Page 1

USER'S MANUAL

* This User's Manual is intended for CJ-70 and CJ-60.

Thank you very much for purchasing the CJ-70/60.

• To ensure correct and safe usage with a full understanding of this

product's performance, please be sure to read through this manual

completely and store it in a safe location.

• Unauthorized copying or transferral, in whole or in part, of this

manual is prohibited.

• The contents of this operation manual and the specifications of this

product are subject to change without notice.

• The operation manual and the product have been prepared and tested

as much as possible. If you find any misprint or error, please inform

us.

Page 2

CJ-70

CJ-60

For the USA

FEDERAL COMMUNICATIONS COMMISSION

RADIO FREQUENCY INTERFERENCE

STATEMENT

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules.

These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated

in a commercial environment.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference

to radio communications.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Unauthorized changes or modification to this system can void

the users authority to operate this equipment.

The I/O cables between this equipment and the computing

device must be shielded.

NOTICE

Grounding Instructions

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Check with qualified electrician or service personnel if the

grounding instructions are not completely understood, or if in

doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept the tool’s

plug.

Repair or replace damaged or worn out cord immediately.

Operating Instructions

KEEP WORK AREA CLEAN. Cluttered areas and benches

invites accidents.

DON’T USE IN DANGEROUS ENVIRONMENT. Don’t

use power tools in damp or wet locations, or expose them to

rain. Keep work area well lighted.

DISCONNECT TOOLS before servicing; when changing

accessories, such as blades, bits, cutters, and like.

REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure the switch is in off position before plugging in.

USE RECOMMENDED ACCESSORIES. Consult the

owner’s manual for recommended accessories. The use of

improper accessories may cause risk of injury to persons.

NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Don’t leave tool until it comes to a

complete stop.

For Canada

CLASS A NOTICE

This Class A digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

CLASSE A AVIS

Cet appareil numérique de la classe A respecte toutes les

exigences du Règlement sur le matériel brouilleur du

Canada.

ROLAND DG CORPORATION

1-6-4 Shinmiyakoda, Hamamatsu-shi, Shizuoka-ken, JAPAN 431-2103

MODEL NAME : See the MODEL given on the rating plate.

RELEVANT DIRECTIVE : EC MACHINERY DIRECTIVE (89/392/EEC)

EC LOW VOLTAGE DIRECTIVE (73/23/EEC)

EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE (89/336/EEC)

ROLAND DG CORPORATION

1-6-4 Shinmiyakoda, Hamamatsu-shi, Shizuoka-ken, JAPAN 431-2103

MODEL NAME : See the MODEL given on the rating plate.

RELEVANT DIRECTIVE : EC MACHINERY DIRECTIVE (89/392/EEC)

EC LOW VOLTAGE DIRECTIVE (73/23/EEC)

EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE (89/336/EEC)

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Page 3

11

Table of Contents

To Ensure Safe Use..............................................................................................................................2

About the Labels Affixed to the Unit....................................................................................4

1 Checking Accessories ..............................................................................................................................6

2 Part Names and Functions ......................................................................................................................6

3 Setting Up and Connection......................................................................................................................8

Setting Up ....................................................................................................................................................8

Connection ...................................................................................................................................................9

4 Five Modes.............................................................................................................................................. 10

5 For Details on the Drain Tank ................................................................................................... 11

6 Installing Ink Cartridges......................................................................................................................... 11

7 Installing the Cutter ................................................................................................................................ 13

Adjusting the Cutter Blade ....................................................................................................................... 14

8 Powerup................................................................................................................................................... 14

9 Loading the Material .............................................................................................................................. 15

10 Printing Test ............................................................................................................................................ 19

11 Cutting Test............................................................................................................................................. 20

12 Downloading Printing/Cutting Data ..................................................................................................... 21

13

Ending Cutting and Printing Operations

................................................................................................. 21

14 When Not in Use.................................................................................................................................... 22

When Not in Use for a Prolonged Period... .............................................................................................. 23

15 When Moving the Unit........................................................................................................................... 23

16 Other Functions ...................................................................................................................................... 24

To Perform Long Printing/Cutting ........................................................................................................... 24

Remove the Printed Material, then Reload the Material and Perform Cutting......................................... 25

Align the Printing and Cutting Positions

......................................................................................................... 26

Performing Cutting or Printing at the Desired Location........................................................................... 29

17 Maintenance............................................................................................................................................ 30

Replacing the Ink Cartridges .................................................................................................................... 30

If the "INK EMPTY" message appears while printing................................................................................ 31

If the "INK EMPTY" message appears during setup .................................................................................. 31

Replacing the Blade .................................................................................................................................. 31

Cleaning the Ink Heads............................................................................................................................. 32

Cleaning .................................................................................................................................................... 32

18 Acceptable Media Widths ..................................................................................................................... 33

19 Blades and Materials ............................................................................................................................. 35

20 About the Printing/Cutting Area ........................................................................................................... 36

21 Display Menus Flowchart...................................................................................................................... 37

22 Description of Keys and Display Menus............................................................................................. 40

23 What to Do If........................................................................................................................................... 43

What to Do If... ......................................................................................................................................... 43

Messages ................................................................................................................................................... 45

24 Specifications.......................................................................................................................................... 46

Windows is registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

Copyright © 1997 ROLAND DG CORPORATION

Page 4

22

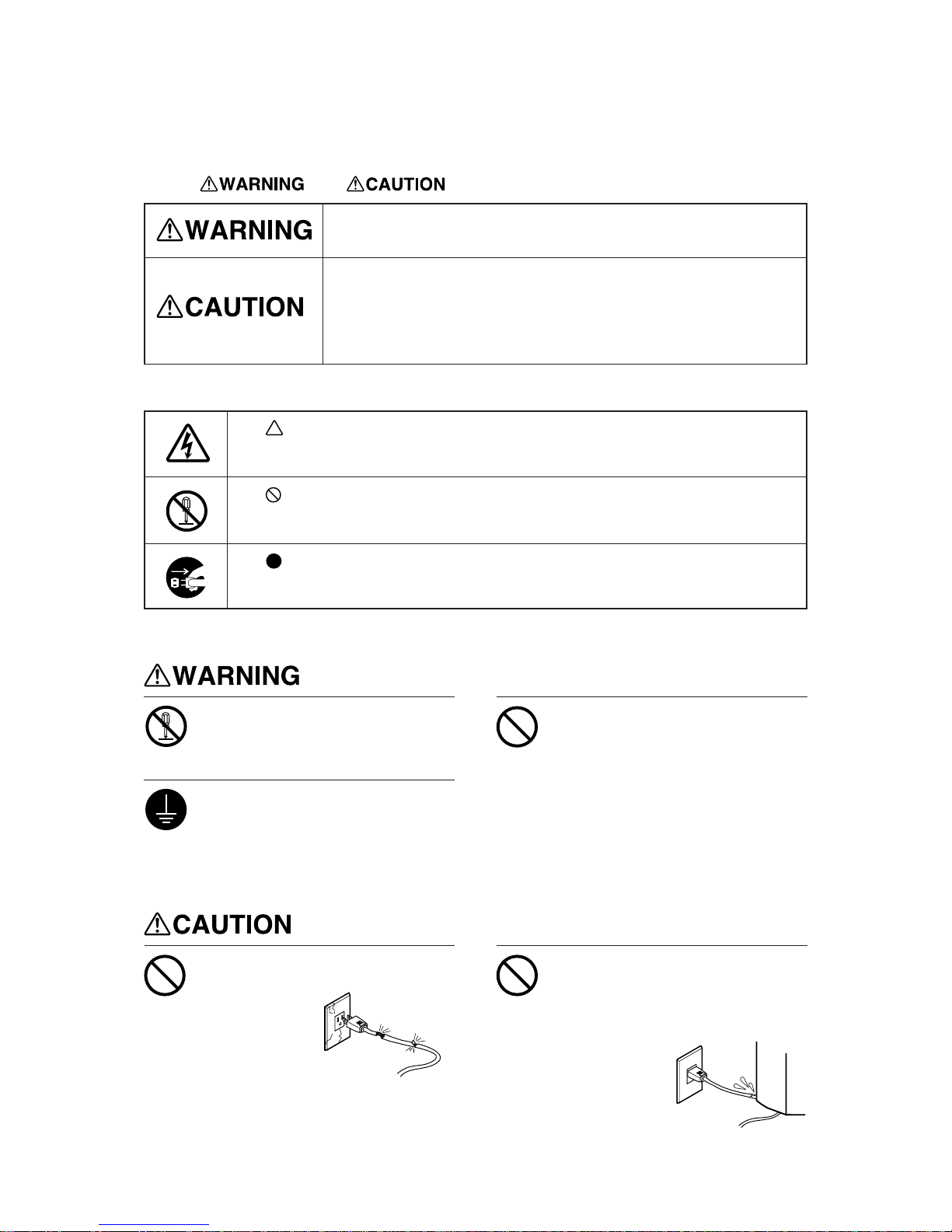

To Ensure Safe Use

Used for instructions intended to alert the user to the risk of death or severe

injury should the unit be used improperly.

