Page 1

PowerFlex® Digital DC Drive

USER MANUAL

Firmware Version 1.006 - 2.001

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

www.rockwellautomation.com/literature) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for solid

state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect

or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility

or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

http://

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING: Identifies information about practices or

circumstances that can cause an explosion in a hazardous

!

environment, which may lead to personal injury or death, property

damage, or economic loss.

Important: Identifies information that is critical for successful application and

understanding of the product.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard, and recognize the consequences.

Shock Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that dangerous voltage may be

present.

Burn Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that surfaces may be at

dangerous temperatures.

PowerFlex, DriveExplorer, DriveTools SP, DPI, and SCANport are either trademarks or registered trademarks of Rockwell Automation, Inc.

Klixon® is a registered trademark of Sensata Technologies, Inc.

PowerFlex Digital DC Drive User Manual

Page 3

Summary of Changes

Manual Updates

The information below summarizes the changes to the PowerFlex Digital

DC Drive User Manual, publication 20-UM001… since the October 2007

release.

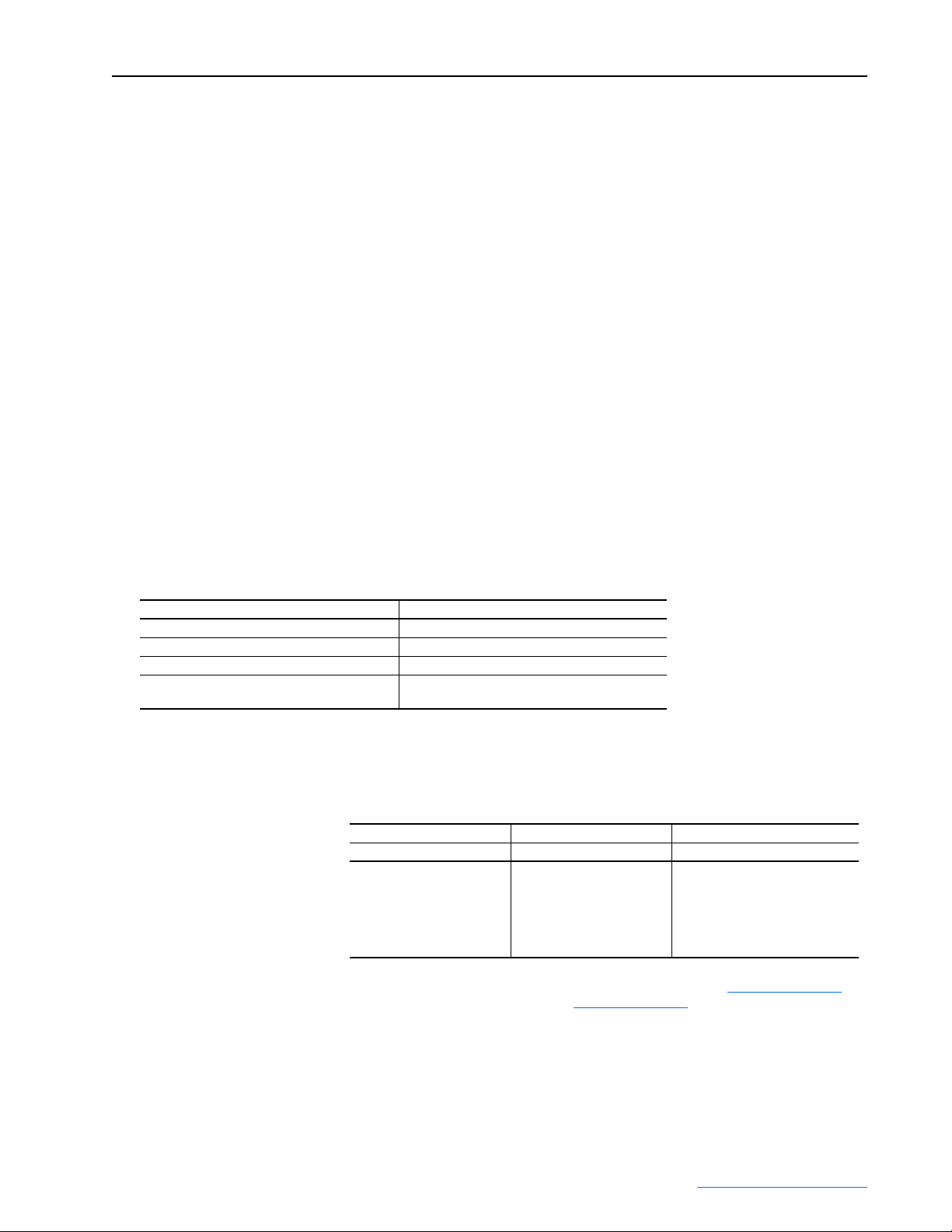

Change Page(s)

Updated the Using Contactors section to include new Contactor Control selections

for configuring AC versus DC contactors.

Added the “Cable and Wiring Recommendations” table. 1-14

Updated the “Typical Power Wiring Diagrams” to include terminal and parameter

designations.

Added “Sourcing Digital Outputs, 24V DC external supply” diagram to I/O Wiring

examples.

Added an illustration and instructions for routing I/O and control wiring. 1-42

Added a graphical indicator for parameters accessible only when parameter 211

[Param Access Lvl] = 1 “Advanced”.

Added parameter 1409 [Jog Off Delay], to allow you to specify the minimum delay

between removing the Jog input and commanding the main contactor to open.

This delay reduces the wear on the contactor when repeatedly opening and

closing the Jog input over a short period of time.

Added parameter 1410 [Jog Ramp Time], to allow you to set the rate of

acceleration and deceleration while the Jog function is active.

Changed option 3 "Quick Stop" to "Fast Stop" for parameters 354 [Aux Inp Flt Cfg]

and 365 [OverTemp Flt Cfg].

Changed option 35 “Fld Weak En” to “Force MinFld” for parameters 133-144

[Digital Inx Sel].

Added option 64 “Invert Flt” to parameters 133-144 [Digital Inx Sel], to allow a

digital input wired to an inverting fault device to issue an “Inverting Fault” (F37).

Updated the options for parameter 1391 [ContactorControl] to accommodate the

use of a AC or DC contactor with or without a dynamic brake resistor.

Added the new “Inverting Fault” (F37) fault to indicate that the associated inverting

fault device has opened.

Updated the following drive specifications:

• Maximum short circuit rating

• Control speed regulation

• Torque regulation

Updated the fuses identified in the “Drive Power Circuit Protection” tables. A-7

Updated the “Control Power Circuit Protection Fuses” tables and fuse location

illustrations.

Added the “Lug Kit Specifications” table. A-21

Added the instructions for operating the PowerFlex DC drive in field weakening

mode and using a DC contactor and/or an inverting fault device in the armature

circuit with firmware version 1.006.

Updated the “Fine Tuning the Speed Regulator” procedure. C-29

Updated the terminal numbers indicated in the Digital Inputs/Outputs block

diagram.

Updated the Ramp Reference block diagram to include the new parameter 1410

[Jog Ramp Time].

Removed the 20-COMM-L communication adapter from the compatible

Communication Adapter Kits table.

1-9

1-17

1-39

3-1

3-24

3-29

3-53

3-65

3-65

3-67

4-5

A-2

A-15

C-5

D-3

D-7

E-1

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 4

soc-ii

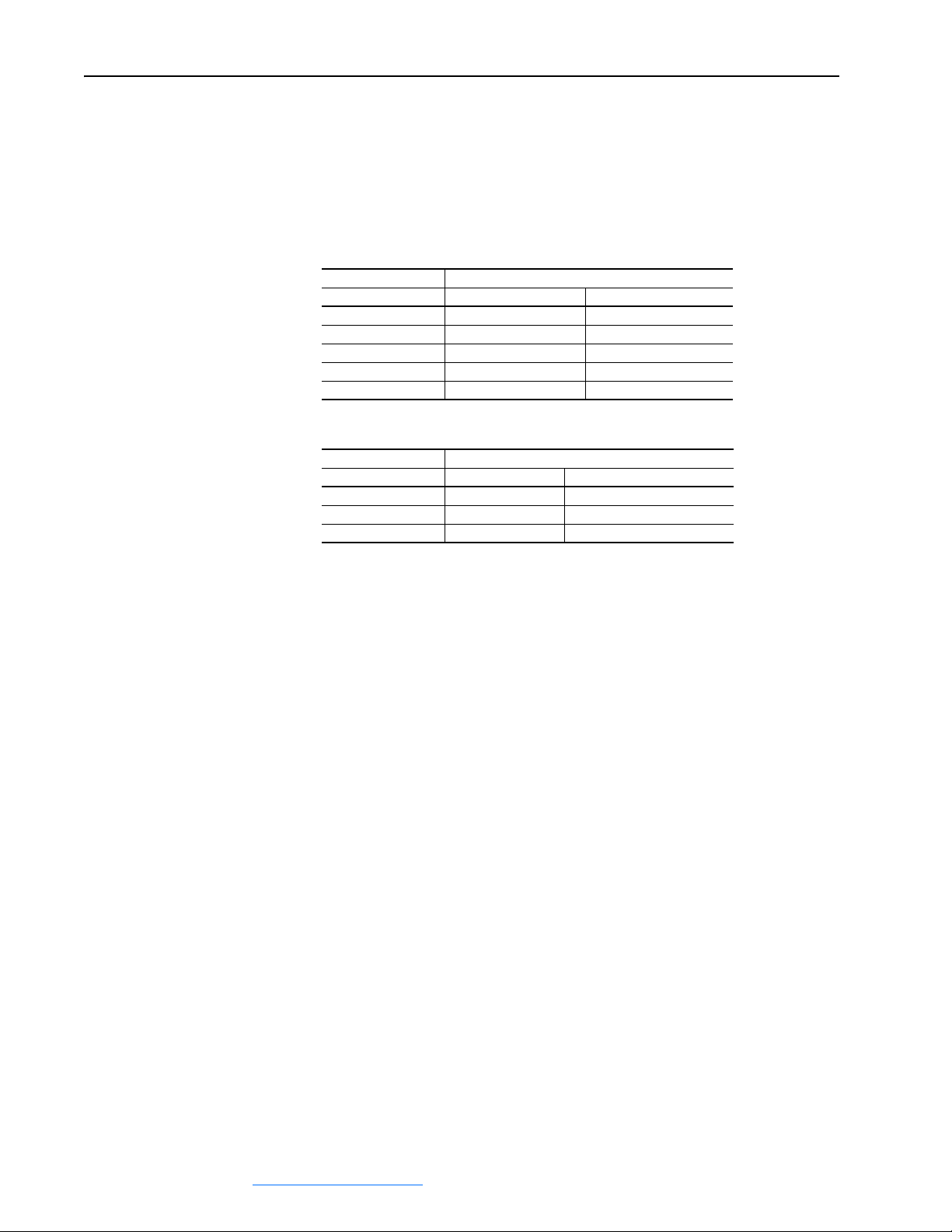

The information below summarizes the changes to the PowerFlex Digital

DC Drive User Manual, publication 20-UM001… since the initial release.

