Page 1

Distributed Power System SA500 Drive

Diagnostics, Troubleshooting,

and Start-Up Guide lines

Instruction Manual

S-3022-1

Page 2

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

The thick black bar shown on the outside margin of this page will be used throughout this instruction manual to

signify new or revised text or figures.

ATTENTION:Only qualified personnel familiar with the construction and operation of this

equipment and the hazards involved should install, adjust, operate, or service this equipment.

!

Read and understand this manual and other applicable manuals in their entirety before

proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input power has been

disconnected. After disconnecting input power from the DC bus supply, wait five (5) minutes and

then measure the voltage at the POS and NEG terminals of the DC bus supply and each Power

Module to ensure the DC bus capacitors are discharged before touching any internal components.

Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:For brushless motor applications, changing any resolver wiring, breaking the

resolver coupling, replacing the resolver, or replacing the motor and resolver for any reason

requires that the shaft alignment test be performed again. Resolver wiring changes always affect

shaft alignment. A resolver change and/or a new motor/resolver combination will affect the shaft

alignment. Improper shaft alignment can cause motor overspeed when the motor is started. Failure

to observe this precaution could result in bodily injury.

ATTENTION:The user must provide an external, hardwired emergency stop circuit outside of the

drive circuitry. This circuit must disable the system in case of improper operation. Uncontrolled

machine operation may result if this procedure is not followed. Failure to observe this precaution

could result in bodily injury.

ATTENTION:Inserting or removing a module or its connecting cables may result in unexpected

machine motion. Turn off power to the rack before removing a module or its connecting cables.

Failure to observe these precautions could result in bodily injury.

ATTENTION:Only qualified Rockwell personnel or other trained personnel who understand the

potential hazards involved may make modifications to the rack configuration, variable

configuration, and application tasks. Any modifications may result in uncontrolled machine

operation. Failure to observe these precautions could result in damage to equipment and bodily

injury.

ATTENTION:Registers and bits in the UDC module that are described as “read only” or for “system

use only” must not be written to by the user. Writing to these registers and bits may result in

improper system operation. Failure to observe this precaution could result in bodily injury.

ATTENTION:The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

The information in this user’s manual is subject to change without notice.

AutoMax™ is a trademark of Rockwell Automation.

©1998 Rockwell International Corporation

Page 3

Chapter 1 Introduction

1.1 Related Publications........................................................................................1-1

1.2 Typographical Conventions .............................................................................1-2

Chapter 2 Diagnostics and Troubleshooting

2.1 Definition of Terms Used in Diagnostics and Troubleshooting........................2-1

2.2 Power-up Diagnostics in the UDC Module and PMI........................................2-3

2.3 Interlock Tests ................................................................................................. 2-3

2.4 Run-time Diagnostics ......................................................................................2-3

2.4.1 Drive Faults...........................................................................................2-4

2.4.1.1 How the System Reacts to Drive Faults .................................2-4

2.4.1.2 MCR Output Control ......... ...... ....... ....................................... .. 2-5

2.4.2 Drive Warnings...................................................................................... 2-5

2.4.3 How to Clear the Drive Fault and Drive Warning Registers .................. 2-6

Chapter 3 PMI Operating Modes

3.1 Idle Mode......................................................................................................... 3-1

3.2 PMI Run Mode................................................................................................. 3-1

3.3 Alignment Test Mode....................................................................................... 3-4

C

ONTENTS

Chapter 4 Installation and Start-Up Guidelines

4.1 Using the AutoMax Programming Executive to Access the Rack ...................4-1

4.2 Installation Requirements................................................................................4-2

4.3 Installing the Motor ............................. ....... ...... ....... ...... ....... ............................ 4-3

4.4 Installing the Drive........................ ...... ....................................... ....... ...... ....... .. 4-3

4.4.1 Cabinet-Enclosed Wall-Mounted Drives................................................ 4-3

4.4.2 Floor-Mounted Drives...................... ...... ....... ...... ....... ...... ...................... 4-3

4.4.3 Panel-Mounted Drives........................................................................... 4-3

4.5 Wiring the Power Module ................................................................................4-3

4.6 Basic Drive Interconnections........ ...... ....... ...... ....................................... ....... .. 4-4

4.7 Drive Inspection and Start-up Guidelines........................................................4-4

4.7.1 What To Do After Unexpected Test Results ......................................... 4-5

4.7.2 Recommended Test Equipment............................................................ 4-7

4.7.3 Physically Inspecting the Equipment..................................................... 4-7

4.7.4 Physically Inspecting the Motor............................................................. 4-8

4.7.5 Checking the Installation with Power Off............................................... 4-8

4.7.6 Testing Power Modules with Power On ................................................ 4-9

4.7.7 I/O Verification..................................................................................... 4-10

4.7.7.1 Testing UDC/PMI Communication Status............................. 4-10

4.7.7.2 Testing Rail I/O Registers .....................................................4-11

4.7.7.3 Testing Feedback Registers and Bits ................................... 4-12

4.7.7.4 Testing the UDC Module Test Switch Register.....................4-13

4.7.7.5 Testing UDC Module Meter Ports.........................................4-14

4.7.8 Performing Uncoupled Motor Tests. ....................................... ...... ....... 4-14

4.7.9 Running Dynamic Motor Tests............................................................ 4-15

4.7.10Updated Drawings and Software Listings ...........................................4-16

Table of Contents

I

Page 4

Appendix A Drive Fault Register ................................................................................................. A-1

Appendix B Drive Warning Register............................................................................................ B-1

Appendix C Interlock Register ..................................................................................................... C-1

Appendix D Summary of UDC Module Drive Fault Indicators .....................................................D-1

Appendix E Power Module LED Summary.................................................................................. E-1

Appendix F Status of Data in the AutoMax Rack After

a STOP_ALL Command or STOP_ALL Fault.......................................................... F-1

Appendix G AutoMax Prog rammi ng Ex ecuti ve Acces s Levels........................ ....... ...... ....... ...... ..G-1

Index ..................................... ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ..Index-1

II

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 5

List of Figures

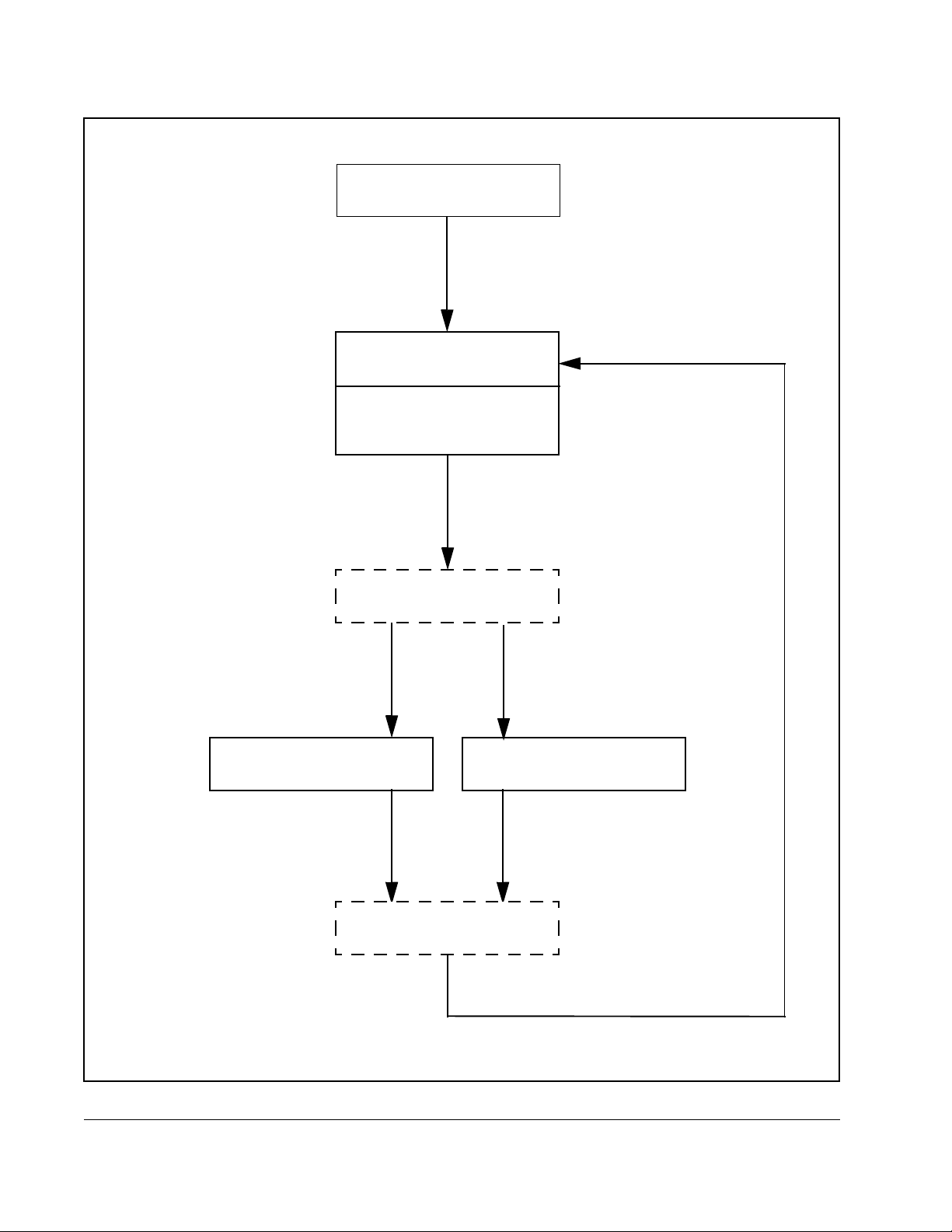

Figure 2.1 – PMI Operating Modes Overview........... ....... ...... ....... ...... ....... ...... .........2-2

Figure 3.1 – PMI Operating Modes and Diagnostics................................................3-3

