Page 1

Reference Manual

Original Instructions

PlantPAx Distributed Control System

System Release 4.6

IMPORTANT This manual applies to PlantPAx System Release 4.5/4.6.

For PlantPAx System Release 5.0, see PROCES-UM100.

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Table of Contents

Preface

Purpose of the Reference Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

System Architecture Overview Architecture Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

System Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Critical System Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

System Procurement Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 2

System Element

Recommendations

PlantPAx Software Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Process Automation System Server (PASS) . . . . . . . . . . . . . . . . . . . . . . 18

PASS Server Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configure the FactoryTalk Directory . . . . . . . . . . . . . . . . . . . . . . . 20

Engineering Workstation (EWS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Engineering Workstation Application Server (AppServ-EWS) . . . . 21

Operator Workstation (OWS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Operator Workstation Application Server (AppServ-OWS) . . . . . . 22

Independent Workstation (IndWS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

AppServ-Info (Historian). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

AppServ-Info (VantagePoint) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

AppServ-Info (SQL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Asset Management Server (AppServ-Asset). . . . . . . . . . . . . . . . . . . . . . 25

Batch Management Server (AppServ-Batch). . . . . . . . . . . . . . . . . . . . . 26

Domain Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Controller Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Simplex Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Redundant Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Skid-based Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Determining I/O Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Sizing Control Strategies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 3

Page 4

Table of Contents

Chapter 3

System Application

Recommendations

Alarm System

Recommendations

Infrastructure

Recommendations

Controller Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

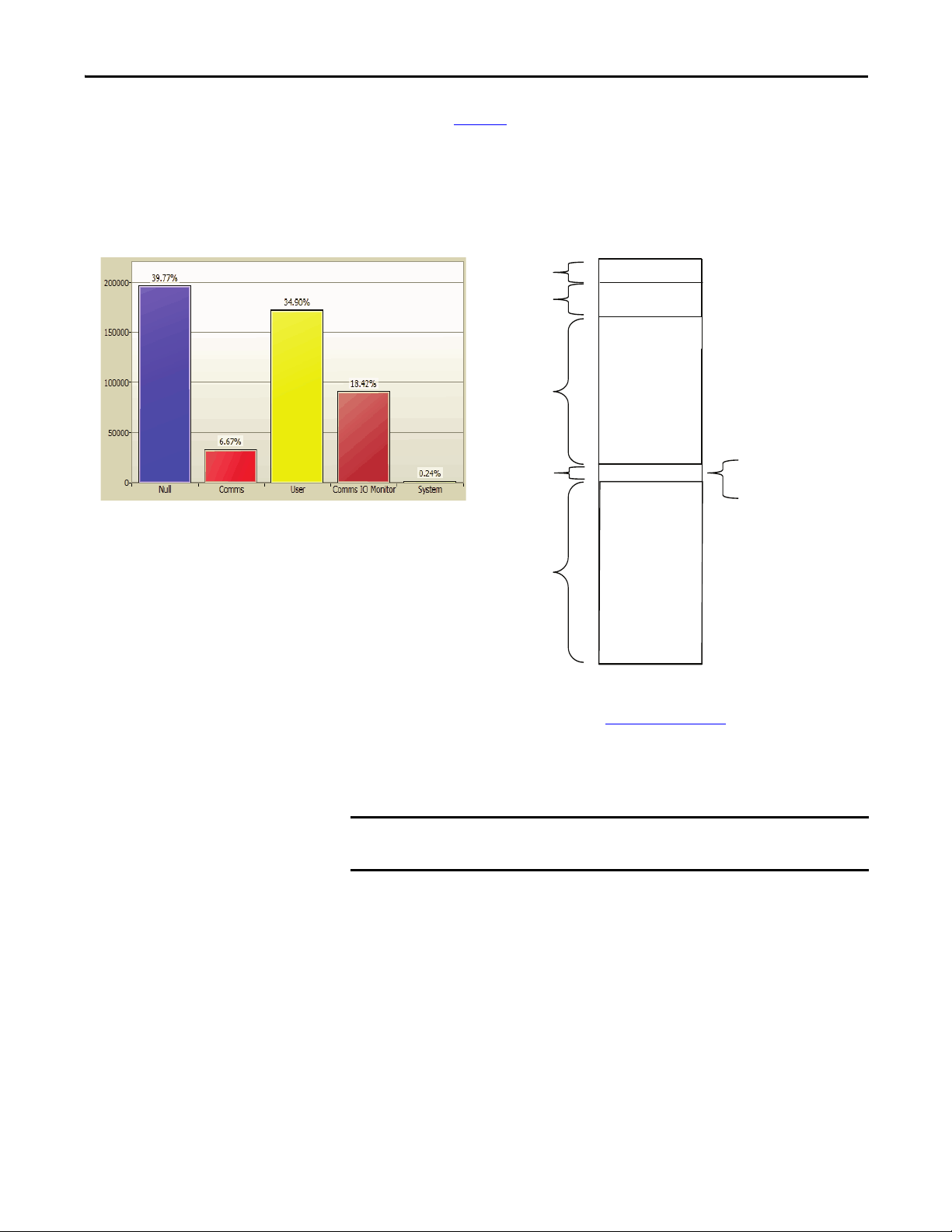

Task Configuration and CPU Utilization . . . . . . . . . . . . . . . . . . . 38

Estimate Controller CPU Utilization . . . . . . . . . . . . . . . . . . . . . . . 40

Use of Program Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Tag and Memory Allocation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Controller-to-Controller Communication . . . . . . . . . . . . . . . . . . 47

Controller I/O Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Using Add-On Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

FactoryTalk View Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Rockwell Automation Library of Process Objects. . . . . . . . . . . . . . . . 53

Additional Application Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Chapter 4

FactoryTalk Alarm and Event Software . . . . . . . . . . . . . . . . . . . . . 55

Using the Library of Process Objects for Alarms. . . . . . . . . . . . . . 59

Alarm State Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Monitoring Your Alarm System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Chapter 5

Physical Access Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Infrastructure Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Traditional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Virtual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Virtual PlantPAx Configuration Recommendations . . . . . . . . . . . . . 67

Servers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Virtual Networks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Resource Pool Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Operating System Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Domains and Workgroups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Domain Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Windows Workgroup Recommendations . . . . . . . . . . . . . . . . . . . 73

Server and Workstation Time Synchronization . . . . . . . . . . . . . . 73

Operating System Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Network Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Ethernet Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 5

Chapter 6

Table of Contents

Field Device Integration

Recommendations

Batch Management and Control

Recommendations

Device Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

FactoryTalk AssetCentre for Enterprise Solution . . . . . . . . . . . . 78

EtherNet/IP Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

EtherNet/IP I/O Communication Options . . . . . . . . . . . . . . . . . 79

ControlNet Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

ControlNet I/O Communication Options . . . . . . . . . . . . . . . . . . 80

DeviceNet Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

DeviceNet Communication Options. . . . . . . . . . . . . . . . . . . . . . . . 81

HART Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

HART Communication Options. . . . . . . . . . . . . . . . . . . . . . . . . . . 82

FOUNDATION Fieldbus Recommendations . . . . . . . . . . . . . . . . . . 83

FOUNDATION Fieldbus Communication Options . . . . . . . . 83

PROFIBUS PA Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

PROFIBUS PA Communication Options. . . . . . . . . . . . . . . . . . . 85

Motor Control Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Chapter 7

FactoryTalk Batch Critical System Attributes . . . . . . . . . . . . . . . . . . . 90

Batch Guidelines for Logix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Using a Redundant System with a FactoryTalk Batch Server . . . . . . 91

Information Management

Recommendations

Chapter 8

FactoryTalk Historian Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Tips and Best Practices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Architectural Best Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

FactoryTalk VantagePoint Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Tips and Best Practices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 5

Page 6

Table of Contents

Chapter 9

Maintenance

Recommendations

PlantPAx System Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Host Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Virtual Image Disaster Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Hypervisor Management Applications . . . . . . . . . . . . . . . . . . . . . . 97

Application Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Controller Project File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

FactoryTalk Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

PASS Servers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Network Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Data Back up and Restore. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Historian Configuration and Data . . . . . . . . . . . . . . . . . . . . . . . . . 100

Batch Configuration and Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

AssetCentre Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

SQL Server Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Backup Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Retention Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

System Storage Rates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Security Audit Logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Microsoft Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Use Antivirus Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Software Patches and Firmware Updates . . . . . . . . . . . . . . . . . . . . . . . 106

Use Proactive Industrial Security Advisory Index. . . . . . . . . . . . 106

Verify Software Patches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Compare Latest Firmware Updates . . . . . . . . . . . . . . . . . . . . . . . . 107

Considerations for Software and Firmware Upgrades. . . . . . . . 107

Rockwell Automation Services and Support . . . . . . . . . . . . . . . . . . . . 108

Appendix A

Verify and Monitor Your System

Additional Monitoring Resources. . . . . . . . . . . . . . . . . . . . . . . . . . 109

