Page 1

查询RCM1637U-A供应商

RCM1637U-A

Liquid crystal displays

MOSAIC DISPLAY UNIT

RCM1637U-A

Thanks to the high contrast and wide viewing angle of the RCM1637U-A, which is provided by its unique design

technology, this module brings forth new applications in brand new LCD fields. ROHM large-sized LCD units are perfect

displays for information or sign boards. As a media for informational display, large-sized LCD units must possess high

visibility, wide viewing angles, and other such superior qualities. ROHM large-sized LCDs boast an excellent track record

and possess guaranteed functionality for assured satisfaction in a variety of situations.

Applications

!!!!

Indoor information board (airport, train station, bus depot), In-hall or in-store display, public message board.

Features

!!!!

1) Most suitable for the alphabet and number display including German, French and Spanish.

2) Wide viewing angle and high contrast.

3) Compact and light weight for easy assembly.

4) Low power consumption.

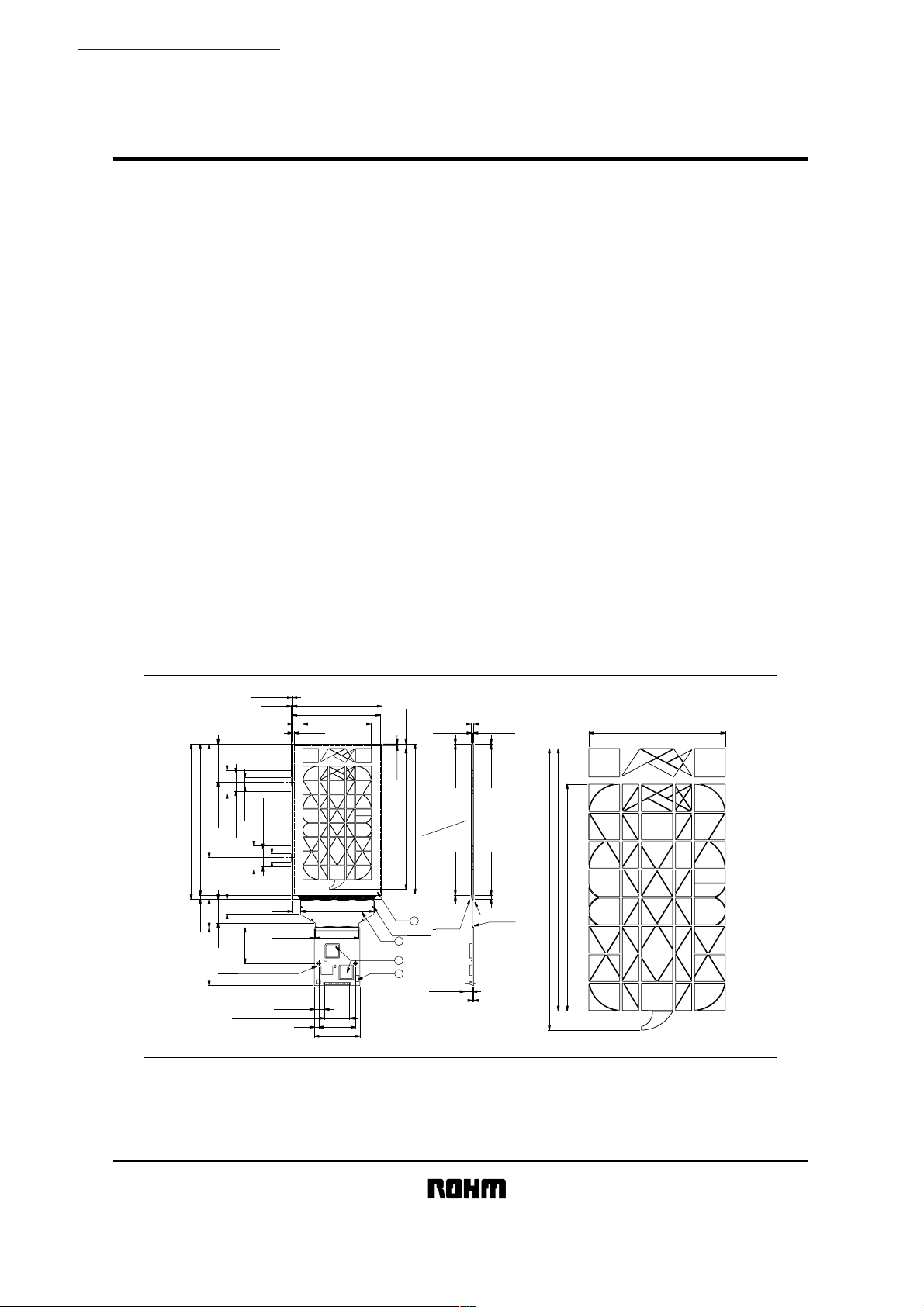

External dimensions

!!!!

