Page 1

System Security

Design Guidelines

Reference Manual

Original Instructions

Page 2

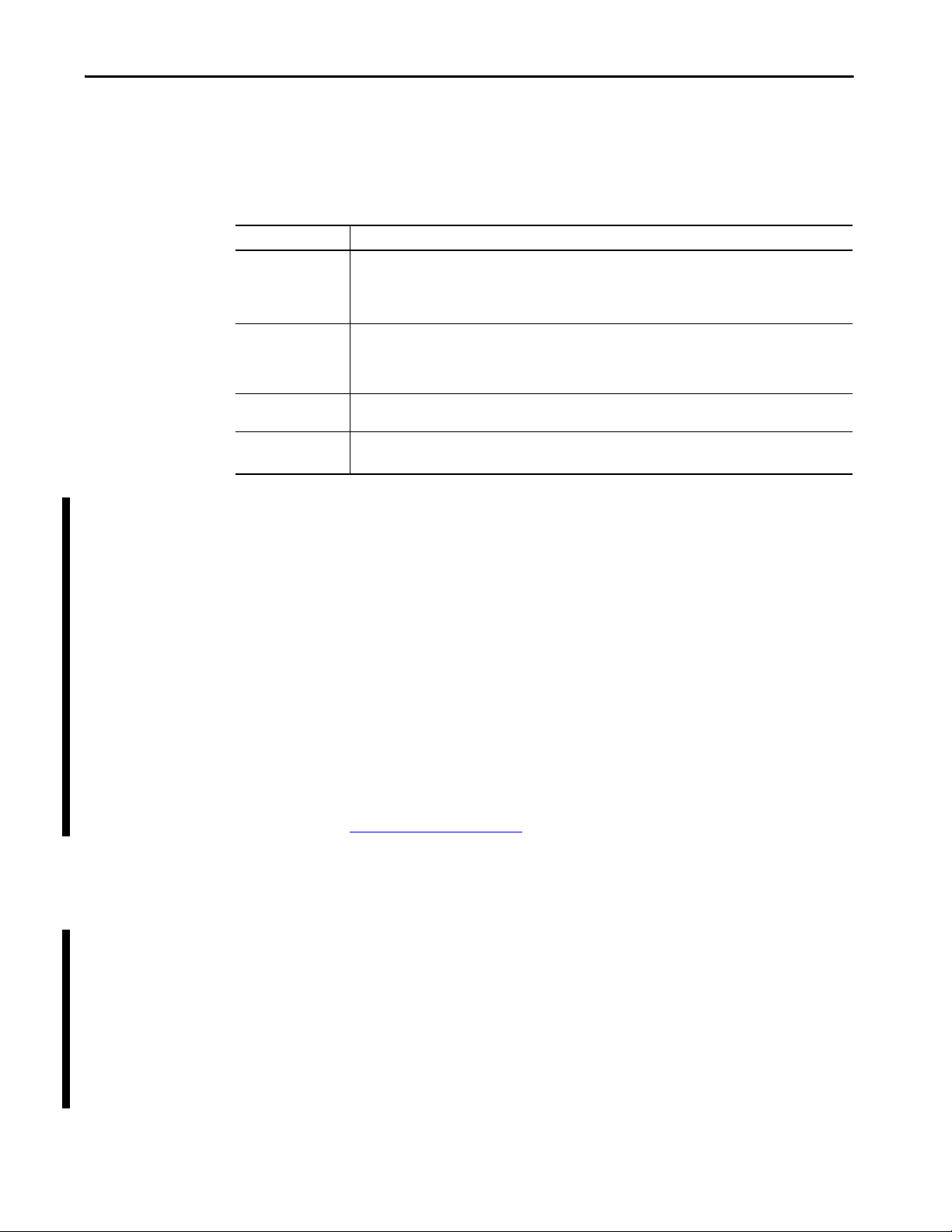

Publication Title Reference Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

ATT EN TI ON : Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc

Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements

for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 3

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

How Can I Get Help To Manage My Security Risk? . . . . . . . . . . . . . . 5

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 1

Vulnerabilities How Rockwell Automation Handles Vulnerabilities . . . . . . . . . . . . . . 8

Report a Suspected Product Vulnerability . . . . . . . . . . . . . . . . . . . . 8

Public Vulnerability Disclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Supply Chain Vulnerabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Threat Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2

System Security Security Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Security Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Defense-in-Depth Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Notifications That Rockwell Automation Provides. . . . . . . . . . . 16

Security with Rockwell Automation Products . . . . . . . . . . . . . . . . . . . 16

Standard Security Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Secure Networks and

Communication

Chapter 3

Converged Plantwide Ethernet (CPwE). . . . . . . . . . . . . . . . . . . . . . . . . 19

Logical Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Network Firewalls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Deep Packet Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Industrial Demilitarized Zone (IDMZ) . . . . . . . . . . . . . . . . . . . . . . . . . 23

Control Access to the Industrial Zone. . . . . . . . . . . . . . . . . . . . . . . 24

Remote Desktop Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Industrial Firewall Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Stratix 5950 Security Appliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Control Device Communication Ports . . . . . . . . . . . . . . . . . . . . . . 27

Switch and Routing Platforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Stratix Managed Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Secure Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

CIP Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Wireless Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 3

Page 4

Table of Contents

Chapter 4

Harden the Control System Patch Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Microsoft Patches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Product Change Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Hardware Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Software and Firmware Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Workstation Hardening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

FactoryTalk Directory Application . . . . . . . . . . . . . . . . . . . . . . . . . 34

Physical Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Device Hardening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Digitally Signed Firmware and Software . . . . . . . . . . . . . . . . . . . . . 35

High Integrity Add-On Instructions . . . . . . . . . . . . . . . . . . . . . . . . 36

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 5

Manage User Access FactoryTalk Services Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Control Data Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

FactoryTalk Administration Console Software. . . . . . . . . . . . . . . 41

Studio 5000 Logix Designer Application . . . . . . . . . . . . . . . . . . . . 41

FactoryTalk Security Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Policies and Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Centralized Security Authority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Security Authority Identifier (SAID). . . . . . . . . . . . . . . . . . . . . . . . 43

FactoryTalk View Site Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Protect Controller Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

License-based Source and Execution Protection . . . . . . . . . . . . . . 45

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter 6

Monitor and Recover Audit and Change Management with FactoryTalk AssetCentre

Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Backups via FactoryTalk AssetCentre Software . . . . . . . . . . . . . . . . . . 49

Component Change Detection and Logging for Controllers . . . . . . 50

Chapter 7

Disposal Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Appendix A

History of Changes SECURE-RM001D-EN-P, March 2020 . . . . . . . . . . . . . . . . . . . . . . . . 53

SECURE-RM001C-EN-P, December 2019 . . . . . . . . . . . . . . . . . . . . . 53

SECURE-RM001B-EN-P, April 2019 . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 5

Preface

This publication provides guidelines for how to use Rockwell Automation

products to improve the security of your industrial automation system.

For information on patch management options, security advisory details, and

general news and awareness on industrial security from the Rockwell

Automation Office of Product Safety and Security, see the Industrial

Cybersecurity capabilities web page.

How Can I Get Help To Manage My Security Risk?

Summary of Changes

The Knowledgebase Technote Industrial Security Advisory Index

specific product security alerts, advisories, and recommendations. Subscribe to

this index to receive notifications.

To address specific concerns, or to report issues, contact us

at secure@ra.rockwell.com

Block.

Rockwell Automation Network & Security Services consulting services are

available to assist customers assess and improve the state of security of

industrial control systems that use Rockwell Automation and other vendor

control products. We provide a holistic approach to manage your network

infrastructure and security throughout its lifecycle. For more information, see

Industrial Cybersecurity Services

This manual contains the following new information as indicated.

Top ic Pag e

New chapter on vulnerabilities, how to report suspected

vulnerabilities, and how Rockwell Automation responds

to reports.

Updates to patch management 31

Updates to version descriptions for software and

firmware

. Communicate securely via our PGP Public Key

.

7

33

points to

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 5

Page 6

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Security Configuration User Manual, SECURE-UM001 Describes how to configure and use Rockwell Automation products to improve the security

CIP Secur ity with Rockwell Au tomation Products Application Technique,

SECURE-AT001

Converged Plantwide Ethernet (CPwE) Design and Implementation Guide,

publication ENET-TD001

Industrial Firewalls within a Converged Plantwide Ethernet Architecture White

Paper, publication ENET-WP011

Deploying Industrial Firewalls within a Converged Plantwide Ethernet Architecture

Design and Implementation Guide, publication ENET-TD002

Guidelines on Firewalls and Firewall Policy Recommendations of the National Institute of Standards and Technology

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Product Certifications website,

http://www.rockwellautomation.com/global/certification/overview.page

of your industrial automation system.

Describes how to implement the Common Industrial Protocol (CIP™) Security standard in

your control system.

Provides guidelines for how to design, implement, and manage industrial Ethernet

networks.

Provides guidelines for how to implement industrial firewalls.

Outlines use cases for how to design, deploy, and manage industrial firewalls.

Provides general guidelines for how to install a Rockwell Automation industrial system.

Provides declarations of conformity, certificates, and other certification details.

You can view or download publications at

http://www.rockwellautomation.com/global/literature-library/overview.page

To order paper copies of technical documentation, contact your local

Allen-Bradley distributor or Rockwell Automation sales representative.

.

6 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 7

Chapter 1

Vulnerabilities

A vulnerability is a flaw or weakness in a product or system that can be

exploited to compromise product or system confidentiality, integrity, or

availability.

Risk and vulnerability assessments are the starting point for any security policy

implementation. Vulnerability assessments examine your situation from

technologies, policies, procedures, and behaviors. An assessment provides a

picture of your current security posture (current risk state) and what you need

(mitigation techniques) to get to a preferred state (acceptable risk state).

Rockwell Automation recommends the formation of a multi-discipline team of

operations, engineering, IT, and safety representatives to collaborate in the

development and deployment of your industrial security policy.