Change Page(s)

Removed erroneous derating information. 1-2

Updated AC Input Voltages tables. 1-15

Updated “AnalogCflct” Alarm description to include parameters 1323-1327 [DPI Px

Select].

Updated Agency Certification Information. A-1

Added notation regarding required installation in a Pollution Degree 2 environment. A-1

Updated the Maximum Short Circuit Ratings data. A-2

Added footnote regarding coil voltage to DC Loop Contactor table information. A-19

Updated block diagrams to correct parameter numbers and names. D-2

, A-1

4-7

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 5

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Summary of

Manual Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . soc-i

Changes

Preface Overview

Who Should Use this Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-1

What is in this Manual?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-1

Drive Storage Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-1

Drive Nameplate Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-2

Drive Frame Sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-2

Reference Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-2

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-3

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-3

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-4

Chapter 1 Installation and Wiring

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Operating Conditions and Temperatures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Minimum Mounting Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Mounting Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Lifting PowerFlex DC Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Mounting Frame C Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Removing the Drive Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Frame A Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Frame B and C Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Line Reactors / Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Using Contactors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

AC Input Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

DC Output Contactors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Dynamic Brake Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Control Power Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

General Grounding Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Safety Ground (PE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Power Feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Encoder Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Tachometer Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Power Circuit Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Cable and Wiring Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Power Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

AC Input Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

DC Output Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Typical Power Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Armature Converter Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Field Circuit Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Field Current Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Thermistors and Thermal Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Control Circuit Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Frame C Heatsink Cooling Fans and Armature Fuse Signal Terminals . . . . . . . . . . . 1-31

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 6

2

I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

DIP Switch and Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

I/O Signal and Control Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

I/O Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Digital Encoder Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

DC Analog Tachometer Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-42

I/O and Control Wire Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-42

Chapter 2 Drive Start Up

Drive Start Up Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Before Applying Power to the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Applying Power to the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Speed-Up Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Configuring the Speed Zero Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Adaptive Speed Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Chapter 3 Programming and Parameters

About Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

How Parameters are Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

File–Group–Parameter Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Numbered List View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Cross Reference Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Basic Parameter View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Advanced Parameter View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Monitor File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Motor Control File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Speed Command File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Dynamic Control File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Applications File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Utility File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Communications File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

Input / Output File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

Parameter Cross Reference – by Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-72

Parameter Cross Reference – by Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-77

Chapter 4 Troubleshooting

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Faults and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Drive Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

HIM Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Manually Clearing Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Fault Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Clearing Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Alarm Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Common Drive Symptoms and Corrective Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Drive will not start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Drive starts but motor does not turn and no armature current. . . . . . . . . . . . . . . . . . . 4-12

The motor does not reach commanded speed.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

The motor is turning in the wrong direction.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

The motor reaches maximum speed immediately.. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Testpoint Codes and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Page 7

Appendix A Supplemental Drive Information

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

IP20 (NEMA UL/Type Open) Watts Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Communication Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Typical Programmable Controller Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Logic Command/Status Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Drive Power Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Frame A and B Fuse Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Frame C Fuse Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Control Power Circuit Protection Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

AC Input Line Reactors and AC Input Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

DC Output Contactors and Dynamic Brake Resistor Kits . . . . . . . . . . . . . . . . . . . . . . . A-19

DC Contactor Crimp Lug Kit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-21

Appendix B HIM Overview

External and Internal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

LCD Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

ALT Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Using the S.M.A.R.T. List Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Viewing and Editing Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

LCD HIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Removing/Installing the HIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

3

Appendix C Application Notes

Analog Input Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Example 1:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Example 2:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Analog Input Signal Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Current / Speed Curve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Droop Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Field Weakening Mode Configuration (v1.006) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Using a DC Contactor Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Using a DC Contactor and a Dynamic Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Using an Inverting Fault Device Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Using a DC Contactor and an Inverting Fault Device. . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Using a DC Contactor, a Dynamic Brake and an Inverting Fault Device. . . . . . . . . . . C-7

PID Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Configure a Line Speed Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Configure the Feedback Signal in the Follower Drive(s) . . . . . . . . . . . . . . . . . . . . . . C-10

Configure the Tension Set Point Signal in the Follower Drive(s). . . . . . . . . . . . . . . . C-12

Reference Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

“Auto” Speed Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

“Manual” Speed Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

Changing Speed Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

Torque Reference Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

Auto/Manual Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

Speed Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-15

Scale Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

Linking Parameters Via the Scale Block Parameters . . . . . . . . . . . . . . . . . . . . . . . . . C-17

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 8

4

Speed Regulation Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-17

Adaptive Speed Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-17

Speed Up Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-20

Speed Threshold Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-20

Speed Zero Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-22

Speed Draw Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-23

Start At Powerup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-24

Fine Tuning the Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-25

Manually Adjusting the Current Regulator Tune Settings. . . . . . . . . . . . . . . . . . . . . . C-26

Fine Tuning the Field Current Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-26

Fine Tuning the Speed Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-29

Fine Tuning the Voltage Regulator in the Field Converter . . . . . . . . . . . . . . . . . . . . . C-31

Tuning the Field Current Curve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-33

Appendix D Control Block Diagrams

Diagram Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Appendix E Installing a Communication Adapter

Communication Adapter Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

What The Communication Adapter Kit Includes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Tools That You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Installing the Communication Adapter Module in the Drive . . . . . . . . . . . . . . . . . . . . . . E-2

Appendix F Optional Analog and Digital I/O Expansion Circuit Board

What This Option Board Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

I/O Expansion Board Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Appendix G Optional 115V AC to 24V DC I/O Converter Circuit Board

What This Option Board Provides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

I/O Converter Board Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

Index

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 9

Preface

Overview

The purpose of this manual is to provide you with the basic information

needed to install, start-up and troubleshoot the PowerFlex DC drive.

For information on . . . See page . . .

Who Should Use this Manual?

What is in this Manual? Preface-1

Drive Storage Conditions Preface-1

Drive Nameplate Data Preface-2

Reference Materials Preface-2

Drive Frame Sizes Preface-2

Manual Conventions Preface-3

General Precautions Preface-3

Catalog Number Explanation Preface-4

Preface-1

Who Should Use this Manual?

What is in this Manual?

Drive Storage Conditions

This manual is intended for qualified personnel. You must be able to

program and operate DC drives. In addition, you must have an

understanding of the parameter settings and functions detailed in this

manual.

The PowerFlex DC User Manual is designed to provide installation, basic

start-up information, and drive parameter definitions. For detailed drive

information, please refer to “Reference Materials” on page Preface-2

list of additional publications.

If it is necessary to store the drive for any length of time before installation,

follow these storage guidelines in order to ensure satisfactory operation at

start up and to maintain warranty coverage:

• After receipt and inspection, repack the drive in its original shipping

container and store in a clean, dry place.

• Place where the ambient temperatures do not exceed -25°C (-13°F) or

+55°C (131°F)

• Place where the relative air humidity range does not exceed 5% - 95%.

for a

• At an altitude of less than 3,000 meters (10,000 ft.) above sea level.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 10

p-2 Overview

Drive Nameplate Data

Drive Frame Sizes

The PowerFlex DC drive contains a data nameplate located on the side of

each drive that identifies the specific model number design, applicable AC

input power and DC output power data. All communication with Rockwell

Automation personnel concerning this product should include this

information.

Cat No.

20P41AD4P1RA0NNN

UL Type OPEN/IP20

Input: 460VAC 50/60 Hz 3.3A 3 Phase

Output: 500VDC 4.1A REGEN 1.0HP

1 Min Overload Amps

3 Sec Overload Amps

DC Field:

Input: 460VAC 50/60 Hz 10A max. 1 Phase

Output: 360VDC 10A max.

Regulator Power: 115/230VAC 50/60 Hz 1.0/0.5A 1 Phase

MFD. in 2XXX on MMM DD

Made in Italy

6.2

8.2

EXAMPLE ONLY

Series: A

I/O: 24VDC (Standard)

Original Firmware V. 1.001

N223

Frame: A

Serial Number: A23E0042

C

Ind. Cont.

Eq. 31KF

Listed

Note: Certification

R

US

Marks Location.

Refer to the data

nameplate label

on your drive for

actual agency

certifications.

Similar PowerFlex DC drive sizes are grouped into frame sizes to simplify

spare parts ordering, dimensioning, etc. Refer to the Catalog Number

Explanation on page Preface-4 for a list of drive catalog numbers and their

respective frame sizes.

Reference Materials

The following manuals are recommended for general drive information:

Title Publication Available Online at . . .

Preventive Maintenance of Industrial Control and

Drive System Equipment

Safety Guidelines for the Application, Installation

and Maintenance of Solid State Control

A Global Reference Guide for Reading Schematic

Diagrams

Guarding Against Electrostatic Damage 8000-4.5.2

DRIVES-TD001…

SGI-1.1

100-2.10

www.rockwellautomation.

com/literature

For Allen-Bradley Drives Technical Support:

Title Online at . . .

