Page 1

CX-24/12

USER’S MANUAL

Thank you very much for purchasing the CX-24/12.

• To ensure correct and safe usage with a full understanding of this product's performance, please be sure

to read through this manual completely and store it in

a safe location.

• Unauthorized copying or transferral, in whole or in

part, of this manual is prohibited.

• The contents of this operation manual and the

specifications of this product are subject to change

without notice.

• The operation manual and the product have been

prepared and tested as much as possible. If you find

any misprint or error, please inform us.

• Roland DG Corp. assumes no responsibility for any

direct or indirect loss or damage which may occur

through use of this product, regardless of any failure

to perform on the part of this product.

Page 2

Contents

Contents

To Ensure Safe Use .................................. 3

About the Labels Affixed to the Unit .............................. 5

Pour utiliser en toute sécurité.................... 6

À propos des étiquettes collées sur l'appareil .................. 8

1 Checking Supplied Items .................... 9

2 Part Names and Functions................ 10

2-1 Front View ........................................................... 10

2-2 Rear V iew ............................................................ 10

2-3 Operation Panel ................................................... 11

3 Preparing the CX-24/12 .................... 12

3-1 Setting.................................................................. 12

3-2 Connection........................................................... 13

3-3 Installing the Driver............................................. 15

3-4 Port Setting .......................................................... 15

5 Performing a Self-test ....................... 34

6 Plotting on Paper Media.................... 35

7 Repeating the Same Cutting ............. 36

8 About the Blades and Materials ........ 38

8-1 Blade and Material Combinations ....................... 38

8-2 About the Materials ............................................. 39

9 Display Menu Descriptions................ 42

9-1 How to Read This Chapter .................................. 42

9-2 Display Menu Descriptions ................................. 42

10 Display Menu Flowchart.................... 48

11 What to Do If... .................................. 49

4 Basic Operation................................. 17

4-1 Installing Blade.................................................... 17

4-2 Loading the Material ........................................... 18

4-3 Turning on the Power .......................................... 21

4-4 Checking Material Feed....................................... 23

4-5 When Performing Long Cutting .......................... 24

4-6 Setting the Origin Point ....................................... 25

4-7 Performing a Cutting Test (How to Adjust Blade

Force/Adjusting the Cutter Blade)....................... 26

4-8 Downloading Cutting Data.................................. 28

4-9 Applying the Completed Cutout.......................... 31

4-10 When Cutting is Completed ................................ 33

11-1 If the CX-24/12 Doesn't Run... ............................ 49

11-2 The Material Slips Away from the Pinch Rollers

during the Cutting Process................................... 50

11-3 Uncut Areas Remain, or Areas are Not Cleanly Cut.

51

11-4 The Results of Cutting are Displaced, and Uncut

Portions Remain .................................................. 51

11-5 Error Messages .................................................... 52

12 Instruction Support Chart .................. 53

13 Specifications .................................... 54

Index ....................................................... 56

Windows® and MS-DOS are registered trademarks or trademarks of Microsoft® Corporation in the United States and/or other countries.

Macintosh is registered trademark or trademark of Apple Computer, Inc. in the USA and other countries.

IBM is a registered trademark of International Business Machines Corporation.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated.

Copyright © 2000 Roland DG Corporation

2

http://www.rolanddg.com/

Page 3

To Ensure Safe Use

About and Notices

Used for instructions intended to alert the user to the risk of death or severe

injury should the unit be used improperly.

Used for instructions intended to alert the user to the risk of injury or material

damage should the unit be used improperly.

* Material damage refers to damage or other adverse effects caused with

respect to the home and all its furnishings, as well to domestic animals or

pets.

About the Symbols

The symbol alerts the user to important instructions or warnings. The specific meaning of

the symbol is determined by the design contained within the triangle. The symbol at left means

"danger of electrocution."

The symbol alerts the user to items that must never be carried out (are forbidden). The

specific thing that must not be done is indicated by the design contained within the circle. The

symbol at left means the unit must never be disassembled.

The symbol alerts the user to things that must be carried out. The specific thing that must

be done is indicated by the design contained within the circle. The symbol at left means the

power-cord plug must be unplugged from the outlet.

Do not disassemble, repair, or

modify.

Doing so may lead to fire or abnormal

operation resulting in injury.

Ground the unit with the ground

wire.

Failure to do so may result in risk of

electrical shock in the even of a mechanical

problem

Do not use while in an abnormal

state (i.e., emitting smoke, burning

odor, unusual noise, or the like).

Doing so may result in fire or electrical

shock.

Immediately switch off the power, unplug

the power cord from the electrical outlet,

and contact your authorized Roland dealer

or service center.

Do not use with any electrical power

supply that does not meet the

ratings displayed on the unit.

Use with any other power supply may lead

to fire or electrocution.

3

Page 4

Do not use with a damaged power

cord or plug, or with a loose

electrical outlet.

Use with any other

power supply may

lead to fire or

electrocution.

Do not injure or modify the electrical

power cord, nor subject it to

excessive bends, twists, pulls,

binding, or pinching, nor place any

object of weight on it.

Doing so may

damage the

electrical power

cord, leading to

electrocution or

fire.

When not in use for extended

periods, unplug the power cord from

the electrical outlet.

Failure to do so may

result in danger of

shock, electrocution,

or fire due to

deterioration of the

electrical insulation.

Do not attempt to unplug the power

cord with wet hands.

Doing so may

result in electrical

shock.

Install on a stable surface.

Failure to do so

may result in

falling of the unit,

leading to injury.

When unplugging the electrical

power cord from the power outlet,

grasp the plug, not the cord.

Unplugging by pulling the cord may damage

it, leading to fire or electrocution.

Do not allow liquids, metal objects

or flammables inside the machine.

Such materials

can cause fire.

Do not touch the tip of the blade

with your fingers.

Doing so may result in injury.

Do not place the hands or anything

else on the platen when switching

on the power.

Doing so may result in injury.

(The cutting carriage moves simultaneously

when the power is switched on.)

Do not place hands near the platen

while in operation.

Doing so may result in injury.

4

Page 5

About the Labels Affixed to the Unit

These labels are affixed to the body of this product.

The following figure describes the location and content of these messages.

Do not place hands near the platen

while in operation.

In addition to the

NOTICE

: Indicates information to prevent machine breakdown or malfunction and ensure correct use.

: Indicates a handy tip or advice regarding use.

Model name

Rating label

Use a rated power supply.

and symbols, the symbols shown below are also used.

5

Page 6

Pour utiliser en toute sécurité

Avis sur les avertissements

Utilisé pour avertir l'utilisateur d'un risque de décès ou de blessure grave en

cas de mauvaise utilisation de l'appareil.

Utilisé pour avertir l'utilisateur d'un risque de blessure ou de dommage

matériel en cas de mauvaise utilisation de l'appareil.

* Par dommage matériel, il est entendu dommage ou tout autre effet

indésirable sur la maison, tous les meubles et même les animaux

domestiques.

À propos des symboles

Le symbole attire l'attention de l'utilisateur sur les instructions importantes ou les

avertissements. Le sens précis du symbole est déterminé par le dessin à l'intérieur du triangle.

Le symbole à gauche signifie "danger d'électrocution".

Le symbole avertit l'utilisateur de ce qu'il ne doit pas faire, ce qui est interdit. La chose

spécifique à ne pas faire est indiquée par le dessin à l'intérieur du cercle. Le symbole à

gauche signifie que l'appareil ne doit jamais être démonté.

Le symbole prévient l'utilisateur sur ce qu'il doit faire. La chose spécifique à faire est

indiquée par le dessin à l'intérieur du cercle. Le symbole à gauche signifie que le fil électrique

doit être débranché de la prise.

Ne pas démonter, réparer ou

modifier.

Le non-respect de cette consigne pourrait

causer un incendie ou provoquer des

opérations anormales entraînant des

blessures.

Mettre l'appareil à la masse avec une

prise de terre.

Le non-respect de cette consigne pourrait

entraîner des décharges électriques en

cas de problème mécanique.

Ne pas utiliser si l'appareil est dans

un état anormal (c'est-à-dire s'il y a

émission de fumée, odeur de brûlé,

bruit inhabituel etc.).

Le non-respect de cette consigne pourrait

provoquer un incendie ou des décharges

électriques.

Éteindre l'appareil immédiatement,

débrancher le fil électrique de la prise et

communiquer avec le revendeur autorisé

Roland ou le centre de service.

Ne pas utiliser avec une alimentation

électrique non conforme à la norme

indiquée sur l'appareil.

Une utilisation avec toute autre alimentation

électrique pourrait provoquer un incendie

ou une électrocution.

6

Page 7

Ne pas utiliser avec une fiche ou un

fil électrique endommagé ou avec

une prise mal fixée.

Une négligence à

ce niveau pourrait

provoquer un

incendie ou une

électrocution.

Ne pas endommager ou modifier le

fil électrique. Ne pas le plier, le

tordre, l'étirer, l'attacher ou le serrer

de façon excessive. Ne pas mettre

d'objet ou de poids dessus.

Une négligence à

ce niveau pourrait

endommager le fil

électrique ce qui

risquerait de

provoquer une

électrocution ou un

incendie.

Débrancher le fil lorsque l'appareil

reste inutilisé pendant une longue

période.

Une négligence à ce niveau pourrait

provoquer des décharges électriques,

une électrocution ou

un incendie dû à une

détérioration de

l'isolation électrique.

Ne pas essayer de débrancher le fil

avec des mains mouillées.

Une négligence à

ce niveau pourrait

provoquer des

décharges

électriques.

Installer l’appareil sur une surface

stable.

Une négligence à

ce niveau pourrait

provoquer la chute

de l’appareil et

entraîner des

blessures.

Saisir la fiche et non le fil électrique

lorsque vous débranchez.

Débrancher en tirant sur le fil pourrait

l'endommager et risquer de provoquer un

incendie ou une électrocution.

Ne pas introduire de liquide, d'objet

métallique ou inflammable dans

l'appareil.

Ce genre de

matériel peut

provoquer un

incendie.

Ne pas toucher l'extrémité de la

lame avec les doigts.

Une négligence à ce niveau pourrait

provoquer des blessures.

Ne pas mettre les mains ni quoi que

ce soit sur le coulisseau au moment

de mettre sous tension.

Une négligence à ce niveau peut provoquer

des blessures.

(Le chariot de coupe se déplace lorsque

l'appareil est mis sous tension.)

Ne pas mettre les mains près du

coulisseau pendant le

fonctionnement de l'appareil.

Une négligence à ce niveau peut provoquer

des blessures.

7

Page 8

À propos des étiquettes collées sur l'appareil

Ces étiquettes sont collées à l'extérieur de l'appareil.

Les dessins suivants indiquent l'endroit et le contenu des messages.

Avant

N'approchez pas vos mains du

plateau de travail quand le chariot

est en mouvement.

Arrière

Nom du modèle

Étiquette des caractéristiques

électriques

Utiliser l'alimentation appropriée

8

Page 9

1 Checking Supplied Items

This product includes the items shown below.

Before starting use, make sure all the items are present.

1 Checking Supplied Items

Power cord: 1 Roland Software Package

CD-ROM: 1

Blade holder

(XD-CH3) : 1

Pin

Startup manual: 1 To Ensure Safe Use: 1

Roller base: 1 Blade: 1

* CX-24 only

9

Page 10

2 Part Names and Functions

2 Part Names and Functions

In explanations that are common for both the CX-24 and the CX-12, figures depicting the CX-24 are used.

2-1 Front View

Pinch roller (Left)

This presses down on the material to hold it in place.

Set this at the left-hand edge

of the material.

Grit roller

This rotates to

feed the material

forward and

backward.

Guide line marks

The edges of the

material is aligned with

the lines when loading.

Knife guide

The separating blade (included

with the CX-24 only) is inserted

and slid across this.

This makes it possible to separate a piece of material from the

roll while still loaded in place.

Blade protector

Pinch roller (Right)

This presses down on the

material to hold it in place.

Set this at the right-hand

edge of the material.

Cutting carriage

The blade holder (or

pen) is installed here.

