Page 1

This manual links to KnowledgeBase Article SMC Flex Soft Starter

Parameters, which contains the parameters; download the spreadsheets

now to ensure offline access.

SMC Flex Soft Starters

Bulletin 150-F

User Manual

Original Instructions

Page 2

SMC Flex Soft Starters User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc

Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements

for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 3

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

View Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Summary of Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Product Overview Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Starting Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Soft Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Linear Speed Acceleration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Current Limit Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Selectable Kickstart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pump Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Dual Ramp Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Full-voltage Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preset Slow Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stopping Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Coast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Soft Stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Linear Speed Deceleration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pump Stop

Braking Control Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Smart Motor Braking (SMB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Slow Speed with Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Accu-Stop

Protection and Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Overload. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Underload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Undervoltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Overvoltage

Unbalance

Stall Protection and Jam Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ground Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ground Fault Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Ground Fault Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Thermistor/PTC Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Excessive Starts/Hour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Overtemperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Open Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Line Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Metering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

(a)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

(a)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

(a)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

(a)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 3

Page 4

Table of Contents

Status Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 2

Installation Receive the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Unpack the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Inspect the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Degree of Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Heat Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Power Factor Correction Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Protective Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Motor Overload Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Two-speed Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Multi-motor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Additional Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

New EMC Compliance – Conducted Emissions . . . . . . . . . . . . . . . . . 36

Chapter 3

Wiring Wiring Terminal Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Line Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Delta Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Power Lugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Control Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Controllers rated 5…480 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Controllers rated 625…1250 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Control Wire Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fan Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Fan Terminations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Control Terminal Designations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Standard Controller Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Soft Stop, Pump Control, and SMB Smart Motor Braking . . . . . . . . . . . 59

Preset Slow Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Slow Speed with Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Special Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Protective Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Multi-motor Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

SMC Flex Controller as a Bypass to an AC Drive . . . . . . . . . . . . . . . . 73

SMC Flex Controller with a Bulletin 1410 Motor Winding Heater . 74

4 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 5

Table of Contents

Dual-voltage Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Low-voltage Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

High-voltage Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Chapter 4

Programming Keypad Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Programming Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Parameter Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Random Access Memory (RAM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Read-only Memory (ROM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Parameter Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Soft Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Current Limit Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Dual Ramp Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Full Voltage Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Linear Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Programming Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Basic Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Motor Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Chapter 5

Metering Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

View Metering Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Chapter 6

Optional HIM Operation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Human Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Chapter 7

Communication Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Communication Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Human Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Keypad Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Connect the Human Interface Module to the Controller . . . . . . . . . 97

Control Enable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

HIM and COMM Card Control Enable . . . . . . . . . . . . . . . . . . . . . . . . . 98

Loss of Communication and Network Faults. . . . . . . . . . . . . . . . . . . . . . . 99

SMC Flex Controller-specific Information. . . . . . . . . . . . . . . . . . . . . . . . . 99

Default Input/Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 100

Variable Input/Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . 100

Bit Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Reference/Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Parameter Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Scale Factors for PLC Communication. . . . . . . . . . . . . . . . . . . . . . . . 102

Display Text Unit Equivalents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Configuring DataLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Criteria for Using DataLink. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 5

Page 6

Table of Contents

Updating Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Chapter 8

Diagnostic Capabilities Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Protection Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Fault Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Clear Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Fault Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Fault and Alarm Auxiliary Indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Fault Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Chapter 9

Troubleshooting Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Power Module Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Shorted SCR Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Appendix A

Renewal Parts Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Appendix B

Renewal Parts Cross Reference Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

6 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 7

Preface

About This Publication

Ter mi no logy

This user manual provides you with the information that is required to

program and operate your SMC™ Flex soft starter.

The SMC Flex controller is modular so that it can help simplify installation and

commissioning. A built-in LCD display, keypad, and flexible communications

provide optimized configuration, advanced performance, diagnostics, and

protection. Three-phase control, electronic overload, and integrated bypass

along with removable control module, power modules, and fan assembly are

combined in a cost-effective package for your demanding applications.

The user manual assumes that the installer is a qualified person with previous

experience and basic understanding of electrical terminology, configuration

procedures, required equipment, and safety precautions.

For safety of maintenance personnel and others who might be exposed to

electrical hazards associated with maintenance activities, follow all local

safety-related work practices (such as NFPA70E, Part II in the United States).

Maintenance personnel must be trained in the safety practices, procedures,

and requirements that pertain to their respective job assignments.

Throughout this publication, we also refer to the SMC Flex soft starter as the

SMC Flex controller. These terms are interchangeable.

View Parameters

Parameter definitions are listed in Excel® spreadsheets in KnowledgeBase. The

spreadsheets let you filter and sort parameters, and add your own setting

values and notes. Table 1

summarizes the information that is in the

spreadsheet.

Knowledgebase Answer ID 1125564, SMC Flex Soft Starter Parameters,

contains the parameters. Download the spreadsheet from this public

article.

You may be asked to log in to your Rockwell Automation web account or

create an account if you do not have one. You do not need a support

contract to access the article.

Table 1 - SMC Flex Parameter Categories

Parameter Group Description

Full Parameter List Full list of all SMC Flex Controller Parameters

Logic Mask Requirements Lists the Logic Mask Codes and Binary equivalents

Parameter Special Behavior

Describes codes that can appear under specific conditions and parameter

configurations

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 7

Page 8

Preface

Summary of Changes

This publication contains the following new or updated information. This list

includes substantive updates only and is not intended to reflect all changes.

Translated versions are not always available for each revision.

Top ic Page

Reformatted pages Throughout

Added information about conducted emissions compliance for EMC directive 35

Added parameter list for control module

Added enumerated binary bit pattern for the Logic Mask parameter 99

Removed Parameter List appendix. This information is contained in the spreadsheet that is attached to this

document.

Removed specifications and accessory appendices. This information is contained in the technical data,

publication 150-TD009

.

parameter

spreadsheet

8 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 9

Product Overview

Chapter 1

Description

The SMC™ Flex controller is modular so that it can help simplify installation

and commissioning. A built-in LCD display, keypad, and flexible

communications provide optimized configuration, advanced performance,

diagnostics, and protection. SMC Flex controllers combine three-phase

control, electronic overload, and integrated bypass along with removable

control module, power modules, and fan assembly in a cost-effective package

for your demanding applications.

• Modular for simplified installation and maintenance

• Built-in LCD and keypad or personal computer software setup

•Integrated bypass

• Nine start/stop modes and three slow-speed modes

• Full metering and diagnostics

Modes of operation include the following:

• Soft start • Full-voltage Start

• Current Limit Start • Dual Ramp Start

• Selectable Kickstart • Pump Start

• Coast-to-rest • Preset Slow Speed

•Soft stop •Pump Stop

• Smart Motor Braking (SMB™) • Accu-Stop™

• Slow Speed with Braking

• Linear Speed Acceleration

(Tachometer required)

Operation

IMPORTANT

The SMC Flex controller can operate standard squirrel-cage induction motors

rated 1…1250 A or Star-delta (wye-delta) type motors rated 1.8…1600 A up to

690V AC, 50/60 Hz. Depending upon the controller type ordered, the control

power input can range from 100…240V AC or 24V AC/DC. Verify voltage on the

product before you apply power.

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 9

The three controller options are Standard Control, Pump Control, and

Brake Control. Some modes of operation are only available on certain

controllers, such as Smart Motor Braking on Brake Control. Consider the

available modes of operation for a controller when configuring a catalog

number to order. You can upgrade an existing controller to another

control option by replacing the control module. Consult your local

Rockwell Automation sales office or Allen-Bradley distributor.

Page 10

Chapter 1 Product Overview

Time (seconds)

Ramp Time

Start

Run

% Voltage

Initial

Tor que

100%

Starting Modes

The SMC Flex Smart Motor Controller provides the following starting modes

of operation as standard:

Starting Modes

Soft Start Pump Control Mode

Linear Speed Acceleration Dual Ramp Start

Current Limit Start Full-voltage Start

Selectable Kickstart Preset Slow Speed

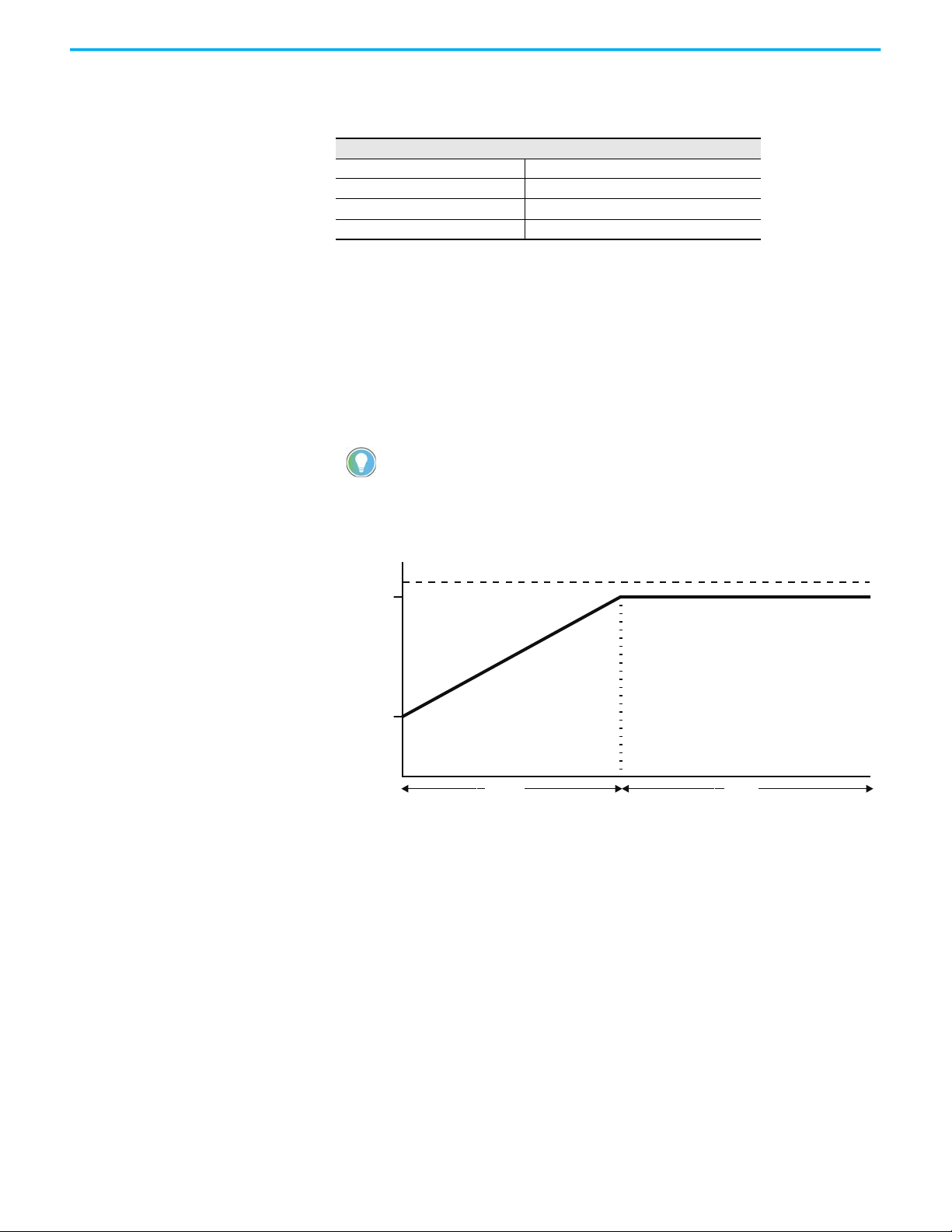

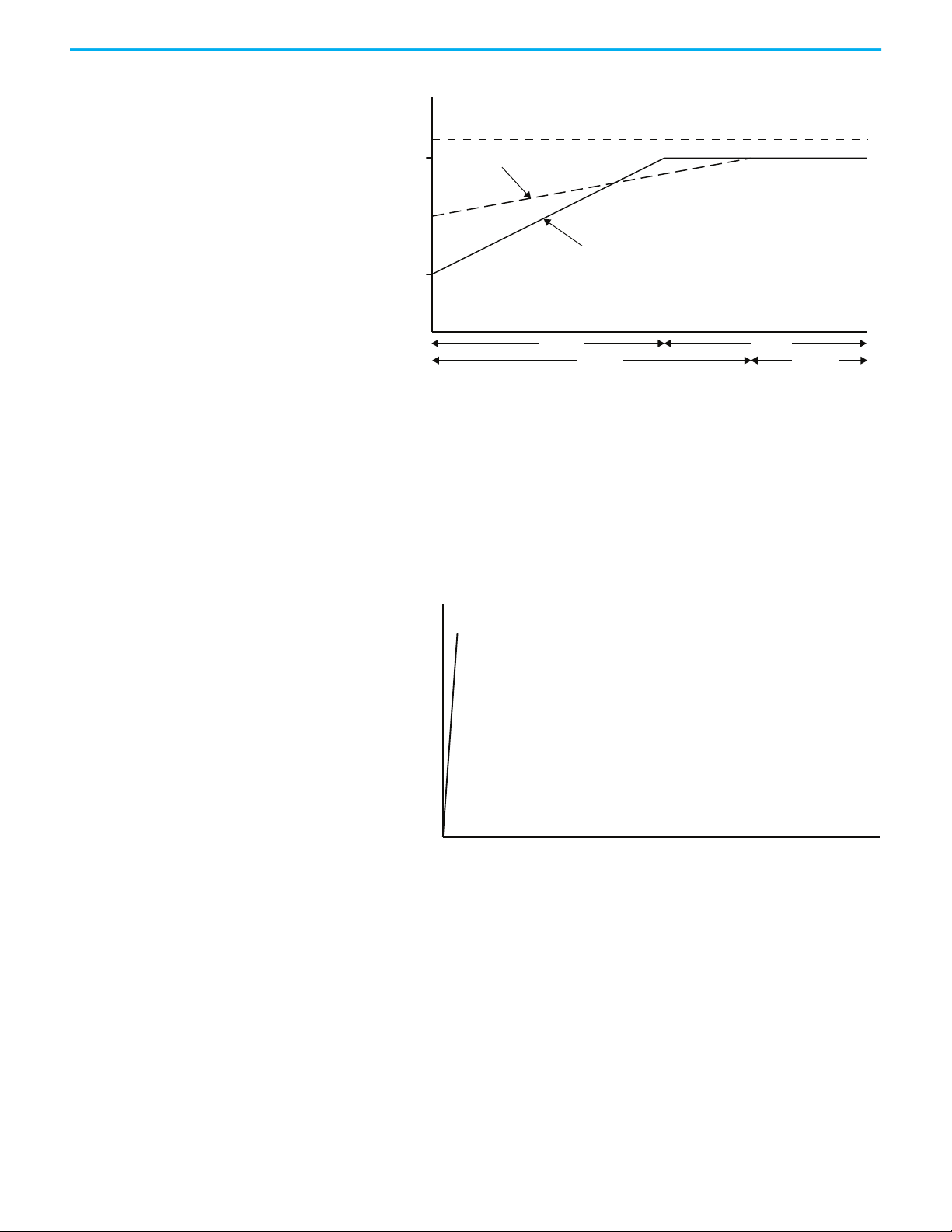

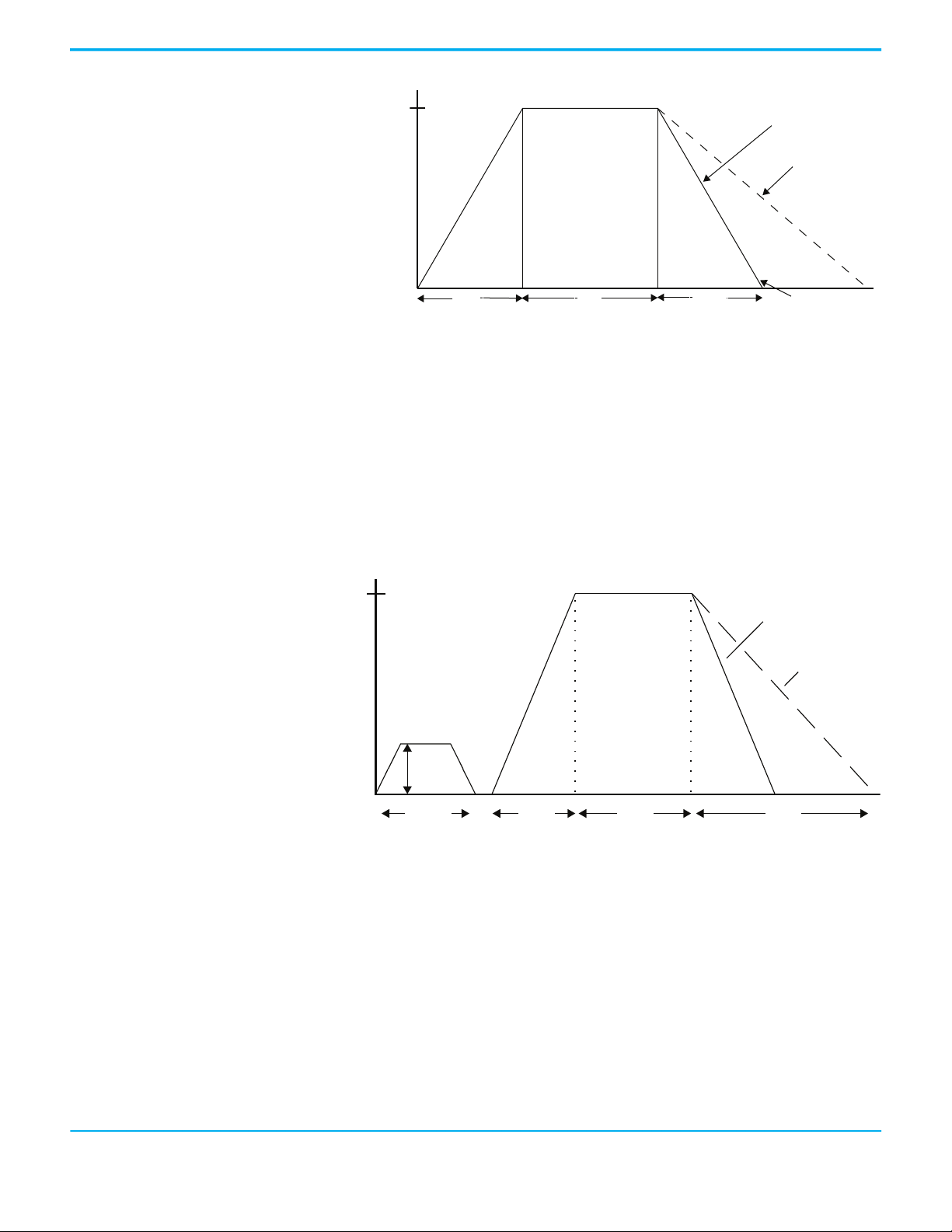

Soft Start

Soft Start limits the current throughout the soft start, and covers the largest

number of general applications. The motor is given an initial torque setting.

From the initial torque level, the output voltage to the motor is steplessly

increased (ramped) during the acceleration ramp time. Initial torque setting

and acceleration ramp time are user adjustable.

A motor’s torque curve is not a linear function and depends on both applied

voltage and current. If the soft starter ramped voltage that is applied to the

motor is sufficient for it to develop enough torque to overcome the inertia of the

load, the motor could quickly accelerate to full speed in less than the configured

ramp time when using the Soft Start mode.

Figure 1 - Soft Start Timing Diagram

Linear Speed Acceleration

With this type of starting mode, the motor acceleration is at a constant rate.

The controller accelerates the motor in a linear fashion from the off (0 speed)

condition to full speed condition in the time configured in the user-defined

ramp time (0…30 seconds). Kickstart is available with this option.

A tachometer input (0…5V DC) is required to perform this start mode.

Linear Speed Acceleration presents the least amount of stress on mechanical

components. An initial torque value is configured to define a motor starting

10 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

value.

Page 11

Chapter 1 Product Overview

% Speed

Ramp Time

100%

Time (seconds)

Start Run

Stop

Stop Time

Linear Acceleration Linear Deceleration

% Full Load Current

50%

600%

Current Limit

Time (seconds)

Start

Figure 2 - Linear Speed Acceleration Timing Diagram

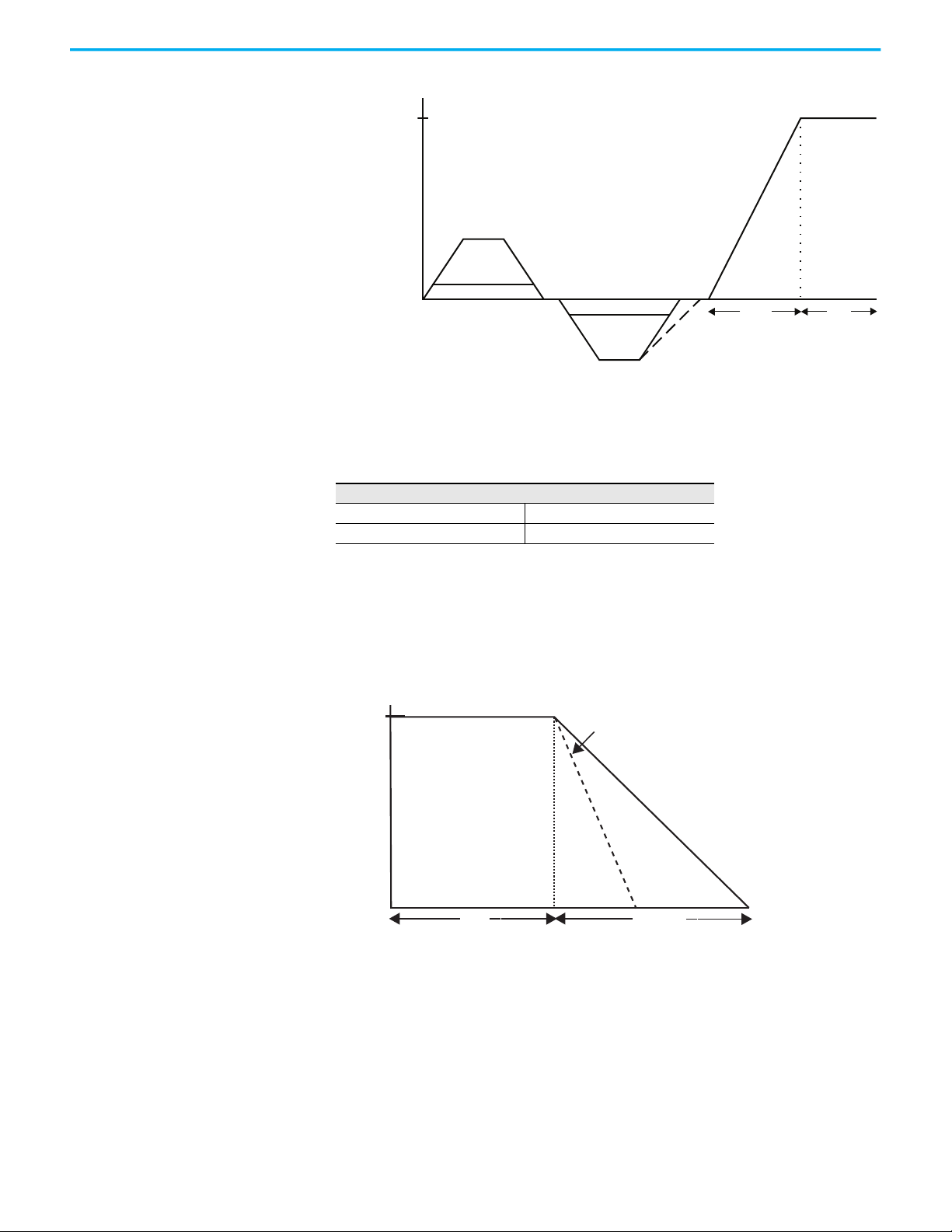

Current Limit Start

Current Limit Start provides a current limit-controlled start by maintaining a

constant current to the motor. Use this method when it is necessary to limit

the maximum starting current. You can adjust the starting current and

current limit starting ramp time.

