Quick Start Guide

00825-0100-4928, Rev AE

December 2019

Rosemount™ 928 Wireless Gas Monitor

Integrated Wireless Gas Monitoring

Quick Start Guide December 2019

Safety information

Read this Quick Start Guide before working with this product.

The United States has two toll-free assistance numbers and one international number.

Customer Central: 1 800 999 9307 (7:00 a.m. to 7:00 p.m. Central Time)

National Reponse Center: 1 800 654 7768 (24 hours a day) for equipment service needs

International: 1 952 906 8888

NOTICE

This guide provides configuration and basic installation information for the Rosemount 928. It does

not provide diagnostic, maintenance, service, troubleshooting, Intrinsically Safe (I.S.) installation, or

ordering information. Refer to the Rosemount 928 Wireless Gas Monitor Reference Manual for more

information.

The manual and this guide are also available electronically on Emerson.com/Rosemount.

NOTICE

Read this document before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before installing,

using, or maintaining this product. For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

United States - 1-800-999-9307 (7:00 am to 7:00 pm Central Time)

Asia Pacific- 65 777 8211

Europe/Middle East/Africa - 49 (8153) 9390

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours—includes Canada)

Outside of these areas, contact your local Emerson representative.

WARNING

Explosions

Explosions could result in death or serious injury.

Ensure that only qualified personnel perform the installation.

Installation of device in an explosive environment must be in accordance with appropriate local,

national, and international standards, codes, and practices.

Before connecting a handheld communication device in an explosive atmosphere, ensure the

instruments are installed in accordance with Intrinsically Safe or non-incendive field wiring

practices.

Verify that the operating atmosphere of the transmitter is consistent with the appropriate

hazardous locations certifications.

When connecting an external device to the Rosemount 928's discrete output in a hazardous area,

ensure that the external device is installed in accordance with Intrinsically Safe or non-incendive

field wiring practices.

2 Emerson.com/Rosemount

December 2019 Quick Start Guide

WARNING

Electrical shock

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end

users’ equipment. This could be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your

system. Restrict physical access by unauthorized personnel to protect end users’ assets. This is true for

all systems used within the facility.

CAUTION

Nuclear applications

The products described in this document are not designed for nuclear qualified applications. Using

non-nuclear qualified products in applications that require nuclear-qualified hardware or products may

cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact an Emerson sales representative.

CAUTION

Installation problems

Only install the Rosemount 928 and all other wireless devices after the Wireless Gateway has been

installed and is functioning properly. Power up wireless devices in order of proximity from the Wireless

Gateway, beginning with the closest. This will result in a simpler and faster network installation.

Quick Start Guide 3

Quick Start Guide December 2019

CAUTION

Shipping considerations for wireless products

Battery hazards remain when cells are discharged.

The unit was shipped to you without the power module installed. Remove the power module prior

to shipping.

Each power module contains two "C" size primary lithium batteries. Primary lithium batteries are

regulated in transportation by the US Department of Transportation and are also covered by IATA

(International Air Transport Association), ICAO (International Civil Aviation Organization), and

ARD (European Ground Transportation of Dangerous Goods). It is the shipper's responsibility to

ensure compliance with these or any other local requirements. Consult current regulations and

requirements before shipping.

The power module with the wireless unit contains two "C" size primary lithium/thionyl chloride

batteries. Each battery contains approximately 2.5 grams of lithium, for a total of 5 grams in each

pack. Under normal conditions, the battery materials are self-contained and are not reactive as

long as the batteries and the pack integrity are maintained. Take care to prevent thermal,

electrical, or mechanical damage. Protect contacts to prevent premature discharge.

Power modules should be stored in a clean and dry area. For maximum battery life, storage

temperature should not exceed 86 °F (30 °C).

The power module has surface resisitivity greater than one gigaohm and must be properly

installed in the wireless device enclosure. Take care during transportation to and from the point of

installation to prevent electrostatic charge buildup.

Contents

Overview......................................................................................................................................5

Install the sensor.......................................................................................................................... 7

Install the power module............................................................................................................10

Bench configuration...................................................................................................................12

Guided setup..............................................................................................................................14

Calibrating the sensor................................................................................................................ 23

Manual setup............................................................................................................................. 35

Wireless considerations..............................................................................................................41

Electrical.................................................................................................................................... 45

Verify operating atmosphere..................................................................................................... 46

Install the transmitter.................................................................................................................47

Verify wireless network communication.....................................................................................51

Verify operation......................................................................................................................... 54

External alarm device electrical connections.............................................................................. 57

Product certifications................................................................................................................. 61

Declaration of Conformity..........................................................................................................66

4 Emerson.com/Rosemount

December 2019 Quick Start Guide

1 Overview

The Rosemount™ 928 Wireless Gas Monitor is used with the Rosemount 628

Series of sensor modules.

The sensor fits integrally into the transmitter without the use of tools. Make

electrical connections when the sensor module is fully seated in the

transmitter sensor housing.

Note

Use Rosemount 928 only with the Rosemount 928 Transmitter.

CAUTION

The Ingress Protection (IP) filter must be installed.

If the IP filter is not installed, damage may occur to the sensor inside the

Rosemount 628.

Do not operate the transmitter without the correct IP filter installed in

the sensor module.

When installing the IP filter, verify that the IP filter gasket is in place, is

properly aligned, and that it does not block the white filter media. Refer

to Figure 1-1.

When handling the IP filter, avoid contact with the filter media.

Verify that all three legs are fully latched by pushing upward on each leg

of the IP filter.

Avoid getting water inside the IP filter.

Do not attempt to clean the IP filter.

Do not rinse or spray the IP filter with water.

Do not immerse the IP filter in water.

Quick Start Guide 5

Quick Start Guide December 2019

Figure 1-1: IP Filter

A. IP filter housing

B. IP filter gasket

C. Filter media

6 Emerson.com/Rosemount

December 2019 Quick Start Guide

2 Install the sensor

The sensor is held in place using a tight-fitting seal and snap connections.

The sensor is connected to the transmitter by two latching tabs that fit into

the bottom portion of the housing as shown in the figure below. The seal

between the transmitter housing and the sensor assembly is designed so

that a snug, airtight fit is achieved between the two assemblies when

properly installed.

Procedure

1. Remove the sensor from its packaging.

2. If installing a sensor on the transmitter for the first time, remove the

protective plastic cap from the sensor housing at the bottom of the

transmitter.

3. The sensor contains a keying feature that ensures that it cannot be

forced into the transmitter housing in an incorrect alignment.

Confirm that the keying feature is aligned by rotating it into position

before installing the module into the transmitter.

4. Slide the sensor assembly up into the transmitter housing until it is

completely seated.

Quick Start Guide 7

Quick Start Guide December 2019

Figure 2-1: Inserting the Sensor into the Transmitter

A. Rosemount 928 Transmitter housing

B. Rosemount 628 Universal Gas Sensor

C. Latching tabs

5. To ensure a firm latch and seal, push the module upward until the

two latching tabs are fully engaged. Push up on the bottoms of the

latching tabs after they are seated.

6. Allow the trannsmitter to warm up before continuing.

Refer to the following table for maximum warm up times based on

gas type. During the warm up period, the displayed values, alerts,

and gas concentrations will not reflect actual measurements;

readings will not be transmitted.

Gas type

Hydrogen sulfide (H2S) One minute

Oxygen (O2) Seven minutes

Carbon monoxide (CO) One minute

8 Emerson.com/Rosemount

Maximum warm up period

December 2019 Quick Start Guide

Postrequisites

To remove the sensor, compress the latching tabs and pull downward until it

is released from the transmitter housing.

Quick Start Guide 9

Quick Start Guide December 2019

3 Install the power module

To perform configuration, the sensor must be installed in a functional

transmitter. The transmitter is powered by the Emerson 701 SmartPower

Module - Black.

Procedure

1. Remove the rear housing cover.

A. Rear housing cover

2. Connect the Emerson 701 SmartPower Module - Black.

™

3. Verify the connection by viewing the LCD display.

10 Emerson.com/Rosemount

December 2019 Quick Start Guide

4. Replace the rear housing cover and completely tighten.

5. Allow the transmitter to warm up before continuing.

Refer to Table 3-1 for maximum warm-up times based on gas type.

During the warm-up period, the displayed values, alerts, and gas

concentrations do not reflect actual measurements; readings are not

transmitted.

Table 3-1: Maximum Warm-up Periods

Gas type Maximum warm-up period

Hydrogen sulfide (H2S) One minute

Oxygen (O2) Seven minutes

Carbon monoxide (CO) One minute

Quick Start Guide 11

Quick Start Guide December 2019

4 Bench configuration

The transmitter receives any HART® communication from a handheld Field

Communicator or from an AMS Wireless Configurator.

Remove the rear housing cover to expose the terminal block and HART

communication terminals; then connect the power module to power the

device for configuration.

4.1 Bench configure using a Field Communicator

A transmitter Device Description (DD) is required for HART

communication.

To connect to the transmitter using a handheld communication device, refer

to Guided setup. To obtain the latest DD, go to EmersonProcess.com/

DeviceFiles and then visit the Emerson web page for your handheld device.

