Page 1

Discrete Machine

Performance Solution

Target Machine Efficiency Improvements

Powered by RSBizWare

User’s Guide

Doc ID BWDMPS-UM001A-EN-E

Page 2

Contacting

Rockwell Software

Technical Support Telephone—1-440-646-5800

Technical Support Fax—1-440-646-5801

World Wide Web—www.rockwellsoftware.com

Copyright Notice

Trademark Notice

Copyright © 2004 Rockwell Software Inc. All rights reserved. Printed in USA.

This manual and any accompanying Rockwell Software products are copyrighted by Rockwell

Software Inc. Any reproduction and/or distribution without prior written consent from Rockwell

Software Inc. is strictly prohibited. Please refer to the license agreement for details.

The Rockwell Software logo, RSLogix Emulate 5, RSLogix Emulate 500, RSLinx, RSLogix 5,

RSLogix 500, RSLogix Frameworks, RSLogix SL5, RSView32, RSView, AdvanceDDE, RSSql,

RSBizWare Production Client, RSBizWare Historian, RSBizWare BatchHistorian, RSBizWare

PlantMetrics, RSBizWare Scheduler, RSBizWare Enterprise Manager, RSBizWare Batch, and

RSBizWare Batch Archiver are trademarks of Rockwell Software Inc., a Rockwell Automation

company.

VersaView is a trademark of Rockwell Automation, Inc.

Microsoft, Windows, ActiveX, and Visual Basic are registered trademarks, and Windows NT,

Windows 2000, Windows XP, Microsoft Access, Microsoft Excel, Microsoft SQL Server, and

Visual SourceSafe are trademarks of the Microsoft Corporation.

Oracle is a registered trademark of Oracle Corporation.

SAP, SAP Logo, mySAP.com, R/2, R/3, ABAP, and BAPI are trademarks or registered trademarks

of SAP AG in Germany and in several other countries all over the world.

OLE for Process Control (OPC) is a registered trademark of the OPC Foundation.

ControlNet is a trademark of ControlNet International.

DeviceNet is a trademark of the Open DeviceNet Vendors Association.

Ethernet is a registered trademark of Digital Equipment Corporation, Intel, and Xerox

Corporation.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated.

All other trademarks and registered trademarks are the property of their respective holders and are

hereby acknowledged.

Warranty

This Rockwell Software product is warranted in accord with the product license. The product’s

performance will be affected by system configuration, the application being performed, operator

control, and other related factors.

This product’s implementation may vary among users.

This manual is as up-to-date as possible at the time of printing; however, the accompanying

software may have changed since that time. Rockwell Software reserves the right to change any

information contained in this manual or the software at anytime without prior notice.

The instructions in this manual do not claim to cover all the details or variations in the equipment,

procedure, or process described, nor to provide directions for meeting every possible contingency

during installation, operation, or maintenance.

ii

Page 3

Contents

1 • Welcome to the Discrete Machine Performance Solution 1

Chapter objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

What is the Discrete Machine Performance Solution? . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features and benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Intended audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System installer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Line operator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Report user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Where can I go for help? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Get Discrete MPS training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Get phone support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Get web support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Get on-site support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Get consulting services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Contact us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 • Discrete MPS Hardware Installation 7

Chapter objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Top and side view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Before unpacking the computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Packing list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Shipping/transporting the computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

European Union Directive compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Environmental considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Mounting hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

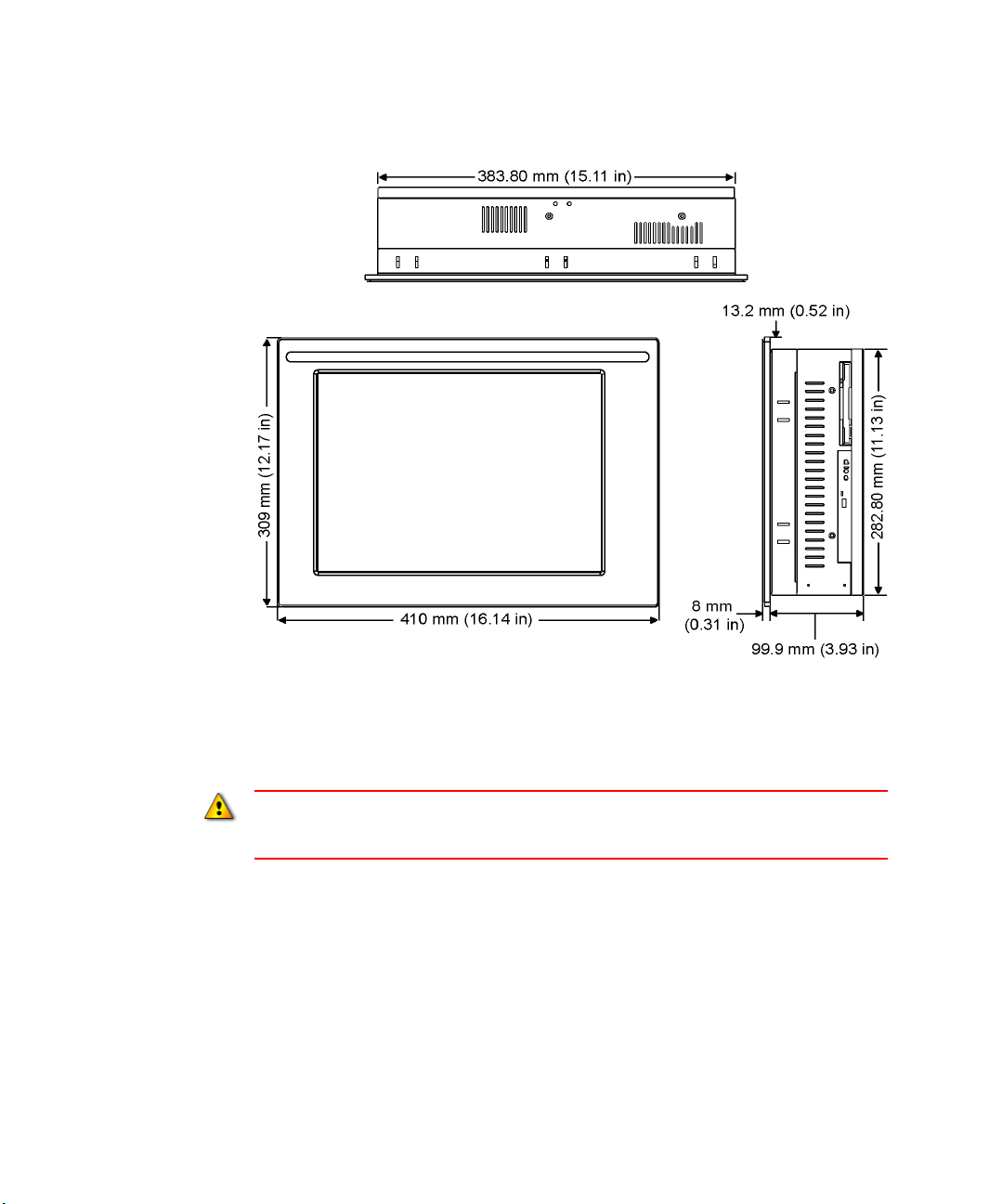

Mounting dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

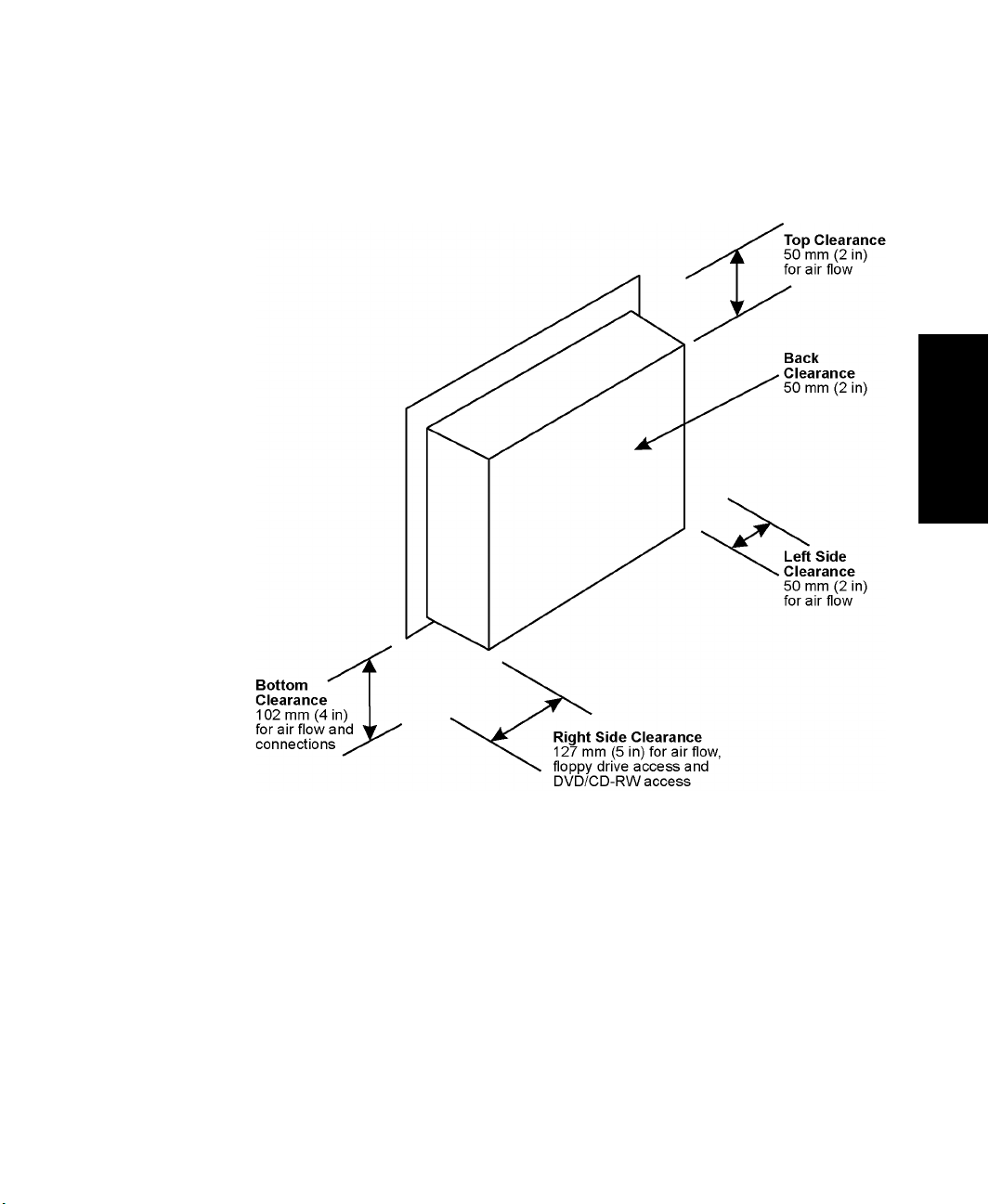

Mounting clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting clearances for the Integrated Display Computer . . . . . . . . . . . . . . . . . 13

Panel cutout dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Panel mounting guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

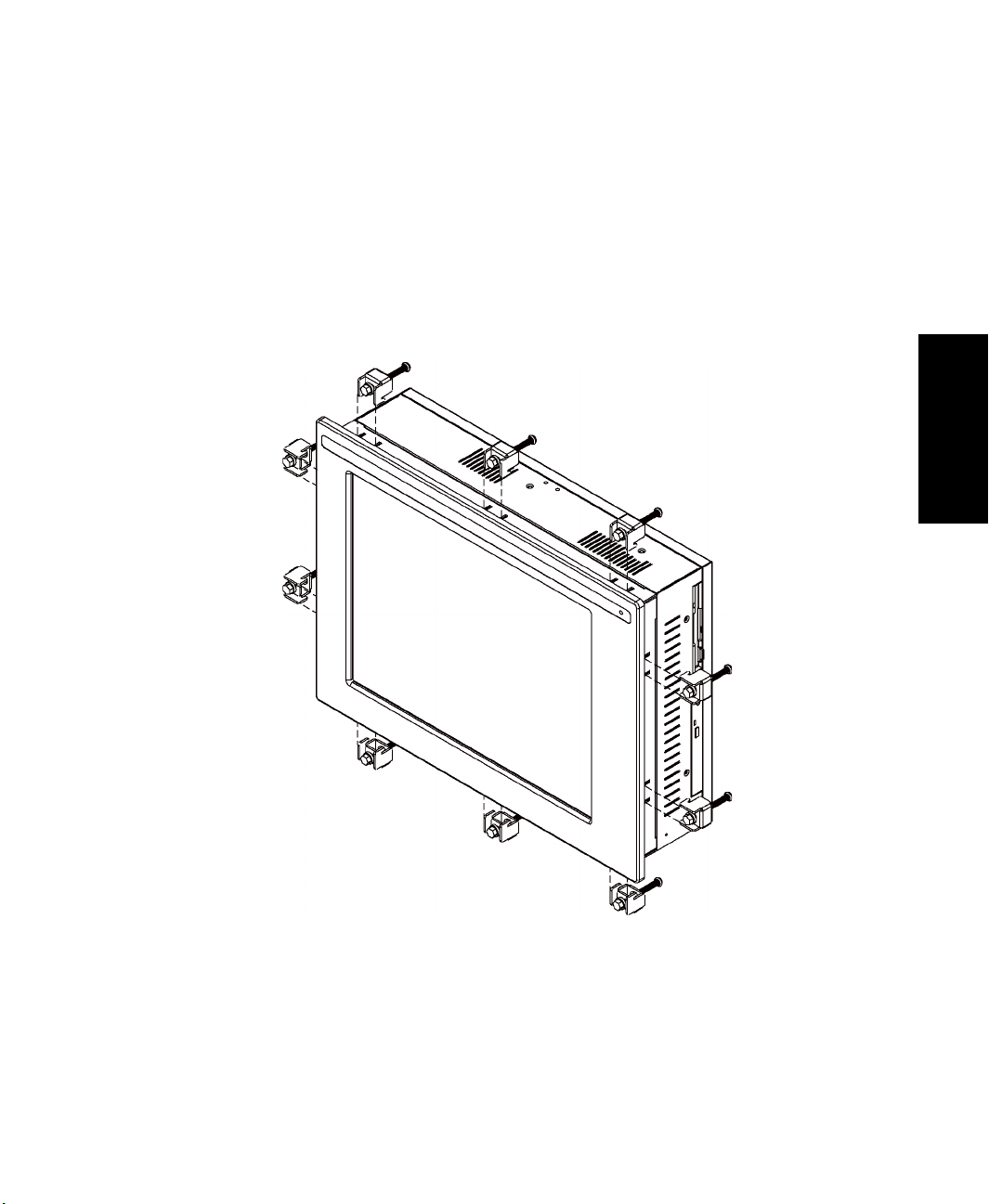

Installing computer in panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connecting a keyboard and pointing device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting AC power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting to a network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

iii

Page 4

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

3 • Initial Operation and Setup 19

Chapter objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operating guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operator access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Boot-up sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Initial configuration steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Using a touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Touchscreen serial port usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Driver software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Resistive touchscreen technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Calibrating the touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4 • Collecting Performance Data 23

Chapter objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

What is the OEE rating?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

User-defined summarization criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Configuring a workcell availability calendar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Step 1 • Define time patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Step 2 • Configure Composite Time Patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Step 3 • Schedule exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 • Discrete MPS Configurator Application 35

Chapter objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Exploring the user interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

The Configuration Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

The Configuration Work Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

The Configuration Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Main screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

General settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Workcells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Efficiency Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Part Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Ideal Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Availability Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Running status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Digital Events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Multistate Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Breakdown Justification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Manual Justification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Automatic Justification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

iv

Page 5

CONTENTS

Process Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Summarization events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Strings Localization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Generating the application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Workcell Description changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 • Discrete MPS Operator Interface 57

Chapter objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Exploring the Operator Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Graphical Keyboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Main overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Workcell menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Performance analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Digital Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Multistate Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Process Variable trends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Summarization Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Breakdown justification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

• • • • •

7 • Discrete MPS Reporting 71

Chapter objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Available reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Accessing reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

