Page 1

Distributed Power System

SD3100 DC Power Modules

1250A, 1650A, 3000A DC

Instruction Manual

S-3064

Page 2

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

ATTENTION:Only qualified personnel familiar with the construction and operation of this

equipment and the hazards involved should install, adjust, operate, or service this equipment.

!

Read and understand this manual and other applicable manuals in their entirety before

proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:Verify that all sources of AC and DC power are deenergized and locked out or tagged

out in accordance with the requirements of ANSI/NFPA 70E, Part II.

ATTENTION:The user must provide an external, hardwired stop circuit outside of the drive

circuitry. This circuit must disable the system in case of improper operation. Uncontrolled machine

operation may result if this procedure is not followed. Failure to observe this precaution could

result in bodily injury.

ATTENTION:The system may contain stored energy devices. To avoid the hazard of electrical

shock, verify that all voltage on capacitros has been discharged before attempting to service,

repair, or remove a drive system or its components. You should only attempt the procedures in

this manual if you are qualified to do so and are familiar with solid-state control equipment and

the safety procedures in publication 70E.

ATTENTION:An incorrectly applied or incorrectly installed drive system can result in component

damage and/or a reduction in product life. Wiring or application errors–such as undersizing the

motor, incorrect or inadequate AC supply, and excessive ambient temperatures–can result in the

malfunction of hte drive equipment.

ATTENTION: The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

ATTENTION:This drive system contains parts and assemblies that are sensitive to ESD

(electrostatic discharge). Static control precautions are required when installing, testing, or

repairing this assembly. Component damage can result if ESD control procedures are not

followed. If you are not familiar with static control procedures, refer to Rockwell Automation

publication 8000-4.5.2,

on ESD protection.

Guarding Against Electrostatic Damage

, or another adequate handbook

The information in this users manual is subject to change without notice.

AutoMax™ is a trademark of Rockwell Automation

©1998 Rockwell International Corporation

Page 3

Chapter 1 Introduction

1.1 Field Power Module.........................................................................................1-3

1.2 Standard Features...........................................................................................1-3

1.3 Optional Features............................................................................................1-4

1.4 Related Publications........................................................................................ 1-4

1.5 Terms Used in this Manual..............................................................................1-5

Chapter 2 Mechanical/Electrical Description

2.1 Mechanical Overview ......................................................................................2-2

2.1.1 Control Components .............................................................................2-2

2.1.2 Power Components............................................................................... 2-3

2.1.2.1 Incoming Power ...................................................................... 2-3

2.1.2.2 Armature Power Components.................................................2-4

2.1.2.3 Field Power Module Components........................................... 2-7

2.2 Electrical Overview..........................................................................................2-7

2.3 1250A Power Module Description ................................................................... 2-9

2.3.1 1250A Power Module Component Layout........................................... 2-10

2.3.2 1250A Power Module Dimensions...................................................... 2-12

2.4 1650A Power Module Description .................................................................2-13

2.4.1 1650A Power Module Component Layout........................................... 2-14

2.4.2 1650A Power Module Dimensions...................................................... 2-16

2.5 3000A Power Module Description .................................................................2-17

2.5.1 3000A Power Module Component Layout........................................... 2-18

2.5.2 3000A Power Module Dimensions...................................................... 2-20

C

ONTENTS

Chapter 3 Installation Guidelines

3.1 Planning the Installation ..................................................................................3-1

3.2 Physically Installing the Power Module ...........................................................3-2

3.3 Wiring AC Input Power to the Power Module .................................................. 3-2

3.3.1 AC Input Wire Selection ........................................................................ 3-2

3.3.2 Making an Input Entry Hole................................................................... 3-3

3.3.3 Connecting the AC Input Wires to the Busbars..................................... 3-3

3.4 Wiring AC Input to the Field Power Module..................................................... 3-4

3.4.1 Installing the Field Isolation Transf ormer .............................................. 3-4

3.5 Wiring the Motor .............................................................................................. 3-5

3.5.1 Selecting Wires for the Armature and Field Lines.................................3-5

3.5.2 Connecting the Motor to the Power Module..........................................3-5

3.6 Installing Feedback Devices................................... ...... ....... ...... ....... ...... ....... .. 3-6

3.7 Meter Port Connections...................................................................................3-7

3.8 Grounding the Drive ........................................................................................3-7

3.9 For Information on Initial Start-Up of the Drive................................................ 3-8

Table of Contents

I

Page 4

Chapter 4 Maintenance and Troubleshooting

4.1 Recommended Test Equipment.......................................................................4-1

4.2 System Diagnostics..........................................................................................4-2

4.2.1 Power Module Faults.............................................................................4-2

4.2.1.1 Shorted SCR Fault (Bit 0)........................................................4-2

4.2.1.2 AC Line Synchronization Fault (Bit 3)......................................4-2

4.2.1.3 Instantaneous Overcurrent Fault (Bit 4) ..................................4-3

4.2.1.4 Conduction Timeout Fault (Bit 5).............................................4-3

4.2.1.5 Loss of Field Fault (Bit 6).........................................................4-3

4.2.2 Power Module Warnings........................................................................4-3

4.2.2.1 Three-phase Bridge SCR Not Firing Warning (Bit 0)...............4-3

4.2.2.2 Low Line Voltage/Phase Missing Warning (Bit 1)....................4-3

4.2.2.3 Synchronization Loss Fault Avoided Warning (Bit 3) ..............4-4

4.2.2.4 Current Reference Limit Warning (Bit 4) .................................4-4

4.2.2.5 Identification Test Error Warning (Bit 5) ..................................4-4

4.2.2.6 Field Power Module Overcurrent Warning (Bit 6)....................4-4

4.2.2.7 Fan Loss Warning (Bit 12).......................... .............................4-4

4.3 Component Replacement ................................................................................4-4

4.3.1 Spare Parts Kits.....................................................................................4-4

4.3.2 PMI Regulator........................................................................................4-5

4.3.3 Parallel Gate Amplifier...........................................................................4-5

4.3.4 Field Power Module...............................................................................4-5

4.3.4.1 Replacing Internal Field Power Module AC Input Fuses.........4-5

4.3.4.2 Replacing Field Power Module Components ..........................4-6

Appendix A Technical Specifications........................................................................................... A-1

Appendix B Schematics............................................................................................................... B-1

Appendix C Replacement Parts ....... ...... ....... ...... ....... ...... ...... ....... ....................................... ...... .. C-1

Index ..................................... ...... ....... ...... ....... ...... ....................................... ...... ....... ..Index-1

II

SD3100 Power Modules

Page 5

List of Figures

Figure 1.1 – SD3100 Catalog Numbering Scheme .................................................. 1-1

Figure 2.1 – SD3100 Power Module System Components ......................................2-1

Figure 2.2 – Regulator Assembly .............................................................................2-2

Figure 2.3 – Armature Bridge (Non-Regenerative)................................................... 2-5

Figure 2.4 – Armature Bridge (Regenerative)...........................................................2-6

Figure 2.5 – 1250A Power Module Component Layout..........................................2-10

Figure 2.6 – 1250A Power Module Dimensions .....................................................2-12

Figure 2.7 – 1650A Power Module Component Layout..........................................2-14

Figure 2.8 – 1650A Power Module Dimensions .....................................................2-16

Figure 2.9 – 3000A Power Module Component Layout..........................................2-18

Figure 2.10 – 3000A Power Module Dimensions ................................................... 2-20

Figure 3.1 – Area Available for Conduit Entry (Top View of Leftmost Bay).............. 3-3

Figure 3.2 – Field Terminal Wiring............................................................................3-4

Figure 3.3 – Drive I/O Connections (TB4) ................................................................ 3-6

Figure 3.4 – Resolver and Analog Input Connections (TB5) .................................... 3-6

Figure 3.5 – Meter Port Connections (TB6)..............................................................3-7

Figure 3.6 – SD3100 Grounding...............................................................................3-8

Figure A.1 – Altitude Derating Chart.........................................................................A-1

Figure A.2 – Power Dissipation vs. Armature Current (1250A Power Module) ........A-3

Figure A.3 – Recommended Circuit Breaker Settings (1250A Power Module) ........A-3

Figure A.4 – AC Input Busbars (1250A Power Module)...........................................A-4

Figure A.5 – Power Dissipation vs. Armature Current (1650A Power Module) ........A-6

Figure A.6 – Recommended Circuit Breaker Settings (1650A Power Module) ........A-6

Figure A.7 – AC Input Busbars (1650A Power Module)...........................................A-7

Figure A.8 – Power Dissipation vs. Armature Current (3000A Power Module .........A-9

Figure A.9 – Recommended Circuit Breaker Settings (3000A Power Module) ........A-9

Figure A.10 – AC Input Busbars (3000A Power Module) .......................................A-10

Figure A.11 – Air Baffle Layout (1250A and 1650A Power Modules).....................A-11

Figure A.12 – Air Baffle Layout (3000A Power Module).........................................A-12

Figure B.1 – DC Blower Motor Connections.............................................................B-1

Figure B.2 – 1250A and 1650A Power Modules (Non-Regenerative), Sheet 1........B-2

Figure B.3 – 1250A and 1650A Power Modules (Non-Regenerative), Sheet 2........B-3

Figure B.4 – 1250A and 1650A Power Modules (Regenerative), Sheet 1 ...............B-4

Figure B.5 – 1250A and 1650A Power Modules (Regenerative), Sheet 2 ..............B-5

Figure B.6 – 3000A Power Module (Regenerative), Sheet 1....................................B-6

Figure B.7 – 3000A Power Module (Regenerative), Sheet 2....................................B-7

Table of Contents

III

Page 6

IV

SD3100 Power Modules

Page 7

List of Tables

Table 1.1 – SD3100 Drive Options........................................................................... 1-2

Table 1.2 – Field Power Module Part Numbers........................................................1-3

Table 1.3 – Distributed Power System DC Drives Documentation........................... 1-4

Table 1.4 – Related Motor Control Center Documentation.......................................1-5

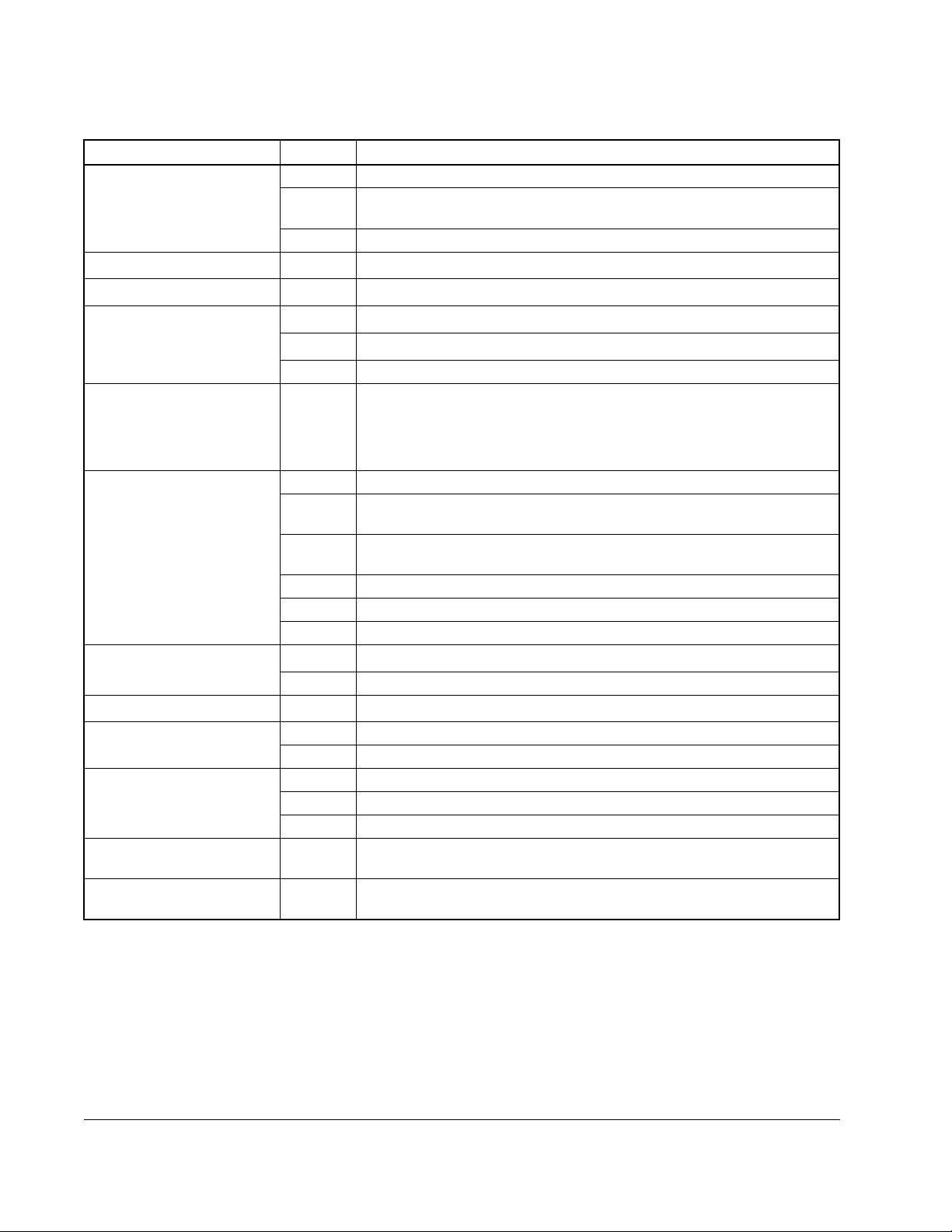

Table 2.1 – 1250A Configurations............................................................................ 2-9

