Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

Distributed Power System

SA500 AC Power Modules

615055-1R (14 Amp)

615055-1S (28 Amp)

615055-1T (35 Amp)

615055-1V (48 Amp)

Instruction Manual

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

S-3018-1

Page 3

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

The thick black bar shown on the left margin of this paragraph will be used throughout this manual to signify

new or revised text or figures.

ATTENTION:Only qualified personnel familiar with the construction and operation of this

equipment and the hazards involved should install, adjust, operate, or service this equipment.

!

Read and understand this manual and other applicable manuals in their entirety before

proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:Only qualified Rockwell personnel or other trained personnel who understand the

potential hazards involved may make modifications to the rack configuration, variable

configuration, and application tasks. Any modifications may result in uncontrolled machine

operation. Failure to observe this precaution could result in damage to equipment and bodily injury .

A TTENTIO N:The user must provide an external, hardwired emergency stop circuit outside of the

drive circuitry. This circuit must disable the system in case of improper operation. Uncontrolled

machine operation may result if this procedure is not f ollowed. Failure to observe this precaution

could result in bodily injury.

ATTENTION:Registers and bits in the UDC module that are described as “read only” or for “system

use only” must not be written to by the user. Writing to these registers and bits may result in

improper system operation. Failure to observe this precaution could result in bodily injury.

ATTENTION:For brushless motor applications, changing any resolver wiring, breaking the

resolver coupling, replacing the resolver, or replacing the motor and resolver for any reason

requires that the shaft alignment test be performed again. Resolv er wiring changes always affect

shaft alignment. A resolver change and/or a new motor/resolver combination will affect the shaft

alignment. Improper shaft alignment can cause motor ov erspeed when the motor is started. Failure

to observe this precaution could result in bodily injury.

ATTENTION:The Power Module contains static-sensitive parts and assemblies. When not

installed in the P ower Module, components should be stored in anti-static bags. F ailure to observe

this precaution could result in damage to, or destruction of, the equipment.

ATTENTION:The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

The information in this user’s manual is subject to change without notice.

AutoMax™ is a trademark of Rockwell Automation.

©1998 Rockwell International Corporation

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

Chapter 1 Introduction

1.1 Distributed Power System (DPS) Overview ....................................................1-2

1.2 SA500 Drive Overview .................................................................................... 1-3

1.3 Related Publications........................................................................................1-4

Chapter 2 Power Module Mechanical Description

2.1 LED Indicators.................................................................................................2-3

2.2 Power Module Faceplate Connectors .............................................................2-6

2.2.1 Fiber-Optic Ports ...................................................................................2-7

2.2.2 Rail Ports...............................................................................................2-7

2.2.3 Resolver Feedback Connect or........................................ ....... ...... ....... .. 2-8

2.2.4 Drive I/O Connector ............................................................................2-10

Chapter 3 Power Module Electrical Description

3.1 Power-Up Routine ........................................................................................... 3-1

3.2 DC-to-DC Converter........................................................................................3-2

3.3 Resolver Interface ........................................... ....... ...... ....... ...... ....... ...... ....... .. 3-2

Chapter 4 Installation Guidelines

4.1 Wiring and Grounding...................................................................................... 4-1

4.2 Power Module Installation ...............................................................................4-1

4.3 Fiber-Optic Connection....................................................................................4-6

4.4 Drive I/O Connections ..................................................................................... 4-6

4.5 Rail Port Connection........................................................................................4-8

4.6 Resolver Feedback Connect ion ............................. ...... ....... ...... ....... ...... .........4-8

4.6.1 Resolver Input Connections ............................................ ....... ...... ....... 4-10

4.6.1.1 Resolver Calibration....................................................... ....... 4-11

4.6.1.2 Resolver Alignment........................ ...... .................................4 -12

4.6.1.3 Resolver Feedback Precauti on s ........................................... 4-13

4.6.2 Analog Input........................................................................................4-14

4.7 Constant Power Calibration........................................................................... 4-14

4.8 Power Module Replacement .........................................................................4-17

C

ONTENTS

Chapter 5 Diagnostics and Troubleshooting

Appendix A Technical Specifications...........................................................................................A-1

Appendix B Brushless Industrial Motor Data and Curves............................................................B-1

Appendix C Custom DC Bus Supplies .........................................................................................C-1

Appendix D UDC Register Cross-Reference ...............................................................................D-1

Table of Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5.1 Drive Faults (UDC Register 202/1202)............................................................ 5-1

5.2 Power Module Warnings (UDC Register 203/1203)........................................ 5-3

5.3 Power Module Failure......................................................................................5-4

I

Page 5

Appendix E Status of Data in the AutoMax Rack After a

STOP_ALL Command or STOP_ALL Fault.............................................................E-1

Appendix F PMI Regulator Block Diagram.................................................................................. F-1

Appendix G Power Circuitry Block Diagram ................................................................................G-1

Appendix H Compliance with Electromagnetic Compatibility Standards.....................................H-1

Appendix I SA500 Power Module Output Current Overload Ratings...........................................I-1

Index ...........................................................................................................................Index-1

II

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

SA500 Power Modules

Page 6

List of Figures

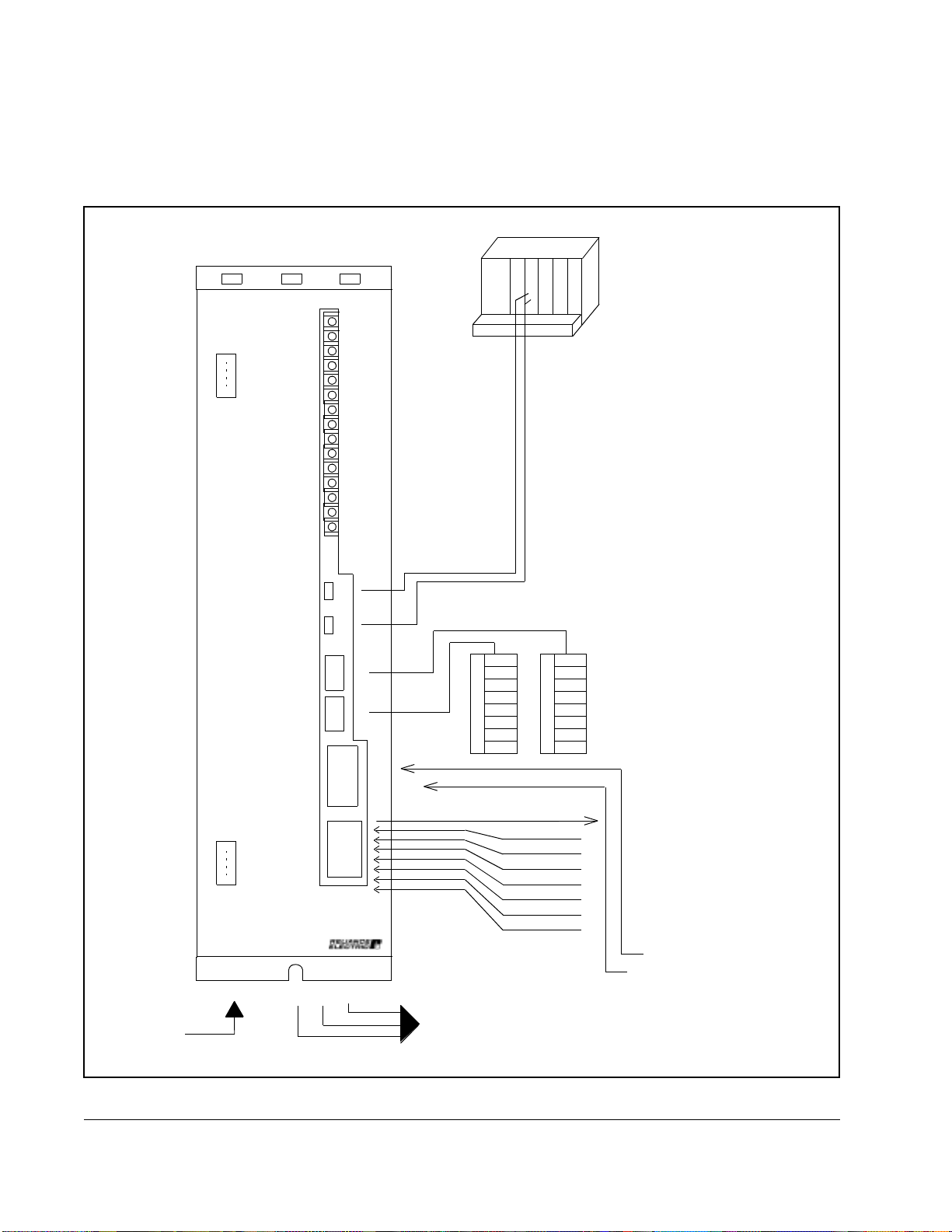

Figure 1.1 – SA500 Drive Hardware Configuration ..................................................1-2

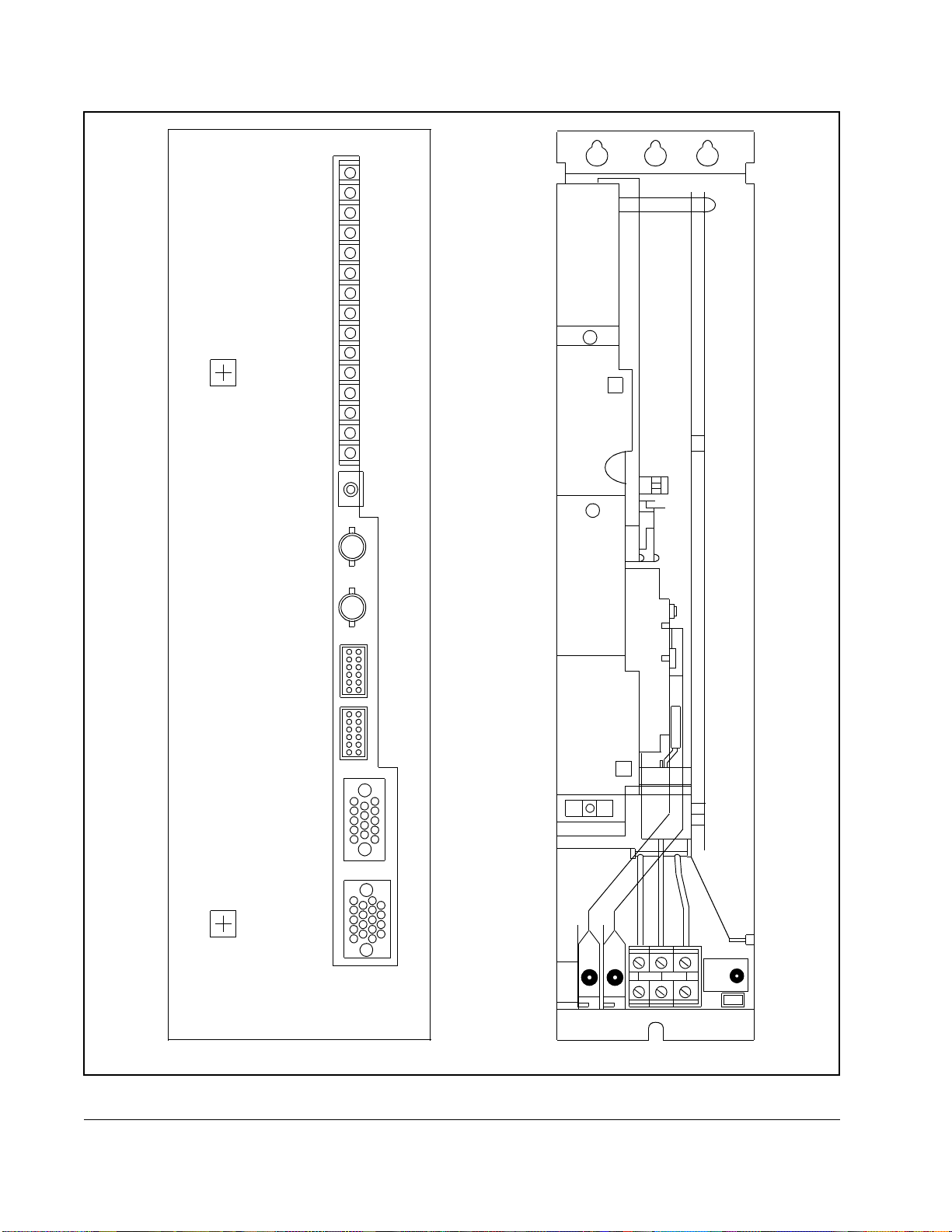

Figure 2.1 – SA500 Power Module With Cover and Without Cover ......................... 2-2