Procedure

1. On the Home screen, select Configure.

2. Do one of the following:

• On the Configure screen, select Guided Setup to verify or change

initial configuration settings. Refer to Guided setup. Refer to the

Field Communicator subsections for each configuration task.

• On the Configure screen, select Manual Setup to verify or change

all configuration settings, including optional advanced settings.

Refer to Manual setup. Refer to the Field Communicator

subsections for each configuration task.

®

3. When finished, select Send to implement configuration changes.

4. When configuration is completed, remove the HART

communications leads from the COMM terminals on the terminal

block and replace the rear housing cover.

4.2

12 Emerson.com/Rosemount

Bench configure AMS Wireless Configurator

AMS Wireless Configurator is capable of connecting to devices directly,

using a HART® modem, or though a Wireless Gateway.

Procedure

1. In the AMS Device Explorer pane, select the HART Modem 1.

2. In the device pane, double-click the device icon.

3. Select Configure.

4. In the Configure pane, do one of the following:

December 2019 Quick Start Guide

• Select Guided Setup to verify or change initial configuration

settings. Refer to Guided setup. Refer to the AMS Wireless

Configurator subsections for each configuration task.

• Select Manual Setup to verify or change all configuration settings,

including optional advanced settings. Refer to Manual setup.

Refer to the AMS Wireless Configurator subsections for each

configuration task.

5. When finished, select Send to implement configuration changes.

Quick Start Guide 13

Quick Start Guide December 2019

5 Guided setup

Guided setup contains basic configurations settings. The Guided Setup

menus are useful during initial configuration.

Note

Emerson developed the Field Communicator Guided Setup configuration

procedures using Emerson AMS Trex™ Device Communicator. The menus are

identical to those found in other Field Communicators, but are navigated

using touch screens rather than fast keys. Refer to the manual for your

handheld communicator device for more information.

WARNING

Explosions

Do not connect to the COMM terminals when an explosive atmosphere is

present.

Procedure

1. Remove the rear housing.

2. Connect the HART® communication leads to the HART terminals on

the handheld communicator.

3. Connect the HART communication leads to the COMM terminals on

the transmitter terminal block (A and B).

14 Emerson.com/Rosemount

December 2019 Quick Start Guide

A. +Comm terminal

B. -Comm terminal

4. Start your handheld communicator device. If necessary, open the

HART Field Communicator application on your handheld device to

establish HART communication.

Refer to the manual for your handheld communicator device for

more information.

5. On the Overview screen, select Configure.

6. On the Configure screen, select Guided Setup.

Postrequisites

Refer to Basic setup throughConfiguring process alerts.

5.1

Basic setup

5.1.1 Basic setup using Field Communicator

Procedure

1. On the Guided Setup screen, select Basic Setup.

2. On the Device Information screen, select any of the following and

configure as needed. Otherwise, continue with Step 3.

• Long tag: Enter an identifier for the device up to 32 characters

long using the virtual keypad. The Long tag field is blank by

default and does not display if left blank.

Quick Start Guide 15

Quick Start Guide December 2019

• Tag: Enter an identifier for the device up to eight uppercase

alphabetic and numeric characters long using the virtual keypad.

The Tag field is blank by default and does not display if left blank.

• Descriptor: Enter a description of the device up to 16 alphabetic,

numeric, and special characters long. The Descriptor field is blank

by default and does not display if left blank.

• Message: Enter a message up to 32 alphabetic, numeric, and

special characters long. The Message field is blank by default,

does not display if left blank, and may be used for any purpose.

3. On the Device Information screen, select Next.

4. On the Basic Setup screen, select OK to confirm successful

completion of basic setup.

5.1.2 Basic setup using AMS Wireless Configurator

Procedure

1. On the Guided Setup tab, in the Initial Setup field, select Basic Setup.

2. On the Device Information tab, configure any of the following as

needed. Otherwise, continue with Step 3.

• Long tag: Enter an identifier for the device up to 32 characters

long using the virtual keypad. The Long tag field is left blank by

default and does not display if left blank.

• Tag: Enter an identifier for the device up to eight uppercase

alphabetic and numeric characters long using the virtual keypad.

The Tag field is blank by default and does not display if left blank.

• Descriptor: Enter a descriptor of the device up to 16 alphabetic,

numeric, and special characters long. The Descriptor field is blank

by default and does not display if left blank.

• Message: Enter a message up to 32 alphabetic, numeric, and

special characters long. The Message field is left blank by default,

does not display if left blank, and may be used for any purpose.

3. On the Basic Setup screen, select Next.

4. Select Finish.

5.2

16 Emerson.com/Rosemount

Joining the transmitter to a wireless network

To communicate with the Wireless Gateway and the host system, you must

use the wireless network to configure the transmitter.

This procedure is the wireless equivalent of connecting wires from a

transmitter to the host system. Using Field Communicator or AMS Wireless

Configurator, enter the network ID and join key so that they match the

December 2019 Quick Start Guide

network ID and join key of the Wireless Gateway and other devices in the

network. If the network ID and join key are not identical, the transmitter will

not communicate with the network. You can obtain the network ID and join

key from the Wireless Gateway on the Setup → Network → Settings page

on the web server.

Note

The amount of time required to join the new device or devices to the

network is dependent on the number of devices being joined and the

number of devices in the current network. One new device joining an

existing network with multiple devices may take up to five minutes. Multiple

new devices joining an existing network may take up to 60 minutes.

5.2.1 Join a wireless network using Field Communicator

Procedure

1. On the Guided Setup screen, select Join to Network.

2. On the Join to Network screen, use the numeric keypad to enter the

WirelessHART® network ID.

The network ID must match the Wireless Gateway network ID. Refer

to the System Settings → Network → Network Settings page in the

Wireless Gateway web-based user interface for the network ID.

3. Select OK.

4. On the Join Key screen, use the hexadecimal keypad to enter the first

part of the join key.

The join key must match the Wireless Gateway join key. Refer to the

System Settings → Network → Network Settings page in the

Wireless Gateway web-based user interface for the join key.

5. Select OK.

6. Repeat Step 4 and Step 5 to configure the remaining keys to join the

Wireless Gateway.

5.2.2 Join a wireless network using AMS Wireless Configurator

Procedure

1. On the Guided Setup tab, in the Wireless field, select Join Device to

Network.

2. On the Join Device to Network tab, enter the network ID and join key.

3. Select Next.

4. Follow the steps in the wizard to complete the network

configuration.

Quick Start Guide 17

Quick Start Guide December 2019

5.3 Update rate considerations

Before configuring the wireless update rate for your wireless devices,

evaluate the safety concerns, conditions, and wireless network in your

facility to select the current update rate to meet your needs.

When specifying the update rate, consider the potential for toxic gas

release, the severity of potential gas concentration that may be released,

and whether the device is located in a populated area. The default update

rate is eight seconds and is appropriate for most applications. You may use a

more frequent update rate if desired. A less frequent update rate extends

transmitter power module life and optimizes Wireless Gateway device

capacity.

Consider the speed with which you want to be alerted to a dangerous

condition of toxic gas. Emerson does not recommend reporting by

exception for the Rosemount 928 Wireless Gas Monitors or Emerson

Wireless Gateways due to its potential adverse effect on Wireless Gateway

capacity and network integrity. Therefore, select an update rate for all

wireless gas monitors that corresponds to the safety needs of your facility

but does not exceed the capacity of the Wireless Gateway or your wireless

network.

Note

The configured wireless update rate does not affect the LCD display and the

optional alarm output (if installed) update rates.

5.3.1 Configure the update rate using Field Communicator

Procedure

1. On the Guided Setup screen, select Configure Update Rate.

2. On the Configure Update Rate screen, do one of the following:

• a. For an update rate from 1 to 60 seconds, select an update

rate from the list.

b. Select OK.

• a. For update rates greater than 60 seconds, select 61-3600

seconds from the list.

b. Enter the update rate in number of seconds. For example,

enter 1800 seconds for 30 minutes.

c. Select OK.

18 Emerson.com/Rosemount

December 2019 Quick Start Guide

3. On the Emerson Wireless Gateway Optimizations screen, select Yes -

Enable Optimizations to save and use wireless optimizations or

select No - Disable Optimizations to reject wireless optimizations.

Note

Wireless gateway optimizations combine process measurement and

device diagnostic messages from field devices to the wireless

gateway, saving network bandwidth. If you don't use optimizations,

you will need more message packets to receive the same amount of

information. Emerson recommends enabling wireless gateway

optimizations unless they are incompatible with the wireless

gateway.

4. Select OK.

5. On the Configure Update Rate screen, select OK to confirm successful

update rate configuration.

5.3.2 Configure the update rate using AMS Wireless Configurator

Procedure

1. On the Guided Setup tab, in the Wireless field, select Configure

Update Rate to configure the frequency at which the device reports

measurement and diagnostic information.

2. On the Configure Update Rate screen, do one of the following:

• a. Select an update rate from 1 to 60 seconds from the list.

b. Select Next.

• a. Select 61-3600 from the list.

b. Type the number of seconds for an update rate from 61

seconds to 60 minutes. For example, enter 1800 seconds

for 30 minutes.

c. Select Next.

