Rosemount 3051SFP Operating Manual

Reference Manual

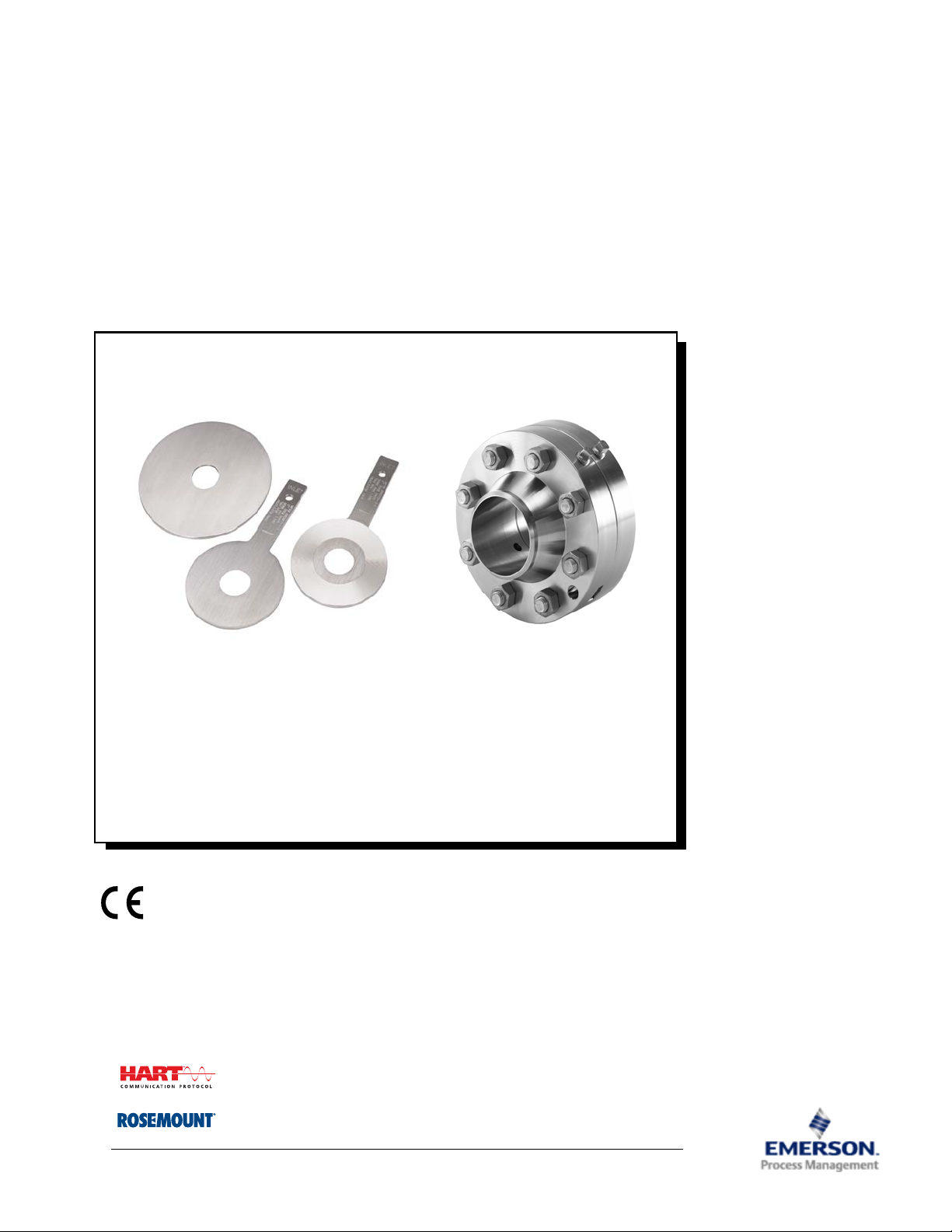

Rosemount 1495

Orifice Plate

Rosemount 1496

Orifice Flange Union

00809-0100-4792, Rev CB

February 2014

Rosemount 1495 Orifice Plate, 1496 Orifice

Flange Union

www.rosemount.com

Reference Manual

NOTICE

00809-0100-4792, Rev CB

Rosemount 1495, 1496

February 2014

Rosemount 1495 Orifice Plate

Rosemount 1496 Orifice Flange Union

Read this manual before working with the product. For personal and system safety, and for optimum product

performance, make sure you thoroughly understand the contents before installing, using, or maintaining this

product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers.

Customer Central: 1-800-999-9307 (7:00 a.m. to 7:00 p.m. CST)

Technical support, quoting, and order-related questions.

North American Response Center: 1-800-654-7768

24 hours a day – Includes Canada Equipment service needs.

For equipment service or support needs outside the United States, contact your local Emerson Process

Management representative.

The products described in this document are NOT designed for nuclear qualified applications.

Using non-nuclear qualified products in applications that require nuclear qualified hardware or products may

cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson Process Management

Sales Representative.

1

Reference Manual

00809-0100-4792, Rev CB

Contents

1Section 1: Introduction

2Section 2: Installation, location, and orientation

3Section 3: Hardware installation for Rosemount 1495 Orifice

Table of Contents

February 2014

Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Service support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Receiving and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Straight run requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Plate

1495 Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Bore types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1495 Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

1495 Weights (estimated). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4Section 4: Hardware installation for Rosemount 1496 flange

union

1496 Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

1496 Flange union components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

1496 Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

ASME B16.36-1996 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

1496 Weights (estimated) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table of Contents

3

Table of Contents

February 2014

Reference Manual

00809-0100-4792, Rev CB

AAppendix A: Specifications and reference data

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Return of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Sizing and how to order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Rosemount 1495 configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Rosemount 1496 configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Options (include with selected model number) . . . . . . . . . . . . . . . . . . . . . . . . . . .48

BAppendix B: Recommended installation requirements

Recommended Straight Run Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

ISO 5167-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

AGA Report No. 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

ASME MFC-3M-2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Bolt torque recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

CAppendix C: Calculation data sheet

4

Table of Contents

Reference Manual

00809-0100-4792, Rev CB

Section 1: Introduction

February 2014

Section 1 Introduction

Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Service support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

1.1 Using this manual

This product manual provides installation and configuration instructions for the Rosemount 1495 Orifice Plate,

Rosemount 1496 Flange Union.This section contains an explanation of each section of the manual and an

installation checklist.

Section 2: Installation, location, and orientation explains initial inspection, operating limitations, and

in what location and orientation to install the orifice plate and associated hardware.

Section 3: Hardware installation for Rosemount 1495 Orifice Plate explains how to install the Orifice

Plate in either existing orifice flanges or with the Rosemount 1495 Orifice Plate.

Section 4: Hardware installation for Rosemount 1496 Flange Union explains how to install the 1496

Flange Union.

Appendix A: Specifications and reference data supplies reference and specification data, as well as

ordering information.

Appendix B: Recommended installation requirements shows the recommended straight run

requirements and bolt torques used for orifice plate installations.

Appendix C: Calculation data sheet

Introduction

1

Section 1: Introduction

February 2014

1.2 Service support

To expedite the return process outside of the United States, contact the nearest Emerson

Process Management representative.

Within the United States, call the Rosemount National Response Center using the

1-800-654-RSMT (7768) toll-free number. This center, available 24 hours a day, will assist you

with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a Return Material

Authorization (RMA) number. The center will also ask for the process material to which the

product was last exposed.

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of and understand the hazard. If the product being returned was exposed to a

hazardous substance as defined by OSHA, a copy of the required Material Safety Data

Sheet (MSDS) for each hazardous substance identified must be included with the returned

goods.

Reference Manual

00809-0100-4792, Rev CB

Rosemount National Response Center representatives will explain the additional information

and procedures necessary to return goods exposed to hazardous substances.

1.3 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of in

accordance with local and national legislation/regulations.

2

Introduction

Reference Manual

00809-0100-4792, Rev CB

Section 2: Installation, Location, and Orientation

Section 2 Installation, location, and

orientation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Receiving and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Installation configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Straight run requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

This section describes the orientation, location and alignment limits for installing the

Rosemount 1495 Orifice Plate, 1496 Flange Union. Read it thoroughly before starting the

installation.

2.1 Safety messages

February 2014

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Please refer to the following safety messages

before performing any operation in this section.

Failure to follow these installation guidelines could result in death or serious injury:

* Make sure only qualified personnel perform the installation.

2.2 Installation checklist

The following list is a summary of the steps required to complete a Rosemount 1495 Orifice

Plate installation. If this is an entirely new installation, begin with step 1. If the Flange Union is

already in place, verify that the orifice flange size and rating match the recommended specifications, and begin with step 5.

1. Determine where the Rosemount 1495 Orifice Plate, 1496 Flange Union is to be placed

within the piping system.

2. Establish the proper orientation as determined by the intended service for the orifice plate.

3. Review Appendix B: Recommended Installation Requirements .

4. Confirm the Rosemount 1495 and/or 1496 configurations.

5. Measure the pipe’s internal diameter (ID), preferably at 1 x ID from the orifice flange

(upstream or downstream), or at the tap location for flange taps.

Installation, Location, and Orientation

3

Section 2: Installation, Location, and Orientation

February 2014

NOTE

Providing the pipe internal diameter at the time of purchase is necessary to maintain published

orifice plate accuracy.

6. Install the hardware. Refer to Section 3: Installation instructions for 1495 Orifice Plate

installation and Section 4: Hardware installation for Rosemount 1496 Flange Union for 1496

Orifice flange union installation.

7. Check for leaks.

8. Commission the orifice plate flowmeter.

2.3 Receiving and inspection

Rosemount 1495 Orifice Plates, 1496 Flange Unions are available in different models and with

different options, so it is important to inspect and know which model you have before

beginning installation.

Reference Manual

00809-0100-4792, Rev CB

Upon receipt of the shipment, check the packing list against the material received and the

purchase order. Report any damage to the carrier.