Figure 2.2 – Power Module External Connectors.....................................................2-6

Figure 2.3 – Location of Rail Fuse on PMI Regulator PC Board .............................. 2-8

Figure 2.4 – Resolver Feedback Connector Pinout.................................................. 2-9

Figure 2.5 – Analog Input Circuit............................................................................ 2-10

Figure 2.6 – Drive I/O Connector Pinout.................................................................2-11

Figure 2.7 – Auxiliary Input Circuit.......................................................................... 2-11

Figure 2.8 – Run Permissive Input (RPI) Circuit..................................................... 2-12

Figure 3.1 – Resolver Data Format (12-Bit Mode)....................................................3-2

Figure 3.2 – Resolver Data Format (14-Bit Mode)....................................................3-3

Figure 3.3 – External Strobe Input Circuit.................................................................3-3

Figure 3.4 – External Strobe Input Circuit Timing Diagram ...................................... 3-4

Figure 4.1 – Power Module Mounting Dimensions...................................................4-3

Figure 4.2 – DC Bus Supply Wiring..........................................................................4-5

Figure 4.3 – Terminal Block Connections for Drive I/O ............................................4-7

Figure 4.4 – Terminal Block Connections for Resolver and Analog Input................ 4-9

Figure 4.5 – Typical Motor Operation in the Constant Torque and

Constant Power Regions....................................................................4-15

Table of Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

III

Page 7

IV

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

List of Tables

Table 1.1 – SA500 Power Modules.......................................................................... 1-1

Table 1.2 – SA500 Documentation (Binder S-3002) ................................................1-4

Table 4.1 – Recommended Motor Wire Sizes..........................................................4-4

Table 4.2 – Rail I/O Instruction Manuals...................................................................4-8

Table 4.3 – Standard Resolver Connections..........................................................4-10

Table 4.4 – Recommended Resolver Cables.........................................................4-10

Table 4.5 – STATOR_IZ Tunable Values...............................................................4-16

Table of Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

V

Page 9

VI

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

C

HAPTER

1

Introduction

The AutoMax Distributed Power System SA500 AC Power Modules provide AC power

to, and control of, brushless motors and squirrel-cage induction motors from 1–15HP.

Each Power Module contains the Power Module Interface (PMI) Regulator printed

circuit board and the inverter used to convert DC power to AC power for the motor.

Depending upon their power requirements, up to six Power Modules can be

daisy-chained together and operated from one SA500 DC Bus Supply, which provides

the Power Modules a nominal 325 VDC input power. The DC Bus Supply is described

in instruction manual S-3017.

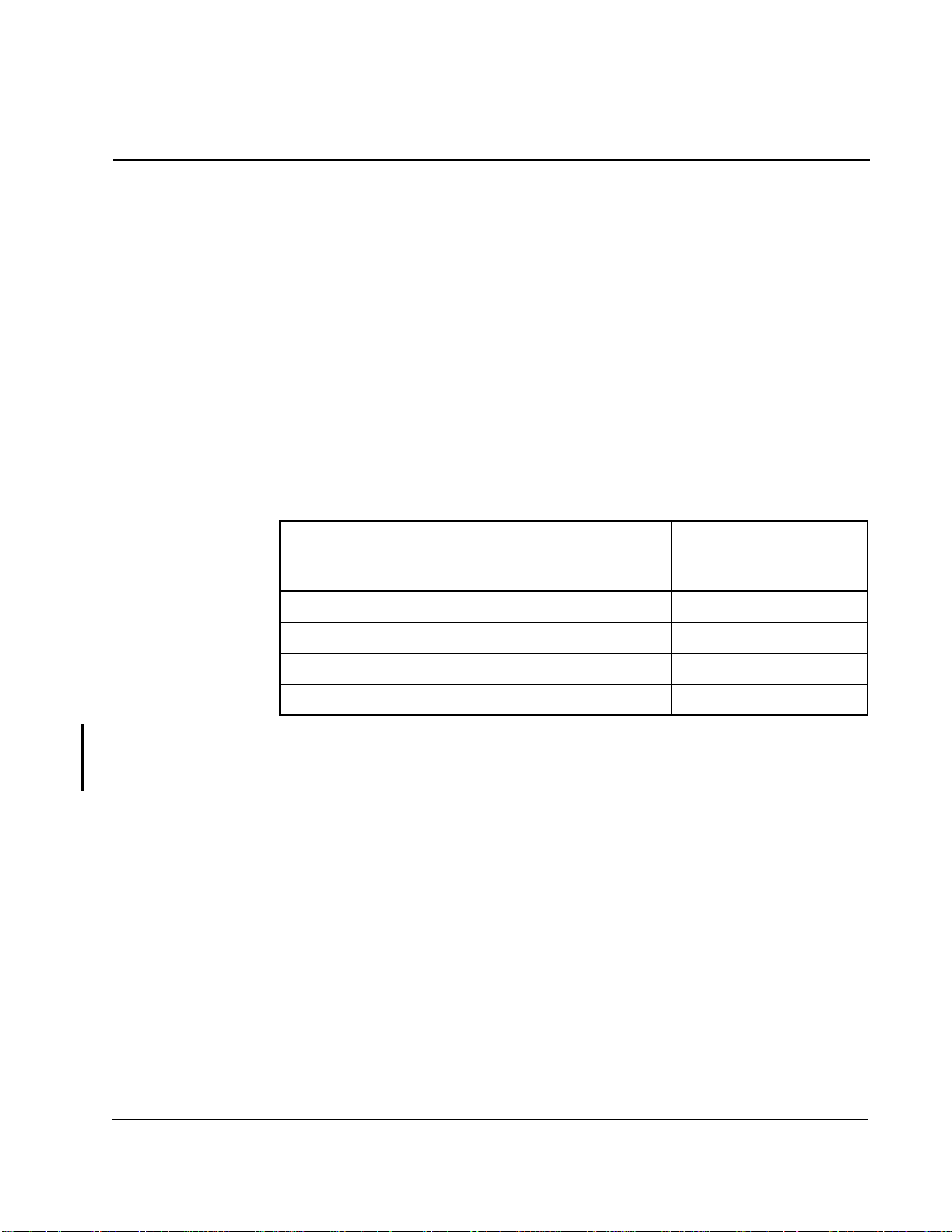

The SA500 Power Modules are available in four sizes with a range of current ratings to

complement the variety of motors available. See table 1.1 below.

Table 1.1 – SA500 Power Modules

Maximum Output

Current (RM S)

(0.5 seconds)

1

Part Number

Continuous Current

Rating (RMS)

615055-1R 14 A 17.5 A (125%)

615055-1S 28 A 35 A (125%)

615055-1T 35 A 70 A (200%)

615055-1V 48 A 106 A (220%)

1. Power Module output current overload rating charts are provided in Appendix I.

Power Module specifications are listed in Appendix A. Detailed speed-torque curves

and engineering data f or SA500 motors are included in Appendix B.

