Page 1

SERVICE NOTES

PNC-1860 / 1410 / 1210

Specifications

Mechanism ............................... Media-movement method

Driving method .........................Digital control servo motor

Maximum cutting area .............. [PNC-1860] 1195 mm (W) x 24998 mm (L) (47"x 984-1/8")

Acceptable material widths ......[PNC-1860] 90 mm—1372 mm (3-1/2"—54")

Tools ........................................Cutters:Special cutter for CAMM-1 series

Max.cutting speed ....................During cutting:850 mm/sec. (in all directions)

Cutting speed ...........................10 mm/sec.— 850 mm/sec. (in increments of 10 mm/sec.)

Blade force ...............................20 gf — 350 gf (in increments of 10 gf)

Software resolution ..................0.025 mm / step

Distance accuracy .................... Error of less than +/- 0.2% of distance travelled, or 0.1mm, whichever is grater

Repetition accuracy.................. 0.1 mm or less

Interface ................................... Parallel (Centronics compatible), Serial (RS-232C)

Buffer size ................................ 1 Mbyte (Expandable up to 3 Mbyte)

Instruction system .................... CAMM-GL III (mode1 and mode2)

Switches ................................... Power switch

Control switches .......................

LED .......................................... POWER LED, SETUP LED

Display .....................................Liquid crystal display unit; 16-character by 2 lines

Power consumption.................. [117V] 1.0A, [220-230V] 0.5A, [230-240V] 0.5A, [100V] AC100V+/-10 % 50/60Hz 1.0A

Acoustic noise level.................. [Cutting mode] under 62dB (A), [Standby mode] under 40dB (A) (According to ISO 7779)

Dimensions ................................. [PNC-1860] 1575 mm (W) x 300 mm (D) x 286 mm (H) (62-1/16" (W) x 11-13/16" (D) x 11-5/16" (H) )

Weight ......................................[PNC-1860] 38 kg (83.8 lb.), [PNC-1410] 28.5 kg (62.8 lb.), [PNC-1210] 22.5 kg (49.6 lb.)

Temperature............................. 5—40ºC (41—104ºF)

Humidity ................................... 35%—80% (non-condensing)

Accessories................................. [100V Only] MANUAL,USE JP PNC-1860 [26015127], ADAPTER PLUG [13499209] , AC CORD 100V 3P [23495214]

Others ......................................CARTON PNC-1860 [22605193], CARTON PNC-1410 [22605109], CARTON PNC-1210 [22605192]

[PNC-1410] 889 mm (W) x 24998 mm (L) (35"x 984-1/8")

[PNC-1210] 585 mm (W) x 24998 mm (L) (23"x 984-1/8")

[PNC-1410] 90 mm—1067 mm (3-1/2"—42")

[PNC-1210] 50 mm—762 mm (1-15/16"—30")

Pens:Water-based fiber-tipped pens, 32 color plotter pens (options)

Thick water-based fiber-tipped pens (options)

During tool-up:1202 mm/sec. (in 45º direction)

, , , , ENTER, MENU, TEST, SETUP

[PNC-1410] 1270 mm (W) x 300 mm (D) x 286 mm (H) (50-1/16" (W) x 11-13/16" (D) x 11-5/16" (H) )

[PNC-1210] 965 mm (W) x 300 mm (D) x 296 mm (H) (62-1/16" (W) x 11-13/16" (D) x 11-11/16" (H) )

[Others] TOOL,ALIGNMENT [21935110], SHEET SEPARATOR [12569419], TWEEZERS [12569656],

MANUAL,USE EN PNC-1860 [26015128], AC CORD 117V [13499109], AC CORD (220V) [23495125]

AC CORD (240V) [23495124], AC CORD KP-610 240VE, BS [13499111]

Structure & Spare Parts

Electrical Section

Replacement of Main Parts

Supplemental Information

Trouble Shooting

Adjustment

Supplement

1

2

3

4

5

6

7

Interface Specifications

[Parallel]

Standard...................................In compliance with the specifications of Centronics

Input signals .............................STROBE (1BIT), DATA (8BITS)

Output signals .......................... BUSY (1BIT), ACK (1BIT)

Level of input/output signals..... TTL level

Transmission method ............... Asynchronous

Contents

1 Structure & Spare Parts

1-1 COVERS........................................................................................1

1-2 FRAME .......................................................................................... 2

1-3 X/Y-DRAIVE UNIT .........................................................................3

1-4 CARRIAGE ....................................................................................4

1-5 CHASSIS ....................................................................................... 5

1-6 PINCH ROLLER ............................................................................ 6

2 Electrical Section

2-1 WIRING MAP.................................................................................7

2-2 MAIN BOARD ASS'Y..................................................................... 8

2-3 POWER BOARD ASS'Y .............................................................. 12

2-4 SUB BOARD ASS'Y .................................................................... 15

3 Replacement of Main Parts

3-1 PEN CARRIAGE ASSEMBLY ..................................................... 17

3-2 DRIVE PULLEY ASSEMBLY....................................................... 19

3-3 CARRIAGE WIRE........................................................................ 22

3-4 PINCH ROLLER ASSEMBLIES .................................................. 24

3-5 CUTTER PROTECTION.............................................................. 24

4 Adjustment

4-1 Special Tool ................................................................................. 25

[Serial]

Standard...................................RS-232C specifications

Transmission method ............... Asynchronous, duplex data transmission

Transmission speed .................2400, 4800, 9600, 19200 (selected using panel keys)

Parity check..............................Odd, Even, or None (selected using panel keys)

Data bits ...................................7 or 8 bits (selected using panel keys)

Stop bits ................................... 1 or 2 bits (selected using panel keys)

Handsheke ...............................DTR or Xon/Xoff (selected using panel keys)

4-2 Service Mode ............................................................................... 26

4-3 System Report ............................................................................. 27

4-4 Tool Height Adjustment ............................................................... 28

4-5 Spacer Bed Adjustment ............................................................... 30

4-6 Pen Pressure Adjustment ............................................................ 33

4-7 Wire Tension Adjustment............................................................. 37

4-8 Motor Balance Adjustment........................................................... 39

4-9 Calibration.................................................................................... 41

4-10 Softlanding Adjustment................................................................ 44

5 Supplemental Information

5-1 OPERATIONAL SEQUENCE ...................................................... 47

5-2 SENSOR MAP ............................................................................. 48

6 Trouble Shooting

6-1 ERROR MESSAGE ..................................................................... 49

6-1-1 OTHER MESSAGE .....................................................................51

6-2 TROUBLE SHOOTING................................................................ 52

7 Supplement

7-1 MAINTENANCE CHECK LIST .................................................... 57

Second Edition

PNC-1860 '02Jan.DE0

Printed in Japan

DE0031496SN R1-1

Page 2

Typographic Conventions/ About the Labels Affixed to the Unit

Typographic Conventions

Following marks describes as follows.

: Tips and advice before the adjustment.

: Indicates tightening torque.

Torque

: Indicates amout for Pen Pressure and Tension.

: Indicates clearance.

: Electric charge. Do not touch when power is on.

: The wiring terminal intended for connecetiion of the protective earthing con-

ductor associateed with the supply wiring. Do not disconnect the cable of this

terminal except the time of replacement.

About the Labels Affixed to the Unit

These labels are affixed to the body of this product.

1Model Name

2Serial NO.

3Voltage

4Power consumption

5CAMM-1 CAUTION LABEL No.453

4

3

Unauthorized copying or transferral, in whole or in part, of this manual is prohibited.

Copyright © 1996 ROLAND DG CORPORATION

5

1

2

Page 3

1 Structure & Spare Parts

1-1 COVERS

1 Structure & Spare Parts

3

3

4

**coluwn shows as below.

8

7

2

2

1

4

8

1

1

10

16

11

16

1

3

8

7

8

5

7

1

6

6

12

9

15

5

4

14

13

3

1

8

2

1

5

3

If the part is not used,

it is blank.

PNC-1860

PNC-1410

If the part is used,

it is marked " ".

