Page 1

Studio 5000 Logix Emulate Getting Results Guide

Original Instructions

Page 2

Studio 5000 Logix Emulate Getting Results Guide

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and

for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 3

Table of Contents

Preface

Installation

Overview

Summary of changes .................................................................................. 7

Additional resources ................................................................................... 7

Legal Notices ................................................................................................ 8

Chapter 1

Install Studio 5000 Logix Emulate ........................................................... 11

Uninstall Studio 5000 Logix Emulate ...................................................... 12

Chapter 2

Overview of Studio 5000 Logix Emulate .................................................. 15

Differences between Logix5000 controllers and Studio 5000 Logix

Emulate controllers .................................................................................... 15

Special instructions for Studio 5000 Logix Emulate ............................... 17

Use Studio 5000 Logix Emulate in project development ........................ 17

Floating point calculations ........................................................................ 18

Get assistance when using Studio 5000 Logix EmulateError! Bookmark

not defined.

Start the Studio 5000 Logix

Emulate application

Configure the Studio 5000 Logix

Emulate application

Chapter 3

Start Studio 5000 Logix Emulate .............................................................. 19

Studio 5000 Logix Emulate ....................................................................... 19

Hide slots in the virtual chassis ............................................................... 20

Hide the computer name in the virtual chassis ...................................... 20

Change the update rate ............................................................................. 20

Keep Studio 5000 Logix Emulate on top .................................................. 21

Chapter 4

Configure Studio 5000 Logix Emulate .....................................................23

Create a Studio 5000 Logix Emulate controller ......................................23

Set the speed of time for a Studio 5000 Logix Emulate controller ....... 25

Create simulated I/O ................................................................................. 26

Create a 1789-SIM module in the virtual chassis .................................... 26

Create a 1756-Module in a Studio 5000 Logix Designer project ............ 27

Remove a module ...................................................................................... 28

Clear the configuration of the virtual chassis ......................................... 28

Configure trace windows.......................................................................... 29

Chapter 5

Change the mode of an

emulated controller

Rockwell Automation Publication LGEM5K-GR016L-EN-E 3

Change the mode of a Studio 5000 Logix Emulate controller ............... 31

Change a Studio 5000 Logix Emulate controller to Program mode ...... 31

Page 4

Table of Contents

Connect an emulated controller

to Studio 5000 Logix Designer

Change all Studio 5000 Logix Emulate controllers to Program mode ...32

Change a Studio 5000 Logix Emulate controller to Run mode ..............32

Change all Studio 5000 Logix Emulate controllers to Run mode ...........32

Change a Studio 5000 Logix Emulate controller to Remote mode ........ 33

Set the mode of a Studio 5000 Logix Emulate controller to Single Scan

...................................................................................................................... 33

Emulator Controller Status Indicators ..................................................... 34

Simulator Module Status Indicators ........................................................ 35

Chapter 6

Connect a Studio 5000 Logix Emulate controller to Studio 5000 Logix

Designer ..................................................................................................... 37

Create a communications driver for a Studio 5000 Logix Emulate

controller ..................................................................................................... 37

Configure a Studio 5000 Logix Designer project to use the Studio 5000

Logix Emulate controller .......................................................................... 38

Configure communications in a Studio 5000 Logix Designer project .. 39

Connect a Studio 5000 Logix Emulate controller from a remote

computer ..................................................................................................... 39

Connect an emulated controller

to a FactoryTalk View project

through RSLinx Enterprise

Connect an emulated controller

to a FactoryTalk View project

through OPC

Breakpoint and tracepoint

instructions

Chapter 7

Connect a Studio 5000 Logix Emulate controller to a FactoryTalk View

project through FactoryTalk Linx ............................................................. 41

Prerequisites .............................................................................................. 41

FactoryTalk Linx module in the virtual chassis ...................................... 42

Configure a FactoryTalk Linx server for Studio 5000 Logix Emulate ... 42

Tag Browser in FactoryTalk View ME or FactoryTalk View SE .............. 43

Chapter 8

Connect a Studio 5000 Logix Emulate controller to a FactoryTalk View

project through OPC .................................................................................. 45

Create an OPC topic for a Studio 5000 Logix Emulate controller ......... 45

Create a communications node in a FactoryTalk View project ............. 46

Configure a tag in a FactoryTalk View project ......................................... 47

Chapter 9

Program breakpoints and tracepoints .................................................... 49

Breakpoints ............................................................................................... 49

Example BPT instruction ................................................................... 50

Program a BPT instruction................................................................. 50

Breakpoint trace window .................................................................... 51

4 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 5

I/O simulation

Trace windows

Table of Contents

Tracepoints ................................................................................................. 51

Example TPT instruction .................................................................... 52

Program a TPT instruction ................................................................. 52

Tracepoint trace window ..................................................................... 53

String formats for a tracepoint or breakpoint instruction ..................... 53

Types for formatting tag values .......................................................... 54

Chapter 10

Simulate I/O ............................................................................................... 57

Configure a produced tag ......................................................................... 57

Make the producer an I/O module of the consumer .............................. 58

Create a consumed tag ............................................................................... 59

Chapter 11

Work with trace windows ......................................................................... 61

Open a trace window ................................................................................. 61

Open trace windows for new traces automatically .................................. 61

Close all trace windows ............................................................................. 62

Remove all traces ....................................................................................... 62

Log new traces to disk ............................................................................... 62

Log traces to a new log file ......................................................................... 63

Stop logging traces to a log file ................................................................ 64

Snapshots of Studio 5000 Logix

Emulate controller states

Index

Chapter 12

Work with snapshots of Studio 5000 Logix Emulate controller states . 65

Save a snapshot of the state of multiple Studio 5000 Logix Emulate

controllers ................................................................................................... 65

Restore the state of multiple Studio 5000 Logix Emulate controllers .. 66

Rockwell Automation Publication LGEM5K-GR016L-EN-E 5

Page 6

Page 7

Preface

The Studio 5000 Automation Engineering & Design Environment® combines

engineering and design elements into a common environment. The first

element is the Studio 5000 Logix Designer® application. The Logix Designer

application is the rebranding of RSLogix 5000® software and will continue to

be the product to program Logix 5000™ controllers for discrete, process,

batch, motion, safety, and drive-based solutions.

The Studio 5000® environment is the foundation for the future of

Rockwell Automation® engineering design tools and capabilities. The Studio

5000 environment is the one place for design engineers to develop all

elements of their control system.

Summary of changes

This manual includes new and updated information. Use these reference

tables to locate changed information.

Global changes

None for this release.

New or enhanced features

This table contains a list of topics changed in this version, the reason for the

change, and a link to the topic that contains the changed information.

Topic Name Reason

Connect a Studio 5000 Logix Emulate

controller from a remote computer on page 39

Removed steps in topic that identifies FactoryTalk Linx

Information Gateway to connect Studio 5000 Logix Emulate

from a remote computer.

Additional resources

This document contains additional information concerning related Rockwell

Automation products.

Resource Description

Product Certifications webpage, available at

http://ab.rockwellautomation.com

Provides declarations of conformity, certificates,

and other certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature. To order paper copies of

technical documentation, contact your local Rockwell Automation distributor

or sales representative.

Rockwell Automation Publication LGEM5K-GR016L-EN-E 7

Page 8

Preface

Legal Notices

Copyright notice

Copyright © 2020 Rockwell Automation Technologies, Inc. All Rights

Reserved. Printed in USA.

This document and any accompanying Rockwell Software products are

copyrighted by Rockwell Automation Technologies, Inc. Any reproduction

and/or distribution without prior written consent from Rockwell Automation

Technologies, Inc. is strictly prohibited. Please refer to the license agreement

for details.

End User License Agreement (EULA)

You can view the Rockwell Automation End-User License Agreement ("EULA")

by opening the License.rtf file located in your product's install folder on your

hard drive.

Other Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses. Copies of those licenses are

included with the software. Corresponding Source code for open source

packages included in this product are located at their respective web site(s).

Alternately, obtain complete Corresponding Source code by contacting

Rockwell Automation via the Contact form on the Rockwell Automation

website: http://www.rockwellautomation.com/global/about-

us/contact/contact.page

Please include "Open Source" as part of the request text.

