rotork CML-250, CMQ-500, CML-100, CMR-100, CMR-50 Installation & Maintenance Instructions Manual

...

CMA Range

Installation & Maintenance Instructions

Redefining Flow Control

Linear, Rotary and Quarter-Turn

Control Valve Actuators

Contents

Section Page

Introduction 3

General Information 4

Hazardous Area Approvals 9

Installation & Setup 11

Mounting the Actuator 15

Electrical Installation 23

Basic Setup 26

Menu Structure 43

Status (Alarms), Fault History & Default Menus 44

Fault History Menu 46

Default Menu 48

Advanced Menu 51

Dimensional Drawings 56

Power Ratings 59

Linear CML Rotary CMR

THIS MANUAL CONTAINS IMPORTANT SAFETY

INFORMATION. PLEASE ENSURE IT IS THOROUGHLY

READ AND UNDERSTOOD BEFORE INSTALLING,

OPERATING OR MAINTAINING THE EQUIPMENT.

2

Quarter-Turn

CMQ

DUE TO WIDE VARIATIONS IN THE TERMINAL

NUMBERING OF ACTUATOR PRODUCTS, ACTUAL

WIRING OF THIS DEVICE SHOULD FOLLOW THE PRINT

SUPPLIED WITH THE UNIT.

Introduction

Rotork Process Controls designs, manufactures,

and tests its products to meet many national

and international standards. For these products

to operate within their normal specifications,

they must be properly installed and maintained.

The following instructions must be followed and integrated

with your safety program when installing and using Rotork

Process Controls products:

• Read and save all instructions prior to installing, operating

and servicing this product.

• If you don’t understand any of the instructions, contact

Rotork Process Controls for clarification.

• Follow all warnings, cautions and instructions marked on,

and supplied with, the product.

• Inform and educate personnel in the proper installation,

operation and maintenance of the product.

• Install equipment as specified in Rotork Process Controls

installation instructions and per applicable local and

national codes. Connect all products to the proper

electrical sources.

• To ensure proper performance, use qualified personnel to

install, operate, update and maintain the unit.

• When replacement parts are required, ensure that the

qualified service technician uses replacement parts

specified by Rotork Process Controls. Substitutions may

result in fire, electrical shock, other hazards, or improper

equipment operation.

• Keep all product protective covers in place (except

when installing, or when maintenance is being performed

by qualified personnel), to prevent electrical shock,

personal injury or actuator damage.

• Operation of actuator in an inappropriate fashion

may cause harm or damage to unit or other equipment

surroundings.

Redefining Flow Control

3

General Information

INTRODUCTION

This manual has been produced to enable a competent user

to install, operate, adjust and inspect the Rotork Range of

Compact Control Valve Actuators.

The electrical installation, maintenance and use of these

actuators should be carried out in accordance with the

National Legislation and Statutory Provisions relating to

the safe use of this equipment applicable to the site of

installation.

For the UK: Electricity at Work Regulations 1989 and the

guidance given in the applicable edition of the ‘IEE Wiring

Regulations’ should be applied. Also the user should be fully

aware of their duties under the Health and Safety at Work

Ac t 1974.

For the USA: NFPA70, National Electrical Code

The mechanical installation should be carried out as outlined

in this manual and also in accordance with any relevant

national standard codes of practice. If the actuator nameplate

indicates that it is suitable for use in a Potentially Explosive

Atmospheres (Hazardous Areas) then the actuator is suitable

for use in Zone 1 and Zone 2 (or Div 1 and Div 2) hazardous

area classifications, as defined by the actuator’s nameplate

marking.

Any equipment connected to the actuator should be of

an equivalent (or better) hazardous area certification. The

installation, maintenance and use of the actuator installed in

a hazardous area must be carried out by a competent person

and in accordance with all relevant codes of practice for the

particular Hazardous Area certification.

Any inspection or repair of Hazardous Area approved

actuators should not be undertaken unless it conforms to

National Legislation and Statutory Provisions relating to the

specific Hazardous Area.

®

is applicable.

Only Rotork approved actuator replacement parts should

be used. Under no circumstances should any modification

or alteration be carried out on the actuator, as this could

invalidate the conditions under which its certification was

granted.

Access to live electrical conductors is forbidden in a

Hazardous Area unless it is done under a special permit

to work, otherwise all power should be isolated and the

actuator moved to a non-hazardous area for repair or

attention.

Only persons competent by virtue of their training or

experience should be allowed to install, maintain and repair

Rotork actuators. Work undertaken must be carried out in

accordance with instructions in the manual. The user and

those persons working on this equipment should be familiar

with their responsibilities under any statutory provisions

relating to the Health and Safety of their workplace.

ENCLOSURE MATERIALS

The enclosures on the Rotork Range of Control Valve

Actuators are manufactured from aluminium alloy with

stainless steel fasteners.

The user must ensure that the operating environment and any

materials surrounding the actuator cannot lead to a reduction

in the safe use of, or the protection afforded by, the actuator.

Where appropriate the user must ensure the actuator is

suitably protected against its operating environment.

Should further information and guidance relating to the safe

use of the Rotork Control Valve Actuator Range be required,

it will be provided on request.

4

General Information

GENERAL ACTUATOR DESCRIPTION

Building on Rotork’s historical success with innovative

technology, the CMA offers a highly accurate and responsive

method of automating control valves and pumps without the

complexity and cost of a pneumatic supply.

With a minimum resolution of 0.2% of full stroke for Linear

& Quarter-turn units and 0.6% of full stroke for Multi-turn,

the Rotork CMA range helps to maximize product quality

and plant capacity.

CMA range actuators are self contained, purpose designed

and built for continuous remote electrical operation of

control valves.

CMA range of actuators delivers a series of sizes suitable

for almost all linear, quarter- turn and rotary control valve

and pump applications requiring exact position control and

unrestricted continuous modulation.

