Rosemount 3051SMV, 3051S, 3051SF Series Quick Installation Manual

Quick Installation Guide

Step 1: Mount the Transmitter

Step 2: Consider Housing Rotation

Step 3: Set Switches

Step 4: Connect Wiring and Power Up

Step 5: Flow Configuration

Step 6: Verify Device Configuration

Step 7: Trim the Transmitter

Product Certifications

Start

End

00825-0100-4803, Rev BA

April 2011

Rosemount 3051SMV

Rosemount 3051S MultiVariable™

Transmitter

Rosemount 3051SF Series Flowmeter

MultiVariable Transmitter

¢00825-0100-4801J¤

www.rosemount.com

Quick Installation Guide

IMPORTANT NOTICE

WARNING

00825-0100-4803, Rev BA

Rosemount 3051SMV

© 2011 Rosemount Inc. All rights reserved. All marks property of owner. Rosemount and the

Rosemount logotype are registered trademarks of Rosemount Inc.

Rosemount Inc.

8200 Market Boulevar d

Chanhassen, MN USA 55317

T (US) (800) 999-9307

T (Intnl) (952) 906-888 8

F (952) 949-7001

Emerson Process Management

Asia Pacific Private Limited

1 Pandan Crescent

Singapore 128461

T (65) 6777 8211

F (65) 6777 0947/65 6777 0743

This installation guide provides basic guidelines for the Rosemount 3051S MultiVariable

transmitter (reference manual document number 00809-0100-4803). It also provides the

basic 3051S MultiVariable transmitter configuration guidelines for the 3051SFA (reference

manual document number 00809-0100-4 809), 3051SFC (reference manual docume nt

number 00809- 0100-4810), and 3051SFP (refere nce manual document number

00809-0100-468 6). It does not provide ins tructions for diagno stics, mainten ance, service , or

troubleshooting. Refer to the 3051S MultiVariable transmitter reference manual for more

instruction. All documents are available electronically at

www.emersonprocess.com/rosemount.

Emerson Process Management

GmbH & Co. OHG

Argelsrieder Feld 3

82234 Wessling

Germany

T 49 (8153) 9390 , F49 (8153) 939172

Beijing Rosemount Far East Instrument

Co., Limited

No. 6 North Street, Hepingli, Dong Cheng District

Beijing 100013, China

T (86) (10) 6428 2233

F (86) (10) 6422 8586

April 2011

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in accordance with the

appropriate local, na tional, and internati onal sta ndards, codes, a nd practices. P lease review

the approvals sec tion of the 3051S MultiVariable transmitter reference manual

(00809-0100-4803) for any restrictions associated with a safe installation.

• Before connecting a Field communica tor in an explosive atmosphere, ensure the

instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

• In an Explosion-proof/Flameproof installation, do not remove the transmitter covers

when power is applied to the unit.

Process leaks may cause harm or result in death.

• Install and tighten process connectors before applying pressure.

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock.

2

Quick Installation Guide

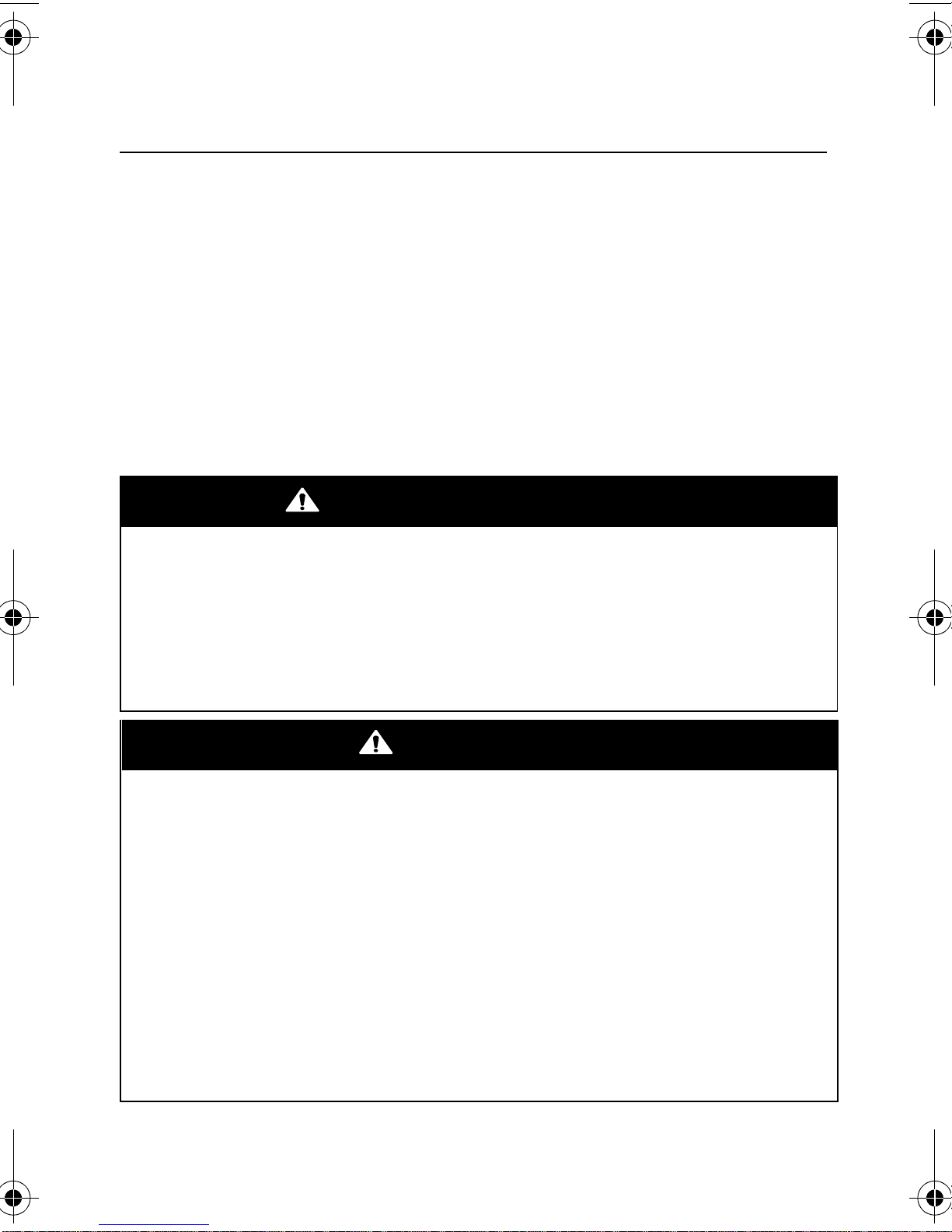

STEP 1: MOUNT THE TRANSMITTER

00825-0100-4803, Rev BA

April 2011

Liquid Flow Applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Mount the transmitter so that the

drain/vent valves are oriented

upward.

