Rockwell Automation 1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix, 1769 Compact GuardLogix, 1789 SoftLogix Programming Manual

...Page 1

Programming Manual

Logix 5000 Controllers Major, Minor, and I/O Faults

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix,

1769 Compact GuardLogix, 1789 SoftLogix, 5069

CompactLogix, 5069 Compact GuardLogix, Studio 5000

Logix Emulate

Publication 1756-PM014M-EN-P

Original Instructions

Page 2

Logix 5000 Controllers Major, Minor, and I/O Faults

personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

temperatures.

for Personal Protective Equipment (PPE).

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and

2 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 3

Summary of changes

Topic Name

Reason

This manual includes new and updated information. Use these reference

tables to locate changed information.

Grammatical and editorial style changes are not included in this summary.

Global changes

The Legal noticeshave been updated.

New or enhanced features

This table contains a list of topics changed in this version, the reason for the

change, and a link to the topic that contains the changed information.

Minor Fault Codes on page 33 Updated the Minor Fault Code list to include minor fault type 16,

code 1.

Major fault codes on page 25 Updated the Major Fault Code list to include major fault type 4,

code 95.

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 3

Page 4

Page 5

Summary of changes

Major Faults

Minor Faults

I/O Fault Codes

Index

Table of Contents

Preface

Additional resources ................................................................................... 7

Legal Notices ............................................................................................... 7

Chapter 1

Major Fault State ......................................................................................... 9

Recover from a major fault ................................................................... 9

Important points regarding Add-On Instructions ............................ 10

Fault handling during prescan and postscan .................................... 11

Placement of fault routines ................................................................. 12

Choose where to place the fault routine ............................................. 12

Create a fault routine for a program ......................................................... 13

Change a fault routine assignment of a program ............................. 14

Create a routine for the controller fault handler ..................................... 15

Create a routine for the power-up handler .............................................. 17

Programmatically clearing a major fault .................................................. 19

Create a data type to store fault information ................................... 20

Write a routine to clear the fault ......................................................... 21

Clear a major fault during prescan .......................................................... 22

Test a fault routine .....................................................................................23

Create a user-defined major fault ............................................................ 24

Major fault codes ....................................................................................... 25

Chapter 2

Identify minor faults ................................................................................. 31

Minor fault examples ...........................................................................32

Minor fault codes ........................................................................................ 33

Chapter 3

Indications of I/O faults ............................................................................ 37

I/O Fault Codes ......................................................................................... 38

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 5

Page 6

Page 7

Resource

Description

Manual, publication 1756-RM003

available instruction for a Logix5000 controller.

and other certification details.

Legal Notices

Preface

This manual shows how to monitor and handle major and minor controller

faults. The manual also provides lists of major, minor, and I/O fault codes to

use to troubleshoot the system.

This manual is one of a set of related manuals that show common procedures

for programming and operating Logix 5000 controllers.

Additional resources

For a complete list of common procedures manuals, refer to the

Logix 5000

Controllers Common Procedures Programming Manual, publication 1756PM001.

The term Logix 5000 controller refers to any controller based on the Logix

5000 operating system.

These documents contain additional information concerning related

products from Rockwell Automation.

Logix5000 Controllers General Instructions Reference

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates,

Provides programmers with details about each

View or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation publishes legal notices, such as privacy policies, license

agreements, trademark disclosures, and other terms and conditions on the

Legal Notices

page of the Rockwell Automation website.

End User License Agreement (EULA)

You can view the Rockwell Automation End-User License Agreement ("EULA")

by opening the License.rtf file located in your product's install folder on your

hard drive.

Open Source Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses. Copies of those licenses are

included with the software. Corresponding Source code for open source

packages included in this product are located at their respective web site(s).

Alternately, obtain complete Corresponding Source code by contacting

Rockwell Automation via the Contact form on the Rockwell Automation

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 7

Page 8

Preface

website: http://www.rockwellautomation.com/global/about-

us/contact/contact.page

Please include "Open Source" as part of the request text.

A full list of all open source software used in this product and their

corresponding licenses can be found in the OPENSOURCE folder. The default

installed location of these licenses is

Files\Rockwell\Help\FactoryTalk Services Platform\Release

Notes\OPENSOURCE\index.htm

C:\Program Files (x86)\Common

.

8 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 9

IMPORTANT

IMPORTANT

Example:

Major Fault State

Chapter 1

Major Faults

This chapter explains major fault codes and how to work with them in the

Logix Designer application.

If a fault condition occurs that prevents an instruction from running, the

instruction aborts and the controller reports a major fault. A major fault halts

logic execution and the controller switches to faulted mode (the OK LED

flashes red).

Depending on the application, you may not want all major faults to shut down

the system. If you do not want all major faults to shut down the system, create

a fault routine to clear the fault and let the application continue to run.

The process of resuming execution after the fault clears is known as fault

recovery.

Do not use fault routines to continually clear all faults on the controller. Program the

fault routine to be selective in the types and number of faults cleared. It is also a

good idea to log the fault occurrence to analyze it later.

When an instruction generates an error due to a fault (for example, a COP with an

indirect addressing programming error), the fault routine skips the instruction and

does not run. This occurs with all instructions.

In a system that uses recipe numbers as indirect addresses, an incorrectly typed number

could produce a major fault.

To keep the entire system from shutting down in the event of this fault, program a fault

routine to clear type 4, code 20, major faults.

See also

Create a routine for the controller fault handler on page 15

Recover from a major fault

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 9

Clear a major fault during prescan on page 22

These examples show fault routines with logic that take specific action after a

major fault. If the fault clears, the faulted instruction does not run and

execution resumes with the next instruction.

Page 10

Chapter 1 Major Faults

Important points regarding

Example 1

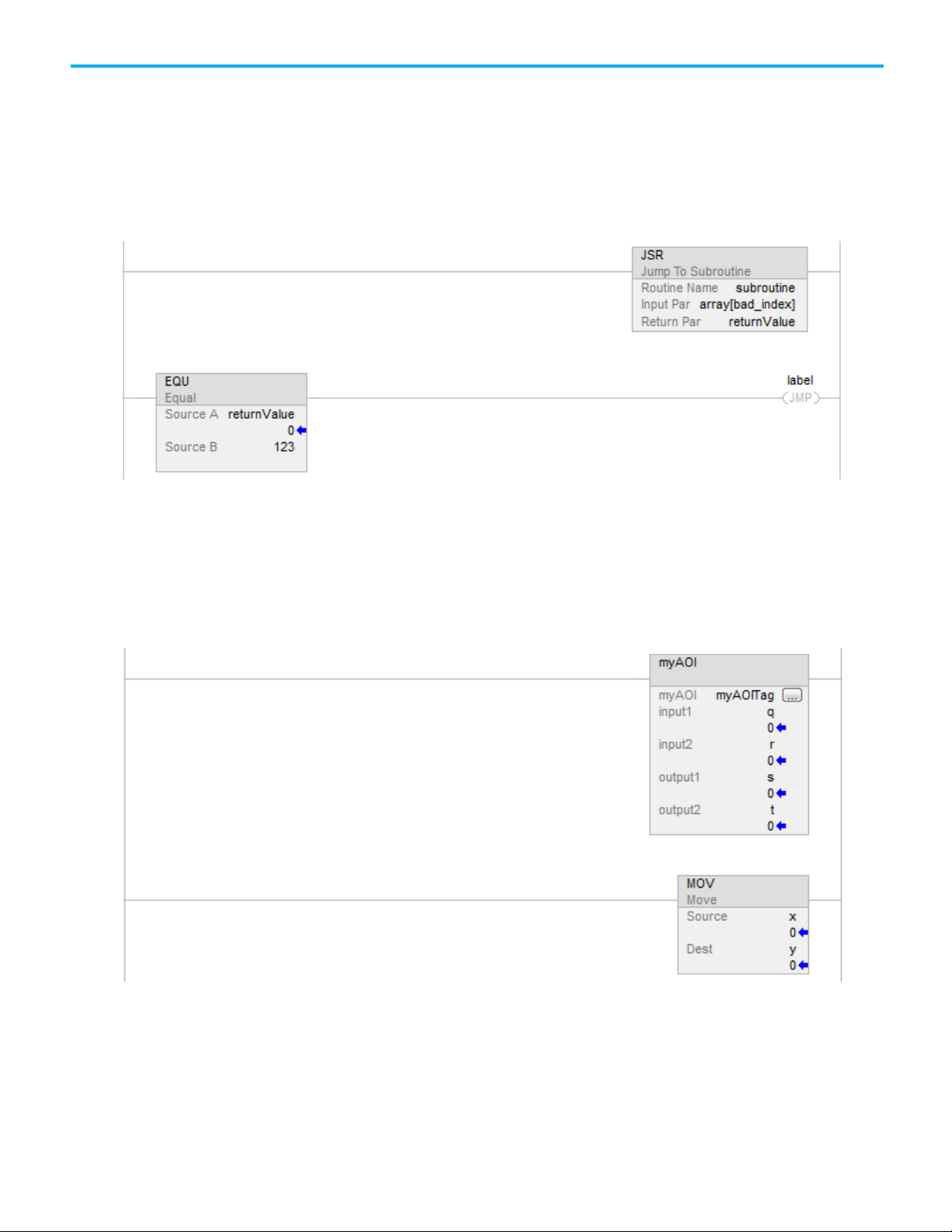

In this example, a JSR instruction passes an input parameter containing an

indirect address that is out of bounds. If the fault clears, the JSR instruction

aborts (the subroutine does not run) and execution resumes with the EQU

instruction.

Example 2

In this example, the logic inside an Add-On Instruction generates a fault.

While the logic of an Add-On Instruction may look like a subroutine, it is not–

the Add-On Instruction is an instruction. When a fault occurs inside an AddOn Instruction, the remainder of the Add-On Instruction aborts. If the fault

clears, execution resumes with the MOV instruction.

Add-On Instructions

10 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Keep these considerations in mind when using Add-On Instructions and

major faults.

• The Add-On Instruction stops running at the instruction that caused

the fault. This means that the remainder of the scan mode routine does

not run.

Page 11

Fault handling during

Chapter 1 Major Faults

• If the fault clears, execution resumes at the instruction following the

top-level Add-On Instruction invocation. For example, assume the

Add-On Instruction myAoi in Example 2 invokes a nested Add-On

Instruction myNested, which invokes another nested Add-On

Instruction inner. Furthermore, assume that an instruction inside of

inner causes a fault. If the fault clears, execution resumes with the

MOV instruction (the remainder of inner does not execute; the

remainder of myNested does not execute; and the remainder of myAoi

does not execute.)

• During prescan:

• The Logic routine runs (in prescan mode).

• The Prescan routine runs (in normal scan mode).

• During postscan:

• The Logic routine runs (in postscan mode).

• The Postscan routine runs (in normal scan mode).

