Page 1

RS485 DF1

Communications Module

M/N RECOMM-485

Instruction Manual

D2-3514

Page 2

The information in this manual is subject to change without notice.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Throughout this manual, the following notes are used to alert you to safety

considerations:

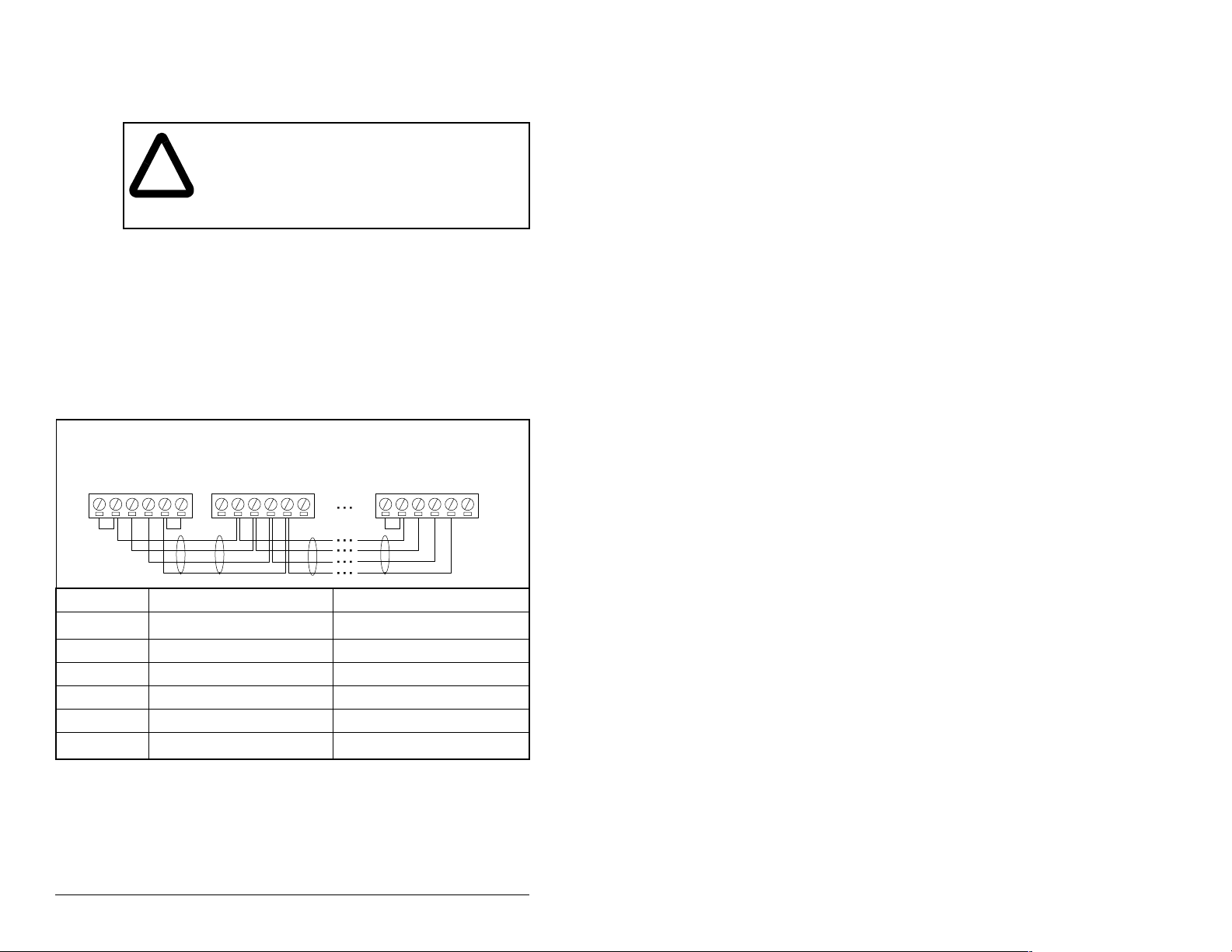

ATTENTION: Identifi es informat ion about practices or

circumstances that can lead to personal injury or death, property

damage, or economi c loss.

!

Important: Identifies information th at i s c riti cal for s uc cess ful a ppl ic ati on and

understanding of the product.

ATTENTION: The drive ma y contain hig h voltages t hat can cause

injury or death. Remove all power from the drive, and then verify

power has been removed before installing or removing an RS485

!

DF1 module. Failure to observe these precautions could result in

severe bodily injury or loss of life.

ATTENTION: Only qualified electrical personnel familiar with

drive and power products an d the associated machinery sho ul d

plan or implement the install at ion, start u p, conf i gu ration, and

subsequent mainten ance of the product using an RS 485 DF1

module. Read and und er stand th is manual in its entirety before

proceeding. Failure to observe these precautions could result

bodily injury and/or damage to equipment.

ATTENTION: DPI host prod uct s mus t no t be dir ec t l y con ne ct ed

together via RECBL-xxx cables. Unpredictable behavior due to

timing and other internal procedures can result if two or more

devices are connect ed in this manner. Failure to observe this

precaution could result in bo di ly in jury and/or damage to

equipment.

ATTENTION: If the RS485 DF1 module is transmitting control

I/O to the drive, the drive ma y fa ul t when you reset the module.

Determine h ow your dr ive will respond b efore res etting a mo dule.

Failure to observe this pre caution could result bodily inju ry

and/or damage to equipment.

ATTENTION: Comm Flt Acti on (paramete r 10) lets you de termine

the action of the module and connected drive if communications

are disrupted. By default, this parameter faults the drive. You can

set this p ara meter so that the d rive co ntin ues t o run. Preca ution s

should be taken to ensure that the setting of this parameter does

not create a hazard of injury or equipment damage. When

commissioning the dr ive, verify that your system responds

correctly to various situations (for example, a disconnected cable

or a faulted controller). F ailu re to observe this precaution co ul d

result bodily injury and/o r da m age to equipment.

ATTENTION: When a system is configured for the first time, there

may be unintended or incorrect machine motion. Disconnect the

motor from the machine or process during initial system test i ng.

Failure to observe this precaution could result in bodily injury

and/or damage to equipment.

Windows is a trademar k of Microsoft Corporation.

Reliance, SP600, VS Utilities, and DPI are trademarks of Rockwell Autom ation.

©2002 Rockwell Automation. All rights reserved.

Page 3

CONTENTS

Chapter 1 Introduction

1.1 Module Features.......................................... ..... ...... ...... .1-1

1.2 Related Documentation.................................................1-2

1.3 Getting Assistance from Reliance Electric..................... 1-2

Chapter 2 Getting Started

2.1 Required Equipment......................................................2-2

2.2 Installation Checklist ......................................................2-3

Chapter 3 Installing the RS485 DF1 Module

3.1 Preparing for an Installation...........................................3-1

3.2 Commissioning the Module ........................................... 3-1

3.3 Connecting the Module to the Drive ..............................3-3

3.4 Connecting the Module to the Network.......................... 3-6

3.5 Applying Power.............................................................. 3-7

Chapter 4 Configuring the RS485 DF1 Module

4.1 Configuration Tools........................................................ 4-1

4.2 Using the LCD OIM to Configure the Module................ 4-2

4.3 Setting the Node Address.............................................. 4-2

4.4 Setting the Data Rate....................................................4-3

4.5 Setting the Error-Checking Method ...............................4-3

4.6 Setting the I/O Configuration .........................................4-4

4.7 Setting a Fault Action..................................................... 4-5

4.7.1 Setting the Fault Configuration Parameters........4-6

4.7.2 Resetting the Module........................................... 4-6

4.8 Viewing the Module Configuration.................................4-8

Chapter 5 Using VS Utilities on the RS485 Network

Chapter 6 Troubleshooting the Module and Network

6.1 Understanding the Status Indicators..............................6-1

6.1.1 DRIVE Status Indicator........................................6-2

6.1.2 MS Status Indicator.............................................6-3

6.1.3 NET A Status Indicator........................................ 6-4

6.1.4 NET B Status Indicator........................................ 6-5

6.2 Module Diagnostic Items....................... ...... .................. 6-5

6.3 Viewing and Clearing Events......................................... 6-7

Contents

I

Page 4

Appendix A Technical Specifications...................................................... A-1

Appendix B RS485 DF1 Module Parameters ..........................................B-1

Appendix C Logic Command/Status Words.............................................C-1

Glossary ..................................................................................Glossary-1

Index .......................................................................................Index-1

II

RS485 DF1 Communications Module

Page 5

List of Figures

Figure 2.1 – Components of the RS485 DF1 Module................................. 2-1

Figure 3.1 – Setting the Module’s Node Address....................................... 3-2

Figure 3.2 – Setting the Data Rate.............................................................3-2

Figure 3.3 – DPI Ports and Internal Interface Cables................................. 3-4

Figure 3.4 – Mounting the Module.............................................................. 3-5

Figure 3.5 – Typical Network Connections................................................. 3-6

Figure 4.1 – Accessing the Module Parameters using the LCD OIM.........4-2

Figure 4.2 – RS485 DF1 Node Address Screen on an LCD OIM............... 4-2

Figure 4.3 – Data Rate Screen on an LCD OIM.........................................4-3

Figure 4.4 – Error-Checking Method Screen on an LCD OIM.................... 4-3

Figure 4.5 – I/O Configuration Screen on an LCD OIM.............................. 4-4

Figure 4.6 – Fault Action Screen on an LCD OIM...................................... 4-5

Figure 4.7 – Reset Screen on an LCD OIM................................................ 4-7

Figure 5.1 – Typical RS485 DF1 Network.................................................. 5-1

Figure 5.2 – Connecting to the Network.....................................................5-1

Figure 5.3 – Node Selection Screen: Multiple Nodes Selected.................. 5-2

Figure 5.4 – Results of Search of Selected Nodes.....................................5-2

Figure 5.5 – Result of Device Read Performed by VS Utilities...................5-3

Figure 5.6 – Expanding Each Node............................................................ 5-3

Figure 5.7 – Accessing the Parameters in the Selected Device................. 5-4

Figure 6.1 – Status Indicators (Location on Drive May Vary)..................... 6-1

Figure 6.2 – Viewing and Clearing Events Using an LCD OIM...................6-7

Contents

III

Page 6

IV

RS485 DF1 Communications Module

Page 7

List of Tables

Table 2.1 – Equipment Shipped with the RS485 DF1 Module....................2-2

Table 2.2 – Required User-Supplied Equipment........................................2-2

Table 4.1 – Configuration Tools..................................................................4-1

Table 4.2 – Selections for Drive Response to Communication Fault..........4-5

Table 4.3 – Fault Configuration Parameters...............................................4-6

Table 4.4 – Module Configuration Status Parameters................................4-8

Table 6.1 – DRIVE Status Indicator: State Definitions................................6-2

Table 6.2 – MS Status Indicator: State Definitions .....................................6-3

Table 6.3 – NET A Status Indicator: State Definitions................................6-4

Table 6.4 – NET B Status Indicator: State Definitions................................6-5

Table 6.5 – Module Diagnostic Items..........................................................6-5

Table 6.6 – Event Codes and Descriptions.................................................6-8

Contents

V

Page 8

VI

RS485 DF1 Communications Module

Page 9

CHAPTER 1

Introduction

This manual provides information about the RS485 DF1

Communications module (RECOMM-485) and using it with DPI

AC drives, such as SP600 drives. It is intended for qualified

electrical personnel familiar with installing, programming, and

maintaining AC drives and networks.