A full list of all open source software used in this product and their

corresponding licenses can be found in the OPENSOURCE folder included

with these Release Notes. The default installed location of these licenses is

C:\Program Files (x86)\Common

Files\Rockwell\Help\<Product>\ReleaseNotes\OPENSOURCE\index.htm.

Trademark Notices

Allen-Bradley, Rockwell Automation, and Rockwell Software are trademarks

of Rockwell Automation, Inc.

Any Rockwell Automation software or hardware not mentioned here is also a

trademark, registered or otherwise, of Rockwell Automation, Inc.

8 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 9

Preface

Other Trademarks

All other trademarks are the property of their respective holders and are

hereby acknowledged.

Trademarks not belonging to Rockwell Automation are property of their

respective companies

Warranty

This product is warranted in accordance with the product license. The

product’s performance may be affected by system configuration, the

application being performed, operator control, maintenance, and other

related factors. Rockwell Automation is not responsible for these intervening

factors. The instructions in this document do not cover all the details or

variations in the equipment, procedure, or process described, nor do they

provide directions for meeting every possible contingency during installation,

operation, or maintenance. This product’s implementation may vary among

users.

This document is current as of the time of release of the product; however, the

accompanying software may have changed since the release. Rockwell

Automation, Inc. reserves the right to change any information contained in

this document or the software at any time without prior notice. It is your

responsibility to obtain the most current information available from Rockwell

when installing or using this product.

Contact Rockwell Automation

Customer Support Telephone — 1.888.382.1583

Online Support — http://www.rockwellautomation.com/support/

Rockwell Automation Publication LGEM5K-GR016L-EN-E 9

Page 10

Page 11

Installation

Chapter 1

Install Studio 5000 Logix Emulate

Installing Studio 5000® Logix Emulate™ installs FactoryTalk® Services

Platform, FactoryTalk Activation, and RSLinx® Classic, if those applications

are not yet installed. Any previous installation of RSLogix™ Emulate 5000 or

Studio 5000 Logix Emulate upgrades when you install Studio 5000 Logix

Emulate. Installing Studio 5000 Logix Emulate on a computer that has a

SoftLogix™ 5800 controller installed is not allowed.

Before you begin

Uninstall any SoftLogix 5800 controller.

To install Studio 5000 Logix Emulate:

1. Log onto the computer as an administrator or a user with

administrative privileges.

2. Insert the Studio 5000 Logix Emulate CD-ROM into the CD-ROM

drive o

does not, use Windows Explorer to navigate to the CD-ROM drive and

double-click the Setup.exe

installation s

3. Complete the following:

f the computer. The setup program starts automatically. If it

file. The Welcome to the Studio 5000

creen of the installation wizard opens.

Select Language. Select the language that the Studio 5000 Logix

Emulate application is to display.

Name. Type your name.

Company. Type the name of your company.

Installation location. Type or browse to the location to install Studio

5000 Logix Emulate. The default location is C:\Program Fifes

(x86)\Rockwell Software.

4. Click Next. The

the required configuration, and then the Options screen opens.

Tip:

5. Click Install. The Software License Agreements screen opens.

Rockwell Automation Publication LGEM5K-GR016L-EN-E 11

By default, both RSLinx Classic and Studio 5000 Logix Emulate are

selected for installation. To view the items installed with each application,

such as Online Help, and their required disk space, select the application

name on the left. The items installed with the application appear on the

right. You cannot change the applications or items to install.

System Re

quirements

screen displays the progress

of

Page 12

Chapter 1 Installation

6. To accept the license agreements for the applications you are

installing, click Accept all. To not accept the license agreements, click

Decline or click Back to open the Options screen. The Installation

Progress screen opens.

Prerequisites are installed and the progress for the installation of each

application appears. When the installation of the applications is

complete, the Summary screen opens.

7. Activate Studio 5000 Logix Emulate by completing the following:

Serial number. The serial number of the Studio 5000 Logix Emulate

application.

Product key. The product key for the Studio 5000 Logix Emulate

application.

8. (optional) To use FactoryTalk Activation Manager to activate the

installed applications:

a. Click Explore more options.

b. Click Open FactoryTalk Activation Manager.

Uninstall Studio 5000 Logix

Emulate

c. From the Manage Activations tab, click Get New Activations.

d. Select the activation method to use, and then follow the on-screen

instructions to obtain the activations.

e. After activating the software, click Restart now to restart the

computer to complete the installation.

9. Click Finish.

Tip:

On computers running Studio 5000 Logix Emulate, do not use Sleep mode

or Hibernate mode to avoid possible emulated controller watchdog faults

and project loss.

See also

Uninstall Studio 5000 Logix Emulate on page 12

Start Studio 5000 Logix Emulate on page 19

Rockwell Automation recommends removing all modules from the virtual

chassis before uninstalling Studio 5000 Logix Emulate. Do not remove the

RSLinx Classic or RSLinx Classic Lite modules.

To uninstall Studio 5000 Logix Emulate:

1. Log on to the computer as an administrator or as a user with

administrative privileges.

2. From the Studio 5000 Logix Emulate window, right-click each module

and then click Remove.

12 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 13

Chapter 1 Installation

3. From the Windows Control Panel, go to Programs and Uninstall a

program, right-click Studio 5000 Logix Emulate, and then click

Uninstall.

4. Click Yes.

5. If prompted to close applications before uninstalling, select one of the

following and then click OK:

Automatically close Applications and attempt to restart them after

setup is complete.

Do not close the applications. A reboot may be required.

6. If you select Automatically close Applications and attempt to restart

them after set up is complete, restart the applications that were listed.

If you choose Do not close the applications, reboot your computer.

The uninstall is complete.

See also

Install Studio 5000 Logix Emulate on page 11

Rockwell Automation Publication LGEM5K-GR016L-EN-E 13

Page 14

Page 15

Overview

Chapter 2

Overview of Studio 5000 Logix Emulate

Studio 5000 Logix Emulate is a software application that emulates the

behavior of Logix5000™ controllers. Studio 5000 Logix Emulate allows

experimentation with and the debugging of application code in a controlled

environment without investing in Logix5000 controllers and I/O modules.

Studio 5000 Logix Emulate allows for the testing of HMI applications without

using a physical controller.

Program and access the emulated controller from the computer where Studio

5000 Logix Emulate is installed, or remotely through FactoryTalk Linx

Gateway.

Studio 5000 Logix Emulate for Operator Training (OTS) activates with a

unique license managed by FactoryTalk Activation. Software activation is a

process that identifies that a legitimate copy of Studio 5000 Logix Emulate is

installed on the computer.

Studio 5000 Logix Emulate for Operator Training (OTS) is licensed on a per

controller basis. Order the appropriate catalog number for the number of

controllers (represented by xx) needed to connect to external applications. For

example:

9310-WEDOT

Sxx

Differences between

Logix5000 controllers and

Studio 5000 Logix Emulate

controllers

Studio 5000 Logix Emulate contains a virtual chassis that allows configuring

emulation modules. Emulation modules run as Windows services that

simulate the behavior of Logix5000 controllers and certain I/O modules.

Windows services are applications that run without interfaces of their own.

See also

Studio 5000 Logix Emulate on page 19

A Studio 5000 Logix Emulate controller simulates most of the behaviors of

Logix5000 controllers.

Do not depend on the Studio 5000 Logix Emulate controller to match the

performance and operation of a Logix5000 controller. Some instructions are

interpreted differently in an emulated controller than in a physical controller.

Execution times for instructions and program files are significantly different in

an emulated controller than in a physical controller.