Refer to Hazardous Area Approval section for further detail

concerning approved actuators

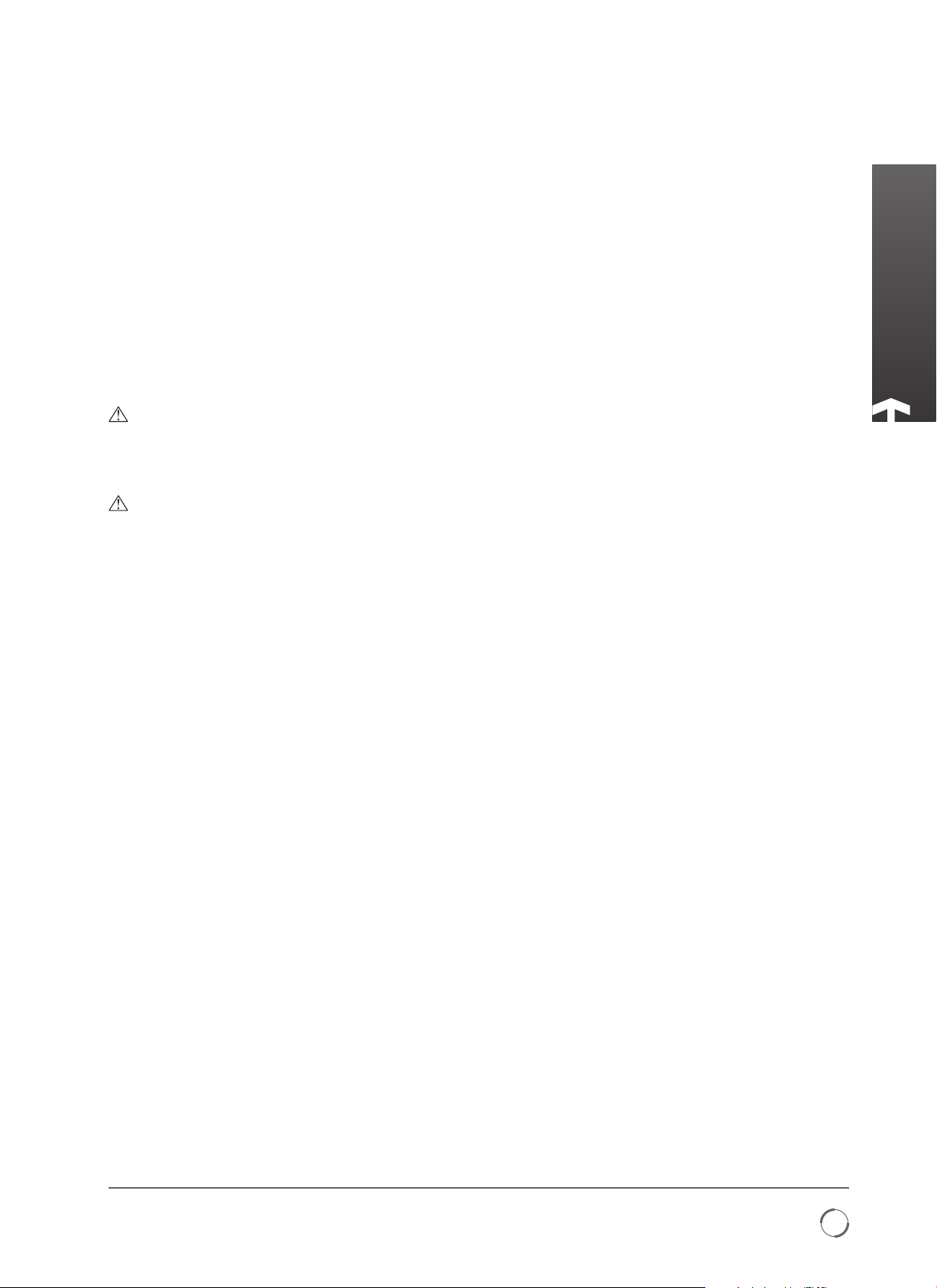

CML - Linear

The CML is a high precision linear actuator. It is capable of

producing up to 750 pounds of force and a maximum of 2

inch stroke length at a speed of up to .063 inches per second.

NOTE: Thrust and Speed are dependant on frame size.

See page 7 for full details.

CMQ - Quarter-Turn Actuators

The CMQ is a high precision quarter-turn actuator capable

of producing between 250 to 1000 inch pounds at speeds

between 10 to 22 seconds 90 degree operating times.

NOTE: Torque and operating times are dependant on

frame size.

See page 7 for full details.

CMR - Rotary

The CMR is a high precision rotary unit with torque outputs

between 50 to 250 inch pounds at output speeds between

5 to 12 RPM depending on frame size.

NOTE: Torque and operating times are dependant on

frame size.

The actuator comprises:

• Absolute Encoder

• LCD User Interface

• DC brushless electric motor

• Simple, maintenance free geartrain

• Motor controller with travel and

torque/thrust adjustment

• Manual Overide

• Hazardous area certification meeting

international and national requirements

Redefining Flow Control

5

General Information

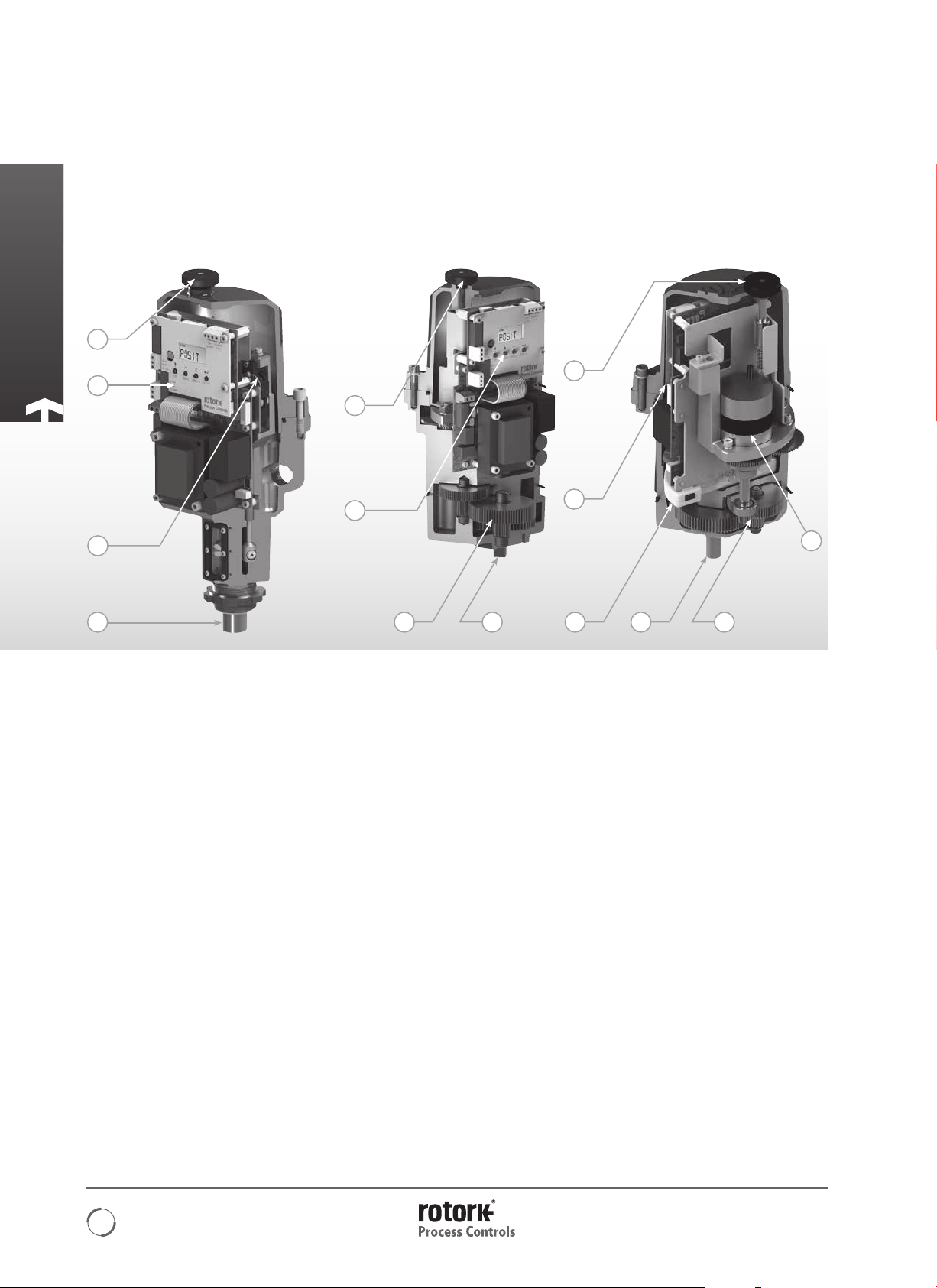

Advanced Engineering

CML

Linear Actuator

4

2

1

6

CMQ

Quarter-Turn Actuator

4

2

5 6

CMR

Rotary Actuator

4

2

61

3

5

1 Encoder Technology

The CMA utilizes absolute encoder technology where a

unique digital code corresponds to the angular position

(CMQ), stroke length (CML) or rotary (CMR) position of the

actuator.

To achieve high resolution, the position sensor location

eliminates any backlash effect in the gearing. The sensor is

a 12-bit rotary magnetic encoder, fitted at the output gear

stages, removing any internal backlash effect that may exist in

the drive train.

2 User Interface

The CMA LCD display is a 6-character, single line display.

Two graphic symbols are provided for notification of alarm

conditions. The menu style is an intuitive common tree

structure similar in function to the menu system used on PCs.

Two relays can be programmed to close upon reaching a

desired position or any other available fault condition among

the programmable options.

3 DC Brushless Motor

The CMA uses a high efficiency, continuous rated, brushless

DC motor. This allows maintenance-free operation even with

continuous unrestricted modulation duty.

4 Hand Drive

A hand drive mechanism is provided as standard for all CMA

actuators to allow manual operation of the valve. Pressing

down on the hand-knob shaft allows it to engage a gear

in the upper section of the drive train. Releasing causes the

spring to disengage the gear.

5 Geartrain

The simple yet durable high efficiency spur gear drive is

lubricated for life. It has proven high reliability.

The CML and CMQ standard build is capable of resisting any

back drive from the load, up to 125% of the rated thrust or

torque of the actuator.

6 Output Drive

The CMQ base conforms to MSS SP-101 or ISO5211.

The CMR and CML may be adapted to suit individual valves.