The RS485 DF1 Communications module allows an RS485 DF1

Master device to access the SP600 drive using:

• Logic Command/Reference (Start, Stop, Reference, etc.)

• Logic Status Feedba ck

• Datalinks A-D

• Explicit Messages

It also allows VS Utilities configuration software (version 1.01 or

higher) to connect to an SP600 drive using a Serial Converter

module (RECOMM-232 ) and co mmun icate with othe r SP600 dri ves

using an RS485 connection.

The module is mounted in the drive an d receive s its required power

from the drive. It can be used with other products that implement

DPI, which is a peripheral communication interface. Refer to the

documentatio n for your prod uct for sp ecific informa tio n about ho w it

works with this module.

1.1 Module Features

The RS485 DF1 Communications module features the following:

• Switches that ena ble y ou to set a no de ad dress and n etwor k dat a

rate before applying power to the drive. Alternatively, you can

disable these switches and use parameters to configure these

features.

• Status indicators that report the status of the drive

communications, module, and network. They are visible both

when the cover is opened and when it is closed.

• I/O, including Logic Command/Reference and up to four pairs of

Datalinks that may be configured for your application using a

parameter.

Introduction

1-1

Page 10

• A number of tools to configure the module and connected drive.

These tools include the LCD OIM and VS Utilities software.

• User-defined fault ac tions that determine how the modu le and the

drive respond to communication disruptions on the network.

1.2 Related Documentation

Refer to the following related publications as necessary for more

information. All of the publications are available from

http://www.theautomationbookstore.com or

http://www.reliance.com.

• D2-3485 SP600 AC Drive User Manual

• D2-3501 SP600 AC Drive User Manual (6SB401Series)

• D2-3488 VS Utilities Getting Results Manual

Online help installed with the software

• 1770-6.5.16 DF1 Protocol and Command Set Reference Manual

1.3 Getting Assistance from Reliance

Electric

If you have any questions or problems with the products described

in this instruction manual, contact your loca l R eli anc e El ectric sales

office.

1-2

For technical assistance, call 1-800-726-8112. Before calling,

please review the trou ble sh ooting section of this ma nua l and check

the Reliance drives website for additional information. When you

call this number, you will be asked for the drive model number and

this instruction manual number.

RS485 DF1 Communications Module

Page 11

CHAPTER 2

Getting Started

This chapter provides:

• A description of the RS485 DF1 module’s components

• A list of parts shipped with the module

• A list of user-supplied parts required for installing the module

• An installation checklist

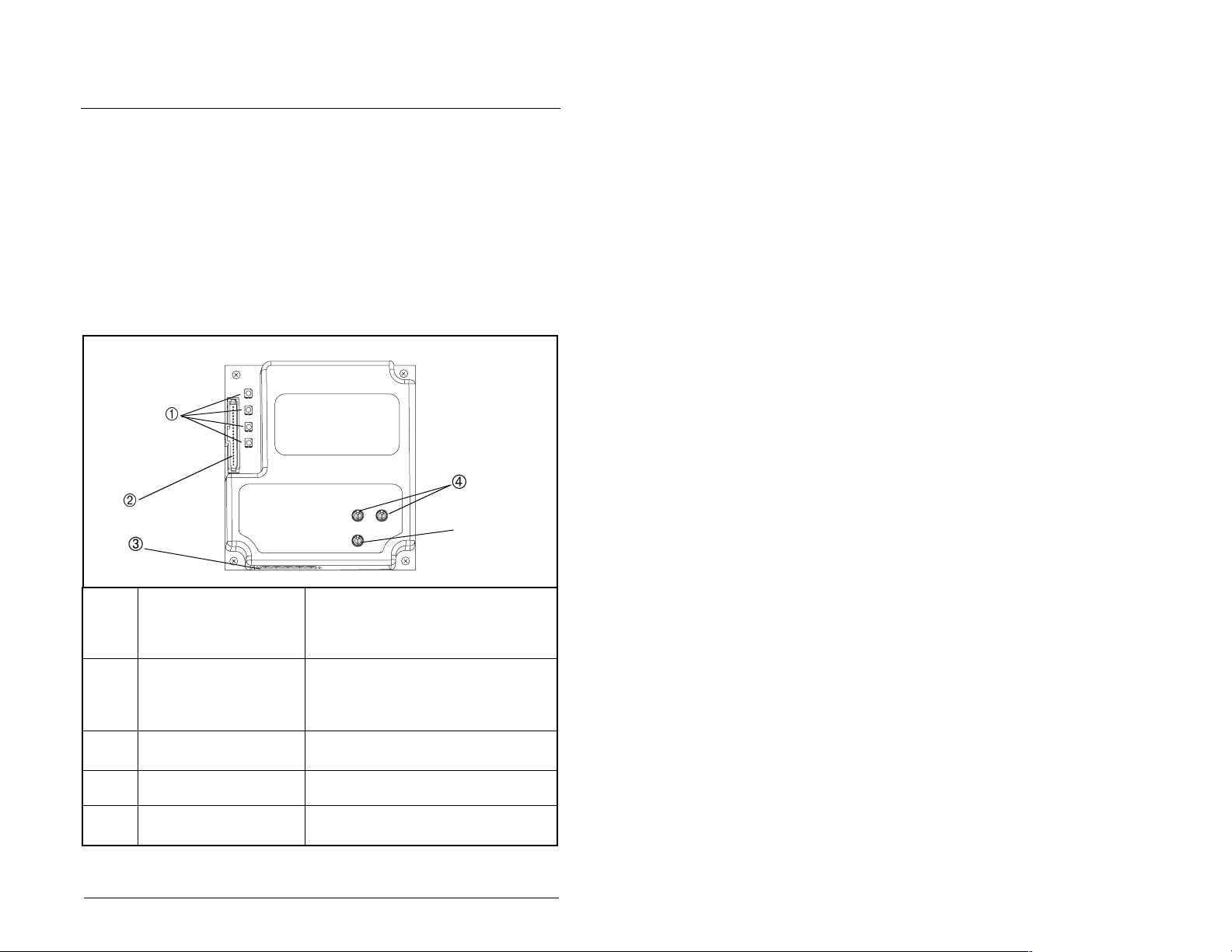

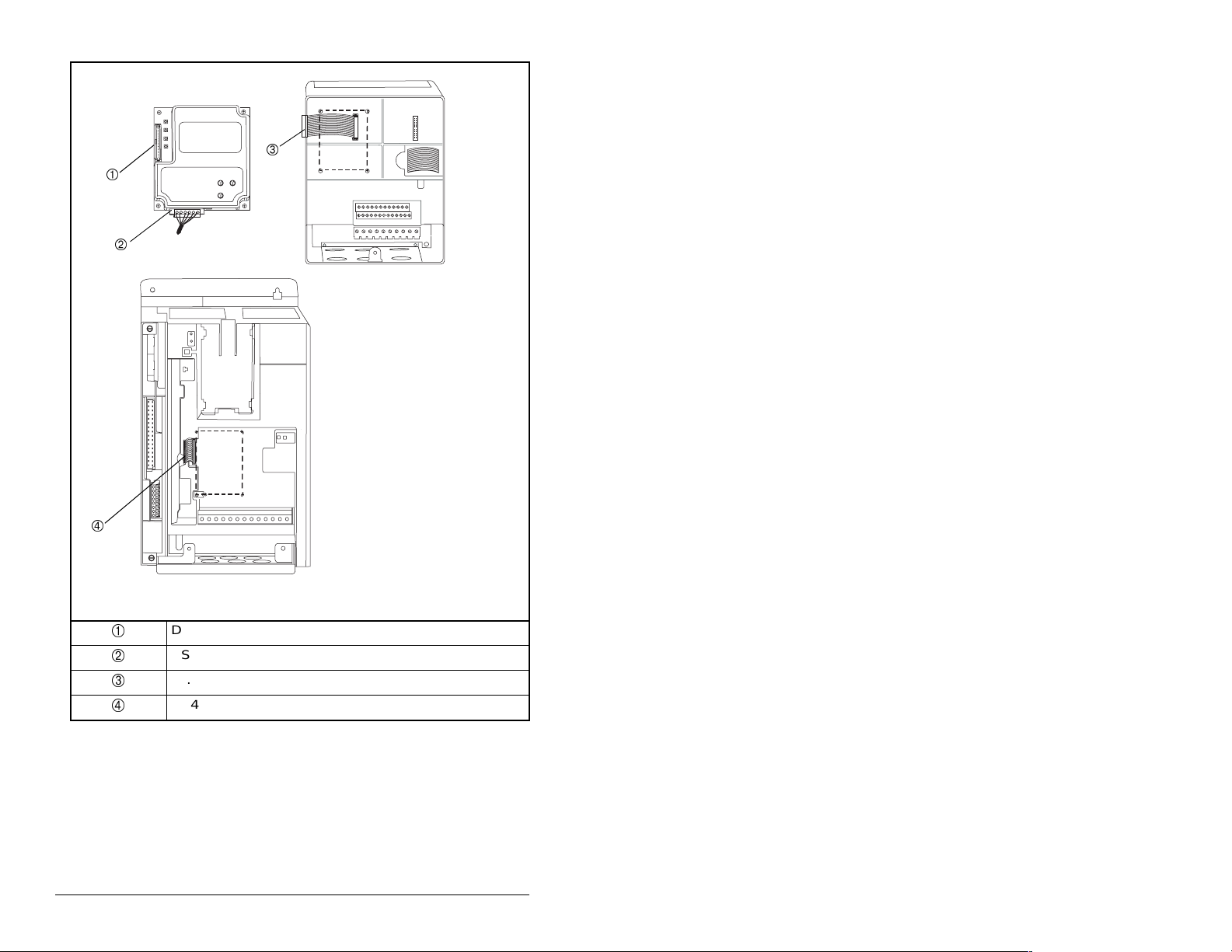

Status Indicators Four LEDs to indicate the status of the

DPI Connector A 20-pin, single-row shrouded male

RS485 DF1 Connector A 6-pin connector to which a 6-pin

Node Address Switches Switches to set the node address.

Data Rate Switch Switch to set the RS485 DF1 dat a rate

Getting Started

connected drive, module, and net work.

Refer to chapter 6 for more information

about the LEDs.

header. An Internal Interface cable

connects to this con ne cto r and one on

the drive.

linear plug can be connected.

at which the module communicates.

Figure 2.1 – Components of the RS485 DF1 Module

2-1

Page 12

2.1 Required Equipment

Table 2.1 lists the equipment shipped with the RS485 DF1 module.

When you unpack the module, verify that the package includes all

of these items.