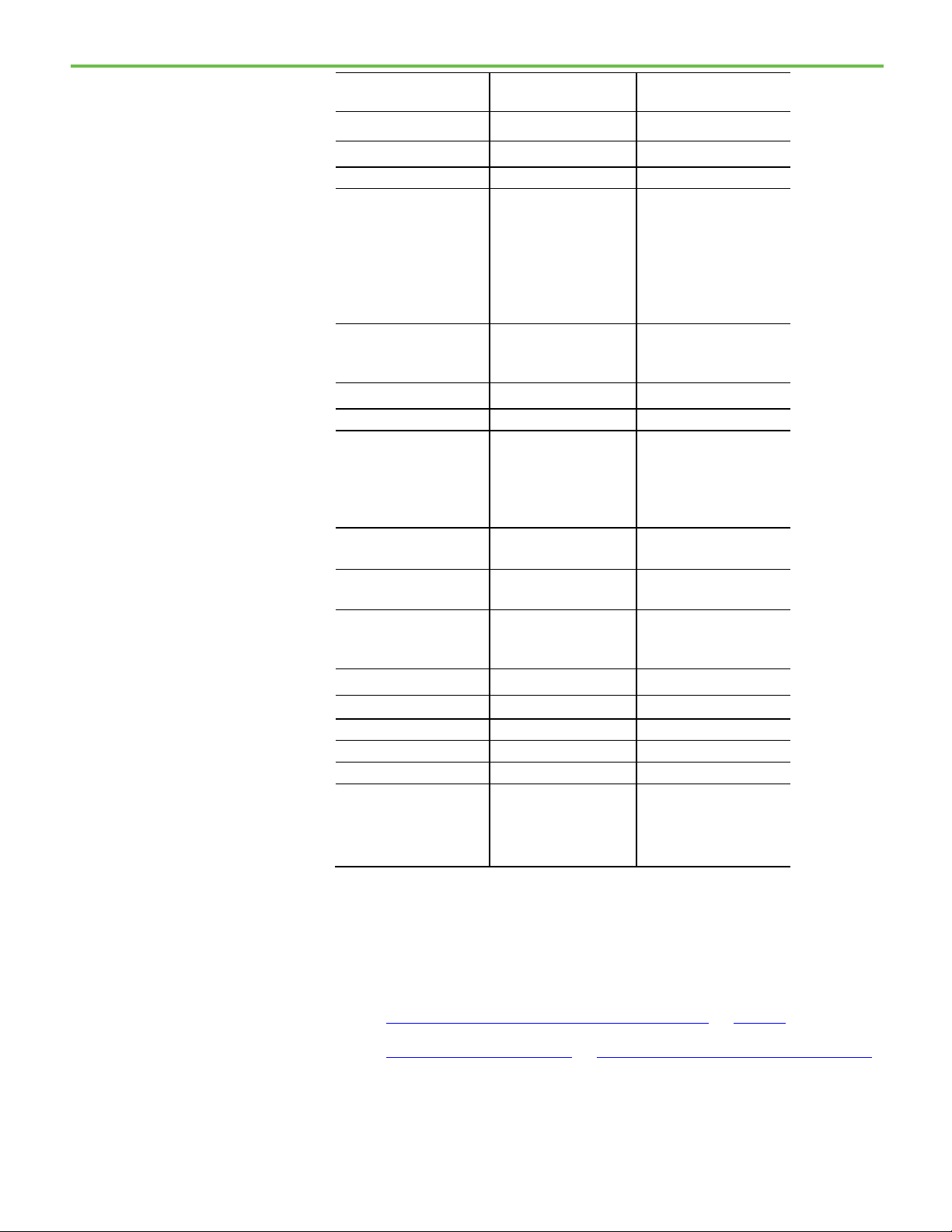

The differences between Logix5000 controllers and Studio 5000 Logix

Emulate controllers includes:

Rockwell Automation Publication LGEM5K-GR016L-EN-E 15

Page 16

Chapter 2 Overview

Studio 5000 Logix Emulate

Feature Logix5000 controller

controller

Breakpoints and tracepoints Not supported Supported1

Control real I/O Supported Not supported

Forcing Supported Supported

Interface to non-Rockwell

Software HMI software

Programming languages Ladder diagram, function

DDE/OPC (requires RSLinx

Classic Professional, RSLinx

Classic Single Node, RSLinx

Classic OEM, or FactoryTalk

Linx Gateway; RSLinx Classic

Lite does not support DDE or

OPC)

block, sequential function

chart, and structured text

DDE/OPC (requires RSLinx

Classic Professional, RSLinx

Classic Single Node, RSLinx

Classic OEM, or FactoryTalk

Linx Gateway; RSLinx Classic

Lite does not support DDE or

OPC)

Ladder diagram, function

block, sequential function

chart, and structured text

Messaging Supported Supported (local only)

Motion instructions Supported Supported (virtual axes only)

Jump to subroutines (JSR

instructions)

Supported Supported – however,

parameters are passed to the

subroutine in reverse order

(the last parameter is passed

first)

Jump to external routines

Supported

2

Not supported

(JXR instructions)

Communications through

Supported Supported

RS232 ports

Communications with

Supported Supported

FactoryTalk View ME and

FactoryTalk View SE

Time scaling Not supported Supported

Single Scan mode Not supported Supported

Network cards Yes Not supported

Task priority levels 16 3

Trending Yes Yes

Online editing of ladder,

Yes Yes

function block, sequential

function chart and structured

text programs

1.

Supported only in ladder diagram programming.

2.

Supported only in SoftLogix5800TM controllers.

3.

Supported only in version 13 and higher.

3

See also

Create a Studio 5000 Logix Emulate controller on page 23

Floating point calculations on page 18

16 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 17

Chapter 2 Overview

Special instructions for

Studio 5000 Logix Emulate

Use Studio 5000 Logix

Emulate in project

development

Studio 5000 Logix Emulate uses tracepoint (TPT) and breakpoint (BPT)

instructions that do not

These instructions are available on the Debug tab of the Studio 5000 Logix

Designer® instruction palette.

Tracepoint instructions can record data values to monitor how those values

change. Display these values in a window or log the values to disk.

Breakpoint instructions can stop ladder logic execution when a given set of

conditions are true. Trace back through the logic to determine why the

conditions became true.

appear in the normal Logix5000 instructi

on set.

See also

Example BPT instruction on page 50

Example TPT instruction on page 52

Studio 5000 Logix Emulate is used to validate logic, such as the logic behind

HMI systems, before it is put into Logix5000 controllers. This is a brief

outline of how to implement Studio 5000 Logix Emulate in the development

of a project for increased productivity.

To use Studio 5000 Logix Emulate in project development

1. In Studio 5000 Logix Designer®, create a new project using the Studio

5000 Logix Emulate controller type.

2. Configure the Studio 5000 Logix Designer project to match the

configuration of the virtual chassis. Create a Studio 5000 Logix

Emulate controller and simulated I/O to emulate the application.

3. Develop the logic for an application and configure it to run on the

emulated controller. Use symbolic tags for I/O points and alias them to

simulated

and consumed tags. Using tags in FactoryTalk View ME and

FactoryTalk View SE to simulate I/O is supported.

4. Download the program to the emulated controller and debug it using

the tools in Studio 5000 Logix Designer.

5. After verifying the program operation with the emulated controller,

save a copy of the project for reference.

6. In Studio 5000 Logix Designer, change the controller type of a project

to use the physical controller that runs the application. Reconfigure the

I/O for the project to use the modules for the application.

7. Re-alias the I

application.

I/O modules or other emul

/O points in the project to use the I/O modules for th

ated controllers using produced

e

Rockwell Automation Publication LGEM5K-GR016L-EN-E 17

Page 18

Chapter 2 Overview

8. Remove any tracepoint and breakpoint instructions used in the

project. These do not work in a physical controller.

9. Verify the project and correct any errors.

10. Download the project to the physical controller.

Floating point calculations

There are instruction differences across programming languages, and across

Logix platforms. These examples use the operation i = n / m where all the

operands are integers:

Ladder DIV instructions perform an integer divide operation and store

the immediate result in the destination. For n = 800 and m = 1000, i is

equal to 0.

The DIV function block instruction only does floating point operation.

If necessary, the function block instruction converts the inputs to reals

and then, if necessary, converts the result from a real to the

destination type. In this example, n is converted to 800 and m is

converted to 1000. The result of the operation is 0.8. That result then

gets converted to an integer where rounding rules apply and the final

destination value is 1. This difference between ladder and function

block instructions applies to all Logix platforms. Function block

instructions only perform floating point operations.

18 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 19

Chapter 3

Start the Studio 5000 Logix Emulate application

Start Studio 5000 Logix Emulate

Studio 5000 Logix Emulate

Start Studio 5000 Logix Emulate to create and configure emulated controllers

and simulated I/O modules. Emulated controllers and other modules reside

in the slots of the virtual chassis just as they would in a physical chassis.

To start Studio 5000 Logix Emulate

Click Start > All Programs > Rockwell Software > Studio 5000 Logix

Emulate. The Studio 5000 Logix Emulate window opens.