6

General Information

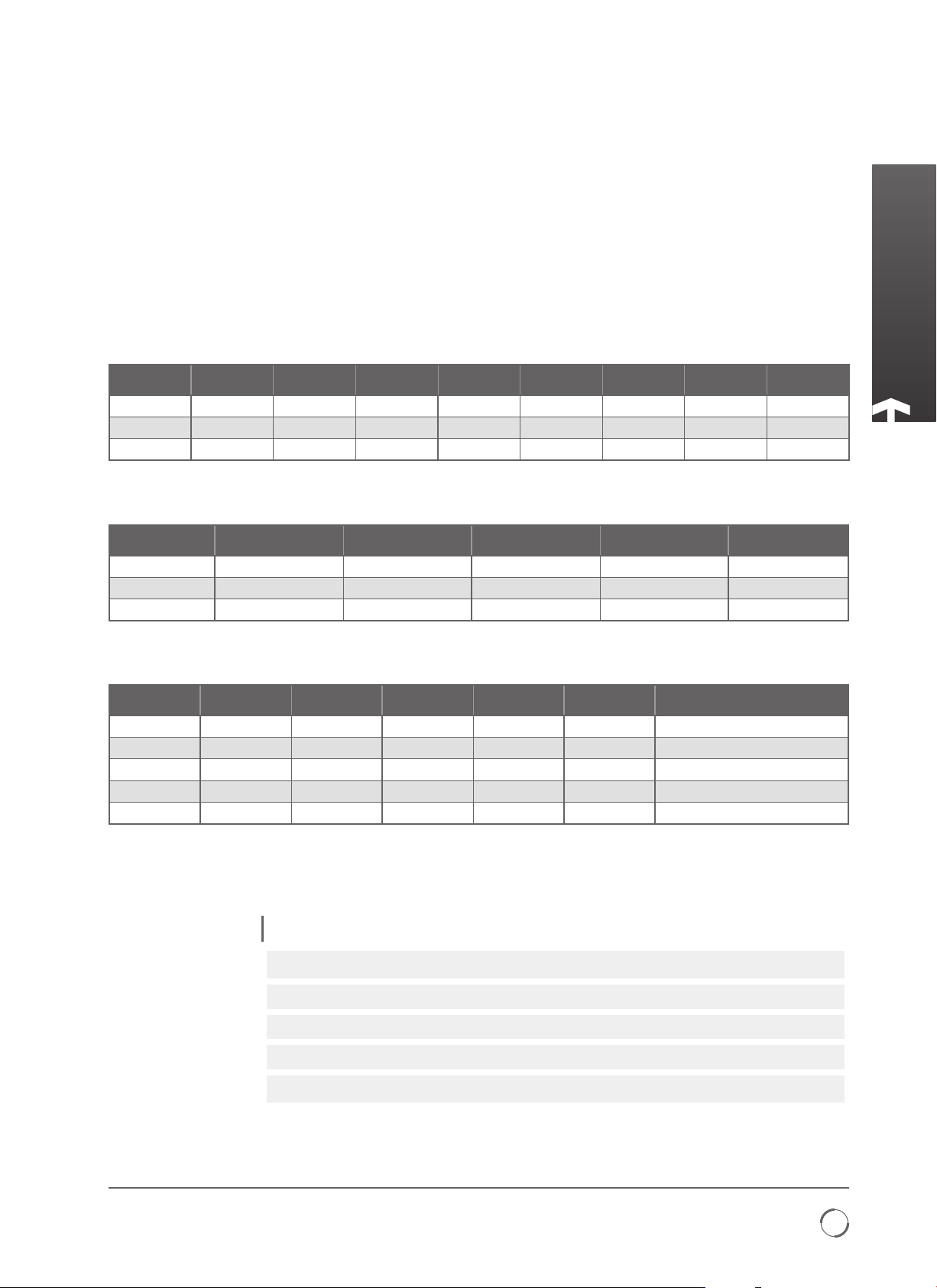

Mechanical Performance

The rated force (thrust or torque) for each size of actuator is

detailed below. The minimum settable force is 40% of the

maximum rated. Operating time tolerance +/-10%.

The CML and CMQ can resist backdriving forces from the

valve up to 125% of rated load without movement.

CML: Linear Actuator

All CMA actuators are factory calibrated.

Model

CML-100 40 177.9 100 444.8 0.25 6.35 1.5 38.1

CML-250 100 444.8 250 1112 0.125 3.18 1.5 38.1

CML-750 300 1334.5 750 3336.2 0.063 1.68 2 50.8

Min Thrust

(lbf)

Min Thrust

(N)

Max Thrust

(lbf)

Max Thrust

(N)

Speed

(inches/sec)

Speed

(mm/sec)

Stroke

(inches)

CMQ: Quarter-Turn Actuator

Model

CMQ-250 100 11.3 250 28.2 10

CMQ-500 200 22.6 500 56.5 15

CMQ-1000 400 45.2 1000 113.0 22

Min Torque

(lbf.in)

Min Torque

(Nm)

Max Torque

(lbf.in)

Max Torque

(Nm)

Time for Quarter-

Turn (secs)

CMR: Rotary Actuator

Model

CMR-50 20 2.3 50 5.6 11

CMR-100 40 4.5 100 11.3 10

CMR-125 50 5.6 125 14.1 18

CMR-200 80 9.0 200 22.6 5

CMR-250 100 11.3 250 28.2 10

Min Torque

(lbf.in)

Min Torque

(Nm)

Max Torque

(lbf.in)

Max Torque

(Nm)

Speed (RPM)

Total turns

available

90º to 320 turns in 2º

90º to 320 turns in 2º

90º to 320 turns in 2º

90º to 320 turns in 2º

90º to 320 turns in 2º

Stroke

(mm)

increments

increments

increments

increments

increments

Vibration, Shock and Noise

CMA actuators are suitable for applications where vibration and shock severity does not exceed the following:

Type Level

Plant induced vibration

1 g RMS total for all vibration within the frequency range of 10 to 1000Hz.

Shock 5 g peak acceleration.

Seismic 2 g acceleration over a frequency range of 1 to 50 Hz if it is to operate during and after the event.

5 g over a frequency range of 1 to 50 Hz if it is only required to maintain structural integrity.

Emitted noise

Levels quoted are those present at the actuator mounting interface. It should be noted that the effects of vibration are cumulative and therefore an actuator

subjected to significant levels may have reduced life.

Independent tests have shown that at 1 m generated noise does not exceed 61 db (A).

Redefining Flow Control

7

General Information

RECEIVING / INSPECTION

Carefully inspect for shipping damage. Damage to the

shipping carton is usually a good indication that it has

received rough handling. Report all damage immediately to

the freight carrier and Rotork Controls Ltd.

Unpack the product and information packet taking care to

save the shipping carton and any packing material should

return be necessary. Verify that the items on the packing list

or bill of lading agree with your own documentation.

Rotork cannot accept responsibility for deterioration caused

on-site once the covers are removed. Every Rotork actuator

has been fully tested before leaving the factory to give

years of trouble free operation providing it is correctly

commissioned, installed and sealed.

WARNING

Before installing the actuator, make sure that it is

suitable for the intended application. If you are unsure

of the suitability of this equipment for your installation

consult Rotork prior to installation.

WARNING: ELECTRIC SHOCK HAZARD

Installation and servicing must be performed only by

qualified personnel.

WARNING: ELECTROSTATIC DISCHARGE

This equipment houses static sensitive devices. To

protect the internal components never touch the

printed circuit boards without using electrostatic (ESD)

control procedures.

STOR AGE

If your actuator cannot be installed immediately store it in a

dry place until you are ready to connect incoming cables.

If the actuator has to be installed but cannot be cabled it is

recommended that any plastic cable entry plugs are replaced

with PTFE sealed metal plugs.

EQUIPMENT RETURN

If your Rotork actuator has been correctly installed and sealed

it will give years of trouble free service.

Should you require technical assistance or spares, Rotork

guarantees the best service in the world. Contact your local

Rotork representative or the factory direct at the adress on

the nameplate, quoting the actuator type and serial number.

ABBREVIATIONS USED IN THIS MANUAL

A Ampere

AC Alternating Current

°C Degrees Celsius

CW Clockwise

ACW Anti-clockwise

CCW Counter-clockwise

DC Direct Current

°F Degrees Fahrenheit

G Earth Ground

Hz Hertz

kg Kilogram

L Line (power supply)

lbf Pounds Force

lbf.in Inch Pounds

lbf.ft Foot Pounds

mA Milliamp

mfd Microfarad

mm Millimeters

N Newton (force)

NEMA National Electrical

Manufacturing

Association

Nm Newton Meter

NPT National Pipe Thread

PCB Printed Circuit Board

PL Position Limit switch

RPM Revolutions per

Minute

SEC Second

V Volts

VA Volt Amps

VAC Volts AC

VDC Volts DC

VR Variable Resistance

W Watt

WARRANTY INFORMATION

Warranty: Subject to the following, Rotork Process Controls

expressly warrants the products manufactured by it as

meeting the applicable Rotork Process Controls product

specifications and that such products are free from defects

in material and workmanship for a period of one (1) year

from the date of delivery. The foregoing is the sole and

exclusive warranty made by Rotork Process Controls with

respect to the products. Rotork Process Controls makes no

other warranties, either express or implied (including, without

limitation, warranties as to merchantability or fitness for a

particular purpose). The purchaser retains responsibility for

the application and functional adequacy of the offering.