3. On the Wireless Gateway Optimization screen, select Yes - Enable

Optimizations to save and use wireless optimizations or select No Disable Optimizations to reject wireless optimizations.

Note

Wireless gateway optimizations combine process measurement and

device diagnostic messages from field devices to the wireless

gateway, saving network bandwidth. If you don't use optimizations,

you will need more message packets to receive the same amount of

information. Emerson recommends enabling wireless gateway

Quick Start Guide 19

Quick Start Guide December 2019

optimizations unless they are incompatible with the wireless

gateway.

4. Select Next.

5. Select Next and then select Finish to save the update rate

configuration.

5.4 Configuring the device display mode

The device display mode defines whether or how frequently the LCD display

is turned on to display selected dynamic variables screens. Disabling the

display mode or selecting a less frequent display mode extends power

module life.

5.4.1 Configure the device display mode using Field Communicator

Procedure

1. On the Guided Setup screen, select Configure Device Display.

2. On the Device Display Options screen, select one of the following

display mode options.

• Disabled: The display is turned off. This is useful if the display will

never be viewed locally.

• On Demand: The display is on when the gas monitor is connected

to a handheld communication device or when it receives a signal

from its wireless gateway.

• Periodic: The display is on only during updates at the configured

update rate.

• High Availability: The display is always on regardless of the

configured update rate. This is the default display mode option.

3. Select OK to save the selected device display options.

Note

When a handheld communication device is connected to the transmitter,

the LCD display is in High Availability mode. Selecting and accepting the On

Demand or Periodic options does not take effect until approximately five

minutes after the handheld communicator device is disconnected. Selecting

and displaying Disabled takes effect immediately.

20 Emerson.com/Rosemount

December 2019 Quick Start Guide

5.4.2 Configure the device display mode using AMS Wireless Configurator

Procedure

1. On the Guided Setup tab, in the Optional Setup field, select Configure

Device Display.

2. Select one of the following display mode options:

• Disabled: The display is turned off. This is useful if the display will

never be viewed locally.

• On Demand: The display is on when the gas monitor is connected

to a handheld communication device or when it receives a signal

from its wireless gateway.

• Periodic: The display is on only during updates at the configured

update rate.

• High Availability: The display is always on regardless of the

configured update rate. This is the default display mode option.

3. Follow the steps in the wizard to configure the device display mode.

5.5 Configuring process alerts

Process alerts allow you to configure the device to send a HART® message

when the configured data point is exceeded. Alerts remain active if the set

points are exceeded and the alert mode is ON. Process alerts are displayed

on a handheld communication device, on the AMS Device Manager status

screen, on the Wireless Gateway web interface, on host systems with which

the Wireless Gateway communicates, and in the error section of the LCD

display (if so configured).

The gas concentration may be latched. If you select Latch Concentration

Alarms, the alarm output is latched until the alert is manually cleared. You

can manually reset a latched gas concentration alarm by removing and

reinstalling the power module. Refer to the Removing the power module

section in the Rosemount 928 Wireless Gas Monitor Reference Manual and

Install the power module. Latched alarms do not remain latched following a

device reset or power model failure.

You can reset a latched gas concentration alarm by using Field

Communicator or AMS Wireless Configurator. Refer to the Clearing latched

alarms section in the Reference Manual for information about clearing

latched alarms. If you select Not Latched, the gas concentration alarm clears

automatically when the gas concentration level dissipates below the

specified High Concentration Threshold.

Clearing alert history clears process alert history for other alerts, but does

not clear latched gas concentration alerts. Refer to the Clearing process alarm

Quick Start Guide 21

Quick Start Guide December 2019

history section in the Reference Manual. You may query alert history for

other process alerts to determine whether they have been active.

5.5.1 Configure process alerts using Field Communicator

Procedure

1. On the Guided Setup screen, select Configure Process Alerts.

2. On the Process Alerts screen, select a process alert to configure.

3. On the selected process alert screen, select Mode.

4. On the Mode screen, select Enabled.

5. Select OK.

6. On the Alert Limit screen, use the numeric keypad to enter an alert

limit for the selected process alert based on your needs and local

regulations.

7. Select OK.

8. On the selected process alert screen, select Next.

9. On the Configure Process Alerts screen, select OK to confirm

successful process alert configurations.

10. Repeat Step 2 through Step 9 as necessary to configure additional

process alerts.

5.5.2 Configure process alerts using AMS Wireless Configurator

Procedure

1. On the Guided Setup tab, in the Optional Setup field, select Configure

Process Alerts.

The Process Alerts window is displayed.

2. In the Mode list, in the HI-HI Alarm field, select Enabled to enable the

alarm.

3. In the Alert Limit field, enter an alert limit for the selected process

alert based on your needs and local regulations.

4. Repeat Step 2 and Step 3 if necessary to configure the Hi Alarm

process alert.

5. Select Next.

6. Select Next to confirm successful process alert configuration.

7. Select Finish.

22 Emerson.com/Rosemount

December 2019 Quick Start Guide

6 Calibrating the sensor

Calibrating the sensor ensures that the analog, digital, and discrete outputs

accurately transmit the target gas concentrations registered by the module.

Although Emerson calibrated the device at the factory, you must calibrate it

at the following times to ensure accuracy and correct operation:

• During installation.

• At least every 180 days throughout the device's service life.

• When replacing the sensor.

The Rosemount 628 Universal Gas Sensor is a smart sensor. As such, it

retains its own calibration information. It must be connected to a

transmitter to calibrate, but the calibration settings are stored in the sensor

itself rather than in the transmitter. You may uninstall the sensor from a

transmitter and reinstall it in another transmitter without affecting its

calibration.

CAUTION

If you are calibrating in a windy environment (over five mph), use a

calibration cup to ensure calibration accuracy.

Note

You do not need a conventional calibration cup to calibrate the sensor.

Connect calibration tubing (PVC tubing, 3/16-in. ID, 5/16-in. OD) directly to

the fitting on the IP filter assembly (part number 00628-9000-0001).

6.1

Calibrate using Field Communicator

Note

Emerson developed the Field Communicator guided setup configuration

procedures in this manual using Emerson AMS Trex Device Communicator.

The menus are identical to those found in other Field Communicators, but

you navigate using touch screens rather than fast keys. Refer to the manual

for your handheld communication device for more information.

WARNING

Explosions

Do not connect to the COMM terminals when an explosive atmosphere is

present.

Quick Start Guide 23

A

B

Quick Start Guide December 2019

Procedure

1. Connect the HART® communication leads from the Field

Communicator HART terminals to the COMM terminals on the

terminal block of the transmitter.

A. +COMM terminal

B. -COMM terminal

2. Establish communication between the transmitter and the Field

Communicator.

3. On the Home screen, select Configure.

4. On the Configure screen, select Guided Setup.

5. On the Guided Setup screen, select Calibrate Sensor.

6. Select OK to accept the current date as the calibration date and

continue.

7. Acknowledge the warning. If necessary, remove the loop from

automatic control.

Note

Calibration of an O2 sensor is unlikely to use a true zero value for its

lower limit; one must calibrate the sensor to a known lower percent

oxygen value (such as 15 percent oxygen level by volume) in order to

"zero" the sensor as outlined in the remainder of the calibration steps

below.

8. When calibrating for H2S and CO, expose the sensor to clean air to

zero the reading. When calibrating for O2, expose the sensor to a

24 Emerson.com/Rosemount

December 2019 Quick Start Guide

known percent of oxygen content calibration gas (recommended 15

percent oxygen by volume) to be used as the "zero" calibration value.

If the ambient air may contain trace amounts of target gas or other

gases (for example, carbon monoxide from engine exhaust) that may

interfere with zeroing the device, do the following:

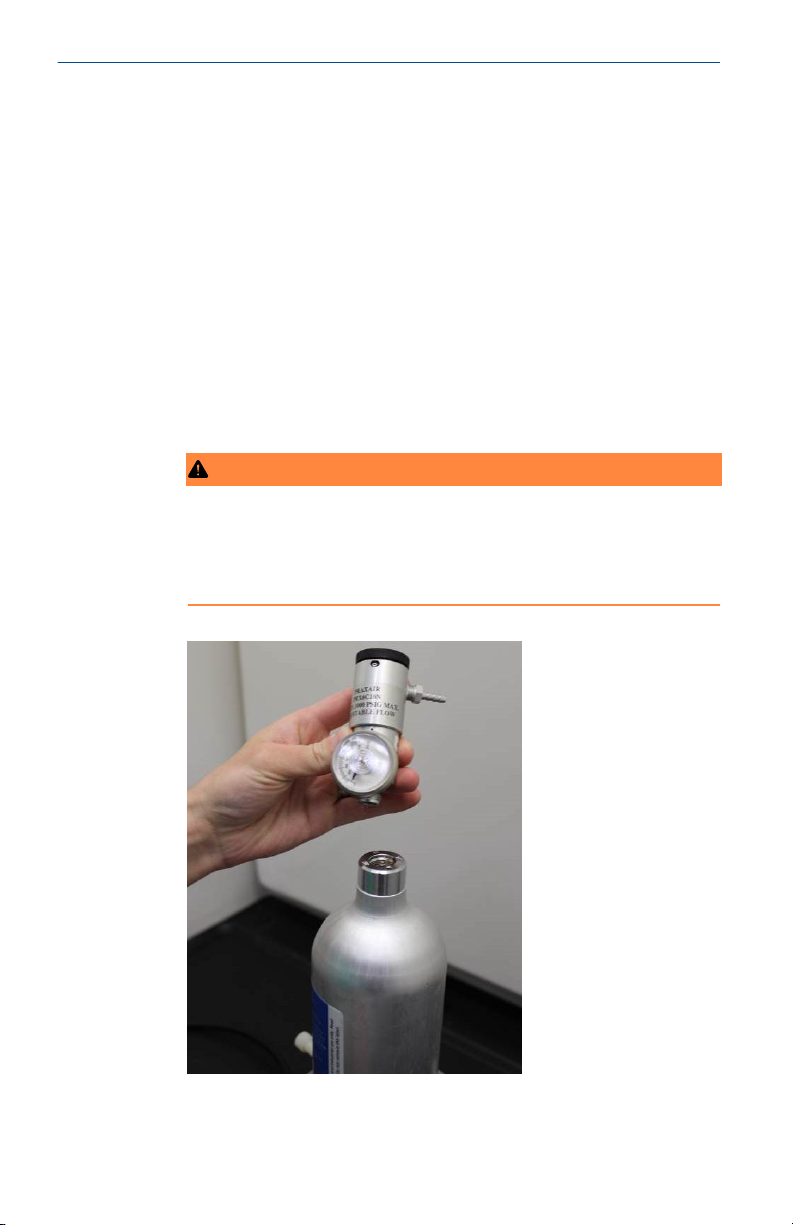

a) Obtain a cylinder of verified clean air (H2S and CO) or a

cylinder of verified percent oxygen content calibration gas

(O2) and a length of calibration tubing (PVC tubing, 3/16-in.

ID, 5/16-in. OD).

b) Install a regulator on the clean air/percent known oxygen

content gas cylinder.

c) Attach a length of calibration tubing (PVC tubing, 3/16-in. ID,

5/16-in. OD) from the regulator on the cylinder to the fitting

on the IP filter assembly (part number 00628-9000-0001).

d) Release the clean air/known percent oxygen specified

calibration gas to the sensor.

Quick Start Guide 25

Quick Start Guide December 2019

Note

If you need a long length of calibration tubing to reach the

device, make allowances for a delay in response time from

the sensor while the clean air travels the length of the

calibration tubing.

e) Complete Step 13 through Step 14

f) Turn off the clean air (or percent oxygen specified calibration

gas) when the sensor is correctly zeroed.

9. Select OK when the zero measurement reading stabilizes.

Note

Negative measurement readings may occur and are normal during

zeroing.

10. Wait while the Field Communicator performs zero adjustment.

11. Select OK to accept the new zero measurement.

12. Select OK to accept the new zero.

13. On the Calibrate Sensor screen, enter a gas concentration level that

corresponds to the concentration of calibration gas that will be

applied during calibration.

For oxygen, use 20.9 percent oxygen from clean air. This step may be

performed with surrounding air if no contaminants are present.

14. Select OK.

26 Emerson.com/Rosemount

December 2019 Quick Start Guide

15. Install a regulator on the target gas source.

WARNING

Toxic gas

Before performing the next step, verify that the regulator is closed to

avoid releasing target gas into the air during calibration.

16. Attach a length of calibration tubing (PVC tubing, 3/16-in. ID, 5/16in. OD) from the regulator on the target gas source to the fitting on

the IP filter assembly (part number 00628-9000-0001).

Quick Start Guide 27

Quick Start Guide December 2019

17. Release the target gas from the target gas source.

Emerson recommends a flow rate of 1.0 liters per minute to ensure a

consistent sensor reading.

Note

If you need a long length of tubing to reach the device, make

allowances for a delay in response time from the sensor while the

target gas travels the length of the calibration tubing.

A gas concentration should begin to register on the LCD display and

gradually increase to the calibration gas concentration level. The gas

concentration level shown on the device display may not exactly

match that shown on the label of the target gas source.

28 Emerson.com/Rosemount

December 2019 Quick Start Guide

18. Wait while the gas concentration measurement stabilizes.

Refer to Figure 6-1.

Figure 6-1: Typical Calibration Profile

A. Gas concentration ppm

B. Time (in seconds)

C. Gas concentration measurement has stabilized

19. Select OK when the gas concentration measurement stabilizes at or

near the target gas concentration level.

20. Wait while the Field Communicator calibrates.

When the calibration process finishes, the Field Communicator

displays the new adjusted reading.

21. Select OK.

Note

If you can't calibrate the sensor, verify that the correct sensor is

installed, the correct target gas is being applied, and the IP filter is

not clogged or obstructed. A sensor that cannot accept a new

calibration may have reached the end of its service life. Replace the

sensor and repeat this procedure. Refer to the Replace the gas sensor

section in the Rosemount 928 Wireless Gas Monitor Reference

Manual.

22. Select Accept calibration and then select OK.

The Field Communicator displays the Service Reminder screen if a

service reminder is configured and enabled.

23. Select OK to accept the service reminder date or enter another date.

Quick Start Guide 29

Quick Start Guide December 2019

Refer to the Service Reminders section of the Rosemount 928 Wireless

Gas Monitor Reference Manual for more information.

24. Shut off the target gas flow at the regulator.

25. Detach the calibration tubing from the regulator on the target gas

source and from the IP filter inlet on the bottom of the sensor.

6.2 Calibrate using AMS Wireless Configurator

Procedure

1. On the Guided Setup tab, in the Initial Setup field, select Calibrate

Sensor.

2. On the Calibrate Sensor screen, select Next to accept the current date

as the calibration date and continue.

3. On the Warning screen, select Next.

4. When calibrating for H2S, and CO, expose the sensor to clean air to

zero the reading. When calibrating for O2, expose the sensor to a

known percent oxygen content calibration gas (recommended 15

percent oxygen by volume) to be used as the "zero" calibration value.

If the ambient air may contain trace amounts of target gas or other

gases (for example, carbon monoxide from engine exhaust) that may

interfere with zeroing the device, do the following:

a) Obtain a cylinder of verified clean air (H2S and CO) or a

cylinder of verified percent oxygen content calibration gas

(O2) and a length of calibration tubing (PVC tubing, 3/16-in.

ID, 5/16-in. OD).

30 Emerson.com/Rosemount

December 2019 Quick Start Guide

b) Install a regulator on the clean air/known percent oxygen

content gas cylinder.

c) Attach a length of calibration tubing (PVC tubing, 3/16-in.

OD, 5/16-in. OD) from the regulator on the cylinder to the IP

filter on the bottom of the sensor.

d) Release the clean air/known percent oxygen specified

calibration gas to the sensor.

Note

If you need a long length of calibration tubing to reach the

device, make allowances for a delay in response time from

the sensor while the clean air travels the length of the

calibration tubing.

Quick Start Guide 31

Quick Start Guide December 2019

e) Perform Step 5 through Step 7.

f) Turn off the clean air/known percent oxygen specified

calibration gas when the sensor is correctly zeroed.

5. Select Next when the zero measurement reading stabilizes.

6. Select Next.

7. Select Accept New Zero.

8. Select Next.

9. On the Calibrate Sensor screen, enter a gas concentration level that

corresponds to the concentration of the calibration gas that will be

applied during calibration.

The value must be between 5 ppm and 100 ppm.

10. Select Next.

WARNING

Toxic gas

The regulator may release gas into the air during calibration.

Before starting the next step, verify that the regulator is closed.

11. Install a regulator on the target gas source.

32 Emerson.com/Rosemount

December 2019 Quick Start Guide

12. Attach a length of calibration tubing (PVC tubing, 3/16-in. ID, 5/16in. OD) from the regulator on the target gas source to the IP filter

inlet on the bottom of the sensor.

13. Release the target gas from the target gas source.

Emerson recommends a flow rate of 1.0 liters per minute to ensure a

consistent sensor reading.

Note

If you need a long length of calibration tubing to reach the device,

make allowances for a delay in response time from the sensor while

the target gas travels the length of the calibration tubing.

A gas concentration should begin to register on the device display

and gradually increase to the calibration gas concentration level. The

gas concentration level shown on the device display may not exactly

match that shown on the label attached to the target gas source.

Quick Start Guide 33

Quick Start Guide December 2019

14. Wait while the gas concentration measurement stabilizes.

Refer to Figure 6-2.

Figure 6-2: Typical Calibration Profile

A. Gas concentration ppm

B. Time (in seconds)

C. Gas concentration measurement has stabilized

15. Select Next when the gas concentration measurement stabilizes at

or near the target gas concentration level.

16. Wait while the AMS Wireless Configurator calibrates.

When the calibration process finishes, the new adjusted reading is

displayed.

17. Select Next.

18. Select Accept calibration.

19. Select Next.

The Service Reminder screen is displayed if a service reminder is

configured and enabled.

20. Select Next to accept the service reminder date or enter another

date.

Refer to the Service reminders section of the Rosemount 928 Wireless

Gas Monitor Reference Manual for more information.

21. Shut off the target gas flow at the regulator.

22. Detach the calibration tubing from the regulator on the target gas

source and from the IP filter inlet on the bottom of the sensor.