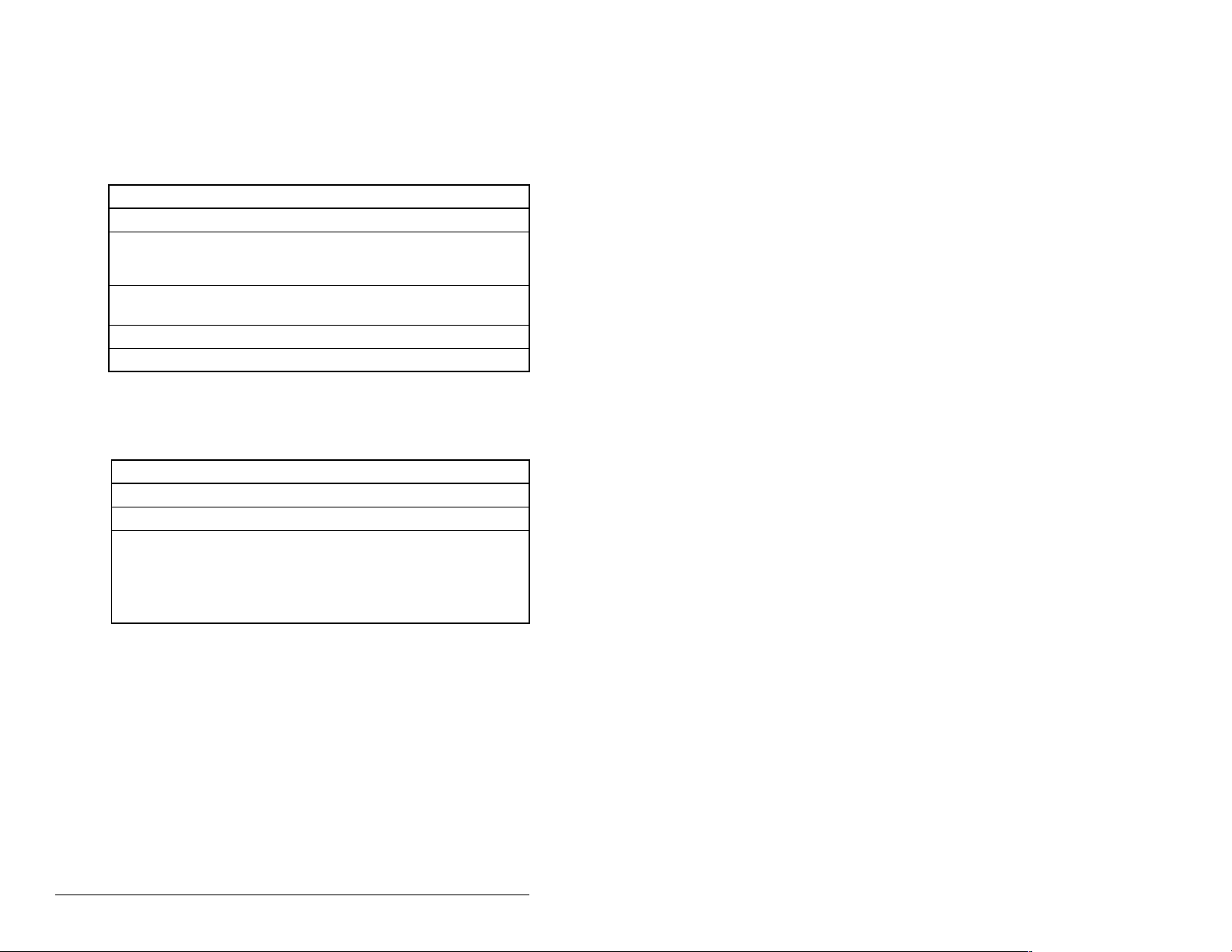

Table 2.1 – Equipment Shipped with the RS485 DF1 Module

Item Description

One RS485 DF1 Communication Module

One 2.54 cm (1 in) and one 15.24 cm (6 in) Internal Interface

cable (only one of these cables is needed to connect the module

to the drive)

One six-pin linear RS485 DF1 plug (connected to the RS485 DF1

connector on the module)

One grounding wrist strap

One RS485 DF1 Communication Module User Manual (D2-3415)

Table 2.2 lists user-supplied equipment also required to install and

configure the module.

Table 2.2 – Required User-Supplied Equipment

Item Description

Small flathead or Phillips screwdriver

RS485 cable (Belden 3106A or equivalent is recommended)

Configuration tool, such as

• SP600 LCD OIM

• VS Utilities

• with Serial Converter Module (M/N RECOMM-232)

2-2

RS485 DF1 Communication Module

Page 13

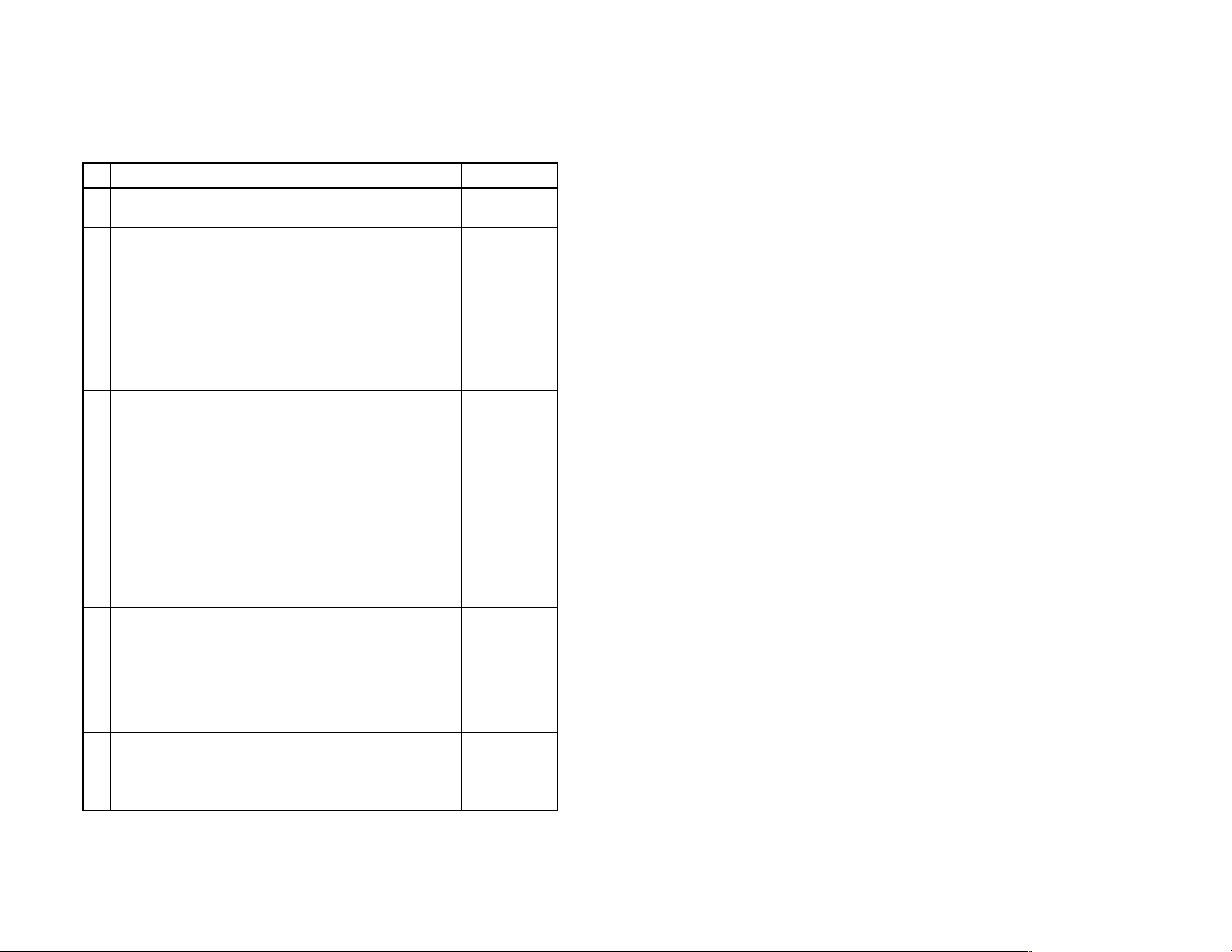

2.2 Installation Checklist

This section is designed to help experienced users start using the

RS485 DF1 modu le. If you ar e unsure h ow to compl ete a step , refe r

to the referenced chapter.

✔

Step Action Refer to:

❒

❒

❒

❒

❒

❒

❒

1 Review the safety precautions for the

module.

2 Verify that the drive is properly installed.

3 Commission the module.

Set a unique node address and the

appropriate data rate using the switches on

the module. If desired, you can disable the

switches and use parameter settings

instead.

4 Install the module.

Verify that the drive is not powered. Then,

connect the module to the network using an

RS485 cable and to the drive using the

Internal Interface cable. Use the captive

screws to secure and ground the module to

the drive.

5 Apply power to the module.

Apply power to the drive. (The module

receives power from the drive.) The status

indicators should be green. Refer to chapter

6 for more information if there is a problem.

6 Configure the module for your

application.

Set the parameters for the follo wing fe atures

as required by your application:

• I/O configuration

• Fault actions

7 Apply power to the RS485 DF1 master.

Verify that the master and the network are

installed and functi oni ng in acc ord anc e with

RS485 DF1 standards.

Throughout

this manual

SP600 AC

Drive User

Manual

Chapter 3

Chapter 3

Chapter 3

Chapter 4

Getting Started

2-3

Page 14

2-4

RS485 DF1 Communication Module

Page 15

CHAPTER 3

Installing the

RS485 DF1 Module

Chapter 3 provides instructions for installing the module on an

SP600 drive.

3.1 Preparing for an Installation

Before installing the module, verify that you have all required

equipment. Refer to chapter 2, Getting Started, for a list of

equipment.

3.2 Commissioning the Module

To commiss ion th e modu le, yo u must set a un ique no de address o n

the network, the data rate used by the network, and the errorchecking method. (Refer to the BCC and CRC entries in the

Glossary for more information about these error-checking

methods.)

Important: New settings are recognized only when power is

applied to the module or it is reset. If you change a

setting, cycle power or reset the module.

ATTENTION: The RS485 DF1 module contains

ESD- (Electrostatic Discharge) sensitive parts that

!

Important: To guard a gains t dev ice m alfunc tion, you m ust w ear a

Step 1. Set the module’s node address by rotating the node

Important: Each node on the network must have a unique

Installing the RS485 DF1 Module

can be damaged if you do not follow ESD control

procedures. Static control precautions are required

when handling the mo dule. Failure to o bserve these

precautions could result in damage to equipment.

grounding wrist strap when installing the module.

address switches to the desired value for each digit as

shown in figure 3.1.

address.

3-1

Page 16

2

3

1

0

9

7

8

2

3

4

1

0

5

9

6

4

5

6

7

8

Setting Description

00 to 99 The node address used by the module if switches are

enabled. The default switch setting is 01.

Important: If the Data Rate switch is set to “PGM”

(Program), the module will use the setting of DF1 Addr Cfg

(module parameter 3) for the node address. The default

setting of this parameter is 1. Refer to chapter 4,

Configuring the RS485 DF1 Module, for more information.

Figure 3.1 – Setting the Module’s Node Address

Step 2. Set the Data Rate switch as shown in figure 3.2.

19.2K

9600

4800

2400

1200

38.4K

PGM

Setting Description

1200

The module is set to the respective data rate.

2400

4800

9600

19.2K

38.4K

PGM The module uses the setting of DF1 Rate Cfg (module

parameter 5) for the dat a rate. 9600 is the de fault pa rameter

setting. Refer to chapter 4, Configuring the RS485 DF1

Module for more information.

Figure 3.2 – Setting the Data Rate

3-2

RS485 DF1 Communications Module

Page 17

3.3 Connecting the Module to the Drive

ATTENTION:The SP600 drive may contain high

voltages that can cause injury or death. Remove

!

Step 1. Remove power from the drive.

Step 2. Use static control precautions.

