Page 1

PowerFlex Drives with

TotalFORCE Control Built-in

EtherNet/IP Adapter

Catalog Numbers 20G, 20J, 6000T

User Manual

Original Instructions

Page 2

PowerFlex Drives with TotalFORCE Control Built-in EtherNet/IP Adapter User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential

Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory

requirements for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 3

Table of Contents

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Download Firmware, AOP, EDS, and Other Files . . . . . . . . . . . . . . . . . . . . 7

Summary of Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Getting Started Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dual Ethernet Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Equipment Shipped with the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

User-supplied Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Choose an Ethernet Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2

Configure the Adapter Configuration Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setting the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Use Switches to Set the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting the Interface to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Apply Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Start-up Status Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configuring and Verifying Key Drive Parameters. . . . . . . . . . . . . . . 20

Use Interface Parameters to Set the IP Address . . . . . . . . . . . . . . . . . . . . 21

Using a HIM to Access Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Using a BOOTP or DHCP Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setting the Data Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Setting Communication Hierarchy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Setting a Controller Hierarchy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Setting a Fault Action. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Changing the Fault Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Resetting the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Restore Interface Parameters to Default Configurations . . . . . . . . . . . . 28

Viewing the Interface Status Using Parameters . . . . . . . . . . . . . . . . . . . . 29

Updating the Interface Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Configuring the Drive in a Logix

System

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 3

Chapter 3

Establish Communication by Using RSLinx Classic Software. . . . . . . . 31

Obtain Add-on Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Create Logix Controller Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Add the Drive to the Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Configure Input and Output Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Download the Configuration to the Controller . . . . . . . . . . . . . . . . . . . . . 39

Page 4

Table of Contents

Correlate the Drive with the Controller . . . . . . . . . . . . . . . . . . . . . . . . 40

Configuration to Aid in

Field-Failure Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Use Firmware Supervisor to Update Firmware . . . . . . . . . . . . . . . . . . . . . 42

Using Automatic Device Configuration (ADC) . . . . . . . . . . . . . . . . . . . . . 44

Configure the Drive for ADC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

ADC and Logix Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Power Peripheral Changes When Using ADC with PowerFlex 755T

Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Special Considerations For 20-750-S1 Safe Speed Module (S1). . . . 49

Special Considerations for Communications and Option Developers

Kit Option Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Testing ADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Monitoring ADC Progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Programmatically Monitoring Connection Status and the ADC

Configuration Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Best Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Chapter 4

Using the I/O About I/O Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Understanding the Logix 5000 Controller I/O Image . . . . . . . . . . . . . . . 55

Using Logic Command/Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Using Reference/Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Using Datalinks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Example of Ladder Logic Program Information . . . . . . . . . . . . . . . . . . . . 58

Create Ladder Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 5

Using Message Instructions About Message Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Send a MSG Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

ControlLogix Controller Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Ladder Logic Program to Read a Single Parameter . . . . . . . . . . . . . . 64

Formatting a Message to Read a Single Parameter . . . . . . . . . . . . . . 64

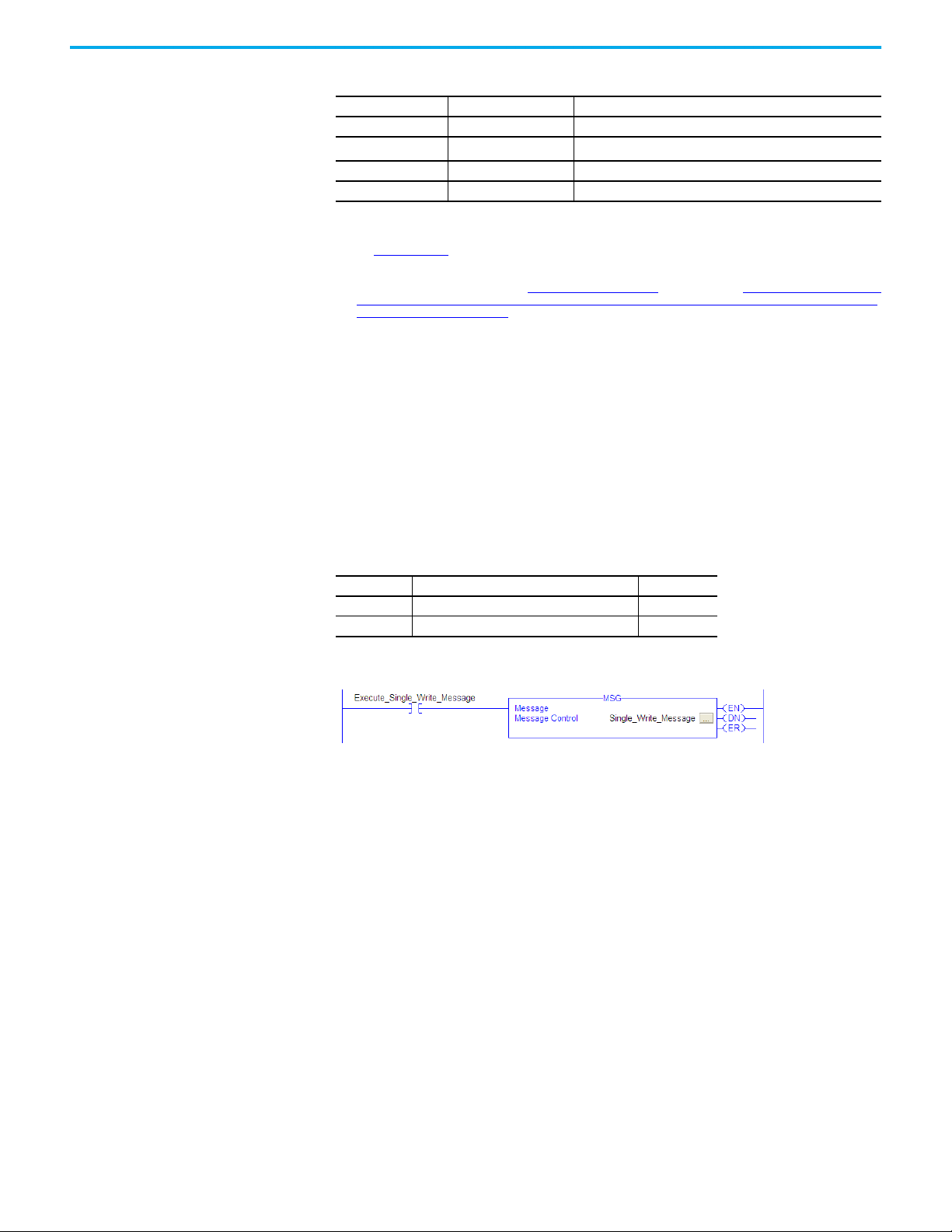

Ladder Logic Program to Write a Single Parameter . . . . . . . . . . . . . 65

Formatting a Message to Write a Single Parameter . . . . . . . . . . . . . 66

Ladder Logic Program to Read Multiple Parameters . . . . . . . . . . . . 67

Formatting a Message to Read Multiple Parameters. . . . . . . . . . . . . 67

Ladder Logic Program to Write Multiple Parameters. . . . . . . . . . . . 69

Formatting a Message to Write Multiple Parameters. . . . . . . . . . . . 70

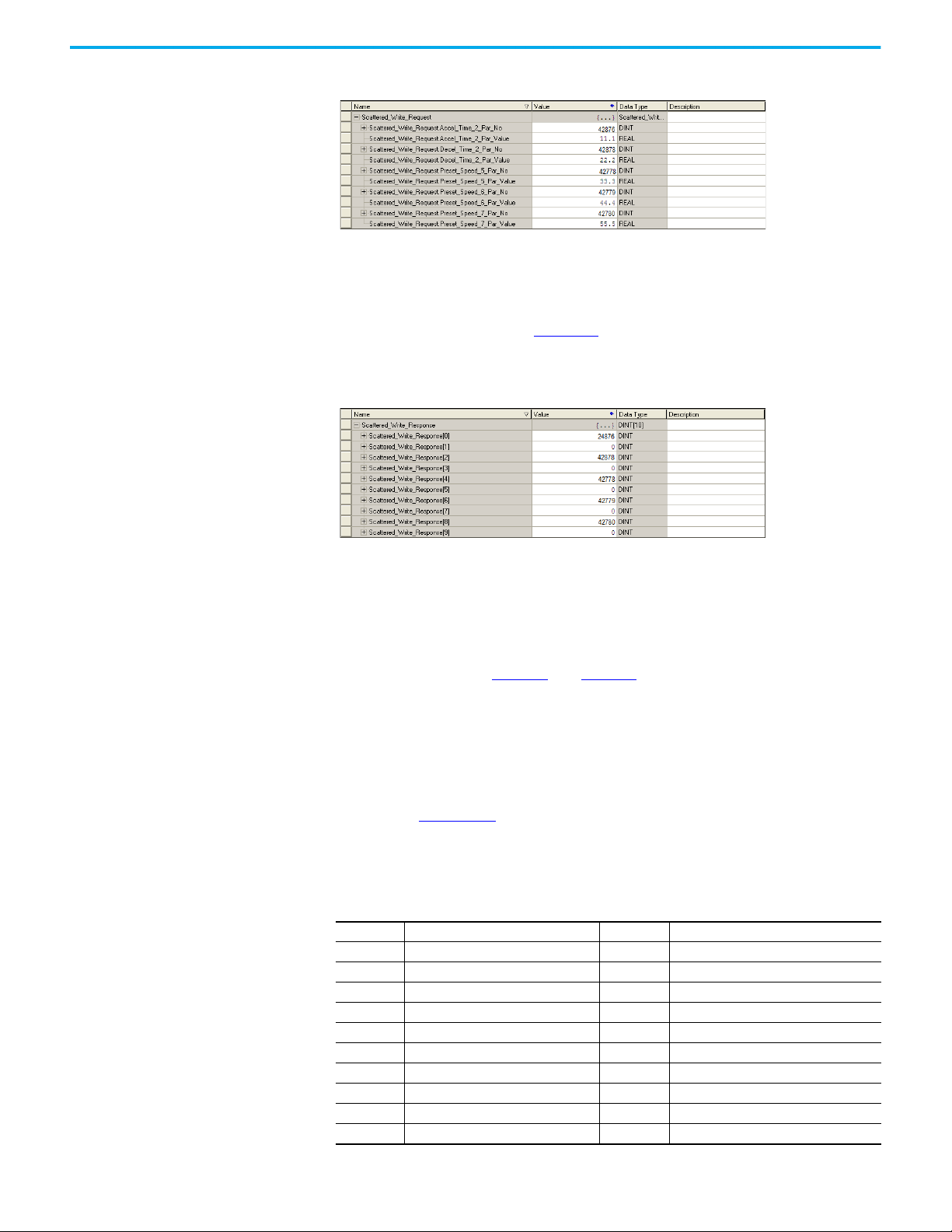

Explanation of Request and Response Data for Scattered Read

Multiple Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Chapter 6

Troubleshooting Viewing Interface Diagnostic Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Viewing and Clearing Events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

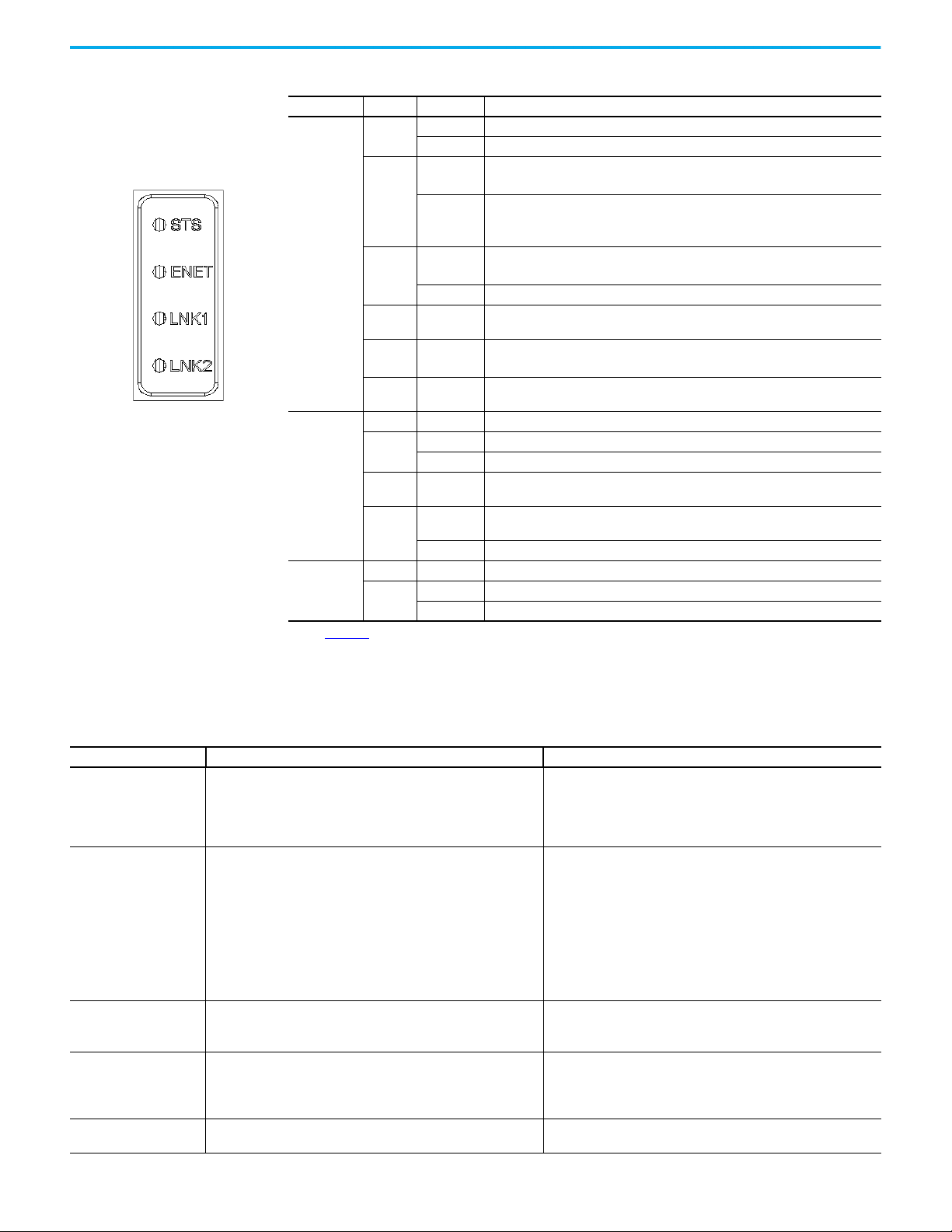

Drive Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

ENET Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

LNK1 Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 5

Tab le o f Content s

LNK2 Status Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Appendix A

Specifications Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Appendix B

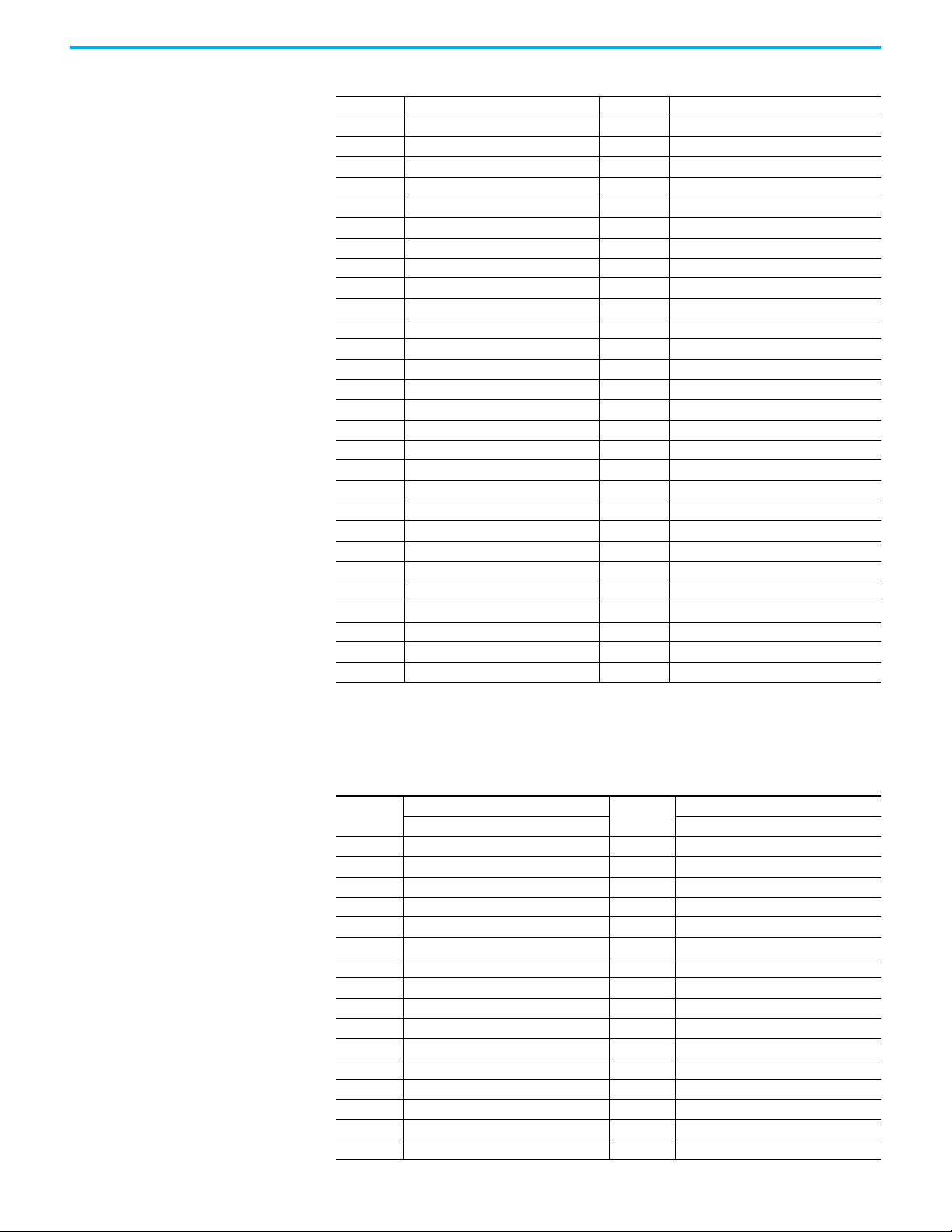

Interface Parameters How Parameters Are Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Appendix C

EtherNet/IP Objects Supported Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Identity Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Assembly Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

PCCC Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

DPI Device Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

DPI Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Formulas for Converting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

DPI Fault Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

DPI Alarm Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

DPI Diagnostic Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

DPI Time Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Host DPI Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Formulas for Converting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

TCP/IP Interface Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Ethernet Link Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Appendix D

Logic Command/Status Words Drive Products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Logic Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Bus Supply Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Glossary

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 5

Page 6

Table of Contents

Notes:

6 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 7

Preface

About This Publication

Conventions Used in This Manual

Download Firmware, AOP, EDS, and Other Files

Summary of Changes

This manual provides information about the dual-port, built-in EtherNet/IP™

adapter in PowerFlex® 755T drives and bus supplies, PowerFlex 6000T, and

how to use the adapter for network communication.

These conventions are used throughout this manual:

Parameter names are shown in the format Device Parameter xxx - [*] or Host

Parameter xxx - [*]. The xxx represents the parameter number. The *

represents the parameter name—for example, Device Parameter 01 -

[Operating Mode].

• Where a parameter is referenced outside of the native port, it is

referenced as Port#:Parameter# [parameter name]

(0:301 - [Net Addr Scr] or 10:350 - [Vref Source])

Download firmware, associated files (such as AOP, EDS, and DTM), and access

product release notes from the Product Compatibility and Download Center at

rok.auto/pcdc

This publication contains the following new or updated information. This list

includes substantive updates only and is not intended to reflect all changes.

.

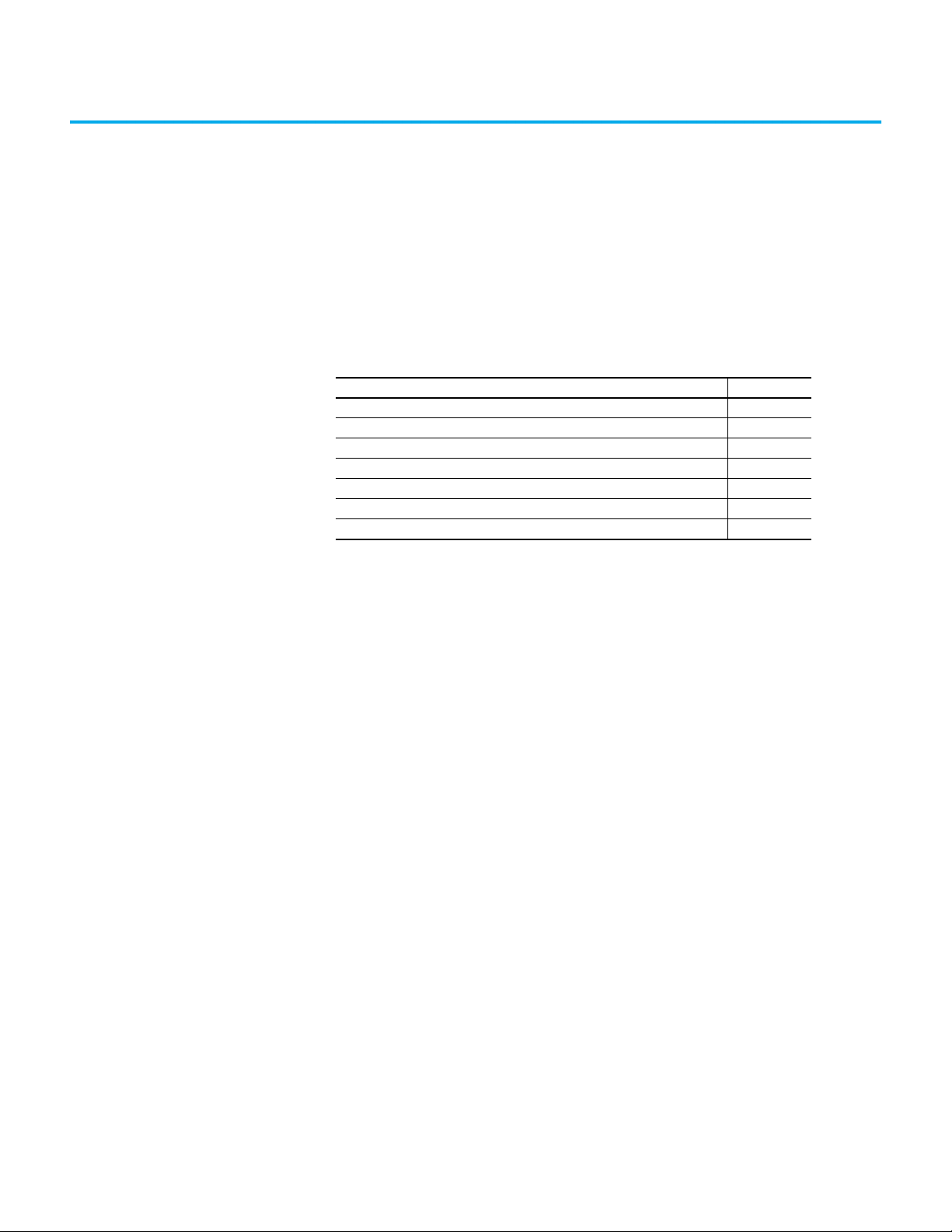

Topic Page

Updated template throughout

General update throughout

Added information for PowerFlex 6000T drives throughout

Corrected PCR ID 778 on page numbering and pdf view setting throughout

Updated Additional Resources table 8

Changed all “ControlFLASH” instances to “ControlFLASH Plus” throughout

Updated Connected Component Workbench software release version to 11 12, 15, 17, 75

