Rosemount™ 214C Sensor

Quick Start Guide

00825-0400-2654, Rev DB

May 2021

Quick Start Guide May 2021

Contents

About this guide...........................................................................................................................3

Wiring diagram for RTDs.............................................................................................................. 5

Wiring diagram for thermocouples.............................................................................................. 6

Additional RTD specifications....................................................................................................... 7

Additional thermocouple specifications....................................................................................... 9

Product certifications................................................................................................................. 10

Declaration of Conformity..........................................................................................................23

China RoHS................................................................................................................................ 25

2 Emerson.com/Rosemount

May 2021 Quick Start Guide

1 About this guide

This guide provides basic guidelines for Rosemount 214C Sensor models. If

the sensor was ordered assembled to a temperature thermowell or

transmitter, see the appropriate product literature for information on

configuration and hazardous locations certifications.

1.1 Safety messages

NOTICE

Complications can arise when the sensors and the transmitters to which they

are assembled are certified to compatible, but each has different approvals.

Be aware of the following situations:

• If an I.S. approved Rosemount 214C Sensor is ordered with a housing, a

transmitter enclosed in that housing may have a different I.S. approval

rating. Refer to the transmitter IS certificate if applicable.

• If a sensor and transmitter have different certifications, or if either has

more certifications than the other, installation must comply with the

most restrictive requirements required by either component. This is

especially (but not exclusively) relevant when combination approvals are

ordered on either the sensor or transmitter. Review certifications on

both the sensor and transmitter for installation requirements and ensure

installation of the sensor/transmitter assembly complies with a single

certification that is shared by both of these components and that meets

the requirements of the application.

WARNING

Explosion

Explosions could result in death or serious injury.

Installation of sensor in an explosive environment must be in accordance

with appropriate local, national, and international standards, codes, and

practices.

Quick Start Guide 3

Quick Start Guide May 2021

WARNING

Conduit/cable entries

Unless marked, the conduit/cable entries in the housing use a ½–14 NPT

thread form. Entries marked “M20” are M20 × 1.5 thread form. On

devices with multiple conduit entries, all entries will have the same

thread form. Only use plugs, adapters, glands, or conduit with a

compatible thread form when closing these entries.

When installing in a hazardous location, use only appropriately listed or

Ex certified plugs, glands, or adapters in cable/conduit entries.

Only use plugs, adapters, glands, or conduit with a compatible thread

form when closing these entries.

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

CAUTION

Refer to Product Certification section of this Quick Start Guide

documentation.

4 Emerson.com/Rosemount

Red

Red

White

White

Red

Red

White

Red

Red

White

Black

Black

Yellow

May 2021 Quick Start Guide

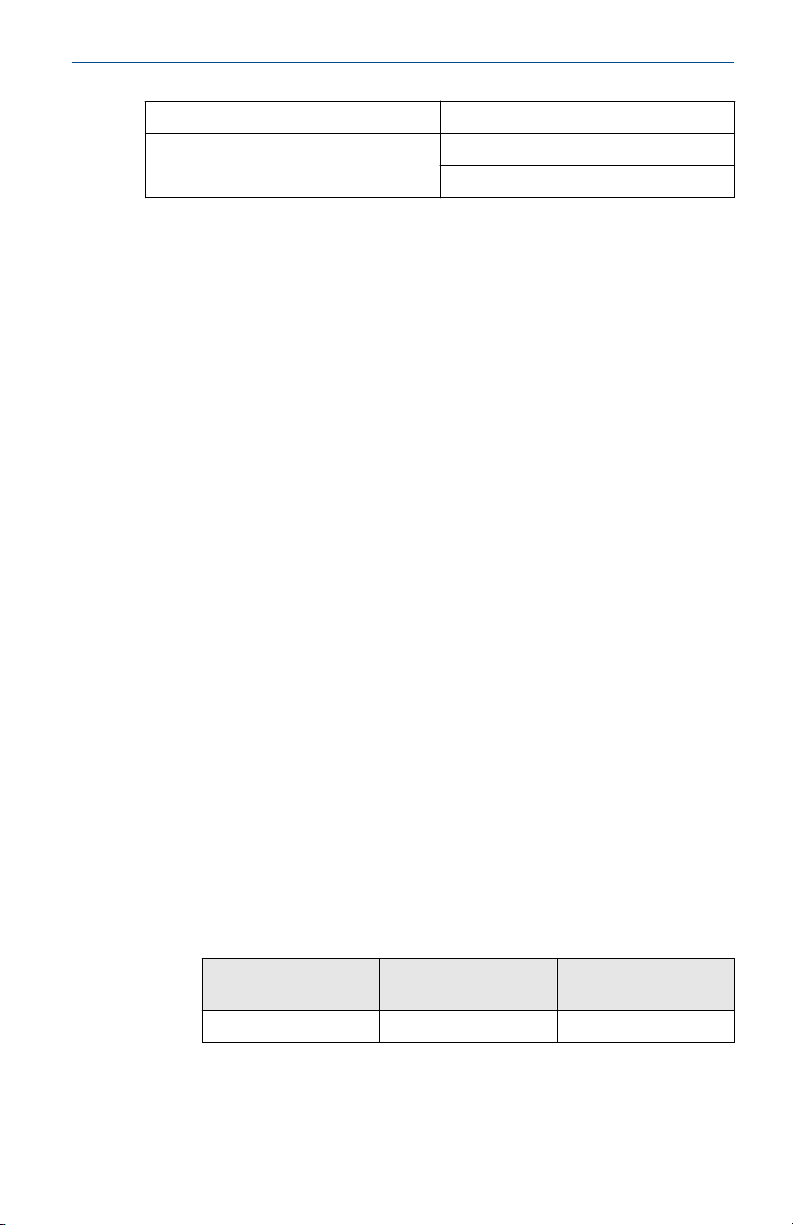

2 Wiring diagram for RTDs

Figure 2-1: RTD Lead Wire Configuration per IEC 60751 - Single Element

3-wire 4-wire

Note

To configure a single element, 4-wire RTD as a 3-wire system, connect only

one white lead. Insulate or terminate the unused white lead in a manner that

prevents shorting to the ground. To configure a single element, 4-wire RTD

as a 2-wire system, connect matching colored wires first and then connect

the paired wires to the terminal.