Operation panel

Serial (RS-232C) Input Connector

This is for connecting a crossover serial (RS232C) cable (sold separately).

Parallel (Centronics)

Input Connector

This is for connecting a

printer cable (sold

separately).

2-2 Rear View

Sheet loading lever

This is for loading and unloading

material.

Power switch

Pressing the "|" side turns on the power.

Pressing the "O" side turns off the power.

Power connector (AC IN)

10

Page 11

2-3 Operation Panel

2 Part Names and Functions

[MENU/PARAM] Key

This selects whether turning the dial

chooses menu items or changes

setting values.

Pressing this key changes the

location of the menu cursor.

[TEST] Key

This performs a cutting test. You can

use it to make sure that the blade

force is appropriate.

Position Key

This moves the blade (or pen) and

the material.

Display

This displays the various menus and setting

values, as well as error messages.

[ENTER] Key

This is used to choose menu items and confirm

settings.

Pressing it during operation pauses operation.

Dial

This is used to change menu items and settings.

[ORIGIN] Key

This sets the origin point at the present position

of the blade.

11

Page 12

3 Preparing the CX-24/12

3 Preparing the CX-24/12

3-1 Setting

NOTICE

Ground the unit with the ground

wire.

Failure to do so may result in risk of

electrical shock in the even of a mechanical

problem

Install on a stable surface.

Failure to do so

may result in

falling of the unit,

leading to injury.

Do not use with any electrical power

supply that does not meet the

ratings displayed on the unit.

Use with any other power supply may lead

to fire or electrocution.

When moving the machine, do not attempt to lift or carry it by grasping the top portion of the machine. Lift and

carry the machine by holding it with your hands along the left and right sides of the machine.

Never install this unit in any of the following situations, as it could result in damage:

• Places where the installation surface is unstable or not level.

• Places with excessive electrical noise.

• Places with excessive humidity or dust.

• Places with poor ventilation, because the CX-24/12 generates considerable heat during operation.

• Places with excessive vibration.

Make sure the unit is placed on a stable, sturdy surface.

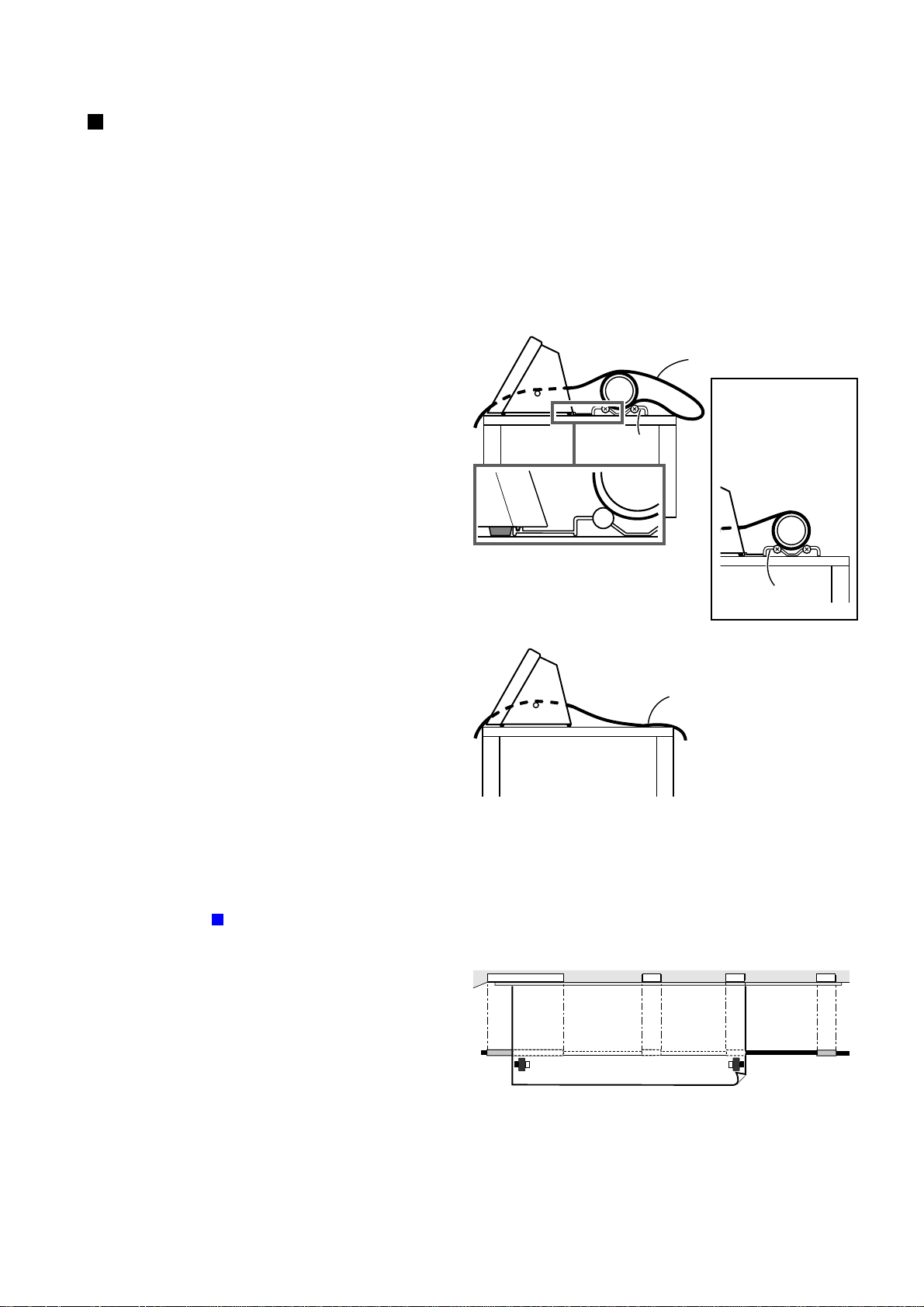

Installing requires the space shown below.

CX-24

950 mm (37-7/16 in.) wide, 500 mm (19-11/16 in.) in

depth, and 300 mm (11-13/16 in.) in height.

CX-12

650 mm (25-5/8 in.) wide, 500 mm (19-11/16 in.) in

depth, and 300 mm (11-13/16 in.) in height.

The material moves during cutting. Do not place

obstacles that may obstruct the material at the front and

rear of the machine.

300 mm

(11-13/16 in.)

CX-24: 950 mm (37-7/16 in.)

CX-12: 650 mm (25-5/8 in.)

500 mm

(19-11/16 in.)

12

Page 13

3-2 Connection

3 Preparing the CX-24/12

NOTICE

Connect the cable to either the parallel or the serial port. Be sure that the power to both the computer and the

main unit is switched off when connecting the cable.

Securely connect the power cord, computer I/O cable and so on so that they will not be unplugged and cause

failure during operation. Doing so may lead to faulty operation or breakdown.

For IBM PC or PC compatibles

Parallel (Centronics)

Input Connector

Serial (RS-232C) Input

Connector

RS-232C connector on the computer

Printer connector on the computer

Parallel (Centronics) cable

Serial (RS-232C) cable

Cables are available separately.

One which you are sure

matches the model of computer

being used should be selected.

For Macintosh

Serial Input Connector

Printer Port

Modem Port

Connect to either port.

Crossover serial cable

Cables are available separately.

13

Page 14

3 Preparing the CX-24/12

Connecting the Power Cord

Power connector

Power cord

Power outlet

14

Page 15

3 Preparing the CX-24/12

3-3 Installing the Driver

The included Roland Software Package CD-ROM contains a Windows-based program and driver for performing cutting with the CX-24/

12.

CAMM-1 DRIVER

This software is required when sending data from a Windows-based program to the CX-24/12. If you're using Windows, be sure to install

this driver.

Refer to the included Startup Manual and install them on your computer.

3-4 Port Setting

The CX-24/12 automatically detects the port used for connection to the computer.

However, if cutting data is not sent correctly, check the communication parameters for the driver and use the display menu on the CX-24/

12 to make the same settings as for the driver.

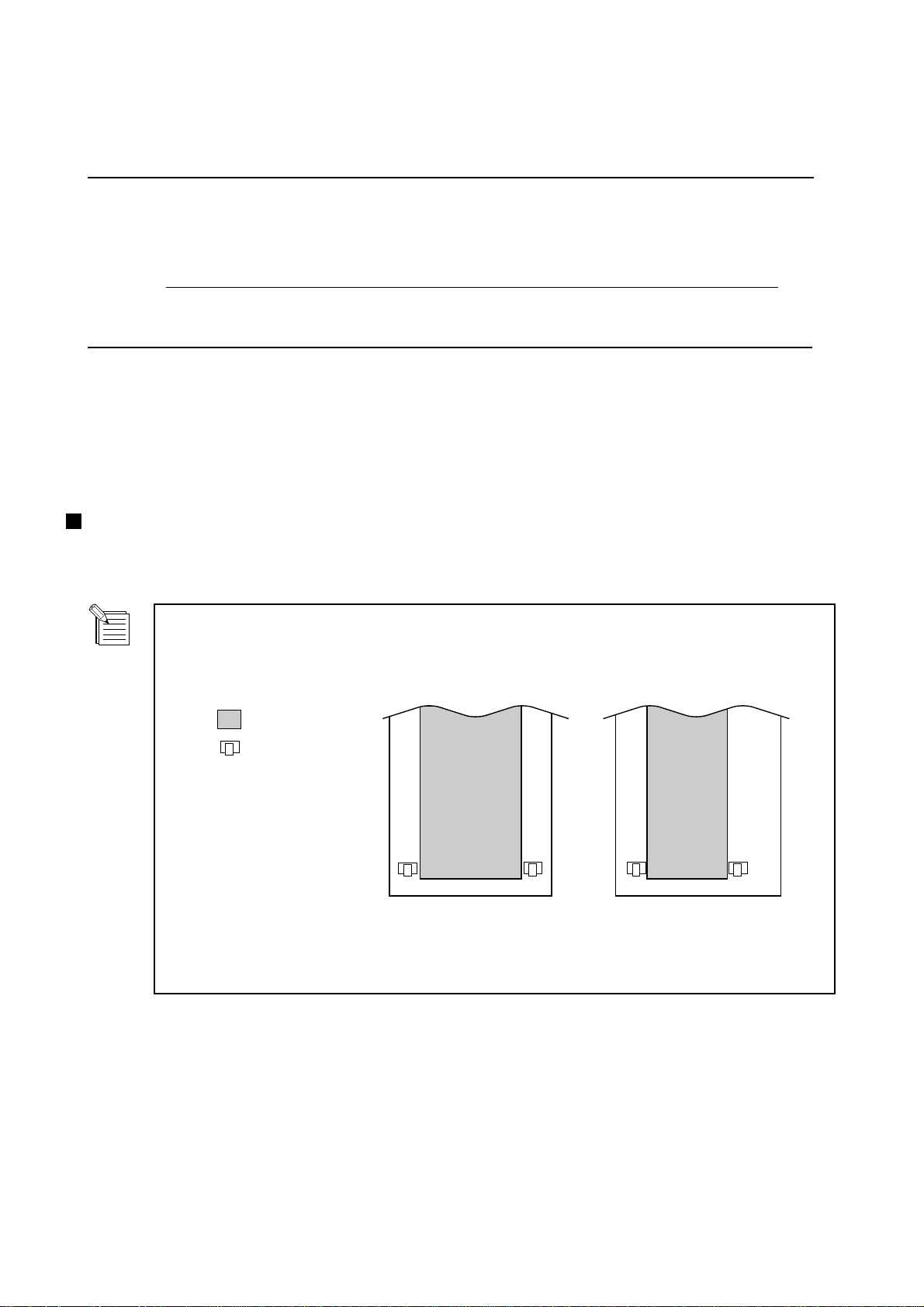

Checking the Communication Parameters for the Driver

Click [Start].

1

Point to [Settings] and click [Printers].

The [Printers] folder appears.

Right-click on the icon for the driver of the model

2

you're using then click [Properties].

The [Roland CAMM-1 CX** **Properties] dialog

box appears.

For the CX-24:

[Roland CAMM-1 CX-24]

For the CX-12:

[Roland CAMM-1 CX-12].

