Page 1

Installation Instructions

PowerFlex 700 Phase Monitor Relay Replacement

SK-G9-RELAY-F9

This publication provides the steps needed to replace a PowerFlex 700 Frame 9

Phase Monitor Relay. This relay verifies correct phasing of the three-phase blower

that is used for drive cooling.

Before proceeding, read the following:

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive

parts and assemblies. Static control precautions are required when

installing, testing, servicing or repairing this assembly. Component

damage may result if ESD control procedures are not followed. If you are

not familiar with static control procedures, reference Guarding Against

Electrostatic Damage, publication 8000-4.5.2 or any other applicable ESD

protection handbook.

ATTENTION: Only qualified personnel familiar with adjustable frequency

AC drives and associated machinery should perform maintenance/repair of

the system. Failure to comply may result in personal injury and/or

equipment damage.

ATTENTION: To avoid an electric shock hazard, verify that the voltage on

the bus capacitors has discharged before performing any work on the

drive. Measure the DC bus voltage at the +DC & –DC terminals of the

Power Terminal Block (refer to the User Manual for location). The voltage

must be zero.

For additional PowerFlex 700 drive information, refer to the following

publications online at: www.rockwellautomation.com/literature.

Title Publication

PowerFlex 700 Series B User Manual 20B-UM002

Frame 7-10 Installation Instructions 20B-IN014

Wiring and Grounding Guidelines for PWM AC Drives DRIVES-IN001

Preventive Maintenance of Industrial Control and Drive System Equipment DRIVES-TD001

Safety Guidelines for the Application, Installation and Maintenance of Solid

State Control

A Global Reference Guide for Reading Schematic Diagrams 100-2.10

Guarding Against Electrostatic Damage 8000-4.5.2

SGI-1.1

To order paper copies of technical documentation, contact your local Rockwell

Automation distributor or sales representative. To find your local distributor or

sales representative, visit www.rockwellautomation.com/locations

For Drives Technical Support see www.ab.com/support/abdrives

.

.

