Page 1

SP200 AC Drive

Quick Start Guide

Commande SP200 AC

Guide de mise en route Quick Start

Frequenzumrichter SP200

Kurzanleitung

Inverter SP200

Guida di avviamento rapido

Inversor CA SP200

Guia de Inicialização Rápida

Guía rápida del variador de

velocidad para motores de

corriente alterna SP200

Manuel d’utilisation

Bedienerhandbuch

Manuale delle instruzioni

Manual de Instruções

Manual de instrucciones

Instruction Manual

D2-3418-1

Page 2

The information in this manual is subject to change without notice.

Throughout this manual, the following notes are used to alert you to safety

considerations:

ATTENTION: Identifies information about practices or circumstances

that can lead to personal injury or death, property damage, or

economic loss.

!

Important:Identifies information that is critical for successful application and

understanding of the product.

ATTENTION: Only qualified personnel familiar with the construction

and operation of this equipment and the hazards involved should

install, adjust, operate, and/or service this equipment. Read and

!

understand this document in its entirety before proceeding. Fail ure to

observe this precaution could result in severe bodily injury or loss of

life.

ATTENTION: After disconnecting input power, wait three minutes to

insure that DC bus capacitors are discharged. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION: The user is responsible for conforming with all

applicable local and national codes. Failure to observe this precaution

could result in severe bodily injury or loss of life.

ATTENTION: Checking the direction of motor rotation requires

rotating parts and/or electrical circuits to be exposed. Stay clear if the

motor must be running. Disconnect, lockout, and tag the power source

if contact must be made. Failure to observe this precaution could result

in severe bodily injury or loss of life.

SP200 and Reliance are trademarks of Rockwell Automation.

©1998 Rockwell International Corporation

Page 3

L’information contenue dans le présent manuel est susceptible d’être modifiée sans

préavis.

Tout au long du manuel, les remarques suivantes sont utilisées pour attirer l’attention

de l’utilisateur sur un problème de sécurité :

ATTENTION : Ceci identifie des renseignements concernant des

usages ou des situations pouvant provoquer des dommages corporels

ou entraîner la mort, causer des dégâts matériels ou une perte d’ordre

!

économique.

Important : Ceci identifie des renseignements critiques à la réussite de l’application et

de la compréhension du produit.

ATTENTION : Seul du personnel qualifié et familiarisé avec la

fabrication et le fonctionnement de ce matériel et les risques qu’il

comporte doit procéder à l’’installation, au réglage, au fonctionnement

!

et/ou à l’entretien de ce matériel. Il est impératif de lire et de bien

assimiler ce document dans son intégralité avant de procéder à une

opération quelconque. Tout défaut d’observation de ces précautions

peut entraîner de graves dommages corporels ou même la mor t.

ATTENTION : Après coupure de l’alimentation électrique, attendre 3 minutes pour s’assurer que les condensateurs du bus

d’alimentation en courant continu se sont déchargés. Tout défaut

d’observation de ces précautions peut entraîner de grav es dommages

corporels ou même la mort .

ATTENTION : L’utilisateur est responsable du respect des normes

locales et/ou nationales en vigueur. Tout défaut d’observation de ces

précautions peut entraîner de graves dommages corporels ou même

la mort.

ATTENTION : La vérification du sens de rotation du moteur exige

d’exposer les parties tournantes et/ou les circuits électriques. Rester

à l’écart si le moteur doit tourner. Couper la source d’alimentation,

l’isoler et l’étiqueter s’il faut établir un contact. Tout défaut d’observation

de ces précautions peut entraîner de graves dommages corporels ou

même la mort.

SP200 et Reliance sont des marques de commerce de Rockwell Automation.

Page 4

Die in diesem Handbuch enthaltenen Angaben können ohne vorherige Ankündigung

geändert werden.

In diesem Handbuch werden die folgenden Hinweise verwendet, um auf Sicherheitsaspekte aufmerksam zu machen.

ACHTUNG: Kennzeichnet Angaben zu Arbeitsweisen und Umständen, die zu V erletzungen oder gar zum Tode, sowie zu Sachschäden

oder wirtschaftlichen Verlusten führen können.

!

Wichtig:Kennzeichnet Angaben, die für den erfolgreichen Betrieb und das Verstehen

des Produkts notwendig sind.

ACHTUNG: Die Montage und die Einstellungen sowie der Betrieb

und/oder die Wartung dieser Anlage sollen ausschließlich durch

qualifiziertes Personal, das mit der Bauweise und dem Betrieb dieser

!

Anlage und den damit verbundenen Gefahren vertraut ist, erfolgen.

Vor weiteren Schritten ist darauf zu achten, daß das Bedienerhandbuch vollständig gelesen und verstanden worden ist. Die Nichteinhaltung dieser Sicherheitsmaßnahme kann schwere oder tödliche

Körperverletzungen zur Folge haben.

ACHTUNG: Nach Abschaltung der Stromzufuhr 3 Minuten warten,

um die Entladung der Gleichstrom-Buskondensatoren

sicherzustellen. Die Nichteinhaltung dieser Sicherheitsmaßnahme

kann schwere oder tödliche Körperverletzungen zur Folge haben.

ACHTUNG: Der Bediener trägt die Verantwortung dafür, daß alle

geltenden örtlichen und nationalen Vorschriften eingehalten werden.

Die Nichteinhaltung dieser Sicherheitsmaßnahme kann schwere oder

tödliche Körperverletzungen zur Folge haben.

ACHTUNG: Zur Überprüfung der Laufrichtung des Motors müssen

die Drehteile und/oder die Schaltkreise freigelegt werden. Solange

der Motor läuft, ist Abstand zu halten. Wenn die Berührung der Anlage

notwendig ist, vorher Stromzufuhr trennen, sperren und die Stromquelle kennzeichnen. Die Nichteinhaltung dieser Sicherheitsmaßnahme kann schwere oder tödliche Körperverletzungen zur Folge

haben.

SP200 und Reliance sind Warenzeichen Rockwell Automation.

Page 5

Le informazioni contenute in questo manuale possono cambiare senza preavviso.

In tutto il manuale si trovano le seguenti note di avvertimento per la sicurezza

dell’operatore:

ATTENZIONE: identif ica informazioni su modi di operare o

circostanze che possono causare infortuni personali o la morte,

danni a beni di proprietà o perdita economica.

!

Importante: identifica informazioni cruciali per la comprensione e l’uso appropriato del

prodotto.

ATTENZIONE: l’installazione, la regolazione, l’operazione e/o la

manutenzione di questo dispositivo devono essere eseguite solamente da personale qualificato a conoscenza della struttura e del

!

funzionamento del prodotto e dei relativi pericoli. Prima di procedere,

leggere e capire per intero questo manuale. L ’inosservanza di questa

precauzione può causare gravi infortuni personali o la morte.

ATTENZIONE: dopo aver scollegato la potenza di ingresso, attendere 3 minuti affinché i condensatori C.C. del bus si scarichino.

L’inosservanza di questa precauzione può causare gravi infortuni

personali o la morte.

ATTENZIONE: è responsabilità dell’utente conformarsi ad ogni

norma locale e nazionale dispositiva in materia. L’inosservanza di

questa precauzione può causare gravi infortuni personali o la morte.

ATTENZIONE: per il controllo della direzione della rotazione del

motore le parti rotanti del motore e/o i circuiti elettrici devono essere esposti. Mantenere le distanze se il motore deve stare in moto.

Scollegare, bloccare ed etichettare la sorgente di alimentazione se è

necessario stabilire il contatto. L’inosservanza di questa precauzione

può causare gravi infortuni personali o la morte.

SP200 e Reliance sono marchi di Rockwell Automation.

Page 6

As informações contidas neste manual estão sujeitas a mudanças sem aviso prévio.

Através deste manual, as seguintes notas são usadas para alertar sobre as

considerações de segurança:

ATENÇÃO: Identifica informações sobre práticas ou circunstâncias

que podem resultar em morte ou ferimentos pessoais, dano de

propriedade ou perda financeira.

!

Importante: Identifica a informação que é essencial para a aplicação bem-sucedida e

o entendimento do produto.

ATENÇÃO: Somente pessoal qualificado e familiarizado com a

construção e operação destes equipamentos e os perigos envolvidos

deve instalar, ajustar, operar e/ou reparar este equipamento. Leia e

!

entenda todo este documento antes de continuar. Se esta precaução

não for observada pode resultar em lesão corporal grave ou morte.

AT ENÇÃO: Após desconectar a força de entrada, aguarde 3 minutos

para garantir que os capacitores de barramento CC estejam

descarregados. Se esta precaução não for observada pode resultar

em lesão corporal grave ou morte.

ATENÇÃO: O usuário é responsável pela conformidade com todos

os regulamentos locais e nacionais aplicáveis. Se esta precaução não

for observada pode resultar em lesão corporal grave ou morte.

AT ENÇÃO: A verificação da direção da rotação do motor requer a

exposição das peças em rotação e/ou circuitos elétricos. Não fique

perto do motor se ele estiver funcionando. Desconecte, bloqueie e

identifique a fonte de energia se for preciso tocar no motor. Se esta

precaução não for observada pode resultar em lesão corporal grave

ou morte.

La información incluida en esta manual está sujeta a cambios sin previo aviso.

Page 7

Las siguientes notas se utilizan a través del manual para llamar su atención hacia

ciertos aspectos relacionados con su seguridad:

ATENCIÓN: Indica información referente a prácticas o circunstancias

que pueden ocasionar lesiones personales o la muerte, daños a la

propiedad o pérdidas económicas.

!

Importante: Indica información esencial para el uso correcto del producto y la

comprensión adecuada del mismo.

1

ATENCIÓN: Únicamente el personal familiarizado con la estructura

y funcionamiento de este equipo –así como con los riesgos implícitos–

deberá instalar, ajustar, operar y/o dar servicio a este equipo. Lea y

!

entienda este documento en su totalidad antes de proseguir con el

uso del producto. De no observarse esta precaución, pueden sufrirse

lesiones corporales graves o la muerte.

AT ENCIÓN: Después de desconectar la corriente de entrada, espere

3 minutos para asegurarse de que los condensadores del de corriente

continua (CC) no estén cargados. De no observarse esta precaución,

pueden sufrirse lesiones corporales graves o la muerte.

AT ENCI ÓN: El usuario es responsable de cumplir con todos los

códigos locales y nacionales aplicables. De no observarse esta

precaución, pueden sufrirse lesiones corporales graves o la muerte.

AT ENCI ÓN: Para poder verificar la dirección de rotación del motor

es necesario descubrir partes giratorias y/o circuitos eléctricos. Apártese en caso de que el motor deba estar en marcha. Desconecte,

apague y señale con una etiqueta la fuente de energía, en caso de

que deba hacerse contacto. De no observarse esta precaución, pueden sufrirse lesiones corporales graves o la muerte.

SP200 y Reliance son marcas comerciales de Rockwell Automation.

Page 8

Page 9

i

está diseñada para proporcionarle información básica acerca del variador de

following page, a manual in the requested language will be sent to you when it is available.

Le guide de mise en route SP200 Quick Start est conçu pour fournir l'information de base

concernant le variateur de vitesse SP200. Il est prévu à l'usage des personnes possédant de

l'expérience en matière d'installation et de fonctionnement de tels produits.

Le manuel d'utilisation du var iate ur SP2 00 (D 2-340 8) four nit d es rens eignements détaillés au

sujet de l'installation, du câblage, de la programmation et du dépannage du variateur. Le

manuel d'utili sat i on D2 - 34 08 n 'e s t act ue ll e me nt d isp on i ble q u'e n an g l ais. Toutefois, si vous

indiquez la langue de votre choix sur le formulaire de la page suivante, un manuel vous sera

expédié dans la langue demandée dès lors qu'il sera disponible.

Die Kurzanleitung SP200 enthält die wesentlichsten Angaben für den Frequenzumrichter SP200

und richtet sich an Bediener, die bereits Erfahrung mit der Montage und dem Betrieb von Antrieben

aufweisen.

Das Bedienerhandbuch Frequenzumrichter SP200 (D2-3408) liefert detaillierte Angaben zu

Montage, Verdrahtung, Programmierung und Fehlersuche. Das Bedienerhandbuch D2-3408 liegt

gegenwärtig nur auf Englisch vor. Sollten Sie dieses jedoch in einer der auf der nächsten Seite

angeführten Sprachen benötigen, so kreuzen Sie bitte die entsprechende Sprache an, und Sie

erhalten das Handbuch in der gewünschten Sprache, sobald es verfügbar ist.

La guida di avviamento rapido dell’SP200 ha lo scopo di fornire informazioni di base sull’inverter

SP200. La guida si rivolge ad utenti esperti nell’installazione e nell’uso degli inverter.

Il Manuale delle istruzioni sull’inverter SP200 (D2-3408) fornisce informazioni dettagliate

sull’installazione, i collegamenti elettrici e la diagnostica dell’inverter. Al momento il manuale delle

istruzioni è disponibile solo in Inglese. Tuttavia, se sul modulo a pagina seguente ci indicherete la

vostra lingua preferita, una copia del manuale in detta lingua vi verrà spedito quando sarà

disponibile.

O SP200 Quick Start é projetado para fornecer informações bá si c as s o br e o Inversor CA SP200. É

projetado para os usuários experientes na instalação e operação de inversores.

O manual de instrução do Inversor CA SP200 (D2-3408) fornece informações detalhadas com

relação à instalação, fiação, programação e solução de problemas do inversor. Atualmente, o

manual de instrução D2-3408 só está disponível em inglês. Contudo, se você indicar a sua opção

de idiomas no formulário da página seguinte, lhe enviaremos um manual no idioma solicitado,

quando estiver disponível.

La

velocidad para motores de corriente alterna SP200. La guía está orientada a los usuarios con

experiencia en la instalación y funcionamiento de reguladores de velocidad variable.

El manual de instrucciones (D2-3408) del variador de velocidad para motores de corriente alterna

SP200 ofrece información detallada acerca de la instalació n, cableado, programación,

identificación y solución de fallos del variador. Actualmente, el manual de instrucciones D2-3408 se

encuentra disponible sólo en inglés. Sin embargo, si usted indica el idioma de su preferencia en el

formulario que aparece en la siguiente página, se le enviará un manual en el idioma solicitado tan

pronto como esté disponible.

The SP200 Quick Start is intended to provide basic information about the SP200 AC Drive. It is

Guía rápida SP200

intended for users experienced in installing and operating drives.

The SP200 AC Drive instruction manual (D2-3408) provides detailed information regarding drive

installation, wiring, programming, and troubleshooting. Instruction manual D2-3408 is currently

available in English only. Howev er, if you indicate your choice of languages on the form on the

Page 10

ii

Demande de Manuel d’utilisation D2-3408 pour le variateur de vitesse SP200

Vormerkung für Bedienerhandbuch D2-3408 für den Wech selstromantrieb SP200

Solicitud de manual de instrucciones D2-3408 del variador de velocidad para motores de corriente alterna SP200

Copy this form. Complete the mailing information below. Mail or f ax the completed f orm to:

Photocopier ce formulaire et remplir la partie ci-dessous concernant le destinataire. Envoyer par la poste ou télécopier le formulaire rempli à:

Kopieren Sie bitte dieses Formular und geben Sie Ihre genaue Anschrift an. Senden Sie das Formular per Post oder Fax an:

Copiare questo modulo. Compilarlo. Spedirlo per posta o fax a:

Copie este formulário. Preencha a informação para correspondência abaixo. Envie o for mulár io preenchido por correio ou fax.

