Page 1

Fieldbus Solutions

for Rockwell

Automation’s

Integrated

Architecture

ProcessLogix, ControlLogix, and

PLC5

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations,

codes and standards. In no event will Allen-Bradley be responsible or

liable for indirect or consequential damage resulting from the use or

application of these products.

Any illustrations, charts, sample programs, and layout examples

shown in this publication are intended solely for purposes of

example. Since there are many variables and requirements associated

with any particular installation, Allen-Bradley does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this publication, notes may be used to make you aware of

safety considerations. The following annotations and their

accompanying statements help you to identify a potential hazard,

avoid a potential hazard, and recognize the consequences of a

potential hazard:

WARNING

Identifies information about practices or

circumstances that can cause an explosion in a

hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

!

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage, or economic loss.

!

IMPORTANT

Identifies information that is critical for successful

application and understanding of the product.

Page 3

About this Document

Preface

Contents guide

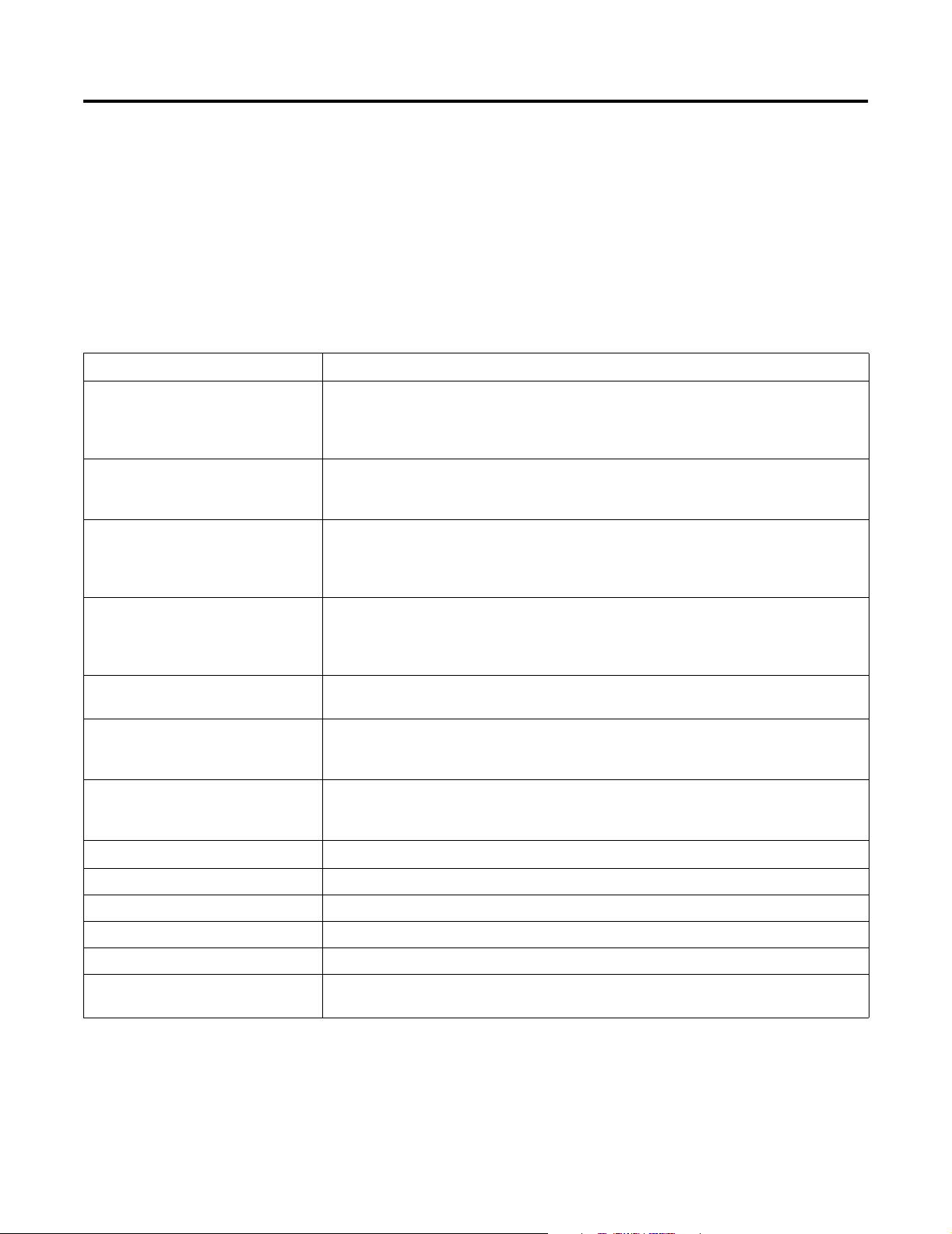

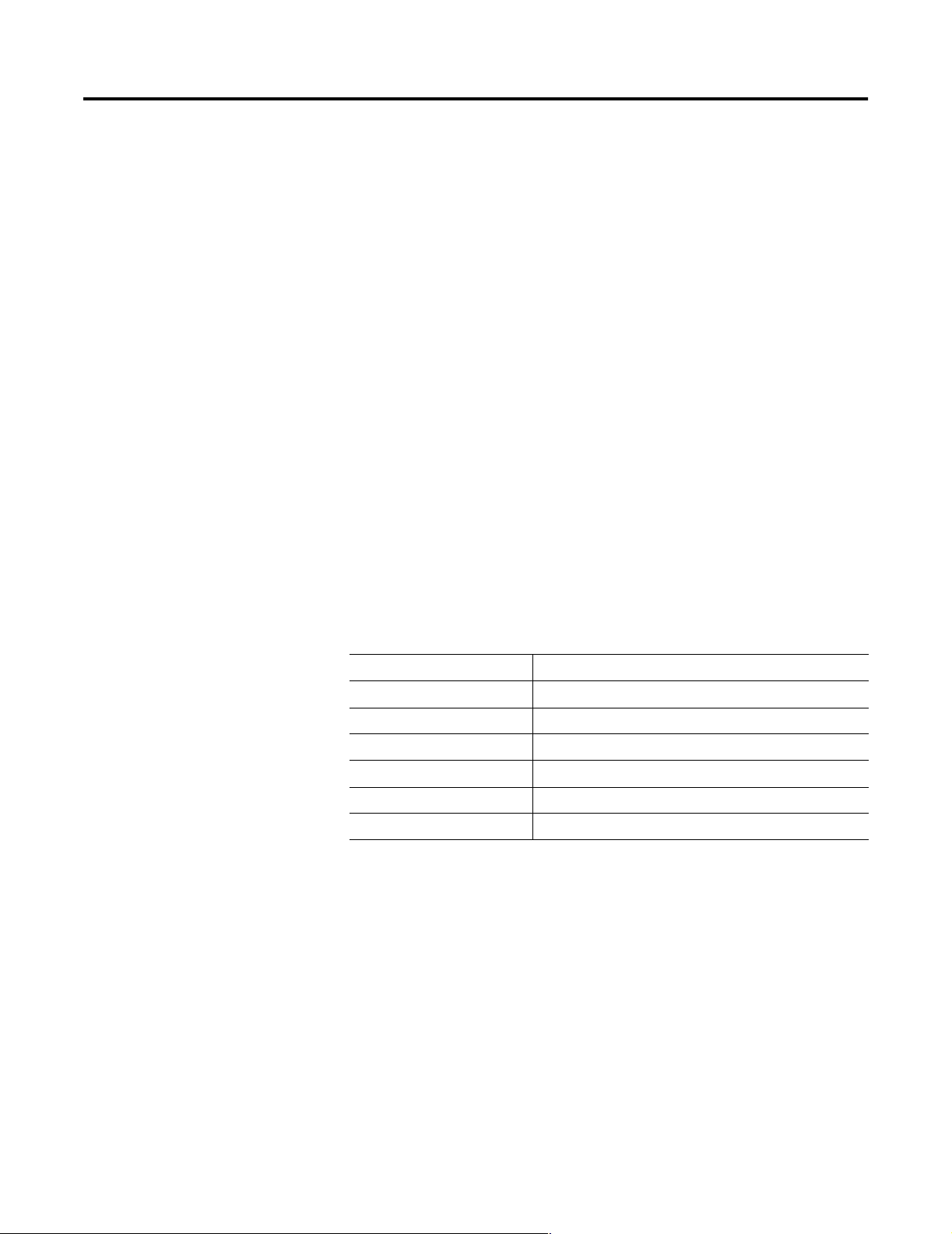

Table P.A Content Summary

The following table summarizes each chapter in this document.

Read this chapter: If you need to:

Chapter 1, The Fieldbus Communication

Model or network layer?

Chapter 2, Integrating Fieldbus into

ProcessLogix R400.0

Chapter 3, Planning Considerations be responsible for setting up the hardware infrastructure to support fieldbus devices. This

Chapter 4, Configuration be the one configuring the control strategy through Control Builder. This section provides

Chapter 5, Operation be monitoring system operation. This section provides an overview of functions you can monitor

Chapter 6, General Maintenance,

Checkout and Calibration

become familiar with the Fieldbus Foundation is or what constitutes the FOUNDATION

Fieldbus® technology. This section also includes descriptions of some standard fieldbus

function blocks and describes the role of Device Descriptions and block parameters for general

reference.

gain some insight on what functional relationships result from the integration of fieldbus

devices with a ProcessLogix system. The information in this section will be helpful background

for planning and configuring your control strategy.

section identifies the things you should consider before installing any equipment and provides

detailed procedures for how to install the Fieldbus Interface Module (FIM) and its companion

Remote Termination Panel (RTP).

detailed procedures for including fieldbus functional components in your overall control

strategy. It includes creating hardware blocks, making templates, associating blocks, assigning

modules, assigning devices, and loading components

through Station displays and the Monitoring tab in Control Builder.

be responsible for maintaining and trouble shooting system operation. This section provides

information about replacing components, upgrading firmware in uncommissioned devices, and

checking device calibration.

Chapter 7, Using the

ControlNet-to-FOUNDATION Fieldbus

H1 Linking Device

Appendix A

Appendix B reference Fieldbus status display indications.

Appendix C define the mode change conditions.

Appendix D review general Fieldbus wiring considerations.

Appendix E use Fieldbus Library Manager to create device template for Control Builder

Appendix F follow a hands-on example explaining how to configure and monitor a field bus device using

1 Publication 1757-UM006A-EN-P - May 2002

use the 1788-CN2FF H1 Linking Device.

reference

the 1788-CN2FF.

the standard function block parameters.

Page 4

About this document P-2

Conventions

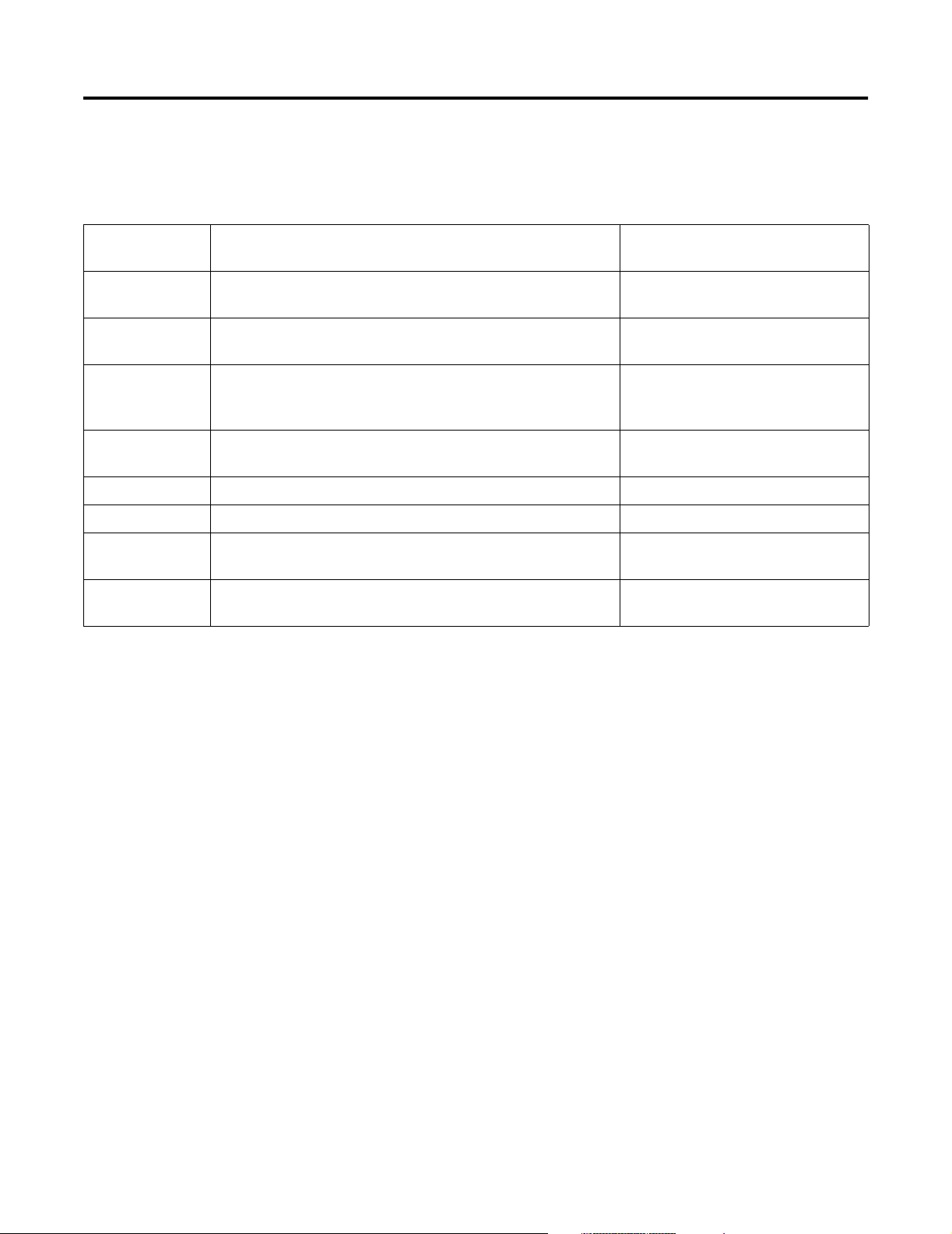

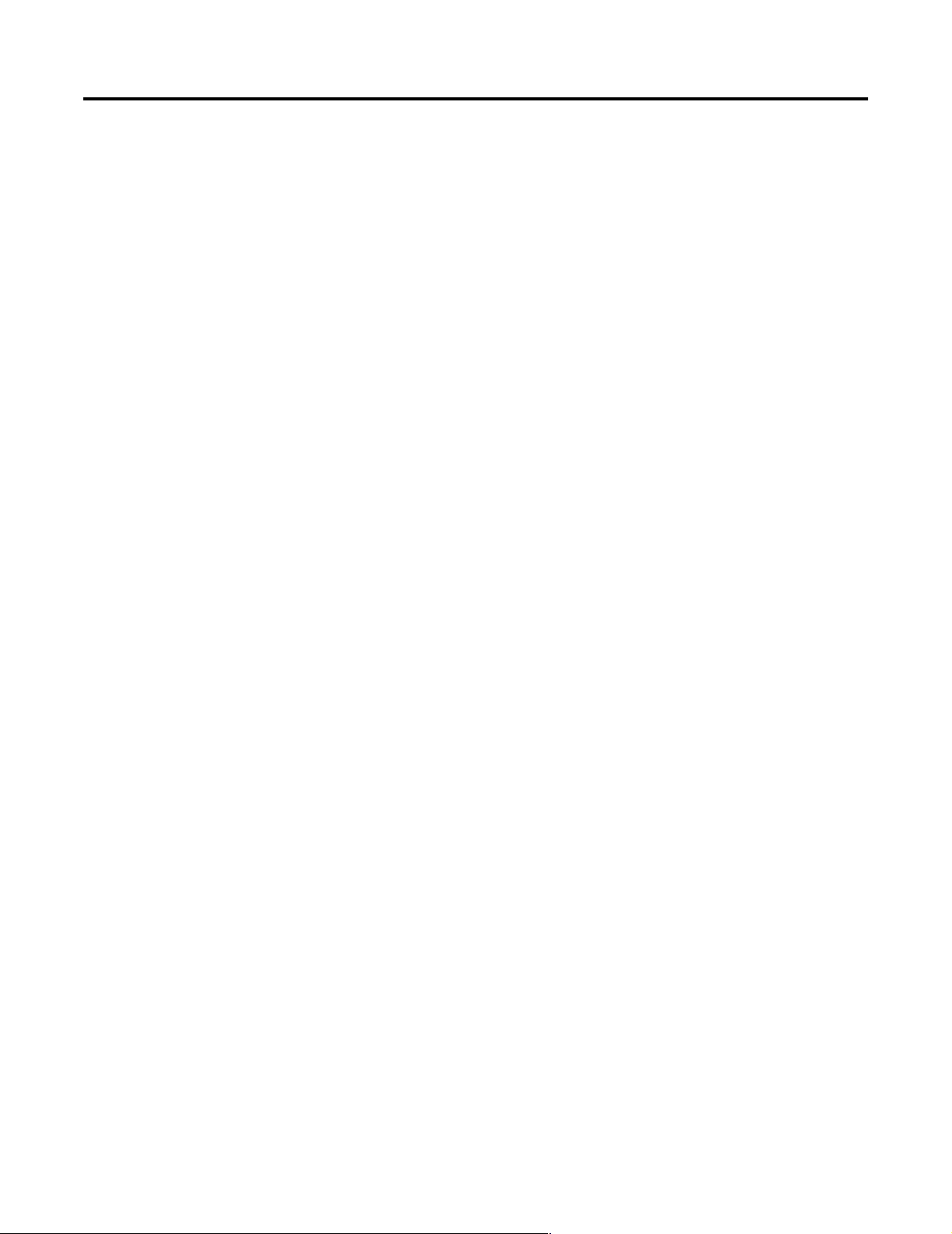

Table P.B Convention Definitions

Term /Type

Representation

Click Click left mouse button once. (Assumes cursor is positioned on

Double-click Click left mouse button twice in quick succession. (Assumes

Drag Press and hold left mouse button while dragging cursor to new

Right-click Click right mouse button once. (Assumes cursor is positioned on

<F1> Keys to be pressed are shown in angle brackets. Press <F1> to view the online Help.