A vulnerability assessment provides, at a minimum:

• An inventory of existing devices and software.

• Detailed observation and documentation of intended system operation.

• Identification of possible vulnerabilities.

• Prioritization of each vulnerability based on the impact and exploitation

potential.

The Common Vulnerability Scoring System (CVSS) is a free, open industry

standard for assessing the severity of vulnerabilities. Rockwell Automation

includes CVSS-based scores in Product Security Advisory notices to help

customers assess their risk and exposure, including how prioritize responses

and resources according to a specific threat. For more information, see

Common Vulnerability Scoring System Specification Document

The outcome of a vulnerability assessment can include mitigation techniques

that bring an operation into an acceptable risk state.

Actions that are taken after a risk assessment can include the following:

• New firewall controls

• New switch ports to lock down

• Stronger password policies

• Removal of unused software programs

• Improved procedures for managing the connection of external devices,

such as USB devices

• New or patched versions of firmware or software

.

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 7

Page 8

Chapter 1 Vulnerabilities

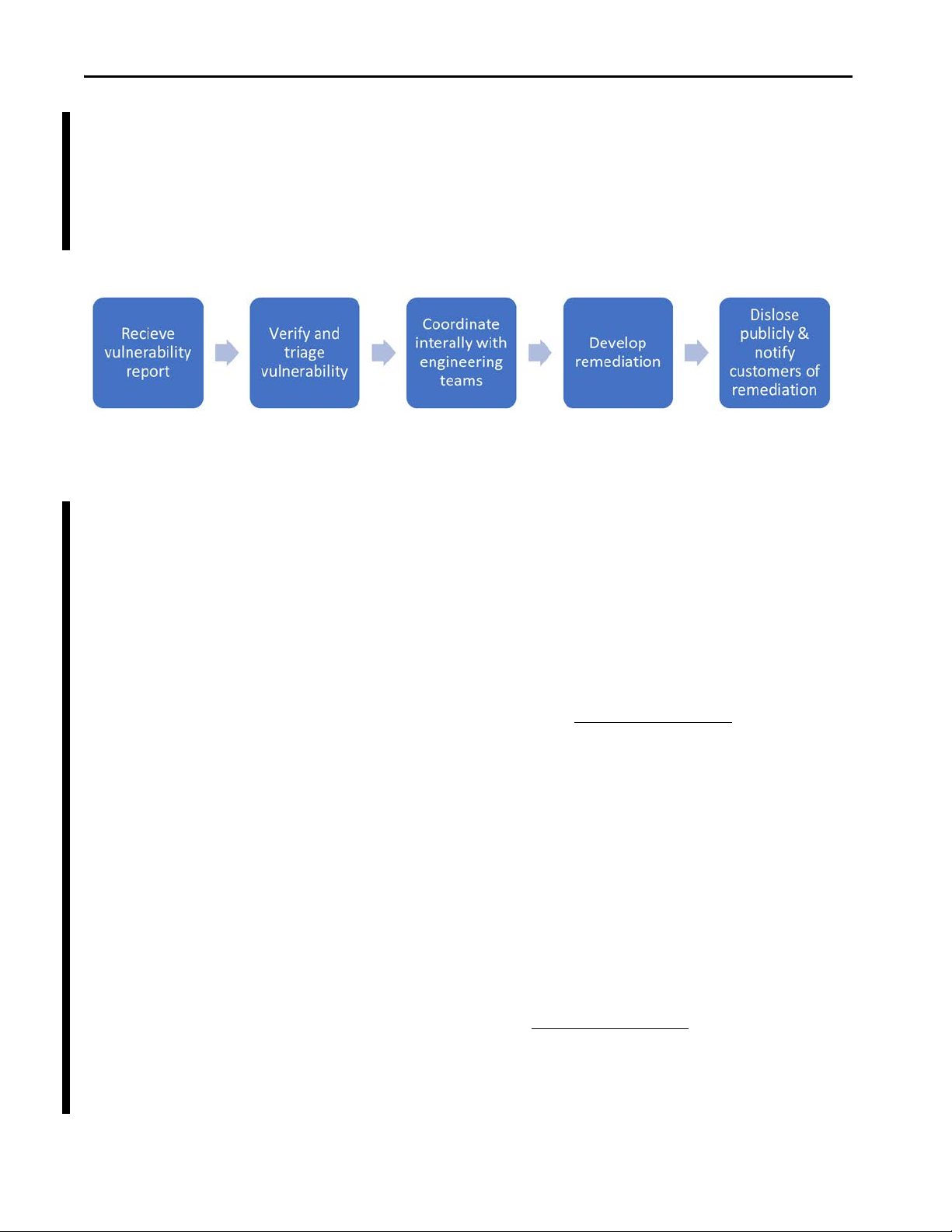

How Rockwell Automation Handles Vulnerabilities

Rockwell Automation recognizes the importance of security in industrial

control systems and is investing in its products, people, partnerships, and

integrated consulting services (Network & Security Services – NSS) to

enhance the security in our products and maintain productivity. Rockwell

Automation provides detailed and actionable information about security

vulnerabilities to help customers make informed decisions on what steps they

need to take to improve their security.

Report a Suspected Product Vulnerability

Rockwell Automation encourages submissions of suspected vulnerabilities as

soon as they are discovered. Rockwell Automation maintains a formalized

process to identify, assess, and remediate reported vulnerabilities for those

products that are in the Active or Active Mature state.

The Product Security Incident Response Team (PSIRT) at Rockwell

Automation responds to suspected vulnerabilities within Rockwell

Automation products. Reporters are strongly encouraged to file a vulnerability

report with the PSIRT via email at secure@ra.rockwell.com

The PSIRT works with reporters to understand and validate reports.

The PSIRT:

• Requests that the reporter keep any communication confidential

• Assigns a tracking ID to the vulnerability report

• Reviews and responds, usually within two business days

• Advises the reporter of significant changes in the status of any

vulnerability reported to the extent possible without revealing

information provided to us in confidence

• Works to remediate reported vulnerabilities in a timely manner.

The Rockwell Automation PSIRT encourages the encryption of sensitive

information prior to sharing over email. To request instructions on how to use

our public key, contact us at secure@ra.rockwell.com

The Rockwell Automation PSIRT may contact the reporter via email or an

another agreed upon communications mechanism throughout the disclosure

process.

.

.

8 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 9

Vulnerabilities Chapter 1

The PSIRT asks that reporters adhere to the following :

• Play by the rules. This includes following the guidelines, as well as any

other relevant agreements.

• Report any vulnerability discovered promptly.

• Avoid violating the privacy of others, disrupting our systems, destroying

data, or harming user experience.

• Use only our PSIRT email to discuss vulnerability information with us,

unless otherwise agreed upon with the PSIRT.

• Keep the details of any discovered vulnerabilities confidential until

Rockwell Automation identifies a resolution.

• If a vulnerability provides unintended access to data, limit the amount of

data you access to the minimum required to demonstrate the issue.

Cease testing and submit a report immediately if you encounter any user

data during testing, such as personally identifiable information (PII),

personal healthcare information (PHI), credit card data, or proprietary

information.

• Only interact with test accounts you own or with explicit permission

from the account holder.

• Do not engage in extortion.

• Comply with all applicable laws.

Public Vulnerability Disclosure

The PSIRT discloses vulnerability details, mitigations, and solutions via the

Knowledgebase Technote Industrial Security Advisory Index

You can find additional information on the Industrial Cybersecurity

capabilities web page.

Rockwell Automation recognizes the hard work of reporters and provides

recognition within the advisories, unless otherwise specified. We recognize

reporters if they are the first to report a unique vulnerability and the report

triggers a product change.

The Rockwell Automation Vulnerability Disclosure Policy draws on the

United States Core Terms compiled by disclose.io, the vulnerability disclosure

guidance set forth by the CERT Coordination Center (CERT/CC) at

Carnegie Mellon University, and ISO 29147 and ISO 30111, which define

standards for receiving and processing vulnerability reports. Rockwell

Automation defines a reporter as an individual or organization that notifies a

vendor or coordinator of a suspected product vulnerability. Coordinators, on

the other hand, are defined as an individual or organization that coordinates

vulnerability information to affected parties.

.

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 9

Page 10

Chapter 1 Vulnerabilities

When conducting vulnerability research according to this policy, Rockwell

Automation considers the research to be:

• Authorized in accordance with the Computer Fraud and Abuse Act

(CFAA) (and/or similar state laws). Rockwell Automation will not

initiate or support legal action against you for accidental, good faith

violations of this policy.

• Exempt from the Digital Millennium Copyright Act (DMCA).

Rockwell Automation will not bring a claim against you for

circumvention of technology controls.

• Exempt from restrictions in our Terms & Conditions that would

interfere with conducting security research. Rockwell Automation

waives those restrictions on a limited basis for work done under this

policy.

• Lawful, helpful to the overall security of the Internet, and conducted in

good faith.

If at any time you have concerns or are uncertain whether your security

research is consistent with this policy, please email secure@ra.rockwell.com

before going any further.

.

Supply Chain Vulnerabilities

Threat Model

Rockwell Automation also prioritizes supply-chain vulnerabilities, especially if

a vulnerability affects more than one Rockwell Automation product. The

PSIRT accept reports regarding third-party components if the vulnerabilities

are disclosed in a multi-party, coordinated effort supported by a third-party

coordinator such as DHS CISA or the CERT/CC.

Threat modeling is a procedure to analyze network, application, and physical

security. A threat model identifies objectives and vulnerabilities, and then

defines countermeasures to mitigate the effects of threats to the system.

1. Describe the assets to protect.

Create classes of assets and information that you want to protect. For

example, a controller, the controller configuration, or recipe data in the

controller. Be as specific as possible. For example, include the following:

• serial number

•MAC ID

• IP address

•user access

• device dependencies

Prioritize the assets. Define the type of protection for each asset confidentiality, integrity, or availability.