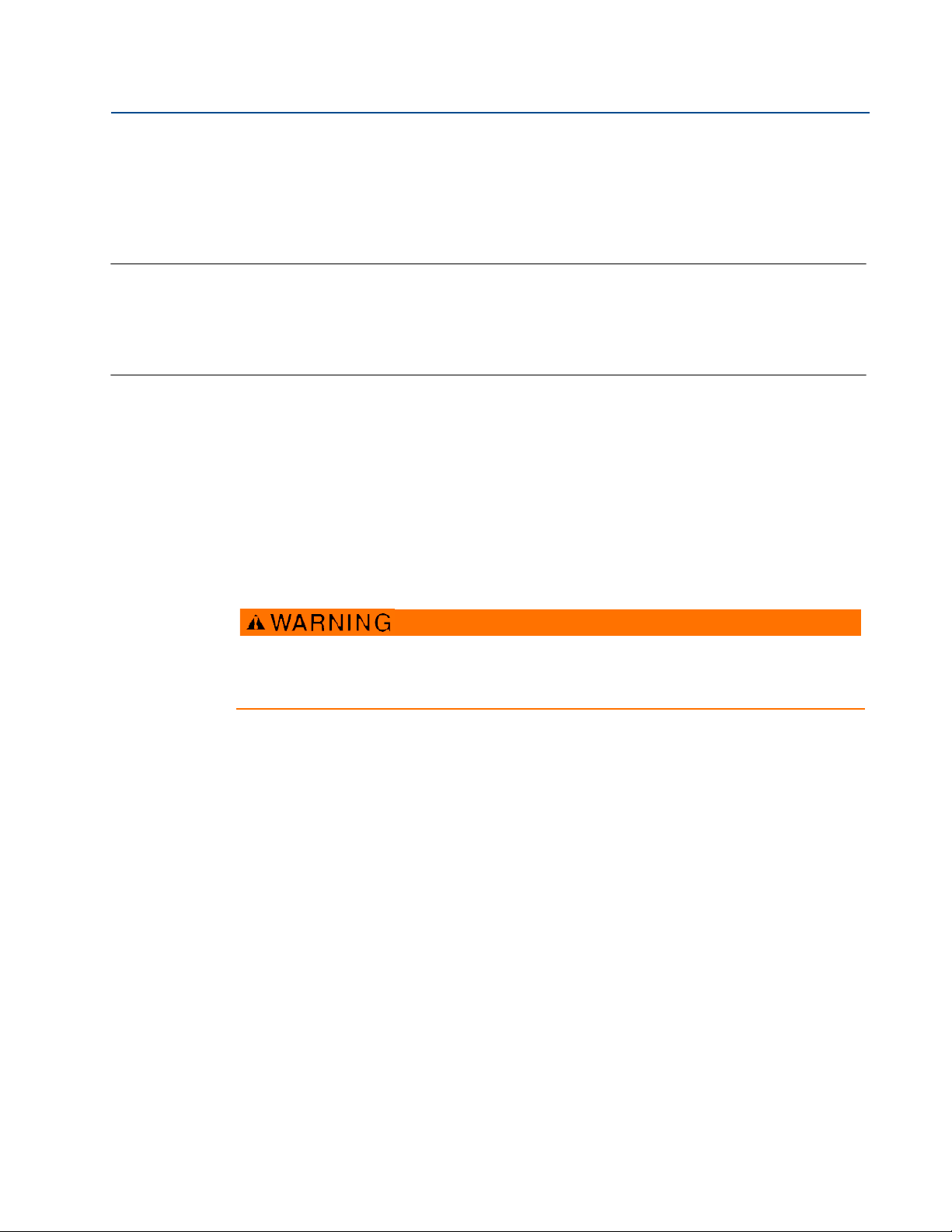

2.4 Installation configuration

The Orifice Flowmeter Assembly must be installed in the proper orientation relative to the pipe

and the fluid measured.

Gas applications

Mount hardware upward to allow moisture to drain out and not fill the impulse piping:

Slope impulse piping at least one inch per foot (8 centimeters per meter) downward

from the transmitter toward the process connection.

4

Installation, Location, and Orientation

Reference Manual

00809-0100-4792, Rev CB

Liquid applications

Mount hardware downward to allow the escape of trapped vapor in the impulse piping:

Slope impulse piping at least one inch per foot (8 centimeters per meter) upward from

Vent all gas from the liquid piping legs.

Prevent sediment deposits in the impulse piping.

Keep the liquid head balanced on both legs of the impulse piping.

Section 2: Installation, Location, and Orientation

February 2014

the transmitter toward the process connection.

Steam applications

Mount hardware to allow for a water leg in the impulse piping:

In steam or other elevated temperature services, do not allow the temperatures at the

transmitter process flanges to exceed 300 °F (149 °C).

Do not blow down impulse piping through the transmitter. Flush the lines with the

blocking valves closed and refill the lines with water before resuming measurement

Keep the liquid head balanced on both legs of the impulse piping.

Flow

Installation, Location, and Orientation

5

Section 2: Installation, Location, and Orientation

February 2014

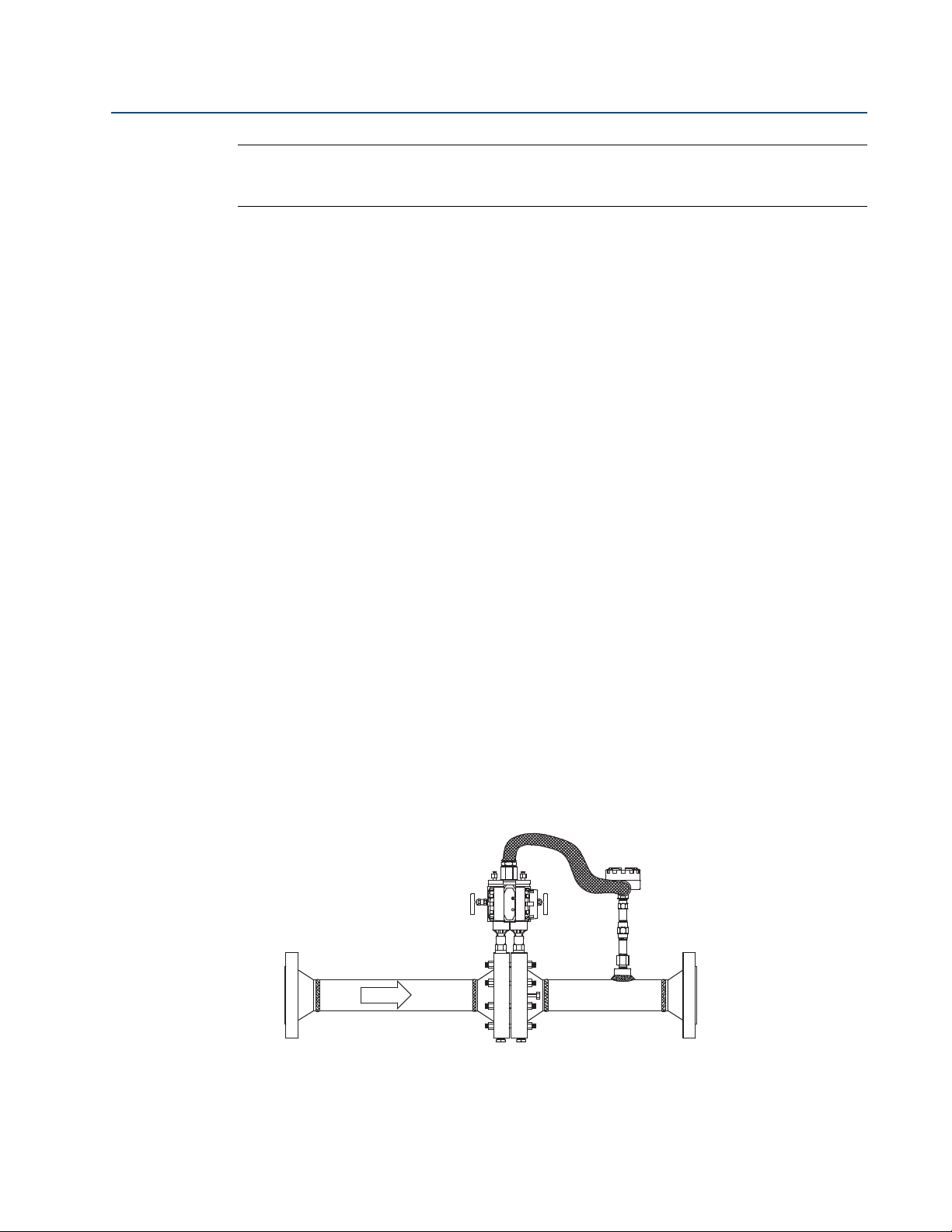

Other installation considerations:

Orient the high side of transmitter to measure upstream of the DP element.

Orient the low side of transmitter to measure downstream of the DP element.

Temperature taps and thermowells should be located downstream of the DP element.

Flow Conditioners and Straighteners are always located upstream of the DP element.

Refer to Appendix B: Recommended Installation Requirements .