PNC-1210

PARTS LIST -Main Parts- PARTS LIST -Supplemental Parts-

Parts No. Parts Name Parts Name

1

22355444SZ

2 22025148 COVER,FRONT PNC-1210 • 2 SCREW BINDING HEAD Cr 3X6

22025161 COVER,FRONT PNC-1410 • 3 SCREW BINDING HEAD BC 3X8

22025147 COVER,FRONT PNC-1860 • 4

3 22025150 COVER,RAIL PNC-1210 • 5 SCREW DOUBLE SEMS BC 3X6

22025158 COVER,RAIL PNC-1410 • 6 SCREW DOUBLE SEMS BC 3X8

22025149 COVER,RAIL PNC-1860 • 7 TAPE SCOTCH TAPE #250 W=25MM

4 22065234 COVER,SIDE L PNC-1860 • • • 8 WASHER SPRING Cr M3

5 22065243 COVER,SIDE R PNC-1860 • • •

6 22325106 HINGE,001 • • •

7 22325108 HINGE,003 • • •

8 22505106 LABEL,CAMM-1 PRO NO.546 • •

9 22255302 LCD COVER • • •

10 15029402 LCD RCM2065R-A 16*2 • • •

7393321010

11

12 22055272 PLATE,F COVER PNC-1860 • • •

13 22055262 PLATE,MAGNET PNC-1860 • • •

14 22055180 PLATE,SW COVER PNC-1860 • • •

15 22665174 SHEET,SW PANEL PNC-1860 • • •

16 22155567 SPACER M3X5 • • •

BASE OF SW PANEL • • • 1 SCREW BINDING HEAD Cr 3X4

SCREW BINDING HEAD+FW

Ni 3X8

PANEL BOARD ASS'Y • • •

1

Page 4

1 Structure & Spare Parts

W

1-2 FRAME

1

}

3

e

9

3

5

5

5

0

}

}

23

}

}

1

q

}

e

3

2

w

22

12

17

4

8

1

6

1

19

3

21

15

8

10

6

4

6

{

5

16

8

11

9

3

{

2

24

11

16

5

7

14

2

8

18

3

13

17

20

7

0

5

3

5

7

9

PARTS LIST -Main Parts-

Parts No. Parts Name * * Parts No. Parts Name * *

1 22805134 ASS'Y,GRIT ROLLER PNC-1210 • 20 22055176 PLATE,SHUTTER PNC-1210 •

22805135 ASS'Y,GRIT ROLLER PNC-1410 • 22055177 PLATE,SHUTTER R PNC-1860 • •

22805136 ASS'Y,GRIT ROLLER PNC-1860 • 21 22185318 RAIL,GUIDE PNC-1210 •

2 22175870 ASS'Y,GRIT ROLLER PNC-1860 • • • 22185320 RAIL,GUIDE PNC-1410 •

3 22115106 BEARING HOUSING A • • •

4 22005104 BED,PNC-1210 • 22 22175609 ROLL DRIVE GEAR • • •

22005106 BED,PNC-1410 • 23 22075106 SET,G-ROLLER PNC-1210 •

22005105 BED,PNC-1860 • 22075107 SET,G-ROLLER PNC-1410 •

5 21985104 BRACKET,SENSOR PNC-1860 • • • 22075105 SET,G-ROLLER PNC-1860 •

6 23465140

7 23465139

CABLE-ASSY PAPERSENS F PNC1860 ••• 24 22145381 SHAFT,X-DRIVE PNC-1210 •

CABLE-ASSY PAPERSENS R PNC1860 • • • 22145387 SHAFT,X-DRIVE PNC-1410 •

8 22165165 COLLAR • • • 22145380 SHAFT,X-DRIVE PNC-1860 •

9 22025146 COVER,GUIDE F PNC-1210 •

22025159 COVER,GUIDE F PNC-1410 •

22025144 COVER,GUIDE F PNC-1860 •

10 22025145 COVER,GUIDE R PNC-1210 •

22025160 COVER,GUIDE R PNC-1410 •

22025143 COVER,GUIDE R PNC-1860 •

22435108SZ FAN MOTOR • • •

11

12 22115570 FRAME,L PNC-1860 • • •

13 22115569 FRAME,R PNC-1860 • • •

14 22045160 GEAR COVER • • •

15 22265102 PAD,CUTTER PNC-1210 •

22265106 PAD,CUTTER PNC-1410 •

22265103 PAD,CUTTER PNC-1860 •

16 15229754 PAPER SENSOR • • •

17 11539105 PIN 2.5*8 SUS BTYPE H7 • • •

18 22055259 PLATE,RAIL PNC-1410 •

22055172 PLATE,RAIL PNC-1860 •

19 22055260 PLATE,SHUTTER L PNC-1410 •

22055175 PLATE,SHUTTER L PNC-1860 •

22185315SZ RAIL,GUIDE PNC-1860 •

PARTS LIST -Supplemental Parts-

1 SCREW BINDING HEAD Cr 3X4

2 SCREW BINDING HEAD Cr 3X12

3 SCREW HEXAGONAL CAP BC 3X6

4 SCREW HEXAGONAL CAP BC 4X10

SCREW HEXAGONAL CAP+F

5

6 SCREW DOUBLE SEMS BC 3X6

7 SCREW TP BINDING HEAD BC 3X6

8 SCREW DOUBLE SEMS BC 3X12

9 SCREW DOUBLE SEMS BC 3X45

0 SCREW DOUBLE SEMS BC 4X8

{ SCREW FLAT HEAD Cr 3X8

} SCREW SOCKET SET Cr 3X3

q WASHER FLAT FIVER M3

w WASHER FLAT Cr 3X8X0.5

e LABEL TAPE,GUIDE

Parts Name

Cr 4X12

2

Page 5

1Structure&SpareParts

PARTS LIST

PARTS LIST

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

⑭

⑮

⑯

1-3X・Y-DRIVEUNIT

⑬

7

③

11

10

16

④

9

3

⑤

26

25

15

2

⑬

26

13

⑪

17

RevisedRevised

Revised

RevisedRevised

20

⑩

⑥

14

①

5

24

12

⑪

5

21

⑧

⑧

⑧

⑧

18

⑦

⑬

23

⑫

4

⑧

⑬

8

6

1

⑥

⑧

⑧

1

②

14

⑦

⑮

⑭

⑮

⑨

⑯

⑤

19

⑯

22

1

-Main Parts-

Parts No. Parts Name

1

22805129

2

22355318

3

22355316

4

22355315

5

22175815

6

23465143

7

23465141

8

23465144

9

23475120

10

13169102

11

22265295

12

22175608

13

12399313

14

21995102

15

7393321020

16

12399102

17

22055171

18

21975106

19

12179723

20

22145122

21

22145345

22

22035318

23

22145170

24

21945105

21945106

21945104

25

12369428

26

12369447

ASS'Y,MOTOR PNC-1860

BASE,I/F BOARD PNC-1860

BASE,SW COVER PNC-1860

BASE,Y-MOTOR PNC-1860

BEARING F8-16ZZ (metal)

CABLE-ASSY C POWER PNC-1860

CABLE-ASSY COVER SW PNC-1860

CABLE-ASSY G POWER PNC-1860

CABLE-CARD 26P 350L BB

COVER SW R (AVT3234)

CUSHION

DRIVE GEAR

FILTER(E) TR-20-10-10

FLANGE,MOTOR PNC-1860

I/F BOARD ASS'Y

MAGNET CATCH TL-105

PLATE,ORIGIN PNC-1860

PULLEY HD42.2 S16(B30C35.5)

PULLEY WITH BEARING

SHAFT STAY NO.1

SHAFT,PULLEY PNC-1860

STAND OF IDLE PULLEY

STAY,COVER RAIL PNC-1860

WIRE,Y-DRIVE PNC-1210

WIRE,Y-DRIVE PNC-1410

WIRE,Y-DRIVE PNC-1860

BINDER BASE KNP-20

WIRE CLIP CA-14

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

•

•

• • •

• • •

-Supp ementa Parts-

Parts Name

E-RING ETW-6 Cr M6

PIPE POLY 4X8X10

SCREW BINDING HEAD BC 2X8

SCREW BINDING HEAD BC 3X6

SCREW HEXAGONAL CAP BC 3X6

SCREW HEXAGONAL CAP Cr 3X8

SCREW HEXAGONAL CAP BC 3X16

SCREW HEXAGONAL CAP BC 4X6

SCREW HEXAGONAL CAP Cr 4X8

SCREW HEXAGONAL CAP BC 4X10

SCREW DOUBLE SEMS BC 3X6

SCREW DOUBLE SEMS BC 3X12

SCREW DOUBLE SEMS BC 4X8

SCREW PAN HEAD BC 4X14

WASHER FLAT BC 3X8X0.5

WASHER FLAT Cr 4X8X0.5

•

3

Page 6

1 Structure & Spare Parts

1-4 CARRIAGE

0

8

3

9

2

1

2

9

6

7

11

10

6

4

1

8

1

5

5

3

7

2

4

SPRING, BACK UP PNC-960

** SPRING, BACK UP PNC-960 should

be fixed as in the above figure.

