Page 1

Installation Instructions

RDD-Series Rotary Direct Drive Bearingless

Motors

Catalog Numbers RDB-B2151, RDB-B2152, RDB-B2153

Topic Page

Important User Information 2

Catalog Number Explanation 3

Before You Begin 4

Install the Motor 8

Remove the Motor 16

Connector Data 18

Product Dimensions 19

Connector Information 21

Specifications 21

Additional Resources 22

About the Rotary Direct Drive Bearingless Motors

RDD-Series direct drive motors feature single-turn or multi-turn high resolution

encoders. These bearingless housed motors provide a compact design for direct

drive applications.

Page 2

2 RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls, publication

SGI-1.1

, is available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

, describes some important differences between solid state

Publication RDB-IN001A-EN-P — October 2009

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard and recognize the consequences.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that surfaces may reach dangerous temperatures.

Page 3

RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions 3

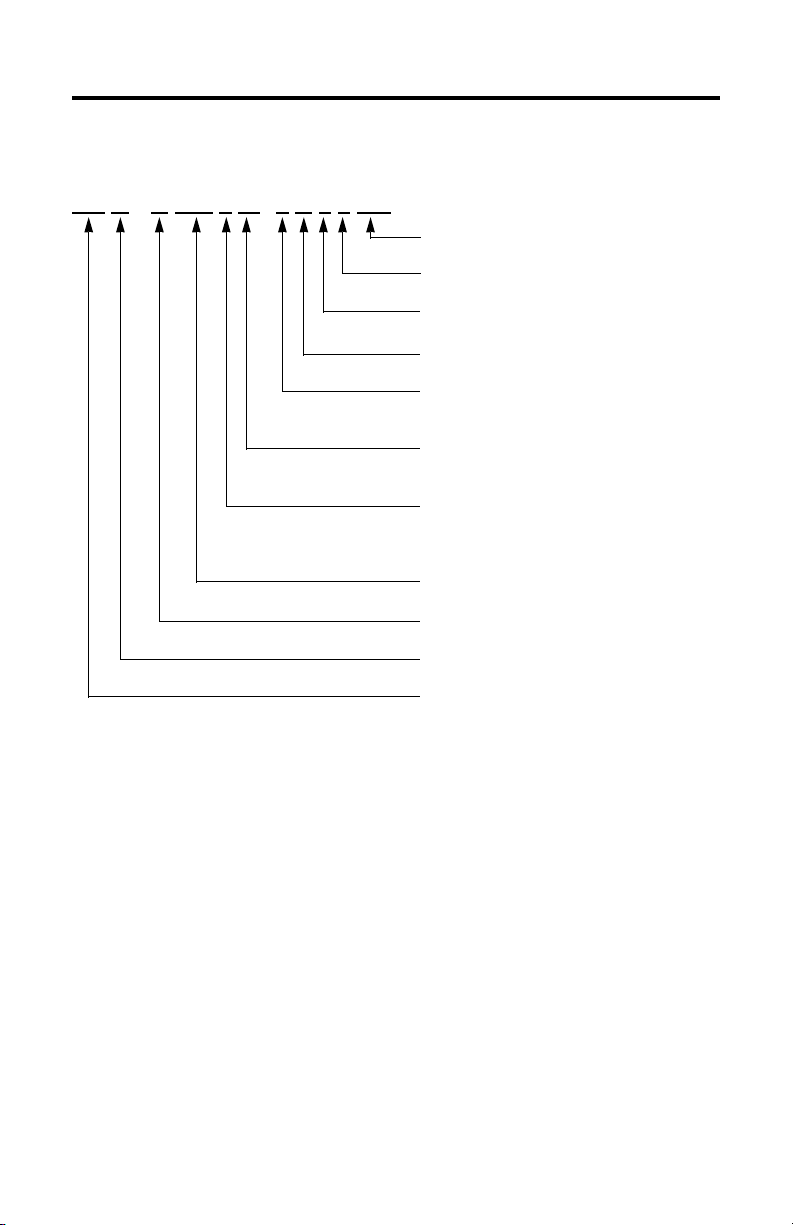

RD B -B 215 3 C -7B 7 2 AA

Catalog Number Explanation

FACTORY DESIGNATED OPTIONS

AA = Standard

BRAKE

2 = No Brake

CONNECTORS

7 = Circular, Right Angle, 180° Rotatable

ENCLOSURE/SHAFT

B = IP65 Housing/Blind Bore

FEEDBACK

3 = Single-turn High Resolution Heidenhain

7 = Multi-turn High Resolution Heidenhain

BASE SPEED

9 = 750 rpm @ 440V

C = 1000 rpm @ 440V

MAGNET STACKS

1 = One Stack

2 = Two Stacks

3 = Three Stacks

FRAME SIZE - Bolt Circle Diameter (BCD)