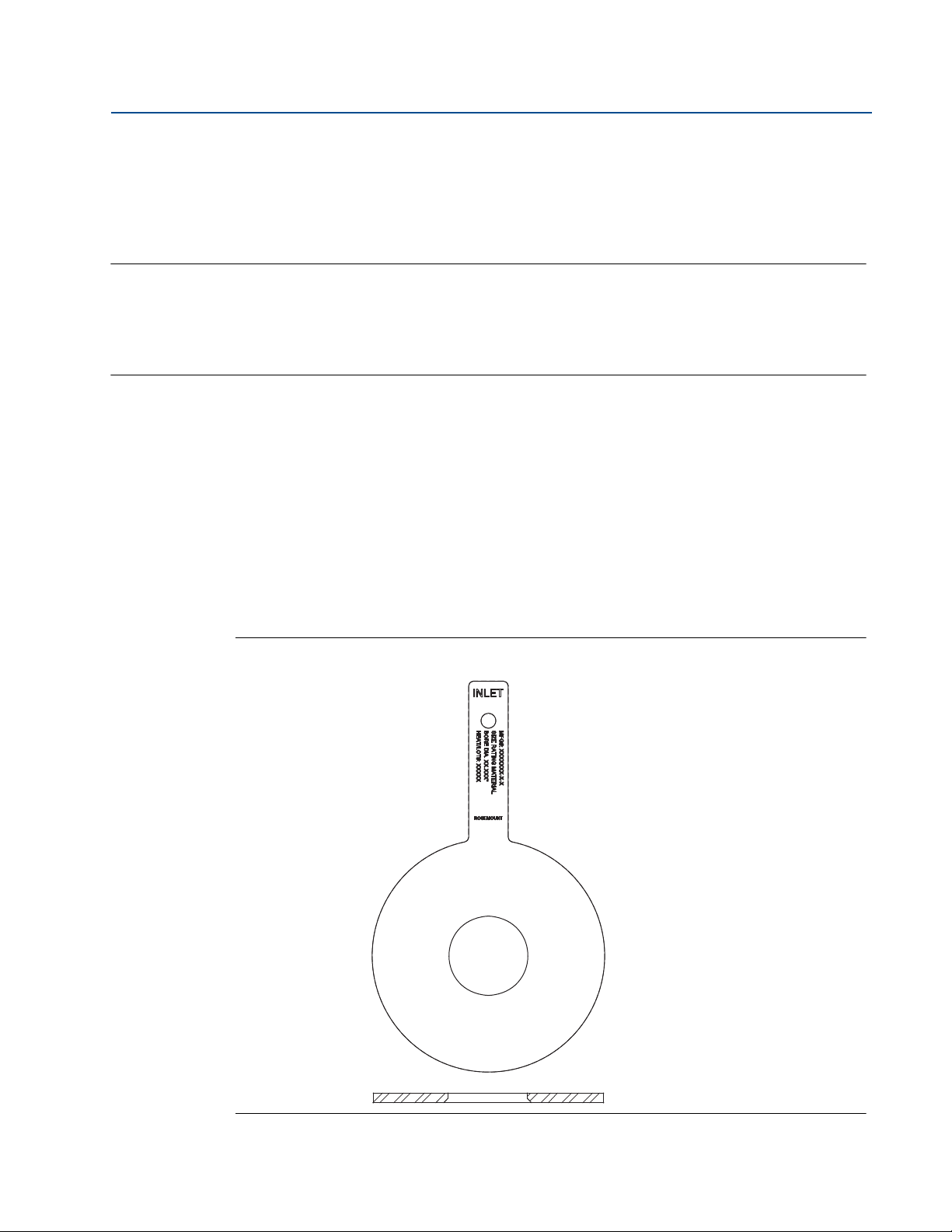

The handle of the orifice plate has the word “Inlet” stamped on the side that faces

upstream.

To correct for installation effects, the transmitter should be zeroed after mounting.

2.5 Straight run requirements

To obtain published accuracy, sufficient straight run is required to produce a fully developed

flow profile. Shorter straight run lengths are possible, but accuracy will be affected. Consult the

Factory for further information. Refer to Appendix B: Recommended Installation Requirements

for recommended straight pipe lengths.

Reference Manual

00809-0100-4792, Rev CB

6

Installation, Location, and Orientation

Reference Manual

00809-0100-4792, Rev CB

Section 3: Hardware Installation for Rosemount 1495 Orifice Plate

Section 3 Hardware installation for

Rosemount 1495 Orifice Plate

1495 types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

1495 dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

1495 weights (estimated) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

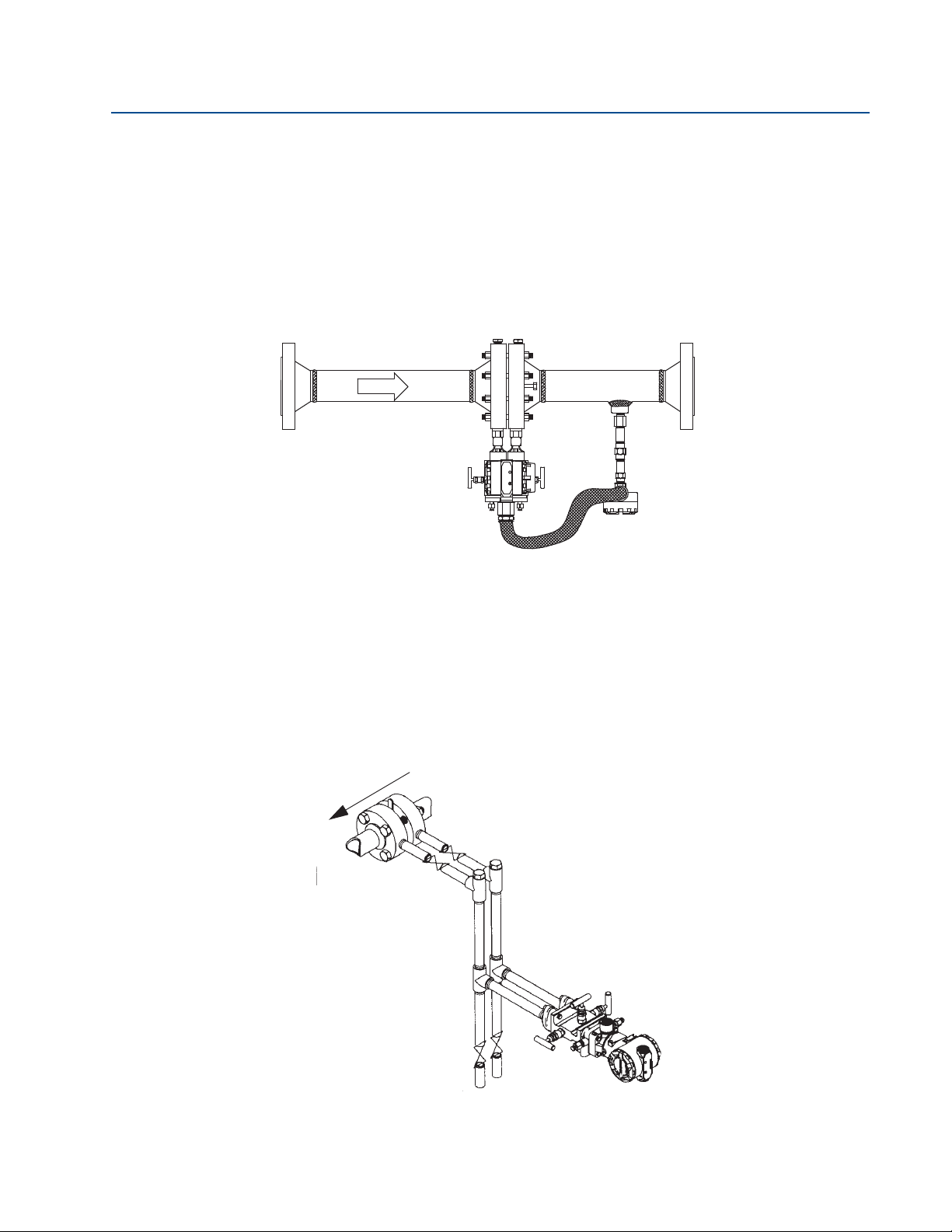

3.1 1495 types

This section provides hardware installation instructions for the Rosemount 1495 Orifice Plate.

Installation procedures are similar for all services. Service-specific instructions are provided

where necessary. Otherwise, all instructions in this section apply to all services. For more

information on 1495 Orifice Plate types, see

page 6.

February 2014

Refer to transmitter installation instructions where applicable.