Figure 3 - Current Limit Start Timing Diagram

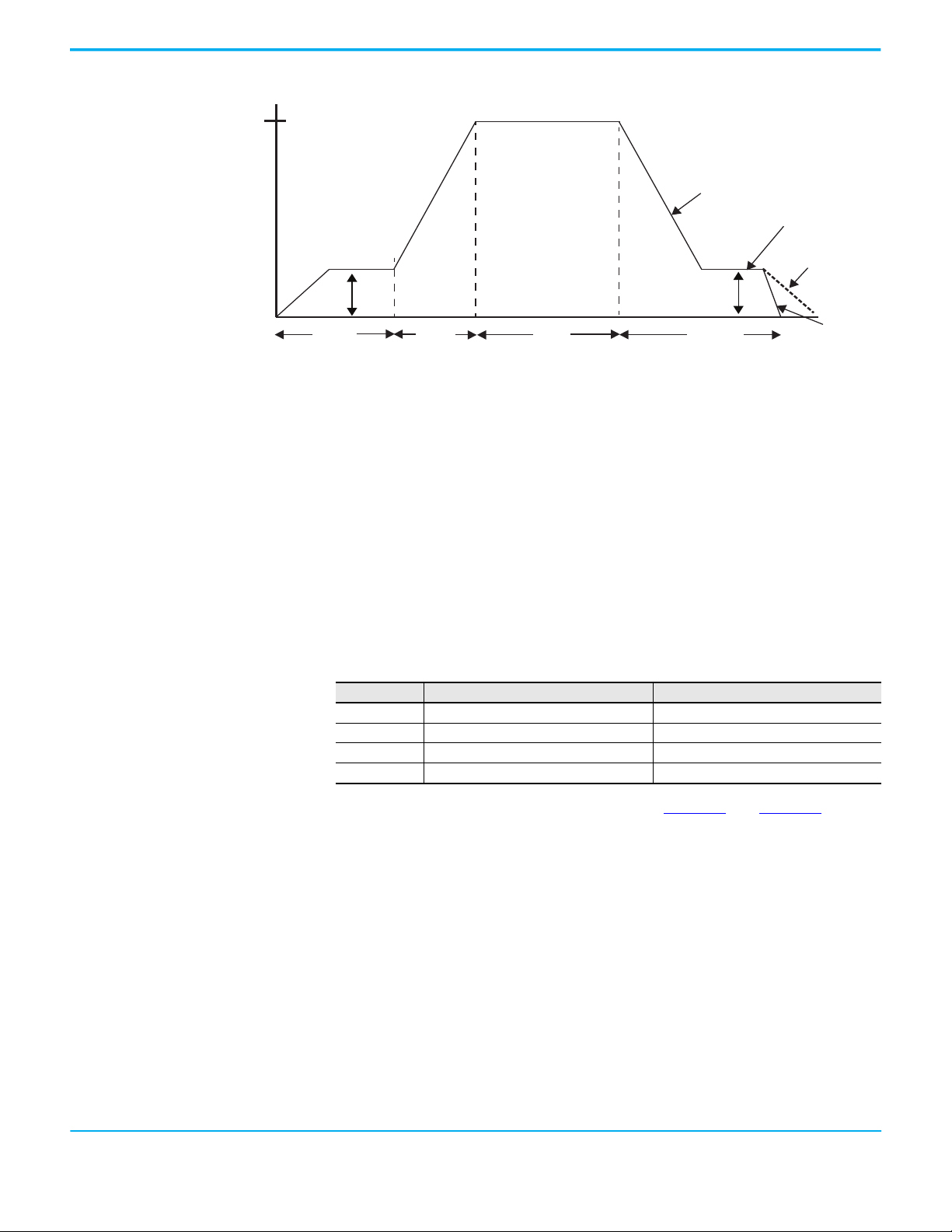

Selectable Kickstart

The kickstart feature provides a boost at startup to break away loads that can

require a pulse of current/torque to get started. It is intended to provide a

current/voltage pulse for a short time. Kickstart is available in Soft Start,

Current Limit, Linear Speed Acceleration, and Pump Control modes.

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 11

Page 12

Chapter 1 Product Overview

% Voltage

Initial

Tor que

100%

Kickstart

Time

Time (seconds)

Start

Run

Kickstart

Level

Soft stop

Soft stop

Coast-to-Rest

100%

Time (seconds)

Run

Motor Speed

Pump Start

Ramp Time

Pump Stop

Stop Time

Figure 4 - Selectable Kickstart Timing Diagram

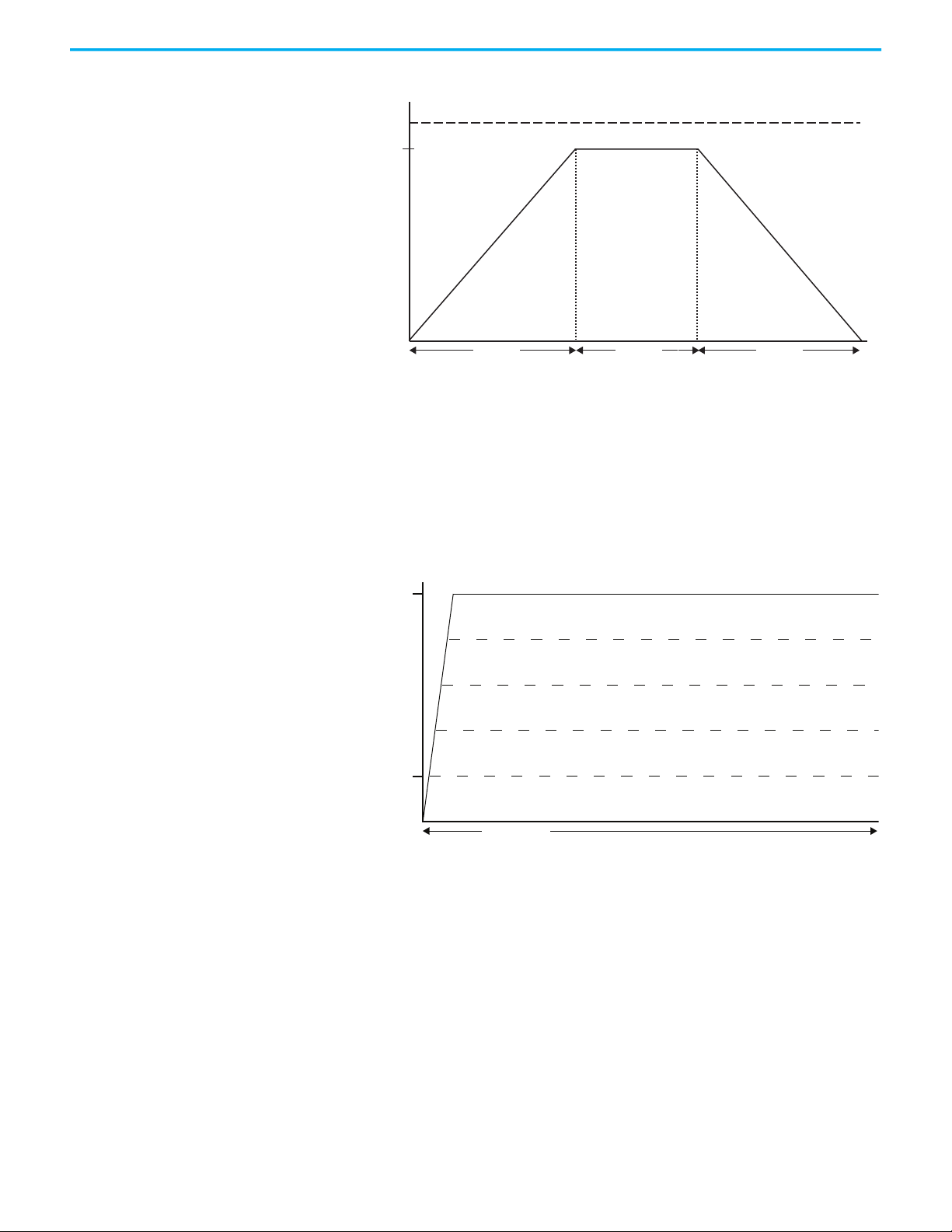

Pump Control Mode

Use Pump Control Mode to reduce surges in a fluid piping system and the

resulting fluid hammer or check valve slam that is caused by starting or

stopping a centrifugal pump at full voltage and full speed. This mode increases

pump life by reducing pump cavitations. To provide these benefits, the

microprocessor of the SMC Flex controller generates a motor start curve that

follows the starting characteristics of a centrifugal pump and monitors

operation during start to deliver reliable pump starts.

Figure 5 - Pump Control Mode Timing Diagram

Dual Ramp Start

Dual Ramp Start is useful on applications with variable loads, starting torque,

and start time requirements. Dual Ramp Start gives you the ability to select

between two separate start profiles via any programmable auxiliary input.

Each start profile can use any of the available starting modes.

12 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 13

Chapter 1 Product Overview

% Voltage

Time (seconds)

Current Limit 2

Current Limit 1

100%

Initial

Torque 2

Initial

Torque 1

Ramp Time 2

Ramp Time 1

Start 1

Run 1

Start 2

Run 2

100%

Time (seconds)

% Voltage

Figure 6 - Dual Ramp Start Timing Diagram

Full-voltage Start

Full-voltage Start is used in applications that require across-the-line starting.

The SMC Flex controller performs like a solid-state across-the-line contactor.

Full inrush current and locked-rotor torque are realized. You can program the

SMC Flex controller to provide a full-voltage start in which the output voltage

to the motor reaches full voltage in 250 ms.

Figure 7 - Full-voltage Start Timing Diagram

Preset Slow Speed

Use Preset Slow Speed on applications that require slow speed moves for

positioning material. You can set the Preset Slow Speed at either 7% (low) or

15% (high) in the forward direction. You can program reverse speed and 10%

(low) or 20% (high) of the base speed setting. No reversing contacts are

required. To help achieve more-accurate stops, braking is also a part of this

function. You can program two independent preset slow speed parameters for

both speed and direction.

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 13

Page 14

Chapter 1 Product Overview

Motor Speed

100%

15% - High

Time (seconds)

Start

Run

Forward

Reverse

7% - Low

20% - High

10% - Low

% Voltage

100%

Time (seconds)

Stop Time

Run Soft stop

Coast-to-Rest

Figure 8 - Preset Slow Speed Timing Diagram

Stopping Modes

The SMC Flex Smart Motor Controller provides the following Stopping Modes

of operation as standard:

Stopping Modes

Coast Linear Speed Deceleration

Soft stop Pump Stop

Coast

Configure the stop mode to Coast sets the controller to perform a motor coastto-stop maneuver.

Figure 9 - Coast-to-stop Timing Diagram

14 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 15

Chapter 1 Product Overview

% Voltage

100%

Time (seconds)

Stop Time

Run

Soft stop

% Speed

Ramp Time

100%

Time (seconds)