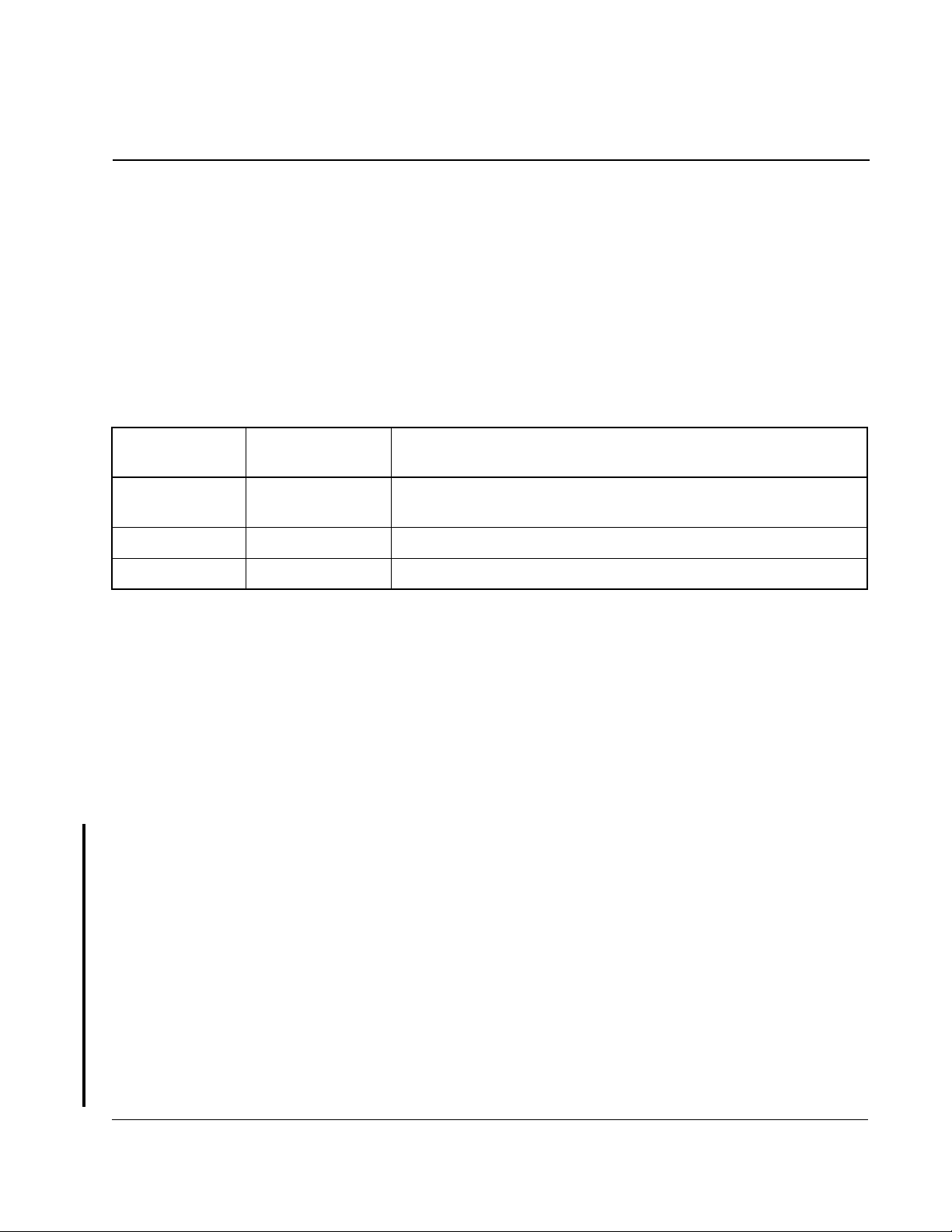

Figure 4.1 – POS and NEG Terminals on the DC Bus Supply................................. 4-6

Table of Contents

III

Page 6

IV

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 7

List of Tables

Table 1.1 – SA500 Documentation (Binder S-3002) ................................................1-1

Table 3.1 – PMI Operating Modes............................................................................3-1

Table 4.1 – UDC/PMI Communication Status Register Formats............................ 4-10

Table 4.2 – Rail I/O Register Formats....................................................................4-11

Table 4.3 – Feedback Registers and Bits...............................................................4-12

Table of Contents

V

Page 8

VI

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 9

C

HAPTER

1

Introduction

This instruction manual is divided into two sections: 1) a description of SA500 drive

diagnostics and troubleshooting, 2) start-up guidelines. This manual is intended for

users of SA500 drives who have training and experience in AC drive control and who

are familiar with all other SA500 drive documentation.

The diagnostics and troubleshooting chapters (chapters 2-3) describe the error

checking built into the PMI Regulator operating system and how to use warning and

fault registers, LEDs, and the error log to diagnose drive problems.

Chapter 4 provides guidelines on starting up Distributed Power SA500 AC drives.

Although initial start-up services are usually provided by Rockwell personnel, it is

recommended that the user become familiar with the general guidelines in this chapter

in order to be better prepared to work with the Rockwell service engineer.

This manual does not describe specific applications of the standard SA500 hardware

and software. Always refer to the wiring diagrams supplied with your system for

information specific to your installation.

1.1 Related Publications

You user must become familiar with the other instruction manuals that describe the

SA500 drive system. The documentation that describes the SA500 drive is listed in

table 1.1.

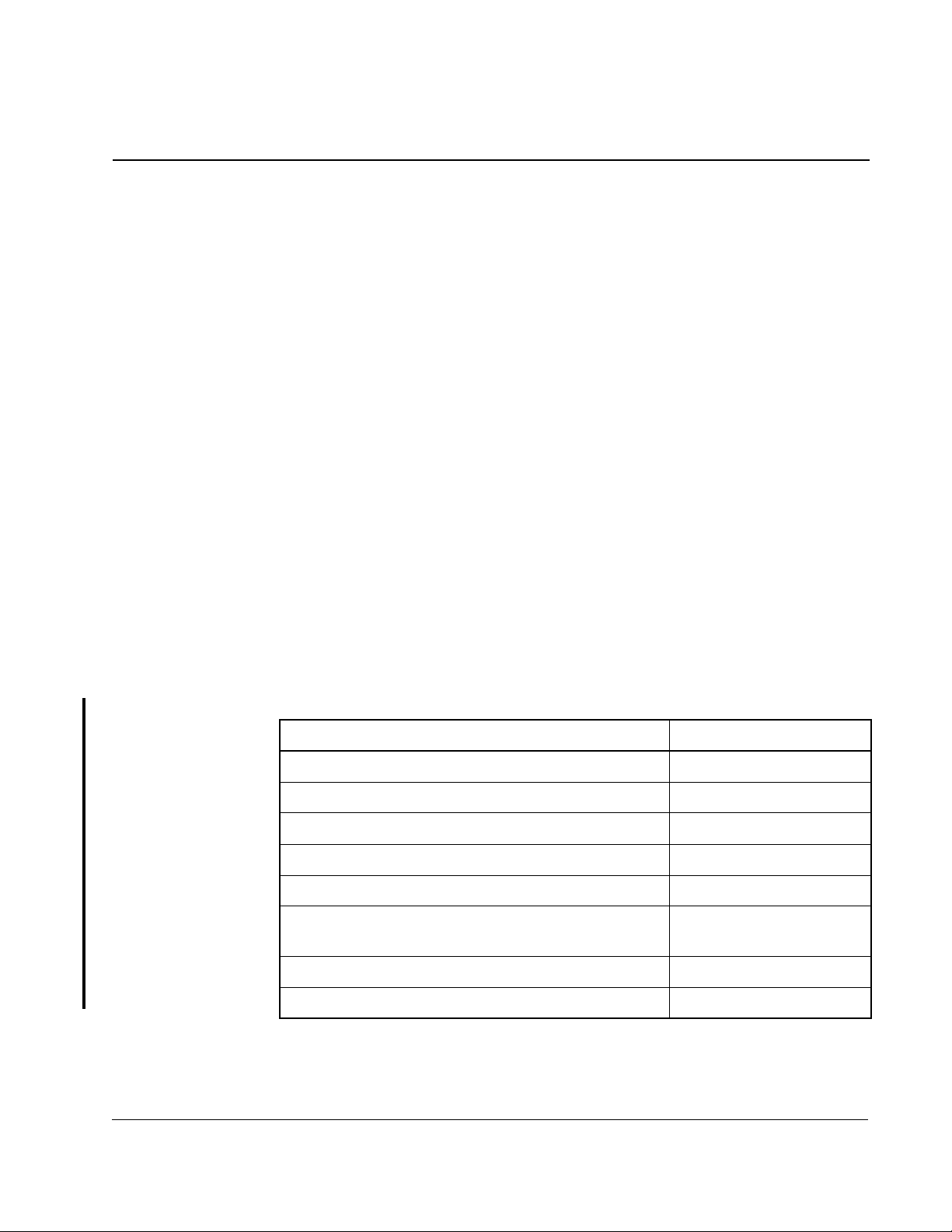

Table 1.1 – SA500 Documentation (Binder S-3002)

Document Document Part Number

DPS Overview S-3005

Universal Drive Controller Module S-3007

Fiber Optic Cabling S-3009

SA500 DC Bus Supply S-3017

SA500 AC Power Modules S-3018

SA500 Diagnostics, Troubleshooting, & Start-Up

Guidelines

SA500 Information Guide S-3024

SA500 Drive Configuration & Programming S-3044

Additional information about using the SA500 drive is found in the prints and other

documentation shipped with each drive system. Always consult the prints and other

documents shipped with your drive system for specific information about installing,

operating, and maintaining your drive.

S-3022

Introduction

1-1

Page 10

1.2 Typographical Conventions

The following typographical conventions are used in this manual:

•

Variable names

Variables names are shown in all capital letters followed by the appropriate

terminating character. The variable names shown in this manual are suggested

names only and may vary from the names used in your application.

Example: MCR@

•

Register names

Register names are shown with the initial letters capitalized followed by the

corresponding register number for both drive A and drive B. The drive A register

number is shown first followed by the drive B register number (A/B).

Example: Drive Fault register (202/1202)

•

Bit names

Individual bit names are shown with the initial letters capitalized. Also shown, in

parentheses, is the bit’s register number, bit number, and suggested variable name.

