Page 1

Using the SP200 AC Drive

Demo Unit

M/N D1SP2001

Instruction Manual

D2-3474

Page 2

The information in this manual is subject to change without notice.

Throughout this manual, the following notes are used to alert you to

safety considerations:

!

Important:

!

ATTENTION:

circumstances that can lead to personal injury or death,

property damage, or economic loss.T Trad

Identifies information that is critical for successful

application and understanding of the product.

ATTENTION:

construction and operation of this equipment and the

hazards involved should install, adjust, operate, and/or

service this equipment. Read and understand this

document in its entirety before proceeding. Failure to

observe this precaution could result in severe bodily

injury or loss of life.

ATTENTION:

three minutes to insure that DC bus capacitors are

discharged. Failure to observe this precaution could

result in severe bodily injury or loss of life.

ATTENTION:

with all applicable local and national codes. Failure to

observe this precaution could result in severe bodily

injury or loss of life.

ATTENTION:

requires rotating parts and/or electrical circuits to be

exposed. Stay clear if the motor must be running.

Disconnect, lockout, and tag the power source if contact

must be made. Failure to observe this precaution could

result in severe bodily injury or loss of life.

Identifies information about practices or

Only qualified personnel familiar with the

After disconnecting input power, wait

The user is responsible for conforming

Checking the direction of motor rotation

Trademarks not belonging to Rockwell Automation are property of their respective companies.

©2000 Rockwell International Corporation

Page 3

C

ONTENTS

Chapter 1 Introduction

1.1 What Is a Variable-Speed Drive? ......1-1

1.2 About the SP200 Drive ...................... 1-1

Chapter 2 Setting Up the Demo Unit

2.1 Demo Unit Components and Wiring ..2-1

2.2 Connecting Power to the Demo Unit .2-2

Chapter 3 Programming Basics

3.1 Parameter Menu Structure ................ 3-1

3.2 Parameter Types ............................... 3-1

3.3 How To Display and Adjust

Parameter Values Using the Keypad.3-2

Chapter 4 Running the Demo Unit

4.1 The Labs............................................4-1

Chapter 5 Troubleshooting the Demo Unit

Contents

I

Page 4

II

Using the SP200 AC Drive Demo Unit

Page 5

C

HAPTER

Introduction

This manual describes how to use the SP200 demo unit.

For complete product information, refer to Installing and

Operating the SP200 AC Drive (D2-3408).

1.1 What Is a Variable-Speed Drive?

A variable-speed drive is an electronic device that controls

the speed, torque, horsepower, and direction of an AC or DC

motor.

Variable-speed drives offer:

• Improved process control by enabling you to control

virtually any process variable and to control your process

remotely with electrical interfaces.

• Reduced operating costs by enabling you to match the

motor speed to the load requirements.

• Reduced maintenance by providing a “soft-start” capability

that limits inrush current to reduce stress on mechanical

parts.

1

1.2 About the SP200 Drive

Typical applications for the SP200 AC drive include fans,

pumps, conveyors, and other small machines where inside

panel or inside machine mounting is available.

The SP200 drive is best suited for applications with these

requirements:

• A three-phase 1/2 to 2 HP AC induction motor is used.

• Single-phase input ratings (up to 1.5 HP) operate on 115

V or 230 V and produce 230 V, three-phase output in both

cases.

Introduction

1-1

Page 6

• Three-phase ratings available in both 230 V and 460 V.

• Operator control options include local keypad or remote

keypad. A CopyCat keypad is available for applications

where quick editing and transfer of settings to multiple

drives is desired.

The SP200 drive comes in three different control models to

match specific needs:

• Model A: Single Channel Analog - for control from one

analog signal or a speed pot.

• Model B: Preset Speed - for up to eight specific speeds

controlled by three on/off digital inputs.

• Model C: Dual Channel Analog - for applications that can

take advantage of an operation between two analog

signals. Choose from PI, add, or multiply functions.

1-2

Using the SP200 AC Drive Demo Unit

Page 7

C

HAPTER

2

Setting Up the Demo Unit

Before running the demo, take a moment to become familiar

with the demo unit components and how the unit is wired.