Gas Flow Applications

1. Place taps in the top or side of

Rosemount 3051SMV

the line.

2. Mount beside or above the taps.

Steam Flow Applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Fill impulse lines with water.

3

Quick Installation Guide

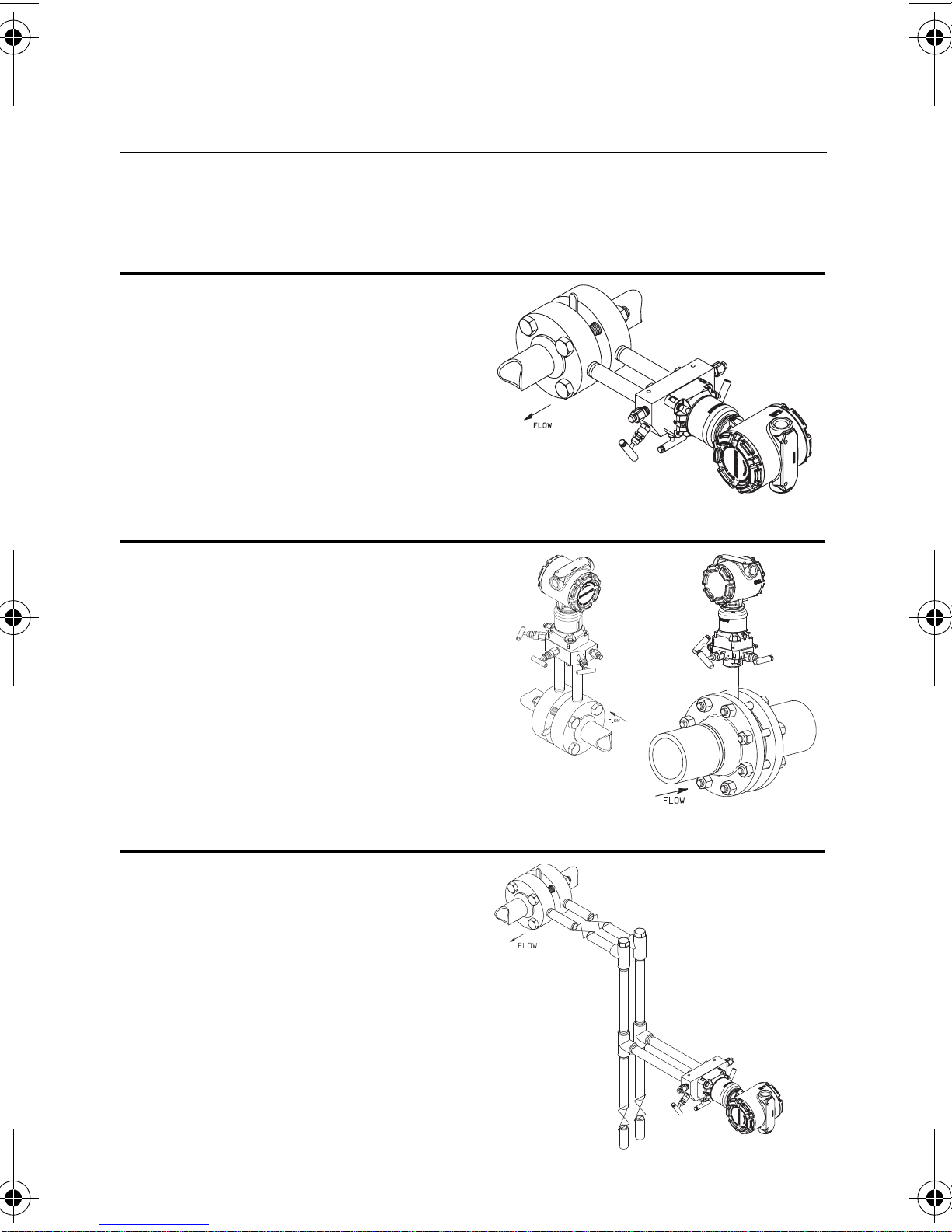

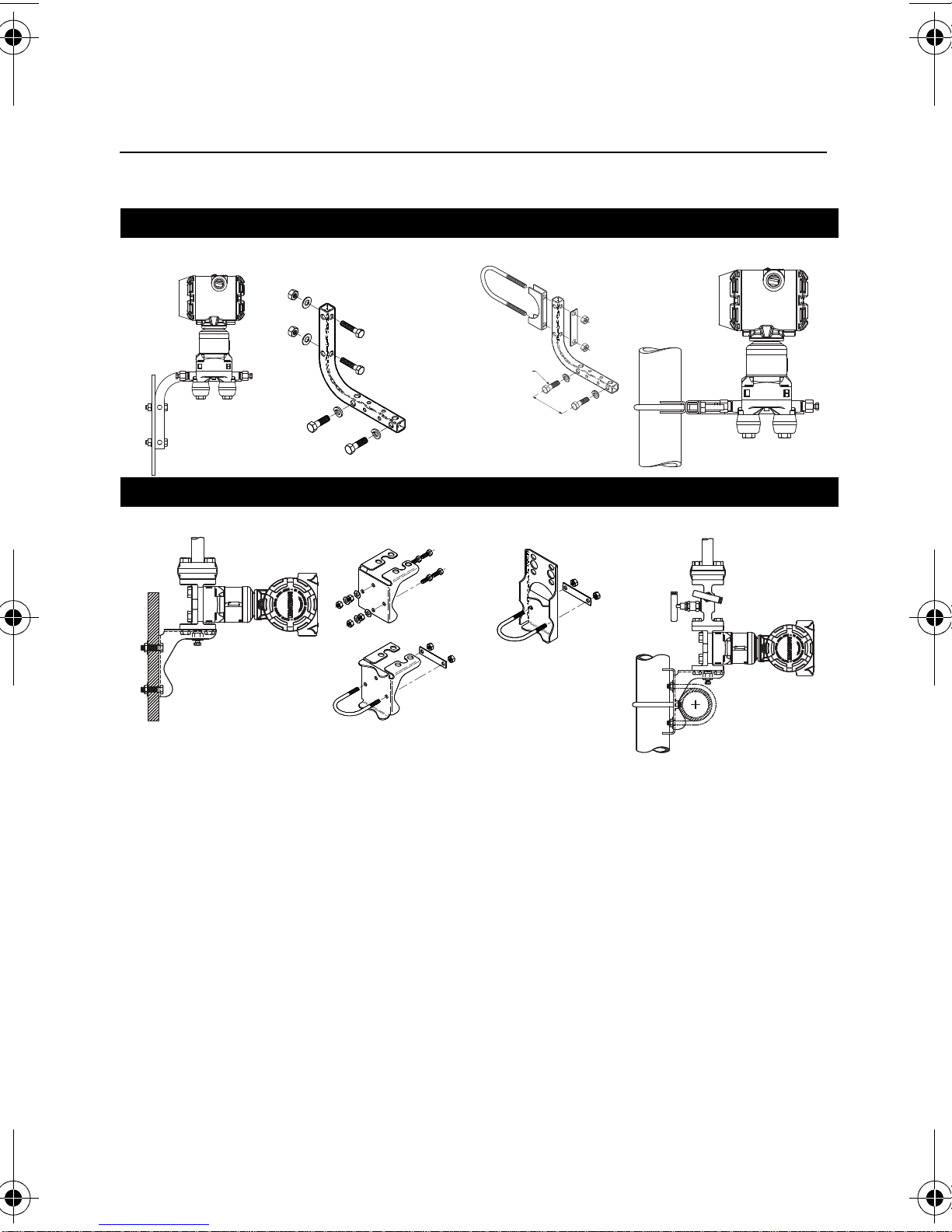

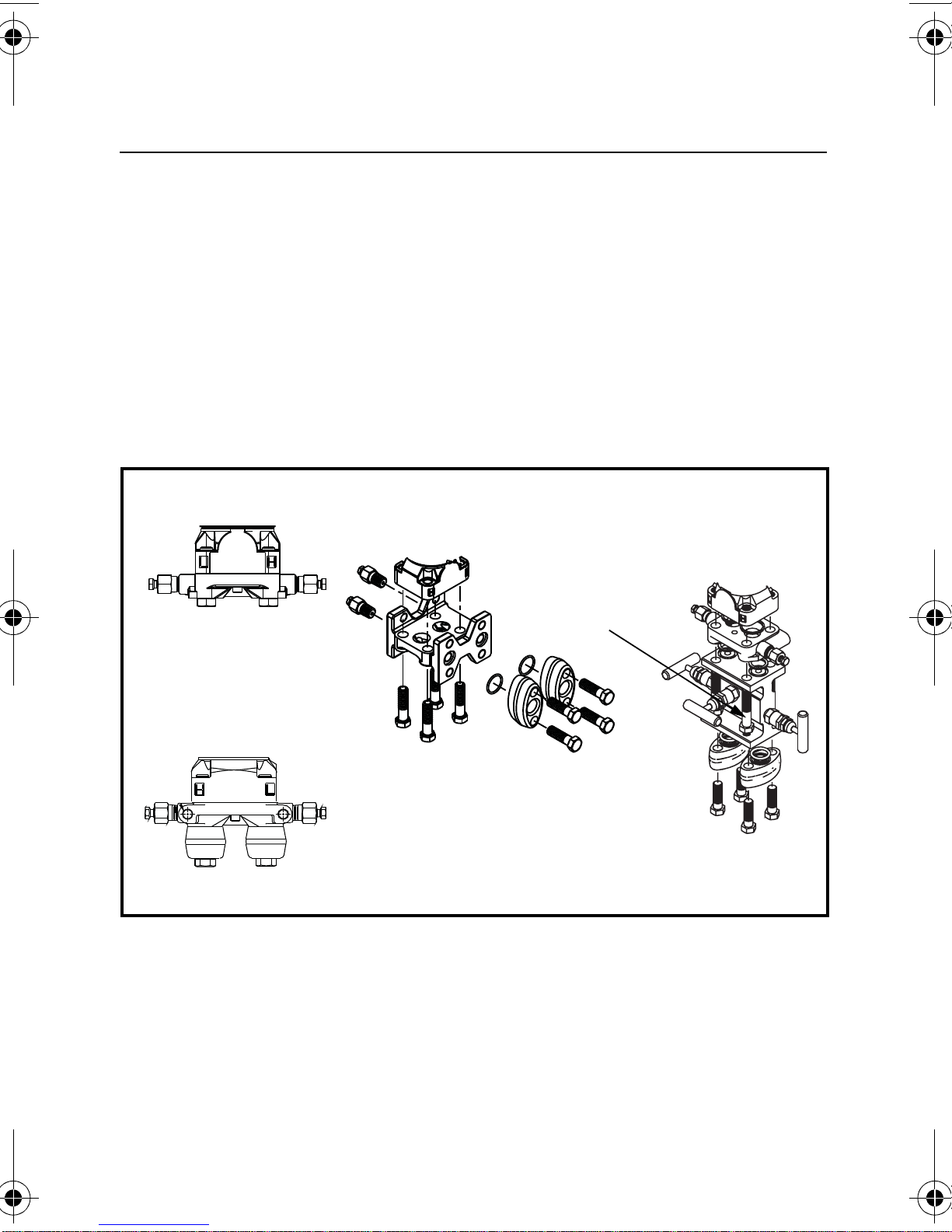

Pipe MountPanel Mount

Pipe Mount

Panel Mount

00825-0100-4803, Rev BA

Rosemount 3051SMV

Mounting Brackets

Coplanar™ Flange

Tr aditional Flange

April 2011

4

Quick Installation Guide

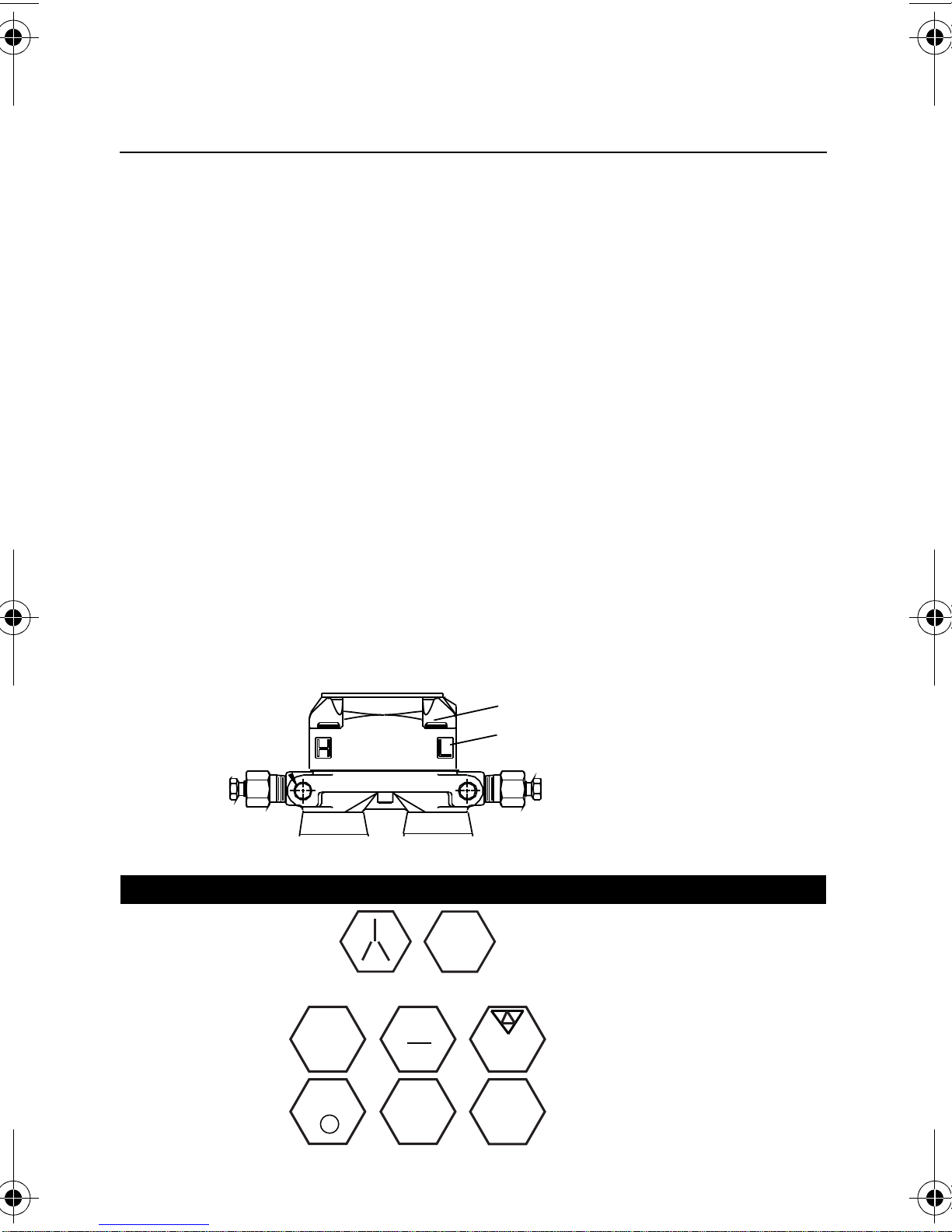

4 x 1.75-in.

(44 mm)

4 x 2.88-in.

(73 mm)

A. Transmitter with

Coplanar Flange

B. Transmitter with

Coplanar Flange and

Optional Flange

Adapters

C. Transmitter with

Traditional Flange and

Optional Flange

Adapters

D. Transmitter with

Coplanar Flange

and Optional

Manifold and Flange

Adapters

4 x 1.75-in.

(44 mm)

4 x 1.50-in.

(38 mm)

