Page 1

System Design for

Control of

Electrical Noise

Reference Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or part, without written permission of Rockwell Automation,

is prohibited.

does not assume responsibility

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage or economic loss.

!

Attention statements help you to:

•

identify a hazard

•

avoid a hazard

•

recognize the consequences

IMPORTANT

Allen-Bradley is a registered trademark of Rockwell Automation.

Identifies information that is critical for successful

application and understanding of the product.

Page 3

Table of Contents

Preface

Electrical Noise Control Overview

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Contents of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . P-3

Chapter 1

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

What is Electrical Noise?. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Understanding the Need for Electrical Noise Control . . . . . . 1-1

CE Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Best Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Noise Control Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Noise Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Noise Victims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Coupling Mechanisms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Conducted Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Mutual Inductance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Electromagnetic Radiation. . . . . . . . . . . . . . . . . . . . . . . 1-6

Solutions for Reducing Noise . . . . . . . . . . . . . . . . . . . . . . . 1-6

Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Measuring Effectiveness . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

High Frequency (HF) Bonding

Chapter 2

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Understanding the Source of Electrical Noise . . . . . . . . . . . 2-1

Noise Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Noise Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

The Ground Plane Principle . . . . . . . . . . . . . . . . . . . . . 2-3

Extending the Ground Plane Principle. . . . . . . . . . . . . . 2-5

Grounding a PCB to the Drive Chassis . . . . . . . . . . . . . 2-5

Noise Solutions Using the Ground Plane Principle . . . . . . . 2-6

Grounding to the Component Mounting Panel. . . . . . . . 2-6

Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Adjacent Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Grid and Raised Floor. . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Mezzanine Floor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Machine Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

New Buildings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Existing Buildings. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Grounding (Safety Earth) . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

iPublication GMC-RM001A-EN-P — July 2001

Page 4

ii Table of Contents

Segregating Sources and Victims

Shielding Wires, Cables, and

Components

Chapter 3

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Understanding the Segregation Concept . . . . . . . . . . . . . . . 3-1

Noise Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Ensuring CE Compliance at Build Time . . . . . . . . . . . . . 3-2

Zone Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Component Categories . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Routing Wires and Cables Within a Panel . . . . . . . . . . . . . . 3-4

Wire and Cable Categories . . . . . . . . . . . . . . . . . . . . . . 3-6

Routing System Wires and Cables Between Panels. . . . . . . . 3-8

Chapter 4

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Understanding the Shielding Concept . . . . . . . . . . . . . . . . . 4-1

Ferrite Sleeves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Ferrite Sleeve Limitations. . . . . . . . . . . . . . . . . . . . . . . . 4-4

Mixing Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Filtering Noise

Contact Suppression

Chapter 5

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Understanding the Filtering Concept . . . . . . . . . . . . . . . . . . 5-1

Commercial AC Line Filters for Low Voltage Circuits . . . 5-1

General Purpose 0-24V ac/dc Filters . . . . . . . . . . . . . . . 5-2

Filter Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Performance Test Set-up . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Ultrasonic Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Xenon Flashing Beacons (strobe lights). . . . . . . . . . . . . . . . 5-5

AC Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Earth Leakage/Ground Fault . . . . . . . . . . . . . . . . . . . . . 5-6

Chapter 6

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Understanding Contact Suppression for AC Circuits . . . . . . . 6-1

Methods of AC Contact Suppression . . . . . . . . . . . . . . . 6-2

Understanding Contact Suppression for 24V dc Circuits . . . . 6-3

Methods of DC Contact Suppression . . . . . . . . . . . . . . . 6-3

Contact Suppression Effects . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Power Distribution

Publication GMC-RM001A-EN-P — July 2001

Chapter 7

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Understanding Noise in Power Wiring . . . . . . . . . . . . . . . . 7-1

Three-Phase Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . 7-1

Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Single Phase Power Supplies . . . . . . . . . . . . . . . . . . . . . . . 7-4

Page 5

Motor Wiring

High Speed Registration Inputs

Table of Contents iii

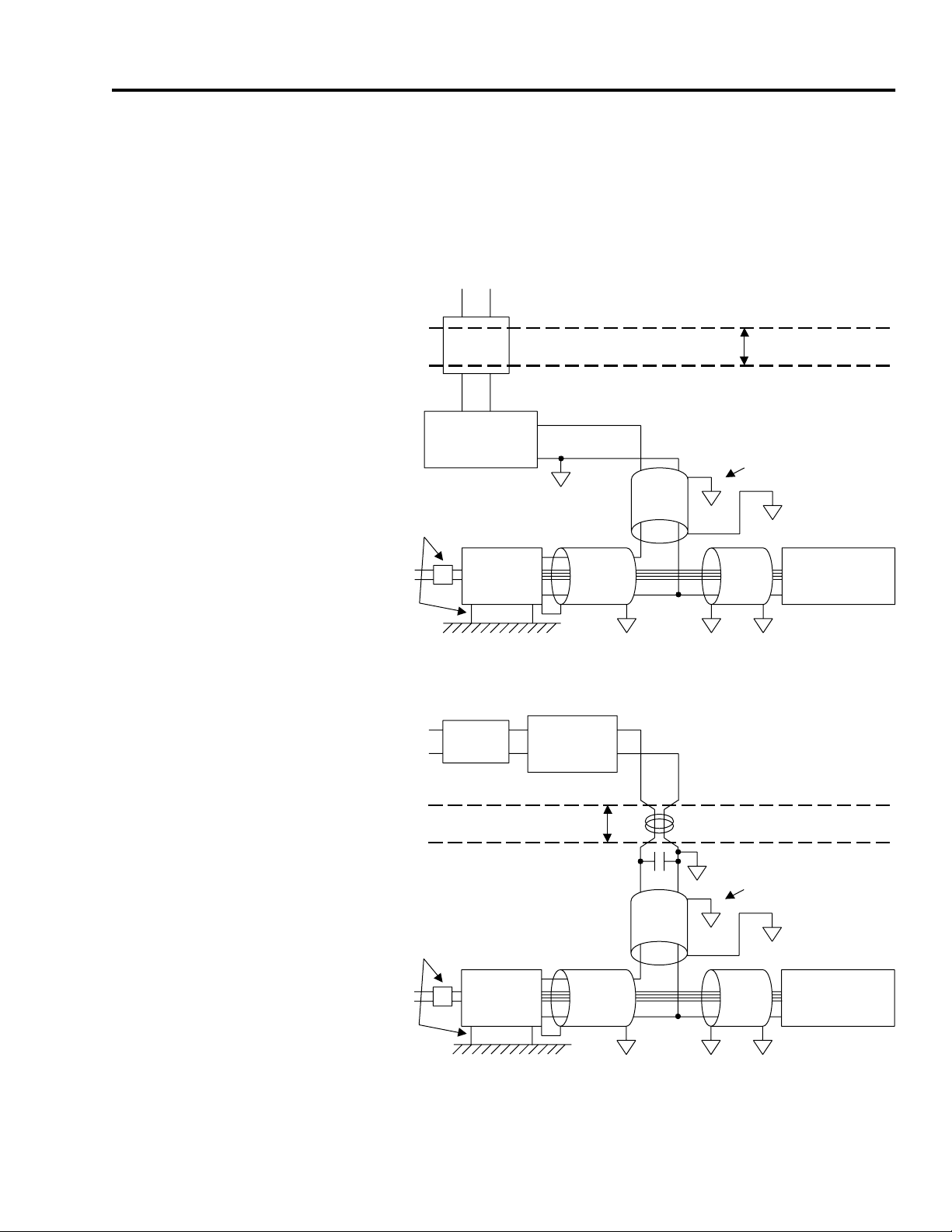

24V dc Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

24V dc Distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

24V dc PSU Zoning Methods. . . . . . . . . . . . . . . . . . . . . 7-5

Linear PSU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Special Applications for 24V dc PSUs . . . . . . . . . . . . . 7-11

Chapter 8

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Understanding Noise in Motor Power Wiring . . . . . . . . . . . 8-1

Shielding Motor Power Cables . . . . . . . . . . . . . . . . . . . . . . 8-2

Grounding Motor Power Cable Shields . . . . . . . . . . . . . . . . 8-2

Applying Ferrite Sleeves. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Splicing Motor Power Cables . . . . . . . . . . . . . . . . . . . . . . . 8-3

Handling Excess Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Installing Long Motor Cables . . . . . . . . . . . . . . . . . . . . . . . 8-4

Chapter 9

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Understanding Registration Inputs . . . . . . . . . . . . . . . . . . . 9-1

Noise Reduction Methods. . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Shared Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Dedicated Power Supply. . . . . . . . . . . . . . . . . . . . . . . . 9-4

Detection Device Mounting. . . . . . . . . . . . . . . . . . . . . . 9-4

Proximity Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Signal Noise Filter Options. . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Single Voltage Input (24V or 5V). . . . . . . . . . . . . . . . . . 9-6

Dual Voltage Inputs (24V or 5V) . . . . . . . . . . . . . . . . . . 9-7

Registration Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Error Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Software Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Encoders

Measuring Noise Reduction

Effectiveness

Chapter 10

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Understanding Encoders . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Noise Reduction Methods. . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Driver Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Power Supply Wiring Options . . . . . . . . . . . . . . . . . . . . . 10-3

Chapter 11

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Understanding Noise Measurement. . . . . . . . . . . . . . . . . . 11-1

Publication GMC-RM001A-EN-P — July 2001

Page 6

iv Table of Contents

Methods for Measuring Noise . . . . . . . . . . . . . . . . . . . . . . 11-1

Measuring Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Oscilloscope Specifications . . . . . . . . . . . . . . . . . . . . . 11-2

Oscilloscope Settings for Measuring Noise Peaks . . . . . 11-2

E-Field Sniffing Method. . . . . . . . . . . . . . . . . . . . . . . . 11-3

H-Field Sniffing Method . . . . . . . . . . . . . . . . . . . . . . . 11-4

Direct Voltage Measurement Method . . . . . . . . . . . . . . 11-4

Grounding Your Probe (reference ground) . . . . . . . . . 11-6

Ground Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

Differential Measurements . . . . . . . . . . . . . . . . . . . . . . 11-7

Scope Probe Lead Extension . . . . . . . . . . . . . . . . . . . . 11-9

Checking Your Method for Effectiveness . . . . . . . . . . . 11-9

Identifying the Noise Source . . . . . . . . . . . . . . . . . . . 11-10

Intermittent Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

General Guidelines for Measuring Noise . . . . . . . . . . . . . 11-10

What are Acceptable Noise Levels? . . . . . . . . . . . . . . 11-10

Field Strength Meters . . . . . . . . . . . . . . . . . . . . . . . . 11-11

Monitoring for Noise. . . . . . . . . . . . . . . . . . . . . . . . . 11-11

Noise Control Supplement

Appendix A

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Grounding Cable Shields . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Pigtails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Clamping at the Circular Section . . . . . . . . . . . . . . . . . . A-2