20B-IN027A-EN-P

Page 2

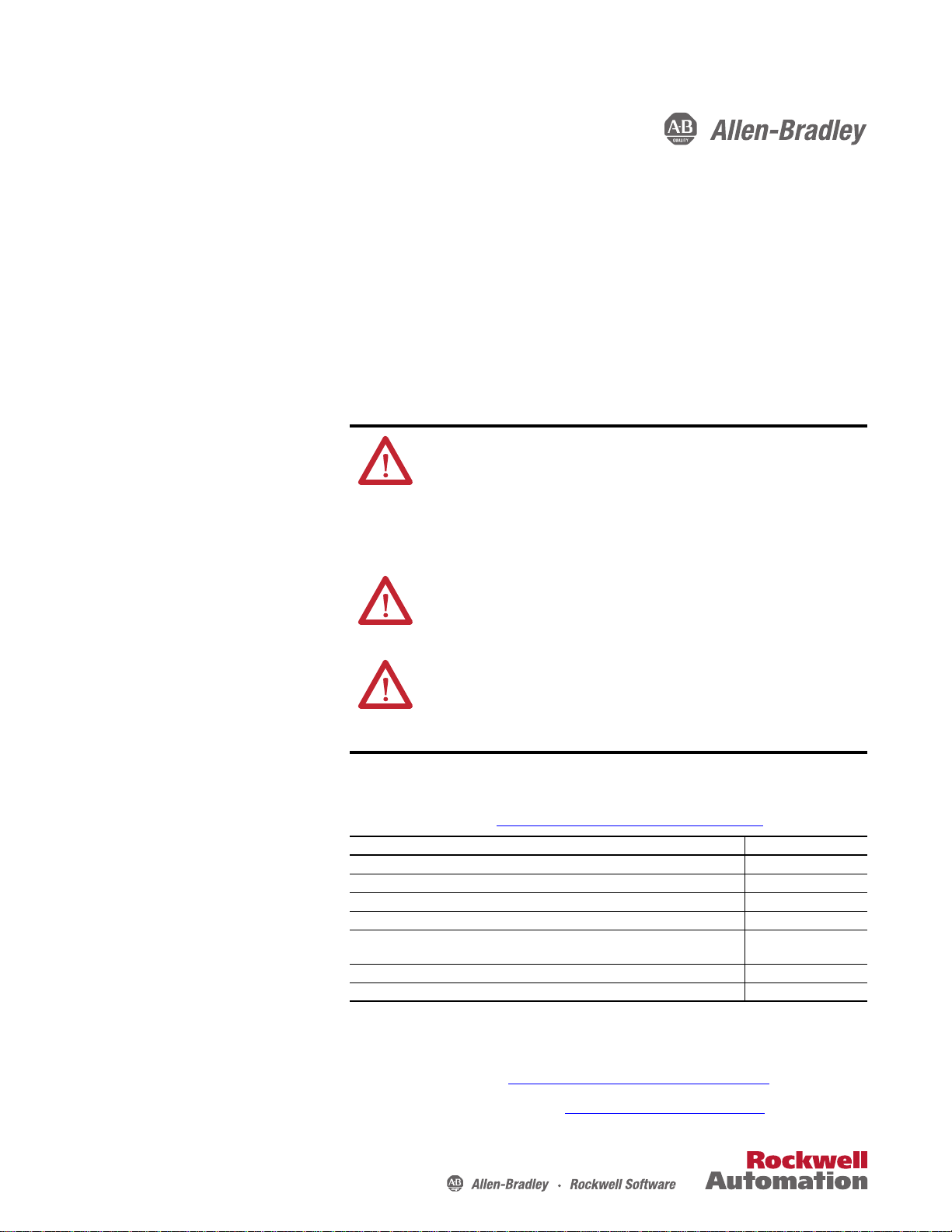

PowerFlex 700 Phase Monitor Relay Replacement

Type A

Drives Manufactured before January 20, 2011

(see below)

Type B

Drives Manufactured January 20, 2011 and after

(see page 3

)

Identifying the Relay

Two types of Phase Monitor Relays are used in Frame 9 drives depending on the

date of manufacture. Refer to Figure 1

and determine the relay type currently

installed in your drive. Next, locate the corresponding replacement procedure.

Figure 1 - Relay Identification

Replacing the Relay

Type A - Drives Manufactured before January 20, 2011

1. Verify that all power to the drive has been removed.

2. Usi ng Figure 1

A.” If not, refer to the procedure on page 3

3. Locate terminals L1, L2 and L3 on the existing relay. Verify that the wires

connected to each terminal are labeled correctly, then remove the wires.

4. Cut and insulate the two wires connected to A1 and A2. These wires will

not be used with the replacement relay. Ensure that the wire ends are well

insulated using wire nuts and tape. Secure the loose ends to the wire

harness.

5. The wires just cut and insulated are routed to the “120V” and “N”

terminals of TB-9. Trace these wires back to TB-9 and disconnect. Insulate

the ends and secure to the wire harness.

, verify that the relay installed in your drive matches “Type

.

ATTENTION: To guard against possible equipment damage and/

or personal injury, ensure that the wires previously disconnected

from the relay and TB-9 are thoroughly insulated (using wire nuts

and tape) and secured to the wire harness.

2 Rockwell Automation Publication 20B-IN027A-EN-P - March 2011

6. Remove the wire connected to terminal 21 of the relay. Relabel this wire

“25.”

Page 3

PowerFlex 700 Phase Monitor Relay Replacement

➊

➍

➌

➋

➎

7. Remove the wire connected to terminal 24 of the relay. Relabel this wire

“28.”

8. Remove the end clamps from the DIN rail. Remove the relay and discard.

9. Mount the new relay to the DIN rail and install end clamps.

10. Connect wire numbers 25 and 28 to the corresponding terminals of the

new relay.

11. Connect the L1, L2 and L3 wires to the corresponding terminals of the

new relay.

