Page 1

SP120 AC Drive

Installation and Operation Manual

115 VAC, Single-Phase

230 VAC, Single-Phase or Three-Phase

460 VAC, Three-Phase

0.2 to 3.7 kW (0.25 to 5.0 HP)

Manual de instalación y operación

del variador de CA SP120

115V CA, monofásico

230V CA, monofásico o trifásico

460V CA, trifásico

0.2 a 3.7 kW (0.25 a 5.0 HP)

Inversor SP120 CA

Manual de instalação e operação

115 VCA, monofásico

230 VCA, monofásico ou trifásico

460 VCA, trifásico

0,2 a 3,7 kW (0,25 a 5,0 HP)

Instruction Manual

Manual de instrucciones

Manual de Instrução

D2-3456-2

Page 2

The information in this manual is subject to change without notice.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

The thick black bar shown on the outside margin of this page will be used throughout this instruction manual to

signify new or revised text or figures.

ATTENTION: The SP120 AC drive contains high voltage DC bus capacitors which take time to

discharge after removal of input power . Bef ore working on the drive, wait fiv e minutes f or capacitors to

!

discharge to safe voltage levels. Darkened display LEDs are not an indication that capacitors have

discharged to safe voltage lev els. F ailure to observe this precaution could result in severe bodily injury

or loss of life.

ATTENTION: This drive generates dangerous electrical voltages and controls potenti ally dangerous

rotating mechanical parts. Disregarding the guidelines provided in this manual may result in severe

bodily injury or loss of life.

ATTENTION: Only personnel familiar with the drive and associated machinery should plan or

implement the installation, start-up and subsequent maintenance of the system. F ailure to comply may

result in bodily injury and/or damage to the equipment.

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitiv e parts and assemblies. Static

control precautions are required when installing, testing, servicing or repairing this assembly.

Component damage may result if ESD control procedures are not followed. Failure to observe this

precaution could result in damage to the equipment.

ATTENTION: The drive is intended to be installed with a fixed ground connection. The protective

ground only offers protection for the drive , not against personal injury. According to EN 50178, it is not

recommended to use the SP120 drive on protective fault current switches as, due to a possible DC

component (rectifier load), the sensitivity of the safety switch will be reduced in the event of a failure.

If unavoidable, only type B RCDs should be used. As a precautionary measure, the EN 50178

regulations should be observed. Failure to observe this precaution c ould result in se v ere bo dily injury

or loss of life.

ATTENTION: An incorrectly applied or installed drive can result in component damage or reduction

in product life. Wiring or application errors such as undersizing the motor, supplying an incorrect or an

inadequate AC supply, or excessive ambient temperatures may result in system malfunction. Failure

to observe this precaution could result in damage to the equipment.

ATTENTION: To prevent any injuries or damage, do not touch any components located within the

housing – either with your hands or with any other objects – if input voltage is applied or if the DC bus

capacitors are not discharged. Do not carry out any work on the wiring or check any signals if input

voltage is applied.

ATTENTION: Ensure that the input voltage corresponds to the voltage indicated on the product

nameplate. Environmental influences such as high temper atures and high relative humidity are to be

avoided as well as dust, dirt, and corrosive gases. The mounting location should be well v entilated and

not exposed to direct sunlight. Install the device upright on a non-flammable, vertical wall. Failure to

observe this precaution could result in damage to the equipment.

ATTENTION: The drive start/stop and enable control circuitry includes solid-state components. If

hazards due to accidental contact with moving machninery or unintentiojnal flow of liquid, gas, or solids

exist, an additional hardwired stop circuit is required to remov e AC input power to the drive . Failure to

observe this precaution could result in severe bodily injury or loss of life.

ATTENTION: All the pertinent safety regulations, e.g. accident prevention regulations, professional

association regulations, EN, VDE regulations etc., must be observed. As these regulations are

implemented differently in diff erent countries, the user mus t observe the regulations that apply f or his

particular country. Failure to observe this precaution could result in severe bodily injury or loss of life.

Reliance is a trademark of Rockwell Automation.

©2000 Rockwell International Corporation

Page 3

La información de este manual está sujeta a cambios sin previo aviso.

Las siguientes notas se utilizan en todo el manual para llamar la atención del lector hacia ciertos aspectos relacionados

con su seguridad:

ATENCIÓN: Indica información referente a prácticas o circunstancias que pueden causar

lesiones o la muerte, daños a bienes o pérdidas económicas.

!

Importante: Identifica información esencial para el uso correcto del producto y la comprensión adecuada del mismo.

ATENCIÓN: El variador de CA S P120 co ntiene ca pacit ores de b us de CC de alta te nsión que req uieren

tiempo para descarg arse después de descon ectar la pote ncia de ent rada. Antes de trabaj ar en el v ariador,

espere cinco minutos para que los capacitores se descarguen a niveles seguros de tensión. Si las luces

!

Reliance es una marca registrada de Rockwell Automation.

indicadoras de la pantalla se oscurecen no signi fica que los capacitores se h an descargado a nivele s seguros

de tensión. De no observarse esta precaución, pueden sufrirse lesiones corporales graves o la muerte.

ATENCIÓN: Este variador gene ra tension es eléctricas pel igrosas y controla partes me cánicas gira torias

potencialmente peligrosas. La desatención a los lineamientos proporcionados en este manual puede

ocasionar lesiones corporales graves o la muerte.

ATENCIÓN: Únicamente el personal familiarizado con el variador y la maquinaria relacionada deberá

planificar o realiza r la instalación, el arr anque y el mantenimiento ul terior del sistema. De lo cont rario, pueden

sufrirse lesiones corporales y/o daño al equipo.

ATENCIÓN: Este variador contiene partes y conjuntos sensibles a ESD (Descarga Electrostática). Al

instalar, probar, dar mantenimiento o reparar este conjunto es necesario tomar ciertas precauciones de

control. Si no se s iguen los p rocedi mient os de contro l d e ESD, pued en oca siona rse da ños a l compo nen te.

El no seguir estas precauciones puede dar como resultado daño al equipo.

ATENCIÓN: El variador está diseñ ado pa ra ins talars e con una conexión fija a tie rra. L a tierr a pr otectora

sólo ofrece protección para el variador, no contra lesiones personales. De acuerdo a la EN 50178, no se

recomienda el uso del v a riador SP120 en los inte rruptores pro tectore s de co rriente de f allo y a que , debid o

a un componente posible de CC (carga del rectificador), la sensibilidad del interruptor de seguridad se

reducirá en caso de un fallo . Si es inevitab le, sólo se debe u sar el tipo B RCD . Como una medi da precautoria,

se deben observar los reglamentos de la EN50178. De no observarse esta precaución, pueden sufrirse

lesiones corporales graves o la muerte.

ATENCIÓN: Un variador utiliz ado o instalad o en f orma incorrecta puede oc asionar daños al componente

o reducir la vida ú til de l product o . Los e rrores de insta lación de condu ctores eléc tricos o de aplicac ión tale s

como el uso de u n mot or de me nor ta maño, un sum inist ro de alime ntaci ón de CA incorre cto o inad ecuad o,

o temperaturas a mbiente excesiv as pueden ocasionar un mal funcionamiento del sis tema. El no seguir estas

precauciones puede dar como resultado daño al equipo.

ATENCIÓN: Para evitar cualquier lesión o daño, no toque ningún componente localizado dentro del

alojamiento - con sus manos o con cualquier otro objeto- si la tensión de entrada está aplicada o si los

capacitores de bus de CC no es tán descar gados . No lle v e a cabo nin gún traba jo en el cab lead o o v erifique

alguna señal si la tensión de entrada está aplicada.

ATENCIÓN: Asegúrese que la tensión de entrada corresponde a la tensión indicada en la placa de

identificación del producto. Se deben evitar las influencias ambientales como las temperaturas altas y la

humedad relativ a alta así como el po lv o , la suci edad y los gas es corrosiv os . La ubicac ión de montaj e debe

estar bien ventilada y no estar expuesta a los rayos directos del sol. Instale el dispositivo con la parte

superior orientada hacia arriba, en un a pared vertical no inflam able. El no se guir estas precauc iones puede

dar como resultado daño al equipo.

ATENCIÓN: Los circuitos de arranque/parada y de control de habilitación del variador incluyen a los

componentes de estado sólido. Si existe algún riesgo debido al contacto accidental con la maquinaria en

movimiento o al flujo accidental de líquido, gas o sólidos, será necesario contar adicionalmente con un

circuito alambrad o para parad a a fin de eliminar la po tencia de entrad a de CA al variado r. De no observarse

esta precaución, pueden sufrirse lesiones corporales graves o la muerte.

ATENCIÓN: Se deben observar todos los reglamentos de seguridad pertinentes, por ejemplo los

reglamentos de prevención de accidentes, los reglamentos de la asociación profesional, la EN, los

reglamentos VDE, etc. Como estos reglamentos se implementan en f orma diferente en los diferentes paíse s,

el usuario debe observar los reglamentos que aplican para su país particular. De no observarse esta

precaución, pueden sufrirse lesiones corporales graves o la muerte.

Page 4

As informações contidas neste manual estão sujeitas a alterações sem aviso prévio.

As notas seguintes são usadas neste manual para alertá-lo sobre considerações relativas à segurança:

ATENÇÃO: Identifica informações sobre práticas ou circunstâncias que podem resultar em

lesões pessoais ou morte, dano de propriedade ou perda financeira.

!

Importante: Identifica a informação que é essencial para uma aplicação bem-sucedida e o entendimento do

produto.

Importante: A linha preta, na margem externa, será usada no manual para indicar modificações ou

informações novas.

ATENÇÃO: O inversor SP120 possui capacitores de barramento CC de alta tensão que demoram para

descarregar após a remoç ão da a limen tação de e ntr ada. Ag uarde c inco m in utos antes de tr aba lhar co m o

!

inverso r para q ue os c apacitore s desc arreguem a nív eis s eguros d e tensão. LEDs de ex ibição escurec idos

não são uma indicação de que os capacitores estejam descarregados a níveis seguros de tensão. A não

observância desta precaução pode resultar em lesão corporal grave ou morte.

ATENÇÃO: Este inversor gera tens ões elétricas perigosas e controla peças mecânicas rotativ as que podem

ser potencialmente p erigosas . Se as orientaçõe s dadas ne ste ma nual f orem ignorada s poderá res ultar em

lesão corporal grave ou morte.

ATENÇÃO: Somente o pessoal que estiver familiarizado com o inversor e maquinário relacionado deve

planejar ou implementar a instalação, start-up (partida) e manutenção subseqüente do sistema. Caso

contrário, poderá resultar em lesão pessoal e/ou dano nos equipamentos.

ATENÇÃO: Este inversor possui pe ças e conjuntos sensíveis à ESD (Electrost ati c Di sc ha rge – D es ca rga

Eletrostática). As precauções de controle estático são necessárias durante a instalação, testes, serviços

de manutenção ou re paros deste conjunto . Se os procedimento s de controle de ESD não f orem obedecidos ,

poderá hav er dano s no s co mp onentes. A não observância desta prec au çã o pod erá res ul tar em danos no

equipamento.

A TENÇÃO: O inversor foi projetado para ser instalado com um aterramento fixo. O terra protetor oferece

proteção para o in verso r e não contra le são pessoal . De acordo com o EN5017 8, não se recome nda o uso

do inversor SP120 em chaves de corrente com proteção contra falhas uma vez que, devido ao provável

componente CC (carga do retifica dor), a sen sibil idade da cha v e de s egura nça se rá reduzi da no e v e nto de

uma falha. Se não for possível e vitar seu uso, somente o tipo B RCD dev e ser utilizado. Como uma medida

de precaução, devem-se observar os regulamentos EN 50178. A inobservância desta precaução pode

resultar em lesão corporal grave ou morte.

ATENÇÃO: A instalação ou aplicação indevida do inversor pode resultar em danos aos componentes ou

redução da vida útil do p r odu to. Erros de apli ca ção ou fiação, tai s c om o o s ub dim en si ona mento do motor,

suprimento de alimentação incorreta ou indevida de CA, ou temperaturas ambientes excessivas podem

resultar no funcioname nto inde vido do siste ma. A inobservância desta pre caução poderá resultar em dano

no equipamento.

ATENÇÃO: Para evitar lesões ou danos, não toque em nenhum dos componentes localizados no interior

da caixa – nem com a s mãos nem com objetos – se a tensão de entrad a estiver aplicada ou se os capacitores

de barramento C C não estiv erem des carregados . Não f aça nen hum trabal ho na fiaçã o nem v erifique sina is

quando a tensão de entrada estiver aplicada.

ATENÇÃO: Certifique-se de que a tensão de entrada corresponde à tensão indicada na placa

de identificação do produto . D e vem -se e vitar a s influên cias amb ientais , tais com o temper atur as e umid ade

relativa elevadas, poeira, sujeira e gases corrosivos. O local de montagem deve ser bem ventilado, sem

exposição di reta à luz do sol. Instale o dispositiv o v erticalmente sobre um a parede ve rtical e não inflamáv el.

A inobservância desta precaução poderá resultar em danos no equipamento.

ATENÇÃO: O circuito de capacitação de controle e partida/par ada do inversor inclui com ponentes de estado

sólido. Se ho uver riscos de vi do ao con tato acidental com o mo v im ento do m aqu iná rio o u flu xo i nde se jad o

de líquido, gá s ou sóli dos, é necessário um circu ito de parada adicional com fio s pa ra remover a potênci a

de entrada CA ao inversor. A inobservância desta precaução pode resultar em lesão corporal g rave ou morte.

A TENÇÃO: T odos os regulamentos d e segurança pertinentes , como os regula mentos de pre venção co ntra

acidentes, regulam entos de associações prof issionais, EN, regulamento s VDE, etc., dev em ser observados.

Uma vez que estes regulamentos são implementados de forma diversa em diferentes países, o usuário

deve observar o s regula mentos que se apli cam ao seu paí s em questão . A inobs ervância desta pre caução

pode resultar em lesão corporal grave ou morte.

Reliance é uma marca registrada da Rockwell Automation.

Page 5

Chapter 1 Introduction

1.1 Conventions Used in This Manual...................................................................1-1

1.2 Model Number Description .............................................................................. 1-1

1.3 Receiving Your New Drive............................................................................... 1-2

1.3.1 Unpacking the Drive..............................................................................1-2

1.3.2 Inspecting the Drive ..................................... ...... ....... ...... ....... ...... ....... .. 1-2

1.3.3 Storage and Operating Conditions........................................................ 1-2

1.4 Drive Nameplate Label ....................................................................................1-3

1.5 Drive Features.................................................................................................1-4

Chapter 2 Installing and Wiring the Drive

2.1 Minimum Airflow Clearances...........................................................................2-1

2.2 Mounting the Drive .......... ............................................. ....... ...... ......................2-2

2.3 Terminal Block Locations ................................................................................2-2

2.4 Wiring Power to the Drive................................................................................2-3

2.4.1 Power Terminal Block Descriptions.......................................................2-4

2.4.2 Power Terminal Block Wiring Specifications......................................... 2-4

2.4.3 Branch Circuit Protection Devices......................................................... 2-5

2.4.4 Input Power Conditioning......................................................................2-5

2.4.5 Motor Protection.................................................................................... 2-6

2.4.6 Grounding the Drive..............................................................................2-6

2.5 Wiring the Control Terminal Block...................................................................2-7

2.6 Programmable Digital Input Functions

(Control terminal block inputs 1 through 5).................................................... 2-11

English

CONTENTS

Contents

Chapter 3 Parameters and Programming

3.1 Programming the Drive Using the Keypad ...................................................... 3-1

3.1.1 Programming Examples........................................................................ 3-3

3.2 Parameter Descriptions ...................................................................................3-7

3.2.1 D Group - Display and Diagnostic Parameters (Read Only).................3-7

3.2.2 F Group – Basic Function Parameters..................................................3-8

3.2.3 A Group – Advanced Function Parameters...........................................3-9

3.2.4 b Group – Advanced Control and Protection Parameters................... 3-16

3.2.5 C Group – Intelligent I/O and Communication Parameters.................3-19

Chapter 4 Troubleshooting the Drive

4.1 How To Clear a Fault....................................................................................... 4-1

4.2 Drive Fault Descriptions ..................................................................................4-1

4.3 Possible Drive Problems and Corrective Actions ............................................ 4-3

4.4 Other Displays on the Keypad.........................................................................4-4

Appendix A Technical Specifications...........................................................................................A-1

Appendix B PID Loop Block Diagram ..........................................................................................B-1

Appendix C CE Compliance.........................................................................................................C-1

I

Page 6

English

II

SP120 AC Drive Installation and Operation

Page 7

English

List of Figures

Figure 1.1 – Model Number Structure ......................................................................1-1

Figure 1.2 – SP120 Drive Nameplate Label .............................................................1-3

Figure 1.3 – Drive Features...................................................................................... 1-4

Figure 2.1 – Minimum Airflow Clearances................................................................ 2-1

Figure 2.2 – Terminal Block Locations .....................................................................2-2

Figure 2.3 – Power Wiring Block Diagram................................................................2-3

Figure 2.4 – Power Terminal Block...........................................................................2-4

Figure 2.5 – Grounding the Drive .............................................................................2-6

Figure 2.6 – Typical Control Terminal Connections..................................................2-7

Figure 2.7 – Control Terminal Block and Fault Relay Terminal Block ......................2-8

Figure 3.1 – Programming Overview........................................................................ 3-2

Contents

III

Page 8

English

IV

SP120 AC Drive Installation and Operation

Page 9

English

List of Tables

Table 2.1 – Power Terminal Block Wiring Specifications .........................................2-4

Table 2.2 – Branch Circuit Protection.......................................................................2-5

Table 2.3 – AC Line Rectors and DC Chokes ..........................................................2-5

Table 2.4 – Control Terminal and Fault Relay Terminal Descriptions ......................2-8

Table 2.5 – Programmable Digital Input Functions.................................................2-12

Table 3.1 – Keypad Functions.................................................................................. 3-1

Table 3.2 – LED Functions .......................................................................................3-2

Table 4.1 – Drive Faults............................................................................................4-1

Table 4.2 – Drive Problems ......................................................................................4-3

Table 4.3 – Other Displays on the Keypad............................................................... 4-4

Contents

V

Page 10

English

VI

SP120 AC Drive Installation and Operation

Page 11

This chapter describes the SP120 AC drive and how to identify it based on its model

number. It also provides receiving information and a description of the drive

nameplate and other features.

