Quick Start Guide

00825-0100-4160, Rev CB

Rosemount™ 2160 Wireless Level

Detector

Vibrating Fork

September 2020

Quick Start Guide September 2020

Contents

About this guide...........................................................................................................................3

Installation................................................................................................................................... 6

Configuration.............................................................................................................................14

Product certifications................................................................................................................. 22

2 Rosemount 2160 Wireless Level Detector

September 2020 Quick Start Guide

1 About this guide

This Quick Start Guide provides basic guidelines for the Rosemount 2160.

Refer to the Rosemount 2160 Reference Manual for more instructions. The

manual and this guide are also available electronically at Emerson.com/

Rosemount.

NOTICE

Power module considerations.

• Each Power Module contains two "C" size primary lithium/thionyl chloride

batteries. Each battery contains approximately 2.5 grams of lithium, for

a total of 5 grams in each pack. Under normal conditions, the battery

materials are self-contained and are not reactive as long as the batteries

and the pack integrity are maintained. Care should be taken to prevent

thermal, electrical or mechanical damage. Contacts should be protected

to prevent premature discharge.

• Battery hazards remain when cells are discharged.

• Use caution when handling the power module. The Power Module may

be damaged if dropped from heights in excess of 20 ft. (6 m).

• Power modules should be stored in a clean and dry area. For maximum

battery life, storage temperature should not exceed 86 °F (30 °C).

• The power module may be replaced in a hazardous area. The power

module has surface resistivity greater than one gigaohm and must be

properly installed in the wireless device enclosure. Care must be taken

during transportation to and from the point of installation to prevent

electrostatic charge build-up.

Shipping considerations for wireless products.

• The unit was shipped to you without the power module installed.

Remove the power module prior to shipping.

• Each power module contains two “C” size primary lithium batteries.

Primary lithium batteries are regulated in transportation by the U. S.

Department of Transportation, and are also covered by IATA

(International Air Transport Association), ICAO (International Civil

Aviation Organization), and ARD (European Ground Transportation of

Dangerous Goods). It is the responsibility of the shipper to ensure

compliance with these or any other local requirements. Consult current

regulations and requirements before shipping.

Quick Start Guide 3

Quick Start Guide September 2020

WARNING

Failure to follow safe installation and servicing guidelines could result in

death or serious injury.

• Ensure the level detector is installed by qualified personnel and in

accordance with applicable code of practice.

• Use the level detector only as specified in this manual. Failure to do so

may impair the protection provided by the level detector.

• The weight of a level detector with a heavy flange and extended fork

length may exceed 37 lb. (18 kg). A risk assessment is required before

carrying, lifting, and installing the level detector.

Explosions could result in death or serious injury.

• Verify that the operating atmosphere of the level detector is consistent

with the appropriate hazardous locations certifications.

• Before connecting a handheld communicator in an explosive

atmosphere, ensure that the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring practices.

• In explosion-proof/flameproof and non-incendive/type n installations, do

not remove the housing covers when power is applied to the level

detector.

• Both housing covers must be fully engaged to meet flameproof/

explosion-proof requirements.

WARNING

Process leaks could result in death or serious injury.

• Ensure the level detector is handled carefully. If the process seal is

damaged, gas might escape from the vessel (tank) or pipe.

4 Rosemount 2160 Wireless Level Detector

September 2020 Quick Start Guide

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

CAUTION

Hot surfaces

The flange and process seal may be hot at high process

temperatures.

Allow to cool before servicing.

Quick Start Guide 5

OK

OK

A

B

A

B

OK

OK

OK

C

A

B

Quick Start Guide September 2020

2 Installation

2.1 Fork alignment in a pipe installation

Figure 2-1: Correct Fork Alignment for Pipe Installation

A. Tri Clamp process connections have a circular notch

B. Threaded process connections have a groove

2.2 Fork alignment in a vessel (tank) installation

Figure 2-2: Correct Fork Alignment for Vessel (Tank) Installation

6 Rosemount 2160 Wireless Level Detector

A. Tri Clamp process connections have a circular notch

B. Threaded process connections have a groove

Flanged process connections have a circular notch

C.

A

B

A

B

September 2020 Quick Start Guide

2.3 Mounting the threaded version

2.3.1 Seal and protect the threads

• Use anti-seize paste or PTFE tape according to site procedures.

A gasket may be used as a sealant for BSPP (G) threaded connections.

