Rosemount TankRadar Pro Technical Description

www.rosemount-tg.com

Technical Description

501026En, Ed. 3, Rev E

July 2007

Radar Level Gauge

Technical Description

501026En, Ed. 3, Rev E

July 2007

TankRadar Pro

3

Contents

System overview ________________________________________________ 5

Features _______________________________________________________ 6

Measurement principle ___________________________________________ 6

Applications ____________________________________________________ 7

Select the right Pro gauge ________________________________________ 8

Transmitter Head versions ________________________________________________8

Software modules _______________________________________________________8

Antenna versions ________________________________________________ 9

Cone antenna __________________________________________________________9

Parabolic antenna ______________________________________________________10

Still-pipe Array antenna __________________________________________________ 11

Process seal antenna ___________________________________________________12

Rod antenna __________________________________________________________13

Flanges _______________________________________________________ 13

Measuring range _______________________________________________ 14

System integration _____________________________________________ 15

4-20 mA HART® systems ________________________________________________15

TRL/2 eldbus systems __________________________________________________16

Foundation™ eldbus systems ____________________________________________16

Mechanical mounting ___________________________________________ 17

Free propagation _______________________________________________________17

Pipe installation ________________________________________________________18

Electrical connections ___________________________________________ 18

Specications _________________________________________________ 19

Product certicates _____________________________________________ 22

TankRadar Pro

Technical Description

501026En, Ed. 3, Rev E

July 2007

4

Copyright © July 2007

by Rosemount Tank Radar AB.

Technical data is subject to change without prior notice.

Rosemount Tank Radar AB accepts no responsibility for any errors that may appear in

this description.

Viton®, and Kalrez® are registered trademarks of Du Pont Performance Elastomers.

Hastelloy® is a registered trademark of Haynes International.

Monel® is a registered trademark of International Nickel Co.

HART® is a registered trademark of the HART Communication Foundation

FOUNDATION is a trademark of the Fieldbus Foundation.

DeltaV® is a trademark of Emerson Process Management group of companies.

All other marks are the property of their respective owners.