215 = 215 mm

VOLTAGE RATING

B = 400V Class

HOUSING TYPE

B = Bearingless Housing

BULLETIN NUMBER

RD = Rotary Direct Drive Servo Motor

Publication RDB-IN001A-EN-P — October 2009

Page 4

4 RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions

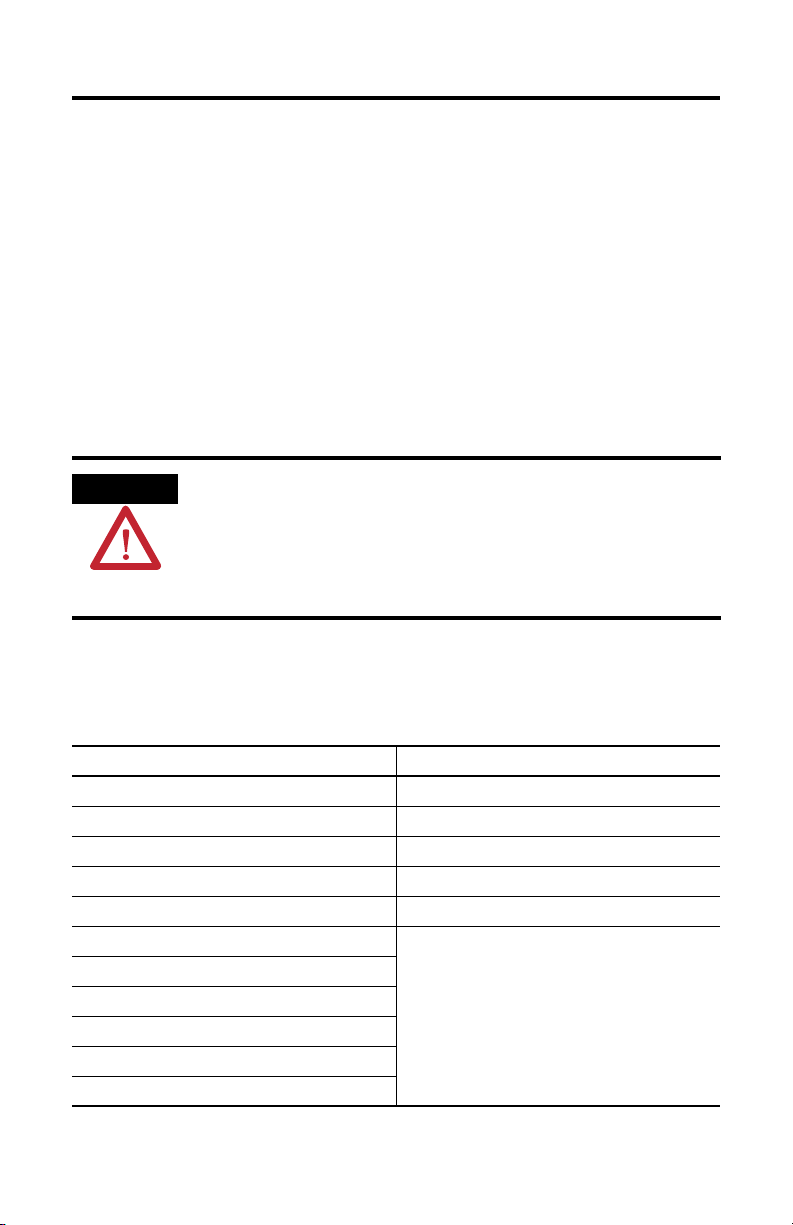

ATTENTION

Before You Begin

Remove all packing material, wedges, and braces from within and around the item.

After unpacking, verify the nameplate catalog number against the purchase order.

1. Remove the motor carefully from its shipping container.

2. Visually inspect the motor frame, mounting pilot, and connectors for

damage.

3. Notify the carrier of any shipping damage immediately.

4. Retain the cardboard cover and protective paper sleeving from the mounting

end of the motor.

Magnetized material within the motor is exposed whenever the protective cover is

removed and before the motor is mounted.

Accidental entry of foreign material can harm motor performance.

Always cover the mounting end of motor immediately after removing the motor or its

protective cover. This will greatly reduce the possibility of magnetic or non-magnetic

particles accidentally entering the motor.

Required Tools

These tools are needed to install or remove the product.

