Page 1

DeviceNet Adapter

for use with

DPI AC Drives

M/N RECOMM-DNET

Instruction Manual

D2-3478

Page 2

The information in this manual is subject to change without notice.

Trademarks not belonging to Rockwell Automation are

property of their respective companies.

Throughout this manual, the following notes are used to alert you to safety

considerations:

ATTENTION:

circumstances that can lead to personal injury or death, property

damage, or economic los s.

Identifies information ab out practices or

!

Important:Identifies inf ormation that is cri tic al for successful app lication and

understanding of the product.

ATTENTION:

injury or death. Remove all power from the drive, and then verify

power has been removed before installing or rem ovi ng a

!

DeviceNet adapter. Failure to observe these precautions coul d

result in severe bodily injury or loss of life.

ATTENTION:

drive and power products and the associ a t ed machinery should

plan or implement the in st all at i on, st art up, configuration, and

subsequent mainten ance of the product using a DeviceNet

adapter. Read and understand this manual in its entirety before

proceeding. Failure to observe these pr ecautions could result

bodily injur y and/or damage to equip m ent.

ATTENTION:

together via RECBL-x xx cables. Un pre di ct able behavior d ue t o

timing and other internal procedures can resu l t if two or m or e

devices are connected in this manner. Failure to observe this

precaution could result bodily injury and/or damage to equipment.

A TTENTION:

to the drive, the drive may fault when you reset the adapter.

Determine how your drive will respond before resetting an adapter .

Fail ure to observe t his precaut i on could result bodily injury and/

or damage to equipme nt .

ATTENTION:

Flt Action (34) let you determine the action of the adapter and

connected drive if communic at ions are disrupted. By default,

these parameters fault the dri ve. You can set these param eters

so that the drive continues to run. Precautions should be taken

to ensure that the setti ngs of these parameters do not create a

hazard of injur y or equipment damage. Failure to observe this

precaution could result bodily injury and/or damage to equipment.

A TTENTION:

may be unintended or incorrect machine motion. Disconnect the

motor from the machine or process during initial system testing.

Fail ure to observe t his precaut i on could result bodily injury and/

or damage to equipme nt .

The drive may contain high voltages that can cause

Only qualified electr ic al personnel familiar with

DPI host products must not be directly connected

If the DeviceNet adapter is tra nsmitting contr ol I/O

Comm Flt Action (10), Idle Flt Action (11), and Pe er

When a system is configured for the first time, the re

DeviceNet is a trademark of the Open DeviceNet Vendor Association.

Windows, Windows NT, and Microsoft are tradem arks of Microsoft Corporation.

RSLinx, RSLogic, and RSN et Worx are tradem arks of Rockwell Software.

Reliance, SP600, VS Utilities, DPI, SLC, and PLC5 are trademarks of Rockwell

Automation.

©2001 Rockwell Automation. All rights reserved.

Page 3

C

ONTENTS

Chapter 1 Introduction

1.1 DeviceNet Adapter Features......................................... 1-1

1.2 Related Documentation.................................................1-2

1.3 Conventions Used in This Manual.................................1-3

1.4 Getting Assistance from Reliance Electric..................... 1-3

Chapter 2 Getting Started

2.1 DeviceNet Adapter Components................................... 2-1

2.2 Required Equipment......................................................2-2

2.3 Installation Checklist ......................................................2-3

Chapter 3 Installing the DeviceNet Adapter

3.1 Preparing for an Installation........................................... 3-1

3.2 Commissioning the DeviceNet Adapter.........................3-1

3.3 Connecting the Adapter to the Network......................... 3-3

3.4 Connecting the Adapter to the Drive..............................3-4

3.5 Applying Power.............................................................. 3-5

Chapter 4 Configuring the DeviceNet Adapter

4.1 Configuration Tools........................................................ 4-1

4.2 Using the LCD OIM to Configure the Adapter............... 4-2

4.3 Using RSNetWorx for DeviceNet...................................4-2

4.3.1 Setting Up RSLinx for RSNetWorx for DeviceNet4-2

4.3.2 Going Online with RSNetWorx for DeviceNet ..... 4-4

4.3.3 Creating an Electronic Data Sheet (EDS) File..... 4-5

4.3.4 Accessing and Editing Parameters...................... 4-6

4.4 Setting the Node Address.............................................. 4-7

4.5 Setting the Data Rate....................................................4-8

4.6 Setting the I/O Configuration .........................................4-8

4.7 Selecting Master-Slave or Peer-to-Peer........................ 4-9

4.7.1 Setting a Master-Slave Hierarchy........................4-9

4.7.2 Setting an Adapter To Transmit Peer-to-Peer

Data................................................................... 4-10

4.7.3 Setting an Adapter To Receive Peer-to-Peer

Data................................................................... 4-12

4.8 Selecting COS, Cyclic, or Polled I/O............................4-15

4.8.1 Using COS (Change of State)Data Exchange...4-15

4.9 Setting a Fault Action...................................................4-17

4.9.1 Changing the Fault Action................................. 4-17

4.9.2 Setting the Fault Configuration Parameters...... 4-18

4.10Resetting the Adapter..................................................4-19

4.11Viewing the Adapter Configuration.............................. 4-20

Contents

I

Page 4

Chapter 5 Configuring the Scanner

5.1 Configuring a Simple Network: An Example..................5-1

5.2 Setting Up the Scan List ................................................5-2

5.3 Mapping the Drive Data in the Scanner.........................5-6

5.3.1 Mapping the Input I/O..........................................5-6

5.3.2 Mapping the Output I/O .......................................5-7

5.4 Saving the Configuration................................................5-8

Chapter 6 Using I/O Messaging

6.1 About I/O Messaging .....................................................6-1

6.2 Understanding the I/O Image.........................................6-2

6.3 Using Logic Command/Status .......................................6-4

6.4 Using Reference/Feedback ...........................................6-4

6.5 Using Datalinks..............................................................6-4

6.5.1 Rules for Using Datalinks ....................................6-4

6.5.2 32-Bit Parameters Using 16-Bit Datalinks ...........6-5

6.6 Sample Ladder Logic Programs ....................................6-6

6.6.1 Sample ControlLogix Ladder Logic Program....... 6-7

6.6.2 Sample PLC-5 Ladder Logic Program.................6-9

6.6.3 Sample SLC Ladder Logic Program..................6-11

Chapter 7 Using Explicit Messaging

7.1 About Explicit Messaging................................... ..... ......7-1

7.2 Formatting Explicit Messages for a ControlLogix

Controller.......................................................................7-2

7.3 Formatting Explicit Messages for a PLC or SLC

Controller.......................................................................7-4

7.4 Running Explicit Messages............................................7-7

7.5 ControlLogix Example....................................................7-8

7.6 PLC-5 Example............................................................7-10

7.7 SLC Example...............................................................7-12

Chapter 8 Troubleshooting the DeviceNet Adapter and Network

8.1 Understanding the Status Indicators..............................8-1

8.1.1 DRIVE Status Indicator........................................8-2

8.1.2 MS Status Indicator.............................................8-3

8.1.3 NET A Status Indicator........................................8-4

8.2 Adapter Diagnostic Items...............................................8-5

8.3 Viewing and Clearing Events........................................8-7

II

DeviceNet Adapter for use with DPI AC Drives

Page 5

Appendix A

Technical Specifications .....................................................A-1

Appendix B

Appendix C

Appendix D

Appendix E

Glossary

Index

DeviceNet Adapter Parameters...........................................B-1

DeviceNet Objects...............................................................C-1

Logic Command/Status Words ............................................D-1

Master-Slave I/O Configuration............................................E-1

.................................................................................Glossary-1

......................................................................................Index-1

Contents

III

Page 6

IV

DeviceNet Adapter for use with DPI AC Drives

Page 7

List of Figures

Figure 2.1 – Components of the DeviceNet Adapter..................................2-1

Figure 3.1 – Setting the Node Address.......................................................3-2

Figure 3.2 – Setting the Data Rate.............................................................3-2

Figure 3.3 – Connecting a 5-Pin Linear Plug to the Cable..........................3-3

Figure 3.4 – DPI Ports and Internal Interface Cables.................................3-4

Figure 3.5 – Mounting and Grounding the DeviceNet Adapter...................3-5

Figure 4.1 – Accessing the DeviceNet Parameters using the LCD OIM.....4-2

Figure 4.2 – Configure Drivers Dialog Box with a Configured Driver..........4-3

Figure 4.3 – Sample DeviceNet Network (Graph View)..............................4-4

Figure 4.4 – EDS Wizard Screen................................................................4-6

Figure 4.5 – Sample SP600 Drive Dialog Box (Drive Parameters Tab) .....4-7

Figure 4.6 – DeviceNet Node Address Screen on an LCD OIM.................4-7

Figure 4.7 – DeviceNet Data Rate Screen on an LCD OIM........................4-8

Figure 4.8 – I/O Configuration Screen on an LCD OIM..............................4-8

Figure 4.9 – Master-Slave Input Screen on an LCD OIM...........................4-9

Figure 4.10 – Master-Slave Output Screen on an LCD OIM....................4-10

Figure 4.11 – Peer Out Enable Screen on an LCD OIM...........................4-10

Figure 4.12 – Peer A Output Screen on an LCD OIM...............................4-11

Figure 4.13 – Peer B Output Screen on an LCD OIM...............................4-11

Figure 4.14 – Min Peer TX Time and Peer Out Skip Screens on an

LCD OIM ............................................................................4-11

Figure 4.15 – Peer Input Enable Screen on an LCD OIM.........................4-12

Figure 4.16 – Peer Node to Input Screen on an LCD OIM.......................4-12

Figure 4.17 – Peer A Input Screen on an LCD OIM.................................4-12

Figure 4.18 – Peer B Input Screen on an LCD OIM.................................4-13

Figure 4.19 – Peer Logic Command Mask Screen on an LCD OIM.........4-13

Figure 4.20 – Peer Reference Adjust Screen on an LCD OIM.................4-14

Figure 4.21 – Minimum Peer Receiving Time Screen on an LCD OIM....4-14

Figure 4.22 – Peer Fault Action Screen on an LCD OIM..........................4-15

Figure 4.23 – I/O Configuration Screens on an LCD OIM........................4-16

Figure 4.24 – COS Status Mask Configuration Screen on an LCD OIM..4-16

Figure 4.25 – COS Fdbk Change Configuration Screen on an LCD OIM.4-16

Figure 4.26 – Fault Action Screens on an LCD OIM.................................4-18

Figure 4.27 – Reset Screen on an LCD OIM............................................4-19

Figure 5.1 – Sample DeviceNet Network....................................................5-1

Figure 5.2 – Configuration View (Graph Tab).............................................5-2

Figure 5.3 – Scanlist Page in the Scanner Module Dialog Box..................5-3

Figure 5.4 – Edit I/O Parameters Dialog Box..............................................5-3

Figure 5.5 – Input Page on the Scanner Module Dialog Box......................5-6

Figure 5.6 – Output Page on the Scanner Module Dialog Box...................5-7

Contents

V

Page 8

Figure 6.1 – Sample I/O Image with All I/O Enabled...................................6-2

Figure 6.2 – Sample I/O Image with Only Logic/Reference and Datalink B

Enabled ..................................................................................6-3

Figure 6.3 – Sample ControlLogix Ladder Logic Program..........................6-7

Figure 6.4 – Sample ControlLogix Ladder Logic Program

(continued)..............................................................................6-8

Figure 6.5 – Sample PLC-5 Ladder Logic Program....................................6-9

Figure 6.6 – Sample PLC-5 Ladder Logic Program (continued)...............6-10

Figure 6.7 – Sample SLC Ladder Logic Program.....................................6-11

Figure 6.8 – Sample SLC Ladder Logic Program (continued)..................6-12

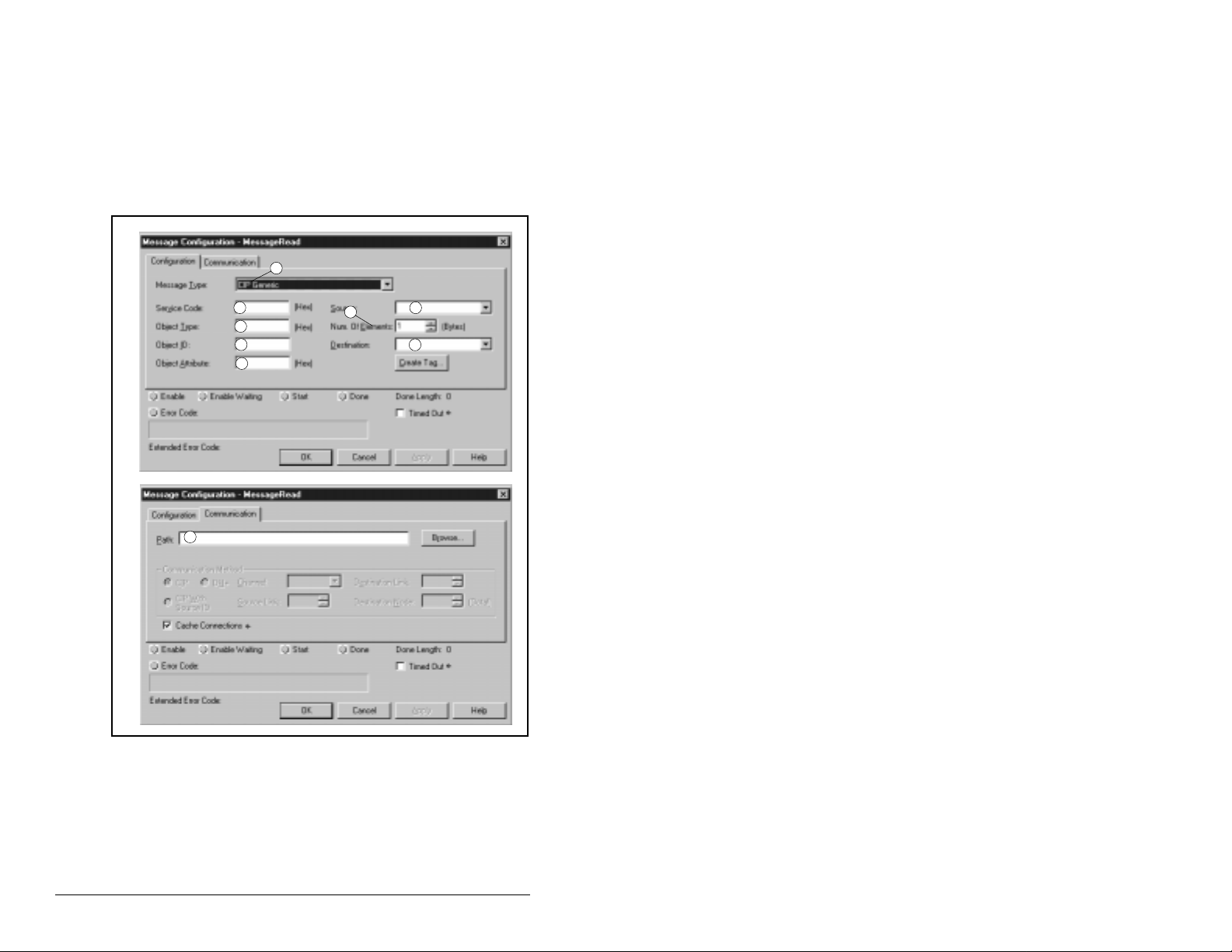

Figure 7.1 – ControlLogix Message Format in RSLogix 5000....................7-2

Figure 7.2 – PLC Explicit Message Format.................................................7-4

