Page 1

ICS Regent

®

PD-6002

Communications Modules

RS-232, RS-422 and RS-485

(T3150A)

Issue 1,

Communications modules provide a serial communications

interface between the controller and external equipment.

Communications modules are commonly used to connect the

controller to the computer running the

application, serial printers, man-machine interfaces,

distributed control system gateways, and other peer-to-peer

controllers.

W

INTERPRET

March, 06

Features

·

Two isolated serial ports per module.

·

Supports RS-232, RS-422 and RS-485 standards.

•

Regent R2, Guarded Peer-Link, and Modbus protocols.

·

Front panel indicators on each module show communi

status and transmit/receive activity.

·

TÜV certified for safety, Risk Class 5.

Module Operation

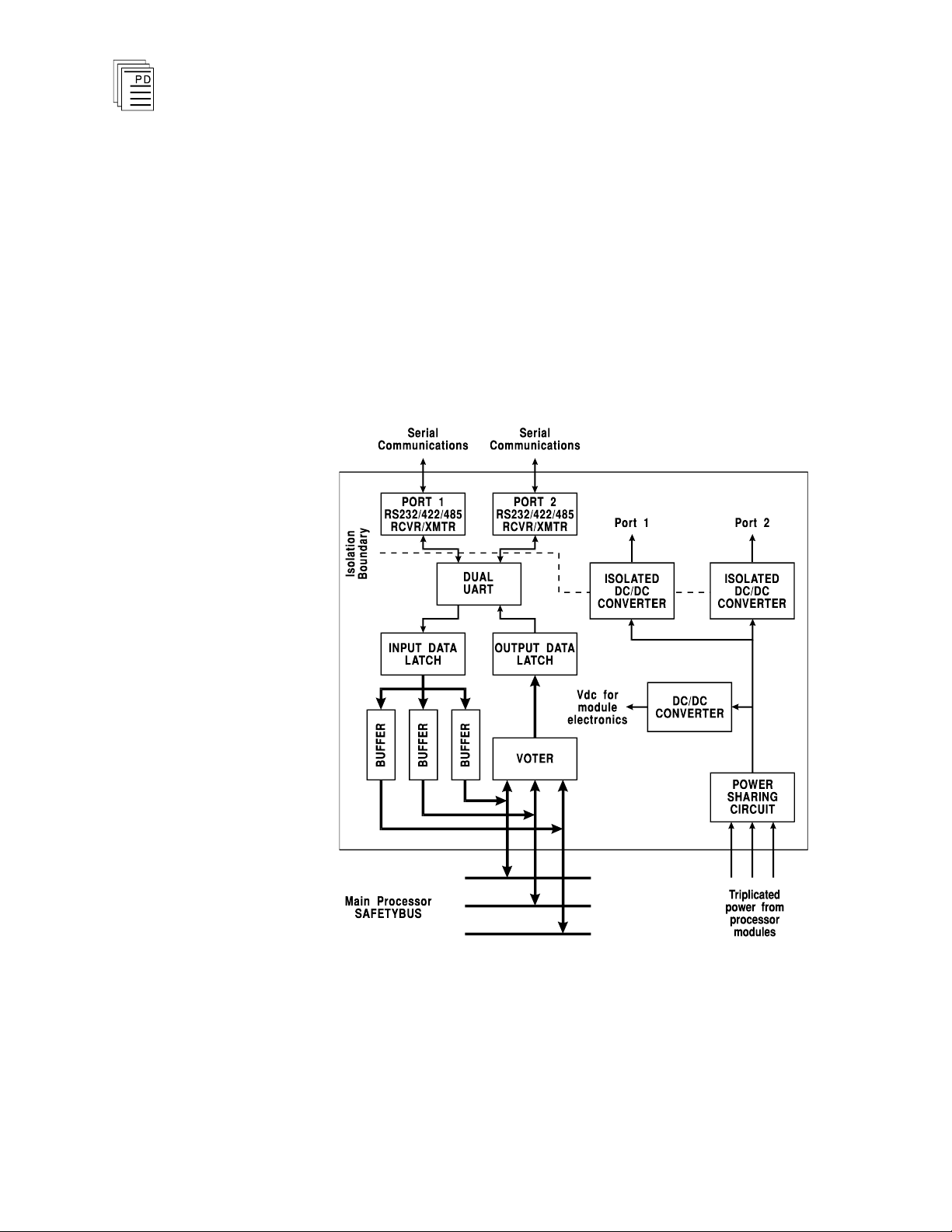

A block diagram of a typical communications module is shown

in Figure 1.

Communications modules are serial receiver-transmitters

that provide an electrical interface for RS-232, RS-422, and

RS-485 communications equipment.

Each communications module receives power from all three of

the processor modules. A power-sharing circuit

communications modules receives the power from the three

cations

in each of the

Industrial Control Services

1

Page 2

Communications Modules

(T3150A)

processor modules and combines it through a diode OR power

sharing circuit. This ensures that if one processor module's

power supply fails, the communications module will continue

to operate by drawing power from the two remaining power

supplies, and the system's communications functions are

maintained.