See Rotork Process Controls’s General Conditions of Sale Product, for complete warranty information.

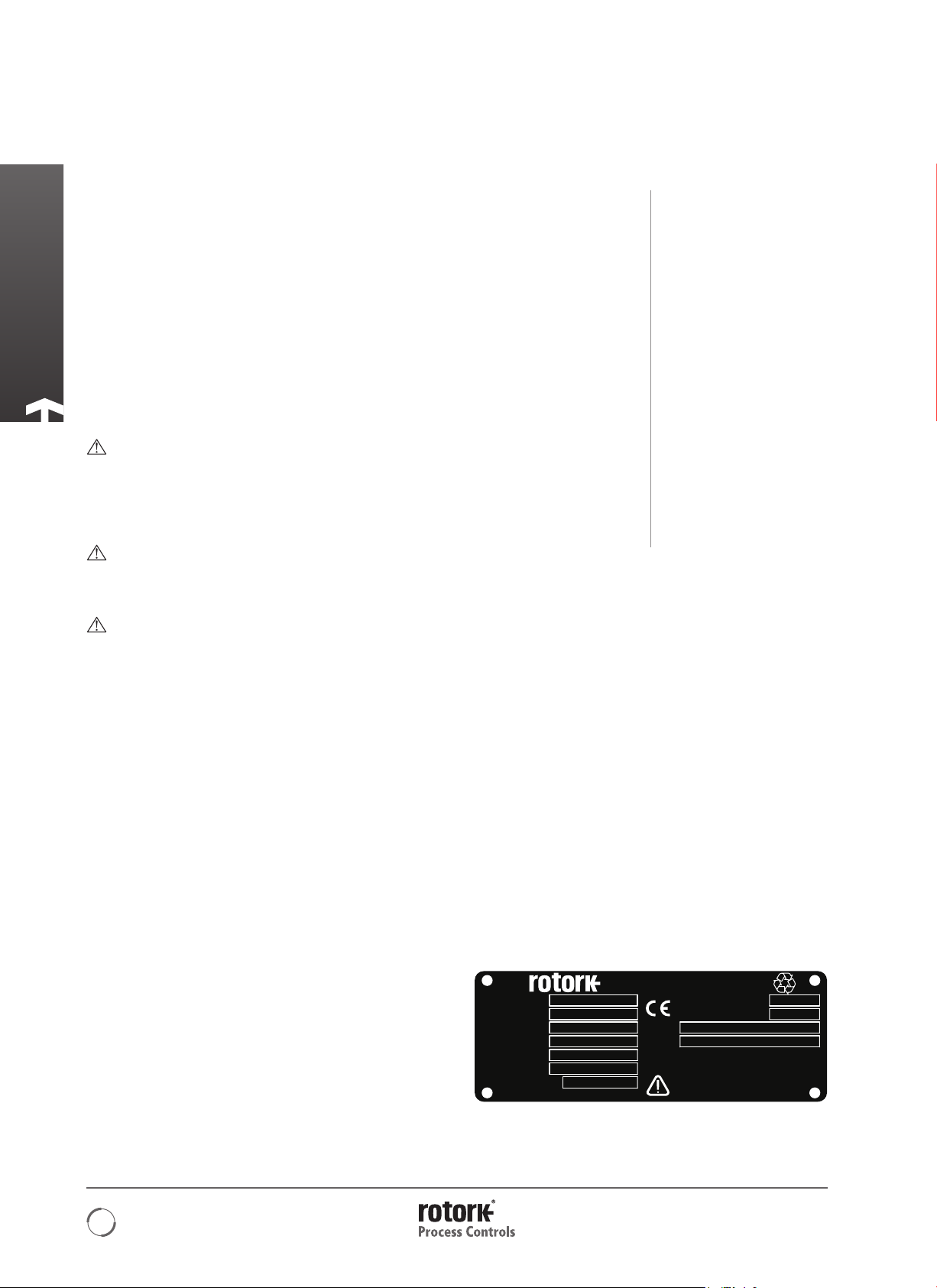

IDENTIFICATION LABEL

An identification label is attached to each actuator. When

ordering parts, requesting information or service assistance,

please provide all of the label information. You must supply

the serial number with all enquiries.

ROTORK PROCESS CONTROLS

MILWAUKEE, WI, USA.

www.

Serial number

Wiring diagram

Actuator type

Output max.

Enclosure

Actuator supply

Rated current

M1895423942

M00-00

CML-250

2224 N

IP67

120/240

.com

0518

1

Amp

Unit weight

Year of manufacture

8

2012

47568-1

Kg

Fig 9.1 Actuator identification label.

8

Hazardous Area Approvals

The CMA is suitable for both indoor and outdoor use up to

an altitude of 5,000 m and is watertight to IP67.

Refer to the actuator nameplate for it’s specific

approval details.

European - Hazardous Area ATEX (94/9/EC) II 2 c T4 GD

Ex d IIB T4 Gb, Ex t IIIC T120 °C Db

EN60079-0 and EN60079-1

Ambient Temperature Range:

-20 to +65 °C (-4 to +150 °F)

*Option -40 to +60 °C (-40 to +140 °F)

Ex d IIC T4 Gb, Ex t IIIC T120 °C Db

EN60079-0 and EN60079-1

Ambient Temperature:

Range -20 to +65 °C (-4 to +150 °F)

*Option -40 to +60 °C (-40 to +140 °F)

International - Hazardous Area IECEx

Ex d IIB T4 Gb, Ex t IIIC T120 °C Db

IEC60079-0 and IEC60079-1

Ambient Temperature Range:

-20 to +65 °C (-4 to +150 °F)

*Option -40 to +60 °C (-40 to +140 °F)

Ex d IIC T4 Gb, Ex t IIIC T120 °C Db

IEC60079-0 and IEC60079-1

Ambient Temperature Range:

-20 to +65 °C (-4 to +150 °F)

*Option -40 to +60 °C (-40 to +140 °F)

USA - Hazardous Area

FM. Explosionproof, Class I, Div 1, Groups C & D, T4

Ambient Temperature Range:

-20 to +65 °C (-4 to +150 °F)

*Option -40 to +60 °C (-40 to +140 °F)

FM. Explosionproof, Class I, Div 1, Groups C & D, T4

Ambient Temperature Range:

-20 to +65 °C (-4 to +150 °F)

*Option -40 to +60 °C (-40 to +140 °F)

FM. Dust Ignitionproof, Class II, Div 1, Groups E, F & G, T4

Ambient Temperature Range:

-20 to +65 °C (-4 to +150 °F)

*Option -40 to +60 °C (-40 wto +140 °F)

Note: A start corresponds to 1% position change on Linear

and Quarter-turn variants and 36º for multi-turn variants.