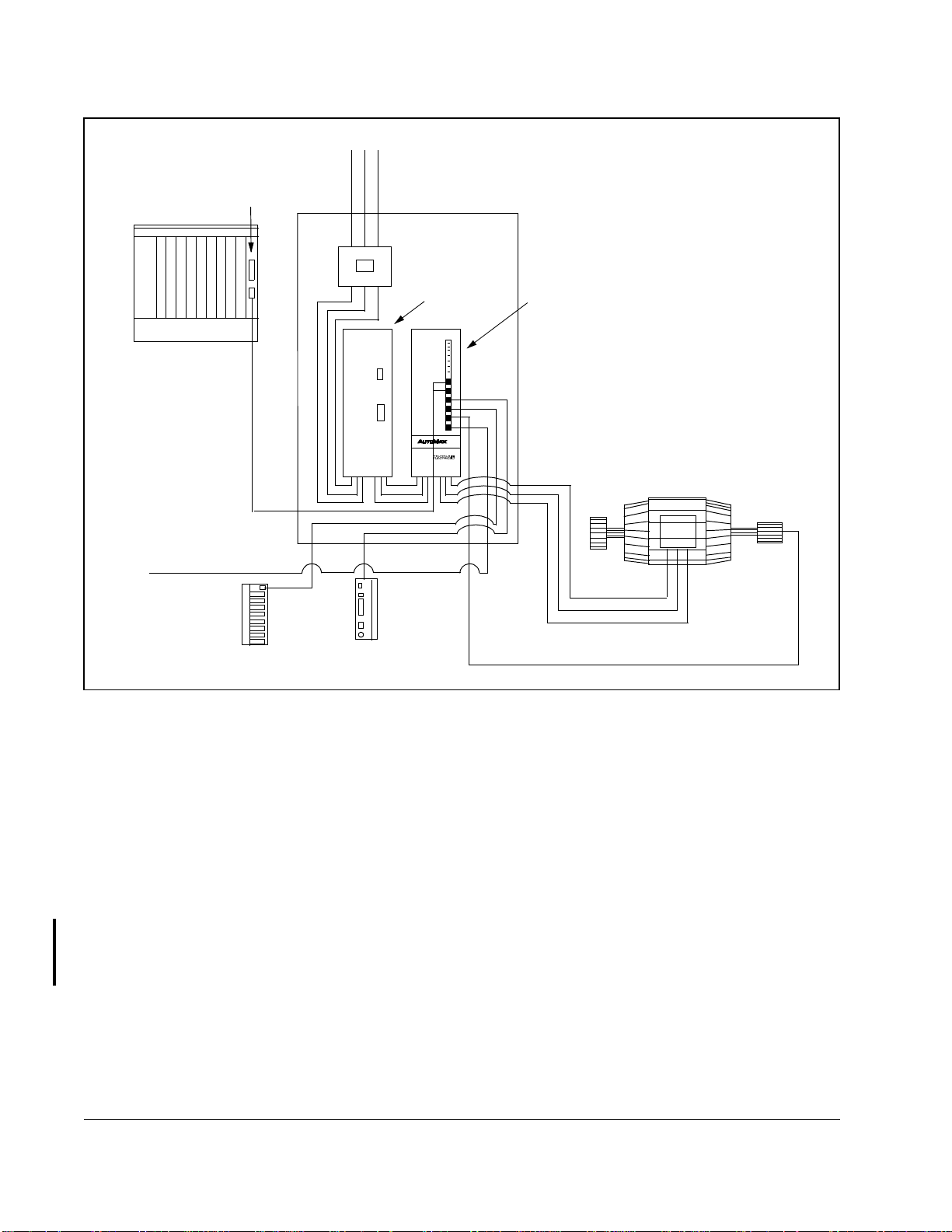

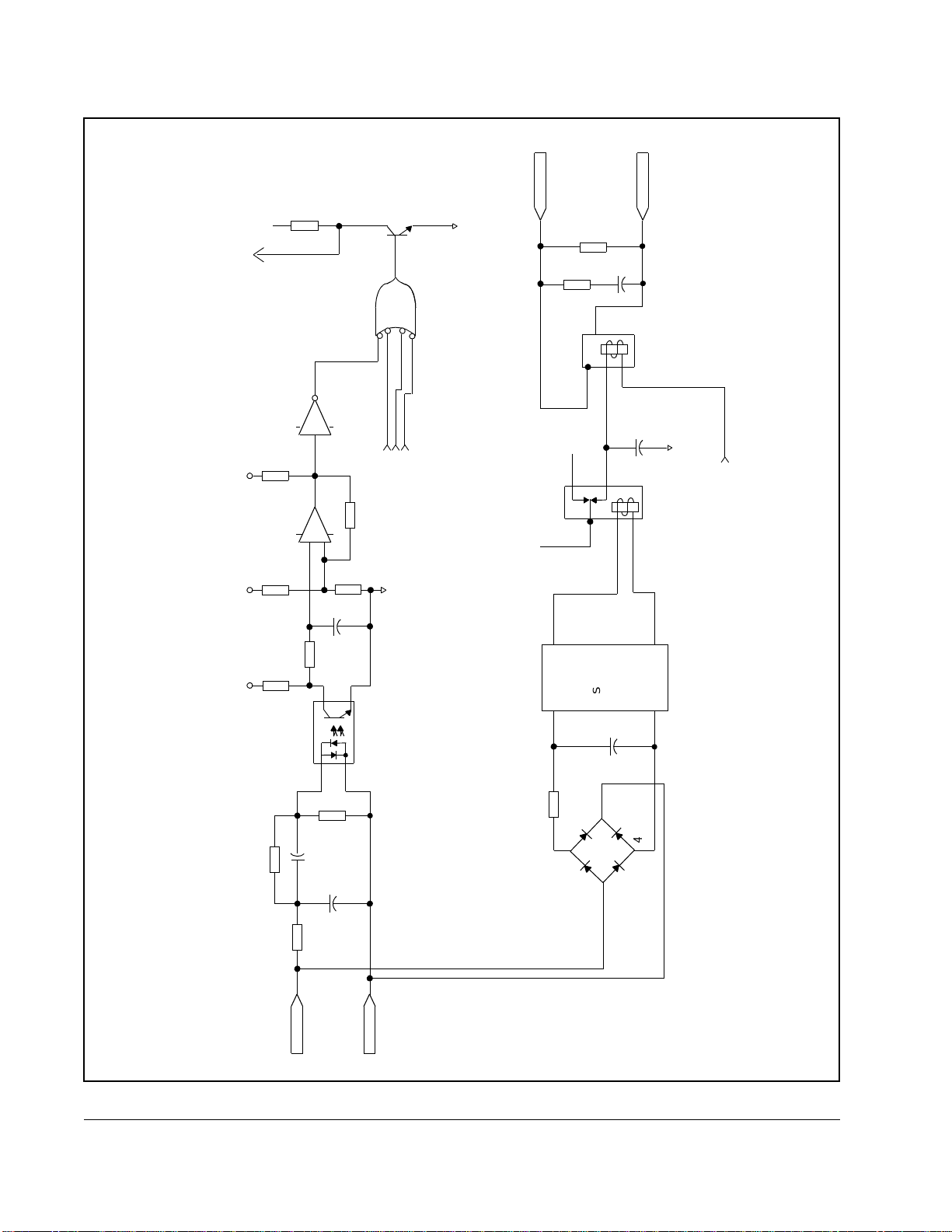

Figure 1.1 shows a typical SA500 drive configuration.

Introduction

1-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

Universal Drive

Controller Module

AutoMax Rack

Fiber-Optic Link

(up to 750 m)

Drive I/O

AC Line

SA500

DC Bus

Supply

SA500

Power

Module

Resolver

Motor

Digital Rail Analog Rail

Figure 1.1 – SA500 Drive Hardware Configuration

Resolver Fe edback

1.1 Distributed Power System (DPS) Overview

The SA500 is a member of the AutoMax Distributed Power System (DPS) family of

drives. DPS is a programmable microprocessor-based control system that is capable

of real-time control of AC and DC drives. Each Universal Drive Controller (UDC)

module (B/M O-57552) in the AutoMax rack allows the AutoMax Processor to control

up to two drives (20 maximum from one rack). The UDC module communicates over a

fiber-optic link with the PMI located in the SA500 Power Module. The Power Module

can be located up to 750 meters (2500 feet) from the AutoMax rack.

Each DPS drive is controlled by an application task running in the UDC module. All

programming and configuration of the SA500 drive is performed using the AutoMax

Programming Executive software. The SA500 drive requires version 3.4 or later of the

Programming Executive.

1-2

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

1.2 SA500 Drive Overview

An SA500 drive consists of a DC Bus Supply and a Power Module which supplies

three-phase AC power to an induction motor or a permanent magnet brushless motor .

The SA500 DC Bus Supply rectifies three-phase 230 VA C power to provide a constant

DC voltage for the Pow er Module. A three-phase bridge consisting of three SCRs and

three diodes controls the currents during charging of the DC bus capacitor. During

charging, the phase angle of the SCR firing is shifted as a function of time to control

the charging current.

The DC Bus Supply includes a braking circuit, consisting of a bi-polar transistor switch

and a resistor. A DC-to-DC converter within the Power Module senses the DC bus

voltage and switches the braking resistor across the DC bus if a preset threshold is

exceeded. If the capacity of the internal braking resistor is exceeded, the drive’s ability

to dissipate energy may be increased by using an external braking resistor. See

instruction manual S-3017 for more information.

Depending upon the power drawn by the individual Power Modules, the DC Bus

Supply can support up to six Power Modules, each powering one motor. If more than

six Power Modules need to be supplied by a common DC bus, if the capacity of the

DC bus is exceeded, or if the capacity of the braking circuit is exceeded, a

custom-designed DC b us supply may be used with the SA500 Power Modules. The

custom DC bus may be regenerative or non-regenerative. Energy storage capacitors

must be provided with the custom DC bus (or separately). See Appendix C for more

information.

The SA500 Power Module consists of the PMI Regulator (commonly referred to as the

PMI) and power circuitry to invert the DC bus voltage to three-phase 230 VAC for the

motor. The power bridge consists of six bipolar transistors (three dual-transistor

modules).

The PMI receives its operating system, all configuration data, and all commands

including the torque reference from a UDC module in the AutoMax rack via fiber-optic

cables. The PMI executes the torque control algorithm that controls the motor. The

control type is determined by the operating system contained in the PMI. There are

four types of control available: 1) vector, 2) brushless, 3) vector - speed loop

enhanced, and 4) brushless - speed loop enhanced. The operating system is selected

during UDC module configuration.

The UDC module executes the outer (major) control loops. The UDC task (task A or

task B, depending upon the fiber-optic port to which the Power Module is connected)

controls drive sequencing and the alignment of the resolver in brushless applications.

The UDC task provides the torque ref erence to the PMI and communicates with other

upper-level control tasks in the AutoMax rack.

The UDC module and the PMI are tightly synchronized through the fiber-optic link.

The PMI sends all feedback signals, including warning and fault information, speed

feedback, rail data, and gain data, to the UDC before each UDC task scan. Speed

feedback sampling in the Power Module is synchronized to within 1 µsec of the UDC

scan. The operating system in the PMI continuously performs diagnostic checks and

displays the results on the Power Module faceplate LEDs.

Introduction

The PMI also provides connections to digital and analog rails, as well as digital drive

I/O. The PMI scans the rail and drive I/O while the regulation algorithm is running. This

permits the I/O data to be integrated into the control algorithm as required.

1-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

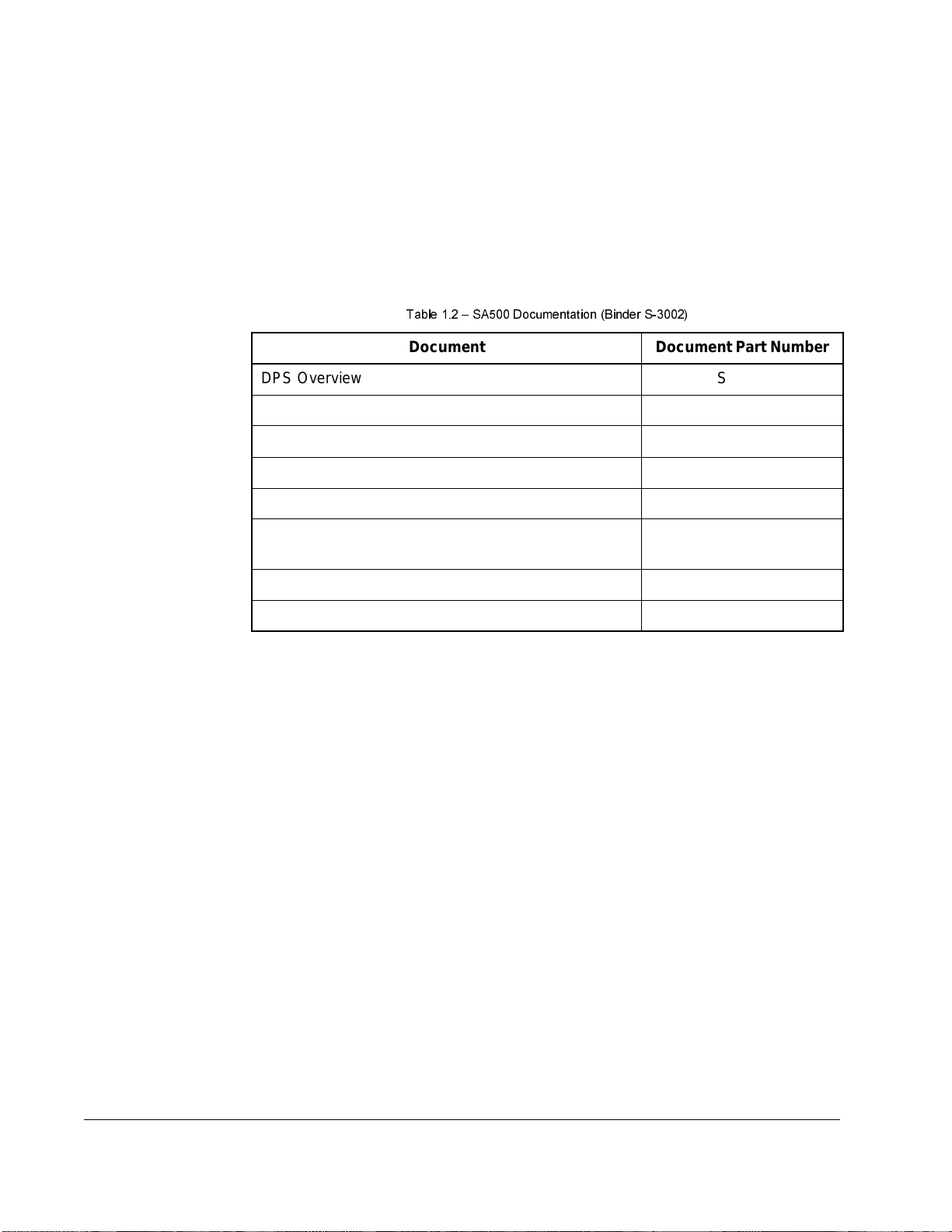

1.3 Related Publications

This instruction manual provides a description of the SA500 Power Module hardware.

Installation guidelines are also provided. Note that this instruction manual does not

describe specific applications of the standard hardware or software.

For more information, refer to the instruction manuals contained in the SA500 drive

binder, S-3002, as listed in table 1.2. It is assumed that the user is familiar with these

other manuals in S-3002 before installing, operating, or performing maintenance upon

SA500 Power Modules. Refer to these instruction manuals as needed.

:

7DEOH ¤ 6$ 'RFXPHQWDWLRQ %LQGHU 6

Document Document Part Number

DPS Overview S-3005

Universal Drive Controller Module S-3007

Fiber Optic Cabling S-3009

SA500 DC Bus Supply S-3017

SA500 AC Power Modules S-3018

SA500 Diagnostics, Troubleshooting, & Start-Up

S-3022

Guidelines

SA500 Information Guide S-3024

SA500 Drive Configuration & Programming S-3044

Additional information about using SA500 Power Modules is found in the other

instruction manuals, prints, and documents shipped with each drive system. Always

consult the prints shipped with the drive system for specific mounting and connecting

information about your drive.