Added information on using the Enhanced HIM Integrated Touch Screen Display with

PowerFlex 6000T drives

Revised instructions for setting IP address using a HIM page 21

Updated information on establishing communication by using RSLinx Classic Software 31

Updated information on AOP and corrected PCR ID 736 on broken links 32

Updated information on creating Logix Controller project 33

Moved Appendix A Status Indicators to topic within Chapter 6 Troubleshooting 75

12, 17, 75

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 7

Page 8

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

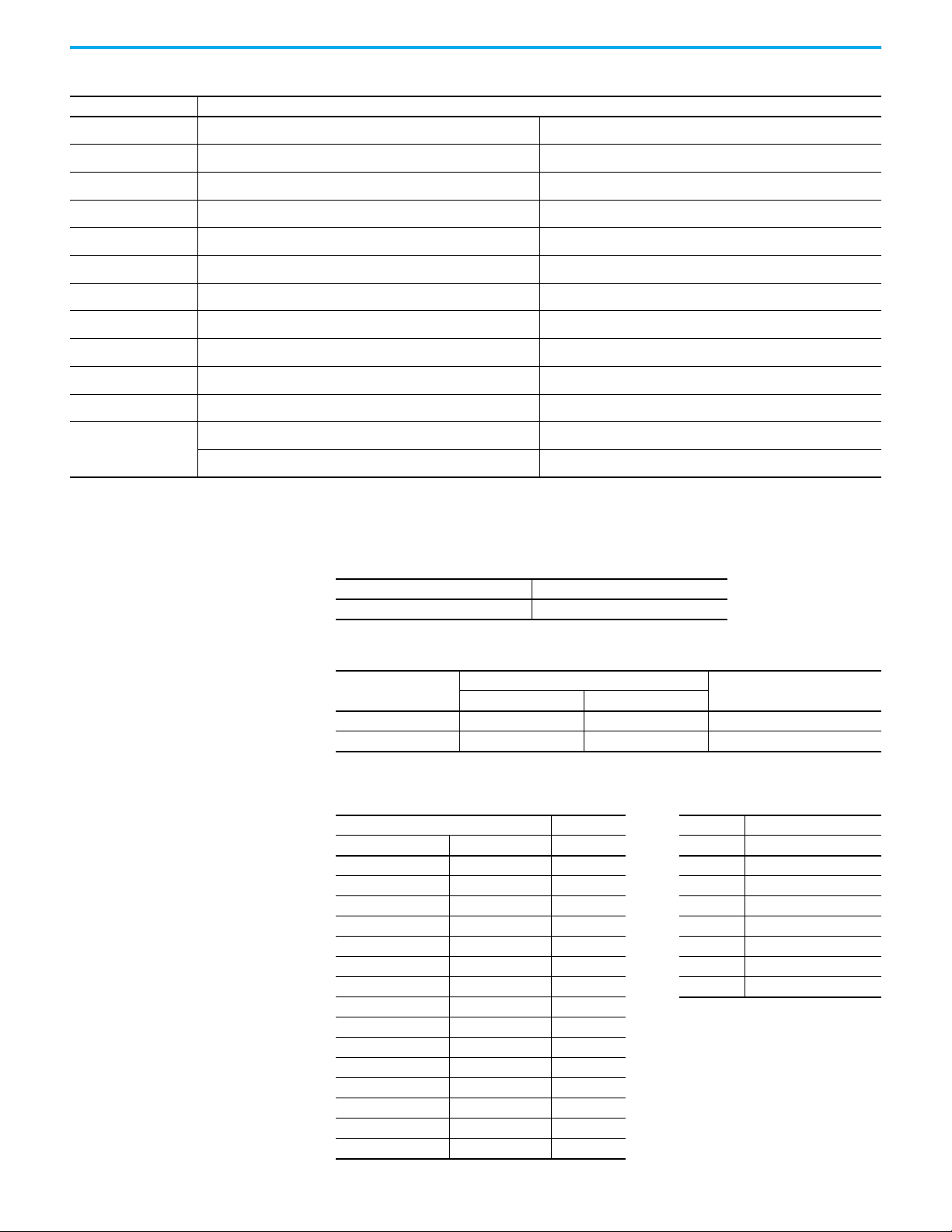

Resource Description

PowerFlex 750-Series Products with TotalFORCE Installation Instructions,

publication 750-IN100

PowerFlex 755TM IP00 Open Type Kits Installation Instructions,

publication 750-IN101

PowerFlex Drives with TotalFORCE Control Programming Manual,

publication 750-PM100

PowerFlex 750-Series Products with TotalFORCE Control Technical Data,

publication 750-TD100

PowerFlex 755TM IP00 Open Type Kits Technical Data, publication 750-TD101

PowerFlex 750-Series Products with TotalFORCE Control Hardware Service

Manual, publication 750-TG100

PowerFlex 750-Series Safe Speed Monitor Option Module Safety Reference

Manual, publication 750-RM001

PowerFlex 750-Series Safe Torque Off Option Module User Manual,

publication 750-UM002

PowerFlex 750-Series ATEX Option Module User Manual, publication 750-UM003

PowerFlex 6000T Drives Installation Instructions, publication 6000-IN100 Provides instructions for installing PowerFlex 6000T drives and related equipment.

PowerFlex 6000T Drives Programming Manual, publication 6000-PM100

Industry Installation Guidelines for Pulse Width Modulated (PWM) AC Drives,

publication DRIVES-AT003

Drives in Common Bus Configurations with PowerFlex 755TM Bus Supplies

Application Techniques, publication DRIVES-AT005

Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives,

publication DRIVES-IN001

Product Certifications website, rok.auto/certifications

. Provides declarations of conformity, certificates, and other certification details.

Provide the basic steps to install PowerFlex 755TL low harmonic drives, PowerFlex 755TR

regenerative drives, and PowerFlex 755M drive systems.

Provides instructions to install IP00 Open Type Kits in user-supplied enclosures.

Provides detailed information on:

• I/O, control, and feedback options

• Parameters and programming

• Faults, alarms, and troubleshooting

Provides detailed information on:

• Drive and bus supply specifications

• Option specifications

• Fuse and circuit breaker ratings

Provides detailed information on:

• Kit selection

• Kit ratings and specifications

• Option specifications

Provides detailed information on:

• Preventive maintenance

•Component testing

• Hardware replacement procedures

These publications provide detailed information on installation, set-up, and operation of the 750Series safety option modules.

Provides detailed information on drive features, programming parameters, and troubleshooting

faults and alarms.

Provides basic information on enclosure systems, considerations to help protect against

environmental contaminants, and power and grounding considerations for installing Pulse Width

Modulated (PWM) AC drives.

Provides basic information to wire properly and ground the following products in common bus

applications:

• PowerFlex 755TM drive system for common bus solutions

• PowerFlex 750-Series AC and DC input drive

• Kinetix® 5700 servo drives

Provides basic information to properly wire and ground PWM AC drives.

You can view or download publications at rok.auto/literature

8 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

.

Page 9

Chapter 1

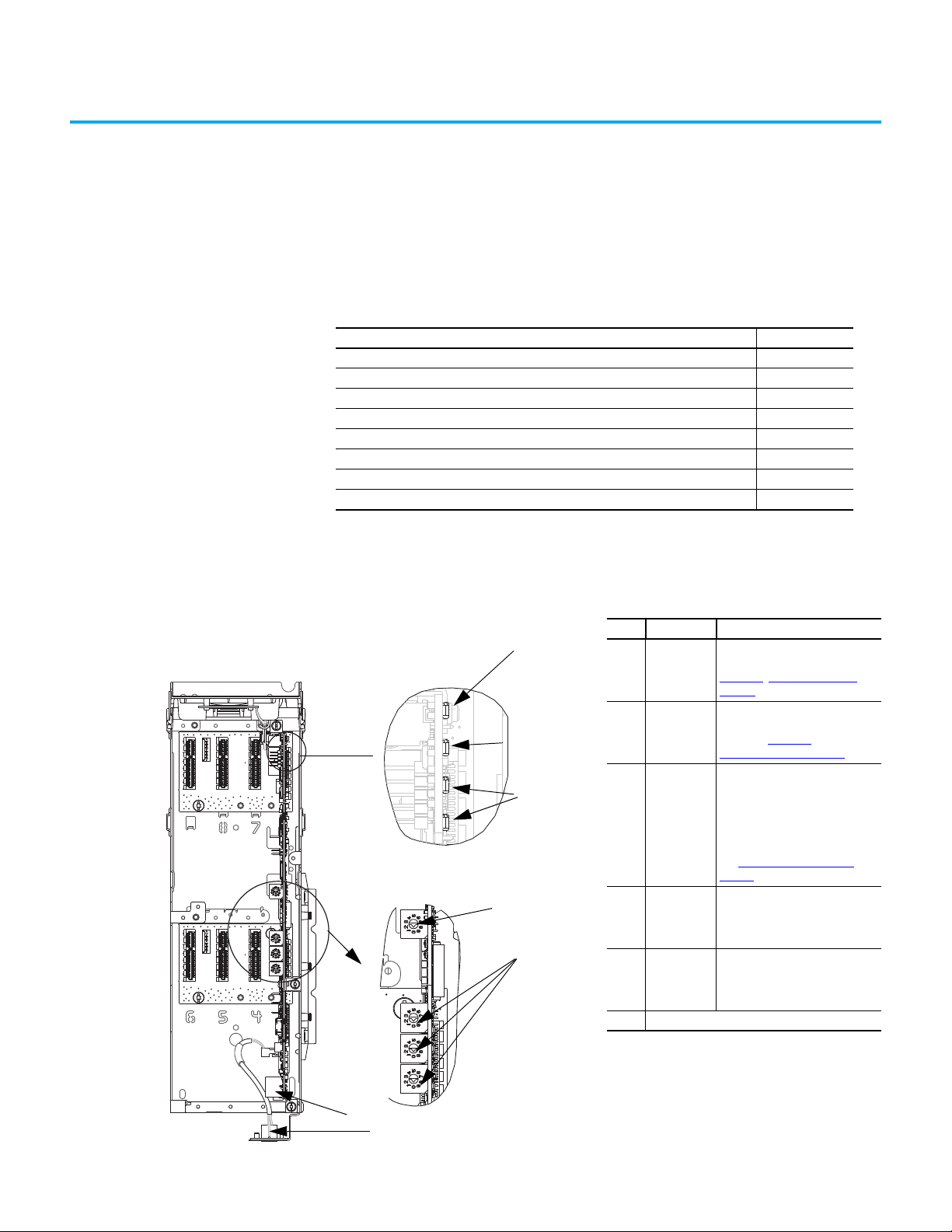

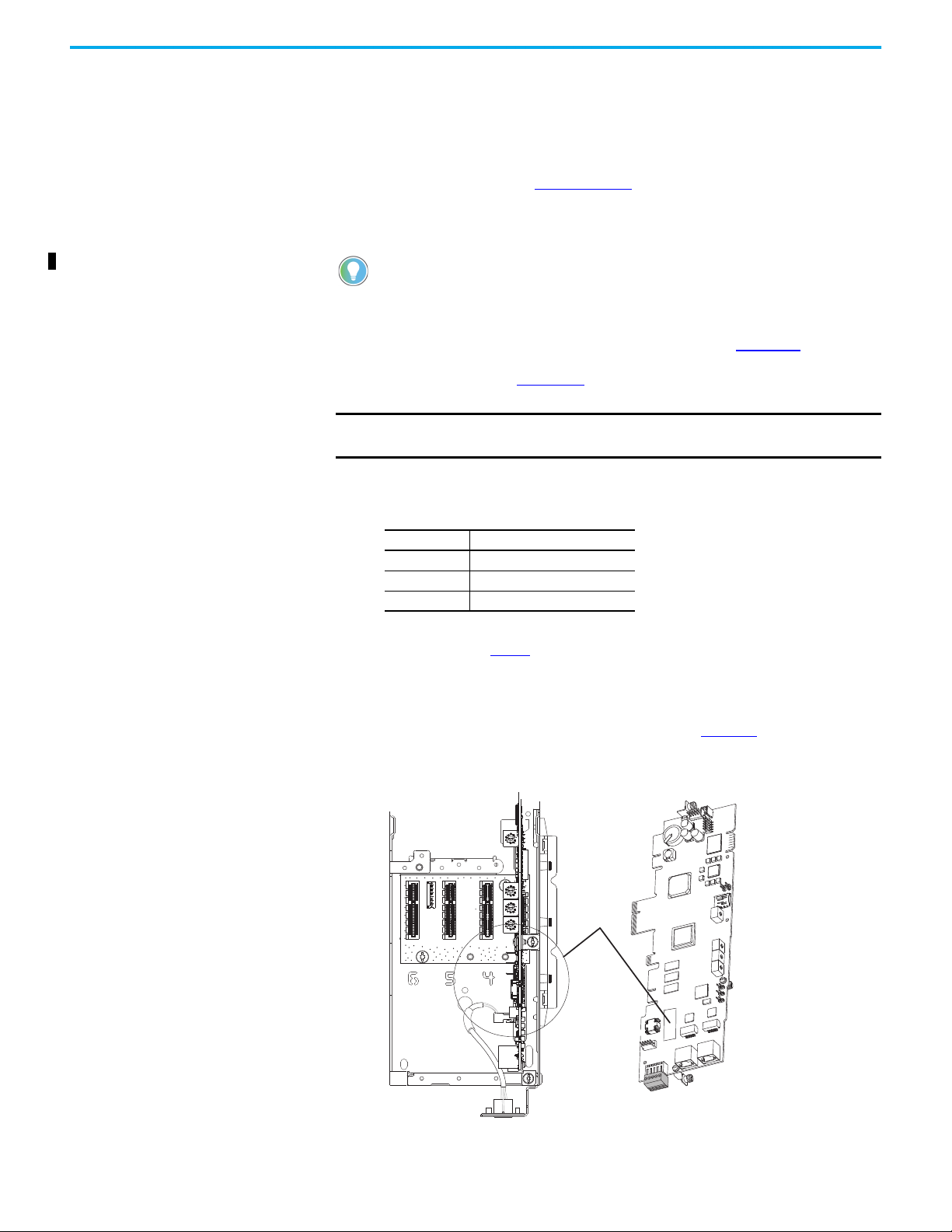

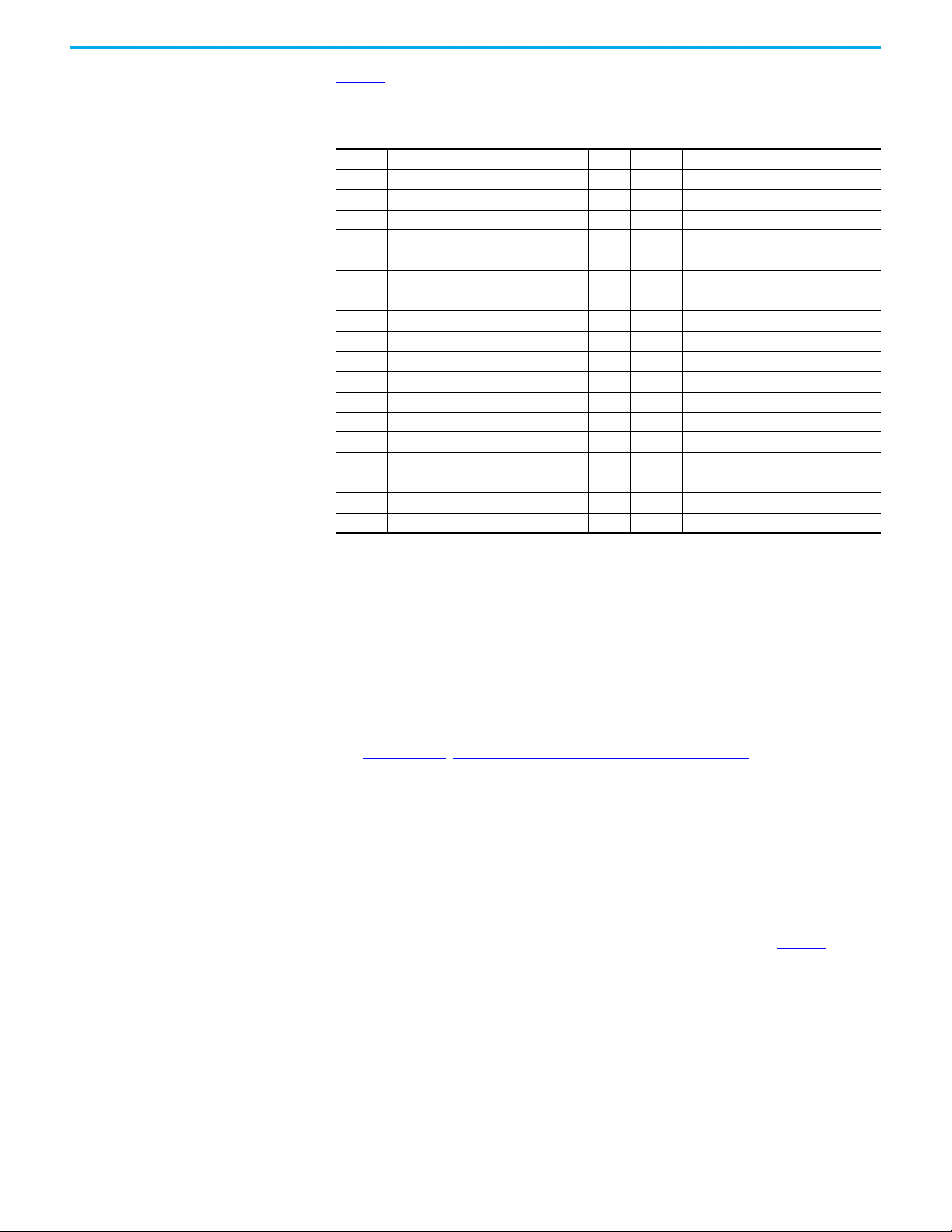

Item Part Description

1

Status

Indicator ENET

Indicates the overall status of

network communication. See

Chapter 6

, Troubleshooting on

page 75.

2

Status

indicators LNK1 and

LNK2

Indicates the status of the network

link to each of the two physical

ports. See Chapter 6

,

Troubleshooting on page 75.

3

IP address

Switches

Sets the IP address of the interface

(port 0) when not using any of

these other methods:

• Interface parameters

•BOOTP server

• DHCP server firmware

See Setting the IP Address on

page 16 for details.

4

Ethernet

Connectors

RJ45 connectors for the Ethernet

cable. The connectors are CAT-5

compliant to deliver data over a

100 Base-TX Ethernet networks.

5

DPI Port 2 and

3

Cable connection for DPI port 2

handheld and remote options. DPI

port 3 is available by using a DPI

splitter part number 1203-S03.

6 Reserved

Drive Control Pod

Drive STS Indicator

Components that are shown have the HIM

bezel open and the drive cover removed

1

3

4

5

2

6

Ones

Position

Hundreds

Position

Tens

Position

Getting Started

The built-in EtherNet/IP adapter, on the main control board of the drive, is

used for network communication.

Topic Page

Components 9

Fea tur es 10

Dual Ethernet Ports 10

Required Equipment 12

Equipment Shipped with the Drive 12

User-supplied Equipment 12

Choose an Ethernet Switch 13

Safety Precautions 13

Components

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 9

Page 10

Chapter 1 Getting Started

Features The features of the built-in EtherNet/IP adapter include the following:

• Switches are used to set an IP address before power is applied to the

drive. Other methods are also available to configure the IP address:

- Interface parameters

- BOOTP (Bootstrap Protocol) server

- DHCP (Dynamic Host Configuration Protocol) server

• Indicators that report the status of the built-in EtherNet/IP adapter and

network communication. They are visible when the drive cover is open or

closed.

• Controller hierarchy that can be configured to transmit data to and from

a controller.

• Parameter-configured 32-bit datalinks in the I/O to meet application

requirements: 16 datalinks to write data from the network to the drive,

and 16 datalinks to read data to the network from the drive.

• Explicit Messaging support.

• User-defined fault actions to determine how the built-in

EtherNet/IP adapter and its host drive respond to the following:

- I/O messaging communication disruptions (Comm Flt Action)

- Controllers in Program mode (Idle Flt Action)

- Message (MSG) instructions for drive control via PCCC or the

Common Industrial Protocol (CIP™) based network Assembly Object

(Msg Flt Action)

• Automatic Device Configuration (ADC) and Studio 5000 Logix

Designer® application feature, which supports the automatic download

of configuration data.

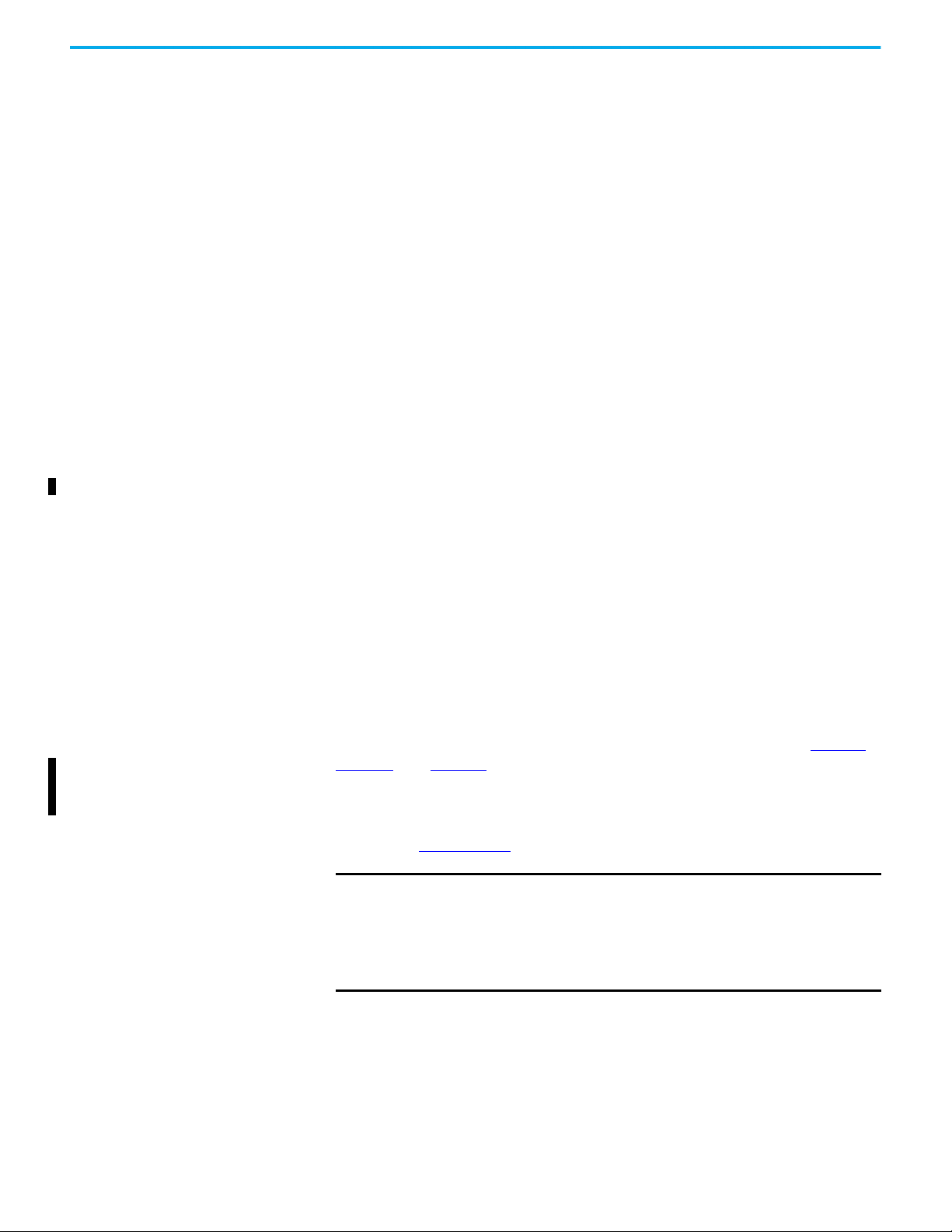

Dual Ethernet Ports

Dual Ethernet ports provide connection for star, linear, or Device Level Ring

(DLR) network topologies.