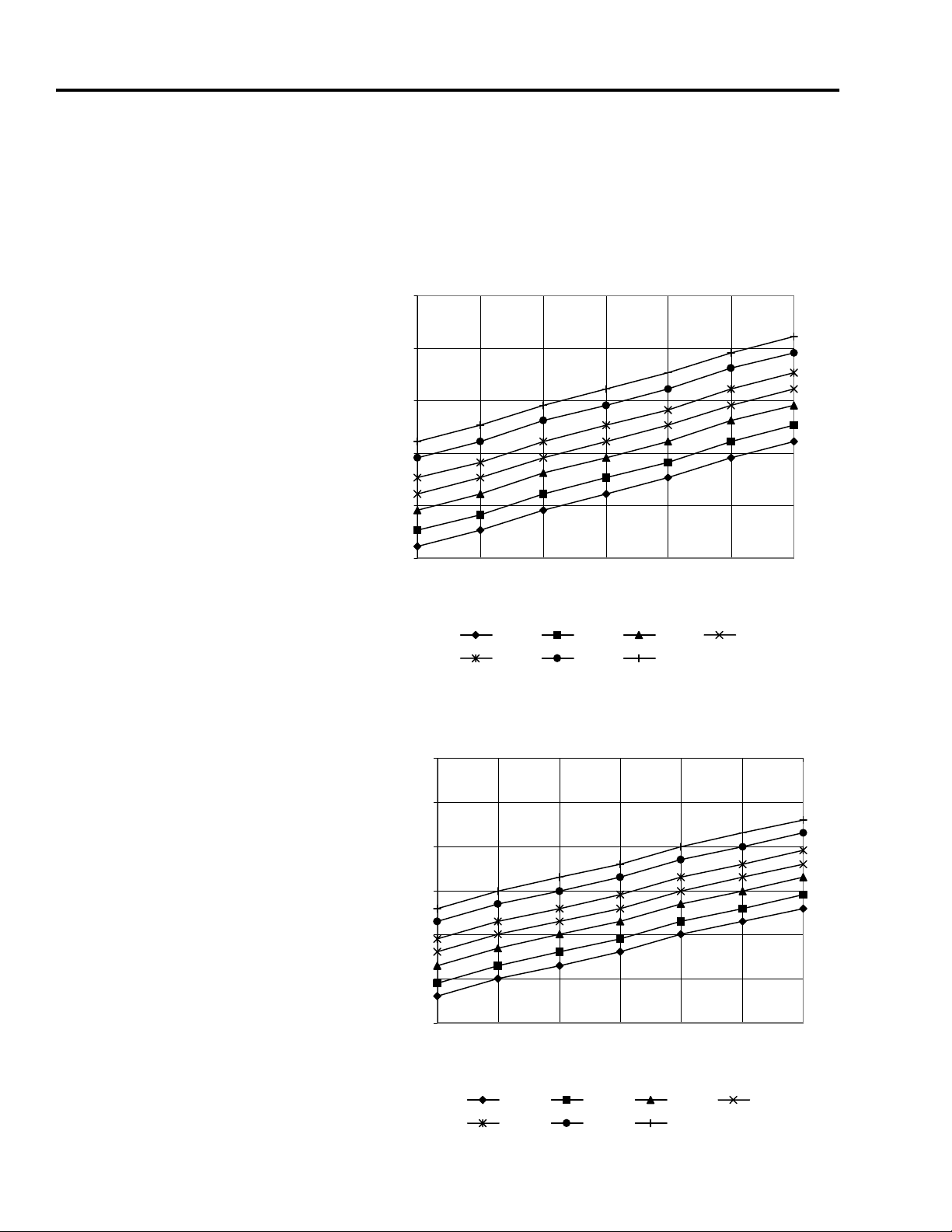

Wire Segregation Test Results . . . . . . . . . . . . . . . . . . . . . . . A-5

Test Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Conclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Switch-Mode DC Power Supplies . . . . . . . . . . . . . . . . . . . . A-8

Background Information . . . . . . . . . . . . . . . . . . . . . . . . A-8

Grounding the Common . . . . . . . . . . . . . . . . . . . . . . . . A-9

DC Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Positioning the PSU within the Panel . . . . . . . . . . . . . . A-11

AC Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Using Separate DC Power Supplies . . . . . . . . . . . . . . . A-12

Using a Dynamic Braking Contactor . . . . . . . . . . . . . . . . . A-13

Reducing Dynamic Braking Circuit Noise. . . . . . . . . . . A-14

Bonding Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

Wire Forms an Antenna . . . . . . . . . . . . . . . . . . . . . . . A-15

Inductance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

Noise Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

EMC Product Suppliers

Publication GMC-RM001A-EN-P — July 2001

Appendix B

EMC Product Suppliers. . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Page 7

Preface

Read this preface to familiarize yourself with the rest of the manual.

The preface covers the following topics:

• Who should use this manual

• The purpose of this manual

• Contents of this manual

• Related documentation

• Conventions used in this manual

• Allen-Bradley support

Who Should Use this Manual

Purpose of this Manual

Use this manual if you are responsible for the circuit design and

layout of wiring panels or the installation and mounting of

Allen-Bradley products. Specifically, the following disciplines should

be included:

• Circuit designers

• Panel layout designers

• Panel builders and electricians

• Electrical technicians

In addition, you should have an understanding of:

• Drive control and basic electronics

• Appropriate electrical codes

This manual outlines the practices which minimize the possibility of

noise-related failures and that comply with noise regulations. It gives

you an overview of how electrical noise is generated (sources), how

the noise interferes with routine operation of drive equipment

(victims), and examples of how to effectively control noise.

This manual applies in general to Allen-Bradley drives products. For

information on specific Allen-Bradley motion products refer to Noise

Control Supplement - Motion Products Reference Manual (publication

GMC-RM002x-EN-P).

Publication GMC-RM001A-EN-P — July 2001

Page 8

P-2 Preface

Contents of this Manual

The contents of this manual are described in the table below.

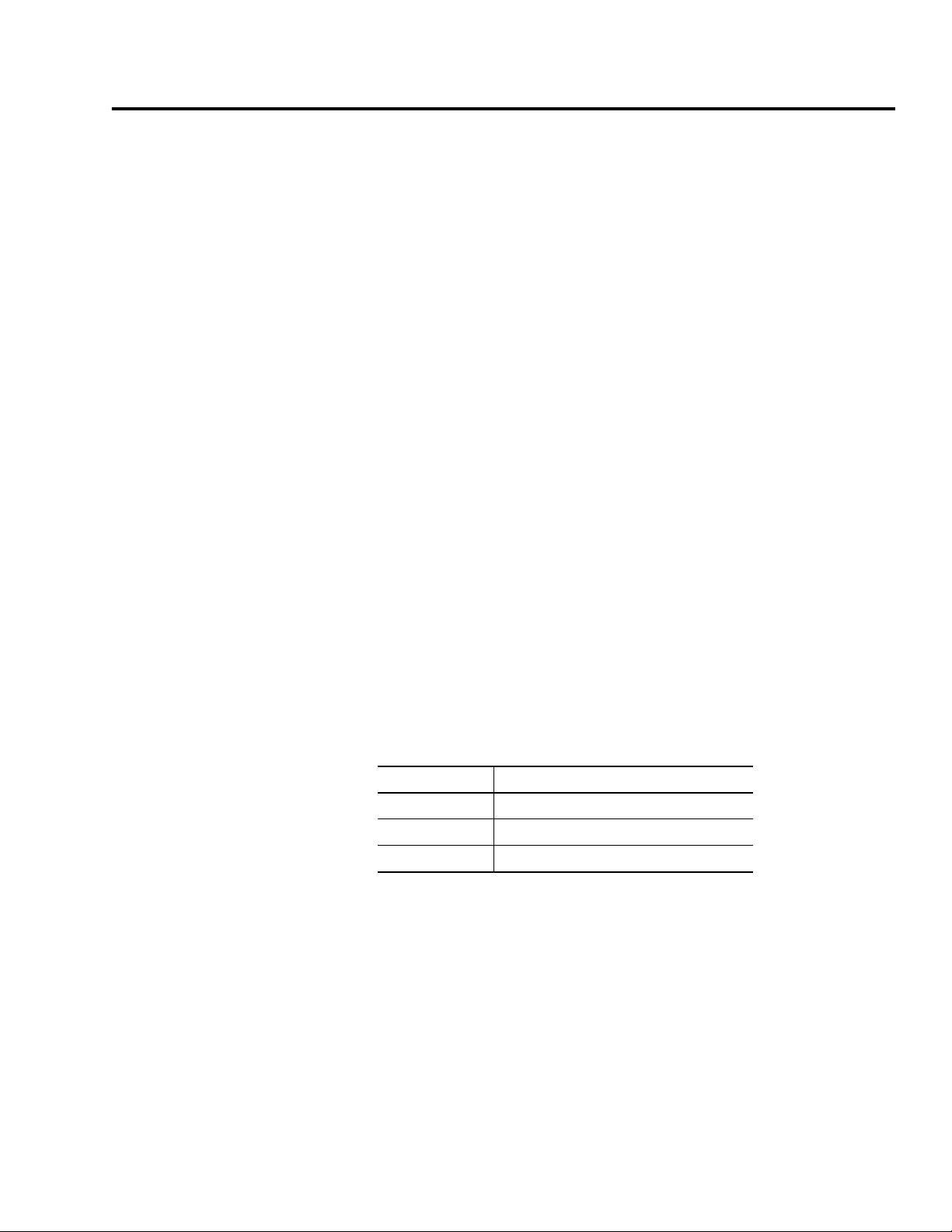

Chapter Title Contents

Preface Describes the purpose, background, and

scope of this manual. Also specifies the

audience for whom this manual is

intended.

1 Electrical Noise Control

Overview

2 High Frequency (HF) Bonding Describes the ground plane principle and

3 Segregating Sources and

Victims

4 Shielding Wires, Cables, and

Components

5 Filtering Noise Describes how low-pass filters and ferrite

Provides a brief understanding of the need

for electrical noise control, how noise

affects system performance, noise

coupling methods, and solutions.

provides techniques for bonding devices,

panels, machines, floors, doors, and

buildings.

Describes how establishing zones within

your system for noise sensitive or noise

generating components can reduce

electrical noise coupling.

Describes how using shielded cable or

steel shields can reduce electrical noise.

sleeves can reduce electrical noise.

6 Contact Suppression Describes how contact suppressors for

relays and various other switches can

reduce electrical noise.

7 Power Distribution Describes bonding, segregating, shielding,

and filtering techniques for use when

routing AC and DC power.

8 Motor Wiring Describes shielding, grounding, and

splicing techniques for use with motor

wiring.

9 High Speed Registration

Inputs

10 Encoders Describes bonding, segregating, shielding,

11 Measuring Noise Reduction

Effectiveness

Appendix A Noise Control Supplement Provides background information on

Appendix B EMC Product Suppliers Provides a list of EMC product suppliers,

Describes how wiring sensitive to

electrical noise benefits from proper noise

reduction strategies.

and filtering techniques for use with

encoders.

Describes the equipment, methods, and

various guidelines for measuring noise

levels and noise reduction effectiveness.

specific topics related to electrical noise

control.

the products they offer, and internet

website.

Publication GMC-RM001A-EN-P — July 2001

Page 9

Preface P-3

Related Documentation

The following documents contain additional information related to

electrical noise control. To obtain a copy, contact your local

Allen-Bradley office or distributor.

