Page 1

SP500 AC Drive

Installation and Operation Manual

Version 3.1

Instruction Manual

D2-3356-5

Page 2

The information in this manual is subject to change without notice.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

The thick black bar shown on the outside margin of this page will be used throughout this instruction manual to

signify new or revised text or figures.

ATTENTION:Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, and/or service this

!

equipment. Read and understand this manual in its entirety before proceeding.

Reliance, ReSource, and AutoMax are trademarks of Rockwell Automation.

©1999 Rockwell International Corporation

Page 3

Chapter 1 Introduction

1.1 Who Should Use This Manual......................................................................... 1-1

1.2 Installation Overview .......................................................................................1-1

1.3 Requesting Assistance from Reliance Electric ................................................ 1-1

Chapter 2 Learning About the SP500 Drive

2.1 Standard Features...........................................................................................2-1

2.2 Drive Description ............................................................................................. 2-2

2.3 Identifying the Drive by Model Number ........................................................... 2-6

2.3.1 Power Ratings and NEMA Enclosure Ratings ...................................... 2-7

2.3.2 Enclosure Ratings and Sizes ................................................................ 2-8

2.4 Component Locations......................... ....... ...... ....... ....................................... .. 2-8

2.5 Option Kits..................................................................................................... 2-13

Chapter 3 SP500 System Planning

3.1 Installation Site Requirements......................................................................... 3-1

3.1.1 Determining the Total Area Required for Installation ............................ 3-2

3.1.2 Providing Proper Air Flow Clearances ..................................................3-4

3.1.3 Verifying the Drive’s Power Loss Rating ............................................... 3-4

3.2 Wiring Requirements .......................................................................................3-4

3.2.1 Verifying Conduit Sizes ......................................................................... 3-4

3.2.2 Recommended Power Wire Sizes......................................................... 3-4

3.2.3 Recommended Control and Signal Wire Sizes ..................................... 3-6

3.2.4 Recommended Motor Lead Lengths..................................................... 3-6

3.3 Selecting Input AC Line Branch Circuit Fuses.................................................3-8

3.4 Installing an Emergency Stop.......................................................................... 3-9

3.4.1 Complying with Machinery Safety Standard EN 60204-1:1992 ............3-9

3.5 Motor Considerations ......................................................................................3-9

3.5.1 Single-Motor Applications...................................................................... 3-9

3.5.2 Multiple-Motor Applications ....................................... ...... ....... ...... ....... 3-10

CONTENTS

Contents

Chapter 4 Installing the Drive

4.1 Mounting the Drive .......... ....... ...... ...... ....... ...... ....... ....................................... .. 4-1

4.2 Routing Wires.................................................................................................. 4-1

4.3 Installing External Components........................................... ...... ....... ...... ....... .. 4-6

4.3.1 Disconnects........................ ...... ....... ...... ....... ...... ....... ...... ....... ...............4-6

4.3.2 Input AC Line Branch Protection........................................................... 4-6

4.3.3 Transformers.........................................................................................4-6

4.3.4 Output Contactors................................................................................. 4-7

4.3.5 Mechanical Motor Overload Protection.................................................4-7

4.4 Setting the Analog Input Jumper on the Regulator Board............................... 4-7

4.5 Preparing the Motor.........................................................................................4-8

I

Page 4

Chapter 5 Wiring the Drive

5.1 Input Power Wiring...........................................................................................5-1

5.2 Signal and Control Wiring ................................................................................5-3

5.2.1 Analog Speed Reference Wiring ...........................................................5-3

5.2.2 Analog Output Wiring.............................................................................5-4

5.2.3 Digital Input Wiring.................................................................................5-4

5.2.4 Snubber Resistor Wiring........................................................................5-8

5.2.5 Output Status Relay Wiring .................................................................5-10

5.3 Output Power Wiring......................................................................................5-10

5.4 Grounding ......................................................................................................5-11

Chapter 6 Completing the Installation

6.1 Checking the Installation With the Power Off...................................................6-1

6.2 Checking Drive Operation................................................................................6-2

Chapter 7 Keypad and Display Operation

7.1 Display Description ..........................................................................................7-1

7.2 Key Descriptions ..............................................................................................7-2

7.3 LED Descriptions .............................................................................................7-3

7.4 Program Mode .................................................................................................7-4

7.5 Monitor Mode ...................................................................................................7-5

7.5.1 Displaying the Percent Selected Speed Reference...............................7-6

7.5.2 Scaling the RPM Display and Reference Using F-08............................7-6

7.6 Drive Control....................................................................................................7-6

7.6.1 Changing the Reference Using the Keypad ..........................................7-7

Chapter 8 Programming Reference

8.1 Displaying or Changing Parameter Values ......................................................8-1

8.2 Ensuring Program Security ........... ...... ...... ....... ...... ....................................... ...8-3

8.3 Parameter Descriptions....................................................................................8-5

Chapter 9 Troubleshooting Reference

9.1 Verifying DC Bus Voltage.................................................................................9-1

9.2 Troubleshooting the Drive Using Fault Codes .................................................9-3

9.3 Accessing and Clearing the Error Log .............................................................9-5

9.4 Checking the Drive’s Power Module Circuitry with the Power Off....................9-7

Appendix A Technical Specifications...........................................................................................A-1

Appendix B Record of User Settings........................................................................................... B-1

Appendix C Alphabetical Listi ng of Parameters..................... ....... ...... ....... .................................. C-1

Appendix D Compliance with Machinery Safety Standard EN-60204-1:1992.............................D-1

Appendix E Compliance with Electromagnetic Compatibility Standards..................................... E-1

Appendix F Replacement Parts ....... ...... ....... ...... ....... ...... ...... ....... ...... ....................................... .. F-1

Glossary ..................................... ...... ....... ...... ....... ...... ....................................... ...... ... Glossary-1

Index ..................................... ...... ....... ...... ....... ...... ....................................... ...... ....... ..Index-1

II

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 5

List of Figures

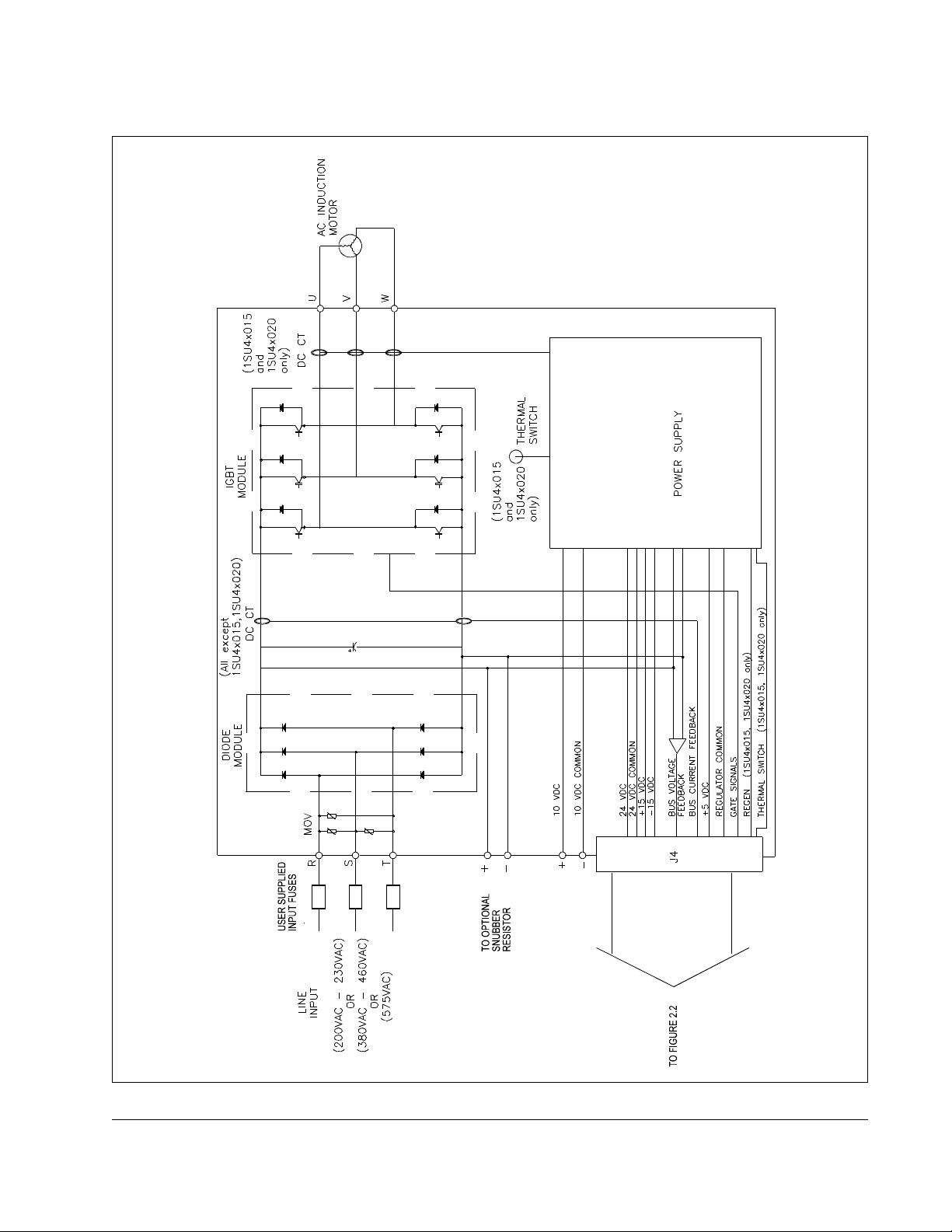

Figure 2.1 – SP500 System Diagram....................................................................... 2-3

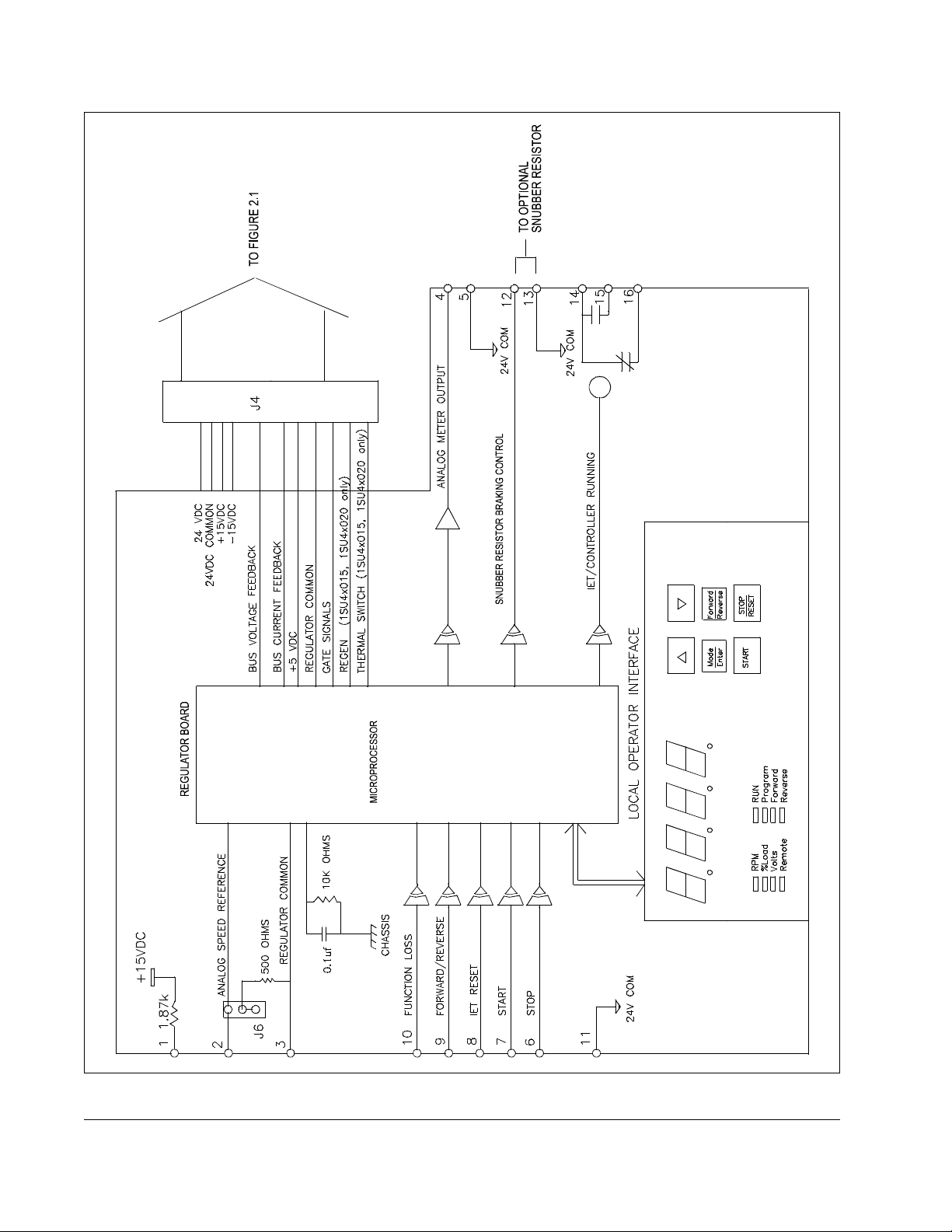

Figure 2.2 – SP500 System Diagram (Continued) ................................................... 2-4