Copie este formulario. Llene la información postal que aparece en la parte inferior. Envíe el formulario por correo o fax a:

Request for SP200 AC Drive Instruction Manual D2-3408

Richiesta del manuale D2-3408 con le istruzioni sull’inverter SP200

Solicitação para o Manual D2-3408 de Instrução do SP200 AC

Reliance Electric Company

RGA - Attn: Annie Brown

25001 Tungsten Road

Cleveland, OH 44117

USA

Fax: 216.266.7120

Name/Nom/Nome/Nombre

Company/Enterprise/Firma/Società/Empresa/Compañía

Street Address/Adresse (Rue)/Straße/Indirizzo/Endereço/Dirección

City/State/Ville/Stadt/Città/Cidade/Ciudad Zip/Code Postal/Postleitzahl

Codice Postale/Zona Postal/Zona

Country/Pays/Land/Nazione/País

❒ English

❒ França is

❒ Deutsch

❒ Italiano

❒ Português

❒ Español

Page 11

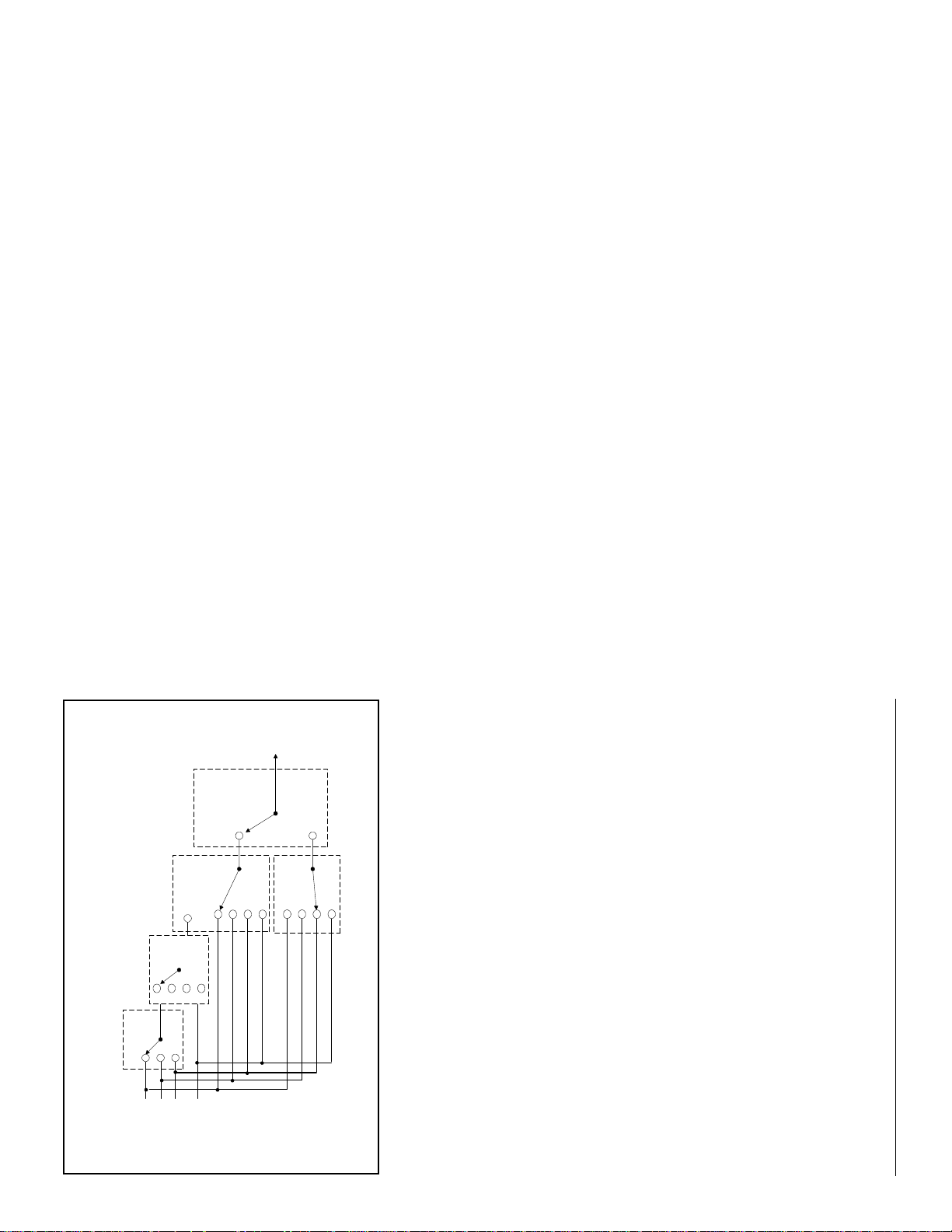

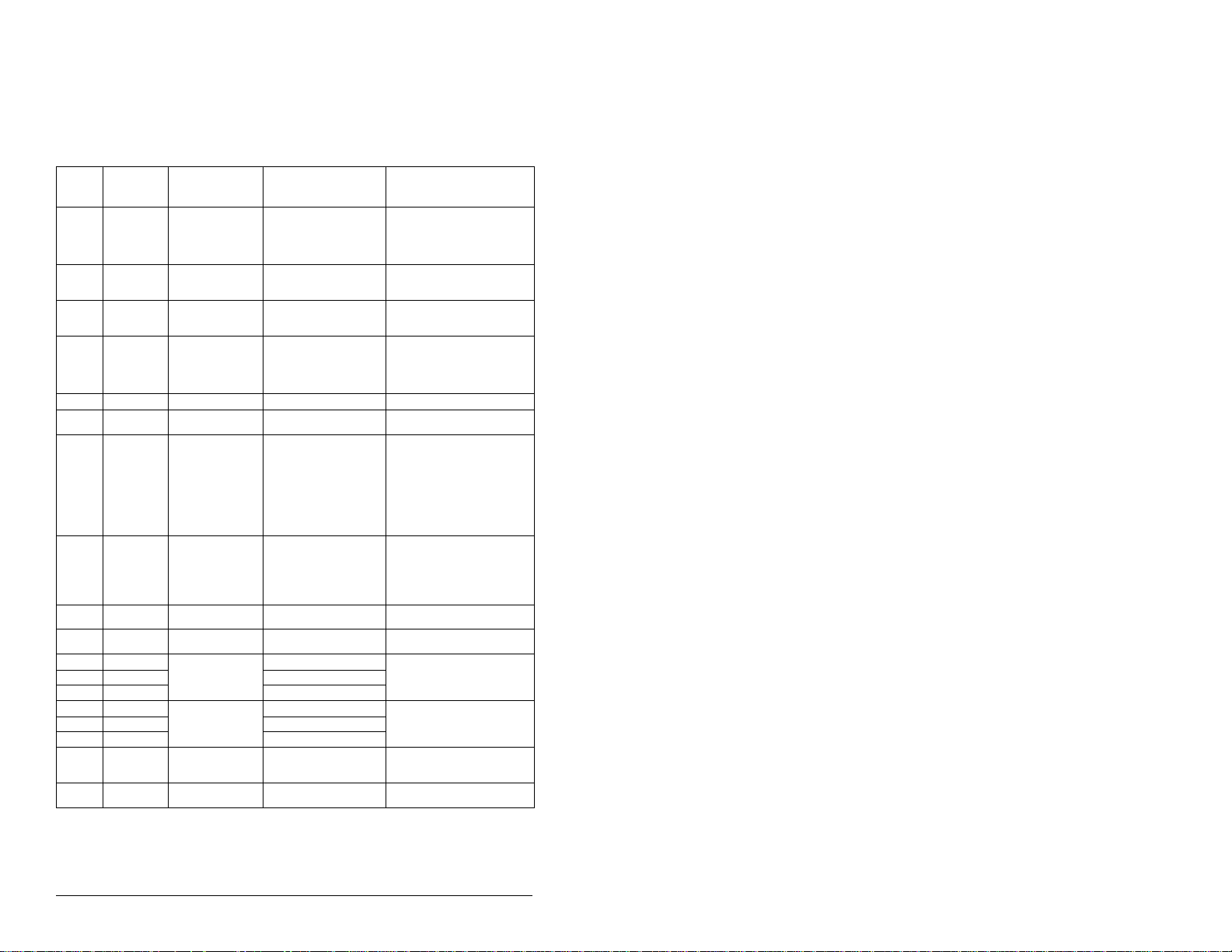

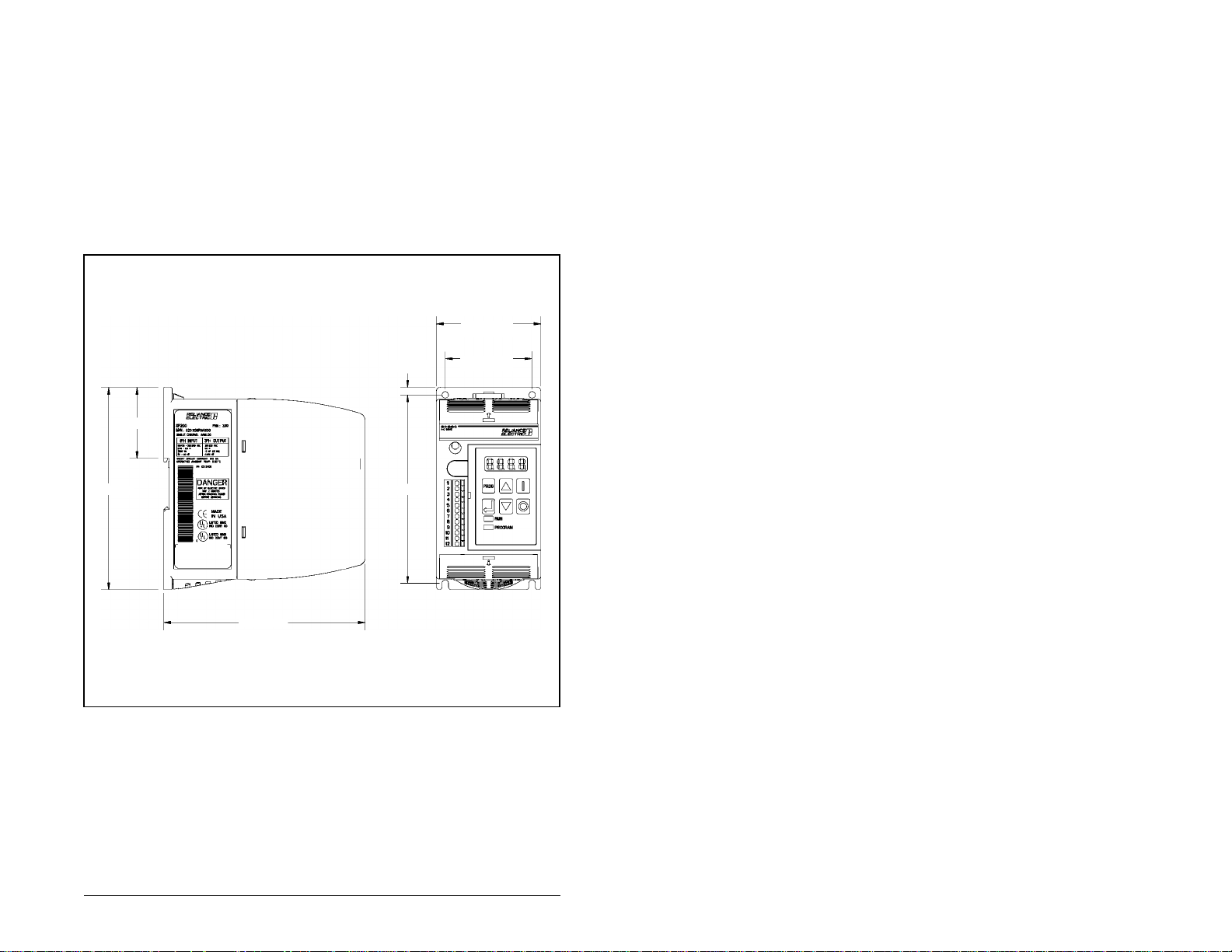

Drive Identification

Item Description

1 Nameplate

2 OK (green) / Fault (red) LED

3 Control Signal Ter m inal Block

4 Motor Output Terminal Block

5Fan

6 Bottom Finger Guard

7 Optional Local Keypad

8 Top Finger Guard

9 AC Input Power Terminal Block

SP200 AC Drive Components

S20 4

SP200

Voltage

Input

2 = 200-240 V, 3-phase; 230 V, 3-phase

4 = 380-480 V, 3-phase; 460 V, 3-phase

X = Selectable:

100-120 V, 1-phase; 230 V, 3-phase

or

200-240 V, 1-phase; 230 V, 3-phase

Y = 200-240 V, 1-phase; 230 V, 3-phase

Enclosure Type

0 = Protected chassis

Drive Identification

Output

Model Number Structure

-

0 3P5 A1 0

0 0

(Reserved - not used)

(Reserved - not used)

(Reserved - not used)

Model (Control Type)

A1 = Single Channel Analog

B1 = Preset Speed

C1 = Dual Channel Analog

Output Current (Horsepower)

1P3 = 1.3 A (0.5 HP)

2P0 = 2.0 A (1.0 HP)

2P3 = 2.3 A (0.5 HP)

3P5 = 3.5 A (2.0 HP)

4P2 = 4.2 A (1.0 HP)

6P0 = 6.0 A (1.5 HP)

7P0 = 7.0 A (2.0 HP)

