Page 1

PowerFlex 40 Configured AC Drives

INSTALLATION INSTRUCTIONS

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

www.rockwellautomation.com/literature) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for solid

state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect

or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility

or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

http://

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING: Identifies information about practices or

circumstances that can cause an explosion in a hazardous

!

environment, which may lead to personal injury or death, property

damage, or economic loss.

Important: Identifies information that is critical for successful application and

understanding of the product.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard, and recognize the consequences.

Shock Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that dangerous voltage may be

present.

Burn Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that surfaces may be at

dangerous temperatures.

PowerFlex, DriveExplorer, DriveExecutive, DPI, and SCANport are either trademarks or registered trademarks of Rockwell Autom ation, Inc.

Page 3

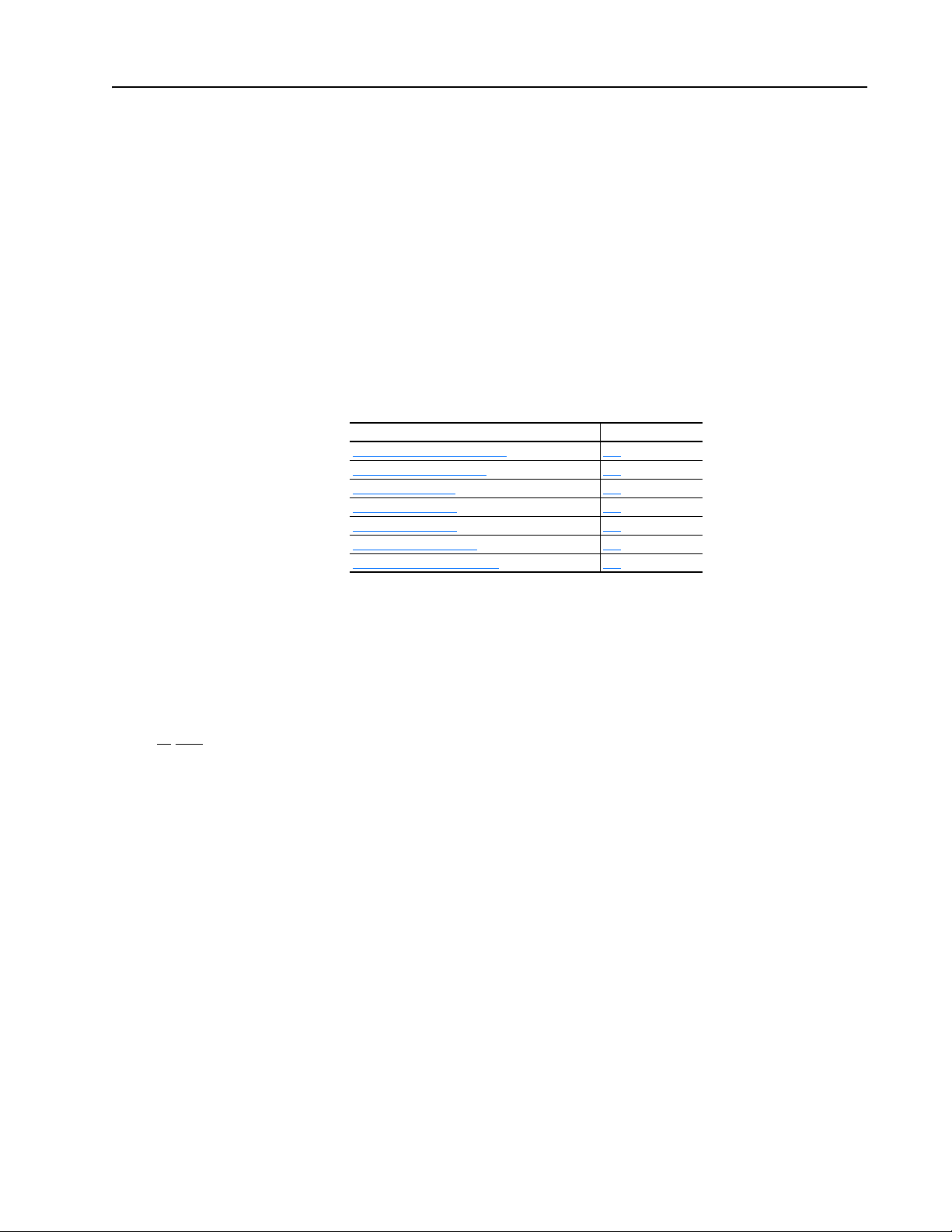

Table of Contents

Preface Overview

Who Should Use this Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-1

What Is Not in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-1

Reference Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-2

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-2

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-3

Compliance Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-3

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-4

Chapter 1 PowerFlex 40 Standard Configured Drive Standard Features and Options

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Enclosure Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Communication Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Power Disconnect Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Operator Device Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Quick Disconnects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

I/O Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Chapter 2 Control Wiring Overview

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Control Wiring Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Schematic Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter 3 Mechanical Installation

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Layout Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Appendix A Specifications

Appendix B Replacement Parts

Publication 23B-IN001G

Page 4

2 Table of Contents

Notes:

Publication 23B-IN001G

Page 5

Overview

Preface

Who Should Use this Manual?

The purpose of this manual is to provide basic information needed to install

PowerFlex

®

40 Adjustable Frequency AC Standard Configured Drives.

User documentation for the PowerFlex 40 Standard Configured Drives

includes these Installation Instructions and the PowerFlex 40 User Manual,

Publication 22B-UM001…. Both manuals are required to properly install

and operate PowerFlex 40 Adjustable Frequency AC Standard Configured

Drives.

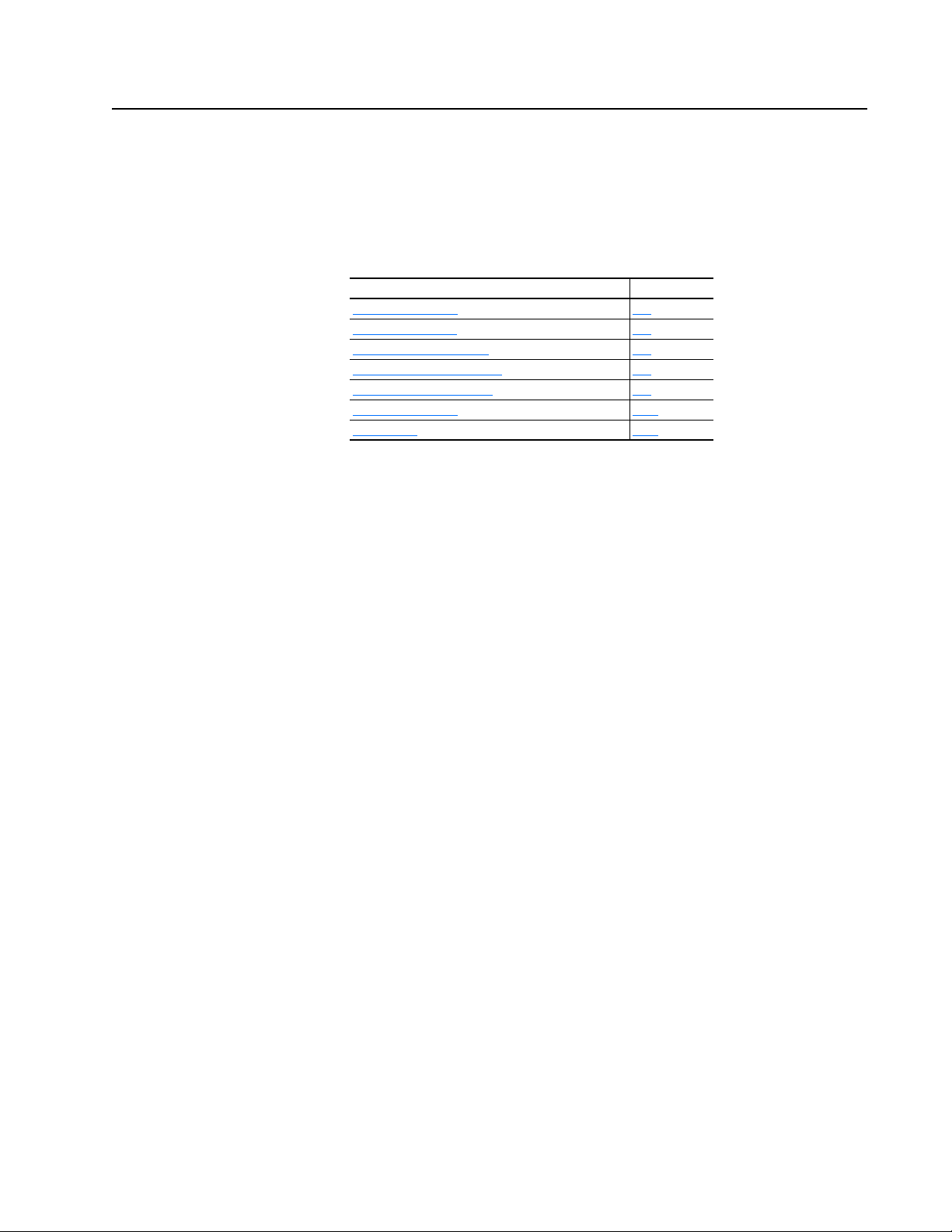

For information on … See page …

Who Should Use this Manual?

What Is Not in this Manual P-1

Reference Materials P-2

Manual Conventions P-2

General Precautions P-3

Compliance Certification P-3

Catalog Number Explanation P-4

P-1

This manual is intended for qualified personnel. You must be able to

program and operate Adjustable Frequency AC Drive devices. In addition,

you must have an understanding of the parameter settings and functions.

What Is Not in this Manual

The PowerFlex 40 Adjustable Frequency AC Standard Configured Drives

Installation Instructions is designed to provide only basic installation and

operation information. For this reason, the following topics have not been

included:

• Troubleshooting

• Start-Up

• Programming and Parameters

Please refer to the PowerFlex 40 User Manual for detailed drive

information.

Publication 23B-IN001G

Page 6

P-2 Overview

Reference Materials

The following manuals are recommended for general drive information:

Title Publication Available Online at …

Wiring and Grounding Guidelines for Pulse

Width Modulated (PWM) AC Drives

Preventive Maintenance of Industrial Control

and Drive System Equipment

Safety Guidelines for the Application,

Installation and Maintenance of Solid State

Control

A Global Reference Guide for Reading

Schematic Diagrams

Guarding Against Electrostatic Damage 8000-4.5.2

DRIVES-IN001…

DRIVES-TD001…

SGI-1.1

0100-2.10

www.rockwellautomation.com/

literature

For detailed PowerFlex 40 information including drive parameters,

programming, start-up, troubleshooting, specifications:

Title Publication Available Online at …

PowerFlex 40 User Manual 22B-UM001…

PowerFlex Reference Manual PFLEX-RM001…

www.rockwellautomation.com/literature

The latest version of this Installation Instructions can be obtained online at …

www.rockwellautomation.com/literature

For Allen-Bradley Drives Technical Support:

Title Online at …

Allen-Bradley Drives Technical Support www.ab.com/support/abdrives

Manual Conventions

• To help differentiate parameter names and LCD display text from other

text, the following conventions will be used:

– Parameter Names will appear in [brackets].

For example: [DC Bus Voltage].

– Display Text will appear in “quotes.” For example: “Enabled.”

• The following words are used throughout the manual to describe an

action:

Word Me aning

Can Possible, able to do something

Cannot Not possible, not able to do something

May Permitted, allowed

Must Unavoidable, you must do this

Shall Required and necessary

Should Recommended

Should Not Not recommended

Publication 23B-IN001G

Page 7

General Precautions

Overview P-3

ATTENTION: This drive contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control

!

precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with

static control procedures, reference A-B publication 8000-4.5.2,

“Guarding Against Electrostatic Damage” or any other applicable

ESD protection handbook.

ATTENTION: An incorrectly applied or installed drive can

result in component damage or a reduction in product life. Wiring

!

or application errors, such as, undersizing the motor, incorrect or

inadequate AC supply, or excessive ambient temperatures may

result in malfunction of the system.

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should plan or

!

implement the installation, start-up and subsequent maintenance

of the system. Failure to comply may result in personal injury

and/or equipment damage.

Compliance Certification

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before performing

!

any work on the drive. Measure the voltage at the drive (Refer to

the PowerFlex 40 User Manual for test point locations). The

voltage must be zero.

Certifications are applicable to approved program defined options.

U.S./Canada UL: UL508C

CUL: CAN/CSA-C22.2 No. 14

Please refer to the PowerFlex 40 User Manual, publication 22B-UM001,

for additional information.