Figure 7.3 – SLC Explicit Message Format.................................................7-4

Figure 7.4 – Explicit Message Process.......................................................7-7

Figure 7.5 – Data Format for a Read and Write Parameter (1 of 2)............7-8

Figure 7.6 – Data Format for a Read and Write Parameter (2 of 2)............7-9

Figure 7.7 – Sample ControlLogix Ladder Logic Program..........................7-9

Figure 7.8 – Sample PLC-5 Ladder Logic Program..................................7-11

Figure 7.9 – Sample SLC Ladder Logic Program.....................................7-13

Figure 8.1 – Status Indicators (location on drive may vary)........................8-1

Figure 8.2 – VIewing and Clearing Events Using an LCD OIM...................8-7

VI

DeviceNet Adapter for use with DPI AC Drives

Page 9

List of Tables

Table 2.2 – Equipment Shipped with the DeviceNet Adapter..................... 2-2

Table 2.3 – Required User-Supplied Equipment........................................ 2-2

Table 4.1 – Configuration Tools.................................................................. 4-1

Table 4.2 – Procedure for Setting Up RSLinx for RSNetworx for DeviceNet 4-3

Table 4.3 – Viewing Devices on the DeviceNet Network using RSNetWorx. 4-4

Table 4.4 – Procedure for Creating an EDS File........................................ 4-5

Table 4.5 – Procedure to Access and Edit Parameters Using RSNetWorx 4-6

Table 4.6 – Selections for Drive Response to Communication Fault........4-17

Table 4.7 – Fault Configuration Parameters............................................. 4-18

Table 4.8 – Adapter Configuration Status Parameters ............................ 4-20

Table 5.1 – Host Products Using 16-Bit Reference/Feedback & Datalinks 5-4

Table 5.2 – Host Products Using 32-Bit Reference/Feedback &Datalinks. 5-5

Table 5.3 – Scan Rates.............................................................................. 5-5

Table 5.4 – Scanner Module Memory Locations ........................................5-7

Table 5.5 – Scanner Module Memory Locations ........................................5-8

Table 6.1 – Tags for the Sample ControlLogix Program.............................6-7

Table 6.2 – Control File for Block Transfers...............................................6-9

Table 7.1 – ControlLogix Message Requests and Responses...................7-3

Table 7.2 – Number of Transaction Blocks Reserved for Explicit Messaging 7-5

Table 7.3 – PLC / SLC Explicit Message Requests.................................... 7-5

Table 7.4 – PLC / SLC Explicit Message Responses................................. 7-6

Table 7.5 – Tags for the Sample Explicit Messaging Program...................7-9

Table 7.6 – Request Data for Read of Drive Parameter 101.................... 7-10

Table 7.7 – Response Data for Read of Drive Parameter 101.................7-10

Table 7.8 – Request Data for Write to Drive Parameter 101....................7-10

Table 7.9 – Response Data for Write to Drive Parameter 101................. 7-10

Table 7.10 – Request Data for Read of Drive Parameter 101.................. 7-12

Table 7.11 – Response Data for Read of Drive Parameter 101............... 7-12

Table 7.12 – Request Data for Write to Drive Parameter 101..................7-12

Table 7.13 – Response Data for Write to Drive Parameter 101 ............... 7-12

Table 8.1 – DRIVE Status Indicator: State Definitions................................8-2

Table 8.2 – MS Status Indicator: State Definitions .....................................8-3

Table 8.3 – NET A Status Indicator: State Definitions................................8-4

Table 8.4 – Diagnostic Items Accessed Using VS Utilities ........................ 8-5

Table 8.5 – Event Codes and Descriptions ................................................8-7

Contents

VII

Page 10

VIII

DeviceNet Adapter for use with DPI AC Drives

Page 11

C

HAPTER

Introduction

This manual pr ovides information about the DeviceNet adapter

(RECOMM-DNET) and using it with SP600 drives. The adapter is

mounted in t he SP600 drive and receives its required power from

the drive and from the DeviceNet network.

The DeviceNet adapter can be used with other products that

implement DPI. DPI is a peripheral communication inter face. Refer

to the documentation for your product for specific information about

how it works with the adapter.

This manual is intended for qualified electrical personnel familiar

with installing, programming, and maintaining AC drives and

DeviceNet networks.

1.1 DeviceNet Adapter Features

The DeviceNet adapter features the following:

Switches that enable you to set a node addres s and netw ork dat a

•

rate before applying power to the SP600 drive. Alternatively, you

can disable the switches and use parameters to configure these

features.

1

Introduction

A number of configuration tools that can be used to configure the

•

adapter and connected drive. The tools include the Operator

Interface Module (OIM) on the drive, network software such as

RSNetWorx for DeviceNet, or drive-configuration software such

as VS Utilities.

Status indicators that report the status of the drive

•

communications, adapter, and network. They are visible both

when the cover is opened and when it is closed.

I/O, including Logic Command/Reference and up to four pairs of

•

Datalinks, that may be configured for your application using a

parameter.

Explicit and UCMM (Un connecte d Me ssage Ma nag er) messag es

•

are supported.

Multiple data exchange methods, including polled, cyclic, and

•

change of state (COS), that can be used to tr ansmit data betw een

the network and adapter.

1-1

Page 12

Master-slave or peer-to-peer hierarchies that can be set up so

•

that the adapter and connected SP600 drive transmit data to and

from either a scanner or another SP600 drive on the network.

User-defined fault actions that determine how the adapter and

•

SP600 drive respond to communication disruptions on the

network and controllers in idle mode.

Faulted node recovery is supported. You can configure a device

•

even when it is faulted on the network if you have a configuration

tool that uses faulted node recovery and have set the data rate

switch to “PGM” (Program). With the PGM setting, the adapter

uses parameter settings for the data rate and node address

instead of switch settings.

1.2 Related Documentation

Refer to the following related publications as necessary for more

information. All of the publications are available from

http://www.theautomationbookstore.com.

D2-3485 SP600 AC Drive User Manual

•

D2-3488 VS Utilities Getting Results Manual

•

Online help installed with the software

DN-2.5 DeviceNet Produ c t Overview

•

DN-6.7.2 DeviceNet Cable System Planning and

•

Installat ion Manual

1-2

DN-6.5.16 DeviceNet Starter Kit

•

1756-5.66 ControlLogix DeviceNet Scanner

•

Installat ion Instructions

9399-WAB32GR Getting Results with RSLinx

•

Online help installed with the software

9399-RL53GR RSLogix 5 Getting Results Guide

•

Online help installed with the software

9399-RL50GR RSLogix 500 Getting Results Guide

•

Online help installed with the software

9399-RLD300GR RSLogix 5000 Getting Results Guide

•

Online help installed with the software

9399-DNETGR RSNetWorx for DeviceNet Getting Results

•

Guide

Online help installed with the software

1747-5.8 DeviceNet Scanner Module Installation

•

Instructions

DeviceNet Adapter for use with DPI AC Drives

Page 13

1747-6.5.2 DeviceNet Scanner Module Configuration

•

Manual

1747-5.8 DeviceNet Scanner Module Installation

•

Instructions

1771-6.5.118 DeviceNet Scanner Module Configuration

•

Manual

1.3 Conventions Used in This Manual

The following conventions are used throughout this manual:

Menu commands are shown in bo ld type face and follow the

•

format

Menu > Command

For example, if you read “

the File menu and then click the Open command.

Parameters will be referenced as follows:

•

Parameter Name ( Parameter Number)

For example: DPI Port (1)

.

Select File > Open

,” you should c lick

1.4 Getting Assistance from Reliance

Electric

If you have any questions or problems with the products described

in this instruction manual, contact your local Reliance Electric sales

office. For technical assistance, call 1-800-726-8112.

Introduction

1-3

Page 14

1-4

DeviceNet Adapter for use with DPI AC Drives

Page 15

C

HAPTER

Getting Started

This chapter provides:

• A description of the DeviceNet adapter’s components

• A list of parts shipped with the adapter

• A list of user-supplied parts required for installing the adapter

• An installation checklist

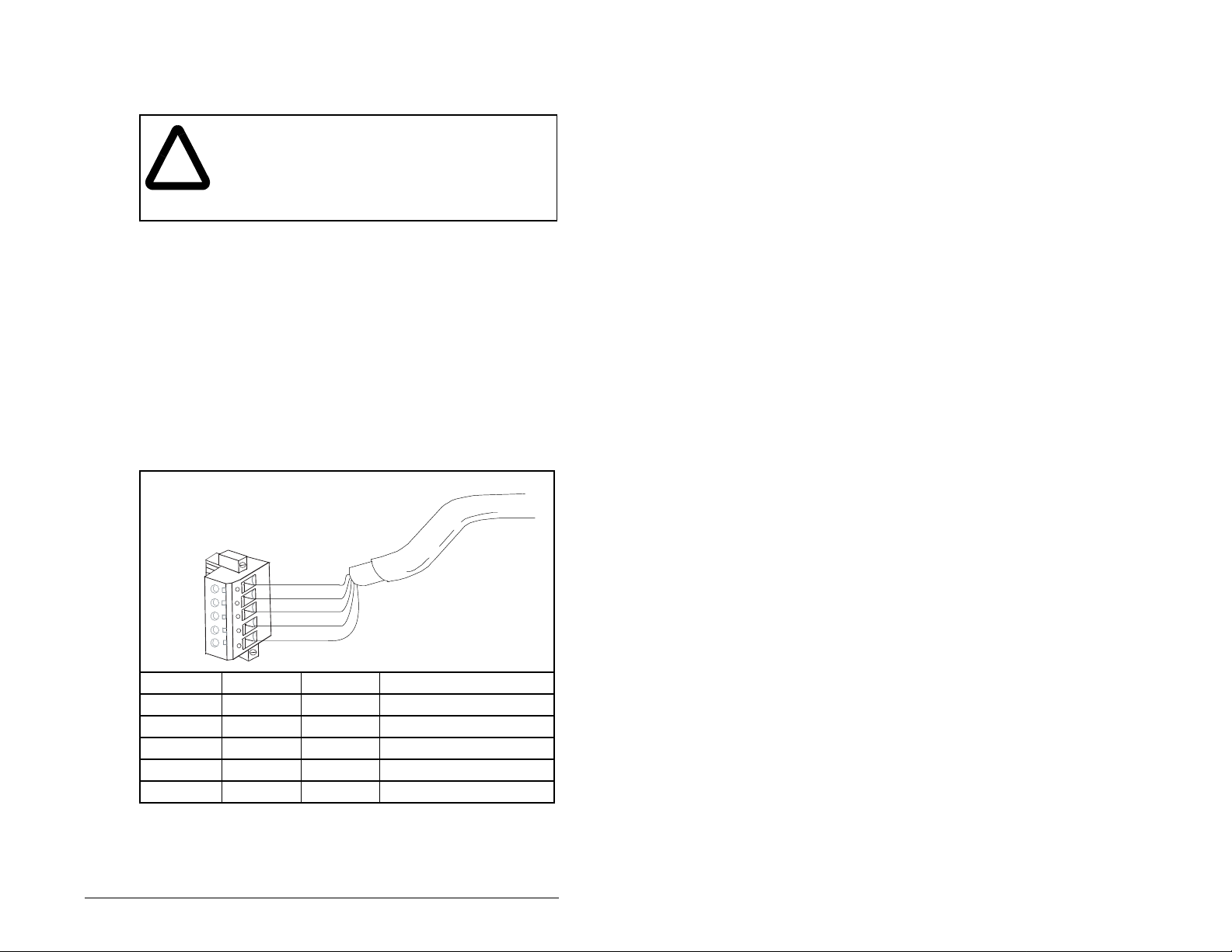

2.1 DeviceNet Adapter Components

1

2

4

2

3

Status Indicators

➀

DPI Connector A 20-pin, single-row shrouded male

➁

DeviceNet Connec tor A 5- pi n co nne ctor to which a 5-pin lin ear

➂

Node Address Switches Switches for setting the node address.

➃

Data Rate Switch

➄

Figure 2.1 – Components of the DeviceNet Adapter

Getting Started

Three LEDs that indicate the status of the

connected drive, adapter, and network.

Refer to Chapter 8, Troubleshooting.

header. An Internal Interface cable is

connected to this connector and a

connector on the drive. See table 2.2.

plug can be connected.

Switch for setting the DeviceNet data rate

at which the adapter communicates.

5

2-1

Page 16

2.2 Required Equipment

Table 2.2 lists the equipment shipped with the DeviceNet adapter.

When you unpack the adapter, verify that the package includes all

of these it ems.