For: Read This Document: Document Number:

Specific advice on motion products Noise Control Supplement - Motion Products GMC-RM002x-EN-P

Advice specific to large systems Industrial Automation Wiring and Grounding Guidelines for Noise

Immunity

Advice specific to large systems Installing, Operating and Maintaining Engineered Drive Systems

(Reliance Electric)

Safety advice Safety Guidelines for the Application, Installation, and

Maintenance of Solid-State Control

IEEE industry standards for electrical

equipment installation

A text book on noise reduction techniques Noise Reduction Techniques in Electronic Systems

A text book on grounding techniques for the

control of EMI

IEEE Guide for the Installation of Electrical Equipment to

Minimize Electrical Noise Inputs to Controllers from External

Sources

Henry W. Ott

Published by Wiley-Interscience

Grounding for the Control of EMI

Hugh W. Denny

Published by Don White Consultants

1770-4.1

D2-3115-2

SGI-1.1

IEEE 518

N/A

N/A

1

A text book on solving interference problems Solving Interference Problems in Electronics

Ralph Morrison

Published by Wiley-Interscience

A technical paper on EMI emissions EMI Emissions of Modern PWM ac Drives

Gary L. Skibinski, Russel J. Kerkman, & Dave Schlegel

IEEE Industry Applications Magazine, Nov./Dec. 1999

A text book on EMC EMC for Product Designers

Tim Williams

Published by Newnes

1

Available in future. Check with The Automation Bookstore.com or your Allen-Bradley sales representative for

documentation availability.

Conventions Used in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural

steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Words that you type or select appear in bold.

• When we refer you to another location, the section or chapter

name appears in italics.

N/A

N/A

N/A

Publication GMC-RM001A-EN-P — July 2001

Page 10

P-4 Preface

Publication GMC-RM001A-EN-P — July 2001

Page 11

Electrical Noise Control Overview

Chapter

1

Chapter Objectives

What is Electrical Noise?

This chapter provides a brief understanding of the need for electrical

noise control, how noise affects system performance, noise coupling

methods and solutions. This chapter covers the following topics:

• What is electrical noise

• Understanding the need for electrical noise control

• Noise control basics

• Coupling mechanisms

• Solutions for reducing noise

• Implementation

• Measuring effectiveness

Electrical noise is voltage spikes, generated by the routine operation

of selected system components (sources), that interfere (due to a

coupling mechanism) with the routine operation of other selected

system components (victims).

Understanding the Need for

In Europe, a system must satisfy EMC regulations. It must also work

reliably without suffering from noise-induced failures.

Electrical Noise Control

CE Compliance

Most equipment is CE marked. This means it is certified to be

compliant with European Directives which comprise two main

requirements:

• Potential noise sources must be limited in noise output to a

• Potential victims of noise must be hardened to withstand a higher

specified level.

noise level.

Publication GMC-RM001A-EN-P — July 2001

Page 12

1-2 Electrical Noise Control Overview

In both cases, equipment must be installed to manufacturers

recommendations to achieve compliance. The frequency range

covered is 150kHz to 1GHz, though the upper limit is likely to be

raised as operation frequencies increase.

Despite this, a CE compliant industrial drive system may still suffer

functional failures due to electrical noise. Additional measures are

often necessary to prevent noise from being coupled between source

and victim. The frequency range involved in system failures is

generally confined between 200kHz and 10MHz.

Best Practices

Most industrial control products do not utilize high frequencies

directly, but they can generate them in the form of noise. Logic

circuits are affected by this noise, so you need to be able to control it.

Noise Control Basics

Because it is far less expensive to apply noise control measures during

system installation than it is to redesign and fix a malfunctioning

system, we recommend you implement the best-practice procedures

described in this document.

If basic measures are implemented rigorously, a reliable system

should result. However, if just one wire is routed incorrectly or a filter

is missed, it may be enough to cause problems. Experience shows that

it is very difficult to ensure that these measures are applied 100% of

the time. If all possible measures are taken (incorporating

redundancy), the system is likely to be more tolerant of minor

mistakes in implementation.

A typical industrial control system will contain a mixture of noise

sources and potential victims. Problems are caused when a coupling

mechanism is introduced.

Noise Sources

Publication GMC-RM001A-EN-P — July 2001

Typical noise sources include:

• Mechanically switched inductive loads create intense intermittent

noise.

• PWM drive power outputs create intense continuous noise.

• Switch-mode DC power supplies can create continuous noise.

Page 13

Electrical Noise Control Overview 1-3

• Microprocessor clocks can generate high levels of noise at the

clock frequency and its harmonics.

• Contact switching.

Of the noise sources listed above, only contact switching noise can be

reduced at the source by the system builder.

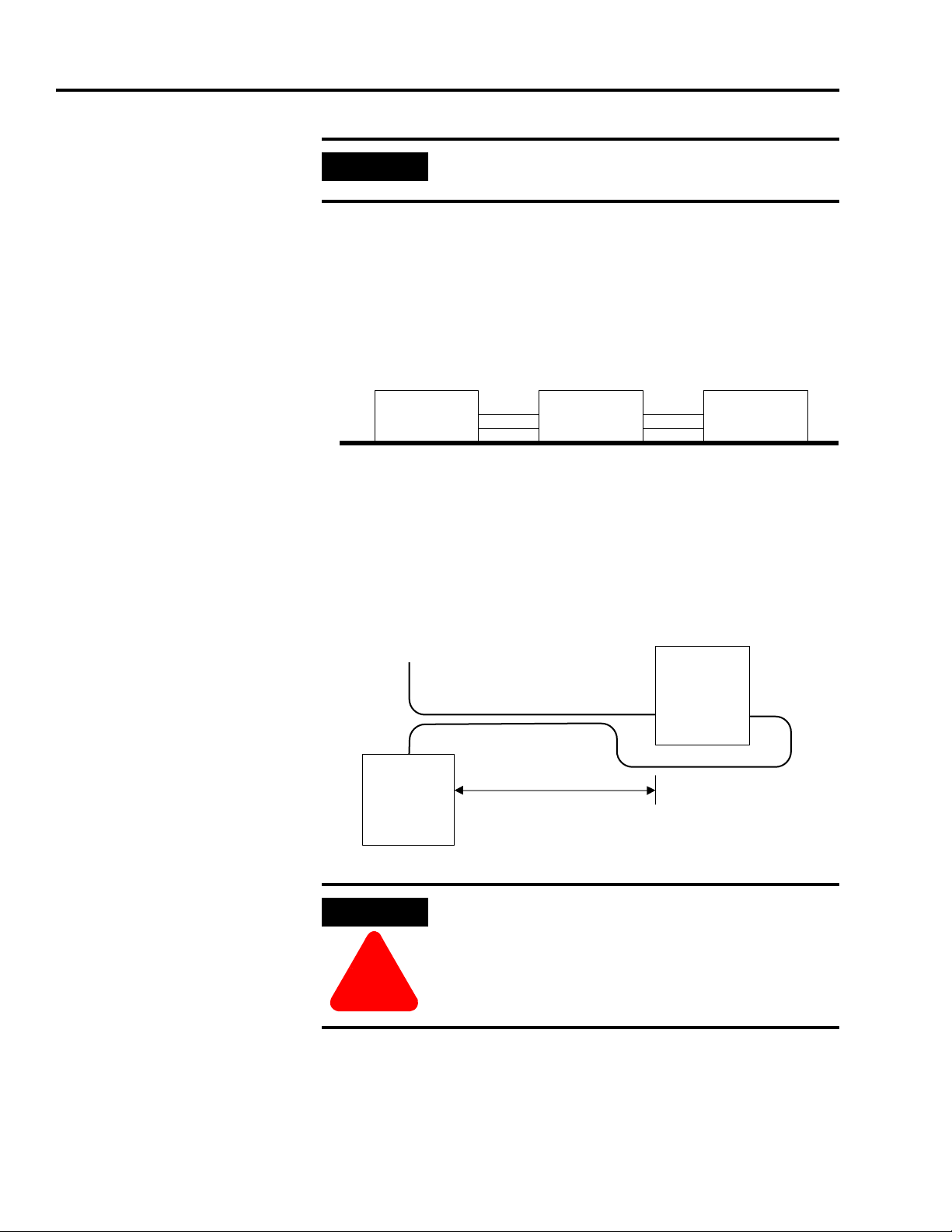

Refer to the figure below for an example of a typical noise source.

Figure 1.1

Switch-Mode Power Supply Noise Measurement

AC

Line

Filter

+24V

24V dc PSU

DC common

Ground Plane - conductive metal panel

No load connected

Noise voltage

measured here

Refer to Figure 1.2 for an example of six volt noise spikes from a

typical 24V dc power supply. The spikes usually contain frequencies

above 10 MHz.

Figure 1.2

Switch-Mode Power Supply Noise

10V

8

6

4

2

0

-2

-4

-6

6.0V pk

-8

-10V

-10123456789

Sitop Power 20 with 3 phase input - no load

Common Mode Noise +24 Volts to Backplane

ms

Publication GMC-RM001A-EN-P — July 2001

Page 14

1-4 Electrical Noise Control Overview

Noise Victims

Typical noise victims include the following:

• Microprocessor controlled devices

• Analog devices

• Encoder and registration interfaces

Refer to Figure 1.3 for an example of a typical victim.

Figure 1.3

A victim TTL gate is easily triggered

Noisy circuit carrying 6V spikes

comprising mainly 10 MHz

5V TTL gate

Coupling Mechanisms

100 pF = 200 Ω

50 Ω

Signal Source

(zero impedance)

1

Refer to the section Capacitance below for an explanation of the 200 ohm impedance. Generally, most potential

victims are better protected than this.

@ 10 MHz

Victim TTL gate receives 1.2V spikes

1

The source noise level and the victim’s sensitivity are normally outside

the control of the system designer so that it is necessary to concentrate

on the transmission of noise between them.

The coupling mechanism is the means by which electrical noise

interferes with the routine operation of equipment. This section

describes the four common coupling mechanisms for electrical noise

transmission.

Publication GMC-RM001A-EN-P — July 2001

Conducted Noise

Noise is conducted directly by system power wiring. A common route

for conducted noise is the 24V dc distribution wiring.

Page 15

Electrical Noise Control Overview 1-5

Capacitance

At radio frequencies (RF) the capacitance between two adjacent wires

is significant. Two insulated wires touching each other and only 1.0

meter (39.0 in.) long form a capacitance of approximately 100 pF

(Pico Farads). At 10 MHz the impedance is only 200 ohms.

Fortunately, the effect reduces as the square of the separation

distance. Refer to Figure 1.4 for an example of capacitive coupling.

Figure 1.4

Capacitive Coupling

Stray

capacitance

Circuit A

Separation distance

Circuit B

Mutual Inductance

At radio frequencies (RF) the inductance of a straight wire is

significant. A length of wire 1.0 meter (39 in.) has an inductance of

µ

approximately 1.0

ohms.

Two adjacent wires have mutual inductance forming a transformer.

Fortunately, the effect reduces as the square of the separation

distance. Refer to Figure 1.5 for an example of inductive coupling.

Figure 1.5

Inductive Coupling

H (Micro Henry). At 10 MHz the impedance is 60

Stray

inductance

Circuit A

Magnetic coupling

Circuit B

Separation distance

Publication GMC-RM001A-EN-P — July 2001

Page 16

1-6 Electrical Noise Control Overview

Electromagnetic Radiation

An example of electromagnetic radiation is radio transmission.

Industrial control wiring systems are large, wideband antenna which

radiate noise signals to the world. These signals (together with

conducted noise) are the primary target of the European regulations,

but rarely cause system malfunctions.