34 Emerson.com/Rosemount

December 2019 Quick Start Guide

7 Manual setup

Manual setup includes all available configuration settings. You may use it to

change specific settings configured during initial setup without using the

Guided Setup menus. You may also use it to configure advanced optional

settings.

Note

Emerson developed the Field Communicator manual setup configuration

procedures in this manual using Emerson AMS Trex Device Communicator.

The menus are identical to those found in other Field Communicators, but

are navigated using touch screens rather than fast keys. Refer to the manual

for your handheld communicator device for more information.

Procedure

1. Connect the HART® communications leads to the HART terminals on

the handheld communicator.

A. +COMM terminal

B. -COMM terminal

WARNING

Explosions

Do not connect to the COMM terminals when an explosive

atmosphere is present.

Quick Start Guide 35

Quick Start Guide December 2019

2. Connect the HART communication leads to the COMM terminals on

the terminal block.

3. Start your handheld communicator device. If necessary, open the

HART Field Communicator on your handheld device to establish

HART communication.

Refer to the manual for your handheld communicator device for

more information.

4. On the Overview screen, select Configure.

5. On the Configure screen, select Manual Setup.

Postrequisites

Complete Configuring display options, Configuring security settings, and

Configuring device information as needed.

7.1 Configuring display options

The primary variable (gas concentration) is displayed by default on the LCD

display.

To configure the display of additional dynamic variable items, do the

following:

7.1.1 Configure display options using Field Communicator

Procedure

1. On the Manual Setup screen, select Display.

2. On the Display screen, select Display Options.

3. Select a display option or options to alternate displaying with the

primary variable (gas concentration):

• Concentration

• Percent of Range

• Sensor Temp (gas sensor module temperature)

• Electronics Temp (electronics temperature)

• Supply Voltage

4. Select On.

5. Select OK.

6. Repeat Step 3 through Step 5 for additional display options.

7. On the Display Options screen, select Send.

36 Emerson.com/Rosemount

December 2019 Quick Start Guide

8. On the Send screen, do one or more of the following:

• Select Display Options if you want to review the selected

display options.

• Select Cancel to return to the Display Options screen. Pending

changes to display options are preserved.

• Select Discard to return to the Display Options screen and discard

pending changes. Select OK to confirm or Cancel to return to the

previous screen.

• Select Send to send display option changes to the device.

9. Select Back to return to the Manual Setup screen.

7.1.2 Configure display options using AMS Wireless Configurator

Procedure

1. On the Manual Setup page, select the Display tab.

2. On the Display tab, select a display option or options to alternate

displaying with the primary variable (gas concentrations).

• Concentration

• Percent of Range

• Sensor Temperature (gas sensor module temperature)

• Electronics Temperature

• Supply Voltage

3. Select Send.

4. In the Confirm Device Configuration Change dialog box, select a reason

for the change from the Service Reason list. Select Details if you want

to view additional information.

5. Select Yes.

7.2

Configuring security settings

You have the option to configure security settings to protect the device

from unauthorized configuration changes.

7.2.1 Configure security settings using a Field Communicator

Procedure

1. On the Manual Setup screen, select Security.

2. Configure the following security settings as required.

Quick Start Guide 37

Quick Start Guide December 2019

• Write Protect: If you select No (the default option), you may view

and edit device configuration settings. If you select Yes, you may

view device configuration settings but not edit them.

• Lock Device: If you select Unlock, you may access the device with

any host to view and edit configuration settings. If you select

Lock (the default option), you cannot access the device with any

host to view and edit configuration settings until a host unlocks

the device. To change this option, do the following:

a. On the Security screen, select Lock/Unlock.

b. On the Select HART Lock option screen, select Lock or

Unlock to change the setting.

c. Select OK.

On the Security screen, the Device is Locked field displays On

when the device is locked and Off when the device is unlocked.

• Over the Air Upgrade: If you select Unlock (the default option),

you can upgrade the transmitter radio with programming sent

over the air. If you select Lock, the transmitter prevents over-theair radio upgrades.

7.2.2 Configure security settings using AMS Wireless Configurator

Procedure

1. On the Manual Setup page, select the Security tab.

2. Configure the following security settings as needed:

• Write Protection: If you select No (the default option) you can

view and edit device configuration settings. If you select Yes, you

will not be able to view and edit the configuration settings.

• Radio Upgrade: If you select Unlock (the default option), you can

upgrade the transmitter radio with programming sent over the

air. If you select Lock, you will not be able to upgrade the radio

over the air.

• Lock Device: If you select Unlock (the default option), you can

access the device with any host to view and edit configuration

settings. If you select Lock, you will not be able to access the

device with any host to view and edit configuration settings until

a host unlocks the device. To change this option, do the

following:

a. Select Lock/Unlock.

b. In the HART Lock list, select Lock or Unlock to change the

setting.

38 Emerson.com/Rosemount

December 2019 Quick Start Guide

c. Select Finish.

In the HART Lock field, the Device is Locked check box is selected

when the device is locked.

3. When you are finished making changes, select Send to update the

device configuration.

7.3 Configuring device information

7.3.1 Configure device information using Field Communicator

Procedure

1. On the Manual Setup screen, select Device Information.

2. On the Device Information screen, select any of the following and

configure as needed.

• Long tag: Enter an identifier for the device up to 32 characters

long using the virtual keypad. The Long tag field is blank by

default and does not display if left blank.

• Tag: Enter an identifier for the device up to eight uppercase

alphabetic and numeric characters long using the virtual keypad.

The Tag field is left blank by default and does not display if left

blank.

• Descriptor: Enter a description of the device up to 16 alphabetic,

numeric, and special characters long. The Descriptor field is blank

by default and does not display if left blank.

• Message: Enter a message up to 32 alphabetic, numeric, and

special characters long. The Message field is blank by default,

does not display if left blank, and may be used for any purpose.

• Date: Enter a date in mm/dd/yyy format using the virtual keypad.

The date may be used for any purpose, such as recording the date

of the most recent calibration.

3. When you have finished making changes, select Send.

4. On the Send screen, do one of the following:

• Select Cancel to return to the Device Information screen. Pending

changes are preserved.

• Select Discard to return to the Device Information screen and

discard pending changes. Select OK to confirm or Cancel to

return to the previous screen.

• Select Send to send display option changes to the device.

5. Select Back to return to the Manual Setup screen.

Quick Start Guide 39

Quick Start Guide December 2019

7.3.2 Configure device information using AMS Wireless Configurator

Procedure

1. On the Manual Setup page, select the Device Information tab.

2. Enter any of the following as needed:

• Long tag: Enter an identifier for the device up to 32 characters

long. The Long Tag field is blank by default and does not display if

left blank.

• Tag: Enter an identifier for the device up to eight uppercase

alphabetic and numeric characters long. The Tag field is blank by

default and does not display if left blank.

• Descriptor: Enter a description of the device up to 16 characters

long. The Descriptor field is blank by default and does not display

if left blank.

• Message: Enter text up to 32 characters long. The Message field is

blank by default, does not display if left blank, and may be used

for any purpose.

• Date: Enter a date in mm/dd/yyyy format. The date may be used

for any purpose, such as recording the date of the most recent

calibration.

3. When you have finished making changes, select Send to update the

device configuration.

40 Emerson.com/Rosemount

December 2019 Quick Start Guide

8 Wireless considerations

8.1 Power up sequence

Only install the transmitter and all other wireless devices after you have

installed the wireless gateway and the gateway is functioning properly.

Install the Emerson 701 SmartPower™ Module - Black into the transmitter to

power the device. Power up wireless devices in order of proximity from the

gateway, beginning with the closest. This results in a simpler and faster

network installation. Enable active advertising on the gateway to ensure that

new devices join the network faster. Refer to the reference manual for your

wireless gateway for more information.

8.2 Antenna position

Position the antenna vertically straight up and, if the application

requirements allow, approximately three feet (one meter) from any large

Quick Start Guide 41

Quick Start Guide December 2019

structure, building, or conductive surface to allow for clear communication

with other devices.

Figure 8-1: Antenna Position

42 Emerson.com/Rosemount

December 2019 Quick Start Guide

8.3 Conduit entries

Upon installation, ensure that each conduit entry is either sealed with a

conduit plug using appropriate thread sealant or has a conduit fitting or

cable gland installed with appropriate thread sealant.