Table 2.2 – Equipment Shipped with the DeviceNet Adapter

Item Description

DeviceNet adapter

2.54 cm (1 in) and 15.24 cm (6 in) Internal Interface cables

(Only one cable is needed to connect the adapter to the drive)

Five-pin linear DeviceNet plug (connected to the DeviceNet

connector on the adapter)

Grounding wrist strap

DeviceNet Adapter User Manual (D23478)

Table 2.3 lists user-supplied equipment also required to install and

configure the DeviceNet adapter.

Table 2.3 – Required User-Supplied Equipment

Item Description

A small flathead screwdriver

DeviceNet cable

• Thin cable with an outside diameter of 6.9 mm (0.27 in.) is

recommended

Configuration tool, such as:

•LCD OIM

• VS Utilities

• RSNetWorx for DeviceNet

• Serial Converter

Computer with a DeviceNet communications adapter installed

(such as 1784-PCD, 1784-PCID, 1784-PCIDS, or 177-KFD)

Controller configuration software (examples: RSLogix5,

RSLogix500, or RSLogix 5000)

2-2

DeviceNet Adapter for use with DPI AC Drives

Page 17

2.3 Installation Checklist

This section is designed to help experienced users start using the

DeviceNet adapter. If you are unsure how to complete a step, refer

to the referenced chapter.

Step Action Refer to

✔

1

❒

❒

❒

❒

❒

❒

Review the safety precautions for the

adapter.

2

Verify that the SP600 drive is properly

installed.

3

Commission the adapter.

Set a unique node address and the

appropriate data rate using the swit che s o n

the adapter. If desired, you can disable the

switches and use parameter settings

instead.

4

Install the adapter.

Verify that the SP600 drive and DeviceNet

network are not powered. Then, connect

the adapter to the network using a

DeviceNet cable and to the drive using the

Internal Interface cable. Use the captive

screws to secure and ground the ada pter to

the drive.

5

Apply power to the adapter.

The adapter receives power from the drive

and network. Apply power to the network

and to the drive. The status indicators

should be gre en. If they fla sh re d, there is a

problem. Refer to Chapter 8,

Troubleshooting.

6

Configure the adapter for your

application.

Set the parameters for the following

features as required by your application:

• Node address and data rate (if the Data

Rate switch is set to “PGM”).

• I/O configuration.

• Change of State, Cyclic, or polled I/O

data exchange.

• Master-slave or peer-to-peer hierarchy.

• Fault actions.

Throughout

this manual

SP600 AC

Drive User

Manual

Chapter 3,

Installing

the

DeviceNet

Adapter

Chapter 3,

Installing

the

DeviceNet

Adapter

Chapter 3,

Installing

the

DeviceNet

Adapter

Chapter 4,

Configuring

the

DeviceNet

Adapter

Getting Started

2-3

Page 18

Step Action Refer to

✔

7

❒

❒

❒

Apply power to the DeviceNet master

and other devices on the network.

Verify that the master and network are

installed and functi oning in accordanc e with

DeviceNet st andards, a nd then apply p ower

to them.

8

Configure the scanner to communicate

with the adapter.

Use a network tool such as RSNetWorx for

DeviceNet to configure the scanner on the

network. Make sure to:

• Set up the scan list.

• Map the adapter data to the scan list.

• Save your DeviceNet configu ra tion to the

scanner and a file.

9

Create a ladder logic program.

Use a programming tool such as RSLogix

to create a ladder logic program that

enables you to do the following:

• Control the adapter and connected drive.

• Monitor or configure the drive using

Explicit Messages.

Device N et

Cable

System

Planning

and

Installation

Manual

Chapter 5,

Configuring

the Scanner

Chapter 6,

Using I/O

Messaging

Chapter 7,

Using

Explicit

Messaging

2-4

DeviceNet Adapter for use with DPI AC Drives

Page 19

C

HAPTER

Installing the

DeviceNet Adapter

Chapter 3 provides instructions for installing the DeviceNet adapter

in an SP600 drive.

3.1 Preparing for an Installation

Before installing the DeviceNet ada pter:

• Read the

DN-2.5, and the

Installation Manual

provide information on selecting cables, setting up a network, and

network basics.

• Verify that you have all required equipment. R efer to chapter 2,

Getting Started.

3.2 Commissioning the DeviceNet

Adapter

DeviceNet Product O verview Manual

DeviceNet Cable System Planning and

, Publication DN-6.7.2. These manuals will

, Publication

3

To commission the adapter, you must set a unique node address

and the data rate that is used b y the net work. (Ref er to the Glossary

for details about data rates and node addresses.)

Important:

Step 1. Set the node address switches as shown in figure 3.1.

Installing the DeviceNet Adapter

New settings are recognized o nly when po wer is appli ed

to the adapter. If you change a setting, cycle power.

ATTENTION:

ESD- (Electrostatic Discharge) sensitive parts that

!

can be damaged if you do not follow ESD control

procedures. Static con trol p recaut ions are r equired

when handling the ada pter. F ailure to obs erve these

precautions could result in damage to equipment.

The DeviceNet adapter contains

3-1

Page 20

1

0

9

2

8

Tens

Digit

3

7

2

3

4

1

0

5

6

4

9

5

6

7

8

Ones

Digit

Setting Description

0-63 Node address used by the adapter if switches are

enabled. The default switch setting is 63. Node

address 63 is also the default address used by all

uncommissioned devices. Do not use this address

as the final adapter addr ess.

Important:

If the Data Rate switch is set to “PGM”

(Program), the adapter will use the setting of DN

Addr Cfg (3) for the node address. The default

parameter setting is 63. Refer to chapter 4,

Configuring the Devic eNet Adap ter.

64-99 Do not use. The adapter does not recognize these

addresses.

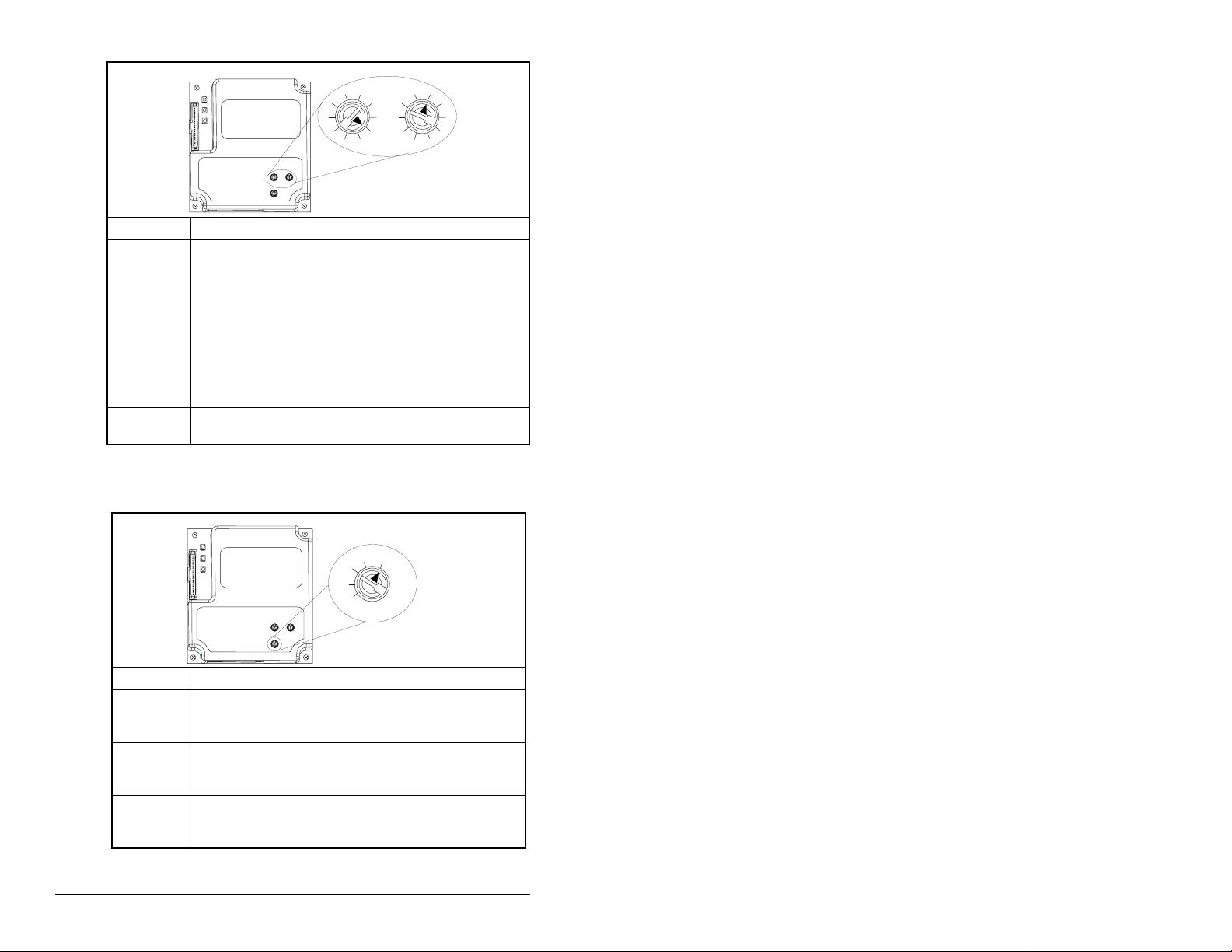

Figure 3.1 – Setting the Node Address

Step 2. Set the data rate switch as shown in figure 3.2

3-2

500K

250K

125K

PGM

AUTO

Setting Description

Auto The adapter is set to the data rate used by other

network devices. Another device on the network

must be set to a data rate.

125 K

The adapter is set to the respective data rate.

250 K

500 K

PGM The adapter uses the setting of DN Rate Cfg (5) for

the data rate. Refer to chapter 4, Conf iguring the

DeviceNet Adapter.

Figure 3.2 – Setting the Data Rate

DeviceNet Adapter for use with DPI AC Drives

Page 21

3.3 Connecting the Adapter to the

Network

ATTENTION:

that can cause injury or death. Remove all power

!

Step 1. Remove power from the network and drive.

Step 2. Use static control precautions.

Step 3. Connect a DeviceNet cable to the network, and route it

Important:

Step 4. Connect a 5-pin linear plug to the DeviceNet cable. Refer

from the drive, and then verify power has been

removed before installing or removing a DeviceNet

adapter. F ailure to observe thes e precautio ns could

result in severe bodily injury or loss of life.

through the bottom of the SP600 drive. DeviceNet thin

cable with an outside diameter of 6.9 mm (0.27 in.) is

recommended. (See figure 3.5.)

Maximum cable length depends on data rate. Refer to

data rate

to figure 3.3.

Note that a 10-pin linear plug is not supported. Use the

5-pin linear plug shipped with the adapter.

5

4

3

2

1

The drive may contain high voltages

in the Glossary.

Red

White

Bare

Blue

Black

Terminal Color Signal Function

5 Red V+ Power Supply

4 White CAN_H Signal High

3 Bare SHIELD Shield

2 Blue CAN_L Signal Low

1BlackV– Common

Figure 3.3 – Connecting a 5-Pin Linear Plug to the Cable

Step 5. Connect the DeviceNet cable to the adapter and secure it

with the two screws (see figure 3.4).

Installing the DeviceNet Adapter

3-3

Page 22

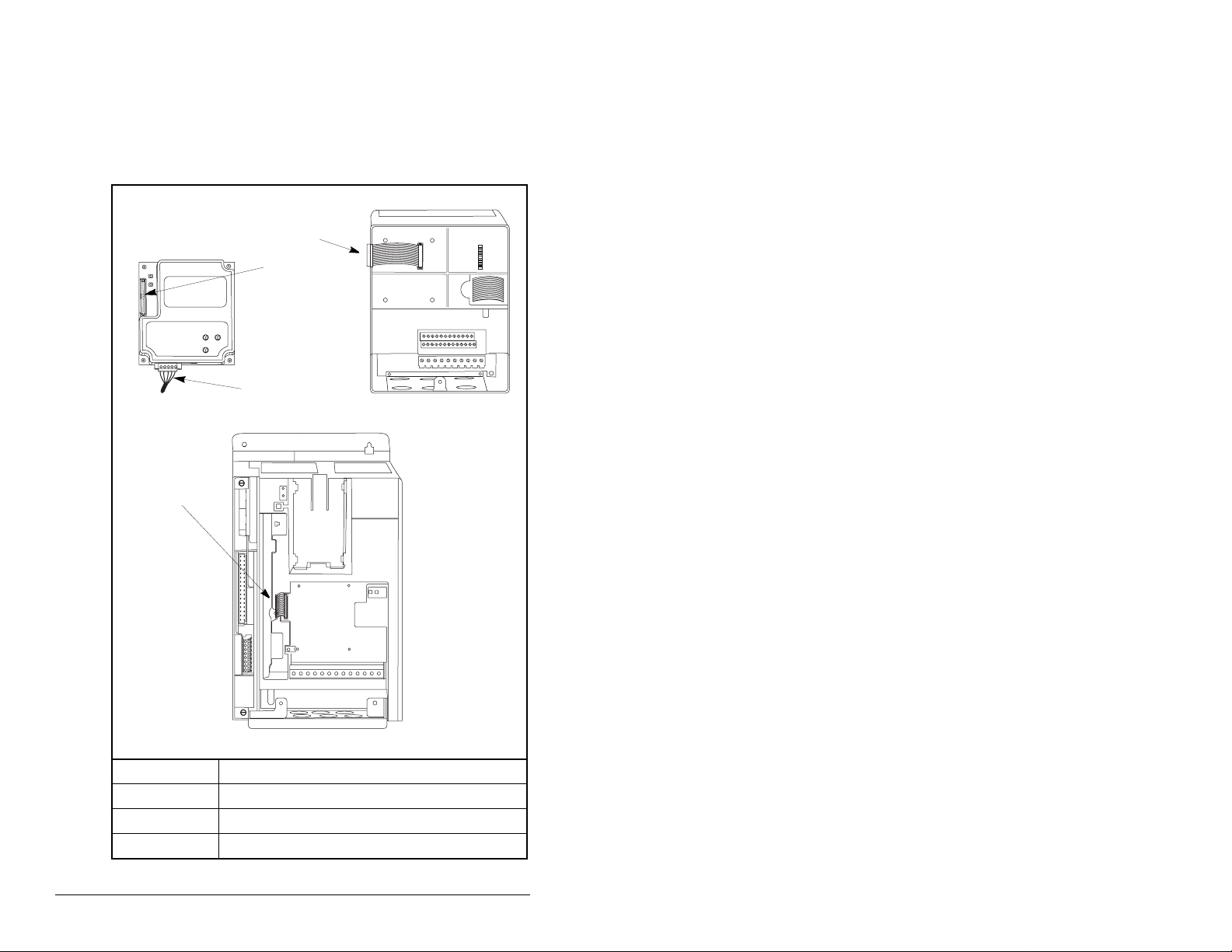

3.4 Connecting the Adapter to the Drive

Step 1. Remove power from the drive and network.