Solutions for Reducing Noise

This method: In this

category:

HF (high frequency)

Bonding

Segregation Coupling

Shielding Coupling

Filtering Coupling

Coupling

Reduction

Reduction

Reduction

Reduction

Noise reduction solutions are categorized as coupling reduction and

source reduction. There are four main methods used to reduce the

coupling of noise between source and victim. However, contact

suppression is the only source reduction technique that can be

directly applied by the system builder. Refer to the table below for a

summary.

Is defined as: For more

information refer to:

Maintaining all

metalwork at the same electrical potential. This

method is low cost and the basis for all other methods. It works by

ensuring all equipment chassis are at the same potential at all

The chapter High

Frequency (HF)

Bonding.

frequencies. If different potentials exist the voltage difference is

seen as common-mode noise on all interconnecting wiring.

Separating sources and victims of electrical noise into zones. Noise

coupling reduces with the square of separation distance. Zoning is

zero cost (within limits).

Using shielded cable and steel barriers (Faraday cage effect) to

reduce electrical noise. Because of its relatively high cost, shielding

is used with discretion.

Using low-pass filters to attenuate RF noise. Relatively low cost but

impractical for every wire.

The chapter

Segregating Sources

and Victims.

The chapter Shielding

Wires, Cables, and

Components.

The chapter Filtering

Noise.

Contact

Suppression

Source

Reduction

Adding contact suppression to mechanical switches to reduce noise.

Generally, the one noise source directly influenced by the system

builder.

Publication GMC-RM001A-EN-P — July 2001

The chapter Contact

Suppression.

Page 17

Electrical Noise Control Overview 1-7

Implementation

This application: Is defined as: For more

Routing AC and DC

power

Routing motor

power cables

Wiring high speed

registration inputs

Routing encoder

power cables

Applying bonding, segregating, shielding, and filtering techniques to

AC and DC power supplies and the associated wiring.

Applying shielding, grounding, and splicing techniques to motor

power cable installation.

Applying all the noise reduction methods available to improve the

performance of noise sensitive wiring.

Applying bonding, segregating, shielding, and filtering techniques to

encoder installation.

Measuring Effectiveness

Implementation involves applying the methods summarized in the

table on page 1-6 to the applications as shown in the table below.

information refer to:

The chapter Power

Distribution.

The chapter Motor

Wiring.

The chapter High

Speed Registration

Inputs.

The chapter Encoders.

Measuring noise reduction effectiveness involves using an

oscilloscope to test for noise during implementation. It also involves

monitoring for noise after implementation should updates to the

system affect system performance.

This application: Is defined as: For more

information refer to:

Measuring

effectiveness

Testing for electrical noise during implementation, identifying the

sources of noise, determining acceptable noise levels, and

monitoring for noise on an on-going basis.

The chapter

Measuring Noise

Reduction

Effectiveness.

Publication GMC-RM001A-EN-P — July 2001

Page 18

1-8 Electrical Noise Control Overview

Publication GMC-RM001A-EN-P — July 2001

Page 19

High Frequency (HF) Bonding

Chapter

2

Chapter Objectives

Understanding the Source of Electrical Noise

This chapter describes the ground plane principle and techniques to

extend the ground plane to devices, panels, machines, floors, doors,

and buildings. This chapter covers the following topics:

• Understanding the source of electrical noise

• Noise solutions using a ground plane

• Grounding (safety earth)

The most common source of electrical noise is due to switching of

PWM output stages.

Two examples of how noise is generated by a drive system are given

on the following pages.

Publication GMC-RM001A-EN-P — July 2001

Page 20

2-2 High Frequency (HF) Bonding

Noise Example 1

The transistors impose a 600V step change in the wire B (typically less

than 200nS). Stray capacitance A charges very rapidly causing a

current spike. This is the dominant noise source in PWM (Pulse Width

Modulated) drive systems.

The current circulates through stray capacitance C, bonding

impedance D, bonding impedance E, bonding impedance F, and back

to stray capacitance A. A voltage spike will appear between motor

frame and machine structure (Vd), between machine structure and the

panel (Ve) and between the panel and drive chassis (Vf).

The circuit of an encoder mounted on the motor will then have a

voltage spike of amplitude Vd + Ve relative to the panel and to any

input circuit on the panel, potentially a noise victim.

The noise voltages are proportional to the impedance of the bonds

(voltage = current x impedance). If these are reduced to zero, no

voltage will appear between encoder and panel.

Figure 2.1

Switching noise affecting encoder signal

Drive

Heatsink

(connected

to chassis)

F

IMPORTANT

Panel

The quality of bonding techniques applied during

installation directly affects the noise voltages

+600V dc

Stray

capacitance

A

B

Transistor block

DC common

Impedance due to

poor bonding

between system components.

Motor

Windings

C

Encoder

D

E

Machine Structure

Publication GMC-RM001A-EN-P — July 2001

Page 21

High Frequency (HF) Bonding 2-3

Noise Example 2

Stray capacitance I charges very rapidly. Current circulates via stray

capacitances H, bond G, bond F, and A. In this way, a voltage Vf + Vg

is developed between the drive chassis and true-ground.

Any remote equipment grounded to this true-ground and wired to the

drive will have this noise voltage imposed upon its incoming signal.

Figure 2.2

Switching noise affecting incoming power

AC line

Stray capacitance

to ground

H

G

F

Drive

Heatsink

(connected

to chassis)

Impedance due to

poor bonding

Panel

I

A

+600V dc

Stray

capacitance

Transistor

block

DC common

Many other noise sources exist in a typical system and the advantage

of good bonding holds true for all.

The Ground Plane Principle

The purpose of High Frequency (HF) bonding is to present a defined

low impedance path for HF noise currents returning to their source.

IMPORTANT

Most textbooks on radio frequency (RF) techniques describe the

ground plane (GP) as the ultimate ground reference and an absolute

requirement for controlling RF current paths.

Noise current must and will return to source. If a safe

path is not provided, it may return via victim wiring

and cause circuits to malfunction.

Publication GMC-RM001A-EN-P — July 2001

Page 22

2-4 High Frequency (HF) Bonding

The ground plane principle was originally developed by printed

circuit board (PCB) designers for high frequency circuits. In

multi-layer PCBs a minimum of two copper layers are used with one

being designated the ground or common. This layer covers as large an

area as possible and each IC common is tied directly to it. In addition,

each IC Vss (+5V) pin is decoupled by a 0.1

µ

F capacitor to the

ground plane as close as possible to the pin. The capacitor presents a

very low impedance at RF hence any induced noise current generates

minimal voltage.

The fundamental property of a ground plane is that every point on its

surface is at the same potential (and zero impedance) at all

frequencies. At high frequencies this is more effective than the use of

single point grounding schemes. This is because wire has significant

inductance at RF and just a few inches can create an unacceptable

voltage drop. Refer to the section Bonding Surfaces in Appendix A for

more information.

Figure 2.3

Ground plane layer in a double-sided printed circuit board

Vss pin

Vdd pin

(common)

Ground plane

layer

Insulation

layer

Integrated Circuit

Interconnect

layer

(+5V)

Decoupling Capacitor

(Vss to ground)

Ground plane construction has proved so successful that it is now

universal in PCB design for all but the most price-sensitive and low

frequency circuits. Single-sided PCBs are not generally used for RF or

TTL circuits.

Publication GMC-RM001A-EN-P — July 2001

Page 23

High Frequency (HF) Bonding 2-5

Extending the Ground Plane Principle

The same theory holds true regardless of scale, (the earth being the

ultimate and literal ground plane) and can be used at control cabinet

level or even building level, but requires rigorous implementation.

A ground plane does not have to be flat, but gentle curves prove more

effective than sharp corners. Area is what matters. Even the outer

surface of a machine structure can be used.

Grounding a PCB to the Drive Chassis

In the figure below, a PCB ground plane is extended by bonding it to

the drive chassis.

Figure 2.4

PCB ground plane extended to the drive chassis

Drive

chassis

Printed circuit

board (PCB)

Guidelines for the system builder include:

PCB copper

interconnection

layer

PCB copper

ground plane layer

bonded to drive chassis

• When permitted, the control circuit common should be grounded.

• Some products do not permit grounding of the control common,

µ

but may allow grounding to chassis via a 1.0

F, 50V ceramic

capacitor. Check your installation manual for details.

Publication GMC-RM001A-EN-P — July 2001

Page 24

2-6 High Frequency (HF) Bonding

Noise Solutions Using the Ground Plane Principle

In this section, examples of how to apply the ground plane principle

are described.

Grounding to the Component Mounting Panel

In the example below, the drive chassis ground plane is extended to

the mounting panel. The panel is made of zinc plated steel to ensure a

proper bond between chassis and panel.

Figure 2.5

Drive chassis ground plane extended to the panel

Drive ground plane (chassis)

bonded to panel

Publication GMC-RM001A-EN-P — July 2001

Note: Where TE and PE terminals are provided, ground each

separately to the nearest point on the panel using flat braid.

Plated vs. Painted Panels

In an industrial control cabinet, the equivalent to the copper ground

layer of a PCB is the mounting panel. To make use of the panel as a

ground plane it must be made of zinc plated mild steel or if painted,

the paint must be removed at each mounting point of every piece of

metal-clad equipment (including DIN rails).

Zinc plated steel is strongly recommended due to its inherent ability

to bond with the drive chassis and resist corrosion. The disadvantage

with painted panels, apart from the cost in labor time to remove the

Page 25

High Frequency (HF) Bonding 2-7

paint, is the difficulty in making quality control checks to verify if

paint has been properly removed, and any future corrosion of the

unprotected mild steel will compromise noise performance.

Plain stainless steel panels are also acceptable but are inferior to zinc

plated mild steel due to their higher ohms-per-square resistance.

Though not always available, a plated cabinet frame is also highly

desirable since it makes HF bonding between panel and cabinet

sections more reliable.

Painted Components

Mating surfaces must be cleaned of paint and the exposed surfaces

protected against corrosion with conductive paint or petroleum jelly.

Anodized Aluminum Components

Mating surfaces must be cleaned of anodizing and the exposed

surfaces protected against corrosion.

EMC Filters

Filter performance depends entirely on close coupling between the

filter case and the drive chassis (or other load chassis). They should

be mounted as close as possible to the load and on the same panel. If

a painted panel is used, short braid straps should be used to tie the

two chassis together. As a temporary remedy, an effective means of

coupling filter case and drive chassis is to lay a single piece of

aluminum foil beneath the two chassis.

Doors

For doors 2 m (78 in.) in height, bond with two or three (three is

preferred) braided straps (top, bottom, and center).

EMC seals are not normally required for industrial systems.