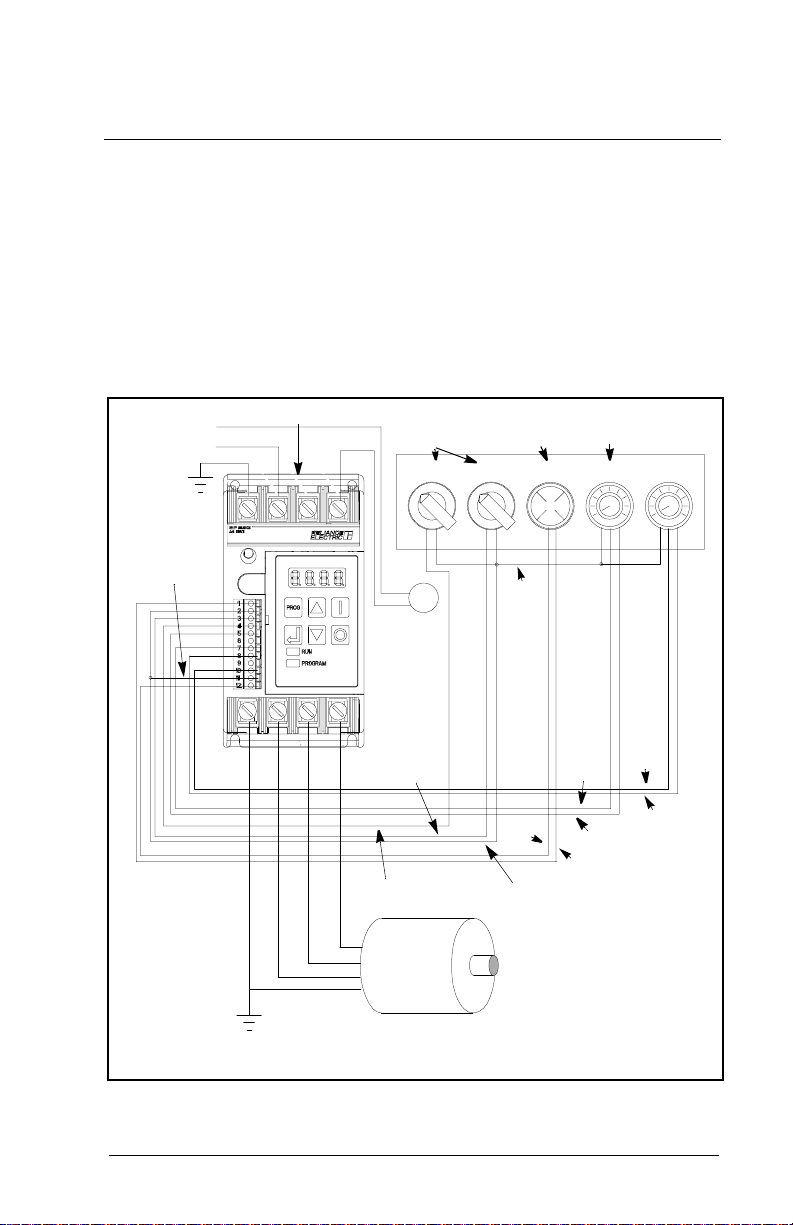

2.1 Demo Unit Components and Wiring

115 VAC

GND

Gray

L1

L2

SP200 DRIVE

TOGGLE

SWITCHES

STOP RUN CONF IN

Fuse

Red

Orange

Motor

INDICATOR

LAMP

0 1

Brown

White

Brown

SPEED

POT

CONF OUT ANALOG

CHAN #1

R

Green

Ye l l o w

Black

Violet

ANALOG

CHAN #2

Blue

GND

Figure 2.1 – SP200 AC Drive Demo Components and Wiring

Setting Up the Demo Unit

2-1

Page 8

2.2 Connecting Power to the Demo Unit

The SP200 AC drive demo unit is powered by a grounded

115 VAC input. Follow these steps to connect the power cord

to the demo unit.

Step 1. Stand the demo unit on a flat surface with the

handle and cover latches facing you.

Step 2. Open both latches and lift the cover. Then slide the

cover to the right to remove.

Step 3. The power cord is stored in the cover of the demo

unit. Press down on the spring-loaded fasteners

inside the cover to access the power cord.

Step 4. Turn the demo unit around and stand it on its feet so

that it faces you.

Step 5. Plug the power cord into the receptacle on the left

side of the demo unit.

Step 6. Plug the power cord into a grounded 115 VAC

outlet.

