Page 1

Solar Turbine

Addendum

Ver sion 6.0

Instruction Manual

D2-3406

Page 2

The information in this manual is subject to change without notice.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

ATTENTION:Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, or service this equipment.

!

Read and understand this manual and other applicable manuals in their entirety before

proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:The user must provide an external, hardwired emergency stop circuit outside of

the drive circuitry . This circuit must disable the system in case of improper operation. Uncontrolled

machine operation may result if this procedure is not followed. F ailure to observe this precaution

could result in bodily injury.

ATTENTION:The user is responsible for conforming with all applicable local, national, and

international codes. F ailure to observe this precaution could result in damage to, or destruction

of, the equipment.

Reliance is a trademark of Rockwell Automation.

©1999 Rockwell International Corporation

Page 3

Chapter 1 Introduction

1.1 Intended Audience........................................................................................... 1-1

1.2 Other Required Manuals ................................................................................. 1-1

Chapter 2 About the Drive and Cabinet

2.1 Identifying the Solar Turbine Drive by Model Number and Ratings................. 2-1

2.2 Enclosure Rating .............................................................................................2-2

2.3 Identifying Solar Turbine Cabinet Components...............................................2-2

Chapter 3 Cabinet Mounting and Wire Routing

3.1 Mounting the Drive .... ...... ....... ...... ...... ....... ...... ....... ...... ....... ............................3-1

3.1.1 Verifying the Drive’s Watts Loss Rating ....................................... ....... .. 3-2

3.2 Cabinet Wire Routing ...................................................................................... 3-3

3.3 Grounding the Cabinet .................................................................................... 3-6

Chapter 4 Installing Power Wiring

4.1 Installing Fuses for Branch Circuit Protection.................................................. 4-1

4.2 Installing a Required External/Separate Input Disconnect ..............................4-1

4.3 Installing Power Wiring from the DC Power Supply to the Drive’s Internal

DC Bus Terminals ...........................................................................................4-3

4.4 Recommended Motor Lead Lengths...............................................................4-5

CONTENTS

Chapter 5 Troubleshooting the Drive

5.1 Verifying that DC Bus Capacitors are Discharged...........................................5-1

5.2 Replacement Parts....................................................... ....... ...... ....... ...............5- 1

Appendix A Solar Turbine Drive Parameters...............................................................................A-1