PARTS LIST -Main Parts- PARTS LIST -Supplemental Parts-

Parts No. Parts Name

1 22805133 ASS'Y,CARRIAGE PNC-1860 • • • 1 SCREW DOUBLE SEMS BC 3X6

2 23475119 CABLE-CARD 8P 1630L BB • 2 SCREW DOUBLE SEMS BC 3X8

23475122 CABLE-CARD 8P 1930L BB • 3 SCREW DOUBLE SEMS BC 3X10

23475121 CABLE-CARD 8P 2230L BB • 4 SCREW PAN HEAD Cr 2X4

7393321030

3

4 22045399 CARRIAGE COVER • • • 6 WASHER FLAT

5 22175828 GUIDE BEARING 2 • • • 7 WASHER OUT SIDE TEETH Cr M4

22175343AS

6

7 22205134 HOLDER,PEN • • • 9 CUSHION CABLE HOLD 2 FELT L=40

8 22175122 SPRING,BACKUP PNC-960 • • • 0 BINDER T-18S

9 22145181

10 22155586 PEN HOLDER NUT • • •

11 22285352 PEN HOLDER BOLT • • •

CARRIAGE BOARD ASS'Y • • • 5 SCREW HEXAGONAL CAP BC 4X6

GUIDE BEARING ASS'Y • • • 8 CUSHION CABLE HOLD 1 FELT L=10

STAY,CARRIAGEBOARD PNC-1860

**

•••

Parts Name

Cr 2X4.3X0.4

4

Page 7

1-5 CHASSIS

1 Structure & Spare Parts

4

3

23

18

0

19

15

0

16

2

23

3

5

9

17

6

7

7

23

5

9

5

6

10

13

15

5

9

9

12

3

2

4

7•8

11

21

5

14

20

1

{

22

1

8

1

5

PARTS LIST -Main Parts- PARTS LIST -Supplemental Parts-

Parts No. Parts Name

1 13429746 AC INLET • • • 1 SCREW BINDING HEAD SUS 4X5

2 23465132

3 23465134

4 22815112 CHASSIS,PNC-1210 • 4 SCREW SEMS Cr 3X10

22815114 CHASSIS,PNC-1410 • 5 SCREW DOUBLE SEMS BC 3X6

22815111 CHASSIS,PNC-1860 • 6 SCREW DOUBLE SEMS BC 3X8

5 12559567 FUSE • • • 7 SCREW DOUBLE SEMS Cr 4X8

6 12559574 FUSE • • • 8 SCREW OVAL HEAD BC 3X8

7 12559444

8 12559570 FUSE 5X20 230/240V • • • 0 NUT HEXAGONAL+SPW Cr M4

9 12559570 FUSE 5X20 • • • { WASHER IN SIDE TEETH Cr M4

10 12189834 FUSE HOLDER FA252B • • •

7393315000

11

7393318000

12

13 13129170 POWER SW AJ7201B • •

14 15449118 ROM A • • •

15 22355168 RUBBER FOOT • • •

16 22165132 SPACER,BED LOWER PNC-1860 • • •

17 22165128 SPACER,BED UPPER PNC-1860 • • •

7393321040

18

22455108U0

19

20 23465157

21 23505898 WIRE,B GRX-410 • • •

22 23505899 WIRE,C GRX-410 • • •

23 12369428 BINDER BASE KNP-20 • • •

CABLE-ASSY POWER PNC-1860

CABLE-ASSY POWERSIGNAL PNC1860

FUSE 5 X 20 SB4 TIME RAG 100/117V

MAIN BOARD ASS'Y •

POWER BOARD ASS'Y • •

TRANS BOARD • • •

TRANSFORMER-PW PNC-1860 • • •

CABLE-ASS'Y JUNBIWIRE A PNC-960

**

Parts Name

••• 2 SCREW BINDING HEAD BC 4X12

••• 3 SCREW HEXAGONAL CAP BC 4X12

••• 9 NUT HEXAGONAL Cr M4

•••

5

Page 8

1 Structure & Spare Parts

1-6 PINCH ROLLER

1

2

1

10

8

11

3

8

7

3

3

5

2

9

2

6

3

4

6

3

3

3

7

3

3

5

3

2

3

2

1

12

11

12

6

3

4

6

3

PARTS LIST -Main Parts- PARTS LIST -Supplemental Parts-

Parts No. Parts Name * * Parts Name

1 22805130

2 22805131

3 22175847 GRX-450 PINCHROLL • • 3 ERING ETW-3 Cr M3

4 22145404 LEVER OF PINCH ROLL • • •

5 22145831 PIN NO.1 • • •

6 22145832 PIN NO.2 • • •

7 22115722 PINCH ROLL FRAME • • •

8 22175105 PINCH ROLL SPRING • • •

9 22175877 PINCH ROLLER • • •

10 22055170 PLATE,P-ROLLER PNC-1860 • • •

11 22145616 PNC-900 SET LEVER • • •

12 22175128

ASS'Y,P-ROLLER M PNC-1860

ASS'Y,P-ROLLER L R PNC-1860

SPRING,M P-ROLLER PNC-1860

•• 1 SCREW TP BINDING HEAD BC 3X6

••• 2 WASHER FLAT Cr 4X7X0.5

••

6

Page 9

2 Electrical Section

PNC-1860

PNC-1410

PNC-1210

If the part is used,

it is marked " ".

If the part is not used,

it is blank.

CN4

CN3

CN4

CN3

CN2

CN11

CN6

CN1

CN11

PANEL

BOARD

LCD

CARRIAGE BOARD

CN9

CN10

PAPERSENS R

COVER SW

PAPERSENS F

11

12

13

14

15

16

POWER SW

AJ7201B

FUSE HOLDER

FA252B

1

2

3

4

5

6

CN1

CN9

POWER BOARD ASSY

9

10

AC INLET

SUP-J3G-E

TRANS

FORMER

PNC-1860

FAN MOTOR

FAN MOTOR

DRAM BOARD

ASSY

FACTORY OPTION

CN5

SOLENOID

7

8

POWER

SUPPLY

SERVO

MOTOR

DRIVE

FAN

CONTROL

L6203 L6203

DRAM

2Mbyte

I/F

BOARD

+5V

+40V

+15V

-15V

MAINBOARD ASSY

DRAM

1Mbyte

CENTORO

CONT

LATCH

EPROM

512Kbyte

CPU

DATABUS

Exciton

M60205

SERVOCHIP

MBCG10692

SOLDRIVE

MTD2005

EEPROM

4Kbit

D/A

PCM55

16MHz

49.152MHz

16MHz

DATABUS

ADDRESSBUS

CN2 CN1

DRIVER

SERIAL

PARALLEL

CN12

CN13

CN14

CN5

CN4

CN2

CARIAGE

MOTOR

GRIT

MOTOR

CN6

CN5

CN3

TRANSE BOARD

**

PNC-1860/1410 uses two FAN MOTORS.

PNC-1210 uses only one on CN5.

**

PARTS LIST -Main Parts-

Parts No. Parts Name * * Parts No. Parts Name * *

1 23465157 CABLE ASSY JUNBIWIRE A PNC-960 • • • 10 23465144 CABLE - ASSY G POWER PNC1860 • • •

2 23505898 GRX-410 JUNBIWIRE B • • • 11 23475121 CABLE - CARD 8P 1930L BB •

3 23505899 GRX-410 JUNBIWIRE C • • • 23475122 CABLE - CARD 8P 2230L BB •

4 23465158 CABLE ASSY JUNBIWIRE D PNC-960 • • • 23475119 CABLE - CARD 8P 1630L BB •

5 23465135 CABLE - ASSY JUNBIWIRE E PNC1860 • 12 23465142 CABLE - ASSY LCD PNC-1860 • • •

23465145 CABLE - ASSY JUNBIWIRE E PNC1410 • 13 23475120 CABLE - CARD 26P 350L BB • • •

23465137 CABLE - ASSY JUNBIWIRE E PNC1210 • 14 23465141 CABLE - ASSY COVER SW PNC1860 • • •

6 23465136 CABLE - ASSY JUNBIWIRE F PNC1860 • 15 23465140 CABLE-ASSY PAPERSENS F PNC1860 • • •

23465146 CABLE - ASSY JUNBIWIRE F PNC1410 • 16 23465139 CABLE-ASSY PAPERSENS R PNC1860 • • •

23465138 CABLE - ASSY JUNBIWIRE F PNC1210 •

7 23465132 CABLE - ASSY POWER PNC1860 • • •

8 23465134

CABLE - ASSY POWER SIGNAL PNC1860

•••

9 23465143 CABLE - ASSY C POWER PNC1860 • • •

2-1 WIRING MAP

2 Electrical Section

2

**coluwn shows as below.

7

Page 10

2 Electrical Section

2-2 MAIN BOARD ASS'Y

2

DESCRIPTION

3

MAIN BOARD

ASS'Y [7393315000]

CABLE CARD 26P 350L BB

[23475120]

KURA

FUJIKURA

FUJIKU

FUJIKURA

Character

printed side.

1

A

A

7

Indicates revision of the circuit board.

1DIP SW

NO . FUNCTION ON OF F

1 Model Selection PNC1860

2 Model Selection PNC1410

3 Model Selection PNC1210

4 Pen Down Wait Wait time ON Wait time OFF

5 Reserved

6 Reserved Always OFF

7 Reserved

8 Reserved

BIT#4 is a function to make the pen wait for 0.5

seconds after the pen down before cutting. Set

it OFF usually.

8

2

2VR

VR No. Function

VR1

(1KVR)

VR2

(22KVR)

Use for Pen Pressure Adjustment.

Use for Pen Pressure Adjustment.