Start Run

Stop

Stop Time

Linear Acceleration Linear Deceleration

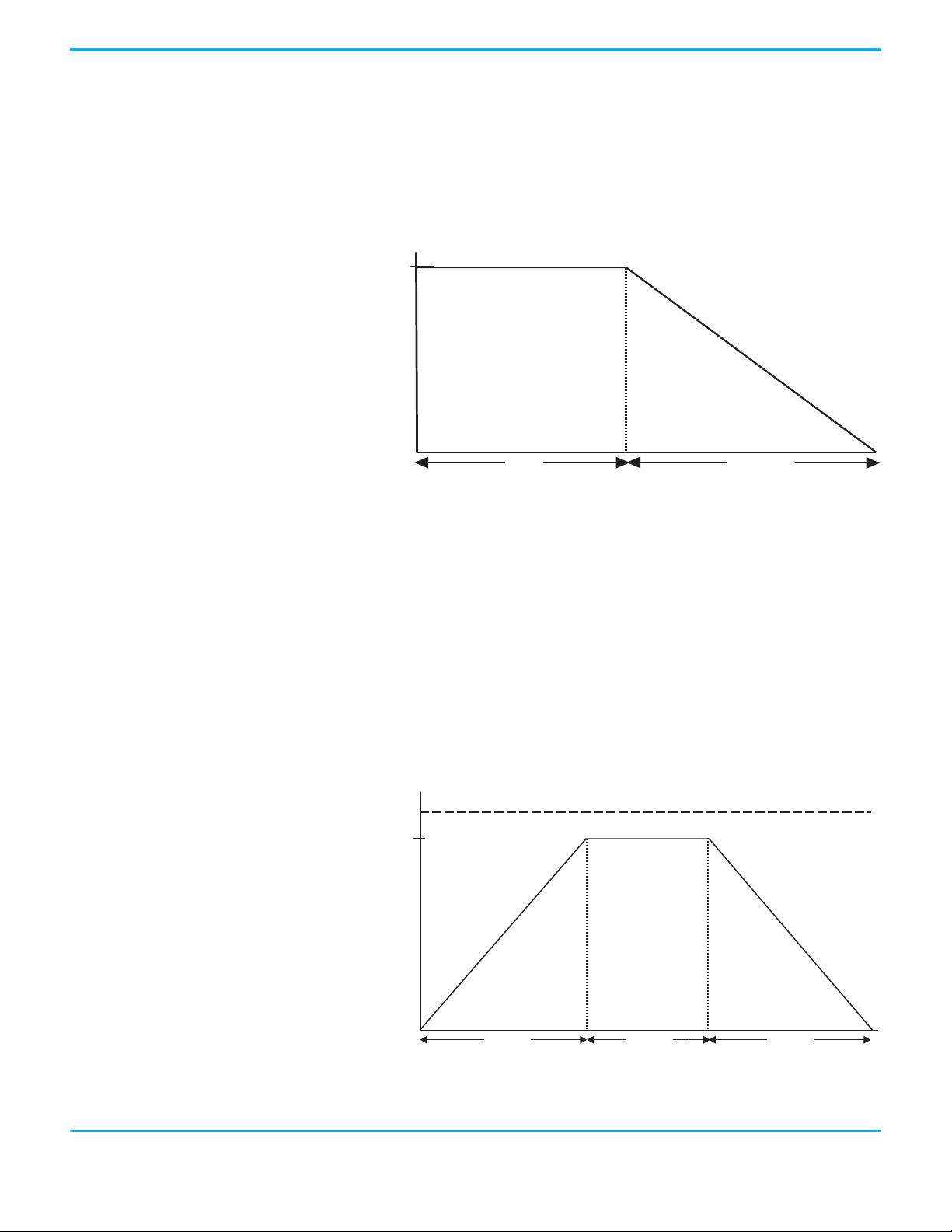

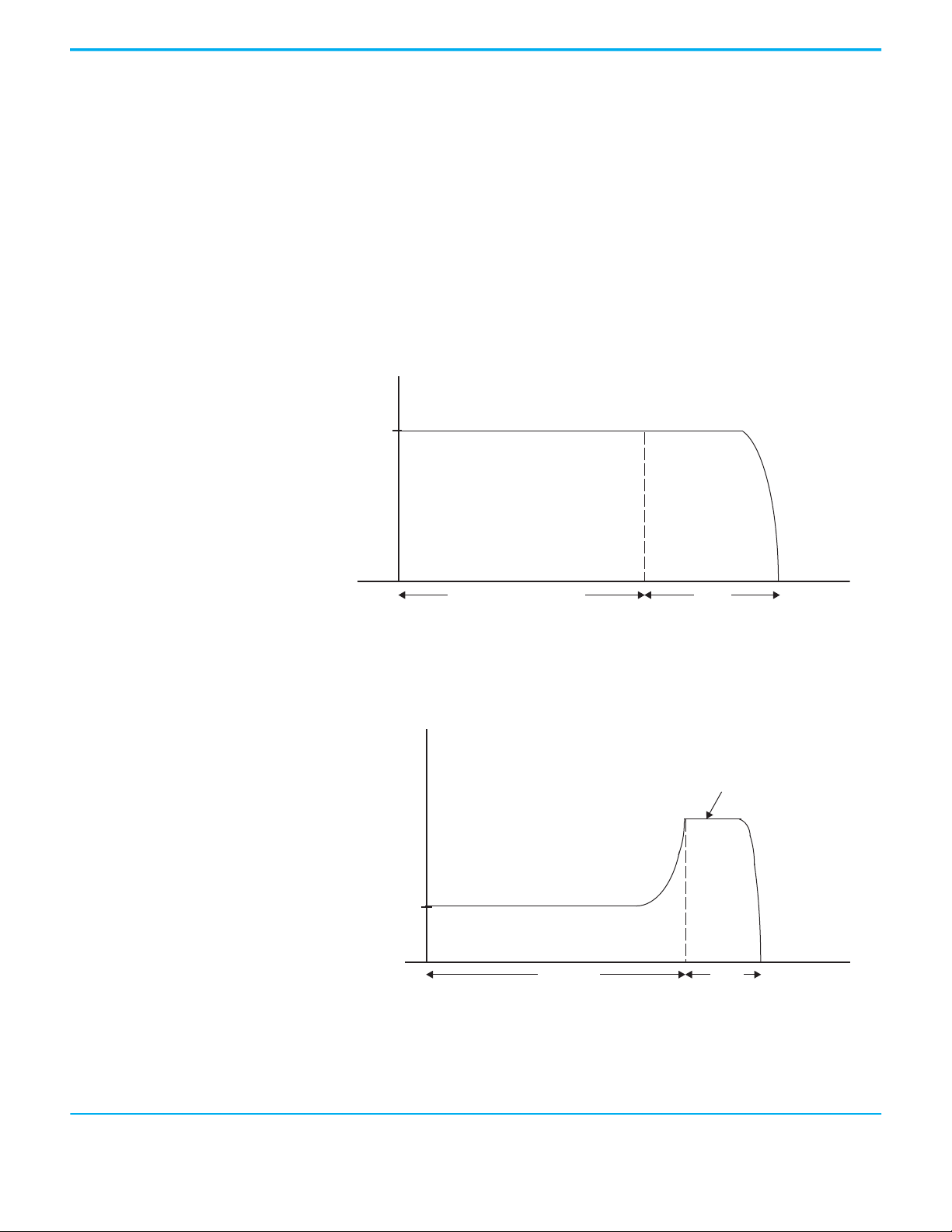

Soft Stop

(a)

The soft stop mode can be used in applications that require an extended stop

time. You can adjust the voltage ramp down time from 0...120 seconds. The

load stops when the programmed stop time has elapsed or the voltage ramp

drops to a point where the load torque is greater than the motor torque.

Figure 10 - Soft Stop Timing Diagram

Linear Speed Deceleration

(a)

Configuring the motor stop mode to Linear Speed Deceleration mode

commands the motor to stop from full speed to zero speed following a linear

ramp based on the user-configured stop time. This stopping mode requires a

tachometer input (0…5V DC).

You do not need to set up Linear Stop even if you have programmed a linear

start. The Linear Stop cannot brake the motor/load and reduce the stopping

time.

Figure 11 - Linear Speed Deceleration Timing Diagram

(a) Not intended to be used as an emergency stop. Consult the applicable standards for emergency stop requirements.

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 15

Page 16

Chapter 1 Product Overview

100%

Time (seconds)

Run

Motor Speed

Pump Start

Ramp Time

Pump Stop

Stop Time

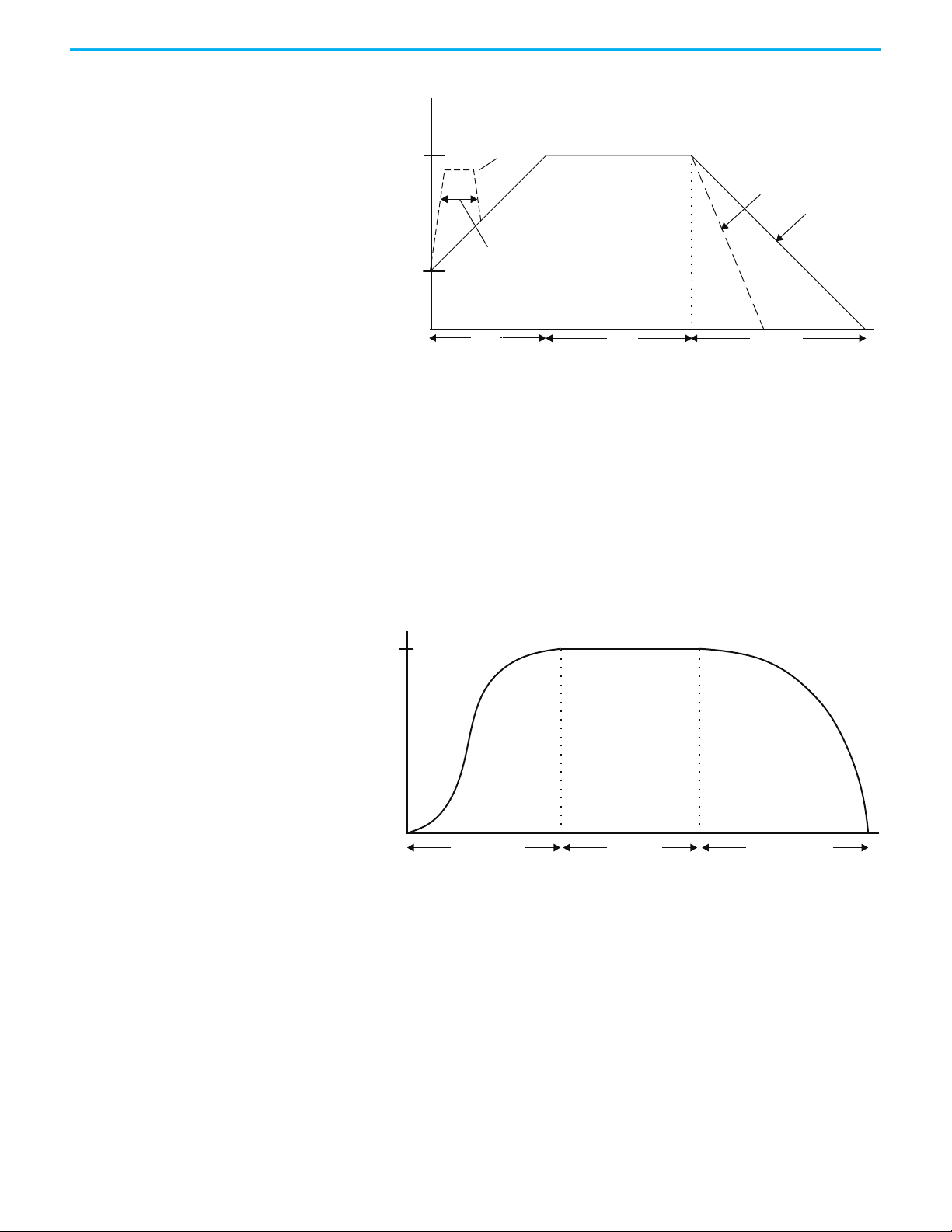

Pump Stop

(a)

Just as starting a centrifugal pump at full voltage causes fluid hammer and

check valve slam, stopping a centrifugal pump that is running at full speed can

also produce the same results. The Pump Stop mode of the SMC Flex generates

a motor stop curve, which follows the stop characteristics of a centrifugal

pump. The motor stop curve results in the gradual decrease in motor speed.

IMPORTANT

Pump stopping can cause motor heating, depending on the mechanical

dynamics of the pumping system. Select the lowest stopping time

setting that satisfactorily stops the pump.

Figure 12 - Pump Stop Timing Diagram

Braking Control Modes

(a)

The SMC Flex Smart Motor Controller provides the following braking control

modes of operation as standard:

Braking Control Modes

SMB—Smart Motor Braking Accu-Stop Slow Speed with Braking

Smart Motor Braking (SMB)

(a)

SMB provides motor braking for applications that require the motor to stop

faster than a coast-to-rest. Braking control with automatic zero speed shutoff

is fully integrated into the design of the SMC Flex controller. This design

facilitates a clean, straight-forward installation and eliminates the

requirement for additional hardware (for example, braking contactors,

resistors, timers, and speed sensors). The micro-processor based braking

system applies braking current to a standard squirrel-cage induction motor.

The strength of the braking current is programmable from 0…400% of full-load

current.

(a) Not intended to be used as an emergency stop. Consult the applicable standards for emergency stop requirements.

16 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 17

Figure 13 - SMB Timing Diagram

Motor Speed

Automatic Zerospeed Shutoff

100%

Time (seconds)

Start

Run Brake

Smart Motor Braking

Coast-to-Rest

Stop Time

Motor Speed

100%

Time (seconds)

Slow

Speed

Run

7 or 15%

Braking

Coast-to-Rest

StopStart

Chapter 1 Product Overview

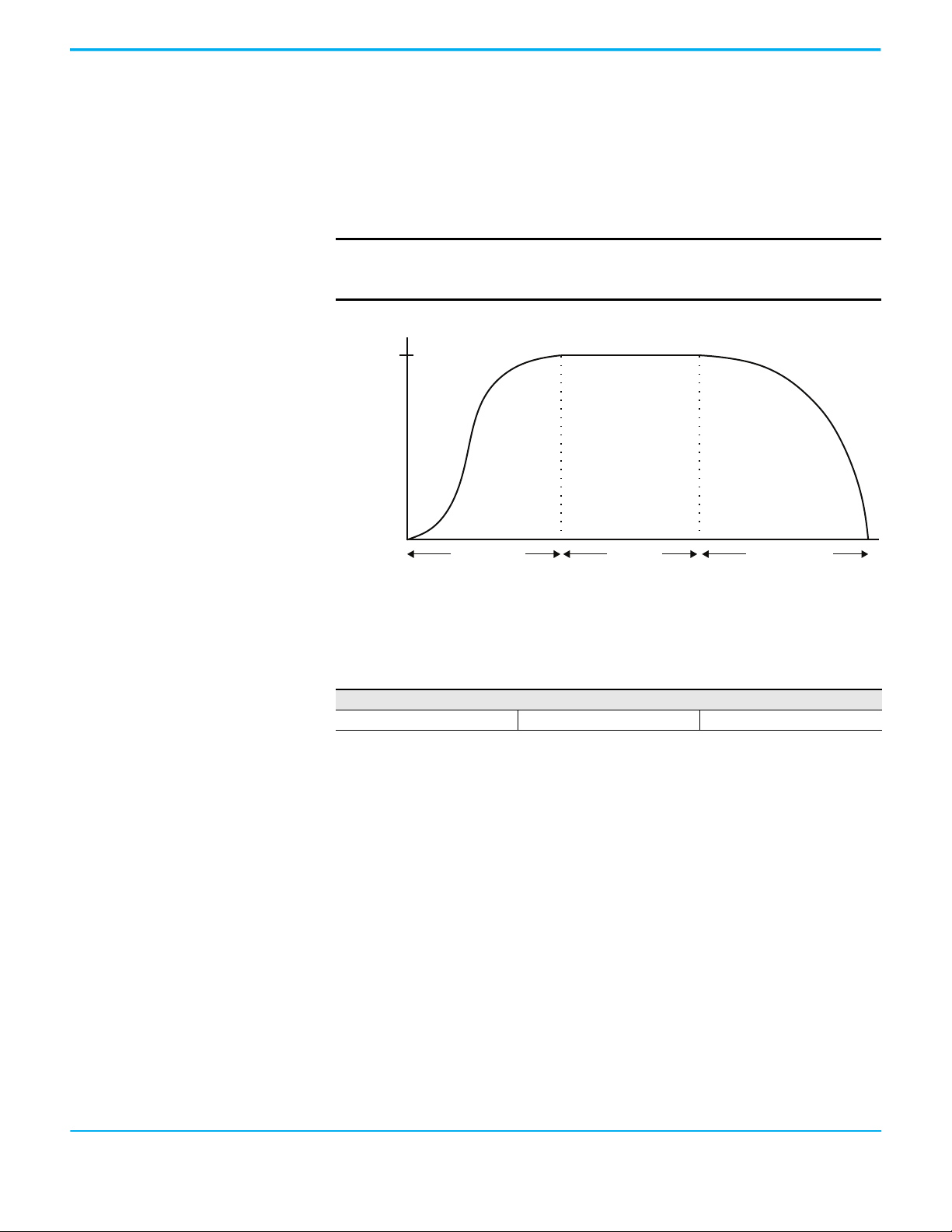

Slow Speed with Braking

(a)

Slow Speed with Braking is used on applications that require slow speed (in

the forward or reverse direction) for positioning or alignment and also require

braking control to stop. Preset Slow Speed provides either 7% of base speed

(low) or 15% of base speed (high) settings in the forward direction. Braking

current is adjustable from 0…400%.