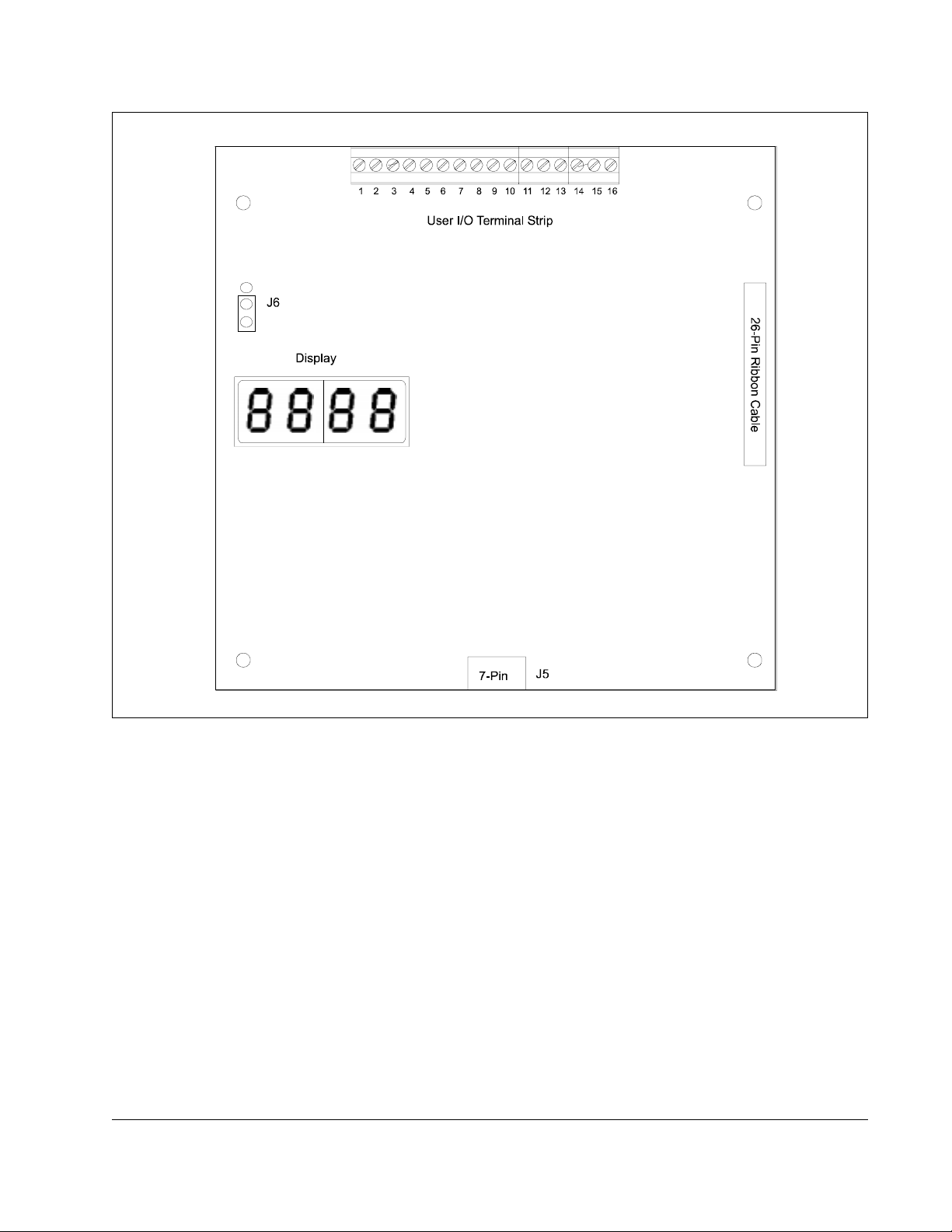

Figure 2.3 – Regulator Board Component Locations ...............................................2-5

Figure 2.4 – Identifying the Drive Model Number..................................................... 2-6

Figure 2.5 – Enclosure A Component Locations ......................................................2-9

Figure 2.6 – Enclosure B Component Locations ....................................................2-10

Figure 2.7 – Enclosure C Component Locations....................................................2-11

Figure 2.8 – Enclosure D Component Locations....................................................2-12

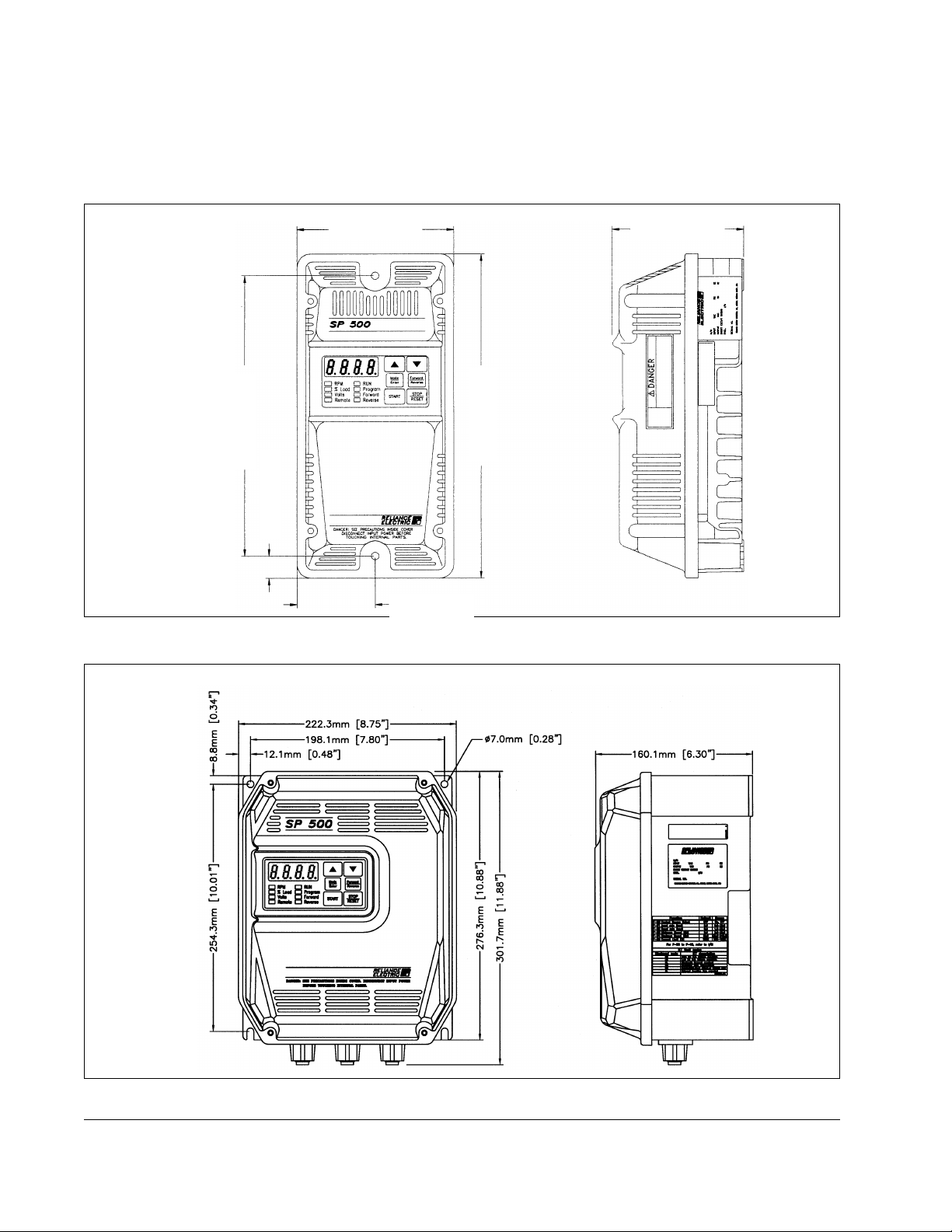

Figure 3.1 – Enclosure A Dimensions ......................................................................3-2

Figure 3.2 – Enclosure B Dimensions ......................................................................3-2

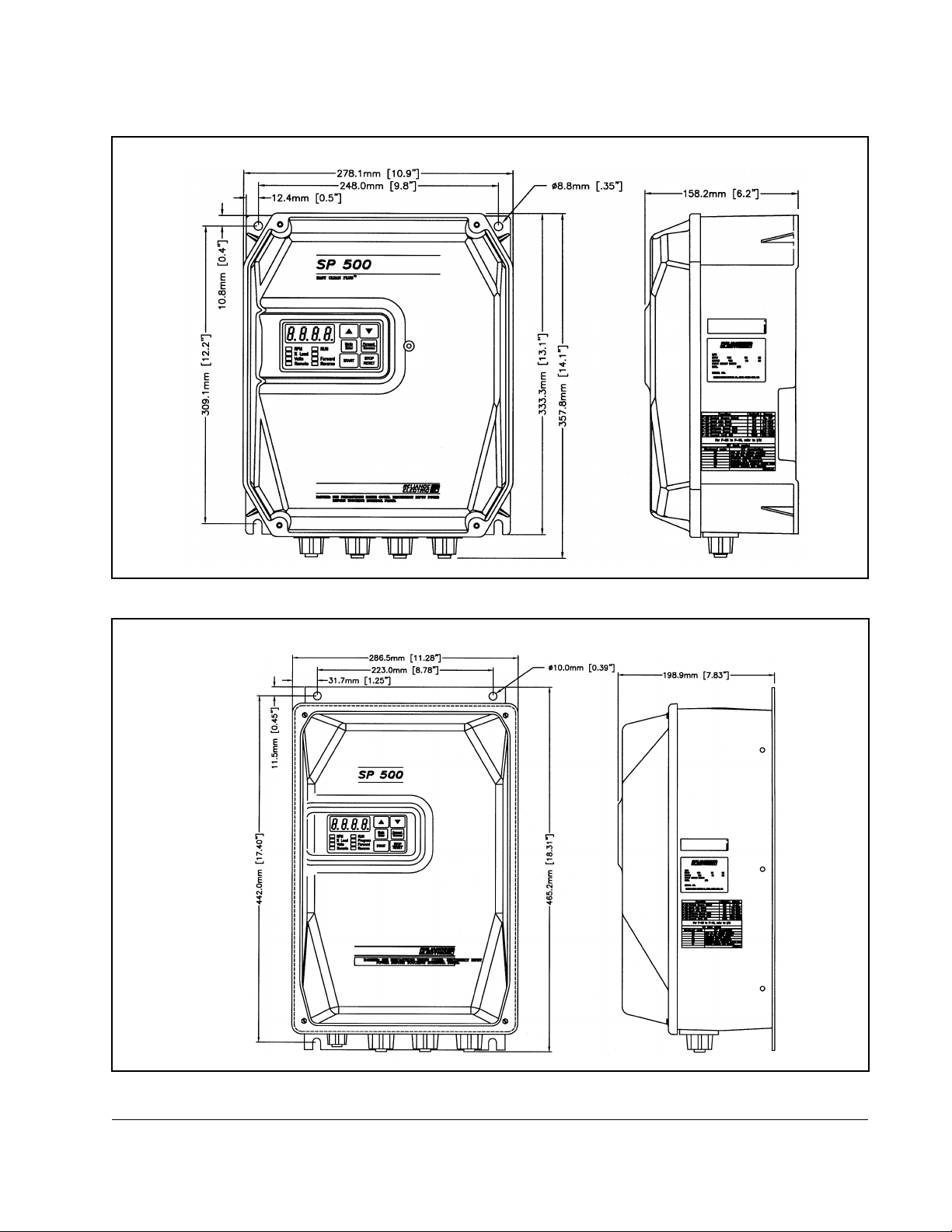

Figure 3.3 – Enclosure C Dimensions......................................................................3-3

Figure 3.4 – Enclosure D Dimensions......................................................................3-3

Figure 3.5 – How to Measure Motor Lead Lengths .................................................. 3-6

Figure 4.1 – Enclosure A Wire Routing Locations.................................................... 4-2

Figure 4.2 – Enclosure B Wire Routing Locations....................................................4-3

Figure 4.3 – Enclosure C Wire Routing Locations....................................................4-4

Figure 4.4 – Enclosure D Wire Routing Locations....................................................4-5

Figure 4.5 – Jumper J6 Settings for the Analog Input Speed Reference ................. 4-8

Figure 5.1 – Typical Electrical Connections.............................................................. 5-2

Figure 5.2 – Typical Control Terminal Strip Connections......................................... 5-3

Figure 5.3 – Analog Speed Reference Wiring Connections.....................................5-4

Figure 5.4 – Analog Output Wiring Connections ......................................................5-4

Figure 5.5 – Two-Wire Start/Stop Sample Control Wiring........................................5-5

Figure 5.6 – Three-Wire Start/Stop Sample Control Wiring.....................................5-5

Figure 5.7 – Multi-Speed Preset Sample Control Wiring.......................................... 5-6

Figure 5.8 – Terminal Usage During Multi-Speed Preset Operation ........................5-7

Figure 5.9 – Snubber Resistor Wiring Connections for M/N 1SU2xxxx Drives ........5-9

Figure 5.10 – Snubber Resistor Wiring Connections for M/N 1SU4xxxx and

1SU5xxxx Drives................................................................................ 5-9

Figure 5.11 – Output Status Relay Wiring Connections.........................................5-10

Figure 7.1 – SP500 Keypad and Display..................................................................7-1

Figure 7.2 – SP500 Menu Structure......................................................................... 7-4

Figure 7.3 – Example of a Program Mode Display..................................................7-5

Figure 7.4 – Example of a Monitor Mode Display..................................................... 7-6

Figure 8.1 – Manual Torque Boost Adjustment Range.............................................8-7

Figure 8.2 – Volts/Hertz Curve .................................................................................8-8

Figure 9.1 – DC Bus Terminals on Model 1SU1xxxx and 1SU2xxxx Drives............9-2

Figure 9.2 – DC Bus Terminals on Model 1SU4xxxx and 1SU5xxxx Drives (except

1SU4x015, 1SU4x020)................... ...... ....... ...... ....... ...... ....... ...............9-2

Figure 9.3 – DC Bus Terminals on Model 1SU4x015 and 1SU4x020 Drives........... 9-2

Contents

III

Page 6

IV

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 7

List of Tables

Table 2.1 – SP500 Model Number Notation............................................................. 2-6

Table 2.2 – Power and NEMA Enclosure Ratings.................................................... 2-7

Table 2.3 – SP500 Option Kits ...............................................................................2-13

Table 3.1 – Air Flow Clearances............................................................................... 3-4