Refer to Appendix A for specifications and mounting dimensions for the SP120 line

filter modules.

1.1 Conventions Used in This Manual

To help differentiate parameter names and parameter settings from other text

the following conventions will be used:

• Parameter numbers and names are shown in the following way:

OUTPUT FREQUENCY]

d01 [

• Parameter settings for inputs and outputs are shown with the setting number

followed by the alpha description in {braces}. For example, 18{RS}.

English

CHAPTER 1

Introduction

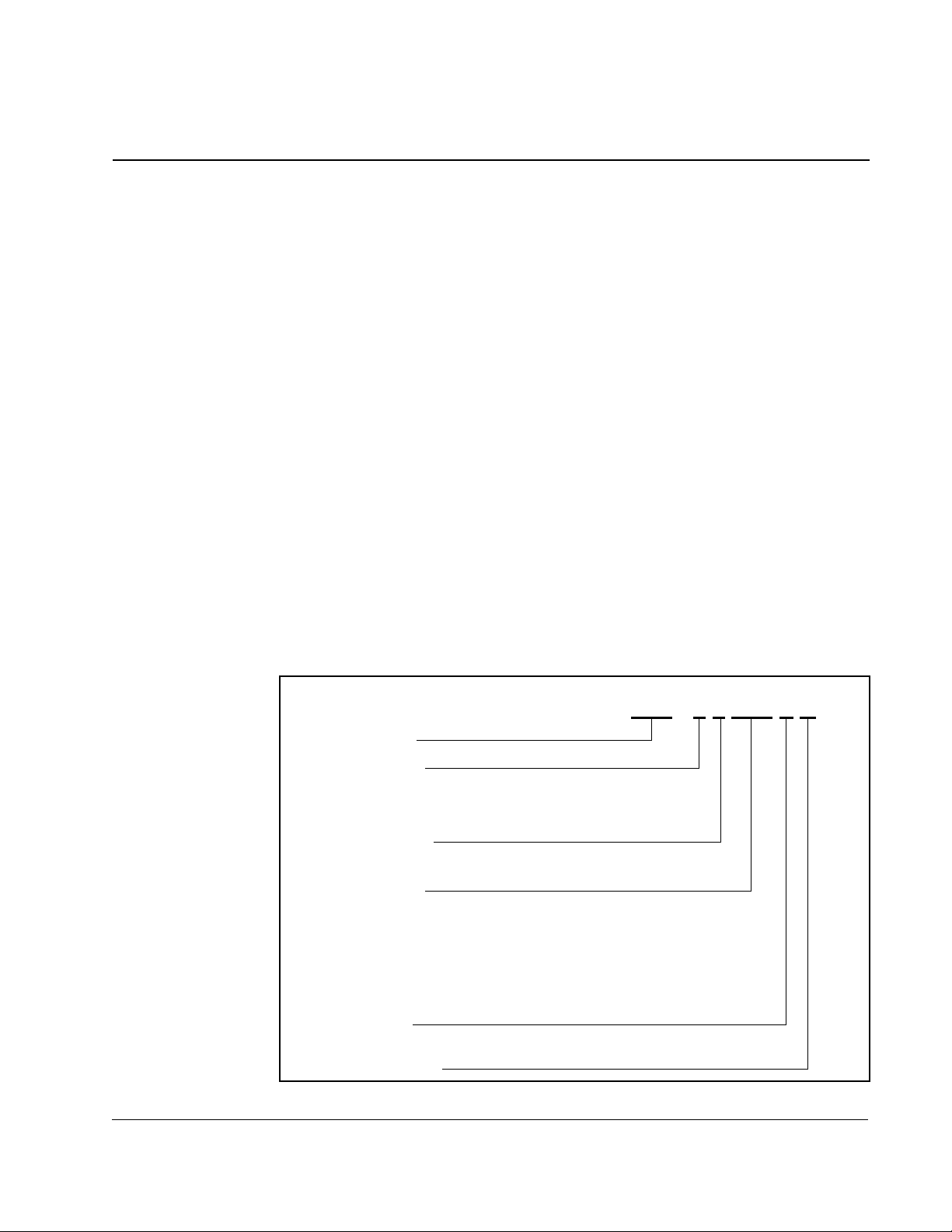

1.2 Model Number Description

Figure 1.1 below describes the SP120 AC drive model numbering structure. Note that

not all combinations can be configured as a drive. Refer to Appendix A,

Specifications,

for more information.

S12 = SP120

Voltage Rating

1 = 115 VAC (

2 = 230 VAC (

4 = 460 VAC (

Enclosure Type

0 = protected chassis IP20

Output Current

1P4 = 1.4 A (0.25 HP (0.2 kW) @ 230 V) 5P0 = 5.0 A (1.5 HP 1.1 kW) @ 230 V)

1P5 = 1.5 A (0.5 HP (0.4 kW) @ 460 V) 5P5 = 5.5 A (3 HP (0.4 kW) @ 460 V)

2P5 = 2.5 A (1 HP (0.75 kW) @ 460 V) 7P1 = 7.1 A (2.0 HP (1.5 kW) @ 230 V)

2P6 = 2.6 A (0.5 HP (0.4 kW) @ 230 V) 8P6 = 8.6 A (5 HP (3.7 kW) @ 460 V)

3P0 = 3.0 A (0.75 HP (0.55 kW) @ 230 V) 010 = 10 A (3.0 HP (0.4 kW) @ 230 V)

3P8 = 3.8 A (2 HP (1.5 kW) @ 460 V) 015 = 15 A (5.0 HP 3.7 kW) @ 230 V)

4P0 = 4.0 A (1.0 HP (0.75 kW) @ 230 V)

L = Keypad

D = DeviceNet

1φ

)

1φ or 3φ

3φ

)

)

Technical

S12 - 2 0 1P4 L U

Introduction

U = 60 Hz (Default)

Figure 1.1 – Model Number Structure

1-1

Page 12

English

1.3 Receiving Your New Drive

It is your responsibility to thoroughly inspect the equipment before accepting shipment

from the freight company. Check the item(s) received against your purchase order. If

any items are obviously damaged, do not accept delivery until the freight agent notes

the damage on the freight bill.

1.3.1 Unpacking the Drive

Remove all packing material, wedges, or braces from within and around the drive.

Remove all packing material from the heat sink. Leave the debris cover in place on

the top of the drive.

If you find any concealed damage during unpacking, notify the freight agent. Also,

leave the shipping container intact and have the freight agent make a visual inspection

of the equipment to verify damage.

1.3.2 Inspecting the Drive

After unpacking, check the item(s) nameplate catalog number against your purchase

order. An explanation of the model numbering system for the SP120 drive is provided

in Figure 1.1 as an aid for nameplate interpretation.

Important: Before you install and start up your SP120 drive, inspect for mechanical

integrity. Look closely for loose parts, wires and connections.

1.3.3 Storage and Operating Conditions

Follow these recommendations to prolong drive life and performance:

• Store within an ambient temperature range of –25

• Store within a relative humidity range of 20 to 90%, non-condensing.

• Avoid storing or operating the drive where it could be exposed to a corrosive

atmosphere.

• Protect from moisture and direct sunlight.

• Operate within an ambient temperature range of –10

Important: To operate the drive between 40

adjustments:

• Reduce the carrier frequency to 2 kHz

• Reduce the output current to 80% of the drives rated current

• Remove the debris cover from the top of the drive

o

C to 70 oC.

o

C to 40 oC.

o

C and 50 oC, make the following

1-2

SP120 AC Drive Installation and Operation

Page 13

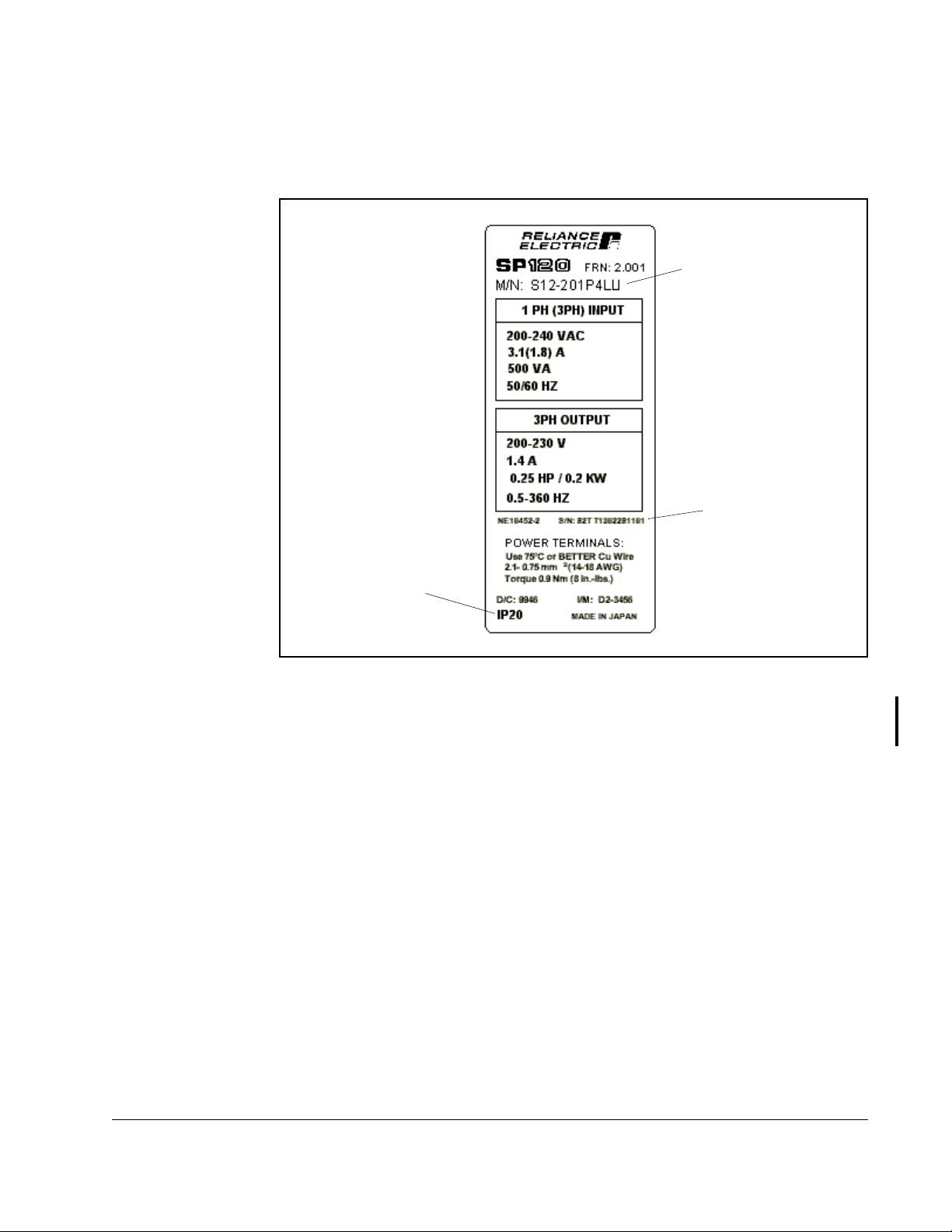

1.4 Drive Nameplate Label

Figure 1.2 depicts a typical SP120 drive nameplate label.

English

Model Number

Serial Number

Enclosure Rating

Figure 1.2 – SP120 Drive Nameplate Label

Important: The IP20 enclosure rating applies only when the SP120 AC drive is wired

for 3-phase input power. The drive is not IP20 rated when wired for

single-phase input power.

Introduction

1-3

Page 14

English

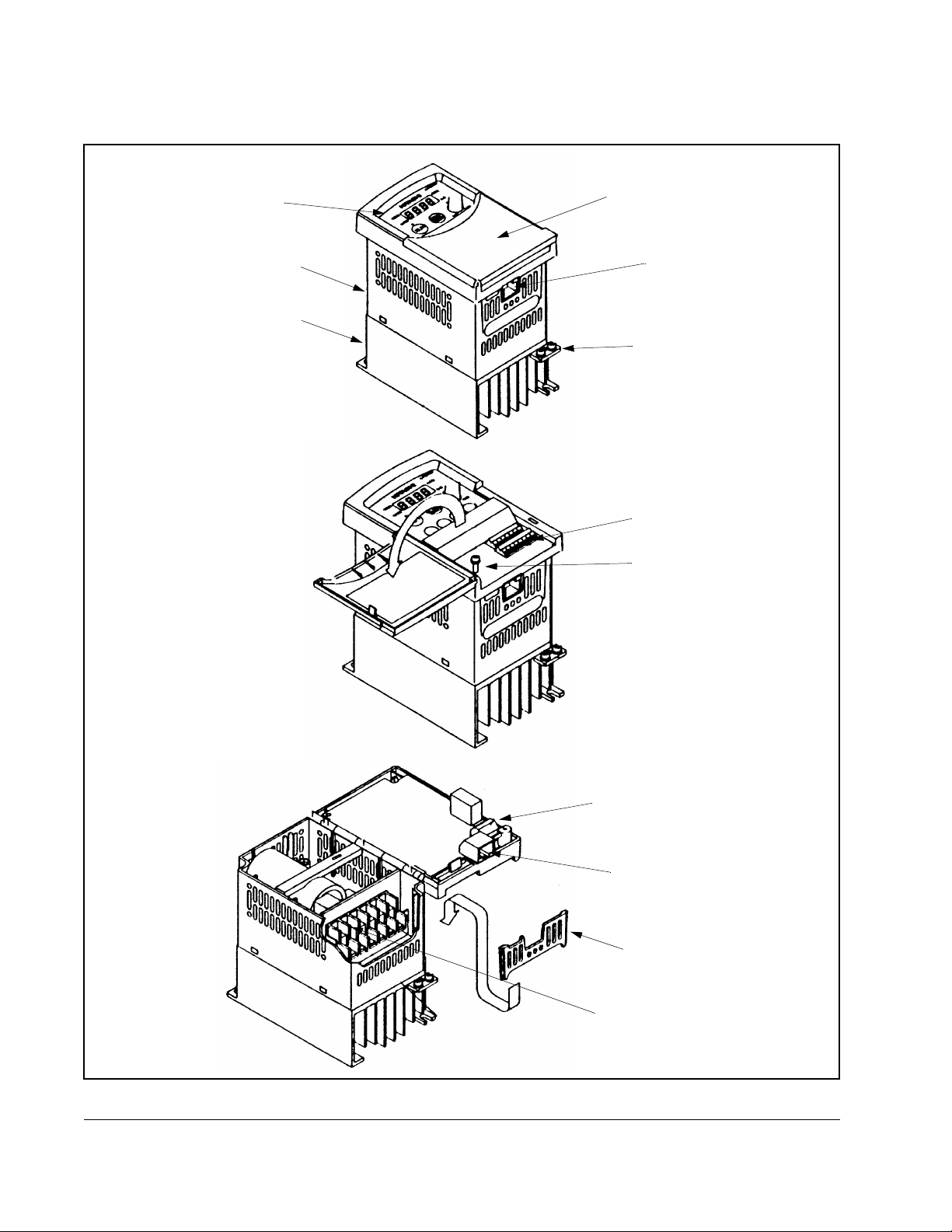

1.5 Drive Features

control panel

enclosure

heat sink

front cover

RS-422 serial interface

PE connection (M4 screw)

control terminals

screw

To wire the power terminals and

fault indication relay, loosen the

screw and open the control unit.

