Page 1

Distributed Power System

High Power SA3000

AC Power Modules

850020 – 11xxx, 21xxx (534 Amp)

850020 – 12xxx, 22xxx (972 Amp)

850020 – 13xxx, 23xxx (1457 Amp)

Instruction Manual

S-3038

Page 2

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

ATTENTION:Only qualified personnel familiar with the construction and operation of this

equipment and the hazards involved should install, adjust, operate, or service this equipment.

!

Read and understand this manual and other applicable manuals in their entirety before

proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:DC bus capacitors retain hazardous voltages after input power has been

disconnected. After disconnecting input power, wait ten (10) minutes for the DC bus capacitors

to discharge. Open the cabinet doors and check the voltage across the DC bus bars, 347 A,B,C

(+ bus) and 345 A,B,C (- bus), with an external voltmeter to ensure the DC bus capacitors are

discharged before touching any internal components. Failure to observe this precaution could

result in severe bodily injury or loss of life.

ATTENTION:The user must provide an external, hardwired emergency stop circuit outside of the

drive circuitry. This circuit must disable the system in case of improper operation. Uncontrolled

machine operation may result if this procedure is not followed. Failure to observe this precaution

could result in bodily injury.

ATTENTION: The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

The information in this users manual is subject to change without notice.

AutoMax™ is a trademark of Rockwell Automation

©1998 Rockwell International Corporation

Page 3

Chapter 1 Introduction

1.1 Standard Features...........................................................................................1-1

1.2 Optional Features............................................................................................1-2

1.3 Power Module Part Numbers ..........................................................................1-3

1.4 Related Publications........................................................................................ 1-4

1.5 Related Hardware and Software ..................................................................... 1-4

Chapter 2 Mechanical/Electrical Description

2.1 Mechanical Description ...................................................................................2-1

2.1.1 Power Module Components..................................................................2-1

2.2 Electrical Description .......................................................................................2-6

Chapter 3 Installation Guidelines

3.1 Installation Planning ........................................................................................3-1

3.2 Wiring .............................................................................................................. 3-2

3.2.1 Fuses ....................................................................................................3-2

3.2.2 Wire Sizes.............................................................................................3-2

3.2.3 Wire Routing ......................................................................................... 3-3

3.3 Grounding........................................................................................................ 3-3

3.4 Installing the Power Module Cabinet.. ....... ...... ....... ...... ....... ...... ....... ...... .........3-3

C

ONTENTS

Chapter 4 Diagnostics and Troubleshooting

4.1 Required Test Equipment................................................................................4-1

4.2 Power Module Tests with Input Power Off ...................................................... 4-2

4.3 Power Module Faults and Warnings................................................................ 4-4

4.3.1 Power Module Faults ............................................................................ 4-5

4.3.1.1 DC Bus Overvoltage Fault ......................................................4-5

4.3.1.2 DC Bus Overcurrent Fault....................................................... 4-5

4.3.1.3 Ground Current Fault..............................................................4-5

4.3.1.4 Instantaneous Overcurrent Fault ............................................4-6

4.3.1.5 Local Power Interface Fault ....................................................4-6

4.3.1.6 Charge Bus Time-Out Fault ....................................................4-6

4.3.1.7 Overtemperature Fault...................................... ....... ...... ....... .. 4-6

4.3.2 Power Module Warnings ....................................................................... 4-7

4.3.2.1 DC Bus Overvoltage Warning................................................. 4-7

4.3.2.2 DC Bus Undervoltage Warning............................................... 4-7

4.3.2.3 Ground Current Warning......................................................... 4-7

4.3.2.4 Load Sharing Warning ............................................................4-7

4.3.2.5 Overtemperature Warning .................................................... .. 4-8

4.4 Replacing Power Module Fuses and Sub-Assemblies.................................... 4-8

4.4.1 Replacing Fuses ...................................................................................4-8

4.4.2 Replacing an IGBT Phase Module Assembly ..................................... 4-15

4.4.2.1 Replacing an IGBT................................................................ 4-17

4.4.3 Replacing the Pre-charge Assembly...................................................4-17

4.4.4 Replacing a Blower Assembly............................................................. 4-18

4.4.4.1 Replacing a Blower Filter...................................................... 4-19

4.4.5 Replacing a Bus Capacitor Assembly ................................................. 4-19

4.5 Replacing the Power Module Cabinet ........................................................... 4-20

Table of Contents

I

Page 4

Appendix A Technical Specifications........................................................................................... A-1

Appendix B SA3000 Internal DC Bus Control ............................................................................. B-1

Appendix C Replacement Parts ....... ...... ....... ...... ....... ...... ...... ....... ....................................... ...... .. C-1

Index ..................................... ...... ....... ...... ....... ...... ....................................... ...... ....... ..Index-1

II

High Power SA3000 AC Power Modules

Page 5

List of Figures

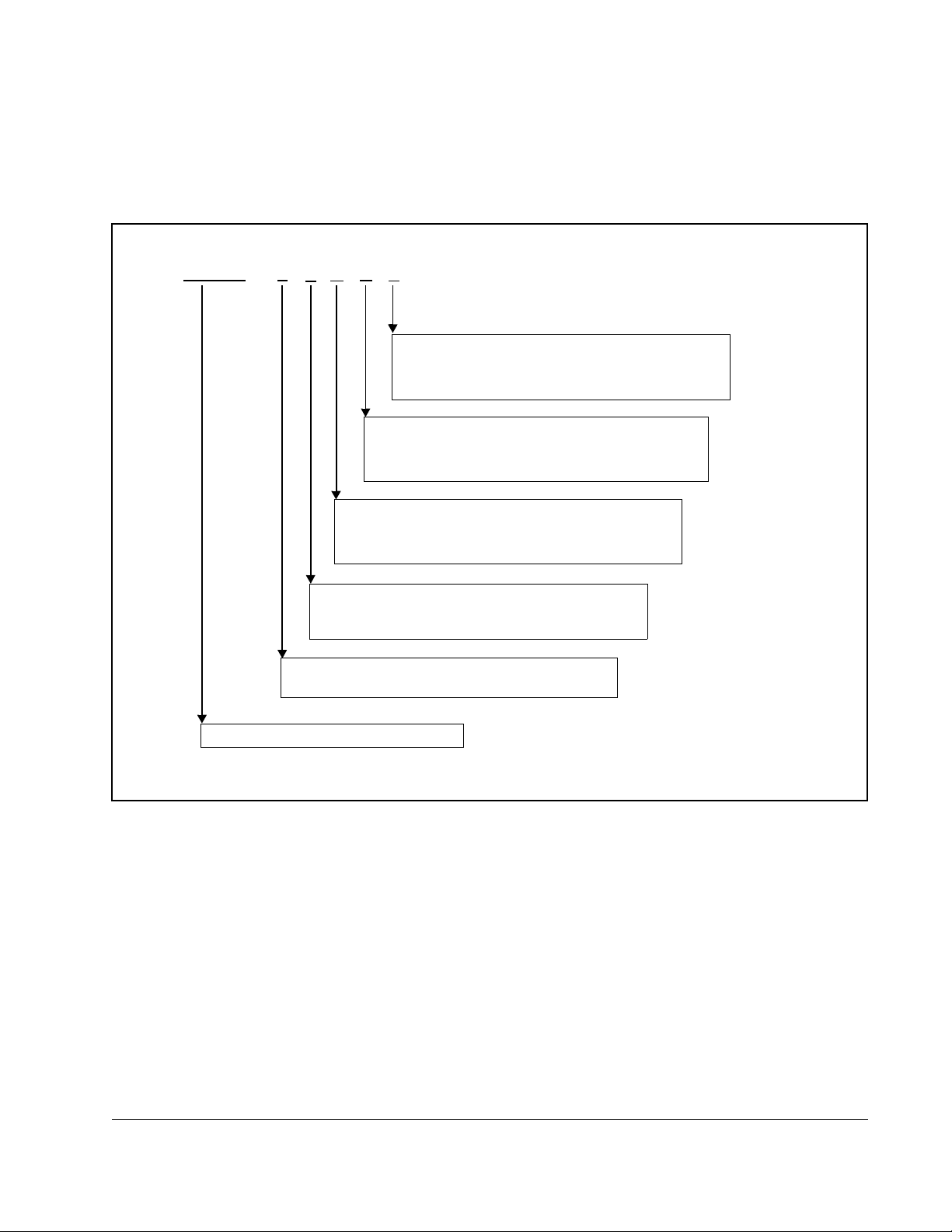

Figure 1.1 – SA3000 Power Module Part Numbering Scheme ................................1-3