Publication RDB-IN001A-EN-P — October 2009

Tools Required Value

Hex bit, 150 mm (6

Hex bit, 25 mm (1

Torque wrench Capable of applying at least 45 N•m (35 lb•ft)

Screwdriver Phillips #4

Pry bar Flat blade

Micrometer N/A

Straight edge

Caliper

Runout indicator

Cleaning cloth

Flashlight

in.) minimum length 6 mm

in.) minimum length 8 mm

Page 5

RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions 5

Prolonging Motor Life

Thoughtful design and proper maintenance can increase the life of this motor.

Follow these guidelines to maximize the life of the motor:

• Always provide a drip loop in each cable to carry liquids away from the

connection to the motor.

• If design requirements permit, provide shields that protect the motor

housing, shaft bore, seals, and their junctions from contamination by

foreign matter or fluids.

• Inspect the motor for damage or wear on a regular basis. If damage or

excessive wear is observed, replace the item.

Preventing Electrical Noise

Electromagnetic interference (EMI), commonly called electrical noise, can reduce

motor performance. Effective techniques to counter EMI include filtering the AC

power, using shielded cables, separating signal cables from power wiring, and

practicing good grounding techniques.

Follow these guidelines to avoid the effects of EMI:

• Isolate the power transformers or install line filters on all AC input power

lines.

• Physically separate signal cables from motor cabling and power wiring.

Do not route signal cables with motor and power wires, or over the vent

openings of servo drives.

• Ground all equipment by using a single-point parallel ground system that

employs ground bus bars or large straps. If necessary, use additional

electrical noise reduction techniques to reduce EMI in noisy environments.

Refer to the System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001

, for additional information on reducing the effects of EMI.

Publication RDB-IN001A-EN-P — October 2009

Page 6

6 RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions

ATTENTION

Build and Route Cables

Knowledgeable cable routing and careful cable construction improves system

performance.

Follow these guidelines to build and install cables:

• Keep wire lengths as short as physically possible.

• Route noise sensitive wiring (encoder, serial, I/O) away from input power

and motor power wiring.

• Separate cables by 0.3 m (1 ft) minimum for every 9 m (30 ft) of parallel

run.

• Ground both ends of the encoder cable shield and twist the signal wire

pairs to prevent electromagnetic interference (EMI) from other equipment.

Do not tightly gather or coil the excess length of a power cable. Heat is generated within a

cable whenever power is applied. Always position a power cable so it may freely dissipate

any heat.

A power cable should not be coiled, except for temporary use when building or testing a

machine. If you temporarily coil a power cable, you must also derate the cable to meet

local code or follow an authoritative directive, such as Engineering Section 310.15(C) of

the NEC Handbook.

Failure to observe these safety procedures could result in personal injury or equipment

damage.