1-4

fault indication relay terminals

RS-422 serial interface

terminal cover

power terminals

Figure 1.3 – Drive Features

SP120 AC Drive Installation and Operation

Page 15

English

CHAPTER 2

Installing and Wiring the Drive

ATTENTION:The installation, commissioning and maintenance of these

drives may only be carried out by experienced personnel who are

!

thoroughly familiar with the functioning of the equipment and the entire

machine. Failure to observe this precaution could result in severe bodily

injury or loss of life.

ATTENTION:The devices feature DC-bus capacitors that are energized

even when the input supply is switched off. For this reason wait at least

5 minutes after switching off the input supply before you open the device

and start working on it. T ake care that you do not touch any live parts.

Failure to observe this precaution could result in severe bodily injury or

loss of lif e.

ATTENTION:Do not apply input voltage to the output terminals U/T1,

V/T2 and W/T3 as drive damage could occur.

ATTENTION:Contact the motor or machine manufacturers if standard

motors with frequencies greater than 60 Hz will be used in your

application. Failure to observe this precaution could result in damage to

equipment.

This chapter describes how to mount the SP120 drive and its external components.

Also shown are the locations and methods of wiring the power terminal block and the

control terminal block.

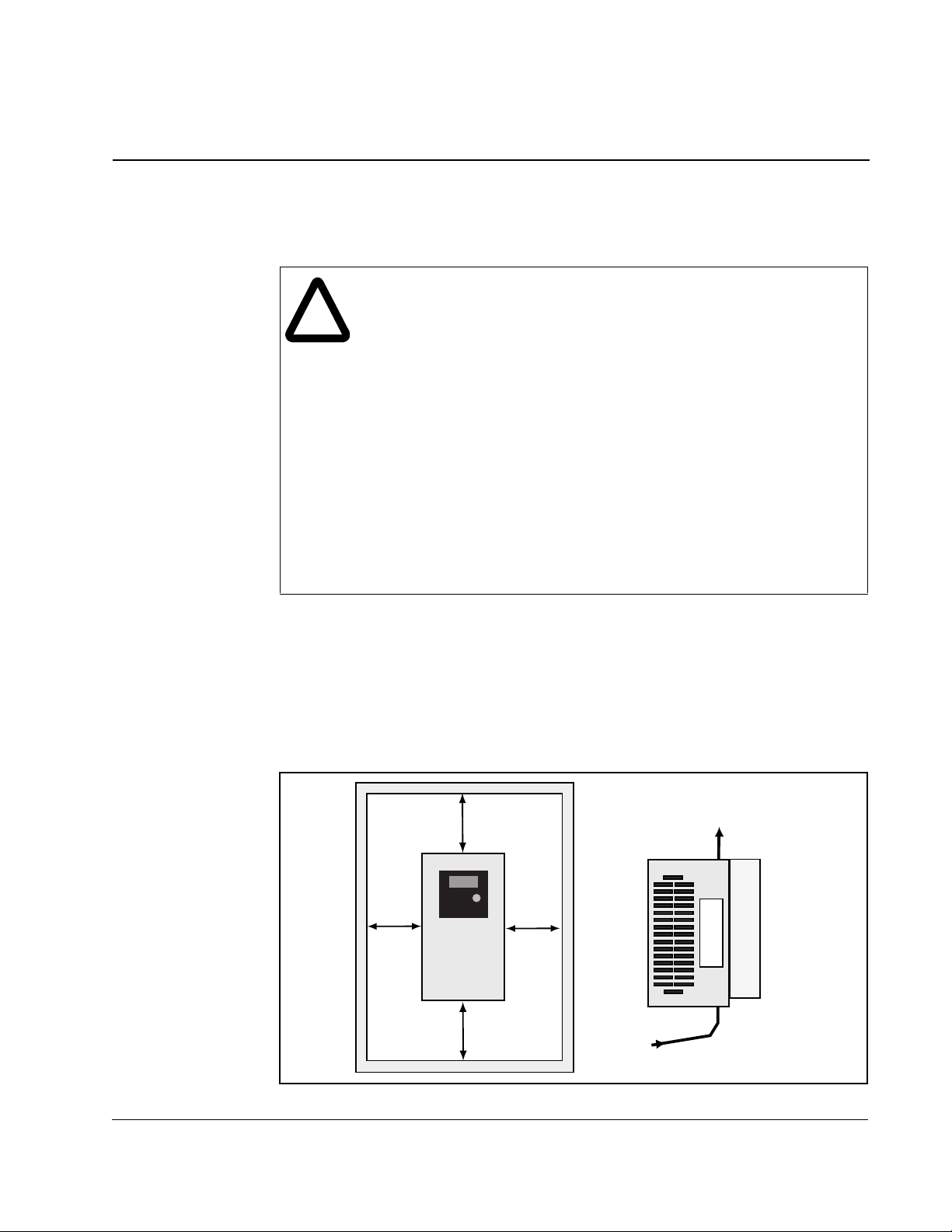

2.1 Minimum Airflow Clearances

The drive should be installed using the minimum airflow clearances shown in figure

2.1.

100 mm

(3.94 in)

30 mm

(1.18 in)

SP120

Drive

30 mm

(1.18 in)

100 mm

(3.94 in)

Air

Circulation

Installing and Wiring the Drive

Figure 2.1 – Minimum Airflow Clearances

2-1

Page 16

English

2.2 Mounting the Drive

Mount the drive on a flat, vertical, and level surface. The drive must be mounted

vertically (top up) for proper heat dissipation. Refer to Appendix A for drive mounting

dimensions.

Install the drive with four (4) M4 x .07 (8-32) screws. Torque the mounting screws to

1.2 Nm (11 lb/in).

Ensure that debris cover is in place when installing the drive to prevent filings, cable

insulation and dust from entering the drive.

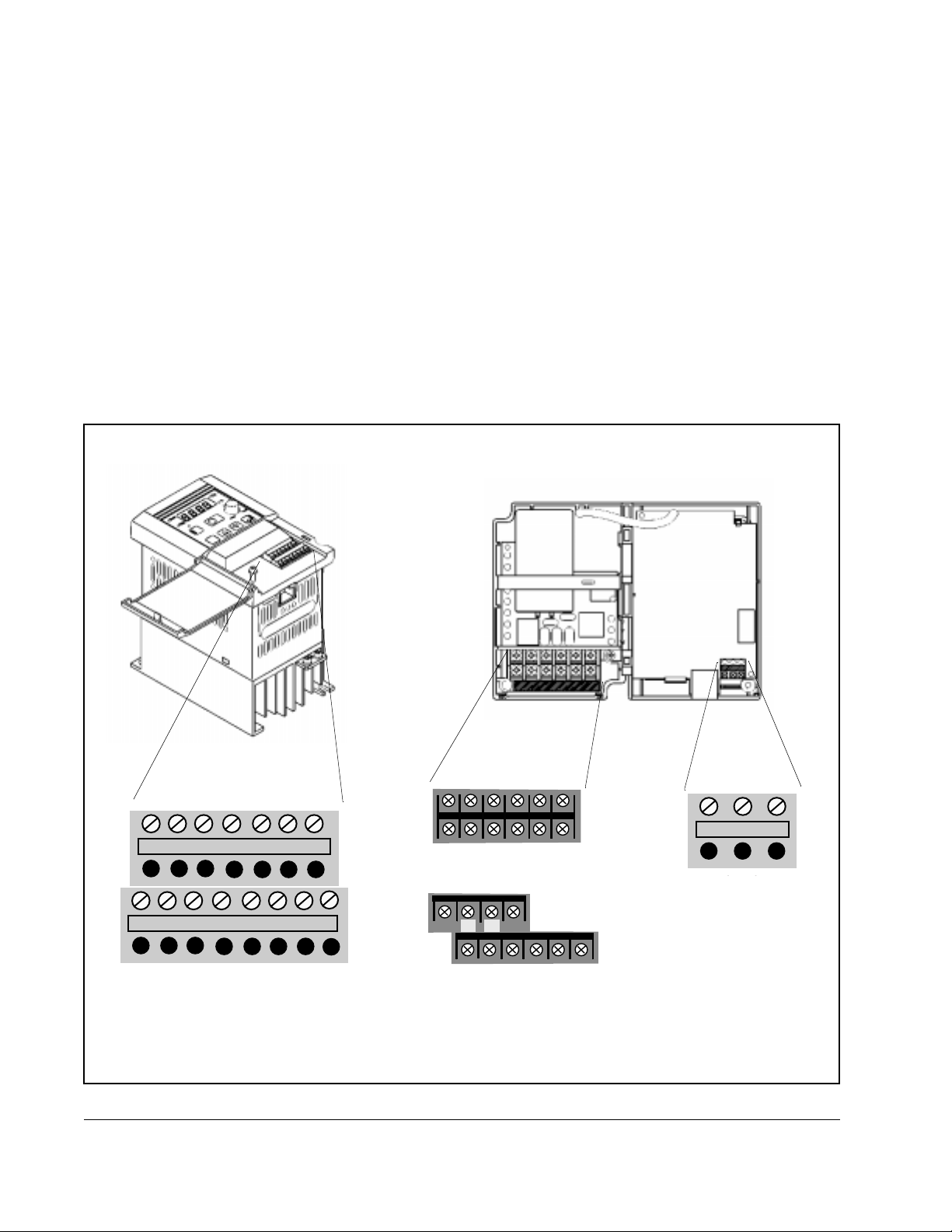

2.3 Terminal Block Locations

Figure 2.2 shows the locations of the power, control, and fault relay terminal blocks.

2-2

L 5 4 3 2 1 P24

HO0I L

Control terminal block

Control Terminal Block

FM CM

21211

+1

*

L1 N/L3

L2

Power terminal block, AA01 - AA03 ratings only

S12-201P4LU / 202P6LU / 203P0LU

+1

(/)

L1 N/L3

Power terminal block, all ratings except AA01 -AA03

All other model numbers

S12-20015LU only - L1, L2, L3

*

Not Used

-

U/T1V/T2W/T3

+

––

-

L2

U/T1V/T2W/T3

* *

*

–

+

Power Terminal Block

Figure 2.2 – Terminal Block Locations

*

* Not used

Fault relay

terminal block

SP120 AC Drive Installation and Operation

AL1 AL2

AL0

F ault Relay

Terminal Block

Page 17

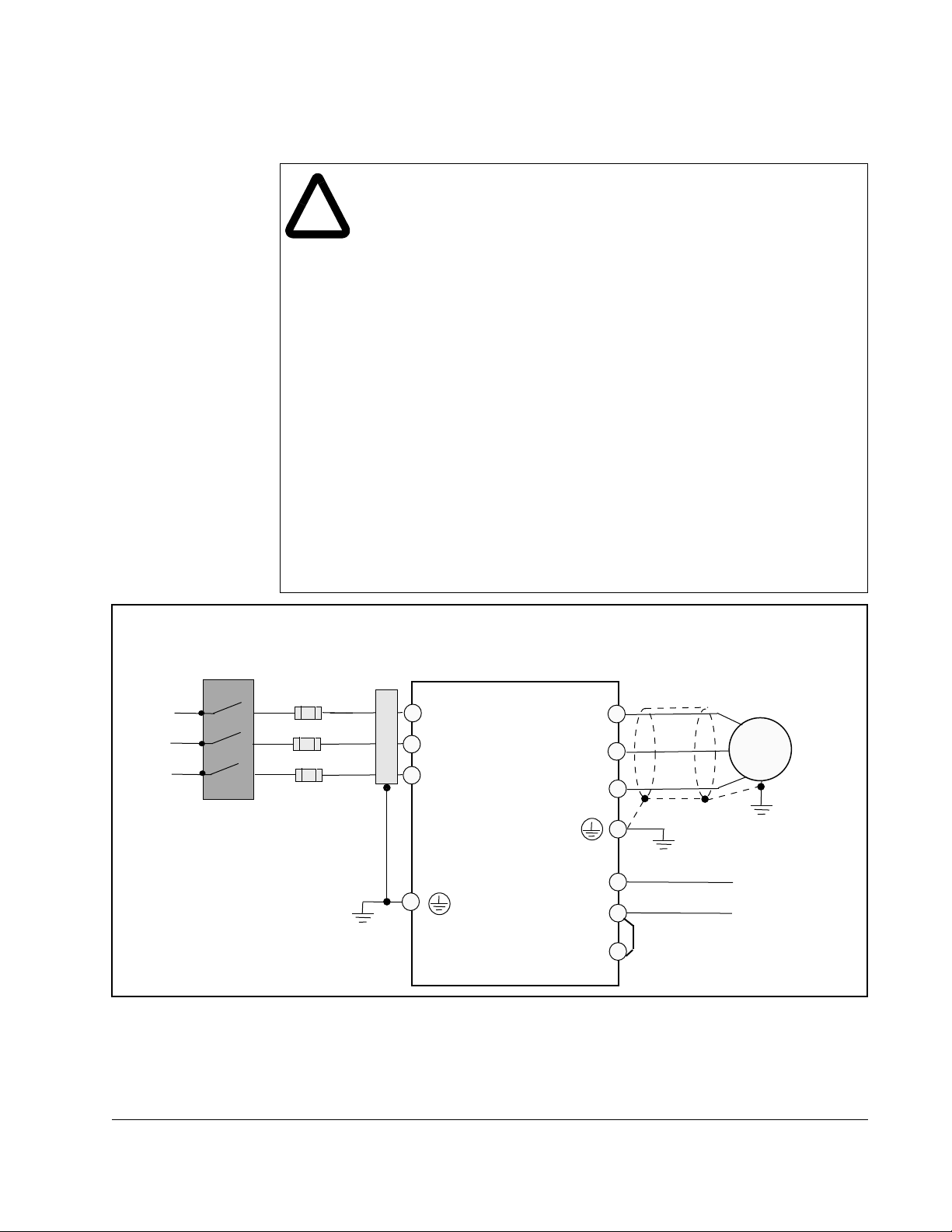

2.4 Wiring Power to the Drive

ATTENTION:Ensure that the input voltage corresponds to the voltage

indicated on the product nameplate. Failure to observe this precaution

!

could result in severe bodily injury or loss of life.

ATTENTION:In normal operation apply the START/STOP commands

via the control terminals or the control panel and not by disconnecting

and reapplying input power to the drive or motor contactor. If it is

necessary to use this method for starting and stopping, or if frequent

cycling of power is unavoidable, make certain it does not occur more

than once every five minutes. Do not install any capacitors or suppressors

to the drive output terminals. Failure to observe this precaution could

result in damege to equipment.

ATTENTION:Exercise particular caution if automatic restart is activated.

To prev ent injuries caused by automatic restarting of the drive following

a power failure, install a switching component at the input that is

deactivated in the event of a power f ailure and that may only be manually

switched on again on return of the power supply (e.g., contactor, etc.).

Failure to observe this precaution could result in severe bodily injury or

loss of lif e.

ATTENTION:If the distribution system capacity exceeds the drive’s

maximum symmetrical fault short-circuit current of 5,000 amps,

additional impedance must be added to the AC line supplying the drive

to limit available current in the event of a fault. Failure to observe this

precaution could resu lt in dam age to the equi pme nt.

