-) or neutral

(tied with other GND)

K1-2: V+

Power supply: 15…40 VDC (+)

or 12…28 VAC (Phase)

K1-3: -►

Protective ground (see note below)

Terminals

Description

K2-4: GND

Ground (tied with other GND)

K2-3: GND

Ground (tied with other GND)

K2-2: OUT2

Temperature output (+)

K2-1: OUT1

Relative humidity or dew point (+)

Terminals

Description

K3-4: D-

RS-485 Bi-directional

TX- / RX -

K3-3: D+

RS-485 Bi-directional

TX+ / RX +

K3-2: GND

Ground / Power supply (-)

K3-1: PWR

DC (+) 15…24 VDC (+)

(optional, see note below)

Terminal block diagram (analog outputs and digital option)

Type D and W (horizontal mount)

Notes:

Terminal K1-3: this terminal (protective or earth ground) is not tied with GND. If so desired, K1-3 can be tied

with GND by closing a solder pad on the PCB

Terminal block K3 (RS-485): terminals K3-1 and K3-2 can be used to power the HF53 from a 15 to 24 VDC

power supply connected to the RS-485 main data line. In this case, do not use terminals K1-1 and pin K1-2

(normally used to power the HF53).

USB or TCP/IP port: this port is optional

Measuring humidity or temperature only

Operation of the HF53 does not require both current loops to be closed. When using the HF53 to measure

either humidity only or temperature only, close only the loop that is being used.

Using the ROTRONIC HW4 software, any unused output of the HF53 can be disabled.

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 19

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

19 of 36

Document title

U

B

DC

DC

V+

GND

OUT2

OUT1

GND

U

B

DC

DC

V+

GND

OUT2

OUT1

GND

6.4.3 HF54: 3-wire transmitter, galvanic isolation of the analog outputs

Electrical diagram for voltage outputs

The maximum permissible cable length

can be determined under consideration

of the voltage drop caused by the

current flowing to the devices connected

to the unit. The voltage drop in the cable

depends both on cable resistance and

on the equivalent resistance of the

devices connected in parallel to the unit.

The total resistance connected to each

unit output should be at least 1000

ohms. Cable resistance should not be

more than 1/1000 of the load resistance.

Electrical diagram for current outputs

The maximum permissible cable length,

connecting the unit to other devices, is

determined by the total resistance

resulting from the addition of the cable

resistance and that of the devices

connected in series with the unit. This

resistance should not exceed 500 ohms.

Terminal block diagram (analog outputs only)

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 20

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

20 of 36

Document title

Terminals

Description

K1-1: GND

Power supply (-) or neutral

K1-2: V+

Power supply: 15…40 VDC (+)

or 12…28 VAC (Phase)

K1-3: -►

Protective ground (see note below)

Terminals

Description

K2-4: GND

Ground (tied with other GND)

K2-3: GND

Ground (tied with other GND)

K2-2: OUT2

Temperature output (+)

K2-1: OUT1

Relative humidity or dew point (+)

Terminals

Description

K2-4: GND

Ground (tied with other GND)

K2-3: GND

Ground (tied with other GND)

K2-2: OUT2

Temperature output (+)

K2-1: OUT1

Relative humidity or dew point (+)

Terminals

Description

K6-1: GND

Power supply (-) or neutral

K6-1: V+

Power supply: 15…40 VDC (+)

or 12…28 VAC (Phase)

K6-3: -►

Protective ground (see note below)

Type D and W (horizontal mount)

Type D (vertical mount)

Note: Terminals K1-3 or K6-3 (protective or earth ground) are not tied with GND. If so desired, K1-3 or K6-3

can be tied with GND by closing a solder pad on the PCB (B18)

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 21

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

21 of 36

Document title

Terminals

Description

K1-1: GND

Power supply (-) or neutral

K1-2: V+

Power supply: 15…40 VDC (+)

or 12…28 VAC (Phase)

K1-3: -►

Protective ground (see note below)

Terminals

Description

K2-4: GND

Ground (tied with other GND)

K2-3: GND

Ground (tied with other GND)

K2-2: OUT2

Temperature output (+)

K2-1: OUT1

Relative humidity or dew point (+)

Terminals

Description

K3-4: D-

RS-485 Bi-directional

TX- / RX -

K3-3: D+

RS-485 Bi-directional

TX+ / RX +

K3-2: GND

Ground

K3-1: PWR

Not used

Terminal block diagram (analog outputs and digital option)

Type D and W (horizontal mount)

Notes:

Terminal K1-3: this terminal (protective or earth ground) is not tied with GND. If so desired, K1-3 can be tied

with GND by closing a solder pad on the PCB (B18)

USB or TCP/IP port: this port is optional

Measuring humidity or temperature only

Operation of the HF54 does not require both current loops to be closed. When using the HF54 to measure

either humidity only or temperature only, close only the loop that is being used.

