Page 1

Dokument

IMA 208

Rev 1 Page

1 (4)

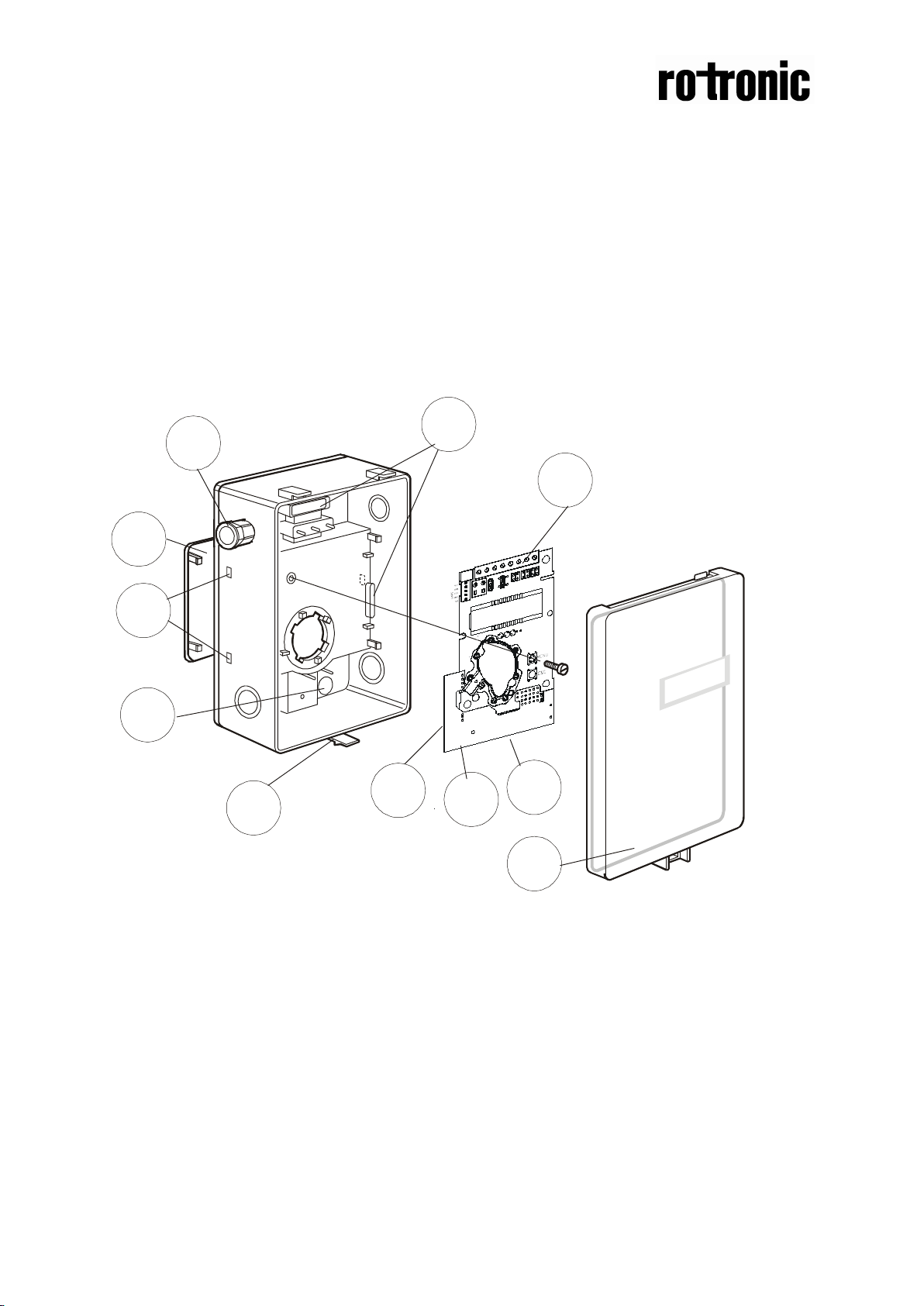

7

5

9

8

3

6

4

2

10

10

1

1 Wall plate

5 Carbon monoxide sensor (not

Installation manual

CF8-W-Disp-CO

in industrial wall mounted housing

CO

/ CO sensor with built-in general purpose

2

controller

Fig. 1

2 PCB (Factory supplied

mounted in box)

3 Temperature sensor for

internal compensation (not

shown)

4 RH sensor for internal

compensation (not shown)

shown)

6 Hole for wall plate hooks

7 Snap-in lid

8 Locking screw of the lid (not

shown)

9 PG9 cable entry bushing

10 Air holes

Page 2

Dokument

IMA 208

Rev 1 Page

2 (4)

