Page 1

Quick Installation Guide

Start

Step 1: Pre-Installation

Step 2: Handling

Step 3: Mounting

Step 4: Installation

(Flanged Sensors)

(Wafer Sensors)

(Sanitary Sensors)

Step 5: Grounding

Step 6: Wiring

Step 7: Basic Configuration

Product Certifications

End

00825-0100-4665, Rev AB

December 2012

Rosemount 8732

Rosemount 8732E Magnetic Flowmeter System with PROFIBUS PA digital fieldbus (Transmitter and Sensor)

www.rosemount.com

¢00825-0100-4725.¤

Page 2

Quick Installation Guide

IMPORTANT NOTICE

WARNING

WARNING

WARNING

Emerson Process Management

Rosemount Flow

7070 Winchester Circle,

Boulder, CO 80301

T (US) (800) 522 6277

T (Intnl) (303) 527 5200

F (303) 530 8459

Emerson Process

Management Flow

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0)318 495555

F +31(0) 318 495556

Emerson Process

Management Asia Pacific

Private Limited

1 Pandan Crescent

Singapore 128461

T (65) 6777 8211

F (65) 6777 0947/65 6777 0743

Emerson FZE

P.O. Box 17033

Jebel Ali Free Zone

Dubai UAE

T e l +971 4 811 8100

Fax +971 4 886 5465

00825-0100-4665, Rev AB

Rosemount 8732

© 2013 Rosemount Inc. All rights reserved. All marks property of owner.

This document provides basic installation guidelines for the Rosemount 8732. It does not

provide instructions for detailed configuration, diagnostics, maintenance, service,

troubleshooting, explosion-proof, flameproof, or intrinsically safe (I.S.) installations. Refer

to the Rosemount 8732 reference manual (document number 00809-0100-4665) for

more instructions. The manual and this QIG are also available electronically on

www.rosemount.com.

Failure to follow these installation guidelines could result in death or serious

injury:

Installation and servicing instructions are for use by qualified personnel only. Do not

perform any servicing other than that contained in the operating instructions, unless

qualified. Verify that the operating environment of the sensor and transmitter is consistent

with the appropriate FM, CSA, ATEX, or IECEx approval.

Do not connect a Rosemount 8732 to a non-Rosemount sensor that is located in an

explosive atmosphere.

December 2012

The sensor liner is vulnerable to handling damage. Never place anything through the

sensor for the purpose of lifting or gaining leverage. Liner damage can render the sensor

useless.

To avoid possible damage to the sensor liner ends, do not use metallic or spiral-wound

gaskets. If frequent removal is anticipated, take precautions to protect the liner ends.

Short spool pieces attached to the sensor ends are often used for protection.

Correct flange bolt tightening is crucial for proper sensor operation and life. All bolts must

be tightened in the proper sequence to the specified torque limits. Failure to observe

these instructions could result in severe damage to the sensor lining and possible sensor

replacement.

Rosemount 8705 Magnetic Flowtube units ordered with non-standard paint options may

be subject to electrostatic discharge.

To avoid electrostatic charge build-up, do not rub the meter body with a dry cloth or clean

with solvents.

2

Page 3

Quick Installation Guide

STEP 1: PRE-INSTALLATION

5.82

(148)

6.48 (165)

7.49 (190)

LOI Cover

4.97

(126)

8.81

(224)

3.00

(76)

3.07

(78)

4.97

(126)

1

/2”-14 NPT, CM20, (3 places)*

1

/2”-14 NPT, (2 places)*

00825-0100-4665, Rev AB

December 2012

Rosemount 8732

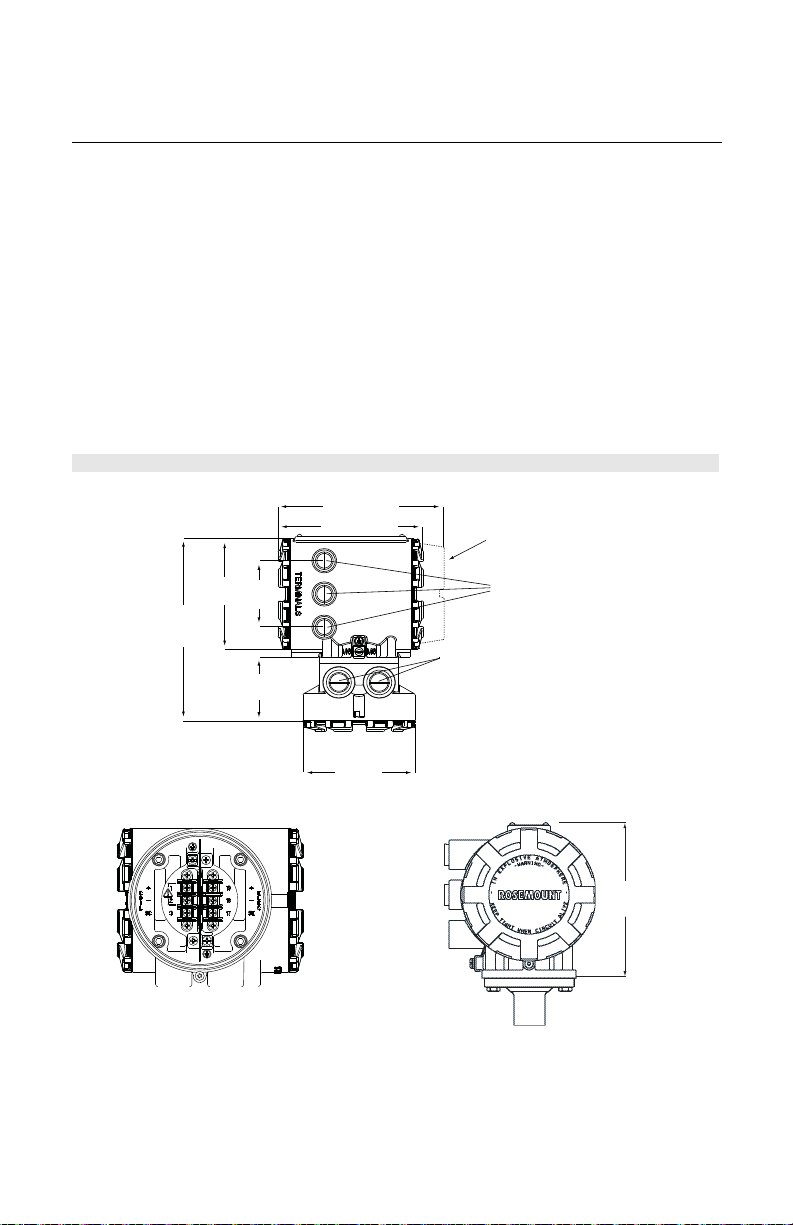

Before installing the Rosemount 8732 Magnetic Flowmeter Transmitter, there are several

pre-installation steps that should be completed to make the installation process easier:

• Identify the options and configurations that apply to your application

• Set the hardware switches if necessary

• Consider mechanical, electrical, and environmental requirements

Mechanical Considerations

The mounting site for the Rosemount 8732 transmitter should provide enough room for

secure mounting, easy access to conduit ports, full opening of the transmitter covers, and

easy readability of the display screen (see Figure 1).

If the Rosemount 8732 is mounted separately from the sensor, it is not subject to limitations

that might apply to the sensor.

Figure 1. Rosemount 8732 Dimensional Drawing

NOTE:

* M20 and PG 13.5 connections are available with the use of threaded conduit adapters.

3

Page 4

Quick Installation Guide

00825-0100-4665, Rev AB

Rosemount 8732

December 2012

Environmental Considerations

To ensure maximum transmitter life, avoid excessive heat and vibration. Typical problem

areas include:

• High-vibration lines with integrally mounted transmitters

• Warm-climate installations in direct sunlight

• Outdoor installations in cold climates.

Remote-mounted transmitters may be installed in the control room to protect the electronics

from the harsh environment and provide easy access for configuration or service.

Both remotely and integrally mounted Rosemount 8732 transmitters require external power

so there must be access to a suitable power source.

Installation Procedures

Rosemount 8732 installation includes both detailed mechanical and electrical installation

procedures.

Mount the Transmitter

At a remote site the transmitter may be mounted on a pipe up to two inches in diameter or

against a flat surface.

Pipe Mounting

To mount the transmitter on a pipe:

1. Attach the mounting bracket to the pipe using the mounting hardware.

2. Attach the Rosemount 8732 to the mounting bracket using the mounting screws.

Hardware Jumpers/Switches

The 8732 PROFIBUS PA electronics board is equipped with two user-selectable hardware

switches. These switches do not have any functionality and should be left in the default

positions as listed below:

Simulate Enable: OFF

Transmitter Security: OFF

Changing the switch position will have no effect on the functionality of the electronics.

Electrical Considerations

Before making any electrical connections to the Rosemount 8732, consider local and plant

electrical standards and be sure to have the proper power supply, conduit, and other

accessories necessary to comply with these standards.

Rotate Transmitter Housing

The electronics housing can be rotated on the sensor in 90° increments by loosening the

four mounting bolts on the bottom of the housing, and reinstalling the bolts. When the

housing is returned to its original position, be sure the surface is clean and there is no gap

between the housing and the sensor. When rotating the housing more than 90° , be sure to

disconnect the wiring from the electronics board and reconnect once the housing is securely

tightened in the desired orientation.