Ordering information ____________________________________________ 24

Transmitter Head ______________________________________________________24

Antennas _____________________________________________________________25

Cone antenna ______________________________________________________25

Cone antenna, extended _____________________________________________26

Cone antenna with integrated purging ___________________________________27

Parabolic antenna ___________________________________________________28

1- and 2-in. Still-pipe antennas _________________________________________29

Still-pipe Array antenna _______________________________________________30

Process Seal antenna ________________________________________________ 31

Rod antenna _______________________________________________________32

Model Code Example ________________________________________________32

Patents _______________________________________________________ 33

Technical documentation for TankRadar Pro ________________________ 33

Technical Description

501026En, Ed. 3, Rev E

July 2007

TankRadar Pro

5

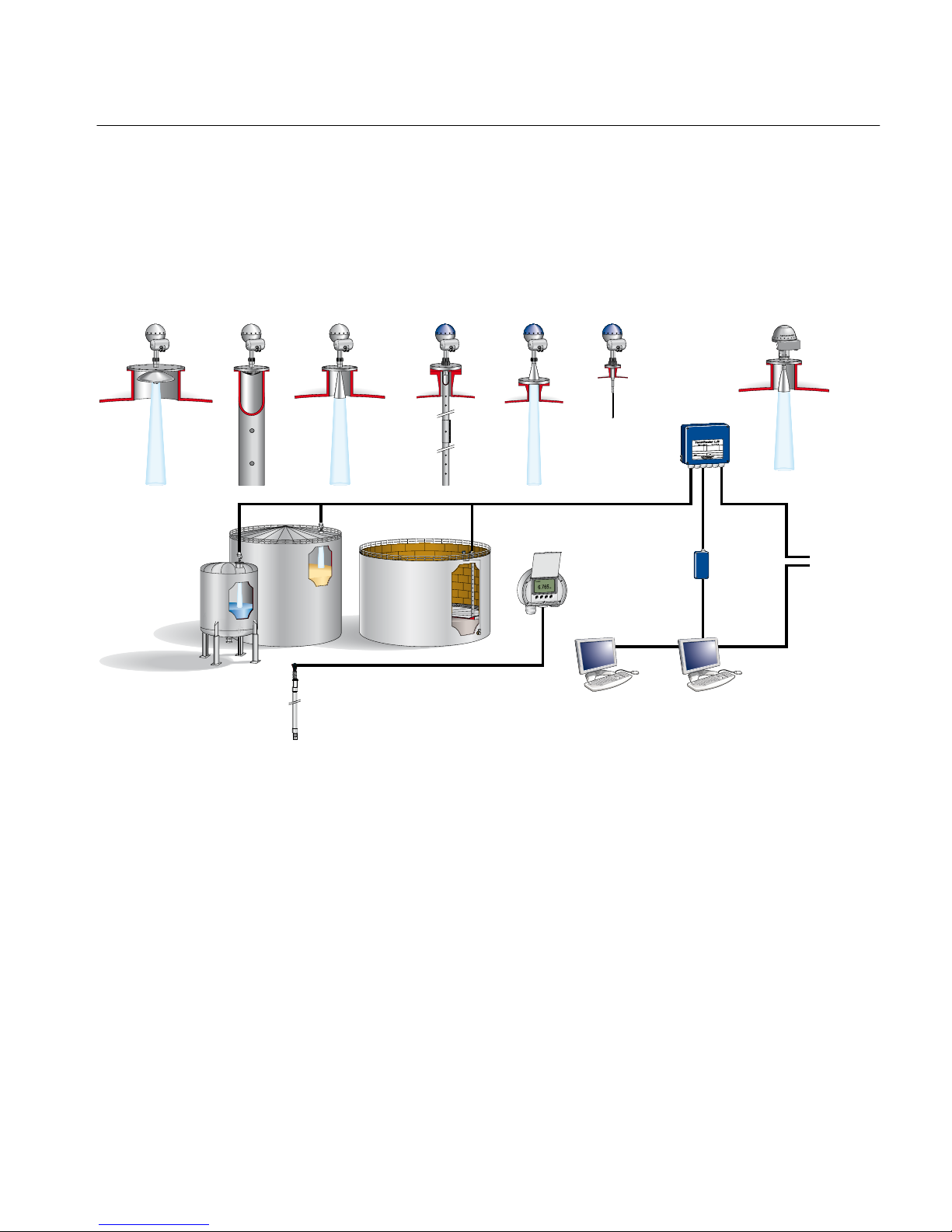

System overview

Temperature

Sensor

Pro Parabolic

Antenna Gauge

Pro Still-pipe

Array

Antenna Gauge

Pro Cone

Antenna

Gauge

RTG 3900

TankRadar Rex

Field

Communication

Unit

2210 Display

Unit

Field Bus

Modem

TankMaster PC

Workstations in

network

Alternative

Connections

to DCS

Pro Still-pipe

Antenna Gauge

Pro Process

Seal Antenna

Gauge

Pro Rod

Antenna

Gauge

TankRadar Pro

Technical Description

501026En, Ed. 3, Rev E

July 2007

TankRadar ® Pro with its exible conguration is suitable

for both stand-alone applications and large-scale plant

installations with various tank types.

The FMCW method is based on a radar

sweep with continuous changes in

frequency.

f

1

f

0

f

max

f

1

f

0

f

min

Frequency (GHz)

