Page 1

Quick Start

PlantPAx System Application Templates

System Release 3.0

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, PlantPAx, RSLog ix, RSLinx, FactoryTalk, Integrated Architecture, Logix5000, ControlLogix, Com pactLogix, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Configure the Controller Application

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before Using This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PlantPAx Quick Start Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Controller Template Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Download the PlantPAx Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Open Your Template. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Modify Controller Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Configure Controller Task Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Add Modules to Local Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Configure Network Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configure I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Add Remote I/O Chassis and Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Download the Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Create Your HMI Project

Chapter 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

HMI Template Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Download the PlantPAx Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Load the HMI Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Create Your HMI Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Deploy Your HMI Template. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Configure Your Data Servers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Configure Your Alarm Servers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Add Controllers to Data Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Set Runtime Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 3

Page 4

Table of Contents

Chapter 3

Start Using Your HMI Project

Add Basic System Diagnostics

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Observe the Template Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Create Your OWS Client File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Explore Template Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Alarm Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

System Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Navigation Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 4

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Download the PlantPAx Library. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Add Diagnostics to the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Add Controller Diagnostics to a HMI Project . . . . . . . . . . . . . . . . . . . . . . 55

Configure PASS Server Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Add These Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Access the Quick Start Worksheet

Index

Appendix A

Enable Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Using the Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 5

Preface

IMPORTANT

Code

Sy

T

Co

e

&

Procure

Sy

&

Conguration

Config ure the Controller

Create Your HMI Project

Start Using Your HMI

46250

Add System Diagnostics

About This Publication

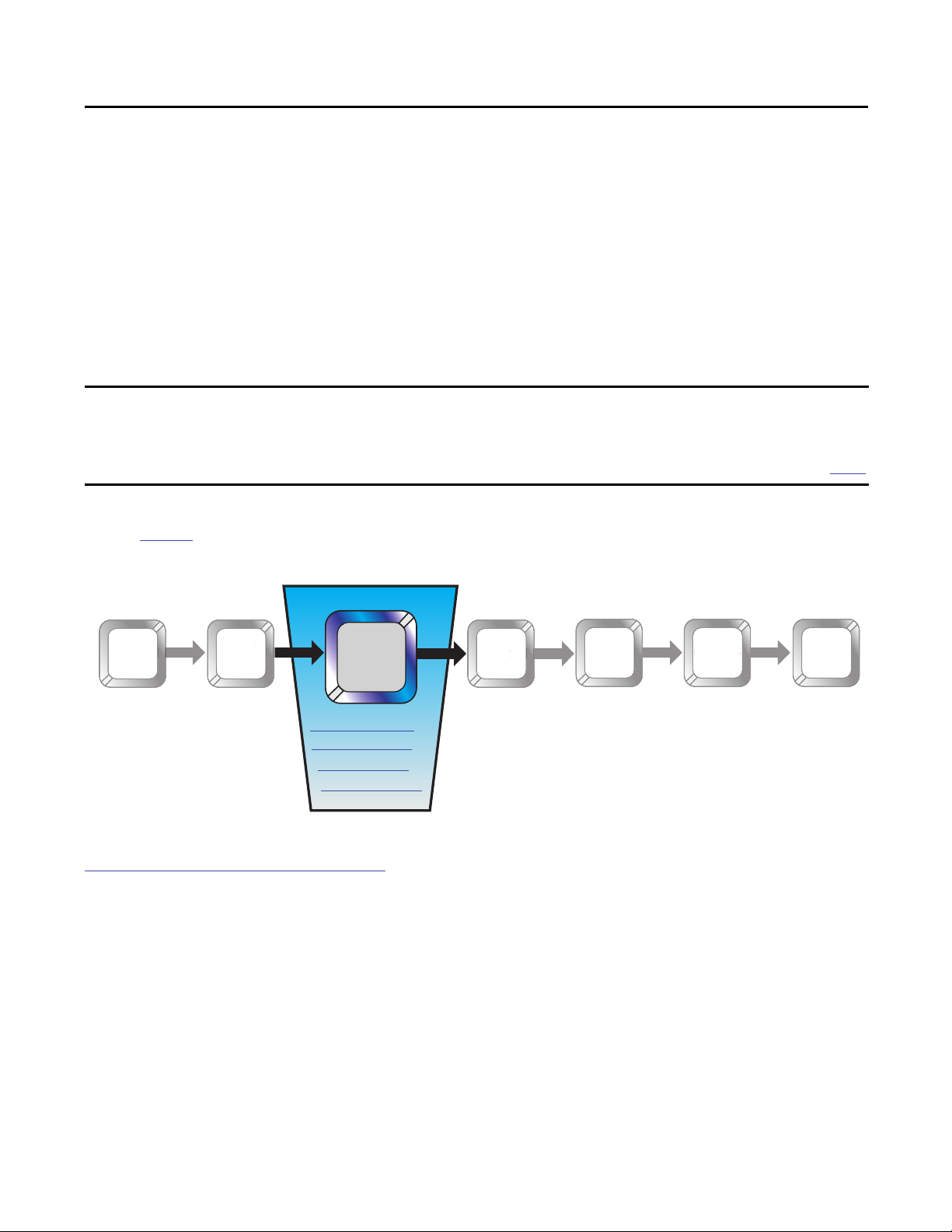

The purpose of this quick start is to describe how to apply application templates to start development of your PlantPAx™

Process Automation System. Basic procedures explain how to configure pre-built controller and human-machine interface

(HMI) templates to provide an application framework with these goals:

• Provides a consistent starting point for system implementation

• Promotes a standardized application framework for control systems and process skids to provide a unified

system experience

• Reduces implementation risks and promotes application practices for optimal system performance

Before using this guide, you must have an installed system available to follow the procedures in this guide. You also need to make

sure your system is properly sized by using the PlantPAx System Estimator (PSE). The PSE is part of the Integrated Architecture™

Builder (IAB) tools.

For more information on system resources, such as Define and Procure and System Set-up, see the Additional Resources on page 8

This guide walks you through the tasks for applying the templates that provide a starting point for your application specific

code. In Figure 1

, the lesson goals are underlined per chapter.

.

Figure 1 - Quick Start Manual Scope

Dene

Den

&

Procure

stem

Set-up &

Set-up

Conguration

Apply

Templates

Application

Application

Specic

Specic

Code

System

stem

Test

est

Commission Support

mmission Support

System

The application templates described in this guide are downloaded from the Knowledgebase Answer ID 62682 at

http://www.rockwellautomation.custhelp.com

. Typically, you apply application templates on your Process Automation

System Server (PASS) and HMI visualization client by using the Engineering Workstation (EWS). Once the templates are

applied, you run your application on the Operator Workstation (OWS) to review results.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 5

Page 6

Preface

IMPORTANT

46249

OWS PASS Server EWS

IMPORTANT

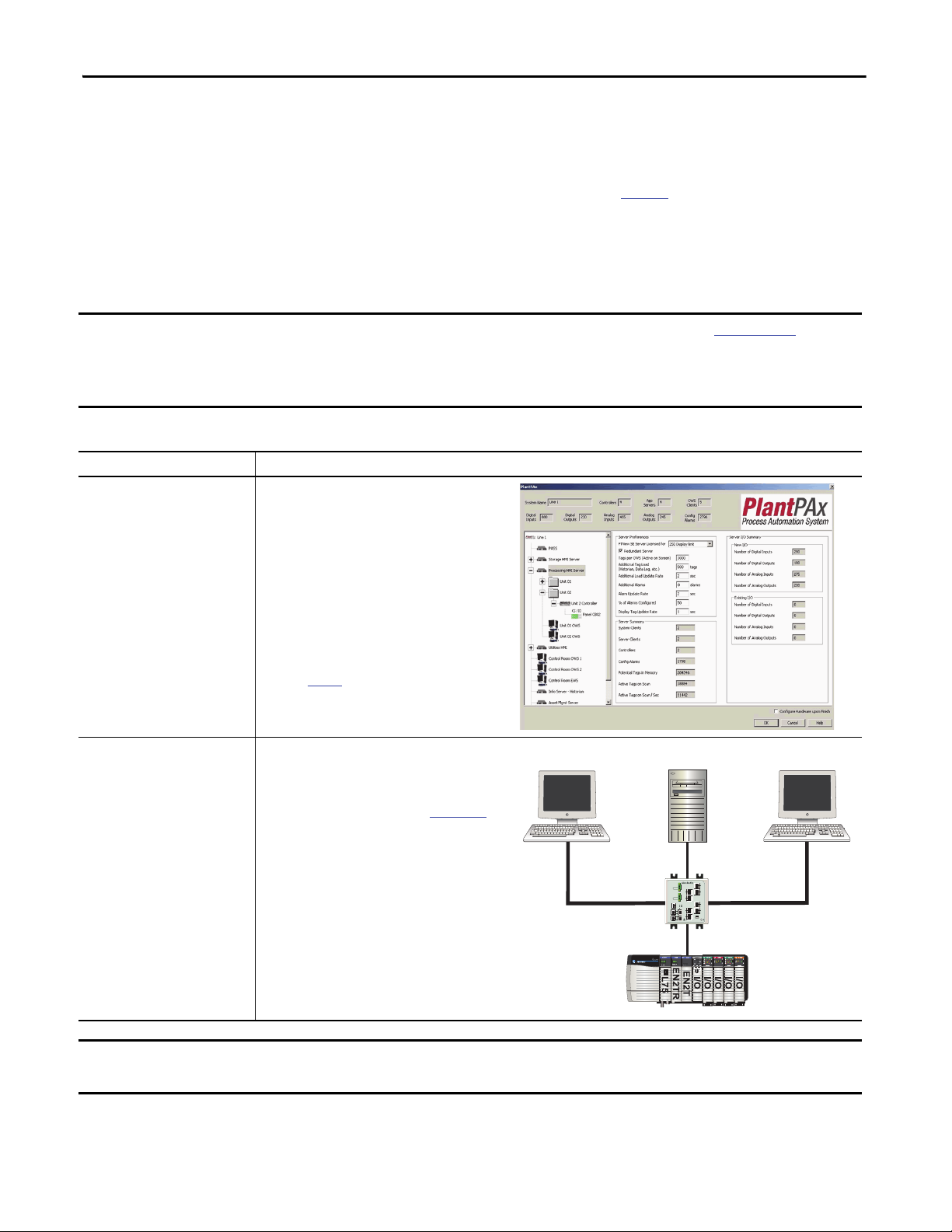

Before Using This Publication

You can use the tasks described in this publication only after first completing some prerequisite tasks. For example, you

must have your workstations and servers installed and communicating on a network. Ta b l e 1

The procedures in this quick start use the following software versions:

• RSLogix™ 5000 software, version 20.x

• FactoryTalk® View software, version 7.0.

We suggest that you refer to the PlantPAx Process Automation System Reference Manual, publication PROCES-RM001,

for system guidelines during and after you use this guide. For example, the reference manual documents recommended task

configurations applied by the procedures contained within this guide. There also are recommended rules to follow when creating

your specific configuration after completing this quick start.

Table 1 - Required Tasks to Complete before Using This Quick Start

Objective Task Descriptions

Define the system • Collect requirements. For example, I/O counts,

redundancy, simplex controllers, and so forth

• Choose the controller family, I/O family, network

topology. For example, EtherNet/IP, Ring or Star,

Control Logix®, CompactLo gix™

• Size your system based on requirements

• Create system layout by assigning slots and

IP addresses, chassis locations, I/O counts, and so forth

describes the prerequisites.

IMPORTANT: The system must be defined and sized

properly by using the PSE (shown at right) that is part of

the IAB tool. The worksheet that is included with this

guide (see page 69

requirements but is a helpful tool for defining information

that you need for template initiation. To size a system, use

the PSE.

Install the system • Set up infrastructure. For example, install computer

hardware, wire networks, configure network switches

• Install servers and workstations (PASS, OWS, EWS)

If using virtual image templates, see the Virtual Image

Templates User Manual, publication 9528-UM001

or

Configure the operating system and NIC cards, join a

domain, and install software

• Set up the FactoryTalk Directory (FTD) server

• Install controller hardware (c hassis, power supply,

modules)

• Test communication. For example, ping or use RSWho

to locate each server, workstation, and controller

IMPORTANT: The FTD location must be specified for each

workstation and server on your system.

It’s possible to follow the tasks in this quick start without the entire production environment. However, a minimal set up is

required, including PASS servers and controllers.

) cannot determine sizing

6 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 7

Preface

IMPORTANT

Before You Begin

The beginning of each chapter contains the following information. Read these sections carefully before beginning work in

each chapter:

• Before You Begin – This section lists the steps that must be completed and decisions that must be made before

starting that chapter. This section defines the minimum amount of preparation required before completing the

current chapter.

• What You Need – This section lists the tools that are required to complete the steps in the current chapter. This

includes, but is not limited to, hardware and software.

• Follow These Steps – This illustrates the steps in the current chapter and identifies which steps are required to

complete the examples by using the section.

PlantPAx Quick Start Worksheet

The PlantPAx Quick Start Worksheet can help you determine the information required for following the procedures in

this guide. The worksheet is a Microsoft Excel macro-enabled workbook (.xlsm). As information is entered, additional

entry fields are dynamically created to collect more information.

You do not have to use the worksheet with the procedures in this quick start.