If a fault occurs while processing the Logic routine, the Add-On Instruction

aborts (the remainder of the Logic routine does not run and the pre-scan and

post-scan routines do not run). If the fault clears, execution resumes at the

instruction following the top-level Add-On Instruction invocation.

prescan and postscan

See also

Create a fault routine for a program on page 13

The behavior of each instruction varies depending on the mode in which it

runs–true, false, prescan, or postscan. For details about what a specific

instruction does in each mode, see the

Instructions Reference Manual, publication number 1756-RM003.

• Prescan provides a system-defined initialization of the user program

when the controller switches from program mode to run mode.

• Postscan provides a system-defined re-initialization of the logic

invoked from an SFC action, when the action shuts down (if SFCs are

configured for Automatic Reset).

If an array index is out of range during prescan, the controller could generate

a major fault. There are a number of ways this could happen: the controller

loses power, encounters a major fault, or the project is saved while online.

Because the user program, during prescan and postscan, cannot assign values

to tags, the only way to correct these issues is to manually initialize the index

variables using the Logix Designer application or to write a fault handler to

ignore the array faults during prescan. To reduce the need for manual

intervention, the Logix Designer application includes an internal fault

Logix 5000 Controllers General

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 11

Page 12

Chapter 1 Major Faults

values when an action is shut down.

To clear the fault when

See this section

Condition

Fault Type

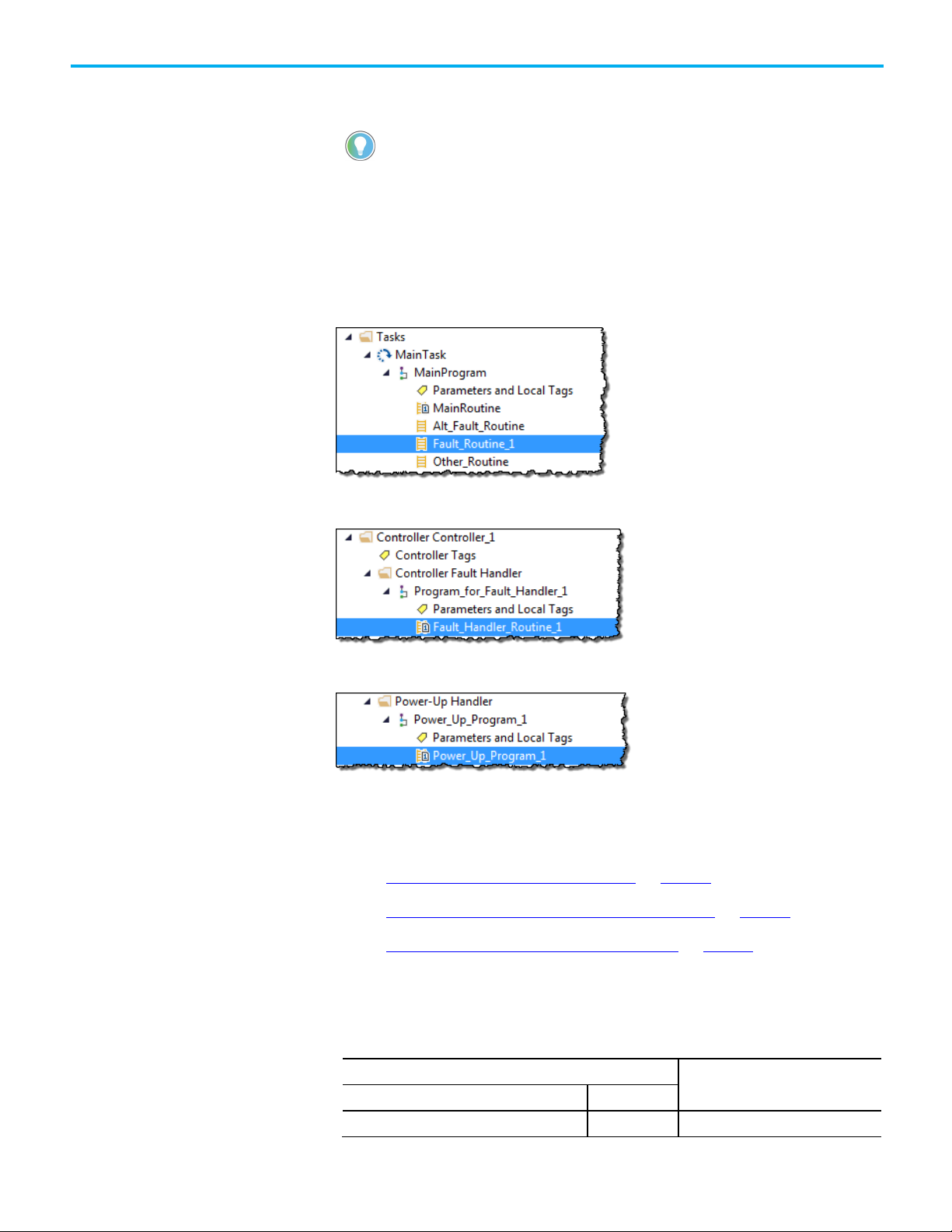

Placement of fault routines

Choose where to place the

handler. This handler is only used during prescan and only clears array faults

(type 4, fault codes of 20 of 83).

Tip: Array faults are not ignored during postscan because the user program controls index tag

Use a fault routine to program logic to take specific action after a fault, such

as clearing the fault and continuing to run. Configure fault routines to a

program, controller, or to the Power-Up Handler.

ProgramFaultRoutine

ControllerFaultRoutine

Power-UpFaultHandlerRoutine

See also

Create a fault routine for a program on page 13

Create a routine for the controller fault handler on page 15

Create a routine for the power-up handler on page 17

fault routine

12 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Where to place the fault routine depends on the type of fault. Use this table to

determine where in the project to configure the fault routine.