Redefining Flow Control

9

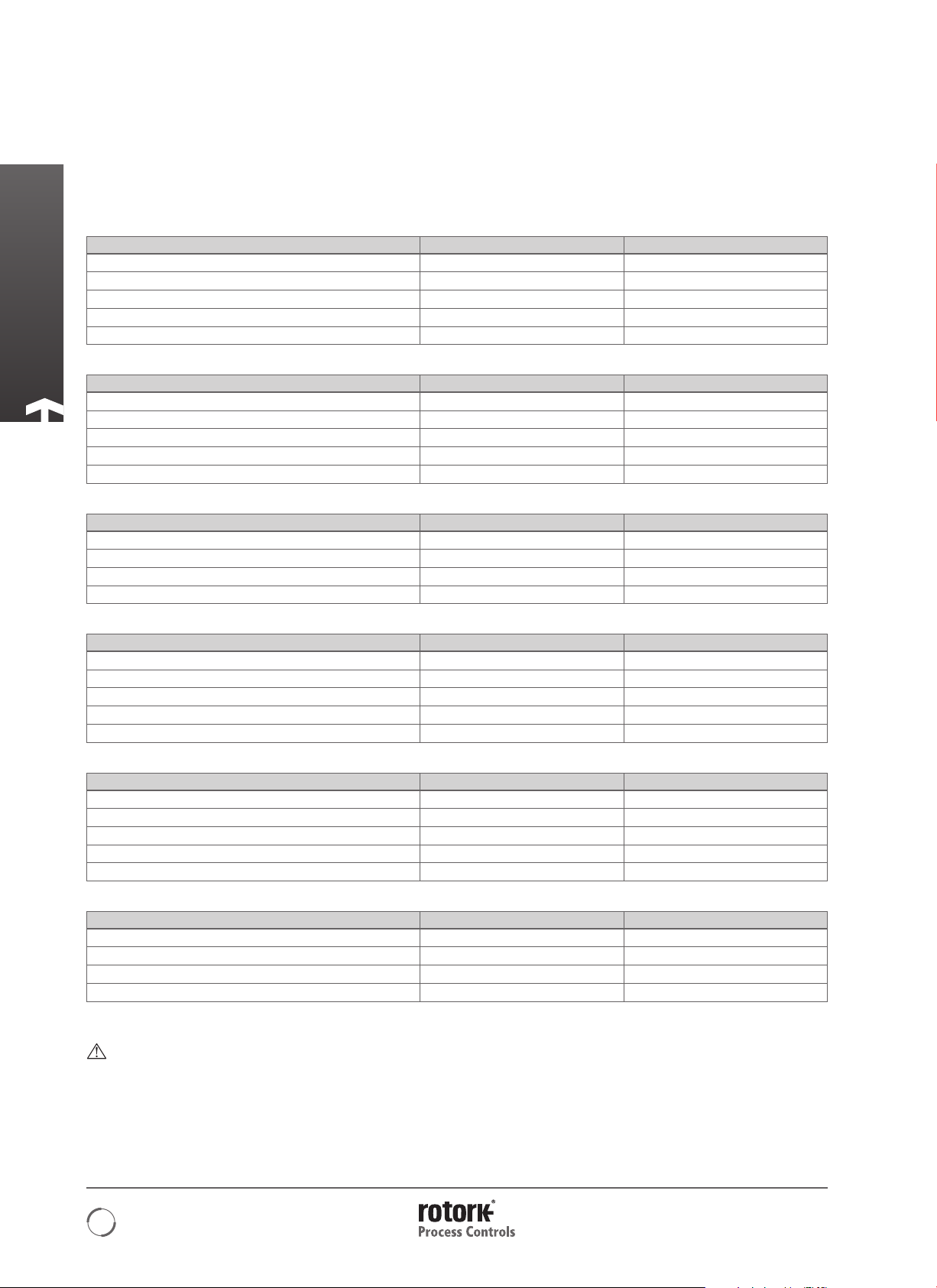

Hazardous Area Approvals

Special Conditions For Safe Use (ATEX & IECEx approved actuators)

In accordance with clause 5.1 of IEC/EN 60079-1, the critical dimensions of the flamepaths are:

CML-100/250

Flamepath Maximum Gap (mm) Maximum Width L (mm)

Lid/base 0.15 12.8

Base/pinion shaft 0.145 13.5

Base/feedback shaft bush -0.02 13.7

Feedback shaft bush/feedback shaft 0.06 13.7

Handknob shaft/lid 0.1 25.9

CMQ-250/500

Flamepath Maximum Gap (mm) Maximum Width L (mm)

Lid/base 0.15 12.8

Base/pinion shaft 0.235 29.8

Base/feedback shaft bush -0.02 13.7

Feedback shaft bush/feedback shaft 0.06 13.7

Handknob shaft/lid 0.1 25.9

CMR-50/100/200

Flamepath Maximum Gap (mm) Maximum Width L (mm)

Lid/base 0.15 12.8

Base/pinion shaft 0.235 29.8

Base/output shaft 0.145 12.8

Handknob shaft/lid 0.1 25.9

CML-750

Flamepath Maximum Gap (mm) Maximum Width L (mm)

Lid/base 0.15 12.8

Base/pinion shaft 0.235 37.3

Base/feedback shaft bush -0.02 13.7

Feedback shaft bush/feedback shaft 0.06 13.7

Handknob shaft/lid 0.1 25.9

CMQ-1000

Flamepath Maximum Gap (mm) Maximum Width L (mm)

Lid/base 0.15 12.8

Base/pinion shaft 0.235 37.3

Base/feedback shaft bush -0.02 13.7

Feedback shaft bush/feedback shaft 0.06 13.7

Handknob shaft/lid 0.1 25.9

CMR-125/250

Flamepath Maximum Gap (mm) Maximum Width L (mm)

Lid/base 0.15 12.8

Base/pinion shaft 0.235 37.3

Base/ourtput shaft 0.145 13

Handknob shaft/lid 0.1 25.9

Note: Negative Sign denotes an interference fit.

WARNING

The equipment utilises a non-metallic outer coating

and has a potential static hazard. Clean only with a

damp cloth.

10

Installation & Setup

COMMISSIONING

The Rotork CMA Range of actuators provide simple, safe and

rapid commissioning.

TOOLS & EQUIPMENT REQUIRED

(General Guideline Only)

Top Cover Fixings - 6mm Allen Wrench

Electrical Connections - Terminal Screw Driver

Command & Feedback - 4 to 20 mA Command

source/meter

Actuator to Valve fixings - As Required.

CAUTION

It is essential that the setup procedure is carried

out when the valve is not under working process

conditions, as full valve movement may occur.

IMPORTANT

It is essential that the actuator is mounted correctly to

the valve!

The height of the yoke or pillar and mounting plate, in

relation to the top of the valve spindle is critical to ensure

full stroke movement of the valve.

The Installation & Setup will include the following steps:

1. Ensure valve position is noted and safe (Offline).

2. Actuator output shaft is retracted. (Linear Units only)

3. Actuator is in closed position. (Rotary Units only).

4. Mount and align actuator to valve.

5. Set limits of travel.

6. Configure control and indication parameters

Redefining Flow Control

11

Installation & Setup

INSTALLING YOUR ACTUATOR

The following instructions must be followed and integrated

into your safety program when installing and using Rotork

products.

• Read and save all instructions prior to installing,

operating and servicing this product.

• If you don’t understand any of the instructions contact

Rotork for clarification.

• Follow all warnings, cautions and instructions marked on

and supplied with the product.

• Inform and educate personnel in the proper installation,

operation and maintenance of the product.

Install equipment as specified in Rotork installation

instructions and as per applicable local and national

codes of practice. Connect all products to the proper

electrical sources.

• To ensure proper performance, use only qualified

personnel to install, operate, update and maintain

the unit.

• When replacement parts are required, ensure that the

qualified service technician uses only replacement parts

specified by Rotork.

• Substitutions will invalidate any hazardous area

certification and may result in fire, electrical shock, other

hazards or improper operation.

• Keep all product protective covers in place (except during

installation or maintenance by qualified personnel)

to prevent electrical shock, personal injury or damage

to equipment.

• Operation of the actuator in an inappropriate fashion

may cause harm or damage to the unit or surrounding

equipment.

The end user should take care when assessing the local

ambient temperature to take into account the heat from any

connecting pipe-work or inherent heat from process plant etc.

WARNING

Before installing the actuator, make sure that it is suitable for

the intended application. If you are unsure of the suitability

of this equipment for your installation consult Rotork prior to

installation.

WARNING: ELECTRIC SHOCK HAZARD

Installation and servicing must be performed only by

qualified personnel.

WARNING: ELECTROSTATIC DISCHARGE

This equipment houses static sensitive devices. To protect the

internal components never touch the printed circuit boards

without using electrostatic (ESD) control procedures.

WARNING: ENCLOSURE MATERIALS

CMA actuator castings are manufactured from aluminium

alloy with stainless steel fasteners. The user must ensure that

the operating environment and any materials surrounding the

actuator cannot lead to a reduction in the safe use of, or the

protection afforded by the actuator. Where appropriate the

user must ensure the actuator is suitably protected against its

operating environment.

HANDWHEEL OPERATION

The handwheel is located on

the top cover of the CMA (All

Variants). Push and hold the

hand wheel down and rotate

to extend/retract or rotate the

actuator output drive.

Fig. 12.1

Verify direction of output shaft rotation for clockwise

operation of the handwheel. (Varies with frame size).

WARNING: OPERATING BY HAND

Note that under no circumstances should any

additional lever device such as a wheel key or wrench

be applied to the hand-wheel in order to develop more

force when closing or opening the valve as this may

cause damage to the valve and/or actuator. It may also

cause the valve to become stuck in the seated or back

seated position.

