Page 1

Plastic Molding Module

(Cat. No. 1771-QDC)

Clamp and Eject Mode

Page 2

Important User Information

Because of the variety of uses for this product and because of the differences

between solid state products and electromechanical products, those responsible

for applying and using this product must satisfy themselves as to the

acceptability of each application and use of this product. For more information,

refer to publication SGI–1.1 (Safety Guidelines For The Application,

Installation and Maintenance of Solid State Control).

The illustrations, charts, and layout examples shown in this manual are intended

solely to illustrate the text of this manual. Because of the many variables and

requirements associated with any particular installation, Allen–Bradley

Company cannot assume responsibility or liability for actual use based upon the

illustrative uses and applications.

No patent liability is assumed by Allen–Bradley Company with respect to use of

information, circuits, equipment or software described in this text.

Reproduction of the contents of this manual, in whole or in part, without written

permission of the Allen–Bradley Company is prohibited.

Throughout this manual we make notes to alert you to possible injury to people

or damage to equipment under specific circumstances.

ATTENTION: Tells readers where people may be hurt, machinery

may be damaged, or economic loss can occur if procedures are not

followed properly.

ATTENTION helps you:

- identify a hazard

- avoid the hazard

- recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

Important: We recommend you frequently backup your application programs

on appropriate storage medium to avoid possible data loss.

1993 Allen-Bradley Company

PLC is a registered trademark of Allen-Bradley Company

ProSet, PanelView

, PanelBuilder

, Inc.

, Inc.

, and ERC are trademarks of AllenBradley Company

, Inc.