Contents

I

Page 4

II

Solar Turbine Addendum

Page 5

List of Figures

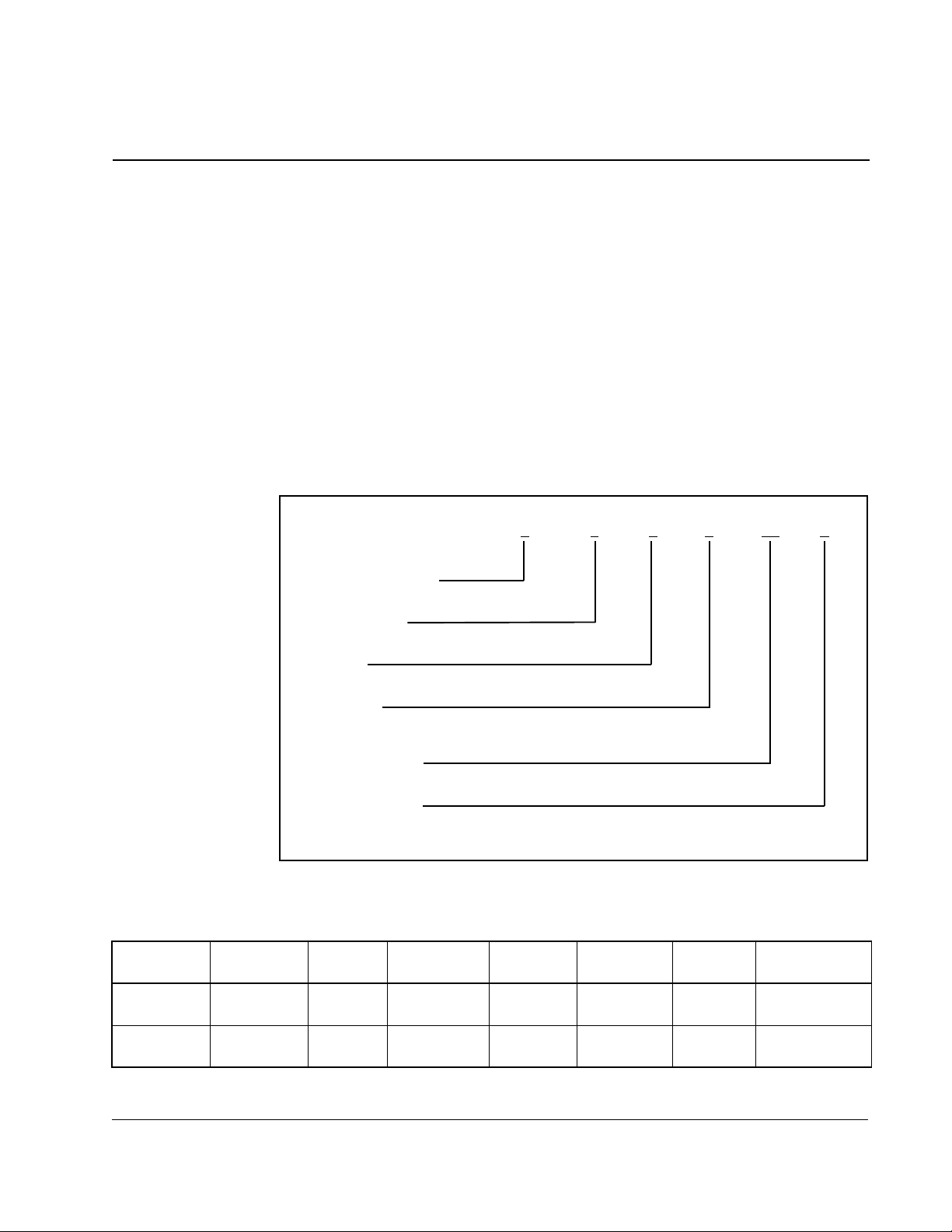

Figure 2.1 – Identifying the Drive Model Number .....................................................2-1