2.3.2 Threaded vessel (tank) or pipework connection

• Vertical installation.

• Horizontal installation.

A. Tighten using the hexagon nut only

B. Gasket for BSPP (G) threaded connection

Quick Start Guide 7

A

A

Quick Start Guide September 2020

2.3.3 Threaded flange connection

Procedure

1. Place the customer-supplied flange and gasket on the vessel (tank)

nozzle.

A. Gasket (customer supplied)

2.

Tighten the bolts and nuts with sufficient torque for the flange and

gasket.

3. Screw the level detector into the flange thread.

A. Tighten using the hexagon nut only

B. Gasket for BSPP (G) threaded connection

8 Rosemount 2160 Wireless Level Detector

A

September 2020 Quick Start Guide

2.4 Mounting the flanged version

Procedure

1. Lower the level detector into the nozzle.

A. Gasket (customer supplied)

2. Tighten the bolts and nuts with sufficient torque for the flange and

gasket.

Quick Start Guide 9

A

Quick Start Guide September 2020

2.5 Mounting the Tri Clamp version

Procedure

1. Lower the level detector into the flange face.

A. Seal (supplied with Tri Clamp)

2. Fit the Tri Clamp.

10 Rosemount 2160 Wireless Level Detector

A

B

September 2020 Quick Start Guide

2.6 Wireless battery installation

To install the battery that supplies all power to the Rosemount 2160:

Procedure

Remove the housing cover on the battery compartment side.

1.

2.

Connect the battery.

3. Replace the battery cover and tighten to safety specification (metalto-metal).

Figure 2-3: Wireless Battery Installation

A. Battery cover

Battery

B.

Quick Start Guide 11

Quick Start Guide September 2020

2.7 Position the antenna

The antenna should be positioned vertically, either straight up or straight

down, and it should be approximately 3 ft. (1 m) from any large structure,

building, or conductive surface to allow for clear communication to other

devices.

Figure 2-4: Antenna Positioned Vertically

2.8 Adjust LCD meter orientation (optional)

If a device display is ordered, it will be shipped attached to the level detector.

The display is ordered in the level detector model number, option code M5.

2.8.1 Rotate the device display

The device display can be rotated in 90-degree increments.

Procedure

1.

Squeeze the two black tabs on opposite sides of the display.

2. Gently pull out the display.

3. Rotate the display to the desired orientation, and snap the display

into place.

Note

If the device display four-pin connector is inadvertently removed

from the interface board, carefully re-insert the connector before

snapping the device display back into place.

12 Rosemount 2160 Wireless Level Detector

A

H

3

/32 in.

Torque 30 in-lb (3 Nm)

September 2020 Quick Start Guide

2.9 Adjust housing orientation (optional)

To improve field access to wiring or to better view the optional LCD display:

Procedure

Loosen the set screw until the level detector housing can rotate

1.

smoothly.

Do not unscrew all the way. Rotating the housing, without this screw

in place, can damage the internal wiring.

2.

First, rotate the housing clockwise to the desired location.

If the desired location cannot be achieved due to thread limit, rotate

the housing counterclockwise.

3. Re-tighten the set screw.

Figure 2-5: Housing Rotation

A. Do not attempt to rotate the housing beyond the thread limit

Quick Start Guide 13

Quick Start Guide September 2020

3 Configuration

3.1 Configuration procedure

Follow these steps for proper configuration:

Procedure

Get started with your preferred configuration tool.

1.

a)

AMS Wireless Configurator (see AMS Wireless Configurator)

b) Handheld communicator

2. Join device to wireless network.

a) Insert the power module (see Wireless battery installation).

b) Connect to device (see Connect to device).

c) Configure update rate (see Configure update rate).

d) Obtain network ID and join key.

e) Enter network ID and join key.

f) Verify device joins Network.

3. Configure device.

a) Connect to device (see Connect to device).

b) Configure using basic setup.

c) Consider optional guided setups.

4. Verify the fork status (dry or wet) is as expected.

3.2 Get started with your preferred configuration tool

3.2.1 AMS Wireless Configurator

The AMS Wireless Configurator is the recommended software tool for

wireless network devices, and is supplied with the Emerson Wireless

Gateway. Refer to the AMS Wireless Configurator Manual Supplement for

further information.

Configuration can be done by connecting to the wireless network devices

either point-to-point using a HART modem or wirelessly through the

Gateway (see Figure 3-1). Initial configuration to join a device to the wireless

network must be done point-to-point.