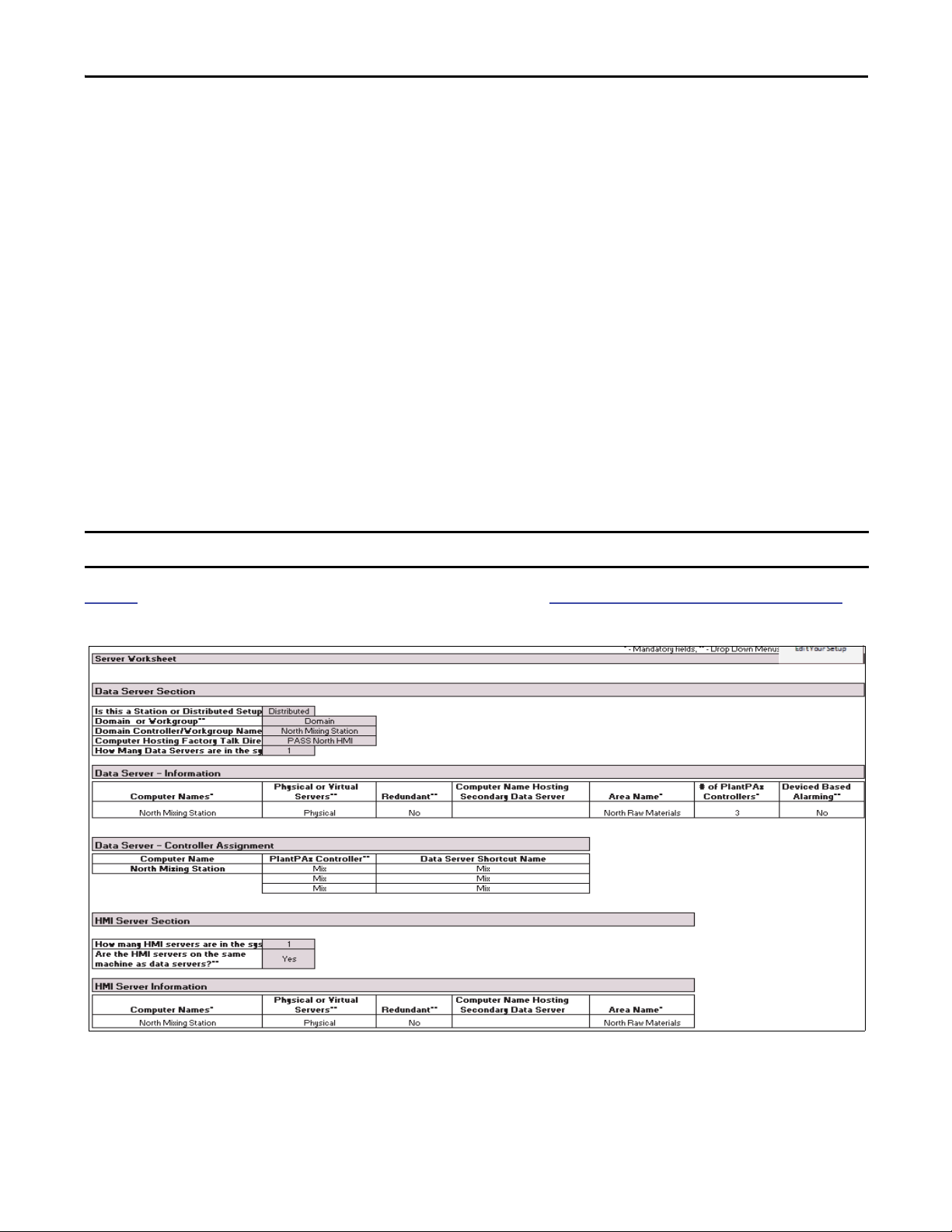

Figure 2

Figure 2 - Quick Start Worksheet Example

shows an example of a portion of the completed worksheet. See Access the Quick Start Worksheet on page 69.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 7

Page 8

Preface

Additional Resources

These documents contain additional information concerning related products from Rockwell Automation.

Resource Description

Define and Procure

PlantPAx Process Automation System Selection Guide, publication PROCES-SG001

1756 ControlLogix Controllers Technical Data, publication 1756-TD001 Contains specifications for ControlLogix controllers.

Virtualization for Process Automation Systems, publication PROCES-WP007 Explains and illustrates virtual servers, topologies, and PlantPAx system

System Setup and Configuration

PlantPAx Process Automation System Reference Manual, publication PROCES-RM001

Virtual Image Templates User Manual, publication 9528-UM001 Provides catalog numbers and details for using virtual image templates for setting up

FactoryTalk View Site Edition (SE) Installation Guide, publication VIEWSE-IN003

FactoryTalk Alarms and Events System Configuration Guide, publication FTAE-RM001 Provides details on how to install, configure, and use FactoryTalk Alarms and Events

FactoryTalk AssetCentre Installation Guide, publication FTAC-IN005

FactoryTalk Batch Installation Guide, publication BATCH-IN011 Provides information and procedures for installing FactoryTalk Batch software.

ControlLogix System User Manual, publication 1756-UM001 Explains how to use traditional and extreme environment ControlLogix controllers.

ControlLogix Enhanced Redundancy System User Manual, publication 1756-UM535

Ethernet-to-the-Factory 1.2 Design and Implementation Guide, publication ENET-TD001 Provides collaborative design guidelines based on the Cisco Ethernet-to-the-Factory

ControlLogix and CompactLogix 5370 Segmentation Methods for Plant-wide/Site-wide

Networks with OEM Convergence-ready Solutions, publication ENET-AT004

Application Specific Code

Logix5000 Controllers Common Procedures Programming Manual,

publication 1756-PM001

Logix5000 Controllers General Instructions Reference Manual, publication 1756-RM003 Provides programming controller applications by using relay ladder instructions.

Logix5000 Controllers Advanced Process Control and Drives Instructions Reference

Manual, publication 1756-RM006

PlantPAx Library of Process Objects, publication PROCES-RM002

Apply Templates

PlantPAx Library of Logix Diagnostic Objects, publication PROCES-RM003

FactoryTalk View SE Edition User Manual, publication VIEWSE-UM006

Provides information to assist with equipment procurement for your PlantPAx system.

recommendations.

Provides characterized recommendations for implementing your PlantPAx system.

virtual machines.

Provides ‘how to’ tasks for installing and deploying HMI applications that can involve

multiple users and servers, distributed over a network.

services as part of a FactoryTalk-enabled automation system.

Provides installation instructions for monitoring your factory automation system.

Provides information on the installation and configuration for an enhanced redundancy

controller system for greater availability.

solution and the Rockwell Automation® Integrated Architecture solution.

Highlights the design considerations of various network segmentation methodologies

to assist plant engineers with managing their industrial automation and control

system (IACS) traffic flow, and OEMs to develop convergence-ready solutions to help

simplify integration.

Provides links to a collection of programming manuals that describe how you can use

procedures that are common to all Logix5000™ controller projects.

Provides details on process control and drives instructions.

Provides general considerations for the PlantPAx system library of process objects.

Provides Add-On Instructions for monitoring and diagnostic information of

Logix co ntrollers.

Provides details on how to use this software package for developing and running humanmachine interface (HMI) applications that can involve multiple users and servers,

distributed over a network.

You can view or download publications at http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or Rockwell Automation sales representative.

8 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 9

Chapter 1

Configure the Controller Application

In this chapter, you learn how to configure controller templates that aid consistent controller implementation, including

the use of periodic tasks and setting appropriate task priorities. You complete the following tasks:

• Download the controller templates based on system requirements

• Apply the template to your controller

• Configure EtherNet/IP communication modules for the controller

•Configure I/O modules

• Add HART modules with diagnostic capability, if applicable

• Add remote I/O chassis connections

The described tasks are to be repeated for each controller that is being configured within your system.

Before You Begin

You must complete these tasks before using this chapter:

• Prerequisites listed on page 6

• Information needed per controller:

– Controller names and types, including if redundancy is to be used

– Controller task rates for the application based on tasks used in sizing calculations in the PSE

– Network adapter IP addresses

– Local and remote I/O rack configuration

What You Need

You have RSLogix 5000 software installed and able to communicate with the controllers. If this is a virtual environment,

the virtual image templates are deployed.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 9

Page 10

Chapter 1 Configure the Controller Application

TIP

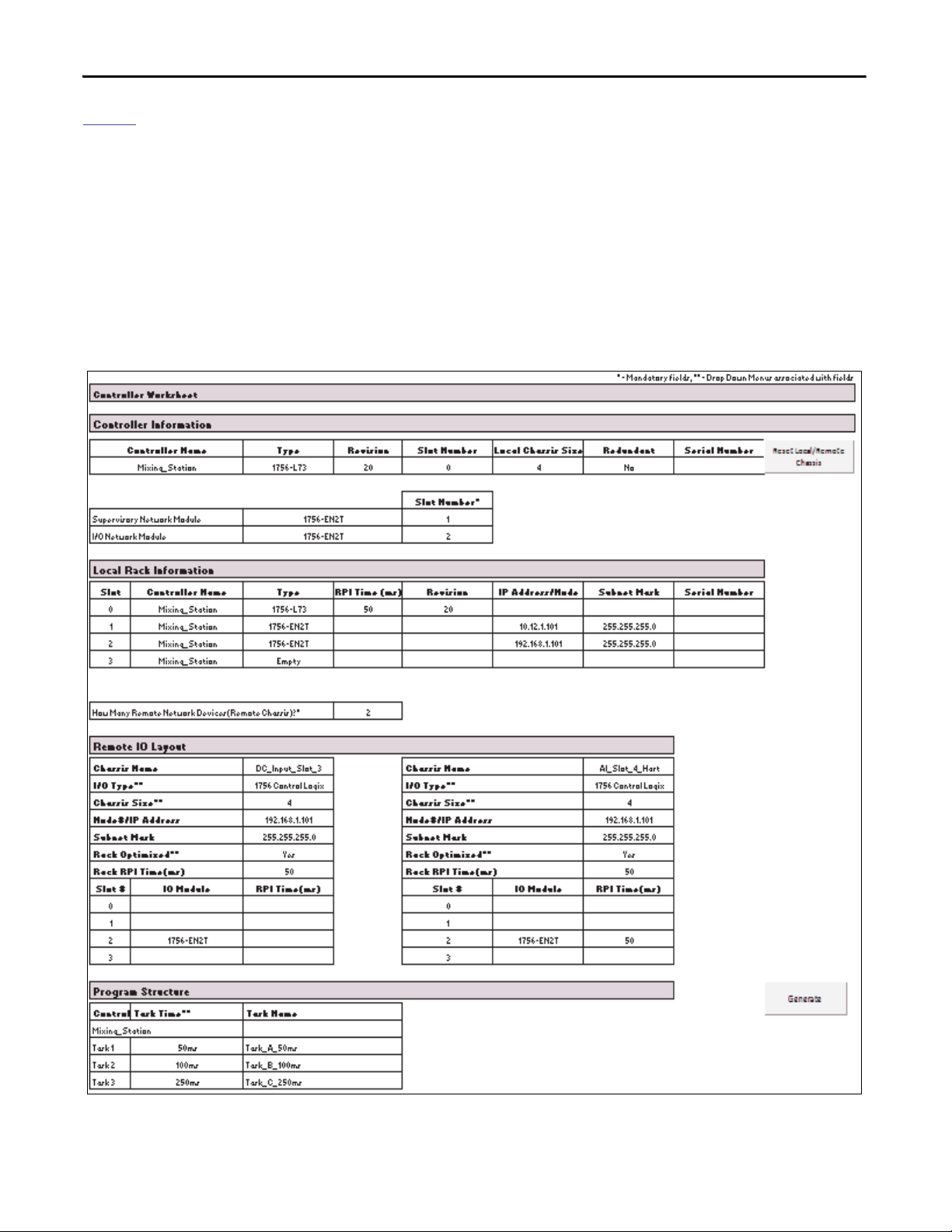

Figure 3 shows an example of the information required for this chapter based on a sample project using the PlantPAx Quick

Start Worksheet. The worksheet is a useful aid in completing tasks in this chapter. The controller sections of the worksheet

include the following:

• Basic controller information, such as the controller name, firmware revision, and slot number

• Local rack information

•Remote I/O layout

•Controller task rates

The PlantPAx Quick Start Worksheet is not the same tool as the PSE, which sizes an application based on system requirements. The

worksheet merely documents pre-determined system elements defined by the PSE.

Figure 3 - Example of the Controller Worksheet Section

10 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 11

Configure the Controller Application Chapter 1

Start

Download the PlantPAx Library

on page 13

Op en You r Temp lat e

on page 13

Modify Controller Properties

on page 14

Configure Cont roller Task Rate s

on page 16

Add Modules to Local Chassis

on page 17

Configure Network Adapters

on page 18

Configure I/O Modules

on page 19

Add Remote I/O Chassis and Modules

on page 20

Download the Project

on page 21

Follow These Steps

The following tasks outlined below describe how to configure your template with a Logix5000 controller. You could

already be familiar with many of these tasks, depending on your knowledge of Logix controllers. However, we suggest that

you follow these steps to set up your controller for optimal performance of your PlantPAx system.

The procedures in this chapter have to be completed for each controller in your project.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 11

Page 12

Chapter 1 Configure the Controller Application

IMPORTANT

Controller Template Overview

Controller templates provide the necessary task configurations that are required for the PlantPAx system. Controller

template options also are provided with pre-loaded PlantPAx Library content if the PlantPAx Library is to be used. Library

content definitions use controller memory, so use the guidance in Tab le 2

application.