Publication 23B-IN001G

Page 8

P-4 Overview

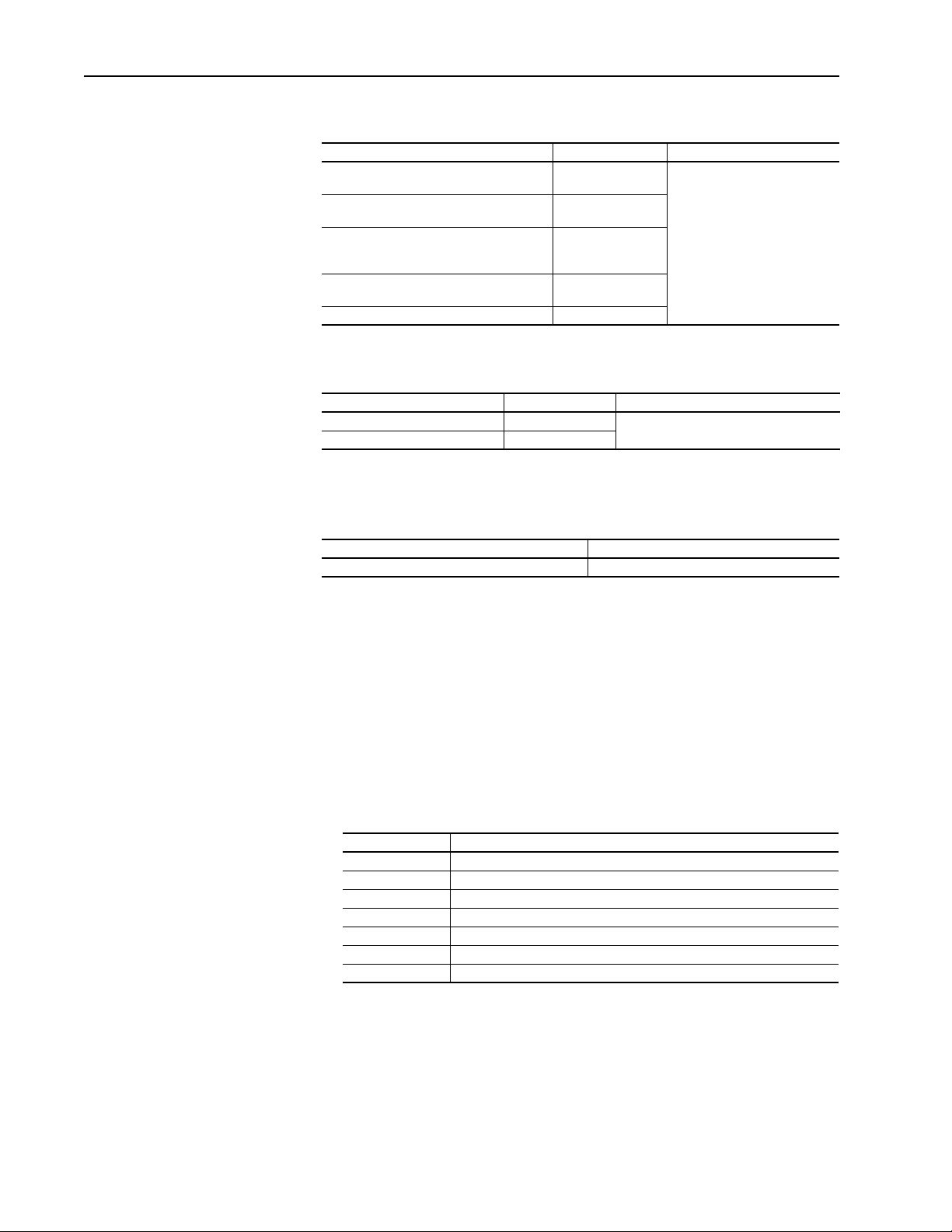

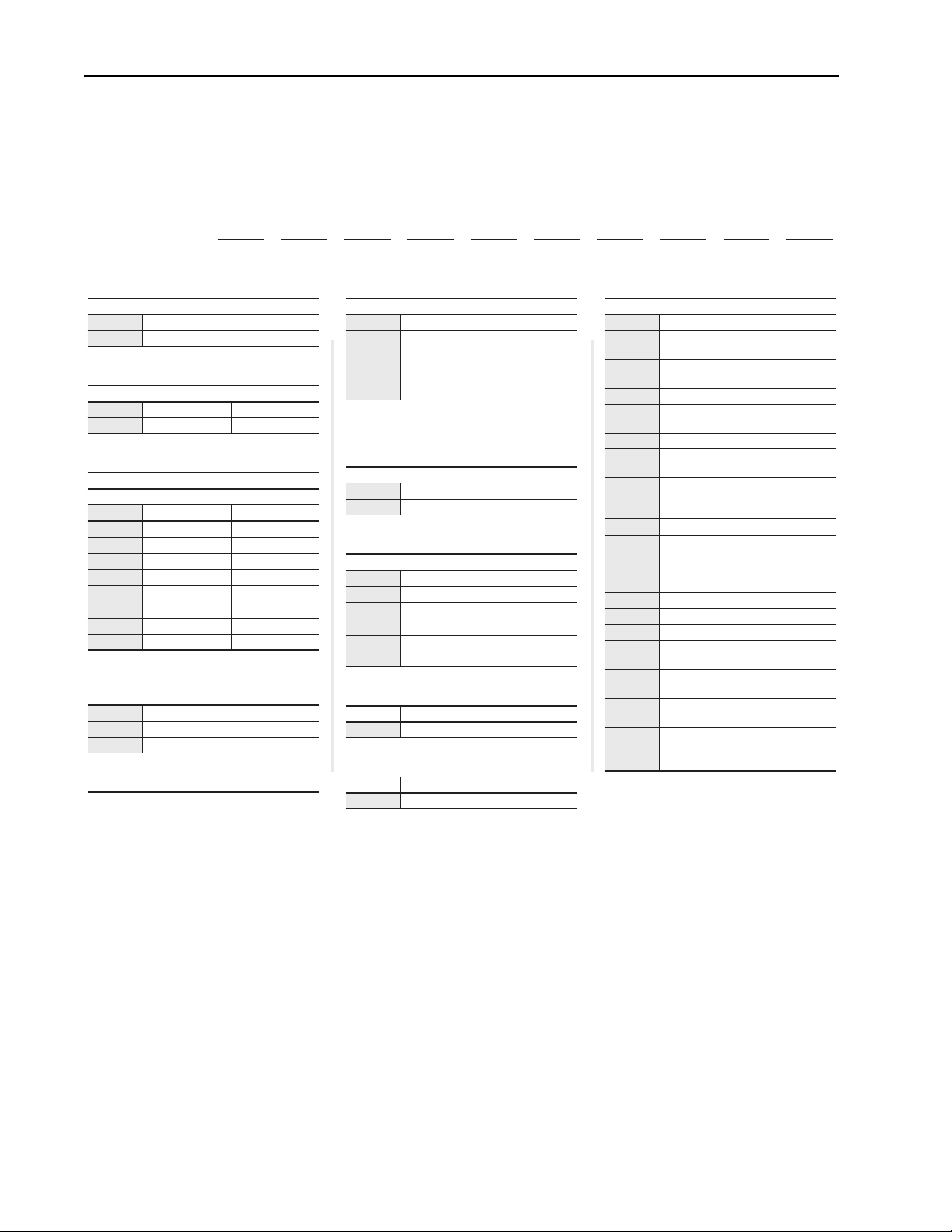

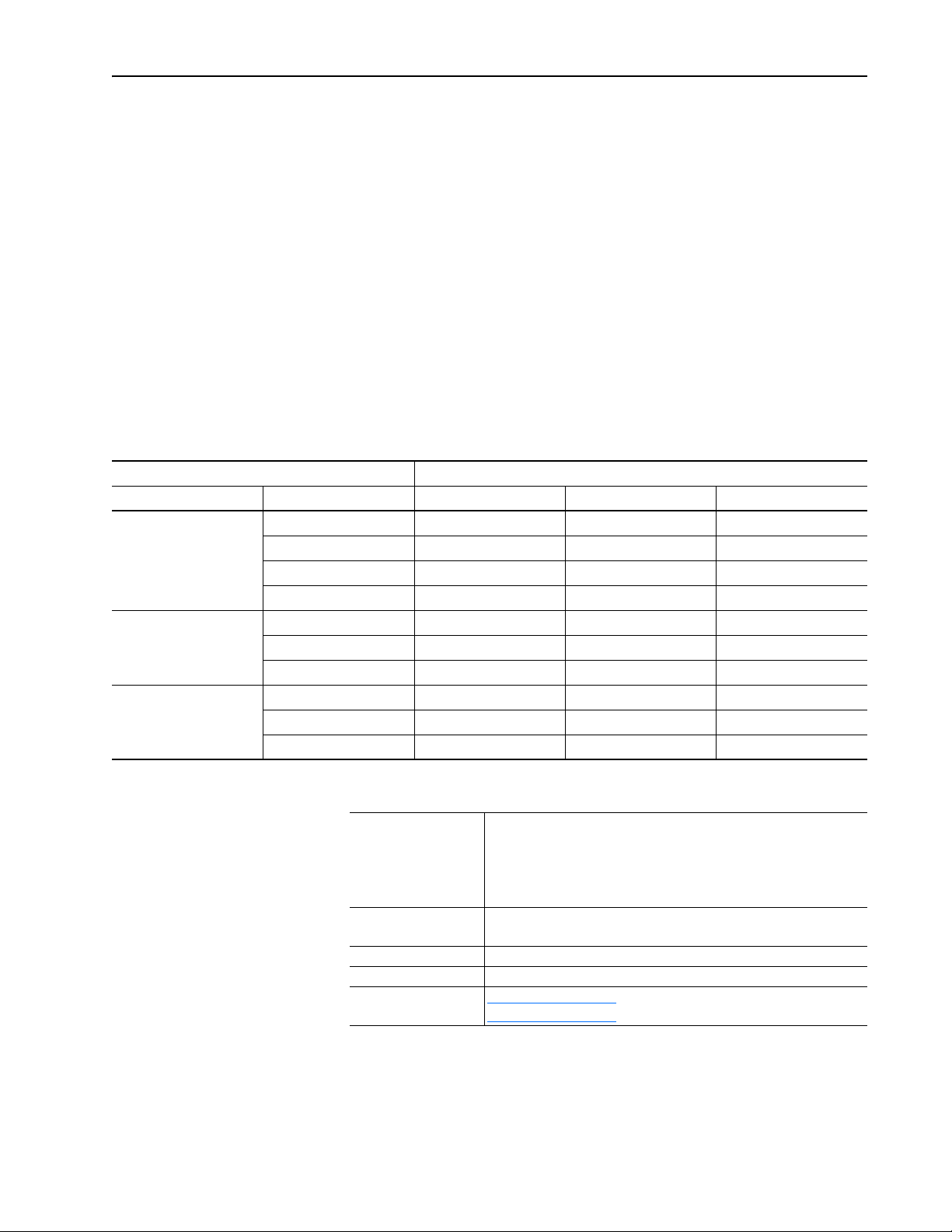

Catalog Number Explanation

1-3 4 56-8 9 10111213141516+

23B –

D 4P0 D 1 0 4 N N – P6

The PowerFlex 40 Adjustable Frequency AC Standard Configured Drives

catalog numbering scheme is shown below.

Position

abcdefghi j

a

Drive

Code Type

23B PowerFlex 40

b

Voltage Rating

Code Voltage Ph.

D 480V ac 3

c

Amp Rating

480V 60Hz Input

Code Amps kW (Hp)

1P4 1.4 0.4 (0.5)

2P3 2.3 0.75 (1.0)

4P0 4.0 1.5 (2.0)

6P0 6.0 2.2 (3.0)

010 10.5 4.0 (5.0)

012 12 5.5 (7.5)

017 17 7.5 (10)

024 24 11 (15)

d

Enclosure

Code Enclosure

C NEMA/UL Type 4X ‡

D NEMA/UL Type 4 ‡

‡ The design of the PowerFlex 40 Standard

Configured Drive supports indoor and outdoor

applications that are not in direct sunlight.

Code Interface Module

1 Fixed Keypad on Drive

Display with Digital Speed Control

F

This option changes the enclosure rating to

indoor only.