<Ctrl>+<C> Keys to be pressed together are shown with a plus sign. Press <Ctrl>+<C> to close the window.

File->New Shows menu selection as menu name followed by menu

>D:\setup.exe< Data to be keyed in at prompt or in an entry field. Key in this path location

Meaning Example

object or selection.)

cursor is positioned on object or selection.)

screen location and then release the button. (Assumes cursor is

positioned on object or selection to be moved.)

object or selection.)

selection

The following table summarizes the terms and type representation

conventions used in this Guide.

Click the Browse button.

Double click the Station icon.

Drag the PID function block onto the

Control Drawing.

Right-click the AND function block.

Click File->New to start new drawing.

>D:\setup.exe<.

Publication 1757-UM006A-EN-P - May 2002

Page 5

About this document P-3

Rockwell Automation Technical Support

Rockwell Automation offers support services worldwide, with over 75

sales/support offices, 512 authorized distributors, and 260 authorized

systems integrators located throughout the United States alone, plus

Rockwell Automation representatives in every major country in the

world.

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Obtain Technical Product Support

If you need to contact Rockwell Automation for technical assistance,

first call your local Rockwell Automation representative, then:

If you need to contact Rockwell Automation for technical assistance,

try one of the following methods:

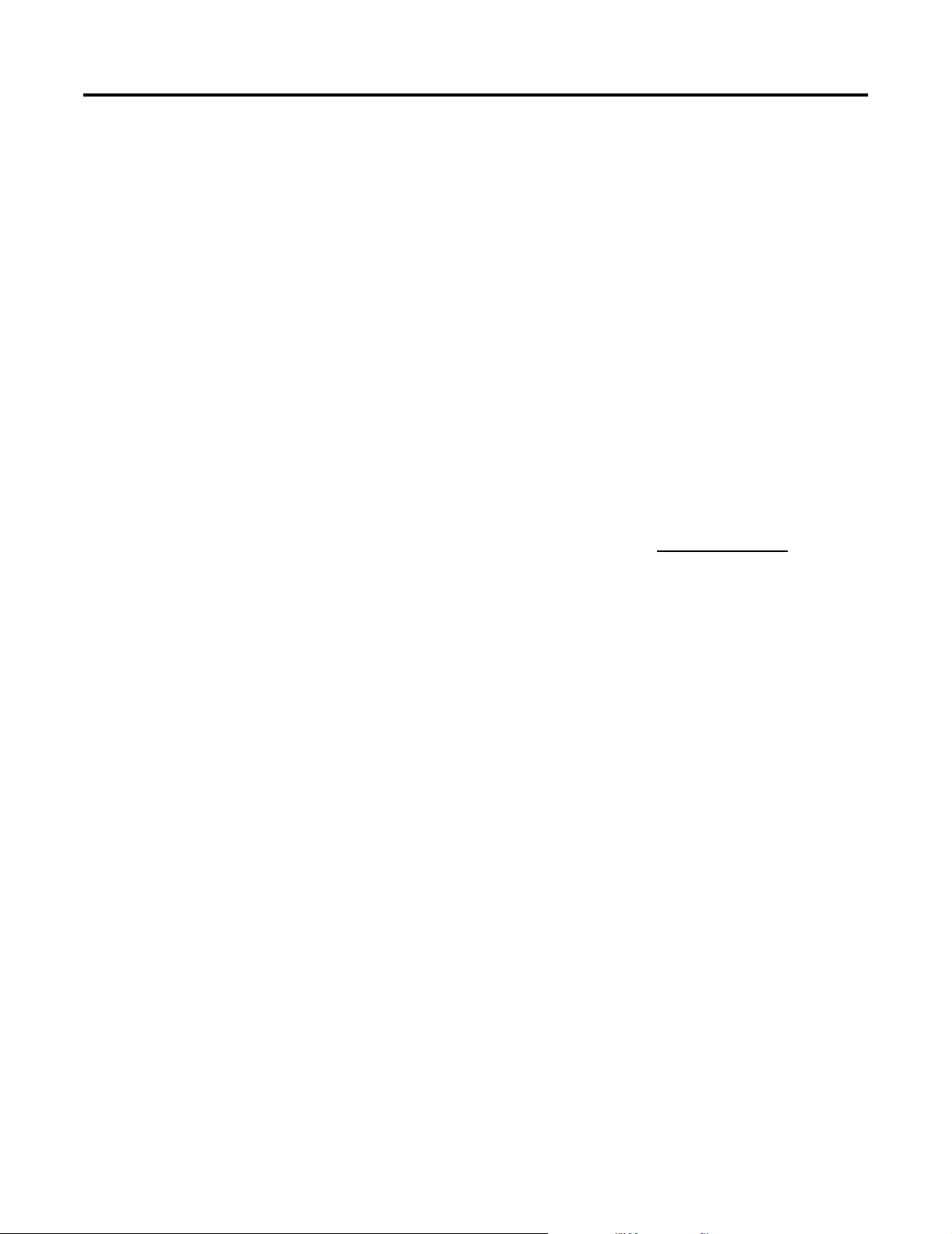

Type of technical support: Access at:

Personalized Service Call your local Rockwell Automation representative

Pre-sales Technical Support 1.440.646.3638 (3NET)

Post-sales Technical Support 1.440.646.5800

Email your questions racleasktheexpert@ra.rockwell.com

Internet www.ab.com

Publications www.theautomationbookstore.com

Your Questions or Comments about This Manual

If you find a problem or have a comment about this manual, please

notify us of it on the enclosed How Are We Doing? form (at the back

of this manual).

If you have any suggestions about how we can make this manual

more useful to you, please contact us at the following address:

Rockwell Automation, Allen-Bradley Company, Inc.

Control and Information Group

Technical Communication

1 Allen-Bradley Drive

Mayfield Heights, OH 44124-6118

Publication 1757-UM006A-EN-P - May 2002

Page 6

About this document P-4

Notes:

Publication 1757-UM006A-EN-P - May 2002

Page 7

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Preface

About this Document

The Fieldbus Communication

Model

Contents guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Rockwell Automation Technical Support . . . . . . . . . . . . . . P-3

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Obtain Technical Product Support . . . . . . . . . . . . . . . . P-3

Your Questions or Comments about This Manual . . . . . P-3

Chapter 1

Fieldbus Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

About the Fieldbus Foundation. . . . . . . . . . . . . . . . . . . 1-1

Want more information? . . . . . . . . . . . . . . . . . . . . . . . . 1-1

What is Fieldbus? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Open Communications Architecture . . . . . . . . . . . . . . . 1-3

Communication Layer Description . . . . . . . . . . . . . . . . 1-4

Standard Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

About Modes of Operation. . . . . . . . . . . . . . . . . . . . . . 1-8

Analog Input Block . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Analog Output Block . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Bias/Gain Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Control Selector Block . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Discrete Input Block . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Discrete Output Block . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Manual Loader Block . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Proportional/Derivative Block . . . . . . . . . . . . . . . . . . . 1-21

Proportional/Integral/Derivative Block . . . . . . . . . . . . . 1-23

Ratio Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Device Descriptions and Block Parameters. . . . . . . . . . . . . 1-27

About Device Descriptions . . . . . . . . . . . . . . . . . . . . . . 1-27

Device Description Language . . . . . . . . . . . . . . . . . . . . 1-27

Device Description infrastructure . . . . . . . . . . . . . . . . . 1-28

Foundation Fieldbus Performance . . . . . . . . . . . . . . . . . . . 1-29

Performance Calculation Considerations . . . . . . . . . . . . 1-29

v Publication 1757-UM006A-EN-P - May 2002

Page 8

vi Table of Contents

Chapter 2

Integrating Fieldbus into Rockwell

Automation Logix System

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Background - the goals of integration . . . . . . . . . . . . . . 2-1

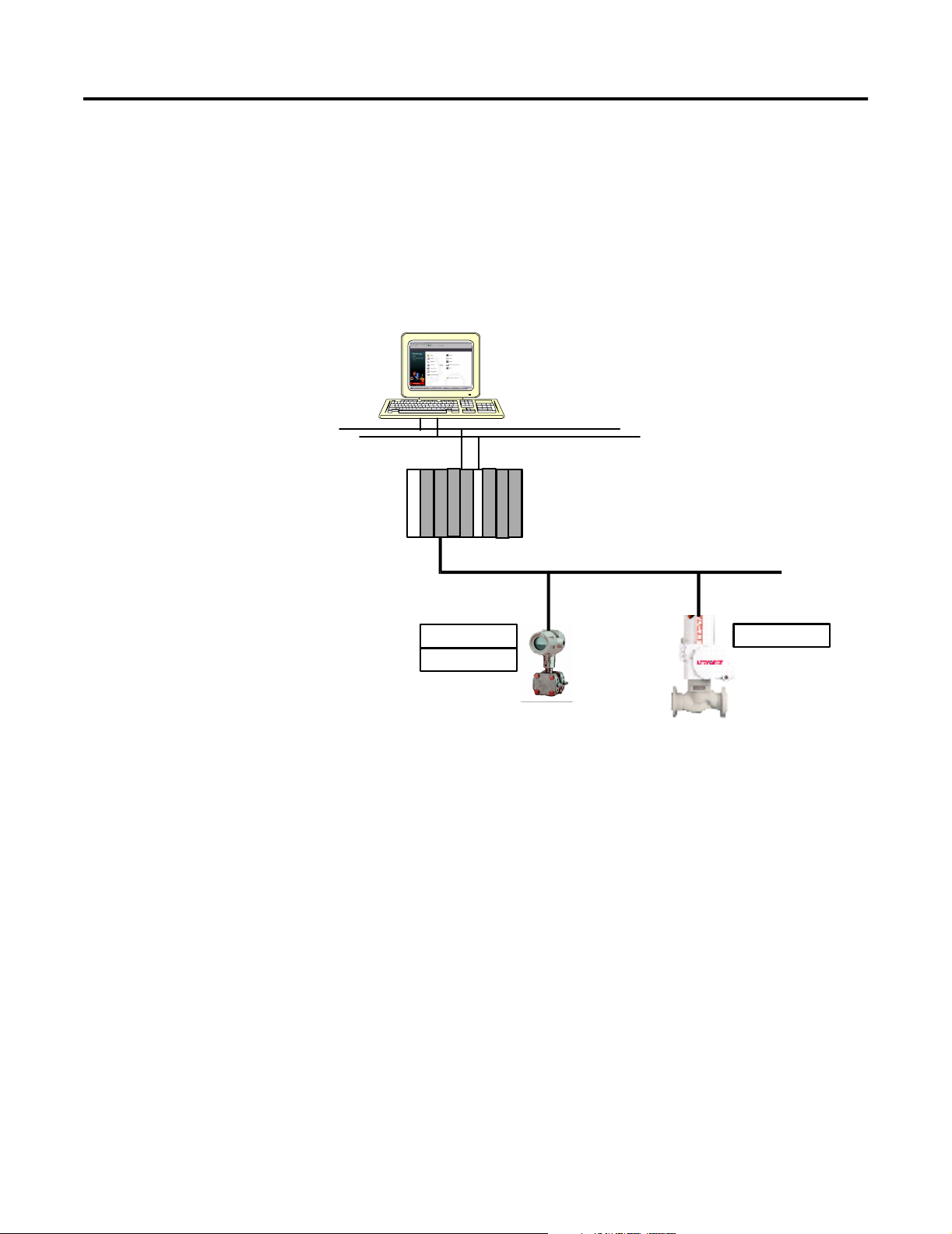

Fieldbus Integrated Architecture . . . . . . . . . . . . . . . . . . 2-2

Fieldbus Interface Modules - The Key

to an Integrated System . . . . . . . . . . . . . . . . . . . . . 2-3

Configuration Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Foundation Fieldbus Configuration Tool . . . . . . . . . . . . 2-5

Centralized Operator Interface . . . . . . . . . . . . . . . . . . . 2-5

Network Management description . . . . . . . . . . . . . . . . 2-6

System Management Description . . . . . . . . . . . . . . . . . 2-6

About the Device Object . . . . . . . . . . . . . . . . . . . . . . . 2-7

About the VFD Object . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Fieldbus Device Analog Input Integration . . . . . . . . . . . 2-7

Fieldbus Analog Input data manipulation . . . . . . . . . . . 2-8

Fieldbus device Analog Output or PID integration. . . . . 2-9

Fieldbus Analog Output or PID data manipulation . . . . 2-11

Fieldbus device Discrete Input integration. . . . . . . . . . . 2-13

Fieldbus Discrete Input data manipulation . . . . . . . . . . 2-14

Fieldbus device Discrete Output data integration. . . . . . 2-15

Fieldbus Discrete Output data manipulation . . . . . . . . . 2-16

Interface Connections Summary . . . . . . . . . . . . . . . . . . 2-16

Fieldbus status data details . . . . . . . . . . . . . . . . . . . . . . 2-17

Fieldbus Status Indications . . . . . . . . . . . . . . . . . . . . . . 2-18

Control Mode Interaction. . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Fieldbus Block Modes Versus Processlogix Modes. . . . . 2-19

Control Mode Priorities and Indications . . . . . . . . . . . . 2-20

Rotary Switch Model versus Toggle Switch Model . . . . . 2-21

Display indications and mode calculation . . . . . . . . . . . 2-23

Link and Block Schedules . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Link Active Scheduler (LAS) . . . . . . . . . . . . . . . . . . . . . 2-24

Link Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Function block execution schedule. . . . . . . . . . . . . . . . 2-26

Tags, Addresses, and Live List . . . . . . . . . . . . . . . . . . . . . . 2-28

Tag and address assignments . . . . . . . . . . . . . . . . . . . . 2-28

Live List and Uncommissioned Devices. . . . . . . . . . . . . 2-29

Foundation Fieldbus Performance . . . . . . . . . . . . . . . . . . . 2-30

Notification Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Fieldbus versus ProcessLogix Alarm Priorities . . . . . . . . 2-32

Fieldbus Alarm Conditions . . . . . . . . . . . . . . . . . . . . . . 2-33

Alert Object Formal Model . . . . . . . . . . . . . . . . . . . . . . 2-35

Publication 1757-UM006A-EN-P - May 2002

Page 9

Chapter 3

Table of Contents vii

1757-FIM Planning Considerations

Configurating the 1757-FIM

Reference Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Installation declaration . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

FIM and I/O module allowance . . . . . . . . . . . . . . . . . . 3-3

Fieldbus network references. . . . . . . . . . . . . . . . . . . . . 3-3

Fieldbus wiring selection and calculation . . . . . . . . . . . 3-4

Installing 1757-FIM Fieldbus Interface Module . . . . . . . . . . 3-4

Installing 1757-RTP Remote Terminator . . . . . . . . . . . . . . . 3-4

Chapter 4

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Configuring Fieldbus Components In a Control Strategy . . . 4-3

About ProcessLogix control strategy configuration. . . . . 4-3

Example Application and Control Strategy

for Procedural Reference . . . . . . . . . . . . . . . . . . . . 4-4

System Management Timers . . . . . . . . . . . . . . . . . . . . . 4-6

ACSYNCINTR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Adding Fieldbus Interface Module to Project . . . . . . . . . 4-9