English

Input power supply

Disconnect

Device

Fuses

Optional

Filter

L1

L2

N/L3

U/T1

V/T2

W/T3

SP120

AC Drive

Figure 2.3 – Power Wiring Block Diagram

3

Phase

Motor

_

DC Bus

+

+1

Installing and Wiring the Drive

2-3

Page 18

English

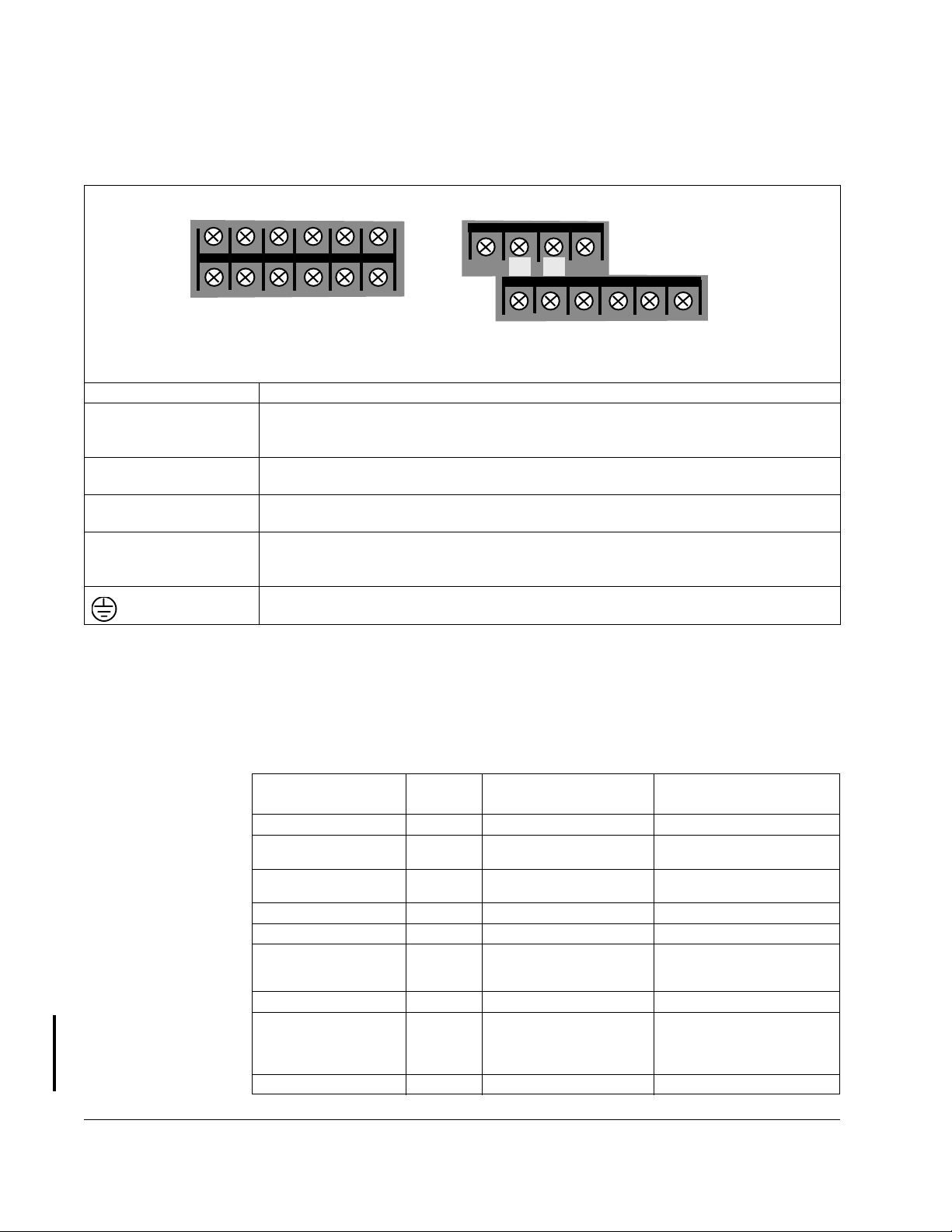

2.4.1 Power Terminal Block Descriptions

Figure 2.4 provides descriptions of the power terminal block.

+1

*

*

L1 N/L3

L2

AA01 - AA03 Power terminal block

S12-201P4LU/202P6LU/203P0LU

*

Not Used

–

+

-

*

* *

U/T1V/T2W/T3

*

All ratings except AA01 - AA03 Power terminal block

* Not used

Terminal Description

L1, L2, N/L3 Connection to incoming power.

For single phase input applications, connect the AC input power to input terminals

L1 and N/L3.

U/T1, V/T2, W/T3 Motor connections.

Use star or delta connection of the motor in accordance with the rated voltage.

+

+1

+

DC Bus connections.

Use these connections for an optional DC brake chopper.

Connection for DC bus reactor.

These terminals are connected by a copper bridge. For applications requiring a DC

bus reactor, remove the bridge prior to installing the reactor. Refer to figure 2.3.

Protective earth ground connection. Refer to figure 2.3.

Figure 2.4 – Power Termion al Block

(/)

L1 N/L3

L2

-

U/T1V/T2 W/T3

–

+

+1

All other model numbers

S12-20015LU only - L1, L2, L3

2.4.2 Power Terminal Block Wiring Specifications

The following table lists the terminal block wiring specifications for SP120 drives.

Table 2.1 – Power Terminal Block Wiring Specifications

Screw

Model

S12-101P4LU M4 5.3 – 1.3 (10 – 16) 1.3 – 1.2 (11.5 – 10.6)

S12-102P6LU

S12-104P0LU

S12-201P4LU

S12-202P6LU

S12-203P0LU M3.5 2.1 – 1.3 (14 – 16) 0.9 – 0.8 (8.0 – 7.0)

S12-204P0LU M4 5.3 – 1.3 (10 – 16) 1.3 – 1.2 (11. 5 – 10.6)

S12-205P0LU

S12-207P1LU

S12-20010LU

S12-20015LU M4 5.3 – 3.3 (10 – 12) 1.3 – 1.2 (11.5 – 10.6)

S12-401P5LU

S12-402P5LU

S12-403P8LU

S12-405P5LU

S12-408P6LU M4 5.3 – 2.1 (10 – 14) 1.3 – 1.2 (11. 5 – 10.6)

Size

M4 5.3 – 2.1 (10 – 14) 1.3 – 1.2 (11.5 – 10.6)

M3.5 2.1 – 0.75 (14 – 18) 0.9 – 0.8 (8.0 – 7.0)

M4 5.3 – 2.1 (10 – 14) 1.3 – 1.2 (11.5 – 10.6)

M4 5.3 – 1.3 (10 – 16) 1.3 – 1.2 (11.5 – 10.6)

Max/Min Wire Size mm

(AWG)

2

Max/Min Torque

Nm (in/lb)

2-4

SP120 AC Drive Installation and Operation

Page 19

2.4.3 Branch Circuit Protection Devices

The following table shows the minimum recommended values for the branch circuit

protection devices:

Table 2.2 – Branch Circuit Protection

Fuse Rating (Class J) Circuit Breaker Type

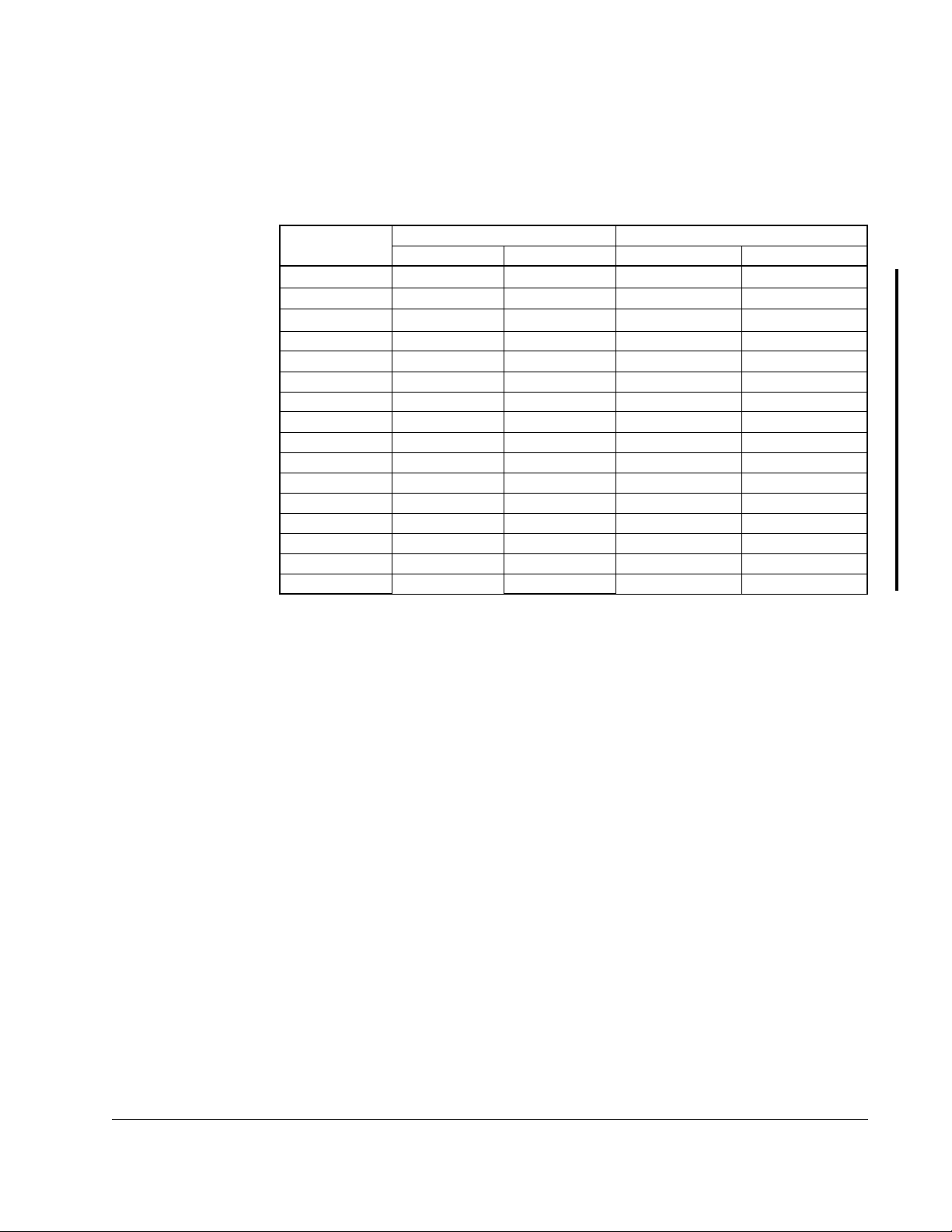

Model Single-Phase Three-Phase Single-Phase Three-Phase

S12-101P4LU 10A N/A 140M-D8N-C10

S12-102P6LU 15 A N/A 140M-D8N-C16

S12-104P0LU 20 A N/A 140M-D8N-C25

S12-201P4LU 10 A 10 A 140M-D8N-C10 140M-D8N-B40

S12-202P6LU 10 A 10 A 140M-D8N-C10 140M-D8N-B63

S12-203P0LU 10 A 10 A 140M-D8N-C10 140M-D8N-B63

S12-204P0LU 15 A 15 A 140M-D8N-C16 140M-D8N-C10

S12-205P0LU 15 A 15 A 140M-D8N-C16 140M-D8N-C10

S12-207P1LU 20 A 15 A 140M-D8N-C16 140M-D8N-C16

S12-20010LU 30 A 20 A 140M-D8N-C25 140M-D8N-C16

S12-20015LU N/A 30 A N/A 140M-D8N-C25

S12-401P5LU N/A 3 A N/A 140M-D8N-B25

S12-402P5LU N/A 6 A N/A 140M-D8N-B40

S12-403P8LU N/A 10 A N/A 140M-D8N-B63

S12-405P5LU N/A 10 A N/A 140M-D8N-C10

S12-408P6LU N/A 15 A N/A 140M-D8N-C16

English

N/A

N/A

N/A

2.4.4 Input Power Conditioning

The drive is suitable for connection to input power within the rated voltage of the drive

(see specifications). The power factor of the input power supply must not exceed .99.

Compensation systems must ensure that overcompensation does not occur at any

time.

If the drive must be installed in any of the following conditions, a 3% impedance input

line reactor must be used:

• line has intermittent noise spikes in excess of 2000 V

• frequent voltage dips occur

• the drive is operated on a generator

• line has power factor correction capacitors

• several drives are linked via a short common power supply bus bar

Installing and Wiring the Drive

2-5

Page 20

English

Drive HP

S12-x01P4xx 0.25 RL-00201 12 2RB003 20

S12-x01P5xx 0.50 RL-00202 20 2RB003 20

S12-x02P5xx 1.0 RL-00201 12 4RB002 12

S12-x02P6xx 0.50 RL-00204 6 4RB002 12

S12-x03P0xx 0.75 RL-00401 3 4RB002 12

S12-x03P8xx 2.0 RL-00402 6.5 4RB003 15

S12-x04P0xx 1.0 RL-00401 3 9RB003 7.5

S12-x05P0xx 1.5 RL-00801 1.5 9RB003 7.5

S12-x05P5xx 3.0 RL-00402 6.5 9RB004 11.5

S12-x07P1xx 2.0 RL-00801 1.5 12RB003 4

S12-x08P6xx 5.0 RL-00802 3.0 12RB004 15

S12-x0010xx 3.0 RL-01201 1.25 18RB003 2.75

S12-x0015xx 5.0 RL-01801 0.8 25RB04 1.75

2.4.5 Motor Protection

Table 2.3 – AC Line Reactors and DC Chokes

AC Line Reactors DC Chokes

MTE Part No. mH MTE Part No. mH

SP120 drives feature electronic overload protection to monitor the motor current. In

the case of multi-motor operation, thermal contacts or positive temperature coefficient

(PTC) resistors must be used for each motor. In the case of motor lead lengths greater

than 50 meters (165 feet), motor reactors should be used.

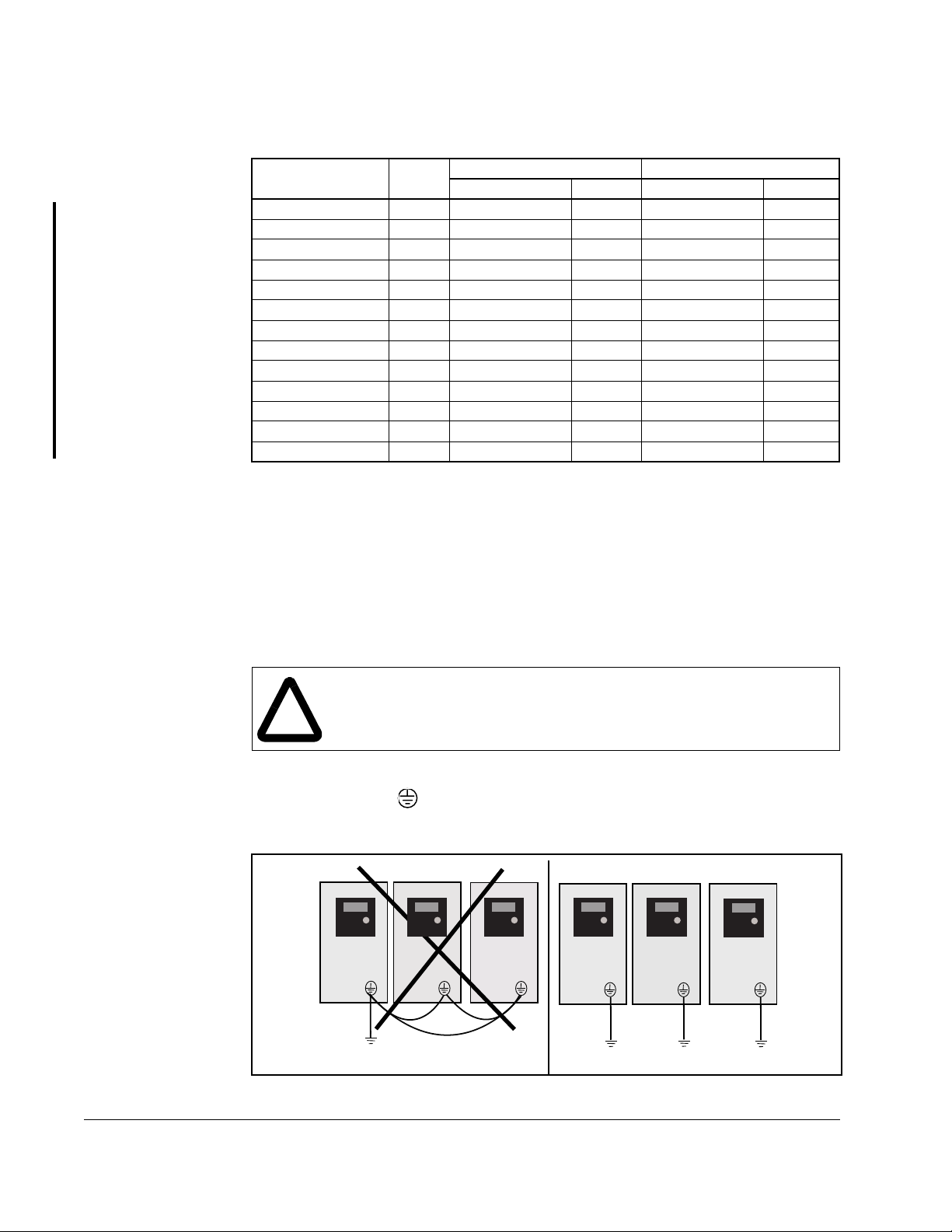

2.4.6 Grounding the Drive

ATTENTION:The SP120 drive has a high leakage current and must be

permanently hard wired to ground. Failure to observe this precaution

!