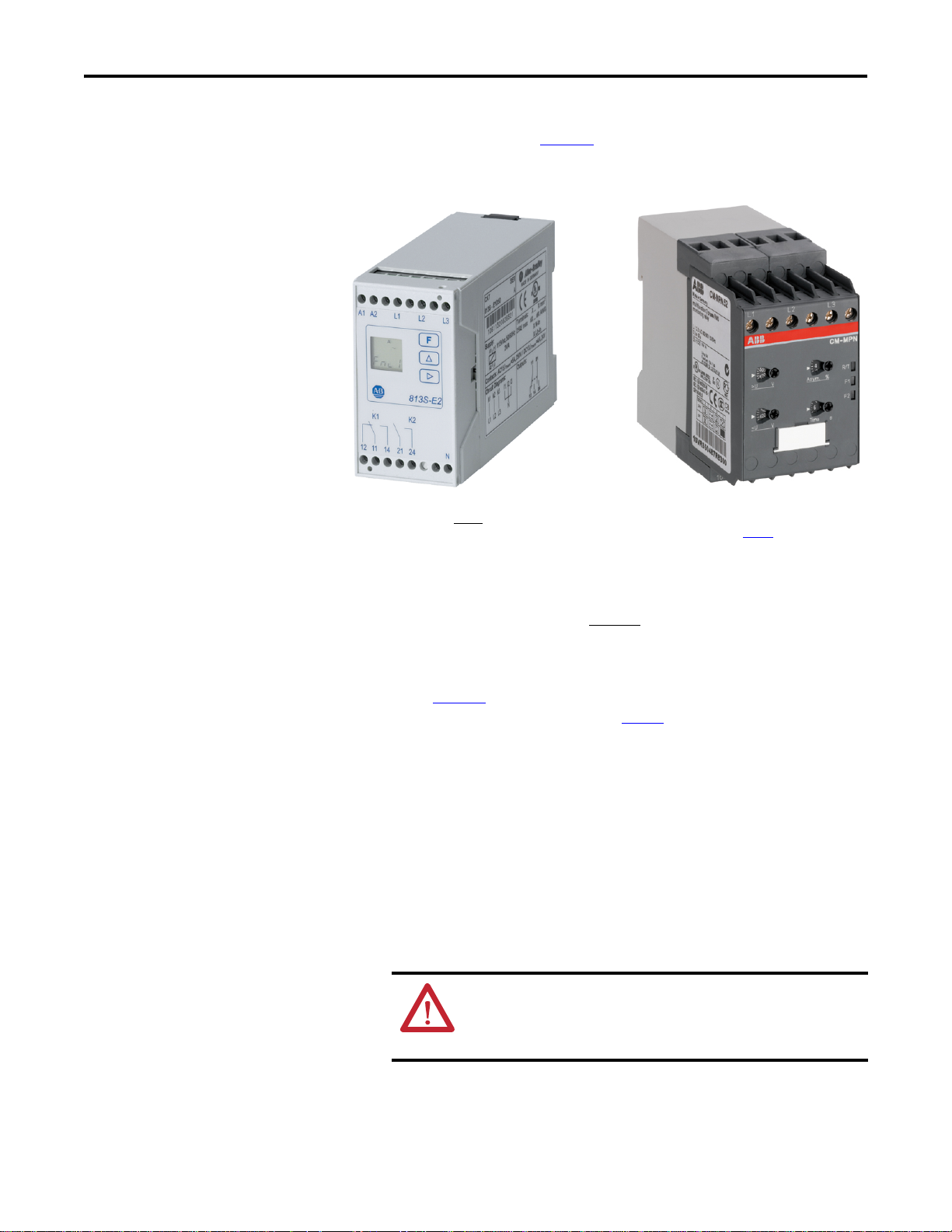

12. Verif y the fo llo wi ng a dj us tm ents :

No.

(see Figure 2

) Adjustment Setting

➊ DIP Switches OFF

➋ Overvoltage Threshold Set to maximum (580V)

➌ Undervoltage Threshold Set to minimum (350V)

➍ Phase Unbalance Threshold Set to maximum (25%)

➎ Delay Set to minimum (0 s)

Figure 2 - Replacement Relay Adjustments

L1 L2 L3

580

UV

350

UV

16

15 18 26 25 28

15

Asym. %

6

Time s

R/T

F1

F2

43 21

ON

OFF

13. Apply power and check for proper operation.

If phasing is correct, the “R/T” LED will illuminate.

If phasing is not correct, the “F1” and “F2” LEDs will alternately

illuminate. Refer to the PowerFlex 700 Frame 7…10 Installation

Instructions, publication 20B-IN014 for troubleshooting information.

Type B - Drives Manufactured January 20, 2011 and after

1. Verify that all power to the drive has been removed.

2. Usi ng Figure 1

B.” If not, refer to the procedure on page 2

Rockwell Automation Publication 20B-IN027A-EN-P - March 2011 3

, verify that the relay installed in your drive matches “Type

.

Page 4

PowerFlex 700 Phase Monitor Relay Replacement

www.rockwellautomation.com

Americas: Rockwell Automation, 1201 South Second Street,

Milwaukee, WI 53204-2496 USA,

Tel:

(1) 414.382.2000, Fax: (1) 414.382.4444

Europe

/

Middle East/Africa: Rockwell Automati

on,

Pegasus Park, De Kleetlaan 12a,

1831 Diegem, Belgium,

Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Power, Control and Information Solutions Headquarters

*PN-111987*

PN-111987

3. Locate terminals L1, L2 and L3 on the relay. Verify that the wires

connected to each terminal are labeled correctly, then remove the wires.

4. Locate the wires connected to terminals 25 and 28 of the relay and verify

that they are labeled correctly. Remove the wires from the relay.

5. Remove the end clamps from the DIN rail. Remove the relay and discard.

6. Mount the new relay to the DIN rail and install end clamps.

7. Connect wire numbers 25 and 28 to the corresponding terminals of the

new relay.

8. Connect the L1, L2 and L3 wires to the corresponding terminals of the

new relay.

9. Verif y the fo llo wi ng a dj us tm ents :

No.

(see Figure 2

) Adjustment Setting

➊ DIP Switches OFF

➋ Overvoltage Threshold Set to maximum (580V)

➌ Undervoltage Threshold Set to minimum (350V)

➍ Phase Unbalance Threshold Set to maximum (25%)

➎ Delay Set to minimum (0 s)

10. Apply power and check for proper operation.

If phasing is correct, the “R/T” LED will illuminate.

If phasing is not correct, the “F1” and “F2” LEDs will alternately

illuminate. Refer to the PowerFlex 700 Frame 7…10 Installation

Instructions, publication 20B-IN014 for troubleshooting information.

U.S. Allen-Bradley Drives Technical Support - Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, E-mail: support@drives.ra.rockwell.com,

Online: www.ab.com/support/abdrives

Publication 20B-IN027A-EN-P – March 2011 PN-111987

Copyright © 2011 Rockwell Automation, Inc. All rights reserved. Printed in USA.

Loading...

Loading...