Publication GMC-RM001A-EN-P — July 2001

Page 26

2-8 High Frequency (HF) Bonding

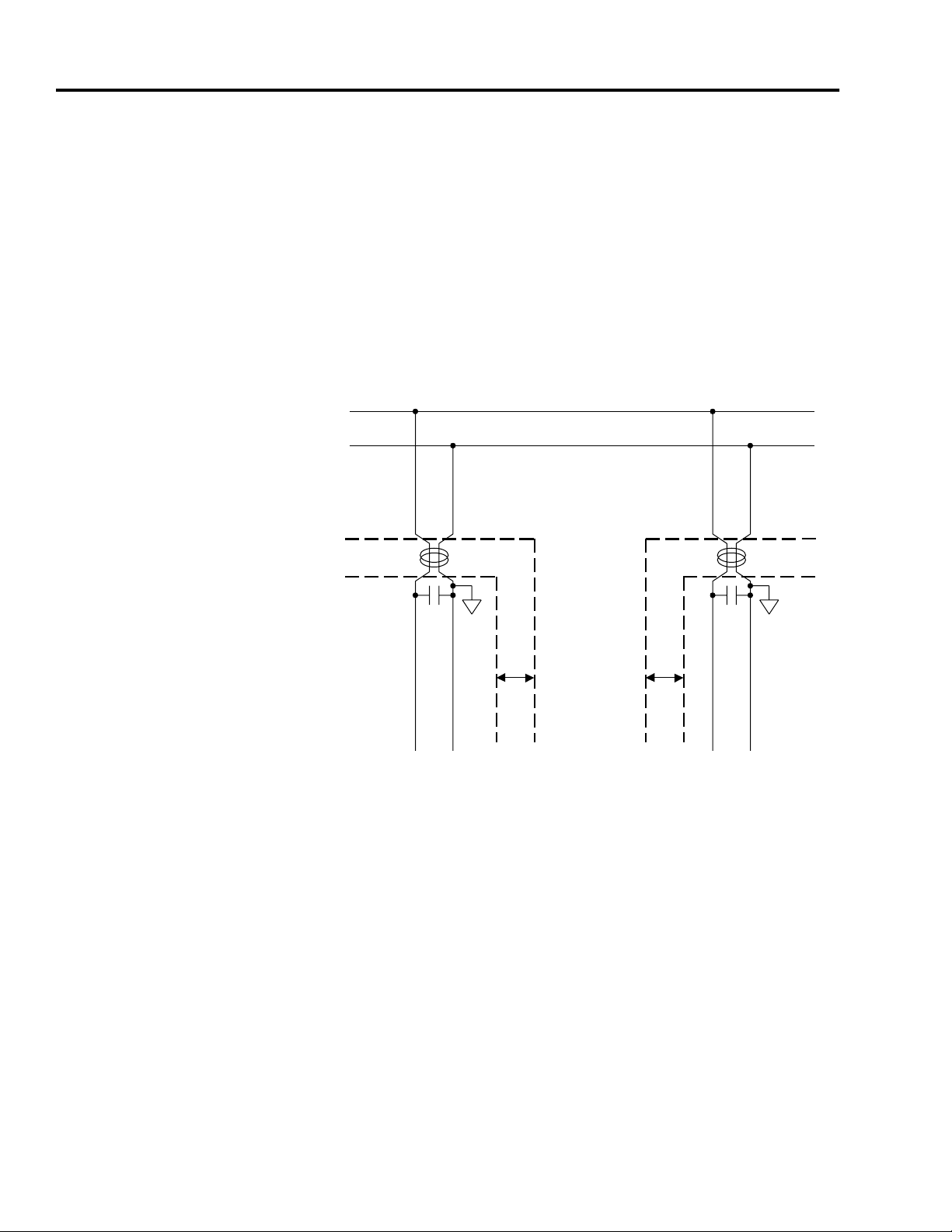

Adjacent Panels

Bond adjacent panels by mounting multiple flat straps between the

panels. As an alternative, mount a filler plate between the panels

using multiple fasteners along the edges of the plate.

Figure 2.6

Panel ground plane extended to adjacent panels

Adjacent panels

bonded to extend

the ground plane

Cabinet ground plane

(component mounting panel)

Ground plane extended to side panel

by bonding to main panel

Publication GMC-RM001A-EN-P — July 2001

Page 27

High Frequency (HF) Bonding 2-9

Grid and Raised Floor

Bonding cabinet panels and machine chassis to a ground grid below a

raised floor is the best possible grounding scheme and commonly

used in computer mainframe installations, but rarely used in industrial

environments.

Ideally the grid squares should be 1 m (39 in.) or less.

Figure 2.7

Panel ground plane extended to a grid beneath a raised floor

Machine structure used as ground plane

Cabinet ground plane (panel)

bonded to floor ground plane

Copper strip laid on the floor,

(also bonded to machine structure).

Grid ground plane.

covered by a false floor

Publication GMC-RM001A-EN-P — July 2001

Page 28

2-10 High Frequency (HF) Bonding

Mezzanine Floor

A mezzanine floor makes a very effective ground plane if the floor

panels are aluminum or galvanized steel and bonded at their edges

every 1 m (39 in.) minimum. Machine structure, floor, and both panels

form one large ground plane.

Figure 2.8

Panel ground plane extended to a mezzanine floor

Mezzanine floor ground plane

Cabinet ground plane

(panel) bonded

to Mezzanine

floor ground plane

Machine structure

bonded to floor

Machine structure used as ground plane

Machine structure

bonded to floor

Publication GMC-RM001A-EN-P — July 2001

Page 29

High Frequency (HF) Bonding 2-11

Machine Structure

If the machine structure covers a large portion of the system area and

is constructed of a conductive material with all sections closely

bonded, then it too will form an excellent ground plane. Care should

be taken to ensure paint is removed at the bonds and the connections

protected against corrosion.

Figure 2.9

Panel ground plane extended to the machine structure

Machine structure used as ground plane

bonded to structure ground plane by

Panel ground plane

clean and dirty wireways

Bond the panel(s) to the machine structure as tight as possible, but if

this proves difficult, construct a low impedance path using the

following guidelines:

• Use a zinc-plated tray, as wide as practical, and join sections by

overlapping with several fasteners across the width. The

perforations will not reduce performance (refer to Figure 2.10).

• EMC trunking (plated at joint surfaces with conductive gaskets)

also makes a good bond.

• Short and wide is the requirement for any HF bonding material.

Panel(s) should be located as close to the machine structure as

practical and the bond should be firmly attached at both the

machine structure and the control panel (not the cabinet outer

panels).

• Multiple trays/trunking are better.

Note that copper wire safety earth bonding is still required. Refer to

the section Grounding (Safety Earth) at the end of this chapter for

more information.

Publication GMC-RM001A-EN-P — July 2001

Page 30

2-12 High Frequency (HF) Bonding

Figure 2.10

Extending the panel ground plane using cable tray

Multiple

fasteners

Zinc plated

steel main

panel

Same

width

Note: A ground plane does not have to be flat.

Must be directly bonded

here and at the

machine structure

Zinc plated

steel cable tray

(wider is better)

New Buildings

In new installations it is possible to specify that the structural steel

columns are bonded together beneath the floor. This is similar in

concept to the special floor grid shown earlier (refer to Figure 2.7),

but inferior due to the large grid squares.

Cabinet ground plane (panel)

Publication GMC-RM001A-EN-P — July 2001

The panels are bonded by a flat strip or braid to the nearest steel

column. The floor, machine structure, and panels form a large, but

relatively ill-defined ground plane.

Figure 2.11

Panel ground plane extended to the building

Machine structure used as ground plane

Steel

Column

Steel

Column

bonded to nearest

building steel

Building ground plane.

Copper strip laid into the floor

bonding columns together.

Page 31

High Frequency (HF) Bonding 2-13

Existing Buildings

The nearest building steel structures between the machine and control

cabinets may be used to bond to.

If there is more than 20 m (65 ft) between the building structural steel

closest to the motor and the building structural steel closest to the

control panel, the ground between these two structural points should

be checked and enhanced, if necessary, using at least 25 mm (1 in.)

wide wire braid.

Limits

A ground plane sub-panel may only be considered part of a larger

ground plane when bonded sufficiently well at RF. For this purpose

wide thin strips are more effective than wire. Refer to the section

Bonding Surfaces in Appendix A for more information.

≤

• Length

• Shorter = better

• Wider = better

• Thickness is not an issue. Thin is acceptable (even foil is very

effective, but fragile).

The building example shown in Figure 2.11 normally falls outside

these requirements.

In cases where the maximum 10:1 bonding aspect ratio limit cannot

be satisfied, a differential noise voltage must be assumed to exist

between each semi-isolated ground plane. All wiring entering a

ground plane will carry this noise voltage and must be dealt with at

the point of entry.

A ground plane is just as effective if it is perforated or made up of a

matrix of flat conductors, provided that the apertures are smaller than

one quarter of the wavelength of the highest troublesome frequency.

width x 10 is the generally accepted maximum ratio.

Publication GMC-RM001A-EN-P — July 2001

Page 32

2-14 High Frequency (HF) Bonding

Grounding (Safety Earth)

Grounding refers to safety grounding and although the safety ground

circuit and the noise current return circuit may sometimes share the

same path and components, they should be considered as totally

different circuits with different requirements. The object of safety

grounding/bonding is to ensure that all metalwork is at the same,

ground (or Earth) potential at power frequencies.

The copper wire typically specified by regulatory bodies has little

effect at the high frequencies involved in noise problems.

ATTENTION

Safety ground circuits are extremely important and

all relevant local and international regulations must

be adhered to and take precedence over any

guidance given in this document.

!

Generally, safety dictates that all metal parts are connected to safety

earth with separate copper wire of appropriate gauge.

Most equipment has specific provisions to connect a safety ground or

PE (protective earth) directly to it.

These ground wires should be terminated directly to a bonded PE

ground bar, but lengths are not important provided the ground plane

strategy is followed (refer to the section The Ground Plane Principle).

Publication GMC-RM001A-EN-P — July 2001

Page 33

Segregating Sources and Victims

Chapter

3

Chapter Objectives

Understanding the Segregation Concept

This chapter describes how establishing zones within your panel for

noise sensitive or noise generating components can reduce coupling

of electrical noise. This chapter covers the following topics:

• Understanding the segregation concept

• Zone classification

• Routing wires and cables within a panel

• Routing system wires and cables between panels

You can avoid many of the problems caused by noise by grouping

sources and victims (along with their associated wiring) in zones

according to their noise performance rather than arranging for

neatness, tradition, or convenience.

Noise Zones

The three noise zones are defined in the table below.

This noise zone: Has this relative noise level:

Very-Dirty High

Dirty Moderate

Clean Low

This descriptive terminology (very-dirty, dirty, and clean) is chosen for

maximum clarity. Most noise documents assign numbers to the zones,

but there is no consistent numbering scheme. The descriptive

approach allows you to see the true meaning of a zone at a glance,

without having to remember a code.