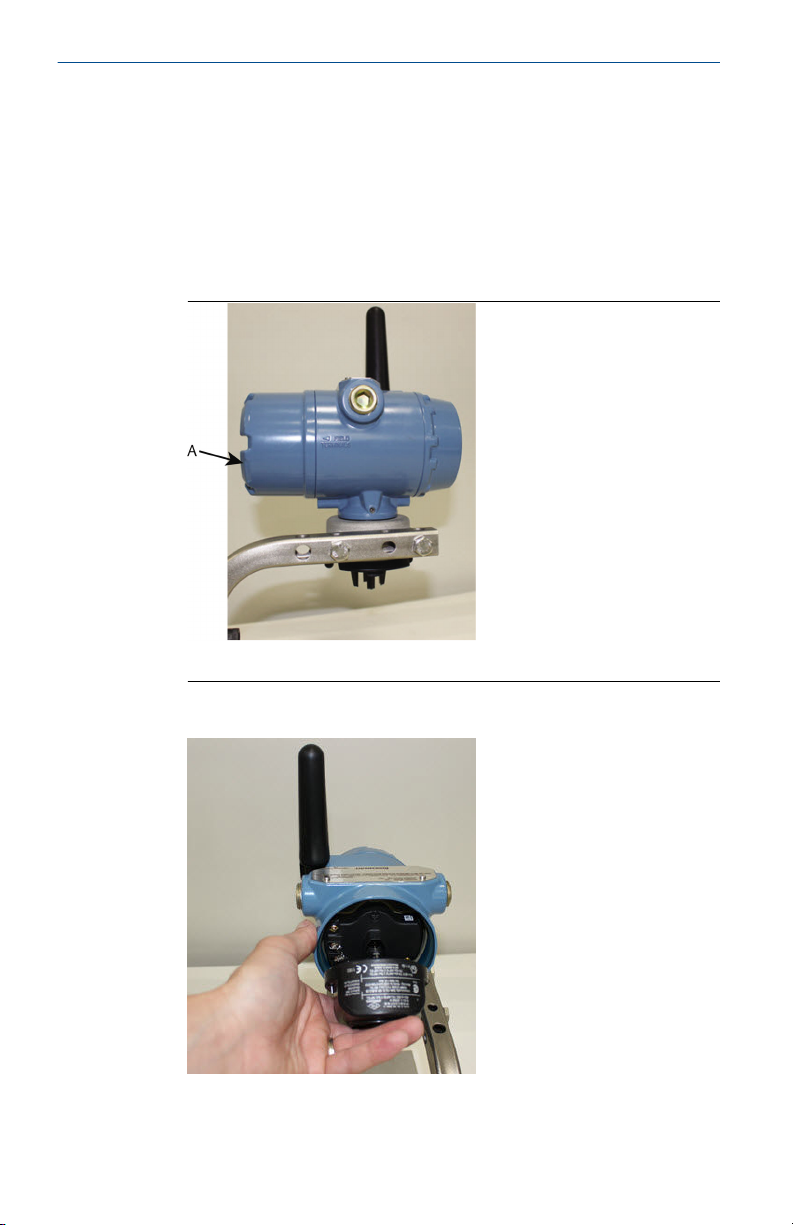

Figure 8-2: Conduit Entries

A. Conduit entries

8.4

Quick Start Guide 43

Choosing an installation location and position

When choosing an installation location and position, take into account

access to the transmitter for ease of power module and sensor replacement.

For best performance, install the antenna vertically with space between

objects in a parallel metal plane, such as a pipe or metal framework, as the

pipes or framework may adversely affect the antenna's performance.

The Rosemount 928 is a diffusion-based gas monitor. This means that the

target gas must actually come into contact with the electrochemical sensor

for the device to register a signal. Each target gas has a unique density and

behaves differently depending on the density of the surrounding

Quick Start Guide December 2019

atmosphere. For example, hydrogen sulfide is considered a heavier-than-air

gas and tends to settle in low-lying areas when released into the air.

Install all transmitters with the sensor module facing downwards. Install

devices with sensors for heavier-than-air gases close to ground level, ideally

between 12 in. (30.5 cm) above the ground and a breathing zone of a

worker (3- 6 ft. [0.9 - 1.8 m] above grade level).

44 Emerson.com/Rosemount

December 2019 Quick Start Guide

9 Electrical

9.1 Handling the power module

The Rosemount 928 is self-powered. The included Emerson 701 SmartPower

Module-Black contains two "C" size primary lithium/thionyl chloride

batteries. Each battery contains approximately .1 oz. (2.5 grams) of lithum,

for a total of .2 oz. (5 grams) in each pack. Under normal conditions, the

battery materials are self-contained and are not reactive as long as the

batteries and the power module are maintained. Take care to prevent

thermal, electrical, or mechanical damage. Protect contacts to prevent

premature discharge.

CAUTION

Equipment damage

The Power Module may be damaged if dropped from heights in excess of 20

ft. (6 m).

Use caution when handling the power module.

9.2 Making electrical connections (Rosemount 928XSS01 and 928XUT01 only)

Make electrical connections through the cable entry in the side of the

connection head. Be sure to provide adequate clearance for cover removal.

See Conduit entries

Quick Start Guide 45

Quick Start Guide December 2019

10 Verify operating atmosphere

Verify that the operating atmosphere of the transmitter and the sensor is

consistent with the appropriate hazardous locations certifications.

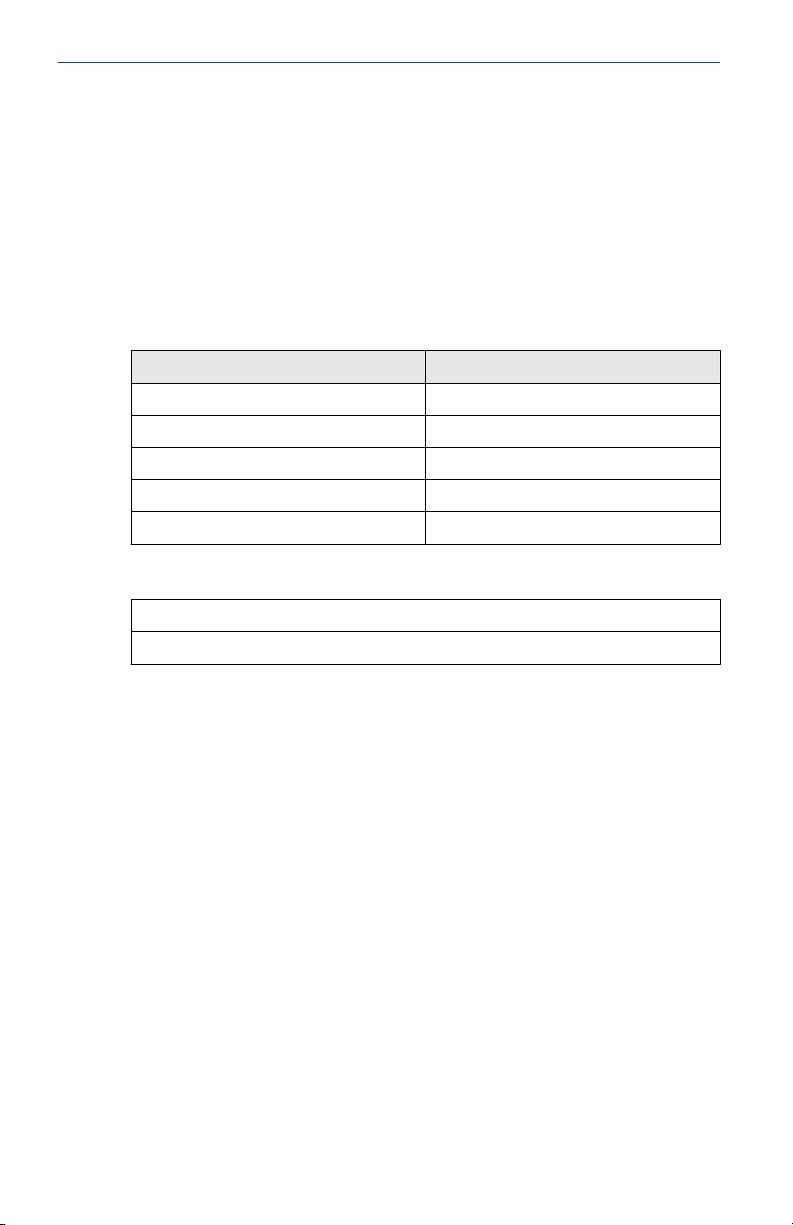

Table 10-1: Temperature Guidelines

Operating limit Transmitter storage limit Sensor storage

-40 to 140 °F

-40 to 60 °C

-40 to 185 °F

-40 to 85 °C

recommendation

34 to 45 °F

1 to 7 °C

Note

The electrochemical cells in the sensor have a limited shelf life. Store sensor

modules in a cool location that is not excessively humid or dry. Storing

sensors for periods longer than three months may shorten their useful

service life.

46 Emerson.com/Rosemount

December 2019 Quick Start Guide

11 Install the transmitter

The transmitter is designed to use the B4 Universal Mounting Bracket. This

curved, stainless steel bracket includes a U-bolt and fasteners for mounting

the transmitter to a 2-in. (50.8 mm) pipe or pole. The B4 bracket attaches

directly to the transmitter. You can also use the B4 bracket in other

mounting configurations, such as mounting the transmitter to a wall or a

panel.

11.1 Pipe mount

Required equipment

• Mounting kit (part number 03151-9270-0004)

— One 2-in. (50.8 mm) U-bolt assembly

— One B4 mounting bracket

— Two 5/16-18 x 1¼-in. bolts

— Two washers

• A ¼-in. combination wrench and adjustable wrench

Quick Start Guide 47

Quick Start Guide December 2019

Figure 11-1: Pipe Mounting

Dimensions are in inches [millimeters].