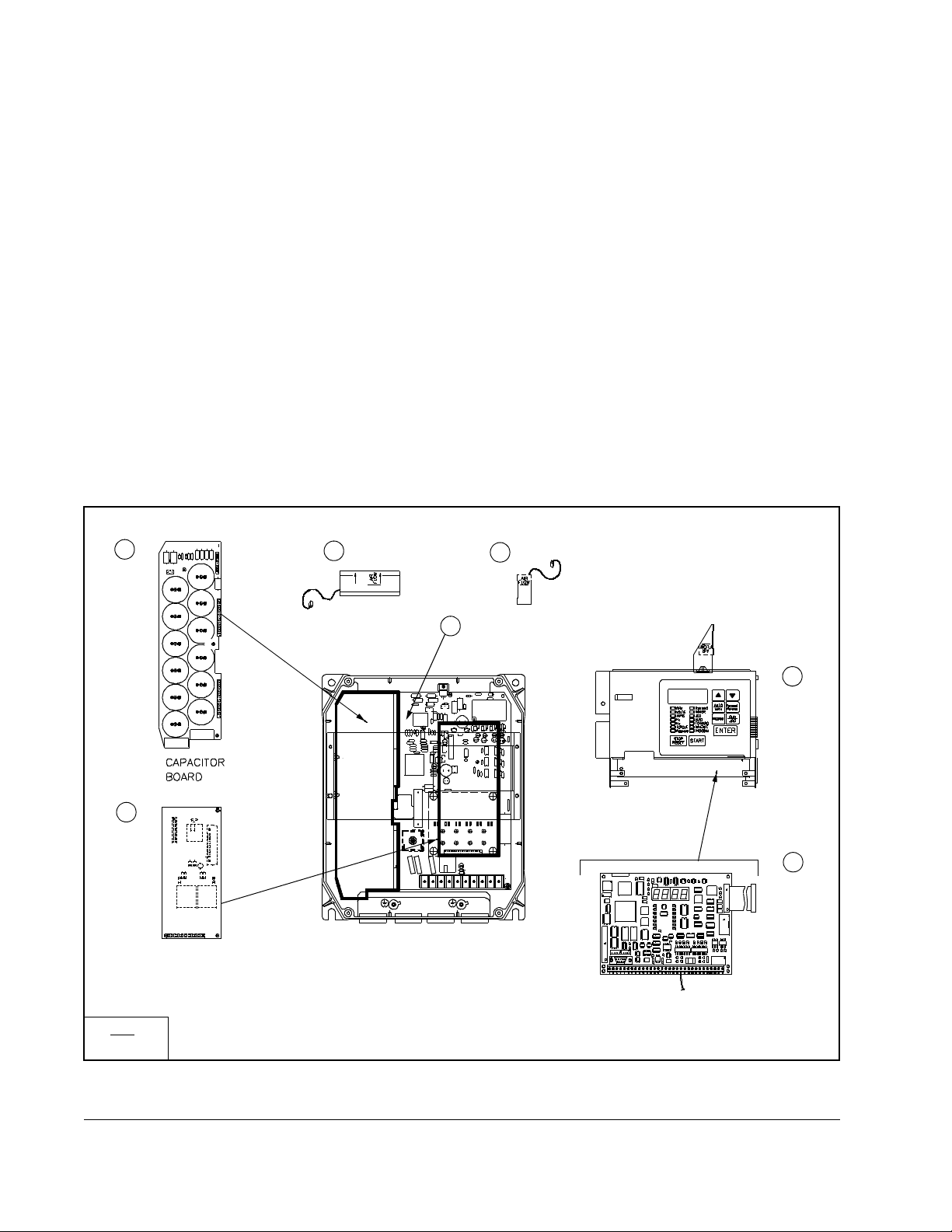

Figure 2.2 – Solar Turbine 1 HP Drive Component Locations..................................2-2