Ground the drive by connecting a ground wire from the drive’s input grounding

terminal (labeled PE ) uninterrupted to earth ground. Be sure to separate the

drive’s grounding pole from those of other electrical machinery. If multiple drives are

used, make certain each drive is grounded separately (see figure 2.5).

could result in severe bodily injury or loss of life.

SP120 DriveSP120 DriveSP120 DriveSP120 Drive

SP120 Drive

SP120 Drive

2-6

Protective

Earth

Ground

Protective

Earth

Ground

Figure 2.5 – Grounding the Drive

SP120 AC Drive Installation and Operation

Page 21

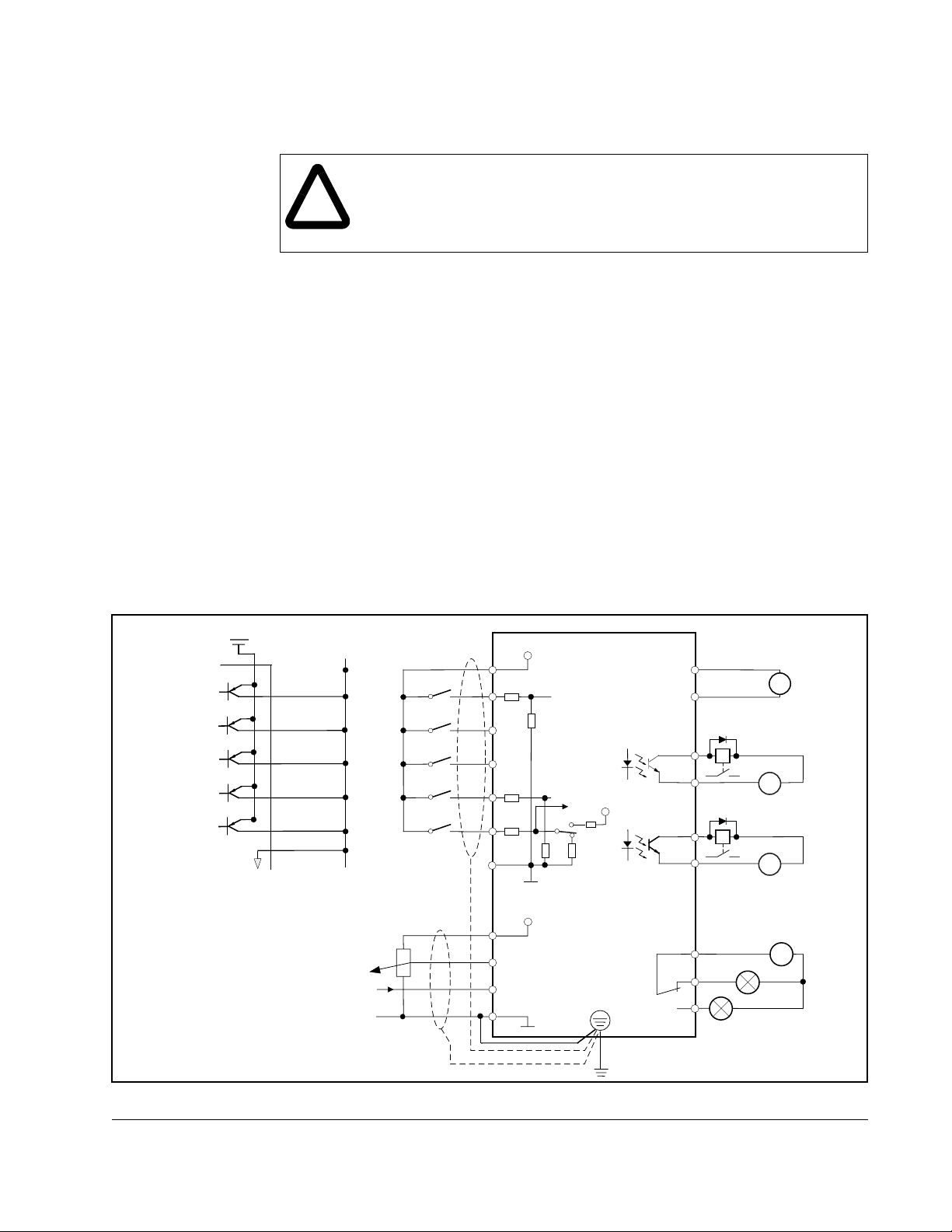

2.5 Wiring the Control Terminal Block

ATTENTION:Control terminals are isolated, but not tied to earth ground.

If terminal (L) on the control terminal block is not grounded, exposed

!

Ensure that the following requirements are met when wiring the control terminal block:

• Run all signal wiring in either a shielded cable or separate metal conduit.

• Do not exceed control wiring length of 20 meters (65.6 feet).

• Use 0.75 mm

0.5-0.6 Nm (4.4-5.3 in lb).

• Use 18 AWG to 28 AWG (0.75 to 0.14 mm

wire for all other signal connections. Torque all connections to 0.2 to 0.25 Nm (1.77

to 2.21 in lb).

conductors, shields or metal conductors can be at hazardous voltage

levels. Failure to observe this precaution could result in severe bodiy

injury or loss of life.

2

(18 AWG) wire for the alarm relay. Torque the mounting screws to

2

), twisted pair, shielded, or 3-conductor

English

• Avoid crossing the power lines or motor lines with the control wires. If they must

cross, ensure that they cross at right angles (90

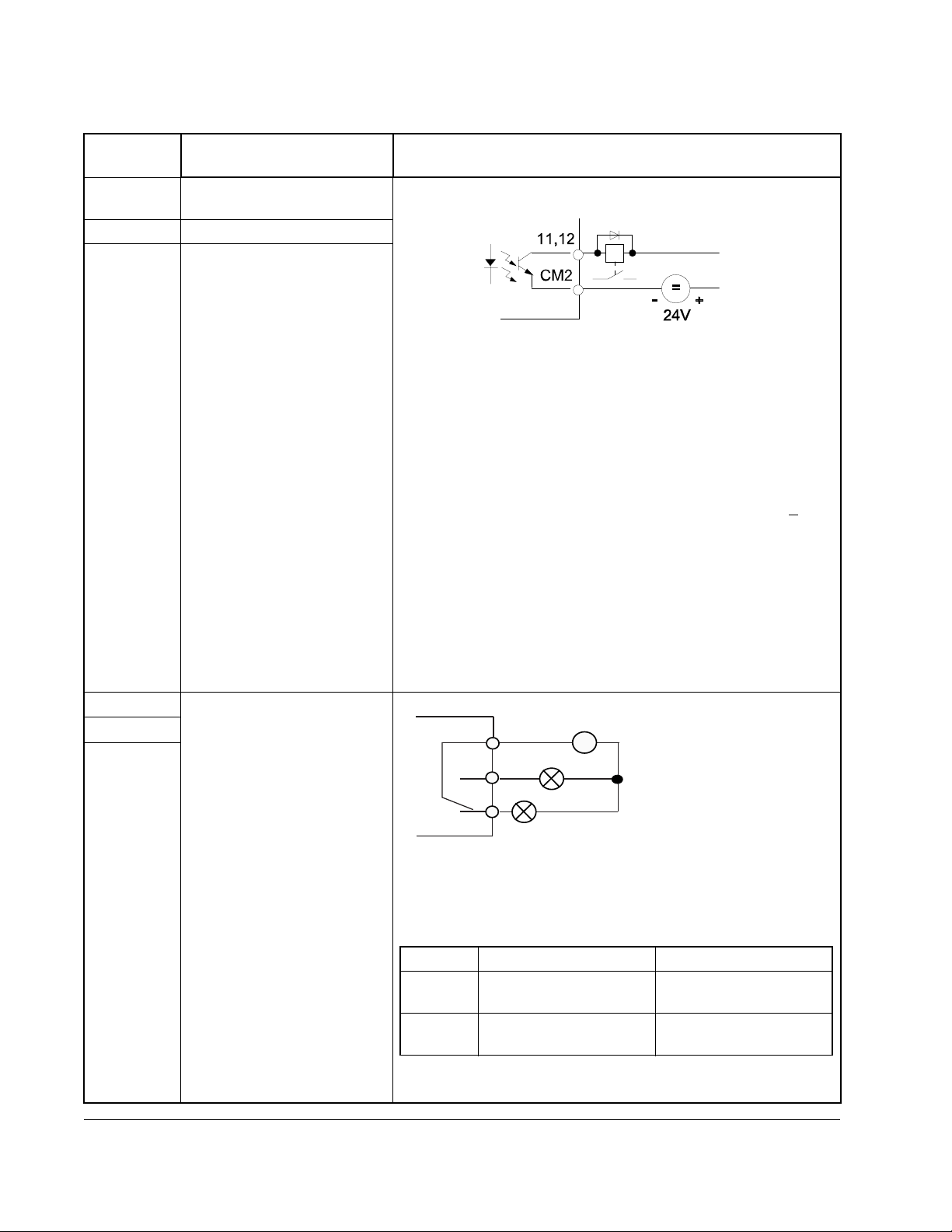

• If using transistor outputs 11 or 12 with an inductive load such as a relay, install a

recovery diode parallel to the relay, as shown in figure 2.6, to prevent damage to the

output.

Figure 2.6 shows typical control terminal connections.

24V

IMPORTANT: Only one frequency

source may be connected at a time.

If more than one reference is

connected at the same time,

an undetermined frequency

reference will result.

To improve noise immunity, the

control terminal block common

(terminal L) must be connected

to ground terminal/protective earth.

External

Power

1-2k Ohm Pot.

Internal

Power

P24

1

2

3

4

5

L

Frequency Reference

0-10V

4-20mA

P24

1

4.4k

2

3

4

4.4k

5

4.4k

L

H

O

OI

L

24V

680

10V

680

PTC

680

5.1k

5V

o

).

FM

L

11

CM2

12

CM2

AL0

AL1

AL2

V

=

–

24V

=

–

24V

Fault Relay

230V AC

~

0-10V

+

+

Installing and Wiring the Drive

Figure 2.6 – Typical Control Terminal Connections

2-7

Page 22

English

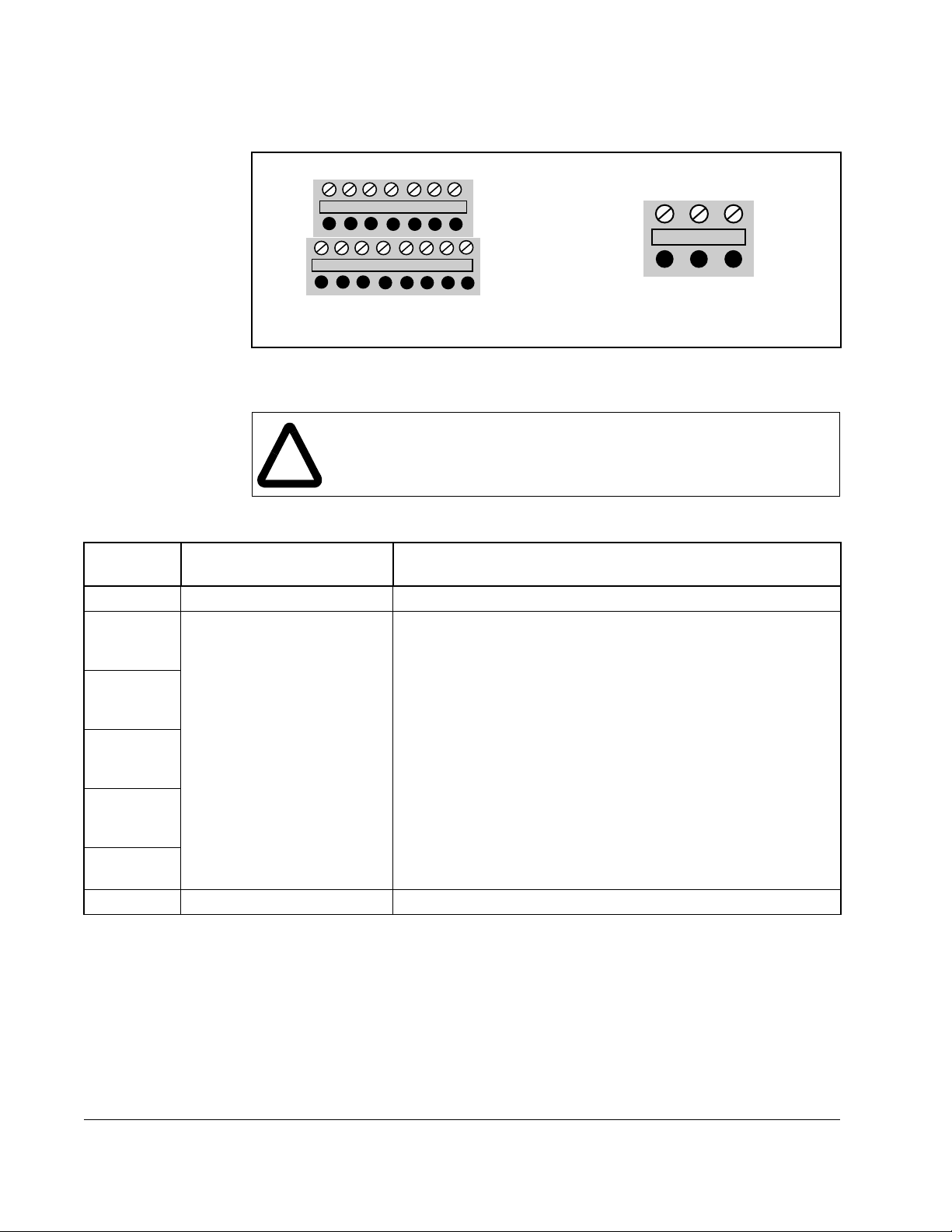

Figure 2.7 and table 2.4 provide descriptions of the drive control terminals and fault

relay terminals.

L 5 4 3 2 1 P24

AL1 AL2

AL0

Fault relay

HO0I L

Control T erminal Block

Control Terminal Block

ATTENTION:Do not jumper or short circuit terminals H and L or P24

and L. Failure to observe this precaution could result in damage to, or

!

Table 2.4 – Control Terminal and Fault Relay Terminal Descriptions

destruction of, the equipment.

FM CM

21211

Figure 2.7 – Control Terminal Block and Fault Relay Terminal Block

Fault Relay

terminal block

Terminal Block

Control

Terminal Function Description

P24 24 V DC 24 V potential or digital inputs 1-5, max. load 30 mA

1 Programmable Digital Inputs.

26 V max, 5 KΩ input

impedance.

2

Digital inputs 1 – 5 are fully programmable level triggered

inputs. An overview of the possible functions can be found in

the digital input description table in section 2.6

The inputs are fully programmable with these exceptions:

• No two inputs can have the same function

3

4

5

L 0 V 0 V potential for output FM

• Only input 5 can be programmed as PTC.