Transmitted

Reected

Time

∆

f

t

0t1

∆

t

∆

f ~ ∆t ~∆d

d

6

• Multi-purpose radar level gauge

• No moving parts and no contact with the liquid

• No maintenance

• Highest reliability

• Easy installation

• High accuracy

• Handles difcult tank conditions due to

ultra-high sensitivity and unique signal

processing features

• High exibility with interchangeable

Transmitter Heads and antennas

• A wide array of antennas and versions for

best performance in all applications

• Interactive setup with Windows ® based PC

software or via display unit

• Analog 4-20 mA superimposed with HART ®,

and digital Probus ® DP, Foundation™ eldbus

or TRL/2 eldbus outputs

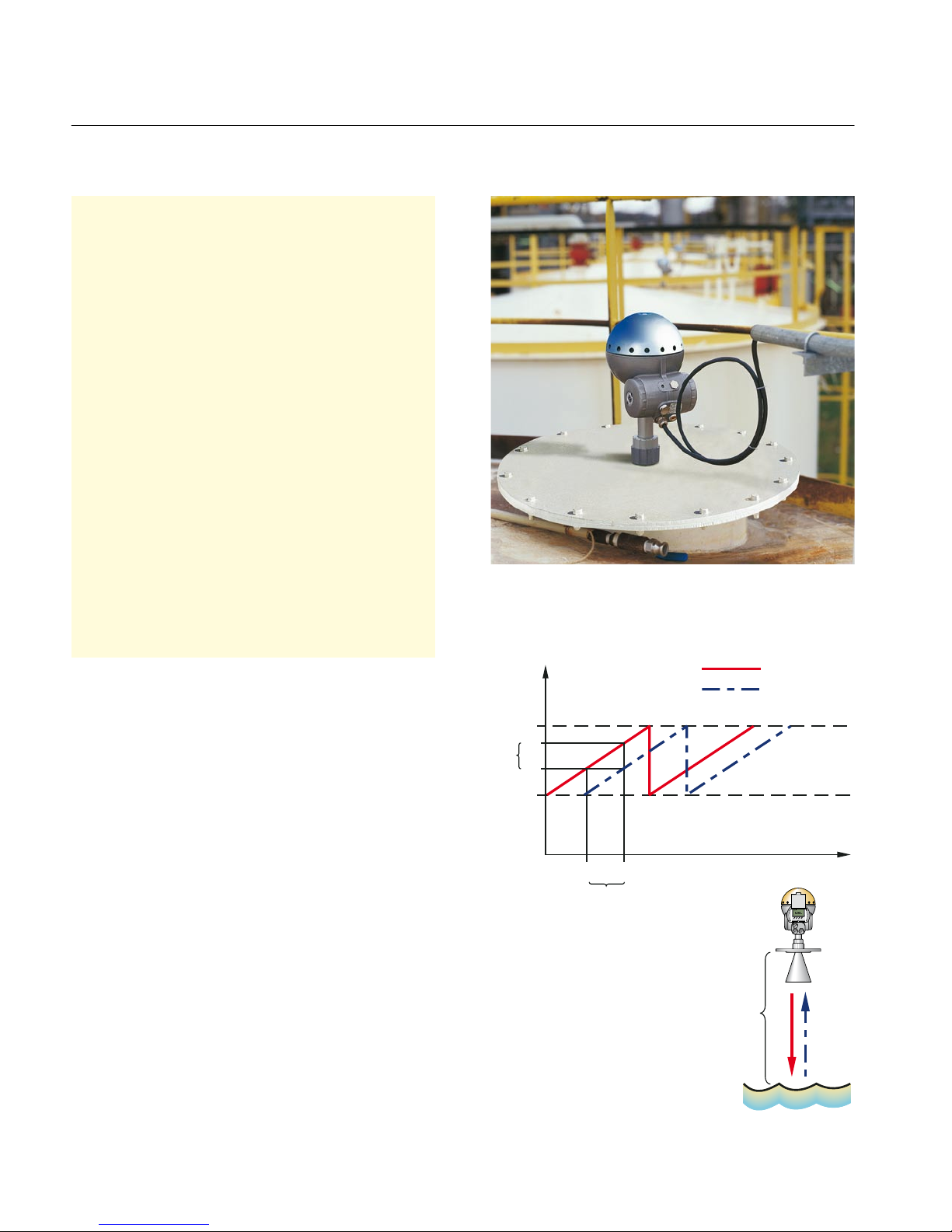

Measurement principle

The level of the liquid (or solid) is measured by radar

signals transmitted from the antenna at the tank top.

After the radar signal is reected by the liquid surface

the echo is picked up by the antenna. As the signal is

varying in frequency the echo has a slightly different

frequency compared to the signal transmitted at that

moment. The difference in frequency is proportional

to the distance to the liquid, and can be accurately

calculated. This method is called FMCW (Frequency

Modulated Continuous Wave) and is used in all high

performance radar gauges.

TankRadar Pro uses the 10 GHz frequency band

to get optimum balance between beamwidth and

sensitivity to antenna contamination.