Examples of different EtherNet/IP network topologies are shown in Figure 1

Figure 2

applicable to PowerFlex drives with TotalFORCE® technology with the built-in

Ethernet/IP adapter. For information about linear and Device Level Ring

(DLR) topologies, see EtherNet/IP built-in Switch Technology,

publication ENET-AP005

, and Figure 3. These examples show a PowerFlex 755T drive, but are

.

IMPORTANT

The adapter has EtherNet/IP built-in switch technology, and ENET1 and

ENET2 network ports to connect to a linear or Device Level Ring (DLR)

network in a subnet.

You cannot use the ENET1 and ENET2 network ports as two network

interfaces that are connected to two different Internet Protocol (IP)

subnets.

,

10 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 11

Figure 1 - Connecting the Ethernet Cable in a Star Topology Network

Controller

PowerFlex 755T drives

(1)

External

Ethernet

Switch

Computer with Ethernet

Connection

To other

EtherNet/IP

networks

(1)

The Ethernet cable can be connected to the adapters ENET1 or ENET2 network port.

Controller

PowerFlex 755T drives

(1)

External

Ethernet Switch

Computer with Ethernet

Connection

To other

EtherNet/IP

networks

(1)

The adapters ENET1 and ENET2 network ports are both used.

Controller

PowerFlex 755T drives

(1)

Computer with Ethernet

Connection

To other

EtherNet/IP

networks

Ethernet Tap

1783-ETAP

((1)

The adapters ENET1 and ENET2 network ports are both used.

Ethernet Tap

1783-ETAP

Figure 2 - Connecting the Ethernet Cable in a Linear Topology Network

Chapter 1 Getting Started

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 11

Figure 3 - Connecting the Ethernet Cable in a DLR Topology Network

Page 12

Chapter 1 Getting Started

Required Equipment Some required equipment that is used with the built-in EtherNet/IP adapter is

shipped with the drive. The sections that follow describe some of the other

user-supplied equipment that is also required.

Equipment Shipped with the Drive

Because the EtherNet/IP adapter is built in the main control board in the drive,

it is always a part of the drive. There are no separate physical installation

instructions for the interface.

User-supplied Equipment

To configure the built-in EtherNet/IP adapter, you must supply the following:

• A small screwdriver for setting the network address switches.

• An Ethernet cable.

• An Ethernet switch (see Choose an Ethernet Switch

• A computer connection to the EtherNet/IP network.

on page 13).

See the EtherNet/IP Media Planning and Installation Manual, available from the

Open DeviceNet® Vendor Association (ODVA) at https://www.odva.org

details on how to use the required media components and how to plan for

install, verify, troubleshoot, and certify your EtherNet/IP network.

for

Configuration Tool Options

Any of the following configuration tools can be used:

• 20-HIM-A6 and 20-HIM-C6S for PowerFlex 755T drives

• Integrated touch screen display (eHIM) or standard HIM (20-750-CS6)

for PowerFlex 6000T drives

• Connected Components Workbench™ software release 11 or later

Connected Components Workbench software is the recommended

standalone software tool for use with PowerFlex drives. Download it for

free from the Product Compatibility and Download Center (PCDC) at

rok.auto/pcdc

• Controller configuration software, such as RSLogix 5000® software,

version 20, or Studio 5000 Logix Designer application, version 21 and

later, which also supports Automatic Device Configuration (ADC).

For versions earlier than version 30, you must install the Add-on Profile

(AOP) available from the PCDC at rok.auto/pcdc

.

.

12 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 13

Chapter 1 Getting Started

Choose an Ethernet Switch

If the built-in EtherNet/IP adapter is used to communicate with a controller

that has multicast connections, a managed switch that supports IGMP

snooping is suggested. EtherNet/IP implicit (I/O) messaging can be

configured to use IP multicast to distribute I/O control data, which is

consistent with the CIP-based network Producer/Consumer model. If multiple

built-in EtherNet/IP adapters are connected to the switch in a redundant

configuration, a managed switch is required. A managed switch also provides

useful diagnostic features such as port mirroring.

The built-in EtherNet/IP adapter supports unicast connections. Unicast is the

default setting when adding the drive to the I/O controller. When all built-in

EtherNet/IP adapters are installed as unicast devices, then an IGMP snooping

(managed) switch is not needed.

The choice of a switch involves many factors. See Ethernet Reference Manual

publication ENET-RM002

switches from Rockwell Automation, see the Stratix® Industrial Networks

Infrastructure At-a-Glance, publication ENET-QR001

for details. For more information about industrial

.

Safety Precautions Read the following safety precautions carefully.

ATTENTION: Risk of injury or equipment damage exists.

• Only personnel familiar with drive and power products and the associated

machinery can plan or implement the installation, start up, configuration. Only

qualified personnel can perform subsequent maintenance of the drive by using

this built-in interface. Failure to comply can result in injury and/or equipment

damage.

• The built-in adapter contains electrostatic discharge (ESD) sensitive parts that

can be damaged if you do not follow ESD control procedures. ESD control

precautions are required when handling the interface. If you are unfamiliar with

ESD control procedures, see Guarding Against Electrostatic Damage,

publication 8000-SB001

• When a system is configured for the first time, unintended or incorrect machine

motion can occur. Disconnect the motor from the machine or process during

initial system testing.

.

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 13

Page 14

Chapter 1 Getting Started

Notes:

14 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 15

Chapter 2

Configure the Adapter

This chapter provides instructions and information for setting the parameters

to configure the built-in EtherNet/IP adapter.

Topic Page

Configuration Tools 15

Setting the IP Address 16

Connecting the Interface to the Network 17

Apply Power 18

Start-up Status Indications 18

Configuring and Verifying Key Drive Parameters 20

Use Interface Parameters to Set the IP Address 21

Using a HIM to Access Parameters 21

Using a BOOTP or DHCP Server 23

Setting the Data Rate 24

Setting Communication Hierarchy 25

Setting a Controller Hierarchy 25

Setting a Fault Action 27

Changing the Fault Action 27

Resetting the Adapter 28

Restore Interface Parameters to Default Configurations 28

Viewing the Interface Status Using Parameters 29

Updating the Interface Firmware 30

For a list of parameters, see Appendix B

definitions of terms in this chapter, see the Glossary

, Interface Parameters on page 85. For

.

Configuration Tools The built-in EtherNet/IP adapter stores parameters and other information in

nonvolatile storage (NVS). The following tools can be used to access the

interface parameters.

Tool See

PowerFlex 20-HIM-A6 or 20-HIM-C6S HIM page 21

BOOTP server page 23

DHCP server page 23

Connected Components Workbench software,

release 11 or later

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 15

rok.auto/pcdc, or online help (installed with the software)

Page 16

Chapter 2 Configure the Adapter

Ones

Position

Hundreds

Position

Tens

Position

Setting the IP Address There are four ways to configure the built-in EtherNet/IP adapter IP address:

• Interface Rotary Switches — Use the switches when working on a

simple, isolated network (with IP addresses in the range, 192.168.1.xxx),

and you prefer a simplified node addressing method that has other

products with switches to set their IP addresses. See Use Switches to Set

the IP Address on page 16.

• Interface Parameters — Use interface parameters for more flexibility

when configuring the IP address. To use parameters as the source for the

IP address, set the rotary switches to 999. Set 0:300 - [Net Addr Sel] to ‘1’

(Parameters). The IP address, subnet mask, and gateway address come

from the values set using the associated interface 0:302...313. See Use

Interface Parameters to Set the IP Address on page 21.

• BOOTP — Use BOOTP when you want to configure an IP address, subnet

mask, and gateway address for the interface by using a BOOTP server. To

use BOOTP as the source for the IP address, set the rotary switches to

999. Set 0:300 - [Net Addr Sel] to ‘2’ (BOOTP).

See Using a BOOTP or DHCP Server

• DHCP (Dynamic Host Configuration Protocol) Use DHCP when you

want to configure an IP address, subnet mask, and gateway address for

the interface by using a DHCP server. To use DHCP as the source for the

IP address, set the rotary switches to 999.

Set 0:300 - [Net Addr Sel] to ‘3’ (DHCP).

See Using a BOOTP or DHCP Server

on page 23 for details.

on page 23 for details.

IMPORTANT

Regardless of the method that is used to set the interface IP address, each

node on the EtherNet/IP network must have a unique IP address. To

change an IP address, you must set the new value and then remove and

reapply power to (or reset) the interface.

Use Switches to Set the IP Address

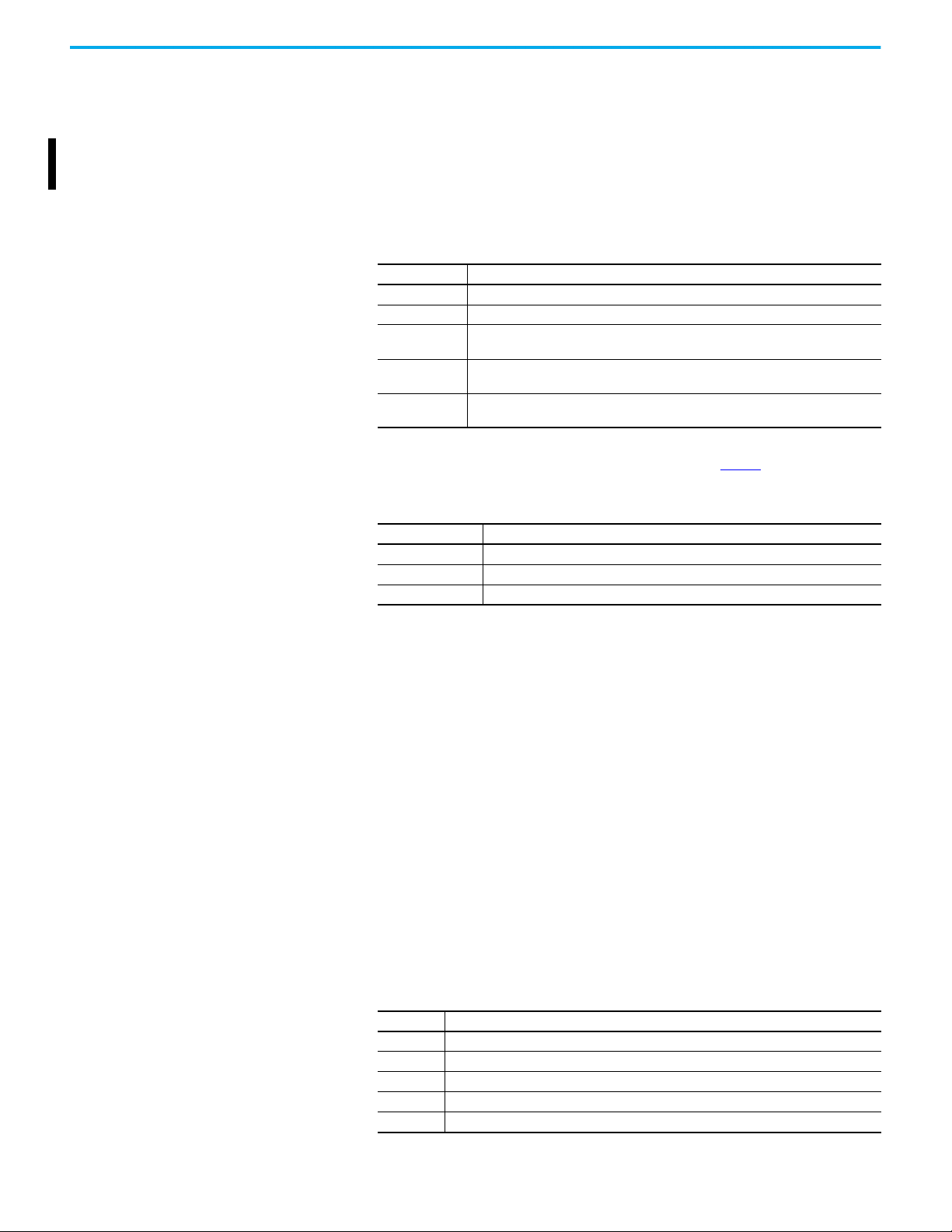

Figure 4 - Setting the IP Address Switches

The three interface switches are grouped near the middle of the drive. These

switches are read when the drive powers up, and represent three decimal

digits from top to bottom. If set to a valid address (001…254), the interface uses

that value as the last octet of its IP address (192.168.1.xxx, where xxx = the

16 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 17

Chapter 2 Configure the Adapter

rotary switch settings), along with a subnet mask of 255.255.255.0 and a

gateway address of 192.168.1.1. Also, the setting for interface 0:300 - [Net Addr

Sel] is automatically ignored.

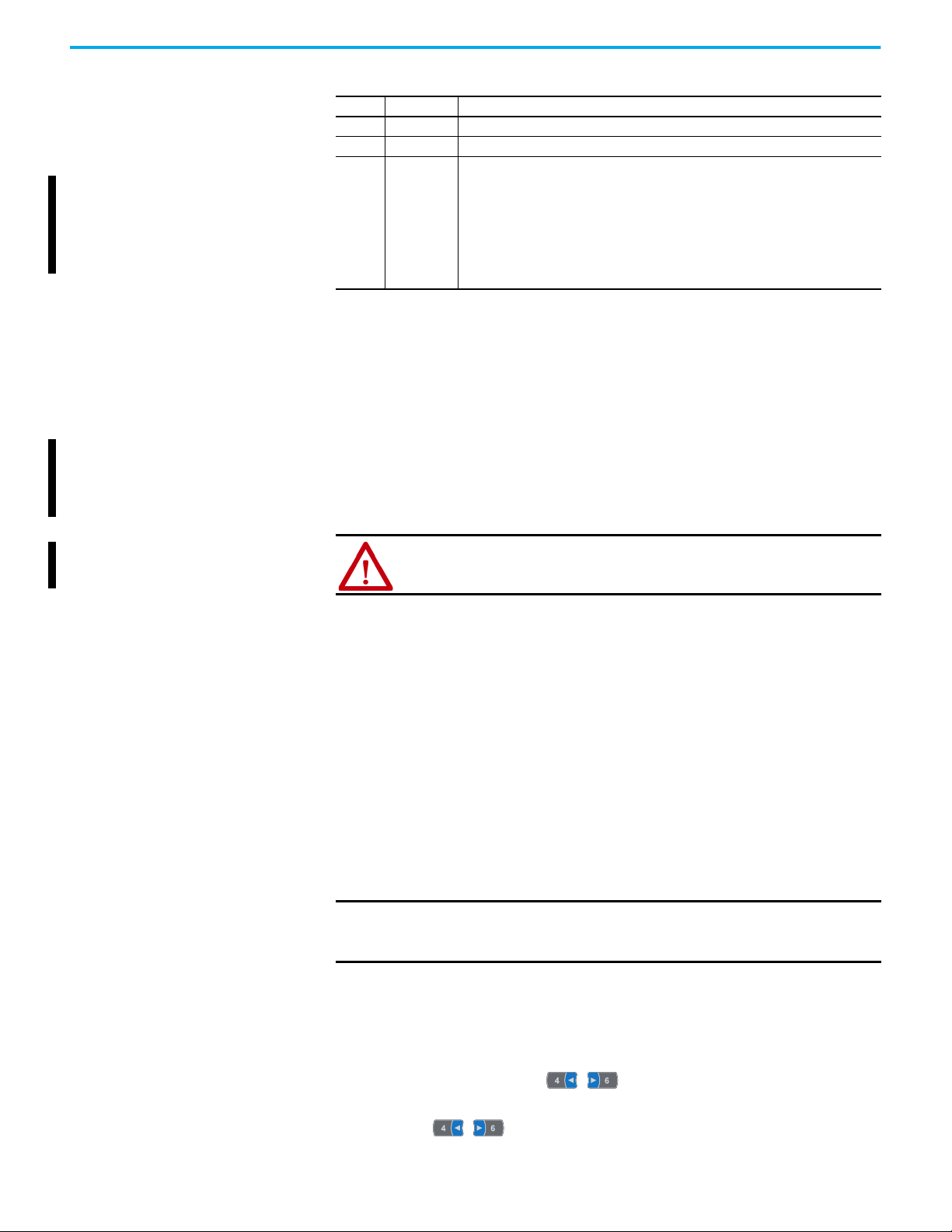

Table 1 - IP Address Switches Settings

Settings Description

001…254

888

999

Any other setting Reserved.

The adapter uses the rotary switch settings for the IP address (192.168.1.xxx, where xxx = the rotary

switch settings). The value that is stored in 0: 300 - [Net Addr Sel] is automatically ignored.

Resets the adapter IP address and other EtherNet/IP communication settings to factory defaults.

Thereafter, the drive must be powered down, the switches set to a correct value (001…254 or 999),

and then the drive must be powered up again to accept the new address.

Disables the rotary switches, and requires using one of the following:

• 0:300 - [Net Addr Sel] selects the source for the interface IP address, which is one of the

following:

–Adapter Parameters

– BOOTP server (default)

– DHCP server firmware

Connecting the Interface to the Network

IMPORTANT

When using the interface rotary switches, set the IP address before power

is applied because the interface uses the switch settings that it detects

when it first receives power.

The switch settings can be verified by viewing Port 0 Diagnostic Item number

68, see Table 21 on page 78

with any of the following drive configuration tools:

• 20-HIM-A6 and 20-HIM-C6S for PowerFlex 755T drives

• Integrated touch screen display (eHIM) or standard HIM (20-750-CS6)

for PowerFlex 6000T drives.

• Connected Components Workbench software, release 11 or later.

Also, you can use 0:301 - [Net Addr Src], a read-only parameter, to verify the

active setting for 0:300 - [Net Addr Sel].

ATTE NT IO N: Risk of injury or death exists. The PowerFlex drive can contain high

voltages that can cause injury or death. Remove power from the drive, and then

verify that power has been discharged before connecting the built-in EtherNet/IP

adapter to the network. Verify that the DC bus has been discharged.

1. Remove power from the drive and discharge any stored power.

2. To access the drive control pod, open the drive door.

3. Use electrostatic discharge (ESD) control precautions.

4. Connect one end of an Ethernet cable to the network.

See Figure 5

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 17

for an example of wiring to an EtherNet/IP network.

Page 18

Chapter 2 Configure the Adapter

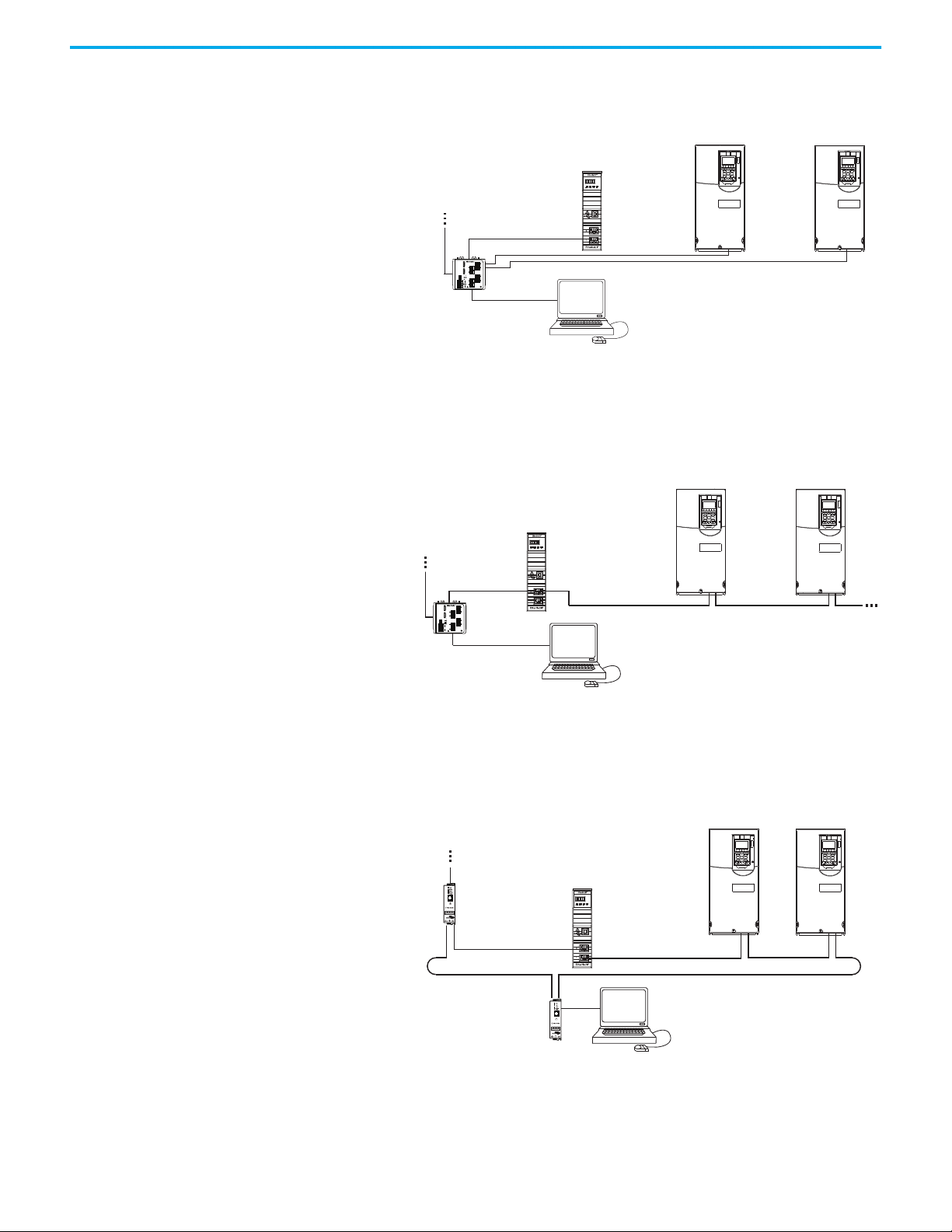

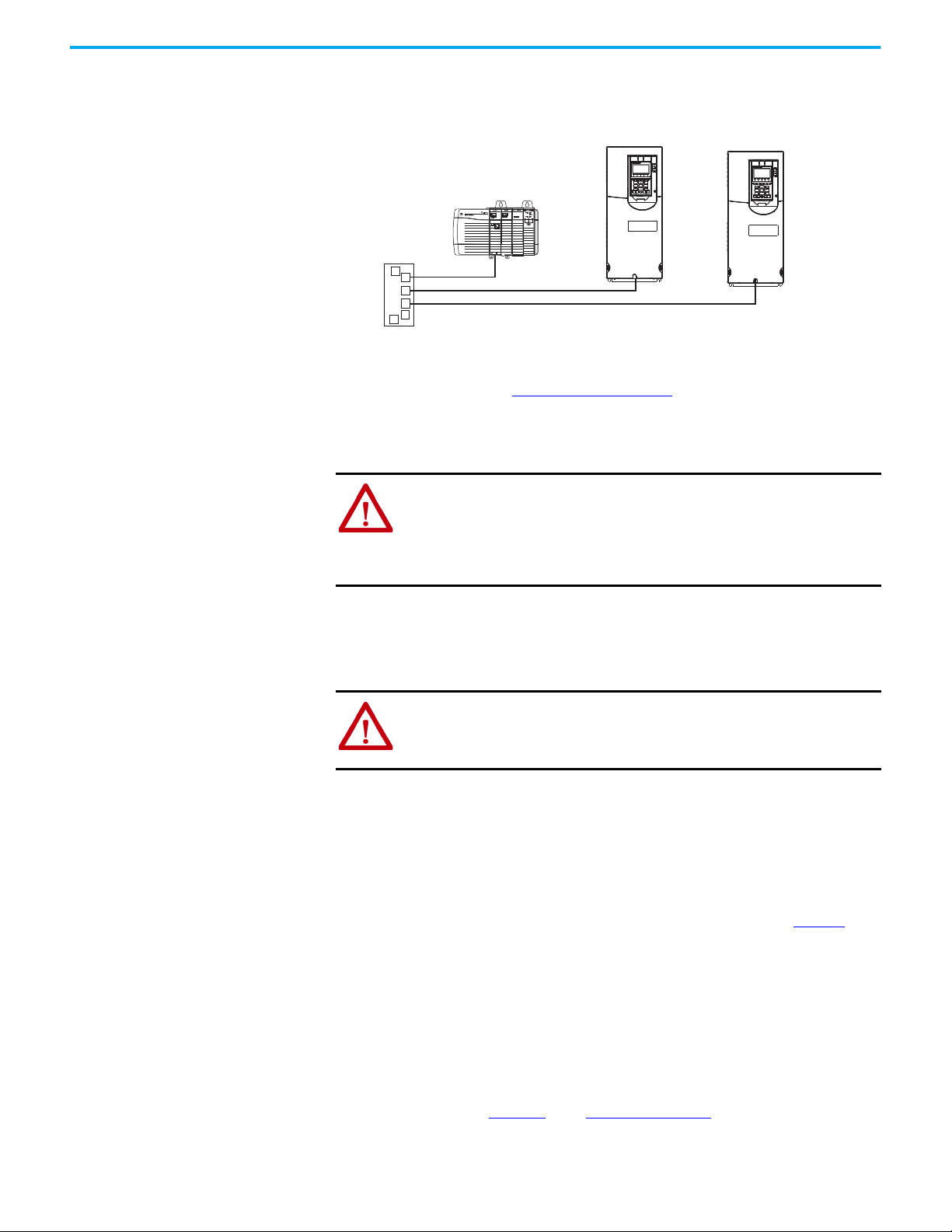

Ethernet Switch

Controller

PowerFlex 755T drives

(each with built-in EtherNet/IP adapter)

Apply Power

Figure 5 - Connecting the Ethernet Cable to the Network

5. Route the other end of the Ethernet cable through the bottom plate of the

drive to either of the Ethernet connectors on the bottom edge of the control

board. See item 4 in Components on page 9.