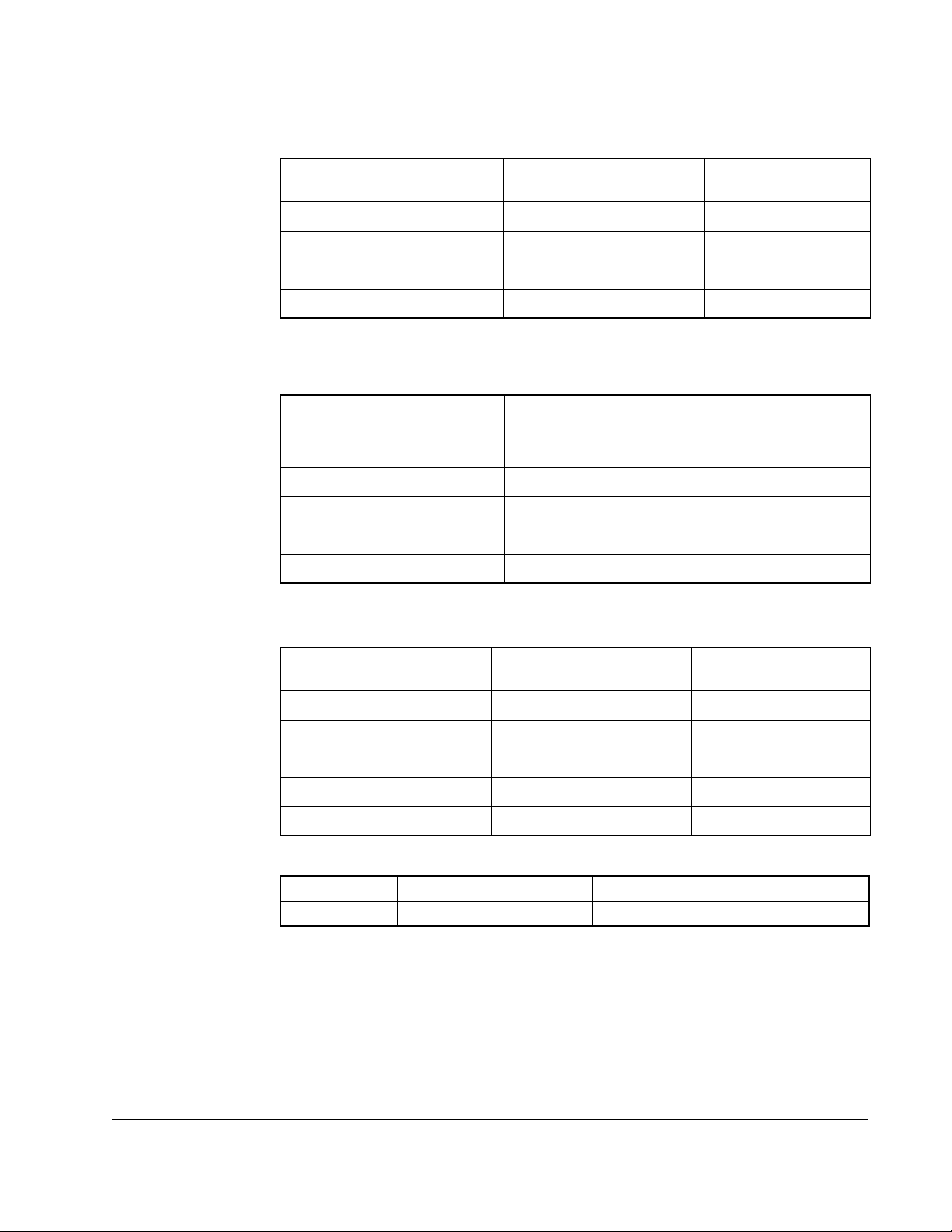

Table 3.2 – Recommended Power Wire Sizes for M/N 1SU1xxxx and

1SU2xxxx Drives...................................................................................3-5

Table 3.3 – Recommended Power Wire Sizes for M/N 1SU4xxxx and

1SU5xxxx Drives...................................................................................3-5

Table 3.4 – Recommended Power Wire Sizes for M/N 1SU4x015 and

1SU4x020 Drives.................................................................................. 3-5

Table 3.5 – Recommended Power Terminal Tightening Torque..............................3-5

Table 3.6 – Recommended Control and Signal Wire Sizes and Tightening Torque 3-6

Table 3.7 – Motor Lead Lengths...............................................................................3-7

Table 3.8 – Reactors ................................................................................................3-7

Table 3.9 – AC Input Line Fuse Selection Values.................................................... 3-8

Table 7.1 – Key Descriptions.................................................................................... 7-2

Table 7.2 – Drive Status LED Descriptions .............................................................. 7-3

Table 7.3 – Monitor Mode LED Descriptions............................................................ 7-3

Table 8.1 – Multi-Speed Presets Digital Inputs.......................................................8-15

Table 8.2 – Auto-Restartable Faults.......................................................................8-16

Table 9.1 – Drive Faults and Corrective Actions ......................................................9-3

Table 9.2 – Resistance Checks for Input Diodes......................................................9-8

Table 9.3 – Resistance Checks for IGBTs................................................................9-8

Contents

V

Page 8

VI

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 9

This chapter describes the manual’s intended audience and provides an overview of

the SP500 d rive’s installation process.

1.1 Who Should Use This Manual

This manual is intended for qualified electrical personnel responsible for installing,

programming, starting up, and maintaining the SP500 drive.

1.2 Install at io n Overview

This manual describes how to install and troubleshoot the SP500 drive. Drive

installati on consists of the following basic tasks:

• Plan your installation using the guidelines presented in chapter 3. If your installation

must be in compliance with Electromagnetic Compatibility Standards, read

Appendix E also.

• Mount the drive and install external components according to the guidelines

presented in chapter 4.

CHAPTER 1

Introduction

• Wire the drive’s input power , output power, and control signal terminal strip using the

instructions in chapter 5.

• Adjust parameter values, if required. The parameters are described in chapter 8. For

quick reference, the factory-set values are listed in Appendix B.

• Perform the power-off and power-on checks described in chapter 6 to complete the

installation.

If problems occur during drive operation, refer to chapter 9. Appendix F lists the parts

of the drive that can be replaced.

Before you begin the installation procedure, become familiar with the drive by reading

chapter 2, which provides an overview of the drive and its features, chapter 7, which

describes the operation of the keypad and the display, and Appendix A, which lists the

drive’s technical specifications.

1.3 Requesting Assistance from Reliance Electric

If you have any questions or problems with the products described in this instruction

manual, contact your local Reliance Electric sales office. For technical assistance, call

1-800-726-8112, Monday through Friday, 8:00 AM to 5:00 PM (EST).

Introduction

1-1

Page 10

1-2

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 11

Learning About the SP500 Drive

This chapter describes the SP500 drive and how to identify it based on its model

number. This chapter also provides power and enclosure rating information.

2.1 Standard Features

The SP500 drive has the following features:

• On-board keypad and display providing:

Start/Stop/Reset control

Forward/Rev erse (reverse-disable selectable)

Setpoint adjustment

Motor RPM, %load, or output voltage display

Drive diagnostics

• 500 millisecond power dip ride-through

• 150% overload for one minute (nominal)

CHAPTER 2

• 0.5 to 240 Hz three-phase voltage output

• NEMA 1 and NEMA 4/12 enclosures

• A snubber resistor braking signal and a scaled voltage analog output

(0 to 10 VDC) which is proportional to:

Output frequency

Output amps

Output voltage

Selected reference

• Quiet motor operation with high carrier frequency selection

• Drive protection

Overcurrent

Short circuit

Ground fault

Overvoltage

Undervoltage

Overtemperature

• UL/CSA electronic overload that meets NEC/CEC requirements

Learning About the SP500 Drive

2-1

Page 12

• User-selectable relay contact for indications of drive running, drive faulted, or drive

at selected speed

• User-selectable power-up start, auto-restart, and coast-to-rest or ramp-to-rest stop

functions

• User-selectable local or remote operation

• 29 user-adjustable software parameter s

2.2 Drive Description

The SP500 drive is an AC PWM (pulse-width-modulated) inverter that operates on

single- or three-phase power. See figures 2.1 and 2.2. AC input power is applied to the

drive’s input terminals. Voltage transients are suppressed by three

metal-oxide-varistor (MOV) suppressors. These suppressors keep any input voltage

transients within the maximum voltage rating of the input diode module.

The input diode module rectifies the incoming AC voltage into a constant DC bus

voltage which is filtered by the DC bus capacitor bank. An internal DC-to-DC power

supply uses power from the DC bus and provides the necessary voltages required by

the drive. Under regulator software control, the IGBT (insulated-gate

bipolar-transistor) inverter bridge converts the constant DC voltage into an AC PWM

waveform. The regulator switches the IGBT inverter bridge using a 4, 6, or 8 kHz

carrier frequency (user-selectable). A low carrier frequency maximizes the power

rating of the drive but also increases acoustic noise. A high carrier frequency selection

reduces acoustic noise but results in a derating of the drive’s efficiency.

The volts per hertz (V/Hz) regulator governs the open-loop operation of the drive for

adjustable-speed performance of AC induction and synchronous motors. The

regulator maintains a ratio of voltage to output frequency that provides constant or

variable torque across a wide speed range. Drive operation can be adjusted by the

parameters entered through the keypad. A microprocessor on the Regulator board

controls drive regulation. See figure 2.3. The Regulator board accepts internal power

feedback signals and an external speed reference signal. The Regulator board

provides display data for a four-character display, which is used to indicate drive

parameters, parameter values, and fault codes.

The drive can be controlled either locally through the keyboard and display (see

section 7) or remotely through the terminal strip (see section 5).

The drive is intended to operate trip-free under any condition. The drive uses selected

signals to extend the acceleration (starting) and deceleration (stopping) rates of the

motor when an overcurrent condition occurs. When a fault does occur, however, the

regulator generates an instantaneous electronic trip (IET) signal to turn the drive off

(coast-to-rest). The drive stores an indication or record of the IET fault, which can be

viewed on the four-character display. After a fault, the STOP/RESET key or a

user-supplied IET RESET pushbutton must be pressed to reset the IET signal and

clear the fault from the drive.

2-2

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 13

.

Learning About the SP500 Drive

Figure 2.1 – SP500 System Diagram

2-3

Page 14

Figure 2.2 – SP500 System Diagram (Continued)

2-4

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 15

Figure 2.3 – Regulator Board Component Locations

Learning About the SP500 Drive

2-5

Page 16

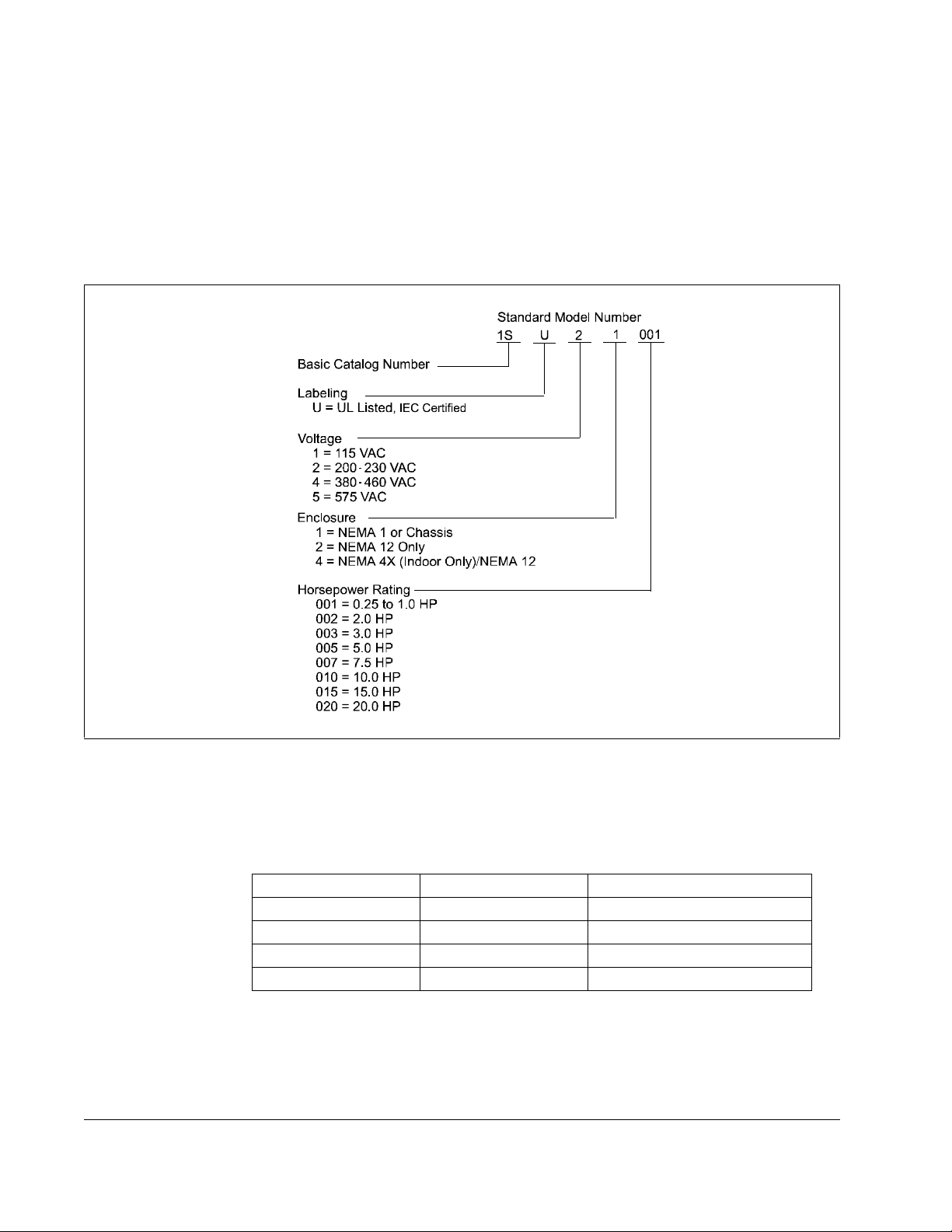

2.3 Identifying the Drive by Model Number

A model number identifies each SP500 AC drive. See figure 2.4. This number appears

on the shipping label and on the drive’s nameplate located on the right side of the

drive housing. The drive’s model number contains codes that indicate: input voltage

range, enclosure rating, and horsepower rating. See section 2.3.1 for more

information on the drive power ratings. See section 2.3.2 for more information on the

drive enclosure ratings.