About and Notices

Used for instructions intended to alert the user to the risk of injury or material

damage should the unit be used improperly.

* Material damage refers to damage or other adverse effects caused with

respect to the home and all its furnishings, as well to domestic animals or

pets.

About the Symbols

The symbol alerts the user to important instructions or warnings. The specific meaning of

the symbol is determined by the design contained within the triangle. The symbol at left means

"danger of electrocution."

The symbol alerts the user to items that must never be carried out (are forbidden). The

specific thing that must not be done is indicated by the design contained within the circle. The

symbol at left means the unit must never be disassembled.

The symbol alerts the user to things that must be carried out. The specific thing that must

be done is indicated by the design contained within the circle. The symbol at left means the

power-cord plug must be unplugged from the outlet.

Do not disassemble, repair, or

modify.

Doing so may lead to fire or abnormal

operation resulting in injury.

Ground the unit with the ground

wire.

Failure to do so may result in risk of

electrical shock in the even of a mechanical

problem

Use only with a power supply of the

same rating as indicated on the unit.

Use with any other power supply may lead

to fire or electrocution.

Do not use with a damaged power

cord or plug, or with a loose

electrical outlet.

Use with any other

power supply may

lead to fire or

electrocution.

Do not injure or modify the electrical

power cord, nor subject it to

excessive bends, twists, pulls,

binding, or pinching, nor place any

object of weight on it.

Doing so may

damage the

electrical power

cord, leading to

electrocution or

fire.

Page 5

33

When not in use for extended

periods, unplug the power cord from

the electrical outlet.

Failure to do so may

result in danger of

shock, electrocution,

or fire due to

deterioration of the

electrical insulation.

When unplugging the electrical

power cord from the power outlet,

grasp the plug, not the cord.

Unplugging by pulling the cord may damage

it, leading to fire or electrocution.

Do not allow liquids, metal objects

or flammables inside the machine.

Such materials

can cause fire.

Unpacking, installation, and moving

must be carried out by two or more

persons.

Failure to do so

may result in

falling of the

unit, leading to

injury.

Install in a level and stable location.

Otherwise the unit may tip over and cause

injury.

Use the joining screws to secure the

unit to the stand.

Failure to do so

may result in

falling of the unit,

leading to injury.

Roll material must be placed at a

predetermined shaft position.

Failure to do so may

result in falling of the

roll, leading to injury.

Release the caster locks for the

stand before attempting to move.

Otherwise the unit may tip over and cause

injury.

Use care to avoid pinching the

fingers when placing the unit on the

stand.

Doing so may

result in injury.

Do not insert your fingers in the ink

cartridge ports.

Doing so may

result in injury.

Do not touch the tip of the blade

with your fingers.

Doing so may result in injury.

Do not place hands within the space

to the front or rear of the unit while

in operation.

Doing so may result in injury.

Page 6

44

Do not lean on or place a heavy

object on the unit.

Otherwise the unit may tip over and cause

injury.

When closing the front cover, take

care not to pinch the fingers.

Doing so may result in injury.

Store ink cartridges out of the reach

of children.

If ink contacts the eyes, flush

immediately with water.

About the Labels Affixed to the Unit

These labels are affixed to the body of this product.

The following figure describes the location and content of these messages.

Front

Do not allow the hands within the

space to the front or rear of the unit

while in operation.

Ne pas introduire les mains sur la

partie frontale et postérieure de la

machine pendant son utilisation.

Do not insert your fingers in the ink

cartridge ports.

Ne pas introduire les doigts dans les

cassettes d' encre.

Page 7

55

Do not dismantle the cartridge.

Keep out of reach of children.

Do not store the cartridge in high or freezing temperatures.

Ne pas démonter la cartouche.

Conserver hors de la portée des enfants.

Ne pas emmagasiner á das températures hautes ou basses.

Ink cartridge

: Indicates information to prevent machine breakdown or malfunction and ensure correct use.

: Indicates a handy tip or advice regarding use.

In addition to the

and symbols, the symbols shown below are also used.

When closing the front cover, take care not to

pinch the fingers.

Il faut faire attention á ne pas se pincer les doigts

pendant la fermeture du couvercle frontal.

Rear

Do not allow the hands within

the space to the front or rear

of the unit while in operation.

Ne pas introduire les mains

sur la partie frontale et

postérieure de la machine

pendant son utilisation.

Rating label

Page 8

6

Check the following to make sure that you received all the items that were shipped along with the unit.

1 Checking Accessories

Power cord: 1 Blade for sheets: 1 Blade holder: 1 Alignment tool: 1 Drain tank: 1

User’s manual: 1Quick Poster Disks: 2

CAMM JET DRIVER

for windows® 95 and

windows® 3.1 Disk: 1

2 Part Names and Functions

* In this manual, sections that explain commons points for the CJ-70/60 use only illustrations of the CJ-70. Some details of the CJ-60

differ from the figure.

Do not touch the Y rail or the inner sides of the left and right covers.

Touching the area shown may cause the fingers to be soiled by grease or ink, and may result in diminished

image quality.

Do not put hands insideDo not put hands inside

Entire Y -rail portion

Page 9

7

Front View

Serial (RS-232C)

Connector

Power Connector

[AC IN]

Main power switch

Sheet Loading Lever

Pinch roller (right)

This is positioned at the lefthand edge of the material.

Operation panel

(See "22 Description of Keys and Display Menus")

Pinch roller (middle)

This is positioned centrally

between the left and right

pinch rollers.

Ink cartridge ports

Platen

Guide lines

These serve as a guide

for aligning the material

when loading it.

Cutting carriage

The cutting carriage is

where the cutter is

mounted.

Printing carriage

Parallel (Centronics)

Connector

Front cover

If the cover is opened while the

system is operating, it will

execute an emergency stop.

Pinch roller (left)

This is positioned at the righthand edge of the material.

Drain tank

Rear View

Knife guide

Cutter protector

Grit roller

Page 10

8

3 Setting Up and Connection

Setting up

For an explanation of how to assemble the unit and the stand (PNS-70/60), refer to the “ASSEMBLY INSTRUCTIONS” included with

the stand.

When using the unit while mounted on a stand, be sure to ensure a sufficient amount of installation space for the unit. The required

installation spaces for each model are listed below.

CJ-70: 2500 mm (98-7/16") wide, 900 mm (35-7/16") depth, and 1500 mm (59-1/16") high

CJ-60: 2300 mm (90-9/16") wide, 900 mm (35-7/16") depth, and 1500 mm (59-1/16") high

The material moves while printing/cutting is in progress. Objects which may obstruct material movement must not be placed within 60

cm (23-5/8") to the front or rear of the unit.

Mount the stack box on the stand as indicated in the diagram.

Stack box (The stack box is

included with the PNS-70/60.)

Use this to hold media.

Stand

Drain tank

Be sure to install the drain tank before switching on the power.

Never install this unit in any of the following situations, as it could result in damage:

Places where the installation surface is unstable or not level.

Places with excessive electrical noise.