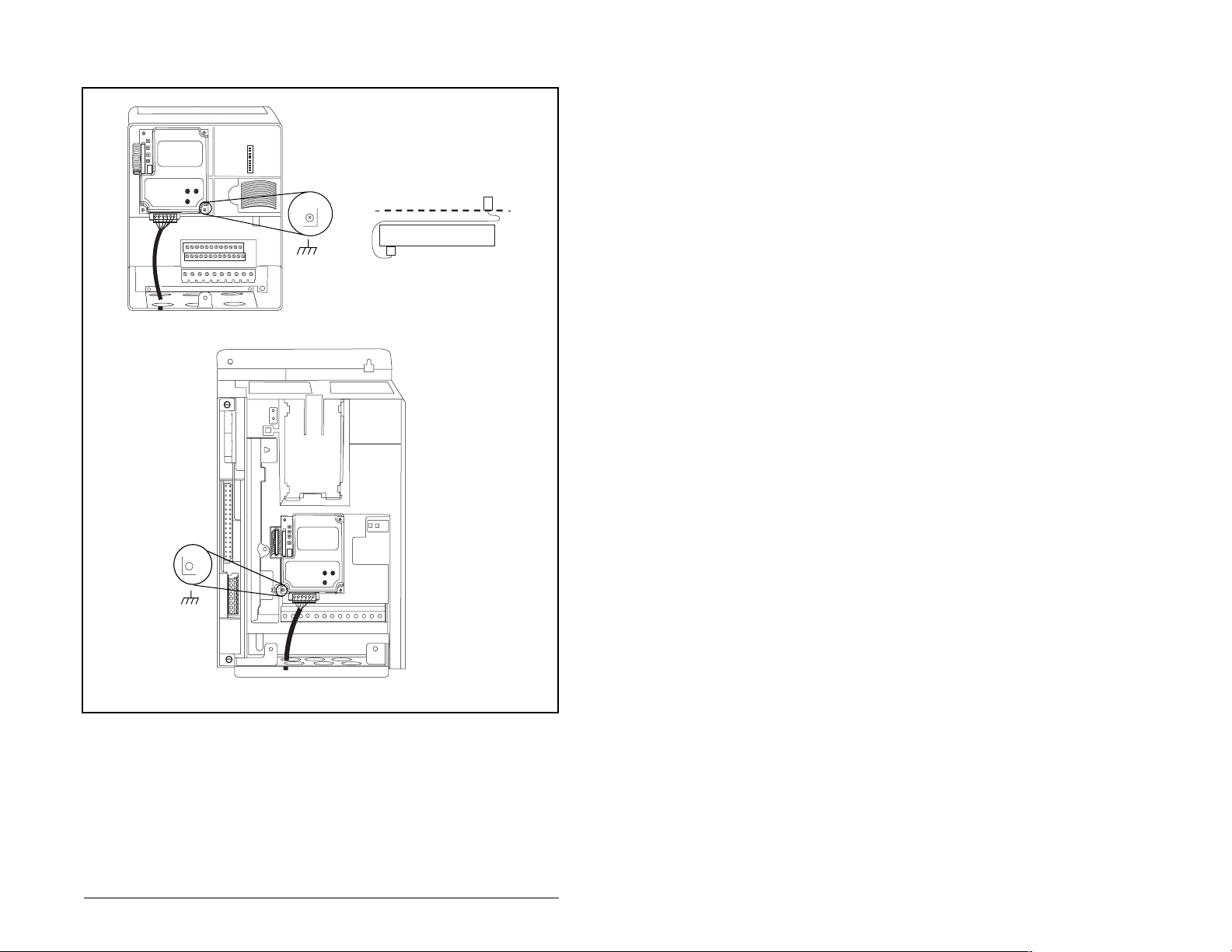

Step 3. Connect the Inte rnal Interfa ce cable to the DPI port o n the

Step 4. For 1-20 HP SP600 drives, fold the Internal Interface

power from the dr ive, and then verify powe r has been

discharged before inst a lli ng or remo vi ng a modu le .

Failure to observe this precaution could result in

severe bodily injury or loss of life.

drive and then to the DPI connector on the module. See

figure 3.3.

cable behind the module and mount the module on the

drive using the four captive screws. See figure 3.4.

For frame 2 and larger SP600 drives, mount the module

on the drive using the four captive screws to secure and

ground it to the drive.

Important: All screws must be tightened since the module is

grounded through a screw. The recommended

tightening torque is 0.9 N-m (8 in-lb).

Installing the RS485 DF1 Module

3-3

Page 18

RS485 DF1 Module

SP600 Drive

Frame 2 and Larger

SP600 Drive

1-20 HP

3-4

DPI Connector

RS485 Connector

15.24 cm (6 in) Internal Interface cable

2.54 cm (1 in) Internal Interface cable

Figure 3.3 – DPI Ports and Internal Interface Cables

RS485 DF1 Communications Module

Page 19

SP600 Drive

1-20 HP

Drive

Module

Internal Interface cable

folded behind the module

and in front of the drive

Figure 3.4 – Mounting the Module

Installing the RS485 DF1 Module

SP600 Drive

Frame 2 and Larger

3-5

Page 20

3.4 Connecting the Module to the

Network

ATTENTION:The SP600 drive may contain high

voltages that can cause injury or death. Remove

!

Step 1. Remove power from the drive.

Step 2. Use static control precautions.

Step 3. Connect an RS485 cable to the network, and route it

Step 4. Connect a 6-pin linear plug to the RS485 cable.

Step 5. Connect the cable to the module.

See figure 3.5 for typical network connections.

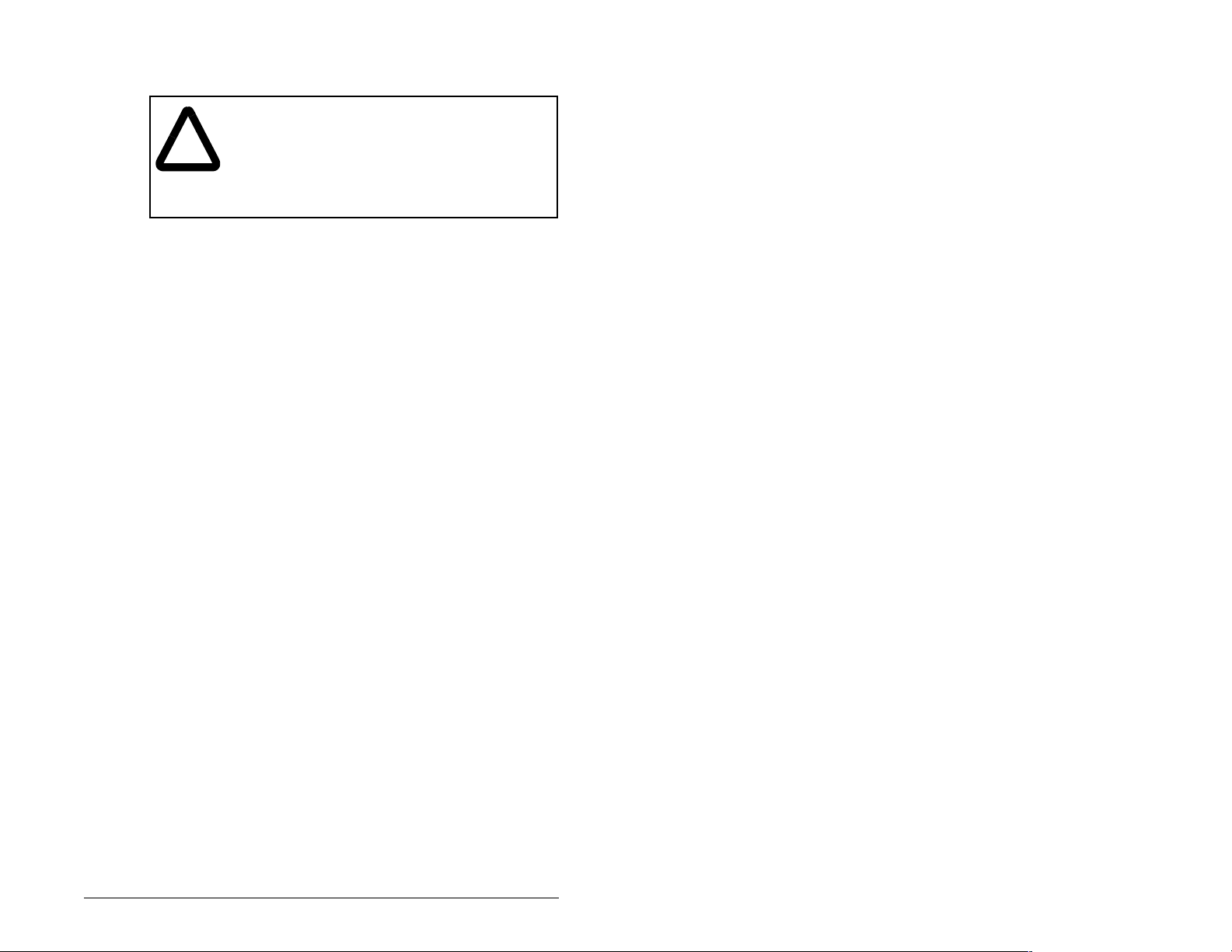

Node 1 Node 2 Node "n"

power from the drive, and then verify power has

been discharged before installing or removing a

module. Failure to observe this precaution could

result in severe bodily injury or loss of life.

through the bottom of the drive.

TERMAB

COM

SHIELD

GND

TERMAB

COM

SHIELD

GND

TERMAB

COM

SHIELD

GND

Terminal Signal Function

GND

Chassis Ground

1

Shield GND termination

SHIELD Shield Shield RC termination

COM Common Signal Common

B Signal B Tx Rx DA Signal A Tx Rx D+

TERM

1

The shield must be grounded at a single point on the network (jumper terminals

SHIELD and GND).

2

Jumper terminals TERM and A on the modules at the end of the RS485 network.

This enables a built-in RC termination network on the module.

Termination

Figure 3.5 – Typical Network Connections

2

3-6

Signal RC termination

RS485 DF1 Communications Module

Page 21

3.5 Applying Power

ATTENTION:Unpredictable operation m ay oc cu r

if parameter settings and switch settings are not

!

compatible with your application. Verify that

settings are compatible with your application

before applying power to the drive. Failure to

observe these precautions could result in severe

bodily injury of loss of life.

Step 1. Close the door or reinstall the cover on the drive. The

Step 2. Ensure th at the m odule will hav e a uni que ad dress on the

Step 3. Apply power to the drive. The module receives its power

Step 4. If the Data Rate switch is set to “PGM,” use a

Step 5. Verify that the master and network are installed and

status indicators can be viewed on the front of the drive

after power has been applied.

network and is set at the correct data rate. If a new data

rate or address is needed, reset the switches (refer to

Commissioning the Modul e, sec tion 3.2).

from the connected drive. When you apply power to the

product for the first time, the status indicators should be

green after an initialization. If there is a problem, refer to

chapter 6.

configuration tool to set the data rate and node address

parameters in the module (refer to chapter 4, Configuring

the RS485 DF1 Module).

functioning in accordance with RS485 DF1 standards.

Installing the RS485 DF1 Module

3-7

Page 22

3-8

RS485 DF1 Communications Module

Page 23

CHAPTER 4

Configuring the

RS485 DF1 Module

Chapter 4 provides instructions and information for setting the

parameters in the module.

For a complete list of parameters, refer to Appendix B, RS485 DF1

Module Parameters. For defini tio ns of term s in this chap ter, refer to

the Glossary.

4.1 Configuration Tools

The module sto res p a r am ete rs and other information in its own no nvolatile memory. Therefore, you must access the module to view

and edit its parameters. Table 4.1 lists the tools that can be used to

access the mo dule parameters.