Page 3

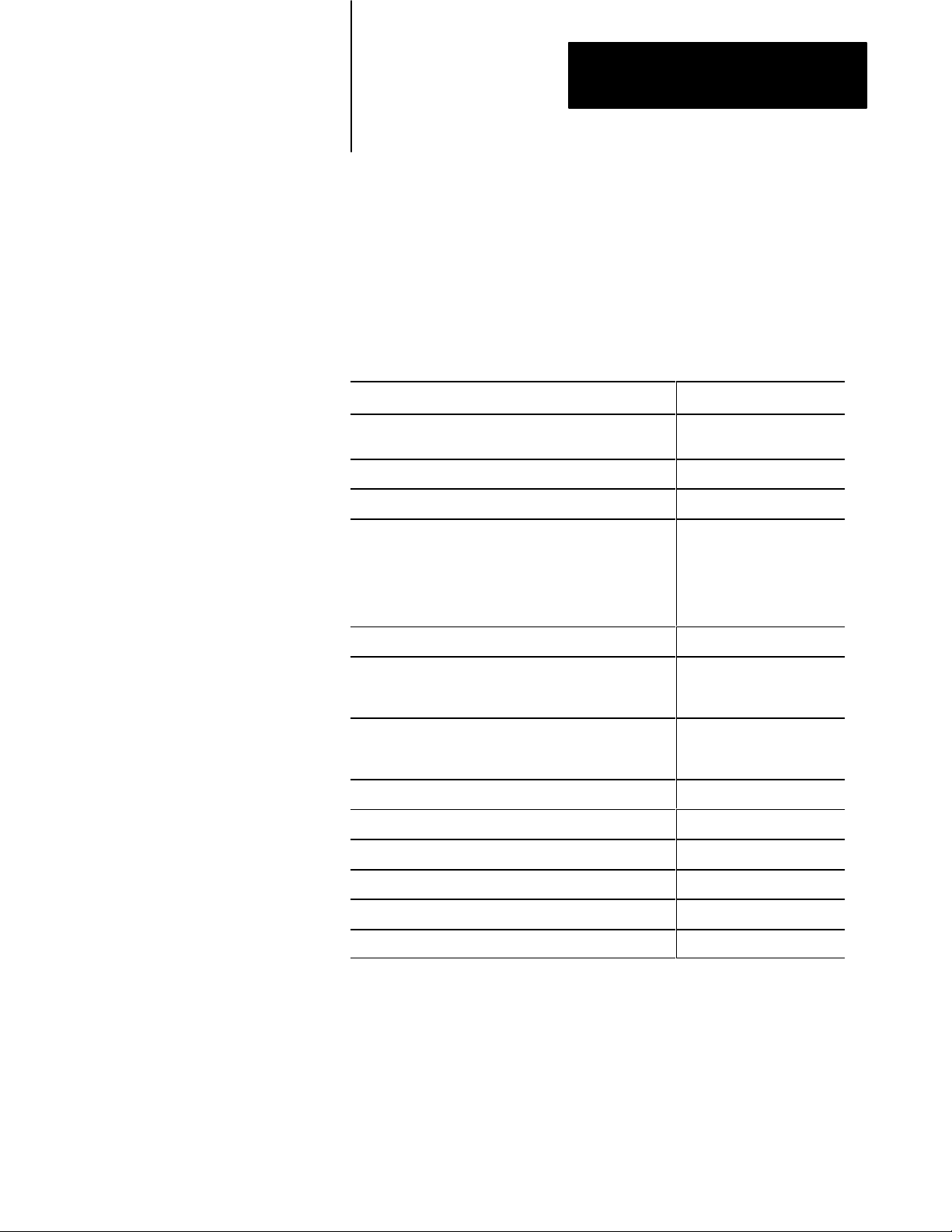

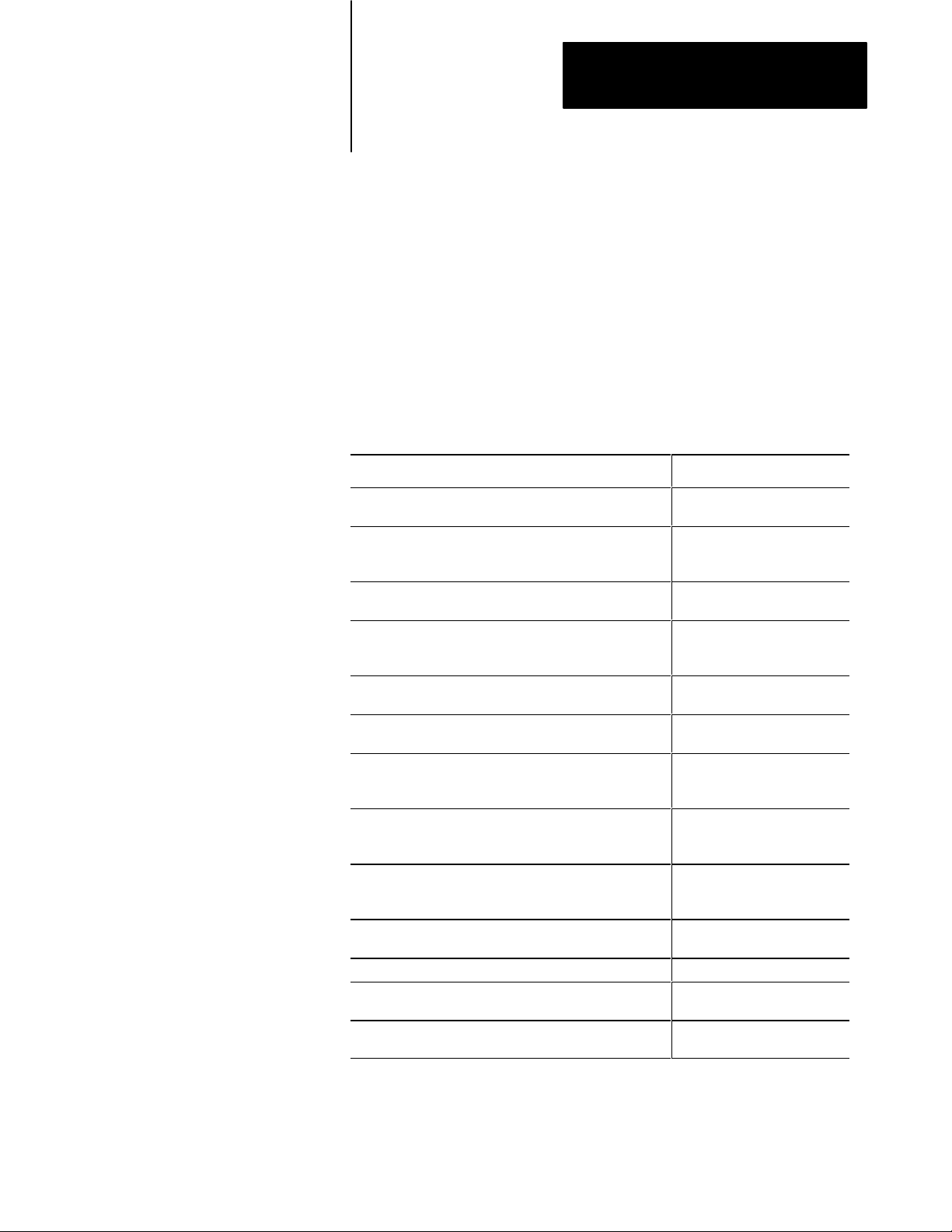

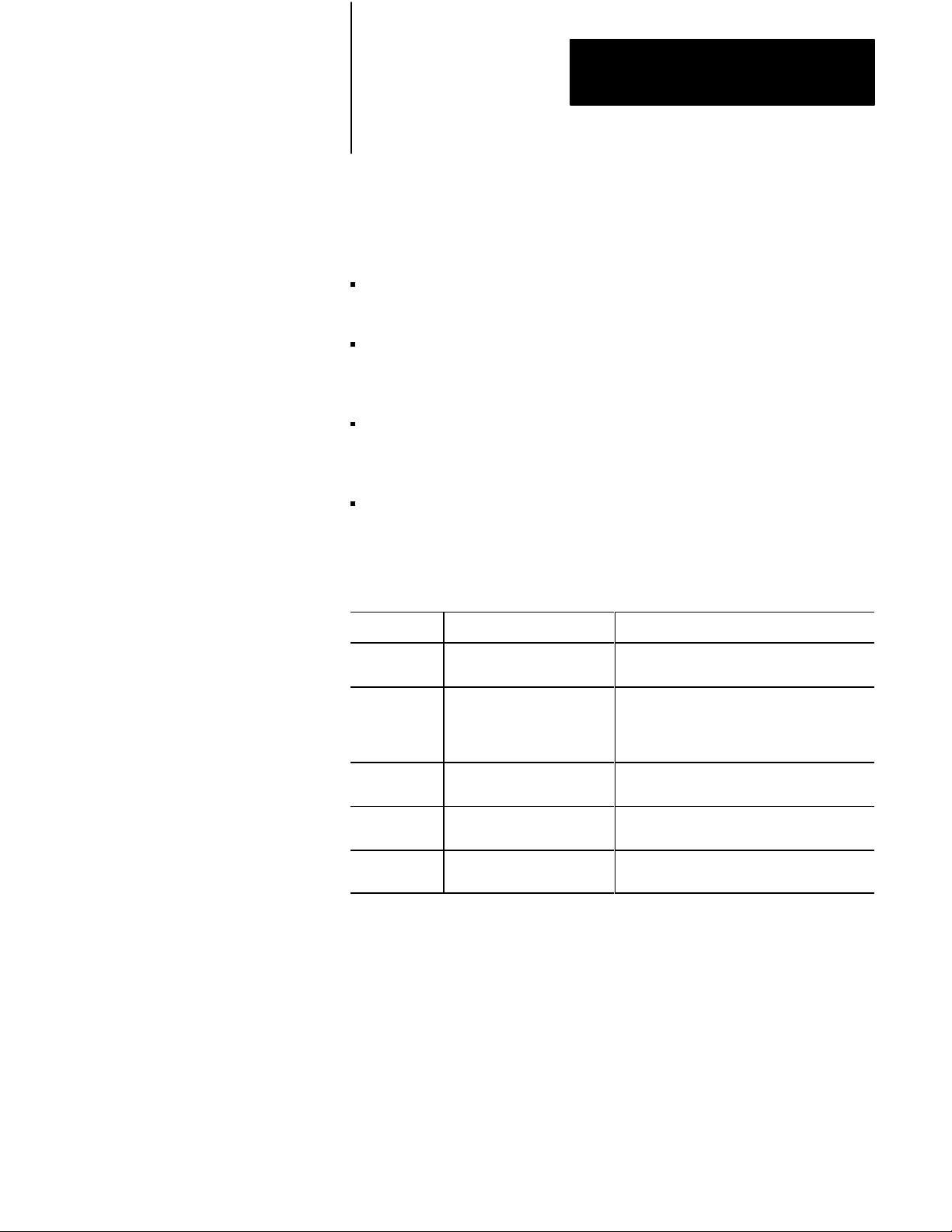

Summary of Changes

Summary of Changes

Summary of Changes

We revised this publication to include changes due to upgrading the

1771-QDC/B module to a 1771-QDC/C.

For These Changes Refer to Page or Chapter

Lossofsensor detection

input range changed back to 0.00 to 10V dc

Added the section, Record I/O Ranges 21

Added data codes to configuration worksheets. Chapter 3 and Appendix A

Reversed the order of chapters 3 and 4 to present the

download procedure for the MCC block before the download

procedure for the other data blocks.

Revised the download procedure for the MCC block

(chapter 3) and for other command blocks (chapter 4).

Changed the chapter title to better describe the task. Chapter 6

Added data codes to Configuration Block worksheets.

Added headers to improve the organization

Added data codes to Profile Block worksheets.

Added headers to improve the organizatrion

36, 311

A3, A4

Chapters 3 and 4

Chapter 7 and Appendix A

Chapter 7

Chapter 8 and Appendix A

Chapter 8

Placed 2page worksheets on facing pages Chapter 8

Changed the title Test Your Values to Test for Linearity. Chapter 9

Changed our recommendation on module calibration. 113

Added Block ID codes to blank worksheets. Appendix A

Revised the index. Index

Minor corrections as found

To Help You Find Changes

To help you find these changes, we added change bars as shown to the left.