3.1.1 Bore types

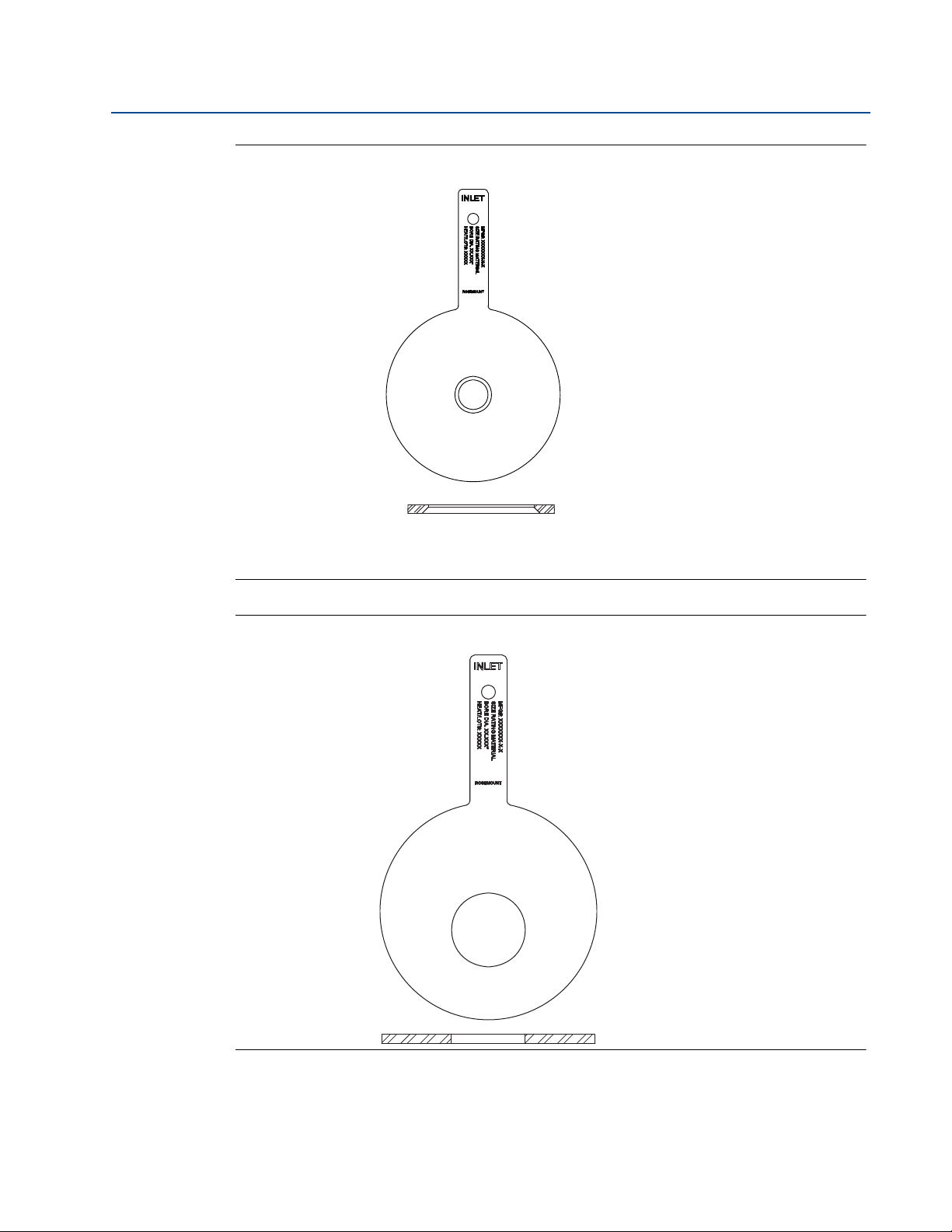

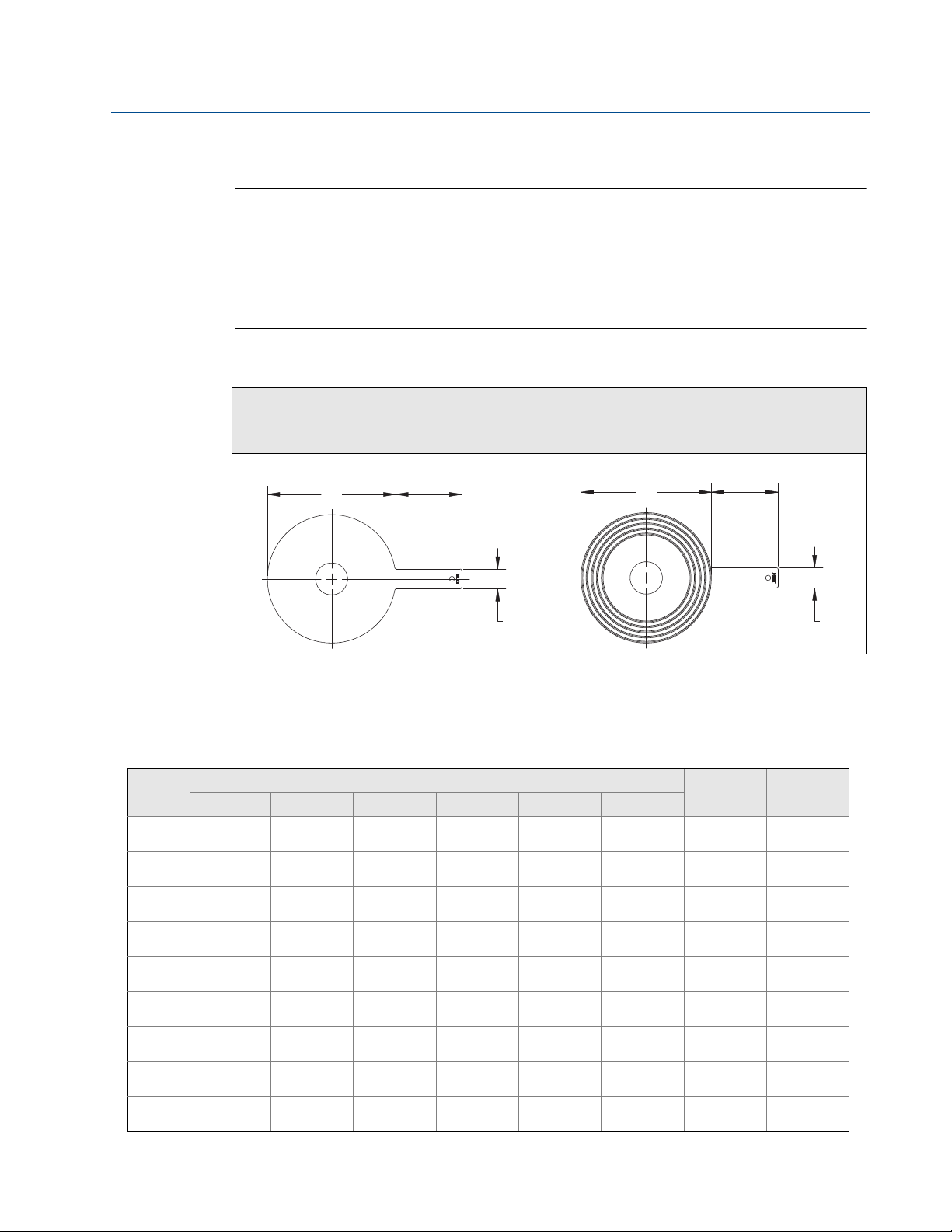

Figure 3-1. Concentric Square-Edged (standard)

Hardware Installation

7

Section 3: Hardware Installation for Rosemount 1495 Orifice Plate

February 2014

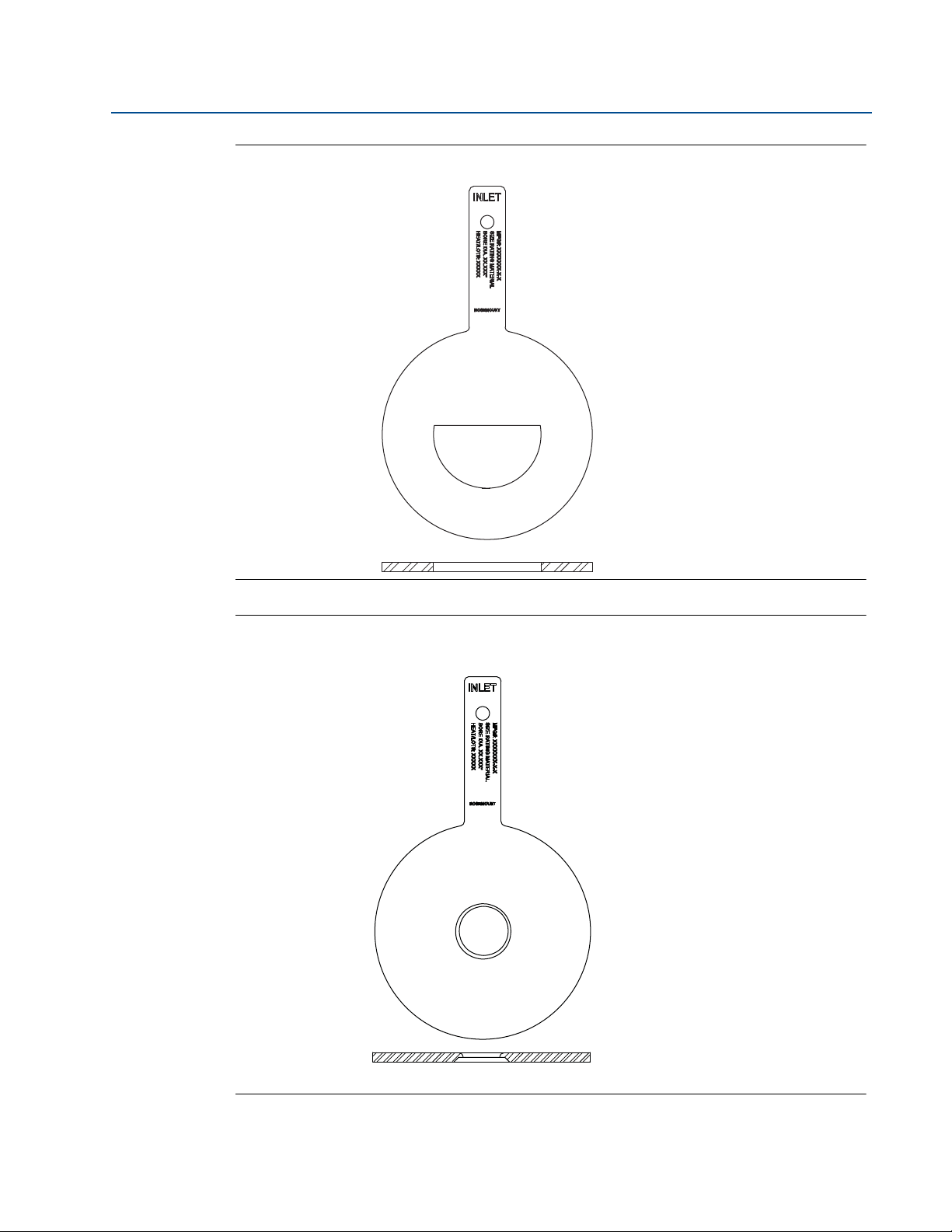

Figure 3-2. Conical Entrance Bore (Option Code TC)