Controller templates are distributed with the PlantPAx Library of Process Objects. To download the templates, see Knowledgebase

Answer ID 62682 at https://www.rockwellautomation.custhelp.com

when selecting the appropriate template for your

.

For each controller, you must choose one of three templates to begin system configuration. Tab le 2

and Tab le 3 show the

templates that are recommended (denoted by ‘X’) based on the selected controller.

Table 2 - PlantPAx Controller Templates and ControlLogix Controllers

Simplex Controllers Redundant Controllers

1756-L71 1756-L72 1756-L73 1756-L74 1756-L75 1756-L73 1756-L74 1756-L75

User memory 2 MB 4 MB 8 MB 16 MB 32 MB 8 MB 16 MB 32 MB

No libraryXXXXXXXX

Basic library

All library

(1) B asic library template is approximately 0.4 MB.

(2) All library template is approximately 1.2 MB.

Table 3 - PlantPAx Controller Templates and CompactLogix Controllers

User memory 0.75 MB 2 MB

No library X X

Basic library

All library

(1)

(2)

(1)

(2)

XXXXXXXX

XXXX XX

1769-L24ER-QBFC1B 1769-L33ER

XX

(1) B asic library template is approximately 0.4 MB.

(2) All library template is approximately 1.2 MB.

Table 4 - Contro ller Template Descr iptions

Template Name

No library RSL5k_18_Template_PlantPAx_noLib.acd No PlantPAx Library of Process Objects.

Basic library RSL5k_v18_Template_PlantPAxLib_3_0_00_basic.acd

All library RSL5k_18_Template_PlantPAxLib_3_0_00_all.acd Complete PlantPAx Library of Process Objects.

(1) PlantPAx Library 3.0 supports RSLogix 5000 software version 18 and later. Templates are provided with software version 18 so they can be used in any later supported version of RSLogix 5000.

(2) The service release number (boldfaced) can change as ser vice revisions are created.

12 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

(1)

Description

(2)

PlantPAx Library of Process Objects, includes diagnostics and the following Process Add-On

Instructions: P_AIn, P_Alarm, P_AOut, P_DIn, P_Gate, P_DOut, P_Intlk, P_Mode, P_Motor,

P_Perm, P_Reset, P_ValveSO, P_VSD, P_PIDE, T_ADD, T_Clock, T_DST, T_Valid.

Page 13

Configure the Controller Application Chapter 1

TIP

TIP

Download the PlantPAx Library

Follow these steps to download a controller template that is included in the PlantPAx Library of Process Objects.

1. Open the Knowledgebase Answer ID 62682 at http://www.rockwellautomation.custhelp.com.

2. Click the download link to access the zip files in the PlantPAx Library of Process Objects.

3. Select the V3.0 zip file and download the files to a folder.

You will need to access these Library files again so place the folder in a convenient location.

4. Unzip the files to your folder.

The controller templates described in Tab le 4 are distributed with the Library in a folder titled, Templates.

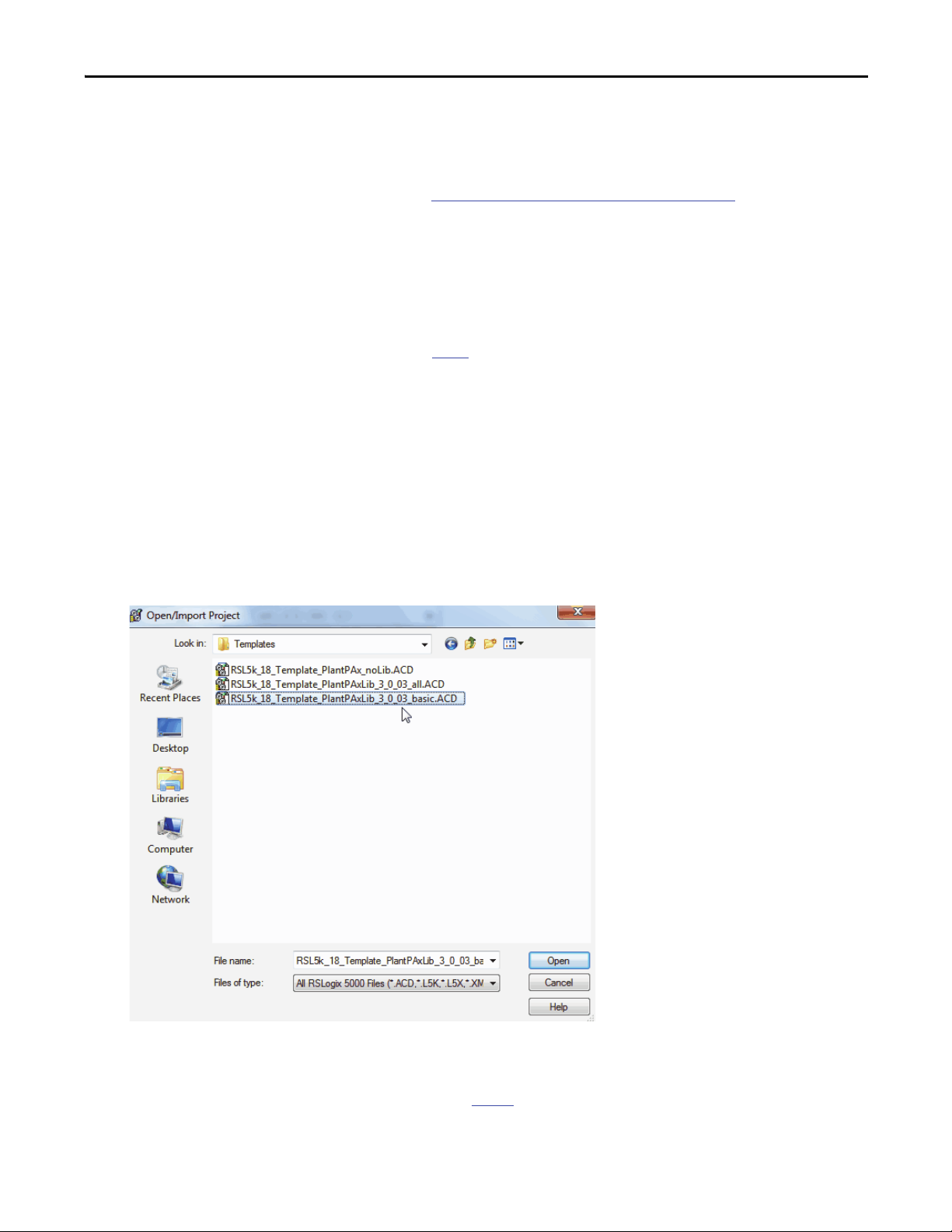

Open Your Template

Follow these steps to open the controller template that is appropriate for your target controller.

1. Open RSLogix 5000 software.

2. From the File menu, choose Open.

3. From the Look in pull-down menu, browse to the Templates folder where the downloaded PlantPAx Library files

are stored.

4. Select the appropriate controller template and click Open to begin applying the template to the target controller.

If you do not have RSLogix 5000 software version 18 installed, you will be prompted to change the firmware revision upon

opening the template. Follow steps 4…7 on page 15

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 13

.

Page 14

Chapter 1 Configure the Controller Application

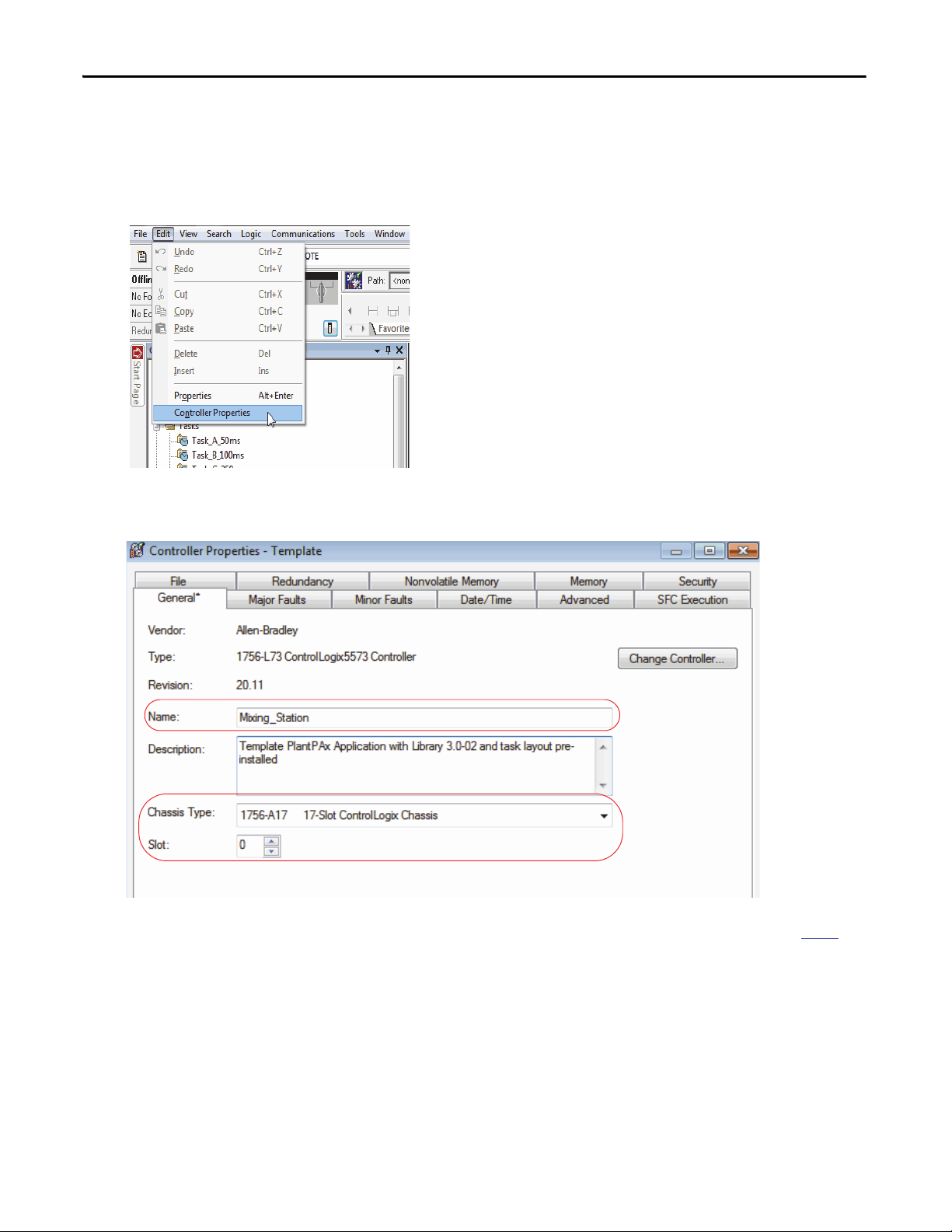

Modify Controller Properties

Follow these steps to modify the controller properties to associate the template to the target controller.

1. From the Edit menu, choose Controller Properties.

2. On the Controller Properties dialog box, type the name of the controller, slot number, and chassis type for the

target controller.

3. Click Change Controller if your controller is not the type or firmware revision shown. Otherwise, skip to step 8

14 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

.

Page 15

4. From the Type pull-down menu, choose a controller

IMPORTANT

IMPORTANT

Refer to Table 2 on page 12 to make sure the controller has enough memory for the selected template.

5. From the Revision pull-down menu, choose your firmware revision.

Configure the Controller Application Chapter 1

The revision number for the firmware must match the version level of the software being used. For PlantPAx system

release 3.0, select revision 20.

If you are using redundancy (see step 8

), we recommend you verify the software that you are using supports redundancy.

6. Click OK.

A dialog box appears with a warning if the controller type or revision has changed.

7. Click Yes.

8. If the target controller is redundant, click the Redundancy tab and check the Redundancy Enabled checkbox.

Otherwise, skip this step.