10 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 11

Vulnerabilities Chapter 1

2. Describe the policies that govern the assets

The policies are typically control-based in that they define who can do

what to which asset. Other policies can define attributes such as asset

availability, version control, or confidentiality requirements.

Because policies are written in a general manner, they are supported with

procedures, standards, and guidelines to provide the details on how to

implement, enforce, and monitor the policy.

3. Characterize the assets and their supporting systems

Examine the assets in their information systems and identify

information flows that affect the assets. Characterize the systems and

software that are part of the information flow.

• How are the assets accessed?

• Who can copy, move, or modify them?

• What methods can be used to interact with them?

• Do they exist in multiple locations?

• How are multiple copies synchronized?

4. Identify threats to the assets

For each asset, identify how and where to enforce the policy that governs

the asset. Based on the type of protections for the asset, examine the

information flows, systems characterizations, and enforcement

mechanisms. Identify potential threats (such as threats to

confidentiality, threats to integrity, and threats to availability).

For example:

• ‘System goes off line’ is a threat to availability.

• ‘Database synchronization fails’ is a threat to integrity.

5. Characterize the threats

For each threat, enumerate the mechanisms (vulnerabilities) that can

cause the potential threat to become an actual threat. Keep the

vulnerabilities as broad as possible in scope.

6. Visualize

Use a network diagram and overlay system information, asset locations,

information flows, enforcement points, and vulnerabilities. Annotate

the diagram with available resources (people, money, equipment).

Use this visualization as a method to divide the system into manageable

pieces. This visualization also shows relationships and possible

consequences when you make changes.

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 11

Page 12

Chapter 1 Vulnerabilities

7. Strategize

Use the visualization to find:

• Patterns that suggest enterprise-wide solutions rather than local or

point solutions.

• Interactions of resources and ease of affecting the network.

• Possibilities of vulnerabilities being exploited.

• Develop backup and restore procedures.

Group vulnerabilities and their locations. Identify methods to address as

many of the vulnerabilities as possible with one change or small set of

changes.

Remember that not all vulnerabilities need new technology to address

the issues. Proper configuration, privilege, and access control are key, and

can often be improved without harming production facilities.

8. Verify

• Map every proposed change directly to a threat to an asset.

• Make sure that the change does not introduce a new threat to another

asset.

Verify that no policy enforcement point can be circumvented.

12 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 13

Chapter 2

RESET

SERIAL

CON / AUX

GE WAN 0

5VDC

-4.QA

FE 1SLFE 0

SL

FE 3SLFE 2

SLSL

SYS

ACT

LAN

EIP Mod

EIP Net

Setup

GPS

TimeCD

3 1

4 2

Out

1 2

Speed

Duplex

PRP

DLR

PoE

Alarms PSU

12345 6789 1011122526

13

1458912

10/100/1000 PoE+

100/1000 SFP

100/1000 SFP+

GPS ANT. DIG.TimeCode ANA.TimeCode

Console Alarm

TOD

16 17 20 21 24

25

OUTINOUT

IN

28

2724212223201718191613 14 15 28

Express

Setup

Disp.

Mode

L

NHiL

N

Hi

Lo

100-240V-, 50-60Hz, 2A

100-250V , 2A

24-60V , 10A 24-60V , 10A

100-250V , 2A

100-240V-, 50-60Hz, 2A

Lo

PSU1 PSU2

Module

Status

Network

Activity

Network

Status

1734-AENT

Point Bus

Status

System

Power

Field

Power

Module

Status

Network

Activity

Network

Status

1734-AENT

Point Bus

Status

REDUNDANCY MODULE

OK

COMM

PRI

D+

D-

MBRK

SHLD

IN1

1

2

IN2

COM

W

V

U

+

-

Mod

Net

5500S2

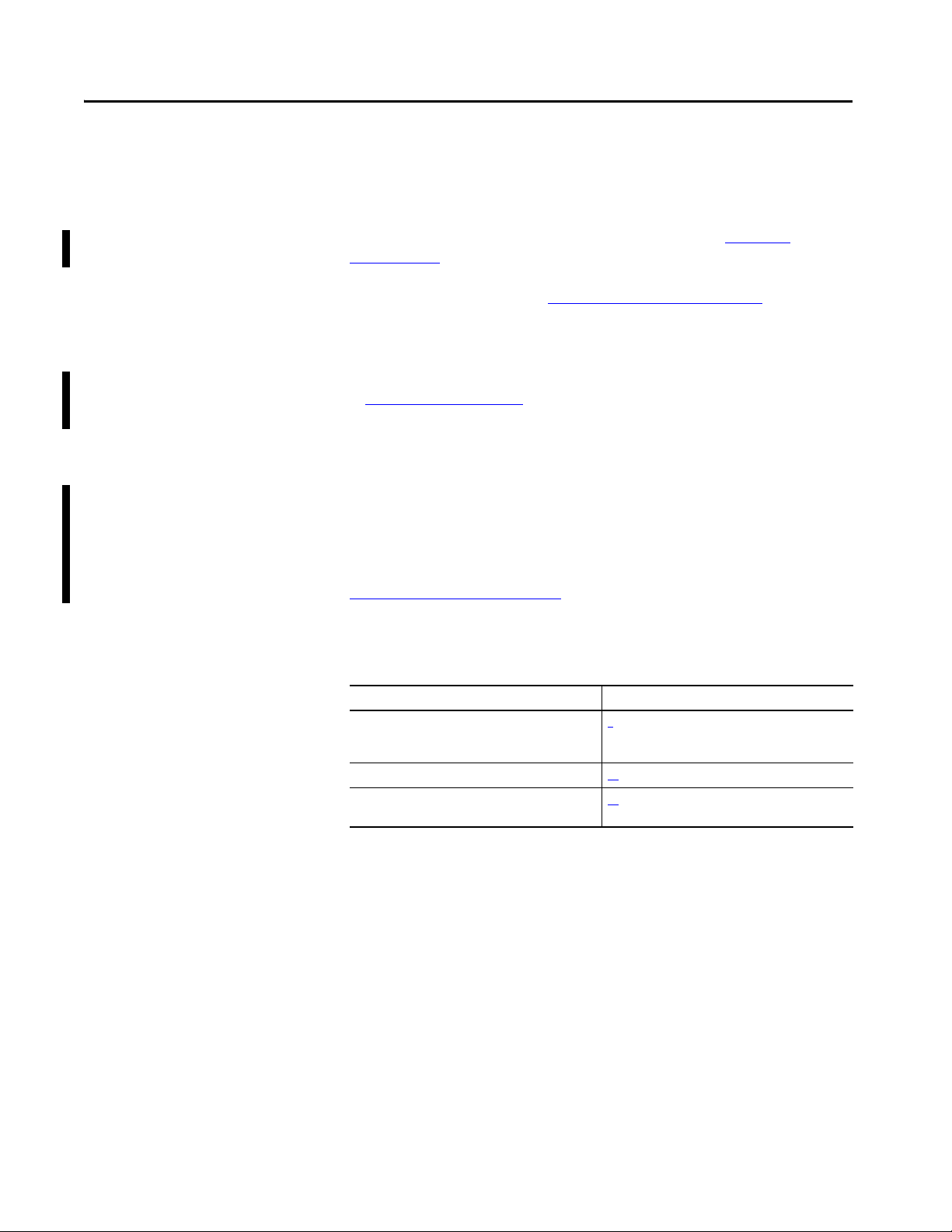

32791M

Internet

Plant/Enterprise LAN

Firewall

Firewall

Firewall

Process LAN

Level 3

Levels 0… 2

Levels 4 and 5

System Security

Just as the nature of manufacturing and industrial operations has changed, so

have the security risks. More connected operations can create more potential

entrance points for industrial security threats. Threats can come in many forms

– physical versus digital, internal versus external, or malicious versus

unintentional.

In the industrial automation and control system (IACS), follow common

industry standards, such as the Purdue Enterprise Reference Architecture

model, to define:

• Security zones - those assets that have the same security requirements

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 13

• Trusts within security zones - relationships between assets that support

identification, authentication, accountability, and availability.

Page 14

Chapter 1 System Security

Industrial security must address a wide range of concerns, including:

• Safeguard intellectual property and other valuable information.

• Safeguard operations from intrusions that could impact productivity,

product quality, operator safety, or the environment.

• Maintain critical infrastructure systems, especially systems in regulated

areas like energy and water/waster-water management.

• Maintain high-availability traffic policies for networks.

• Enable and control remote access to industrial operations.

Security Basics

Industrial security must be comprehensive. Extend security policies from the

enterprise through the plant level and to end devices. Address risks across your

people, processes, and technologies. Involve collaboration between IT and OT

personnel for design, management, and regular communication on expected

system functional requirements and policy compliance.

A robust approach to security includes the development and implementation

of the appropriate activities to complete the following steps:

• Identify the cybersecurity risk to systems, assets, data, and capabilities.

• Protect critical infrastructure services.

• Detect cybersecurity events.

• Respond to a detected cybersecurity event.

• Recover from and restore any capabilities or services that were impaired

due to a cybersecurity event.

Cybersecurity is the collection of technologies, processes and practices that

help protect networked computer systems from unauthorized use or harm.

Cybersecurity addresses cyber- attacks, which are offensive in nature and

emphasize network penetration techniques, and cyber-defenses, which are

defensive in nature and emphasize counter-measures intended to help

eliminate or mitigate cyber- attacks.