1

Page 12

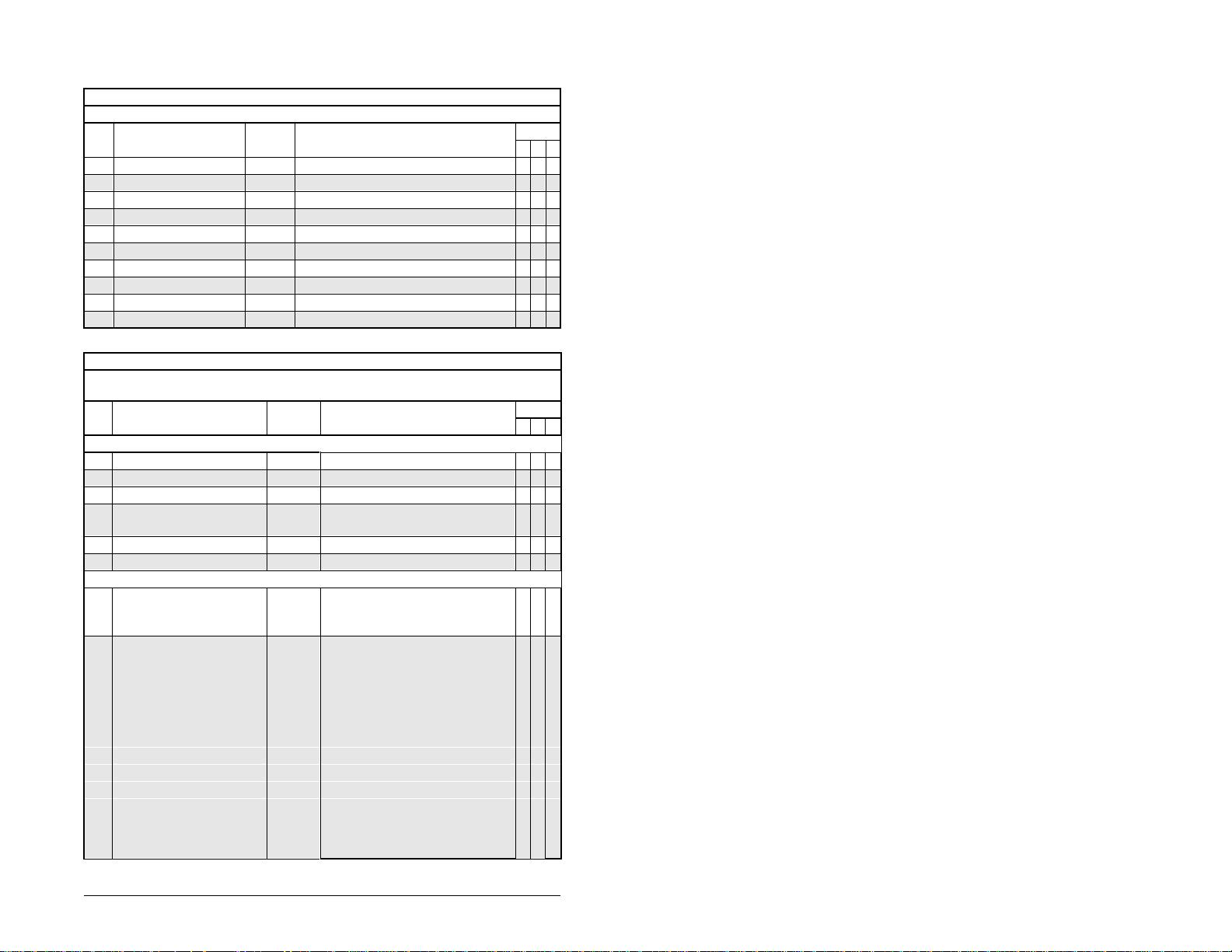

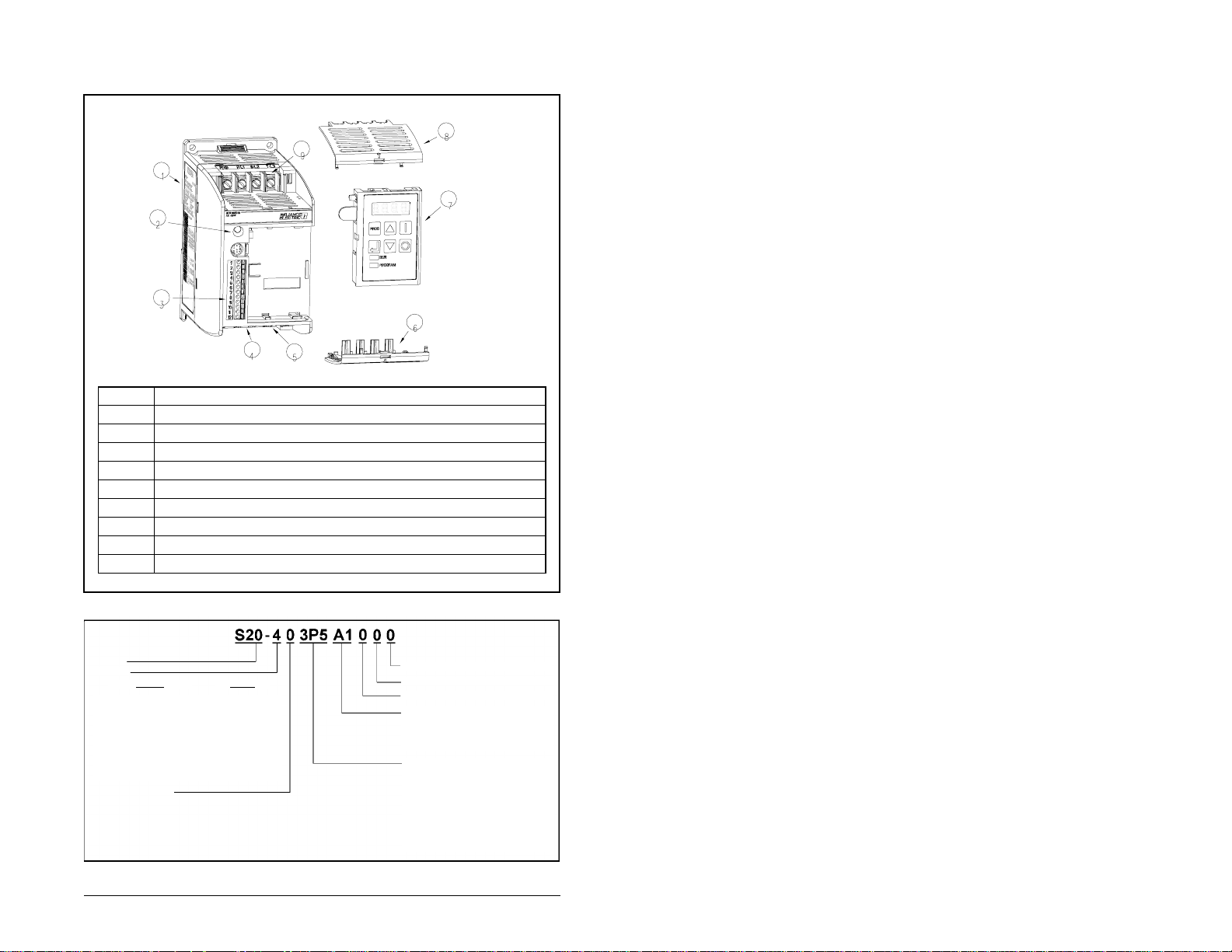

Technical Specifications

AC Input

Voltage

100-120,

1-phase

200-240,

1-phase

200-240,

3-phase

380-460,

3-phase

1

The input voltage range has a tolerance of ±10%, 47 to 63 Hz.

2

Recommended fuse type: UL Class J or CC, 600 V, time delay.

3

Device must meet UL 489 for UL purposes.

AC

Output

1

Voltage HP

230,

3-phase

230,

3-phase

230,

3-phase

460,

3-phase

0.5

1.0

1.5

0.5

1.0

1.5

2.0

0.5

1.0

2.0

0.5

1.0

2.0

Input

Current

(Amps)

9.4

17.2

24.6

4.7

8.6

12.3

14.3

2.7

5.0

8.3

1.5

2.4

4.1

Output

Current

(Amps)

2.3

4.2

6.0

2.3

4.2

6.0

7.0

2.3

4.2

7.0

1.3

2.0

3.5

Fuse

Rating

(Amps)

15 or 16

30

40

10

15 or 16

20

25

6

10

15 or 16

3 or 4

6

10

2

Control Inputs

• Rated voltage: 10 VDC to 24 VDC (±10%)

• Load (each): 10 mA minimum, 20 mA maximum

• Maximum allowable off-state leakage current: 1.5 V / 2.0 mA

Speed Reference Input

• Analog input impedance: 0 to 10 V: ≥100 kΩ

4 to 20 mA input: ~250 Ω

Circuit

Breaker

Rating

15

30

40

10

15

20

25

15

Typical

Power

3

Loss (W)

(A)

25

45

70

25

45

70

75

5

7

25

40

70

3

4

7

25

30

50

Relay Output

• Rated current and voltage: 0.5 A maximum at 125 VAC

1.0 A maximum at 30 VDC

Operating Performance

• Input frequency resolution: 0.4% analog, 0.1 Hz digital

• Output frequency resolution: 0.1%

• Output voltage regulation: 3%

• Power dip control ride through time: 100 msec minimum

Ambient Conditions

°

• Operating temperature: 0 to 50

• Storage temperature: -40

C (32° F to 122° F)

°

C to 85° C (-40° F to 185° F)

• Humidity: 0 to 95% non-condensing

• Elevation: 1000 meters (3300 ft) maximum without derating. For every 91.4 meters

(300 ft) above 1000 meters, derate the current by 1%. Above 3000 meters,

(10,000 ft), consult your Reliance Electric Sales Office.

2

SP200 AC Drive Quick Start Guide

Page 13

Standards and Approvals

• UL508C

• CSA22.2

• EN50178, EN60204-1 for Low Voltage Directive

• EN50081-1, EN50082-2, parts of EN61800-3 for EMC

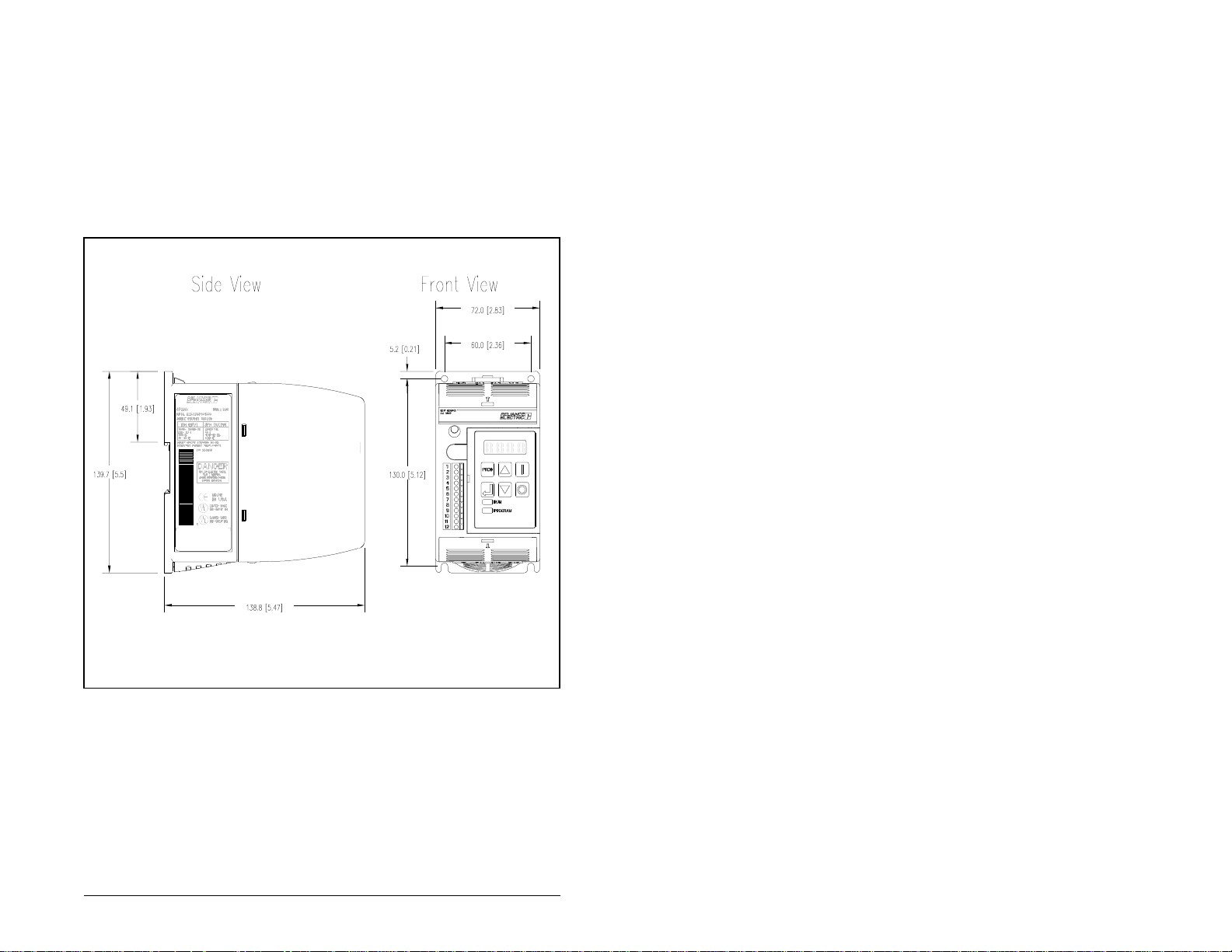

Mounting and Clearanc e Dimensions

• Top and bottom clearance is 38.1 mm [1.5 in].

• Side clearance is 25.4 mm [1.0 in] on the right if installation/removal of the

keypad is required.

Mounting and Clearance Dimensions

3

Page 14

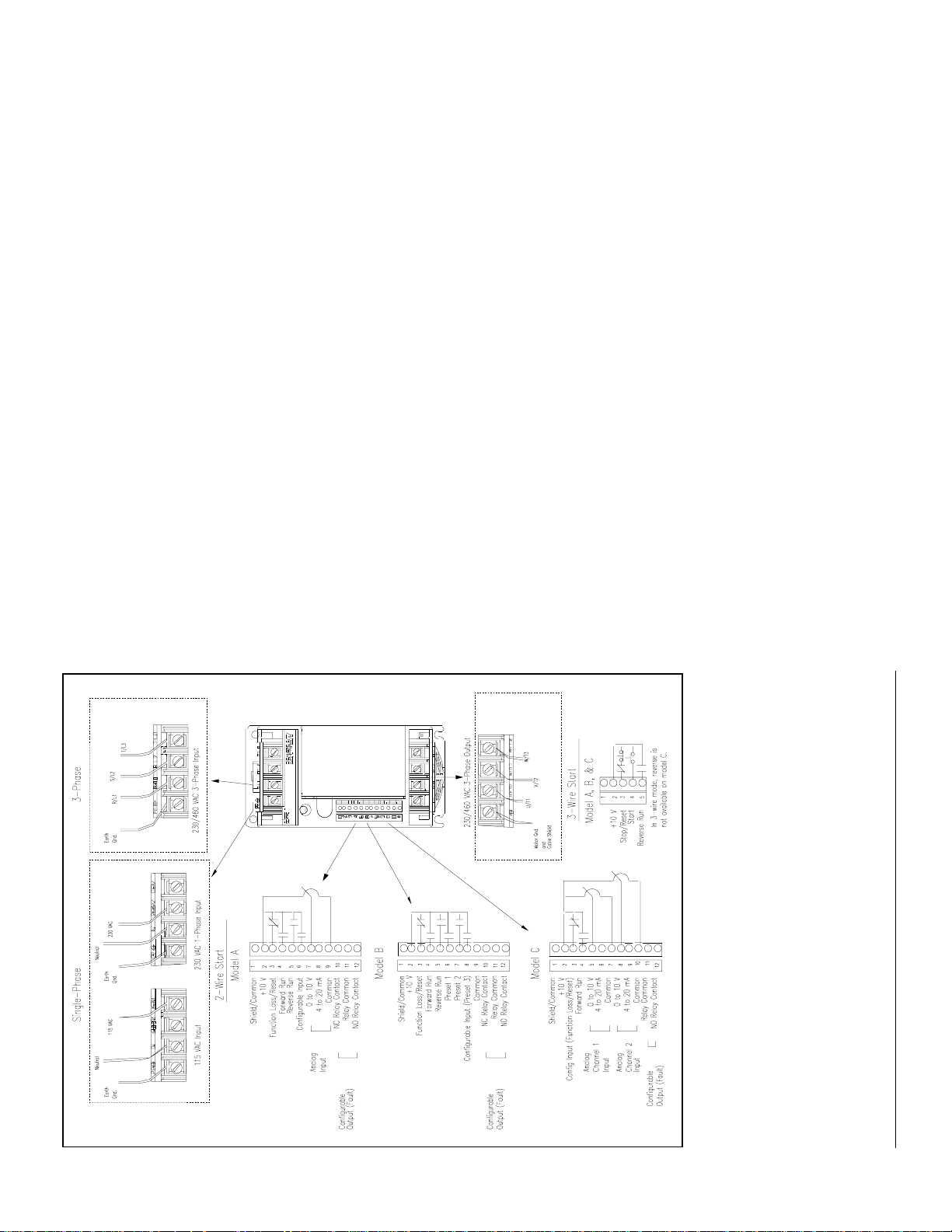

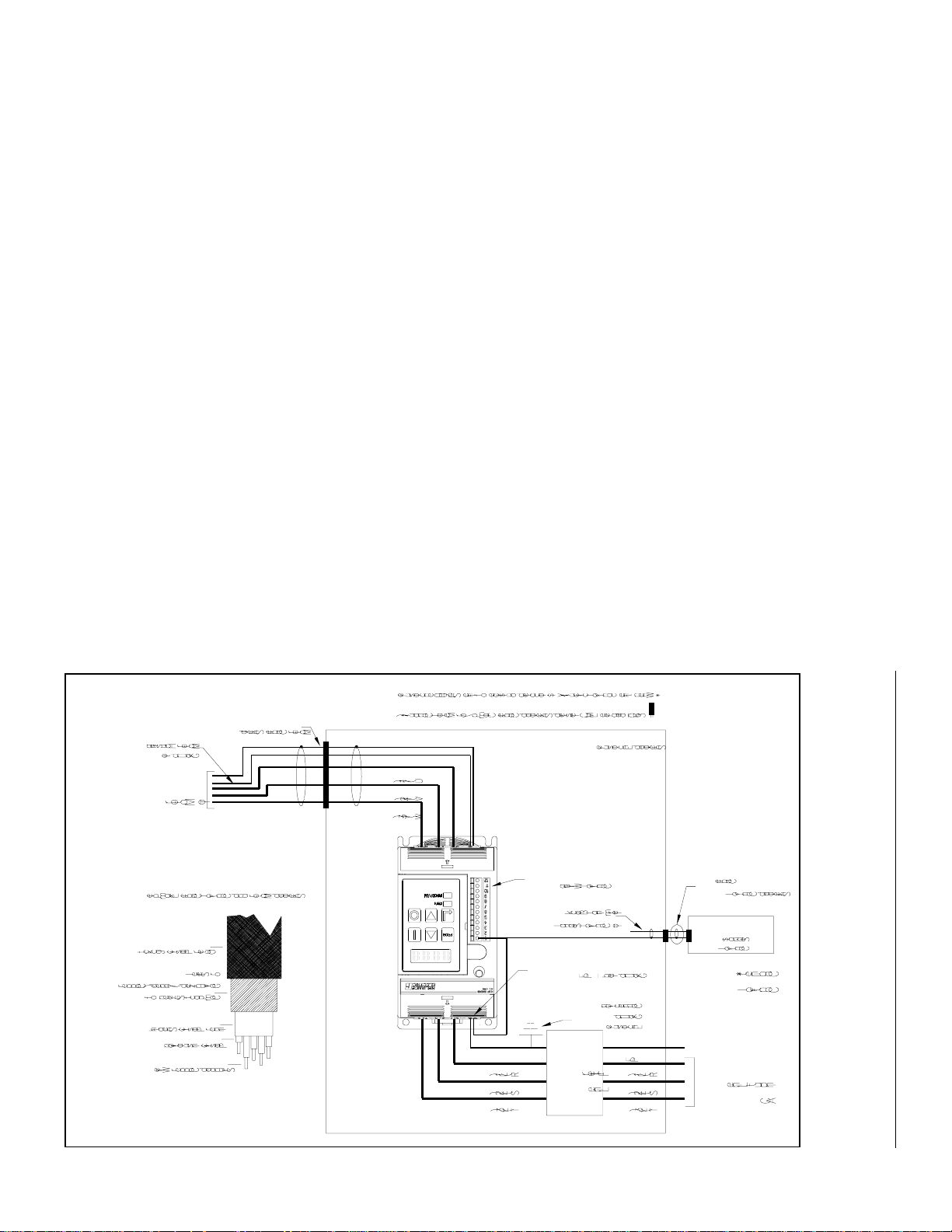

Wiring AC Power and Control Terminals

The following Attention statements apply to the wiring diagram on the facing page:

ATTENTION: This equipment is at line voltage when AC power is

connected. Disconnect and lockout all ung rounded conductors of the

AC power line before working on the unit. Failure to observe this

!

precaution could result in severe bodily injury or loss of life.

ATTENTION: Many local and national electrical codes require that an

input disconnect be provided in the incoming power lines. Failure to

observe this precaution could result in severe bodily injury or loss of

life.

ATTENTION: Many local and national electrical codes require that

upstream branch protection be provided to protect input power wiring.

Failure to observe this precaution could result in severe bodily injury

or loss of life.

ATTENTION: If the distribution system capacity exceeds the drive’s

maximum symmetrical fault short-circuit current of 100,000 amps,

additional impedance must be added to the AC line supplying the drive

to limit available current in the event of a fault. F ail ure to observe this

precaution could result in damage to, or destruction of, the equi pment.

AT TENTION:The user must provide an external, hardwired

emergency stop circuit outside of the SP200 drive circuitry . This circuit

must disable the system in case of improper operation. Uncontrolled

machine operation may result if this procedure is not followed.F ailure

to observe this precaution could result in severe bodily injury or loss

of life.

ATTENTION: If 2-wire control is selected, the drive will immediately

run when powered up in the presence of a forward or rev erse run

command. Failure to observe this precaution could result in severe

bodily injury or loss of life.

ATTENTION: The 4-pin circular connector (located directly above the

control terminals) may increase to a hazardous voltage level if the

control shield terminal (terminal 1) is left ungrounded. Failure to

observe this precaution could result in severe bodily injury or loss of

life.

4

SP200 AC Drive Quick Start Guide

Page 15

5

(16 AWG) wire.

2

(12 AWG) wire.

2

(26 AWG) to 1.5 mm

2

Power Terminal Information

• The terminal blocks accept up to 4 mm

• The recommended tightening torque is 1.35 Nm (12 in-lb).

Control Terminal Information

• The terminal block is isolated from input power.

• Control wires should be shielded and routed separately from the power wires.

• The terminal block accepts 0.14 mm

• The maximum control wire length is 30 meters (100 ft).

Wiring AC Power and Control Terminals

Page 16

Motor Cable Recommendations

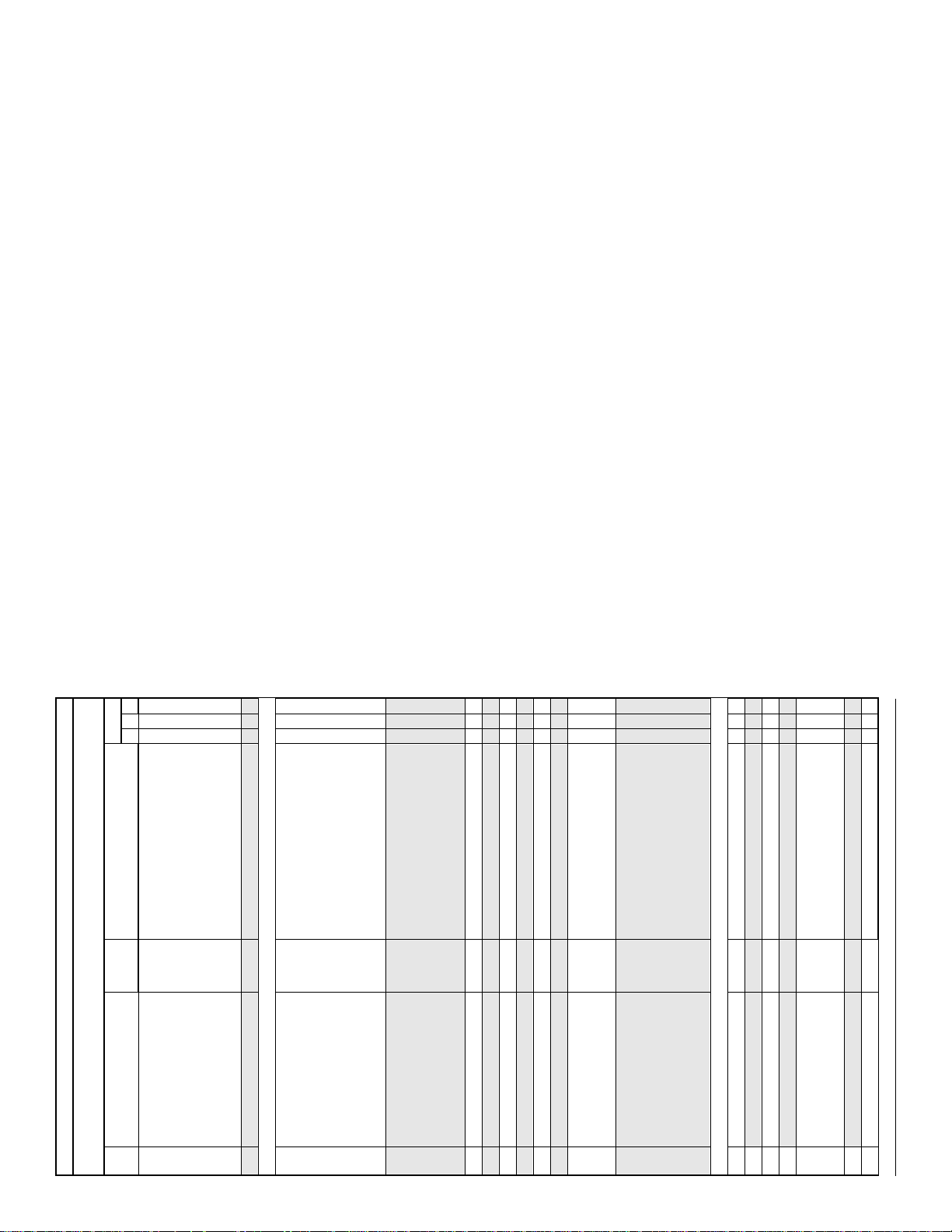

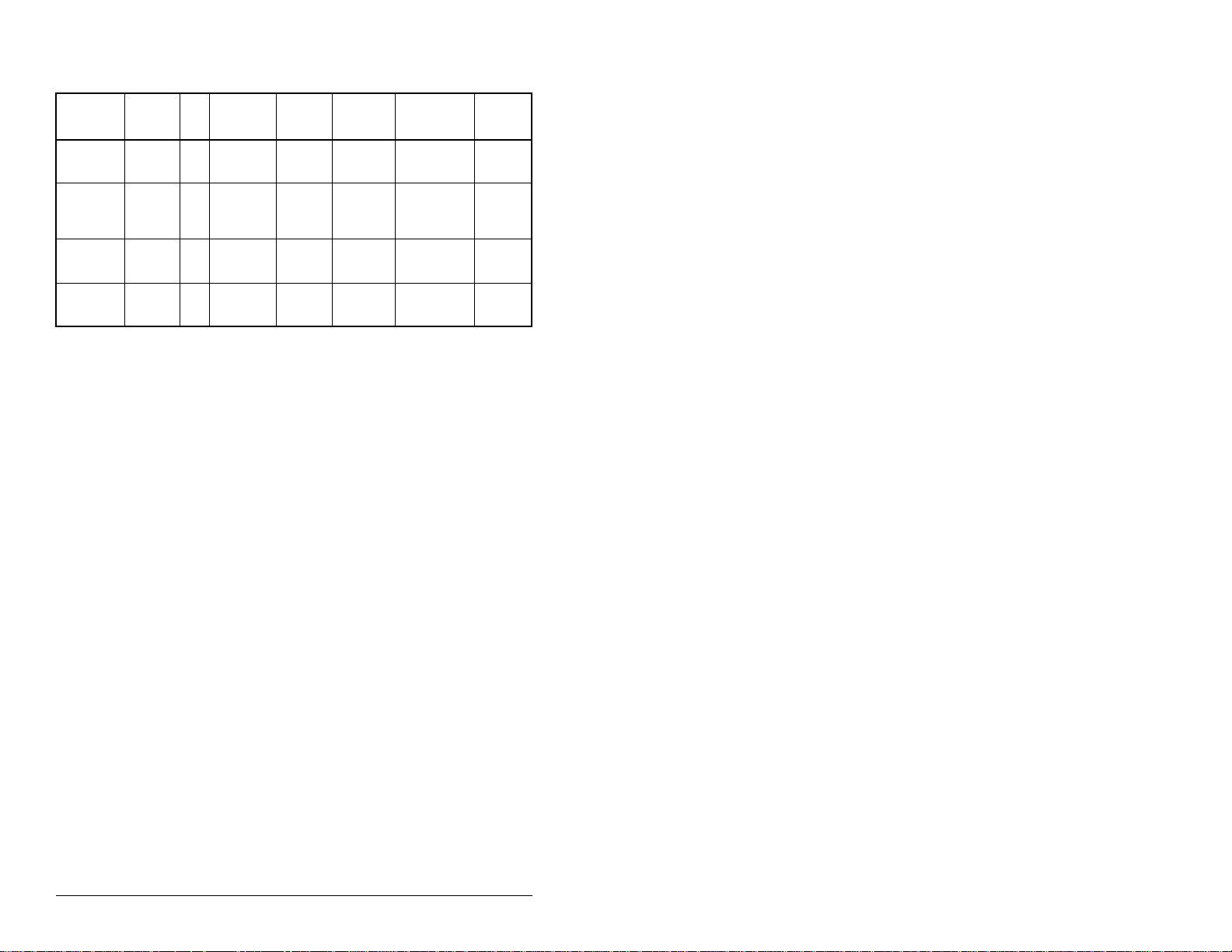

Drive-to-Motor Cable Distance

The cable distance between the drive and motor is limited f or t he f oll owing tw o reasons:

1. Long drive-to-motor cables can produce peak voltages that can damage motors

having an electrical insulation system less than that of MG-1 (1600 V). The use of

output line reactors can affect the limit. Use the table on the following page to

determine the maximum distance that may be applied with a non MG-1 motor (for

example, a motor with an insulation of 1000 V peak).

2. Long drive-to-motor cables also produce current that is capacitively coupled to

ground. This can cause the drive to fault and misrepresent the cause. The use of

output line reactors and cable shields or conduit can affect the limit. Use the table

on the followi ng page to det ermine the maximum distance under which the SP200

drive may be applied.

Both of the limitations described above must be considered for your installation. The

smaller of these two numbers will dictate your final limit.

Drive-to-Motor Wire Type

The type of wire that is recommended to be used between the drive and motor is

dependent on the environment in which it is used. The use of wire with PVC (PolyVinyl

Chloride) insulation is restricted to certain conditions. A common example of this wire

type is THHN. In these conditions where PVC is not recommended, XLPE (Cross

Linked PolyEth y lene) is recommended. An example of this wire type is XHHW-2. The

action of pulling wire through 90° bends in conduit removes some of the wire’s

insulation. For this reason, extra care should be taken during this process and a wire

with above average insulation thickness should be chosen.

Recommended Wire Type(s)

Condition

Dry

Wet XLPE XHHW-2

1

When using wire with PVC type insulation, standard 15mil thickness is adequate

under normal conditions; however, when multiple motor’s wires are run in the same

conduit for more than 50 ft (15m), and the voltage is greater than 240V + 10%, 20 mil

or greater thickness is recommended.

6

Insulation Type(s) Example(s)

PVC

XLPE

1

THHN

XHHW-2

SP200 AC Drive Quick Start Guide

Page 17

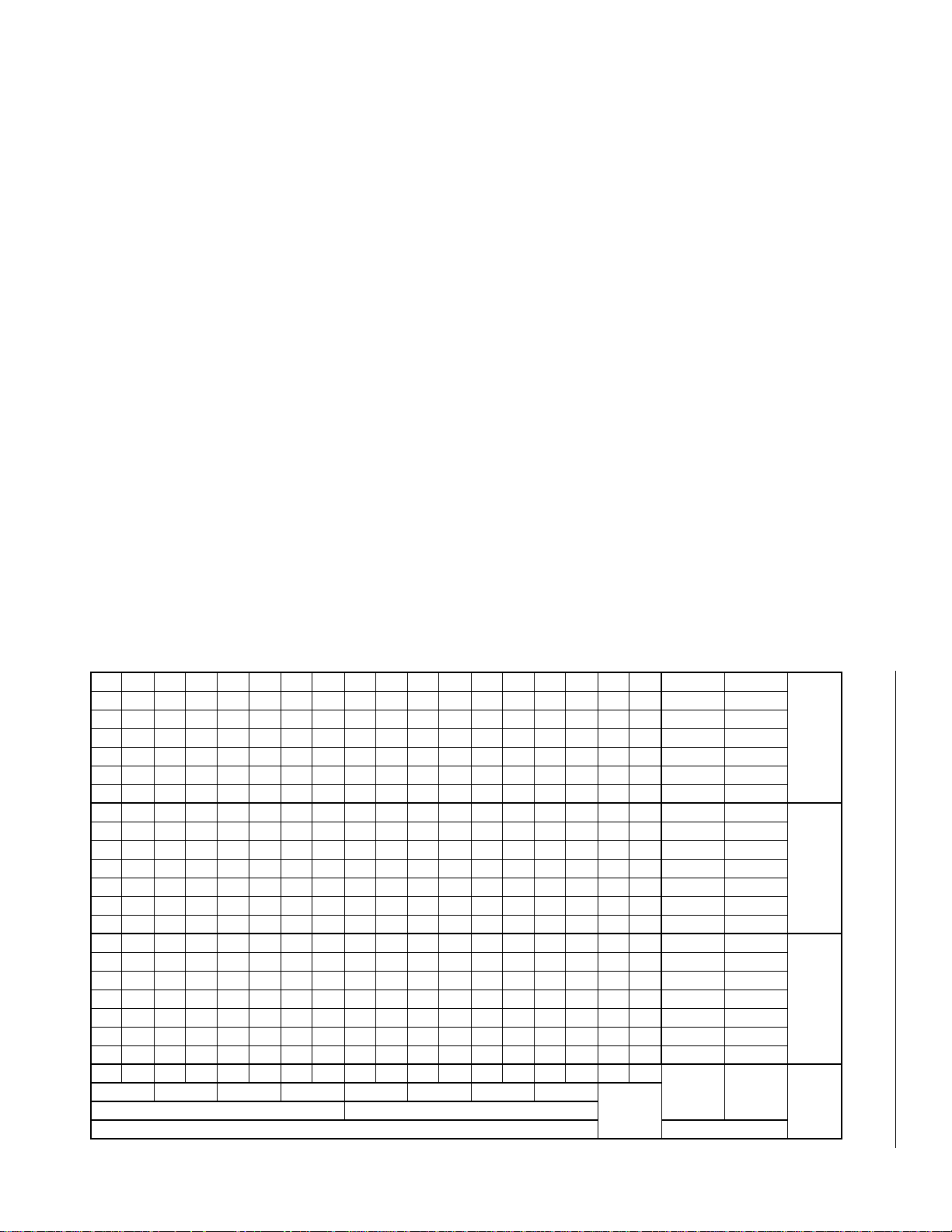

460 2.0 (1.5) 300 91 200 61 200 61 200 61 170 52 400 122 400 122 400 122 400 122

460 1.0 (0.75) 300 91 120 37 100 30 100 30 100 30 300 91 300 91 300 91 300 91

460 0.5 (0.37) 300 91 100 30 100 30 100 30 90 27 175 53 175 53 175 53 150 46

240 2.0 (1.5) — — 600 183 600 183 500 152 300 91 600 183 600 183 600 183 60 0 183