4

Page 5

Quick Installation Guide

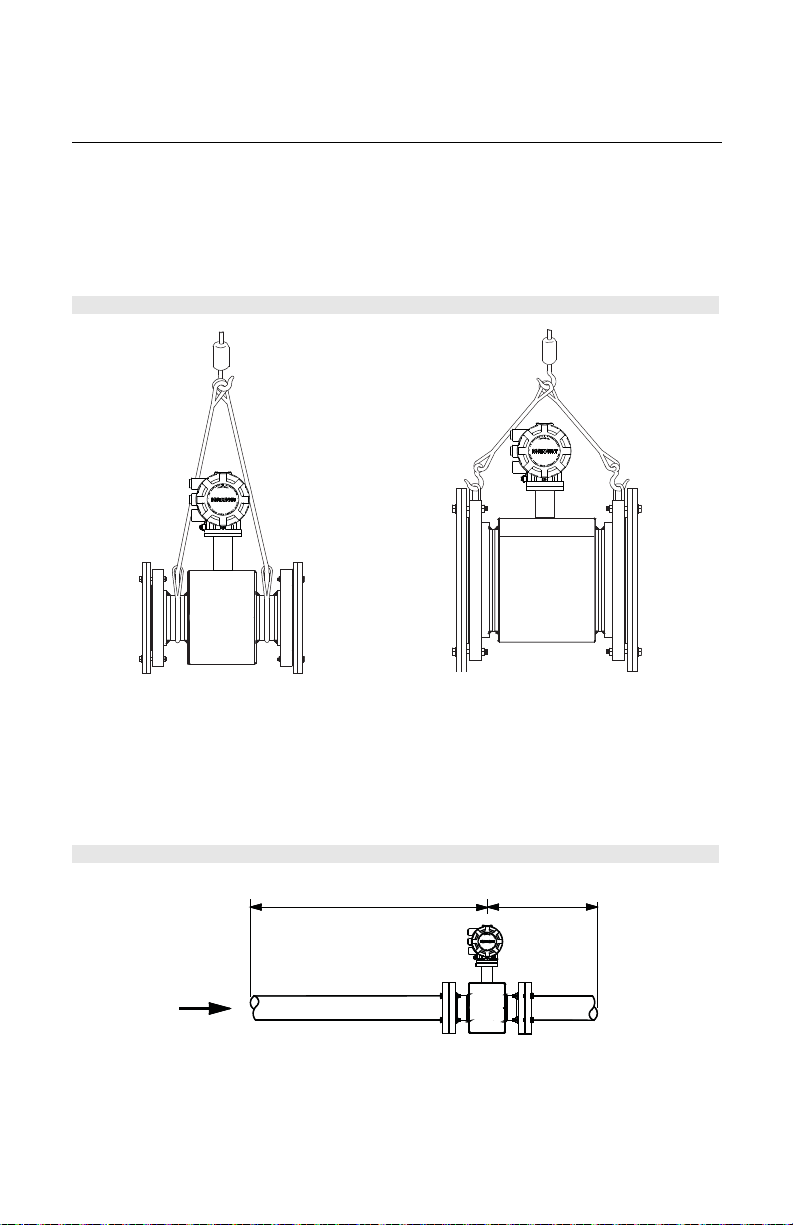

STEP 2: HANDLING

STEP 3: MOUNTING

½- through 4-in. Sensors

6-in. and Larger Sensors

5 Pipe Diameters

2 Pipe Diameters

Flow

00825-0100-4665, Rev AB

December 2012

Handle all parts carefully to prevent damage. Whenever possible, transport the system to

the installation site in the original shipping containers. PTFE-lined sensors are shipped with

end covers that protect it from both mechanical damage and normal unrestrained distortion.

Remove the end covers just before installation.

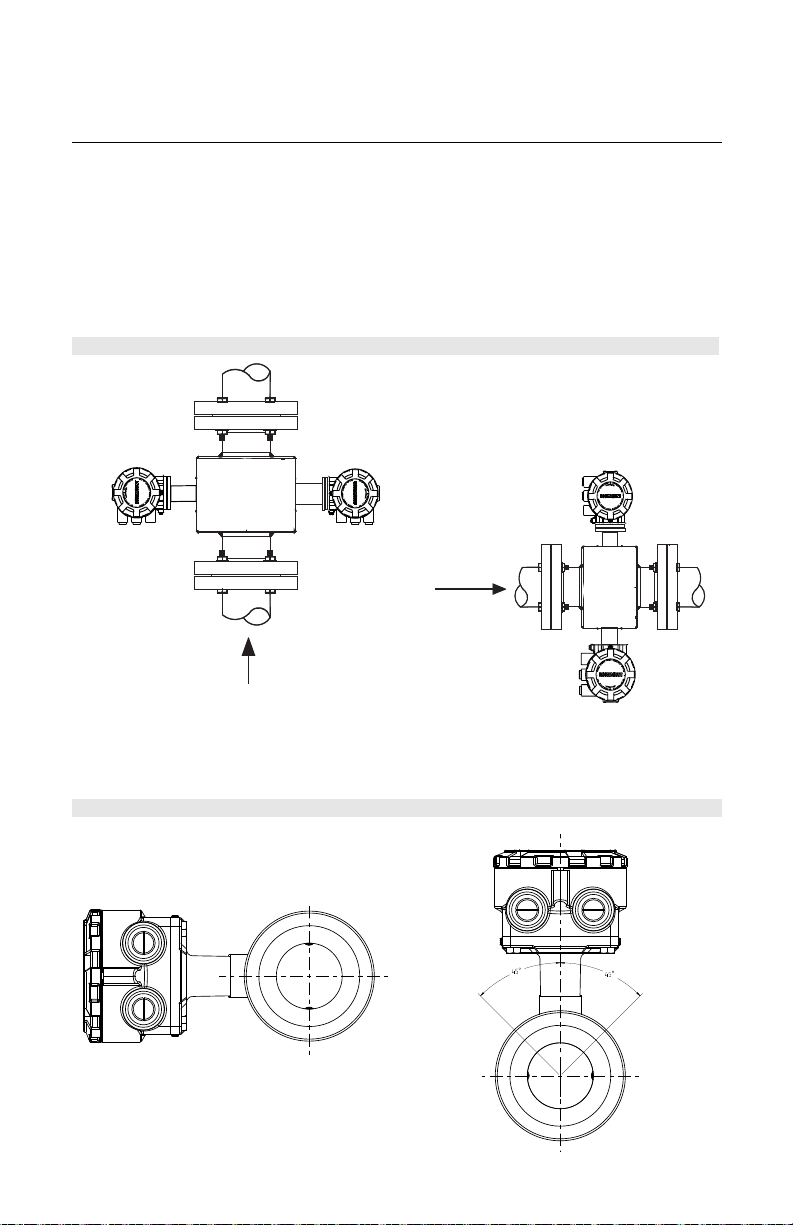

Figure 2. Rosemount 8705 Sensor Support for Handling

Rosemount 8732

Upstream/Downstream Piping

T o ensure specification accuracy over widely varying process conditions, install the sensor a

minimum of five straight pipe diameters upstream and two pipe diameters downstream from

the electrode plane (see Figure 3).

Figure 3. Upstream and Downstream StraightPipe Diameters

Installations with reduced straight runs from 0 to 5 pipe diameters are possible. In reduced

straight pipe run installations, performance will shift. Reported flow rates will still be highly

repeatable.

5

Page 6

Quick Installation Guide

FLOW

FLOW

00825-0100-4665, Rev AB

Rosemount 8732

December 2012

Flow Direction

The sensor should be mounted so the FORWARD end of the flow arrow, shown on the

sensor identification tag, points in the direction of flow through the sensor.

Sensor Location

The sensor should be installed in a position that ensures the sensor remains full during

operation. Vertical installation allows upward process fluid flow and keeps the

cross-sectional area full, regardless of flow rate. Horizontal installation should be restricted

to low piping sections that are normally full.

Figure 4. Sensor Orientation

The electrodes in the sensor are properly orientated when the two measurement electrodes

are in the 3 and 9 o’clock positions or within 45° from the vertical, as shown on the right of

Figure 5. Avoid any mounting orientation that positions the top of the sensor at 90° from the

vertical position as shown on the left of Figure 5.

Figure 5. Mounting Position

Incorrect

Correct

6

Page 7

Quick Installation Guide

STEP 4: INSTALLATION

00825-0100-4665, Rev AB

December 2012

Rosemount 8732

Flanged Sensors

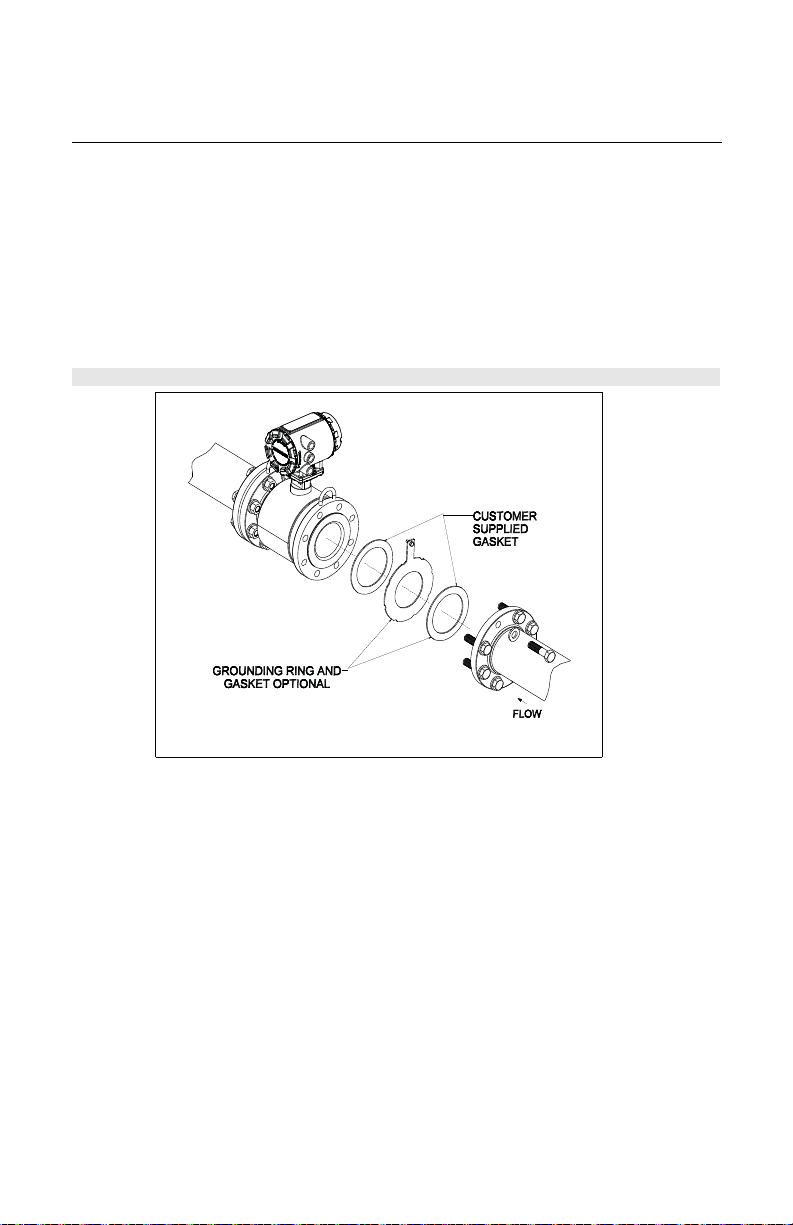

Gaskets

The sensor requires a gasket at each of its connections to adjacent devices or piping. The

gasket material selected must be compatible with the process fluid and operating conditions.