Additional isolated power converters provide isolated power to

the two serial ports. This isolation provides protection from

external

from affecting module operations.

communications cable signal noise and grounding

-

2

Figure 1. Block Diagram of Communications Module.

The Dual UART (universal asynchronous receiver/trans

mitter) buffers incoming and outgoing communications

characters. The triplicated processor modules interrupt once

Industrial Control Services

Page 3

Communications Modules

(T3150A)

every millisecond to read characters from or write characters

to the communications module.

When the processor modules read characters from the

communications module, the communications module sends

characters through triplicated bus drivers to the processor

Safetybus. The processor modules vote this triplicated data

and perform communications processing. When the processor

modules write data to the communications module, the

triplicated data is voted by the communications modules and

sent to the dual UART where it is then transmitted out the

associated port.

The communications modules’ two serial ports operate

independently and can both be configured differentl

y.

Electrical configuration is done by changing jumper settings

to select point-to-point or multidrop configurations. The ports

can be used to support a wide variety of functions including

Regent R2 protocol, Modbus protocol, ASCII output, and

Guarded Peer-Link communications. The

W

INTERPRET

application is used to configure the appropriate port functions

and specify baud rate, data format, parity, and node number.

Testing and Diagnostics

The modules triplicated Safetybus interface ensures that no

failure in the module will effect the operation of the Regent

system or other module. Extensive fault detection and

annunciation of critical redundant circuits helps ensure that

processors will not accept erroneous data from a faulty

module.

Each type of communications module has a unique

identification code that is read by the controller. This code

lets the controller know what type of module is installed in

each communications slot. If a module is removed and

replaced with a module of a different type the pro

indicate a COMM error.

cessors will

The processor modules perform background diagnostic checks

on the module to test bus driver circuits and check the

communications module ID codes. Communications message

format, framing, checksum, and other communications errors

PD-6002

Mar-06

3

Page 4

Communications Modules

are checked by the processor modules’ normal

communications processing.

Failures result in a COMM module error indication at the

processor modules and a COMM error at the communications

module.

(T3150A)