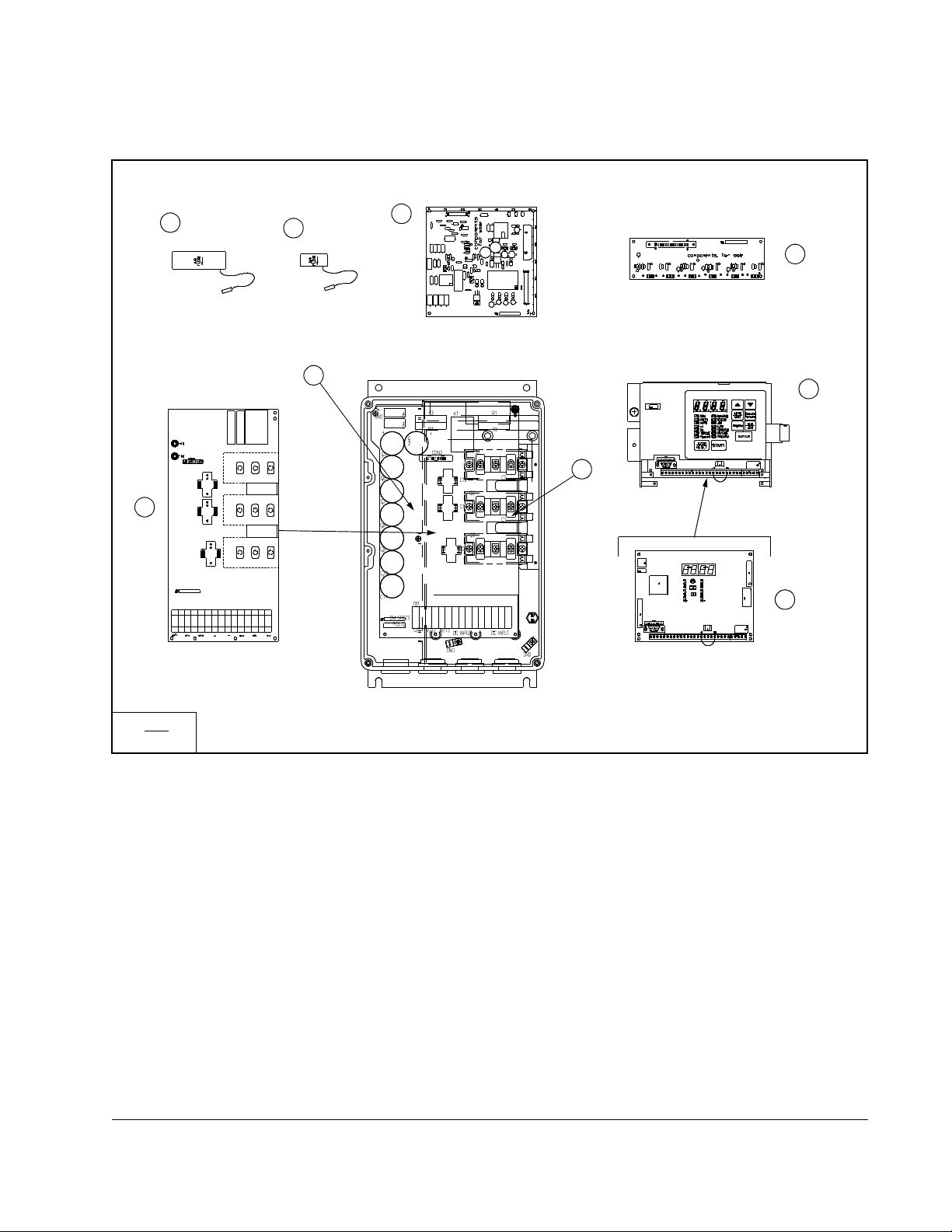

Figure 2.3 – Solar Turbine 5 HP Drive Component Locations..................................2-3

Figure 3.1 – Drive Dimensions .................................................................................3-2

Figure 3.2 – Wire Routing Locations for 1 HP Drive.................................................3-4

Figure 3.3 – Wire Routing Locations for 5 HP Drive.................................................3-5

Figure 4.1 – Typical Electrical Connections.............................................................. 4-2

Figure 4.2 – DC Input Terminals............................................................................... 4-4

Contents

III

Page 6

IV

Solar Turbine Addendum

Page 7

List of Tables

Table 2.1 – Drive Ratings .........................................................................................2-1

Table 3.1 – Drive Dimensions and Weights.............................................................. 3-1

Table 3.2 – Power and NEMA Enclosure Ratings.................................................... 3-2

Table 4.1 – Recommended Input Line Fuse Ratings ...............................................4-1

Table 4.2 – Recommended Power Wire Sizes......................................................... 4-3

Table 4.3 – Terminal Tightening Torques.................................................................4-4

Table 4.4 – Recommended Motor Lead Lengths .....................................................4-5

Table 5.1 – Solar Turbine Drive Replacement Parts ................................................5-2

Contents

V

Page 8

VI

Solar Turbine Addendum

Page 9

This addendum covers the features and specifications that are unique to the

GV3000/SE Solar Turbine drives. GV3000/SE Solar Turbine drives operate from a

120 VDC input, requiring a different power supply than standard GV3000/SE drives.

Only product information that is unique to Solar Turbine drives is covered in this

addendum. This addendum must be used along with the GV3000/SE software and

hardware instruction manuals listed in section 1.2.

1.1 Intended Audience

This addendum is intended for the following qualified personnel:

• Rockwell Automation Global Technical Service personnel who are familiar with the

features described.

• Product end users

1.2 Other Required Manuals

CHAPTER 1

Introduction

This addendum must be used with the following publications:

• D2-3359 GV3000/SE AC General Purpose (Volts/Hertz) and Vector Duty Drive

Software Start-Up and Reference Manual

• D2-3360 GV3000/SE AC Power Modules Hardware Reference, Installation, and

Troubleshooting

Introduction

1-1

Page 10

1-2

Solar Turbine Addendum

Page 11

CHAPTER 2

About the Drive and Cabinet

This chapter describes how to identify the Solar Turbine drive and cabinet layout using

the Solar Turbine model number and drive power ratings. Internal cabinet component

drawings are also provided.