Step 2. Use static control precautions.

Step 3. Connect the Internal Interface cable to the DPI port on the

drive and then to the DPI connector on the adapter.

➀

➁

➂

DeviceNet Adapter

➃

SP600 AC Drive

25-40 HP @ 460 V

➀

➁

➂

➃

Figure 3.4 – DPI Ports and Internal Interface Cables

15.24 cm (6 in.) Internal Interface cable

DPI Connector

DeviceNet cable

2.54 cm (1 in.) Internal Interface cable

SP600 AC Drive

1-20 HP @ 460 V

3-4

DeviceNet Adapter for use with DPI AC Drives

Page 23

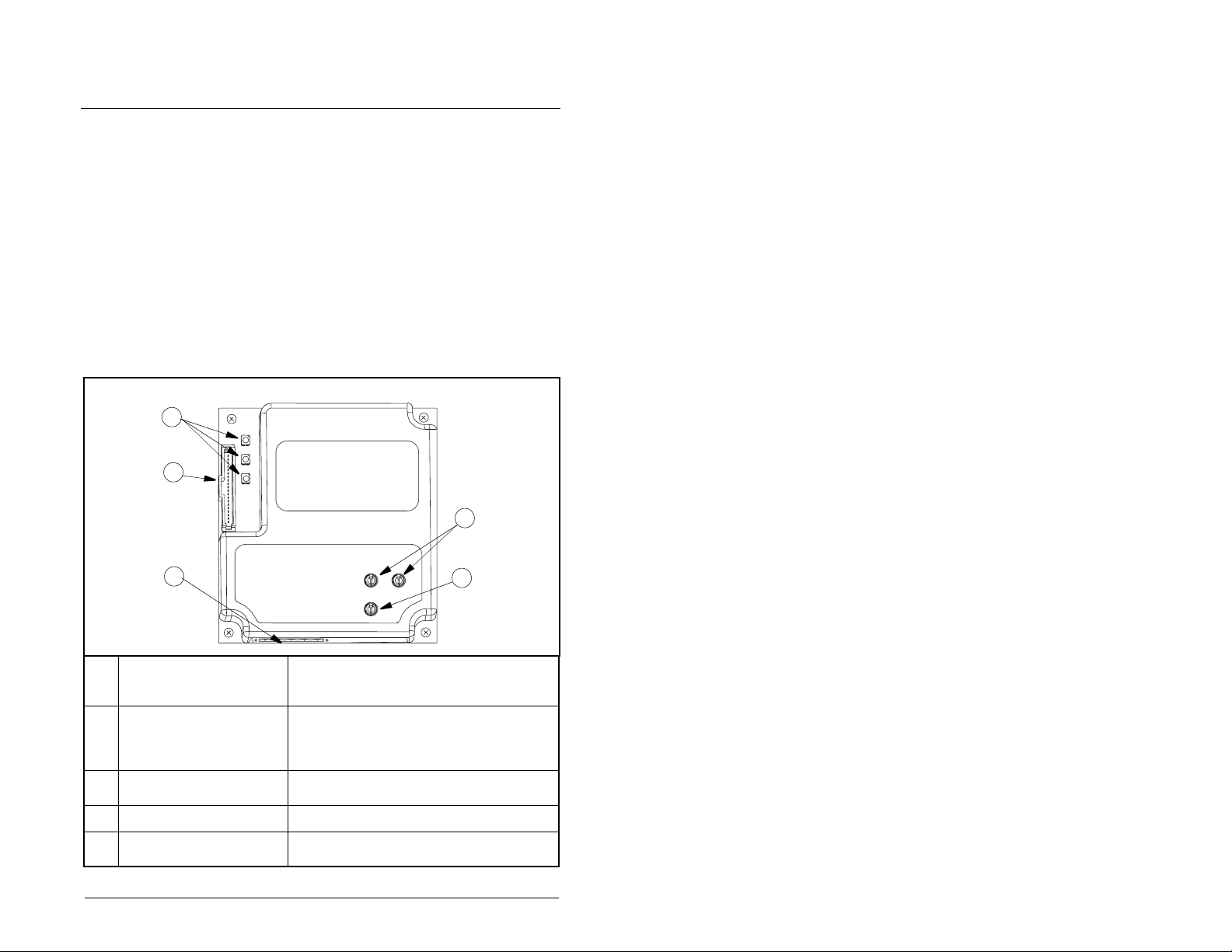

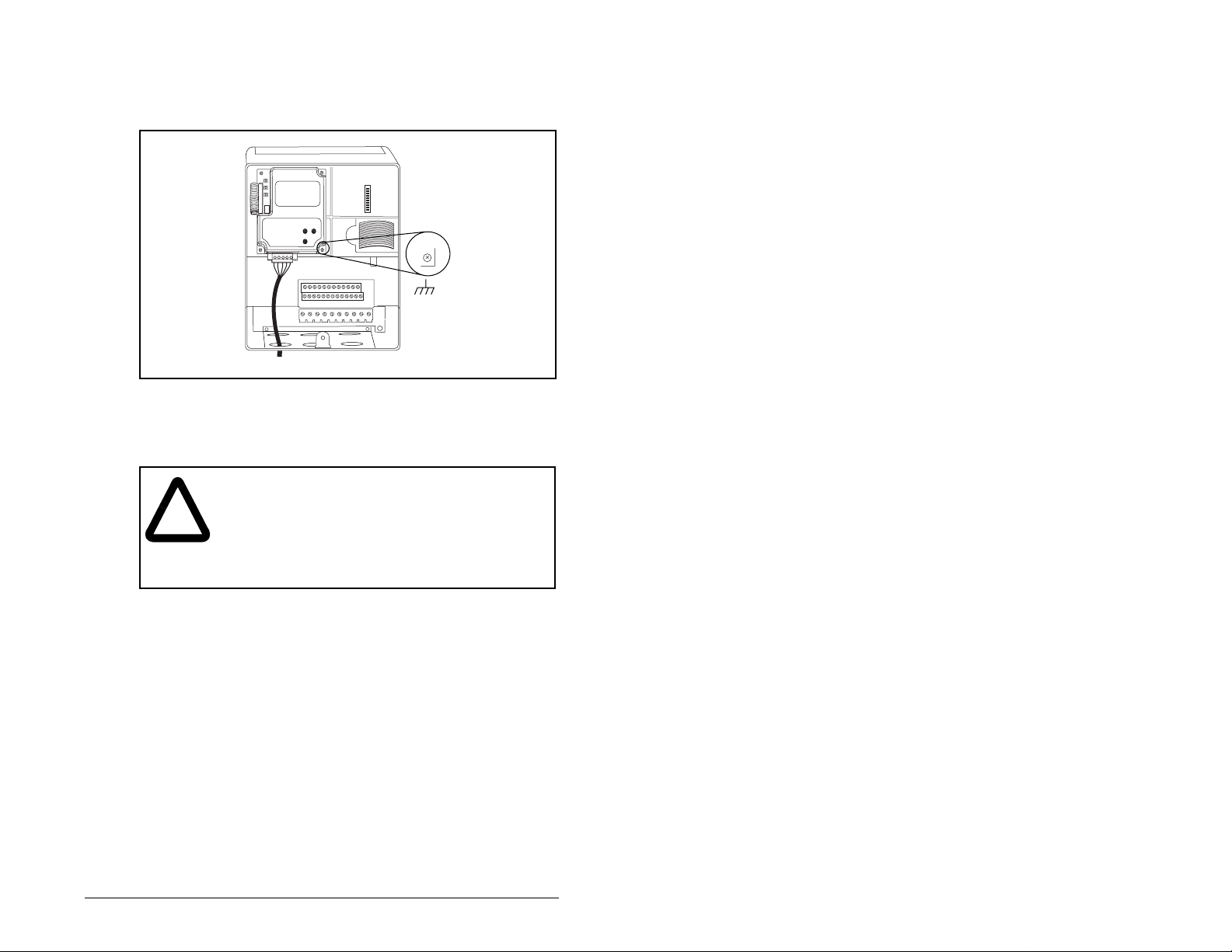

Step 4. Mount the adapter on the drive, using the four captive

Important:

screws to secure it in place and ground it to the drive.

On an SP600 drive, tighten the screw in the lower right

hole to ground the adapter.

SP600 AC Drive

Figure 3.5 – Mounting and Grounding the DeviceNet Adapter

3.5 Applying Power

ATTENTION:

you fail to verify th at par ameter s etting s and s wi tch

!

Step 1. Close the door or reinstall the cover on the drive. The

Step 2. Ensure that the adapter will have a unique address on the

Step 3. Apply power to the network.

Step 4. Apply power to the drive. The adapter receives its power

Installing the DeviceNet Adapter

settings are compa tible with y our applica tion. V erify

that settings are compatible with your application

before applying power to the drive. Failure to

observe these precautions could result in severe

bodily injury or loss of life.

status indicators can be viewed on the front of the drive

after power has been applied .

network and is set at the correct da ta rate or to autoba ud. If

a new data rate or address is needed, reset its switches

(refer to section 3.2).

from the connected drive and network. When you apply

power to the product and network for the first time, the

status indicators should be green after an initialization. If

the status indicators are red, there is a problem. Refer to

chapter 8, Troubleshooting the DeviceNet Adapter and

Network.

Unpredictable ope ration ma y occur if

3-5

Page 24

Step 5. If the data rate switch is set to “PGM,” use a configuration

Step 6. Apply power to the master device (scanner) and other

tool to set the data rate and node address parameters in

the adapter (see chapter 4, Configuring the DeviceNet

Adapter). If you are using RSNetWorx for DeviceNet, you

need to create a point-to-point connection to the drive.

devices on the networ k.

3-6

DeviceNet Adapter for use with DPI AC Drives

Page 25

C

Configuring the

DeviceNet Adapter

Chapter 4 provides instructions and information for setting the

parameters in the DeviceNet adapter.

For a list of parameters, refer to Appendix B, DeviceNet Adapter

Parameters. For definitions of terms in this chapter, refer to the

Glossary.

4.1 Configuration Tools

The DeviceNet adapter stores parameters and other information in

its own non-volatile memory. Therefore, you must access the

adapter to view and edit its parameters. Table 4.1 lists the tools that

can be used to access the adapter parameters.

Table 4.1 – Configuration Tools

Tool Refer To:

VS Utilities Software VS Utilities online help

LCD OIM Section 4.2

RSNetWorx for DeviceNet Section 4.3

HAPTER

4

RSNetWorx for DeviceNet (version 2.22.18) and RSLinx (version

2.10.118) were u sed for exam pl es in this manual. Different v e rsio ns

of software may differ in appearance and procedures.

Note that explicit messaging can also be used to configure a

DeviceNet adapter and drive. Refer to Chapter 7, Using Explicit

Messaging.

Configuring the DeviceNet Adapter

4-1

Page 26

4.2 Using the LCD OIM to Configure the

Adapter

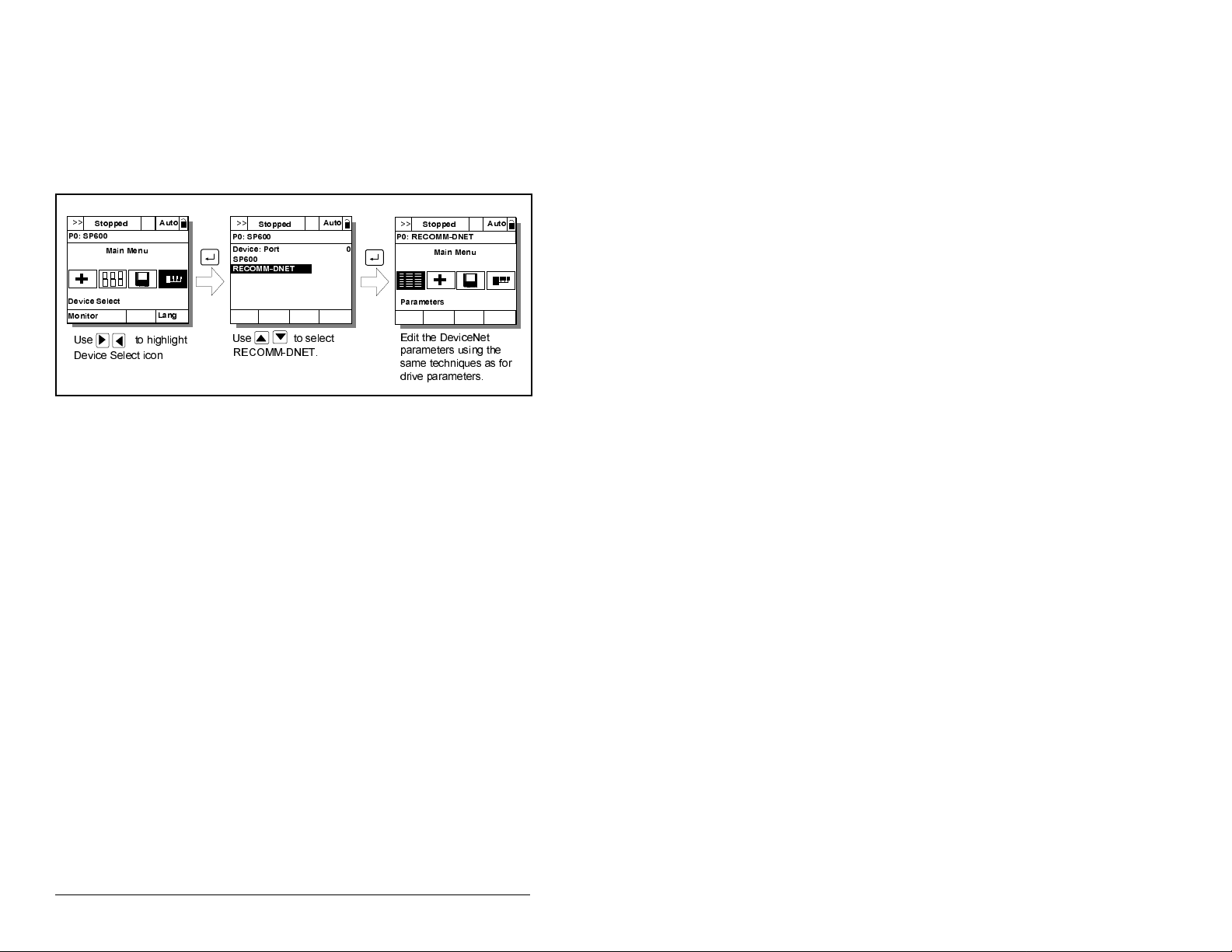

Use the procedure in figure 4.1 to access the parameters on the

DeviceNet adapter using the LCD OIM. If you are unfamiliar with

the operation of the LCD OIM, refer to the SP600 AC Drive User

Manual (D2-3485) f or mo re information.