Front Panel

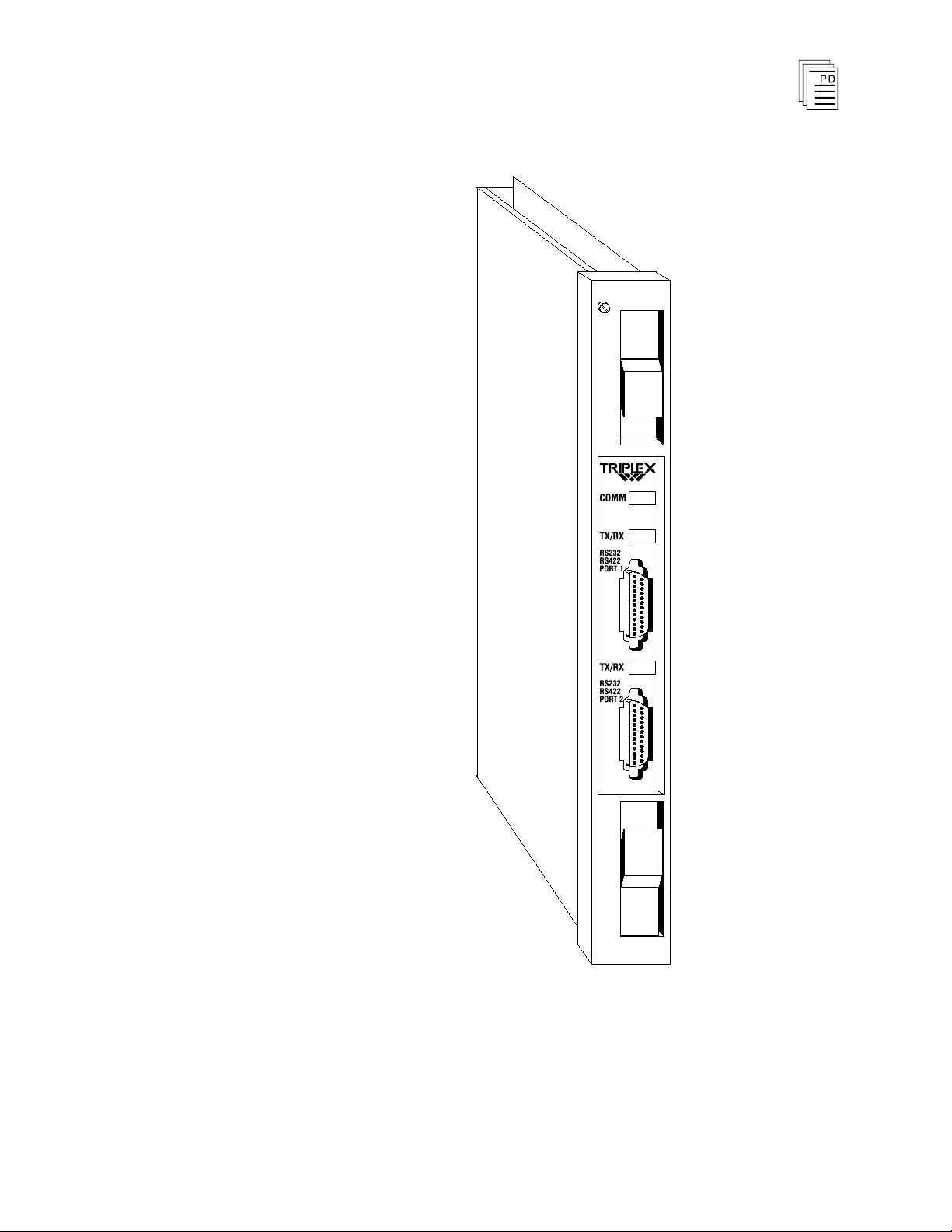

Figure 2 shows t

he physical features of the communications

modules. The front panel of each module contains indicators

showing overall module health, and the transmit and receive

status of each channel. In addition to the front panel

indicators, each communications module has two DB-25

connectors (female).

COMM Indicator

This red and green LED pair indicates the overall health of

the module. During normal operation the green LED is on. If

a communications module fault is detected, the red LED turns

on and the green LED

Transmit/Receive Indicators

turns off.

These green LEDs are connected directly to the serial signal

lines and flash while data are being transmitted or received.

The TX LED flashes as data are sent from the module, and

the RX LED flashes as data are received by the module.

4

Industrial Control Services

Page 5

Communications Modules

(T3150A)

PD-6002

Mar-06

Figure 2. Communications Module.

5

Page 6

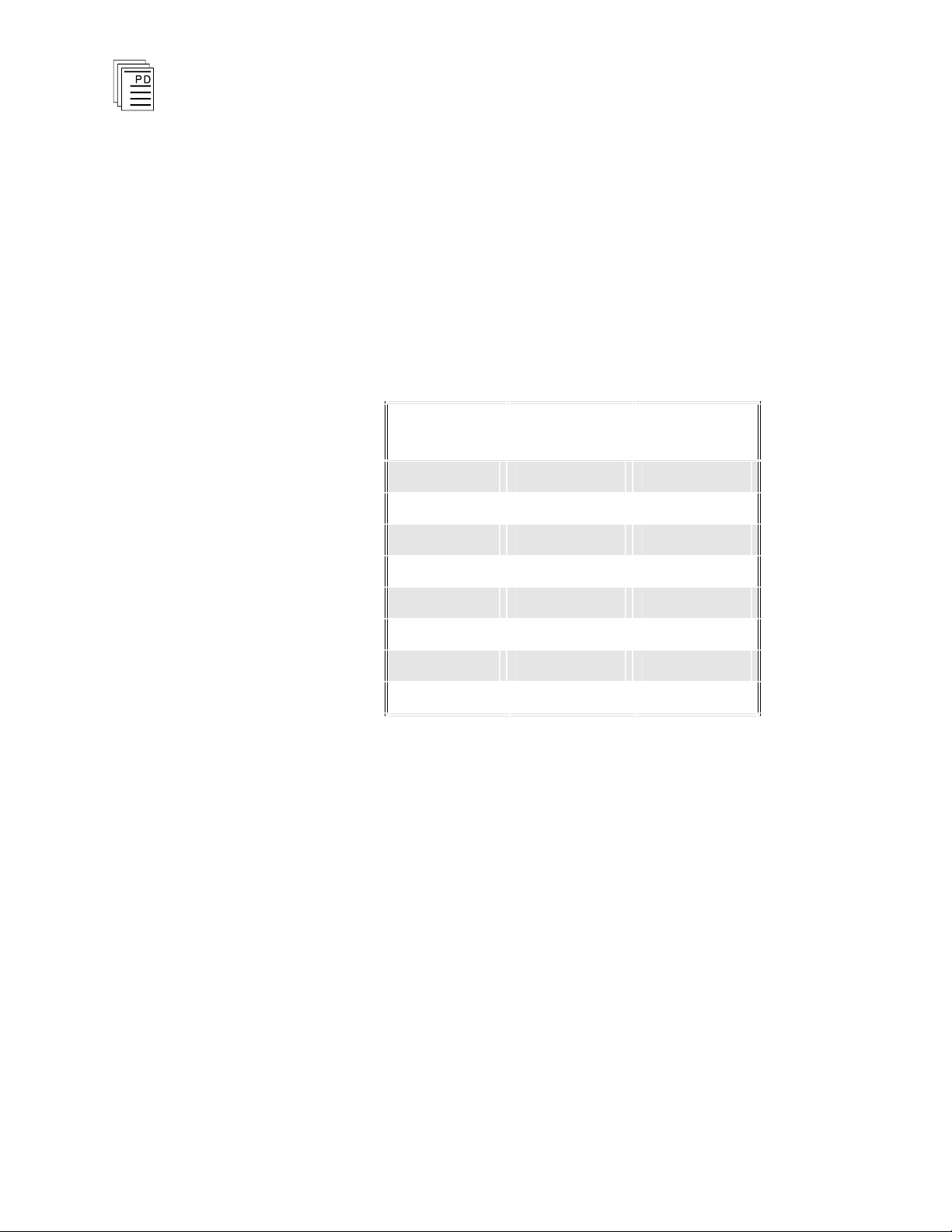

Pin No.