The execution of an instruction faults 4 Creating a Fault Routine for a Program

Page 13

To clear the fault when

See this section

Condition

Fault Type

A motion axis faults

11

mode

Handler

Create a fault routine for a

Communication with an I/O module fails 3 Creating a Routine for the Controller

Watchdog timer for a task expires 6

Chapter 1 Major Faults

Fault Handler

program

The controller powers up in Run or Remote Run

1 Creating a Routine for the Power-Up

See also

Create a fault routine for a program on page 13

Create a routine for the controller fault handler on page 15

Create a routine for the power-up handler on page 17

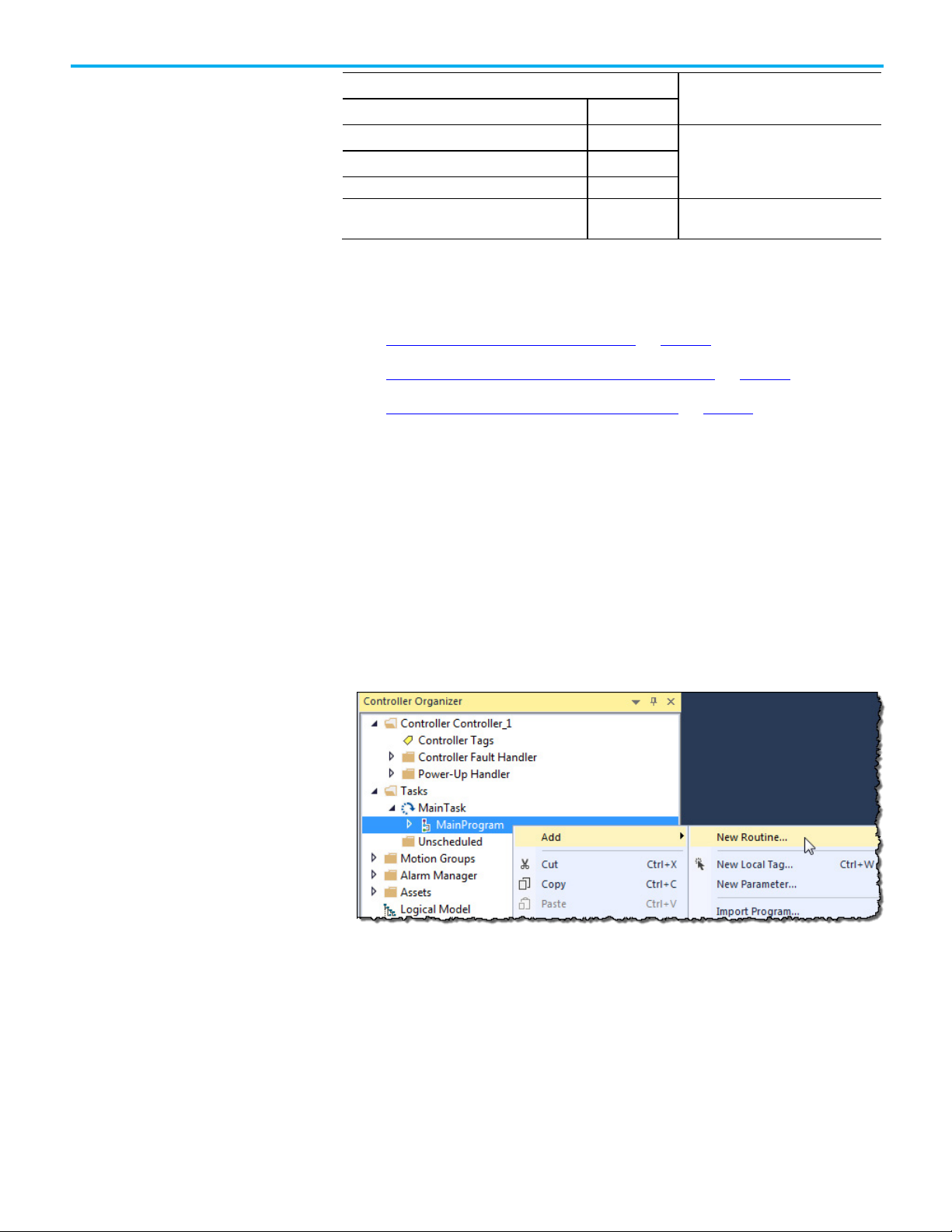

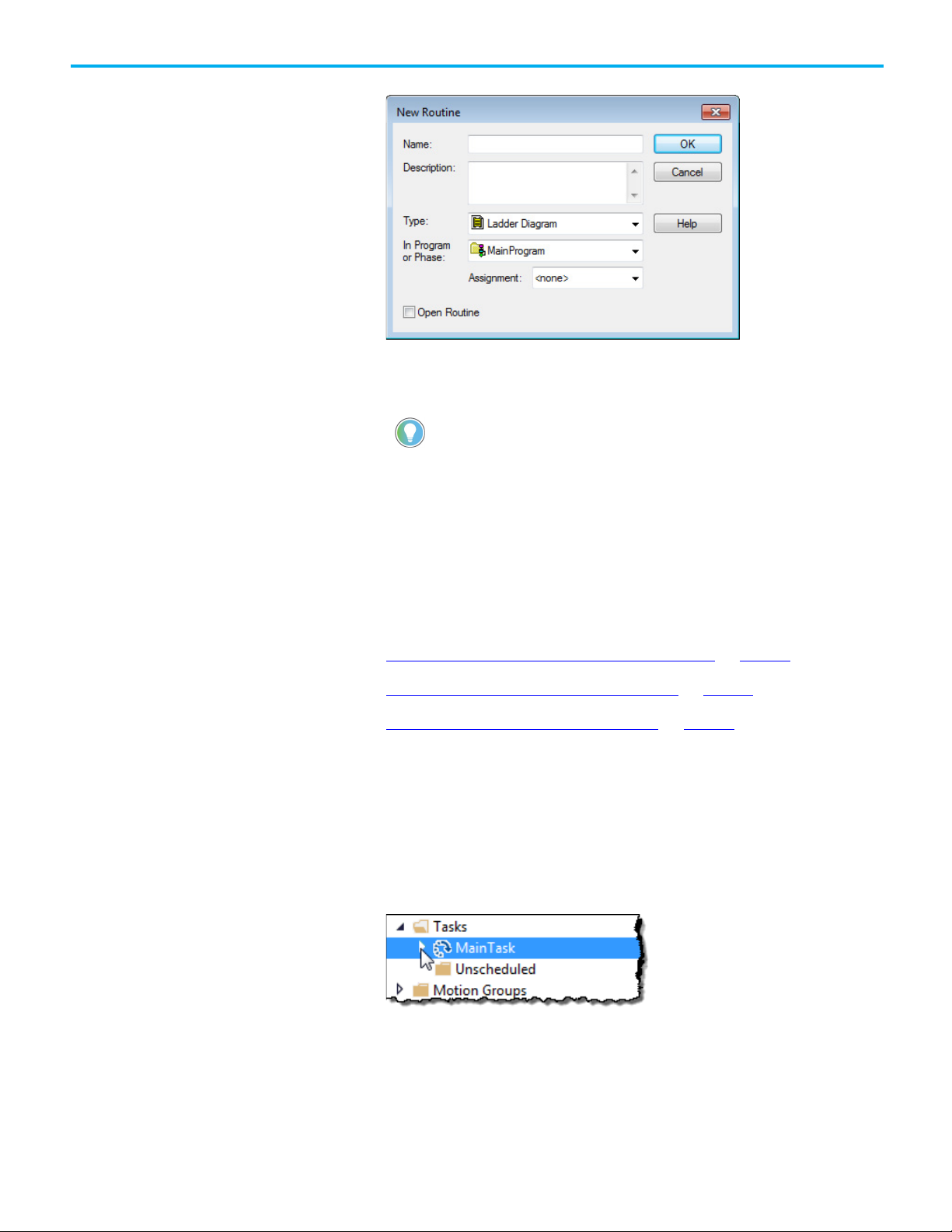

Configure any routine as the fault routine for a program. The routine

executes when a program fault occurs before the controller transitions to

fault mode.

To create a fault routine for a program:

1. Open the project in the Logix Designer application.

2. In the Controller Organizer, right-click MainProgram and select

Add>New Routine.

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 13

3. On the New Routine dialog box, in Name, type the name of the

routine.

Page 14

Chapter 1 Major Faults

Change a fault routine

4. (optional) In Description, type a description of the routine.

5. In Type, use the default setting, Ladder Diagram.

6. In In Program or Phase, use the default setting, MainProgram.

Tip: If creating a fault routine for the Power-Up Handler or Controller Fault Handler, specify

the program name of either program in In Program or Phase.

7. In Assignment, select Fault.

8. (optional) Select Open Routine to immediately open the ladder logic

program.

9. Select OK.

assignment of a program

See also

Create a routine for the controller fault handler on page 15

Create a routine for the power-up handler on page 17

Choose where to place the fault routine on page 12

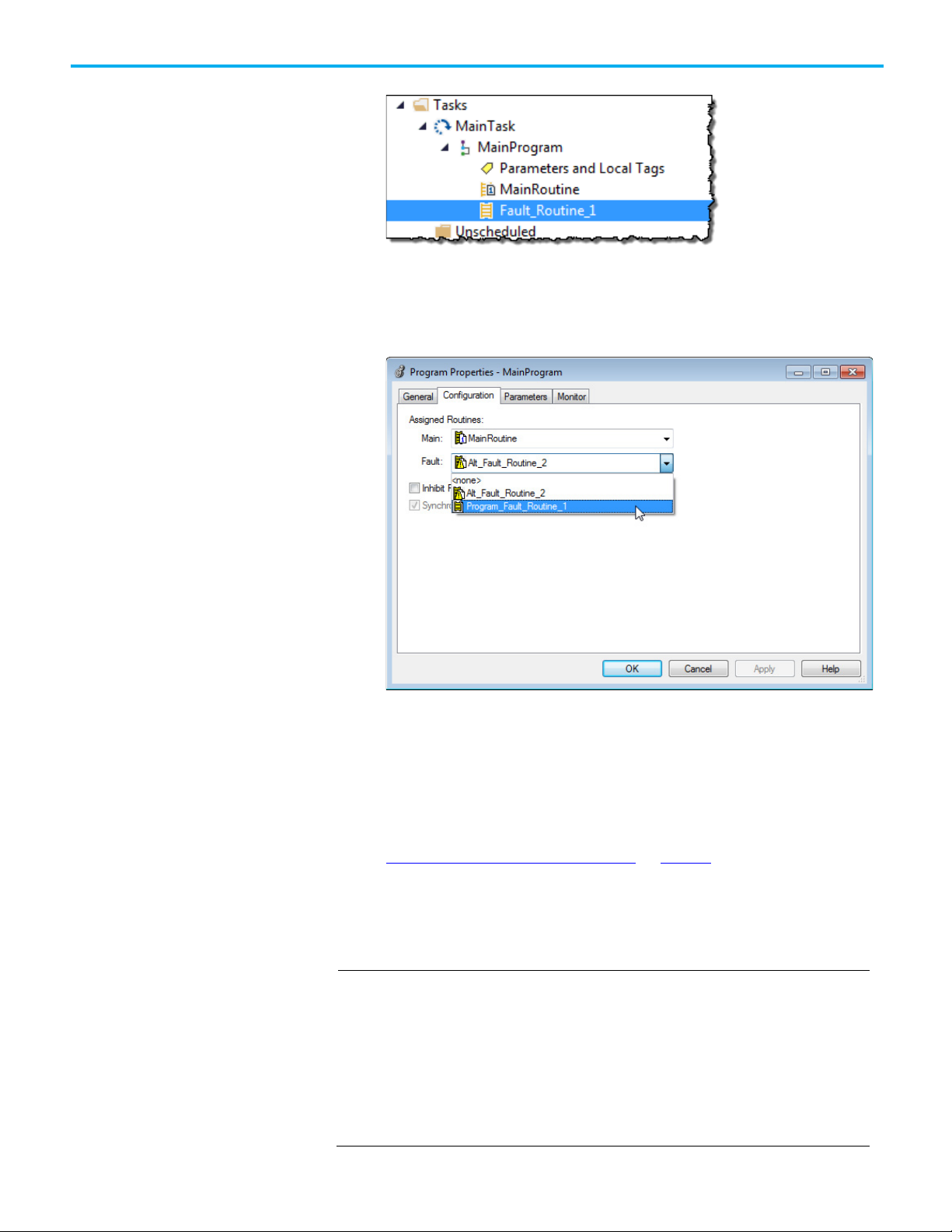

Complete these steps to change the routine assigned as the fault routine.

To change a fault routine assignment of a program:

1. In the Controller Organizer, expand the MainTask.

14 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 15

IMPORTANT

This occurs with all instructions.

Chapter 1 Major Faults

If there is already a fault routine, it appears in the MainProgram.

2. Right-click MainProgram and select Properties.

3. On the Program Properties - MainProgram dialog box, select the

Configuration tab.

4. In Fault, choose the routine to be the program’s fault routine.

Create a routine for the controller fault handler

5. Select OK.

The program specified in step 4 is now indicated as the fault routine in

the MainProgram.

See also

Create a fault routine for a program on page 13

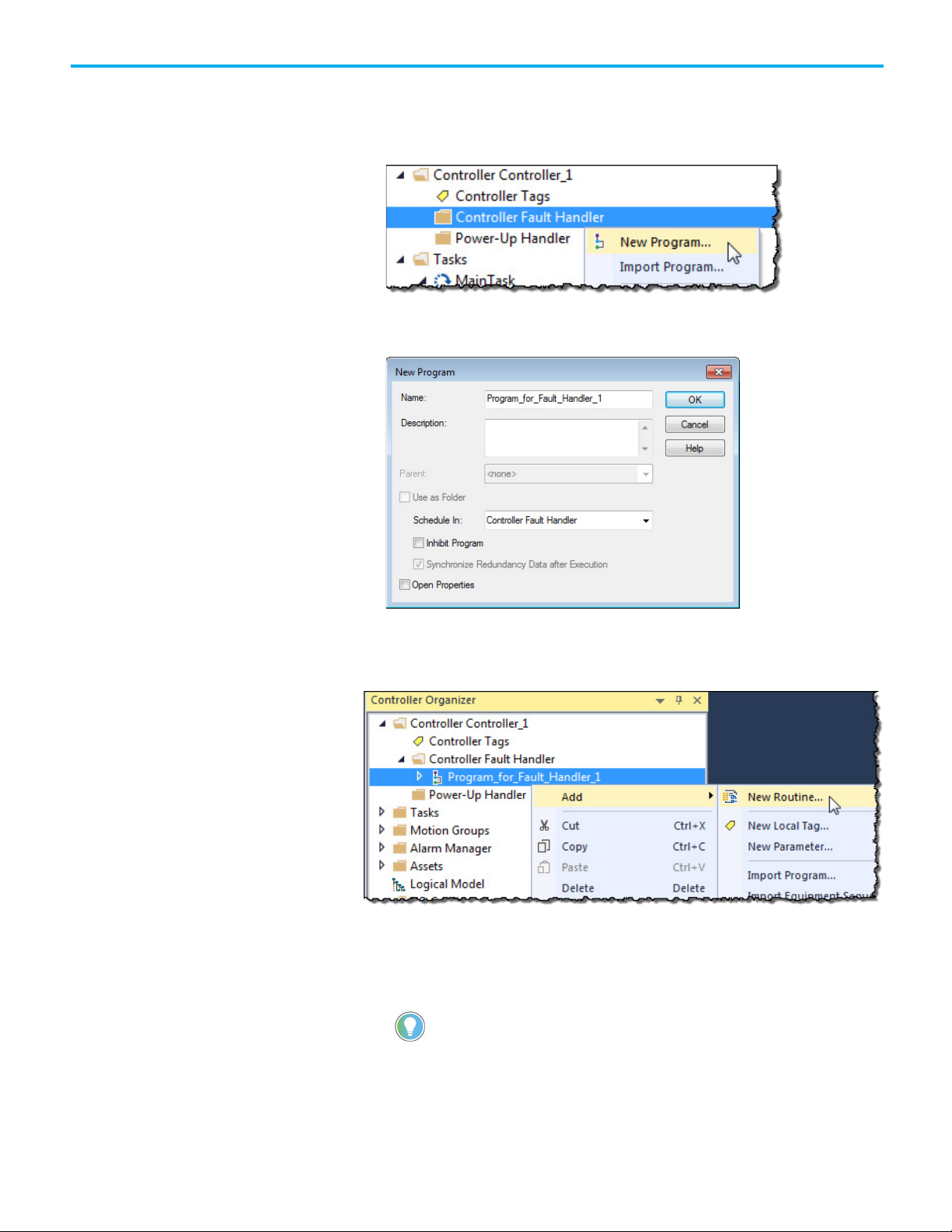

Use these steps to create a fault routine to operate as the controller fault

handler. Program tags are automatically created during this process.