Health

Appendix B

System Software Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Glossary

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

6 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

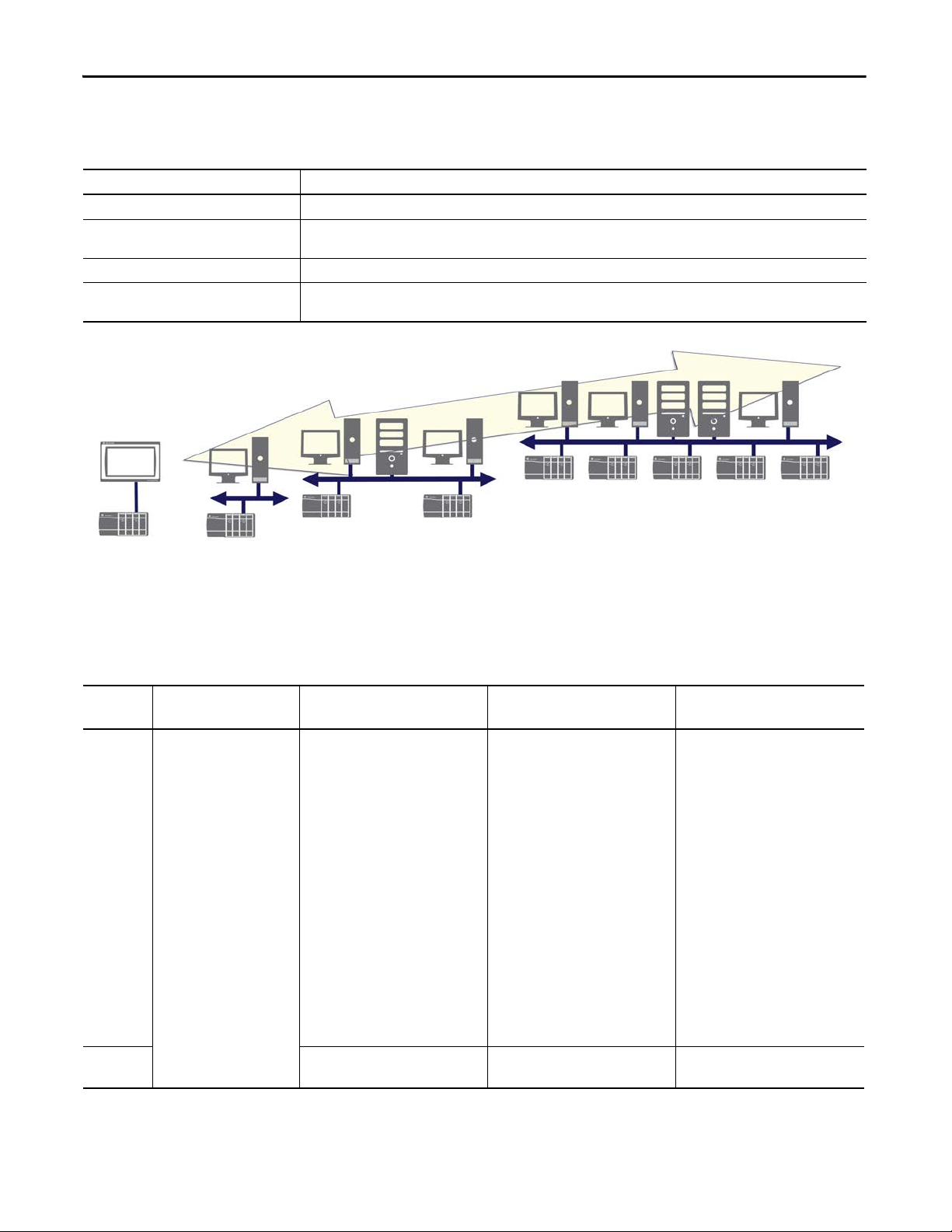

Page 7

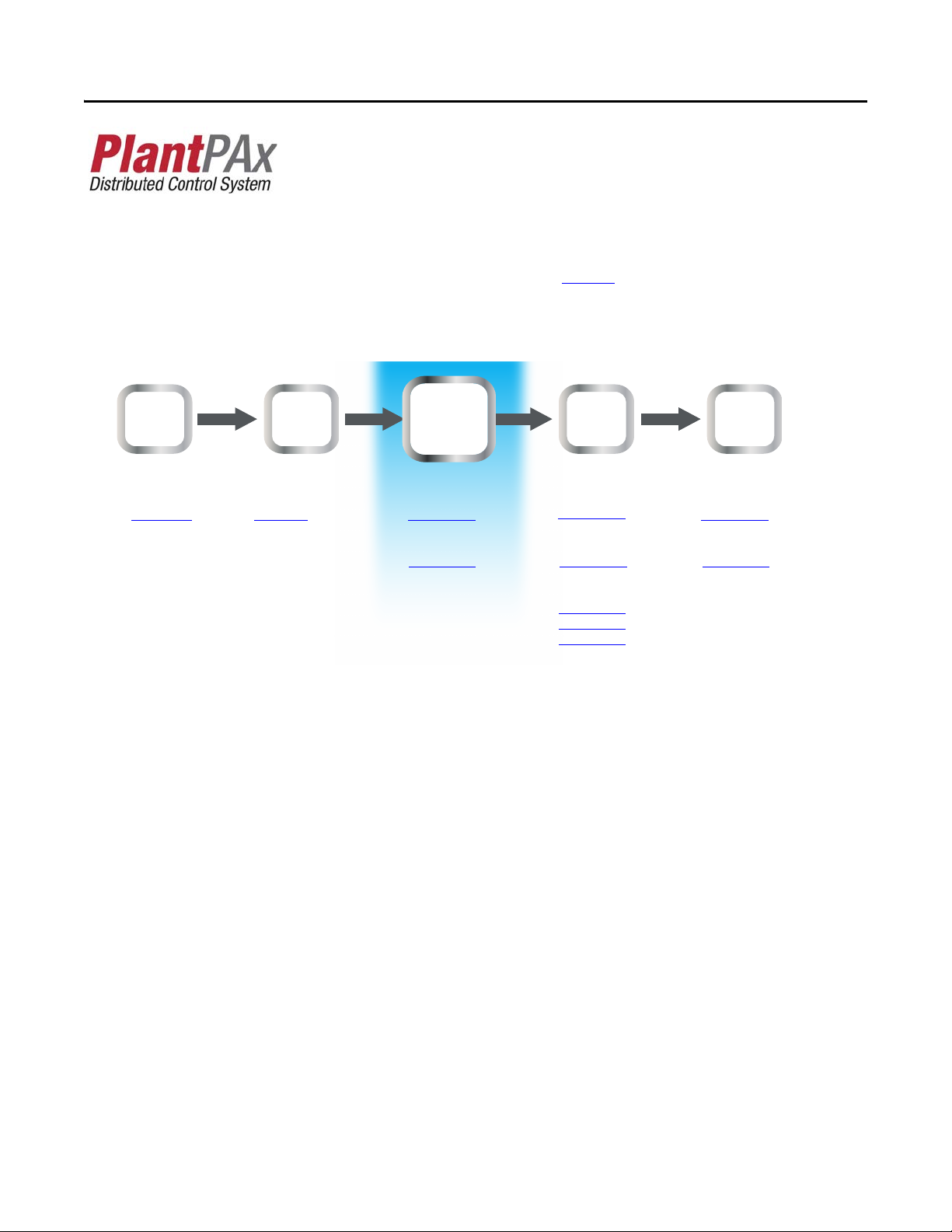

The PlantPAx® system provides a modern approach to distributed control. The

Dene and

Procure

Install Prep

Develop Operate

• Selection Guide

PROCES-SG001

• Virtualization User Manual

9528-UM001

• Infrastructure User Manual

PROCES-UM001

• Reference Manual

PROCES-RM001

• Application User Manual

PROCES-UM003

• Reference Manual

PROCES-RM001

• Library of Process Objects

PROCES-RM002

PROCES-RM013

PROCES-RM014

• Verify and Troubleshoot User Manual

PROCES-UM004

• Reference Manual

PROCES-RM001

system shares common technology (Integrated Architecture® system) with all

other automation disciplines in the plant. This approach creates a seamless

information flow across the plant for optimization opportunities and enables a

Connected Enterprise.

Our scalable platform provides you with the flexibility to implement a system

appropriate for your application. Figure 1

the highlighted section) that are available to help design and implement your

system requirements.

Figure 1 - PlantPAx System Implementation and Documentation Strategy

Preface

shows the documents (this manual in

• Define and Procure - Helps you understand the elements of the PlantPAx

system to make sure that you buy the proper components.

•Install - Provides direction on how to install the PlantPAx system.

•Prep - Provides guidance on how to get started and learn the best practices

to follow before you develop your application.

•Develop - Describes the actions and libraries necessary to construct your

application that resides on the PlantPAx system.

•Operate – Provides guidance on how to verify and maintain your systems

for efficient operation of your plant.

Purpose of the Reference Manual

The PlantPAx Reference Manual builds on the Selection Guide, which specifies

system sizing guidelines and catalog numbers for procurement. This manual

elaborates on the system sizing and application rules that you need to follow to

configure a PlantPAx system.

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 7

Page 8

Preface

We strongly recommend that you use the PlantPAx virtual image templates and

Rockwell Automation® Library of Process Objects for best system performance

and functionality. If you are not able to use the templates or the library, you still

must follow the guidelines and rules from the Selection Guide and this Reference

Manual. These guide posts make sure that you achieve PlantPAx system

performance.

The PlantPAx system utilizes a set of Critical System Attributes (CSAs) as

performance metrics. Your system performance can meet the CSA metrics if you

follow the sizing guidelines and application rules that are defined in these

documents and the PlantPAx System Estimator (PSE).

Summary of Changes

This manual contains new and updated information as indicated in the

following table.

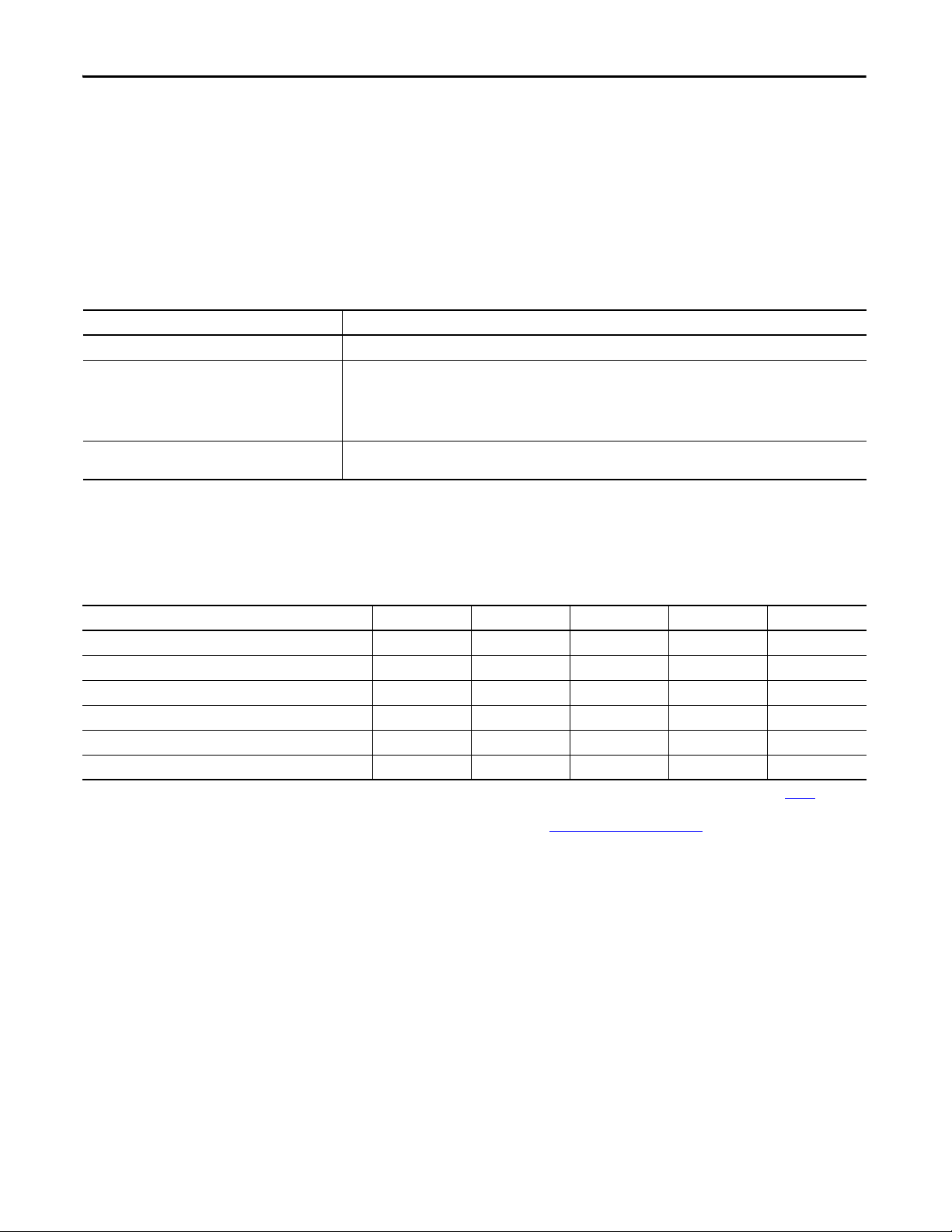

Top ic Pag e

120 OWS clients available in distributed architecture 14

Updates characterized software releases 17

Adds hard disk size for virtual system elements 19, 20, 21, 22,

Updates software components of system elements 111

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Table 1 - System Core Resources

Resource Description

PlantPAx Distributed Control System Selection Guide,

publication PROCES-SG001

PlantPAx Distributed Control System Infrastructure

Configuration User Manual, publication PROCES-UM001

PlantPAx Distributed Control System Application

Configuration User Manual, publication PROCES-UM003

PlantPAx Distributed Control System Verification and

Troubleshooting User Manual, publication PROCES-UM004

Rockwell Automation Library of Process Objects,

publication PROCES-RM002

Rockwell Automation Library of Logix Diagnostic Objects,

publication PROCES-RM003

Rockwell Automation Library of Steam Table Instructions,

publication PROCES-RM004

Rockwell Automation Library of Process Objects: Logic

Instructions Reference Manual,

publication PROCES-RM013

Rockwell Automation Library of Process Objects: Display

Elements Reference Manual,

publication PROCES-RM014

Provides basic definitions of system elements and sizing guidelines for procuring a PlantPAx system.

Provides screen facsimiles and step-by-step procedures to configure infrastructure components for your

system requirements.

Provides the steps necessary to start development of your PlantPAx Distributed Control System.

Provides checklist worksheets to verify and document that your system design aligns with PlantPAx

system recommendations.

Provides information on how to use the Rockwell Automation Library of Process Objects.

Provides Add-On Instructions for monitoring and diagnostic information of Logix controllers.

Provides Add-On Instructions for calculating temperature and pressure steam tables.

Provides controller codes and tags for Rockwell Automation Library objects. The objects are grouped by family and

attached as Microsoft Excel® files to the manual PDF file.

Provides common display elements for the Rockwell Automation Library. For improved accessibility, the elements are

combined into one manual.

24, 25, 26, 27

8 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 9

Table 1 - System Core Resources

Resource Description

PlantPAx Hardware Specifications and Certifications,

publication PROCES-SR027

PlantPAx Sequencer Object Reference Manual,

publication PROCES-RM006

FactoryTalk® View SE Edition User Manual,

publication VIEWSE-UM006

FactoryTalk View SE Installation Guide,

publication VIEWSE-IN003

FactoryTalk Alarms and Events System Configuration Guide,

publication FTAE-RM001

ControlLogix® System User Manual,

publication 1756-UM001

ControlLogix Enhanced Redundancy System User Manual,

publication 1756-UM535

Logix5000™ Controllers Design Considerations Reference

Manual, publication 1756-RM094

Logix5000 Controllers Common Procedures Programming

Manual, Publication 1756-PM001

Logix5000 Controllers General Instructions Reference

Manual, publication 1756-RM003

Logix5000 Controllers Advanced Process Control and Drives

Instructions Reference Manual, publication 1756-RM006

Logix 5000 Controllers Execution Time and Memory Use

Reference Manual, publication 1756-RM087

PlantPAx Logix Batch and Sequence Manager Reference

Manual, publication PROCES-RM007

Provides information on PlantPAx system hardware specifications and certifications.