1-4

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

C

HAPTER

2

Power Module Mechanical Description

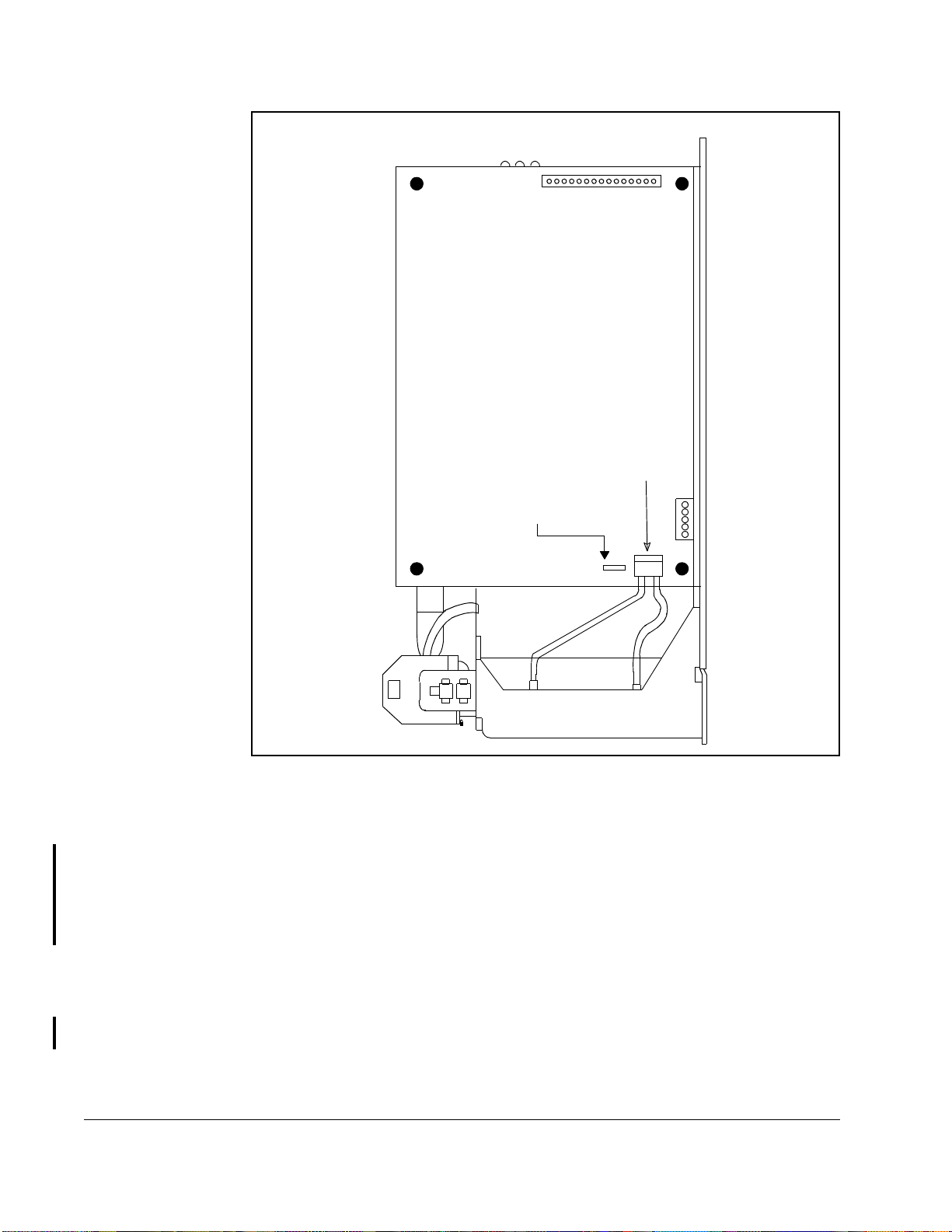

Power Modules of all four ratings are the same size, consisting of a sheet metal

enclosure, cooling fans, heatsink, a power supply PC board, inverter power devices,

and the PMI Regulator PC board. A DC-to-DC converter supplies power to the PMI

and to Hall-effect devices used for current feedback.

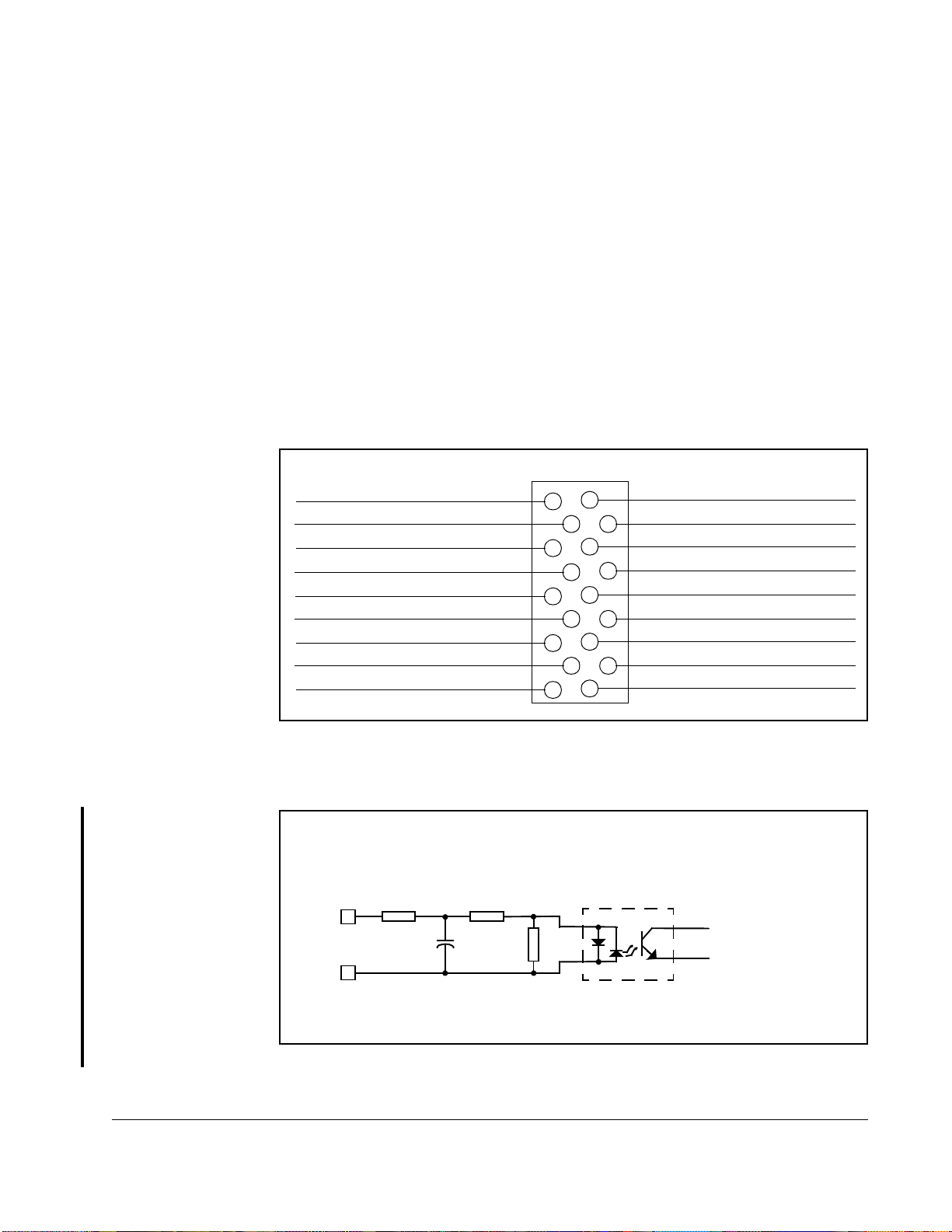

The faceplate of the Power Module has 15 LEDs, two rail I/O ports, fiber-optic transmit

and receive ports, a resolver f eedback connector for speed feedback and analog input

signals, and a drive I/O connector for dedicated and general-purpose drive I/O. A

push-button labeled “RE-BOOT” allows the PMI Regulator to be reinitialized. This

allows ne Power Module to be reset without powering down the entire DC bus and all

the Power Modules on it. When the button is pressed, all I/O is reset, the PMI executes

its power-up routine, and then requests its operating system from the UDC module.

The SA500 Power Module is cooled by forced air . Air enters through the bottom of the

module and exits through the top . The two f ans at the bottom of the Power Module are

internally connected and powered via a 24V supply produced by the DC-to-DC

converter. The PMI monitors the temperature of the Power Module heatsink and

reports an overtemperature condition in register 202/1202, bit 0.

Two quarter-turn fasteners on the faceplate allow removal of the Power Module cover.

Mounting holes are provided on flanges that extend above and below the module.

Module dimensions are listed in Appendix A. See figure 2.1 for views of the module

with and without its cover.

Note that motor-mounted resolvers are required for speed and position feedback on

SA500 drives. Resolvers are included with every SA500 brushless and induction

motor.

Power Module Mechanical Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-1

Page 15

PWR OK

OK

COMM OK

P.M. FLT

EXT FLT

RAIL FLT

FDBK OK

RPI

MCR

AUX IN1

AUX IN2

AUX IN3

AUX IN4

AUX IN5

AUX OUT

RE-BOOT

XMT

COMM

LINK

RCV

P1

P2

P3

RAIL

PORT 0

P4

RAIL

PORT 1

P5

RESOLVER

FEEDBACK

P6

DRIVE I/O

WITH COVER ON WITH COVER REMOVED

Figure 2.1 – SA500 Power Module With Cover and Without Cover

2-2

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

2.1 LED Indicators

The LEDs on the faceplate of the Power Module indicate the status of the PMI,

inverter, fiber-optic link, rail I/O, resolver feedback signal, and drive I/O. The status of

the LEDs is also reported in the UDC module’s dual port memory. See the SA500

Drive Configuration and Programming instruction manual (S-3044) for a complete

description of the following status bits. Note that all faults indicated by the LEDs

(except for the RAIL FLT LED) will result in the PMI disabling the power device gates,

which will cause the motor to coast to a stop.

The LED indicators on the module faceplate are defined as follows:

PWR OK

OK

COMM OK

(green) - The “PWR OK” LED indicates that all power supply voltages

for the PMI are at acceptable operating levels. The status of

the DC-to-DC converter is available in the UDC module’s dual

port memory (register 202/1202, bit 12). This LED also

indicates that the DC bus is powered up.

(green) - When power is applied to the P ower Module, the LED will turn

on to indicate the PMI has passed its internal power-up

diagnostics. After power-up, this LED will turn off if the

internal watchdog times out. This will cause the drive to

disable the gate drive circuitry in the inverter.

(green) - When lit, this LED indicates messages are being received

correctly over the fiber-optic link from the UDC module. If this

LED is off, it indicates there is a fault in the link or that the

UDC module is unable to communicate.

If the PMI does not receiv e a message from the UDC module

for two or more CCLK periods, or logs two consecutive

communication errors of any type, the PMI processor will shut

the drive down.

Detailed information about the communication link (e.g.,

number of messages sent and received, CRC error count) is

displayed in the UDC/PMI Communication Status Registers

(80-89/1080-1089) on the UDC module.

P.M. FLT

Power Module Mechanical Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

(red) - When lit, this LED indicates that one of the fault conditions

listed below has been detected in the Power Module:

•

Overtemperature

Corresponding UDC location: Register 202/1202, bit 0

•

DC bus overvoltage

Corresponding UDC location: Register 202/1202, bit 2

•

Vcc (+5V) supply undervoltage

Corresponding UDC location: Register 202/1202, bit 3

2-3

Page 17

EXT FLT (red) - When lit, this LED indicates that one of the following external

fault conditions has occurred:

•

Overcurrent fault

Corresponding UDC location: Register 202/1202, bit 1

•

User-programmed fault

Corresponding UDC location: Register 101/1101, bit 2

•

Overspeed fault

Corresponding UDC location: Register 202/1202, bit 10

RAIL FLT (red) - When lit, this LED indicates communication between an I/O

rail and the PMI has been disrupted, or that a rail has been

configured but is not plugged in.