3Electric Maintenance Parts

IC.No. Parts No. Description Function

U31 15189105 MTD2005 Solenoid Driver

Page 11

2 Electrical Section

MAIN BOARD_1/3 Circuit Diagram

+5

R1

10K

P11

+5

CE0.1u

A11

A13

A15

WRH(LBS)/PA5

VSS

VSS

VSS

+5

1

2

3

4

5

MNR35J5ASJ103

A16

A17

A18

A20

88

A21

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A0/(HBS)

AD15

AD14

AD13

AD12

AD11

AD10

AD9

AD8

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

CS7/WAIT

CS6

CS5/RAS

CS4

CS3/CASL

CS2

CS1/CASH

CS0

RD/PA6

WRL(WR)/PA4

VSS

VSS

VSS

VSS

92

RA3

U3

45

44

43

42

40

39

37

36

35

34

33

31

30

A9

29

A8

28

A7

27

A6

26

A5

25

A4

23

A3

22

A2

21

A1

20

19

18

17

16

14

12

11

10

9

8

7

6

5

3

2

1

54

53

52

51

49

48

47

46

57

56

55

69

CK

HD6437021

+5

D7

D12

D14

R6

+5

RA2

1

2

3

4

5

MNR35J5ASJ103

1

2

U10A

3

74HC32F

D10

RA6

1

2

3

4

5

D8

0

10

9

8

7

6

NON

D9

D11

D13

D15

295279

A21

23

A20

22

A19

21

A5

20

A4

19

A3

18

A2

17

A1

16

A0

15

D7

14

D6

13

D5

12

D4

11

D3

10

D2

9

D1

8

D0

7

38

39

41

34

35

36

37

27

30

26

56

57

58

6

10

25

9

68

8

69

7

6

67

3

4

5

+5

31

32

24

335380

40

RA8 RMLS8103J

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

U11

82

83

84

85

86

87

88

89

71

72

73

74

70

75

76

77

78

81

90

91

92

93

94

95

96

97

98

99

100

59

60

61

62

63

66

64

65

42

43

44

45

46

47

48

49

50

51

54

55

1

P3

12

13

VIEWLED

PAUSELED

SERVOSRCH

SERVOSRCL

SRVGAINCNT

FANCNT

SENSORREAD

PENFORCE

SERVOCS

SRVINTVCT

CENTRORD

+5 +5

2

1

28

S1

1

2

3

4

5

6

7

8

KSD-08

RA9 MNR34J5A101

4

3

2

1

RA10 MNR34J5A101

4

3

2

1

R17

R18

U18D

11

74HC08

R24

R23

R19

4

3

2

1

RA11 MNR34J5A101

4

3

2

1

RA12 MNR34J5A101

SRVSRCH

SRVSRCL

SRVGAIN

P4

/SRVCS

/CRD

P5

P6

P7

554

663

772

881

554

663

772

881

554

663

772

881

554

663

772

881

100

100

CE1000p

100

100

100

16

15

14

13

12

11

10

9

C7

CE1000p

NON

D1A

21

21

D2A

21

D3A

D4A

21

C8

C9

CE1000p

C17

C18

NON

NON

9

10

4

5

C10

CE1000p

U10C

74HC32F

U10B

74HC32F

DA227

DA227

DA227

DA227

DA227

DA227

DA227

DA227

34

34

34

34

C11

CE1000p

C19

NON

C12

CE1000p

C20

NON

D1B

D2B

D3B

D4B

CE1000p

C21

NON

8

6

C13

C22

C14

CE1000p

NON

9

10

C15

CE1000p

C23

NON

SENS

PENFRC

/SRVINTV

FAN

U18C

74HC08

C16

CE1000p

C24

NON

C25

NON

R3

470

8

PLED0

PLED1

SK0

SK1

KD0

KD1

KD2

KD3

KD4

KD5

KD6

KD7

+5

RS

RXW

LE

LD0

LD1

LD2

LD3

LD4

LD5

LD6

LD7

C26

NON

C27

R5

2.7K

CN4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

IL-S2T2-14EF

CN3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

IL-S2T2-15EF

2

A21

+5

RA7

1

2

3

4

5

D0D1D2D3D4D5D6

NON

10

9

8

7

6

10

9

8

7

6

A19

A21

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

+5

RA5

1

2

3

4

5

A0A1A2A3A4A5A6

TXDB

RXDB

TXDA

RXDA

+5 +5

R31

R30

10K

10K

/DSRA

/DTRA

/RTSA

CRDY

U1

8

+5

7

NU

6

ORG

5

GND

93LC66

/INTSRV

+5

C1

C2

CE0.1u

7

2

3

CS

SK

DI

DO

RUN

PENPH

SNS

RSTIN

CT

1

2

3

4

SERVOINT

SERVORUN

P1

P2

PENPHASE

8

U2

+5

RST

VREF

GND

4

7705-B

+5

P8

P9

5

1

C3

CE0.1u

10

9

8

7

6

MNR35J5ASJ103

TXDB

RXDB

TXDA

RXDA

C6

CE22p

C5

CE22p

/DSRA

/DTRA

/RTSA

CRDY

RA1

1

2

3

4

5

MNR35J5ASJ103

+5

R2

470

C4

CE0.1u

+5

RA4

1

2

3

4

5

A7

A8

A10

A12

A14

+5

79

78

77

96

95

94

93

71

Y1

16MHz

72

91

90

89

87

86

85

84

83

10

+5

9

8

7

6

74

100

99

98

97

68

67

66

65

64

62

61

60

58

75

76

10

9

8

7

6

MNR35J5ASJ103

+5

MD2

MD1

MD0

PB11/TXD1

PB10/RXD1

PB9/TXD0

PB8/RXD0

EXTAL

XTAL

PB7

PB6

PB5

PB4

PB3

PB2

PB1

PB0

NMI

IRQ7/PB15

IRQ6/PB14

IRQ5/PB13

IRQ4/PB12

IRQ3/DREQ1/PA15

IRQ2/DACK1/PA14

IRQ1/DREQ0/PA13

IRQ0/DACK0/PA12

PA11

PA10

PA9/IRQOUT/AH

PA8/BREQ

PA7/BACK

WDTOVF

RESET

VCC13VCC38VCC63VCC73VCC80VCC

VSS4VSS

VSS

152432415059708182

A9

VSS

CN1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

TX14-40R-6ST-N1

D[0..15]

D[0..15]

A[0..21]

A[0..21]

+5

1

2

3

4

5

D0

6

D1

7

D2

8

D3

9

D4

10

D5

11

D6

12

D7

13

D8

14

D9

15

D10

16

D11

17

D12

18

D13

19

D14

20

D15

21

/RAS1

22

/RAS2

23

/CASL

24

/CASH

25

/WE

26

RA1

27

RA2

28

RA3

29

RA4

30

RA5

31

RA6

32

RA7

33

RA8

34

RA9

35

RA10

36

37

38

39

40

R47

100

R46

A1

4

A2

3

A3

2

A4

1

A5

4

A6

3

A7

2

A8

1

A9

R11 100

A10

R12 100

R13 100

R14 100

R15 100

R16 100

100

RA13 MNR34J5A101

554

663

772

881

RA14 MNR34J5A101

554

663

772

881

10

11

12

13

16

17

18

19

20

9

8

23

7

22

10

11

12

13

16

17

18

19

20

9

8

23

7

22

U4

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

RAS

CAS

WE

OE

MN414800CSJ

U5

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

RAS

CAS

WE

OE

MN414800CSJ

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

VSS

VSS

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

VSS

VSS

D0

2

D1

3

D2

4

D3

5

D4

24

D5

25

D6

26

D7

27

6

NC

21

NC

+5

+5

NC

NC

+5

+5

+5

15

28

1

14

D8

2

D9

3

D10

4

D11

5

D12

24

D13

25

D14

26

D15

27

6

21

+5

15

28

1

14

5

6

74ALS112F

14

15

16

13

18

17

+5

4

U8A

3

J

Q

PR

1

CLK

2

K

Q

CL

15

U7

119

2

3

11

6

7

8

4

5

A11

A12

A17

DE

JP1

NON

+5

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A18

U6

12

A0

11

A1

10

A2

9

A3

8

A4

7

A5

6

A6

5

A7

27

A8

26

A9

23

A10

25

A11

4

A12

28

A13

29

A14

3

A15

2

A16

30

A17

31

A18

NON

D0

13

D0

D1

14

D1

D2

15

D2

D3

17

D3

D4

18

D4

D5

19

D5

D6

20

D6

D7

21

D7

24

OE

22

CE

1

NC

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

+5

TM27C240-10JL

+5

40

11

+5

GND

30

D10

D11

D12

D13

D14

D15

GND

U9

D0

19

D0

D1

18

D1

D2

17

D2

D3

16

D3

D4

15

D4

D5

14

D5

D6

13

D6

D7

12

D7

10

D8

D8

9

D9

D9

8

D10

7

D11

D12

6

D13

5

D14

4

D15

3

2

CE

20

OE

21

A0

22

A1

23

A2

24

A3

25

A4

26

A5

27

A6

28

A7

29

A8

31

A9

32

A10

33

A11

34

A12

35

A13

36

A14

37

A15

38

A16

39

A17

1

VPP

/RESET

D[0..15]

A[0..21]

/RD

/WR

9

Page 12

2 Electrical Section

MAIN BOARD_2/3 Circuit Diagram

+5

2

/RESET

D[0..15]