ATTENTION: Risk of equipment damage, injury, or death exists.

• Unpredictable operation can occur if you fail to verify that parameter settings are

compatible with your application. Verify that settings are compatible with your

application before power is applied to the drive.

• Wear personal protective equipment (PPE) to avoid death or injury when applying

power with the drive door open.

1. Close the cabinet door for the drive.

2. Apply power to the drive.

The built-in EtherNet/IP adapter receives its power from the drive.

ATTENTION: Risk of injury or equipment damage exists. When a system is

configured for the first time, there can be unintended or incorrect machine

motion. Disconnect the motor from the machine or process during initial

system testing.

3. Check the status indicators either by using status parameters, HIM

status, or the software tool status.

When you apply power to the built-in EtherNet/IP adapter for the first

time, its EtherNet/IP status indicator is steady green or flashes green

after an initialization.

If it is red or remains off, see Start-up Status Indications on page 18

.

Start-up Status Indications

18 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

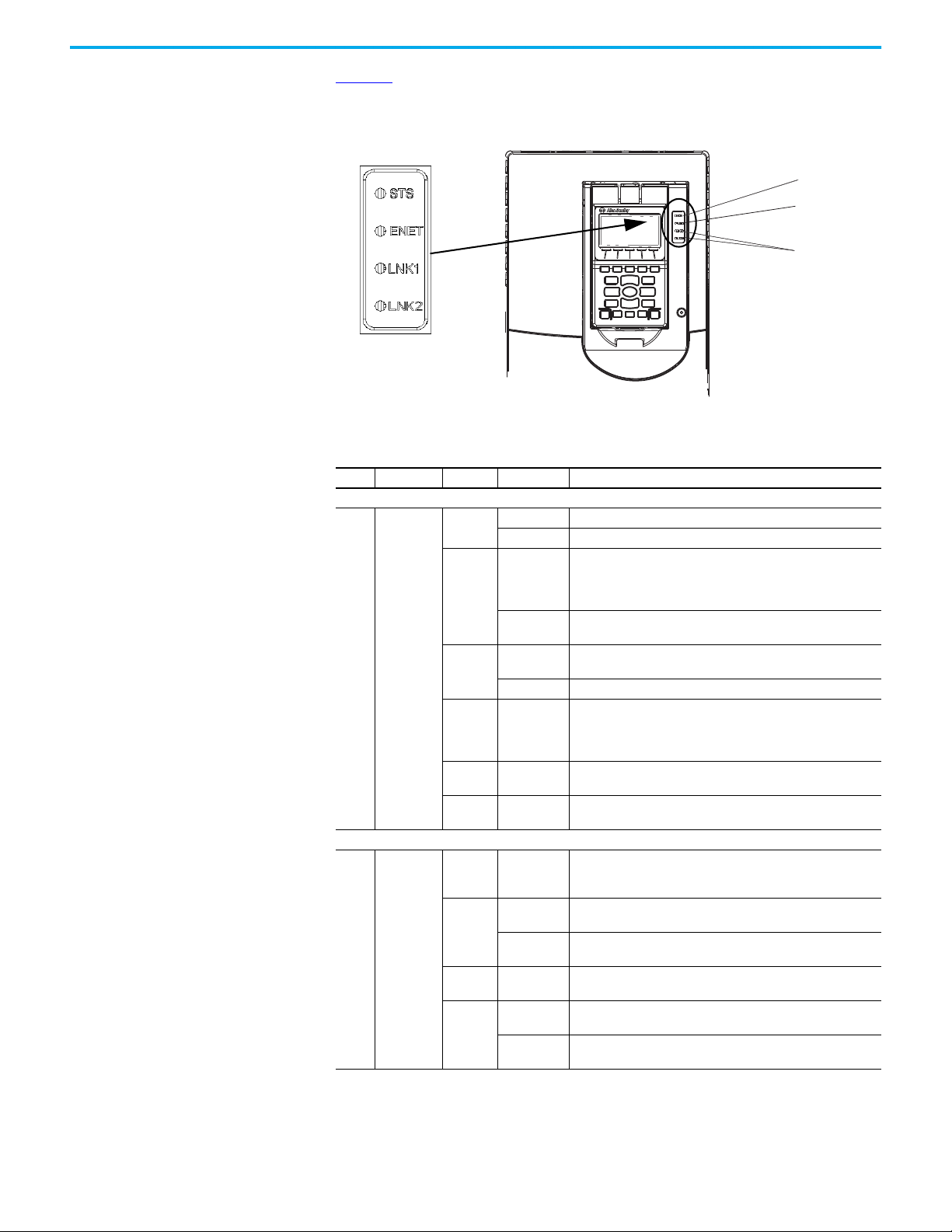

After power is applied, the drive STS (status) indicator and the built-in

EtherNet/IP adapter ENET, LNK1, and LNK2 status indicators can be

monitored via status parameters, HIM status, and the software tool status. If

personal protective equipment is worn, you can also view status indicators on

the front of the drive (Figure 6

status indications.

). See Table 2 on page 19 for possible startup

Page 19

Chapter 2 Configure the Adapter

1

2

3

Figure 6 shows an example of the drive status indicator location near a HIM

under the drive cover. Your HIM may appear differently or in another location.

Figure 6 - Drive and Interface Status Indicators

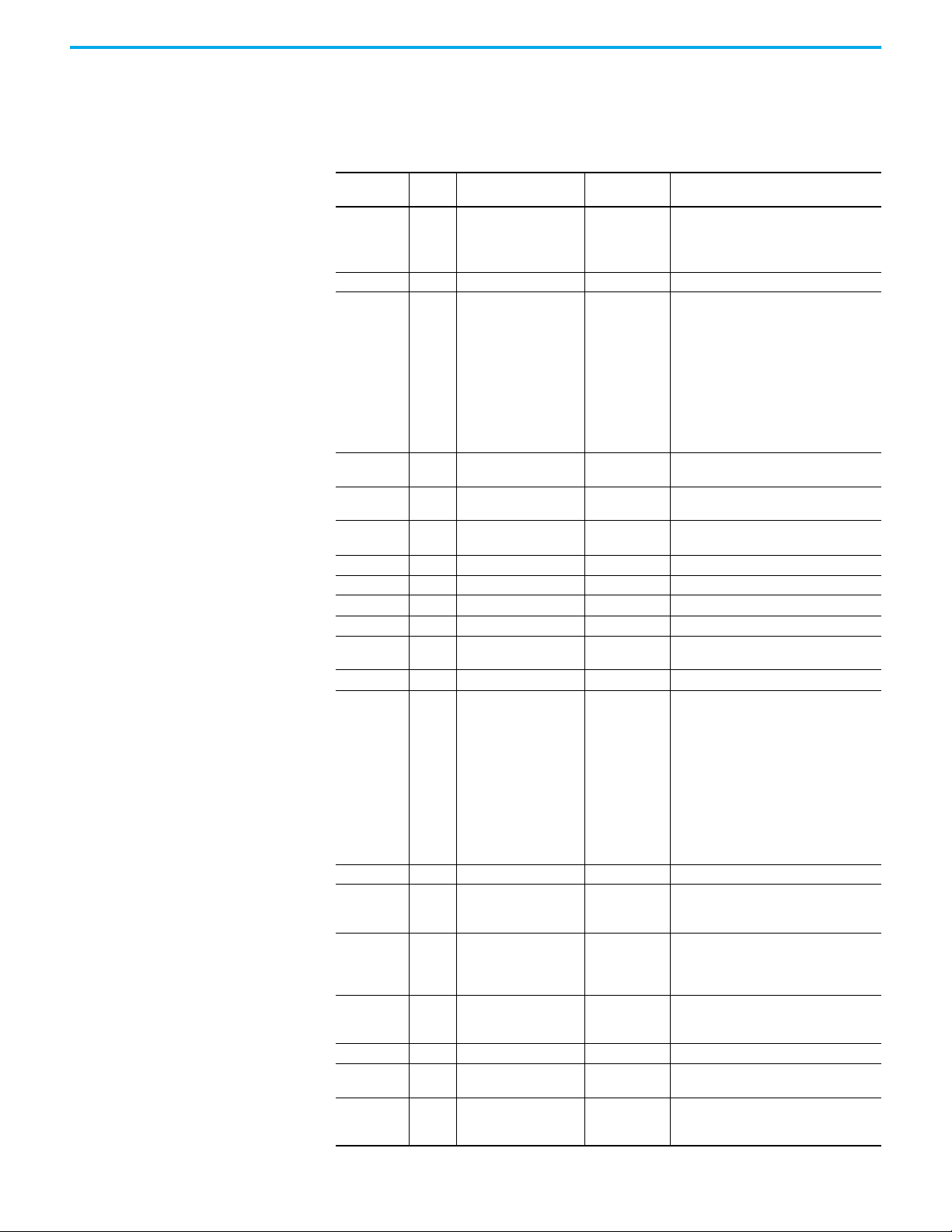

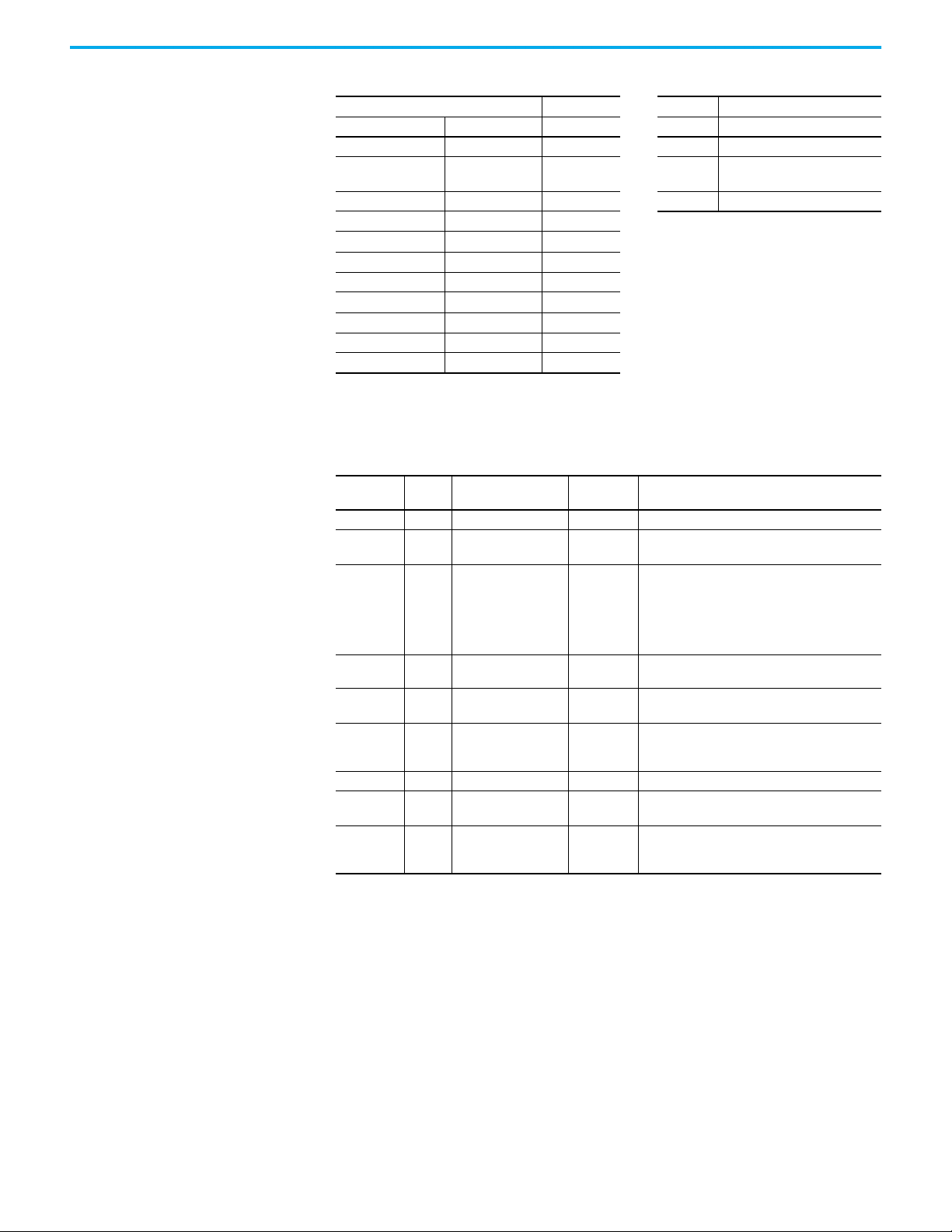

Table 2 - Drive and Interface Start-up Status Indications

Item Name Color State Description

Drive STS Indicator

Green

Yellow

1 STS (Status)

Red

Red/

Yellow

Yellow/

Green

Green/Red

Built-in EtherNet/IP adapter Status Indicators

Unlit Off

Red

2ENET

Red/Green

Green

Flashing Drive ready but is not running, and no faults are present.

Steady Drive is running and no faults are present.

When running, a type 2 (non-configurable) alarm condition exists –

Flashing

the drive continues to run. When stopped, a start inhibit condition

exists and the drive cannot be started (see drive 0:603 - [Start

Inhibit]).

Steady

Flashing

A type 1 (configurable) alarm condition exists, but the drive

continues to run.

A major fault has occurred. The drive stops. it cannot be started

until the fault condition is cleared.

Steady A non-resettable fault has occurred.

A minor fault has occurred. If not enabled a minor fault, acts like a

Flashing

Alternately

major fault. If minor faults are enabled and the drive is running, the

drive continues to run. The system is brought to a stop under

system control. The fault must be cleared to continue.

Flashing

Alternately

Flashing

Alternately

When running, a type 1 (configurable) alarm exists and the drive

continues to run.

The drive is updating firmware.

The interface and/or network is not powered, the interface is not

properly connected to the network, or the interface needs an IP

address.

A network connection has timed out, the rotary switches have been

changed since power-up, or the network configuration is invalid.

The interface failed the duplicate IP address detection test or its

DCHP lease has expired.

The interface is performing a self-test.

The interface is properly connected, but the drive is not controlled

by the network.

The interface is properly connected, and the drive is controlled by

the network.

Flashing

Steady

Flashing

Alternately

Flashing

Steady

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 19

Page 20

Chapter 2 Configure the Adapter

Table 2 - Drive and Interface Start-up Status Indications (Continued)

Item Name Color State Description

Unlit Off The interface does not have an Ethernet link.

LNK1 and

3

LNK2

Green

(100 Mbps)

or

Yellow

(10 Mbps)

Flashing

Steady

The interface is properly connected and is transmitting or receiving

data packets on the network.

The interface is properly connected, but is not transmitting or

receiving on the network.

After verifying correct operation, place the drive HIM bezel to its closed

position if necessary and install the drive cover. See Drive Status Indicator

Descriptions on page 80 for more details.

Configuring and Verifying Key Drive Parameters

The drive can be separately configured for the command logic and reference

functions in various combinations. For example, you could set the drive to

have the logic command come from a peripheral or terminal block but have the

reference come from the network. Or you could set the drive to have its control

come from the network with the reference that comes from another peripheral

or terminal block. Or you could set the drive to have both its logic command

and reference come from the network.

The following steps in this section assume that the drive receives the logic

command and reference from the network.

1. To access the required parameters in this procedure, verify that drive

parameter 0:30 - [Access Level] is set to ‘1’ (Advanced) or ‘2’ (Expert).

2. To set the drive velocity reference, use drive 10:1800 - [VRef A Sel].

a. Set the Port field to ‘10 - Pri MtrSideCtrl’ as shown.

b. Set the Parameter field to point to Port 0, which contains the

EtherNet/IP adapter.

c. Then choose Parameter 211 [Emb Enet Ref].

3. Verify that drive 10:350 - [VRef Source] matches your entry to 10:1800

[VRef A Sel].

Any velocity reference that is commanded from the network can be

monitored by using 0:1914 - [VRef Command]. If a problem occurs, this

verification step provides the diagnostic capability to determine whether

the drive, interface, or the network is the cause.

4. If hard-wired discrete digital inputs are not used to control the drive,

verify that all unused digital input drive parameters are set to ‘0’ (Not

Used). These parameters are located in Port 0, in the file Feedback and I/

O, group Command.

20 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 21

Chapter 2 Configure the Adapter

Default = 0.0.0.0 255.255.255.255

[IP Addr Cfg 1]

[IP Addr Cfg 2]

[IP Addr Cfg 3]

[IP Addr Cfg 4]

Use Interface Parameters to Set the IP Address

By default, the interface is configured to use a DHCP server as the source for

the IP address interface, subnet mask, and gateway address. To use interface

parameters instead, you must first change the source for the node address to

Parameters by using 0:300 - [Net Addr Sel]. Set the associated interface

parameters as described in the following subsections.

Using a HIM to Access Parameters

If your drive has a HIM, it can be used to access parameters in the interface.

From the Status screen (20-HIM-A6 or 20-HIM-C6S) or the Dashboard

Parameters tab (eHIM), navigate to Port 0 where the built-in EtherNet/IP

adapter resides.

From the Port 0, you can set the source for the network address, set the

IP address, subnet mask, and gateway address.

For details on how to view and edit parameters, see PowerFlex 20-HIM-A6/C6S HIM (Human Interface Module) User Manual,

publication 20HIM-UM001

.

Change the Source for the Network Address

1. Verify that the IP address switches, see Table 1 on page 17 are set to 999.

2. Set the value of 0:300 - [Net Addr Sel] to ‘1’ (Parameters).

3. Reset the interface by cycling power or by using the HIM as described in

Resetting the Adapter

on page 28.

4. Set the IP address, subnet mask, and gateway address by using interface

parameters by performing the steps in the following subsections.

Set the IP Address

1. Verify 0:300 - [Net Addr Sel] is set to ‘1’ (Parameters).

2. Set the value of 0:302 - [IP Addr Cfg 1] … 305 - [IP Addr Cfg 4] to a unique

IP address.

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 21

Page 22

Chapter 2 Configure the Adapter

Default = 0.0.0.0 255.255.255.255

[Subnet Cfg 1]

[Subnet Cfg 2]

[Subnet Cfg 3]

[Subnet Cfg 4]

Default = 0.0.0.0 255.255.255.255

[Gateway Cfg 1]

[Gateway Cfg 2]

[Gateway Cfg 3]

[Gateway Cfg 4]

Set the Subnet Mask

1. Verify 0:300 - [Net Addr Sel] is set to ‘1’ (Parameters).

2. Set the value of 0:306 - [Subnet Cfg 1] … 309 - [Subnet Cfg 4] to the desired

value for the subnet mask.

• The subnet mask cannot be 0.0.0.0.

• The gate way address can be 0.0.0.0. If the gateway address is 0.0.0.0, the

drive can only communicate with devices on the same subnet as the

drive. It is not able to communicate with devices on other subnets.

• If the gateway address is not set to 0.0.0.0, then it must be set to an

address that is on the same subnet as the IP address of the drive.

Set the Gateway Address

1. Verify 0:300 - [Net Addr Sel] is set to ‘1’ (Parameters).

2. Set the value of 0:310 - [Gateway Cfg 1] … 313 - [Gateway Cfg 4] to the IP

address of the gateway device.

• The subnet mask cannot be 0.0.0.0.

• The gateway address can be 0.0.0.0. If the gateway address is 0.0.0.0, the

PowerFlex 755T can only communicate with devices on the same subnet

as the drive. It is not able to communicate with devices on other subnets.

• If the gateway address is not set to 0.0.0.0, then it must be set to an

address that is on the same subnet as the IP address of the drive.

3. Reset the interface by cycling power or by using the HIM as described in

Resetting the Adapter

on page 28.