Example: Fault Reset bit (register 100/1100, bit 8, FLT_RST@)

•

Parameter entry screen titles

Parameter entry screen titles and the parameters themselves are shown with the

initial letters capitalized.

Example: Feedback Data parameter entry screen

1-2

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 11

C

HAPTER

Diagnostics and Troubleshooting

The Distributed Power System contains built-in comprehensive diagnostics. In order

to diagnose and correct problems quickly, it is important to understand the types of

diagnostics that are performed, when they are performed, and how the results are

reported. This chapter describes the different types of diagnostics performed by the

system’s modules and how the results of these diagnostics are reported. This chapter

also describes how the system reacts if an error is detected.

An overview of these modes is shown in figure 2.1. The Distributed Power System

provides diagnostics at each level of operation as shown in figure 3.1.

Use these figures as a reference to quickly identify the system's requirements for

entering and operating in each mode. These figures also refer to specific sections in

the manual that provide additional information.

2.1 Defini tion of Terms Used in Diagnostics and

Troubleshooting

For the purpose of describing diagnostics and troubleshooting, this instruction manual

will use specific terms to refer to the types of errors that can be detected by the PMI

and the response of the PMI and UDC module to those errors.

diagnostic

A

There are three types of diagnostics in SA3100 drives: power-up diagnostics, interlock

diagnostics, and run-time diagnostics.

drive fault

A

shut the drive down. Faults are reported in the Drive Fault register (202/1202) of the

UDC module and in the error log for the UDC task in which the fault occurred.

drive shut-down

A

occurs.

drive warning

A

indicates the drive is not operating in an optimum manner. Drive warnings will not

shut the drive down.

error

An

Interlock diagnostics

in response to a drive control request from the programmer, e.g., PMI_RUN@, in

register 100/1100 of the UDC module dual port memory.

Power-up diagnostics

all printed circuit board modules.

Run-time diagnostics

background task after it has received its operating system from the UDC module.

is a software routine specifically designed to check for error conditions.

is an error specifically checked for by the PMI operating system that will

occurs when any fault reported in the Drive register (202/1202)

is an error specifically checked for by the PMI operating system that

is any condition other than the desired condition.

are those diagnostics performed by the PMI operating system

consist of the initial tests for basic functionality performed by

are those diagnostics performed continuously by the PMI as a

2

Diagnostics and Troubleshooting

2-1

Page 12

POWER-UP

DIAGNOSTICS

IDLE

SELECT PMI_RUN@

OR ALN_TST@

CLOSE MCR

2-2

PMI RUN

ALIGN RESOLVER

OPEN MCR

Figure 2.1 – PMI Operating Modes Overview

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 13

2.2 Power-up Diagnostics in the UDC Module and PMI

Power-up diagnostics execute in the UDC module in the AutoMax™ rack and in the

PMI in the Power Module. When power is applied to the AutoMax rack, the UDC

module performs a series of self-tests. When all of the tests are successfully

completed, the CARD OK LED on the UDC module's faceplate will turn on. If a failure

occurs, the OS OK LED will flash rapidly.

When power is applied to the Power Module, the PMI performs a series of self-tests.

When all of the tests are successfully completed, the OK LED on the Power Module’s

faceplate will turn on. If a failure occurs, the P.M. FLT LED on the Power Module will

flash rapidly.

If a UDC module or a Power Module does not pass its power-up tests, it must be

replaced. After all of the power-up tests are passed, the system continues its

power-up routine. The PMI requests the appropriate operating system from the UDC

module. The UDC module downloads the operating system and the parameter

configuration data, if available, to the PMI. The PMI then runs under the control of its

operating system and begins performing the run-time diagnostics. Run-time

diagnostics are descr ib ed in sec ti on 2.4.

2.3 Interlock Tests

Interlock tests are performed by the PMI whenever one of the PMI's operating modes

is selected by the programmer through the Drive Control register (100/1100). These

diagnostics verify that all conditions required for the operating mode selected are

satisfied. If the interlock tests are completed successfully, then the operating mode

requested by the programmer can be entered. If any of the interlock diagnostics fails,

the PMI will latch a bit in the Interlock register (205/1205) corresponding to the first

diagnostic test that failed, and the requested operating mode will not be entered (i.e.,

the PMI will remain in the idle mode).

If an interlock test failure occurs, follow the procedure below:

Step 1. Reset the command bit that is currently set in the Drive Control register

Step 2. Correct the condition that caused the test failure.

Step 3. Set the desired command bit in the Drive Control register (100/1100).

The PMI will perform the interlock tests each time a rising edge is detected on the

command bits. The results of subsequent interlock tests will overwrite the previous

test’s results.

2.4 Run-time Diagnostics

Run-time diagnostics are performed continuously by the PMI after its operating

system has been downloaded by the UDC module. These diagnostics test the status

of the PMI and the connected hardware and also check the integrity of the

communication link between the UDC module and the PMI.

Diagnostics and Troubleshooting

(100/1100).

2-3

Page 14

The results of the diagnostics are stored in either the Drive Warning register

(203/1203) or the Drive Fault register (202/1202) in the UDC module's dual port

memory. How drive faults and drive warnings are indicated and how they affect the

operation of the drive is described in the following sections.

2.4.1 Drive Faults

When the PMI detects any of the conditions identified in the Drive Fault register, it will

shut down the drive as described below. To determine the cause of a drive shutdown,

the following indicators are provided:

•

Drive Fault register (202/1202)

The PMI will set a bit in the Drive Fault register to indicate the condition that caused

the shutdown. The interlock tests check this register for fault conditions that have

occurred. Refer to Appendix A for a complete description of the Drive Fault Register.

•

Drive Status Register (200/1200)

The PMI will set the Fault Detected bit (bit 8, FLT@) of the Drive Status register when

a drive fault has been detected.

•

LEDs on the UDC module

If either LED (DRV FLT A or DRV FLT B) is on, a drive fault has been detected for the

drive using that communication channel.

•

LEDs on the Power M odu le

The Power Module’s faceplate contains 15 status/fault LED board. Refer to Appendix

E for LED definitions.

•

Error log for the UDC task

The error log for the task in which the fault occurred is accessed through the ON LINE

menu of the AutoMax Programming Executive. A list of the drive fault error codes can

be found in Appendix D. Refer to appropriate AutoMax Programming Executive

instruction manual for more information regarding the Programming Executive and the

ON LINE menu.

2.4.1.1 How the System Reacts to Drive Faults

As described in section 2.4.1, if the PMI detects any of the conditions identified by the

Drive Fault register, it will shut down the drive. This means that the PMI responds by

immediately disabling the gates of the power devices, causing the motor to begin a

coast-to-rest stop. The PMI will wait 100 msec after the fault before turning off the

MCR output.

Note that the UDC task is not stopped automatically is a drive fault causes a

shut-down of the drive. The user must ensure that the application task(s) test the

Drive Fault register (202/1202) and takes any appropriate action if a fault is detected.

2-4

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 15

2.4.1.2 MCR Output Control

The MCR output on the Power Module is used to control an output contactor. This

output contactor, sometimes referred to as an M-contactor, disconnects power from

the motor. This option is selected during UDC module parameter configuration. If the

programmer selects to connect the MCR output to an output contactor, auxiliary

contacts from this device must be wired to the AUX IN1/MFDBK input as feedback.

The PMI operating system will wait for AUX IN1/MFDBK to turn on before executing

any operating mode.

The Run Permissive input (RPI) on the Power Module and the MCR output are

interlocked in hardware. The MCR output can be turned on only when the RPI is

asserted. The MCR output itself is under the control of the PMI. Application tasks

have no direct control of the MCR output. RPI is controlled by the user. When RPI is

off, MCR cannot be activated.

The following conditions will cause the MCR output to turn off:

•

Absence of the RPI signal

•

Occurrence of a drive fault

•

Control algorithm is turned off (PMI_RUN@ = 0)

When any of the above conditions occurs, the PMI will disable the power device gates

and the motor will begin a coast-to-rest stop. The PMI will wait 100 msec and then turn

off the MCR output.

In addition, if the RPI signal is removed, the MCR output and gate power will be

removed under hardware control within approximately 0.5 seconds of the removal of

the RPI signal to provide an additional interlock. This is done regardless of the actions

taken by the PMI.

2.4.2 Drive Warnings

The PMI will check for conditions that are not serious enough to shut down the drive,

but may affect its performance. If the PMI detects any of the conditions described in

the Drive Warning register, it will set the appropriate bit but will NOT shut down the

drive. The user must ensure that the application task tests the Drive Warning register

(203/1203) and takes any appropriate action if a warning condition is detected.

The PMI will also set the Warning Detected bit (register 200/1200, bit 9, WRN@) if a

drive warning has been detected.

Appendix B provides a complete description of the Drive Warning register.

rail faults, drive warnings are not indicated by LEDs (a rail fault will turn on the RAIL

FLT LED on the Power Module).

error log.

Except for

Drive warnings are not displayed in the UDC task's

Diagnostics and Troubleshooting

2-5

Page 16

2.4.3 How to Clear the Drive Fault and Drive Warning Registers

After a drive fault has been detected, the programmer must do the following before the

drive can be restarted:

Step 1. Reset the command bit that is currently set in the Drive Control register

(100/1100).

Step 2. Correct the fault.

Step 3. Set and reset the Fault Reset bit (register 100/1100, bit 8, FLT_RST@) to

clear the Drive Fault register (200/1200). (Note that the Fault Reset bit is

edge sensitive.)

Step 4. Set the desired command bit in the Drive Control register (100/1100).

After a drive warning has been detected, the programmer can clear the entire Drive

Warning register by setting and resetting the Warning Reset bit (register 100/1100,

bit 9, WRN_RST@). (Note that the Warning Reset bit is edge sensitive.)

2-6

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 17

C

HAPTER

3

PMI Operating Modes

The PMI's default operating mode is idle. All other operating modes are selected by

the programmer in the Drive Control register (100/1100). T ab le 3.1 shows the available

operating modes. Note that the operating modes are mutually exclusive, i.e., only one

mode may be enabled at a time (this is checked by the interlock tests).

The PMI's operating modes are shown in figure 3.1 and are described in the following

sections.