Table 2.2 – 1250A Power Module Symbol-to-Component Reference....................2-11

Table 2.3 – 1650A Configurations.......................................................................... 2-13

Table 2.4 – 1650A Power Module Symbol-to-Component Reference....................2-15

Table 2.5 – 3000A Configurations.......................................................................... 2-17

Table 2.6 – 3000A Power Module Symbol-to-Component Reference....................2-19

Table 3.1 – Recommended AC Input Wiring ............................................................3-2

Table 3.2 – Isolation Transformer Wiring Requirements ..........................................3-4

Table 3.3 – Armature Wire Selection........................................................................3-5

Table 3.4 – Field Wire Selection...............................................................................3-5

Table 4.1 – Field Power Module Input Fuses ........................................................... 4-5

Table A.1 – Electrical Specifications (1250A Power Module)...................................A-2

Table A.2 – Electrical Specifications (1650A Power Module)...................................A-5

Table A.3 – Electrical Specifications (3000A Power Module)...................................A-8

Table of Contents

V

Page 8

VI

SD3100 Power Modules

Page 9

C

HAPTER

1

Introduction

SD3100 DC Power Modules convert fixed voltage and frequency three-phase AC

power to adjustable voltage DC power, which can be used to supply the armature or

field of a DC motor. An SD3100 Power Module operates within the AutoMax

Distributed Power System (DPS) environment, and is controlled by the AutoMax

Programming Executive software. The Power Module communicates with the AutoMax

system via an internally mounted Power Module Interface (PMI) rack, which contains

the drive’s control circuits and executes the motor control algorithm.

The SD3100 configuration provides control of DC motors, rated 700 to 2500 HP, with

current ratings of 1250, 1650, and 3000A. Input voltages of 460, 575, and 660 VAC

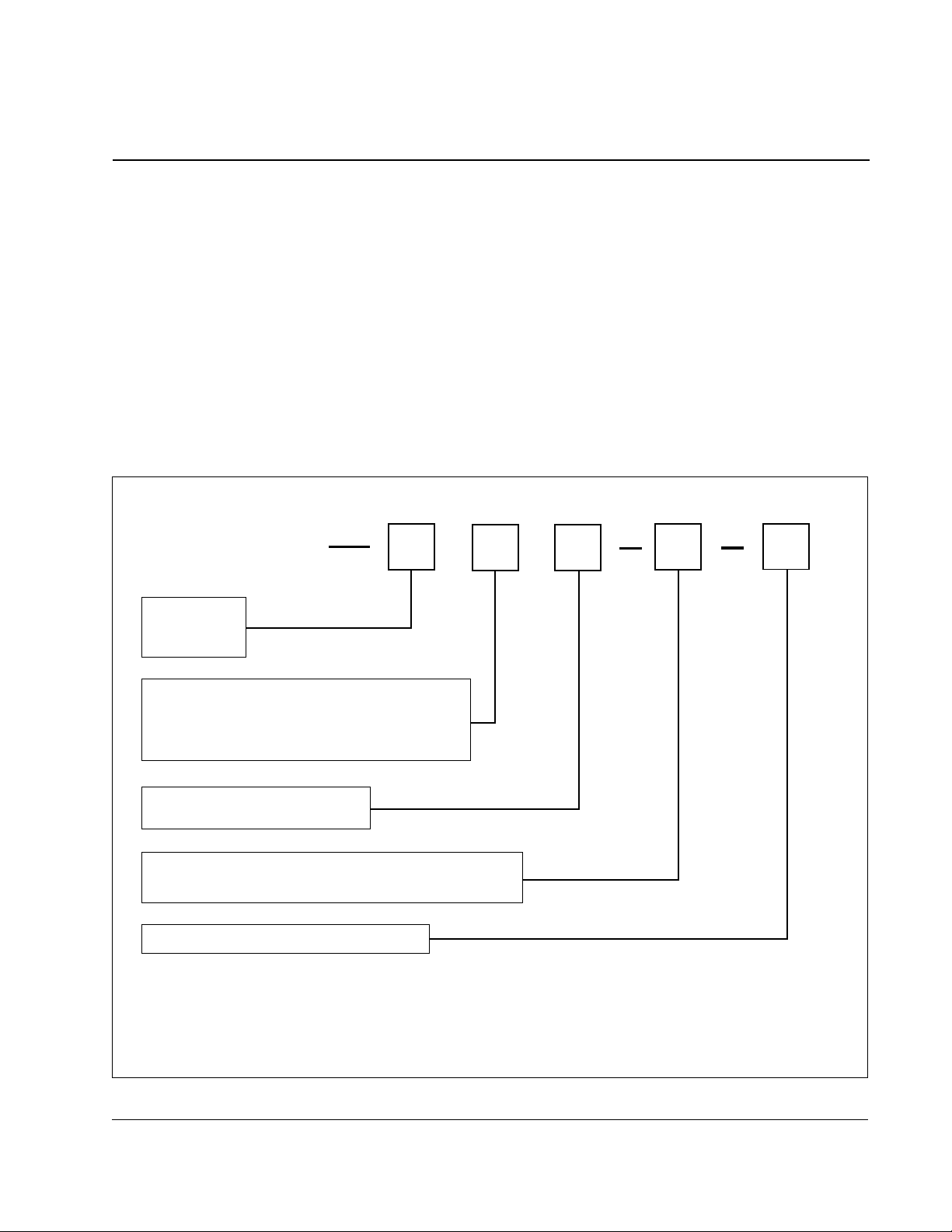

are available. Figure 1.1 shows the SD3100 catalog numbering scheme.

Distributed Power

System Drive Numb er

SD3100

B = 460 VAC

C = 575 VAC

F = 660 V AC

64 = 700 HP

65 = 750 HP

66 = 800 HP

67 = 900 HP

N = Non-regenerative, 6-pulse

R = Regenerative, 6-pulse

AA = NEMA Type 1 w ithout gaskets and door fan filters

AJ = NEMA Type 1 with g askets and door fan filters

Refer to table 1.1, SD3100 Drive Options.

68 = 1000 HP

69 = 1250 HP

70 = 1500 HP

71 = 1750 HP

AC Input

Voltage

72 = 2000 HP

73 = 2250 HP

74 = 2500 HP

3

B

1

HP

64

Unit

Configuration

N

2

Enclosure Options

AA

4

1. A separately-ordered, separately-mounted 7.5 to 25kVA field isolation transformer is required. See section 1.1.

2. Units accommodate top ent ry and bottom exit. An additional sec ti on is required f or bottom entry.

A separate additional section is required for top exit.

3. Non-regenerative units not offered for 3000A modules.

4. Add option codes here. Separate option codes with dashes.

Figure 1.1 – SD3100 Catalog Numbering Scheme

Introduction

1-1

Page 10

Table 1.1 – SD3100 Drive Options

Drive Option Code Description

6P Standard capacity control transformer with primary fusing

Control Po w er Sourc e

1

6TB

6SC 115 VAC control power supplied by others

2

Dynamic Braking Cont act or

Unit Door Nameplate

1

14DB Dynamic braking contactor option

M3EW White background with black lettering; phenolic label

14WLBL

Miscellaneous

J12

J11 Audio phone jack

Auxiliary Contact s 989X

14BN (1) NEMA 1 FVNR starter assembly internally mounted with 30A fuse blocks

14B2N (2) NEMA 1 FVNR starter assemblies internally mounted with 30A fuse

Blower Starters

5, 6

14B2NX (2) NEMA 2 FVNR starter assemblies internally mounted with 60A fuse

14BI (1) IEC 24A starter assembly internally mounted with 30A fuse blocks

14B2I (2) IEC 24A starter assemblies internally mounted with 30A fuse blocks

14B2IX (2) IEC 30A starter assemblies internally mounted with 60A fuse blocks

14LSP

Protection

14AFL Air flow loss swit ches

Field Su pply Upgra de

Incoming Protecti on

8, 9

1

14FX Field supply upgrade for fields requiring 15 to 60A

CM Circuit breaker

LF Line fuses

HB1600 1600A AC power bus for 1250A units with 460 or575 VAC inputs

5

Horizontal Power Bus

HB2000 2000A AC power bus for 1250 and 1650A units with 460 or 575 VAC inputs

HB3000 3000A AC power bus for 1250 and 1650A units with 460 or 575 VAC inputs

Horizontal Control Bus CB90

Input Option 14HBC

1. User must select one option from this group.

2. This option includes a dynamic braking contactor mounted in a separate 20” MCC section.

3. Cloth wire labels are standard. Datab labels provide a clear plastic cover on top of the labels for added protection.

4. User must supply 115 VAC control power and wiring to the duplex receptacle.

5. User may select one option from this group.

6. Fuses and overload elements are user-supplied and must be power-matched to the installation.

7. Line RC suppressor is required for installations where the primary of the distribution transformer is 2300 VAC or greater.

8. Standard Field Power Module is rated to supply field currents up to 15A. The upgrade provides a Field Power Module rated up to 60A.

(Nominal field currents based on 85% efficiency, unit control power usage, and a 300V field supply.)

9. A separately-ordered, separately-mounted 7.5kVA to 25kVA field isolation transformer is required. See the following section.

115 VAC control power, factory wired from 115 VAC control bus to drive unit

(1250 and 1650A units only). Requires option CB90

Brady Datab™ wire labels

15 VDC, 15A duplex receptacle, user-wired

(2) normally open and (2) normally close d contactors mounted in ternally in

•

3

4

1250/1650A unit, or

(4) normally open and (4) normally close d contactors mounted in ternally in

•

3000A unit

blocks

blocks

Line RC suppressor module

7

90A AC control bus for 1250 and 1650A units that have a horizontal power

bus option

AC pow er input is wired from the horizo ntal thru-bu s to the circuit br eake r/line

fuses for 1250 and 1650A units that have a horizontal power bus option

1-2

SD3100 Power Modules

Page 11

1.1 Field Power Module

The single-phase Field Power Module is integrally mounted within the SD3100 Power

Module to provide the motor field excitation. The Field Po wer Module is rated 15 or 60

amps at 230/460 VAC . The 15A unit is supplied as standard. The 60A unit is available

as an option.

The Field Power Module requires a separately-ordered, separately-mounted field

isolation transformer. The Field Power Module’s AC input lines are connected through

the isolation transformer to the L1 and L3 inputs of the SD3100. The 15A module

requires a step-down transformer rated up to 7.5kVA (application dependent). The

60A module requires a step-down transformer rated 7.5kVA to 25kVA (application

dependent). All systems operate on three-phase 50/60 Hz., 460 to 660 VAC.

The Field Power Module is available in the configurations listed in table 1.2.

Table 1.2 – Field Power Module Part Numbers

Part No. Amps AC Input Description Mounting

805405-3R

805405-5R

1. For application information see instruction manual S-3060.

1

1

15 230 / 460 VAC Reversing (S2R) Integral

60 230 / 460 VAC Reversing (S2R) Integral

1.2 Standard Features

SD3100 DC Power Modules have the following features:

•

Three-phase 460, 575, or 690 VAC input

•

1250, 1650, and 3000 amp units

•

S6 (non-regenerating) and S6R (regenerating) configurations

•

15 amp Field Power Module

•

DC output contactor

•

PE / TE bus

•

Choice of incoming circuit breaker or input line fuse protection

•

Electronic motor overload protection

•

SCR power semiconductors / dv/dt protection

•

SCR leg fuses

•

Cell chokes

•

Protection against unequal current sharing among SCRs

•

Protection from AC line dips and transients

•

Top AC entry / Bottom DC exit

Introduction

•

Power through-bus (1250A and 1650A Power Modules)

1-3

Page 12

•

115VAC control bus (90A)

•

Fiber-optic communication with the Distributed Power System Universal Drive

Controller (UDC) module

•

Drive nameplate - white/black letters

1.3 Optional Features

The following features are available as options:

•

60 amp Field Power Module

•

NEMA blower starter

•

IEC blower starter

•

Air flow switch

•

Line suppressor

•

115 VAC convenience outlet

•

Phone jack

1.4 Related Publications

The instruction manuals in binder S-3000 describe the other system hardware, system

software, and communications, as listed in table 1.3. It is assumed that the user is

familiar with these manuals before installing, operating, or performing maintenance

upon SD3100 DC Power Modules. Further information pertaining to SD3100 Power

Modules can be found in instruction manuals S-3045 and S-3060, as listed in the

table.