Step 7. Use the on/off switch located next to the power cord

to apply power to the unit, if necessary.

2-2

Using the SP200 AC Drive Demo Unit

Page 9

C

HAPTER

Programming Basics

To program the drive for a specific application, you display

the appropriate parameter and adjust it as required. The

parameters are used to define characteristics of the drive.

3.1 Parameter Menu Structure

The SP200 drive has two kinds of parameters: program

parameters (P-xx), which configure the drive operation, and

display parameters (d-xx), which display information

regarding the drive status.

Table 3.1 – Parameter Organization

Range Parameter Group Parameter Type

3

P-00 to P-05

P-10 to P-13

P-20 to P-29

P-30 to P-38

P-40 to P-48

P-50 to P-55

P-60 to P-64

d-00 to d-09 Display Parameters Display Parameters

Protection

Digital Input/Output

Speed Reference

Dynamic Control

Fixed Speeds

V/Hz Curve

Utility

Program Parameters

3.2 Parameter Types

There are three types of parameters:

Tunable

•

drive is running or stopped.

Configurable

•

only while the drive is stopped.

Read-only

•

Programming Basics

parameters can be adjusted or changed while the

parameters can be adjusted or changed

parameters cannot be adjusted.

3-1

Page 10

3.3 How To Display and Adjust Parameter Values Using the Keypad

The keypad is located on the front panel of the drive demo

unit.

Table 3.2 – Keypad Description

1

9

2

8

3

7

4

6

5

The display shows either a parameter number or a parameter value.

1

The parameter numbers are preceded by either a “P-” or a “d-”.

2

3

4

5

6

3-2

PROG

The key toggles between display and program modes. The

PROGRAM LED

turns off when the drive is in display mode.

In display mode, the key scrolls through the display parameters.

In program mode, this key toggles between the parameter number

and parameter value.

The

RUN LED

or reverse direction. The

direction.

The

PROGRAM LED

turns off when the drive is in display mode.

In display mode, the key decrements the local speed reference.

In program mode, this key decrements the parameter number or

parameter value.

(5) turns on when the drive is in program mode and

turns on when the drive is running in either the forward

RUN LED

turns on when the drive is in program mode and

flashes while the drive is changing

Using the SP200 AC Drive Demo Unit

Page 11

Table 3.2 – Keypad Description

7

The key issues stop and fault reset commands to the drive.

8

The key issues start commands to the drive when

P-10 = 1.

9

In display mode, the key increments the local speed reference.

In program mode, this key increments the parameter number or

parameter value.

The following table provides detailed steps for keypad

operation.

Table 3.3 – Keypad Operation

Desired Action User Steps

Start the unit

Stop the unit

Increment the local

speed reference

Decrement the local

speed reference

View the value of

the present display

parameter

View the number of

the present display

parameter

Increment the

display parameter

number

Press to start the drive.

Note that for to work, a connection must be

present between terminals 2 and 3. In addition,

parameter P-10 must be set to 1.

Press to stop the drive.

While in display mode (

PROGRAM LED

is off), press

to increase speed.

While in display mode (

to decrease speed.

While in display mode (

PROGRAM LED

PROGRAM LED

is off), press

is off), the

value of the present display parameter is normally

displayed.

While in display mode (

PROGRAM LED

is off), press

and release once. The present display

parameter number will be displayed for 2 seconds.

The display will then return to the present

parameter value.

While in display mode (

PROGRAM LED

is off), press

until the desired parameter is displayed.

Following a 2-second delay, the parameter value

will be displayed.

Programming Basics

3-3

Page 12

Table 3.3 – Keypad Operation

Desired Action User Steps

Increment the

program parameter

number

Decrement the

program parameter

number

Increment the

current program

parameter value

Decrement the

current program

parameter value

Clear faults

1. Press until the

2. Press until the desired number is displayed.

1. Press until the

2. Press

1. Press until the

2. Press while the desired program parameter

3. Press until the desired value is displayed.

1. Press until the

2. Press while the desired program parameter

3. Press until the desired value is displayed.

Press

PROG

enter program mode.

PROG

enter program mode.

until the desired number is displayed.

PROG

enter program mode.

number is displayed.

PROG

enter program mode.

number is displayed.

.