Figure 2-2: RTD Lead Wire Configuration per IEC 60751 - Dual Element

3-wire

Quick Start Guide 5

( – )

( + )

( + )

( + )

( – )

( – )

Quick Start Guide May 2021

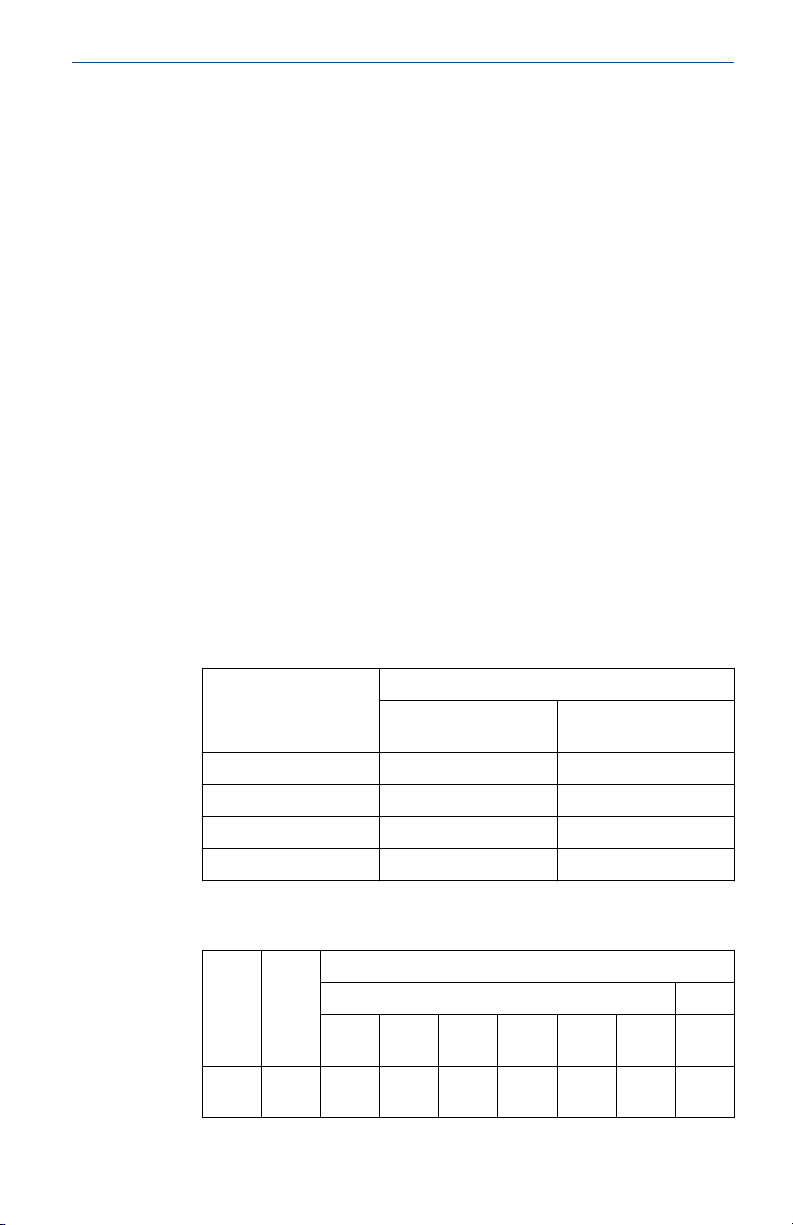

3 Wiring diagram for thermocouples

Figure 3-1: Thermocouple Lead Wire Configuration

Single thermocouple, 2-wire Dual thermocouple, 4-wire

Table 3-1: Thermocouple Wire Color

IEC 60584 Themocouple ASTM E230 Thermocouple

Type POS (+) NEG (-) POS (+) NEG (-)

J Black White White Red

K Green White Yellow Red

T Brown White Blue Red

Note

Dual thermocouple sensors are shipped with one pair of the wires shrinkwrapped together.

6 Emerson.com/Rosemount

May 2021 Quick Start Guide

4 Additional RTD specifications

Note

All specifications in this section apply to all RTDs unless noted otherwise. All

RTDs meet and/or exceed type and routine tests for sensors/thermometers

per IEC 60751:2008.

4.1 Insulation resistance

1000 MΩ minimum insulation resistance when measured at 500 VDC at

room temperature.

4.2 Insulation resistance at elevated temperature

Insulation resistance at elevated temperatures for sensor types RT, RH, and

RW are tested and meet requirements according to IEC 60751:2008 6.5.1.

4.3 Time response

Sensor response time tested in flowing water according to IEC 60751:2008

6.5.2.

Sensor type RT: T50 average = 8.5 seconds; T90 average = 22.9 seconds

Sensor type RH: T50 average = 9.15 seconds; T90 average = 24.1 seconds

Sensor type RW: T50 average = 9.0 seconds; T90 average = 24.4 seconds

4.4

4.5

4.6

4.7

Quick Start Guide 7

Stability

Stability at upper temperature limit tested and meets requirements

according to IEC 60751:2008 6.5.3.

Effects of temperature cycling

Effect of temperature cycling tested and meets requirements according to

IEC 60751:2008 6.5.5.

Hysteresis

Effect of hysteresis tested and meets requirements according to IEC

60751:2008 6.5.6.

Self heating

Self-heating tested and meets requirements according to IEC 60751:2008

6.5.7.

Quick Start Guide May 2021

4.8 Process immersion

Minimum immersion depth tested according to IEC 60751:2008 6.5.8.

Sensor type RT, single: Minimum immersion depth = 30 mm

Sensor type RT, dual: Minimum immersion depth = 45 mm

Sensor type RH, single and dual: Minimum immersion depth = 40 mm

Sensor type RW, single and dual: Minimum immersion depth = 50 mm

4.9 Vibration limits

Vibration tested according to IEC 60751:2008 6.6.4.

Sensor type RT ordered with VR1: Meets 10 g vibration between 20 and 500

Hz for 150 hours.

Sensor type RT and RH: Meets 3 g vibration between 20 and 500 Hz for 150

hours.