Page 4

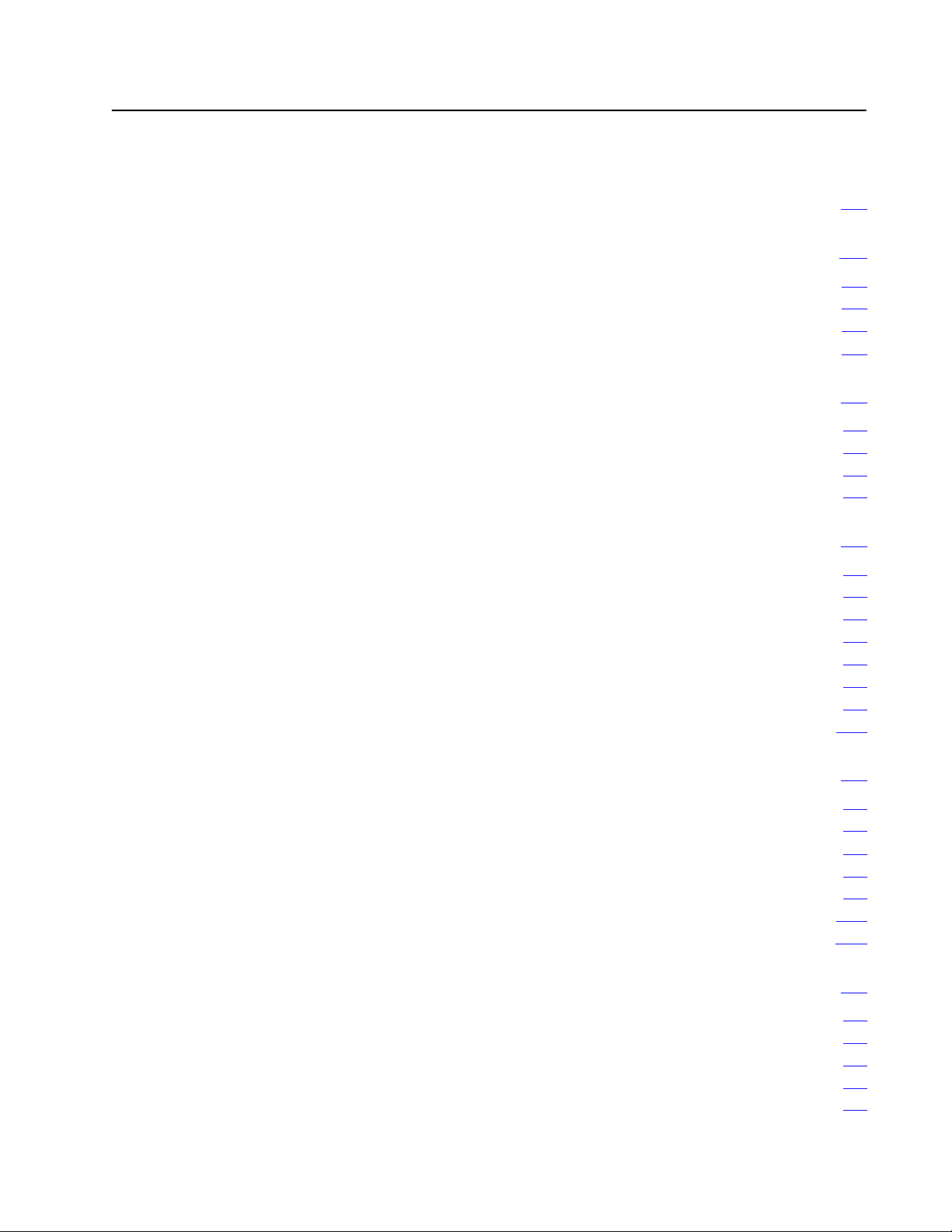

Table of Contents

Summary of Changes 11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using This Manual P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual

Objectives

Audience P2

Use

Related

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of T

erms P2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publications

Overview of the Clamp and Eject Mode 11. . . . . . . . . . . . . . .

P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Clamp and Eject Mode Operation 11

Clamp Control 12

Ejector Control 18

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

Install the QDC Module 21. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Record

Set Module Jumpers 22

Key Your I/O Chassis 25

Install Your QDC Module 26

Wire

Ground and Shield Your I/O Devices 29

Plan for ESTOPs and Machine Interlocks 211

Objectives

I/O Ranges

the QDC Module

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

Configure the QDC Module's Inputs and Outputs 31. . . . . . . .

Chapter

Select Module Parameters and I/O Ranges 32

Determine Initial Sensorconfiguration Values 35

Download

Use the Setoutput Operation to Move the Clamp and Ejector 39

Complete your Sensor Configuration 311

Optional Configurations 317

Objectives

MCC V

alues to the QDC Module

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

37. . . . . . . . . . . . . . . . .

. . . .

Overview of Remaining Configuration Procedures 41. . . . . .

Chapter

Configuration Concepts 41

Special Command and Status Blocks 42

Overview of the Remaining Configuration Procedures 43

Enter Data Table Values and Download Command Blocks 44

Objectives

41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . .

Page 5

Table of Contentsii

Jog Your Machine 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Determine

Jog Your Machine 54

Configure Jogs for the Screw and Injection Cylinder 56

Objectives

Initial Clamp and Ejector Jog V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alues 52. . . . . . . . . . . . . .

. . . . . . . . . . .

Select Command and Status Bits to Sequence

Machine Operation 61. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Assess Your Logic Requirements 61

Use

Chapter

Use Configuration Command Block Worksheets 72

Procedure to Determine and Record Worksheet Values 724

Determine

Select the T

Determine Word Selections: Set ERC Values and Timer Presets 726

Determine Unselected Valve Setoutput Values 728

Set your Accel/Decel Ramp Rates 731

Determine Setoutput Values for End of Profiles 732

Set Pressure Control Limits 733

Set V

Set Profile Gain Constants and Pressure Alarm Setpoints 737

Enter and Download your Worksheet Values 738

Objectives

. . . . . . . . . . . . . . . . . . . . . . . .

Bit T

ables 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objectives

. . . . . . . . . . . . . .

. . . . . . . . .

Bit Selections: Assign Module Outputs for

Your Control Valves 724. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ype of PID Algorithm

. .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

elocity Control Limits

. . . . . . .

. . . . . . . . . . . . . . . .

61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

725. . . . . . . . . . . . . . . . . . . . . . . . .

735. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load

Initial Profile V

Chapter

Determine and Enter Setpoints for the Clamp Close Profile (CPC) 81

Determine Bit Selections for Worksheet 8A 84

Determine Word Values for Worksheet 8A 85

Enter and Download Your Worksheet Values 87

Determine and Enter Clamp Open Profile (OPC) 88

Determine Bit Selections for Worksheet 8B 810

Determine Word Values for Worksheet 8B 811

Enter and Download your Worksheet Values 813

Determine and Enter Ejector Profile (EPC) 814

Determine Bit Selections for Worksheet 8C 816

Determine Word Values for Worksheet 8C 819

Enter and Download your Worksheet Values 822

Objectives

alues for Machine Tuning 81. . . . . . . . . .

81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

Page 6

Table of Contents iii

Span Your Clamp and Ejector Valves 91. . . . . . . . . . . . . . . . .

Chapter

Span Your Low Pressure Close Valve 93

Span Your Clamp Close Pressure Valve(s) 99

Span Your Clamp Close Velocity (Flow) Valve(s) 914

Span Your Clamp Open Pressure Valve(s) 918

Span Your Clamp Open Velocity (Flow) Valve(s) 923

Span Your Ejector Pressure Valve(s) 927

Span Your Ejector Velocity (Flow) Valve(s) 934

Objectives

91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

Tune Your Machine 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Chapter Assumptions 101

Openloop or Closedloop? 102

What to do Next 103

Tune in Closedloop Mode 103

Other Tuning Considerations 1011

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshoot with LED's 111. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Use

Module

Objectives

LED'

s to Troubleshoot Your QDC Module 111. . . . . . . . . . . . . . .

Calibration

111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blank Worksheets A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