4 x 1.75-in.

(44 mm)

4 x 2.25-in.

(57 mm)

00825-0100-4803, Rev BA

April 2011

Rosemount 3051SMV

Bolting Considerations

If the transmitter installation requires assembly of a process flange,

manifold, or flange adaptors, follow these assembly guidelines to

ensure a tight seal for optimal performance characteristics of the

transmitter. Only use bolts supplied with the transmitter or sold by

Emerson Process Management as spare parts. Figure 1 illustrates

common transmitter assemblies with the bolt length required for

proper transmitter assembly.

Figure 1. Common Transmit ter Assemblies

5

Quick Installation Guide

Module Isolator Plate

Bolt

B7M

316

316

316

SW

316

STM

316

R

B8M

00825-0100-4803, Rev BA

Rosemount 3051SMV

April 2011

Bolts are typically carbon steel or stainless steel. Confirm the material

by viewing the markings on the head of the bolt and referencing

Figure 3. If bolt material is not shown in Figure 3, contact the local

Emerson Process Management representative for more information.

Use the following bolt installation procedure:

1. Carbon steel bolts do not require lubrication and the stainless steel

bolts are coated with a lubricant to ease installation. However, no

additional lubricant should be applied when installing either type of

bolt.

2. Finger-tighten the bolts.

3. Torque the bolts to the initial torque value using a crossing p attern.

See Figure 3 for initial torque value.

4. Torque the bolts to the final torque value using the same crossing

pattern. See Figure 3 for final torque value.

5. Verify that the flange bolts are protruding through the module

isolator plate before applying pressure.

Figure 2. Module Isolator Plate

Figure 3. Torque Values for the Flange and Flange Adap ter Bolts

Bolt Material Head Markings Initial T orque Final Torque

Carbon Steel

(CS)

Stainless Steel

(SST)

300 in.-lbs. 650 in.-lbs.

150 in.-lbs. 300 in.-lbs.