Figure 14 - Slow Speed with Braking Timing Diagram

Accu-Stop

(a)

Use Accu-Stop in applications that require controlled position stopping.

(a) Not intended to be used as an emergency stop. Consult the applicable standards for emergency stop requirements.

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 17

During stopping, braking torque is applied to the motor until it reaches the

configured preset slow speed value (7% or 15%) and holds the motor at this

speed until a stop command is given. Braking torque is then applied until the

motor reaches zero speed. Braking current is programmable from 0…400% of

full-load current.

Page 18

Chapter 1 Product Overview

Motor Speed

100%

Time (seconds)

Slow

Speed

Run

7% or 15%

Braking

Coast-to-Rest

BrakeStart

Slow Speed

Slow Speed

Braking

7% or 15%

Figure 15 - Accu-Stop Timing Diagram

Protection and Diagnostics

This section describes the protection and diagnostic features that the SMC

Flex controller provides.

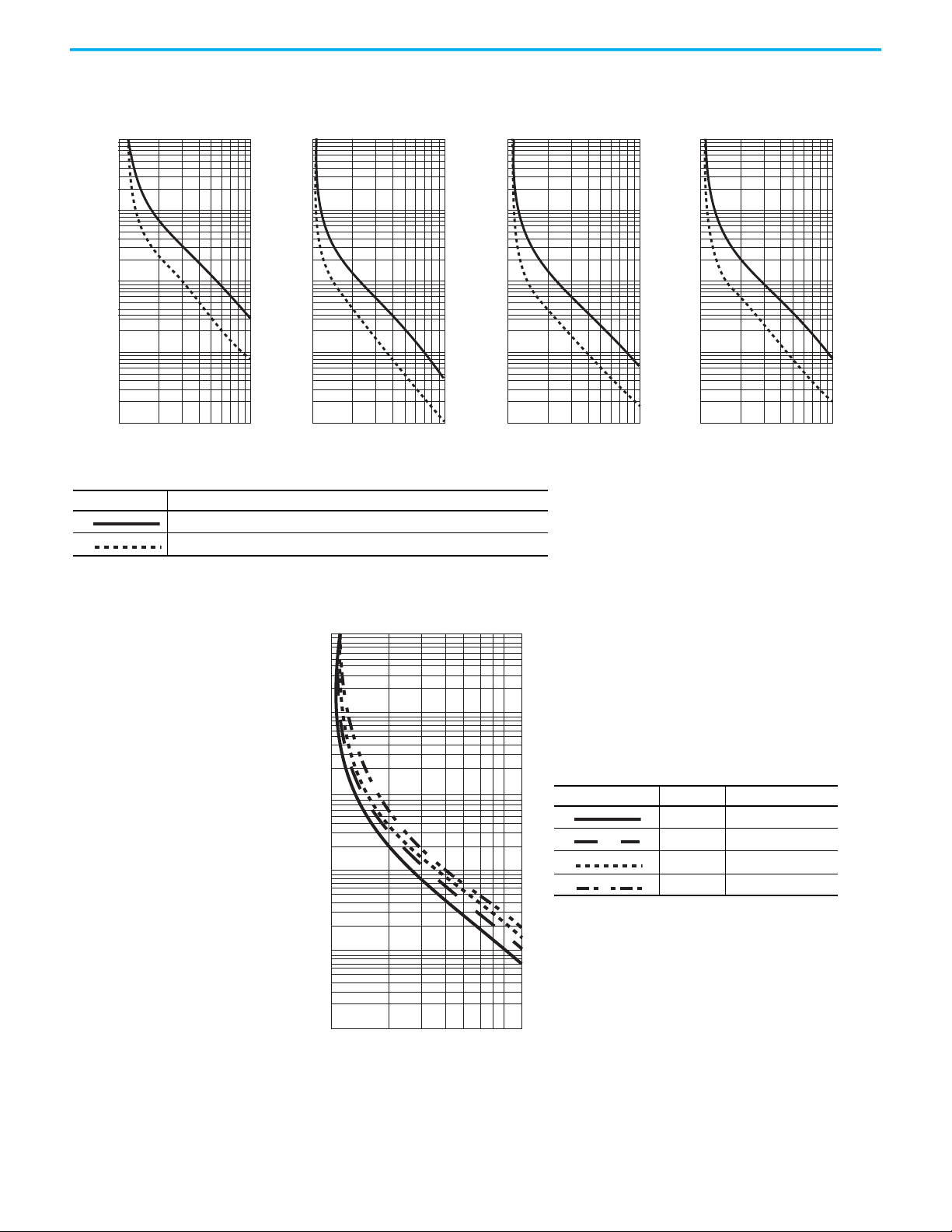

Overload

The SMC Flex controller meets applicable requirements as a motor overload

protective device. Thermal memory provides added protection and is

maintained even when control power is removed. The built-in overload

controls the value that is stored in Parameter 12, Motor Thermal Usage; an

Overload Fault occurs when this value reaches 100%. The programming

parameters in this section provide application flexibility and easy setup.

Parameter No. Parameter Range

44 Overload Class Off, 10, 15, 20, 30

47 Overload Reset Manual – Auto

46 Motor FLC 1.0…2200 A

45 Service Factor 0.01…1.99

The trip rating is 117% of the programmed FLC. Figure 16

the overload trip curves for the available trip classes.

and Figure 17 provide

Underload

(a)

Utilizing the underload protection of the SMC Flex controller, motor operation

can be halted if a sudden drop in current is sensed.

The SMC Flex controller provides an adjustable underload trip setting from

0…99% of the programmed motor full-load current rating. You can adjust the

Trip delay time from 0…99 seconds.

(a) Underload protection is disabled during slow speed and braking operations.

18 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 19

Figure 16 - Overload Trip Curves

1

10

100

1000

100000

1

01

4 5 6 7 832 9

1

10

100

1000

100000

1

01

4 5 6 7 832 9

1

10

100

1000

100000

1

01

4 5 6 7 832 9

1

01

4 5 6 7 832 9

0.1

1.0

10.0

100.0

1000.0

Graph Line Description

Approximate trip time for 3-phase balanced condition from COLD start

Approximate trip time for 3-phase balanced condition from HOT start

Approx. Trip Time [s]

Multiples of FLC

Class 10 Class 15 Class 20 Class 30

Multiples of FLC Multiples of FLC Multiples of FLC

Approx. Trip Time [s]

Approx. Trip Time [s]

Approx. Trip Time [s]

Graph Line Trip Class Auto Reset Time [s]

10 90

15 135

20 180

30 270

Seconds

Percent Full Load Current Setting

Chapter 1 Product Overview

Figure 17 - Restart Trip Curves after Auto Reset

100000

1000

100

10

1000%100% 1000%100%

1

0

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 19

Page 20

Chapter 1 Product Overview

Undervoltage

You can halt motor operation if a sudden drop in voltage is detected by

utilizing the undervoltage protection of the SMC Flex controller.

The SMC Flex controller provides an adjustable undervoltage trip setting from

0…99% of the programmed motor voltage. You can adjust the trip delay time

from 0…99 seconds.

You can program an alarm (pre-fault) indication level to indicate when the unit

is getting close to faulting. The alarm modification information is displayed

through the LCD, HIM, Communication (if applicable) and alarm contact

closing.

Overvoltage

You can halt motor operation if a sudden increase in voltage is detected by

utilizing the overvoltage protection of the SMC Flex controller.

The SMC Flex controller provides an adjustable overvoltage trip setting from

0…199% of the programmed motor voltage. Trip delay time can be adjusted

from 0…99 seconds.

(a)

(a)

You can program an alarm (pre-fault) indication level to indicate when the unit

is getting close to faulting. The alarm modification information is displayed

through the LCD, HIM, Communication (if applicable) and alarm contact

closing.

Unbalance

The SMC Flex controller can detect an unbalance in line voltages. You can halt

motor operation if the unbalance is greater than the desired range.

The SMC Flex controller provides an adjustable unbalance setting from 0…25%

of the line voltages. Trip delay time can be adjusted from 0…99 seconds.

You can program an alarm (pre-fault) indication level to indicate that the unit

is getting close to faulting. The alarm modification information is displayed

through the LCD, HIM, Communication (if applicable) and alarm contact

closing.

(a)

(a) Undervoltage, overvoltage, and voltage unbalance protection are disabled during braking operation.

20 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 21

Chapter 1 Product Overview

600%

% FLC

Time [s]

Programmed Start Time

Stall

% FLC

Time [s]

Running

Jam

User-defined Trip Level

Stall Protection and Jam Detection

Motors can experience locked-rotor currents and develop high torque levels if

a stall or a jam occurs. These conditions can result in breakdown of the

winding insulation or mechanical damage to the connected load. The

SMC Flex controller provides both stall protection and jam detection for

enhanced motor and system protection. A jam level (as a percent of motor FLC)

is configurable for both an alarm and motor shutdown (fault). In addition,

both stall and jam conditions let you set a delay time before initiating an alarm

(jam only) or motor shutdown (fault).

Stall protection is user adjustable from 0.0…10.0 seconds (in addition to the

ramp time programmed).

Figure 18 - Stall Protection

Jam detection lets you determine the jam level (up to 1000% of the motor’s FLC

rating) and the delay time (up to 99.0 seconds) for application flexibility.

Figure 19 - Jam Detection

100%

(a) (b)

You can program an alarm (pre-fault) indication level to indicate when the unit

is getting close to faulting. The alarm modification information is displayed

through the LCD, HIM, Communication (if applicable) and alarm contact

closing.

(a) Jam detection is disabled during slow speed and braking operation.

(b) Unit self-protects in a jam condition.