Allen-Bradley Drives Technical Support www.ab.com/support/abdrives

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 11

Overview p-3

Manual Conventions

General Precautions

• To help differentiate parameter names and LCD display text from other

text, the following conventions will be used:

– Parameter Names will appear in [brackets].

For example: [Armature Voltage].

– Display Text will appear in “quotes.” For example: “Enabled.”

• The following words are used throughout the manual to describe an

action:

Word Me aning

Can Possible, able to do something

Cannot Not possible, not able to do

something

May Permitted, allowed

Must Unavoidable, you must do this

Shall Required and necessary

Should Recommended

Should Not Not recommended

ATTENTION: This drive contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control

!

precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with

static control procedures, reference A-B publication 8000-4.5.2,

“Guarding Against Electrostatic Damage” or any other applicable

ESD protection handbook.

ATTENTION: An incorrectly applied or installed drive can

result in component damage or a reduction in product life. Wiring

!

or application errors, such as, undersizing the motor, incorrect or

inadequate AC supply, or excessive surrounding air temperatures

may result in malfunction of the system.

ATTENTION: Only qualified personnel familiar with DC drives

and associated machinery should plan or implement the

!

installation, start-up and subsequent maintenance of the system.

Failure to comply may result in personal injury and/or equipment

damage.

ATTENTION: An incorrectly applied or installed bypass system

can result in component damage or reduction in product life. The

!

most common causes are:

• Wiring AC line to drive output or control terminals.

• Improper bypass or output circuits not approved by

Allen-Bradley.

• Output circuits which do not connect directly to the motor.

Contact Allen-Bradley for assistance with application or wiring.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 12

p-4 Overview

Catalog Number Explanation

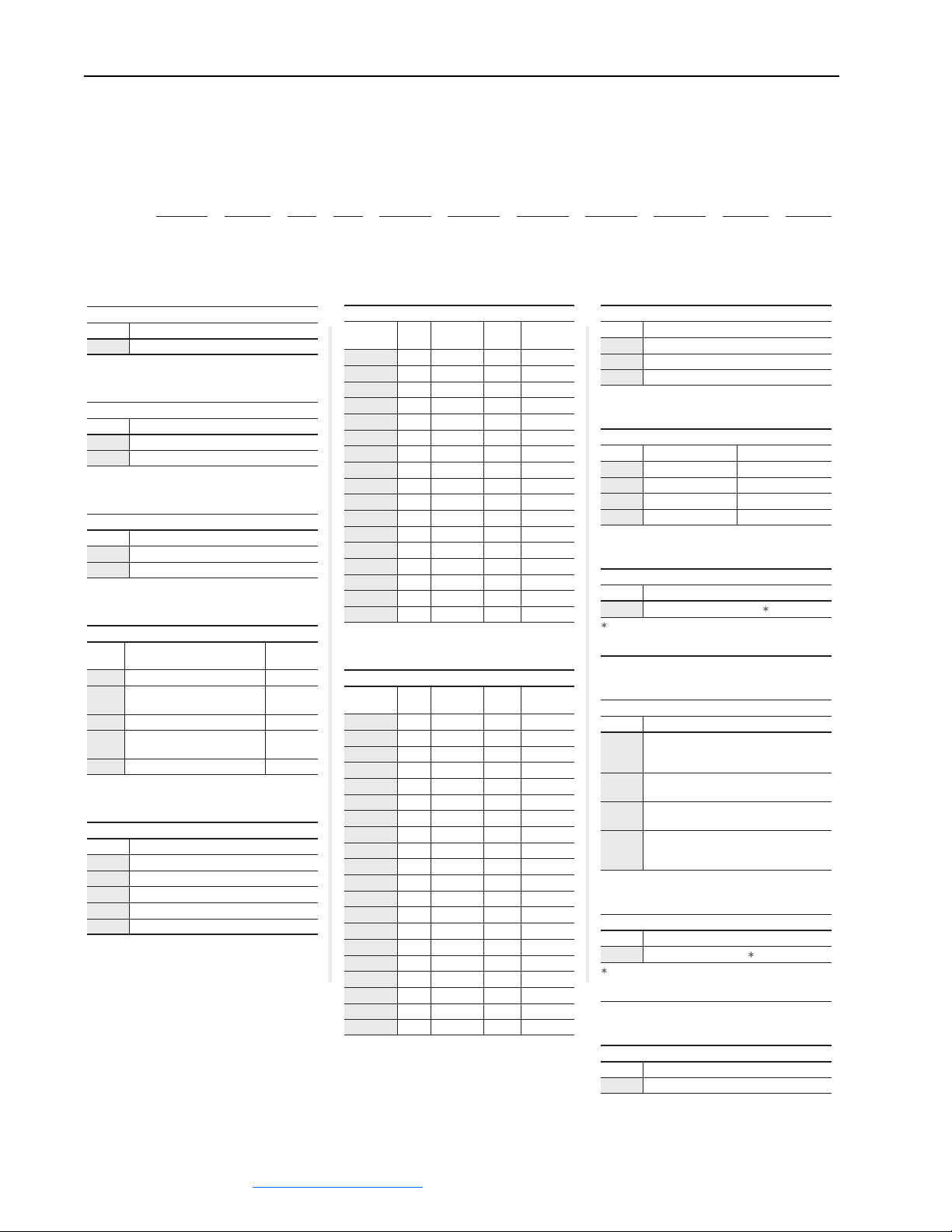

Position

1-3 4 5 6 7 8-10 11 12 13 14 15 16

20P 4 1 A D 4P1 R N 0 N N N

abcdef gh i jkl

a

Drive

Code Type

20P PowerFlex DC

b

Motor Operation

Code Type

2 Two Quadrant Operation

4 Four Quadrant Operation

c

Input Type

Code Type

1 6 Pulse

2 12 Pulse

d

Enclosure

Code Enclosure Rating

A IP20, NEMA/UL Type Open

IP43, NEMA/UL Type 1 -

B

G IP54, NEMA/UL Type 12

IP54, NEMA/UL Type 12 -

H

N IP00, NEMA/UL Type Open

Filter

Fan/Filter

e

Input Voltage

Code Voltage

B 230V ac

C 400V ac

D 460V ac

E 600V ac

F 690V ac

Conform.

Coat

No

No

No

No

No

f1

230V, 60 Hz Input

Code Hp

7P0 1.5 7 A 10

9P0 2 9 A 10

012 3 12 A 10

020 5 20 A 10

029 7.5 29 A 10

038 10 38 A 10

055 15 55 A 10

073 20 73 A 14

093 25 93 A 14

110 30 110 A 14

146 40 146 B 20

180 50 180 B 20

218 60 218 B 20

265 75 265 B 20

360 100 360 B 20

434 125 434 B 20

521 150 521 C 20

Armature

Amps

Frame

f2

460V, 60 Hz Input

Code Hp

4P1 2 4.1 A 10

6P0 3 6 A 10

010 5 10 A 10

014 7.5 14 A 10

019 10 19 A 10

027 15 27 A 10

035 20 35 A 10

045 25 45 A 10

052 30 52 A 10

073 40 73 A 14

086 50 86 A 14

100 60 100 A 14

129 75 129 A 14

167 100 167 B 20

207 125 207 B 20

250 150 250 B 20

330 200 330 B 20

412 250 412 B 20

495 300 495 C 20

667 400 667 C 20

Armature

Amps

Frame

Field

Amps

Field

Amps

g

Field Supply

Code Type

A Three-Phase Regulated

F Fixed Field w/Economy

R Single-Phase Regulated

h

Packaging/Documentation

Code Shipping Carton User Manual

0No No

AYes Yes

NYes No

QNo Yes

i

HIM

Code Operator Interface

0 Blank Cover

Standard - for additional selections, refer to the

PowerFlex Digital DC Drive Technical Data,

publication 20P-TD001. . .

j

I/O Options

Code Control

I/O Expansion Card (4 Additional 24V

A

dc Digital Inputs & Outputs, 2 Analog

115V ac Conversion Card (8 Digital

B

C

N

I/O Expansion Card + 115V ac

None (8 - 24V dc Digital Inputs &

Outputs, 3 Analog Outputs and 2

Outputs)

Inputs & Outputs)

Conversion

Analog Inputs are Standard)

k

Communication Options

Code Description

N

Standard - for additional selections, refer to the

PowerFlex Digital DC Drive Technical Data,

publication 20P-TD001. . .

None

l

Cabinet Options

Code Type

N None

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 13

Chapter 1

Installation and Wiring

This chapter provides information on mounting and wiring the PowerFlex

DC drive.