Publication RDB-IN001A-EN-P — October 2009

Page 7

RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions 7

SHOCK HAZARD

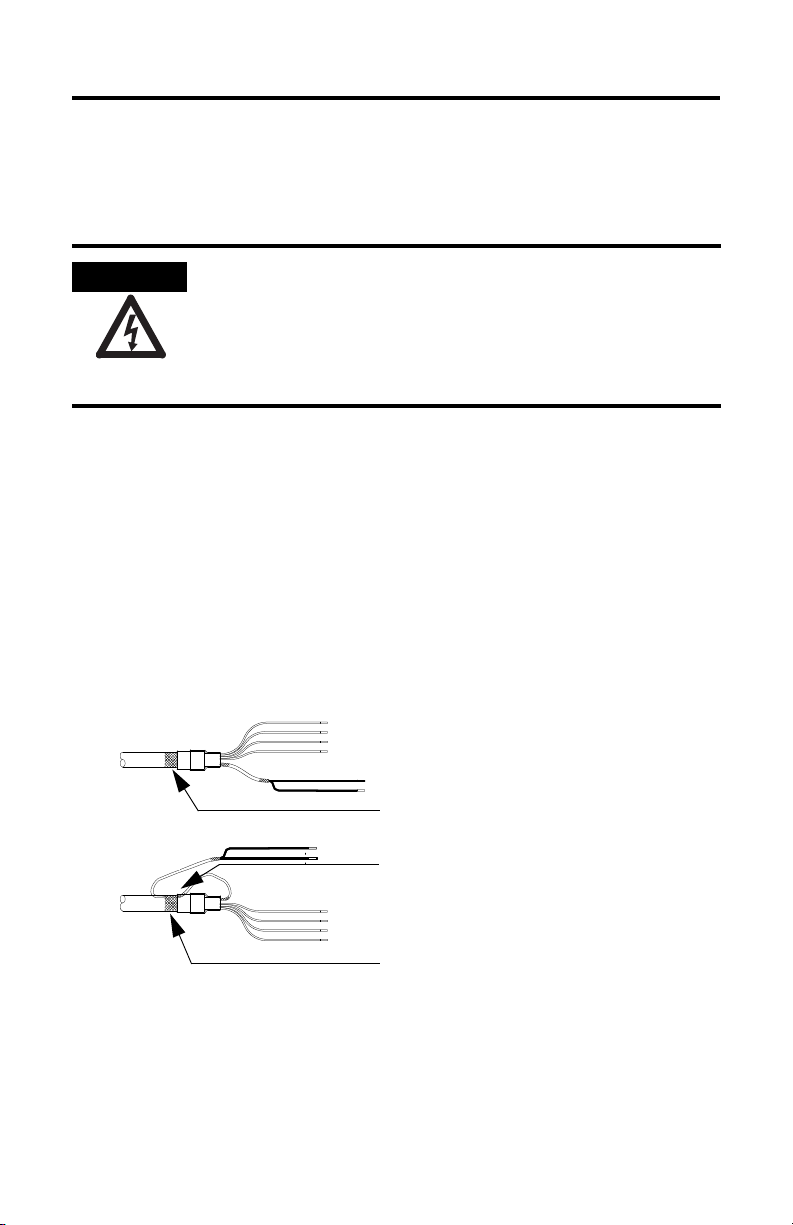

Shielded Signal Wires (one pair shown) within Power

Cable

Overall Power Cable Shield

Signal Wire Shield Contacts Overall Power

Cable Shield

Factory Supplied

Field Modified

All power and signal wire shields must connect to

machine ground.

Ground the Shielded Signal Wires within a Power Cable

Always ground the shield on any signal wires inside a power cable. Connecting this

shield to chassis ground reduces the potential for voltage inductance and EMI.

If any shield on a power cable is not grounded, high voltage can be present on that

shield.

Make sure there is a connection to ground for all shield wires inside a power cable, and

for the overall power cable shield.

Failure to observe safety precautions could result in personal injury or damage to

equipment.

Follow these steps to ground the shield wire on a 2090-CPBM7DF-xxAFxx or

2090-XXNPMF-xxSxx power cable.

1. Loop the signal wire pair to the overall cable shield as shown in the

diagram.

• Cable 2090-CPBM7DF-xxAFxx (shown) contains one signal wire pair.

• Cable 2090-XXNPMF-xxSxx contains two signal wire pairs.

2. Clamp all signal wire shields and the overall power-cable shield in the

power cable (chassis) ground clamp on the drive.

Grounding of Signal Wire Shields in a Power Cable

Publication RDB-IN001A-EN-P — October 2009

Page 8

8 RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions

ATTENTION

ATTENTION

ATTENTION

Install the Motor

All motors include a mounting pilot for aligning the motor on the machine.

Preferred fasteners are hardened steel. The installation must comply with all local

regulations and use equipment and installation practices that promote safety and

electromagnetic compatibility.

Unmounted motors, disconnected mechanical couplings, loose shaft keys, and

disconnected cables are dangerous if power is applied.

Disassembled equipment should be appropriately identified (tagged-out) and access to

electrical power restricted (locked-out).

Before applying power to the motor, remove the shaft key and other mechanical couplings

that could be thrown by the motor.

Failure to observe these safety precautions could result in personal injury.

Servo drive power must be turned off before connecting or disconnecting the cables to the

motor, and if a cable is left disconnected at the motor end.

Arcing or unexpected motion could occur if the feedback, power, or brake cables are

connected or disconnected while power is applied to the servo drive.

Failure to observe these safety procedures could result in personal injury or damage to the

motor and equipment.

Publication RDB-IN001A-EN-P — October 2009

Do not attempt to open or modify this motor.

Only an authorized Allen-Bradley repair center shall service this item. Refer to Rockwell

Automation Support for assistance to locate the nearest repair center.

Failure to observe safety precautions could result in personal injury or damage to

equipment.

Page 9

RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions 9

BURN HAZARD

Prepare the Motor for Installation

Follow these steps to prepare a motor for installation.

1. Verify sufficient clearance, heatsink mass, and air flow for the motor so it

stays within the operating temperature range of 0…40 °C (32…104 °F).

Do not enclose the motor unless cooling air is forced across the motor, and

keep other heat producing devices away from the motor. Heatsink

requirements are listed in a footnote to the Specifications

Outer surfaces of a motor can reach high temperatures, 125 °C (275 °F), during operation.

Take precautions to prevent accidental contact with hot surfaces. Consider motor surface

temperature when selecting connections and cables to install on a motor.