Publication GMC-RM001A-EN-P — July 2001

Page 34

3-2 Segregating Sources and Victims

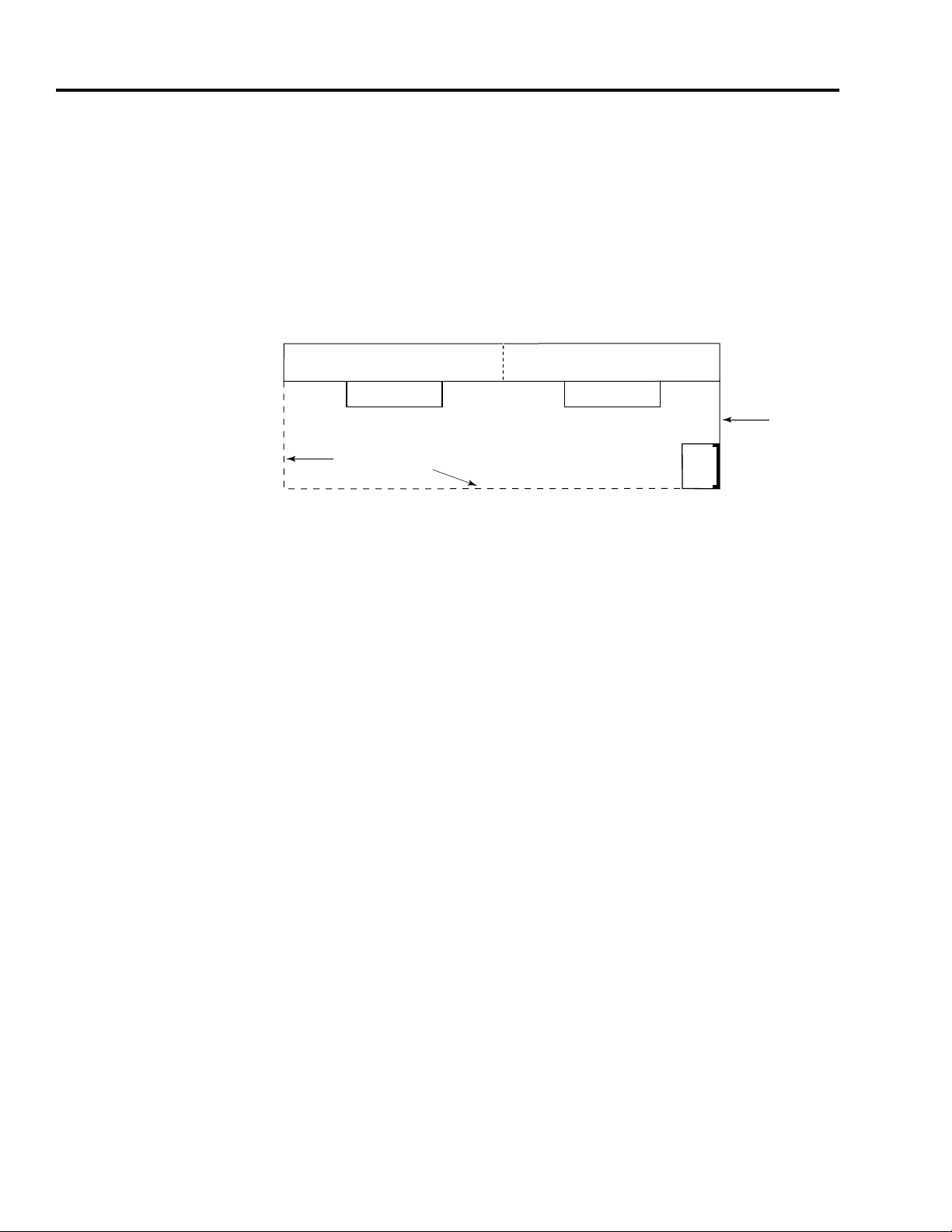

Figure 3.1 shows how you can create three zones in a standard panel

or cabinet enclosure. The very-dirty items are placed in the right/front

section. The dirty items are placed behind them in the right/rear

section and the least noisy (clean) items are placed in the left/rear

section.

Figure 3.1

Relative position of noise zones on the panel

Main Panel or Cabinet

(top view)

Clean wireway and component

mounting section

Dirty wireway and component

mounting section

Right side

divider panel

Left side and front panels (if cabinet)

Very-Dirty

cable tray and

component mounting

A side panel is fitted on the right to support the power cable shield

clamps and any very-dirty wires, cables, or components. This leaves

the main panel free for the clean and dirty zones.

Note: It is preferable to mount PLC and motion control equipment in a

separate cabinet away from power control equipment (motor

starters, etc.).

Ensuring CE Compliance at Build Time

Ensuring CE compliance is aided by the use of detailed physical panel

layouts, together with wiring schedules to specify precise wire routing

and zone categories. Periodic checks during installation are

recommended to achieve full CE compliance.

As an aid to the technicians wiring the panel, the use of grey

wireways for the clean zone and black wireways for the dirty zone

helps ensure proper segregation of cables. For example, this makes a

communication cable running in a dirty wireway easier to see.

Zone Classification

Publication GMC-RM001A-EN-P — July 2001

You can classify each cable or device based on these two factors:

• How much noise does the cable/device generate/radiate?

• How sensitive is the device connected via the cable to electrical

noise?

Page 35

Segregating Sources and Victims 3-3

Component Categories

The table below indicates which noise zone components fall into as a

general reference for component segregation

Note: An X in multiple zones indicates that the component straddles

the two zones. Under these circumstances it is important to

position the component in the correct orientation.

Component Very-

Dirty Clean

Dirty

PWM Drives/Amplifiers

1

XXX

Dynamic braking components X

External Dump Resistor (unshielded) X

External Dump Resistor (shielded)

2

X

AC Line Filter X X

Dump Resistor module (metal-clad)

2

X

Switch-mode DC power supply X

Ultrasonic Transducer

3

X

Contactors X

MCB X

Switched 24V dc loads

4

X

(e.g., E-stop/Piltz circuit, solenoids, relays, etc.)

Encoder buffer board X

PLC X

Registration 24V dc supply filter X

Dirty to Clean filter X X

Linear DC power supply X

Other 24V dc none-switched loads X

Data/Communication devices X

Analog devices X

1

The connector/terminal block locations on the drive will normally dictate the zone geometry since it

normally has connections in all categories. Design zones around the drive(s).

2

Bond chassis to the main panel or drive chassis. Refer to the chapter High Frequency (HF) Bonding for more

information.

3

Refer to the chapter Filtering Noise for more information.

4

All inductive switched loads must be suppressed. Refer to the chapter Contact Suppression for more

information.

Publication GMC-RM001A-EN-P — July 2001

Page 36

3-4 Segregating Sources and Victims

Routing Wires and Cables Within a Panel

The following figures provide examples of how to route clean, dirty,

and very-dirty wireways or cable trays within a panel.

Figure 3.2

Routing clean and dirty cables

Main Panel

(front view)

Power

distribution

Barrier

Sensitive

equipment

PLC

C

C

A

PSU

Dirty Zone

(black wireway)

PWM

Drive

PWM

Drive

Clean Zone

(grey wireway)

Clean

B

Dirty

Relays

Observe the following guidelines when planning your panel layout

for clean and dirty cables:

• The plated steel barrier between clean and dirty wireways allow

them to run close together.

• If dirty power is required at A, then run it via wireway B using

shielded cable. Refer to the chapter Shielding Wires, Cables, and

Components for more information.

• The vertical wireway at C is not good practice as it encourages the

creation of loops. Refer to the section Minimizing Loops later in

this chapter.

• The use of different colored wireways (e.g., grey for clean and

black for dirty) encourages good segregation.

Publication GMC-RM001A-EN-P — July 2001

Page 37

Figure 3.3

Routing very-dirty cables

Segregating Sources and Victims 3-5

Dirty Zone

(black wireway)

Clean Zone

(grey wireway)

Main Panel

(front view)

PWM

Drive

PWM

Drive

Right Side Panel

(inside view)

PWM

Drive

PWM

Drive

Segregation from

clean/dirty zone

Zinc plated cable tray

Drive power connections

(forming bridge to cable tray)

Very-Dirty Zone

(white cable tray)

Divider panel

Divider panel bonded with braided strap

to main panel (three places)

Observe the following guidelines when planning your panel layout

for very-dirty cables:

• Power cables bridge across to the drive terminals from the cable

tray on the right.

• The cable tray is bonded to the divider panel using braided strap.

If no divider panel is used, then bond cable tray to main panel.

• A divider panel is used on the right to segregate very-dirty wiring

from the clean zone of the next panel to the right.

• The divider panel is bonded with braided straps to the main panel

at top, center, and bottom.

Clean and

Dirty Zone

Cable tray bonded with

braided strap to main/

divider panel

• Use 25.4 mm (1.0 in.) wide braided strap for bonding (preferred

method). Braided strap 12.7 mm (0.5 in.) wide is acceptable.

Publication GMC-RM001A-EN-P — July 2001

Page 38

3-6 Segregating Sources and Victims

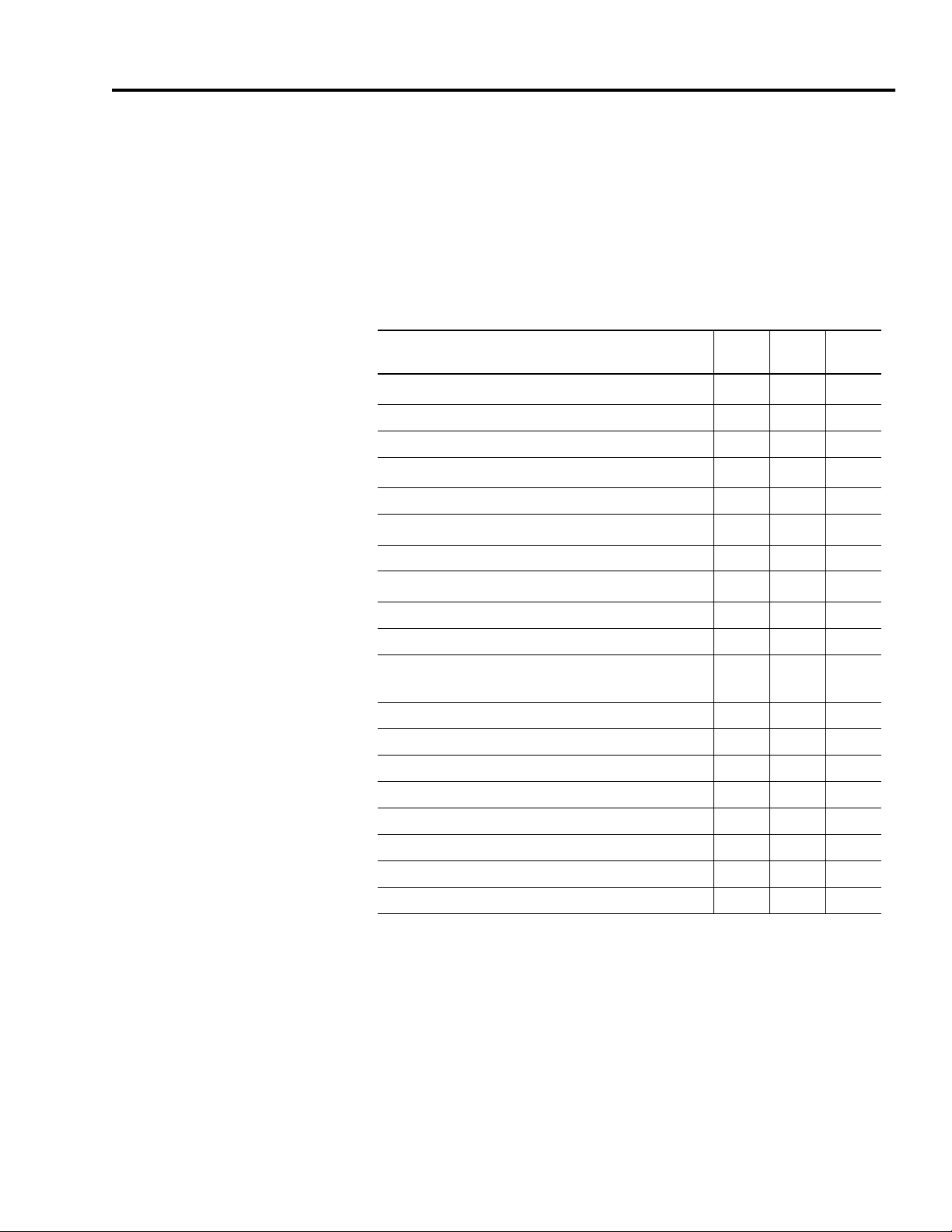

Wire and Cable Categories

The table below indicates the best zone for running cables and wires.