Provides a flexible controller-based step sequencing solution that reduces engineering time by automating common

operator procedures.

Provides details on how to use this software package for developing HMI applications that can involve multiple users

and servers, which are distributed over a network.

Contains procedures for installing FactoryTalk View SE software.

Provides details on how to install, configure, and use FactoryTalk Alarms and Events services as part of a

FactoryTalk-enabled automation system.

Explains how to use traditional and extreme environment ControlLogix controllers.

Provides information on the installation and configuration for an enhanced redundancy controller system for

greater availability.

Details how to design and optimize Logix5000 controller applications.

Provides links to a collection of programming ma nuals that describe how you can use procedures that are common to all

Logix5000 controller projects.

Provides programming controller applications by using relay ladder instructions.

Provides details on process control and drives instructions.

Provides a complete list of instruction execution time and memory usage information for Logix5000 controllers in your

Studio 5000 Logix Designer® programming software.

Explains a controller-based batch and sequencing solution that leverages the Logix Control Platform and

FactoryTalk View software for integrated control and visualization.

Preface

Table 2 - Infrastructure Resources

Resource Description

PlantPAx Virtualization User Manual,

publication 9528-UM001

EtherNet/IP Network Configuration,

publication ENET-UM001

Ethernet Design Considerations Reference Manual,

publication ENET-RM002

Converged Plantwide Ethernet (CPwE) Design and

Implementation Guide, publication ENET-TD001

Troubleshoot EtherNet/IP Networks,

publication ENET-AT003

1756 ControlLogix Communication Modules Specifications

Technical Data, publication 1756-TD003

Application Note: Segmentation Methods within the

Cell/Area Zone, publication ENET-AT004

Stratix® Managed Switches User Manual,

publication 1783-UM007

Stratix Ethernet Device Specifications Technical Data,

publication 1783-TD001

Stratix/Infrastructure Product Family Quick Reference

Drawing, publication IASIMP-QR029

Describes how to use the PlantPAx virtua l image templates for configuring virtual machines.

Explains Logix5000 tools that are used in EtherNet/IP topologies and network operation.

Explains the infrastructure components that allow this open network to communicate seamlessly throughout a plant,

from shop floor to top floor.

Provides collaborative design guidelines that are based on the Cisco Ethernet-to-the-Factory solution and the Rockwell

Automation Integration Architecture solution.

Provides guidelines for troubleshooting an EtherNet/IP network, such as setting speed and duplex.

Contains specifications for the ControlLogix network communication modules.

Provides design considerations of network segmentation methodologies for the ControlLogix and

CompactLogix™ 5370 controllers.

Describes the embedded software features and tools for configuring and managing the Stratix 5410, Stratix 5400, and

the Stratix 5700 Ethernet managed switches.

Provides switch specifications, certifications, and the latest product information.

Illustration that shows options for connecting your plant network by using standard Ethernet technology.

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 9

Page 10

Preface

Table 2 - Infrastructure Resources

Resource Description

ControlNet Coax Media Planning and Installation Guide,

publication CNET-IN002

ControlNet Fiber Media Planning and Installation Guide,

publication CNET-IN001

ControlNet Modules in Logix5000 Control Systems User

Manual, publication CNET-UM001

Product Compatibility and Download Center at

http://www.rockwellautomation.com/

rockwellautomation/support/pcdc.page

Provides procedures for planning, installing, and implementing a ControlNet network.

Website helps you find product-related downloads including firmware, releas e notes, associated software, dri vers, tools

and utilities.

Table 3 - Field Device Integration Resources

Resource Description

FactoryTalk AssetCentre Installation Guide,

publication FTAC-IN005

FactoryTalk AssetCentre Product Profile,

publication FTALK-PP001

EtherNet/IP and ControlNet to FOUNDATION Fieldbus

Linking Device, publication 1788-UM057

1788-EN2PAR User Manual, publication 1788-UM056 Describes the installation and operation of the 1788-EN2PAR linking device.

1788-CN2PAR User Manual, publication 1788-UM055 Describes the installation and operation of the 1788-CN2PAR linking device.

ControlLogix HART Analog I/O Modules User Manual,

publication 1756-UM533

Promass 83 Flowmeter via PROFIBUS PA to the PlantPAx

Process Automation System, publication PROCES-AP022

DeviceNet System Quick Reference,

publication DNET-QR001

CENTERLINE® Motor Control Centers with EtherNet/IP,

publication 2100-TD031

CENTERLINE 2500 Motor Control Centers with EtherNet/IP

Network, publication 2500-TD003

Integrate E+H Instruments in a PlantPAx System

Integration Document, publication PROCES-SG003

Provides installation instructions for monitoring your factory automation system.

Explains this tool for securing, managing, versioning, tracking, and reporting automation-related asset information

across yo ur entire enterprise.

Describes the installation and operation of the 1788-EN2FFR and 1788-CN2FFR linking devices.

Contains information on how to install, configure, and troubleshoot ControlLogix HART

analog I/O modules.

Provides procedures for the design and implementation of PROFIBUS PA equipment.

Provides procedures for configuring applications on the DeviceNet® network.

Describes cable system construction and components that are associated with an EtherNet/IP network that is factoryinstalled in CENTERLINE 2100 and CENTERLINE 2500 and IntelliCENTER® motor control centers (MCCs).

Provides a step-by-step approach to integrating HART devices from Endress+Hauser into the PlantPAx system.

Table 4 - Batch Resources

Resource Description

FactoryTalk Batch User's Guide, publication BATCH-UM011 Provides a complement of FactoryTalk recipe management, component guidelines, and software installation

FactoryTalk Batch Installation Guide,

publication BATCH-IN002

PlantPAx Batch Design Considerations Reference Manual,

publication PROCES-RM008

Batch Application Toolkit Quick Start,

publication IASIMP-QS042

PhaseManager™ User Manual, publication LOGIX-UM001 Explains how to define a state model for your equipment and develop equipment phases.

10 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

procedures.

Provides information and procedures for installing FactoryTalk Batch software.

Provides guidance on selected batch implementation topics in a PlantPAx system.

Provides a framework for how to use the tasks to complete the components of the Toolkit.

Page 11

Table 5 - Process Safety Resources

Resource Description

Using ControlLogix in SIL 2 Applications Safety Reference

Manual, publication 1756-RM001

Redundant I/O System User Manual

publication 1715-UM001

AADvance Solutions Handbook, publication ICSTT-RM447

AADvance System Build Manual, publication ICSTT-RM448

AADvance Configuration Guide, publication ICSTT-RM405 Defines how to configure an AADvance controller by using the AADvance Workbench to meet your Safety Instrument

AADvance Safety Manual, publication ICSTT-RM446

AADvance Troubleshooting and Repair Manual, publication

ICSTT-RM406

ControlLogix components that are supported in SIL 2 configurations.

Describes how to install and configure the 1715 Redundant I/O system with a ControlLogix Enhanced

Redundancy System.

Explains the features, performance, and functionality of the AADvance controller and systems. It sets out some

guidelines on how to specify a system to meet your application requirements.

Provides experienced panel builders with information on how to assemble a system, switch on and validate the

operation of a controller.

Function (SIF) application requirements.

Defines mandatory standards and makes recommendations to safely apply AADvance controllers for a SIF application.

Explains how to use traditional and extreme environment ControlLogix controllers.

Provides plant maintenance personnel with information on how to trace and repair a fault in an AADvance system and

perform routine maintenance tasks.

You can view or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Preface

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 11

Page 12

Preface

Notes:

12 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 13

Chapter 1

EWS PASS

Domain

Control ler

Application Servers Multiple OWS

Device Level Ring Topology

System Architecture Overview

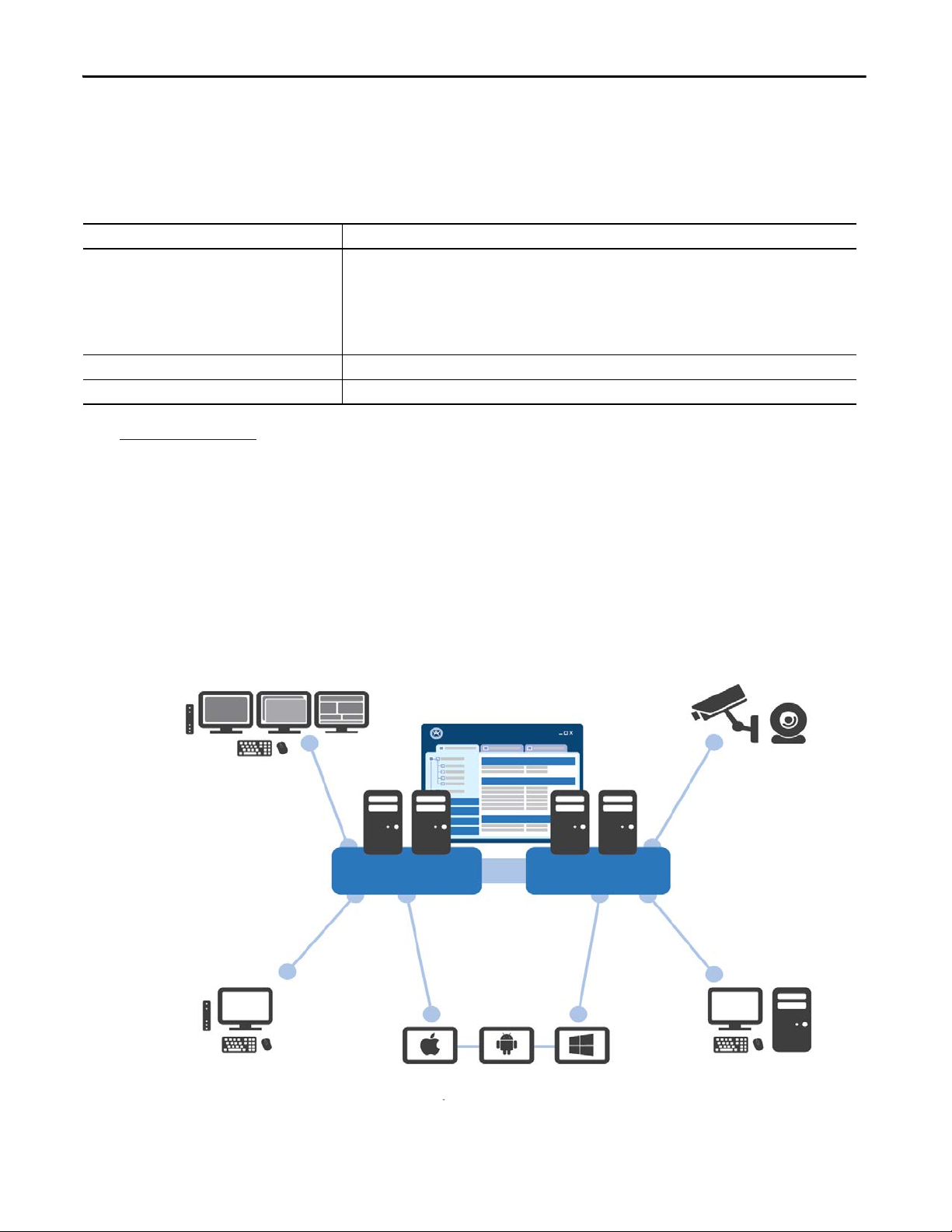

The PlantPAx® system uses standard Rockwell Automation® Integrated

Architecture® (IA) products to build a distributed control system (DCS).

Our modern DCS is scalable, flexible, and open while still providing the

reliability, functionality, and performance expected from a DCS.

This section describes the system elements and architectures that you can use to

configure a PlantPAx system.

Top ic Pag e

Architecture Classes 14

System Elements 14

Critical System Attributes 15

System Procurement Tools 16

Rockwell Automation characterizes a DCS based on its size or architecture class. A ‘characterized’ classification yields system performance data and recommended hardware and software configurations.