120 / 240 1.5 (1.1) — — 600 183 600 183 500 152 300 91 600 183 600 183 600 183 600 183

120 / 240 1.0 (0.75) — — 600 183 600 183 500 152 400 122 600 183 600 183 600 183 600 183

120 / 240 0.5 (0.37) — — 300 91 280 85 280 85 280 85 600 183 600 183 600 183 600 183

460 2.0 (1.5) 80 24 220 67 200 61 170 52 130 40 600 183 600 183 600 183 200 183

460 1.0 (0.75) 40 12 180 55 140 43 100 30 100 30 600 183 600 183 600 18 3 400 122

460 0.5 (0.37) 15 5 120 37 100 30 100 30 90 27 200 61 200 61 200 61 150 46

240 2.0 (1.5) — — 600 183 400 122 300 91 200 61 600 183 600 183 600 183 600 183

120 / 240 1.5 (1.1) — — 600 183 400 122 300 91 200 61 600 183 600 183 600 183 600 183

120 / 240 1.0 (0.75) — — 500 152 300 91 300 91 200 61 600 183 600 183 600 183 600 183

120 / 240 0.5 (0.37) — — 400 122 300 91 300 91 100 30 600 183 600 183 600 183 600 183

460 2.0 (1.5) 20 6 220 67 180 55 180 55 100 30 400 122 400 122 400 122 400 122

460 1.0 (0.75) 25 8 120 37 100 30 100 30 100 30 300 91 300 91 300 91 300 91

460 0.5 (0.37) 50 15 100 30 100 30 100 30 90 27 175 53 175 53 175 53 150 46

240 2.0 (1.5) — — 600 183 600 183 500 152 300 91 600 183 600 183 600 183 600 183

120 / 240 1.5 (1.1) — — 600 183 600 183 500 152 300 91 600 183 600 183 600 183 600 183

120 / 240 1.0 (0.75) — — 500 152 500 152 400 122 300 91 600 183 600 183 600 183 600 183

ft m ft m ft m ft m ft m ft m ft m ft m ft m

2 kHz 4 kHz 6 kHz 8 kHz 2 kHz 4 kHz 6 kHz 8 kHz

Shielded Cable or Wires in Conduit Unshielded Cable

SP200 Drive Limit

Limit

Motor

1000 V

Volts HP (kW)

Input

Drive Rating

Motor

3 % at

Drive

3 % at

None 120 / 240 0.5 (0.37) — — 250 76 250 76 250 76 200 61 600 183 600 183 600 183 600 183

Reactor

7

Motor Cable Recommendations

Page 18

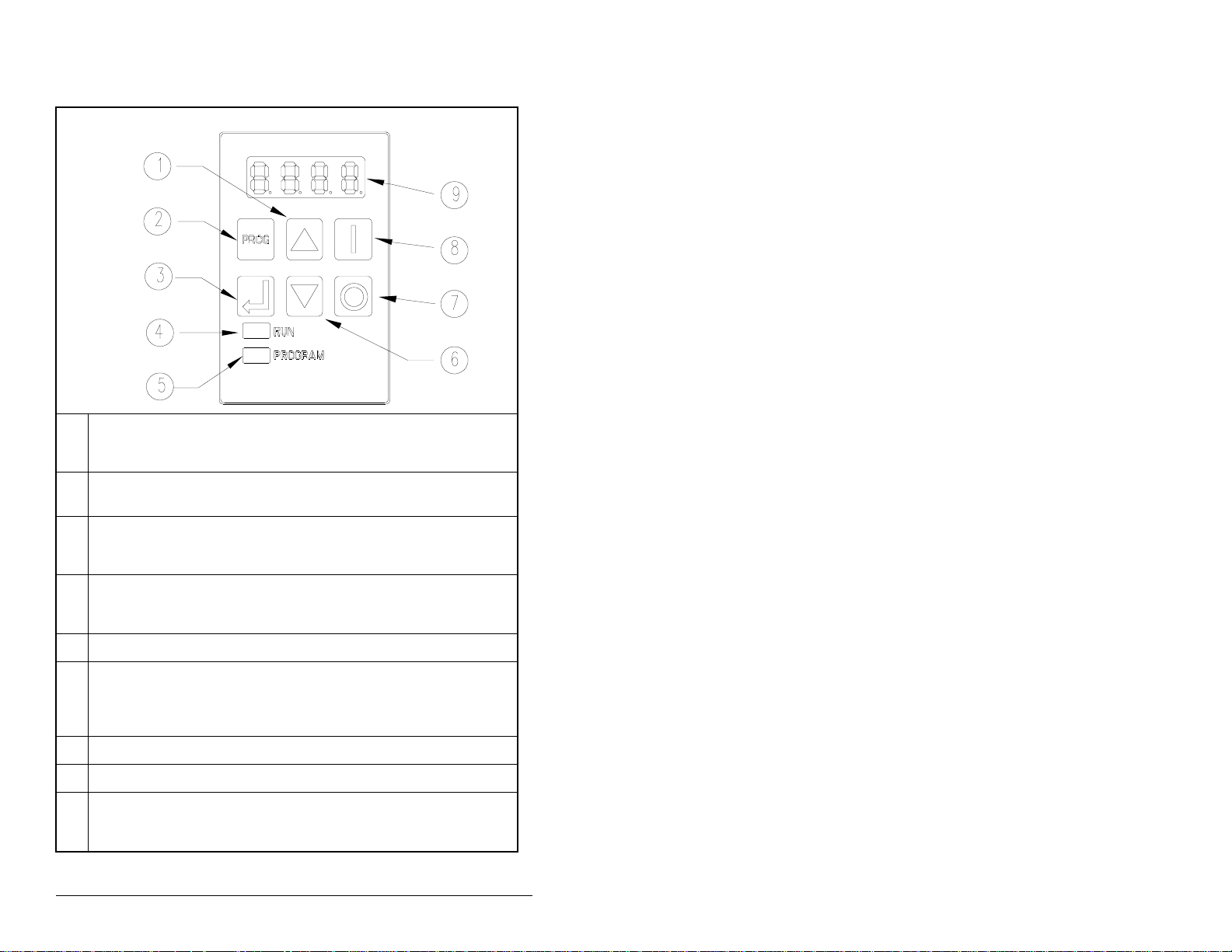

Local Keypad Operation

1 In display mode, the UP ARROW key increments the local speed reference.

In program mode, this key increments the parameter number or parameter

value.

2 The PROGRAM key toggles between display and program modes. The

PROGRAM LED (5) turns on when the drive is in program mode.

3 In display mode, the ENTER key increments to the next display parameter.

In program mode, this key toggles between the parameter number and

parameter value.

4 The RUN LED turns on when the drive is running in either the foward or

reverse direction. The RU N LED flashes while the drive is changing

direction.

5 The PROGRAM LED turns on when the drive is in program mode.

6 In display mode, the DOWN ARROW key decrements the local speed

reference.

In program mode, this ke y decrements the par ameter number or parameter

value.

7 The STOP key issues stop and fault rese t commands to the drive.

8 The START key issues start commands to the drive when P-10 = 1.

9 The display shows either a parameter number or a parameter value.

The parameter numbers are preceded by either a “P-” or a “d-”.

8

SP200 AC Drive Quick Start Guide

Page 19

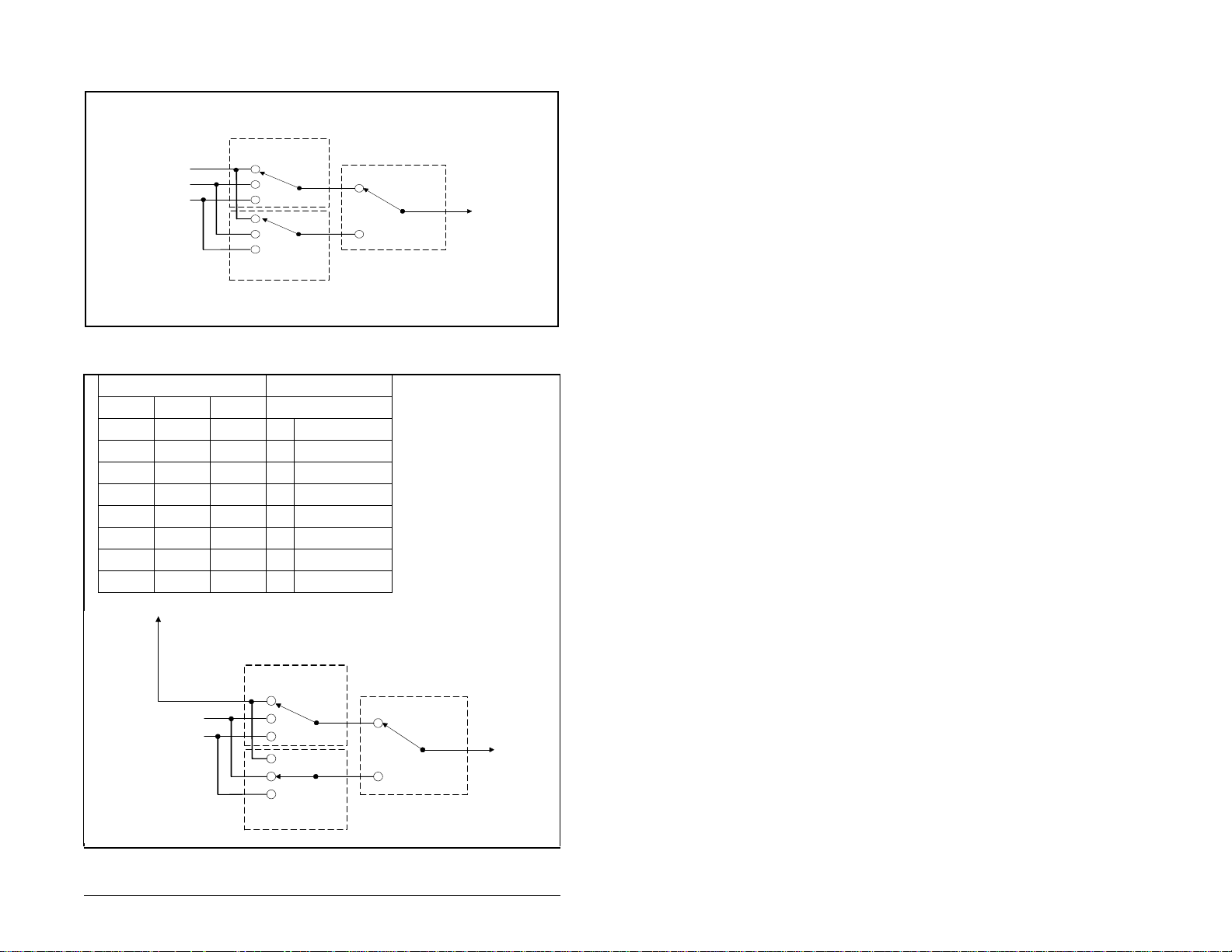

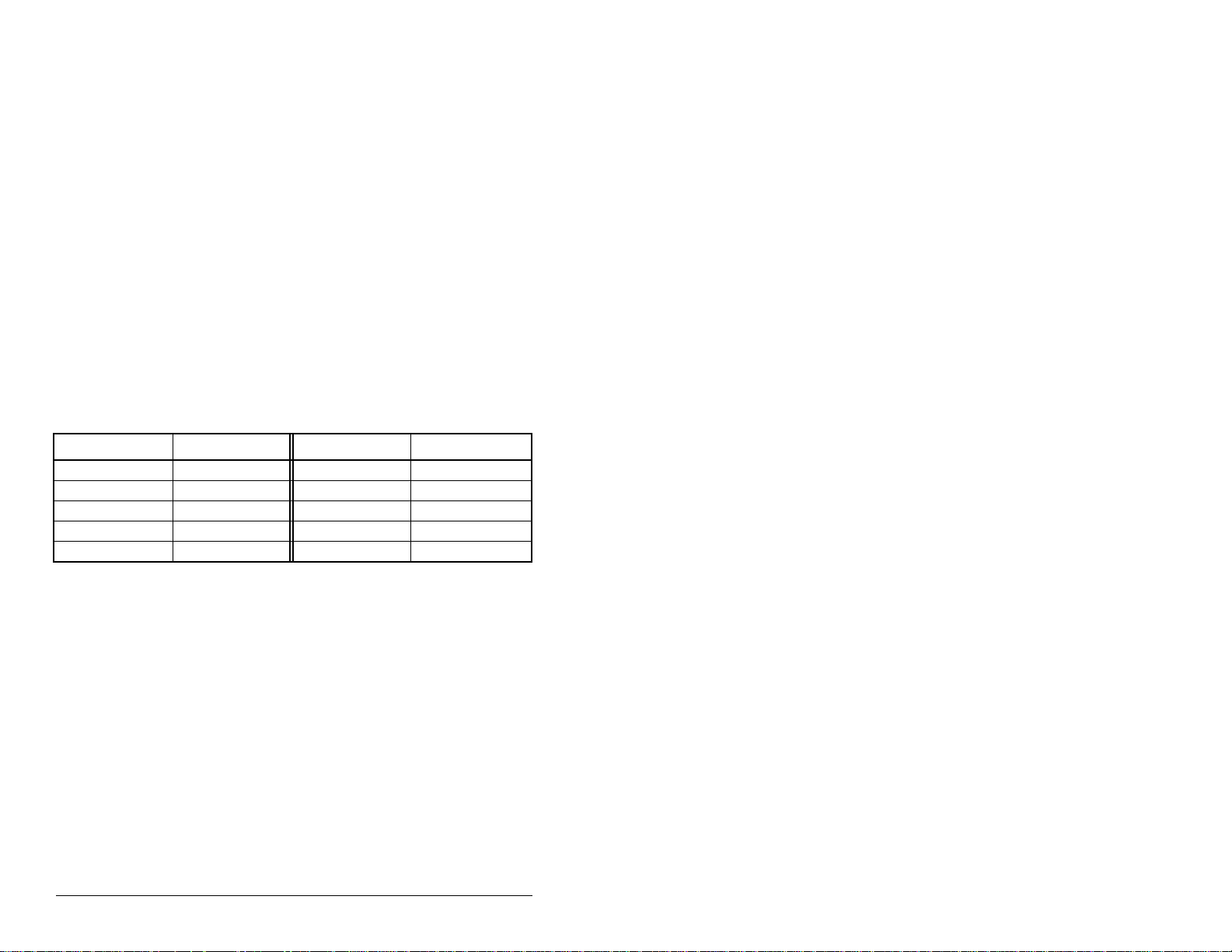

Selecting a Speed Reference

Main

Analog Input 1

Keypad Frequency

Internal Frequency

0

1

2

0

1

2

Speed Reference Source for Model A Drives

Input Terminal Status Resulting Speed

Term 8 Term 7 Term 6 Parameter

0 0 0 41 Preset Speed 1

0 0 1 42 Preset Speed 2

0 1 0 43 Preset Speed 3

0 1 1 44 Preset Speed 4

1 0 0 45 Preset Speed 5

1 0 1 46 Preset Speed 6

1 1 0 47 Preset Speed 7

1 1 1 48 Preset Speed 8

Speed

Ref

(P-20)