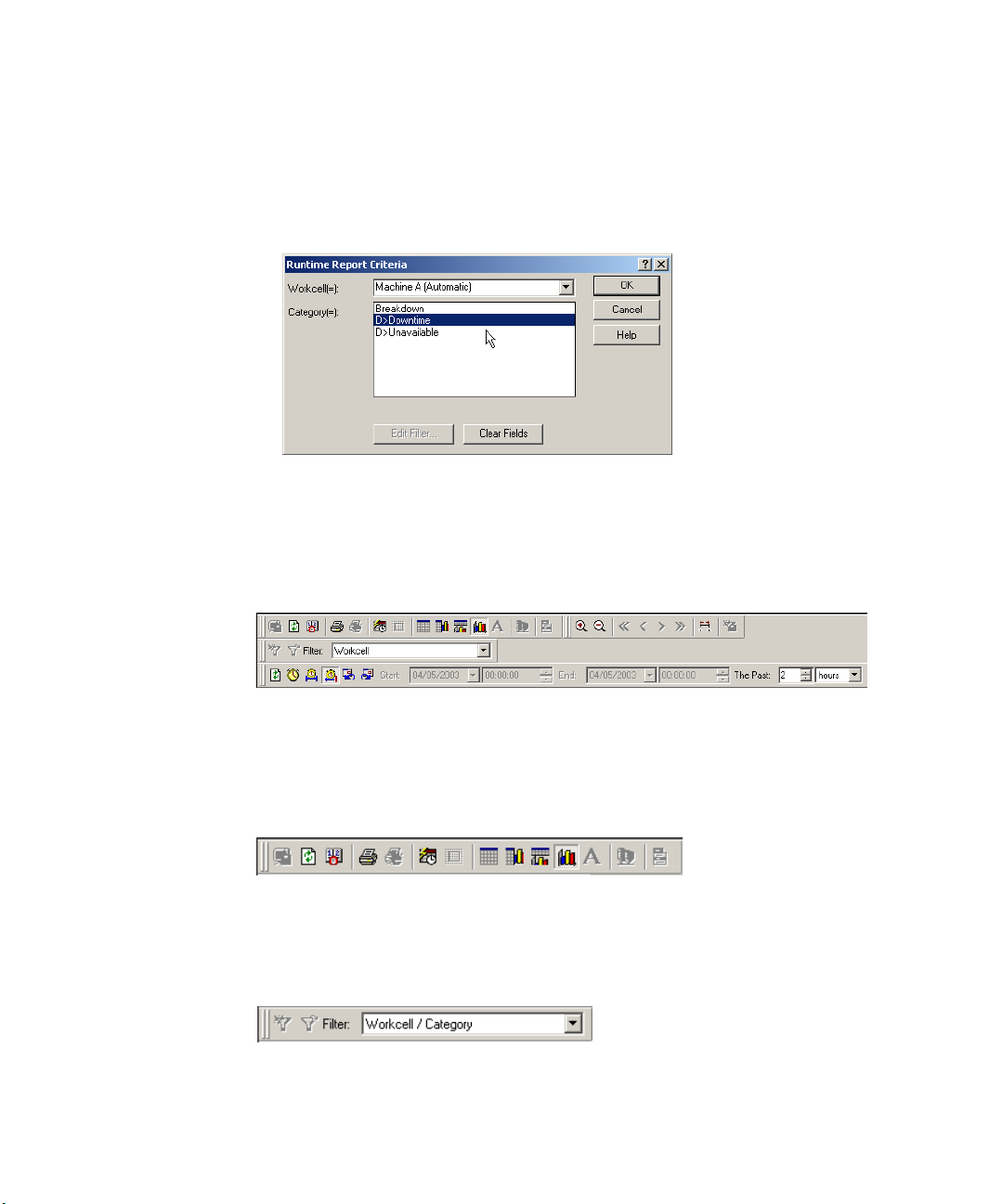

Report display options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

General toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Filter toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Time Selection toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Time Selection Tools toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

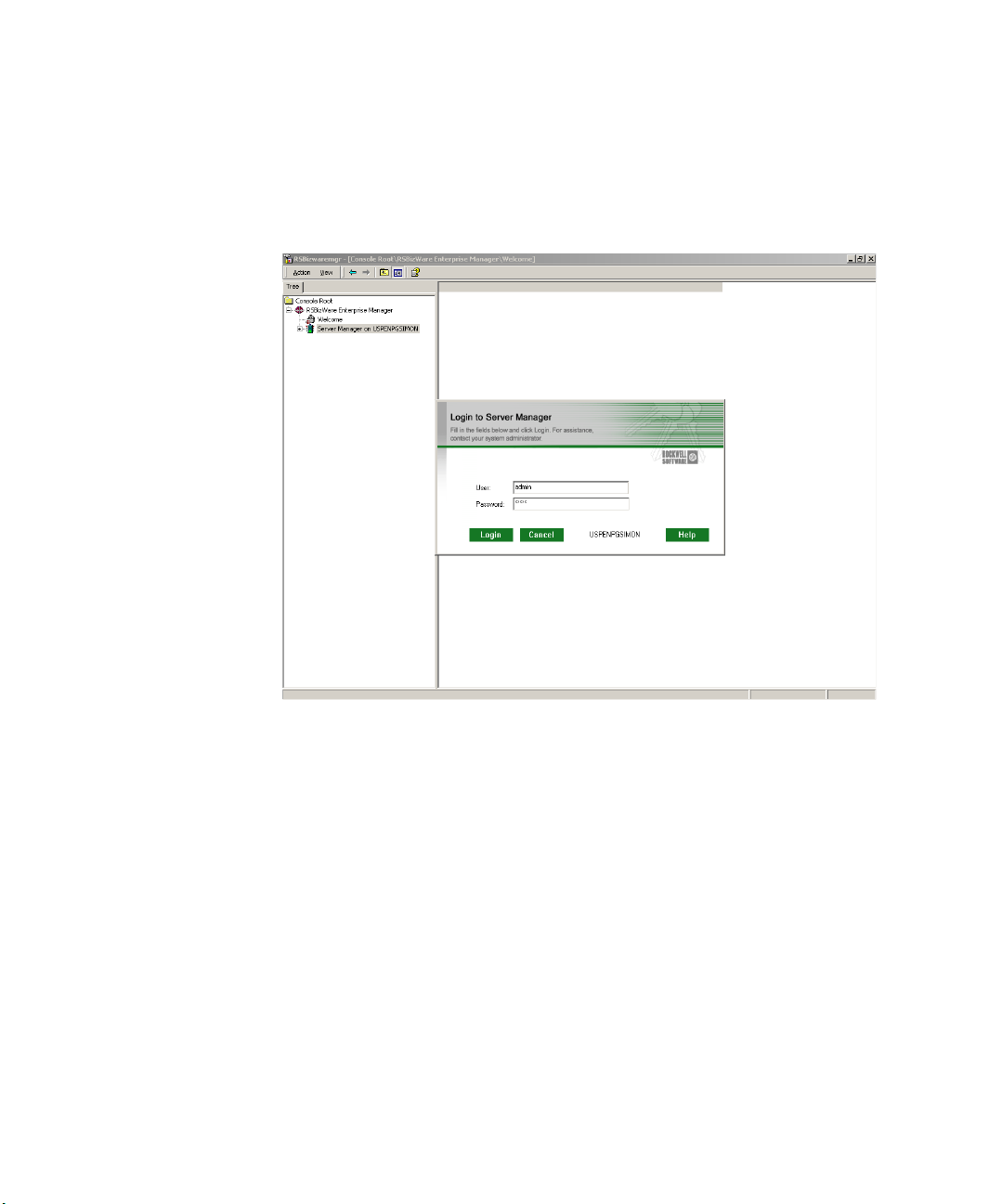

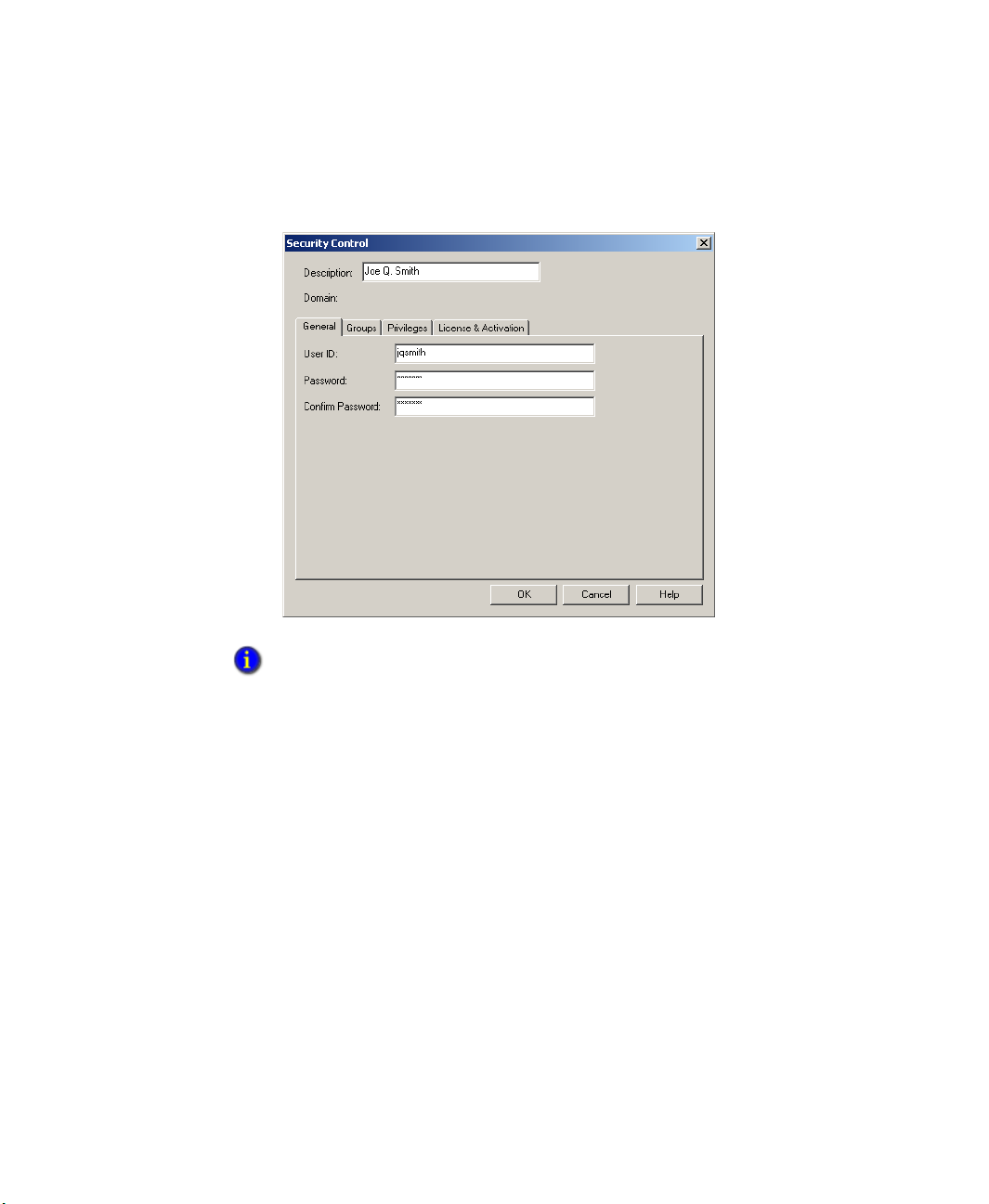

Managing report login accounts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

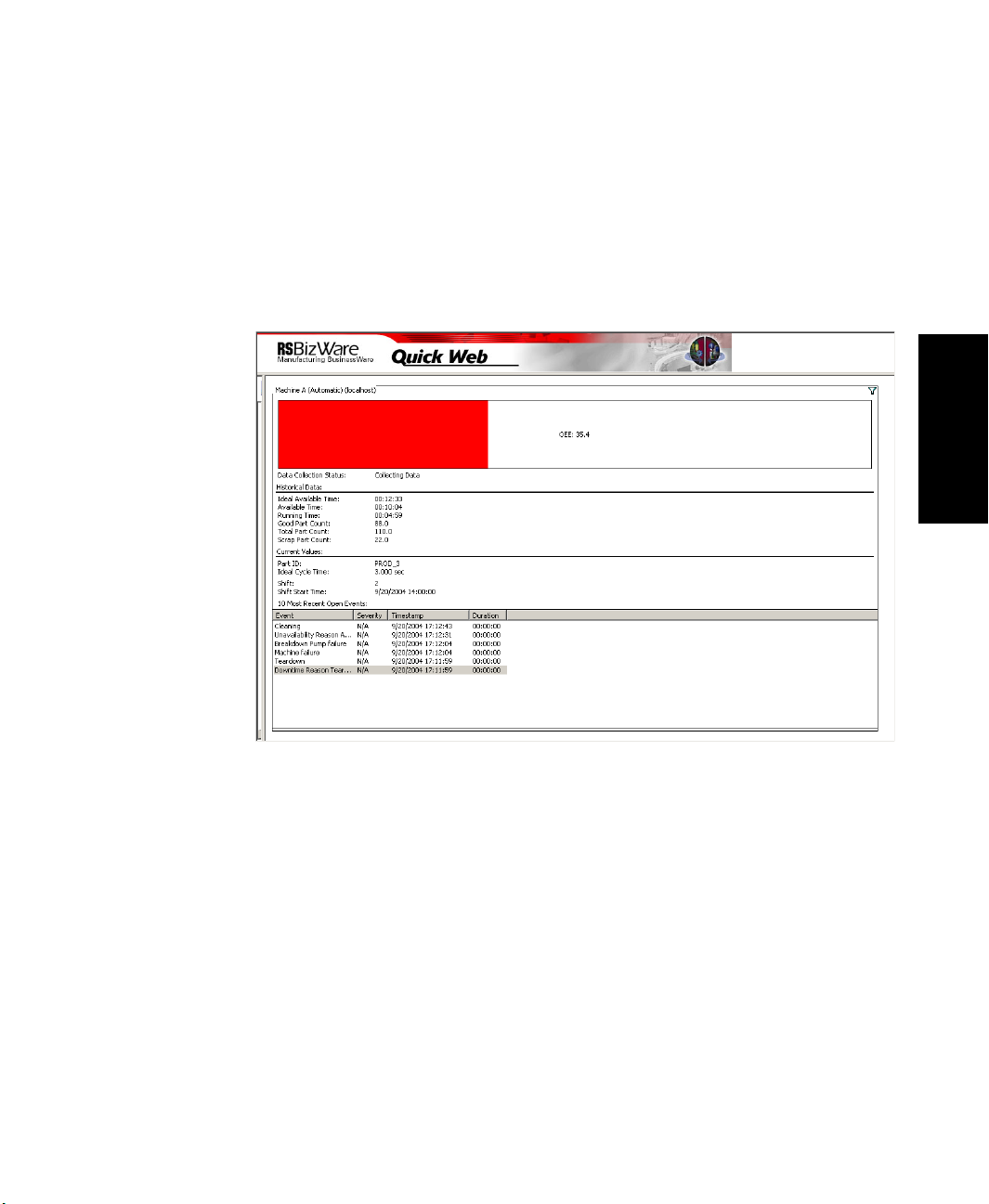

Report samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Performance Analysis OEE Details by Workcell. . . . . . . . . . . . . . . . . . . . . . . . . 79

Performance Analysis OEE Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

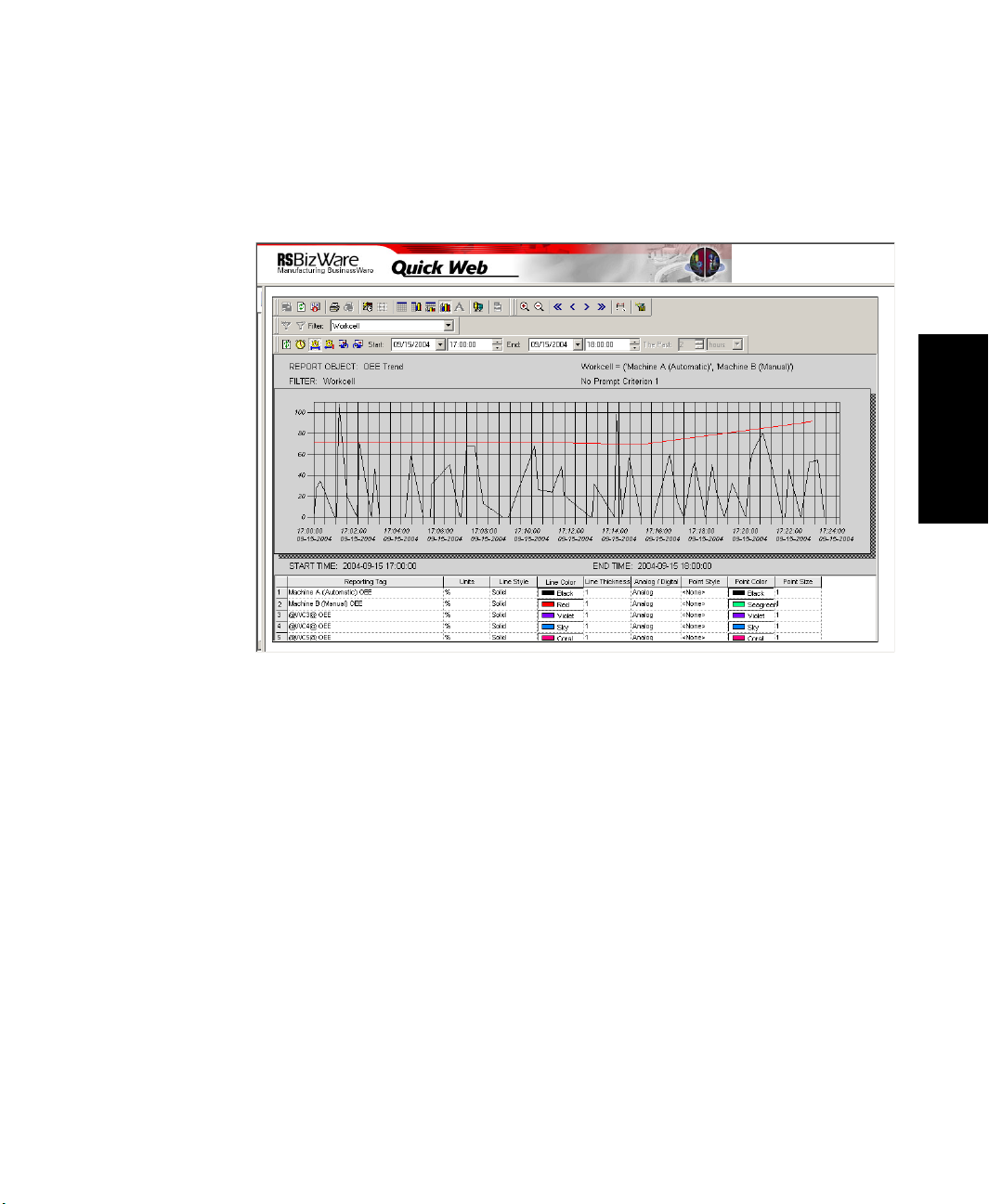

Performance Analysis OEE Trend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