The main goals of cybersecurity in an industrial setting:

• Availability: maintain and never give up control in a control system

• Confidentiality: protect proprietary information and only let

individuals with a need-to-know have access to the information

• Integrity: ensure that the information flowing through the system has

not been tampered with

14 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 15

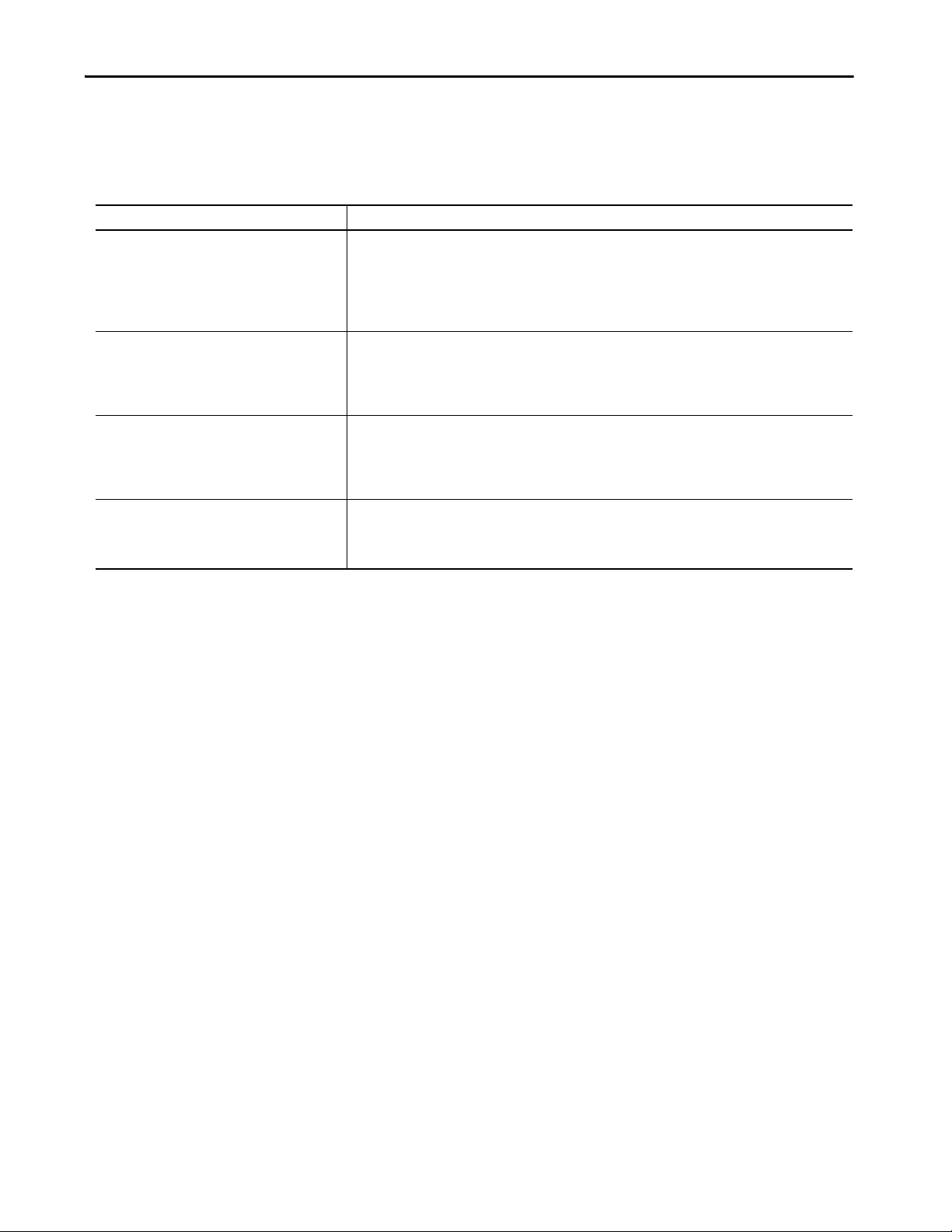

Security Standards

There are a number of resources that organizations can use as a basis to manage

security and risk within the IACS. These resources can help organizations

develop a security management program.

Resource Description

ISA/IEC 62443 Standard Industrial Automation and Control Systems (IACS) Security (formerly ISA-99)

This standard addresses network and system security and defines the provision of multiple security protections,

especially in layers, with the intent to delay, if not block, an attack.

This standard a lso recommends password structures.

NIST 800-82

Framework

NIST Cybersecurity

Framework

NCCIC Agency National Cybersecurity and Communications Integration Center

Guide to Industrial Control Systems (ICS) Security

This framework provides recommendations for securing an IACS. The standard covers the use of firewalls, the

creation of demilitarized zones and intrusion detection capabilities, along with effective security policies, training

programs, and incident response mechanisms.

This framework provides guidelines that help organizations align cybersecurity activities with business

requirements, risk tolerances, and resources.

This agency provides recommendations for secure architecture design.

The United States Department of Homeland Security (DHS) includes the

Cybersecurity & Infrastructure Security Agency (CISA). CISA manages a

repository of alerts, advisories, and reports (ICS-CERT) for industrial control

systems.

• Alerts: provide timely notification to critical infrastructure owners and

operators concerning threats to critical infrastructure networks.

• Advisories: provide timely information about current security issues,

vulnerabilities, and exploits.

• Reports: provide Technical Information Papers (TIPs), Annual Reports

(Year in Review), and 3rd-party products applicable to industrial control

system owners/operators.

• Newsletters: periodic publication of security news and information

applicable to industrial control system owners/operators.

System S ecurity Chapter 1

For more information, see Cybersecurity and Infrastructure Security Agency >

Industrial Control Systems

.

Defense-in-Depth Security

Industrial security is best implemented as a complete system across your

operations. Common to security standards is the concept of defense-in-depth

(DiD). DiD security establishes multiple layers of protection based on diverse

technologies through physical, electronic, and procedural safeguards. Just like a

bank uses multiple security measures – such as video cameras, a security guard,

and a vault – DiD helps make sure that threats encounter multiple lines of

defense. DiD also assumes the implementation of cybersecurity policies that

include operations planning, user training, and physical access security

measures.

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 15

Page 16

Chapter 1 System Security

A defense-in-depth security approach consists of six main components:

• Policies and Procedures

•Physical

•Network

•Computer

•Application

•Device

Defense-in-depth employs a comprehensive approach to leverage multiple

methods to mitigate risks. To apply defense-in-depth, understand the

relationship of intruders (threats and threat actors) and vulnerabilities to the

controls (standards, detection methods, and countermeasures).

A threat actor, through intent, capability, or opportunity, poses a threat to the

IACS when the threat compromises operations, personnel, or technology and

exploits an existing weakness or vulnerability. Base countermeasures on best

practices, standards, and established company security policies.

Countermeasures protect critical assets through multiple layers of defense.

Organizations must constantly adjust and refine security countermeasures to

maintain protection against known and emerging threats.

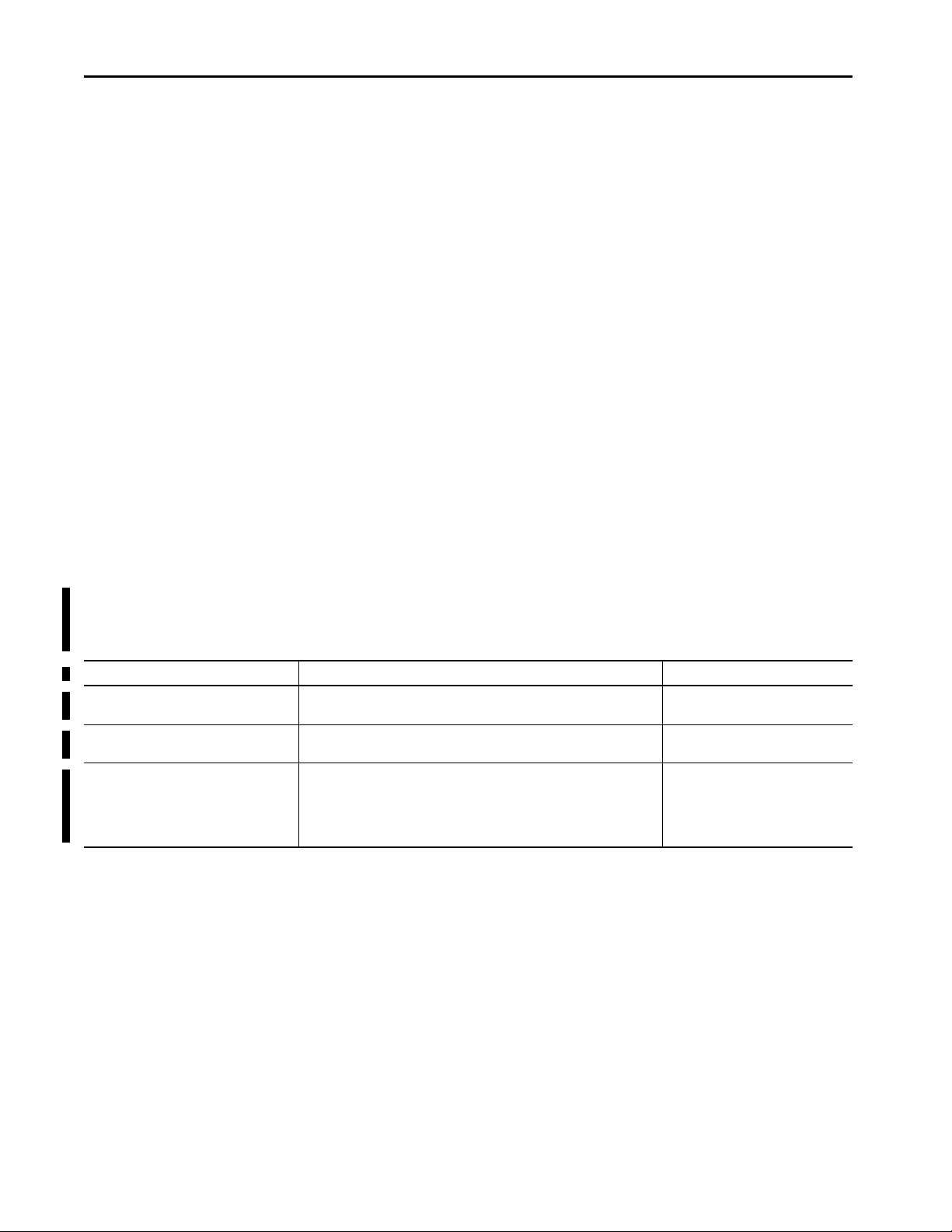

Notifications That Rockwell Automation Provides

Rockwell Automation provides these types of product notices.