!!

6WRSSHG

3 63

0DLQ 0HQX

'HYLFH 6HOHFW

0RQLWRU

8VH WR KLJKOLJKW

'HYLFH 6HOHFW LFRQ

$XWR

/DQJ

!!

6WRSSHG

3 63

'HYLFH 3RUW

63

5(&200'1(7

8VH WR VHOHFW

5(&200'1(7

$XWR

!!

6WRSSHG

3 5(&200'1(7

0DLQ 0HQX

3DUDPHWHUV

(GLW WKH 'HYLFH1HW

SDUDPHWHUV XVLQJ WKH

VDPH WHFKQLTXHV DV IRU

GULYH SDUDPHWHUV

Figure 4.1 – Accessing the DeviceNet Parameters using the LCD OIM

4.3 Using RSNetWorx for DeviceNet

RSNetWorx for DeviceNet is a Rockwell Software application that

can be used t o set up DeviceNet net wo rks and confi gure c onnec ted

devices.

4.3.1 Setting Up RSLinx for RSNetWorx for

DeviceNet

To use RSNetWorx for DeviceNet, you must first set up a driver in

RSLinx. The driver provides a communications link between the

computer and DeviceNet network. See table 4.2 and figure 4.2 for

this procedure.

$XWR

4-2

DeviceNet Adapter for use with DPI AC Drives

Page 27

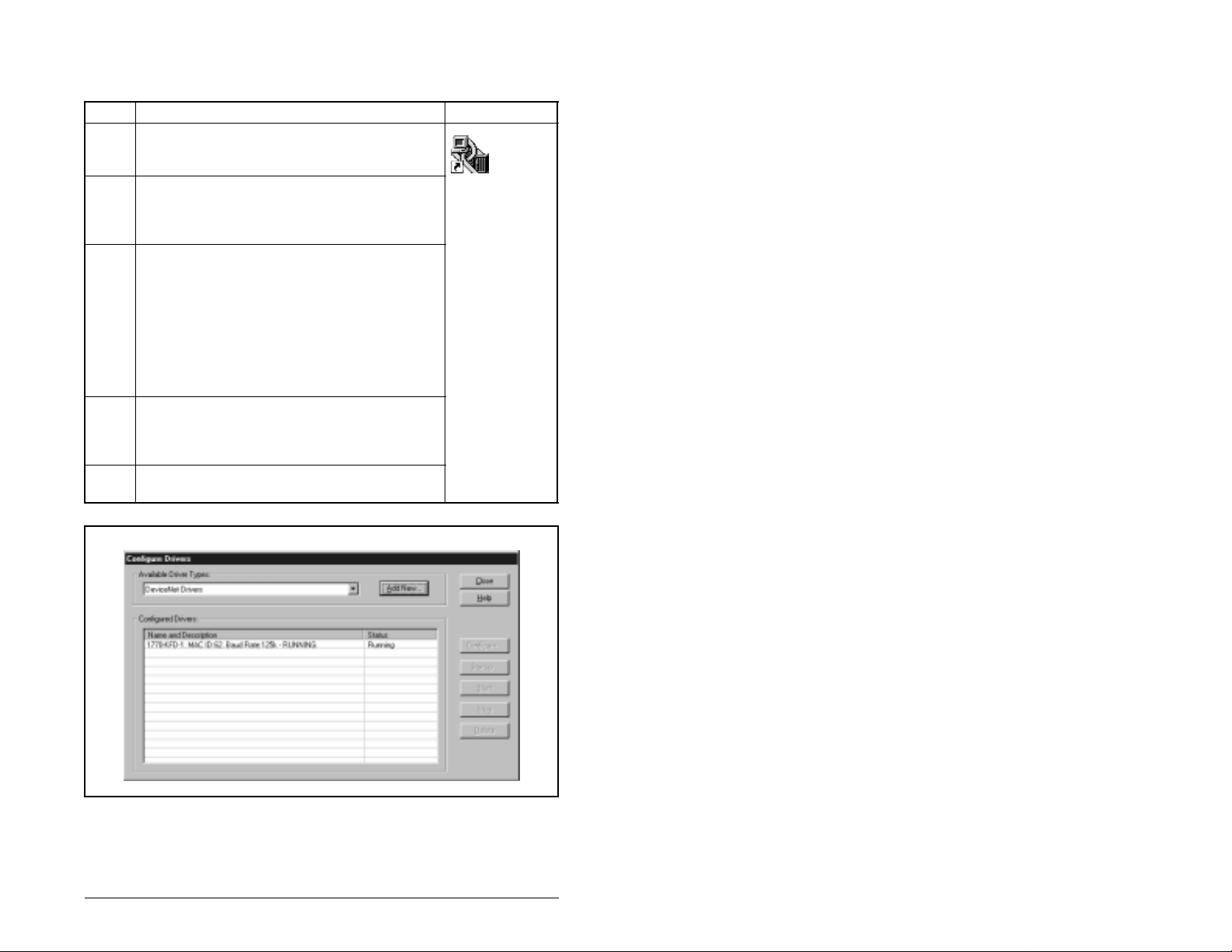

Table 4.2 – Procedure for Setting Up RSLinx for RSNetworx for DeviceNet

Step Action Icon

1. Start RSLinx, and select

Configure Drivers

Drivers dialog box. See figure 4.2.

Communications >

to display the Configure

Shortcut to

RSLinx

2. In the Available Dr iver Types box, select

DeviceNet Drivers

, and then click

Add New

.

The DeviceNet Driver Selection dialog box

appears.

3. In the Available DeviceNet Drivers list, select

the adapter connected to your computer, and

then click

. A Driver Confi guration dialog

Select

box appears.

Configure the driver for your computer and

network settings, and then click OK. The

Configure Drivers dialog box reports the

progress of the configuration. Then, the Add

New RSLinx Driver dialog box appears.

4. Type a name (if desired), and then click OK.

The Configure Drivers dialog box reappears,

and the new driver is in the Confi gu r ed Driv ers

List.

5. Click

to close the dialog box. Leave

Close

RSLinx running.

Figure 4.2 – Configure Drivers Dialog Box with a Configured Driver

Configuring the DeviceNet Adapter

4-3

Page 28

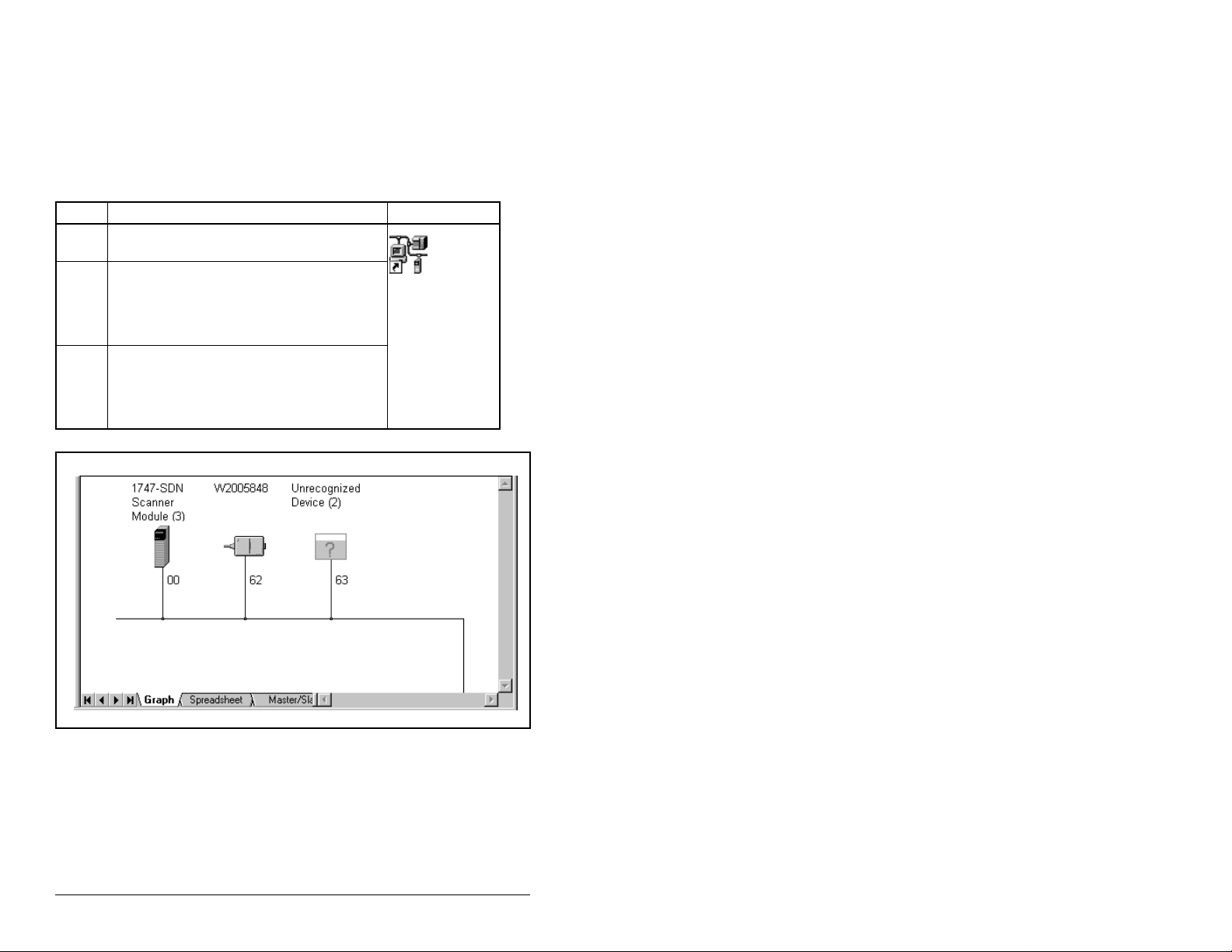

4.3.2 Going Online with RSNetWorx for DeviceNet

You can view the devices on a De viceNet netw ork by going onlin e. A

device may appear as an unrecognized device (node 63 in figure

4.3) if RSNetWorx for DeviceNet does not have an Electronic Data

Sheet (EDS) file for it. See table 4.3 for the procedure to view

devices.

Table 4.3 – Viewing Devices on the DeviceNet Network using RSNetWorx

Step Action Icon

1. After setting up a driver in RSLinx, start

RSNetWorx for DeviceNet.

2. Select

3. Click OK to go online. The devices on the

Network > Online

for Network dialog box appears, RSLinx

has multiple drivers configured. Select

your DeviceNet network, and click OK. A

prompt appears.

network appear in the Configuration View.

You can select Graph, Spreadsheet, or

Master/Slave views. Figure 4.3 shows a

sample network in a Graph view.