9. Click OK to save your controller settings.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 15

Page 16

Chapter 1 Configure the Controller Application

IMPORTANT

TIP

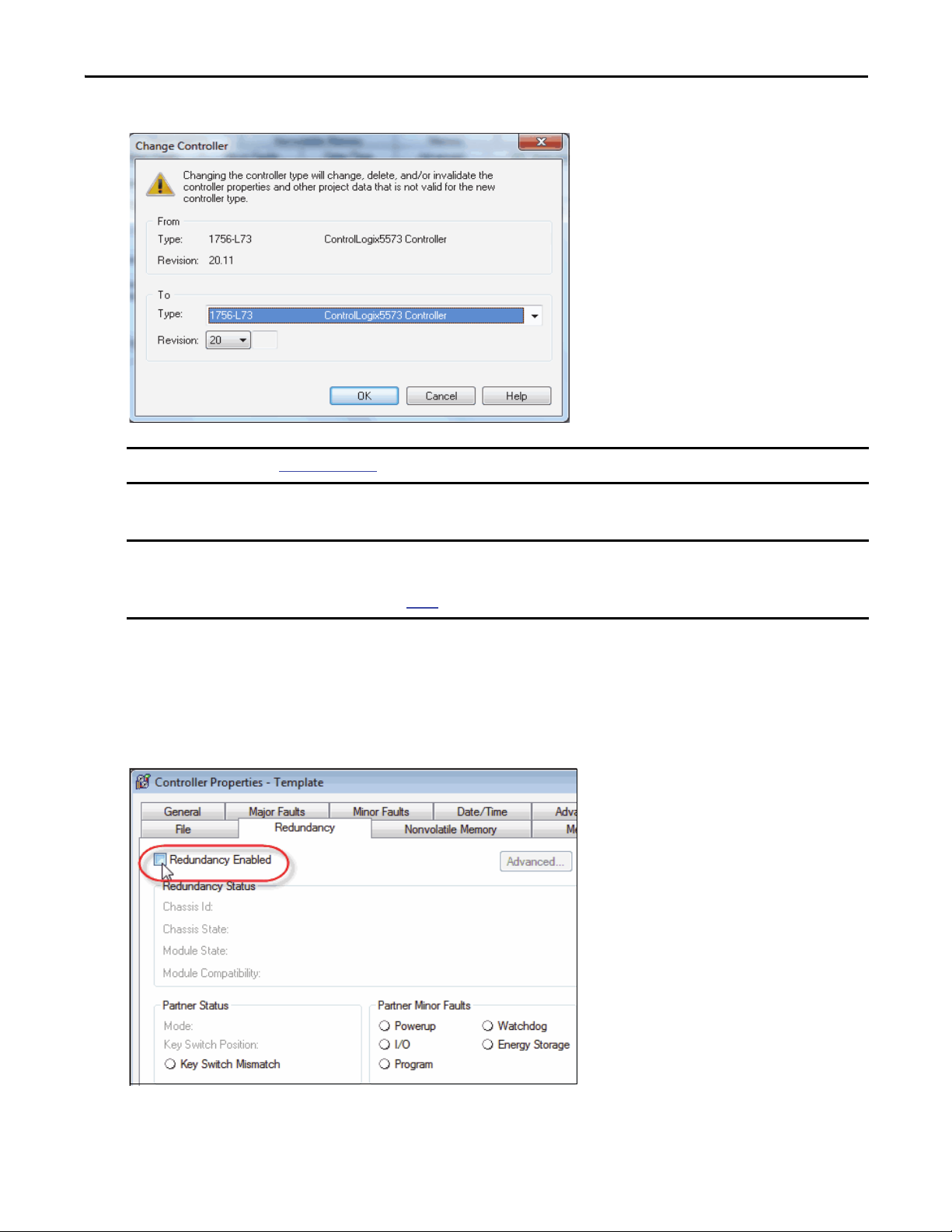

Configure Controller Task Rates

The controller template contains nine predefined periodic tasks, eight of

these named Task A…H. There is a separate periodic task named Controller

Status, which is used to collect system diagnostics, for example, by using the

L_CPU Add-On Instruction.

Each task is set to execute at a defined time interval from 50 ms…10 s, with

faster tasks getting higher priority.

Best practice is for your task setup to match the execution rates used during

system sizing, with unused tasks being deleted or inhibited.

We recommend that you use a minimal number of periodic tasks to provide required execution rates. A controller is typically

configured with four periodic tasks: fast, medium, slow, and a dedicated task for diagnostics. For details, see Task Configuration

and CPU Utilization in the PlantPAx Process Automation System Reference Manual, publication PROCES-RM001

.

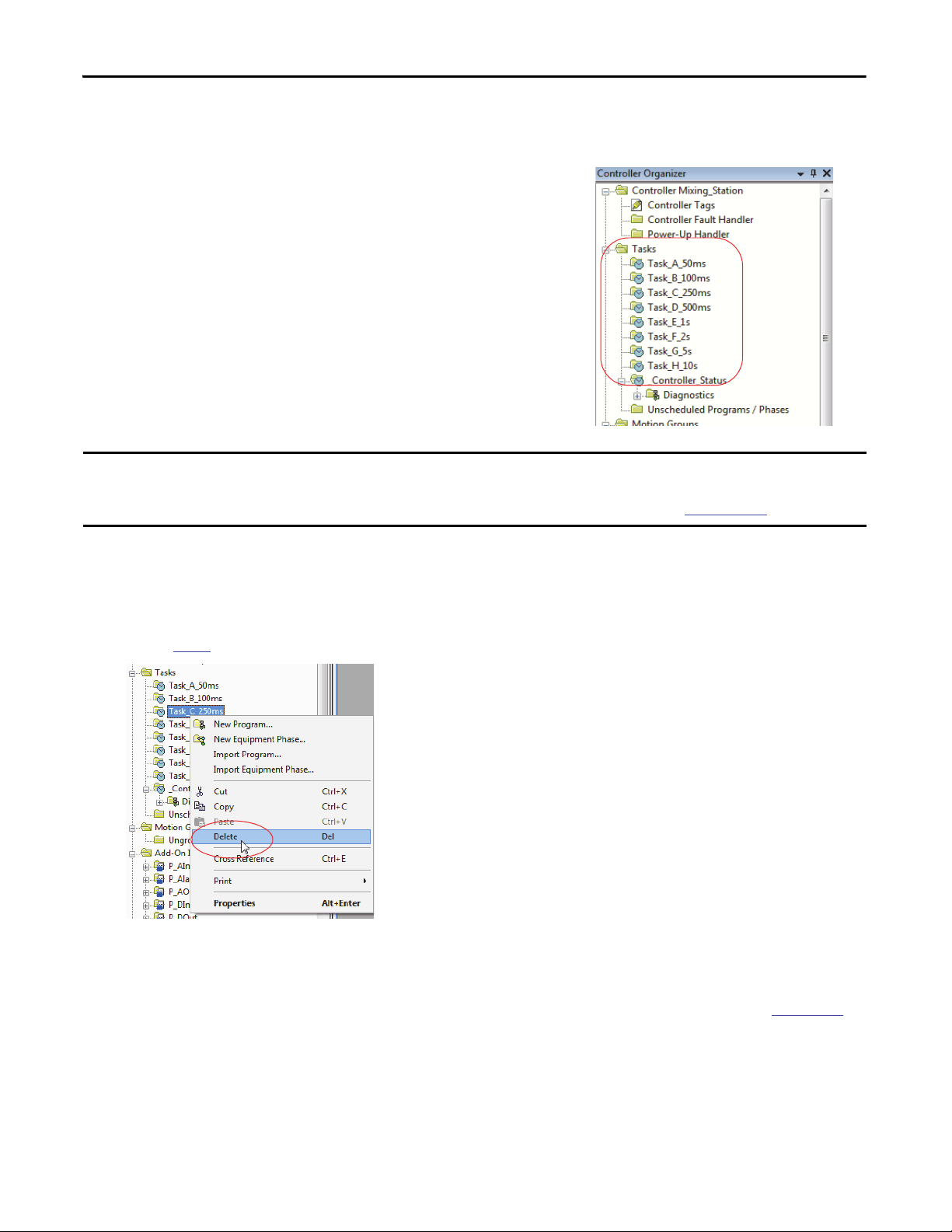

As stated above, there is the possibility that not all of the tasks are used for your application. Follow these steps to delete

unused tasks.

1. From the Controller Organizer in RSLogix 5000 software, right-click a task and choose Delete.

2. Repeat step 1

3. Review your final task configuration to verify it matches your sizing calculation in the PSE.

for each unnecessary task

Periodic tasks do not have programs attached when a project is created in RSLogix 5000 software. You must create

programs and routines per task. For procedures, see the ControlLogix Systems User Manual, publication 1756-UM001.

16 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 17

Configure the Controller Application Chapter 1

TIP

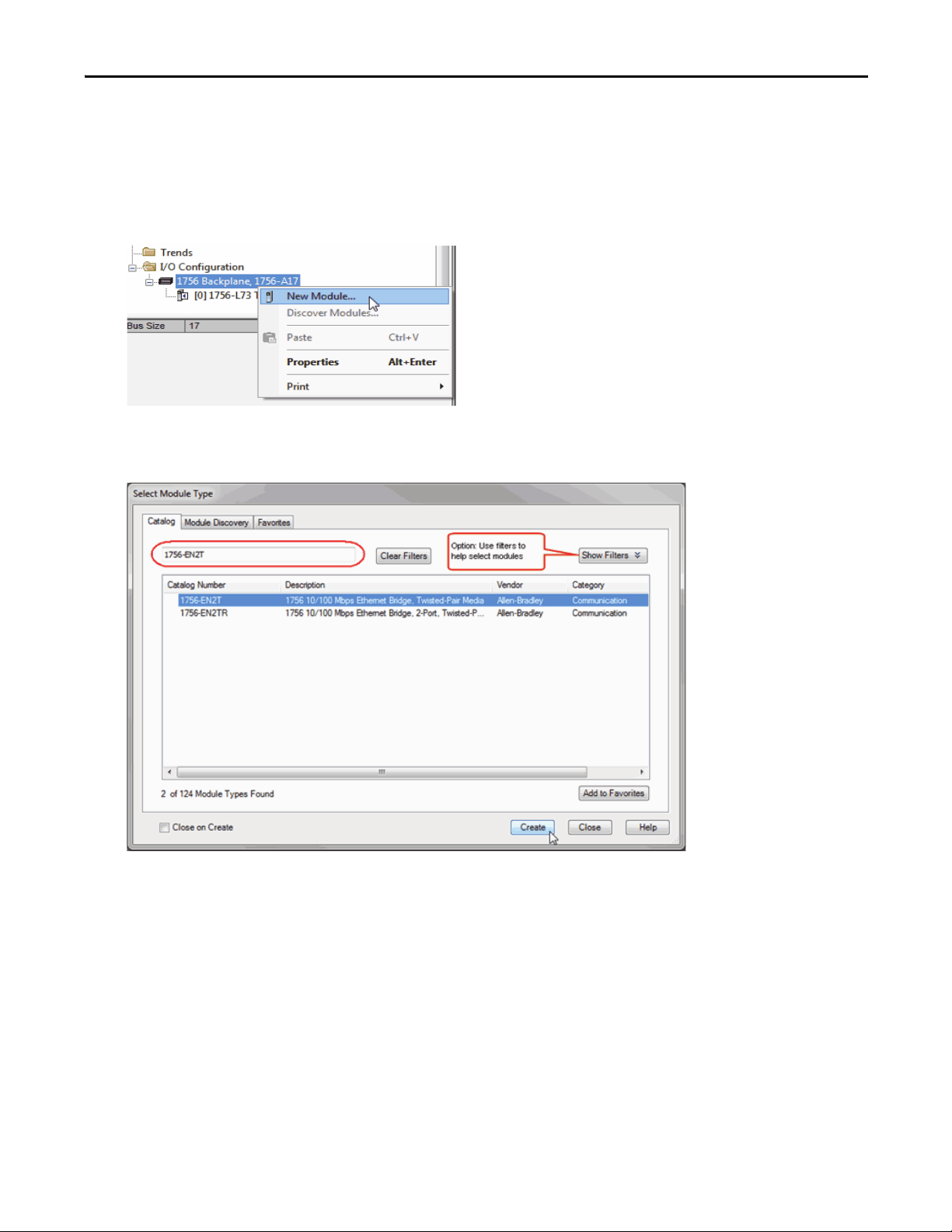

Add Modules to Local Chassis

In this section, you are adding all the necessary modules to your local chassis, including network adapters and I/O modules,

to the I/O tree of a Logix controller.

1. In the Controller Organizer, right-click the backplane and choose New Module.

2. In the Search field, type a catalog number of a module that you are adding.

The example shows a 1756-EN2T network adapter being selected.

To make it easier to locate a particular module, use the filters to view only the module types you need.

The Module Discovery tab takes you through the I/O tree of the Logix controller to determine which modules you need to

configure or modify. The tab is active if the controller is online and the network path is valid.

3. Select a module and click Create.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 17

Page 18

Chapter 1 Configure the Controller Application

TIP

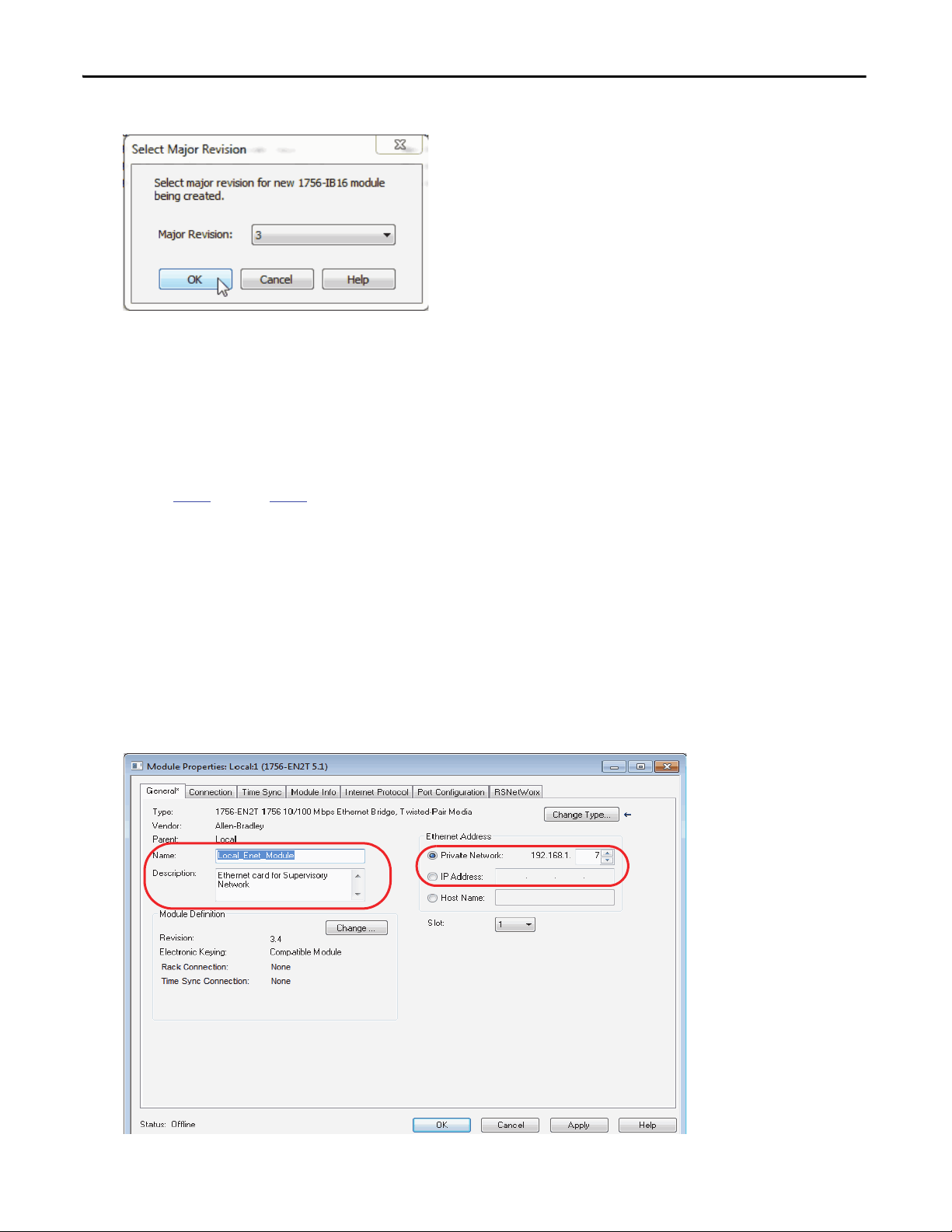

If applicable for your selected module, from the Major Revision pull-down menu, choose a firmware revision.