Metallic or spiral-wound gaskets can damage the liner. Gaskets are required on each side of

a grounding ring. All other applications (including sensors with lining protectors or a

grounding electrode) require only one gasket on each end connection.

Figure 6. Flanged gasket placement

Flange Bolts

NOTE

Do not bolt one side at a time. Tighten each side simultaneously. Example:

1. Snug left

2. Snug right

3. Tighten left

4. Tighten right

Do not snug and tighten the upstream side and then snug and tighten the downstream side.

Failure to alternate between the upstream and downstream flanges when tightening bolts

may result in liner damage.

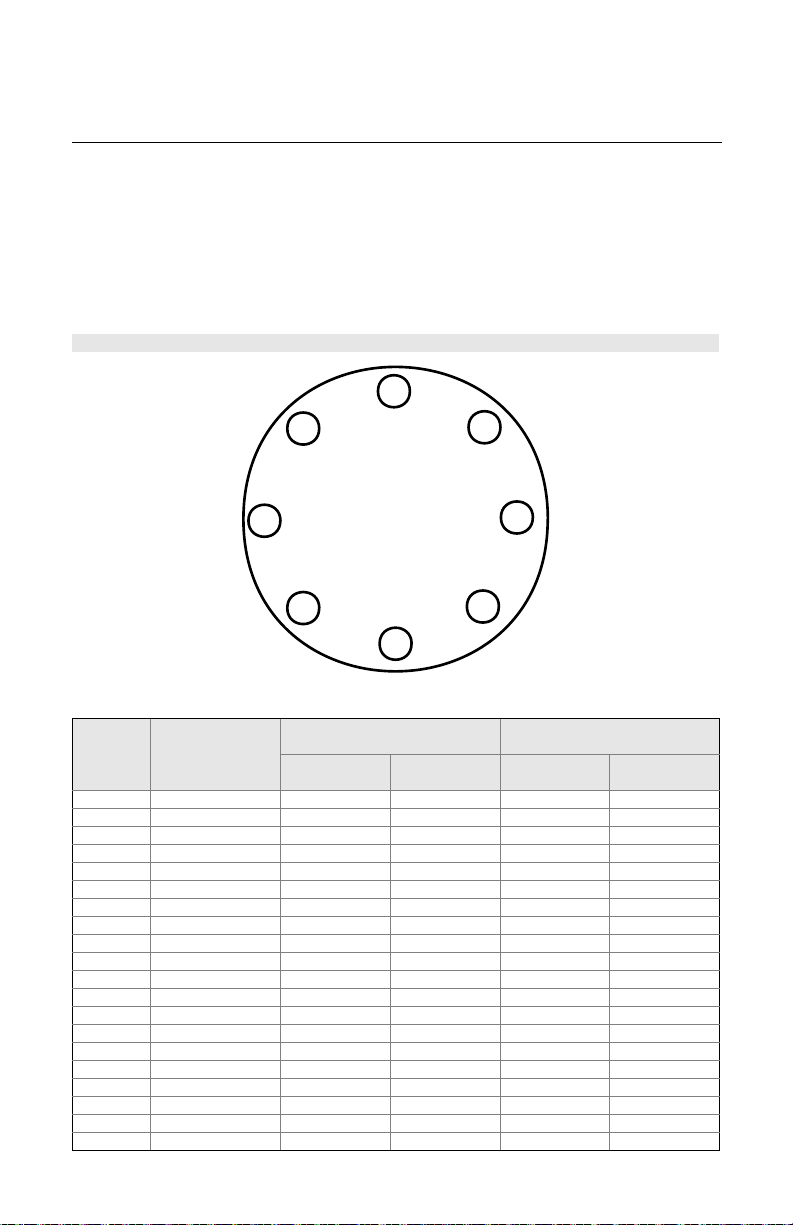

Suggested torque values by sensor line size and liner type are listed in Table 1 for ASME

B16.5 and Table 2 for EN flanges. Consult the factory if the flange rating of the sensor is not

listed. Tighten flange bolts on the upstream side of the sensor in the incremental sequence

shown in Figure 7 to 20% of the suggested torque values. Repeat the process on the

downstream side of the sensor. For sensors with more or less flange bolts, tighten the bolts

in a similar crosswise sequence. Repeat this entire tightening sequence at 40%, 60%, 80%,

and 100% of the suggested torque values or until the leak between the process and sensor

flanges stop.

7

Page 8

Quick Installation Guide

1

5

3

7

8

4

6

2

8-bolt

00825-0100-4665, Rev AB

Rosemount 8732

If leakage has not stopped at the suggested torque values, the bolts can be tightened in

additional 10% increments until the joint stops leaking, or until the measured torque value

reaches the maximum torque value of the bolts. Practical consideration for the integrity of

the liner often leads the user to distinct torque values to stop leakage due to the unique

combinations of flanges, bolts, gaskets, and sensor liner material.

Check for leaks at the flanges after tightening the bolts. Failure to use the correct tightening

methods can result in severe damage. Sensors require a second tightening 24 hours after

the initial installation. Over time, sensor liner materials may deform under pressure.

Figure 7. Flange Bolt Torquing Sequence

December 2012

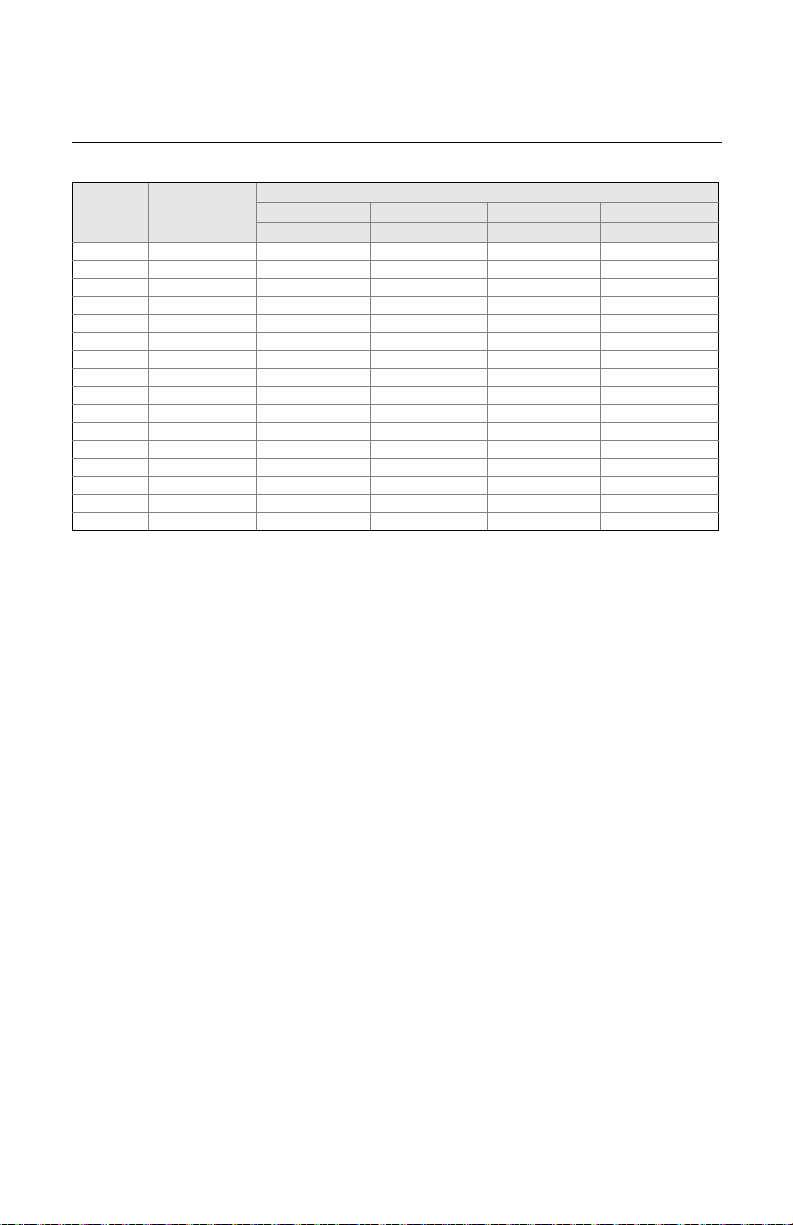

Table 1. Suggested Flange Bolt Torque Values for Rosemount 8705 and 8707 High-Signal Sensors

Polyurethane/Neoprene/

PTFE/ETFE/PFA liners

Class 150

Size Code Line Size

005 0.5-in. (15 mm) 8 8 - 010 1- in. (25 mm) 8 12 - 015 1.5-in. (40 mm) 13 25 7 18