Click the [Detail] tab.

3

Click the [Port Settings] to display the communication parameters for the driver.

15

Page 16

3 Preparing the CX-24/12

Making the Settings from the Menu on the CX-24/12

The display menu can only be used to make settings when material is loaded and set up. Before attempting to make menu settings, refer

to "4-3 Turning on the Power" and put the CX-24/12

1

in a set-up state.

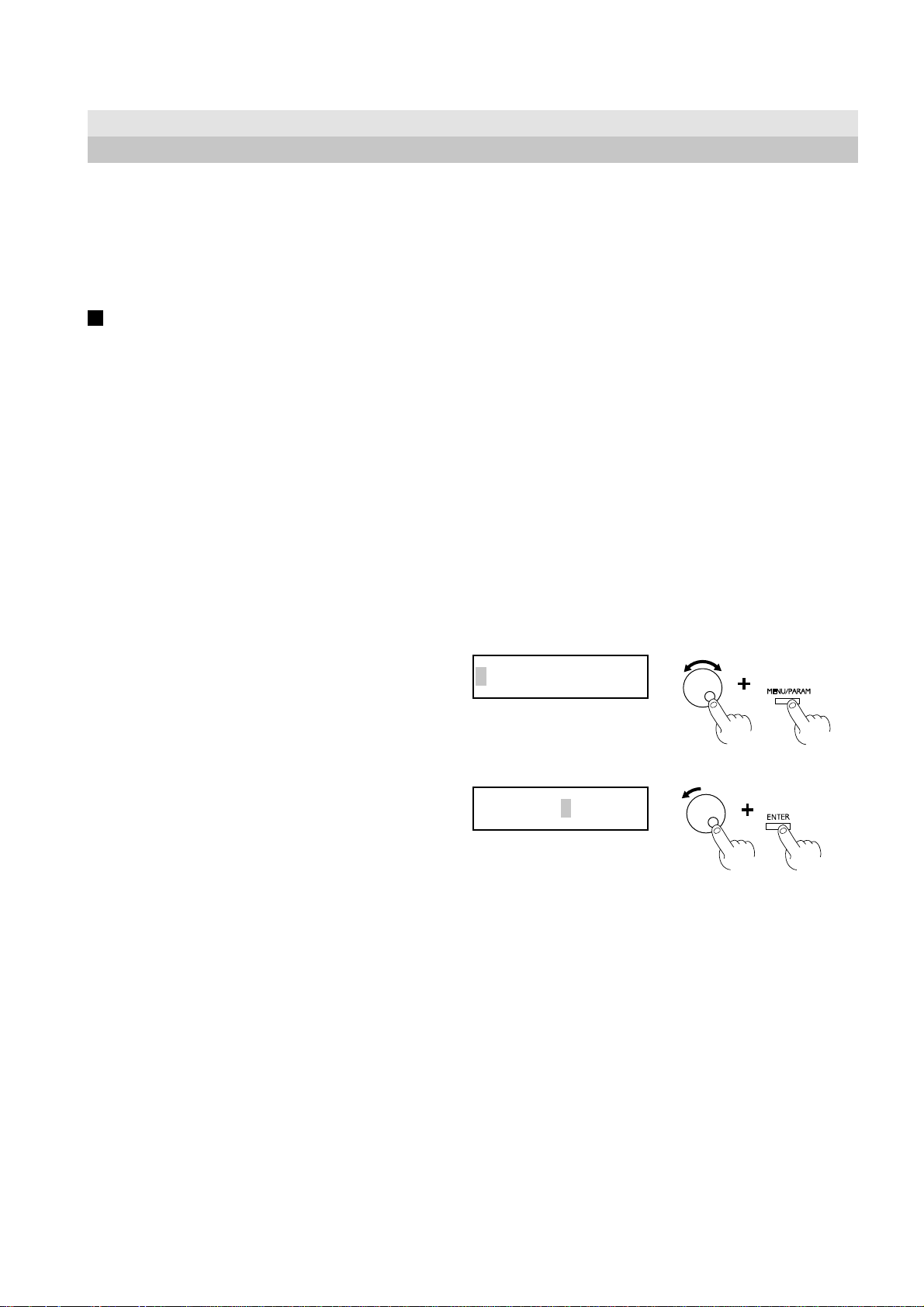

Turn the dial to display the screen shown at right.

Press the [MENU/PARAM] key.

Turn the dial to display the port where the cable is

connected, then press the [ENTER] key to confirm

2

the setting.

If you chose [SERIAL] in step 2, the screen for

setting the bit rate appears.

3

Turning the dial clockwise successively displays the

screens for setting the bit rate, data bit, stop bit, parity

checking, and hardware handshaking (flow control).

Turning the dial counterclockwise returns to the menu

in step 1 without making any changes.

At the screen where the setting items are displayed,

you can change the setting values by pressing the

[MENU/PARAM] key and turning the dial.

For more information about how to make settings, see

"4-3 Switching On the Power - Making Menu

Settings with the Control Panel."

I/O | <AUTO>

I/O | <AUTO>

Back to the screen in step 1

#BAUD.| <9600>

#DATA.| <8>

#STOP.| <1>

#PARITY| <NONE>

Turned

clockwise

#HANDS.|<H-WIRE>

Turned counterclockwise

16

Page 17

4 Basic Operation

4-1 Installing Blade

Do not touch the tip of the blade

with your fingers.

Doing so may result in injury.

4 Basic Operation

NOTICE

Insert a pin into the blade holder.

Be sure to support the tool mounting screw from below when installing the blade holder.

Cutting quality may become poor if installed without supporting the screw in this way.

1

Insert a blade into the blade holder.

2

Pin

Blade holder

Blade holder

Blade

Loosen the screw shown in the figure.

3

Screw

17

Page 18

4 Basic Operation

While supporting the screw from below, insert into

the blade holder from above.

4

Tighten the screw securely.

5

Tug the blade holder upward to make sure it does not

come loose.

Insert until the collar of

the blade holder touches

the rim of the hole.

Screw

4-2 Loading the Material

NOTICE

On the CX-24, use the control panel to choose the configuration of the loaded material.

On the CX-12, there is no menu for choosing the configuration of the material.

Acceptable material widths

(horizontal dimension)

Length

(vertical direction)

Do not use excessive force when lifting the sheet loading lever.

Doing so may damage it.

CX-24

Width

50 to 700 mm (1-15/16 to 27-3/4 in.)

For flat material, 100 mm or more; for roll material,

no restriction

No other restrictions (* Accuracy assured within a

range of up to 1,600 mm (63 in.))

CX-12

50 to 395 mm (1-15/16 to 15-1/2 in.)

No restrictions (* Accuracy assured within a

range of up to 1,600 mm (63 in.))

For more information about the range in which cutting is possible, see "8 About the Blades and Material

18

About Cutting Area."

Page 19

Loading the Material

Before you load material, make sure the sheet loading lever is lowered.

- If you are using roll material, start with step 1.

- If you are using piece material, start with step 2.

Pass the end of the material between the pinch rollers

1

and the grit rollers so that it extends from the front of

the unit.

- If You Are Using the Roller Base

On the CX-24, use the roller base. On the CX-12,

either see "- When Not Using the Roller Base," or

secure in place roll material as a substitute for the

roller base.

Roller Base

4 Basic Operation

Pull out the portion

to cut from the roll.

When loaded as

shown in the figure,

correct feed cannot

be performed.

2

- If You Are Not Using the Roller Base

Position the material so that both edges are above the

grit rollers.

For more information about the width of the material

and the positions of the grit rollers, see "8-2 About the

Material

- CX-24

Loadable Material Width."

When viewed from the front, align so that the

right-hand edge of the material is above any of

the grit rollers and the left-hand edge is above the

long grit roller.

Roller Base

Separate the necessary length for

cutting from the roll.

The white areas of the rails serve as a guide for positioning

the grit rollers.

For material with a width of 6 in., place the material above the

grit roller at the left-hand edge.

19

Page 20

4 Basic Operation

- CX-12

Position the material so that the left and right

edges are each above one of the grit rollers.

Align so that the left and right edges of the material

are parallel with the guide lines.

3

The white areas of the rails serve as a guide for positioning

the grit rollers.

Guide line marks

Using the stickers on the rails as a guide, adjust the

positioning of the left and right pinch rollers above

4

the grit rollers.

Make sure the end of the material has been pulled out

farther toward the front than the blade protector.

5

OK

Stickers

Not OK

Blade protector

Material's edge

Raise the sheet loading lever.

This lowers the pinch rollers to hold the material in

6

place.

Make sure the end of the material

does not catch on this groove.

20

Page 21

4-3 Turning on the Power

Do not place the hands or anything

else on the platen when switching

on the power.

Doing so may result in injury.

(The cutting carriage moves simultaneously

when the power is switched on.)

Turn on the CX-24/12.

4 Basic Operation

Putting the Machine in the Setup State

Use the control panel to put the CX-24/12 in the setup state (the state for receiving data).

For the CX-24:

Turn the dial.

When the display shows the type of load material,

1

press the [ENTER] key.

The cutting carriage starts to move.

SELECT | ROLL

ROLL: Roll material

EDGE: When performing cutting from the

front edge of the material

PIECE: Flat material such as standard-

size and piece material

21

Page 22

4 Basic Operation

The width of the material is detected and the unit is

made ready for cutting.

2

* When flat material is loaded, the material moves

to the front and rear to detect the length of the

material as well.

At this time, if the material is crooked and looks

like it might come loose from the pinch rollers, or

actually does come loose, reload the material.

For the CX-12:

Press the [ENTER] key.

1

The cutting carriage starts to move.

The width of the material is detected and the unit is

2

made ready for cutting.

SETUP -> ENTER

Making Menu Settings with the Control Panel

How to View the Display

Press the [MENU/PARAM] key to change the

location of the cursor.

This is the menu item.

When the cursor is on the left

side, turning the dial cycles

through the menu items.

OFFSET| <0.250>

This is the setting value for the menu item

appearing on the left side.

When the cursor is on the right side, turning the dial

changes the setting value. Press the [ENTER] key to

confirm the setting.

22

Page 23

4 Basic Operation

4-4 Checking Material Feed

Make sure that the material does not come loose from the pinch rollers while cutting is in progress.

On the CX-24, when you choose [PIECE] as the material type, the material is moved forward and backward in order to detect the length

of the material.

There is no need to perform the steps described below in order to make sure that the material does not come loose at this time.

Turn the dial to display the screen shown at right.

Press the [MENU/PARAM] key.

1

This displays the menu for setting the material-feed

length.

Turn the dial to change the value to the required

length of material for cutting. When the display

2

shows the desired value, press the [ENTER] key.

The display changes to the menu for performing

material feed.

When the screen shown at right appears, press the

[ENTER] key again.

3

A length of material corresponding to the setting you

made in step 2 is fed out.

If the material is crooked and looks like it might come

loose from the pinch rollers, or actually does come

loose, please reload the material.

AREA |< 1.0m>

AREA | < 1.0m>

AREA | MOVE

* To perform material feed using the value

displayed in step 1, then after step 2, simply

press the [ENTER] key, and material feed is

performed.

23

Page 24

4 Basic Operation

4-5 When Performing Long Cutting

Cutting a length of 1.5 m (59 in.) or more requires

material that is at least 50 mm (2 in.) wider than the

necessary cutting width.

1.5 m (59 in.) or more

Prepare material that is at least

50 mm (2 in.) wider than the

necessary cutting width.

Refer to the figure at right and move the pinch rollers.

Position the pinch rollers so that each one is 25 mm (1

1

in.) from the respective left or right edge of the

material.

Raise the sheet loading lever to secure the material in

2

place.

25 mm

(1 in.) or more

25 mm

(1 in.) or more

Before performing material feed, pull out the required

3

length of material from the roll material.

Refer to the previous section, "4-4 Checking Material

4

Feed," and perform material feed.

If the material comes loose, then reload the material.

24

Page 25

4-6 Setting the Origin Point

Loading material and pressing the [ENTER] key automatically sets the origin point for cutting.

The origin point set when you do this varies according to model and the shape of the selected material.