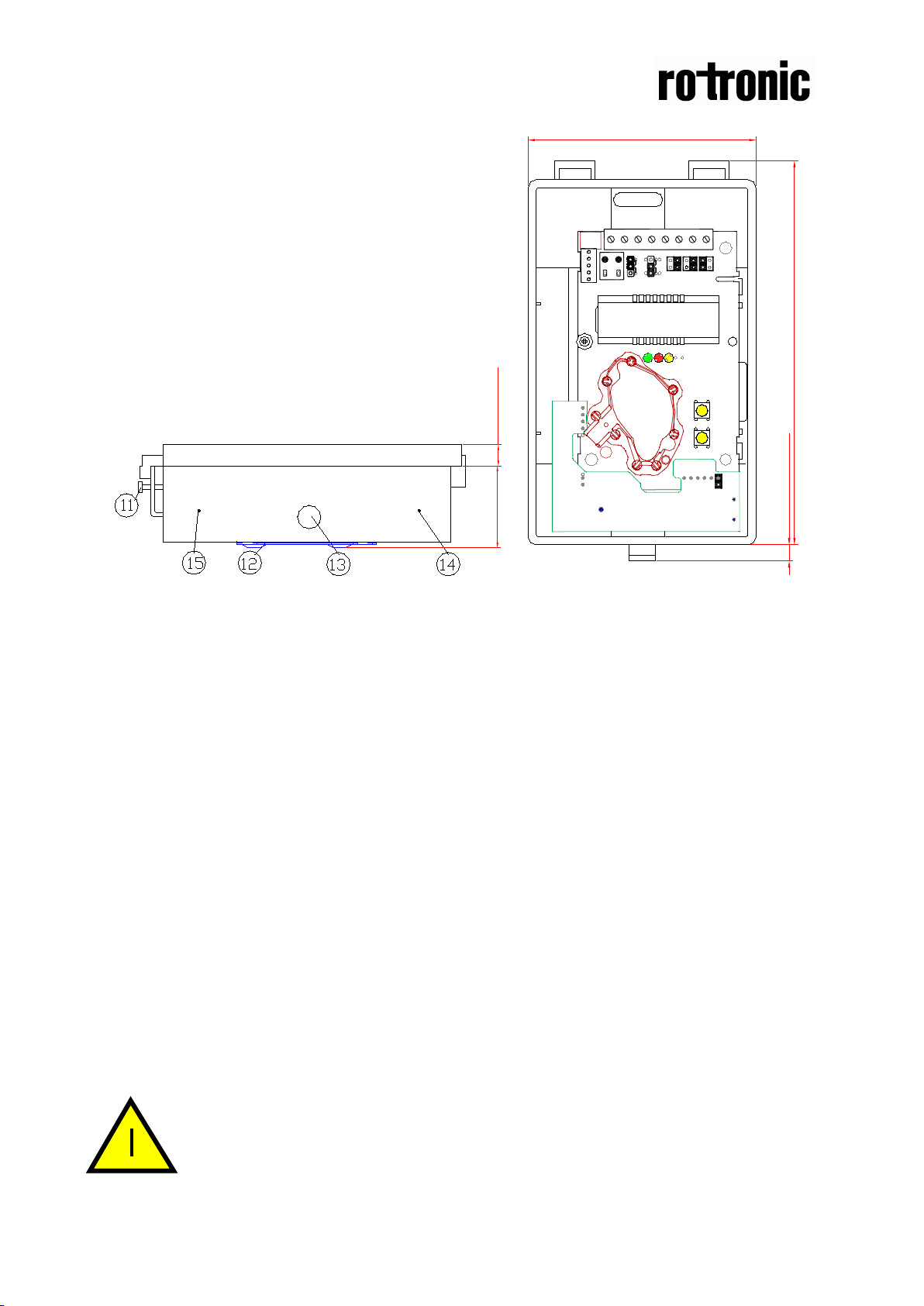

38,5 (1,5)

10 (0,39)

9,5 (0,37)

85 (3,35)

142 (3,58)

Please note! Normally the PCB should not be removed from the

Fig. 2

11 Lid locking screw

12 Wall plate

13 Screw to hold the wall plate

14 Marking to drill hole for PG7

15 Marking to drill hole for PG9

Wall Mounting Instruction

1. Dismount the wall plate. The sensor is delivered with the wall plate mounted.

The wall plate has to be removed before the sensor is mounted onto the wall.

Unscrew the screw on the side of the box. See figure 3.

2. Screw the wall plate onto the wall. The sensor should be mounted 1 to 1,8 m

above the floor. The wall plate has holes for three screws. Drill holes for 3,5mm

screws and put dowel into them. Dowels and screws 3,5 x 25mm are included

in a plastic bag

3. Attach the sensor box to the wall plate. It is done by a snap-in fitting. The wall

plate has three hooks that fit in holes in the sensor box. Fasten the screw on the

side of the box.