Table 4.1 – Configuration Tools

Tool R efer to:

VS Utilities Software VS Utilities online help

LCD OIM Section 4.2

Configuring the RS485 DF1 Module

4-1

Page 24

4.2 Using the LCD OIM to Configure the

Module

Use the procedure in figure 4.1 to access the parameters on the

RS485 DF1 module using the LCD OIM. If you are unfamiliar with

the operation of the LCD OIM, refer to the SP600 AC Drive User

Manual (D2-3485 or D2-3501) for more information.

>>

Stopped

P0: SP600

Main Menu

Device Select

Monitor

Use to highlight

Device Select icon

Auto

Lang

>>

Stopped

P0: SP600

Device: Port 0

SP600

RECOMM-485

Use to select

RECOMM-485.

Auto

Figure 4.1 – Accessing the Module Parameters using the LCD OIM

4.3 Setting the Node Address

If the Data Rate switch on the module is set to “PGM,” the value of

module parameter 3 (DF1 Addr Cfg) determines the node address.

Step 1. Set the value of module parameter 3 (DF1 Addr Cfg) to a

unique node address.

Port 5 Device

RECOMM-485

Parameter #: 3

DF1 Addr Cfg

1

0 <> 99

Default = 1

>>

Stopped

P5: RECOMM-485

Main Menu

Parameters

Edit the RS485 DF1

parameters using the

same techniques as for

drive parame ters.

Auto

4-2

Figure 4.2 – RS485 DF1 Node Address Screen on an LCD OIM

Step 2. Reset the module. Refer to section 4.7.2, Resetting the

Module.

RS485 DF1 Communications Module

Page 25

4.4 Setting the Data Rate

If the Data Rate switch on the module is set to “PGM,” the value of

module parameter 5 (DF1 Rate Cfg) determines the RS485 DF1

data rate. Your application may require a different setting.

Step 1. Set the value of module parameter 5 (DF1 Rate Cfg) to

the data rate at which your network is operating. Refer to

figure 4.3.

Port 5 Device

RECOMM-485

Parameter #: 5

DF1 Rate Cfg

3

9600 bps

Figure 4.3 – Data Rate Screen on an LCD OIM

Value Baud Rate

0 1200 bps

1 2400 bps

2 4800 bps

3 9600 bps (default)

4 19.2 kbps

5 38.4 kbps

Step 2. Reset the module. Refer to section 4.7.2, Resetting the

Module.

4.5 Setting the Error- Checking Method

Two types of error-checking methods are used with the DF1

protocol: Cyclic Redundancy Check (CRC) and Block Check

Character (BCC). (Refer to the Glossary for a description of each

method.)

Step 1. Set the value of module parameter 24 (CRC/BCC) to the

method used by the network as shown in figure 4.4.

Port 5 Device

RECOMM-485

Parameter #: 24

CRC/CBC

0

BCC

Value Selection

0 BCC (default)

1CRC

Figure 4.4 – Error-Checking Method Screen on an LCD OIM

Step 2. Reset the module. Refer to section 4.7.2, Resetting the

Module.

Configuring the RS485 DF1 Module

4-3

Page 26

4.6 Setting the I/O Configuration

The I/O configuration determines the type of data sent to the drive.

This is a two-part process: enabling/disabling the data transmitted

between the module and the drive, and identifying the data

transmitted between the module and the master (i.e., scanner).

Step 1. Enable or disable the data transmitted between the

module and the drive by setting the bits in module

parameter 12 (DPI I/O Config).

A “1” enables the I/O. A “0” disables the I/O. Bit 0 is the

right-most bit. In figure 4.5, it is highlighted and equals

“1.”

Port 5 Device

RECOMM-485

Parameter #: 12

DPI I/O Config

xxxxxxxxxxx0000

Cmd/Ref b00

Figure 4.5 – I/O Configuration Screen on an LCD OIM

Bit Description

0 Logic Command/Reference (Default)

1Datalink A

2Datalink B

3Datalink C

1

4Datalink D

5 - 15 Not Used

Step 2. If Logic Command/Reference is enabled (default),

configure the parameters in the drive to accept the Logic

Command and Reference from the module. For example,

set Speed Ref A Sel (SP600 drive parameter 90) to

“Network” so that the drive uses the Reference from the

module. Also, verify that SP600 drive para meter 89 (Logic

Source Sel) is configured to recei ve the desired logic from

the module.

Step 3. If you enabled one or mor e Datali nks (option al), configu re

parameters in the drive to determine the source and

destination of dat a in the Data link(s). Also, e nsure that the

RS485 DF1 module is the only module us in g the enabled

Datalink(s).

Step 4. Reset the module. Refer to section 4.7.2, Resetting the

Module.

The module is ready to receive I/O from the master (i.e., scanner).

You must now configure the scanner to recognize and transmit I/O

to the module.

4-4

RS485 DF1 Communications Module

Page 27

4.7 Setting a Fault Action

By default, when communications are disrupted (for example, a

cable is disconnected) or the scanner is idle, the drive responds by

faulting if it is using I/O from the network.

You can configure a different response to communication

disruptions using module parameter 10 (Comm Flt Action).

ATTENTION:Module parameter 10 (Comm Flt

Action) lets you det erm ine the ac ti on of the module

!

Set the value of module parameter 10 (Comm Flt Action) to the

desired response a s shown in t able 4.2 . See figure 4 .6 for a sa mple

LCD OIM Fault Action screen.

Table 4.2 – Selections for Drive Response to Communication Fault

Value Action Description

0 Fault (default) The drive is faulted and stopped

1 Stop The drive is stopped, but not

2 Zero Data The drive is sent 0 for output data

3 Hold Last The drive continues in its present

4 Send Flt Cfg The drive is sent the data that you

and connected drive if communications are

disrupted. By defau lt, this parameter faul ts the drive.

Y ou can set the parameter so that the driv e continues

to run. Precautions should be taken to ensure that

the setting of this parameter does not create a risk

of injury or equipment damage.

(Default).

faulted.

after a communi cations disru ption.

This does not command a stop.

state.

set in the fault configuration

parameters 14 through 23 (Flt Cfg

Logic through Flt Cfg D2 In).

Figure 4.6 – Fault Action Screen on an LCD OIM

Changes to this parameter take effect immediately. A reset is not

required.

Configuring the RS485 DF1 Module

Port 5 Device

RECOMM-485

Parameter #: 10

Comm Flt Action

0

Fault

4-5

Page 28

4.7.1 Setting the Fault Configuration Parameters

If you set module param eter 10 (Comm Flt Ac tion) to “Send Fl t Cfg,”

the values in the par ameters show n in table 4.3 are sent to t he drive

after a communications fault occurs. Yo u must set these parameters

to values required by your application.

Table 4.3 – Fault Configuration Parameters

Parameter

Number Name Description

14 Flt Cfg Logic A 16-bit value sent to the drive

for Logic Command.

15 Flt Cfg Ref A 32-bit value (0 to 429 4967295)

16 - 23 Flt Cfg x1 In

Flt Cfg x2 In

Changes to these par ameters t ake ef fect immedia tely. A reset is not

required.

sent to the drive as a Reference

or Datalink.

Important: If the drive uses a

16-bit Reference or 16-bit

Datalinks, the most significant

word of the value must be set to

zero (0) or a fault will occur.

4.7.2 Resetting the Module

4-6

Changes to swit ch settin gs or some modul e paramet ers req uire that

you reset the module before the new settings take effect. You can

reset the module by cycling power to the drive or by using module

parameter 9 (Reset Module).

ATTENTION: If the module is transmitting control

I/O to the drive, the drive may fault when you reset

!

the module. Determi ne h ow yo ur dri ve w ill respond

before resetting a connected module. Failure to

observe this precaution could result in bodily injury

or damage to equipment.

RS485 DF1 Communications Module

Page 29

Set module parameter 9 (Reset Module) to “Reset Module.” See

figure 4.7.

Port 5 Device

RECOMM-485

Parameter #: 9

Reset Module

1

Reset Module

Figure 4.7 – Reset Screen on an LCD OIM

Value Description

0 Ready (default)

1 Reset Module

2 Set Defaults

When you enter 1 (“Reset Module”) the module is immediately

reset. When you enter 2 (“Set Defaults”) the module sets all

module parameters to their factory-default settings. The module

should be reset after performing a “Set Defaults.”

The value of this parameter is restored to 0 (“Ready”) after the

module is reset.

Configuring the RS485 DF1 Module

4-7

Page 30

4.8 Viewing the Module Configuration

The parameters in table 4.4 provide information about how the

module is configured. You can view these parameters at any time.

Table 4.4 – Module Configuration Status Parameters

No. Name Description

01 DPI Port The port to which the module is connected. This will usually be

02 DPI Data Rate The data rate used by the drive. This data rate is set in the

04 DF1 Addr Actual The node address actually used by the module. This will be

06 DF1 Rate Actual The DF1 data rate actually used by the module. This will be

07 Ref/Fdbk Size The size of the Reference/Feedback (16 bits or 32 bits). It is

08 Datalink Size The size of the Datalinks (16 bits or 32 bits). It is set in the

11 Active Cfg The source from which the module address and data rate are

13 DPI I/O Active The I/O used by the module. The value of this parameter will

25 CRC/BCC Act The actual error-checking method selected.

26 Dup Msg Detect Determines if the module ignores messages with duplicate

port 5.

drive and the module detects it.

one of the following values:

• The address set by the Node Address switches on the

module.

• The value of module parameter 3 (DF1 Addr Cfg) if the

switches have been disabled.

one of the following values:

• The data rate set by the Data Rate switch on the module.

• The value of module parameter 5 (DF1 Rate Cfg) if the

switches have been disabled.

set in the drive and the module automatically uses the correct

size.

drive and the module automatically uses the correct size.

taken. This will either be switches on the module or

parameters in EEPROM. It is determined by the switch

settings on the module.

be equal to the value of module parameter 12 (DPI I/O Config)

unless the parameter was changed and the module was not

reset.

Bit Definitions

Bit

Default

TNS IDs. Normally set to Enable (default). Set to Disable if

using a ProSoft 3150-DFM module or any device that does not

increment the TNS ID.

01234576

10000xxx

0 = Cmd/Ref

1 = Datalink A

2 = Datalink B

3 = Datalink C

4 = Datalink D

5 = Not Used

6 = Not Used

7 = Not Used

4-8

RS485 DF1 Communications Module

Page 31

CHAPTER 5

Using VS Utilities

on the RS485 Network

Chapter 5 provides instructions for configuring VS Utilities (version

1.01 or higher) to access SP600 drives on the RS485 network.

Figure 5.1 shows a typical RS485 DF1 network.

VS Utilities

To connect to the network using VS Utilities:

Step 1. Select Ex

5.2.

VS Utilities

Using VS Utilities on the RS485 Network

RECOMM-232

Serial Converter

Module

Figure 5.1 – Typical RS485 DF1 Network

plore > Connect > Network as shown in figure

Figure 5.2 – Connecting to the Network

SP600 DrivesPC Running

5-1

Page 32

Step 2. Select Single to connect to a singl e node on th e netwo rk.

Select Multiple to connect to multiple nodes and enter

the node range (figure 5.3).

“Offline” or “Online” text will be displayed next to the

number to show if the particular node is present on the

network. In this example, two nodes with DF1 addresses

of 1 and 2 will be accessed.

Figure 5.3 – Node Selection Screen: Multiple Nodes Selected

Step 3. Click Connect.