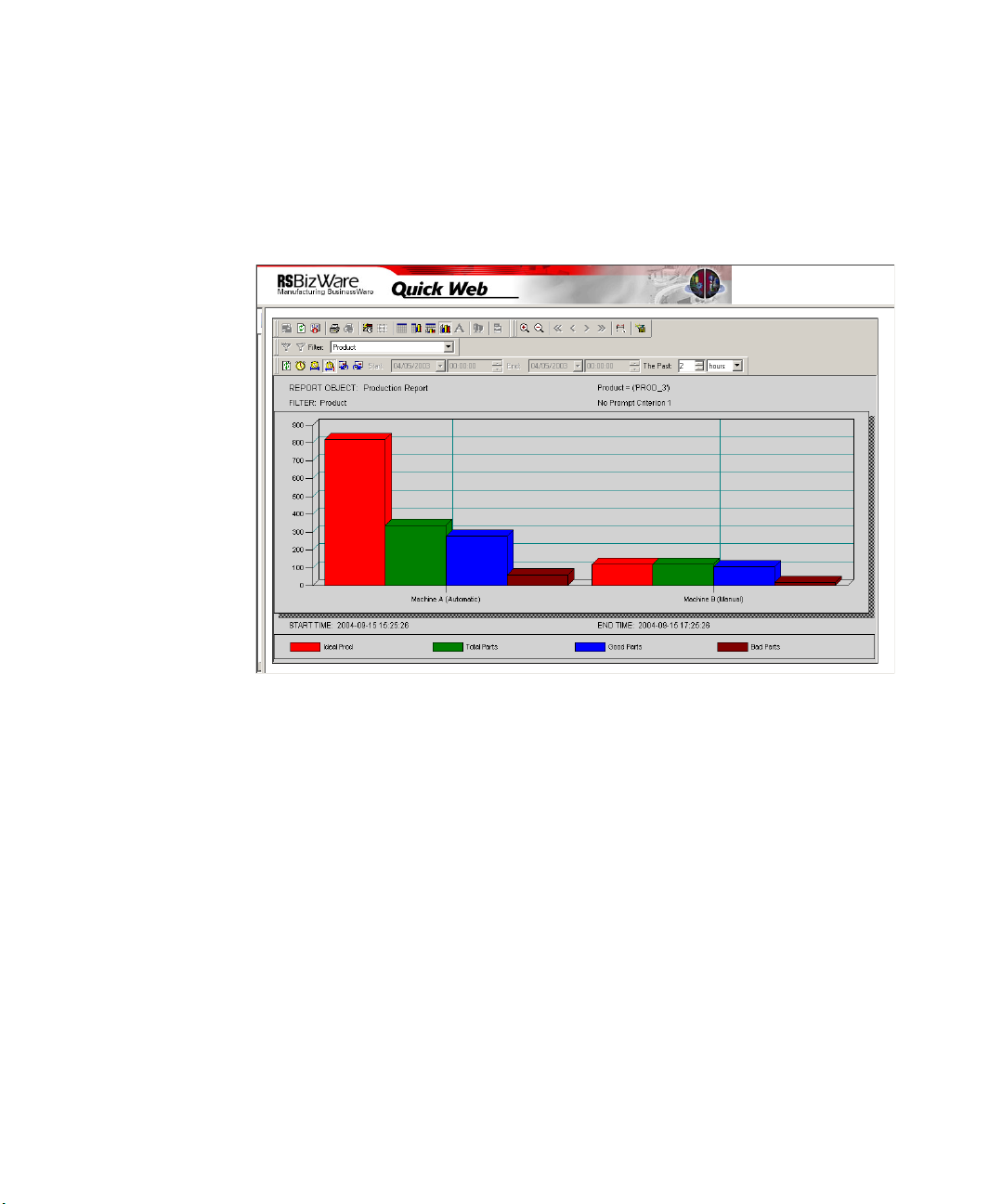

Performance Analysis Production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Performance Analysis Production by Shift (text). . . . . . . . . . . . . . . . . . . . . . . . . 83

Performance Analysis Production by Shift (bar chart). . . . . . . . . . . . . . . . . . . . . 84

Digital Events Total Duration (bar chart). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Digital Events Total Duration (pie chart) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

v

Page 6

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

Digital Events Number of Occurrences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

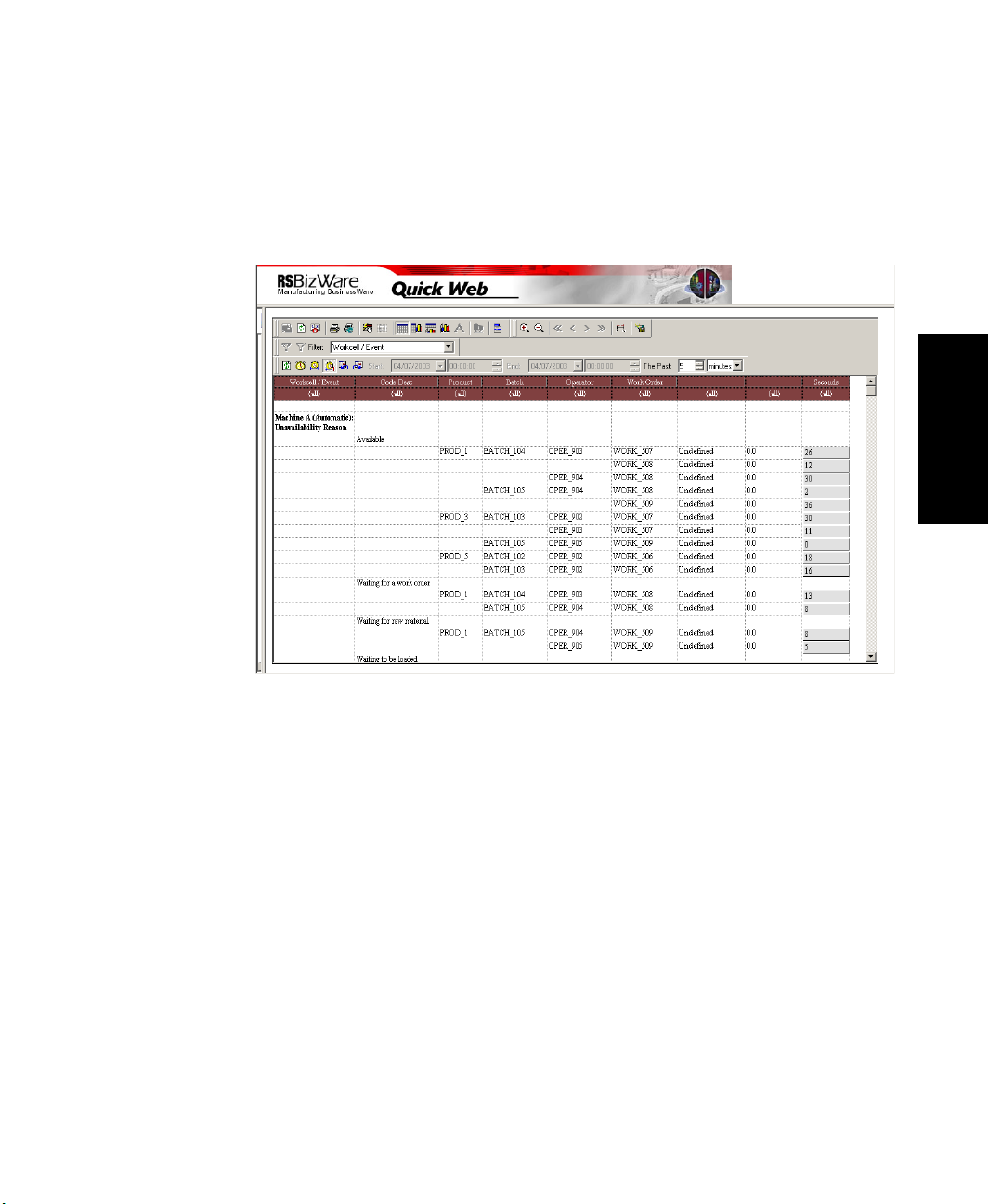

Digital Events Detailed List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Analog Events Total Duration by Day (text) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

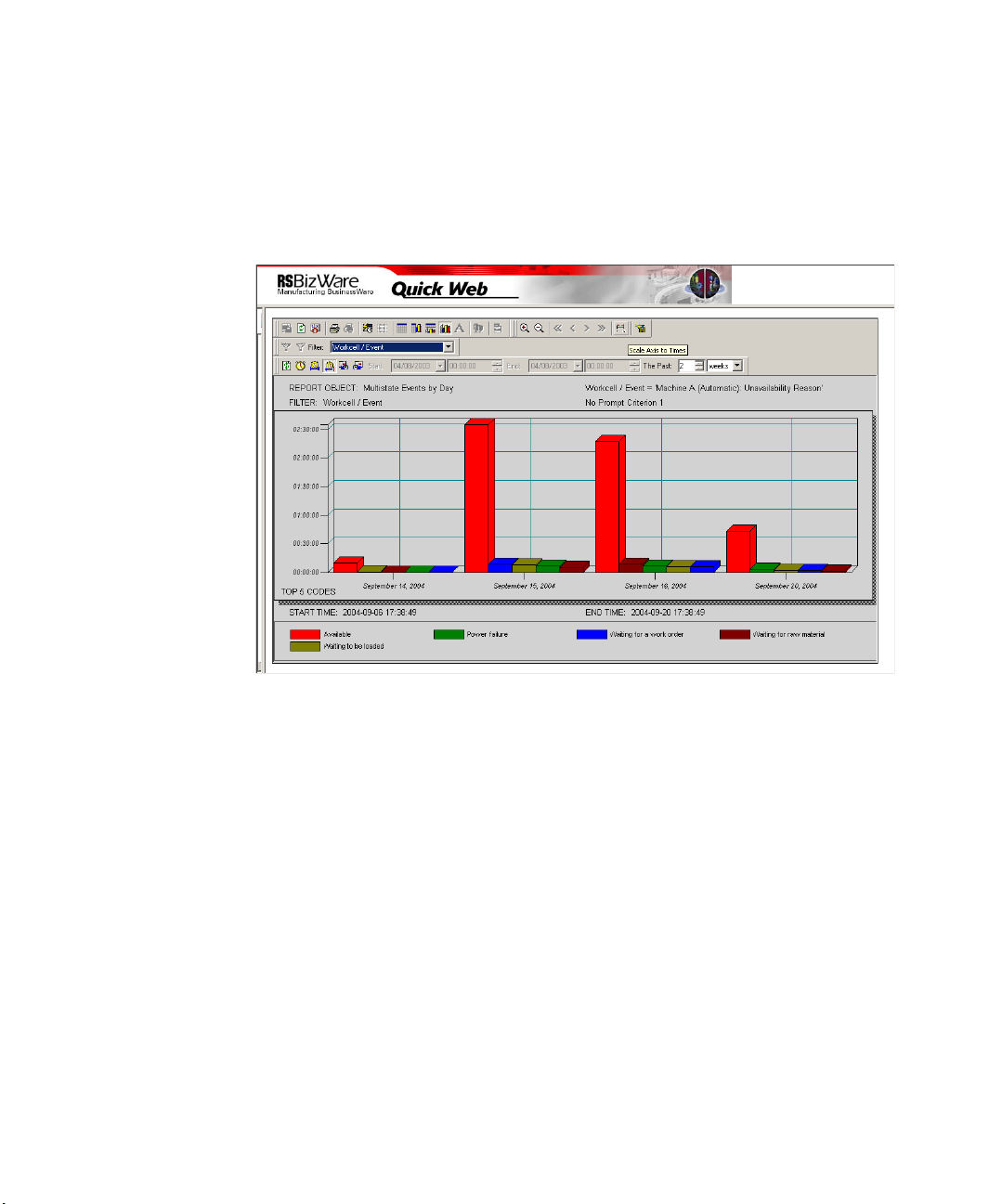

Analog Events Total Duration by Day (bar chart) . . . . . . . . . . . . . . . . . . . . . . . . 90

Analog Events Total Duration by Summarization Event . . . . . . . . . . . . . . . . . . . 91

Counters Total by Month (text) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

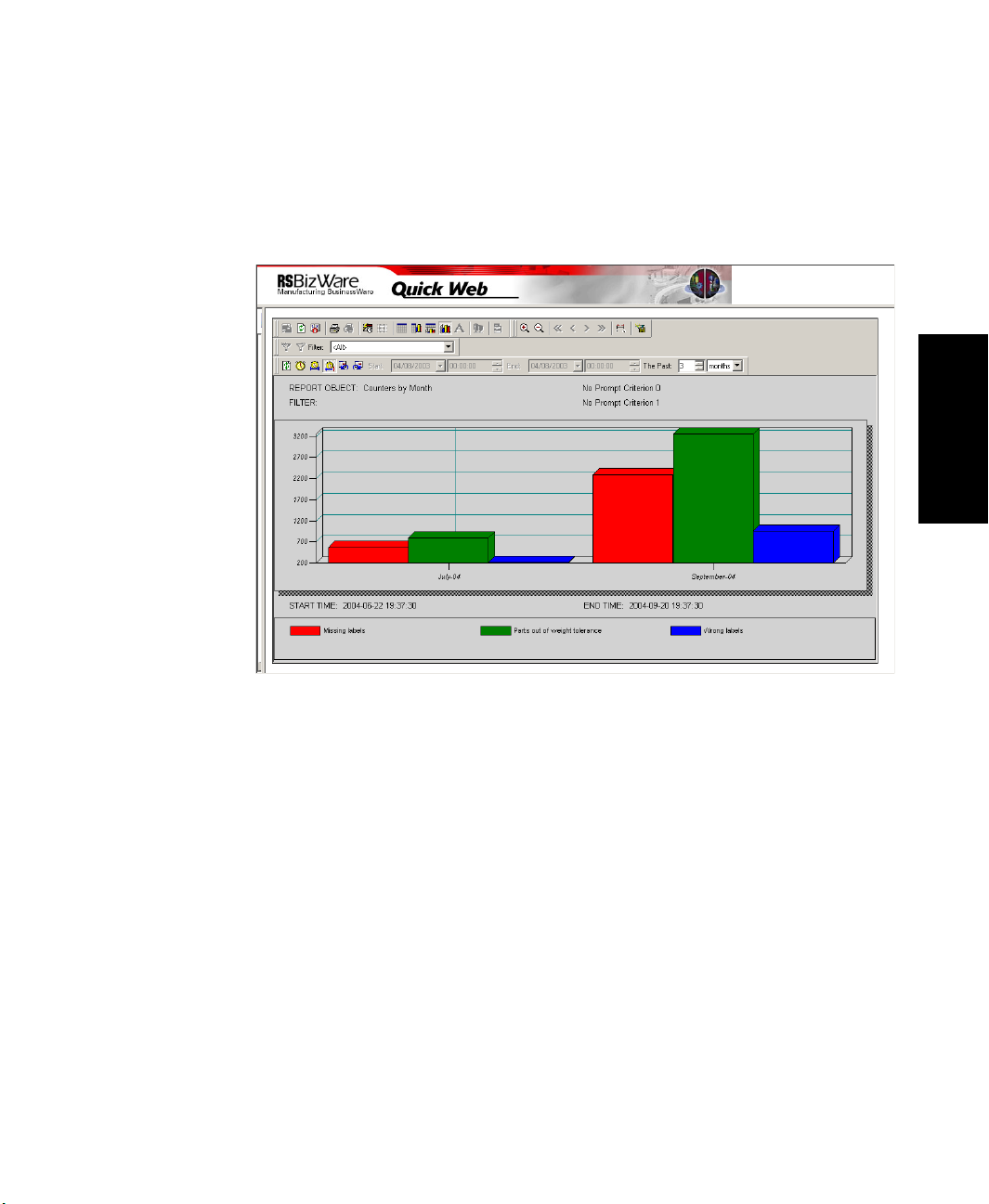

Counters Total by Month (bar chart) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Breakdowns Total Duration (pie chart) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Breakdowns Total Duration by Summarization Event. . . . . . . . . . . . . . . . . . . . . 95

Process Variables Trend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

A • System Troubleshooting 97

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

VersaView Integrated Display Computer problems . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Computer interface problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Index 99

vi

Page 7

1

Welcome to the Discrete Machine Performance Solution

Chapter objectives

This chapter provides an overview of the Discrete Machine Performance Solution, the

intended audience for this document, and sources of assistance for this product.

What is the Discrete Machine Performance Solution?

Companies in the discrete and repetitive manufacturing industries are being challenged by

management to maximize production from existing lines, to meet required cycle-times

and delivery dates for each product, and to reduce costs. To meet this challenge,

production management is striving to operate the equipment at its highest efficiency.

Real-time identification of production assets that are not performing to a standard is

critical to maintaining world-class efficiency. A thorough understanding of the details

behind production performance will allow you to identify sources of production

inefficiencies and to maximize asset utilization.

Historically, many custom solutions have been developed but have often failed to fulfill

expectations, essentially due to problems of long development times, high costs, and lack

of configurability.

The Discrete Machine Performance Solution (Discrete MPS) is a pre-developed system,

created to provide visualization and analysis of production asset performance based on

data acquired from a production control system. The Discrete MPS provides an industrial

computer with a standard operator interface application, and the ability to use a remote

web browser to access standard reports. The Discrete MPS is built using other successful

Rockwell Automation components, and is designed to be configured quickly to match the

production configuration or to be re-configured should the production configuration

change.

1 • Welcome

Features and benefits

Discrete MPS offers the following features and benefits:

Calculates the Overall Equipment Effectiveness (OEE) for a workcell to evaluate its

performance.

Process Event and Process Variable tracking.

Downtime duration and reason code tracking.

1

Page 8

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

The ability to track the performance and process data for up to five workcells.

Visibility and analysis tools for real-time and historical process information.

Pre-developed Operator Interface displays.

Pre-developed reports.

A configuration application used to configure the site-specific production details.

An entire solution based on a single industrial computer.

Intended audience

This User’s Guide is designed to help you understand how to access and use the Discrete

MPS product.

This document is intended for the following types of users:

System installer

This is an individual who installs the Discrete MPS computer and connects it to the plant

systems.

This individual should be familiar with:

Installation of industrial computers on the plant floor

Control systems

Ethernet networking

This user will be most interested in the following chapters of this document:

Discrete MPS Hardware Installation

Initial Operation and Setup

System configurator

This is an individual who configures the Discrete MPS so that it can capture performance

data from the control system and present the real time information to the line operator and

the historical reports to the Report User.

This individual should be familiar with:

Process information (machine, line, and plant)

Control systems

The OEE calculation

The Microsoft Windows operating system

2

Page 9

1 • WELCOME TO THE DISCRETE MACHINE PERFORMANCE SOLUTION

This user will be most interested in the following chapters of this document:

Initial Operation and Setup

Collecting Performance Data

Discrete MPS Configurator Application

Line operator

This is the individual who uses the Discrete MPS Operator Interface on the shop floor.

He/she will make use of the Discrete MPS Operator Interface to enter any information that

is not automatically collected from the control system and, if required, he will select the

proper justification reason for a breakdown.

This individual should be familiar with:

Process information (machine, line)

Use of a plant floor HMI

Use of a touchscreen

This user will be most interested in the following chapters of this document:

Discrete MPS Operator Interface

• • • • •

1 • Welcome

Report user

This is the individual who makes use of the reports provided by the Discrete MPS.

This individual should be familiar with:

Process information (machine, line, and plant)

The Microsoft Internet Explorer Web browser

This user will be most interested in the following chapters of this document:

Discrete MPS Reporting

Where can I go for help?

Our commitment to your success starts with the suite of learning aids and assistance we

provide for the Discrete MPS. You have the following options for getting additional

information about this product:

Get Discrete MPS training

One of the best ways to increase your proficiency at using Rockwell Software products is

to attend Rockwell Software training programs. Our training programs can help you

master the basics and show you how to unleash the full potential of our software.

3

Page 10

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

We offer a wide range of training programs, from regularly scheduled classes conducted at

Rockwell Software facilities, to custom-tailored classes conducted at your enterprise. The

size of each class is kept small intentionally to maximize student engagement.

If you would like more information about our training programs, visit the Rockwell

Software site on the World Wide Web or contact the Rockwell Software Training

Coordinator. Our World Wide Web address and telephone numbers appear on the inside

front cover of this document.

Get phone support

Rockwell Software’s support team of outstanding professionals provides top-notch

technical support — monitoring and tracking your experience with our products to pave

the road to your success in understanding and improving your factory performance.

Questions concerning installation and the use of the software are handled by the Rockwell

Automation Customer Support Center, staffed Monday through Friday — except U.S.

holidays — from 8 AM to 5 PM Eastern time zone for calls originating within the U.S.

and Canada.

To reach the Customer Support Center, call 440-646-5800 and follow the prompts. For

calls originating outside the U.S./Canada, locate the number in your country by visiting

support.rockwellautomation.com

and selecting the Phone Support link.

W

HEN YOU CALL

When you call, you should be at your computer prepared to give the following

information:

your a support contract number

the type of control system hardware you are using

the exact wording of any errors or messages that appeared on your screen

a description of what happened and what you were doing when the problem occurred

a description of how you attempted to solve the problem

Get web support

In addition to phone support, the Rockwell Automation Customer Support Center offers

extensive online knowledgebases of tech notes and frequently asked questions for support

of non-urgent issues. These databases are updated daily by our support specialists.

To receive regular e-mail messages with links to the latest tech notes, software updates,

and firmware updates for the products that are of interest to you or to submit an online

support request, visit support.rockwellautomation.com/supportrequests

4

.

Page 11

1 • WELCOME TO THE DISCRETE MACHINE PERFORMANCE SOLUTION

Get on-site support

Rockwell Automation field support engineers are located around the globe to provide

assistance with special projects, unexpected problems, or emergency situations on-site.

Field support engineers are available for dispatch 24x7x365 and can arrive at many

locations the same day.

To learn more about this and other support services, visit

support.rockwellautomation.com

.

Get consulting services

Rockwell Automation provides expert consulting and turnkey implementation of the

RSBizWare suite. Please contact your local representative for more information.

Contact us

We strive to help all of our customers become successful in their manufacturing

improvement efforts. Toward this objective, we invite you to contact your local

representative or Rockwell Software at any time that we may be of service to you.

• • • • •

1 • Welcome

5

Page 12

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

6

Page 13

2

Discrete MPS Hardware Installation

Chapter objectives

This chapter describes installation of the VersaView Integrated Display Computer.

Features

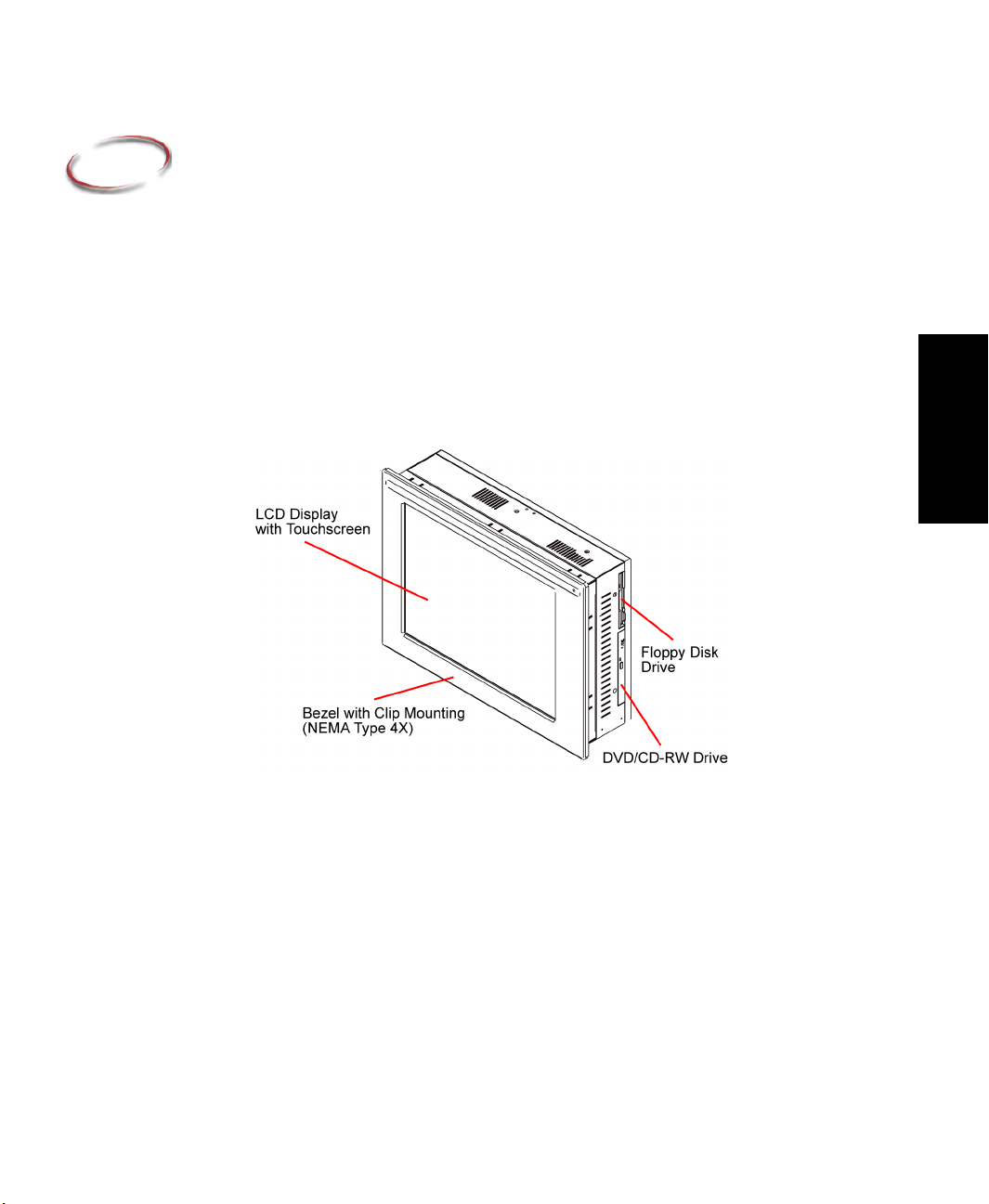

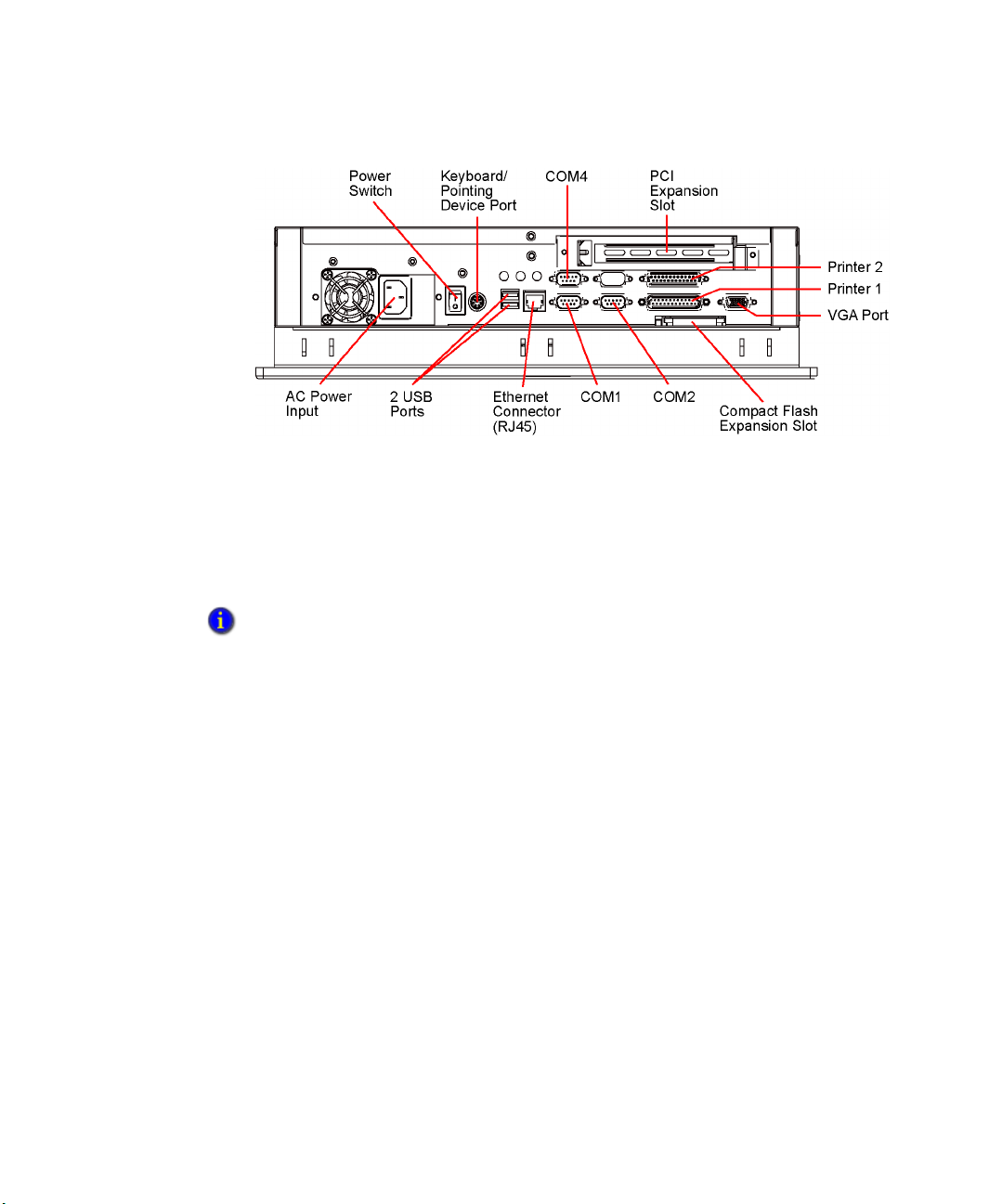

The following illustrations show the major features and controls of the VersaView

Integrated Display Computer.

Top and side view

2 • Installation

7

Page 14

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

Note: The VersaView that ships with the Discrete MPS has two PS/2 ports.

Before unpacking the computer

Before unpacking your new computer, inspect the shipping carton for damage. If damage

is visible, immediately contact the shipper and request assistance. Otherwise, proceed

with unpacking.

Make sure you keep all the original packaging for the computer in case you need to return the

computer for repair. Both the inner and outer packing cartons should be used to ensure adequate

protection for any units returned for service.

Packing list

Computer with operating system pre-installed

Microsoft XP Pro License

Mounting clips

AC power cord

Accessories CD-ROM (red) containing touchscreen driver, video drivers, Ethernet

drivers, and technical documentation

Recovery CD-ROM (blue)

Quick Start guide

8

Page 15

Shipping/transporting the computer

If, after you have installed the VersaView computer, you must ship it via common carrier

or otherwise transport it to another location, you must first remove the unit from the panel

and place it in its original packing material.

Do not ship or otherwise transport the VersaView computer while it is installed in a door or panel.

You must uninstall the computer and place it in its original packing material before shipping or

transporting the unit. If you ship or transport the computer while it is installed in a door or panel,

you may severely damage the unit. Rockwell Automation is not responsible for damage incurred

to the computer if it is shipped or transported while still installed in a door or panel.

European Union Directive compliance

The VersaView Integrated Display Computer meets the European Union Directive

requirements when installed within the European Union or EEA regions and has the CE

mark. A copy of the Declaration of Conformity is available at the Rockwell Automation /

Allen-Bradley Internet site: www.ab.com

The VersaView Integrated Display Computer is intended to operate in an industrial or control

room environment, which utilizes some form of power isolation from the public low voltage mains.

Some VersaView computer configurations may not comply with the EN 61000-3-2 Harmonic

Emissions standard as specified by the EMC Directive of the European Union. Obtain permission

from the local power authority before connecting any VersaView computer configuration that

draws more than 75 watts of AC power directly from the public mains.

.

• • • • •

2 • DISCRETE MPS HARDWARE INSTALLATION

2 • Installation

To comply with EN 55024, the Ethernet LAN cable must be less than 30 m [98.42 ft.] long, and it

must only be used indoors (i.e., not exit the building at any point). All other I/O cables must be

less than 3 m [9.842 ft.] long, and must only be used indoors.

Enclosures

Mount the VersaView Integrated Display Computer in a panel or enclosure to protect the

internal circuitry. Versions with a gestated bezel meet NEMA Type 1, 12, 4, 4X (indoor

9

Page 16

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

use only) and IEC IP66 only when mounted in a panel or enclosure having an equivalent

rating.

Environment and enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overfatigue

Category II applications (as defined in IEC publication 60664-1), at altitudes up to 2000 meters

without darting.

This equipment is considered Group 1, Class A industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions, there may be potential difficulties ensuring

electromagnetic compatibility in other environments due to conducted, as well as radiated,

disturbance. This equipment is supplied as “open type” equipment. It must be mounted within an

enclosure that is suitably designed for those specific environmental conditions that will be present

and appropriately designed to prevent personal injury resulting from accessibility to live parts.

The interior of the enclosure must be accessible only by the use of a tool. Subsequent sections of

this publication may contain additional information regarding specific enclosure type ratings that

are required to comply with certain product safety certifications. See NEMA Standards

publication 250 and IEC publication 60529, as applicable, for explanations of the degrees of

protection provided by different types of enclosure. Also, see the appropriate sections in this

publication, as well as the Allen-Bradley publication 1770-4.1 (

Grounding Guidelines

), for additional installation requirements pertaining to this equipment.

Industrial Automation Wiring and

10

Environmental considerations

Follow these guidelines to help ensure that the computer provides safe and reliable

service.

Ensure that sufficient space is available around air inlets and outlets to provide the

circulation necessary for cooling. Never allow air passages to become obstructed.

Allow enough room within the enclosure for adequate ventilation. The ambient

temperature around the computer must be between 0-50 °C (32-122 °F). Also

consider heat produced by other devices in the enclosure. You may need a usersupplied fan, heat exchanger, or air conditioner to meet this condition in some

installations.

Remember that heat rises. The temperature at the top of an enclosure is often much higher than

the rest of the enclosure if air is not circulating.

Page 17

The VersaView Integrated Display Computer is designed to operate at a range of extremes.

However, it is not good design practice to continuously operate the computer at the highest end

of the specified temperature range. While the product will operate at its highest specified

temperature, the overall life span of any electronic device is shortened when it operates at its

highest rated temperature.

Ensure that the humidity of the ambient air will not exceed specified limits. In very dry

environments, static charges build up very readily. Proper grounding of the equipment through

the AC power cord can help reduce the likelihood of static discharges, which may cause shocks

and damage electronic components.

Leave the computer’s enclosure or cover in place at all times during operation. The cover affords

protection against high voltages inside the computer and inhibits radio-frequency emissions that

might interfere with other equipment.

Mounting hardware

The VersaView Integrated Display Computer is shipped with 10 mounting clips, which

are used for mounting in a panel or enclosure.

• • • • •

2 • DISCRETE MPS HARDWARE INSTALLATION

2 • Installation

Tools required

In addition to the tools required to make the cutout, you will need a #2 Phillips

screwdriver.

Mounting dimensions

The following figures show mounting dimensions for the VersaView Integrated Display

Computer. Dimensions are in mm [in]:

11

Page 18

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

12

Mounting clearances

Allow adequate space for mounting, air flow, and maintenance. The figure below shows

recommended minimum clearances to other components within the rack or enclosure.

The VersaView Integrated Display Computer should not be operated within a confined space of

the dimensions shown below unless adequate ventilation or other cooling methods are used to

lower the air temperature within the enclosure.

Page 19

2 • DISCRETE MPS HARDWARE INSTALLATION

Mounting clearances for the Integrated Display Computer

• • • • •

2 • Installation

13

Page 20

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

Panel cutout dimensions

Panel mounting guidelines

Observe the precautions below when installing the computer in a panel:

Confirm that there is adequate space behind the panel. A cabinet with a minimum

depth of 127 mm (5.0 in) is sufficient.

14

Supporting panels should be at least 14 gauge to ensure proper sealing against water

and dust and to provide proper support. The mounting hardware supplied

accommodates panels up to 6.25 mm (0.25 in) thick.

Supporting panels must be cut to specifications before installation.

Installing computer in panel

To install the computer in a panel using mounting clips:

Disconnect all electrical power from the panel before making cutout.

Make sure area around the panel cutout is clear.

Take precautions so that metal cuttings do not enter any components that are already installed in

the panel.

Failure to follow these warnings may result in personal injury or damage to the panel

components.

Page 21

2 • DISCRETE MPS HARDWARE INSTALLATION

1. Cut an opening in the panel using the appropriate panel cutout dimensions provided

above.

2. Make sure the computer sealing gasket is properly positioned on the terminal. This

gasket forms a compression-type seal; do not use sealing compounds.

3. Place the computer in the panel cutout.

4. Install the mounting clips. The mounting clips slide into the slots on the top, bottom

and sides of the computer.

• • • • •

2 • Installation

15

Page 22

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

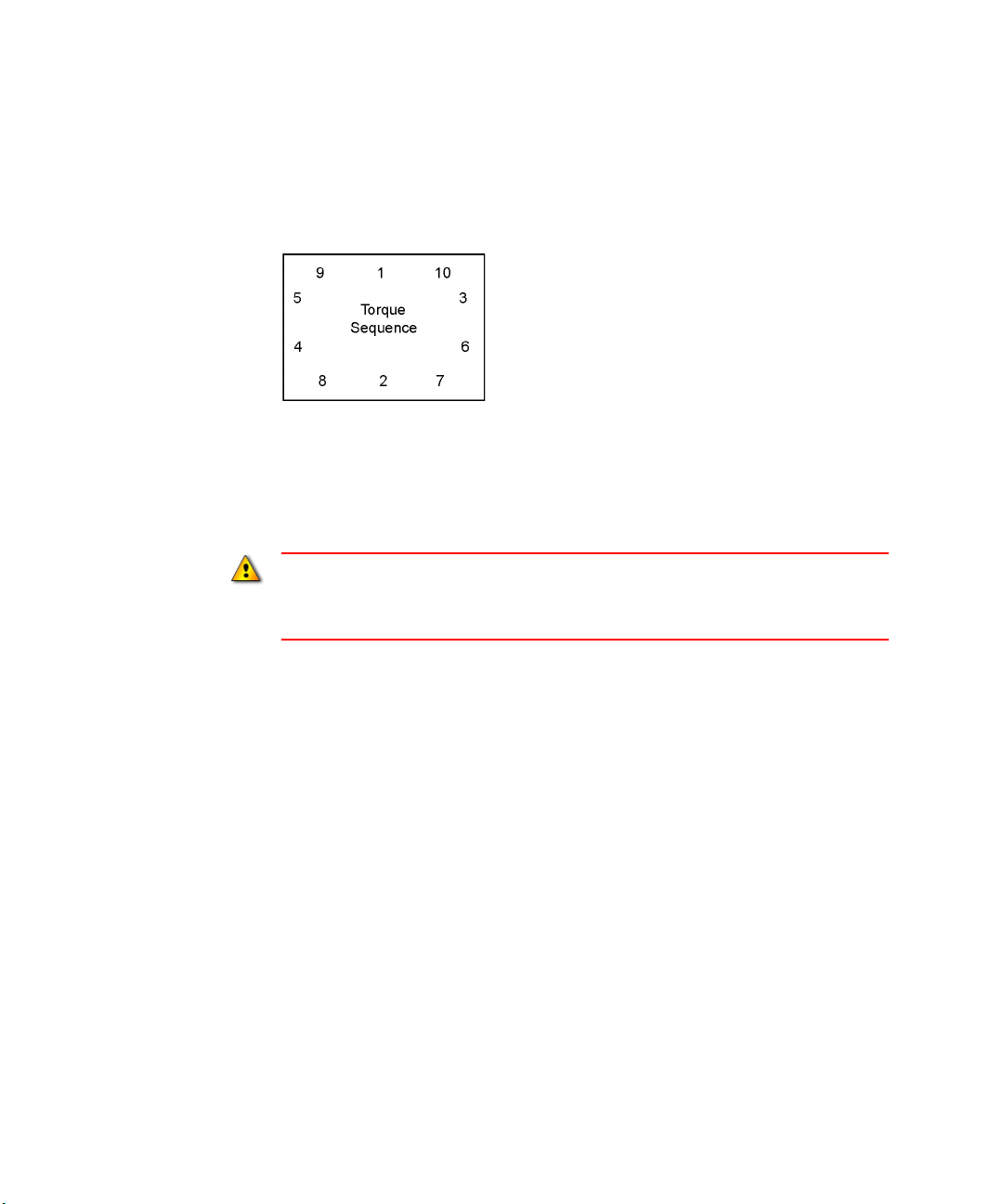

5. Gradually tighten the clips one at a time around the bezel using the specified

sequence. Note that the sequence begins with the center clips and continues to the

corner clips.

Repeat this process at least three times until the clips are hand-tight and the gasket is

compressed uniformly against the panel.

Tighten mounting clips to a torque of 10 in-lbs (1.1 N•m) in the sequence shown

above. Do not over-tighten.

Tighten mounting clips to a torque of 10 in-lbs (1.1 N•m) to provide a proper seal and prevent

damage to the VersaView computer. Rockwell Automation assumes no responsibility for

water or chemical damage to the terminal or other equipment within the enclosure because

of improper installation.

16

Connecting a keyboard and pointing device

A keyboard and pointing device can be plugged individually into the PS/2 port on the

bottom of the computer. There are separate PS/2 ports for the keyboard and the pointing

device.

Page 23

Connecting AC power

A standard IEC 320 power cord provides power to the VersaView Integrated Display

Computer. The power supply input will accept 120/240V AC. The power supply is

autoswitching. Ensure that sufficient power is available.

Select an electrical outlet carefully before plugging in your computer:

The power cord must be connected to an outlet having an earth ground (three-prong outlet).

Failure to follow this warning could result in severe electrical shock.

Installing computer in a panel, enclosure or rack that is already connected to earth ground will

satisfy this requirement. Otherwise, connect your computer to earth ground using a 16 AWG or

larger external wire.

The ground wire should have green insulation with a yellow stripe for easy identification.

The outlet should have its own disconnect. Do not plug the computer into an outlet that is

connected to the main electrical disconnect.

To prevent problems resulting from power surges or unexpected power failure, protect the outlet

with its own fuses or circuit breakers, as well as an Uninterrupted Power Supply (UPS) system.

• • • • •

2 • DISCRETE MPS HARDWARE INSTALLATION

2 • Installation

Always shut down the operating system prior to removing power. Failure to do so will cause

performance degradation and eventual failures in the operating system.

Connecting to a network

The VersaView Integrated Display Computer accommodates CAT5 twisted pair Ethernet

cabling with RJ45 connectors to support 100 Mbps network data transfer.

Performance degradation of your Ethernet communications is likely to result if the unit or cables

are subjected to extreme radiated or conducted high-frequency noise. It is the user’s

responsibility to properly route cables and condition input power in order to improve

communication reliability. Proper cable routing and power conditioning is required to ensure

reliable Ethernet communications in industrial environments. Rockwell Automation recommends

that all Ethernet cabling be routed through dedicated metal conduits. Installing ferrite bead filters

at cable ends may also improve reliability.

17

Page 24

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

18

Page 25

3

Initial Operation and Setup

Chapter objectives

This chapter discusses initial setup procedures and operation of the system.

Operating guidelines

We recommend the following operating guidelines for the VersaView Integrated Display

Computer:

Avoid turning the system on and off frequently.

Always use the proper power down procedures as required by your operating system,

such as the Shut Down command in Microsoft® Windows.

Do not turn off the computer until a message appears telling you that it is safe to do so.

Do not operate the VersaView Integrated Display Computer with covers removed. An

electrical shock hazard exists. In addition, removing the covers will disrupt air flow

and may result in overheating. All covers are required to maintain EMI shield.

After shutting the system off, do not move the computer or turn it back on again until the hard

drive has come to a complete stop (it takes about 30 seconds).

Operator access

3 • Setup

Operator access is limited to the front panel of the VersaView computer. This includes the

display and touchscreen. Access to components behind the rack or panel in which the

computer is installed is restricted to authorized and properly trained personnel.

Boot-up sequence

To boot up the system:

1. Apply power to the VersaView computer. The computer performs a Power On Self

Test (POST) in which it tests the processor board, memory, keyboard, and certain

peripheral devices.

2. The computer displays the progress of the POST and initialization of accessory

devices.

19

Page 26

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

3. If your system does not boot up, after previously booting successfully, refer to the

VersaView 6181P Integrated Display Computers User Manual for diagnostic and

troubleshooting information.

4. The computer will then display the startup dialogs for the operating system that has

been installed.

Initial configuration steps

During the first initial boot of the computer, several configuration windows are shown and

must be completed.

1. Initially, the Windows 2000 Professional splash screen is shown. A progress bar at the

bottom indicates startup progress.

2. A Windows 2000 Setup dialog box opens with the message “Please wait…” After

about 20 seconds this dialog will close automatically.

3. The Windows 2000 Professional Setup dialog box opens with the message “Welcome

to the Windows 2000 Setup Wizard.” Select Next to continue with the setup.

4. On the License Agreement dialog window, read the terms of the agreement. Select I

accept this agreement and then select Next to continue.

5. On the Regional Settings dialog window, customize the Windows locale setting and

keyboard layout if necessary. US English settings are the defaults; no changes are

necessary to select these. Select Next to continue.

20

6. On the Personalize Your Software dialog window, enter a Name and Organization that

the Windows Operating System will use as the identification for various operations.

Select Next to continue.

7. On the Computer Name and Administrator Password dialog window, enter the

Computer Name that has been assigned to identify this computer on the network and

enter the password to use for this computer's Administrator user account. Select Next

to continue.

After the Discrete MPS on-site services are completed, do not change the computer name

assigned to the computer. Changing the computer name will prevent the Discrete MPS from

functioning properly.

8. On the Date and Time Settings dialog window, set your local date, time and time zone

for the system clock. Select Next to continue.

Page 27

9. On the Workgroup or Computer Domain dialog window, assign the computer as a

member of the appropriate Domain or Workgroup for your network. Select Next to

continue.

If your computer is being placed on a domain you will be prompted for a network

administrator login.

After network configuration, the computer will automatically restart and attempt to log in

with the administrator user account.

After rebooting, complete any network configuration required for the computer. By

default, the computer is configured to obtain an IP address automatically (dynamically

obtain an IP address from a network server).

After the Discrete MPS on-site services are completed, do not change the password for the

administrator user account. Changing the password for the administrator user account will

prevent the Discrete MPS from functioning properly.

Using a touchscreen

The VersaView Integrated Display Computer is equipped with a touchscreen. The

touchscreen and the touchscreen controller are both factory installed and connected.

• • • • •

3 • INITIAL OPERATION AND SETUP

3 • Setup

Touchscreen serial port usage

The touchscreen controller for a VersaView computer connects internally to the COM2

serial port. The touchscreen is factory configured with the proper COM2 and touchscreen

driver settings, so no user configuration is required.

If for any reason these settings are corrupted, reset the COM2 serial port to 9600bps, 8

data bits, 1 stop bit, no parity.

Driver software

The touchscreen driver is already loaded on the computer. The driver software is also

provided on a floppy diskette.

The touchscreen utility defaults to COM1 serial port setting. You must change this setting to

COM2 when reloading the touchscreen driver.

Resistive touchscreen technology

Resistive touchscreens are activated by pressure applied to the touchscreen by an

operator’s finger. You can operate a resistive touchscreen while wearing gloves.

21

Page 28

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

Resistive touchscreens consist of two layers:

A lower layer (glass substrate) with a resistive coating and a voltage applied.

An upper layer (cover sheet) with a conductive coating.

Clear spacer dots separate the two layers.

When a user presses the upper layer onto the lower layer, the upper layer receives the

voltage applied to the lower layer. The touchscreen controller detects the change in

voltage on the upper layer and alternates voltage horizontally and vertically through the

layers. The voltage transferred to the upper layer is proportional to the location of the

touch on the screen.

Do not use sharp instruments to activate the touchscreen. Scratching the surface of the

touchscreen can damage the unit.

Calibrating the touchscreen

The touchscreen supplied with the VersaView computer is factory installed and calibrated.

In the event that you need to recalibrate the touchscreen, use the following procedure:

To calibrate the touchscreen:

1. Locate the calibration utility in the Control Panel or insert the touchscreen driver

diskette in the floppy drive of the computer.

22

2. Using the appropriate commands for your operating system, run the calibration utility.

3. Follow the instructions in the calibration utility to complete the calibration process.

Page 29

4

Collecting Performance Data

Chapter objectives

This chapter provides an description of some of the concepts and configuration necessary

to collect performance data using the Discrete MPS.

The

Discrete MPS Configuration Workbook

for determining the information necessary to configure the Discrete MPS.

What is the OEE rating?

Discrete MPS uses an OEE (Overall Equipment Effectiveness) model to measure the

performance of manufacturing equipment. The OEE model yields a single performance

rating for every activity area (workcell, line, area, or plant) being monitored, thereby

providing a simple way to determine quickly if an activity area is performing adequately.

The OEE value can be used to assess a single machine’s performance over time or to

compare the performance of machines to each other.

Three components contribute to an OEE value: availability, throughput, and quality. Each

is a percentage, and the OEE value is the product of these three percentages, and therefore

is also a percentage.

Availability is the ratio of running time to available time. Available time may be defined

by a schedule or modified by planned downtime events such as preventive maintenance.

Available time may also be modified by events, such as being starved for parts or being

blocked by a downstream process.

Availability RunningTime AvailableTime⁄=

Excel file provides a step-by-step process and tips

4 • Performance Data

Throughput is the performance of a machine when it is running compared to its ideal

cycle time. The ideal cycle time will depend upon the product being produced and is

measured in units of seconds per part.

Throughput TotalParts IdealCycleTime×()RunningTime⁄=

Quality is the percentage of good parts that are produced.

GoodParts TotalParts Scrap–=

Quality GoodParts TotalParts⁄=

The OEE calculation that is used by Discrete MPS is the product of these three

components:

23

Page 30

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

OEE Availability Throughput

RunningTime

OEE

-----------------------------------------

AvailableTime

× Quality×=

TotalParts IdealCycleTime×

---------------------------------------------------------------------------------

×

This reduces to:

OEE

IdealCycleTime GoodParts

----------------------------------------------------------------------------------=

AvailableTime

×

Discrete MPS gathers and stores all of the raw data necessary to make this calculation for

specific time periods, as well as by activity area, by part number, and by shift. All of the

individual components of the calculation are stored and available for analysis.

OEE is a valuable method of analyzing performance because it is widely recognized and

can be applied to any type of industry, factory, or machine. Further, Discrete MPS

supports the collection of detailed event data, which can be used to analyze the specific

causes of inefficiencies.

Refer to “Efficiency Analysis” on page 39 for a description of how to configure Discrete

MPS to determine OEE.

User-defined summarization criteria

A summarization criterion is a Discrete MPS Performance Parameter field for which

activity area data can be collected. When the value of the field changes, it triggers the

summarization of historical performance data for the activity area in the Discrete MPS

Workcell report data source. The collected values can then be used to filter OEE

performance data for the activity area. For example, if your system is configured to collect

Part ID (a default summarization criterion) for an activity area, you will be able to

calculate the OEE performance for the activity area when it is producing a particular kind

of part. In addition to the default summarization criteria — Shift, Part ID, and Ideal Cycle

Time — for which Discrete MPS can collect data values, you can configure up to five

user-defined summarization criteria, or flex fields, to represent the fields that are most

important to your organization. User-defined summarization criteria function just as the

default summarization criteria do, but, because they are user-defined, they allow you to

tailor Discrete MPS to meet your organization’s data collection and summarization needs.

RunningTime

GoodParts

------------------------------

×=

TotalParts

24

The following are sample uses of user-defined summarization criteria:

An Operator ID user-defined summarization criterion that will allow you to collect

operator IDs and to report on the OEE value for a specific operator.

A Lot Number user-defined summarization criterion that will allow you to collect lot

numbers and report on the OEE value for a specific lot of products.

Page 31

A Test/Production State user-defined summarization criterion that will allow you to

report on the OEE value for parts that were produced when the activity area was in a

Production state only.

Refer to “Summarization events” on page 47 for a description of how to configure

Summarization Criteria in the Discrete MPS.

Configuring a workcell availability calendar

Discrete MPS allows you to create the time patterns that will be used to calculate the

amount of available time for a workcell. It is not necessary for you to use a time pattern to

define available time for a workcell; however, if you do, the OEE calculation for the

activity area will not be negatively impacted by the periods of time when the workcell is

scheduled to be unavailable (e.g., weekends, evenings).

Time Patterns are created using the RSBizWare Production Client application. To define

Time Patterns you must login with the System Administrator user account.

An external keyboard and mouse must be connected to be able to configure a workcell

availability calendar.

• • • • •

4 • COLLECTING PERFORMANCE DATA

Step 1 • Define time patterns

A time pattern defines the availability of a workcell over time, which repeats as necessary

during the workcell schedule. We can define the duration of the repeating period as a Day,

Week, or Custom. A Day duration defines a time pattern for a 24-hour day, a Week

duration defines a time pattern for a standard 7-day week, and the Custom duration

defines a time pattern for an arbitrary duration, such as a 14-day cycle or an 8-hour shift.

A time pattern is composed of a default value and a series of time spans. The default value

defines the value of the time pattern during intervals where no time span is specified. Each

time span specifies a start time, end time, value (e.g., Available, Unavailable), and

optional report name for the span. The default value for the time pattern and the value for

the time span can be a named state, a numeric value, or another time pattern. Named states

are simply a set of values (e.g., 1, 0) to which you have applied descriptions (e.g.,

Available, Unavailable).

The ability to reference other time patterns allows us to build time patterns from other

time patterns.

As an example, below are the steps to define three shift time patterns, a Work Day time

pattern that is made up of the shifts, and a Work Week time pattern made up of five Work

Days.

25

4 • PerformancData

Page 32

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

Our example schedule follows a time pattern that consists of three 8-hour shift periods —

each with a 30-minute break (Unavailable) — that make up the work day. This time

pattern applies Monday through Friday, and the facility is closed (Unavailable) during the

weekends. The example makes use of the Custom, Day, and Week duration options.

First, we must define the three shift time patterns.

1. Select Configure > Time Pattern... from the main menu to display the Time Patterns

dialog.

26

2. Right-click on a folder in the Time Patterns box at the left-hand side of the dialog and

select New Time Pattern from the shortcut menu that will display. A new time

pattern will display in the Time Pattern tree.

3. The default name of the time pattern (New Time Pattern) is highlighted to indicate

that it is ready to be changed. Enter the new name for the time pattern,

Shift A

and

press the Enter on your keyboard to accept the changes.

4. You will notice that the Default Value Type is set to State and the Default Va lu e is

set to Unavailable. This indicates that any periods of time that are not specified as

Available in the Time Spans list will be designated as unavailable.

5. Our shift times will be relative to the start and end times specified in the Work Day

time pattern, so clear the Lock Times check box above the Time Spans list.

Page 33

4 • COLLECTING PERFORMANCE DATA

6. We want our shift to last 8 hours. Click the browse button (...) next to the Duration

box. The Time Pattern Duration dialog will display.

• • • • •

7. Select the Custom option for Duration Type and enter a duration of

8 Hours

. Press

OK to return to the Time Patterns dialog.

8. In the Report Name box, enter

Shift A

. In the Shift number box, enter the shift

number that you want to use to refer to this shift when reporting on the Discrete MPS

data that is collected. For this example, enter

1

in the Shift box.

9. Right-click on the time span grid at the right and select New Time Span... from the

shortcut menu. The Time Span dialog will display.

4 • PerformancData

10. Make sure the Val u e Ty p e is set to

State

and the Va lu e is set to

Available

.

27

Page 34

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

11. Specify this time span as starting at hour 0 and ending at hour 4. Remember that our

shift times are relative, so these times mean “start of shift” and “4 hours into shift

time.”

12. Click OK to save your changes and close the dialog.

13. Create a second time span. Set the Va lue to

4:30

starting at

and ending at 8.

Available

and specify this time span as

14. Click OK to save your changes and return to the Time Patterns dialog. Because we set

the Default Value of the time pattern to

spans is unavailable (i.e., shows a capacity of

Unavailable

0

in the time pattern chart).

, the half hour between time

15. Now we will make two copies of Shift A. To make a copy of the time pattern, right

click on

Shift A

in the Time Patterns box and select Duplicate from the shortcut

menu. The new copy of the shift is displayed in the tree. Change the name of the new

shift to Shift B. Create another copy of Shift A and name it Shift C.

28

16. Click on Time Pattern

window. Change its Report Name to

Shift B

to display its properties in the Time Patterns

Shift B

and its Shift number to 2 so that data

collected during times covered by this time pattern will be logged under this reporting

information.

17. Edit Time Pattern

number to

3

.

Shift C

to change its Report Name to

Shift C

and its Shift

Page 35

4 • COLLECTING PERFORMANCE DATA

W

ORK DAY TIME PATTERN

Now that we have built our shift time patterns, we can use them to build the Work Day

time pattern.

• • • • •

1. With the Time Patterns dialog open, create a new time pattern and name it

Work Day

2. Leave the Report Name and Shift fields blank; data will be recorded using the report

information defined in the individual shift time patterns that we will reference in the

time spans.

3. Create a time span for the first shift in this time pattern. In the Time Span dialog,

select Time Pattern from the Va lue Ty p e drop-down and Shift A from the Va lue

drop-down. The Time Span dialog uses the 0 hour to represent 12:00 midnight. Set

the Start time to

0

(midnight) and the End time to 8 (8:00 AM). The Shift A time

span should look like the example below:

.

4 • PerformancData

4. Press OK to save your changes and close the dialog.

5. Create a time span for Shift B. Start the shift at 8. We want this time span to end at

4:00 PM, and because times must be entered in a 24-hour format, specify this time

span as ending at 16.

29

Page 36

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

6. Create a time span for Shift C. Start the shift at 16 and end it at 24.

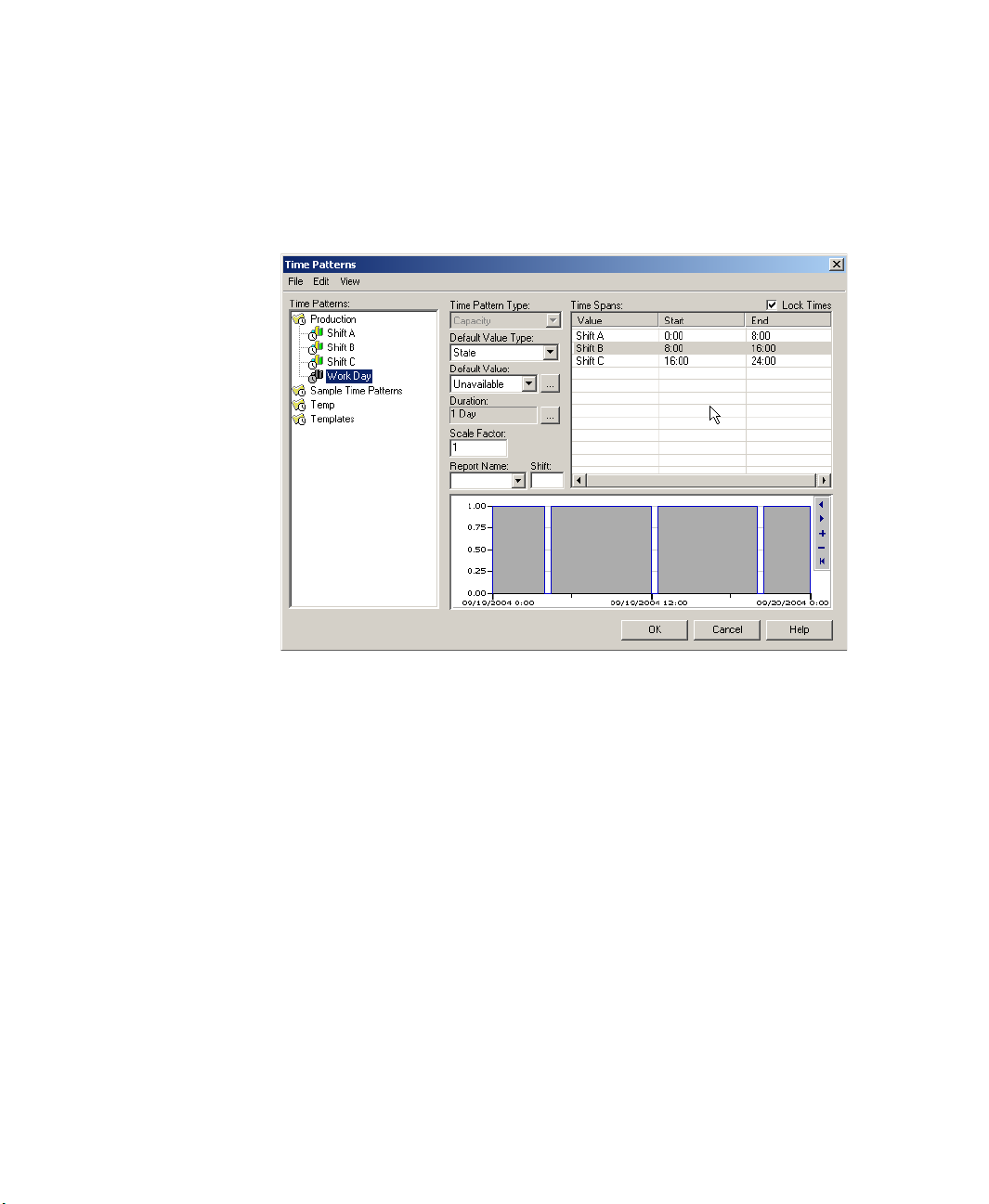

After you have completed these steps, the Work Day time pattern should look like the

example below:

30

W

ORK WEEK TIME PATTERN

Now that we have built our Work Day time pattern, we can use this to build the Work

Week time pattern.

1. With the Time Patterns dialog open, create a new time pattern and name it

.

Week

Work

2. Click the browse button (...) next to the Duration box. The Time Pattern Duration

dialog will display.

3. Change the time pattern duration to 1 Week and press OK to return to the Time

Patterns dialog.

4. Create the first time span for this work week. Select Time Pattern from the

Va lu eTyp e drop-down, and select the time pattern named Work Day for the Va lue .

Enter the first time span as starting on

Tuesday

on

at 0 (Tuesday at midnight).

Monday

at 0 (Monday at midnight) and ending

5. Repeat this for Tuesday, Wednesday, Thursday, and Friday.

Page 37

4 • COLLECTING PERFORMANCE DATA

After you have completed these steps, the Work Week should look like the example

below:

• • • • •

Take a few minutes to look at the other time patterns that are provided with the sample

data. These samples will illustrate how to create other types of time patterns.

6. Press OK to save the changes that you have made and close the Time Patterns dialog.

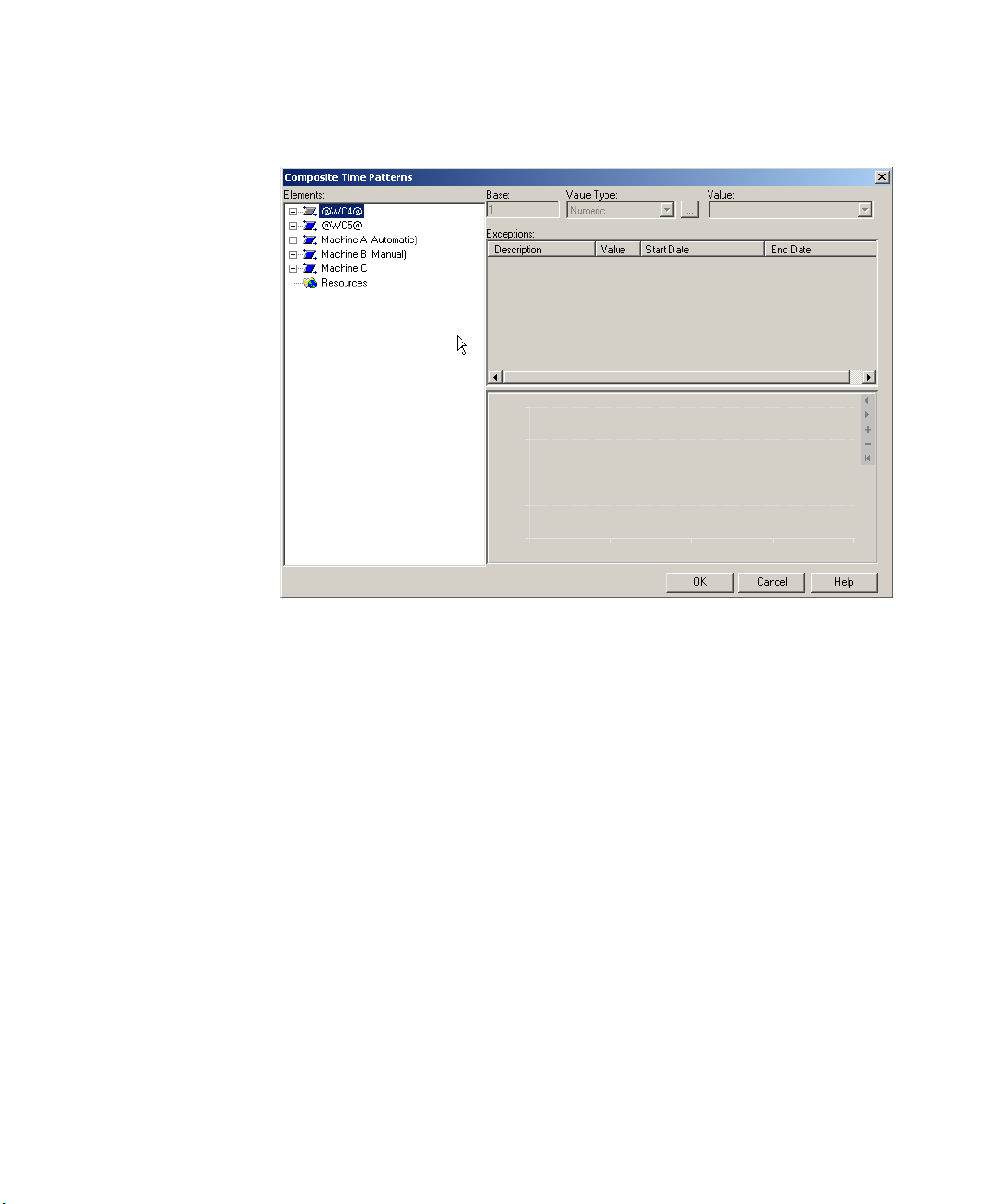

Step 2 • Configure Composite Time Patterns

A composite is a base time pattern that is associated with a workcell. The time pattern

defines the normal schedule for the workcell and the composite may have exceptions that

define any changes to the normal schedule.

As an example, below are the steps to assign the time pattern Work Week as the base time

pattern for the workcells.

1. Select Configure > Composite Time Pattern... from the main menu. The Composite

Time Patterns dialog will display.

31

4 • PerformancData

Page 38

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

32

2. In the Elements tree at the left of the dialog, find the Discrete MPS workcells that have

been defined. Click on the Capacity tree item under a workcell.

3. To define a workcell’s capacity, we must assign a time pattern to the workcell. Select

Time Pattern from the Value Type list box and Work Wee k from the Va lu e list.

Page 39

4 • COLLECTING PERFORMANCE DATA

• • • • •

Note: You are associating a time pattern with one workcell only. If you want to associate the

time pattern with all the workcells, you will need to make this association with each workcell

separately.

Step 3 • Schedule exceptions

A Composite Time Pattern may have exceptions that define irregular, but expected,

changes to the normal schedule. These exceptions may be outages (unavailable times)

such as holidays or planned maintenance periods, or additional available times such as

overtime hours or extended seasonal hours.

As an example, below are the steps needed to schedule an exception for New Year’s Day.

1. Display the Composite Time Patterns dialog. Expand the tree for the first workcell and

click on the Capacity entry. Right-click on the Exceptions grid and select New...

from the shortcut menu to display the Exceptions dialog.

2. Enter

3. Select State from the Value Ty p e box and Unavailable from the Va lu e box.

4. Specify this exception as starting on January 1, 2005 at 0 and ending on January 2,

New Year’s Day

2005 at 0.

in the Description box.

33

4 • PerformancData

Page 40

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

34

5. You will notice that the first workcell is listed in the Application box on the lower

right side of the dialog. This indicates that you are creating this exception for this first

workcell only. This does not mean that the exception applies to the other workcells.

If you want to apply this exception to another workcell, highlight the name of the

workcell in the Elements box on the left and click the arrow button (>) to move the

individual workcell.

6. Press OK to save your changes and return to the Composite Time Patterns dialog.

7. Press OK to save your changes and close the dialog.

Page 41

5

Discrete MPS Configurator Application

Chapter objectives

This chapter provides an overview of the Discrete MPS Configurator Application. The

Configurator Application is used to configure the Discrete MPS to collect and display

process data.

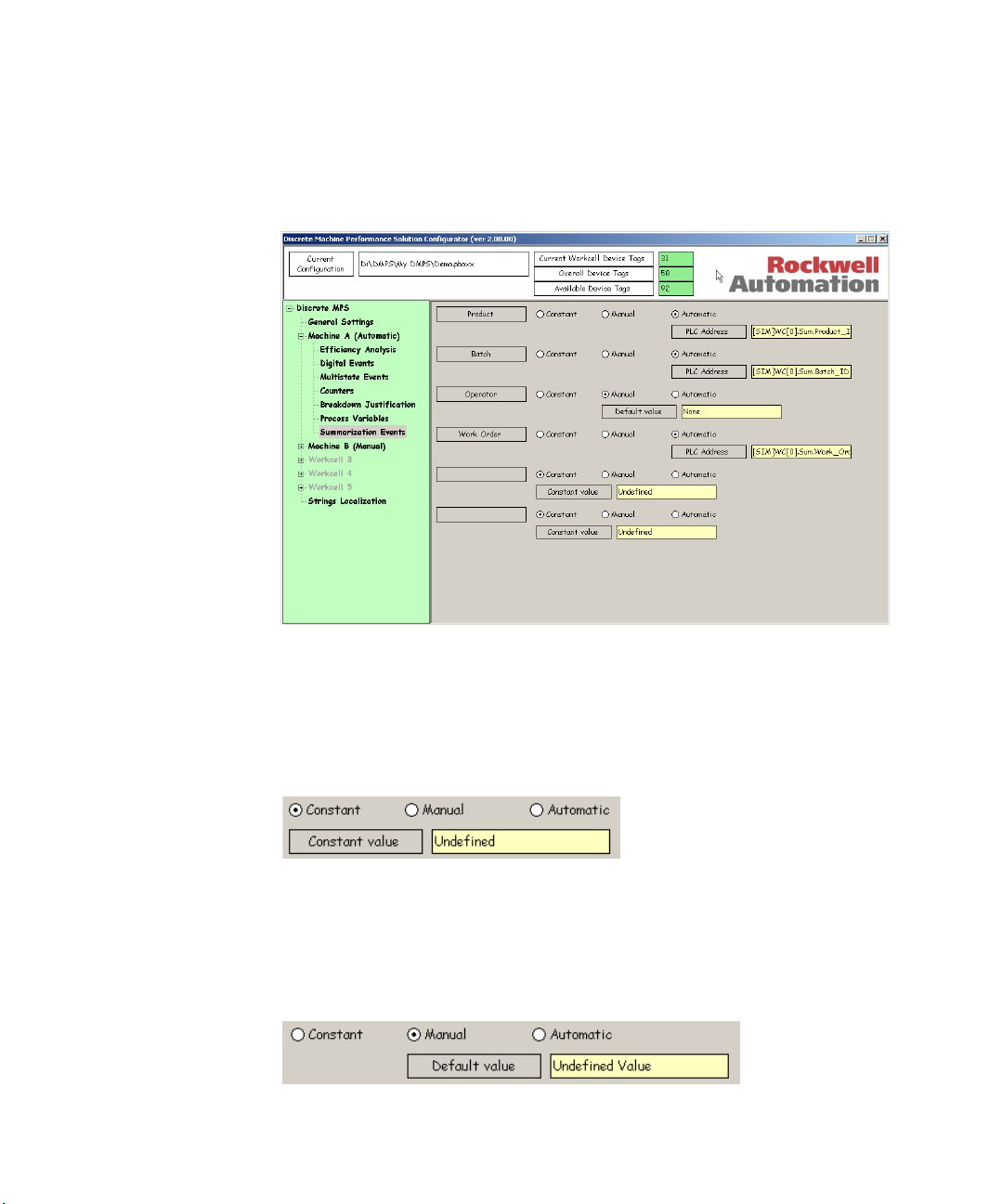

Exploring the user interface

When you start the Configurator, you will notice that the user interface is made up of three

main sections: the Configuration Explorer, the Configuration Work Area, and the

Configuration Status Bar.

The Configuration Explorer

The Configuration Explorer is a hierarchical navigation tool used to organize the Discrete

MPS configuration properties. It contains the following items: five workcells, General

Settings and String Localizations.

35

5 • Configurator

Page 42

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

The Configuration Work Area

When you click on an item in the Configuration Explorer, the specified configuration

screen will display in the work area to the right of the Configuration Explorer.

The work area is the region where configuration users can create and modify workcell

properties.

The Configuration Status Bar

The current configuration name and general information about the available tags and the

used tags are displayed in the Configuration Status Bar.

An external keyboard and mouse must be connected to be able to use the functionality provided

by the Configurator.

Main screen

36

The Main Screen has several buttons that perform Configurator application functions.

Click the:

New button to create a new configuration. Click Ye s in the confirmation dialog box to

clear any unsaved modification in the open configuration.

Page 43

Open… button to load an existing configuration. The standard Windows file open

dialog box will appear. Choose between the XML and the Binary file format. Select

the file and click the Open button.

Save button to save the current configuration to disk. The configuration will be saved

in both the XML and Binary format.

Save As… button to save the current configuration with a different name. The

standard Windows save dialog box will appear. Enter a file name and click the Save

button.

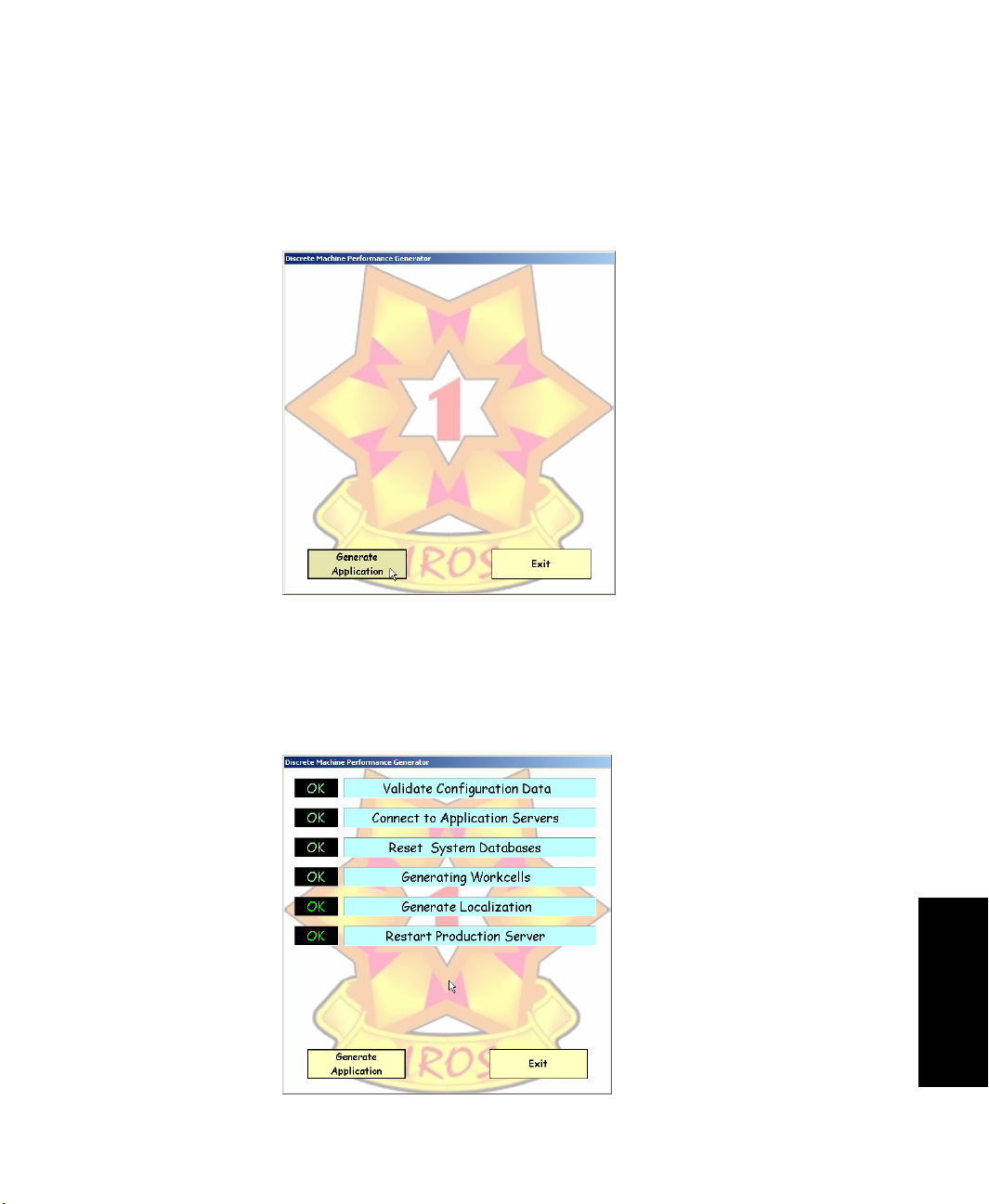

Generate button to start the Discrete MPS application generator. The Discrete MPS

application generator will move the information stored in the current configuration to

the Discrete MPS user interface and to the Discrete MPS database. Make sure that

RSView is open and that the Discrete MPS application is loaded. Click the Yes button

in the confirmation dialog box to proceed.

Close button to exit from the application.

General settings

General Settings are common to all workcells.

• • • • •

5 • DISCRETE MPS CONFIGURATOR APPLICATION

37

5 • Configurator

Page 44

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

1. Select the OPC Server from the OPC Server list. RSLinx is the preferred choice to

connect to Allen Bradley PLCs.

2. A Product ID and up to five other summarization events may be defined for the

workcells. Refer to “User-defined summarization criteria” on page 24 for information

about summarization events. Enter a Summary Event Description for all summary

event values that will be managed in the system configuration.

Note: The Summary Event Descriptions are displayed on the Operator Interface displays

and on the reports.

Workcells

1. Select any of the five available workcells in the Configuration Explorer to display the

main workcell display in the Configuration Work Area.

38

2. Check Enable Workcell and assign a Workcell Description to the selected workcell.

To show the configuration properties of the selected workcell, click the plus sign (+)

on the left of the workcell name in the Configuration Explorer.

Note: The Workcell Description is displayed in the Configurator, on the Operator Interface

displays and on the reports.

Page 45

Efficiency Analysis

1. Select Efficiency Analysis in the Configuration Explorer to display the Efficiency

Analysis screen in the Configuration Work Area:

• • • • •

5 • DISCRETE MPS CONFIGURATOR APPLICATION

2. The Configuration Work Area is divided in four sections. Each section contains a

different data category: Part Counters, Ideal Cycle Time, Availability Status, and

Running Status.

Part Counters

The Part Counters are part of the “Throughput” and “Quality” values in the OEE equation.

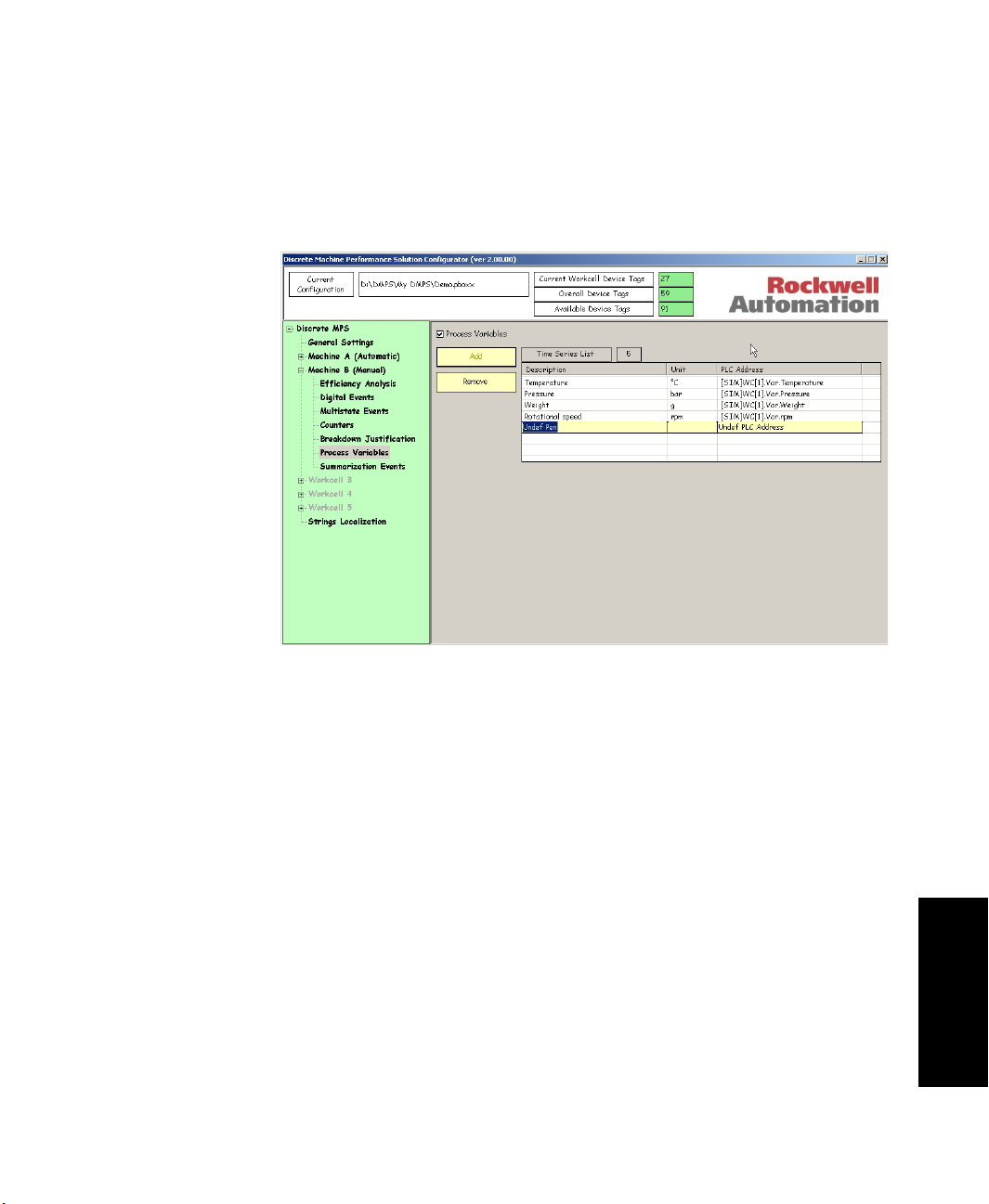

They indicate how many parts were produced by the workcell. Discrete MPS does not

care what unit is the measure of the Part Count value, because it is just comparing the rate

of items produced to the value given for the ideal cycle time. It is not necessary to collect

all three count values; however, at a minimum, you must collect the good part count or be

able to calculate good part count from the part counts that you collect.

Check:

Total Parts Counter to collect the total number of parts produced by the workcell.

Enter a description for the produced units (i.e., bottles, screws, liters…) and enter the

PLC address of the total parts counter.

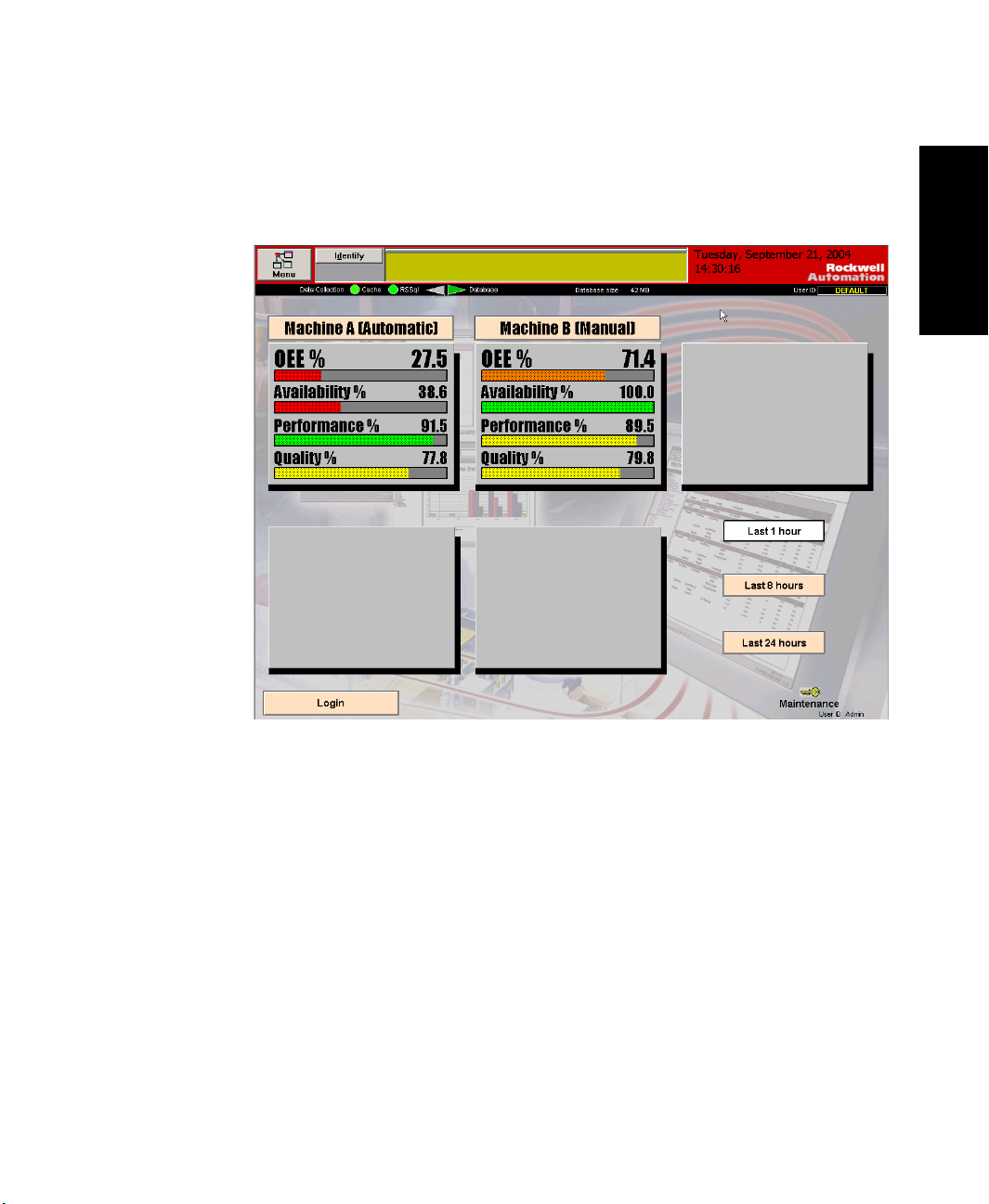

39

5 • Configurator

Page 46

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

Good Part Counter to collect the total number of good parts produced by the

workcell. Enter a description for the good produced parts (i.e., good bottles, good

screws…) and enter the PLC address of the good parts counter.

Bad Part Counter to collect the total number of bad parts produced by the workcell.

Enter a description for the bad produced units (i.e., scrap bottles, bad screws…) and

enter the PLC Address of the bad parts counter.

Ideal Cycle Time

The Ideal Cycle Time is part of the “Throughput” value in the OEE equation. It indicates

the length of time, in seconds, between sequentially produced parts when the machine is

running at maximum speed. If the workcell is producing parts slower than the ideal cycle

time, the OEE rating will be negatively impacted.

Select the:

Constant radio button and enter a value if the Ideal Cycle Time does not change.

Manual radio button and enter a default value to allow the line operator to enter the

Ideal Cycle Time manually, according to the operating mode of the machine.

Automatic radio button and enter a PLC address if the Ideal Cycle Time is available

in the control system.

40

Availability Status

The Availability Status is part of the “Availability” value in the OEE equation. This status

is the Monitored Availability, which indicates when the workcell is supposed to be

available to produce parts.

Select:

Manual and enter a default value to allow the line operator to select the Availability

Status through the Discrete MPS Operator Interface.

Automatic and enter a PLC address to collect the Availability Status directly from the

control system.

Discrete MPS applies the Boolean “AND” operator to the Scheduled Availability (refer to

“Collecting Performance Data” on page 23) and the Monitored Availability for a workcell

to determine the Availability value that is used in the OEE rating. This means that the

workcell is considered Available ONLY if both Scheduled Availability and Monitored

Availability indicate an Available state.

Page 47

Running status

The Running parameter allows the control system to indicate when the workcell is

actually producing parts.

1. Select Manual and select a default value to allow the line operator to select the

Running Status through the Discrete MPS Operator Interface.

2. Select Automatic and enter a PLC address to collect the Running Status directly from

the control system.

Digital Events

By defining digital events, you can direct Discrete MPS to monitor specific bits in the

plant control system, and maintain historical records on the behavior of those data points.

This feature is extremely powerful to collect extra data that you would like to associate

with the existing performance data. Digital Events will help you to investigate the root

causes of poor performances of a workcell.

A digital event is activated when the corresponding PLC tag goes high.

1. Select Digital Events in the Configuration Explorer to open the Digital Events

Configuration screen in the Configuration Work Area.

• • • • •

5 • DISCRETE MPS CONFIGURATOR APPLICATION

2. Check Digital Events in the Configuration Work Area to enable the digital events

collection. The table containing the list of the defined digital events will be displayed.

5 • Configurator

41

Page 48

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

3. Click the Add button to insert a new digital event, click the Remove button to delete

the selected digital event.

4. Click on the right arrows of the Category to choose a category for the digital event.

Select New Category to create a new category.

5. Click on Description to modify the description for the digital event.

6. Click on the PLC Address to modify the PLC address for the digital event.

Multistate Events

A multistate event is used to codify a set of events with an integer number. This number is

used as an index to an Event Lookup Table to retrieve the full description of the events.

The multistate events are especially useful to represent the status of a machine.

42

1. Select Multistate Events in the Configuration Explorer to open the Multistate Events

Configuration screen in the Configuration Work Area.

2. Check Multistate Events in the Configuration Work Area to enable the multistate

events collection. The table containing the list of the defined multistate events and the

Event Lookup Table will be displayed.

3. Click the Add button to insert a new multistate event, click the Remove button to

delete the selected multistate event. You can define up to five multistate events for

each workcell.

Page 49

4. An Event Lookup Table is created for every defined multistate event. Select a

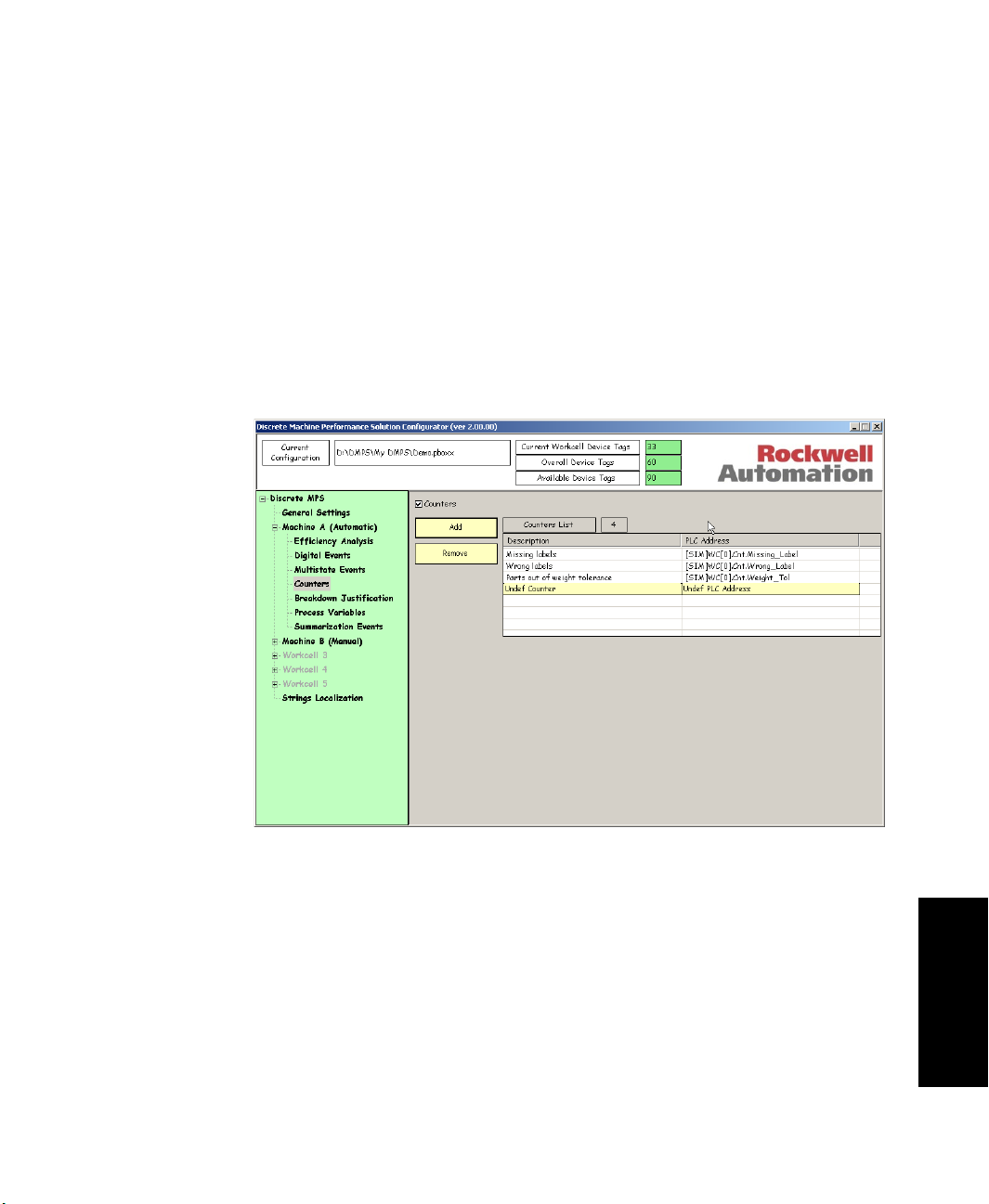

Counters

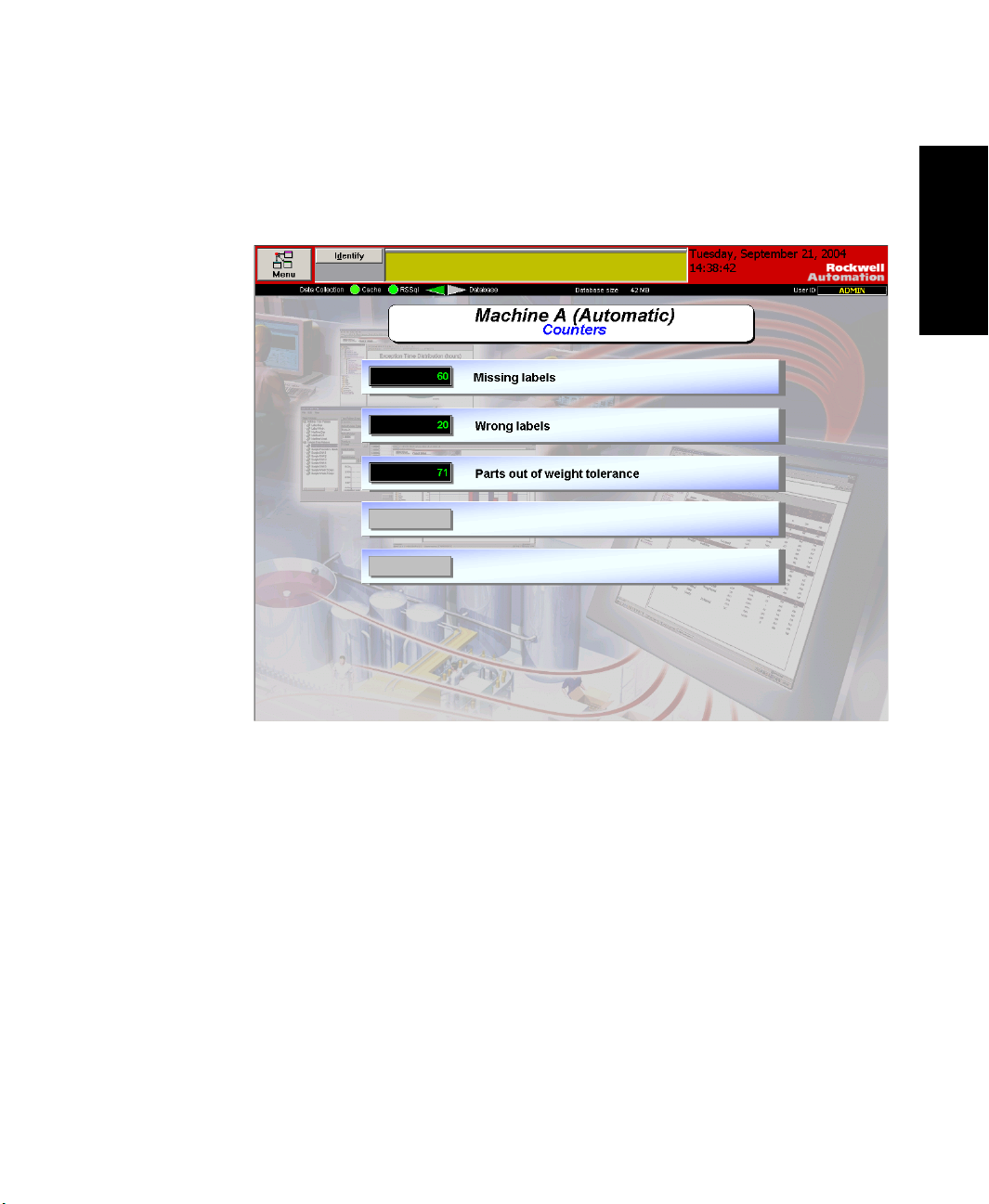

A counter is used to keep track of the number of occurrences of an event. Discrete MPS

can read a counter directly from the PLC and store its increasing value in the database.

• • • • •

5 • DISCRETE MPS CONFIGURATOR APPLICATION

multistate event. The corresponding Event Lookup Table will appear in the bottom

part of the Multistate Event Configuration Screen. Click the Add button to append a

new line to the Event Lookup Table. Click the Insert button to create a new line in the

Event Lookup Table before the selected row. Click the Remove button to delete the

selected line from the Event Lookup Table.

1. Select Counters in the Configuration Explorer to open the Counters Configuration

screen in the Configuration Work Area.

2. Check Counters in the Configuration Work Area to enable the counters collection.

The table containing the list of the defined counters will be displayed.

3. Click the Add button to insert a new counter. Enter the address of the PLC tag where

the counter is located.

4. Click the Remove button to delete the selected counter.

5 • Configurator

43

Page 50

DISCRETE MACHINE PERFORMANCE SOLUTION USER’S GUIDE

• • • • •

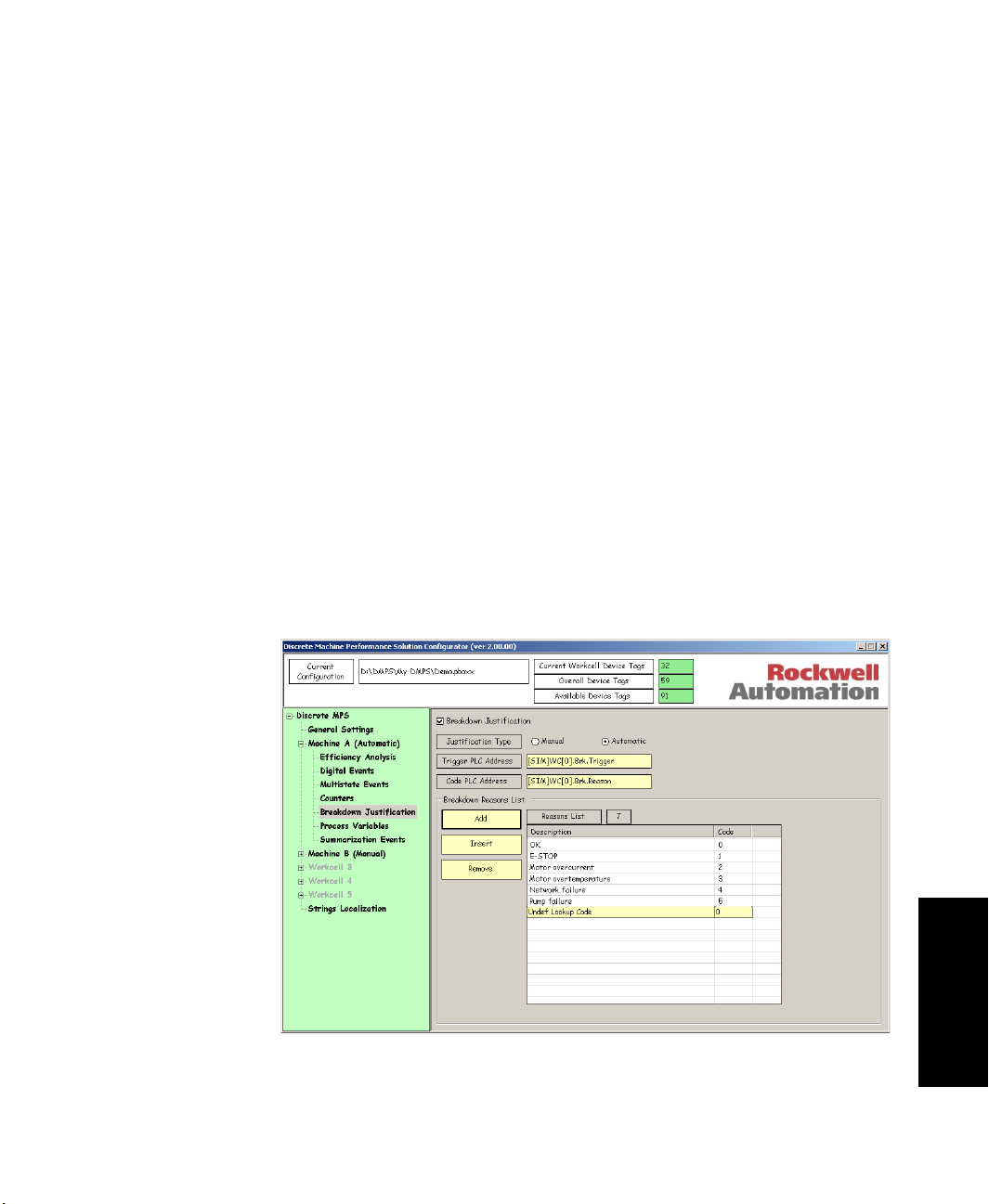

Breakdown Justification

Assigning a justification to a breakdown is a typical issue in the analysis of the