22 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 23

Chapter 2 Configure the Adapter

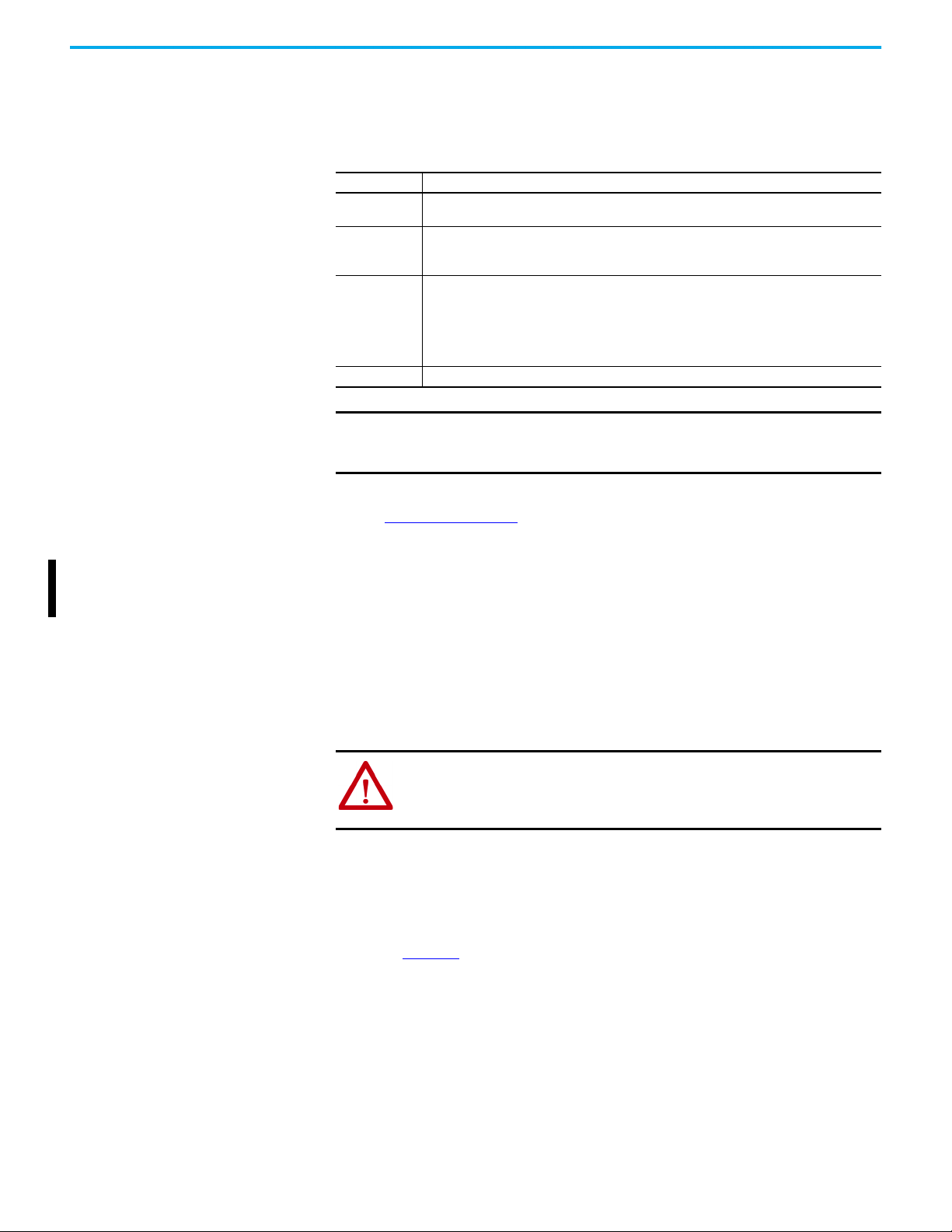

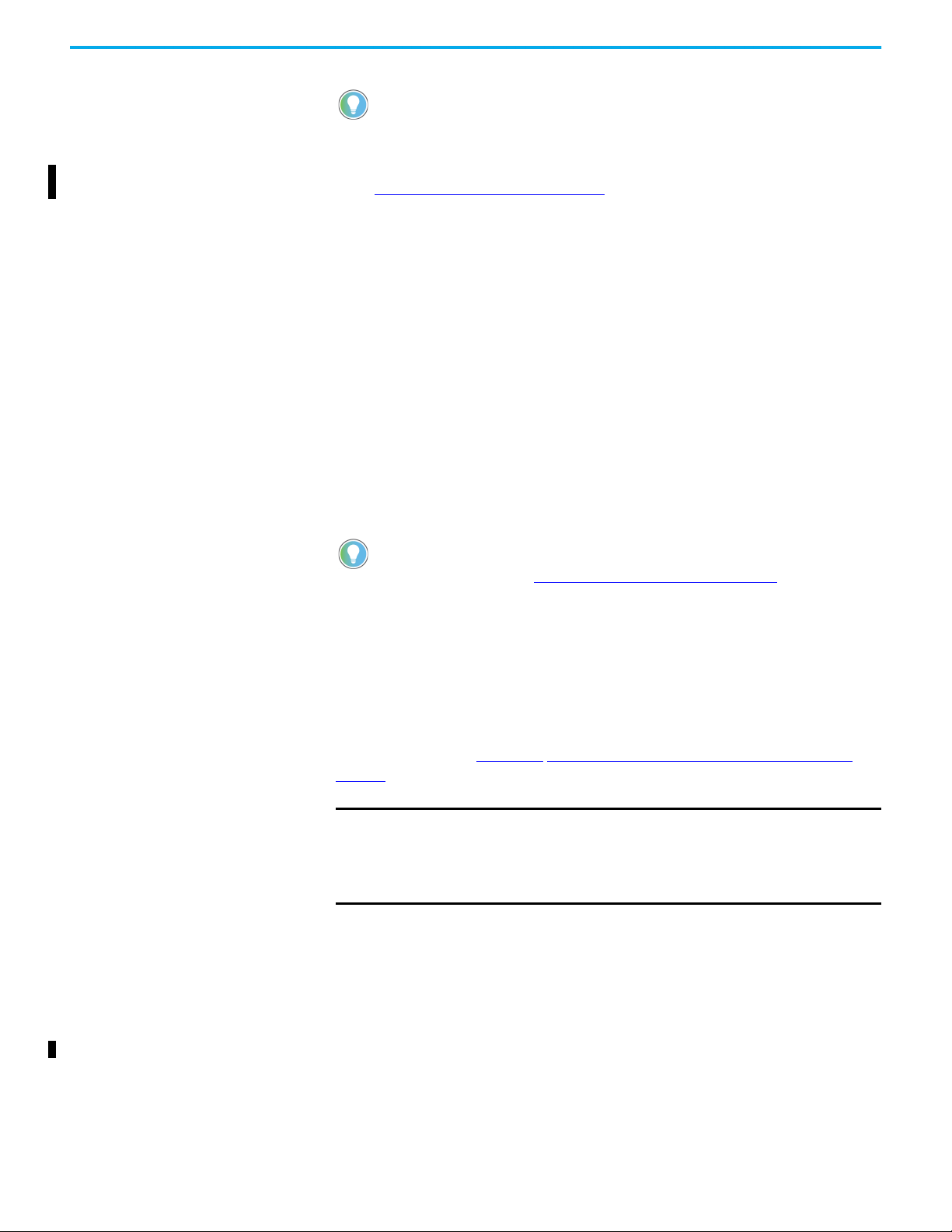

Value Setting

1Parameters

2BOOTP

3DHCP (default)

Ethernet

Address

(MAC) Label

Location

Drive Control Pod

Ethernet Connectors

Front View - Main Control Board

Using a BOOTP or DHCP Server

There are various BOOTP and DHCP servers available. The following

instructions use the Rockwell Automation BOOTP/DHCP Server. This is a free

standalone program that incorporates the functionality of standard BOOTP

and DHCP utilities with a graphical interface page installed automatically as

part of the RSLinx® software. It is available at the Product Compatibility and

Download Center (PCDC) at rok.auto/pcdc

. From the website, choose the ‘Find

Downloads’ link and search for the word ‘BOOTP’). See the Read-me file and

online Help for directions and more information.

If the PowerFlex 6000T, 755TM, 755TR, or 755TL drive is connected to a

Stratix 6000 or Stratix 8000 managed Ethernet switch and the drive is set

for BOOTP or DHCP mode, the ‘dynamic IP address assignment by port’

(Stratix 6000) or ‘DHCP persistence’ (Stratix 8000) feature can be used to

set the IP address for the drive. For more details, see the Stratix 6000

Ethernet-Managed Switch User Manual, publication 1783-UM001

, or the

Stratix 8000 and Stratix 8300 Ethernet Managed Switches User Manual,

.

IMPORTANT

publication 1783-UM003

When the DHCP lease expires, the adapter stops communicating on the

network. A power cycle or option module reset is required.

1. Depending on the type of server (BOOTP or DHCP) being used, set 0:300

- [Net Addr Sel] to either ‘2’ (BOOTP) or ‘3’ (DHCP) respectively.

2. Make note of the Ethernet Address (MAC) of the interface hardware,

which is used in step 5

.

There are two ways to find the media access control (MAC) address:

• Remove the drive cover and locate the hardware Ethernet Address

label on the main control board of the drive (Figure 7

Figure 7 - Location of the Interface Hardware Address Label

).

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 23

Page 24

Chapter 2 Configure the Adapter

• Use the HIM to access drive Port 0 and access the built-in EtherNet/IP

adapter DIAGNOSTIC folder screen. Then scroll to Diagnostic Items

43…48 (HW Addr 1…6) to view the hardware Ethernet Address (MAC) of

the interface. Finally, convert these decimal values to hex values.

The eHIM uses local subnet to detect the drive connected to the Stratix

switch. You are able to view the drive profile and change the IP address

in the Device Definition page within the overview tab.

3. On a computer that is connected to the EtherNet/IP network, start the

BOOTP/DHCP software.

4. Edit the Network Settings to match your network.

Box Type

Subnet Mask The subnet mask for the built-in EtherNet/IP of the interface network.

Gateway The IP address of the gateway device on the network of the interface.

Primary DNS

Secondary DNS

Domain Name

Optional - the address of the primary Domain Name Service (DNS) server that is used to

locate devices on the network by name instead of by IP address.

Optional - the address of the secondary DNS server to be used on the local end of the link

for negotiating with remote devices when the primary DNS server is unavailable.

Optional - The text name that corresponds to the network containing the BOOTP/DHCP

server and the drive being configured.

5. In the BOOTP/DHCP Request History list, either double-click the

Ethernet Address (MAC) of the interface noted in step 2

, or click New in

the Relation List.

6. Edit the following:

Box Type

IP address A unique IP address for the interface

Host Name Optional - a text name for the drive being configured

Description Optional - text to describe the device that is saved only in the BOOTP/DHCP software

7. After the BOOTP/DHCP Server has provided an IP address, to assign this

configuration permanently to the interface, select the device in the

Relation List, and click Disable BOOTP/DHCP.

When power is cycled on the interface, it uses the configuration that you

assigned it and does not issue new BOOTP or DHCP requests.

8. From the File menu, choose Save to save the Relation List.

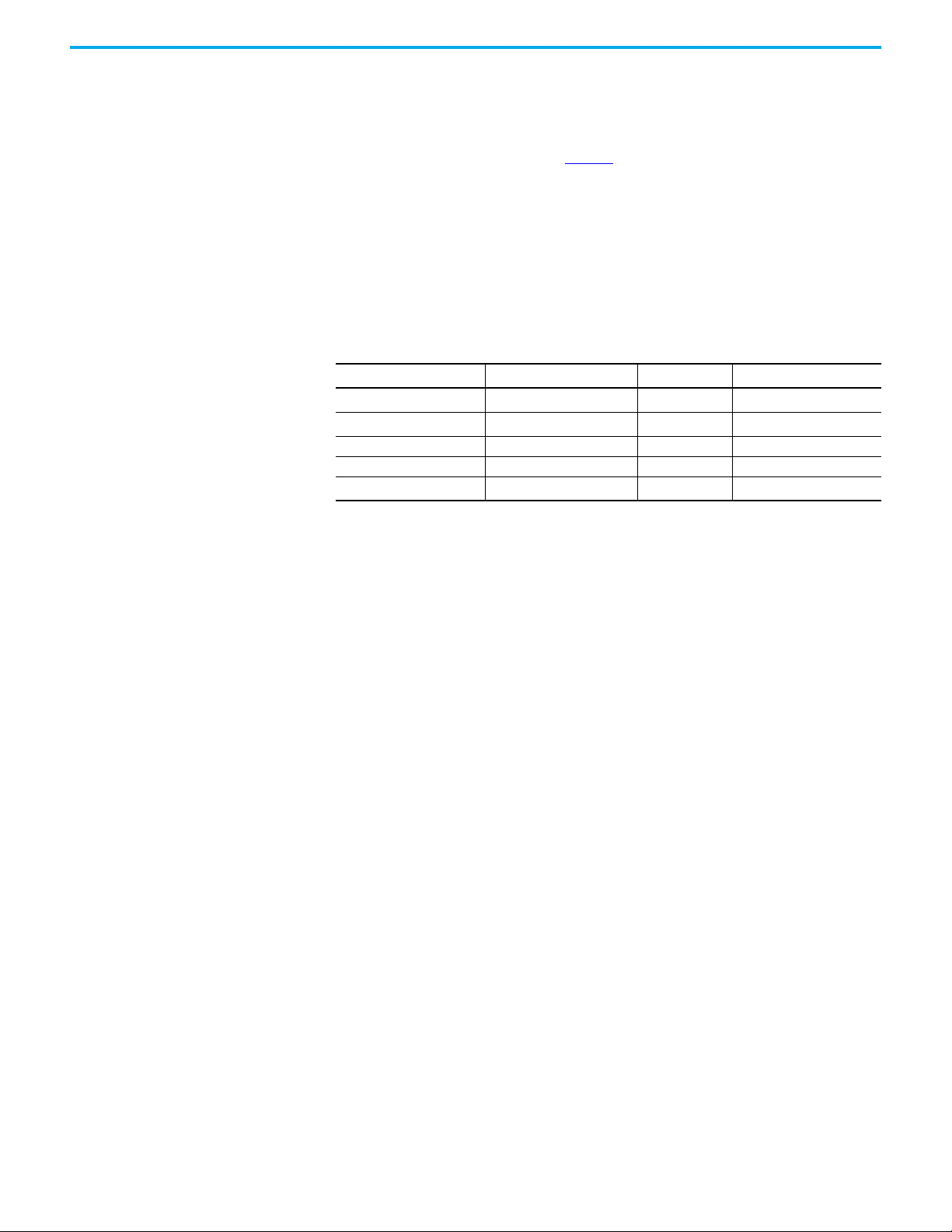

Setting the Data Rate By default, the interface is set to autodetect, so it automatically detects the data

rate and duplex setting that is used on the network. If you must set a specific

data rate and duplex setting, use the 0:314 - [Net Rate Cfg 1] and 0:316 - [Net

Rate Cfg 2] values. These values determine the Ethernet data rate and duplex

settings that the interface uses to communicate.

1. Verify that the Ethernet cable is connected to Ethernet port 1 or port 2 to

change the data rate or duplex setting. Port 1 is the connector closest to

the front edge of the control board.

2. Set the value of 0:314 - [Net Rate Cfg 1] or 0:316 - [Net Rate Cfg 2] to the

data rate at which your network is operating.

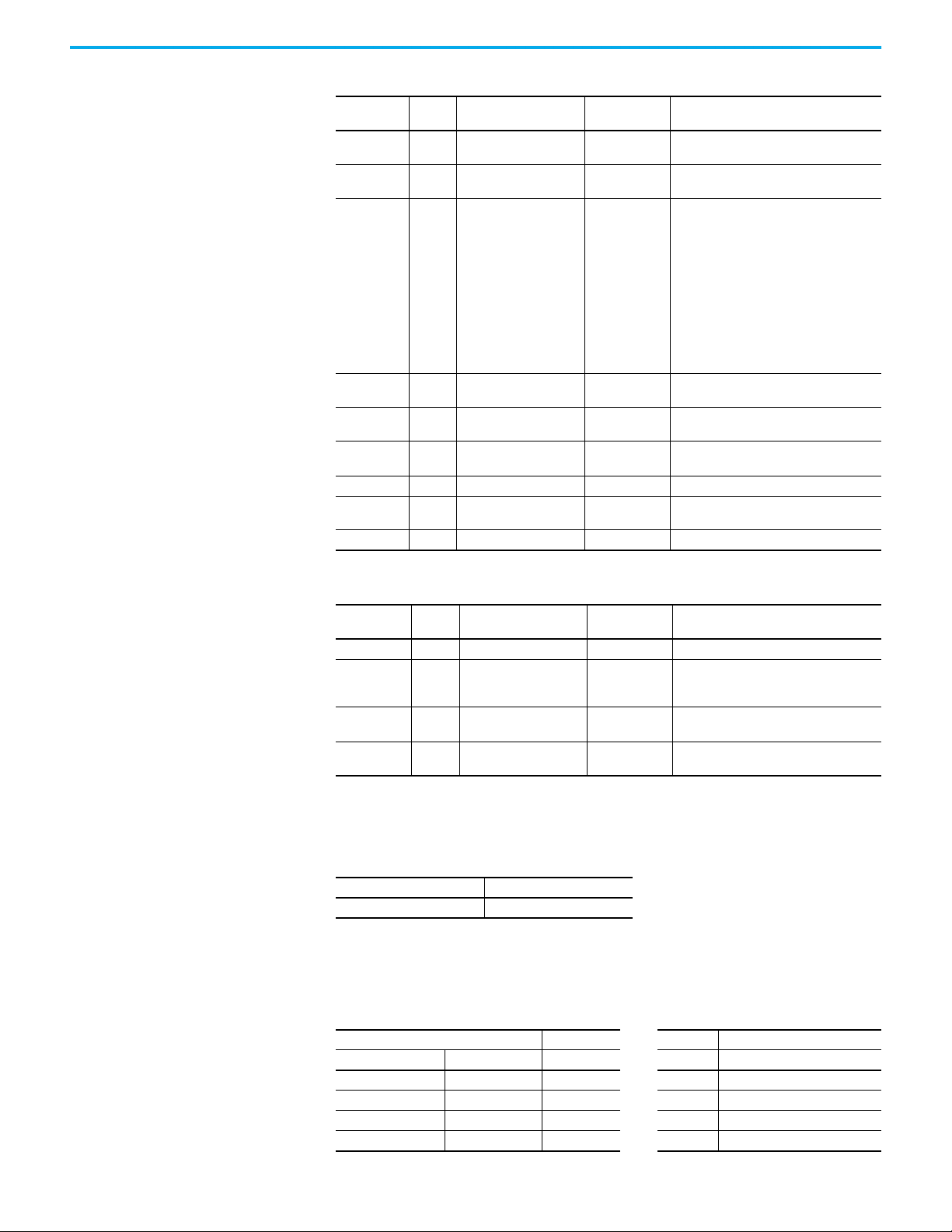

Value Data Rate

0 Autodetect (default)

110 Mbps Full

210 Mbps Half

3 100 Mbps Full

4 100 Mbps Half

24 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 25

Chapter 2 Configure the Adapter

Auto detection of the data rate and duplex works only if the device (usually

a switch) on the other end of the cable is also set to detect the rate/duplex.

If one device is using fixed data rate/duplex, the other device must use the

same fixed settings.

3. Reset the interface by cycling power or by using the HIM as described in

Resetting the Adapter on page 28.

Setting Communication Hierarchy

A hierarchy determines the type of device with which the interface exchanges

data. In a controller hierarchy, the interface exchanges data with the

ControlLogix® controller or another communication bridge.

When a multicast I/O connection is used or when the interface does not have a

valid gateway address, the controller must be on the same IP subnet as the

interface to establish an I/O connection.

Setting a Controller Hierarchy

To set the Controller hierarchy, follow the instructions in this section to enable

datalinks to read and write data.

When using the ControlLogix controller, there is no need to configure

datalink parameters. They are assigned when configuring the drive Addon Profile, see Configure Input and Output Data on page 36

Enable Datalinks to Write Data

The controller output image (controller outputs-to-drive) always contains the

logic command and reference fields. It can also have 0...16 additional 32-bit

parameters (datalinks). They are configured using 0:321 - [DL From Net 01] …

336 - [DL From Net 16]. The output connection size in the controller determines

the number of datalinks that are actively used. See the respective controller

example sections in Chapter 3

page 31 for more information on setting the connection size.

Configuring the Drive in a Logix System on

.

IMPORTANT

When using a ControlLogix controller, configure the datalink parameters now

as described in this section.

0:321 - [DL From Net 01] …336 - [DL From Net 16] control which parameters

receive the values from the network. These parameters apply to the drive,

option module, or any other connected peripheral. You can use a HIM, or

another drive configuration tool, such as Connected Components Workbench

software, to select the drive or peripheral by port number and the parameter by

name. As an alternate method, set the parameter value manually by number by

using this formula:

From Net Parameter Value = (10000 * Port Number) + (Destination Parameter Number)

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 25

Always use the datalink parameters in consecutive numerical order. Start

with the first parameter. For example, use 0:321… 323 to configure three

datalinks to write data. Otherwise, the network I/O connection size is larger

than necessary, which needlessly increases controller response time and

memory usage.

Page 26

Chapter 2 Configure the Adapter

For example, if you want to use 0:321 - [DL From Net 01] to write to Parameter

3 of an optional encoder card plugged into drive Port 5. By using the formula,

the value for 0:321- [DL From Net 01] would be (10000 * 5) + (3) = 50003.

Follow these steps to enable datalinks to write data.

1. Set the values of only the required number of contiguous controller-todrive datalinks that write data to the drive and are included in the

network I/O connection.

2. Reset the drive by cycling power to the drive or by using the Reset Device

function of the HIM located in the DIAGNOSTIC folder for the drive. See

Resetting the Adapter

on page 28.

3. Because the logic command and reference are always used in the

interface, configure the parameters in the drive to accept the logic

command and reference from the interface.

When using the controller for speed reference via the interface, set two

fields in drive 10:1800 - [VRef A Sel].

a. Set the Port field for the drive.

b. Set the Parameter field to point to the parameter containing the

reference value received from the parameter containing the reference

value that is received from the embedded EtherNet/IP adapter 0:211 -

[Emb Enet Ref].

Also, verify that the mask parameters in the drive, (for example,

0:41 - [Logic Mask]) are configured to receive the desired logic

command from the interface. See the drive documentation for details.

The interface is ready to receive input data and transfer control data

from the controller.

Next, configure the controller to recognize and transmit I/O to the interface.

See Chapter 3

Configuring the Drive in a Logix System on page 31.

Enable Datalinks to Read Data

The controller input image (drive-to-controller inputs) always contains the

logic status and feedback fields. It can also have 0...16 additional 32-bit

parameters (datalinks). They are configured using 0:340 - [DL To Net 01] … 355 -

[DL To Net 16]. The input connection size in the controller determines the

number of datalinks that are actively used. See the respective controller

example sections in Chapter 3

page 31 for more information on setting the connection size.

IMPORTANT

Always use the datalink parameters in consecutive numerical order. Start

with the first parameter. For example, use 0:340…344 to configure five

datalinks to read data. Otherwise, the network I/O connection size is larger

than necessary, which needlessly increases controller response time and

memory usage.

Configuring the Drive in a Logix System on

When using a ControlLogix controller, configure the datalink parameters now

as described in this section.

0:340 - [DL To Net 01] … 355 - [DL To Net 16] configure which parameters in the

drive, interface, or any other connected peripheral send the values to the

26 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 27

Chapter 2 Configure the Adapter

network. Select the drive or peripheral by port number and the parameter by

name. Use the HIM, or another drive configuration tool such as Connected

Components Workbench software. As an alternate method, use this formula to

set the parameter value manually by number:

To Net Parameter Value = (10000 * Port Number) + (Origination Parameter Number)

For example, suppose that you want to use 0:340 - [DL To Net 01] to read

Parameter 2 of an optional I/O card plugged into drive Port 6. By using the

formula, the value for 0:340 - [DL To Net 01] would be (10000 * 6) + (2) = 60002.

Follow these steps to enable datalinks to read data.

1. Set the values of only the required number of contiguous drive-tocontroller datalinks that read data from the drive and are included in the

network I/O connection.