Using the ROTRONIC HW4 software, any unused output of the HF54 can be disabled.

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 22

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

22 of 36

Document title

Terminals

Description

K1-1: GND

Power supply (-) or neutral

(tied with other GND)

K1-2: V+

Power supply: 5…40 VDC (+)

or 12…28 VAC (Phase)

K1-3: -►

Protective ground (see note below)

Terminals

Description

K3-4: D-

RS-485 Bi-directional

TX- / RX -

K3-3: D+

RS-485 Bi-directional

TX+ / RX +

K3-2: GND

Ground / Power supply (-)

(tied with other GND)

K3-1: PWR

DC (+) 15…24 VDC (+)

(optional, see note below)

6.4.4 HF556: digital output

Connectors and terminal block diagram

Notes:

Terminal K1-3: this terminal (protective or earth ground) is not tied with GND. If so desired, K1-3 can be tied

with GND by closing a solder pad on the PCB (B18)

Terminal block K3 (RS-485): terminals K3-1 and K3-2 can be used to power the HF55 from a 15 to 24 VDC

power supply connected to the RS-485 main data line. In this case, do not use terminals K1-1 and pin K1-2

(normally used to power the HF55).

WARNING: Connecting a device to an active Ethernet network can disrupt communications on the network.

Before connecting the HF5, make sure that it is properly configured for your network.

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 23

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

23 of 36

Document title

~

AC

DC

AC L

AC N

OUT2

OUT1

GND

B2

6.4.5 HF557: digital output, PoE (power over Ethernet)

This model is powered from the Ethernet LAN and has no terminal blocks.

WARNING: Connecting a device to an active Ethernet network can disrupt communications on the network.

Before connecting the HF5, make sure that it is properly configured for your network.

6.4.6 HF56: 85…240 VAC supply voltage

Electrical diagram for voltage outputs

The maximum permissible cable length can be determined under consideration of the voltage drop caused by

the current flowing to the devices connected to the unit. The voltage drop in the cable depends both on cable

resistance and on the equivalent resistance of the devices connected in parallel to the unit. The total

resistance connected to each unit output should be at least 1000 ohms. Cable resistance should not be more

than 1/1000 of the load resistance.

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 24

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

24 of 36

Document title

Terminals

Description

K6-1: -►

Protective ground

K6-2

Power supply phase: 85 to 240 VAC

K6-3

Power supply neutral 85 to 240 VAC

Terminals

Description

K2-4: GND

Ground (tied with other GND)

K2-3: GND

Ground (tied with other GND)

K2-2: OUT2

Temperature output (+)

K2-1: OUT1

Relative humidity or dew point (+)

~

AC

DC

AC L

AC N

B2

OUT2

OUT1

GND

Electrical diagram for current outputs

The maximum permissible cable length, connecting the unit to other devices, is determined by the total

resistance resulting from the addition of the cable resistance and that of the devices connected in series with

the unit. This resistance should not exceed 500 ohms.

Terminal block diagram (analog outputs only)

F1: fuse (soldered to PCB)

Note: If so desired, K2-3 and K2-4 can be tied with the protective ground by closing solder pad B2 on the PCB

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 25

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

25 of 36

Document title

Terminals

Description

K6-1: -►

Protective ground

K6-2

Power supply phase: 85 to 240

VAC

K1-3

Power supply neutral 85 to 240

VAC

Terminals

Description

K2-4: GND

Ground (tied with other GND)

K2-3: GND

Ground (tied with other GND)

K2-2: OUT2

Temperature output (+)

K2-1: OUT1

Relative humidity or dew point (+)

Terminals

Description

K3-4: D-

RS-485 Bi-directional TX- / RX -

K3-3: D+

RS-485 Bi-directional TX+ / RX +

K3-2: GND

Ground (tied with other GND)

K3-1

Not Used

USB or

TCP/IP

Terminal block diagram (analog outputs and digital option)

RS-485

RS485 + USB

RS-485 + Ethernet

Note: If so desired, K2-3 and K2-4 can be tied with the protective ground by closing solder pad B2 on the PCB

USB or TCP/IP port: this port is optional

Measuring humidity or temperature only

Operation of the HF56 does not require both current loops to be closed. When using the HF56 to measure

either humidity only or temperature only, close only the loop that is being used.