See also

Studio 5000 Logix Emulate on page 19

Configure Studio 5000 Logix Emulate on page 23

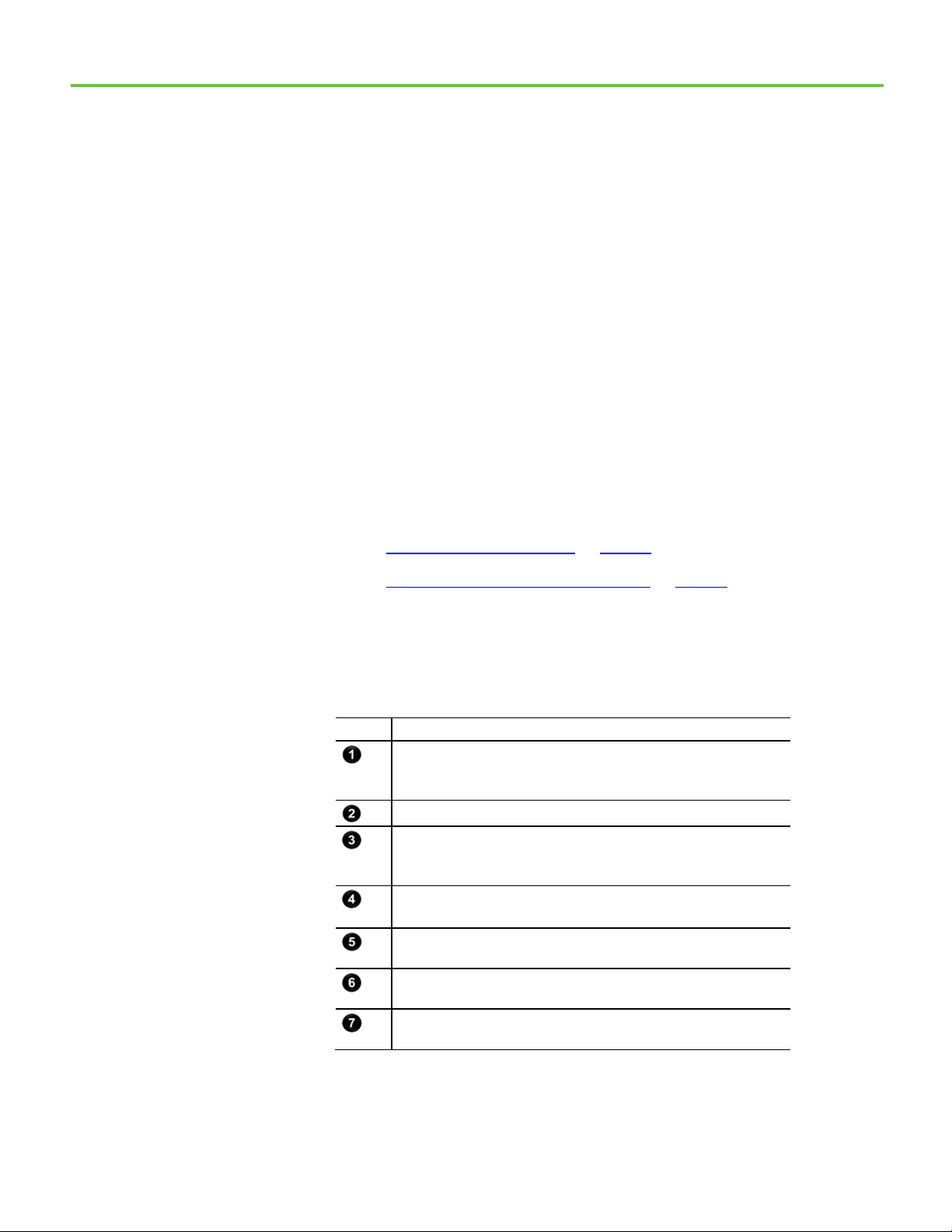

This is an example of Studio 5000 Logix Emulate with a standard emulated

controller, an Operator Training System enabled controller, and two 1789-SIM

I/O modules.

Item Description

The RSLinx Classic module represents a communication module for the chassis.

By default, the RSLinx Classic module resides in slot 0. Specify a different slot

position when configuring the Virtual Backplane driver in RSLinx Classic.

A Studio 5000 Logix Emulate controller.

An Emulate 5570 OTS controller. This OTS controller is activated in Studio 5000

Logix Emulate for Operator Training and enables a high speed interface for

connectivity to third party Operator Training Systems.

A 1789 simulated I/O module. Clicking the terminal cover of the module opens the

module.

A red box around a module indicates that the module is selected. Right-clicking a

module displays configuration options.

Slots that hold emulated controllers or 1789-SIM I/O modules. Clicking Slot >

Create Module creates a module.

Button that hides slots 9 through 16 to make the display of the virtual chassis

smaller.

Rockwell Automation Publication LGEM5K-GR016L-EN-E 19

Page 20

Chapter 3 Start the Studio 5000 Logix Emulate application

See also

Hide slots in the virtual chassis on page 20

Hide the computer name in the virtual chassis on page 20

Change the update rate on page 20

Keep Studio 5000 Logix Emulate on top on page 21

Hide slots in the virtual chassis

Hide the computer name in the virtual chassis

Hide slots 9-16 if those slots are not in use, or to make the virtual chassis take

up less screen space.

To hide slots in the virtual chassis:

Click View > Hide Slots 9-16. The slots are hidden in the virtual chassis.

See also

Hide the computer name in the virtual chassis on page 20

Hide the computer name to not display the name at the top of the Studio 5000

Logix Emulate window.

To hide the computer name in the virtual chassis

Click View > Compact. The Computer box at the top of Studio 5000

Logix Emulate is hidden.

See also

Hide slots in the virtual chassis on page 20

Change the update

Change the rate at which displayed modules update. The changed rate takes

effect immediately and affects all modules in the virtual chassis.

rate

To change the update rate

Click Options > Auto Refresh Rate.

Select the update rate:

Normal. Update the module display once every second.

High. Update the module display twice every second.

Low. Update the module display once every two seconds.

20 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 21

See also

Configure Studio 5000 Logix Emulate on page 23

Chapter 3 Start the Studio 5000 Logix Emulate application

Keep Studio 5000 Logix Emulate on top

Configure the Studio 5000 Logix Emulate window to have it appear on top of

any other windows that may be open on the computer.

To keep Studio 5000 Logix Emulate on top

Click Options > Always On Top.

See also

Hide slots in the virtual chassis on page 20

Hide the computer name in the virtual chassis on page 20

Rockwell Automation Publication LGEM5K-GR016L-EN-E 21

Page 22

Page 23

Configure the Studio 5000 Logix Emulate

application

Chapter 4

Configure Studio 5000 Logix Emulate

Create a Studio 5000 Logix Emulate controller

To configure Studio 5000 Logix Emulate, in the virtual chassis, create a

Studio 5000 Logix Emulate controller, set the speed of the Studio 5000 Logix

Emulate controller, create simulated I/O, and configure trace windows. You

can then change the mode of the Studio 5000 Logix Emulate controller.

See also

Create a Studio 5000 Logix Emulate controller on page 23

Set the speed of time for a Studio 5000 Logix Emulate controller on

page 25

Create a 1789-SIM module in the virtual chassis on page 26

Create a 1756-Module in a Studio 5000 Logix Designer project on page

27

A virtual chassis can have up to 16 emulated controllers at one time. The

performance of the computer may be affected if it runs multiple emulated

controllers simultaneously.

To create a Studio 5000 Logix Emulate controller

1. From the Studio 5000 Logix Emulate window, click Slot > Create

Module.

2. From the Module Type box, select Emulate 55x0 Controller. For

example, select Emulate 5570 Controller.

Tip:

3. In the Slot box, select or type the slot where the emulated controller is

to reside. This can be in any slot except the slot occupied by the RSLinx

Classic module.

Tip:

Rockwell Automation Publication LGEM5K-GR016L-EN-E 23

Other controller types such as Emulate 55x0 OTS and Emulate 55x0 SIM

may be available, depending on your license.

The RSLinx Classic module appears in Slot 0 by default. To place the Studio

5000 Logix Emulate controller in Slot 0, move the RSLinx Classic module to a

slot other than Slot 0.