Reference Manual

00809-0100-4792, Rev CB

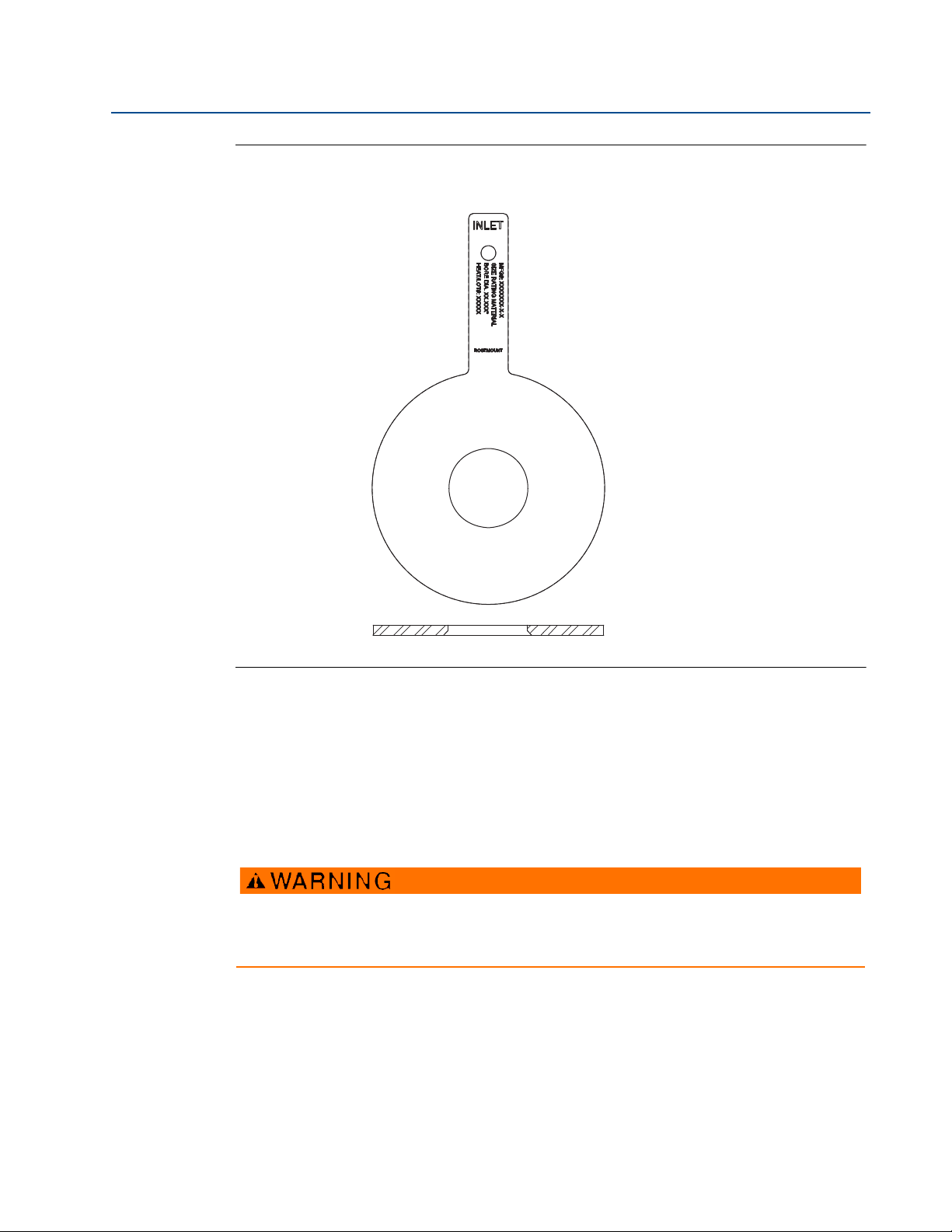

Figure 3-3. Eccentric Bore (Option Code TE)

8

Hardware Installation

Reference Manual

00809-0100-4792, Rev CB

Section 3: Hardware Installation for Rosemount 1495 Orifice Plate

February 2014

Figure 3-4. Segmental Bore (Option Code TS)

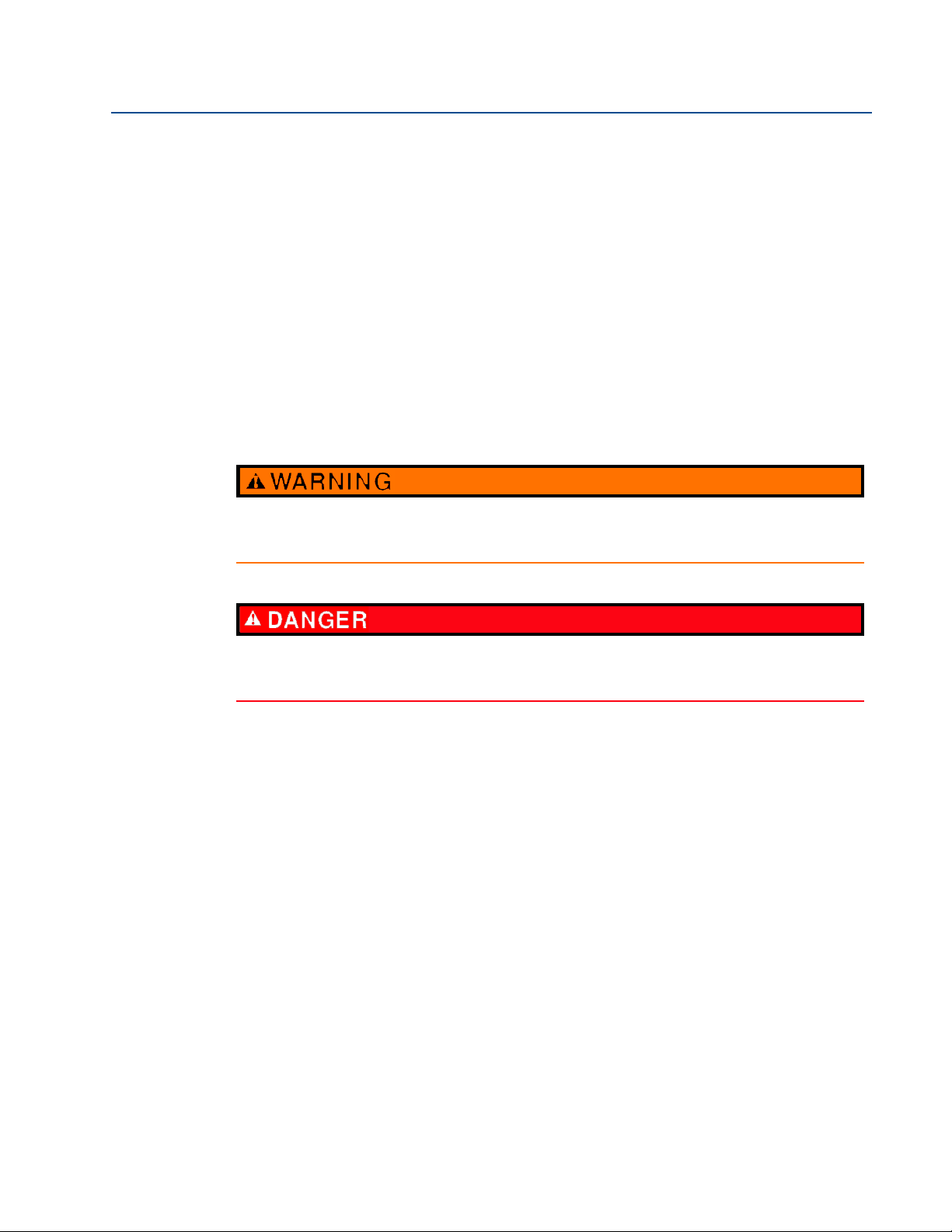

Figure 3-5. Quadrant Edged Bore (Option Code TQ)

Hardware Installation

9

Section 3: Hardware Installation for Rosemount 1495 Orifice Plate

February 2014

Figure 3-6. Restriction Orifice - Beveled Bore (Option Code RO)

Reference Manual

00809-0100-4792, Rev CB

3.2 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Please refer to the following safety messages

before performing any operation in this section.

Failure to follow these installation guidelines could result in death or serious injury:

* Make sure only qualified personnel perform the installation.

10

Hardware Installation

Reference Manual

00809-0100-4792, Rev CB

Section 3: Hardware Installation for Rosemount 1495 Orifice Plate

3.3 Installation instructions

Step 1: Determine the proper placement

Determine the proper placement by ensuring adequate straight run. See Appendix B:

Recommended Installation Requirements

Step 2: Determine the proper orientation

To determine the proper orientation, see “Installation Configuration” on page 2.

Step 3: Weld the flange union

To weld the flange union, see “Step 3: Weld the Flange Union” on page 2.

.

February 2014

Personal hazard! To prevent injury, remove pressure and drain pipe assembly before

installing or removing orifice plate.

If the process fluid is caustic or otherwise hazardous, the procedure outlined here must be

modified as required to prevent death or serious injury to personnel.

Step 4: Install the orifice plate

General installation instructions to install (or remove) the orifice plate are as follows:

1. Make certain the pipeline is not under pressure and has been drained or purged.

2. Loosen all studs and nuts.

3. Remove the studs in one half of the flange union.

4. Spread flange union by turning jackscrews clockwise.

5. Install new plate or remove existing plate for replacement or inspection.

Hardware Installation

6. Install new gaskets when installing plate. It is recommended to install new gaskets each

time orifice flange union is separated.

7. Release the flange union by turning Jackscrews counter clockwise.

8. Replace studs.

9. Tighten studs in a star pattern. See

“Bolt Torque Recommendations” on page 196.

11

Section 3: Hardware Installation for Rosemount 1495 Orifice Plate

A

C

A

C

February 2014

NOTE

Refer to published standards (AGA3, ASME MFC-3M, ISO 5167 for installation guidelines.

Once the orifice plate is installed, proceed by installing connection systems, manifolds, and/or

transmitters per manufacturer’s recommended specifications and plant standards.

NOTE

Universal style orifice plates are designed for installation into junior or senior orifice fittings as

well as into RTJ Plate Holders.