CRDY

/CRD

SENS

+5

R34

3.3K

CE1000p

C28

14

15

D0

D1

D2

D3

D4

D5

D6

D7

1

2

3

U13A

CEXT

REXT/CEXT

A

B

CLR

74HC123F

U16

1

DIR

19

G

9

A8

8

A7

7

A6

6

A5

5

A4

4

A3

3

A2

2

A1

74LS245

13

Q

4

Q

U18A

1

2

74HC08

PAPERR

11

B8

B7

B6

B5

B4

B3

B2

B1

PAPERF

12

COVER

13

PINCHROLL

14

YLIMIT

15

16

17

18

P10

PAPERSENSORREAR

PAPERSENSORFRONT

COVERSW

TOCARIAGEBOARD

U14A

12

74LS07

+5

10

U27B

13

PR

CLK

CL

RA16

D

10

8

7

6

5

4

3

2

1

12

11

74HC74

6

7

8

9

MNR35J5ASJ103

CE470p

+5

9

Q

8

Q

3

+5

CN11

1

2

3

4

IL-S2T2-04EF

CN9

1

2

3

IL-S2T2-03EF

CN10

1

2

IL-S2T2-02EF

CN6

IL-FPC-8ST-N

C35

U12E

10

74LS14

5

Q

6

Q

5

4

3

2

1

C36

CE470p

Y-LIMIT

PINCHROLL

SOL+

SOL-

4

PR

CLK

CL

1

C37

CE470p

11

U14B

34

74LS07

U27A

2

D

3

74HC74

+5

R25

R26

R27

R28

R29

C38

C39

CE470p

CE470p

SOL+

SOL-

100

100

100

100

100

U12F

1312

74LS14

U26

D6

D4

D2

D0

D1

D3

D5

D7

Q0

5

Q1

6

Q2

9

Q3

12

Q4

15

Q5

16

Q6

19

Q7

G

11

74LS373

2

3

D0

4

D1

7

D2

8

D3

13

D4

14

D5

17

D6

18

D7

OC

1

ifD6

ifD4

ifD2

ifD0

ifD1

ifD3

ifD5

ifD7

/DSRA

TXDA

TXDB

/DTRA

/RTSA

R351KR36

RXDB

RXDA

1K

BUSY

/ACK

/STB

RXDB

/DSRA

TXDA

TXDB

RXDA

/DTRA

/RTSA

ifD7

ifD6

ifD5

ifD4

ifD3

ifD2

ifD1

ifD0

+5

CN2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

TOI/FBOARD

IL-FPC-26ST-N

5

9

11

13

1

5 6

3 4

12

13

9

10

13

12

U13B

6

CEXT

7

REXT/CEXT

9

A

10

B

11

CLR

U14C

74LS07

U14D

74LS07

U14E

74LS07

U14F

74LS07

U12A

74LS14

U12C

74LS14

U12B

74LS14

U10D

74HC32F

+

BA10324A

+

BA10324A

U25C

U25D

74HC123F

6

8

10

12

2

11

8

14

5

Q

12

Q

10

C43

100u/63V

+

+40

C54

100u/25V

+

-15

C53

100u/25V

+

C40

100u/25V

+

+5

+5

CN5

1

4

2

5

3

6

5566-06A

TOPOWERBOARD

+5

PC1

CE0.1u

PC11

CE0.1u

PC21

CE0.1u

PC2

CE0.1u

PC12

CE0.1u

PC28

CE0.1u

PC3

CE0.1u

PC13

CE0.1u

PC29

CE0.1u

PC4

CE0.1u

PC14

CE0.1u

PC30

CE0.1u

PC5

CE0.1u

PC15

CE0.1u

PC6

CE0.1u

PC16

CE0.1u

PC7

CE0.1u

PC17

CE0.1u

PC8

CE0.1u

PC18

CE0.1u

PC9

CE0.1u

PC19

CE0.1u

PC10

CE0.1u

PC20

CE0.1u

11

13

10

J

PR

CLK

K12Q

CL

14

U8B

Q

74ALS112

9

7

Page 13

2 Electrical Section

MAIN BOARD_3/3 Circuit Diagram

PENFRC

PENPH

A[0..21]

D[0..15]

RUN

/SRVCS

/RD

/WR

/INTSRV

/SRVINTV

/RESET

U20

4

+5

2

GND

SG531T49.152MHz

C30

C31

CE1000p

RA15

6

OUT

NC

5

6

7

8

5

6

7

8

4

3

2

1

4

3

2

1

1234567

CN13

IL-G-7P-S3T2-E

+5

1

2

3

4

RA22

881

772

663

554

MNR34J5A102

C29

C32

CE1000p

CE1000p

MNR34J5A330

12345

CN12

IL-G-6P-S3T2-E

+5

CE1000p

U19

D6

D13Q1

D4

D24Q2

D2

D37Q3

D0

D48Q4

D1

D513Q5

D3

D614Q6

D5

D717Q7

D7

D818Q8

11

CLK

1

CLR

74HC273F

A[0..21]

D[0..15]

U12D

74LS14

3

4

5

1

+5

R7

0

U17

A12Y1

A2

A3

A4

A56Y5

A67Y6

A78Y7

A89Y8

G1

G2

74LS541

18

17

Y2

16

Y3

15

Y4

14

13

12

11

3

1

19

98

xpha

xphb

ypha

yphb

SRVGAIN

2

DA6

5

DA4

6

DA2

9

DA0

12

DA1

15

DA3

16

DA5

19

DA7

+40

+5

DA7

DA6

DA5

DA4

DA3

DA2

DA1

DA0

R21

10K

1

2

3

4

5

6

7

8

P25

R20

10K

RA23

16

OM

15

14

13

12

11

10

9

GL

EXBM16D8AL

A1

81

A2

82

A3

83

A4

84

A5

85

A6

86

D0

68

D1

69

D2

70

D3

71

D4

72

D5

73

D6

74

D7

75

76

66

67

87

77

64

80

91

92

xpha

99

100

xphb

ypha

61

yphb

62

P26

88

89

94

95

63

96

97

98

93

+5

R22

10K

+5

TR2

DTC114EF

B3C

U23

1

+5

VR1

1KVR

U25B

VR2

22KVR

C47

CE1000p

1

2

5

6

7

8

9

10

11

12

13

14

16

17

18

19

20

21

22

23

24

25

26

27

30

31

57

58

59

60

32

33

34

35

36

37

38

39

41

42

43

44

45

46

47

48

49

50

51

52

55

56

R4

470

E

2

D9

SEL-6414E

BA10324A

R44

100K

P19 P20

P23 P24

DX0

DX1

DX2

DX3

DX4

DX5

DX6

DX7

DX8

DX9

DX10

DX11

P29

P28

DY0

DY1

DY2

DY3

DY4

DY5

DY6

DY7

DY8

DY9

DY10

DY11

2

C

5

6

P15P16

D7A

DA227

E

TR1

1

+

-

P21

B

P22

2

3

D7B

DA227

1

4

3

DTC114EF

7

R45

8.2K

C48

CE0.01u

P18

P17

DX11

DX10

DX9

DX8

DX7

DX6

DX5

DX4

DX3

DX2

DX1

DX0

DY11

DY10

DY9

DY8

DY7

DY6

DY5

DY4

DY3

DY2

DY1

DY0

4

5

R40

100K

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

U18B

74HC08

U25A

BA10324A

R39

100K

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16(LSB)

20

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16(LSB)

20

+5

COM

-15

COM

-15

3

2

23

U28

+VS

VOUT

-VS

24

+5

23

U29

+VS

VOUT

-VS

24

6

PC22

CE0.1u

IBPO

IOUT

RFB

PC23

CE0.1u

PC24

CE0.1u

IBPO

IOUT

RFB

PC25

CE0.1u

+5

+

-

SJ

SJ

411

P12

22

21

19

18

17

PCM55

22

21

19

18

17

PCM55

R56

10K

1

R60

10K

R37

NON

R48

R49

C49

CE2200p

R52

R53

C51

CE2200p

2.2K

2.2K

2.2K

2.2K

R50

47K

R54

47K

C55

CE0.01u

3

2

5

6

+

-

-15

+

-

R57

2.2K

+5

8

U30A

V+

M5220L

V-

4

C50

CE2200p

R51

PC27

U30B

M5220L

C52

CE2200p

R55

R58

8.2K

C56

4700p

PC26

CE0.1u

1

47K

CE0.1u

7

47K

+5

25

3

5

23

24

6

22

2

26

4

1

SRVSRCH

SRVSRCL

FAN

U31

MTD2005

VCC

ALM

PHA

PHB

DECAY

ENAA

ENAB

VREFA

VREFB

CR

VSA

RSA

11

R59

1/2W

P14

P13

P27

13

PG

VMMA

VMMB

OUT1

OUT2

OUT3

OUT4

LGA

LGB

VSB

NC

NC

NC

NC

17

RSB

8

20

10

12

14

18

7

21

9

15

16

19

27

100K

R43

SOL-

SOL+

SERVOMUTE

VFC

PFC

MOTORGAIN

VFG

PFG

SERVOSRCH

SERVOSRCL

FAN

C46

CE1000p

SOL-

SOL+

CN14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

5483-15A

2

11

Page 14

2 Electrical Section

VR No. Function

OFS-1

(10KVR)

Use for Motor Balance Adjustment

OFS-2

(10KVR)

Use for Motor Balance Adjustment

GAIN-1

(1KVR)

Use for Motor Balance Adjustment

GAIN-2

(1KVR)

Use for Motor Balance Adjustment

Parts No. Description

A 12559567 FUSE 5x20 CEE-1AT WICKMANN

B 12559570 FUSE 5x20 CEE-2AT WICKMANN

C 12559574 FUSE 5x20 CEE-5AT WICKMANN

2-3 POWER BOARD ASS'Y

DESCRIPTION

2

3

POWER BOARD ASS'Y [7393318000]