Features

Technical Description

501026En, Ed. 3, Rev E

July 2007

TankRadar Pro

7

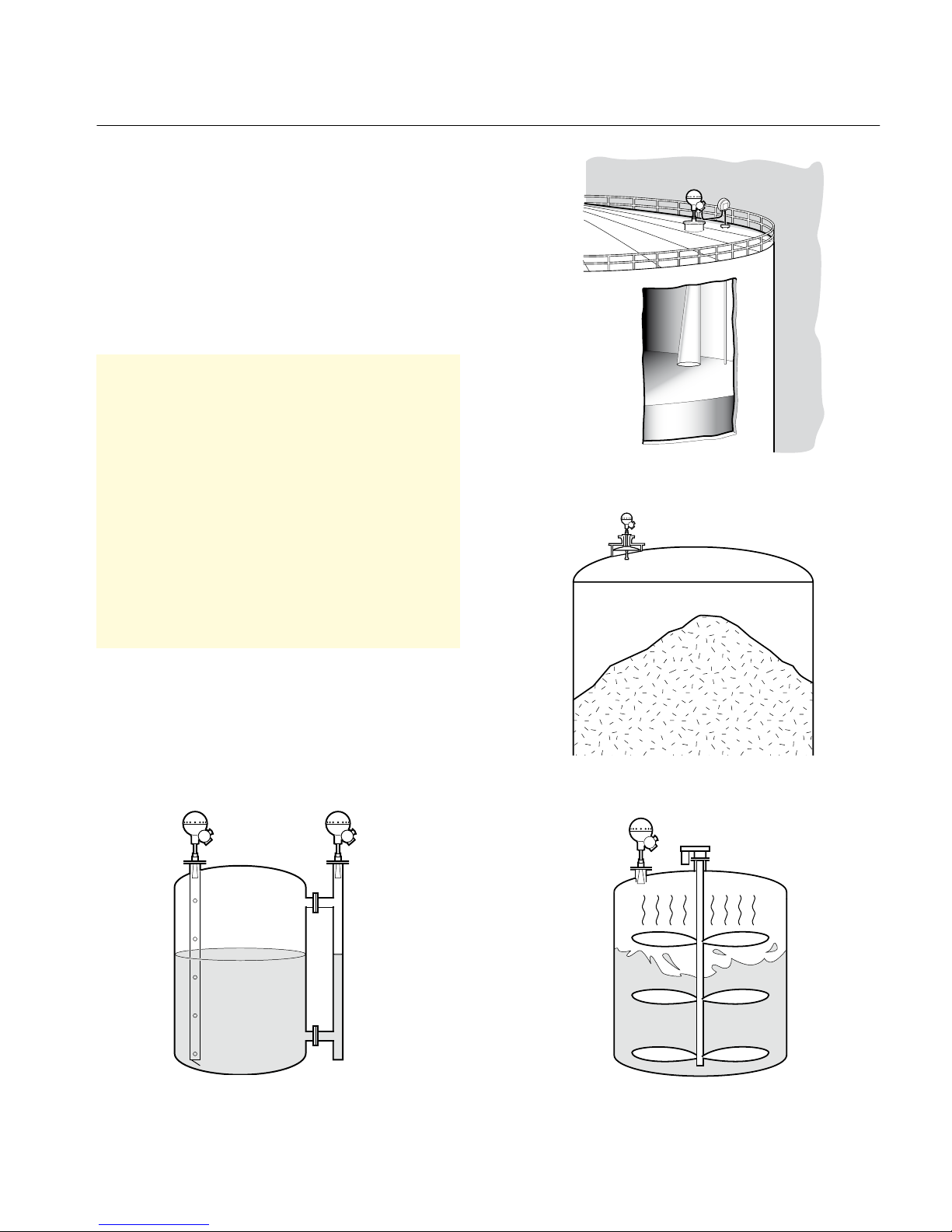

TankRadar Pro uses state-of-the art microwave

technology to get highest reliability and precision.

It measures the level of liquids, slurries as well as

many solids. The gauge operates in a wide range

of temperatures, pressures, vapor gas mixtures and

various process conditions.

The applications include:

• Storage tanks at reneries and tank terminals

• LPG storage

• Power plants

• Chemical & petrochemical industry

• Pharmaceutical

• Food and beverage

• Water and sewage treatment

• Hydroelectric power generation and dams

• Cement, powder, wood chips and other solid

material applications

Applications in tanks with agitators require a radar gauge

with TankRadar Pro’s high sensitivity and advanced signal

processing to separate the measuring signal from noise

created by disturbances.

Still-pipe or bridle mounting is recommended for LPG

applications, where the surface sometimes is boiling, and for

some extremely turbulent conditions. The pipe reduces foam

and turbulence and also increases surface reection.

TankRadar Pro parabola and cone versions provide free

propagation, high accuracy level measurement in storage

tanks.

Solid materials, like cement, often give extremely small radar

reections, requiring the most sensitive antenna, the 20”

parabolic.

Applications

TankRadar Pro

Technical Description

501026En, Ed. 3, Rev E

July 2007

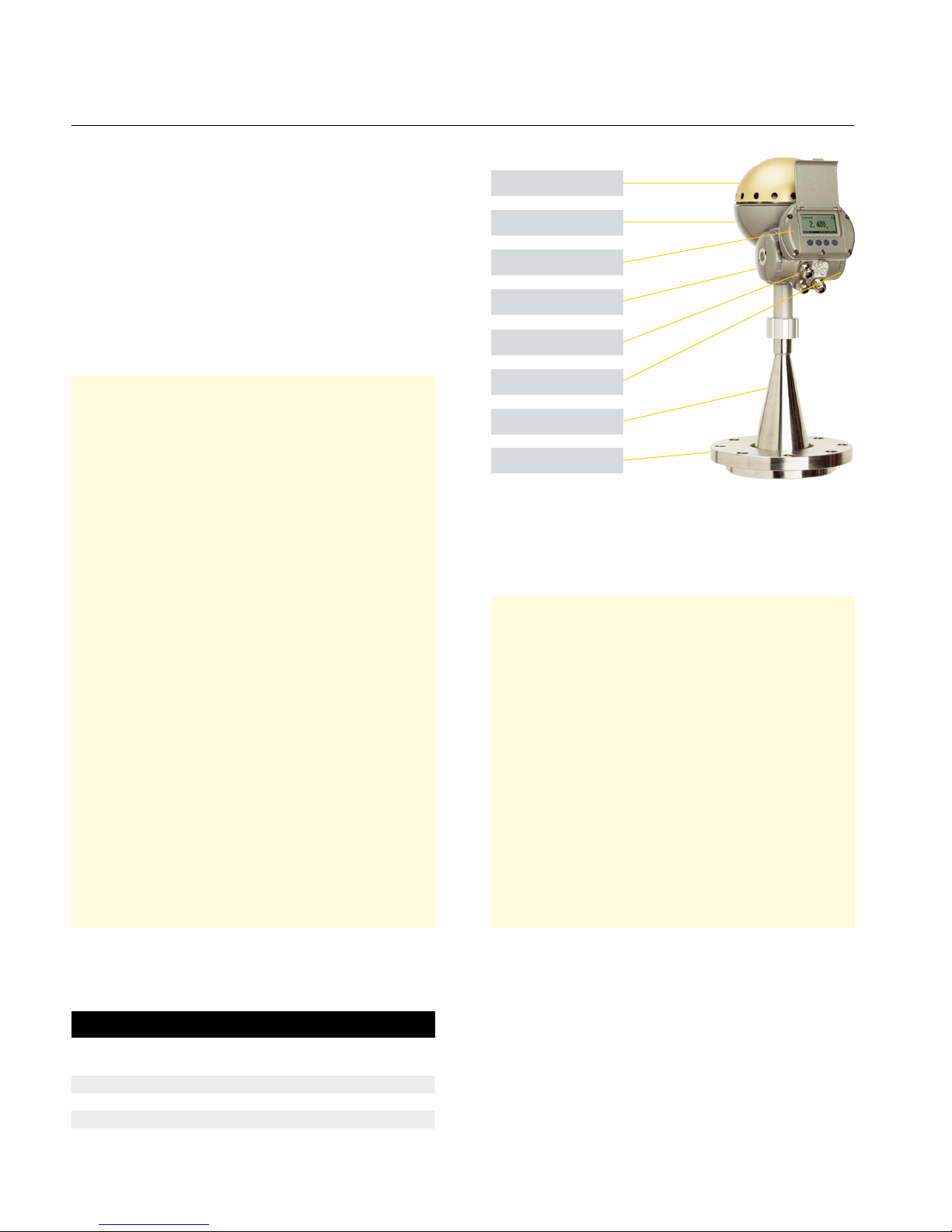

Antenna

Tank connection

Weather protection

Electronic housing

Display unit

Junction box Ex (e)