Sensor type RW: Meets 1 g vibration between 20 and 500 Hz for 150 hours.

4.10 Functional specifications

Power

Environmental

Overvoltage Category I

Pollution Degree 4

8 Emerson.com/Rosemount

May 2021 Quick Start Guide

5 Additional thermocouple specifications

Note

All specifications in this section apply to all thermocouple types unless noted

otherwise. All thermocouples meet and/or exceed type and routine tests for

sensors/thermometers per IEC 61515:2016.

5.1 Insulation resistance

1000 MΩ minimum insulation resistance when measured at 500 VDC at

room temperature.

5.2 Time response

Sensor response time tested in flowing water according to IEC 61515:2016

5.3.2.8.

Grounded: T50 average = 1.9 seconds; T90 average = 4.0 seconds

Ungrounded: T50 average = 2.8 seconds; T90 average = 7.3 seconds

5.3 Process immersion

Minimum immersion depth tested according to IEC 60751:2008 6.5.8.

Grounded thermocouples: Minimum immersion depth = 5 mm

Ungrounded thermocouples: Minimum immersion depth = 10 mm

5.4

5.5

Quick Start Guide 9

Continuity

Electrical continuity and polarity are tested and meet requirements

according to IEC 61515:2016 5.3.2.

Functional specifications

Power

Environmental

Overvoltage Category I

Pollution Degree 4

Quick Start Guide May 2021

6 Product certifications

Rev 2.7

European Directive information

A copy of the EU Declaration of Conformity can be found at the end of the

Quick Start Guide. The most recent revision of the EU Declaration of

Conformity can be found at Emerson.com/Rosemount.

Ordinary Location Certification

The Rosemount 214C has been examined and tested to determine that the

design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

Note

The terminal strip in the Aluminum with Terminal Strip (AT1 or AT3)

connection head requires sensor lead wires to have a wire termination (Ex:

Bootlace ferrule or spade lug).

North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code

(CEC) permit the use of Division marked equipment in Zones and Zone

marked equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined

in the respective codes.

6.1

North America

6.1.1 E5 USA Explosionproof (XP) and Dust-Ignitionproof (DIP)

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

1. Flameproof joints are not intended for repair.

2. Cable entries must be used which maintain the ingress protection of

10 Emerson.com/Rosemount

70044744

FM 3600:2011, FM 3615:2006, UL 50E:2007, UL

61010-1:2010, ANSI/ISA 60529:2004

XP CL I, DIV 1, GP B, C, D; DIP CL II, DIV 1, GP E, F, G; CL III; T6

(-50 °C ≤ Ta ≤ +80 °C), T5 (-50 °C ≤ Ta ≤ +95 °C); Seal not

required; installed per Rosemount drawing 00214-1030; Type

4X† and IP 66/67; V

the enclosure. Unused cable entries must be filled with suitable

blanking plugs.

35 VDC, 750 mW

max

max

May 2021 Quick Start Guide

6.1.2 N5 USA Division 2 (NI)

Certificate

Standards

70044744

FM 3600:2011, FM 3611:2004, UL 50E:2007, UL

61010-1:2010, ANSI/ISA 60529:2004

Markings

NI CL I, DIV 2, GP A, B, C, D; T6 (-50 °C ≤ Ta ≤ +80 °C), T5 (-50 °C

≤ Ta ≤ +95 °C); installed per Rosemount drawing 00214-1030;

Type 4X† and IP 66/67; V

35 VDC, 750 mW

max

max

6.1.3 E6 Canada Explosionproof (XP) and Dust-Ignitionproof (DIP)

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

1. Flameproof joints are not intended for repair.

2. Cable entries must be used which maintain the ingress protection of

70044744

CAN/CSA C22.2 No. 0:2010, CAN/CSA No. 25-1966 (R2000),

CAN/CSA C22.2 No. 30-M1986 (R2012), CAN/CSA C22.2 No.

94-M1991 (R2011), CAN/CSA C22.2 No. 61010-1:2012

XP CL I, DIV 1, GP B*, C, D; DIP CL II, DIV 1, GP E, F, G; CL III; T6

(-50 °C ≤ Ta ≤ +80 °C), T5 (-50 °C ≤ Ta ≤ +95 °C); Seal not

required; installed per Rosemount drawing 00214-1030; Type

4X† and IP 66/67; V

35 VDC, 750 mW

max

max

the enclosure. Unused cable entries must be filled with suitable

blanking plugs.

6.1.4 N6 Canada Division 2

Certificate

Standards

Markings

†

Spring loaded indicator has reduced ingress and dust ratings. Spring loaded

sensors must be installed in a thermowell to maintain dust and ingress

ratings. Un-painted aluminum enclosures are Type 4 rated. *Assembly is not

Canada Explosionproof (E6) rated to Group B if the AT1 (Aluminum with

Terminal Strip) connection head is used.

Quick Start Guide 11

70044744

CAN/CSA C22.2 No. 0:2010, CAN/CSA C22.2 No. 94-M1991

(R2011), CAN/CSA No. 213-M1987 (R2013), CAN/CSA C22.2

No. 61010-1:2012

CL I, DIV 2, GP A, B, C, D; T6; (–50 °C ≤ Ta ≤ +80 °C), T5 (–50 °C

≤ Ta ≤ +95 °C); installed per Rosemount drawing 00214-1030;