Registers 0-23 are available in the UDC module for rail

variable configuration and diagnostic purposes. If a rail

communication problem is detected and logged in register 4,

10, 16, or 22, then bit 13 in the Drive Warnings register

(203/1203) will be set.

Note that rail faults will not cause the drive to shut down. The

user must ensure that the application task tests the rail fault

registers and forces appropriate action in the event of a fault.

FDBK OK (green) - When lit, this LED indicates that the Resolver & Drive I/O

module is receiving feedback from the resolver and that no

resolver feedback faults have been detected.

If the LED is off, it indicates the following fault:

•

Feedback broken wire fault. The resolver sine and/or

cosine signals are missing, or the resolver gain tunable

(RES_GAN%) has been set too low.

Corresponding bit location: Register 202/1202, bit 8

The signals associated with the following LEDs interface to the Power Module via the

Drive I/O connector. See figure 2.6.

RPI (green) - When lit, this LED indicates that the run permissive input

(RPI) signal is detected on pin A. The RPI signal typically

originates from the drive's coast-to-rest stop circuit.

Corresponding bit location: Register 201/1201, bit 0.

MCR (amber) - When lit, this LED indicates the MCR (motor control relay)

output signal is being driven on (pin P). The MCR output is

under the control of the PMI. This LED will turn on when the

drive is put into run and will turn off when the drive is idle. The

use of a motor control relay is optional.

2-4

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

AUX IN1 (green) - When lit, this LED indicates the presence of a 115 volt signal

on this input (pin C). This LED is used for M-contactor

feedback when the programmer has configured an output

contactor between the Power Module and the motor. The use

of an M-contactor is optional.

Corresponding bit location: Register 201/1201, bit 1.

AUX IN2 (green) - When lit, this LED indicates the presence of a 115 volt signal

on this input (pin E).

Corresponding bit location: Register 201/1201, bit 2.

AUX IN3 (green) - When lit, this LED indicates the presence of a 115 volt signal

on this input (pin H).

Corresponding bit location: Register 201/1201, bit 3.

AUX IN4 (green) - When lit, this LED indicates the presence of a 115 volt signal

on this input (pin K).

Corresponding bit location: Register 201/1201, bit 4.

.

AUX IN5 (green) - When lit, this LED indicates the presence of a 115 volt signal

on this input (pin M).

Corresponding bit location: Register 201/1201, bit 5.

.

AUX OU T (amber) - When lit, this LED indicates the output signal has been

turned on (pin S).

Corresponding bit location: Register 101/1101, bit 4.

Power Module Mechanical Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-5

Page 19

2.2 Power Module Faceplate Co nnectors

The following sections describe the Power Module faceplate connectors. Figure 2.2

shows the external connections to the Power Module.

CU

PS

DCP

U

PWR OK

OK

COMM OK

P.M. FLT

EXT FLT

RAIL FLT

FDBK OK

RPI

MCR

AUX IN1

AUX IN2

AUX IN3

AUX IN4

AUX IN5

AUX OUT

RE-BOOT

AutoMax

FROM

D-C BUS

SUPPLY

XMTCOMM

LINK

RCV

RAIL

PORT 0

RAIL

PORT 1

RESOLVER

FEEDBACK

DRIVE I/O

AutoMax SA500

DISTRIBUTED POWER SYSTEM

AC POWER MODULE

POS NEG U V W GND

RAIL I/O

MCR

AUX IN1

AUX IN2

AUX IN3

AUX IN4

AUX IN5

AUX OUT

RPI

RESOLVER FEEDBACK

ANALOG INPUT

TO MOTOR

2-6

Figure 2.2 – Power Module External Connectors

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

2.2.1 Fiber-Optic Ports

Transmit (XTM) and receive (RCV) ports are provided on the faceplate of the Power

Module for connection to the fiber-optic link with the UDC module in the AutoMax rack.

The Power Module is shipped with dust caps covering the fiber-optic ports. To prevent

dust accumulation and the resulting loss of signal integrity, the dust caps should not

be removed until the fiber-optic cables are installed, and should be replaced if the

cables are disconnected.

!

2.2.2 Rail Ports

Two rail ports (0 and 1) on the faceplate of the Power Module support direct

connection to digital and analog rail modules. All combinations of the modules listed

below are supported.

•

M/N 45C001A

•

M/N 45C630

•

M/N 45C631

•

M/N 61C345

•

M/N 61C346

•

M/N 61C350

•

M/N 61C351

•

M/N 61C365

•

M/N 61C366

ATTENTION:

the UDC module and to its corresponding PMI Regulator before viewing

the fiber-optic cable or transmitter under magnification. Viewing a

powered fiber-optic transmitter or connected cable under magnification

may result in damage to the eye. For additional information ref er to ANSI

publication Z136.1-1981. Failure to observe this precaution could result

in bodily injury.

Digital I/O Rail (J-3012)

4-Decade Thumbwheel Switch Input Module (J-3654)

4-Digit LED Output Module (J-3655)

4-Channel Analog Current Input Rail (J-3689)

4-Channel Analog Voltage Input Rail (J-3688)

2-Channel Analog Voltage Input/Output Rail (J-3672)

2-Channel Analog Current Input/Output Rail (J-3673)

4-Channel Analog Current Output Rail (J-3694)

4-Channel Analog Voltage Output Rail (J-3695)

T urn off, lock out, and tag power to both the rack containing

Digital I/O modules can be mixed in an I/O rail connected to the P ower Module. Analog

rail modules must be used in the rail mode only. Note that Local Heads (M/N 61C22)

are not supported.

These rails receive the 5V power required for their operation through their connection

to the PMI. If the PMI is reset or power is removed, all outputs are turned off. Rail

cables must not be connected or disconnected under power.

The PMI contains the fusing f or the rail I/O. The P ower Module cov er must be removed

to replace the rail fuse. See figure 2.3 for the location of the rail fuse. See Appendix A

for the rail fuse specification.

The rail update rate is asynchronous to the UDC task and UDC-to-PMI

communications. While the regulation algorithm is running, digital rails are updated

every 5 msec (both ports). Analog rails are updated every 20 msec (both ports).

Power Module Mechanical Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-7

Page 21

RIGHT SIDE VIEW

RAIL FUSE

FAN

POWER

2-8

Figure 2.3 – Location of Rail Fuse on PMI Regulator PC Board

2.2.3 Resolver Feedback Connector

The faceplate connector labeled “RESOLVER FEEDBACK” is used to connect the

resolver to the Power Module. This connector will also accept a signal from an analog

tachometer or other analog field device as long as the signal is within the correct

voltage range. (Note that the tachometer cannot be used for speed feedback.) A 24V

digital input that serves as a strobe for latching the resolver position externally is also

supplied.

Both a resolver and an analog device may be connected to the module (e.g., the

analog input may be used for tension or position feedback at the same time that the

resolver input is used for speed feedback). However, only the resolver will be

monitored for an overspeed condition. See the SA500 Drive Configuration and

Programming instruction manual, S-3044, for more information.

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

ATTENTION:For brushless motor applications, changing any resolver

wiring, breaking the resolver coupling, replacing the resolver , or replacing

!

the motor and resolver for any reason requires that the shaft alignment

test be performed again. Resolver wiring changes always affect shaft

alignment. A resolver change and/or a new motor/resolver combination

will affect the shaft alignment. Improper shaft alignment can cause motor

overspeed when the motor is started. F ailure to observe this precaution

could result in bodily injury.

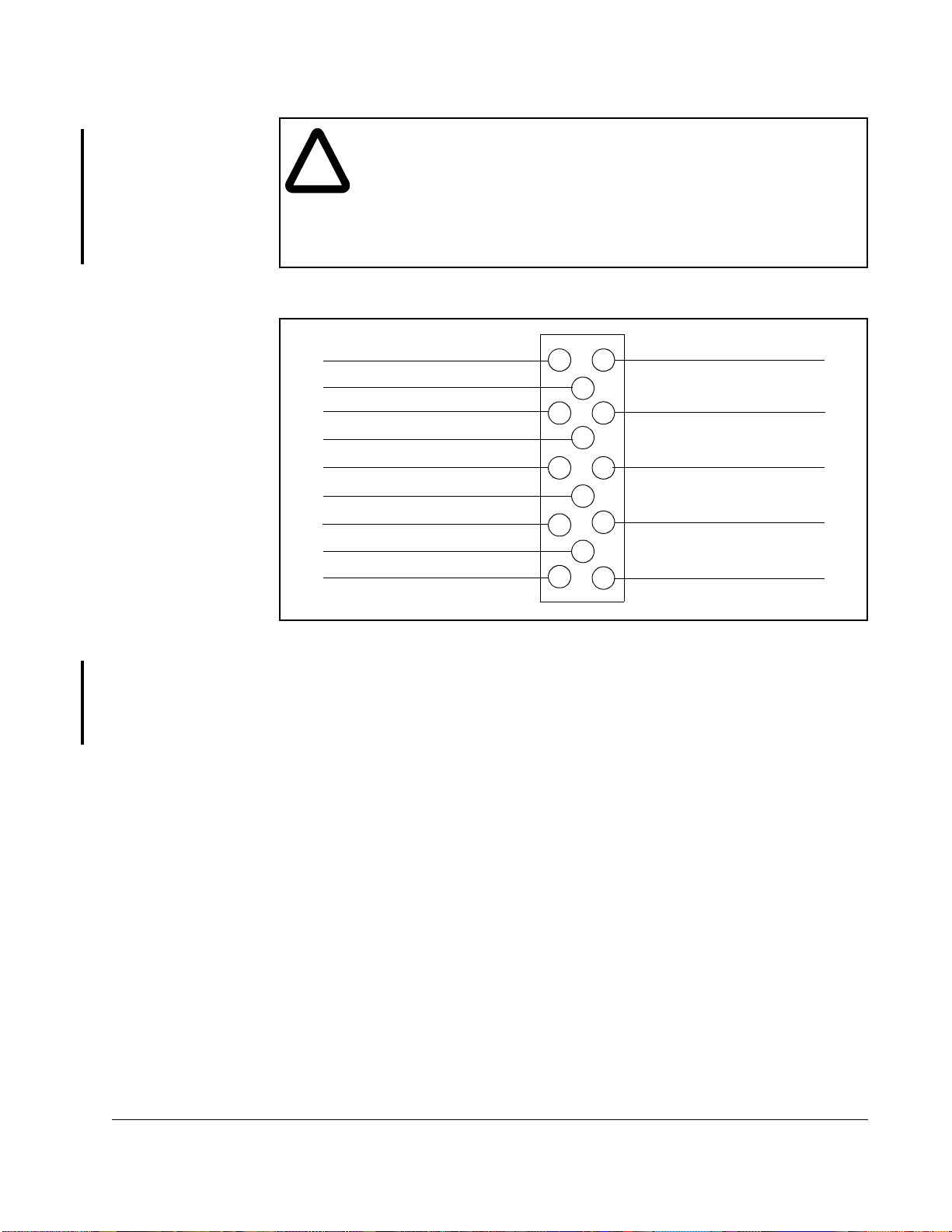

The Resolver Feedback connector pinout is shown in figure 2.4.