2-6

Figure 2.4 – Identifying the Drive Model Number

All SP500 drives described in this instruction manual function in the same manner. To

identify the mechanical differences between certain models, the manual uses the

notation in table 2.1.

Table 2.1 – SP500 Model Number Notation

Model Notation Input Voltage Horsepower

1SU1xxxx 115 VAC ¼ - 1 HP

1SU2xxxx 208 - 230 VAC 1, 2, 3, 5, 7.5, 10 HP

1SU4xxxx 380 - 460 VAC 1, 2, 3, 5, 7.5, 10, 15, 20 HP

1SU5xxxx 575 VAC 1, 2, 3, 5, 7.5, 10 HP

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 17

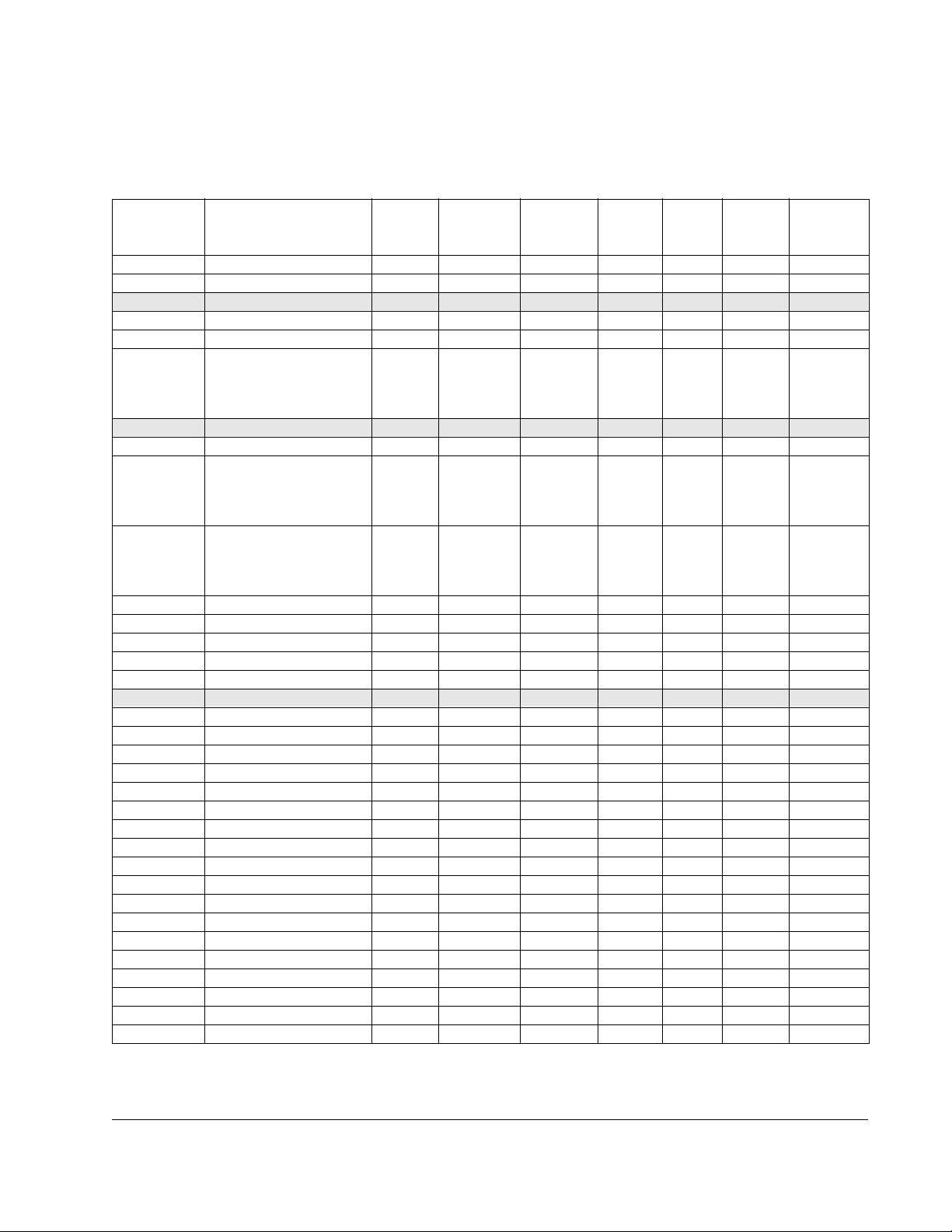

2.3.1 Power Ratings and NEMA Enclosure Ratings

Table 2.2 provides SP500 drive power and NEMA enclosure ratings.

Table 2.2 – Power and NEMA Enclosure Ratings

Model

Number

Input Power

and Horsepower

Rating*

NEMA

Rating

Enclosure

Size**

AC Input

Volts

Input

Amps

Input

KV A

Output

Amps*

Power

Loss

Watts***

1SU11001 Single-Phase - 1 HP 1 A 115 13.1 1.5 6.8 80

1SU14001 Single-Phase - Demo ---- ---- 115 5.2 0.6 2.0 80

1SU21001 Single-Phase - 1 HP 1 A 200-230 5.0 1.3 1.7 70

1SU24001 Single-Phase - 1 HP 4X/12 A 200-230 5.0 1.3 1.7 70

1SU21002 Single-Phase - 2 HP

4 kHz Carrier

6 kHz Carrier

8 kHz Carrier

1

A

200-230

200-230

200-230

19.1

17.2

15.3

4.4

4.0

3.5

7.5

7.0

6.5

120

120

120

1SU21001 Three-Phase - 1 HP 1 A 200-230 7.0 2.8 5.0 70

1SU24001 Three-Phase - 1 HP

4 kHz Carrier

6 kHz Carrier

8 kHz Carrier

1SU21002 Three-Phase - 2 HP

4 kHz Carrier

6 kHz Carrier

8 kHz Carrier

4X/12 A

1A

200-230

200-230

200-230

200-230

200-230

200-230

6.4

5.2

5.2

9.9

9.3

8.7

2.6

2.0

2.0

4.0

3.8

3.5

4.5

3.6

3.6

7.5

7.0

6.5

70

70

70

70

70

70

1SU24002 Three-Phase - 2 HP 4X/12 C 200-230 9.9 4.0 7.5 120

1SU21003 Three-Phase - 3 HP 1 C 200-230 12.5 5.0 10.6 210

1SU24003 Three-Phase - 3 HP 4X/12 C 200-230 12.5 5.0 10.6 210

1SU21005 Three-Phase - 5 HP 1 C 200-230 17.2 6.9 14.2 250

1SU24005 Three-Phase - 5 HP 4X/12 C 200-230 17.2 6.9 14.2 250

1SU41001 Three-Phase - 1 HP 1 B 380-460 2.5 2.0 2.1 60

1SU44001 Three-Phase - 1 HP 4X/12 B 380-460 2.5 2.0 2.1 60

1SU41002 Three-Phase - 2 HP 1 B 380-460 4.2 3.3 3.4 100

1SU44002 Three-Phase - 2 HP 4X/12 B 380-460 4.2 3.3 3.4 100

1SU41003 Three-Phase - 3 HP 1 B 380-460 6.4 5.1 5.3 140

1SU44003 Three-Phase - 3 HP 4X/12 B 380-460 6.4 5.1 5.3 140

1SU41005 Three-Phase - 5 HP 1 B 380-460 9.9 8.0 8.2 180

1SU44005 Three-Phase - 5 HP 4X/12 B 380-460 9.9 8.0 8.2 180

1SU41007 Three-Phase - 7.5 HP 1 C 380-460 13.4 10.7 11.1 210

1SU44007 Three-Phase - 7.5 HP 4X/12 C 380-460 13.4 10.7 11.1 210

1SU41010 Three-Phase - 10 HP 1 C 380-460 17.2 13.7 14.2 250

1SU44010 Three-Phase - 10 HP 4X/12 C 380-460 17.2 13.7 14.2 250

1SU41015 Three-Phase - 15 HP 1 D 380-460 25.4 20.2 21.0 375

1SU42015 Three-Phase - 15 HP 12 D 380-460 25.4 20.2 21.0 375

1SU41020 Three-Phase - 20 HP 1 D 380-460 32.7 26.1 27.0 600

1SU42020 Three-Phase - 20 HP 12 D 380-460 32.7 26.1 27.0 600

1SU51001 Three-Phase - 1 HP 1 B 575 2.0 2.0 1.6 50

1SU54001 Three-Phase - 1 HP 4X/12 B 575 2.0 2.0 1.6 50

Learning About the SP500 Drive

2-7

Page 18

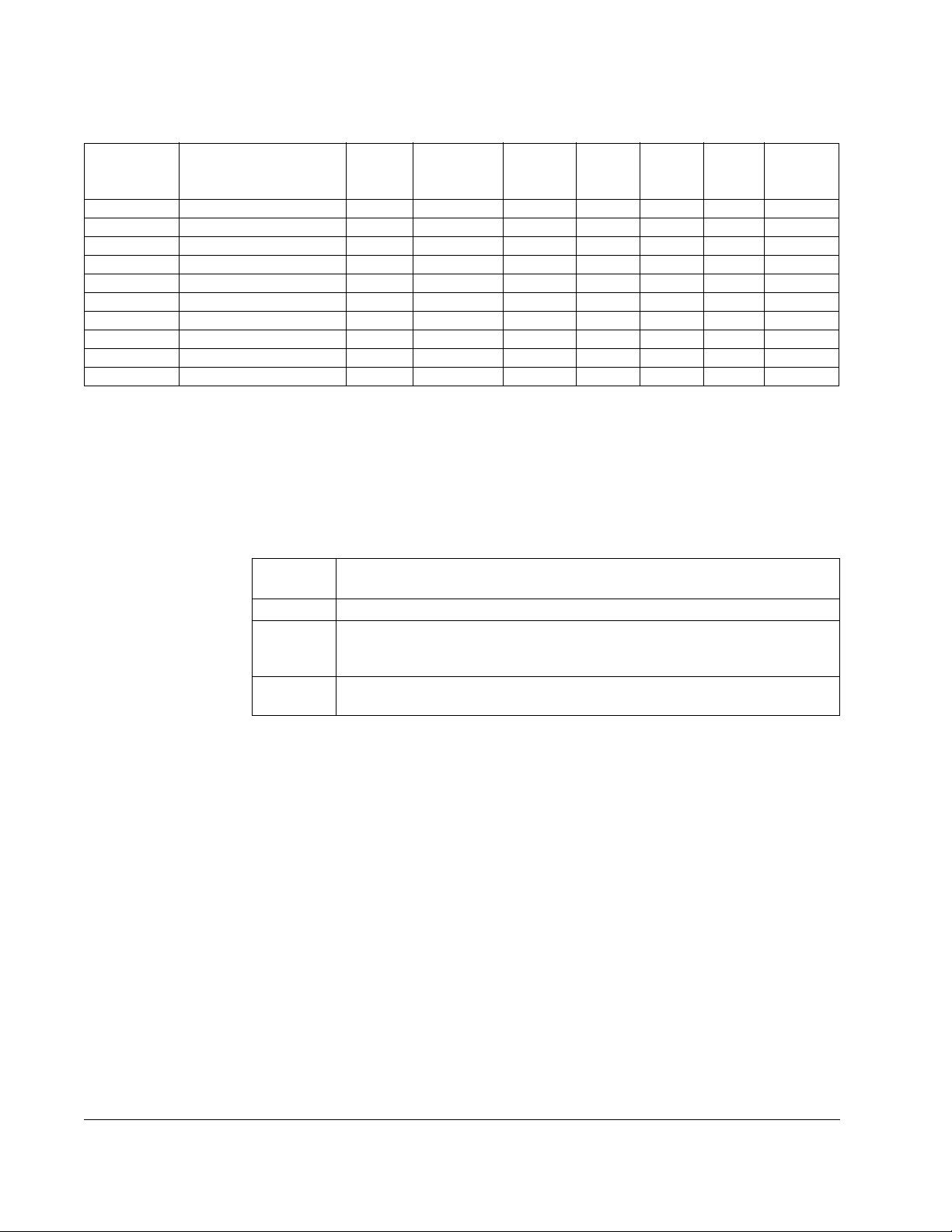

Table 2.2 - Power and NEMA Enclosure Ratings (Continued)

Model

Number

Input Power

and Horsepower

Rating*

NEMA

Rating

Enclosure

Size**

AC Input

Volts

Input

Amps

Input

KV A

Output

Amps*

Power

Loss

Watts***

1SU51002 Three-Phase - 2 HP 1 B 575 3.4 3.3 2.7 90

1SU54002 Three-Phase - 2 HP 4X/12 B 575 3.4 3.3 2.7 90

1SU51003 Three-Phase - 3 HP 1 B 575 5.2 5.1 4.3 120

1SU54003 Three-Phase - 3 HP 4X/12 B 575 5.2 5.1 4.3 120

1SU51005 Three-Phase - 5 HP 1 B 575 7.5 7.5 6.2 150

1SU54005 Three-Phase - 5 HP 4X/12 B 575 7.5 7.5 6.2 150

1SU51007 Three-Phase - 7.5 HP 1 C 575 10.9 10.9 9.0 180

1SU54007 Three-Phase - 7.5 HP 4X/12 C 575 10.9 10.9 9.0 180

1SU51010 Three-Phase - 10 HP 1 C 575 14.5 14.4 12.0 250

1SU54010 Three-Phase - 10 HP 4X/12 C 575 14.5 14.4 12.0 250

* To properly size the drive for motor nameplate horsepower and amps, refer to section 3.5 for more information. Derating for 4, 6, 8kHz

carrier frequencies is not required except for the units indicated.