Table 3.1 – PMI Operating Modes

Operating

Mode

Idle N/A The PMI’s default operating mode during which no algorithms are

PMI Run 0 Executes the torque, speed, or position control algorithm.

Alignment Test 1 Enables the resolver alignment procedure for brushless drives.

Drive Control

Register Bit Mode Description

running.

3.1 Idle Mode

The PMI's default operating mode after passing the power-up diagnostics is idle.

When in idle mode, the PMI is waiting for a command from the Drive Control register

(100/1100) to change operating modes.

In order for the PMI to enter the requested operating mode, the Interlock tests must be

passed. If any of the Interlock tests fails, or if any fault is latched in the Drive Fault

register (202/1202), the PMI will remain in the idle mode.

The PMI will return to the idle mode when it exits any of the other operating modes.

3.2 PMI Run Mode

To execute the control algorithm(s), the programmer sets:

PMI Operating Modes

•

the PMI Run Enable bit (register 100/1100, bit 0, PMI_RUN@) for the torque minor

loop

and, if required,

•

the Speed Loop Enable bit (register 100/1100, bit 3, SPD_ON@) for the speed

minor loop

•

the Position Loop Enable bit (register 100/1100, bit 4, POS_ON@) for the position

minor loop.

3-1

Page 18

Before the control algorithm(s) can be executed, all of the following conditions must be

met:

•

The interlock tests, register 205/1205, must be passed successfully. See

section 2.3.

•

The M-contactor must be closed, if configured. See section 2.4.1.2.

•

The UDC task in the AutoMax rack must be running. The status of the UDC task is

indicated by the UDC Task Running bit (register 100/1100, bit 15, UDC_RUN@).

If any of these requirements are not met or if a fault is latched in the Drive Fault

register (202/1202), the PMI will remain in the idle mode.

If these requirements are met, the PMI will execute the torque minor loop, and if

selected, the speed and position minor loops. At this time, the PMI will set the PMI On

bit (200/1200, bit 0, PMI_ON@) to indicate that the torque minor loop is executing.

Important: Note that if a brushless motor is being used, the resolver and rotor shafts

must be aligned before the torque minor loop is executed or the motor

may not run properly. This is not tested by the Interlock tests as a

requirement to enter the PMI run mode. See section 3.3 for description of

this procedure.

The torque minor loop executes until one of the following occurs:

•

The PMI Run Enable bit (register 100/1100, bit 0, PMI_RUN@) is reset by the

application task.

•

A drive fault is detected. Refer to Appendix A for a description of the Drive Fault

register.

•

The RPI signal (register 201/1201, bit 0) is removed.

The speed minor loop executes until one of the following occurs:

•

The Speed Loop Enable bit (register 100/1100, bit 3, SPD_ON@) is reset by the

application task.

•

The PMI Run Enable bit (register 100/1100, bit 0, PMI_RUN@) is reset by the

application task.

•

A drive fault is detected. Refer to Appendix A for a description of the Drive Fault

register.

•

The RPI signal (register 201/1201, bit 0) is removed.

The position minor loop executes until one of the following occurs:

•

The Position Loop Enable bit (register 100/1100, bit 4, POS_ON@) is reset by the

application task.

•

The Speed Loop Enable bit (register 100/1100, bit 3, SPD_ON@) is reset by the

application task.

•

The PMI Run Enable bit (register 100/1100, bit 0, PMI_RUN@) is reset by the

application task.

3-2

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 19

•

A drive fault is detected. Refer to Appendix A for a description of the Drive Fault

register.

•

The RPI signal (register 201/1201, bit 0) is removed.

POWER-UP

DIAGNOSTICS

SECTION 2.2

IDLE

SECTION 3.1

SELECT PMI_RUN@

or ALN_TST@

INTERLOCK TESTS OK

and

PMI_RUN@ OR ALN_TST@

MCR CLOSED or NOT USED

and

PMI_RUN@ REG 100 BIT 0

PMI RUN

SECTION 3.2

PMI_RUN@ OFF REG 100 BIT 0

or

F AULT PRE SENT R EG 202

or

RPI MISSING REG 201 BIT 0

INTERLOCK TESTS FAILED

CLOSE MCR

SECTION 2.4.1.2

MCR DID NOT CLOSE

MCR CLOSED or NOT USED

and

ALN_TST@ REG 100 BIT 2

and

CONFIGURED FOR BRUSHLESS DC

ALIGN RESOLVER

SECTION 3.3

ALN_TST@ OFF REG 100 BIT 1

or

FAULT PRESENT REG 202

or

RPI MISSING REG 201 BIT 0

OPEN MCR

SECTION 2.4.1.2

PMI Operating Modes

Figure 3.1 – PMI Operating Modes and Diagnostics

3-3

Page 20

3.3 Alignment Test Mode

For SA500 drives controlling brushless DC motors, the reso lver shaft and the rotor

shaft must be aligned in order to ensure that maximum torque is generated. Therefore,

an alignment procedure must be performed before the torque, speed, and position

minor loops are executed. The alignment procedure automatically determines the

offset required to bring the rotor and the stator fields 90° apart. This procedure must

be performed whenever the resolver has been disconnected from the motor for any

reason, including reversing cosine leads to the resolver.

ATTENTION:

wiring, breaking the resolver coupling, replacing the resolver, or replacing

!

Important:

The programmer sets the Enable Resolver Alignment Test bit (register 100/1100, bit 1,

ALN_TST@) to request the PMI to execute the alignment procedure. Before the

alignment test can be executed, all of the following conditions are required:

•

The interlock tests (described in section 2.3) must be passed successfully.

•

The M-contactor, if configured, must be closed (described in section 2.4.1.2).

If any of the requirements are not met of if a fault is latched in the Drive Fault register

(202/1202), the PMI will remain in the idle mode.

If these requirements are met, the PMI will execute the alignment procedure.

the motor and resolver for any reason requires that the shaft alignment

test be performed again. Resolver wiring changes always affect shaft

alignment. A resolver change and/or a new motor/resolver combination

will affect the shaft alignment. Improper shaft alignment can cause motor

overspeed when the motor is started. Failure to observe this precaution

could result in bodily injury.

This procedure will cause the motor to move less than one revolution in

both forward and reverse direction for under three minutes. Uncouple the

motor from the load to run this test if this motion would be harmful to your

machine.

For brushless motor applications, changing any resolver

3-4

When the alignment procedure is successfully completed, the PMI will set the

Alignment OK bit (register 200/1200, bit 1, ALN_OK@). The programmer can then

turn off the Enable Resolver Alignment Test bit. This will also turn off the Alignment

OK bit. The result of this test is written to the tunable variable RES_ALN% by the PMI.

If a problem is detected during the alignment procedure (e.g., the incorrect number of

motor poles or resolver type was entered during configuration), the Tuning Aborted

Warning bit (register 203/1203, bit 5, WRN_TUN@) is set. When the alignment

procedure is turned off, the PMI returns to the idle state.

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 21

C

HAPTER

4

Installation and Start-Up Guidelines

$77(17,21

RSHUDWLRQ RI WKLV HTXLSPHQW DQG WKH KD]DUGV LQYROYHG VKRXOG LQVWDOO

!

This section describes general guidelines that should be followed when verifying the

correct in stal latio n of th e driv e ha rdw are a nd in perf ormi ng the driv e st art-up . F or more

information regarding installation guidelines, refer to instruction manual D2-3115

(Installing, Operating, and Maintaining Engineered Drive Systems).

As part of the start-up procedure, the AutoMax Programming Executive software is

used to verify the status of drive I/O and to make drive adjustments. Section 4.1

describes some of the restrictions imposed by the AutoMax Programming Executive

software.

DGMXVW RSHUDWH RU VHUYLFH WKLV HTXLSPHQW 5HDG DQG XQGHUVWDQG WKLV

PDQXDO DQG RWKHU DSSOLFDEOH PDQXDOV LQ WKHLU HQWLUHW\ EHIRUH SURFHHGLQJ

)DLOXUH WR REVHUYH WKLV SUHFDXWLRQ FRXOG UHVXOW LQ VHYHUH ERGLO\ LQMXU\ RU

ORVV RI OLIH

$77(17,21

ORFDO QDWLRQDO DQG LQWHUQDWLRQDOFRGHV)DLOXUH WRREVHUYH WKLVSUHFDXWLRQ

FRXOG UHVXOW LQ GDPDJH WR RU GHVWUXFWLRQ RI WKH HTXLSPHQW

2QO\ TXDOLILHG SHUVRQQHO IDPLOLDU ZLWK WKH FRQVWUXFWLRQ DQG

7KH XVHU LV UHVSRQVLEOH IRU FRQIRUPLQJ ZLWK DOO DSSOLFDEOH

4.1 Using the AutoMax Programming Executive to

Access the Rack

The AutoMax Programming Executive enables four users to access and work in the

same rack simultaneously. However, certain restrictions exist when more than one

user is working in a rack.

•

The maximum number of users is four (4) per rack (one user connected directly to

the rack and three users connected via the DCS/AutoMax Network, or four users

connected via the DCS/AutoMax Network).

•

Data access is required for the user to Set/Force COMMON variables. All users

must assure that variable values are not written over by other users working in the

rack.

•

Task access is required for the user to load a single task and to Set/Tune/Force

LOCAL variables in a task. Only one user will be granted Task access for each task

in the rack.

•

Rack access is required to load the rack configuration and to load all application

tasks (AutoMax tasks and UDC tasks).

•

If a user has Rack access, no other user can make changes in that rack. All other

users will be limited to monitoring tasks and variables.

Installation and Start-Up Guidelines

4-1

Page 22

•

Each user can monitor up to 16 COMMON and/or LOCAL variables.

•

A maximum of 32 LOCAL variables per UDC module can be monitored, regardless

of the number of users.

•

A maximum of 16 variables per rack can be forced.

Appendix G describes the type of access required by the user in order to carry out

common Programming Executive operations. Refer to the AutoMax Programming

Executive instruction manual for more specific information.