RS232

Signal

RS422/485

Signal

2 TX

(not used)

3 RX

(not used)

7

GND

GND

9

(not used)

+ 5 VDC

10

(not used)

TX (-)

11

(not used)

RX (-)

22

(not used)

TX (+)

23

(not used)

RX (+)

Communications Modules

(T3150A)

Application

Communications Port Connections

Each communications port has a DB-25, female connector on

the front of the module. The RS232 and RS422/485 signals

are internally connected to the DB-25 connector pins as shown

in Table 1. Refer to Figures 3 through 5 for recommended

communications cable requirements and connections.

Table 1. Communications Port Pin-out.

Recommended Ca

For multidrop and Guarded Peer-Link communications a

Belden cable type 813x (where x = number of pairs) is

recommended. The cable has the following characteristics

that are important:

120 Ohm, Characteristic Impedance

Twisted Pairs

Overall shield

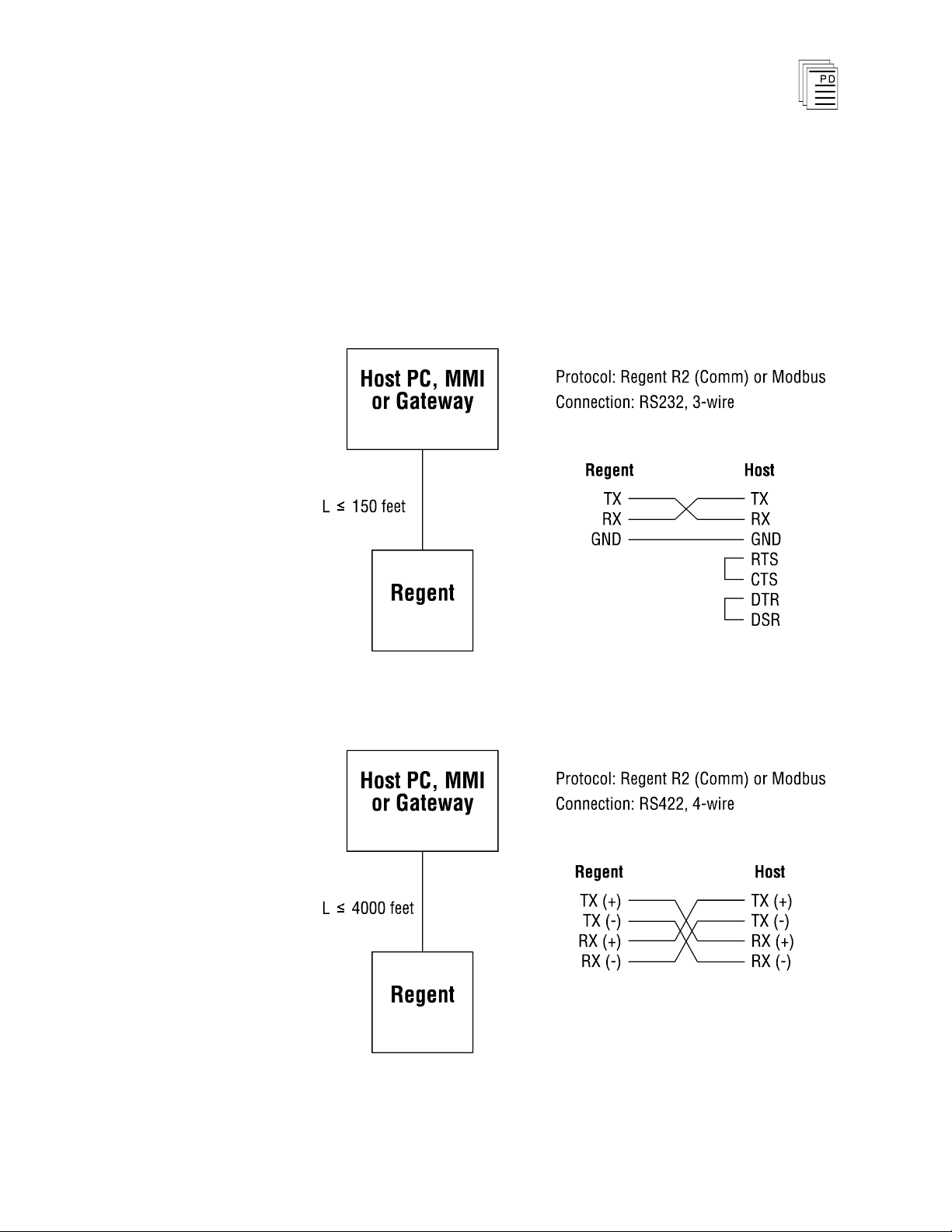

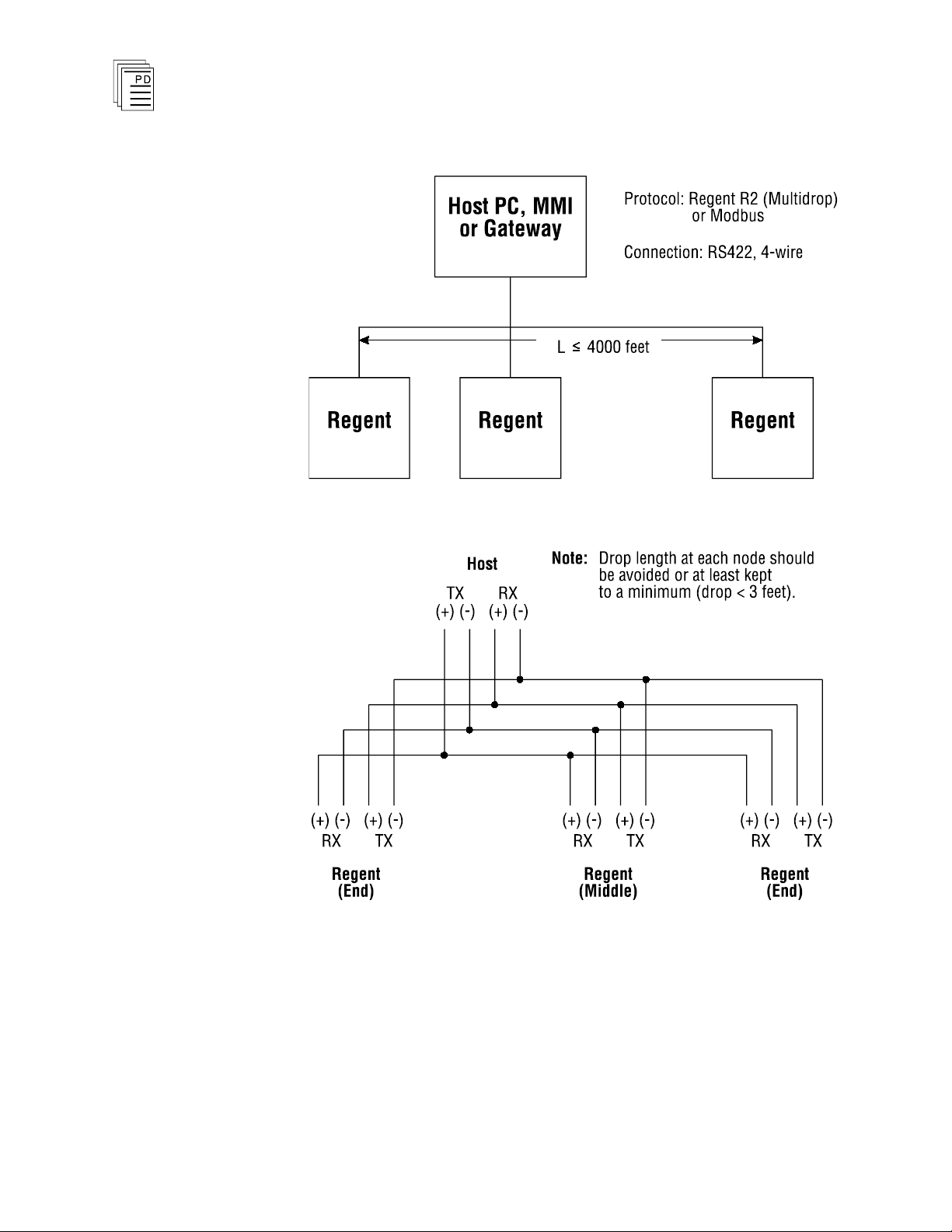

Communications Configurations

The communications module supports a variety of

communications configurations which are shown in Figures

through 5. Figure 3 illustrates two point-to-point

ble Type

3

6

Industrial Control Services

Page 7

Communications Modules

(T3150A)

configurations, one using RS232 connections for short

distances and the other using RS422 connections for longer

distances. Figure 4 illustrates multidrop connections between

2 or more Regents and a PC or other communications device

supporting Regent R2 or Modbus protocols. Figure

5

illustrates multidrop connections between 2 or more Regents

using the Guarded Peer-Link protocol.

PD-6002

Mar-06

Figure 3. Point-to-P

7

oint Communications.

Page 8

Communications Modules

(T3150A)

8

Figure 4. Multidrop Communications.