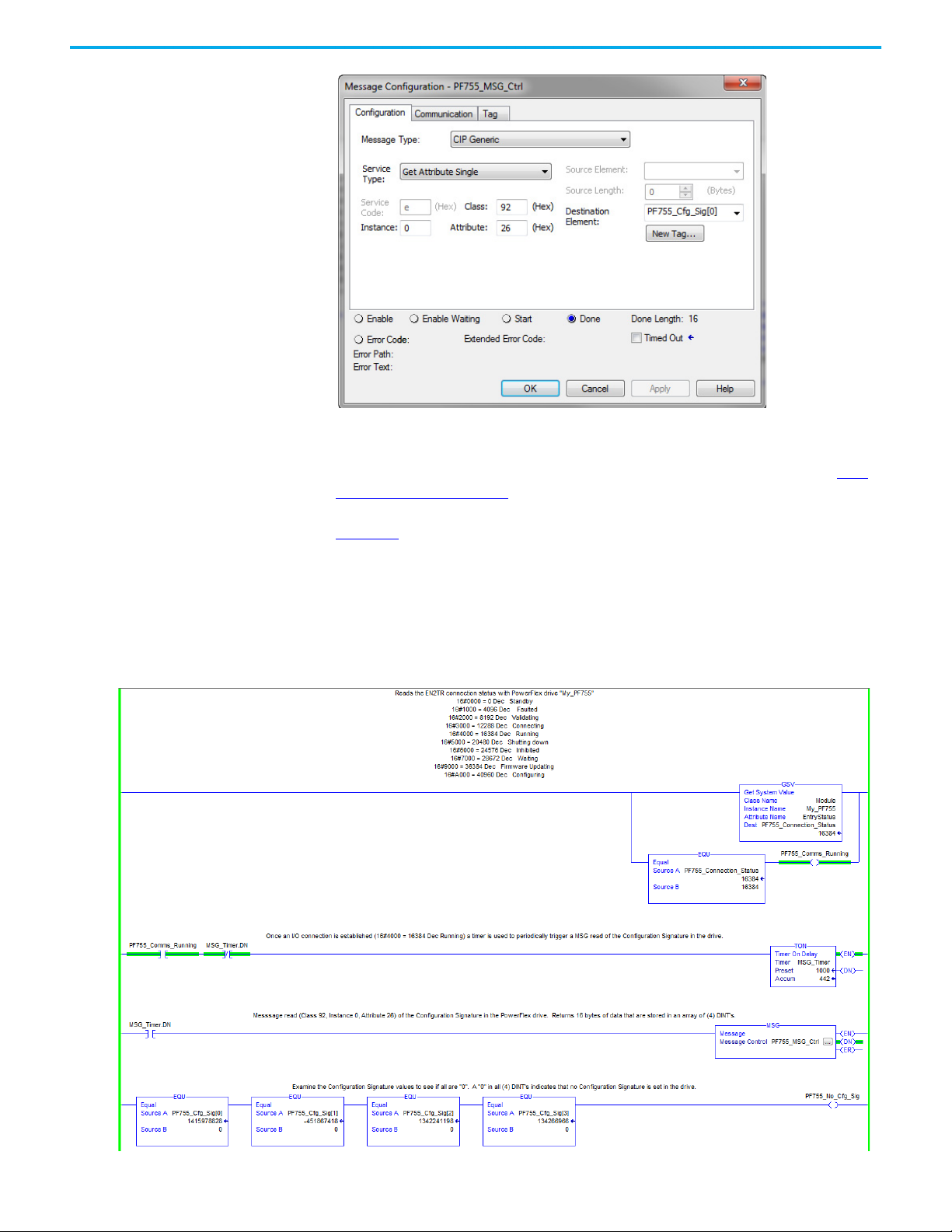

2. Reset the interface by cycling power or by using the HIM described in

Resetting the Adapter

on page 28.

The interface is configured to send output data to the controller. Configure the

controller to recognize and transmit I/O to the interface. See Chapter 3

Configuring the Drive in a Logix System on page 31

.

Setting a Fault Action By default, when the drive is controlled by the network or receives information

from the network; communication is disrupted. The drive responds by

faulting, if it is using I/O from the network. Possible causes include that the

network cable is disconnected, the controller is idle (in Program mode or

faulted), or an MSG instruction that is used for drive control is disrupted. You

can configure another response to these faults:

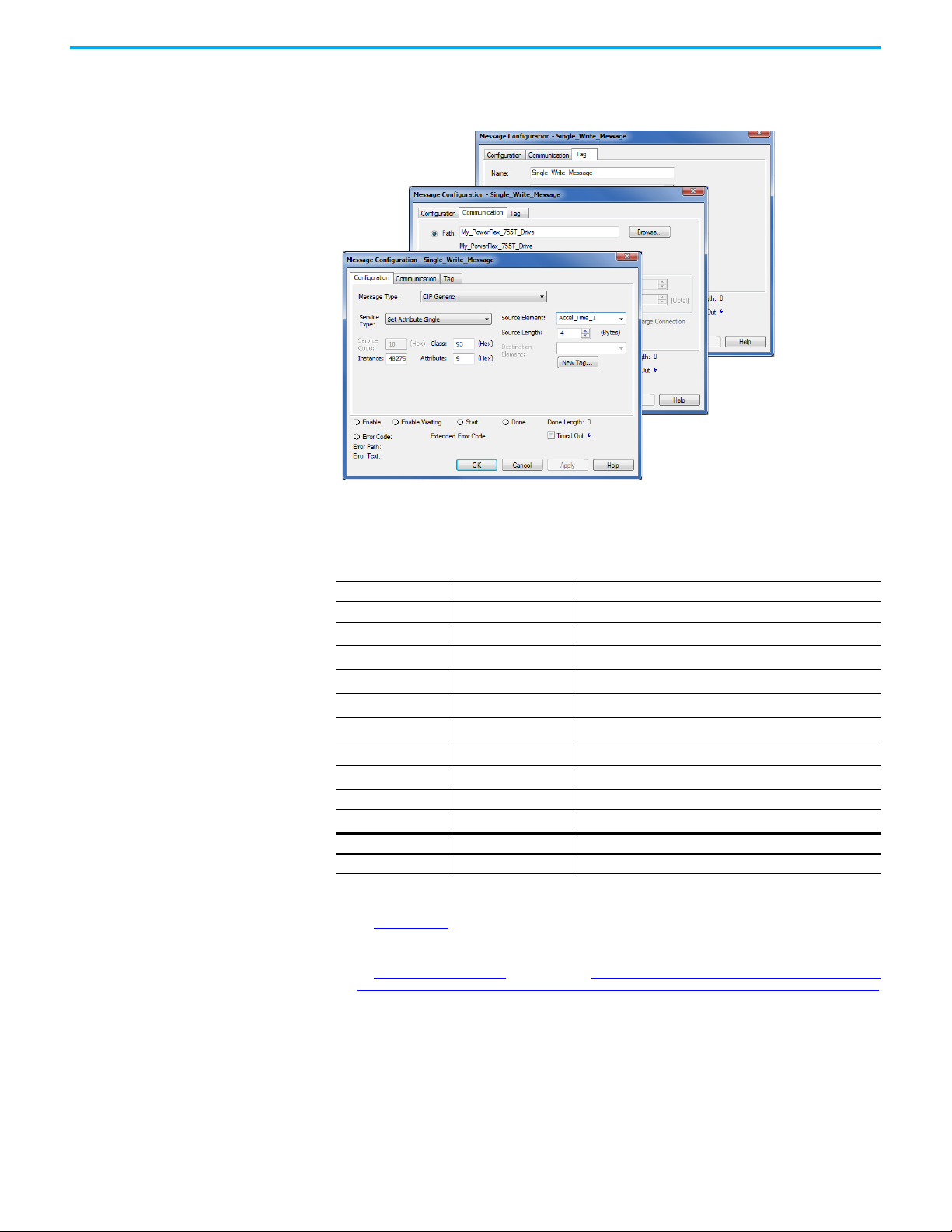

• Disrupted I/O communication by using 0:360 - [Comm Flt Action]

• An idle controller by using 0:361 - [Idle Flt Action]

• Disrupted Explicit Messaging for drive control via PCCC or the CIPbased network Assembly Object by using 0:363 - [Msg Flt Action]

ATTE NT IO N: Risk of injury or equipment damage exists. By default, these

parameters fault the drive:

• 0:360 - [Comm Flt Action]

• 0:361 - [Idle Action]

• 0:363 - [Msg Flt Action]

You can configure these parameters so that the drive continues to run. However,

verify that the settings of these parameters do not create a risk of injury or

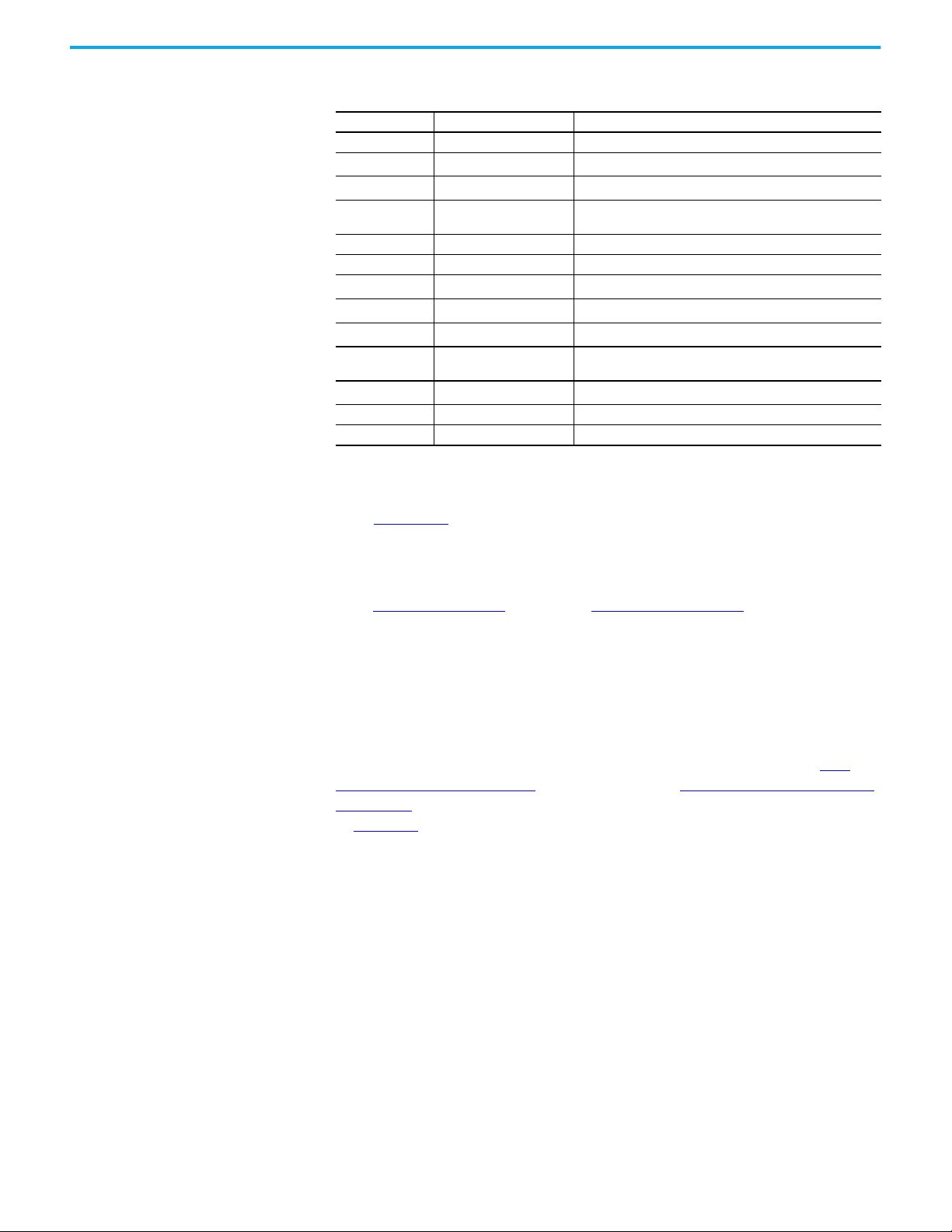

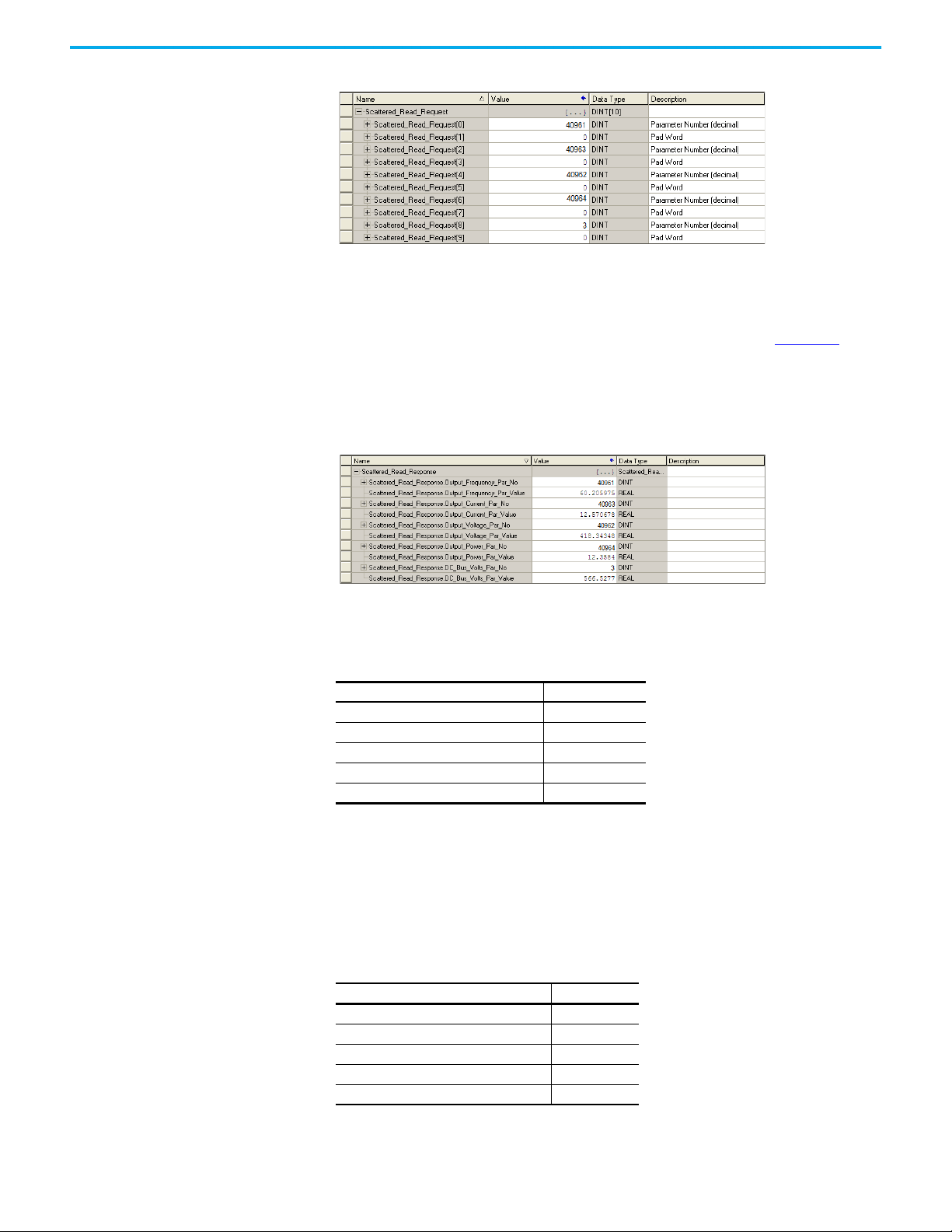

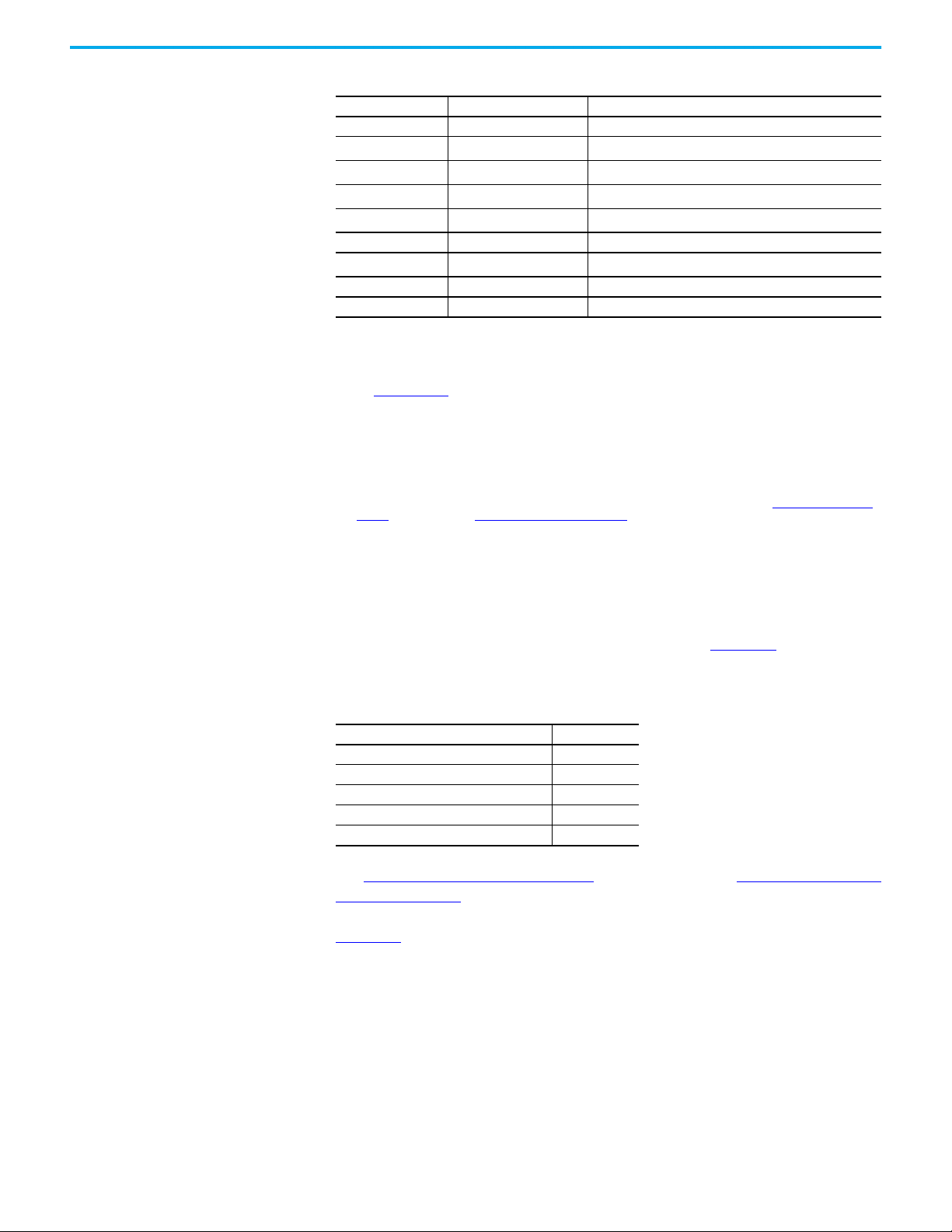

equipment damage. When commissioning the drive, verify that your system

responds correctly to various situations.

Changing the Fault Action

Set the values of 0:360 - [Comm Flt Action], 361 - [Idle Flt Action], and 363 [Msg Flt Action] to an action that meets your application requirements.

Table 3 - Fault Action Parameters

Value Action Description

0 Fault The drive is faulted and stopped (default).

1 Stop The drive is stopped, but not faulted.

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 27

Page 28

Chapter 2 Configure the Adapter

Table 3 - Fault Action Parameters (Continued)

Value Action Description

2 Zero Data The drive is sent ‘0’ values for data. This value does not command a stop.

3 Hold Last The drive continues in its present state.

The drive is sent the data that you set in the fault configuration parameters:

• 0:364 - [Flt Cfg Logic] - A 32-bit value that is sent to the drive for logic

command

4Send Flt Cfg

• 0:365 - [Flt Cfg Ref] - A 32-bit REAL (Floating Point) value that is sent to

the drive for reference

• 0:366 - [Flt Cfg DL 01] … 381 - [Flt Cfg DL 16]) - A 32-bit Integer value that

is sent to the drive for a datalink. If the destination of the datalink is a

REAL (Floating Point) parameter, you must convert the desired value

to the binary representation of the REAL value.

Changes to these parameters take effect immediately. A reset is not required.

If communication is disrupted and then re-established, the drive automatically

receives commands over the network again.

Resetting the Adapter Changes to rotary switch settings and some interface parameters require that

you reset the adapter before the new settings take effect. You can reset the

interface by cycling power or by using the Reset Device function of the HIM

located in the DIAGNOSTIC folder for the drive.

Restore Interface Parameters to Default Configurations

ATT EN TI ON : Risk of injury or equipment damage exists. If the adapter is transmitting

control I/O to the drive, the drive can be faulted when you reset the adapter. Determine

how your drive responds before resetting the adapter.

Interface parameters can be restored in two ways:

• ALL—restores ALL parameters on the port to their default configuration

values.

• MOST—restores MOST parameters on the port —except the following,

which are used for network setup Port 0:

• 0:300 - [Net Addr Sel]

• 0:302…305 - [IP Addr Cfg 1…4]

• 0:306…309 - [Subnet Cfg 1…4]

• 0:310…313 - [Gateway Cfg 1…4]

• 0:314 - [Net Rate Cfg 1]

• 0:316 - [Net Rate Cfg 2]

IMPORTANT

Because the built-in EtherNet/IP adapter is part of Port 0, restoring the

port defaults also resets other drive configuration settings that are

made in Port 0.

Using a 20-HIM-A6 or 20-HIM-C6S HIM

Follow these steps to restore interface parameters to their default

configuration values.

1. From the Status screen, scroll to Port 0, which is the drive

port contains the built-in EtherNet/IP interface.

2. Use the key to scroll to Port 0, which is the drive port contains

the built-in EtherNet/IP interface.

28 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 29

Chapter 2 Configure the Adapter

3. Display the last viewed folder, select the key.

4. To scroll to the MEMORY folder, use the keys.

5. To select Set Defaults, use the or key.

6. Press the (Enter) key.

The Set Defaults popup box appears.

7. Press the (Enter) key again.

The warning popup box appears.

8. Reset parameters to their default configuration values by selecting the

appropriate option:

• To restore MOST parameters to default configurations, press the

MOST soft key.

• To restore ALL parameters, press the ALL soft key.

• To cancel, press the ESC soft key.

Viewing the Interface Status Using Parameters

IMPORTANT

When performing a Set Defaults, the drive can detect a conflict and then

not allow this function to occur. If a conflict happens, first resolve the

conflict and then repeat this Set Defaults procedure. Common reasons for

a conflict include a drive that is running or a controller in Run mode.

9. Reset the interface by cycling power or by using the HIM as described in

Resetting the Adapter

on page 28.

Using enhanced HIM

Reset parameters to their default configuration by navigating to the

Parameters tab (enhanced HIM) and click the Reset to Defaults button.

The following parameters provide information about the status of the

interface. You can view these parameters at any time.