Reference Out (+)

Reference Out (-)

Sine Input (+)

Cosine Input (+)

External Strobe Input (+)

External Strobe Input (-)

Not Used

Not Used

Analog Input (+)

Figure 2.4 – Resolver Feedback Connector Pinout

A

B

D

E

H

J

L

M

P

Sine Input (-)

C

Cosine Input (-)

F

K

Key Pin

N

Analog Input (-)

Analog Input Shield

R

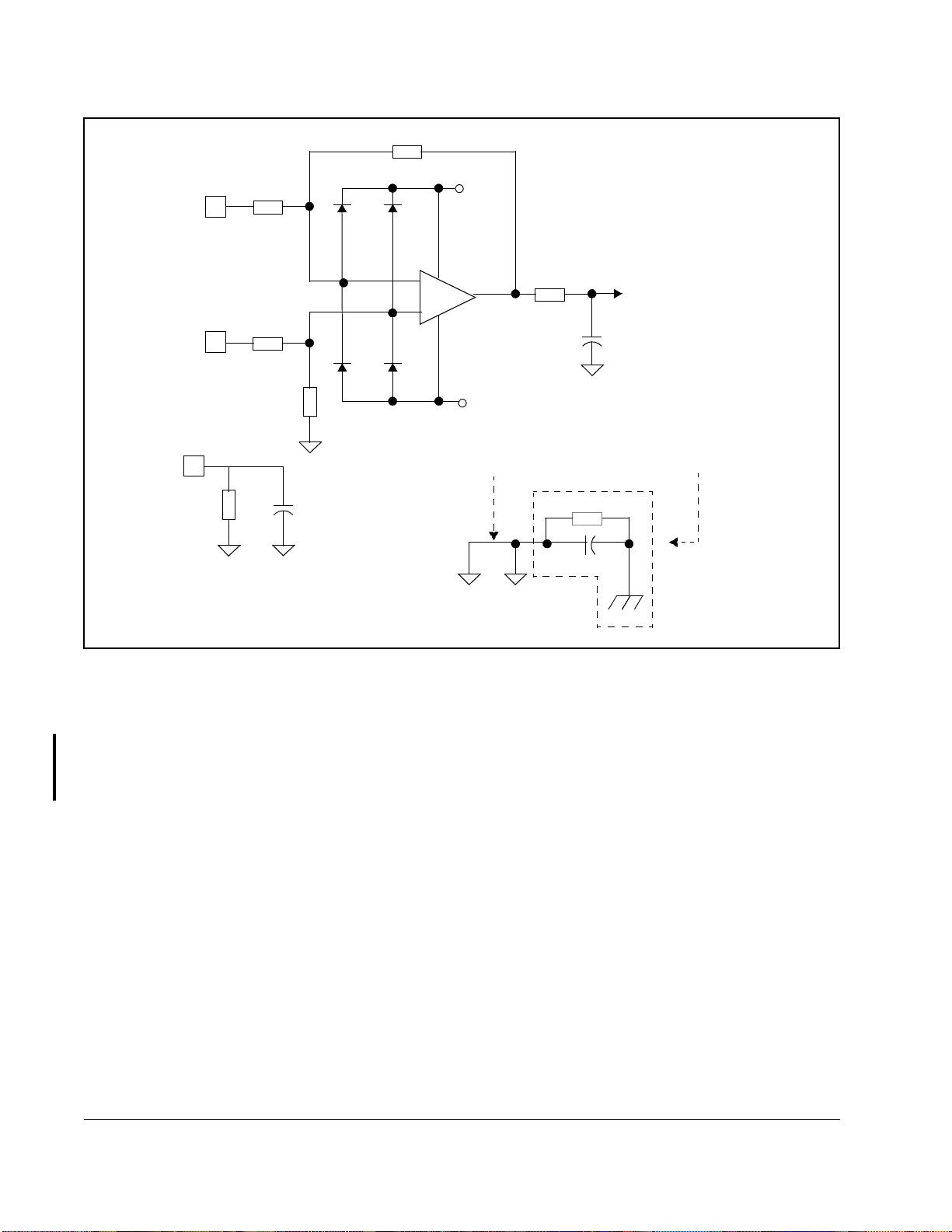

The analog input operates over the range of +/-10V differential (+/-30V common

mode). It is the user's responsibility to ensure that the input signal is scaled to conform

to this range. The input is bandwidth-limited to 320 Hz. The resolution of the input is

12 bits (11 bits plus sign) or 4.88 mV per bit. The input impedance is 1.3 megohms

and is resistively isolated. The analog input circuit is shown in figure 2.5.

If an analog tachometer is not used, the input may be used f or other purposes as long

as the signal is within the correct voltage range. The PMI sends the analog input data

to the UDC module immediately before it is needed by the UDC module for the next

UDC task scan. The analog input data is stored in UDC register 214/1214. The v alue

may range from -2048 (-10 volts) to +2047 (+10 volts).

Power Module Mechanical Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-9

Page 23

312K

ANALOG -

ANALOG+

ANALOG SHIELD

1K

AGND

1.04M

1.04M

312K

DGND

.33

F

µ

AGND

+15 V

–

+

-15 V

THIS CONNECTION

IS MADE WITH THE

DC/DC CONVERTER

DGND

AGND

20K

5600 pF

TO A/D

SUBSYSTEM

AGND

THESE COMPONENTS

ARE ON THE PMI

REGULATOR

10K

.33 µF

Figure 2.5 – Analog Input Circuit

2.2.4 Drive I/O Connector

The connector labeled “DRIVE I/O” is used for digital I/O connections to standard

drive-related signals, such as M-contactor status, the run permissive input (RPI) for

the drive, or for other user-designated functions. Six digital inputs and two digital

outputs are provided. Five of the inputs (AUX IN1 to AUX IN5) and one of the outputs

are user-programmable.

The digital drive I/O operates with 115VAC (50/60Hz) nominal line voltage. All input

and output channels have isolated commons with an isolated voltage rating limited to

150VAC. All inputs and outputs have isolation voltage ratings of 1500 volts between

the I/O and the PMI Regulator's power supply. See figures through for the input and

output circuit diagrams.

The RPI input and the MCR output are interlocked in hardware on the module. The

MCR output is activated only when the RPI signal is asserted (by the user) and the

MCR output is being commanded on by the PMI. The PMI will begin the process to

turn off the MCR output when any of the following conditions occurs:

•

The RPI input signal is removed

•

A drive fault occurs

•

The torque control algorithm is turned off (TRQ_RUN = 0)

2-10

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

If any of these events occurs, the PMI will wait f or 100 msec and then turn off the MCR

RPI IN (+)

AUX IN2 (+)

AUX IN1/MFDBK (+)

AUX IN3 (+)

AUX IN4 (+)

AUX IN5 (+)

MCR OUT (+)

AUX OUT (+)

Key Pin

A

C

E

H

K

M

P

S

U

B

D

F

J

L

N

R

T

V

RPI IN (-)

AUX IN1/MFDBK (-)

AUX IN2 (-)

AUX IN3 (-)

AUX IN4 (-)

AUX IN5 (-)

MCR OUT (-)

AUX OUT (-)

Not Used

330

15K

182

DIGITAL

OUT TO

MICROPROCESSOR

.1uF

AUX INPUTS

output. If the RPI signal is remov ed, the MCR output will be turned off and gate pow er

will be removed under hardware control within approximately 0.5 second to provide an

additional level of protection.

The user has the option of having an M-contactor (i.e., an output contactor) on the

output of the Power Module. This option is available during UDC parameter

configuration. The M-contactor is controlled by the MCR output, which is under the

control of the PMI processor. If the choice is made to connect the MCR to the output

contactor, the contacts must be wired to the AUX IN1/MFDBK input. The PMI will then

wait for this signal to turn on before executing the control algorithm. The status of the

AUX IN1/ MFDBK input is reported in register 201/1201, bit 1. If this configuration

choice is not made, the AUX IN1 input can be used for any user-designated purpose.

The status of the drive I/O is indicated in UDC register 201/1201 and by eight LEDs on

the module faceplate. In the event of a power loss or if a system reset command is

initiated by the PMI, all outputs are turned off.

The Drive I/O connector pinout is shown in figure 2.6.

Power Module Mechanical Description

Figure 2.6 – Drive I/O Connector Pinout

Figure 2.7 shows the auxiliary input interface circuit.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The run permissive input (RPI) circuit is shown in figure 2.8.

Figure 2.7 – Auxiliary Input Circuit

2-11

Page 25

DGND = ON

+15V

GATE KILL

+15V = OFF

DGND

MCR_OUT+

MCR_OUT-

6

124

5

3

1 = On

Other Faults

0 = Off

10

3 4

+5V

–

+

1

8

1/2

Second

Delay

M-Contactor

12

DGND

1

+

-

+

6

7

+15V

7

-

6

1

+5V +5V

+

–

DGND

6

4

1

3

Shunt

Regulator

3

2

2-12

RPI_IN+

RPI_IN-

Figure 2.8 – Run Permissive Input (RPI) Circuit

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

C

HAPTER

3

Power Module Electrical Description

DC input voltage to the Power Module is supplied by a DC bus, normally the SA500

DC Bus Supply. The inverter bridge in the Power Module converts the constant

potential DC voltage from the DC bus to three-phase AC power for the motor. The

inverter bridge consists of six bi-polar transistors. Interlock circuitry ensures that the

upper phase and lower phase U, V, and W transistors are never turned on at the same

time.

The inverter bridge can regenerate energy to the DC bus. During regeneration, the

inverter returns energy from the motor to the DC bus. Howev er, the SA500 DC Bus

Supply cannot pass this regenerative current back to the AC line. Instead, it stores the

excess energy in its capacitors. It can then pass this surplus energy to other Power

Modules on the bus that need motoring current, or it can dissipate the energy through

DC bus braking resistors. See the DC Bus Supply instruction manual (S-3017) for

specifications on the regeneration limits of the DC Bus Supply and for more

information about braking resistors.

The regulator circuitry and UDC communication interface is contained on a single PC

board, the Power Module Interface (PMI) Regulator. This PC board contains control

circuitry for the inverter, resolver and drive I/O circuitry, and fiber-optic transceivers for

communication with the UDC module in the AutoMax rack. The PMI’s main function is

torque regulation for brushless motors and induction motors.

The PMI contains a RISC (reduced instruction set computer) microprocessor

operating at 16 MHz. High speed communication with the UDC module is controlled

by an onboard serial communications controller. Data is transmitted over the

fiber-optic link at 10 Mbit/sec using the High-Le vel Data Link Control (HDLC) protocol.

Data integrity is checked using a CRC (cyclic redundancy check) error detection

scheme.

The PMI contains an on-board watchdog timer that is enabled when power is applied

to the PMI. Once activated, the on-board CPU must continually reset the watchdog

timer within a specified time or the PMI will shut down. The MCR output, typically used

to control a motor contactor, will be turned off under hardware control within 0.5

seconds if the watchdog times out. (The MCR output is also turned off if the RPI input

turns off.) To reset the watchdog, you must either cycle power or press the RE-BOOT

button on the faceplate.

Any faults in the Po wer Module will cause the PMI to turn off the control signals to the

power devices (bipolar transistors) that switch the DC bus voltage to the motor.

3.1 Power-Up Routine

When power is applied to the Power Module, the LEDs will blink three times as a test

and the PMI will perform a series of internal diagnostics. The P.M. FLT LED on the

faceplate will flash if the Power Module fails any of these diagnostics. If the diagnostics

are passed, the OK LED on the faceplate will turn on.

Power Module Electrical Description

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-1

Page 27

The PMI will automatically request its operating system from the UDC module as soon

as communications are established over the fiber-optic link. After the operating system

has been downloaded from the UDC module (a process that takes approximately 0.5

seconds), the PMI Regulator will send a feedback message. The UDC module will

respond with a command message and configuration data. The information sent

contains configuration data as well as the synchronization information necessary for

the PMI to determine when to send feedback messages to the UDC module once

UDC application tasks are put into run.

The PMI uses non-volatile EPROM memory to store the initial start-up software and

power-up diagnostics and to establish communication with the UDC module. After

power-up, the module stores data in and operates out of volatile SRAM. If power is

removed from the Power Module, all data and the module’s operating system will be

lost. When power is returned to the Power Module, the PMI module will begin its

normal power-up routine.

3.2 DC-to-DC Converter

A DC-to-DC converter in the Power Module provides the DC voltages necessary for

the operation of the PMI. The converter is connected to DC input power internally

when the Power Module is connected to the DC Bus Supply.