Notification Description Customer Action

Product Safety Advisory (PSA) Issued when a product failure may result in significant loss of capital equipment,

Product Notice (PN) Issued when a product failure may result in significant commercial loss or customer

Product Security Advisory Issued for security alerts and security recommendations where such risks stem

Security with Rockwell Automation Products

personal injury, or death.

dissatisfaction.

from cyber-attacks.

These advisories are intended to raise customer awareness of risks to affected

product operation or performance and also supply relevant recommendations for

how to reduce or remove the risk associated with a vulnerability.

Security is not a static end state, it is an interactive process. No single

product, methodology, or technology fully secures control networks. The

remaining chapters in this reference manual highlight Rockwell Automation

products that help manage:

• Identification, authentication, and user access

•Network segmentation and data flow

• Data confidentiality

• System integrity

• Resource availability and response to events

Required

Strongly Recommended

Strongly Recommended

16 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 17

System S ecurity Chapter 1

Standard Security Components

In addition to the Rockwell Automation products described in this

publication, there are also references to these additional technologies.

Component Description

Microsoft® Active Directory service Use Active Directory for authentication and authorization in a Windows domain.

Active Directory (AD) is a directory service that Microsoft developed for Windows domain networks. It is included in

most Windows Server operating systems as a set of processes and services.

A server that runs the Active Directory Domain S ervices (AD DS) is called a domain controller. The domain controller

authenticates and authorizes all users and computers in a Windows domain type network. The domain controller

assigns and enforces security policies for all computers and software updates.

RADIUS protocol You can use the Remote Authentication Dial-In User Service (RADIUS) protocol to manage access to the Internet or

Cisco® TACACS+ protocol You can use the Cisco Terminal Access Controller Access-Control System Plus (TAC ACS+) to manage remote

IEEE 802.1x authentication You can use 802.1x authentication to manage port-based access for devices that want to connect to a network.

internal networks, wireless networks, and integrated email services.

The RADIUS protocol is a network protocol that provides centralized authentication, authorization, and accounting

(AAA) management for users. The RADIUS protocol is often used by Internet service providers (ISPs) and enterprises

to manage access to the Internet or internal networks, wireless networks, and integrated email services.

authentication for networked access control through a centralized server.

The Cisco TACACS+ protocol manages authentication, authorization, and accounting (AAA) services. The TACACS+

protocol uses the Transmission Control Protocol (TCP). Since TCP is a connection-oriented protocol, TACACS+ does

not have to implement transmission control. TACACS+ encrypts the full content of each packet.

802.1x authentication secures communication between authenticated and authorized devices. You can connect this

access control to the Active Director y to create a central administration connection for both network mana gement

and network access. This access control is the preferred method to create a central network access layer.

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 17

Page 18

Chapter 1 System Security

Notes:

18 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 19

Chapter 3

DAPWAP

DAPWAP

DAPWAP

SMC-Flex

EscSel

Lang

1734-AENTR

Module

Status

Network

Activity

Network

Status

Link 1

Activity

Status

Link 2

Activity

Status

Point Bus

Status

System

Power

Field

Power

1734-AENTR

Module

Status

Network

Activity

Network

Status

Link 1

Activity

Status

Link 2

Activity

Status

Point Bus

Status

System

Power

Field

Power

Module

Status

Network

Activity

Network

Status

1734-AENT

Point Bus

Status

System

Power

PanelView Plus 1250PanelView Plus 1250

Mod

Net

5700

Mod

Net

5700

Mod

Net

5700

32792M

IFW

Enterprise Cloud

Site Operations

Level 3

Enterprise Zone

Levels 4 and 5

Industrial Demilitarized Zone (IDMZ)

Industrial Zone

Level 3

Cell/Area Zone

Levels 0, 1, and 2

Cell/Are a Zone

Levels 0, 1, and 2

Cell/A rea Zone

Levels 0, 1, and 2

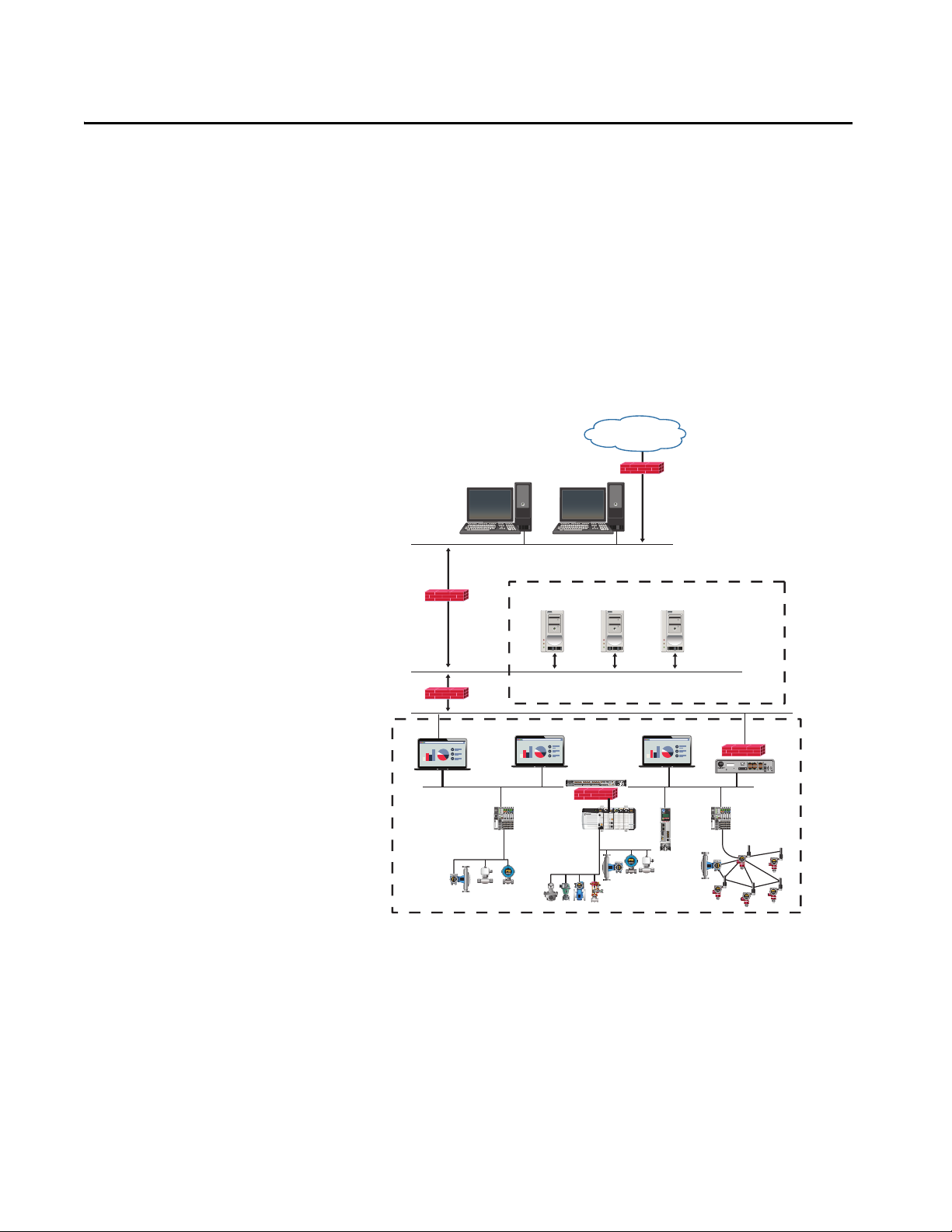

Secure Networks and Communication

The continuing trend in networking is the convergence of technology,

operational technology (OT) with information technology (IT). Technologies

like the Ethernet and EtherNet/IP™ (Common Industrial Protocol over an

Ethernet network) protocols help enable network technology convergence.

Network technologies that filter, block, and control access help secure

networks. You can also select control products that offer security options.