Using the ROTRONIC HW4 software, any unused output of the HF56 can be disabled.

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 26

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

26 of 36

Document title

Terminals

Description

K6-1: -►

Protective ground

K6-2

Power supply phase: 85 to 240

VAC

K6-3

Power supply neutral 85 to 240

VAC

Terminals

Description

K3-4: D-

RS-485 Bi-directional TX- / RX -

K3-3: D+

RS-485 Bi-directional TX+ / RX +

K3-2: GND

Ground (tied with other GND)

K3-1

Not Used

USB or

TCP/IP

6.4.7 HF566: 85…240 VAC supply voltage, digital output only

Terminal block diagram (analog outputs and digital option)

RS-485

RS485 + USB

RS-485 + Ethernet

USB or TCP/IP port: this port is optional

6.4.8 Grounding (all models)

We generally recommend grounding the (-) side of the power supply, especially if the electronics will be

subjected to a low humidity environment (35 %RH or less).

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 27

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

27 of 36

Document title

7 Operation

7.1 HF5 analog outputs

Use the HW4 software to configure the analog outputs of the HF5 as desired, complete the mechanical and

electrical installation, connect the probe and simply power up the HF5.

7.2 HF5 digital outputs

The digital outputs of the HF5 use the standard RO-ASCII protocol and do not offer any other option. Users

who wish to read the measurement data without the HW4 software should consult ROTRONIC.

The different types of digital interface available with the HF5 are best used with a PC with the HW4 software

installed (version 3.0.0 or higher). In principle, users should be able to use communication software other than

HW4 to read measurement data from the HF5. In this case, communication is limited to the RDD (data

request) and REN (RS-485 address change) commands described separately in document E-M-AC3000-CP.

IMPORTANT: Depending on the type of digital interface, either the PC or the HF5 must be configured

by the user as indicated below.

a) USB connection

Prior to connecting the HF5 to a USB port you must install the ROTRONIC USB driver on the PC (available

from the HW4 CD or from www.rotronic-humidity.com). For instructions see the HW4 manual E-M-HW4v3-

Main (§ 7.3)

b) Ethernet (TCP/IP) connection

Prior to connecting the HF5 to an active Ethernet network you must configure the TCP/IP settings of the HF5

using either the HW4 software (version 2.1.0 or higher) or the TCP/IP configuration tool available from

www.rotronic-humidity.com. For instructions see the HW4 manual E-M-HW4v3-Main (§ 7.4) and technical

note IN-E-TCPIP-Conf

WARNING: Connecting a device to an active Ethernet network can disrupt communications on the network.

Before connecting the HF5, make sure that it is properly configured for your network

c) RS-485 serial interface (multi-drop)

Instructions for using the HF5 with a RS-485 network are provided in the following manuals:

E-M-HW4v3-Main (§ 7.5), E-M-HW4v3-F2-005 and E-DV04-RS485.01.

Notes:

o Instruments connected to the same RS-485 network must use the same baud rate and each instrument

must be given a unique RS-485 address (the address requirement applies to the HF5 but not to its probe)

o RS-485 Compatibility: The communications protocol used by the HF5 is the RO-ASCII protocol. This

protocol is not compatible with the protocol used by the previous generation of ROTRONIC products. Do

not connect legacy products and the HF5 to the same RS-485 multi-drop network.

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 28

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

28 of 36

Document title

Main Menu

Menu Items

Selections / Information

Notes

Device Settings

Units

Metric / English

Contrast

LC display contrast adjustment

Trend

On / Off

Trend indication on the display

Device Information

Version

Firmware version

Serial Nbr

Serial number

Address

RS-485 address

MENU key: open / close menu

ENTER key: menu item selection

Menu navigation keys + / Change value up / down

The specifications of the RS-485 interface are as follows:

Baud rate : 19200

Parity : none

Data bits : 8

Stop bits : 1

7.3 Display and keypad option

Except for the HF52 (2-wire circuit type), the LC

display of the HF5 has a backlight.