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 21

Page 22

Chapter 1 Product Overview

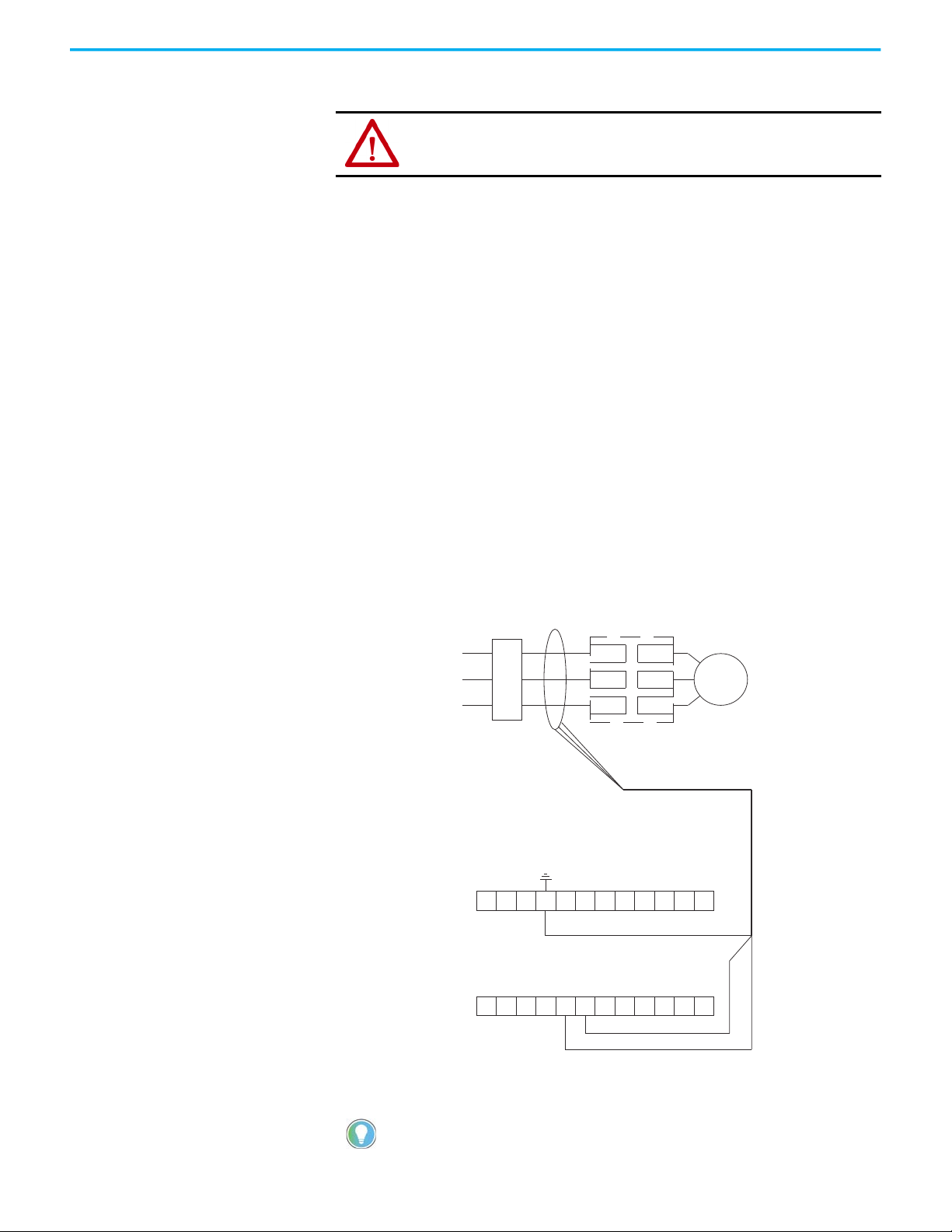

Branch Protection

(1)

(1) Customer supplied.

(2) Cat. No. 825-CBCT or Flex-Core Cat. No. 126-252

Motor

(1)

SMC Flex Controller

SMC Flex Control Terminals

3-Phase Input Power

Shield

Black

White

11

Black

White

Shield

(1)

(2)

L1/1

L2/3

L3/5

T1/2

T2/4

T3/6

12 13 14 15 16 17 18 19 20 21 22

23 24 25 26 27 28 29 30 31 32 33 34

Ground Fault

ATTENTION: The ground fault sensing feature of the SMC Flex controller is intended

for monitoring purposes only. It is not intended as a ground fault circuit interrupter

for personnel protection as defined in Article 100 of the National Electrical Code

(NEC) and has not been evaluated to UL 1053.

In isolated or high impedance-grounded systems, core-balanced current

sensors are typically used to detect low-level ground faults that are caused by

insulation breakdowns or entry of foreign objects. Detection of such ground

faults can be used to interrupt the system to help prevent further damage, or to

alert the appropriate personnel to perform timely maintenance.

The ground fault detection capabilities of the SMC Flex controller require the

use of an external sensor. The external sensor lets you enable Ground Fault

Trip, Ground Fault Alarm, or both.

For 5…480 A devices, the recommended sensor is a Cat. No. 825-CBCT core

balance current transformer for 1…5 A core-balanced ground fault protection.

For 625…1250 A devices, the recommended sensor is listed here and provides

5…25 A core-balanced ground fault protection.

• Manufacturer: Flex-Core

• Description: 600V Rated Current Transformer

• Catalog Number: 126-252

• CT Ratio:2500:5

Figure 20 - Core Balance Current Transformer

22 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

When you connect the ground fault sensors, the secondary of the CT should be

shorted until you complete the connection to the SMC Flex control module.

Page 23

Chapter 1 Product Overview

Ground Fault Trip

The SMC Flex controller trips with a ground fault (GF) indication if:

• No other fault currently exists

• Ground fault protection is enabled

• GF Inhibit Time (Parameter 75) has expired

• GF Current is equal to or greater than the GF Trip Level (Parameter 73)

for a time period greater than the GF Trip Delay (Parameter 74)

Table 2 - Ground Fault Trip Parameters

Parameter No. Parameter Name Description

73 Gnd Flt Level

74 Gnd Flt Delay

75 Gnd Flt Inh Time

IMPORTANT

The ground fault inhibit timer starts after the maximum phase of load

Defines the ground fault current at which the SMC

Flex controller trips

Defines the time period a ground fault condition

must be present before a trip occurs

Inhibits a ground fault trip from occurring during

the motor starting sequence

Adjustment

Range

1.0…5.0 A or

5.0…25 A

0.1…250 s

0…250 s

current transitions from 0 A to 30% of the device’s minimum FLA Setting

or the GF Current is greater than or equal to 0.5 A. The SMC Flex

controller does not begin monitoring for a ground fault condition until

the Gnd Flt Inh Time expires.

Ground Fault Alarm

The SMC Flex controller indicates a Ground Fault Alarm if:

• No warning currently exists

• Ground fault alarm is enabled

• GF Inhibit Time (Parameter 75) has expired

• GF Current is equal to or greater than the Gnd Flt A Lvl (Parameter 77)

Table 3 - Ground Fault Alarm Parameters

Parameter No. Parameter Name Description Adjustment Range

77 Gnd Flt A Lvl

78 Gnd Flt A Dly

Defines the ground fault current at which the SMC

Flex controller indicates a warning

Defines the time period a ground fault alarm

condition must be present before a trip occurs

1.0…5.0 A or

5.0…25 A

0…250 s

Thermistor/PTC Protection

The SMC Flex controller provides terminals 23 and 24 for the connection of

positive temperature coefficient (PTC) thermistor sensors. PTC sensors are

commonly embedded in motor stator windings to monitor the motor winding

temperature. When the motor winding temperature reaches the PTC sensor’s

temperature rating, the PTC sensor’s resistance transitions from a low to high

value. Because PTC sensors react to actual temperature, enhanced motor

protection can be provided to address such conditions as obstructed cooling

and high ambient temperatures.

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 23

Page 24

Chapter 1 Product Overview

1330

550

250

100

20

10

-20 °C 0 °C

TNF -20K

TNF -5K

TNF

TNF +20K

TNF +5K

4000

Table 4 defines the SMC Flex PTC thermistor input and response ratings:

Table 4 - PTC Input Ratings

Description Value

Response resistance 3400 Ω ± 150 Ω

Reset resistance 1600 Ω ± 100 Ω

Short-circuit Trip Resistance 25 Ω ± 10 Ω

Maximum Voltage at PTC Terminals (RPTC = 4 kW) <7.5V

Maximum Voltage at PTC Terminals (RPTC = open) 30V

Maximum Number of Sensors 6

Maximum Cold Resistance of PTC Sensor Chain 1500 Ω

Response Time 800 ms

Figure 21

illustrates the required PTC sensor characteristics that are specified

in IEC-34-11-2.

Figure 21 - PTC Sensor Characteristics per IEC-34-11-2

PTC Trip

The SMC Flex controller trips with a PTC indication if:

• No other fault currently exists

• PTC protection is enabled

The resistance across terminals 23 and 24 is either greater than the relay’s

response resistance or less than the short-circuit trip resistance.

Excessive Starts/Hour

The SMC Flex controller lets you program the allowed number of starts per

hour (up to 99). This helps minimize motor stress caused by repeated starting

over a short time period.

24 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 25

Chapter 1 Product Overview

Overtemperature

The SMC Flex controller uses the value in Parameter 119 to monitor the

temperature of the SCRs and Bypass by using internal thermistors. When the

maximum rated temperature of the power poles is reached, the unit shuts

down and restart is inhibited.

An overtemperature condition can indicate inadequate ventilation, high

ambient temperature, overloading, or excessive cycling. After the temperature

is reduced to allowable levels, the fault can be cleared.

Open Gate

An open gate fault indicates that improper SCR firing, typically caused by an

open SCR gate, has been detected on one of the power poles. Before the

controller shuts down, it attempts to start the motor a total of three times.

Line Faults

The SMC Flex controller continually monitors line conditions for abnormal

factors. Pre-start protection includes:

• Line Fault (with phase indication)

- Line voltage loss

- Missing load connection

- Shorted SCR

Running protection includes:

• Line Fault (no phase indication)

- Line voltage loss

- Missing load connection

You can toggle Phase Reversal protection either On or Off. Phase Reversal

protection is functional only at pre-start.

Metering

Power monitoring parameters include:

• Three-phase current (Parameters 4, 5, and 6)

• Three-phase voltage (Parameters 1, 2, and 3)

• Power in kW (Parameter 7)

• Power usage in kWH (Parameter 8)

• Power factor (Parameter 11)

• Motor thermal capacity usage (Parameter 12)

• Elapsed time (Parameter 9)

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 25

Page 26

Chapter 1 Product Overview

DPI

Voltage measurement is not available during the braking operation of the

Smart Motor Braking, Accu-Stop, and Slow Speed with Braking control

options.

The elapsed time and kWH values are automatically saved to memory on

power down.

Motor thermal capacity usage is determined by the built-in electronic thermal

overload. An overload fault occurs when this value reaches 100%.

I/O

The SMC Flex controller can accept up to two inputs and four outputs that are

controlled over a network. The two inputs are controlled at terminal 16 (Option

Input #1, Parameter 132), and terminal 15 (Option Input #2, Parameter 29). For

these two inputs, see Table 26

Table 40

for the bit identification.

You can program the Stop Input to meet the desired stop functionality by

using these two terminals as inputs.

for the parameter settings and Table 39 and

The four outputs are Aux #1 (Parameter 107), Aux #2 (Parameter 110), Aux #3

(Parameter 108), and Aux #4 (Parameter 109). All auxiliary contacts are

programmable to the function found in Table 26

. If the outputs are

programmed to Network or Network NC, they can be controlled over a

Network. See Table 40

, which defines the Logic Command Word (Control).

Communication

A serial interface port (DPI) is provided as standard, which lets you connect the

SMC Flex controller connection to the Bulletin 20-HIM LCD interface

modules.

Figure 22 - DPI Location

You can connect two peripheral devices to the DPI. The maximum output

current through the DPI is 280 mA.

26 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 27

Chapter 1 Product Overview

Port 5 — DPI

Communications

Port 2

Ports 2 and 3 when two

HIMs are connected with a

splitter

Aux #1

Aux #2 Aux #3

Aux #4

PTC

TACH

Ground

Fault

Stop

Start

Option Input #1

Option Input #2

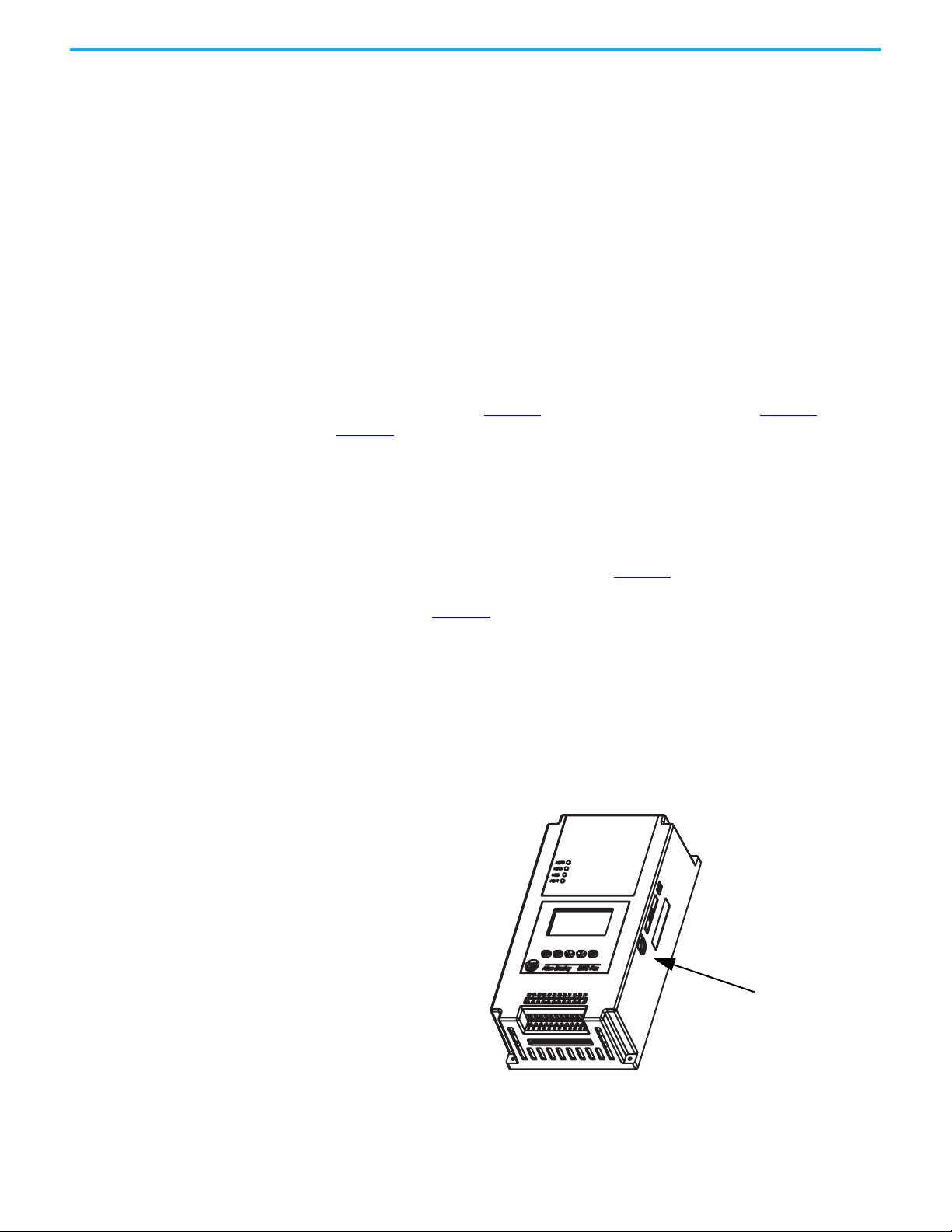

Programming

Status Indication

Setup is easy with the built-in keypad and three-line, 16 character backlit LCD.