4. Click OK.

5. On the New Module dialog box, type a module name, description, and slot number (and IP address if adding a

communication module).

Make sure the slot number for the module in the chassis is correct.

6. Click OK.

7. Repeat step 1

through step 6 to add each module in the local chassis of the target controller.

Configure Network Adapters

In this section, you learn how to select and configure network adapters to communicate with PASS servers and remote

I/O chassis.

1. In the Controller Organizer, double-click the module to be configured.

2. On the Module Properties dialog box, modify the module name, if necessary.

For example, Supervisory_Network or Remote_IO_Local.

18 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 19

3. Type the Ethernet address for the module in the chassis.

IMPORTANT

4. Click OK.

Configure the Controller Application Chapter 1

5. Repeat step 1

through step 4 to configure each network adapter in the local chassis of the target controller.

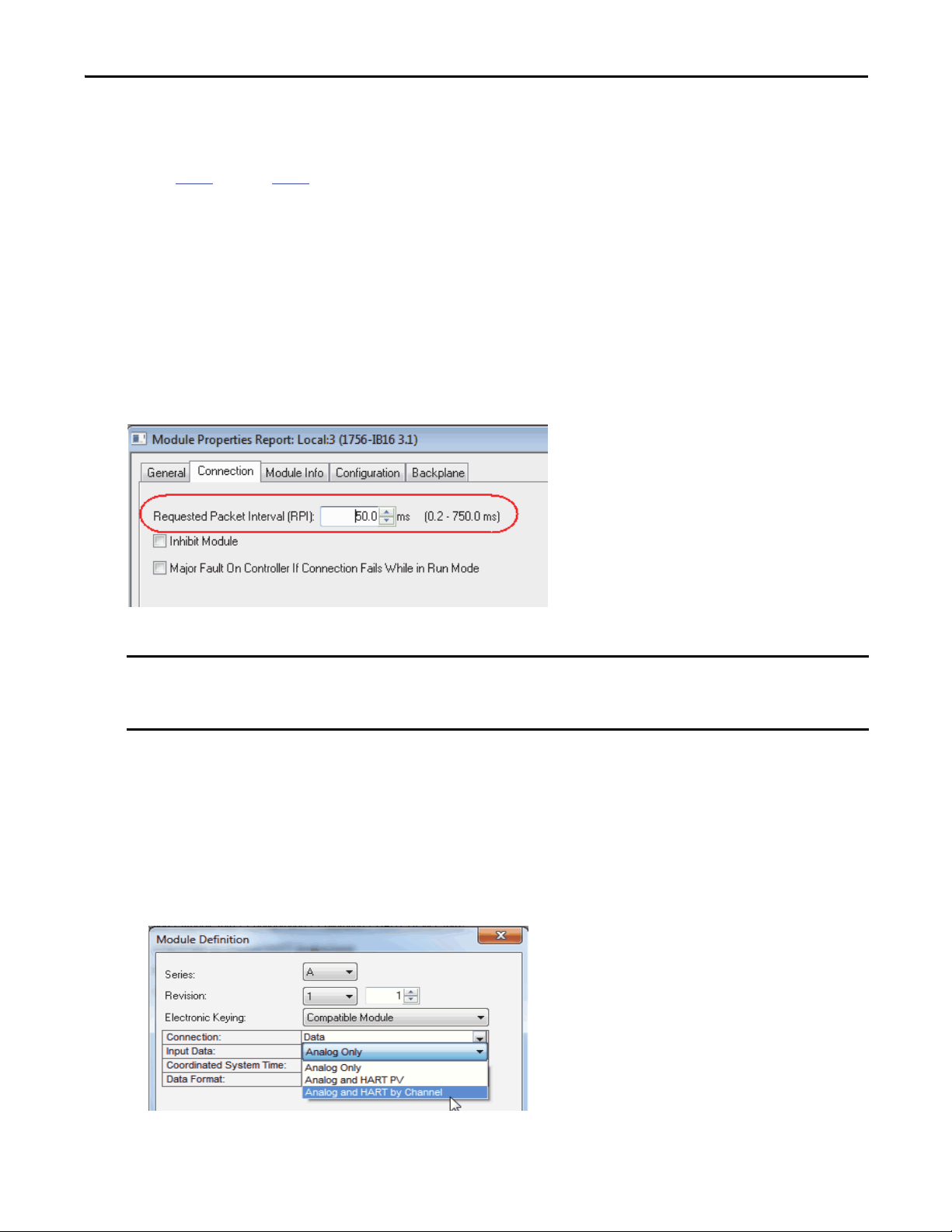

Configure I/O Modules

Follow these steps to configure local analog and digital I/O modules with a Requested Packet Interval (RPI) and module

definition, if applicable. The RPI is the amount of elapsed time for an exchange of data between the controller

and module.

1. In the Controller Organizer, double-click the I/O module to be configured.

2. On the Module Properties dialog box, click the Connection tab.

3. Set the RPI and click OK.

An RPI that is set too fast can affect controller performance. We suggest that you specify an RPI that is two times faster

than task execution or based on inherent properties of the signal being measured. For example, a 250 ms task requires a

125 ms time, but temperature measurements can be set slower as they are unlikely to change that quickly.

For certain device types, there can be additional configuration required. For example, when using a HART module,

you have to change the module definition to collect HART data.

4. Follow these steps to modify the module definition:

a. On the New Module dialog box, click Change in the Module Definition area.

b. From the Input Data pull-down menu, choose from the list.

For example, Analog and HART by Channel.

c. Click OK.

d. Click Yes if a warning message appears that you are changing the module definition.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 19

Page 20

Chapter 1 Configure the Controller Application

5. Repeat step 1 through step 4 to configure each I/O module in the local chassis of the target controller.

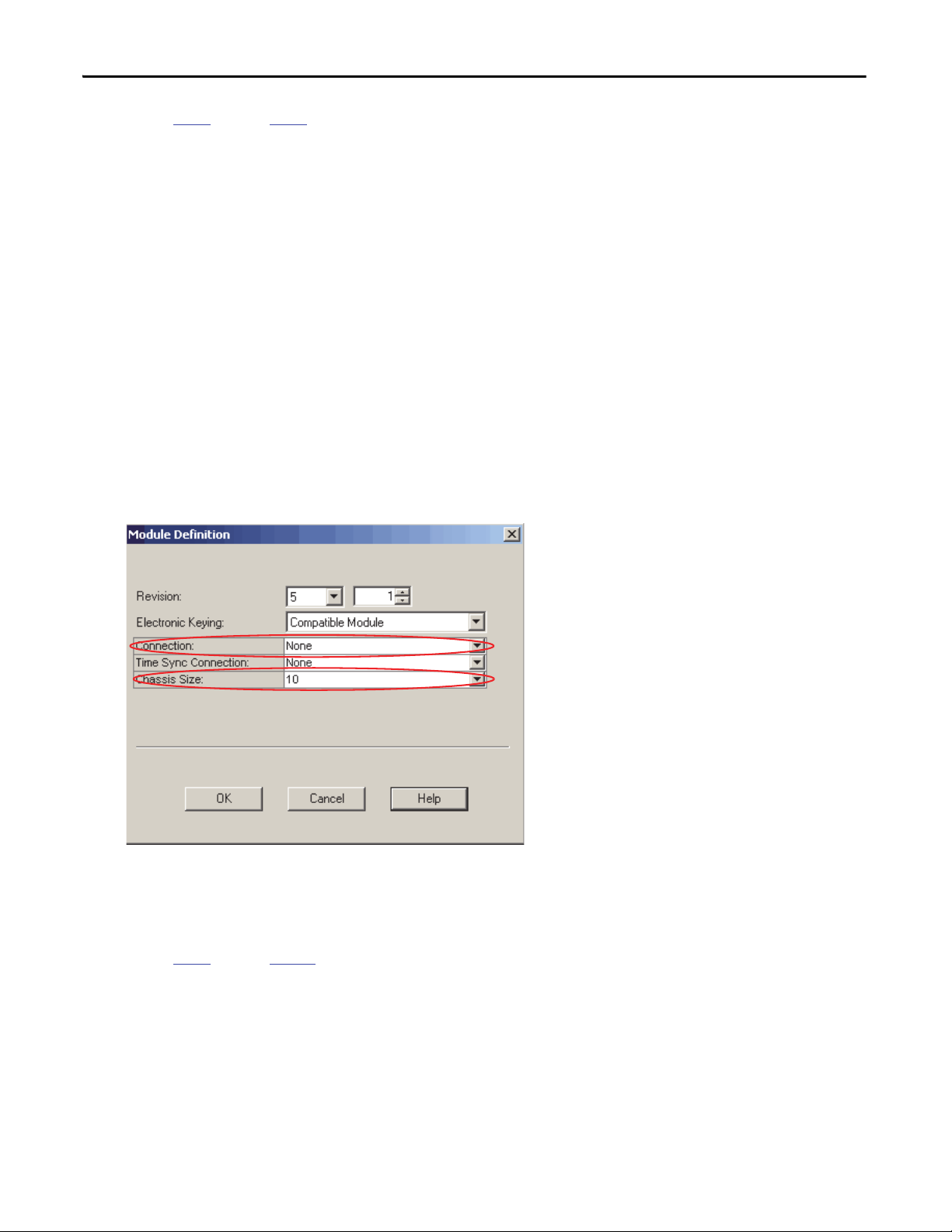

Add Remote I/O Chassis and Modules

Follow these steps to add the remote I/O chassis and associated I/O modules for the target controller.

1. In the I/O Configuration tree, right-click the remote I/O network adapter and choose New Module.

2. Type a catalog number to search for the network adapter in the remote I/O chassis.

3. Select a network adapter and click Create.

4. Type the chassis name and description based on the target controller.

5. Type an IP address and a slot number for this module.

6. Click Change.

7. On the Module Definition dialog box, from the Connection pull-down menu, choose None to collect all of the

diagnostic data.

8. From the Chassis Size pull-down menu, choose the size for the first remote chassis.

9. Click OK.

10. To add a module to the remote chassis, right-click the remote communication module and choose New Module.

11. Follow the previous steps in this chapter for adding digital and analog I/O modules to the remote chassis.

12. Repeat step 1

20 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

through step 11 for each remote I/O chassis.