Places with excessive humidity or dust.

Places with poor ventilation, because the CJ-70/60 generates considerable heat during operation.

Places with excessive vibration.

Places exposed to strong illumination or direct sunlight.

Unpacking, installation, and moving

must be carried out by two or more

persons.

Failure to do so

may result in

falling of the

unit, leading to

injury.

Install in a level and stable location.

Otherwise the unit may tip over and cause

injury.

Page 11

9

The type of interface -- parallel (in compliance with specifications of Centronics) or serial (RS-232C) -- is automatically detected.

If a serial (RS-232C) interface is used, the communication parameters are set using the LCD menu. Be sure that the settings you make

match the communication-parameter settings that have been made on the computer (including the operating system, application software,

and driver software). (See "21 Display Menus Flowchart".)

Connection

Parallel interface cable or

Serial interface cable

Serial connector

Use only with a power supply of the

same rating as indicated on the unit.

Use with any other power supply may lead

to fire or electrocution.

Ground the unit with the ground

wire.

Failure to do so may result in risk of

electrical shock in the even of a mechanical

problem

Before connecting the cable, make sure the computer's power and the CJ-70/60's main power switch are

switched off.

Securely connect the power cord, computer I/O cable and so on so that they will not be unplugged and cause

failure during operation. Doing so may lead to faulty operation or breakdown.

Arrange the power cord and interface connection cable to prevent tripping when moving around the unit.

Parallel connector Power connector [AC IN]

Power outlet

Power cord

Serial connector

Parallel connector

* Cables are available separately. One which

you are sure matches the model of computer

being used should be selected.

Page 12

10

4 Five Modes

The CJ-70/60 has the following five modes (operating states).

Main power switch

(Rear of CJ-70/60)

Turn on when you first use the system, and after

that point it is generally left on.

Please do not turn it off unless transporting the

main unit, or if the system is not to be used for

long periods of time.

Sub power switch

POWER key

(control panel)

NOT

READY

READY

BUSY

SLEEP

PAUSE

This mode is in effect

immediately after the

POWER key is pressed to

switch on the CJ-70/60.

Loading material and

pressing the SETUP key

caused the material size

to be detected and enables

the READY mode.

The CJ-70/60 can accept

data from the host when

in this mode.

The CJ-70/60 is receiving

data from the host and

performing printing or

cutting

The SLEEP mode is enabled when

the CJ-70/60 has been inactive for

a specified time. (When in the

SLEEP mode, the POWER LED

flashes once per second.)

To release the SLEEP mode...

- Touch any key on the control

panel.

- Send data from the computer.

- Open the front cover.

Pressing the PAUSE key causes operation to

stop temporarily.

Press the PAUSE key again to resume

operation.

Pressing the SETUP key while paused causes

remaining data to be cleared and returns to

the NOT READY mode.

If the material is removed while paused, the

CJ-70/60 goes into the NOT READY mode.

Use this switch to turn power on and off in

daily operation.

When power is turned on the system will enter

the NOT READY state (power on but sheet

not set).

When the power is turned on for the first time,

or turned on after removing the ink, the system

will execute ink fill.

This operation takes several minutes.

Page 13

11

5 For Details on the Drain Tank

The drain tank is mounted as shown in the figure. The bottom plug and the cap for the drain tank will be needed if you must repackage

the product. Please do not throw them away.

3 4

Put a water-absorbent, combustible material

such as a sponge or cloth into the plastic bag,

and soak up the ink.

Combustible

material such as a

sponge or cloth

Incineration

Drain tank

1) Detach the bottom plug

from the CJ-70/60.

2) Remove the cap for the drain tank and attach

the drain tank to the unit by screwing it on in

the direction of the arrow. Line up the threads

on the drain tank with the threads on the unit,

and screw on the tank without applying

excessive force.

Leave this mounted unless transporting the

main unit, or when it is full. Under normal use,

only a small amount of ink should collect in

this tank.

1 2

Press the key to switch off the power.

Remove the drain tank and attach the bottom plug

instead.

POWER LED goes out

If any ink gets on your hands or clothing, wash it off as soon as possible. Ink stains may become difficult to remove

if allowed to stand.

Dispose of ink in the drain tank as described below.

When preparing to move the unit, remove the drain tank and attach the bottom plug instead. Discard any ink that has collected in the

drain tank and cap the tank securely.

Drain tank

Bottom plug

Combustibles

Close the plastic bag, and dispose of it as combustible rubbish.

Page 14

12

6 Installing Ink Cartridges

Store ink cartridges out of the reach

of children.

Do not insert your fingers in the ink

cartridge ports.

Doing so may

result in injury.

If ink contacts the eyes, flush

immediately with water.

Do not remove any ink cartridges except when shipping the CJ-70/60.

Use only the ink specified for the machine. Dye inks cannot be used on a CJ-70/60 unit for which pigment inks

are specified, and pigment inks cannot be used on a CJ-70/60 unit for which dye inks are specified.

If ink runs out, replace immediately with an ink cartridge designed especially for the CJ-70/60. Do not attempt

to refill and reuse an empty ink cartridge.

If an ink cartridge is removed, replace it immediately with a new one.

Do not attempt to disassemble an ink cartridge.

Unused ink cartridges should be stored unopened at a temperature of -20°C (-4°F) to 40°C (104°F). Do not

store in a location subject to temperatures beyond this range.

If any ink gets on your hands or clothing, wash it off as soon as possible. Ink stains may become difficult to remove

if allowed to stand.

Page 15

13

Open the doors to the ink cartridge ports and insert the ink cartridges.

Ink cartridge ports

Yellow

Cyan

Magenta

Black

Pigment ink

specified

Dye ink

specified

Be sure to install only the dedicated ink

cartridges that have been specified for the

machine.

Dye inks cannot be used on a CJ-70/60

unit for which pigment inks are specified,

and pigment inks cannot be used on a CJ70/60 unit for which dye inks are

specified.

If the cartridge is

marked with PIGMENT

it contains pigment ink,

otherwise dye ink.

When the power is turned on for the first time, or turned on after removing the ink, the system will execute ink fill.

This operation takes several minutes.

When inserting the cartridge, make sure that it is

inserted into the correct slot for that color.

Insert a blade into the blade holder until it snaps

into place with an audible click.

1 2

Loosen the tool securing screw on the tool carriage.

Support the tool securing screw from below and install

the blade holder. Insert the blade holder until the collar

is flush with the carriage. Tighten the tool securing

screw until the blade holder is secured in place.

Loosen Tighten

Cutting carriage

Push-pin

Blade holder

Blade

7 Installing the Cutter

Do not touch the tip of the blade

with your fingers.

Doing so may result in injury, and the

cutting performance of the blade will be

impaired.

When cutting is performed after printing, the cap tip of the blade holder may scratch the printed surface. If this

is the case, lengthen the cutter blade extension.

Page 16

14

Roland CAMM JET

Ver.4.00

INSTALL

DRAIN TANK

FILL INK

NOW PROCESSING..

"SHEET SELECT"

When stock vinyl film is to be cut, tighten the cap all the

way (2.5 mm (about 0.1") of blade extension).

Adjusting the Cutter Blade

Tighten the cap until

gap is eliminated

Amount of cutter blade

extension: 2.5 mm (about

0.1") (maximum length)

Turn the cap as

shown by the arrow

1)

Gap

Amount of cutter

blade extension:

0 mm

2)

Amount of cutter

blade extension

Thickness of the carrier paper

Thickness of the

sheet portion

Turn the cap as

shown by the arrow

Cap

Blade adjustment may be necessary when:

- cutting material whose carrier paper is thinner than the material itself

- cutting material with no carrier paper

Each indicator tick corresponds to 0.1 mm (about 0.004"), and adjustment for 0.5 mm (about 0.02") can be made by rotating the

cap one full turn.

Turn the cap as shown by the

arrow to align the tip of the

blade with the tip of the cap

1

When using for the first time turn on the

main power switch on the rear of the unit.

Be sure to mount the drain tank before turning on the power. Refer to section "5 For Details on the Drain Tank".