Cable glands

Junction box Ex (i)

8

A TankRadar Pro gauge consists of a Transmitter

Head and a tank connection including antenna.

The Transmitter Head, as well as the electronics

inside, is interchangeable without opening the tank.

Transmitter Head versions

The Transmitter Head is available in four basic

versions:

• Lite

Intended for applications in non-hazardous areas

only. Suitable for tanks without internal structures and

agitators, e.g. certain storage tanks, water, dam

applications etc. The Lite version has FFT calculations

enabled providing an instrument accuracy of

± 10 mm (± 0.4 in.). Echoxer, FHAST™ and MET™

are available as options.

• Standard

For hazardous applications in most tanks (also spherical or bullet tanks, and tanks with internal structures).

The Standard version includes the Echoxer software

which more accurately than standard FFT maps all

microwave interference sources. The Standard

instrument accuracy is ± 10 mm (± 0.4 in.) which can

be improved to ± 5 mm (± 0.2 in.) using the optional

FHAST™ software module.

• Gold

Gold is the most advanced version for difcult

applications in tanks with agitators, heating coils and

other disturbances. It includes the Echoxer software,

FHAST™ software for increased accuracy plus MET™

software for further increased disturbance echo

handling. Instrument accuracy is ± 5 mm (± 0.2 in.).

• Platinum

For high accuracy tank gauging applications, Platinum

is the best TankRadar Pro choice. It includes the

FHAST™ software and selected hardware for

maximum performance. Instrument accuracy is

± 3 mm (± 0.12 in.) for parabolic, still-pipe array and

8-in. cone antennas.

Volume calculation for symmetrical tanks is included

in all versions. Strapping table for non-symmetrical

tanks is available as an option.

Software modules

Various options make it possible to optimize the

gauge for different applications:

• Fast Fourier Transformation (FFT)

Fast Fourier Transformation is a signal processing

technique used to map the echo structure of the tank.

• Echoxer

A software module that makes it possible to measure on

the surface in spite of strong disturbance echoes from

mechanical structures such as agitators and bafes.

• Fast High Accuracy Signal Technology (FHAST™)

A module that improves the efciency of the signal

processing by limiting the region to be analyzed around

the surface. This results in an improved accuracy of

± 5 mm (± 0.2 in.).

• Multiple Echo Tracking (MET™)

Improves the resolution and accuracy in echo disturbed

regions and close to the tank bottom. Continuous

measurement on multiple disturbing echoes facilitates

identication of the actual surface echo.

All software options are possible to upgrade in the

eld without any changes in electronics. Upgrades

are made by entering a new start code in the gauge

and can be done on a temporary basis for trial

purposes.