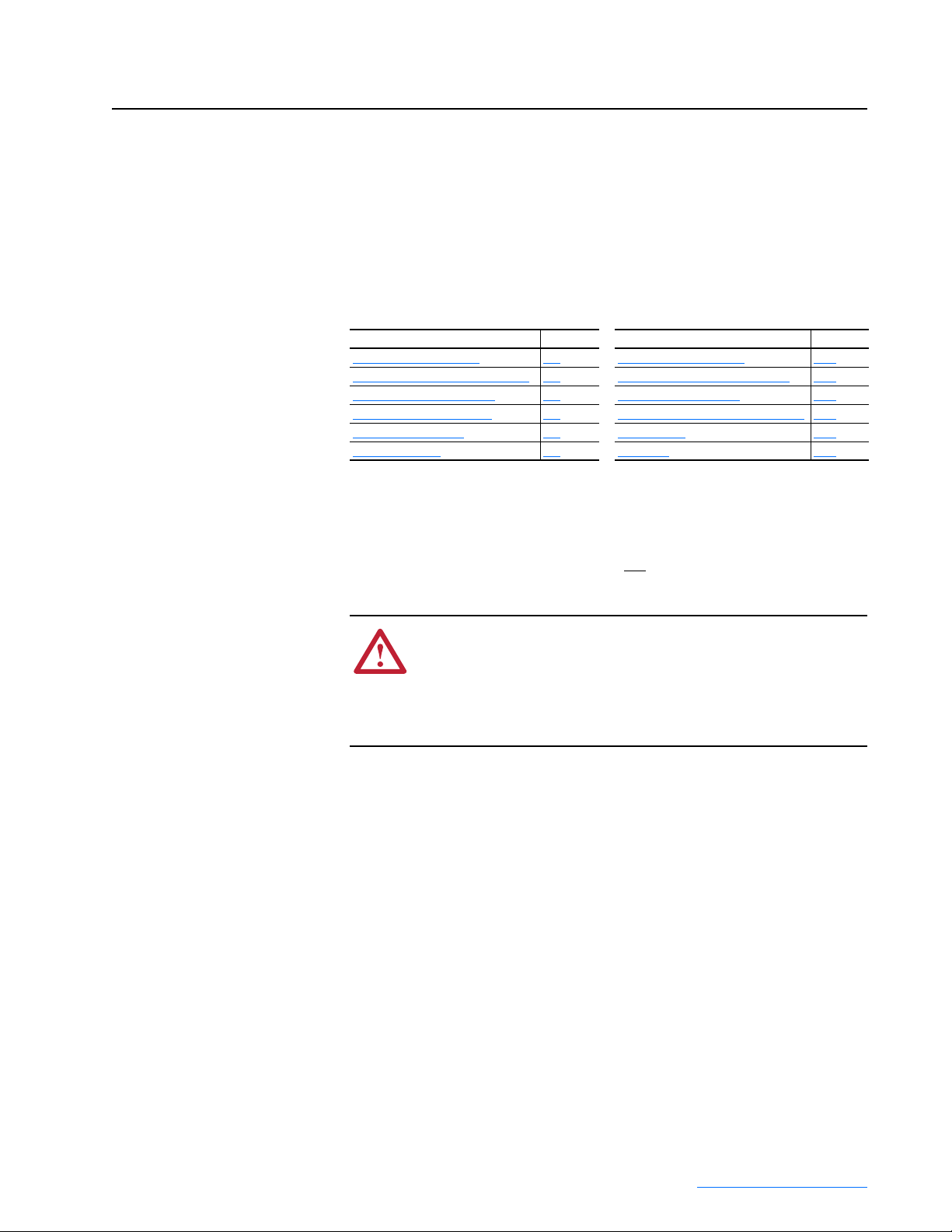

For information on . . See page For information on. . See page

Mounting Considerations

Mounting Dimensions and Weights 1-3 General Grounding Requirements 1-12

Lifting PowerFlex DC Drives 1-5 Power Circuit Protection 1-13

Removing the Drive Covers 1-7 Cable and Wiring Recommendations 1-14

Line Reactors / Filters 1-9 Power Wiring 1-15

Using Contactors 1-9 I/O Wiring 1-32

Most start-up difficulties are the result of incorrect wiring. Every precaution

must be taken to assure that the wiring is done as instructed. All items must

be read and understood before the actual installation begins.

1-2 Control Power Protection 1-11

Important:The PowerFlex DC drive is not

motor applications.

ATTENTION: The following information is merely a guide for

proper installation. Rockwell Automation cannot assume

!

responsibility for the compliance or the noncompliance to any

code, national, local or otherwise for the proper installation of this

drive or associated equipment. A hazard of personal injury and/or

equipment damage exists if codes are ignored during installation.

designed for use with multiple

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 14

1-2 Installation and Wiring

Mounting Considerations

Operating Conditions and Temperatures

PowerFlex DC drives are designed to operate at 0° to 50° C surrounding air

temperature without derating. The drive must be mounted in a clean, dry

location. Contaminants such as oils, corrosive vapors and abrasive debris

must be kept out of the enclosure. NEMA/UL Type Open, IP20 enclosures

are intended for indoor use primarily to provide a degree of protection

against contact with enclosed equipment. These enclosures offer no

protection against airborne contaminants.

Minimum Mounting Clearances

Minimum clearance requirements (indicated in Figure 1.1) are intended to

be from drive to drive. Other objects can occupy this space; however,

reduced airflow may cause protection circuits to fault the drive. The drive

must be mounted in a vertical orientation as shown below and must not be

mounted at an angle greater than 30° from vertical. In addition, inlet air

temperature must not exceed the product specification.

Figure 1.1 Drive Enclosure Minimum Mounting Clearances

10 mm

(0.4 in.)

150 mm (6.0 in.)

PORT

MOD

NET A

NET B

STS

10 mm

(0.4 in.)

150 mm (6.0 in.)

PORT

MOD

NET A

NET B

150 mm (6.0 in.)

STS

10 mm

(0.4 in.) (2.0 in.)

50 mm

Airflow through

the drive must

not be impeded.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 15

Installation and Wiring 1-3

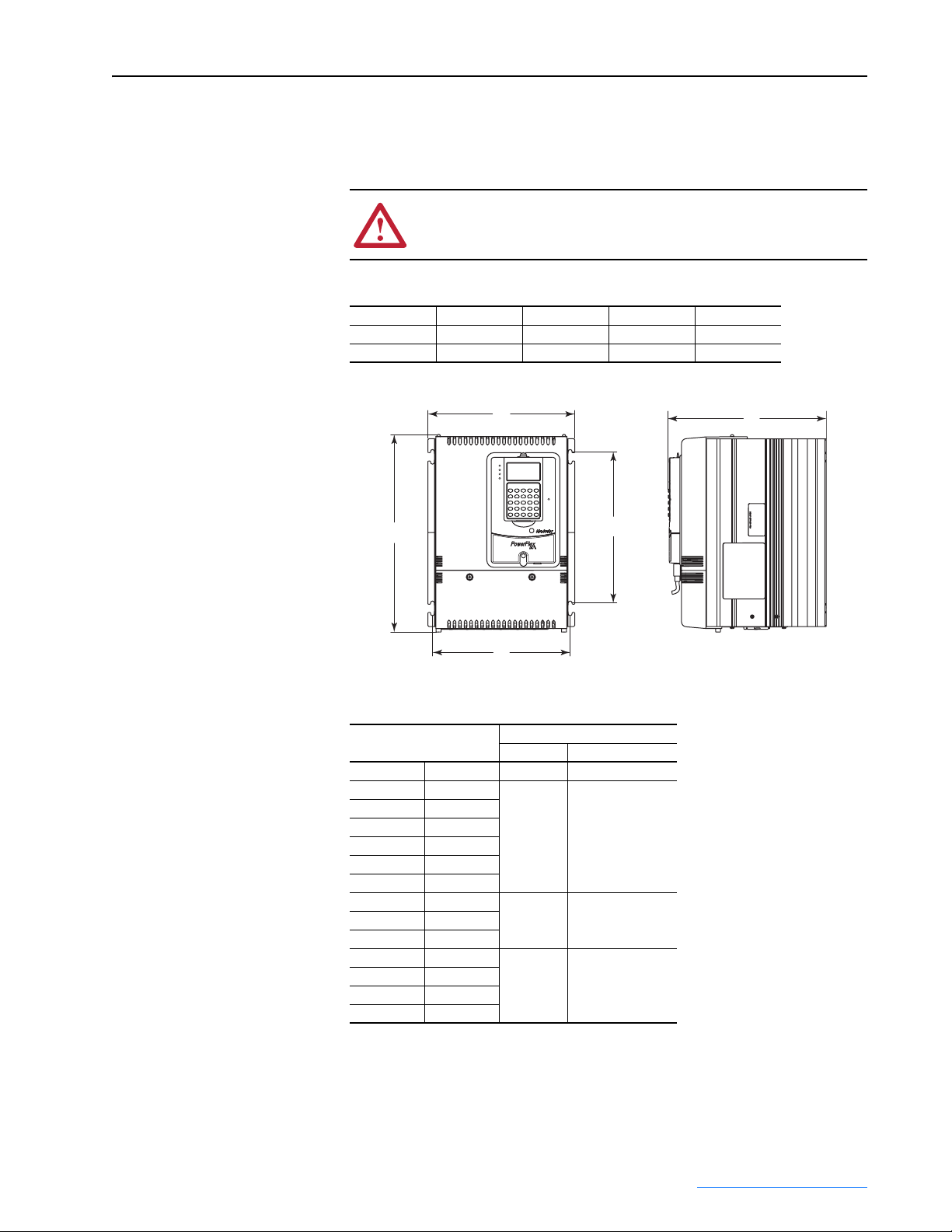

Mounting Dimensions and Weights

The PowerFlex DC drive is available in a NEMA/UL Type Open, IP20

enclosure. Following all mounting instructions in order to ensure proper

operation.

ATTENTION: Remove all loose packing materials, including

the container(s) of desiccants (if any), from the drive enclosure

!

before mounting and energizing the drive.

Figure 1.2 Frame A Approximate Dimensions

ABCA1B1

mm (in.) mm (in.) mm (in.) mm (in.) mm (in.)

267 (10.5) 359 (14.0) 287 (11.3) 250 (9.8) 275 (10.8)

A

PORT

MOD

NET A

NET B

STS

B

B1

C

A1

Table 1.A Frame A Weights

Weight

Drive Current Rating Code

230V 460V kg (lbs.) kg (lbs.)

7P0 4P1 8.4 (19.5) 10.5 (23.1)

9P0 6P0

012 010

020 014

– 019

029 027

038 035 8.8 (19.4) 11 (24.3)

055 045

– 052

073 073 10.8 (23.8) 13 (28.7)

093 086

110 100

– 129

Drive Drive & Packaging

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 16

1-4 Installation and Wiring

Figure 1.3 Frame B Approximate Dimensions

A A1A2B B1C

mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.)

311 (12.2) 275 (10.8) 16.5 (0.65) 388 (15.3) 375 (14.8) 350 (13.8)

A

A1

PORT

MOD

NET A

NET B

STS

B1

A2

Table 1.B Frame B Weights

Weight

Drive w/ND Rating Code

230V 460V kg (lbs.) kg (lbs.)