4 Basic Operation

Model

CX-24

CX-12

CX-24/12, in addition to the foregoing locations, you can freely set the origin point (0, 0) anywhere in the cutting area.

Setting the origin point at an uncut area of the material lets you use the material with less waste.

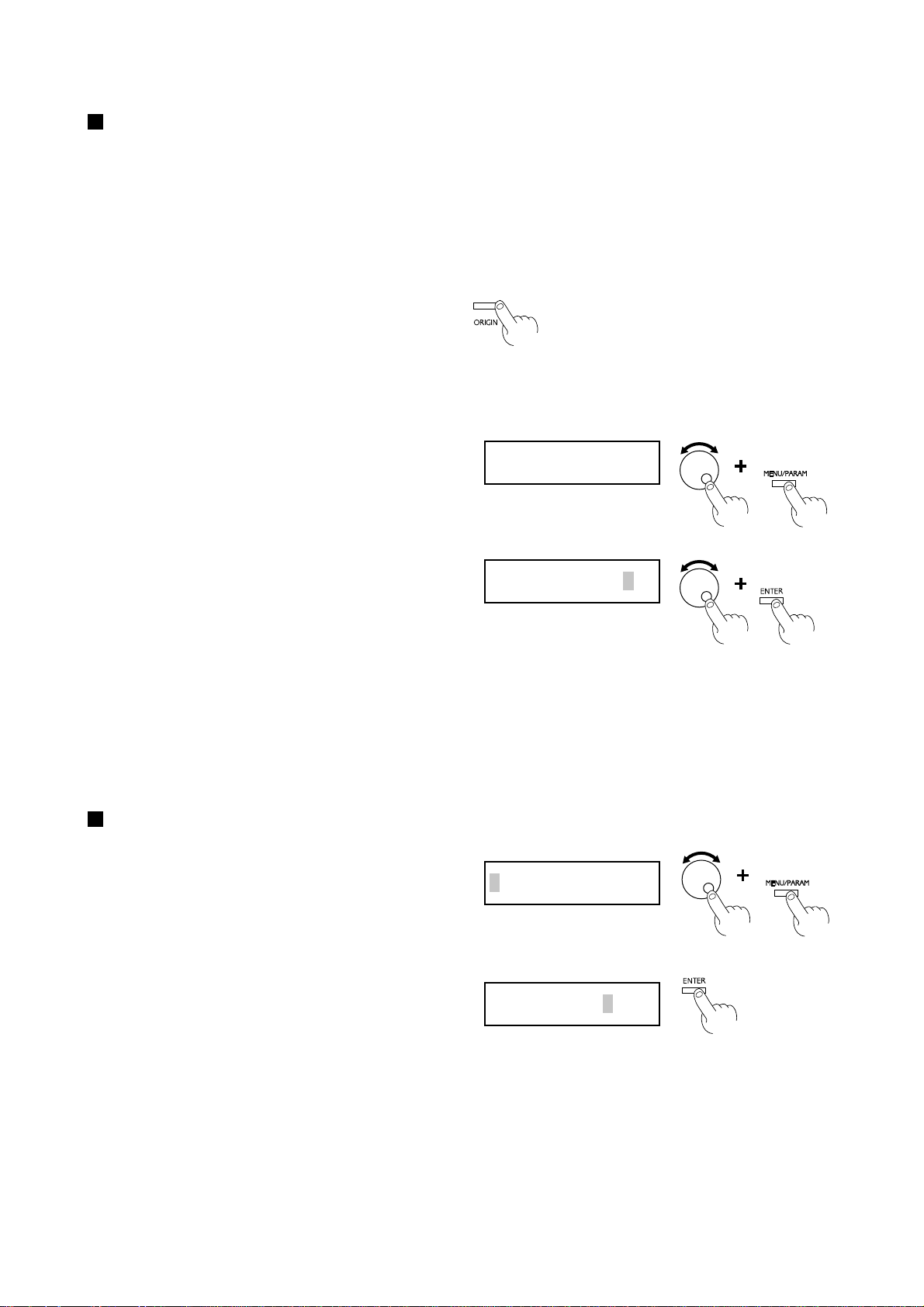

To set the origin point where you want, follow the steps below.

Before setting the origin point, load the material.

Refer to "4-2 Loading the Material" and load the

1

material.

Use the position keys to move the center of the blade

2

holder to the location where you want to set the origin

point.

Material shape selected from the menu

[ROLL]

[EDGE]

[PIECE]

There is no material-selection menu.

- Near the left pinch roller

- Near the right pinch roller when the [ROTATE] menu

item is set to ON

- At the front lower left of the material

- Near the front lower right of the material when the

[ROTATE] menu item is set to ON

- Near the left pinch roller

- Near the right pinch roller when the [ROTATE] menu

item is set to ON

Location of the origin point

Press the [ORIGIN] key. The message [ORIGIN

SETTING] flashes on the display, and the origin point

3

is set.

ORIGIN SET

25

Page 26

4 Basic Operation

4-7 Performing a Cutting Test (How to Adjust Blade

Force/Adjusting the Cutter Blade)

Before carrying out actual cutting, you may wish to perform a "cutting test" to check whether the unit produces the cutout satisfactorily.

This is done by examining the results of the cutting test, and adjusting the blade force and the amount of blade extension. The cutting test

should be repeated until the appropriate cutting conditions for the material in use are discovered.

If smooth cutting cannot be performed, use the display menu to adjust the blade force.

If adjusting the blade force does not produce good cutting results, then adjust the amount of blade extension from the blade holder.

Cutting Test

If a material has not yet been loaded, then refer to "4-2 Loading the Material" to load the material correctly.

Use the position keys to move the blade holder.

Move to the position where the cutting test is to be

1

performed.

Press the [TEST] key for 0.5 seconds or more.

2

The shape shown in the figure at right is cut at the

present location of the blade.

3

Peel off the material to check the result of the cutting

test.

If the results are not as described in step 3, use the

control panel to gradually raise the blade force.

4

* Note that an area of approximately 2 square

centimeters (a little less than a square inch) is

required to make a test cutout

Peel this off first.

The square should

remain, without

peeling off.

Peel this off next.

The blade should leave faint

traces on the base paper of the

material.

26

Page 27

4 Basic Operation

Turn the dial to display the screen shown at right.

Press the [MENU/PARAM] key.

1

The menu for setting the blade force appears.

Turn the dial clockwise to increase the blade force in

steps of 10 g.

2

When the display shows the desired value, press the

[ENTER] key.

When adjusting the blade force, take into account the

type and thickness of the material you are using, and

3

the hardness of the blade. (See "8-1 Blade and

Material Combinations.")

If the adjustment of the blade force is not correct, the

symptoms shown at right may occur.

FORCE | < 80g>

FORCE | < 80g>

Too large

Too small

- The material may be torn

- Blade life will be shortened

- Cutter blade extends through the

base paper, and normal advancing of the material becomes

impossible

- The CX-24/12 may be damaged.

- The material may not be cut

satisfactorily

Adjusting the Amount of Blade Extension

If cutting is not performed smoothly even after you have adjusted the blade force, then adjust the amount of blade extension for the tip of

the blade extending from the blade holder.

If you're using the included material or an equivalent general material, then tighten the cap all the way to the top

(maximum amount of blade extension: 2.5 mm (0.0984 in.) ).

When cutting material having base paper that is thin with respect to the material (material thickness), or material

having no base paper, the amount of blade extension should be adjusted so that the blade does not cut through the base

paper.

Remove the blade holder

Remove the blade holder.

1

Adjust the amount of blade extension a little at a time,

performing cutting tests to check the results.

2

When the cutting tests show that the blade leaves

faint traces on the backing paper, the amount of blade

extension is optimal.

Use the following as a guide for calculating the

amount of blade extension.

Amount of

cutter blade

extension

Thickness of

=+

the material

portion

Thickness of

the base paper

2

Min. : 0 mm

0.1 mm

Turning the tip by an amount

corresponding to one large

scale gradation extends the blade

by 0.1 mm (0.00394 in.).

Adjustment for 0.5 mm (0.0197

in.) can be made by rotating the

cap one full turn.

Max. : 2.5 mm

(0.0984 in.)

27

Page 28

4 Basic Operation

4-8 Downloading Cutting Data

NOTICE

Using the CX-24/12 to cut data created using a program requires the CAMM-1 driver.

The CAMM-1 driver is in the included Roland Software Package. For information on how to install it, take a look at the included Startup

Manual.

The explanations in this section assume that the CAMM-1 driver is already installed.

When loading a flat material the CX-12 that has been cut, be sure to use a flat material that is about 70 mm (213/16 in.) longer than the vertical size of the cutting data. If data larger than the vertical length of the material

is sent, the CX-12 will attempt to cut the data even if it does not all fit in the material. This means that the

material is dislodged from the grit roller, and cutting continues with no material. This can cause not only

breakage to the blade but also damage to the unit, and adequate care is required to prevent this.

If the material becomes dislodged or there is a problem in operation, then immediately press the [ENTER] key

or turn off the power switch on the left side of the machine.

Making the Settings for the CAMM-1 Driver

Make the driver settings for the cutting range and blade conditions to enable output from the computer.

The cutting range is determined by the positioning of the pinch rollers. Set the cutting range for the driver so

that it fits within this range.

If a size that is identical to the load material is specified and data is laid out accordingly, there may be portions

which cannot be cut.

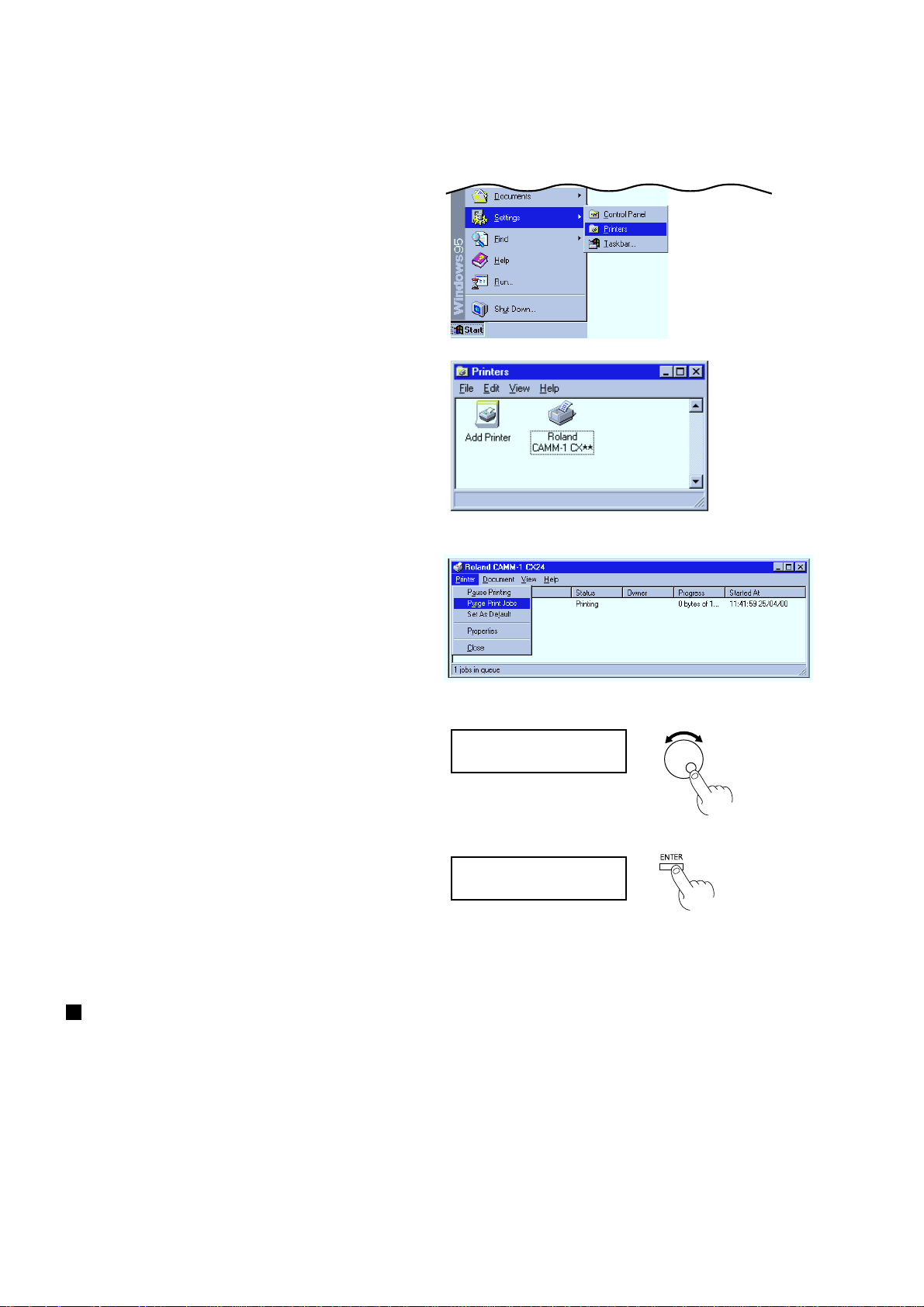

:Cutting area

:Pinch roller

The range that can be cut changes according to the positioning of the pinch rollers. If you're using flat material,

use the program to specify a value that is about 70 mm (2-13/16 in.)shorter than the vertical size of the

material. For more information about the cutting range, see "8-2 About Cutting Area."