1VR

10mm

10mm

10mm

PFC-5000

PFC-5000

5566-06A

D5SBA20

10000u/25V

10mm

T2A

B

T5A

C

104

PFC-5000

PFC-5000

470u/25V 470u/25V

470u/16V

10mm

10mm 10mm

AN7705F AN7915F AN7815F

10mm

104

1000u/35V 1000u/35V

20mm

10mm

20mm

10mm

20mm

-

1B4B1

A

5566-10A

+

10mm

A

20mm

25mm

15mm

15mm

10mm

103

OFS-1

683

L6203

10mm

1SS130

103

1KVR

S2L20U

223223

25mm

104

103

1SS130

10KVR

122

S2L20US2L20U

25mm

15mm

104

472

25mm

472

uPC494

224

103

102

102

M5220L

103

102

1SS130

681

102

10mm

333

104

10mm

15mm

103

10mm

2FUSE

3Electric Maintenance Parts

IC.No. Parts No. Description Function

Q3 15129444 2SB1551 40/20 VSelector

102

472

103

222

223

332

104

472

104

101

104

Q8 15119105 2SC4849 Fan Driver

U13 15199294 AN7705F 5V Regulator

U14 15199133 AN7815F 15V Regulator

U15 15199134 AN7915F -15V Regulator

U6 15219174 NJU201AD Gain selector

U10 15199952 L6203 Carriage Motor Driver

U11 15199952 L6023 Grit Motor Driver

U7 15199901 micorPC494C Carriage Motor Controller

U8 15199901 micorPC494C Grit Motor Controller

U2, U3 & U5 15189106 M5220L OP Amp for motor

S2L20U

223

25mm

10mm

104

104

472

104

101

10mm

223

10mm 10mm10mm20mm

L6203

104

5566-04A

25mm

10mm 10mm

103

472

uPC494

102

102

10mm

15mm

103

10mm

104

R33/2W R33/2W

10mm

224

25mm

25mm

25mm

DTA114EF

472

DTC114EF

103

222

223

332

102

103

15mm

M5220L

104

472

1SS130

OFS-2

122

681

1SS130

333

GAIN-2

102

10mm

1KVR

5483-15AX

20mm

103

M5220L

104 104

1SS130

1SS130

104

15mm

103

1SS130

10KVR

683

103

104

103

15mm

220u/63V

74HC175

103

10mm

1SS130

1SS130

104

104

10mm

103

1SS130

1SS130

10mm

10mm

104

NJU201A

5566-02A

10mm

104

1SS130

1SS130

20mm

15mm15mm

GAIN-1

S2L20U

PFC-5000

10mm

2.5mm

220u/63V

20mm

1SR35

2SB1551

223

PFC-5000

223

DTC114EF

T2A

B

104

104

10mm

104

104

B

T2A

332/2W

D5SBA20

PFC-5000

10000u/63V

100u/63V

CL02BE181

5267-02A

PFC-5000

S2L20U

5267-02A

15mm

10mm

2SC4849

101

151

DTA114EF

30mm

30mm

30mm

10mm

25mm

10mm

25mm

102

10mm

10mm

12

POWER BOARD

2

MADE IN JAPAN

1

Indicates revision of the circuit board.