020 2-in. (50 mm) 19 17 14 11

025 2.5-in. (65 mm) 22 24 17 16

030 3-in. (80 mm) 34 35 23 23

040 4-in. (100 mm) 26 50 17 32

050 5-in. (125 mm) 36 60 25 35

060 6-in. (150mm) 45 50 30 37

080 8-in. (200 mm) 60 82 42 55

100 10-in. (250 mm) 55 80 40 70

120 12-in. (300 mm) 65 125 55 105

140 14-in. (350 mm) 85 110 70 95

160 16-in. (400 mm) 85 160 65 140

180 18-in. (450 mm) 120 170 95 150

200 20-in. (500 mm) 110 175 90 150

240 24-in. (600 mm) 165 280 140 250

300 30-in. (750 mm) 195 375 165 350

360 36-in. (900 mm) 280 575 245 575

8

(pound-feet)

Class 300

(pound-feet)

Linatex/Adiprene liner

Class 150

(pound-feet)

Class 300

(pound-feet)

Page 9

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

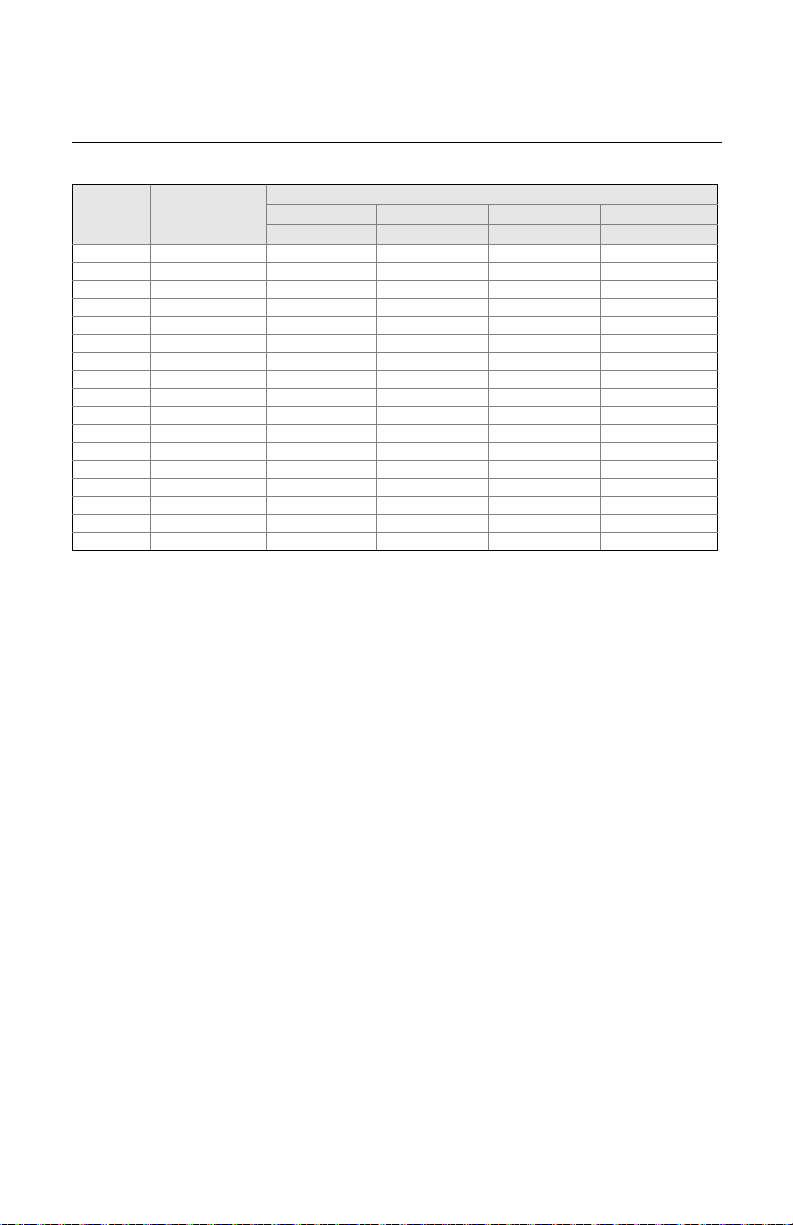

Table 2. Flange Bolt Torque and Bolt Load Specifications for 8705(EN 1092-1)

PN10 PN 16 PN 25 PN 40

Size Code Line Size

005 0.5-in. (15 mm) 10

010 1-in. (25 mm) 20

015 1.5-in. (40 mm) 50

020 2-in. (50 mm) 60

025 2.5-in. (65 mm) 50

030 3-in. (80 mm) 50

040 4-in. (100 mm) 50 70

050 5.0-in (125 mm) 70 100

060 6-in. (150mm) 90 130

080 8-in. (200 mm) 130 90 130 170

100 10-in. (250 mm) 100 130 190 250

120 12-in. (300 mm) 120 170 190 270

140 14-in. (350 mm) 160 220 320 410

160 16-in. (400 mm) 220 280 410 610

180 18-in. (450 mm) 190 340 330 420

200 20-in. (500 mm) 230 380 440 520

240 24-in. (600 mm) 290 570 590 850

(Newton-meter) (Newton-meter) (Newton-meter) (Newton-meter)

PTFE/ETFE liner

Rosemount 8732

9

Page 10

Rosemount 8732

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

Table 2.

(continued) Flange Bolt Torque and Bolt Load Specifications for 8705 (EN 1092-1)

Polyurethane, Linatex, Adiprene and Neoprene Liners

Size Code Line Size

010 1-in. (25 mm) 20

015 1.5-in. (40 mm) 30

020 2-in. (50 mm) 40

025 2.5-in. (65 mm) 35

030 3-in. (80 mm) 30

040 4-in. (100 mm) 40 50

050 5.0-in. (125 mm) 50 70

060 6-in. (150mm) 60 90

080 8-in. (200 mm) 90 60 90 110

100 10-in. (250 mm) 70 80 130 170

120 12-in. (300 mm) 80 110 130 180

140 14-in. (350 mm) 110 150 210 280

160 16-in. (400 mm) 150 190 280 410

180 18-in. (450 mm) 130 230 220 280

200 20-in. (500 mm) 150 260 300 350

240 24-in. (600 mm) 200 380 390 560

PN 10 PN 16 PN 25 PN 40

(Newton-meter) (Newton-meter) (Newton-meter) (Newton-meter)

10

Page 11

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

Rosemount 8732

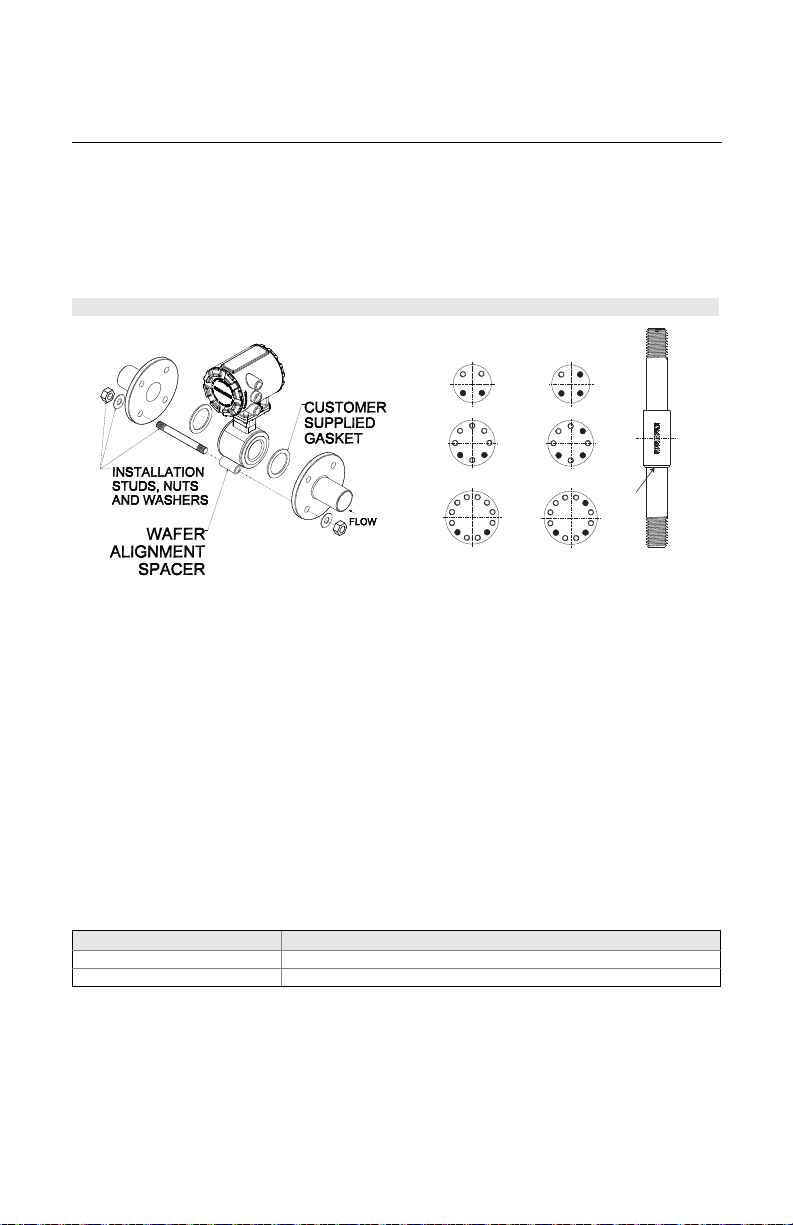

Wafer Sensors

Gaskets

The sensor requires a gasket at each of its connections to adjacent devices or piping. The gasket

material selected must be compatible with the process fluid and operating conditions. Metallic or

spiral-wound gaskets can damage the liner. Gaskets are required on each side of a

grounding ring. See Figure 8 below.

Figure 8. Wafer gasket placement

Spacer Installation

Horizontal meters

Alignment

1. On 1.5 through 8-inch (40 through 200 mm) line sizes. Rosemount strongly recommends

installing the alignment spacers provided to insure proper centering of the wafer sensor

between the process flanges. Sensor sizes of 0.15, 0.30, 0.5 and 1 in. (4 through 25

mm), do not require alignment spacers.

2. Insert studs for the bottom side of the sensor between the pipe flanges and center the

alignment spacer in the middle of the stud. See Figure 8 for the bolt hole locations

recommended for the spacers provided. Stud specifications are listed in Table 3.