PROGRAM LED

PROGRAM LED

PROGRAM LED

PROGRAM LED

turns on to

turns on to

turns on to

turns on to

3-4

Using the SP200 AC Drive Demo Unit

Page 13

C

HAPTER

4

Running the Demo Unit

The demo consists of five step-by-step labs to acquaint you

with the basic operation of the drive.

Purpose of the labs

Lab 1 This lab has two parts:

Lab 2 Learn how to use the display parameters

Lab 3 Learn how to use configured inputs and

Lab 4 Learn how to set up various stopping

Lab 5 Learn how to set up an avoidance

4.1 The Labs

:

a. Learn the steps required to reset the

drive to factory defaults.

b. Learn how to set up a basic

configuration that uses external I/O.

This lab sets the drive up for the next four

labs. Run Lab 1 first.

to view drive status.

outputs.

methods.

frequency.

Lab 1a: Resetting the drive to factory defaults.

Tools required

Step 1. Turn on the demo unit using the power switch.

Step 2. Press until the

Running the Demo Unit

: None

PROG

program mode.

PROGRAM LED

turns on to enter

4-1

Page 14

Step 3. Press or until P-60 [

displayed.

RESET TO DEFAULTS

] is

Step 4. Press

to display the value of P-60 (0 should be

displayed).

Step 5. Press to change the value to 1(Reset All Values

to Factory Defaults).

Step 6. Press to accept the value.

The drive’s factory defaults have been restored.

Lab 1b: Setting up a basic drive configuration that uses

external I/O control.

Step 1. Press until the

PROG

PROGRAM LED

turns on to enter

program mode.

Step 2. Press or until P-00 [

MINIMUM SPEED

] is

displayed.

Step 3. Press to display the value of P-00.

Step 4. Press or until the value 5 is displayed. This

sets the minimum speed to 5 Hz.

Step 5. Press to accept the value.

Step 6. Press until P-01 [

MAXIMUM SPEED

] is displayed.

4-2

Step 7. Press

to display the value of P-01.

Step 8. Press or to change the value to 60, if

necessary.

Step 9. Press to accept the displayed value.

Step 10. Repeat this process for all of the parameters listed

in table 4.2. The parameter settings are based on

the demo unit’s motor nameplate data listed below.

Note that the demo unit contains a Mode l C SP200 drive.

• 1600 RPM

• .22 A FLA

• 60 Hz

Using the SP200 AC Drive Demo Unit

Page 15

Table 4.1 – Parameter Values for Basic Configuration

No. Parameter Name Value

P-00

P-01

P-02

P-03

P-05

P-10

P-20

P-30

P-31

P-34

P-50

P-51

MINIMUM SPEED

MAXIMUM SPEED

MOTOR OVERLOAD CURRENT

REVERSE DISABLE

CURRENT LIMIT

START CONTROL

MAIN SPEED REFERENCE

ACCELERATION TIME

DECELERATION TIME

STOP CONTROL

BASE VOLTAGE

BASE SPEED

1 3.0 sec

1 3.0 sec

5 Hz

60 Hz

0.4 A

0

150%

2 (2-Wire Start)

0 (Analog Input 1)

0 (Ramp-to-Rest)

100 V

60 Hz

The drive is now programmed with a basic configuration that

uses external I/O control.

Step 11. Turn the

Step 12. Turn the

drive starts and the

Step 13. Turn the

CONF IN

STOP/RUN

ANALOG CHAN

switch to 1.

switch to

RUN LED

. Notice that the

RUN

turns on.

#1 switch (the main speed

reference) fully clockwise to run the drive at

maximum speed (60 Hz).

Step 14. Turn the

ANALOG CHAN

#1 switch fully

counter-clockwise to run the drive at minimum

speed (5 Hz).

Step 15. Turn the

STOP/RUN

switch to

to stop the drive.

STOP

Step 16. Change the value of parameter P-10 to 1 (Keypad

Control).

Step 17. Turn the

STOP/RUN

switch to

. Note that the drive

RUN

does not start because the start control is now the

keypad. Also notice that the

on.

Step 18. Turn the

Step 19. Press

turns on.

LED

RUN LED

STOP/RUN

.

switch to

STOP

Notice that the drive starts and the

does not turn

.

RUN

Step 20. Press to stop the drive.

Step 21. Change the value of parameter P-10 back to 2.