2.1 Identi fying the Solar Turbine Drive by Model Number

and Ratings

The Solar Turbine drive is available in 1 HP and 5 HP versions. Each drive can be

identified by its model number. See figure 2.1. This number appears on the shipping

label and on the drive’s nameplate. The drive’s model number includes the Power

Module and the Regulator. Drive power ratings are provided in table 2.1.

N NA N NN N

Horsepower Ratings

Drive

M/N

1G0160S NEMA 1

5G0160S NEMA 1

Enclosure

Type

IP20 V6.04

IP20 V6.04

Regulator Ty pe

G = V/Hz only

Voltage

0 = 120V DC

Enclosure

1 = NEMA 1

Regulator Version

60 = Version 6.0

Hardware Version

S =Special

Figure 2.1 – Identifying the Drive Model Number

Table 2.1 – Drive Ratings

Output

Power

1 HP 120 VDC 13.4 A 90 VAC 11.1 A 3 to 200 Hz

5 HP 120 VDC 37.0 A 90 VAC 30.4 A 3 to 200 Hz

Input

Volts

Input

Amps

Output

Volts

Output

Amps

Output

Frequency

About the Drive and Cabinet

2-1

Page 12

2.2 Enclosure Rating

The Solar Turbine 1 HP and 5 HP cabinets have a NEMA 1 enclosure rating:

NEMA 1: Vented. Contains a communication access door that allows access to the

communication port without removing the cover. Intended for general-purpose indoor

applications.

2.3 Identifying Solar Turbine Cabinet Components

The Solar Turbine drive has the following main components. The identification

numbers provided correspond to the numbers used in figure 2.2 (1 HP) and figure 2.3

(5 HP).

1. Capacitor Board/Input Capacitors 6. Current Feedback Board

2. Fan Assembly 7. Regulator Board

Internal Fan Assembly

3.

4. Power Board 9. Signal Board

5. Membrane Switch (Keypad/Bracket) 10. Gate Driver Board

8. IGBT Module

1

6

MN

1G0160S

CURRENT FEEDBACK

BOARD

2

FAN ASSEMBLY

4

3

FAN ASSEMBLY

(INTERNAL)

5

MEMBRANE SWITCH

(KEYP AD/BRACKET)

7

REGULATOR

BOARD

2-2

Figure 2.2 – Solar Turbine 1 HP Drive Component Locations

Solar Turbine Addendum

Page 13

2

3

9

10

FAN ASSEMBLY

4

POWER BOARD

MN

5G0160S

FAN ASSEMBLY

(INTERNAL)

1

Figure 2.3 – Solar Turbine 5 HP Drive Component Locations

SIGNAL BOARD

8

IGBT

MODULE

GATE DRIVER BOARD

5

MEMBRANE SWITCH

(KEYPAD/BRACKET)

7

REGULATOR BOARD

About the Drive and Cabinet

2-3

Page 14

2-4

Solar Turbine Addendum

Page 15

Cabinet Mounting and Wire Routing

This chapter provides information on how to mount the Solar Turbine drive. Also

shown are the entry areas where wiring is to be routed in and out of the drive.

Please refer to instruction manual D2-3360 for detailed information on planning your

drive installation and for further information on proper wiring routing of power and

signal wiring and grounding of GV3000/SE drives.

3.1 Mounting the Drive

Attach the drive to the vertical surface selected using the four (4) mounting holes

provided. In order to maintain a flat mounting surface and to ensure that bolt tightness

is maintained, use washers under the bolt heads. Refer to table 3.1 and figure 3.1 for

mounting dimensions. Use the following user-supplier mounting bolts and washers:

1 HP Solar Turbine Drives: M8 (5/16”)

5 HP Solar Turbine drives: M8 or M10 (5/16” or 3/8”)

CHAPTER 3

Table 3.1 – Drive Dimensions and Weights

HP Rating Dim. A Dim. B Dim. C Dim. D Dim E. Weight

1 HP 280.6 mm

11.05"

5 HP 288.0 mm

11.34"

338.4 mm

13.32"

463.0 mm

18.23"

248.0 mm

9.76"

223.0 mm

8.78"

309.1 mm

12.17"

442.0 mm

17.40"

200.0 mm

7.87"

238.1 mm

9.37"

9 kg

20 lbs

15.75 kg

35 lbs

Cabinet Mounting and Wire Routing

3-1

Page 16

A

C

E

D

Figure 3.1 – Drive Dimensions

B

3.1.1 Verifying t h e Drive’s Watts Loss Rating

When mounting the drive inside another enclosure, you should determine the watts

loss rating of the drive from table 3.2. Ensure adequate ventilation is provided based

on the drive’s watts loss rating.