Software modules in available Pro versions

Explosion

approval

FFT FHAST™

Increased

accuracy

Echoxer

Disturbance

echo handling

MET™

Improved

resolution

Lite - X Option Option Option

Standard X X Option X Option

Gold X X X X X

Platinum X X X Option -

Select the right Pro gauge

Technical Description

501026En, Ed. 3, Rev E

July 2007

TankRadar Pro

4002001000 300-40

60

55

50

40

30

20

10

-1

0

5

798

-15

145

73

0

75239221232 570-40

1

1

2

2

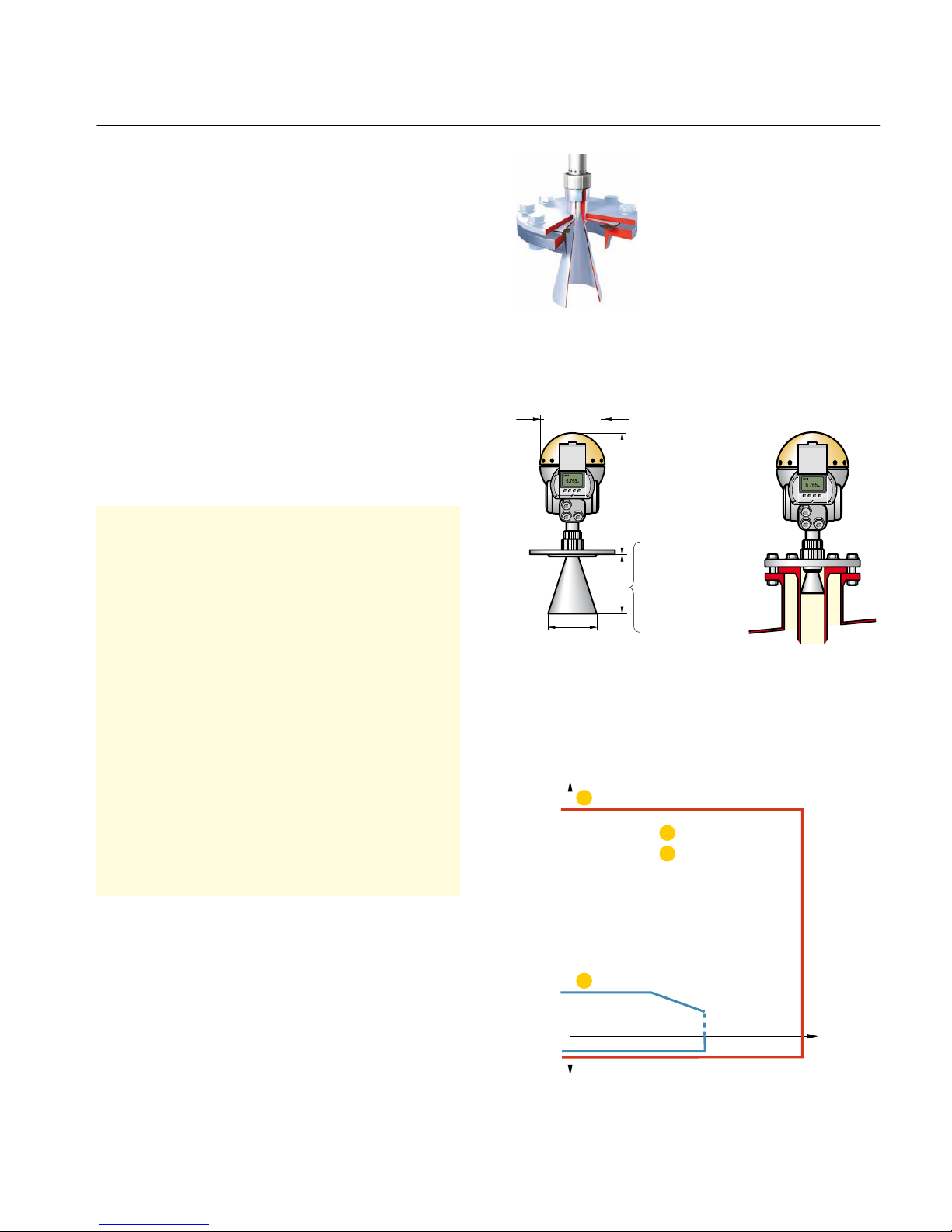

The relation between temperature and maximum pressure

for cone antennas.

The thin antenna plate prevents the

ange from exposure to the tank

environment.

2 in. : 70 (2.76)

3 in. : 95 (3.74)

4 in. : 150 (5.91)

6 in. : 260 (10.24)

8 in. : 370 (14.57)

2 in. : 56 (2.20)

3 in. : 70 (2.76)

4 in. : 93 (3.66)

6 in. : 141 (5.55)

8 in. : 189 (7.44)

200 (7.87)

mm (inch)

400

(15.75)

Temperature (°F)

Temperature (°C)

Pressure (bar)

Pressure (psig)

Quartz

PTFE

2-in. Still-pipe Antenna

TankRadar Pro can be equipped with different

antennas to fulll various requirements. The tank

connection, including antenna, is the only part

exposed to the tank atmosphere. The cone antenna

is most commonly used. When selecting antenna

dimension, it is generally recommended to use as

large antenna diameter as possible.

Cone antenna

The cone antenna is suitable for liquid applications.

It can be used for both free propagation and still-pipe

mounted installations. Thanks to the unique ange

clamp solution the existing tank ange can be used

as tank connection. The gauge can also be delivered

with ange included.

• Standard cone antennas for 3-, 4-, 6- and 8-in. tank

openings. The 3-, 4- and 6-in. cones can be extended

to t long tank nozzles. See pages 24-32, “Ordering

Information”, for standard ange options.

• A 1- and 2-in. version is available together with a

still-pipe solution.

• For larger pipes, use the still-pipe array antennas.

• Materials exposed to the tank atmosphere:

Sealing in PTFE or quartz. Antenna in Stainless

Steel, Hastelloy® C-22, Titanium gr. 2, Monel® 400 or

Tantalum.

O-ring in Viton® uoroelastomer or Kalrez®

peruoroelastomer.

• Special material such as Hastelloy® C-22,

Titanium gr. 2, Monel® 400 and Tantalum.

• Accuracy up to ± 5 mm (± 0.2 in.) using the FHAST™

software option.

• Accuracy with 8-in. cone up to ± 3 mm (± 0.12 in.)

using the Platinum version.

See page 18 for description of still-pipe installations.

For pressure and temperature restrictions depending

on ange and O-ring selection, see page 21.