Type 4X† and IP 66/67; V

35 VDC, 750 mW

max

max

Quick Start Guide May 2021

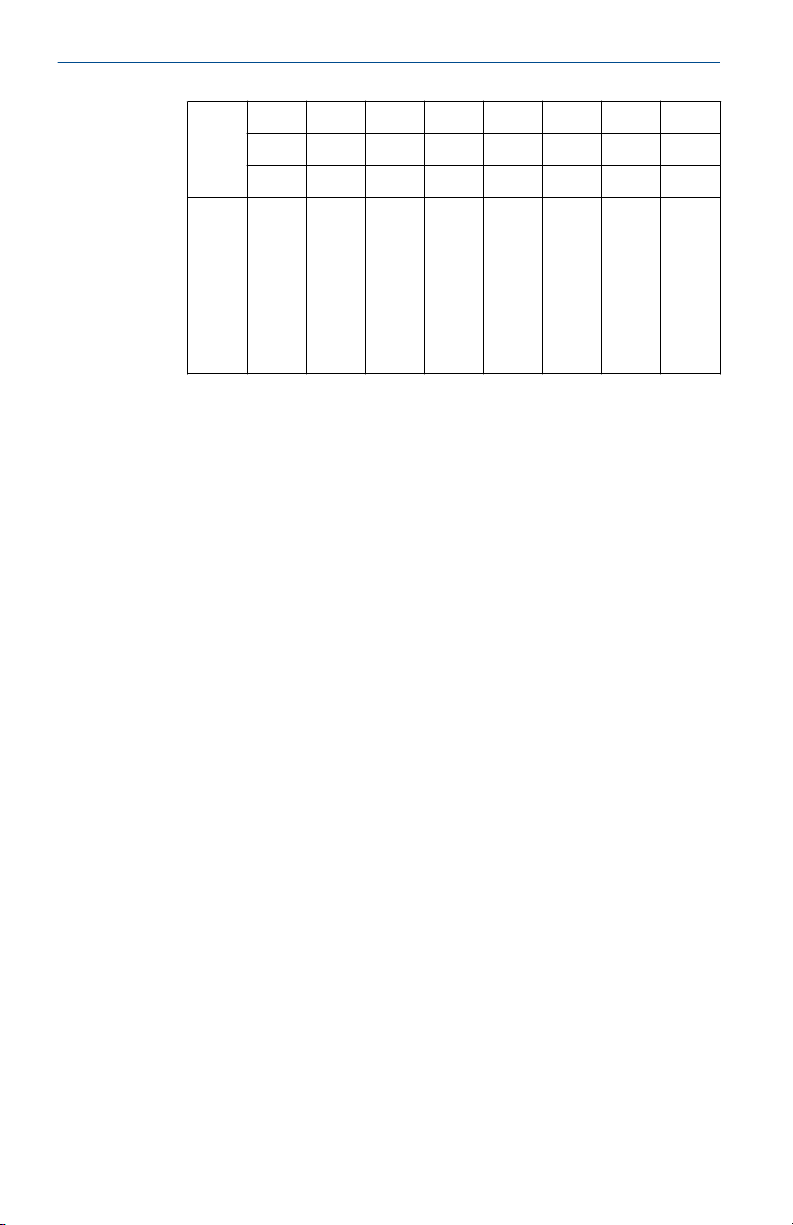

6.2 Europe

6.2.1 E1 ATEX Flameproof

Certificate

Standards

Markings

DEKRA 19ATEX0076 X

EN IEC 60079-0: 2018, EN 60079-1: 2014

II 2 G Ex db IIC T6…T1 Gb, (-60 °C ≤ Ta ≤ +80 °C)

Special Conditions for Safe Use (X):

1. Flameproof joints are not intended for repair.

2. Non-Standard Paint options may cause risk from electrostatic

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

3. When provided on their own, the adapter style sensors must be

assembled to a suitable Ex db enclosure with a free internal volume

no greater than 550 cm3.

4. Guard DIN sensors against impacts greater than 4J.

Process temperature

range (°C)

-60 °C to +80 °C -60 °C to +80 °C T6

-60 °C to +95 °C -60 °C to +80 °C T5

-60 °C to +130 °C -60 °C to +80 °C T4

-60 °C to +195 °C -60 °C to +80 °C T3

-60 °C to +290 °C -60 °C to +80 °C T2

-60 °C to +440 °C -60 °C to +80 °C T1

(1)

Ambient temperature

range (°C)

(1)

Temperature class

(1) Min. process temperature and min. ambient temperature is limited to

-50 °C for models with enclosure designation “AD1” or “SD1”

6.2.2 I1 ATEX Intrinsic Safety

Certificate

Standards

Markings

Thermocouples; Pi = 500 mW T6 -60 °C ≤ Ta ≤ +70 °C

12 Emerson.com/Rosemount

Baseefa16ATEX0101X

EN 60079-0:2012+A11:2013, EN 60079-11:2012

II 1 G Ex ia IIC T5/T6 Ga (SEE CERTIFICATE FOR SCHEDULE)

May 2021 Quick Start Guide

RTDs; Pi = 192 mW T6 -60 °C ≤ Ta ≤ +70 °C

RTDs; Pi = 290 mW T6 -60 °C ≤ Ta ≤ +60 °C

T5 -60 °C ≤ Ta ≤ +70 °C

Special Conditions for Safe Use (X):

The equipment must be installed in an enclosure which affords it a degree of

ingress protection of at least IP20.

6.2.3 N1 ATEX Zone 2

Certificate

Standards

Markings

BAS00ATEX3145

EN 60079-0:2012+A11:2013, EN 60079-15:2010

II 3 G Ex nA IIC T5 Gc (-40 °C ≤ Ta ≤ 70 °C)

6.2.4 ND ATEX Dust Ignitionproof

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

1. Non-Standard Paint options may cause risk from electrostatic

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

2. When provided on their own, the adapter style sensors must be

assembled to a suitable Ex tb enclosure with a free internal volume

no greater than 550 cm3.

3. The spring loaded adapter style sensors and DIN style sensors must

be installed in a thermowell to maintain Ex tb protection.

4. The contact indicating adapter style sensor does not meet the

requirements for type of protection “tb”.

DEKRA 19ATEX0076 X

EN IEC 60079-0:2018, EN 60079-31:2014

II 2 D Ex tb IIIC T130 °C Db, (-60 °C ≤ Ta ≤ +80 °C)

Process temperature

range (°C)

-60 °C to +100 °C -60 °C to +80 °C T130 °C

(1) Min. process temperature and min. ambient temperature is limited to

Quick Start Guide 13

(1)

-50 °C for models with enclosure designation “AD1” or “SD1”.