The table also shows how the use of ferrite sleeves and shielded cable

can reduce the noise effects of dirty and very-dirty wires and cables.

Note: Some items have two entries (one shielded and one not

shielded).

Zone Method

Cable and Wire Category

VeryDirty

Dirty Clean Ferrite

Sleeve

1

Shielded

2

Cable

Three Phase between Line Filter and

Drive

Three Phase between Line Filter and

Drive

Extended DC bus X

Extended DC bus X X

PWM Drive/Inverter to Motor Power

PWM Drive/Inverter to Motor Power X X

PWM Drive/Inverter to Sine Wave

Filter

Sine Wave Filter to Motor X

CM Choke to Motor Power X

CM Choke to Motor Power X X

Line Terminator - Motor Power X

Line Terminator - Motor Power X X

External Dump Shunt Resistor X

External Dump Shunt Resistor X X

Contactor to AC Motor X

Contactor to AC Motor X X

X

XX

3

X

X

Publication GMC-RM001A-EN-P — July 2001

Three Phase Supply Power X

Single Phase Supply Power X

24V Hydraulic/Pneumatic - solenoids X

Motor Feedback Resolver X X

PLC digital I/O X

Dedicated Drive Inputs (except

registration)

Limit Switches X

Push buttons X

X

Page 39

Cable and Wire Category

Segregating Sources and Victims 3-7

Zone Method

VeryDirty

Dirty Clean Ferrite

Sleeve

1

Shielded

2

Cable

Proximity Switches (except

X

registration)

Photoelectric Cell X

24V dc Relay X

Transformer Indicator Lamp X

Data/Communications

4

XX X

Encoder/Resolver X X

Logic circuit power X X

High Speed Registration inputs

5

XX

PLC Analog I/O X X

PLC High Speed Counter input X X

1

An X in this column indicates a ferrite sleeve fitted to the wire is recommended.

2

An X in this column indicates a shielded cable is recommended.

3

Keep unshielded conductors as short as possible and separated from dirty and clean cables as far as possible.

4

Refer to the section Data/Communications Cables below for more information.

5

Refer to the chapter High Speed Registration Inputs for more information.

Note: Grounding power cable shields at entry to the cabinet is recommended.

Data/Communications Cables

Data and communication cables that come from a remote structure

(refer to the chapter High Frequency (HF) Bonding) will carry noise

on their shields. Follow the guidelines listed below when installing

data or communication cables.

• Follow the product manual recommendations for termination

resistors, minimum and maximum length, etc.

• Carefully segregate data and communication cables from dirty and

especially very-dirty cables.

• Ground shields to the panel at the point of entry when permitted.

Check your manual for the recommended procedure. Connecting

to the 360° shield is preferable to the use of pigtails. If pigtails

must be used, they should be kept short. Refer to the section

Grounding Cable Shields in Appendix A for more information on

grounding cable shields.

• Refer to the chapter Filtering Noise for more information.

Publication GMC-RM001A-EN-P — July 2001

Page 40

3-8 Segregating Sources and Victims

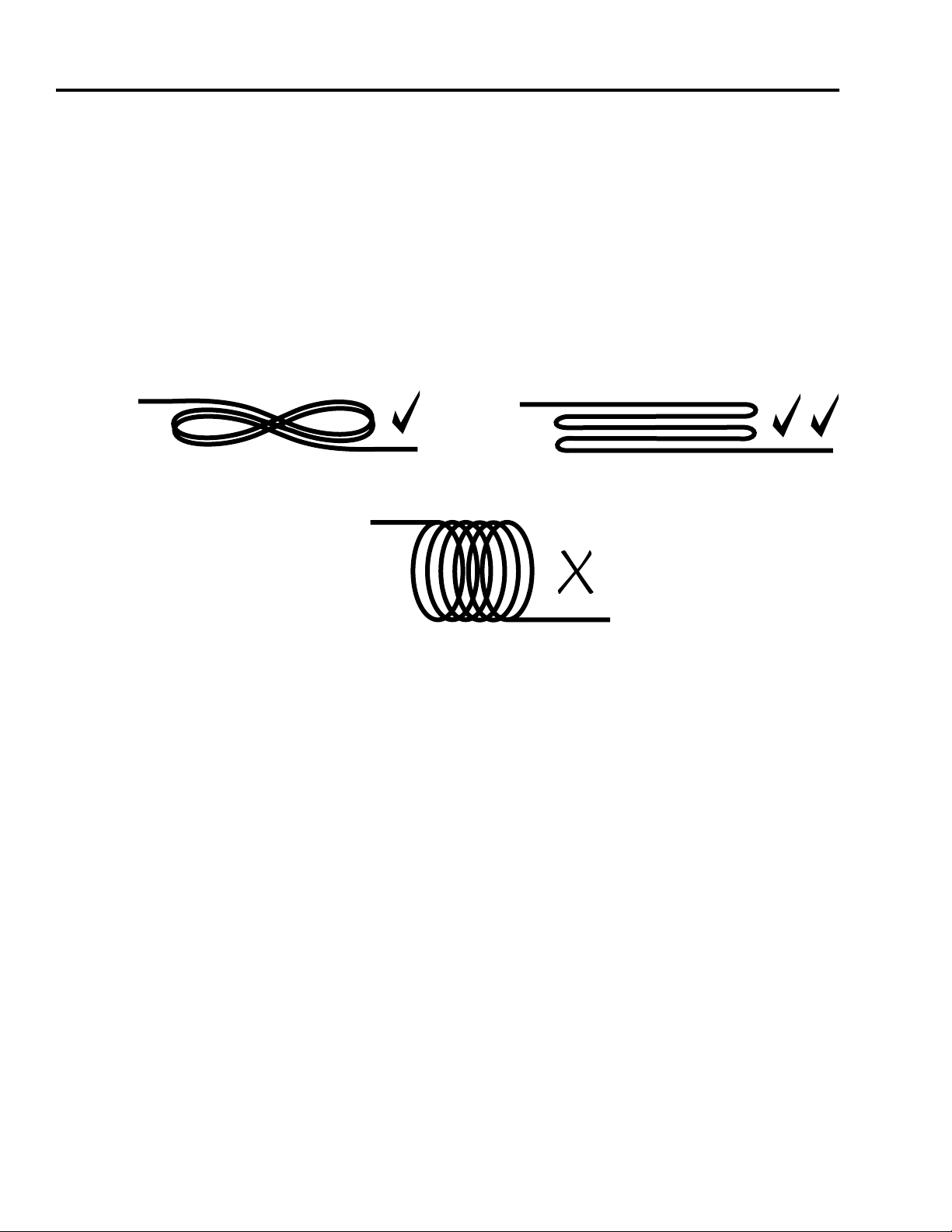

Minimizing Loops

Wires that form a loop make an efficient antennae. Run feed and

return wires together rather than allowing a loop to form. Twisting the

pair together further reduces the antennae effects. Refer to the figure

below for an illustration.

Note: This applies to potential victim wiring too. Antennae work

equally well in both receive and transmit modes.

Figure 3.4

Avoiding loops in wiring designs

Not Recommended

Routing System Wires and Cables Between Panels

Switch

Switch

Good Solution

Better Solution

Switch

Follow the same segregation guidelines when wiring between panels

and machine devices.

• Maintain clean, dirty, and very-dirty noise zones.

• Always use separate, grounded, metal wireways.

Publication GMC-RM001A-EN-P — July 2001

Page 41

Chapter

Shielding Wires, Cables, and Components

4

Chapter Objectives

Understanding the Shielding Concept

This chapter describes how using shielded cable or steel shields can

reduce electrical noise coupling. This chapter covers the following

topics:

• Understanding the shielding concept

• Ferrite sleeves

• Mixing categories

You can avoid many of the problems caused by noise by shielding

sources and victims (along with their associated wiring) with the use

of shielded cable or a supplementary steel shield.

If sources and victims cannot be sufficiently segregated it may be

possible to prevent noise coupling by shielding as shown in the figure

below.

Figure 4.1

Wire segregation vs. shield

Minimum segregation is

150 mm (6.0 in.) within a panel

Clean Zone

Dirty Zone

Grounded steel shield

allows minimal segregation

distance.

Publication GMC-RM001A-EN-P — July 2001

Page 42

4-2 Shielding Wires, Cables, and Components

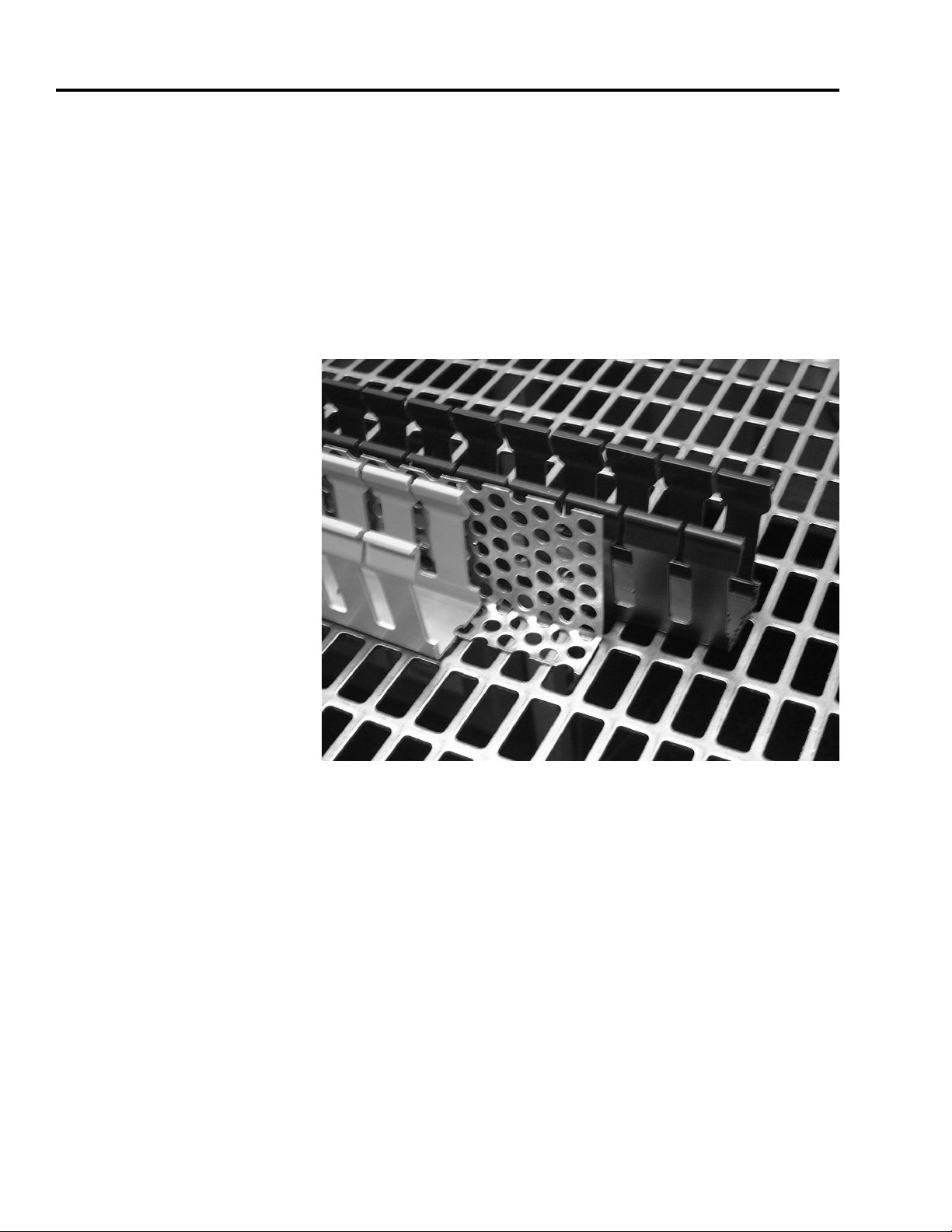

In the shielding example below the grey plastic wireway (front) is

shielded by 0.7 mm (0.03 in.) thick perforated and plated sheet steel.