(127.475)

174±0.3

−1.0

+1.5

32

4±0.3 (170)

65±0.5

(42.525)

20.5Max.

26.5Max.

(17)

(27)

2−φ3.96 Hole

(Units : mm)

0.3Max.

1Max.

11.9±0.3

10Max.

26.5Max.

20.5Max.

10Max.

1.3±0.5 (48.4)

(40)

+0.15

−0

(P2.54×11)27.94

(11.53)

100±0.3

98Min.

(76.2)

2Max.

82±0.3(9)

41±0.1

(5)

51±0.5

2Max.

4−Hole

2

3

4

5±0.3

(158)

168Min.

VIEWING ANGLE

1

1.1±0.1

(6:00)

UV REGIN

(8.54)

2.75±0.3

1.1±0.1

0.7±0.7

0.7±0.7

0.7±0.7

4.7±0.7

UV REGIN

UV REGIN

(1.6)

147

158

127

(79.2)

Page 2

Liquid crystal displays

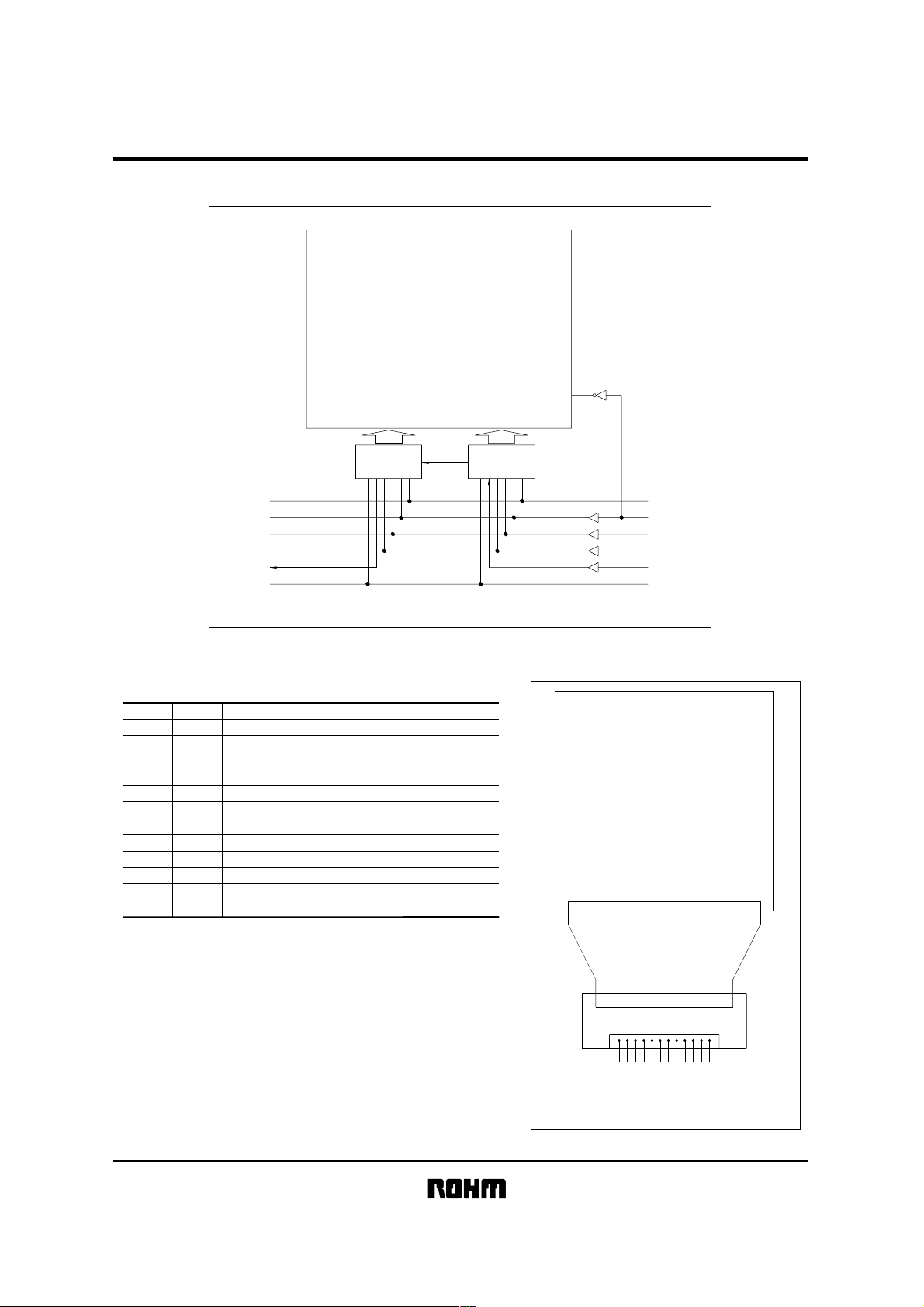

Block diagram

!!!!

RCM1637U-A

MOSAIC

105 SEGMENT

LCD

80 CHANNEL

12

V

DD

11

M

10

CL1

9

CL2

8

DO

7

GND

OUTPUT

Pin functions

!!!!

(1) Input (CN1)

VDD

M

CL1

CL2

DI

GND

GND

DO

CL2

CL1

M

V

IN / OUT

Charge 5Volt

−

Alternating signal of LCD operating output

IN

Data latch signal (display at descending edge)

IN

IN

Shift resistor signal (displayed at descending edge)

IN

Display data signal (1: Lighting 0: Non-Lighting)

−

Ground electric potential

−

Ground electric potential

OUT

Display data signal

OUT

Shift resistor signal

OUT

Data latch signal

OUT

Alternating signal

−

DD

5Volt

Pin No. Symbol Function

1

2

3

4

5

6

7

8

9

10

11

12

LCD Driver

with

Outputs

LCD Driver

with

80 CHANNEL

Outputs

1

V

DD

2

M

3

CL1

4

CL2

5

DI

6

GND

INPUT

Pin

!!!!

LCD

MV

CC

012

OUTPUT

FPC

PCB

LLDDO

21D

DCGG

LINN

2DD

INPUT

VM

C

L

D

1

D

1325769111 8 4

No

Page 3

Liquid crystal displays

Absolute maximum ratings

!!!!

Parameter Symbol Limits Unit

Power supply

voltage

Input voltage

Operating temperature

Storage temperature

Electrical characteristics

!!!!

Circuit

LCD operation

(VDD = 5.0V, GND = 0V, Ta = 25°C)

(Ta = 25°C)