. If the Browse

Shortcut to

RSNetWorx

4-4

Figure 4.3 – Sample DeviceNet Network (Graph View)

DeviceNet Adapter for use with DPI AC Drives

Page 29

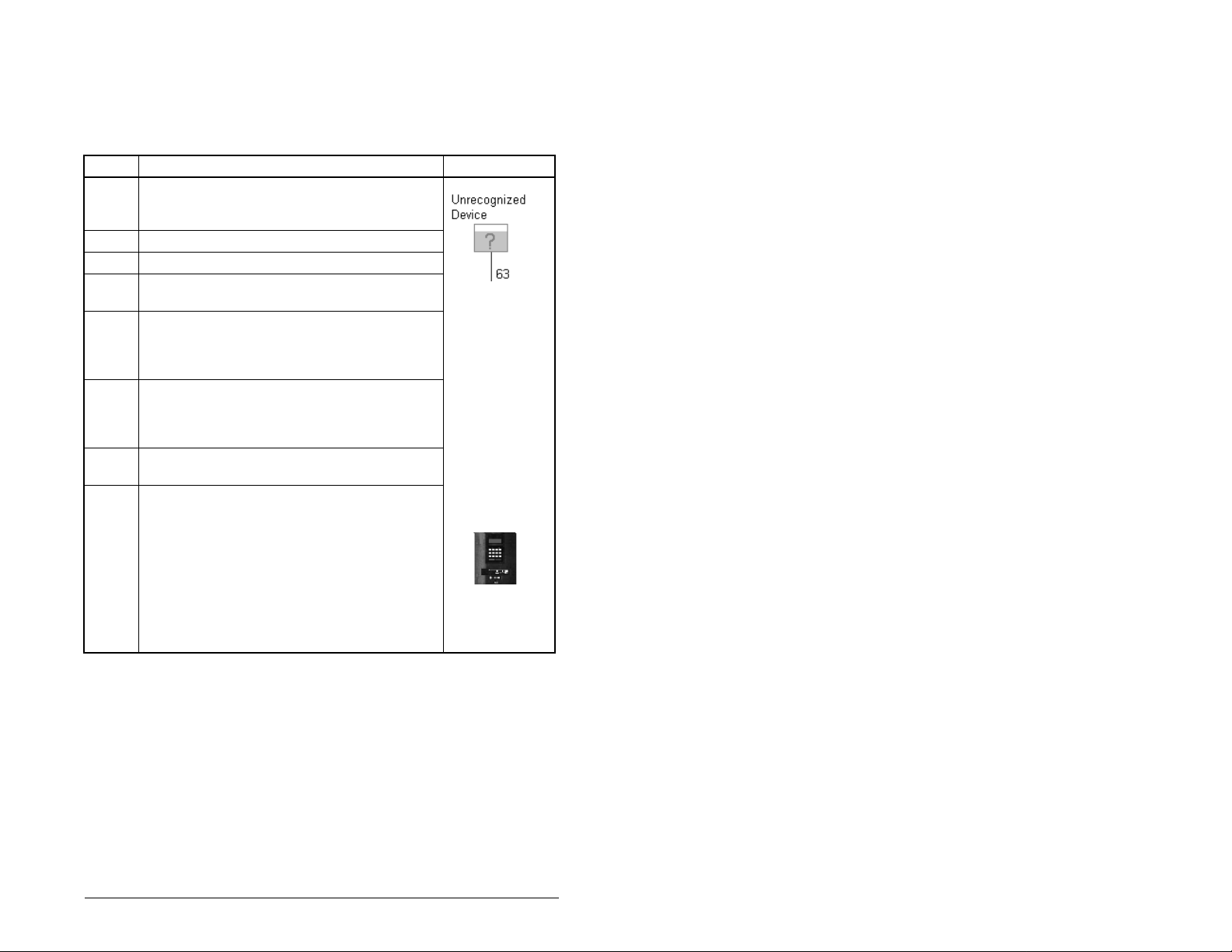

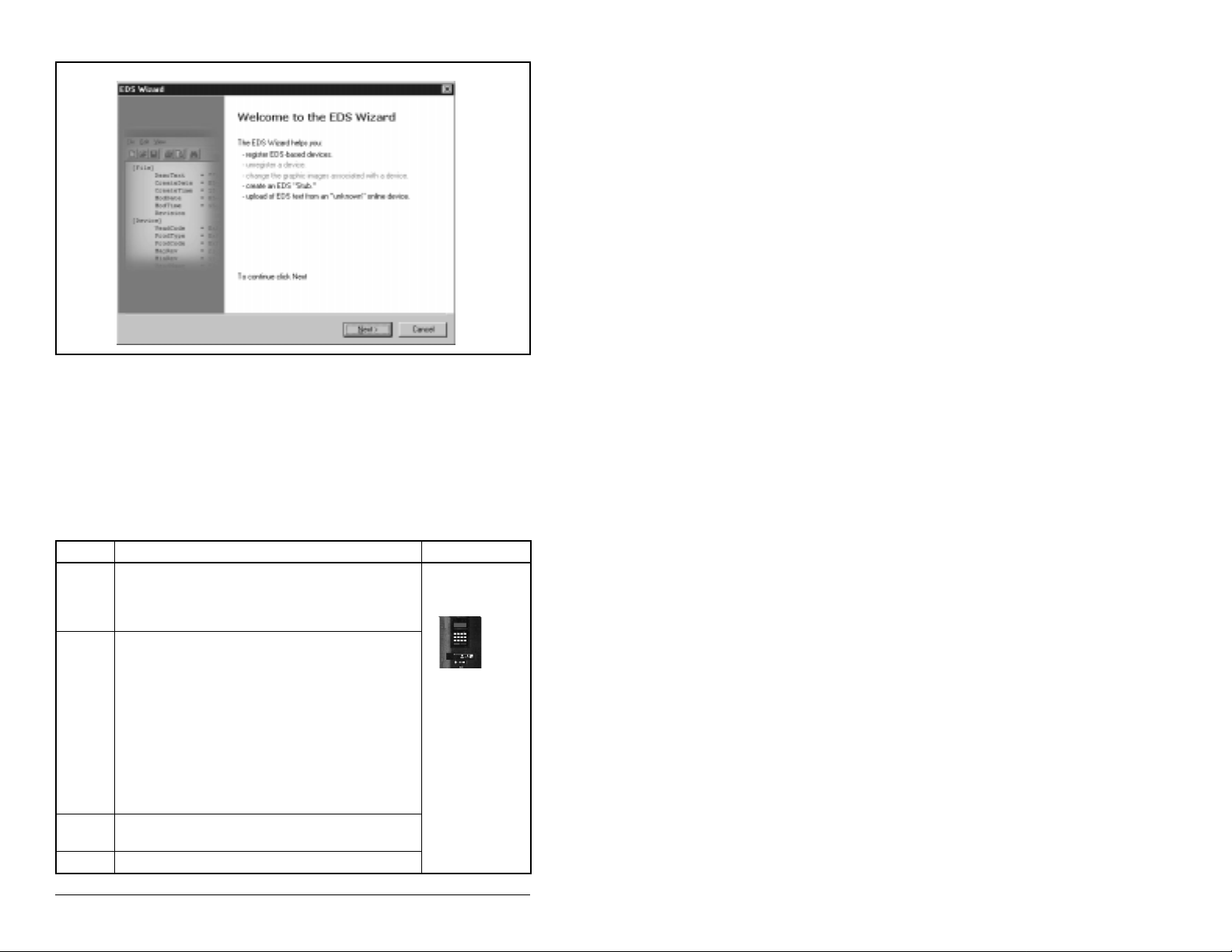

4.3.3 Creating an Electronic Data Sheet (EDS) File

If the adapter and drive appear as an unrecognized device, create

an EDS file for it using the procedure in table 4.4.

Table 4.4 – Procedure for Creating an EDS File

Step Action Icon

1. Right-click the “Unrecognized Device” icon ,

and select

EDS Wizard (figure 4.4) appears.

2. Click

3. Select

4. Type a description (if desired), and then click

Next

5. Under Polled, select

Input Size and Output Size boxes, and then

click

from the drive and adapter.

6. Click

node. We recommend that you use the icon f or

your product. You can change icons by clic king

Change icon

7. Click

Next

8. Click

icon represents the SP600 drive and adapter

in the Configuration View.

Important:

(versions 2.22.18 and earlier) replaces 32-bit

values with exponential values. For the EDS

file to work in RSNetWorx, you must edit the

EDS file, replacing exponential values with

32-bit val ues (typic ally 42 949 67295 ), and then

restart RSNetWorx.

Register Device

to display the next step.

Next

Upload EDS

.

. RSNetWorx will upload the EDS fil e

Next

to display the icon options for the

Next

to view a summary, and then click

Next

again to accept it.

to finish the EDS creation. A new

Finish

RSNetWorx for DeviceNet

, and then click

.

in the menu. The

Enabled

, type 4 in the

Next

.

SP600

AC Drive

Configuring the DeviceNet Adapter

4-5

Page 30

Figure 4.4 – EDS Wizard Screen

4.3.4 Accessing and Editing Parameters

Parame ters i n th e d rive and adapter can be edited with RSNetWorx

using the procedure in table 4.5. The adapter parameters are

appended to the list of drive parameters. In figure 4.5, for example,

the drive has 387 parameters, so parameter 388 is the first adapter

parameter.

Table 4.5 – Procedure to Access and Edit Parameters Using RSNetWorx

Step Action Icon

1. After creating an EDS file, right-click on the

2. Click the

3. In the Current Value column, double-click a

4. Click

icon for the SP600 drive and adapter and

select

Properties

appears.

Device Parameters

If an EDS Editor message appears, click

to load the parameter values in the

Upload

drive to the computer.

Parameters are displayed in numerical order

under Par amet er. You can either scroll through

the list or select a specif ic group of paramete rs

in the Groups box. The available groups and

the numbers of the adapter parameters will

vary based on the type of drive that is

connected to the adapter.

value to edit it.

Apply

. The SP600 Drive dialog bo x

tab (figure 4.5).

to save changes to the device.

SP600

AC Drive

4-6

DeviceNet Adapter for use with DPI AC Drives

Page 31

SP600 Standard

Figure 4.5 – Sample SP600 Drive Dialog Box (Drive Parameters Tab)

4.4 Setting the Node Address

If the adapter Data Rate switch is set to “PGM,” the value of DN

Addr Cfg (3) determines the node address.

Step 1. Set the v alue of DN Add r Cfg (3) to a unique node addre ss.

See figure 4.6. Do not use node address 63 because all

new devices use it as the default address. Address 63 is

also used for Automatic Device Replacement (ADR).

Port 5 Device

RECOMM-DNET

Parameter #: 3

DN Addr Cfg

63

Figure 4.6 – DeviceNet Node Address Screen on an LCD OIM

Step 2. Reset the adapter. Refer to sec tion 4.10, Resetting the

Adapter, for this procedure.

If you are using RSNetW orx f or De viceN et, select

Browse Path

Configuring the DeviceNet Adapter

to see the new address; then delete the old address.

Default = 63

0 <> 63

Network > Single

4-7

Page 32

4.5 Setting the Data Rate

If the adapter Data Rate switch is set to “PGM,” the value of

DN Rate Cfg (05) determines the DeviceNet data rate. See figure

4.7. The Autobaud setting will detect the data rate used on the

network if another device is setting the data rate. Your application

may require a different setting.

Step 1. Set the value of DN Rate Cfg (05 ) to t he data rate at which

your network is operating.

Port 5 Device

RECOMM-DNET

Parameter #: 5

DN Rate Cfg

3

Autobaud

Figure 4.7 – DeviceNet Data Rate Screen on an LCD OIM

Value Baud Rate

0 125 kbps

1 250 kbps

2 500 kbps

3 Autobaud (Default)

Step 2. Reset the adapter. Refer to section 4.10 for this procedure.

4.6 Setting the I/O Configuration

The I/O configuration determines the type of data sent to the drive.

Logic Command/Status, Reference/Feedback, and Datalinks may

be enabled or disabled. A “1” enables the I/O. A “0” disables it.

Step 1. Set the bits in DPI I/O Confg (13). Bit 0 is the right-most bit.

In figure 4.8, it is highlighted and equals “1.”

Port 5 Device

RECOMM-DNET

Parameter #: 13

DPI I/O Config

xxxx xxxx xxx0 000

Cmd/Ref b00

1

Bit Description

0 Logic Command/Reference (Default)

1 Datalink A

2 Datalink B

3 Datalink C

4 Datalink D

5-15 Not Used

4-8

Figure 4.8 – I/O Configuration Screen on an LCD OIM

Step 2. Set a master-slave or peer-to-peer hierarchy. Refer to

section 4.7.

DeviceNet Adapter for use with DPI AC Drives

Page 33

Step 3. If you enabled Logic Command/Reference, configure the

parameters in the drive to accept the logic and reference

from the adapter . F or e xample , set Sp eed Ref A Sel (90 ) in

an SP600 drive to “Network” so that the drive uses the

reference from the adapter.

Step 4. If you enabled one or more Datalinks, configure

parameters in the drive to determine the source and

destination of data in the Datalink(s). Also, ensure that the

DeviceNet adapter is the only adapter using the enabled

Datalink(s).

Step 5. Reset the adapter. Refer to the section 4.10 for this

procedure.

4.7 Selectin g Mas ter-Sla ve or

Peer-to-Peer

A hierarchy determines the type of device with which the adapter

exchanges data. In a

master-slave

exchanges data with a scanner. In a

adapter can exchange data with one or more DeviceNet adapter(s)

connected to SP600 drives that have similar data structures.

4.7.1 Setting a Master-Slave Hierarchy

Step 1. Enable the desired I/O in DPI I/O Config (13). Refer to

Step 2. Set the bits in M-S Input (25). This parameter determines

figure 4.8.

the data transmitted from the scanner to the drive. A “1”

enables the I/O. A “0” disables the I/O. Bit 0 is the

right-most bit. In figure 4.9, it is highlighte d and equa ls “1.”

hierarchy, an adapter

peer-to-peer

hierarchy, an

Port 5 Device

RECOMM-DNET

Parameter #: 25

M-S Input

xxxx xxxx xxx0 000

Cmd/Ref b00

Figure 4.9 – Master-Slave Input Screen on an LCD OIM

Configuring the DeviceNet Adapter

Bit Description

0 Logic Command/Reference (Default)

1 Datalink A Input

2 Datalink B Input

3 Datalink C Input

1

4 Datalink D Input

5-15 Not Used

4-9

Page 34

Step 3. Set the bits in M-S Output (26). This parameter determines

the data transmitted from the drive to the scanner. A “1”

enables the I/O. A “0” disables the I/O. Bit 0 is the

right-most bit. In figure 4.10, it is highlighted and equals

“1.”

Port 5 Device

RECOMM-DNET

Parameter #: 26

M-S Output

xxxxxxxxxxx0000

Status/Fdbk b00

Figure 4.10 – Master-Slave Output Screen on an LCD OIM

1

Bit Description

0 Status/Feedback (Default)

1 Datalink A Output

2 Datalink B Output

3 Datalink C Output

4 Datalink D Output

5-15 Not Used

Step 4. Reset the adapter. Refer to section 4.10 for this procedure.

The adapter is ready to receive I/O from the master (i.e., scanner).

You must now configure the scanner to recognize and transmit I/O

to the adapter. Refer to chapter 5, Configuring the Scanner.

4.7.2 Setting an Adapter To Transmit Peer-to-Peer

Data

Step 1. Verify that Peer Out Enable (41) is set to Off. This

parameter must be set to Off while you configure some of

the peer output parameters. See figure 4.11.