Ambient temperature

range (°C)

(1)

Maximum surface

temperature “T”

Quick Start Guide May 2021

6.3 International

6.3.1 E7 IECEx Flameproof

Certificate

Standards

Markings

IECEx DEK 19.0041X

IEC 60079-0: 2017, IEC 60079-1: 2014

Ex db IIC T6…T1 Gb (-60 °C ≤ Ta ≤ +80 °C)

Special Conditions for Safe Use (X):

1. Flameproof joints are not intended for repair.

2. Non-Standard Paint options may cause risk from electrostatic

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

3. When provided on their own, the adapter style sensors must be

assembled to a suitable Ex db enclosure with a free internal volume

no greater than 550 cm3.

4. Guard DIN sensors against impacts greater than 4J.

Process temperature

range (°C)

-60 °C to +80 °C -60 °C to +80 °C T6

-60 °C to +95 °C -60 °C to +80 °C T5

-60 °C to +130 °C -60 °C to +80 °C T4

-60 °C to +195 °C -60 °C to +80 °C T3

-60 °C to +290 °C -60 °C to +80 °C T2

-60 °C to +440 °C -60 °C to +80 °C T1

(1)

Ambient temperature

range (°C)

(1)

Temperature class

(1) Min. process temperature and min. ambient temperature is limited to

-50 °C for models with enclosure designation “AD1” or “SD1”.

6.3.2 I7 IECEx Intrinsic Safety

Certificate

Standards

Markings

Thermocouples; Pi = 500 mW T6 -60 °C ≤ Ta ≤ +70 °C

14 Emerson.com/Rosemount

IECEx BAS 16.0077X

IEC 60079-0:2011, IEC 60079-11:2011

Ex ia IIC T5/T6 Ga (SEE CERTIFICATE FOR SCHEDULE)

May 2021 Quick Start Guide

RTDs; Pi = 192 mW T6 -60 °C ≤ Ta ≤ +70 °C

RTDs; Pi = 290 mW T6 -60 °C ≤ Ta ≤ +60 °C

T5 -60 °C ≤ Ta ≤ +70 °C

Special Condition for Safe Use (X):

The equipment must be installed in an enclosure which affords it a degree of

ingress protection of at least IP20.

6.3.3 N7 IECEx Zone 2

Certificate

Standards

Markings

IECEx BAS 07.0055

IEC 60079-0:2011, IEC 60079-15:2010

Ex nA IIC T5 Gc; T5 (–40 °C ≤ Ta ≤ +70 °C)

6.3.4 NK IECEx Dust Ignitionproof

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

1. Non-Standard Paint options may cause risk from electrostatic

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information

2. When provided on their own, the adapter style sensors must be

assembled to a suitable Ex tb enclosure with a free internal volume

no greater than 550 cm3.

3. The spring loaded adapter style sensors and DIN style sensors must

be installed in a thermowell to maintain Ex tb protection.

4. The contact indicating adapter style sensor does not meet the

requirements for type of protection “tb”.

IECEx DEK 19.0041X

IEC 60079-0:2017 and IEC 60079-31:2013

Ex tb IIIC T130 °C Db, (-60 °C ≤ Ta ≤ +80 °C)

Process temperature

range (°C)

-60 °C to +100 °C -60 °C to +80 °C T130 °C

(1) Min. process temperature and min. ambient temperature is limited to

Quick Start Guide 15

(1)

-50 °C for models with enclosure designation “AD1” or “SD1”.

Ambient temperature

range (°C)

(1)

Maximum surface

temperature “T”

Quick Start Guide May 2021

6.4 Brazil

6.4.1 E2 Brazil Flameproof & Dust Ignitionproof

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

1. Refer to certificate for details regarding process and ambient

2. When the Rosemount 214C Sensor is provided with an enclosure

3. The non-metallic label on the device may store an electrostatic

4. The display covers were impacted at 4 J according to a low risk of

5. Flameproof joints are not intended for repair.

6. The stand-alone Rosemount 214C Sensors without an enclosure

UL-BR 17.0199X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-1:2016,

ABNT NBR IEC 60079-31:2014

Ex db IIC T6…T1 Gb T6 (-50 °C ≤ Ta ≤ +80 °C), T5 (-50 °C ≤ Ta ≤

+95 °C), T4…T1 (-50 °C ≤ Ta ≤ +100 °C); Ex tb IIIC T130 °C Db

(-50 °C ≤ Ta ≤ +100 °C)

temperature limits.

with a display cover, the maximum ambient shall be 95 °C.

charge and become a source of ignition in Group III atmospheres.

Care shall be taken to reduce electrostatic build-up. For example, the

non-metallic label may be rubbed with a damp cloth.

mechanical danger. Guard the display covers against impact energies

greater than 4J.

must be assembled to a suitable Ex certified enclosure of a volume no

greater than 0.55 L to maintain the types of protection “db” and

“tb”.

7. The spring loaded sensors and DIN sensors must be installed in a

thermowell to maintain IP6X ratings.

8. Contact indicating sensors do not meet requirements for protection

type “Ex tb” and therefore are not “Ex tb” rated on this certificate.

6.4.2 I2 Brazil Intrinsic Safety

Certificate

Standards

Markings

16 Emerson.com/Rosemount

UL-BR 18.0257X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-11:2013

Ex ia IIC T6…T5 Ga Thermocouples: Pi = 500 mW, T6 (-60 °C ≤

Ta ≤ +70 °C) RTDs: Pi = 192 mW, T6 (-60 °C ≤ Ta ≤ +70 °C) Pi =

290 mW, T6 (-60 °C ≤ Ta ≤ +60 °C), T5 (-60 °C ≤ Ta ≤ +70 °C)

May 2021 Quick Start Guide

Special Conditions for Safe Use (X):

The equipment must be installed in an enclosure which affords it a degree of

ingress protection of at least IP20.