4.2 Installatio n Re qu irements

The installation must meet the following requirements:

Ambient Temperature

•

Power Modules: 0 to 60° C (32 to 140° F)

Cooling

•

Air for cooling must be of sufficient quality and flow to avoid recycling the heated

exhaust air back into the drive air inlets.

Relative humidity

•

5 - 95%, non-condensing

Altitude

•

Maximum 1000 meters (3300 feet) above sea level.

Refer to instruction manual S-3018 for derating information when operating above

1000 meters.

Air Quality

•

Clean

No flammable vapors, chemical fumes, or oil vapor.

Clearances

•

Must allow access to the equipment within the cabinet for inspection, maintenance,

and replacement.

•

Must provide non-restricted air flow to and from the intake and exhaust openings.

See the following instruction manuals for more detailed information about installation

requirements:

•

S-3018 SA500 Power Modules

•

S-3017 SA500 DC Bus Supplies

4-2

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 23

4.3 Installing the Motor

The motor should be installed in accordance with its own installation instructions.

Refer to the instruction manual that was provided for the motor (in the Instruction

Book) for specific instructions.

4.4 Installing the Drive

The drive is most often supplied in its own NEMA 1 enclosure. It is also available in

NEMA 4 and NEMA 12 cabinets, in free standing floor-mounted cabinets, in an open

panel configuration for mounting in the customer’s enclosure, or in a custom-built

control room.

4.4.1 Cabinet-Enclosed Wall-Mounted Drives

The drive in a wall-mounted NEMA 1 enclosure is force ventilated by means of its own

internal cooling fan(s) and additional cabinet fans. Air is drawn into the enclosure

through slots in the cabinet bottom and in the lower portion of the cabinet sides. Air is

forced out through internally shielded slots near the top of the cabinet sides. Air intake

and exhaust openings are unfiltered.

NEMA 4 and NEMA 12 cabinet enclosures are unventilated. Although an internal

circulating fan is employed to move air around within the confines of the cabinet to

better utilize the cabinet skin for heat dissipation and reduce internal hot spots, there

is no air exchange with the atmosphere outside of the enclosure.

4.4.2 Floor-Mounted Drives

NEMA 1 free-standing floor-mounted cabinets draw cooling air from slots in the lower

portion of the cabinet door and force air through slots near the door’s top, if a cabinet

fan is supplied. NEMA 4 and NEMA 12 floor-mounted cabinet enclosures are

unventilated.

4.4.3 Panel-Mounted Drives

The drive is available as a panel-mounted assembly where mounting of the drive

within a customer-supplied enclosure is desired. In these instances, the user is

responsible for ensuring that the maximum temperature within this enclosure remains

at or below the rated ambient temperature under worst-case operating conditions.

Note that the same fan-cooling as described in the previous two sections will be

provided for the Power Module.

4.5 Wiring the Power Module

V erify that the input power to the DC bus supply is of the correct voltage and sufficient

ampacity to support the Power Module’s input current requirements. Note that the

maximum available current from the DC bus supply must be less than the Power

Module’s short circuit current rating (RMS). Refer to the drive cabinet and motor

nameplates for correct current ratings and input power information.

Installation and Start-Up Guidelines

4-3

Page 24

4.6 Basic Drive Interconnections

$77(17,21

FDELQHW LWVHOI LV QRW JURXQGHG D JURXQG ZLUH PXVW EH FRQQHFWHG WR WKH

!

The SA500 drive requires interconnecting wiring per applicable codes between the

drive and the following:

•

motor

•

operator ’s control station (if used)

•

resolver

•

UDC module

•

earth ground

Refer to the Elementary Diagram (W/E) (and the Interconnection Diagram (W/I) if

provided) supplied with your drive for these interconnections. Be sure that the W/E

number corresponds to that on the drive’s cabinet or Power Module nameplate. All

interconnecting wiring must be sized and installed in conformance with the National

Electrical Code and applicable local or other codes.

GULYH FDELQHW WR SURYLGH VDIHW\ IRU SHUVRQQHO $OVR WKH PRWRU IUDPHVKRXOG

EH JURXQGHG E\ VROLGO\ FRQQHFWLQJ D JURXQG ZLUH WR D VFUHZ LQ WKH FRQGXLW

ER[ )DLOXUH WR REVHUYH WKHVH SUHFDXWLRQV FRXOG UHVXOW LQ VHYHUH ERGLO\

LQMXU\ RU ORVV RI OLIH

$77(17,21

ORFDO QDWLRQDO DQG LQWHUQDWLRQDO FRGHV )DLOXUH WR REVHUYH WKLV

SUHFDXWLRQV FRXOG UHVXOW LQ GDPDJH WR RU GHVWUXFWLRQ RI WKH HTXLSPHQW

,I \RXU GULYH FDELQHW LV PRXQWHG LQ VXFK D ZD\ WKDW WKH

7KH XVHU LV UHVSRQVLEOH IRU FRQIRUPLQJ ZLWK DOO DSSOLFDEOH

Unless a standard pre-built fiber-optic cable was included with your system, the

fiber-optic cabling that links the UDC module(s) in the AutoMax rack with the Power

Module(s) containing the PMI(s) must be installed by someone experienced in

installing fiber-optic cables. Unless you have in-house expertise in installing fiber-optic

cable, it is recommended that you contact an experienced contractor to perform the

installation. Information regarding the selection and installation of fiber-optic cabling is

contained in the Distributed Power System Fiber-Optic Cabling instruction manual

(S-3009).

4.7 Drive Inspection and Start-up Guidelines

$77(17,21

RSHUDWLRQ RI WKLV HTXLSPHQW DQG WKH KD]DUGV LQYROYHG VKRXOG LQVWDOO

!

DGMXVW RSHUDWH RU VHUYLFH WKLV HTXLSPHQW 5HDG DQG XQGHUVWDQG WKLV

PDQXDO DQG RWKHU DSSOLFDEOH PDQXDOV LQ WKHLU HQWLUHW\ EHIRUH SURFHHGLQJ

)DLOXUH WR REVHUYH WKLV SUHFDXWLRQ FRXOG UHVXOW LQ VHYHUH ERGLO\ LQMXU\ RU

ORVV RI OLIH

$77(17,21

power has been disconnected. After disconnecting input power from the

DC bus supply, w ait five (5) minutes and then measure the voltage at the

POS and NEG terminals of the DC bus supply and each Power Module

to ensure the DC bus capacitors are discharged before touching any

internal components. Failure to observe this precaution could result in

severe bodily injury or loss of life.

2QO\ TXDOLILHG SHUVRQQHO IDPLOLDU ZLWK WKH FRQVWUXFWLRQ DQG

DC bus capacitors retain hazardous voltages after input

4-4

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 25

Use the procedures that follow to locate any shipping damage to the drive, to verify

proper installation and field wiring, and to start the drive.

Recommended Start-Up Sequence

1. Physical inspection of equipment

2. Motor checks

3. Preliminary inspection with power off

4. Inspection with power on

5. I/O verification

Before attempting to perform this start-up procedure, you should be familiar with the

general arrangement and function of the drive equipment and should verify that it has

been installed and wired as described in the following documents, which are included

in the Instruction Book provided with your drive system: Wiring Diagrams (W/Ds),

Elementary Diagrams (W/Es), Panel Layout Diagrams (W/Ls), Operator's Station

Diagrams (W/Os), and Interconnection Diagrams (W/Is) if supplied.

4.7.1 What To Do After Unexpected Test Results

If it is not possible to obtain the correct meter reading or proper operation during any

of the tests or adjustment procedures described in the following sections, perform the

following steps:

Step 1. Stop the drive.

Step 2. Turn off and lock out all incoming power.

$77(17,21

power has been disconnected. After disconnecting input power from the

!

Step 3. Wait five minutes to allow the DC bus voltage to dissipate.

Step 4. Measure the voltage at the POS and NEG terminals on the DC bus supply

DC bus supply, w ait five (5) minutes and then measure the voltage at the

POS and NEG terminals of the DC bus supply and each Power Module

to ensure the DC bus capacitors are discharged before touching any

internal components. Failure to observe this precaution could result in

severe bodily injury or loss of life.