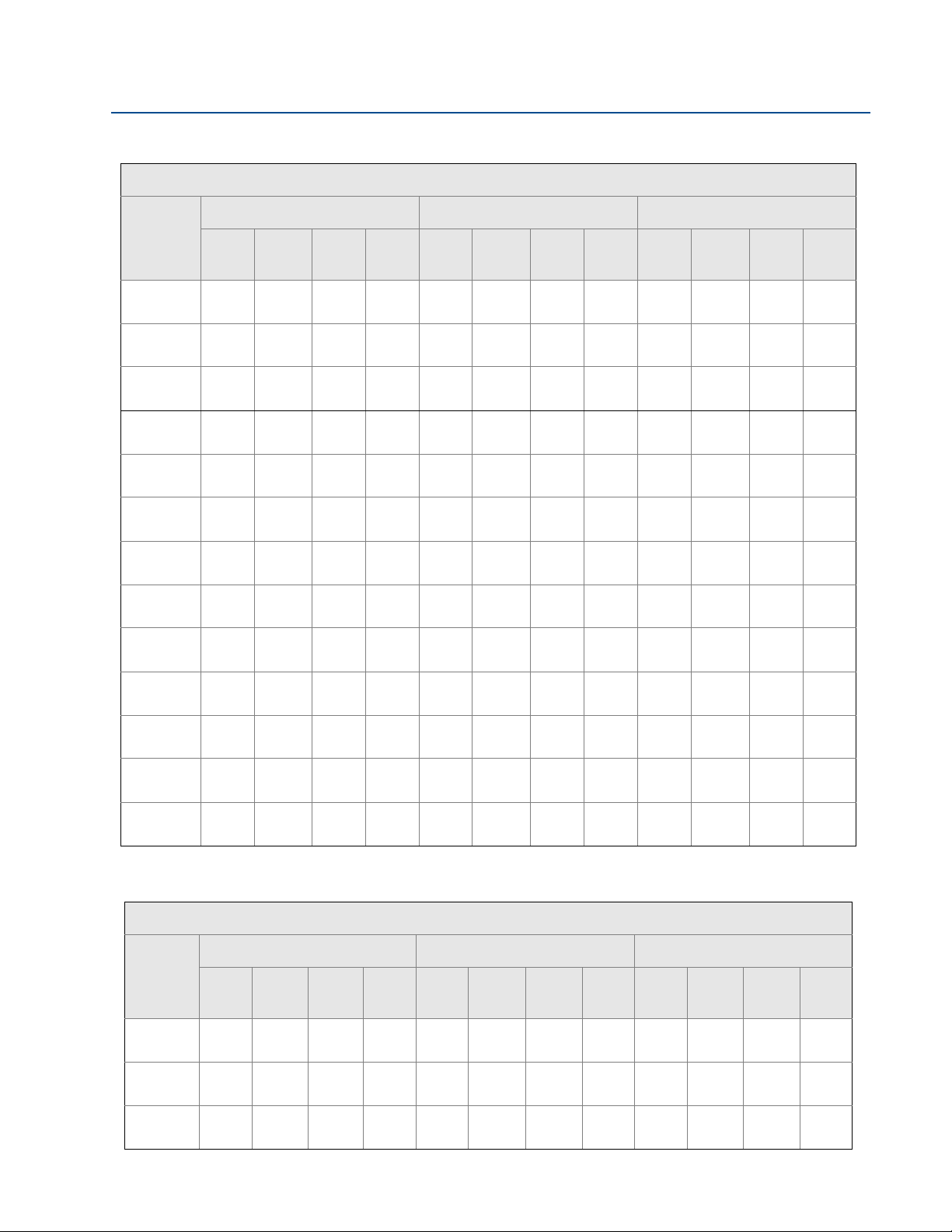

Figure 3-7. Paddle Types

1495PC Orifice Paddle Type

(paddle, square edged, concentric)

Reference Manual

00809-0100-4792, Rev CB

1495PG Orifice Paddle Type

(paddle, square edged, concentric, spiral

finish)

B

A. Diameter

B. Handle Length

C. Handle Width

Line

size

2-in. 4.125

21/2-in. 4.875

3-in. 5.375

4-in. 6.875

6-in. 8.750

8-in. 11.000

10-in. 13.375

12-in. 16.125

14-in. 17.750

150# 300# 600# 900# 1500# 2500#

(104.78)

(123.82)

(136.53)

(174.63)

(222.25)

(279.4)

(339.73)

(409.58)

(450.85)

(111.13)

(130.18)

(149.23)

(180.98)

(250.83)

12.125

(307.98)

14.250

(361.95)

16.625

(422.26)

19.125

(485.78)

Diameter for paddle type

4.375

5.125

5.875

7.125

9.875

4.375

(111.13)

5.125

(130.18)

5.875

(149.23)

7.625

(193.7)

10.500

(266.7)

12.625

(320.675)

15.750

(400.05)

18.000

(457.2)

19.375

(339.725)

5.625

(142.875)

6.500

(165.1)

6.625

(168.275)

8.125

(206.375)

11.375

(288.925)

14.125

(358.775)

17.125

(434.975)

19.625

(498.475)

20.500

(520.7)

(1)

5.625

(142.875)

6.500

(165.1)

6.875

(174.625)

8.250

(209.55)

11.125

(282.575)

13.875

(352.425)

17.125

(434.975)

20.500

(520.7)

22.750

(577.85)

5.750

(146.05)

6.625

(168.275)

7.750

(196.85)

9.250

(234.95)

12.500

(317.5)

15.250

(387.35)

18.750

(476.25)

21.625

(549.275)

—

B

Handle

length

4.0

(101.6)

4.0

(101.6)

4.0

(101.6)

4.0

(101.6)

4.0

(101.6)

6.0

(127)

6.0

(152.4)

6.0

(152.4)

6.0

(152.4)

Handle

width

1.00

(25.4)

1.00

(25.4)

1.00

(25.4)

1.00

(25.4)

1.00

(25.4)

1.5

(38.1)

1.5

(38.1)

1.5

(38.1)

1.5

(38.1)

12

Hardware Installation

Reference Manual

Diameter

00809-0100-4792, Rev CB

Section 3: Hardware Installation for Rosemount 1495 Orifice Plate

February 2014

Line

size

16-in. 20.250

18-in. 21.500

20-in. 23.750

24-in. 28.125

(1) Measurement is in inches (millimeters).

150# 300# 600# 900# 1500# 2500#

21.250

(514.35)

(546.1)

(603.25)

(714.375)

(539.75)

23.375

(593.725)

25.625

(650.875)

30.375

(771.525)

1495UC Orifice Universal Type

(universal, square edged, concentric) Line size Diameter for universal type

(1) Measurement is in inches (millimeters).

Diameter for paddle type

22.250

(565.15)

24.000

(609.6)

26.750

(679.45)

31.000

(787.4)

22.625

(574.675)

25.000

(635.00)

27.375

(695.325)

32.875

(835.025)

(1)

Handle

length

25.250

(641.35)

27.625

(701.675)

29.625

(752.475)

35.500

(901.7)

2-in. 2.437 (61.8998)

21/2-in. 2.812 (71.4248)

3-in. 3.437 (87.2998)

4-in. 4.406 (111.912)

6-in. 6.437 (163.5)

8-in. 8.437 (214.3)

10-in. 10.687 (271.45)

12-in. 12.593 (319.862)

14-in. 14.000 (355.6)

16-in. 16.000 (406.4)

18-in. 18.000 (457.2)

20-in. 20.000 (508)

24-in. 24.000 (609.6)

—

—

—

—

6.0

(152.4)

6.0

(152.4)

6.0

(152.4)

6.0

(152.4)

Handle

width

1.5

(38.1)

1.5

(38.1)

1.5

(38.1)

1.5

(38.1)

(1)