8 Powerup

Leave the main power switch on, and

turn the power off and on in daily use

with the sub power switch.

2

Press the key.

The POWER LED lights up

When the power is turned on for the first time, or

turned on after removing the ink

The POWER LED lights up

The system will execute ink fill.

This operation takes several minutes.

Attach the drain tank, and press

key.

Page 17

15

Shaft

Sheet hanger

9 Loading the Material

1

When passing the shaft through the stopper,

be sure to loosen the mounting screws on

the stopper first.

2) Align the media flange with the roll sheet edges, matching the roll sheet center ID.

(The media flange is included with the stand.)

Stopper

Stopper retaining screws

Shaft

Media flange

Media flange

3) Install the two shafts on the sheet hanger and place the roll material on top of the shafts.

(The brake, E Hexagon-head socket screws (middle), and hex wrench (small) are included

with the stand.)

1) Pass the stopper onto the shaft to match the width of the

roll material to be used.

(The shafts (2 pieces), stoppers (2 pieces), and stopper

retaining screws (2 pieces) are included with the stand.)

Sheet hanger

Roll material

Sheet hanger

Shaft

Hexagonal wrench

(Small)

E Hexagon-head socket

screws (Middle)

Mount the

brake here.

Brake

When using sheet material (standard-size sheets or sheet scraps), follow steps 2 and 3, and steps 5 and 6.

Roll material must be placed at a

predetermined shaft position.

Failure to do so may

result in falling of the

roll, leading to injury.

Page 18

16

1) Position the right-hand edge of the material over the right-hand grit roller.

Move the material from side to side until the left-hand edge of the material is positioned over one of the short grit

rollers.

Align the material with the guide lines so that it is loaded straight.

2

Pinch roller (left) Pinch roller (right)Pinch roller (middle)

2) Position the left- and right-hand pinch

rollers over the grit rollers.

Move the middle pinch roller to a

position above the grit roller intermediate between the left- and right-hand

pinch rollers.

Make sure the left and right margins are the same size

Stickers showing the

locations of the grit rollers

Move the pinch rollers to inside

the edges of the material

Guide lines

Do not place the pinch roller

above the rear material sensor

hole of bed, to avoid miss

sensing materials.

Rear Material sensor hole

* These illustrations show the CJ-70. On the CJ-60, the positions of the grit rollers differ from those shown here.

Loading roll material

When the prefeed check function is enabled (i.e., set to "ENABLE")

* The prefeed check function is enabled as the factory default setting.

Correct

Side view Top view

Pass under the shaft and

pull out over the platen

Do not allow any slack to

form in the material until

the pinch rollers are

lowered and the material

is secured in place.

Rolled Material

Rolled Material

Make the material perpendicular to

the CJ-70/60.

Page 19

17

Incorrect

Side view Top view

Rolled Material

Material is slack

NG

Rolled Material

Loaded sheet is crooked

NG

When the prefeed check function is disabled (i.e., set to "DISABLE")

Correct

Side view Top view

No slack

Rolled Material

Rolled Material

Make the material perpendicular to

the CJ-70/60.

Incorrect

Side view Top view

Rolled Material

Rolled Material

Loaded sheet is crooked

NG

Material is slack

NG

* Refer to "22 Description of Keys and Display Menus" on the prefeed check function.

When using the optional TU-70/60 (automatic media take-up unit for the CAMM JET), set the

prefeed function to "DISABLE" to disable this function.

Page 20

18

Press the key.

The sheet size is detected, and the CJ-70/60 is readied for plotting or cutting.

* If "PREFEED" is set to "ENABLE," pressing the key causes the sheet to be fed

for the length that has been set.

Changing the "PREFEED" setting to "ENABLE" is recommended when using rolled

material.

For more information, see "22 Description of Keys and Display Menus".

6

The SETUP LED lights up

When using sheet material

• If the material curls toward the material face (cut face), it will cause the material to slip when loaded onto the CJ-

70/60, and may adversely affect printing/cutting. In this case pre-bend the material downward so that the material

edge is not caught the front cover and guard bar during operation.

• If the material strikes the shaft that is installed on the stand, then remove the shaft.

Raise the sheet loading levers to secure the

material in place.

3

Use the and keys to

choose the material configuration.

5

SELECT SHEET

ROLL EDGE PIECE

ROLL: If roll material has been loaded, only the width of

the material is detected.

EDGE: If roll material has been loaded, the width of the

material and the position of the front edge are

detected.

PIECE: If sheet material has been loaded, the width and

length of the material are detected.

If using roll material, move the provisionally tightened

stopper to match the width of the material, then

securely tighten the stopper retaining screw.

4

Media flange

Stopper retaining screw

Sheet loading lever

* If and only if the prefeed function is enabled (i.e., set to

"ENABLE"), then after securing the material in place,

pull out some material from the roll.

Pull out material from the roll

Roll material

Page 21

19

10 Printing Test

Load a material, then close the front cover.

1

2

Press the key

HEAD CLEANING

ALL

HEAD CLEANING

TEST PRINT

HEAD CLEANING

MAGENTA & YELLOW

HEAD CLEANING

BLACK & CYAN

Use or

to select.

Displayed only when

the BUSY LED is dark

Press .

Head cleaning starts.

Cleaning corresponding Heads until you can't see any

difference between four rectangle of each color.

CY

K

M

K

You can check the printing quality before actually starting to print.

If there are any missing dots or other evidence

of a drop in printing quality, clean the head.

Press the

key to execute [TEST PRINT].

Page 22

20

For optimum performance, it is necessary to set cutting conditions that match the material, giving consideration to the material's thickness and type of material. The CJ-70/60 has an internal "cutting test" to check the cutting conditions. This "cutting test" allows you to

determine settings for the cutting speed, blade force and the amount of offset.

Experiment with different settings for different types of material and adjust the configuration accordingly.

Install a blade and load a material, then close the

front cover.

1 4

Confirm the cutting speed and the blade force.

Peel off the round section (marked by ).

Confirm that you can peel off the square section

(marked by ), but do not remove it. Also

remove the square section (marked by ).

If the blade leaves a slight trail on the carrier

paper, you have achieved optimum cutting speed

and blade force.

Then, peel this off

Peel off first

Origin (Position of the tool

installed in step 2)

2

Press the key. Cutting test starts.

3

Use the , , and

keys to move the tool carriage to the place where

the cutting test is to be performed.

The remaining cross-shaped area is used to check

whether the offset value is set correctly.

When the offset value has been correctly set, the

corners of the figure should appear cleanly cut as

shown in A of the figure below. If the offset value

is too small, the corners will appear slightly

rounded as illustrated by B; an offset value which

is too large will result in a cut figure similar to C.

5

AB

C

If the material was not cut correctly in steps (1) through (5) of the cutting test, change the cutting conditions (see "21 Display Menus

Flowchart").

Repeat the cutting test and adjustment until the optimal cutting speed, blade force, and blade compensation are found.

Incorrect cutting conditions may cause symptoms such as those described below. Take care to ensure that the cutting conditions are

correct.

11 Cutting Test

Cutting speed Blade force Blade compensation

Corners flare outward,

with "horns."

Corners are rounded.

Some parts of the sheet remain uncut.

• The sheet is easily torn.

• The cutter requires frequency replacement.

• Cutting extends through the base paper,

and normal advancing of the sheet

becomes impossible.

• The unit suffers damage.

Some parts of the sheet remain uncut.

Cutting takes more time.

Too fast

Too slow

Too large

Too small

Too small

Too large

Page 23

21

12 Downloading Printing/Cutting Data

13

Ending Cutting and Printing Operations

Press the key.

The cutting carriage moves to

the right.

1

The SETUP LED goes out

2

Press down the sheet loading levers and

remove the material.

3

If you wish to cut off the piece of the

rolled material containing the cut or

printed area, place a commercially

available cutter knife in the knife guide

groove, and draw it along the groove to cut

the material.