Table 1.3 – Distributed Power System DC Drives Documentation

Publication Number Description

S-3000 Distributed Power System DC Drives Binder

S-3005 AutoMax Distributed Power System Overview

S-3006 SD3000 Drive Configuration and Programming

S-3007 Universal Drive Controller Module

S-3008 Power Module Interface Rack and Modules

S-3009 Fiber Optic Cabling

S-3011 Diagnostics, Troubleshooting and Start-up Guidelines

Related DPS Documentation

S-3045 DPS Parallel Gate Amplifier System

S-3060 DPS Single-Phase Field Power Modules

1-4

SD3100 Power Modules

Page 13

Installation of the motor control center (MCC) is described in the manuals listed in

table 1.4.

Table 1.4 – Related Motor Control Center Documentation

Publication Number Description

2100-5.5 Instructions - Receiving, Handling, And Storing Motor

Control Centers

2300-5.1 Bulletin 2300 Family of Drive Systems Hardware

Additional information about using SD3100 Power Modules as part of a Distributed

Power System is found in the wiring diagrams, prints, and other documentation

shipped with each drive system. Always consult the prints shipped with the drive for

specific mounting and connecting information about your system.

1.5 Terms Used in this Manual

The terms listed in this section have the specific meanings given below when they

appear in this manual.

Application

software is being used.

Armature Power Module

power bridge and related hardware components used to control the armature current.

Diagnostic

error conditions.

Drive

Power Module as a means or apparatus for transmitting motion to a machine or

machine part.

Drive warning

for by the PMI operating system. Drive warnings are reported in register 203/1203 in

the UDC. A drive warning will not shut down the drive. System response is determined

by the application task.

Error

Drive fault

that will shut down the drive. Drive faults are reported in register 202/1202 in the UDC.

Field Power Module

Field Power Module is integrally mounted within the SD3100 Power Module.

- The process for which the combination of hardware and control

- the power structure containing the three-phase SCR

- a software routine or hardware circuit specifically designed to check for

- the combination of a UDC, a PMI, a Field Power Module, and an Armature

- a potentially hazardous or undesirable operating condition checked

- any operating condition other than the desired one.

- an error, specifically checked for by the PMI Processor operating system,

- a single-phase power unit, used to supply the motor field. The

Introduction

Non-regenerative drive

(S6 configuration).

Regenerative drive

or reverse (S6R configuration).

- a drive capable of motoring operation only

- a drive capable of motoring or regenerating operation, forward

1-5

Page 14

1-6

SD3100 Power Modules

Page 15

LINE FUSES OR CIRCUIT BREAKER

L1

L2

C

HAPTER

2

Mechanical/Electrical Description

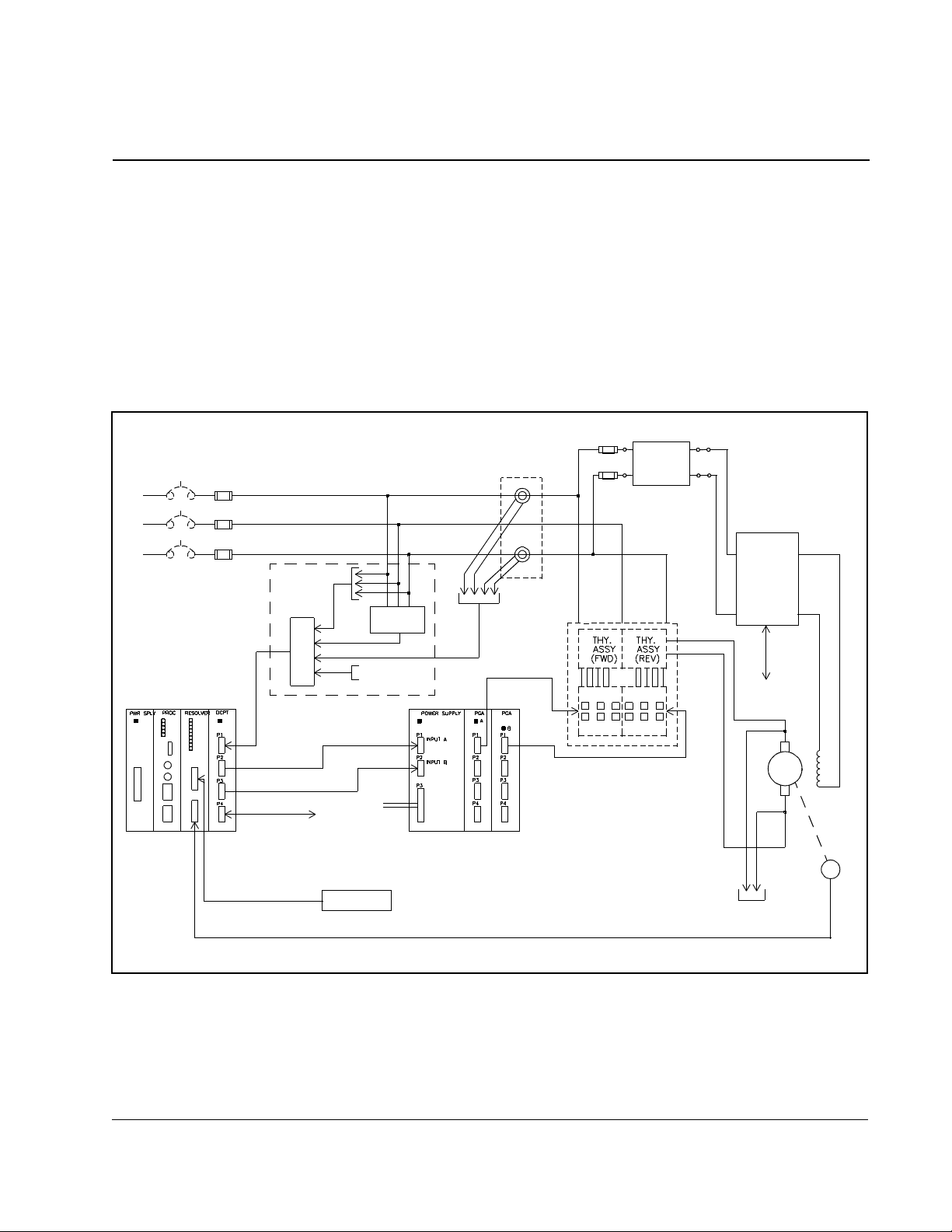

Rockwell Automation SD3100 DC Power Modules are built using a Distributed Power

System PMI regulator and a high-horsepower silicon-controlled rectifier (SCR) bridge.

All components are housed in a NEMA 1 metal enclosure.

This chapter provides general information on the mechanical and electrical

characteristics of SD3100 Power Modules, followed by specific information on the

1250A, 1650A, and 3000A units.

FU-A

CURRENT

XFMRS

FU-B

EXTERNAL

FIELD ISO

XFMR

L3

PMI RACK

RESISTOR

SCALING

MODULE

ARMATURE

FEEDBACK

FWD GATE SIGNALS

REV GATE SIGNALS

TO FIEL D

POWER MODULE

DELTA/WYE

PHASING

XFMR

FROM DC

ARMATURE

SCALING UNI T

115 VAC

PGA RACK

DRIVE I/O

Figure 2.1 – SD3100 Power Module System Components

FWD GATE

SIGNALS

REV GATE

SIGNALS

RESOLVER FEEDBACK

GATE COUPLING CIRCUITS

ARMATURE PO WER

STRUCTURE (S6R)

FIELD

POWER

MODULE

L1

L2

L3

TO P4/

DCPT

+

DC

MOTOR

–

RESOLVER

TO RESISTOR

SCALING UNIT

Mechanical/Electrical Description

2-1

Page 16

2.1 Mechanical Overview

The SD3100 Power Module is composed of the basic components shown in figure 2.1.

These components consist of:

Contr ol components

•

System and control for the Power Module, and

Power components

•

2.1.1 Control Components

The control components are contained in the regulator assembly, along with the Field

Power Module. The regulator assembly is mounted in the lower compartment of the

Power Module’s Disconnect Bay.

FU-A

FIELD

ISOLATION

XFRM

FUSES

that provide the interface to the AutoMax Distributed Power

that convert AC line power to DC power for the motor.

FU-B

SCALING

UNIT

TB1

PMI

RACK

FIELD

POWER

MODULE

PGA

RACK

FWD

REV

TO GATE

COUPLERS

TB2

TB3 TB4

Figure 2.2 – Regulator Assembly

TB5

TB6

The PMI rack contains the four modules that make up the PMI Regulator: the PMI’s

Power Supply, Processor module, Resolver and Drive I/O module, and DC Power

Technology module. The PMI Processor executes the control algorithm and

communicates with the AutoMax processor via its fiber-optic ports. The Resolver and

Drive I/O module provides the interface for speed feedback and control signals. The

DC Pow er Technology module provides the armature feedback, armature forward gate

control, armature reverse gate control (regenerative models only), and the field

feedback and gate control signals for the Field Power Module.

2-2

SD3100 Power Modules

Page 17

Below the PMI rack is a DPS Parallel Gate Amplifier (PGA), which provides isolation

and amplification of the forward and reverse gate drive signals. The Field Power

Module is mounted to the left of the PMI and PGA racks. At the top of the assembly

are the field isolation transformer fuses and a scaling unit that conditions the armature

feedback signals received via terminal block TB1. T erminal blocks at the bottom of the

assembly provide connection for the field gate and feedback signals (TB2), control

power (TB3), drive I/O (TB4), the resolver (TB5), and the meter ports (TB6). The

forward and reverse armature gate coupler circuits connect to the control circuitry at

the lower right of the compartment.

The Power Module is shipped with the PMI Regulator and all related control

components installed. The PMI is described in detail in the Power Module Interface

Rack and Modules instruction manual (S-3008). Please refer to this manual for further

information. Additional information on the PGA can be found in instruction manual

S-3045.

2.1.2 Power Components

Power components manage and handle the power of the drive under the direction of

the PMI regulator. The power components consist of:

•

the incoming power components

•

the armature power bridge components

•

the Field Power Module

2.1.2.1 Incoming Power

The incoming power components handle the input power and provide it to the Field

Power Module and armature power bridge assemblies.

The following components are used to provide incoming power:

•

circuit breaker or input line fuses

•

user-supplied input line reactor or isolation transformer

•

control power and Field Power Module tap

•

user-supplied field isolation transformer

•

AC line RC suppressor

Circuit Breaker

Power Modules are provided with circuit breakers to protect the input power wiring.

Recommended circuit breaker settings are shown in Appendix A.

Input Line Reactor or Isolation Transformer

The SD3100 system requires a user-supplied line reactor or isolation transformer to

reduce peak currents and harmonics in the incoming power lines. This device is

needed to provide isolation to other equipment on the power lines during regeneration.

Important:

Mechanical/Electrical Description

Failure to use an input isolation device may result in damage to the Power

Module during regeneration.

2-3

Page 18

Control Power and Field Power Module Tap

The first (L1) and third (L3) phase of the incoming power are tapped off and fused to

provide single-phase AC power to the primary of the control power transformer and

the Field Power Module.

Field Isolation Transformer

A user-supplied field isolation transformer must be installed on the AC input of the

Field Power Module as described in section 3.4.1 of this manual. Using a field

isolation transformer provides the following advantages:

•

Provides power matching to the Field Power Module.

•

Permits the Field Power Module to continue operating in the event of a ground fault

in the field windings of the motor.

•

Provides a known minimum AC input impedance for the snubbers to operate

against.

•

Protects other circuits sharing the same power source from line notching

interference caused by the Field Power Module.

•

Provides source impedance to guarantee SCR protection in the event of a short

circuit.

AC Line RC Suppressor

The optional AC line RC suppressor is a device used for limiting line voltage spikes

when the medium voltage source to the primary of the distribution transformer is

switched. This option is required for a primary voltage of 2300V or greater.

Output Inductor

Note that some systems may require an output inductor in series with the armature,

especially for some DC motors that do not have enough internal inductance for a

proper armature commutation process.

2.1.2.2 Armature Power Components

The armature power components convert the 3-phase AC input to a DC output used

for powering the motor armature.