14 Rosemount 2160 Wireless Level Detector

September 2020 Quick Start Guide

Get the latest Device Descriptor (DD)

The Device Descriptor (DD) is a support file containing the information

required by host systems and handheld communicators to utilize the

capabilities and functions of a field instrument.

Prerequisites

The Rosemount 2160 DD is typically installed together with AMS Wireless

Configurator. To download the latest HART® DD, visit the Emerson Device

Install Kit site at: Emerson.com/DeviceInstallKits

Procedure

After downloading, add the DD to AMS Wireless Configurator.

Close AMS Wireless Configurator.

a)

b) Go to Start → Programs → AMS Device Manager and select Add

Device Type.

c) Browse to the downloaded DD files and select OK.

Need help?

In the Add Device Type application, select the Help button for more

information on how to complete this operation.

Configure the HART® modem interface

Before connecting to the device using a HART modem, the HART modem

interface must be configured in AMS Wireless Configurator.

Procedure

1.

Close AMS Wireless Configurator.

Go to Start → Programs → AMS Device Manager and select

2.

Network Configuration.

3. Select Add.

4. In the drop down list, select HART modem and then select Install.

5. Follow the on-screen instructions.

Need help?

In the Network Configuration application, select the Help button for more

information on how to complete this operation.

Quick Start Guide 15

Quick Start Guide September 2020

Configure the wireless network interface

Before connecting to the device wirelessly using a Wireless Gateway, the

wireless network must be configured in AMS Wireless Configurator.

Procedure

1.

Close AMS Wireless Configurator.

2. Go to Start → Programs → AMS Device Manager and select

Network Configuration.

3. Select Add.

4. In the drop-down list select Wireless Network and then select

Install.

5. Follow the on-screen instructions.

Need help?

In the Network Configuration application, select the Help button for more

information on how to complete this operation.

3.2.2 Handheld communicator

Configuration can be done by connecting to the wireless network devices

directly to the communication terminals of the level detector (see Figure

3-1).

Get the latest Device Descriptor (DD)

If the DD is not installed on a handheld communicator supplied by Emerson,

see the appropriate User’s Manual available at Emerson.com/

FieldCommunicator for instructions on how to update to the latest DD.

3.3 Join device to wireless network

3.3.1 Power up the wireless device

Prerequisites

Make sure that the Wireless Gateway is installed and functioning properly

before any wireless field devices are powered.

Wireless devices should be powered up in order of proximity from the

Gateway, beginning with the closest. This will result in a simpler and faster

network installation.

Procedure

1.

Install the power module.

Wireless battery installation for the procedure.

See

2. Enable Active Advertising on the Gateway to ensure that new

devices join the network faster.

16 Rosemount 2160 Wireless Level Detector

$

&

%

1 2 3

4 5 6

7 809

September 2020 Quick Start Guide

See the Emerson Wireless Gateway Reference Manual for more

information.

3.3.2 Connect to device

Procedure

1. Connect a handheld communicator or a HART® modem to the

communication terminals as shown in Figure 3-1.

2. Do one of the following:

• AMS Wireless Configurator:

a. Start AMS Wireless Configurator.

b. Select View → Device Connection View.

c. Double click the device under the HART modem.

• Handheld communicator:

— Turn on the handheld communicator and connect to the

device.

Figure 3-1: Connect to Device

A. Communication terminals

B. Handheld communicator

HART modem

C.

Quick Start Guide 17

Quick Start Guide September 2020

3.3.3 Configure update rate

The Update Rate is the frequency at which a new measurement is

transmitted over the wireless network. The default update rate is 1 minute.

This may be changed at commissioning, or at any time using AMS Wireless

Configurator or a handheld communicator. The update rate is user

selectable from 4 seconds to 60 minutes.

Procedure

1.

2. Select Configure Update Rate, and follow the instructions.

Configure → Guided Setup → Wireless Setup.

Select

Note

If the time between each update is too long, the high/low alerts may

be triggered too late.

3.3.4 Obtain the Network ID and join key

In order to communicate with the Wireless Gateway, and ultimately the host

system, the level detector must be configured to communicate on the

wireless network. This step is the wireless equivalent of connecting wires

from a level detector to the host system.

Procedure

• From the Wireless Gateway's integrated web interface, select Setup →

Network → Settings.