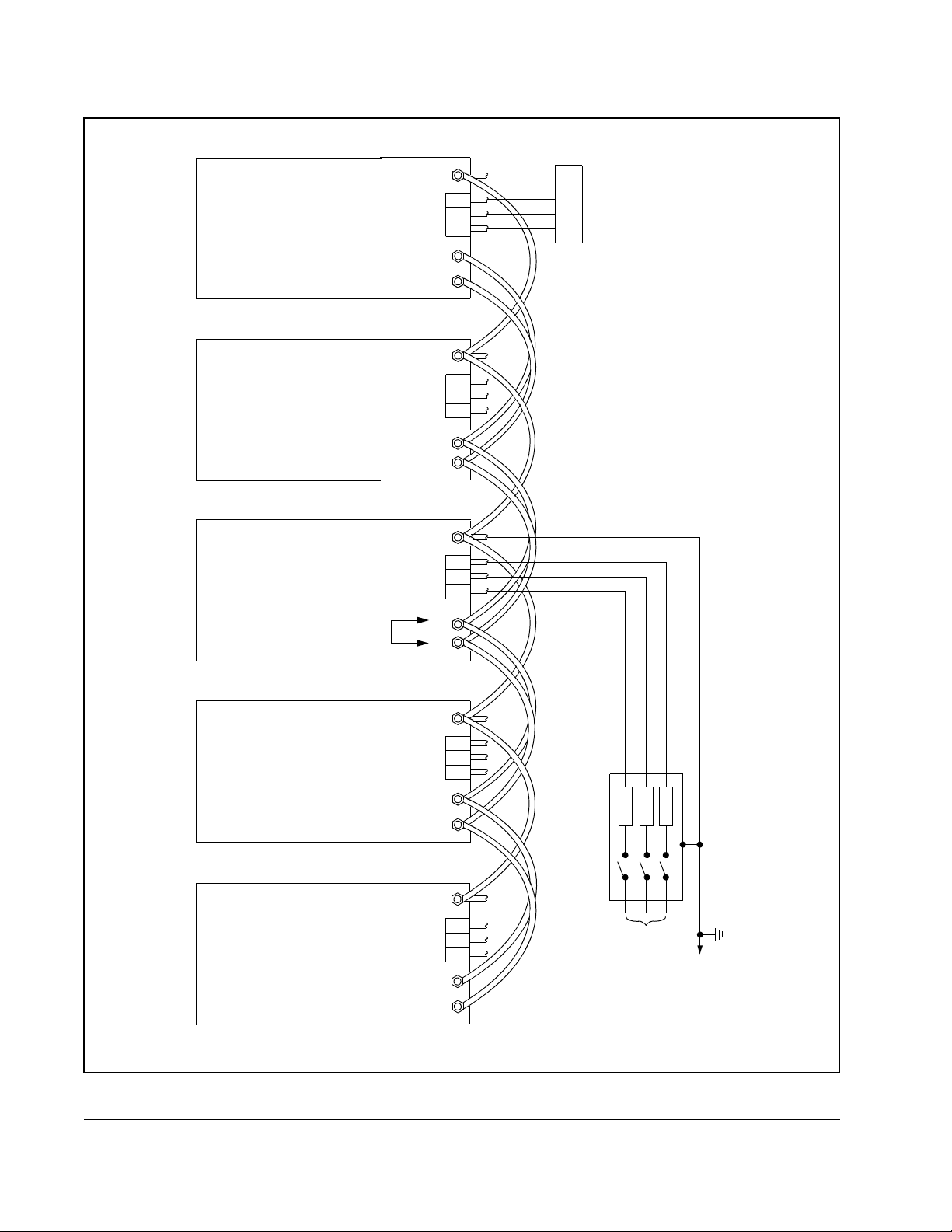

and each Power Module before working on any unit. Refer to figure 4.1.

When the DC bus potential is down to less than 5 volts, touch a 50 ohm,

50 W or larger resistor to each unit’s POS and NEG terminals for 20 seconds

to allow any remaining voltage to dissipate.

Remove the resistor and re-measure the DC bus potential to ensure the DC

bus capacitors are completely discharged.

DC bus capacitors retain hazardous voltages after input

Installation and Start-Up Guidelines

4-5

Page 26

SA500 AC

SA500 AC

UVW

Power Module

Power Module

NEG GND

POS

GND

UVW

NEG

POS

GND

L3

Motor

NEG

POS

GND

NEG

POS

GND

NEG

POS

L1 L2

VW

U

UVW

Fuse

Fuse

Fuse

Fuse Disconnecting Switch

PE

Voltage

AC Input

(3-Phase)

To grounding rod

or Building Steel

SA500

Supply

DC Bus

Measure

DC Bus

Voltage

Here

SA500 AC

Power Module

SA500 AC

Power Module

4-6

Figure 4.1 – POS and NEG Terminals on the DC Bus Supply

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 27

Step 5. Verify the following:

a. All connections are in strict conformance to the wiring diagrams.

b. There are no loose or broken connections.

c. There are no damaged components.

Step 6. Repeat the original test that failed.

4.7.2 Recommended Test Equipment

Rockwell recommends the following test equipment:

•

Isolated oscilloscope with a current probe and x100 probe for DC bus

measurements. An isolation transformer is needed to isolate the oscilloscope and

any other equipment.

•

AC and DC clamp-on ammeters

•

Isolated multimeter having a sensitivity of 20KΩ/volt

•

Chart recorder

•

Isolated voltmeter

•

50 ohm, 50W resistor for discharging bus capacitors

•

Appropriate safety equipment, e.g., safety glasses and safety gloves

A megohmmeter (megger) may be used to reliably verify the absence of inadvertent

grounding of the motor. Failure to follow proper procedure when using a megger may

cause damage to the drive.

$77(17,21

WKH URWDWLQJ HTXLSPHQW DQG WKH GULYH FDELQHW 7KLV ZLOO SUHYHQW GDPDJH

!

WR HOHFWURQLF FLUFXLWU\ 3RZHU 0RGXOHV DQG WKHLU DVVRFLDWHG FLUFXLWV HWF

GXH WR WKH KLJK YROWDJH JHQHUDWHG E\ WKH PHJJHU )DLOXUH WR REVHUYH WKLV

SUHFDXWLRQ FRXOG UHVXOW LQ GDPDJH WR RU GHVWUXFWLRQ RI WKH HTXLSPHQW

,I D PHJRKPPHWHU LV XVHG GLVFRQQHFW DOO OHDGV EHWZHHQ

4.7.3 Physically Inspecting the Equipment

Before operating the equipment, DISCONNECT AND LOCK OUT ALL INCOMING

LINE POWER AND CONTROL POWER TO THE DRIVE and perform the following

steps:

Step 1. Carefully inspect the Power Module and other drive components for physical

damage. Verify free operation of all switch relays, auxiliary contacts, and

contactors.

Step 2. Visually inspect internal wiring for loose or broken connections or damaged

wires.

Step 3. Visually check for damaged components.

Step 4. Check fuses.

Step 5. Verify that all shutdown interlocks around the machine are operational.

Installation and Start-Up Guidelines

4-7

Page 28

4.7.4 Physically Inspecting the Motor

Carefully read and understand the instruction manual that describes your motor. Then

make the following motor inspection. Refer to section 4.7.1, What to Do After

Unexpected Test Results, for more information.:

Step 1. Disconnect and lockout all incoming line power and control power to the

drive.

Step 2. Check that the motor is installed according to the motor’s instruction manual.

Step 3. If possible, uncouple the motor from the driven machinery.

Step 4. Rotate the motor shaft by hand to check that the motor is free from any

binding or mechanical load problem.

Step 5. Check that no loose items such as shaft keys, couplings, etc., are present.

Step 6. Check all connections for tightness and proper insulation.

Step 7. Check that the interior of the motor is clean and dry.

$77(17,21

DQG ORRVH URWDWLQJ SDUWV WR SUHYHQW WKHP IURPIO\LQJ RII 5HSODFH DOO FRYHUV

!

DQG SURWHFWLYH GHYLFHV )DLOXUH WR REVHUYH WKHVH SUHFDXWLRQV FRXOG UHVXOW

LQ GDPDJH WR HTXLSPHQW DQG ERGLO\ LQMXU\

%HIRUH VWDUWLQJ WKH PRWRU UHPRYH DOO XQXVHG VKDIW NH\V

4.7.5 Checking the Installation with Power Off

Perform the following tests to verify that:

•

Correct power is being supplied to the drive

•

Wiring has been done properly

•

There are no grounds in the magnetic control circuits or rotating equipment

•

All safety devices are in place and functional.

Step 1. If the drive is powered up, disconnect and lock out all incoming line power

and control power to the drive. Refer to section 4.7.1 for additional

information on measuring and discharging DC bus voltage.

If the drive is not under power, proceed to step 2.

$77(17,21

power has been disconnected. After disconnecting input power from the

!

DC bus supply, w ait five (5) minutes and then measure the voltage at the

POS and NEG terminals of the DC bus supply and each Power Module

to ensure the DC bus capacitors are discharged before touching any

internal components. Failure to observe this precaution could result in

severe bodily injury or loss of life.

DC bus capacitors retain hazardous voltages after input

4-8

Step 2. Visually check that the AC supply to the DC bus supply is of the correct

voltage and frequency and that the plant supply branch from which the drive

is to be operated is of sufficient ampacity to supply drive input current

requirements.

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 29

Step 3. Verify that all drive components have been properly installed and interwired

per the instructions provided in the wiring diagrams (W/Ds, W/Es, W/Ls,

W/Os, and W/Is).

Step 4. Rotate the 1/4 turn cover fasteners securing the Power Module cover.

Remove the cover. Inspect the Power Module for cables that may have come

loose during shipping. Replace and re-secure the Power Module cover.

Step 5. Check for grounds in the magnetic control circuits. Always use an ohmmeter

to check for grounds in resolver circuits.

Step 6. Check rotating equipment for grounds.

Step 7. Check for tight connections on all wiring.

Step 8. Check circuit breaker trip settings.

Step 9. Verify that all safety devices are in place.

Step 10. Check fuses.

4.7.6 Testing Power Modules with Power On

$77(17,21

RSHUDWLRQ RI WKLV HTXLSPHQW DQG WKH KD]DUGV LQYROYHG VKRXOG LQVWDOO

!

The following steps are required to test SA500 Power Modules before they can be put

into service.

Perform the following steps before attempting to start the drive:

Step 1. Check the DC bus supply’s DC power levels.

DGMXVW RSHUDWH RU VHUYLFH WKLV HTXLSPHQW 5HDG DQG XQGHUVWDQG WKLV

PDQXDO DQG RWKHU DSSOLFDEOH PDQXDOV LQ WKHLU HQWLUHW\ EHIRUH SURFHHGLQJ

)DLOXUH WR REVHUYH WKLV SUHFDXWLRQ FRXOG UHVXOW LQ VHYHUH ERGLO\ LQMXU\ RU

ORVV RI OLIH

$77(17,21

H[WUHPH FDXWLRQ DV KD]DUGRXV YROWDJH H[LVWV )DLOXUH WR REVHUYH WKLV

SUHFDXWLRQ FRXOG UHVXOW LQ VHYHUH ERGLO\ LQMXU\ RU ORVV RI OLIH

$77(17,21

WKH GULYH LI QHFHVVDU\ ,I WKH LQSXW SRZHU GLVFRQQHFW DQGRU VWRS

SXVKEXWWRQ DUH RXW RI \RXU UHDFK KDYH DQ DVVRFLDWH VWDWLRQHG WR RSHUDWH

WKHP LQ WKH HYHQW RI GULYH PDOIXQFWLRQ GXULQJ WKHVH LQLWLDO SRZHU FKHFNV

DQG GULYH DGMXVWPHQW )DLOXUH WR REVHUYH WKLV SUHFDXWLRQ FRXOG UHVXOW LQ

GDPDJH WR HTXLSPHQW DQG ERGLO\ LQMXU\

a. Verify that DC input power to the Power Module is off.

b. Connect a DC voltmeter to the POS and NEG terminals on the Power

Module.