Table 3.2 – Power and NEMA Enclosure Ratings

Output

HP

Rating

1 HP 1 120 13.4 11.1 11.1 11.1 210

5 HP 1 120 37.0 30.4 30.4 30.4 600

3-2

NEMA

Rating

Input

Volts

Input

Amps

Amps at

2kHz

Output

Amps at 4

kHz

Output

Amps at 8

kHz

Power Loss Watts

(Full Load)

Solar Turbine Addendum

Page 17

3.2 Cabinet Wire Routing

All wiring should be installed in conformance with the applicable local, national, and

international codes (for example, NEC/CEC). Signal wiring, control wiring, and power

wiring must be routed in separate conduits to prevent interference with drive

operation. Figures 3.2 and 3.3 show the wire routing of the cabinet for 1 HP and 5 HP

drives, respectively.

ATTENTION:Do not route signal and control wiring with power wiring in

the same conduit. This can cause interference with drive operation.

!

Refer to instruction manual D2-3360 for detailed instructions on cabinet wire routing.

Failure to observe this precaution could result in damage to, or

destruction of, the equipment.

Cabinet Mounting and Wire Routing

3-3

Page 18

Regulator Terminal Strip

Power Strip Terminals

Ground Terminals

Signal Control

(Terminal Strip)

Input Power

or

Snubber Resistor

Braking

User Wire Routing

Motor Leads

or

Input Power

and Motor Leads

Cover

Base

(4) .875 [22/2 mm] diameter

Holes (Nema 1)

3-4

Figure 3.2 – Wire Routing Locations for 1 HP Drive

Solar Turbine Addendum

Page 19

Regulator Terminal Strip

Power Strip Terminals

Ground Terminals

Signal Control

(Terminal Strip)

Input Power

Snubber Resistor

or

Braking

User Wire Routing

(1) .875 [22.2mm] diameter

Hole (NEMA 1)

Bottom View

Motor Leads

or

Input Power

and Motor Leads

Cover

Base

(3) 1.094 [27.8mm] diameter

Holes (Nema 1)

Cabinet Mounting and Wire Routing

Figure 3.3 – Wire Routing Locations for 5 HP Drive

3-5

Page 20

3.3 Grounding the Cabinet

ATTENTION:The user is responsible for conforming with all applicable

local, national, and international codes. Failure to observe this precaution

!

The Solar Turbine drive should be grounded in accordance with the instructions given

for mounting a GV3000/SE drive in instruction manual D2-3360.

could result in damage to, or destruction of, the equipment.

3-6

Solar Turbine Addendum

Page 21

CHAPTER 4

Installing Power Wiring

This chapter describes how to connect 120 volt DC input power to a 1 HP or 5 HP

GV3000/SE Solar Turbine drive. Guidelines for motor lead lengths are also provided.

Please refer to instruction manual D2-3360 for complete information on wiring a

GV3000/SE drive.

4.1 Installing Fuse s for Branch Circuit Protection

ATTENTION:Most codes require that upstream branch protection be

provided to protect input power wiring. Failure to observe this precaution

!

Install the required, user-supplied branch circuit protection fuses according to the

applicable local, national, and international codes (e.g., NEC/CEC). The fuses must

be installed in the line before the drive input terminals. See figure 4.1. Fuse value

recommendations are provided in table 4.1.

could result in severe bodily injury or loss of life.

Table 4.1 – Recommended Input Line Fuse Ratings

Drive HP Rating Input Voltage (+/- 10%) Fuse Rating

1 HP 120 VDC 25A

5 HP 120 VDC 70A

1.Recommended fuse type: UL Class J, 600V, time delay, or equiv alent.