Parameters are organized in a three-level menu structure that uses a text

format for straightforward programming.

Figure 23 - Built-in Keypad and LCD

• Four programmable hard contact outputs are provided as standard. All

auxiliary contacts are programmable for the following states:

• Normal (selectable N.O./N.C.)

• Up-to-Speed (selectable N.O./N.C.)

• Alarm (selectable N.O./N.C.)

• Fault (selectable N.O./N.C.)

• Network Control (selectable N.O./N.C.)

• External Bypass (N.O. only)

Figure 24 - Control Terminals

Network inputs can be obtained via proper programming of Option Input #1

(Parameter 132) and Option Input #2 (Parameter 24).

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 27

Page 28

Chapter 1 Product Overview

Notes:

28 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 29

Chapter 2

Installation

This chapter explains how to receive, unpack, and set up the SMC™ Flex

controller.

Receive the Controller

Unpack the Controller

Inspect the Controller

Storage

It is your responsibility to thoroughly inspect the equipment before accepting

the shipment from the freight company. Check the item(s) received against the

purchase order. If any items are damaged, it is your responsibility not to

accept delivery until the freight agent has noted the damage on the freight bill.

Should any concealed damage be found during unpacking, it is again your

responsibility to notify the freight agent. The shipping container must be left

intact and the freight agent should be requested to make a visual inspection of

the equipment.

Remove all packing material, wedges, or braces from within and around the

controller.

After you unpack the controller, check the item(s’) nameplate catalog number

against the purchase order.

Keep the controller in its shipping container prior to installation. If the

equipment is not to be used for an extended period, you must store it

according to the following instructions in order to maintain warranty

coverage.

Lifting

• Store in a clean, dry location.

• Maintain an ambient temperature range of –20… +75 °C (–4…+167 °F).

• Store within a relative humidity range of 0% to 95%, noncondensing.

• Do not store equipment where it could be exposed to a corrosive

atmosphere.

• Do not store equipment in a construction area.

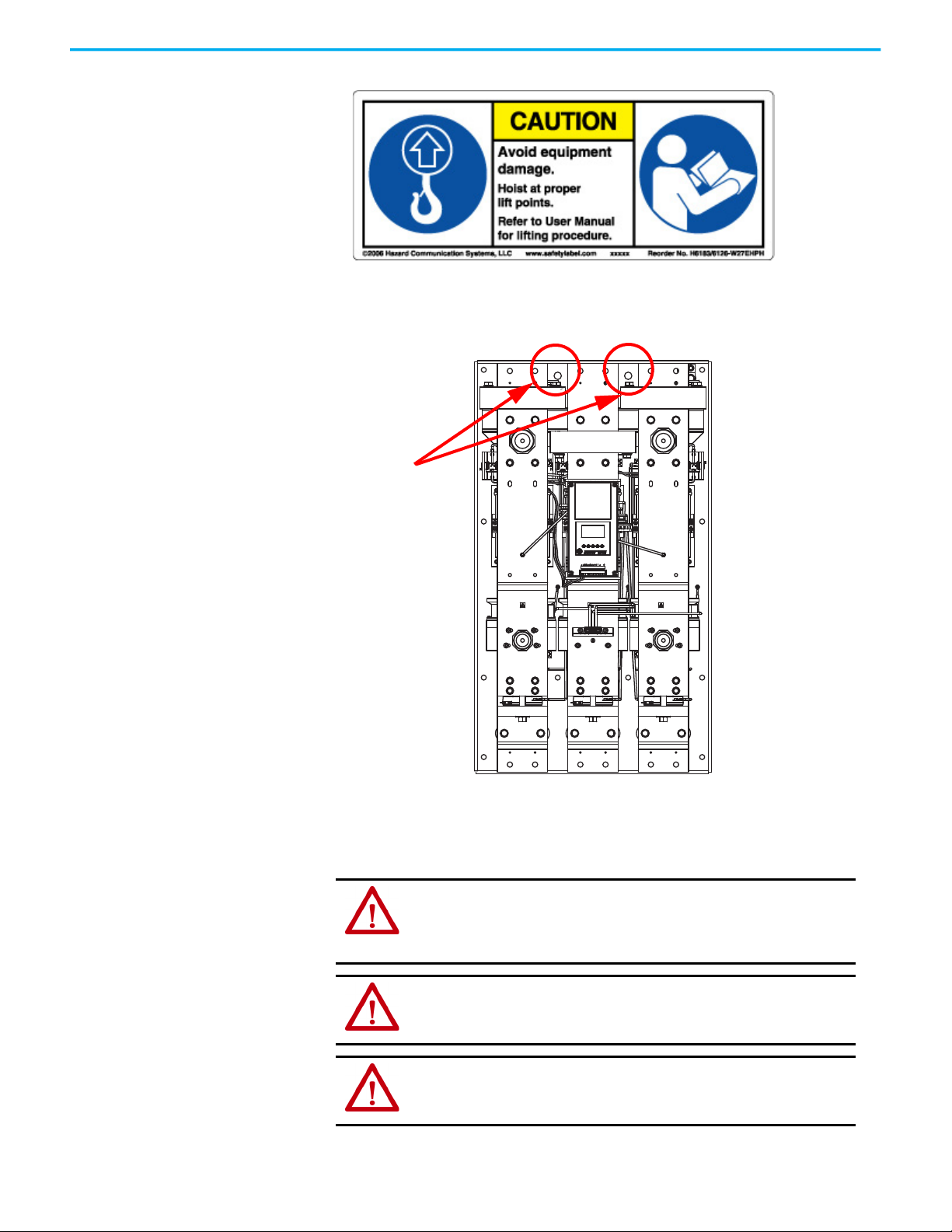

For controllers rated 625…1250 A, the device should only be lifted from

designated lifting points. The lifting points are designed to accept a 1/2…13

threaded hoist ring capable of lifting 2500 pounds. Figure 26

points.

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 29

shows the lifting

Page 30

Chapter 2 Installation

Lifting Points

Figure 25 - Lifting Caution Label

Figure 26 - Lifting Points

General Precautions

In addition to the precautions listed throughout this manual, you must read

and understand the following statements, which are general to the system.

ATTENTION: The controller contains ESD- (electrostatic discharge) sensitive

parts and assemblies. Static control precautions are required when installing,

testing, servicing, or repairing the assembly. Component damage may result if

ESD control procedures are not followed. If you are not familiar with static

control procedures, refer to applicable ESD protection handbooks.

ATTENTION: An incorrectly applied or installed controller can damage

components or reduce product life. Wiring or application errors, such as

undersizing the motor, incorrect or inadequate AC supply, or excessive

ambient temperatures, may result in malfunction of the system.

ATTENTION: Only personnel familiar with the controller and associated

machinery should plan or implement the installation, start-up, and subsequent

maintenance of the system. Failure to do this may result in personal injury

and/or equipment damage.

30 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 31

Chapter 2 Installation

ATTENTION: Hazardous voltages that can cause shock, burn, or death are

present on L1, L2, L3, T1, T2, T3, T4, T5, and T6.

ATTENTION: Power terminal covers can be installed to prevent inadvertent

contact with terminals. Disconnect the main power before servicing the motor

controller or associated wiring.

Degree of Protection

Heat Dissipation

Enclosures

The SMC Flex soft starters have an IP00 or IP2X protection rating, depending

on the size. You must install the device in IP54 (Type 2) switchgear cabinets,

taking into account the ambient conditions. Make sure that no dust, liquids, or

conductive parts can enter the soft starter. Soft starter operation produces

waste heat (heat loss). See Table 5

Smart Motor Controllers Technical Data, publication 150-TD009

or the SMC-3™, SMC Flex, and SMC-50™

.

Table 5 provides the maximum heat dissipation at rated current for the

controllers. Heat dissipation is reduced for currents that are lower than rated

value.

Table 5 - Maximum Heat Dissipation

SMC Rating [A] 5 25 43 60 85 108 135 201 251 317 361 480 625 700 970 1250

Max. Watts 70 70 81 97 129 91 104 180 198 225 245 290 446 590 812 1222

The open-style design of the SMC Flex controller requires that it be installed in

an enclosure. The internal temperature of the enclosure must be kept within

the range of 0…50°C.

For Type 12 (IP54) enclosures, the guidelines that are shown in Table 6

are

recommended to limit the maximum controller ambient temperature.

There should be a clearance of at least 15 cm (6 in.) above and below the

controller. This area allows air to flow through the heatsink.

Table 6 - Minimum Enclosure Size

Controller Rating [A]

5 610 (24) 406 (16) 254 (10)

25 610 (24) 406 (16) 254 (10)

43 610 (24) 406 (16) 254 (10)

60 610 (24) 406 (16) 254 (10)

85 610 (24) 406 (16) 254 (10)

108 762 (30) 610 (24) 305 (12)

135 762 (30) 610 (24) 305 (12)

201 965 (38) 762 (30) 356 (14)

251 965 (38) 762 (30) 356 (14)

317 1295 (51) 914 (36) 356 (14)

361 1295 (51) 914 (36) 356 (14)

480 1295 (51) 914 (36) 356 (14)

625…780 2286 (90) 762 (30) 508 (20)

970…1250

(2)

B Height A Width C Depth

Non-Combination Controller [mm (in.)]

2286 (90) 762 (30) 508 (20)

IP65 (Type 4/12)

(1)

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 31

Page 32

Chapter 2 Installation

Table 6 - Minimum Enclosure Size (Continued)

Controller Rating [A]

5 610 (24) 406 (16) 254 (10)

25 610 (24) 406 (16) 254 (10)

43 610 (24) 406 (16) 254 (10)

60 610 (24) 406 (16) 254 (10)

85 610 (24) 406 (16) 254 (10)

108 965 (38) 762 (30) 356 (14)

135 965 (38) 762 (30) 356 (14)

201 965 (38) 762 (30) 356 (14)

251 965 (38) 762 (30) 356 (14)

317 1524 (60) 965 (38) 356 (14)

361 1524 (60) 965 (38) 356 (14)

(3)

480

(4)

480

625…780 2286 (90) 1397 (55) 508 (20)

970…1250

970…1250

(1) Larger enclosure may be required based on options selected. Consult your local Rockwell Automation Sales office or

Allen-Bradley distributor.

(2) 970 and 1250 A SMC Flex controllers require a door-mounted fan that is capable of delivering 240 cfm. Appropriate inlet and

outlet filtering is required.

(3) Use this row for 460V -58 and 575V -59.

(4) Use this row for 460V -59 and 575V -60 and -61

(2)

5 610 (24) 406 (16) 254 (10)

25 610 (24) 406 (16) 254 (10)

43 610 (24) 406 (16) 254 (10)

60 610 (24) 406 (16) 254 (10)

85 610 (24) 406 (16) 254 (10)

108 965 (38) 762 (30) 356 (14)

135 965 (38) 762 (30) 356 (14)

201 965 (38) 762 (30) 356 (14)

251 965 (38) 762 (30) 356 (14)

317 1295 (51) 914 (36) 356 (14)

361 1295 (51) 914 (36) 356 (14)

480 1295 (51) 914 (36) 356 (14)

625…780 2286 (90) 1397 (55) 508 (20)

(2)

B Height A Width C Depth

Combination Controllers with Fusible Disconnect

1524 (60) 965 (38) 356 (14)

2286 (90) 889 (35) 508 (20)

2286 (90) 1397 (55) 508 (20)

Combination Controllers with Circuit Breaker

2286 (90) 1397 (55) 508 (20)

IP65 (Type 4/12)

(1)

Mounting

All units are fan cooled. It is important to locate the controller in a position

that allows air to flow vertically through the power module. The controller

must be mounted in a vertical plane and have a minimum of 15 cm (6 in.) free

space above and below the controller.