** Refer to section 2.3.2 for more information on enclosure sizes.

*** Full-load at all carrier frequencies. Refer to section 3.1.3 for more information.

2.3.2 Enclosure Ratings and Sizes

Each of the SP500 drives have one of the following NEMA ratings:

NEMA

Rating Description

1 Vented. For general-purpose indoor applications.

4X/12 Not vented. Supplied with base and keypad gaskets. For use in indoor

environments that require a water-tight and dust-tight enclosure. An

enclosure with this NEMA rating encompasses both ratings (4X and 12).

12 Intended for use in indoor environments that require a dust-tight and

drip-tight enclosure.

2-8

See table 2.2 for a listing of drive model numbers and their individual NEMA ratings.

For clarity in this manual, SP500 drive enclosures are identified by size as enclosures

A through D. Refer to table 2.2 for a listing of the drive model numbers and their

individual enclosure sizes. Refer to section 3.1.1 for the dimensions of enclosures A

through D.

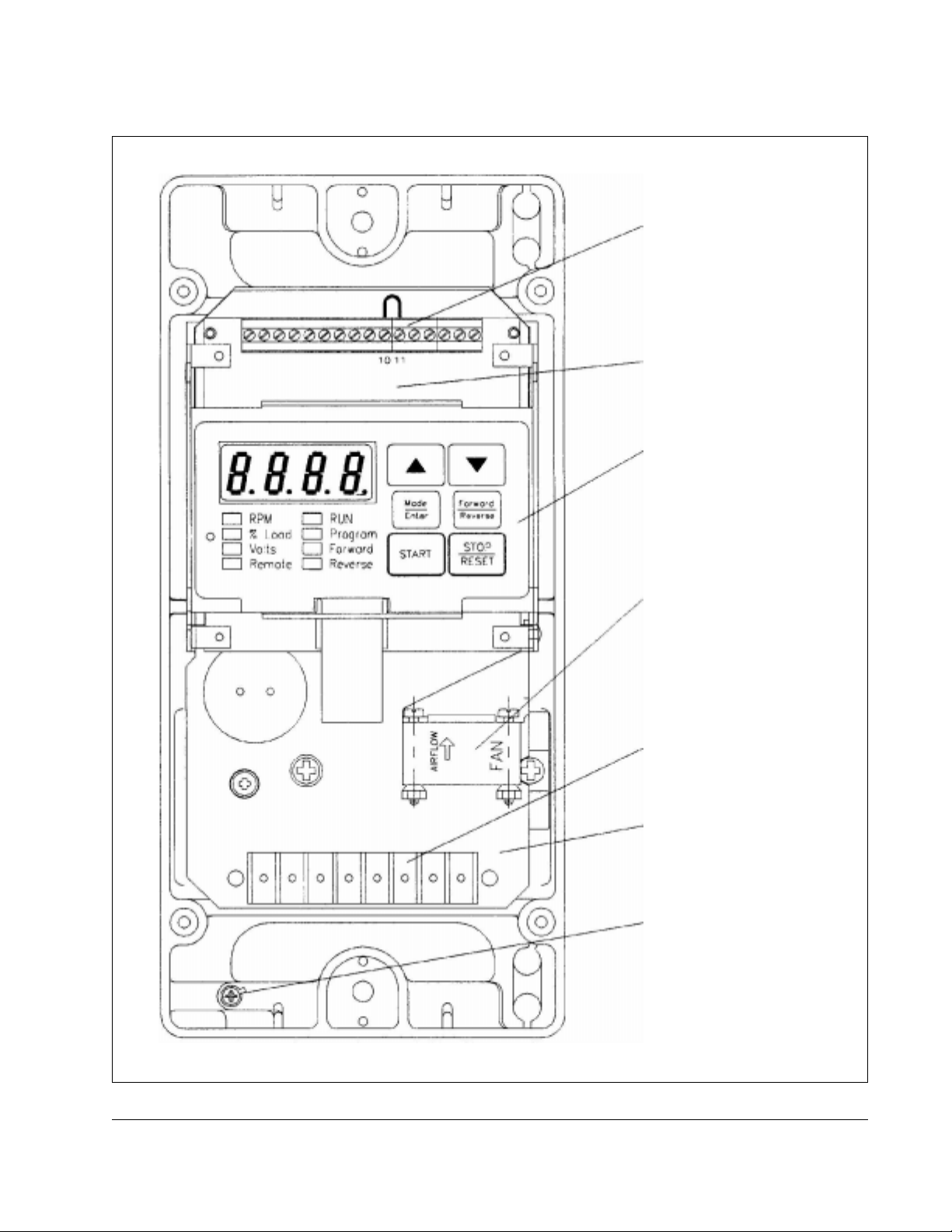

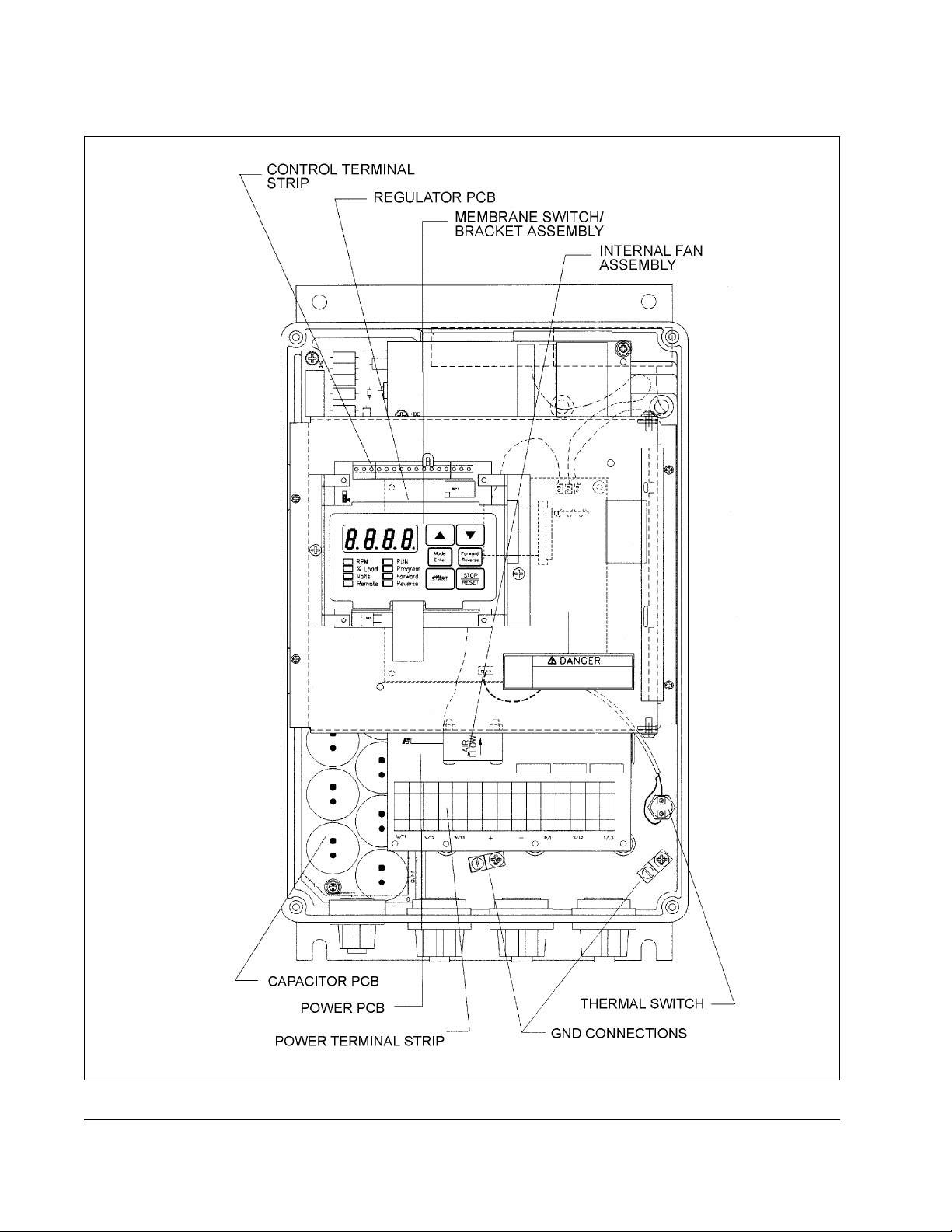

2.4 Component Locations

Figures 2.5 through 2.8 show the main components of the SP500 drives (enclosures A

through D). Appendix F lists replacement parts.