6

Quick Installation Guide

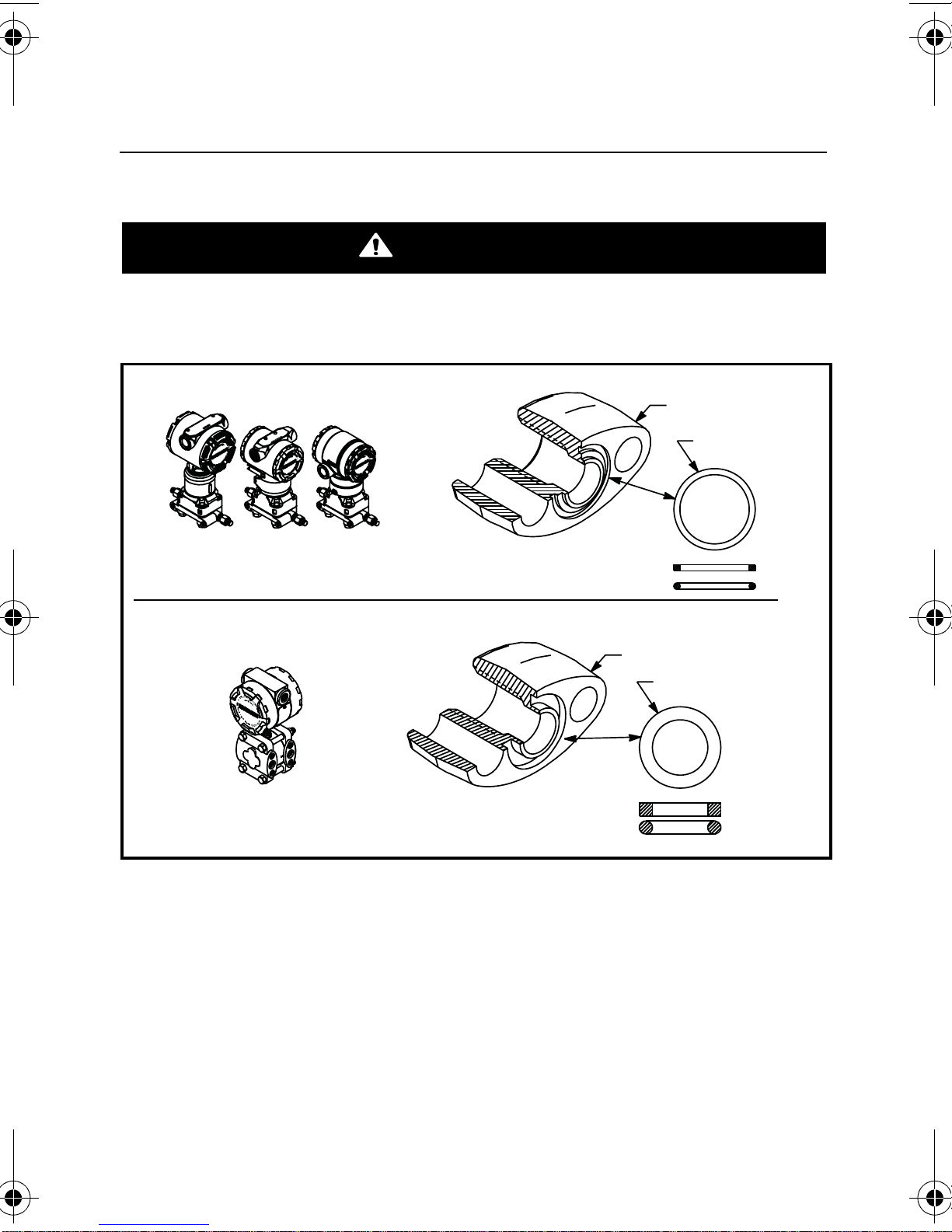

WARNING

Rosemount 3051S / 3051 / 2051 / 3095

Rosemount 1151

Flange Adapter

O-ring

Flange Adapter

O-ring

PTFE Based

Elastomer

PTFE

Elastomer

00825-0100-4803, Rev BA

April 2011

Rosemount 3051SMV

O-rings with Flange Adaptors

Failure to install proper flange adapter O-rings may cause process leaks, which

can result in death or serious injury. The two flange adapters are distinguished

by unique O-ring grooves. Only use the O-ring that is designed for its specific

flange adapter, as shown below.

Whenever the flange or adapters are removed, visually inspect the

o-rings. Replace them if there are any signs of damage, such as nicks

or cuts. If the o-rings are replaced, re-torque the flange bolts and

alignment screws after installation to compensate for seating of the

o-rings.