In the program you're using, from the [File] menu,

choose [Print Setup] to display the [Printers] dialog box.

1

* The names of the menu items may be different,

depending on the program you're using.

For the CX-24, choose [Roland CAMM-1 CX-24]. For

2

the CX-12, choose [Roland CAMM-1 CX-12]. Then

click [Properties].

28

Page 29

Click the [Size] tab and make the settings for the

cutting range at the screen shown at right.

3

Click the [Tools] tab.

4

Clicking the drop-down arrow displays the numerals

[1] through [8] and the [Machine Settings] selections.

To specify the speed for performing cutting using the

driver, choose a number from [1] to [8] and enter the

cutting conditions. The values you set here do not

change until you register a new setting. Entering

conditions that you use often enables you to make the

settings you want by simply choosing the corresponding number. When you do this, the machine settings

for the CX-24/12 are disabled.

To perform cutting using the conditions set with the

CX-24/12, choose [Machine Settings].

Click [OK].

4 Basic Operation

* When you are performing cutting, clear the selection for [Fill Pitch].

In the [Printers] dialog box, click [OK].

In the program window, lay out the cutting data so

5

that it fits within the displayed cutting range.

Send the cutting data from the program to the CX-24/

12.

6

Pausing Cutting Operations

Pressing the [ENTER] key displays a screen like the one shown below and pauses cutting.

PAUSE | <CONT.>

- To resume cutting without change

Press the [PAUSE] key again.

29

Page 30

4 Basic Operation

- To stop cutting

Halt transmission of cutting instructions from the computer.

Click [Start]. Click [Settings], then click [Printers].

1

Double-click the printer icon.

For the CX-24:

2

For the CX-12:

[Roland CAMM-1 CX-24]

[Roland CAMM-1 CX-12].

At the [Printers] menu, click [Purge Print Jobs]. Make

3

sure the displayed data for the file being printed

disappears.

Turn the dial on the CX-24/12 to choose [END].

4

Pressing the [ENTER] key displays the message

5

shown at right, and cutting stops.

PAUSE | <STOP>

SUSPENDED

When Continuing with Cutting on the Same Piece of Material

Set the origin point at an uncut location on the

material (the location where you want to cut next).

1

For information on how to set the origin point, see "4-

6 Setting the Origin Point."

Send the cutting data from the program to the CX-24/

12.

2

30

Page 31

4-9 Applying the Completed Cutout

When cutting ends, affix the material you created.

- Before you affix the material, cleaning the location where you want to affix it to remove any dust or grease.

- When applying on a transparent medium such as window glass, it may be helpful to draw guide lines on the back

of the glass with a water-based pen (so that the lines can be wiped off after applying the material).

- If air bubbles are formed under the affixed material, use a needle to pop the bubble, then press out the air to

obtain a complete seal.

Removing the Material

Piece material

4 Basic Operation

Turn the dial to display the screen shown at right.

1

Press the [MENU/PARAM] key.

When the screen at right appears, press the [ENTER]

key.

2

The cutting carriage moves to the right.

Lower the sheet loading lever.

3

SETUP | <ON>

SETUP | ON->OFF

Remove the material.

4

31

Page 32

4 Basic Operation

- For Roll Materials, or When Detaching Only a Cut Portion

commercially available knife to sever the material along the knife

guide.

Knife Guide

Use tweezers to peel off unneeded portions of the

material you created.

1

* You should have weed boarders or rectangles

drawn around work to facilitate weeding.

Stick application tape over the completed work.

2

Press down firmly on the application tape to remove

air bubbles. If you do not press firmly enough the cut

area will not stick to the surface.

Transfer the material you created to the application

tape.

3

Decide where to affix the material, then affix it,

4

making sure that it is not misaligned.

Rub over the application tape to make sure the work

is firmly stuck in place. Then peel off the application

tape.

32

Page 33

4-10 When Cutting is Completed

When not in use for extended

periods, unplug the power cord from

the electrical outlet.

Failure to do so may

result in danger of

shock, electrocution,

or fire due to

deterioration of the

electrical insulation.

4 Basic Operation

NOTICE

Loosen the screw shown in the figure and remove the

1

blade holder from the cutting carriage.

Press the pin shown in the figure and detach the blade

holder.

2

If a blade was used, wipe the blade with a soft cloth

to remove any material that may cling to it.

Do not leave the tool mounting screws tightened. Tightening the screw makes it more difficult to install the

blade holder.

Screw

Pin

Blade holder

Blade

Lower the sheet loading lever then remove the

material.

3

Turn off the power.

4

* Use a soft, dry cloth to wipe down the CX-24/12.

33

Page 34

5 Performing a Self-test

5 Performing a Self-test

The CX-24/12 is equipped with a "self-test" function to conveniently allow you to check whether or not it is capable of operating

normally. If the CX-24/12 is not performing correctly, follow the steps below to perform a self-test.

A computer is not required in order to carry out the self-test.

Refer to "4-1 Installing a Blade" and install the blade

holder to the cutting carriage on CX-24/12.

1

Hold down the [ ] key on the panel while you turn

2

the power on.

Refer to "4-2 Loading the Material" and load the

material.

3

When the display shows the screen at right, press the

[ENTER] key to start the operation check.

4

Operations is normal if the figure shown at right is

cut.

CX-24 CX-12

SELECT | ROLL SETUP -> ENTER

34

Page 35

6 Plotting on Paper Media

6 Plotting on Paper Media

Before cutting, plotting using pen and paper can ensure that your design is correct without wasting materials.

This feature can also be used to plot template designs on thick materials that may not be able to cut.

* Since the design of the CX-24/12 differs inherently from that of dedicated plotters, it does not accommodate functions

such as high-speed plotting, automatic pen changes, pen dry protection, or the like.

Acceptable pens and paper media

Acceptable paper : High-quality paper

Acceptable pens : Water-based fiber-tipped pens

Thick water-based fiber-tipped pens

Refer to "4-1 Installing a Blade" and install the pen

by following the same steps as for installing a blade.

1

Acceptable paper widths :

CX-24 50 to 700 mm (1-15/16 to 27-3/4 in.)

CX-12 50 to 395 mm (1-15/16 to 15-1/2 in.)

Refer to "4-2 Loading the Material" and load the

paper by following the same steps as for loading

2

material.

If you're using the CX-24, then when the menu for

selecting the type of material appears, choose

[PIECE].

Turn the dial to display the screen shown at right.

3

Press the [MENU/PARAM] key.

Turn the dial to display <0 (PEN)>, then press the

[ENTER] key.

4

When the plot data is sent from the computer, plotting

starts.

5

OFFSET| <0.250>

OFFSET| <0(PEN)>

35

Page 36

7 Repeating the Same Cutting

7 Repeating the Same Cutting

The CX-24/12 can store the data sent from the computer in a buffer (a temporary memory area), and use this data to repeat cutting.

In the setup state, when cutting data is sent, the data is buffered at the same time that cutting starts.

Data sent until the setup state is released can be recut.

- Even after the setup state is released, data for recutting does not disappear until new data is sent from the

computer.

- When the power is switched off, any existing data in the buffer is deleted.

- If the buffer becomes full while data is being sent, recutting cannot be performed.

When this happens, running [REPLOT] displays the message "DATA TOO LARGE."

- When there is no data in the buffer, the message "NO DATA" appears.

Preparing the Cutting Data

When you repeat cutting, all data in the buffer is called up and cut. Before you send data from the computer, delete all the data in the

buffer in the CX-24/12.

Turn the dial to display the screen shown at right.

1

Press the [MENU/PARAM] key.

Turn the dial to display <CLEAR>, then press the

[ENTER] key.

2

The data in the buffer is deleted.

Refer to "4-8 Downloading Cutting Data" and send

the cutting data from the computer.

3

REPLOT| START

REPLOT| CLEAR

36

Page 37

Getting Ready for Recutting

Repeating cutting without replacing the material

Use the position keys to move the blade holder to the

1

location for setting a new origin point.

Press the [ORIGIN] key to set the origin point.

2

Repeating cutting on different material

7 Repeating the Same Cutting

Turn the dial to display the screen shown at right.

Press the [MENU/PARAM] key.

1

Turn the dial to display the screen shown at right.

2

Press the [ENTER] key.

The setup state is released.

Load the new material. For information on how to

3

load the material, see "4-2 Loading the Material."

Performing Recutting

Turn the dial to display the screen shown at right.

1

Press the [MENU/PARAM] key.

SETUP | <ON>

SETUP | ON->OFF

REPLOT| START

Press the [ENTER] key.

2

Recutting starts.

REPLOT| START

37

Page 38

8 About the Blades and Materials

8 About the Blades and Materials

8-1 Blade and Material Combinations

The table below provides information on combinations of materials and blades, cutting conditions, and useful life.

The figures for blade life are only estimates. The conditions described below may not apply all cases.

Before you perform cutting, be sure to carry out a cutting test to check and adjust the quality. (See "4-7 Performing a Cutting Test.")

If uncut areas remain even when you raise the blade force more than 50 or 60 gf higher than the values shown below, the blade has

reached the end of its service life. Replace with a new blade.

Blade

ZEC-U1005

ZEC-U5025

ZEC-U1715

* The values for lifespan are intended to serve as a general guide when cutting materials of identical type.

Material

General Signage Vinyl

General Signage Vinyl

Reflective Vinyl

Fluorescent Vinyl

Rubber material for

sandblasting stencil

Tool-force

50 to 150 gf

30 to 100 gf

120 to 200 gf

100 to 200 gf

100 to 200 gf

Speed

40 cm/sec.

40 cm/sec.

40 cm/sec.

40 cm/sec.

10 cm/sec.

Amount of cutter

blade extension

0.25 mm (0.01 in.)

0.25 mm (0.01 in.)

0.25 mm (0.01 in.)

0.25 mm (0.01 in.)

0.25 mm (0.01 in.)

Life of a blade

(General guide)

8000 m (314960 in.)

4000 m (157480 in.)

4000 m (157480 in.)

4000 m (157480 in.)