3. Place the sensor between the flanges. Make sure that the alignment spacers are

properly centered on the studs. For vertical flow installations slide the oring over the stud

to keep the spacer in place. See Figure 8. To ensure the spacers match the flange size

and class rating for the process flanges see Table 4.

4. Insert the remaining studs, washers, and nuts.

5. Tighten to the torque specifications shown in Table 5. Do not overtighten the bolts or the

liner may be damaged.

Table 3. Stud Specifications

Nominal Sensor Size Stud Specifications

0.15 – 1 inch (4 – 25 mm) 316 SST ASTM A193, Grade B8M Class 1 threaded mounted stu ds

1.5 – 8 inch (40 – 200 mm) CS, ASTM A193, Grade B7, thread ed mounting studs

NOTE

Sensor sizes of 0.15, 0.30, and 0.5 in. mount between AMSE 1/2-inch flanges. Using carbon

steel bolts on sensor sizes of 0.15, 0.30, 0.5 and 1 in. (15 and 25 mm), rather than the

required stainless steel bolts, will degrade the flow sensor measurement.

Vertical meters

O-ring

11

Page 12

Rosemount 8732

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

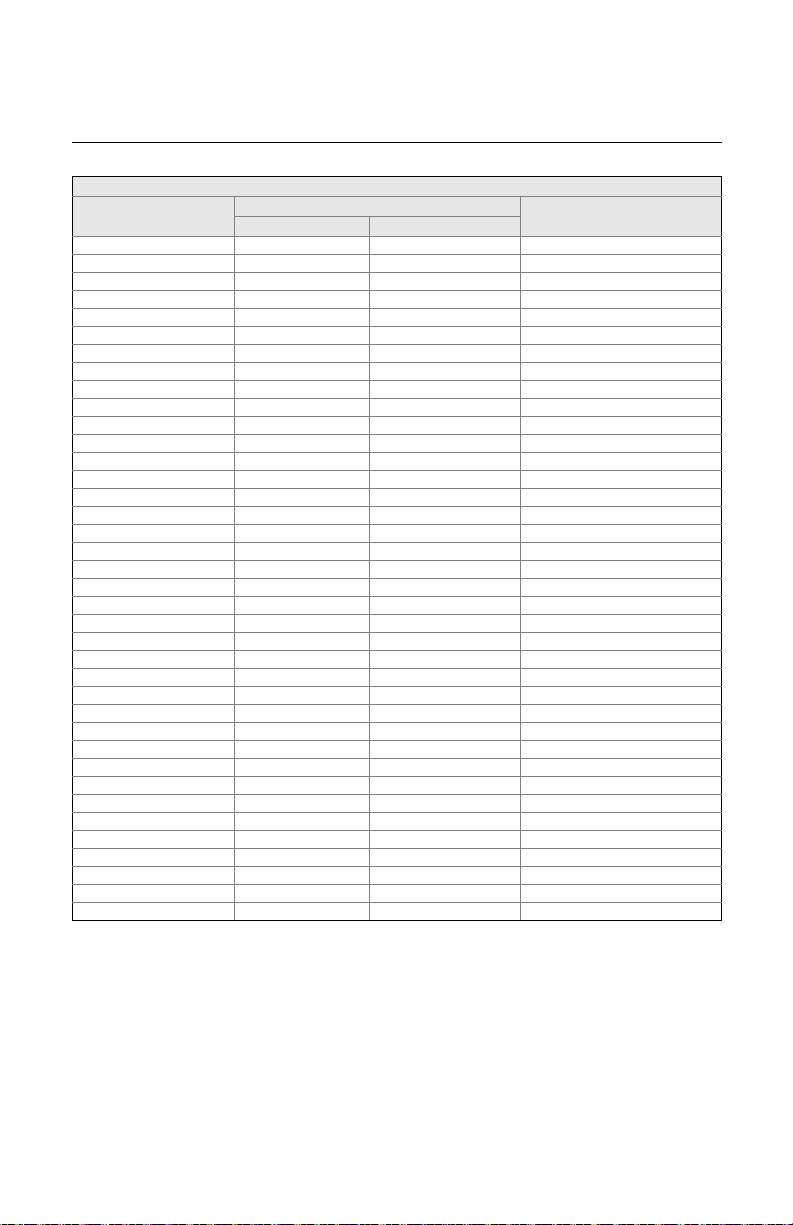

Table 4. Rosemount Alignment Spacer Table

Dash No.

0A15 1.5 40 JIS 10K-20K

0A20 2 50 JIS 10K-20K

0A30 3 80 JIS 10K

0B15 1.5 40 JIS 40K

AA15 1.5 40 ANSI - 150#

AA20 2 50 ANSI - 150#

AA30 3 80 ANSI - 150#

AA40 4 100 ANSI - 150#

AA60 6 150 ANSI - 150#

AA80 8 200 ANSI - 150#

AB15 1.5 40 ANSI - 300#

AB20 2 50 ANSI - 300#

AB30 3 80 ANSI - 300#

AB40 4 100 ANSI - 300#

AB60 6 150 ANSI - 300#

AB80 8 200 ANSI - 300#

AB15 1.5 40 ANSI - 300#

AB20 2 50 ANSI - 300#

AB30 3 80 ANSI - 300#

AB40 4 100 ANSI - 300#

AB60 6 150 ANSI - 300#

AB80 8 200 ANSI - 300#

DB40 4 100 DIN - PN10/16

DB60 6 150 DIN - PN10/16

DB80 8 200 DIN - PN10/16

DC80 8 100 DIN - PN25

DD15 1.5 150 DIN - PN10/16/25/40

DD20 2 50 DIN - PN10/16/25/40

DD30 3 80 DIN - PN10/16/25/40

DD40 4 100 DIN - PN25/40

DD60 6 150 DIN - PN25/40

DD80 8 200 DIN - PN40

RA80 8 200 AS40871-PN16

RC20 2 50 AS40871-PN21/35

RC30 3 80 AS40871-PN21/35

RC40 4 100 AS40871-PN21/35

RC60 6 150 AS40871-PN21/35

RC80 8 200 AS40871-PN21/35

Rosemount Alignment Spacer Table

Line Size

Flange Rating(in) (mm)

To order an Alignment Spacer Kit (qty 3 spacers) use p/n 08711-3211-xxxx along with the

Dash No. above.

12

Page 13

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

Rosemount 8732

Flange Bolts

Wafer sensors require threaded studs. See Figure 7 for torque sequence. Always check for

leaks at the flanges after tightening the flange bolts. All sensors require a second torquing

24 hours after initial flange bolt tightening.

Table 5. Rosemount 8711 Torque Specifications

Size Code Line Size Pound-feet Newton-meter

15F 0.15 inch (4 mm) 5 7

30F 0.30 inch (8 mm) 5 7

005 0.5 inch (15 mm) 5 7

010 1 inch (25 mm) 10 14

015 1.5 inch (40 mm) 15 20

020 2 inch (50 mm) 25 34

030 3 inch (80 mm) 40 54

040 4 inch (100 mm) 30 41

060 6 inch (150 mm) 50 68

080 8 inch (200 mm) 70 95

13

Page 14

Quick Installation Guide

User supplied clamp

User supplied gasket

00825-0100-4665, Rev AB

Rosemount 8732

December 2012

Sanitary Sensors

Gaskets

The sensor requires a gasket at each of its connections to adjacent devices or piping. The

gasket material selected must be compatible with the process fluid and operating conditions.

Gaskets are supplied between the IDF fitting and the process connection fitting, such as a

Tri-Clamp fitting, on all Rosemount 8721 Sanitary sensors except when the process

connection fittings are not supplied and the only connection type is an IDF fitting.

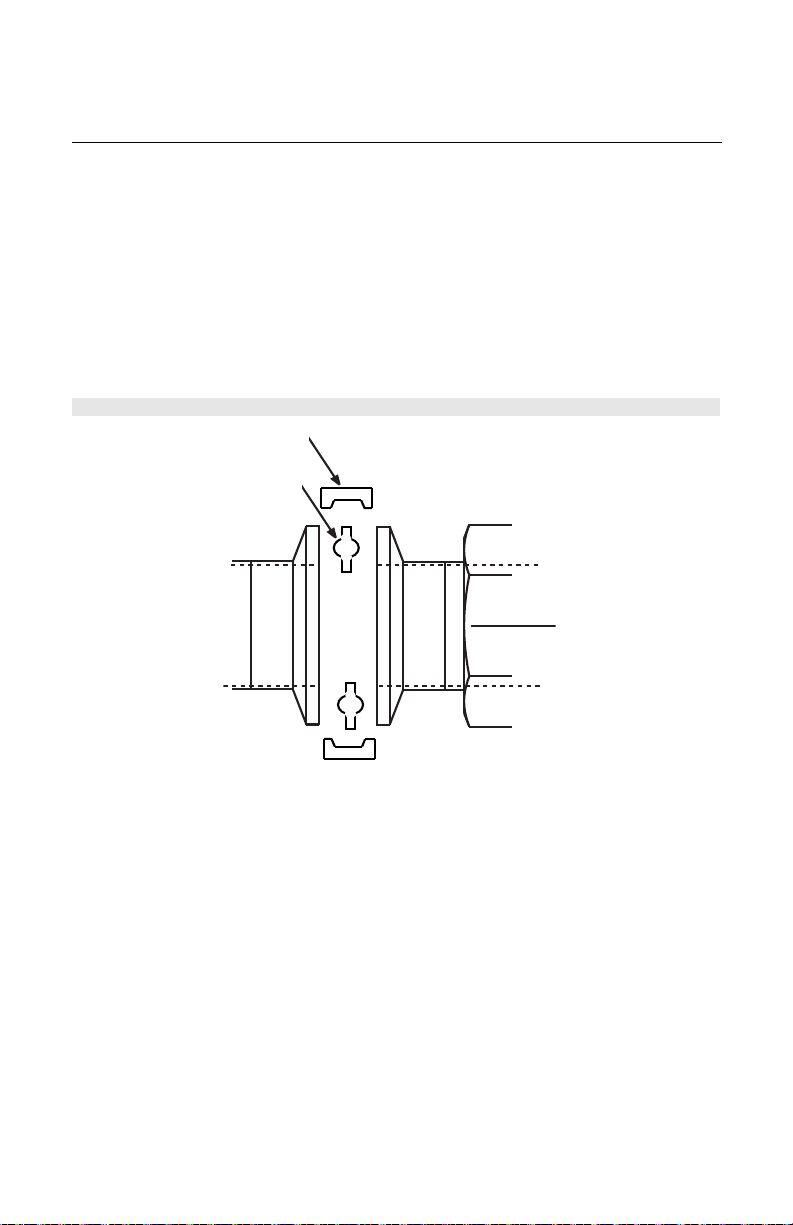

Alignment and Bolting

Standard plant practices should be followed when installing a magmeter with sanitary

fittings. Unique torque values and bolting techniques are not required.