Code Rating

0 Not Filtered

Code Version

4 RS485 (Standard)

C ControlNet

D DeviceNet

E EtherNet/IP

P PROFIBUS DP

Code Rating

N Reserved

Code Rating

N Reserved

e

HIM

Fixed Keypad on Drive and LCD

HIM on Enclosure Door

(22-HIM-C2S)

f

Emission Class

g

Version

h

i

j

Options

Code Description

-E22

-E23

-P3 Motor Circuit Protector

-P3T

-P6 Disconnect Switch - Fused

-P6T

-R3

-R4 DeviceNet Point I/O w/IB4 (4 Inputs)

-R5

-S1

-S4 Auto/Manual S.S. (Speed Ref.)

-S7 Start and Stop P.B.

-S8 Forward/Reverse S.S.

-S18

-S20

-S21

-S22

-S23 Clear Fault P.B.

DeviceNet Quick Disconnect

(Bottom)

DeviceNet Quick Disconnect (Left

Side)

Motor Circuit Protector (Customer

wiring into top of device)

Disconnect Switch - Fused

(Customer wiring into top of device)

DeviceNet I/O (4 In/2 Out) w/Spring

Return HOA and Power Disconnect

Aux. Contact

-R3 plus 4 I/O Quick Disconnects

and (1) 24V DC Receptacle

Hand/Off/Auto S.S.

(Start/Stop/Speed Ref.)

Door Mounted Local Speed Pot (1-

Tur n )

Local/Remote and Local Control

Off/Run Forward Selector Switches

Local/Off/Remote with 1 N.O.

Interposing Relay

Spring Return Hand/Off Auto S.S.

(Start/Stop/Speed Ref.)

Publication 23B-IN001G

Page 9

Chapter 1

PowerFlex 40 Standard Configured Drive Standard Features and Options

Chapter Objectives

Standard Features

This chapter describes the standard features and operation for PowerFlex 40

Standard Configured Drives and associated options.

For information on … See page …

Standard Features

Enclosure Options 1-2

Communication Options 1-3

Power Disconnect Options 1-4

Operator Device Options 1-9

Quick Disconnects 1-15

I/O Options 1-16

This package integrates the Standard PowerFlex 40 drive. The PowerFlex

40 drive can be used for Volts per hertz or Sensorless Vector applications

and offers an Autotune feature allowing the drive to adapt to individual

motor characteristics.

The PowerFlex 40 is assembled in an enclosure which includes the

following features…

• NEMA/UL Type 4/4X - indoor and outdoor applications other than

direct sunlight.

• Flange mount drive/external heatsink reducing overall enclosure size.

(1)

1-1

• Mounting feet - orientation is adjustable per customer requirements.

If required, the drive can be removed from the front of the enclosure for

ease of assembly or repair.

Low cost, highly configurable I/O inputs and/or 0-10V/4-20 mA outputs

that are not used by program standard features and options are available for

customer use.

(1)

The enclosure does not normally protect electrical equipment from

condensation, corrosion or contamination, which may occur within the

enclosure or enter via the conduit or unsealed openings. Users must

make adequate provisions to safeguard against such conditions, and

satisfy themselves that the equipment is properly protected. For further

information on criteria associated with NEMA enclosure ratings, refer to

NEMA standards Publication No. 250-1991. When optional Door

Mounted HIM is supplied, enclosure is rated indoor only. See enclosure

options for specific enclosure style quoted.

Publication 23B-IN001G

Page 10

1-2 PowerFlex 40 Standard Configured Drive Standard Features and Options

Enclosure Options

NEMA/UL Type 4 (Position 9, Code D)

The enclosure provided is a NEMA/UL Type 4, painted mild steel, which

supports both NEMA/UL Type 4 and NEMA/UL Type 12 applications.

Type 4 enclosures are intended for indoor or outdoor use primarily to

provide a degree of protection against windblown dust and rain, splashing

water, and hose directed water, and to be undamaged by the formation of ice

on the enclosure. They are designed to meet hose-down, dust, and external

icing and rust resistance design tests. Doors and openings will be gasket

sealed. There are no ventilation openings within the enclosure to allow for

free exchange of inside and outside air.

Note: If optional Door Mounted HIM is not supplied, the design of the

PowerFlex 40 Standard Configured Drive supports indoor and outdoor

applications that are not in direct sunlight.

NEMA/UL Type 4X (Position 9, Code C)

The enclosure provided is a NEMA/UL Type 4X. The material is type 304

stainless steel. Type 4X enclosures are intended for indoor or outdoor use

primarily to provide a degree of protection against corrosion, windblown

dust and rain, splashing water, and hose directed water, and to be

undamaged by the formation of ice on the enclosure. They are designed to

meet hose-down, dust, and external icing and rust resistance design tests.

Doors and openings will be gasket sealed. There are no ventilation openings

within the enclosure to allow for free exchange of inside and outside air.

Note: If optional Door Mounted HIM is not supplied, the design of the

PowerFlex 40 Standard Configured Drive supports indoor and outdoor

applications that are not in direct sunlight.

Publication 23B-IN001G

Page 11

PowerFlex 40 Standard Configured Drive Standard Features and Options 1-3

Communication Options

DeviceNet (Position 12, Code D)

The DeviceNet option is drive mounted and consists of the DeviceNet

communication adaptor (22-COMM-D) and adaptor cover (22B-CCB for

frame B drives or 22B-CCC for frame C drives). When DeviceNet is

present, no other communication option is available other than the HIM.

When used as a slave, the HIM will have limited functionality. For details

related to the DeviceNet option, refer to the PowerFlex DeviceNet Adapter

User Manual, publication 22COMM-UM003….

To review this schematic see

Figure 2.1 on page 2-2 and Figure 2.3 on page 2-4.

EtherNet/IP (Position 12, Code E)

The EtherNet/IP option is drive mounted and consists of the EtherNet/IP

communication adaptor (22-COMM-E) and adaptor cover (22B-CCB for

frame B drives or 22B-CCC for frame C drives). When EtherNet/IP is

present, no other communications option is available other than the HIM.

When used as a slave, the HIM will have limited functionality. For details

related to the EtherNet/IP option, refer to the PowerFlex EtherNet/IP

Adapter User Manual, publication 22COMM-UM004….

To review this schematic see

Figure 2.1 on page 2-2 and Figure 2.3 on page 2-4.

PROFIBUS (Position 12, Code P)

The PROFIBUS option is drive mounted and consists of the PROFIBUS

communication adaptor (22-COMM-P) and adaptor cover (22B-CCB for

frame B drives or 22B-CCC for frame C drives). When PROFIBUS is

present, no other communication option is available other than the HIM.

When used as a slave, the HIM will have limited functionality. For details

related to PROFIBUS option, refer to the PowerFlex PROFIBUS Adapter

User Manual, publication 22COMM-UM005….

To review this schematic see

Figure 2.1 on page 2-2 and Figure 2.3 on page 2-4.

ControlNet (Position 12, Code C)

The ControlNet option is drive mounted and consists of the ControlNet

communication adaptor (22-COMM-C) and adaptor cover (22B-CCB for

frame B drives or 22B-CCC for frame C drives). When ControlNet is

present, no other communication option is available other than the HIM.

When used as a slave, the HIM will have limited functionality. For details

related to ControlNet option, refer to the PowerFlex ControlNet Adapter

User Manual, publication 22COMM-UM006….

To review this schematic see

Figure 2.1 on page 2-2 and Figure 2.3 on page 2-4.

Publication 23B-IN001G

Page 12

1-4 PowerFlex 40 Standard Configured Drive Standard Features and Options

Power Disconnect Options

Drive Motor Circuit Protector (Position 16+, Code -P3)

The Drive Motor Circuit Protector option is factory installed and provides a

manual means of disconnecting input power to the drive. The Allen-Bradley

Bulletin 140M switch is designed to meet short circuit requirements for

branch circuit protection. The rotary style handle is padlockable in On or

Off position. This option has a 65 kA short circuit withstand rating. Over

load protection is supplied by the drive not the motor circuit protector.

Incoming customer supplied power cables terminate at terminals R, S, T

(L1, L2, L3) located on the bottom of the device.

Component Specifications

Switch A-B Bulletin 140M, 480V, 65 kA short circuit withstand rating

3-pole, Rod operated

UL listed, CE Approved, CSA Certified

Handle Rotary style handle through the door, Door interlocked

Padlockable in On or Off position, Defeatable in the On position

IP66 (Type 3R, 3, 12, 4, 4X)

Drive Motor Circuit Protector (Position 16+, Code -P3T)

The Drive Motor Circuit Protector option is factory installed and provides a

manual means of disconnecting input power to the drive. The Allen-Bradley

Bulletin 140M switch is designed to meet short circuit requirements for

branch circuit protection. The rotary style handle is padlockable in On or

Off position. This option has a 65 kA short circuit withstand rating. Over

load protection is supplied by the drive not the motor circuit protector.

Incoming customer supplied power cables terminate at terminals R, S, T

(L1, L2, L3) located on the top of the device.

Component Specifications

Switch A-B Bulletin 140M, 480V, 65 kA short circuit withstand rating

3-pole, Rod operated

UL listed, CE Approved, CSA Certified

Handle Rotary style handle through the door, Door interlocked

Padlockable in On or Off position, Defeatable in the On position

IP66 (Type 3R, 3, 12, 4, 4X)

Publication 23B-IN001G

Page 13

PowerFlex 40 Standard Configured Drive Standard Features and Options 1-5

Drive Input Fused Disconnect Switch (Position 16+, Code -P6)

The Drive Input Fused Disconnect Switch option is factory installed and

provides a manual means of disconnecting input power to the drive. The

Allen-Bradley Bulletin 194R switch is designed to meet disconnect switch

requirements for branch circuit protection. The rotary style handle is

padlockable in On or Off position. This option has a 100 kA short circuit

withstand rating. Class J fuses are supplied with the disconnect switch.

Incoming customer supplied power cables terminate at terminals R, S, T

(L1, L2, L3) located on the bottom of the device.

Component Specifications

Switch A-B Bulletin 194R, 600V, 100 kA short circuit withstand rating

Integral class J fuses, Captive terminal clamps

3-pole, Rod operated

UL listed, CE Approved, CSA, ASTA, and LOVAG Certified

Handle Rotary style handle through the door, Door interlocked

Padlockable in On or Off position, Defeatable in the On position

True switch status indication

IP66 (Type 3R, 3, 12, 4, 4X)

Drive Input Fused Disconnect Switch (Position 16+, Code -P6T)

The Drive Input Fused Disconnect Switch option is factory installed and

provides a manual means of disconnecting input power to the drive. The

Allen-Bradley Bulletin 194R switch is designed to meet disconnect switch

requirements for branch circuit protection. The rotary style handle is

padlockable in On or Off position. This option has a 100 kA short circuit

withstand rating. Class J fuses are supplied with the disconnect switch.

Incoming customer supplied power cables terminate at terminals R, S, T

(L1, L2, L3) located on the top of the device.

Component Specifications

Switch A-B Bulletin 194R, 600V, 100 kA short circuit withstand rating

Integral class J fuses, Captive terminal clamps

3-pole, Rod operated

UL listed, CE Approved, CSA, ASTA, and LOVAG Certified

Handle Rotary style handle through the door, Door interlocked

Padlockable in On or Off position, Defeatable in the On position

True switch status indication

IP66 (Type 3R, 3, 12, 4, 4X)

Publication 23B-IN001G

Page 14

1-6 PowerFlex 40 Standard Configured Drive Standard Features and Options

Main Fuses (F1-F3)

ATTENTION: Most codes require that upstream branch circuit

protection be provided to protect input power wiring. Install the

!

fuses recommended in Table 1.A

Failure to observe this precaution could result in damage to, or

destruction of, the equipment.

Input line branch circuit protection fuses must be used to protect the input

power lines. If input fuses are not provided with your drive, recommended

fuse values are shown in Table 1.A

1.A are applicable for one drive per branch circuit. No other load may be

applied to that fused circuit.

The recommended fuse type for all PowerFlex 40 Standard Configured

Drives is UL Class J.