DD

V

VDD−V

V

IN

Topr

Tstg

RCM1637U-A

−0.3 ~ +7.0

EE

−0.3 ~ +7.0

−0.3 ~

VDD+0.3

−20 ~ +70

−40 ~ +85

V

V

V

°C

°C

Parameter

Input high level voltage

Input low level voltage

Output high level voltage

Output low level voltage

Input LCD voltage

Comsumpting current

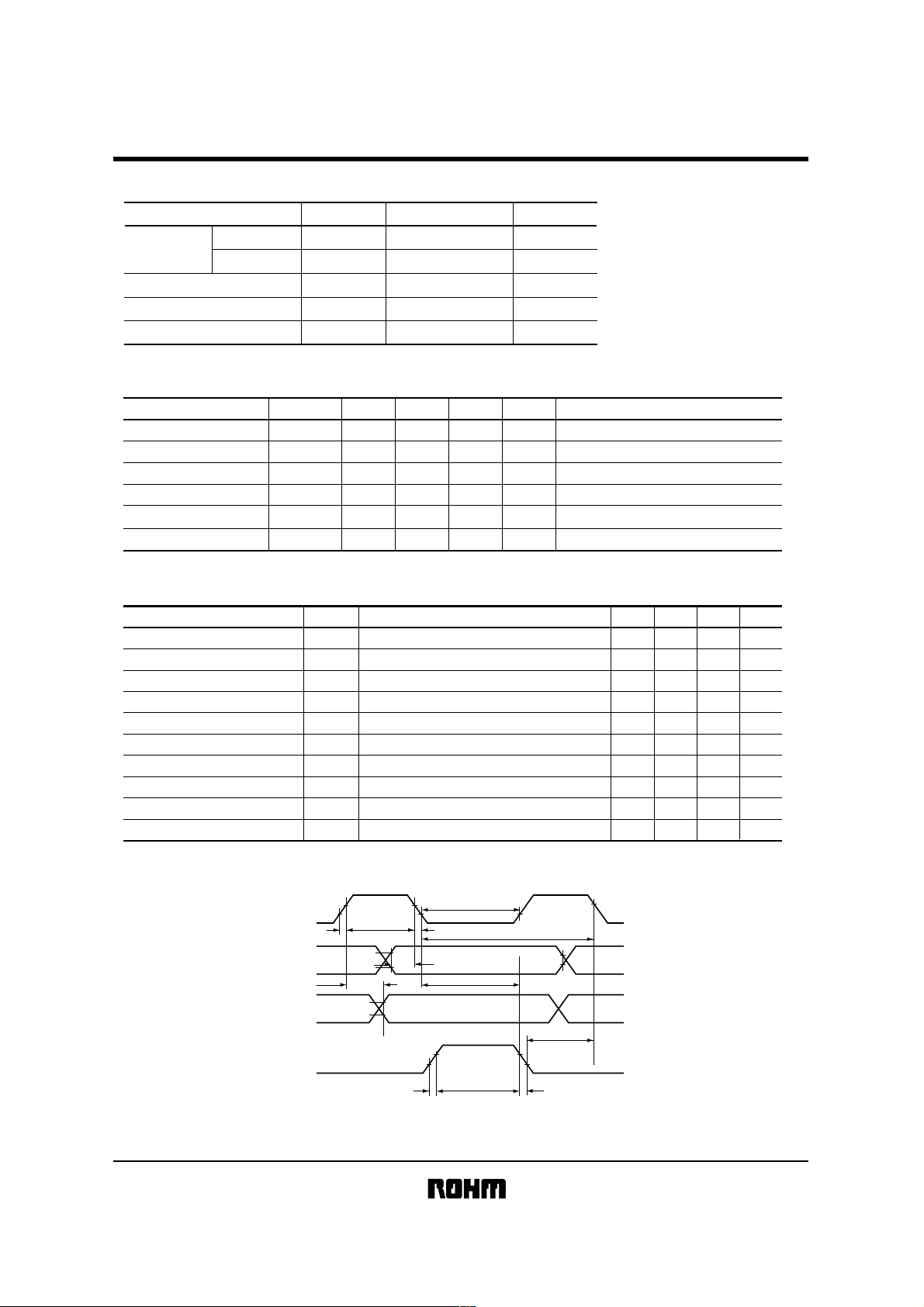

AC characteristics

!!!!

Parameter

Data shift flequency

Clock high level width

Clock low level width

Data setup time

Clock setup time 1

Clock setup time 2

Data hold time

Clock rise / fall time

Output delay time

Alternating signal

Symbol Min. Typ. Max. Unit Conditions

V

IH

V

IL

OH

V

V

OL

VLCD

I

DD

0.8V

V

−

DD

−

DD

−0.4

−

−

−

−

−

−

5.0

−

V

0.2V

0.4

6.0

DD

−

−

V

V

DD

OH

= −0.4mA

I

V

OL

= +0.4mA

I

V

V

mA

f

CL

= 1MHz, fM = 100Hz

(VDD = 5.0V, GND = 0V, Ta = 25°C)

Symbol

CL

f

tCWH

CWL

t

tSU

tSL

tLS

tDH

tct

tpd

M

f

Applicable terminal

CL2

CL1, CL2

CL2