Alternate

Speed

Ref

(P-21)

Configurable

Input

(P-11 = 3)

Speed

Reference

Keypad Frequency

Internal Frequency

Speed Reference Source for Model B Drives

Selecting a Speed Reference

Main

0

1

2

0

1

2

Speed

Ref

(P-20)

Alternate

Speed

Ref

(P-21)

Configurable

Input

(P-11 = 3)

Speed

Reference

9

Page 20

Process

0

Select

(P-28)

Process Ref

1

0

Main

4

(P-29)

Operation

2

1

2

Ref

Speed

0

3

(P-20)

1

Speed

Input

(P-11 = 3)

Configurable

2

3

Reference

Ref

Speed

Alternate

0

1

(P-21)

2

SP200 AC Drive Quick Start Guide

3

Speed Reference Source for Model C Drives

Analog Input 1

Internal Frequency

Keypad Frequency

Analog Input 2

10

Page 21

Drive Parameters

Display Parameters

(Read Only)

Units / Model

No. Name Default Range A B C

d-00 Command Frequency 0.1 Hz 0 - 240.0 x x x

d-01 Output Frequency 0.1 Hz 0 - 240.0 x x x

d-02 Output Current 0.1 A 0 - 200 (% of rated current) x x x

d-03 Bus Voltage 1 V 0 - 1000 x x x

d-04 Fault Code Annn alphanumeric code x x x

d-05 Input Status decimal 0000 - 7111 x x x

d-06 Drive Rating decimal x x x

d-07 Firmware Version Annn alphanumeric code x x x

d-08 Analog Input 1 Units 0.1 % 0 - 110.0 x x

d-09 Analog Input 2 Units 0.1 % 0 - 110.0 x

Program Parameters

(Parameters that can be programmed only while the drive

No. Name Default Range A B C

Group 0: Protection

P-00Minimum Speed * 0 Hz 0 - Maximum Speed x x x

P-01Maximum Speed * 60 Hz Minimum Speed - 240 x x x

P-02Motor Overload Current x.x A 20% - 200% of drive’s rated current x x x

P-03Reverse Disable * 0 0 = reverse enabled

P-04 Auto Restart Attempts 0 0 - 10 x x x

P-05Current Limit 150 % 10% - 150% of drive’s rated current x x x

Group 1: Digital Input / Output

P-10Start Control * 2 1 = keypad control

P-11Configurable Input * 2 (A) 0 = function loss (P-10 ≠ 3) x

is stopped are indicated by an asterisk *)

Units / Model

1 = reverse disabled

2 = 2-wire control

3 = 3-wire control

1 (B) 1 = disabled x

0 (C) 1 = preset x

1 = reverse run (2-wire) x

2 = jog (P-10 ≠ 1)

2 = jog (P-10 ≠ 1 or 3)

3 = alternate spd ref select x x

3 = alt spd ref select (P-10 ≠ 3) x

4 = n.c. coast-to-stop x x

4 = n.c. coast-to-stop (P-10 ≠ 3)

5 = secondary accel/decel x x

5 = sec accel/decel (P-10 ≠ 3)

x x x

x

x

x

x

x

x

x x

x

x

x

x

x

x

Drive Parameters

11

Page 22

x

x

xxx

xxx

x

x

x

xxx

xxx

x

x

x

x

xxx

x

x

x

x

xxx

xxx

xxx

SP200 AC Drive Quick Start Guide

analog input 2

output

1 = no fault/auto restarting x x x

2 = run x x x

3 = at frequency x x x

4 = above frequency x x x

5 = above current x x x

0 = preset speeds

1 = keypad

2 = Internal / Jog Frequency (P-40)

3 = analog input 2

4 = Process Operation (P-29)

0 = preset speeds

1 = keypad

2 = Internal / Jog Frequency (P-40)

3 = analog input 2

1 = keypad

2 = Internal / Jog Frequency (P-40)

and analog input 2

1 = multiply Process Ref (P-28)

2 = PI control

3 = inverted PI control

1 = coast-to-rest

2 = DC injection

Program Parameters

Units / Model

is stopped are indicated by an asterisk *)

(Parameters that can be programmed only while the drive

Deceleration Time 1 5.0 sec 0 - 600.0 x x x

Deceleration Time 2 10.0 sec 0 - 600.0 x x x

No. Name Default Range A B C

P-12 Configurable Output 0 0 = no fault x x x

P-13Configurable Output Level 0.0 0 - 999.9 (only when P-12 = 4 or 5) x x x

Group 2: Speed Reference

P-20Main Speed Reference 0 0 = analog input 1

P-21Alternate Speed Reference 1 0 = analog input 1

P-23Analog Input 1 Gain 100.0 % 0 - 110.0 x x

P-25Analog Input 2 Gain 100.0 % 0 - 110.0 x

P-22Analog Input 1 Offset 0.0 % 0 - 110.0 x x

P-24Analog Input 2 Offset 0.0 % 0 - 110.0 x

P-27Process Integral Gain 0.00 0 - 10.0 (0 = off) x

P-26Process Proportional Gain 0.00 0 - 10.0 (0 = off) x

P-28Process Reference 0 0 = analog input 1

P-29Process Operation 0 0 = add Process Ref (P-28) and

Group 3: Dynamic Control

P-30Acceleration Time 1 5.0 sec 0 - 600.0 x x x

P-31

P-32Acceleration Time 2 10.0 sec 0 - 600.0 x x x

P-33

P-34Stop Control 0 0 = ramp-to-rest

DC Brake Current 50 % 10 - 150 x x x

P-35

P-36DC Brake Time at Stop 0.5 sec 0 - 20.0 x x x

12

Page 23

13

x x x

xxx

x x

0 - 230 or 0 - 460 x x x

Group 5: V / Hz

460 V

P-50Base Voltage 230 V /

P-51Base Frequency 60 Hz 0 - 240 x x x

P-53Breakpoint Frequency 0 Hz 0 - 240 x x x

P-52Breakpoint Voltage 0 V 0 - 230 or 0 - 460 x x x

P-55Auto Torque Boost 3.0 % 0 - 10 x x x

P-54Boost Voltage 11 / 23 V 0 - 46 or 0 - 92 x x x

Group 6: Utility

Program Parameters

Units / Model

is stopped are indicated by an asterisk *)

(Parameters that can be programmed only while the drive

No. Name Default Range A B C

P-37Avoidance Frequency 0.0 Hz 0 - 240.0 x x x

P-38Avoidance Frequency Band 0.0 Hz 0 - 30.0 x x x

Group 4: Fixed Speeds

P-41Preset Speed 1 2.5 Hz 0 - 240.0 x

P-42Preset Speed 2 5.0 Hz 0 - 240.0 x

P-43Preset Speed 3 10.0 Hz 0 - 240.0 x

P-44Preset Speed 4 20.0 Hz 0 - 240.0 x

P-45Preset Speed 5 30.0 Hz 0 - 240.0 x

P-46Preset Speed 6 40.0 Hz 0 - 240.0 x

P-47Preset Speed 7 50.0 Hz 0 - 240.0 x

P-40Internal / Jog Frequency 60.0 Hz 0 - 240.0 x x x

P-48Preset Speed 8 60.0 Hz 0 - 240.0 x

P-61Program Password OFF OFF / ON ; entering 257 toggles

P-60Reset to Defaults * 0 0 - 1; entering 1 performs a reset x x x

the setting

displays

displays

P-63Units at Analog Max 0 0 - 9999; scales d-08 and d-09

P-62Units at Base Frequency 0 0 - 9999; scales d-00 and d-01

P-64Carrier Frequency 2 kHz 2 - 8 x x x

Drive Parameters

Page 24

Compliance with EU Requirements

The SP200 drive is CE-marked for Low Voltage (LV) Directive 73/23/EEC and all

applicable standards when installed as described within the Low Voltage section that

follows. It also has been tested to meet Electromagnetic Compatibility (EMC) Directive

89/336/EEC when installed as described within the Electromagnetic Compatibility

section that follows. Contact the Rockwell AutoFax service in the United States at

216-646-7777 (or your local Rockwell A utomation office if out side the U .S.) for copies of

the Declaration of Conformity (DOC).

Conformity of the SP200 drive to EU directives does not guarantee that the entire

system will conform. For EMC, many other factors can affect the total installation, and

only direct measurements can verify total conformity. It is the responsibility of the

machine manufacturer (or end user, if the machine is being modified or used beyond

manufacturer’s specifications) to comply.

Low Voltage Directive 72/23/EEC

• Follow all general precautions and ATTENTION statements throughout this manual.

• Provide an earth ground connection to the PE terminal.

• Install in a protective enclosure which restricts access to IP 20 rated devices as

required by your national and local codes and regulatory agencies.

Electromagnetic Compatibility Directive 89/336/EEC

• Install the SP200 drive and Input Mains Filter (see the table below) in a t ypical IEC or

NEMA metal (shielded) enclosure as shown in the figure on the following page.

Adhere to maximum motor cable lengths as specified on page 7 (≤ 25 m).

Drive Model

Number

S20-X02P3..... S20-MF1-Y014 S20-204P2..... S20-MF1-45P0

S20-X04P2..... S20-MF1-Y014 S20-207P0..... S20-MF1-49P5

S20-X06P0..... S20-MF1-Y014 S20-401P3..... S20-MF1-45P0

S20-Y07P0..... S20-MF1-Y014 S20-402P0..... S20-MF1-45P0

S20-202P3..... S20-MF1-45P0 S20-402P3..... S20-MF1-45P0

Refer to

• Keep all input power , output po wer , and control signal wiring, both inside and outside

enclosure, physically separate from one another.

SP200 Mains Filters

Filter Model Number

(D2-3420) for filter dimensions and weights.

• Connect the enclosure to the SP200 PE input (top) terminal.

• Connect the enclosure to earth ground.

• Use shielded cable with a ground conductor or individual conductors in grounded

metal conduit for motor power wiring on the output side of the drive, both inside and

outside the enclosure, all the way to the motor. Bring the shield as close to the output

power terminals as possible. Connect the motor cable ground and shield to the

ground terminal on the output (bottom) side of the SP200 drive. Connect the

opposite end of the motor cable ground conductor and shield to the motor housing.

• Use shielded cable or grounded metal conduit for control wiring both inside and

outside the enclosure, all the way to the control source. Bring the shield as close to

the control terminals as possible. Connect the shield to the SP200 shield/common

(terminal 1) and to the PE terminal on the input side (top) of the SP200 drive. Also

connect the opposite end of the shield to the common of the device that is controlling

the SP200 drive.

• Use EMC-tested 360 degree cable clamps to connect the motor and control shields

to the enclosure cable exit point(s) and to the motor housing. Contact points must be

clean and free of paint or nonconductive coating.

• Make certain all ground connections provide a low impedance path for high

frequency signals.

Drive Model

Number

Filter Model Number

14

SP200 AC Drive Quick Start Guide

Page 25

Grounding, Control, and Motor Connections

15

Compliance with EU Requirements

Page 26

Fault Codes and Troubleshooting

• If no fault condition exists , the LED will be green.

• If a fault condition exists, the LED will be continuously red when a local keypad is

connected, or flashing red when a local keypad is not connected.

• All faults can be reset by cycling the reset control input, pressing the stop key, or

cycling power, except as noted in Corrective Action in the table below.

Display

1

Number of

Fault LED

Code

Flashes

CF 2

FL 2

LU 3

HU 4

dO 5

OL 5

OH 6

OC 7

CL 8

UF 9

J1 10

J2 10

J3 10

J4 10

J5 10

J6 10

CH 11

UP 12

Auto Resettable

Fault

Description Fault Cause Corrective Action

Control Input Illegal control input

Function Loss Start attempt while

Under Voltage

Over Voltage1

Drive Overload

Motor Overload

Over

Temperature

Over Current1

(300%)

Bad Keypad

Connection

Negative Slope Con flicting parameter

Ground Short Phase U - Verify output wiring is correct

Phase to Phase

Short

Checksum Failure Parameter value out of

Microprocessor

Fault

sequence.

STOP (Function Loss)

input is off.

1

- Low input line.

- Temporary loss of

input line.

- High input line.

- Decel time too fast.

- Overhauling load.

1

Excessive driven load. Reduce the load.

1

Excessive driven load. - Verify P-02 is set correctly.

- Operating environment

1

is too hot.

- Fan is blocked or not

operating.

- Excessive driven load.

- Shaft rotation blocked.

- Excessive driven load.

- Output wiring is

incorrect or shorted.

Bad connection from

keypad to drive.

values.

Phase V

Phase W

Phase U - V - Verify output wiring is

Phase U - W

Phase V - W

range.

Internal processor error. Cycle power. If fault persists,

- 3-wire: Verify Start and Jog

inputs are not both ON.

- 2-wire: Verify that only one

input (Forward, Reverse, or

Jog) is on.

Verify STOP (Function Loss)

input is ON before attempting

to start drive.

Check input line to verify

voltage is within operating

specifications.

- Check input line to verify

voltage is within operating

specifications.

- Increase decel time.

- Reduce the load.

- Verify the ambi ent

temperature is < 50

- Verify clearance above/

below drive.

- Check for fan obstruction.

Replace fan if required.

- Reduce the carrier

frequency (P-64).

- Reduce the load.

- Check for obstructions to

shaft rotation or reduce

excessive load.

Increase accel / decel time.

-

- Verify output wiring is

correct.

Verify keypad is properly

connected to drive.

Adjust values of parameters P-50 through P-54.

- Verify output phase is not

grounded.

- Verify motor is not damaged.

correct.

- Verify motor is not damaged.

Load default parameter values

(P-60 =1), then cycle power. If

fault persists, replace drive.

replace drive.

°.

16

SP200 AC Drive Quick Start Guide

Page 27

Identification du variateur

Article Description

1 Plaque d'identification

2 Diode électroluminescente : O.K. (vert) / Faute (rouge)

3 Bornier de commande

4 Bornier de la sortie moteur

5 Ventilat eur

6 Cache de protection inférieur

7 Console de commande et de programmation option

8 Cache de protection supérieur

9 Bornier d'alimentation 20 ou 30 AC

Composants du variateur SP200

SP200

Tension

Entrée

2 = 200-240 V, triphasé ; 230 V, triphasé

4 = 380-480 V, triphasé ; 460 V, triphasé

X = 2 choix possibles :

100-120 V, monophasé ; 230 V, triphasé

ou

200-240 V, monophasé ; 230 V, triphasé

Y = 200-240 V, monophasé ; 230 V, triphasé

Type d’enceinte

0 = IP20

Sortie

Structure du numéro de modèle

Identification du variateur

(Réservé - non utilisé)

(Réservé - non utilisé)

(Réservé - non utilisé)

Modèle (ty pe de commande)

A1 = Analogique (1 entrée)

B1 = Vitesse préselectionnée

C1 = Analogique (2 entrées)

Courant de sortie

(kW)

1P3 = 1,3 A (0,37 kW)

2P0 = 2,0 A (0,75 kW)

2P3 = 2,3 A (0,37 kW)

3P5 = 3,5 A (1,5 kW)

4P2 = 4,2 A (0,75 kW)

6P0 = 6,0 A (1,1 kW)

7P0 = 7,0 A (1,5 kW)

1-f

Page 28

Spécifications techniques

2

disjoncteur

Cal.