4.2 Installing a Required External/Separate Input

Disconnect

An input disconnect must be installed in the line before the drive input terminals in

accordance with local, national, and international codes (e.g., NEC/CEC). The

disconnect should be sized according to the in-rush current as well as any additional

loads the disconnect might supply. The trip rating for the inrush current (10-12 times

full load current) should be coordinated with that of the input isolation transformer, if

used. Refer to instruction manual D2-3360 for additional information.

1

Installing Power Wiring

4-1

Page 22

User

Supplied

User’s 120 VD C

Supply

_

+

Manual

Disconnect

DC Fuses

User

S u p p lie d

5 HP Drive: Terminals B1 and B2

*

1 HP Drive: Terminals (+) and (–)

Motor Overload Relay

(If Electronic O verload

Is Not Used)

B1

(+)

*

B2

(–)

~

UVW

T2 T3

T1

M

*

Solar Turbine

Power Module

GND

PE

4-2

Figure 4.1 – Ty pical Electrical Connections

Solar Turbine Addendum

Page 23

4.3 Installing Power Wiring from the DC Power Suppl y to

the Drive’s Internal DC Bus Terminals

ATTENTION:Do not route signal and control wiring in the same conduit

with power wiring. This can cause interference with drive operation.

!

Use the following steps to connect DC input power to the drive:

Step 1. Wire the DC input power leads by routing them according to drive type. Refer

Type of Wiring Terminals Size of Wire (Maximum)

Output Power U/T1, V/T2, W/T3

DC Input Power +, –

Failure to observe this precaution could result in damage to, or

destruction of, the equipment.

ATTENTION:If the GV3000/SE drive is connected to an external DC

bus, the user is responsible for DC bus short-circuit protection. Failure

to observe this precaution could result in damage to, or destruction of,

the equipment.

to figures 3.2 and 3.3. Table 4.2 contains the recommended power wiring

sizes.

Table 4.2 – Recommended Power Wire Sizes

2

(1 HP)

2

(5 HP)

Ground

12 AWG, 3 mm

6 AWG, 13 mm

Step 2. Connect the DC input power leads to terminals + and – (1 HP drive) or B1

and B2 (5 HP drive) on the power terminal strip (see figure 4.2).

ATTENTION:On the 5 HP Solar T urbine drive, the positive DC input must

be connected to the (+) terminal. The negative DC input must be

!

connected to the (–) terminal. These terminals cannot be interchanged.

Failure to observe this precaution could result in damage to, or

destruction of, the equipment.

Installing Power Wiring

4-3

Page 24

ATTENTION:On the 5 HP Solar T urbine drive, the positive DC input must be connected to the

(+) terminal. The negative DC input must be connected to the (–) terminal. These terminals

!

cannot be interchanged. Failure to observe this precaution could result in damage to, or

destruction of, the equipment.

1 HP Drive

U/T1

B1 B2

(+) (-)

DC Inputs

W/T3V/T2

DC Bus

U/T110V 10 COM

Motor Leads

Volts

5 HP D rive

W/T3V/T2

4-4

Motor Leads

Step 3. Tighten the DC input power terminals to the proper torque, as listed in

DC P ositive

Input

Figure 4.2 – DC Input Terminals

DC Negative

Input

table 4.3.

Table 4.3 – Terminal Tightening Torques

Drive Terminals Maximum Tightening Torque

1 HP All 1.08 Newton-meters (9.5 in-lbs)

5 HP All 13.5 Newton-meters (10 ft-lbs)

Solar Turbine Addendum

Page 25

4.4 Recommended Motor Lead Lengths

The following motor lead lengths are recommended to reduce line disturbances and

noise.

Table 4.4 – Recommended Motor Lead Lengths

Maximum Lead Length in Feet

Carrier Frequency

Drive Power Rating

1 HP 500 500 500

5 HP 800 500 500

Refer to instruction manual D2-3360 for detailed instructions on installing output

power wiring.