With the exception of the reset setting, which must be NO

(active high), all of the inputs can be set as NO (active high) or

NC (active open) via parameters C11 [

DIGITAL INPUT 5 LOGIC].

C15 [

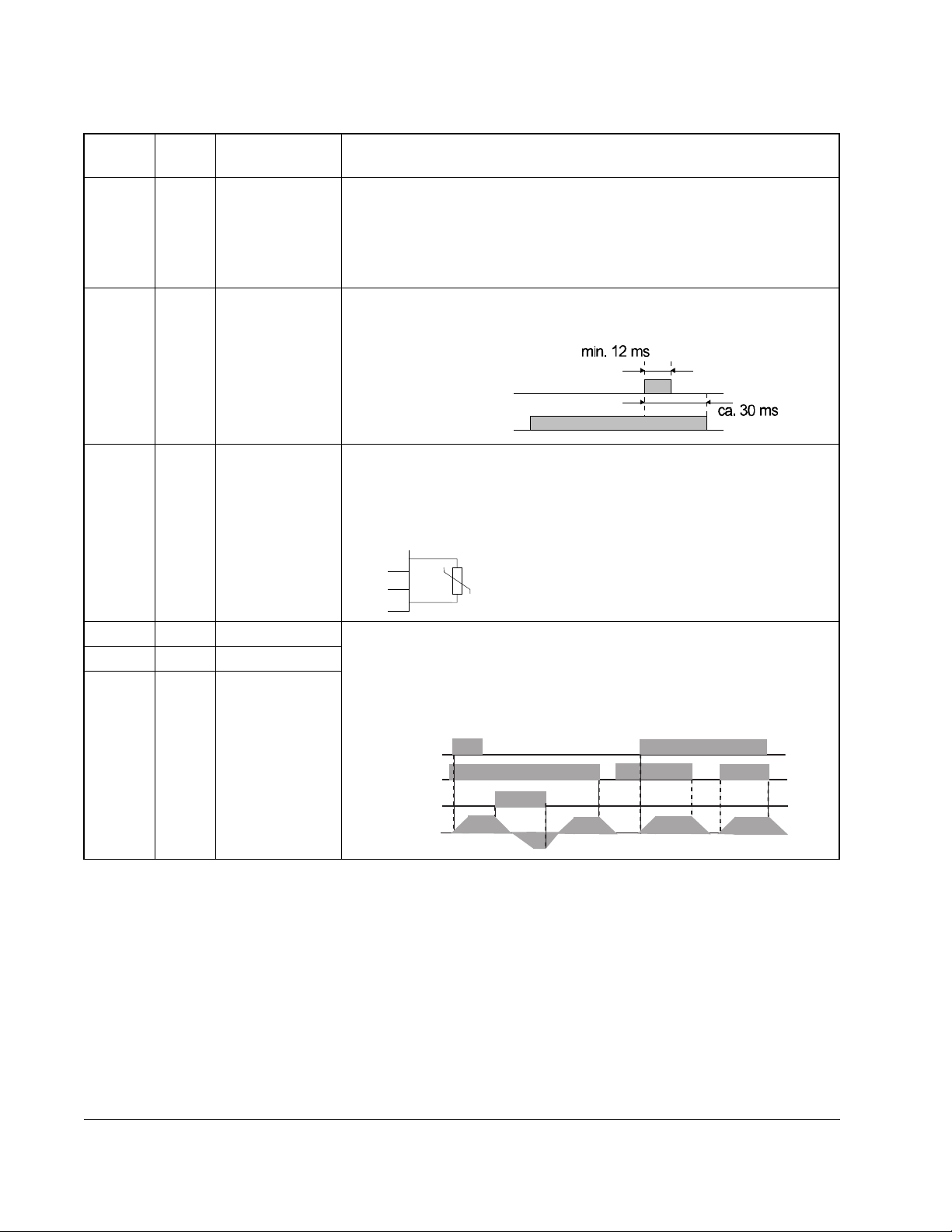

Note: A signal must be applied to the digital inputs for at least

12 msec in order to be read by the drive.

DIGITAL INPUT 1 LOGIC] to

2-8

SP120 AC Drive Installation and Operation

Page 23

Table 2.4 – Control Terminal and Fault Relay Terminal Descriptions

Control

Terminal Function Description

H 10 V Reference Voltage for

Analog Frequency

Command

O Voltage Analog Input

Frequency Command

(0-10 V)

OI Current Analog Input

Frequency Command

(4-20 mA)

L 0 V Reference Potential for

Frequency Comand Inputs

Potentiometer

1 to 2 kOhm

H

O

OI

L

PE PE

nominal 0-10 V nominal 0-20 mA

H

+

O

Input impedance

OI

10 kOhm

L

Input OI for 4-20 mA is activated when one of the digital inputs

is set to 16{AT} via parameters C01 [

DIGITAL INPUT 5].

[

The analog input reference can be adjusted using parameters

ANALOG FREQUENCY MINIMUM] to A16 [ANALOG FILTER

A11 [

SELECT].

If no digital input is programmed as 16{AT}, the set values are

the sum of O and OI.

FM Programmable Analog

Output

This output can be used to monitor the output frequency of the

drive (either Analog or Pulse) or the motor current. This output

is programmable using parameter C23 [

Analog or Pulse Output

Frequency or Motor Current

Analog Signal

Frequency or Current

English

4-19.6 mA0-9.6 V

H

O

+

-

DIGITAL INPUT 1] to C05

OUTPUT FM].

Pulse Signal (50% duty cycle)

Frequency only

Input impedance

OI

250 Ohm

L

PE

Installing and Wiring the Drive

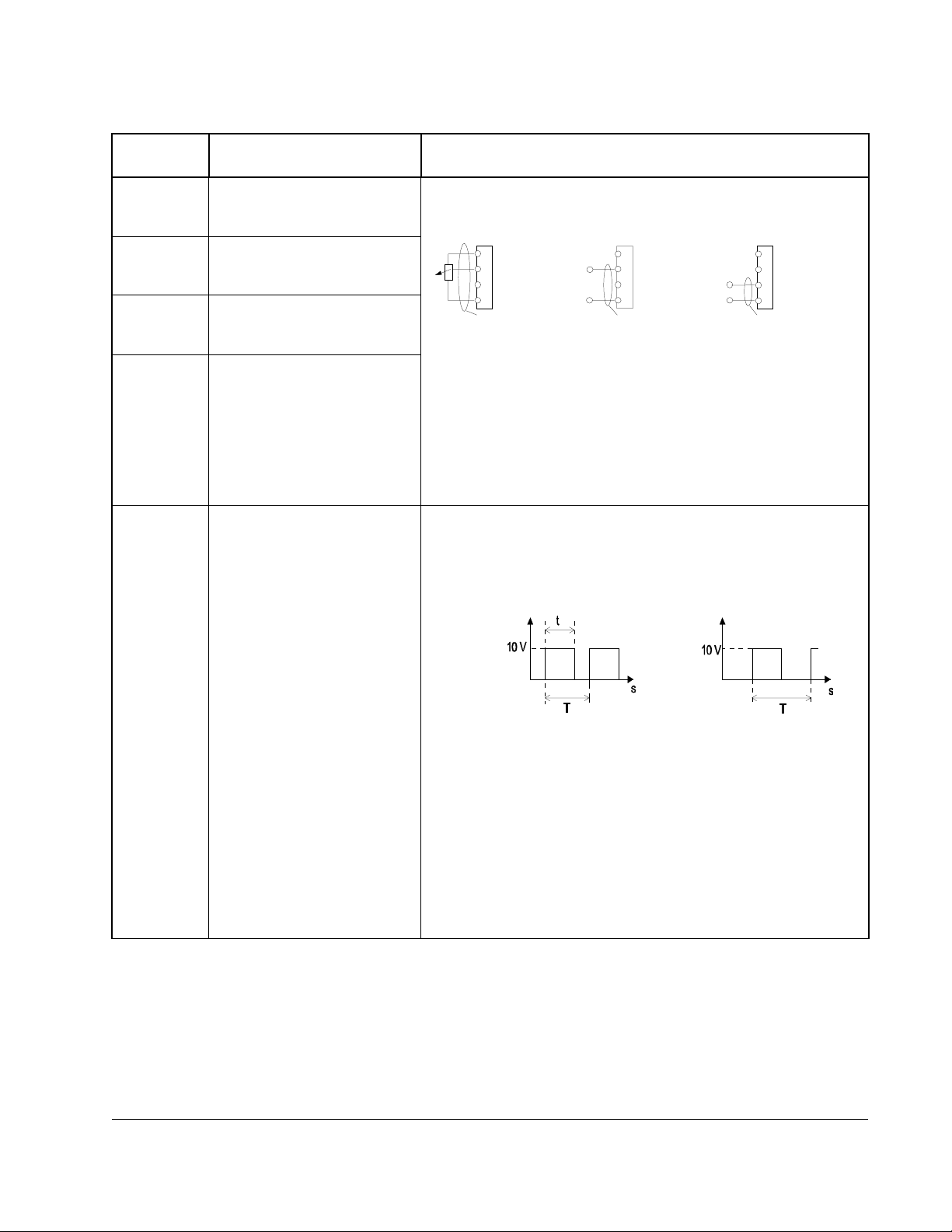

T = 4 ms (constant) T = (Variable)

Analog Signal: The relation t/T (duty cycle) changes

proportionally with the frequency or current. The maximum

voltage of 10V (100% duty cycle) is reached when the

maximum frequency or 200% of the rated current is reached.

Parameter b81 [

OUTPUT FM FACTOR] may be used as a scaling

factor.

Accuracy: +/- 5% for frequency , +/- 20% for current

Pulse Signal: Frequency = output frequency x b86 [

DISPLAY SCALE FACTOR], but the maximum frequency is 3.6 kHz

PROCESS

(ex. Freq = 60Hz x 60 = 3.6kHz).

2-9

Page 24

English

Table 2.4 – Control Terminal and Fault Relay Terminal Descriptions

Control

Terminal Function Description

CM2 Reference potential for

outputs 11 and 12

12 Programmable Digital Output

11 Programmable Digital Output

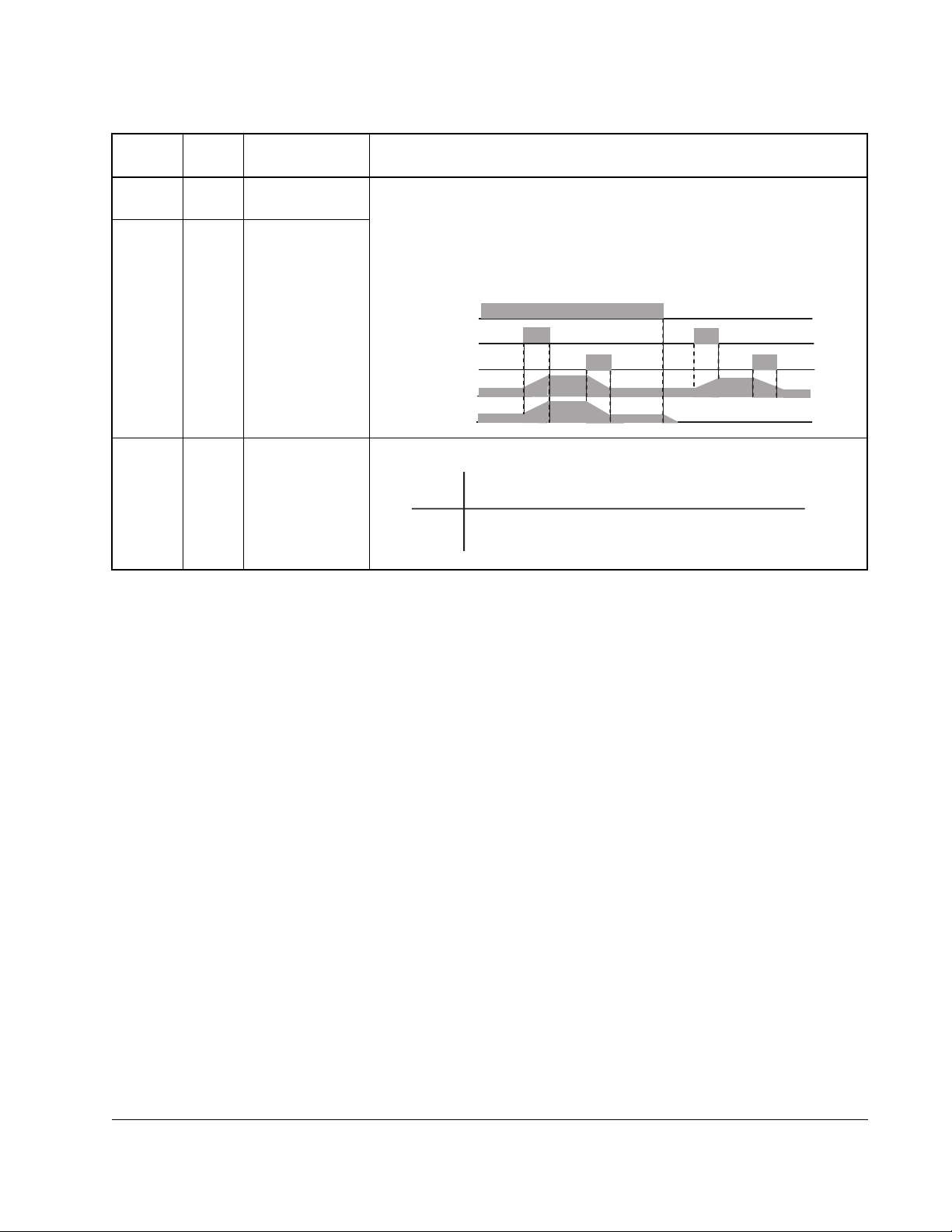

AL0 Fault Relay

AL1

AL2

Transistor output, max. 27 Vdc, 50 mA

The outputs can be programmed as either NO (active high) or

NC (active open) contacts using parameter C31 [

OUTPUT 11LOGIC] and C32 [DIGITAL OUTPUT 12 LOGIC].

The following 6 settings may be programmed using parameter

DIGITAL OUTPUT 11] and C22 [DIGITAL OUTPUT 12]:

C21 [

00{RUN} = Motor Running (Signal if output frequency > 0.5 Hz)

01{FA1} = At frequency (Signal when the set frequency is

reached and that frequency is > 0.5Hz)

02{FA2} = Above frequency (Signal if output frequencies >

frequencies set under parameter C42 [

FREQUENCY ACCEL SETTING] or C43 [ABOVE

FREQUENCY DECEL SETTING] and > 0.5 Hz).

03{OL} = Motor overload (Signal if the motor current exceeds

the value set under C41 [

04{OD} = PID-deviation (Signal if the deviation between the set

value and the actual value returned is greater than the

value set under C44 [

PID DEVIATION SETTING]). Only

available if the PID control A71 [

05{AL} = Fault (Signal if a fault is indicated)

AL0

AL1

230VAC

∼

DIGITAL

the

ABOVE

OVERLOAD ALARM SETTING]

PID ENABLE] is active.

250 VAC, 2.5 A resistive

0.2A inductive

30 VDC, 3.0A resistive

0.7A inductive

2-10

AL2

Faulted / De-energized State

Parameter C33 [

FAULT RELAY AL1 LOGIC] can be used to invert

min. 100 VAC, 10mA

5 VDC 100 mA

the operation.

C33 C33 = 01 C33 = 00

AL0 - AL1 Open when Faulted

Open when Power Off

AL0 - AL2 Closed when Faulted

Closed when Power Off

Closed when Faulted

Open when Power Off

Open when Faulted

Closed when Power Off

The fault relay is set with a time delay of approximately 2 sec

after the power is switched on.

SP120 AC Drive Installation and Operation

Page 25

2.6 Programmable Digital Input Functions

(Control terminal block inputs 1 through 5)

The function of the digital inputs 1 through 5 are programmed via the corresponding

parameters: C01 [

programming guidelines must be followed:

• No two inputs can be programmed for the same function.

• The PTC input (setting 19) is only programmable on input terminal 5.

The digital inputs can be programmed to respond to NO (Active High) or NC (Active

Open) inputs via parameters C11 [

LOGIC].

!

DIGITAL INPUT 1] through C05 [DIGITAL INPUT 5]. The following

DIGITAL INPUT 1 LOGIC] through C15 [DIGITAL INPUT 5

ATTENTION:All digital inputs respond to level sensitive commands.