Figure 9. Rosemount 8721 Sanitary Installation

14

Page 15

Quick Installation Guide

STEP 5: GROUNDING

Grounding Rings or Lining

Protectors

00825-0100-4665, Rev AB

December 2012

Use Table 6 to determine which process grounding option to follow for proper installation.

The sensor case should be earth grounded in accordance with national and local electrical

codes. Failure to do so may impair the protection provided by the equipment.

Table 6. Process Grounding Installation

Type of Pipe

Conductive Unlined

Pipe

Conductive Lined

Pipe

Non-Conductive

Pipe

Figure 10. Grounding Straps or Grounding Electrode in Lined Pipe

Grounding

Straps

See Figure 10 Not Required Not Required See Figure 11

Insufficient

Grounding

Insufficient

Grounding

Process Grounding Options

Grounding

Rings

See Figure 11 See Figure 10 See Figure 11

See Figure 12 See Figure 13 See Figure 12

Grounding

Electrode

Rosemount 8732

Lining

Protectors

Figure 11. Grounding with Grounding Rings or Lining Protectors

15

Page 16

Rosemount 8732

Grounding Rings or Lining

Protectors

Figure 12. Grounding with Grounding Rings or Lining Protectors

Figure 13. Grounding with Grounding Electrode

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

16

Page 17

Quick Installation Guide

STEP 6: WIRING

Coil Drive

and

Electrode

Cables

Power

Outputs

Power

Outputs

Coil Drive

and

Electrode

Cables

Power

Outputs

Power

Outputs

00825-0100-4665, Rev AB

December 2012

Rosemount 8732

This wiring section covers the connection between the transmitter and sensor, the

PROFIBUS PA fieldbus segment, and supplying power to the transmitter . Follow the conduit

information, cable requirements, and disconnect requirements in the sections below.

Conduit Ports and Connections

Both the sensor and transmitter junction boxes have ports for 1/2-inch NPT conduit

connections with optional CM20 or PG 13.5 connections available. These connections

should be made in accordance with national, local, and plant electrical codes. Unused ports

should be sealed with metal plugs. Proper electrical installation is necessary to prevent

errors due to electrical noise and interference. Separate conduits are not necessary for the

coil drive and signal cables, but a dedicated conduit line between each transmitter and

sensor is required. Shielded cable must be used for best results in electrically noisy

environments. When preparing all wire connections, remove only the insulation required to

fit the wire completely under the terminal connection. Removal of excessive insulation may

result in an unwanted electrical short to the transmitter housing or other wire connections.

For flanged sensors installed into an application requiring IP68 protection, sealed cable

glands, conduit, and conduit plugs that meet IP68 ratings are required.

Conduit Requirements

A single dedicated conduit run for the coil drive and signal cable is needed between the

sensor and the remote transmitter. See Figure 14. Bundled cables in a single conduit are

likely to create interference and noise problems in the system. Use one set of cables per

conduit run.

Figure 14. Conduit Preparation

Wrong Correct

17

Page 18

Quick Installation Guide

STEP 6 CONTINUED...

Cable Shield

1.00

(26)

NOTE

Dimensions are in inches (millimeters).

00825-0100-4665, Rev AB

Rosemount 8732

December 2012

Run the appropriate size cable through the conduit connections in your magnetic flowmeter

system. Run the power cable from the power source to the transmitter. Run the coil drive

and signal cables between the flowmeter sensor and transmitter.

• Installed signal wiring should not be run together and should not be in the same cable

tray as AC or DC power wiring.

• Device must be properly grounded or earthed according to local electric codes.

• Rosemount combination cable part number 08732-0753-1003 (ft.) or 08732-0753-2004

(m) is required to be used to meet EMC requirements.

Transmitter to Sensor Wiring

The transmitter can be integral to the sensor or remotely mounted following the wiring

instructions.

Remote Mount Cable Requirements and Preparation

For installations using the individual coil drive and signal cable, lengths should be limited to

less than 1,000 feet (300 meters). Equal length cable is required for each. See Table 7.

For installations using the combination coil drive and signal cable, lengths should be limited

to less than 330 feet (100 meters). See Table 7.

Prepare the ends of the coil drive and signal cables as shown in Figure 15. Limit the

unshielded wire length to 1-inch on both the coil drive and signal cables. Any unsheathed

wire should be wrapped with proper insulation. Excessive lead length or failure to connect

cable shields can create electrical noise resulting in unstable meter readings.

Figure 15. Cable Preparation Detail

18

Page 19

Quick Installation Guide

WARNING

00825-0100-4665, Rev AB

December 2012

Table 7. Cable Requirements

To order cable specify length as quantity desired. 25 feet = Qty (25) 08732-0753-1003

Description Length Part Number

Coil Drive Cable (14 AWG)

Belden 8720, Alpha 2442

or equivalent

Signal Cable (20 AWG)

Belden 8762, Alpha 2411

or equivalent

Combination Cable

Coil Drive Cable (18 AWG) and

Signal Cable (20 AWG)

ft

m

ft

m

ft

m

Rosemount 8732

08712-0060-0001

08712-0060-2013

08712-0061-0001

08712-0061-2003

08732-0753-1003

08732-0753-2004

Potential Shock Hazard Across Terminals 1 & 2 (40 Vac).

Wiring the Transmitter to the Sensor

When using individual cables for coil drive and signal refer to Table 8. If using the

combination coil drive and signal cable refer to Table9. See Figure16 for transmitter

specific wiring diagram.

1. Connect the coil drive cable using terminals 1, 2, and 3 (ground).

2. Connect the signal cable using terminals 17, 18, and 19.

Table 8. Individual Coil and Signal Cables

Transmitter Terminal Sensor Terminal Wire Gauge Wire Color

1 1 14 Clear

2 2 14 Black

3 or Ground 3 or Ground 14 Shield

17 17 20 Shield

18 18 20 Black

19 19 20 Clear

Table 9. Combination Coil and Signal Cable

Transmitter Terminal Sensor Terminal Wire Gauge Wire Color

1 1 18 Red

2 2 18 Green

3 or Ground 3 or Ground 18 Shield

17 17 20 Shield

18 18 20 Black

19 19 20 White

19

Page 20

Quick Installation Guide

Sensors

00825-0100-4665, Rev AB

Rosemount 8732

Figure 16. Remote Mount Wiring Diagram

NOTE

When using the Rosemount supplied combination cable, the signal wires for terminals 18

and 19 contain an additional shield wire. These two shield wires should be tied with the main

shield wire at terminal 17 at the sensor terminal block and cut back to the insulation in the

transmitter junction box. See Figure 17.

Figure 17. Combination Coil and Signal Cable Wiring Diagram

Coil Drive Cable

Signal Cable

December 2012

Transsmiter

Cut Shield

1 Red 2 Green 3 Shield 17 Shield 18 Black 19 White

Tube

17 Shield 18 Black 19 White1 Red 2 Green 3 Shield

20

Page 21

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

Rosemount 8732

Integral Mount Transmitters

The interconnecting wire harness for an integral mount transmitter is installed at the factory.

See Figure 18. Do not use cable other than that supplied by Emerson Process

Management, Rosemount, Inc.

Figure 18. 8732EST Integral Mount Wiring Diagram

21

Page 22

Quick Installation Guide

Control Room

00825-0100-4665, Rev AB

Rosemount 8732

December 2012

PROFIBUS PA Fieldbus Connection Wiring

Transmitter Communication Input

The PROFIBUS PA fieldbus communication requires a minimum of 9 V dc and a maximum

of 32 V dc at the transmitter communication terminals. Do not exceed 32 V dc at the

transmitter communication terminals. Do not apply ac line voltage to the transmitter

communication terminals. Improper supply voltage can damage the transmitter.

Field Wiring

Power independent of the transmitter power supply must be supplied for PROFIBUS PA

fieldbus communications. Use shielded, twisted pair for best results. In order to get

maximum performance in new applications, twisted pair cable specifically designed for

fieldbus communications should be used. The number of devices on a fieldbus segment is

limited by the power supply voltage, the resistance of the cable, and the amount of current

drawn by each device. See Table10 for cable specifications.

Table 10. Ideal Cable Specifications for Fieldbus Wiring

Characteristic Ideal Specification

Impedance 100 Ohms ± 20% at 31.25 kHz

Wire Size 18 AWG (0,8 mm2)

Shield Coverage 90%

Attenuation 3 db/km

Capacitive Unbalance 2 nF/km

Power Conditioning

Each fieldbus power supply requires a power conditioner to decouple the power supply

output from the fieldbus wiring segment.

Figure 19. Power Connections

22

Page 23

Quick Installation Guide

–PA signal

+PA signal

00825-0100-4665, Rev AB

December 2012

Transmitter Wiring Connection

Follow the steps listed below to wire the model 8732E PROFIBUS PA Fieldbus transmitter:

1. Ensure Power Conditioner and cable meet the requirements shown above in 'Field

Wiring'

2. Ensure the transmitter is not powered

3. Route Fieldbus wire through appropriate conduit entry

4. Connect one Fieldbus wire to terminal 1 and the other Fieldbus wire to terminal 2.The

8732E Fieldbus transmitter is polarity insensitive. See Figure 20.