When changing the project to use a physical Logix5000 controller, make sure

the rack and slot configurations in the project match those in the control

system. Otherwise, proper communication with the physical controller cannot

occur.

Page 24

Chapter 4 Configure the Studio 5000 Logix Emulate application

4. Click OK to accept the changes and add the emulated controller to the

virtual chassis. Click Cancel to not create the emulated controller.

Tip:

The only modules that function with the emulated controller are the Emulate

55x0 Controller, 1789-SIM 32 Point Input/Output Simulator, Emulate 55x0

OTS, and Emulate 55x0 SIM.

5. If an emulated controller is created in the same slot, and the

configuration for the module is not deleted when the controller is

removed, a prompt appears to use the previous configuration or reset

the configuration to default values:

To use the previous configuration, click Use the Configuration from

the Previous Controller.

To reset the configuration, click Reset the Configuration to Default

Values. If the configuration is reset to its default values, the name of

the emulated controller remains the same.

If there was a program in the deleted emulated controller, the

controller name and the date the program was last downloaded into

the controller appear. To load this program into the emulated

controller, select the Load Saved Controller Image from Previous

Instance check box.

Using a previously loaded controller image may result in unexpected operation.

Make sure the program is correct before running emulations.

6. On the General screen, complete:

Version. Select the version of Studio 5000 Logix Emulate used to

create the project to emulate.

Startup Mode. Select the startup mode for the controller. Select

either Remote Program or Last Controller State.

Memory Size. Specify the memory size for the emulated controller.

Make this property equal to the memory size of the controller you

are emulating.

Periodic Save Interval. Save the current controller information,

including program, data, and configuration information,

periodically. Type the frequency, in minutes. The default is 10

minutes.

Enable Periodic Save. Select this option to save the controller

information using the time range entered in the Periodic Save

Interval box.

7. Click Next. The System screen opens.

8. On the System screen, complete:

Continuous Task Dwell Time. Specify the time, in milliseconds,

between the end of the continuous task and the start of the next

execution of the continuous task. This is the time available for all

other Windows applications. The range is 0-100 milliseconds. The

default is 10 milliseconds.

24 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 25

Chapter 4 Configure the Studio 5000 Logix Emulate application

CPU Affinity. If the emulated controller is running on a computer

that has more than one CPU, set the CPU to run the emulated

controller. The emulated controller can run on one CPU only.

Channel 0 Serial Port. To emulate serial communications with a

Logix5000 controller, set the computer serial port to emulate

Channel 0 of the Logix5000 controller.

9. Click Finish. The emulated controller appears in the indicated slot of

the virtual chassis.

Tip:

Right-clicking a slot on in the virtual chassis and then clicking Create creates

an emulated controller or module in the slot. The slot number is entered

automatically.

See also

Set the speed of time for a Studio 5000 Logix Emulate controller on

page 25

Set the speed of time for a Studio 5000 Logix Emulate controller

Set the speed of time to slow down program execution in the emulated

controller. Slowing the speed of time slows down timers and adds additional

time to the program scan time. This allows for more time to observe program

execution as it occurs.

The speed of time is set as a percentage of real time. When the speed of time

is set to 100%, program execution occurs in real time. Setting the speed of

time to another value slows program execution by an amount proportional to

the selected percentage. For example, setting the speed of time to 60 percent

makes actions that normally take one second take approximately 1.67 seconds.

Changes to the speed of time take effect immediately.

To set the speed of time for a Studio 5000 Logix Emulate controller

1. Right-click the emulated controller and then click Configure

Emulation. The Configure Emulation window opens.

Tip:

2. Under the Speed of Time area at the top of the window, drag the slider

to adjust the speed of time in one percent increments or enter the

percentage manually in the available % box in the lower right corner of

the Speed of Time area.

The Configuration Emulation window cannot open for Operator Training

controllers.

Rockwell Automation Publication LGEM5K-GR016L-EN-E 25

Page 26

Chapter 4 Configure the Studio 5000 Logix Emulate application

4. Click Confirm Time % Change. The % box in the lower left corner of

the Speed of Time area indicates the last value set for the speed of

time.

Tips:

To set the speed of time to 100% without dragging the slider or entering

To set the speed of time to 0% without dragging the slider or entering a

See also

Create a Studio 5000 Logix Emulate controller on page 23

Create simulated I/O on page 26

a value, click 100% NOW.

value, click 0% NOW. Setting the speed of time to 0% stops program

execution.

Create simulated I/O

Create a 1789-SIM module in the virtual chassis

To create simulated I/O, create a 1789-SIM module in the virtual chassis, and a

1756-Module in the Studio 5000 Logix Designer project.

See also

Create a 1789-SIM module in the virtual chassis on page 26

Create a 1756-Module in a Studio 5000 Logix Designer project on page

27

Use a simulated I/O module (1789-SIM) to simulate discrete I/O with Studio

5000 Logix Emulate. This is the only form of I/O that Studio 5000 Logix

Emulate simulates. This module resides in the virtual chassis and provides

inputs and outputs to use in logic programs.

In Studio 5000 Logix Designer, the simulated I/O module is called

1756-Module.

In Studio 5000 Logix Emulate, the simulated I/O module is called 1789-

SIM.

To create a 1789-SIM module in the virtual chassis

1. In the virtual chassis, click Slot > Create Module.

2. In the Select Module window, from the Module Type list, select 1789-

SIM 32 Point Input/Output Simulator.

3. In the Slot box, select or type the slot number for the SIM module, and

then click OK. The Select Device window opens and displays the slot

number for the module.

26 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 27

Chapter 4 Configure the Studio 5000 Logix Emulate application

4. If a 1789-SIM module is deleted from this slot without clearing its

configuration, a message appears stating that previous configuration

information exists for the module. To retain the previous

configuration, click Use the Previous Configuration.

To reset the module to its default values, click Reset the Configuration

to Default Values.

5. Click Next. The General window opens.

6. In the Label for 1789-SIM Module Marquee box, type the name of the

SIM module so that the name scrolls across the face of the module.

This helps identify the module while it is in the virtual chassis. When

not entering a name, Studio 5000 Logix Emulate uses Simulator Module

by default.

Tip:

Another method for simulating I/O is to use another emulated controller to

produce and consume tags.

See also

Create a 1756-Module in a Studio 5000 Logix Designer project on page

27

Create a 1756-Module in a

Studio 5000 Logix Designer

project

Create a simulated module in the Studio 5000 Logix Designer project. The

simulated I/O module in Studio 5000 Logix Designer is called 1756-Module.

This module is called 1789-SIM in the virtual chassis.

To create a 1756-Module in a Studio 5000 Logix Designer project

1. In the Studio 5000 Logix Designer Controller Organizer, right-click

the I/O Configuration folder, and then click New Module.

2. In the Select Module Type dialog box, type 1756-Module in the Search

box.

3. From the Modules list, select 1756-Module, and then click Create.

4. In the New Module window, enter these parameters for the module:

Name. The name of the module.

Description (optional). The function of the module in the system.

Comm Format. The type of I/O in simulation.

Slot. The slot in the virtual chassis of the module.

5. In the New Module dialog box, specify the connection parameters for

the module:

Read/write connections: Listen only connections:

Input Assembly Instance 1 Input Assembly Instance 1

Input Size 2 Input Size 2

Output Assembly Instance 2 Output Assembly Instance 3

Output Size 1 Output Size 1

Configuration Assembly Instance 16 Configuration Assembly Instance 16

Configuration Size 0 Configuration Size 0

Rockwell Automation Publication LGEM5K-GR016L-EN-E 27

Page 28

Chapter 4 Configure the Studio 5000 Logix Emulate application

6. Click OK. Another Module Properties window opens.

7. Specify the Requested Packet Interval (RPI).

Tip:

Enter at least 50.0 ms for the RPI. The connection fails if the RPI is less than 50 ms. This

1756-Module uses the generic module profile with a default RPI of 5.0 milliseconds.

This value must change.

8. Click OK.

See also

Create a 1789-SIM module in the virtual chassis on page 26

Remove a module

Remove either an emulated controller or a 1789-SIM module from the virtual

chassis. Removal of a module cannot be undone. Recreate the module.