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 13

Page 14

Chapter 1 System Architecture Overview

Station Architecture

Distributed Architecture- Multiple PASS Servers

Distributed Architecture- Single PASS Server

Skid Controller

S

ca

l

a

b

l

e

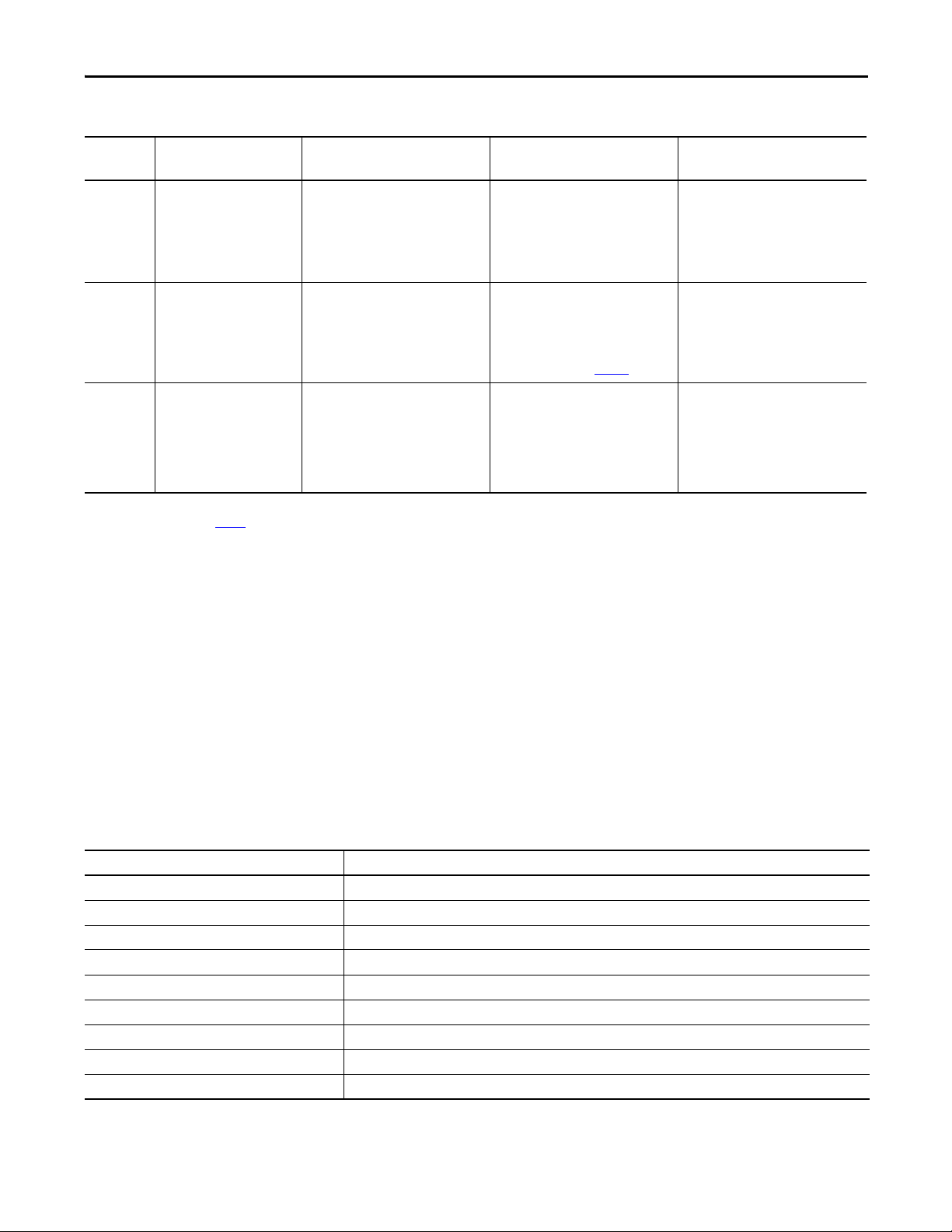

Architecture Classes

Architecture classes define reference architectures that are based on the size of the

required system.

Architecture Description

Skid Skid architecture with a skid controller and PanelView™ for monitoring data.

Station A single station that acts as a PlantPAx Automation System Server (PASS), Operator Workstation (OWS), and

Distributed - Single server This architecture has a single PASS server and supports multiple OWSs and EWSs.

Distributed - Multiple servers This architecture has multiple PASS servers and supports multiple OWSs and EWSs. You can add servers for more capacity or to

Engineering Workstation (EWS).

segregate servers by operating areas.

System Elements

System elements are the different elements of a PlantPAx DCS. Elements can be

deployed on your system depending on the needs of the application.

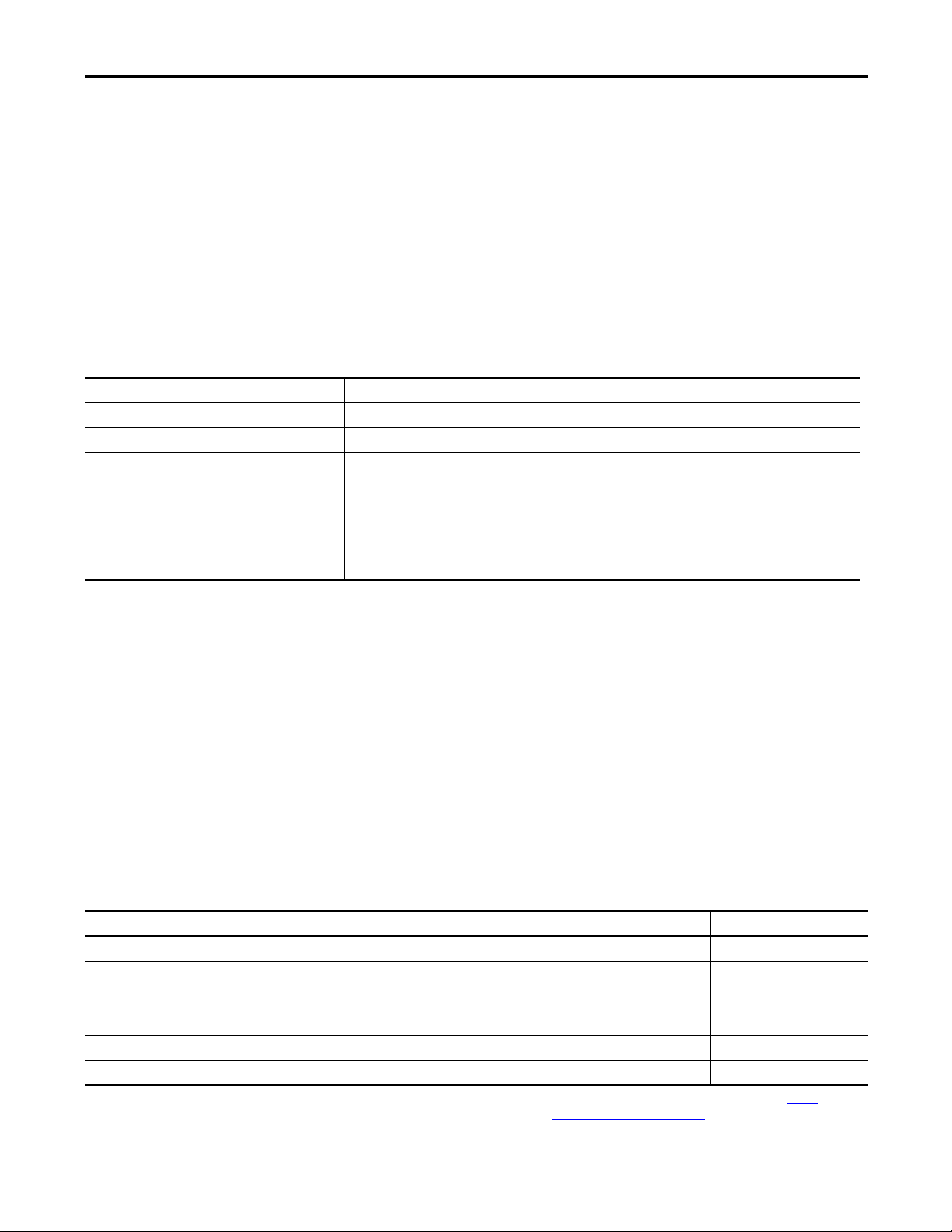

Table 6 - Architectures and System Elements

System

Element

PASS Not applicable. Single workstation serves as PASS, EWS,

EWS Included in independent workstation 1 EWS required. 1 EWS required.

Skid Architecture Station Architecture Distributed Architecture

(single PASS (consolidated))

and OWS in an independent workstation

For smaller systems, one PASS

(consolidated) is required that typically

includes the following:

• FactoryTalk® Directory server

• HMI server

• Data server

• Alarm and Event Server

The PASS-C supports functions that

otherwise are hosted on application

servers. The PASS-C single computer

includes the following in a single

workstati on:

• PAS S

• FactoryTalk Historian

• AppServ-Asset Management

• AppServ-VantagePoint

• AppServ-Info (SQL)

IMPORTANT: An additional PASS-C is

required for redundan cy.

Distributed Architecture

(single to multiple PASS servers)

One PASS required and includes one or

more of the following:

• FactoryTalk Directory server

• HMI server

• Data server

• Alarm and Event Server

Additional PASS as needed (up to 10

servers or redundant server pairs).

Can have as many as 5 EWSs.

(1)

14 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 15

Table 6 - Architectures and System Elements

System Architecture Overview Chapter 1

System

Element

OWS Not applicable. Operator

Controllers CompactLogix controller. 1...5 ControlLogix® controllers. 1...5 ControlLogix controllers.

Application

servers

(1) These values are product maximum limits. It’s possible that achieving these limits on your system is not feasible based on your system design. Use the PlantPAx System Estimator to make sure that your

system is sized properly (see page 16

Critical System Attributes

Skid Architecture Station Architecture Distributed Architecture

(single PASS (consolidated))

interface typically

accomplished with PanelView

Plus operator terminal or thin

client connected to a

distributed architecture.

Not applicable. In chassis

historian and in controller

batch capabilities are available.

Can also be integrated with a

distributed architecture.

).

Included in independent workstation Included in PASS-C.

An .ISO file is available for any single,

physical computer.

IMPORTANT: PASS-C supports up to

10 clients.

IMPORTANT: PASS-C supports up to five

redundant contro llers.

Use the PlantPAx System Estimator to

verify your design. See page 16

AppServ-Asset Management as needed.

AppServ-Batch as needed.

AppServ-Information Management (SQL,

Historian, or VantagePoint®) as needed.

Additional servers can be added as your

system scales. For example,

AppServ-Batch, AppServ-Information

Management.

IMPORTANT: An additional PASS-C is

required for redundan cy.