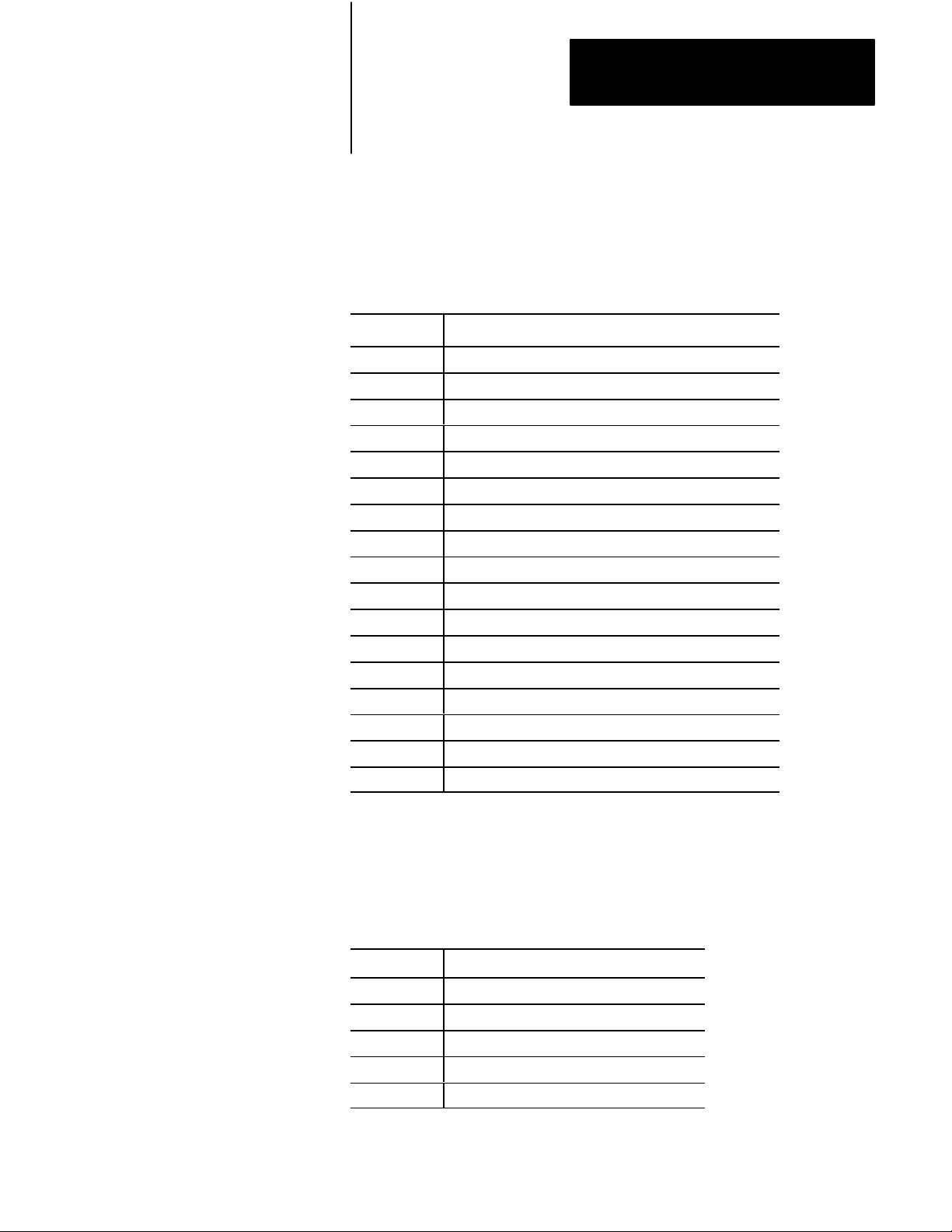

Using This Manual

Preface

Manual

Objectives

Use this preface to familiarize yourself with this manual so you can use it

effectively. This manual shows you how to apply the QDC module to your

molding machine in the minimum length of time.

Since this manual is task oriented, we recommend that you perform these

tasks in the following order:

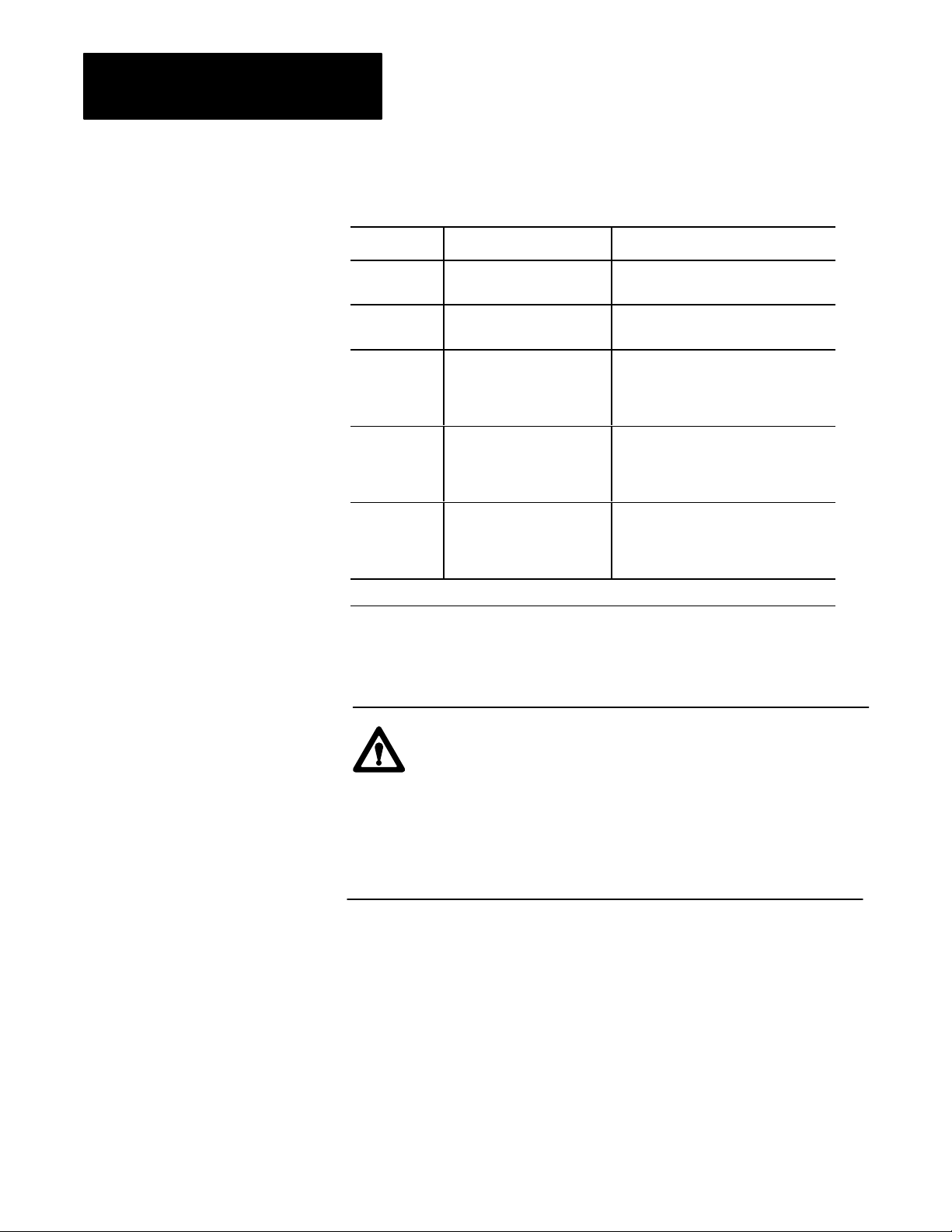

Perform this task: As discussed in this chapter:

Browse through the entire manual to become familiar with

its contents.

Overview of clamp and eject operation: how the QDC

module controls the clamp and eject phases of your

injection molding system.

Install the QDC module. This includes such tasks as wiring

and setting jumpers.

Configure the QDC module mode to match your specific

application. This includes configuring your QDC module to

communicate to the different inputs and outputs.

Overview of remaining configuration procedures that you

are to perform through the remainder of this manual.

Jog the Clamp and Ejector. This task requires jog setpoints

to be configured along with jog pressure alarm setpoints.

Set up communications between your PLC and the QDC

module. This task includes selecting command and status

bits that you use when writing your ladder logic.

Load initial configuration values for the QDC module. This

task requires you to determine and enter values into the

clamp and ejector configuration blocks.

Load your initial profile values for the QDC module. This

task is performed in preparation to run and span your

machine's valves.

Span your clamp and ejector valves. This is done using

setoutput and openloop modes.

Tune the machine in closedloop mode. Chapter 10

Troubleshoot problems that may occur during module

operation.

Refer to this appendix for a blank copy of each worksheet

contained in this manual.