(A)

15

30

40

10

15

20

25

5

7

15

3

4

7

Cal.

fusibles

(A)

15 ou 16

30

40

10

15 ou 16

20

25

6

10

15 ou 16

3 ou 4

6

10

1

Tension

sortie

CA CV

230,

triphasé

230,

triphasé

230,

triphasé

460,

triphasé

Tension

entrée CA

100-120,

monophasé

200-240,

monophasé

200-240,

triphasé

380-460,

triphasé

1

La plage des tensions d'entrée a une tolérance de ±10%, 47 à 63 Hz.

2

Type de fusible recommandé : UL classe J ou CC, 600 V, action retardée.

3

Le dispositif doit être conforme à la norme UL 489 pour les besoins UL.

0,5

1,0

1,5

0,5

1,0

1,5

2,0

0,5

1,0

2,0

0,5

1,0

2,0

Courant

entrée

(A)

9,4

17,2

24,6

4,7

8,6

12,3

14,3

2,7

5,0

8,3

1,5

2,4

4,1

Courant

sortie

(A)

2,3

4,2

6,0

2,3

4,2

6,0

7,0

2,3

4,2

7,0

1,3

2,0

3,5

Signaux de commande (entrées)

• Tension nominale : 10 Vcc à 24 Vcc (±10%)

• Charge (chacune) : 10 mA minimum, 20 mA maximum

• Courant de fuite maximum permissible à l'état bloqué : 1,5 V / 2,0 mA

Consigne de vitesse

• Impédance d'entrée analogique : 0 à 10 V : ≥ 100 Ω

4 à 20 mA : ~250 Ω

Sortie relais

• Courant et tension nominaux : 0,5 A maximum sous 125 Vca

1,0 A maximum sous 30 Vcc

Dissi-

3

pation

(W)

25

45

70

25

45

70

75

25

40

70

25

30

50

Performances

• Résolution fréquence d'entrée : analogique 0,4%, numérique 0,1 Hz

• Résolution fréquence de sortie : 0,1%

• Contrôle tension de sortie : 3%

• Durée des intervalles entre chutes de tension : 100 ms minimum

Conditions ambiantes

• Température de serv ice : 0 à 50° C (32° F à 122° F)

• Température de stockage : -40° C à 85° C (-40° F à 185° F)

• Humidité : 0 à 95%, sans condensation

• Altitude : 1 000 mètres (3 300 pieds) maximum sans de’classement. Pour chaque

incrément de 91,4 mètres (300 pieds) au-dessus de 1 000 mètres, réduire le courant

nominal de 1%. Au-dessus de 3 000 mètres (10 000 pieds), consulter le service

commercial de Reliance Electric.

2-f

Guide de mise en route du variateur SP200

Page 29

Normes et agréments

• UL508C

• CSA22.2

• EN50178, EN60204-1 relativement à la Directive basse tension

• EN50081-1, EN50082-2, parties de EN61800-3 pour les compatibilités

électromagnétiques

Montage et côtes d'enco mb re men t

Vue latérale

49,1 [1,93]

139,7 [5,5]

138,8 [5,47]

Vue de face

5,2 [0,21]

130,0 [5,12]

72,0 [2,83]

60,0 [2,36]

• Espacement en haut et en bas de 38,1 mm [1,5 po.].

• Espacement latéral de 25,4 mm [1,0 po.] sur la droite si l'installation ou le retrait

de la console de programmation est nécessaire.

Montage et côtes d'encombrement

3-f

Page 30

Câblage des borniers d'alimentation en

courant alternatif (CA) et de commande

Les avertissements suivants s'appliquent au schéma de câblage de la page opposée :

ATTENTION : Cet équipement contient des potentiels élevés lorsque

l'alimentation CA est connectée. Débrancher et isoler tous les

conducteurs de l'alimentation CA non mis à la terre avant d'entre-

!

prendre un travail sur le variateur. Tout défaut d'observation de ces

précautions peut entraîner de graves dommages corporels ou même

la mort.

ATTENTION : De nombreux codes locaux et nationaux exigent qu'un

interrupteur général soit installé sur l’alimentation secteur avant la

distribution au variateur. Tout défaut d'observation de ces précautions peut entraîner de graves dommages corporels ou même la mort.

ATTENTION : De nombreux codes locaux et nationaux exigent

qu'une protection en amont sur les phases soit fournie pour protéger

l'alimentation du variateur. Tout défaut d'observation de ces précautions peut entraîner de grav es dommages corporels ou même la mort.

ATTENTION : Si la capacité du système de distribution dépasse

l'intensité maximale du courant de court-circuit à défaut symétrique

du variateur, (100 kA), il faut ajouter un l'impédance sur la ligne de

courant alternatif alimentant le variateur pour limiter le courant

disponible en cas de défaut. Tout défaut d'observation de ces

précautions peut entraîner des dégâts matériels ou la destruction

de l'équipement.

ATTENTION : L'utilisateur doit fournir un circuit d'arrêt d'urgence

externe et câblé en dehors des circuits du variateur SP200. Ce circuit

doit pouvoir désactiver le système en cas de fonctionnement anormal.

Un fonctionnement incontrôlé de la machine pourrait survenir si

l’installation d’un tel circuit n’est pas effectuée. Tout défaut d'observation de ces précautions peut entraîner de graves dommages corporels

ou même la mort.

ATTENTION : Si une commande à deux fils est choisie, le variateur

se met immédiatement en marche lorsqu'il est mis sous tension en

présence d'une commande de marche avant ou de marche arrière.

T out défaut d'observation de ces précautions peut entraîner de graves

dommages corporels ou même la mor t .

ATTENTION : La tension du connecteur circulaire à quatre broches

(situé directement au-dessus des borniers de la commande) peut

atteindre un niveau dangereux si la borne de blindage du variateur

(borne 1) n'est pas mise à la masse. Tout déf aut d'observation de ces

précautions peut entraîner de graves dommages corporels ou même

la mort.

4-f

Guide de mise en route du variateur SP200

Page 31

Alimentation triphasée

Alimentation monophasée

5-f

(16 AWG).

2

En mode trois fils, la marche

arrière n'est pas disponible

Entrée 230/460 Vca triphasée

Mise à

la terre

230 Vca

Neutre

Mise à

la terre

115 Vca

Neutre

Mise à la

terre

Entrée monophasée 230 Vca

Modèle A

+10 V

Démarrage deux fils

Blindage/commun

Entrée 115 Vca

0 à 10 V

Commun

4 à 20 mA

Marche avant

Marche arrière

Entrée configu rable

Dévalidation/réinitialisation

Entrée

analogique

Modèle B

Relais NF

Relais NO

Commun relais

Sortie conf ig ur abl e

(défaut)

+10 V

Blindage/commun

Dévalidation/réinitialisation

Sortie 230/460 Vca triphasée

Mise à la terre

moteur et blindag e de

câble

Modèle C

Commun

Relais NF

Marche avant

Marche arrière

Entrée vit présel 1

Entrée vit présel 2

Relais NO

Commun relais

Entrée configurable (réglage 3)

Sortie configurable

(défaut)

+10 V

Blindage/commun

+10 V

Modèles A, B et C

Démarrage trois fils

Arrêt/réinitialisation

0 à 10 V

0 à 10 V

Commun

4 à 20 mA

Marche avan t

Entrée

analogique

canal 1

Entrée

analogique

Config. entrée (Dévalidation/réinitialisation)

sur le modèle C.

Démarrage

Marche arrière

Commun

4 à 20 mA

Relais NO

Commun relais

canal 2

Sortie configurable

(défaut)

(12 AWG).

2

(26 AWG) à 1,5 mm

2

Renseignements concernant les borniers de l'alimentation électrique

indépendamment des fils de l'alimentation électrique.

• Les borniers acceptent des fils de calibre jusqu'à 4 mm

• Le couple de serrage recommandé est de 1,35 Nm (12 po.-livre).

Renseignements concernant le bornier de la commande

• Le bornier est isolé de l'alimentation d'entrée.

• Les fils de la commande doivent être blindés et acheminés séparément,

• Le bornier accepte des fils de calibre de 0,14 mm

Câblage des borniers d'alimentation en courant alternatif (CA) et de commande

• La longueur maximum du câble de la commande est de 30 mètres (100 pieds).

Page 32

Recommandations au sujet du câble

de moteur

Distance de câble entre le variateur et le moteur

La distance de câble entre le variateur et le moteur doit être limitée pour les deux

raisons suivantes :

1. Un long câble entre le variateur et le moteur peut produire une tension de

crête susceptible d'endommager le moteur lorsque l’isolement électrique du

moteur est inférieur à 1 600 V. L'emploi de selfs en sortie peut affecter la valeur

crête. Utiliser le tableau de la page suivante pour déterminer la distance maximum supportable avec un moteur dont l'isolement est prévu pour une crête de

tension de 1 000 V.

2. Un long câble entre le variateur e t le mo teur pe ut aussi eng endr er un c ouplage capacitif du courant vers la terre. Ceci peut provoquer une défaillance du

variateur et en cacher la cause. L'emploi de selfs et de blindage ou de conduits de

câble en sortie peut affecter ce courant. Utiliser le tableau de la page suivante

pour déterminer la distance maximum supportable entre le variateur SP200 et le

moteur.

Les deux limites décrites ci-dessus doivent être prises en compte pour l'installation.

La plus faible de ces deux valeurs est celle à considérer comme la limite.

Type de câblage à utiliser entre la commande

et le moteur

Le type de câblage qu'il est recommandé d'utiliser entre le variateur et le moteur

dépend de l'environnement fonctionnel. L'usage de câble avec isolement en PVC

(chlorure de polyvinyle) est réservé dans certaines conditions. Un exemple courant

de ce type de câble est le THHN. Dans les cas où le PVC n'est pas indiqué, il est

recommandé d'utiliser le XLPE (polyéthylène réticulé). Le XHHW-2 est un exemple de

ce type de câble. Le fait de tirer les câbles à travers des conduits coudés à 90 degrés

use et enlève une partie de l'isolant des câbles. Pour cette raison, il faut prendre des

précautions supplémentaires au cours de ce processus et choisir un câble dont

l'épaisseur d'isolant est supérieure à la moyenne.

Types de câbles recommandés

Ambiance

Sèche

Humide XLPE XHHW-2

1

Lorsqu'un câble avec isolant de type PVC est utilisé, l'épaisseur standard de 15 mil

[1 mil = 1/1 000 de pouce] est adaptée aux conditions normales ; toutefois, si les

câbles multiples d'un moteur passent dans un même conduit sur une distance de

plus de 15 mètres (50 pieds) de long et que la tension dépasse 240 V +10%, il est

recommandé d'utiliser une épaisseur supérieure ou égale à 20 mil.

6-f

Types d'isolan ts Exemples

PVC

XLPE

1

Guide de mise en route du variateur SP200

THHN

XHHW-2

Page 33

460 2,0 (1,5) 300 91 200 61 200 61 200 61 170 52 400 122 400 122 400 122 400 122

7-f

460 1,0 (0,75) 300 91 120 37 100 30 100 30 100 30 300 91 300 91 300 91 300 91

460 0,5 (0,37) 300 91 100 30 100 30 100 30 90 27 175 53 175 53 175 53 150 46

240 2,0 (1,5) — — 600 183 600 183 500 152 300 91 600 183 600 183 600 183 600 183

120 / 240 1,5 (1,1) — — 600 183 600 183 500 152 300 91 600 183 600 183 600 183 600 183

120 / 240 1,0 (0,75) — — 600 183 600 183 500 152 400 122 600 183 600 183 600 183 600 183

120 / 240 0,5 (0,37) — — 300 91 280 85 280 85 280 85 600 183 600 183 600 183 600 183

moteur

3% côté

460 2,0 (1,5) 80 24 220 67 200 61 170 52 130 40 600 183 600 183 600 183 200 183

460 1,0 (0,75) 40 12 180 55 140 43 100 30 100 30 600 183 600 183 600 183 400 122

460 0,5 (0,37) 15 5 120 37 100 30 100 3 0 90 27 200 61 200 61 200 61 150 46

240 2,0 (1,5) — — 600 183 400 122 300 91 200 61 600 183 600 183 600 183 600 183

120 / 240 1,5 (1,1) — — 600 183 400 122 300 91 200 61 600 183 600 183 600 183 600 183

120 / 240 1,0 (0,75) — — 500 152 300 91 300 91 200 61 600 183 600 183 600 183 600 183

120 / 240 0,5 (0,37) — — 400 122 300 91 300 91 100 30 600 183 600 183 600 183 600 183

ligne

3% côté

460 2,0 (1,5) 20 6 220 67 180 55 180 55 100 30 400 122 400 122 400 122 400 122

460 1,0 (0,75) 25 8 120 37 100 30 100 3 0 100 30 300 91 300 91 300 91 300 91

460 0,5 (0,37) 50 15 100 30 100 30 100 30 90 27 175 53 175 53 175 53 150 46

240 2,0 (1,5) — — 600 183 600 183 500 152 300 91 600 183 600 183 600 183 600 183

120 / 240 1,5 (1,1) — — 600 183 600 183 500 152 300 91 600 183 600 183 600 183 600 183

120 / 240 1,0 (0,75) — — 500 152 500 152 400 122 300 91 600 183 600 183 600 183 600 183

120 / 240 0,5 (0,37) — — 250 76 250 76 250 76 200 61 600 183 600 183 600 183 600 183

pieds m pieds m pieds m pieds m pieds m pieds m pieds m pieds m pieds m

2 kHz 4 kHz 6 kHz 8 kHz 2 kHz 4 kHz 6 kHz 8 kHz

Câble blindé ou fils dans conduit Câble non blindé

Limite pour variateur SP200

1 000 V

moteur

Limite pour

d'entrée CV (kW)

Tension

Spécif. de la commande

Aucune

Self

Recommandations au sujet du câble de moteur

Page 34

Console de commande et de

programmation - Fonctionnement

1 En mode Affichage, la touche r incrémente la référence locale de vitesse.

En mode Programmation, cette touche incrémente le numéro de paramètre ou

la valeur du para m ètre.

2 La touche PROG (Programmation) fait basculer entre les modes Affichage et

Programmation. La diode électroluminescente (LED) PROG (Programmatio n)

(5) s'allume lorsque le v ariat eur se trouve en mode Programmation.

3 En mode Affichage, la touche ENTRÉE incrémente jusqu'à l'aff i chage du

paramètre suivant. En mode Programmat ion, cette touche fait basculer entre

le numéro de paramètre et l a valeur du paramètre.

4 La LED MARCHE s'allume lorsque le variateur est actionné, en marche avant

ou en marche arrière. La LED MARCHE clignote lorsque le v ariat eur chan ge de

direction.

5 La LED PROG s'allume lorsque le variateur est en mode Programmation.

6 En mode Affichage, la touche s diminue par incréments la référence locale

de vitesse.

En mode Programmation, cette touche diminue par incréments le numéro de

paramètre ou la valeur du paramètre.

7 La touche STOP lance des ordres d'arrêt et de réinitialisation de défaut à

du variateur.

8 La touche DÉMARRAGE lance des ordres de démarrage au variateur lorsque

P-10 = 1.

9 L'affichage indique, soit un numéro de paramètre, soit une valeur de paramètre.

Les numéros de paramè tre sont précédés, soit par « P- », soit par « d- ».