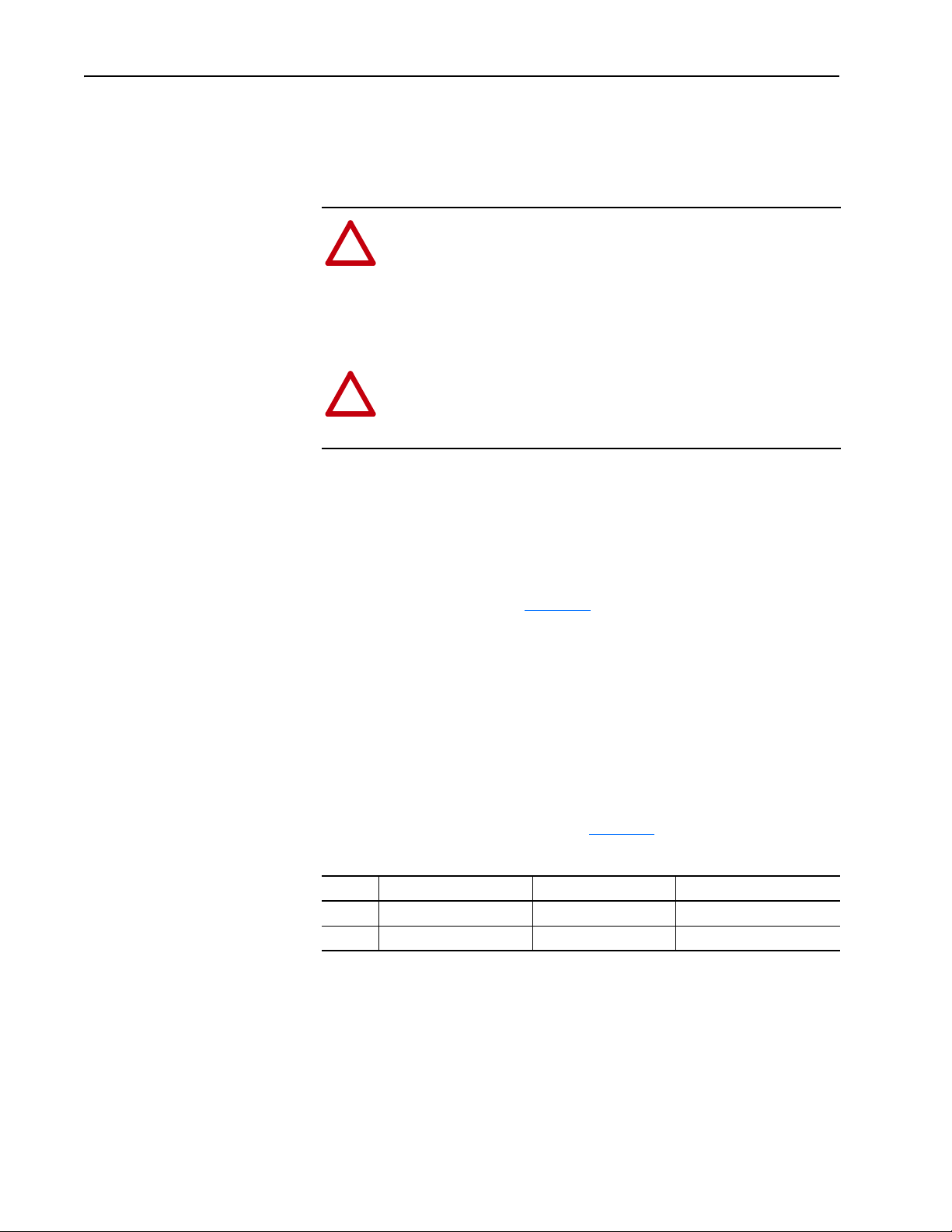

Table 1.A Branch Fusing

Voltage Rating Drive Rating HP Fuse Rating Amps

480V AC 0.5 3

1.0 6

2.0 10

3.0 15

5.0 20

7.5 25

10 30

15 50

. Do not exceed the fuse ratings.

. The input fuse ratings listed in Tabl e

Publication 23B-IN001G

Page 15

PowerFlex 40 Standard Configured Drive Standard Features and Options 1-7

Input Power Wiring

Refer to the PowerFlex 40 User Manual for additional detailed information

about input power wiring recommendations and selection.

ATTENTION: Protect the contents of the options cabinet from

metal chips and other debris while drilling the conduit openings.

!

Failure to observe this precaution could result in damage to, or

destruction of, the equipment.

ATTENTION: Do not route signal and control wiring with

power wiring in the same conduit. This can cause interference

!

with drive operation. Failure to observe this precaution could

result in damage to, or destruction of, the equipment.

To connect AC input power to the drive package:

❏ 1. Select the proper wire size according to NEC and all applicable local

codes and standards. Note that you must punch openings in the Option

Cabinet of the desired conduit size, following NEC and all applicable

local codes and standards. Power terminal block specifications are listed

in Table 1.B

.

❏ 2. Connect the three-phase AC input power leads (three-wire VAC) to the

appropriate terminals. Connect the AC input power leads to terminals

L1, L2, L3 on the fused disconnect switch or motor circuit protector.

Note: Drive Input Fused Disconnect Switch (-P6) and Drive Motor

Circuit Protector (-P3) options are bottom fed. Drive Input Fused

Disconnect Switch (-P6T) and Drive Motor Circuit Protector (-P3T)

options are top fed.

❏ 3. Tighten the AC input terminal power terminals to the proper torque

according to drive type as shown in Table 1.B

Table 1.B Component Current Ratings and Wire Sizing

PowerFlex 40 SPD Drive Rating - 480V

HP Continuous

Current Rating

Amps

0.5-3 30 2.5 mm

5-7.5 30 3.5 mm

10-15 60 4.0 mm

(1)

Wire is Black Hypalon.

(2)

Maximum/minimum sizes that the terminal block will accept - these are not recommendations.

Factory Power

Wire Size

(14 AWG)

(12 AWG)

(10 AWG)

(1)(2)

2

2

2

.

Customer

Terminal Wire

Size

2.5-8.4 mm

(14-8 AWG)

2.5-8.4 mm

(14-8 AWG)

2.5-16.0 mm

(14-4 AWG)

2

2

2

Operating Torque

4.0 N-m

(35 lb.-in.)

4.0 N-m

(35 lb.-in.)

4.0 N-m

(35 lb.-in.)

Publication 23B-IN001G

Page 16

1-8 PowerFlex 40 Standard Configured Drive Standard Features and Options

Output Power Wiring

Refer to the PowerFlex 40 User Manual for additional detailed information

about output power wiring recommendations and selection.

ATTENTION: Unused wires in conduit must be grounded at

both ends to avoid a possible shock hazard caused by induced

!

voltages. Also, if a drive sharing a conduit is being serviced or

installed, all drives using this conduit should be disabled to

eliminate the possible shock hazard from cross-coupled motor

leads. Failure to observe these precautions could result in bodily

injury.

ATTENTION: Do not route signal and control wiring with

power wiring in the same conduit. This can cause interference

!

with drive operation. Failure to observe this precaution could

result in damage to, or destruction of, the equipment.

To connect AC output power wiring from the drive to the motor:

❏ 1. Wire the three-phase AC output power motor leads by routing them

according to the drive option type. Note that you must punch openings in

the option cabinet of the desired conduit size, following NEC and all

applicable local codes and standards. Power terminal block

specifications are listed in Table 1.C

.

Do not route more than three sets of motor leads through a single

conduit. This will minimize cross-talk that could reduce the effectiveness

of noise reduction methods. If more than three drive/motor connections

per conduit are required, shielded cable must be used. If possible, each

conduit should contain only one set of motor leads.

❏ 2. Connect the three-phase AC output power motor leads to terminals

U, V, W (T1, T2, T3) on the power terminal block located on the drive.

❏ 3. Tighten the three-phase AC output power terminals to the proper torque

according to drive type as shown in Table 1.C

Table 1.C AC Output Power Terminal Block Specifications

Frame Maximum Wire Size

2

B 5.3 mm

C 8.4 mm

(1)

Maximum/minimum sizes that the terminal block will accept - these are not recommendations.

(10 AWG) 1.3 mm2 (16 AWG) 1.7-2.2 N-m (16-19 lb.-in.)

2

(8 AWG) 1.3 mm2 (16 AWG) 2.9-3.7 N-m (26-33 lb.-in.)

(1)

Minimum Wire Size Recommended Torque

.

Publication 23B-IN001G

Page 17

PowerFlex 40 Standard Configured Drive Standard Features and Options 1-9

Operator Device Options

Hand/Off/Auto Selector Switch (Position 16+, Code S1)

This 800F door mounted operator device is factory installed and provides a

Hand/Off/Auto selector switch.

The Hand/Off/Auto selector switch will start the drive in Hand mode and

stop the drive in Off mode. In Auto mode the drive will be stopped and

started from remote contact closures. In all cases, the Stop input to the drive

must be present before the drive will start.

The Hand/Off/Auto selector switch also determines the source of the

actual drive speed reference. In Hand mode, speed source is parameter

A072 [Preset Freq 2]. In Auto mode, speed source is parameter A071

[Preset Freq 1].

If the door mounted speed potentiometer (Option S18) is supplied and it is

intended to be the speed reference in Hand mode, set parameter A052

[Digital In2 Sel] to option 13 “10V In Ctrl”. Refer to the table below and the

PowerFlex 40 User Manual, publication 22B-UM001, for other options.

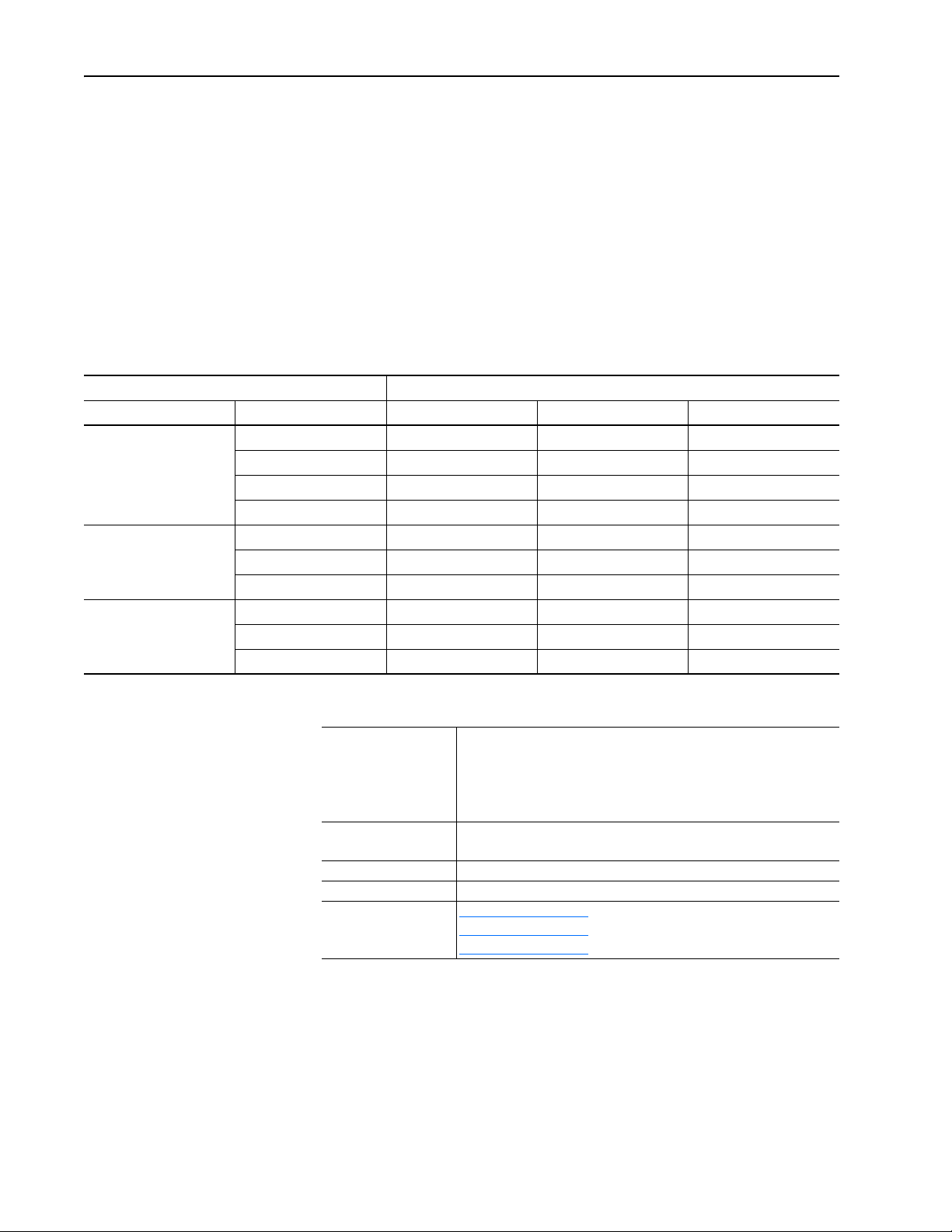

Hand/Off/Auto Selector Switch (Code S1)

Speed Reference Parameter Settings

Hand Mode Auto Mode P038 [Speed Reference] A051 [Digital In1 Sel] A052 [Digital In2 Sel]

Preset Speed Preset Speed 4 “Preset Freq” 4 “Preset Freq” 4 “Preset Freq”

Analog Input (0-10V) 4 “Preset Freq” 13 “10V In Ctrl” 4 “Preset Freq”

Analog Input (4-20mA) 4 “Preset Freq” 14 “20mA In Ctrl” 4 “Preset Freq”

Communication Port

Speed Pot (Door) Preset Speed 4 “Preset Freq” 4 “Preset Freq” 13 “10V In Ctrl”

Analog Input (4-20mA) 4 “Preset Freq” 14 “20mA In Ctrl” 13 “10V In Ctrl”

Communication Port

HIM (Door) Preset Speed 4 “Preset Freq” 4 “Preset Freq” 6 “Comm Port”

Analog Input (0-10V) 4 “Preset Freq” 13 “10V In Ctrl” 6 “Comm Port”

Analog Input (4-20mA) 4 “Preset Freq” 14 “20mA In Ctrl” 6 “Comm Port”

(1)

Communication port will have both logic and reference control.