VS Utilities will perform a search within the range of the

selected nodes and list them as shown in figure 5.4.

VS Utilities

5-2

Figure 5.4 – Results of Search of Selected Nodes

RS485 DF1 Communications Module

Page 33

Step 4. Click on each node to have VS Utilities perform a device

read as shown in figure 5.5. A “+” w i ll a ppe ar to th e le f t of

the node upon completion.

VS Utilities

Node 1: - SP600

Node 2: - SP600

Figure 5.5 – Result of Device Read Performed by VS Utilities

Step 5. Click on the “+” for each node to expand the information

as shown in figure 5.6.

VS Utilities

Node 1: - SP600

0 - SP600 240V 4.2A

1 - LCD OIM

2 - RECOMM-232 RS232 DF1

5 - RECOMM-485 RS485 DF1

Node 2: - SP600

Node 2: - SP600

0 - SP600 240V 4.2A

1 - LCD OIM

5 - RECOMM-485 RS485 DF1

Figure 5.6 – Expanding Each Node

Using VS Utilities on the RS485 Network

5-3

Page 34

Step 6. Click on the desired item to access its parameters as

shown in figure 5.7.

VS Utilities

Node 1: - SP600

0 - SP600 240V 4.2A

1 - LCD OIM

2 - RECOMM-232 RS232 DF1

5 - RECOMM-485 RS485 DF1

Node 2: - SP600

0 - SP600 240V 4.2A

1 - LCD OIM

5 - RECOMM-485 RS485 DF1

Figure 5.7 – Accessing the Parameters in the Selected Device

5-4

RS485 DF1 Communications Module

Page 35

CHAPTER 6

Troubleshooting the

Module and Network

Chapter 6 contains information for troubleshooting the RS485 DF1

module and the network.

6.1 Understanding the Status Indicators

The module has four status indicators. They can be viewed on the

module or through the drive cover. (See figure 6.1.)

➀

➁

➂

➀

➁

➂

➃

➃

Status

Number

➀

➁

➂

➃

Indicator Description Refer to...

DRIVE DPI Connection Status Section 6.1.1

MS Module St a t us Section 6.1.2

NET A DF1 Status Section 6.1.3

NET B DF1 Traffic Section 6.1.4

Figure 6.1 – Status Indicators (Location on Drive May Vary)

Troubleshooting the Module and Network

6-1

Page 36

6.1.1 DRIVE Status Indicator

Table 6.1 – DRIVE Status Indicator: State Definitions

Status Cause Corrective Action

Off The module is not

Flashing

Red

Solid

Red

Orange The module is

Flashing

Green

Solid

Green

powered or is not

connected properly to

the drive.

The module is not

receiving a ping

message from the

drive.

The drive has refused

an I/O connection from

the module.

Another DPI peripheral

is using the same DPI

port as the module.

connected to a product

that does not support

Reliance Electric DPI

communications.

The module is

establishing an I/O

connection to the drive

or module parameter

12 (DPI I/O Config) is

configured for all I/O

disabled.

The module is properly

connected and is

communicating with the

drive.

• Securely connect the

module to the dri ve using the

Internal Interface cable.

• Apply power to the drive.

• Verify that cables are

securely connected.

• Cycle power to the drive.

Important: Cycle power to the

product after m aking any of the

following corrections:

• Verify that all DPI cables are

securely connected and not

damaged. Replace cables if

necessary.

• Verify that the DPI Host

supports Datalinks.

• Configure the module to u se

a Datalink that is not already

being used by another

peripheral.

• Connect the module to a

product that supports

Reliance Electric DPI

communications (for

example, SP600 drives).

• Verify the se ttin gs in modu le

parameter 12 (DPI I/O

Config).

• Normal behavior if no DPI

I/O is enabled. No action is

required.

• No action is required.

6-2

RS485 DF1 Communications Module

Page 37

6.1.2 MS Status Indicator

Table 6.2 – MS Status Indicator: State Definitions

Status Cause Corrective Action

Off The module is not

Flashing

Red

Solid

Red

Flashing

Green

Solid

Green

powered.

The module has

failed the firmware

test.

The module has

failed the hardware

test.

The module is

operational but is not

transferring I/O data.

The module is

operational and

transferring I/O data.

• Securely connect the module

to the SP600 drive using the

Internal Interface cable.

• Apply power to the drive.

• Clear faults in the module.

• Cycle power to the drive.

• If cycling power does not

correct the problem, the

parameter settings may have

been corrupted. Reset defau lts

and reconfigure the module.

• If resetting defaults does not

correct the problem, flash the

module with the latest fi rmware

release.

• Cycle power to the drive.

• Replace the module.

• Place the scanner in RUN

mode.

• Program the controller to

recognize and transmit I/O to

the module.

• Configure the module for the

program in the controller.

• Normal behavior if no DPI I/O

is enabled.

• No action required.

Troubleshooting the Module and Network

6-3

Page 38

6.1.3 NET A Status Indicator

Table 6.3 – NET A Status Indicator: State Definitions

Status Cause Corrective Actions

Off The module is not

Flashing

Green

Solid

Green

Flashing

Red

powered or the

module is not

properly

connected to the

network.

The module is

properly

connected, but it is

not communicating

with any devices

on the network.

The module is

properly

connected and

communicating on

the network.

A network

connection has

timed out.

• Securely connect th e module to

the drive using the Internal

Interface cable.

• Correctly connect the RS485

cable to the DF1 plug.

• Apply power to the drive.

• Place the controller in RUN, or

apply power to the peer device

that will send I/O.

• Program a controller or peer

device to recognize and

transmit I/O to the module.

• Configure the module for the

program in the controller or the

I/O from the peer source.

• No action required.

• Place the scanner in RUN, or

apply power to the peer device

that will send I/O.

• Check the amount of traffic on

the network.

6-4

RS485 DF1 Communications Module

Page 39

6.1.4 NET B Status Indicator

Table 6.4 – NET B Status Indicator: State Definitions

Status Cause Corrective Actions

Off The module is not

receiving data over

the network.

• Place the controller in RUN, or

apply power to the peer device

that will send I/O.

• Program a controller peer

device to recognize and

transmit I/O to the module.

• Configure the module for the

program in the controller or the

I/O from the peer device.

Flashing

Green

The module is

receiving data over

the network.

• No action required.

6.2 Module Diagnostic Items

Table 6.5 lists diagnostic items that can be accessed using

VS Utilities software or the LCD OIM.

Table 6.5 – Module Diagnostic Items

No. Event Description

1 Common Logic

Cmd

2 Prod Logic Cmd The current value of the Product Specific Logic

3 Reference The current value of the Product Specific

4 Common Logic Sts The current value of the Common Logic Status

5 Product Logic

Status

6 Feedback The current value of the Product Specific

The current value of the C ommon Logic

Command being transmitted to the host by this

peripheral.

Command being transmitted to the host by this

peripheral.

Reference being transmitted to the host by the

peripheral.

being received from the host by this peripheral.

The current value of the Product Specific Status

being received from the host by this peripheral.

Feedback being received from the host by this

peripheral.

Troubleshooting the Module and Network

6-5

Page 40

Table 6.5 – Module Diagnostic Items (Continued)

No. Event Description

7

Datalink A1 In

8

Datalink A2 In

9

Datalink B1 In

10

Datalink B2 In

11

Datalink C1 In

12

Datalink C2 In

13

Datalink D1 In

14

Datalink D2 In

15

Datalink A1 Out

16

Datalink A2 Out

17

Datalink B1 Out

18

Datalink B2 Out

19

Datalink C1 Out

20

Datalink C2 Out

21

Datalink D1 Out

22

Datalink D2 Out

The current value of the specified Datalink In

being transmitted to th e host by th e module. If the

module has not ena bled th e Dat ali nk, th e valu e is

0.

The current value of the specified Datalink Out

being received from the host by the module.

23 Field Flash Cnt The current value of the Field Flash Counter (that

is, the number of time s this dev ice has been flash

updated).

24 DPI Rx Errors The current value of the DPI CAN Receive Error

Counter register.

25 DPI Tx Errors The current value of the DPI CAN Transmit Error

Counter register.

26 Clear DF1 Counts Ready = No action.

Enable = Clears all DF1 counter parameters.

27 DF1 Packets Sent The number of DF1 packets sent by the

peripheral.

28 DF1 Packets Rcvd The number of DF1 packets received by the

peripheral.

29 Undelivered Msgs Reports the number of DF1 packets that were

sent by the peripheral, but not acknowledged.

30 ENQs Received Reports the number of ENQ requests recei ved by

the peripheral.

31 NAK Bak Packet The number of responses receiv ed (BCC o r CRC

calculated by peripheral did not match that in the

packet).

32 NAK No Memory The number of requests received by the

peripheral that could not processed due to

insufficient memory available to buffer the

incoming packet.

33 Duplicate Msgs The number of duplicate messages received by

the peripheral. A duplicate message is detected

when the SRC, TNS, and CMD files of two

consecutive messages are identical.

6-6

RS485 DF1 Communications Module

Page 41

Table 6.5 – Module Diagnostic Items (Continued)

No. Event Description

34 PCCC I/O Timeout The I/O communication timeout value (secs)

before the action selected in module parameter

10 (Comm Flt Action) is taken.

35 Data Rate SW The value of the Data Rate switch on the module.

36 Node Address SW The value of the Node Address swi tch on the

module.

6.3 Viewing and Clearing Eve nts

The module maintains an event queue that reports the history of its

actions. You can view the event queue using an LCD OIM or

VS Utilities software.

To View and Clear Events Using an LCD OIM

Use the procedure shown in figure 6.2 to access the event queue

using the LCD OIM. Note that you must have the RECOMM-485

module as the selected device to access the event queue.

>>

Stopped Auto

P0: RECOMM-485

Main Menu

Diagnostics

Monitor

Highlight Diagnostics icon

Lang

Diagnostics:

View Event Queu e

Device Version

OIM Version

Highlight item

1

EvtQ# : E#xxxxx

Online @ 500kbps

Clrqu

Press F2 key to

clear event queue

Figure 6.2 – Viewing and Clearing Events Using an LCD OIM

Troubleshooting the Module and Network

6-7

Page 42

Events

Many events in the event queue occur under normal operation. If

you encounter unexpected communications problems, the events

may help you or Reliance Electric personnel troubleshoot the

problem. Table 6.6 lists events that may appear in the event queue.

Table 6.6 – Event Codes and Descriptions

Code Event Description

1 No Event Empty event queue entry.

2 DPI Bus Off Flt A bus-off condition was detected on DPI. This

3 Ping Time Flt A ping message was not received on DPI

4 Port ID Flt The mod ule is not conn ected t o a correct po rt

5 Port Change Flt The DPI port changed.

6 Host Sent Reset The DPI product issued this because it was

7 EEPROM Sum Flt The EEPROM in the module is corrupt.

8 Online @ 125 kbps The module and DPI product are

9 Online @ 500 kbps The module and DPI product are

10 Bad Host Flt The module was connected to an

1 1 Dup. Port Flt Another peripheral with the same port number

12 Type 0 Login The module has logged in for type 0 control.

13 Type 0 Time Flt The module has not received a type 0 status

14 DL Login The module has logged into a Datalink.

15 DL Reject Flt The host rejected an attempt to log in to a

16 DL Time Flt The module has not received a Datalink

17 Control Disabled The module has se nt a “Soft Control Disable”

18 Control Enabled The module has sent a “Soft Control Enable”

19 PCCC IO Time Flt The module has not received a PCCC control

event may be caused by loose or broken

cables or by noise.

within the specified time.

on a DPI product.

reset.

communicating at 125 kbps.

communicating at 500 kbps.

incompatible product.

is already in use.

message within the specified time.