Port 5 Device

RECOMM-DNET

Parameter #: 41

Peer Out Enable

0

Off

Value Setting

0 Off (Default)

1On

4-10

Figure 4.11 – Peer Out Enable Screen on an LCD OIM

Step 2. Select the source of the data to output to the network in

Peer A Output A (39). If you are transmitting a 32-bit

Reference or 32-bit Datalink, only Peer A Output will be

available. Peer B Output cannot be used. See figure 4.12.

DeviceNet Adapter for use with DPI AC Drives

Page 35

Port 5 Device

RECOMM-DNET

Parameter #: 39

Peer A Output

1

Cmd/Ref

Figure 4.12 – Peer A Output Screen on an LCD OIM

Value Description

0 Off (Default)

1 Logic Command/Reference

2-5 Datalink A, B, C, or D

Input

6-9 Datalink A, B, C, or D

Output

Step 3. If desired, sel ec t an add itional source of the d ata to o utp ut

to the network in Peer B Output (40). See figure 4.13.

Port 5 Device

RECOMM-DNET

Parameter #: 40

Peer B Output

2

DL A Input

Figure 4.13 – Peer B Output Screen on an LCD OIM

Value Description

0 Off (Default)

1 Logic Command/Reference

2-5 Datalink A, B, C, or D

Input

6-9 Datalink A, B, C, or D

Output

Step 4. Set Peer Out Time (42) and Peer Out Skip (43) to establish

the minimum and maximum intervals between Peer

messages. The minimum interval is set in Peer Out Time

(42). The maximum interval is the value of Peer Out Time

(42) multiplied by the value of Peer Out Skip (43). See

figure 4.14.

Port 5 Device

RECOMM-DNET

Parameter #: 42

Peer Out Time

10.00 Secs.

0 <> 10.00

Port 5 Device

RECOMM-DNET

Parameter #: 43

Peer Out Skip

1

1 <>16

Figure 4.14 – Min Peer TX Time and Peer Out Skip Screens on an LCD OIM

Step 5. Set Peer Out Enable (41) to On. The adapter will transmit

the data selected in Peer A Output (39) and Peer B Output

(40) to the network. Anoth er adapter must be c onfigured to

receive the data.

Configuring the DeviceNet Adapter

4-11

Page 36

4.7.3 Setting an Adapter To Receive Peer-to-P eer Data

Step 1. Verify that Peer Inp Enable (37) is set to Off. This

parameter must be set to Off while you configure some of

the peer input parameters. See figure 4.15.

Port 5 Device

RECOMM-DNET

Parameter #: 37

Peer Inp Enable

0

Off

Figure 4.15 – Peer Input Enable Screen on an LCD OIM

Value Setting

0 Off (Default)

1On

Step 2. Select the node from which you want to receive data in

Peer Note to Inp (35). Valid nodes must have

RECOMM-DNET adapters connected to drives wit h similar

data structures. See figure 4.16.

Port 5 Device

RECOMM-DNET

Parameter #: 35

Peer Node to Inp

0

0 <>63

Figure 4.16 – Peer Node to Input Screen on an LCD OIM

Default = 0

4-12

Step 3. Select the destination of the data that is input to the drive

in Pee r A Input ( 30). If y ou are receiv ing a 32 -bit Ref erence

or 32-bit Datalink, only Peer A Input will be available. Peer

.

B Input cannot be used. See figure 4.17.

Port 5 Device

RECOMM-DNET

Parameter #: 30

Peer A Input

1

Cmd/Ref

Figure 4.17 – Peer A Input Screen on an LCD OIM

DeviceNet Adapter for use with DPI AC Drives

Value Description

0 Off (Default)

1 Logic Command/Reference

2 5 Datalink A, B, C, or D

Input

Page 37

Step 4. If desired, select the destination of the data to input to the

drive in Peer B Input (31). See figure 4.18.

Port 5 Device

RECOMM-DNET

Parameter #: 31

Peer B Input

2

DL A Input

Figure 4.18 – Peer B Input Screen on an LCD OIM

Value Description

0 Off (Default)

1 Logic Command/Reference

2 5 Datalink A, B, C, or D

Input

Step 5. If you are receiving a Logic Command, set the bits in it that

should be used in Peer Cmd Mas k (3 2). T he b it d efi nitions

for the Logic Command word will depend on the drive to

which the adapter is connected. Refer to the drive

documentation.

If the adapter receives a Logic Command from both a

master device and a peer device, each command bit must

have only one source. The source of command bits set to

“0” will be the master device. The source of command bits

set to “1” will be the peer device. See figure 4.19.

Port 5 Device

RECOMM-DNET

Parameter #: 32

Peer Cmd Mask

000000000000000

Bit 0 B00

0

Value Description

0 Ignore this command bit.

(Default)

1 Use this command bit.

Figure 4.19 – Peer Logic Command Mask Screen on an LCD OIM

Step 6. If you are receiving a Reference, set the scale in Peer Ref

Adjust (33). It can be scaled between 0.00 and 199.99%.

See figure 4.20.

ATTENTION:

(33) take effect immediately. A drive receiving its

!

Reference from peer I/O will receive the newly

scaled Reference, resulting in a change of speed.

Failure to observe this precaution could result in

bodily injury or damage to, or destruction of,

equipment.

Configuring the DeviceNet Adapter

Note that changes to Peer Ref Adjust

4-13

Page 38

Port 5 Device

RECOMM-DNET

Parameter #: 33

Peer Ref Adjust

0.00 %

0.00 <> 199.99

Figure 4.20 – Peer Reference Adjust Screen on an LCD OIM

Default = 0.00%

Step 7. Set Peer Inp Timeout (36) to the maximum amount of time

the adapter will wait for a message before timing out. See

figure 4.21.

Important:

This value mu st be gr eater tha n the produc t of Peer Out

Time (42) multiplied by Peer Out Skip (43) in the

adapter from which you are receiving I/O.

Port 5 Device

RECOMM-DNET

Parameter #: 36

Min Peer Rx Time

10.00 Secs.

0.01 <> 180.00

Figure 4.21 – Minimum Peer Receiving Time Screen on an LCD OIM

Default = 10.00 Secs

Step 8. Peer Flt Action (34) specifies the action that the adapter

will take if it times out. See figure 4.22. For details, refer to

section 4.9.

ATTENTION:

Peer Flt Action (34) lets you det ermine

the action of the adapter and connected drive if

!

communications are disrupted. By default, this

parameter faults the drive. You can set this

parameter so that the drive continues to run.

Precautions should be taken to ensure that the

setting of this parameter does not create a hazard

of injury or equipment damage. Failure to observe

these precautions could result in bodily injury or

damage to equipment.

4-14

DeviceNet Adapter for use with DPI AC Drives

Page 39

Port 5 Device

RECOMM-DNET

Parameter #: 34

Peer Flt Action

0

Fault

Figure 4.22 – Peer Fault Action Screen on an LCD OIM

Value Description

0 Fault (Default)

1Stop

2 Zero Data

3 Hold Last

4 Send Flt Cfg

Step 9. Set Peer Inp Enable (37) to On. The adapter is now

configured to receive I/O from the specified node. Ensure

that the specified node is configured to transmit I/O.

4.8 Selecting COS, Cyclic, or Polled I/O

The data exc hange (someti mes calle d allocati on) is the me thod that

the adapter uses to exchange data on the DeviceNet network. The

adapter can be configured to use one of the following data

exchanges:

• COS (change of state)

• Polled and COS

•Cyclic

• Polled and cyclic

•Polled

If “polled and COS” or “polled and cyclic” is used, the adapter

receives the I/O from the polled messages. It transmits its Logic

Status and Feedback in COS or cyclic messages. Other data is

transmitted in polled messages.

Cyclic and polled dat a exchanges are co nfi gure d in th e sc anner, so

you only need to set the I/O configuration in the adapter. COS data

exchange must be configured in both the adapter and the scanner.

You need to set the I/O configuration and COS parameters in the

adapter.

4.8.1 Using COS (Change of State) Data Exchange

Step 1. Set bit 0 (the Logic Command/Reference bit) in DPI I/O

Config ( 13) to 1 (En abled) and bit 0 (the Logic

Status/Feedback bit) in M-S Output (26) to 1 (Enabled).

Changes to bits in the Logic Status or Feedback trigger

messages in COS data exchange. See figure 4.23.

Configuring the DeviceNet Adapter

4-15

Page 40

Port 5 Device

RECOMM-DNET

Parameter #: 13

DPI I/O Config

xxxx xxxx xxx0 000

Cmd/Ref b00

Figure 4.23 – I/O Configuration Screens on an LCD OIM

1

Port 5 Device

RECOMM-DNET

Parameter #: 26

M-S Output

xxxx xxxx xxx0 000

Status/Fdbk b00

1

Step 2. Set the bits in the Logic Status word that should be

checked for changes in COS Status Mask (27). See figure

4.24. The bit definitions f or the Status Ma sk will depend on

the drive to which you are connected. Refer to the drive

documentation.

Port 5 Device

RECOMM-DNET

Parameter #: 27

COS Status Mask

000000000000000

Bit 0 b00

Figure 4.24 – COS Status Mask Configuration Screen on an LCD OIM

1

Value Description

0 Ignore this logic bit. (Default)

1 Check this logic bit.

Step 3. Set the amount of change to the F e edbac k that is requ ired

to trigger a Change of state message in COS Fdbk

.

Change (28). See figure 4.25.

Port 5 Device

RECOMM-DNET

Parameter #: 28

COS Fdbk Change

0

0 <> 4294967295

4-16

Figure 4.25 – COS Fdbk Change Configuration Screen on an LCD OIM

The adapter is now configured for COS data exchange. You must

configure the scanner to allocate it using COS (see chapter 5,

Configuring the Scanner).

DeviceNet Adapter for use with DPI AC Drives

Page 41

4.9 Settin g a Fault Action

By default, when communications are disrupted (for example, a

cable is disconnected) or the scanner is idle, the drive responds by

faulting if it is using I/O from the network.

You can configure a different response to communication

disruptions using Comm Flt Action (10) and a different response to

an idle scanner using Idle Flt Action (11).

ATTENTION:

Action (11) let you determine the action of the

!

adapter and connecte d drive if c ommunic ations are

disrupted or the scanner is idle. By default, these

parameters fault the drive. You can set these

parameters so that the drive continues to run.

Precautions should be taken to ensure that the

settings of these pa rameters do no t create a hazard

of injury or equipment damage. Failure to observe

these precautions could result in bodily injury or

damage to, or destruction of, equipment.

Comm Flt Action (10) and Idle Flt

4.9.1 Changing the Fault Action

Set the values of Comm Flt Action (10) and Idle Flt Action (11) to

the desired responses as shown in table 4.6. See figure 4.26 for

sample LCD OIM Fault Action Screens.

Table 4.6 – Selections for Drive Response to Communication Fault

Value Action Description

0 Fault The drive is faulted and stopped. (Default)

1 Stop The drive is stopped, but not faulted.

2 Zero Data The drive is sent 0 for output data after a

3 Hold Last The drive continues in its present state after a

4 Send Flt

Cfg

communications disruption. This does not

command a stop.

communications disruption.

The drive is sent the data that you set in the fault

configuration parameters Flt Cfg Logic (15)

through Flt Cfg D2 In (24).

Configuring the DeviceNet Adapter

4-17

Page 42

Port 5 Device

RECOMM-DNET

Parameter #: 10

Comm Flt Action

0

Fault

Figure 4.26 – Fault Action Screens on an LCD OIM

Port 5 Device

RECOMM-DNET

Parameter #: 11

Idle Flt Action

0

Fault

Changes to these parame ters ta k e effect immediate ly. A reset is not

required.

4.9.2 Setting the Fault Configuration Parameters

If you set Comm Flt Action (10), Idle Flt Action (11), or Peer Flt

Action (34) to the “Send Flt Cfg,” the values in parameters shown in

table 4.7 are sent to the drive after a communications fault and/or

idle fault occurs. You must set these parameters to values required

by your application.

Table 4.7 – Fault Configuration Parameters

Parameter Name Description

15 Flt Cfg Logic A 16-bit value sent to the drive for Logic

Command.

16 Flt Cfg Ref A 32-bit value (0 – 4294967295) sent to the

17 – 24 Flt Cfg x1 In

or Flt Cfg x2

In

drive as a Re ference or Datalink.

Important:

If the drive uses a 16-bit

Reference or 16-bit Datalinks, the most

significant word of the value must be set to

zero (0) or a fault will occur.

4-18

Changes to these parame ters ta k e effect immediate ly. A reset is not

required.

DeviceNet Adapter for use with DPI AC Drives

Page 43

4.10 Resetting the Adapter

Changes to switch settings on some adapter parameters require

that you reset the adapter before the new settings take effect. You

can reset the adapter by cycling power to the drive or by using

Reset Module (9).

ATTENTION:

I/O to the drive, the drive may fault when you reset

!

Set Reset Module (9) to 1 (Reset Module). See figure 4.27.

Port 5 Device

RECOMM-DNET

Parameter #: 9

Reset Module

When you enter

reset. When you enter

adapter parameters to their factory-default settings. The value of

this parameter will be restored to

reset.

the adapter . Determine ho w your driv e will respond

before resetting a connected adapter. Failure to

observe these precautions could result in bodily

injury or damage to equipment.

1

Reset Module

Figure 4.27 – Reset Screen on an LCD OIM

1 (Reset Module)

If the adapter is transmitting control

Value Description

0 Ready (Default)

1 Reset Module

2 Set Defaults

, the adapter will be immediately

2 (Set Defaults)

, the adapter will set all

0 (Ready)

after the adapter is

Configuring the DeviceNet Adapter

4-19

Page 44

4.11 Viewing the Adapter Configuration

The parameters in table 4.8 provide information about how the

adapter is configured. You can view these parameters at any time.

Table 4.8 – Adapter Configuration Status Parameters

Number Name Description

01 DPI Port The port on the drive to which the adapter is

02 DPI Data

Rate

04 DN Addr

Actual

06 DN Rate

Actual

07 Ref/Fdbk

Size

08 Datalink

Size

12 DN Active

Cfg

connected. Usually, it is port 5.