Running the Demo Unit

4-3

Page 16

Lab 2: Using the display parameters to view drive

status.

Tools required

Step 1. Press

: None

PROG

until the

PROGRAM LED

turns off to enter

display mode.

Step 2. Press once. The letter "d" will be displayed

along with a two-digit number.

Step 3. Continue to depress (multiple times) to cycle

through all the display parameters.

Note:

When you stop or pause at a display parameter for

more than 2 seconds, the value of that parameter is

displayed.

Step 4. Press

until parameter d-01 [

OUTPUT FREQUENCY

is displayed.

Step 5. Turn the

Step 6. Turn the

Step 7. Turn the

CONF IN

STOP/RUN

ANALOG CHAN

switch to 1.

switch to

RUN

.

#1 switch fully clockwise to

run the drive at maximum speed. The display

should read at or near 60.0 Hz.

Step 8. Turn the

ANALOG CHAN

#1 switch fully

counter-clockwise to run the drive at minimum

speed. The display should read 5.0 Hz.

]

Step 9. Press

Step 10. Turn the

Lab 3: Using configured inputs and outputs.

Tools required:

A configured input is an input that can be programmed to

perform various functions. On the demo unit, the

switch is wired as the configured input to terminals 2 and 6

on the drive’s terminal strip.

Running the Demo Unit

FREQUENCY

until parameter d-00 [

COMMAND

] is displayed. The display should read

5.0 Hz, which is the value of the main speed

reference,

STOP/RUN

ANALOG CHAN

#1.

switch to

to stop the drive.

STOP

None

CONF IN

4-4

Page 17

A configured output is an output that can be programmed to

indicate various conditions. On the demo unit, the red

indicator lamp is hardwired to the configurable output

OUT

CONF

terminals on the drive’s terminal strip (terminals 11 and 12).

In this lab, you will program the configured input as a function

loss interlock and as a reversing switch. You will program the

configured output to indicate various conditions.

Before proceeding with this lab, do the following:

Step 1. Be sure the drive is stopped and the

switch is in the

Step 2. Verify that P-10 [

position.

STOP

START CONTROL

] is set to 2. This

STOP/RUN

will set the start control to 2-wire control.

To set P-10, use the following procedure:

a. Press until the

PROG

PROGRAM LED

turns on.

b. Press or until P-10 is displayed.

c. Press

to display the value of P-10.

d. Press or until 2 is displayed.

e. Press to accept the value.

Lab 3a: Programming the input as a function loss

interlock.

A function loss is a hardwired input to the drive that can act

as an interlock from some other equipment. If that other

equipment fails or stop operating, this will cause a Function

Loss fault in the drive (fault code FL is displayed). This fault

will keep the drive from starting or will stop the drive if it is

operating.

The switch labeled

Step 1. Verify that the

Step 2. Verify that the

Step 3. Set P-11 [

Running the Demo Unit

position.

CONF IN

CONFIGURABLE INPUT

is wired as the configured input.

CONF IN

STOP/RUN

switch is in the 1 position.

switch is in the

STOP

] to 0 (Function Loss).

4-5

Page 18

Step 4. Turn the

rotate to the commanded speed selected on the

speed pot (

Step 5. Turn the

following things that occur:

• The drive faults, and the motor coasts to a stop.

• The drive displays the fault code FL (Function

Loss).

STOP/RUN

ANALOG CHAN

CONF IN

switch from 1 to 0. Note the

switch to

#1).

. The motor should

RUN

• The drive status

changes from green (OK) to

LED

red (problem exists).

• The

Step 6. Turn the

STOP/RUN

and

RUN

CONF IN

PROGRAM LED

switch back to 1, and turn the

switch back to

s turn off.

. Notice that nothing

STOP

happens because the fault condition prohibits the

drive from running.

Step 7. Press to reset the fault and note the following:

• The FL fault code is not displayed.

• The drive status

changes from red to green.

LED

Lab 3b: Programming the input as a reversing switch.

Step 1. Set P-11 [

CONFIGURABLE INPUT

] to 1. This programs

the drive to run in the opposite direction when the

configurable input is on.

Step 2. Verify that the

position and that the

STOP/RUN

switch is in the

CONF IN

switch is in the 0

STOP

position.