The following components make up the armature power circuitry:

•

armature SCR bridge (and its subordinate components)

•

leg fuses

•

gate coupler cards (GCCs)

•

DC contactor

2-4

SD3100 Power Modules

Page 19

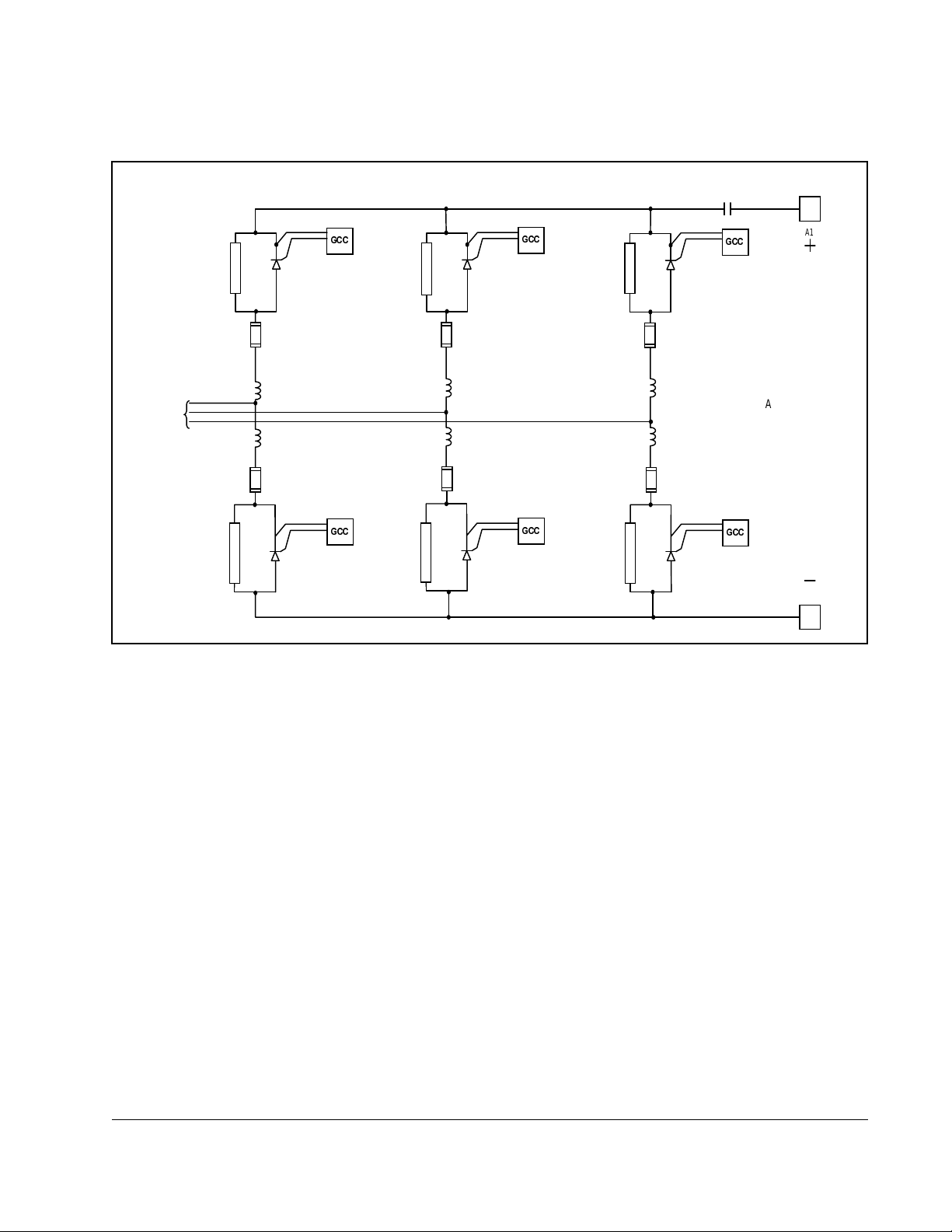

The non-regenerative bridge is shown in figure 2.3. Cell fuses protect the thyristors in

the event of a bridge failure.

Main

Contactor

3-Phase

AC

Input

SNUBBER

SNUBBER

*&&

*&&

SNUBBER

SNUBBER

*&&

*&&

Figure 2.3 – Armature Bridge (Non-Regenerative)

SNUBBER

SNUBBER

*&&

*&&

A1

Armature

Voltage

A2

Mechanical/Electrical Description

2-5

Page 20

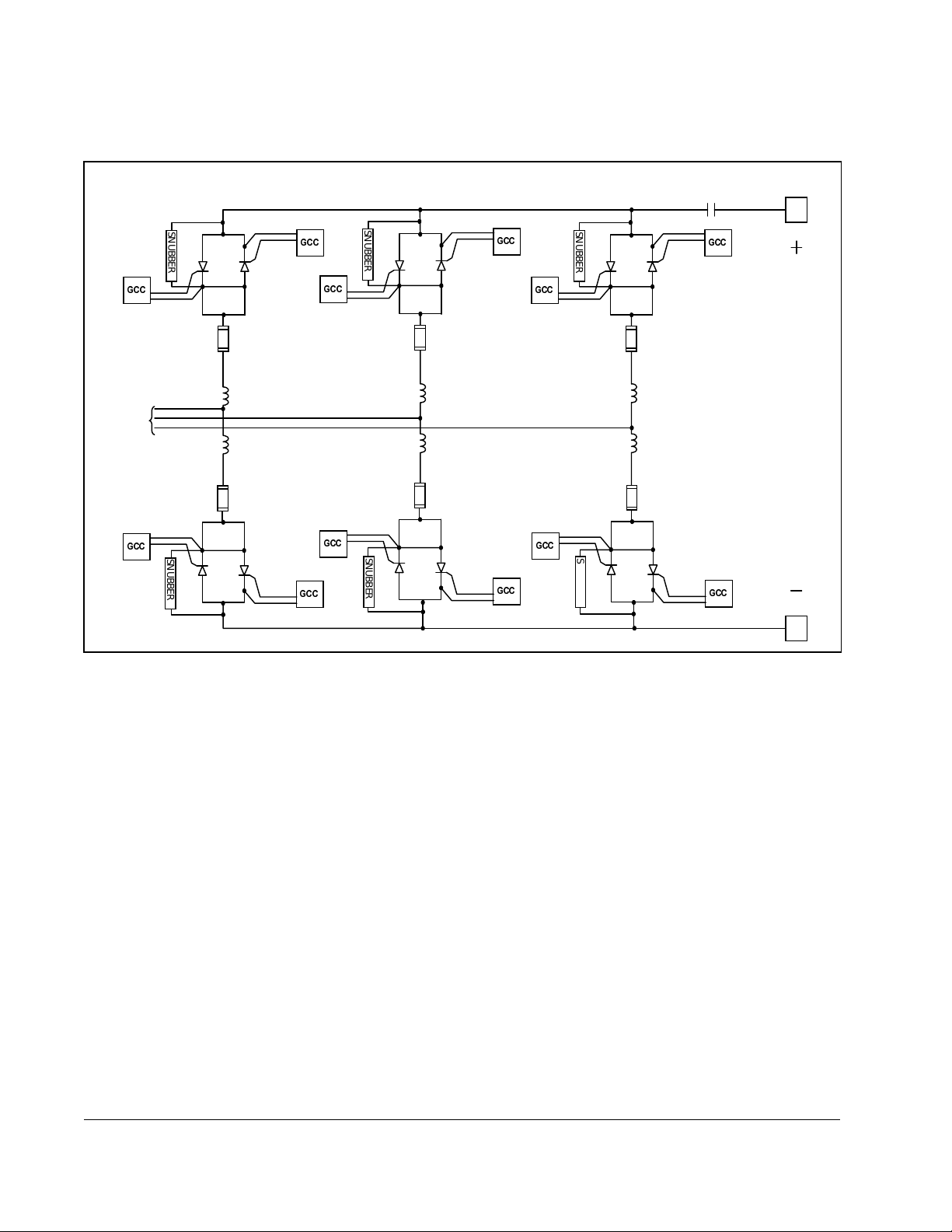

The regenerative bridge, shown in figure 2.4, allows the bridge to direct regenerated

power back onto the incoming lines.

Main

Contactor

*&&

3-Phase

AC

Input

*&&

SNUBBER

SNUBBER

*&&

*&&

SNUBBER

*&&

*&&

SNUBBER

Figure 2.4 – Armature Bridge (Regenerative)

*&&

*&&

*&&

*&&

SNUBBER

SNUBBER

*&&

*&&

A1

Armature

Voltage

A2

2-6

Armature Bridge Components

The armature bridge consists of the following components:

•

Silicon-Controlled Rectifiers (SCRs)

Each Power Module uses silicon-controlled rectifiers (SCRs) in the armature bridge

to switch the incoming 3-phase AC power to DC output power.

These SCRs allow current to flow from anode to cathode when two conditions are

met. First, like a diode, the SCR must be forward biased. Second, an appropriate

pulse must be applied to the gate (through the pulse transformer board).

The current will continue through the SCR until the voltage across it reverses and

the current drops to zero (line commutation).

•

Snubbers

Snubbers (resistor/capacitor assemblies) are installed in parallel with the SCRs to

protect the SCRs from rapid voltage changes (inductive kick) when the SCRs switch

off by suppressing and dissipating the excess voltage.

SD3100 Power Modules

Page 21

•

Gate Coupler Cards

Gate coupler cards amplify the gate signal pulses from the DC Power Technology

module to trigger the SCRs. In addition, these cards provide gate driver isolation

from the control circuits in the PMI rack.

•

Main DC Contactor

The main DC contactor is used to isolate the DC motor armature and to interrupt

the DC current to the motor armature. Coil voltage to the contactor is controlled by

contacts from the pilot relay.

2.1.2.3 Field Power Module Components

The Field Power Module operates on single-phase AC, which must be taken from the

three-phase armature power bridge’s L1 and L3 input lines. The incoming AC must be

supplied to the Field Power Module through an isolation transformer.

The Field Power Module rectifier consists of 8 SCRs in two full-wave bridges,

connected in anti-parallel. Snubber protection is provided to permit operation on a

common bus with other Power Modules. A Hall effect device is used to monitor the DC

output current.

$ ILHOG FO DPS DVVHPEO\ LV SURYLGHG WR PRQLWRU WKH YROWD JH EHWZHHQ WKH )LHOG 3RZHU

0RGXOH©V RXWSXW WHUPLQDOV DQG ,I DQ RYHUY RO WDJH RFFXUV WKH ILHOG FODPS

ILUHV D FURZEDU 6&5 WKDW VDIHO\ GL VVLSDWH V WKH HQHUJ\ LQ WKH ILHOG

2.2 Electrical Overview

SD3100 DC Power Modules convert fixed voltage and frequency three-phase AC

power to adjustable voltage DC power for motor armatures, fields, or other

applications that require controlled DC power. Power Module operation is

programmed and controlled in the UDC module in the AutoMax rack and the PMI

Processor in the drive’s internal PMI rack.

Incoming power is supplied from a three-phase AC line. A phasing transformer

provides AC line sequencing and zero-crossing information for each input phase to

determine when SCRs should be fired. The Power Module is capable of auto-phasing

under software control and can adapt to ABC or ACB phase rotation.

The non-regenerative Power Module rectifier consists of 6 SCRs, configured in a

full-wave power bridge. The regenerative Power Module rectifier consists of 12 SCRs

in two full-wave bridges, connected in anti-parallel. Snubber circuits provide dv/dt

protection for the SCRs in each bridge leg.

The firing angle for each SCR is determined by the current regulation algorithm

executing in the PMI Processor. SCR gating signals are provided by the DC Power

Technology module, under the control of the PMI Processor. The gating signals and

firing angles are synchronized with the AC line. The PMI Processor regulates the

current for the application by varying the point in the AC line cycle at which forward

SCR conduction begins. The PMI Processor receives the current reference from the

UDC module in the AutoMax rack. The UDC runs the application task that provides

overall control of the Power Module.

The three-phase SCR power bridge in a non-regenerative Power Module controls

forward rotation (motoring) only. Torque is in the same direction as rotation.

Mechanical/Electrical Description

2-7

Page 22

The two anti-parallel SCR power bridges in a regenerative Power Module control the

direction of motor rotation and the direction of torque, in both forward (motoring) and

reverse (regenerating) directions. The regenerative Power Module allows for

regeneration of power into the AC line under the condition of an overhauling load.

Field Power Module

Operation of the Field Power Module is programmed and controlled in the UDC

module in the AutoMax rack and the PMI Processor in the PMI rack. The firing angle

for each SCR is determined by the field current regulation algorithm executing in the

PMI Processor. The field SCR gating signals are provided by the DC Power

Technology module, under the control of the PMI Processor.

The firing angle for each SCR is synchronized with the AC line feeding it. The PMI

Processor regulates the amount of motor field current by varying the point in the AC

line cycle at which forward conduction begins. The PMI Processor receives the field

current reference from the UDC module in the AutoMax rack. The UDC runs the

application task that provides overall control of the application.

For a full description of the Field Power Module, please refer to instruction manual

S-3060.