(1)

4 “Preset Freq” 6 “Comm Port” 4 “Preset Freq”

(1)

4 “Preset Freq” 6 “Comm Port” 13 “10V In Ctrl”

Component Specifications

Bulletin 800F

Devices

IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

10 amp contacts

2

(22–12 AWG) maximum

Hand/Off/Auto

Selector Switch

Screw terminals, 0.3–3.5 mm

3 position, Maintained

4 N.O. contacts

Legend Plate 30 x 50 mm, Black with white lettering

Wiring 0.8 mm

2

(18 AWG), Blue

Schematics Figure 2.4 on page 2-5

Figure 2.5 on page 2-6

This option is not compatible with Codes R3, R5, S4, S7, S20, S21 or S22.

Publication 23B-IN001G

Page 18

1-10 PowerFlex 40 Standard Configured Drive Standard Features and Options

Auto/Manual Selector Switch (Position 16+, Code S4)

This 800F door mounted operator device is factory installed and provides an

Auto/Manual selector switch.

The Auto/Manual selector switch determines the source of the actual drive

speed reference. Using 2-wire control in Auto mode, speed source is

parameter A071 [Preset Freq 1]. In Manual mode, the speed source is

parameter A072 [Preset Freq 2].

If the door mounted speed potentiometer (Option S18) is supplied and it is

intended to be the speed reference in Manual mode, set parameter P052

[Digital In2 Sel] to option 13 “10V In Ctrl”. Refer to the table below and the

PowerFlex 40 User Manual, publication 22B-UM001, for other options.

Auto/Manual Selector Switch (Code S4)

Speed Reference Parameter Settings

Manual Mode Auto Mode P038 [Speed Reference] A051 [Digital In1 Sel] A052 [Digital In2 Sel]

Preset Speed Preset Speed 4 “Preset Freq” 4 “Preset Freq” 4 “Preset Freq”

Analog Input (0-10V) 4 “Preset Freq” 13 “10V In Ctrl” 4 “Preset Freq”

Analog Input (4-20mA) 4 “Preset Freq” 14 “20mA In Ctrl” 4 “Preset Freq”

Communication Port

Speed Pot (Door) Preset Speed 4 “Preset Freq” 4 “Preset Freq” 13 “10V In Ctrl”

Analog Input (4-20mA) 4 “Preset Freq” 14 “20mA In Ctrl” 13 “10V In Ctrl”

Communication Port

HIM (Door) Preset Speed 4 “Preset Freq” 4 “Preset Freq” 6 “Comm Port”

Analog Input (0-10V) 4 “Preset Freq” 13 “10V In Ctrl” 6 “Comm Port”

Analog Input (4-20mA) 4 “Preset Freq” 14 “20mA In Ctrl” 6 “Comm Port”

(1)

Communication port will have both logic and reference control.

(1)

4 “Preset Freq” 6 “Comm Port” 4 “Preset Freq”

(1)

4 “Preset Freq” 6 “Comm Port” 13 “10V In Ctrl”

Component Specifications

Bulletin 800F

Devices

IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

10 amp contacts

2

(22–12 AWG) maximum

Auto/Manual

Selector Switch

Screw terminals, 0.3–3.5 mm

2 position, Maintained

1 N.C. contact

Legend Plate 30 x 50 mm, Black with white lettering

Wiring 0.8 mm

2

(18 AWG), Blue

Schematics Figure 2.6 on page 2-7

Figure 2.7 on page 2-8

Figure 2.8 on page 2-9

This option is not compatible with Codes R3, R5, S1, S20, S21 or S22.

Publication 23B-IN001G

Page 19

PowerFlex 40 Standard Configured Drive Standard Features and Options 1-11

Start and Stop Push Buttons (Position 16+, Code S7)

This option provides factory installed 800F Start and Stop push buttons.

In all cases, the Stop input to the drive must be present before the drive will

start. Using 3-wire control, speed source is parameter A070 [Preset Freq 0].

The Stop push button may also be used as a fault reset.

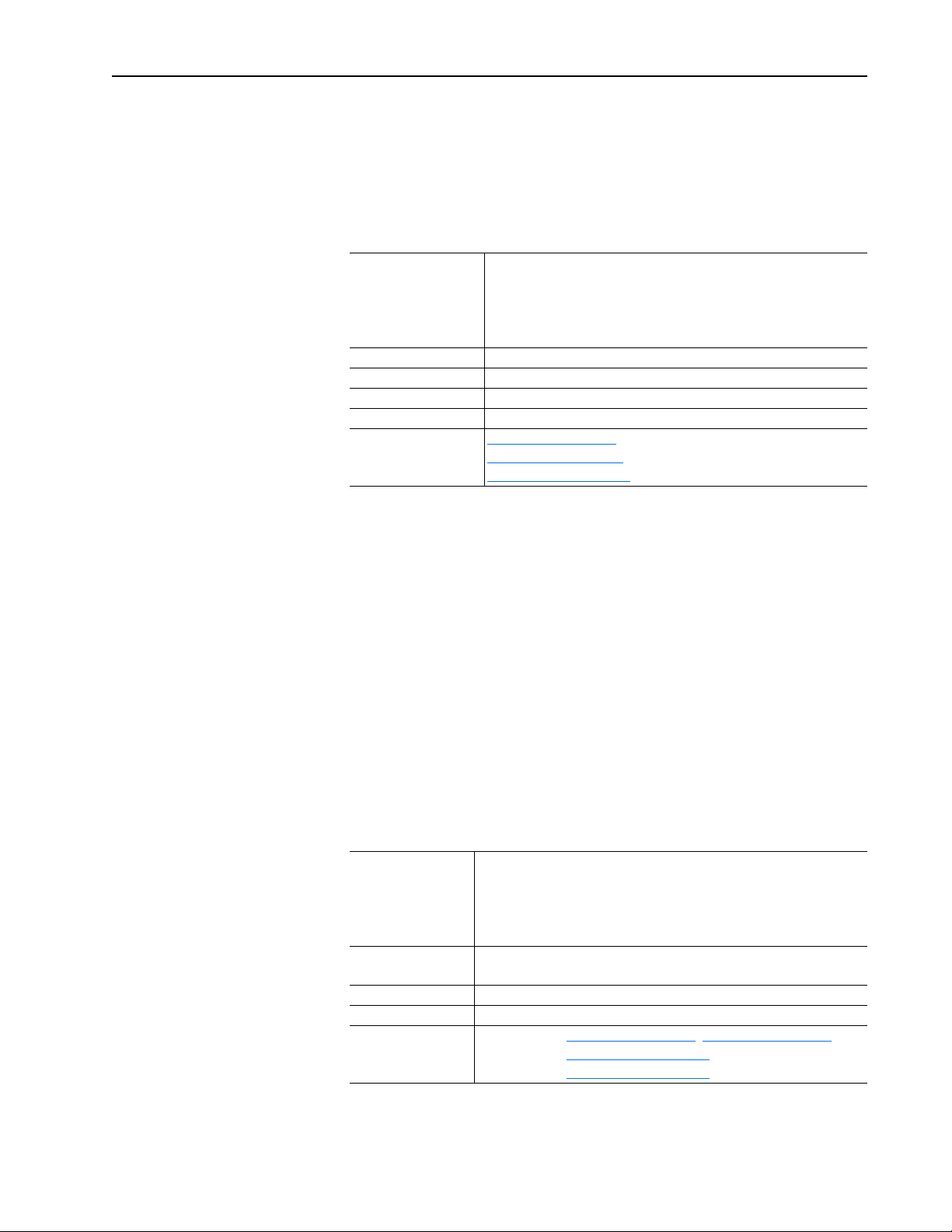

Component Specifications

Bulletin 800F

Devices

Start Push Button Flush head, Green, 1 N.O. contact

Stop Push Button Extended head, Red, 1 N.C. contact

Legend Plate 30 x 50 mm, Black with white lettering

Wiring 0.8 mm

Schematics Figure 2.7 on page 2-8

This option is not compatible with Codes R3, R5, S1, S20, S21, S22 or S23.

IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

10 amp contacts

Screw terminals, 0.3–3.5 mm

2

(18 AWG), Blue

Figure 2.9 on page 2-10

Figure 2.10 on page 2-11

2

(22–12 AWG) maximum

Forward/Reverse Selector Switch (Position 16+, Code S8)

This 800F door mounted operator device is factory installed and provides a

Forward/Reverse selector switch.

When configured for 2-wire control, the drive will start when the selector

switch is set to Forward. When the selector switch is set to Reverse, the

drive will run in reverse. If the selector switch is operated while the drive is

running, a change of direction command will occur. If the drive is stopped

and the selector switch is operated, a change of direction command will

occur. The speed source is parameter P070 [Preset Freq 0].

When configured for 3-wire control (Code S7 with S8), the selector switch

only changes direction. The drive is started and stopped via the Start and

Stop push buttons (Code S7).

Component Specifications

Bulletin 800F

Devices

Forward/Reverse

Selector Switch

Legend Plate 30 x 50 mm, Black with white lettering

Wiring 0.8 mm

Schematics 2-Wire Control: Figure 2.5 on page 2-6

IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

10 amp contacts

Screw terminals, 0.3–3.5 mm

2-Wire: 2 position, Maintained, 1 N.O. & 1 N.C. contacts

3-Wire: 2 position, Maintained, 1 N.C. contact

2

(18 AWG), Blue

Figure 2.11 on page 2-12

3-Wire Control: Figure 2.10 on page 2-11

2

(22–12 AWG) maximum

, Figure 2.8 on page 2-9,

This option is not compatible with Codes R3, R5, S20 or S21.

Publication 23B-IN001G

Page 20

1-12 PowerFlex 40 Standard Configured Drive Standard Features and Options

Local Speed Potentiometer (Code S18)

This option provides a factory installed 800F door mounted one turn

potentiometer for speed control. The device provides the speed source when

no digital inputs are active.

When this option is provided, it becomes the speed source for the Hand

mode of the Hand/Off/Auto selector switch (Option S1) and the Manual

mode of the Auto/Manual selector switch (Option S4).

Component Specifications

Bulletin 800F

Devices

Speed Potentiometer 1-turn, 10k, 2.25W, 500V

Legend Plate 30 x 50 mm, Black with white lettering

Wiring 0.8 mm

Schematic Figure 2.13 on page 2-14

This option is not compatible with Codes R3-R5.

IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

Screw terminals, 0.3–3.5 mm

2

(18 AWG), Blue

2

(22–12 AWG) maximum

Local Control Off/Run Forward and Local/Remote Selector Switches

(Code S20)

This option provides two factory installed 800F door mounted selector

switches. The Local/Remote selector switch determines the source of the

start, stop, speed and direction commands. In Local mode, the factory

default setting for parameter P038 [Speed Reference] = 4 “Preset Freq.”

In Remote mode, the factory default setting for parameter A051 [Digital In1

Sel] = 6 “Comm Port.” The Off/Run Forward selector switch allows the

drive to be started and stopped when in Local Control.

Component Specifications

Bulletin 800F Devices IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

10 amp contacts

Screw terminals, 0.3–3.5 mm

Local Control Off/Run

Forward Selector Switch

Local/Remote

Selector Switch

Legend Plate 30 x 50 mm, Black with white lettering

Wiring 0.8 mm

Schematic Figure 2.12 on page 2-13

2 position, Maintained, 1 N.O. contact

2 position, Maintained, 1 N.O. contact

2

(18 AWG), Blue

2

(22–12 AWG) maximum

Publication 23B-IN001G

This option is not compatible with Codes R3, R5, S1, S4, S7, S8, S21 or

S22.