146 167 25.5 (56.2) 27.5 (60.6)

180 207

218 –

265 250 29.5 (65.0) 31.5 (69.4)

360 330 32 (70.5) 34 (75)

434 412

Drive Drive & Packaging

B

C

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 17

Installation and Wiring 1-5

Figure 1.4 Frame C Approximate Dimensions

A A1 B B1 B2 B3 B4 C

mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.) mm (in.)

521 (20.5) 499 (19.7) 511 (20.1) 400 (15.7) 200 (7.9) 55 (2.2) 56 (2.2) 416 (16.4)

A1 C

B4

PORT

MOD

NET A

NET B

B1

B

B2

B3

STS

Lifting PowerFlex DC Drives

A

Table 1.C Frame C Weights

Weight - Regenerative Drives Weight - Non-regenerative Drives

Drive w/ND Rating Code

230V 460V kg (lbs.) kg (lbs.) kg (lbs.) kg (lbs.)

– 495 61 (134.5) 74 (163.1) 57 (125.7) 70 (154.3)

521 667 65 (143.3) 81 (178.6) 62 (136.7) 75 (165.3)

Drive Drive & Packaging Drive Drive & Packaging

The dimensions and weights specified above must be taken into

consideration when mounting the device. Use the proper equipment to

safely lift and hold the weight of the drive while mounting.

ATTENTION: To guard against possible personal injury or

equipment damage . . .

!

• Inspect all lifting hardware for proper attachment before lifting

the drive.

• Do Not allow any part of the drive or lifting mechanism to

make contact with electrically charged conductors or

components.

• Do Not subject the drive to high rates of acceleration or

deceleration while transporting to the mounting location or

when lifting.

• Do Not allow personnel or their limbs directly underneath the

drive when it is being lifted and mounted.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 18

1-6 Installation and Wiring

Mounting Frame C Drives

All lifting equipment and lifting components (hooks, bolts, lifts, slings,

chains, etc.) must have a minimum

Important:Verify that all mounting screws are properly tightened before

and after drive operation.

1. Verify the hole pattern on the panel to which the drive will be mounted.

Refer to Figure 1.4 on page 1-5

2. Insert, but do not tighten, one bolt in one of the top holes in the panel.

The bolt must be fully threaded into the panel before hanging the drive.

3. Insert the properly sized and rated lifting hooks into the holes on the

lifting flanges at the top of the drive. To limit the pull in forces on the

drive, the lifting devices connected to the hooks must be long enough to

make the angle between the chain or cable and a vertical line extending

up from the flange center less than 45 degrees as illustrated below.

Figure 1.5 Lifting Angle

lifting capacity of 453.6 kg (1,000 lb.).

.

Angle Must Be Less

Than 45 Degrees

Lifting flange

4. Lift the drive into place on to the bolt installed in the panel.

5. Install the remaining five bolts into the panel. Tighten all bolts to a

torque of 22.6 N•m (200 lb•in).

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 19

Installation and Wiring 1-7

Removing the Drive Covers

The lower protective cover must be removed in order to access the drive’s

power and I/O terminals. The upper cover only needs to be removed to

install an optional communication adapter and service the drive. (Refer to

Installing a Communication Adapter on page E-1

Frame A Drives

You must remove both the lower protective cover and the power terminal

cover on frame A drives to access the power terminals.

Remove the Power Terminal Cover

Remove the two screws as shown below and slide the cover down and off

the chassis.

Figure 1.6 Frame A Power Terminal Cover Removal

for information.)

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 20

1-8 Installation and Wiring

Remove the Lower Protective Cover

Remove the two screws as shown below and, while gently lifting along the

top edge, slide the cover down and off the chassis.

Figure 1.7 Frame A Lower Cover Removal

PORT

MOD

NET A

NET B

STS

Frame B and C Drives

Loosen, but do not remove, the two screws that secure the bottom cover.

Then, slide the cover down until the screw heads line up with the key holes

and lift the cover off the chassis.

Figure 1.8 Frame B & C Drive Cover Removal

Frame B Shown

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 21

Installation and Wiring 1-9

Line Reactors / Filters

Using Contactors

When connecting the drive directly to the main distribution system an AC

line reactor must be used to guard against system disturbance. The type of

line reactor used depends upon the following:

• the current absorbed by the AC input

• the AC input voltage

• the relative short circuit voltage

• the AC input frequency

Refer to AC Input Line Reactors and AC Input Contactors on page A-17

a list of recommended AC line reactors.

When using an AC input contactor, the IEC AC1 rating of the contactor

must be equal to the rated thermal (RMS) current value at the mains input of

the drive.

Drive configurations for AC or DC contactors, with or without a dynamic

brake, are as follows (refer to Typical Power Wiring Diagrams on page 1-17

for wiring examples):

• When only an AC contactor is used:

❏ Set parameter 1391

value)

(1)

[ContactorControl] to 1 “AC Cntctr” (default

for

❏ Set one [Relay Out x Sel] parameter and one [Digital Inx Sel]

parameter to “Contactor” (default value for parameters 1392

Out 1 Sel] and 140

• When only a DC contactor is used:

❏ Set parameter 1391

❏ Set one [Relay Out x Sel] parameter and one [Digital Inx Sel] to

“Contactor” (default value for parameters 1392

and 140

• When an AC contactor and dynamic brake contactor are used:

❏ Set parameter 1391

❏ Set one [Relay Out x Sel] parameter (1392 [Relay Out 1 Sel] or 629

[Relay Out 2 Sel]) to “Contactor” and the other relay output to

“ContactorDB”

❏ Set one [Digital Inx Sel] parameter to “Contactor” (default value

for parameter 140

[Digital In8 Sel])

[Digital In8 Sel])

[ContactorControl] to 3 “DC Cntctr”

[Relay Out 1 Sel]

[ContactorControl] to “AC Cntctr+DB”

[Digital In8 Sel])

(1)

[Relay

(1)

(1)

Par 1391 [ContactorControl] is contained in the “Advanced” parameter configuration group. Refer to How

Parameters are Organized on page 3-3 for more information.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 22

1-10 Installation and Wiring

• When a DC contactor and dynamic brake contactor are used:

❏ Set parameter 1391

❏ Set one [Relay Out x Sel] parameter (1392 [Relay Out 1 Sel] or 629

[Relay Out 2 Sel]) to “Contactor” and the other relay output to

“ContactorDB”

❏ Set one [Digital Inx Sel] parameter to “Contactor” (default value

for parameter 140

• When a contactor is NOT used:

❏ Set parameter 1391

❏ Do NOT set either [Relay Out x Sel] parameter to “Contactor” or

“ContactorDB”

❏ Do NOT set any [Digital Inx Sel] parameter to “Contactor”

When operating a drive with firmware version 1.006 in field weakening

mode with a DC contactor and/or inverting fault device installed in the

armature circuit, refer to Field Weakening Mode Configuration (v1.006) on

page C-5.

[ContactorControl] to “DC Cntctr+DB”

[Digital In8 Sel])

[ContactorControl] to “None”

(1)

(1)

AC Input Contactors

Refer to AC Input Line Reactors and AC Input Contactors on page A-17 for

a list of recommended AC input contactors.

DC Output Contactors

A DC output contactor can be used to connect the output of the armature

circuit to the DC motor. If a DC output contactor is used, an AC input

contactor is not needed.

Refer to DC Output Contactors and Dynamic Brake Resistor Kits on

page A-19 for a list of recommended DC output contactors.

Dynamic Brake Resistors

Refer to DC Output Contactors and Dynamic Brake Resistor Kits on

page A-19 for a list of recommended dynamic brake resistor kits.

(1)

Par 1391 [ContactorControl] is contained in the “Advanced” parameter configuration group. Refer to How

Parameters are Organized on page 3-3 for more information.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 23

Installation and Wiring 1-11

Control Power Protection

The 115V / 230V AC control circuit power input terminals U2 and V2 are

required to be short circuit protected. This protection can be provided by

using standard time delay fuses or a circuit breaker.

The time delay fuses or circuit breaker must be selected to survive the short

circuit available current of the feeder source for this circuit and the inrush

current of the drive’s power supply.

The rating of the fuses or circuit breaker should be sized mainly to protect

the wiring from the fuses/circuit breaker connections to terminals U2 and

V2, and not nuisance trip or blow from the inrush current.

The table below lists the input current characteristics of the control power.

Table 1.D Control Power Protection

Drive Current

Rating Code

Frame

A

B & C

(1)

230V 460V 115V 230V 115V 230V

7P0 4P1

110 129

146 167

521 667

Refer to Catalog Number Explanation on page Preface-4, positions 8-10 for corresponding drive HP rating,

armature amp rating and field amp rating.

(1)

Control Power Supply

Rated input current Inrush input current

Board ID Power

SW1-31 60 W 1 A 0.5 A 20 A 10 Athrough through

SW2-32 110 W 1.2 A 0.7 A 15 A 7.5 Athrough through

Control power input should be supplied by a power source that is stabilized

and buffered from the power system transients. The control power of many

drives can be fed from a single source, as long as proper distribution

protection is provided.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 24

1-12 Installation and Wiring

General Grounding Requirements

The drive Safety Ground - PE must be connected to system ground.

Ground impedance must conform to the requirements of national and local

industrial safety regulations and/or electrical codes. The integrity of all

ground connections should be periodically checked.

For installations within a cabinet, a single safety ground point or ground bus

bar connected directly to building steel should be used. All circuits

including the AC input ground conductor should be grounded

independently and directly to this point/bar.

ATTENTION: In order to comply with the essential

requirements of the CE Low Voltage Directive 2006/95/EC,

!

PowerFlex DC drives may not be powered from a corner-earthed

(TN with one phase earthed) supply system. Although

PowerFlex DC drives are compliant with the requirements of the

CE Low Voltage Directive when powered from an IT or

impedance-earthed supply system, power must be removed from

the drive as soon as possible after an earth fault is detected in the

power system to satisfy CE safety requirements related to the

insulation system of the drive.