DI

CL2

CL1

DI

CL1, CL2

DO

M

Min.

−

470

470

120

220

220

120

−

−

50

Typ.

−

−

−

−

−

−

−

−

−

100

Max.

1

−

−

−

−

−

−

50

250

150

Unit

MHz

ns

ns

ns

ns

ns

ns

ns

ns

Hz

Timing characteristics

!!!!

CL2

DI

DO

CL1

V

V

IH

V

IL

t

ct

t

pd

t

CWH

V

IH

V

IL

V

OH

V

OL

V

V

iL

t

t

CWL

t

ct

t

SU

IH

ct

Fig.1

t

DH

t

SL

t

CWH

IH

t

LS

t

ct

Page 4

Liquid crystal displays

Optical characteristics

!!!!

(Ta = 25°C)

RCM1637U-A

1

2

3

ParameterNo.

Response time

Viewing Range

Contrast ratio

Symbol

Vertical

horizontal

Tr

Td

θ

φ

K

Temperature (°C)

25

25

25

25

25

(Note 1) Driving pulse

Static drive

V

op

0

op

-V

1 / f

f = Frequency

(Note 2) Response time definition and condition

OFFON

I

OFF

I

0.91

I

ON

T

r

d

T

T

0.11

Tr : The time required to activate from non-selecting

wave pattern to selecting wave pattern and to change

90% for darken.