Knife guide

Commercial cutter knife

For Materials with a Strong Adhesive Layer

If you are using a material with a strong adhesive layer, the adhesive layer may adhere to itself immediately when cut. This means that

even though the material has actually been cut, it may appear as if it has not been cut, and blade force may mistakenly be set too high. If

a cutting test shows that the material peels easily and the blade traces on the carrier paper are optimal, then the material is being cut.

Take care not to set the blade force excessively high.

Opening the front cover causes an emergency stop to occur, and printing may not be carried out correctly if

operation is resumed.

To pause printing or cutting for any other reason than an emergency stop, press the

key.

Note pressing the

key to pause operation may result in differing image quality before and after the

pause. It is a good idea to avoid pausing operation while printing is in progress whenever possible.

Printing or cutting is started when data is sent.

Allowing the printing carriage to stand for a long period after an emergency stop may result in clogging of the

head and, in some cases, damage to the printing head.

Page 24

22

14 When Not in Use...

Loosen the tool securing screw on the

tool carriage, then remove the blade

holder from the tool carriage.

3 4

Press the push-pin and remove the blade from the blade

holder.

1 2

Lower the sheet loading levers and remove the material.

If the SETUP LED is lighted, press the

key.

The carriage moves to the right.

The SETUP LED goes out

Loosen

Tool securing

screw

Blade holder

Cutting

carriage

Blade holder

Push-pin

If a blade was used, wipe

the blade with a soft cloth

to remove any material

that may cling to it.

Blade

5

Press the key to switch off the power.

The printing carriage moves to the standby position and the head is capped.

If the printing carriage is already at the standby position, no movement takes place.

There is no need to turn off the main power switch.

POWER LED goes out

Printing carriage

Standby position

After detaching the blade holder from the tool carriage, do not tighten the tool setscrew. Leave this screw loose.

Tightening the screw makes the hole for inserting the holder to progressively smaller, which on turn makes it

difficult to install the blade holder.

When not in use, leave the pinch rollers in the raised state. The pinch rollers may be deformed if allowed to

remain in the lowered state.

Page 25

23

When Not in Use for a Prolonged Period...

15 When Moving the Unit...

1

Press the key to switch off the power.

The printing carriage moves to the standby

position and the head is capped.

If the printing carriage is already at the

standby position, no movement takes place.

POWER LED goes out

2

Turn off the main power

switch.

3

Unplug the power cord

from the electrical outlet.

Printing carriage

Standby position

2

INK CONTROL

INK EMPTY

3

MENU

INK CONTROL

Press the key to make the following

screen appear on the display.

Press the key and key to make

the following screen appear on the display.

4

Use the key to select "PUMP-UP," then

press the

key.

The following screen appears on the display, and the

sub power is automatically switched off.

5

POWER LED goes out

PUMP-UP

NOW PROCESSING..

8

Referring to "Unpacking and Repacking" on the packing carton, secure the printing head in place and pack the unit in the

carton.

When the POWER LED

goes out, turn off the main

power switch.

6

Detach the power cord and the cable connecting

the unit to the computer.

Remove the discharge tank. Refer to "5 For Details on

the Drain T ank" for disposal of the ink within the tank.

7

INK CONTROL

PUMP-UP

Ink discharge is carried out about ten minutes.

Do not switch off the main power with the ink head in an uncapped state (i.e., while the printing carriage is on the platen).

If you leave the printing carriage uncapped for a long time, doing so may result in clogging of the ink head, making it

unusable.

Before switching off the main power, be sure to press the

key to switch off the sub power for the CJ-70/60.

1

Remove the material, blade holder, and ink cartridge.

When moving the CJ-70/60, first remove any ink remaining in the unit and secure the printing head in place.

Page 26

24

16 Other Functions

To Perform Long Printing/Cutting

When performing printing or cutting over a length of 1.5 m (60") or more, first feed out the required length of material. Then follow the

steps below to load the material.

Guide lines

25 mm

(1")

or more

Close the front cover.

Press the key

Press the key

Press the key

Press the key

Press the key

Press or to change the value.

Press or to

select [ROLL].

Press twice.

Press until the

following screen appears.

Set this to the

length of the

material to be

printed or cut.

MENU

PRINT QUALITY

MENU

PREFEED

PREFEED

DISABLE

PREFEED

ENABLE( 1.0m)

LENGTH

1.0m 1.0m

SELECT SHEET

ROLL EDGE PIECE

Use the control panel to make the following settings.

The set length of material is fed out.

Make sure that the material remains held by the pinch rollers.

If the material does come loose from the pinch rollers, set it in place again.

Pull out the material from the roll and pass it through

the unit.

Use material that is wider by 50 mm (2") or more

than the width of the printing or cutting to be

performed.

4 1

6

2

3

Guide lines

25 mm

(1")

or more

5

Page 27

25

Press the key and key to make

the following screen appear on the display.

1 4

Send the printing data from the computer.

Three crop marks are automatically printed on the

left and right areas at the front edge of the

material.

Press the

key to make the following

screen appear on the display.

2

CROP MARK

DISABLE DISABLE

3

CROP MARK

DISABLE PRINT

5

When printing is finished press the key,

remove the material and carry out lamination (or

whatever further processing needs to be done).

When done, reload the material in the same

position used for printing, and press the

key. (The SETUP LED lights up.)

Rear

Front

Crop marks

Install the alignment tool on the cutting carriage.

6

Remove the Printed Material, then Reload the Material and Perform Cutting

7

Rear

Front

1) Set the base point

Use the arrow keys to move

the tip of the alignment tool

to the square crop mark at

the lower right area of the

material, then press the

key.

2) Set the align point

Use the arrow keys to move

the tip of the alignment tool

to the square crop mark at

the lower left area or upper

right area of the material,

then press the

key.

• The align point cannot be set to both the lower left and upper right points.

• The align point cannot be set if the angle between the base point and the align point is 5 degrees or more.

• Marks set with the application software (such as crop marks) cannot be used.

MENU

CROP MARK

Remove the alignment tool from the cutting

carriage and install the blade holder.

8 9

Send the cutting data from the computer.

Use the

key to select "PRINT," then

press the

key.

Page 28

26

Align the Printing and Cutting Positions

Materials expand and contract in response to absorbed ink

and atmospheric humidity. The degree of size change

depends on the material, backing material, and ambient

temperature and humidity. In general, materials which absorb

moisture easily expand and contract more easily.

There is very little effect when only cutting or printing is

used, but if printing is followed by cutting, it is possible that

the cutting line may be offset from the printing line.

Use the key to select "ALIGN," then

press the

key.

Press the key and key to make

the following screen appear on the display.

1 4

Send the printing data from the computer.

Crop mark is automatically printed on the right

area at the front edge of the material.

MENU

CROP MARK

Press the key to make the following

screen appear on the display.

2

CROP MARK

DISABLE DISABLE

3

CROP MARK

DISABLE ALIGN

7

Rear

Front

Set the base point

Use the arrow keys to

move the tip of the

alignment tool to the

square crop mark at the

lower right area of the

material.

6

Install the alignment tool on the cutting carriage.

5

When cutting data is sent after printing is finished,

the carriage moves to the origin point and a

message appears on the display.

SET BASE POINT

The align point is set automatically, and

correction is performed.

• The align point cannot be set if the

angle between the base point and the

align point is 5 degrees or more.

Rear

Front

Crop mark

1 CROP MARK

Material expansion/contraction before and after printing is corrected as it occurs. The offset value set for this method is deleted when

new data is sent, or the material removed. This method is suitable when temperature and humidity are unstable, or differing materials are

often used.

Corrections applying to all output should be set with "2 HEAD ADJUST" or "3 CALIBRATION".

There are three ways to correct this offset.

Cutting line

Cutting line

Page 29

27

8

Without moving the cutting carriage, remove the

alignment tool and attach the blade holder.

9

Press the key to

start cutting.

2 HEAD ADJUST

Mechanical deviation caused by temperature is corrected, and the correction value stored to the CJ-70/60. If the ambient temperature

variation is low, this correction setting should not have to be changed. The setting will not be erased even if the power is turned off.

Press the key and key to make

the following screen appear on the display.

2

1

Press the key to make the following

screen appear on the display.