Page 21

PowerFlex 40 Standard Configured Drive Standard Features and Options 1-13

Local/Off/Remote Selector Switch With One Normally Open Interposing

Relay (Code S21)

This 800F door mounted operator device and interposing relay option is

factory installed and provides a Local/Off/Remote selector switch.

The Local/Off/Remote selector switch will start the drive in Local mode and

stop it in Off mode. In Remote mode, the drive will be stopped and started

from the factory installed CR1 contact which is energized by a customer

supplied and protected 120V AC source. In all cases, the Stop input to the

drive must be present before the drive will start.

In both Local and Remote modes, the speed source is parameter A070

[Preset Freq 0].

Component Specifications

Bulletin 800F

Devices

Local/Off/Remote

Selector Switch

Interposing Control

Relay

Legend Plate 30 x 50 mm, Black with white lettering

Wiring 0.8 mm

Schematic Figure 2.14 on page 2-15

IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

10 amp contacts

Screw terminals, 0.3–3.5 mm

3 position, Maintained, 2 N.O. contacts

1 relay, 10 amp, 120V AC coil, Octal base

2

(18 AWG), Blue

2

(22–12 AWG) maximum

This option is not compatible with Codes R3, R5, S1, S4, S7, S8, S20 or

S22.

Publication 23B-IN001G

Page 22

1-14 PowerFlex 40 Standard Configured Drive Standard Features and Options

Spring Return Hand-Off-Auto Selector Switch (Code S22)

This 800F door mounted operator device is factory installed and provides a

Hand/Off/Auto selector switch. The Hand position is equipped with a spring

return.

The Hand/Off/Auto selector switch will start the drive while held in Hand

mode and stop the drive in Off mode. The selector switch has a spring return

disallowing the operator to remain in Hand. In Auto mode the drive will be

stopped and started from remote contact closures. In all cases, the Stop

input to the drive must be present before the drive will start.

The Hand/Off/Auto selector switch also determines the source of the actual

drive speed reference. In Hand mode, speed source is parameter A072

[Preset Freq 2]. In Auto mode, speed source is parameter A071 [Preset Freq

1].

If the door mounted speed potentiometer (Option S18) is supplied and it is

intended to be the speed reference in Hand mode, set parameter A052

[Digital In2 Sel] to option 13 “10V In Ctrl.”

Spring Return HOA Selector Switch (Code S22)

Speed Reference Parameter Settings

Hand Mode Auto Mode P038 [Speed Reference] A051 [Digital In1 Sel] A052 [Digital In2 Sel]

Preset Speed Preset Speed 4 “Preset Freq” 4 “Preset Freq” 4 “Preset Freq”

Analog Input (0-10V) 4 “Preset Freq” 13 “10V In Ctrl” 4 “Preset Freq”

Analog Input (4-20mA) 4 “Preset Freq” 14 “20mA In Ctrl” 4 “Preset Freq”

Communication Port

Speed Pot (Door) Preset Speed 4 “Preset Freq” 4 “Preset Freq” 13 “10V In Ctrl”

Analog Input (4-20mA) 4 “Preset Freq” 14 “20mA In Ctrl” 13 “10V In Ctrl”

Communication Port

HIM (Door) Preset Speed 4 “Preset Freq” 4 “Preset Freq” 6 “Comm Port”

Analog Input (0-10V) 4 “Preset Freq” 13 “10V In Ctrl” 6 “Comm Port”

Analog Input (4-20mA) 4 “Preset Freq” 14 “20mA In Ctrl” 6 “Comm Port”

(1)

Communication port will have both logic and reference control.

(1)

4 “Preset Freq” 6 “Comm Port” 4 “Preset Freq”

(1)

4 “Preset Freq” 6 “Comm Port” 13 “10V In Ctrl”

Publication 23B-IN001G

Component Specifications

Bulletin 800F

Devices

IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

10 amp contacts

2

(22–12 AWG) maximum

Hand/Off/Auto

Selector Switch:

Screw terminals, 0.3–3.5 mm

3 position, Hand (spring return), Off, Auto (maintained), 4 N.O.

contacts

Legend Plate 30 x 50 mm, Black with white lettering

Wiring 0.8 mm

2

(18 AWG), Blue

Schematic Figure 2.16 on page 2-17

This option is not compatible with Codes R3, R5, S1, S4, S7, S20 or S21.

Page 23

PowerFlex 40 Standard Configured Drive Standard Features and Options 1-15

Clear Fault Push Button (Code S23)

This option provides a factory installed 800F Clear Fault push button.

Component Specifications

Bulletin 800F

Devices

Clear Fault Push

Button:

Legend Plate 30 x 50 mm, Black with white lettering

Wiring 0.8 mm

Schematic Figure 2.17 on page 2-18

This option is not compatible with Code S7.

IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

10 amp contacts

Screw terminals, 0.3–3.5 mm

Flush head, Black, 1 N.O. contact

2

(18 AWG), Blue

2

(22–12 AWG) maximum

Quick Disconnects

DeviceNet Quick Disconnect - Bottom (Code E22)

A Brad Harrison, 5 pin, bulkhead, male receptacle is provided and wired to

the drive mounted DeviceNet module. The connector is located through the

bottom of the enclosure providing a quick disconnect. This option is

designed to enhance the DeviceNet offering (Position 12, Code D) and is

not compatible with options 4, C, E, P (Position 12), or E23.

To review schematic refer to

To review layout refer to

Figure 2.4 on page 2-5.

Figure 3.4 on page 3-4.

For NEMA/UL Type 4 or less stringent environments, the outer connector

construction is made of plastic designed to withstand washdown conditions.

DeviceNet Quick Disconnect - Left Side (Code E23)

A Brad Harrison, 5 pin, bulkhead, male receptacle is provided and wired to

the drive mounted DeviceNet module. The connector is located through the

left side of the enclosure providing a quick disconnect. This option is

designed to enhance the DeviceNet offering (Position 12, Code D) and is

not compatible with options 4, C, E, P (Position 12), or E22.

To review schematic refer to

To review layout refer to

Figure 2.4 on page 2-5.

Figure 3.4 on page 3-4.

For NEMA/UL Type 4 or less stringent environments the outer connector

construction is made of plastic designed to withstand washdown conditions.

Publication 23B-IN001G

Page 24

1-16 PowerFlex 40 Standard Configured Drive Standard Features and Options

I/O Options

DeviceNet I/O (4 In/2 Out) w/Spring Return HOA and Power Disconnect

Aux. Contact (Position 16+, Code R3)

This option provides a factory installed 800F door mounted operator device,

a 100-DNY42R and a power disconnect auxiliary contact mounted internal

to the cabinet.

The Hand/Off/Auto selector switch will start the drive while held in the

Hand mode and stop it in the Off mode. The default speed reference comes

from parameter P038, option 4 (Preset Freq). The selector switch has a

spring return disallowing the operator to remain in Hand. When in Auto the

default speed reference is derived parameter A051, option 4 (Preset Freq).

The 100-DNY42R is powered by DeviceNet and provides control based on

customer control parameters.

This option is prewired with an auto contact from the Hand/Off/Auto

selector switch between the I/O V+ and IN0 terminals. The main power

disconnect auxiliary contact is wired between the I/O V+ and IN1 terminals

indicating if the disconnect is on or off. Two inputs and two outputs are

available for customer use.

Component Specifications

Bulletin 800F

Devices

Hand/Off/Auto

Selector Switch

Legend Plate 30 x 50 mm, Black with white lettering

Wiring 0.8 mm

100-DNY42R cULus Listed, CSA, CE

Schematic Figure 2.18 on page 2-19

IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

10 amp contacts

Screw terminals, 0.3–3.5 mm

3 position, Hand (spring return), Off, Auto (maintained)

3 N.O. & 3 N.C. contacts

2

(18 AWG), Blue

DeviceLogix™, Rotary address switches

24V DC or 120V AC inputs

High-Capacity transistor or Relay outputs

ODVA Compliance v2.0 Tested

Power Disconnect Auxiliary Contact

1 N.O. & 1 N.C. Side mounted contacts

2

(22–12 AWG) maximum

Publication 23B-IN001G

This option must be used with the drive mounted DeviceNet option D

(Position 12) and is not compatible with options R4, R5, S1, S4, S7, S8,

S20, S21 or S22. The drive mounted DeviceNet and the 100-DNY42R will

appear as separate nodes on the communication system.

Page 25

PowerFlex 40 Standard Configured Drive Standard Features and Options 1-17

DeviceNet Point I/O w/IB4 (4 Inputs) (Position 16+, Code R4)

This option provides a factory installed 1734-ADNX Point I/O Scanner in

combination with a 1734-IB4 (4 input) four point, 24V DC sink input.

The drive DeviceNet is prewired to the subnet connector of the

1734-ADNX. The customer is required to make the DeviceNet connection

directly to the 1734-ADNX network connector. The 1734-IB4 is connected

via a backplane offering four available inputs for customer use.

The Point I/O Scanner allows data to be gathered from the drive mounted

DeviceNet and the 1734-IB4 (4 input) appear as one node on the

communication system.

Refer to publication 1734-IN051 for more detail on the 1734-IB4.

Component Specifications

1734-ADNX Devices IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

10 amp contacts

Screw terminals, 0.3–3.5 mm

1734-IB4 Devices Refer to publication 1734-IN051

Schematic Figure 2.19 on page 2-20

2

(22–12 AWG) maximum

This option must be used with the drive mounted DeviceNet option D

(Position 12) and is not compatible with options 4, C, E, P (Position 12),

R3, or R5.

Note: Customer is required to supply external 24V DC/AC to power

1734-ADNX scanner.

Publication 23B-IN001G

Page 26

1-18 PowerFlex 40 Standard Configured Drive Standard Features and Options

DeviceNet I/O (4 In/ 2 Out) w/Spring Return HOA, Power Disconnect

Aux. Contact, and 4 I/O Quick Disconnects (Position 16+, Code R5)

This option provides a factory installed 800F door mounted operator device,

a 100-DNY42R mounted internal to the cabinet, a power disconnect

auxiliary contact, four I/O quick disconnects, and a 24V DC male

receptacle.

The Hand/Off/Auto selector switch will start the drive while held in the

Hand mode and stop it in the Off mode. The default speed reference comes

from parameter P038, option 4 (Preset Freq). The selector switch has a

spring return disallowing the operator to remain in Hand. When in Auto the

default speed reference is derived parameter A051, option 4 (Preset Freq).

The 100-DNY42R is powered by DeviceNet and provides control based on

customer control parameters. The inputs and outputs are powered by

customer supplied 24V DC.

This options is prewired with an auto contact from the Hand/Off/Auto

selector switch between the I/O V+ and IN0 terminals. The main power

disconnect auxiliary contact is wired between the I/O V+ and IN1 terminals

indicating if the disconnect is on or off. The four I/O quick disconnects

allow the customer to quickly connect to the remaining two inputs and

outputs that are available for customer use.

Component Specifications

Bulletin 800F

Devices

Hand/Off/Auto

Selector Switch

Legend Plate 30 x 50 mm, Black with white lettering

Wiring 0.8 mm

100-DNY42R cULus Listed, CSA, CE

Receptacle Shell Black anodized machined aluminum

Connector Insert Nylon

Contacts Machined brass with gold over nickel plating

Schematic Figure 2.20 on page 2-21

IEC style, Internationally rated

Meet IP65/IP66 and NEMA/UL Type 4/4X/13

UL Listed, CSA Certified

10 amp contacts

Screw terminals, 0.3–3.5 mm

3 position, Hand (spring return), Off, Auto (maintained)

3 N.O. & 3 N.C. contacts

2

(18 AWG), Blue

DeviceLogix™, Rotary address switches

24V DC or 120V AC inputs

High-Capacity transistor or Relay outputs

ODVA Compliance v2.0 Tested

Power Disconnect Auxiliary Contact

1 N.O. & 1 N.C. Side mounted contacts

2

(22–12 AWG) maximum

This option must be used with the drive mounted DeviceNet option D

(Position 12) and is not compatible with options R3, R4, S1, S4, S7, S8,

S20, S21 or S22. The drive mounted DeviceNet and the 100-DNYR42 will

appear as separate nodes on the communication system.