Figure 1.9 Typical Grounding

AC Mains Supply

Safety

Ground

Earth

L1

L2

L3

Transformer

/

PE1

PORT

MOD

NET A

NET B

STS

U

V

C

W

D

AC Line

Reactor

All wires (including motor

ground) must be connected

inside the motor terminal box.

Safety Ground (PE)

This is the safety ground for the drive that is required by code. This point

must be connected to adjacent building steel (girder, joist), a floor ground

rod or bus bar (see above). Grounding points must comply with national and

local industrial safety regulations and/or electrical codes.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 25

Installation and Wiring 1-13

Power Feeder

Each power feeder from the substation transformer to the drive must be

provided with properly sized ground cables. The conduit or cable armor

should be bonded to the substation ground at both ends. Each transformer

enclosure and/or frame must be bonded to ground at a minimum of two

locations.

Encoder Ground Connections

If used, must be routed in grounded steel conduit. The conduit must be

grounded at both ends. The encoder cable shield must be connected to the

shield ground on the drive side. Do not connect the encoder cable shield to

ground on the motor side.

Tachometer Ground Connections

If used, ground connections must be routed in grounded steel conduit. The

conduit must be grounded at both ends. Ground the cable shield at the drive

end only using the shield clamps on the grounded metal plate supporting the

control board (refer to I/O Terminal Block Locations on page 1-36

shield clamp location).

for

Power Circuit Protection

It is recommended that you install the PowerFlex DC drive with fast acting

fuses to protect the armature converter on the AC input and DC output (for

four quadrant drives only) sides. Internally mounted fuses for armature

converter protection are provided with 230V, 521A and 460V, 495A and

667A frame C PowerFlex DC drives. Refer to Drive Power Circuit

Protection on page A-7 for a list of replacement fuses and general fuse

locations.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 26

1-14 Installation and Wiring

Cable and Wiring Recommendations

Category

Power 1 AC Power (600V

Control 5 115V AC/DC

Signal

(Process)

Signal

(Comm.)

Wiring

Class Signal Definition Signal Example Cable Type 1 2/3/4 5/6 7/8 9/10/11

Or Greater)

2 AC Power (Less

Than 600V)

3 DC Power DC Motor Armature

4 DC Power DC Motor Field

Logic

115V AC Power Power Supplies,

6 24V AC/DC Logic PLC I/O

7 Analog Signals,

DC Supplies

Digital (Low

Speed)

8 Digital (High

Speed)

9 Serial

Communication

11 Serial

Communication

(Greater Than

20k Baud)

Use the following cable and spacing recommendations for all drives sizes:

2.3kV 3/ph AC Lines Per NEC &

460V 3/ph AC Lines 3/9 in.

Relay Logic/PLC I/O

Motor Thermostat

Instruments

Reference/feedback

Signal, 5 To 24V DC

TTL

I/O, Encoder, Count

Pulse Tach

RS-232

(20-COMM-R), 422

To Ter m ina l s /

printers

PLC Remote I/O,

PLC Data Highway

Local Codes

Shielded Cable

– Belden 8735,

8737, 8404

Shielded Cable

– Belden 9728,

9730

Shielded Cable

– Belden

RS-232 –

8735, 8737

RS-422 –

9729, 9730

Twinaxial

Cable –

Belden 9463,

A-B 1770-CD

0 3/9 in.

(76/229 mm)

3/9 in.

(76/229 mm)

3/18 in.

(76/457 mm)

Minimum Spacing Between Classes

Steel Conduit/Tray

(76/229 mm)

0 3/6 in.

3/6 in.

(76/152 mm)

3/12 in.

(76/305 mm)

See Note 6 1/3 in.

3/9 in.

(76/229 mm)

(76/152 mm)

03/9 in.

3/9 in.

(76/229 mm)

3/18 in.

(76/457 mm)

3/12 in.

(76/305 mm)

(76/229 mm)

(25/76 mm)

See Note 6 1/2/5

See Note 6 1/2/5

See Note 6 1/2/5

0 1/3 in.

(25/76 mm)

0–

See Spacing

Notes,

page 1-15

2/3/4/5

Example:

Spacing relationship between 480V AC incoming power leads and 24V DC

logic leads:

• 480V AC leads are Class 2; 24V DC leads are Class 6

• For separate steel conduits, the conduits must be 3 inches (76 mm) apart

• In a cable tray, the two groups of leads are to be 6 inches (152 mm) apart

Wiring

Category

Power

Control

Note: Cells removed from example table for clarity only.

Class Signal Definition Signal Example 1

2 AC Power (less

than 600V)

6 24V AC/DC

Logic

Minimum Spacing Between Classes

Steel Conduit/Tray

2/3/4 5/6

460V 3/Ph AC

Lines

PLC I/O 3/6 in.

(76/152 mm)

3/6 in.

(76/152 mm)

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 27

Installation and Wiring 1-15

Spacing Notes:

1. Both outgoing and return current carrying conductors are to be pulled in same conduit or laid adjacent in

tray.

2. Cables of the following classes can be grouped together.

A. Class 1; Equal to or above 601 volts.

B. Classes 2, 3 and 4 may have their respective circuits pulled in the same conduit or layered in the same

tray.

C. Classes 5 and 6 may have their respective circuits pulled in the same conduit or layered in the same

tray. Note: Bundle may not exceed conditions of NEC 310.

D. Classes 7 and 8 may have their respective circuits pulled in the same conduit or layered in the same

tray. Note: Encoder cables run in a bundle may experience some amount of EMI coupling. The circuit

application may dictate separate spacing.

E. Classes 9, 10 and 11 may have their respective circuits pulled in the same conduit or layered in the

same tray. Communication cables run in a bundle may experience some amount of EMI coupling and

corresponding communication faults. The application may dictate separate spacing.

3. All wires of class 7 through 11 MUST be shielded per the recommendations.

4. In cable trays, steel separators are advisable between the class groupings.

5. If conduit is used, it must be continuous and composed of magnetic steel.

6. Spacing of communication cables classes 2 through 6 is:

CONDUIT SPACING: THROUGH AIR:

115 Volts – 1 in. (25 mm) 115 Volts – 2 in. (51 mm)

230 Volts – 1.5 in. (38 mm) 230 Volts – 4 in. (101.5 mm)

380/575 Volts – 3 in. (76 mm) 380/575 Volts – 8 in. (203 mm)

575 volts – proportional to 6 in. (152 mm) per

1000 volts.

Power Wiring

AC Input Voltages

575 volts – proportional to 12 in. (305 mm) per 1000

volts.

PowerFlex DC drives are rated for the following AC input voltages:

Armature Circuit Field Circuit Control Circuit

Terminals U, V, W Terminals U1, V1 Terminals U2, V2

230V ±10 %, 3Ph

400V ±10 %, 3Ph

440V ±10 %, 3Ph

460V ±10 %, 3Ph

480V ±10 %, 3Ph

@ 50/60 Hz ±5 %

(1)

For frame B and C drives only, a jumper must be placed between terminals SA-SB on the Switching Power

Supply circuit board for the control circuits to work with 115V AC input. Refer to Figure 1.26 on page 1-29

terminal block location on frame B drives and Figure 1.27 on page 1-30

drives.

230V ±10 %, 1Ph

400V ±10 %, 1Ph

460V ±10 %, 1Ph

@ 50/60 Hz ±5 %

115V ±15 %, 1 Ph

or

230V ±15 %, 1Ph

@ 50/60 Hz ±5 %

for terminal block location on frame C

(1)

for

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 28

1-16 Installation and Wiring

DC Output Voltages

The output voltages below take into account an AC input undervoltage

within the stated tolerance limits and a voltage drop of 4% due to an AC

input line reactor. It is the same as the rated armature voltage suggested for

the connected motor.

Armature Circuit

AC Input Voltage DC Output Armature Voltage (Terminals C & D)

(Terminals U, V, W) Two Quadrant Drive Four Quadrant Drive

230V ±10 %, 3Ph 260V 240V

400V ±10 %, 3Ph 470V 420V

440V ±10 %, 3Ph 530V 460V

460V ±10 %, 3Ph 560V 480V

480V ±10 %, 3Ph 580V 500V

Field Circuit

AC Input Voltage DC Output Field Voltage

(Terminals U1 & V1) Fixed Field Adjustable Field

230V ±15 %, 1Ph 200V 200V

400V ±15 %, 1Ph 310V 310V

460V ±10%, 1Ph 360V 360V

(1)

The max field voltage is equal to 0.85 x AC input line voltage

(1)

(Terminals C1 & D1)