When drilling or installing near the soft starter, make sure that adequate

measures are taken to protect the device from dust and debris. SeeFigure 27

32 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

.

Page 33

Figure 27 - SMC Flex Mounting Protection

3-Phase Input Power

Branch Protection (1)

Motor (1)

SMC Flex Controller (2)

L1/1

L2/3

L3/5

T1/2

T2/4

T3/6

Power Factor Correction Capacitors (1)

Chapter 2 Installation

Power Factor Correction Capacitors

The controller can be installed on a system with power factor correction

capacitors (PFCCs). The capacitors must be located on the line side of the

controller. This must be done to prevent damage to the SCRs in the SMC Flex

controller.

When it is discharged, a capacitor essentially has zero impedance. For

switching, sufficient impedance should be connected in series with the

capacitor bank to limit the inrush current. One method for limiting the surge

current is to add inductance in the capacitor’s conductors. This can be

accomplished by creating turns or coils in the power connections to the

capacitors.

• 250V — 15 cm (6 in.) diameter coil, 6 loops

• 480…690V — 15 cm (6 in.) diameter coil, 8 loops

Take care in mounting the coils so that they are not stacked directly on top of

each other; stacking causes a canceling effect. Mount the coils on insulated

supports away from metal parts so they will not act as induction heaters. If an

isolation contactor is used, put capacitors in front of contactor.

For further instructions, consult the PFCC vendor.

Figure 28 - Typical Wiring Diagram for Power Factor Correction Capacitors

Note Number Description

1 Customer supplied.

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 33

2 Overload protection is included as a standard feature of the SMC Flex controller.

Page 34

Chapter 2 Installation

3-Phase Input Power

Branch Protection (1)

Motor (1)

SMC Flex Controller (2)

L1/1

L2/3

L3/5

T1/2

T2/4

T3/6

Power Factor Correction Capacitors

(1)

(3) (4)

Figure 29 - Typical Wiring Diagram for Power Factor Correction Capacitors and

Contactor

Note Number Description

1 Customer supplied.

2 Overload protection is included as a standard feature of the SMC Flex controller.

3 Energize 1/2 second before start command to the SMC Flex controller.

Alternate: Energize contactor after up-to-speed.

4 Open contactor after stopping method is complete.

Alternate: Open contactor before initiating a stop

Protective Modules

Motor Overload Protection

Protective modules containing metal oxide varistors (MOVs) can be installed

on controllers rated 5…1250 A and 200…600V, to protect the power

components from electrical transients. The protective modules clip voltage

transients generated on the lines to prevent such surges from damaging the

SCRs.

ATTENTION: When installing or inspecting the protective module, make sure that

the controller has been disconnected from the power source. The protective

module should be inspected periodically for damage or discoloration. Replace if

necessary.

Thermal motor overload protection is provided as standard with the SMC Flex

controller. If the overload trip class is less than the acceleration time of the

motor, nuisance tripping may occur.

ATTENTION: Overload protection should be properly coordinated with the motor.

Two applications require special consideration: two-speed motors, and multimotor protection.

34 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Two-speed Motors

The SMC Flex controller has overload protection available for single speed

motors. When the SMC Flex controller is applied to a two-speed motor, the

Overload Class parameter must be programmed to OFF and separate overload

relays must be provided for each speed.

Page 35

Chapter 2 Installation

Multi-motor Protection

If the SMC Flex controller is controlling more than one motor, individual

overload protection is required for each motor.

Electromagnetic Compatibility (EMC)

The following guidelines are provided for EMC installation compliance.

ATTENTION: This product has been designed for Class A equipment. Use of the

product in domestic environments may cause radio interference, in which case, the

installer may need to employ additional mitigation methods.

Enclosure

Install the product in a grounded metal enclosure.

Wiring

Wire in an industrial control application can be divided into three groups:

power, control, and signal. The following recommendations for physical

separation between these groups is provided to reduce the coupling effect.

• Different wire groups should cross at 90° inside an enclosure.

• Minimum spacing between different wire groups in the same tray

should be 16 cm (6 in.).

• Wire runs outside an enclosure should be run in conduit or have

shielding/armor with equivalent attenuation.

• Different wire groups should be run in separate conduits.

• Minimum spacing between conduits containing different wire groups

should be 8 cm (3 in.).

• For additional guidelines, please refer to Wiring and Grounding

guidelines, publication DRIVES-IN001

.

Additional Requirements

• If linear acceleration is used, a separate conduit or wire way should be

used for the tachometer leads.

• Wire earth ground to control terminal 14.

• Use shielded wire for PTC, Tachometer, and ground fault input.

• Terminate shielded wires to terminal 14.

• Ground fault CT must be inside or within 3 m of metal enclosure.

To meet product susceptibility requirements, ferrite cores need to be added to

the communication lines. When using an external HIM (or DPI interface), a

core should be added to the HIM cable near the SMC Flex control module. The

recommended core is Fair-Rite no. 0431167281 or equivalent. When you are

using a DeviceNet™ circuit, two cores need to be added to the DeviceNet cable

near the SMC Flex control module. The recommended cores are TDK

ZCAT2023 0930H and TDK ZCAT2035 0930 or equivalent. All cores specified

are the split type cores and can be added to existing connections.

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 35

Page 36

Chapter 2 Installation

150-SMCAP

SMC Flex

Controller

100…240V AC control power

≤ 135 A Rating

Fair-Rite Products

2675102002

(5 turns)

Schaffner

FN2090-3-06

Line Load

New EMC Compliance – Conducted Emissions

There are new requirements for conducted emissions per IEC 60947-4-2

≤20kVA that require additional external components for SMC Flex units with

100…240V AC control power (code “D” in catalog string for control voltage) and

rated 135A and below:

• Use Schaffner part number FN2090-3-06 external power line filter for

the control power. Connect to SMC Flex controller terminals 11 and 12.

• Use Fair-Rite Products part number 2675102002 external ferrite core

with 5 turns for the control power earth ground. Connect to SMC Flex

controller terminal 14.

• Use Rockwell Automation Cat. No. 150-SMCAP capacitor module

connected to the incoming 3-phase power (terminals L1, L2, L3). Note:

This is an SMC-50 controller accessory that you can use with SMC Flex

units for this purpose.

Figure 30 - Cat. No. 150-SMCAP Capacitor Module Wiring Configuration

L1 L2 L3

11 12 14

P

N

PE

P’

N’

36 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 37

Chapter 3

(1)

(5)

(4)

(2), (3)

(3)

Wiring

This chapter illustrates basic wiring configurations for the SMC™ Flex

controller.

Wiring Terminal Locations

The SMC Flex controller wiring terminal locations are shown in Figure 31

through Figure 33

. Incoming three-phase power connections are made to

terminals L1/1, L2/3, and L3/5. Load connections to Line motors are made to T1/

2, T2/4, and T3/6; load connections to Wye-Delta motors are made to T1/2, T2/4,

T3/6, T4/8, T5/10, and T6/12.

Figure 31 - Wiring Terminal Locations—5…85 A Devices

Note Number Information

1 Incoming Line Termination

2 Line Motor Connections

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 37

(1)

Delta Motor Connections

3

4 Control Terminations

5 Fan Terminations

(1) IP20 protective covers on Delta termination must be removed when connecting in a Delta configuration.

Page 38

Chapter 3 Wiring

(1)

(5)

(4)

(2), (3)

(3)

Figure 32 - Wiring Terminal Locations—108…480 A Devices

Note Number Information

1 Incoming Line Termination

2 Line Motor Connections

3 Delta Motor Connections

4 Control Terminations

5 Fan Terminations

38 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 39

Figure 33 - Wiring Terminal Locations—625…1250 A Devices

(1)

(3)

(2)

Chapter 3 Wiring

Power Structure

Note Number Information

1 Incoming Line Termination

2 Line Motor Connections

3 Terminal Block CP1 - Common Control Power Connections (Fans, Contactors, and Control Modules)

The SMC Flex controller has an integrated mechanical run contactor on each

phase of the motor to minimize heat generation during run time. These

contacts are pulled in sequentially in the 108…1250 A units. In the 5…85 A units,

these contacts are pulled simultaneously. The SMC Flex controller also has a

built-in current transformer (CT) on each phase of the motor to provide

current readings.

Power Wiring

See the product nameplate or Table 7 for power lug termination information

including:

• Lug wire capacity

• Tightening torque requirements

• Lug kit catalog numbers (108…1250 A devices)

ATTENTION: Failure of solid state power switching components can cause overheating due to a single-phase condition in the

motor. Voltage could be present on output terminals when the SMC Flex controller has line voltage. To prevent injury or

equipment damage, the following is recommended:

ATTENTION: Use of an isolation contactor or shunt trip type circuit breaker on the line side of the SMC Flex controller. This

device should be capable of interrupting the motor’s locked rotor current.

ATTENTION: Connection of this isolation device to an auxiliary contact on the SMC Flex controller. The auxiliary contact should

be programmed for the fault condition. See Chapter 4

Rockwell Automation Publication 150-UM008I-EN-P - October 2020 39

for additional information on programming.

Page 40

Chapter 3 Wiring

SMC Flex Controller

Motor

3~

Isolation Contactor

Isolation Contactor

Isolation Contactor

5/L3

3/L2

1/L1

10/T5

8/T4

12/T6

6/T3

4/T2

2/T1

SMC Flex controller

Motor

3~

Isolation Contactor

Isolation Contactor

Isolation Contactor

5/L3

3/L2

1/L1

10/T5

8/T4

12/T6

6/T3

4/T2

2/T1

Line Connection

The SMC Flex by default is programmed to be connected to a line controlled

motor, as shown in Figure 34

rated between 1…1250 A. An optional isolation contactor can be added to the

circuit to provide galvanic isolation of the motor and final electro-mechanical

removal of power.

Figure 34 - Line-connected Wiring

. These motors typically have 3 leads and must be

Power Lugs

Delta Connection

You can program the SMC Flex controller and connect it to a delta-controlled

motor as shown in Figure 35

must be rated between 1.8…1600 A. We recommend that you add an isolation

contactor to the circuit to provide galvanic isolation of the motor and final

electromechanical removal of power.

Figure 35 - Delta-connected Wiring

Devices that are rated 108…1250 A require power lugs. In some cases, these lugs

are sold in kits of three lugs. Table 7

lugs that are required.

. These motors typically have 6 or 12 leads and

and Table 8 list the number and type of

40 Rockwell Automation Publication 150-UM008I-EN-P - October 2020

Page 41

Table 7 lists the recommended lugs for the SMC Flex controller when it is

configured as a line connection. Table 8

using the SMC Flex controller with a delta connection. Note that devices rated

625…1250 A require the use of a power distribution block when they are used

with a delta connection.

ATTENTION: Terminal covers are available for units rated 108…480 A which

can make the product deadfront (IP2X) safe. See the SMC-3™, SMC Flex, and

SMC-50™ Smart Motor Controllers Technical Data, publication 150-TD009

the appropriate catalog numbers for ordering.

Table 7 - SMC Flex Controller Line Connection Lug Information—5…1250 A Devices

Chapter 3 Wiring

lists the recommended lugs when

for

Controller

Rating

5…85 A — 18…20 mm

108…135 A 199-LF1 18…20 mm

201…251 A 199-LF1 18…20 mm

317…480 A 199-LG1 18…25 mm

625…780 A 100-DL630 32 mm / 64 mm

970 A 100-DL860 26 mm / 48 mm

1250 A

(1) The 1250 A device requires one (1) each of Cat. No. 100-DL630 and 100-DL860.

(1)

Lug Kit Cat.

No.

100-DL630 32 mm / 64 mm

100-DL860 26 mm / 48 mm

Wire Strip Length Conductor Range

2.5…85 mm

16…120 mm

16…120 mm

25…240 mm

70…240 mm

120…240 mm

70…240 mm

120…240 mm

2

(#14…3/0 AWG)

2

(#6…250 MCM)

2

(#6…250 MCM)

2

(#4…500 MCM)

2

(2/0…500 MCM)

2

(4/0…500 MCM)

2

(2/0…500 MCM)

2

(4/0…500 MCM)

Max. No. Lugs/Pole Tightening Torque

Line Side Load Side Wire — Lug Lug — Busbar

— — 11.3 N•m (100 lb.-in.) —

1 1 31 N•m (275 lb.-in.) 17 N•m (150 lb.-in.)