3

HEAD ADJUST

TEST PRINT

5

Install the alignment tool on the cutting carriage.

Use the

key to select "PRINT-CUT ADJ"

then press the

key.

4

6

The SETUP LED

lights up

MENU

HEAD ADJUST

Rear

Front

Use the arrow keys to move the tip

of the alignment tool to the square

crop mark at the lower right area of

the material.

HEAD ADJUST

PRINT - CUT ADJ

Rear

Front

Crop mark

Set here, and press

key.

Crop mark is printed.

Load the material and

press the key.

Page 30

28

6

Press the key to make the following

screen appear on the display.

7

CALIBRATION

Y AXIS

Y AXIS

+0.00% +0.00%

3

Offset expressed as a percentage of total length.

4

Press the key to make the following

screen appear on the display.

5

MENU

CALIBRATION

CALIBRATION

X AXIS

1

As shown in the example below, create data

surrounding a printing area with cutting lines,

and output the data to the CJ-70/60.

2

To calculate the correction value, measure the

lengths of A, B, C and D in the following diagram.

Front

Rear

1 m

(40")

1 m (40")

+

–

–

+

Cutting line

D

C Offset in X direction.

A Offset in

Y direction.

B

Offset of

Y-direction data.

Offset of

X-direction data.

Printing result

If the cutting line is in the + direction

from the printing position, then input

the correction as a -.

If the cutting line is in the - direction

from the printing position, then input

the correction as a +.

Correction value

in Y direction.

Correction value

in X direction.

A Offset in Y direction.

B Offset of Y-direction data.

=

X 100

C Offset in X direction.

D Offset of X-direction data.

=

X 100

Press the key and key to make

the following screen appear on the display.

Cutting line

Printing area

Desired

size

Desired

size

Example)

3 CALIBRATION

If correction with "2 HEAD ADJUST" is done and there is still an offset between the printing and cutting positions, use the following

correction method.

Measure the sheet offset caused by expansion/contraction and store it in the CJ-70/60.

Because different sheet materials have different offsets, either reset the value when using a different sheet material, or use "1 CROP

MARK" to make the adjustment.

This is suitable to places when variation in ambient temperature and humidity are low, and sheets of a single material are used. The

setting will not be erased even if the power is turned off.

Select the "X AXIS" or "Y AXIS" with the

key, and press the key .

Page 31

29

Performing Cutting or Printing at the Desired Location

The printing or cutting origin point should be set.

To release the origin point that has been set...

• Set a new origin point in a different location.

• Press the SETUP key (making the SETUP LED go out).

1

Install the alignment tool on the cutting carriage.

Use the arrow keys to move the tip of the alignment tool. Move the tip of the alignment tool to the point where the

origin is to be set.

2

3

Press the key.

The origin point is set.

The PAUSE LED lights up

When an align point has been set, it is

released if the key is pressed.

8

Input the correction value calculated in step (3).

Select the correction value with the

key,

and press the key.

Page 32

30

17 Maintenance

Replacing the Ink Cartridges

Store ink cartridges out of the reach

of children.

Do not insert your fingers in the ink

cartridge ports.

Doing so may

result in injury.

If ink contacts the eyes, flush

immediately with water.

Do not remove any ink cartridges except when shipping the CJ-70/60.

Use only the ink specified for the machine. Dye inks cannot be used on a CJ-70/60 unit for which pigment inks

are specified, and pigment inks cannot be used on a CJ-70/60 unit for which dye inks are specified.

If ink runs out, replace immediately with an ink cartridge designed especially for the CJ-70/60. Do not attempt

to refill and reuse an empty ink cartridge.

If an ink cartridge is removed, replace it immediately with a new one.

Do not attempt to disassemble an ink cartridge.

Unused ink cartridges should be stored unopened at a temperature of -20°C (-4°F) to 40°C (104°F). Do not

store in a location subject to temperatures beyond this range.

If any ink gets on your hands or clothing, wash it off as soon as possible. Ink stains may become difficult to remove

if allowed to stand.

When removing an ink cartridge, do not rush. Detach the cartridge gently. Sudden movement when detaching

may cause ink to be spilled.

Page 33

31

If the "INK EMPTY" message appears during setup

A cartridge has run out of ink, and printing cannot be started.

If printing data is being sent, this message is displayed and the buzzer sounds. At the same time, operation is paused and the PAUSE

LED flashes. Replace the empty cartridge with a new one and press the PAUSE key to start printing.

If the data being sent is cutting data only, the message is displayed and the bell sounds, but cutting is started.

Replacing the Blade

Refer to "14 When Not in Use..." to remove the blade.

See "7 Installing the Cutter" for a description of how to install a blade.

1

PAUSE LED lights up

Press the

key

to pause printing.

2

Pull out the cartridge for the ink color that has run

out, and replace with a new cartridge.

3

PAUSE LED goes out

Press the key to

resume printing.

* When "INK EMPTY" is set to "PROMPT", the

unit pauses automatically when this message is

displayed.

The unit is almost out of ink. Please replace the ink cartridge.

If this message is ignored and printing is continued without replacing the ink cartridge, image quality may be adversely affected and

exhibit faintness or other problems.

If the "INK EMPTY" message appears while printing

If it becomes necessary to replace the ink cartridge while printing is in progress, the following message is displayed and the buzzer

sounds.

INK EMPTY

******* INK

The color of the ink that has run out is displayed.

Open the ink cartridge port and remove the empty ink cartridge.

Pigment ink

specified

Insert new ink cartridge. (See "6 Installing Ink Cartridges" for an explanation of how to install a new ink cartridge.)

Ink cartridge ports

When installing a new ink cartridge,

be sure to use only the type of ink

cartridge specified for the machine.

Dye inks cannot be used on a CJ-70/

60 unit for which pigment inks are

specified, and pigment inks cannot be

used on a CJ-70/60 unit for which dye

inks are specified.

If the cartridge is

marked with PIGMENT

it contains pigment ink,

otherwise dye ink.

Dye ink

specified

Page 34

32

Press the key

HEAD CLEANING

ALL

HEAD CLEANING

TEST PRINT

HEAD CLEANING

MAGENTA & YELLOW

HEAD CLEANING

BLACK & CYAN

Use or

to select.

Displayed only when

the BUSY LED is dark

Press .

Head cleaning starts.

Cleaning the body

Use water or alcohol to clean, and wipe gently with a clean cloth. Wipe the operation panel and display gently with a clean, soft cloth.

Cleaning the platen

If the platen is dirty clean with alcohol or water and wipe gently with a cloth.

Cleaning the grit rollers

Use a commercially available brush to remove dust and other detritus. Brush

horizontally while rotating the grit rollers.

If dust builds up it may prevent the paper from being held securely, and degrade

plot precision.

Cleaning the pinch rollers

Use a cloth moistened with water or alcohol and wipe gently to clean.

Cleaning the front cover

Use water or alcohol and clean with a soft cloth. If severe a neutral detergent may be used. Never use anything other than water, alcohol

or a neutral detergent.

Cleaning the blade holder cap

Remove the cap, then remove the material debris.

Cleaning

Cleaning the Ink Heads

Maintenance operation is performed automatically when the

key is pressed to switch on the power, so normally there

is no need to clean the unit.

If drop-out occurs with printed images, press the

key to

clean the ink heads.

If this cleaning does not correct the drop-out problem, press the

key, then use the key to display "HEAD

CLEANING" and select "POWERFUL." If performing cleaning

several times at the "POWERFUL" menu does not correct the dropout problem, contact your authorized Roland dealer or service

center to purchase a replacement head.

Never lubricate the mechanisms.

Use a small amount of water or alcohol for cleaning the covers. Never use solvents such as benzene or thinner

can smooth out the material so that it sticks securely.

Before cleaning, press the key to switch off the sub power for the CJ-70/60.

Periodically clean the platen. Attractive printing may become impossible if the platen is soiled.

Do not touch the ink heads or allow the ink heads to come in contact with anything except ink.