Datalink because the Datalink is not

supported or is used by another peripheral.

message within the specified time.

command to the DPI product.

command to the DPI product.

message within the specified timeout interval.

6-8

RS485 DF1 Communications Module

Page 43

Table 6.6 – Event Codes and Descriptions (Continued)

Code Event Description

20 Normal Startup The module successfully started up.

21 Message Timeout A Client-Server message sent by the

peripheral was not completed.

22 DPI Fault Msg The DPI host has faulted.

23 DPI Fault Clear The DPI host transitioned from a faulted to a

non-faulted state.

24 Flt Cfg Error At least one of the Fault Configuration

parameters contains a value greater than

65535 and th e DPI product expects a 16-bit

value.

25 DF1 NAK NAK received.

26 Manual Reset The module was reset by the user.

27 Language CRC Bad The language text memory segment is

corrupt.

Troubleshooting the Module and Network

6-9

Page 44

6-10

RS485 DF1 Communications Module

Page 45

APPENDIX A

Technical

Specifications

Communications

Network

Protocol

Data Rates

Drive

Protocol

Data Rates

Electrical

Consumption

Drive 150 mA at 5 VDC supplied through the drive

Mechanical

Dimensions

Height

Length

Width

Weight 60 g (2 oz)

DF1

1200, 2400, 4800, 9600, 19.2 K, 38.4 K, PGM

If the Data Rate switch is set to “PGM,” the

module will use the setting of module

parameter 5 (DF1 Rate Cfg) for the data rate.

DPI

125 K or 500 K

16 mm (0.625 in)

86 mm (3.34 in)

81 mm (3.16 in)

Environmental

Temperature

Operating

Storage

Relative Humidity 5 to 95% non-condensing

Atmosphere Important: The module must not be

Technical Specifications

-10 to +50°C (14 to 149°F)

-40 to +85°C (-40 to 185°F)

installed in an area where the ambient

atmosphere contains volatile or corrosive

gas, vapor, or dust. If the module is not

going to be installed for a period of time, it

must be stored in an area where it will not

be exposed to a corrosive atmosphere.

A-1

Page 46

Regulatory Compliance

UL 508C and CUL

CE EN61800-3

A-2

RS485 DF1 Communications Module

Page 47

APPENDIX B

RS485 DF1 Module

Parameters

The following information is provided for each module parameter

along with its description:

Parameter Number: Unique number assigned to each

Parameter Name: Unique name assigned to each

Range: Predefined parameter limits or

Default: Factory default setting.

Type: Read Only or Read/Write.

Reset Required: Module must be reset before p arame ter

About Parameter Numbers

The parameters in the RS485 DF1 module are numbered

sequentially. However, depending on the configuration tool used,

they may have different numbers.

Configuration Tool Numbering Schemes

• VS Utilities

•OIM

parameter.

parameter.

selections.

value is recognized.

The module parameters begin with

parameter 1. For example, parameter 01

(DPI Port) is parameter 1 as indicated by

the manual.

RS485 DF1 Module Parameters

B-1

Page 48

1 DPI Port

Range: 0 to 7

Default: 5

Type: Read Only

Reset Required: N/A

Displays the port to w hich the m odule is co nnected. This will usually

be port 5.

2 DPI Data Rate

Range: 0 = 125 Kbps

Default: 0 = 125 Kbps

Type: Read Only

Reset Required: N/A

Displays the dat a rate us ed by the driv e. This rate is set in t he d riv e

and the module detects it.

1 = 500 Kbps

3 DF1 Addr Cfg

Range: 0 to 254

Default: 1

Type: Read/Write

Reset Required: Yes

Sets the node address if the Dat a Rate Sw itc h on the module is se t

to “PGM” (Program).

4 DF1 Addr Actual

Range: 0 to 254

Default: 1

Type: Read Only

Reset Required: N/A

Displays the DF1 node address actually used by the module.

B-2

RS485 DF1 Communications Module

Page 49

5 DF1 Rate Cfg

Range: 0 = 1200 bps

Default: 3 = 9600 bps

Type: Read/Write

Reset Required: Yes

Sets the DF1 data rate if the Data Rate switch on the module is set

to “PGM” (Program).

1 = 2400 bps

2 = 4800 bps

3 = 9600 bps

4 = 19.2 kbps

5 = 38.4 kbps

6 DF1 Rate Actual

Range: 0 = 1200 bps

Default: 3 = 9600 bps

Type: Read Only

Reset Required: Yes

Displays the DF1 data rate actually used by the module.

1 = 2400 bps

2 = 4800 bps

3 = 9600 bps

4 = 19.2 kbps

5 = 38.4 kbps

7 Ref/Fdbk Size

Range: 0 = 16-bit

1 = 32-bit

Default: 0 = 16-bit

Type: Read Only

Reset Required: N/A

Displays the size of the Refer enc e/Feed back. The driv e determ ines

the size of the Reference/Feedback.

8 Datalink Size

Range: 0 = 16-bit

1 = 32-bit

Default: 0 = 16-bit

Type: Read Only

Reset Required: N/A

Displays the size of each Datalink word. The drive determines the

size of Datalinks.

RS485 DF1 Module Parameters

B-3

Page 50

9 Reset Module

Range: 0 = Ready (No action)

Default: 0 = Ready

Type: Read/Write

Reset Required: No

This parameter is a command. It resets the module if set to “Reset

Module.” It restores the module to factory default settings if set to

“Set Defaults.” No action is taken if set to “Ready.” The parameter

resets to “0 = Ready” after the command is performed.

1 = Reset Module

2 = Set Defaults (Restores module to factory-default

settings)

ATTENTION: If the module is transmitting I/O that

controls the drive, the drive may faul t when you reset

!

the module. Determ ine h ow you r d riv e w ill re sp ond

before resetting a connected module. Failure to

observe this precaution cou ld resul t in bod il y inj ury

or damage to equipment.

10 Comm Flt Action

Range: 0 = Fault

Default: 0 = Fault

Type: Read/Write

Reset Required: No

1 = Stop

2 = Zero Data

3 = Hold Last

4 = Send Flt Cfg

B-4

Sets the action that the module ta kes when the modul e d etec t s th at

RS485 DF1 communications have been disrupted. This setting is

effective only if I/O that controls the drive is transmitted though the

module.

ATTENTION: Comm Flt Action (module paramete r

10) lets you determine the action of the module and

!

connected drive if commun ications are disrupted. By

default, this par am ete r fa ults the drive. You can set

this parameter so that the drive continues to run.

Take precautions to ensure that the setting of this

parameter does not create a hazard of injury or

equipment damage. Failure to observe this

precaution could resu lt in bodily injury or dama ge to

equipment.

RS485 DF1 Communications Module

Page 51

11 Active Cfg

Range: 0 = Switches

Default: 0 = Switches

Type: Read Only

Reset Required: N/A

Displays the source from which the module node address and data

rate are taken. This will either be switches on the module or

parameters in EEPROM. The source is determined by the settings

of the switches on the module. See chapter 3, Installing the RS485

DF1 Module, for more information about the switches.

1 = EEPROM

12 DPI I/O Cfg

Range: See figure B.1 .

Default: xxx0 0001

Type: Read/Write

Reset Required: Yes

Configures the I/O that is transferred through the module. See

figure B.1

Figure B.1 – DPI I/O Config (Parameter 12)

RS485 DF1 Module Parameters

Not Used

Not Used

Not Used

Datalink C

Datalink D

Datalink B

00010xxx

Datalink A

Cmd/Ref

01234567

1= I/O Enabled

0= I/O Disabled

x=Not Used

B-5

Page 52

13 DPI I/O Active

Range: See figure B.2.

Default: xxx0 0001

Type: Read Only

Reset Required: N/A

Displays the I/O that the module is actively transmitting. The value

of this parameter will usually be equal to the value of module

parameter 12 (DPI I/O Cfg). See figure B.2.

1= I/O Enabled

Cmd/Ref

01234567

0= I/O Disabled

x=Not Used

Datalink C

Datalink D

Not Used

Not Used

Not Used

Figure B.2 – DPI I/O Active (Parameter 13)

Datalink A

Datalink B

00010xxx

14 Flt Cfg Logic

Range: 0000 0000 0000 0000 to 1111 1111 1111 1111

Default: 0000 0000 0000 0000

Type: Read/Write

Reset Required: No

Sets the Logic Command data that is sent to the drive if module

parameter 10 (Comm Flt Action) is set to “Send Flt Cfg” and

communications are disrupted.

The bit definitio ns will d epend on the produc t to wh ich the mod ule is

connected.

15 Flt Cfg Ref

Range: 0 to 4294967295

Default: 0

Type: Read/Write

Reset Required: No

Sets the Reference data that is sent to the drive if module

parameter 10 (Comm Flt Action) is set to “Send Flt Cfg” and

communications are disrupted.

Important: If the drive uses a 16-bit Ref erence , the most signi fican t

B-6

word of this value must be set to zero (0) or a fault will

occur.

RS485 DF1 Communications Module

Page 53

Flt Cfg A1

16

Flt Cfg A2

17

Flt Cfg B1

18

Flt Cfg B2

19

Flt Cfg C1

20

Flt Cfg C2

21

Flt Cfg D1

22

Flt Cfg D2

23

Range: 0 to 4294967295

Default: 0

Type: Read/Write

Reset Required: No

Sets the data that is sent to the Datalink in the drive if module

parameter 10 (Comm Flt Action) is set to “Send Flt Cfg” and

communications are disrupted.

Important: If the drive uses a 16-bit Ref erence , the most signi fican t

word of this value must be set to zero (0) or a fault will

occur.

24 CRC/BCC Cfg

Range: 0 = BCC (Block Check Character)

Default: 0 = BCC

Type: Read/Write

Reset Required: Yes

1 = CRC (Cyclic Redundancy Check)

Selects the method of error detection for data communications. This

setting must match the method used by the software or controller

communicati ng with the mod ule.

25 CRC/BCC Act

Range: 0 = BCC (Block Check Character)

1 = CRC (Cyclic Redundancy Check)

Default: 0 = BCC

Type: Read Only

Reset Required: N/A

Displays the actual method of error detection used.

RS485 DF1 Module Parameters

B-7

Page 54

26 Dup Msg Detect

Range: 0 = Disable

Default: 1 = Enable

Type: Read/Write

Reset Required: No

Enables/disables duplicate message detection by the module.

Normally, this is set to “Enable” (default). Set to “Disable” if using a

ProSoft 3150-DFM module or any device that does not increment

the TNS (transaction number) ID.

1 = Enable

B-8

RS485 DF1 Communications Module

Page 55

Logic Command/

Appendix C provides the definitions of the Logic Command/Logic

Status words that are used for some products that can be

connected to the RS485 DF1 module. If you do not see the Logic

Command/Logic Status for the product that you are using, refer to

your product’s documentation.