Industrial Control Services

Page 9

Communications Modules

(T3150A)

PD-6002

Mar-06

Figure 5. Guarded Peer-Link Communications.

Protocols and Communications Functions

The protocol and function supported for each port is

configured using the Serial Ports command from the Project

Editor’s Definitions menu in

W

INTERPRET

.

An example of the

Serial Ports dialog is shown in Figure 6.

9

Page 10

Communications Modules

(T3150A)

Figure 6. W

INT

ERPRET

’s Serial Ports Configuration Dialog.

The function and protocol for each type of port that you can

select is briefly described below. For more information on

using the Serial Ports command see Section 4, Working with

Projects, in the Regent User’s Guide.

Comm

Supports the Regent R2 protocol for point-to-point

communications between the Regent and the computer

running the

W

INTERPRET

application. Some third-party Man

Machine-Interface (MMI) products and DCS gateways may

also support point-to-point com

R2 protocol.

Multidrop

munications using the Regent

Supports Regent R2 protocol for multidropped Regents

connected to a PC running the

W

INTERPRET

application (or

other third-party supporting products and gateways). Ports

configured for multidrop communications require a node

number.

-

10

ASCII

Used by the Regent to transmit ASCII output messages to

external serial equipment such as printers and VDUs. ASCII

output messages are programmed using the ASCII output

element in ladder logic function blocks.

Industrial Control Services

Page 11

Communications Modules

(T3150A)

Net Master/Net Slave

Used by the Regent for Guarded Peer-Link communications to

other multidrop Regents. These ports require a node number.

Modbus

Supports connection to external Modbus communications

equipment that acts as a Modbus Master (the Regent is a

Modbus Slave). A Modbus port supports the Modbus RTU

protocol. Modbus ports can be used in point-to-point or

multidrop configurations. These ports require a node number.

Jumper Settings for Point-to-Point and Multidrop Communications

Each port can be independently configured for point-to-point

or multidrop connections. When shipped from the factory,

jumpers on-board the communications module are set for

point-to-point communications. These settings are

appropriate when a single Regent is connected to a PC or

other communications equipment. The port definition can be

COMM, ASCII or Modbus (point-to-point) as described above.

When the port definition is Multidrop, Net Master, Net Slave

or Modbus (multidrop) then the jumper settings on the

module must be changed.