8-f

Guide de mise en route du variateur SP200

Page 35

Choix d'une référence de vitesse

Réf. de vitesse

principale

Entrée analogique

Fréquence clavier

Fréquence interne

Source de référence de vitesse pour le modèle de commande A

Etat des entrées de sélection Vitesse comm andeé

Borne 8 Borne 7 Borne 6 Paramètre

0 0 0 41 Vitesse présélectioneé 1

0 0 1 42 Vitesse présélectioneé 2

0 1 0 43 Vitesse présélectioneé 3

0 1 1 44 Vitesse présélectioneé 4

1 0 0 45 Vitesse présélectioneé 5

1 0 1 46 Vitesse présélectioneé 6

1 1 0 47 Vitesse présélectioneé 7

1 1 1 48 Vitesse présélectioneé 8

(P-20)

2ème référence

de vitesse

(P-21)

Réf. 1

Réf. 2

Entrée

configurable

(P-11 = 3)

Référence

de vitesse

Fréquence clavier

Fréquence interne

Source de référence de vitesse pour le modèle de commande B

Choix d'une référence de vitesse

Réf. de vitesse

principale

0

(P-20)

1

2

0

1

2ème référence

de vitesse

2

(P-21)

Ref. 1

Ref. 2

Entrée

configurable

(P-11 = 3)

Référence

de vitesse

9-f

Page 36

Entrée analogique 1

Référence de

vitesse

Fréquence clavier

Fréquence interne

Entrée analogique 2

Sélection réf.

process

(P-28)

Choix

process

(P-29)

Réf. de

vitesse

principale

(P-20)

2ème

référence

de vitesse

(P-21)

Entrée

configurable

(P-11 = 3)

Source de référence de vitesse pour le modèle de commande C

Guide de mise en route du variateur SP200

10-f

Page 37

Paramètres du variateur

Paramètres d'affichage

(Lecture seule)

Nº Désignation défaut Plage A B C

d-00 Fréquence commandée 0,1 Hz 0 - 240,0 x x x

d-01 Fréquence de sortie 0,1 Hz 0 - 240,0 x x x

d-02 Courant de sortie 0,1 A 0 - 200 (% du courant nominal) x x x

d-03 Tension de bus 1 V 0 - 1000 x x x

d-04 Code de défaut Annn code alphanumérique x x x

d-05 Etat des entrées décimales 0000 - 7111 x x x

d-06 Spécifications du variateur décimales x x x

d-07 Version logiciel Annn code alphanumérique x x x

d-08 Entrée analogique 1 0,1 % 0 - 110.0 x x

d-09 Entrée analogique 2 0,1 % 0 - 110.0 x

Unités/ Modèles

(Les paramètres qui ne peuvent être programmés que si le

variateur est arrêté sont indiqués par un astérisque *)

Nº Désignation défaut Plage A B C

Groupe 0 : Protection

P-00 Vitesse minimum* 0 Hz 0 - vitesse maximum x x x

P-01 Vitesse maximum* 60 Hz Vitesse minimum - 240 x x x

P-02 Courant de surcharge moteur x.x A 20% - 200% du courant nominal de

P-03 Marche arri ère invalide* 0 0 = marche arrière valide

P-04 Tentative de redémarrage

automatique

P-05 Limite du courant 150% 10% - 150% du courant nominal

Groupe 1 : Entrée/Sortie numérique

P-10 Commande de démarrage* 2 1 = commande par la console

P-11 Entrée configurable* 2 (A) 0 = dévalidation (P-10 ≠ 3) x

Paramètres de programmation

Unités/ Modèles

la commande

1 = marche arrière invalide

00 - 10 xxx

du variateur

2 = commande à deux fils

3 = commande à trois fils

1 (B) 1 = invalide x

0 (C) 1 = préselect. x

1 = marche arrière (2 fils) x

2 = impulsions (P-10 ≠ 1) x x

2 = impulsions (P-10 ≠ 1 ou 3) x

3 = autre choix de vitesse de réf. x x

3 = autre choix vit. de réf. (P-10 ≠ 3) x

4 = relais NF à l’arrêt x x

xxx

x x x

x x x

x

x

x

x

x

x

x

x

x

Paramètres du variateur

11-f

Page 38

x

x

xxx

xxx

x

x

x

4 = relais NF à l’arrêt (P-10 ≠ 3) x

5 = accél./décél. secondaire x x

5 = accél./décél. second. (P-10 ≠ 3) x

1 = pas de défaut/redémarrage auto x x x

2 = marche x x x

3 = à la fréquence x x x

4 = au-dessus de la fréquence x x x

5 = au-dessus du courant x x x

0 = vitesses préselect.

1 = console

2 = fréquence interne (P-40)

3 = entrée analogique 2

xxx

x

xxx

x

x

x

0 = vitesses préselect.

1 = console

2 = fréquence interne (P-40)

4 = choix process (P-29) sortie

3 = entrée analogique 2

xxx

1 = console

x

x

x

x

analogique 2

analogique 2

1 = multip. réf. process (P-28) et entrée

2 = Commande PI

2 = fréquence interne (P-40)

3 = commande PI inversée

xxx

xxx

xxx

1 = roue libre

2 = injection CC

Guide de mise en route du variateur SP200

Paramètres de programmation

Unités/ Modèles

variateur est arrêté sont indiqués par un astérisque *)

(Les paramètres qui ne peuvent être programmés que si le

Nº Désignation défaut Plage A B C

P-12 Sortie configurable 0 0 = pas de défaut x x x

0 0 = entrée analogique 1

Temps décélération 1 5,0 s 0 - 600,0 x x x

principale

P-13 Niveau sortie configurable 0,0 0 - 999,9 (seulement si P-12 = 4 ou 5) x x x

Groupe 2 : Référence de vitesse

P-20 Référence de vitesse

P-21 Autre référence de vitesse 1 0 = entrée analogique 1

P-23 Gain entrée analogique 1 100,0% 0 - 110,0 x x

P-25 Gain entrée analogique 2 100,0% 0 - 110,0 x

P-22 Offset entrée analogique 1 0,0% 0 - 110,0 x x

P-27 Gain de process intégral 0,00 0 - 10,0 (0 = arrêt) x

P-24 Offset entrée analogique 2 0,0% 0 - 110,0 x

P-26 Gain de process proportionnel 0,00 0 - 10,0 (0 = arrêt) x

P-29 Choix process 0 0 = ajout réf. process (P-28) et entrée

P-28 Référence de process 0 0 = entrée analogique 1

Groupe 3 : Commande dynamique

Temps décélération 2 10,0 s 0 - 600,0 x x x

P-30 Temps d'accélération 1 5,0 s 0 - 600,0 x x x

P-31

P-32 Temps d'accélération 2 10,0 s 0 - 600,0 x x x

P-33

Courant de freinage CC 50% 10 - 150 x x x

Fréquence à occulter 0,0 Hz 0 - 240,0 x x x

P-41 Vitesse présélectioneé 1 2,5 Hz 0 - 240,0 x

P-34 Commande d'arrêt 0 0 = rampe

P-35

P-36 Temps de freinage CC à l'arrêt 0,5 s 0 - 20,0 x x x

P-37

P-38 Bande de saut de fréquence 0,0 Hz 0 - 30,0 x x x

P-42 Vitesse présélectioneé 2 5,0 Hz 0 - 240,0 x

Groupe 4 : Vitesses fixes

P-40 Fréquence interne 60,0 Hz 0 - 240,0 x x x

12-f

Page 39

x x x

xxx

x x

13-f

0 - 230 ou 0 - 460 x x x

Unités/ Modèles

Paramètres de programmation

variateur est arrêté sont indiqués par un astérisque *)

(Les paramètres qui ne peuvent être programmés que si le

Nº Désignation défaut Plage A B C

P-43 Vitesse présélectioneé 3 10,0 Hz 0 - 240,0 x

P-44 Vitesse présélectioneé 4 20,0 Hz 0 - 240,0 x

P-45 Vitesse présélectioneé 5 30,0 Hz 0 - 240,0 x

P-46 Vitesse présélectioneé 6 40,0 Hz 0 - 240,0 x

P-47 Vitesse présélectioneé 7 50,0 Hz 0 - 240,0 x

460 V

P-48 Vitesse présélectioneé 8 60,0 Hz 0 - 240,0 x

Groupe 5 : V/Hz

P-50 Tension de base 230 V /

P-51 Fréquence de base 60 Hz 0 - 240 x x x

P-53 Fréquence maxi 0 Hz 0 - 240 x x x

P-52 Tension maxi 0 V 0 - 230 ou 0 - 460 x x x

P-55 Boost auto 3,0% 0 - 10 x x x

P-54 Boost 11 / 23 V 0 - 46 ou 0 - 92 x x x

basculer le réglage

P-61 Mot de passe INVALIDE INVALIDE/VALIDE ; entrer 257 pour

Groupe 6 : Utilitaires

P-60 Réinitialisation au défaut* 0 0-1 ; entrer 1 pour réinitialiser x x x

P-62 Unités pour aff. fréquence 0 0-9999 ; ajuste les affichages

d-08 et d-09

d-00 et d-01

P-63 Unités pour aff. consigne anal. 0 0-9999 ; ajuste les affichages

P-64 Fréquence MLI 2 kHz 2 - 8 x x x

Paramètres du variateur

Page 40

Conformité aux normes de l'Union

européenne

Le variateur SP200 porte la marque CE grâce à sa conformité à la Directive 73/23/CEE relative aux

basses tensions et à toutes les normes applicables lorsqu'elle est installée selon les instructions

fournies à la section Basses tensions ci-après. Le variateur a également subi des tests de conformité aux dispositions de la Directive 89/336/CEE relative aux compatibilités électromagnétiques

(CEM) et ces tests remplissent les conditions de la directive lorsque le variateur est installé selon

les instructions fournies à la section Compatibilité électromagnétique ci-après. S'adresser au

service AutoFax de Rockwell, aux Etats-Unis, au 216-646-7777 (ou à l'agence locale Rockwell

Automation en dehors des U.S.A.) pour obtenir une copie de la Déclaration de conformité (DOC).

La conformité du variateur SP200 aux directives de l'Union européenne ne garantit pas la

conformité de l'ensemble du système. En ce qui concerne la CEM, de nombreux autres facteurs

peuvent affecter l'ensemble de l'installation et seules des mesures directes peuvent vérifier la

conformité globale. Il incombe au fabricant de la machine (ou à l'utilisateur final si la machine a été

modifiée ou utilisée sans respecter les spécifications du fabricant) d'assurer la conformité aux

normes et à la réglementation.

Directive 72/23/CEE relative aux basses tensions

• Suivre tous l e s avertissements (ATTENTION) e t to ut e s le s m e su res de pr éc aut i o n in diqués dans

ce manuel.

• Assurer la mise à la terre de la connexion au terminal PE.

• Installer une enceinte protectrice restreignant l'accès aux dispositifs appartenant à la

catégo-rie IP 20 dans le s con dit io ns im pos ées p ar les c ode s et l es orga nes a dm ini str ati fs loca ux

et nationaux.

Directive 89/336/CEE relative aux compatibilités électromagnétiques

• Installer le variateur SP200 et le filtre antiparasite sur l'alimentation secteur (selon les

spécifications ci-dessous) dans une enceinte métallique de type CEI ou NEMA (blindée) comme

indiqué sur la figure de la page suivante. Respecter les limites de longueur maximum du câble

de moteur comme spécifié à la page 7(≤ 25 m

Variateur Filtre Variateur Filtre

S20-X02P3..... S20-MF1-Y014 S20-204P2..... S20-MF1-45P0

S20-X04P2..... S20-MF1-Y014 S20-207P0..... S20-MF1-49P5

S20-X06P0..... S20-MF1-Y014 S20-401P3..... S20-MF1-45P0

S20-Y07P0..... S20-MF1-Y014 S20-402P0..... S20-MF1-45P0

S20-202P3..... S20-MF1-45P0 S20-402P3..... S20-MF1-45P0

Consulter le guide

tous renseignements sur les dimensions et les poids.

• Maintenir l'alimentation d'entrée, l'énergie de sortie et le câblage du signal de commande tant à

l'extérieur qu'à l'intérieur de l'enceinte, physiquement séparés les uns des autres.

• Raccorder l'enceinte à la borne d'entrée (haut) PE du SP200.

• Raccorder l'enceinte à la terre.

• Utiliser du câble blindé avec un conducteur de terre ou des conducteurs individuels dans un

conduit métallique mis à la terre pour le câblage de l'énergie moteur côté sortie de la commande,

tant à l'intérieur qu'à l'extérieur de l'enceinte, sur toute la distance allant jusqu'au moteur. Amener le blindage aussi près que possible des bornes de sortie. Connecter la terre et le blindage du

câble de moteur à la borne de mise à la terre côté sortie (en bas) du variateur SP200. Raccorder

l'extrémité opposée du conducteur de terre et du blindage du câble de moteur au capot du

moteur.

• Utiliser du câble blindé ou un conduit métallique mis à la terre pour le câblage du signal de

commande tant à l'intérieur qu'à l'extérieur de l'enceinte, sur toute la distance allant jusqu'à

la source du signal de commande. Amener le blindage aussi près que possible des bornes

du signal du variateur. Connecter le blindage à la borne commune de blindage (borne 1) du

SP200 et à la borne PE côté entrée (en haut) du variateur SP200. Raccorder aussi l'extrémité

opposée du blindage au commun du dispositif qui contrôle le variateur SP200.

• Utiliser des serre-câbles de 360 degrés, conformes aux conditions CEM, pour raccorder le

moteur et les blindages du signal de commande aux points de sortie de câble de l'enceinte

et au capot du moteur. Les points de contact doivent être propres et dépourvus de peinture

ou de revêtements non conducteurs.

• Vérifier que toutes les connexions de terre assurent un trajet à impédance faible pour les signaux

haute fréquence.

SP200 Mains Filters

).

(D2-3420) [Filtres (D2-3420) secteur du SP200] pour obtenir

14-f

Guide de mise en route du variateur SP200

Page 41

* Lorsque les circuits de commande sont situés en dehors de l'enceinte du SP200.

de moteur

terre-moteur

Liaison mise à la

Blindage du câble

conditions de compatibilité électromagnétique (CEM)

= serre-câble blindé (ou conduit métallique) de 360 degrés répondant aux

Enceinte blindée

15-f

Vers le moteur

de commande

moteur et variateur

Exemple de câble blindé pour

externe

Gaine plastique de protection

galvanisé (étamé)

Ecran compact en cuivre ou acier

interne

Gaine plastique d'étanchéité

Enveloppe isolante en plastique

Fil de cuivre toronné

Câblage du signal

signal de commande

Vers le bornier du

mise à la masse

PE - Languette de

de l'enceinte

mise à la terre

Connexion de

ligne

Filtre de

commande blindé

Câble de signal de

commande

Signaux de

commande*

signaux de

Coffret des

CA

l’alimentation

Ligne de

Connexions de mise à la terre/à la masse des signaux du variateur et du moteur

Conformité aux normes de l'Union européenne

Page 42

Codes de défauts et dépannage

• En l'absence de tout défaut, la LED est verte.

• En cas de défaut, la LED s'allume en rouge, de façon contin ue, lorsque la console de

commande est raccordée et, en l'absence de celle-ci, en clignotant.

• Il est possible de sortir d'une condition de défaut soit en actionnant l’entree de

réinitialisation soit en affuyant sur la touche STOP soit en coupant en appuyant sur

la touche Stop coupant l'alimentation électrique, sauf indication contraire indiquée

dans la colonne « Action correctrice » du tableau ci-dessous.

Code

affiché

1

Réinitialisation possible

Nbre de

clignote-

ments LED

CF 2 Entrée du signal de

FL 2 Perte de fonction Tentative de démarrage

LU 3

HU 4 Surtension

dO 5 Surcharge

OL 5 Surcharge

OH 6

OC 7 Surintensité de

CL 8 Mauvaise connexion Mauvaise connexion entre

UF 9 Pente négative Conflits de valeurs ent re

J1 10

J2 10 Phase V

J3 10 Phase W

J4 10 C ourt-circuit phas e

J5 10 Phase U - W

J6 10 Phase V - W

CH 11

UP 12 Défaut du

Description

de la faute Cause possible Action correctrice

commande

Sous-tension

du bus CC

1

variateur

1

moteur

Surchauffe

1

courant

(300%)

Défaut terre

sortie phase

Erreur checksum

microprocesseur

Séquence d'entrée

invalide.

pendant que l' entrée

STOP (perte de fonction)

est sur Arrêt.

- Tension d’alimentation

1

trop faible.

- Perte momentanée de la

tension d’entrée.

- Tension d’alimentation

1

trop élevée.