Antenna versions

9

TankRadar Pro

Technical Description

501026En, Ed. 3, Rev E

July 2007

230

20050

100 150

0

-40

445

392122

212 302

32

-40

10

+0.2

0.5

0.5

-0.2

145

0

+2.9

-2.9

0

5 73

1

1

1

2

2

mm (inch)

440

(17.32)

162

(6.4)

445 (17.52)

200 (7.87)

Temperature (°F)

Temperature (°C)

Pressure (bar)

Pressure (psig)

Welded

Clamped

10

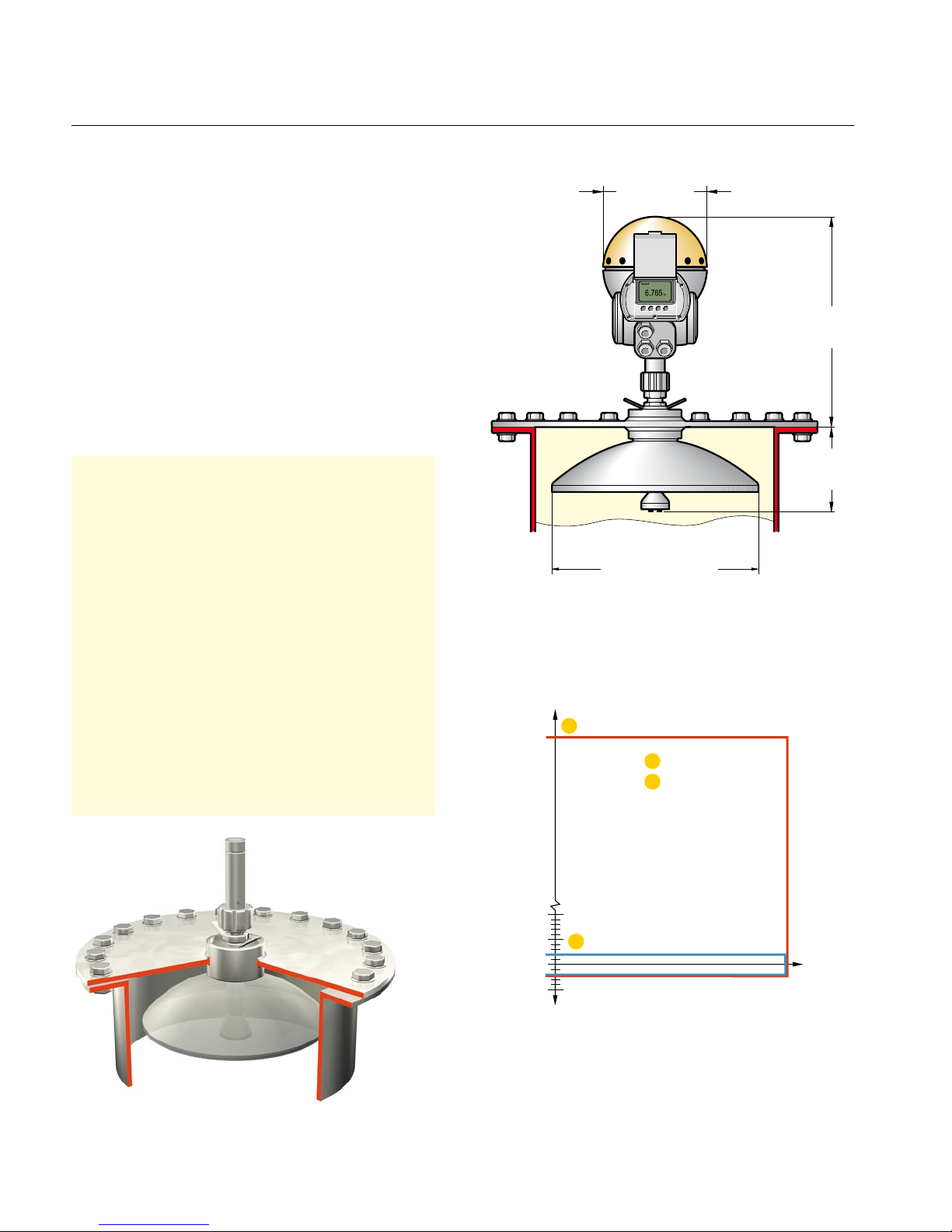

Parabolic antenna

The parabolic antenna is suitable for both liquid and

solid applications. As it has the largest diameter it

has the most narrow radar beam and can be used

for extremely long measuring distances.

The parabolic is also the antenna type most

insensitive to contamination. It can be used in

applications with severe antenna condensation like

asphalt and liquid sulphur.

Two versions are available:

the very easily installed version with clamped

mounting of anges with a 96 mm (3.78-in.) diameter

hole in ange (low pressures) and a welded version

(high pressures).

• Suitable in all tanks with 450 mm (18 in.)

or larger openings.

• Exposed parts in tank: Stainless steel

and FEP/PTFE uoropolymer.

• Best installed accuracy for inventory

applications.

• Highest antenna gain.

• Withstands heavy contamination.

• Flexible PTFE protective cover available for

dusty applications.

• Suitable for long range measurement up

to 100 m (330 ft).

• ± 3 mm (± 0.1 in.) accuracy for platinum

version.

The relation between temperature and maximum pressure for

parabolic antennas.

Parabolic antenna welded to tank opening.