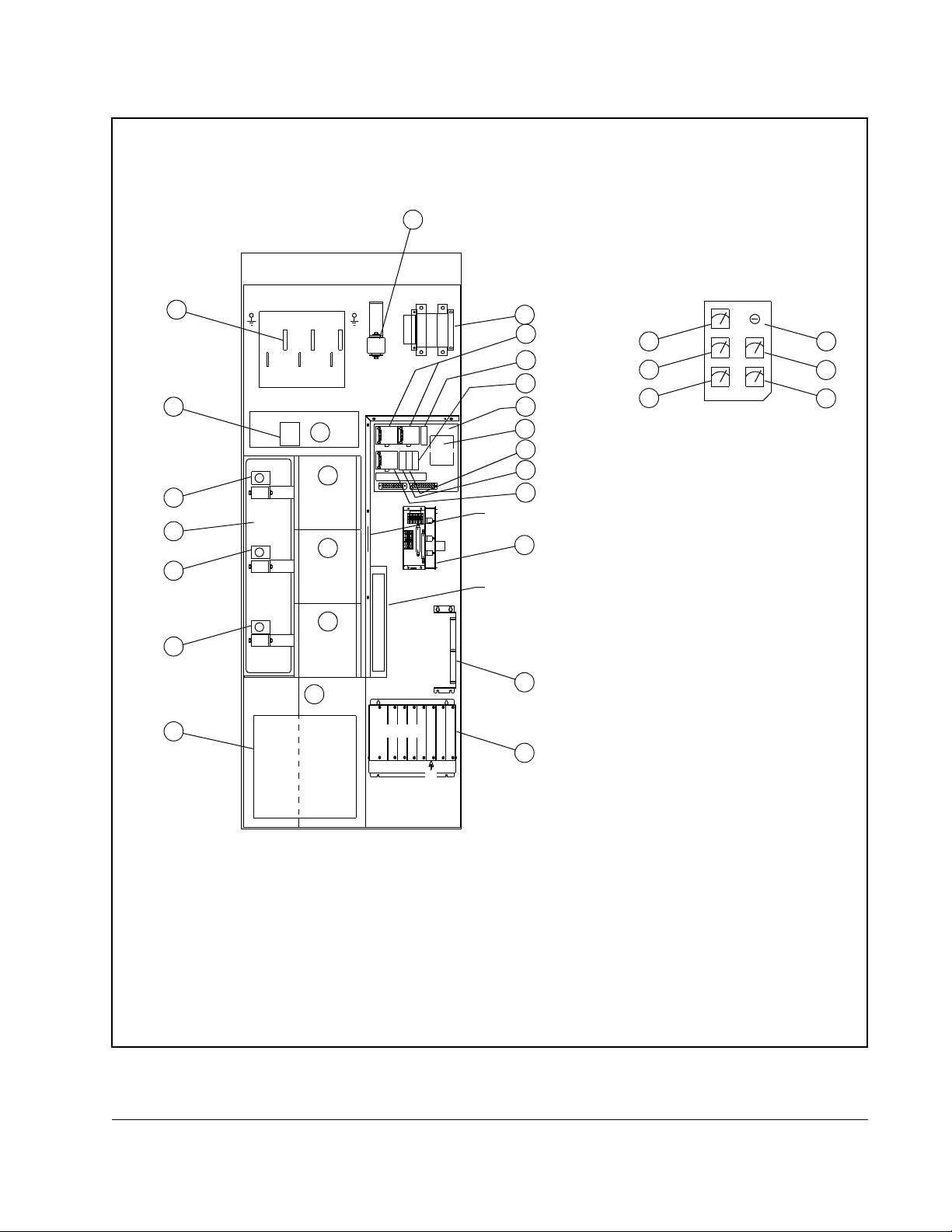

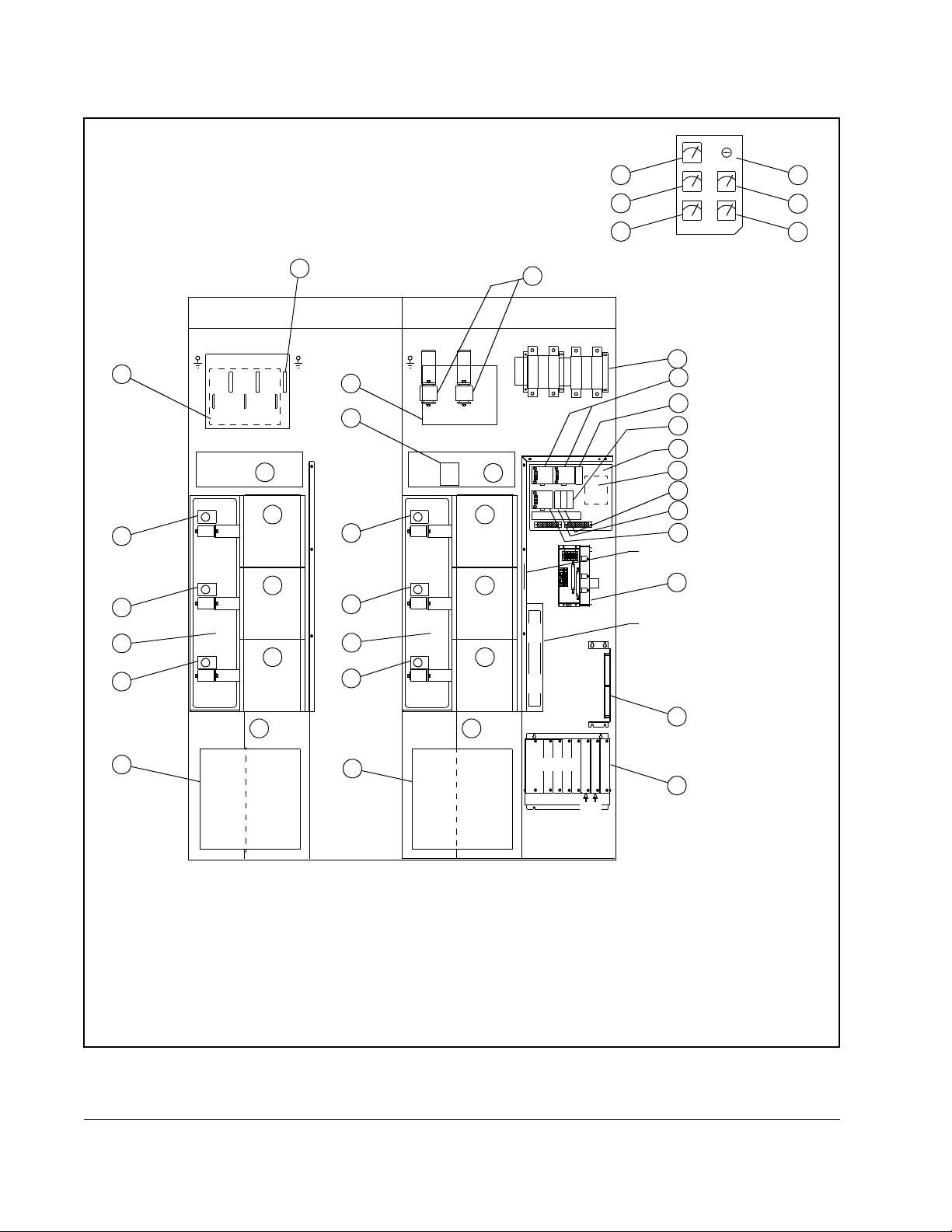

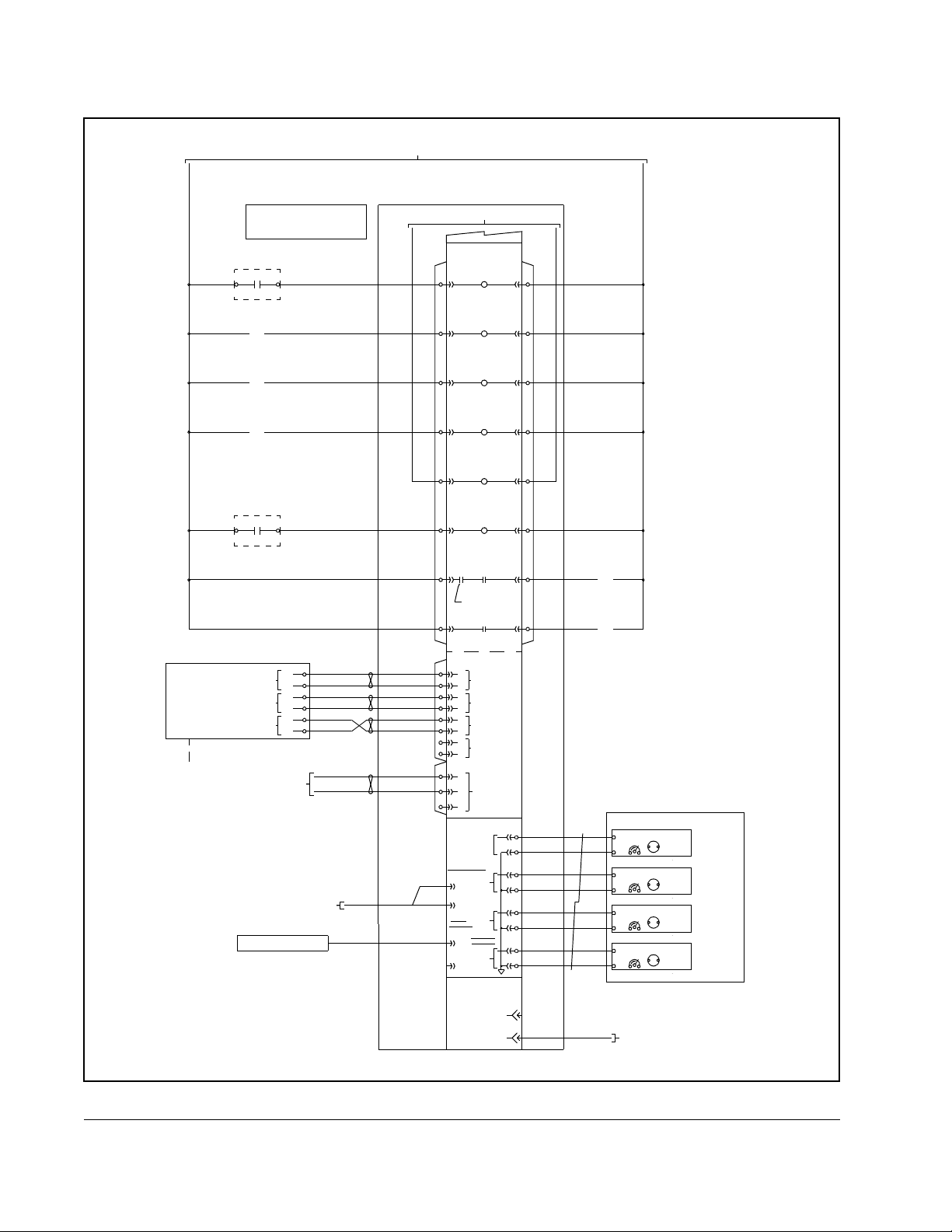

Figure 2.1 – 534A SA3000 Power Module Components.......................................... 2-3

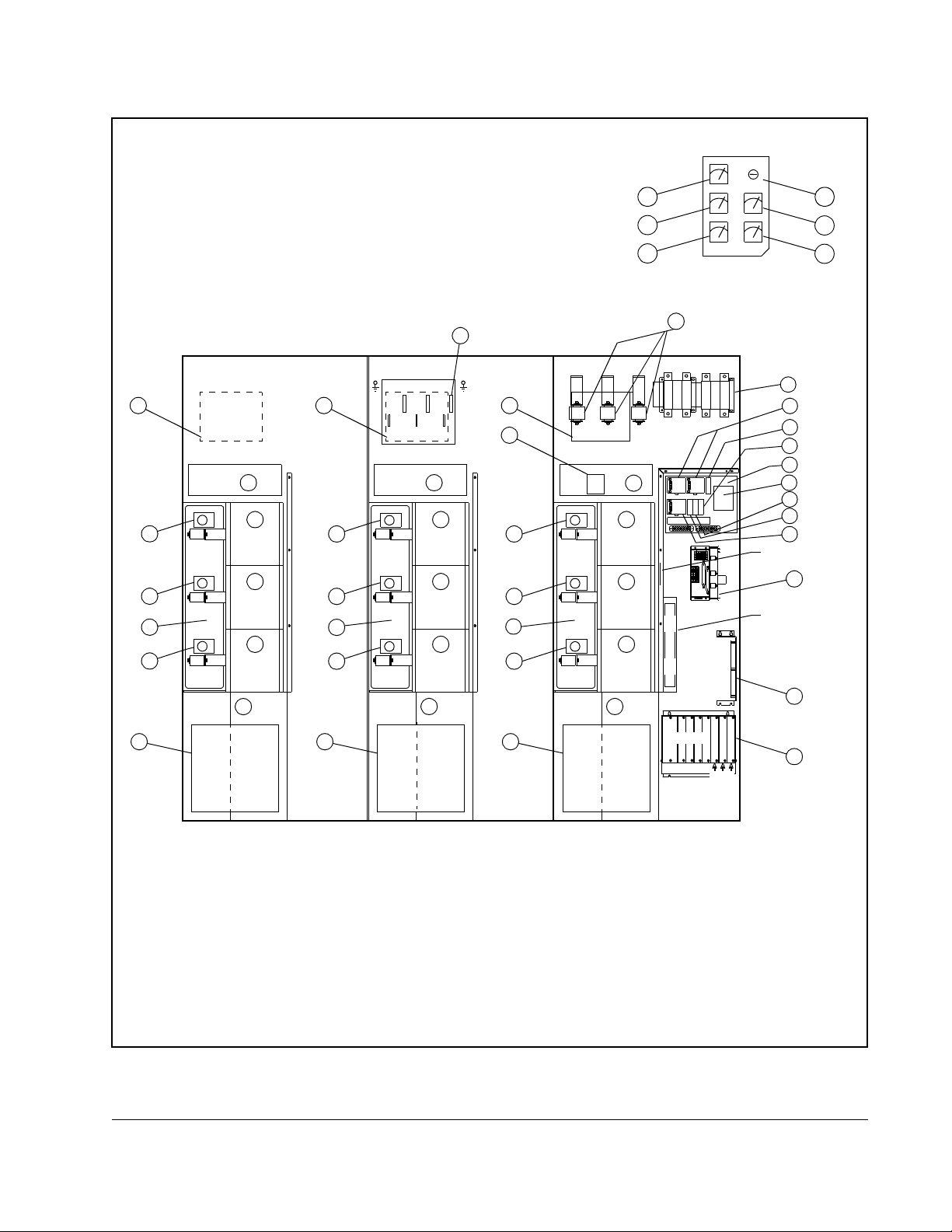

Figure 2.2 – 972A 3000A Power Module Components ............................................2-4

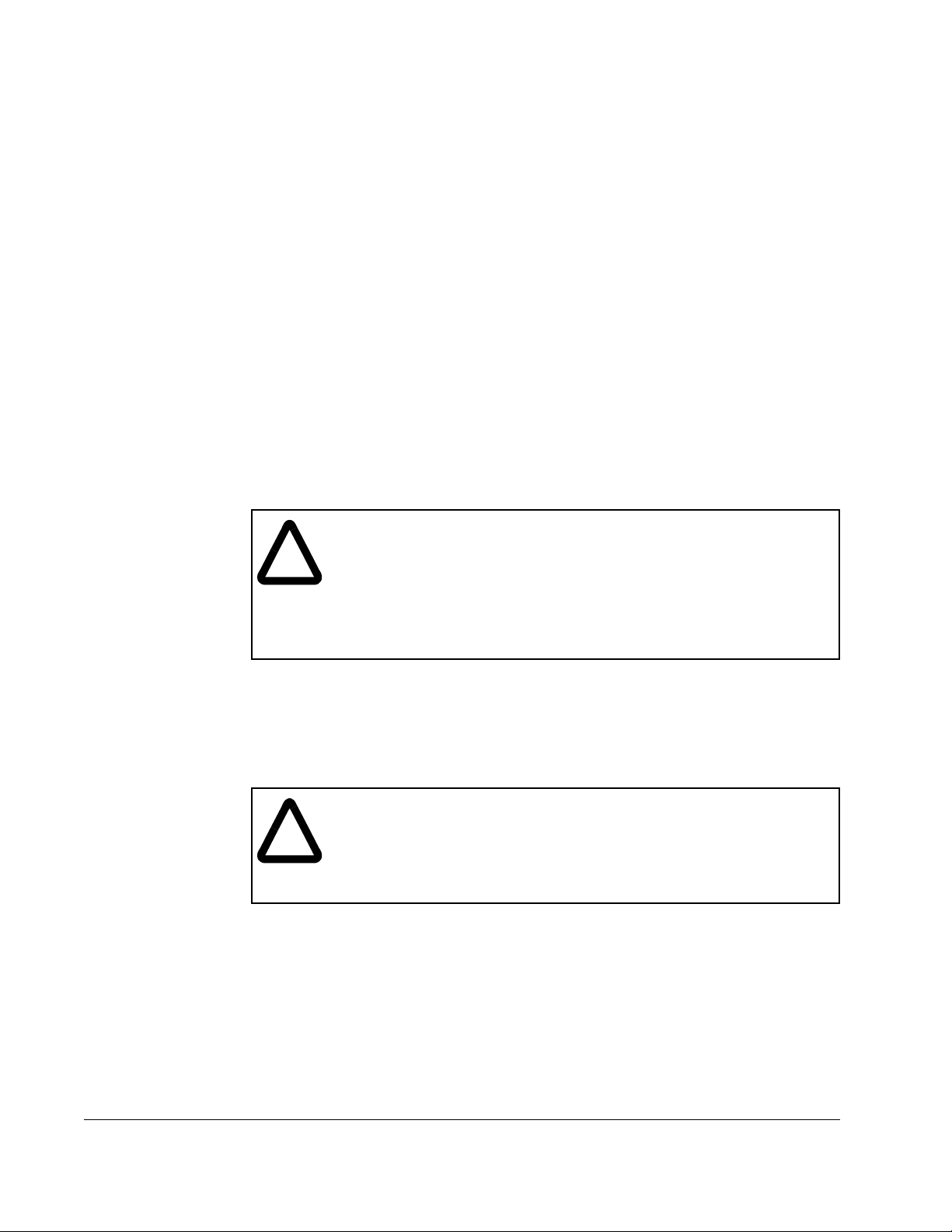

Figure 2.3 – 1457A SA3000 Power Module Components........................................ 2-5