7

Quick Installation Guide

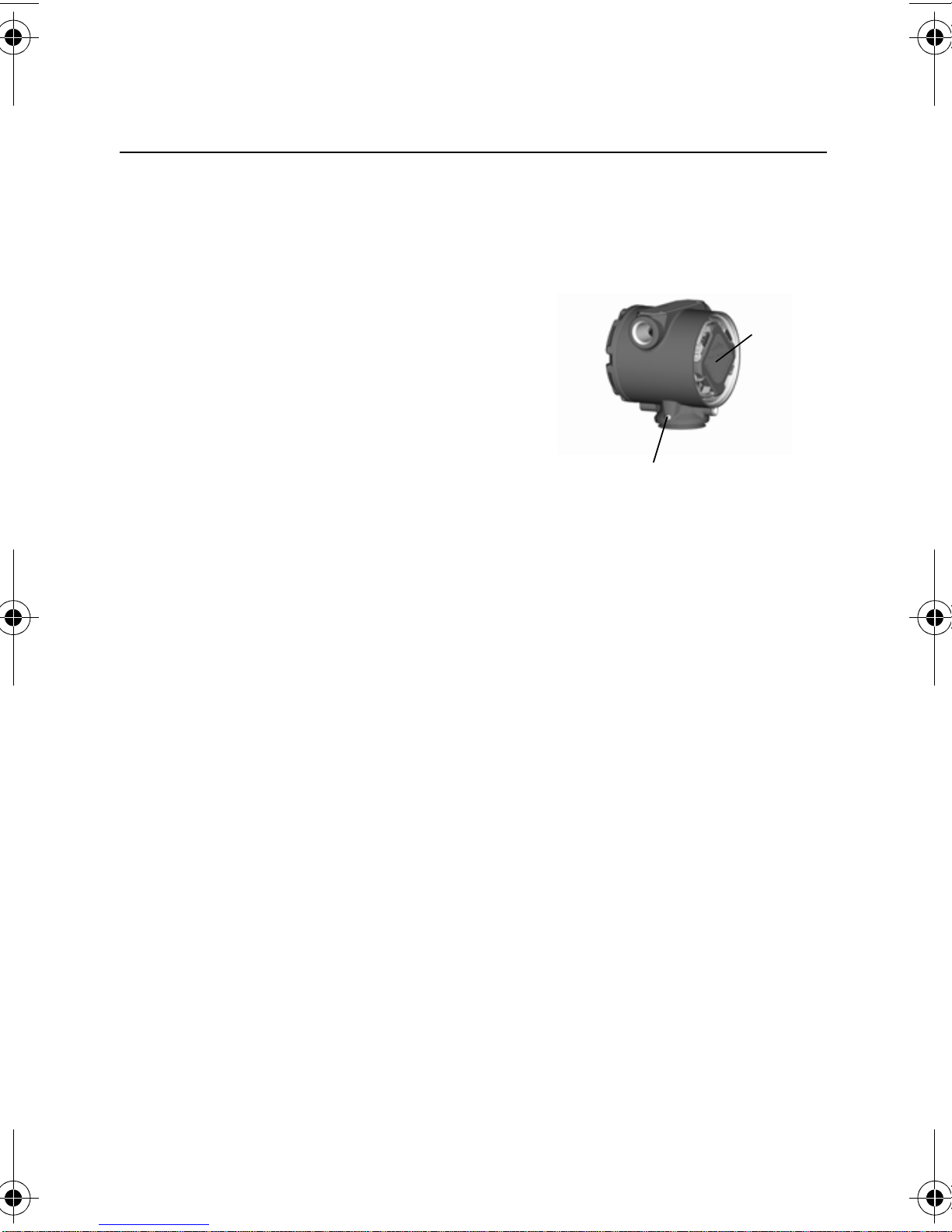

STEP 2: CONSIDER HOUSING ROTATION

Housing Rotation Set Screw

(3/32-in.)

Feature

Board

00825-0100-4803, Rev BA

Rosemount 3051SMV

To improve field access to wiring or to

better view the optional LCD display:

Figure 4. T ransmitter Housing

Set Screw

April 2011

1. Loosen the housing rotation set

screw.

2. Turn the housing up to 180° left or

right of its original (as shipped)

position.

3. Retighten the housing rotation set

screw.

NOTE

Do not rotate the housing more than 180° wit hout first performing a

disassembly procedure (see Section 4 of the 3051S MultiVariable transmitter

reference manual (00809-0100-4803) for more information). Over-rotation

may sever the electrical connection between the sensor module and the

feature board electronics.

8

Quick Installation Guide

STEP 3: SET SWITCHES

Alarm

Security

00825-0100-4803, Rev BA

April 2011

The transmitter’s default configuration sets the alarm condition to high

(HI) and the security to off.

1. If the transmitter is installed, secure the loop and remove power.

2. Remove the housing cover opposite the field terminals side. Do not

remove the housing cover in explosive environments.

3. Slide the security and alarm switches into the preferred position by

using a small screwdriver.

4. Reinstall the housing cover so that metal contacts metal to meet

explosion-proof requirements.

Figure 5. Transmitter Switch Configuration

Rosemount 3051SMV

9

Quick Installation Guide

STEP 4: CONNECT WIRING AND POWER UP

IMPORTANT NOTICE

00825-0100-4803, Rev BA

Rosemount 3051SMV

NOTE

Do not connect the power across the test terminals. Power could damage the

test diode in the test connection. Twisted pa irs yield best result s. Use 24 A WG to

14 AWG wire and do not exceed 5,000 feet (1500 meters).

Use the following steps to wire the transmitter:

1. Remove the cover on the field terminals side of the housing.

2. Connect the positive lead to the “PWR/COMM +” terminal, and the

negative lead to the “PWR/COMM –” terminal.

3. If the optional process temperature input is not installed, plug and

seal the unused conduit connection. If the optional process

temperature input is being utilized, see “Install Optional Process

Temperature Input (Pt 100 RTD Sensor)” on page 13 for more

April 2011

information.

When the enclosed pipe plug is utilized in the conduit opening, it must be

installed with a minimum engagement of five threads in order to comply with

explosion-proof requirements. Refer to the 3051S MultiVariable transmitter

reference manual (document number 00809-0100-4803) for more information.

4. If applicable, install wiring with a drip loop. Arrange the drip loop

so the bottom is lower than the conduit connections and the

transmitter housing.

5. Reinstall the housing cover and tighten so that metal contacts

metal to meet explosion-proof requirements.