The PMI monitors the +5V and the +/-15V supplied via the converter. When these

voltages are above specified levels, the PMI will turn on the PWR OK LED. If the +5V

line falls below a pre-determined level, the PMI turns off power to the gate drivers

under hardware control, and the motor coasts to a stop.

3.3 Resolver Interface

The resolver interface converts analog sine and cosine resolver feedback signals into

digital format. A trac king ratiometric resolver-to-digital (R/D) converter outputs a 12- or

14-bit digital number indicating the absolute electrical position of the resolver shaft.

The resolution (12 or 14 bit) of the R/D converter is selected during drive parameter

entry. A two-bit revolution counter extends operation over four electrical revolutions.

The counter is reset whenever power is turned on to the system or a system reset

command is asserted by the PMI. When 12-bit mode is selected, the resolver data

format will be as shown in figure 3.1. Figure 3.2 shows the resolver data format when

14-bit mode is selected.

bits

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

revolution counter

Figure 3.1 – Resolver Data Format (12-Bit Mode)

resolver data

0 0

3-2

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

Figure 3.2 – Resolver Data Format (14-Bit Mode)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

bits

revolution counter

resolver data

The PMI produces a nominal 26 volt rms 2381 Hertz sine wave reference output

signal which is capable of driving a 500 ohm load. The stator signals (sine and cosine)

are input through a matched isolation transformer pair. The transformers are matched

for gain and phase shift. The ratio of the sine and cosine amplitudes is then converted

to an angular position. Position data is sent to the UDC module by the PMI before

every scan of the UDC task. The UDC task calculates speed using this position data.

The PMI supports two methods of sampling the digital position of the resolver,

time-driven and event-driven. Both methods may be used simultaneously. In the first

method, the position is sampled once per UDC task scan at the rate defined in the

SCAN_LOOP control block in the UDC task. This block tells the UDC task how often

to run based on the CCLK signal on the AutoMax rack backplane. The PMI sends the

position data to the UDC module immediately before it is needed by the UDC module

for the next UDC task scan. Position data measured using this method is stored in the

UDC module's dual port register 215/1215 in the format shown in figure 3.1 or 3.2.

The second method allows position sampling between scans or when an external

event occurs by using an external strobe. The resolver interface includes an isolated

24 volt DC input with a relatively high degree of filtering (approximately 800 Hz). The

external strobe input circuit is shown in figure 3.3.

Vcc

5K

681K 10K

EXTERNAL

STROBE

INPUT

300

300

.33µF

2.55K

1.24K

Figure 3.3 – External Strobe Input Circuit

Figure 3.4 shows the relationship between the time the external strobe is detected and

the point at which the resolver position is sampled. Response time is subject to

temperature, component toler ance, and input voltage level. Note that the input signal

pulse width should be greater than 300 µsec and the frequency should be less than

1000 pulses per second.

Power Module Electrical Description

14K

.01µF

681K

+

TO

475K

MICROPROCESSOR

3-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

EXT. STROBE

INPUT

RESOLVER

POSITION

LATCH

COMMAND

24 V NOM

T

d

T

d

T

pw

Figure 3.4 – External Strobe Input Circuit Timing Diagram

T

per

Td - 250 mSEC TYP.

- 300 mSEC MIN.

T

pw

T

- 1000 mSEC MIN.

per

Strobe input detection is enabled by setting bits 8 and/or 9 in UDC register 101/1101.

The resolver position can be sampled on the strobe input's rising edge, falling edge, or

both. Latched data is sent to the UDC module immediately before it is needed by the

UDC module for the next UDC task scan. Note that the PMI operating system detects

only one edge per UDC scan. If the programmer chooses to have the resolver position

sampled on both edges of the strobe’s input, the leading edge will be detected in one

scan and the falling edge in the next scan.

Position data measured using this method is placed in UDC register 216/1216 in the

format shown in either figure 3.1 or 3.2. Bit 8 of UDC register 201/1201 is set to

indicate that the strobe signal has been detected. This bit is set for only one scan to

allow a strobe to be detected every scan. The UDC task must check this bit each scan

to ensure the validity of the strobe data in register 216/1216. Bit 9 of register 201/1201

is set or cleared when the e xternal strobe is detected and indicates whether the strobe

leve l was rising (1) or falling (0).

3-4

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

C

HAPTER

4

Installation Guidelines

ATTENTION:

operation of this equipment and the hazards involved should install,

!

This chapter describes how to install the P ower Module and connect it to the UDC, the

rail I/O, the drive I/O, and the resolver.

For connection instructions specific to your system, refer to the detailed prints

included in the instruction book shipped with each engineered drive system.

adjust, operate, or service this equipment. Read and understand this

manual and other applicable manuals in their entirety before proceeding.

Failure to observe this precaution could result in severe bodily injury or

loss of life.

ATTENTION:

power has been disconnected. After disconnecting input power from the

DC bus supply, w ait five (5) minutes and then measure the voltage at the

POS and NEG terminals of the DC bus supply and each Power Module

to ensure the DC bus capacitors are discharged before touching any

internal components. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:

local, national, and international codes. Failure to observe this precaution

could result in damage to, or destruction of, the equipment.

Only qualified personnel familiar with the construction and

DC bus capacitors retain hazardous voltages after input

The user is responsible for conforming with all applicable

4.1 Wiring and Grounding

Installation Guidelines

To reduce the possibility of electrical noise interfering with the proper operation of the

drive system, exercise care when installing the wiring between the system and

external devices. For detailed recommendations, refer to IEEE 518.

The grounding stud (GND) on the Power Module must be connected to the grounding

stud on the DC Bus Supply, as shown in figure 4.2. The DC Bus Supply must be

connected to earth ground (PE) and checked with an ohmmeter before power is

applied.

4.2 Power Module Installation

The following procedure is intended to be only a guide to assist you in installing the

Power Module. Refer to the wiring diagrams supplied with your system for more

specific information. Note that there are no user-adjustable potentiometers or jumpers

on the Power Module.

Before installation, ensure that ambient air around the Pow er Module is clean, dry, and

free of flammable or combustible vapors, chemical fumes, oil vapor, steam, and

excessive moisture and dirt.

4-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

Step 1. Mount the Power Module. Power Modules are designed to be mounted

vertically on a flat surface using M5 or #10 screws. The holes in the top

flanges are key-hole shaped and the lower hole is U-shaped to facilitate

mounting.

The Power Module should be mounted in a location with good air flow and

must be in close proximity to the DC Bus Supply. Power Modules should not

be mounted one over another because the exhaust air from the lower Power

Module would feed the air intake of the upper Power Module. The minimum

distance above and below the Power Module is 85 mm (3.4 inches). Allow

13 mm (0.5 inch) between any Power Module and the side wall of an

enclosure. Allow 3 mm (0.125 inch) between individual Power Modules. See

figure 4. 1.

When multiple Power Modules are being installed, the Power Modules with

the highest current rating should be placed closest to the DC Bus Supply.

Note that the Power Modules should be evenly distributed on each side of the

DC Bus Supply. If two Power Modules are being used, one should be

mounted to the left of the Bus Supply and one should be mounted to the

right. If four Power Modules are being used, two should be wired from the left

of the Bus Supply and two from the right. If an odd number of Power Modules

is being used, the P ower Modules should be distributed as evenly as possible

on each side of the Bus Supply. This method of Power Module placement

minimizes wire length, which reduces wire inductance.

See the DC Bus Supply instruction manual (S-3017) for information on how

to calculate the maximum number of Power Modules that can be sourced

from one DC Bus Supply.

4-2

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

(17.5")

445 mm

(9.5")

243 mm

(16.88")

429 mm

2

Air Intake

411 mm

(16.18")

A

Minimum Recommended

Panel Space Requirement

SA500

Module

SA500

Module

AC Power AC Power

Side View

Air Exhaust

12 mm

(0.47")

7 mm

(0.27)

A

Front View

B B B B C

C

Installation Guidelines

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

35 mm

(1.38")

35 mm

(1.38")

SA500

Supply

DC Bus

SA500

SA500

Figure 4.1 – Power Module Mounting Dimensions

r

AC Powe

AC Power

1/4 Turn Cover

Fasteners

#10 (M5)

Mounting Screws

Module

Module

1

Typical

115 mm

(4.5")

Mounting Screw Head Diameter is 10 mm (0.39") maximum

Covers are removed by pulling them straight out as indicated by arrow

A = 102 mm (4") minimum

B = 118 mm (4.62") minimum, 127 mm (5") maximum

1

C = 13 mm (0.5") minimum

2

4-3

Page 33

ATTENTION:To avoid the danger of an electrical shock or burn, only

qualified personnel should install or service this equipment. Disconnect

!

all power before working on this equipment. Dangerous voltages may

exist after power is removed. Check the DC Bus Supply voltages each

time power is removed before servicing. Failure to observe this

precaution could result in severe bodily injury or loss of life.

Step 2. Connect the DC bus wires (POS, NEG, GND) from the DC Bus Supply to the

Power Module. See figure 4.2.

The proper DC bus connection wires are provided with the Bus Supply. Do

not substitute other wires f or those supplied.

Do not over-tighten the nuts on the Power Module and DC Bus terminals.

Use a nut-driver only and limit the torque to 4.0 Nm (36 lb-in).

Step 3. Connect the motor wires to the Power Module’s terminals (U,V,W). See

table 4.1.

Table 4.1 – Recommended Motor Wire Sizes

SA500 AC

Power Modules Motor Terminals Minimum

615055-1R U-V -W,GND

615055-1S U-V-W,GND

615055-1T U-V-W,GND

615055-1V U-V-W,GND

1. Minimum wire size required.

2. Maximum wire size allowed.

4.8 / 21.6 mm

4.8 / 21.6 mm

8.5 / 21.6 mm

13.7 / 21.6 mm

1

/Maximum2 Wire Sizes

2

2

2

2

10 / 4 AWG

10 / 4 AWG

8 / 4 AWG

6 / 4 AWG

Step 4. Apply power to the input wiring of the DC Bus Supply and check the bus

voltage. It should be 325 VDC nominal. Be sure the bus voltage is present at

the Power Module’s input terminals.

4-4

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

SA500 AC

SA500 AC

UVW

Power Module

NEG GND

Motor

Connecting Lugs

M6 Nut

M6 Terminal Post

POS

GND

round Terminals

G

UVW

Power Module

NEG

POS

GND

L3

47

48

External

Braking Resistor

SA500

SA500 AC

Power Module

L1 L2

Supply

DC Bus

NEG

POS

GND

NEG

POS

VW

U

Flat Washers

Lock Washers

Fuse

Fuse

Fuse

Drive or Power

Supply Bus Bar

Positive and Negative Terminals

Fuse Disconnecting Switch

SA500 AC

GND

UVW

Voltage

AC Input

Power Module

NEG

POS

(3-Phase)

Short Circuit Capacity

PE

5000 Amps o r Less

M6 Nut

M6 Terminal Post

Connecting Lugs

Terminal Post Base

Installation Guidelines

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Red Wire*

Black Wire*

Green Wire*

*Wires are 225 mm (8.8") long

Figure 4.2 – DC Bus Supply Wiring

To Grounding Rod

or Building Steel

4-5

Page 35

4.3 Fiber-Optic Connection

ATTENTION:

the UDC module and to its corresponding PMI hardware before viewing

!

Refer to the Distributed Power System Fiber-Optic Cabling instruction manual

(S-3009) for the procedure required to install and test the fiber-optic cable between the

Power Module and the UDC module.

The Power Module is shipped with dust caps covering the fiber-optic ports. The dust

caps should not be removed until the fiber-optic cables are installed and should be

replaced if the cables are disconnected.

the fiber-optic cable or transmitter under magnification. Viewing a

powered fiber-optic transmitter or connected cable under magnification

may result in damage to the eye. For additional information ref er to ANSI

publication Z136.1-1981. Failure to observe this precaution could result

in bodily injury.