Checking link configuration . . . . . . . . . . . . . . . . . . . . . 4-12

Making a Fieldbus Device Template from

a Vendor's DD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Making a fieldbus device template from

existing definition (.DEF) files. . . . . . . . . . . . . . . . . 4-22

Adding a Fieldbus Device to Project . . . . . . . . . . . . . . . 4-24

Assigning a Device to a Link in Project . . . . . . . . . . . . . 4-27

Checking Device Configuration . . . . . . . . . . . . . . . . . . 4-28

Creating Control Module for Sample PID Loop . . . . . . . 4-33

Loading Components Online . . . . . . . . . . . . . . . . . . . . . . . 4-51

About load operations . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

About the new load dialog box . . . . . . . . . . . . . . . . . . 4-52

General load considerations . . . . . . . . . . . . . . . . . . . . . 4-53

Fieldbus Device States . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Fieldbus device matching rules. . . . . . . . . . . . . . . . . . . 4-54

Loading a FIM and its Links . . . . . . . . . . . . . . . . . . . . . 4-55

Loading Link contents or fieldbus device . . . . . . . . . . . 4-57

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

Publication 1757-UM006A-EN-P - May 2002

Page 10

viii Table of Contents

Chapter 5

Operating the 1757-FIM

1757-FIM General Maintenance,

Checkout, and Calibration

Monitoring Fieldbus Functions Through Station Displays . . 5-1

Using Station Detail displays. . . . . . . . . . . . . . . . . . . . . 5-1

Using Station Event Summary display . . . . . . . . . . . . . . 5-2

Monitoring Fieldbus Functions Through Monitoring Tab. . . 5-2

Inactivating/Activating a Link . . . . . . . . . . . . . . . . . . . . 5-2

Monitoring/Interacting with given component/block . . . 5-4

Checking fieldbus device functional class . . . . . . . . . . . 5-5

Checking live list and interacting with

uncommissioned devices . . . . . . . . . . . . . . . . . . . . 5-6

Using the Tools Menu Functions. . . . . . . . . . . . . . . . . . 5-8

Chapter 6

Adding, Removing and Replacing Components . . . . . . . . . 6-1

About Removal and Insertion Under Power . . . . . . . . . 6-1

General Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Upgrading firmware in an uncommissioned device. . . . . . . 6-3

Interpreting Component LED Indications . . . . . . . . . . . . . . 6-5

FIM LED indications. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Checking Fieldbus Device Calibration . . . . . . . . . . . . . . . . 6-6

Using the 1788-CN2FF,

ControlNet-to-FOUNDATION

Fieldbus H1 Linking Device

Chapter 7

Blocks in the Linking Device . . . . . . . . . . . . . . . . . . . . . . . 7-1

Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Configuration of Analog Inputs. . . . . . . . . . . . . . . . . . . 7-2

ControlNet Analog Input Objects . . . . . . . . . . . . . . . . . 7-4

Alarm Handling for Analog Inputs . . . . . . . . . . . . . . . . 7-4

Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Configuration of Analog Outputs . . . . . . . . . . . . . . . . . 7-6

ControlNet Analog Output Objects . . . . . . . . . . . . . . . . 7-7

Discrete Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Configuration of Discrete Inputs . . . . . . . . . . . . . . . . . . 7-9

ControlNet Discrete Input Objects . . . . . . . . . . . . . . . . 7-10

Alarm Handling for Discrete Inputs. . . . . . . . . . . . . . . . 7-10

Discrete Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Configuration of Discrete Outputs . . . . . . . . . . . . . . . . 7-12

ControlNet Discrete Output Objects . . . . . . . . . . . . . . . 7-13

Alarm Handling by the HMI. . . . . . . . . . . . . . . . . . . . . . . . 7-14

Assembly Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

MAI Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

MAO Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

MDI Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Publication 1757-UM006A-EN-P - May 2002

Page 11

Table of Contents ix

MDO Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Viewing Object Information in the NI-FBUS

Configurator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Changing the Linking Device Configuration . . . . . . . . . 7-17

Trends and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Tips for Connecting to a 1756-ENET Controller. . . . . . . . . . 7-19

Appendix A

Standard Function Block

Parameters

Axxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Bxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Cxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Dxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Exxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Fxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Gxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

Hxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-20

Ixxx Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-22

Jxxx Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-24

Kxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-24

Lxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-24

Mxxx Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-27

Nxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-29

Oxxx Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-29

Pxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-32

Qxxx Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-33

Rxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-34

Sxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-39

Txxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-46

Uxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-48

Vxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-49

Wxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-49

Xxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-50

Yxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-50

Zxxx Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-50

Fieldbus Status Display

Indications

Mode Change Conditions

Appendix B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C

Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Publication 1757-UM006A-EN-P - May 2002

Page 12

x Table of Contents

Appendix D

Fieldbus Wiring Considerations

Fieldbus Library Manager

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Fieldbus Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Power Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Signal Degradation Limitations. . . . . . . . . . . . . . . . . . . . . . D-3

Cable Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Cable Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Signal Distortion vs Capacitance . . . . . . . . . . . . . . . . . . . . D-6

Calculating Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Testing the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Repeaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Appendix E

About Fieldbus Library Manager . . . . . . . . . . . . . . . . . . . . E-1

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Menu and toolbar selections. . . . . . . . . . . . . . . . . . . . . E-2

Appendix F

1788-CN2FF Installation Example

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Required Hardware for Installation Example. . . . . . . . . . . . F-2

Required Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Example Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Connecting the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Install the 1788-FFCT Software. . . . . . . . . . . . . . . . . . . . . . F-6

Adding an Interface Device . . . . . . . . . . . . . . . . . . . . . . . . F-7

Finding the Interface Driver Name . . . . . . . . . . . . . . . . F-9

Assigning a Path to the 1788-CN2FF . . . . . . . . . . . . . . F-10

Port Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . F-12

Installing Device Descriptions (DDs) . . . . . . . . . . . . . . . . F-14

Starting NIFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-17

Troubleshooting the Port Configuration . . . . . . . . . . . . . . F-18

NIFB Software Install . . . . . . . . . . . . . . . . . . . . . . . . . F-18

Start FCS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-19

Modifying Device and Function Block Names . . . . . . . F-24

Changing a Tag Name . . . . . . . . . . . . . . . . . . . . . . . . F-26

Configuring the Fieldbus Device. . . . . . . . . . . . . . . . . F-29

Download the Device Configuration. . . . . . . . . . . . . . F-31

Sending Data To the PLC-5, CLX, PLX or SLC . . . . . . . . . . F-36

Schedule Data Transmission to Controllers

with RSNetworx . . . . . . . . . . . . . . . . . . . . . . . . . . F-37

PLC-5 Data Manipulation . . . . . . . . . . . . . . . . . . . . . . F-37

Publication 1757-UM006A-EN-P - May 2002

Page 13

List of Figures

Table of Contents xi

PLC-5 and ControlLogix Applications . . . . . . . . . . . . . . . . F-40

ControlLogix Application. . . . . . . . . . . . . . . . . . . . . . . . . F-41

Schedule the Connection Between the

Controller and the Linking Device. . . . . . . . . . . . . F-44

View the Controller Tags . . . . . . . . . . . . . . . . . . . . . . F-44

Testing the Installation Example . . . . . . . . . . . . . . . . . . . F-46

Messages to PLC-5s and CLX to Get Data from CN2FF . . . F-47

Remote Configuration of a Fieldbus Network via

the 1788-CN2FF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-49

Troubleshooting an Application. . . . . . . . . . . . . . . . . . . . F-51

Publication 1757-UM006A-EN-P - May 2002

Page 14

xii Table of Contents

Publication 1757-UM006A-EN-P - May 2002

Page 15

The Fieldbus Communication Model

Chapter

1

Fieldbus Organization

About the Fieldbus Foundation

The Fieldbus Foundation is a not-for-profit corporation made up of

nearly 120 leading suppliers and customers of process control and

manufacturing automation products. Since its inception in 1994, it is

totally dedicated to developing one standard, “open,” interoperable

field communication model known as F

OUNDATION™ Fieldbus

(1)

.

Want more information?

Visit the Fieldbus Foundation web site at www.fieldbus.org, or the

following address, for more information:

9390 Research Blvd.

Suite II-250

Austin, TX 78759-9780

What is Fieldbus?

There are many digital communication technologies being promoted

as the future replacement for the venerable 4–20 mA analog standard,

and most are self-described as fieldbus. With the exception of

FOUNDATION fieldbus, virtually all of these technologies were

developed for non-process environments such as automotive

manufacturing, building automation, or discrete parts manufacturing,

and later adapted to process control.

Generally, they are well suited to the applications for which they were

originally developed. Some of these technologies are open, some are

proprietary. Every communication technology provides a method for

transmitting data between various devices and a host, and some

provide communications directly between devices. The various

schemes differ in how well they are optimized for moving data

quickly, their suitability for real-time control, the cost of hardware

implementations, their networking capability for branches, spurs and

long distances, and for how power is distributed.

(1)

Sections of this publication has been provided by FOUNDATION Fieldbus.

1 Publication 1757-UM006A-EN-P - May 2002

Page 16

1-2 The Fieldbus Communication Model

Comparisons among “fieldbus technologies” typically reduces to

comparisons of data rates, message length, number of devices on a

segment, etc. These are all important communications issues and each

technology represents a particular set of trade-offs which adapt it to its

original application, and each is rooted in the technology that was

available or in vogue at the time of its development.

Using a strategy exactly opposite of FOUNDATION fieldbus, these

various communications technologies minimize dependence on local

intelligence in deference to minimum device cost, and maximize

reliance on a centralized control architecture. Measurement

instruments in such structures communicate to a central computing

system at the request of that central system. A proprietary control

application, running on the central system processes the field data and

distributes control signals to other devices back in the field.

Regardless of how open the communication scheme may be, the

control application is always proprietary.

The key distinctions between these technologies and FOUNDATION

fieldbus are; FOUNDATION fieldbus provides an open specification

for both communications and the control application. FOUNDATION

fieldbus distributes control functionality across the bus, making

maximum use of local intelligence to improve performance and

reduce total system cost. Devices are required to be interoperable,

providing the user with tools to implement a control system with

products from multiple manufacturers without custom programming.

With FOUNDATION fieldbus, the network is the control system.

Publication 1757-UM006A-EN-P - May 2002

Page 17

The Fieldbus Communication Model 1-3

Open Communications Architecture

FOUNDATION Fieldbus is an enabling technology for dynamically

integrating dedicated field devices with digitally based control

systems. It defines how all “smart” final control devices are to

communicate with other devices in the control network. The

technology is based upon the International Standards Organization's

Open System Interconnection (OSI) model for layered

communications.

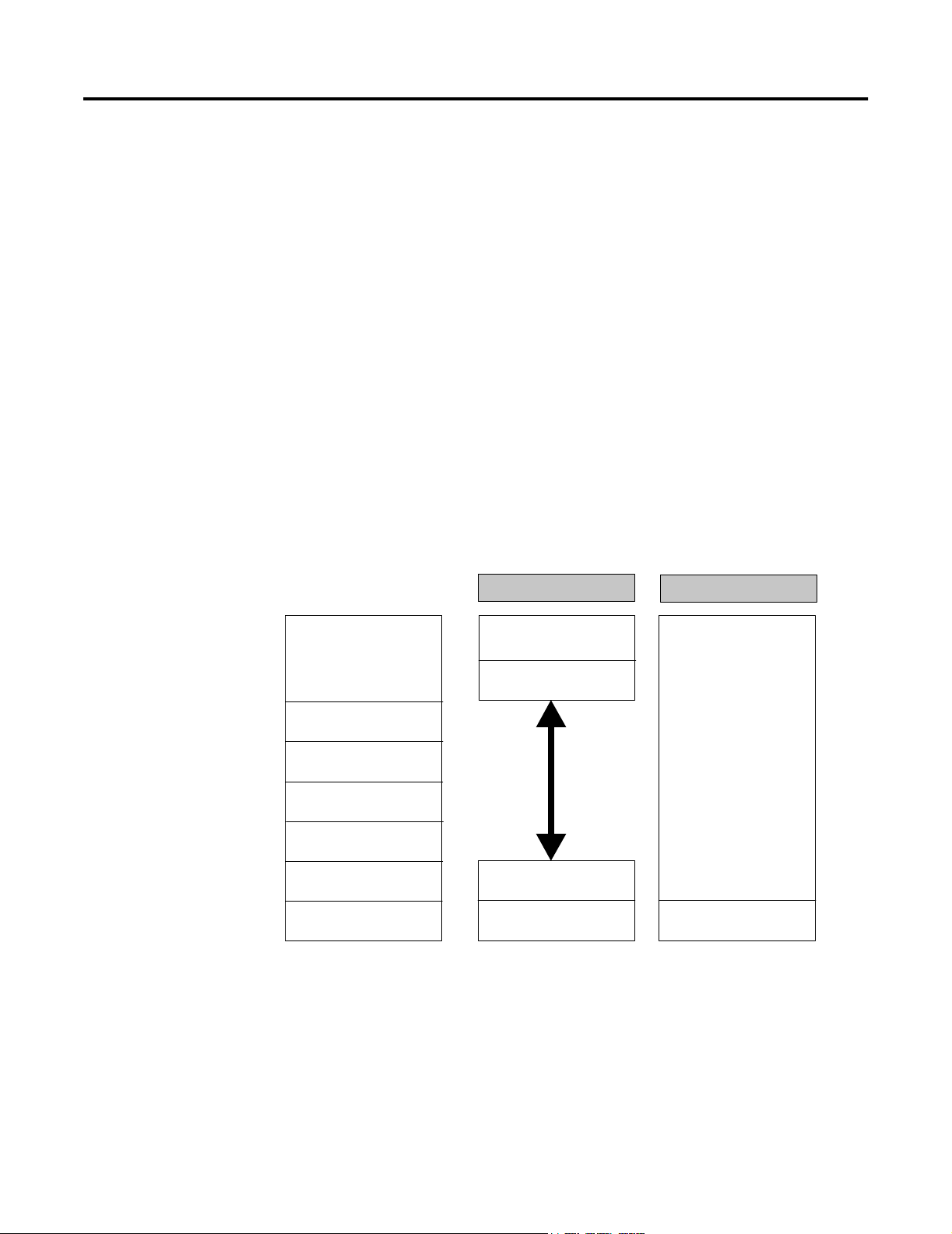

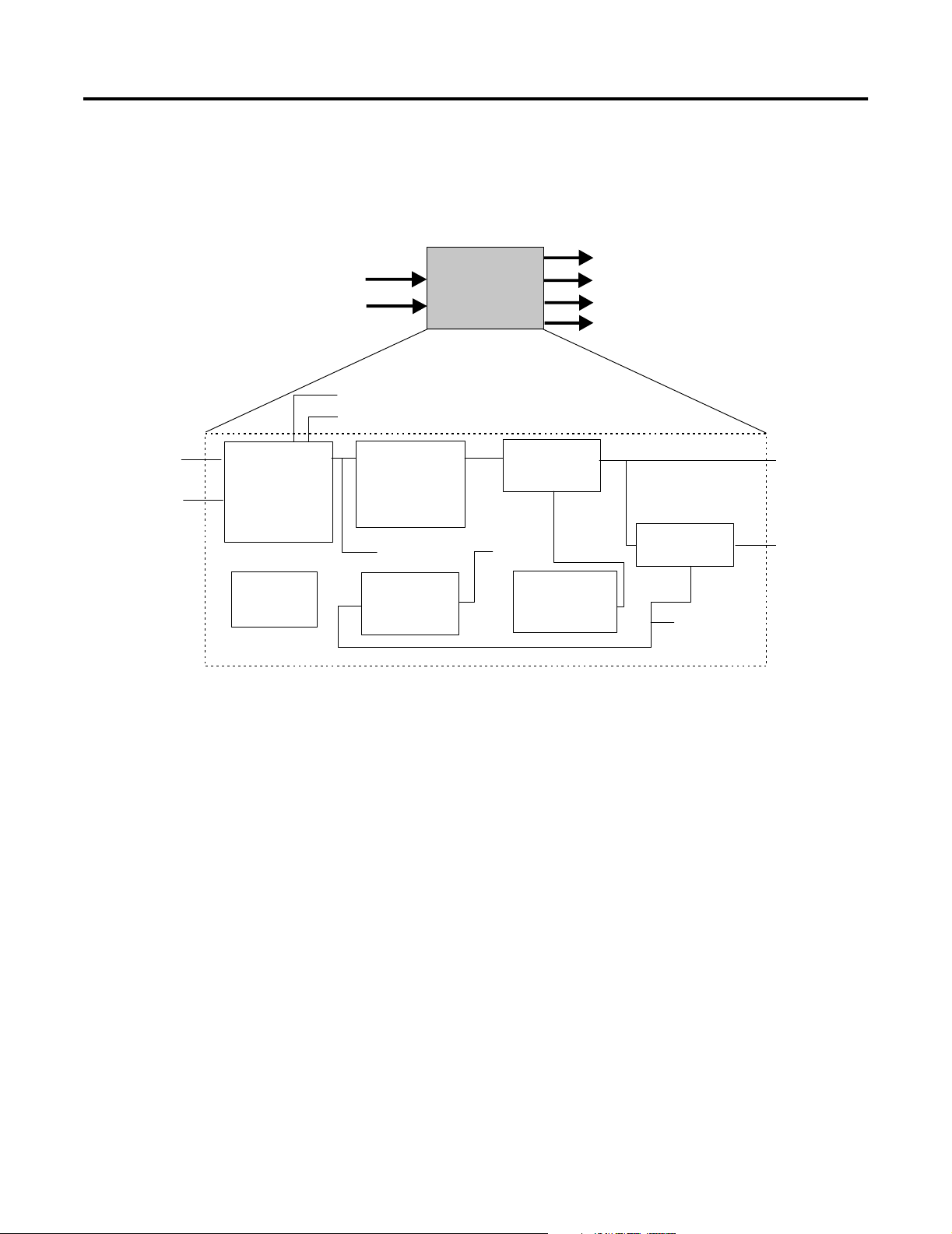

As shown in Figure 1.1, OSI layer 1 is the Physical Layer, OSI layer 2

is the Data Link Layer, and OSI layer 7 is the application layer or the

Fieldbus Message Specification. A Fieldbus Access Sublayer maps the

Fieldbus Message Specification onto the Data Link Layer. Fieldbus

does not use OSI layers 3 to 6, and layers 2 and 7 form the

Communication Stack. Also, the OSI model does not define a User

Application, but the Fieldbus Foundation does.