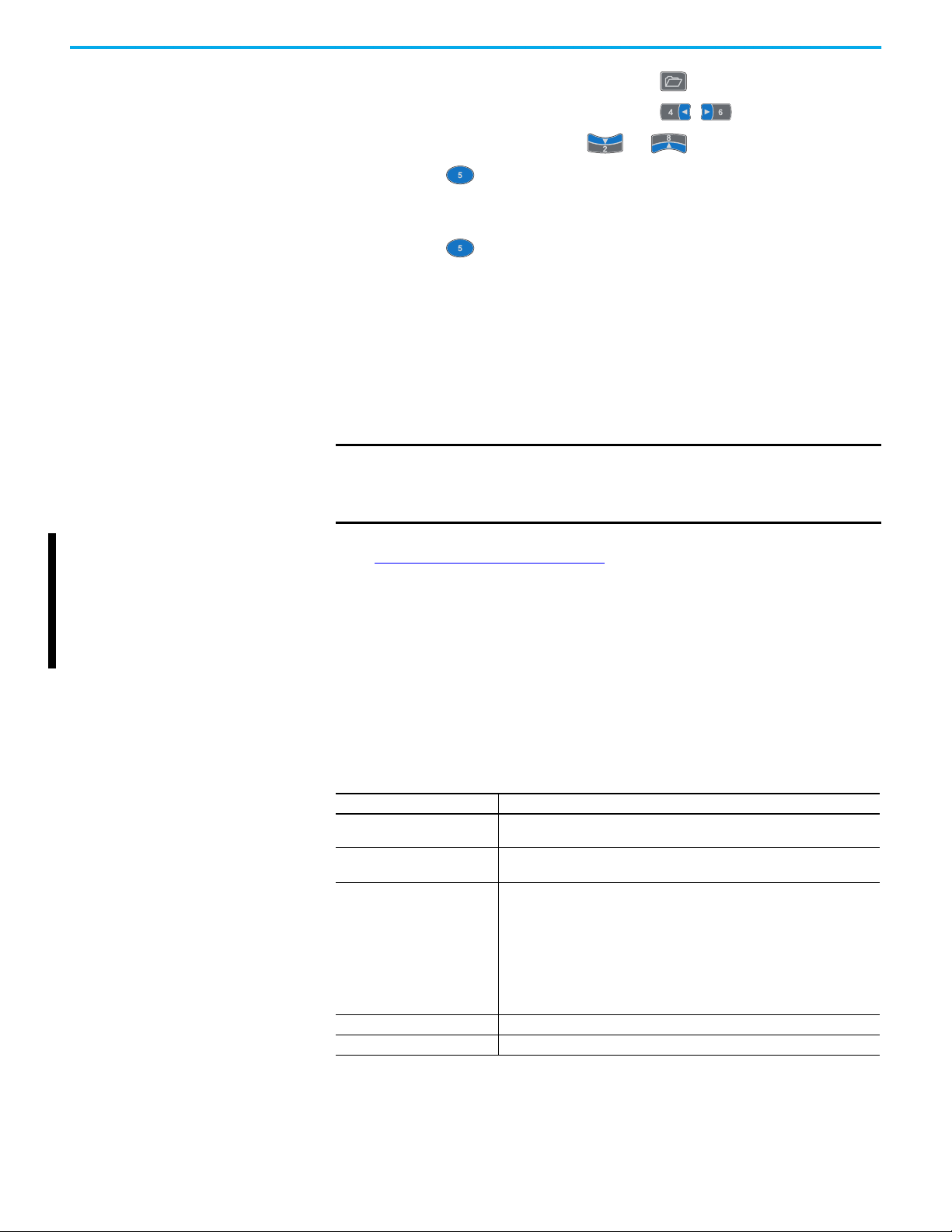

Table 4 - Interface Status Parameters

Interface Parameter Description

0:356 - [DLs From Net Act]

0:357 - [DLs To Net Act]

0:301 - [Net Addr Src]

0:315 - [Net Rate Act 1] The data rate/duplex used by the ENET1 network port on the interface.

0:317 - [Net Rate Act 2] The data rate/duplex used by the ENET2 network port on the interface.

The number of controller-to-drive datalinks that are included in the network I/O

connection (controller outputs).

The number of drive-to-controller datalinks that are included in the network I/O

connection (controller inputs).

Displays the active source for the interface node address, subnet mask, and

gateway address.

‘Switches’ (0) – The address comes from the rotary switches on the main control

board.

‘Parameters’ (1) – The addresses come from 0:302 [IP Addr Cfg 1]…313 [Gateway

Cfg 4].

‘BOOTP’ (2) – The address comes from a BOOTP server on the network.

‘DHCP’ (3) – The address comes from a DHCP server on the network and could be a

Stratix switch.

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 29

Page 30

Chapter 2 Configure the Adapter

Updating the Interface Firmware

The interface firmware is contained within the drive firmware. The interface

firmware can be updated over the network.

When updating firmware over the network, you can use the Allen-Bradley®

ControlFLASH Plus™ software tool.

To obtain a firmware update for this interface, go to rok.auto/pcdc

website contains all firmware update files and associated Release Notes that

describe the following items:

• Firmware update enhancements and anomalies

• How to determine the existing firmware revision

• How to update the firmware using ControlFLASH Plus software

. This

30 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 31

Chapter 3

Configuring the Drive in a Logix System

This chapter provides instructions on how to configure an Allen-Bradley Logix

5000™ controller to communicate with a connected PowerFlex drive.

Topic Page

Establish Communication by Using RSLinx Classic Software 31

Obtain Add-on Profiles 32

Create Logix Controller Project 33

Add the Drive to the Project 34

Configure Input and Output Data 36

Download the Configuration to the Controller 39

Correlate the Drive with the Controller 40

Configuration to Aid in Field-Failure Replacement 42

Use Firmware Supervisor to Update Firmware 42

Using Automatic Device Configuration (ADC) 44

Configure the Drive for ADC 45

ADC and Logix Memory 47

Power Peripheral Changes When Using ADC with PowerFlex 755T Drives 47

Special Considerations For 20-750-S1 Safe Speed Module (S1) 49

Special Considerations for Communications and Option Developers Kit

Option Cards

Testing ADC 50

Monitoring ADC Progress 50

Programmatically Monitoring Connection Status and the ADC Configuration

Signature

Best Practices 54

50

52

Establish Communication by Using RSLinx Classic Software

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 31

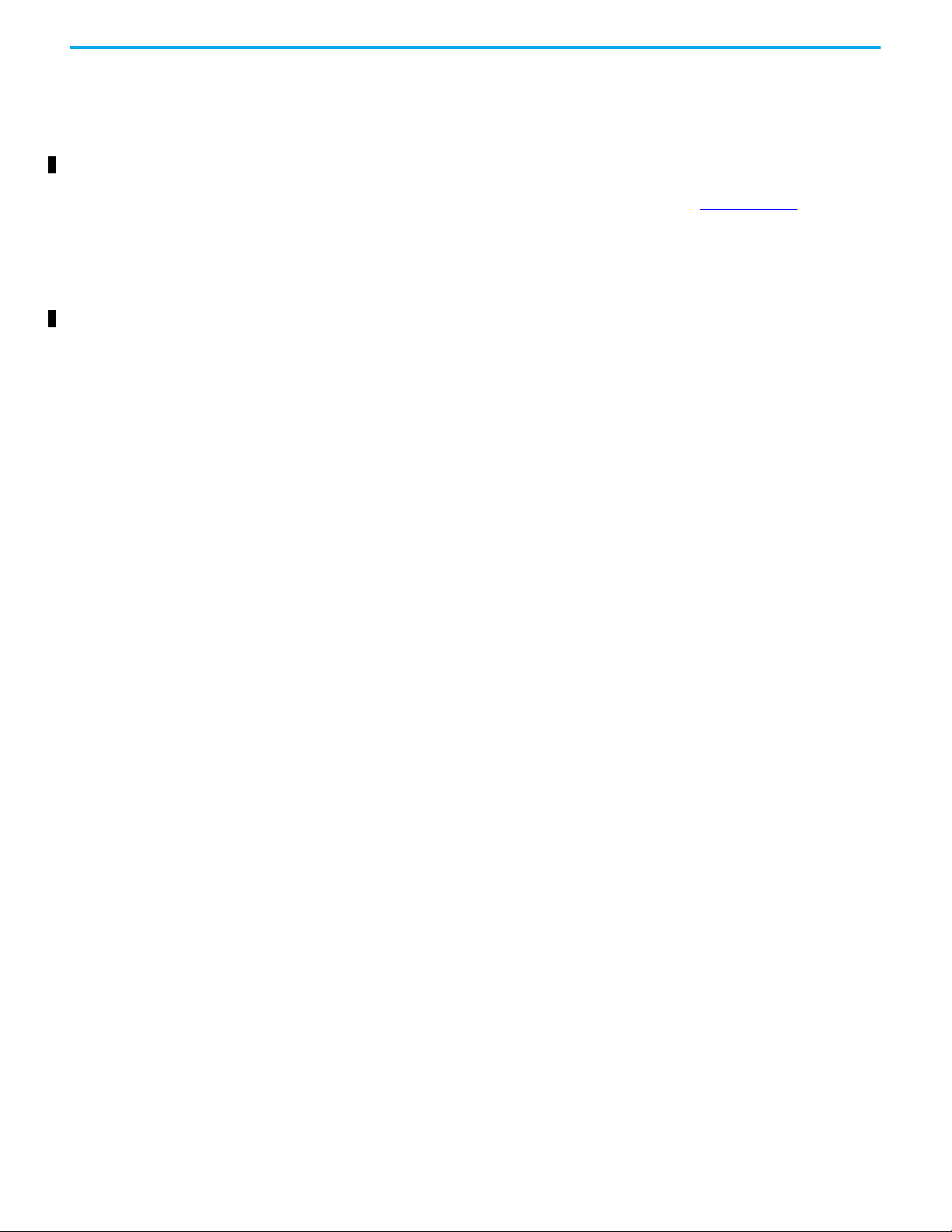

FactoryTalk® Linx connection and RSLinx Classic software, in all its variations

are used to provide a communication link between the computer, network,

and controller.

1. Configure an EtherNet/IP driver in RSLinx Classic software.

2. Keep running RSLinx software and verify that the computer connects

with the drive.

3. From the Communication menu, choose RSWho.

4. In the menu tree, click the ‘+’ next to the Ethernet driver and find your

drive.

Note: If the EtherNet/IP Driver cannot see your drive, as an alternative, use either the

Ethernet devices or the Remote Devices via Linx Gateway RSLinx driver.

Page 32

Chapter 3 Configuring the Drive in a Logix System

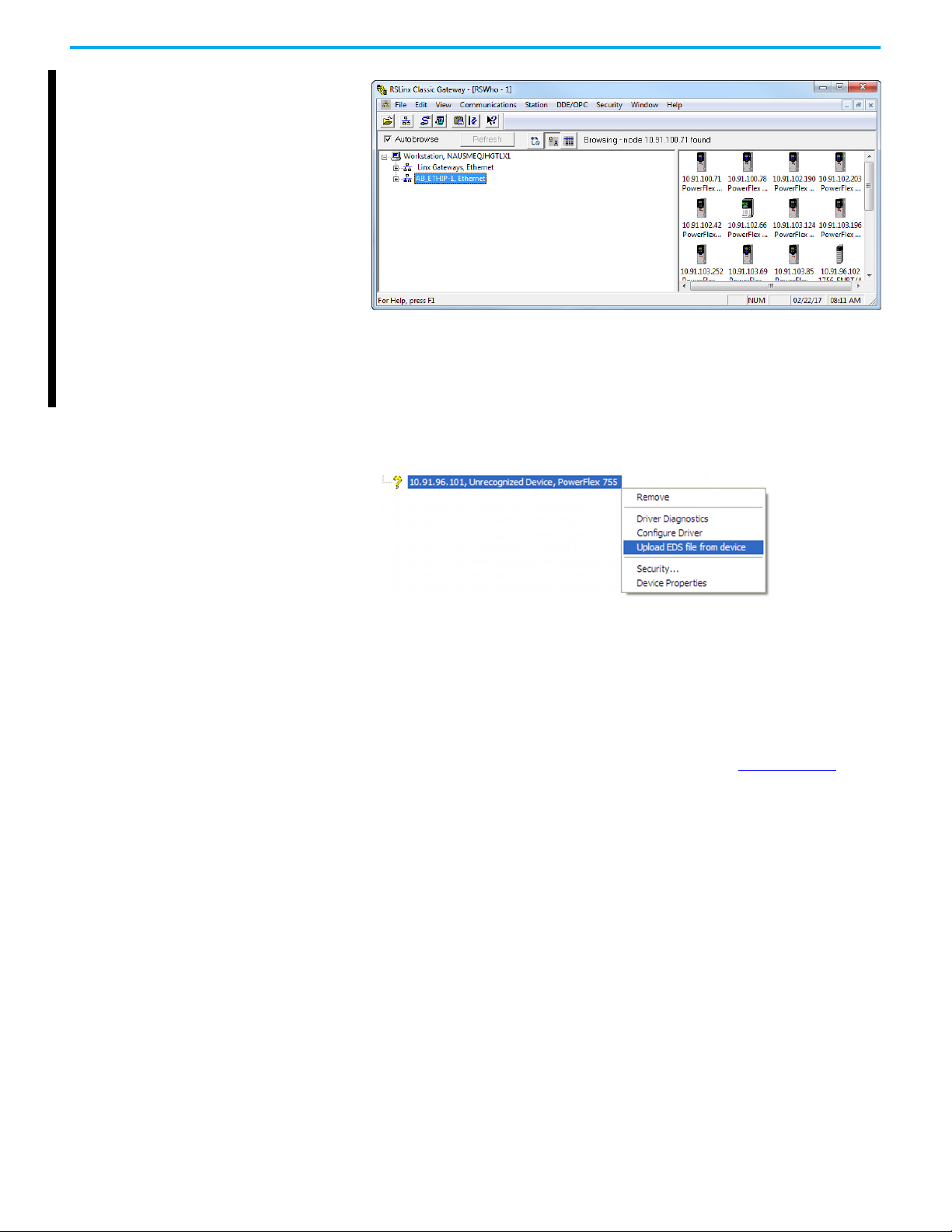

5. If your drive is not recognized, upload the electronic data sheet (EDS) file

from the drive.

a. Right-click your drive.

b. Choose upload EDS file from device.

By uploading the EDS file, it also uploads the icon files for the device. The

question mark changes to a drive icon.

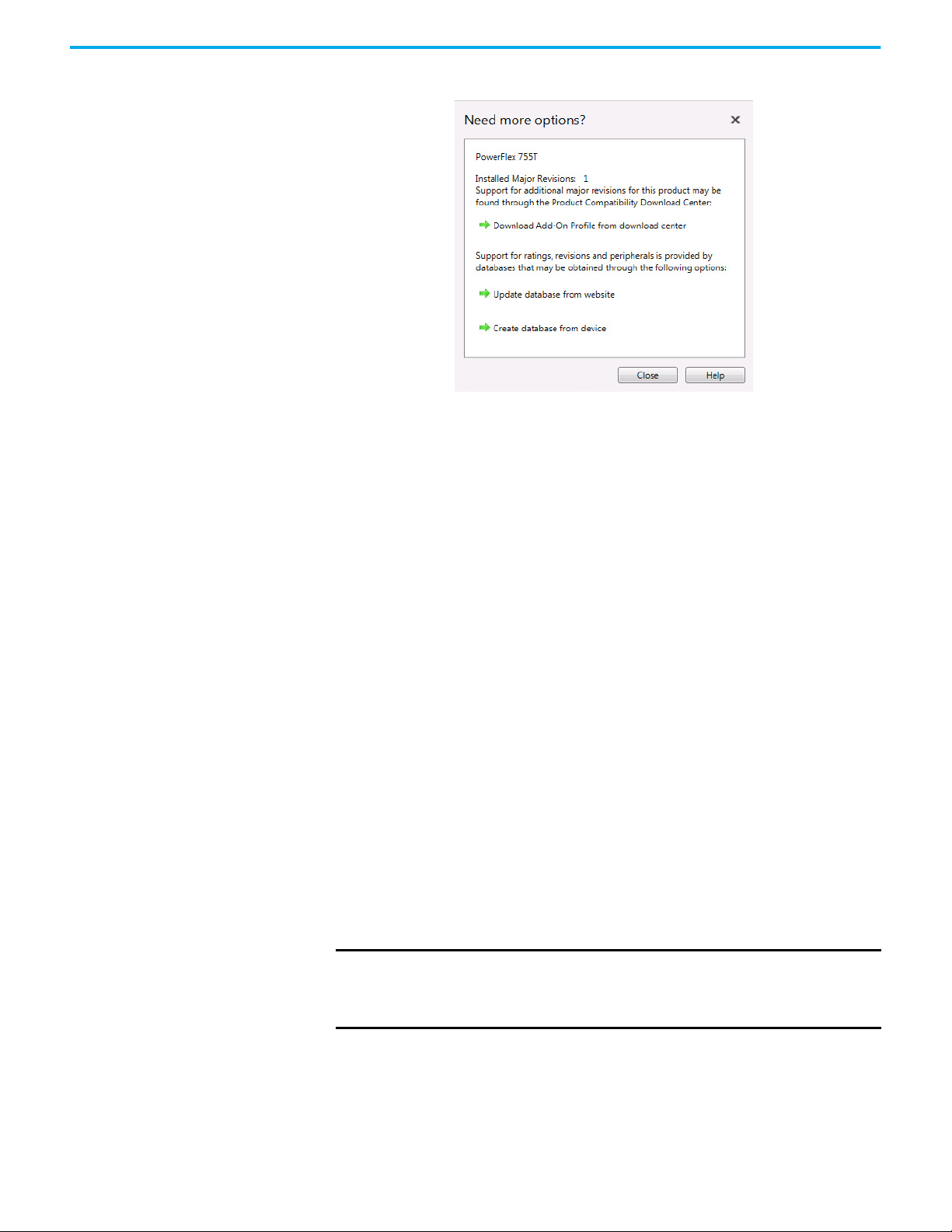

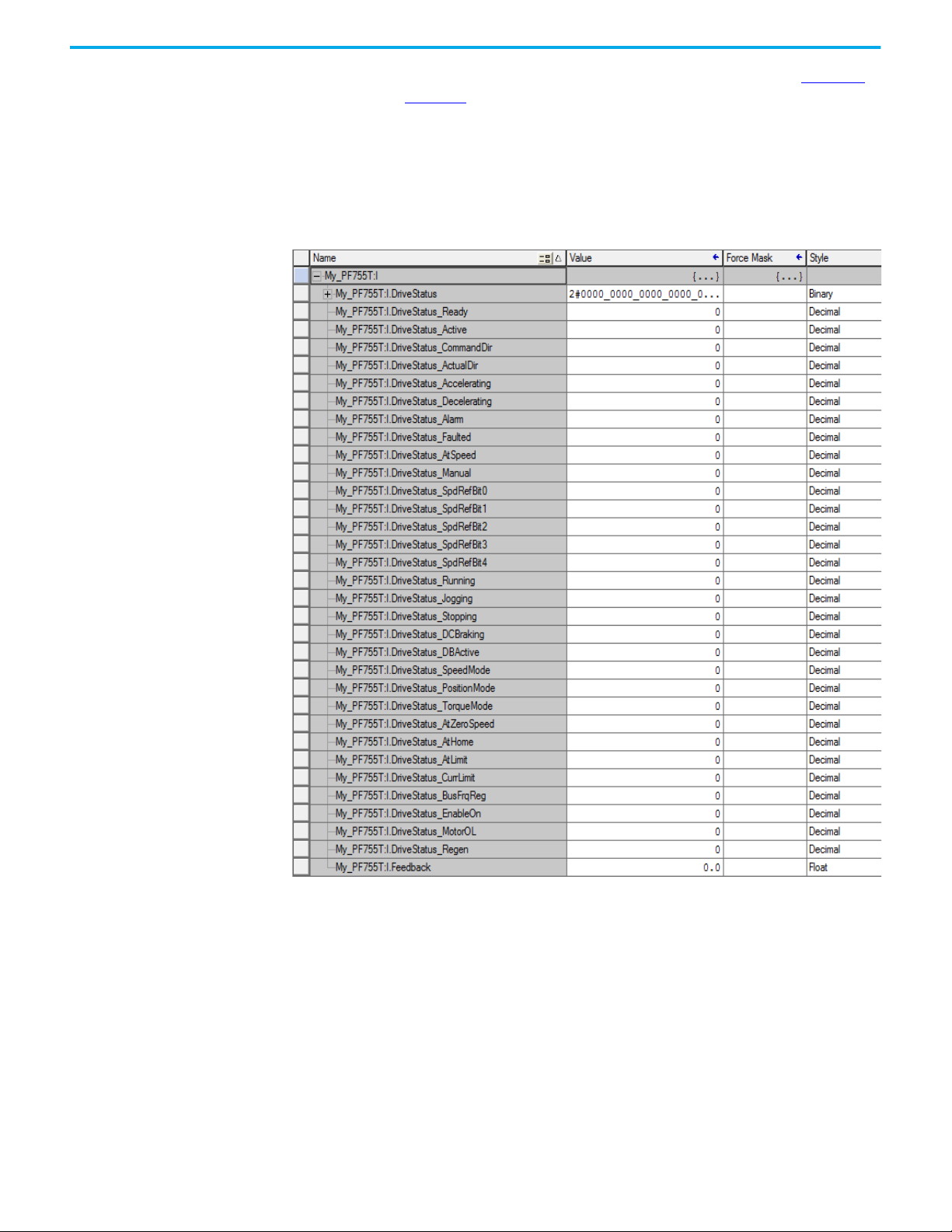

Obtain Add-on Profiles Each version of the Logix Designer application ships with the latest versions of

available AOPs. However, new drives (new AOPs), updates (software

enhancements and anomaly fixes), and device database files that are required

for new firmware releases can occur at any time. If you are missing any of the

following, you can obtain the AOP and database updates via free download at

the Product Compatibility and Download Center (PCDC), rok.auto/pcdc

• An AOP for a specific drive

• A specific feature, such as ADC

• A desired firmware revision in an existing AOP

The Logix Designer application drive Add-on Profiles provide these

advantages:

• Profiles for specific drives that provide descriptive controller tags for

basic control I/O words (logic command/status and reference/feedback)

and datalinks. Additionally, datalinks automatically take the name of the

drive parameter to which they are assigned. All Tags are of the proper

data type so there is no need for manual conversion in the user program.

These profiles substantially reduce I/O mismatch errors and drive

configuration time.

• The drive tab removes the need for a separate drive-softwareconfiguration tool. All drive configuration can be done within the Logix

Designer application.

• Drive configuration settings are saved as part of the controller project

file (.ACD) and also downloaded to the controller.

• Automatic Device Configuration.

:

32 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 33

Chapter 3 Configuring the Drive in a Logix System

To determine your AOP version, left-click on Module Properties icon in the

upper left-hand corner of the Module Properties dialog box, and choose About

Module Profile.