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 19

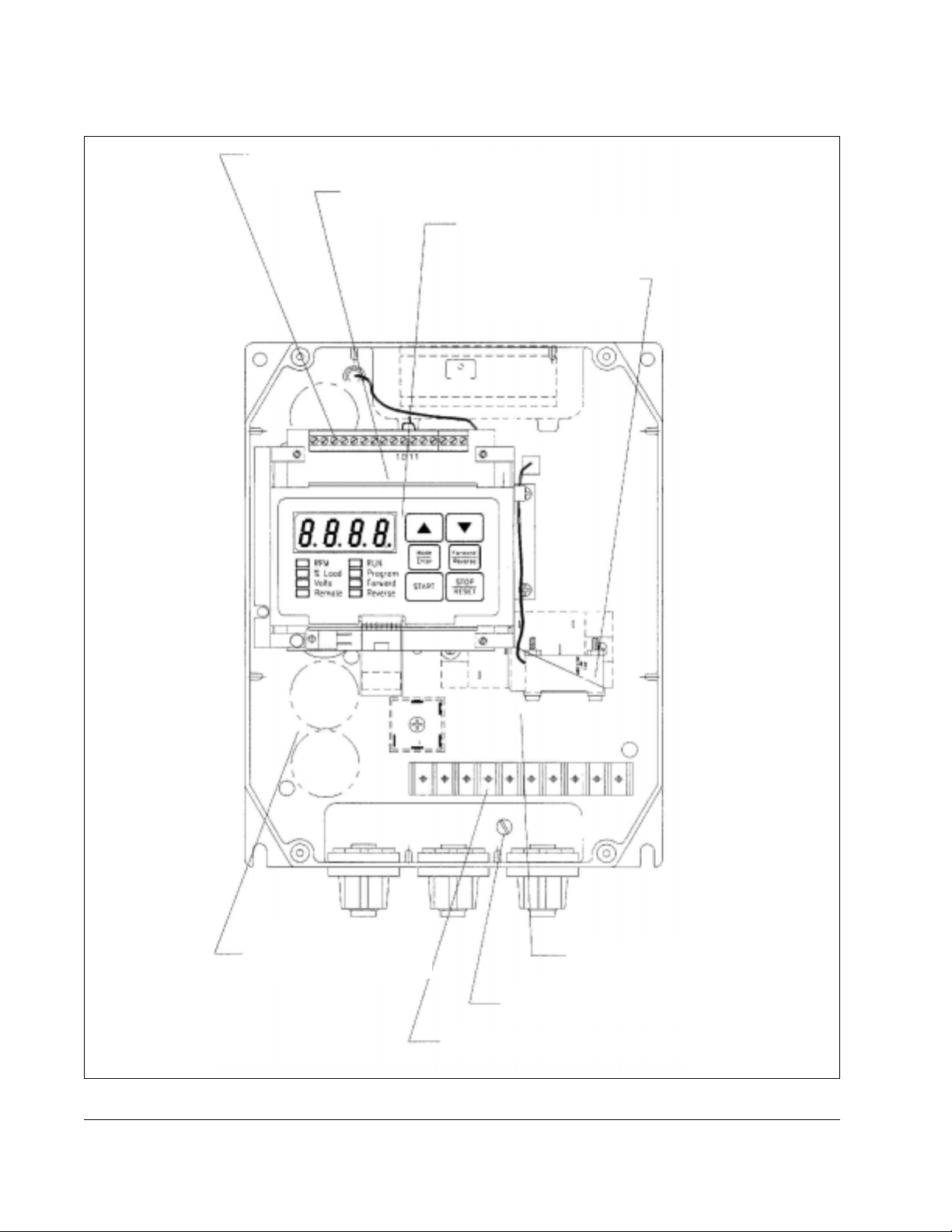

CONTROL STRIP

TERMINAL

REGULATOR PCB

MEMBRANE SWITCH/

BRACKET ASSEMBLY

INTERNAL FAN

ASSEMBLY

Learning About the SP500 Drive

POWER TERMINAL STRIP

POWER PCB

GND CONNECTION

Figure 2.5 – Enclosure A Component Locations

2-9

Page 20

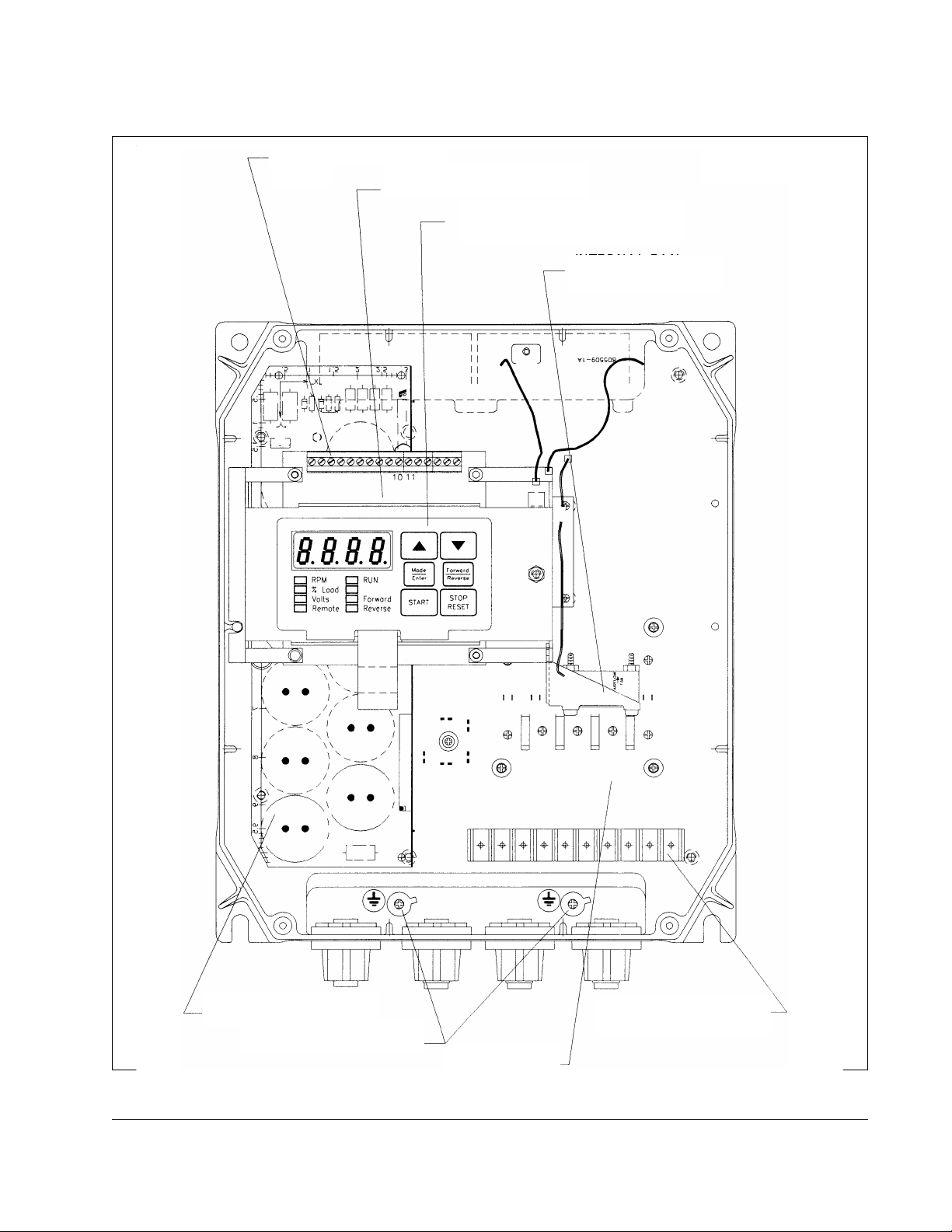

CONTROL TERMINAL STRIP

REGULATOR PCB

MEMBRANE SWITCH/

BRACKET ASSEMBLY

INTERNAL FAN

ASSEMBLY

2-10

CAPACITOR PCB

(3 & 5 HP ONLY)

Figure 2.6 – Enclosure B Component Locations

POWER PCB

GND CONNECTION

POWER TERMINAL STRIP

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 21

CONTROL TERMINAL

CONTROL TERMINAL STRIP

STRIP

REGULATOR PCB

REGULATOR PCB

MEMBRANE SWITCH/

MEMBRANE SWITCH/

BRACKET ASSEMBLY

BRACKET ASSEMBLY

INTERNAL FAN

INTERNAL FAN

ASSEMBLY

ASSEMBLY

CAPACITOR PCB

CAPACITOR PCB

GND CONNECTIONS

GND CONNECTIONS

Learning About the SP500 Drive

POWER PCB

POWER PCB

Figure 2.7 – Enclosure C Component Locations

POWER TERMINAL

POWER TERMINAL

STRIP

STRIP

2-11

Page 22

Figure 2.8 – Enclosure D Component Locations

2-12

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 23

2.5 Option Kits

Table 2.3 provides a listing of the available SP500 option kits.

Table 2.3 – SP500 Option Kits

Option Kit Description

Low Energy Snubber Resistor Braking Kit for

Option Kit

Model Number

2DB2005 D2-3178

Instruction

Manual

M/N 1SU2xxxx Drives

Low Energy Snubber Resistor Braking Kit for

2DB4010 D2-3179

M/N 1SU4xxxx Drives*

Low Energy Snubber Resistor Braking Kit for

M/N 1SU4x015 and 1SU4x020 Drives

Low Energy Snubber Resistor Braking Kit for

2SR40700

D2-3291

2SR41800

2DB5010 D2-3180

M/N 1SU5xxxx Drives*

*Snubber resistor braking kits for M/N 1SU4xxxx and 1SU5xxxx drives require connection to the snubber

resistor braking 10V power supply. See section 5.2.4 for more information.

Learning About the SP500 Drive

2-13

Page 24

2-14

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 25

SP500 System Planning

This chapter provides information that you must consider when planning an SP500

drive installation. Installation site, wiring, and motor application requirements are

included.

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

3.1 Installation Site Requir em e nt s

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding.

ATTENTION:Use of power correction capacitors on the output of the

drive can result in erratic operation of the motor, nuisance tripping,

and/or permanent damage to the drive. Remove power correction

capacitors before proceeding.

ATTENTION:The user is responsible for conforming with all applicable

local, national, and international codes.

CHAPTER 3

It is important to properly plan before installing an SP500 drive to ensure that the

drive’s environment and operating conditions are satisfactory . Note that no devices are

to be mounted behind the drive. This area must be kept clear of all control and power

wiring. Read the following recommendations before continuing with the drive

installation.

Before deciding on an installation site, consider the following guidelines:

• The area chosen should allow the space required for proper airflow as specified in

sections 3.1.1 and 3.1.2.

• Do not install the drive above 1000 meters (3300 feet) without derating output

power. For every 91.4 meters (300 feet) above 1000 meters (3300 feet), derate the

output current by 1%.

• Verify that the drive location will meet the following environmental conditions:

Operating temperature (ambient): 0 to +40°C (32 to 104°F)

Storage temperature (ambient): –40 to +65°C (–40 to +149°F)

Humidity: 5 to 95% (non-condensing)

• Verify that NEMA 1 drives can be kept clean, cool, and dry.

• Be sure NEMA 1 drives are located away from oil, coolants, or other airborne

contaminants.

• Verify that the AC power distribution system meets the service conditions specified

in table A.1.

SP500 System Planning

3-1

Page 26

3.1.1 Determining the Total Area Required for Installation

Figures 3.1 to 3.4 provide drive dimensions for enclosures A through D as an aid in

calculating the total area required by the SP500 drives. Appendix A lists drive weights

121.9 mm (4.8”)146.0 mm (5.57”)

263.5 mm (10.37”)

20.7 mm (0.81”)

73.0 mm (2.88”)

.

Figure 3.1 – Enclosure A Dimensions

304.8 mm (12.00”)

3-2

Figure 3.2 – Enclosure B Dimensions

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 27

Figure 3.3 – Enclosure C Dimensions

SP500 System Planning

Figure 3.4 – Enclosure D Dimensions

3-3

Page 28

3.1.2 Providing Proper Air Flow Clearances

Be sure there is adequate clearance for air ventilation around the drive. For best air

movement, do not mount SP500 drives directly above each other. Note that no

devices are to be mounted behind the drive. This area must be kept clear of all control

and power wiring. See table 3.1 for a listing of the recommended air flow clearances.

Table 3.1 – Air Flow Clearances

Enclosure

ABCD

Minimum distance from the sides of the drive if adjacent to non-heat

producing equipment

Minimum distance from the top and bottom of the drive if adjacent to

non-heat producing equipment

Minimum distance from the sides of the drive if adjacent to other drives 51 mm

Minimum distance from the top and bottom of the drive if adjacent to

other drives

51 mm

”

)

(2

102 mm

(4”)

(2”)

254 mm

(10”)

3.1.3 Verifying the Drive’s Power Loss Rating

When installing an SP500 drive inside of another enclosure, you should consider the

drive’s watts loss rating shown in table 2.2. This table lists the typical full load power

loss watts value under all operating carrier frequencies. Ensure adequate ventilation is

provided based on the drive’s watts loss rating.

3.2 Wiring Requirements

Evaluate the following areas of drive wiring before you do the installation: size of

available conduit, size of power and control wiring, and motor lead lengths.

102 mm

(4”)

102 mm

(4”)

102 mm

(4”)

254 mm

(10”)

102 mm

(4”)

102 mm

(4”)

102 mm

(4”)

254 mm

(10”)

102 mm

(4”)

102 mm

(4”)

102 mm

(4”)

102 mm

(4”)

3-4

3.2.1 Verifying Conduit Sizes

It is important to determine the size of the conduit openings accurately so that the wire

planned for a specific entry point will fit through the opening. Figures 4.1 through 4.4

show conduit opening sizes.

3.2.2 Recommended Power Wire Sizes

Size input power wiring according to applicable codes to handle the drive’s

continuous-rated input current. Size output wiring according to applicable codes to

handle the drive’s continuous-rated output current. Tables 3.2, 3.3, and 3.4 provide

recommended power wiring sizes. Use only copper wire with a minimum temperature

rating of 60/75°C. Table 3.5 contains the recommended tightening torque values for all

power wiring terminals.

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 29

.

Table 3.2 – Recommended Power Wire Sizes for M/N 1SU1xxxx and 1SU2xxxx Drives

Type of Wiring Terminals

AC Input Po wer R, S, T

Output Power U, V, W

DC Bus – , +

Ground GND

*Except for M/N 1SU21002 (single-phase input), 1SU21005, and 1SU24005, for which 12 AWG, 3 (mm2)

wire is recommended.

Table 3.3 – Recommended Power Wire Sizes for M/N 1SU4xxxx and 1SU5xxxx Drives

Type of Wiring Terminals

AC Input Po wer R(L1), S(L2), T(L3)

Output Power U(T1), V(T2), W(T3)

DC Bus – , +

Snubber Resistor +10 VDC, 10 COM

Ground GND

2

* Except for M/N 1SU41010 and 1SU44010, for which 12 AWG, 3 (mm

) wire is recommended.

Size of Wire

(maximum)*

14 AWG, 2 (mm

14 AWG, 2 (mm

14 AWG, 2 (mm

14 AWG, 2 (mm

Size of Wire

(maximum)*

14 AWG, 2 (mm

14 AWG, 2 (mm

14 AWG, 2 (mm

14 AWG, 2 (mm

14 AWG, 2 (mm

2

)

2

)

2

)

2

)

2

)

2

)

2

)

2

)

2

)

Table 3.4 – Recommended Power Wire Sizes for M/N 1SU4x015 and 1SU4x020 Drives

Type of Wiring Terminals

AC Input Po wer R/L1, S/L2, T/L3

Output Power U/T1, V/T2, W/T3

DC Bus – , +

Snubber Resistor –, +

Ground GND

Table 3.5 – Recommended Power Terminal Tightening Torque

Size of Wire

(maximum)

12 AWG, 3 (mm

12 AWG, 3 (mm

12 AWG, 3 (mm

12 AWG, 3 (mm

12 AWG, 3 (mm

Drives Terminals Maximum Tightening Torque

All All power wires 1.08 Newton-meters (9.5 in-lb)

2

)

2

)

2

)

2

)

2

)

SP500 System Planning

3-5

Page 30

3.2.3 Recommen ded Control and Signal Wire Sizes

Table 3.6 shows the recommended wire sizes to connect I/O signals to the terminal

strip on the Regulator board. The minimum wire insulation rating is 600V. Operator

controls can be up to 303 meters (1000 feet) from the SP500 drive. All signal wires

should be twisted-pair.

Table 3.6 – Recommended Control and Signal Wire Sizes and Tightening Torque

Drives Terminals

Minimum

Wire Size

Maximum

All 1–16 20 AWG,

2

0.5 (mm

)

3.2.4 Recommended Motor Lead Lengths

The following motor lead lengths are recommended to reduce line disturbances and

noise. See figure 3.5.

• For applications using one motor, motor lead length should not exceed 76 meters

(250 feet).

• For applications with multiple motors, total motor lead length should not exceed 76

meters (250 feet).

When total lead length exceeds 76 meters (250 feet), nuisance trips can occur,

caused by capacitive current flow to ground. Note that these capacitively-coupled

currents should be taken into consideration when working in areas where drives are

running. If the motor lead length must exceed these limits, the addition of output line

reactors or other steps must be taken to correct the problem. See tables 3.7 and 3.8.

Note that the motor lead lengths shown in table 3.7 are maximum distances. Your

application may be restricted to a shorter motor lead length due to:

• the type of wire

Wire Size

14 AWG,

2 (mm2)

Maximum

Tightening Torque

0.5 Newton-meters

(4.5 in-lb)

• the placement of the wire (for example, in conduit or a cable tray)

• the type of line reactor

• the type of motor

SP500 Drive

38m (125’)

Motor

Motor

All examples represent 76m (250’) of motor lead length.

3-6

38m (125’)

15m (50’)

Motor

61m (200’)

8m (25’)

Motor

Figure 3.5 – How to Measure Motor Lead Lengths

SP500 AC Drive Installation and Operation Manual Version 3.1

61m (200’)

8m (25’)

Motor Motor

SP500 DriveSP500 DriveSP500 Drive

76m (250’)

Motor

Page 31

Table 3.7 – Motor Lead Lengths

SP500 HP

Rating

Filter Type

Maximum Lead

Length in Feet with

230 VAC Motor

Maximum Lead

Length in Feet with

460 VAC Motor

Maximum Lead

Length in Feet with

575 VAC Motor

Carrier Frequency Carrier Frequency Carrier Frequency

4 kHz 6 kHz 8 kHz 4 kHz 6 kHz 8 kHz 4 kHz 6 kHz 8 kHz

1

500 500 500 250 250 250 150 150 150

2 500 500 500 350 350 350 250 200 200

3 1000 1000 1000 400 400 400 250 200 200

None

5 1000 1000 1000 500 500 500 250 200 200

7.5 to 10 N/A N/A N/A 500 500 500 250 250 250

15 to 20 N/A N/A N/A 500 500 500 N/A N/A N/A

1

2 500 500 500 500 500 500

3 1000 1000 1000 1000 1000 1000

5 1000 1000 1000 1000 1000 1000

A 5% MTE

reactor/filter at the

drive.

A reactor/filter is not

required. Above lead

lengths are maximum

distances.

500 500 500 500 500 500

7.5 to 10 N/A N/A N/A 1000 1000 1000 1000 1000 1000

15 to 20 N/A N/A N/A 1000 1000 1000 N/A N/A N/A

1. Note that the lead lengths listed are valid with Reliance Electric inverter duty motors.

2. N/A indicates that the drive does not have this rating or it is not applicable.

.