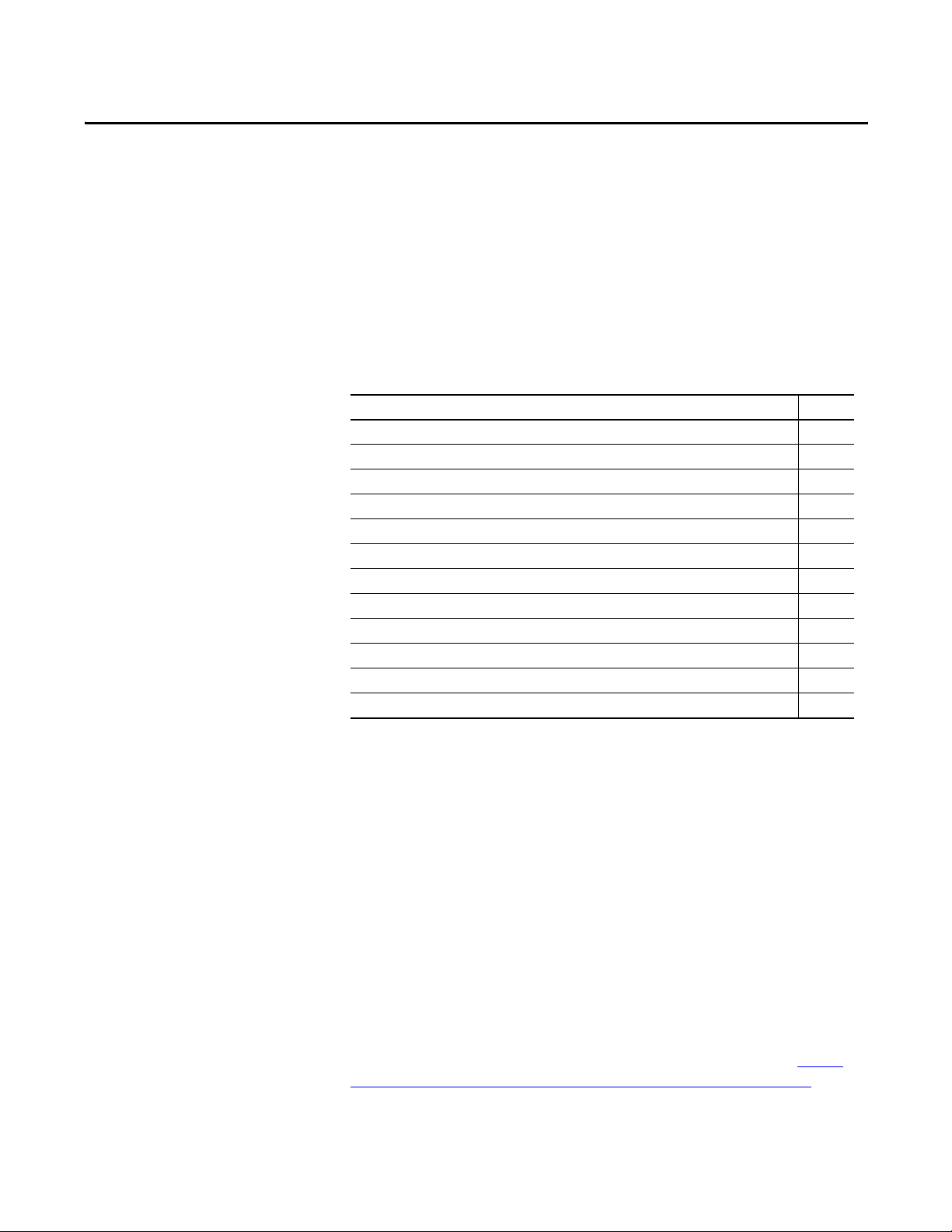

A critical system attribute (CSA) is a visible performance indicator of a

Distributed Architecture

(single to multiple PASS servers)

Can have as many as 120 OWS clients.

There is no hard limit for the number of

controllers. The number of controllers

that can be supported per PASS (data

server) depends on controller selection,

.

controller loading, and number of OWS.

AppServ-Asset Management as needed.

AppServ-Batch as needed.

AppServ-Information Management (SQL,

Historian, or VantagePoint) as needed

AppServ-OWS as needed.

(1)

system-wide characteristic. CSAs are used to define or identify specified levels of

system operation:

• Determine system limits

• Establish system rules

• Establish system recommendations

• Measure system element and system infrastructure performance

The following CSAs are used to verify performance during process

system characterization.

Table 7 - CSA Performance Indicators

Critical System Attribute

Display callup (paint time) A noncached display is called up by the operator and ready for operator use within 2 seconds.

Display update The display updates control information within 1 second.

Steady state alarm time Steady state alarms occurring at 20 per second are timestamped within 1 second.

Alarm burst time All alarms in a burst of 1000 alarms are timestamped within 3 seconds.

Recovery A system element returns to full operation within 5 minutes of the restoration after a failure or loss.

Operator-initiated control Operator-initiated actions are loaded into the controller and the feedback for the operator action is within 2 seconds.

Batch server: operator action time An operator batch command has been acted on by the controller in 1 second.

Batch server: server action time A server batch command has been acted on by the controller in 1 second.

Batch server: controller action time Batch status events display on the operator workstation within 1 second.

(1) CSA performance indicators are a nominal per formance number. The actual system performance c an intermittently deviate from the documented CSA due to system disturbances that can introduce

variability in the network or operating system performance.

(1)

Performance

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 15

Page 16

Chapter 1 System Architecture Overview

System Procurement Tools

The following chapters of this manual contain recommendations and

considerations for how to implement your system. If you have not selected or

procured your PlantPAx system architecture and components, see the

PlantPAx Selection Guide, publication PROCES-SG001

The PlantPAx System Estimator (PSE), which is a part of the Integrated

Architecture® Builder (IAB) software tool, helps you define a PlantPAx system.

The PSE wizard lets you specify your system architecture that is based on your

requirements, and verifies that your process control hardware is sized properly.

When the verification is complete, you can transfer the output of the PSE wizard

into the IAB tool to develop a bill-of-material for the system based on

your inputs.

See http://www.rockwellautomation.com/en/e-tools/configuration.html

access the IAB tool.

, for more information.

to

16 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 17

Chapter 2

System Element Recommendations

PlantPAx® system elements refer to the individual servers, clients, and controllers

that comprise a PlantPAx system. This chapter describes each system element and

its components. A base installation of all server and workstation elements is

available as virtual appliances.

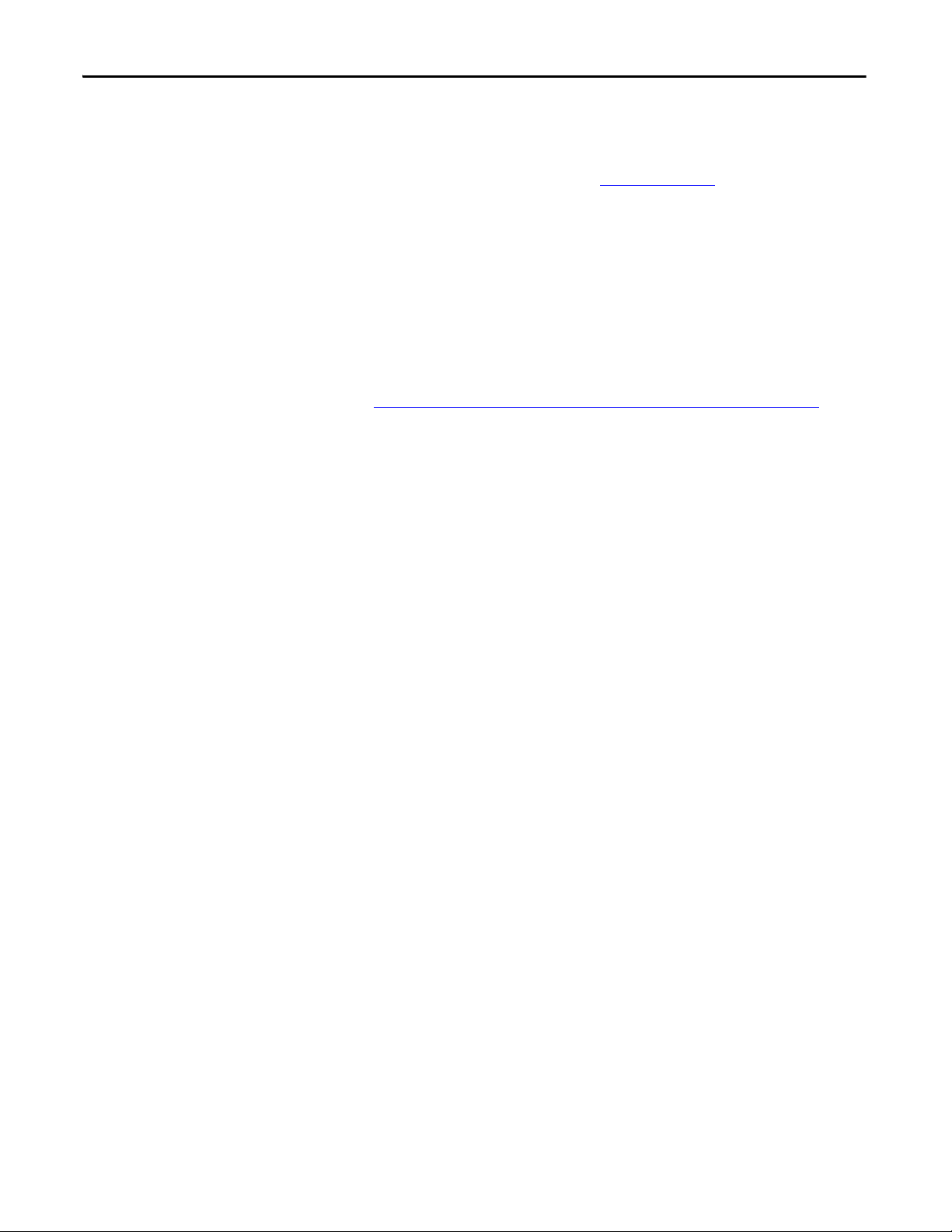

The following table lists where to find specific information.

Top ic Pag e

PlantPAx Software Components 17

Process Automation System Server (PASS) 18

Engineering Workstation (EWS) and Application Server (AppServ-EWS) 20

Operator Workstation (OWS) and Application Server (AppServ-OWS) 21

Independent Workstation (IndWS) 23

AppServ-Info (Historian) 24

AppServ-Info (VantagePoint) 24

AppServ-Info (SQL) 25

Asset Management Server (AppServ-Asset) 25

Batch Management Server (AppServ-Batch) 26

Domain Controller 27

Controller Characteristics 28

PlantPAx Software Components

Integrated Architecture® software components and versions that comprise the

PlantPAx system, include the following:

• Studio 5000 Logix Designer® application, version 31.x

• Studio 5000 Architect™ application, version 4.x

• FactoryTalk® View software, version 11.x

• FactoryTalk Batch software, version 13.x

• FactoryTalk AssetCentre software, version 9.x

• FactoryTalk® VantagePoint® software, version 8.x

• FactoryTalk Historian software, version 6.x

Performance guidelines are based on the use of the software versions listed.

For the latest compatible software information and to download associated

library tools, see the Product Compatibility and Download Center at http://

www.rockwellautomation.com/rockwellautomation/support/pcdc.page.

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 17

Page 18

Chapter 2 System Element Recommendations

Process Automation System Server (PASS)

The Process Automation System Server (PASS) is a required system element that

hosts essential software components to run the system. The essential software

components include the data server, HMI server, and alarm server. The PASS can

be used as a data, HMI, and/or alarm server.

Software Components Description

Fac toryTa lk Network Directory (FTD) server

FactoryTalk Activation server

FactoryTalk View HMI server The human machine interface (HMI) server is configured within your FactoryTalk View Site Edition (SE) application. The

FactoryTalk View Data server The Data server component provides access to information from the process controllers to servers and workstations on

FactoryTalk View Alarm and Event ser ver The Alarm and Event server publishes information from controllers and servers available to all subscribing OWSs. Alarm

Optional

FactoryTalk Batch client software If a Batch Application server is being used on the system, FactoryTalk Batch client components are required to support

(1)

(1)

Secures information from multiple Rockwell Automation® software components across multiple computers and

provides central administration throughout the PlantPAx system. Application components, such as display and security

settings, can be stored in their original environments and made available to the entire PlantPAx system without the

need for duplication.

The FactoryTalk Activation server is part of the FactoryTalk Services Platform. The server allows FactoryTalk-enabled

software products to be activated via files generated by Rockwell Automation over the Internet. This server essentially

manages the files that are required to license Rockwell Automation products on the PlantPAx system.

HMI server stores HMI project components, such as graphic displays, and serves these components to OWSs upon

request. The HMI server also can manage tag databases and log historical data. Multiple HMI servers can exist on the

PlantPAx system. Each HMI server must be on a separate PASS.

the PlantPAx system. FactoryTalk View software supports two types of data servers: Rockwell Automation Device

servers (FactoryTalk Linx software) and OPC Data servers. The Data server that is mention ed in PlantPAx documentation

generally refers to the Rockwell Automation Device servers. Data servers are configured within your FactoryTalk View

SE application. Multiple data servers can exist on the PlantPAx system.

and Event servers are configured within your FactoryTalk View SE application. There are two types of Alarm and Event

servers: device-based and ser ver-based. Device-based Alarm and Event servers are configured as an option to the data

server. Server-based Alarm and Event servers are configured as a separate component. Each server-based Alarm and

Event server must be on a separate PASS.

The Alarm and Event server that is mentioned in PlantPAx documentation refers to the Alarm and Event server that is

server-based. See Alarm System Recommendations on page 55 for more information.

replication of batch-related objects on the displays to the OWS.

(1) In redundant PASS configurations, this component is included on the primary PASS only.