Model

CMA - Linear Extend or Retract

CML-100/250 Retract

CML-750 Extend

CMA - Quarter-turn

CMQ-250 Anticlockwise

CMQ-500 Anticlockwise

CMQ-1000 Anticlockwise

CMA -Rotary

CMR-50 Clockwise

CMR-100 Clockwise

CMR-125 Clockwise

CMR-200 Clockwise

CMR-250 Clockwise

Output When Hand Knob

is Turned Clockwise

12

Installation & Setup

STANDARD ACTUATOR

The standard actuator is not supplied with local control knobs

or external display. Removal of top cover assembly is required

to adjust configuration parameters and facilitate connection

of power and field wiring.

LOCAL INDICATOR

CML has one indicator as standard. All variants can be fitted

with optional extended cover with local display window.

Fig. 13 .1

MAIN PRINTED CIRCUIT BOARD (PCB) LAYOUT

Redefining Flow Control

MainsInput

(Earth stud

located behind)

Fi g . 13.2

Note: Current Position Transmitter(CPT )isloop powered.

Relay1:

N/O

N/C

Common

Relay2:

N/O

N/C

Common

LN

Neutral

Live

Fig 13.3 Main PCB.

REMOTE

POS I T

CPT Feedback-

CPT Feedback+

Demand -

Demand +

13

Installation & Setup

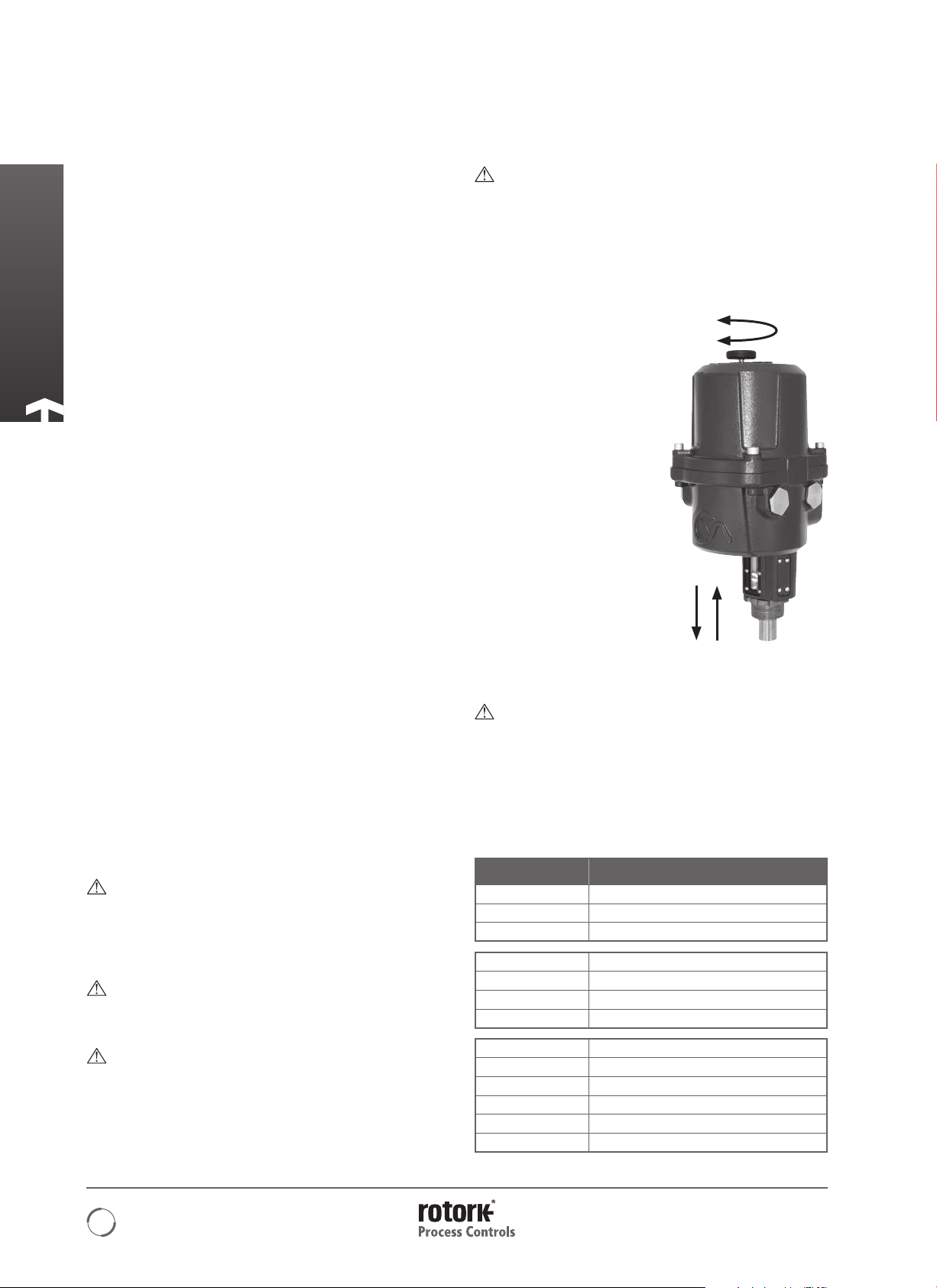

LCD DISPLAY

The main PCB has a LCD Display used to show STATUS and

configuration information

On power up the default screen is the POSIT parameter.

The actuator will indicate Local or Remote mode selected in

top left hand corner of the LCD.

See Basic Setup Mode for details.

SETUP PUSHBUTTONS

Four push button switches are located on the main PCB below

its LCD Display and are used to view and change the actuator

configuration parameters.

The Switch Functions are as follows:

‘UP’

Used to navigate menus in view mode. Increase parameter

values in Edit Mode.

‘DOWN’

Used to navigate menus in view mode. Decrease parameter

values in Edit Mode.

‘MODE/CANCEL’

Used to exit and go to previous Menu.

LOCAL

POS I T

Fig. 14.1

Remote Mode Selected Alarm Active

REMOTE

POS I T

ENTER

Used to enter and save changes to configuration parameters

‘UP’ ‘DOWN’ ‘MODE/CANCEL’ ENTER

Fi g. 14. 2

14

Mounting the Actuator

The CMA Actuator is available for Linear, Quarter-turn or

Rotary valves, dampers or other devices.

Each of these applications may require different methods of

mounting the actuator to the valve.

Typical examples only are described in this publication and do

not cover all possible variants of valve types.

CML - LINEAR UNIT - MOUNTING

CAUTION

It is essential that the actuator mounting procedure is

carried out when the valve is not under working process

conditions, as full valve movement may occur.

IMPORTANT

It is essential that the actuator is mounted correctly to

the valve.

The height of the yoke or pillar and mounting plate, in

relation to the top of the valve spindle is critical to ensure full

stroke movement of the valve.

The Installation & Setup will include the following procedures:

1. Ensure Valve is closed and safe (Offline).

2. Actuator output shaft is retracted.

3. Mount and align actuator to valve.

4. Carry out Basic Setup

CM L-10 0 & CML-2 50

CM L-75 0

Redefining Flow Control

15

Mounting the Actuator

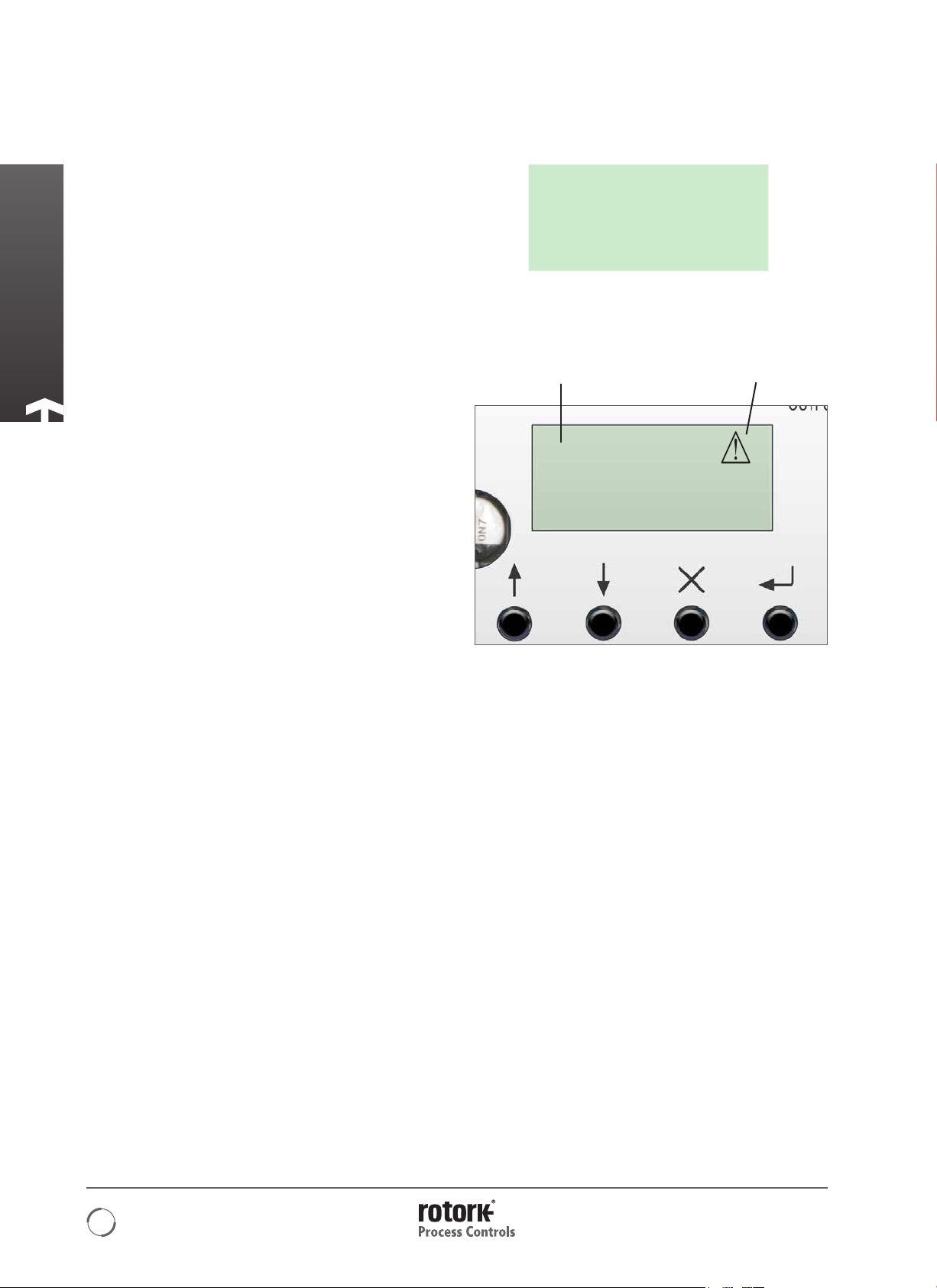

Move Valve stem to the closed position

To enable the actuator to be installed correctly the valve must

be in the closed (down) position to allow fitting of the valve

stem/actuator coupling.

Actuator Output Shaft

The actuator is supplied with the output shaft in the fully

retracted position. If the output shaft is in the extended

position it may be necessary to manually operate the actuator

using the hand wheel to the retracted position to allow

installation. Push and turn the hand wheel to retract the

output shaft.

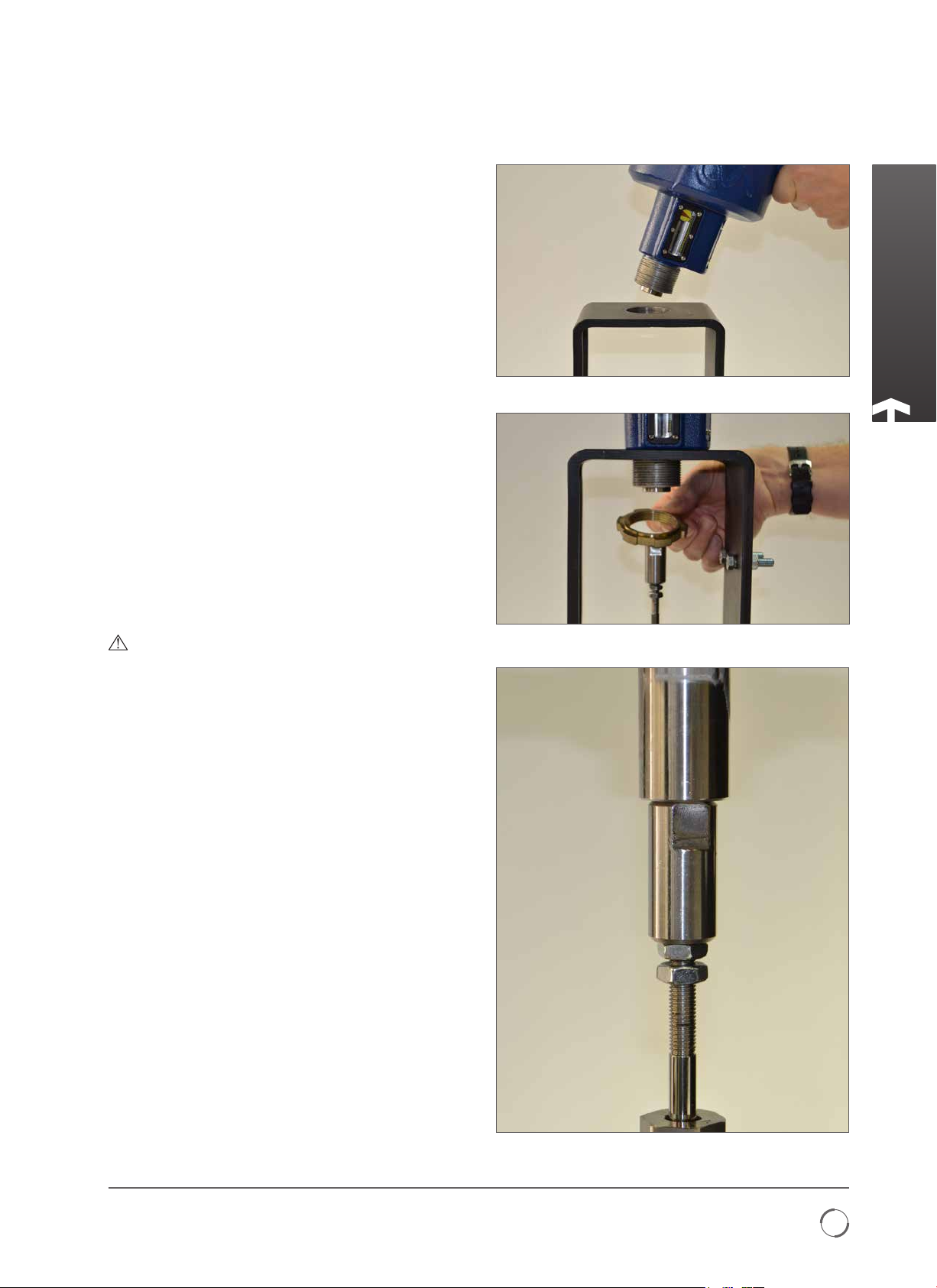

Fig. 16.1

Valve Stem Coupling

Machine the valve stem to actuator output shaft coupling

adaptor to suit. (NOT SUPPLIED)

Fit the coupling to the valve stem. It may be necessary to use

a locking nut to eliminate any backlash.

Leave the coupling loose and free to rotate at this stage.

CML-100 & CML-250 Units Only

Remove the locking ring from the base of the actuator and

position the unit on to the valve mounting flange.

CML-750 Units

Position the actuator on to its mounting flange, fit four off

fixings but do not fully tighten at this stage.