Figure 2.4 – Drive I/O and Processor Card Detail .................................................... 2-8

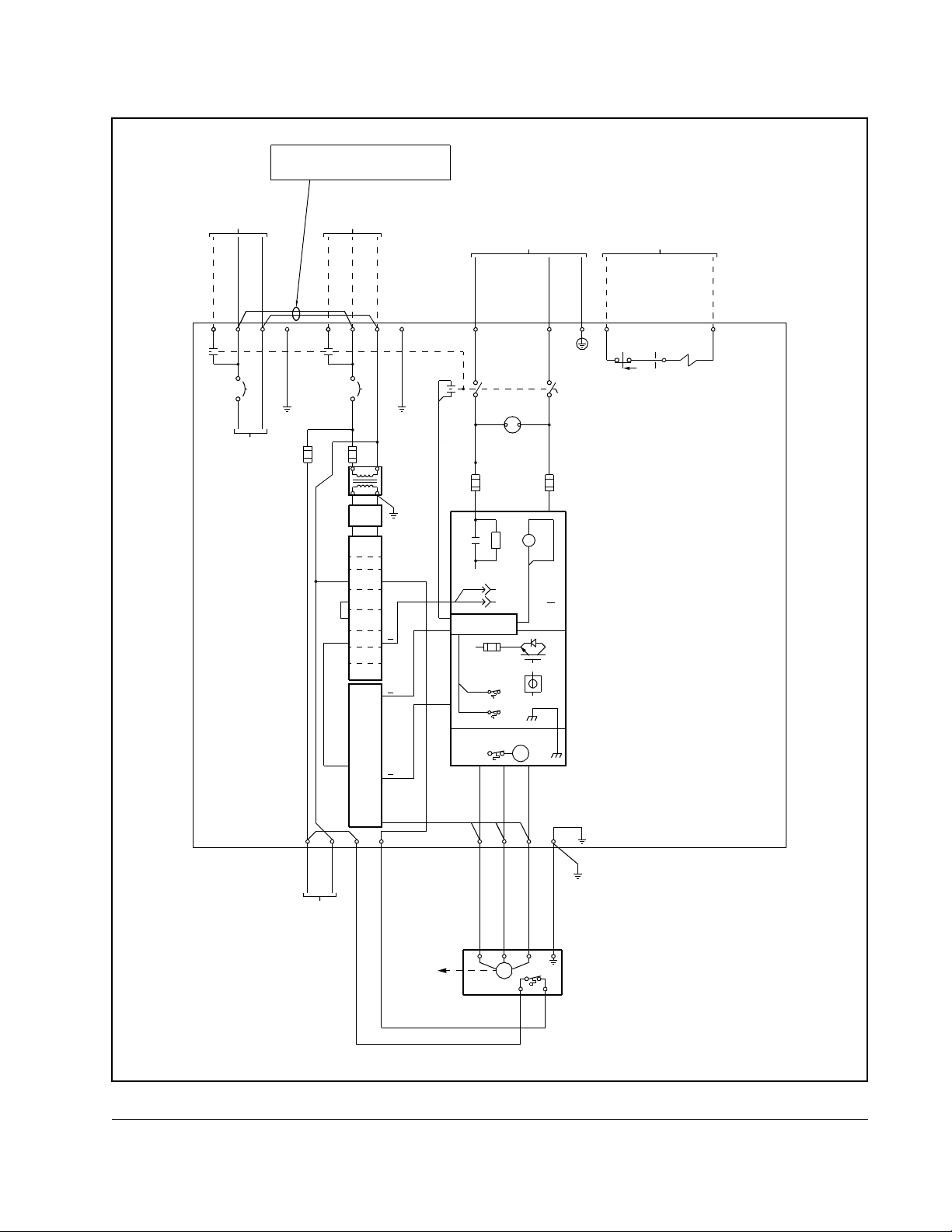

Figure 2.5 – 534A SA3000 Power Module Circuitry ................................................. 2-9

Figure 2.6 – 972A SA3000 Power Module Circuitry ...............................................2-10

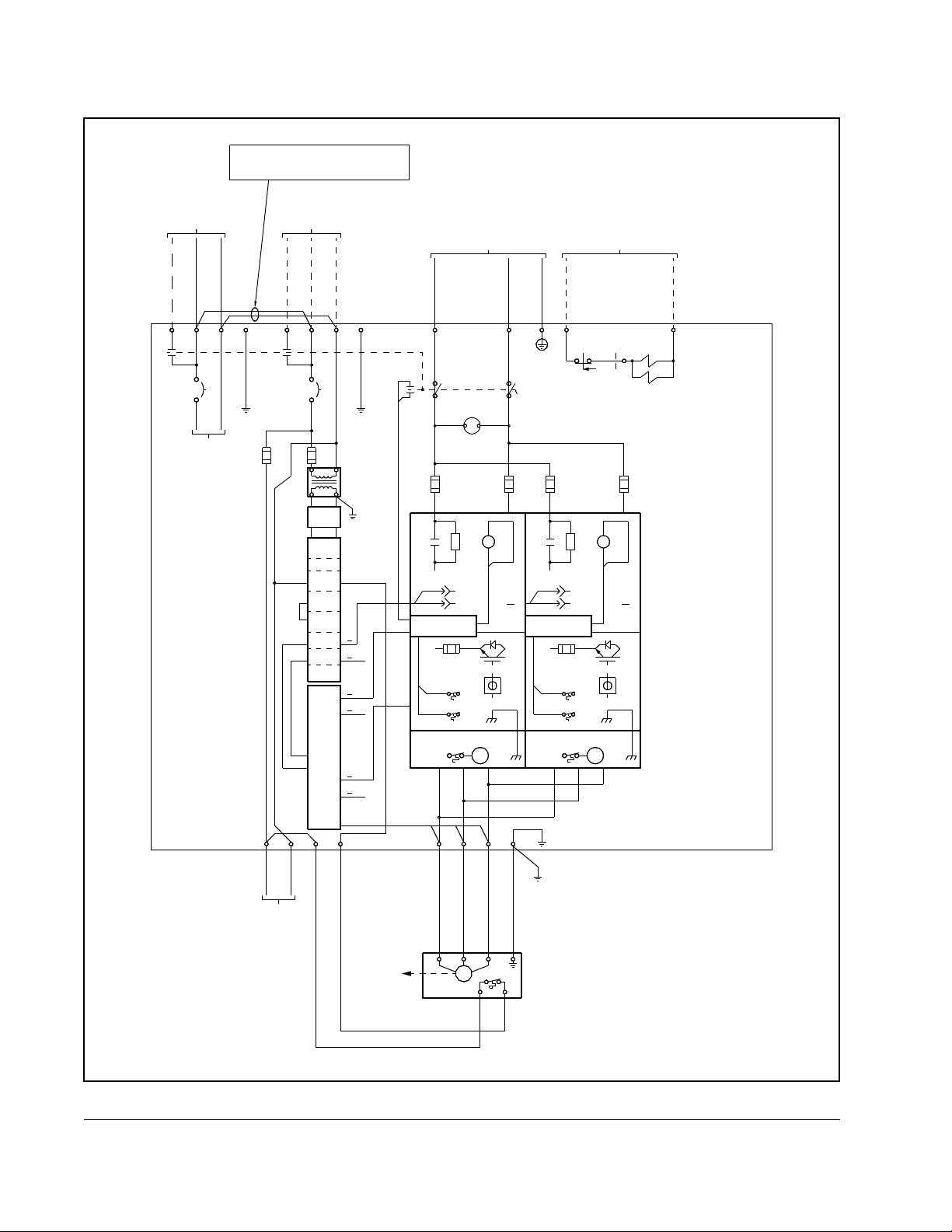

Figure 2.7 – 1457A SA3000 Power Module Circuitry .............................................2-11

Figure 3.1 – 534A Power Module Mounting Dimensions (Single-Bay).....................3-4

Figure 3.2 – 972A Power Module Mounting Dimensions (Double-Bay) ...................3-5

Figure 3.3 – 1457A Power Module Mounting Dimensions (Triple-Bay)....................3-6

Figure 3.4 – SA3000 Power and Ground Connections.............................................3-7

Figure 4.1 – DC Bus Voltage Measuring Points ....................................................... 4-3

Figure 4.2 – 534A SA3000 Power Module Fuse Locations.................................... 4-10

Figure 4.3 – 972A SA3000 Power Module Fuse Locations.................................... 4-11

Figure 4.4 – 1457A SA3000 Power Module Fuse Locations.................................. 4-12

Figure 4.5 – 115VAC Control Power Supply Assemblies....................................... 4-13

Figure 4.6 – 25 KHz. Power Supply........................................................................4-14

Figure 4.7 – IGBT Module Assembly Mounting Bolt Locations ..............................4-17

Table of Contents

III

Page 6

IV

High Power SA3000 AC Power Modules

Page 7

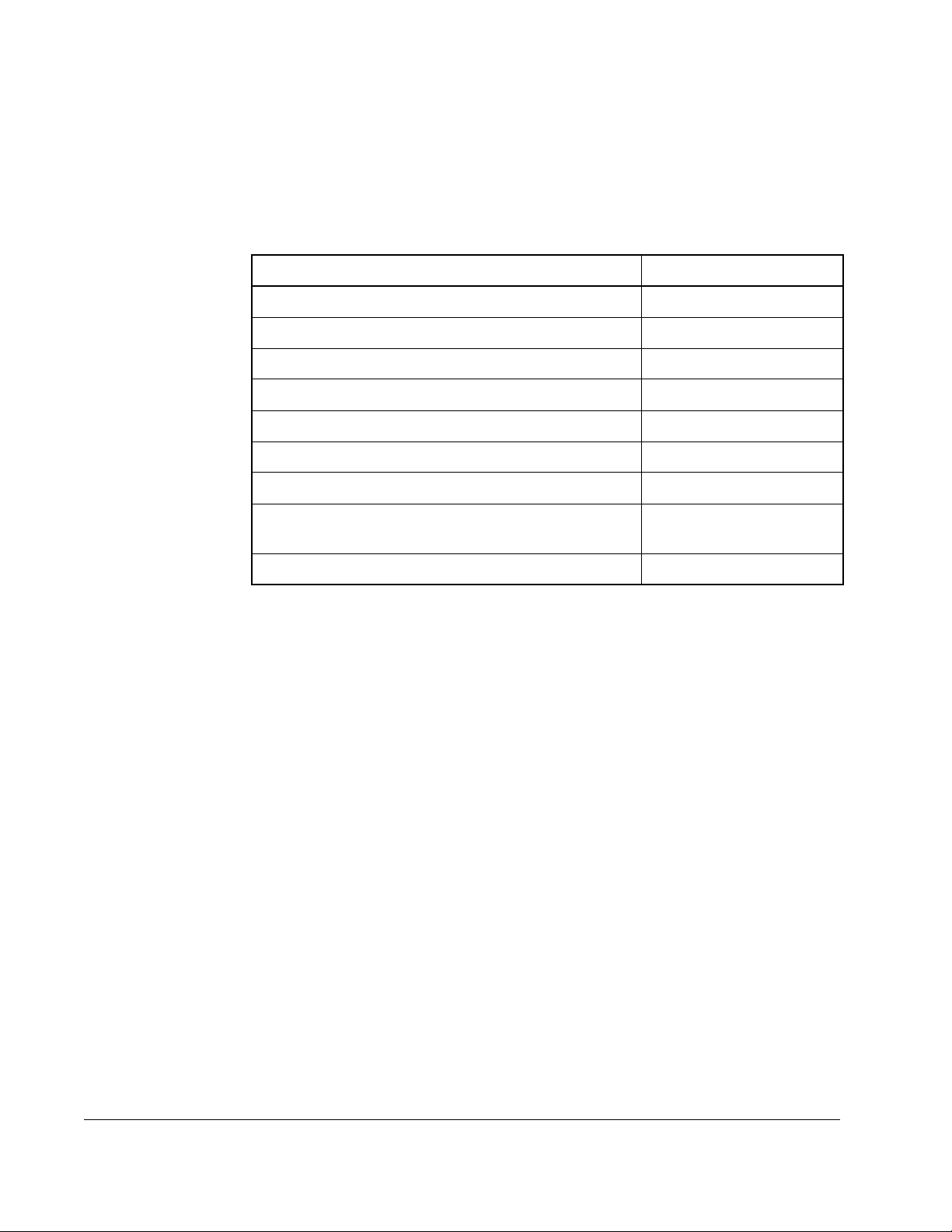

List of Tables

Table 1.1 – SA3000 Power Module Configurations..................................................1-1

Table 1.2 – SA3000 Documentation (Binder S-3001) .............................................. 1-4

Table 3.1 – Fuse Ratings..........................................................................................3-2

Table 3.2 – Recommended DC Bus Input and AC Output Wire Sizes..................... 3-2

Table 3.3 – Terminal Tightening Torques.................................................................3-3

Table 4.1 – DC Bus and Terminal Tests...................................................................4-4

Table 4.2 – IGBT Tests.............................................................................................4-4

Table 4.3 – SA3000 Power Module Faults (Register 202/1202) ..............................4-5

Table 4.4 – SA3000 Warning Register 203 /1203 .................................................... 4-7

Table 4.5 – Power Module Replacement Fuse Specifications .................................4-9

Table of Contents

V

Page 8

VI

High Power SA3000 AC Power Modules

Page 9

C

HAPTER

1

Introduction

The High Power SA3000 Power Modules are variable-voltage, variable-frequency

power inverters for Distributed Power System (DPS) drives. They are designed to

operate from a separate converter (diode bridge, phase-controlled rectifier, SB3000

Synchronous Rectifier, or a common DC bus supply) to drive induction motors at

variable speeds using pulse-width modulation (PWM) technology.

The SA3000 Power Modules are configured in three output current ratings: 534 amp,

972 amp, and 1457 amp when used at a 2 kHz carrier frequency. They have a range

of AC Input voltage ratings. See table 1.1. Nominal DC bus voltage may range from

300 to 800 VDC.

4 kHz operation requires a derating of the AC input current and DC output load current

when compared with operation at 2 kHz. See table 1.1.

The SA3000 Power Module output current ratings given are 100% continuous with no

overload. They may be derated for lower current ratings with overload capability.

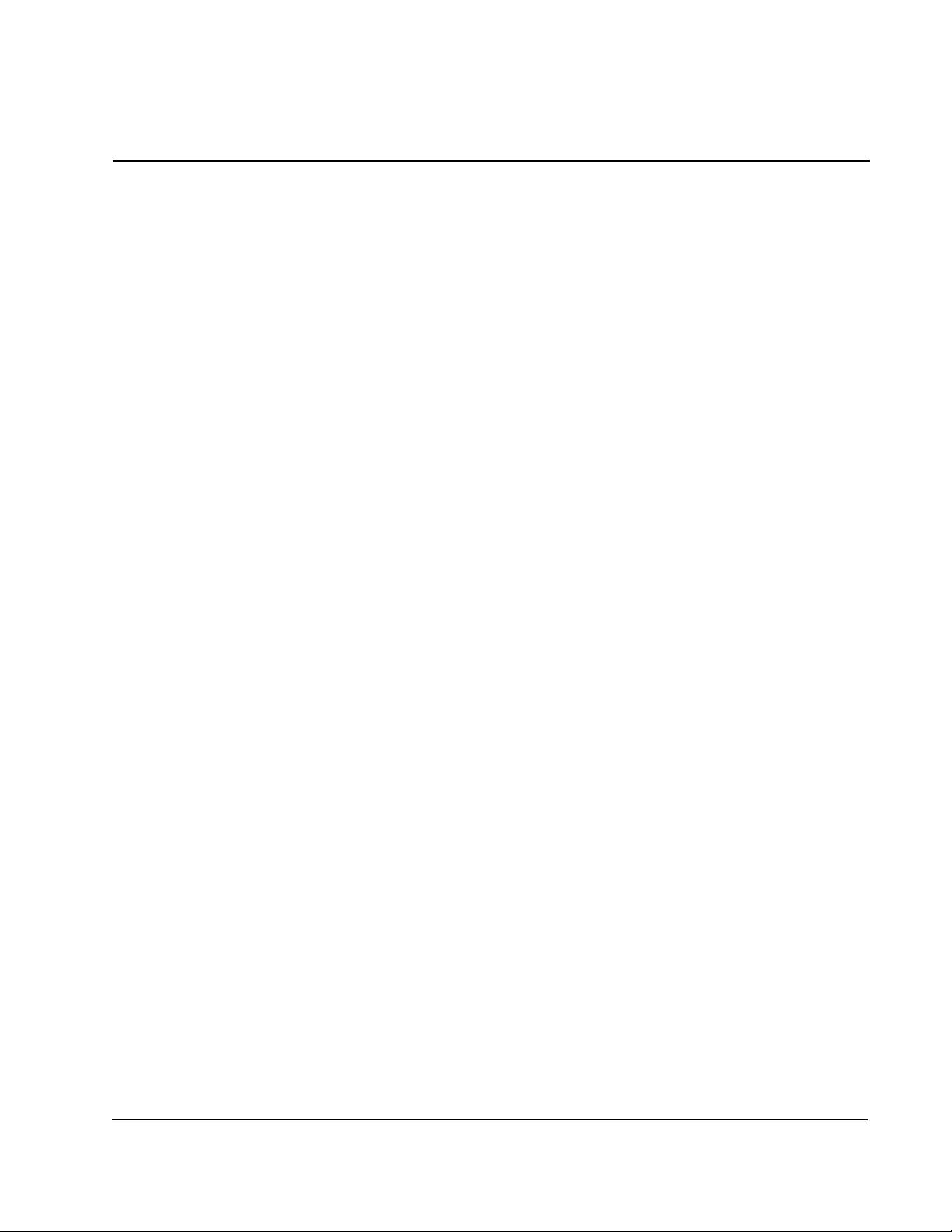

Table 1.1 – SA3000 Power Module Configurations

Output

Base Part

Number

850020-11xxx

850020-21xxx

850020-12xxx

850020-22xxx

850020-13xxx

850020-23xxx

1. Output current ratings at 40° C (104° F) ambient air temperature and 60 Hz. Reduce all output current ratings by 5% when the Power

Module blowers are operated from a 50 Hz power source.

2. Contact Rockwell Automation for duty cycle ratings.

3. 800 VDC if an SA3000/SA3100 unit is used to supply 575 VAC output to the motor.

Cabinet

Type

One Bay

Two Bays 250-820V 972A 890A 1275A 230-460V

Three Bays 250-820V 1457A 1335A 1900A 230-460V

DC Bus

Input Volts

250-820V

Amps

(2 KHz)

3

534A 445A 700A 230-460V

Output

Amps

(4 KHz)

1

Peak

Amps

2

AC Input

Volts

1.1 Standard Features

High Power SA3000 Power Modules have the following standard features:

•

IGBT power semiconductor bridge

•

Carrier switching frequencies from 2 to 4 kHz

•

Input and output short-circuit protection

Introduction

•

Fiber-optic communication with the DPS host, the Universal Drive Controller (UDC)

module

1-1

Page 10

•

Auto-tuning

•

Standard cabinet paint

1.2 Optional Features

The following optional features are available for High Power SA3000 Power Modules

•

DC bus voltage meter

•

Motor ammeter

•

Motor voltmeter

•

Motor torque meter

•

Motor frequency meter

•

Main disconnect

•

Pre-charge

•

Separation of critical and non-critical 115 VAC control power

•

DC bus top hat enclosure

•

Custom cabinet paint

1-2

High Power SA3000 AC Power Modules

Page 11

1.3 Power Module Par t Numbers

SA3000 Power Module part numbers are organized by the number of cabinet bays,

i.e., single (534A), double (972A), or triple (1457A) cabinet bay configurations, in

combination with the supplied options. See figure 1.1.

850020 -1

Cabinet Top

Enclosures:

R

1

Size of Unit

S

T

Pre-charge:

Main

Disconnect:

Meters:

1 = 534A Output - 1 Bay Unit

2 = 972A Output - 2 Bay Unit

3 = 1457A Output - 3 Bay Unit

1 = DC Bus Assembly Enclosure

2 = DC Bus Top Hat Enclosure

T = Supplied - Standard Cabinet Paint

Y = Supplied - Custom Cabinet Paint

X = Not Supplied - Standard Cabinet Paint

Z = Not Supplied - Custom Cabinet Paint

S = Supplied - Standard Cabinet Paint

W = Supplied - Custom Cabinet Paint

X = Not Supplied - Standard Cabinet Paint

Z = Not Supplied - Custom Cabinet Paint

R = Supplied - Standard Cabinet Paint

V = Supplied - Custom Cabinet Paint

X = Not Supplied - Standard Cabinet Paint

Z = Not Supplied - Custom Cabinet Paint

(1)

Introduction

SA3000 Power Module - Base Part Number

1. Top Hat Enclosure accommodates bending radius of DC bus cable (customer supplied).

Figure 1.1 – SA3000 Power Module Part Numbering Scheme

1-3

Page 12

1.4 Related Publications

This manual describes the hardware components of the SA3000 Inverter Power

Module. The other instruction manuals in binder S-3001 describe the SA3000

software, regulator, and communications. Table 1.1 lists the document part numbers.

Table 1.2 – SA3000 Documentation (Binder S-3001)

Document Document Part Number

SA3000 Information Guide S-3023

Drive System Overview S-3005

Universal Drive Controller Module S-3007

Fiber Optic Cabling S-3009

SA3000 Drive Configuration & Programming S-3016

SA3000 Power Module Interface Rack and Modules S-3019

Medium Power SA3000 Power Modules S-3020

SA300 Diagnostics, Troubleshooting, & Start-Up

Guidelines

High Power SA3000 Power Modules S-3038

SA3000 Power Modules are designed to be operated from a common DC bus, which

can be supplied by a Distributed Power System SB3000 Synchronous Rectifier. Refer

to the following manuals for information on the SB3000 Synchronous Rectifier system:

•

S-3034 SB3000 Synchronous Rectifier Configuration and Programming

•

S-3043 High Power SB3000 Power Modules

1.5 Related Hardware and Software

The following related hardware may be purchased separately:

•

P/N 613613-xxS Fiber-optic cable (cable length xx is specified in meters)

•

B/M O-57552 Universal Drive Controller (UDC) module

•

B/M O-57652 Universal Drive Controller (UDC) module EM

S-3021

1-4

High Power SA3000 AC Power Modules

Page 13

Mechanical/Electrical Description

This chapter provides an overview the SA3000 Power Module’s main components and

their mechanical and electrical characteristics.

2.1 Mechanical Description

The High Power SA3000 Power Modules are variable-voltage, variable-frequency

inverters that are housed in protective sheet metal enclosures. The Power Modules

are supplied in single, double, and triple bay cabinet configurations, depending upon

the current rating. See figures 2.1 to 2.3. Power Module dimensions are shown in

figures 3.1 to 3.3.

2.1.1 Power Module Components

The Power Modules have the following main components:

Phase modules

Each Phase module contains four semiconductor IGBTs (insulated gate bi-polar

transistors). IGBT pairs are switched on and off by the integrated Snubber/Gate Driver

module to provide modulated phase voltages (U,V,W) to the motor. Fuses and

thermostats are provided to protect the IGBT modules.

C

HAPTER

2

Snubber/Gate Driver Module

Each Snubber/Gate Driver module, mounted on the IGBT phase module, receives

gating signals via fiber-optic cabling from the GDI module(s) in the PMI rack and

translates the signals into the appropriate voltage and current levels to turn the IGBTs

on and off. Feedback, indicating the integrity of the phase module and IGBTs, is then

sent back to the GDI module(s).

This module also provides snubber circuitry (resistors, diodes, and capacitors) to

control voltage overshoot and undershoot when the IGBTs are switching.

Fiber-Optic Communication

Fiber-optic cabling is used to transmit gate driver signals from the Gate Driver

Interface (GDI) module.These signals are used to turn the IGBTs on and off. IGBT

module feedback status information is sent via the fiber-optic cabling back to the GDI

module(s) in the PMI rack. Fiber-optic cabling is immune to electromagnetic and radio

frequency interference (EMI/RFI) and eliminates ground loops. For more information

on fiber-optic cabling refer to the Distributed Power System Fiber-Optic Cabling

instruction manual (S-3009).

Mechanical/Electrical Description

2-1

Page 14

Local Power Interface module (LPI)

The LPI module is the interface between the SA3000 Power Module and the PMI rack.

It is through this module that information is sent to the SA3000 Power Module and

feedback data is sent back to the PMI rack.

Capacitor Bank Assembly

The capacitor bank's electrolytic capacitors store power locally for the IGBTs.

115 VAC Power Supply Assemb ly

Power Supply Assembly P/N 850100-3S allows for the separation of critical (PMI rack,

25 KHz power supply, DC power supplies) and non-critical (blower motors) 115 VAC

power via two 115 VAC terminal boards and two 25A circuit breakers. Removing the

jumper wires between the two terminal boards provides the separation of critical and

non-critical power. The circuit breakers can be locked in either the ON or OFF position

when the optional locking mechanism is used.

Power Supply Assembly P/N 850100-3R provides one 115 VAC terminal board and

one 25A circuit breaker. This assembly distributes 115 VAC power to the DC power

supplies, the 25 KHz power supply, the PMI rack, and the Power Module blowers. See

figure 4. 5.

25 KHz Power Supply Assembly

The 25 KHz Power Supply Assembly provides power to the six IGBT gate drivers in

each Power Module. 25KHz AC power is used for transformer isolation and noise

immunity. Input power is provided by the 115 VAC power supply. See figure 4.6.

DC Bus Voltage Meter (Option)

The DC Bus Voltage meter, which is connected directly across the DC bus, measures

the DC bus voltage being applied to the power module.

Output Meters (Option)

These meters measure the AC voltage (0-600V), current (0-200 percent of full load),

torque (200-0-200 percent of full load), and frequency (120-0-120Hz) being applied to

the motor. These meters are connected to the PMI Processor’s meter ports, which are

under software control.

Main Disconnect (Option)

Depending on system requirements, a DC input disconnect may be provided. Note

that if a disconnect is supplied, the pre-charge assembly option must also be used if

the Power Module is operating from a constant potential DC bus supply.

Pre-charge Assembly (Option)

The Pre-charge Assembly consists of a contactor, pre-charge resistors, and a printed

circuit board assembly. The contactor bypasses the pre-charge resistor after the bus

voltage reaches a programmable threshold value. A pre-charge control module

communicates with the LPI module and controls the pre-charge contactor.

2-2

High Power SA3000 AC Power Modules

Page 15

18

15

15

15

20

14

6

OUTPUT METER PANEL

(OPTIONAL)

MOTOR

GRD

AC MOTOR OUTPUT

U

MOTOR

GRD

V

W

DISCONNECT SWITCH

A

M

P

F

5

8

9

24

26

23

25

19

POWER MODULE A

PRE-CHARGE ASSEMBLY

4

2

F103

CAPACITOR

3

BANK

PHASE U

2

F104

PHASE V

+24VPS-24V

PS

PS PS

±15V

±15V

PS

PS

25KHZ PS

1

B

C

1

U

U

B

F

F

C

1

3

1

22

11

17

16

7

SALES ORDER

NAMEPLATE

13

CUSTOMER CONTROL WIRING

28

IF USED, THE O U TPUT METER

PANEL IS MOUNTED IN THE CABINET

DOOR OF POWER MODULE A.

27

2

F105

PHASE W

BLOWER

1

ASSEMBLY

PMI RACK

LPI

MODULE

GDI

A

.

D

O

M

.

R

W

P

6

T

O

L

S

10

12

1. Blower Assembly 2. IGBT Phase Module Assembly 3. Capacitor Bank Assembly

4. Pre-charge Assembly

5. DC Disconnect Assembly

1

6. DC bus fuse

7. +/- 15V DC Power Supply 8. 24V DC Power Supplies 9. 115VAC C.B. - Non Critical Pwr

10. Local Power Interface Module 11. 250VA Isolation Transformer 12. Power Module Interface Rack

13. 25KHz Power Supply 14. Reactor Assembly 15. LEM Output Current Sensor

16. Control Fuse (1FU) 17. Control Fuse (3FU) 18. DC Feedback Module

19. 115VAC C.B. - Critical Power 20. Blower Filter 21. Motor Feedback Resistors

22. Power Supply Assembly

25. Motor Ammeter

28. Motor Frequency

1

1

1. Optional

Mechanical/Electrical Description

23. Door Interlock Bypass Switch

26. Motor Voltmeter

Figure 2.1 – 534A SA3000 Power Module Components

1

1

24. DC Bus Voltage Meter

27. Motor Torque Meter

1

1

2-3

Page 16

OUTPUT METER PANEL

(OPTIONAL)

IF USED, THE O U TPUT METER

PANEL IS MOUNTED IN THE CABINET

DOOR OF POWER MODULE A.

24

26

28

23

25

27

15

15

14

15

20

21

MOTOR

GRD

AC MOTOR OUTPUT

U V

MOTOR

GRD

W

14

MOTOR

GRD

B

A

M

M

P

P

F

F

18

POWER MODUL E B

PRE-CHARGE ASSEM B LY

POWER MODUL E A

PRECHARGE ASSEMBLY

4

2

F103

PHASE U

K

N

A

B

15

F103

2

F104

3

F105

PHASE V

R

O

T

I

C

A

P

A

C

2

PHASE W

BLOWER

1

ASSEMBLY

15

15

F104

3

F105

2

PHASE U

K

N

A

B

2

PHASE V

R

O

T

I

C

A

P

A

C

2

PHASE W

1

ASSEMBLY

20

6

DISCONNECT SWITCH

+24V

4

BLOWER

+24V

PS

PS PS

±15V

±15V

PS

PMI RACK

-24V

PS

1

U

U

B

F

F

C

3

1

1

--

25KHZ PS

MODULE

5

8

9

19

22

1

B

C

11

17

16

7

SALES ORDER

NAMEPLATE

13

CUSTOMER

CONTROL WIRING

LPI

GDIGDI

B

A

.

.

D

D

O

O

M

M

.

.

R

R

W

W

P

P

7

6

T

T

O

O

L

L

S

S

10

12

1. Blower Assembly 2. IGBT Phase Module Assembly 3. Capacitor Bank Assembly

4. Pre-charge Assembly

5. DC Disconnect Assembly

1

6. DC bus fuse

7. +/- 15V DC Power Supply 8. 24V DC Power Supplies 9. 115VAC C.B. - Non Critical Pwr

10. Local Power Interface Module 11. 250VA Isolation Transformer 12. Power Module Interface Rack

13. 25KHz Power Supply 14. Reactor Assembly 15. LEM Output Current Sensor

16. Control Fuse (1FU) 17. Control Fuse (3FU) 18. DC Feedback Module

19. 115VAC C.B. - Critical Power 20. Blower Filter 21. Motor Feedback Resistors

22. Power Supply Assembly

25. Motor Ammeter

1

28. Motor Frequency

1. Optional

1

23. Door Interlock Bypass Switch

26. Motor Voltmeter

Figure 2.2 – 972A 3000A Power Module Components

1

2-4

1

24. DC Bus Voltage Meter

27. Motor Torque Meter

High Power SA3000 AC Power Modules

1

1

Page 17

OUTPUT METER PANEL

(OPTIONAL)

IF USED, THE O U TPUT METER

PANEL IS MOUNTED IN THE CABINET

DOOR OF POWER MODULE A.

24

26

28

23

25

27

21

6

C

M

P

F

4

22

2

2

BLOWER

ASSEMBLY

DISCONNECT SWITCH

1

+24VPS-24V+24V

B

PS

PS PS

C

1

U

U

±15V

±15V

B

F

F

C

PS

1

3

1

25KHZ PS

LPI

MODULE

GDIGD

A

.

D

PMI RACK

O

M

.

R

W

P

6

T

O

L

S

I

GDI

B

C

.

.

D

D

O

O

M

M

.

.

R

R

W

W

P

P

8

7

T

T

O

O

L

L

S

S

5

8

9

19

22

11

17

16

7

SALES ORDER

NAMEPLATE

13

CUSTOMER CONTR OL

WIRING

10

12

MOTOR

GRD

AC MOTOR OUTPUT

14

14

MOTOR

GRD

B

WVU

14

A

M

M

P

P

F

F

18

POWER MODULE APOWER MODULE BPOWER MODULE C

PRE-CHARGE AS SE MBLY

4

PRE-CHARGE ASSEMBLY

4

PRE-CHARGE ASSEMBL Y

2

15

F103

PHASE U

K

N

A

B

2

15

F104

3

15

F105

PHASE V

R

O

T

I

C

A

P

A

C

2

PHASE W

BLOWER

1

ASSEMBLY

15

F103

PHASE U

K

N

A

B

2

15

F104

3

15

F105

PHASE V

R

O

T

I

C

A

P

A

C

2

PHASE W

BLOWER

1

ASSEMBLY

2020

15

15

F103

F104

3

15

F105

PHASE U

K

N

A

B

PHASE V

R

O

T

I

C

A

P

A

C

PHASE W

1

20

1. Blower Assembly 2. IGBT Phase Module Assembly 3. Capacitor Bank Assembly

4. Pre-charge Assembly

5. DC Disconnect Assembly

1

6. DC bus fuse

7. +/- 15V DC Power Supply 8. 24V DC Power Supplies 9. 115VAC C.B. - Non Critical Pwr

10. Local Power Interface Module 11. 250VA Isolation Transformer 12. Power Module Interface Rack

13. 25KHz Power Supply 14. Reactor Assembly 15. LEM Output Current Sensor

16. Control Fuse (1FU) 17. Control Fuse (3FU) 18. DC Feedback Module

19. 115VAC C.B. - Critical Power 20. Blower Filter 21. Motor Feedback Resistors

22. Power Supply Assembly

25. Motor Ammeter

28. Motor Frequency

1

1

1. Optional

Mechanical/Electrical Description

23. Door Interlock Bypass Switch

26. Motor Voltmeter

Figure 2.3 – 1457A SA3000 Power Module Components

1

1

24. DC Bus Voltage Meter

27. Motor Torque Meter

1

1

2-5

Page 18

2.2 Electrical Description

DC bus input power is applied to the Power Module through terminals 45 (–) and

47 (+), passes through the optional DC bus disconnect and in-line fuses, and is then

fed to the optional pre-charge circuitry. See figures 2.4 to 2.7.

When pre-charge circuitry is present and DC input power is applied, the internal DC

bus begins charging through the pre-charge resistors. Once the DC bus capacitors

are fully charged (per the programmable threshold value) and all pre-charge criteria

are met, the internal pre-charge contactor closes and bypasses the pre-charge

resistors. If the DC bus disconnect option is not used, the bus supply is responsible for

the charging operation. Refer to Appendix B for additional information on SA3000

internal DC bus control.

The DC bus voltage is filtered and stored by the electrolytic capacitors. Discharge

resistors are designed to discharge the capacitors down to 50 VDC within 5 minutes

after power is removed from the input terminals. However, if a DC bus fuse has blown,

it is possible for a charge to be stored on the DC bus capacitors without being

indicated on the DC bus voltmeter. Wait 10 minutes before working on the unit. Be

sure to measure the DC bus potential of each Power Module capacitor bank before

touching any internal circuitry. See figure 4.1 for test point locations.

ATTENTION:

power has been disconnected. After disconnecting input power, wait ten

!

When the DC bus operating voltage is reached, the connected Inverter Power

Modules may be operated. Note that if an SB3000 Power Module is used to supply the

DC bus, the SB3000 Power Module cannot support the loading of SA3000 Inverter

Power Modules when the soft-charge resistors in the SB3000 are limiting the bus

charging current.

!

The SA3000 inverter power circuitry uses the filtered DC bus voltage to provide the

variable-voltage, variable-frequency output to the motor (terminals U, V, W). The 972

Amp and 1457 Amp units have reactors for load sharing on their outputs. The IGBTs

are switched by the gate drivers on the IGBT phase module under the control of the

PMI rack. A LEM sensor is located on each output phase (U,V,W) of each SA3000

Inverter Power Module (A,B, or C) to provide output current feedback for overcurrent

protection.

(10) minutes for the DC bus capacitors to discharge. Open the cabinet

doors and check the voltage across the DC bus bars, 347 A,B,C (+ bus)

and 345 A,B,C (- bus), with an external voltmeter to ensure the DC bus

capacitors are discharged before touching any internal components.

Failure to observe this precaution could result in severe bodily injury or

loss of life.

ATTENTION:

Module must be in standby or in regeneration whenever the SB3000

Power Module’ s pre-charge contactor opens. The SB3000 Power

Module’s soft-charge resistors may fail if this interlocking restriction is

not observed. Failure to observe this precaution could result in damage

to, or destruction of, the equipment.

DC bus capacitors retain hazardous voltages after input

When used with an SB3000 bus supply , the SA3000 Power

2-6

High Power SA3000 AC Power Modules

Page 19

Each SA3000 Inverter Power Module connected to an SB3000 Power Module

supplied DC bus must have a separate pre-charge resistor and contactor to limit the

current into its capacitor bank. It is the responsibility of the application tasks to make

sure that the SB3000 Power Module is in run before the SA3000 Inverter Power

Module is put into run.

ATTENTION:When used with an SB3000 Power Module, the SB3000

Power Module must be in run before the SA3000 Inverter Power Module

!

If the SB3000 Power Module is not in run, the DC bus voltage will not be high enough

to support the full rating of the SA3000 Inverter Power Module. If the SB3000 Power

Module is shut down due to a fault condition, controlled shutdown of the SA3000

Power Module is the responsibility of the application program running in the SA3000

UDC module.

is put into run. If the pre-charge contactor supplying the SB3000 Power

Module is not closed, running the SA3000 Power Module will damage

the SB3000 pre-charge resistors. Failure to observe this precaution could

result in damage to, or destruction of, the equipment.

Mechanical/Electrical Description

2-7

Page 20

YYYL

FROM 115VAC

YYYN

INDUSTRIAL

DUTY

BRUSHLESS

RESOLVER

P/N

800123-x

DRIVEN BY

MOTOR

PMI RACK AND OPTIONAL

AUTOMATE I/O RAILS

ARE MOUNTED

IN POWER MODULE

ESR

BN

REFERENCE

INPUT

(ROTOR)

SINE

OUTPUT

(STATOR)

COSINE

OUTPUT

(STATOR)

(+)

R1

(-)

R2

(+)

S1

(-)

S3

(+)

S2

(-)

S4

FROM

ANALOG

SIGNAL

FIBER OPTIC COMM. LINK

FROM UDC CARD

I/O RAIL

(IF USED)

FROM T.B. (P2 & N)

DRIVE I/O

B/M O-60031

(C3)

XXX01

XXX03

XXX05

XXX07

XXX11

REF. OUT(+)

XXX21

XXX22

XXX23

XXX24

XXX26

XXX25

XXX31

XXX32

AC

AC

AC

DC

REF. OUT(-)

SIN INPUT(+)

SIN INPUT(-)

COS INPUT(+)

COS INPUT(-)

EXT. TRIG(+)

EXT. TRIG(-)

ANALOG IN(+)

ANALOG IN(-)

SHIELD

1

2

3

4

5

6

(+)

(HI)

AUX

IN1

(HI)

AUX

IN2

(HI)

AUX

IN3

(HI)

AUX

IN4

(HI)

AUX

IN5

(HI)

MCR

(HI)

AUX

OUT

(HI)

ORG

BLU

1RPI

A

3

C AUX IN1

5

E

7

H

9

K AUX IN4

11

M AUX IN5

13

15

S AUX OUT

(+)

1

A

(-)

2

B

3

(+)

D

4

(-)

C

(+)

5

E

(-)

6

F

(+)

7

H

(-)

8

J

1

(+)

P

2

(-)

N

SHLD

3

R

PROCESSOR

B/M

O-60021

(C2)

FIBER OPTIC

COMM LINK

(P2)

XMT

(P3)

RCV

RAIL

PORTS

0

(P5)

1

AC POWER

TECH MODULE

B/M 60023

SYNCH XFER

INTERFACE

RPI

R201_B0

(C3-P2)

R201_B1

AUX IN2

R201_B2

AUX IN3

R201_B3

R201_B4

R201_B5

MCRP

R101_B1

0.5 SECOND

OFF-DELAY AFTER

RPI GOES "LOW"

R101_B4

(C3-P1)

REFERENCE

OUTPUT

SINE

INPUT

COSINE

INPUT

EXTERNAL

TRIGGER

ISOLATED

(±10V=(±2047)

±10V

METER(P4)

PORTS

(P1)

POWER

MODULE

2RPI

(LO)

B

AUX

IN1

4

(LO)

D

AUX

IN2

6

(LO)

F

AUX

IN3

8

(LO)

J

AUX

IN4

10

(LO)

L

AUX

IN5

12

(LO)

N

14

MCR

XXX14

(LO)

R

AUX

OUT

16

T

(P1)

+

1

COM

+

2

COM

+

3

COM

+

4

COM

(C4)

(P1)

(P2)

(LO)

XXX16

CABLE

RUN PERMISSIVE

INTERLOCK

MOTOR THERMOSTAT

BLOWER MOTOR

STARTER FEEDBACK

OPTIONAL METER PACKAGE

0-600V

CALIB

0-200%

CALIB

120Hz-0-120Hz

CALIB

200%-0-200%

CALIB

MOUNTED TO CABINET DOOR

OF POWER MODULE A

TO PARALLEL

INTERFACE MODULE

PMI RACK SLOT C5

MOTOR

VOLTS

MOTOR

CURRENT

MOTOR

FREQUENCY

MOTOR

TORQUE

2-8

Figure 2.4 – Drive I/O and Processor Card Detail

High Power SA3000 AC Power Modules

Page 21

NOTE: THESE JUMPERS ARE REMOVED

WHEN A SEPARATE 115 VAC SUPPLY

IS USED FOR THE PMI RACK.

115VAC FROM A-C

DISTRIBUTION

X

X

X

L

1

A

L1A

X

X

X

L

1

L2L1

C

B

1

TO

BLOWERS

BELOW

CONDITIONED POWER

FROM CRITICAL 115VAC

SUPPLY DISTRIBUTION

W

W

W

D

1

D1

FROM 115VAC

(

R

E

D

)

INTERLOCK

BYPASS

S.R.

D3

SOLENOID

(OPTIONAL)

DOOR

W

W

W

D

(

R

2

E

D

)

D2

SA3000

INVERTER

W/D 30395-11

800VDC FROM SB3000

X

X

X

X

L

2

X

X

X

1

L

1

A

1L1AGRD

3

3

.

2

F

A

U

X

X

X

X

X

1

1

L

L

1

2

GRD

1L1

1L2

1

C

B

1

5

1

.

0

F

A

U

2

5

0

V

A

LINE

FILTER

PMI

P/S

RACK

PROC

DRIVE

I/O

POWER

TECH

PARA

INTER

A

GDI

Y

Y

Y

4

7

(+)

47

P

(

O

R

E

P

C

T

I

H

O

A

N

R

A

G

L

E

)

ORG

BLU

PRE-CHARGE

0-1000 VDC

(OPTIONAL)

F

1

0

1

A

K

1

1

A

GATE

DRIVERS

XMT

RCV

BOARD

F103A-105A

(-)

R

Y

Y

Y

4

5

45

K

1

1

A

GRD

F

1

0

2

A

A

Y

Y

Y

G

R

D

DC BUS

DISCONNECT

(OPTIONAL)

L

X

X

X

L

115VAC

TO DRIVE

I/O CARD

M

V

X

X

X

W

W

M

THERM

P1 P2

LEM

GRD

W

X

X

X

G

R

D

G

A

CON1

CON1

CON1

GDI

LPI

GDI

CARD

GDI

A

LEM

LEM

LEM

CON5

N

X

X

X

N

P2

P1

X

X

X

X

X

X

P

P

2

1

TO

RESOLVER

WARNING

FAULT

BLOWER ASSEMBLY

U

X

X

X

X

X

X

U

V

U

V

MOTOR

Figure 2.5 – 534A SA3000 Power Module Circuitry

GRD

Mechanical/Electrical Description

2-9

Page 22

115VAC FROM A-C

115VAC FROM A-C

DISTRIBUTION

DISTRIBUTION

X

X

X

X

X

X

L

L

1

1

A

L1AL1A L1 L2

25A

NOTE: THESE JUMPERS ARE REMOVED

WHEN A SEPARATE 115 VAC SUPPLY

IS USED FOR THE PMI RACK.

CONDITIONED POWER

FROM CRITICAL 115VAC

SUPPLY DISTRIBUTION

1L1A

X

X

X

1

L

1

A

1L1 GRD

25A

X

X

X

L

2

GRD

C

B

1

800VDC FROM SB3000

X

X

X

X

X

X

1

1

L

L

1

2

1L2

1

C

B

1

Y

Y

Y

4

7

(+) (-)

47

0-1000 VDC

Y

Y

Y

4

5

45 GRD

DISCONNECT

Y

Y

Y

G

R

D

DC BUS

(OPTIONAL)

W

W

W

D

1

D1

(

R

E

D

)

INTERLOCK

BYPASS

S.R.

FROM 115VA C

D3

SOLENOID

(OPTIONAL)

DOOR

W

(

R

W

E

W

D

)

D

2

D2

SA3000

INVERTER

W/D 30395-12

TO

BLOWERS

BELOW

3

.

2

A

X

X

X

L

115VAC

TO DRIVE

I/O CA R D

5

1

3

.

0

F

F

A

U

U

2

5

0

V

A

LINE

FILTER

PMI

P/S

RACK

PROC

DRIVE

I/O

POWER

TECH

PARA

INTER

A

GDI

B

GDI

A

CON1

B

CON1

CON1

GDI

LPI

GDI

CARD

GDI

A

LEM

B

LEM

LEM

CON5

L

P1

N

X

X

X

N

P2

X

X

X

X

X

X

P

P

1

2

(OPTIONAL)

F

1

0

1

A

P

(

O

R

E

P

K

C

T

1

I

H

1

O

A

A

N

R

A

G

L

E

)

GATE

DRIVERS

XMT

ORG

RCV

BLU

PRE-CHARGE

BOARD

F103A-105A

FAULT

BLOWER ASSEMBLY

U V

X

X

X

X

X

X

V

U

F

F

1

1

0

0

1

2

B

A

K

1

R

1

A

A

LEM

M

W GRD

X

X

X

X

X

G

X

W

R

D

K

1

1

B

GATE

DRIVERS

XMT

ORG

RCV

BLU

PRE-CHARGE

BOARD

F103B-105B

WARNINGWARNING

FAULT

BLOWER ASSEMBLY

GRD

R

F

1

0

2

B

K

1

1

B

B

LEM

M

2-10

V

W

TO

RESOLVER

U

MOTOR

M

THERM

P1 P2

G

Figure 2.6 – 972A SA3000 Power Module Circuitry

High Power SA3000 AC Power Modules

Page 23

115VAC FROM A-C

115VAC FROM A-C

DISTRIBUTION

DISTRIBUTION

X

X

X

L

1

A

L1A

25A

W

W

W

I

V

L

1

L2L1

C

B

1

TO

BLOWERS

BELOW

NOTE: THESE JUMPERS ARE REMOVED

WHEN A SEPARATE 115 VAC SUPPLY

IS USED FOR THE PMI RACK.

CONDITIONED POWER

FROM CRITICAL 115VAC

SUPPLY DISTRIBUTION

X

W

W

W

I

V

L

2

GRD

X

X

X

X

X

1

1

L

L

1

1

A

1L11L1A 1L2

25A

5

3

.

2

A

X

X

X

L

115VAC

TO DRIVE

I/O CARD

L

1

3

.

0

F

F

A

U

U

LINE

FILTER

P/S

PROC

DRIVE

I/O

POWER

TECH

PARA

INTER

GDI

GDI

GDI

CON1

CON1

CON1

GDI

GDI

GDI

LEM

LEM

LEM

CON5

NP1P2 U V

X

X

X

X

X

X

P

N

1

800VDC FROM SB3000

ON SHEET YYY

X

X

X

1

L

2

GRD

1

C

B

1

2

5

0

V

A

PMI

RACK

A

B

C

A

B

C

LPI

CARD

A

B

C

X

X

X

P

2

Y

Y

Y

4

7

(+)

47 45

0-1000 VDC

(OPTIONAL)

F

1

0

1

A

P

(

O

R

E

P

K

C

T

1

I

O

N

A

L

)

R

H

1

A

A

R

G

E

GATE

DRIVERS

XMT

ORG

RCV

BLU

PRE-CHARGE

BOARD

F103A-105A

WARNING

FAULT

BLOWER ASSEMBLY

X

X

X

X

X

X

V

U

(-)

M

X

X

X

W

W

Y

Y

Y

4

5

K

1

1

A

A

LEM

X

X

X

G

R

D

Y

Y

G

R

D

GRD

DC BUS

DISCONNECT

(OPTIONAL)

F

1

0

2

A

ORG

BLU

PRE-CHARGE

BOARD

F103B-105B

BLOWER ASSEMBLY

GRD

GRD

WARNING

W

W

W

D

1

D1

F

1

0

1

B

K

1

1

B

DRIVERS

FAULT

(

R

E

D

)

INTERLOCK

BYPASS

R

GATE

XMT

RCV

M

FROM 115VAC

D3

S.R.

SOLENOIDS

(OPTIONAL)

F

1

0

2

B

K

1

1

B

B

LEM

W

W

W

D

(

R

2

E

D

)

D2

SA3000

INVERTER

W/D 30395-13

DOOR

F

1

0

1

C

K

1

1

C

GATE

DRIVERS

ORG

BLU

PRE-CHARGE

BOARD

F103C-105C

WARNING

FAULT

BLOWER ASSEMBLY

XMT

RCV

F

1

0

2

C

K

1

R

1

C

C

LEM

M

Mechanical/Electrical Description

TO

RESOLVER

UVWG

M

THERM

MOTOR

P1 P2

Figure 2.7 – 1457A SA3000 Power Module Circuitry

2-11

Page 24

2-12

High Power SA3000 AC Power Modules

Page 25

This chapter describes the guidelines and wiring recommendations to be followed

when installing High Power SA3000 Power Modules. Installation and replacement

procedures are included for the 534A, 972A, and 1457A Power Modules.

ATTENTION:The user is responsible for conforming with all applicable

local, national, and international codes. Failure to observe this precaution

!

could result in damage to, or destruction of, the equipment.

3.1 Install at io n Planning

SA3000 Power Module current ratings are dependent upon inlet air temperature.

Ratings are given at 40° C (104° F) ambient. Refer to table 1.1 for output current

ratings.

Internal Power Module conditions are monitored by two thermal switches on the

heatsink. One switch is used to indicate a warning condition (register 203/1203, bit 7,

WRN_OT@); the other is used to indicate a fault condition (register 202/1202, bit 7,

FLT_OT@). The thermal warning switch closes at 78° C (172.4° F) ; the thermal fault

switch closes at 85°C (185° F). Refer to the SA3000 Configuration and Programming

instruction manual (S-3042) for more information on faults and warnings.

C

HAPTER

3

Installation Guidelines

Installation Guidelines

Use the following guidelines when planning your SA3000 Power Module installation:

•

The relative humidity around the SA3000 Power Module must be kept between

5 and 90% (non-condensing).

•

Do not install above 1000 meters (3300 feet) without derating. For every 91.4

meters (300 feet) above 1000 meters (3300 feet), the SA3000 Power Module's

current rating is derated 1%.

•

/RFDWH WKH 6$ 3RZHU 0RGXOH LQ D FOHDQ FRRO DQG GU\ DUHD )ROORZ WKH

recommendations given in IEC 68 concerning environmental operating conditions.

•

Be sure surrounding equipment does not block service access to the SA3000

Power Module.

•

$OORZ DGHTXDWH FOHDUDQFH IRU DLU YHQWLODWLRQ 6$ 3RZHU 0RGXOHV SXOO LQ DLU IURP

WKH

bottom of the cabinet and exhaust it through the top of the cabinet. Each cabinet

bay of the SA3000 Po wer Module has one fan. Allow at least 30 cm (12") above and

2 m (6.6') in front of the SA3000 Power Module for adequate air clearance.

•

Individual motor lead lengths cannot exceed 100 meters (328 feet).

•

Refer to the Drive System Installation manual (D2-3115) for more information.

3-1

Page 26

3.2 Wiring

!

System wiring is to be done according to the supplied wiring diagrams (W/Es), which

are application-specific. Sections 3.2.1 through 3.2.3 provide additional information on

fuses and recommended wiring.

3.2.1 Fuses

!

Fuses are provided to protect the Power Module's DC bus, 115 VAC control power

input lines, and individual IGBT phase modules. See table 3.1 for the fuse values.

FPM A,B,C DC Bus 1000 A 1000 VAC 64676-80P

F103 A,B,C

F104 A,B,C

F105 A,B,C

ATTENTION:

local, national, and international codes. Failure to observe this precaution

could result in damage to, or destruction of, the equipment.

ATTENTION:

protection be provided to protect input power wiring. Install the fuses

recommended in table 3.1. Do not exceed the fuse ratings. Failure to

observe this precaution could result in damage to, or destruction of the

equipment.

Fuse

IGBT Phase

1FU 115 VAC 5 A 600 VAC 64676-29R

3FU 115 VAC 3.2 A 600 VAC 64676-29P

The user is responsible for conforming with all applicable

The NEC/CEC requires that upstream branch circuit

Table 3.1 – Fuse Ratings

Circuit

Modules

Fuse Current

Rating

630 A 1000 VAC 64676-79AZ

Fuse Voltage

Rating

Rockwell

P/N

3-2

3.2.2 Wire Sizes

Input wiring should be sized according to applicable codes to handle the SA3000

Power Module's continuous-rated input current. Output wiring should be sized

according to applicable codes to handle the SA3000 Power Module's continuous-rated

output current. Recommended wire sizes are shown in table 3.2. Terminals should be

tightened to the torque values provided in table 3.3.

SA3000 Output Rating

1. NEC-recommended cable types: 40oC (104oF) copper wire.

Table 3.2 – Recommended DC Bus Input and AC Output Wire Sizes

Size of Wire

534A

972A

1457A

2 x 600 Kc Mil (304 mm

3 x 600 Kc Mil (304 mm

4 x 1000 Kc Mil (507 mm

High Power SA3000 AC Power Modules

1

2

)

2

)

2

)

Page 27

DC Bus Input Power: 45, 47 41 Nm (30 lb-ft)

Output Power: U, V, W 41 Nm (30 lb-ft)

115 VAC Input Power: L1, L2 3.5 Nm (2.6 lb-ft)

3.2.3 Wire Routing

Ac output wiring is routed through the top of the cabinet, above terminals 181, 182

and 183. DC input wiring is also routed through the top of the cabinet. DC input wiring

is usually connected to the DC bus in the overhead enclosure that distributes the DC

power to the common DC bus Inverter Power Modules. A DC input disconnect switch

is provided to disconnect DC bus power, providing safe access to the inside of the

SA3000 Power Module cabinet.

3.3 Grounding

Table 3.3 – Terminal Tightening Torques

Terminals Tightening Torque

ATTENTION:

Connect the power module's ground terminals to earth ground using

!

System grounding is to be done according to the supplied wiring diagrams (W/Es) in

accordance with applicable codes. To prevent noise interference and possible

malfunction of this equipment, it is imperative that a good cabinet ground be provided.

The grounding conductor must be as short as possible and be run directly from the

control panel ground terminal to a solid earth ground. It is recommended that the

grounding conductor be the same size conductor as the power wiring. Multi-cabinet

grounding wires should not be daisy-chained but should be run separately to the

common point of earth ground.

properly-sized ground wires. Failure to observe this precaution could

result in severe bodily injury or loss of life.

Ungrounded equipment represents a shock hazard.

3.4 Installing the Power Module Cabinet

Use the following procedure to install the SA3000 Power Module cabinet:

Step 1. Ensure that DC input power leading to the SA3000 Power Module is off.

Step 2. Position the SA3000 Power Module on a level mounting surface. See figures

3.1, 3.2, and 3.3 for cabinet dimensions. Floor mounting dimensions are

included for applications in which the cabinet is to be attached to the floor.

Step 3. Connect the DC bus to terminals 45 (-) and 47(+). See the W/Es. Connect

the GND terminal to earth ground.

Installation Guidelines

Step 4. If used, connect the optional output contactor to the U, V, and W terminals.

Step 5. Connect the motor leads to the output contactor. If an output contactor is not

used, connect the motor leads directly to the U, V, and W terminals. See the

W/Es and figure 3.4.

Step 6. Connect the GND terminal to earth ground.

Step 7. Connect the AC control power input line (two-wire 115 VAC with ground) to

terminals L1 (L), L2 (N), and GND on the control wiring terminal board. See

the W/Es and figure 3.4.

3-3

Page 28

5.85

3.00

(76.2)

(148.6)

9.50

4.00

(241.3)

(101.6)

METER LOCATION IN DOOR

OUTLINE OF OVERHEAD ENCLOSURE

DOOR WIDTH = 32.75 (831.9)

DOOR SWING = 120°

5

)

7

0

8

.

.

3

2

7

(

1.00 (25.4) MAX

CONDUIT PROTRUSION

AIR EXHAUST SLOTS

(IF USED)

FILTER & FAN

28.00

3.00

(711.2)

(76.2)

34.00

(863.6)

*

- 19.00 (482.6).

77.38

(1965.5)

5.38

(136.7)

86.75

(2203.5)

AVAILABLE CONDUIT

ENTRY AREA IN HOOD.

CONDUIT PLATE PROVIDED

.50 D (12.7)

DRIP SHIELD

4.00

(101.6)

MTG STUD - MIN

LENGTH 1.50 (38.1)

DC TOP HAT ENCLOSURE INSTALLED

1.37

(34.8)

COMMON DC BUS ENCLOS URE INSTALLED - 10.00 (254. 0).

3-4

Figure 3.1 – 534A Power Module Mounting Dimensions (Single-Bay)

High Power SA3000 AC Power Modules

23.75

22.38

(603.3)

(568.5)

ADDITIONAL HEIGHT:

ALL DIMENSIONS ARE IN INCHES (MILLIMETERS)

WEIGHT = 1265 LBS (573 KG )

*

Page 29

5.85

(148.6)

9.50

4.00

(241.3)

(101.6)

3.00

(76.2)

(127.0)

28.00

(711.2)

5.00

25.00

(635.0)

2.875

(73.0)

OUTLINE OF OVERHEAD ENCLOSURE

LH DOOR WIDTH = 29.5 (749.3)

RH DOOR WIDTH = 32.75 (831.9)

DOOR SWING = 120°

VENT SLOTS

1.OO (25.4) MAX

CONDUIT PROTRUSION

METER LOCATION IN DOOR

(IF USED)

64.00

(1625.6)

FILTER & FAN

- 19.00 (482.6).

*

3.00

(76.2)

77.37

8

)

3

7

.

.

5

6

3

1

(

(1965.5)

4.00

86.75

(2203.5)

(101.6)

Installation Guidelines

AVAILABLE CONDUIT

ENTRY AREA IN HOOD.

CONDUIT PLATES PROVIDED

DRIP SHIELD

.50 D (12.7)

MTG STUD - MIN

LENGHT 1.50 (38.1)

Figure 3.2 – 972A Power Module Mounting Dimensions (Double-Bay)

DC TOP HAT ENCLOSURE INSTALLED

COMMON DC BUS ENCLOS URE INSTALLED - 10.00 (254. 0).

1.37

(34.8)

23.75

22.38

(603.3)

(568.5)

ALL DIMENSIONS ARE IN INCHES (MILLIMETERS)

WEIGHT = 2175 LBS (985 KG )

ADDITIONAL HEIGHT:

*

3-5

Page 30

5.85

(148.6)

FILTERS & FANS

(127.0)

(127.0)

5.00 5.00

3.00

3.00

4.00

9.50

(101.6)

(241.3)

(76.2)

28.00

(711.2)

25.00

(635.0)

2.875

OUTLINE OF OVERHEAD ENCLOSURE

LH & CENTER DOOR WIDTH = 29.5 (749.3)

RH DOOR WIDTH = 32.75 (831.9)

DOOR SWING = 120°

)

0

.

3

7

(

1.00 (25.4)

MAX CONDUIT

PROTRUSION

METER LOCATION IN DOOR

(IF USED)

94.00

(2387.6)

- 19.00 (482.6).

25.00

(635.0)

(76.2)

*

77.37

(1965.5)

5.38

(136.7)

86.75

(2203.5)

4.00

(101.6)

3-6

AVAILABLE CONDUIT

ENTRY AREA IN HOOD.

CONDUIT PLATES PROVIDED

DRIP SHIELD

MTG STUD - MIN

.50 D (12.7)

LENGHT 1.50 (38.1)

1.37

Figure 3.3 – 1457A Power Module Mounting Dimensions (Triple-Bay)

DC TOP HAT ENCLOSURE INSTALLED

COMMON DC BUS ENCLOSURE INSTALLED - 10.00 (254.0).

23.75

(34.8)

22.38

(568.5)

(603.3)

WEIGHT = 3085 LBS (1398 KG)

ADDITIONAL HEIGHT:

∗

High Power SA3000 AC Power Modules

ALL DIMENSIONS ARE IN INCHES (MILLIMETERS)

Page 31

INPUT VOLTAGE

115 VAC

VOLTAGE 775V

DC BUS INPUT

GND

FUSE

CONNECT BLOCK

115 VAC QUICK

POWER MODULE

NL

4745

+

–

GND

SA3000

MOTOR

OUTPUT CONTACTOR

(OPTIONAL)

MANUAL

DISCONNECT

UVW

Installation Guidelines

Figure 3.4 – SA3000 Power and Ground Connections

3-7

Page 32

3-8

High Power SA3000 AC Power Modules

Page 33

C

HAPTER

4

Diagnostics and Troubleshooting

This chapter describes the equipment needed to check the operation of the Power

Module and the tests to be performed. Included are descriptions of the Power Module

faults and warnings monitored by the Distributed Power System software. Procedures

are also provided for replacing Power Module cabinets, sub-assemblies, and fuses.

ATTENTION:

power has been disconnected. After disconnecting input power, wait ten

!

(10) minutes for the DC bus capacitors to discharge. Open the cabinet

doors and check the voltage across the DC bus bars, 347 A,B,C (+ bus)

and 345 A,B,C (- bus), with an external voltmeter to ensure the DC bus

capacitors are discharged before touching any internal components.

Failure to observe this precaution could result in severe bodily injury or

loss of life.

ATTENTION:

that are static sensitive. Do not touch the boards’ components,

connectors, or leads. Failure to observe this precaution could result in

damage to, or destruction of, the equipment.

DC bus capacitors retain hazardous voltages after input

The SA3000 Power Module contains printed circuit boards

4.1 Required Test Equipment

The following equipment is required when servicing the SA3000 Power Module:

•

an oscilloscope with an impedance of at least 8 megohms

•

a 10:1 probe

•

an isolated voltmeter (1000V DC)

•

a clamp-on ammeter (1500A)

Note that all measuring devices-meters-oscilloscopes that are AC line-powered must

be connected to the AC line through an ungrounded isolation transformer.

Diagnostics and Troubleshooting

ATTENTION:

line powered test instruments used to measure Power Module signals

!

must be isolated from ground through an isolation transformer. This is

not necessary for battery-powered test instruments. Failure to observe

this precaution could result in bodily injury.

ATTENTION:

inadvertent ground internal to the motor, make certain that all leads are

disconnected between the rotating equipment and the Power Module

cabinet. This will prevent damage to electronic circuitry (Power Modules

and their associated circuitry) due to the high voltage generated by the

megger. F ailure to observe this precaution could result in damage to or

destruction of the equipment.

The Power Module is not isolated from earth ground. AC

If a megohmmeter (megger) is used to verify an

4-1

Page 34

4.2 Power Module Tests with Input Power Off

Use the following procedure to perform the SA3000 Power Module tests:

Step 1. Turn off and lock out DC input power.

Step 2. Wait ten minutes to allow the DC bus voltage to dissipate.

ATTENTION:

power has been disconnected. After disconnecting input power, wait ten

!

Step 3. Open the Power Module’s cabinet doors and measure the voltage across

Step 4. Disconnect the motor from the Power Module.

Step 5. Check the DC bus fuses.

(10) minutes for the DC bus capacitors to discharge. Open the cabinet

doors and check the voltage across the DC bus bars, 347 A,B,C (+ bus)

and 345 A,B,C (- bus), with an external voltmeter to ensure the DC bus

capacitors are discharged before touching any internal components.

Failure to observe this precaution could result in severe bodily injury or

loss of life.

each pair of DC bus bars, 347 A,B,C (+ bus) and 345 A,B,C (- bus), with an

external voltmeter to ensure the DC bus capacitors are discharged before

touching any internal components. See figure 4.1.

Be sure to check the DC bus fuses for continuity if an IGBT phase module or

fuse fails in a 972A or 1457A Power Module. Excessive current may have

damaged the DC bus fuses. It is recommended that the DC bus fuses be

replaced whenever an IGBT phase module or fuse fails due to a fault current.

If the DC bus fuses have opened in Power Module A, a bus fault will be

generated. If the DC bus fuses have opened in Power Modules B or C, a bus

fault will not be generated, but an Instantaneous Overcurrent (IOC) fault will

be indicated. This may be the only indication of a blown fuse in Power

Modules B and C.

DC bus capacitors retain hazardous voltages after input

4-2

Step 6. If a fuse is blown, use a multimeter to check the DC bus, bus capacitors,

output terminals, and the output IGBTs. See tables 4.1 and 4.2.

Step 7. If a capacitor is defective, replace the capacitor bank assembly as described

in section 4.4.5. If an IGBT is defective, refer to section 4.4.2.

High Power SA3000 AC Power Modules

Page 35

DISCONNECT SWITCH

MODULE

L

P

I

CB1

1CB1

3FU

PS

-24V

1FU

PS

PS

±15V

+24V

F

P

C

M

F

P

M

B

POWER MODULE A

F

P

M

A

GRD

MOTOR

PRE-CHARGE ASSEMBLY

-+-

+

PHASE U

BANK

25KHZ PS

PHASE V

K

C

A

PCB

LINE

SYNC

AC LINE SYNC

R

I

M

P

BLOWER

ASSEMBLY

PHASE W

CAPACITOR

347A

345A

+BUS

-BUS

W

BLOWER

VU

PHASE U

PHASE V

PHASE W

ASSEMBLY

POWER MODULE B

AC MOTOR OUTPUT

GRD

MOTOR

PRE-CHARGE ASSEMBLY

BANK

ITOR

CAPAC

347B

345B

+BUS

-BUS

Diagnostics and Troubleshooting

POWER MODULE C

PRE-CHARGE ASSEMBLY

PHASE U

BANKCAPACITOR

PHASE V

Figure 4.1 – DC Bus Voltage Measuring Points

PHASE W

BLOWER

ASSEMBLY

347C

345C

+BUS

-BUS

4-3

Page 36

Table 4.1 – DC Bus and Terminal Tests

1

Meter Connections

Scale Expected Test Results

+ -

DC Bus

- Bus (45) + Bus (47)

+ Bus (47) - Bus (45) Capacitor Effect (0 to 200 ohms)

+ 349 A,B,C

X10

X10

Capacitor Effect (0 to 50 ohms)

Capacitor Effect (0 to 500 ohms)

- 349 A,B,C

U+

Bus

Capacitors

W+

X1 2 ohmsV+

+U

X10 Capacitor Effect (0 to 2k ohms)+V

+W

UV

Output

Terminals

X1000 4k to 6k ohmsUW

VW

1. With the motor disconnected

Table 4.2 – IGBT Tests

1

Expected Test

Meter Connections

+ -

Scale

Results

(+/- 10%)

W Phase (lower) + W +347 A,B,C 2k Ω/diode 0.300 ohms

V Phase (lower) + V +347 A,B,C 2k Ω/diode 0.300 ohms

U Phase (lower) + U +347 A,B,C 2k Ω/diode 0.300 ohms

W Phase (upper) - -345 A,B,C W 2k Ω/diode 0.300 ohms

V Phase (upper) - -345 A,B,C V 2k Ω/diode 0.300 ohms

U Phase (upper) - -345 A,B,C U 2k Ω/diode 0.300 ohms

1. With the motor disconnected

4-4

4.3 Power Module Faults and Warnings

The PMI Processor continually runs diagnostics which check for errors that may affect

system operation. Warnings are errors which indicate that the SA3000 Power Module

is not operating in an optimum manner. Warnings will not shut down the SA3000.

Faults are severe errors which will shut down the SA3000. See tables 4.3 and 4.4.

Refer to the SA3000 Drive Configuration and Programming instruction manual

(S-3042) for more information about the Fault and Warning registers.

High Power SA3000 AC Power Modules

Page 37

4.3.1 Power Module Faults

The Power Module faults listed in table 4.3 will cause the SA3000 Power Module to

shut down. In a fault situation, the PMI Processor will command zero current and will

stop firing the Power Module’s IGBTs. Faults must be reset before the SA3000 Power

Module can be restarted.

Table 4.3 – SA3000 Power Module Faults (Register 202/1202)

Bit

Suggested

Variable

Name

UDC

Error

Code

Description Summary

0 FLT_OV@ 1018 The DC Bus Overvoltage bit is set if the DC bus voltage exceeds 925

VDC.

1 FLT_DCI@ 1020 The DC Bus Overcurrent bit is set if the DC bus current exceeds 125%

of the rated SA3000 Power Module current.

2 FLT_GND@ 1021 The Ground Current Fault bit is set if the ground current exceeds the

hardware trip point. See section 4.3.1.3.

3 FLT_IOC@ 1017 The Instantaneous Overcurrent Fault bit is set if an overcurrent is

detected in one of the power devices.

4 FLT_LPI@ 1022 The Local Power Interface bit is set if the power supply voltage on the

LPI module is not within tolerance.

6 FLT_CHG@ 1024 The Charge Bus Timeout Fault bit is set if the DC bus is not fully

charged within 10 seconds of being enabled, if the drive is on and

feedback indicates the pre-charge contactor has opened, or if DC bus

voltage is less than the Power Loss Fault Threshold tunable variable

(PLT_FLT%).

7 FLT_OT@ 1016 The Overtemperature Fault bit is set if the fault level thermal switch

o

(85

C (185o F)) in the SA3000 Power Module opens.

4.3.1.1 DC Bus Overvoltage Fault

The DC Bus Overvoltage bit (bit 0) is set in the Fault register (202/1202) if the DC bus

voltage exceeds 925 VDC. Error code 1018 will also be displayed in the error log of

the UDC task in which the fault occurred.

4.3.1.2 DC Bus Overcurrent Fault

The DC Bus Overcurrent bit (bit 1) is set in the Fault register (202/1202) if the DC bus

current exceeds 125% of the rated SA3000 Power Module current. Error code 1020

will also be displayed in the error log of the UDC task in which the fault occurred.

4.3.1.3 Ground Current Fault

The Ground Current Fault bit (bit 2) is set in the Fault register (202/1202) if the ground

current exceeds the hardware trip point value of 100 Amps. Error code 2021 will also

be displayed in the error log of the UDC task in which the fault occurred.

Note that the Ground Current Fault bit (register 202/1202, bit 2) is not enabled on

SA3000 Power Modules using AC Technology modules, B/M 60023-5 and later. Error

code 2021 will not be displayed as the ground current hardware trip detector was

removed from the AC Technology modules, B/M 60023-5 and later.

Diagnostics and Troubleshooting

4-5

Page 38

4.3.1.4 Instantaneous Overcurrent Fault

The Instantaneous Overcurrent Fault bit (bit 3) is set in the Fault register (202/1202) if

an overcurrent is detected in one of the power devices (IGBTs). Register 204/1204,

bits 0-5, indicates which power device experienced the overcurrent. When 972A and

1457A SA3000 Power Modules are being used, registers 220/1220 and 221/1221

indicate the status of the B and C Power Modules. Error code 1017 will also be

displayed in the error log of the UDC task in which the fault occurred.

4.3.1.5 Local Power Interface Fault

The Local Power Interface Fault bit (bit 4) is set in the Fault register (202/1202) if the

power supply voltage on the LPI module is not within tolerance. Error code 1022 will

also be displayed in the error log of the UDC task in which the fault occurred.

4.3.1.6 Charge Bus Time-Out Fault

The Charge Bus Fault bit (bit 6) is set in the Fault register (202/1202) if one of the

following occurs:

•

the internal DC bus is not fully charged within 10 seconds after the bus enable bit

(register 100/1100, bit 4) is set.

•

the drive is on and feedback indicates that the pre-charge contactor has opened

•

DC bus voltage is less than the value stored in the Power Loss Fault Threshold

(PLT_E0%) tunable variable.

If this bit is set, verify that the incoming DC bus power is at the appropriate level. If the

power level is correct the problem is in one of the SA3000 Power Modules. Bit 8 in

register 204/1204, 220/1220, or 221/1221 will be set to indicate which Power Module

is caused the fault. Error code 1024 will also be displayed in the error log of the UDC

task in which the fault occurred.

4.3.1.7 Overtemperature Fault

The Overtemperature Fault bit (bit 7) is set in the Fault register (202/1202) if the fault

level thermal switch (85

204/1204, 220/1220, or 221/1221 will be set to indicate which SA3000 Power Module

is caused the fault. Error code 1016 will also be displayed in the error log of the UDC

task in which the fault occurred.

o

C (185o F)) in the Power Module opens. Bit 12 in register

4-6

High Power SA3000 AC Power Modules

Page 39

4.3.2 Power Module Warnings

The following warnings indicate conditions which are not serious enough to shut down

the SA3000 Power Module but may affect its performance. See table 4.4. Warnings

cause no action by themselves. Any response to a warning condition is the

responsibility of the application task.

Table 4.4 – SA3000 Warning Register 203 /1203

Suggested

Variable

Bit

Name

0 WRN_OV@ The DC Bus Overvoltage fault bit is set if the DC bus voltage exceeds the

overvoltage threshold value stored in local tunable OVT_E0%.

1 WRN_UV@ The DC Bus Undervoltage bit is set if the DC bus voltage drops below the under

voltage threshold value stored in local tunable UVT_E0%.

2 WRN_GND@ The Ground Current Warning bit is set if the ground current exceeds the ground

fault current level stored in local tunable GIT_EI%.

6 WRN_SHR@ The Load Sharing Warning bit is set if a current sharing problem develops

between parallel SA3000 Power Modules.

7 WRN_OT@ The Overtemperature Warning bit is set if the warning level thermal switch (78° C

o

(172.4

F)) in the SA3000 Power Module opens.

Description Summary

4.3.2.1 DC Bus Overvoltage Warning

The DC Bus Overvoltage bit (bit 0) is set in the Warning register (203/1203) if the DC

bus voltage exceeds the overvoltage threshold value stored in local tunable

OVT_E0%.

4.3.2.2 DC Bus Undervoltage Warning

The DC Bus Undervoltage bit (bit 1) is set in the Warning register (203/1203) if the DC

bus voltage drops below the under voltage threshold value stored in local tunable

UVT_E0%.

4.3.2.3 Ground Current Warning

The Ground Current Warning bit (bit 2) is set in the Warning register (203/1203) if the

ground current exceeds the ground fault current level stored in local tunable GIT_EI%.

4.3.2.4 Load Sharing Warning

The Load Sharing Warning bit (bit 6) is set in the Warning register (203/1203) if a

current sharing problem develops between parallel SA3000 Power Modules. Bits 13,

14, or 15 in registers 204/1204, 220/1220, or 221/1221 will be set to indicate the

Power Module and phase that caused the warning.

Diagnostics and Troubleshooting

4-7

Page 40

4.3.2.5 Overtemperature Warning

The Overtemperature Warning bit (bit 7) is set in the Warning register (203/1203) if

the warning level thermal switch (78

opens. Bit 12 in register 204/1204, 220/1220, or 221/1221 will be set to indicate which

SA3000 Power Module caused the warning.

o

C (172.4o F)) in the SA3000 Power Module

4.4 Replacing Power Module Fuses and Sub-Assemblies

Follow the procedures given in sections 4.4.1 to 4.4.5 to replace the SA3000 Power

Module’s fuses and sub-assemblies.

4.4.1 Replacing Fuses

Use the following procedure to replace a fuse that has blown:

Step 1. Turn off and lock out the AC input power.

Step 2. Wait ten minutes to allow the DC bus voltage to dissipate.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait ten

!

(10) minutes for the DC bus capacitors to discharge. Open the cabinet

doors and check the voltage across the DC bus bars, 347 A,B,C (+ bus)

and 345 A,B,C (- bus), with an external voltmeter to ensure the DC bus

capacitors are discharged before touching any internal components.

Failure to observe this precaution could result in severe bodily injury or

loss of life.

Step 3. Open the cabinet doors and check the voltage across the DC bus bars,

347 A,B,C (+ bus) and 345 A,B,C (- bus), with an external voltmeter to ensure

the DC bus capacitors are discharged before touching any internal

components. See figure 4.1.

Step 4. Remove the blown fuse and install the replacement fuse. Figures 4.2 to 4.6

show the locations of the fuses in the 534A, 972A, and 1457A SA3000 Power

Modules. Table 4.5 provides fuse specifications.

Step 5. Close the cabinet doors and reapply power to the SA3000 Power Module.

4-8

High Power SA3000 AC Power Modules

Page 41

Table 4.5 – Power Module Replacement Fuse Specifications

Rockwell

Fuse Volts Class Type Rating

Part Number Torque Specifications

1FU 600 CC KLDR 5 A 64676-29R -3FU 600 CC KLDR 3.2 A 64676-29P --

FPM A,B,C 1000 Semiconductor 1000 A 64676-80P 41 Nm (30 lb-ft)