A. 2-in. bolt for pipe mounting (clamp shown)

B. 5/16-18 x 1¼-in. bolts for transmitter mounting

11.2

48 Emerson.com/Rosemount

Panel mount

Required equipment

• Mounting kit (part number 03151-9270-0004)

— One B4 mounting bracket

— Two ¼-in. x 1¼-in. bolts

• A 5/16-in. combination wrench or adjustable wrench

• A ¼-in. combination wrench or adjustable wrench

• Two 5/16-18 bolts with nuts and washers (not included)

December 2019 Quick Start Guide

Figure 11-2: Panel Mounting

A. 5/16-18 bolts for panel mounting (not supplied)

B. 5/16-18 x 1¼-in. bolts for transmitter mounting

Dimensions are in inches [millimeters].

11.3

Quick Start Guide 49

Rotate LCD display

You can rotate the LCD display in 90 degree increments by squeezing the

two tabs, pulling the LCD display out, rotating it, and snapping it back into

place.

Note

Although you can rotate the LCD display, always install the transmitter with

the sensor facing downwards.

If the LCD display pins are inadvertently removed from the interface board,

carefully reinsert the pins before snapping the LCD display back into place.

Note

Use only Rosemount Wireless LCD Display part number 00753-9004-0002.

Quick Start Guide December 2019

11.4 Ground the transmitter

The transmitter operates with the housing grounded or floating. Floating

systems, however, can cause extra noise that may affect many types of

readout devices. If the signal appears noisy or erratic, grounding at a single

point may solve the problem. Ground the electronics enclosure in

accordance with local and national installation codes. Ground the

electronics using the internal or external case grounding terminal.

50 Emerson.com/Rosemount

December 2019 Quick Start Guide

12 Verify wireless network communication

In order for the transmitter to communicate with the wireless gateway, and

ultimately the host system, you must configure the transmitter to

communicate with the wireless network. This step is the wireless equivalent

of connecting wires from a transmitter to the host system. If the network ID

and join key are not identical, the transmitter will not communicate with the

network.

You may obtain the network ID and join key from the Wireless Gateway on

the Setup → Network → Settings page on the web server, shown in Figure

12-1.

Figure 12-1: Wireless Gateway Network Settings

Refer to Joining the transmitter to a wireless network.

12.1

Quick Start Guide 51

Verify network join status

The chevron-shaped status bar at the top of the LCD screen indicates the

progress of the network join process. When the status bar is filled, the device

is successfully connected to the wireless network.

Refer to Figure 12-2.

Quick Start Guide December 2019

Figure 12-2: Network Status Bar

12.2 Verify communication using Field Communicator

Procedure

1. On the Overview screen, select Service Tools.

2. On the Service Tools screen, select Communications.

3. Verify the following communications information.

• Communication status: Displays whether the device is connected

to the wireless network.

• Join Mode: Displays the current join mode. Select Join Mode to

change the way that the device joins the wireless network.The

default option is Attempt to join immediately on powerup or

reset. Select Send twice to update the join mode.

• Neighbor Count: Displays the number of available neighboring

devices.

• Advertisement Count: Displays the number of advertisement

packets received.

4. When finished, select Back to return to the Communications screen.

12.3

52 Emerson.com/Rosemount

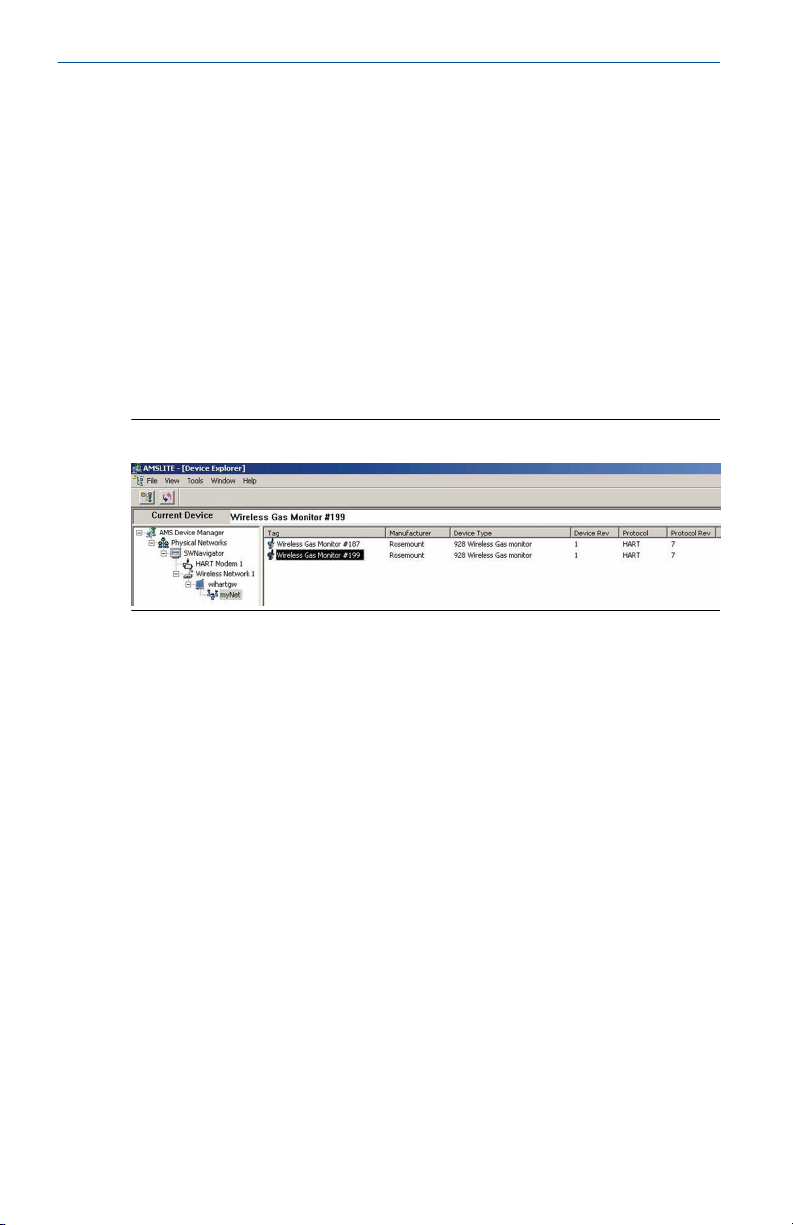

Verify communication using AMS Wireless Configurator

Complete the following steps to verify communications on the device using

the AMS Wireless Configurator.

Procedure

1. Open AMS Wireless Configurator.

2. In the Device Manager pane, expand the wireless network menu.

3. Expand the wireless gateway menu.

4. Select the device list.

5. In the device panel, double-click the device icon.

6. Select Service Tools.

7. In the Service Tools pane, select Communications.

December 2019 Quick Start Guide

8. On the Communications tab, in the Join Status field, verify that all four

network join steps are completed.

12.4 Verify communication using the Wireless Gateway

Open the Wireless Gateway web interface. This page shows whether the

device has joined the network and is communicating properly.

Quick Start Guide 53

Quick Start Guide December 2019

13 Verify operation

There are four ways to verify operation:

• Transmitter LCD display

• Handheld communication device

• Wireless Gateway's integrated web interface

• AMS Device Manager

If you have configured the transmitter with the network ID and join key and

sufficient time has passed, the transmitter will be connected to the network.

When the device has joined the network, it will be displayed in AMS Device

Explorer.

Figure 13-1: AMS Device Explorer

13.1 Verify LCD display operation

Procedure

1. Verify that the display items are correct.

The LCD displays the primary variable (Gas Concentration) by default.

The other variables are:

• Secondary variable (Gas Sensor Module Temperature)

• Tertiary variable (Electronics Temperature)

• Quaternary variable (Supply Voltage)

You may configure these variables to alternate displaying with the

primary variable at the configured update rate. Refer to Configuring

display options if you need to change the display items.

2. Verify that the display mode is correct.

Refer to Configuring the device display mode if you need to change

the display mode.

• Disabled: The display is turned off. This is useful if the display will

never be viewed locally.

54 Emerson.com/Rosemount

December 2019 Quick Start Guide

• On Demand: The display is on when the transmitter is connected

to a handheld communication device or when it receives a signal

from its Wireless Gateway.

• Periodic: The display is on only during updates at the configured

update rate.

• High Availability: The display is always on regardless of the

configured update rate. This is the default display mode option.

3. Press the Diagnostic button to display the TAG, Device ID, Network ID,

Network Join Status, and Device Status screens.

13.2 If there is an immediate alarm

WARNING

Alarm

If the device joins the network and immediately issues an alarm, respond as

though the alarm is real until it is proven false.

If the alarm is false, it is likely due to sensor configuration. Verify the sensor

configuration, alert set points, and alarm set points.

13.3 Troubleshoot communication

If the device is not joined to the network after power up, verify the correct

configuration of the network ID and join key and verify that active

advertising has been enabled on the wireless gateway. The network ID and

Quick Start Guide 55

Quick Start Guide December 2019

join key in the device must match the network ID and join key of the wireless

gateway.

You may obtain the network ID and join key from the wireless gateway on

the Setup → Network → Setttings page on the web interface. You may

change the Network ID and Join Key if necessary. Refer to Joining the

transmitter to a wireless network.