The perforated steel is easy to cut and bend. You can safely route

very-dirty wires in the other (black) wireway behind the shield.

Note: By using grey colored wireway for clean zones and black for

dirty and very-dirty zones you will see more clearly when

shielding is necessary.

Figure 4.2

Shielding example

Ferrite Sleeves

’

Shielded data cables grounded at both ends (important at high

frequencies) may carry noise current due to voltage differences

between the two ends. Because the shields have a low impedance,

currents may be quite high even though voltage is low. These currents

can cause spurious data reception.

By installing ferrite sleeves, the common-mode impedance of the

cable is greatly increased at HF thus blocking the noise currents

without affecting the signal currents.

In Figure 4.3 the capacitor grounding is very effective and avoids

no-grounding rules, but it’s awkward to implement.

Publication GMC-RM001A-EN-P — July 2001

Page 43

Shielding Wires, Cables, and Components 4-3

Figure 4.3

Ferrite sleeves increase common mode impedance

Ferrite sleeve greatly

increases impedance at RF

Signal

Source

Optional capacitor

V

Panel A

Differential noise voltage

Figure 4.4

Common mode rejection in shielded cable

Panel B

In this physical circuit, the core and

shield are effectively connected

together at the transmit end.

Vn is the noise voltage.

In this equivalent circuit, the core

and shield form two windings of a

1:1 transformer.

The ferrite sleeve (more turns are

better) forms a core increasing the

magnetic coupling. The signal is

unaffected.

This is known as a common-mode

choke.

Tra n sm it

Core

Transmit Shield

Plane

Tra n sm it

Core

Transmit Shield

Plane

Vn

Vn

1:1

Vn

Receive Shield

Receive

0V

Receive Shield

Ferrite Sleeve

Receive

Plane

Core

Secondary voltage

matches the

primary voltage.

Plane

The following implementation guidelines apply to ferrite sleeves:

• Always install ferrite sleeves to data cables where specified.

• Always use ferrite sleeves when cable length is greater than 10 m

(30 ft).

Core

• If power frequency ground currents are expected, or measured by

current clamp, one shield/ground connection could be made via a

1uF, 50V capacitor.

Publication GMC-RM001A-EN-P — July 2001

Page 44

4-4 Shielding Wires, Cables, and Components

Ferrite Sleeve Limitations

After implementing all the guidelines presented in this manual, a

properly built system should perform well without ferrite sleeves.

However, by including sleeves in your installation, the system will

avoid problems caused during future modifications.

System installations can benefit from ferrite sleeves, but you should

also realize that ferrite sleeves alone are not a substitute for proper

noise coupling reduction techniques.

As a rule, include sleeves as standard to obtain the most effective

overall system.

For more information about ferrite sleeves, refer to Appendix B.

Mixing Categories

It is often difficult to segregate effectively in a confined space. When

strict segregation isn’t practical, minimize overlap and cross cables at

right angles. Test results in Appendix A show that even a close parallel

run of 0.5 m (20.0 in.) will allow significant noise coupling (refer to

the section Wire Segregation Test Results).

You can convert wiring designated dirty or very-dirty to the next

lower category by means of shielding using either shielded cable or

conduit where required. Figure 4.5 and Figure 4.6 show how this

technique may be used to mix categories without breaking the

segregation rules.

Publication GMC-RM001A-EN-P — July 2001

Page 45

EMC

filter to drive

Very-Dirty Zone

Shielding Wires, Cables, and Components 4-5

In Figure 4.5 the cable is locally shielded to cross another zone. Each

shield is grounded at each boundary and the cable is run close to the

panel. The outer shield A is a thick walled steel conduit.

Figure 4.5

Very-dirty cable in clean zone

Dirty Zone

24V dc I/O

cable

Dirty Zone

Clean

Zone

Dirty Zone

Very-Dirty Zone

Motor power

cable

Analog device

cable

Clean Zone

A

Minimum 150 mm (6.0 in.) segregation

The principle works both ways. In Figure 4.6 the clean cable passes

through a very-dirty zone.

Figure 4.6

Clean cable in very-dirty zone

Dirty Zone

24V dc I/O

cable

Dirty Zone

Very-Dirty

Zone

Dirty Zone

Clean Zone

Encoder

cable

A

Minimum 150 mm (6.0 in.) segregation

Publication GMC-RM001A-EN-P — July 2001

Page 46

4-6 Shielding Wires, Cables, and Components

Publication GMC-RM001A-EN-P — July 2001

Page 47

Filtering Noise

Chapter

5

Chapter Objectives

Understanding the Filtering Concept

This chapter describes how low-pass filters and ferrite sleeves can

reduce electrical noise coupling. This chapter covers the following

topics:

• Understanding the filtering concept

• Filter performance

• Ultrasonic transducers

• AC line filters

If sources and victims are connected by wiring, you can prevent noise

coupling by filtering. Low-pass filters attenuate high frequency noise

without affecting the low frequency signals.

Commercial AC Line Filters for Low Voltage Circuits

Provided that motor cable lengths are short, less than 20 m (60 ft),

commercial AC line filters work well in low voltage circuits. Two-stage

types are preferred.

If motor cable lengths are long, the natural ringing frequency is

typically at too low a frequency (below 300k Hz) to be attenuated by

commercial AC line filters. To determine if your cables are long, refer

to the section Installing Long Motor Cables in Appendix A.

Publication GMC-RM001A-EN-P — July 2001

Page 48

5-2 Filtering Noise

General Purpose 0-24V ac/dc Filters

The filter diagram shown below forms a classic LC low-pass filter.

Figure 5.1

Filter applied to 24V dc power circuit

Grounded

Common

+24V

Com/Neutral

IMPORTANT

The effectiveness of the LC low-pass filter depends

on a perfect bond between the DIN rail and the

ground plane panel.

Figure 5.2

Universal 0-24V ac/dc grounded common filter

Clean side

Floating

Common

Segregation

DIN rail

Publication GMC-RM001A-EN-P — July 2001

Capacitor

Ferrite Sleeve

(choke)

Dirty side

Page 49

Figure 5.3

Floating-Common filter

Filtering Noise 5-3

Clean side

Dirty side

Forming capacitor leads

DIN rail

Capacitors

Ferrite Sleeve

(choke)

The table below lists the part description and part numbers for the

filters shown in Figure 5.2 and Figure 5.3.

Part Description RS Components

Part Number

Newark

Part Number

Filter Performance

Ground Terminal (1 in, 2 out type) 225-4372 N/A

Insulated Terminal (1 in, 2 out type) 426-193 N/A

1 µF, 50V Ceramic Capacitor

Small Ferrite Sleeve

1

Capacitor value is not critical, but it must be a ceramic type.

2

The ferrite specification is not critical, but choose a low frequency type if possible.

3

Alternative ferrite sleeve part numbers: Palomar (FB-102-43) or Schafner (2644665702)

Note: For more information regarding part vendors refer to Appendix B.

1

2

211-5558 29F025

239-056

3

91F6484

The theoretical attenuation of one stage and two stage filters is shown

in the table below.

With this filter: Attenuation @ 1M Hz is:

1 stage (2.8k Hz) 55 dB

2 stage (1.2k Hz 110 dB

Publication GMC-RM001A-EN-P — July 2001

Page 50

5-4 Filtering Noise

M

Performance Test Set-up

The filter performance test included the following components:

• 24V dc power supply with grounded common filter

• Filter mounted to DIN rail

• Relay coil to simulate an inductive load

• 100M Hz sampling digital storage oscilloscope

• Test components mounted on a large zinc plated steel panel

Figure 5.4

Filter test block diagram

easurement point

1 m (39 in.) wire

Switched load

Filter

Filter under

test

24V dc

PSU

Ground Plane - conductive metal panel

Test Results

This test condition: With

No filter:

No Suppression 200V pk 5.5V pk 674mV pk

R/C

5.5V pk 932mV pk 168mV pk

Across coil

100R/0.1uF

R/C

2.5V pk 103mV pk 70mV pk

Across switch

100R/0.1uF

Transorb

14.9V pk 1.8V pk 658mV pk

Across coil

Transorb

8.1V pk 1.4V pk 1.2V pk

Across switch

With

Capacitor only:

With Capacitor

and ferrite sleeve:

Suppression

Publication GMC-RM001A-EN-P — July 2001

Diode 12V pk 63mV pk 63mV pk

Note: Voltages were measured between the measurement point and the ground plane (refer to Figure 5.4 for

exact location.

Page 51

Filtering Noise 5-5

Ultrasonic Transducers

Xenon Flashing Beacons (strobe lights)

Ultrasonic transducers often induce high noise levels onto their DC

supply and signal lines. To reduce noise using ultrasonic transducers:

1. Mount two DC filters close to the device with ferrite sleeves

between the capacitors and the sensor.

2. Feed the DC power supply through one sleeve.

3. Bring out the analog signal via the other sleeve.

Note: Use shielded cable for the analog signal.

The filter ground should be close coupled to the machine metalwork

close to the sensor.

Strobe lights can generate high voltage transients on their 24V dc

supply lines. To reduce this source of noise, try using one of these

two alternatives.

• Mount a DC filter close to the lamp (ferrite sleeve on the lamp

side) with its common attached to chassis ground.

AC Line Filters

• Use shielded cable between lamp and control panel, with DC filter

at the point where the cable leaves the panel.

AC line filters contain capacitors connected between phase and the

filter chassis. Line voltage is with respect to ground. The capacitor

allows a small but potentially dangerous amount of current to flow to

ground.

ATTENTION

To avoid personal injury and/or damage to

equipment, ensure AC line filter capacitors are

properly connected to safety (PE) ground.

!

Publication GMC-RM001A-EN-P — July 2001

Page 52

5-6 Filtering Noise

Figure 5.5

Line filter earth leakage path

L

Line

N

Leakage current

E

Load

Three phase filters are theoretically balanced so the net ground

current should be zero. However, a failure of any one capacitor or

severe unbalance would cause ground current to flow and trip a

circuit breaker.

Earth Leakage/Ground Fault

Earth Leakage Circuit Breakers (ELCB) and Ground Fault Interrupters

(GFI) are typical European and US terms for the same device.

The ground/earth current may cause nuisance tripping of Earth

Leakage Breakers. Uprated units may help in some cases.

Three phase filters, being balanced, are much less likely to give

problems than single phase types.

Publication GMC-RM001A-EN-P — July 2001

Page 53

Contact Suppression

Chapter

6

Chapter Objectives

Understanding Contact Suppression for AC Circuits

This chapter describes how contact suppressors for solenoids, relays,

and various other switches can reduce electrical noise. This chapter

covers the following topics:

• Understanding contact suppression for AC circuits

• Understanding contact suppression for 24V dc circuits

• Contact suppression effects