Step 3. Turn the

direction of motor rotation. Turn the

to

STOP

STOP/RUN

to stop the drive.

switch to

, and notice the

RUN

STOP/RUN

switch

Step 4. Turn the

Important:

Running the Demo Unit

CONF IN

switch to 1, and notice that the

direction of motor rotation is reversed. Turn the

CONF IN

switch to 0 to stop the drive.

If you set the

CONF IN

STOP/RUN SWITCH

switch is set to 1, or vice versa, a drive

to

while the

RUN

fault will occur and CF will be displayed. The

drive stops if more than one input (forward,

reverse, or jog) is on.

4-6

Page 19

If this fault occurs, turn the

and the

STOP

to reset the fault.

CONF IN

STOP/RUN

switch to 0. Then press

Lab 3c: Programming the configurable output.

switch to

The red indicator lamp (

CONF OUT

) on the demo unit is

hardwired to the configurable output on the terminal strip

(terminals 11 and 12).

Step 1. Set P-12 [

CONFIGURABLE OUTPUT

] to 0 (No Fault).

This programs the output to turn on when the drive

is not faulted.

Step 2. Turn the

STOP/RUN

switch to

. (The motor should

RUN

rotate).

Step 3. Turn the

CONF IN

switch to 1. Notice the drive now

displays a CF fault code. Also note that the red

indicator lamp is off.

Step 4. Turn the

switch to

CONF IN

STOP

switch to 0, and the

.

RUN/STOP

Step 5. Press to reset the fault. Notice that the CF

code on the display is gone, and the red indicator

lamp is now on.

Step 6. Set P-12 to 2 (Running). This programs the output

to turn on when the drive is commanded to run.

Step 7. Turn the

Turn the

STOP/RUN

CONF IN

switch to

, then back to

RUN

STOP

switch to 1, then back to 0. Notice

when the red indicator lamp turns on and off.

Step 8. Set P-12 to 3 (At Frequency). This programs the

configured output to turn on when the output from

the drive equals the speed set by the speed

reference pot,

ANALOG CHAN

#1 (commanded

frequency speed).

Step 9. Turn the

STOP/RUN

switch to

. Notice that the red

RUN

indicator lamp does not turn on immediately, but

remains off until the output is equal to the speed

reference. Rotate the speed pot clockwise and

counter-clockwise and watch the red indicator lamp.

.

Step 10. Set P-12 to 4 (Above Frequency). This programs

Running the Demo Unit

the configured output to turn on when the drive

exceeds a specified frequency.

4-7

Page 20

Step 11. Set P-13 [

CONFIGURABLE OUTPUT LEVEL

This sets the level at which the output will turn on to

30.0 Hz.

Step 12. Turn the speed pot (

clockwise. The red indicator lamp should be on.

ANALOG CHAN

] to 30.0.

#1) fully

Step 13. Press to enter display mode.

Step 14. Press

PROG

until d-01 [

OUTPUT FREQUENCY

] is

displayed.

Step 15. Slowly turn the speed pot counter-clockwise. Notice

that the red indicator lamp turns off when the

frequency drops below 30.0 Hz.

Step 16. Set the s

TOP/RUN

switch to

STOP

.

Lab 4: Programming various stopping methods.

Tools required:

None

This lab consists of three parts:

a. Programming the drive for a coast-to-rest stop.

b. Programming the drive for a ramp-to-rest stop.

c. Programming the drive for DC injection braking.

Lab 4a: Programming the drive for a coast-to-rest stop.

Step 1. Press until the

PROG

PROGRAM LED

turns on to enter

programming mode.

Step 2. Press or until P-34 [

STOP CONTROL

] is

displayed.

Step 3. Press to display the value of P-34.

Step 4. Set P-34 to 1 (Coast-to-Rest).

Step 5. Turn the

Step 6. Press to enter display mode.

Running the Demo Unit

Note:

The drive may be at the default value of 0

(Ramp-to-Rest), which means the output voltage

and frequency is lowered based on the decel time.

During the previous labs, you may have noticed

how quickly the drive stopped.

pot (

ANALOG CHAN

PROG

STOP/RUN

switch to

#1) fully clockwise.

and turn the speed

RUN

4-8

Page 21

Step 7. Press , if necessary, until d-01 [

FREQUENCY

] is displayed.

COMMAND

Step 8. Turn the

STOP/RUN

switch to

. Notice that the

STOP

output frequency immediately drops to 0. Notice

how long it takes the motor to stop.