2-8

SD3100 Power Modules

Page 23

2.3 1250A Power Module Description

Table 2.1 – 1250A Configurations

Input Voltage (VAC) Output HP

460 700-750

575 750-900

660 700-1000

The 1250A Power Module is supplied in the configurations shown in table 2.1. The

1250A Power Module has the following features:

•

The 1250A Power Module uses twelve SCRs (regenerative) or six SCRs

(non-regenerative) in the armature bridge to convert the 3-phase AC input to a DC

output. The SCRs are built into a heatsink assembly that is cooled by the bridge fan.

•

The 1250A Power Module is protected from incoming fault currents by a circuit

breaker or input line fuses. The components of the Power Module (the armature

bridge, field bridge, and control components) are protected by fuses, MOVs,

snubbers, and/or chokes.

•

The 1250A Power Module is constructed and housed in three bays. The first bay

contains the AC input and control hardware, the second bay contains the armature

bridge hardware, and the third bay contains the DC output hardware.

•

The 1250A Power Module can be built to allow alternative input entry, using either

an optional bottom-entry bay (on the left of the disconnect bay) or an optional

top-hat extension over the AC input bay.

•

The 1250A Power Module can be built with an optional through bus assembly,

allowing the 1250A Power Module and other connected Power Modules to tap off

power from the same AC input.

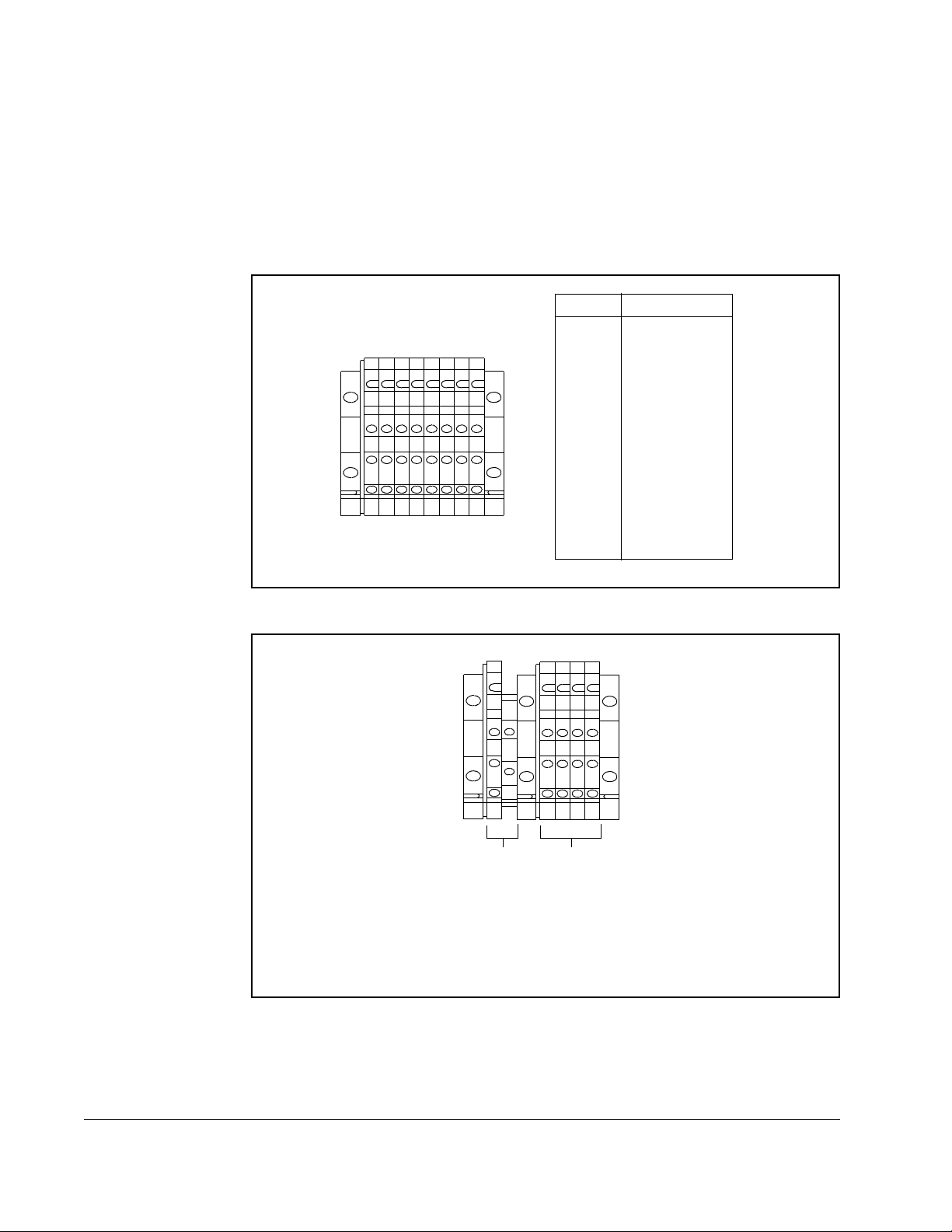

Figures 2.5 and 2.6 show component locations and Power Module dimensions.

Please refer to these figures when installing or servicing the Power Module. Refer to

Appendix B for wiring diagrams of both the regenerative and non-regenerative

versions of the Power Module.

Mechanical/Electrical Description

2-9

Page 24

2.3.1 1250A Power Module Component Layout

PP1 PP2 PP3

F51*

ACT1 ACT3

L1 L2 L3

SP1

SP2

SP3

SP4

*

F31,

F32,

F33

FU-B

FU-A

F14 F 15

F16

F14 F15

CB11*

or

F52*

EA4

SCALING

UNIT

MP

R1

A2(-)

M1

F17,

F18,

F19

M11

*

F27,

*

F28,

F29

M12

A1(+)

*

*

A14R

F53*

F1,

*

F2,

F3

TB1

PMI

RACK

TB1FAN

A11F

F12

F12A

F9 F9A

A14F

A11R

PP4 PP5 PP6

A16R

A13F

F11 F11A F10

F8

F8A

A16F

A13R

F7

A12R

A12F

A15F

F10A

F7A

A15R

D1

2-10

FIELD

SUPPLY

TB2

TB3

TB4

PT2

TB5

PGA

RACK

TB6

FWD REV

'LVFRQQHFW %D\ %ULGJH %D\ &RQWDFWRU %D\

Figure 2.5 – 1250A Power Module Component Layout

SD3100 Power Modules

Page 25

Table 2.2 – 1250A Power Module Symbol-to-Component Reference

Symbol Description Option 460 VAC 575 VAC 660 VAC

A1(+), A2(-) Armature outputs

A11F - A16F Armature pulse transformer PCB

A11R - A16R Armature pulse transformer PCB

ACT1, ACT3 Line current transformers 2000:1

CB11 Circuit breaker ∗ 1200A, N-frame

F51 - F53

AC line fuses

1

∗ 1200A, KRPC

D1 M1 bridge diode

EA4 Line RC suppressor ∗

F1 - F3 Control branch/feedback PCB fuses 1A KTK 1A KTK 10A A70P

F7 - F12,

F7A - F12A

F14, F15

Armature bridge cell fuses

Control power transformer, primary

fuses

$ 9 0

$ ./'5 9

10A, 1500V

Form 101-Type 4

F16 Control power xfmr, secondary fuse 9A KLDR, 600V

F17 - F19,

F27 - F29

Blower motor fuses ∗

F31 - F33 Line RC snubber fuses ∗ 25A KTK 25A KTK 25A A70P

FU-A, FU-B

External field isolation

transformer fuses

15A unit: 30A, 700V

60A unit: 100A, 700V

FWD Forward gate connector

REV Reverse gate connector

M1 DC armature contactor 1800A

M11, M12 Blower motor starters ∗

MP Main pilot for pilot relay

PP1 - 6 Armature power poles

PT2 Control transformer 2kV A

R1 M1 suppressor resistor 1k Ω, 50Ω

SP1 - 3 Line-to-line MOVs 460J, 320VAC 550J, 385VAC 600J, 420VAC

SP4 Neutral-to-ground MOV 760J, 680VAC 760J, 680VAC 1050J, 750VAC

TB1-F AN Bridge fan & capacitor terminal block

TB1 Armature fee dback terminal block

TB2 Field terminal block

TB3 Control power terminal block

TB4 Drive I/O terminal block

TB5 Resolver feedback terminal block

TB6 Meter ports connector

1. Note that if the 1250A unit has the AC line fuse option, the 1650A unit’s busbars are used in place of the standard 1250A busbars. See

Appendix A for busbar illustrations.

Mechanical/Electrical Description

2-11

Page 26

2.3.2 1250A Power Module Dimensions

20 inches

(508 mm)

91.5 inches

(2324 mm)

2-12

20 inches

(508 mm)

20 inches

(508 mm)

Figure 2.6 – 1250A Power Module Dimensions

35 inches

(889 mm)

20 inches

(508 mm)

20 inches

(508 mm)

For other details on the 1250A Power Module and its components, please refer to the

appendices of this manual.

SD3100 Power Modules

Page 27

2.4 1650A Power Module Description

Table 2.3 – 1650A Configurations

Input Voltage (VAC) Output HP

460 800-1000

575 1000-1250

660 1250

The 1650A Power Module is supplied in the configurations shown in table 2.3. The

1650A Power Module has the following features:

•

The 1650A Power Module uses twelve SCRs (regenerative) or six SCRs

(non-regenerative) in the armature bridge to convert the 3-phase AC input to a DC

output. The SCRs are built into a heatsink assembly that is cooled by the bridge fan.

•

The 1650A Power Module is protected from incoming fault currents by a circuit

breaker or input line fuses. The DC output is protected from fault currents by a DC

contactor. The components of the Power Module (the armature bridge, field bridge,

and control components) are guarded by fuses, MOVs, snubbers, and/or chokes.

•

The 1650A Power Module is constructed and housed in three bays. The first bay

contains the AC input and control hardware, the second bay contains the armature

bridge hardware, and the third bay contains the DC output hardware.

•

The 1650A Power Module can be built to allow alternative input entry, using either

an optional bottom-entry bay (to the left side of the disconnect bay) or an optional

top-hat extension over the AC input bay.

•

The 1650A Power Module can be built with an optional through bus assembly,

allowing the 1650A Power Module and other connected Power Modules to tap off

power from the same AC input.

Figures 2.7 and 2.8 show component locations and Power Module dimensions.

Please refer to these figures when installing or servicing the Power Module. Refer to

Appendix B for wiring diagrams of both the regenerative and non-regenerative

versions of the Power Module.

Mechanical/Electrical Description

2-13

Page 28

2.4.1 1650A Power Module Component Layout

PP1 PP2 PP3

F51*

ACT1 ACT3

L1 L2 L3

SP1

SP2

SP3

SP4

*

F31,

F32,

F33

FU-B

FU-A

F14 F 15

F16

F14 F15

CB11*

or

F52*

EA4

SCALING

UNIT

MP

R1

A2(-)

M1

F17,

F18,

F19

M11

*

F27,

*

F28,

F29

M12

A1(+)