Figure 1.1 OSI versus Fieldbus communication model

OSI Model

Application Layer

7

Presentation Layer

6

5

4

3

2

1

Session Layer

Transport Layer

Network Layer

Data Link Layer

Physical Layer

Fieldbus Model

User Application

Fieldbus Message

Specification

Fieldbus Access

Sublayer

Data Link Layer

Physical Layer

User Application

Communication

Stack

Physical Layer

Publication 1757-UM006A-EN-P - May 2002

Page 18

1-4 The Fieldbus Communication Model

Communication Layer Description

The following table provides a summarized description of the

communication layers that make up the FOUNDATION Fieldbus. The

Fieldbus Foundation maintains a complete library of detailed

reference specifications including a Technical Overview, and Wiring

and Installation Guides.

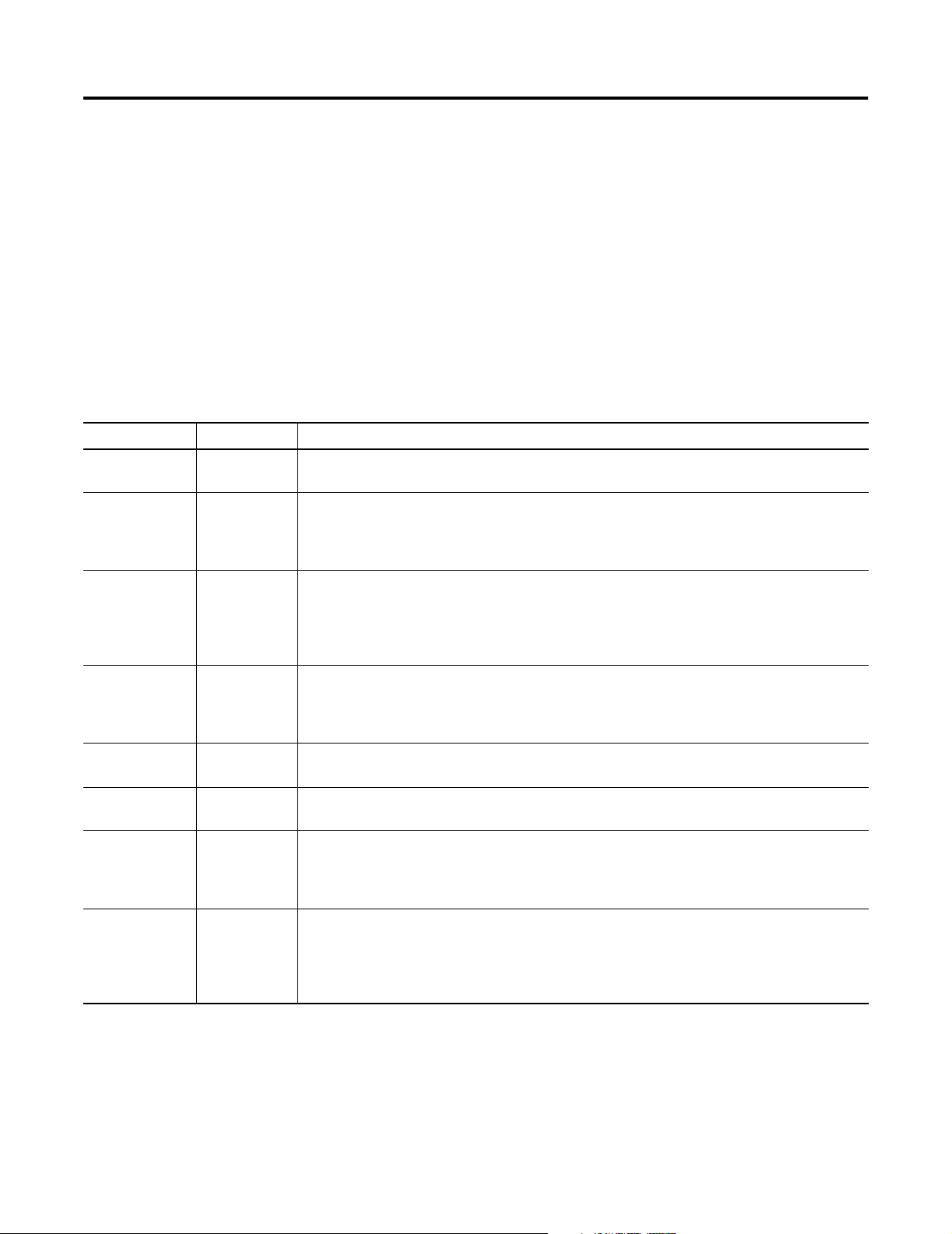

Table 1.A Communication Layer Descriptions

Layer Functional Description Associated Terms

Physical Defines the transmission medium for fieldbus signals and the message conversion tasks

to/from the Communication Stack.

Based on the Manchester Biphase-L Encoding technique, so a F

device interprets a positive transition in the middle of a bit time as logical “0” and a

negative transition as logical “1”.

Complies with existing International Electrotechnical Commission (IEC 1158-2) and the

Instrumentation, Systems, and Automation Society (ISA S50.02) physical layer

standards. And, it can be used with existing 4 to 20mA wiring.

Data Link (DLL) Defines how messages are transmitted on a multi-drop network. It uses a deterministic

centralized bus scheduler called a Link Active Scheduler (LAS) to manage access to the

fieldbus. It controls scheduled and unscheduled communications on the fieldbus in a

publish/subscribe environment.

Identifies device types as Basic Device, Link Master, or Bridge. A Link Master device

type can become a Link Active Scheduler (LAS) for the network.

Fieldbus Access

Sublayer (FAS)

Fieldbus

Message

Specification

(FMS)

Defines the types of services used to pass information to the Fieldbus Message

Specification layer. The types of services are defined as Virtual Communication

Relationships (VCR).

The VCR types are Client/Server, Report Distribution, and Publisher/Subscriber. The

Client/Server type handles all operator messages. The Report Distribution type handles

event notification and trend reports. The Publisher/Subscriber type handles the

publishing of User Application function block data on the network.

Defines how fieldbus devices exchange User Application messages across the fieldbus

using a set of standard message formats. It uses object descriptions that are stored in

an object dictionary (OD) to facilitate data communication. The OD also includes

descriptions for standard data types such as floating point, integer, Boolean, and

bitstring.

A Virtual Field Device (VFD) mirrors local device data described in the OD. A physical

device may have more than one VFD.

Provides these communication services to standardize the way the User Applications

such as function blocks communicate over the fieldbus - Context Management, Object

Dictionary, Variable Access, Event, Upload/Download, and Program Invocation.

Uses a formal syntax description language called Abstract Syntax Notation 1 (ASN-1) to

format FMS messages and applies special behavioral rules for certain types of objects.

OUNDATION Fieldbus (FF)

H1, 31.25 kbit/s signal rate

H1 Link

H1 Segment

HSE, High Speed Ethernet

Compel Data (CD) message

Pass Token (PT) message

Time Distribution (TD)

message

Live List

Link Active Scheduler (LAS)

Virtual Communication

Relationship (VCR)

Object Dictionary (OD)

Virtual Field Device (VFD)

Network Management

Information Base (NMIB)

System Management

Information Base (SMIB)

Publication 1757-UM006A-EN-P - May 2002

Page 19

The Fieldbus Communication Model 1-5

Table 1.A Communication Layer Descriptions

Layer Functional Description Associated Terms

User

Application or

Function Block

Application

Process (FBAP)

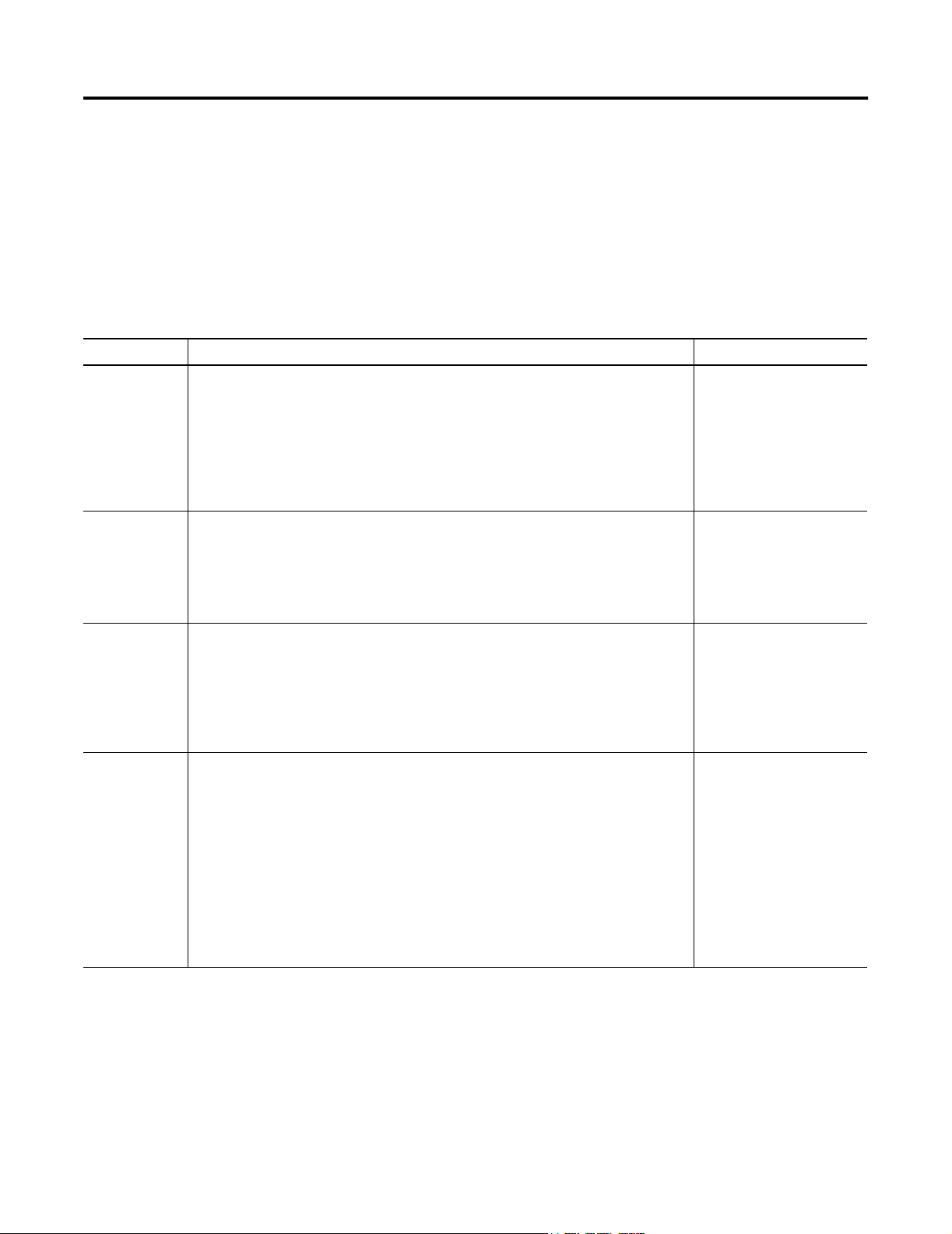

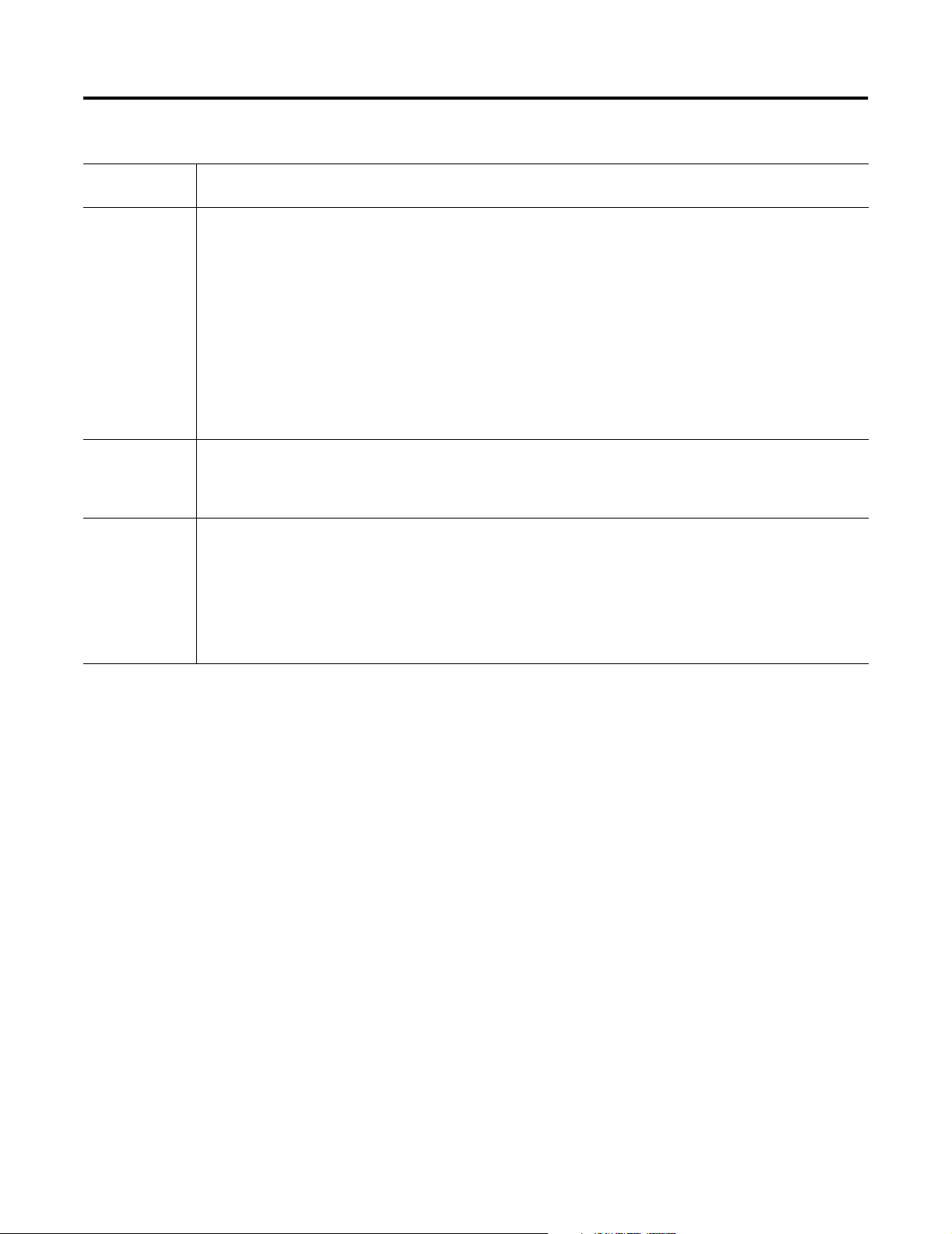

Defines blocks to represent different types of application functions. The three types of

blocks are the Resource block, the Function block, and the Transducer block. See

Figure 1.2.

The Resource block is used to describe characteristics of the fieldbus device such as the

device name, manufacturer, and serial number. Each fieldbus device requires one

Resource block.

The Function block is used to define the specific characteristics of the process control

function. The Fieldbus Foundation provides a set of pre-defined function blocks. A single

fieldbus device can include many Function blocks to achieve the desired control

functionality. See the following section, Standard Function Blocks for more information.

The Transducer block is used to interface Function blocks with local input/output

devices. They read sensors and command outputs, and contain information such as

calibration date and sensor type. One Transducer block is usually included for each input

or output Function block.