All chapters

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Chapter 8

Chapter 9

Chapter 11

Appendix A

P-1

Page 8

Preface

Using this Manual

Audience

of T

Use

erms

Before attempting to apply the QDC module to a molding machine we

assume that you are:

an injection molding professional

an experienced programmer (especially with A-B PLC-5 processors)

familiar with hydraulics

We use these abbreviations:

Abbreviated Name: Item:

QDC module 1771QDC Plastic Molding Module

PLC Processor PLC5 Programmable Controller

T47 or T50 terminal 1784T47 or 1784T50 Industrial Terminal

ProSet 600 Software

PanelView Terminal PanelView Operator Interface Terminal (2711KC1)

ERC

ProSet 600 Injection Molding Operator Interface

Software (6500PS600)

Expert Response Compensation

The following table presents other terms we use in this manual:

Term: Definition:

Selected Valve In multivalve systems, depending on the configured profile, the QDC

module controls one valve and presets the setting of the remaining

valves to produce moldingmachine profiles. We call the valve being

controlled by the QDC module's algorithms the selected valve.

Multiple axis of control, such as the clamp and ejector cylinders, may

require additional control valves.

Unselected Valves In multivalve systems, depending on the configured profile, the QDC

module controls one valve and presets the remaining valves to

produce moldingmachine profiles. We call the valves that are

preset with an open loop percentage setpoint the unselected valves.

Profile A group of mold/part setpoints which define a given machine

operation to the QDC module.

Command Block Blocks downloaded from the PLC data table to the QDC module to

make configuration changes or to initiate machine actions.

Status Block Blocks used by the QDC module to relay information to the PLC

processor about the QDC module's current operating status.

Profile Block Command block containing mold/part setpoints.

Configuration Block Command block containing machine setpoints.

Direct Acting Valve An analog control valve that delivers increasing velocity or pressure

with increasing signal input.

Reverse Acting Valve An analog control valve that delivers increasing velocity or pressure

with decreasing signal input.