Varies according to

material type

38

Page 39

8 About the Blades and Materials

8-2 About the Materials

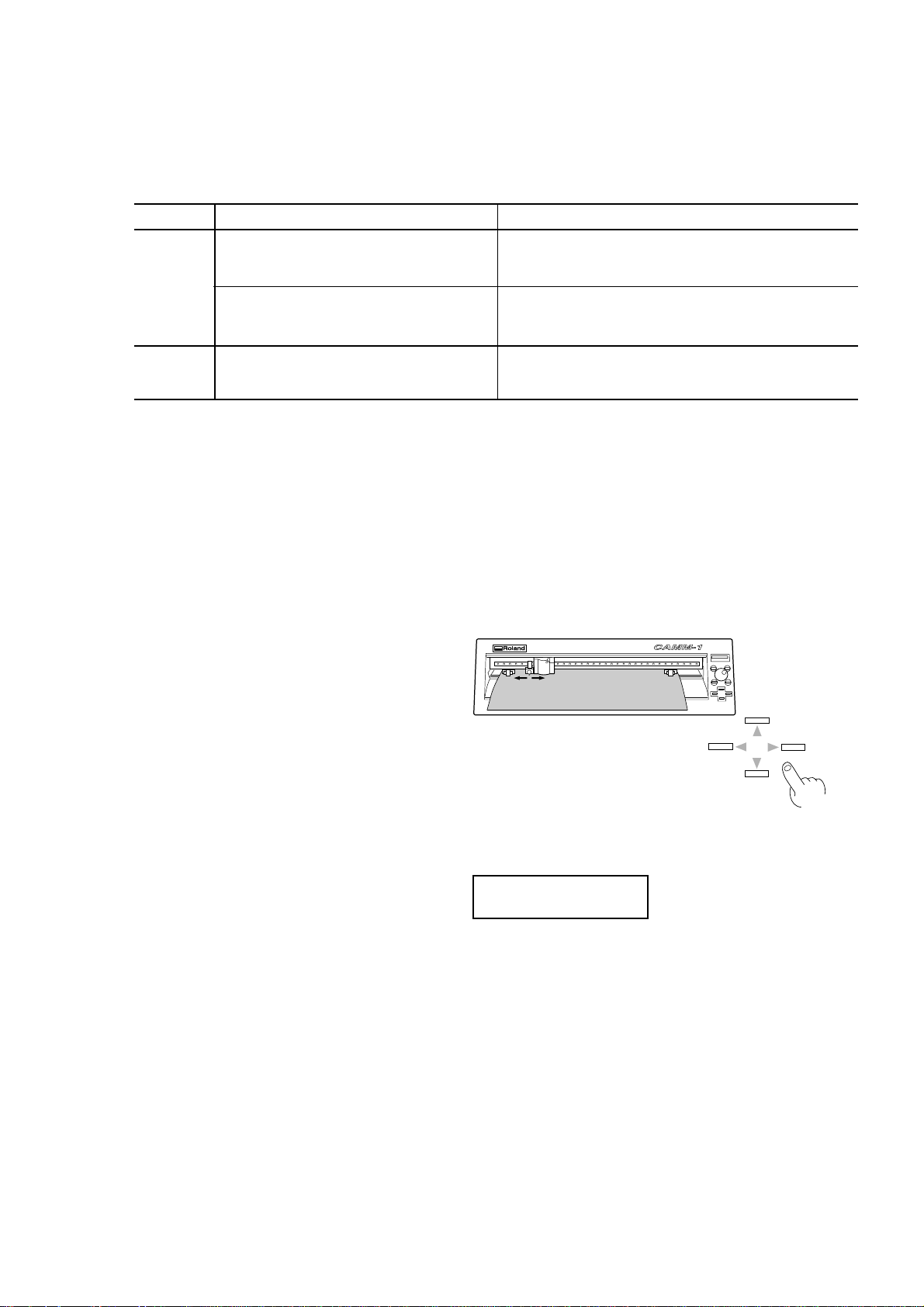

Loadable Material Width

The location of the grit rollers (where the material is held in place by the pinch rollers) differs according to the model.

Referring to the figure below, place the material on the grit rollers and check where it can be held in place by the pinch rollers.

CX-24

: Grit roller

: Pinch roller (left) : Pinch roller (right)

Approx.150 mm (5-7/8 in.)

Approx. 305 mm (12 in.)

Approx. 457 mm (17-15/16 in.)

Approx. 610 mm (24 in.)

Material with a

width of 150 mm

(5-7/8 in.)

* Make sure the pinch rollers are positioned above the grit rollers.

Material with a

width of 305 mm

(12 in.)

700 mm (27-1/2 in.)

Material with a width

of 457 mm (17-15/16

in.)

Material with a

width of 610 mm

(24 in.)

The left-hand pinch roller can be moved within this range.

When loading material with a width other than one indicated above, move the left-hand pinch roller.

CX-12

: Grit roller

Approx. 150 mm (5-7/8 in.)

Approx. 305 mm (12 in.)

Material with a

width of 150 mm

(5-7/8 in.)

* Make sure the pinch rollers are positioned above the grit rollers.

395 mm (15-1/2 in.)

Material with a

width of 305 mm

(12 in.)

: Pinch roller (left) : Pinch roller (right)

When loading material with a width other than one indicated above, move the

left and right pinch rollers to match the width of the material.

39

Page 40

8 About the Blades and Materials

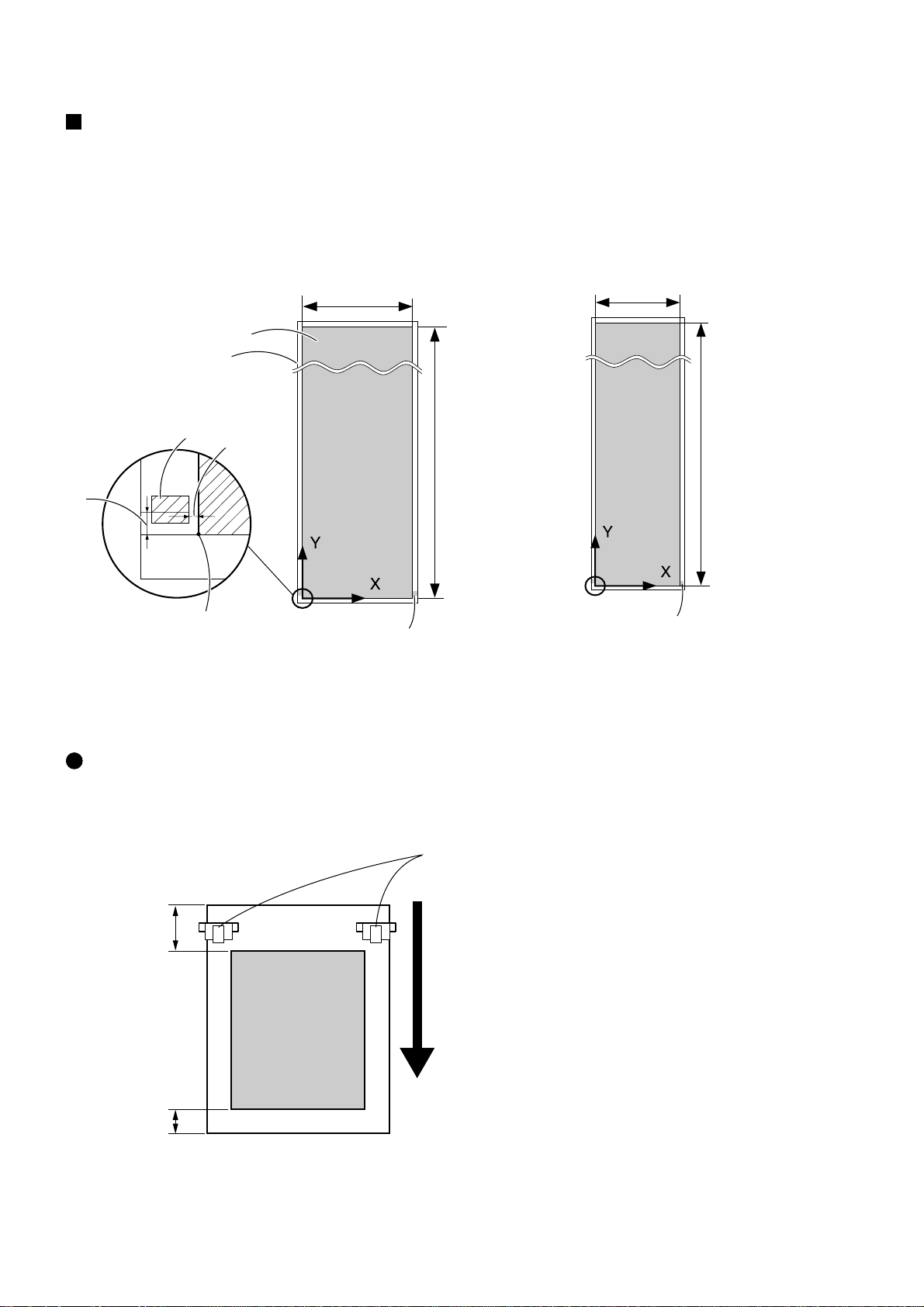

About the Cutting Area

The cutting area along the horizontal plane (the direction in which the tool carriage moves) is determined by the position of the pinch

rollers. The workable area spans the length between the two rollers, minus a margin of about 1 mm (about 0.04 in.) on both sides.

If you selected [PIECE] on the CX-24, then when the length of the material is 1,600 mm (63 in.) or more, the CX-24 determines it to be

roll material, and sets the length at 24,998 mm (984-1/8 in.).

<CX-24> <CX-12>

Max.

584 mm (23 in.)

Cutting Area

Material

Max.

280 mm (11in.)

Pinch roller (Left)

About 15 mm (about 9/16 in.)

Initial cutting coordinate origin point (0,0)

About 1 mm

(about 0.04in.)

Max. 24,998 mm (984-1/8 in.)

(Accuracy assured within a range of

up to 1,600 mm (63 in.))

Pinch roller (Right) Pinch roller (Right)

Max.24,998 mm (984-1/8 in.)

(Accuracy assured within a range of

up to 1,600 mm (63 in.))

When loading flat material

When you're using flat material, material that is at least 70 mm (2-13/16 in.) longer than the vertical size of the cutting data is required.

This is the length required for the pinch rollers to feed out the material to the front and rear. Refer to the figure below and ensure margins

at the front and rear of the material.

Pinch roller

50 mm

(2 in.)

20 mm

(13/16 in.)

40

Page 41

A material with edge holes for sprocket feed

Material for sprocket-feed use has feed holes along both edges.

If the material is loaded with these holes lying over the pinch

rollers, material feed cannot be performed correctly.

Do not put the pinch rollers on the hole area at the edges.

Rubber Sandblast Stencils

Use rubber sandblast stencils that meet the conditions shown in the

figure at right.

A) Materials with a material thickness of 1 mm (0.04 in.) or

less

B) Materials with only carrier paper on both flanks of the

material

Position the left and right pinch rollers above the strips of carrier

paper.)

Carrier paper

B) 15 mm (9/16 in.) or more B) 15 mm (9/16 in.) or more

8 About the Blades and Materials

Material A) 1 mm (0.04 in.)

or less

C) Materials with carrier paper which is hard enough to

withstand material feed

41

Page 42

9 Display Menu Descriptions

9 Display Menu Descriptions

9-1 How to Read This Chapter

The explanations in this chapter use the following format.

FORCE | < 50g>

This indicates the factory

default value.

This indicates the number

of steps required to set a

numerical value.

Stored in Memory

Factry Default

Setting Range

Steps

Description

9-2 Display Menu Descriptions

Yes

50 g

30 to 200 g

10 g

This sets the blade force used when

cutting material.

Perform a cutting test and set the

conditions to match the loaded material

and the installed cutter.

This is the information

that appears on the

display.

When set to "Yes," the

setting values are stored

in memory even when the

power is switched off.

This indicates the range in

which settings can be

made, or the range of

selectable choices.

This section provides an

explanation of functions

and matters that require

caution.

SELECT

SELECT | ROLL

SETUP

SETUP | <ON>

* Only CX-24

Stored in Memory

Factry Default

Selection Choices

Description

Stored in Memory

Selection Choices

Description

No

ROLL

ROLL, EDGE, PIECE

ROLL:

This performs cutting using roll material.

EDGE:

When using roll material, cutting is performed from the front-left edge of the

material.

* When the setting for [ROTATE] on the display menu is [ON], cutting is

PIECE:

This performs cutting using standard-size material or piece material.

No

ON, OFF

When this is on, cutting data can be received and various menu settings can

be made.

performed from the front-right edge.

42

Page 43

9 Display Menu Descriptions

FORCE

FORCE | < 50g>

SPEED

SPEED |<40cm/s>

Stored in Memory

Factry Default

Setting Range

Steps

Description

Stored in Memory

Factry Default

Setting Range

Steps

Description

Yes

50 g

30 to 200 g

10 g

This sets the blade force used when cutting material.