When wiring to screw terminals, crimped lugs are recommended. Tighten the terminals to

ensure adequate contact. Both transmitter covers must be fully engaged to meet explosion

proof requirements. Do not remove the transmitter covers in an explosive atmosphere when

the transmitter is powered.

Figure 20. 8732E PROFIBUS PA Fieldbus Wiring Diagram

Rosemount 8732

23

Page 24

Quick Installation Guide

12

18

24

30

36

42

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Power Supply (Volts)

I = Supply current requirement (Amps)

V = Power supply voltage (Volts)

Supply Current (Amps)

00825-0100-4665, Rev AB

Rosemount 8732

December 2012

Powering the Transmitter

The 8732E transmitter is designed to be powered by 90-250 Vac, 50–60 Hz or 12–42 Vdc.

Before connecting power to the Rosemount 8732E, consider the following standards and be

sure to have the proper power supply, conduit, and other accessories. Wire the transmitter

according to national, local, and plant electrical requirements for the supply voltage. See

Figure 21.

Figure 21. DC Power Supply Current Requirements

Supply Wire Requirements

Use 12 to 18 AWG wire rated for the proper temperature of the application. For connections

in ambient temperatures above 140 °F (60 °C), use a wire rated for 176 °F (80 °C). For

ambient temperatures greater than 176 °F (80 °C), use a wire rated for 230 °F (110 °C). For

DC powered transmitters with extended cable lengths, verify that there is a minimum of 12 V

DC at the terminals of the transmitter.

Disconnects

Connect the device through an external disconnect or circuit breaker. Clearly label the

disconnect or circuit breaker and locate it near the transmitter and per local electrical

control.

Installation Category

The installation category for the 8732E is (Overvoltage) Category II.

Overcurrent Protection

The Rosemount 8732E flowmeter transmitter requires overcurrent protection of the supply

lines. Maximum ratings of overcurrent devices are shown in Table 11.

Table 11. Overcurrent Limits

Power System Fuse Rating Manufacturer

95-250 V AC 2 Amp, Quick Acting Bussman AGC2 or Equivalent

12-42 V DC 3 Amp, Quick Acting Bussman AGC3 or Equivalent

24

Page 25

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

8732E Power Supply

For AC power applications (90-250 VAC, 50-60 Hz) connect AC Neutral to terminal 9 (AC

N/L2) and connect AC Line to terminal 10 (AC/L1). For DC power applications connect

negative to terminal 9 (DC -) and positive to terminal 10 (DC +). Units powered by 12-42 V

DC power supply may draw up to 1 amp of current. See Figure 22 for terminal block

connections.

Figure 22. 8732E Transmitter Power Connections

Rosemount 8732

Cover Jam Screw

For transmitter housings shipped with a cover jam screw, the screw should be properly

installed once the transmitter has been wired and powered up. Follow these steps to install

the cover jam screw:

1. Verify that the cover jam screw is completely threaded into the housing.

2. Install the transmitter housing cover and verify that the cover is tight against the housing.

3. Using an M4 hex wrench, loosen the jam screw until it contacts the transmitter cover.

4. Turn the jam screw an additional

(Note: Application of excessive torque may strip the threads.)

5. Verify that the cover cannot be removed.

1

/2 turn counterclockwise to secure the cover.

25

Page 26

Quick Installation Guide

00825-0100-4665, Rev AB

Rosemount 8732

December 2012

Step 7: Basic Configuration

Quick Start-Up

Once the magnetic flowmeter system is installed and communication is established,

configuration of the transmitter must be completed. The standard transmitter configuration,

without Option Code C1, Custom Configuration, is shipped with the following parameters:

Engineering Units: ft/s

Sensor Size: 3-in.

Sensor Calibration Number: 100000501000000

Assigning Device Node Address and Ident Number

The 8732E Magnetic Flowmeter Transmitter with PROFIBUS PA fieldbus is shipped with a

temporary address. T o change the Node Address and Ident Number , use the features of the

Local Operator Interface (LOI) or a configuration tool. The tools do the following:

• Change the Node Address to a user specified address on the network.

• Change the Ident Number to determine if the device will operate in Generic mode or

Manufacturer Specific mode. This setting affects the GSD file required by the host

system.

Flow-Specific Block Configuration

AI Block

The Analog Input (AI) function block provides the primary interface of the measurement to

the control and/or monitoring systems. To properly configure the device, the following

parameters should be reviewed and configured to ensure that the device is correctly

configured.

1. The first parameter is CHANNEL. The CHANNEL parameter defines which transducer

block measurement is used by the AI block. In the 8732E Magnetic Flowmeter

Transmitter, the channel will always be set to Flow. There is no other option for this

variable.

2. The second parameter is the LINEARIZATION TYPE. This parameter defines the

relationship between the block input and the block output. Since the 8732E Magnetic

Flowmeter Transmitter does not require linearization, this parameter will always be set to

No Linearization. This means that the AI block will only apply scaling, filtering, and limit

checking to the input value.

3. The third parameter is PV_SCALE. The Transducer Block VOLUME_FLOW_UNITS

define the unit of measure of the primary variable input and are directly related to the

choice of the PV_SCALE UPPER RANGE and LOWER RANGE values.

4. The fourth parameter is OUT_SCALE. The output from the AI Block is scaled according

to the relationship of the PV_SCALE and OUT_SCALE UPPER RANGE and LOWER

RANGE values.

5. The fifth group of parameters are the alarm limits. The High and Low warning and Fault

Alarm limits should be configured relative to the OUT_SCALE UPPER RANGE and

LOWER RANGE values to set the control limits for the primary variable.

26

Page 27

Quick Installation Guide

Totalizers

Basic Setup

Detailed Setup

Totalizer 1

Totalizer 2

Totalizer 3

Flow Units

Sensor Size

Cal Number

Damping

Coil Frequency

PROFIBUS

AI Block Conf

LOI Config

Trims

8714i

Total 3 Value

Total 3 Conf ig

Tota l 3 Set

Tota l 3 Mode

Tota l 3 Units

Total 3 Preset

Device Address

Ident Selector

AI PV Scale

AI Out Scale

Total 1Va lue

Total 1 C onfig

Tota l 2 Val ue

Total 2 Config

Total 1 Set

Total 1 Mode

Total 1 Unit s

Total 1 Preset

Total 2 Set

Total 2 Mode

Total 2 Unit s

Total 2 Preset

PV Scale URV

Out Scale LRV

Out Scale Unit

Out Scale URV

Out Scale LRV

Run 8714i

View Results

TubeSignature

Measurements

Display Timing

Language

Write Lock

Auto Zero Trim

Universal Trim

Values

Re-signature

Recall Values

Coil Resist

Coil Signature

Electrode Res

PV

Totaliz er 1

Totaliz er 2

Totaliz er 3

Coil Resist

Coil Signature

Electrode Res

00825-0100-4665, Rev AB

December 2012

Rosemount 8732

Slot Configuration

The 8732E has 4 slots that must be configured. If a slot is not going to be used, it must be

configured as an empty slot.

Figure 23 shows an example of a basic slot configuration for the Primary Variable (PV or

Flow), and the totalized flow value.

Figure 23. Basic Slot Configuration

Consult the GSD file for more details on what each slot can be configured for.

Figure 24. 8732E PROFIBUS P A LOI Menu Tree

27

Page 28

Quick Installation Guide

00825-0100-4665, Rev AB

Rosemount 8732

December 2012

Product Certifications

Approved Manufacturing Locations

Rosemount Inc. — Eden Prairie, Minnesota, USA

Fisher-Rosemount Technologias de Flujo, S.A. de C.V. — Chihuahua, Mexico

Emerson Process Management Flow — Ede, The Netherlands

Asia Flow Technology Center — Nanjing, China

EUROPEAN DIRECTIVE INFORMATION

The EC declaration of conformity can be found on page 35. The most recent revision can be

found at www.rosemount.com.

Type n protection type in accordance with EN50021

• The installation of external connections and the plugging of any unused entries must be

carried out using appropriate Ex e or Ex n cable glands and blanking plugs, component

certified by an approved Certification Body.

CE Marking

Complies with EN 61326-1 : 2006

For Rosemount 8732E transmitters:

Complies with Essential Health and Safety Requirements:

EN 60079-0: 2006

EN 60079-1: 2007

EN 60079-7: 2007

EN 60079-11: 2007

EN 60079-15: 2005

EN 61241-0: 2004

EN 61241-1: 2006

International Certificates

C-Tick Marking

Rosemount Inc. complies with the following IEC Requirements.

For Rosemount 8732E transmitters:

IEC 60079-0 : 2004

IEC 60079-0: 2007

IEC 60079-1 : 2007

IEC 60079-7 : 2006

IEC 60079-11 : 2006

IEC 60079-15: 2005

IEC 61241-0 : 2004

IEC 61241-1 : 2004

28

Page 29

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

NOTE

For the 8732E transmitters with a local operator interface (LOI), the lower ambient

temperature limit is -20 °C.

NOTE

For intrinsically safe (IS) outputs on the 8732E output option code F must be selected.

IS outputs for Class I, Division 1, Groups A, B, C, D. Temp Code – T4 at 60 °C

IS outputs for Ex de [ia] IIB or IIC T6

NOTE

For the 8732E transmitters with a local operator interface (LOI), the lower ambient

temperature limit is -20 °C.