The upper line corresponds to relative humidity the

bottom line corresponds to temperature.

If enabled the third line corresponds to the calculated

Parameter.

The display can be configured to show a trend indicator on each line:

▲: increasing value

▼: decreasing value

In the event of an alarm the display shows the symbol [ ! ] to the right of the value.

For instructions about configuring the display, see the following HW4 manual: E-M-HW4v3-F2-005.

7.4 Internal menu (optional keypad and display)

Note: Unauthorized access to the menu can be prevented by disabling the “display menu” setting

(use the HW4 software > Device Manager > Display)

Model HF52 (2-wire circuit type):

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 29

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

29 of 36

Document title

Main Menu

Menu Items

Selections / Information

Notes

Type

Device type

Name

Device name

User defined

Probe Information

Version

Firmware version

Serial Nbr

Serial number

Address

RS-485 address

Name

Device name

User defined

Main Menu

Menu Items

Selections / Information

Notes

Device Settings

Units

Metric / English

Back Light

Key Press / On / Off

Display backlight mode

Contrast

LC display contrast adjustment

Trend

On / Off

Trend indication on the display

Device Information

Version

Firmware version

Serial Nbr

Serial number

Address

RS-485 address

Type

Device type

Name

Device name

User defined

Probe Information

Version

Firmware version

Serial Nbr

Serial number

Address

RS-485 address

Name

Device name

User defined

SensorTest

Humidity sensor status

Off / Good / SQ-Tuned / Bad

Record

On / Off

Data recording by the probe

(max. 2000 values)

Humidity Adjust

RefValue

Humidity reference value

± 0.1 %RH steps

Acquired

Number of cal. points in probe

memory

<Acquire>

Save cal. point to probe memory

<Delete>

Erases all calibration points

<Adjust>

Effect depends on number of

calibration points

Temperature Adjust

RefValue

Temperature reference value

± 0.1 ˚C steps

<Adjust>

1-point adjustment only (offset)

Other HF5 models:

o Record: both the recording mode (start / stop and the log interval cannot be changed from the menu and

are as configured with the ROTRONIC HW4 software

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 30

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

30 of 36

Document title

HF32

Vertical mount: the service connector is

located either on the left side or on the

right side of the enclosure.

Horizontal mount: the service

connector is located at the bottom of

the enclosure (black arrow)

o SensorTest: Off means that the humidity sensor has not been tested due to the configuration settings of

the test. For a description of the automatic humidity sensor test and drift compensation (SQ-tuning) see

documents E-T-AC3000-DF-V1 and E-M-HW4v3-F2-005

7.5 Displayed parameters (optional keypad and display)

When the menu is not active, press the ENTER key to change which parameters are shown on the display:

o Relative humidity and temperature

o Relative humidity , temperature and calculated parameter (when the calculated parameter is

enabled)

8 Maintenance

8.1 Service cable

IMPORTANT:

o Use service cable AC3009 with all 2-wire, loop powered transmitters. This cable powers up the

transmitter via the service connector. Do not use any other method for powering the transmitter when

using this cable AC3009 as this will create a ground loop and damage the transmitter. For the same

reasons do not use cable AC3006 with a 2-wire, loop powered transmitter.

o Use service cable AC3006 with all 3-wire transmitters as well as with digital models. This cable does

not provide power to the transmitter and the transmitter should powered separately when using this

cable

Both cables AC3006 and AC3009 convert UART (service connector) to USB and are used to connect the

transmitter to a USB port of a PC running the ROTRONIC HW4 software. Prior to using any of these

cables, the ROTRONIC USB driver must be installed on the PC. Both the driver and the installation

instructions (document E-M-HW4v3-Main) are located on the HW4 CD.

8.2 Location of the service connector (mini USB type)

WARNING: the service connector is a UART interface with a mini-USB connector type. Do not connect the

service connector directly to the USB port of a PC or hub.

The service connector can be accessed without opening the enclosure after removing the small red sealing

cover.

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 31

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

31 of 36

Document title

8.3 Periodic calibration check of the probe

Both the Pt 100 RTD temperature sensor used in the probe and associated electronics are very stable

and should not require any calibration after the initial factory adjustment.

Long term stability of the ROTRONIC Hygromer humidity sensor is typically better than 1 %RH per year.

For maximum accuracy, calibration of the probe should be verified every 6 to 12 months. Applications

where the probe is exposed to significant pollution may require more frequent verifications.