56 Emerson.com/Rosemount

December 2019 Quick Start Guide

14 External alarm device electrical connections

The discrete output of the transmitter (Rosemount 928XSS01 and

928UTX01) can trigger an optional, customer-supplied external alarm

device.

Note

The transmitter cannot power external devices. It acts as a switch that closes

the power circuit of a connected external device activated by a HI-HI alarm if

configured to do so.

You can configure an external power supply and alert device to issue a local

alarm when the detected gas concentration level exceeds the specified high

concentration threshold. You can configure the local alarm to latch the

alarm output until the alarm is manually cleared or query the device to

detect whether this option is installed. Examples of alarm mechanism

options include:

• Audible alarm

• Visual alarm (for example, a flashing light)

• Initiate action (for example, close valves, initiate facility evacuation, call

emergency services)

WARNING

Alarm

If installing an optional, customer-supplied external alarm device, verify

proper function.

Verify that gas concentrations in the area have dissipated to a safe level

before clearing local or digital alarms.

When connecting an external device to the monitor's discrete output in a

hazardous area, ensure that the external device is installed in accordance

with Intrinsically Safe or non-incendive field wiring practices.

The transmitter does not need to be connected to a wireless network for

the external alarm device to function. However, the low battery, no

measurement, or sensor failure alerts will not be available.

There are two possible connection methods for the external alarm device:

• Four-wire: This connection method (most common) uses a set of two

wires for an Intrinsically Safe (IS) input power supply. Another set of two

input wires is used for a separate IS alarm mechanism.

• Two-wire: This connection method combines an IS power source, such as

an internal battery, and alarm device into one package.

You may also add an optional, customer-supplied alarm suppression button.

Quick Start Guide 57

Quick Start Guide December 2019

14.1 Connect an external alarm device

Procedure

1. On the transmitter's main housing, remove the rear housing cover to

expose the terminal block.

A. +Barrier power

B. -Barrier power

C. +Output to alarm

D. -Output to alarm

E. +Comm terminal

F. -Comm terminal

2. On the main housing, remove one of the conduit plugs.

3. Route the barrier power and alarm output wiring into the main

housing.

4. Connect the wiring to the external device on the terminal block

according to the terminal labels. Do one of the following:

Note

Shield alarm wiring for noise immunity.

• Perform four-wire installation. This is the most common

configuration. Refer to Figure 14-1.

58 Emerson.com/Rosemount

December 2019 Quick Start Guide

Figure 14-1: Four-Wire Installation

A. Intrinsically Safe power (in)

B. External alarm

C. External alarm suppression button (optional)

• Perform two wire installation. Refer to Figure 14-2.

Quick Start Guide 59

Quick Start Guide December 2019

Figure 14-2: Two-Wire Installation

A. Voltage in

B. External alarm with Intrinsically Safe power

C. External alarm suppression button (optional)

5. Connect the wiring to the external device according to the

manufacturer's instructions.

6. Verify that the external device functions properly.

a) Perform a bump test.

Refer to the Bump Testing section in the Rosemount 928

Wireless Gas Monitor Reference Manual.

b) If available, use the external device's manual test function to

verify proper function.

Refer to the external device documentation for more

information.

60 Emerson.com/Rosemount

December 2019 Quick Start Guide

15 Product certifications

Rev 3.3

15.1 European Directive information

The most recent revision of the EC Declaration of Conformity can be found

at www.Emerson.com/Rosemount under Documentation.

15.2 Telecommunication compliance

All wireless devices require certification to ensure that they adhere to

regulations regarding the use of the RF spectrum. Nearly every country

requires this type of product certification. Emerson is working with

governmental agencies around the world to supply fully compliant products

and remove the risk of violating country directives or laws governing

wireless device usage.

15.3 FCC and IC

This device complies with Part 15 of the FCC rules. Operation is subject to

the following conditions: This device may not cause harmful interference.

This device must accept any interference received, including interference

that may cause undesired operation. This device must be installed to ensure

a minimum antenna separation distance of 7.81 in. (20 cm) from all persons.

15.4 Ordinary location certification

As standard, the transmitter has been examined and tested to determine

that the design meets basic electrical, mechanical, and fire protection

requirements by a nationally recognized testing laboratory (NRTL) as

accredited by the Federal Occupational Safety and Health Administration

(OSHA).

15.5

15.6

15.6.1 USA

Quick Start Guide 61

Installing in North America

The U.S. National Electrical Code® (NEC) and Canadian Electrical Code (CEC)

permit the use of Division marked equipment in Zones and Zone marked

equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined

in their respective codes.

Hazardous location certificates

I5 U.S.A. Intrinsically Safe (IS)

Certificate

CSA 70138122

Quick Start Guide December 2019

Standards

FM 3600–2011, FM 3610–2010, UL Standard 50—11th

edition, UL 61010–1—3rd edition, ANSI/ISA–60079–0

(12.00.01)–2013, ANSI/ISA–60079–11 (12.02.01)–2014

Markings

IS CL I, DIV 1, GP A, B, C, D T4 Ex ia IIC T4 Ga;

T4 (-40 °C ≤ Ta ≤ +50 °C) when installed according to

Rosemount drawing 00928-1010;

Class 1, Zone 0, AEx ia IIC T4 Ga;

Type 4X

Table 15-1: Entity Parameters

Input (power) parameters Output (alarm) parameters

Ui - 28 Vdc Uo - 28 Vdc

Ii - 93.3 mA Io -93.3 mA

Pi - 653 mW Po - 653 mW

Ci - 5.72 nF Co - 77 nF

Li - 0 Lo - 2 mH

Table 15-2: HART® Comm Parameters

Uo - 1.9 Vdc

Io - 32 µA

Special Conditions for Safe Use (X):

1. For use only with the Emerson Model 701PBKKF, the Computation

Systems, Inc. MHM-89004, or the Perpetuum Ltd. IPM71008/

IPM74001.

2. The surface resistivity of the antenna is greater than 1 GΩ. To avoid

electrostatic discharge buildup, it must not be rubbed or cleaned

with solvents or dry cloth.

3. Substitution of components may impair Intrinsic Safety.

15.6.2 Canada

I6 Canada Intrinsically Safe (IS)

Certificate

Standards

62 Emerson.com/Rosemount

CSA 70138122

CAN/CSA C22 No. 0–10, CAN/CSA C22.2 No. 94.2-15, CAN/

CSA-60079-0–2015, CAN/CSA-60079-11–2014, CAN/CSAC22.2 61010-1–2012

December 2019 Quick Start Guide

Markings

IS CL I, DIV 1, GP A, B, C, D T4;

Ex ia IIC T4 Ga;

T4 (-40 °C ≤ Ta ≤ +50 °C) when installed according to

Rosemount drawing 00928-1010;

Type 4X

Refer to Table 15-1.

Special Conditions for Safe Use (X):

1. For use only with the Emerson Model 701PBKKF, the Computations

Systems, Inc. MHM-89004, or the Perpetuum Ltd. IPM71008/

IPM74001.

Pour utilization uniquement avec Emerson Model 701PBKKF,

Computation Systems, Inc MHM-89004, ou Perpetuum Ltd. IPM71008/

IPM74001.

2. The surface resistivity of the antenna is greater than 1 GΩ. To avoid

electrostatic discharge buildup, it must not be rubbed or cleaned

with solvents or a dry cloth.

La résistivité de surface du boȋtier est supérieure à un gigaohm. Pour

éviter l’accumulation de charge électrostatique, ne pas frotter ou

nettoyer avec des produits solvants ou un chiffon sec.

3. Substitution of components may impair Intrinsic Safety.

La substitution de composants peut compromettre la sécurité

intrinsèque.

15.6.3 Europe

I1 ATEX Intrinsically Safe (IS)

Certificate

Standards

Markings

Refer to Table 15-1 and Table 15-2.

Special Conditions for Safe Use (X):

1. Under certain extreme circumstances, the non-metallic parts

incorporated in the enclosure of this equipment may generate an

ignition capable of electrostatic charge. Therefore, the equipment

shall not be installed in a location where the external conditions are

Quick Start Guide 63

Sira17ATEX2371X

EN 60079-0:2012 + A11:2013, EN 60079-11:2012

II1 G

Ex ia IIC T4 Ga;

T4 (-40 °C ≤ Ta ≤ +50 °C)

Type IP66

Quick Start Guide December 2019

conducive to the build-up of electrostatic charge on such surfaces. In

addition, the equipment shall only be cleaned with a damp cloth.

2. The transmitter may contain more than 10 percent aluminum and is

considered a potential risk ignition by impact or friction. Care must

be taken into account during installation and use to prevent impact

or friction.

3. The equipment shall be powered by Emerson 701PBKKF. An

alternative power source shall be the CSI MHM-89004, as these

devices have output parameters that are equal or less onerous than

the parameters of the 701PBKKF.

4. Only the 375, 475, or AMS Trex Communicators may be used with

the Rosemount 928.

15.6.4 International

I7 IECEx Intrinsically Safe (IS)

Certificate

Standards

Markings

IECEx SIR 17.0091X

IEC 60079-0:2011, IEC 60079-11:2011

Ex ia IIC T4 Ga;

T4 (-40 °C ≤ Ta ≤ +50 °C)

Type IP66

Refer to Table 15-1 and Table 15-2.