Hardware Installation

13

Section 3: Hardware Installation for Rosemount 1495 Orifice Plate

A

B

C

February 2014

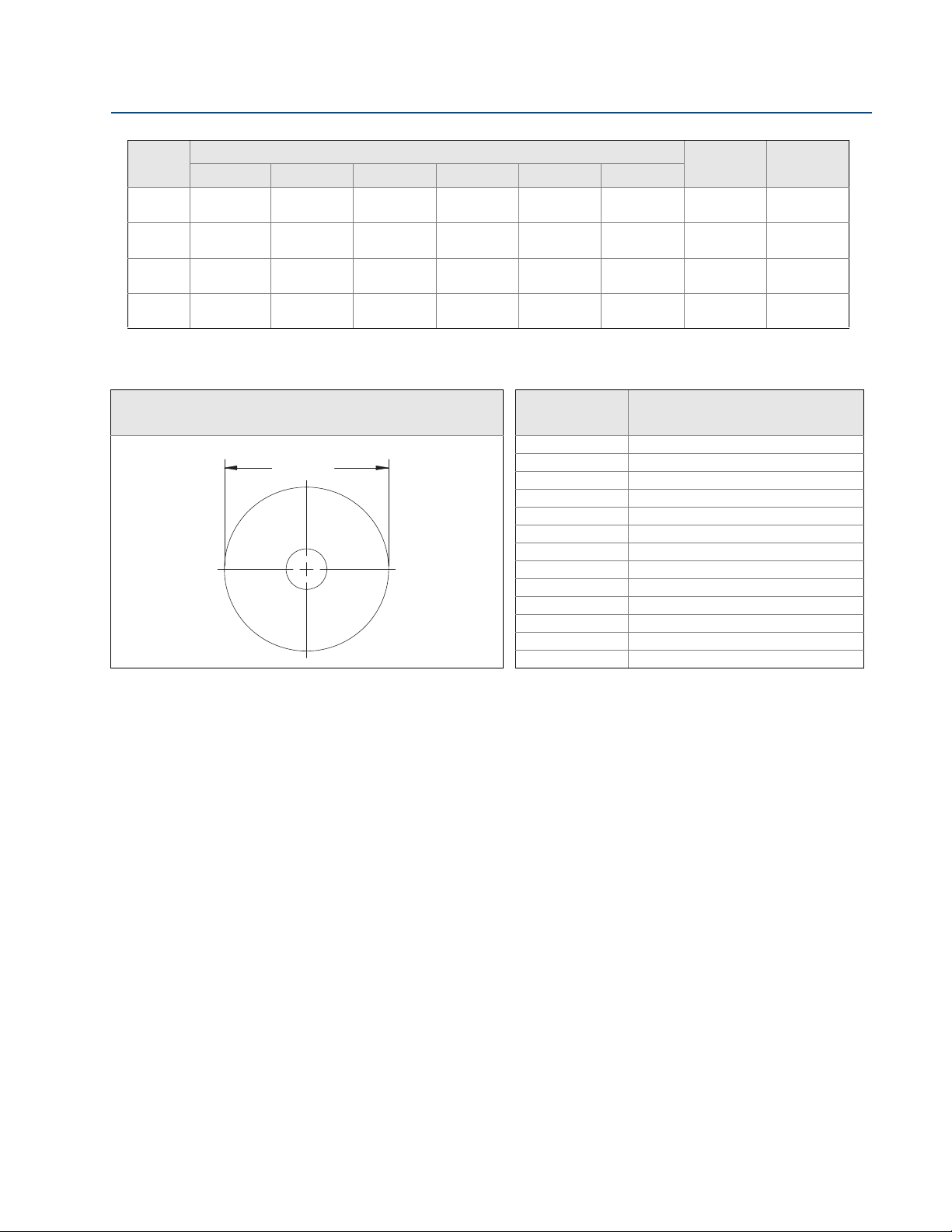

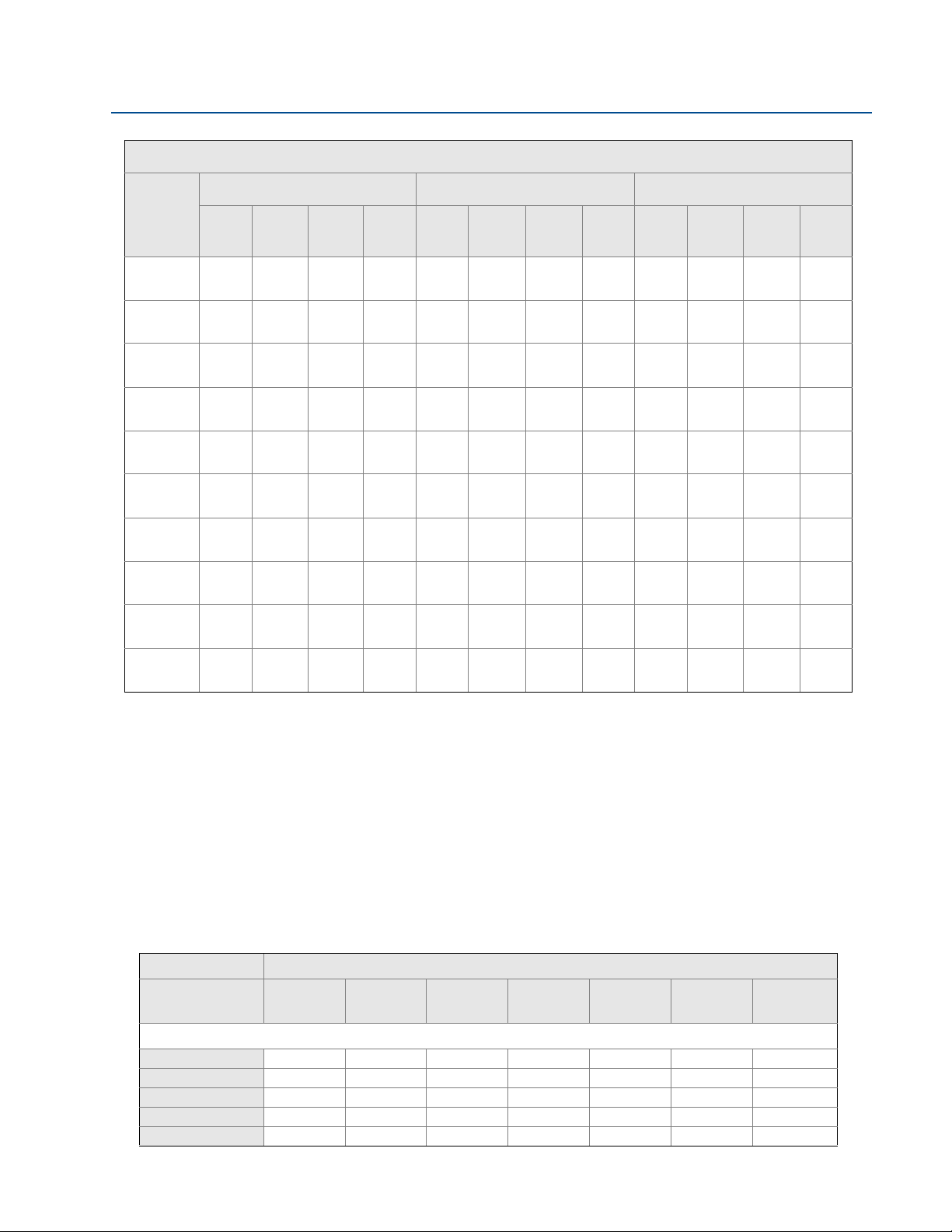

3.4 1495 dimensional drawings

Figure 3-8. 1495 Paddle Type Orifice Plate (DIN, Paddle, Square edged, Concentric)

A. Diameter

B. Handle Length

C. Handle Width

Reference Manual

00809-0100-4792, Rev CB

TABLE 1. 1495 Orifice Plate Dimensions

(1)

Diameter (max) – by flange rating

DN

DN 50 4.21 (107) 4.21 (107) 4.21 (107) 4.21 (107) 4.45 (113) 4.69 (119) 1.5

DN 65 5 (127) 5 (127) 5 (127) 5 (127) 5.43 (138) 5.67 (144) 1.5

DN 80 5.6 (142) 5.6 (142) 5.6 (142) 5.6 (142) 5.82 (148) 6.06 (154) 1.5

DN 100 6.38 (162) 6.38 (162) 6.61 (168) 6.61 (168) 6.85 (174) 7.09 (180) 1.5

DN 125 7.56 (192) 7.56 (192) 7.64 (194) 7.63 (194) 8.27 (210) 8.54 (217) 1.5

DN 150 8.58 (218) 8.58 (218) 8.82 (224) 8.82 (224) 9.72 (247) 10.12 (257) 1.5

DN 200 10.74 (273) 10.74 (273) 11.18 (284) 11.42 (290) 12.17 (3 09) 12.76 (324) 1.5

DN 250 12.91 (328) 12.95 (3 29) 13.39 ( 340) 13.86 (352) 14.33 (364) 15.39 (391) 1.5

PN 10 PN 16 PN 25 PN 40 PN 63/64 PN 100

DN 300 14.88 (378) 15.11 (3 84) 15.75 ( 400) 16.42 (417) 16.69 (424) 18.03 (458) 1.5

DN 350 17.24 (438) 17.48 (4 44) 17.99 ( 457) 18.66 (474) 19.13 (486) 20.16 (512) 1.5

Handle

width

(40)

(40)

(40)

(40)

(40)

(40)

(40)

(40)

(40)

(40)

Handle

length

6.3

(160)

6.3

(160)

6.3

(160)

6.3

(160)

6.3

(160)

6.3

(160)

6.3

(160)

6.3

(160)

6.3

(160)

6.3

(160)

DN 400 19.25 (489) 19.49 (4 95) 20.24 ( 514) 21.49 (546) 21.38 (543) 22.52 (572) 1.5

14

6.3

(40)

Hardware Installation

(160)

Reference Manual

A

B

C

00809-0100-4792, Rev CB

Section 3: Hardware Installation for Rosemount 1495 Orifice Plate

February 2014

TABLE 1. 1495 Orifice Plate Dimensions

(1)

Diameter (max) – by flange rating

Handle

DN

DN 450 21.22 (539) 21.85 (5 55) 22.24 ( 565) 22.48 (571) Not

DN 500 23.39 (594) 24.29 (617) 24.57 (624) 24.72 (628) 25.87 (657) 27.72 (704) 1.5

DN 600 27.36 (695) 28.9 (734) 28.78 (731) 29.41 (747) 30.08 (764) 32.01(813) 1.5

(1) Measurement is in inches (millimeters).

PN 10 PN 16 PN 25 PN 40 PN 63/64 PN 100

Not

Applicable

Applicable

width

1.5

(40)

(40)

(40)

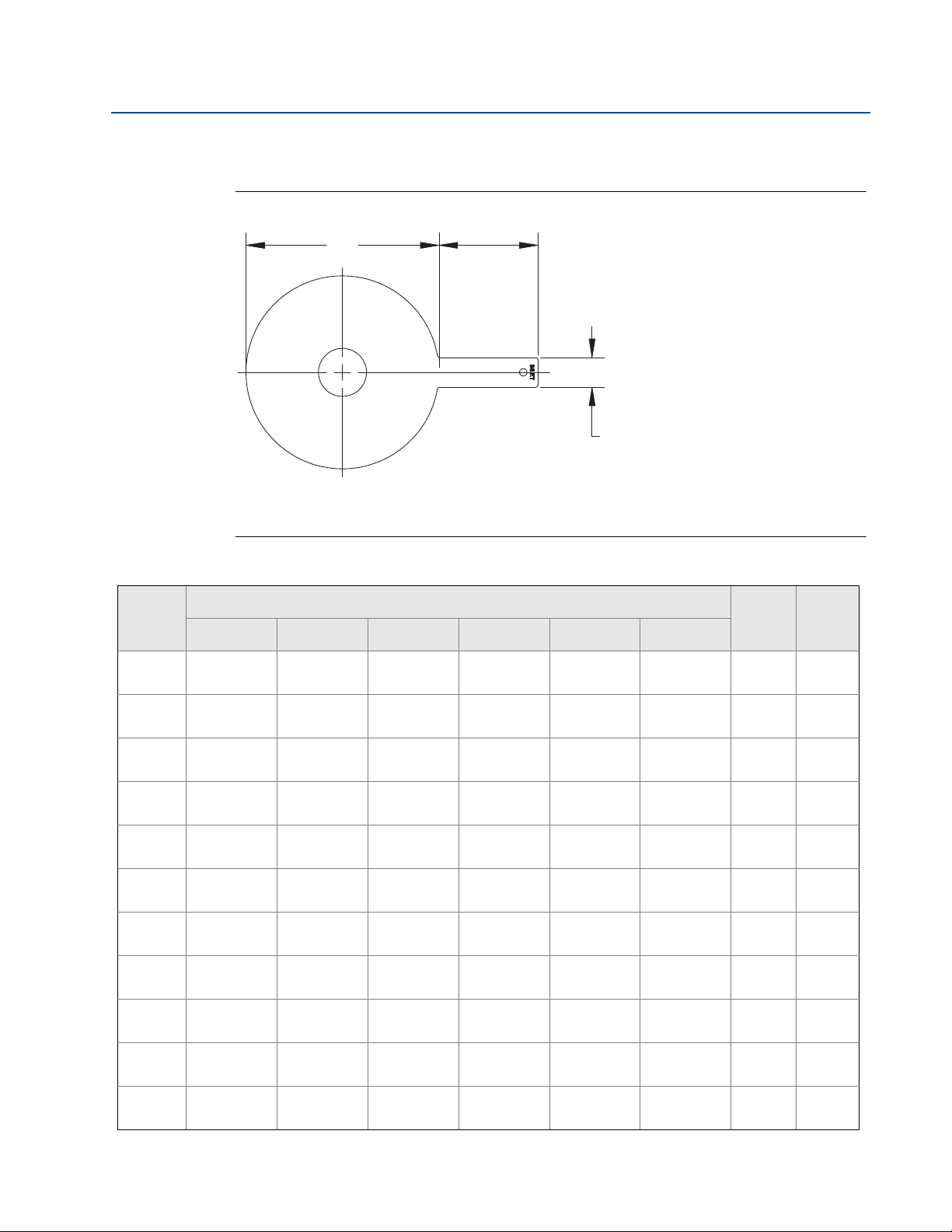

Figure 3-9. Integral Plate Holder (if ordered)

Handle

length

6.3

(160)

8.0

(200)

8.0

(200)

Hardware Installation

A. See Ta ble 3-1 and Tab le 3-2.

B. See

Table 3-1 and Ta ble 3-2 .