10

Quick Installation Guide

RL 250

Power

Supply

Power

Supply

RL 250

00825-0100-4803, Rev BA

April 2011

Rosemount 3051SMV

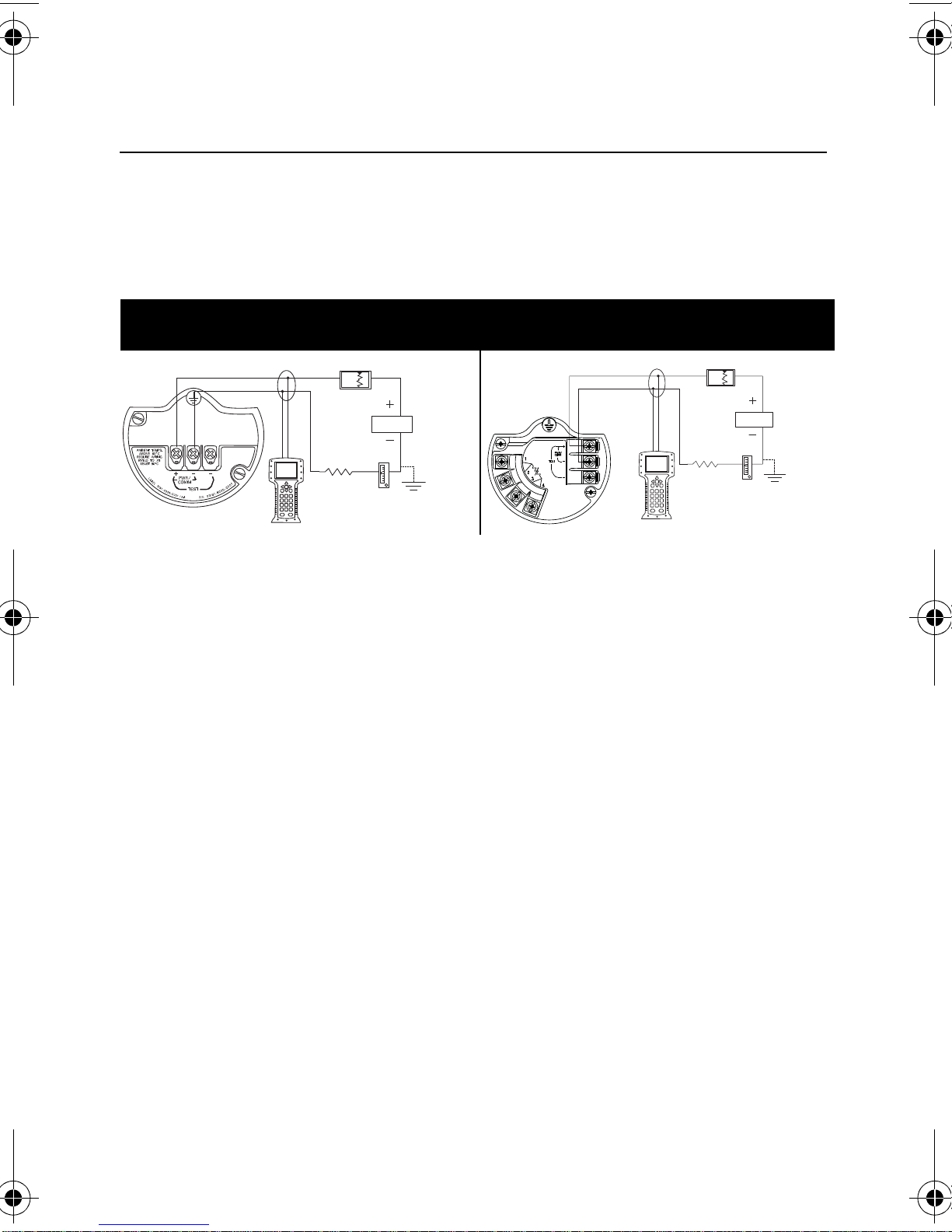

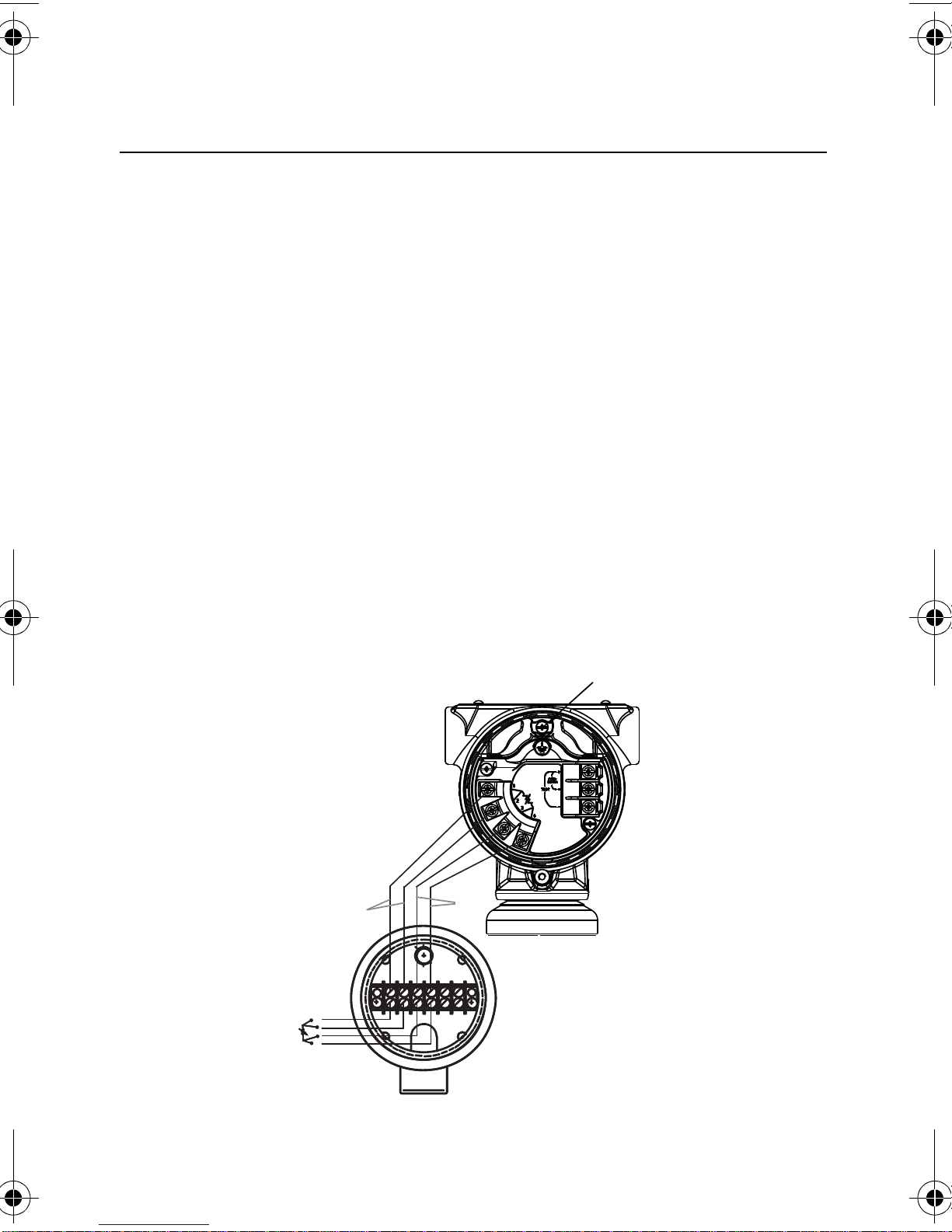

Figure 6 shows the wiring connections necessary to power a 3051S

MultiV ariable transmitter and enable communications with a hand-held

Field Communicator.

Figure 6. Transmitter Wiring

3051SMV without Optional Process

Temper at u r e C o nn e c t io n

3051SMV with Optional Process

Temperature Connection

NOTE

Installation of the tran sient protectio n terminal block does no t provide transient

protection unless the 3051S MultiVariable transmitter housing is properly

grounded.

Conduit Electrical Connector Wiring (Option GE or GM)

For 3051S MultiV ariable transmitters with conduit electrical connectors

GE or GM, refer to the cordset manufacturer’s installation instructions

for wiring details. For FM Intrinsically Safe, Division 2 hazardous

locations, install in accordance with Rosemount drawing 03151-1009

to maintain outdoor rating (NEMA 4X and IP66.) See Appendix B of

the 3051S MultiVariable transmitter reference manual

(00809-0100-4803).