These associated objects are also defined in the User Application: Link Objects, Trend

Objects, Alert Objects, and View Objects. They provide linking between internal Function

block inputs and outputs, trending of Function block parameters, reporting of alarms and

events, viewing of predefined block parameter sets through one of four defined views.

The four defined views are View 1 - Operation Dynamic, View 2 - Operation Static, View

3 - All Dynamic, and View 4 - Other Static.

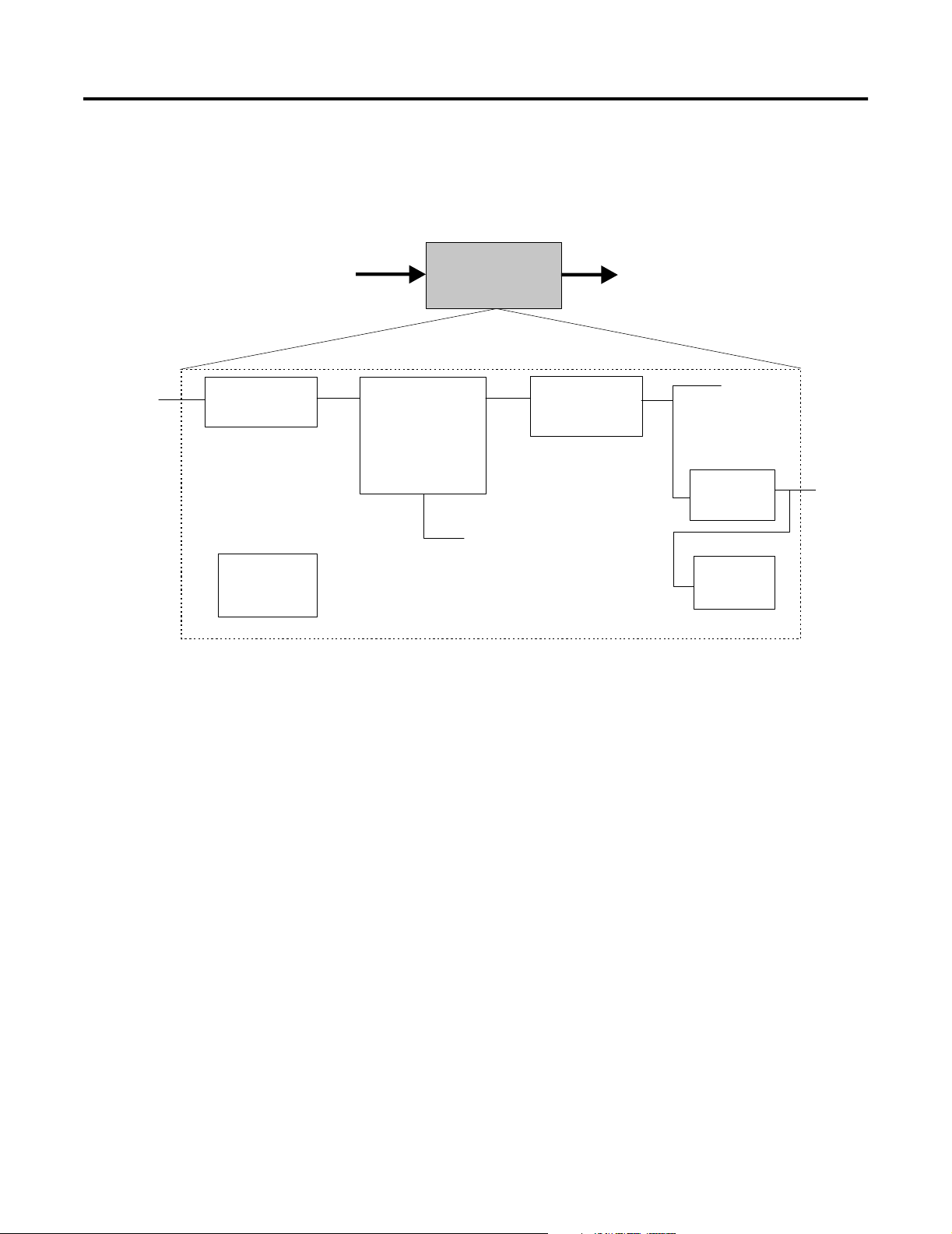

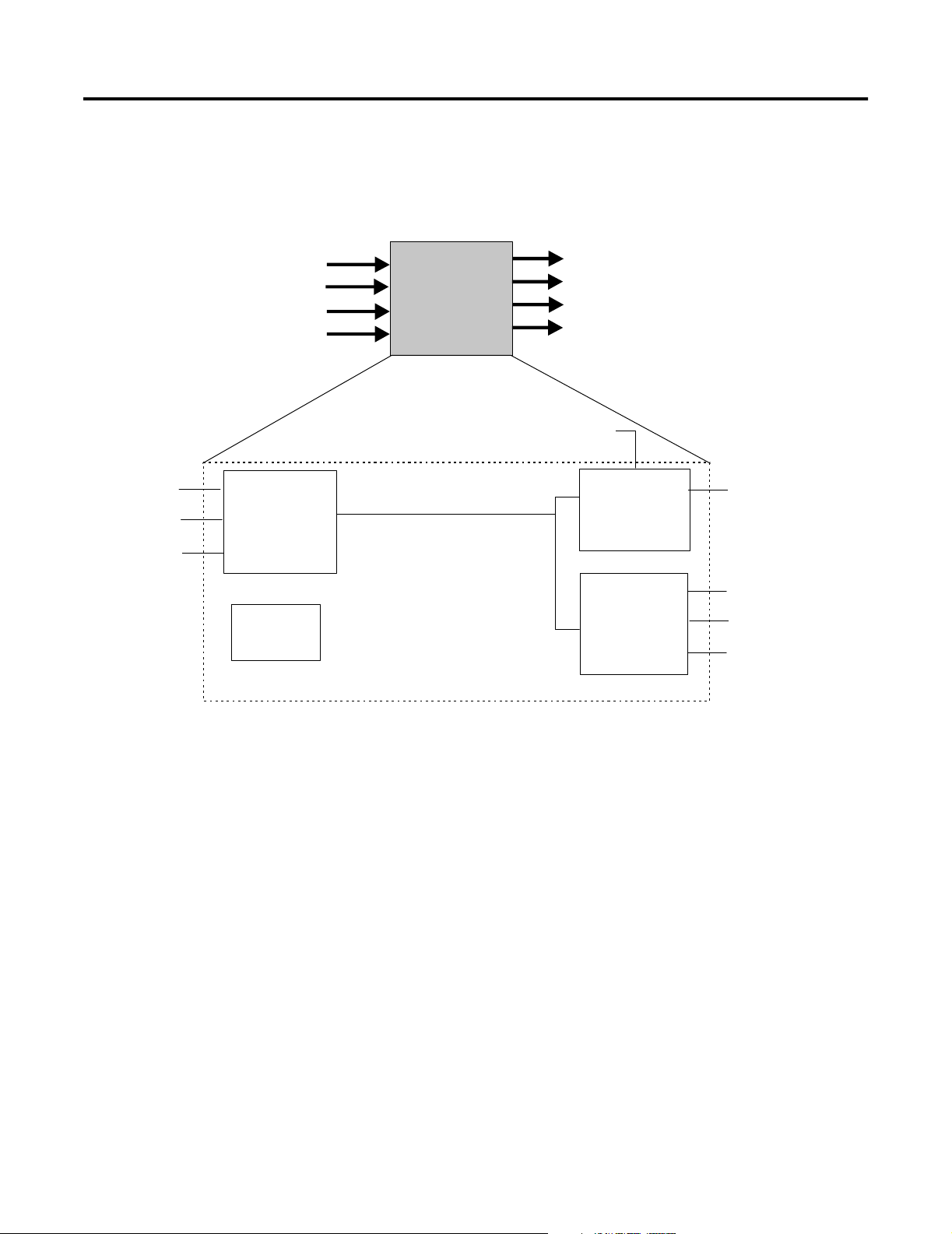

Figure 1.2 Function Block Application Process based on blocks

Fieldbus Foundation

Defined Blocks

User Application

Resource

Block

Resource block

Function block

Transducer block

Link Objects

Trend Objects

Alert Objects

View Objects

View 1 - Operation Dynamic

View 2 - Operation Static

View 3 - All Dynamic

View 4 - Other Static

Transducer

Block

Function

Block

Communication

Stack

Physical Layer

Fieldbus

Publication 1757-UM006A-EN-P - May 2002

Page 20

1-6 The Fieldbus Communication Model

Standard Function Blocks

The key to fieldbus interoperability is the User Application or

Function Block Application Process (FBAP) that defines standard

function blocks that can reside in field devices and be interconnected

as a distributed process control system. A function block is a named

entity that has inputs, outputs, and parameters. It performs certain

functions that operate on its inputs and produce outputs in

accordance with its assigned parameters. The Fieldbus Foundation

Function Blocks are similar in nature to the Function Blocks used to

build control strategies in the Control Builder application in the

ProcessLogix system.

The Fieldbus Foundation provides the standard Function Blocks listed

below for basic control functionality. They also support additional

blocks for more complex applications. Please refer to the applicable

Fieldbus Foundation specification for more information about these

additional blocks.