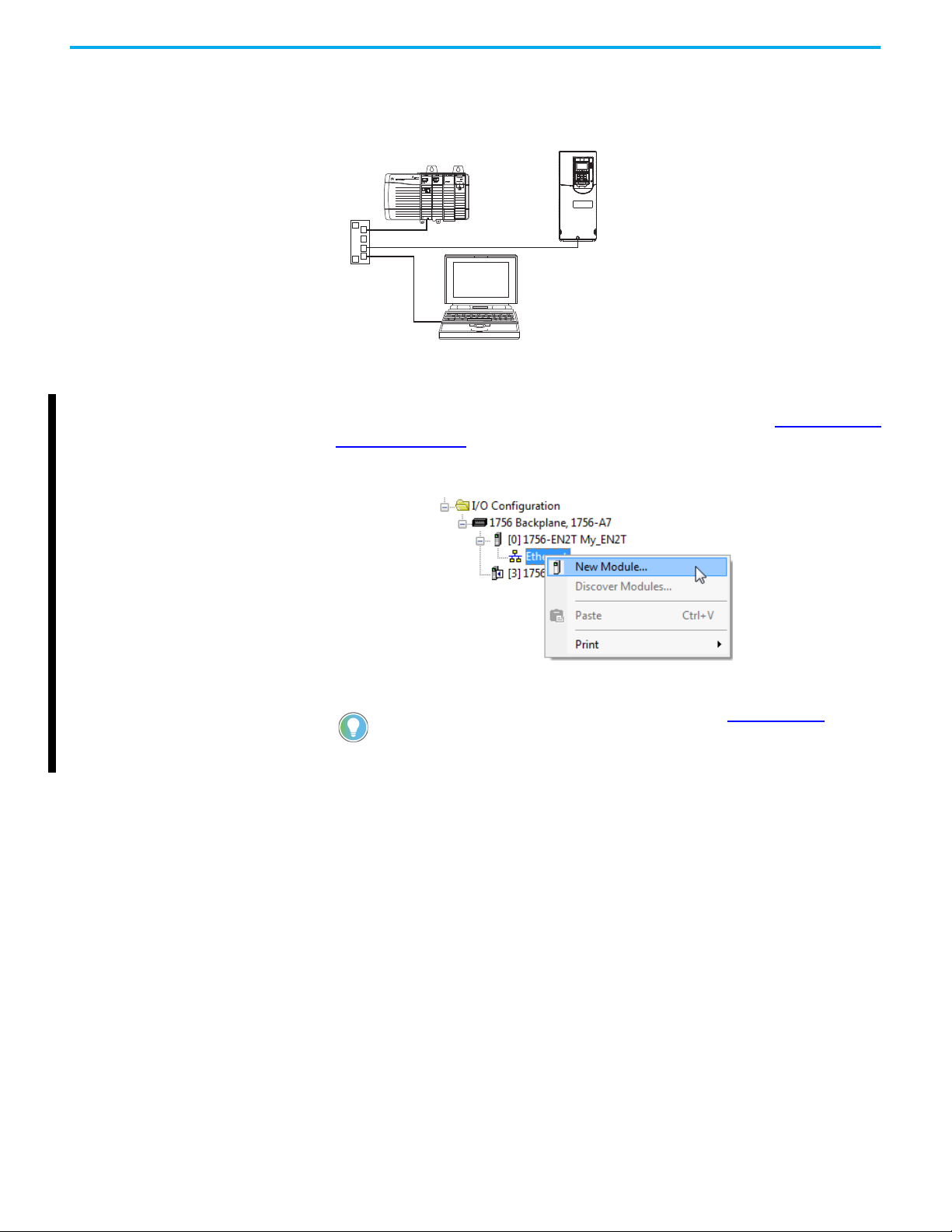

Create Logix Controller Project

Go to Product Compatibility and Download Center at rok.auto/pcdc

download the latest drive Add-on Profile for the drive.

Before you can add your drive, you must create a Logix Designer application

project that includes a Logix 5000 controller with a connection to the

EtherNet/IP network. Some controllers require an Ethernet communication

module, while others feature an embedded Ethernet port for network

communication. See the user manual for your controller for information on

configuring a Logix 5000 controller in the Logix Designer application at

rok.auto/literature

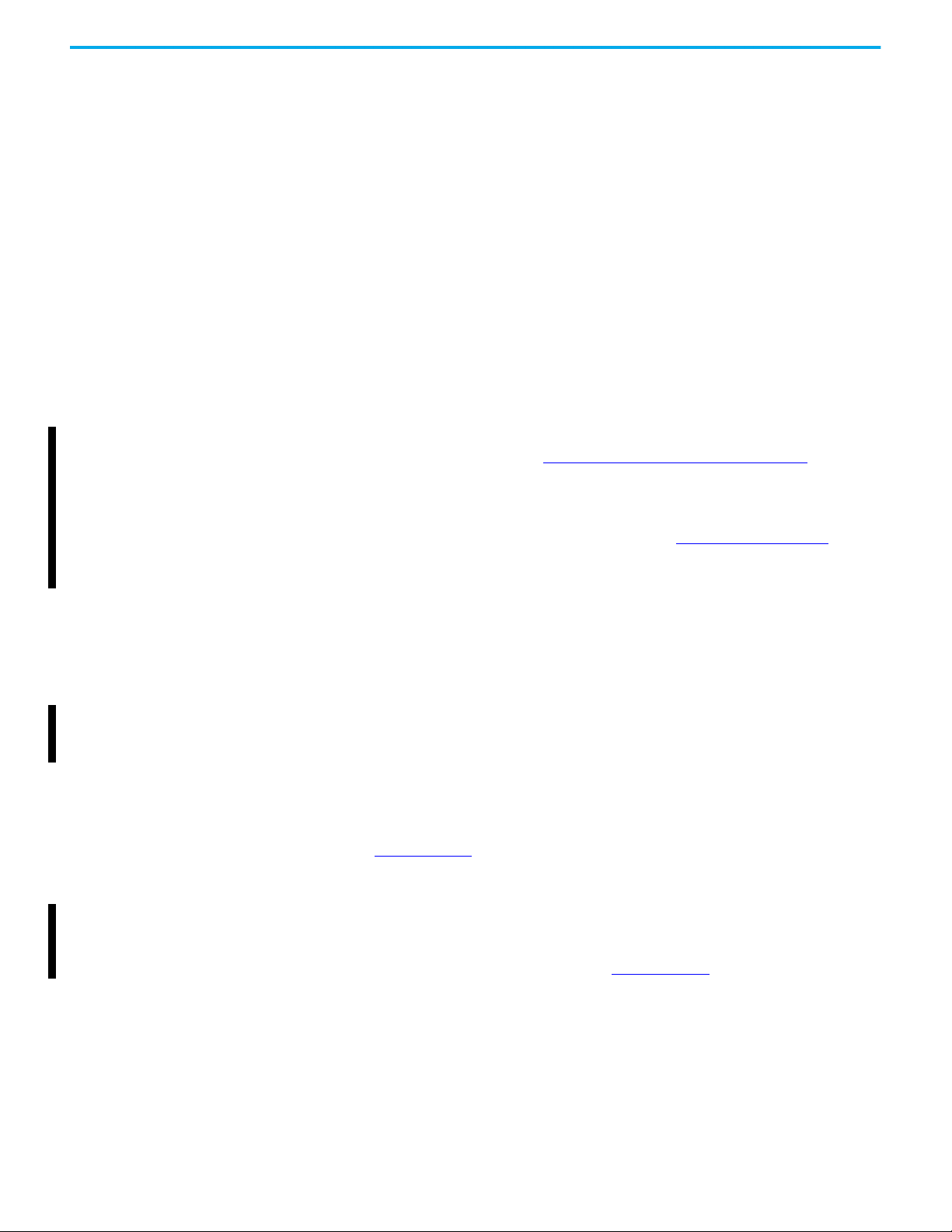

This section provides the steps to configure a simple EtherNet/IP network (see

Figure 8

communicate with a drive by using logic command/status, reference/

feedback, and 32 datalinks (16 to read and 16 to write) over the network.

). In our example, we configure a ControlLogix controller to

.

to

Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021 33

Page 34

Chapter 3 Configuring the Drive in a Logix System

IP address 10.91.166.21

PowerFlex 755T drive with built-in

EtherNet/IP adapter

Computer with Ethernet

Connection

Ethernet Switch

Figure 8 - Example ControlLogix Controller EtherNet/IP Network

IP address 10.91.166.96

ControlLogix Controller

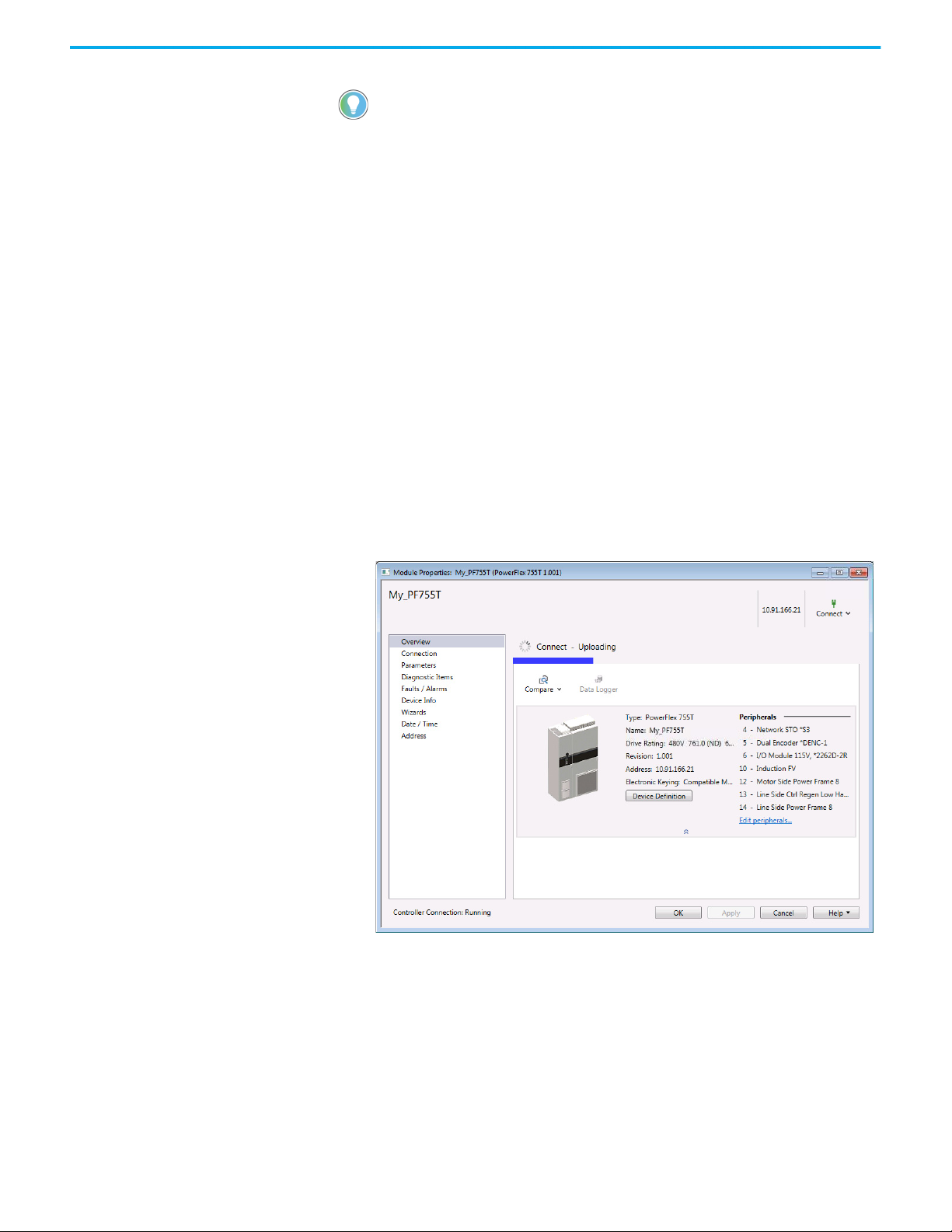

Add the Drive to the Project To transmit data between the controller and the drive, you must add the drive

as a child device to the parent Ethernet connection. See section Obtain Add-on

Profiles on page 32 to determine which AOP version you are currently using.

1. In the tree view, right-click the Ethernet network under the Ethernet

bridge and choose New Module to display the Select Module dialog box.

2. From the list, select your drive.

If the desired PowerFlex drive is not shown, go to rok.auto/pcdc and

download the latest Add-on Profile.

3. Click Create.

34 Rockwell Automation Publication 750COM-UM009B-EN-P - April 2021

Page 35

Chapter 3 Configuring the Drive in a Logix System

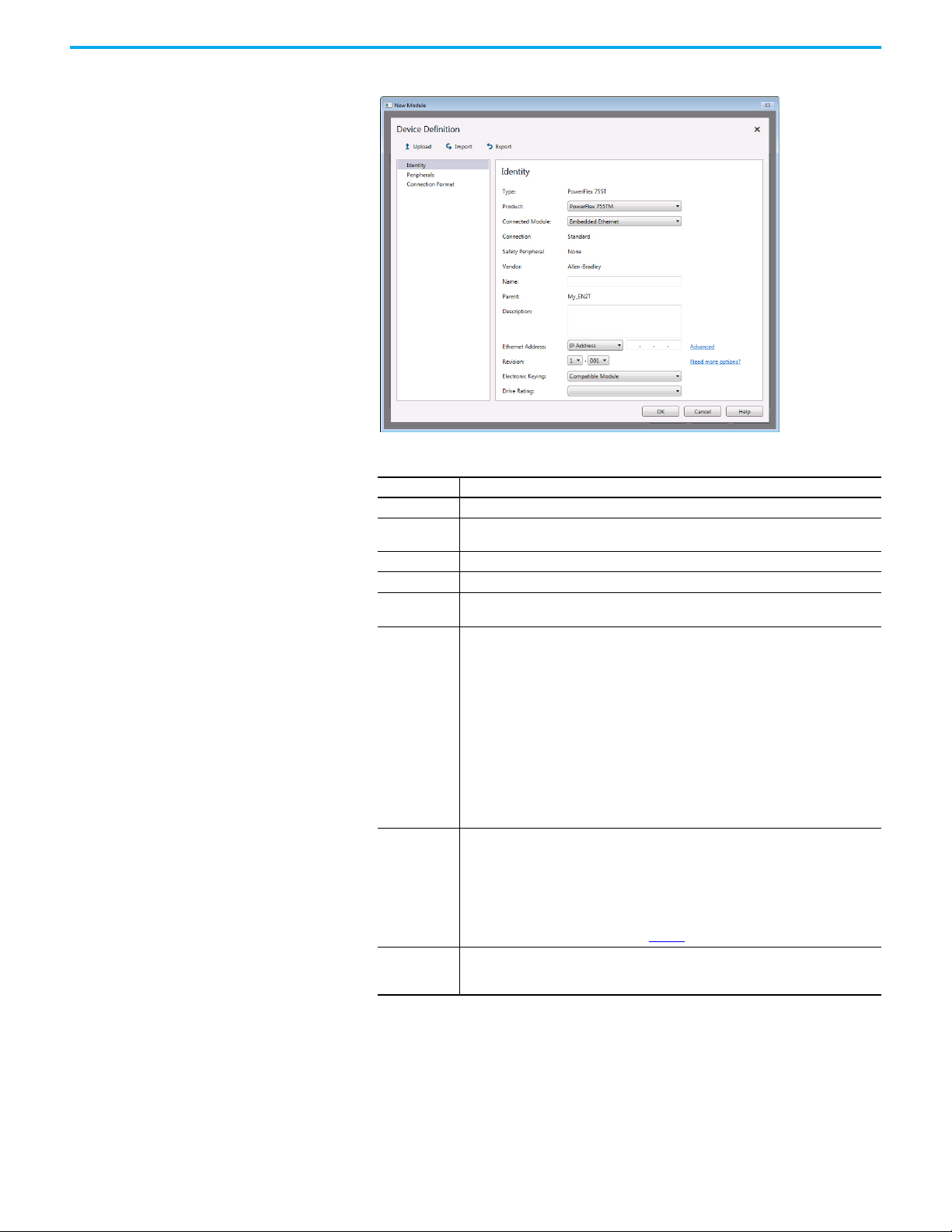

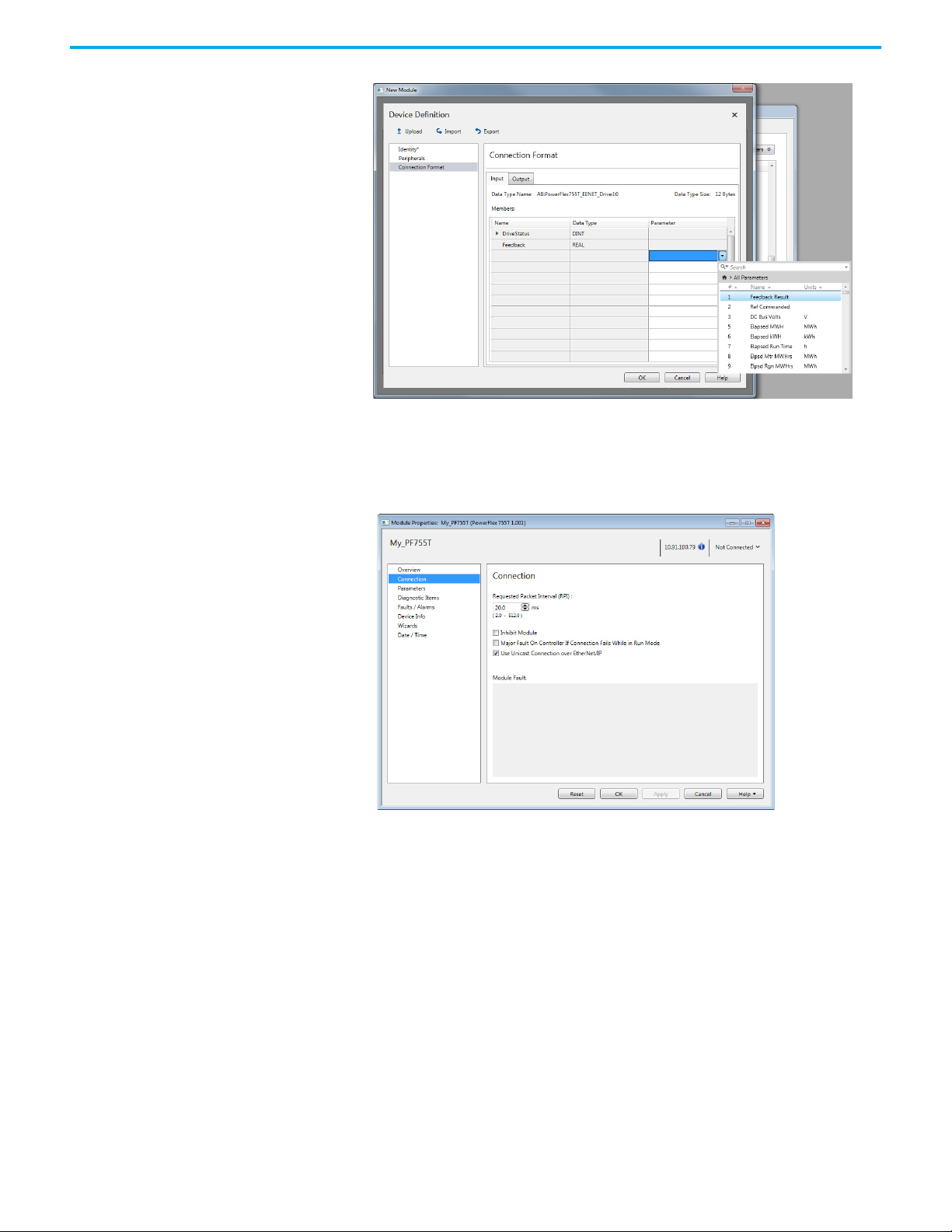

The Device Definition window for the drive appears.

4. On the Identity page, edit the following data about the drive.

Box Setting

Product Select the type of drive used, if necessary.

Connected

Module

Name A name to identify the drive.

Description Optional – description of the drive.

Ethernet

Address

Revision

Electronic

Keying

Drive Rating

Select the Ethernet connection that is used by the drive.

The IP address of the drive. Click the Advanced link if Network Address Translation (NAT) is

used.

The major and minor revision of the firmware in the drive. If the desired major and minor

revision for the drive is not listed, the drive database is not installed on your computer. To

get the correct database revision, click the ‘Need more options?’ link to:

Create Database Device: Creates a database from an online network drive.

– To locate the desired drive, navigate the RSLinx software RSWho dialog box.

– Select the desired drive, and click OK. Data is uploaded from the drive to create the

database on the computer.

– Close the Device Definition window and then reopen it to display the new revision.

Update Database from website: When a drive is not available online, do the following:

– Automatically opens the Product Compatibility and Download Center website with the

necessary database install file listed.

– Download the file.

– Close the Device Definition window.

– Reopen it to display the new revision.

Compatible Module is recommended when Firmware Supervisor is not used to

update a replacement of this drive. The ‘Compatible Module’ setting for Electronic Keying

verifies that the physical module is consistent with the software configuration before the

controller and bridge make a connection. Make sure to set the correct revision in this dialog

box. See the online Help for additional information on this and other Electronic Keying

settings.

When using Firmware Supervisor to store firmware for the drive, always choose ‘Exact

Match’. When using ADC, see the table on page 47

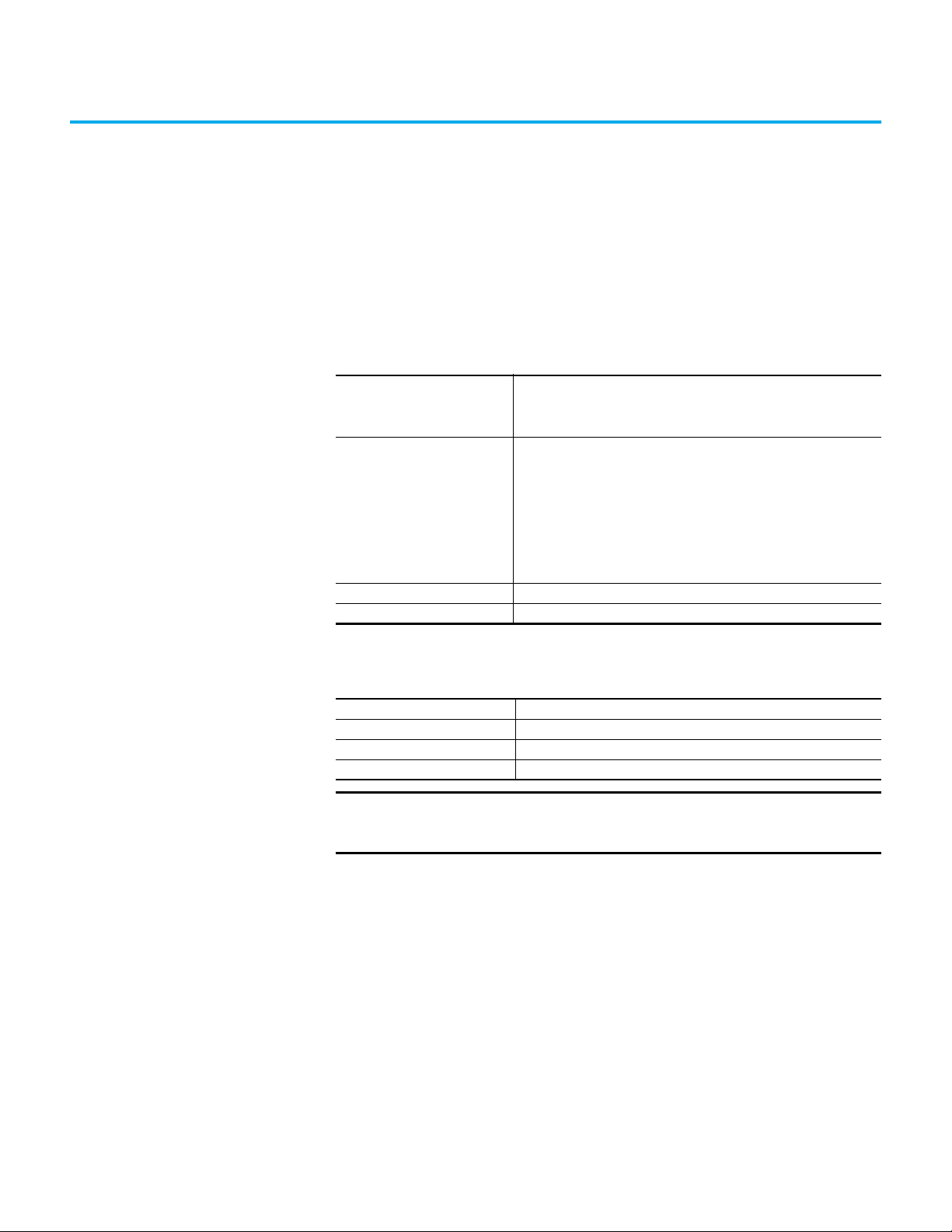

The voltage and current rating of the drive. If the drive rating is not listed, the drive database