18 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 19

System Element Recommendations Chapter 2

IMPORTANT

PASS Server Redundancy

PASS servers can be configured as redundant for the following software

components:

• HMI server

• Data server

• Alarm server

When you enable redundancy in FactoryTalk View Studio software, select the

option to ‘Continue using the secondary server even when the primary server

becomes available again’ to avoid excessive switchovers. This option lets you

manage replication of application changes made before or after the

switchover occurs. We recommend that you configure your HMI displays to

indicate when the system is running without backup.

The FactoryTalk Directory server information is cached on each computer that is

participating in a distributed application. If the FTD server computer is

disconnected from the network or fails, the OWS, EWS, and other application

servers can continue to access everything within the application. This

functionality applies as long as the computer has already accessed the FTD server.

Table 8.1 - PA SS Virtual Requirements

Category Requirement

Virtual infrastructure Required:

Operating system Windows Server 2016 operating system, 64 bit

(1) All numbers and figures are referenced for initial sizi ng only. The values can be adjusted for system performance if needed.

(2) See Resource Pool Allocation

on page 69.

• 4 vCPU

• 8 GB vRAM min

• 60 GB vHardDisk

Recommended CPU and memory allocation:

• High priority Resource pool

(1)

(2)

Table 8.2 - PASS Traditional Requirements

Category Requirement

Traditional infrastructure The PASS must be installed on server-class hardware. The following are sample specifications that are based on PlantPAx

system characterization:

• Intel Xeon Multicore processor (4 cores or greater)

• 2.40 GHz CPU min

• 8 GB RAM min

• Ethernet card that supports redundant media if NIC-teaming is used (If you plan to use a motherboard-NIC make sure

that it supports redundant media)

PASS - C (for small and medium systems) For systems with fewer than 2000 I/O points, the PASS - Consolidated contains HMI, data collection, decision-making,

Operating system Windows Server 2016 operating system, 64 bit

and asset management servers. These combined tools form a basic PlantPAx system in a single server, referred to|

as consolidated.

The PASS must be installed on server-class hardware. The following are sample specifications based on PlantPAx

system characterization:

• Intel® Xeon E-31270 v5

• 3.60 GHz CPU min

• 32 GB RAM min

• Ethernet card that supports redundant media if NIC-teaming is used (If you plan to use a motherboard-NIC make sure

it supports redundant media)

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 19

Page 20

Chapter 2 System Element Recommendations

IMPORTANT

Configure the FactoryTalk Directory

Before starting a project, you must install FactoryTalk Directory (FTD) services

on the computer that is hosting the FTD or the PASS. The FTD server manages

applications that can exist on multiple clients and servers on separate computers

on the PlantPAx system.

To configure the FTD, see the PlantPAx Distributed Control System

Infrastructure Configuration User Manual, publication PROCES-UM001

.

Engineering Workstation (EWS)

The EWS supports system configuration, application development, and

maintenance functions. This workstation is the central location for monitoring

and maintaining the system operation.

If a batch application server is used, the FactoryTalk Batch client and editor

components are required to configure the FactoryTalk Batch system and

configure the FactoryTalk objects on the displays.

Table 9.1 - EWS Virtual Requirements

Category Requirement

Virtual infrastructure Required:

Operating system Windows 10 operating system, 64 bit

(1) All numbers and figures are referenced for initial sizi ng only. The values can be adjusted for system performance if needed.

(2) See Resource Pool Allocation

Table 9.2 - EWS Traditional Requirements

Category Requirement

Traditional infrastructure The EWS must be installed on workstation-class hardware. The following are sample specifications based on PlantPAx

Operating system Windows 10 operating system, 64 bit

on page 69

• 2 vCPU

• 4 GB vRAM min

• 100 GB vHardDisk

Recommended CPU and memory allocation:

• Normal priority Resource pool

system characterization.

• Intel Core 2 Duo

• 2.40 GHz CPU min

• 4 GB RAM min

• Ethernet card that supports redundant media if NIC-teaming is used (If you plan to use a motherboard-NIC make

sure that it supports redundant media)

(1)

(2)

20 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 21

System Element Recommendations Chapter 2

Engineering Workstation Application Server (AppServ-EWS)

The AppServ-EWS uses Microsoft® Remote Desktop Services (RDS) technology

to serve multiple instances of the EWS as thin clients from a single server. Thin

clients can run applications and process data on a remote computer. The

recommended limit is five RDS client connections per AppServ-EWS.

Table 10 - AppServ-EWS Virtual Requirements

Category Requirement

Virtual infrastructure Required:

• 4 vCPU

• 8 GB vRAM min

• 100 GB vHardDisk

Recommended CPU and memory allocation:

• Normal priority Resource pool

Thin client We recommend a maximum of 5 FactoryTalk View SE clients per application server

Operating system Windows Server 2016 operating system, 64 bit

(1) All numbers and figures are referenced for initial sizi ng only. The values can be adjusted for system performance if needed.

(2) See Resource Pool Allocation

Operator Workstation (OWS)

on page 69

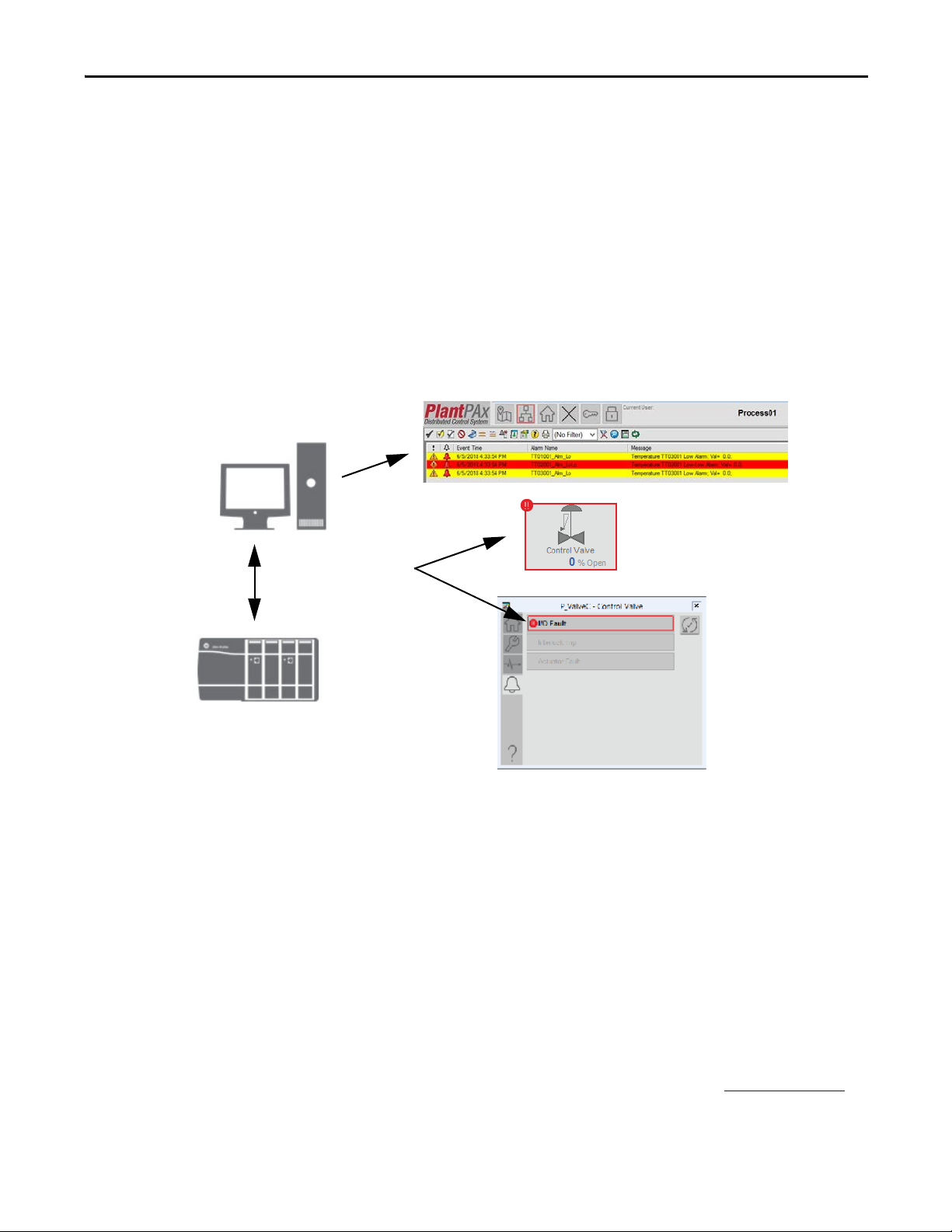

The operator workstation (OWS) provides the graphical view and interface into

(1)

(2)

the process. The OWS supports operator interaction and is not meant to support

development or maintenance activities, although these activities are possible if

desired.

FactoryTalk View Site Edition (SE) client software must be installed on the

OWS. The OWS also can contain clients for non-core application servers, such

as FactoryTalk Batch, FactoryTalk Historian, or FactoryTalk AssetCentre.

Table 11.1 - OWS Virtual Requirements

Category Requirement

Virtual infrastructure Required:

Operating system Windows 10 operating system, 64 bit

(1) All numbers and figures are referenced for initial sizi ng only. The values can be adjusted for system performance if needed.

(2) See Resource Pool Allocation

on page 69

• 2 vCPU

• 4 GB vRAM min

• 40 GB vHardDisk

Recommended CPU and memory allocation:

• High priority Resource pool

Table 11.2 - OWS Traditional Requirements

Category Requirement

Traditional infrastructure The OWS must be installed on workstation-class hardware. The following are sample specifications based on PlantPAx

Operating system Windows 10 operating system, 64 bit

system characterization:

• Intel Core 2 Duo

• 2.40 GHz CPU min

• 4 GB RAM min

• Ethernet card that supports redundant media if NIC-teaming is used (If you plan to use a motherboard-NIC make

sure that it supports redundant media)

(1)

(2)

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 21

Page 22

Chapter 2 System Element Recommendations

Deliver multiple sessions to multiple

monitors and customized virtual

screens on a single thin client.

Access feeds from USB and IP cameras.

Deliver applications based on

what is assigned to the

terminal or user.

Deliver content to the right person

at the right time and place.

Get mobile access to applications specific to a user’s role.

Manage and deliver virtual

desktops while running PCs

as a thin client.

ThinManager

Remote Desktop Servers Virtual Resources

Operator Workstation Application Server (AppServ-OWS)

The AppServ-OWS uses Microsoft Remote Desktop Services (RDS) technology

to serve multiple instances of the OWS as thin clients from a single server. Thin

clients can run applications and process data on a remote computer. The

recommended limit is 10 RDS connections per AppServ-OWS.

Table 12 - AppServ-OWS Virtual Requirements

Category Requirement

Virtual infrastructure Required:

• 8 vCPU

• 16 GB vRAM min

• 60 GB vHardDisk

Recommended CPU and memory allocation:

• High priority Resource pool

Thin client We recommend a maximum of 10 FactoryTalk View SE clients per application server

Operating system Windows Server 2016 operating system, 64 bit

(1) All numbers and figures are referenced for initial sizi ng only. The values can be adjusted for system performance if needed.

(2) See Resource Pool Allocation

on page 69

(1)

(2)

ThinManager Server Options

The AppServ-OWS system element virtual image template is pre-configured

with Remote Desktop Services (RDS). RDS includes the ThinManager® Server

installation file. You can configure the AppServ-OWS as your ThinManager

Server and deploy up to 10 OWS sessions to simplify the management of all

devices and users.

ThinManager increases your productivity, visualization, mobility, and security

from one easy-to-use, centralized, and scalable management platform

.

22 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 23

System Element Recommendations Chapter 2

Safely and securely deliver your content to any combination of device, user, and

location with the following features:

• Boost productivity by reducing the time that is spent to manage computers

• Enhance visualization by delivering your content to where you need it and

the way you want the content shown

• Extend security through encrypted communications, active directory, and

secure thin clients

• Smart mobility where QR codes, Bluetooth, Wi-Fi, and GPS make sure

that devices receive content in authorized areas

For more information, contact your Rockwell Automation representative.

Independent Workstation (IndWS)

Table 13 - IndWS Traditional Requirements

Category Requirement

Traditional infrastructure The IndWS must be installed on workstation-class hardware. The following are sample specifications based on

Operating system Windows 10 operating system, 64 bit

The independent workstation (IndWS) combines the roles of the PASS, EWS,

and OWS in one computer. This workstation can be used as a ‘shadow system’ for

emergency purposes

PlantPAx system characterization:

• Intel Multicore processor (4 cores or greater)

• 2.40 GHz CPU min

• 8 GB RAM min

• Ethernet card that supports redundant media if NIC-teaming is used (If you plan to use a motherboard-NIC make

sure that it supports redundant media)

.