P-2

Page 9

Preface

Using this Manual

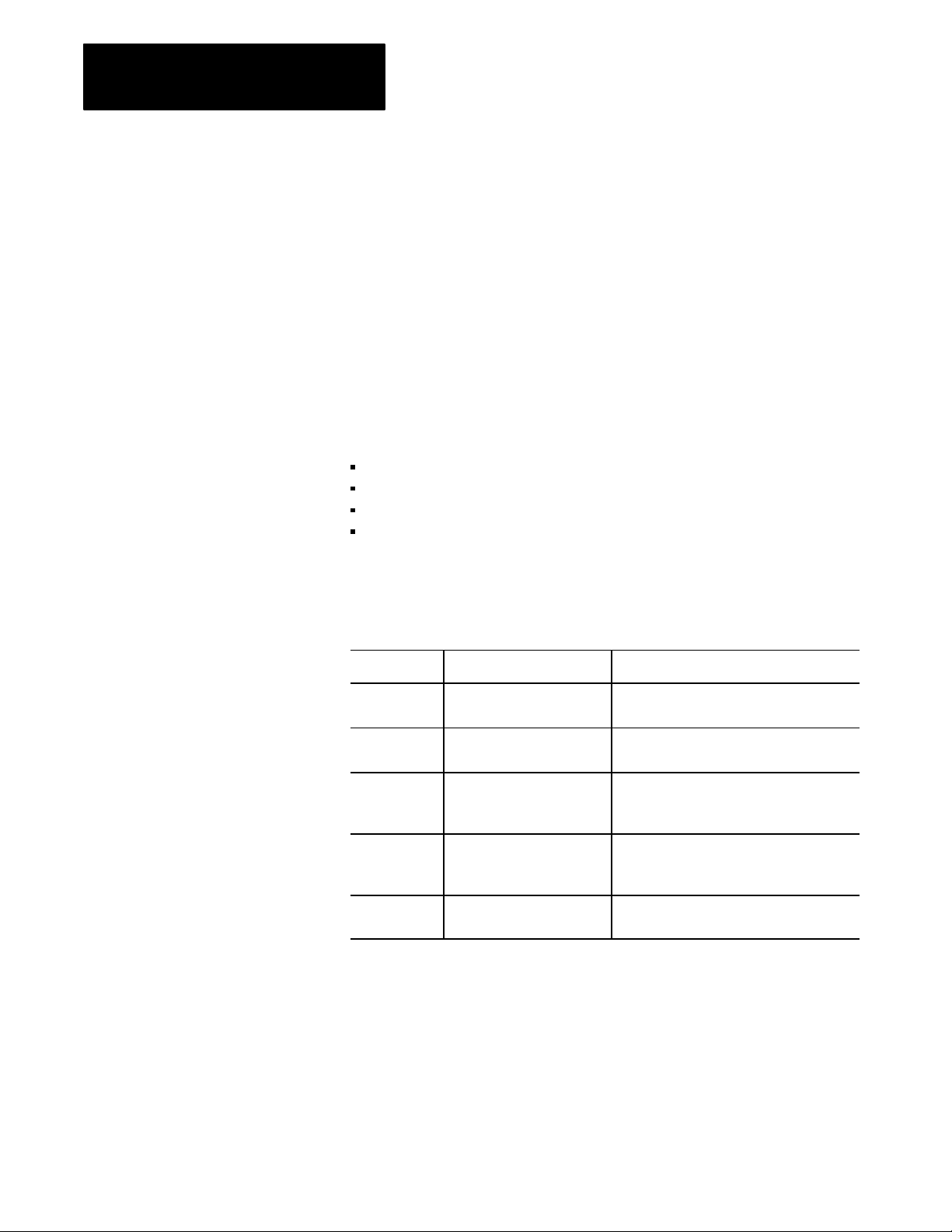

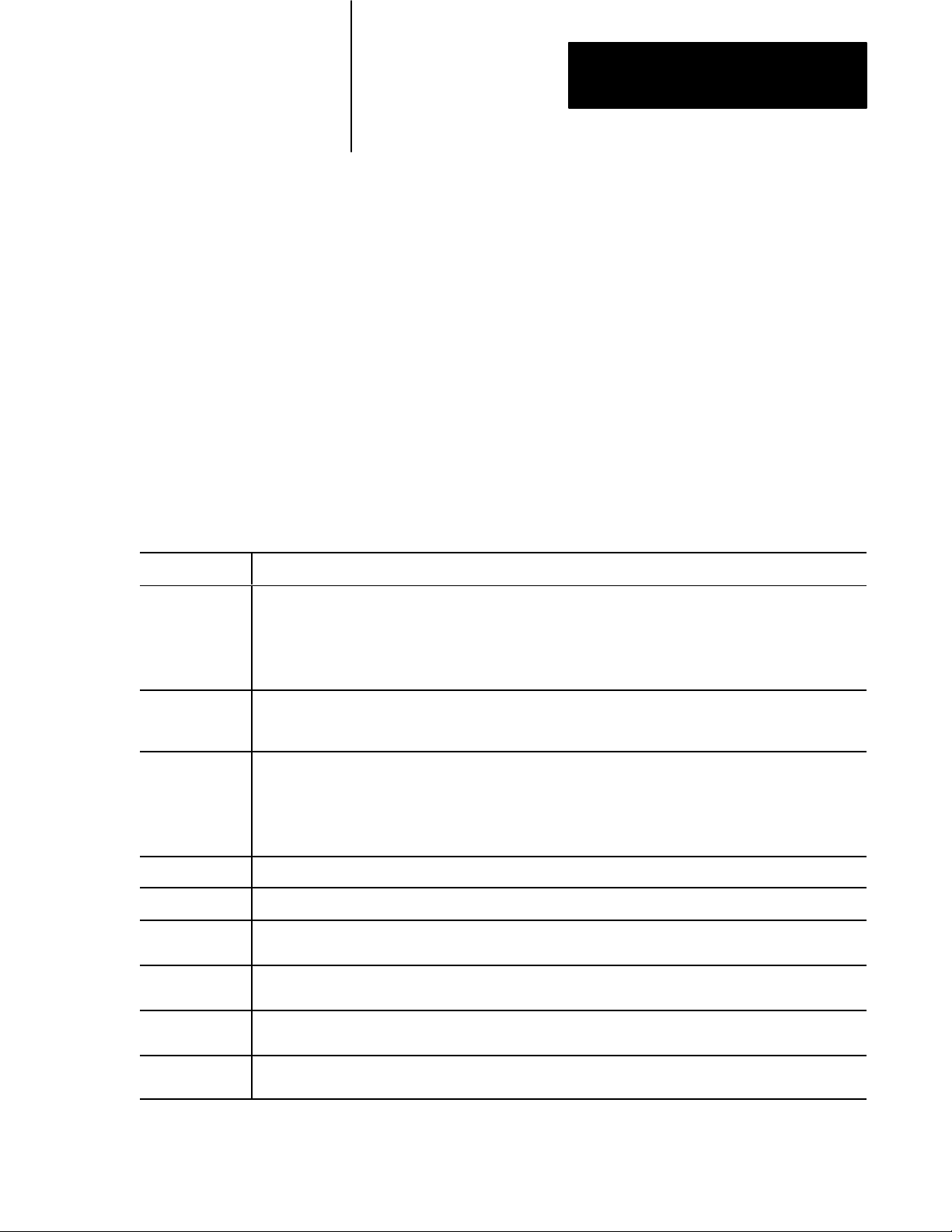

Command Blocks

Command blocks provide the parameters that control machine operation.

Command blocks are transferred from the PLC processor to the QDC

module by means of block transfer write (BTW) instructions in software

ladder logic. Command block abbreviations are:

Acronym: Description:

MCC Module Configuration Block

JGC Jog Configuration Block

FCC First Clamp Close Configuration Block

SCC Second Clamp Close Configuration Block

TCC Third Clamp Close Configuration Block

LPC Low Press Clamp Close Configuration Block

CPC Clamp Close Profile Block

FOC First Clamp Open Configuration Block

SOC Second Clamp Open Configuration Block

TOC Third Clamp Open Configuration Block

OSC Clamp Open Slow Configuration Block

OPC Clamp Open Profile Block

EAC Ejector Advance Configuration Block

ERC Ejector Retract Configuration Block

EPC Ejector Profile Block

DYC Dynamic Command Block

CLC Clamp & Eject ERC Values Block

Status Blocks

Status blocks report current status of molding-machine operation. Status

blocks are returned from the QDC module to the PLC processor by means

of block transfer read (BTR) instructions in software ladder logic. Status

block abbreviations are:

Acronym: Description:

SYS System Status Block

CPS Clamp Close Profile Status Block

OPS Clamp Open Profile Status Block

EPS Ejector Profile Status Block

CLS Clamp & Eject ERC Values Status Block

P-3

Page 10

Preface

Using this Manual

Word and Bit Numbering

The QDC module stores data in command and status blocks. Each word

location in a command or status block is identified by an alphanumeric

code containing the block acronym and word number. For example, word

09 of the Module Configuration Command Block (MCC) is identified as

MCC09.

Identify bits in a word location by adding bit numbering to the abbreviated

word location. For example:

Specific: MCC09-B15 General: MCCxx-Byy

where:

MCC = Module Configuration Command Block

xx=word number (01-64)

B = bit identifier

yy = bit number (00-15)

Related

Publications

The following table lists documentation necessary for the successful

application of the QDC Module:

Publication

17856.6.1 PLC5 Family Programmable

6200N8.001 6200 PLC5 Programming

17716.5.88 Plastic Molding Module

17716.5.85

17716.5.86

17716.5.93

17714.10 Plastic Molding Module

#:

Use this documentation: To:

Controller Installation Manual

Software Documentation Set

Reference Manual

Plastic Molding Module User

Manual for other modes

Application Guide

Install the PLC processor and I/O modules.

Select instructions and organize memory

when writing ladder logic to run your machine.

Information on block transfers between PLC

processor and QDC module. Also,

information on PLC data transfer logic.

Configure, program, install, and operate your

QDC module to control molding operations.

Help select the module mode and match your

QDC module to your hydraulic layout.

P-4

Page 11

Preface

Using this Manual

Reference information for the QDC module is contained in a separate

document titled “Plastic Molding Module Reference Manual”. Take time

now to familiarize yourself with this reference manual’s content and

purpose. The four sections, in brief, include:

a summary of each data block used by the QDC module for all

command and status blocks (abbreviated command and status blocks)

the programming error codes returned by the QDC module on a block

by block basis as well as recommended procedures to correct these

errors

a detailed listing and explanation of each command word and bit used

by the QDC module, as well as each status word and bit returned from

the QDC module

operational, mechanical, electrical, and environmental specifications

about your module

If you have purchased the Pro-Set 600 software, you also need the

following documentation:

Publication

65006.5.11 ProSet 600 Software

65006.5.12 ProSet 600 Software

65006.5.13 ProSet 600 Software

65006.5.14 ProSet 600 Software

65006.5.15 ProSet 600 Software

#:

Use this documentation: To:

Designer's Guide

Assembly Manual

Overlay Installation Manual

Customization Manual

Reference Manual

Select the ProSet 600 software that matches

the requirements of your molding machine.

Transfer your ProSet 600 software from a

floppy to your hard drive. Add overlays into

your PLC processor and PanelView application

files.

Install ProSet 600 overlay(s) into your

application files.

Customize your ProSet 600 build for your

machine control requirements.

Support customizing your software

control system.

P-5

Page 12

Chapter

1

Overview of the Clamp and Eject Mode

Chapter

Objectives

Clamp and Eject Mode Operation

Clamp Phase: Description:

1st Close

2nd Close

3rd Close

Low Pressure

Close

This chapter presents an overview of the 1771-QDC Plastic Molding

Module’s Clamp and Eject Mode. A summary of clamp and eject features

is followed by sample applications of the QDC Module in Clamp and Eject

Mode.

Important: This manual assumes you have already read your Plastic

Molding Module Application Guide (pub. no. 1771-4.10) and have chosen

Clamp and Eject as your QDC module’s mode of operation.

When you select the Clamp and Eject mode of operation, you can use the

following phases:

Table 1.A

Glossary

You can program a singlestep clampclose profile and not use a second or third profile. Or, you can program up to

three clampclose profiles that let you do the following at up to three different points in the clampclose phase:

• pick up a third mold plate

• set cores

• pick up or drop out pumps to change clamp speed or pressure

To guard against damaging the mold when the two mold surfaces make contact and to detect part obstructions, you

close the mold slowly with low pressure in closedloop or openloop control. Low Pressure Close can only be

controlled through a pressure vs. position profile.

of Clamp and Eject Mode

1st Open

2nd Open

3rd Open

Open Slow

Eject Phase: Description:

Ejector Advance You advance the ejector in a singlestep or in multiple steps using closedloop or openloop control. Multiple strokes

Ejector Retract You retract the ejector in a singlestep or in multiple steps using closedloop or openloop control. Multiple strokes

Tip Strokes You can shake the part off the ejector tip by programming rapid singlestroke interim ejector cycles starting after the

Forward Dwell You can pause after the first advance stroke or before the last retract stroke to let a robot remove the part when the

You can program a singlestep clampopen profile and not use a second or third profile. Or, you can program up to

three clampopen profiles that let you do the following at up to three different points in the clampopen phase:

• drop out a third mold plate

• pull cores

• drop out or pick up pumps to change clamp speed or pressure

To decelerate the moving platen to accurately position it before ejecting of the part.

may be programmed.

may be programmed.

first advance stroke and ending before the last retract stroke.

ejectors are extended.