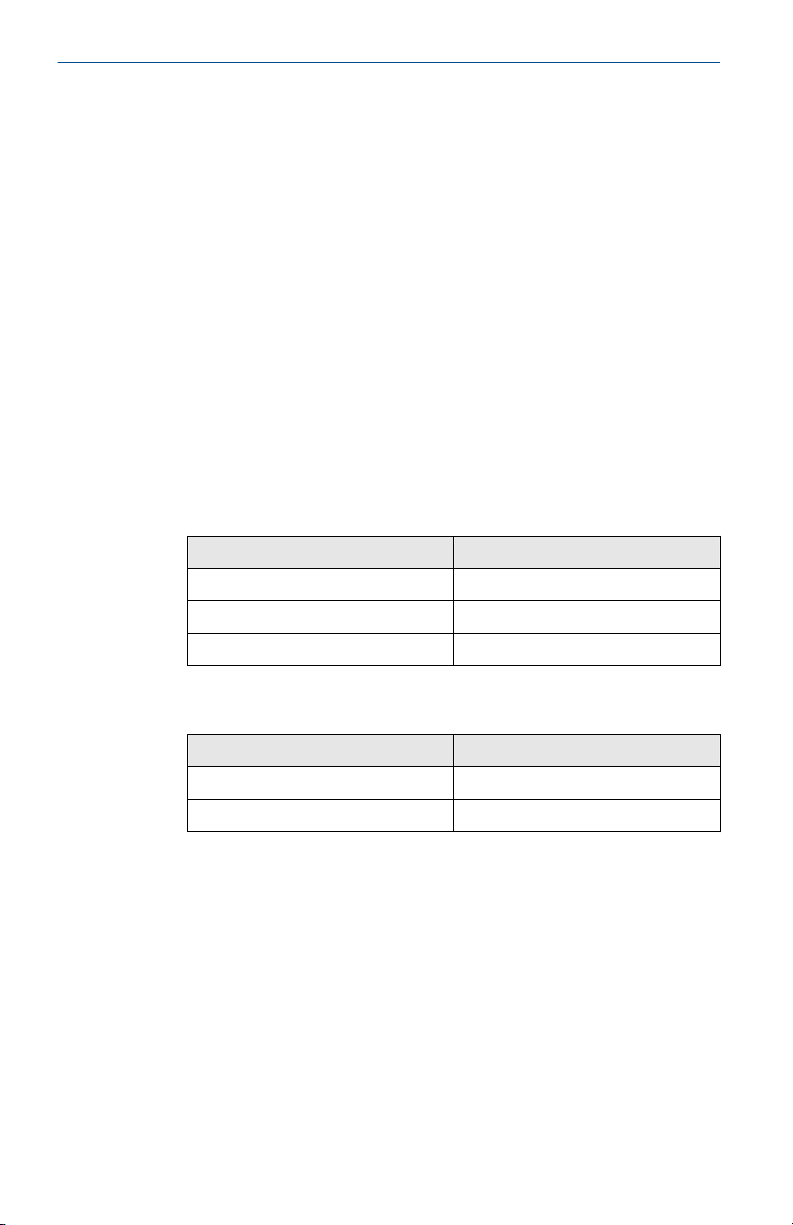

6.5 China

6.5.1 E3 China Flameproof

Certificate

Standards

GYJ17.1010X (CCC 认证)

GB 3836.1-2010, GB 3836.2-2010, GB 12476.1-2013, GB

12476.5-2013

Markings

Ex d IIC T6~T1 Gb, Ex tD A21 IP6X T130 °C

*Dust Ignitionproof approvals/markings are only available through the K3

option code

产品安全使用特殊条件

证书编号后缀“X”表明产品具有安全使用特殊条件:

1. 涉及隔爆接合面的维修须联系产品制造商.

2. 非金属铭牌可能带来静电放电危险,产品用于爆炸性粉尘危险场所

时需要采取措施以防止静电积聚.

产品使用注意事项

1. 产品温度组别和使用环境温度的关系为:

温度组别

T6 -50 ℃ ≤ Ta≤ +80 ℃ -50 ℃ ≤ Ta ≤ +80 ℃

T5 -50 ℃ ≤ Ta≤ +95 ℃ -50 ℃ ≤ Ta ≤ +95 ℃

T4~T1 -50 ℃ ≤ Ta≤ +100 ℃ -50 ℃ ≤ Ta ≤+95 ℃

T130 ℃ -50 ℃ ≤ Ta≤ +100 ℃ -50 ℃ ≤ Ta ≤+95 ℃

环境温度

AR1、SR1、AD1、

SD1、AT1、AJ1、AJ2

AR2、SR2

2. 产品温度组别和过程温度的关系为:

外壳

类型扩展长度

T6 T5 T4 T3 T2 T1 T130

AR2,

SR2无扩展

Quick Start Guide 17

55 70 95 95 95 95 95

过程温度(℃)

气体 粉尘

℃

Quick Start Guide May 2021

3’’ 55 70 100 100 100 100 100

6’’ 60 70 100 100 100 100 100

9’’ 65 75 110 110 110 110 110

AR1,

SR1,

AD1,

SD1,

AT1,

AJ1,

AJ2

任何

长度

85 100 135 200 300 450 130

3. 产品外壳设有接地端子,用户在使用时应可靠接地.

4. 安装现场应不存在对产品外壳有腐蚀作用的有害气体.

5. 现场安装时,电缆引入口须选用国家指定的防爆检验机构按检验认

可、具有 Ex d ⅡC Gb,Ex tD A21 IP6X 防爆等级的电缆引入装置或堵

封件,冗余电缆引入口须用堵封件有效密封.

6. 用于爆炸性气体环境中,现场安装、使用和维护必须严格遵守“断电

后开盖!”的警告语。用于爆炸性粉尘环境中,现场安装、使用和维

护必须严格遵守“爆炸性粉尘场所严禁开盖!”的警告语.

7. 用于爆炸性粉尘环境中,产品外壳表面需保持清洁,以防粉尘堆

积,但严禁用压缩空气吹扫.

8. 用户不得自行更换该产品的零部件,应会同产品制造商共同解决运

行中出现的故障,以杜绝损坏现象的发生.

9. 产品的安装、使用和维护应同时遵守产品使用说明书、

GB3836.13-2013“爆炸性环境 第 13 部分:设备的修理、检修、修

复和改造”、GB/T3836.15-2017“爆炸性环境 第 15 部分:电气装置

的设计、选型和安装”、GB/T3836.16-2017“爆炸性环境 第 16 部

分:电气装置的检查和维护”、GB50257-2014“电气装置安装工程爆

炸和火灾危险环境电力装置施工及验收规范”和 GB15577-2007“粉

尘防爆安全规程”的有关规定。

6.5.2 I3 China Intrinsic Safety

Certificate

Standards

Markings

18 Emerson.com/Rosemount

GYJ18.1024X (CCC 认证)

GB 3836.1-2010, GB 3836.4-2010, GB 3836.20-2010

Ex ia IIC T5/T6 Ga

May 2021 Quick Start Guide

产品安全使用特殊条件

证书编号后缀“X”表明产品具有安全使用特殊条件:产品必须安装于具有

IP20 外壳防护等级的外壳内方可使用.

