Page 1

Allen-Bradley

Thermocouple/

Millivolt Input

User

Module

(Cat. No. 1794-IT8)

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for example. Since there are

many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Allen-Bradley publication SGI–1.1, “Safety Guidelines For The

Application, Installation and Maintenance of Solid State Control”

(available from your local Allen-Bradley office) describes some

important differences between solid-state equipment and

electromechanical devices which should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen–Bradley

Company, Inc. is prohibited.

Throughout this manual we make notes to alert you to possible

injury to people or damage to equipment under specific

circumstances.

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

death, property damage, or economic loss.

Attention helps you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for

successful application and understanding of the product.

Important: We recommend you frequently backup your application

programs on appropriate storage medium to avoid

possible data loss.

DeviceNet, DeviceNetManager, and RediSTATION are trademarks of Allen-Bradley Company, Inc.

PLC, PLC–2, PLC–3, and PLC–5 are registered trademarks of Allen-Bradley Company, Inc.

Windows is a trademark of Microsoft.

Microsoft is a registered trademark of Microsoft

IBM is a registered trademark of International Business Machines, Incorporated.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Page 3

The information below summarizes the changes to the

company-wide templates since the last release.

New Information

Updated Information

The following new information has been added to this manual:

• the “L” type thermocouple selection has been added for use in

some European markets.

Calibration procedures have been revised to eliminate 1 method in

order to better control calibration results.

Change Bars

The areas in this manual which are different from previous editions

are marked with change bars (as shown to the right of this paragraph)

to indicate the addition of new or revised information.

Publication

1794-6.5.7 – April 1997

Page 4

soc–ii Summary of Changes

Publication

1794-6.5.7 – April 1997

Page 5

Table of Contents

Overview of Flex I/O and

your Thermocouple/mV

Module

How to Install Your

Thermocouple/mV Input

Module

Chapter 1

Chapter Objectives

The FLEX I/O System

How

FLEX I/O Analog Modules Communicate with Programmable

Controllers

Typical

Communication Between an Adapter and a Module

Features

Chapter Summary

of your Modules

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Y

European

Power Requirements

Installing

Connecting

Module

Chapter Summary

ou Install Y

Union Directive Compliance

EMC Directive

Low V

oltage Directive

Wiring

the T

the Module

Wiring for the Thermocouple/mV Module

Example

T

erminal Base Unit

Example

T

emperature T

Indicators

our Input Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

erminal Base Units (1794-TB2 and -TB3 shown)

of Millivolt Input Wiring to a 1794-TB3

3-wire Thermocouple Wiring to a 1794-TB3T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

erminal Base Unit

. . . . . . . . . . . . . . . . . . .

. .

1–1

1–1

1–1

1–2

1–3

1–3

2–1

2–1

2–1

2–1

2–2

2–2

2–3

2–4

2–5

2–7

2–7

2–8

2–8

Module Programming

Chapter 3

Chapter Objectives

Block

T

ransfer Programming

Sample

Chapter Summary

programs for FLEX I/O Analog Modules

PLC-3 Programming

PLC-5 Programming

PLC-2 Programming

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication

1794-6.5.7

3–1

3–1

3–2

3–2

3–3

3–4

3–4

Page 6

Table of Contentsii

Writing Configuration to

and Reading Status from

your Module with a Remote

I/O Adapter

How Communication Takes

Place and I/O Image Table

Mapping with the

DeviceNet Adapter

Chapter 4

Chapter Objectives

Configuring Y

Range

Input

Scaling

Hardware

Throughput

Reading Data From Y

Mapping

Thermocouple/mV

Thermocouple/mV Input Module (1794-IT8) Read

Thermocouple/mV

Word/Bit

Chapter Summary

our Thermocouple/mV Module

Selection

First Notch Filter

Data for the Analog Modules

Input Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

in Normal Mode

our Module

Input Module (1794-IT8) Image T

Input Module (1794-IT8) W

Descriptions for the 1794-IT8 Thermocouple/mV

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

Chapter 5

Chapter Objectives

About DeviceNet Manager

Polled I/O Structure

Adapter

System

Mapping

Thermocouple/mV

Defaults

Input Status W

Throughput

Data into the Image T

Thermocouple/mV Input Module (1794-IT8) Read

Thermocouple/mV

Word/Bit

Input Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ord

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

able

. . . . . . . . . . . . . . . . . . . . . . . .

Input Module (1794-IT8) Image T

Input Module (1794-IT8) W

Descriptions for the 1794-IT8 Thermocouple/mV

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

able Mapping

. . . . . . . . . .

rite

. . . . . . . . . .

able Mapping

. . . . . . . . . .

rite

. . . . . . . . . .

4–1

4–1

4–2

4–2

4–3

4–3

4–4

4–4

4–4

4–4

4–5

4–5

4–7

5–1

5–1

5–1

5–2

5–3

5–3

5–3

5–3

5–4

5–4

5–7

Calibrating Your Module

Publication

1794-6.5.7

Chapter 6

Chapter Objective

General

Tools

Removing

Manually

Information

and Equipment

Lead Wire or Thermocouple Extension Wire Resistance

Method

1 6–2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Method

2 6–3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating your Thermocouple/mV Input Module

Flow

Chart for Calibration Procedure

Calibration

Wiring

Read/Write W

Offset

Gain

Setups

Connections for the Thermocouple Module

Calibration

Calibration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

ords for Calibration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

6–1

6–1

6–2

6–2

.

6–4

6–5

6–6

6–6

6–7

6–7

6–8

Page 7

Table of Contents iii

Specifications

Calibrating Y

Software (Cat. No. 1787-MGR)

Offset

Gain

our Thermocouple/mV Module using DeviceNetManager

. . . . . . . . . . . . . . . . . . . . . . . .

Calibration

Calibration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Specifications

Derating Curve

Resolution Curves for Thermocouples

Type

B Thermocouple

Type

E Thermocouple

Type

C Thermocouple

Type J Thermocouple

Type

K Thermocouple

Type

R Thermocouple

Type

S Thermocouple

Type

T Thermocouple

Type

N Thermocouple

Worst Case Accuracy for the Thermocouple/mV Module

Error

Due to Open Circuit Current Through Loop Resistance

Worst

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Case Repeatability for the Thermocouple/mV Input Module

. . . . . . .

. . . .

6–9

6–9

6–1

A–1

A–2

A–3

A–3

A–3

A–4

A–4

A–5

A–5

A–6

A–6

A–7

A–7

A–8

A–8

1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermocouple Restrictions

(Extracted from NBS

Monograph 125 (IPTS–68))

Appendix B

General

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B

(Platinum – 30% Rhodium vs Platinum – 6% Rhodium) T

Thermocouples

E (Nickel–Chromium vs Copper–Nickel <Constantan*>) Type

Thermocouple

J (Iron vs Copper–Nickel <Constantan*>) T

K (Nickel–Chromium vs Nickel–Aluminum) T

R

(Platinum–13% Rhodium vs Platinum) and

S (Platinum–10% Rhodium vs Platinum) T

T (Copper vs Copper–Nickel <Constantan*>) T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ype Thermocouple

ype Thermocouple

ype Thermocouples

ype Thermocouple

ype

. . .

. .

B–1

B–1

B–2

B–2

B–4

B–5

B–5

Publication

1794-6.5.7

Page 8

Table of Contentsiv

Publication

1794-6.5.7

Page 9

Using This Manual

Preface

Preface Objectives

Audience

Vocabulary

What This Manual Contains

Read this preface to familiarize yourself with this manual and to

learn how to use it properly and efficiently.

We assume that you have previously used an Allen-Bradley

programmable controller, that you are familiar with its features, and

that you are familiar with the terminology we use. If not, read the

user manual for your processor before reading this manual.

In addition, if you are using this module in a DeviceNet system, you

must be familiar with:

• DeviceNetManager

• Microsoft Windows

TM

Software, cat. no. 1787-MGR

TM

In this manual, we refer to:

• the individual thermocouple/mV module as the “module.”

• the programmable controller as the “controller” or the

“processor.”

The contents of this manual are as follows:

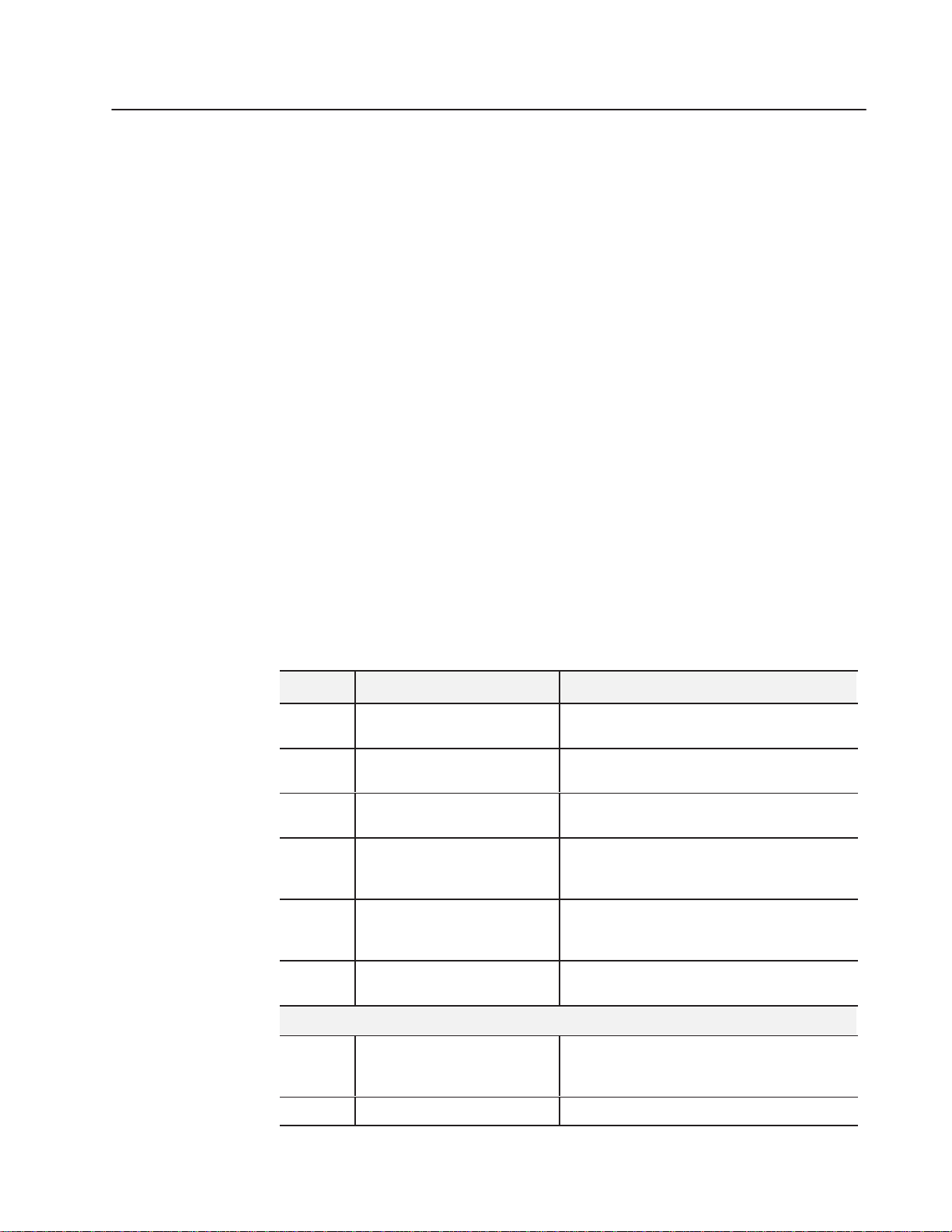

Chapter Title What’s Covered

1

2

3 Module Programming

4

5

6 Calibrating Your Module

Appendix

A Specifications

B Thermocouple Restrictions Extracted from NBS Monograph 125 (IPTS–68)

Overview of Flex I/O and Your

Thermocouple/mV Module

How to Install Your

Thermocouple/mV Input Module

Writing Configuration to and Reading

Status from Your Module with a

Remote I/O Adapter

How Communication Takes Place

and I/O Image Table Mapping with

the DeviceNet Adapter

Describes features, capabilities, and hardware

components.

Installation and connecting wiring

Block transfer programming and programming

examples

Describes block transfer write and block transfer read

configurations, including complete bit/word descriptions.

Describes communication over the I/O backplane

between the module and the adapter, and how data is

mapped into the image table.

Lists the tools needed, and the methods used to

calibrate the thermocouple input module

Module specifications, derating curve, resolution curves

for thermocouples, worst case accuracy and error due

to open circuit current.

Publication

1794-6.5.7 – April 1997

Page 10

Using This ManualP–2

Catalog

Conventions

For Additional Information

Number

1787-MGR DeviceNetManager Software User Manual 1787-6.5.3

1794 1794 FLEX I/O Product Data 1794-2.1

1794-ADN DeviceNet Adapter 1794-5.14 1794-6.5.5

1794-ASB/C Remote I/O Adapter 1794-5.46 1794-6.5.9

We use these conventions in this manual:

In

this manual, we show: Like this:

that there is more information about a topic

in another chapter in this manual

that there is more information about the

topic in another manual

More

For additional information on FLEX I/O systems and modules, refer

to the following documents:

Publications

Description

Industrial Automation Wiring and Grounding Guidelines 1770-4.1

Installation

Instructions

User

Manual

Summary

This preface gave you information on how to use this manual

efficiently. The next chapter introduces you to the remote I/O

adapter module.

Publication

1794-6.5.7 – April 1997

Page 11

Chapter

1

Overview of FLEX I/O and your

Thermocouple/mV Module

Chapter Objectives

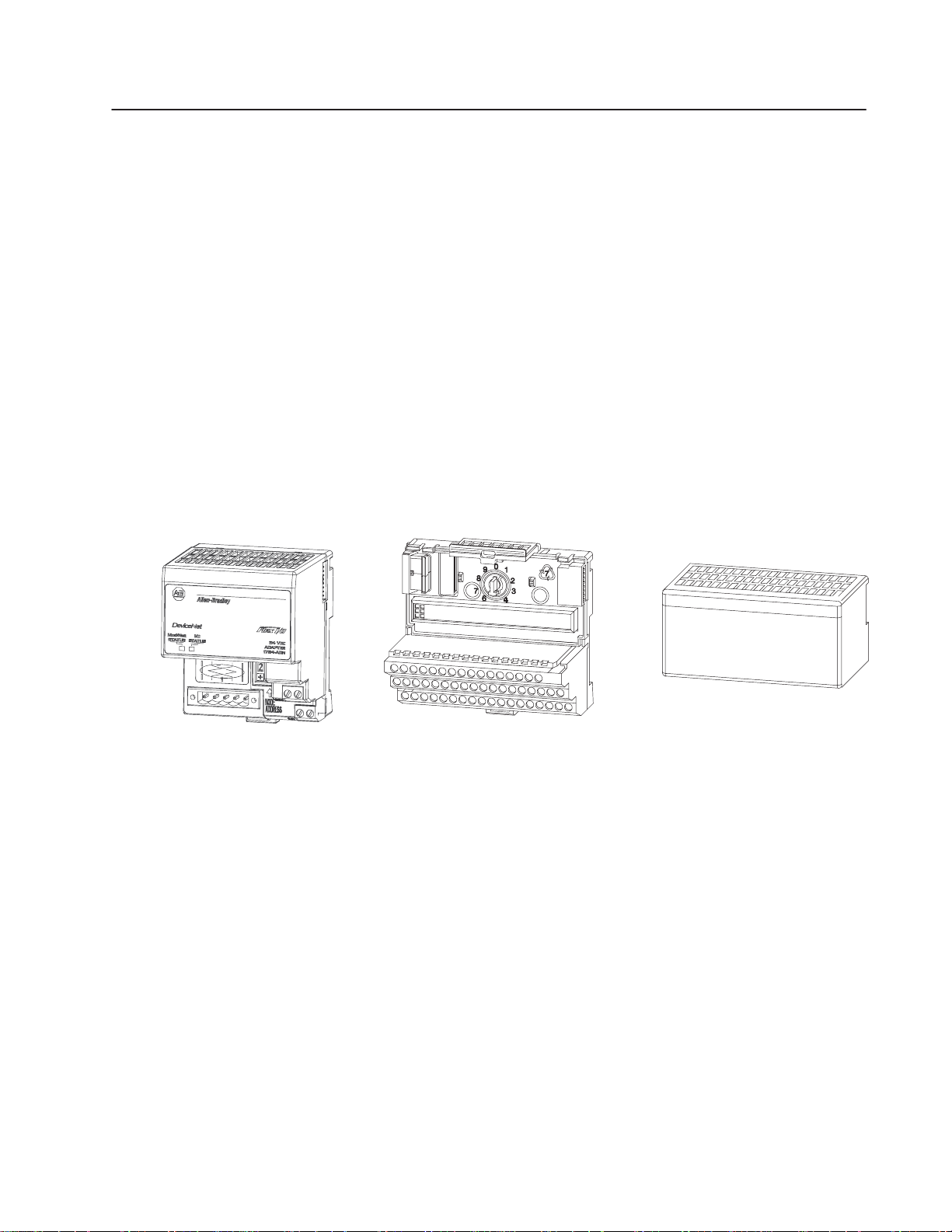

The FLEX I/O System

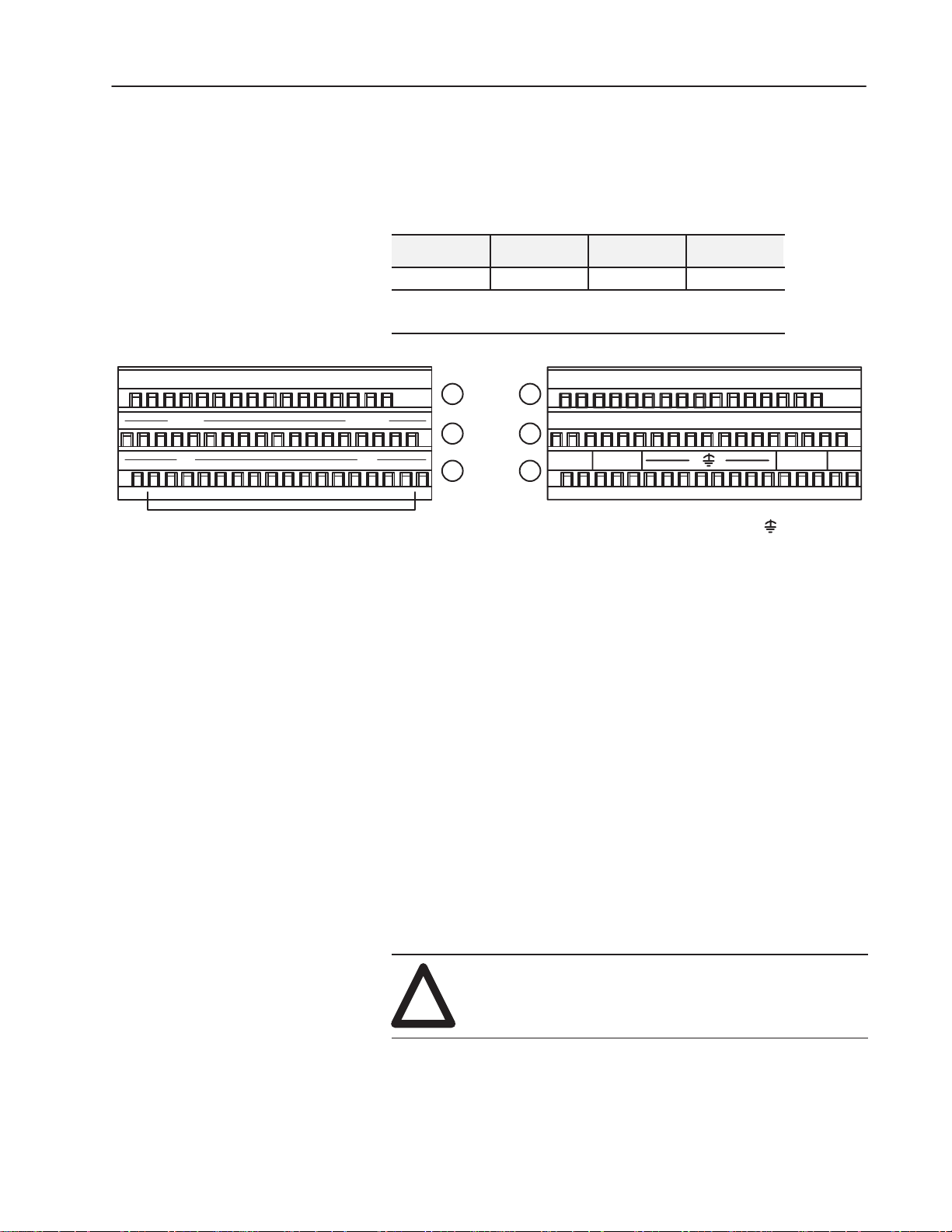

Adapter/Power Supply Terminal Base I/O Module

In this chapter, we tell you:

• what the FLEX I/O system is and what it contains

• how FLEX I/O modules communicate with programmable

controllers

• the features of your thermocouple module

FLEX I/O is a small, modular I/O system for distributed

applications that performs all of the functions of rack-based I/O. The

FLEX I/O system contains the following components shown below:

How FLEX I/O Analog Modules Communicate with Programmable Controllers

20125

• adapter/power supply – powers the internal logic for as many as

eight I/O modules

• terminal base – contains a terminal strip to terminate wiring for

thermocouple or millivolt inputs.

• I/O module – contains the bus interface and circuitry needed to

perform specific functions related to your application

FLEX I/O thermocouple/mV modules are block transfer modules

that interface analog signals with any Allen-Bradley programmable

controllers that have block transfer capability. Block transfer

programming moves input or output data words between the

module’s memory and a designated area in the processor data table.

Block transfer programming also moves configuration words from

the processor data table to module memory.

Publication

1794-6.5.7

Page 12

Overview of FLEX I/O and your Thermocouple/mV Module 1–2

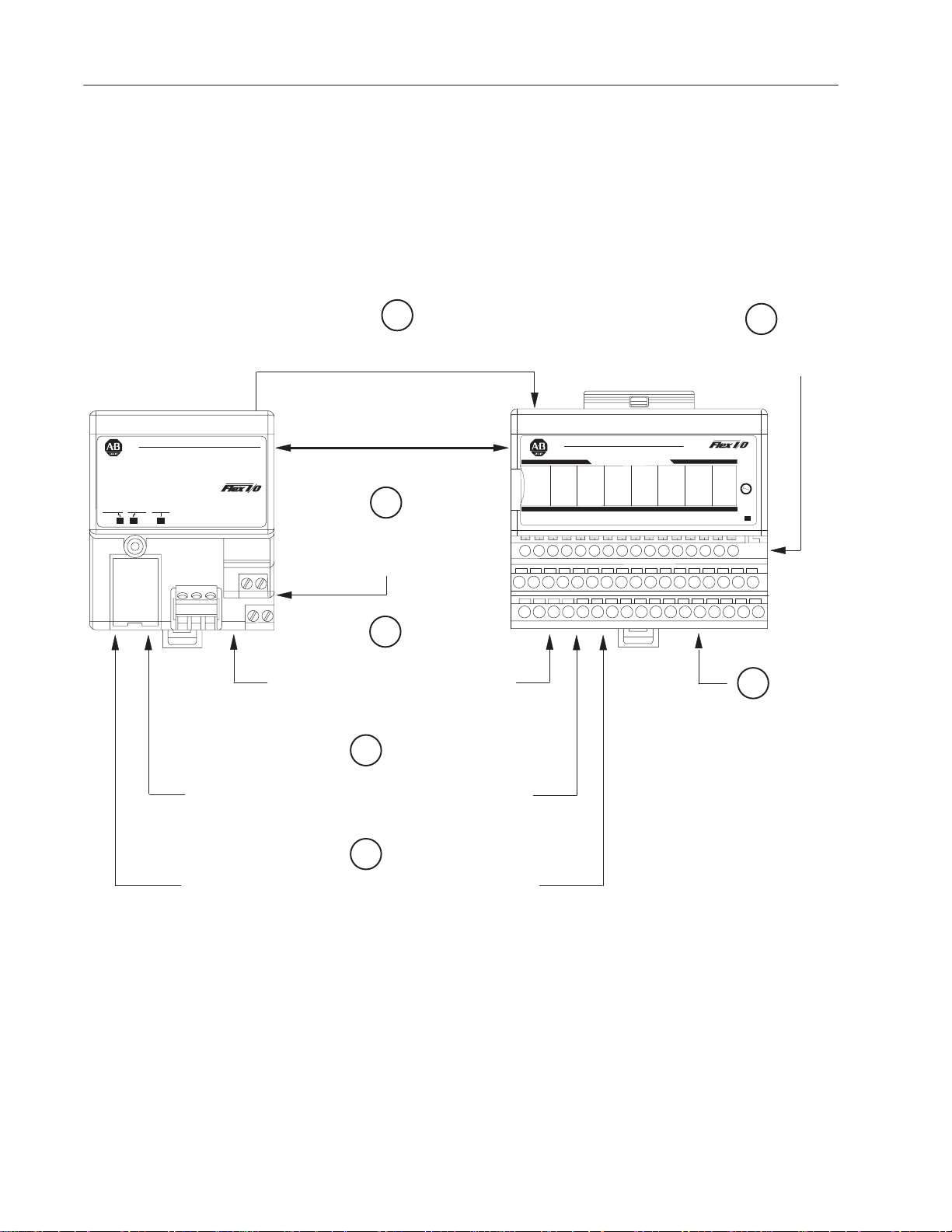

The adapter/power supply transfers data to the module (block

transfer write) and from the module (block transfer read) using BTW

and BTR instructions in your ladder diagram program. These

instructions let the adapter obtain input or output values and status

from the module, and let you establish the module’s mode of

operation. The illustration describes the communication process.

Typical Communication Between an Adapter and a Module

ADAPTER

ACTIVE FAULT

Allen-Bradley

LOCAL

FAULT

1

The adapter transfers your configuration data

to the module using a BTW.

Flexbus

POWER SUPPLY

RIO ADAPTER

1794-ASB

24VDC

4

Your ladder program instructs the

adapter to perform a BTR of the values

and stores them in a data table.

5

The adapter and module determine

that the transfer was made without error and

input values are within specified range.

6

Your ladder program can use and/or move the data (if valid)

before it is written over by the transfer of new data in a

subsequent transfer.

INPUT

0

+– +–

External devices transmit

analog signals to the module.

Allen-Bradley

THERMOCOUPLE

INPUT 8 CHANNEL

INPUT 2 INPUT 4 INPUT 6INPUT 1 INPUT 3 INPUT 5 INPUT 7

+–+–+– +–+–+–

The module converts analog signals

into binary format and stores these

values until the adapter requests

their transfer.

2

1794–IT8

3

OK

3

Publication

7

Your ladder program performs BTWs to the module only when

you power it up, or any time you wish to reconfigure the module.

1794-6.5.7

Page 13

Overview of FLEX I/O and your Thermocouple/mV Module 1–3

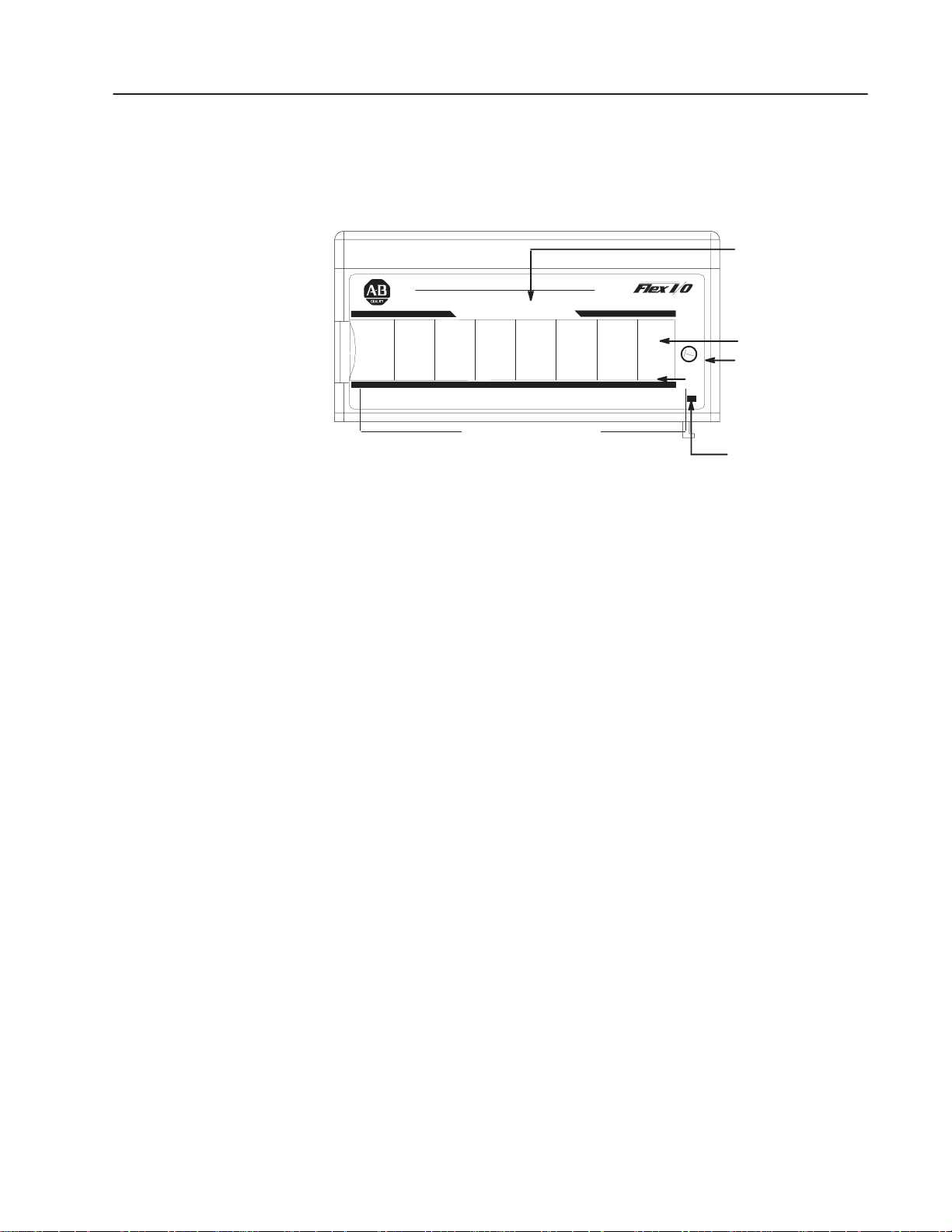

Features of your Modules

The module label identifies the keyswitch position, wiring and

module type. A removable label provides space for writing

individual designations per your application.

1794-IT8

Module Type

Allen-Bradley

INPUT

0

+– +–

THERMOCOUPLE

INPUT 2 INPUT 4 INPUT 6INPUT 1 INPUT 3 INPUT 5 INPUT 7

+– +– +– +–+–+–

INPUT 8 CHANNEL

Input Designators

1794–IT8

Removable Label

3

Keyswitch

OK

Position

Indicator (#3)

Power On Indicator

The thermocouple/mV module comes with 2 cold junction

compensators. These are designed to mount in designated positions

on the temperature terminal base unit (cat. no. 1794-TB3T). Refer to

chapter 2 for installation instructions for the cold junction

compensator assemblies.

Chapter Summary

In this chapter, you learned about the FLEX I/O system and the

thermocouple module, and how they communicate with

programmable controllers.

Publication

1794-6.5.7

Page 14

Overview of FLEX I/O and your Thermocouple/mV Module 1–4

Publication

1794-6.5.7

Page 15

Chapter

How to Install Your

Thermocouple/mV Input

Module

In this chapter, we tell you:

• how to install your module

• how to set the module keyswitch

• how to wire the terminal base

• about the indicators

2

Before You Install Your Input Module

European Union Directive Compliance

Before installing your thermocouple/mV module in the I/O chassis:

You need to: As described under:

Calculate the power requirements of all

modules in each chassis.

Position the keyswitch on the terminal base Installing the Module, page 2–4

ATTENTION: The Thermocouple module does not

receive power from the backplane. +24V dc power

!

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards,

in whole or in part, documented in a technical construction file:

• EN 50081-2EMC – Generic Emission Standard, Part 2 –

Industrial Environment

• EN 50082-2EMC – Generic Immunity Standard, Part 2 –

Industrial Environment

must be applied to your module before installation. If

power is not applied, the module position will appear

to the adapter as an empty slot in your chassis.

Power Requirements, page 2-2

This product is intended for use in an industrial environment.

Publication

1794-6.5.7

Page 16

2–2

How to Install Your Thermocouple/mV Input Module

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements and

Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines For

Noise Immunity, publication 1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

• Automation Systems Catalog, publication B111

Power Requirements

The wiring of the terminal base unit is determined by the current

draw through the terminal base. Make certain that the current draw

does not exceed 10A.

ATTENTION: Total current draw through the

terminal base unit is limited to 10A. Separate power

!

!

connections may be necessary.

ATTENTION: Do not daisy chain power or ground

from the thermocouple terminal base unit to any ac or

dc discrete module terminal base unit.

Publication

1794-6.5.7

Page 17

How to Install Your Thermocouple/mV Input Module

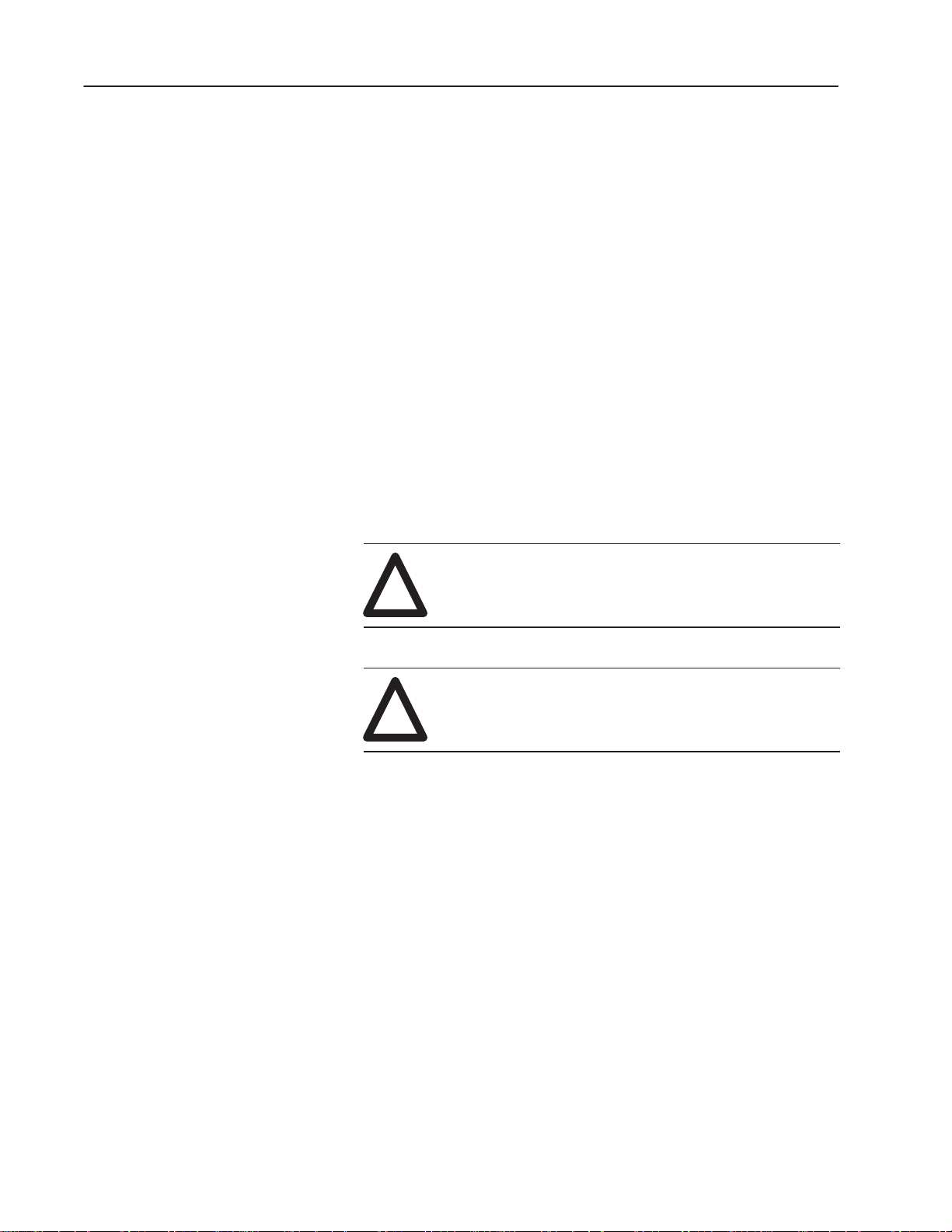

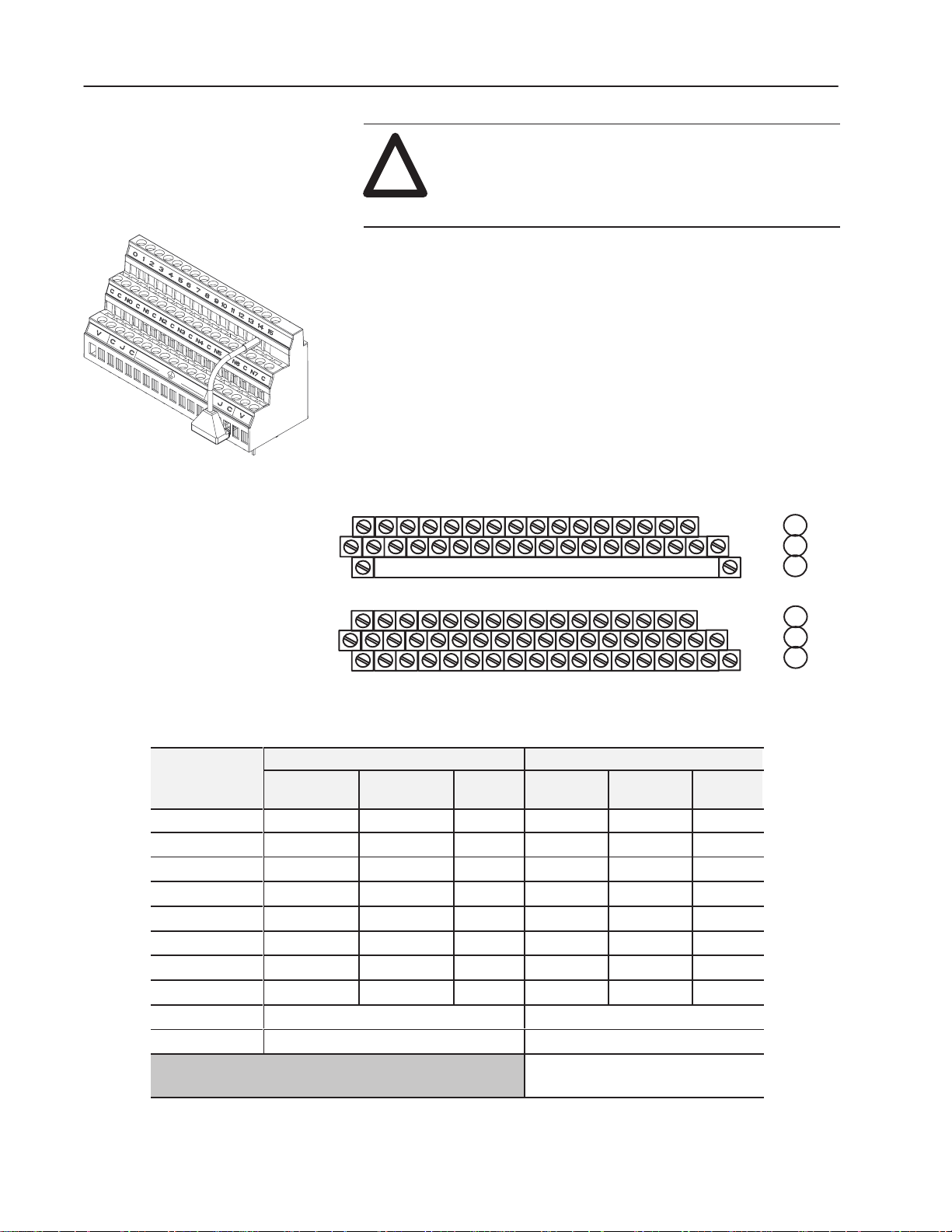

Methods of wiring the terminal base units are shown in the

illustration below.

Wiring the Terminal Base Units (1794-TB2 and -TB3 shown)

ATTENTION: Do not daisy chain power or

!

ground from the thermocouple terminal base unit to

any ac or dc discrete module terminal base unit.

2–3

Daisy-chaining

Individual

24V dc or

120V ac

24V dc

Thermocouple

or Analog Module

24V dc

24V dc

Thermocouple module wiring separate from discrete wiring.

Note: All modules must be analog modules for this configuration.

Wiring

when total current draw is less than 10A

Discrete

Module

Thermocouple

or Analog Module

Thermocouple

or Analog Module

Thermocouple

or Analog Module

Discrete

Module

Note: Use this configuration if using any

“noisy” dc discrete I/O modules in your system.

Thermocouple

or Analog Module

Discrete

Module

Combination

24V dc

24V dc

W

iring when total current draw is greater than 10A

Discrete

Module

Note: All modules powered by the same power supply

must be analog modules for this configuration.

T

otal current draw through any base unit must not be greater than 10A

Thermocouple

or Analog Module

Thermocouple

or Analog Module

Thermocouple

or Analog Module

Publication

1794-6.5.7

Page 18

2–4

How to Install Your Thermocouple/mV Input Module

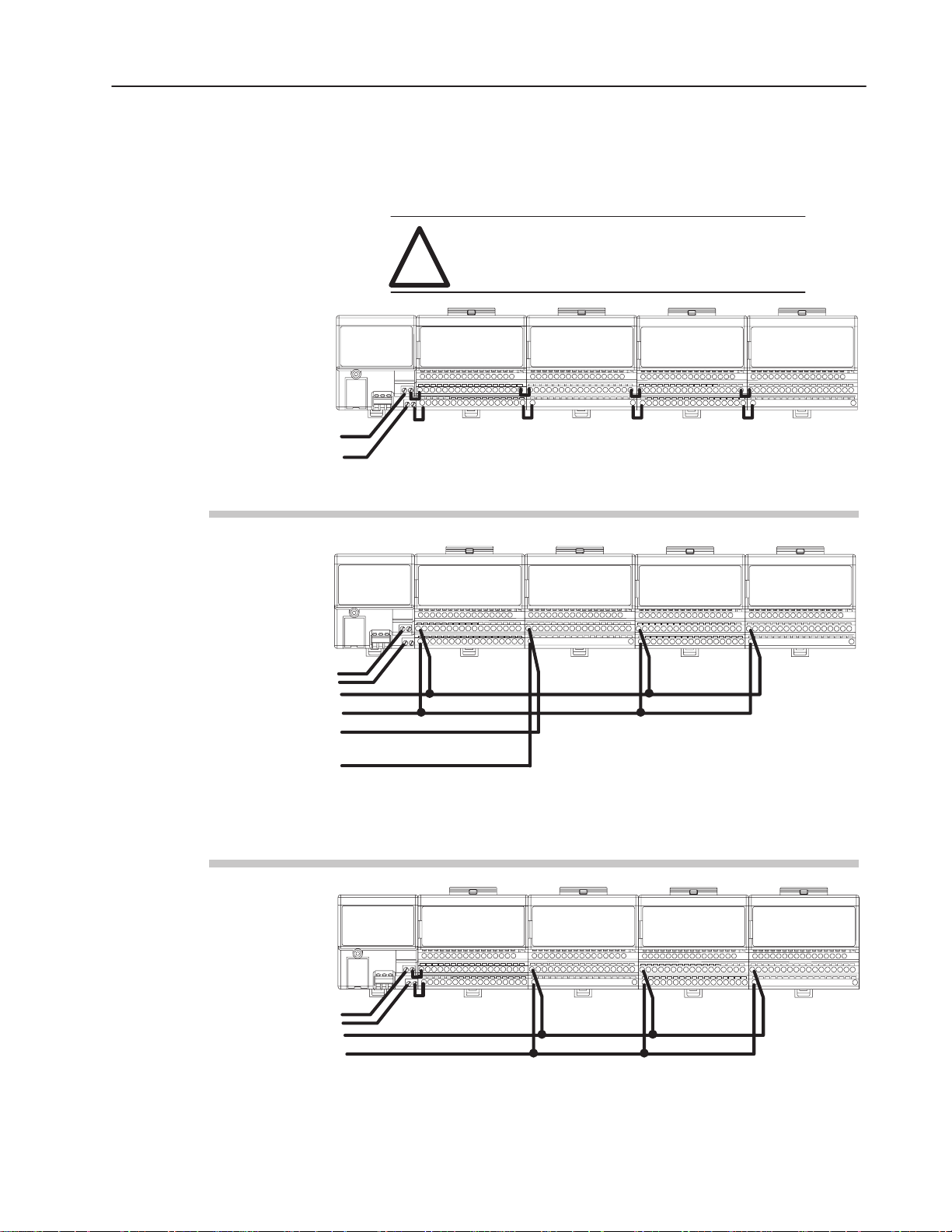

Installing the Module

The thermocouple/mV module mounts on a 1794-TB2, -TB3 or

-TB3T terminal base unit.

Important: You must use a 1794-TB3T terminal base unit if you

are using the thermocouple/mV module for

thermocouple inputs. You can use the 1794-TB2 or

-TB3 terminal base for millivolt inputs only.

7

3

4

1. Rotate the keyswitch (1) on the terminal base unit (2) clockwise

to position 3 as required for the thermocouple/mV module.

2. Make certain the flexbus connector (3) is pushed all the way to

the left to connect with the neighboring terminal base/adapter.

You cannot install the module unless the connector is fully

extended.

1

2

6

5

ATTENTION: Remove field-side power before

removing or inserting the module. This module is

!

designed so you can remove and insert it under

backplane power. When you remove or insert a

module with field-side power applied, an electrical arc

may occur. An electrical arc can cause personal injury

or property damage by:

• sending an erroneous signal to your system’s field

devices causing unintended machine motion

• causing an explosion in a hazardous environment

Repeated electrical arcing causes excessive wear to

contacts on both the module and its mating connector.

Worn contacts may create electrical resistance.

3. Before installing the module, check to make sure that the pins on

the bottom of the module are straight so they will align properly

with the female connector in the base unit.

4. Position the module (4) with its alignment bar (5) aligned with

the groove (6) on the terminal base.

5. Press firmly and evenly to seat the module in the terminal base

unit. The module is seated when the latching mechanism (7) is

locked into the module.

Publication

6. Repeat the above steps to install the next module in its terminal

base unit.

1794-6.5.7

Page 19

How to Install Your Thermocouple/mV Input Module

2–5

Connecting Wiring for the Thermocouple/mV Module

1794-TB2

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

COM COM

VV

V = 24V dc

COM

= 24V dc common

These

and 1794-TB3

terminals on 1794-TB3 only

Thermocouple/mV module wiring is made through the terminal base

unit on which the module mounts. The module comes with 2 cold

junction compensators for use when using the thermocouple module

in the thermocouple mode.

Compatible terminal base unit are:

Module 1794-TB2 1794-TB3 1794-TB3T

1794-IT8 Yes

1

The

1794-TB3T terminal base unit contains connections for cold junction

compensation for use with thermocouple modules.

2

For millivolt inputs only

2

.

Yes

2

1794-TB3T

A

0

–15

B

16–33

C

34–51

.

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

A

C N0 C N1 C N2 C CN3 C N4 C N5 C N6 C N7

C

B

VCJC CJCV

C

Where:

V = 24V dc

C = 24V dc common

CJC = cold junction compensation

1

Yes

N = additional input

Connecting Wiring using a 1794-TB2, -TB3 and -TB3T Terminal

Base Units

= chassis ground

1. Connect the individual signal wiring to numbered terminals on

the 0–15 row (A) on the terminal base unit. Connect the high side

(+) to the even numbered terminals, and the low side (–) to the

odd numbered terminals. See Table 2.A.

2. Connect shield return to the associated terminal on row B, as

shown in Table 2.A.

• On 1794-TB2 and -TB3 bases only: terminate shields to the

associated shield return terminals on row (B).

• On 1794-TB3T bases only: terminate shields to terminals 39

to 46 on row C.

3. Connect +24V dc to terminal 34 on the 34-51 row (C), and 24V

common to terminal 16 on the B row.

Important: To reduce susceptibility to noise, power analog modules

and discrete modules from separate power supplies.

ATTENTION: Do not daisy chain power or ground

from the thermocouple terminal base unit to any ac or

!

dc discrete module terminal base unit.

Publication

1794-6.5.7

Page 20

2–6

Thermocouple

2

2

inals 36, 37, 38 and 47, 48, 49 are cold junction

How to Install Your Thermocouple/mV Input Module

Cold Junction Compensator

Pt.No. 969424-01

ATTENTION: The Thermocouple/mV module does

not receive power from the backplane. +24V dc power

!

must be applied to your module before installation. If

power is not applied, the module position will appear

to the adapter as an empty slot in your chassis.

4. On 1794-TB3T terminal base units: Connect the cold junction

compensation (CJC) wiring to terminals 36, 37 and 38 for inputs

0 through 3, and terminals 47, 48 and 49 for inputs 4 through 7.

Connect the tail of the cold junction compensator to any of the

associated thermocouple input terminals: 0 through 7 for CJC

connected to 36, 37 and 38; or 8 through 15 for CJC connected to

47, 48 and 49. The tail of the cold junction compensator shares

a terminal with an input.

5. If daisy chaining the +24V dc power to the next base unit,

connect a jumper from terminal 51 on this base unit to terminal

34 on the next base unit.

1234567891011121314150

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

16

1 51

34

0 –15

16–33

34–51

1794-TB2

1234567891011121314150

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

16

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

0

16–33

34–51

1794-TB3, -TB3T

–15

A

B

C

A

B

C

Table 2.A

Wiring

connections for the 1794-IT8 Thermocouple Input Module

2

Shield

Return

Channel

1794-TB2, -TB3 Terminal Base Units 1794-TB3T Terminal Base Unit

High Signal

Terminal (+)

Low Signal

Terminal (–)

Shield

Return

High Signal

Terminal (+)

Low Signal

Terminal (–)

0 0 1 17 0 1 39

1 2 3 19 2 3 40

2 4 5 21 4 5 41

3 6 7 23 6 7 42

4 8 9 25 8 9 43

5 10 11 27 10 11 44

6 12 13 29 12 13 45

7 14 15 31 14 15 46

24V dc Common 16 thru 33 16, 17, 19, 21, 23, 25, 27, 29, 31 and 33

+24V dc power 1794-TB2 – 34 and 51; 1794-TB3 – 34 thru 51 34, 35, 50 and 51

1

Terminals

39 to 46 are chassis ground.

T

erm

compensator terminals.

1

Publication

1794-6.5.7

Page 21

How to Install Your Thermocouple/mV Input Module

ATTENTION: The thermocouple/mV modules do

not receive power from the backplane. +24V dc power

!

must be applied to your module before operation. If

power is not applied, the module position will appear

to the adapter as an empty slot in your chassis. If the

adapter does not recognize your module after

installation is completed, cycle power to the adapter.

ATTENTION: Total current draw through the

terminal base unit is limited to 10A. Separate power

!

connections to the terminal base unit may be necessary.

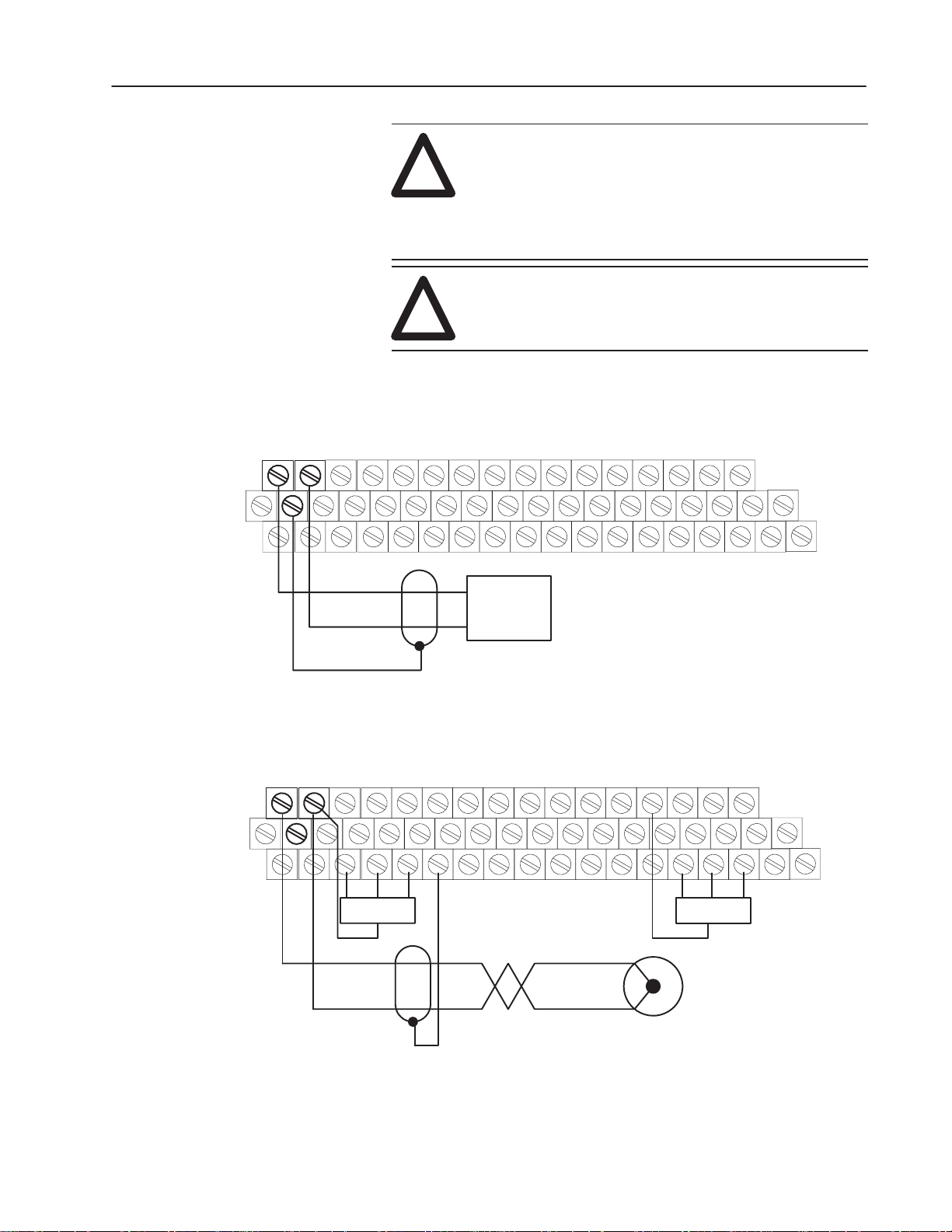

Example of Millivolt Input Wiring to a 1794-TB3

Terminal Base Unit

12 34567891011121314150

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

16

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

2–7

0

–15

16–33

34–51

1794-TB3

+

Millivolt

Source

–

Millivolt input Channel 1

Channel 0 (Terminals 0, 1 and 17)

Example of 3-wire Thermocouple Wiring to a 1794-TB3T

Temperature Terminal Base Unit

12 34567891011121314150

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

16

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

CJC CJC

+

–

1794-TB3T

0

16–33

34–51

Cold

Junction Compensator

Allen-Bradley PN 969424–01

(2 supplied with module)

–15

Channel 0 (Terminals 0, 1 and 39)

Publication

1794-6.5.7

Page 22

2–8

How to Install Your Thermocouple/mV Input Module

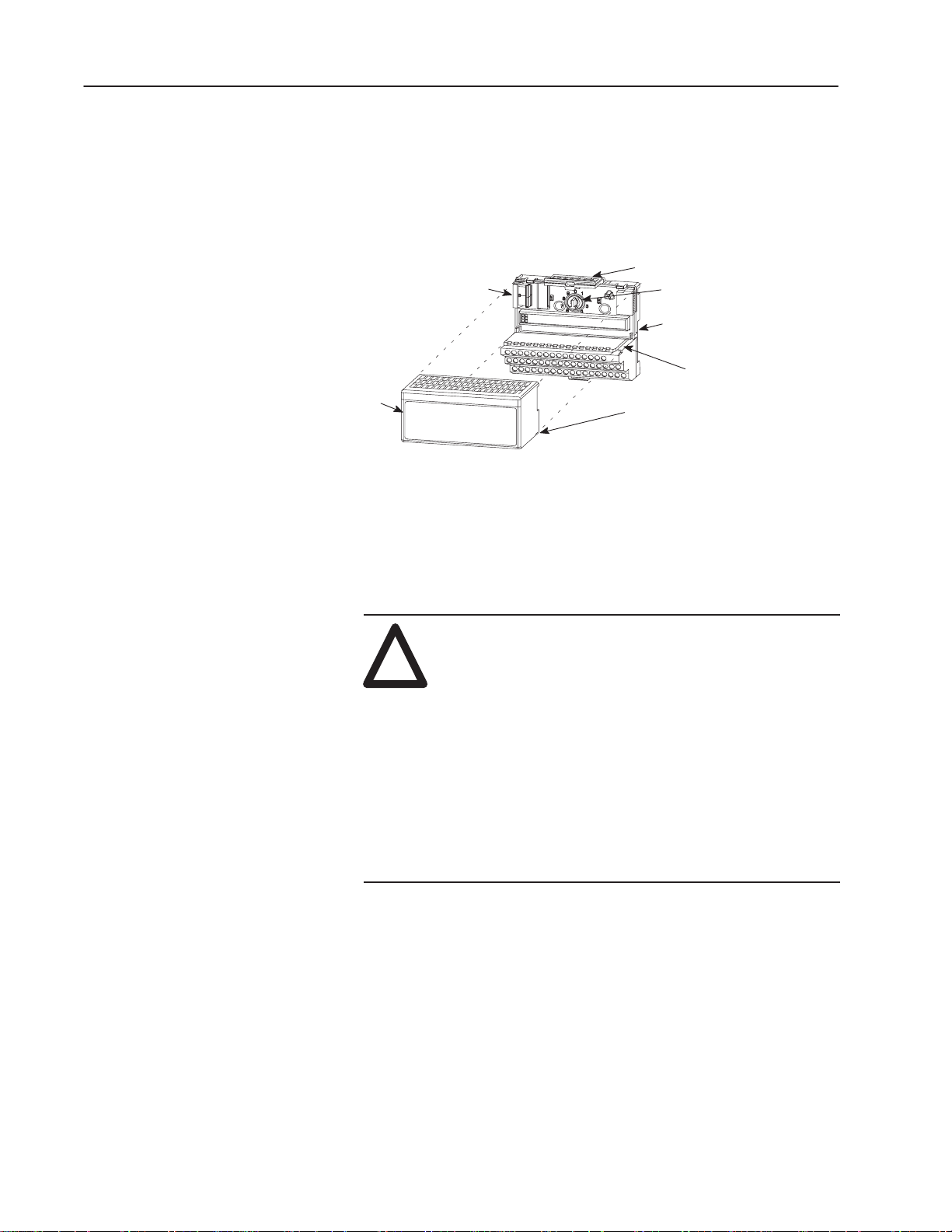

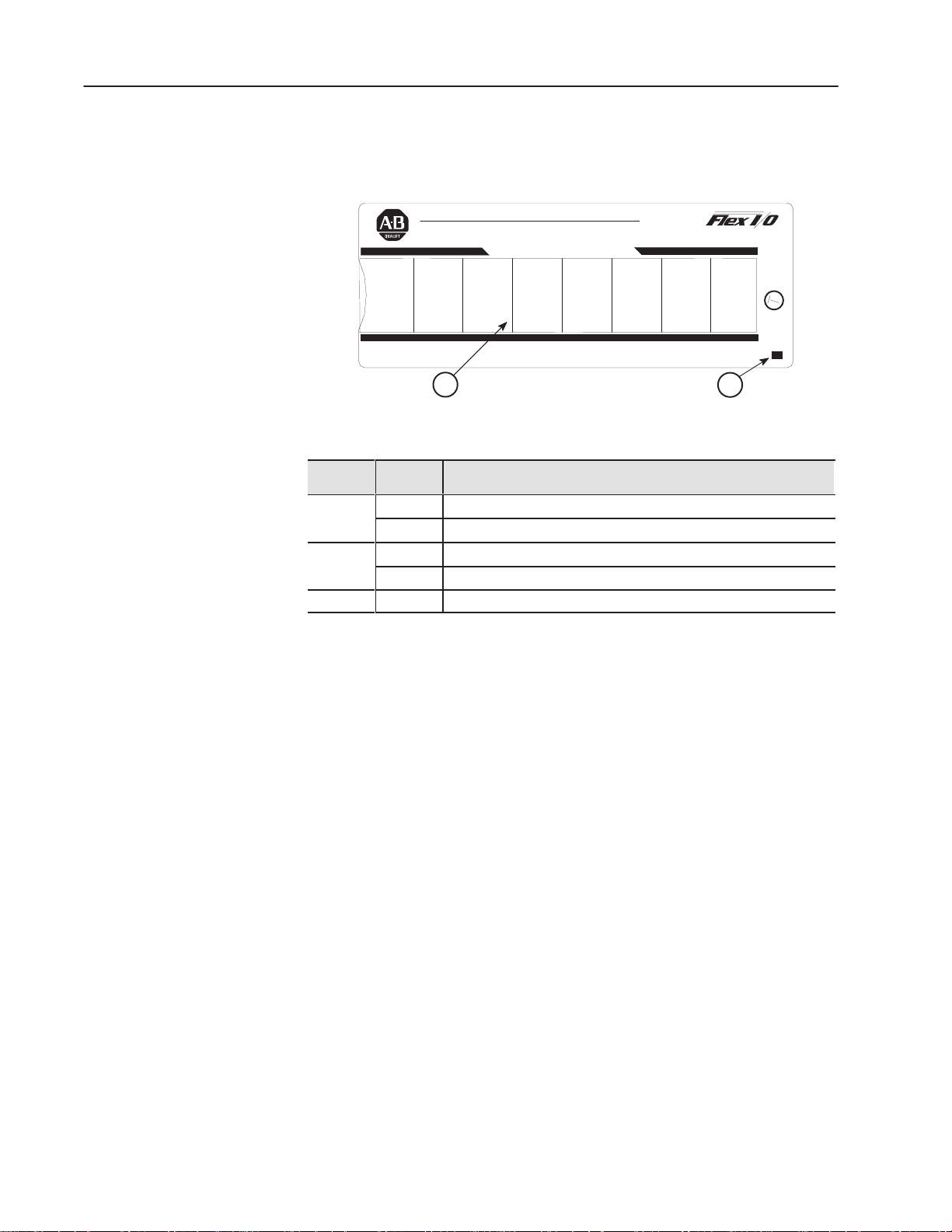

Module Indicators

The thermocouple/mV module has one status indicator that is on

when power is applied to the module. This indicator has 3 different

states:

Allen-Bradley

THERMOCOUPLE INPUT 8 CHANNEL

INPUT

0

+– +–

A = Status Indicator – indicates diagnostic results and configuration status

B = Insertable label for writing individual input designations

Color State Meaning

Red On Indicates a critical fault (diagnostic failure, etc.)

Blinking Indicates a noncritical fault (such as open sensor, input out of range, etc.)

Green On Module is configured and fully operational

Blinking Module is functional but not configured

Off Module not powered

INPUT 2 INPUT 4 INPUT 6INPUT 1 INPUT 3 INPUT 5 INPUT 7

+– +–+– +–+–+–

1794–IT8

3

OK

AB

Chapter Summary

In this chapter, you learned how to install your thermocouple/mV

module in an existing programmable controller system and how to

wire to the terminal base units.

Publication

1794-6.5.7

Page 23

Chapter

3

Chapter Objectives

Block Transfer Programming

In this chapter, we tell you about:

• block transfer programming

• sample programs for the PLC-3 and PLC-5 processors

Your thermocouple/mV module communicates with the processor

through bidirectional block transfers. This is the sequential operation

of both read and write block transfer instructions.

A configuration block transfer write (BTW) is initiated when the

thermocouple module is first powered up, and subsequently only

when the programmer wants to enable or disable features of the

module. The configuration BTW sets the bits which enable the

programmable features of the module, such as scaling, alarms,

ranges, etc. Block transfer reads are performed to retrieve

information from the module.

Block transfer read (BTR) programming moves status and data from

the module to the processor’s data table. The processor user program

initiates the request to transfer data from the module to the processor.

The transferred words contain module status, channel status and

input data from the module.

ATTENTION: If the thermocouple/mV module is

not powered up before the remote I/O adapter, the

!

The following sample programs are minimum programs; all rungs

and conditioning must be included in your application program. You

can disable BTRs, or add interlocks to prevent writes if desired. Do

not eliminate any storage bits or interlocks included in the sample

programs. If interlocks are removed, the program may not work

properly.

Your program should monitor status bits and block transfer read

activity.

adapter will not recognize the module. Make certain

that the thermocouple/mV module is installed and

powered before or simultaneously with the remote I/O

adapter. If the adapter does not establish

communication with the module, cycle power to the

adapter.

Publication

1794-6.5.7

Page 24

3–2

Module Programming

Sample programs for FLEX I/O Analog Modules

The following sample programs show you how to use your analog

module efficiently when operating with a programmable controller.

These programs show you how to:

• configure the module

• read data from the module

These example programs illustrate the minimum programming

required for communication to take place.

PLC-3 Programming

Block transfer instructions with the PLC-3 processor use one binary

file in a data table section for module location and other related data.

This is the block transfer control file. The block transfer data file

stores data that you want transferred to your module (when

programming a block transfer write) or from your module (when

programming a block transfer read). The address of the block

transfer data files are stored in the block transfer control file.

The same block transfer control file is used for both the read and

write instructions for your module. A different block transfer

control file is required for every module.

Program

Action

At power-up in RUN mode, or when the

processor is switched from PROG to RUN,

the user program enables a block transfer

read. Then it initiates a block transfer write

to configure the module.

Thereafter, the program continuously

performs read block transfers.

Note: You must create the data file

for the block transfers before you

enter the block transfer instructions.

The pushbutton allows the user to

manually request a block transfer write.

A sample program segment with block transfer instructions is shown

in Figure 3.1, and described below.

Figure 3.1

PLC-3 Family Sample Program Structure

BTR

BLOCK XFER READ

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

BTW

BLOCK XFER WRITE

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

7

0

0

#B3:0

#B4:0

11

7

0

0

#B3:0

#B5:0

3

1

2

Pushbutton

Power-up Bit

B4:10

03

Block Transfer

Read Done Bit

B3:0

15

Block Transfer

rite Done Bit

W

B3:0

05

EN

Done

DN

ER

13

Enable

EN

Done

DN

Error

ER

Enable

12

15

Error

02

05

03

Publication

1794-6.5.7

Page 25

Module Programming

PLC-5 Programming

The PLC-5 program is very similar to the PLC-3 program with the

following exceptions:

1. Block transfer enable bits are used instead of done bits as the

conditions on each rung.

2. Separate block transfer control files are used for the block

transfer instructions.

Figure 3.2

PLC-5 Family Sample Program Structure

3–3

Program

Action

At power-up in RUN mode, or when the

processor is switched from PROG to RUN,

the user program enables a block transfer

read. Then it initiates a block transfer write

to configure the module.

Thereafter, the program continuously performs read block transfers.

The pushbutton allows the user to

manually request a block transfer write.

BTR Enable Bit

1

2

Power-up Bit

N12:0

15

Pushbutton

N13:10

03

BTW Enable Bit

N12:5

15

BTR

BLOCK

TRANSFER READ

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS: N

BTW

BLOCK

TRANSFER WRITE

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS: N

N12:0

N13:0

N12:5

N13:20

EN

2

1

DN

0

ER

11

EN

2

1

DN

0

ER

3

Publication

1794-6.5.7

Page 26

3–4

Module Programming

PLC-2 Programming

The 1794 analog I/O modules are not recommended for use with

PLC-2 family programmable controllers due to the number of digits

needed for high resolution.

Chapter Summary

In this chapter, you learned how to program your programmable

controller. You were given sample programs for your PLC-3 and

PLC-5 family processors.

Publication

1794-6.5.7

Page 27

Chapter

Writing Configuration to and

Reading Status from your

Module with a Remote I/O

Adapter

4

Chapter Objectives

Configuring Your Thermocouple/mV Module

In this chapter, we tell you about:

• configuring your module’s features

• entering your data

• reading data from your module

• the read block format

Because of the wide variety of possible configurations, you must

configure your module to conform to the specific application that

you have chosen. The module is configured using a group of data

table words that are transferred to the module using a block transfer

write instruction.

The software configurable features available for the thermocouple

module are:

• input/output range selection, including full range and bipolar

• selectable first notch filter

• data reported in

Note: PLC-5 family programmable controllers that use 6200

software (version 5.2 or later) programming tools can take advantage

of the IOCONFIG utility to configure these modules. IOCONFIG

uses menu-based screens for configuration without having to set

individual bits in particular locations. Refer to your 6200 software

literature for details.

o

F, oC, unipolar or bipolar count

Publication

1794-6.5.7 – April 1997

Page 28

4–2

r ocoupl

Writing Configuration to and Reading Status from your Module with a Remote I/O Adapter

Range Selection

Input Scaling

Individual input channels are configurable to operate with the

following sensor types:

Sensor Type Range

Voltage Millivolt –76.50 to +76.50mV

Thermocouple

Type B 300 to 1800oC

Type E –230 to 1000oC

Type J –195 to 1200oC

Type K –230 to 1372oC

Type R –50 to 1768oC

Type S –50 to 1768oC

Type T –195 to 400oC

Type N –270 to 1300oC

Type C 0 to 2315oC

Type L –175 to 800oC

You select individual channel ranges using write words 1 and 2 of

the block transfer write instruction.

Scaling lets you report each channel in actual engineering units.

Scaled values are in integer format.

Input Type Range Scaling Maximum Resolution

Millivolt –76.50 to +76.50mV –7650 to +7650

Type B 300 to 1800oC 3000 to 18000 0.1oC

Type E –230 to 1000oC –2300 to 10000 0.1oC

Type J –195 to 1200oC –1950 to 12000 0.1oC

Type K –230 to 1372oC –2300 to 13720 0.1oC

Type R –50 to 1768oC –500 to 17680 0.1oC

Type S –50 to 1768oC –500 to 17680 0.1oC

Type T –195 to 400oC –1950 to 4000 0.1oC

Type N –270 to 1300oC –2700 to 13000 0.1oC

Type C 0 to 2315oC 0 to 23150 0.1oC

Type L –175 to 800oC –1750 to 8000 0.1oC

Type B 572 to 3272oF 5720 to 32720 0.1oF

Type E –382 to 1832oF –3820 to 18320 0.1oF

Type J –319 to 2192oF –3190 to 21920 0.1oF

Type K –382 to 2502oF –3820 to 25020 0.1oF

Type R –58 to 3214oF –580 to 32140 0.1oF

Type S –58 to 3214oF –580 to 32140 0.1oF

Type T –319 to 752oF –3190 to 7520 0.1oF

Type N –450 to 2372oF –4500 to 23720 0.1oF

Type C 32 to 4199oF 320 to 41990 0.1oF

Type L –283 to 1472oF –2830 to 14720 0.1oF

Note:

In thermocouple mode, scaled number has an implied decimal point 1 digit from the right. For example, if reading is

18000, temperature is 1800.0. In millivolt mode, the implied decimal point is to the left of the last 2 digits. For example, if

reading is 2250, actual reading is 22.50mV

10µV

Publication

1794-6.5.7 – April 1997

Page 29

Writing Configuration to and Reading Status from your Module with a Remote I/O Adapter

You select input scaling using the designated words of the write

block transfer instruction. Refer to the Bit/Word description for write

word 0, bits 00 and 01.

4–3

Hardware First Notch Filter

A/D Filter First Notch

Frequency

(effective resolution)

Number of channels

scanned

1 325 145 85 75 55 37 31 28

2 650 290 170 150 110 74 62 56

3 975 435 255 225 165 111 93 84

4 1.3s 580 340 300 220 148 124 112

5 1.625s 725 425 375 275 185 155 140

6 1.95s 870 510 450 330 222 186 168

7 2.275s 1.015s 595 525 385 259 217 196

8 2.60s

1

Default

setting

(16-bits)

10Hz

A hardware filter in the analog to digital converter lets you select a

frequency for the first notch of the filter. Selection of the filter

influences the analog to digital output data rate and changes the

module throughput. Module throughput is a function of the number

of inputs used and the first notch filter. Both of these influence the

time from a thermocouple input to arrival at the backplane.

Throughput in Normal Mode

25Hz

(16-bits)

1

1.16s 680 600 440 296 248 224

50Hz

(16-bits)

60Hz

(16-bits)

System Throughput (in ms and s)

100Hz

(16-bits)

250Hz

(13-bits)

500Hz

(11-bits)

1000Hz

(9-bits)

Publication

1794-6.5.7 – April 1997

Page 30

4–4

Writing Configuration to and Reading Status from your Module with a Remote I/O Adapter

Reading Data From Your Module

Mapping Data for the Analog Modules

Read programming moves status and data from the thermocouple

input module to the processor’s data table. The processor’s user

program initiates the request to transfer data from the

thermocouple/mV input module to the processor.

The following read and write words and bit/word descriptions

describe the information written to and read from the

thermocouple/mV input module. The module uses up to 11 words of

input image and up to 3 words of output image. Each word is

composed of 16 bits.

Thermocouple/mV Input Module (1794-IT8) Image Table Mapping

Module

Image

Reserved

Input Data Channel 0

I/O Image

Input Size

1 to 11 Words

Output Size

0 to 3 Words

Overrange

Calibration Mask

Input Data Channel 1

Input Data Channel 2

Input Data Channel 3

Input Data Channel 4

Input Data Channel 5

Input Data Channel 6

Input Data Channel 7

Underrange

Calibration Status

Configuration

Thermocouple Type

Thermocouple Type

Thermocouple/mV Input Module (1794-IT8) Read

Decimal

Bit

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read Word 0 Reserved

1 Channel 0 Input Data

2 Channel 1 Input Data

3 Channel 2 Input Data

4 Channel 3 Input Data

5 Channel 4 Input Data

6 Channel 5 Input Data

7 Channel 6 Input Data

8 Channel 7 Input Data

Publication

1794-6.5.7 – April 1997

Page 31

Writing Configuration to and Reading Status from your Module with a Remote I/O Adapter

4–5

Bit

9 Overrange Bits Underrange Bits

Bad

Cal

10 0 0 0 0 0

Cal

Done

Cal

Range

0 Diagnostic Status

PwrUpBad

Thermocouple/mV Input Module (1794-IT8) Write

Dec.

Bit

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Cal

Write Word 0 8-Bit Calibration Mask

1 Thermocouple 3 Type Thermocouple 2 Type Thermocouple 1 Type Thermocouple 0 Type

2 Thermocouple 7 Type Thermocouple 6 Type Thermocouple 5 Type Thermocouple 4 Type

Where: FDF

= fixed digital filter bit

Clk

Cal hi

Cal lo

Filter Cutoff FDF Data Type

Word/Bit Descriptions for the 1794-IT8 Thermocouple/mV

Input Module

Decimal

Word

Bit

(Octal Bit)

Description

Structure

CJC

over

00010203040506070809101112131415Decimal

00010203040506071011121314151617Octal Bit

CJC

Under

Read Word 0 00–15 (00–17) Reserved

Read Word 1 00–15 (00–17) Channel 0 Input data

Read Word 2 00–15 (00–17) Channel 1 Input data

Read Word 3 00–15 (00–17) Channel 2 Input data

Read Word 4 00–15 (00–17) Channel 3 Input data

Read Word 5 00–15 (00–17) Channel 4 Input data

Read Word 6 00–15 (00–17) Channel 5 Input data

Read Word 7 00–15 (00–17) Channel 6 Input data

Read Word 8 00–15 (00–17) Channel 7 Input data

Read Word 9

Read Word 10

00–07 (00–07) Underrange bits – these bits are set if the input signal is below the input channel’s minimum range.

08–15 (10–17) Overrange bits – these bits are set if 1), the input signal is above the input channel’s maximum range,

or 2), an open detector is detected.

00 (00) Cold Junction sensor underrange bit. – this bit is set if the cold junction temperature is below 0oC.

01 (01) Cold Junction sensor overrange bit. – this bit is set if the cold junction temperature is above 70oC.

02 (02) Bad Structure – this bit is set if an invalid thermocouple type is selected.

03 (03) Powerup bit – this bit is set (1) until configuration data is received by the module.

04–06 (04–06) Critical Error bits – If these bits are anything other than all zeroes, return the module to the factory for

repair

07 (07) Unused – set to 0

08 (10) Calibration Range bit – set to 1 if a reference signal is out of range during calibration

09 (11) Calibration Done bit – set to 1 after an initiated calibration cycle is complete.

10 (12) Calibration Bad bit – set to 1 if the channel has not had a valid calibration.

11–15 (13–17) Unused – set to 0

Publication

1794-6.5.7 – April 1997

Page 32

4–6

Word

Writing Configuration to and Reading Status from your Module with a Remote I/O Adapter

Decimal

Bit

(Octal Bit)

Description

Write Word 0

00–01 (00–01) Module Data Type

Bit 01 00 Definition

0 0oC (default)

0 1oF

1 0 Bipolar counts scaled between –32768 and +32767

1 1 Unipolar counts scaled between 0 and 65535

Bit 02 (02) Fixed Digital Filter – When this bit is set (1), a software digital filter is enabled. This filter settles to

100% of a Full Scale step input in 60 times the selected first notch filter time shown on page 4–3.

(Default – filter disabled.)

03–05 (03–05) A/D Filter First Notch Frequency

Bit 05 04 03 Definition

0 0 0 10Hz (default)

0 0 1 25Hz

0 1 0 50Hz

0 1 1 60Hz

1 0 0 100Hz

1 0 1 250Hz

1 1 0 500Hz

1 1 1 1000hZ

06 (06) Calibration High/Low bit – This bit is set during gain calibration; reset during offset calibration.

07 (07) Calibration clock – this bit must be set to 1 to prepare for a calibration cycle; then reset to 0 to initiate

calibration.

08–15 (10–17) Calibration mask – The channel, or channels, to be calibrated will have the correct mask bit set. Bit 8

corresponds to channel 0, bit 9 to channel 1, and so on.

Publication

1794-6.5.7 – April 1997

Page 33

Word

Writing Configuration to and Reading Status from your Module with a Remote I/O Adapter

Decimal

Bit

(Octal Bit)

Description

4–7

Write Word 1

Write Word 2

00–03 (00–03) Channel 0 Thermocouple Type

Bit 03 02 01 00 Thermocouple Type – Range

0 0 0 0 Millivolts (default)

0 0 0 1 B 300 to 1800oC (572 to 3272oF)

0 0 1 0 E –230 to 1000oC (–382 to 1832oF)

0 0 1 1 J –195 to 1200oC (–319 to 2192oF)

0 1 0 0 K –230 to 1372oC (–382 to 2502oF)

0 1 0 1 R –50 to 1768oC (–58 to 3214oF)

0 1 1 0 S –50 to 1768oC (–58 to 3214oF)

0 1 1 1 T –195 to 400oC (–319 to 752oF)

1 0 0 0 C 0 to 2315oC (32 to 4199oF)

1 0 0 1 N –270 to 1300oC (–450 to 2372oF)

1 0 1 0 L -175 to 800oC (-283 to 1472oF)

1 0 1 1 Reserved

1 1 0 0 Module reports cold junction temperature for channels 00–03

1 1 0 1 Module reports cold junction temperature for channels 04–07

1 1 1 0 Reserved

1 1 1 1 No sensor connected (do not scan)

04–07 (04–07) Channel 1 Thermocouple Type (see bits 00–03)

08–11 (10–13) Channel 2 Thermocouple Type (see bits 00–03)

12–15 (14–17) Channel 3 Thermocouple Type (see bits 00–03)

00–03 (00–03) Channel 4 Thermocouple Type (see write word 1, bits 00–03)

04–07 (04–07) Channel 5 Thermocouple Type (see write word 1, bits 00–03)

08–11 (10–13) Channel 6 Thermocouple Type (see write word 1, bits 00–03)

12–15 (14–17) Channel 7 Thermocouple Type (see write word 1, bits 00–03)

Chapter Summary

In this chapter, you learned how to configure your module’s features

and enter your data.

Publication

1794-6.5.7 – April 1997

Page 34

4–8

Writing Configuration to and Reading Status from your Module with a Remote I/O Adapter

Publication

1794-6.5.7 – April 1997

Page 35

Chapter

Chapter

ectives

Polled I

Structure

How Communication Takes

Place and I/O Image Table

Mapping with the DeviceNet

Adapter

5

Obj

About DeviceNet Manager

More

/O

In this chapter, we tell you about:

• DeviceNetManager software

• I/O structure

• image table mapping

• factory defaults

DeviceNetManager software is a software tool used to configure

your Flex I/O DeviceNet adapter and its related modules. This

software tool can be connected to the adapter via the DeviceNet

network.

You must know and understand how DeviceNet Manager works in

order to add a device to the network. Refer to the DeviceNetManager

Software User Manual, publication 1787-6.5.3, and the DeviceNet

Adapter Module User Manual, publication 1794-6.5.5.

Output data is received by the adapter in the order of the installed

I/O modules. The Output data for Slot 0 is received first, followed

by the Output data for Slot 1, and so on up to slot 7.

The first word of input data sent by the adapter is the Adapter Status

Word. This is followed by the input data from each slot, in the order

of the installed I/O modules. The Input data from Slot 0 is first after

the status word, followed by Input data from Slot 2, and so on up to

slot 7.

Network

Network WRITE

READ

DeviceNet Adapter

Read Data

Adapter

Status

Slot 0 Input Data

Slot 1 Input Data

...

Slot 7 Input Data

Write Data

Slot 0 Output Data

Slot 1 Output Data

...

Slot 7 Output Data

...

...

Read

Write

I/O Module

Slot 0

I/O Module

Slot 1

Publication

I/O Module

...

1794-6.5.7 – April 1997

Slot 7

Page 36

5–2

ault

How Communication Takes Place and I/O Image Table Mapping with the DeviceNet Adapter

Adapter Input Status Word

The input status word consists of:

• I/O module fault bits – 1 status bit for each slot

• node address changed – 1 bit

• I/O status – 1 bit

I/O Module Fault Bits

15Bit: 01234567810 through 15

9

Not Used

I/O State Bit

Node Address Changed Bit

Slot 7

Slot 6

Slot 5

Slot 4

The adapter input status word bit descriptions are shown in the

following table.

Bit Description Bit Explanation

0 This bit is set (1) when an error is detected in slot position 0.

1 This bit is set (1) when an error is detected in slot position 1.

2 This bit is set (1) when an error is detected in slot position 2.

I/O Module F

Node Address Changed 8

I/O State 9

3 This bit is set (1) when an error is detected in slot position 3.

4 This bit is set (1) when an error is detected in slot position 4.

5 This bit is set (1) when an error is detected in slot position 5.

6 This bit is set (1) when an error is detected in slot position 6.

7 This bit is set (1) when an error is detected in slot position 7.

This bit is set (1) when the node address switch setting has been

changed since power up.

Bit = 0 – idle

Bit = 1 – run

10 thru 15 Not used – sent as zeroes.

Slot 3

Slot 2

Slot 1

Slot 0

Publication

Possible causes for an I/O Module Fault are:

• transmission errors on the Flex I/O backplane

• a failed module

• a module removed from its terminal base

• incorrect module inserted in a slot position

• the slot is empty

The node address changed bit is set when the node address switch

setting has been changed since power up. The new node address does

not take affect until the adapter has been powered down and then

powered back up.

1794-6.5.7 – April 1997

Page 37

How Communication Takes Place and I/O Image Table Mapping with the DeviceNet Adapter

5–3

System Throughput

SEE

PAGE 4–3

Mapping Data into the Image Table

System throughput, from analog input to backplane, is a function of:

• the configured A/D filter first notch frequency

• the number of channels actually configured for connection to a

specific sensor

The A/D converter which converts channel 0 through 7 analog data

to a digital word provides a programmable first notch filter. You can

set the position of the first notch of this filter during module

configuration. The selection influences the A/D output data rate, thus

affecting system throughput.

The number of channels included in each input scan also affects

system throughput.

FLEX I/O thermocouple module data table mapping is shown below.

Thermocouple/mV Input Module (1794-IT8) Image Table Mapping

Module

Image

Reserved

Input Data Channel 0

I/O Image

Input Size

1 to 11 Words

Output Size

0 to 3 Words

Overrange

Calibration Mask

Input Data Channel 1

Input Data Channel 2

Input Data Channel 3

Input Data Channel 4

Input Data Channel 5

Input Data Channel 6

Input Data Channel 7

Underrange

Calibration Status

Configuration

Thermocouple Type

Thermocouple Type

Thermocouple/mV Input Module (1794-IT8) Read

Dec.

Bit

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read Word 1 Reserved

Read Word 2 Channel 0 Input Data

Read Word 3 Channel 1 Input Data

Read Word 4 Channel 2 Input Data

Read Word 5 Channel 3 Input Data

Read Word 6 Channel 4 Input Data

Publication

1794-6.5.7 – April 1997

Page 38

5–4

How Communication Takes Place and I/O Image Table Mapping with the DeviceNet Adapter

Bit

Read Word 7 Channel 5 Input Data

Read Word 8 Channel 6 Input Data

Read Word 9 Channel 7 Input Data

Read Word 10 Overrange Bits Underrange Bits

Bad

Read Word 11 0 0 0 0 0

Cal

Cal

Done

Cal

Range

0 Diagnostics

Pwr

Up

Bad

Structure

Thermocouple/mV Input Module (1794-IT8) Write

Dec.

Bit

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Cal

Write Word 1 8-Bit Calibration Mask

Write Word 2 Thermocouple 3 Type Thermocouple 2 Type Thermocouple 1 Type Thermocouple 0 Type

Write Word 3 Thermocouple 7 Type Thermocouple 6 Type Thermocouple 5 Type Thermocouple 4 Type

Where: FDF

= fixed digital filter bit

Clk

Cal hi

Cal lo

Filter Cutoff FDF Data Type

Word/Bit Descriptions for the 1794-IT8 Thermocouple/mV

Input Module

CJC

over

00010203040506070809101112131415Dec.

00010203040506071011121314151617Octal Bit

CJC

Under

Decimal

Word

Read Word 1 00–15 (00–17) Reserved

Read Word 2 00–15 (00–17) Channel 0 Input data

Read Word 3 00–15 (00–17) Channel 1 Input data

Read Word 4 00–15 (00–17) Channel 2 Input data

Read Word 5 00–15 (00–17) Channel 3 Input data

Read Word 6 00–15 (00–17) Channel 4 Input data

Read Word 7 00–15 (00–17) Channel 5 Input data

Read Word 8 00–15 (00–17) Channel 6 Input data

Read Word 9 00–15 (00–17) Channel 7 Input data

Read Word 10

Read Word 11

00–07 (00–07) Underrange bits – these bits are set if the input signal is below the input channel’s minimum range.

08–15 (10–17) Overrange bits – these bits are set if 1), the input signal is above the input channel’s maximum range,

Bit

(Octal Bit)

or 2), an open detector is detected.

00 (00) Cold Junction sensor underrange bit. – this bit is set if the cold junction temperature is below 0oC.

01 (01) Cold Junction sensor overrange bit. – this bit is set if the cold junction temperature is above 70oC.

02 (02) Bad Structure – this bit is set if there is an invalid thermocouple type selected.

Description

Publication

1794-6.5.7 – April 1997

Page 39

How Communication Takes Place and I/O Image Table Mapping with the DeviceNet Adapter

continu

Decimal

Word

Bit

(Octal Bit)

Description

5–5

Read Word 11

ed

Write Word 1

03 (03) Powerup bit – this bit is set (1) until configuration data is received by the module.

04–06 (04–06)

Critical Fault bits – If these bits are anything other than zero, return the module to the factory for repair.

07 (07) Unused – set to 0

08 (10) Calibration Range bit – set to 1 if a reference signal is out of range during calibration

09 (11) Calibration Done bit – set to 1 after an initiated calibration cycle is complete.

10 (12) Calibration Bad bit – set to 1 if the channel has not had a valid calibration.

11–15 (13–17) Unused – set to 0

00–01 (00–01) Module Data Type

Bit 01 00 Definition

0 0oC (default)

0 1oF

1 0 Bipolar counts scaled between –32768 and +32767

1 1 Unipolar counts scaled between 0 and 65535

Bit 02 (02) Fixed Digital Filter – When this bit is set (1), a software digital filter is enabled. This filter settles to

100% of a Full Scale step input in 60 times the selected first notch filter time shown on page 4–3.

Default – filter disabled.

03–05 (03–05) A/D Filter First Notch Frequency

Bit 05 04 03 Definition

0 0 0 10Hz (default)

0 0 1 25Hz

0 1 0 50Hz

0 1 1 60Hz

1 0 0 100Hz

1 0 1 250Hz

1 1 0 500Hz

1 1 1 1000hZ

06 (06) Calibration High/Low bit – This bit is set during gain calibration; reset during offset calibration.

07 (07) Calibration clock – this bit must be set to 1 to prepare for a calibration cycle; then reset to 0 to initiate

calibration.

08–15 (10–17) Calibration mask – The channel, or channels, to be calibrated will have the correct mask bit set. Bit 8

corresponds to channel 0, bit 9 to channel 1, and so on.

Publication

1794-6.5.7 – April 1997

Page 40

5–6

Word

How Communication Takes Place and I/O Image Table Mapping with the DeviceNet Adapter

Decimal

Bit

(Octal Bit)

Description

Write Word 2

Write Word 3

00–03 (00–03) Channel 0 Thermocouple Type

Bit 03 02 01 00 Thermocouple Type – Range

0 0 0 0 Millivolts (default)

0 0 0 1 B 300 to 1800oC (572 to 3272oF)

0 0 1 0 E –230 to 1000oC (–382 to 1832oF)

0 0 1 1 J –195 to 1200oC (–319 to 2192oF)

0 1 0 0 K –230 to 1372oC (–382 to 2502oF)

0 1 0 1 R –50 to 1768oC (–58 to 3214oF)

0 1 1 0 S –50 to 1768oC (–58 to 3214oF)

0 1 1 1 T –195 to 400oC (–319 to 752oF)

1 0 0 0 C 0 to 2315oC (32 to 4199oF)

1 0 0 1 N –270 to 1300oC (–450 to 2372oF)

1 0 1 0 L -175 to 800oC (-283 to 1472oF)

1 0 1 1 Reserved

1 1 0 0 Module reports cold junction temperature for channels 00–03

1 1 0 1 Module reports cold junction temperature for channels 04–07

1 1 1 0 Reserved

1 1 1 1 No sensor connected (do not scan)

04–07 (04–07) Channel 1 Thermocouple Type (see bits 00–03)

08–11 (10–13) Channel 2 Thermocouple Type (see bits 00–03)

12–15 (14–17) Channel 3 Thermocouple Type (see bits 00–03)

00–03 (00–03) Channel 4 Thermocouple Type (see write word 2, bits 00–03)

04–07 (04–07) Channel 5 Thermocouple Type (see write word 2, bits 00–03)

08–11 (10–13) Channel 6 Thermocouple Type (see write word 2, bits 00–03)

12–15 (14–17) Channel 7 Thermocouple Type (see write word 2, bits 00–03)

Publication

1794-6.5.7 – April 1997

Page 41

How Communication Takes Place and I/O Image Table Mapping with the DeviceNet Adapter

5–7

Defaults

Each I/O module has default values associated with it. At default,

each module will generate inputs/status and expect

outputs/configuration.

Module Defaults for: Factory Defaults Real Time Size

Catalog

Number

1794-IT8 8 Thermocouple Input 11 4 10 0

Description

Input

Default

Output

Default

Input

Default

Output

Default

Factory defaults are the values assigned by the adapter when you:

• first power up the system, and

• no previous stored settings have been applied.

For analog modules, the defaults reflect the actual number of input

words/output words. For example, for the 8 thermocouple input

analog module, you have 11 input words, and 4 output words.

You can change the I/O data size for a module by reducing the

number of words mapped into the adapter module, as shown in “real

time sizes.”

Real time sizes are the settings that provide optimal real time data to

the adapter module.

More

Analog modules have 15 words assigned to them. This is divided

into input words/output words. You can reduce the I/O data size to

fewer words to increase data transfer over the backplane. For

example, an 8 thermocouple input module has 11 words input/4

words output with factory default. You can reduce the write words to

0, thus eliminating the configuration setting and unused words. And

you can reduce the read words to 10 by eliminating the calibration

status words.

For information on using DeviceNetManager software to configure

your adapter, refer to the DeviceNetManager Software User Manual,

publication 1787-6.5.3.

Publication

1794-6.5.7 – April 1997

Page 42

5–8

How Communication Takes Place and I/O Image Table Mapping with the DeviceNet Adapter

Publication

1794-6.5.7 – April 1997

Page 43

Chapter

Calibrating Your Module

6

Chapter Objective

General Information

In this chapter we tell you:

• what tools are needed to calibrate

• how to calibrate out lead wire resistance

• calibrate your module manually

• calibrate your module using DeviceNetManager software

Your module is shipped to you already calibrated. If a calibration

check is required,follow the procedure below.

Perform module calibration periodically, based on your application.

Module calibration may also be required to remove module error due

to aging of components

In addition, calibration may be required to eliminate long lead wire

resistance to open circuit detection current. See “Error Due to Open

Circuit Current Through Loop Resistance” in Appendix A.

Calibration can be accomplished using any of the following methods:

• manual calibration, as described below.

• 6200 I/O CONFIGURATION software (version 5.2 or later)–

refer to your 6200 software publications for procedures for

calibrating.

• DeviceNetManager Software – refer to your DeviceNetManager

software documentation for the DeviceNet Adapter Module, Cat.

No. 1794-ADN. Some portion of this calibration is included here

for use by personnel proficient with DeviceNet Adapter

configuration software.

Important: You can use a 1794-TB2 or -TB3 terminal base unit if

you are using the thermocouple/mV module in the

millivolt mode only. You must use a 1794-TB3T

terminal base unit for all thermocouple uses.

Publication

1794-6.5.7 – April 1997

Page 44

6–2

or

Calibrating Your Module

Tools and Equipment

Tool or Equipment Description

Precision Voltage Source

Thermocouple Simulator

and Calibration source

Industrial Terminal and

Interconnect Cable

Removing Lead Wire or Thermocouple Extension Wire Resistance

In order to calibrate your thermocouple input module you will need

the following tools and equipment:

0–100mV, 1µV resolution

Programming terminal for A–B family processors

Analogic 3100, Data Precision 8200

or equivalent

Thermocouple Simulator/Calibrator

Model 1120

The thermocouple/mV module has open circuit detection. This is

accomplished by a 1µA current source in the module. This current

flowing through the lead wire or thermocouple extension wire

generates an error or offset voltage in the reading. Use the “Error

Due to Open Circuit Current Through Loop Resistance” in appendix

A to determine if the magnitude of the error is acceptable.

Calibrate this error out as follows:

Ectron Corporation

8159 Engineer Road

San Diego, CA 92111-1980

1

2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 150

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

16

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

1794-TB3, -TB3T

Ω

1 2 3 4 5 6 7 8 9 10 11 12 13 14 150

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

16

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

Disconnect the lead wires at the terminal base unit.

a.

b.

Measure total loop resistance of both lead/extension wires and thermocouple.

c.

If using a sensor other than a thermocouple, disconnect the lead wires at the

sensor and tie together for this measurement. Reconnect after measurement.

d.

After measuring, remove ohmmeter

.

1794-TB3, -TB3T

a.

Decade Box

Voltage Source

Set decade box to value determined in step 1, and connect in series with a preci

sion voltage source.

b. Connect

c.

Perform an of

to the input terminals of the particular channel you are calibrating.

fset and gain calibration as outlined later in this chapter

0

–15

16–33

34–51

0

–15

16–33

34–51

A

B

C

Thermocouple

or

Sensor

A

B

C

-

Thermocouple

.

or

Sensor

Publication

Disconnected

1794-6.5.7 – April 1997

Page 45

3

1 2 3 4 5 6 7 8 9 10 11 12 13 14 150

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

16

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

1794-TB3, -TB3T

a.

Remove the decade box and voltage source.

b.

Reconnect the lead wires to the input terminals for this channel.

c.

Repeat this procedure for the remaining channels.

Calibrating Your Module

0

–15

A

16–33

B

34–51

C

6–3

Thermocouple

or

Sensor

Manually Calibrating your Thermocouple/mV Input Module

You must calibrate the module in a FLEX I/O system. The module

must communicate with the processor and a programming terminal.

You can calibrate input channels in any order, or all at once.

Before calibrating your module, you must enter ladder logic into the

processor memory, so that you can initiate BTWs to the module, and

read inputs from the module.

Important: In order to allow the internal module temperature to

stabilize, energize the module for at least 40 minutes

before calibrating.

Module calibration consists of:

• Applying a reference to the desired input(s).

• Sending a message to the module indicating which inputs to read

and what calibration step is being performed (offset).

The module stores this input data.

• Applying a second reference signal to the module, and sending a

second message indicating which inputs to read and what

calibration step is being performed (gain).

The module computes new calibration values for the inputs.

Once the calibration is complete, the module reports back status

information about the procedure.

The following flow chart shows the procedure for calibration

Important: Perform the offset calibration procedure first, then the

gain calibration procedure.

Publication

1794-6.5.7 – April 1997

Page 46

6–4

Calibrating Your Module

Apply

reference signal for of

calibration to each channel to

be calibrated.

Flow Chart for Calibration Procedure

fset

Apply reference signal for gain

calibration to each channel to

be calibrated.

Exit

Set corresponding bits in the

calibration mask and set cal

Hi/Lo = 0

BTW

Set cal–clk =1

BTW

BTR

NO

Cal–done = 1

?

YES

NO

Bad–cal = 0

Cal–range = 0

?

YES

Set cal–clk =0

Exit

Retain corresponding bits in

the calibration mask and set

cal Hi/Lo = 1

BTW

Set cal–clk =1

BTW

BTR

NO

Cal–done = 1

?

YES

NO

Bad–cal = 0

Cal–range = 0

?

YES

Set cal–clk =0

and