*

*

A14R

F53*

F1,

*

F2,

F3

TB1

PMI

RACK

TB1FAN

A11F

F12

F12A

F9 F9A

A14F

A11R

PP4 PP5 PP6

A16R

A13F

F11 F11A F10

F8

F8A

A16F

A13R

F7

A12R

A12F

A15F

F10A

F7A

A15R

D1

2-14

FIELD

SUPPLY

TB2

TB3

TB4

PT2

TB5

PGA

RACK

TB6

FWD REV

'LVFRQQHFW %D\ %ULGJH %D\ &RQWDFWRU %D\

Figure 2.7 – 1650A Power Module Component Layout

SD3100 Power Modules

Page 29

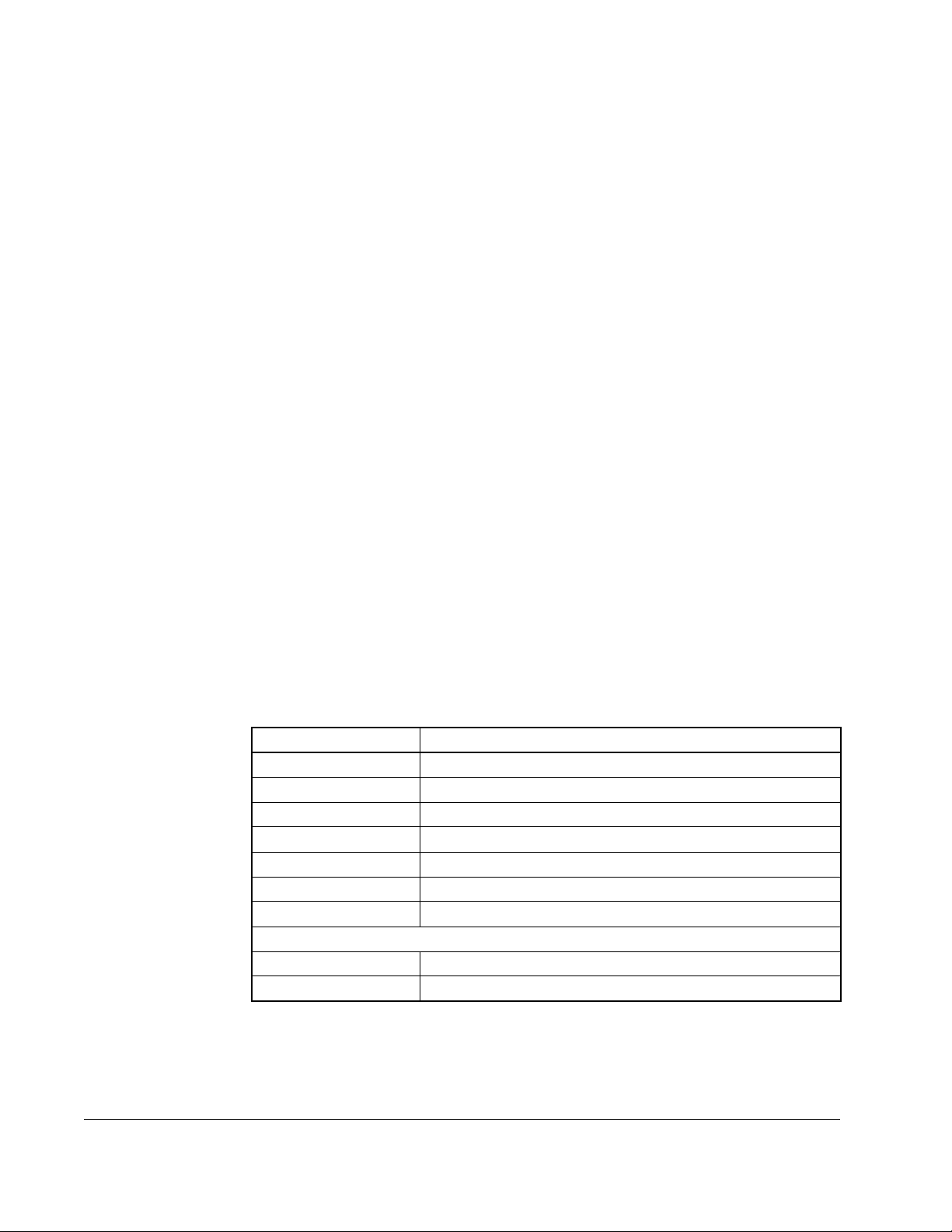

Table 2.4 – 1650A Power Module Symbol-to-Component Reference

Symbol Description Option 460 VAC 575 VAC 660 VAC

A1(+), A2(-) Armature outputs

A11F - A16F Armature pulse transformer PCB

A11R - A16R Armature pulse transformer PCB

ACT1, ACT 3 Line current transducer 3000:1

CB11 Circuit breaker ∗ 1600A, R-frame

F51 - F53 AC line fuses ∗ 1600A, KRPC

D1 M1 bridge diode

EA4 Line RC suppressor ∗

F1 - F3 Control branch/feedback PCB fuses 1A KTK 1A KTK 10A A70P

F7 - F12,

F7A - F12A

F14, F15

Armature bridge cell fuses

Control power transformer, primary

fuses

$ 9 0

$ ./'5 9

10A, 1500V

Form 101-Type 4

F16 Control power xfmr, secondary fuse 9A KLDR, 600V

F17 - F19,

F27 -F 29

Motor blower fuses ∗

F31 - F33 Line RC snubber fuses ∗ 25A KTK 25A KTK 25A A70P

FU-A, FU-B

External field isolation

transformer fuses

15A unit: 30A, 700V

60A unit: 100A, 700V

FWD Forward gate connector

REV Reverse gate connector

M1 DC armature contactor 3000A

M11, M12 Motor blower starters ∗

MP Main pilot for pilot relay

PP1 - PP6 Armature power poles

PT2 Con tr ol transfor mer 2kVA

R1 M1 suppressor resistor 1k Ω, 50Ω

SP1 - SP3 Line-to-line MOVs 460J, 320VAC 550J, 385VAC 600J, 420VAC

SP4 Neutral-to-ground MOV 760J, 680VAC 760J, 680VAC 1050J, 750VAC

TB1-F AN Bridge fan & capacitor terminal block

TB1 Armature feedback terminal block

TB2 Field terminal block

TB3 Control power terminal block

TB4 Drive I/O terminal block

TB5 Resolver feedback terminal block

TB6 Meter port connector

Mechanical/Electrical Description

2-15

Page 30

2.4.2 1650A Power Module Dimensions

20 inches

(508 mm)

91.5 inches

(2324 mm)

2-16

20 inches

(508 mm)

20 inches

(508 mm)

Figure 2.8 – 1650A Power Module Dimensions

35 inches

(889 mm)

20 inches

(508 mm)

20 inches

(508 mm)

For other details on the 1650A Power Module and its components, please refer to the

appendices of this manual.

SD3100 Power Modules

Page 31

2.5 3000A Power Module Description

Table 2.5 – 3000A Configurations

Input Voltage (VAC) Output HP

460 1250-1750

575 1500-2250

660 1500-2500

The 3000A Power Module is supplied in the configurations shown in table 2.5. The

3000A Power Module has the following features:

•

The 3000A Power Module uses twelve SCRs in the armature bridge to convert the

3-phase AC input to a DC output. The SCRs are built into a heatpipe assembly that

is cooled by the bridge fan.

•

The 3000A Power Module is protected from incoming fault currents by a circuit

breaker or line fuses. The DC output is protected from fault currents by a DC

contactor. The components of the Power Module (the armature bridge, field bridge,

and control components) are protected by fuses, MOVs, snubbers, and/or chokes.

•

The 3000A Power Module is constructed and housed in four bays. The first bay

contains the AC input and control hardware, the second bay contains the fuses, the

third bay contains the armature bridge hardware, and the fourth bay contains the

DC output hardware.

•

The 3000A Power Module has a standard top-hat extension over the disconnect bay

for the AC input. The Power Module can also be built to allow an alternative input

entry, using an optional bottom-entry bay (on the left side of the disconnect bay).

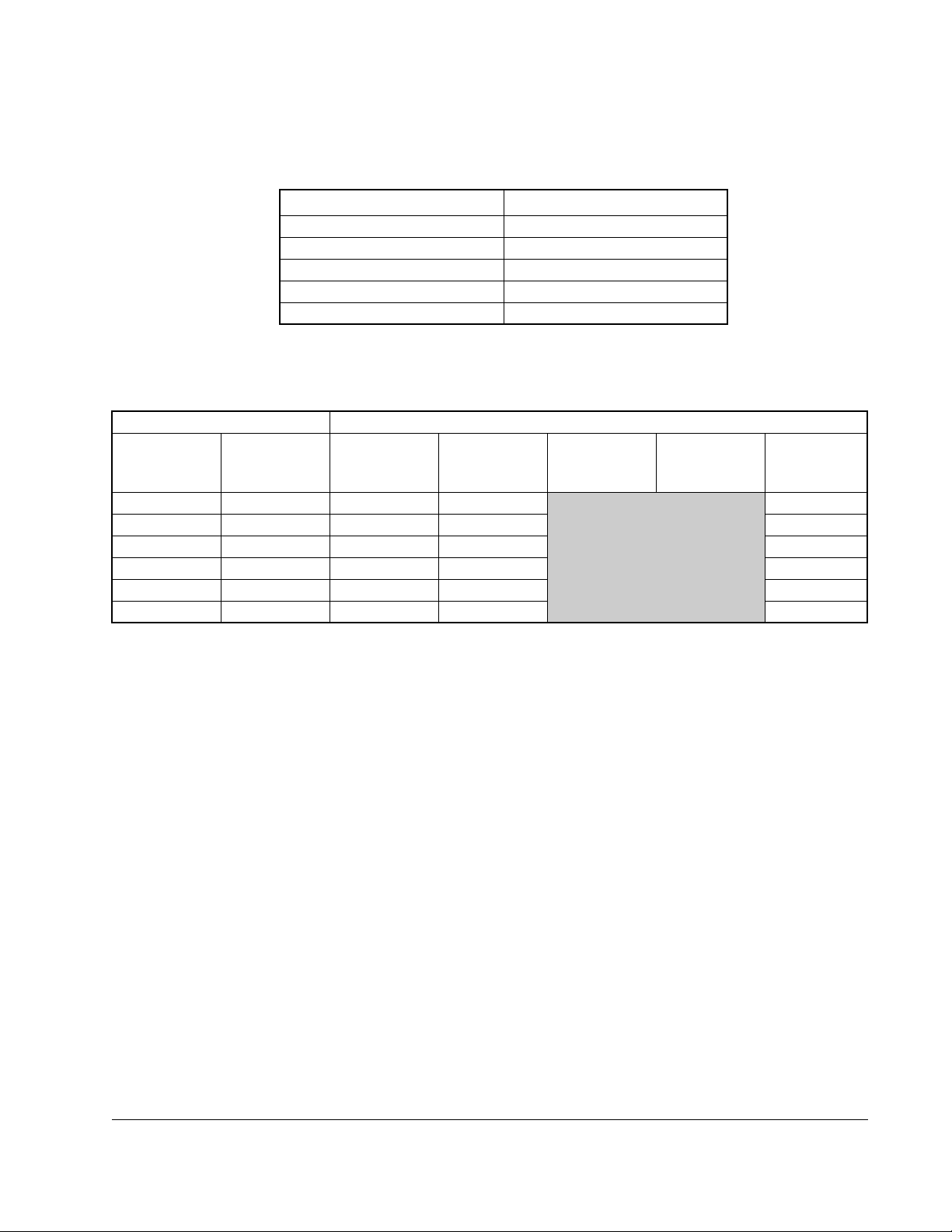

Figures 2.9 and 2.10 show component locations and Power Module dimensions.

Please refer to these figures when installing or servicing the Power Module. Refer to

Appendix B for wiring diagrams of both the regenerative and non-regenerative

versions of the Power Module.

Mechanical/Electrical Description

2-17

Page 32

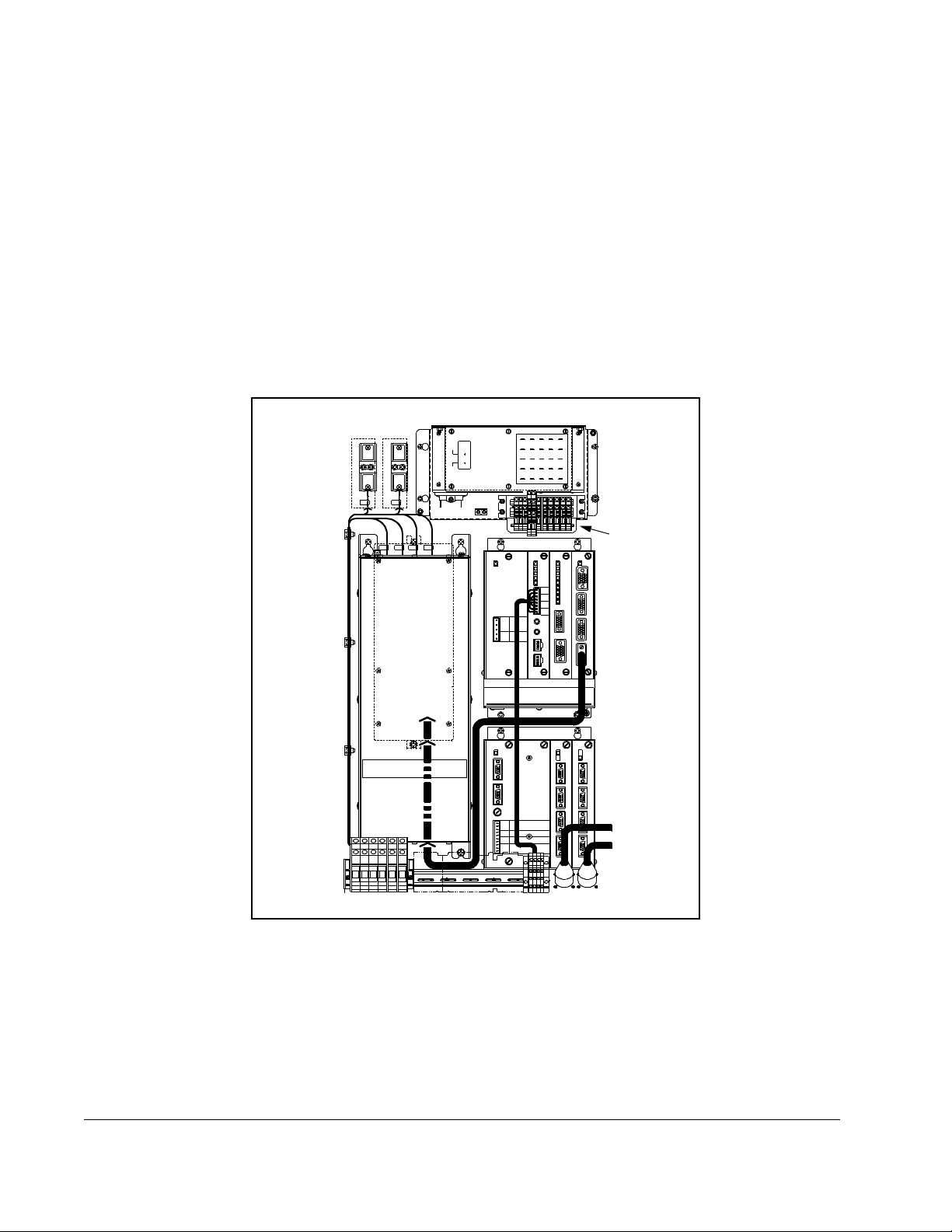

2.5.1 3000A Power Module Component Layout

F51

*

L1A L2A L3A

SP1

FU-B

FU-A

F15

F14

F16

F14 F15

FIELD

SUPPLY

CB11*

SP2

SP3

SCALING

UNIT

or

F52*

SP4

F53*

ACT3ACT1

F1, F2,

F3

TB1

PMI

RACK

PGA

RACK

F10

F11

F12

S1

A14R

A11F

A16R

A13F

F8

F7

F9

S1A S2A

A11R

A14F

A13R

A16F

PP3PP2PP1

M1

S2

PP6PP5PP4

A12R

A15F

S3

R1

MP

∗

F27

F28

F29

∗

∗

F17

F18

F19

∗

M11 M12

S3A

A15R

A12F

FAN1

A2(-) A1(+)