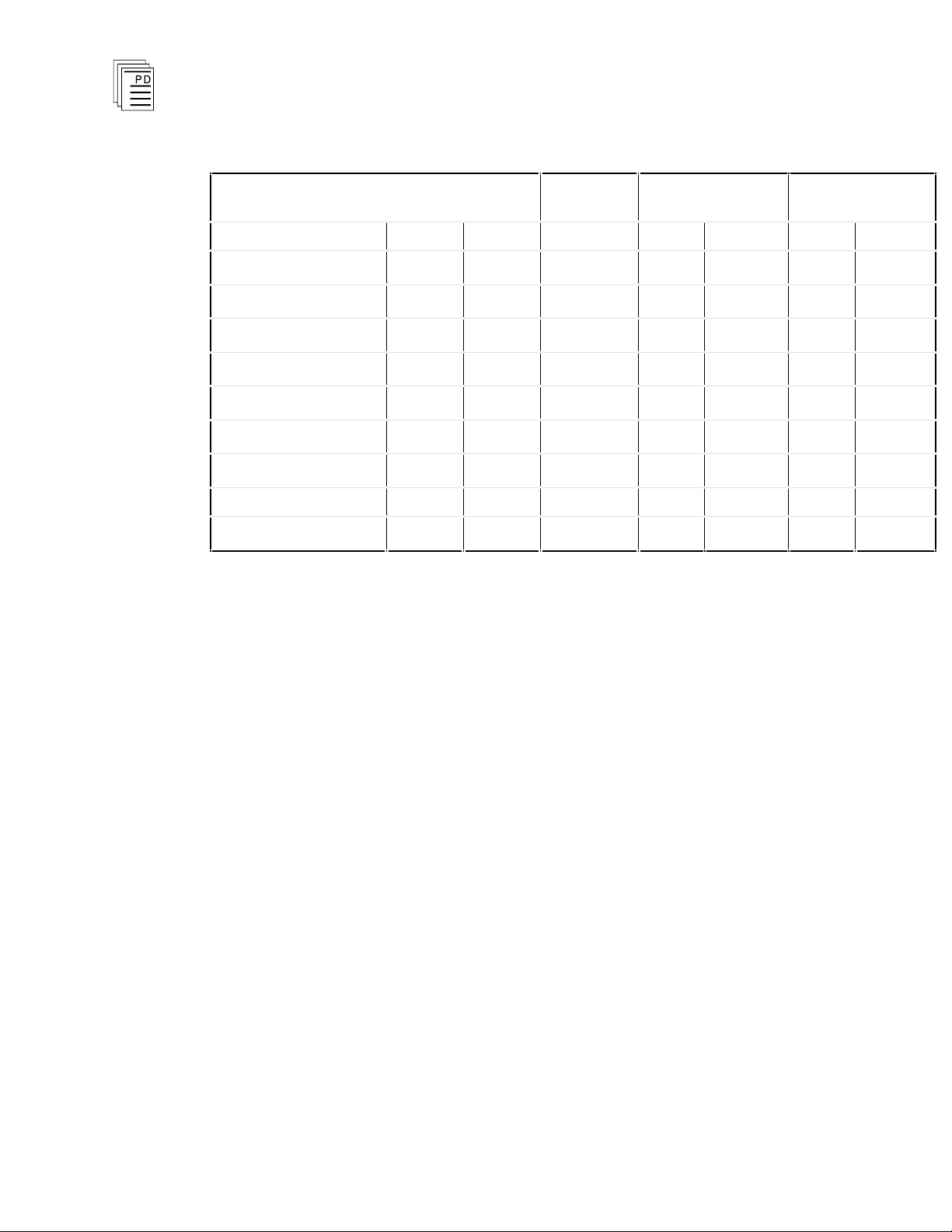

Changing Jumper Settings

The jumper settings on the module are used to determine how

the transmit lines of the serial ports are controlled and also

determine if internal termination, pull-up and pull-down

resistors are connected to the serial lines. Table 2 shows the

proper jumper settings for point-to-point, multidrop (Regent

R2 or Modbus) and Guarded Peer-Link communications.

PD-6002

Mar-06

11

Page 12

Note: n

indicate

s jumper installed

Point-to

-

Point

Multidrop (Regent

R2 or Modbus)

Guarded Peer

-

Link

Description

Port 1

Port 2

End Middle

End

Middle

TX pair terminator

E101

E201 n

RX pair terminator

E102

E202

n

n n

TX (-) pull-up

E111

E211 n

RX (-

) pull-up

E112

E212

n

n n

TX (+) pull-down

E121

E221

n

RX (+) pull-down

E122

E222

n

n n

Transmit control

E131

E231

n n n

n

Transmit control

E132

E232

Transmit control

E133

E233

n n n

n

Note:

Communications Modules

(T3150A)

Table 2. Communication Module Jumper Settings.

Termination, Pull-up and Pull-down Resistor Jumpers

When the module is used for RS422 or RS485

communications, the jumper positions for the internal

termination, pull-up and pull-down resistors must be

considered. Each termination resistor connects an internal

120 Ohm resistor across a specific differential pair and the

pull-up and pull-down resistors connect a 1K Ohm resistor

between each signal line and +5V or Comm. These resistors

should be connected only at the end nodes of the multidrop

communication network. Nodes in the middle should not have

t

hese jumpers connected.

12

Figure 7 identifies the signal lines, resistors and jumpers

associated with each port. Only the transmit (TX+ and TX

-)

and receive (RX+ and RX-) signal pairs are shown. Other

jumpers and resistors for signal pairs CTS, RTS, DTR and

DSR are also located on the module but they are not used by

serial communications for the Regent and their jumper

positions are not important.

If desired, you can install the termination, pull-up and pull

down resisters e

xternal to the communications module at the

-

ends of the multidrop network. In this case position the

jumpers in each communications module for a “middle”

Industrial Control Services

Page 13

Communications Modules

(T3150A)

Regent. With each communications module’s jumper settings

the same, module replacement is simpler. A single spare

module can replace any communications module without the

need to position the jumpers specifically for “end” or “middle”

Regents before replacement. Refer to the communications

port pin numbers shown in Figure 7 t

external connection of the resistors.

o determine the proper

PD-6002

Mar-06

13

Page 14

Communications Modules

(T3150A)

14

Figure 7. RS422/485 Internal Signal Resistors.

To change the jumper settings the communications module

must be removed from the controller chassis and

disassembled.

Industrial Control Services

Page 15

Communications Modules

(T3150A)

Module Removal and Disassembly

Using a small slotted screwdriver, loosen the retaining screw

near the top of the communications module.

Pull open both removal levers on the front of the module. The

module will disengage from the controller chassis. W

hen it is

disengaged, carefully slide the module out of the controller

chassis.

With the module removed, use a #2 Phillips screwdriver to

remove the two screws from the left side of the module.

Remove the four Phillips screws from the right side of the

module (see Figure 8). Remove only those screw indicated in

Figure 8.

PD-6002

Figure 8. Communications Module Disassembly.

Mar-06

After removing the screws, separate the printed circuit board

from it protective metal frame.

15

Page 16

Note:

Communications Modules

Refer to Table 2 to identify the proper jumper settings for

your application’s communications configuration. Position

the jumpers as needed on the module. Figure 9 shows the

locations of the jumpers on board the module.