When programming the fault handler, remember that any instruction that is skipped

as part of the fault-handling program does not run when the main tasks and

associated programs run.

For example, if the fault handler skips a JSR instruction that is causing a major fault,

then that JSR instruction, including all of the programming within the subroutine,

does not run.

When an instruction generates an error due to a fault (for example, a COP with an

indirect addressing programming error), the instruction is skipped and does not run.

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 15

Page 16

Chapter 1 Major Faults

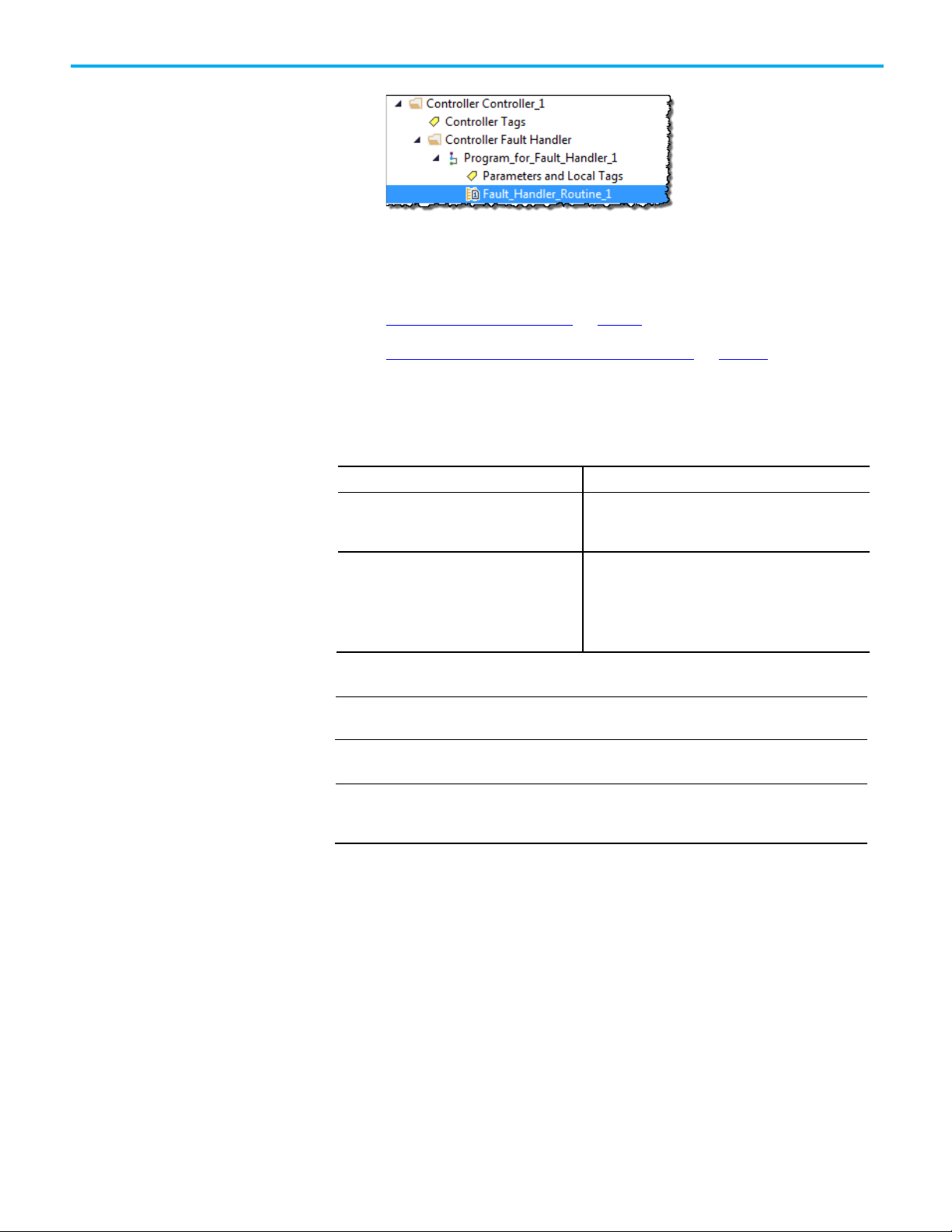

To create a routine for the controller fault handler:

1. In the Controller Organizer, right-click Controller Fault Handler and

select New Program.

2. On the New Program dialog box, in Name, type a program name.

Verify that Schedule in is set to Controller Fault Handler.

3. Select OK.

4. In the Controller Organizer, right-click the program created in step 2

and select Add>New Routine.

5. On the New Routine dialog box, in Name, type a name for the routine.

6. In Type, choose the type of routine to create. The default is Ladder

Diagram.

7. In Assignment, use the default setting, Main.

Tip: Even though Fault is an option in the Assignment, assigning the routine as a fault

routine within the Controller Fault Handler is not necessary.

8. Select OK.

16 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 17

To

Do this

the controller enters the faulted state.

IMPORTANT

IMPORTANT

Create a routine for the

power-up handler

Chapter 1 Major Faults

The fault routine is created in the Controller Fault Handler program.

9. Double-click the fault routine to edit it.

See also

Recover from a major fault on page 9

Fault handling during prescan and postscan on page 11

The Power-Up Handler is an optional task that executes when the controller

powers up in Run or Remote Run modes.

Prevent the controller from returning to Run or

Remote mode

Direct the controller to take specific actions,

then resume normal operation when power

restored

Do not use fault routines to continually clear all faults on the controller. Program the

fault routine to be selective in the types and number of faults cleared.

When an instruction generates an error due to a fault (for example, a COP with an

indirect addressing programming error), the routine skips the instruction and the

instruction does not run. This occurs with all instructions.

Leave the routine for the Power-Up Handler empty. When

power restored, a major fault (type 1, code 1) occurs and

In the Power-Up Handler fault routine, complete these

steps.

1. Clear the major fault (type 1, code 1).

2. Run the appropriate logic for the specific actions

required.

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 17

Page 18

Chapter 1 Major Faults

To create a routine for the power-up handler:

1. In the Controller Organizer, right-click Power-Up Handler and select

New Program.

2. On the New Program dialog box, in Name, type a program name.

3. Select OK. The program is added to the Power-Up Handler.

4. Right-click the program you created in step 2 and click

Add>New Routine.

18 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 19

within the Power-Up Handler is not necessary.

IMPORTANT

IMPORTANT

instruction does not run. This occurs with all instructions.

Programmatically clearing

Chapter 1 Major Faults

5. On the New Routine dialog box, in Name, type the name of the

routine.

6. In Assignment, keep the default setting, Main.

Tip: Even though Fault is an option in Assignment, assigning the routine as a fault routine

7. Click OK. The fault routine is added to the Power-Up Handler.

a major fault

8. Double-click new routine to edit.

See also

Major fault codes on page 25

To programmatically clear a major fault that occurs during the execution of

the project:

• Create a data type to store fault information

• Write a fault routine to clear the fault

Do not use fault routines to continually clear all faults on the controller. Program the

fault routine to be selective in the types and number of faults cleared.

When an instruction generates an error due to a fault (for example, a COP with an

indirect addressing programming error), the routine skips the instruction and the

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 19

Page 20

Chapter 1 Major Faults

Attribute

Data Type

Instruction

Description

Create a data type to store

fault information

See also

Create a data type to store fault information on page 20

Write a routine to clear the fault on page 21

Logix 5000 controllers store system information in objects. Unlike PLC-5 or

SLC 500 controllers, there is no status file.

• To access system information, use a Get System Value (GSV) or Set

System Value (SSV) instruction.

• To get status information about a program, access the Program object.

• To get fault information for the program, access the MajorFaultRecord

attribute of the Program object.

MajorFaultRecord DINT[11] GSV

SSV

Records major faults for this program.

Specifies the program name to determine which

Program object to use, or specifies THIS to

access the Program object for the program that

contains the GSV or SSV instruction.

To simplify access to the MajorFaultRecord attribute, complete these steps to

create a user-defined data type.

1. In the Controller Organizer, right-click User-Defined and select New

Data Type.

2. On the New Data Type window, enter the data type information as

shown in the table.

20 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 21

Data Type: FAULTRECORD

Name

Description

of the Program object.

Members

Type

INT

Decimal

Fault type (program, I/O, and so forth)

Code

INT

Decimal

Unique code for the fault

Info

DINT[8]

Hex

Fault specific information

Write a routine to clear the

Name Data Type Style Description

Time_Low DINT Decimal Lower 32 bits of the fault timestamp

Time_High DINT Decimal Upper 32 bits of the fault timestamp

3. Select OK.

See also

Major fault codes on page 25

Chapter 1 Major Faults

FAULTRECORD

Stores the MajorFaultRecord attribute or MinorFaultRecord attribute

value

value

fault

Minor fault codes on page 33

A fault routine normally contains logic to identify the program fault. Some

fault routines also contain logic to clear the fault. If a fault clears, the routine

continues executing at the instruction immediately after the instruction that

caused the program fault, and the controller does not enter fault mode. If a

fault routine does not clear the fault, the controller invokes the Controller

Fault Handler program.

Use this example to write a fault routine to clear a major fault.

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 21

Page 22

Chapter 1 Major Faults

Item

Reason

Description

structure, enter the first member of the tag.

type of fault that you want to clear.

clear.

clears and the controller resumes execution.

If controller is revision

Then

(out of range) produces a major fault.

12.x

See the release notes for the firmware of your controller.

array subscript that is beyond the range of the array (out of range).

IMPORTANT

Clear a major fault during

Gets the fault type and

code

Checks for a specific

fault.

Sets the fault code

and fault type to zero

Clears the fault The SSV instruction writes:

The GSV instruction:

• Accesses the MajorFaultRecord attribute of this program. This attribute stores information about the fault.

Stores the fault information in the major_fault_record (of type FAULTRECORD) tag. When the tag is based on a

•

The first EQU instruction checks for a specific type of fault, such as program, I/O. In Source B, enter the value for the

The second EQU instruction checks for a specific fault code. In Source B, enter the value for the code that you want to

The first CLR instruction sets the value of the fault type in the major_fault_record tag to zero.

Add the second CLR instruction sets the value of the fault code in major_fault_record tag to zero.

• The new values to the MajorFaultRecord attribute of this program.

• The values contained in the major_fault_record tag. Because the Type and Code member are set to zero, the fault

See also

Create a data type to store fault information on page 20

prescan

If the controller faults immediately after it switches to Run mode, examine

the prescan operation for the fault. Depending on the revision of the

controller, an array subscript that is beyond the range of the array (out of

range) during prescan might cause a fault.

11.x or earlier During prescan, an array subscript that is beyond the range of the array

13.0 or later During prescan, the controller automatically clears any faults due to an

This example shows a fault routine that clears a major fault that occurs during

prescan.

It is good programming practice to check for a specific fault before clearing that

fault.

22 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 23

Item

Reason

Description

• When the controller begins to run the logic, the CPU_scanning bit is always on.

caused the fault.

is too large, or a POS or LEN value of a CONTROL structure is invalid.

set to zero, the fault clears and the logix starts running again.

Test a fault routine

Chapter 1 Major Faults

Identifies when the

controller is in

prescan.

Gets the fault type and

code

Checks for a specific

fault

Clears the fault The SSV instruction does the following:

The program's fault routine uses the status of this bit to determine if the fault occurred during

prescan or normal scan of the logic.

• During prescan, this bit is off. During prescan, the controller resets all bits referenced by OTE

instructions.

The GSV instruction does the following:

• Accesses the program's MajorFaultRecord attribute. This attribute stores information about the

fault.

• Stores the fault information in the major_fault_record (of type FAULTRECORD) tag. When entering a

tag that is based on a structure, enter the first member of the tag.

The first EQU instruction checks for a fault of Type 4, which means that an instruction in this program

The second EQU instruction checks for a fault of Code 20, which means that either an array subscript

The first CLR instruction sets the value of the fault type in the major_fault_record tag to zero.

The second CLR instruction sets the value of the fault type in the major_fault_record tag to zero.

• Writes the new values to the program's MajorFaultRecord attribute.

• Writes the values contained in the major_fault_record tag. Because the Type and Code member are

See also

Use a JSR instruction to test a program's fault routine without creating an

error (simulate a fault).

To test a fault routine:

1. Create a BOOL tag to initiate the fault.

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 23

Fault handling during prescan and postscan on page 11

Page 24

Chapter 1 Major Faults

Example:

2. In the main routine or a subroutine of the program, enter this rung,

where:

• test_fault_routine is the tag to initiate the fault.

• Fault_Routine is the fault routine of the program.

When test_fault_routine is on, a major fault occurs and the controller

executes Fault_Routine.

See also

Create a user-defined major fault on page 24

Create a user-defined major fault

To suspend (shut down) the controller based on conditions in the application,

create a user-defined major fault. With a user-defined major fault:

• The fault type = 4.

• Define a value for the fault code. Choose a value between 990 and 999.

Logix Designer reserves these codes for user-defined faults.

• The controller handles the fault the same as other major faults:

• The controller changes to the Program mode and stops executing

the logic.

• Sets the outputs to their configured state or value for faulted mode.

When Tag_1.0 = 1, produce a major fault and generate a fault code of 999.

To create a user-defined major fault:

1. Create a fault routine for the program if one does not exist.

2. Configure the program to use the fault routine if it is not already

assigned.

3. In the main routine of the program, enter this rung, where:

• Tag_1.0 is the tag used to initiate the fault

• Fault_Routine_1 is the fault routine of the program

• 999 is the value of the fault code

24 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 25

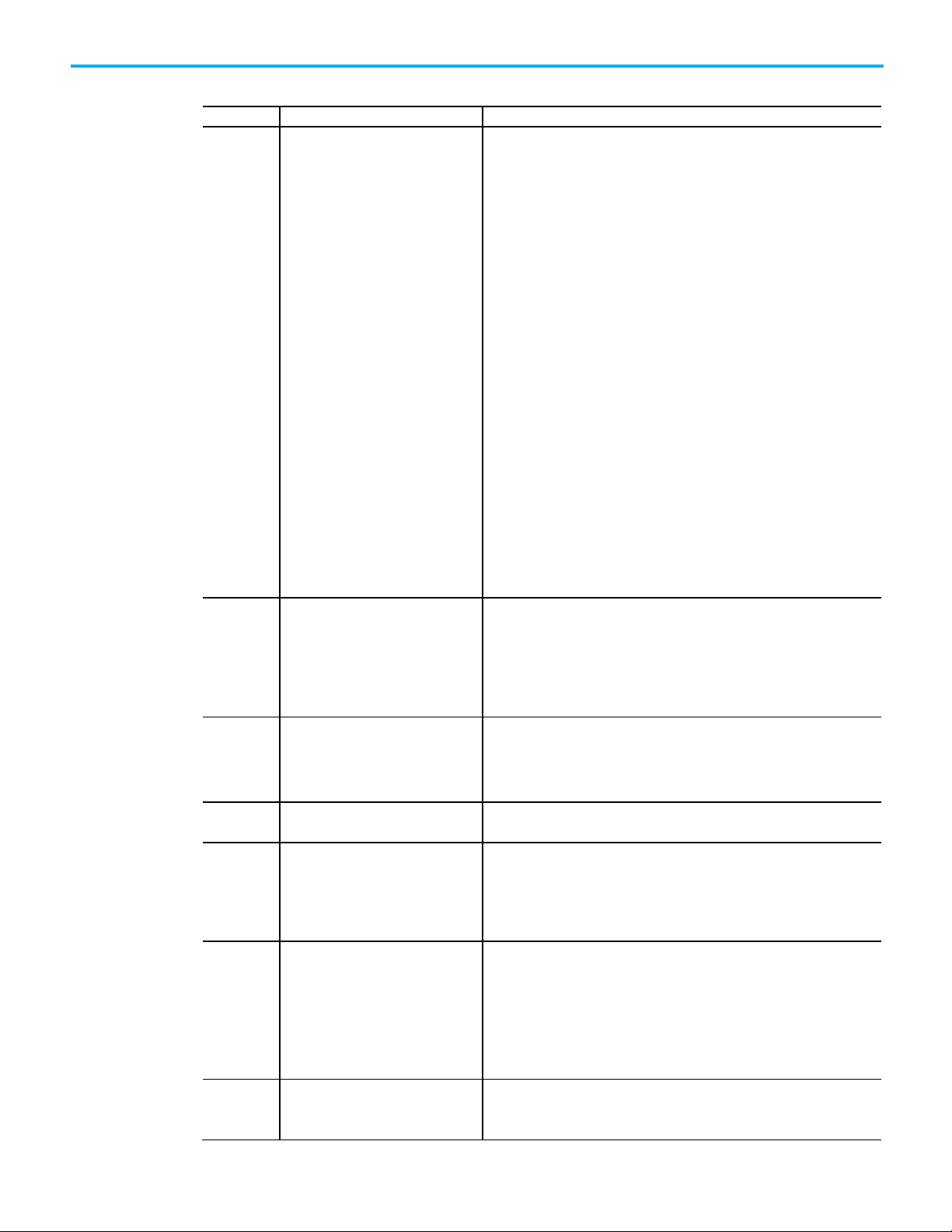

Type

Code

Cause

Recovery Method

1 1 The controller powered on in Run mode.

Execute the power up handler.

Major fault codes

4. When the major fault occurs, the controller enters faulted mode.

Outputs go to the faulted state. The Major Faults tab in the Controller

Properties dialog box displays code 999.

See also

Create a fault routine for a program on page 13

Change a fault routine assignment of a program on page 14

Major fault codes on page 25

The type and code correspond to the type and code displayed in these

locations.

• Controller Properties dialog box, Major Faults tab

• Program object, MajorFaultRecord attribute

Chapter 1 Major Faults

The major fault list includes:

1 16 I/O communication configuration fault detected.

(CompactLogix 1768-L4x controllers only.)

1 40 If the controller uses a battery, then the battery

does not contain enough charge to save the user

program on power down.

If the controller uses an ESM (Energy Storage

Module), then the ESM does not contain enough

charge to save the user program on power down.

1 60 For a controller with no memory card installed,

the controller:

• Detected a non-recoverable fault.

• Cleared the project from memory.

Reconfigure the number of communication modules on the 1768 bus

side of the controller:

• 1768-L43 has a maximum of two modules.

• 1768-L45 has a maximum of four modules.

• Up to four Sercos modules

•

Up to two NetLinx communication modules

To recover from the fault:

• For controllers that use a battery, replace the battery.

• For controllers that use an ESM (Energy Storage Module):

• Allow the ESM to fully charge before powering down the

controller.

• Replace the ESM if the ESM is removable, or replace the

controller if the ESM is not removable.

•

If the problem persists, contact Rockwell Automation support.

To recover from the fault:

1. Clear the fault.

2. Download the project.

3. Change to Remote Run or Run mode.

If the fault persists:

Before cycling power to the controller, record the state of the OK and RS232

status indicators.

Contact Rockwell Automation support.

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 25

Page 26

Chapter 1 Major Faults

Type

Code

Cause

Recovery Method

• Cleared the project from memory.

mode.

21

program conversion process.

.LEN is invalid.

array size or go beyond dimensions defined.

instruction.

error.

accumulated value.

accumulated.

4

42

JMP to a label that did not exist or was deleted.

Correct the JMP target or add the missing label.

subroutine.

4

90

Using a safety instruction outside a safety task.

Place the safety instruction inside the safety task.

4

94

Nesting limits exceeded.

Restructure the project to reduce the subroutine nesting levels.

error.

1 61 For a controller with a memory card installed, the

controller:

• Detected a non-recoverable fault.

• Wrote diagnostic information to the memory

card.

1 62 For a controller with a Secure Digital (SD) card

installed, the controller:

• Detected a nonrecoverable fault.

• Wrote diagnostic information to the memory

card.

To recover from the fault:

1. Clear the fault.

2. Download the project.

3. Change to Remote Run/Run mode.

If the fault persists, contact Rockwell Automation support.

To recover from the fault:

1. Clear the fault.

2. Download the project.

3. Change to Remote Run or Run mode.

If the fault persists, contact Rockwell Automation support.

When in this state, the controller will not open

any connections or allow a transition to Run

3 16 A required I/O module connection failed. To recover from the fault, check:

• The I/O module is in the chassis.

• The electronic keying requirements.

• The Controller Properties Major Faults tab and the Module

Properties Connection tab for more information about the fault.

3 20

3 23 At least one required connection was not

Possible problem with the chassis. Not recoverable - replace the chassis.

Wait for the controller I/O light to turn green before changing to Run

established before going into Run mode.

mode.

4 16 Unknown instruction encountered. Remove the unknown instruction. This probably happened due to a

4 20 Array subscript too big, control structure .POS or

Adjust the value to be within the defined range. Don’t exceed the

4 21 Control structure .LEN or .POS < 0. Adjust the value so that it is > 0.

4 31 The parameters of the JSR instruction do not

match those of the associated SBR or RET

4 34 A timer instruction has a negative preset or

4 82 A sequential function chart (SFC) called a

Pass the appropriate number of parameters. If too many

parameters are passed, the extra ones are ignored without any

Fix the program to not load a negative value into timer preset or

Remove the jump back to the calling SFC.

subroutine and the subroutine tried to jump back

to the calling SFC. Occurs when the SFC uses

either a JSR or FOR instruction to call the

4 83 The data tested was not inside the required

limits. This occurs with array subscripts used

Adjust the value to be within the valid range. Do not exceed the

array size or go beyond the dimensions defined.

with Boolean arrays and bit level addressing.

4 84 Stack overflow. Reduce the subroutine nesting levels or the number of parameters

passed.

4 89 In an SFR instruction, the target routine does not

Correct the SFR target or add the missing step.

contain the target step.

4 91 Equipment Phase instruction is being called from

Only use the instruction in an Equipment Phase program.

outside an Equipment Phase program.

4 95 The built-in instruction contains an internal

26 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Contact Rockwell Automation support.

Page 27

Type

Code

Cause

Recovery Method

much with a single controller).

unlocked.

revision of the controller.

checksum.

7

44

Failed to restore processor memory.

Contact Rockwell Automation support.

limit.

limit, and then execute Motion Axis Fault Reset.

limit.

limit, and then execute Motion Axis Fault Reset.

Chapter 1 Major Faults

4 990 -

999

6 1 Task watchdog expired.

User-defined major fault.

User task has not completed in specified period

of time. A program error caused an infinite loop,

Increase the task watchdog, shorten the execution time, make the

priority of this task higher, simplify higher priority tasks, or move

some code to another controller.

or the program is too complex to execute as

quickly as specified, or a higher priority task is

keeping this task from finishing (trying to do too

7 40 Store to nonvolatile memory failed. To recover from the fault:

• Try again to store the project to nonvolatile memory.

• If the project fails to store to nonvolatile memory, replace the

memory board.

If you are using a 1756-L7x controller, verify that the SD card is

•

7 41 Load from nonvolatile memory failed due to

controller type mismatch.

Change to a controller of the correct type or download the project

and store it on the memory card.

7 42 Load from nonvolatile memory failed because

the firmware revision of the project in

Update the controller firmware to the same revision level as the

project that is in nonvolatile memory.

nonvolatile memory does not match the firmware

7 43 Load from nonvolatile memory failed due to bad

Contact Rockwell Automation support.

7 50 The log file certificate can not be verified. When

the controller starts up it attempts to verify the

log file key/certificate combination. Depending

on the verification, the controller takes one of

the following actions:

• If the controller verifies the existing log file

certificate, the controller continues with

existing log directory.

• If the existing certificate cannot be verified,

the controller logs a major fault and attempts

to create a new certificate.

• If the controller successfully creates a new

certificate, it creates a backup log

subdirectory, moves the existing files to that

directory, and continues logging and signing

with the new verification key and log file

certificate.

• If the controller cannot create a new

certificate, the controller writes log entries

to the existing log directory, but does not

update signature files in that directory.

8 1 Attempted to place controller in Run mode with

keyswitch during download.

11 1 Actual position has exceeded positive overtravel

Clear the fault and power cycle the controller. If the problem

persists, contact Rockwell Automation support.

Wait for the download to complete and clear the fault.

Move axis in negative direction until position is within overtravel

11 2 Actual position has exceeded negative overtravel

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 27

Move axis in positive direction until position is within overtravel

Page 28

Chapter 1 Major Faults

Type

Code

Cause

Recovery Method

tolerance.

Fault Reset.

Reset.

signals are not in quadrature.

11 6 Drive Fault input was activated.

Clear Drive Fault, and then execute Motion Axis Fault Reset.

module.

fault.

module.

11

10

Motor fault has occurred.

See the DriveFaults axis tag for more information.

11

11

Motor thermal fault has occurred.

See the DriveFaults axis tag for more information.

11

12

Motor thermal fault has occurred.

See the DriveFaults axis tag for more information.

11

14

Drive enable input fault has occurred.

Re-enable the drive enable input and clear the fault.

11

15

Drive phase loss fault has occurred.

Restore full power connection to the drive and clear the fault.

clear the major fault.

system.

modes to Run.

11 3 Actual position has exceeded position error

Move the position within tolerance and then execute Motion Axis

11 4 Encoder channel A, B, or Z connection is broken. Reconnect the encoder channel, and then execute Motion Axis Fault

11 5 Encoder noise event detected or the encoder

Fix encoder cabling, and then execute Motion Axis Fault Reset.

11 7 Synchronous connection incurred a failure. First execute Motion Axis Fault Reset. If that does not work, pull

servo module out and plug back in. If all else fails, replace servo

11 8 Servo module has detected a serious hardware

Replace the module.

11 9 Asynchronous Connection has incurred a failure. First execute Motion Axis Fault Reset. If that does not work, pull

servo module out and plug back in. If all else fails, replace servo

11 13 SERCOS ring fault has occurred.

Verify the integrity of the SERCOS fiber-optic ring network and the

devices on it.

11 16 Drive guard fault has occurred. See the GuardFaults axis tag for more information.

11 32 The motion task has experienced an overlap. The group’s coarse rate is too high to maintain correct operation.

Clear the group fault tag, raise the group’s update rate, and then

12 32 Power to a disqualified secondary controller has

been cycled and no partner chassis or controller

was found upon power up.

To recover from the fault, verify that:

• A partner chassis is connected.

• Power is applied to both redundant chassis.

• Partnered controllers have the same:

• catalog number.

• slot number.

• firmware revision.

12 33 An unpartnered controller has been identified in

the new primary chassis after a switchover.

To recover from the fault, either:

• Remove the unpartnered controller and troubleshoot the cause of

the switchover.

• Add a partner controller to the secondary chassis.

Troubleshoot the cause of the switchover, and synchronize the

•

12 34 Just after a switchover occurs, the keyswitch

positions of the primary and secondary

controllers are mismatched.

The old primary controller is in Program mode

and the new primary controller is in Run mode.

To recover from the fault, either:

• Change the keyswitches from Run to Program to Run mode twice

to clear the fault.

Use the Logix Designer application to go online with the

•

controllers. Then, clear the faults and change both the controllers’

28 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 29

Type

Code

Cause

Recovery Method

program again to allow the safety task to run.

14 8 Coordinated System Time Master (CST) not found.

Clear the fault. Configure a device to be the CST master.

replace the safety partner.

temperature and apply the required clearance around the chassis.

specific initialization fault has occurred.

specific axis fault has occurred.

Motion Fault bits for details about the fault that occurred.

Chapter 1 Major Faults

14 1 Safety Task watchdog expired.

User task has not completed in a specified

period of time. A program error caused an

infinite loop, the program is too complex to

execute as quickly as specified, a higher priority

task is keeping this task from finishing, or the

Clear the fault.

If a safety task signature exists, safety memory is re-initialized and

the safety task begins executing.

If a safety task signature does not exist, you must re-download the

program to allow the safety task to run.

Reinsert the safety partner, if it was removed.

safety partner has been removed.

14 2 An error exists in a routine of the safety task. Correct the error in the routine in the user-program logic.

14 3 Safety Partner is missing. Install a compatible safety partner.

14 4 Safety Partner is unavailable. Install a compatible safety partner.

14 5 Safety Partner hardware is incompatible. Install a compatible safety partner.

14 6 Safety Partner firmware is incompatible. Install a compatible safety partner.

14 7 Safety task is inoperable.

This fault occurs when the safety logic is invalid,

for example a mismatch in logic exists between

the primary controller and safety partner, a

watchdog timeout occurred, or memory is

Clear the fault.

If a safety task signature exists, safety memory is re-initialized

using the safety task signature and the safety task begins

executing.

If a safety task signature does not exist, you must download the

corrupt.

14 9 Safety partner nonrecoverable controller fault. Clear the fault and download the program. If the fault persists,

17 34 Controller internal temperature has exceeded

operating limit.

17 37 Controller has recovered from an internal

temperature fault.

Measures should be taken to reduce the ambient temperature of the

module. Follow the recommended limits for the ambient (inlet)

Generated when the controller recovers from automatic shutdown.

Shutdown occurs when the modules's temperature exceeds the

temperature threshold of the preservation fault. When the

temperature decreases to a suitable level, this re-enables the

controller voltages and generates the Type 17, Code 37 fault.

18 1 The CIP Motion drive has not initialized correctly. To determine corrective action, see Initialization Faults Attributes

for details about the type of fault that occurred.

18 2 The CIP Motion drive has not initialized correctly.

This fault is indicated when a manufacturer-

18 3 The Physical Axis Fault bit is set, indicating a

fault on the physical axis.

To determine the corrective action, see CIP Initialization Fault - Mfg

attributes for details about the fault that occurred.

To determine corrective action, see CIP Axis Fault attributes for

details about the fault that occurred.

18 4 The Physical Axis Fault bit is set, indicating fault

on the physical axis.

To determine corrective action, see CIP Initialization Fault - Mfg

attributes attributes for details about the fault that occurred.

This fault is indicated when a manufacturer-

18 5 A motion fault occurred. To determine corrective action, see the Motion Fault attribute and

18 6 A CIP Motion Drive fault has occurred.

Reconfigure the faulted motion module to correct the fault.

Usually the fault affects all the axis associated

with the module and all of the associated axes

are shutdown.

18 7 A motion group fault has occurred.

Reconfigure the entire motion subsystem to correct the fault.

Usually the fault affects all of the axes

associated with a motion group.

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 29

Page 30

Chapter 1 Major Faults

Type

Code

Cause

Recovery Method

Motion Drive was unsuccessful.

cannot be recovered.

specific APR fault has occurred.

Guard Safety functionality is used.

the transition to run or test mode.

the controller.

18 8 A fault has occurred during the configuration of a

CIP Motion Drive.

Typically, this fault occurs after an attempt to

update an axis configuration attribute of a CIP

18 9 An Absolute Position Recovery (APR) fault has

occurred and the absolute position of the axis

18 10 An Absolute Position Recovery (APR) fault has

occurred and the absolute position of the axis

cannot be recovered.

This fault is indicated when a manufacturer-

18 128 A fault specific to the Guard Motion safety

function has occurred.

This fault is applicable only when a drive with

20 1 A required license is missing or expired during

See also

Minor fault codes on page 9

To determine the corrective action, see the Configuration Fault in

the Attribute Error Code and Attribute Error ID attributes associated

with the motion or 1756-ENxT module.

To determine the corrective action, see the APR Fault to determine

the cause of the fault.

To determine the corrective action, see the APR Fault - Mfg

attributes to determine the cause of the fault.attributes

To determine the corrective action, see the Guard Motion attributes

and Guard Status bits to determine the cause of the fault.

Insert a CmCard containing all licenses required by the project in

I/O fault codes on page 38

30 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 31

To check for a

Do this

power supply (UPS) fault

Name

Data Type

Style

Type

INT

Decimal

Code

INT

Decimal

Info

DINT[8]

Hex

S:MINOR remains set until the end of the scan.

Identify minor faults

Minor Faults

This chapter explains minor fault codes and how to work with them in the

Logix Designer application.

Use this table to understand how to use ladder logic to monitor information

about common minor faults.

Task overlap 1. Enter a GSV instruction that gets the FaultLog object, MinorFaultBits attribute.

2. Monitor bit 6.

Load from nonvolatile

memory

1. Enter a GSV instruction that gets the FaultLog object, MinorFaultBits attribute.

2. Monitor bit 7.

Chapter 2

Serial port fault 1. Enter a GSV instruction that gets the FaultLog object, MinorFaultBits attribute.

2. Monitor bit 9.

Low battery, energy storage

status or uninterruptable

Instruction-related fault 1. Create a user-defined data type that stores the fault information. Name the data type FaultRecord

1. Enter a GSV instruction that gets the FaultLog object, MinorFaultBits attribute.

2. Monitor bit 10.

and assign the following members.

TimeLow DINT Decimal

TimeHigh DINT Decimal

1. Create a tag that stores the values of the MinorFaultRecord attribute.

2. From the Data Type menu in step 1 of this instruction, choose the data type.

3. Monitor S:MINOR.

4. Use a GSV instruction to get the values of the MinorFaultRecord attribute if S:MINOR is on.

5. Reset S:MINOR if you want to detect a minor fault that is cause by another instruction.

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 31

See also

Minor fault codes on page 33

Page 32

Chapter 2 Minor Faults

Example:

or is missing.

Example:

• If S:MINOR is set, the GSV instruction gets information about the fault and resets S:MINOR.

Minor fault examples

Use these examples to check for minor faults.

Checks for a low battery warning

Checks for a minor fault.

Minor_fault_check times for 1 minute (60000 ms) and then automatically restarts itself.

Every minute, minor_fault_check.DN turns on for one scan. When this occurs, the GSV instruction gets the value of

the FaultLog object, MinorFaultBits attribute, and stores it in the minor_fault_bits tag. Because the GSV instruction

only runs once every minute, the scan time of most scans is reduced.

If minor_fault_bits.10 is on, depending on the controller, the battery is low or the ESM or UPS needs to be replaced

Checks for a minor fault that is caused by a specific instruction

Check for a minor fault that is caused by an instruction.

• Multiply value_a by 1000000 and check for a minor fault, such as a math overflow.

• To make sure that a previous instruction did not produce the fault, the rung first clears S:MINOR.

• The rung then executes the multiply instruction.

• If the instruction produces a minor fault, the controller sets S:MINOR.

32 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 33

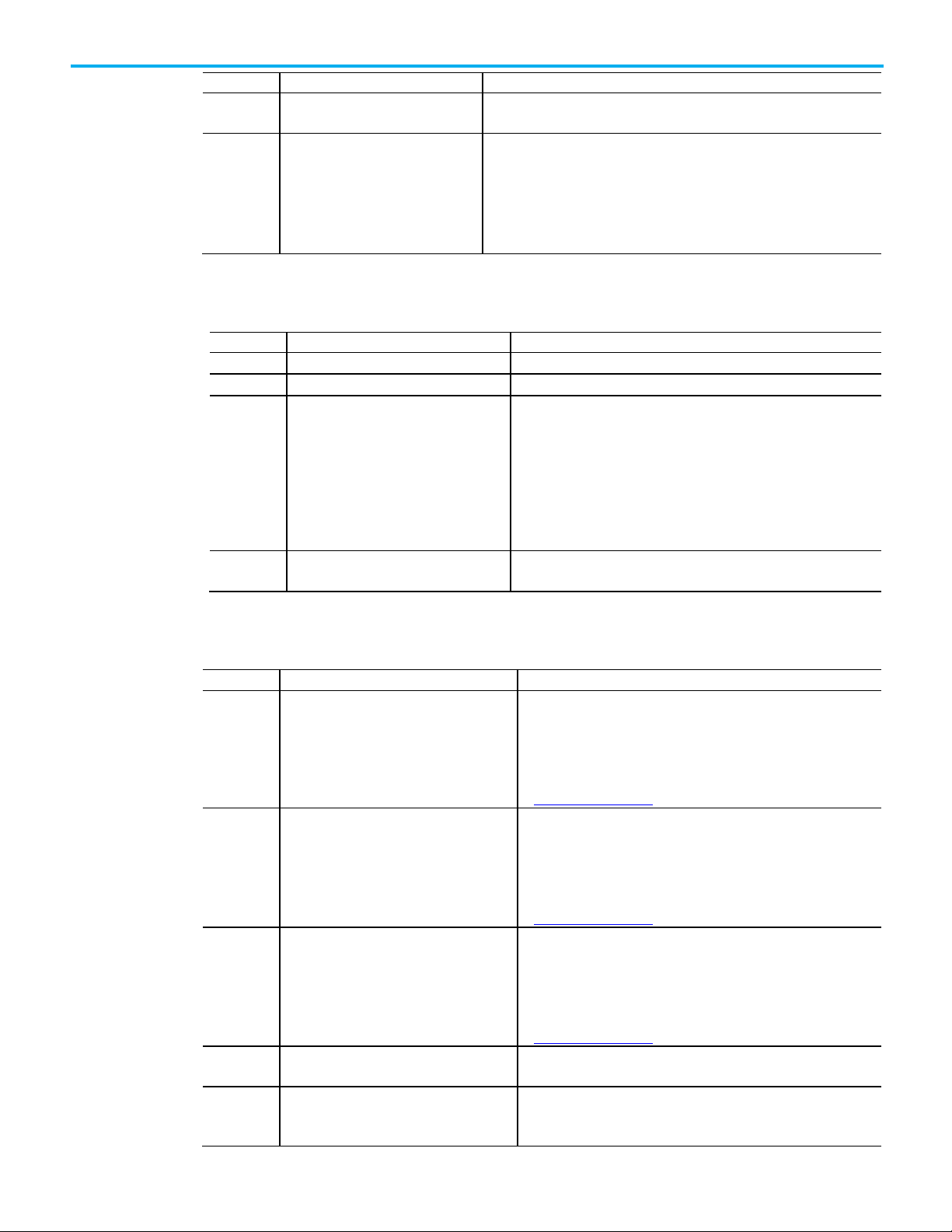

Type

Code

Cause

Recovery Method

has failed.

Module RPI Overlap faults.

Minor fault codes

See also

Create a data type to store fault information on page 20

Chapter 2 Minor Faults

Minor faults get recorded in these locations.

• Controller Properties dialog box, Minor Faults tab

• Program object, MinorFaultRecord attribute

The minor fault list includes:

1 15 • A 1769 power supply is connected directly to the

controller’s 1768 CompactBus, with an invalid

configuration.

The 1768 power supply powering the controller

•

3 1 Bus off condition. The connections between the

controller and the I/O modules are broken.

3 94 The current RPI update of an I/O module overlaps

with its previous RPI update.

• Remove the power supply from the 1768 CompactBus and

cycle power to the system.

• Replace the power supply.

Complete these steps to identify the source of the BUS OFF

fault:

The number of local expansion modules in the project matches the

number of modules that are physically installed in the system.

All mounting bases are locked and I/O modules are securely installed on

mounting bases.

All 1734 POINT I/O modules are configured to use the Autobaud rate.

If these steps do not remedy the fault condition, contact

Rockwell Automation support.

Set the RPI rate of the I/O modules to a higher numerical value.

Rockwell Automation recommends that the CompactLogix 5370

L2 and CompactLogix 5370 L3 control systems do not run with

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 33

Page 34

Chapter 2 Minor Faults

Type

Code

Cause

Recovery Method

Knowledgebase Answer ID 1028837.

adjusting values.

was not found.

4

35

PID delta time 0.

Adjust the PID delta time so that it is > 0.

4

36

PID setpoint out of range.

Adjust the setpoint so that it is in range.

string contains.

or equal to the DATA size of the Source.

• Delete the AHL instruction.

to execute again.

bit 7.

persists.

3 100 The potential exists for data integrity loss with the

module because either or both of the input/output

size > 16 bytes and the module does not support

start and end integrity.

Recover methods:

• Decrease input/output sizes to <= 16 bytes which avoids data

integrity loss concern.

• Contact the module provider to inquire about a version that

supports the start and end integrity function.

For more information, see Rockwell Automation

•

4 4 An arithmetic overflow occurred in an instruction. Fix program by examining arithmetic operations (order) or

4 5 In a GSV/SSV instruction, the specified instance

4 6 In a GSV/SSV instruction, either:

Check the instance name.

Check the Class name and Attribute name.

• Specified Class name is not supported

• Specified Attribute name is not valid

4 7 The GSV/SSV destination tag was too small to hold

Fix the destination or source so it has enough space.

all of the data.

4 30 Bad parameters passed through to the ASCII port. Verify the ASCII configuration settings.

4 51 The LEN value of the string tag is greater than the

DATA size of the string tag.

• Check that no instruction is writing to the LEN member of the

string tag.

In the LEN value, enter the number of characters that the

•

4 52 The output string is larger than the destination. Create a new string data type that is large enough for the

output string. Use the new string data type as the data type for

the destination.

4 53 The output number is beyond the limits of the

destination data type.

Either:

• Reduce the size of the ASCII value.

•

Use a larger data type for the destination.

4 56 The Start or Quantity value is invalid. • Check that the Start value is between 1 and the DATA size of

the Source.

Check that the Start value plus the Quantity value is less than

•

4 57 The AHL instruction failed to execute because the

serial port is set to no handshaking.

6 2 Periodic task overlap.

Periodic task has not completed before it is time

6 3 Event task overlap.

Event task has not completed before it is time to

execute again.

7 49 When the controller loads a project from

Either:

• Change the Control Line setting of the serial port.

Make changes such as simplifying programs, lengthening the

period, or raising the relative priority.

Make changes such as simplifying programs, lengthening the

period, raising the relative priority, or slowing the triggering

event.

Clear the fault.

nonvolatile memory, it logs this minor fault and

sets the FaultLog object, MinorFaultBits attribute,

34 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

9 0 Unknown error while servicing serial port Contact Rockwell Automation Technical Support if the problem

9 1 The CTS line is not correct for current

configuration.

Disconnect and reconnect the serial port cable to the controller.

Verify cabling is correct.

Page 35

Type

Code

Cause

Recovery Method

• A station number greater than 254 was encountered.

unspecified.

Port Protocol tab, under Controller Properties.

10

10

Battery not detected or needs to be replaced.

Install new battery.

replaced.

attribute or controller program at power down.

controller program at power down.

recovered.

type and fault code.

Chapter 2 Minor Faults

9 2 Poll list error.

A fault was detected with the DF1 master’s poll list,

such as specifying more stations than the size of

the file, specifying more than 255 stations, trying

to index past the end of the list, or polling the

broadcast address (STN #255).

9 3 The RS-232 DF1 Master Active Station Tag is

9 5 DF1 slave poll timeout.

Check for the following errors:

• Total number of stations is greater than the space in the poll

list tag.

• Total number of stations is greater than 255.

• Current station pointer is greater than the end of the poll list

tag.

Specify a tag to be used for the Active Station Tag on the Serial

Determine and correct delay for polling.

The poll watchdog timed out for slave. The master

has not polled this controller in the specified

amount of time.

9 9 The modem contact is lost.

Correct modem connection to the controller.

The DCD or DSR control lines are not being

received in the proper sequence and/or state.

9 10 Data has been dropped or lost from the serial port. Slow down the rate at which the initiator is sending data.

10 11 Safety partner battery not detected or needs to be

10 12 The Energy Storage Module (ESM) is not installed.

Install new battery.

Install an ESM in the controller.

If the controller is powered-down, the

WallClockTime attribute and program are not

maintained.

10 13 The installed ESM is not compatible with the

controller.

10 14 The ESM needs to be replaced due to a hardware

Replace the installed ESM with one that is compatible with the

controller.

Replace the ESM.

fault.

It is not capable of maintaining the WallClockTime

10 15 The ESM cannot store enough energy in the ESM to

maintain the WallClockTime attribute or the

10 16 The uninterruptable power supply (UPS) is missing

or not ready.

Replace the ESM.

Either:

• Install the UPS.

• Check the UPS to make sure it is adequately charged to

provide backup power in the event of power loss.

10 17 The UPS battery has failed and needs to be

Replace the battery in the UPS.

replaced.

13 21 Wall Clock Time out of range. Make sure the Wall Clock Time is set to the correct date/time.

14 12 The Safety project is configured as SIL2/PLd and a

Safety Partner is present.

16 1 This fault occurs when the buffer that stores

unwritten controller log messages runs out of

room and overwrites log messages.

Make sure there is no Safety Partner installed to the right of the

primary controller.

To remove the state that causes this fault, insert an SD Card

into the controller and wait for the controller log to write out the

messages from the controller log buffer.

Log messages that have already been overwritten cannot be

17 1...n An internal controller diagnostic has failed. Contact Rockwell Automation Technical Support with the fault

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 35

Page 36

Chapter 2 Minor Faults

Type

Code

Cause

Recovery Method

Technical Support for further assistance.

controller is in run or test mode.

in the controller.

17 35 Controller internal temperature is approaching

operating limit.

Measures should be taken to reduce the ambient temperature

of the module. Follow the recommended limits for the ambient

(inlet) temperature and apply the required clearance around the

chassis.

17 36 A fan is not present, or is not maintaining desired

Replace the fan.

speed.

19 4 Ethernet Port Fault EtherNet/IP data storm detected.

Investigate network traffic on the Ethernet port and clear the

fault. If problems persists, contact Rockwell Automation

20 1 A required license is missing or expired while the

Insert a CmCard containing all licenses required by the project

See also

Major fault codes on page 25

I/O fault codes on page 38

36 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 37

Indications of I/O faults

Chapter 3

I/O Fault Codes

This chapter explains I/O fault codes and how to work with them in the Logix

Designer application.

The indication of I/O faults displays in various ways depending on the

controller.

• The I/O indicator of the controller (shown in examples below) flashes

green or red.

• The controller status display indicates I/O fault messages.

• The I/O status indicator and messages show in the controller status

area of the Logix Designer application. The indicator flashes green or

red and the corresponding status message indicates an error.

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 37

Page 38

Chapter 3 I/O Fault Codes

Code

String

Explanation and Possible Causes/Solutions

I/O Fault Codes

• A yellow warning symbol appears on the module in the

I/O Configuration tree of the Logix Designer application.

• A module fault code and description appear in the Connection tab of

the Module Properties dialog box.

Depending where the fault code displays, the code format contains either the

full Hexadecimal number (for example, 16#000A) or the last characters of the

code (for example, #000A).

This table lists common I/O fault codes and a corresponding description and

recovery method when applicable. Each code is listed by the full Hexadecimal

number.

Faults 16#0000 - 16#00ff

16#0001 Connection Error. A connection to a module failed.

38 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Page 39

Code

String

Explanation and Possible Causes/Solutions

module’s rotary switch settings.

specified in the I/O configuration tree of the Logix Designer application.

16#0007

Connection Request Error: Bad Class.

A service request is unconnected, but should be connected.

not supported by the module.

Chapter 3 I/O Fault Codes

16#0002 Resource unavailable.

Either:

• there are not enough connections available either for the controller or

for the communication module being used to connect through.

Check the connection use of the controller or communication module. If

all of the connections are used, try to free some of the used

connections or add another module to route the errant connection

through.

• the I/O memory limits of the controller are exceeded.

Check the I/O memory available and make program or tag changes if

needed.

• the I/O module targeted does not have enough connections available.

Check the number of controllers making a connection to this I/O module

and verify that the number of connections is within the limits of the I/O

module.

16#0005 Connection Request Error: Bad Class The controller is attempting to make a connection to the module and has

received an error.

Either:

• the configured address for the connection to the module is incorrect.

• the module in use (that is, the physical module) is different than the

module specified in the I/O configuration tree and is therefore causing

the connection or service to fail.

The fault may occur even when the module passed the electronic

keying test. This may result when Disable Keying or Compatible Module

options were used in the module configuration instead of the Exact

Match option.

Despite passing the electronic keying test, the module being connected

to does not have the same features or settings as the module specified

in the I/O configuration tree and does not support the connection or

service being attempted.

Check the module in use and verify that it exactly matches the module

specified in the I/O configuration tree of the Logix Designer application.

If you are using a 1756-DHRIO module, verify that the Channel type

selected in the software (DH+ or remote I/O network) matches the

16#0006 Connection Request Error: Bad Class.

16#0008 Service Request Error: Unsupported Service The controller is attempting to request a service from the module that is

Rockwell Automation Publication 1756-PM014M-EN-P - September 2020 39

Either:

• the response buffer is too small to handle the response data.

• the module in use (that is, the physical module) is different than the

module specified in the I/O configuration tree and is therefore causing

the connection or service to fail.

The fault may occur even when the module passed the electronic

keying test. This may result when Disable Keying or Compatible Module

options were used in the module configuration instead of the Exact

Match option.

Despite passing the electronic keying test, the module being connected

to does not have the same features or settings as the module specified

in the I/O configuration tree and does not support the connection or

service being attempted.

Check the module in use and verify that it exactly matches the module

Page 40

Chapter 3 I/O Fault Codes

Code

String

Explanation and Possible Causes/Solutions

applicable.

Refer to the Module Info tab to determine the exact cause.

16#000D

Object already exists.

An I/O map instance is created where the instance is already in use.

be changed.

to perform requested service.

Verify that the correct module is being targeted.

16#0014

Undefined or unsupported attribute.

A MSG instruction is configured to change an attribute that does not exist.

Verify that the correct module is being targeted.

Code

String

Explanation and Possible Causes/Solutions

16#0009 Module Configuration Invalid: parameter error.

Tip: Additional Fault Information for this fault

will be displayed as a hex code on the

Connection Tab.

The configuration for the module is invalid. The module configuration may

have been changed in the Data Monitor or programmatically.

If available for the module, access the Connections tab of the Module

Properties dialog box for the additional fault code. The additional fault

code indicates the configuration parameter that is causing the fault. You

may have to correct multiple parameters before this fault is cleared and

connection is properly established.

16#000A

An attribute in the Get_Attributes_List or

Set_Attributes_List has a non-zero status.

Either:

• a connection is being created where the connection type is invalid.

• an object attribute or tag value is invalid.

If an object attribute or tag is invalid, export the Logix Designer file, then

re-import it. Reschedule the ControlNet network after re-importing if

16#000C Service Request Error: Invalid mode/state

for service request.

The controller is attempting to request a service from the module and has

received an error. First, verify that the module is not faulted.

For an I/O module, this may indicate that the module has one of these

conditions:

• Limited communication, but has a Major Fault

• A firmware update needs to be completed or is currently being

completed.

16#000E Attribute value cannot be set. A MSG instruction is configured to change an attribute value that cannot

16#000F Access permission denied for requested

service.

16#0010 Mode or state of module does not allow object

A MSG instruction has been configured to delete a map object that cannot

be deleted.

The state of the device prevents a service request from being handled.

16#0011 Reply data too large. The reply to a message has a data size that is too large for the

destination.

Change the destination to a tag that can handle the data size and type

being returned.

16#0013 Module Configuration Rejected: Data size too

small.

16#0015 Module Configuration Rejected: Data size too

large.

The configuration for the module is invalid - not enough configuration

data was sent.

The configuration for the module is invalid - too much configuration data

was sent.

Faults 16#0100 - 16#01ff

16#0100 Connection Request Error: Module in Use. • The connection being accessed is already in use.

40 Rockwell Automation Publication 1756-PM014M-EN-P - September 2020

Either:

• The controller is attempting to make a specific connection to a module

and the module cannot support more than one of these connections.

• The target of a connection recognizes that the owner is attempting to

remake a connection that is already running.

Page 41

Code

String

Explanation and Possible Causes/Solutions

specified in the I/O configuration tree of the Logix Designer application.

Configure both the Owner and the Listen-Only connection as Multicast.

16#0107

Connection Request Error: Unknown type.

A connection being accessed was not found.

Chapter 3 I/O Fault Codes

16#0103 Service Request Error: CIP transport class

not supported.

16#0106 Connection Request Error: Module owned

and configured by another controller.

Module may accept only one connection if

Unicast is used.

Either:

• The controller is requesting services not supported by the module.

• The module in use (that is, the physical module) is different than the

module specified in the I/O configuration tree and is therefore causing

the connection or service to fail.

The fault may occur even when the module passed the electronic keying

test. This may result when Disable Keying or Compatible Module options

were used in the module configuration instead of the Exact Match option.

Despite passing the electronic keying test, the module being connected

to does not have the same features or settings as the module specified

in the I/O configuration tree and does not support the connection or

service being attempted.

Check the module in use and verify that it exactly matches the module

An ownership conflict occurred for the connection.

One of these conditions exists:

• The Connection Request to this module has been rejected due to an

Ownership conflict with another Owner (for example, another Controller).

This may occur with modules such as output modules that only allow a

single Owner to configure and control its outputs.

This fault may also occur if the module is configured as Listen Only and

supports only one connection.

• If the Owner is connected to the module using a Unicast connection over

EtherNet/IP, other connections to the module fail since the Owner

controls the one connection.