Table 3-1 and Ta ble 3-2.

C. See

15

Section 3: Hardware Installation for Rosemount 1495 Orifice Plate

February 2014

Table 3-1. Integral Plate Holder Dimensions for 150#, 300#, and 600#

Flange rating

150# 300# 600#

Reference Manual

00809-0100-4792, Rev CB

Line size

2-in.

(DN 50)

2 1/2-in.

(DN 65)

3-in.

(DN 80)

4-in.

(DN 100)

6-in.

(DN 150)

8-in.

(DN 200)

10-in.

(DN 250)

12-in.

(DN 300)

14-in.

(DN 350)

16-in.

(DN 400)

Ring

no.

R-22 3.56 5.50 1.06 R-23 3.69 5.50 1.06 R-23 3.69 5.50 1.06

R-25 4.31 6.50 1.06 R-26 4.44 6.50 1.06 R-26 4.44 6.50 1.06

R-29 4.81 6.50 1.06 R-31 5.31 6.50 1.06 R-31 5.31 6.50 1.06

R-36 6.19 6.50 1.06 R-37 6.31 6.50 1.06 R-37 6.31 6.50 1.06

R-43 7.94 7.50 1.06 R-45 8.75 7.50 1.06 R-45 8.75 7.50 1.06

R-48 10.06 7.50 1.06 R-49 11.06 7.50 1.06 R-49 11.06 7.50 1.06

R-52 12.31 8.50 1.06 R-53 13.19 8.50 1.06 R-53 13.19 8.50 1.06

R-56 15.31 8.50 1.06 R-57 15.44 8.50 1.06 R-57 15.44 8.50 1.06

R-59 15.94 8.50 1.06 R-61 16.94 8.50 1.06 R-61 16.94 8.50 1.06

R-64 18.06 8.50 1.19 R-65 18.94 8.50 1.19 R-65 18.94 8.50 1.19

A B C

Ring

no.

A B C

Ring

no.

A B C

(DN 450)

(DN 500)

(DN 600)

Line size

16

18-in.

20-in.

24-in.

2-in.

(DN 50)

2 1/2-in.

(DN 65)

3-in.

(DN 80)

R-68 20.69 8.50 1.19 R-69 21.44 8.50 1.19 R-69 21.44 8.50 1.19

R-72 22.31 8.50 1.25 R-73 23.50 8.50 1.25 R-73 23.50 8.50 1.25

R-76 26.81 8.50 1.44 R-77 27.88 8.50 1.44 R-77 27.88 8.50 1.44

Table 3-2. Integral Plate Holder Dimensions for 900#, 1500#, and 2500#

Flange rating

900# 1500# 2500#

Ring

no.

R-24 4.19 6.50 1.06 R-24 4.19 6.50 1.06 R-26 4.44 6.50 1.06

R-27 4.69 6.50 1.06 R-27 4.69 6.50 1.06 R-28 4.83 6.50 1.19

R-31 5.31 6.50 1.06 R-35 5.81 6.50 1.06 R-32 5.50 7.50 1.19

A B C

Ring

no.

A B C

Ring

no.

A B C

Hardware Installation

Reference Manual

00809-0100-4792, Rev CB

Section 3: Hardware Installation for Rosemount 1495 Orifice Plate

February 2014

Flange rating

900# 1500# 2500#

Line size

4-in.

(DN 100)

6-in.

(DN 150)

8-in.

(DN 200)

10-in.

(DN 250)

12-in.

(DN 300)

14-in.

(DN 350)

16-in.

(DN 400)

18-in.

(DN 450)

20-in.

(DN 500)

24-in.

(DN 600)

Ring

no.

R-37 6.31 6.50 1.06 R-39 6.81 6.50 1.06 R-38 6.81 7.50 1.31

R-45 8.75 7.50 1.06 R-46 8.81 7.50 1.19 R-47 9.75 8.50 1.44

R-49 11.06 7.50 1.06 R-50 11.25 7.50 1.44 R-51 11.88 9.50 1.69

R-53 13.19 8.50 1.06 R-54 13.38 8.50 1.44 R-55 14.63 9.50 2.00

R-57 15.44 8.50 1.06 R-58 15.88 9.50 1.44 R-60 17.25 10.50 2.13

R-62 17.13 8.50 1.31 R-63 17.50 9.50 1.88 — — — —

R-66 19.13 8.50 1.44 R-67 19.63 10.50 2.13 — — — —

R-70 21.75 8.50 1.56 R-71 22.13 10.50 2.13 — — — —

R-74 23.75 8.50 1.56 R-75 24.25 11.50 2.13 — — — —

R-78 28.25 10.50 1.88 R-79 28.63 11.50 2.44 — — — —

A B C

Ring

no.

A B C

Ring

no.

A B C

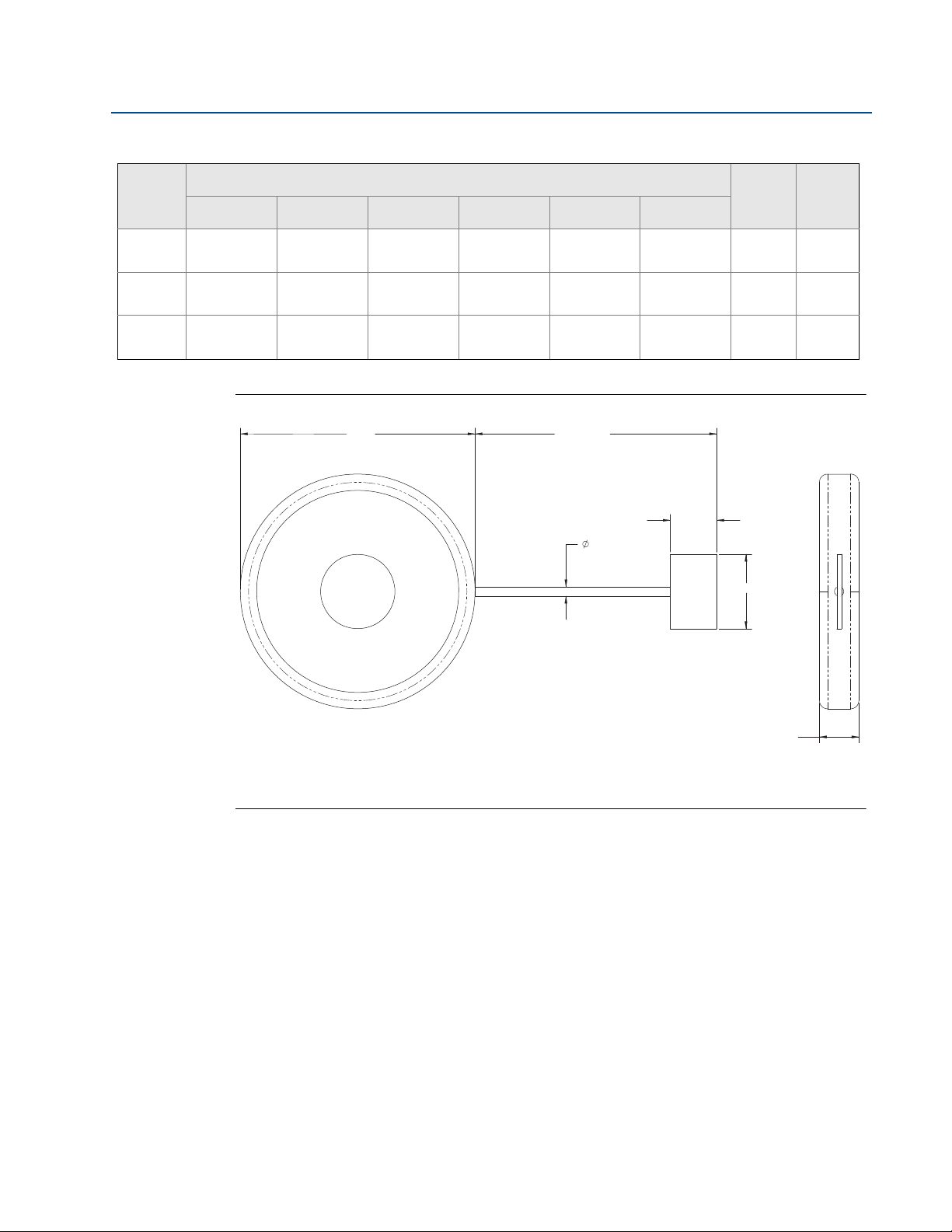

3.5 1495 weights (estimated)

Weights are in pounds (kilograms).

Estimated weight based on:

Paddle Style

Beta = 0.65 (schedule standard pipe)

316/316L SST materials of construction

Any deviation in configuration may affect estimated weights.

Line size

2 in.

Flange rating

(50 mm)

ANSI thickness = 0.125 in. (3.2 mm)

A3 ANSI Class 300 0.68(0.31) 0.89(0.40) 1.12(0.51) 1.58(0.72) 2.91(1.32) 4.50(2.04) 6.09(2.76)

A6 ANSI Class 600 0.68(0.31) 0.89(0.40) 1.12(0.51) 1.79(0.81) 3.27(1.48) 4.85(2.20) 7.36(3.34)

A6 ANSI Class 900 1.04(0.47) 1.34(0.61) 1.39(0.63) 2.02(0.91) 3.82(1.73) 5.99(2.72) 8.65(3.92)

AF ANSI Class 1500 1.04(0.47) 1.34(0.61) 1.48(0.67) 2.07(0.94) 3.66(1.66) 5.79(2.63) 8.65(3.92)

AT ANSI Class 2500 1.08(0.49) 1.39(0.63) 1.85(0.84) 2.57(1.17) 4.58(2.08) 6.92(3.14) 10.30(4.67)

Hardware Installation

2.5 in.

(64 mm)

3 in.

(80 mm)

4 in.

(100 mm)

6 in.

(150 mm)

8 in.

(200 mm)

10 in.

(250 mm)

17

Loading...

Loading...