Fig. 16.2

Fig. 16.3

16

Fig. 16.4

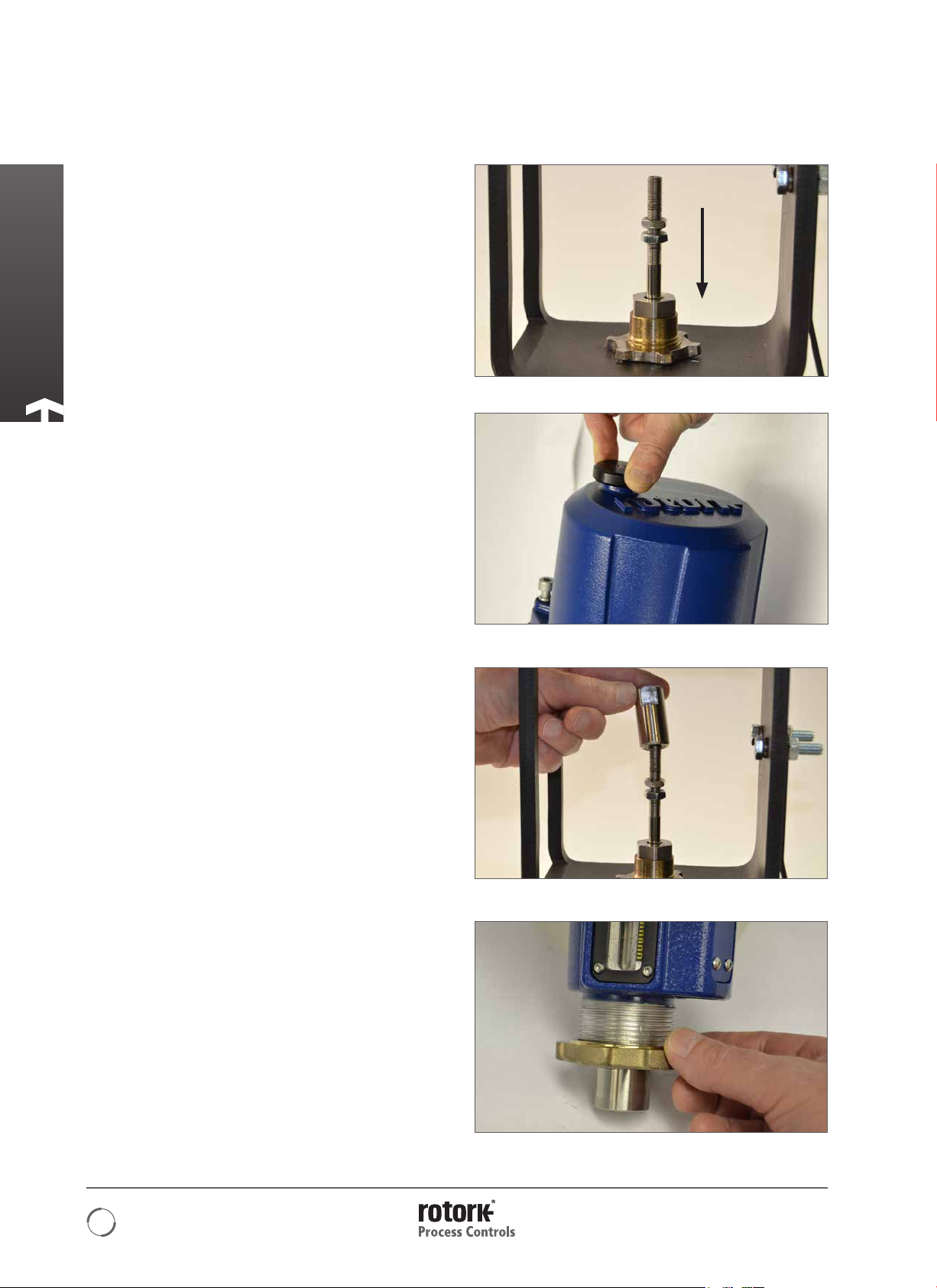

Mounting the Actuator

Replace the locking ring.

DO NOT FULLY TIGHTEN AT THIS STAGE.

Extend the actuator output shaft to bring the end of the shaft

and the coupling together. Rotate the coupling as required

to get a good firm contact between the valve stem and the

output shaft.

Adjust and tighten locking nut(s) if fitted on valve stem side of

the coupling. Ensure that the actuator is centrally aligned with

the valve stem.

If the actuator output shaft reaches its fully extended position

it will be necessary to retract the actuator shaft a sufficient

distance to allow adjustment of the coupling to ensure a tight

shut off in thrust seating valves.

Fig. 17.1

WARNING

It is critical that there is correct alignment between

actuator output shaft and the valve stem.

Note: Mis-alignment will result in increased mechanical

wear and possible damage to the valve stem.

CML-100 & CML-250 Units only

Tighten the locking ring fully to secure the actuator in

position. Push and turn the manual override to verify correct

operation of the valve.

CML-750 Units

Tighten the four fixings fully.

Fi g . 17. 2

Go to page 23 for electrical installation and basic setup

instructions.

Redefining Flow Control

Fi g . 17. 3

17

Mounting the Actuator

CMQ - QUARTER-TURN UNIT - MOUNTING

CAUTION

It is essential that mounting procedure is carried out

when the valve is not under working process conditions,

as full valve movement may occur.

IMPORTANT

It is essential that the actuator is mounted correctly to

the valve, damper or other device.

The Installation & Setup will include the following procedures:

1. Prepare the Drive Coupling.

2. Ensure Valve position is noted and safe (Offline).

3. Mount and align actuator to valve.

4. Adjust Actuator Stop Bolts.

5. Carry out Basic Setup.

ACTUATOR STOP BOLTS

The Quarter-turn CMQ actuators have two end of travel stop

bolts adjustable between 80 to 100 degrees of travel rotation.

The Stop Bolts are set to a nominal 90 degrees of travel at

the factory. These must be adjusted to suit the required valve

travel BEFORE attempting to set the electrical travel limits.

The Clockwise end of travel stop bolt is on the right as viewed

in Fig. 18.2.

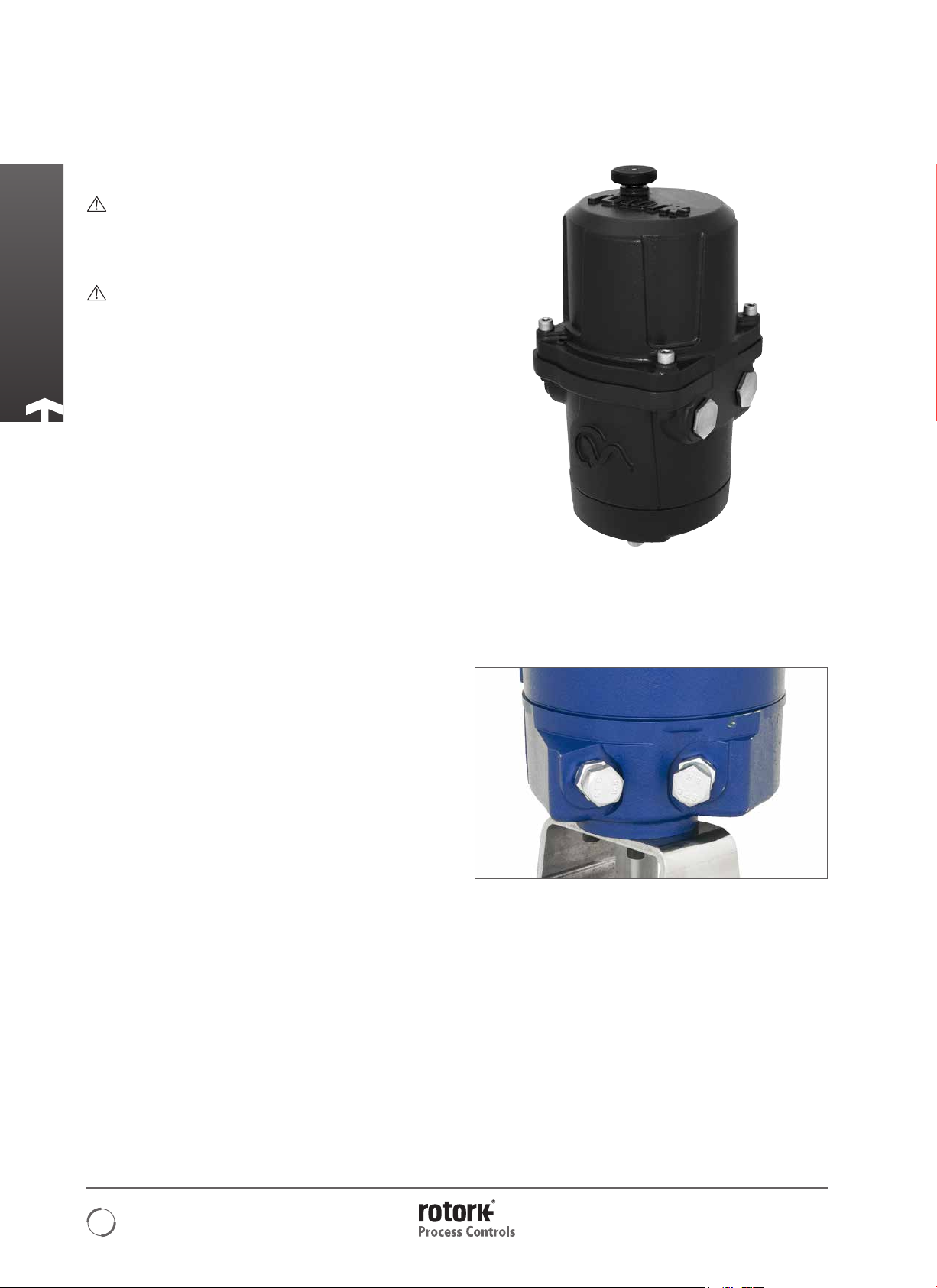

Fig. 18.1

Fig. 18 .2

18

Loading...

Loading...