Failure to observe safety precautions could result in personal injury or damage to

equipment.

2. Wipe the machine shaft and motor bore to remove excess grease or

contaminants.

A light oil coating is acceptable.

table.

Publication RDB-IN001A-EN-P — October 2009

Page 10

10 RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions

Small Shaft

Diameter

Large Shaft

Diameter

Pilot

Diameter

Small Shaft Length

Overall Shaft Length

Pilot

Recess

Machine

Mounting

Surface

Verify Machine Mounting Dimensions

Verify proper fit of the motor to the machine mount by measuring the following

machine mounting dimensions.

1. Verify these dimensions are within the measurement range in the table:

• Pilot diameter

• Shaft diameter, small and large

• Shaft length, small and overall

2. Verify the Total Indicator Readout (TIR) of these dimensions is less than the

value in the table when measured with a dial indicator:

• Shaft runout

• Pilot concentricity

• Mounting surface perpendicularity

Machine Mounting Dimensions

Publication RDB-IN001A-EN-P — October 2009

Page 11

RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions 11

RDB-B2151, RDB-B2152, RDB-B2153 Machine Mounting Dimensions

Attribute Value

Pilot diameter 163.989…164.014 mm (6.4563…6.4372 in.)

Shaft diameter, small 70.985…71.000 mm (2.7947…2.7953 in.)

Shaft diameter, large 71.985…72.000 mm (2.8340…2.8346 in.)

Shaft length, small

RDB-B2151

RDB-B2152

RDB-B2153

Shaft length, overall

RDB-B2151

RDB-B2152

RDB-B2153

Shaft runout 0.13 mm (0.005 in.) max

Pilot concentricity 0.10 mm (0.004 in.) max

Mounting surface perpendicularity 0.10 mm (0.004 in.) max

48.60…49.40 mm (1.915…1.945 in.)

82.60…83.40 mm (3.255…3.285 in.)

116.60…117.40 mm (4.595…4.625 in.)

103.87…104.13 mm (4.031…4.149 in.)

137.87…138.13 mm (5.371…5.489 in.)

171.87…172.13 mm (6.711…6.829 in.)

Publication RDB-IN001A-EN-P — October 2009

Page 12

12 RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions

IMPORTANT

3

1

2

Mount the Motor

Follow the diagram and steps below to install a motor on the machine.

The preferred motor-mounting orientation is with the feedback and power connectors on

the bottom of the motor. The preferred orientation improves environmental protection.

Alternate alignment ports are shown in the Product Dimensions

Step Description

1 Center motor on shaft.

2 Position motor on machine shaft and mate pilot in the machine recess.

3 Using an alternating pattern, insert and tighten fasteners.

drawing.

Publication RDB-IN001A-EN-P — October 2009

Page 13

RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions 13

ATTENTION

Tighten the Compression Coupling

Follow these steps to secure the motor on the machine shaft.

1. Remove the black cap screw from the hole A using a Phillips #4 screwdriver.

Refer to the motor outline on page 19

for the location of the compression

coupling fitting and alignment pin.

2. Use a 6 mm hex bit to tighten the compression coupling in hole A to

29.8 N•m (22 lb•ft)

Improper torque values may cause the machine shaft to slip in the compression coupling.

This may generate sufficient friction and heat to permanently weld the motor hub to the

machine shaft.

Failure to observe this safety precaution could result in damage to the motor and the

machine.

.

Secure the Shipping Hardware

Follow these steps to secure loose hardware used during motor installation and to

prepare the motor for use.

1. Remove the silver shipping alignment pin from hole B, and insert it in

hole A.

2. Insert the black cap screw in hole B.

3. Tighten the alignment pin and the cap screw to the value specified in this

table.

Motor Cat. No. Fastener Type Torque Value

RDB-B215x Alignment pin with

8 mm hex head

RDB-B215x Cap screw 3.4 N•m (2.5 lb•ft)

18.0 N•m (13 lb•ft)

4. Rotate the machine shaft or load by hand to verify free rotation of the motor.

Publication RDB-IN001A-EN-P — October 2009

Page 14

14 RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions

ATTENTION

IMPORTANT

Power Connector Feedback Connector

O-ring Removed O-ring

Threaded Plug - Install O-ring SpeedTec Plug - Remove O-ring

Align the flat surfaces

before securing connection.

Attach the Motor Cables

Follow these steps to attach the feedback and power/brake cables after the motor is

mounted.

Make sure that cables are installed and restrained to prevent uneven tension or flexing at

the motor-to-cable connections.

Excessive and uneven lateral force at the motor connectors can result in the connector’s

environmental seal opening and closing as the cable flexes.