Page 35

33

CJ-70

Acceptable media widths

Sheet material : 160 mm — 1372 mm (6-5/16"— 54")

Roll material : 160 mm — 1320 mm (6-5/16"— 52") (When using roll material, the loadable material width is narrower

than for a flat sheet by an amount corresponding to the dimensions of the media flanges.)

18 Acceptable Media Widths

Do not set the pinch roller here.

54" (approx. 1372 mm)

12" (approx. 305 mm)

42" (approx. 1067 mm)

36" (approx. 914 mm)

30" (approx. 762 mm)

24" (approx. 610 mm)

(1*)(2*)(3*)

Material

18" (approx. 457 mm)

54" (approx. 1372 mm)

50" (approx. 1270 mm)

150 mm

48" (approx. 1219 mm)

Material

with a

width 48"

Material with a width

of 50" or more

Material with

a width 42"

Material with

a width 36"

Material with

a width 30"

Material

with a width

24"

Material with

a width 18"

Material with

a width 12"

(5-7/8")

(1*) Position of the pinch roller (middle) when using

material with a width of 30"

(2*) Position of the pinch roller (middle) when using

material with a width of 36" or 42"

(3*) Position of the pinch roller (middle) when using

material with a width of 48", 50" or 54"

The right-hand movable pinch roller can be moved within this range.

When loading material with a width other than one indicated above, move the right-hand movable pinch roller.

: Grit roller

: Pinch roller (left)

: Pinch roller (right)

: Pinch roller (middle)

Page 36

34

CJ-60

Acceptable media widths

Sheet material : 160 mm — 1100 mm (6-5/16"— 43-5/16")

Roll material : 160 mm — 1050 mm (6-5/16"— 41-5/6") (When using roll material, the loadable material width is

narrower than for a flat sheet by an amount corresponding to the dimensions of the media flanges.)

(1*) Position of the pinch roller (middle) when using

material with a width of 36"

(2*) Position of the pinch roller (middle) when using

material with a width of 41-5/6" or more

: Grit roller

: Pinch roller (left)

: Pinch roller (right)

: Pinch roller (middle)

Do not set the pinch roller here.

43-5/16" (approx. 1100 mm)

12" (approx. 305 mm)

41-5/6" (approx. 1050 mm)

36" (approx. 914 mm)

24" (approx. 610 mm)

(1*)(2*)

Material

18" (approx. 457 mm)

150 mm

43-5/16" (approx. 1100 mm)

Material with

a width 36"

Material

with a width

24"

Material with

a width 18"

Material with

a width 12"

(5-7/8")

Material with a

width of 41-5/6"

or more

Page 37

35

C

D

AB

19 Blades and Materials

edalBlairetaMecrofedalBdeepsgnittuCnoitasnepmocedalBedalbafoefiL

5001U-CEZlynivegangislareneGfg051—05).ces/"464.33(.ces/mc58)"48900.0(mm52.0)"069413(m0008

lynivegangislareneGfg001—03

5205U-CEZlynivevitcelfeRfg002—021).ces/"464.33(.ces/mc58)"48900.0(mm52.0)"084751(m0004

lynivtnecseroulFfg002—001

This section indicates the proper cutting conditions for various types of materials, as well as blade life spans. Cutting conditions and

blade life vary according to the hardness of the material and the usage environment. Making the settings for the conditions described

below does not automatically guarantee attractive cutting results in all situations. Before performing actual cutting, be sure to carry out a

cutting test and make any necessary adjustments (see "11 Cutting Test"). If the material is not cut through completely even when the

tool force is increased by 50 to 60 gf more than the tool force values shown below, it means that the useful life of the blade has ended.

Replace with a new blade.

* The values for life span are intended to serve as a general guide when cutting materials of identical type.

Conditions for Usable Materials

A) Cuttable material thickness : 0.08 to 0.22 mm (0.00315" to 0.00866") (depending on material composition)

B) Maximum material thickness, including base paper (peeled-off paper)

: 0.4 mm (0.0157")

C) Maximum diameter for roll material : 180 mm (7-1/16") (surface to be printed or cut must face outward)

D) Core inner diameter for roll material: 50.8 or 76.2 mm (2" or 3")

E) Maximum weight for roll material : [CJ-70] 20 kg (44.1 lb.) [CJ-60] 17 kg (37.5 lb.)

F) Roll material with a starting edge that is not taped down

Side view of roll material

Page 38

36

20 About the Printing/Cutting Area

The printing/cutting area along the horizontal plane (the direction in which the carriage moves) is determined by the position of the pinch

rollers. The workable area spans the length between the two rollers, minus a margin of about 1 mm (about 0.04") on both sides.

If "PIECE" has been selected and material length (the distance in the X direction as shown in the figure) is 1,885 mm (74-3/16") (1,257

mm (49-7/16") x 1.5) on the CJ-70 or 1,537 mm (60-1/2") (1,025 mm (40-5/16") x 1.5) on the CJ-60, the area is the same as when

"EDGE" has been chosen.

If "ROLL" or "EDGE" has been selected, the material length (the distance in the X direction as shown in the figure) is set to 24,998 mm

(984-1/8").

* The arrows in the figure indicating the X and Y directions indicate

respectively the positive directions of the X axis and Y axis.

Printing/cutting

coordinates origin (0, 0)

20 mm (13/16")

(If the material configuration

is "EDGE" or "PIECE.")

Approx. 15 mm

(about 9/16")

Pinch roller (right)

10 mm

(3/8")

Approx. 1 mm

(about 0.04")

Printing/cutting area

Material

Max.:

[CJ-70] 1257 mm (49-7/16)

[CJ-60] 1025 mm (40-5/16")

Max.: 24998 mm

(984-1/8")

Pinch roller (left)

10 mm

(3/8")

Approx. 1 mm

(about 0.04")

Approx. 15 mm

(about 9/16")

20 mm (13/16")

(If the material configuration is "EDGE" or "PIECE.")

Page 39

37

21 Display Menus Flowchart

For details about each of the menus, see the "22 Description of Keys and Display Menus."

TOOL OFFSET

0.250mm 0.250mm

0.000 mm—1.500 mm

(In increments of 0.025 mm)

Press the key

Use or to select the value.

Press to enable the setting.

Press the key

HEAD CLEANING

ALL

HEAD CLEANING

TEST PRINT

HEAD CLEANING

MAGENTA & YELLOW

HEAD CLEANING

BLACK & CYAN

Use or

to select.

Displayed only when

the BUSY LED is dark

Press .

Head cleaning starts.

Use the keys to choose the

type of material

Roland CAMM JET

Ver.4.00

Press the key

Roland CAMM JET

Load the material and press

the key

W1010mm L 1320mm

SUPER MIRROR

FINE CRPO

NORMAL

DRAFT

Length of the loaded material

Status of setting is displayed

Data is sent

SELECT SHEET

ROLL EDGE PIECE

SELECT SHEET

TRANSPARENT

If "MEDIA TYPE"

is "OPAQUE"

If "MEDIA TYPE"

is "CLEAR"

INSTALL

DRAIN TANK

When the power is turned on for the first

time, or turned on after removing the ink

Attach the drain tank,

and press

FILL INK

NOW PROCESSING..

The system will execute

ink fill.

key.

Press the key

20 gf—350 gf

(In increments of 10 gf)

TOOL FORCE

50gf 50gf

Use or to select the value.

Press to enable the setting.

TOOL SPEED

85 cm/s 85 cm/s

1 cm/s—85 cm/s

(In increments of 1 cm/s)

Press the key

Use or to select the value.

Press to enable the setting.