Publication 23B-IN001G

Page 27

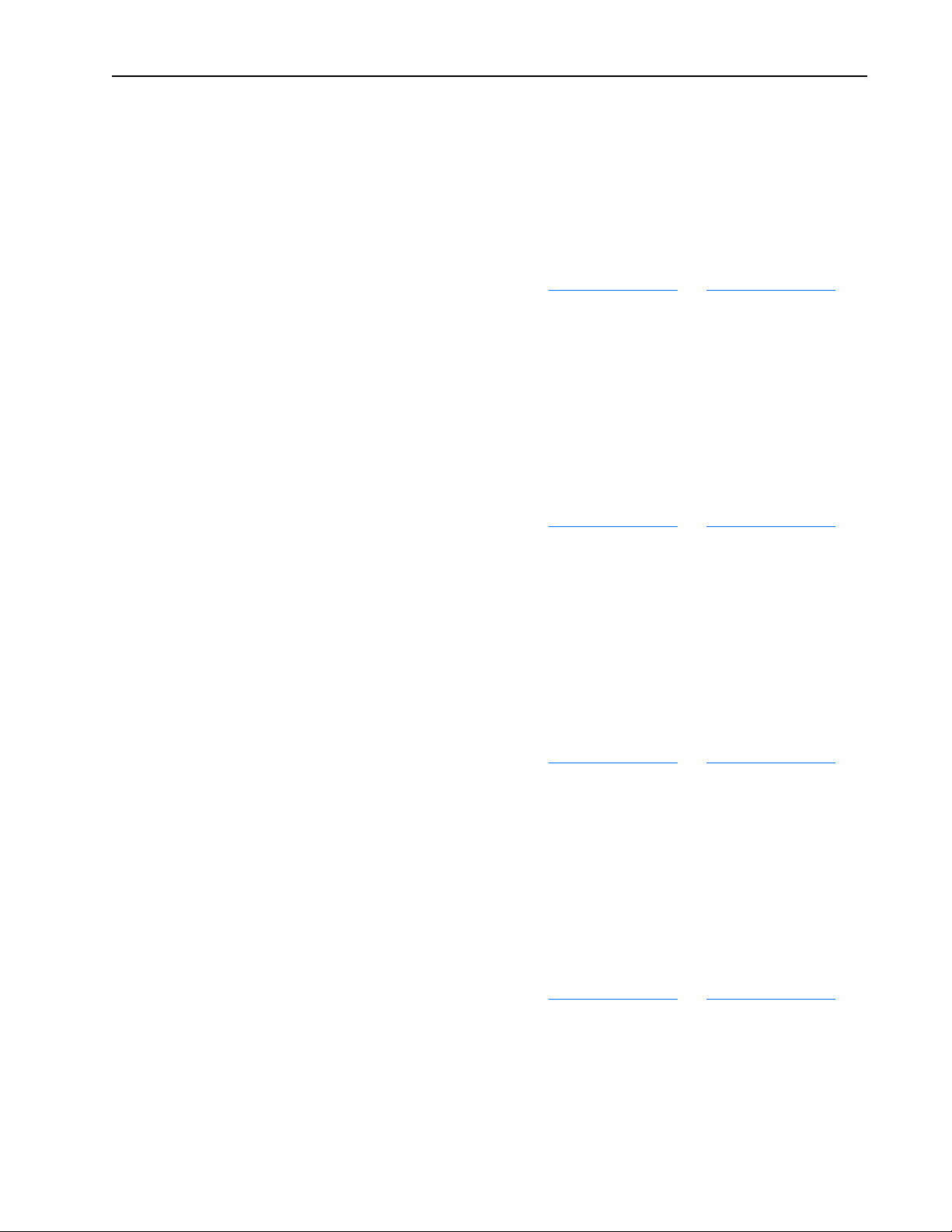

Control Wiring Overview

Chapter 2

Chapter Objectives

Control Wiring Overview

This chapter describes the control and signal wiring connection options.

For information on … See page …

Control Wiring Overview

Schematic Drawings 2-2

2-1

Refer to the PowerFlex 40 User Manual for additional detailed information

about control and signal wiring.

The Control I/O Terminal Block (TB1) and Relay Terminal Block (TB2)

located on the drive Main Control Board provide terminals for interfacing

customer supplied control inputs and outputs. All analog and discrete

control wiring will be made at these terminals.

To connect control and signal wiring to the drive package:

❏ 1. Wire the control and signal leads by routing them according to the drive

option type. Note that you must punch openings in the option cabinet of

the desired conduit size, following NEC and all applicable local codes

and standards. I/O terminal block specifications are listed in Table 2.A

.

Control and signal wires should be separated from power wires by at

least 0.3 meters (1 foot).

❏ 2. Connect the control and signal wiring to the I/O terminals located on the

drive.

❏ 3. Tighten the I/O terminals to the proper torque according to drive type as

shown in Table 2.A

Table 2.A I/O Terminal Block Specifications

Voltage Rating Maximum Wire Size

208-460V AC 1.3 mm

(1)

Maximum/minimum sizes that the terminal block will accept - these are not recommendations.

.

(1)

Minimum Wire Size Torque

2

(16 AWG) 0.13 mm2 (26 AWG) 0.5-0.8 N-m (4.4-7 lb.-in.)

Publication 23B-IN001G

Page 28

2-2 Control Wiring Overview

Schematic Drawings

Figure 2.1 Power Distribution Option

Publication 23B-IN001G

Page 29

Figure 2.2 Drive Ratings

Control Wiring Overview 2-3

Publication 23B-IN001G

Page 30

2-4 Control Wiring Overview

Figure 2.3 Control Logic Options 4, C, D, E & P

Publication 23B-IN001G

Page 31

Figure 2.4 Control Logic Option S1

Control Wiring Overview 2-5

Publication 23B-IN001G

Page 32

2-6 Control Wiring Overview

Figure 2.5 Control Logic Option S1 & S8

Publication 23B-IN001G

Page 33

Figure 2.6 Control Logic Option S4

Control Wiring Overview 2-7

Publication 23B-IN001G

Page 34

2-8 Control Wiring Overview

Figure 2.7 Control Logic Option S4 & S7

Publication 23B-IN001G

Page 35

Figure 2.8 Control Logic Option S4 with S8

Control Wiring Overview 2-9

Publication 23B-IN001G

Page 36

2-10 Control Wiring Overview

Figure 2.9 Control Logic Option S7

Publication 23B-IN001G

Page 37

Figure 2.10 Control Logic Option S7 and S8

Control Wiring Overview 2-11

Publication 23B-IN001G

Page 38

2-12 Control Wiring Overview

Figure 2.11 Control Logic Option S8

Publication 23B-IN001G

Page 39

Figure 2.12 Control Logic Option S20

Control Wiring Overview 2-13

Publication 23B-IN001G

Page 40

2-14 Control Wiring Overview

Figure 2.13 Control Logic Option S18

Publication 23B-IN001G

Page 41

Figure 2.14 Control Logic Option S21

Control Wiring Overview 2-15

Publication 23B-IN001G

Page 42

2-16 Control Wiring Overview

Figure 2.15 Control Logic Option S22

Publication 23B-IN001G

Page 43

Figure 2.16 Control Logic Option S22 & S8

Control Wiring Overview 2-17

Publication 23B-IN001G

Page 44

2-18 Control Wiring Overview

Figure 2.17 Control Logic Option S23

Publication 23B-IN001G

Page 45

Control Wiring Overview 2-19

Figure 2.18 Control Logic Option R3 with P3/P3T or P6/P6T

Publication 23B-IN001G

Page 46

2-20 Control Wiring Overview

Figure 2.19 Control Logic Option R4

Publication 23B-IN001G

Page 47

Control Wiring Overview 2-21

Figure 2.20 Control Logic Option R5 with P3/P3T or P6/P6T

Publication 23B-IN001G

Page 48

2-22 Control Wiring Overview

Figure 2.21 Interconnect Wire & Parts List

Publication 23B-IN001G

Page 49

Mechanical Installation

Chapter 3

Chapter Objectives

Mounting Considerations

This chapter provides information on mounting a PowerFlex 40 Standard

Configured Drive.

For information on … See page …

Mounting Considerations

Dimensions 3-2

Layout Drawings 3-4

ATTENTION: The following information is merely a guide for

proper installation. The Allen-Bradley Company cannot assume

!

responsibility for the compliance or the noncompliance to any

code, national, local or otherwise for the proper installation of this

drive or associated equipment. A hazard of personal injury and/or

equipment damage exists if codes are ignored during installation.

3-1

Environment

Before deciding on an installation site, verify that the PowerFlex Drive

Packages are not installed in an area where the ambient atmosphere contains

volatile or corrosive gas, vapors or dust. The drives are to be installed per

the environmental rating they have been designed for.

Maximum Surrounding Air Temperature

PowerFlex 40 Standard Configured Drives are designed to operate at -10° to

40°C (14° to 104°F) surrounding air temperature. The design of the

PowerFlex Standard Configured Drive supports indoor and outdoor

applications that are not in direct sunlight.

Minimum Mounting Clearances

Be sure there is adequate clearance for air circulation around the drive. For

best air movement, do not mount drives directly above each other. Note that

no devices are to be mounted behind the drive. This area must be kept clear

of all control and power wiring.

Publication 23B-IN001G

Page 50

3-2 Mechanical Installation

Figure 3.1 Minimum Mounting Clearances

Dimensions are in millimeters and (inches).

Drive or

other device

152.4

(6.00)

Dimensions

355.1

(13.98)

342.4

(13.48)

Figure 3.2 Frame B Dimensions

Dimensions are in millimeters and (inches).

405.9

(15.98)

393.2

(15.48)

(0.37)

304.8

(12.00)

9.4

285.8

(11.25)

152.4

(6.00)

355.6

(14.00)

O

F

F

336.6

(13.25)

ON

152.4

(6.00)

152.4

177.8

(7.00)

(6.00)

69.3

(2.73)

ON

O

F

F

287.5

(11.32)

Publication 23B-IN001G

6.35

(0.25)

Optional mounting bracket orientation.

Page 51

Figure 3.3 Frame C Dimensions

Dimensions are in millimeters and (inches).

Mechanical Installation 3-3

Frame C

460.8

(18.14)

427.2

(16.82)

(0.63)

406.4

(16.00)

9.7

(0.38)

16.0

457.2

(18.00)

425.2

(16.74)

P3 Option

383.3

(15.09)

P6 Option

364.2

(14.34)

177.8

(7.00)

ON

O

F

F

146.1

(5.75)

Detail

19.1

(0.75)

19.1 (0.75)

12.7 (0.50)

Publication 23B-IN001G

Page 52

3-4 Mechanical Installation

Layout Drawings

Figure 3.4 PowerFlex 40 Frame B Layout Drawing

Publication 23B-IN001G

Page 53

Figure 3.5 PowerFlex 40 Frame C Layout Drawing

Mechanical Installation 3-5

Publication 23B-IN001G

Page 54

3-6 Mechanical Installation

Figure 3.6 PowerFlex 40 General Option Layout Drawing

Publication 23B-IN001G

Page 55

Appendix A

Specifications

Table A.A Standard Configured Drive Products

Input/Output Ratings Output Frequency: 0-400 Hz (Programmable)

Approvals

Fuses and Power

Disconnecting Means

Protective Features Over Voltage: 480V AC Input – Trip occurs at 810V DC bus voltage (equivalent to 575V AC incoming line)

Environment Ambient Operating Temperature, NEMA 4/12, 4X (IP66): –10 to 40 degrees C (14 to 104 degrees F)

Control Carrier Frequency: 2-4 kHz. Drive rating and heat calculations are based on 4 kHz.

(1) The design of the PowerFlex 40 Standard Configured Drive NEMA 4/12 and 4X packages support indoor and outdoor applications that are not in direct sunlight.

When optional Door Mounted HIM is supplied, enclosure is rated for indoor use only.

Table A.B Standard PowerFlex 40 Drives

Digital Control Inputs

(Input Current = 6 mA)

Analog Control Inputs 4-20mA Analog: 250 ohm input impedance

Control Output Programmable Output (form C relay)

Fuses and Circuit Breakers Recommended Fuse Type: UL Class J, CC, T or Type BS88; 600V (550V) or equivalent.