Table 3.8 – Reactors

SP500 HP Rating

230 Volt

5% MTE Reactor

480 Volt

5% MTE Reactor

1 RL-00402 RL- 00 202 RL-00203

2 RL-00403 RL-00404

3 RL-00403 RL-00404

5 RL-00803 RL-00804

7.5 RL-01203 RL-00803

10 RL-01803 RL-01203

15 RL-02503

20 RL-03503

1. MTE standard reactors can be used on SP500 drives with carrier frequency settings up to 8 kHz.

2. All reactors listed are UL-recognized (UL-506 File #E53094) and CSA certified (CSA File #LR29753).

600 Volt

5% MTE Reactor

SP500 System Planning

3-7

Page 32

3.3 Selecting Input AC Line Branch Circuit Fuses

ATTENTION:Most codes require that upstream branch circuit protection

be provided to protect input power wiring. Install the fuses recommended

!

Input line branch circuit protection fuses must be used to protect the input power lines.

See figure 5.1. Table 3.9 shows recommended fuse values. These fuse ratings are

applicable for one drive per branch circuit. No other load may be applied to that fused

circuit. Note that contactors and circuit breakers are not recommended for AC input

line branch protection.

in table 3.9. Do not exceed the fuse ratings.

Table 3.9 – AC Input Line Fuse Selection V alues

Model

Number

1SU11001 20A

1SU14001 12A

1SU21001 10A

1SU24001 10A

1SU21002 30A

1SU21001 12A

1SU24001 12A

1SU21002 20A

1SU24002 20A

1SU21003 25A

1SU24003 25A

Fuse

Rating*

Model

Number

1SU41001 6A 1SU51001 4A

1SU44001 6A 1SU54001 4A

1SU41002 8A 1SU51002 7A

1SU44002 8A 1SU54002 7A

1SU41003 12A 1SU51003 10A

1SU44003 12A 1SU54003 10A

1SU41005 25A 1SU51005 15A

1SU44005 25A 1SU54005 15A

1SU41007 25A 1SU51007 20A

1SU44007 25A 1SU54007 20A

1SU41010 35A 1SU51010 25A

1SU44010 35A 1SU54010 25A

1SU41015 45A

Fuse

Rating*

Model

Number

Fuse

Rating*

1SU21005 35A 1SU42015 45A

1SU24005 35A 1SU41020 55A

1SU42020 55A

* Recommended fuse type: UL Class J, 600V, time-delay, or equivalent.

3-8

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 33

3.4 Installing an Emergency Stop

ATTENTION:The user must provide an external, hardwired emergency

stop circuit outside of the drive circuitry. This circuit must disable the

!

Depending upon the requirements of the application, the SP500 drive can be

programmed to provide either a coast-to-rest (default) or a ramp-to-rest (user-option)

operational stop without physical separation of the power source from the motor. Refer

to sections 5.2 and 8.3 (parameter F-16) for more information on how to program an

operational stop.

In addition to the operational stop, users must provide a hardwired emergency stop

external to the drive. The emergency stop circuit must contain only hardwired

electromechanical components. Operation of the emergency stop must not depend on

electronic logic (hardware or software) or on the communication of commands over an

electronic network or link.

3.4.1 Complying with Machinery Safety Standard EN 60204-1:1992

This section applies to users who must comply with machinery safety standard

EN 60204-1:1992, part 9.2.5.4, Emergency Stop.

The SP500 drive coast-to-rest stop is a category 0 operational stop.The ramp-to-rest

stop is a category 1 operational stop.

system in case of improper operation. Uncontrolled machine operation

may result if this procedure is not followed.

The required external hardwired emergency stop must be either a category 0 or 1

stop, depending on the user’s risk assessment of the associated machinery. In order

to fully comply with machinery safety standard EN 60204-1:1992, part 9.2.5.4, at least

one of the two stop methods must be a category 0 stop. Refer to Appendix D for more

information.

3.5 Motor Considerations

To obtain motor nameplate horsepower, the drive’s output current rating at the

selected carrier frequency should be equal to or greater than motor nameplate

current. If the motor nameplate current rating is higher than the drive’s output current

rating, derate motor horsepower by the ratio of the drive’s output ampere rating (at the

selected carrier frequency) to the motor nameplate current. Note that this

approximation is only accurate if the drive and the motor have nearly the same rating.

3.5.1 Single-Motor Applications

Size the drive and motor for the load and speed requirements of the specific

application.

The motor’s operating current must not exceed the drive’s rated output current (at the

selected carrier frequency). In addition, the motor’s horsepower rating (for example, 1,

2, 3, 5, 7, 10, 15, and 20 HP) must not be more than one horsepower range larger

than the drive’s horsepower rating.

SP500 System Planning

3-9

Page 34

If the motor will be operated below one-half of its rated speed, the motor overload

relay may not protect the motor because of reduced cooling action due to the reduced

speed. A motor thermostat, internal to the motor, should be installed to monitor the

actual temperature of the windings.

3.5.2 Multiple- Motor Applications

One drive can run two or more motors. Adhere to the following requirements to assure

correct drive operation in this case:

• When starting and stopping all the motors at the same time (using the drive for

starting and stopping), the sum of the full-load sine wave currents of all the motors

must be equal to or less than the maximum sine wave output current at the selected

carrier frequency for the drive.

For example: I

FLA

+I

FLA

+I

FLA

=I

TLA

(Motor 1) (Motor 2) (Motor 3) (Total Load)

Where: I

<100% rated drive output at the selected carrier frequency

TLA

• When one or more of the motors connected to the output of the drive are to start

independently (using a secondary switching device to add or remove the motor from

the circuit):

Any motor that starts or stops while the drive is running must have a current rating

less than 10% of the maximum sine wave current rating of the drive at the selected

carrier frequency.

The sum of the maximum full-load sine wave currents of all the motors connected

continuously to the drive must be less than the maximum output current rating under

all conditions.

Note that each motor requires separate thermal overload protection (for example, a

motor relay or a motor thermostat).

3-10

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 35

This chapter shows how to mount the SP500 drive and its external components. Also

shown are the entry areas for routing wiring in and out of the drive.

4.1 Mounting the Drive

Attach the drive to the selected flat, vertical surface using the mounting holes

provided. Enclosure A drives have two mounting holes, which are accessible after the

cover is removed. Enclosure B, C, and D drives have four mounting holes. In order to

maintain a flat mounting surface and to ensure that bolt tightness is maintained, use

washers under the bolt heads. Refer to figures 3.1 through 3.4 for drive mounting

dimensions. Use the following user-supplied mounting bolts and washers:

• Enclosure A drives: two M6 (1/4”)

• Enclosure B drives: four M8 (5/16”)

• Enclosure C drives: four M8 (5/16”)

• Enclosure D drives: four M8 or M10 (5/16” or 3/8”)

CHAPTER 4

Installing the Drive

4.2 Routing Wires

All wiring should be installed in conformance with the applicable local, national, and

international codes (e.g., NEC/CEC). Signal wiring, control wiring, and power wiring

must be routed in separate conduits to prevent interference with drive operation. Do

not route wires behind the drive. Use grommets when hubs are not provided to guard

against wire chafing. Figures 4.1 through 4.4 show the wire routing, grounding

terminal, and power terminal strips of the SP500 drives.

ATTENTION:Do not route signal and control wiring in the same conduit

with power wiring. This can cause interference with drive operation.

!

Do not route more than three sets of motor leads through a single conduit. This will

minimize cross-talk that could reduce the effectiveness of noise reduction methods. If

more than three drive/motor connections per conduit are required, you must use

shielded cable. If possible, each conduit should contain only one set of motor leads.

ATTENTION:Unused wires in conduit must be grounded at both ends

to avoid a possible shock hazard caused by induced voltages. Also, if a

!

drive sharing a conduit is being serviced or installed, all drives using this

conduit should be disabled to eliminate the possible shock hazard from

cross-coupled motor leads.

Installing the Drive

4-1

Page 36

.

4-2

Figure 4.1 – Enclosure A Wire Routing Locations

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 37

Installing the Drive

Figure 4.2 – Enclosure B Wire Routing Locations

4-3

Page 38

Figure 4.3 – Enclosure C Wire Routing Locations

4-4

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 39

Figure 4.4 – Enclosure D Wire Routing Locations

Installing the Drive

4-5

Page 40

4.3 Installing External Components

Install the input power and output power components that are located outside of the

SP500 enclosure. See figure 5.1. The following sections describe disconnect,

transformer, and AC line branch protection installation.

4.3.1 Disconnects

An input disconnect (for example, a switch or circuit breaker) must be installed in the

line before the drive input terminals in accordance with local, national, and

international codes (e.g., NEC/CEC). Size the disconnect according to the inrush

current as well as any additional loads the disconnect might supply. Coordinate the

trip rating for the current (10 to 12 times the full load current) with that of the input

isolation transformer, if used. Refer to section 4.3.3 for additional information.

4.3.2 Input AC Line Branch Protection

ATTENTION:Most codes require that upstream branch protection be

provided to protect input power wiring.

!

User-supplied branch circuit protection fuses must be installed according to the

applicable local, national, and international codes (for example, NEC/CEC). The fuses

must be installed in the line before the drive’s AC input terminals. Table 3.9 provides

fuse values.

4.3.3 Transformers

ATTENTION:Distribution capacity above the maximum recommended

system KVA rating (100 KVA for 115/230 VAC, 1000 KVA for

!

Input isolation transformers may be needed to help eliminate the following:

460/575 VA C) requires the use of an isolation transformer, a line reactor,

or other means of adding similar impedance to the drive’s input power

wiring.

ATTENTION:When the AC line is shared directly with other SCRrectified drives, an optional snubber resistor braking kit might be required

to alleviate excess DC bus voltage

• Damaging line voltage transients.

• Line noise from the drive back to the incoming power source.

• Damaging currents that could develop if a point inside the drive becomes grounded.

Observe the following guidelines when installing an isolation transformer:

• A power disconnecting device must be installed between the power line and the

primary of the transformer. If the power disconnecting device is a circuit breaker, the

circuit breaker trip rating must be coordinated with the inrush current (10 to 12 times

the full load current) of the transformer.

4-6

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 41

• Do NOT use an input isolation transformer rated more than 100 KV A for 230 VAC (or

1000 KVA for 460 VAC) with less than 5% impedance directly ahead of the drive

without additional impedance between the drive and the transformer.

If your SP500 application requires the use of an output transformer, contact Reliance

Electric for assistance.

4.3.4 Output Contactors

ATTENTION:Any disconnecting means wired to drive output terminals

U, V, and W must be capable of disabling the drive if opened during drive

!

Output contactors provide a positive means of disconnecting the motor from the drive.

If your SP500 application requires the use of output contactors, contact Reliance

Electric for assistance.

operation. If opened during drive operation, the drive will continue to

produce output voltage between U, V, W. An auxiliary contact must be

used to simultaneously disable the drive or output component damage

may occur.

4.3.5 Mechanical Motor Overload Protection

To provide the motor with overload protection, local, national, and international codes

(for example, NEC/CEC) require that a motor thermostat, internal to the motor, be

installed or an electronic thermal motor overload relay, sized to protect the motor, be

installed between the motor and the drive’s output termin als.

The Electronic Thermal Overload parameter (F-14) may be used in place of the

electronic thermal motor overload relays in single motor applications. Note, however,

that temperature-sensing devices integral to the motor are the best way of thermallyprotecting AC motors under all conditions. Parameter F-14 must be enabled to provide

overload protection. Refer to section 8.3 for the parameter description.

In multiple motor applications, each motor must have its own user-supplied overload

protection.

4.4 Setting the Analog Input Jumper on the Regulator Board

SP500 drives have an analog speed reference input. This is a jumper-selectable 0 to

10 VDC or 0 to 20 mA input with programmable gain and offset adjustments

(parameters F-11 and F-12). Jumper J6 on the Regulator board is set to match the

type of incoming analog signal, either voltage or current. See figures 2.2, 4.5, and 5.3.

Refer to section 5.2.1 for more information.

Installing the Drive

4-7

Page 42

1 2 3 4 165 6 7 8 9 10 11 12 13 14 15

J6

Figure 4.5 – Jumper J6 Settings for the Analog Input Speed Reference

Use the following procedure to set jumper J6:

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

!

Step 1. Turn off and lock out input power. Wait five minutes.

Step 2. Remove the cover from the drive by unscrewing the four cover screws.

Step 3. Verify that the DC bus voltage is zero by following the procedure in section

Step 4. Locate jumper J6 on the Regulator board. Refer to figure 2.3.

Step 5. Move the jumper to the desired setting as shown in figure 4.5.

Step 6. Reattach the cover.

(5) minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components.

9.1.

0-20 mA

0-10 VDC

4-8

Step 7. Reapply input power.

Step 8. Verify that parameters F-11 and F-12 are correctly set.

Note that if the setting of jumper J6 is changed, the regulator software will not

automatically detect it. Verify that parameters F-11 (gain) and F-12 (offset) are set

correctly before starting the drive.

4.5 Preparing the Motor

Follow these guidelines when preparing to install the motor:

• Verify that the motor is the appropriate size to use with the drive.

• Verify that the total motor lead length does not exceed the values given in section

3.2.4.

• Follow the instructions in the motor instruction manual when installing the motor.

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 43

• Verify that the motor is properly aligned with the application’s machine to minimize

unnecessary motor loading due to shaft misalignment.

• If the motor is accessible when it is running, install a protective guard around all

exposed rotating parts.

Installing the Drive

4-9

Page 44

4-10

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 45

This chapter describes how to wire the SP500 drive including: input wiring, control and

signal wiring, output wiring, and grounding.

5.1 Input Power Wiring

Use the following steps to connect AC input power to the drive:

Step 1. Verify that the AC input power to the drive corresponds to the drive’s

nameplate voltage and frequency.

Step 2. Wire the AC input power leads by routing them according to the type of

enclosure. See figures 4.1 through 4.4. See tables 3.2 through 3.4 for

.

recommended wire sizes.