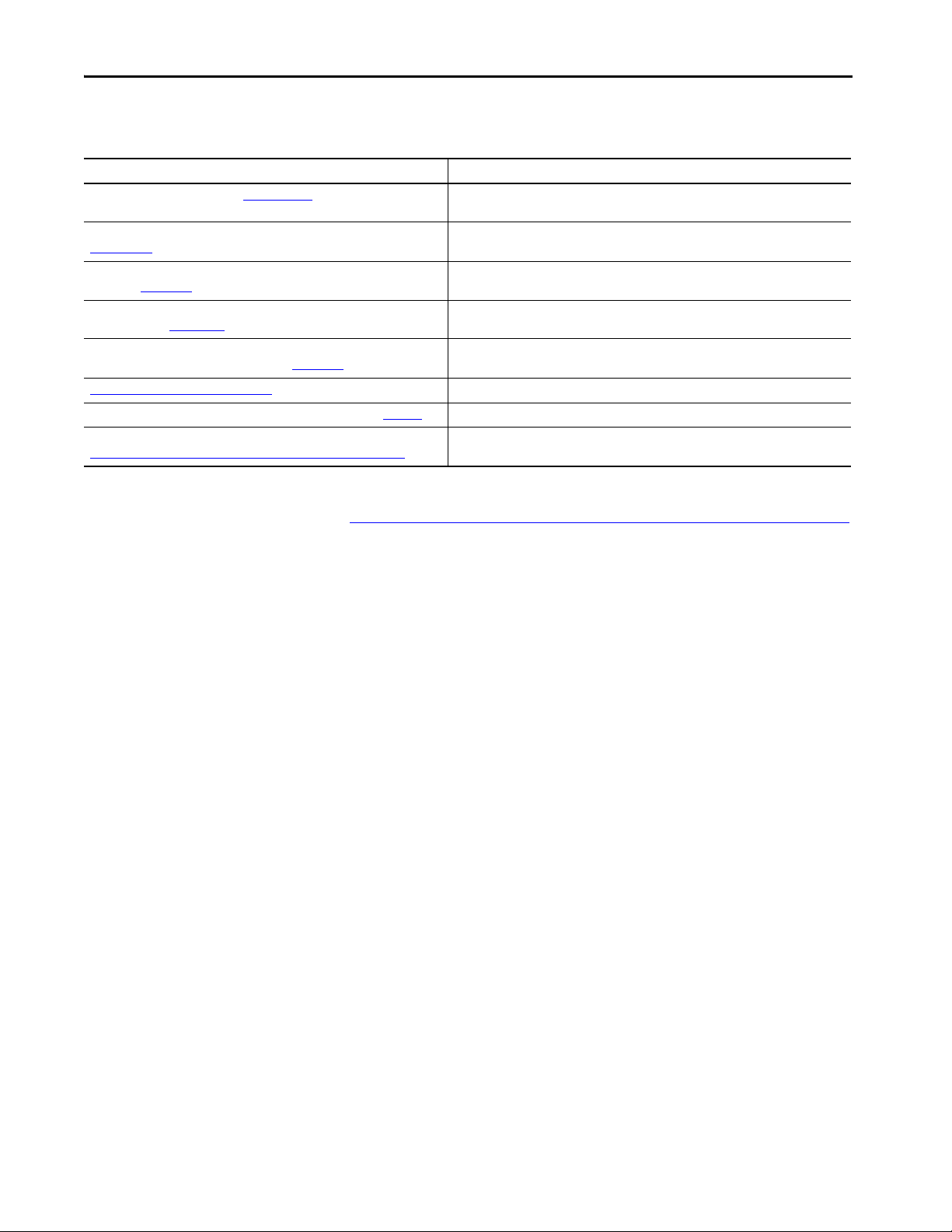

Converged Plantwide Ethernet (CPwE)

Converged Plantwide Ethernet (CPwE) reference architectures, a Rockwell

Automation and Cisco® collaboration, use industry standards to model

characterized network architectures for use in an industrial network security

framework. This industrial network security framework establishes a

foundation for network segmentation for both traffic management and policy

enforcement. The industrial network security framework uses a

defense-in-depth approach and is aligned to industrial security standards.

For more information, see Converged Plantwide Ethernet (CPwE) Design and

Implementation Guide, ENET-TD001

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 19

Page 20

Chapter 2 Secure Networks and Communication

32796M

Level 5

Level 4

Level 3

Level 2

Level 1

Level 0

Enterprise Network

Email and Internet Site Business Planning and Logistics Network

Enterprise Security Zone

Levels 4 and 5

Remote Desktop

Gateway services

Industrial Security Zones

Level 3

Cell/A rea Zones

Levels 0, 1, and 2

Patch

Management

Email

Web

Application

Server

Web S ervi ces

Operations

Application

Server

Reverse

Proxy

Sensors Drives Actuators Robots

Fac tor yTal k

Client

Fact or yTalk

Client

Batch

Control

Discrete

Control

Drive

Control

Continuous

Process

Safety

Control

Operator

Interface

Engineering

Work stat ion

Operator

Interface

Fact oryTa lk

Application

Server

Fact or yTalk

Directory

Engineering

Work stat ion

Remote Access

Server

Industrial DMZ

Logical Zones

CPwE logical zones employ common industry standards to organize the plant

functions into levels, and the IEC-62443 (formerly ISA-99) standard to

organize the levels into functional and security zones. The goal is to define

smaller, more manageable areas, such as:

•connected LANs

•broadcast domains

•fault domains

•domains of trust

You can use physical or logical segmentation to define zones.

Infrastructure Benefits

Segmented physical: simplex, unidirectional A unidirectional network only lets data pass from one side of a network connection to another, and not the other

Segmented physical: duplex, bidirectional A bidirectional network lets data pass from both sides of a network connection.

Segmented logical: duplex, bidirectional CPwE industrial network security framework – IDMZ, VLANs, VRF, switch hierarchy (Layer 2 / 3)

20 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

direction.

The controlled interface that comprises the send and receive elements of a unidirectional network acts as a one-way

communication protocol break’ between the two network domains.

Connect, segment, encrypt, and cloak your critical assets and networks with crypto-IDs.

Page 21

Secure Networks and Communication Chapter 2

Outside

Interface

Inside

Interface

10.10.30.10 10.10.30.10

Firewall

Allow ICMP (ping) Traffic

To 10.10.30.20

Allow HTTPS Traffic

To 10.10.10.30

Block All Other Traffic

ACE

ACE

ACE

ACL

Network Firewalls

A firewall is a software or hardware device that separates zones. A firewall

permits or denies network traffic based on preconfigured policies or rules.

One type of preconfigured rule is an access control list (ACL). An ACL

contains permit and deny statements. Each permit or deny statement is an

access control entry (ACE).

This type of firewall control is stateful packet inspection (SPI) and operates by

tracking legitimate connections. SPI rejects attempted connections from

sources without a connection history. If you use a packet crafting tool in an

attempt to gain access, the firewall rejects packets with sequence numbers that

are out of range.

Firewall Guidelines

Firewalls are good security boundary appliances.

32793M

• Your firewall is only as good as your rules.

• If a rule permits traffic from a host on one side of the firewall to the

other side of the firewall, a compromised host is hard to detect.

• Use Network Address Translation (NAT) to isolate private network

addresses from public addresses.

• Inspect traffic for conformance with proper protocol behavior.

• Regularly monitor the firewall for rule updates, reports and metrics, and

firmware and software patches.

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 21

Page 22

Chapter 2 Secure Networks and Communication

32794M

Firewall

Outside Inside

DPI

Firewall

Poli cy

DPI

Inspection

1

2

3

Deep Packet Inspection

Another type of firewall control is deep packet inspection (DPI). DPI inspects

application-layer traffic and examines packets traversing the firewall. This

inspection examines IP address and port information, as well as the type of

traffic and the data (if unencrypted), to enforce rules.

DPI examines the contents of a particular packet, and then either records that

information for statistical purposes or performs an action on the packet. This

information can then be forwarded to intrusion detection systems (IDS) and

intrusion prevention systems (IPS).

• Intrusion detection systems (IDS) inspect traffic on a network but do

not affect traffic in any way; IDS only logs or alerts on malicious traffic.

• Intrusion prevention systems (IPS) inspect traffic on a network and can

block malicious traffic.

1. Traffic enters the firewall.

2. Firewall policies are applied.

3. If a DPI rule applies, the packet is sent to an IDS or IPS rules engine for

action.

22 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 23

Secure Networks and Communication Chapter 2

Level 5

Level 4

Level 3

Level 2

Level 1

Level 0

Enterprise Network

Email and Internet Site Business Planning and Logistics Network

Enterprise Security Zone

Levels 4 and 5

Remote Desktop

Gateway services

Industrial Security Zones

Level 3

Cell/A rea Zones

Levels 0, 1, and 2

Patch

Management

Email

Web

Application

Server

Web S ervi ces

Operations

Application

Server

Reverse

Proxy

Sensors Drives Actuators Robots

Fac tor yTal k

Client

Fact or yTalk

Client

Batch

Control

Discrete

Control

Drive

Control

Continuous

Process

Safety

Control

Operator

Interface

Engineering

Work stat ion

Operator

Interface

Fact oryTa lk

Application

Server

Fact or yTalk

Directory

Engineering

Work stat ion

Remote Access

Server

Industrial DMZ

Industrial Demilitarized Zone (IDMZ)

The industrial demilitarized zone (IDMZ) is a critical perimeter that acts as a

buffer zone. The IDMZ provides a barrier between the Industrial and

Enterprise Zones and lets the zones securely share data and services.

32796M

IDMZ Best Practices

Practice Consideration

Services Replicate critical services in the industrial zone, consider the following:

Availability Apply redundant network routers, switches, firewalls, and links to maintain overall network availability

Scalability At small sites, use combined core and distribution switches.

Routing Use link-state routing protocols or EIGRP for Layer 3 load balancing and convergence

• Domain Services, such as LDAP or Active Directory

• Naming services, such as DNS and WINS

• IP address services, such as DHCP

• Time services, such as NTP and PTP

Larger or growing sites separate core and distribution switches to avoid over-subscription on uplinks.

Use EIGRP to simplify configuration

If standard protocols are required, use OSPF

IDMZ Guidelines

• All network traffic from either side of the IDMZ terminates in the

IDMZ; no traffic directly traverses the IDMZ.

• The IDMZ is the only path between Industrial and Enterprise Zones.

• There are no common protocols in each logical firewall.

• EtherNet/IP control traffic does not traverse the IDMZ; it remains in

the Industrial Zone.

• The IDMZ does not store primary services.

• All data is transient; the IDMZ does not store data.

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 23

Page 24

Chapter 2 Secure Networks and Communication

Enterprise Network Enterprise Network Enterprise Network

Plant Network Plant Network Plant Network

Router

(Zone-Based)

Firewall IDMZ

Silver

Gold

Platinum

• Use an application data mirror to move data in and out of the IDMZ.

• Limit outbound connections from the IDMZ.

• Be able to turn off access to the Industrial Zone via the firewall

• Set up functional subzones within the IDMZ to segment access to data

and services (IT, OT, trusted partner)

• The IDMZ is also a demarcation line for segmenting network policies

between the Enterprise and Industrial Zones.

• Segment network services such as Quality of Service (QoS), Virtual

LANS (VLANs), and multicast traffic. These services exist in both the

Enterprise and Industrial Zones and should be segmented.

Control Access to the Industrial Zone

Set up functional subzones in the IDMZ to segment access to data and services.