T urn off, lock out, and tag power to both the rack containing

4.4 Drive I/O Connections

The Drive I/O Cable (M/N 612401-T) provides the connection between the Drive I/O

connector and a 16-point terminal block. The cable has an 18-pin connector on one

end for connection to the Drive I/O Connector . Near the connector, the cable is labeled

“C3-P2.” Near the terminal block connections, the cable is labeled “I/O.” Refer to

figure 4.3 for the terminal block connections.

4-6

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

Cable No. 612401-T

RPI (HI)

RPI (LO)

AUX IN 1 (HI)

AUX IN 1 (LO)

AUX IN 2 (HI)

AUX IN 2 (LO)

AUX IN 3 (HI)

AUX IN 3 (LO)

AUX IN 4 (HI)

AUX IN 4 (LO)

AUX IN 5 (HI)

AUX IN 5 (LO)

MCR (HI)

MCR (LO)

AUX OUT (HI)

AUX OUT (LO)

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

12

13

13

14

14

15

15

16

1

2

3

4

5

6

7

8

9

I/O

WIRE

NUMBER

1BRN

2 WHT/BRN

3RED

4 WHT/RED

5ORG

6 WH T/O RG

7YEL

8 WHT/YEL

9

10

11 BLU

12 WHT/BLU

13 VIO

14 WHT/VIO

15 GR Y

16 WHT/GRY

WIRE

COLOR

GRN

WHT/GRN

Installation Guidelines

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Figure 4.3 – Terminal Block Connections for Drive I/O

4-7

Page 37

4.5 Rail Port Connection

Analog and digital I/O rails are connected to the Power Module using an I/O

Interconnect Cable (M/N 45C5). Refer to the appropriate instruction manual for the

installation and wiring procedures for your equipment. See table 4.2.

Table 4.2 – Rail I/O Instruction Manuals

Model No. Description Manual

45C001A Digital Rails and Modules J-3012

45C630 4-Decade Thumbwheel Switch Input Module J-3654

45C631 4-Digit LED Output Module J-3655

61C345 4-Channel Analog Current Input Rail J-3689

61C346 4-Channel Analog Voltage Input Rail J-3688

61C350 2-Channel Analog Voltage Input/Output Rail J-3672

61C351 2-Channel Analog Current Input/Output Rail J-3673

61C365 4-Channel Analog Current Output Rail J-3694

61C366 4-Channel Analog Voltage Output Rail J-3695

4.6 Resolver Feedback Connection

A cable is provided with your system for connection to the Resolver Feedback

connector on the Power Module faceplate. The cable part number is stamped onto the

cable and should be compared to the wiring diagrams shipped with your system.

The Resolver and Analog Input cable (M/N 612426-S) provides the connection

between the Resolver Feedback connector and eight- and three-point terminal blocks.

The eight-point terminal block is used for resolver connections. The three-point

terminal block is used for analog input connections.

The cable has a 14-pin connector on one end for connection to the Resolver

Feedback connector and is divided into two smaller cables, labeled “ANALOG” and

“RESOLVER.” The cable labeled “ANALOG” connects to the three-point terminal

block. The cable labeled “RESOLVER” connects to the eight-point terminal block.

Near the connector, the cable is labeled “C3-P1”.

The connector is secured to the Power Module faceplate with two screws. When

attaching the cable, alternately tighten each screw a few turns at a time until the

connector is securely attached. Follow the same procedure to loosen the screws when

removing the connector.

Refer to figure 4.4 for the terminal block connections.

4-8

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

ANALOG INPUT

ANALOG INPUT

(+)

(–)

Cable No. 612426-S

1

2

1

1

2

SHIELD

REFERENCE OUT

REFERENCE OUT

SINE INPUT

SINE INPUT (–)

COSINE INPUT

COSINE INPUT

(+)

(–)

(+)

(+)

(–)

3

4

5

6

1

2

3

4

5

6

3

ANALOG

1

2

3

4

5

6

RESOLVER

EXT. TRIGGER

EXT. TRIGGER

(+)

(–)

7

8

9

10

7

7

7

8

8

Figure 4.4 – Terminal Block Connections for Resolver and Analog Input

WIRE

NUMBER

ANALOG

1BLK

2 CLEAR

3 DRAIN (SHIELD)

RESOLVER

1BRN

2 WHT/BRN

3RED

4 WHT/RED

5ORG

6WHT/ORG

7YEL

8 WHT/YEL

WIRE

COLOR

Installation Guidelines

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4-9

Page 39

4.6.1 Resolver Input Connections

The resolver input connections are shown in table 4.3.

Note that Distributed Power Systems are designed to be used with the standard

resolvers listed in this table 4.3 and in Appendix A.

Table 4.3 – Standard Resolver Connections

Resolver Resolver & Drive I/O Module

Connector Pin

Resolver

Winding 613469-1,-2

Reference

Input

Sine Output S1+

Cosine

Output

1. Connections listed give a positive speed signal for counter-clockwise motor rotation (when f acing the end opposite the output shaft). To

reverse the polarity of this signal, interchange the cosine input leads (terminals 5 and 6).

R1+

R2–

S3–

S2+

S4–

A

B

C

D

E

F

800123,

800123-1 800123-2 TB

1

2

3

4

5

6

A

B

D

F

G

E

1

2

3

4

5

6

7

8

Faceplate

Conn Pin Resolver Module

A

+–Ref. Output

B

D

+–Sine Input

C

F

E

H

J

–

Cosine Input

+

+

Ext. Strobe

–

1

1

Typical voltage levels associated with the resolver are as follows:

Reference:

•

This is a 2381 Hz sine wave with a typical amplitude of approximately

26V RMS. When measuring any of the resolver signals, make sure that the meter

used can respond to 2381 Hz accurately or use an oscilloscope.

Sine or cosine feedback:

•

This is a 2381 Hz signal with an amplitude that varies

with the rotation of the shaft. Maximum amplitude (as the shaft turns) should be

approximately 11.8V at the feedback connector. Voltages may be different

depending on the installation. The system adjusts the signal levels to develop 11.8V

maximum at the module input.

Table 4.4 lists the cables that may be used for resolver connection.

Table 4.4 – Recommended Resolver Cables

Recommended Maximum

Distance Per Resolver Type

X1 X2

Part No.

417900

No. of

Twisted

Pairs

Length

of Twist

Twists

Per Inch

Size mm

(AWG)

2

-207CG 3 12.7(8.5 mm (2(3) 0.823 (18) 255 m (850 ft) 240 m (800 ft)

-76EAD 1 12.7(8.5 mm (2(3) 1.31 (16) 320 m (1050 ft) 310 m (1025 ft)

See Appendix A for maximum resolver speed specifications.

4-10

SA500 Power Modules

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

4.6.1.1 Resolver Calibration

The resolver input can be used with X1 and X2 resolvers with cable distances as

shown in table 4.4.

The PMI contains circuitry to synchronize the reference waveform to within 10 degrees

of the returning waveforms. This synchronization corrects for any phase shift which

can occur between the reference and stator signal (i.e., stator signals lagging the

reference) due to unbalanced wire impedance. The impedance increases as the cable

length increases. The synchronization is done automatically at power up after the PMI

receives the configuration data from the UDC module informing it that a resolver has

been selected for speed feedback.

The programmer must use the following calibration procedures to adjust the gain to

the proper level and balance the sine/cosine waveforms. These procedures should be

performed during initial system installation, if the resolver is replaced, or if the resolv er

cabling is changed (e.g., the cable is lengthened, shortened, or a different cable type

is used). After the calibration procedures are performed, the gain and balance values

are sent, along with other feedback data, to the UDC module to be stored for use at

subsequent power ups. The values are stored in local tunables with the reserved

names RES_BAL% and RES_GAN%.

Note that Distributed Power System drives are designed to be used with the standard

resolvers listed in table 4.3 and described in Appendix A. The validity of the results of

these calibration procedures is not guaranteed if resolvers other than those specified

are used.

Gain Calibration

The gain calibration is performed when the value stored in RES_GAN% equals zero

(i.e., at initial system start-up or by the operator setting the value to zero). This

procedur e may be perf ormed whil e the reso lv er is turning o r statio nary . Do not per fo rm

this procedure while the minor loop is running (i.e., bit 0 of register 200/1200 is set) or

a drive fault will be generated (register 202/1202, bit 8).

The procedure adjusts the gain to bring the stator voltages to a nominal 11.8 VAC at

the board’s input. The range of the gain adjustment is 0-37 VAC at the rotor with a

resolution of 0.15V. The nominal value is 26 V A C. When the gain calibration procedure

is completed, bit 6 of UDC register 201/1201 will be set, and the gain value will be

stored in RES_GAN%. Large gain values (close to 255) may indicate a problem with

the resolver wiring or connections. Always check the value stored in RES_GAN% after

the gain calibration procedure has been completed.

Note that the resolver must be connected to the motor in order f or this procedure to be

completed. If the system determines a maximum gain v alue (255) and detects a

broken wire (indicated by bit 8, register 202/1202) while attempting to calibrate the

gain, it will assume that a resolver is not connected. When the broken wire bit is

cleared by the operating system (indicating that a resolver has been connected), the

gain calibration will automatically re-start. If bit 6 of register 201/1201 is not set, the

calibration procedure has not been completed.

Installation Guidelines

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4-11

Page 41

Balance Calibration

The balance calibration procedure is initiated by setting UDC register 101/1101, bit 6

(RES_CAL@) after turning the drive on. The procedure takes from a few seconds to

one minute to complete. It must be performed while the resolver is rotating at 5 RPM

minimum speed (speed does not have to be constant). The faster the resolver is

turning, the faster the balance calibration procedure will be performed. Balance

calibration compensates for different cable lengths or characteristics. For example,

one twisted-pair wire can yield more or less capacitance than another twisted-pair

wire of the same length. Therefore, one channel could have more or less voltage on it

than the other. If each stator winding has different capacitance on it, different

response curv es result. These curves should be equal for optimum performance.

The balance calibration procedure minimizes oscillations that occur due to imbalances

between channels by adding capacitance to the sine or cosine channel. The operating

system calculates the capacitance value which yields the smallest velocity variations

with sine/cosine magnitudes within 1% of each other. Due to the characteristics of the

cable or to noise problems, it is possible that the magnitudes will not be within 1% of

each other. In this case, the system will calculate the capacitance value that minimizes

velocity variations. When the balance calibration procedure is completed, bit 7 of UDC

register 201/1201 will be set, and the balance value will be stored in RES_BAL%. If

the sine/cosine magnitudes are not within 5% of each other, bit 5 of UDC register

203/1203 (Tuning Aborted Warning) will also be set.

Checking Calibration Procedure Results

As described previously, bits 6 and 7 of UDC register 201/1201 will be set to indicate

the gain and balance calibration procedures, respectively, have been completed.

These bits do not indicate that the procedures were successful or that the resulting

values are valid. After each test, check the value stored in the local tunables

RES_GAN% and RES_BAL%. If either value is near or at its maximum value, it may

indicate a problem.

After the balance test, check the Tuning Aborted Warning bit (bit 5, UDC register

203/1203). This bit will be set if the balance calibration procedure was unsuccessful or

yielded unexpected results. Failures may be caused by leaving the resolver

unconnected during the procedure or using cable runs beyond the recommended

lengths (refer to table 4.4). Calibration procedure failures will not prevent the operation

of the drive.

Refer to the SA500 Drive Configuration and Programming instruction manual (S-3044)

for more information about these local tunables.

4.6.1.2 Resolver Alignment

Resolver alignment is required for SA500 drives controlling brushless motors. The

alignment procedure automatically determines the offset required to bring the rotor

and stator fields in the motor 90° apart. This procedure will cause the motor to

move less than one revolution in both the f orward and reverse directions for

less than one minute. Uncouple the motor from the load to run this test if this

motion could cause personal injury or would be harmful to your machine.

4-12

Note that this procedure should be performed at the lesser of the following two values:

•

Rated motor current, or

•

70% of the Power Module rated current