Note: the HygroClip 2 probe cannot be adjusted when connected to model HF52 (2-wire circuit

type)

a) Procedure for adjusting the probe using the optional keypad (except model HF52)

Temperature adjustment

The keypad of the HF5 allows only a 1-point adjustment of temperature. The effect of a 1-point

temperature adjustment is to add the same offset to all measured values.

When temperature is stable, press the MENU key to show the internal menu on the display

Use the (-) key to select Temperature Adjust and press the ENTER key

Make sure that the text line beginning with RefValue is highlighted and press the ENTER key

Use the (+) or (-) key to change the reference value to match the temperature reference

Use the (-) key to highlight the Adjust text line and press the ENTER key

The HF5 confirms the adjustment with the message “Adjust OK”

Press the MENU key twice to exit the menu and return the HF5 to normal operation

Notes:

o Any temperature adjustment should be done prior to adjusting humidity.

o The calibration point is automatically deleted from the probe memory after an adjustment

o Because the HF5 has no real time clock, the date of the adjustment is not written to the probe. If

retaining the adjustment date is important, use the HW4 software to adjust the probe.

Humidity adjustment

The keypad of the HF5 allows a multi-point adjustment of humidity. The effect of a humidity adjustment

depends on the number of calibration points present in the probe memory prior to the adjustment:

- one calibration point: offset added to all measured values

- two calibration points: offset and slope

- three or more calibration points: offset, slope, linearity

For maximum accuracy use at least 3 to 4 calibration points distributed equally across the measurement

range of interest. The calibration points (maximum 100) can be acquired in any order but we recommend

going from low humidity values to high humidity values.

When humidity is stable, press the MENU key to show the internal menu on the display

Use the (-) key to select Humidity Adjust and press the ENTER key

Make sure that the text line beginning with RefValue is highlighted and press the ENTER key

Use the (+) or (-) key to change the reference value to match the reference humidity

Use the (-) key to highlight the Acquire text line and press the ENTER key

Note that the “Acquired” counter is incremented by 1 (number of calibration points in the probe

memory)

When all calibration points have been acquired, use the (-) key to highlight the Adjust text line and

press the ENTER key. Do not adjust the probe before having acquired all calibration points.

The HF5 confirms the adjustment with the message “Adjust OK”

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 32

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

32 of 36

Document title

Press the MENU key twice to exit the menu and return the HF5 to normal operation

Notes:

o All calibration points are automatically deleted from the probe memory after an adjustment

o Instructions for using the ROTRONIC calibration devices and humidity standards are provided in

document E-M-CalBasics

o Because the HF5 has no real time clock, the date of the adjustment is not written to the probe. If

retaining the adjustment date is important, use the HW4 software to adjust the probe.

b) Using the HW4 software to adjust the probe connected to a HF5 (except model HF52):

Use the appropriate model of service cable (see Maintenance > Service Cable) to connect the

service connector of the HF5 to a USB port of a PC with the HW4 software installed. Note that the

ROTRONIC USB driver must be installed on the PC as explained in the HW4 manual E-M-HW4v3-

Main. In the case of the HF55, a connection with the PC can be established via the USB

(ROTRONIC USB driver) or Ethernet interface.

Start HW4 on the PC and search for the HF5 (HW4 Main Menu Bar > Devices and Groups > Search

for USB Masters).

After finding the HF5 with HW4, expand the device tree to see the HF5 functions. Select Probe and

Probe Adjustment.

For further instructions see HW4 manual E-M-HW4v3-A2-001

8.4 Cleaning or replacing the probe dust filter

See document E-M-HC2 Probes-V1

8.5 Validation of the output signals transmission

If so desired, transmission of the HF5 output signals can be validated by using the simulator function. The

HW4 software is required to enable and configure this function. When this function is enabled the HF5

generates fixed digital and analog signals as specified by the user. For instructions see document

E-M-HW4v3-F2-005

9 Firmware updates

Firmware updates will be available on the ROTRONIC website for downloading. Firmware files are given a

name that shows both to which device the file applies and the version number of the firmware. All firmware

files have the extension HEX. Procedure for updating the firmware:

Use the appropriate model of service cable (see Maintenance > Service Cable) to connect the

service connector of the HF5 to a USB port of a PC with the ROTRONIC HW4 software installed.