Perform a cutting test and set the conditions to match the loaded material and

the installed cutter.

Yes

40 cm/s

1 to 40 cm/s

1 cm/s when in the range of 1 to 10 cm/s

5 cm/s when in the range of 10 to 40 cm/s

This sets the speed used when cutting material.

Set this to a suitable value for the loaded material and installed blade.

OFFSET

OFFSET| <0.250>

AREA

AREA |< 1.0m>

Stored in Memory

Factry Default

Selection Choices

Description

Stored in Memory

Factry Default

Selection Choices

Description

Yes

0.250 mm

0 mm (PEN), 0.175 mm, 0.250 mm, 0.500 mm

This sets the amount of offset for the tip of the blade.

Set a value that matches the conditions for the blade installed.

When using the included test material and blade or equivalent parts, cutting

can be performed using the factory-default settings.

Yes

1.0 m

-24.9 to 24.9 m

This ensures that the material will not come loose during cutting by feeding

out the length of material to be cut before actually performing cutting.

When performing continuous cutting on the same material, this can also be

used to make sure that there is enough remaining material to cut the data that

will be sent.

43

Page 44

9 Display Menu Descriptions

REPLOT

REPLOT | START

ROTATE

ROTATE| <OFF>

Stored in Memory

Selection Choices

Description

Stored in Memory

Factry Default

Selection Choices

Description

No

START, CLEAR

START

This performs cutting using the data in the replot buffer when the [ENTER]

key is pressed.

CLEAR

This deletes the data in the replot buffer when the [ENTER] key is pressed.

Yes

OFF

ON, OFF

When set to ON, the origin point is set at the lower right of the material, and

the text (or image) is rotated by 90 degrees.

* When rotated, the coordinate axis changes.

The pairs of arrows indicate the positive directions along the X and Y

axis

ROTATE: [ON]

SMOOTH

SMOOTH.| <ON>

Stored in Memory

Factry Default

Selection Choices

Description

Origin point

ROTATE: [OFF]

Origin point

Yes

ON

ON, OFF

ON

This cuts smooth curves for circular arcs and the like.

Note that small text and intricate shapes may be cut with rounded corners.

OFF

Choose this if corners become rounded when set to [ON].

44

Page 45

9 Display Menu Descriptions

WEIGHT

WEIGHT| <LIGHT>

CALL

CALL| <USER1>

RESTORE

RESTORE| <USER1>

Stored in Memory

Factry Default

Selection Choices

Description

Stored in Memory

Factry Default

Selection Choices

Description

Stored in Memory

Yes

LIGHT

LIGHT, HEAVY

Sets the weight of the material. If material feed is not performed smoothly,

set this switch to [HEAVY].

When set to [HEAVY], the upper limit for the cutting speed is set at 10 cm/

sec., and the force used to move the material and the blade increases. This

should normally be set to [LIGHT].

Yes

USER1

USER1 to 8

This calls up the setting values stored using [RESTORE].

Yes

I/O

I/O | <AUTO>

Factry Default

Selection Choices

Description

Stored in Memory

Factry Default

Selection Choices

Description

USER1

USER1 to 8

This stores the setting values for the respective menu items that are now

being used.

The menu items that you can register are as follows.

FORCE, SPEED, OFFSET, and WEIGHT

You can call up stored setting by using [CALL].

Yes

AUTO

AUTO, PARA, SERIAL

This specifies the type of interface for connection to the computer.

AUTO

This selects the port automatically. The communication parameters for a

serial connection are set according to the settings made on the CX-24/12.

If the interface is not recognized correctly when set to AUTO, use the menu

to choose the type of interface you're using.

PARA (PARALLEL)

Choose this when connected to the computer using a parallel cable.

SERIAL

Choose this when connected to the computer using a serial cable.

45

Page 46

9 Display Menu Descriptions

#BAUD.

#BAUD.| <9600>

#DATA.

#DATA.| <8>

#STOP.

#STOP.| <1>

Stored in Memory

Factry Default

Selection Choices

Description

Stored in Memory

Factry Default

Selection Choices

Description

Stored in Memory

Factry Default

Yes

9600

9600, 4800

This sets the communication speed for a serial connection.

It is displayed only when connected to the computer using a serial cable.

Yes

8

8, 7

This sets the number of data bits for a serial connection.

It is displayed only when connected to the computer using a serial cable.

Yes

1

#PARITY

#PARITY| <NONE>

#HANDS.

#HANDS.|<H-WIRE>

Selection Choices

Description

Stored in Memory

Factry Default

Selection Choices

Description

Stored in Memory

Factry Default

Selection Choices

Description

1, 2

This sets the number of stop bits for a serial connection.

It is displayed only when connected to the computer using a serial cable.

Yes

NONE

NONE, ODD, EVEN

This sets the type of parity checking for a serial connection.

It is displayed only when connected to the computer using a serial cable.

Yes

H-WIRE

H-WIRE, XONOFF

This makes the setting for hardware handshaking (flow control) for a serial

connection.

46

Page 47

9 Display Menu Descriptions

LANG.

LANG. |< ENGLIS>

UNIT

UNIT | <Metric>

DEMO CUT

DEMO CUT

Stored in Memory

Factry Default

Selection Choices

Description

Stored in Memory

Factry Default

Selection Choices

Description

Description

Yes

ENGLISH

ENGLIS,

This selects the language for messages on the display. To display this menu,

switch on the power while holding down the [MENU/PARAM] key.

Yes

Metric

Metric, Inch

This selects the unit of measurement for numerical values shown on the

display.

To display this menu, switch on the power while holding down the [MENU/

PARAM] key, then turn the dial clockwise.

This menu is for performing checks when the CX-24/12 is not operating

correctly.

To display this menu, switch on the power while holding down the [ ] key.

, Deut., FRANÇ, , ITAL.,PORTUG,

INITIALIZE EEROM

INITIALIZE EEROM

Description

[ENTER] returns the settings to their factory defaults.

To display this menu, switch on the power while holding down the [ENTER]

key.

47

Page 48

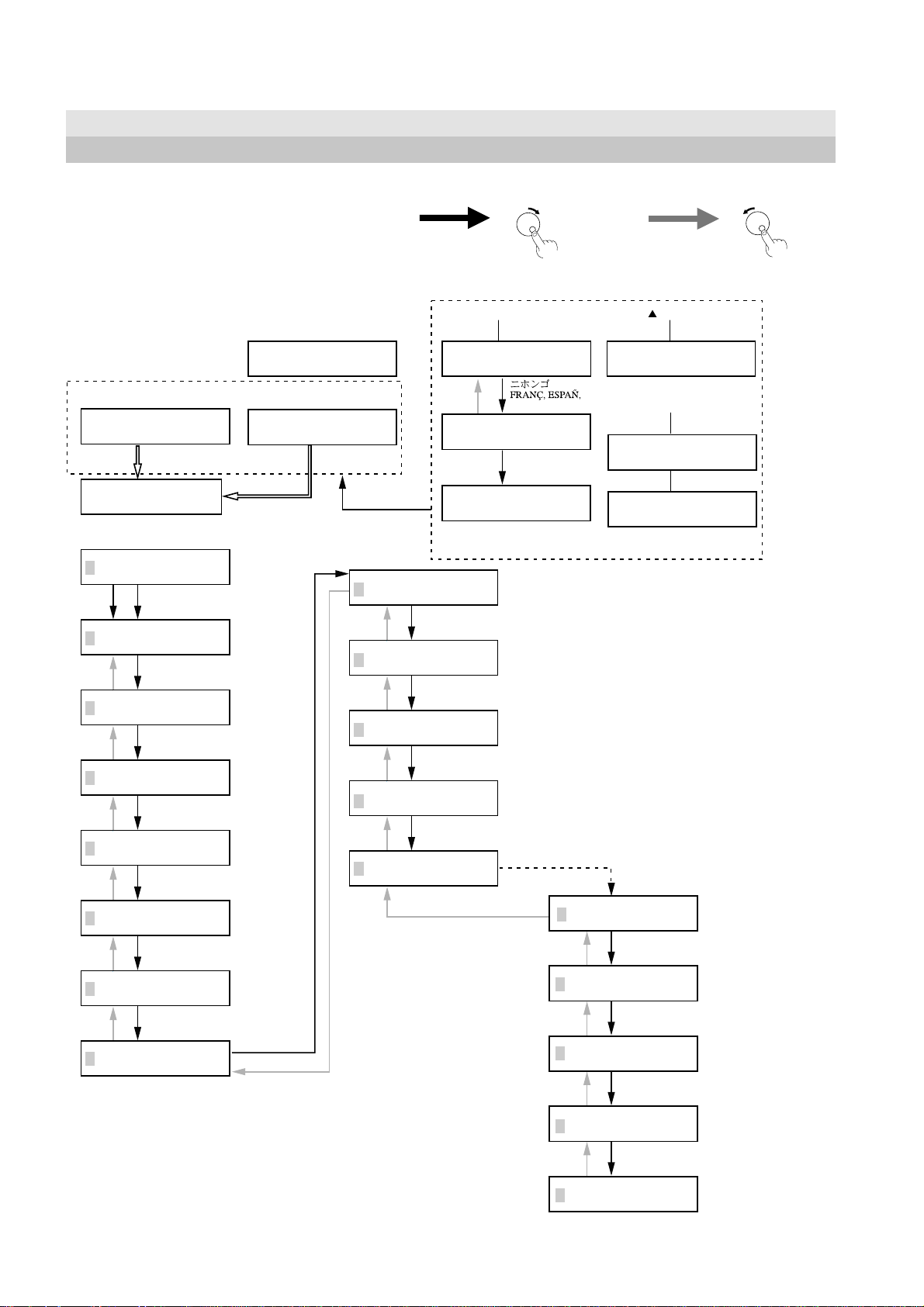

10 Display Menu Flowchart

10 Display Menu Flowchart

To display the setting values for the various menu items,

press the [MENU/PARAM] key. For detailed information on

how to make menu settings, see "4-3 Switching On the

Power - Making Menu Settings with the Control Panel."

Turned clockwise

Turned counterclockwise

SELCT | ROLL

ROLL, EDGE, PIECE

[ENTER]

NOW LOADING..

WIDTH | *****mm

SETUP | <ON>

ON, OFF

FORCE | < 80g>

30 to 200 g (In steps of 10 g )

SPEED | <40cm/s>

1 to 40 cm/s

(1 cm/s when in the range of 1 to 10 cm/s

5 cm/s when in the range of 10 to 40 cm/s)

OFFSET| <0.250>

0 mm (PEN), 0.175 mm,

0.250 mm, 0.500 mm

AREA | < 1.0m>

-24.9 to 24.9 m (In steps of 0.1 m)

Roland DG Corp.

SETUP -> ENTER

[ENTER]

The display changes

when settings are finished.

SMOOTH.| <ON>

WEIGHT| <LIGHT>

CALL | <USER1>

RESTORE| <USER1>

I/O | <AUTO>

[MENU/PARAM] +POWER ON

[ ] +POWER ON

LANG. |<ENGLIS> DEMO CUT

, Englis, Deut.

PORTUG

ITAL.,

[ENTER] +POWER ON

UNIT |<Metric>

Metric, Inch

EXIT

[ENTER]

ON, OFF

LIGHT, HEAVY

USER1 to USER8

USER1 to USER8

AUTO, PALA, SERIAL

When connected with a serial cable,

choose [SERIAL] or [AUTO] and press

[ENTER].

INITIALIZE EEROM

ENTER->START INT

[ENTER] returns the settings to

their factory defaults.

#BAUD.| <9600>

4800, 9600

REPLOT| START

START, CLERA

ROTATE| <OFF>

ON, OFF

#DATA.| <8>

8, 7

#STOP.| <1>

1, 2

#PARITY| <NONE>

NONE, ODD, EVEN

#HANDS.|<H-WIRE>

H-WIRE, XONOFF

48

Page 49

11 What to do if...

11 What to Do If...

11-1 If the CX-24/12 Doesn't Run...