φ = 180°, θ = 10

°

Td : The time required to activate from selecting wave

pattern to non-selecting wave pattern and to change

90% for darken.

φ = 180°, θ = 10

°

Typ. Max.

Min.

400

90

35

−

−

65

−

150

−

45

−

0

−

50

0

0

Unit

800

100

ms

300

100

60

deg

270

−−

Note

(Note 2)

(Note 3)

K≥3

φ = 180°, θ = 10°

(1) φ : Angle which an obsever will become Z Z’.

(2) θ : When obsevers position is consideres as flat X,Y

over a projector angle which makes Y Y’.

(3) Greatest viewing angle derection : Time axis which

represent best contrast ratio.

(Note 4) Definition of contrast ratio

<Definition

>

Luminous intensity at off

n

segment transmissivity

Contrast ratio =

Luminous intensity at on

segment transmissivity

Positive type n = 1, Negative type n = -1

<Measurement conditions

>

Drive conditions: Specific value condition

Viewing angle: φ = 180°, θ = 10

°

(Note 5) Optical measuring equipment theory plan

Inspecting

Light source

material

Measuring Light

Specific measuring

equipment

LC−4M

(Note 3) Definition of viewing angle (φ, θ)

Z (θ = 0°)

Viewing angle 12:00

Y (φ = 0°)

X'

(φ = 90°)

θ2

1

θ

X

(φ = 270°)

Y (φ = 180°)

Viewing angle 6:00

Thermostat

Page 5

Liquid crystal displays

Data format

!!!!

(data and display mapping)

RCM1637U-A

3

2

105

105

1

2

104

5

4

23

24

22

25

30

32

21

27

28

39 40

38

37

36

35

26

29

31

33

34 43

15

14

13

12

16

17

18

46

19

20

45

41

42

44

6

7

8

9

10

11

47

58

48

49

50

51

52

54

53

103

101

100

95

102

97

99

576059

56

55 61

94

93

92

96

91

90

89

88

87

98

66

65

64

62

63

85

84

8386

82

67

81

80

79

78

77

76

68

69

75

74

70

73

71

72

FIRST DATA

D1 D2 D3 D103 D104 D105 D106 D107 D159 D160

effective data invalid data

LAST DATA

Page 6

Liquid crystal displays

Timing chart

!!!!

M

CL1

CL1

CL2

DATA

RCM1637U-A

f

M

f

CL

SEG

COM

Note) LCD operation output voltage

M DATA SEG Voltage

1

1

0

0

1

0

1

0

COM Voltage

GND

GND

DD

V

V

DD

DD

V

GND

GND

DD

V

Page 7

RCM1637U-A

Liquid crystal displays

Operation notes

!!!!

(1) Handling instruction

••••

Attention must be paid to avoid external shock, which will cause operational failure.

••••

Polarizer on the surface is gentle and can be damaged easily by scratch, thus please take extra care when handling.

For surface termination, please wipe off with alcohol.

••••

The liquid used in the LCD panel is a harmful substance and must not be licked or awallowed. If you touch this liquid,

wash it out completely.

••••

Do not touch IC lead and terminal.

••••

Do not expose to direct sunlight for a long period of time and if it will be used at direct sunlight, recommend to use

UV cut filter.

••••

For storage please avoid in high temperature, high humidity. When long-term storage is required, keep the panels in

low temperature (5°C ∼ 25°C) and low humidity.

••••

To prevent TAB damage, TAB bent time must be up to twice.

(2) Operational instruction

••••

Please do not connect or take away the LCD module to the system in the condition of power on.

••••

Please input signal after LCD module power is turned on when turning off. Please turn off from input signal. In worst

case IC can be broken by ratch up phenomenon.

(3) Mounting instruction

••••

In the circuit CMOS-IC is used. Please be careful for ESD.

••••

Protection sheet is put on LCD module surface and back side. At removing the sheet, electric static is generated. So

it must be removed slowly and recommend to use Ion blower etc.

(4) Cautions for LCD with FPC

••••

Do not pend nor pull FPC.

••••

Do not hold FPC with fingers directly nor suspend FPC.

••••

When bending FPC, keep 5mm from the edge of grass (FPC joint) and bend toward Mother board side.

(5) Production

••••

Production in Japan or China.

Loading...

Loading...