Note that the ROTRONIC USB driver must be installed on the PC as explained in the HW4 manual

E-M-HW4v3-Main. In the case of the HF55, a connection with the PC can be established via the

USB (ROTRONIC USB driver) or Ethernet interface.

Copy the firmware update file from the ROTRONIC website to the PC.

Start HW4 software on the PC and search for the HF5 (HW4 Main Menu Bar > Devices and Groups

> Search for USB Masters).

After finding the HF5, expand the device tree to see the HF5 functions. Select Device Manager. In

the Device Manager menu bar select Tools > Firmware Update. For instructions see document

E-M-HW4v3-F2-005

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 33

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

33 of 36

Document title

General

HF52

HF53 / HF54 / HF56

HF556 / HF557 / HF566

Device type

Humidity temperature

transmitter with analog

output signals

Humidity temperature

transmitter with analog

output signals and

optional digital output

Humidity temperature

transmitter with digital

output

Circuit type

2-wire, loop powered

3-wire

Mechanical configuration types

D and W

Power supply and connections

HF52

HF53 / HF54 / HF56

HF556 / HF557 / HF566

Supply voltage (VDD)

10…28VDC

V min = 10 V + (0.02 x

Load*) *Load

resistance in ohms.

HF53: 15…40 VDC or

12…28 VAC

HF54: 9 to 36 VDC or

7 to 24 VAC

Galvanic isolation

HF56: 85 to 240 VAC

47 to 63 Hz

Galvanic isolation

HF556: 5…40 VDC or

12…28 VAC

HF557: PoE

HF566: 85 to 240 VAC

47 to 63 Hz

Typical current consumption

2 x 20 mA

HF53 / HF54: 100 mA

HF56:

< 50 mA at 85 VAC

< 35 mA at 240 VAC

HF 556: with USB

interface: 100 mA

HF556 / HF557 with

Ethernet interface: 300

mA

HF566:

< 50 mA at 85 VAC

< 35 mA at 240 VAC

Electrical connections

Terminal blocks and 1 x

M16 cable grip or ½”

conduit adapter

HF53 / HF54:Terminal

blocks and 1 x M16

cable grip or ½” conduit

adapter

HF56: Terminal blocks

and 2 x M16 cable grip

or ½” conduit adapter

HF556: Connector (USB

or Ethernet), terminal

blocks (power supply

and RS-485) and 1 x

M16 cable grip or ½”

conduit adapter

HF557: Ethernet

Connector

HF566: Connector (USB

or Ethernet), terminal

blocks (power supply

and RS-485) and 2 x

M16 cable grip or ½”

conduit adapter

Polarity protection

Protective diode on V+ (except HF56, HF57 and HF58)

Fuse

HF56 / HF566: 2A fuse, soldered to PCB

Humidity and temperature

measurement

See document E-M-HC2 Probes > Specifications

10 Technical data

10.1 Specifications

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 34

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

34 of 36

Document title

Calculated parameters

HF52

HF53 / HF54 / HF56

HF556 / HF557 / HF566

Psychrometric calculations

Dew point (Dp) above and below freezing

Frost point (Fp) below freezing and dew point above freezing

Wet bulb temperature (Tw)

Enthalpy (H)

Vapor concentration (Dv)

Specific humidity (Q)

Mixing ratio by weight (R)

Vapor concentration at saturation (Dvs)

Vapor partial pressure (E)

Vapor saturation pressure (Ew)

Start-up time and data refresh rate

HF52

HF53 / HF54 / HF56

HF556 / HF557 / HF566

Start-up time

14 s (typical)

3.s (typical)

3 s (typical)

Data refresh rate

5 s (typical)

1 s (typical)

1 s (typical)

Configurable analog outputs

HF52

HF53 / HF54 / HF56

Output 1

Can be made to correspond to any parameter

Parameter

User configurable with the ROTRONIC HW4 software

Scale

User configurable with the ROTRONIC HW4 software

Output 2

Can be made to correspond to any parameter

Parameter

User configurable with the ROTRONIC HW4 software

Scale

User configurable with the ROTRONIC HW4 software

Output 1 and Output 2

Signal type

4…20 mA

0…20 mA

4… 20 mA

0… 1 V

0… 5 V

0… 10 V

(user configurable)

User configurable scaling limits

-999.99 … +9999.99 engineering units

Short circuit tolerant

Yes Maximum external load

500 Ω

500 Ω (current output)