Page 15

POWER BOARD_1/2 Circuit Diagram

2 Electrical Section

FROM MAIN

CN2

5483-15AX

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

SERVOMute/Live

VFC

PFC

MotorGainH/L

VFG

PFG

MtrSrcH/OFF

MtrSrcL/OFF

FanPWMOff/On

MHPOW

MLPOW

FAN

VFB

R43

V+

145

R67

NON

R51100K

U2A

1

M5220L

CP6

CE0.1u

-15

U6A

23

13

NJU201A

C28

PO0.068u/50V

R23

10K

C20

PO4700p/50V

C51 NON

C26

PO0.033u/50V

CP5

CE0.1u

3

2

R45

100

+15

+15

84

+

-

V-

-15

VR3 1KVR

R16

1.2K

GainC

R44

1K

680

C24

PO0.1u/50V

OfsetC

+15

-15

VR1

10KVR

R49

100K

D13

R19

10K

D12

1SS130

R27

10K

R69

4.7K

R1

10K2%

C55

1SS130

CE0.1u

U2B

5

+

-

D9

1SS130

84

V+

+

-

V-

-15

M5220L

1SS130

D5

10K2%

R2

1K1%

CP7

CE0.1u

U3A

M5220L

CP8

CE0.1u

7

D10

1SS130

1K1%

R20

1K1%

10K

R100

3.3K

R28

2.2K

2

D23

NON

1

+5

D6

1SS130

D11

1SS130

C11

PO0.022u/50V

+5

R33

4.7K

R4

R3

1

6

R32

+15

3

2

VREF

C14

PO0.01u/50V

C13

PO0.01u/50V

R30

4.7K

Q1

DTA114EF

3

Q9

DTC114EF

OPEN:MUTEON

+15

CP1

CE0.1u

12

14

U7

3

FB

2

INV1

1

NONI1

15

INV2

16

NONI2

4

DEAD

13

OC

PO0.01u/50V

+5

2

3

2 1

R18

1

10K

C15

9

1

REF

C1

E1

C2

E2

C5R

GND

7

U9

D14Q1

D25Q2

D312Q3

D413Q4

CLK

CLR

+5

+5

UPC494

6

R31

4.7K

Q1

Q2

Q3

Q4

74HC175

CP13

CE0.1u

+5

8

9

11

10

R14

1K

+

C53

220u/63V

2

3

7

6

10

11

15

14

C9

CE0.1u

11

5

7

9

CE0.22u

C7

EN

IN1

IN2

VREF

6

GND

VX

2

VS

SENSE

10

U10

BOOT1

OUT1

OUT2

BOOT2

L6203

R10

0.33/2W

C1

CE0.022u

4

3

1

8

C2 CE0.022u

D1

S2L20U

C3

R12

NON

NON

D2

S2L20U

CN1

1

2

5566-02A

2

+5 +5

9

U6C

1011

NJU201A

+15

CP14

CE0.1u

8

U6B

NJU201A

76

VFB

R46

C29 PO0.068u/50V

R24

10K

C23

VR4

1KVR

R17

1.2K

PO4700p/50V

C52

GainG

C27

PO0.033u/50V

R48

100

3

2

R47

1K

680

C25

PO0.1u/50V

OfsetG

+15

-15

VR2

10KVR

R50

100K

NON

+15

84

+

V-

-15

V+

CP12

16

NJU201A

R68

NON

100K

R52

CE0.1u

CP11

U5A

1

M5220L

CE0.1u

U6D

10K

+5

1SS130

D8

D14

1SS130

+15

CP2

CE0.1u

C17

PO0.01u/50V

R101

3.3K

R29

2.2K

D24

NON

1 2

C12

PO0.022u/50V

PO0.01u/50V

C16

R34

4.7K

U8

3

FB

2

INV1

1

NONI1

15

INV2

16

NONI2

4

DEAD

13

OC

GND

7

14

REF

12

+5

C1

E1

C2

E2

C5R

UPC494

6

VY

EN

IN1

IN2

VREF

6

GND

2

VS

SENSE

10

R11

0.33/2W

U11

BOOT1

OUT1

OUT2

BOOT2

L6203

C4

CE0.022u

4

3

1

8

C5

CE0.022u

C6

D3

S2L20U

NON

R13

NON

D4

S2L20U

CN9

1

2

3

4

5566-04A

+5

8

9

11

10

R15

1K

+

C54

220u/63V

C10

CE0.1u

11

5

7

9

C8

CE0.22u

D16

1SS130

R22

10K

R70

4.7K

R5

D15

1SS130

10K2%

C56

CE0.1u

5

6

1514

5

6

R6

R7

+

-

+

-

D18

1SS130

10K2%

1K1%

U3B

M5220L

U5B

M5220L

1SS130

D7

7

R21

7

D17

1SS130

R9

1K1%

R8

1K1%

-15

CP15

CE0.1u

13

Page 16

2 Electrical Section

2

POWER BOARD_2/2 Circuit Diagram

CN3

FROMTRANCE

5566-10A

10

10

5

5

9

9

4

4

8

8

3

3

7

7

2

2

6

6

1

1

C39

NON

1

FS5

1

PFC5000

C33

NON

C34

NON

FS3

1

PFC5000

FS1

1

PFC5000

C30

NON

FS7

PFC5000

2

2

2

F6

2

CEE-5AT

F5

CEE-1AT

F4

CEE-1AT

F1

CEE-2AT

1

FS6

1

FS4

1

FS2

1

FS8

PFC5000

PFC5000

PFC5000

3

PFC5000

1SR35-400A

D30

1 2

1

D27

D5SBA20

+

2

3

2

1

2

1

+

2

4

4

4

+

-

2

D26

1B4B1

D25

D5SBA20

2

2

3

R63

3.3K2W

MHPOW

MLPOW

C42

+

1000u/35V

C43

+

1000u/35V

C40

+

10000u/25V

C46

+

10000u/63V

Hi/Off

Low/Off

C36

CE0.1u

C35

CE0.1u

1

C31

CE0.1u

R60

22K

3

R62

NON

3

U14

AN7815F

1

U15

2

U13

AN7705F

VI

VI

VI

3

R59

22K

2

Q10

DTC114EF

1

Q4

1 2

3

R61

NON

2

Q11

NON

1

GND

2

1

GND

AN7915F

VO

GND

2

Q3

2SB1551

NON

VO

VO

3

3

3

C32

CE0.1u

C38

CE0.1u

C37

CE0.1u

+

D28

S2L20U

+

C41

470u/16V

C44

+

470u/25V

C45

470u/25V

+15

-15

+5

FS9

1

FS11

1

PFC5000

2

PFC5000

2

F2

F3

CEE-2AT

CEE-2AT

1

1

FS10

PFC5000

FS12

PFC5000

VX

2

VY

2

+15-15VX +5

R71

2.2K

CN8

1

2

3

4

5

6

7

8

DPX

CN4

1

2

3

4

5

6

5566-06A

TOMAIN

14

FAN

D29

S2L20U

VX

C49

NON

+5

1

Q7

3

DTA114EF

R66

2

150

R64

NON

R65

100

Q8

2SC4849

C50

+

100u/63V

L1

CL02BE181

TP11TPTP12TP

CN5

1

2

5267-02A

CN6

1

2

5267-02A

forFanControl

Page 17

2-4 OTHER CIRCUIT BOARDS

DESCRIPTION

1 PANEL BOARD ASS'Y [7393321010]

2 I/F BOARD ASS'Y [7393321020]

3 CARRIAGE BOARD ASS'Y [7393321030]

4 TRANS BOARD [7393321040]

2 Electrical Section

EVQ22707K

331

SEL-6414E-TP5

1SS130

Long

TRANS BOARD

4

[7393321040]

GND

PANEL BOARD

MADE IN JAPAN

TRANSE BOARD SUB 4/4

1SS130

MADE IN JAPAN

EVQ22707K

1SS130

SUB1/4

10mm

PANEL BOARD

1

ASS'Y [7393321010]

10mm

RMLA4330J

RMLS4102J

RMLA4330J

RMLS8103J

56364-060-BXE

SUB2/4

RMLS4332J

101

RMLA4330J

104

DS14C238WM

10mm

1SS130

104

10u/25V

10u/25V

10mm

74LS245N

10mm

10mm

10mm

IL-FPC-26-S1T1-SBN

2Electric Maintenance Parts

IC.No. Parts No. Description Function

U3 15199905 DX14C238WMX RS232C Driver

2

I/F BOARD

ASS'Y [7393321020]

2

331

Long

SEL-6414E-TP5

1SS130

EVQ22707K

1SS130

EVQ22707K

EVQ22707K

1SS130

10mm

EVQ22707K

CABLE-ASSY PANEL PNC-1860

1SS130

EVQ22707K

1SS130

EVQ22707K

MADE IN JAPAN

I/F BOARD

10mm

10mm

10mm

10mm

DBLC-J25SAF-20L9

10u/25V

10u/25V

CARIAGE BOARD

MADE IN JAPAN

5mm

IL-FPC-8SL-N

273

SUB 3/4

IL-S-02P-S2L2-EF

222

151

10u/25V

104

GP1S53

3 CARRIAGE BOARD

ASS'Y [7393321030]

15

Page 18

2 Electrical Section

OTHER CIRCUIT BOARDS_1/1 Circuit Diagram

+5

2

CN4

1

2

PLED0

3

PLED1

4

SK0

5

SK1

6

KD0

7

KD1

8

KD2

9

KD3

10

KD4

11

KD5

12

KD6

13

KD7

14

ILS-14P-S2L2-EF

PanelBoard

CN6

1

2

3

4

5

6

7

8

IL-FPC-8SL-N

R4

330

R5

330

+5

D10

SEL-6414E

+5

Y-LIMIT

PINCHROLL

SOL+

SOL-

D11

SEL-6414E

+5

R3

27K

C7

CE2200p

C1

10u/25V

CN3

S1

EVQ21307K

S2

EVQ21307K

S3

EVQ21307K

S4

EVQ21307K

S5

EVQ21307K

S6

EVQ21307K

S7

EVQ21307K

S8

EVQ21307K

R2

150

1

3

U2

GP1S53

2

4

D2

1SS130

D3

1SS130

D4

1SS130

D5

1SS130

D6

1SS130

D7

1SS130

D8

1SS130

D9

1SS130

C6

CE0.1u

CN5

1

2

IL-S-2P-S2L2-EF

CN7

1

2

IL-S-2P-S2T2-EF

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

IL-FPC-26ST-N

N.C.

+

CD7

CD6

CD5

CD4

CD3

CD2

CD1

CD0

BUSY

/ACK

/STB

C2

10u/25V

C3

10u/25V

TXDA

RXDA

/RTSA

RXDB

/DTRA

/DSRA

TXDB

CD7

CD6

CD5

CD4

CD3

CD2

CD1

CD0

CP2

CE0.1u

+

+

7

5

3

1

11

15

5

6

18

4

19

22

21

17

18

17

16

15

14

13

12

11

RA4

887

665

443

221

RMLA4330J

U3

V+

V-

T1IN

R1OUT

T2IN

R2OUT

T3IN

R3OUT

T4IN

R4OUT

B1

B2

B3

B4

B5

B6

B7

B8

+5

+5

CP1

CE0.1u

U1

A1

A2

A3

A4

A5

A6

A7

A8

G

DIR

74ALS245

9

C1+

VCC

C1-

C2+

C2-

T1OUT

R1IN

T2OUT

R2IN

T3OUT

R3IN

T4OUT

R4IN

GND

MAX238CWG

8

RA1

RMLS8103J

+5

RA2

2

3

4

5

6

7

8

9

19

1

+5

RMLA4330J

7

5

3

1

7

5

3

1

RA3

RMLA4330J

887

665

443

221

887

665

443

221

D1

1SS130

R1

10

12

13

14

2

7

1

3

24

23

20

16

C4

10u/25V

+

+

C5

10u/25V

54321

54321

RA6

RMLS4102J

1

14

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

13

100

CN2

DBLC-J25SAF-20L9

987654321

987654321

10

11

12

13

14

15

16

17

18

1

RA5

RMLS4332J

CN1

1

2

3

4

5

6

7

8

9

56364-060-BXE

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

554433221

CariageBoard

16

InterfaceBoard

Page 19

3 Replacement of Main Parts

3 Replacement of Main Parts

Following table describes the necessary adjustment after the replacement of each parts.

Replacement Parts Necessary Adjustment

CARRIAGE MOTOR ASSEMBLY

DRIVE GEAR

GRIT MOTOR ASSEMBLY

ROLL DRIVE GEAR

CARRIAGE WIRE

PEN CARRIAGE ASSEMBLY

MAIN BOARD ASSEMBLY

POWER BOARD ASSEMBLY

Motor Backlash Adjustment, Wire Tension Adjsutment, Motor Balance Adjustment

Motor Backlash Adjustment, Wire Tension Adjustment

Motor Backlash Adjustment, Motor Balance Adjustment

Motor Backlash Adjustment

Wire Tension Adjustment

Tool Height Adjustment, Pen Pressure Adjustment

Pen Pressure Adjustment

Motor Balance Adjustment, Calibration

3-1 PEN CARRIAGE ASSEMBLY_REMOVING

Remove the CARRIAGE COVER.

1

Remove SCREW A and WASHER fixing the wire.

Remove the CARRIAGE CABLE and the CARRIAGE

2

BOARD ASS'Y.

3

CARRIAGE COVER

SCREW A

WASHER

CARRIAGE CABLE

CARRIAGE

BOARD ASS'Y

Remove the CARRIAGEBOARD STAY and take off the PEN

3

CARRIAGE ASSEMBLY.

CARRIAGEBOARD

STAY

PEN CARRIAGE

ASSEMBLY

17

Page 20

3 Replacement of Main Parts

3-1 PEN CARRIAGE ASSEMBLY_FIXING

3

Make sure there is no looseness in the PEN CARRIAGE

1

ASSEMBLY when fixing it to the GUIDE RAIL.

Put the 0.25 mm ink pen to the PEN CARRIAGE

2

ASSEMBLY and push it down with your finger at the

positions shown in the figure. Make sure that the pen tip

lands within +/- 0.5 mm from the center of the CUTTER

PROTECTION. If not, fix the PEN CARRIAGE ASSEMBLY

again.

GUIDE RAIL

PEN CARRIAGE

ASSEMBLY

CUTTER

PROTECTION

18

Page 21

3-2 DRIVE PULLEY ASSEMBLY_REMOVING

Remove the PEN CARRAIGE ASSEMBLY (Page 17 ).

1

Loosen the SCREW A and SCREW B in order.

3 Replacement of Main Parts

SCREW B

SCREW A

3

Remove the CARRIAGE WIRE as shown in the figure.

2

Loosen the SCREW fixing the CARRIAGE MOTOR.

3

CARRIAGE WIRE

SCREW

Remove the SHAFT STA Y.

4

CARRIAGE MOTOR

SHAFT STAY

19

Page 22

3 Replacement of Main Parts

3

Remove the DRIVE PULLEY ASSEMBLY.

5

Loosen the SCREWS A shown in the figure and pull out the

6

CARRIAGE WIRE.