3.3.5 Enter network ID and join key

The level detector must be configured with the same Network ID and Join

Key as the Wireless Gateway in order to join the network. Use AMS Wireless

Configurator or a handheld communicator to enter the Network ID and Join

Key.

Procedure

1.

Select

Configure → Guided Setup → Wireless Setup.

2. Select Join Device to Network, and follow the instructions.

Postrequisites

If the level detector is not to be commissioned yet, remove the power

module and fasten the housing cover. This is to conserve power module life

and to ensure safe transportation of the level detector. The power module

should be inserted only when the device is ready to be commissioned.

18 Rosemount 2160 Wireless Level Detector

September 2020 Quick Start Guide

3.3.6 Verify the wireless network has been joined

The wireless network connection can be verified in four ways, further

described in this section:

• At the optional display

• Using AMS Wireless Configurator

• In the Wireless Gateway's integrated web interface

• Using a handheld communicator

If the level detector was correctly configured with the Network ID and Join

Key, and sufficient time has passed, the level detector should be connected

to the wireless network. It usually takes a few minutes to join the wireless

network. If the wireless network has not been joined, see the

troubleshooting section in the Rosemount 2160 Reference Manual.

Verify by using the optional display

Procedure

1.

Unscrew the display cover.

Press the DIAG button.

2.

The display will show: Tag, Device Serial Number, Network ID,

Network Connection Status, and Supply Voltage screens. .

When the network diagnostic status is displayed as “NETWK OK”, the

wireless network has been joined successfully.

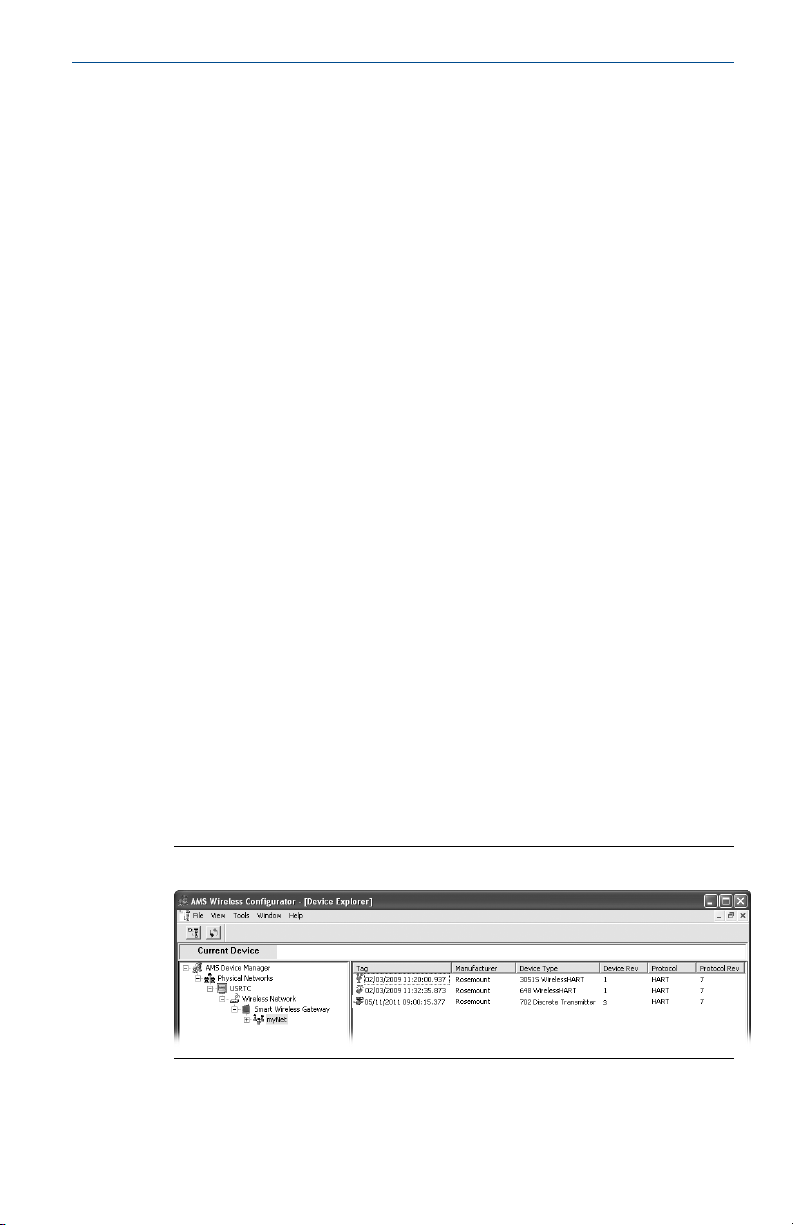

Verify with AMS Wireless Configurator

Procedure

• Start the AMS Wireless Configurator.

When the device has joined the network, it appears in the AMS Wireless

Configurator window (see Figure 3-2).

Figure 3-2: AMS Wireless Configurator Screen

Quick Start Guide 19

Quick Start Guide September 2020

Verify by Gateway

Procedure

1.

To use the Wireless Gateway's integrated web interface, navigate to

the Explorer → Status page.

This page shows the current devices joined to the wireless network

and communicating properly.

2. Locate the level detector in the HART Tag column and verify all status

indicators are good (green).

It may take several minutes for the level detector to join the wireless

network and be seen on the Gateway's integrated web interface.

Verify by using a handheld communicator

Prerequisites

Do not remove the power module. Removing the power module may cause

the device to drop off the network.

Note

In order to communicate with a handheld communicator, the device must

be powered by the power module.

Procedure

1. Connect the handheld communicator (see

2. Select Service Tools → Communications.

3. Select Join Status.

Figure 3-1).

3.4 Configure device using Guided Setup

The options available in the Guided Setup wizard include all items required

for basic operation. All basic configuration parameters are described in

Configuration Parameters.

3.4.1 Start Guided Basic Setup using AMS Wireless Configurator

The options available in the Basic Setup wizard include all items required for

basic operation.

Procedure

1.

Start AMS Wireless Configurator.

Select View → Device Connection View.

2.

3. Double-click the device icon.

4. Select Configure → Guided Setup.

5. Select Basic Setup and follow the on-screen instructions.

20 Rosemount 2160 Wireless Level Detector

September 2020 Quick Start Guide

3.4.2 Start Guided Basic Setup using a handheld communicator

The options available in the Basic Setup wizard include all items required for

basic operation.

Procedure

1.

Turn on the handheld communicator and connect to the level

detector.

Select Configure → Guided Setup.

2.

3. Select Basic Setup and follow the on-screen instructions.

3.4.3 Optional guided setups

Consider optional guided setups such as Configure Device Display and

Configure Alerts.

Procedure

1.

Select

Configure → Guided Setup.

2. Select the desired wizard, and follow the instructions.

Additional configuration parameters are available in the Manual

Setup menu.

Quick Start Guide 21

Quick Start Guide September 2020

4 Product certifications

4.1 European Union directive information

The most recent revision of the EU Declaration of Conformity can be found

at Emerson.com/Rosemount.

4.2 Telecommunication compliance

All wireless devices require certification to ensure that they adhere to

regulations regarding the use of the RF spectrum. Nearly every country

requires this type of product certification. Emerson is working with

governmental agencies around the world to supply fully compliant products

and remove the risk of violating country directives or laws governing

wireless device usage.

4.3 FCC and IC

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following conditions: This device may not cause harmful interference

and this device must accept any interference, including any interference that

may cause undesired operation of the device. This device must be installed

to ensure a minimum antenna separation distance of 8 in. (20 cm) from all

persons.

4.4 Overfill approval

Certificate

TÜV-tested and approved for overfill protection according to the German

DIBt/WHG regulations. Certified under safety devices for tanks and piping

related to water pollution control.

Z-65.11-518

4.5 NAMUR approval

The NAMUR NE95 type test report is available upon request. Complies with

NAMUR NE21.

22 Rosemount 2160 Wireless Level Detector

September 2020 Quick Start Guide

4.6 U.S.A.

4.6.1 Intrinsic Safety (IS), Non-Incendive (NI), Dust Ignition-proof (DIP)

I5

Summary of product certification

Protections

Project ID

Markings

Enclosure

Special Conditions for Safe Use

1. Use with Rosemount SmartPower® option P/N 753-9220-0001 only.

2. Warning – Potential Electrostatic Charging Hazard – The enclosure is

partially constructed from plastic. To prevent the risk of electrostatic

sparking, use only a damp cloth to clean the plastic surfaces.

Intrinsic Safety (IS)

Non-Incendive (NI)

Dust Ignition-proof (DIP)

3036541

IS Class I/II/III, Division 1, Groups A, B, C, D, E, F, and G

IS Class I, Zone 0, AEx ia IIC

NI Class I, Division 2, Groups A, B, C, and D

DIP Class II/III, Division 1, Groups E, F, and G

T4 (Ta = -58 °F to +158 °F / -50 °C to +70 °C)

Type 4X / IP66

4.7 Canada

4.7.1 Canada Intrinsic Safety (IS)

I6

Summary of product certification

Protections

Project ID

Markings

Control

drawing

Enclosure

Special Condition for Safe Use

Use with Rosemount SmartPower® option P/N 753-9220-0001 only.

Quick Start Guide 23

Intrinsic Safety (IS)

1786345

Class I, Division 1, Groups A, B, C, and D, T3C

Intrinsically Safe when installed in accordance with Rosemount

drawing 71097/1271

Type 4X / IP66

Single process seal

Quick Start Guide September 2020

4.7.2 Canadian Registration Number

CRN

0F04227.2C

The requirements of CRN are met when a Rosemount 2160 CSA-approved

vibrating fork level detector model is configured with 316/316L stainless

steel (1.4401/1.4404) process-wetted parts and either NPT threaded or 2-in.

to 8-in. ASME B16.5 flanged process connections.

4.8 Europe

4.8.1 ATEX Intrinsic Safety (IS)

I1

Summary of product certification

Protection

Certificate

Markings

Safety

instructions

Special Conditions For Safe Use (X)

1. Use with Rosemount SmartPower options P/N 753-9220-0001 only.

Intrinsic Safety (IS) for gas atmospheres

Baseefa 09ATEX0253X

II 1 G

Ex ia IIC T5...T2 Ga

IP66

See Instructions for hazardous area installations (I1 and I7)

2. The surface resistivity of the antenna is greater than 1 GΩ. To avoid

electrostatic charge build-up, it must not be rubbed or cleaned with

solvents or a dry cloth.

3. The Rosemount 2160 enclosure is made of aluminum alloy and given

a protective epoxy coating; however, care should be taken to protect

it from impact or abrasion if located in a Zone 0.

24 Rosemount 2160 Wireless Level Detector

September 2020 Quick Start Guide

4.9 International

4.9.1 IECEx Intrinsic Safety (IS)

I7

Summary of product certification

Protection

Certificate

Markings

Safety

instructions

Special Conditions for Safe Use

1. For use with Rosemount SmartPower options P/N 753-9220-0001

only.

2. The surface resistivity of the polymeric antenna is greater than 1GΩ.

To avoid electrostatic charge build-up, it shall not be rubbed or

cleaned with solvents or a dry cloth.

3. Warning – potential electrostatic charging hazard – The enclosure is

partially constructed from plastic. To prevent the risk of electrostatic

sparking, use only a damp cloth to clean the plastic surfaces.

Intrinsic Safety (IS) for gas atmospheres

IECEx BAS 09.0123X

Ex ia IIC T5-T2

IP66

See Instructions for hazardous area installations (I1 and I7)

4.10 Korea

4.10.1 KTL Intrinsic Safety (IS)

IP

Summary of product certification

Protection

Certificates

Markings

4.10.2 Korean Testing Laboratory (KTL), KCC mark for ordinary locations use

GP

Certificate

Quick Start Guide 25

Intrinsic Safety (IS)

13-KB4BO-0213X

Ex ia IIC T5...T2

Ta (see table in the certificate)

KCC-REM-ERN-RMDSWIT2160XXX

Quick Start Guide September 2020

4.11 China

4.11.1 NEPSI Intrinsic Safety (IS)

I3

Summary of product certification

Protection

Certificate

Standards

Markings

Safety

instructions

Special Conditions for Safe Use

1. The 701PBKKF SmartPower Black Power Module (p/n

00753-9220-0001) provided by the manufacturer should be used.

2. The surface resistivity of the polymeric antenna is greater than 1 GΩ.

To avoid electrostatic charge build-up, it shall not be rubbed or

cleaned with solvents or a dry cloth.

Intrinsic Safety (IS)

GYJ20.1149X (CCC 认证)

GB 3836.1-2010

GB 3836.4-2010

GB 3836.20-2010

Ex ia IIC T5-T2 Ga

See the certificate.

3. The Rosemount 2160 enclosure is made of aluminum alloy and given

a protective epoxy coating. However, care should be taken to protect

it from impact or abrasion if located in Zone 0.

4.12 Technical Regulations Customs Union (EAC)

4.12.1 Technical Regulation Customs Union (EAC) Intrinsic Safety (IS)

IM

Summary of product certification

Protection

Certificate

Markings

Special Conditions For Safe Use (X)

See certificate for special conditions

26 Rosemount 2160 Wireless Level Detector

Intrinsic Safety (IS)

RU C-GB.AB72.B.00916

0Ex ia IIC T5...T2 Ga X

Ta (see table in the certificate)

September 2020 Quick Start Guide

4.13 Instructions for hazardous area installations (I1 and I7)

Model numbers covered:

2160X**S***********I1******

2160X**E***********I1******

2160X**S***********I7******

2160X**E***********I7******

(“*” indicates options in construction, function, and materials).

The Rosemount 2160 may be used in a hazardous area with

1.

flammable gases and vapors with apparatus groups IIC, IIB and IIA,

and temperature classes T1 to T5. The temperature class of the

installation will be determined from the highest process or ambient

temperature. The temperature class of the installation will be

determined from the highest process or ambient temperature.

2.

It is a special condition of the certification that the temperature of

the electronics housing is in the range of –50 to 70 °C. The

Rosemount 2160 must not be used outside this range. Limit the

external ambient temperature if the process temperature is high.

3. Suitably trained personnel shall carry out installation in accordance

with the applicable code of practice.

4. The user should not repair this equipment.

5. If equipment is likely to come into contact with aggressive

substances, it is the user’s responsibility to take suitable precautions

that prevent it from being adversely affected, thus ensuring the type

of protection is not compromised.

Aggressive substances: Acidic liquids or gases that may attack

metals or solvents that may affect polymeric materials.

Suitable precautions: Regular checks as part of routine inspections

or establishing from a material's data sheet that it is resistant to

specific chemicals.

6. Special conditions of use

a. The user is to ensure the ambient air temperature (Ta) and

the process temperature (Tp) are within the range detailed

above for the T class of the specific flammable gases or vapors

present.

b. The surface resistivity of the antenna is greater than 1

gigaohm. To avoid electrostatic charge build-up, it must not

be rubbed or cleaned with solvents or a dry cloth.

Quick Start Guide 27

Quick Start Guide September 2020

c. The Rosemount 2160 enclosure is made of aluminum alloy

and given a protective epoxy coating; however, care should

be taken to protect it from impact or abrasion if located in an

area where Equipment Protection Level Ga is required (Zone 0

locations).

7.

Technical data

ATEX coding: II 1 G, Ex ia IIC T5...T2 Ga

a.

b. IECEx coding: Ex ia IIC T5-T2

c. Temperature:

2160X**S***********I1******,

2160X**S***********I7******:

Temperature

classes

T5,T4,T3,T2,T1 104 °F (40 °C) 176 °F (80 °C)

T4,T3,T2,T1 158 °F (70 °C) 212 °F (100 °C)

T4,T3,T2,T1 140 °F (60 °C) 239 °F (115 °C)

T3,T2,T1 122 °F (50 °C) 302 °F (150 °C)

Maximum ambient

air temperature

(Ta)

Maximum process

temperature (Tp)

Minimum ambient air temperature (Ta) = –40 °F (–40 °C)

Minimum process temperature (Tp) = –40 °F (–40 °C)

2160X**E***********I1******,

2160X**E***********I7******:

Temperature

classes

T5,T4,T3,T2,T1 104 °F (40 °C) 176 °F (80 °C)

T4,T3,T2,T1 158 °F (70 °C) 239 °F (115 °C)

T3,T2,T1 149 °F (65 °C) 365 °F (185 °C)

T2,T1 140 °F (60 °C) 500 °F (260 °C)

Maximum ambient

air temperature

(Ta)

Maximum process

temperature (Tp)

Minimum ambient air temperature (Ta) = –58 °F (–50 °C)

Minimum process temperature (Tp) = –94 °F (–70 °C)

d.

Materials: Refer to the Rosemount 2160

Product Data Sheet.

e. Year of manufacture: Printed on the product label.