Page 21

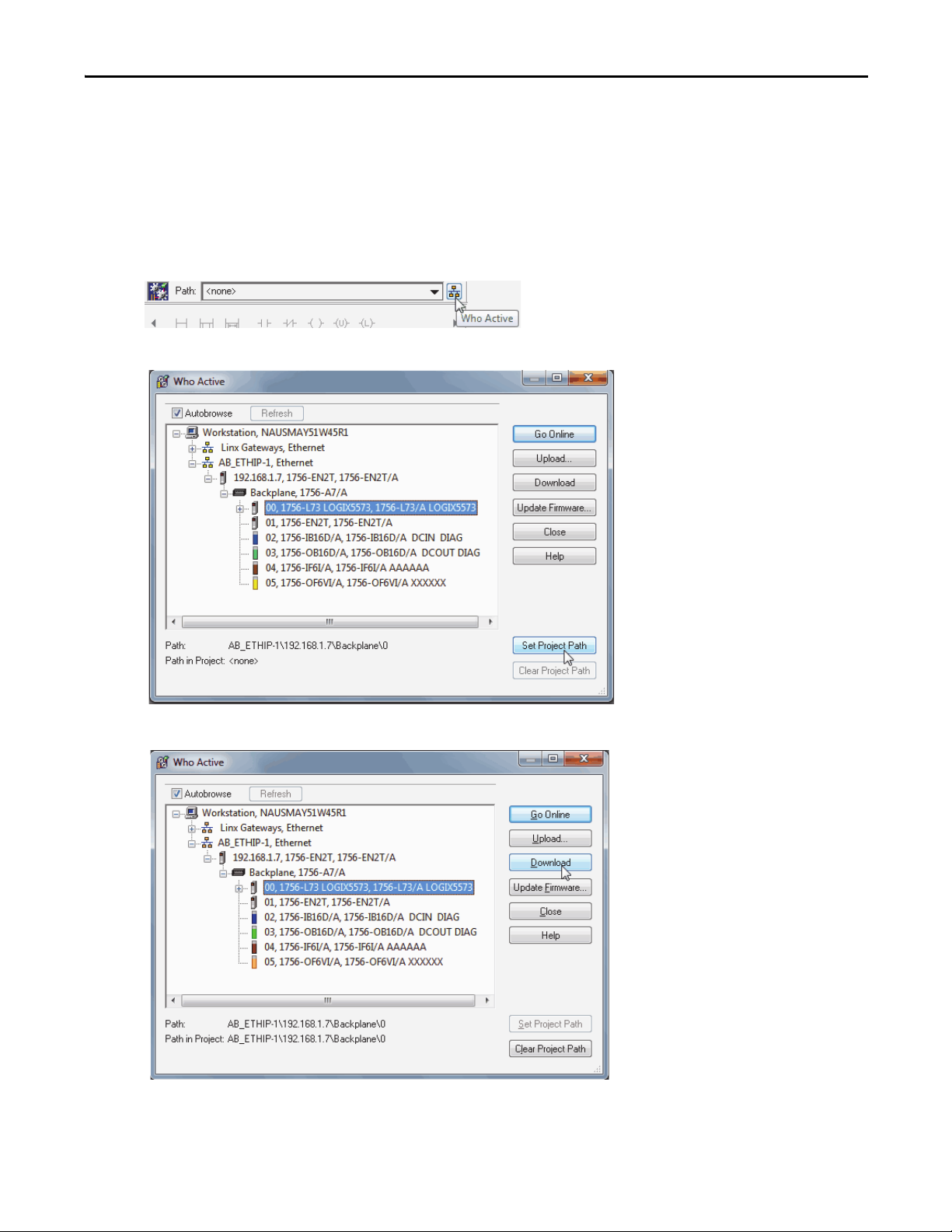

Download the Project

Follow these steps to download your project to a controller.

1. Make sure your controller is in Remote Program mode.

2. If necessary, set a path to the controller.

a. Click the Who Active icon.

b. In the Who Active dialog box, navigate to your controller and click Set Project Path.

Configure the Controller Application Chapter 1

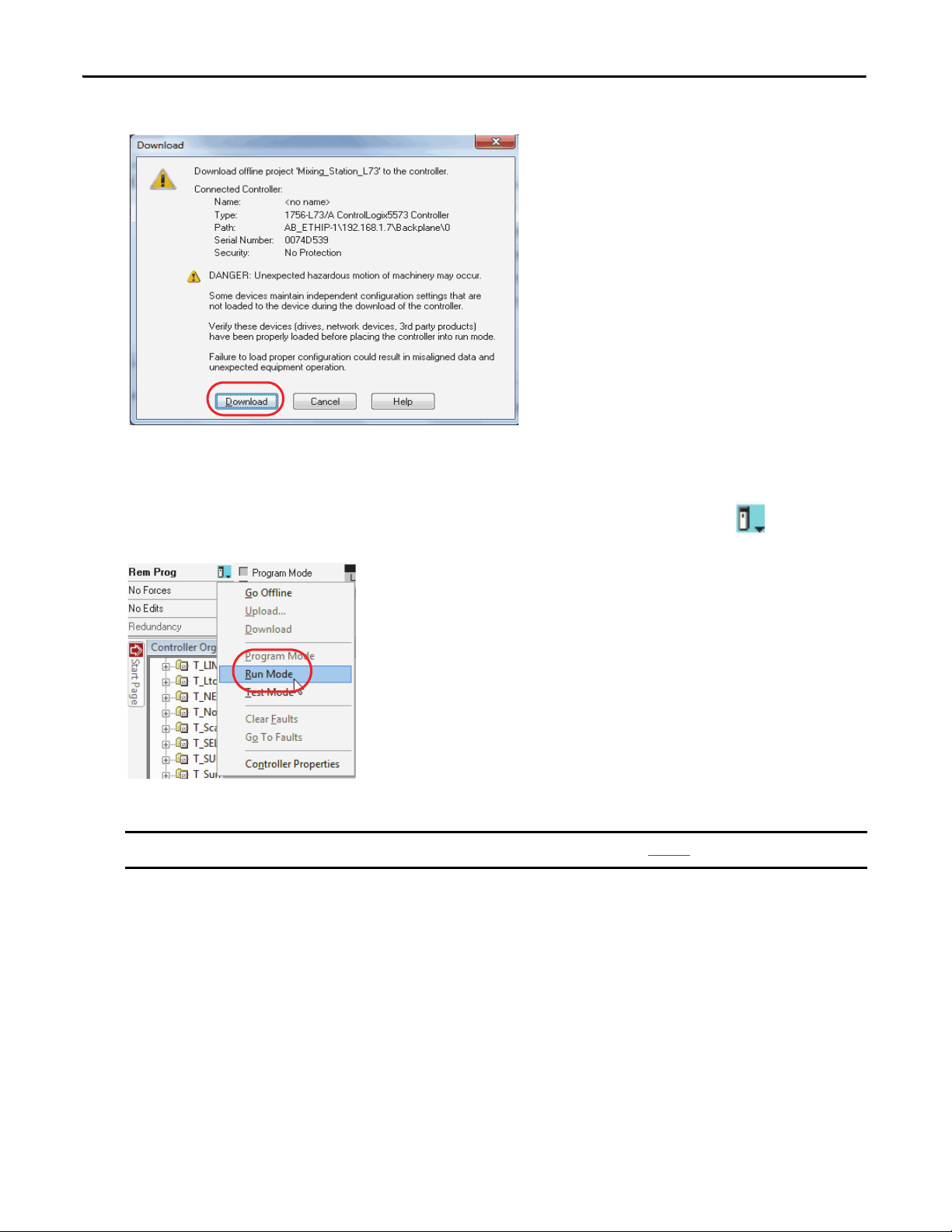

3. Click Download.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 21

Page 22

Chapter 1 Configure the Controller Application

IMPORTANT

4. Click Download again.

Your project is downloaded to your controller.

5. Place your controller in whatever mode is necessary.

For example, if you want the controller in Remote Run mode, from the Mode pull-down menu , choose

Run Mode.

6. When finished, save the file to a convenient location.

Repeat the tasks in this chapter for the next controller, if applicable, starting on page 13.

22 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 23

Chapter 2

Create Your HMI Project

In Chapter 1, you learned how to structure the controller application for your system. In this chapter, you create your HMI

project to follow PlantPAx system recommendations by using the PlantPAx HMI templates.

To build an HMI project, you must complete the following tasks:

• Download and select an HMI template

• Create all logical servers (data, HMI, and alarms, if applicable) and configure communication and system settings

• In the process of creating your HMI servers, apply the PlantPAx HMI template to your project

The HMI project is built by using one of three software components: HMI servers, Data servers, or Tag Alarm and Event

servers. All of these software components are assigned to a PASS server.

Before You Begin

You must complete these tasks before using this chapter:

• Tasks described in Before Using This Publication on page 6

– Define the system

where they are hosted)

– Install the system

• You identify the target screen resolution on your OWS

(for example, determine the number of HMI, Data, and Alarm and Event servers to be used

(PASS servers must be installed and available)

, including the following:

What You Need

To complete tasks in this chapter, you need FactoryTalk View SE

client software, version 7.0, running on a PASS server. You can use an

EWS to implement the steps in this chapter.

The illustration shows an example of an HMI project structure.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 23

Page 24

Chapter 2 Create Your HMI Project

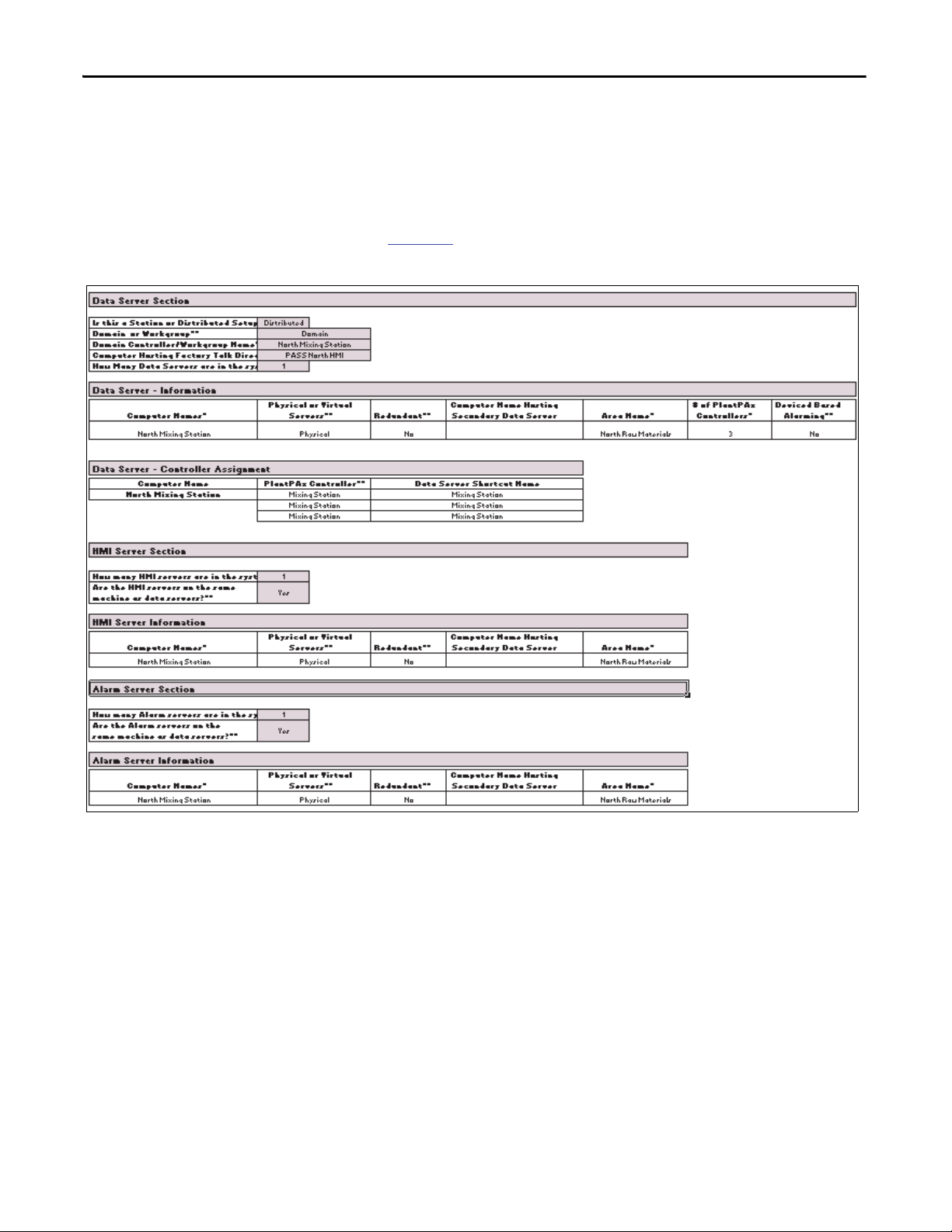

The server section of the worksheet is a useful aid for completing tasks in this chapter. The worksheet sections include the

following:

• Information from the PSE sizing tool:

– Number of servers and controllers

– Domain or workgroup

• Information about the controller used in Chapter 1

Figure 4 - PASS Worksheet Example

, such as controller name and IP addresses

24 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 25

Follow These Steps

Start

Download the PlantPAx Library

on page 26

Load the HMI Template

on page 26

Create Your HMI Project

on page 29

Deploy Your HMI Template

on page 30

Configure Your Data Servers

on page 33

Configure Your Alarm Servers

on page 35

Add Controllers to Data Server

on page 38

Set Runtime Security

on page 40

These steps describe how to create your HMI project.

Create Your HMI Project Chapter 2

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 25

Page 26

Chapter 2 Create Your HMI Project

TIP

HMI Template Overview

There are three HMI templates available for download on the Knowledgebase Answer ID 62682

at http://www.rockwellautomation.custhelp.com

the EWS, and your system data is viewed on the OWS.

Table 5 - HMI Template Names and Display Resolutions

Name Supported Resolution

FTVSE_7_P1FHD_3_0_00.apa 1920 x 1080, Full HD

FTVSE_7_P1SXGA_3_0_00.apa 1280 x 1024, SXGA

FTVSE_7_P1WXGA_3_0_00.apa 1366 x 768, WXGA

PlantPAx HMI templates are provided as local site edition back-up files. All of the above templates include the following

attributes:

• Basic display layout

• Navigation

• FactoryTalk View Alarms and Events displays

. For most systems, you load the templates on the PASS server by using

Download the PlantPAx Library

If you have not done so already, complete the task on page 13 to download the HMI template files in the PlantPAx Library

of Process Objects.

The HMI templates described in Tabl e 5 are distributed with the Library in a folder titled, Templates.