产品使用注意事项

1. 产品使用环境温度和温度组别的关系为:

传感器类型 最大输入功率 Pi

热电偶 500 T6 -60 ℃ ~ +70 ℃

RTD 192 T6 -60 ℃ ~ +70 ℃

RTD 290 T6 -60 ℃ ~ +60 ℃

(mW)

2. 本安电气参数:

热电偶:

最高输入电压最大输入电流最大输入功

Ui (V) Ii (mA) Pi (mW) Ci (pF) Li (nH)

60 100 500 75 600

最高输出电压

Uo (V)

0.1 50 25

RTD:

最高输入电

压

Ui (V) Ii (mA) Pi (mW) Ci (pF) Li (nH)

60 100 192/290 75 600

最大输入电流最大输入功

率

最大输出电流

Io (mA)

率

温度组别 使用环境温度

T5 -60 ℃ ~ +70 ℃

最大内部等效参数

最大输出功率

Po (mW)

最大内部等效参数

3. 该产品必须与已通过防爆认证的关联设备配套共同组成本安防爆系

统方可使用于爆炸性气体环境。其系统接线必须同时遵守本产品和

所配关联设备的使用说明书要求,接线端子不得接错.

4. 用户不得自行更换该产品的零部件,应会同产品制造商共同解决运

行中出现的故障,以杜绝损坏现象的发生.

Quick Start Guide 19

Quick Start Guide May 2021

5. 产品的安装、使用和维护应同时遵守产品使用说明书、

GB3836.13-2013“爆炸性环境 第 13 部分:设备的修理、检修、修

复和改造”、GB3836.15-2000“爆炸性气体环境用电气设备 第 15 部

分:危险场所电气安装(煤矿除外)”、GB3836.16-2006“爆炸性气

体环境用电气设备 第 16 部分:电气装置的检查和维护(煤矿除

外)”、GB3836.18-2010“爆炸性环境 第 18 部分:本质安全系统”和

GB50257-2014“电气装置安装工程爆炸和火灾危险环境电力装置施

工及验收规范”的有关规定.

6.5.3 N3 China Zone 2

Certificate

Standards

Markings

GYJ18.1025 (CCC 认证)

GB 3836.1-2010, GB 3836.8-2014

Ex nA IIC T5 Gc, T5 (-40 °C ≤ Ta ≤ +70 °C)

产品使用注意事项

1. 产品使用环境温度为:-40 ℃~+70 ℃

2. 输入参数:

类型 输入参数 Ui

变送器 42.4 V

热电阻端子 5 V

热电偶端子 0 V

3. 产品外壳内可以安装如下温度变送器模块:

型号

644 系列 GYJ15.1502

248 系列 GYJ15.1089

防爆合格证编号

4. 现场安装时,电缆引入口须选用经国家指定的防爆检验机构检验认

可、具有 Ex e ⅡC Gb 或 Ex nR ⅡC Gc 防爆等级的电缆引入装置或堵封

件,冗余电缆引入口须用堵封件有效密封。电缆引入装置或封堵件

的安装使用必须遵守其使用说明书的要求并保证外壳防护等级达到

IP54 (符合 GB4208-2008 标准要求)以上.

5. 用户不得自行更换该产品的零部件,应会同产品制造商共同解决运

行中出现的故障,以杜绝损坏现象的发生.

6. 产品的安装、使用和维护应同时遵守产品使用说明书、

GB3836.13-2013“爆炸性环境 第 13 部分:设备的修理、检修、修

复和改造”、GB3836.15-2000“爆炸性气体环境用电气设备 第 15 部

20 Emerson.com/Rosemount

May 2021 Quick Start Guide

分:危险场所电气安装(煤矿除外)”、GB3836.16-2006“爆炸性气

体环境用电气设备 第 16 部分:电气装置的检查和维护(煤矿除

外)”和 GB50257-2014“电气装置安装工程爆炸和火灾危险环境电

力装置施工及验收规范”的有关规定.

6.6 Korea

6.6.1 EP Korea Flameproof

Certificate

Markings

Special Condition for Safe Use (X):

Refer to certificate for Special Conditions for Safe Use.

17-KA4BO-0305X

Ex d IIC T6…T1, T6 (-50 °C ≤ Ta ≤ +80 °C), T5 (-50 °C ≤ Ta ≤ +95

°C), T4…T1 (-50 °C ≤ Ta ≤ +100 °C)

6.6.2 IP Korea Intrinsic Safety

Certificate

Markings

Special Condition for Safe Use (X):

Refer to certificate for details regarding process and ambient temperature

limits as well as Special Conditions for Safe Use.

17-KA4BO-0304X

Ex ia IIC T6/T5

6.6.3 KP Korea Flameproof, Dust Ignitionproof, and Intrinsic Safety

Certificate

Markings

Special Condition for Safe Use (X):

Refer to certificate for details regarding process and ambient temperature

limits as well as Special Conditions for Safe Use.

17-KA4BO-0306X in addition to the EP and IP certificate

numbers

Ex tb IIIC T130 °C, T130 °C (-50 °C ≤ Ta ≤ +100 °C) in addition to

the markings for EP and IP

6.7

Russia

6.7.1 EM Technical Regulation Customs Union TR CU 012/2011 (EAC) Flameproof

Markings

Quick Start Guide 21

1Ex db IIC T6…T1 Gb X, T6 (–55 °C ≤ Ta ≤ +80 °C), T5 (–55 °C ≤

Ta ≤ +95 °C), T4…T1 (–55 °C ≤ Ta ≤ +100 °C)

Quick Start Guide May 2021

Special Condition for Safe Use (X):

Refer to certificate for Special Conditions for Safe Use.