DRIVE PULLEY

ASSEMBLY

SCREW

CARRIAGE WIRE

SCREWS A

20

Page 23

3-2 DRIVE PULLEY ASSEMBLY_FIXING

3 Replacement of Main Parts

Fix the CARRIAGE WIRE to the DRIVE PULLEY

1

ASSEMBLY (Page 22).

Fix the DRIVE PULLEY ASSEMBLY to the MOTOR BASE.

Fix the CARRIAGE MOTOR by checking the backlash.

2

DRIVE PULLEY ASSEMBLY

MOTOR BASE

3

Fix the SHAFT STAY temporary to the FRAME R.

3

Tighten the SCREW A for the SHAFT STAY until the

4

PULLEY SHAFT makes contact with the SHAFT STA Y.

Tighten the SCREWS B.

FRAME R

SHAFT STAY

SHAFT STAY

SCREW B

SCREW A

PULLEY SHAFT

21

Page 24

3 Replacement of Main Parts

3-3 CARRIAGE WIRE_WINDING

Be careful with the direction of the IDLE PULLEY in case of

1

removing it.

3

Fix the end of the CARRIAGE WIRE to the DRIVE PULLEY

2

ASSEMBLY.

IDLE PULLEY

DRIVE PULLEY

ASSEMBLY

Fix the DRIVE PULLEY ASSEMBLY to the machine. (Page

3

21)

Fix the CARRIAGE MOTOR by checking the backlash.

4

CARRIAGE WIRE

22

CARRIAGE

MOTOR

Page 25

Wind the CARRIAGE WIRE around the DRIVE PULLEY

5

ASSEMBLY from the bottom to the top.

- Make sure the CARRIAGE WIRE doesn't cross over.

3 Replacement of Main Parts

DRIVE PULLEY ASSEMBLY

Rotate the DRIVE PULLEY ASSEMBLY until the

6

CARRIAGE WIRE comes to its center.

Fix the PEN CARRIAGE ASSEMBLY at the center part of

7

the GUIDE RAIL.

Move the PEN CARRIAGE ASSEMBLY back and forward in

a whole distance to remove the slack in the CARRIAGE

WIRE.

CARRIAGE WIRE

DRIVE PULLEY

ASSEMBLY

GUIDE RAIL

3

CARRIAGE WIRE

Adjust the Wire Tension. (Page 37)

8

PEN CARRIAGE

ASSEMBLY

23

Page 26

3 Replacement of Main Parts

3-4 PINCH ROLLER ASSEMBLIES_FIXING

Tapered type is used for left and right PINCH ROLLERS.

1

Be careful when replacing them.

Flat type is used for the MIDDLE PINCH ROLLER one.

3

MIDDLE PINCH ROLLER

PINCH ROLLER

3-5 CUTTER PROTECTION_FIXING

Leave the equal space at both ends of CUTTER

1

PROTECTION.

Make sure the CUTTER PROTECTION is not bumpy by

2

pushing it with your finger.

CUTTERÅ@PROTECTION

24

Page 27

4 Adjustment

4-1 Special Tool

Table shows a list of special tools recommended by Roland DG Corp.

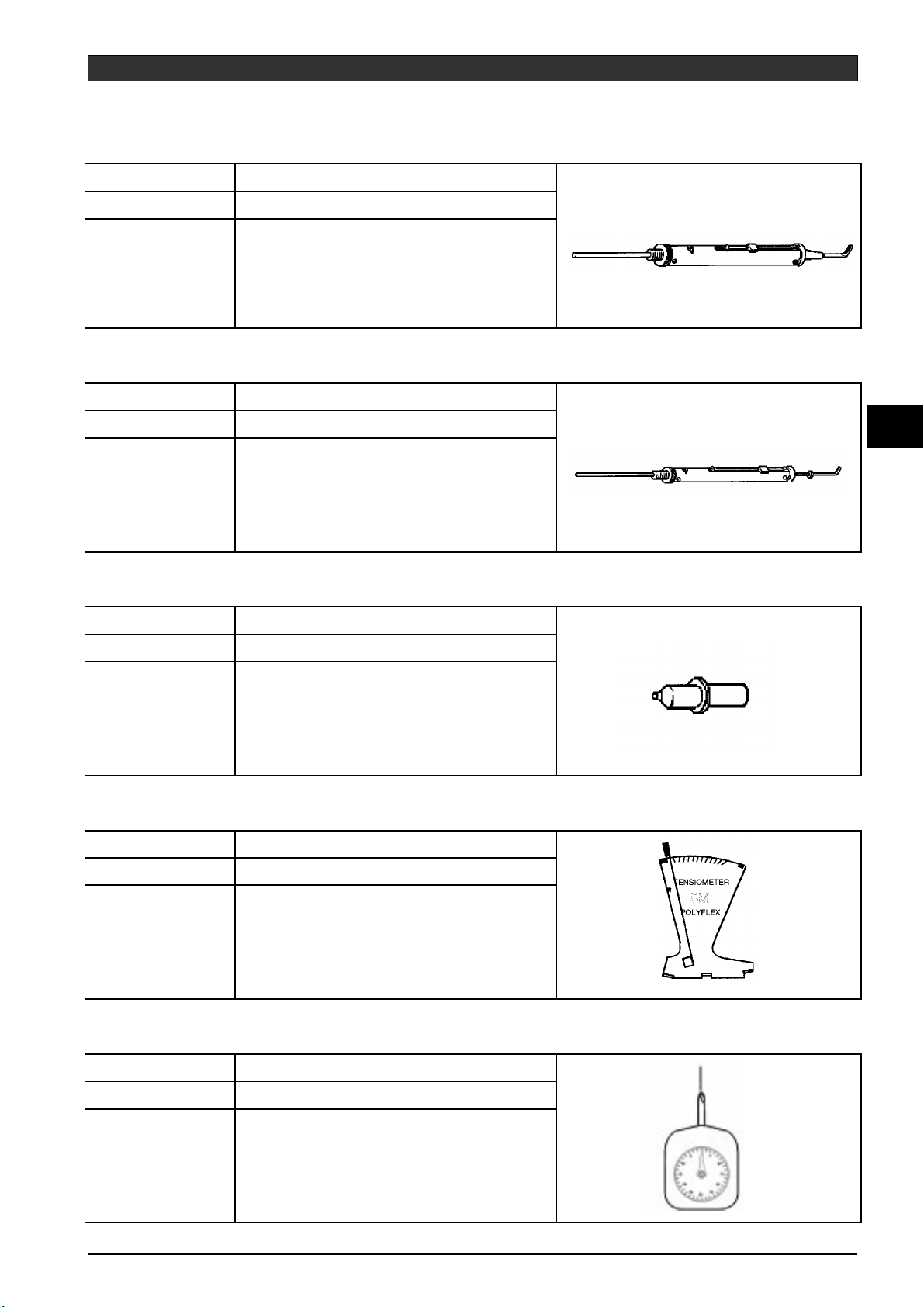

Tool No. ST-001

Tool name TENSION GAUGE 1500g

Purpose Motor backlash

Tool No. ST-002

4 Adjustment

Tool name TENSION GAUGE 300g

Purpose Pen Pressure Adjustment

Tool No. ST-006

Tool name WHITE DUMMY PEN

Tool Height Adjustment

Purpose Spacer Bed Adjustment

Pen Pressure Adjustment

Tool No. ST-011

Tool name TENSION METER

4

Purpose Wire Tension Adjustment

Tool No. ST-012

Tool name DIAL TENSION METER DT-30 (30g)

Purpose Pen Pressure Adjustment

25

Page 28

4 Adjustment

4-2 Service Mode

[ ],[ ],[ ] + POWER ON

vice mode

ver1.10

Displays EPROM version.

[ ],[ ] key to select.

4

[ENTER] key to carry out.

Sensor

DRAM

EEROM

Ageing

Force

Key

Calib.

Checks whether sensor is functioning properly.

SENSOR ON = 1, SENSOR OFF = 0

[MENU ] key

Checks whether DRAM is functioning properly.

[MENU ] key

Checks whether EEROM is functioning properly.

[MENU ] key

This is for MOTOR BALANCE ADJUSTMENT. (page39)

[MENU ] key

This is for PEN PRESSURE ADJUSTMENT. (page33)

[MENU ] key

Push panel key in sequence of [MENU],[ENTER],

[ ],[ ],[ ],[ ],[SETUP],[TEST]key to check.

[MENU ] key

This is for calibration. (page41)

Landing

LIMITED INITIALIZE

Data which has been set by the

user inside the EEROM will be

initialized. Turn on the power

while pressing the [ENTER] key.

User initialize

NO YES

ENTER

User parameter

initializing..

[MENU ] key

This is checking softlanding function. (page44)

[MENU ] key

ALL INITIALIZE

All data inside EEROM, including

Service Mode settings, will be

initialized. Turn on the power

while pressing [left], [right] and

[ENTER] keys.

EEROM all init.

NO YES

ENTER

EEROM all init.

Initializing..

SERIAL INTERFACE CHECK

Turn on the power while

pressing the [right] key.

RS232C check NG!

Error bit= 1111

STxD-SRxD error

TxD-RxD error

DTR-CTS error

RTS-DSR error

Connection

2 (TxD) 3 (RxD)

4 (RTS) 6 (DSR)

5 (CTS) 20 (DTR)

14 (STxD) 16 (SRxD)

26