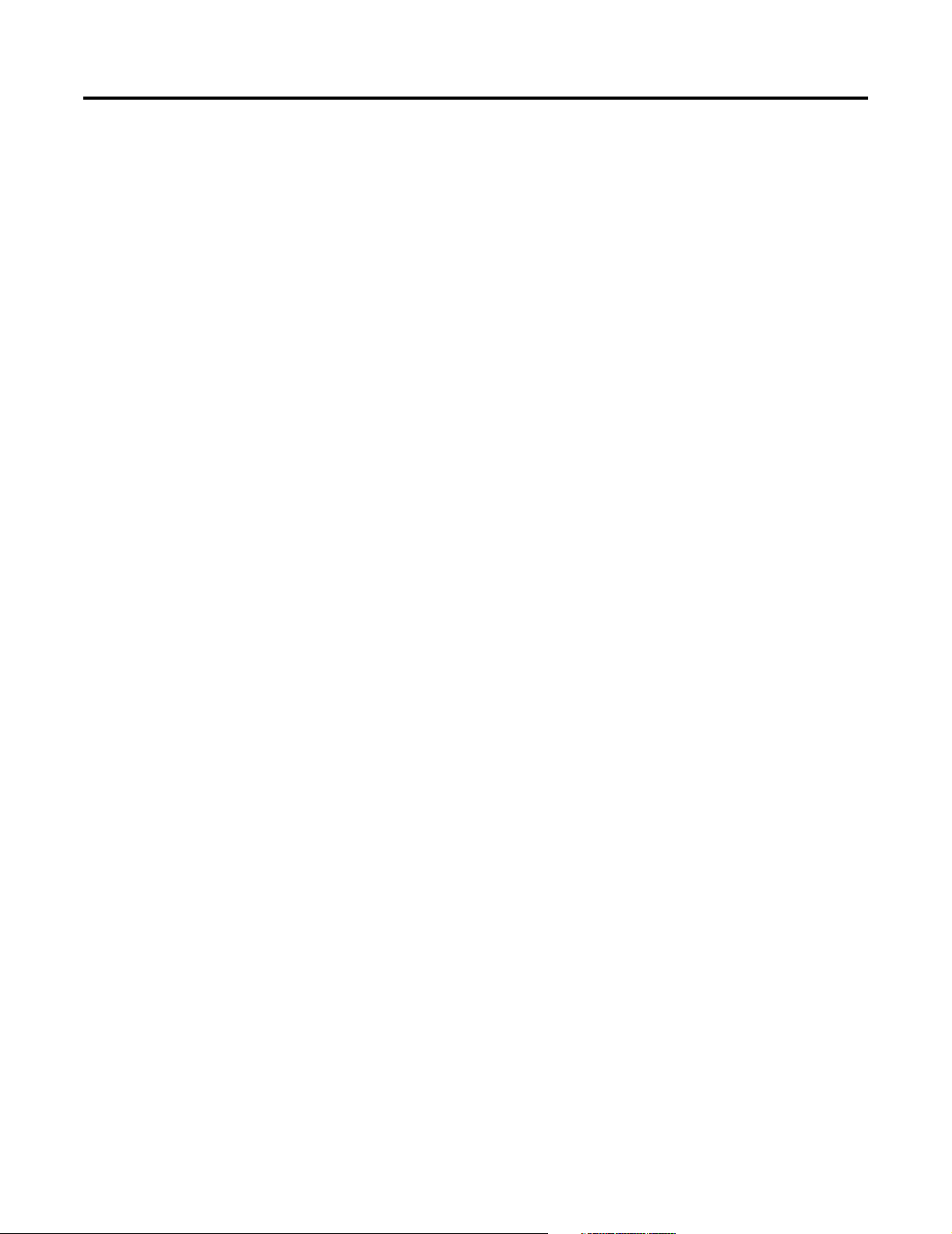

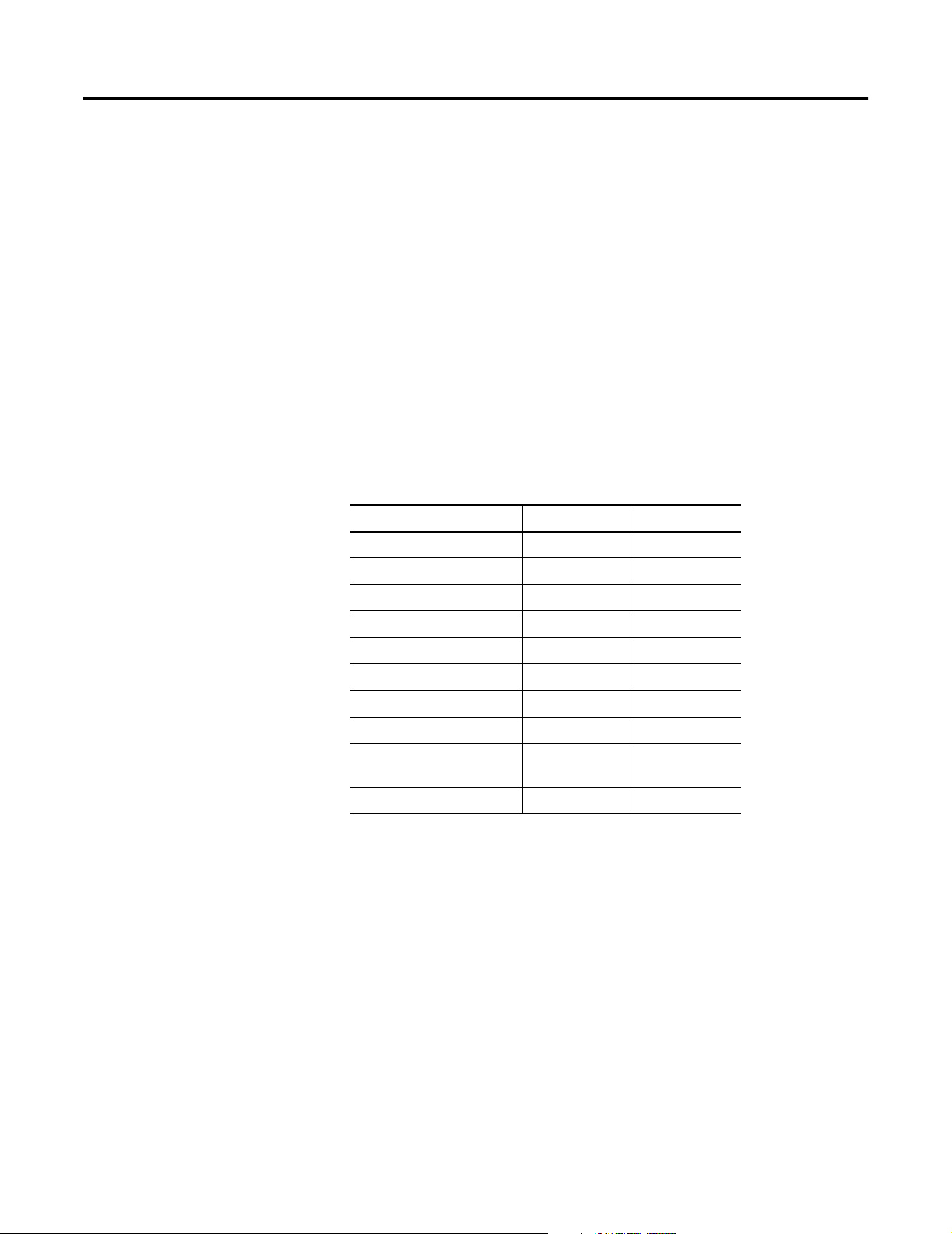

Table 1.B Function Block Specifications

Function Block Abbreviation Class

Analog Input AI Input

Analog Output AO Output

Bias/Gain BG Control

Control Selector CS Control

Discrete Input DI Input

Discrete Output DO Output

Manual Loader ML Control

Proportional/Derivative PD Control

Proportional/Integral/Deriva

tive

Ratio RA Control

PID Control

Publication 1757-UM006A-EN-P - May 2002

Page 21

The Fieldbus Communication Model 1-7

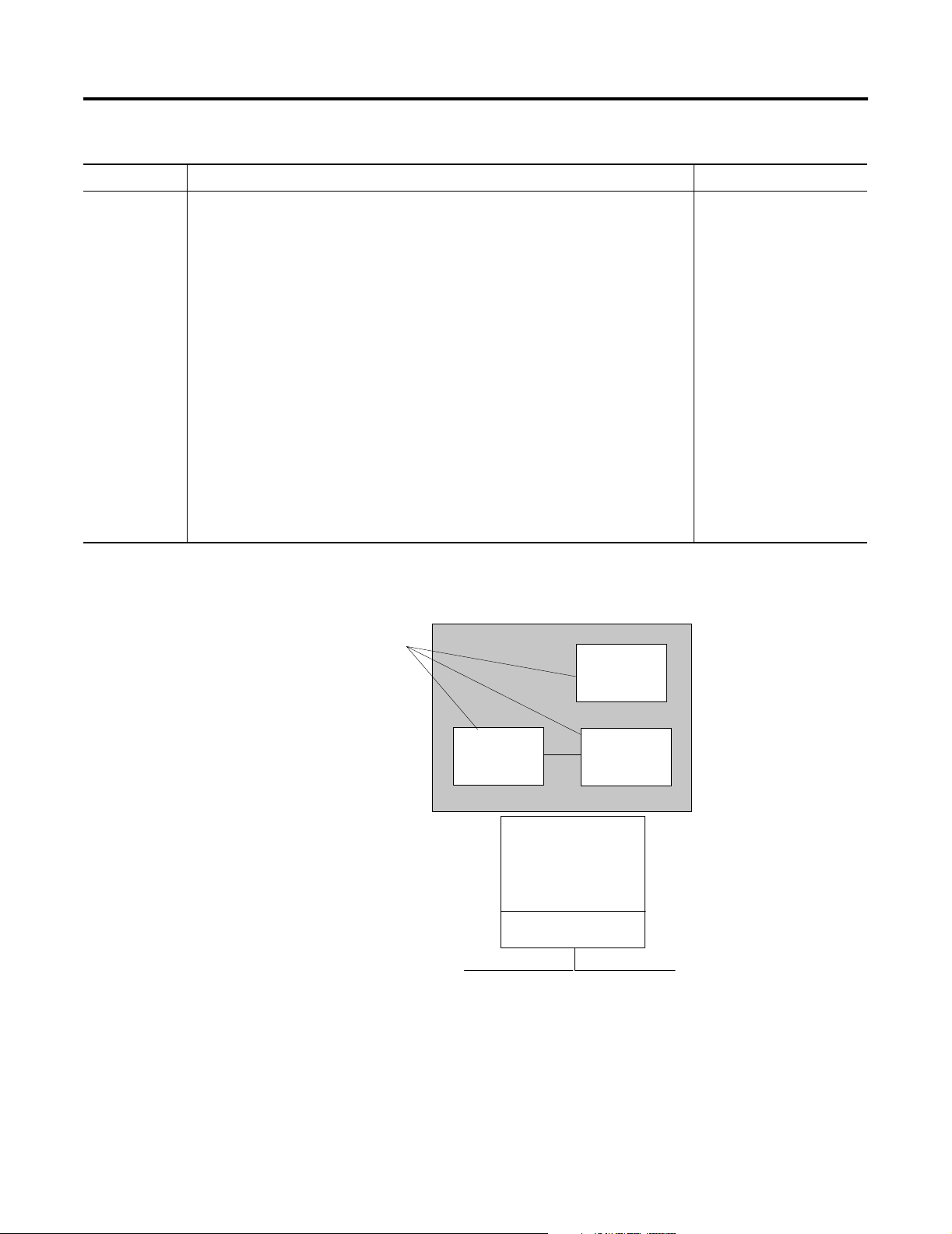

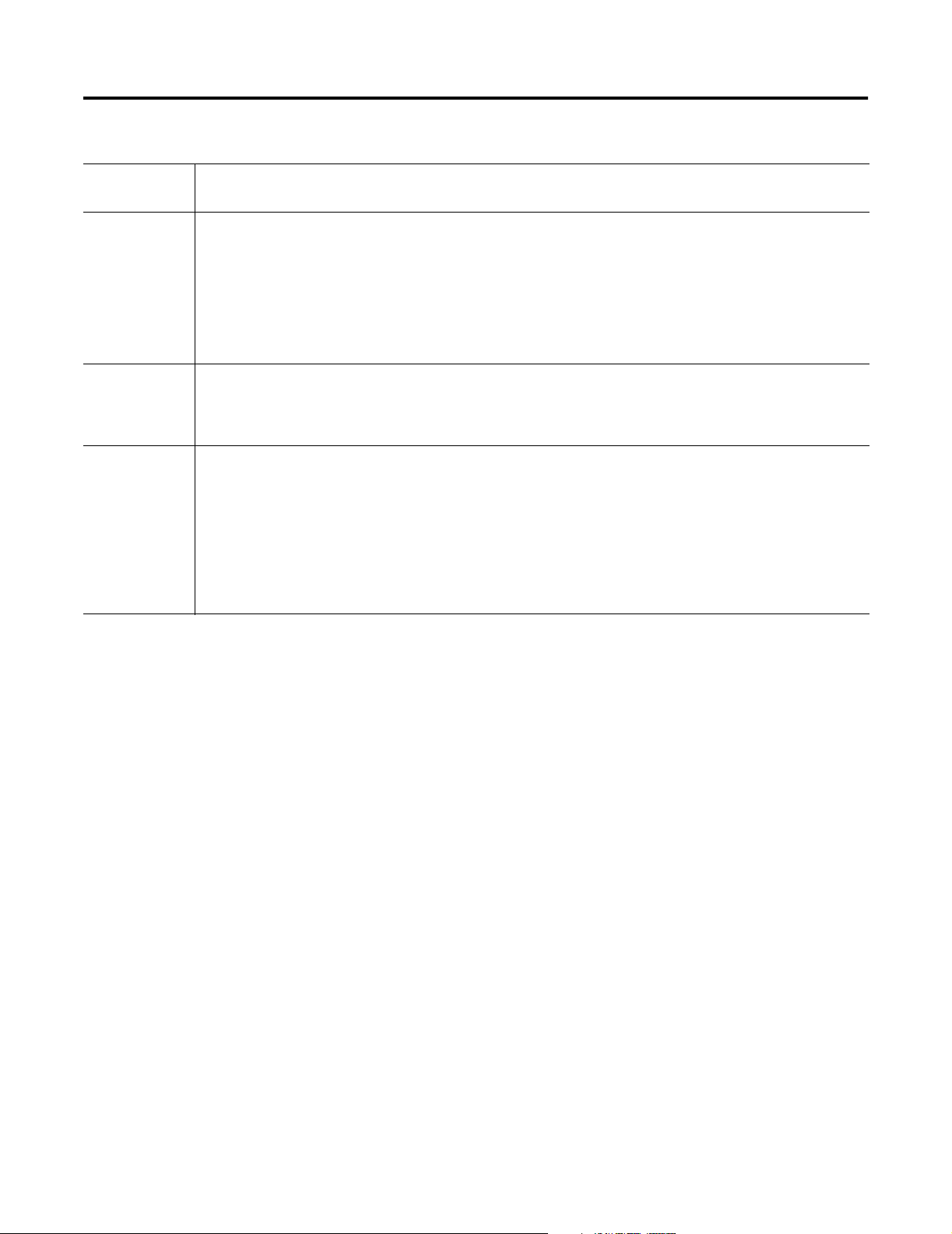

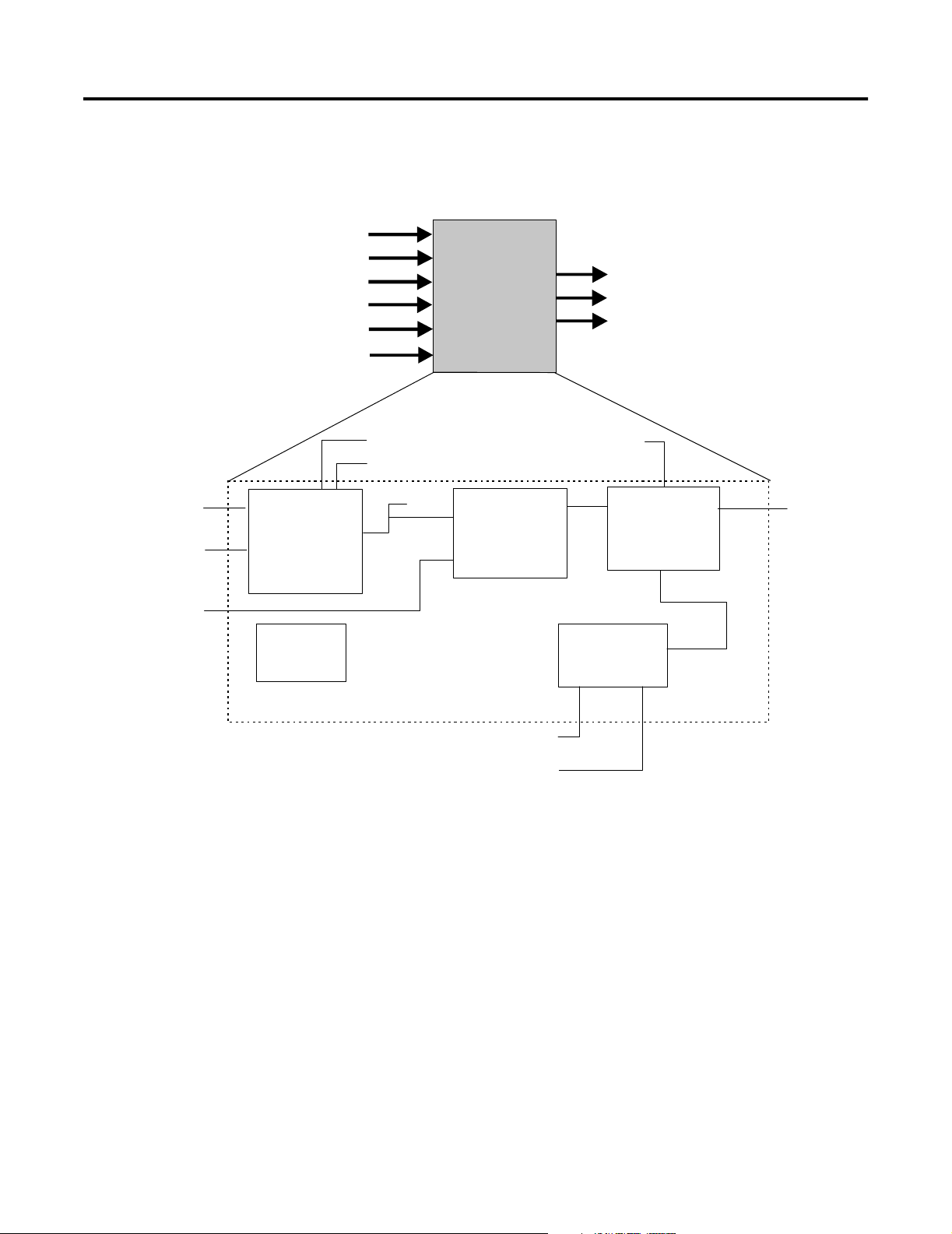

Function blocks make it possible to build a control loop using fieldbus

devices that include the appropriate Function block types. For

example, a pressure transmitter that contains an Analog Input and

Proportional/Integral/Derivative blocks can be used with a valve

containing an Analog Output block to form a control loop, as shown

in Figure 1.3.

Figure 1.3 Using Function Blocks in Fieldbus Devices to Form a Control Loop

AI Block

PID Block

Fieldbus

AO Block

Device 1

Device 2

Publication 1757-UM006A-EN-P - May 2002

Page 22

1-8 The Fieldbus Communication Model

About Modes of Operation

Every Function block includes a mode parameter with configured

permitted modes. This structured parameter is composed of the actual

mode, the target mode, the permitted mode, and the normal mode.

The normal mode is the desired operating mode. The actual mode

reflects the mode used during block execution. The target mode may

be set and monitored through the mode parameter. The permitted

mode defines the allowable target mode settings. The following table

provides a summary of the available modes of operation and their

effect on operation.

Table 1.C Modes of Operation

Mode Abbreviation Operation Effect

Out of Service OOS The block is not being evaluated. The output is maintained at the last value, an assigned failsafe

value -last value or configured failsafe value. Set Point is maintained at last value.

Initialization

Manual

IMan The block output is being set in response to the back-calculation input parameter status. When

status is no path to the final output element, control blocks must initialize to provide for bumpless

transfer, when the condition clears. The Set Point may be maintained or initialized to the Process

Variable parameter value.

Local Override LO Applies to control and output blocks that support a track input parameter. Also, manufacturers may

provide a local lockout switch on the device to enable the Local Override mode. The block output is

being set to track the value of the track input parameter. The algorithm must initialize to avoid a

bump, when the mode switches back to the target mode. The Set Point may be maintained or

initialized to the Process Variable parameter value.

Manual Man The block is not being calculated, although it may be limited. The operator directly sets it through an

interface device. The algorithm must initialize to avoid a bump, when the mode switches. The Set

Point may be maintained, initialized to the Process Variable parameter value, or initialized to the Set

Point value associated with the previous (retained) target mode.

Automatic Auto The block's normal algorithm uses a local Set Point value to determine the primary output. An

operator may set the value of the Set Point through an interface device.

Cascade Cas The block's normal algorithm uses a Set Point value fed through the Cascade input parameter from

another block to determine the primary output value.

Remote

Cascade

Remote-Out ROut The block's output is being set by a Control Application running on an interface device through the

RCas The block's Set Point is being set by a Control Application running on an interface device through

the remote-cascade in parameter. The block's normal algorithm uses this Set Point to determine the

primary output value. The block maintains a remote-cascade out parameter to support initialization

of the control application, when the block mode is not remote-cascade.

remote-output in parameter. The algorithm must initialize to avoid a bump, when the mode

switches. The block maintains a remote-output out parameter to support initialization of the Control

Application, when the block mode is not remote-output. The Set Point may be maintained or

initialized to the Process Variable parameter value.

Publication 1757-UM006A-EN-P - May 2002

Page 23

The Fieldbus Communication Model 1-9

Analog Input Block

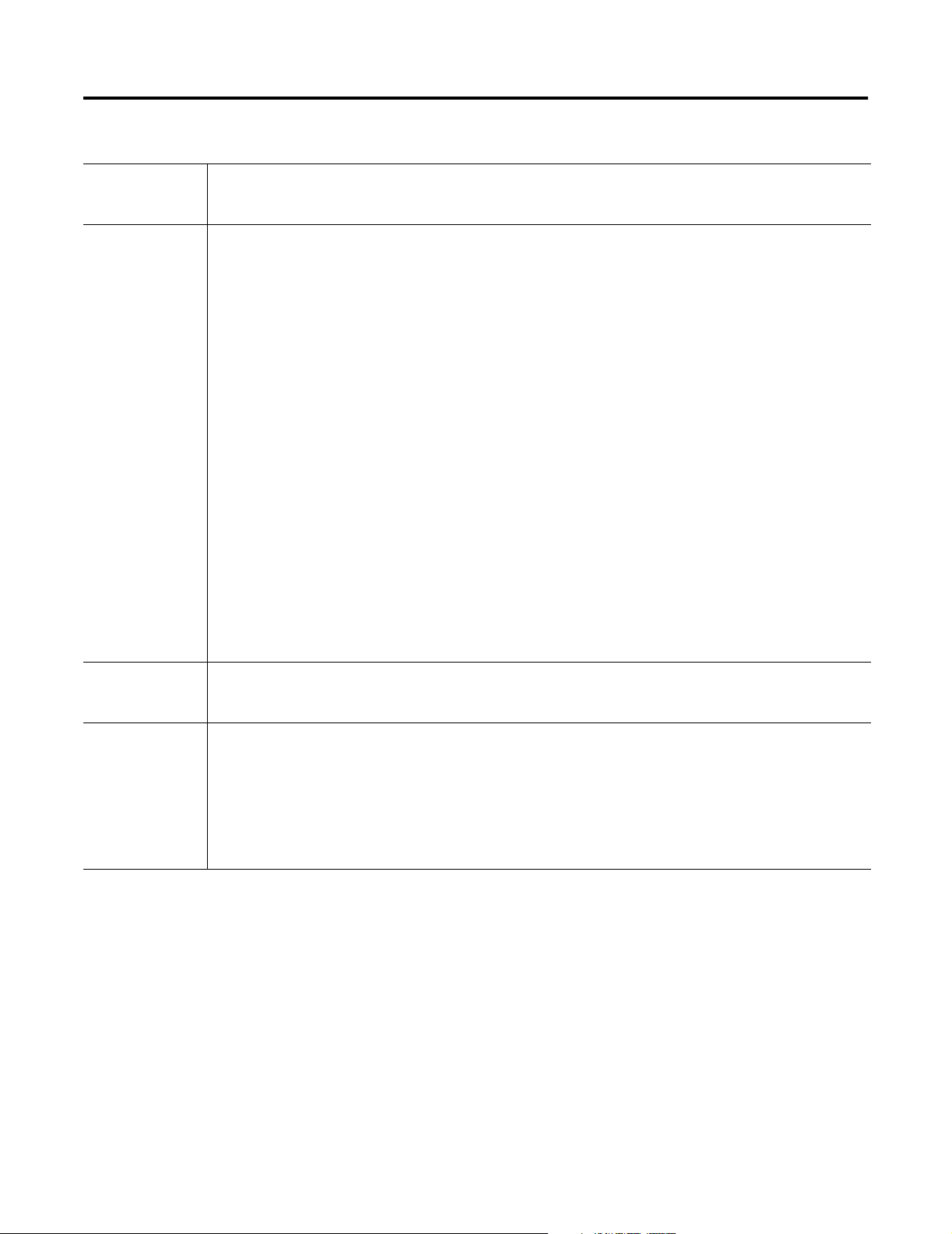

Figure 1.4 Functional Schematic for Analog Input Function Block

CHANNEL

Transducer

Simulate

SIMULATE

Mode

SHED_OPT

Convert

L_TYPE

LOW_CUT

XD_SCALE

OUT_SCALE

AI

FIELD_VAL

Filter

PV_FTIME

OUT

PV

Output

Alarms

HI/LO

OUT

Publication 1757-UM006A-EN-P - May 2002

Page 24

1-10 The Fieldbus Communication Model

Table 1.D Analog Input Block Specifications

Description The AI function block takes the input data from a Transducer block and calculates an output to be fed to other fieldbus

function blocks. A functional schematic of the block is shown in Figure 1.4 for reference.