Page 40

38

MENU

HEAD ADJUST

HEAD ADJUST

TEST PRINT

HEAD ADJUST

HORIZ. MAGENTA

HEAD ADJUST

HORIZ. CYAN

HEAD ADJUST

HORIZ. YELLOW

HEAD ADJUST

VERT. MAGENTA

HEAD ADJUST

VERT. CYAN

HEAD ADJUST

VERT. YELLOW

HEAD ADJUST

BIDIRECTION

HEAD ADJUST

PRINT-CUT ADJ

MENU

INK CONTROL

INK CONTROL

INK EMPTY

INK CONTROL

FILL INK

MENU

COLOR CHART

INK CONTROL

PUMP-UP

MENU

PRINT QUALITY

PRINT QUALITY

NORMAL NORMAL

MENU

DRYING

DRYING

NONE NONE

MENU

MIRROR

MIRROR

DISABLE DISABLE

MENU

MEDIA TYPE

MEDIA TYPE

OPAQUE OPAQUE

MENU

CROP MARK

CROP MARK

DISABLE>DISABLE

MENU

DITHER

DITHER

CLUSTER>CLUSTER

MENU

VECTOR MODE

VECTOR MODE

COMMAND COMMAND

MENU

TIME OUT

TIME OUT

NONE NONE

MENU

AUTO ROTATE

AUTO ROTATE

DISABLE>DISABLE

MENU

FACTORY DEFAULT

MENU

SERIAL PORT

SERIAL PORT

BAUDRATE

SERIAL PORT

PARITY

SERIAL PORT

HANDSHAKE

FACTORY DEFAULT

NOW PROCESSING..

MENU

OVER PRINT

OVER PRINT

NONE NONE

MENU

UP SPEED

UP SPEED

85cm/s 85cm/s

MENU

INSTRUCTION

INSTRUCTION

RD-GL3 RD-GL3

INK CONTROL

CHANGE INK

NONE, 10 sec—990 sec

(In increments of 10 sec)

DISABLE/ENABLE

NONE, 10 sec—990 sec

(In increments of 10 sec)

DISABLE/ENABLE

OPAQUE/CLEAR

DISABLE/ALIGN/PRINT

CLUSTER/SCATTER

COMMAND/CUT/PRINT

Press the key

NORMAL/DRAFT/SUPER/

BISUPER/FINE/BIFINE

10,20,30,40,50,60,70,

80,85 (cm/s)

RD-GL3/RD-GL2

NONE, 2—9TIMES

Page 41

39

HORIZ. MAGENTA

+0 > +0

HORIZ. CYAN

+0 > +0

HORIZ. YELLOW

+0 > +0

VERT. MAGENTA

+0 > +0

VERT. CYAN

+0 > +0

VERT. YELLOW

+0 > +0

BIDIRECTION

+0.0 > +0.0

PRINT-CUT ADJ

BY CURSOR

MENU

PEN SETUP

PEN SETUP

ALL

PEN SETUP

PEN No 0

PEN No**

COLOR INDEX

PEN SETUP

PEN No15

PEN No**

WIDTH

WIDTH

0.35mm>0.35mm

COLOR INDEX

0 > 0

PREFEED

ENABLE( 1.0m)

LENGTH

1.0m 1.0m

MENU

CALIBRATION

CALIBRATION

X AXIS

X AXIS

+0.00% >+0.00%

CALIBRATION

Y AXIS

Y AXIS

+0.00% >+0.00%

MENU

SLEEP

SLEEP

15min 15min

MENU

HEAD CLEANING

HEAD CLEANING

TEST PRINT

HEAD CLEANING

NORMAL [KC]

HEAD CLEANING

NORMAL [MY]

HEAD CLEANING

POWERFUL [KC]

HEAD CLEANING

POWERFUL [MY]

MENU

SYSTEM INFO.

MENU

PREFEED

PREFEED

DISABLE

INK EMPTY

LATER > LATER

BAUDRATE

9600 > 9600

PARITY

NONE >NONE

HANDSHAKE

H-WIRE >H-WIRE

BIDIRECTION

TEST PRINT

-10—+10

(In increments of 1)

-10—+10

(In increments of 1)

-10—+10

(In increments of 1)

-2/-1/+0/+1/+2

-2/-1/+0/+1/+2

-2/-1/+0/+1/+2

-20.0—+20.0

(In increments of 0.5)

No 1—No14

0.13, 0.18, 0.25, 0.35,

0.50, 0.65, 0.70, 0.80,

0.90, 1.00, 1.40, 2.00,

3.00, 5.00, 8.00, 12.0 (mm)

0—255

(In increments of 1)

0.5 m—25.0 m

(In increments of 0.5 m)

-0.19%—+0.19%

(In increments of 0.01%)

-0.19%—+0.19%

(In increments of 0.01%)

NONE, 15 min.—120 min.

(In increments of 15 min.)

19200/9600/4800

NONE/EVEN/ODD

XON/OFF / NONE /

BOTH / H-WIRE

LATER/PROMPT

MENU

FEED MARGIN

FEED MARGIN

20mm 20mm

0 mm—100 mm

(In increments of 5 mm)

• Moves to the previous menu

screen or the next menu screen

• Selects the value for a setting

• Moves to a submenu screen

• Moves to the previous menu

screen

• Executes the menu

• Locks in the value for a setting

• When NOT READY:

Returns to the

"SELECT SHEET" screen

When READY:

Returns to the

"W **** mm L **** mm" screen

Page 42

40

Key Top menu Submenus Function Setting range Default value

CUTTER —

This sets the blade force used for cutting. 20 gf to 350 gf 30 gf

FORCE

Perform a cutting test and set this to an appropriate value (in increments of 10 gf)

for the material and blade to be used.

CUTTER —

This sets the amount of offset for the blade shaft and the 0.000 mm to 1.5000 mm 0.250 mm

OFFSET

blade. (in increment of

0.025 mm)

CUTTER —

This sets the speed used for cutting. 1 cm/s—85 cm/s 50 cm/s

SPEED

Perform a cutting test and set this to an appropriate value (in increments of 1 cm/s)

for the material and blade to be used.

——

This cuts a test pattern in a piece of material for adjusting — —

the blade force, cutting speed, and blade compensation.

——

When in the "READY" mode, these move the material — —

and the cutting carriage.

When a menu is displayed, these move among the menu

items.

——

This enters the menu mode. — —

The and keys move to the next menu,

the moves to a submenu, and the key

moves to the previous screen.

——

This is used to accept, execute, or save the item shown on — —

the display.

——

This makes the present tool position the new origin point. — —

This point is used as a reference for the align point.

Any previously set align point is canceled.

——

This sets the align point for canceling out any — —

misalignment (tilting) of the material.

The angle of the material, referenced from the base point,

is stored in memory. Any angle of 5° or less may be set.

This setting is valid only when cutting.

——

This forces the tool to move up or down. — —

——

This detects the size of the material and enters the READY — —

mode, where printing or cutting are possible.

——

In the READY mode or BUSY mode, this pauses — —

operation.

Pressing this key again cancels the paused state.

Pressing the SETUP key while paused causes remaining

data to be cleared and returns to the NOT READY mode.

The unit goes into the NOT READY mode if the material

is removed while paused.

HEAD

This performs cleaning of the ink head. — —

CLEANING

Using the CLEANING key causes a certain amount of

head wear and also consumes a certain amount of ink, so

use of this key should be kept to a minimum.

ALL

ALL: All four heads (magenta, yellow, black, and cyan)

are cleaned.

TEST PRINT

TEST PRINT: Test printing is performed in a range of

approx. 130 mm x 15 mm (5-1/8" x 9/16").

If a problem in printing occurs, follow this by

performing cleaning for the heads.

MAGENTA &

MAGENTA & YELLOW: Only these two heads

YELLOW

(magenta and yellow) are cleaned.

BLACK &

BLACK & CYAN: Only these two heads (black and

CYAN

cyan) are cleaned.

——

This switches on and off the power . — —

22

Description of Keys and Display Menus

Page 43

41

*1: The settings for data length (8 bits) and the stop bit (1 bit) cannot be changed.

Top menu Submenus Function Setting range Default value

PRINT QUALITY

This selects the quality level for printing. — NORMAL

The settings for print quality are, in order of increasing quality, DRAFT,

NORMAL, BIFINE, FINE, BISUPER, and SUPER. Please note that

printing times also grow longer as the quality level is increased.

NORMAL

Printing is performed in one direction. Normally this setting is selected.

DRAFT

High-speed, bidirectional printing is performed.

SUPER

Printing is performed in four passes per stroke. Printing is in one direction.