11

Quick Installation Guide

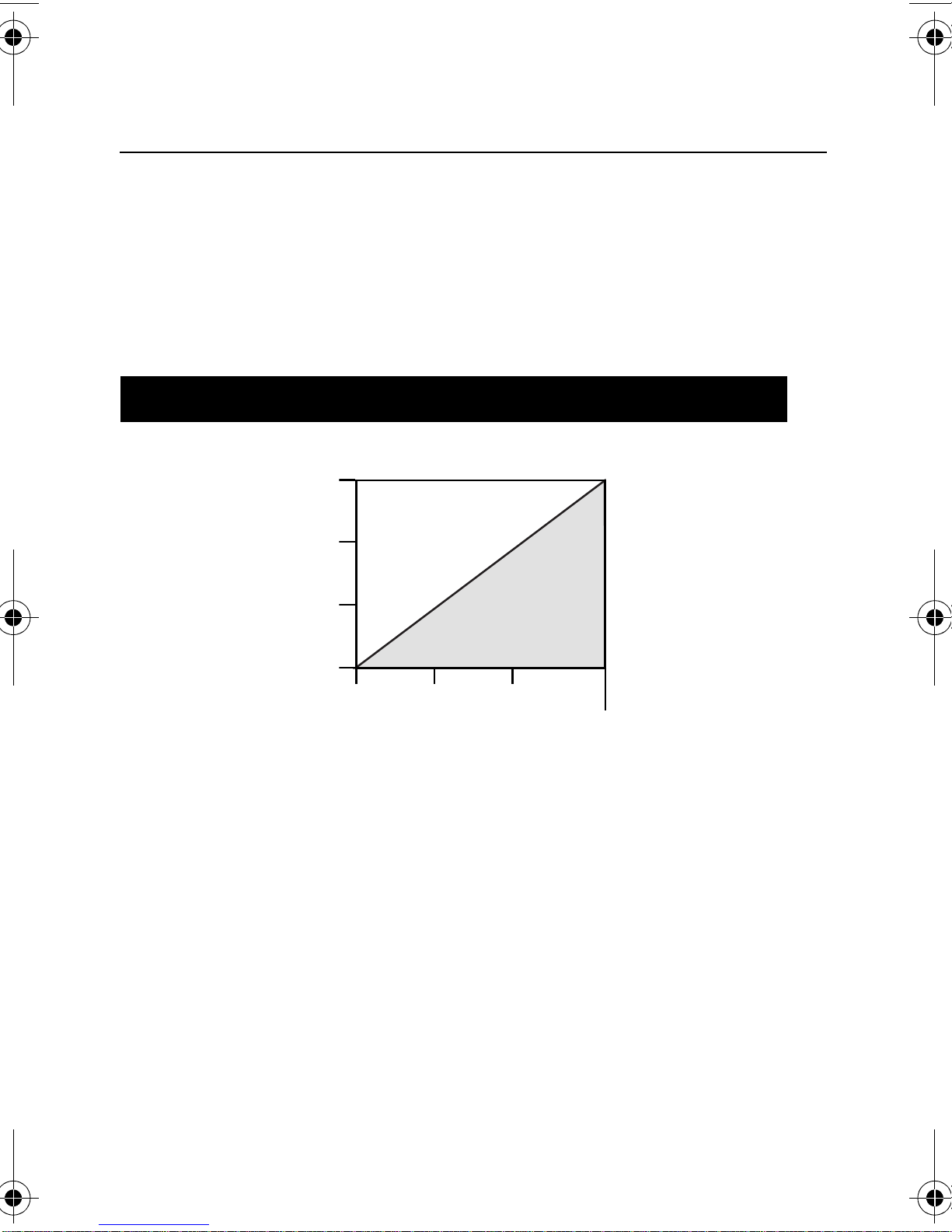

Voltage (Vdc)

Load (Ohms)

Operating

Region

1322

1000

500

0

12.0 20 30

42.4

00825-0100-4803, Rev BA

Rosemount 3051SMV

April 2011

Power Supply

The dc power supply should provide power with less than two percent

ripple. The total resistance load is the sum of the resistance of the

signal leads and the load resistance of the controller, indicator , intrinsic

safety barriers, and related components.

Figure 7. Load Limitation

3051S MultiVariable Transmitter

Maximum Loop Resistance = 43.5 x (Power Supply Voltage – 12.0)

HART communication requires a minimum

12

loop resistance of 250.

Quick Installation Guide

RTD Cable Assembly

Wires

Red

White

Pt 100

RTD

Sensor

Ground Lug

00825-0100-4803, Rev BA

April 2011

Rosemount 3051SMV

Install Optional Process Temperature Input

(Pt 100 RTD Sensor)

NOTE

To meet ATEX/IECEx Flameproof certification, only ATEX/IECEx Flameproof

Cables (Temperature Input Code C30, C32, C33, or C34) may be used.

1. Mount the Pt 100 RTD Sensor in the appropriate location.

NOTE

Use shielded four-wire cable for the process temperature connection.

2. Connect the RTD cable to the 3051S MultiVariable transmitter by

inserting the cable wires through the unused housing conduit and

connect to the four screws on the transmitter terminal block. An

appropriate cable gland should be used to seal the conduit opening

around the cable.

3. Connect the RTD cable shield wire to the ground lug in the

housing.

Figure 8. 3051S MultiVariable Transmitter RTD Wiring Connection

13

Quick Installation Guide

STEP 5: FLOW CONFIGURATION

00825-0100-4803, Rev BA

Rosemount 3051SMV

April 2011

Engineering Assistant 6.1 or Later

The 3051SMV Engineering Assistant 6.1 or later is PC-based software

that performs configuration, maintenance, diagnostic functions, and

serves as the primary communication interface to the 3051S

MultiVariable transmitter with the Fully Compensated Mass and

Energy Flow Feature Board.

The 3051SMV Engineering Assistant software is required to complete

the flow configuration.

Installation and Initial Setup

The following are the minimum system requirements to install the

3051SMV Engineering Assistant software:

• Pentium-grade Processor: 500 MHz or faster

• Operating System: Windows 2000(32-bit), Windows XP

Professional (32-bit), or Windows 7 (32-bit)

• 256 MB RAM

• 100 MB free hard disk space

• RS232 serial port or USB port (for use with HART modem)

• CD-ROM

14

Loading...

Loading...