2QO\ TXDOLILHG SHUVRQQHO IDPLOLDU ZLWK WKH FRQVWUXFWLRQ DQG

7KLV SURFHGXUH LV SHUIRUPHG ZLWK SRZHU RQ ([HUFLVH

%HIRUH SURFHHGLQJ PDNH VXUH WKDW \RX FDQ TXLFNO\ VWRS

Step 2. If the motor uses 3-phase AC to power its blower motor, verify proper blower

Installation and Start-Up Guidelines

c. Apply power to the drive and verify that the DC voltage level is correct.

motor rotation. Check to see that air is being forced into the motor. If air flow

is reversed (air is being pulled out of the motor), remove AC input power from

the blower motor and interchange any two AC line power wires feeding the

blower motor. Note that the blower motor must be wired to a fixed AC power

source and not to the Power Module.

4-9

Page 30

4.7.7 I/O Verification

I/O verification consists of ensuring that all physical I/O is properly connected and

functional, and that all critical registers and bits can be accessed in the UDC dual port

memory. Before verifying the I/O, ensure that the following have been loaded to the

AutoMax rack. Note that the application tasks should not be put into run before you

have verified all I/O.

•

AutoMax Processor and UDC operating systems

•

Rack configuration

•

Drive parameters

•

All application tasks

The procedures described in the following sections are performed using the Monitor

I/O function in the AutoMax Programming Executive software.

4.7.7.1 Testing UDC/PMI Communication Status

This section describes how to test the UDC/PMI communication status registers. Use

the AutoMax Programming Executive software I/O Monitor function to display the

UDC/PMI Communication Status registers in the format listed in table 4.1.

Table 4.1 – UDC/PMI Communication Status Register Formats

Drive

A / B Register Name (format)

80 / 1080 UDC Module Ports A/B Status (binary)

81 / 1081 UDC Module Ports A/B Receive Count (decimal)

82 / 1082 UDC Module Ports A/B CRC Error Count (decimal)

83 / 1083 UDC Module Ports A/B Format Error Count (decimal)

84 / 1084 PMI A/B Status (binary)

85 / 1085 PMI A/B Receive Count (decimal)

86 / 1086 PMI A/B CRC Error Count (decimal)

87 / 1087 PMI A/B Format Error Count (decimal)

88 / 1088 UDC Module Ports A/B Fiber-Optic Link Status (hexadecimal)

89 / 1089 UDC Module Ports A/B Transmitted Message Count (decimal)

Step 1. Examine registers 80/1080 and 84/1084 for any errors reported to the UDC

module and PMI related to UDC/PMI communication. If any bits in these

registers are on, try to determine what caused the error.

Step 2. Examine registers 81/1081 and 85/1085 for the number of messages

received by the UDC module and PMI. Over time, this 16-bit value should

increase to its maximum value (32767) and then roll over.

Step 3. Examine registers 82/1082 and 83/1083 (and 86/1086 and 87/1087) for the

number of CRC and format errors received on the UDC module (and PMI). If

either of these values is incrementing, it indicates a problem.

4-10

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 31

Step 4. Examine register 88/1088 for the status of the fiber-optic ports on the UDC

module. If the operating systems are loaded and no tasks are running, the

lower byte should be equal to xx03H (UDC module and PMI are exchanging

data). The upper byte should be equal to 02xxH (communication between the

UDC module and PMI is unsynchronized). Note that “xx” in the byte

descriptions indicates “not used.”

Step 5. Examine register 89/1089 for the number of messages transmitted by the

UDC module. Over time, this 16-bit value should increase to its maximum

value (32767) and then roll over.

4.7.7.2 Testing Rail I/O Registers

This section describes how to test the rail I/O registers if used in your system

configuration. Use the AutoMax Programming Executive software I/O Monitor function

to display the Rail I/O registers in the format listed in table 4.2.

Display these registers in decimal format if they are used for analog I/O. Display t hem

in binary format if they are used for digital I/O.

Drive

A / B Register Name

0 / 12 PMI Port 0, Channel 0

1 / 13 PMI Port 0, Channel 1

2 / 14 PMI Port 0, Channel 2

3 / 15 PMI Port 0, Channel 3

4 / 16 PMI Port 0, Faults (display in binary format)

5 / 17 PMI Port 0, Ch eck Bit Fault Counter (display in decimal format)

6 / 18 PMI Port 1, Channel 0

7 / 19 PMI Port 1, Channel 1

8 / 20 PMI Port 1, Channel 2

9 / 21 PMI Port 1, Channel 3

10 / 22 PMI Port 1, Faults (display in binary format)

11 / 23 PMI Port 1, Check Bit Fault Counter (display in decimal format)

Table 4.2 – Rail I/O Register Formats

Step 1. Test each analog current or voltage output channel being used by writing a

Step 2. Test each analog current or voltage input channel being used by measuring

Step 3. Test each digital input by initiating the input and verifying that the appropriate

Step 4. Test each digital output by forcing the bit on and verifying that the signal is

Installation and Start-Up Guidelines

value between 0 and 4095 to the appropriate register and measuring with an

ammeter or voltmeter to verify the signal on the terminal points (4-20mA or

0-10V) is proportional to the register value.

with an ammeter or voltmeter to verify the signal on the terminal points

(4-20mA or 0-10V) is proportional to the value displayed in appropriate

register.

bit (displayed on the screen) turns on.

present on the terminal points.

4-11

Page 32

4.7.7.3 Testing Feedback Registers and Bits

This section describes how to test the feedback registers and bits. Feedback

information provided by the fault, warning, and interlock registers is described in

Appendices A, B, and C. Use the AutoMax Programming Executive software I/O

Monitor function to display the registers and bits in the format listed in table 4.3.

Table 4.3 – Feedback Registers and Bits

Drive A/B Variable Name Description

200 / 1200

Bit 15 (PMI_OK@)

Drive Status Register

PMI Operating System Loaded

201 / 1201 I/O Status Register

Bit 0 (RPI@) Run Permissive Input

Bit 1 (M_FDBK@) M-Contactor Feedback Input or

(AUX_IN1@) 115VAC Auxiliary Input 1

Bit 2 (AUX_IN2@) 115VAC Auxiliary Input 2

Bit 3 (AUX_IN3@) 115VAC Auxiliary Input 3

Bit 4 (AUX_IN4@) 115VAC Auxiliary Input 4

Bit 5 (AUX_IN5@) 115VAC Auxiliary Input 5

Bit 8 (STR_DET@) External Strobe Detected

203 / 1203 Drive Warning Register

Bit 13 (WRN_RAL@) Rail I/O Communication Error

206 / 1206 (SPD_FB%) Speed Feedback (-4095 to +4095)

207 / 1207 (TRQ_FB%) Torque Feedback (-4095 to +4095)

208 / 1208 (POS_FB%) Position Feedback (-32768 to +32767)

209 / 1209 (POS_REG_OUT%) Position Loop Output (-4095 to +4095)

211 / 1211 (I_FBN%) Current Feedback (normalized) (-4095 to +4095)

213 / 1213 (SPD_ERR%) Speed Error (-4095 to +4095)

214 / 1214 (USER_AIN%) Analog Input (-2048 = -10 V to +2047 = +10V)

215 / 1215 (RES_SCN_POS%) Resolver Scan Position (-32768 to +32767)

216 / 1216 (RES_STR_POS%) Resolver Strobe Position (-32768 to 32767)

217 / 1217 (RPM%) Revolutions Per Minute

218 / 1218 (POS_ERR%) Position Error (-4095 to +4095)

219 / 1219 (SPI_OUT%) Speed Loop P+I Output (-4095 to +4095)

220 / 1220 (WR2_COMP%) Speed Loop Feedforward Output (-4095 to +4095)

221 / 1221 (SLP_RPM%) RPM Slip

4-12

Step 1. Verify that register 200/1200, bit 15 is on. This bit is on when PMI operating

system has been successfully downloaded from the UDC module to the PMI.

Step 2. Check each of the inputs identified by bits 1 through 5 of register 201/1201 by

applying 115V to the appropriate pins on the Drive I/O connector on the

Resolver and Drive I/O module and verifying that the appropriate bit is on.

Refer to the SA500 Power Modules instruction manual (S-3018) for the

pinout description.

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 33

Step 3. You may want to create a separate monitor screen for registers 206/1206

through 221/1221 and save it. This will allow you to recall the screen later,

without having to enter the entire list each time you need to monitor feedback

registers. (Note that registers 210/1210 and 212/1212 are not used.)

Step 4. Check the User Analog Input (register 214/1214) by applying an input signal

to the appropriate pins on the Resolver Feedback connector on the Resolver

and Drive I/O module and verifying that register 214/1214 displays an

appropriate value. Refer to instruction manual S-3018 for additional

information.

Step 5. Test the resolver. Be sure the resolver’s sine/cosine wires are connected per

the W/E diagrams. Monitor the value displayed in the Resolver Scan Position

register (215/1215). The value in this register can range from -32768 to

32767.

Rotate the resolver by hand (by turning the motor shaft if the resolver is

mounted/coupled), first in one direction, then in the other direction. The value

in the register should steadily increase in one direction and steadily decrease

in the other direction. If the value in the register does not change at all or if

the va lue does not incr ease /d ecre ase smoo th ly, a problem may exist wi th the

resolver and/or its wiring.

Step 6. Test the external strobe, if used, as follows. Note that the resolver and

external strobe must be connected.

Force register 101, bit 8 (STR_ENA@, Enable External Strobe) on. Verify

that register 201/1201, bit 8 (STR_DET@, External Strobe Detected) is on.

Check the values displayed for registers 215/1215 (RES_SCN_POS%) and

216/1216 (RES_STR_POS%). The values displayed for these two registers

should be very close, if not identical, if the resolver has not turned. After you

have finished, unforce register 101, bit 8.

4.7.7.4 Testing the UDC Module Test Switch Register

This section describes how to test the UDC module test switch register. Use the

AutoMax Programming Executive software I/O Monitor function to display register

1000 in binary format.

Register 1000 reflects the status of the test switches and LED indicators on the UDC

module.