Function Notes • Supports Out of Service (OOS), Manual (Man), and Automatic (Auto) modes.

• The XD_SCALE units code must match the channel units code, or the block will remain in OOS mode after being

configured.

• The OUT_SCALE is normally the same as the transducer, unless the L_TYPE is set to Indirect or Ind Sqr Root, then

the OUT_SCALE determines the conversion from FIELD_VAL to the output.

• If the mode is Auto, the PV is the value the block puts in OUT.

• If the mode is Man, an operator can write a value to OUT.

• The SIMULATE parameter is for testing purposes only and always initializes in the disabled state.

Equation Options FIELD_VAL = 100 x (channel value - EU@0%) / (EU@100% - EU@0%) [XD_SCALE]

Direct: PV = channel value

Indirect : PV = (FIELD_VAL / 100) x (EU@100% - EU@0%) + EU@0% [OUT_SCALE]

Ind Sqr Root: PV = sqrt(FIELD_VAL / 100) x (EU@100% - EU@0%) + EU@0% [OUT_SCALE]

Parameters

(see Appendix A

for definitions of

each parameter)

ACK_OPTION

ALARM_HYS

ALARM_SUM

ALERT_KEY

BLOCK_ALM

BLOCK_ERR

CHANNEL

FIELD_VAL

GRANT_DENY

HI_ALM

HI_HI_ALM

HI_HI_LIM

HI_HI_PRI

HI_LIM

HI_PRI

IO_OPTS

L_TYPE

LO_ALM

LO_LIM

LO_LO_ALM

LO_LO_LIM

LO_LO_PRI

LO_PRI

LOW_CUT

MODE_BLK

OUT

OUT_SCALE

PV

PV_FTIME

SIMULATE

ST_REV

STATUS_OPTS

STRATEGY

TAG_DESC

UPDATE_EVT

XD_SCALE

Publication 1757-UM006A-EN-P - May 2002

Page 25

CAS_IN

RCAS_IN

BKCAL_OUT

RCAS_OUT

The Fieldbus Communication Model 1-11

Analog Output Block

Figure 1.5 Functional Schematic for Analog Output Function Block

BKCAL_OUT

AO

OUT

RCAS_OUT

Transducer

CAS_IN

RCAS_IN

Setpoint

SP_RATE_DN

SP_RATE_UP

SP_HI_LIM

SP_LO_LIM

Mode

SHED_OPT

Out Convert

PV_SCALE

XD_SCALE

SP

PV Convert

XD_SCALE

PV_SCALE

Output

PV

Failsafe

FSAFE_TIME

FSAFE_VAL

Simulate

SIMULATE

READBACK

OUT

CHANNEL

Publication 1757-UM006A-EN-P - May 2002

Page 26

1-12 The Fieldbus Communication Model

Table 1.E Analog Output Specifications

Description The Analog Output function block converts the set point (SP) value to a number that can be used by the hardware

associated with the CHANNEL selection. A functional schematic of the block is shown in Figure 1.5 for reference.

Function Notes • Can use either the Set point (SP) value after limiting or the Process Variable (PV) value for the BKCAL_OUT value.

• Supports Out of Service (OOS), Local Override (LO), Manual (Man), Automatic (Auto), Cascade (Cas), and Remote

Cascade (RCas) modes.

• The conversion of Set point (SP) to percent of span is based on the PV_SCALE range.

• The conversion of the percent of span to a compatible value for the hardware is based on the XD_SCALE range.

• Use the Increase to Close Option in IO_OPTS to invert the span.

• Use the Cascade mode to transfer the output of another block to the Set point of the AO block.

• If the hardware, such as a valve positioner, supports a readback value, run this value backwards through the XD

scaling to act as the PV for this block. If this is not supported, READBACK is generated from OUT.

• In the Man mode, an operator can write a value to OUT. A manufacturer must put operational limits in the

Transducer, where an operator cannot access them, to permit the Man mode. If Man mode is not permitted, it must

be supported as a transition mode for exiting the OOS mode

• The SIMULATE parameter is for testing purposes only and always initializes in the disabled state.

Equation Options Temp = (SP - EU@0%) / (EU@100% - EU@0%) [PV_SCALE]

OUT = Temp x (EU@100% - EU@0%) + EU@0% [XD_SCALE]

Temp = (READBACK - EU@0%) / (EU@100% - EU@0%) [XD_SCALE]

PV = Temp x (EU@100% - EU@0%) + EU@0% [PV_SCALE]

Parameters

(see Appendix A

for definitions of

each parameter)

ALERT_KEY

BKCAL_OUT

BLOCK_ALM

BLOCK_ERR

CAS_IN

CHANNEL

FSAFE_TIME

FSAFE_VAL

GRANT_DENY

IO_OPTS

MODE_BLK

OUT

PV

PV_SCALE

RCAS_IN

RCAS_OUT

READBACK

SHED_OPT

SIMULATE

SP

SP_HI_LIM

SP_LO_LIM

SP_RATE_DN

SP_RATE_UP

ST_REV

STATUS_OPTS

STRATEGY

TAG_DESC

UPDATE_EVT

XD_SCALE

Publication 1757-UM006A-EN-P - May 2002

Page 27

IN_1

BKCAL_IN

CAS_IN

RCAS_IN

TRK_IN_C

TRK_VAL

The Fieldbus Communication Model 1-13

Bias/Gain Block

Figure 1.6 Functional Schematic for Bias/Gain Function Block

BKCAL_OUT

BG

OUT

RCAS_OUT

CAS_IN

RCAS_IN

IN_1

Setpoint

SP_RATE_DN

SP_RATE_UP

SP_HI_LIM

SP_LO_LIM

Mode

SHED_OPT

BKCAL_OUT

RCAS_OUT

SP

Bias & Gain

GAIN

TRK_IN_D

TRK_VAL

BKCAL_IN

Output

OUT_HI_LIM

OUT_LO_LIM

BAL_TIME

Output Track

TRK_SCALE

OUT

Publication 1757-UM006A-EN-P - May 2002

Page 28

1-14 The Fieldbus Communication Model

Table 1.F Bias/Gain Block Specifications

Description The Bias/Gain function block can be used for biased external feedforward control or to set several unit controllers,

such as boiler masters, from one controller output, such as a plant master. A functional schematic of the block is

shown in Figure 1.6 for reference.

Function Notes • Supports Out of Service (OOS), Initialization Manual (IMan) Local Override (LO), Manual (Man), Automatic (Auto),

Cascade (Cas), and Remote Cascade (RCas) modes.

• The output supports the track algorithm.

• The Balance Ramp option is supported.

• The CONTROL_OPTS selection Act on IR determines whether initialization requests are to be passed on or acted

on locally by changing the BIAS value.

• If the Act on IR option is false, a status of Not Invited (NI) or Initialization Request (IR) at BKCAL_IN will be passed

to BKCAL_OUT. The BKCAL_OUT value will be calculated from the value of BKCAL_IN adjusted for SP and GAIN,

as determined by the control or process status of IN_1. When the upstream block sends an Initialization

Acknowledge (IA) status, this block will send IA status, since its output will now be nearly equal to the value of

BKCAL_IN.

• If the Act on IR option is true, a status of NI or IR at BKCAL_IN results in an adjustment to SP to balance OUT to

the value of BKCAL_IN. The IA status can be sent as soon as IR is detected. BKCAL_OUT will not request

initialization.

• The TRK_VAL input brings in an external value or uses a constant. The TRK_SCALE values convert the TRK_VAL to

a percent of output span value. If the CONTROL_OPTS Track Enable selection is true and TRK_IN_D is true, the

converted TRK_VAL replaces the output (OUT), when the block is in Automatic, Cascade, or Remote Cascade

mode. The CONTROL_OPTS Track in Manual selection must be true for this to occur in Manual mode. If the actual

mode is OOS or IMan, the track request is ignored.

• If the TRK_VAL replaces the OUT, its status becomes Locked Out with Limits set to Constant. The actual mode

goes to LO. The status of RCAS_OUT goes to Not Invited (NI), if not already there.

• If the status of TRK_IN_D is Bad, its last usable value will be maintained and acted upon. If the device restarts,

losing the last usable value, it will be set to false.

• If the status of TRK_VAL is Bad, the last usable value will be used. If there is no last usable value, the present

value of the OUT will be used.

Equation Options In Automatic mode: OUT = (IN_1 + SP) x GAIN

If IN_1 has Non-Cascade status: BKCAL_OUT = (BKCAL_IN / GAIN) - IN_1

If IN_1 has Cascade status: BKCAL_OUT = (BKCAL_IN / GAIN) - SP

Parameters

(see Appendix A for

definitions of each

parameter)

ALERT_KEY

BAL_TIME

BKCAL_IN

BKCAL_OUT

BLOCK_ALM

BLOCK_ERR

CAS_IN

CONTROL_OPTS

GAIN

GRANT_DENY

IN_1

MODE_BLK

OUT

OUT_HI_LIM

OUT_LO_LIM

OUT_SCALE

RCAS_IN

RCAS_OUT

SHED_OPT

SP

SP_HI_LIM

SP_LO_LIM

SP_RATE_DN

SP_RATE_UP

ST_REV

STATUS_OPTS

STRATEGY

TAG_DESC

TRK_IN_D

TRK_SCALE

TRK_VAL

UPDATE_EVT

Publication 1757-UM006A-EN-P - May 2002

Page 29

The Fieldbus Communication Model 1-15

Control Selector Block

Figure 1.7 Functional Schematic for Control Selector Function Block

SEL_1

SEL_2

SEL_3

SEL_1

SEL_2

SEL_3

BKCAL_IN

Selection

SEL_TYPE

Mode

CS

OUT

BKCAL_SEL_1

BKCAL_SEL_2

BKCAL_SEL_3

BKCAL_IN

OUT_HI_LIM

OUT_LO_LIM

Back Calc

Output

OUT

BKCAL_SEL_1

BKCAL_SEL_2

BKCAL_SEL_3

Publication 1757-UM006A-EN-P - May 2002

Page 30

1-16 The Fieldbus Communication Model

Table 1.G Control Selector Block Specifications

Description The Control Selector function block accepts input from up to three control signals and selects one for output based on

the SEL_TYPE setting of High, Middle, or Low. A functional schematic of the block is shown in Figure 1.7 for reference.

Function Notes • All inputs must have the same scaling as OUT, since any one can be selected for OUT.

• Supports Out of Service (OOS), Initialization Manual (IMan) Local Override (LO), Manual (Man), and Automatic

(Auto) modes.

• If an input has a sub-status of Do Not Select, it will not be selected.

• Three separate back calculation outputs (BKCAL_SEL_1, 2, 3) are available - one for each input (SEL_1, 2, 3).

• The status will identify those inputs that are not selected. Control signals that are not selected are limited in one

direction only as determined by the SEL_TYPE selection.

• The value of each BKCAL_SEL_1, 2, 3 output is the same as OUT. The limits of back calculation outputs

corresponding to not-selected inputs will be high for a low selection, low for a high selection, or one of each for a

middle selection.

• If the status of an input is Bad, it is not eligible for selection. If the status of an input is Uncertain, it is treated as

Bad unless the STATUS_OPTS selection is Use Uncertain as Good.

• When all inputs are Bad, the actual mode goes to Manual. This condition will set Initiate Failsafe (IFS) in the output

status, if the STATUS_OPTS setting is IFS if BAD IN.

• If SEL_TYPE selection is Middle and only two inputs are good, the higher input will be selected.

• If the status of BKCAL_IN is Not Invited (NI) or Initialization Request (IR), it is passed back on all three back

calculation outputs. This causes all initializable inputs to initialize to the BKCAL_IN value. Otherwise, if the status

of BKCAL_IN is not normal, it is passed back on the BKCAL_SEL_N, where N is the number of the selected input.

The back calculation outputs for not-selected inputs just have the Not Selected status with the appropriate high or

low limit set.

• When the mode is Manual, no input is selected. All three back calculation outputs will have a Not Invited status

and Constant limits, with a value equal to OUT.

Parameters

(see Appendix A

for definitions of

each parameter)

ALERT_KEY

BKCAL_IN

BKCAL_SEL_1

BKCAL_SEL_2

BKCAL_SEL_3

BLOCK_ALM

BLOCK_ERR

GRANT_DENY

MODE_BLK

OUT

OUT_HI_LIM

OUT_LO_LIM

OUT_SCALE

SEL_1

SEL_2

SEL_3

SEL_TYPE

ST_REV

STATUS_OPTS

STRATEGY

TAG_DESC

UPDATE_EVT

Publication 1757-UM006A-EN-P - May 2002

Page 31

The Fieldbus Communication Model 1-17

Discrete Input Block

Figure 1.8 Functional Schematic for Discrete Input Function Block

Transducer

CHANNEL

Table 1.H Discrete Input Block Specifications

Description The Discrete Input function block takes the discrete input data from a selected Transducer block channel and provides

Simulate

SIMULATE_D

Mode

SHED_OPT

it as an output for other fieldbus function blocks. A functional schematic of the block is shown in Figure 1.8 for

reference.

Optional

Invert

FIELD_VAL_D

DI

Filter

PV_FTIME

OUT

PV_D

Output

Alarms

OUT_D

DISC

Function Notes • Supports Out of Service (OOS), Manual (Man), and Automatic (Auto) modes.

• The FIELD_VAL_D represents the true ON/OFF state of the value from the Transducer, using XD_STATE.

• Use the IO_OPTS Invert selection to do a Boolean NOT function between the field value and the output.

• Use the PV_FTIME to set the time that the input must be in one state before it gets passed to the PV_D.

• The PV_D is always the value that the block places in OUT_D, when the mode is Automatic.

• In Manual mode, if allowed, an operator can write a value to OUT_D.

• The SIMULATE_D parameter is for testing purposes only and always initializes in the disabled state.

Parameters

(see Appendix A

for definitions of

each parameter)

ACK_OPTION

ALARM_SUM

ALERT_KEY

BLOCK_ALM

BLOCK_ERR

CHANNEL

DISC_ALM

DISC_LIM

DISC_PRI

FIELD_VAL_D

GRANT_DENY

IO_OPTS

MODE_BLK

OUT_D

OUT_STATE

PV_D

PV_FTIME

SIMULATE_D

ST_REV

STATUS_OPTS

STRATEGY

TAG_DESC

UPDATE_EVT

XD_STATE

Publication 1757-UM006A-EN-P - May 2002

Page 32

1-18 The Fieldbus Communication Model

CAS_IN_D

RCAS_IN_D

Discrete Output Block

Figure 1.9 Functional Schematic for Discrete Output Function Block

BKCAL_OUT_D

DO

BKCAL_OUT_D

RCAS_OUT_D

OUT_D

RCAS_OUT_D

Transducer

CAS_IN_D

RCAS_IN_D

Setpoint

Mode

SHED_OPT

Optional

Invert

SP_D

Optional

Invert

Output

PV_D

Failsafe

FSAFE_TIME

FSAFE_VAL_D

Simulate

SIMULATE_D

READBACK_D

OUT_D

CHANNEL

Table 1.I Discrete Output Block Specifications

Description The Discrete Output function block converts the value in SP_D to something useful for the hardware linked to the

CHANNEL selection. A functional schematic of the block is shown in Figure 1.9 for reference.