To remove a module

1. Open the virtual chassis.

2. Click Slot > Remove Module.

3. In the Remove Module dialog box, in the Slot field, select or type the

slot location for the module to remove and then click OK. A prompt

appears to confirm the removal of the module.

4. Click OK to remove the module from the virtual chassis.

Tips:

Right-clicking the module and clicking Remove also removes the module.

When removing an emulated controller, remove the emulated controller and

leave its configuration in place, or remove both the emulated controller and

its configuration. To remove the emulated controller and its configuration,

right-click the emulated controller, select Remove, select the Clear module

configuration check box, and then click OK.

See also

Hide slots in the virtual chassis on page 20

Clear the configuration of the virtual chassis on page 28

Clear the configuration of

Automatically clear the configuration of the virtual chassis upon deleting a

module. This resets the configuration of the virtual chassis to the default

the virtual chassis

settings. It also deletes the Saved Controller Image file and External Routine

DLLs.

To clear the configuration of the virtual chassis

From the virtual chassis, click Options > Clear Configuration on

Remove. The Clear module configuration check box is now

automatically selected when deleting a module.

28 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 29

See also

Studio 5000 Logix Emulate on page 19

Chapter 4 Configure the Studio 5000 Logix Emulate application

Configure trace windows

When tracepoint and breakpoint instructions execute, a trace window opens.

Tracepoint and breakpoint instructions are programmed in the Studio 5000

Logix Designer project. Configure how the traces are handled. The

Configuration Emulation window cannot open for Operator Training

controllers.

To configure trace windows

1. In the virtual chassis, right-click the emulated controller with the

configuration to display, and then click Configure Emulation. The

Configuration Emulation window opens.

2. Configure these settings:

Setting: Description:

Ignore If No Value

Changed

TimeStamp Determine how time is recorded in traces:

Display all new traces Display all new traces in a trace window automatically.

Log new traces to disk Automatically log new traces to disk.

Display All Traces Used to display all of the current traces in their trace

Close All Traces Close all of the open trace windows.

Remove All Traces Remove all of the current traces from the trace list.

Close Log File Stop logging traces to a file.

Trace Log File The currently set log file. Browse to set a different log file.

Toggle between recording every trace and only recording

traces where there are changes to the values. If traces

where no value is changed are ignored, the trace windows

do not show traces where the value is not changed.

None. Record no time information in the trace windows.

Delta. Record the difference between the current trace

and the last trace for that particular trace window. The

first trace for the window always shows 0 milliseconds.

Absolute. Records the time that the trace triggered. The

time is in the number of milliseconds since the emulated

controller was last changed to the Run mode.

Selecting a time stamp mode and changing the mode while

a trace window is open results in subsequent traces using

the new time stamp mode.

windows. The current traces are listed by name in the

Configure Emulation window.

See also

Work with trace windows on page 61

Rockwell Automation Publication LGEM5K-GR016L-EN-E 29

Page 30

Page 31

Chapter 5

Change the mode of an emulated controller

Change the mode of a Studio 5000 Logix Emulate controller

Change a Studio 5000 Logix

Emulate controller to

The Studio 5000 Logix Emulate controllers support the modes of Logix5000

controllers. If you have multiple Studio 5000 Logix Emulate controllers within

the virtual chassis, you can change the mode of all of the controllers in the

chassis simultaneously. Changing the mode of multiple controllers at one

time may be beneficial in depicting your application.

Tip:

With the exception of Single Scan mode, you can set the mode of the

emulated controller through either Studio 5000 Logix Emulate or Studio 5000

Logix Designer. To set the mode in Studio 5000 Logix Designer, click

Communications and select the mode.

See also

Change a Logix Emulate controller to Program mode on page 31

Change a Logix Emulate controller to Run mode on page 32

Change a Logix Emulate controller to Remote mode on page 33

Emulator Controller Status Indicators on page 34

Change a single Studio 5000 Logix Emulate controller in the virtual chassis to

Program mode. This mode allows the programing of the emulated controller.

Program mode

To change a Studio 5000 Logix Emulate controller to Program mode

In the virtual chassis, right-click the emulated controller and select

Program. The controller transitions to Program mode.

See also

Change all Studio 5000 Logix Emulate controllers to Program mode on

page 32

Change a Studio 5000 Logix Emulate controller to Run mode on page

32

Set the mode of a Studio 5000 Logix Emulate controller to Single Scan

on page 33

Emulator Controller Status Indicators on page 34

Rockwell Automation Publication LGEM5K-GR016L-EN-E 31

Page 32

Chapter 5 Change the mode of an emulated controller

Change all Studio 5000

Logix Emulate

Change all of the Studio 5000 Logix Emulate controllers in the virtual chassis

to Program mode. This mode allows programming of the emulated

controllers.

controllers to Program

mode

Change a Studio 5000 Logix Emulate controller to Run mode

To change all Studio 5000 Logix Emulate to Program mode

1. Click All Modules > Program. The Program Mode dialog box opens.

Tip:

2. Click OK. The specified emulated controllers transition to Program

mode.

By default, all slots that contain emulated controllers in the virtual chassis

appear selected. To not change all of the emulated controllers to Program mode,

clear the slots of the emulated controllers to not place in Program mode.

See also

Change all Studio 5000 Logix Emulate controllers to Run mode on

page 32

Emulator Controller Status Indicators on page 34

Change an individual Studio 5000 Logix Emulate controller or all emulated

controllers in the virtual chassis to Run mode in order to run the logic

program.

Change all Studio 5000

Logix Emulate controllers to

Run mode

To change a Studio 5000 Logix Emulate controller to Run mode

In the virtual chassis, right-click the emulated controller and select

Run. The controller transitions to Run mode.

See also

Change all Studio 5000 Logix Emulate controllers to Run mode on

page 32

Change a Studio 5000 Logix Emulate controller to Program mode on

page 31

Set the mode of a Studio 5000 Logix Emulate controller to Single Scan

on page 33

Emulator Controller Status Indicators on page 34

Change all Studio 5000 Logix Emulate controllers in the virtual chassis to Run

mode in order to run the logic programs.

32 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 33

Chapter 5 Change the mode of an emulated controller

To change all Studio 5000 Logix Emulate controllers to Run mode

1. Click All Modules > Run. The Run Mode dialog box opens.

Tip:

2. Click OK. The specified emulated controllers transition to Run mode.

By default, all slots that contain emulated controllers in the virtual chassis

appear selected. To not change all of the emulated controllers to Run mode,

clear the slots of the emulated controllers to not place in Run mode.

See also

Change a Studio 5000 Logix Emulate controller to Run mode on page

32

Change all controllers to Program mode on page 32

Emulator Controller Status Indicators on page 34

Change a Studio 5000 Logix Emulate controller to Remote mode

Change a Studio 5000 Logix Emulate controller to Remote mode so that a

software application, such as Studio 5000 Logix Designer, can change the

mode of the emulated controller.

To change a Studio 5000 Logix Emulate controller to Remote mode

In the virtual chassis, right-click the emulated controller and select

Remote. The controller transitions to Remote mode.

See also

Change a Studio 5000 Logix Emulate controller to Program mode on

page 31

Change a Studio 5000 Logix Emulate controller to Run mode on page

32

Connect to a Studio 5000 Logix Emulate controller from a remote

computer on page 39

Emulator Controller Status Indicators on page 34

Set the mode of a Studio

5000 Logix Emulate

controller to Single Scan

Rockwell Automation Publication LGEM5K-GR016L-EN-E 33

Set the mode of the Studio 5000 Logix Emulate controller to Single Scan

mode to run through the logic programs once to view the results. Single Scan

mode is not available in physical controllers. Set each emulated controller to

Single Scan mode individually.

Page 34

Chapter 5 Change the mode of an emulated controller

To set the mode of a Studio 5000 Logix Emulate controller to Single

Scan

Right-click the emulated controller in the virtual chassis and select

Single Scan.

Tip:

See also

Change a Studio 5000 Logix Emulate controller to Program mode on

page 31

Change a Studio 5000 Logix Emulate controller to Run mode on page

32

When the mode of the emulated controller is set to Single Scan and is

placed in Run mode and the single scan completes, a prompt appears to

either run the emulated controller continuously or perform a single scan

again.

Emulator Controller Status

Indicators

The controller has these indicators.