Minimum external load

0 Ω

1000 Ω (voltage output)

0 Ω (current output)

Digital interface

HF52

HF53 / HF54 / HF56

HF556 / HF557 / HF566

Interface type

N/A

Optional: RS-485 or

USB + RS-485 or

Ethernet + RS-485

HF556/ HF566: RS-485

or

USB + RS-485 or

Ethernet + RS-485

HF557: Ethernet

Service connector

HF52

HF53 / HF54 / HF56

HF556 / HF557 / HF566

Interface type

UART (Universal Asynchronous Receiver Transmitter)

Maximum service cable length

5 m (16.4 ft)

General specifications

HF52

HF53 / HF54 / HF56

HF556 / HF557 / HF566

Optional display

LC, 1 or 2 decimals

resolution, no backlight,

trend and alarm

indication

LC, 1 or 2 decimals resolution, backlight, trend and

alarm indication

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 35

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

35 of 36

Document title

Housing material

ABS

Housing protection grade

IP 65

IP 65 (except models with USB or Ethernet)

Physical dimensions

See Models

Weight

250 g (8.8 oz)

Models with small enclosure: 250 g (8.8 oz)

Models with large enclosure: 540 g (1 lb 3 oz)

Conformity with standards

HF52

HF53 / HF54 / HF56

HF556 / HF557 / HF566

CE / EMC immunity

EMC Directive 2004/108/EG: EN 61000-6-1: 2001, EN 61000-6-2: 2005

EN 61000-6-3: 2005, EN 61000-6-4: 2001 + A11

Solder type

Lead free (RoHS directive)

Fire protection class

Corresponds to UL94-HB

FDA / GAMP directives

compatible

Environmental limits

HF52

HF53 / HF54 / HF56

HF556 / HF557 / HF566

Storage and transit

-50…+70 °C / -20...+70 °C (models with display), 0…100 %RH, non condensing

Operating limits at electronics

-25 … +60 °C

-10….60 °C (models

with display)

0…100 %RH, non

condensing

-40 … +60 °C

-10….60 °C (models with display)

0…100 %RH, non condensing

Temperature limits at probe

Depends on probe model

Maximum humidity at sensor

100 %RH up to 80 °C (176 °F)

75 %RH at 100 °C (212 °F)

45 %RH at 125 °C (260 °F)

15 %RH at 150 °C (302 °F)

Maximum air velocity at probe

20 m/s (3,935 ft /min)

Critical environments

Humidity sensor: as per DV04-14.0803.02 - Critical chemicals

Document File Name

Contents

E-M-HC2 Probes-V1

HygroClip 2 (HC2) Humidity Temperature Probes, User Guide

E-M-HC2-accessories

Accessories and parts for probes, indicators and transmitters

E-T-AC3000-DF-V1

AirChip 3000 Description and Main Functions

E-M-HW4v3-DIR

List of the HW4 manuals

10.2 Dew point accuracy

See document E-M-HC2 Probes > Dew point accuracy

11 Accessories

For accessories and parts such as the HW4 configuration software, service cables, calibration accessories

and spare dust filters, please see document E-M-HC2-accessories

12 Supporting documents

© 2009-2013; Rotronic AG E-M-HF5-V2_12

Page 36

E-M-HF5-V2_12

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF5 Humidity Temperature

Transmitters: User Guide

Instruction Manual

Document Type

Page

36 of 36

Document title

Document File Name

Contents

E-M-HW4v3-Main

HW4 software version 3: General instructions and functions common to all

devices

E-M-HW4v3-F2-005

HW4 software version 3: Device Manager - HF5 transmitter

E-M-HW4v3-F2-001

HW4 software version 3: Device Manager – HC2 probe series

E-M-HW4v3-A2-001

HW4 software version 3: Probe Adjustment function AirChip 3000 devices

E-M-HW4v3-DR-001

HW4 software version 3: Data Recording Function AirChip 3000 Devices

E-M-AC3000-CP

AirChip 3000 Communication Protocol Options

E-DV04-RS485.01

RS485 Network Installation and Start-up Guidelines

E-M-TCPIP-Conf

Configuration procedures for ROTRONIC devices

with Ethernet (TCP/IP) interface

E-M-CalBasics

Temperature and humidity calibration basics

Instructions for using the ROTRONIC humidity standards

E-T-HumiDefs

Humidity Definitions

Doc. Release

Date

Notes

_10