Load the HMI Template

The downloaded PlantPAx HMI templates are local site edition back-up files. This task restores the HMI back-up file onto

your system and makes the template available for deployment as you create HMI servers for your project.

1. From the Start menu, run the FactoryTalk View tool Application Manager .

26 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 27

2. Click Site Edition (Local Station) and click Next.

3. Click Restore application and click Next.

Create Your HMI Project Chapter 2

4. Click Browse (…).

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 27

Page 28

Chapter 2 Create Your HMI Project

5. Select a template .apa file that you want to restore and click Open.

6. Leave the default file location and click Next.

7. Type an application name and click Finish.

28 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 29

Create Your HMI Project Chapter 2

Create Your HMI Project

To create your HMI project, in FactoryTalk View Studio software, first you create the network distributed or network

station application, and then you add elements such as areas, HMI servers, Data servers, and Tag Alarm and Event servers.

You assign the servers to their associated PASS servers.

Follow these steps to create your application.

1. From the FactoryTalk View Studio software program, click View Site Edition (Network Distributed)

or View Site Edition (Network Station).

2. Click Continue.

3. Click the New tab, and type an application name and description.

4. From the Language pull-down menu, choose your language.

5. Click Create.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 29

Page 30

Chapter 2 Create Your HMI Project

Deploy Your HMI Template

In this section, you use your HMI template to create your HMI servers. Your HMI project puts each logical server into its

own area.

The HMI server stores project components, such as the graphic displays, and provides the components to the OWSs

upon request.

1. To create a new area, right-click the application name and choose New Area.

2. Type a name and description for the area and click OK.

The area is added to your application. You are ready to add the HMI server to the area.

3. Right-click the area name and choose Add New Server>HMI server.

30 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 31

4. Click Import a project and click Next.

5. On the FactoryTalk View message box, click OK.

Create Your HMI Project Chapter 2

6. From the Project type pull-down menu, choose FactoryTalk View Site Edition Project.

7. Click Browse (…) to locate the file path of the template you named on the Application Manager dialog box

on page 28

.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 31

Page 32

Chapter 2 Create Your HMI Project

IMPORTANT

The file path appears in the Project file text box.

8. Click Next.

9. Type a name and description of the server.

10. From the Computer pull-down menu, choose the PASS server that is to host the HMI server.

11. Click Finish.

All the HMI template files are loaded into the PASS server.

12. Repeat step 1

through step 11 for each HMI server in your project.

We recommend that HMI server redundancy be configured at the end of the project after the majority of your HMI

application is developed.

32 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 33

Create Your HMI Project Chapter 2

Configure Your Data Servers

In this section, you learn how to initiate a Data server, which provides communication between the process controllers and

the servers.

Follow these steps to configure a Data server.

1. Right-click the main application area created for the associated HMI server and choose New Area.

2. Type a name and description of the Data server area.

3. Click OK.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 33

Page 34

Chapter 2 Create Your HMI Project

4. Right-click the Data server area and choose Add New Server>Rockwell Automation Device Server

(RSLinx Enterprise).

5. Type a description of the Data server.

6. Click Browse and select the PASS server that is to host the Data server.

34 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 35

7. On the RSLinx Enterprise Server Properties dialog box, click the Alarms and Events tab.

IMPORTANT

IMPORTANT

8. To disable device-based alarming, clear the Enable alarm and event support checkbox.

The PlantPAx system sizing rules and critical system attributes are based on tag-based alarms. Therefore, we recommend a

limited usage of device-based alarms. If device-base alarming is to be used, make sure additional loading has been

considered. For more information and alarm recommendations, see Chapter 4 in the PlantPAx Process Automation System

Reference Manual, publication PROCES-RM001

The alarm history database requires a separate SQL Server installation. If there is no database selection available under

Alarm History, a database must be created. Refer to the FactoryTalk View Site Edition Installation Guide,

publication VIEWSE-IN003

9. Click Apply, and OK.

.

.

Create Your HMI Project Chapter 2

10. Repeat step 1

through step 9 for each data server in your application.

We recommend that data server redundancy be configured at the end of the project after the majority of your HMI

application is developed.

Configure Your Alarm Servers

In this section, you learn how to configure Alarm and Event servers for tag-based alarms.

1. Right-click the main application area created for the associated HMI server and choose New Area.

2. Type the name and description for the Alarm and Event server area in the application.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 35

Page 36

Chapter 2 Create Your HMI Project

3. Click OK.

4. Right-click the alarm server area and choose Add New Server>Tag Alarm and Event Server.

5. Type a name and description for the Alarm and Event server.

6. From the Computer pull-down menu, choose the PASS server that is to host the Tag Alarm and Event server.

36 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 37

7. Click the Priorities and History tab.

IMPORTANT

IMPORTANT

Create Your HMI Project Chapter 2

8. Check the Enable history checkbox to enable alarm and event history.

9. From the Database definition pull-down menu, choose the alarm history database that was created during the

installation of the FactoryTalk View SE software.

The alarm history database requires a separate SQL server installation. If there is no database selection available under

Alarm and Event History, a database must be created. Refer to the FactoryTalk Alarms and Events System Configuration

Guide, publication FTAE-RM001

.

10. Click Apply, and OK.

11. Repeat step 1

through step 10 for each alarm server in your application.

We recommend that alarm server redundancy be configured at the end of the project after the majority of your HMI

application is developed.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 37

Page 38

Chapter 2 Create Your HMI Project

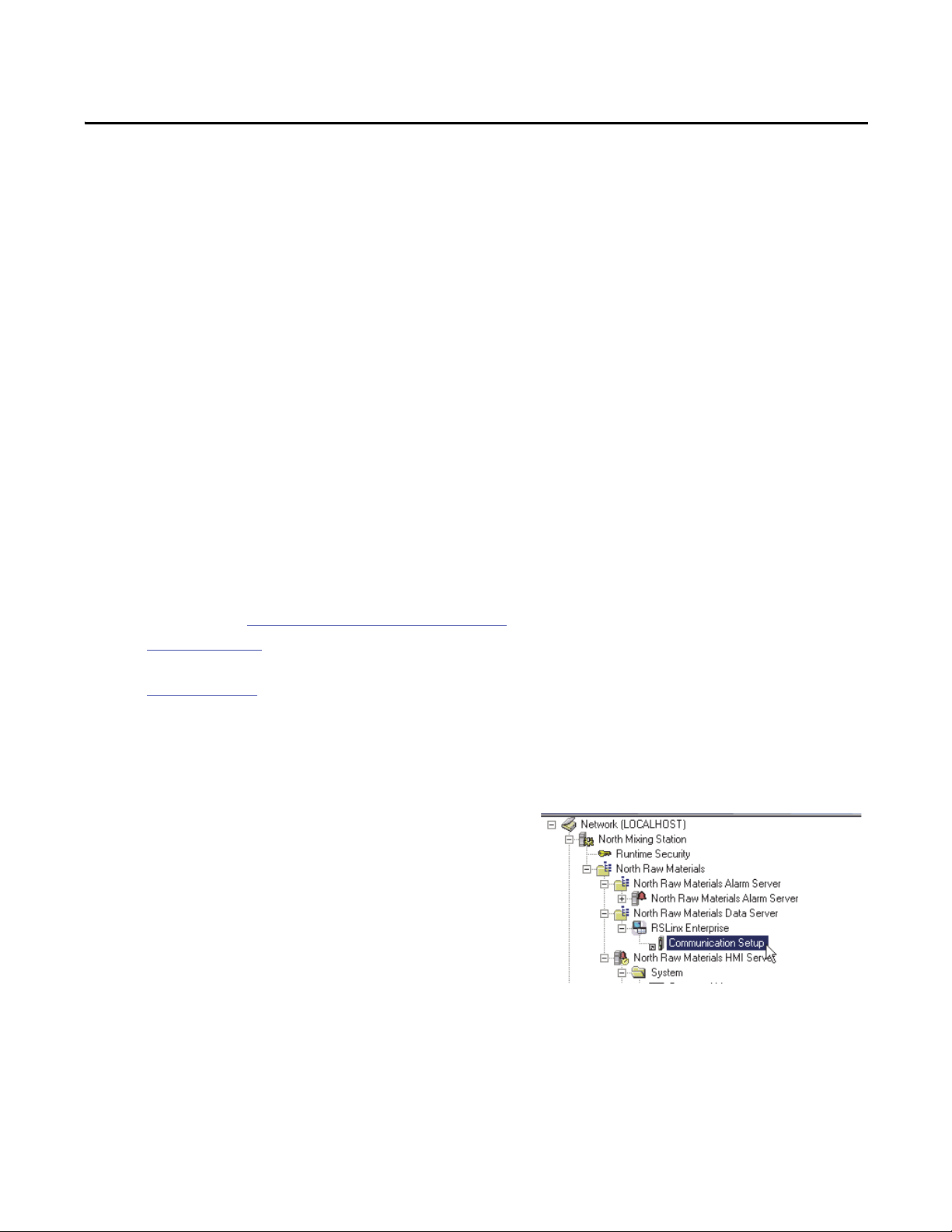

Add Controllers to Data Server

In this section, we create device shortcuts on Data servers so controllers can be connected.

1. In the project tree, click ‘+’ to expand the RSLinx Enterprise data server and double-click Communication Setup.

2. In the Device Shortcuts pane, click Add.

3. For the shortcut name, type the controller name.

4. In the Primary pane, expand the Ethernet driver to select the controller.

5. Click Apply.

38 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 39

6. On the message box, click Yes to apply changes to the shortcut.

Create Your HMI Project Chapter 2

7. Repeat step 1

through step 6 for each Data server and controller combination in your application.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 39

Page 40

Chapter 2 Create Your HMI Project

Set Runtime Security

If you are using the PlantPAx library, you must set up your runtime security to provide each account or group with the

correct FactoryTalk View software security codes. These security codes verify that the correct permissions are provided to

the operator, maintenance personnel, and engineer on the PlantPAx library faceplates.

The PlantPAx library provides guidance on the proper maintenance of the security codes.

Figure 5

Edition User's Guide, publication VIEWSE-UM006

Figure 5 - Runtime Security Settings

is an illustrated example for setting up library security codes. For more information, see the FactoryTalk View Site

.

40 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 41

Chapter 3

Start Using Your HMI Project

In this chapter, you examine the template structure and then create a FactoryTalk View SE software client file for your

OWS. You also become familiar with the features of your HMI template.

Before You Begin

You must complete these tasks before using this chapter:

• Tasks described in Before Using This Publication on page 6

• Load a template and create an HMI project; see Chapter 2 for procedures.

What You Need

FactoryTalk View SE software, version 7.0, must be running on an EWS to view the template structure. You also need an

EWS or OWS with a monitor matching the selected resolution to run the client site and review the template.

For template resolutions, see Table 5 on page 26

The illustration shows the client file (left), display layouts (center), and a HMI template structure.

.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 41

Page 42

Chapter 3 Start Using Your HMI Project

Follow These Steps

These steps describe how to configure your HMI project.

Start

Observe the Template Structure

on page 43

Create Your OWS Client File

on page 44

Explore Template Features

on page 48

42 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 43

Observe the Template Structure

P1

Macros

FRAME

The example tree diagram shows the HMI template

structure. Display and start-up macros are created as part of

the template (shown at the bottom of the example).

The displays included in the template have the following

naming structure:

•(FRAME) is a prefix used on items intended only to

be used as is with minimum customization. These

may be instantiated to create different environments

on large projects.

• P1f is a unique template identifier. This prefix

identifies the template that is being applied as well as

the files that are part of the template.

• Te m p l a t e is used to identify a template that can be

copied multiple times to create application-specific

content. If this is not a template display, this word is

omitted.

• The remaining name is a brief description of the

display file. We suggest that these names be similar

across templates. For example, P1 Home is the initial

display.

Start Using Your HMI Project Chapter 3

Macros configure the initial display structure during

runtime. The start-up macros open the framework files in

the orientation intended. For example, the header display at

the top and the footer display at the bottom.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 43

Page 44

Chapter 3 Start Using Your HMI Project

Create Your OWS Client File

In this section, you create a FactoryTalk View SE client file. Client files are used to launch a FactoryTalk View software

client from the OWS. Once created, this client file can be copied to each OWS.

1. From the FactoryTalk View Studio software Tools menu, choose Launch SE Client.

2. To create a new client file, click New.

3. From the FactoryTalk View SE Client Wizard dialog box, click New.

4. Type the name of the new client file and click Next.

44 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 45

5. Click Network Distributed or Network Station and click Next.

Start Using Your HMI Project Chapter 3

6. From the pull-down menu, choose the name of the application.

7. Click Next.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 45

Page 46

Chapter 3 Start Using Your HMI Project

8. From the Startup macro pull-down menu, choose a startup macro.

The startup macro launches the initial displays and docks the navigation and alarm tool bars.

9. Click Next.

10. Check Maximize window and click Next.

Make sure your selections in the check boxes match the dialog box as shown below.

11. From the FactoryTalk View SE Client Auto Logout dialog box, click Next.

46 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 47

12. Click Save configuration and open FactoryTalk View SE Client now, and click Finish.

Navigation Button Bar

Current Active Alarms

Login/Logout Buttons Current User

Start Using Your HMI Project Chapter 3

When the client file opens, your application window (example below) appears with the layout of the

selected template.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 47

Page 48

Chapter 3 Start Using Your HMI Project

IMPORTANT

Alarm Access

Explore Template Features

This section shows display navigation for your HMI project. We suggest you familiarize yourself with these features to

enhance productivity with your templates.