Module display status

Mode display

Key switch

Controller Status Indicators and Display

Indicator Status Description

RUN

I/O

FRC

RS232

(1)

Off The controller is in any mode but Run mode.

Solid green The controller is in Run mode.

Off Either:

There are no devices in the I/O configuration of the

controller.

The controller does not contain a project. The

controller memory is empty.

Solid green The controller is communicating with all the devices in

its I/O configuration.

Flashing green One or more devices in the I/O configuration of the

controller are not responding.

Flashing red A virtual chassis error was detected. Contact your

Rockwell Automation representative or local distributor

Off No tags contain I/O force values.

I/O forces are inactive (disabled).

Flashing amber At least one tag contains an I/O force value.

I/O force values are inactive (disabled).

Solid amber I/O forces are active (enabled).

I/O force values may or may not exist.

Off No COM port was selected.

Solid green The selected COM port was successfully assigned to

channel 0 of the controller.

34 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 35

Indicator Status Description

Solid red There is a COM port conflict or you selected an invalid

COM port number.

(1)

BAT

OK

1. Note that the behavior of these status indicators are unique to Emulate controllers.

Off Normal operation.

Flashing amber The controller is in Power-up mode.

Solid red Persistent storage for the controller has failed.

Solid red The controller detected a major fault.

Go online, and clear the fault.

If the OK status indicator remains solid red, contact your

Rockwell Automation representative or local distributor.

Solid green The controller is OK.

See also

Change a Studio 5000 Logix Emulate controller to Program mode on

page 31

Change all Studio 5000 Logix Emulate controllers to Program mode on

page 32

Chapter 5 Change the mode of an emulated controller

Simulator Module Status

Indicators

Change a Studio 5000 Logix Emulate controller to Run mode on page

32

Change all Studio 5000 Logix Emulate controllers to Run mode on

page 32

Change a Studio 5000 Logix Emulate controller to Remote mode on

page 33

The 1789-SIM module has these indicators.

Module display

Module status indicators

Simulator Module Status Indicators and Display

Customize the scrolling display when creating the module or by editing the

properties of the module. The display functions as a label and does not provide

status information.

Indicator Status Description

OK

I/O

Off The module is not operating normally.

Green The module is operating normally.

Off Either:

There are no devices in the I/O configuration of an

operating controller.

The controller does not contain a project. The

controller memory is empty.

Rockwell Automation Publication LGEM5K-GR016L-EN-E 35

Page 36

Chapter 5 Change the mode of an emulated controller

Indicator Status Description

See also

Change a Studio 5000 Logix Emulate controller to Program mode on

page 31

Change all Studio 5000 Logix Emulate controllers to Program mode on

page 32

Change a Studio 5000 Logix Emulate controller to Run mode on page

32

Blinking green The SIM module exists in the I/O configuration of an

operating controller. The SIM module is communicating,

but the controller is not in Run mode.

Solid green

The SIM module exists in the I/O configuration of an

operating controller. The SIM module is communicating

and the controller is in Run mode.

Change all Studio 5000 Logix Emulate controllers to Run mode on

page 32

Change a Studio 5000 Logix Emulate controller to Remote mode on

page 33

36 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 37

Chapter 6

Connect an emulated controller to Studio 5000

Logix Designer

Connect a Studio 5000 Logix Emulate controller to Studio 5000 Logix Designer

To connect the Studio 5000 Logix Emulate controller to Studio 5000 Logix

Designer, requires:

Creating a communications driver in either RSLinx Classic or RSLinx

Classic Lite and specifying a slot number for the emulated controller.

Setting the Studio 5000 Logix Designer project to use the emulated

controller.

Configuring communications in the Studio 5000 Logix Designer to use

the communications driver.

Adding the simulated I/O to the Studio 5000 Logix Designer project.

Programing breakpoint and tracepoint instructions.

Tip:

Connect to a Studio 5000 Logix Emulate controller from a remote

computer.

See also

Create a communications driver for a Studio 5000 Logix Emulate

controller on page 37

Configure a Studio 5000 Logix Designer project to use the Studio 5000

Logix Emulate controller on page 38

Configure communications in the Studio 5000 Logix Designer project

on page 39

Create simulated I/O on page 26

Program breakpoints and tracepoints on page 49

Create a communications

driver for a Studio 5000

Logix Emulate controller

Rockwell Automation Publication LGEM5K-GR016L-EN-E 37

Before communicating with a Studio 5000 Logix Emulate controller using

Studio 5000 Logix Designer, create a communication driver for the emulated

controller using RSLinx Classic. Other applications can then communicate

with the emulated controller.

Page 38

Chapter 6 Connect an emulated controller to Studio 5000 Logix Designer

To create a communications driver for a Studio 5000 Logix Emulate

controller

1. In RSLinx Classic, click Communications > Configure Drivers. The

Configure Drivers window appears.

2. From the Available Driver Types list, select the Virtual Backplane

(SoftLogix 58xx, USB) driver.

3. Click Add New. The Add New RSLinx Driver dialog box opens.

4. Accept the default name of the driver, or type a name up to 15

characters, and then click OK. The Configure Virtual Backplane

window opens.

5. In the Slot Number box, specify the slot number where the emulated

controller is to reside and click OK. The default slot number is slot 0.

6. When the new driver appears in the Configured Drivers list, click

Close.

See also

Configure a Studio 5000 Logix Designer project to use the Studio 5000 Logix Emulate controller

Configure communications in the Studio 5000 Logix Designer project

on page 39

Connect a Studio 5000 Logix Emulate controller from a remote

computer on page 39

Before emulating a project, configure the Studio 5000 Logix Designer project

to use the emulated controller.

To configure a Studio 5000 Logix Designer project to use the Studio

5000 Logix Emulate controller

1. In Studio 5000 Logix Designer, open the project to emulate.

2. Click Edit > Controller Properties. The Controller Properties window

opens.

3. On the General tab, set the Slot box to correspond with the slot in the

virtual chassis that contains the emulated controller.

4. Click Change Controller. The Change Controller Type dialog box

opens.

5. From the Type list, select Emulate 55x0 Controller.

6. In the Revision box, click the revision number for the emulated

controller, and then click OK.

38 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 39

See also

Create a communications driver for a Studio 5000 Logix Emulate

controller on page 37

Configure communications in the Studio 5000 Logix Designer project

on page 39

Chapter 6 Connect an emulated controller to Studio 5000 Logix Designer

Configure communications

in a Studio 5000 Logix

Designer project

Before downloading to or going online with the Studio 5000 Logix Emulate

controller, configure communications in the Studio 5000 Logix Designer

project to set the communication path to use the emulated controller.

To configure communications in the Studio 5000 Logix Designer

project

1. In Studio 5000 Logix Designer, open the project to emulate.

2. Click Communications > Who Active. The Who Active window

displays the available network nodes that use the communication

drivers configured in RSLinx Classic.

3. In the tree, click the emulated controller to use for this project.

4. Click Set Project Path.

See also

Create a communications driver for a Studio 5000 Logix Emulate

controller on page 37

Connect a Studio 5000 Logix Emulate controller from a remote computer

Connect a Studio 5000 Logix Emulate controller from a remote

computer on page 39

Remote computers can connect to a computer running Studio 5000 Logix

Emulate. This allows use of programs such as Studio 5000 Logix Designer and

FactoryTalk Batch from a computer other than the one running the Studio

5000 Logix Emulate controller. This allows uploading, downloading, and

editing online as if Studio 5000 Logix Designer is running locally.

To make this type of connection, use RSLinx Classic on the remote computers

to connect to the computer running Studio 5000 Logix Emulate.

To connect a Studio 5000 Logix Emulate controller from a remote

computer

Use RSLinx Classic on the remote computer to connect to the

computer running Studio 5000 Logix Emulate.

Rockwell Automation Publication LGEM5K-GR016L-EN-E 39

Page 40

Chapter 6 Connect an emulated controller to Studio 5000 Logix Designer

See also

Connect a Studio 5000 Logix Emulate controller to a FactoryTalk View

project through FactoryTalk Linx on page 41

Connect a Studio 5000 Logix Emulate controller to a FactoryTalk View

project through OPC on page 45

40 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 41

Chapter 7

Connect an emulated controller to a FactoryTalk

View project through RSLinx Enterprise

Connect a Studio 5000 Logix Emulate controller to a FactoryTalk View project through FactoryTalk Linx

Use either FactoryTalk® Linx™ or RSLinx Classic to connect the Studio 5000

Logix Emulate controller to FactoryTalk View ME or FactoryTalk View SE

projects. Both methods use OLE for Process Control (OPC) to communicate.