6.7.2 IM Technical Regulation Customs Union TR CU 012/2011 (EAC) Intrinsic Safety

Markings

Special Condition for Safe Use (X):

Refer to certificate for details regarding process and ambient temperature

limits as well as Special Conditions for Safe Use.

0Ex ia IIC T5,T6 Ga X

6.7.3 KM Technical Regulation Customs Union TR CU 012/2011 (EAC) Flameproof, Dust-Ignitionproof, and Intrinsic Safety

Markings

Special Condition for Safe Use (X):

Refer to certificate for details regarding process and ambient temperature

limits as well as Special Conditions for Safe Use.

Ex tb IIIC T130 °C Db X in addition to the markings above for EM

and IM.

6.8 Combinations

K1

K3

K7

KA

KB

KC

KD

KE

KM

KN

KP

Combination of E1, I1, N1, and ND

Combination of E3, I3, and N3

Combination of E7, I7, N7, and NK

Combination of E1 and E6

Combination of E5 and E6

Combination of E1 and E5

Combination of E1, E5, and E6

Combination of E1, E5, E6, and E7

Combination of EM and IM

Combination of N1, N5, N6, and N7

Combination of EP and IP

22 Emerson.com/Rosemount

May 2021 Quick Start Guide

7 Declaration of Conformity

Quick Start Guide 23

Quick Start Guide May 2021

24 Emerson.com/Rosemount

214C

2/9/2021

ᴹ

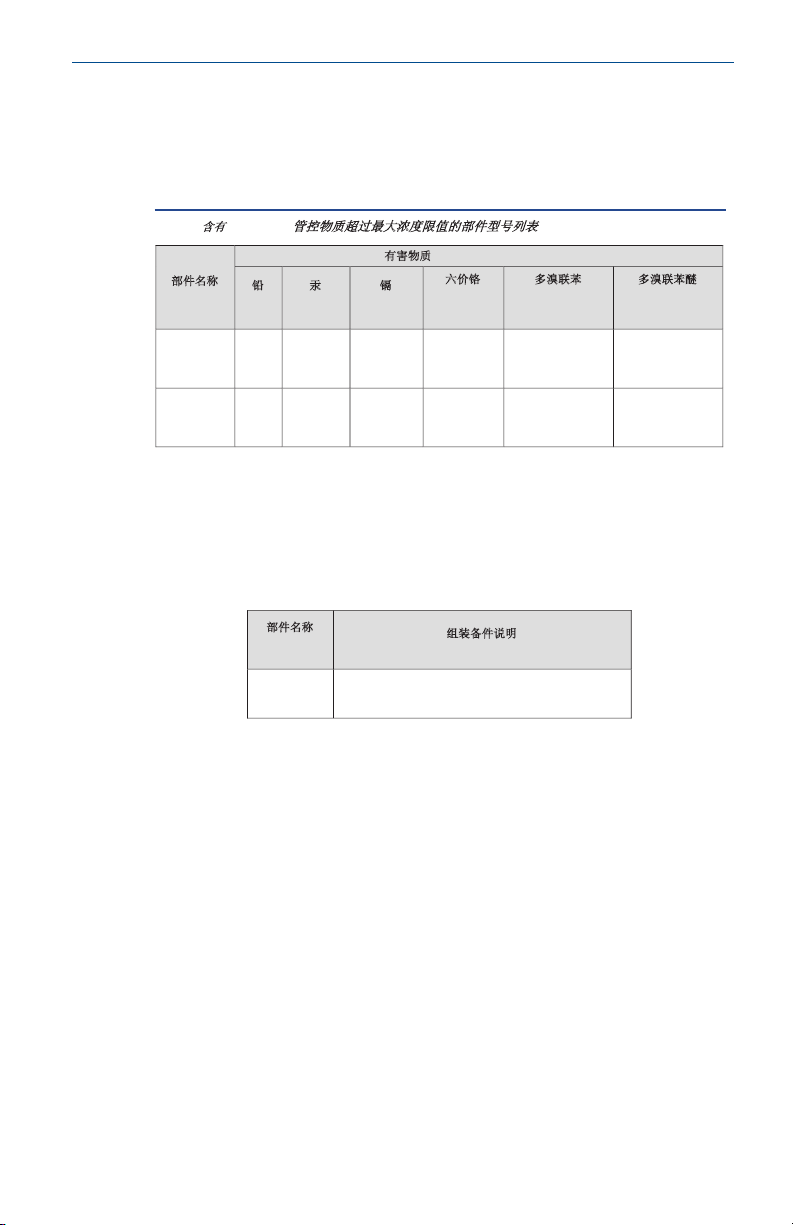

China RoHS

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

214C Temperature Sensor

List of 214C Temperature Sensor Parts with China RoHS Concentration above MCVs

䜘Ԧ〠

Part Name

ᴹᇣ⢙䍘

/ Hazardous Substances

䫵

Lead

(Pb)

⊎

Mercury

(Hg)

䭹

Cadmium

(Cd)

ޝԧ䬜

Hexavalent

Chromium

(Cr +6)

ཊⓤ㚄㤟

Polybrominated

biphenyls

(PBB)

ཊⓤ㚄㤟䟊

Polybrominated

diphenyl ethers

(PBDE)

༣փ㓴Ԧ

Housing

Assembly

O O O O O O

Րᝏಘ㓴Ԧ

Sensor

Assembly

O O O O O O

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit

requirement of GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is

above the limit requirement of GB/T 26572.

䜘Ԧ〠

Part Name

㓴㻵༷Ԧ䈤᰾

Spare Parts Descriptions for Assemblies

༣փ㓴Ԧ

Housing

Assembly

⭥ᆀཆ༣Electrical Housing

May 2021 Quick Start Guide

8 China RoHS

Quick Start Guide 25

Quick Start Guide May 2021

26 Emerson.com/Rosemount

May 2021 Quick Start Guide

Quick Start Guide 27

*00825-0400-2654*

00825-0400-2654, Rev. DB

Quick Start Guide

May 2021

©

2021 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo

is a trademark and service mark of

Emerson Electric Co. Rosemount is a mark

of one of the Emerson family of

companies. All other marks are the

property of their respective owners.

Loading...

Loading...