Is the CX-24/12 power on?

Turn on the power.

Is the CX-24/12 in the setup state?

When the display shows the following message, cutting cannot be performed even when data is sent. When you enable the setup state,

cutting starts.

CX-24 CX-12

SELECT | ROLL SETUP -> ENTER

Choose the loaded material, then press the [ENTER]

key to enable the setup state.

Has operation been paused?

When the following message appears, operation is paused.

To resume cutting, press the [ENTER] key.

PAUSE | <CONT>

To stop operation

Halt transmission of cutting instructions from the

computer.

1

Turn the dial to display the screen shown at right,

then press the [ENTER] key.

2

Press the [ENTER] key to enable the setup state.

PAUSE | <STOP>

If connected via the serial port, do the communication parameters for the CX-24/12 match those of the computer?

Use the display menu to set communication parameters for the CX-24/12 that match the communication parameters for the computer.

Is the computer set up correctly?

Refer to the documentation for the computer you're using and make the correct settings for the memory switches, interface board, and

other communication parameters.

Is the cable used for the connection to the computer connected correctly?

Check the output ports on the CX-24/12 and the computer and reconnect correctly.

Are the computer and the CX-24/12 linked with the right cable?

The type of cable you need is determined by your computer and the program you are using. Even if the computer is the same, running

different program may require a different cable. Use the cable specified in your program.

Are the program settings correct? (Using with MS-DOS.)

Specified output device (Select a model name that matches the instruction set. If the instruction set is different, completely different

instructions may be sent, resulting in an error.)

Refer to the documentation for the program and make the correct settings for the communication parameters and other values.

49

Page 50

11 What to do if...

Has the correct driver selection been made for the application program? (Using with Windows.)

Select the appropriate CX-24/12 driver.

For the CX-24:

[Roland CAMM-1 CX-24]

For the CX-12:

[Roland CAMM-1 CX-12].

Are the settings for the driver program correct? (Using with Windows.)

Make the correct settings for the output port and communication parameters.

11-2 The Material Slips Away from the Pinch Rollers

during the Cutting Process

Are the sheet loading levers lowered?

If the sheet loading levers are raised, then make sure the left and right pinch rollers are within the edged of the material and lower the

sheet loading levers. (Refer to "4-2 Loading the Material".)

Is the material loaded in parallel with the grit rollers?

If the front edge of the material is cut at an angle, trim off an excess portion so that the front edge is parallel with the grit rollers, then

load the material.

Is the material making contact somewhere while cutting is in progress?

Make sure that the left and right edges of the material do not make contact with the inner surfaces of the CX-24/12 during cutting. Such

contact may not only damage the material, but may make normal material feed impossible or cause the material to slip.

When feeding lengthy material, was a check made before cutting to make sure that the material does not slip?

Use the [AREA] display menu to feed out the amount of material to be used (plus a margin of about 0.1 m), and make sure the material

does not come loose from the pinch rollers.

Are the pinch rollers damaged or deformed?

If the material comes loose even when it is loaded correctly, the useful life of the pinch rollers has ended.

If this happens, contact your authorized Roland DG Corp. dealer or service center. (Replacement is a charged service operation.)

50

Page 51

11 What to do if...

11-3 Uncut Areas Remain, or Areas are Not Cleanly Cut.

Are the blade and blade holder securely mounted?

Install these so that there is no looseness .

The blade may be broken.

Replace with a new blade.

Is there any buildup of dust or material adhesive on the tip of the blade?

Check if there are any dirty deposits on the blade. If dirty, remove and clean the blade.

Is there any buildup of pieces of material or dust inside the blade holder?

Take off the tip of the blade holder and remove any pieces of material inside.

Is the amount of blade extension correct?

If the setting for the amount of blade compensation is not correct for the blade, corners may be rounded or have horns.

Refer to "4-7 Performing a Cutting Test."

Are the blade force and cutting speed appropriate for the material being cut?

Perform a cutting test and use the display menu to make the settings for suitable values.

Refer to "4-7 Performing a Cutting Test."

Is the blade protector damaged or deformed?

If material is not cut properly even though the CX-24/12 settings are correct and the blade and cutter holder are installed correctly, the

blade protector may be damaged. If this happens, contact your authorized Roland DG Corp. dealer or service center. (Replacement is a

charged service operation.)

11-4 The Results of Cutting are Displaced, and Uncut

Portions Remain

Is a thick material being used?

When using a thick material, change the display menu setting from "WEIGHT" to "HEAVY."

When performing cutting using roll material, was the amount of material to be cut pulled out before performing cutting.

When the material is pulled out while cutting is being performed, the material may slip or operation may stop due to a motor error.

51

Page 52

11 What to do if...

11-5 Error Messages

Err:Bad Positin

SHEET UNLOADED

DATA OVERFLOW

DATA EMPTY

The location of one or more of the pinch rollers is not correct.

Press the [ENTER] key to clear the error.

Position the pinch rollers appropriately over the grit rollers and

reload the material.

Refer to "4-2 Loading the Material."

When the machine was put into the setup state, no material

was loaded.

The material was removed when the machine was in the setup state.

The material came loose during cutting.

Load the material, then put the machine in the setup state.

Press the [ENTER] key to clear the error.

Refer to "4-2 Loading the Material."

When [REPLOT] was executed, the amount of data sent from

the computer exceeded the buffer size of the CX-24/12.

Reduce the amount of data, then execute [REPLOT].

Refer to "7 Repeating the same cutting."

[REPLOT] was executed when there was no data in the

buffer.

Send the data from the computer, then execute [REPLOT].

Refer to "7 Repeating the same cutting."

The following error messages are displayed for informational purposes when the data described in "Details" is sent. When one of these

error messages appears on the display, sending of data stops and you are not allowed to perform the next operation.

Press the [ENTER] key to clear the error from the display.

Note that even after you clear the error message, the CX-24/12 retains in memory the fact that the error occurred, and so correct cutting

may not be possible even if data continues to be sent. To cancel the error, switch the power off and back on.

Er1:Wrong CMD.

Er2:Wrong No.s

Er3:Out of Range

Meaning

Appears if an instruction that the CX-24/12 cannot interpret is sent.

Meaning

Appears if the number of parameters differs from the permissible

number.

Meaning

Appears if the value specified for a parameter is out of the permissible range.

52

Page 53

11 What to do if...

Er15:RS-232Err

Er16:BufferFlow

Er18:Ind.Error

Meaning

Appears if a framing error, parity error, or overrun error occurs at

the time of data reception.The protocol settings for the CX-24/12

must be made correctly in order to match the settings your computer

is set to use.)

Meaning

Appears if the I/O buffer has overflowed. There is a problem with

the connecting cable, or the settings for Handshaking. Make sure

you are using a cable appropriate for the computer being used. Also,

check that the setting for Handshaking is correct.

Meaning

This appears if an unspecified communication error other than

communication-related errors 10 through 16 occurs.

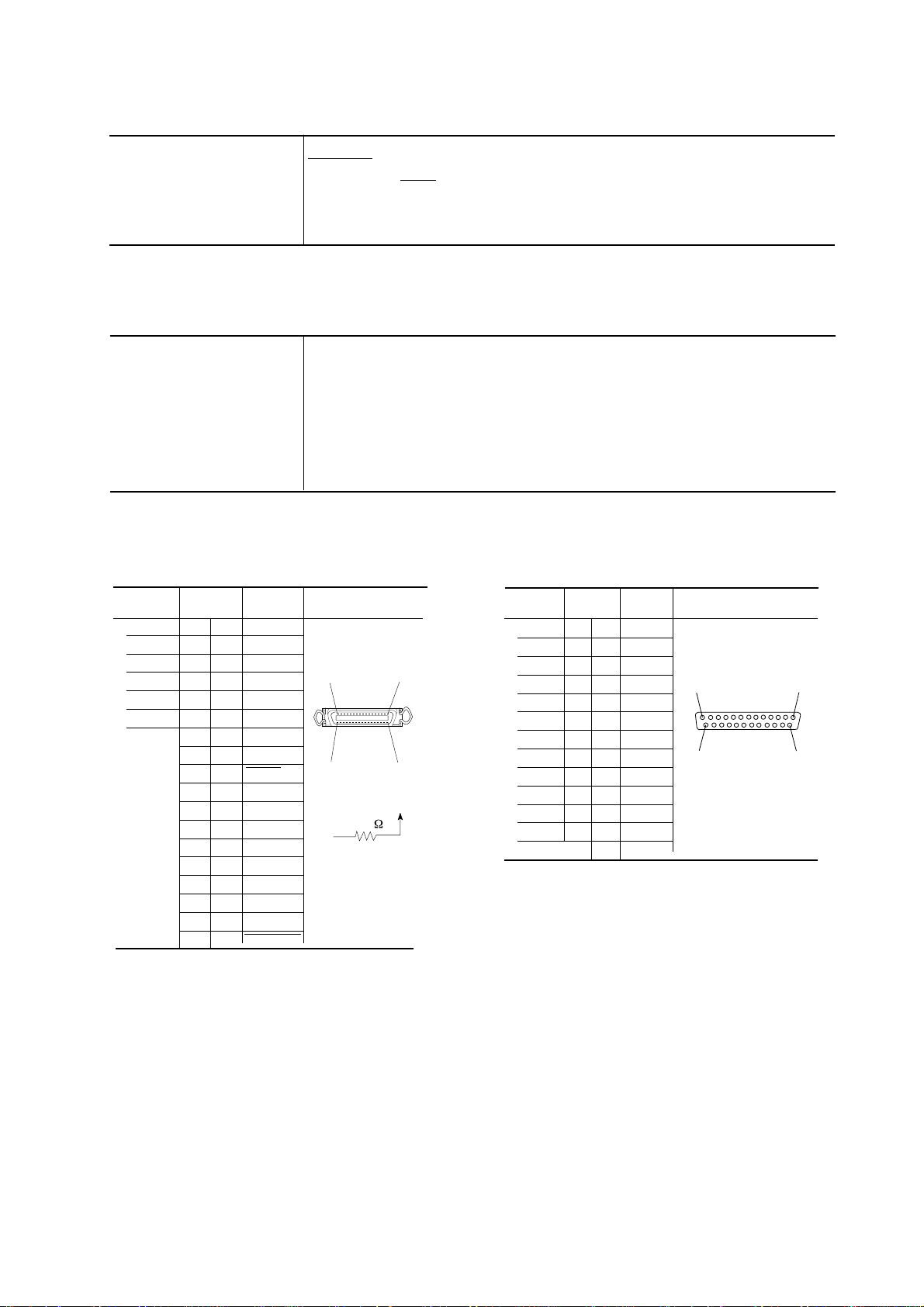

12 Instruction Support Chart

A "CAMM-GL III Programmer's Manual" is available for separate purchase for those wishing to create their own programs for this

machine. For further information, please contact your authorized Roland dealer or service center.

The list uses marks, each of which means:

: Compatible : Ignored : Incompatible

mode 1

Instruction Compatibility Instruction Compatibility Instruction Compatibility Instruction Compatibility Instruction Compatibility

H D M I R

L B X P S

Q N C E A

G K

T ^

mode 2

Instruction Compatibility Instruction Compatibility Instruction Compatibility Instruction Compatibility Instruction Compatibility

AA AR CA CI CP

CS DF DI DR DT

EA ER EW FT IM

IN IP IW LB LT

OA OC OE OF OH

OI OO OP OS OW

PA PD PR PT PU

RA RR SA SC SI

SL SM SR SS TL

UC VS WG XT YT

WD SP

Instruction in mode 1 and mode 2

Instruction Compatibility Instruction Compatibility Instruction Compatibility Instruction Compatibility Instruction Compatibility

!NR !PG !ST !FS

53

Page 54

13 Specifications

13 Specifications

Driving method

Maximum cutting area

Acceptable media widths

Acceptable paper widths

Acceptable paper types

Tools

Max. cutting speed

Blade force

Mechanical resolution

Software resolution

Distance accuracy

Repetition accuracy

Interface

Buffer size

Instruction system

Switches

Control switches

Display

Power consumption

Acoustic noise level

Dimensions

Weight