Inputs do not require a voltage transition (cycle) after a fault condition is

cleared, after input power cycling, or after programming the logic of the

digital input.

All digital inputs can be programmed as NO or NC. However, the start

command should be set as NO (active high) and the stop command

should be set as NC (active open). If set opposite of this, an inadvertent

start or failure to stop could occur should a discrete connection be lost

or control wire come loose. If the user chooses to disregard this safety

practice - the risk assumed by the user can be reduced by assuring that

other safeguards are used to insure proper start and stop operation.

Depending on the application: This may include appropriate emergency

stops, redundant wiring, electronic guards and/or mechanical guards.

Failure to observe this precaution could result in severe bodily injury or

loss of lif e.

English

Installing and Wiring the Drive

Table 2.5 describes the programmable digital input functions.

2-11

Page 26

English

Table 2.5 – Programmable Digital Input Functions

Numeric

Setting

Alpha

Setting Function Description

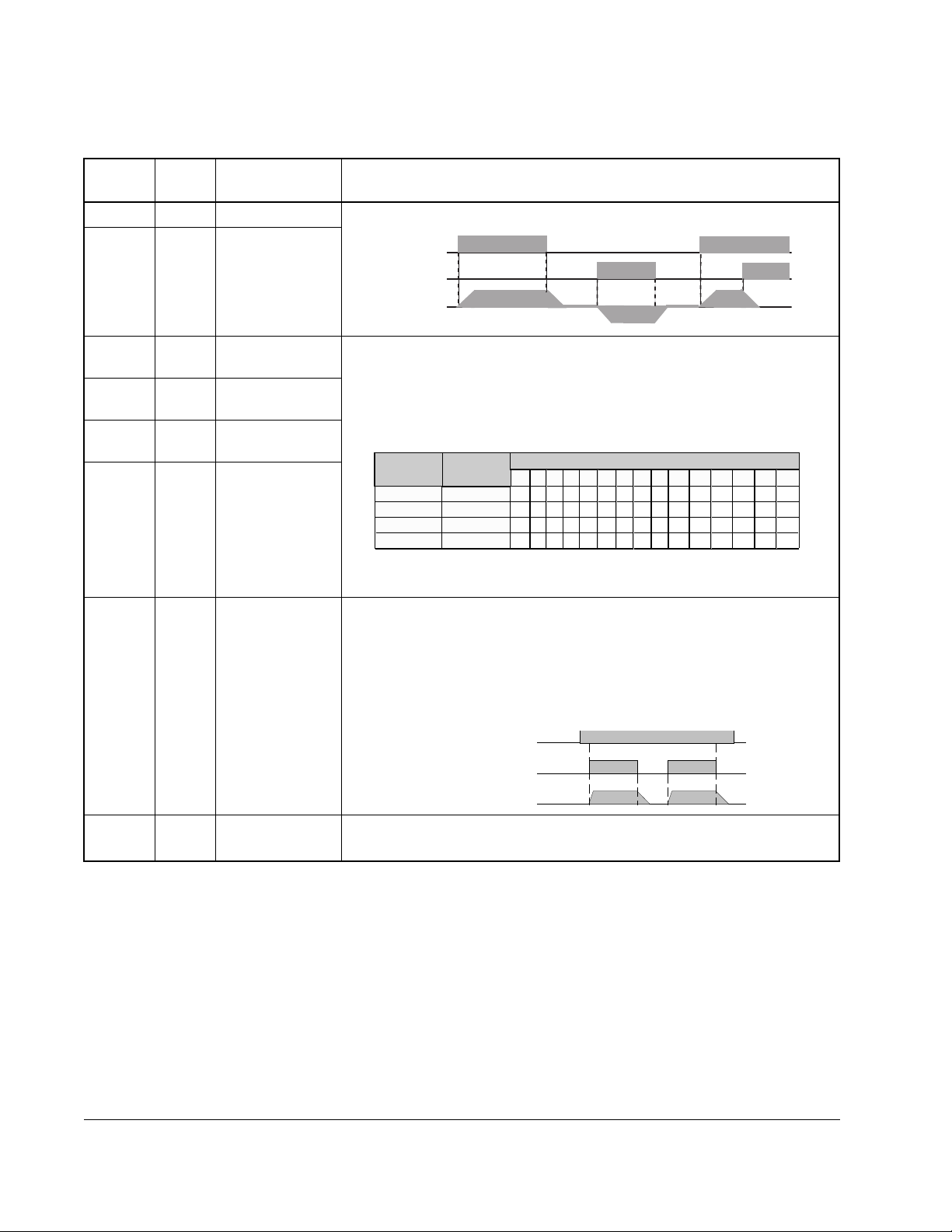

00 {FW} Forward 2-Wire (maintained) Run Forward/Run Reverse settings.

01 {RV} Reverse

02 {CF1} Preset

frequency input

03 {CF2} Preset

frequency input

04 {CF3} Preset

frequency input

05 {CF4} Preset

frequency input

00{FW}(N.O.)

01{RV}(N.O.)

Motor Speed

The preset frequencies may be programmed in two ways:

1. By programming desired preset frequency values via parameters

PRESET FREQUENCY 1] through A35 [PRESET FREQUENCY 15].

A21 [

2. By selecting the corresponding digital input setting and entering the

desired frequency via parameter F01 [

Setting

02

03

04

05

Input

CF1

CF2

CF3

CF4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

ON

ON

ON

ON

ON

ON ON

FREQUENCY COMMAND].

Preset Speed

ON

ON

ON

ON

ON

ON ON

ON ONONONONON

ON ON

ON ON

ON ON ON ON

ON ON ON ON

Note: If any preset frequency input is active, all other frequency

commands will be ignored.

06 {JG} Jog When this input is active, the 00{FW} or 01{RV} inputs will respond to

the frequency programmed via parameter A38 [

JOG FREQUENCY]. The

accel ramp is NOT active.

09 {2CH}

nd

Accel/Decel

2

ramp

The stop command is determined by parameter A39 [

JOG STOP MODE].

Note: The Jog command will not work with 3-wire control.

Input 06 {JG} (NO)

Run CMD (NO)

Motor Speed

2nd Accel/Decel ramp times are activated via this input and programmed

via parameter A92 [

ACCEL TIME 2] and A93 [DECEL TIME 2].

2-12

SP120 AC Drive Installation and Operation

Page 27

Table 2.5 – Programmable Digital Input Functions

English

Numeric

Setting

Alpha

Setting Function Description

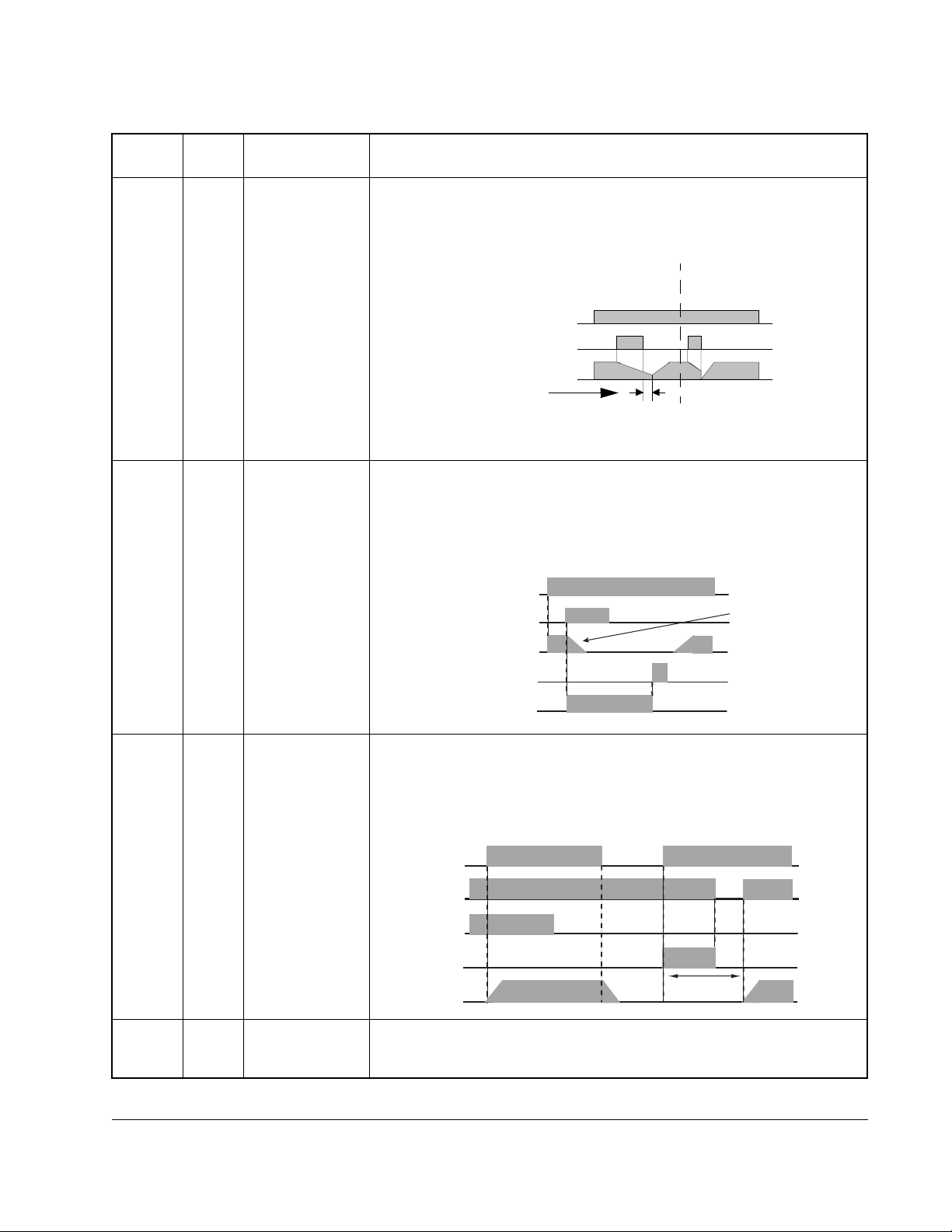

11 {FRS} Coast to Stop The motor voltage will be switched off immediately and the motor will

coast. This function can be programmed to operate in two different

modes via parameter b88 [FRS Select].

synchronization of

motor speed

0 Hz start

Run (NO)

Input 11 {FRS} (NO)

Motor Speed

Waiting time

Note: The drive will start when 11 {FRS} input is removed without

reissuing a start command even if in 3-wire (momentary) control.

12 {EXT} External Fault When this input is active, an E12 fault indication will be issued (e.g. an

input received from thermal contacts). The fault indication will be

cleared with a reset 18 {RS}.

Important: After a reset 18{RS} command, the drive will start again if a

start command is active (00{FW}, 01{RV},or 20 {STA}).

Run (NO)

Input 12 {EXT} (NO)

Motor will

Coast

Motor Speed

Input 18 {RS} (NO)

Fault relay (AL0-Al2) (NO)

13 {USP} Unintentional

Start Protection

on Power Up

This function is designed to guard against unintended starting when

input power is removed and then restored. In this case, if a start/run

command is issued immediately upon/after power is restored an E13

fault will be issued. A new start command or a reset 18 {RS} command

will clear the fault indication.

Power Supply

00{FW} or

01 {RV} (N.O.)

13 {USP}(N.C.)

Fault relay (N.O.)

Motor Speed

Min. 3 Sec

15 {SFT} Program Lock Protects stored parameter values from being overwritten. See

parameter b31 [

PROGRAM LOCK SELECT] for the 4 different levels of

protection.

Installing and Wiring the Drive

2-13

Page 28

English

Table 2.5 – Programmable Digital Input Functions

Numeric

Setting

Alpha

Setting Function Description

16 {AT} 4-20mA Select Activates input terminal OI for use as a 4-20 mA input. If no input

terminal is programmed for this setting, the factory default input is O

(0-10V) and the output frequency will correspond to the value of the

inputs to the O and/or OI control inputs.

Note: Parameter A01 [

FREQUENCY COMMAND SELECT] determines from

what source the output frequency is commanded.

18 {RS} Reset Used to clear a fault condition. If a 18 {RS} command is given during

operation, the output IGBTs are switched off and the motor will coast.

18 {RS} (NO)

Fault indication

19 {PTC} PTC Input This input can only be programmed to digital input terminal 5 and

the PTC should be referenced to terminal L.

If the PTC resistance exceeds 3k Ohms, the output voltage to the motor

will be switched off and an E35 fault code will be issued.

5

L

20 {STA} 3-wire run 3-wire (Momentary) control inputs. Both settings 20 {ST A} and 21 {STP}

21 {STP} 3-wire stop

22 {F/R} 3-wire

must be programmed as digital inputs for 3-wire control to function. If 20

{STA} is programmed into any digital input then 2-wire (maintained)

control will not function.

Forward/Reverse

Note: 3-wire stop command (21 {STP}) cannot be used to clear a fault.

20{STA} (NO)

21{STP} (NC)

22 {F/R (NO)

Motor Speed

2-14

SP120 AC Drive Installation and Operation

Page 29

Table 2.5 – Programmable Digital Input Functions

English

Numeric

Setting

Alpha

Setting Function Description

27 {UP} Remote Control UPThese settings allow digital inputs to increase and decrease the

FREQUENCY

28 {DWN} Remote Control

DOWN

commanded frequency for the drive. Parameter A01 [

COMMAND SELECT] must be set to 02 to activate this function. These

inputs will change the value of parameter F01 [

Hz/sec as defined by parameter A04 [

MAXIMUM FREQUENCY] ÷ (Accel

FREQUENCY COMMAND] in

time or Decel time).

RUN (NO)

27 {UP} (NO)

28 {DWN} (NO)

PF01-

[Freq. Command]

Motor Speed

31 { OPE} Run Comm and

This setting is used to determine the source of the Run commands.

Source Select

Inactive

Active

Start command will come from the control terminals only,

regardless of the setting of PA02 - [Start Command Select]

Start command will come from the start key on the keypad only

regardless of the setting of PA02 - [Start Command Select]

Installing and Wiring the Drive

2-15

Page 30

English

2-16

SP120 AC Drive Installation and Operation

Page 31

CHAPTER 3

Parameters and Programming

This chapter describes how to program the drive and provides a parameter reference

that describes all of the drive parameters.

3.1 Programming the Drive Using the Keypad

ATTENTION:Wait at least 6 seconds after programming the SP120 drive

before issuing a start, reset command, or switching off the power supply.

!

The keypad is located on the front panel of the drive. This is an integrated keypad that

can be used to monitor drive operation, program parameters, and operate the drive.

The PROGram, Up Arrow, Down Arrow, and Enter keys are located inside the front

panel cover. You must open the cover to access these keys. The drive uses a

4-character, 7-segment LED display to show parameter numbers, parameter values,

and diagnostic codes. Refer to section 4.4 for a description of the diagnostic codes.

Failure to wait 6 seconds could result in failure to recognize programming

changes, which could result in bodily injury or damage to equipment.

ATTENTION: If the Stop key is used to clear a fault and there is a valid

run command, the drive will start to run as soon as the fault is cleared

without cycling the run input. Failure to observe this precaution could

result in severe bodi ly injury or loss o f life.

Table 3.1 – Keypad Functions

English

Key Description

PROGram is a dual purpose key. It is used to view parameter

groups and to switch between parameter numbers and values.

PROG

Min

Max

PROGram also acts as an escape key to exit the parameter

values without changing them.

Up Arrow and Down Arro w are used to scroll through

parameters, or to increase and decrease parameter values.

Enter is used to enter the current value into memory.

Start can be activated using A02 [

digital input setting 31{OPE}. When active, the key will start

the motor in the direction of rotation defined in F04 [

DIRECTION].

The Speed Potenti o m e ter can be used to set the

commanded speed. The speed potentiometer can be

activated using A01 [

Stop is used to stop the motor. If the drive has stopped due to

a fault, pressing this key will clear the fault.

FREQUENCY COMMAND SELECT].

START COMMAND SELECT] or

START KEY

Parameters and Programming

3-1

Page 32

English

Table 3.2 – LED Functions

LED Will be on when:

POWER power is applied to the drive (mains supply is switched on).

Important: The DC-bus capacitors and terminals are

energized even when the mains supply is

switched off.

RUN the drive is in operation. For example, if a start command

has been given.