Failure to observe safety precautions could result in damage to the motor and its

components.

1. Form a drip loop in the cable before attaching it.

A drip loop creates a low spot in the cable. Gravity causes any liquid to flow

to the low spot and away from the connectors, thereby reducing the

potential for any liquid to enter the connector.

2. Determine if you should remove the O-ring from the motor connectors.

• Threaded plugs (power or feedback) require an O-ring.

• SpeedTec plugs (power or feedback) do not require an O-ring.

The O-ring on the motor connector dampens the effects of vibration at the

cable-to-motor connection. This creates a more secure connection for a

cable with a threaded plug. O-rings interior to the threaded and SpeedTec

plug provide complete environmental sealing for the connection.

The 2090-XXNPMF-xxSxx power cable and the 2090-XXNFMF-Sxx feedback cable require

an O-ring on the motor connector.

Publication RDB-IN001A-EN-P — October 2009

Page 15

RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions 15

IMPORTANT

TIP

ATTENTION

3. Carefully align the flat surface on the feedback or power/brake cable plug

with the flat surface on the motor connector.

The connector orientation shown is used to clearly show the alignment marker on each

cable socket.

The recommended orientation when installed positions the connectors at the bottom of the

motor.

4. Hand tighten the collar on the plug to fully seat it on the connector.

• The threaded plug requires five to six revolutions.

• The SpeedTec plug requires approximately one-quarter of a revolution.

A fully-seated threaded plug leaves a small opening, approximately

1…4 mm (0.04…0.16 in.), between the connector and the plug.

Do not apply excessive force when mating the cable plug with the motor

connector. If the plug and connector do not go together with light hand

force, realign the flat surfaces and try again.

Keyed connectors and cable plugs must properly align and be hand-tightened the

recommended number of turns.

Improper alignment is indicated by the need for excessive force, such as the use of tools,

to fully seat a plug.

Failure to observe safety precautions could result in damage to the motor and cable, and

their components.

Publication RDB-IN001A-EN-P — October 2009

Page 16

16 RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions

ATTENTION

IMPORTANT

BURN HAZARD

Remove the Motor

Follow these steps to remove a motor from a machine.

Outer surfaces of a motor can reach high temperatures, 125 °C (275 °F), during operation.

Take precautions to prevent accidental contact with hot surfaces. Consider motor surface

temperature when selecting connections and cables to install on a motor.

Failure to observe safety precautions could result in personal injury or damage to

equipment.

Servo drive power must be turned off before connecting or disconnecting the cables to the

motor, and if a cable is left disconnected at the motor end.

Arcing or unexpected motion could occur if the feedback, power, or brake cables are

connected or disconnected while power is applied to the servo drive.

Failure to observe these safety procedures could result in personal injury or damage to the

motor and equipment.

Align the Rotor

Follow these steps to align the rotor prior to dismounting the motor.

Publication RDB-IN001A-EN-P — October 2009

1. Remove the black cap screw from hole B.

Refer to the motor outline on page 19

for the location of the compression

coupling fitting and alignment pin.

2. Use a flashlight to illuminate hole B.

3. Rotate the shaft by hand until the opening for the alignment pin comes into

view in hole B.

4. Remove the alignment pin from hole A, and install it in hole B.

The alignment pin must fully engage the rotor. The shoulder of the alignment pin engages

the rotor when the pin is fully inserted.

5. Use a 8 mm hex bit to tighten the alignment pin in hole B to 18.0 N•m

(13 lb•ft).

Page 17

RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions 17

TIP

ATTENTION

Release the Compression Coupling

Follow these steps to release the compression coupling prior to dismounting the

motor.

1. Use a 6 mm hex bit to loosen the compression coupling in hole A

.

2. Loosen the compression coupling one complete revolution beyond

finger-tight to be sure the coupling releases from the machine shaft.

3. Secure the black cap screw in hole A by tightening it to 3.4 N•m (2.5 ft•lb).

Remove the Motor From the Machine

Follow these steps to remove the motor and to cover the opening before storing it.

1. Remove the fastener from each of the four mounting holes in the motor

faceplate.

2. Slide the motor off the machine shaft.

Notches in the motor-mounting surfaces provide a means to gently pry the motor loose

from the machine.

A flat-bladed pry bar may be used to loosen the motor.

Cover the Mounting End of the Motor

Seal the opening in the motor by performing the following steps.

1. Insert the protective paper sleeving around the rotor.

2. Cover the opening at the mounting end of the motor with the cardboard

cover that came with the motor.

Magnetized material within the motor is exposed whenever the protective cover is

removed and before the motor is mounted.