4. Electrical cable entry . T he box has a fact ory mounted cable entry bushing in

dimension PG9. Never feed more than one cable through each cable entry

bushing, or else gas might leak through!

The lid can be locked with the screw (11) at the bottom of the sensor box.

housing. If for some reason the PCB must be removed it must be

handled carefully and protec t ed fr om el ect rostatic discharge.

Page 3

Dokument

IMA 208

Rev 1 Page

3 (4)

Terminal

Power (+)

24 VAC/DC+ (+-20%), 3W

2W without output load

Out(1)

Analogue Output 1 (+)

0-10 VDC or 0-20 mA,

Connected to via PTC fuse

According to positions of

6

Normally closed relay

loss

Contact free relay

Triggered by register

8

Analogue Output 4 (+)

0-10 VDC

Max 0,5A, 55VDC / 40VAC

(half-wave rectifier protection)

According to positions of

DI1 Digital Input 1

Closed contact current 1mA

Do not apply any voltage

~

~

Electrical connections

The power supply has to be connected to and . is considered as

system ground. The same ground reference has to be used for the CF8-W-Disp-CO unit

and for any connected devic e! Unless different transformers are used, special

precautions need to be taken.

PLEASE NOTE! The signal ground is not galvanically separated

from the CF8-W-Disp-CO power supply!

PLEASE NOTE! The same ground reference has to be used for

the CF8-W-Disp-CO unit and for the control system!

Connection

Out(2)

5

7

Out(4)

Function

Power ground (-)

Analogue Output 2 (+)

Signal Ground (-)

Open at alarm

situations and power

or Open Collector

Electrical Data

24 VAC/DC-

2-10 VDC or 4-20 mA,

Same as Output 1

minimum load 1mA/5V

rated load 0,5A/125VAC;

1A/24VDC

Remarks

See note 1!

OUT1 jumper and start

point selection.

See note 2!

According to positions of

OUT2 jumper and start

point selection.

See note 2!

See note 1!

OUT3

OUT4.

See note 2 & 3!

Table I. Electrical term ina l connec ti ons for CF8-W-Disp-CO

Note 1: The ground terminal is used as negative power supply DC i nput or AC phase ground

(halfwave rectifier) . The signal ground M, protected by a PTC res istor, is the same as power ground

G0 (permitting a ”3-wire” configuration). A single transformer may be used for the entire system.

Note 2: CF8-W-Disp-CO can deliver both a v oltage or a current loop for Out(1) /Out(2). For Out(4) a

voltage output or an open collect or output is selected with jumper Out(4). T o change between volta ge

and current output mod e the hardware jumper s are used. Ther e is one jumper for Out(1) and one for

Out(2), so that one outp ut can be a v oltage output a nd the ot her a c urrent output. Both, v oltage output

and current output, can ha ve start points 0 % (0-10 VD C or 0-20mA) or 20% (2-10 VDC or 4-20mA)

selected from PC software. See the user manual.

Note 3: Current of Open Collector is internally returned to terminal.

Open contact voltage max 5V

on this input!

Page 4

Dokument

IMA 208

Rev 1 Page

4 (4)

DI1

~

+

Numbers in figure 3

Label or marking

Function

3

Out(1)

CO-transmitter 0-100 ppm CO

4

Out(2)

CO2-transmitter 0-2000 ppm CO2

6, 7

Out(3)

Gas alarm CO >35 ppm or CO2 >1500 ppm

8

Out(4)

Error detected or gas alarm

9, 10

DI 1

Extra terminal. Alarm test function (N.O.)

DI1 Switch

Jumper for

start point

Jumper to

protocol

Jumpers to

current outputs

Jumper to choose

linear signal

for alarm

test

Fig. 3.Terminals and jumpers on CF8-W-Disp-CO. The darker positions are default settings.

configuring the

linear output

start point to

0% or 20%

choose

communication

choose between

voltage or

between open

collector or 0-10V

If more holes are needed the box has several drill markings for holes in two

dimensions, PG7 and PG9. Then fast en t he cabl e entr y bushing and seal properly .

Never feed more than one cable through each cable entry bushing, or else gas might

leak through!

The PCB can be removed during the making of holes. The PCB must be handled

carefully and protected from electrostatic discharge!

Start-up of the CF8-W-Disp-CO

Connect the power directly after mounting. The unit works best if the sensor is

continuously powered. The analogue outputs do not need to be connected before

use. An internal delay function prevents the alarm functions of the relay and OUT4

output during 2 minutes after power up. After short power failures the CO

measurements need this power up time to stabilize. The alarm outputs may be tested

after the 2 minutes delay by shorting the switch DI1. After long power failures the

sensor may need several days to restore the measuring functions.

NOTE! The CO probe gives incorrect readings near some chemicals, e

g silicone. This makes certain environments unsuitable for the sensor.

Loading...

Loading...