The IDMZ acts as the buffer between the Enterprise and Industrial Zones.

Most attacks attempt to pivot to other machines on the same network. Use the

firewall, intrusion detection, and intrusion prevention to stop the ‘pivot.’

24 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

32798M

Page 25

Secure Networks and Communication Chapter 2

HTTPS

Remote Desktop Clients

Enterprise Zone

RDP

Windows Server 2008 R2

Remote Desktop Gateway

Application Servers

Historian Server

Active Directory Server

IDMZ

Industrial Zone

Remote Desktop Gateway

The Remote Desktop Gateway is a server role in the Remote Desktop Services

function of Windows Server 2012 and later. The gateway enables authorized

remote users to connect to an internal corporate or private network.

32799M

Remote Desktop Gateway Guidelines

• Remote users connect to internal network resources by using an

encrypted connection, without virtual private network (VPN)

connections.

• The security configuration model lets you control access to specific

internal network resources (point-to-point connection).

• Remote users can connect to resources that are behind firewalls in

private networks and across network address translators (NATs).

• Configure authorization policies to define conditions for remote users

to connect to network resources. For example, specify:

– Who can connect to network resources (user group).

– What network resources (computer group) users can connect to.

– Whether client computers must be members of Active Directory

security groups.

– Whether device redirection is allowed.

– Whether clients need smart card authentication, password

authentication, or either.

• Configure clients to use Network Access Protection (NAP).

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 25

NAP is a health policy technology that lets administrators enforce

requirements, such as security updates, computer configurations, and

other settings.

Page 26

Chapter 2 Secure Networks and Communication

IFW

Default

Network A

Traffic

Network A

Traffic

IFW

Network A

Traffic

Network B

Traffic

Packe t

Packe t

Copy of

the Packet

Industrial Firewall Zones

Stratix 5950 Security Appliance

The Stratix® 5950 security appliance provides firewall, threat defense, and VPN

services. The appliance operates as an industrial DPI firewall with IDS and IPS

capabilities. The security appliance provides firewall, threat defense, and VPN

services. The Stratix 5950 security appliance can operate in the following

modes:

Architecture Mode Description

Inline Transparent Default mode

Use to segment a machine, skid, or unit

from the Cell/Area Zone network. This

mode supports different security

requirements between the larger control

network and the machine/skid or to restrict

ingress and egress traffic.

Inline Routed Use as a Layer 3 ingress and egress router

hop between a production line and a

machine/skid. Monitor or control traffic

firewall or DPI security policies.

Passive Monitor To avoid the possibility of the firewall affecting traffic,

configure a traffic-forwarding interface and connect that

interface to a SPAN por t on a switch.

Stratix 5950 Guidelines

• Use CIP™ (Common Industrial Protocol) Access Control Policy rules to

block specific CIP traffic

• Block CIP actions like CIP Reads, CIP Writes, CIP Administration

Firmware Update, and CIP Administration Download instead of permit

actions.

• CIP DPI rules include host addresses but are not granular enough to a

block specific users or tags.

For more information, see the Stratix 5950 Security Appliance User Manual,

publication 1783-UM010

.

IFW

26 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 27

Secure Networks and Communication Chapter 2

SMC-Flex

EscSel

Lang

Module

Status

Network

Activity

Network

Status

1734-AENT

Point Bus

Status

System

Power

Field

Power

PanelView Plus 1250PanelView Plus 1250

32800M

Com

IN2

IN1

Ref

Com

IN2

IN1

Ref

Com

IN2

IN1

Ref

IFW

Enterprise

Site Operations

Level 3

Industrial Demilitarized Zone

(IDMZ)

Controller - Level 1

Enterprise Zone

Levels 4 and 5

Area Supervisory Control

Level 2

Process - Level 0

Control Device Communication Ports

Customers using firewalls may want to configure communication ports on

devices so that routers forward only Transmission Control Protocol (UDP and

TCP) ports.

For more information, see Knowledgebase Technote TCP/UDP Ports Used by

rockwell Automation Products.

Switch and Routing

Stratix Managed Switches

Platforms

Configure Stratix managed switches to restrict access and segment your

network architecture.

Restriction Guidelines

Physical Restrict access to the control panel or zone enclosure to authorized personnel only.

Use Panduit block-outs for open access ports and lock-ins for copper and fiber media.

Electronic Configure layer 2 media access control address (MAC) security on access ports.

Configure layer 3 access control lists (ACLs).

Define virtual local area networks (VLANs) to segment the cell/area zone into smaller domains of trust.

Disable access ports from the controller and operator interface.

Configure traffic threshold settings to monitor denial-of-service (DOS) attacks.

Enable a cryptographic version of the switch operating system (SSH, HTTPS, SNMPv3).

Manage access to maintenance ports via authentication to the local HMI.

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 27

Page 28

Chapter 2 Secure Networks and Communication

For more information, see the following publications.

Resource Description

Stratix Managed Switches User Manual, publication 1783-UM007 Covers :

Stratix 6000 Managed Switches User Manual, publication 1783-UM001 Covers Stratix 6000 switches.

Stratix 2500 Lightly Managed Switches User Manual, publication 1783-UM009 Covers Stratix 2500 switches.

• Stratix 5400 switches

• Stratix 5410 switches

• Stratix 5700 switches

• ArmorStratix™ 5700 switches

• Stratix 8000 and 8300 switches

Secure Communications

Secure communications between devices to support data integrity, data

confidentiality, and device authenticity.

CIP Security

CIP Security™ is a standard, communication method that helps to provide a

secure data transport across an EtherNet/IP network. The secure data

transport is used between certain connected devices to help protect the devices

from threats posed by unauthorized users with malicious intent.

Rockwell Automation uses the following products to implement CIP Security:

• FactoryTalk® Policy Manager

•FactoryTalk Linx

• Studio 5000® Design Environment

• CIP Security-enabled Allen-Bradley products

For more information on CIP Security, see the CIP Security Application

Te ch ni que , p u b l ica ti o n SECURE-AT001

This additional layer of security reinforces the depth-in-defense approach. The

CIP Security technology does not replace firewalls or other network

infrastructures.

.

28 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 29

Secure Networks and Communication Chapter 2

Wireless Connectivity

Option Description

WPA2-PSK (pre-shared key) authentication • One password for all clients, no user-based authentication

WPA2 Enterprise (802.1x) authentication • WPA2-Enterprise with EAP-TLS is the most secure method

Category Guidelines

Wireless node limitations • The number of wireless clients affects the performance

Latency and jitter • Make sure a channel load is below the limit and the proper wireless QoS policy

Packet loss and reliability • If a wireless frame is not received, it is retransmitted until the retry limit is

Unicast versus multicast • Multicast and broadcast traffic is much less reliable than unicast traffic

In a wireless architecture, always use Wi-Fi Protected Access II (WPA2)

security with Advanced Encryption Standard (AES) encryption.

• PSK is part of device configuration

• Does not provide fast roaming times

• Does not satisfy corporate security policy

• Uses individual user credentials and (optional) security certificates

Requires additional infrastructure and support

• Active Directory

•RADIUS server

• Certificate infrastructure

Wireless Guidelines

• Do not exceed 20 wireless nodes per access point

• Do not exceed 19 wired clients per workgroup bridge

• Keep the total number of Ethernet devices on a VLAN (wired or wireless) below

200 to restrict the amount of broadcast traffic

is applied

• A small percentage of packets is delayed significantly so the application should

handle delayed packets

• Low RPIs (faster than 5 ms) are not useful for wireless applic ations

• Overloading a channel leads to excessive latency and timeouts

• A larger number of wireless nodes increases latency

reached

• An application must tolerate occasional packet loss

• An excessive packet rate causes high packet loss and application timeouts

• A large number of wireless nodes increases the chance of timeouts

• Changes in the RF environment, interference, or unauthorized channel

transmissions can decrease reliability or disrupt wireless communication

• Multicast wireless frames are not acknowledged and not repeated if lost

• Use only unicast EtherNet/IP connections with I/O or produced/consumed tags

• Do not use a ControlLogix® redundancy system with wireless communication

• Configure IGMP snooping and querier in the network infrastructure

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 29

Page 30

Chapter 2 Secure Networks and Communication

Additional Resources

The following publications provide details related to secure network

connections.

Resource Description

Design and Implementation

Deploying Industrial Firewalls within a Converged Plantwide Ethernet Architecture

Design and Implementation Guide, publication ENET-TD002

Site-to-Site VPN to a Converged Plantwide Ethernet Architecture Design an

Implementation Guide, publication ENET-TD012

Deploying Identity Services within a Converged Plantwide Ethernet Architecture

Design and Implementation Guide, publication ENET-TD008

Securely Traversing IACS Data across the Industrial Demilitarized Zone Design and

Implementation Guide, publication ENET-TD009

Deploying 802.11 Wireless LAN Technology within a Converged Plantwide

Ethernet Architecture, publication ENET-TD006

Application

Industrial Firewalls within a Converged Plantwide Ethernet Architecture White

Paper, publication ENET-WP011

Deploying Identity Services within a Converged Plantwide Ethernet Architecture

White Paper, publication ENET-WP037

Securely Traversing IACS Data Across the Industrial Demilitarized Zone White Paper,

publication ENET-WP038

Design Considerations for Securing Industrial Automation and Networks White

Pape r, ENET-WP031

Use cases for designing, deploying, and managing industrial firewalls throughout an IACS

network infrastructure.

Use cases for connecting remote IACS assets to a plant-wi de network architecture. This guide

highlights the key application requirements, technology, and suppor ting design

considerations.

The requirements and design considerations to deploy the Cisco Identity Services Engine

(Cisco ISE) within an IACS architecture.

The requirements and design considerations to deploy an industrial demilitarized zone

(IDMZ) within an IACS architecture.

Wireless LAN network capabilities, with emphasis on equipment connectivity.

Guidelines for designing, deploying, and managing industrial firewalls throughout an IACS.