2-18

TB2

TB3

FAN2-C1

TB4

FAN2

TB5

TB6

FWD REV

PT2

'LVFRQQHFW %D\ )XVH %D\ %ULGJH %D\ &RQWDFWRU %D\

Figure 2.9 – 3000A Power Module Component Layout

SD3100 Power Modules

Page 33

Table 2.6 – 3000A Power Module Symbol-to-Component Reference

Symbol Description Option 460 VAC 575 VAC 660 VAC

A1(+), A2(-) Armature outputs

A11F - A16F Armature pulse transformer PCB

A11R - A16R Armature pulse transformer PCB

ACT1, ACT3 Line current transducer 5000:1

CB11 Circuit breaker ∗ 3000A, SPB-fram e

F51 - F53 AC line fuses ∗ 3000A, KRPC

FAN1 Armature bridge fan 1850 CFM

FAN2 Slide-fan 1589 CFM

FAN2-C2 Fan capacitor 40µF

F1, F2, F3 Control branch/feedback PCB fuses 1A KTK 1A KTK 10A A70P

F7 - F12 Armature bridge cell fuses

F14, F15

Control power transformer, primary

fuses

$ 9 0

$ ./'5 9

10A, 1500V

Form 101-Type 4

F16 Control power xfmr, secondary fuse 9A KLDR, 600V

F17 - F19,

F27 - F29

FU-A, FU-B

Blower motor fuses ∗

External field isolation

transformer fuses

15A unit: 30A, 700V

60A unit: 100A, 700V

FWD Forward gate connector

REV Reverse gate connector

M1 DC armature contactor 3000A

M11, M12 Blower motor starters ∗

MP Main pilot for pilot relay

PP1 - PP6 Armature power poles

PT2 Control transformer 2kVA

R1 M1 suppressor resistor 1k Ω, 50Ω

SP1 - SP3 Line-to-line MOVs 460J, 320VAC 550J, 385VAC 600J, 420VAC

SP4 Neutral-to-ground MOV 760J, 680V AC 760J, 680VAC 1050J, 750VAC

TB1 Armature feedback terminal block

TB2 Field terminal block

TB3 Control power terminal block

TB4 Drive I/O terminal block

TB5 Resolver feedback ter mi nal block

TB6 Meter ports connector

Mechanical/Electrical Description

2-19

Page 34

2.5.2 3000A Power Module Dimensions

20 inches

(508 mm)

91.5 inches

(2324 mm)

2-20

20 inches

(508 mm)

20 inches

(508 mm)

20 inches

(508 mm)

35 inches

(889 mm)

20 inches

(508 mm)

20 inches

(508 mm)

Figure 2.10 – 3000A Power Module Dimensions

For other details on the 3000A Power Module and its components, please refer to the

appendices of this manual.

SD3100 Power Modules

Page 35

C

HAPTER

3

Installation Guidelines

ATTENTION:

operation of this equipment and the hazards involved should install,

!

This chapter describes the guidelines and wiring recommendations to be followed

when installing SD3100 DC Power Modules. Additional information on installing

SD3100 drives can be found in the instruction manuals listed in tables 1.3 and 1.4 on

page 1-4 of this manual.

The installation of the Power Module can be broken down into the following tasks:

•

physically installing the unit

•

wiring AC power into the Power Module

•

wiring DC power out to the motor armature and field

•

grounding the drive

•

installing feedback devices

Note that System wiring is to be done according to the supplied wiring diagrams

(W/Es), which are application-specific.

adjust, operate, or service this equipment. Read and understand this

manual and other applicable manuals in their entirety before proceeding.

Failure to observe this precaution could result in severe bodily injury or

loss of life.

Only qualified personnel familiar with the construction and

Installation Guidelines

3.1 Planning the Installation

Use the following guidelines when planning your Power Module installation:

•

Verify that the selected site will provide sufficient ventilation for the Power Module.

The Power Module’s fan pulls in air from the bottom of the chassis and exhausts it

from the top. The ambient temperature must remain between 0 and 40° C (32 to

131° F).

•

Be sure surrounding components do not block service access to the Power Module.

•

Verify that the relative humidity will be between at 5 and 95% (non-condensing).

•

Do not install the Power Module above 1000 meters (3300 ft) without derating. See

figure A.1, Altitude Derating Chart, in Appendix A.

Refer to figure 2.6 (1250A units), figure 2.8 (1650A units), or figure 2.10 (3000A units)

for Power Module dimensions.

3-1

Page 36

3.2 Physically Installi ng the Power Module

ATTENTION:

incoming AC power. Disconnect, lock out, and tag all incoming power to

!

To move and position the unit at your site, follow the instructions given in publication

2100-5.5, titled

This publication contains instructions for the proper handling, moving, and positioning

of the Power Module.

After the Power Module is properly positioned, follow the instructions given in

publication 2300-5.1, titled

publication describes how to splice busbars, how to attach the Power Module in a

multiple drive configuration, and how to join MCC sections together (if necessary).

the drive before performing the following procedures. Failure to observe

this precaution could result in severe bodily injury or loss of life.

Instructions - Receiving, Handling, And Storing Motor Control Centers

The Power Module is at line voltage when connected to

Bulletin 2300 Family of Drive Systems Hardware

3.3 Wiring AC Input Power to the Power Modul e

ATTENTION:

local, national, and international codes. Failure to observe this precaution

!

To wire AC input power to the Power Module, you will need to do the following:

could result in damage to, or destruction of, the equipment.

The user is responsible for conforming with all applicable

.

. This

•

install an isolation transformer

•

select and provide appropria te inpu t power wire

•

prepare the drive enclosure

•

connect the input power

Take precautions to separate AC and DC power leads from signal leads, such as

resolver or tach wiring, to minimize electromagnetic interference. Wiring should

comply with ANSI/IEEE Standard 518. Follow the instructions on separating wiring

found in the wiring diagrams and in instruction manual D2-3115.

Refer to figure 2.5 (1250A units), figure 2.7 (1650A units), or figure 2.9 (3000A units)

for component and terminal locations.

3.3.1 AC Input Wire Selection

Table 3.1 shows the recommended AC input wiring. Note that this table reflects

NFPA 70, 75° C wiring. Refer to the applicable local codes for specific guidelines.

Table 3.1 – Recommended AC Input Wiring

DC Bus Current

(Amps)

1250 4-500 kcmil

1650 5-500 kcmil

3000 8-500 kcmil

Incoming Wires

(For Each Phase or Connection, AWG)

3-2

SD3100 Power Modules

Page 37

3.3.2 Making an Input Entry Hole

If your Power Module has an extra input bay installed, proceed as follows. If your

Power Module will have a top-hat enclosure over the disconnect bay, mount the

top-hat enclosure before continuing.

To make an input entry hole, select the ideal hole placement (within the constraints

shown in figure 3.1), then perform the steps that follow.

The width allowed is 2.28 inches

shorter than your cabinet's width, as

shown.

Cabinet Width Width of Area

20.00" (508 mm) 17.72" (450 mm)

25.00" (635 mm) 22.72" (577 mm)

30.00" (762 mm) 27.72" (704 mm)

35.00" (889 mm) 32.72" (831 mm)

c

Figure 3.1 – Area Available f or Conduit Entry (Top View of Leftmost Bay)

1.25"

11.50" •

1.14"

3000A units allow a depth of 16.75" for conduit entry.

20.00"

(Back of Enclosure)

Area Available For

Conduit Entry

20.00"

17.72"

(Front of Enclosure)

Step 1. Remove the lifting angle, if it is still attached.

Step 2. Remove the top plate from the disconnect bay (or from the top-hat

enclosure).

Step 3. Punch hole(s) for the AC input entry within the area shown in figure 3.1.

Installation Guidelines

Step 4. Replace the top plate on the drive.

Step 5. Replace the lifting angle.

3.3.3 Connecting the AC Input Wires to the Busbars

Use the following procedure to connect the input wires to the input busbars in the

disconnect bay. Refer to Appendix A for busbar specifications.

Step 1. Thread the input wires through the entry hole on the top of your drive.

Step 2. Fasten the input wires for each phase onto the appropriate phase busbar

(see the busbar illustrations shown in Appendix A).

Step 3. Torque all bolts to 45 lb-ft.

3-3

Page 38

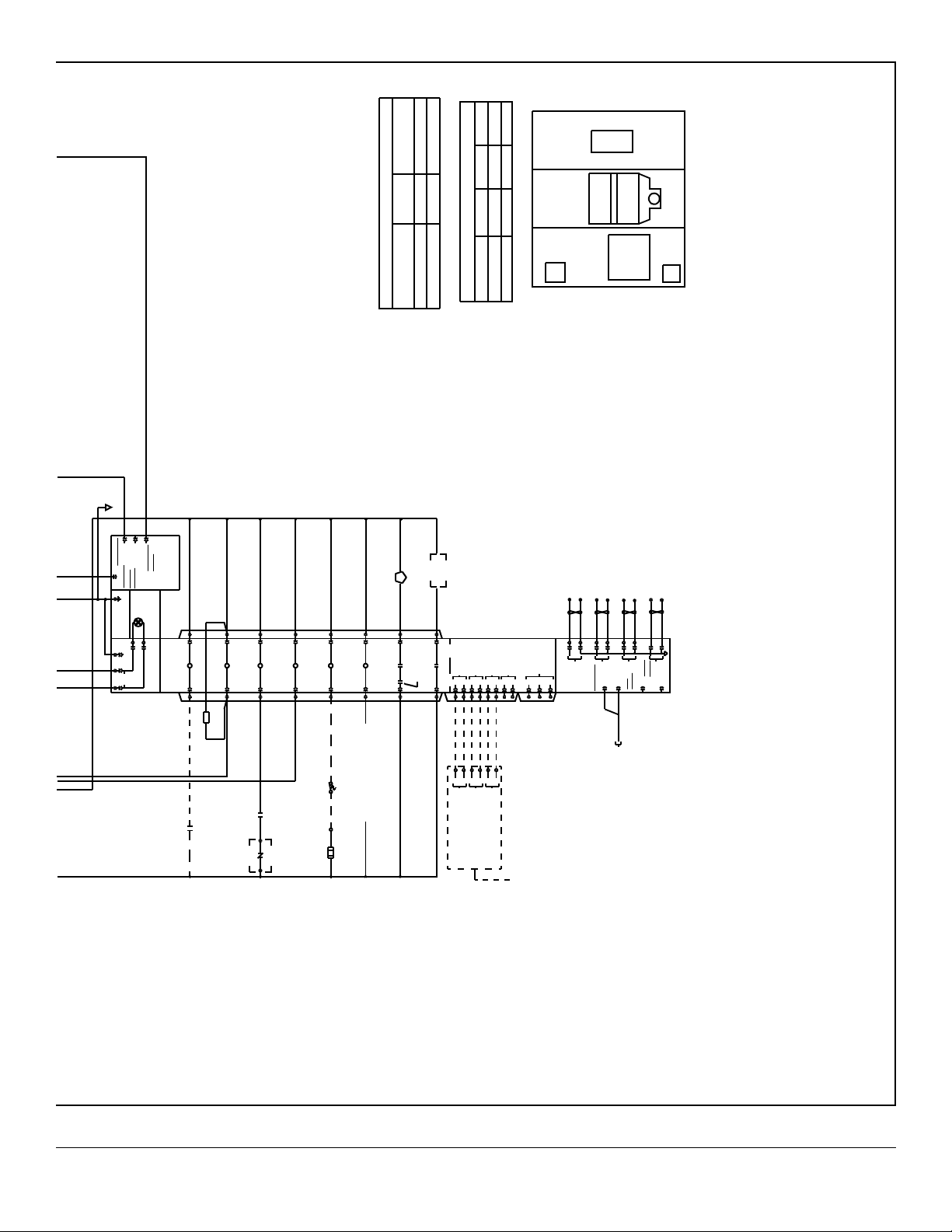

3.4 Wiring AC Input to the Field Power Module

AC power connections to the single-phase Field Power Module are made to terminal

block TB2 at the bottom left of the control compartment. Phase control for the Field

Power Module is determined by the PMI Regulator, which also controls phasing for the

armature power devices. The Field Power Module’s AC input terminals must be

connected to AC input lines L1 and L3 through an isolation transformer. Terminal block

TB2 has been provided for these connections.