28 Rosemount 2160 Wireless Level Detector

EU Declar

ation of Conformity

No: RMD 1076 Rev. I

n

e 3 fo 1 egaP

W

e,

Rosemount Tank Radar AB

Layoutvägen 1

S-435 33 MÖLNLYCKE

Sweden

declare under our sole responsibility that the product,

Rosemount™ 2160 Series

WirelessHART™ Vibrating Fork Liquid Level Switch

manufactured by,

Rosemount Tank Radar AB

Layoutvägen 1

S-435 33 MÖLNLYCKE

Sweden

to which this declaration relates, is in conformity with the provisions of the European Union

Directives, including the latest amendments, as shown in the attached schedule.

Assumption of conformity is based on the application of the harmonized standards and, when

applicable or required, a European Union notified body certification, as shown in the attached

schedule.

(signature)

Manager Product Approvals

(function)

Dajana Prastalo

(name)

28-Aug-20;

(date of issue)

September 2020 Quick Start Guide

4.14 EU Declaration of Conformity

Figure 4-1: EU Declaration of Conformity (Page 1)

Quick Start Guide 29

EU Declara

tion of Conformity

No: RMD 1076 Rev. I

n

e 3 fo 2 egaP

EMC Directive (2014/30/EU)

All Models

Harmonized Standards: EN 61326-1:2013

RED Directive (2014/53/EU)

All Models

Harmonized Standards: EN 300 328: V2.1.1

Other Standards Used: EN 301 489-1: V2.2.0

EN 301 489-17: V3.2.0

EN 61010-1:2010

ATEX Directive (2014/34/EU)

Rosemount 2160X**************I1WA3WK1*

Baseefa 09ATEX0253X – Intrinsically safe

Equipment Group II, Category 1 G (Ex ia IIC T5…T2 Ga)

Harmonized Standards: EN 60079-0:2018

EN 60079-11:2012

(Minor variations in design to suit the application and/or mountin g requirements are identified by alpha/numeric

characters where

indicated * above)

Quick Start Guide September 2020

Figure 4-2: EU Declaration of Conformity (Page 2)

30 Rosemount 2160 Wireless Level Detector

EU Declara

tion of Conformity

No: RMD 1076 Rev. I

n

e 3 fo 3 egaP

ATEX Notified Body

SGS Fimko Oy [Notified Body Number: 0598]

Särkiniementie 3

P.O. Box 30

FI-00211, Helsinki

Finland

ATEX Notified body for Quality Assurance

DNV Nemko Presafe AS [Notified Body Number: 2460]

Veritasveien 1

1322 HØVIK

Norway

September 2020 Quick Start Guide

Figure 4-3: EU Declaration of Conformity (Page 3)

Quick Start Guide 31

含含有有

China RoHS

管管控控物物质质超超过过最最大大浓浓度度限限值值的的部部件件型型号号列列表表

Rosemount 2160

List of Rosemount 2160 Parts with China RoHS Concent ration above MCVs

部部件件 名名称称

Part Name

有有害害 物物质质 / Hazardous Substances

铅铅

Lead

(Pb)

汞汞

Mercury

(Hg)

镉镉

Cadmium

(Cd)

六六价价 铬铬

Hexavalent

Chromium

(Cr +6)

多多溴溴 联联苯苯

Polybrominated

biphenyls

(PBB)

多多溴溴 联联苯苯醚醚

Polybrominated

diphenyl ethers

(PBDE)

电子组件

Electronics

Assembly

XOOOO

O

壳体组件

Housing

Assembly

OOOXO

O

传感器组件

Sensor

Assembly

XOOOO

O

本表格系依据

SJ/T11364

的规定而制作.

This table is proposed in accordance with the provision of SJ/T11364.

O:

意为该部件的所有均质材料中该有害物质的含量均低于

GB/T 26572

所规定的限量要求.

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

意为在该部件所使用的所有均质材料里,至少有一类均质材料中该有害物质的含量高于

GB/T 26572

所规定的限量要求.

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

Quick Start Guide September 2020

4.15 China RoHS

32 Rosemount 2160 Wireless Level Detector

September 2020 Quick Start Guide

Quick Start Guide 33

Quick Start Guide September 2020

34 Rosemount 2160 Wireless Level Detector

September 2020 Quick Start Guide

Quick Start Guide 35

*00825-0100-4160*

00825-0100-4160, Rev. CB

Quick Start Guide

September 2020

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe

GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-

Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/

RosemountMeasurement

©

2020 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric

Co. Rosemount is a mark of one of the Emerson

family of companies. All other marks are the

property of their respective owners.

Loading...

Loading...