Guidelines for designing, deploying, and managing identity services throughout an IACS.

Guidelines for designing, deploying, and managing industrialized demilitarized zones

throughout an IACS.

Guidelines for designing, deploying, and managing secure networks throughout an IACS.

30 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 31

Chapter 4

Harden the Control System

For guidelines on system hardening, see Knowledgebase Technote Rockwell

Automation Customer Hardening Guidelines.

Patch Management

Keep security updates (patches) for both operating system and IACS software

up-to-date. Patches can be critical to mitigate risk.

Verify any update to Rockwell Automation products or third-party products

before implementation. Verify that configuration settings are still correct.

Microsoft Patches

Microsoft® releases a range of security updates for operating systems and other

software products. Rockwell Automation qualifies certain Microsoft updates

that impact Rockwell Automation software products.

It is recommended that you implement a controlled system suitable for your

application and environment. Follow the guidance for Microsoft Patch

Qualifications at:

http://www.rakb-patchtests.com/data/MS_Patch_Qualification/start.htm

Before implementing any Fully Qualified Microsoft updates, verify them on a

non-production system, or when the facility is non-active, to ensure that there

are no unexpected results or side effects.

Microsoft regularly releases security updates. If your system is not connected to

the Internet, you will not automatically receive these updates.

Rockwell Automaton has a MS Patch Qualification team (PQUAL) to qualify

Microsoft security updates against the most popular set of products available

from Rockwell Automation. Results are posted on the Patch Qualification

Portal. For more information, see the Knowledgebase Technote Microsoft Patch

Qualifications.

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 31

Page 32

Chapter 3 Harden the Control System

Product Change Management

Keep your Rockwell Automation systems current to help you achieve improved

security in your systems. Rockwell Automation uses product and version status

policies to help you plan how to keep your system current.

Rockwell Automation assigns the status of a product based on the product

catalog number.

Status Definition

Active Most current offering within a product category.

Active Mature Product is fully supported, but a newer product or family exists. Gain value by migrating.

End of Life Discontinued date announced - actively execute migrations and last time buys. Product generally orderable until the

Discontinued New product no longer manufactured or procured. Repair/exchange services may be available.

discontinued date.

To check the lifecycle status of a product, see the Product Lifecycle Status

website.

Rockwell Automation further classifies product changes to catalog numbers

(versions and revisions) to help customers manage their system.

Change Type Description

Series Change A series change indicates that there was a backward compatible hardware modification or non-field upgradeable

Direct Replacement A direct replacement is any new product that emulates an earlier product. Form, fit, and function are backward

Functional Replacement A functional replacement is any new product with minor form, fit, and function differences. It is not a direct

Engineered Replacement An engineered replacement is any new product with major form, fit, and function differences.

firmware modification to a product.

A series for product with firmware increments the major firmware revision number.

compatible.

No user application changes are needed.

replacement and it does not emulate the earlier product.

Minor application changes are required.

Major application changes are required.

Hardware Series

An alphabetical designator at the end of the product catalog number indicates

the series of the product. The series indicator increments when there is a

hardware change related to form, fit, or function.

• If a product has firmware, a series changes also requires a firmware

revision. However, a firmware revision does not necessitate a series

change.

• A series change can also require a new device profile. The new device

profile is backward compatible to older series of the product.

• An older series product cannot replace a newer series product.

32 Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021

Page 33

Harden the Control System Chapter 3

Software and Firmware Versions

To further understand the state of your system and help you keep the system

current, Rockwell Automation assigns a lifecycle state to each individual

version of a product.

Version State Description

Preferred Versions to adopt to stay current.

Managed Versions to adopt when you cannot use Preferred, typically for following reasons:

Limited Versions that are available for download, but that are not the recommended versions to use. In general, these versions

Retired Versions that are no longer available for download because of security or safety concerns, or lack of suppor t viability.

• Major release versions of Active and Active Mature products remain in the Preferred state for 3 years following release

• The latest version of an Active or Active Mature product is always preferred

When a new minor or sub-minor version is released, the new minor or sub-minor release inherits the major version

lifecycle state and the previous minor or sub-minor version transitions to be a Limited or Retired version.

• Maintain compatibility between non- discontinued hardware and software

• Customer IT/OT lifecycle planning requires extended security coverage through Rockwell Automation patch updates.

Major release versions of select Active and Active Mature products remain in the Managed state for 2 years following the

Preferred state period.

remain available to support customers who have chosen not to stay current.

For more information see the Knowledgebase Technote What is the Rockwell

Automation Software and Firmware version lifecycle policy?.

To check the lifecycle state of a product version, see the product’s entry in the

Product Compatibility and Download Center

website.

Rockwell Automation designs, develops, maintains, and supports Preferred

and Managed versions in accordance with the ISA/IEC 62443-4-1 certified

secure, product development lifecycle.

For Preferred and Managed versions, Rockwell Automation:

• Notifies you of security-related issues in our products, and maintains a

way for you to report back if you encounter security-related issues with

our products.

• Notifies you if security patches for other products used in conjunction

with our products (such as operating systems or anti virus programs)

interfere with the correct operation of our products.

• Makes sure that qualified engineers and cybersecurity experts assess

security-related issues for risk to our products and customers.

• Issues security updates accordingly and updates documentation with the

latest information for how to secure our products.

• Makes software and firmware updates available through our support

website and other support channels.

Rockwell Automation Publication SECURE-RM001E-EN-P - March 2021 33

Page 34

Chapter 3 Harden the Control System

Managed Ethernet Switch

Fac tor yTalk

Directory Server

Engineering

Work stat ion

Managed Ethernet Switch

Domain

Controller

Workstation Hardening

Many IACS solutions use computers and servers to run applications. Consider

these workstations and their operating systems in the overall security plan.

• Use Microsoft Active Directory for authentication and authorization.

• Secure Group security policies.

• Join all workstations to the domain.

• Dedicate workstations to operator and engineering functions, and

remove all other unnecessary applications, services, and ports.

• Install endpoint protection, such as anti virus and anti-malware

software, and keep the definition files up-to-date.

• Minimize users with access to administrative rights.

• Secure USB, CD, and DVD drives so they are available only for

authorized purposes.

• Regularly restart workstations to prevent against memory-only

infections.

• Implement a validated backup and restore process for important data

and systems.

FactoryTalk Directory Application

The FactoryTalk® Directory application is a common service that is used by

FactoryTalk View Site Edition and other Rockwell Automation software

products. The FactoryTalk Directory server hosts a common address lookup of

shared resources among FactoryTalk-enabled products.

REDUNDANCY MODULE

OK

COMM

PRI

REDUNDANCY MODULE

OK

COMM

PRI

REDUNDANCY MODULE

OK

COMM

PRI

D

D

D

D

D

D

D

00 10 00 10

01 11 01 11

C

1

02 12 02 12

O

0

03 13 03 13

U

04 14 04 14

TO

05 15 05 15

T

3

06 16 06 16

P

0

07 17 07 17

U

BATT

V

PROG

FUSE

T

PROC

R

E

M

2

FORCE

RUN

4

COMM

AAB

6

8

10

12

1

14

2

16

1

18

B

2

20

CH 2

22

CH 0

AAB

24

2A

26

28

2B

30

1

32

1A

2

34

1

36

B

1B

2

38

CH 1

40

SEE PROD LITERATURE

FOR BATT REPLACEMENT

INFORMATION

BATTERY INSTALLED

DMY

PLC-5/80

PROGRAMMABLE

CONTROLLER

D

00 10 00 10

00 10 00 10

00 10 00 10

00 10 00 10

00 10 00 10

00 10 00 10

00 10 00 10

01 11 01 11

01 11 01 11

01 11 01 11

01 11 01 11

01 11 01 11

01 11 01 11

01 11 01 11

C

C

C

C

C

C

C

1

1

1

1

1

1

1

02 12 02 12

02 12 02 12

02 12 02 12

02 12 02 12

02 12 02 12

02 12 02 12

02 12 02 12

O

O

O

O

O

O

O

0

0

0

0

0

0

0

03 13 03 13

03 13 03 13

03 13 03 13

03 13 03 13

03 13 03 13

03 13 03 13

03 13 03 13

U

U

U

U

U

U

U

04 14 04 14

04 14 04 14

04 14 04 14

04 14 04 14

04 14 04 14

04 14 04 14

04 14 04 14

TO

TO

TO

TO

TO

TO

TO

05 15 05 15

05 15 05 15

05 15 05 15

05 15 05 15

05 15 05 15

05 15 05 15

05 15 05 15

T

T

T

T

T

T

T

3

3

3

3

3

3

3

06 16 06 16

06 16 06 16

06 16 06 16

06 16 06 16

06 16 06 16

06 16 06 16

06 16 06 16

P

P

P

P

P

P

P

0

0

0

0

0

0

0

07 17 07 17

07 17 07 17

07 17 07 17

07 17 07 17

07 17 07 17

07 17 07 17

07 17 07 17

U

U

U

U

U

U

U

BATT

V

V

V

V

V

V

V

PROG

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

T

T

T

T

T

T

T

PROC

R

E

1

1

1

1

1

1

1

1

M

2

2

2

2

2

2

2

FORCE

3

3

3

3

3

3

3

3

RUN

4

4

4

4

4

4

4

COMM

5

5

5

5

5

5

5

5

AAB

6

6

6

6

6

6

6

7

7

7

7

7

7

7

7

8

8

8

8

8

8

8

9

9

9

9

9

9

9

9

10

10

10

10

10

10

10

11

11

11

11

11

11

11

11

12

12

12

12

12

12

12

1

13

13

13

13

13

13

13

13

14

14

14

14

14

14

14

15

15

15

15

15

15

15

15

2

16

16

16

16

16

16

16

1

17

17

17

17

17

17

17

17

18

18

18

18

18

18

18

B

19

19

19

19

19

19

19

19

2

20

20

20

20

20

20

20

CH 2

21

21