Lab 4b: Programming the drive for a ramp-to-rest stop.

Step 1. Press to enter program mode.

PROG

Step 2. Set P-34 to 0 (Ramp-to-Rest).

Step 3. Press to enter display mode.

PROG

Step 4. Press , if necessary, until the value of d-01

[

COMMAND FREQUENCY

Step 5. Turn the

STOP/RUN

] is displayed.

switch to

RUN. ANALOG CHAN

#1

should be turned fully clockwise. Wait for the drive

to reach full speed.

Step 6. Turn the

STOP/RUN

switch to

. Notice that the

STOP

output frequency and voltage decreases over time

(ramps down) to zero.

Lab 4c: Programming the drive for DC injection braking.

DC injection braking is a stopping method whereby DC

current is applied to a single winding in a motor.

Step 1. Set P-34 to 2 (DC Injection).

Step 2. Set P-35 [

Step 3. Set P-36 [

Step 4. Press to enter display mode.

Step 5. Press , if necessary, until the value of d-01

Step 6. Turn the

Running the Demo Unit

DC BRAKE CURRENT

] to 100. This specifies

the output current level in percent.

DC BRAKE TIME AT STOP

] to 3.0. This sets

the amount of time in seconds that the current

specified in P-35 is applied to the motor. The DC

injection begins when the drive is commanded to

stop.

PROG

[

COMMAND FREQUENCY

STOP/RUN

] is displayed.

switch to

RUN. ANALOG CHAN

#1

should be turned fully clockwise. Wait for the drive

to reach full speed.

4-9

Page 22

Step 7. Turn the

STOP/RUN

switch to

. Notice that the

STOP

output frequency and voltage dropped to 0

immediately.

Step 8. Reset the following parameters:

P-34 to 1

P-35 to 10

P-36 to 0.0

Lab 5: Setting up an avoidance frequency.

Tools required:

None

Avoidance frequency parameters are used to prevent the

drive from continuous operation within a range (band) of

frequencies.

Step 1. Set P-37 [

AVOIDANCE FREQUENCY

] to 30.0 Hz. This

specifies the midpoint of the band.

Step 2. Set P-38 [

AVOIDANCE FREQUENCY BAND

] to 20.0 Hz.

This sets the width of the band. In this case, the

width of the band is set from 20.0 Hz to 40.0 Hz.

Step 3. Turn the speed pot to zero (

ANALOG CHAN

#1 should

be turned fully counter-clockwise).

Step 4. Press to enter display mode. Press , if

necessary, until the value of d-01 [

FREQUENCY

Step 5. Turn the

PROG

] is displayed.

STOP/RUN

switch to

RUN

COMMAND

.

Step 6. Slowly turn the speed pot clockwise, and watch the

display.

Notice that the motor holds up at 20.0 Hz and

speeds up at 40.0 Hz.

Step 7. Press until d-00 [

COMMAND FREQUENCY

] is

displayed.

Step 8. Turn the speed pot to zero, and then slowly turn the

speed pot up and down.

Step 9. Reset the following parameters:

Step 10. Turn the

Running the Demo Unit

Notice when the motor increases in speed, holds

speed, and decreases speed.

P-37 to 0

P-38 to 0

RUN/STOP

switch to

STOP

.

4-10

Page 23

C

HAPTER

5

Troubleshooting

the Demo Unit

Use table 5.1 to troubleshoot any problems you may have

with the demo unit.

For technical assistance, call 1-800-726-8112.

Table 5.1 – Troubleshooting Table

Problem Corrective Action

Display or

are not on.

Demo unit does

not react as

described in labs.

Cannot change

parameter value.

Fault or alarm

code is displayed.

LED

s

• Check power source.

• Check power cord connection.

• Check on/off switch.

• Check fuse.

• Verify that parameter defaults

were restored.

• Verify that parameters were set

correctly.

• If the drive is running, verify that

the parameter is a tunable

parameter.

• Refer to the troubleshooting

section in Installing and Operating

the SP200 AC Drive (D2-3408).

Troubleshooting the Demo Unit

5-1

Page 24

5-2

Using the SP200 AC Drive Demo Unit

Page 25

Page 26

U.S. Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Publication D2-3474– November 2000 Copyright © 2000 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...