North American Certifications

FM Approvals

N0 Non-incendive for Class I, Division 2

Groups A, B, C, and D non-flammable fluids

(T4 at 60 °C: -50 °C Ta +60 °C)

Dust-ignition proof Class II/III, Division 1

Groups E, F, and G (T5 at 60 °C)

Hazardous Locations; Enclosure Type 4X

N5 Non-incendive for Class I, Division 2,

Groups A, B, C, and D flammable fluids

(T4 at 60 °C: -50 °C Ta +60 °C)

Dust-ignition proof Class II/III, Division 1

Groups E, F, and G (T5 at 60 °C)

Hazardous Locations; Enclosure Type 4X

Requires sensors with N5 Approval

Rosemount 8732

E5 Explosion proof for Class I, Division 1

Groups C and D (T6 at 60 °C)

Dust-ignition proof Class II/III, Division 1

Groups E, F, and G (T5 at 60 °C),

Non-incendive for Class I, Division 2

Groups A, B, C, and D flammable fluids

(T4 at 60 °C: -50 °C Ta +60 °C)

Hazardous Locations; Enclosure Type 4X

Canadian Standards Association (CSA)

N0 Non-incendive for Class I, Division 2

Groups A, B, C, and D non-flammable fluids

(T4 at 60 °C: -50 °C Ta +60 °C)

Dust-ignition proof Class II/III, Division 1

Groups E, F, and G (T4 at 60 °C)

Hazardous Locations; Enclosure Type 4X

29

Page 30

Rosemount 8732

European Certifications

E1 ATEX Flameproof

Certificate No: KEMA 07ATEX0073 X

II 2G Ex de IIC T6 or

II 2G Ex de [ia] IIC T6

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

0575

ED ATEX Flameproof

Certificate No.: KEMA 07ATEX0073 X II 2G

Ex de IIB or Ex de [ia] IIB T6 (-50°C Ta +60 °C)

with LOI (-20°C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

0575

ND ATEX Dust

Certificate No: KEMA 07ATEX0073 X

II 1D Ex tD A20 IP66 T100 °C or

with I.S. outputs

II G [Ex ia] IIC

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

IP 66

0575

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

Special conditions for safe use (KEMA 07ATEX0073 X):

Contact Rosemount Inc. for information on the dimensions of the flameproof joints. The

property class of the security screws which attach the flowtube or junction box to the

transmitter is SST A2-70, or SST A4-70.

Installation Instructions:

The cable and conduit entry devices and blanking elements shall be of a certified

flameproof or increased safety type, suitable for the conditions of use and correctly

installed. With the use of conduit, a certified stopping box shall be provided immediately

to the entrance of the enclosure.

30

Page 31

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

N1 ATEX Type n

Certificate No: Baseefa 07ATEX0203X

II 3G Ex nA nL IIC T4

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 42 V DC

max

IP 66

0575

Special conditions for safe use (x):

The apparatus is not capable of withstanding the 500V insulation test required by

Clause 6.8.1 of EN 60079-15: 2005. This must be taken into account when installing the

apparatus.

International Certifications

IECEx

E7 IECEx Flameproof

Certificate No: KEM 07.0038X

Ex IIC or Ex de [ia] IIC T6

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

Rosemount 8732

EF IECEx Flameproof

Certificate No: KEM 07.0038X

Ex de IIB or Ex de [ia] IIB T6

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

NF IIECEx Dust

Certificate No: KEM 07.0038X

Ex tD A20 IP66 T 100 °C

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

Special conditions for safe use (KEM 07.0038X):

Contact Rosemount Inc. for information on the dimensions of the flameproof joints. The

property class of the security screws which attach the flowtube or junction box to the

transmitter is SST A2-70, or SST A4-70.

Installation Instructions:

The cable and conduit entry devices and blanking elements shall be of a certified

flameproof or increased safety type, suitable for the conditions of use and correctly

installed. With the use of conduit, a certified stopping box shall be provided immediately

to the entrance of the enclosure.

31

Page 32

Quick Installation Guide

00825-0100-4665, Rev AB

Rosemount 8732

N7 IECEx Type n

Certificate No: IECEx BAS 07.0062X

Ex nA nL IIC T4

with FISCO / FNICO output

Ex nA nL [ia] IIC T4

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 42 V DC

max

Special conditions for safe use (x)

The apparatus is not capable of withstanding the 500V insulation test required by

Clause 6.8.1 of IEC 60079-15: 2005. This must be taken into account when installing

the apparatus.

NEPSI - China

E3 NEPSI Flameproof

Certificate No: GYJ071438X

Ex de IIC T6 or Ex de [ia] IIC T6

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

EP NEPSI Flameproof

Certificate No: GYJ071438X

Ex de IIB T6 or Ex de [ia] IIB T6

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

December 2012

InMetro - Brazil

E2 InMetro Flameproof

Certificate No: NCC 12.1177 X

Ex de IIC T6 Gb IP66 or

Ex de [ia IIC Ga] IIC T6 Gb IP66

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

EB InMetro Flameproof

Certificate No: NCC 12.1177 X

Ex de IIB T6 Gb IP66 or

Ex de [ia IIC Ga] IIB T6 Gb IP66

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

32

Page 33

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

KOSHA - Korea

E9 KOSHA Flameproof

Certificate No: 2008-2094-Q1X

Ex de IIC or Ex de [ia] IIC T6

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

EK KOSHA Flameproof

Certificate No: 2008-2094-Q1X

Ex de IIB or Ex de [ia] IIB T6

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

V

= 250 V AC or 42 V DC

max

GOST - Russia

E8 GOST Flameproof

Ex de IIC T6 or Ex de [ia] IIC T6

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

IP67

EM GOST Flameproof

Ex de IIB T6 or Ex de [ia] IIB T6

without LOI (-50 °C Ta +60 °C)

with LOI (-20 °C Ta +60 °C)

IP67

Rosemount 8732

33

Page 34

Quick Installation Guide

00825-0100-4665, Rev AB

Rosemount 8732

December 2012

Sensor Approval Information

For

(1)

Rosemount 8707

Sensor

For Non-

flammable

Fluids

Flammable

For

Fluids

Rosemount 8711

Sensor

For Non-

flammable

Fluids

Flammable

For

Fluids

Table 12. Sensor Option Codes

Rosemount 8705

Sensor

For Non-

Approval

Codes

E5

(1) CE Marking is standard on Rosemount 8705, 8711, and 8721.

(2) Available in line sizes up to 8 in. (200 mm) only.

flammable

Fluids

NA • •

N0 • • •

ND • • • • • • •

N1 • • • •

N5 • • • • • •

N7 • • • •

NF • • • •

E1 • • • •

E2 • • • •

E3 • • • •

(2)

E8 • • • •

E9 • • • •

EB • • • •

EK • • • •

EM • • • •

EP • • • •

KD • • • •

Flammable

Fluids

• • • •

Rosemount

8721

Sensors

For Non-

flammable

Fluids

34

Page 35

Quick Installation Guide

EC Declaration of Conformity

No: RFD 1068 Rev. E

FILE ID: 8732E CE Marking Page 1 of 3 8732E_RFD1068E.DOC

We,

Rosemount Inc.

12001 Technology Drive

Eden Prairie, MN 55344-3695

USA

declare under our sole responsibility that the product(s),

Model 8732E Magnetic Flowmeter Transmitter

manufactured by,

Rosemount Inc.

12001 Technology Drive and 8200 Market Boulevard

Eden Prairie, MN 55344-3695 Chanhassen, MN 55317-9687

USA USA

to which this declaration relates, is in conformity with the provisions of the European

Community Directives, including the latest amendments, as shown in the attached schedule.

Assumption of conformity is based on the application of harmonized or applicable technical

standards and, when applicable or required, a European Community notified body certification,

as shown in the attached schedule.

Mark J Fleigle

Vice President Technology and New Products

January 21, 2010

(date of issue)

(name - printed)

(function name - printed)

(signature)

00825-0100-4665, Rev AB

December 2012

Figure 25. Declaration of Conformity

Rosemount 8732

35

Page 36

Rosemount 8732

Schedule

EC Declaration of Conformity RFD 1068 Rev. E

FILE ID: 8732E CE Marking Page 2 of 3 8732E_RFD1068E.DOC

EMC Directive (2004/108/EC)

All Models

EN 61326-1: 2006

LVD Directive (2006/95/EC)

All Models

EN 61010-1: 2001

ATEX Directive (94/9/EC)

Model 8732E Magnetic Flowmeter Transmitter

KEMA 07ATEX0073 X – Flameproof, with Increased Safety Terminal(s),

Intrinsically Safe Output(s), Dust

Equipment Group II, Category 2 G:

Ex d IIB/IIC T6

Ex de IIB/IIC T6

Ex e IIB/IIC (Junctionbox)

Equipment Group II, Category 2 (1) G:

Ex de [ia] IIB/IIC T6 (Transmitter)

Equipment Group II, Category (1) G

[Ex ia] IIC

Equipment Group II, Category 1 D:

Ex tD A20 IP66 T100 ºC

EN 60079-0: 2006

EN 60079-1: 2007

EN 60079-7: 2007

EN 60079-11: 2007

EN 60079-26: 2004

EN 60079-27: 2006

EN 61241-0: 2006

EN 61241-1: 2004

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

36

Page 37

Quick Installation Guide

Schedule

EC Declaration of Conformity RFD 1068 Rev. E

FILE ID: 8732E CE Marking Page 3 of 3 8732E_RFD1068E.DOC

BASEEF07ATEX0203X – Type n, Intrinsically Safe Output

Equipment Group II, Category 3 G

Ex nA nL IIC T4

Equipment Group II, Category 3(1) G

Ex nA nL [ia] IIC T4

EN 60079-0: 2006

EN 60079-15: 2005

EN 60079-11: 2007

ATEX Notified Bodies for EC Type Examination Certificate

KEMA [Notified Body Number: 0344]

Utrechtseweg 310, 6812 AR Arnhem

P.O. Box 5185, 6802 ED Arnhem

The Netherlands

Postbank 6794687

Baseefa [Notified Body Number: 1180]

Rockhead Business Park, Staden Lane

Buxton, Derbyshire SK17 9RZ

United Kingdom

ATEX Notified Body for Quality Assurance

Det Norske Veritas (DNV) [Notified Body Number: 0575]

Veritasveien 1, N-1322

Hovik, Norway

00825-0100-4665, Rev AB

December 2012

Rosemount 8732

37

Page 38

Rosemount 8732

NOTES

Quick Installation Guide

00825-0100-4665, Rev AB

December 2012

38

Loading...

Loading...