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 29

Installation and Wiring 1-17

Typical Power Wiring Diagrams

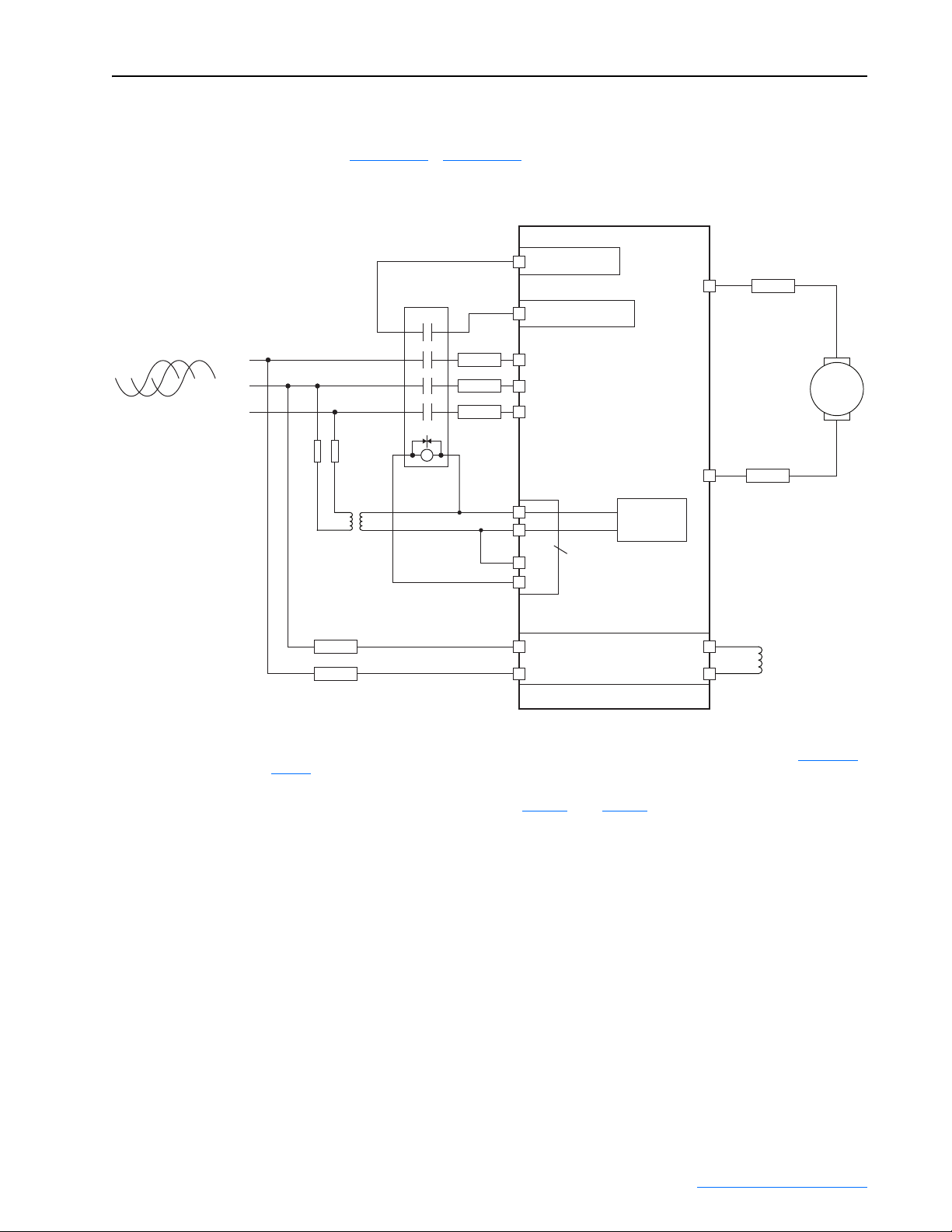

Figure 1.10 - Figure 1.13 represent recommended power wiring

configurations.

Figure 1.10 Power Wiring with AC Input Contactor

3 Phase AC line

(1)

34

(on I/O TB4)

(N.O. Relay)

M1 AC C ontactor

Aux

13 14

L1

L2

L3

FU8 FU9

L1

L2

L3

A1

FU3

T1

FU4

T2

FU5

T3

A2

19 (+24V - on I/O TB2)

U

V

W

PowerFlex DC

Drive

Control

Board P/S

Field Power

460V 115V

FU6

FU7

U2

V2

(3)

35

(3)

36

U1

V1

Control Power /

Relay Terminal

Block

Terminal Block

C

D

C1

D1

(2)

FU1

A1

M

A2

(2)

FU2

F1

F2

(1)

Par 140 [Digital In8 Sel] set to 31 “Contactor”

(2)

Armature output fuses are required on four quadrant and are recommended on two quadrant Frame A and B drives. Fuses with Trip Indicator

Switches are recommended for Inverting Fault protection when the motor will be Field Weakened and run above base speed. Refer to Figure 1.13 on

page 1-19.

(3)

Par 1391 [ContactorControl] = 1 “AC Cntctr” and Par 1392 [Relay Out 1 Sel] = 25 “Contactor”. Important: Terminal 35 and 36 are on the Control

Power / Relay Terminal block, NOT the I/O terminal blocks. See Figure 1.20

through Figure 1.22.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 30

1-18 Installation and Wiring

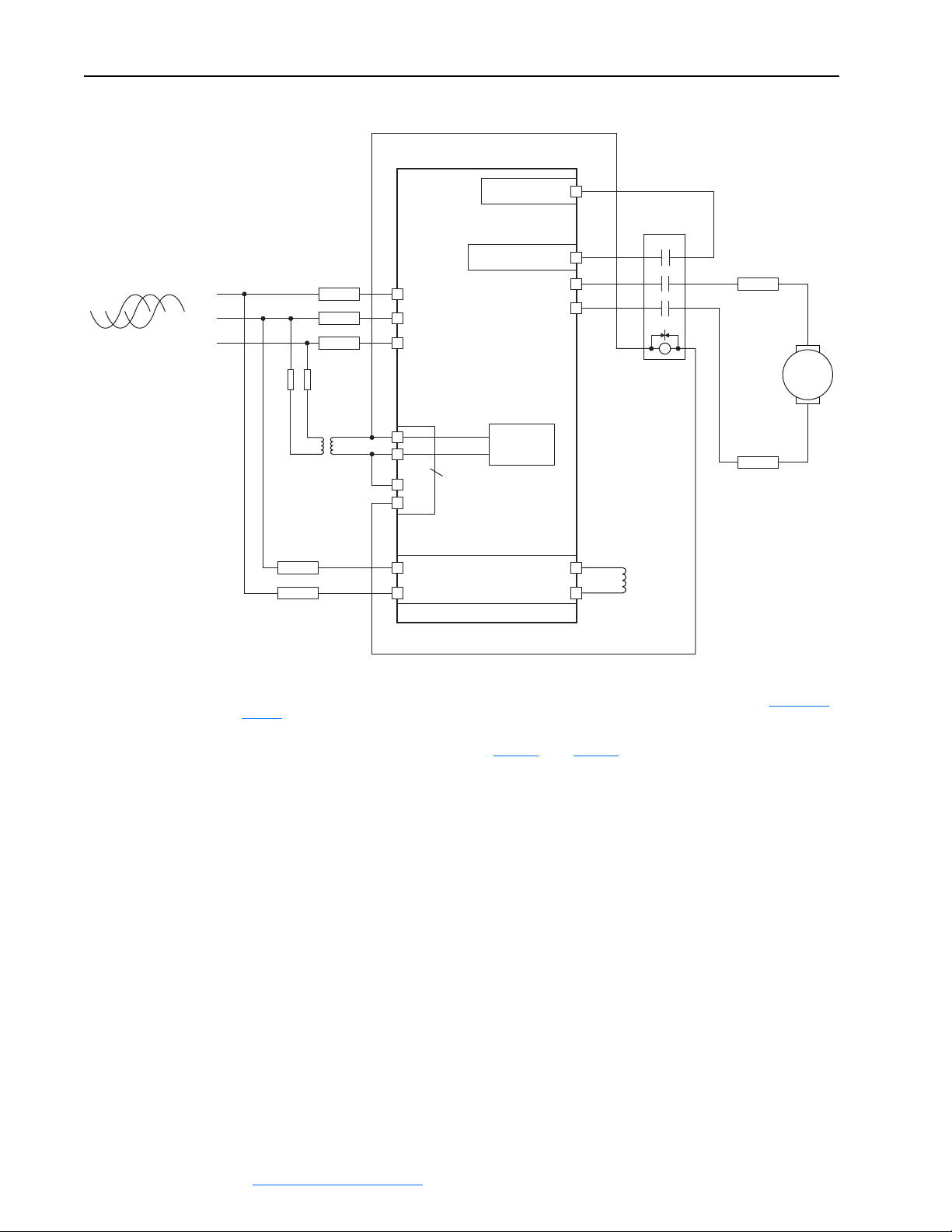

Figure 1.11 Power Wiring with DC Output Contactor

3 Phase AC l i ne

34 (on I/O TB4)

19 (+24V on I/O TB2)

L1

L2

L3

FU8 FU9

FU3

FU4

FU5

460V 115V

FU6

FU7

U

V

W

PowerFlex DC

Drive

U2

V2

Control Power /

(3)

35

Relay Terminal

(3)

Block

36

U1

V1

Field Power

Terminal Block

Control

Board P/S

(1)

(N.O. Relay)

M1 DC Contactor

Aux

13 14

L1

C

D

T1

L2

T2

A1

A2

FU1

(2)

A1

M

A2

(2)

FU2

C1

D1

F1

F2

(1)

Par 140 [Digital In8 Sel] set to 31 “Contactor”

(2)

Armature output fuses are required on four quadrant and are recommended on two quadrant Frame A and B drives. Fuses with Trip Indicator

Switches are recommended for Inverting Fault protection when the motor will be Field Weakened and run above base speed. Refer to Figure 1.13 on

page 1-19.

(3)

Par 1391 [ContactorControl] = 3 “DC Cntctr” and Par 1392 [Relay Out 1 Sel] = 25 “Contactor”. Important: Terminal 35 and 36 are on the Control

Power / Relay Terminal block, NOT the I/O terminal blocks. See Figure 1.20

through Figure 1.22.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 31

Installation and Wiring 1-19

Figure 1.12 Power Wiring with DC Output Contactor and a Dynamic Brake

3 Phase AC l i ne

34 (on I/O TB4)

19 (+24V on I/O TB2)

L1

L2

L3

FU8 FU9

(1)

(2)

Switches are recommended for Inverting Fault protection when the motor will be Field Weakened and run above base speed. Refer to Figure 1.13 on

page 1-19.

(3)

Important: Terminal 35, 36, 75 and 76 are on the Control Power / Relay Terminal block, NOT the I/O terminal blocks. See Figure 1.20

1.22.

FU3

FU4

FU5

460V 115V

FU6

FU7

Par 140 [Digital In8 Sel] set to 31 “Contactor”

Armature output fuses are required on four quadrant and are recommended on two quadrant Frame A and B drives. Fuses with Trip Indicator

Par 1391 [ContactorControl] = 4 “DC Cntctr+DB”, Par 1392 [Relay Out 1 Sel] = 25 “Contactor”, and Par 629 [Relay Out 2 Sel] = 24 “ContactorDB”.