3.4.1 Installing the Field Isolation Transformer

The field isolation transformer should be installed at an appropriate location external

to the Power Module, and in conformance with the NEC/CEC and all applicable local,

national, and international codes. The transformer’s input fuse ratings and required

minimum wire sizes for use with the Field Power Module are listed in table 3.2.

Table 3.2 – Isolation Transformer Wiring Requirements

Field Power Module

(Amps)

Isolation Transformer Fuse

Rating (Maximum Amps)

Minimum Required

Wire Size (AWG)

15 30 #10

60 100 #4

Wire the field isolation transformer as shown in figure 3.2. Connect terminal 31 on TB2

to H2 on the field isolation transformer and terminal 30 to H1. Connect X1 to terminal

L1A and X2 to terminal L3A.

Important:

The isolation transformer must be connected to terminal block TB2 as

shown in figure 3.2. Improper drive regulation and/or fuse clearing may

result if the Field Power Module’s AC inputs are incorrectly wired.

31

TERMINAL

BLOCK

TB2

TO MOTOR

FIELD

37

35

+

–

30

L1A

L3A

3-4

H1

FIELD

ISOLATION

TRANSFORMER

X1

Figure 3.2 – Field Terminal Wiring

H2

X2

SD3100 Power Modules

Page 39

3.5 Wiring the Motor

To wire DC power to the motor, you will need to do the following:

•

select appropriate wires for the armature and field lines

•

connect the motor armature and motor field to the Power Module

Refer to your motor’s installation manual for additional information.

3.5.1 Selecting Wires for the Armature and Field Lines

ATTENTION:

local, national, and international codes. Failure to observe this precaution

!

Refer to table 3.3 for the wire to be used for armature connection and to table 3.4 for

the wire to be used for the field connection.

Power Module Rating

could result in damage to, or destruction of, the equipment.

DC Bus Current

(Amps) Output Wires (AWG)

1250 5-500 kcmil

1650 6-500 kcmil

3000 10-500 kcmil

1250A 10 #4

1650A 10 #4

3000A 10 #4

The user is responsible for conforming with all applicable

Table 3.3 – Armature Wire Selection

Table 3.4 – Field Wire Selection

Output Wires (AWG)

(15 Amp Field)

Output Wires (AWG)

(60 Amp Field)

Installation Guidelines

3.5.2 Connecting the Motor to the Power Module

To connect the motor to the Power Module perform the following steps:

Step 1. Connect the Power Module’s armature outputs, A1(+) and A2(-), to the

motor’s armature leads, A1 and A2. Refer to figure 2.5 (1250A units), figure

2.7 (1650A units), or figure 2.9 (3000A units).

Step 2. Connect the Field Power Module outputs, terminals 37 (+) and 35 (-), to the

motor’s field leads, F1 and F2. Refer to figure 3.2.

Note that for counter-clockwise rotation, connect output A1 to motor lead A1 and

output A2 to motor lead A2. Connect terminal 37 to lead F1 and terminal 35 to

lead F2.

For alternative wiring configurations, please check the motor’s installation manual.

3-5

Page 40

3.6 Installing Feedback Devices

All feedback devices interface to the SD3100 Power Module through the PMI

Regulator. Terminal blocks TB4 and TB5 at the bottom of the control compartment

provide the connections for drive I/O, analog input, and the resolver, as shown in

figures 3.3 and 3.4. Selection and installation of feedback devices is described in the

PMI Rack and Modules instruction manual (S-3008). Please refer to S-3008 when

installing feedback devices.

TB4

39785

412

2

1

3579

6

11

10 12 14 16

864

11 13 15

13 15

16141210

Terminal Signal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

RPI (HI)

RPI (LO)

AUX IN 1 (HI)

AUX IN 1 (LO)

AUX IN 2 (HI)

AUX IN 2 (LO)

AUX IN 3 (HI)

AUX IN 3 (LO)

AUX IN 4 (HI)

AUX IN 4 (LO)

AUX IN 5 (HI)

AUX IN 5 (LO)

MCR (HI)

MCR (LO)

AUX OUT (HI)

AUX OUT (LO)

Figure 3.3 – Drive I/O Connections (TB4)

TB5

1

2

3

2

3

1

Analog

Input:

1 (+)

2 (–)

3 GND

56341

7

2

8

2468

1357

Resolver Input:

1 (+) Reference

2 (–) Output

3 (+) Sine

4 (–) Input

Note:

7,8 Not used

5 (+) Cosine

6 (–) Input

Figure 3.4 – Resolver and Analog Input Connections (TB5)

3-6

SD3100 Power Modules

Page 41

3.7 Meter Port Connections

2468

1357

1357

2468

Terminal

1

2

3

4

5

6

7

8

+

COM

+

COM

+

COM

+

COM

Port 1

Port 2

Port 3

Port 4

TB6

}

}

}

}

Terminal block TB6 at the bottom of the control compartment contains four analog

output ports, as shown in figure 3.5. Each port can be connected to a separate analog

device (e.g., a meter or other data-logging device). The meter port output circuit is

described in the PMI Rack and Modules instruction manual (S-3008). Meter port

configuration is described in the Drive Configuration and Programming instruction

manual (S-3006). Please refer to these two manuals for further information on using

the meter ports. If not configured, the ports default to “not used” and output zero volts.

Installation Guidelines

Figure 3.5 – Meter Port Connections (TB6)

3.8 Grounding the Drive

ATTENTION:

the drive’s ground terminals to earth ground using properly-sized ground

!

wires. Failure to observe this precaution could result in severe bodily

injury or loss of life.

To properly ground the drive, all of the following components of the system must be

grounded:

•

safety ground (PE) to building steel or floor ground loop

•

signal ground (TE) to zero potential bus

•

power feeder

•

motor connections

•

resolver connections

The TE and PE busbars run through the bottom of the drive’s enclosure. The

grounding conductors must be supplied by the user and must be adequately sized in

accordance with NEC/CEC and all applicable local, national, or international codes.

Important:

The TE and PE conductors must be separated by a minimum distance of

20 feet within the user facility.

Ungrounded equipment presents a shock hazard. Connect

3-7

Page 42

Note that the TE signal ground is not used by the SD3100 drive’s control components,

but may be used by other drives in the lineup.

Figure 3.6 shows the typical grounding of the SD3100 drive.

SD3100 Drive Enclosure

Control Xfmr

To control components

on other drives

To Bldg

Steel

Ground Rod or Grid

(only one grounding point

per system)

Figure 3.6 – SD3100 Grounding

X2

TE

PE

Motor

3.9 For Information on Initial Start-Up of the Drive

ATTENTION:

operation of this equipment and the hazards involved should install,

!

adjust, operate, or service this equipment. Read and understand this

manual and other applicable manuals in their entirety before proceeding.

Failure to observe this precaution could result in severe bodily injury or

loss of life.

Instruction manual S-3011,

Troubleshooting, and Start-Up Guidelines

precautions that should be taken when first powering up the SD3100 drive. Please

refer to the appropriate sections of this manual when starting up your drive.

Only qualified personnel familiar with the construction and

Distributed Power System SD3000 Diagnostics,

, describes the procedures to follow and the

3-8

SD3100 Power Modules

Page 43

C

HAPTER

4

Maintenance and Troubleshooting

ATTENTION:

to the Power Module. All phases of the AC power line and control power

!

Routine maintenance should include the periodic checking of all electrical power

connections into and out of the Power Module. The Power Module, its enclosure, and

the PMI rack should be kept clean. Any air filters should be checked and cleaned or

replaced as needed. Adequate cooling air must be provided to the Power Module

whenever the unit is operating.

must be disconnected from the Power Module before it is safe to touch

any internal parts of this equipment. Failure to observe this precaution

could result in severe bodily injury or loss of life.

ATTENTION:

VWDWLFVHQVLWLYH 'R QRW WRXFK WKH ERDUGV© FRPSRQHQWV FRQQHFWRUV RU

OHDGV )DLOXUH WR REVHUYH WKLV SUHFDXWLRQ FRXOG UHVXOW LQ GDPDJH WR

HTXLSPHQW

Equipment is at line voltage when AC power is connected

7KH 3RZHU 0RGXOH FRQWDLQV SULQWHG FLUFXLW ERDUGV WKDW DUH

4.1 Recommended Test Equipment

ATTENTION:The Power Module’s common is not isolated from earth

ground. The test instruments used to measure power module signals

!

An oscilloscope can be used to check the current feedback and the output voltage

waveform. An isolated or portable volt/ohmmeter is also needed for continuity and

ground checks and to test output voltage.

must be isolated from ground through an isolation transformer unless

they are battery powered. Failure to observe this precaution could result

in bodily injury.

The oscilloscope should have an impedance of at least 8 M ohms, a 1:10 probe for

signal circuits, and a 1:100 probe for power circuits. An ungrounded oscilloscope with

differential inputs and two 1:10/1:100 probes is recommended. All measuring devices

that are AC line powered must be connected through an isolation transformer. There

must be no ground connection through the transformer.

Maintenance and Troubleshooting

ATTENTION:

OHDGV DUH GLVFRQQHFWHG EHWZHHQ WKH URWDWLQJ HTXLSPHQW DQG WKH GULYH

!

7KLV ZLOO SUHYHQW GDPDJH WR HOHFWURQLF FLUFXLWU\ 3RZHU 0RGXOHV DQG WKHLU

DVVRFLDWHG FLUFXLWU\ HWF GXH WR WKH KLJK YROWDJH JHQHUDWHG E\ WKH

PHJJHU )DLOXUH WR REVHUYH WKLV SUHFDXWLRQ FRXOG UHVXOW LQ GDPDJH WR RU

GHVWUXFWLRQ RI WKH HTXLSPHQW

,I D PHJRKPPHWHU PHJJHU LV XVHG PDNH FHUWDLQ WKDW DOO

4-1

Page 44

The Power Module may be checked with an ohmmeter for continuity and grounds. Do

not test the Power Module or associated circuitry with a megohmmeter (megger).

Disconnect all leads to the motor if the motor is to be ground-checked with a megger.

Failure to follow proper procedure when using a megger may cause damage to the

Power Module.

4.2 System Diagnostics

Operation of the Power Module is monitored by the PMI Processor. Fault and warning

registers (202/1202 and 203/1203) in the UDC must be used when the system detects

a fault or a warning.

The fault conditions reported in the Drive Fault register result in turning off the drive.

The UDC task is not stopped automatically when a drive fault occurs unless it is

specifically instructed to do so in an application task. The user must ensure that the

AutoMax application task tests register 202/1202 and takes appropriate action if a

fault occurs.

The warnings indicated by the Drive Warning register cause no action by themselves.

Any resulting action is determined by the application task. The user must ensure that

the AutoMax application task monitors register 203/1203 and takes appropriate action

if any of these conditions occurs.

The user should refer to instruction manual S-3006 (SD3000 Drive Configuration and

Programming) for further details on the Drive Fault and Drive Warning registers.

4.2.1 Power Module Faults

The following Power Module faults will cause the drive to shut down by commanding

zero current and stopping the firing of the SCRs. Most faults are signaled by an LED

indicator on the PMI Processor module. The bits in the Drive Fault register (202/1202)

should be examined to determine the cause of the fault. When a fault occurs the

identifying bit will be set. The fault will also be recorded in the error log for the UDC

task in which it occurred.

4.2.1.1 Shorted SCR Fault (Bit 0)

LED indicator: PM FLT

UDC Error Code: 1000

The PMI Processor will not be permitted to enter the run mode if a shorted SCR is

detected. Check register 204/1204 to identify the SCR that has shorted. Refer to

Instruction Manual S-3006.

4.2.1.2 AC Line Synchronization Fault (Bit 3)

LED indicator: EXT FLT

UDC Error Code: 1003