Technical Description

501026En, Ed. 3, Rev E

July 2007

TankRadar Pro

0 20 40 60 80 100

104 140 176 212

120-40

32 68 248-40

0 0

3.6

7.2

14.5

29

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

1

1

2

3

2

3

Pressure (psig)

200 (7.87)

mm (inch)

400

(15.75)

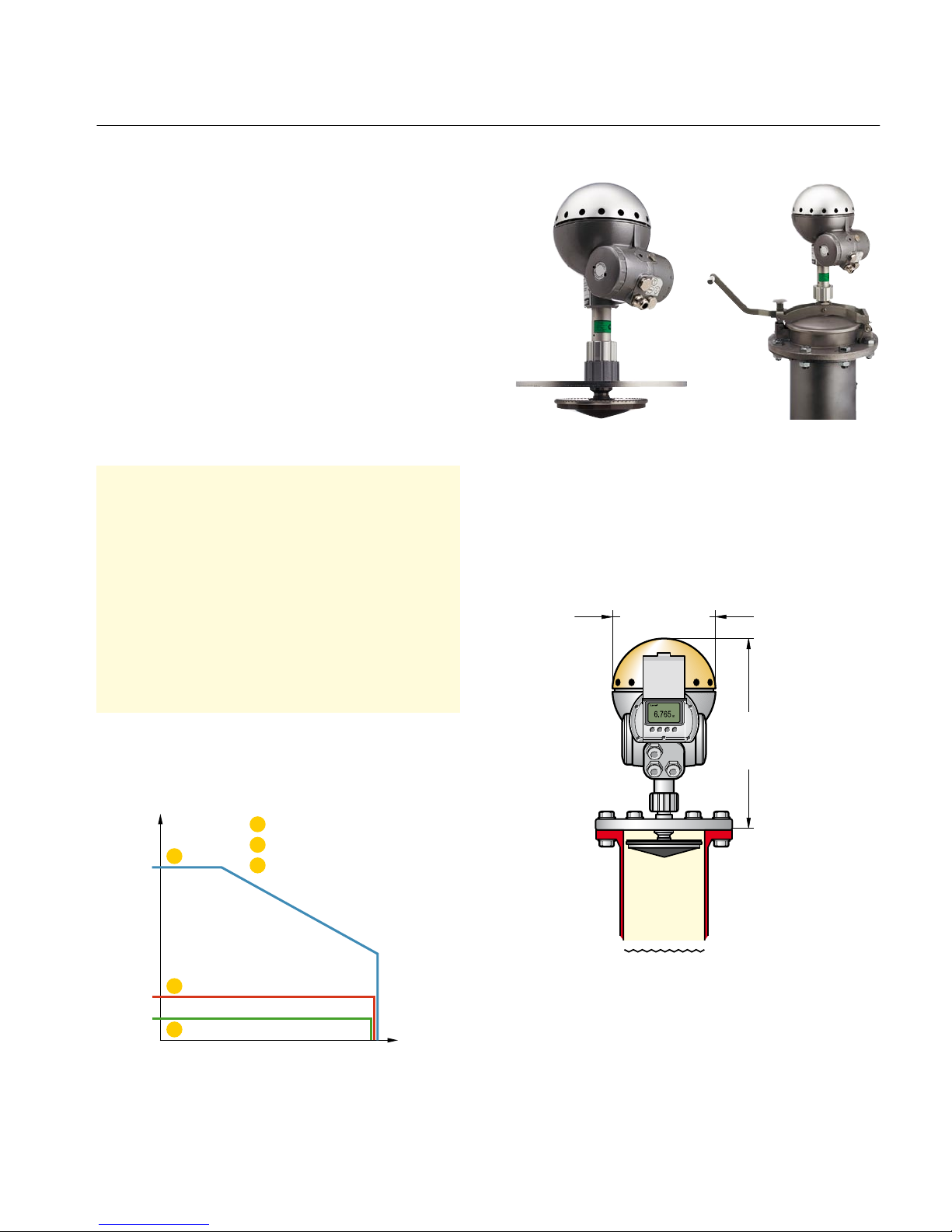

Pro Still-pipe Array Antenna,

xed version.

Pro Still-pipe Array Antenna,

hinged-lid version with

design that enables hand-

dipping.

Hinged Hatch 10 & 12 in.

Temperature (°C)

Pressure (bar)

Hinged Hatch 5,6 and 8 in.

Fixed

Temperature (°F)

11

Still-pipe Array antenna

The Still-pipe Array Antenna with its small-sized

antenna is designed for mounting on existing stillpipes. Typical applications are crude oil tanks with

oating roofs and gasoline/product tanks with or

without inner oating roofs.

The gauge uses a unique patented Low Loss Mode

to transmit the radar waves in the center of the pipe.

This virtually eliminates degradation of the accuracy

due to rust and product deposits inside the pipe.

The Still-pipe Array Antenna is available in two

models, the xed and the hinged-lid version.

The still-pipe must be vertical within 0.5° (0.2 m over

20 m) to obtain highest measurement accuracy.

• Suitable for mounting on existing still-pipes.

• Small-sized antenna for 5-, 6-, 8-, 10- or 12-in.

still-pipes.

• Exposed parts in tank:

Antenna in Polyphenylensuld (PPS).

Sealing in PTFE.

O-ring in Fluorosilicone.

Flange in Acid Proof Steel EN 1.4404

(AISI 316L).

• ± 3 mm (± 0.1 in.) accuracy.

The relation between temperature and maximum pressure for

array antennas.

Loading...

Loading...