When shipped from the factory, no jumpers are installed on

E131, E132, E133, E231, E232 and E233. For multidrop

configurations you will need two jumpers for each port (s

as E131 and E133 for port 1). The default factory settings

include jumpers positioned at E104, E106, E114, E116, E124,

E126, E204, E206, E214, E216, E224, and E226. These

jumpers connect termination, pull-up and pull-down resistors

for the CTS and DSR signal pairs for port 1 and 2. Since the

CTS and DSR signals are not actually used by the module,

you can remove jumpers installed at any of these positions in

order to install them as needed for E131, E132, E133, E231,

E232 or E233.

(T3150A)

uch

16

Industrial Control Services

Page 17

Communications Modules

(T3150A)

PD-6002

Mar-06

Figure 9. Jumper Locations.

Module Assembly and Installation

Position the printed circuit board on the metal frame, guiding

the two 96-pin DIN connectors through the slots in the frame.

17

Page 18

Communications Modules

From the right side of the module, align the four holes in the

printed circuit board wit four metal standoffs. Insert and

tighten the four screws removed from the right side of the

module.

Turn the module over and install the two screws removed from

the left side of the module.

Visually inspect the connector at the back of the

communications module for bent pins. If any pins are bent do

not install the module. Do not try to straighten bent pins.

Return the module to ICS for replacement.

If the pins are in good condition, hold the module with both

hands and open the two module release levers by pulling them

toward you.

Carefully slide the module into the chassis. Be careful to keep

the module aligned while sliding it straight into the chassis.

(T3150A)

The module should mount into the chassis with a

minimum of

resistance. If the module does not mount easily, do not force

it. Remove it and check it for bent or damaged pins. If the

pins look okay, try reinstalling the module.

When the module is almost fully into the chassis, the release

levers will contact the chassis and begin to rotate closed.

Press the levers closed to seat the module in the chassis.

The top release lever on each communications module is

switched. When the lever is in the open position, the module

is disabled.

If the module does

not seem to have seated correctly, open the

release levers and gently pull it back off the seat and out of

the chassis. Check for bent or damaged pins. If the pins look

okay, try reinstalling the module.

After the module is properly seated, tighten the retaining

screw at the top of the module. Fastening the retaining screw

will also help ensure that top (switched) release lever remains

in position.

18

Industrial Control Services

Page 19

Communications Modules

(T3150A)

Maintenance

No periodic maintenance or calibration is required for the

digital input modules. There are no

inside these modules.

Failed modules can be hot replaced. If the module being

replaced has been configured to support multidrop

connections be sure to check the jumper settings and properly

configure the new module’s jumpers before installing it.

Safety Considerations

Communications modules are TÜV certified for Risk Class 5

safety applications as non-interfering and can be used in a

safety system for normal data acquisition functions.

Communications modules are approved for peer-to-peer

communications of safety critical data between two or more

Regent systems in Risk Class 5 safety applications. This

requires the use of redundant Guarded Peer-Link

communications networks where the network connections are

made on redundant communications modules at each Regent.

user replaceable parts

For additional safety considerations involving

communications with the Regent, refer to the Safety

Considerations Section of the Regent User’s Manual.

PD-6002

Mar-06

19

Page 20

Power Requirements

No external power required

(powered by tr

iplicated

processor modules)

Number of Serial Ports

Two

Serial Port Types

RS-232, RS-422, and RS-485

Baud Rates

300 to 19,200

Communications Protocols

Regent R2

Modbus RTU

ASCII Output

Guarded Peer-Link

Serial Port Connector

Module:

Cable:

DB-25, female

DB-25, male

Isolation

1000 volts minimum (serial

device to logic)

1000 volts minimum (serial

port to serial port)

Heat Dissipation

7 Watts, 24 BTUs/hour

Operating Temperature

0°

to 60° C

(32° to 140° F)

Storage Temperature

-40°

to 85° C

(-40°

to 185° F)

Operating Humidity

0 to 95% relative humidity,

non-condensing

Vibration

10 to 55 Hz:

±0.15mm

Shock

Operating:

15 g, ½ sine wave, 11 msec

Communications Modules

(T3150A)

Specifications

20

Industrial Control Services

Page 21

Electromagnetic

Interference

•

IEC 801 Part 2 - Electrostatic

Discharges

•

IEC 801 Part 3 - Radiated

Electromagnetic Fields

•

IEC 801 Part 4 - Transients

and Bursts

Level 3: Contact discharge of

6 kV

Level 3: 10 V/M, 27 MHz 500 MHz

Level 4: 2 kV, 2.5 kHz for t =

60 sec

Safety

Certified to DIN V VDE

0801 for Risk Class 5. Also

designed to meet UL 508 and

CSA 22.2, No. 142-M1981

Dimensions

Height:

Width:

Depth:

13.0" (330 mm)

1.5" (38 mm)

9.0" (229 mm)

Weight

3.0 lbs (1.4 kg)

Communications Modules

(T3150A)

PD-6002

Mar-06

21

Loading...

Loading...