Accidental entry of foreign material can harm motor performance.

Always cover the mounting end of motor immediately after removing the motor or its

protective cover. This will greatly reduce the possibility of magnetic or non-magnetic

particles accidentally entering the motor.

Publication RDB-IN001A-EN-P — October 2009

Page 18

18 RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions

W

V

U

1

2

+

-

Intercontec P/N

CEDE271NN00000051000

Intercontec P/N

AEDC113NN00000200000

1212

3

6

15

15

1

2

4

5

7

8

9

10

10

1111

1313

1414

1717

1616

A

BC

G

H

EL

F

Intercontec P/N

BEDC091NN000200000

Connector Data

These tables identify the pinouts for feedback and power connectors.

(1)

M23 EnDat Feedback

Pin Signal Name Pin Signal Name Pin Signal Name

1 Sin+ A Phase U U Phase U

2 Sin- B Phase V V Phase V

3 Cos+ C Phase W W Phase W

4 Cos- Ground Ground

5 Data+ E Reserved + Reserved

6 Data- F 7CLK+ G 1

8CLK- H 2

9 EPWR 5V L

10 ECOM

11 Reserved

12 Reserved

13 TS+

14 TS15 Reserved

16

17

M23 Power M40 Power

(1) Use a Low-profile EnDat Feedback Module to interface the feedback signal between this motor and a Kinetix drive. The

module provides bi-directional feedback signal conversion between the EnDat encoding of a rotary direct drive motor and

the Hyperface encoding format compatible with Kinetix drives. Refer to Additional Resources

that describes the EnDat Feedback Module and how to interface it with compatible drives.

Publication RDB-IN001A-EN-P — October 2009

on page 22 for information

Page 19

RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions 19

P

HD

AD

RDB-B215x with Connector Size:

M23 Fdbk and M23 Pwr (shown) = 73.1 mm (2.88 in.)

M23 Fdbk and M40 Pwr (not shown) = 81.9 mm (3.22 in.)

104.4 (4.11)

LB

T

EB

LE

LD

E

LA

D

NB

TB

S = Dia. of Bolt Holes

N (Pilot Dia.)

M = Dia. of Bolt Circle

Shipping Alignment Pin

M23 Feedback and Power connectors shown.

Refer to Connector Information

on page 21 for additional information.

Coupling Access Port

with Cap Screw Cover

Location of Alternate

Coupling Access Port and

Shipping Alignment Pin

DB

Customer Interface

Detail of Machine Mounting Shaft

Product Dimensions

B

A

The tables list dimensions for bearingless motors with a single-turn or multi-turn

encoder. Footnotes provide tolerances for the common dimensions.

Publication RDB-IN001A-EN-P — October 2009

Page 20

20 RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions

Bearingless Motor Dimensions

Cat No.

RDB-

B2151 136.7

B2152 83.0

AD Max

mm (in.)

(5.38)

(1)

D

mm (in.)

70.985…

71.0

(2.7947…

2.7953)

DB Max

mm (in.)

71.985…

72.0

(2.8340…

2.8346)

B2153 117.1

(1) If the motor has an M40 power connector, add 18.6 mm (0.73 in.) to this dimension.

(2) Tolerance for this dimension is ±0.4 mm (0.015 in.).

(3) Tolerance for this dimension is ±1.50 mm (0.059 in.) static, ±0.13 mm (0.005 in.) dynamic.

(4) Tolerance for this dimension is ±0.520 mm (0.020 in.).

(5) Tolerance for this dimension is ±0.26 mm (0.010 in.).

Cat No.

RDB-

(1)

LE

mm (in.)

B2151 124.44

(4.899)

(2)

M

mm (in.)

215.0

(8.465)

(3)

N

mm (in.)

164.0

(6.4567)

B2152 158.42

(6.237)

(2)

E

mm (in.)

49.0

(1.93)

(3.27)

(4.61)

NB

mm (in.) P mm (in.)

164.040…

164.090

(6.4583…

6.4602)

(3)

EB

mm (in.)

104.0

(4.09)

138.0

(5.43)

172.0

(6.77)

189.0

(7.44)

(1)

HD

mm (in.)

230.9

(9.09)

(4)

S

mm (in.)

13.50

(0.5315)

B2153 192.43

(7.576)

(1) If the motor has an M40 power connector, subtract 29.67 mm (0.1.17 in.)from this dimension.

(2) Total Indicator Runout (TIR) is 0.25 mm (0.010 in.).

(3) Tolerance for this dimension is +0.014, -0.011 mm (+0.0005, -0.0004 in.).

(4) Tolerance for this dimension is +0.430, -0.0000 mm(+0.0169, -0.0 in.).