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 23

Page 24

Chapter 2 System Element Recommendations

AppServ-Info (Historian)

The Information Management server can include a historian application to

collect, manage, and analyze data.

Table 14.1 - AppServ-Info (Historian) Virtual Requirements

Category Requirement

Virtual infrastructure Required:

Operating system Windows Server 2016 operating system, 64 bit

(1) All numbers and figures are referenced for initial sizi ng only. The values can be adjusted for system performance if needed.

(2) See Resource Pool Allocation

(3) To install FactoryTalk View SE Historian software, version 4.6, with Windows Server 2016, you must install a patch from the Product Compatibility and Download Center at

http://www.rockwellautomation.com/rockwellautomation/support/pcdc.page

on page 69

• 2 vCPU

• 4 GB vRAM min

• 120 GB vHardDisk

Recommended CPU and memory allocation:

• Normal priority Resource pool

Table 14.2 - AppServ-Info (Historian) Traditional Requirements

Category Requirement

Traditional infrastructure The Information Management server must be installed on server-class hardware:

Operating system Windows Server 2016 operating system, 64 bit

• Intel Xeon Multicore processor (4 cores or greater)

• 2.40 GHz CPU min

• 4 GB RAM min

• Ethernet card that supports redundant media if NIC-teaming is used (If you plan to use a motherboard-NIC make

sure that it supports redundant media)

(1)

(2)

(3)

.

AppServ-Info (VantagePoint)

The Information Management server can be used as a decision support tool by

installing VantagePoint software.

Table 15.1 - AppServ-Info (VantagePoint) Virtual Requirements

Category Requirement

Virtual infrastructure Required:

Operating system Windows Server 2016 operating system, 64 bit

(1) All numbers and figures are referenced for initial sizi ng only. The values can be adjusted for system performance if needed.

(2) See Resource Pool Allocation

on page 69.

• 2 vCPU

• 4 GB vRAM min

• 60 GB vHardDisk

Recommended CPU and memory allocation:

• Normal priority Resource pool

Table 15.2 - AppServ-Info (VantagePoint) Traditional Requirements

Category Requirement

Traditional infrastructure The Information Management server must be installed on server-class hardware:

Operating system Windows Server 2016 operating system, 64 bit

• Intel Xeon Multicore processor (4 cores or greater)

• 2.40 GHz CPU min

• 4 GB RAM min

• Ethernet card that supports redundant media if NIC-teaming is used (If you plan to use a motherboard-NIC make

sure that it supports redundant media)

(1)

(2)

24 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 25

System Element Recommendations Chapter 2

AppServ-Info (SQL)

An SQL server can be configured with the Information Management server.

Software such as FactoryTalk AssetCentre, FactoryTalk VantagePoint, and

FactoryTalk Batch use an SQL database to store and access process data.

Additionally, the FactoryTalk Alarm and Event server uses an SQL database to

store information

Table 16.1 - AppServ-Info (SQL) Virtual Requirements

Category Requirement

Virtual infrastructure Required:

Operating system Windows Server 2016 operating system, 64 bit

(1) All numbers and figures are referenced for initial sizi ng only. The values can be adjusted for system performance if needed.

(2) See Resource Pool Allocation

on page 69.

• 2 vCPU

• 4 GB vRAM min

• 120 GB vHardDisk

Recommended CPU and memory allocation:

• Normal priority Resource pool

Table 16.2 - AppServ-Info (SQL) Traditional Requirements

Category Requirement

Traditional infrastructure The Information Management server must be installed on ser ver-class hardware:

Operating system Windows Server 2016 operating system, 64 bit

• Intel Xeon Multicore processor (4 cores or greater)

• 2.40 GHz CPU min

• 4 GB RAM min

• Ethernet card that supports redundant media if NIC-teaming is used (If you plan to use a motherboard-NIC make

sure that it supports redundant media)

(1)

.

(2)

Asset Management Server (AppServ-Asset)

An asset management server (AppServ-Asset) is an extension to the PlantPAx

system that adds maintenance and plant operations to the system. This server

provides the following to improve resource availability:

• Disaster recovery controller data

• Diagnostics

• Calibration

• Real-time monitoring

• Auditing equipment

• Network health

Table 17.1 - AppServ-Asset Virtual Requirements

Category Requirement

Virtual infrastructure Required:

Operating system Windows Server 2016 operating system, 64 bit

(1) All numbers and figures are referenced for initial sizi ng only. The values can be adjusted for system performance if needed.

(2) See Resource Pool Allocation

on page 69

• 2 vCPU

• 4 GB vRAM min

• 60 GB vHardDisk

Recommended CPU and memory allocation:

• Normal priority Resource pool

(1)

(2)

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 25

Page 26

Chapter 2 System Element Recommendations

Table 17.2 - AppServ-Asset Traditional Requirements

Category Requirement

Traditional infrastructure The Information Management server must be installed on server-class hardware:

Operating system Windows Server 2016 operating system, 64 bit

• Intel Xeon Multicore processor (4 cores or greater)

• 2.40 GHz CPU min

• 4 GB RAM min

• Ethernet card that supports redundant media if NIC-teaming is used (If you plan to use a motherboard-NIC make

sure that it supports redundant media)

Batch Management Server (AppServ-Batch)

The batch management server (AppServ-Batch) offers comprehensive batch

management, including recipe management, procedural control of automated

and manual processes, and material management.

Table 18.1 - AppServ-Batch Virtual Requirements

Category Requirement

Virtual infrastructure Required:

Operating system Windows Server 2016 operating system, 64 bit

(1) All numbers and figures are referenced for initial sizi ng only. The values can be adjusted for system performance if needed.

(2) See Resource Pool Allocation

on page 69

• 2 vCPU

• 4 GB vRAM min

• 60 GB vHardDisk

Recommended CPU and memory allocation:

• Normal priority Resource pool

(1)

(2)

Table 18.2 - AppServ-Batch Traditional Requirements

Category Requirement

Traditional infrastructure The Information Management server must be installed on server-class hardware:

Operating system Windows Server 2016 operating system, 64 bit

• Intel Xeon Multicore processor (4 cores or greater)

• 2.40 GHz CPU min

• 4 GB RAM min

• Ethernet card that supports redundant media if NIC-teaming is used (If you plan to use a motherboard-NIC make

sure that it supports redundant media)

26 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 27

System Element Recommendations Chapter 2

Domain Controller

A domain controller is a server that responds to security authentication requests

(log in, verify permissions, and so forth) within the Windows server domain. A

domain grants you access to a number of network resources (such as applications

and printers) with the use of a single user name and password combination.

PlantPAx uses a domain controller to store user account information,

authenticate users, and enforce security policies.

Domain authentication is recommended, whether it’s an existing domain or a

new one. Follow these guidelines for the domain controller:

• Domain controllers are required if there are 10 or more workstations

or servers.

• The domain controllers are separate computers. Do not load any

application software on a domain controller. Load all system application

software on the other computers, such as the PASS, application server,

OWS, and EWS.

• Microsoft support does not recommend applications to be run on a

domain controller, and certainly not applications that require more than

Authenticated User privileges to run.

• The domain controllers must be local to the system workstations and

servers (within the local firewall) and not remote to the system.

Table 19.1 - Domain Virtual Requirements

Category Requirement

Virtual infrastructure Required:

• 1 vCPU

• 4 GB vRAM min

• 40 GB vHardDisk

Recommended CPU and memory allocation:

• Low priority Resource pool

Operating system Windows Server 2016 operating system, 64 bit

(1)

(2)

(1) All numbers and figures are referenced for initial sizi ng only. The values can be adjusted for system performance if needed.

(2) See Resource Pool Allocation

on page 69.

Table 20 - Domain Traditional Requirements

Category Requirement

Traditional infrastructure

Operating system Windows Server 2016 operating system, 64 bit

(1) A Microsoft Excel software license is required.

(1)

The Information Management server must be installed on server-class hardware:

• Intel Xeon Multicore processor (4 cores or greater)

• 2.40 GHz CPU min

• 4 GB RAM min

• Ethernet card that supports redundant media if NIC-teaming is used (If you plan to use a motherboard-NIC make

sure that it supports redundant media)

For redundancy purposes, we recommend that you use at least two domain

controllers in the domain. These domain controllers replicate automatically to

provide high availability and an online configuration backup.

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 27

Page 28

Chapter 2 System Element Recommendations

Controller Characteristics

This section describes the components and sizing attributes for simplex,

skid-based, and redundant controllers.

Simplex Controller

Non-redundant controllers are referred to as simplex controllers.

Table 21 - Simplex Controller Hardware Requirements

Category Cat. No.

Process controller

EtherNet/IP interface • For direct DLR connection: 1756-EN2TR

ControlNet interface (if applicable) • 1756-CN2, 1756-CN2R

(1) If environmental conditions warrant, you can use an extreme temperature controller, for example, the 1756-L74XT. Conformal coated options are also available for protection from harsh environments

that can contain moisture and or chemical contaminants.

(2) As the PlantPAx system release 4.6 uses controller firmware revision 31, implementation requires use of the 1756-L7x controller family. PlantPAx system release 4.6 can co-exist with older

generation contro llers.

(2)

(1)

ControlLogix® 1756-L71, 1756-L72, 1756-L73, or 1756-L74, or 1756-L75 controller

• For direct PRP connection: 1756-EN2TP

• For secure connections: 1756-EN2TSC

• Otherwise: 1756-EN2T, 1756-EN2F (no DLR support)

• For converting topology or media: 1783-ETAP, 1783-ETAP1F, 1783-ETAP2F (supports DLR topology)

• 1756-CNB, 1756-CNBR

Table 22 - Simplex ControlLogix Controller Sizing

(1)

Category

User memory 2 MB 4 MB 8 MB 16 MB 32 MB

Total I/O recommended, max 375 750 1500 2250 2250

Recommended control strategies, max

Total control strategies @ 250 ms, max 60 125 250 250 250

Total control strategies @ 500 ms, max 60 125 250 450 450

Tags/sec delivered to data server, max 10,000 20,000 20,000 20,000 20,000

(1) These values are recommended maximum limits. It’s possible that achieving all of these values in a single controller is not doable. For more detailed sizing, you can use the PSE (see page 16).

(2) The advantages to using the 1756-L75 controller is to maintain common spare parts with redundant systems or if you are doing some memory intensive storage not accounted for in the sizing model.

(3) Recommended maximum control strategies are based on all controller strateg ies being sim ple regulator y control. See Controller I/O Considerations

(3)

1756-L71 1756-L72 1756-L73 1756-L74 1756-L75

60 125 250 450 450

on page 48.

(2)

28 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 29

System Element Recommendations Chapter 2

Redundant Controllers

ControlLogix controllers support redundancy on ControlNet and EtherNet/IP

networks. In a redundant controller system on PlantPAx, you need these components:

• Two 1756 chassis each set up the same with the following:

– Number of slots

– Modules in the same slots

– Redundancy firmware revisions in each module

– Two additional ControlNet or Ethernet nodes outside the redundant

chassis pair

• One 1756-RM2 module per chassis with fiber media

Table 23 - Redundant Controller Hardware Requirements

Category Cat. No.

Process controller ControlLogix 1756-L73, 1756-L74, or 1756-L75 controller

Redundancy module 1756-RM2

Ethernet interface • For direct DLR connection: 1756-EN2TR

• For direct PRP connection: 1756-EN2TP

• For secure connections: 1756-EN2TSC

• Otherwise: 1756-EN2T, 1756-EN2F (no DLR support)

• For converting topology or media: 1783-ETAP, 1783-ETAP1F, 1783-ETAP2F (supports DLR topology)

ControlNet interface (if applicable) • 1756-CN2, 1756-CN2R

• 1756-CNB, 1756-CNBR

(1) If environmental conditions warrant, you can use an extreme temperature controller, for example, the 1756-L74XT. Conformal coated options are also available for protection from harsh environments

that can contain moisture and or chemical contaminants.

(2) The PlantPAx system recommendation is to use only one redundant controller in a chassis with a 1756-RM2 redundancy module. While a 1756-RM2 module can support t wo controllers, the resulting

performance of each controller is not easily predicted.