Function Notes • Supports Out of Service (OOS), Local Override (LO), Manual (Man), Automatic (Auto), Cascade (Cas), and Remote

Cascade (RCas) modes.

• The Set point (SP_D) supports the full cascade sub-function.

• Use the Cascade mode to transfer the output of another block to the Set point (SP_D) of the DO block.

• Use the IO_OPTS Invert selection to do a Boolean NOT function between the field value and the output.

• Use the IO_OPTS Invert selection to do a Boolean NOT function between the SP_D and the output.

• If the hardware supports a readback value, it is used for READBACK_D, and, after accounting for the IO_OPTS

Invert selection, acts as the PV_D for this block. If this is not supported, READBACK is generated from OUT_D.

• In the Man mode, an operator can force the output, in a programmable logic controller sense. If Man mode is not

permitted, it must be supported as a transition mode for exiting the OOS mode

• The SIMULATE_D parameter is for testing purposes only and always initializes in the disabled state.

Parameters

(see Appendix A

for definitions of

each parameter)

ALERT_KEY

BKCAL_OUT_D

BLOCK_ALM

BLOCK_ERR

CAS_IN_D

CHANNEL

FSAFE_TIME

FSAFE_VAL_D

GRANT_DENY

Publication 1757-UM006A-EN-P - May 2002

IO_OPTS

MODE_BLK

OUT_D

PV_D

PV_STATE

RCAS_IN_D

RCAS_OUT_D

READBACK_D

SHED_OPT

ST_REV

STATUS_OPTS

STRATEGY

TAG_DESC

UPDATE_EVT

XD_STATE

SIMULATE_D

SP_D

Page 33

The Fieldbus Communication Model 1-19

Manual Loader Block

Figure 1.10 Functional Schematic for Manual Loader Function Block

IN

BKCAL_IN

ROUT_IN

TRK_IN_D

TRK_VAL

ML

BKCAL_IN

OUT

ROUT_OUT

IN

Filter

PV_FTIME

Mode

SHED_OPT

PV

Alarm

HI/LO

TRK_IN_D

TRK_VAL

ROUT_IN

Output Track

TRK_SCALE

ROUT_OUT

Output

OUT_HI_LIM

OUT_LO_LIM

OUT

Publication 1757-UM006A-EN-P - May 2002

Page 34

1-20 The Fieldbus Communication Model

Table 1.J Manual Loader Block Specifications

Description The Manual Loader function block output is not set by the block's algorithm. Its output can be set by an operator in the

Manual mode or a program in the Remote-Out mode. A functional schematic of the block is shown in Figure 1.10 for

reference.

Function Notes • Supports Out of Service (OOS), Initialization Manual (IMan), Local Override (LO), Manual (Man), and Remote-Out

(ROut) modes.

• Accepts output from an AI block as its input (IN) to get a PV filtered by PV_FTIME.

• The block's algorithm uses value and status for alarming only.

• If selected, the STATUS_OPTS of IFS if BAD IN will work.

• The BKCAL_IN value and status can force balancing of the output.

• The TRK_VAL input brings in an external value or uses a constant. The TRK_SCALE values convert the TRK_VAL to

a percent of output span value. If the CONTROL_OPTS Track Enable selection is true and TRK_IN_D is true, the

converted TRK_VAL replaces the output (OUT), when the block is in Remote-Out (ROut) mode. The CONTROL_OPTS

Track in Manual selection must be true for this to occur in Manual mode. If the actual mode is OOS or IMan, the

track request is ignored.

• If the TRK_VAL replaces the OUT, its status becomes Locked Out with Limits set to Constant. The actual mode goes

to LO. The status of ROUT_OUT goes to Not Invited (NI), if not already there.

• If the status of TRK_IN_D is Bad, its last usable value will be maintained and acted upon. If the device restarts,

losing the last usable value, it will be set to false.

• If the status of TRK_VAL is Bad, the last usable value will be used. If there is no last usable value, the present value

of the OUT will be used.

Parameters

(see Appendix A

for definitions of

each parameter)

ACK_OPTION

ALARM_HYS

ALARM_SUM

ALERT_KEY

BKCAL_IN

BLOCK_ALM

BLOCK_ERR

CONTROL_OPTS

GRANT_DENY

HI_ALM

HI_HI_ALM

HI_HI_LIM

HI_HI_PRIHI_LIM

HI_PRI

IN

LO_ALM

LO_LIM

LO_LO_ALM

LO_LO_LIM

LO_PRI

LO-LO_PRI

MODE_BLK

OUT

OUT_HI_LIM

OUT_LO_LIM

OUT_SCALE

PV

PV_FTIME

PV_SCALE

ROUT_IN

ROUT_OUT

SHED_OPT

ST_REV

STATUS_OPTS

STRATEGY

TAG_DESC

TRK_IN_D

TRK_SCALE

TRK_VAL

UPDATE_EVT

Publication 1757-UM006A-EN-P - May 2002

Page 35

The Fieldbus Communication Model 1-21

Proportional/Derivative Block

Figure 1.11 Functional Schematic for Proportional/Derivative Function Block

IN

BKCAL_IN

CAS_IN

RCAS_IN

ROUT_IN

TRK_IN_D

TRK_VAL

FF_VAL

PD

BKCAL_OUT

OUT

RCAS_OUT

ROUT_OUT

CAS_IN

RCAS_IN

IN

Setpoint

SP_RATE_DN

SP_RATE_UP

SP_HI_LIM

SP_LO_LIM

SP

Filter

PV_FTIME

Mode

SHED_OPT

BKCAL_OUT

RCAS_OUT

Bypass

BYPASS

Control

GAIN

BIAS

BAL_TIME

RATE

Alarm

HI/LO

DEV

FF_VAL

Feed Forward

FF_SCALE

FF_GAIN

BKCAL_HYS

PV

TRK_IN_D

TRK_VAL

Status

BKCAL_IN

ROUT_IN

Output Track

TRK_ SCALE

Output

OUT_HI_LIM

OUT_LO_LIM

ROUT_OUT

OUT

Table 1.K Proportional/Derivative Block

Description The Proportional/Derivative function block provides classic two-mode control function for processes that handle their

own integration. When the Process Variable deviates from the Set point, the PD function acts upon the error to move

the output in a direction to correct the deviation. PD blocks support cascade applications to compensate for the

difference in process time constants of a primary and secondary process measurement. A functional schematic of the

block is shown in Figure 1.11 for reference

Function Notes • Supports Out of Service (OOS), Initialization Manual (IMan), Local Override (LO), Manual (Man), Automatic (Auto),

Cascade (Cas), Remote Cascade (RCas) and Remote-Out (ROut) modes.

• The input (IN) passes through a filter with a time constant (PV_FTIME). The filtered value becomes the Process

Variable (PV) to be used with the Set point (SP) in the block's algorithm.

• The full cascade SP sub-function is used, with rate and absolute limits. Additional control options are available to

have the SP value track the PV value, when the block's actual mode is IMan, LO, Man, or ROut. Limits do not cause

SP-PV tracking.

• The tuning constant used for the Proportional term is GAIN and RATE is used for the Derivative term. Some

controllers use the inverse values of Proportional Band and repeats per minutes for their tuning constants. Users

can choose which tuning constants they want to display.

Publication 1757-UM006A-EN-P - May 2002

Page 36

1-22 The Fieldbus Communication Model

Table 1.K Proportional/Derivative Block

Function Notes

(cont.)

Parameters

(see Appendix A

for definitions of

each parameter)

• A BYPASS switch function is available for operators to use, when secondary cascade controllers have a bad PV and

the Bypass Enable (LSB) CONTROL_OPTS is ON. The Bypass Enable option is required, since some control schemes

may become unstable when BYPASS is ON. An operator can only set the BYPASS switch, when the block is in the

Man or OOS mode. While BYPASS is ON, the SP value, in percent of range, is passed directly to the target output,

and the value of OUT is used for BKCAL_OUT. When block mode switches to Cascade, the upstream block is

requested to initialize to the value of OUT. Upon transition to bypass OFF, the upstream block is requested to

initialize to the PV value, regardless of the Use PV for BKCAL_OUT CONTROL_OPTS status.

• Use the Balance Ramp CONTROL_OPTS to maintain the BIAS value, when the block is in Manual (Man) mode. An

internal value follows the actual value required to maintain balance. When block mode changes to Automatic

(Auto), the internal value ramps to zero contribution in BAL_TIME seconds. If Balance Ramp option is OFF or not

used, the BIAS value immediately changes to follow the changes to the input or output, when the block is in Man

mode.

• Use the Act on IR CONTROL_OPTS to select whether to ignore initialization requests or act on them by changing

the BIAS. If this option is ON, a status of Not Invited (NI) or Initialization Request (IR) at BKCAL_IN causes the BIAS

term to be adjusted to balance OUT to the value of BKCAL_IN.

• Use the Direct Acting CONTROL_OPTS to define how a change in PV relative to the SP affects the output. When

Direct Acting is ON, the output increases when the PV exceeds the SP. When Direct Acting is OFF, the output

decreases when the PV exceeds the SP. Be sure this option is set correctly and never changed while in the

Automatic mode, since it makes the difference between positive and negative feedback. This option setting also

affects the calculation of the limit states for BKCAL_OUT.

• This block includes a Feed Forward algorithm. It accepts a value that is proportional to some disturbance in the

control loop as its FF_VAL input. The FF_SCALE values convert the FF_VAL to a percent of output span value. The

converted value is multiplied by the FF_GAIN and added to the target output of the block's algorithm. If the status

of FF_VAL is Bad, the last usable value will be used to prevent a bump in the output. When the status returns to

Good, the block adjusts its BIAS term to maintain the previous output.

• The TRK_VAL input brings in an external value or uses a constant. The TRK_SCALE values convert the TRK_VAL to

a percent of output span value. If the CONTROL_OPTS Track Enable selection is true and TRK_IN_D is true, the

converted TRK_VAL replaces the output (OUT), when the block is in Automatic (Auto), Cascade (Cas), Remote

Cascade (RCas), or Remote-Out (ROut) mode. The CONTROL_OPTS Track in Manual selection must be true for this

to occur in Manual mode. If the actual mode is OOS or IMan, the track request is ignored.

• If the TRK_VAL replaces the OUT, its status becomes Locked Out with Limits set to Constant. The actual mode goes

to LO. The status of BKCAL_OUT, RCAS_OUT and ROUT_OUT goes to Not Invited (NI), if not already there.

• If the status of TRK_IN_D is Bad, its last usable value will be maintained and acted upon. If the device restarts,

losing the last usable value, it will be set to false.

• If the status of TRK_VAL is Bad, the last usable value will be used. If there is no last usable value, the present value

of the OUT will be used.

• Use the Obey SP limits if Cas or RCas CONTROL_OPTS to use SP value after limiting in Cas or RCas mode.

• Use the Use PV for BKCAL_OUT CONTROL_OPTS to the PV value for the BKCAL_OUT value.

ACK_OPTION

ALARM_HYS

ALARM_SUM

ALERT_KEY

BAL_TIME

BIAS

BKCAL_HYS

BKCAL_IN

BKCAL_OUT

BLOCK_ALM

BLOCK_ERR

BYPASS

CAS_IN

CONTROL_OPTS

DV_HI_ALM

DV_HI_LIM

DV_HI_PRI

DV_LO_ALM

DV_LO_LIM

DV_LO_PRI

FF_GAIN

FF_SCALE

FF_VAL

GAIN

GRANT_DENY

HI_ALM

HI_HI_ALM

HI_HI_LIM

HI_HI_PRI

HI_LIM

HI_PRI

IN

LO_ALM

LO_LIM

LO_LO_ALM

LO_LO_LIM

LO_LO_PRI

LO_PRI

MODE_BLK

OUT

OUT_HI_LIM

OUT_LO_LIM

OUT_SCALE

PV

PV_FTIME

PV_SCALE

RATE

RCAS_IN

RCAS_OUT

ROUT_IN

ROUT_OUT

SHED_OPT

SP

SP_HI_LIM

SP_LO_LIM

SP_RATE_DN

SP_RATE_UP

ST_REV

STATUS_OPTS

STRATEGY

TAG_DESC

TRK_IN_D

TRK_SCALE

TRK_VAL

UPDATE_EVT

Publication 1757-UM006A-EN-P - May 2002

Page 37

The Fieldbus Communication Model 1-23

Proportional/Integral/Derivative Block

Figure 1.12 Functional Schematic for Porportional/Integral/Derivative Function

Block

IN

BKCAL_IN

CAS_IN

RCAS_IN

ROUT_IN

TRK_IN_D

TRK_VAL

FF_VAL

PID

BKCAL_OUT

OUT

RCAS_OUT

ROUT_OUT

CAS_IN

RCAS_IN

IN

Setpoint

SP_RATE_DN

SP_RATE_UP

SP_HI_LIM

SP_LO_LIM

SP

Filter

PV_FTIME

Mode

SHED_OPT

BKCAL_OUT

RCAS_OUT

Bypass

BYPASS

Control

GAIN

RESET

BAL_TIME

RATE

Alarm

HI/LO

DEV

FF_VAL

Feed Forward

FF_SCALE

FF_GAIN

BKCAL_HYS

PV

TRK_IN_D

TRK_VAL

ROUT_IN

Status

BKCAL_IN

OUT_HI_LIM

OUT_LO_LIM

Output Track

TRK_SCALE

Output

ROUT_OUT

OUT

Table 1.L Proportional/Integral/Derivative Block Specifications

Description The Proportional/Integral/Derivative function block provides classic three-mode control function for closed-loop

control applications. When the Process Variable deviates from the Set point, the PID function acts upon the error to

move the output in a direction to correct the deviation. PID blocks support cascade applications to compensate for the

difference in process time constants of a primary and secondary process measurement. A functional schematic of the

block is shown in Figure 1.12 for reference.

Function Notes • Supports Out of Service (OOS), Initialization Manual (IMan), Local Override (LO), Manual (Man), Automatic (Auto),

Cascade (Cas), Remote Cascade (RCas) and Remote-Out (ROut) modes.

• The input (IN) passes through a filter with a time constant (PV_FTIME). The filtered value becomes the Process

Variable (PV) to be used with the Set point (SP) in the block's algorithm. A PID algorithm will not integrate, if the

limit status of the input (IN) is constant.

• The full cascade SP sub-function is used, with rate and absolute limits. Additional control options are available to

have the SP value track the PV value, when the block's actual mode is IMan, LO, Man, or ROut. Limits do not cause

SP-PV tracking.

Publication 1757-UM006A-EN-P - May 2002

Page 38

1-24 The Fieldbus Communication Model

Table 1.L Proportional/Integral/Derivative Block Specifications

Function Notes

(cont.)

• The tuning constant used for the Proportional term is GAIN, RESET is used for the Integral term, and RATE is used

for the Derivative term. Both RESET and RATE are time constants expressed in seconds. Some controllers use the

inverse values of Proportional Band and repeats per minutes for their tuning constants. Users can choose which

tuning constants they want to display.

• A BYPASS switch function is available for operators to use, when secondary cascade controllers have a bad PV and

the Bypass Enable (LSB) CONTROL_OPTS is ON. The Bypass Enable option is required, since some control schemes

may become unstable when BYPASS is ON. An operator can only set the BYPASS switch, when the block is in the

Man or OOS mode. While BYPASS is ON, the SP value, in percent of range, is passed directly to the target output,

and the value of OUT is used for BKCAL_OUT. When block mode switches to Cascade, the upstream block is

requested to initialize to the value of OUT. Upon transition to bypass OFF, the upstream block is requested to

initialize to the PV value, regardless of the Use PV for BKCAL_OUT CONTROL_OPTS status.

• Use the Direct Acting CONTROL_OPTS to define how a change in PV relative to the SP affects the output. When

Direct Acting is ON, the output increases when the PV exceeds the SP. When Direct Acting is OFF, the output

decreases when the PV exceeds the SP. Be sure this option is set correctly and never changed while in the

Automatic mode, since it makes the difference between positive and negative feedback. This option setting also

affects the calculation of the limit states for BKCAL_OUT.

• This block includes a Feed Forward algorithm. It accepts a value that is proportional to some disturbance in the

control loop as its FF_VAL input. The FF_SCALE values convert the FF_VAL to a percent of output span value. The

converted value is multiplied by the FF_GAIN and added to the target output of the block's algorithm. If the status

of FF_VAL is Bad, the last usable value will be used to prevent a bump in the output. When the status returns to

Good, the block adjusts its Integral (RESET) term to maintain the previous output.

• The TRK_VAL input brings in an external value or uses a constant. The TRK_SCALE values convert the TRK_VAL to