Protective Features Motor Protection: I

Dynamic Braking Internal brake IGBT included with all ratings

Environment Altitude: 1000 m (3300 ft) max. without derating

Control Frequency Accuracy

Efficiency: 97.5% (Typical)

9

D

6

E

6

T

X

S

I

L

U

L

®

I

N

D

Q

E

C

T

O

N

UL508C

9

D

6

E

6

T

X

S

I

L

U

L

C

®

I

N

D

Q

E

C

T

O

N

CSA C 22.2 No. 14

140M Motor Circuit Protector: Provides branch circuit protection, 65 kA short circuit withstand

194R Fused Disconnect: Provides branch circuit protection, 100 kA short circuit withstand, Class J fuses

Under Voltage: 480V AC Input – Trip occurs at 390V DC bus voltage (equivalent to 275V AC incoming line)

(1)

Cooling Method: Fan (All drive ratings)

SRC (Source) Mode: 18 – 24 Volts = ON; 0 – 6 Volts = OFF

SNK (Sink) Mode: 0 – 6 Volts = ON; 18 – 24 Volts = OFF

0-10V DC Analog: 100k ohm input impedance

External Pot: 1-10k ohms, 2 Watt minimum

Resistive Rating: 3.0A at 30V DC, 3.0A at 125V AC, 3.0A at 240V AC

Inductive Rating: 0.5A at 30V DC, 0.5A at 125V AC, 0.5A at 240V AC

Opto Outputs

30V DC, 50 mA

Non-inductive

Analog Output (10-bit)

0-10V, 1k ohm Min.

Recommended Circuit Breakers: HMCP circuit breaker or equivalent.

2

t overload protection – 150% for 60 Secs, 200% for 3 Secs (Provides Class 10 protection)

Overcurrent: 200% hardware limit, 300% instantaneous fault

Control Ride Through: Minimum ride through is 0.5 Secs - typical value 2 Secs

Faultless Power Ride Through: 100 milliseconds

Storage Temperature: –40 to 85 degrees C (–40 to 185 degrees F)

Atmosphere: Important: Drive must not be installed in an area where the ambient atmosphere contains

volatile or corrosive gas, vapors or dust. If the drive is not going to be installed for a period of

time, it must be stored in an area where it will not be exposed to a corrosive atmosphere.

Relative Humidity: 0 to 95% non-condensing

Shock (operating): 15G peak for 11ms duration (±1.0ms)

Vibration (operating): 1G peak, 5 to 2000 Hz

Digital Input: Within ±0.05% of set output frequency.

Analog Input: Within 0.5% of maximum output frequency.

Analog Output: ±2% of full scale, 10-bit resolution

Speed Regulation - Open Loop with Slip Compensation: ±2% of base speed across a 40:1 speed range.

1% of base speed across a 60:1 speed range.

Stop Modes: Multiple programmable stop modes including - Ramp, Coast, DC-Brake, Ramp-to-Hold and S Curve.

Accel/Decel: Two independently programmable accel and decel times. Each time may be programmed from 0 -

600 seconds in 0.1 second increments.

Intermittent Overload: 150% Overload capability for up to 1 minute; 200% Overload capability for up to 3 seconds

Electronic Motor Overload Protection: Class 10 protection with speed sensitive response.

Publication 23B-IN001G

Page 56

A-2 Specifications

Notes:

Publication 23B-IN001G

Page 57

Appendix B

Replacement Parts

Table B.A Components

Description Designation Voltage HP Part Number Manufacturer

Motor Circuit

Protector

Option P3 or P3T

MCP1 480V AC 0.5 140M-C2E-B40

1.0 140M-C2E-B63

2.0 140M-D8E-C10

3.0 140M-D8E-C16

5.0 140M-D8E-C25

7.5 140M-F8E-C25

10 140M-F8E-C32

15 140M-F8E-C45

1.0 363333 Allen-Bradley

Replacement Kit

Option P3

(1)

MCP1 480V AC 0.5 363326 Allen-Bradley

2.0 363337 Allen-Bradley

3.0 363341 Allen-Bradley

5.0 363345 Allen-Bradley

7.5 363349 Allen-Bradley

10 363353 Allen-Bradley

15 363357 Allen-Bradley

Operator Handle

Option P3 or P3T

Operator Handle

MCP1 480V AC 0.5-5

7.5-15

190-HS4

140M-C-DN66

MCP1 480V AC 0.5-15 140M-D-HA Allen-Bradley

Adaptor Option P3

or P3T

Operator Shaft

Option P3 or P3T

Operator Terminal

Markings

MCP1 480V AC 0.5-5

7.5-15

194R-NX12

140M-C-DS

MCP1 480V AC 0.5-5.0 A46006-086-01

140M-C-TE

7.5-15 A46006-091-01

140M-F-TE

Disconnect Switch

Option P6 or P6T

Operator Handle

DS1 480V AC 0.5-10 194R-NJ030P3 Allen-Bradley

15 194R-NJ060P3 Allen-Bradley

DS1 480V AC 0.5-15 194R-HS4 Allen-Bradley

Option P6 or P6T

Operator Shaft

DS1 480V AC 0.5-15 194R-R1 Allen-Bradley

Option P6 or P6T

Main Fuses

Option P6 or P6T

F1, F2, F3 480V AC 0.5 LPJ-3SP Bussman

AJT-3 Ferraz-Shawmut

1.0 LPJ-6SP Bussman

2.0 LPJ-10 Bussman

LPJ-10SP Bussman

AJT-10 Ferraz-Shawmut

3.0 LPJ-15 Bussman

LPJ-15SP Bussman

5.0 LPJ-20 Bussman

LPJ-20SP Bussman

AJT-20 Ferraz-Shawmut

7.5 LPJ-25 Bussman

LPJ-25SP Bussman

AJT-25 Ferraz-Shawmut

10 LPJ-30 Bussman

LPJ-30SP Bussman

AJT-30 Ferraz-Shawmut

15 LPJ-50 Bussman

LPJ-50SP Bussman

(1) Replacement Kit includes Motor Circuit Protector and top and bottom terminal labels/instructions. Does not

include handle, adaptor, or connection rod.

(2) Part of Motor Circuit Protector Replacement Kit.

(2)

Allen-Bradley

(2)

Allen-Bradley

(2)

Allen-Bradley

(2)

Allen-Bradley

(2)

Allen-Bradley

(2)

Allen-Bradley

(2)

Allen-Bradley

(2)

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

(2)

(2)

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

(2)

(2)

Publication 23B-IN001G

Page 58

B-2 Replacement Parts

Table B.A Components (Continued)

Description Designation Voltage HP Part Number Manufacturer

Drive Module

(with Heatsink)

Drive Module

(Plate Drive)

EA1 480V AC 0.5 22B-D1P4F104 Allen-Bradley

1.0 22B-D2P3F104 Allen-Bradley

2.0 22B-D4P0F104 Allen-Bradley

3.0 22B-D6P0F104 Allen-Bradley

5.0 22B-D010F104 Allen-Bradley

7.5 22B-D012F104 Allen-Bradley

10 22B-D017F104 Allen-Bradley

15 22B-D024F104 Allen-Bradley

EA1 480V AC 0.5 22B-D1P4H204 Allen-Bradley

1.0 22B-D2P3H204 Allen-Bradley

2.0 22B-D4P0H204 Allen-Bradley

3.0 22B-D6P0H204 Allen-Bradley

5.0 22B-D010H204 Allen-Bradley

7.5 22B-D012H104 Allen-Bradley

10 22B-D017H104 Allen-Bradley

15 22B-D024H104 Allen-Bradley

Table B.B Communication Options

Description Designation Voltage HP Part Number Manufacturer

ControlNet EA1 All All 22-COMM-C Allen-Bradley

DeviceNet EA1 All All 22-COMM-D Allen-Bradley

EtherNet EA1 All All 22-COMM-E Allen-Bradley

PROFIBUS EA1 All All 22-COMM-P Allen-Bradley

Adaptor

Frame B

Frame C

EA1

EA1

All

All

0.5-5.0

7.5-15

22B-CCB

22B-CCC

Allen-Bradley

Allen-Bradley

Table B.C Quick Disconnect Options

Description Designation Voltage HP Part Number Manufacturer

DeviceNet - Bottom E22 All All 41358N Brad Harrison

DeviceNet - L Side E23 All All 41358N Brad Harrison

Table B.D HIM Options

Description Designation Voltage HP Part Number Manufacturer

Door Mounted

IP 66 (NEMA/UL

Ty pe

All All 22-HIM-C2S Allen-Bradley

Publication 23B-IN001G

Page 59

Replacement Parts B-3

Table B.E Operator Devices/Control Options

Option Description Designation Voltage HP Part Number Manufacturer

Option S1 Selector Switch

Mounting Latch

Contact Block - 4 N.O.

Legend Plate

Option S4 Selector Switch

Mounting Latch

Contact Block - 1 N.O.

Contact Block - 1 N.C.

Legend Plate

Option S7 Push Button (Green)

Push Button (Red)

Mounting Latch

Contact Block - 1 N.O.

Contact Block - 1 N.C.

Legend Plate

Legend Plate

Option S8 Selector Switch

Mounting Latch

Contact Block - 1 N.O.

Contact Block - 1 N.C.

Legend Plate

Option S18 Potentiometer/Operator

Legend Plate

Option S20 Selector Switch

Mounting Latch

Contact Block - 1 N.O.

Legend Plate

Legend Plate

Option S21 Selector Switch

Anti-Rotation Switch

Mounting Latch

Contact Block - 2 N.O.

Legend Plate

MOV

Relay

Relay Socket (Base)

Relay Retainer Clip

Option S22 Selector Switch

Mounting Latch

Contact Block - 1 N.O.

Legend Plate

Option S23 Push Button (Black)

Mounting Latch

Contact Block - 1 N.O.

Legend Plate

Option R3/R5 Selector Switch

Aux Contact Adapter

Aux Contact

Aux Contact

(1)

(2)

Contact Block - 5 N.O.

Legend Plate

I/O Module

Quick Disconnect

Quick Disconnect

Terminal Block

Fuse Block

(3)

Fuse

(3)

(3)

(3)

(3)

Option R4 DeviceNet Adaptor

Point I/O Terminal Base

Input I/O Module

(1) P6 and P6T option only.

(2) P3 and P3T option only.

(3) R5 option only.

(4) Option S8 when S7 is not ordered.

(5) Legend plates are not stocked for general sale. A custom quote is required to purchase.

(1)

SS2

SS2

SS2

SS2

SS1

SS1

SS1

SS1

SS1

PB2

PB3

PB2, PB3

PB2

PB3

PB2

PB3

SS3

SS3

SS3

SS3

SS3

RH1

RH1

SS1, SS2

SS1, SS2

SS1, SS2

SS1

SS2

SS2

SS2

SS2

SS2

SS2

CR1

CR1

CR1

CR1

SS2

SS2

SS2

SS2

PB1

PB1

PB1

PB1

SS2

DS1

DS1

MCP1

SS2

SS2

EA4

RCPT1-RCPT4

RCPT5

TB4

F6

F6

EA4

EA4

IB4

All All 800FP-SM32

800F-ALP

800F-X10

354614

All All 800FP-SM22

800F-ALP

800F-X10

800F-X01

354650

All All 800FP-F3

800FP-E4

800F-ALP

800F-X10

800F-X01

354666

354859

All All 800FP-SM22

800F-ALP

800F-X10

800F-X01

(4)

354662

All All 800F-POT6

362657

All All 800FP-SM22

800F-ALP

800F-X10

354702

354786

All All 800FP-SM32

800F-ALC1

800F-ALP

800F-X10

354769

V130LA10A

700-HA 32A1

700-HN125

700HN159

All All 800FP-SL32

800F-ALP

800F-X10

354614

All All 800FP-F2

800F-ALP

800F-X10

382966

All All 800FP-SL32CR

194R-AA

195-GA11

140M-C-ASA11

800F-X10

354614

100-DNY42R

888D-F4AC2-1

888D-M4AE1-1

1492-WTF3

1492-H6

MDA-3

All All 1734-ADNX

1734-TB3SQ10

1734-IB4

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Harris

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Allen-Bradley

Bussmann

Allen-Bradley

Allen-Bradley

Allen-Bradley

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

Publication 23B-IN001G

Page 60

B-4 Replacement Parts

Table B.F Miscellaneous

Description Designation Voltage HP Part Number Manufacturer

Fan FAN All 0.5-5.0 2410ML-05W-B30-B00 NMB Tech

Publication 23B-IN001G

Page 61

Page 62

www.rockwellautomation.com

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation, Vorstlaan/Boulevard du Souverain 36, 1170 Brussels, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Publication 23B-IN001G-EN-P – May 2008 350679-P07

Supersedes 23B-IN001F-EN-P – January 2007 Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Printed in USA.

Loading...

Loading...