C.1 SP600 Drives

Logic Command Word

Logic Bits

15 14 13 12 11 10 9876543210

x Stop 0 = Not Stop

x

x Jog 0 = Not Jog

x Clear Faults 0 = Not Clear Faults

x x Direction 00 = No Command

x Local Control 0 = No Local Control

xMOP

x x Accel Rate 00 = No Command

x x Decel Rate 00 = No Command

APPENDIX C

Status Words

Command Description

1 = Stop

1

Start

Increment

0 = Not Start

1 = Start

1 = Jog

1 = Clear Faults

01 = Forward Command

10 = Reverse Command

11 = Hold Direction Control

1 = Local Control

0 = Not Increment

1 = Increment

01 = Accel Rate 1 Command

10 = Accel Rate 2 Command

11 = Hold Accel Rate

01 = Decel Rate 1 Command

10 = Decel Rate 2 Command

11 = Hold Decel Rate

Logic Command/Status Words

C-1

Page 56

Logic Bits

15 14 13 12 11 10 9876543210

x x x Reference

xMOP

1

A 0 = Not Stop condition (logic 0) must first be present before a 1 = Start condition

will start the drive.

Command Description

Select

Decrement

000 = No Command

001 = Ref. 1 (Ref A Select)

010 = Reserved

011 = Ref. 3 (Preset 3)

100 = Ref. 4 (Preset 4)

101 = Ref. 5 (Preset 5)

110 = Ref. 6 (Preset 6)

111 = Ref. 7 (Preset 7)

0 = Not Decrement

1 = Decrement

Logic Status Word

Logic Bits

1514131211109876543210

x Command

xActual

x Accel 0 = Not Accelerating

x Decel 0 = Not Decelerating

xAlarm0 = No Alarm

x Fault 0 = No Fault

x At Speed 0 = Not At Reference

xxx Local

Status Description

x Ready 0 = Not Ready

x Active 0 = Not Active

Direction

Direction

Control

1 = Ready

1 = Active

0 = Reverse

1 = Forward

0 = Reverse

1 = Forward

1 = Accelerating

1 = Decelerating

1 = Alarm

1 = Fault

1 = At Reference

000 = Port 0 (TB)

001 = Port 1

010 = Port 2

011 = Port 3

100 = Port 4

101 = Port 5

110 = Port 6

111 = No Local

C-2

RS485 DF1 Communications Module

Page 57

Logic Bits

1514131211109876543210

xxxx Reference 0000 = Ref A Auto

Status Description

0001 = Reserved

0010 = Preset 2 Auto

0011 = Preset 3 Auto

0100 = Preset 4 Auto

0101 = Preset 5 Auto

0110 = Preset 6 Auto

0111 = Preset 7 Auto

1000 = Term Blk Manual

1001 = DPI 1 Manual

1010 = DPI 2 Manual

1011 = DPI 3 Manual

1100 = DPI 4 Manual

1101 = DPI 5 Manual

1110 = DPI 6 Manual

1111 = Jog Ref

Logic Command/Status Words

C-3

Page 58

C-4

RS485 DF1 Communications Module

Page 59

GLOSSARY

BCC (Block Check Character) - A technique for error detection in

data commun icati ons. A chara cter i s added to a trans miss ion b lock,

which is compared with a second BCC computer by the receiver to

determine if the transmission is error free.

controller - Also c al led p rogrammable logic c ontr oll er. A solid-state

control system that has a user-programmable memory for storage

of instructions to implement specific functions such as I/O control,

logic, timing, counting, report generation, communication,

arithmetic, and data file manipulation. A controller consists of a

central processor, input/output interface, and memory.

scanner.

CRC (Cyclic Redundancy Check) - A commonly used technique

for error detection in data communications. A polynomial algorithm

is performed on the data, and the resultant checksum is appended

at the end of the frame. The receiving device performs a similar

algorithm.

data rate - The speed at which data is transferred on the RS485

DF1 network. Each device on an RS485 DF1 network must be set

for the same dat a rate. You can set the RS485 DF1 module to 120 0,

2400, 4800, 9600, 19.2 K or 38.4 kbps.

See also

Glossary

Datalink - A type of pointer used by some SP600 drives to transfer

data to and from the controller. Datalinks allow specified parameter

value(s) to be accessed or changed without using explicit

messages. When enabled, each Datalink consumes either four

bytes or eight bytes in both the input and output image table of the

controller. The drive determines the size of Datalinks.

DF1 - A Rockwell Automa tion Datalink la yer protocol that combines

features of subcategories D1 (data transparency) and F1 (two-way

simultaneous transmission with embedded responses) of ANSI

x3.28 specification.

DPI (Drive Peripheral Interface) - A peripheral communication

interface used by various Reliance Electric drives and power

products.

DPI peripheral - A device that provides an interface between DPI

and a network or user. Peripheral devices are also referred to as

“modules” and “adapters .” The RS485 DF 1 module and SP600 OIM

are examples of DPI peripherals.

Glossary-1

Page 60

DPI product - A device that uses the DPI communications interface

to communicate with one or more peripheral devices. For example,

a motor drive such as a SP600 drive is a DPI product. In this

manual, a DPI product is also referred to as “product” or “host.”

fault action - Determines how the module and connected product

act when a communications fault (for example, a cable is

disconnected) occurs or when the scanner is switched out of run

mode. The former uses a communications fault action, and the

latter uses an idle fault action.

fault configuration - When communications are disrupted (for

example, a cable is di sconnected), the module and SP600 drive can

respond with a user-defined fault configuration. The user sets the

data that is sent to the drive in the fault configuration parameters

(parameters 15 (Flt Cfg Logic) through 24 (Flt Cfg D2 In)). When a

fault action para meter is set to use the faul t configura tion and a fault

occurs, the data from these parameters is sent as the Command

Logic, Reference, and/or Datalink(s).

flash update - The process of updating firmware in the module.

The module can be flash updated using the X-Modem protocol and

a RECOMM-232 serial converter.

hold last - When communications are disrupted (for example, a

cable is disconnected), the module and SP600 drive can respond

by holding last. Hold last results in the drive receiving the last data

received via the RS485 D F1 conne ction before the di sruptio n. If the

drive was running and using the reference from the module, it will

continue to run at the same reference.

Glossary-2

II/O data - I/O data, sometimes called “implicit messages” or “input/

output,” transmit time-critical data such as a Logic Command and

Reference. The terms “input” and “output” are defined from the

scanner’s point of view. Output is transmitted by the scanner and

consumed by the module. Input is transmitted by the module and

consumed by the scanner.

Logic Command/Logic Status - The Logic Command is used to

control the SP600 drive (for example, start, stop, direction). It

consists of on e 1 6-bit word of input to the mo dul e from the network.

The definitions of the bits in this word depend on the drive.

The Logic Status is used to monitor the SP600 drive (for example,

operating state, motor direction). It consists of one 16-bit word of

output from the module to the network. The definitions of the bits in

this word depend on the drive.

RS485 DF1 Communications Module

Page 61

module - Devices such as drives, controllers, and computers

usually req uire a module to provide a co mmunication interface

between them and a network such as RS485 DF1. An module

reads data on the netwo rk and transmits it to the connected device.

It also reads data in the device and transmits it to the network.

The RS485 DF1 module connects SP600 drives to an RS485 DF1

network. Modules are sometimes also called “adapters,” “cards,”

“embedded communication options,” “gateways,” and “peripherals.”

node address - An RS485 DF1 network can have as many as 255

devices connected to it. Each device on the network must have a

unique node address from 0 to 254.

non-volatile storage (NVS) - NVS is the permanent memory of a

device. Devices s uch as the modu le and drive store p arameters and

other information in NVS so that they are not lost when the device

loses power. NVS is sometimes called “EEPROM.”

operator interface module (OIM) - A device that can be used to

configure and control a SP600 drive.

PCCC (Programmable Controller Communications Command) The protocol used by some controllers to comm unicate with de vices

on a network. Some software products (for example, VS Utilities)

also use PCCC to communicate.

ping - A message that is sent by a DPI product to its peripheral

devices. They use the ping to gather data about the product,

including whether it can receive messages and whether they can

log in for control.

Glossary

Reference/Feedback - Reference is used to send a referenc e (for

example, speed, frequency, torque) to the p roduct. It consis ts o f one

word of input to the module from the network. The size of the word

(either a 16-bit word or 32-bit word) is determined by the drive.

Feedback is used to monitor the speed of a product. It cons is t s of

one word of output from the module to the network. The size of the

word (either a 16-bit wo rd or 3 2-bi t wo rd) is de term in ed by th e d riv e.

scanner - A separate module (of a multi-module controller) or a

built-in component (of a single-module controller) that provides

communication with modules connected to a network.

See also

controller.

status indicators - LEDs that are used to report the status of the

module, network, and drive. They are on the module and can be

viewed on the front cover of the drive when the drive is powered.

Glossary-3

Page 62

T yp e 0/ Type 1/Type 2 Control - When transmitting I/O, the module

can use diff erent types o f messag es for con trol. The Type 0, T ype 1,

Type 2 control events help Reliance Electric personnel identify the

type of message that a module is using.

transaction number (TNS) - A two-byte field in a DF1 message

packet that is used in combi nation with th e SRC (source no de of the

message) and CMD (command code) bytes to uniquely identify

every message packet. The TNS typically increments each time a

new DF1 messa ge is s ent. The reply me ssage w ill co ntain the same

TNS value.

VS Utilities software - A Windows-based software tool for

monitoring and co nfiguring Re liance Ele ctric produ cts an d module s.

VS Utilities can be used to configure the RS485 DF1 module and

SP600 drives.

zero data - When communications are disrupted (for example, a

cable is disconnec ted) , the mo dule an d drive can res pond wi th zero

data. Zero data results in the drive receiving zero as values for

command data. If the drive was running and using the reference

from the module, it will stay running but at zero reference.

Glossary-4

RS485 DF1 Communications Module

Page 63

INDEX

A

Active Cfg (11), B-5

assistance, technical

, 1-2

B

BCC (Block Check Character), 4-3

C

checklist, installation, 2-3

Comm Flt Action (10)

communications specifications

configuration tools

configuring the module

connecting the module to the drive

connecting the module to the

network

CRC (Cyclic Redundancy Check

CRC/BCC Act (25)

CRC/BCC Cfg (24)

Cyclic Redundancy Check (CRC)

, B-4

, A-1

, 4-1

, 4-1 to 4-8

, 3-6

, B-7

, B-7

D

Data Rate switch, location of, 2-1

Datalink Size (8)

DF1 Addr Actual (4)

DF1 Addr Dfg (3)

DF1 Rate Act (6)

DF1 Rate Actual (6)

DF1 Rate Cfg (5)

dimensions, module

DPI connector

DPI Data Rate (2)

DPI I/O Active (12)

DPI I/O Config (12)

DPI Port (1)

DPI ports

DRIVE status indicator

Dup Msg Detect (26)

, B-3

, B-2

, B-2

, B-3

, B-3

, B-3

, A-1

, 2-1

, B-2

, B-6

, B-5

, B-2

, 3-4

, 6-2

, B-8

, 3-3

, 4-3

, 4-3

E

error-checking method, setting, 4-3

events

codes and descriptions

viewing and clearing

, 6- 8

, 6-7

F

fault action, setting, 4-5

fault configuration parameters,

, 4-6

setting

Flt Cfg A1 (16)

Flt Cfg A2 (17)

Flt Cfg B1 (18)

Flt Cfg B2 (19)

Flt Cfg C1 (20)

Flt Cfg C2 (21)

Flt Cfg D1 (22)

Flt Cfg D2 (23)

Flt Cfg Logic (14)

Flt Cfg Ref (15)

, B-7

, B-7

, B-7

, B-7

, B-7

, B-7

, B-7

, B-7

, B-6

, B-6

I

I/O configuration, 4-4

installation

, 2- 3

checklist