However, it is easier to use FactoryTalk Linx to create the necessary

connections.

Using FactoryTalk Linx to connect the Studio 5000 Logix Emulate controller

to a FactoryTalk View ME or FactoryTalk View SE project requires installing

FactoryTalk Linx on both the computer running the Studio 5000 Logix

Emulate controller and on the computer running FactoryTalk View ME or

FactoryTalk View SE.

FactoryTalk Linx uses FactoryTalk to automatically connect tags for Rockwell

Automation applications. Once FactoryTalk Linx is installed and configured, it

is not necessary to configure anything else to use tags from the Studio 5000

Logix Emulate controller in FactoryTalk View ME and FactoryTalk View SE

projects. Once a tag is used in Logix Emulate, the tag becomes available to

FactoryTalk View ME or FactoryTalk View SE.

For information about using RSLinx Classic to create those connections, see

the FactoryTalk View ME or FactoryTalk View SE documentation.

After configuring the FactoryTalk Linx server for a FactoryTalk View ME or

FactoryTalk View SE project, browse for tags from the Studio 5000 Logix

Emulate controller.

See also

Connect a Studio 5000 Logix Emulate controller to a FactoryTalk View

ME or FactoryTalk View SE project through OPC on page 45

Prerequisites

Rockwell Automation Publication LGEM5K-GR016L-EN-E 41

For FactoryTalk View SE projects, FactoryTalk Linx must be installed on both

the computer running FactoryTalk View SE and the computer running Studio

5000 Logix Emulate. Both computers must use the same FactoryTalk

Directory. If Studio 5000 Logix Emulate and FactoryTalk View SE are installed

on different computers, both computers must use the same network

Directory.

Page 42

Chapter 7 Connect an emulated controller to a FactoryTalk View project through RSLinx Enterprise

Tip:

Install FactoryTalk Linx and the FactoryTalk® Services Platform from the

FactoryTalk View ME or FactoryTalk View SE installation disks.

For FactoryTalk View ME projects, FactoryTalk Linx, Studio 5000 Logix

Emulate, and FactoryTalk View ME must be installed on the same computer.

In this case, the FactoryTalk Directory used must be the local Directory.

FactoryTalk View ME does not support using a network Directory.

FactoryTalk Linx module in the virtual chassis

Configure a FactoryTalk

Linx server for Studio 5000

This example depicts a FactoryTalk Linx module in the virtual chassis.

Item Description

The RSLinx Classic module represents a communication module for the chassis.

By default, the RSLinx Classic module resides in slot 0. Specify a different slot

position when configuring the Virtual Backplane driver in RSLinx Classic.

When Studio 5000 Logix Emulate runs on a computer that is also running

FactoryTalk Linx, a FactoryTalk Linx module occupies the first unoccupied slot in

the chassis. This module cannot be removed unless FactoryTalk Linx is

uninstalled. Specify a different slot position by editing the Virtual Backplane

properties in FactoryTalk Administration Console.

See also

Configure a FactoryTalk Linx server for Studio 5000 Logix Emulate on page 42

Create a FactoryTalk Linx server for Studio 5000 Logix Emulate to connect

the emulated controller to a FactoryTalk View ME or FactoryTalk View SE

project through FactoryTalk Linx.

Logix Emulate

To configure a FactoryTalk Linx server for Studio 5000 Logix

Emulate

1. Make sure the Studio 5000 Logix Emulate controller is in Run mode.

2. Open the FactoryTalk View SE or FactoryTalk View ME project.

3. In the FactoryTalk View Explorer tree, right-click the area to create

the FactoryTalk Linx data server in the project, and then click Add New

Server > Rockwell Automation Device Server (FactoryTalk Linx).

Tip:

4. Type a name for the FactoryTalk Linx server in the Name box, or type a

description for the server in the Description box.

5. In the Computer hosting the FactoryTalk Linx server box, type the

name of the computer running Studio 5000 Logix Emulate. If this

computer is the same as the computer that is running FactoryTalk

View ME and FactoryTalk View SE, type the name of that computer or

type localhost.

The server can exist in the root of the FactoryTalk View ME or FactoryTalk

View SE project.

42 Rockwell Automation Publication LGEM5K-GR016L-EN-E

Page 43

Chapter 7 Connect an emulated controller to a FactoryTalk View project through RSLinx Enterprise

Tip:

For FactoryTalk View ME systems, localhost is the only possible name for

the computer that is hosting the FactoryTalk Linx server.

6. In the Explorer tree of the FactoryTalk View ME or FactoryTalk View

SE project, select the FactoryTalk Linx server and click

Communication Setup. The Communication Setup window opens.

7. Create a device shortcut to the emulated controller to identify which

tags are coming from the emulator in the FactoryTalk View ME and

FactoryTalk View SE Tag Browser.

8. Click Add, and then type a name for the shortcut to appear in the

FactoryTalk View ME or FactoryTalk View SE Tag Browser.

9. Click Apply.

10. When prompted to apply changes, click Yes. The shortcut is associated

with the emulator.

11. Click OK to close the Communication Setup window.

See also

FactoryTalk Linx module in the virtual chassis on page 42

Tag Browser in FactoryTalk View ME or FactoryTalk View SE

Tag Browser in FactoryTalk View ME or FactoryTalk View SE on page

43

This is an example of the Tag Browser in FactoryTalk View ME or FactoryTalk

View SE from which to browse for tags from the FactoryTalk Linx server. For

more information about browsing for tags in a FactoryTalk View project, see

the documentation for FactoryTalk View ME or FactoryTalk View SE.

The shortcut in the FactoryTalk Linx server Communication Setup

window has a corresponding folder at the root level of the FactoryTalk

View ME or FactoryTalk View SE Tag Browser.

The Online folder contains controller tags.

Folders for each program file contain program tags.

See also

Configure a tag in a FactoryTalk View project on page 47

Rockwell Automation Publication LGEM5K-GR016L-EN-E 43

Page 44

Page 45

Chapter 8

Connect an emulated controller to a FactoryTalk

View project through OPC

Connect a Studio 5000 Logix Emulate controller to a FactoryTalk View project through OPC

Create an OPC topic for a Studio 5000 Logix Emulate controller

Studio 5000 Logix Emulate uses OLE for Process Control (OPC) to

communicate with FactoryTalk View ME and FactoryTalk View SE.

Connecting the Studio 5000 Logix Emulate controller to a FactoryTalk View

project requires creating an OPC topic in RSLinx Classic and creating a

communications node and tags in the FactoryTalk View ME or FactoryTalk

View ME project that uses the OPC topic.

See the FactoryTalk View ME and FactoryTalk View SE documentation for

more information.

See also

Connect a Studio 5000 Logix Emulate controller to a FactoryTalk View

project through FactoryTalk Linx on page 41

Use RSLinx Classic Single Node, RSLinx Classic OEM, or FactoryTalk Linx

Gateway to create the OPC topic. RSLinx Classic Lite does not support OPC

communication. For more information about using RSLinx Classic, see the

RSLinx Classic documentation.

To create an OPC topic for a Studio 5000 Logix Emulate controller

1. Open Studio 5000 Logix Emulate and verify that the emulated

controller is running.

2. In RSLinx Classic, click Communications > RSWho to open the

RSWho window.

Tip:

3. In the RSWho window, right-click the Studio 5000 Logix Emulate

controller and select Configure New DDE/OPC Topic. The DDE/OPC

Topic Configuration window opens with the new topic.

4. Click Done to close the DDE/OPC Topic Configuration window and

save the topic.

Rockwell Automation Publication LGEM5K-GR016L-EN-E 45

The Studio 5000 Logix Emulate controller should be visible in the RSWho

window. If it is not, make sure there is a communication driver for the

emulated controller.

Page 46

Chapter 8 Connect an emulated controller to a FactoryTalk View project through OPC

See also

Create a communications driver for a Studio 5000 Logix Emulate

controller on page 37

Create a communications

node in a FactoryTalk View

project

Create a communications node in a FactoryTalk View ME or FactoryTalk View