Step 1. Verify the function of the UDC push-button. When the push-button is

Step 2. Verify the function of the UDC Test Switch. When the switch is in the

Installation and Start-Up Guidelines

pressed, register 1000, bit 0 should be on. When the push-button is released,

this bit should be off.

up-position, register 1000, bit 1 should be on. When the switch is in the

down-position, register 1000, bit 2 should be on. When the switch is in the

center position, both of these bits should be off.

4-13

Page 34

4.7.7.5 Testing UDC Module Meter Ports

This section describes how to test the UDC module meter ports. Use the AutoMax

Programming Executive software Monitor Setup UDC/PMI screen. Check each UDC

Meter Port being used as follows:

Step 1. Map registers that you want to display to UDC meter ports 1, 2, 3, and 4. Set

the desired maximum and minimum values.

Step 2. Using the Monitor I/O screen, force a value within the range configured to

each UDC register being output on the meters.

Step 3. Use a voltmeter to verify that the signal on the terminal points (-10V to +10V)

of each meter port is proportional to the value in the corresponding register.

Step 4. Unforce the registers being output on the meter ports to zero.

4.7.8 Performing Uncoupled Motor Tests

The following tests are performed with the motor uncoupled from the load. Ensure that

the limit values entered through the parameter entry screens are correct.

Step 1. Verify that the parameter screen information (Power Module data, motor

data, speed feedback data, and meter port setup) is correct.

Step 2. Perform the resolver gain calibration procedure. This procedure is described

in the SA500 Power Modules instruction manual (S-3018). The Resolver

Gain Calibration Completed bit (register 201/1201, bit 6, RES_GAN@) will

be set to indicate the procedure is complete. Check the value in the local

tunable RES_GAN%. Large gain values (close to 255) may indicate a

problem with the resolver wiring or connections. Refer to the SA500 Drive

Configuration and Programming instruction manual (S-3044) for a list of the

resolvers that may be used with SA500 drives.

4-14

Step 3. Perform the resolver alignment procedure if you are using a brushless motor.

Refer to section 3.3. note that this procedure can be performed with the

motor coupl ed t o the lo ad. Ho wever , it wi ll caus e the mo to r to mo ve less than

one revolution in both the forward and reverse directions. If this motion would

be harmful to your machine, uncouple the motor from the load before

performing this procedure.

Step 4. The Power Module’s AC output phase rotation must match the resolver’s

orientation. Output phase rotation (UVW or UWV) is determined by setting

the Output Rotation parameter, assuming the motor leads are correctly

connected. Resolver orientation is determined by the cosine lead

connections.

a. Place a value of zero in the External Torque Reference register (register

102/1102, TRQ_REF%). Turn on the drive.

b. Slowly increase the value in register 102/1102.

c. If the motor begins turning, verify that the motor shaft is turning in a

clockwise direction. Examine the contents of the Resolver Scan Position

register (register 215/1215, RES_SCN_POS%). The value in the register

should be increasing.

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 35

If the motor does not turn, place a value of zero in register 102/1102 and

turn off the drive. Change the Output Rotation parameter. Regenerate the

parameter object file and reload it to the rack. Restart the drive. Slowly

increase the value in register 102/1102 and verify that the motor is turning.

d. If the motor shaft is turning in a counter-clockwise direction and the

application requires that a clockwise shaft rotation be identified as

“forward” (i.e., the value in register 215/1215 is increasing), perform the

following:

Turn the drive off and switch the resolver’s cosine wires. Change the

Output Rotation parameter. Regenerate the parameter object file and

reload it to the rack.

ATTENTION:

wiring, breaking the resolver coupling, replacing the resolver, or replacing

!

Step 5. Verify that the motor speed can be regulated. The method used to verify

Step 6. Perform the resolver balance calibration procedure. This procedure is also

the motor and resolver for any reason requires that the shaft alignment

test be performed again. Resolver wiring changes always affect shaft

alignment. A resolver change and/or a new motor/resolver combination

will affect the shaft alignment. Improper shaft alignment can cause motor

overspeed when the motor is started. Failure to observe this precaution

could result in bodily injury.

e. If a brushless motor is used and the resolver has been removed, replaced,

or had its cosine wires changed, the resolver alignment test must be

performed as described in section 3.3.

f. Verify the motor shaft rotation is in the desired direction by repeating steps

a and b.

speed regulation will depend upon your application.

described in the SA500 Power Modules instruction manual (S-3018). The

Resolver Balance Calibration Completed bit (register 201/1201, bit 7,

RES_BAL@) will be on when the procedure is complete. The result of this

procedure is stored in local tunable RES_BAL%.

If the Tuning Aborted Warning bit (register 203/1203, bit 5, WRN_TUN@) is

also on, it indicates that the procedure was unsuccessful (caused by leaving

the resolver uncoupled during the procedure or using longer than

recommended cable runs) or yielded unusual results (sine/cosine

magnitudes are not within 5% of each other).

For brushless motor applications, changing any resolver

4.7.9 Running Dynamic Motor Tests

The dynamic motor tests complete the drive start-up. The drive is tuned by running the

single drive section under test in order to adjust motor tracking, maximum speeds,

vernier adjustments, and machine secti on sp eed adj us tme nts.

The driven machine is then run under actual operating conditions with a load in order

to adjust gain values, feedback devices, limit switches, etc., as required, to obtain the

specified performance.

Installation and Start-Up Guidelines

4-15

Page 36

4.7.10 Updated Drawings and Software Listings

When start-up is performed by Rockwell personnel, the W/E, W/M, W/P drawings, and

all software listings are updated after start-up and are re-issued as revised pages of

the Instruction Book. Refer to Installing, Operating and Maintaining Engineered Drive

Systems (D2-3115) for more information.

4-16

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 37

A

PPENDIX

A

Drive Fault Register

Drive Fault Register 202/1202

The bits in the Drive Fault register indicate the cause of a drive shutdown. The bits in this register are latched

until they are reset by setting the Fault Reset bit (bit 8) of the Drive Control register (100/1100, bit 8). After

turning the Fault Reset bit on, the drive may be re-started after turning the desired command bit in register

100/1100 off and then back on again. If the fault condition still exists, the identifying bit in this register will

immediately be set again.

The fault conditions reported in this register result in turning off the drive. The UDC task is not stopped

automatically if a drive fault occurs unless it is specifically instructed to do so in the application task. The user

must ensure that the AutoMax application task tests register 202/1202 and takes appropriate action if a fault

occurs.

Note that the status of this register is also reported in the error log for the task in which the error occurred.

Power Module Overtemperature Fault Bit 0

The Power Module Overtemperature Fault

bit is set if either of the following conditions

occurs:

•

The PMI detects that motor current exceeds 100% of the Power Module’s

continuous capacity at maximum current for a pre-determined amount of time. At

maximum rated current, this trip will occur in 0.5 second.

•

Hardware detects that the temperature of the Power Module’s heatsink exceeds

the configured maximum rating.

Instantaneous Overcurrent Fault Bit 1

The Instantaneous Overcurrent Fault bit is

set if any of the three motor feedback

currents (Iu, Iv, Iw) exceeds 133% of

maximum RMS current.

DC Bus Overvoltage Fault Bit 2

The DC Bus Overvoltage Fault bit is set if

the DC bus voltage exceeds 400 VDC.

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+

)/7B27#

5HDG RQO\

30 )/7

+

)/7B,2&#

5HDG RQO\

(;7 )/7

+

)/7B29#

5HDG RQO\

30 )/7

Drive Fault Register

A-1

Page 38

Vcc Power Supply Undervoltage Fault Bit 3

The Vcc Power Supply Undervoltage Fault

bit is set if the input to the +5V supply on the

PMI drops below the necessary voltage to

maintain regulation.

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+

)/7B9&&#

5HDG RQO\

30 )/7

Position Error Fault Bit 4

The Position Error Fault bit is set if the

position error exceeds the value set in the

PMI Tach Loss Maximum Position Error

register (register 166/1166).

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+

)/7B63'#

5HDG RQO\

1$

1$

Speed Error Bit 5

The Speed Error Fault bit is set if the

maximum velocity error exceeds the value

set in the PMI Tach Loss Maximum Velocity

Error register (register 156/1156).

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+

)/7B63'#

5HDG RQO\

1$

1$

5HVROYHU %URNHQ :LUH )DXOW %LW

The Resolver Broken Wire Fault bit is set if a

sine or cosine signal from the resolver is

missing due to a broken wire or if the

resolver gain tunable (RES_GAN%) has

been set too low.

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+

)/7B7%:#

5HDG RQO\

)'%. 2.

Overspeed Fault Bit 10

The Overspeed Fault bit is set if the motor’s

velocity exceeds the value entered as the

Overspeed Trip (RPM) configuration

parameter.

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+

)/7B263#

5HDG RQO\

(;7 )/7

PMI Power Supply Fault Bit 12

The PMI Power Supply Fault bit is set if the

PMI power supply is not working correctly

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+

)/7B36#

5HDG RQO\

3:5 2.

A-2

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 39

PMI Bus Fault Bit 13

The PMI Bus Fault bit is set if a problem is

detected with the address and data bus on

the PMI regulator board in the Power

Module

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+

)/7B%86#

5HDG RQO\

1$

UDC Run Fault Bit 14

The UDC Run Fault bit is set if the UDC task

stops while the minor loop is running in the

PMI.

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+

)/7B581#

5HDG RQO\

1$

Communication Lost Fault Bit 15

The Communication Lost Fault bit is set if

the fiber -optic communication between the

PMI Processor and the UDC module is lost

due to two consecutive errors of any type.

+H[ 9DOXH

6XJ 9DU 1DPH

$FFHVV

8'& (UURU &RGH

/('

+

)/7B&20#

5HDG RQO\

&200 2.

This bit is set only after communication between the PMI Regulator and UDC

module has been established. This bit should be used in the run permissive logic for

the drive. Also refer to the CCLK Synchronized bit (register 200/1200, bit 14).

Drive Fault Register

A-3

Page 40

A-4

SA500 Diagnostics, Troubleshooting, and Start-Up Guidelines

Page 41

A

PPENDIX

B

Drive Warning Register

'ULYH :DUQLQJ 5HJLVWHU