ATTENTION:Do not route signal and control wiring with power wiring in

the same conduit.This can cause interference with drive operation.

!

CHAPTER 5

Wiring the Drive

Step 3. Connect the AC input power leads to terminals R,S,T on the power terminal

strip. See figure 5.1.

Step 4. Tighten terminals R and S (single-phase input) or terminals R,S,T (three-

phase input) to the proper torque as shown in table 3.5.

Wiring the Drive

5-1

Page 46

UserSupplied

Manual

Disconnect

Fuse

AC Input

Voltage

R/L1 S/L2 T/L3

GND

GND

UserSupplied

U/T1 V/T2 W/T3

Motor Overload Relay

(Optional if Electronic Overload is Used)

Figure 5.1 – Typical Electrical Connections

~

-

SP500

Drive

~

~

GND

U

U

U

U

U

U

M

5-2

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 47

5.2 Signal and Control Wiring

The terminal strip on the Regulator board provides terminals for connecting signal (for

example, external speed reference and analog output) and control (for example, stop,

start, and function loss) wiring. See figure 5.2. Terminals for the following wire

connections are provided:

• Terminals 1-3: analog speed reference connections

• Terminals 4-5: analog output connections

• Terminals 6-11: digital input connections

• Terminals 12-13: snubber resistor connections

• Terminals 14-16: output status connections

Isolated Reference Voltage

Voltage/Current Speed Reference

Isolated Reference Ground

Analog Meter Output

24 VDC Common

Stop

Start

Analog

Speed

Reference

Analog

Output

Figure 5.2 – Typical Control Terminal Strip Connections

5.2.1 Analog Speed Reference Wiring

Analog speed reference input wiring connects to terminals 1 through 3 on the

Regulator board’s terminal strip. See figure 5.3. This reference signal is jumperselectable for either a 0 to 10 VDC or 0 to 20 mA input. The setting of jumper J6 on the

Regulator board determines whether the input reference is a voltage or current signal.

This reference signal can be provided by either a user-supplied 5K ohm potentiometer

or an external 0-10 VDC/0-20 mA supply. See section 4.4 for more information.

Reset

Digital

Inputs

Function Loss

24 VDC Common

Forward/Reverse

Snubber Resistor Braking Signal

Snubber

Resistor

Braking

Signal

24 VDC Common

Relay Common

N.O. Relay Contact

N.C. Relay Contact

Output

Status

Relay

Wiring the Drive

5-3

Page 48

User-Supplied

Speed Reference

Potentiometer

+10 VDC

5kΩ

Figure 5.3 – Analog Speed Reference Wiring Connections

5.2.2 Analog Output Wiring

Analog output wiring connects to terminals 4 and 5 on the Regulator board’s terminal

strip. See figure 5.4. This is a scaled 0 to 10 VDC output signal that is proportional to

either current speed, percent of load, calculated output voltage, or percent of the

selected reference value, whichever is selected through parameter F-29. This output

signal is available during both local and remote operation.

User-Supplied

Speed Reference

Input Signal

0-10 VDC

or

0-20 mA

or

Load

(User-Supplied

Analog Meter)

5-4

+10V 0V

Figure 5.4 – Analog Output Wiring Connections

5.2.3 Digital Input Wiring

Digital input wiring connects to terminals 6 through 11 on the Regulator board’s

terminal strip. The drive has a 24 VDC power supply that provides the required voltage

for control signals. Enabling or disabling a control signal requires that a contact

(switch) be opened or closed.

Important: The 24 VDC power supply is unregulated and will nominally supply

24 VDC. It is not to be used with any external devices other than the

inputs to the drive.

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 49

Start and Stop Control Wiring

Start and stop control wiring connects to terminals 6, 7, and 11. See figures 5.5 and

5.6. Note that these start/stop wiring connections are not to be used in multi-speed

preset applications which are discussed in the following section.

Start/

Stop

Stop

Start

IET Reset

Forward/Reverse

IET

Reset

Function Loss

Fwd

Rev

24 VDC Common

Function

Loss

Customer

Interlock

Figure 5.5 – Two-Wire Start/Stop Sample Control Wiring

Stop

Start

IET

Reset

Fwd

Rev

Stop

Function

Loss

Start

IET Reset

Function Loss

Forward/Reverse

24 VDC Common

Customer

Interlock

Wiring the Drive

Figure 5.6 – Three-Wire Start/Stop Sample Control Wiring

5-5

Page 50

Multi-Speed Preset Wiring

Multi-speed preset wiring connects to terminals 6 through 8, and 11. See figure 5.7.

When control type 3 is selected through parameter F-00, remote terminal strip control

is enabled with multi-speed presets. This mode of operation changes the functionality

of terminals 6 through 8 and may be used in place of 2- and 3-wire start/stop wiring.

See figure 5.8.

When you enable multi-speed preset operation, the state of terminals 7 and 8

determine the source of the speed reference:

Terminal 7 Terminal 8 Speed Reference Source

0 0 Terminal Strip Analog Input

0 1 Multi-Speed Preset 1 (Parameter F-23)

1 0 Multi-Speed Preset 2 (Parameter F-24)

1 1 Multi-Speed Preset 3 (Parameter F-25)

Start/Stop/IET Reset

Multi-Speed Preset 2

Multi-Speed Preset 1

Fwd

Rev

Function

Loss

Function Loss

Forward/Reverse

Start/Stop/IET Reset

Multi-Speed Preset 2

Multi-Speed Preset 1

Figure 5.7 – Multi-Speed Preset Sample Control Wiring

24 VDC Common

Customer

Interlock

5-6

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 51

F-00 = 0, 1, 2

4

Stop

Start

IET Reset

24 VDC Common

Analog Meter Output

F-00 = 3 (Multi-Speed Presets)

4

Forward/Reverse

Function Loss

24 VDC Common

Braking Signal

Snubber Resistor

Function Loss

24 VDC Common

Analog Meter Output

Figure 5.8 – Terminal Usage During Multi-Speed Preset Operation

Start/Stop/IET Reset

Multi-Speed Preset 2

Forward/Reverse

Multi-Speed Preset 1

24 VDC Common

Braking Signal

Snubber Resistor

IET Reset Control Wiring

IET reset control wiring connects to terminals 8 and 11. See figures 5.5 and 5.6. Note

that these reset wiring connections are not to be used in multi-speed preset

applications. See figures 5.7 and 5.8.

Forward/Reverse Control Wiring

Forward/reverse control wiring connects to terminals 9 and 11. See figures 5.5

through 5.7. Note that the setting of the forward/reverse switch is ignored when

parameter F-17 is equal to 1 (disable reverse operation).

Function Loss Control Wiring

ATTENTION:The user must provide an external, hardwired emergency

stop circuit outside of the drive circuitry. This circuit must disable the

!

system in case of improper operation. Uncontrolled machine operation

may result if this procedure is not followed.

Wiring the Drive

Function loss control wiring connects to terminals 10 and 11. See figures 5.5 through

5.7. Typically, a function loss input is a maintained, normally-closed pushbutton.

A signal must be present at terminal 10 for the drive to run. A factory-installed jumper

connects terminals 10 and 11 which provides that signal. Remove this jumper if a

function loss input, a coast-stop pushbutton, or another external interlock (for

example, a motor thermostat) is used. Removing the jumper allows the drive to stop

when the contact is open.

5-7

Page 52

5.2.4 Snubber Resistor Wiring

Snubber resistor wiring connects to terminals 12 and 13 on the Regulator board’s

terminal strip. See figures 5.9 and 5.10.

Snubber

Resistor

Drive Model Number

1SU2xxxx 1 (+)

Terminals

2 (–)

Control Terminal

Strip Connections

12

13

Power Terminal

Strip Connections

N/A

147 (+)

45 (–)

1SU4xxxx & 1SU5xxxx 1 (+)

2 (–)

147 (+)

45 (–)

13 (+)

14 (–)

1SU4x015 & 1SU4x020 Refer to instruction manual D2-3291.

N/A

12

13

N/A

N/A

(+) DC Bus

(–) DC Bus

N/A

(+) DC Bus

(–) DC Bus

(+) 10V

(–) 10 COM

5-8

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 53

Regulator

Board

Control

Terminal

Strip

12 13

Braking Signal

24 VDC Common

Snubber Resistor

Power

Terminal

Strip

SP500 Drive

Figure 5.9 – Snubber Resistor Wiring Connections for M/N 1SU2xxxx Drives

+-

DC Bus

Volts

Snubber Resistor

+1

-2

Braking Signal

+147

DC Bus Volts

-45

Snubber Resistor

Regulator

Board

Control

Terminal

Strip

Terminal

Figure 5.10 – Snubber Resistor Wiring Connections for M/N 1SU4xxxx and 1SU5xxxx Drives

12 13

24 VDC Common

Braking Signal

Snubber Resistor

Power

Strip

SP500 Drive

+-

DC Bus

Volts

+-

10V 10V

Com

+1

Snubber Resistor

-2

Braking Signal

+147

DC Bus Volts

-45

+13

10V Supply

-14

1

1

Snubber Resistor

1

These connections are not used with

M/N 2SRxxxx Snubber Resistor kits.

Note: The 10V and 10V Com terminals on the power terminal strip

do not exist on 460 VAC 15 HP and 20 HP SP500 drive models.

Depending on your choice of Snubber Resistor kit, you may

need to provide an external 10V source.

Wiring the Drive

5-9

Page 54

5.2.5 Output Status Relay Wiring

Output status wiring connects to terminals 14 through 16 on the Regulator board’s

terminal strip. See figure 5.11. Parameter F-09 specifies the type of status indication

provided by the output relay. See the F-09 parameter description in section 8.3 for

more information.

USER-SUPPLIED

LAMP

N.O.

Figure 5.11 – Output Status Relay Wiring Connections

5.3 Output Power Wiring

Use the following steps to connect AC output power wiring from the drive to the motor:

Step 1. Wire the AC output power leads by routing them according to the type of

enclosure. See figures 4.1 through 4.4. See tables 3.2 through 3.4 for

.

recommended wire sizes.

ATTENTION: Do not route signal and control wiring with power wiring

in the same conduit. This can cause interference with drive operation.

!

Do not route more than three sets of motor leads through a single conduit. This will

minimize cross-talk which could reduce the effectiveness of noise reduction methods.

If more than three drive/motor connections per conduit are required, you must use

shielded cable. If possible, each conduit should contain only one set of motor leads.

USER-SUPPLIED

115 VAC / 24 VDC

(10 mA Min.)

14 15 16

5-10

ATTENTION:Unused wires in conduit must be grounded at both ends

to avoid a possible shock hazard caused by induced voltages. Also, if

!

Step 2. Connect the AC output power motor leads to terminals U, V, and W on the

Step 3. Tighten terminals U, V, and W to the proper torque as shown in table 3.5.

a drive sharing a conduit is being serviced or installed, all drives using

this conduit should be disabled to eliminate the possible shock hazard

from cross-coupled motor leads.

power terminal strip. See figure 5.1.

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 55

5.4 Grounding

ATTENTION:The user is responsible for conforming with all applicable

local, national, and international codes.

!

Use the following steps to ground the drive:

Step 1. Remove the drive’s cover.

Step 2. Run a suitable equipment grounding conductor unbroken from the drive’s

ground terminal to the motor’s ground terminal and then to earth ground. See

figures 4.1 through 4.4 and 5.1.

Step 3. Connect a suitable grounding connector to the motor frame and transformer

(if used). Run each conductor unbroken to earth ground.

When adding more than one grounding conductor wire to a single chassis

ground, twist the conductors together.

Step 4. Reattach the drive’s cover.

Wiring the Drive

5-11

Page 56

5-12

SP500 AC Drive Installation and Operation Manual Version 3.1

Page 57

CHAPTER 6

Completing the Installation

This chapter provides procedures to check the installation.

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

6.1 Checking the Installation With the Power Off

!

Perform the following checks of the drive installation with the power off:

Step 1. Turn off, lock out, and tag the input power to the drive. Wait five minutes.

should install, adjust, operate, and/or service this equipment. Read and

understand this manual in its entirety before proceeding.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

(5) minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components.

Step 2. Check the DC bus potential with a voltmeter as described in section 9.1 to

ensure that the DC bus capacitors are discharged.

Step 3. If an input disconnect is installed, make sure it is in the off position.

Step 4. Make sure the drive interlocks installed around the driven machine are

operational.

ATTENTION:The user must provide an external, hardwired emergency

stop circuit outside of the drive circuitry. This circuit must disable the

!

Step 5. Verify that the user-installed stop pushbutton is wired correctly. Be sure the

system in case of improper operation. Uncontrolled machine operation

may result if this procedure is not followed.

factory-installed jumper at terminals 10 and 11 has been removed so that the

coast-stop pushbutton will work. (Refer to section 5.2.3.)

ATTENTION:Make sure electrical commons are not intermixed in the

drive.

!

Step 6. Remove any debris from around the drive.

Step 7. Check that there is adequate clearance around the drive.

Step 8. Verify that the wiring to the control terminal strip and power terminals is

correct. Refer to chapter 5.

Completing the Installation

6-1

Page 58

Step 9. Check that the wire sizes are within terminal specifications and that the

terminals are tightened to the appropriate torque specifications. Refer to

tables 3.2 through 3.6.

Step 10. Check that the user-supplied branch circuit protection is installed and

correctly rated.

Step 11. Check that the incoming AC power is rated correctly.

Step 12. Check the motor installation and length of motor leads.

Step 13. Disconnect any power correction capacitors connected between the drive

and the motor.

Step 14. Check that any motor thermal switch and the drive’s electronic thermal

overload are enabled (parameter F-15 = ON).

Step 15. Check that the rating of the transformer (if used) matches the drive

requirements and is connected for the proper voltage.

Step 16. Verify that a properly-sized ground wire is installed and that a suitable earth

ground is used. Check for and eliminate any grounds between the motor

frame and the motor power leads. Verify that all ground leads are unbroken.

Step 17. Uncouple the motor from any driven machinery to initially start the drive.

6.2 Checking Drive Operation

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

!

(5) minutes for the DC bus capacitors to discharge and then check the