2 kHz 4 kHz 8 kHz

Installing Power Wiring

4-5

Page 26

4-6

Solar Turbine Addendum

Page 27

CHAPTER 5

Tr oubleshooting the Drive

The GV3000/SE Solar Turbine drive displays alarm and fault codes to signal a

problem detected during self tuning or drive operation. These codes are described in

instruction manual D2-3359. This chapter provides general troubleshooting safety

guidelines and replacement part information that is unique to a 1 HP or 5 HP

GV3000/SE Solar Turbine drive. Refer to D2-3359 and to D2-3360 for detailed

instructions about troubleshooting a GV3000/SE drive and obtaining standard

replacement parts.

5.1 Verifying that DC Bus Capacitors are Discharged

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait fiv e

!

Step 1. Place the input disconnect in the Off position and lock out drive power. Wait

(5) minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

five minutes.

Step 2. Remove the drive’s cover.

Step 3. Verify that there is no voltage at the drive’s input power terminals (refer to

figure 4.2). This ensures that the DC bus capacitors are discharged.

Step 4. Once the drive has been serviced, reattach the drive’s cover.

Step 5. Reapply input power.

5.2 Replacement Parts

Table 5.1 lists the replacement parts that are available from Reliance Electric. See

figures 2.2 and 2.3 for component locations.

Troubleshooting the Drive

5-1

Page 28

Table 5.1 – Solar Turbine Drive Replacement Parts

Description

1

Drive HP Part Number Quantity

1

NEMA 1 Fan Assembly

52

615161-V

1 805538-1S 1

NEMA 1 Cover

5 805547-1S 1

1

Membrane Switch Keypad/Bracket

51

805548-1R

1

Regulator Printed Circuit Board

51

O-56975-200

Capacitor Printed Circuit Board 1 179210 1

Current Feedback Printed Circuit Board 1 O-56935-100 1

1 179211 1

Power Printed Circuit Board

5 O-56973 1

IGBT Module 5 602909-813AW 3

Signal Printed Circuit Board 5 O-56974 1

Gate Driver Board

2

5 O-5 6960 1

1 615159-1R 1

Internal Fan Assembly

1

Components are identified in figure 2.3.

2

Replace the Gate Driver board when the IGBT modules are replaced.

5 615159-1S 1

1

1

1

5-2

Solar Turbine Addendum

Page 29

APPENDIX A

Solar Turbine Drive Parameters

For Solar Turbine drives the following parameters have different default values than

standard GV3000/SE drives:

Solar Turbine

Parameter

P.048 V/Hz

H.000 90

H.017 3

H.021 85

Please refer to Instruction Manual D2-3359 for detailed descriptions of drive

parameters.

Default Setting

Solar Turbine Drive Parameters

A-1

Page 30

A-2

Solar Turbine Appendix

Page 31

INDEX

A

About the drive and cabinet, 2-1 to 2-4

B

Branch circuit protection, 4-1

C

Cabinet components, 2-2 to 2-4

Cabinet mounting, 3-1 to 3-3

Component locations

1 HP drive, 2-2

5 HP drive, 2-3

Components

identifying, 2-2

D

Dimensions, 3-1 to 3-2

Drive parameters, default settings, A-1

Drive ratings, 2-1

Identifying drive by model number and ratings, 2-1

Input disconnect, 4-1

Input terminal identification, 4-4

Intended audience, 1-1

Introduction, 1-1

M

Model number, 2-1

Mounting, 3-1

P

Power wiring, 4-1 to 4-5

DC input, 4-2

motor lead lengths, 4-5

recommended wire sizes, 4-3

R

Replacement parts, 5-1 to 5-2

Required manuals, 1-1

E

Electrical connections, typical, 4-2

Enclosure rating, 2-2, 3-2

F

Fuses, 4-1

I

Identifying, 2-1

Index

T

Terminal tightening torques, 4-4

Troubleshooting, 5-1 to 5-2

verifying DC bus capacitors are discharged, 5-1

W

Watts loss rating, verifying, 3-2

Weight of drive, 3-1

Wire routing, 3-1 to 3- 3

cabinet, 3-3

Index-1

Page 32

Index-2

Solar Turbine Addendum

Page 33

Page 34

U.S. Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication D2-3406-September 1999 Copyright © 1999 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...