The data rate used by DPI in the drive. It will

be either 125 kbps or 500 kbps. It is set in the

drive, and the adapter detects it.

The node address used by the adapter. This

will be one of the following values:

• The address set by the rotary switches.

• The value of DN Addr Cfg (3) if the switches

have been disabled.

• An old address of the switches or parameter

if they have been changed and the adapter

has not been reset.

The data rate used by the adapter. This will b e

one of the following values:

• The data rate set by the DIP switch.

• The value of DN Rate Cfg (5) if the switches

have been disabled.

• An old data rate of the s witches or par amet er

if they have been changed and the adapter

has not been reset.

The size of the Reference/Feedback. It will

either be 16 bits or 32 bits. It is set in the drive

and the adapter automa tical ly use s the c orrect

size.

The size of the Datalinks. It will either be 16

bits or 32 bits. It is set in the drive and the

adapter automatically uses the correct size.

Source from which the adapter node address

and data rate are taken. This will be either

switches or parameters in EEPROM. It is

determined by the settings of the switches on

the adapter.

4-20

DeviceNet Adapter for use with DPI AC Drives

Page 45

Table 4.8 – Adapter Configuration Status Parameters (Contin ued)

Number Name Description

14 DPI I/O

Active

The Reference/Feedback and Datalinks used

by the adapter. This value is the same as DPI

I/O Config (13) unless the parameter was

changed and the adapter was not reset.

Datalink C

Datalink D

Datalink A

Datalink B

Cmd/Ref

00010xxx

01234567

1=Enabled

0=Disabled

x=Not Used

Configuring the DeviceNet Adapter

4-21

Page 46

4-22

DeviceNet Adapter for use with DPI AC Drives

Page 47

C

HAPTER

Configuring the Scanner

A scanner is a separate module of a multi-module controller or a

built-in component of a single-module controller that provides

communication with an adapter connected to a network.

Chapter 5 provides instructions on how to configure a scanner to

communicate with th e De viceNet adapter and the co nnected SP600

drive.

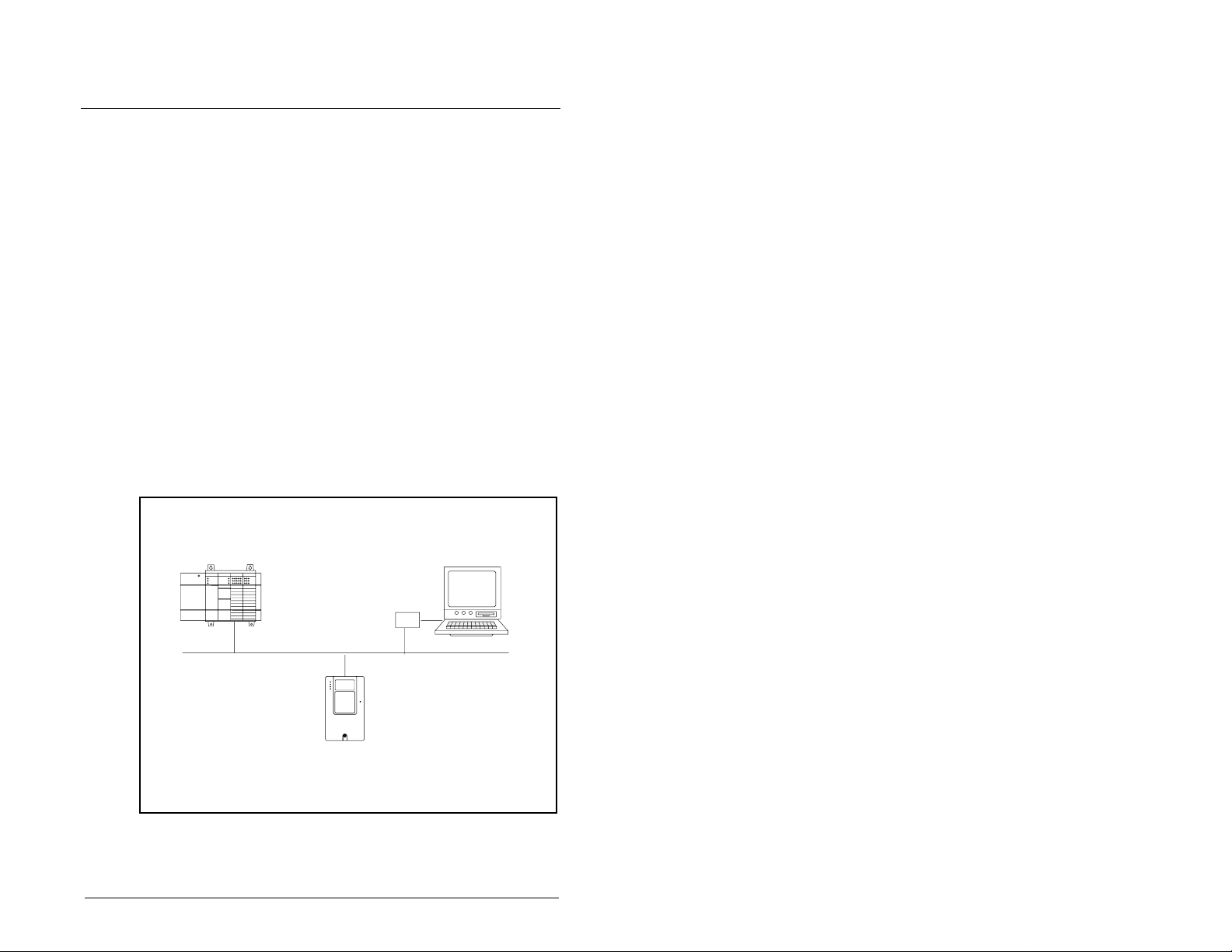

5.1 Configuring a Simple Network:

An Example

After the adapter is configured , the connected driv e and ad apter will

be a single node on the network. This chapter provides the steps

that are needed to configure a simple network like the network in

figure 5.1. In our e xample , we wil l configure the drive f or using Logic

Command/Status and Reference Feedback over the network.

5

Node 0

SCL 500 Controller with

1747-SDN- Scanner

Configuring the Scanner

Node 62

Computer with 1770-KFD and

RSNetWorx for DeviceNet

Node 1

SP600 Drive with

DeviceNet Adapter

Figure 5.1 – Sample DeviceNet Network

5-1

Page 48

5.2 Setting Up the Scan List

For the scanner to communicate with a drive, the scanner must be

configured and the drive’s node number must be added to its scan

list.

Step 1. Go online with RSNetWorx for DeviceNet. Refer to section

Step 2. Right-click the DeviceNet scanner (node 00 in figure 5.2

Important:

Step 3. Click the

Step 4. Click

Step 5. Select the

Step 6. Under Available Devices, select the drive, and then click >

4.3.2. The devices on the network are displayed in the

configuration view as shown in figure 5.2.

SP600

AC Drive

Figure 5.2 – Configuration View (Graph Tab)

and select

appears.

If your scanner is an unrecognized device, you must

create an EDS file f o r it a nd th en configure it. Create an

EDS file by following the instructions in section 4.3.

Configure the scanner using the General and Module

tabs. Click

if you need more information.

upload.

the Scanlist page (figure 5.3) appears.

appear).

(Right Arrow) to add it to the scanlist. See figure 5.3.

Properties

Help

Scanlist

. Data is uploaded fr om the scanner, and then

Upload

Automap on Add

. The Scanner Module dialog box

or refer to your s ca nne r doc um en tati on

tab. A message box prompts you to

box (a check mark will

5-2

DeviceNet Adapter for use with DPI AC Drives

Page 49

.

63 6WDQGDUG

Figure 5.3 – Scanlist Page in the Scanner Module Dialog Box

Step 7. Under Scanlist, select the drive, and then click

Parameters

5.4) appears.

Configuring the Scanner

Edit I/O

. The Edit I/O Parameters dialog box (figure

Figure 5.4 – Edit I/O Parameters Dialog Box

5-3

Page 50

Step 8. Select the type(s) of data exchange (Polled, Change of

State, and /or Cyclic). In our example, we selected Polled.

Step 9. Type the number of bytes that are required for your I/O in

the Rx Size and Tx Size boxes. The size will depend on

the following:

• I/O that you enabled in the adapter. This information can

be found in DPI I/O Active (14) in the adapter.

• Size of the Reference/Feedback and Datalinks in your

drive. This information can be viewed using Ref/Fdbk

Size (7) and Datalink Size (8) in the adapter. A 16-bit

word is two bytes, and a 32-bit word is four bytes.

• The actual size value used in the Rx Size box can be

determined by the setting of the M-S Input parameter as

shown in table E.1 or table E.2 for “Poll Only.”

• The actual size value used in the Tx Size box can be

determined by the sett ing of the M-S Outpu t parameter a s

shown in table E.3 or table E.4 for “Poll Only.”

• Tables 5.1 and 5.2 show common configuration Tx/Rx

sizes.

In our example, we typed 4 in the Rx Size and Tx Size boxes

because we enabled only th e Logic Command/Status for I/O in the

adapter and our drive uses a 16-bit Reference/Feedback.

Both the M-S Input and M-S Output parameters are set to 00001.

Therefore, the Logic Command/Status uses 2 bytes and the

Reference/Feedback uses 2 bytes totaling 4 bytes.

Table 5.1 – Host Products Using 16-Bit Reference/Feedback & Datalinks

1

5-4

Logic

Rx

Size

12 12

16 16

20 20

1

SP600 drives use 16-bit datalinks.

Tx

Size

44

88

Command/

Status

✔✔

✔✔✔

✔✔✔✔

✔ ✔ ✔✔✔

✔ ✔ ✔✔✔✔

DeviceNet Adapter for use with DPI AC Drives

Reference/

Feedback

(16-bit)

Datalinks (16-bit)

ABCD

Page 51

Table 5.2 – Host Products Using 32-Bit Reference/Feedback & Datalinks

Logic

Rx

Size

16 16

24 24

32 32

40 40

Tx

Size

88

Command/

Status

✔✔

✔✔✔

✔✔✔✔

✔✔✔✔✔

✔ ✔ ✔✔✔✔

Step 10. Set the scan rate. See table 5. 3. (Click

Reference/

Feedback

(32-bit)

Datalinks (32-bit)

ABCD

for more

Help

information.)

Table 5.3 – Scan Rates

Data Exchange Rate to set

Polled Polled Rat e

Change of State Heartbeat Rate

Cyclic Send Rate

Step 11. Click OK. If you changed any settings, a Scanner Applet

asks if it is OK to unmap the I/O . Clic k

to continue . The

Yes

Edit I/O Parameters dialog box closes and then the

Scanner Module d ialog bo x (figure 5.3) r eappea rs. You will

map the I/O in the next section in this chapter.

Configuring the Scanner

5-5

Page 52

5.3 Mapping the Drive Data in the

63 Z5(&200'1(7

Scanner

Data from I/O messages must be mapped in the scanner. This

mapping determines where a ladder logic program can find data

that is passed over the network. You must map both the Input I/O

and the Output I/O.

5.3.1 Mapping the Input I/O

Step 1. In the Scanner Module dialog box, click the

figure 5.5. (If necessary, right-click the scanner in the

configuration view (figure 5.2) to display this dialog box.)

63 $& 'ULYH

Input

tab. See

5-6

63 Z5(&200'1(7

Figure 5.5 – Input Page on the Scanner Module Dialog Box

If you selected the

(figure 5.3), RSNetWorx has already mapped the I/O. If it is not

mapped, click

mapping, click

assistance.

Step 2. In the Memory box, select a location in scanner memory

from table 5.4.

Automap on Add

Automap

Advanced

to map it. If you need to change the

and change the settings. Click

DeviceNet Adapter for use with DPI AC Drives

box in the Scanlist page

Help

for

Page 53

Table 5.4 – Scanner Module Memory Locations

Scanner Memory Locations

1747-SDN Discrete or M-File

1756-DNB Assembly Data

1771-SDN Block Xfer 62 – 57

In our example, we are using a 1747-SDN and selected Discrete.

Step 3. In the Start Word box, select the word in memory at which

the data should sta rt. In our ex ampl e, w e sel ected 1. Logi c

Status and Speed Feedback information will be found in

I:1.1 and I:1.2, respectively.

5.3.2 Mapping the Output I/O

Step 1. In the Scanner Module dialog box, click the

See figure 5.6. To display this dialog box, right-click the

scanner in the configuration view (figure 5.2).

63 $& 'ULYH

Output

tab.

Figure 5.6 – Output Page on the Scanner Module Dialog Box

If you selected the

(figure 5.3), RSNetWorx has already mapped the I/O. If it is not

mapped, click

mapping, click

assistance.

Configuring the Scanner

Automap on Add

Automap

Advanced

to map it. If you need to change the

and change the settings. Click

63 Z5(&200'1(7

63 Z5(&200'1(7

box in the Scanlist page

Help

for

5-7

Page 54

Step 2. In the Memory box, select a location in scanner memory

1747-SDN Discrete or M-File

1756-DNB Assembly Data

1771-SDN Block Xfer 62 – 57

In our example, we are using a 1747-SDN scanner and selected

Discrete.

Step 3. In the Start Word box, select the word in memory at which

from table 5.5.

Table 5.5 – Scanner Module Memory Locations

Scanner Memory Locations

the data should sta rt. In our ex ampl e, w e sel ected 1. Logi c

Command and Speed Reference data s hould be written to

O:1.1 and O:1.2, respectively.

5.4 Saving the Configuration

After configuring a scanner, you must download it to the scanner.

You should also save it to a file on your computer.

Step 1. In the Scanner Module dialog box (figure 5.6), click

to save the configuration to the scanner. A Scanner

Configuration Applet appears and asks if it is OK to

download the changes.

Step 2. Click

downloaded and then the Scanner Module dialog box

reappears.

Step 3. Click OK to close the Scanner Module dialog box.

Step 4. Select