Actual layout varies depending on the HMI template selection and the revision being applied.

Alarm Tools

Click the bell icon to access active alarms. Additional icons appear to access an alarm summary, alarm history, shelved

alarms, and an alarm explorer.

Additional Alarm Information

48 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 49

Start Using Your HMI Project Chapter 3

System Status

Forward/Backward/History

System Status

Click the System Status icon to view system diagnostics. Fort more information on diagnostics, see Chapter 4.

Navigation Tools

There are three quick screen navigation buttons: Next, Previous, History.

The Display Navigation Map icon lets you move around your application faster. This feature is typically used for

applications that have more than 10 displays. Use the button bar (page 47

) for less than 10 displays.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 49

Page 50

Chapter 3 Start Using Your HMI Project

The Administrator icon accesses information about the system including display element sizes and version numbers

and security codes.

The View Security icon accesses the Current Security Access display that shows the security level of the

current user. This is a view-only display. A user’s security cannot be changed from this display.

The Repaint/Repair icon can be used when making edits to an application. After a change is made, click

the icon to refresh the application with the changes. This option also can be used to repaint the application if displays are

not shown properly.

50 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 51

Chapter 4

Add Basic System Diagnostics

In this chapter, you learn how to add controller and PASS server diagnostics to your system health screen that is provided in

the HMI template. As you develop your project, you can add additional diagnostics for your system. Add These Additional

Resources are listed at the end of this chapter.

Before You Begin

You must complete these tasks before using this chapter:

• Tasks described in Before Using This Publication on page 6

• Configure your system; see Chapter 1 and Chapter 2 for procedures

• Familiarize yourself with the HMI template; see Chapter 3

for procedures

What You Need

You must have RSLogix 5000 and FactoryTalk View Studio software, the HMI template, and ControlLogix controllers

online to complete the tasks in this chapter.

The sample illustration shows diagnostic displays that are explored in this chapter.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 51

Page 52

Chapter 4 Add Basic System Diagnostics

Start

Download the PlantPAx Library

on page 53

Add Diagnostics to the Controller

on page 53

Add Controller Diagnostics to a HMI Project

on page 55

Configure PASS Server Status

on page 61

Add These Additional Resources

on page 67

Follow These Steps

These steps describe how to configure your system diagnostics.

52 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 53

Add Basic System Diagnostics Chapter 4

TIP

Download the PlantPAx Library

If you have not done so already, complete the task on page 13 to download the Logix diagnostic objects from the PlantPAx

Library of Process Objects.

The diagnostics that you need to complete tasks in the next section are distributed with the Library in the Logix Diagnostic

Objects Library folder.

Add Diagnostics to the Controller

The Logix Controller CPU Utilization (L_CPU) Add-On Instruction faceplate monitors a Logix controller and provides

controller information on the system status page of the HMI template. This status information includes controller CPU

utilization, communication usage, memory usage, task scan times, and controller loading.

Follow these steps to add the Add-On Instruction to an online controller by using RSLogix 5000 software.

1. Open RSLogix 5000 software.

2. Open your target controller application from the saved location in step 6

3. From the Controller Organizer, click the ‘+’ to expand the Controller Status task and the Diagnostics program and

then double-click the LCPU routine.

4. Right-click Rung 0 and choose Import Rungs.

on page 22.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 53

Page 54

Chapter 4 Add Basic System Diagnostics

5. Select the L_CPU L5X file based on your controller revision and click Import.

6. On the Import Configuration dialog box, click OK to create all of the tags and data types that are required for the

Add-On Instruction.

7. Click Import Logic Edits as Pending and click OK.

54 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 55

Add Basic System Diagnostics Chapter 4

8. Type the controller slot number in the MOV instruction.

9. Change the GSV instruction to a CLR instruction that is configured as shown in the illustration.

10. Click the Finalize All Edits in Program icon .

11. Click Yes to finalize all of the edits.

Add Controller Diagnostics to a HMI Project

Follow these steps to add controller diagnostics to your HMI project.

1. Open the project that you created in Chapter 2 in the FactoryTalk View Studio software. See page 29

2. Load the required HMI files for the L_CPU Add-On Instruction as documented in the PlantPAx Library of Logix

Diagnostic Objects Reference Manual, publication PROCES-RM003

3. From your HMI project, right-click a system diagnostic display (for example, P1f System) from the template and

choose Open.

.

.

See page 43

for descriptions of the components in a HMI project.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 55

Page 56

Chapter 4 Add Basic System Diagnostics

4. From your HMI project, right-click Logix Graphics Library and choose Open.

5. Right-click the controller graphic in the L_CPU box and choose Copy.

56 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 57

6. On the P1f System display, right-click anywhere in the window and choose Paste.

Add Basic System Diagnostics Chapter 4

7. Right-click the L_CPU graphics on the P1 System display and choose Global Object Parameter Values.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 57

Page 58

Chapter 4 Add Basic System Diagnostics

TIP

8. Type a shortcut name for the controller and click OK.

Make sure that you put the controller name inside brackets [ ] as shown.

9. Save the display.

10. Open the HMI template that you created in Chapter 3

.

58 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 59

11. On the HMI display, click the System Status icon.

System Status

Add Basic System Diagnostics Chapter 4

On the HMI template, the controller graphic has some animation showing the position of the key switch and

controller status indicators.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 59

Page 60

Chapter 4 Add Basic System Diagnostics

Home Tab

Communication Tab

CPU Usage Tab

Connectio ns Tab

Maintenance Tab

Controller Memory Tab

12. Click the controller to access the controller status faceplate.

Tabs on the faceplate also include information on the CPU usage and the status of controller memory and

connections. For complete details, see the PlantPAx Library of Logix Diagnostic Objects,

publication PROCES-RM003

.

60 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 61

Add Basic System Diagnostics Chapter 4

Configure PASS Server Status

In this section, you learn how to add diagnostics for your PASS servers. These diagnostics provide information on the

software components that run on the PASS, including a HMI server, data server, and alarms and events server.

1. Open Knowledgebase Answer ID 44624 at http://rockwellautomation.custhelp.com

zip attachment.

2. Right-click the file and choose Open.

and download the

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 61

Page 62

Chapter 4 Add Basic System Diagnostics

3. Right-click server status-state cpr9 and choose Extract All.

The example shows the unzipped files.

4. In the FactoryTalk View HMI template, right-click Displays and choose Add Component Into Application.

62 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 63

Add Basic System Diagnostics Chapter 4

5. Open the server status-state cpr9 V505.gfx file from the files that were unzipped in step 3.

6. Right-click the imported display and choose VBA Code.

7. Find the text circled in the example and type the name of your HMI server and data server.

8. Save the changes to the VBA code and close the server status display.

9. Open a system display.

For example, P1x.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 63

Page 64

Chapter 4 Add Basic System Diagnostics

10. From the Objects menu, choose Push Button>Button.

11. Click the display and drag the mouse to draw a button.

12. Click Browse (…) next to Release action.

64 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 65

13. From the All Commands and Macros list, select Display and click Next.

Add Basic System Diagnostics Chapter 4

14. From the File pull-down menu, choose the server status screen.

15. Click Finish.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 65

Page 66

Chapter 4 Add Basic System Diagnostics

16. On the Button Properties dialog box, click the Up Appearance tab.

17. In the Caption text box, type Server Status.

18. Click OK.

19. Save the changes to the P1 System display.

20. Run the client file and access the System Status page.

21. Click Server Status.

66 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 67

Add Basic System Diagnostics Chapter 4

TIP

The Server Status faceplate appears.

The example shows a networked station application with the FactoryTalk server, HMI server, and data server on one

workstation. None of the servers is redundant in this application example.

We recommend that diagnostic alarms for network adapters and I/O modules be added to the Alarm server to be displayed on the

alarm banner and included in the alarm log and history.

Add These Additional Resources

The following resources are available to assist with developing your application.

Topic Description Where To Find Information

DLR diagnostics The device-level ring (DLR) faceplate shows network

status and where a break is in the EtherNet/IP network.

L_ChangeDet, L_Redun, L_TaskMon library objects These PlantPAx Library of Logix Diagnostic Objects

monitor Logix controllers on the network, checking for

changes that impact operation for primary and secondary

controller status.

The DLR diagnostics faceplate application can be

downloaded from the Rockwell Automation Sample Code

website at http://samplecode.rockwellautomation.com

PlantPAx Library of Logix Diagnostic Objects,

publication PROCES-RM003

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 67

Page 68

Chapter 4 Add Basic System Diagnostics

Notes:

68 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 69

Appendix A

Access the Quick Start Worksheet

The Microsoft Excel file attached to this PDF file contains a worksheet that you can use to gather information required for

executing the quick start.

To use the Excel file, click the Attachments link (the paper clip icon) and double-click the Excel file.

Enable Content

Verify that macros are enabled when using the file.

If this is the first time you are opening a Microsoft Excel file, you need to enable macros, if prompted.

Click Enable Content.

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 69

Page 70

Appendix A Access the Quick Start Worksheet

Using the Worksheet

The worksheet is a macro-enabled spreadsheet that contains entry fields. As information is entered, additional entry fields

are dynamically created to collect more information.Where possible, some fields are auto-populated and entries are

verified automatically.

When completed, the worksheet must be saved as an Excel workbook (.xlsm) without the macros enabled. Select the

Edit Your Setup button (circled in Figure 8

the worksheet manually.

The separate portions of the worksheet shown are examples of the information that can be documented for the controllers

and PASS servers.

Figure 6 - Controllers Worksheet

) and the File menu appears to let you save your data. You can then edit

70 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 71

Figure 7 - Controller Detail Worksheet

Access the Quick Start Worksheet Appendix A

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 71

Page 72

Appendix A Access the Quick Start Worksheet

Figure 8 - PASS Worksheet

72 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 73

Figure 9 - PASS Worksheet (continued)

Access the Quick Start Worksheet Appendix A

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 73

Page 74

Appendix A Access the Quick Start Worksheet

Notes:

74 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 75

Index

A

access

worksheet file

adapters

add network

add

controller to data server

modules 17

remote chassis

additional resources

administrator access

alarm

servers configuration

tools 48

application manager

69

18

20

C

change

controller type

module definition 19

chassis

remote modules

client files

44

HMI

CompactLogix

controllers

configure

alarm servers

controller diagnostics

controller templates 9

data servers

HMI servers

I/O modules

network adapters 18

controller

add to data server

change type

CompactLogix

configure templates

ControlLogix

diagnostic configuration

download

enable redundancy

modify properties 14

open template

overview

quick steps

redundant

simplex, redundant

task rates

template description

templates

worksheet example

ControlLogix

controllers

create

HMI project

14

12

35

33

30

19

14

12

12

21

13

12

11

12

controllers

16

12

12

23, 29

20

12

8

50

26

38

15

9

10

35

12

53

38

53

D

data servers

configuration

deploy

HMI template

description

controller templates

diagnostics

controller configuration

quick steps

system

display

HMI templates

navigation map

download

Knowledgebase

project

33

30

52

51

26

49

5

21

E

enable

controller redundancy

examine

HMI project

execution

set task rate

41

19

F

features

HMI template

firmware

revision

48

15

H

HMI

additional resources

client files

create project

deploy templates

load templates 26

quick steps

server configuration

server status 61

software versions

template features

template names and resolutions

template overview

template structure

44

23, 29

30

25

23

48

I

I/O modules

configuration

set RPI

19

19

12

53

15

67

30

26

26

43

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 75

Page 76

Index

K

Knowledgebase

downloads

templates

L

learn about

HMI project

load

HMI templates

M

m 26

manual

5

scope

map

display navigation

modify

controller properties

module

17

add

add remote

change definition

N

navigation

display map

tools

network

49

add adapters

O

overview

controller

HMI templates

P

PlantPAx

reference manual

preface

5

prerequisite

HMI tasks

6

tasks

project

create HMI

download

HMI familiarity 41

properties

modify controller

5

12

23

21

5

29

41

20

49

18

26

26

19

6

14

49

14

quick steps

controller

diagnostics

HMI 25

redundancy

enable controller

repaint

repair

repair

repaint

resolution

HMI templates

resources

additional

revision

firmware

RPI

module execution

scope

manual

security

view display

server

HMI status

worksheet example

simplex

controllers

software

23

HMI

versions

status

system

structure

HMI template

system

diagnostics

status

task rates

controller

tasks

prerequisite

11

52

R

15

50

50

26

8

15

19

S

5

50

61

24

12

6

49

43

51

49

T

16

6

Q

quick start

worksheet

76 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

7

Page 77

templates

12

controller

controller configuration

deploy HMI 30

descriptions for controllers

explore HMI features

HMI names

HMI overview

HMI structure

Knowledgebase 5

load HMI

open controller

purpose 5

tools

alarms

HMI templates

navigation 49

type

change controller

26

26

48

V

versions

6

software

view

50

security

Index

9

12

48

26

43

13

48

14

worksheet

access file

controller example

quick start

server example 24

W

69

10

7

Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013 77

Page 78

Index

Notes:

78 Rockwell Automation Publication PROCES-QS001A-EN-P - October 2013

Page 79

Page 80

Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

software service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

updates, support chats and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more

information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Wor ldwi de Lo cato r

Rockwell Automation representative.

at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

New Product Satisfaction Return

you can find technical and application notes, sample code, and links to

for software

.

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback