Page 1

Reference Manual

R o c k w e l l A u t o m a t i o n Li b r a r y o f P r o c e s s O b j ec t s :

Central Reset (P_Reset)

Version 3.5

IMPORTANT

This manual applies to the Rockwell Automation Library of Process Objects version 3.5 or earlier.

For Rockwell Automation Library of Process Objects version 5.0, see

• PROCES-RM200

For Rockwell Automation Library of Process Objects version 4.0 or later, use the following manuals:

• PROCES-RM013 contains logic instructions

• PROCES-RM014 contains display elements

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, RSLogix, Log ix5000, FactoryTalk, PlantPAx, and ControlLogix are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Central Reset (P_Reset)

Software Compatibility and Content Revision. . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Required Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Controller File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Visualization Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Controller Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Central Reset Input Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Central Reset Output Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Central Reset Local Configuration Tags. . . . . . . . . . . . . . . . . . . . . . . . 11

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Implementation by Using EnableIn False Feature . . . . . . . . . . . . . . . 12

Programming Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Graphic Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Using Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016 3

Page 4

Tab le of Con ten ts

Notes:

4 Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016

Page 5

Preface

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

Software Compatibility and Content Revision

Additional Resources

Table 1 - Summary of Changes

Top ic Pa ge

Changed software version from 3_1 to 3_5 8

Split visualization files table by type and reordered to align with installation requirements 8

For the latest compatible software information and to download the Rockwell

Automation® Library of Process Objects, see the Product Compatibility and

Download Center at

http://www.rockwellautomation.com/rockwellautomation/support/pcdc.page

For general library considerations, see Rockwell Automation Library of Process

Objects, publication PROCES-RM002

.

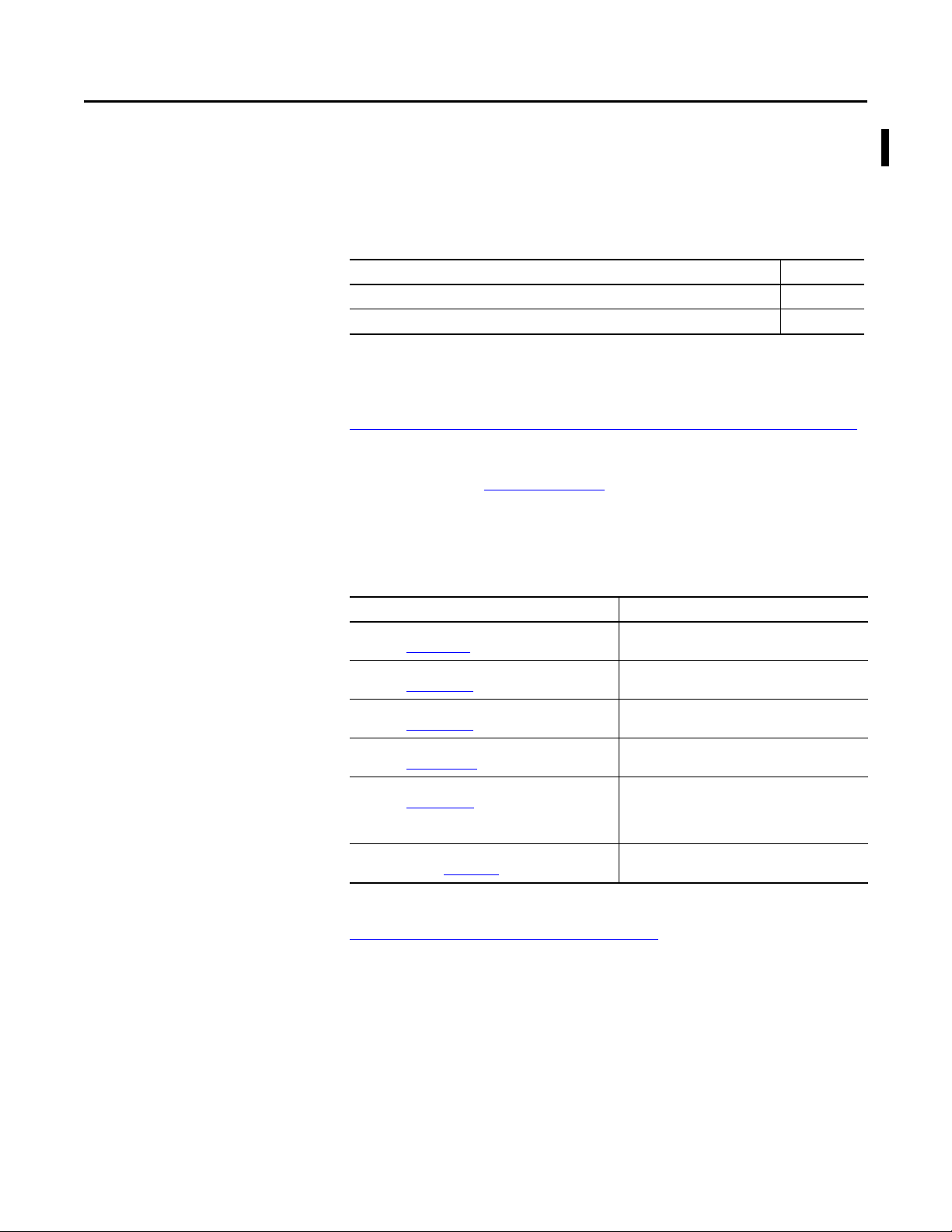

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

PlantPAx® Distributed Control System Selection Guide,

publication PROCES-SG001

PlantPAx Distributed Control System Reference Manual,

publication PROCES-RM001

Rockwell Automation Library of Process Objects,

publication PROCES-RM002

FactoryTalk® View Machine Edition User Manual,

publication VIEWME-U M004

FactoryTalk View Site Edition User Manual,

publication VIEWSE-UM006

Logix5000™ Controllers Add-On Instructions Programming

Manual, publication 1756-PM010

Provides information to assist with equipment

procurement for your PlantPAx system.

Provides characterized recommendations for

implementing your PlantPAx system.

Provides general considerations for the PlantPAx system

library of process objects.

Provides details on how to use this software package for

creating an automation application.

Provides details on how to use this software package for

developing and running human-machine interface

(HMI) applications that can involve multiple users and

servers, distributed over a network.

Provides information for designing, configuring, and

programming Add-On Instructions.

.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016 5

Page 6

Preface

Notes:

6 Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016

Page 7

Central Reset (P_Reset)

Add-On Instruction

The P_Reset (Central Reset) Add-On Instruction provides a central point for

resetting equipment faults. Latched alarms can be reset for a control strategy.

The P_Reset instruction accepts an Operator Reset command, a Program Reset

command, and a Reset Input that can come from a push button, from a higherlevel P_Reset instruction (from a containing control strategy, such as a Unit

Reset sent to a P_Reset at Equipment Module scope), or from any other source.

The P_Reset instruction also includes a Reset Required input for collecting the

Ready to Reset outputs of the various instructions it resets and providing a Ready

to Reset (Reset Required) status that can illuminate a push button or make an

HMI Reset button visible.

Guidelines

The P_Reset instruction includes a timer function that causes its output to be

held on for at least a minimum time. This lets the reset signal be sent via physical

output cards to field devices that require it (for example, motor drives) and gives

time for the cleared status from the device to propagate back to Interlock or

Permissive inputs.

Use this instruction in these situations:

• You want a common reset point (Master Reset) for alarms and fault

conditions for a control strategy, process unit, process cell or equipment

group, process area or plant section, or even a small site. Tie the output of

the P_Reset instruction to the Inp_Reset input of the equipment to

be reset.

• You want a cascading reset strategy, where there is a P_Reset instruction

for a small equipment scope (such as a strategy) that incorporates resets

from wider scope (unit, cell, area, site) resets. Tie the output of the higherlevel P_Reset instruction to the Inp_Reset input of the lower-level

P_Reset instruction.

Do not use this instruction when you want to reset a single piece of equipment

(valve, motor). Use the Operator or Program Reset command directly on the

equipment.

Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016 7

Page 8

Central Reset (P_Reset)

IMPORTANT

Functional Description

Required Files

The P_Reset Add-On Instruction provides the following capabilities:

• Reset output for use by other instructions in a control strategy to reset

latched alarms (for example, P_AIn analog input alarms) or equipment

faults (for example, P_Motor motor faults)

• Operator Reset command for use by the HMI

• Program Reset command for use by control strategies

• Reset input for use by push button inputs or for cascading resets from

higher levels of the control hierarchy

• Reset Required input and Ready for Reset output for use in highlighting

to operators where a reset is required before the equipment can start

• Minimum On Time for the reset output to allow physical equipment to

clear faults and have the clear status propagate through the various

permissive and interlock instructions in the control strategy

Add-On Instructions are reusable code objects that contain encapsulated logic

that can streamline implementing your system. This lets you create your own

instruction set for programming logic as a supplement to the instruction set

provided natively in the ControlLogix® firmware. An Add-On Instruction is

defined once in each controller project, and can be instantiated multiple times in

your application code as needed.

Controller File

The P_Reset_3_5-00_AOI.L5X Add-On Instruction must be imported into the

controller project to be used in the controller configuration. The service release

number (boldfaced) can change as service revisions are created.

Visualization Files

http://www.rockwellautomation.com/global/support/pcdc.pageThis Add-On

Instruction has associated visualization files that provide a common user

interface. These files can be downloaded from the Product Compatibility and

Download Center at

http://www.rockwellautomation.com/rockwellautomation/support/pcdc.page

The visualization file dependencies require Process Library content imports to

occur in a specific order as reflected in the following tables:

• Images

• Global Objects

• Standard Displays

• HMI Tags

• Macros

.

Images are external graphic files that can be used in displays. They must be

imported for FactoryTalk View to make use of them.

8 Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016

Page 9

Central Reset (P_Reset)

When PNG files are imported, they are renamed by FactoryTalk View with

a .bmp file extension, but retain a .png format.

Table 2 - Visualization Files: Images (.png)

FactoryTalk View SE Software FactoryTalk View ME Software Descr iption

All .png files in the images folder All .png files in the images folder These are the common icons used in the global objects and

standard displays for all Process Objects.

The Global Object files (.ggfx file type) in the following table are Process Library

display elements that are created once and referenced multiple times on multiple

displays in an application. When changes are made to a Global Object, all

instances in the application are automatically updated.

Table 3 - Visualization Files: Global Objects (.ggfx)

FactoryTalk View SE Software FactoryTalk View ME Software Descr iption

(RA-BAS) Process Graphics Library (RA-BAS-ME) Process Graphics Librar y Process global object device symbols used to build

process graphics

The Standard Display files (.gfx file type) in the following table are the Process

Library displays that you see at runtime.

Table 4 - Visualization Files: Standard Displays (.gfx)

FactoryTalk View SE Software FactoryTalk View ME Software Descr iption

N/A N/A There are no standard display files for this object

HMI Tags are created in a FactoryTalk View ME application to support tab

switching on Process Library faceplates. The HMI tags may be imported via the

comma-separated values file (.csv file type) in the following table.

Table 5 - Visualization Files: HMI Tags (.csv)

FactoryTalk View SE Software FactoryTalk View ME Software Descr iption

N/A FTVME_PlantPAxLib_Tags_3_5_xx.csv

where xx = the service release number.

These tags must be imported into the

FactoryTalk View ME project to suppor t switching tabs on

any Process Object faceplate.

Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016 9

Page 10

Central Reset (P_Reset)

Controller Code

This section describes the parameter references for this Add-On Instruction.

Central Reset Input Structure

Input parameters include the following:

• Input data elements (Inp_) are typically used to connect field inputs from

I/O modules or signals from other objects.

• Configuration data elements (Cfg_) are used to set configurable

capabilities and features of the instruction.

• Commands (PCmd_, OCmd_, MCmd_) are used by program logic,

operators, and maintenance personnel to request instruction actions.

Table 7 - P_Reset Input Parameters

Input Parameter Data Type Default Description

EnableIn BOOL 1 Ladder Diagram:

If the rung-in condi tion is true, the instruction’s Logic routine executes. If the rung-in con dition is false,

the instruction’s EnableInFalse routine executes.

Function Block Diagram:

If true, or not connected, the instruction’s Logic routine executes. If the parameter is exposed as a pin

and wired, and the pin is false, the instruction’s EnableInFalse routine executes.

Structured Text:

No effect. The instruction’s Logic routine executes.

Inp_Reset BOOL 0 Reset Input: 1 = Reset, from a push button or another object.

Inp_ResetReqd BOOL 1 1 = Reset required, enable Reset button.

Cfg_MinHoldTime DINT 1 Minimum time to hold Reset output true (seconds).

PCmd_Reset BOOL 0 Program command to reset, from other object.

OCmd_Reset BOOL 0 Operator command to reset, from HMI.

Central Reset Output Structure

Output parameters include the following:

• Output data elements (Out_) are the primary outputs of the instruction,

typically used by hardware output modules; however, they can be used by

other application logic.

• Status data elements (Sts_) are bit outputs of the instruction for use by the

HMI. Status bits can also be used by other application logic.

• Ready data elements (Rdy_) are bit outputs of the instruction used by the

HMI to enable or disable command buttons and entry fields.

Table 8 - P_Reset Output Parameters

Output Parameter Data Type Description

EnableOut BOOL Enable Output: The EnableOut signal is not manipulated by this instruction. Its output state always reflects EnableIn input

Out_Reset BOOL 1 = Reset received for this P_Reset scope.

10 Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016

state.

Page 11

Central Reset (P_Reset)

Table 8 - P_Reset Output Parameters

Output Parameter Data Type Description

Sts_Err BOOL 1 = Error in Configuration Invalid Hold Time (use 0…2,147,483).

Rdy_Reset BOOL 1 = Ready for OCmd_Reset (enables HMI button).

P_Reset BOOL Unique Parameter Name for auto-discovery.

Central Reset Local Configuration Tags

Configuration parameters that are array, string, or structure data types cannot be

configured as parameters for Add-On Instructions. Configuration parameters of

these types appear as local tags to the Add-On Instruction. Local tags can be

configured through the HMI faceplates or in Studio 5000 Logix Designer®

application by opening the instruction logic of the Add-On Instruction instance

and then opening the Data Monitor on a local tag. These parameters cannot be

modified by using controller logic or Logix Designer application

export/import functionality.

Tag Name Data Type Default Description

Cfg_Desc STRING_40 'Multiple-Device Reset' Description for display on HMI. The string shows in the title bar of the

Cfg_Label STRING_20 'Reset' Label for graphic symbol displayed on HMI. This string appears on the graphic

Cfg_ Tag ST RING_2 0 'P_R eset' Tagname for di splay o n HMI. Th is str ing show s in th e bottom right of the h ome

faceplate.

symbol.

tab of the faceplate.

Operations

This section describes the primary operations for the P_Reset

Add-On Instruction.

Modes

The P_Reset Add-On Instruction does not have modes and does not contain a

P_Mode instruction instance. The Operator and Program reset commands are

accepted at any time.

Alarms

The P_Reset instruction provides no alarms. However, the instruction is used to

fan out a reset to instructions that have latched alarms.

Simulation

The P_Reset Add-On Instruction does not have a Simulation capability.

Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016 11

Page 12

Central Reset (P_Reset)

Execution

The following table explains the handling of instruction execution conditions.

Condition Description

EnableIn False (false rung) Handling Sets up a low-to-high transition detection scheme. When the instruction is

again scanned as Tr ue, the transition is detected and the reset output pulses

for the required time. Otherwise, EnableIn False processing is identical to

normal true rung processing: the Operator Reset command, Program Reset

command and Reset Input function as in normal processing.

This lets the Reset instruction participate in a control hierarchy by using the

Inp_Reset input, yet be tied to a reset push button by using the rung state.

See the following section for an example.

Refer to the Logix5000 Controllers Add-On Instructions Programming Manual,

publication 1756-PM010

, for more information.

Implementation by Using EnableIn False Feature

For the convenience of Ladder Diagram programmers, the P_Reset instruction

can be used in a Ladder Diagram routine with the Input condition carried by the

Rung-In condition instead of being mapped on a separate branch.

The following illustration shows normal implementation with the input

condition mapped to Inp_Reset on a separate branch.

The following illustration shows EnableIn False implementation with the input

condition mapped to the P_Reset instruction by using the Rung-In state.

12 Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016

Page 13

Central Reset (P_Reset)

The Rung-In condition determines whether the P_Reset instruction's normal

code (Logic Routine) is performed or its EnableIn False code (EnableInFalse

Routine) is performed. In the P_Reset instruction, the EnableIn False code is

identical to the Logic code, except it also arms a one-shot for the Rung-In

condition. When the rung goes Tr u e , the Logic routine one-shot fires and the

Out_Reset output pulses for the configured time, executing a reset.

Use both mapping methods together to provide an additional input to the

P_Reset instruction. This is especially useful in an equipment hierarchy, such as

in Batch applications (Control Module, Equipment Module, Unit, Cell, Area,

and so forth). The Inp_Reset input can be mapped from a higher-level P_Reset

instruction, while the local Reset Pushbutton can be mapped by using the RungIn condition to execute a local equipment reset.

The following illustration shows an EnableIn dual implementation consisting of a

high-level reset by using a mapping branch and a local Reset button by using

Rung-In state mapping.

Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016 13

Page 14

Central Reset (P_Reset)

Programming Example

This example adds a unit-wide reset to an existing Function Block Diagram

motor control strategy for the fan of a cooling tower in a refinery.

Follow these steps to add the P_Reset instruction to your project.

1. In the Function Block Diagram editor, add a P_Reset instance to the

strategy by clicking the Add-On tab of the Language Element toolbar and

selecting the P_Reset instruction. Also add a BOR (boolean OR)

instruction.

2. Click the generic tagname given to the P_Reset instance (P_Reset_01),

then type the tagname you want to give this instance. Right-click the new

tagname and choose ‘New (tagname)...’ and create the tag for this P_Reset

instance. In this example, we entered the name ‘CT_Reset’.

3. Open the properties of the P_Motor and P_Intlk instructions and expose

the Inp_Reset input pin (if not already exposed) and the Rdy_Reset

output pin.

4. Connect these pins to inputs of the BOR block. You need to right-click

each wire and select the ‘Assume Data Available’ option to resolve the

execution order of the blocks.

5. Open the properties of the P_Reset instruction and be sure the

Inp_ResetReqd input pin and Out_Reset output pin are exposed.

6. Connect the Out output of the BOR block to the Inp_ResetReqd input of

P_Reset. This signal is true if any block in the strategy requires a Reset.

7. Connect the Out_Reset output of the P_Reset block to the Inp_Reset

input of each block in the strategy that will receive the unit Reset. This

fans any Reset command received by P_Reset out to the rest of the

strategy.

14 Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016

Page 15

Central Reset (P_Reset)

The figure below shows all the additions to the existing motor control

strategy to add the unit reset function. It also shows example connections

for a hardwired illuminated Reset button.

8. In FactoryTalk View Studio, open the graphic for your motor control

strategy.

9. Open the (RA-BAS) Process Graphics Library Global Objects file.

10. Copy the Reset button object from the Global Objects file into your

strategy graphic.

11. Right click the object and select ‘Global Object Parameter Values’.

12. Press ‘...’ (ellipsis) to open the tag browser.

Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016 15

Page 16

Central Reset (P_Reset)

TIP

13. In the tag browser, select the tag CT_Reset and click OK.

14. Save and run your HMI and logic changes.

Now whenever a condition occurs that requires an operator reset, the reset

button becomes visible. You can click the button to send a reset to all the blocks

in the strategy that need it. Once the reset has propagated through the strategy,

the button disappears.

The Mosquito Station sample application included in the Rockwell Automation

Library download has a Station Reset toolbar button implemented to illustrate

this same method for an entire pump station.

16 Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016

Page 17

Central Reset (P_Reset)

Display Elements

This section describes the Operator Interface for the P_Reset instruction.

Graphic Symbols

The following table describes the graphic symbols of the P_Reset.

Button Description

The same as the reset buttons used in other Process Library Faceplates and screens and is

for use on end-user process graphic displays.

The reset button is inactive.

Using Display Elements

The graphic symbol for the P_Reset instruction can be found in the global object

file (RA-BAS) Process Graphics Library.ggfx. Follow these steps to use the

graphic symbol.

1. Copy the global object from the global object file and paste it in the

display file.

2. In the display, right-click the global object and choose Global Object

Parameter Values.

Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016 17

Page 18

Central Reset (P_Reset)

TIP

The Global Object Parameter Values dialog box appears.

The global object parameter is as follows.

Parameter Required Description

#102 Y Object tag to point to the name of the associated object Add-On

Instruction in the controller.

3. Type the tag or value in the Value column as specified in the Description

column.

Click the ellipsis (. . .) to browse and select a tag.

Values for items marked ‘(optional)’ can be left blank.

4. Click OK.

18 Rockwell Automation Publication SYSLIB-RM008E-EN-E - January 2016

Page 19

Page 20

Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

software service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

updates, support chats and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more

information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Worldwide Locat or

Rockwell Automation representative.

at http://www.rockwellautomation.com/rockwellautomation/sup port/overview.page, or contact your local

New Product Satisfaction Return

you can find technical and application notes, sample code, and links to

for software

.

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

Rockwell Automation maintains current product envirSYSLIB-RM008D-EN-Eonmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental- compliance.page

, available at http://www.rockwellautomation.com/literature/.

.

Publication SYSLIB-RM008E-EN-E - January 2016

Supersedes Publication SYSLIB-RM00 8D-EN-E - August 2014 Copyright © 2016 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...