(1)

(2)

Make sure that each redundant controller has enough memory to store twice the

amount of controller data and I/O memory to support program modifications.

The increased memory usage in a redundant controller provides for a bumpless

transfer during a switchover and makes sure the secondary Logix controller has

the same values in its output image as the primary Logix controller. The extra

memory helps prevent a switchover to a secondary controller with a mixture of

old and new data memory.

When using the PlantPAx System Estimator, the PSE accounts for additional

memory requirements required for redundancy as memory used.

Table 24 - Redundant ControlLogix Controller Sizing

(1)

Category

User memory 8 MB 16 MB 32 MB

Total I/O recommended, max 750 1500 2250

Recommended control strategies, max

Total control strategies @ 250 ms, max 120 120 120

Total control strategies @ 500 ms, max 125 220 220

Tags/sec delivered to data server, max 20,000 20,000 20,000

(1) These values are recommended maximum limits. It’s possible that achieving all of these values in a single controller is not doable. For more detailed sizing, you can use the PSE (see page 16).

(2) Recommended maximum control strategies are based on all controller strategies being simple regulatory control. See Controller I/O Considerations

(3) The advantages to using the 1756-L75 controller is to maintain common spare parts with redundant systems or if you are doing some memory intensive storage not accounted for in the sizing model.

(2)

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 29

1756-L73 1756-L74 1756-L75

125 250 450

on page 48.

(3)

Page 30

Chapter 2 System Element Recommendations

IMPORTANT

Skid-based Controller

The PlantPAx process automation system is a complete, scalable system, from

single controller to a fully distributed set of equipment. You can easily integrate

skid-based equipment into the overall system.

The CompactLogix™ controller platform offers a solution for skid-based

equipment to be part of the overall PlantPAx system if the application requires

the following:

• Control of multiple loops for temperature, pressure, flow, or level

• Operating as a subsystem with sequencing and automation

• Controlled as part of the overall process, accepting reference inputs, and

delivering process variables to a supervisory controller

Be aware of memory usage within the CompactLogix family when

using Library objects. See the PlantPAx Distributed Control System

Application Configuration User Manual, publication PROCES-UM003

for guidance of how to configure controllers with the Library of

Process Objects.

,

.

Table 25 - Skid-based Controller Sizing

(1)

Category

User memory 0.75 MB 1.0 MB 2.0 MB 3.0 MB

Total I/O recommended, max 80 125 250 350

Recommende d control strategies, max

Total control strategies @ 250 ms, max 10 15 30 45

Total control strategies @ 500 ms, max 10 3000 30 45

Tags/sec delivered to data server, max 3000 3000 3000 3000

(1) These values are recommended maximum limits. To achieve all of these values in a single controller is likely not feasible. For more detailed sizing, you can use the PSE (see page 16).

(2) Maximum controller strategy is based on all controller strategies being simple regulatory control. See Controller I/O Considerations

(2)

CompactLogix

1769 -L24ER-QBFC1B

10 15 30 45

CompactLogix

1769-L19ER-BB1

CompactLogix

1769-L33ER

on page 48.

CompactLogix

1769-L36ERM

30 Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019

Page 31

System Element Recommendations Chapter 2

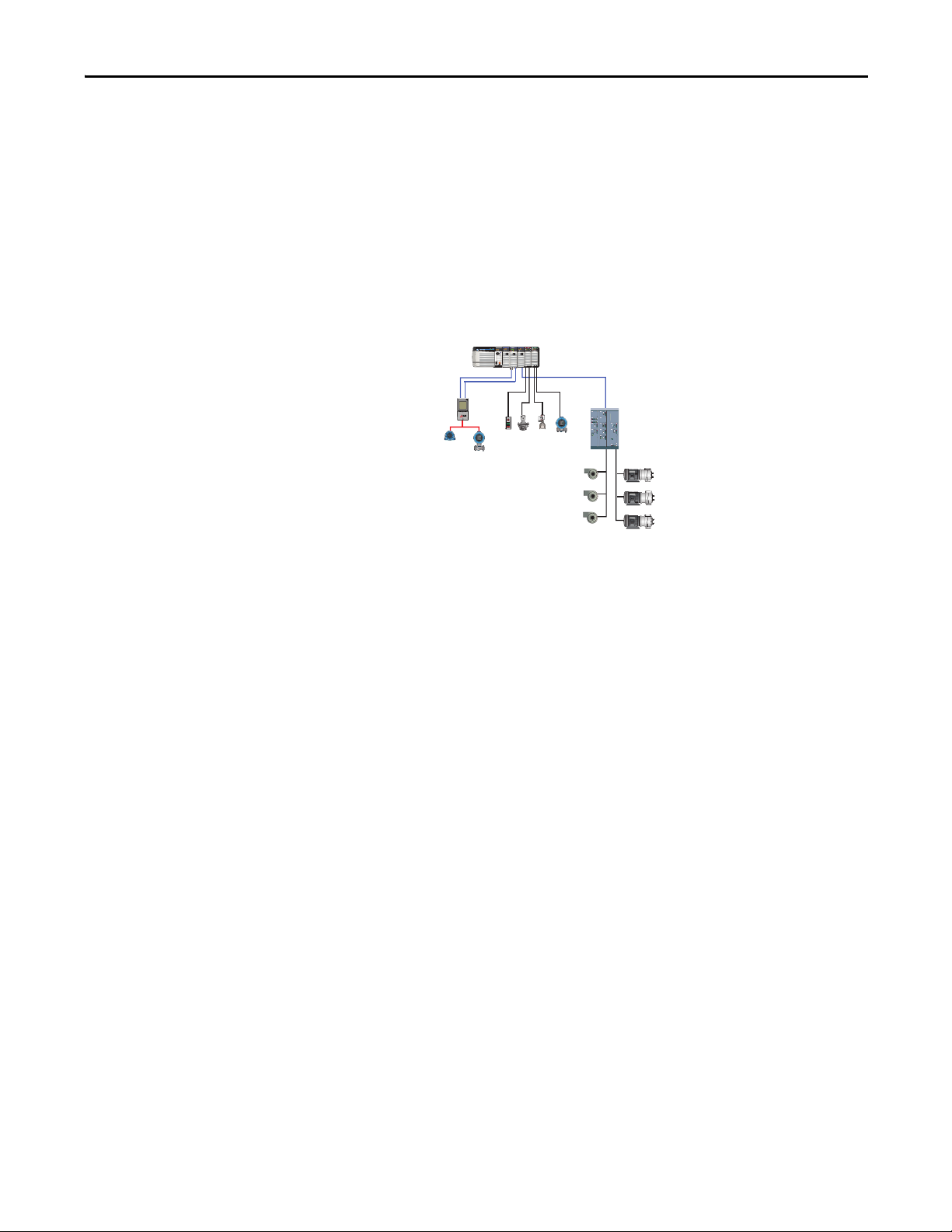

One I/O channel per

each device in a

networked, motor

control center.

One I/O channel per each I/O point on an I/O module.

One I/O channel per each device.

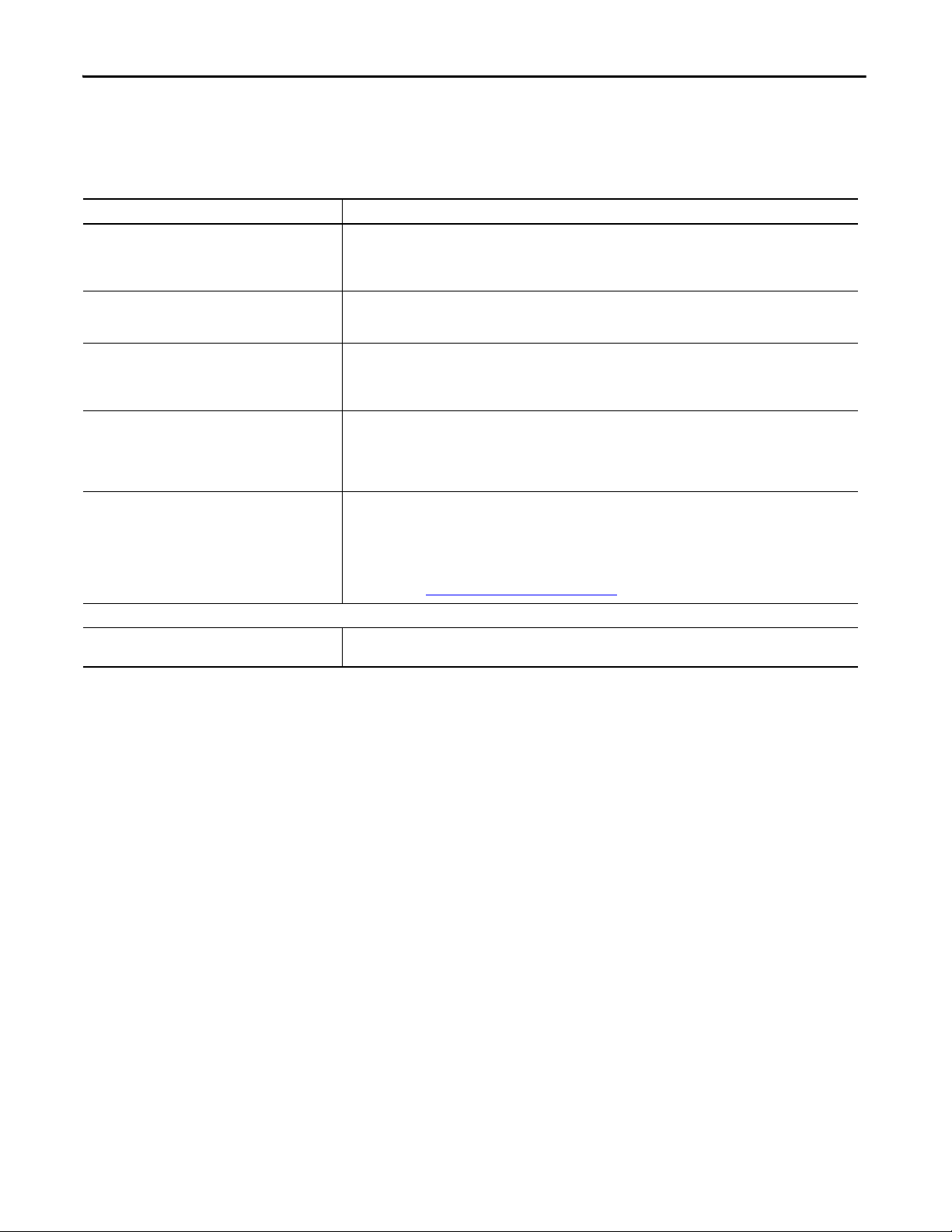

Determining I/O Count

The I/O count for controller sizing is often determined directly from the

application P&ID or plant design. On existing systems where only classic I/O

(for example, 4…20 mA, 24V DC dry contacts, and so forth) is used, the I/O

count can be determined by the number of I/O channels available on the

I/O cards.

When you have integrated smart devices, such as drives or transmitters, on an

EtherNet/IP network, any signal from the device used by your control strategy is

considered an I/O point when using the PSE to size based on control strategies.

For example, an I/O count for a system comprised with the following:

• Two 8-channel 4…20 mA input cards

• One 8-channel 4…20 mA output cards

• Two 16-channel 24V DC dry-contact input cards

• One MCC with six drives

– Each drive provides six signals to the control strategy: speed reference,

actual speed, start, stop, running, and fault.

• Two Coriolis flowmeters on PROFIBUS PA, with each meter providing

three signals for flow, temperature, and density.

We can roughly calculate the following I/O count for the example system:

4…20 mA AI 2 x 8 = 16

4…20 mA AO 1 x 8 = 8

24V DC DI 2 x 16 = 32

MCC 6 x 6 = 36 (6 AI, 6 AO, 12 DI, 12 DO)

Smart instruments 2 x 3 = 6 (6 AI)

___

Controller I/O count 98

Rockwell Automation Publication PROCES-RM001M-EN-P - June 2019 31

This example I/O count method enables you to enter I/O counts into the

PSE to determine an appropriate number of control strategy footprints to

determine sizing.

Page 32

Chapter 2 System Element Recommendations

POWER

ETHERNET

OKTXDRXD

A

B

ST

ST

DIAGNOSTIC

O

K

01234 567

89101112131415

AC OUTPUT

ST

ST

DIAGNOSTIC

O

K