(5) Measurement is the minimum for this dimension.

LA

mm (in.)

14.0

(0.55)

T

mm (in.)

5.0

(0.197)

(4)

LB

mm (in.)

226.05

(8.90)

260.05

(10.24)

294.05

(11.58)

TB Min

mm (in.)

5.5

(0.22)

(5)

LD

mm (in.)

165.70

(6.524)

199.70

(7.862)

233.70

(9.201)

(5)

Publication RDB-IN001A-EN-P — October 2009

Page 21

RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions 21

Connector Information

Connector information includes the manufacturer part numbers for connector

shells, and contacts for power, ground, and feedback pins.

Connector Mount Type

Feedback, M23 90 degree

Power, M23 BEDC091NN000200000 61.193.11 N/A

Power, M40 CEDE271NN00000051000 61.203.11 N/A

(1) Connector shell does not include power, ground, or feedback contacts.

swivel mount

Connector Shell

AEDC113NN00000200000 N/A 61.004.11

(1)

Power and Ground

Contacts

Feedback

Contacts

All connectors are Intercontec SpeedTec type, and include an O-ring installed on

the outer diameter of the cable mounting area.

Specifications

Attribute Value

Temperature, operating 0…40 °C (32…104 °F)

Temperature, storage -30…70 °C (-22…158 °F)

Relative humidity, storage 5…95% noncondensing

Atmosphere, storage Non-corrosive

(1)

IP rating

(1) The motor rating excludes any reduction in the rating resulting from cables, plugs, or connections with a lower rating, and

(2) To obtain this thermal rating, mount RDB-x215 motors on a surface with heat dissipation equivalent to a

(3) International Protection Code (IP65) is roughly equivalent to a NEMA 12 (industrial use dust tight, drip tight).

an unsealed customer machine mounting interface.

457.2 x 457.2 x 12.7 mm (18 x 18 x 0.5 in.) aluminum heatsink.

IP65 - dust tight, water jet

(2)

(3)

Publication RDB-IN001A-EN-P — October 2009

Page 22

22 RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions

Additional Resources

These documents contain additional information concerning related Rockwell

Automation products.

Resource Description

Kinetix 6000 Multi-axis Servo Drives User

Manual, publication 2094-UM001

Kinetix 6200 Multi-axis Servo Drives User

Manual, publication 2094-UM002

Kinetix 7000 Multi-axis Servo Drives User

Manual, publication 2099-UM001

Low-profile EnDat Feedback Module Installation

Instructions, publication 2090-IN020

Allen-Bradley Industrial Automation Glossary,

publication AG-7.1

System Design for Control of Electrical Noise

Reference Manual, publication GMC-RM001

Kinetix Motion Control Selection Guide,

publication GMC-SG001

Information on installing, configuring, starting up, and

troubleshooting for your Kinetix 6000 servo drive system.

Information on installing, configuring, starting up, and

troubleshooting for your Kinetix 6200 servo drive system.

Information on installing, configuring, starting up, and

troubleshooting for your Kinetix 7000 servo drive system.

Information on connecting an EnDat Feedback Module to

interface the feedback signal from an RDD-Series motor

with a Kinetix servo drive system.

A glossary of industrial automation terms and

abbreviations.

Information, examples, and techniques designed to

minimize system failures caused by electrical noise.

Specifications, motor/servo-drive system combinations,

and accessories for Kinetix motion control products.

You can view or download publications at

http://literature.rockwellautomation.com. To order paper copies of technical

documentation, contact your local Rockwell Automation distributor or sales

representative.

Publication RDB-IN001A-EN-P — October 2009

Page 23

Notes:

RDD-Series Rotary Direct Drive Bearingless Motor Installation Instructions 23

Publication RDB-IN001A-EN-P — October 2009

Page 24

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in

using its products. At http://support.rockwellautomation.com

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that you

can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review

the information that's contained in this manual. You can also contact a special

Customer Support number for initial help in getting your product up and running.

, you can find

United States 1.440.646.3434

Outside United States Please contact your local Rockwell Automation representative for any technical

Monday – Friday, 8 a.m. – 5 p.m. EST

support issues.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully

operational when shipped from the manufacturing facility. However, if your

product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the

phone number above to obtain one) to your distributor in order to complete the return

process.

Outside United States Please contact your local Rockwell Automation representative for the return

procedure.

Allen-Bradley, Kinetix, Rockwell Automation, RDD-Series, Rockwell Software, and TechConnect are trademarks of Rockwell

Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication RDB-IN001A-EN-P — October 2009 PN-51289

Copyright © 2009 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...