U

V

W

PowerFlex DC

Drive

V2

U2

(3)

35

Control Power /

(3)

36

Relay Terminal

Block

(3)

75

(3)

76

U1

V1

Field Power

Terminal Block

Control

Board P/S

(1)

C

D

C1

D1

(N.O. Relay)

M1 DC Contactor

Aux

13 14

L1

L2

A1

F1

F2

T1

T2

13

L2

DB

Resistor

A1

A2

T2

(N.C. Relay)

DB Contactor

A2

Aux

14L1T1

through Figure

(2)

FU1

A1

M

A2

(2)

FU2

Figure 1.13 Power Wiring with Armature Output Fuses and Inverting Fault Status

(1)

FU1

C

A1

PowerFlex DC

Drive

(2)

33

(on I/O TB4)

19 (+24V on I/O TB2)

(1)

FU2

D

(1)

Armature output fuses are required on four quadrant and are recommended

on two quadrant Frame A and B drives. Fuses with Trip Indicator Switches are

recommended for Inverting Fault protection when the motor will be Field

Weakened and run above base speed.

(2)

Par 139 [Digital In7 Sel] set to 64 “Invert Flt”.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

M

A2

Page 32

1-20 Installation and Wiring

Armature Converter Connections

Terminals Description

U, V, W Three phase AC input to the armature converter

C, D DC output to the motor armature

PE Safety ground

Figure 1.14 Frame A Armature Converter Terminal Block Location

Front View

Note: Front view of drive shown with bottom protective and power terminal covers removed.

Refer to Removing the Drive Covers on page 1-7

for information on removing the drive covers.

UCV DWPE

ATTENTION: Do not operate the drive with the power

terminal cover removed. Operating the drive with the power

!

terminal cover removed may result in a hazardous condition that

could cause personal injury and/or equipment damage.

Figure 1.15 Frame B Armature Converter Terminal Block Location

PE

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

UCVDW

Page 33

Installation and Wiring 1-21

Figure 1.16 Frame C Armature Converter Terminal Block Location

Front View

PE

UCVDW

Bottom View

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 34

1-22 Installation and Wiring

Table 1.E Armature and Safety Ground (PE) Terminal Specifications

Drive Current

Rating Code

Frame

A7P0 4P1

9P0 6P0

012 010

020 014

–019

029 027

038 035

055 045

–052

073 073

093 086

110 –

–100

–129

B 146 167 U, V, W, C, D 10 50 / 442.5

180 – U, V, W, C, D 10 50 / 442.5

218 207 U, V, W, C, D 10 50 / 442.5

265 250 U, V, W

–330U, V, W

360 412 U, V, W

434 – U, V, W

C 521 495 U, V, W

–667U, V, W

(1)

See to Catalog Number Explanation on page Preface-4, positions 8-10 for corresponding drive HP rating,

armature amp rating and field amp rating.

(1)

Terminals Wire Size and Type

U, V, W, C, D, PE

U, V, W, C, D, PE Terminal Block 12 / 106

PE 8 25 / 221

PE 8 25 / 221

PE 8 25 / 221

C, D

PE 8 25 / 221

C, D

PE 8 25 / 221

C, D

PE 8 25 / 221

C, D

PE 8 25 / 221

C, D

PE 8 25 / 221

C, D

PE 8 25 / 221

See Cable and Wiring

Recommendations on

page 1-14

Terminal Bolt

Size (mm)

5 6 / 53

10 50 / 442.5

10 50 / 442.5

10 50 / 442.5

10 50 / 442.5

10 50 / 442.5

10 50 / 442.5

Tightening Torque

(N•m / lbs•in)230V 460V

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 35

Field Circuit Connections

Terminals Description

U1, V1 Single phase AC input to the field circuit

C1, D1 DC output to the motor field

Figure 1.17 Frame A Field Circuit Terminal Block Location

U1

V1

Installation and Wiring 1-23

C1

D1

Bottom of Drive

Figure 1.18 Frame B Field Circuit Terminal Block Location

U1

V1

C1

D1

Top of drive

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 36

1-24 Installation and Wiring

Figure 1.19 Frame C Field Circuit Terminal Block Location

Front of drive

V1U1C1D1

Table 1.F Field Circuit Wire Sizes and Terminal Specifications

Drive Current Rating

(1)

Code

Frame

All All All U1, V1, C1, D1

(1)

Refer to Catalog Number Explanation on page Preface-4, positions 8-10 for corresponding drive HP rating,

armature amp rating and field amp rating.

(2)

See Cable and Wiring Recommendations on page 1-14 for more information.

Termi nals Wire Size and Type

24-10 AWG/kcmils 0.5 - 0.8 / 4.4 - 7.1

Tightening Torque

(2)

(N

•m / lbs•in)230V 460V

Field Current Resistors

The drive’s control circuit board is factory set to the minimum field current

rating based on the drive size. The setting of DIP switch S14 must be

changed to be ≥ the rated field current specified on the motor nameplate or

possible motor damage may result. In addition, the value selected with

switch S14 must be entered in parameter 374

control software when the drive is commissioned (refer to Drive Start Up on

page 2-1.)

[Drv Fld Brdg Cur] in the

ATTENTION: DIP switch S14 must be set to be ≥ the rated

field current specified on the motor nameplate or possible motor

!

damage may result.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

Page 37

Installation and Wiring 1-25

Compare the field current value of the motor to the rated value of the

internal field converter of the drive (see Table 1.G

below) and set switch

S14 to the closest value.

Note: The configuration of switch S14 is not required if the motor’s field

control is provided via an external source, however, in this case it is

recommended that the switch settings be completed as described above.

Table 1.G DIP Switch S14 Field Current Configuration Settings

ON

3

1

2

Switch ohms 148 330 182 36.4 845 1650

Field current

scale S14-1 S14-2 S14-3 S14-4 S14-5 S14-6 S14-7 S14-8

1.0 A OFF OFF OFF OFF OFF ON

2.0 A OFF OFF OFF OFF ON OFF 845 ohm

3.0 A OFF OFF OFF OFF ON ON 558.8 ohm

5.0 A OFF ON OFF OFF OFF OFF 330 ohm

10.0 A ON OFF OFF OFF OFF OFF 168 ohm

12.9 A ON OFF OFF OFF ON ON 129.2 ohm

17.2 A OFF ON ON OFF ON ON 97 ohm

20.0 A ON OFF ON OFF OFF ON 83 ohm

24.1 A ONONONOFFOFFOFF 69 ohm

4

5

6

DIP

78

Note: Illustration is an example

configuration only. DIP switch S14 must be

set ≥ the rated field current specified on

the motor nameplate or possible motor

damage may result.

Equivalent

Resistance

1650 ohm

Not used

Relay Outputs

Terminals Description

35, 36 Normally open contact. Configured with parameter 1392 [Relay

Out 1 Sel] - set to 25 “Contactor” by default.

Out 2 Sel] - set to 5 “Ready” by default.

78, 79 Motor thermistor connections (PTC)

Maximum

Vol ta ge

250V AC 1A75, 76 Normally open contact. Configured with parameter 629 [Relay

Maximum

Current

Terminals 35 and 36 and 75 and 76 are N.O. relay outputs. The relay output

between terminals 35 and 36 is configured with parameter 1392

[Relay Out

1 Sel]. The relay output between terminals 75 and 76 is configured with

parameter 629

[Relay Out 2 Sel]. See Using Contactors on page 1-9 for

more information.

Thermistors and Thermal Switches

To detect motor overheating and protect the motor from overloading, an

external, user-supplied thermistor (PTC) or thermal switch must be

connected to terminals 78 and 79. The drive’s response to a motor over

temperature fault is configured in parameter 365

temperature sensor is not used, a 1k ohm resistor must be connected

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

[OverTemp Flt Cfg]. If a

Page 38

1-26 Installation and Wiring

between terminals 78 and 79 (installed at the factory). Follow the

appropriate instructions below when installing a thermal sensor.

Thermistors (PTC)

PTC thermistors fitted in the motor can be connected directly to the drive

via terminals 78 and 79. In this case the 1k ohm resistor is not required

between terminals 78 and 79.

Thermal Switches (Klixon

“Klixon” type temperature-dependent contacts can disconnect the drive

from the motor via an external control or can be configured as an external

fault using a digital input on drive. They can also be connected to terminals

78 and 79 in order to indicate a drive “Motor Over Temp” fault (F16),

though this is not recommended due to the noise sensitivity of the current

threshold circuitry. If a thermal switch is used a 1k ohm resistor must be

placed in series between the switch and one of the terminals.

Table 1.H Relay Outputs and Thermistor/Thermal Switch Wire Sizes and

Specifications

Signal Type Terminals

Relay Outputs 35 & 36, 75 & 76

Thermistor and

Thermal Switches

(1)

See Cable and Wiring Recommendations on page 1-14 for more information.

Figure 1.20 Frame A Relay and Thermistor/Thermal Switch Terminal Block Locations

®

) in the Motor Windings

78 & 79

Wire Size and Type

Flexible

(mm2)

0.140 - 1.500 0.140 - 1.500 26-14 0.5 (4.4)

(1)

Multi-core

(mm2)AWG

Tightening

Tor qu e

N•m (lb•in)

Note: Terminals 78 and 79

shown with 1k ohm resistor in

place of temperature sensor.

PowerFlex Digital DC Drive User Manual - Publication 20P-UM001C-EN-P - July 2008

78 79 35 36 75 76

Page 39

Installation and Wiring 1-27

Figure 1.21 Frame B Relay and Thermistor/Thermal Switch Terminal Block Locations

78 79 35 36 75 76

Figure 1.22 Frame C Relay and Thermistor/Thermal Switch Terminal Block Locations

35 36 75 76 78 79