PRG

Hz

A

the drive is being programmed.

output speed is being displayed.

output current is being displayed.

Start Key the Start key has been pressed.

Speed Pot the speed pot is active.

d01

d09

F01

F04

d01d01d01d01

A ..

b ..

C ..

A01

A98

PROG

b01

PROG

PROG

Figure 3.1 – Programming Overview

b89

C01

C91

Parameter

PROG

Saving entered

Parameters

Entry

3-2

SP120 AC Drive Installation and Operation

Page 33

3.1.1 Programming Examples

This section contains four different programming examples to help describe how to

program the SP120 drive.

Initial Power Up

This example shows you how to proceed from the power up parameter value to the

parameter number.

Action Description Display

Apply power to the drive

If you were viewing a display parameter when power was last

removed from the drive, the same display parameter value will

reappear when the drive is re-powered. If you were viewing any

other parameter value when power was removed, the

parameter group or parameter number will appear when the

drive is re-powered.

Press PROGram to switch from the parameter value to the

parameter number.

PROG

English

0.0

d01

Parameters and Programming

3-3

Page 34

English

Scrolling through parameter groups

This example shows you how to check a parameter value without changing the value

of the parameter. For this example, the operation of C21 [

verified.

Action Description Display

Press Up Arrow or Down Arrow to scroll through the

parameter groups, stopping at the C group.

Note: All of the d and F group parameters are

displayed in sequence, but the A, b, and C

parameters are grouped and the group must be

selected to view the parameters within that specified

group. Figure 3.1 details which parameters are in

each group.

Press PROGram to enter into the C group. C01

DIGITAL INPUT 1] should appear on the display.

[

DIGITAL OUTPUT 11] is

C--

C01

PROG

Note: When parameter groups are entered, the

number of the parameter that was being viewed

when you last exited the group will be displayed.

Press Up Arrow to scroll through the parameters

contained within the group, continue pressing Up

Arrow until C21 [

DIGITAL OUTPUT 11] is displayed.

C21

PROG

PROG

PROG

Note: When viewing parameters within the A, b and

C groups the parameters will wrap from A01 through

C91 by pressing Up Arrow or Down Arrow. To view

parameters within the d and F groups, press SELect

until the display shows A - -, b - - or C- -. Once the

group letter is displayed, Up Arrow or Down Arrow

will scroll to the d and F parameters.

Press PROGram to view the parameter value stored

in C21 [

Press PROGram again to exit from the parameter

value back to the parameter number without

changing the stored value.

Press PROGram again to exit from the parameter

number to the parameter group display.

DIGITAL OUTPUT 11].

01

C21

C--

3-4

SP120 AC Drive Installation and Operation

Page 35

Restoring Factory Defaults

This example shows you how to reset the factory defaults of the drive.

Action Description Display

Press Down Arrow to advance to the b parameter

group.

English

b--

PROG

PROG

PROG

PROG

Press PROGram to enter into the b parameter

group.

Press Up Arrow to scroll through the parameters

until b84 [

Press PROGram to view the parameter value stored

in b84 - [

01. If it is not 01, use Up Arrow to change the value

to 01, then press Enter.

Note: The defaults will be reset to the values

determined by b85 [

Press PROGram to return to the parameter number

without changing the stored value.

Press and hold PROGram, Up Arrow, Down Arrow,

and Stop for 3 seconds.

RESET FUNCTIONS] is displayed.

RESET FUNCTIONS] and verify that it is set to

FACTORY DEFAULT SELECt].

b01

b84

01

b84

b84

Parameters and Programming

PROG

Release the Stop Key and continue to hold the

PROGram, Up Arrow, and Down Arrow until the

display begins to blink. Release the remaining keys.

When this is done, 0.0 will be displayed (this is d01

OUTPUT FREQUENCY].

[

0.0

3-5

Page 36

English

Setting Drive Control to the Keypad

This example shows you how to configure the drive for ke ypad control. You will need to

change the values of three parameters to accomplish this.

Step 1. Pr ogram A0 1 [

Step 2. Pr ogram A0 2 [

Step 3. Pr ogram C13 [

Step 4. Verify that F04 [

Action Description Display

PROG

PROG

PROG

Press PROGram to switch from the parameter value to the parameter number.

Press Up Arrow or Down Arrow to scroll through the parameter groups stopping at

the A group.

Press PROGram to enter into the A group.

If a parameter other than A01 [FREQUENCY COMMAND SELECT] is displayed press

Down Arrow until A01 is displayed.

Press PROGram to view the parameter value.

Use Down Arrow to change the value of A01 from the default value of 01 to 00.

This changes the source of the frequency command to the potentiometer on the

fixed keypad.

When the desired value is displayed, press the Enter Key. This writes the new

value to memory. The display will return to the parameter number.

Press Up Arrow to display A02 [START COMMAND SELECT].

Step 5. Verify that C1 through C5 [

reference command from the control terminal block (factory default) to the

speed potentiometer on the keypad.

input from the control terminal block (factory default) to Start on the keypad.

closed contact (NC) to a normally open contact (NO).

FREQUENCY COMMAND SELECT] to change the frequency

START COMMAND SELECT] to change the source of the start

DIGITAL INPUT 3 LOGIC] to change the input from a normally

START KEY DIRECTION] is not set to 2 (Control Terminal).

DIGITAL INPUTS 1-5] are at default values.

d01

A--

A01

00

01

00

A01

A02

3-6

PROG

PROG

Press PROGram to view the parameter value stored in A02.

Use Up Arrow to change the value of A02 from the default value of 01 to 02. This

changes the source of the start input from the control terminal block to the fixed

keypad.

When the desired value is displayed, press Enter. This writes the new value to

memory. The display will return to the parameter number.

Press Down Arrow until C13 [DIGITAL INPUT 3 LOGIC] is displayed.

Press PROGram to view the parameter value.

Use Down Arrow to change the value of C13 from the default value of 01 to 00.

This changes the input to a normally open contact.

When the desired value is displayed, press the Enter Key. This writes the new

value to memory. The display will return to the parameter number.

SP120 AC Drive Installation and Operation

01

02

A02

C13

01

00

C13

Page 37

3.2 Parameter Descriptions

High

Open

High

Open

The sections that follow provide descriptions of all drive parameters, separated by

group.

3.2.1 D Group - Display and Diagnostic Parameters (Read Only)

This group of parameters consists of commonly viewed drive operation conditions

such as output frequency. All parameters in this group are Read Only.

English

Parameter

Number Parameter Name / Description

d01 Output Frequency

Displays the output frequency to the motor.

d02 Output Current

Displays the output current to the motor.

d03 Direction

Displays the present direction of rotation.

d04 PID Process Display

Displays the scaled PID Process variable (feedback). Available only

when the PID control is active. The scale factor is set using A75

PROCESS REFERENCE SCALE FACTOR].

[

d05 Digital Input Status

Displays the status of the 5 digital inputs regardless of how each input

is programmed in C11 [

RELAY AL1 LOGIC].

5 4 3 2 1

DIGITAL INPUT 1 LOGIC] through C33 [ALARM

d06 Output Status

Displays the status of the digital outputs and the fault indication

relays.

AL 12 11

Min./Max.

Range Units

0.0 to 360.0 N/A

0.00 to 999.9 0.01 A

F=Forward

N/A

r=Reverse

o=Stop

0.00 to 100.0 0.01%

N/A N/A

N/A N/A

d07 Process Display

Displays d01 [

PROCESS DISPLAY SCALE FACTOR].

[

Note: If there are more than 4 digits, the LSB will be dropped.

d08 Last Fault

Displays the last fault. The output frequency, motor current, and DC

bus voltage at the time of the last fault can be viewed by pressing

PROGram. If there has not been a fault or the register has been

cleared, then --- will be displayed.

Parameters and Programming

0.00 to 9990 0.01

OUTPUT FREQUENCY] scaled by the variable set in b86

N/A N/A

3-7

Page 38

English

Parameter

Number Parameter Name / Description

d09 Fault Register

Displays the second and third fault. If there are no faults stored in this

register, then --- will be displayed. To view the third fault, press

PROGram.

d16 Elapsed Run Time

Displays the elapsed running time of the drive. The elapsed running

time is the displayed value x 10.

3.2.2 F Group – Basic Function Parameters

Tunable parameters are indicated with an asterisk ( * ) precediing the parameter

number.

Number Parameter Name / Description

*F01 Frequency Command

When A01 [

or 01, this parameter will display the commanded

frequency. When A01 is set to 02, this parameter can

be used to change the commanded frequency on the

fly and write the value into A20 - [

FREQUENCY]. When a preset frequency is active, this

parameter can be used to program or change the

value of the preset input on the fly while writing the

value into the corresponding parameter (A21 [

FREQUENCY 1] to A35 [PRESET FREQUENCY 15]).

Note: The value is changed in real time and written to

memory without using the Enter key.

This parameter can be changed while motor is

running.

*F02 Accel Time 1

Time for the drive to ramp from 0.0 Hz to A04

MAXIMUM FREQUENCY]

[

This parameter can be changed while motor is

running.

*F03 Decel Time 1

Time for the drive to ramp from A04 [

FREQUENCY] to 0.0 Hz

This parameter can be changed while motor is

running.

F04 Start Key Direction

Sets the direction of motor rotation when the drive is

set to Start Key mode, which is controlled by A02

START COMMAND SELECT] and digital input setting 31

[

{OPE}.

FREQUENCY COMMAND SELECT] is set to 00

INTERNAL

PRESET

MAXIMUM

Min./Max.

Range Units

N/A ---

0 to 9999 10

Min./ Max.

Range Units

0.0 to

0.1 Hz N/A

360.0

0.1 to 3000 <1000, 0.1 s

>1000, 1 s

0.1 to 3000 <1000, 0.1 s

>1000, 1 s

00 to 02 00=Forward

01=Reverse

02=Control

Terminal

hours

Factory

Default

10.0

10.0

00

3-8

Digital inputs (C01-C05) settings 00 {FW} and 01

{RV} determine direction of Start Key.

SP120 AC Drive Installation and Operation

Page 39

3.2.3 A Group – Advanced Function Parameters

Tunable parameters are indicated with an asterisk ( * ) preceding the parameter

number.

English

Parameter

Number Parameter Name/ Description

Basic Functions

A01 Frequency Command Select

Selects the source of the frequency command for the

drive. Note: If any preset frequency inputs are active, all

other frequency commands will be ignored.

Settings: 00=Frequency pot

01=Input O/OI (Analog reference)

02=Internal frequency (F01 [

COMMAND]/ A20 [INTERNAL FREQUENCY])

FREQUENCY

A02 Start Command Select

Selects the source of the start command.

Settings: 01=Control terminal block

02=Start Key (Input from Start Key on drive

keypad)

A03 Base Frequency

Set value to rated nameplate frequency of motor

Frequency

Command

Frequency

Minimum

Frequency

A62

100%

Voltage

0

Start

Frequency

b82

Base

Frequency

A03

Maximum

Frequency

A04

Upper

Frequency Limit

A61

Hz

Min./Max

Range Units

00 to 02 Numeric

Factory

Default

01

Value

01 to 02 Numeric

01

Value

50 to 360 1 Hz 60

A04 Maximum Frequency

Highest frequency the drive will output.

Note: If a maximum frequency less than A03 [

FREQUENCY] is needed, use A61 [UPPER FREQUENCY

LIMIT]. Refer to diagram in A03 [BASE FREQUENCY].

Analog input reference adjustment

A11 Analog Frequency Minimum

Sets the frequency that corresponds to a 0V or 4mA

analog signal.

Frequency

A12

A11

A13

0V

4mA

A12 Analog Frequency Maximum

Sets the frequency that corresponds to a 10V or 20mA

analog signal. A value of 0.0 will disable this function.

Refer to diagram in A11 [

Parameters and Programming

ANALOG FREQUENCY MINIMUM].

A14

50 to 360 1Hz 60

BASE

0.0 to 360.0 0.1 Hz 0.0

% Input

Scale

10V

20mA

0.0 to 360.0 0.1 Hz 0.0

3-9

Page 40

English

Parameter

Number Parameter Name/ Description

Analog input reference adjustment (continued)

A13 Analog Input Mi nimum

Sets the starting point (offset) for the analog input

range. Refer to diagram in A11 [

MINIMUM]

ANALOG FREQUENCY

A14 Analog Input Maximum

The ending point (offset) for the analog input range.

Refer to diagram in A11 [

ANALOG FREQUENCY MINIMUM]

A15 Analog Start Select

Sets the output frequency when frequency reference is

below value set in A13 [

Settings: 00 = A11 [

ANALOG INPUT MINIMUM].

ANALOG FREQUENCY MINIMUM]

01 = 0 Hz

Frequency

A12

A15=00

A11

0V

4mA

A13

A15=01

A14

% Input

Scale

10V

20mA

A16 Analog Filter Select

Sets the level of the Analog input smoothing filter where:

1 = low (Bandwidth = 200 Hz)

8 = high (Bandwidth = 25 Hz).

Preset Frequencies

*A20 Internal Frequency

When A01 [

FREQUENCY COMMAND SELECT] is set to 02,

this parameter will provide the drives frequency

command. This parameter will change the frequency

command only after the new frequency is entered into

memory.

Min./Max

Range Units

Factory

Default

0 to 99 1% 0

0 to 100 1% 100

00 to 01 Numeric

01

Value

1 to 8 Numeric

8

Value

0.0 to 360.0 0.1 Hz 60.0

3-10

This value can also be changed via F01 [

COMMAND] if no preset frequency inputs are active.

FREQUENCY

This parameter can be changed while motor is running.

SP120 AC Drive Installation and Operation

Page 41

English

Parameter

Number Parameter Name/ Description

Min./Max

Range Units

Factory

Default

Preset Frequencies (continued)

*A21 Preset Frequency 1 The programmed value sets

*A22 Preset Frequency 2 0.0 to 360.0 0.1 Hz 3.0

*A23 Preset Frequency 3 0.0 to 360.0 0.1 Hz 5.0

*A24 Preset Frequency 4 0.0 to 360.0 0.1 Hz 10.0

*A25 Preset Frequency 5 0.0 to 360.0 0.1 Hz 15.0

*A26 Preset Frequency 6 0.0 to 360.0 0.1 Hz 20.0

*A27 Preset Frequency 7 0.0 to 360.0 0.1 Hz 25.0

*A28 Preset Frequency 8 0.0 to 360.0 0.1 Hz 30.0

*A29 Preset Frequency 9 0.0 to 360.0 0.1 Hz 35.0

*A30 Preset Frequency 10 0.0 to 360.0 0.1 Hz 40.0

*A31 Preset Frequency 11 0.0 to 360.0 0.1 Hz 45.0

*A32 Preset Frequency 12 0.0 to 360.0 0.1 Hz 50.0

*A33 Preset Frequency 13 0.0 to 360.0 0.1 Hz 55.0

*A34 Preset Frequency 14 0.0 to 360.0 0.1 Hz 60.0

*A35 Preset Frequency 15 0.0 to 360.0 0.1 Hz 0.0

the frequency that the drive

outputs when selected. (Refer

to digital input settings table in

Chapter.2).

Note: If a preset frequency

input is active, the keypad

frequency pot and analog

frequency commands will be

ignored.

Note: The value of any Preset

Frequency can be changed via

FREQUENCY COMMAND]

F01 [

when the Preset Frequency is

activated via the digital inputs.

These parameters can be

changed while motor is

running.

*A38 Jog Frequency

0.0 to 360.0 0.1 Hz 0.0

0.5 to 9.9 0.1Hz 5.0

This parameter sets the frequency the drive will output

when it receives a valid jog command.

This parameter can be changed while motor is running.

A39 Jog Stop Mode

This parameter sets the stop method when the jog input

00 to 02 Numeric

Value

01

is removed.

Settings: 00=Coast

01=Ramp

02=DC Brake (See A53 [

A55 [

DC HOLD TIME])

DC WAIT TIME] –

Parameters and Programming

3-11

Page 42

English

z

Parameter

Number Parameter Name/ Description

V/F Characteristics / Boost

A41 Boost Select

Used to select auto or manual boost

Settings: 00=Manual Boost

01=Auto Boost

*A42 Manual Boost Voltage

Sets the boost level as a percent of A82 [

This parameter can be changed while motor is running.

Voltage

100%

A42

A43

30Hz