1-1

Page 13

Chapter 1

Overview of the Clamp and Eject Mode

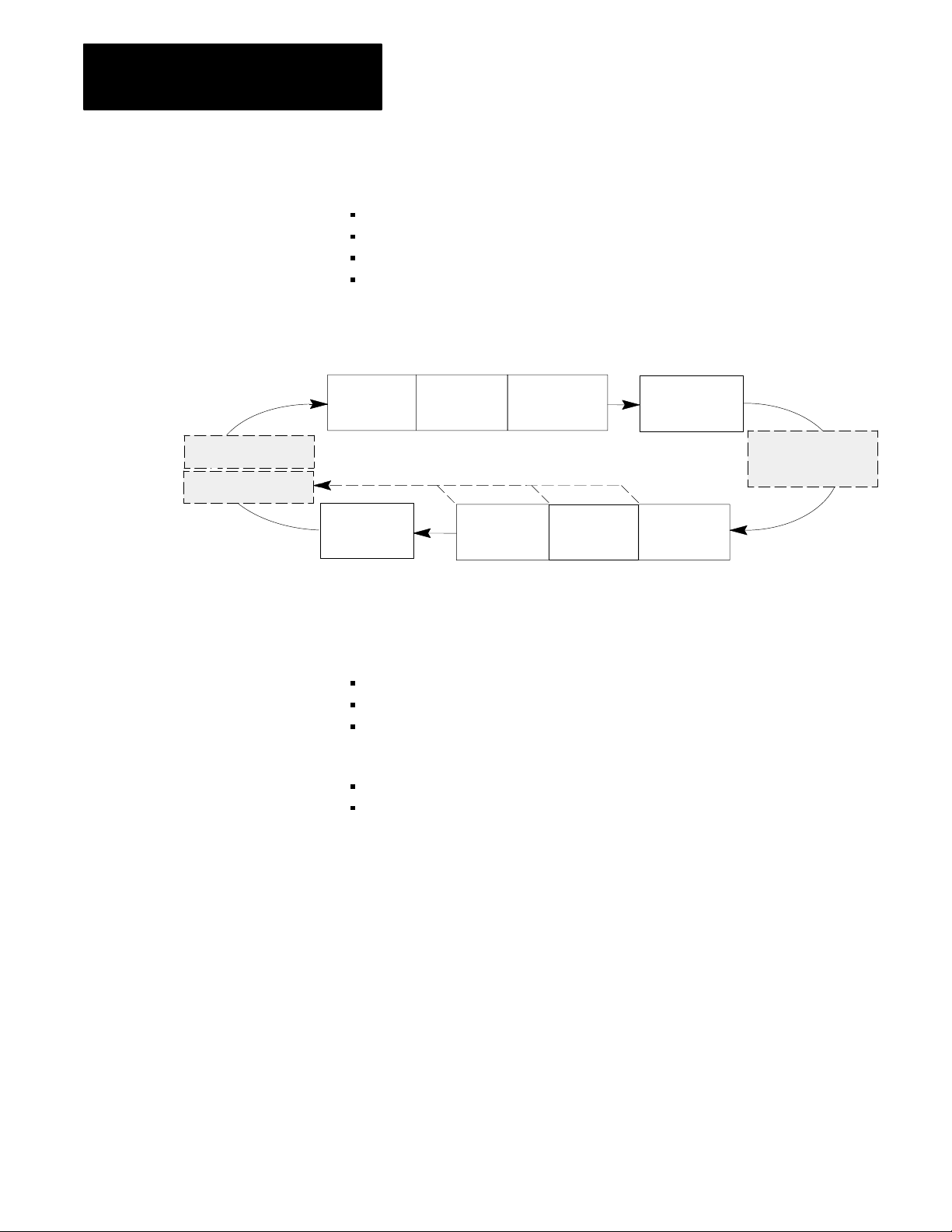

Clamp Control

Ejector retract

Ejector advance

You control clamp operation with these phases:

clamp close

low pressure close

clamp open

open slow

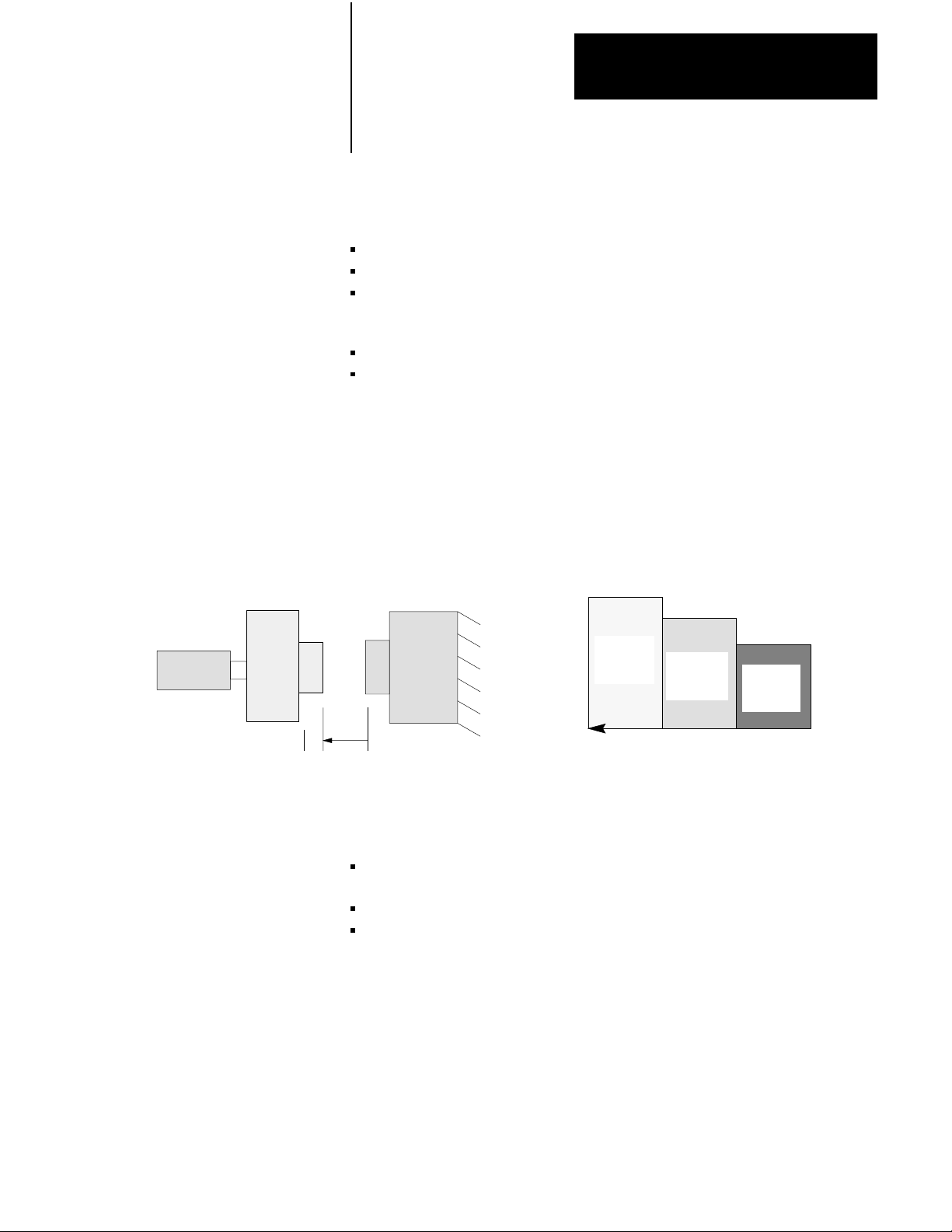

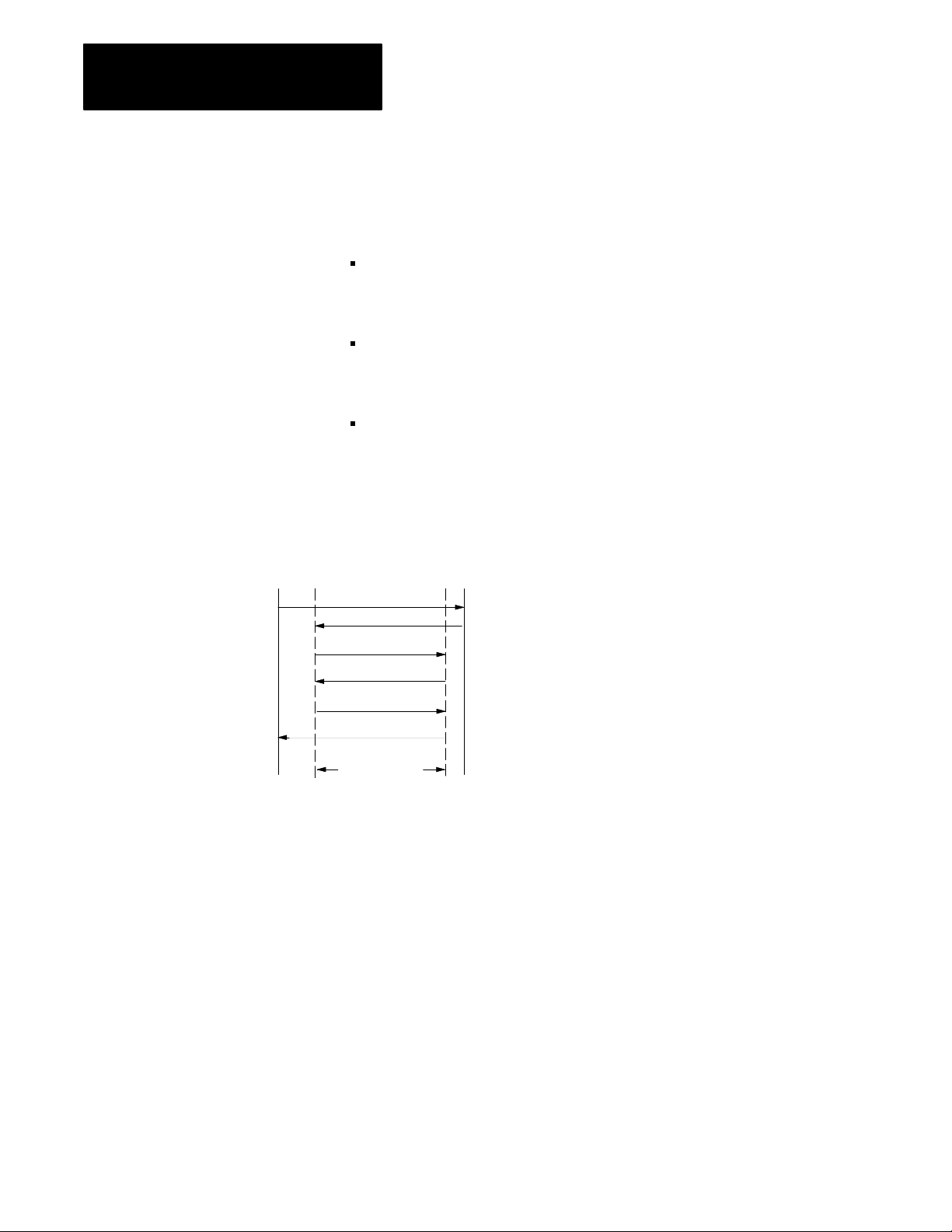

Figure 1.1

Clamp

1st

Close

Open

Slow

Portion of a T

ypical Machine Cycle

2nd

Close

3rd

Open

3rd

Close

Low Pressure

Close

2nd

Open

Clamp Close

Inject

1st

Open

Three separate clamp close profiles may be configured:

first close

second close

third close

You may select from these control modes:

velocity vs. position

pressure vs. position

Use Clamp Close to move the platen from the fully open position (L) to

some position X at a relatively high velocity or pressure. X is a position

relatively close to the stationary platen yet far enough away to allow

deceleration into Low Pressure Close. This prevents the platens from

coming together at a high velocity.

1-2

Page 14

Chapter 1

Overview of the Clamp and Eject Mode

Clamp

Cylinder

L

Moving

Platen

Figure 1.2

Example

Clamp Close

0

X

Stationary

Platen

Velocity

1st

Close

Profile

2nd

Close

Profile

Position

3rd

Close

Profile

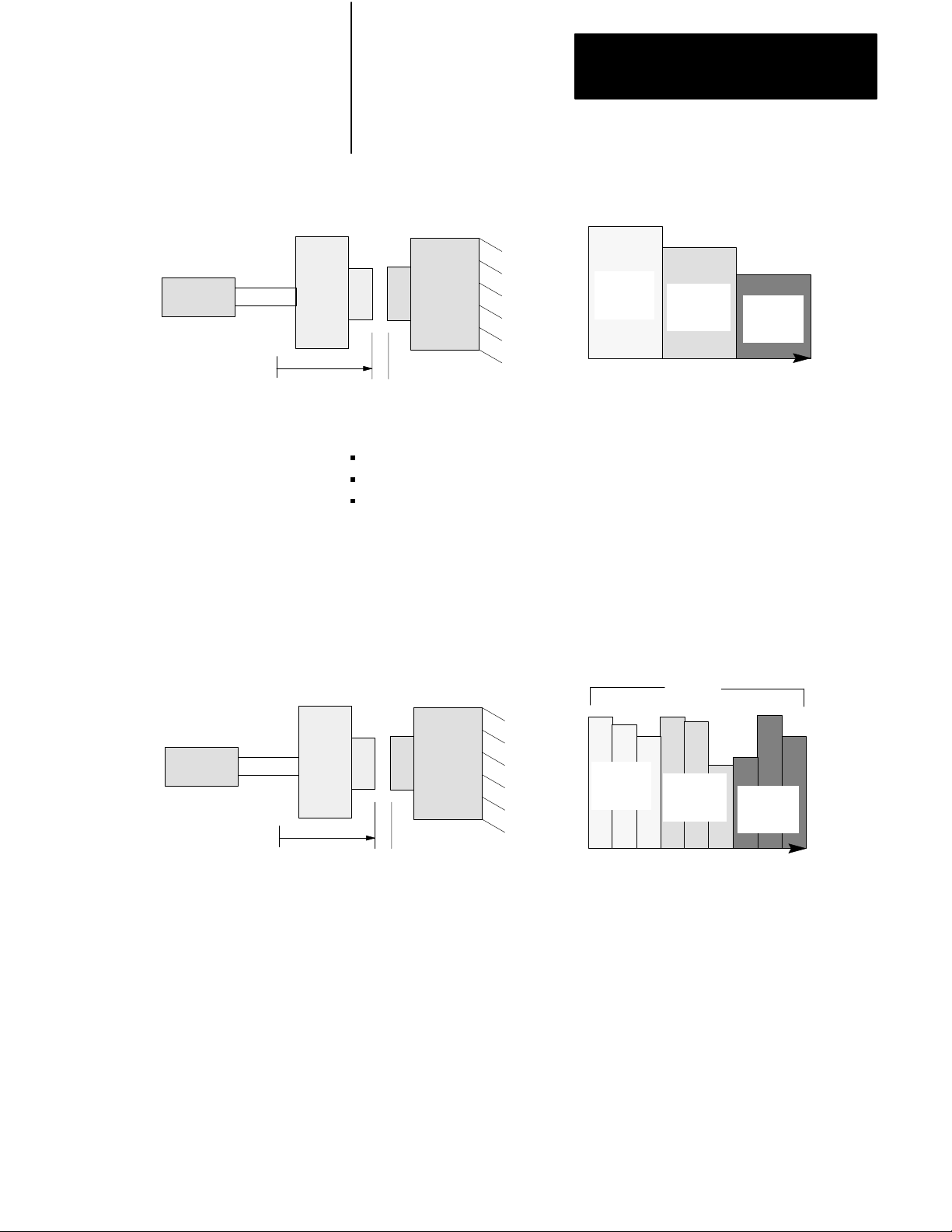

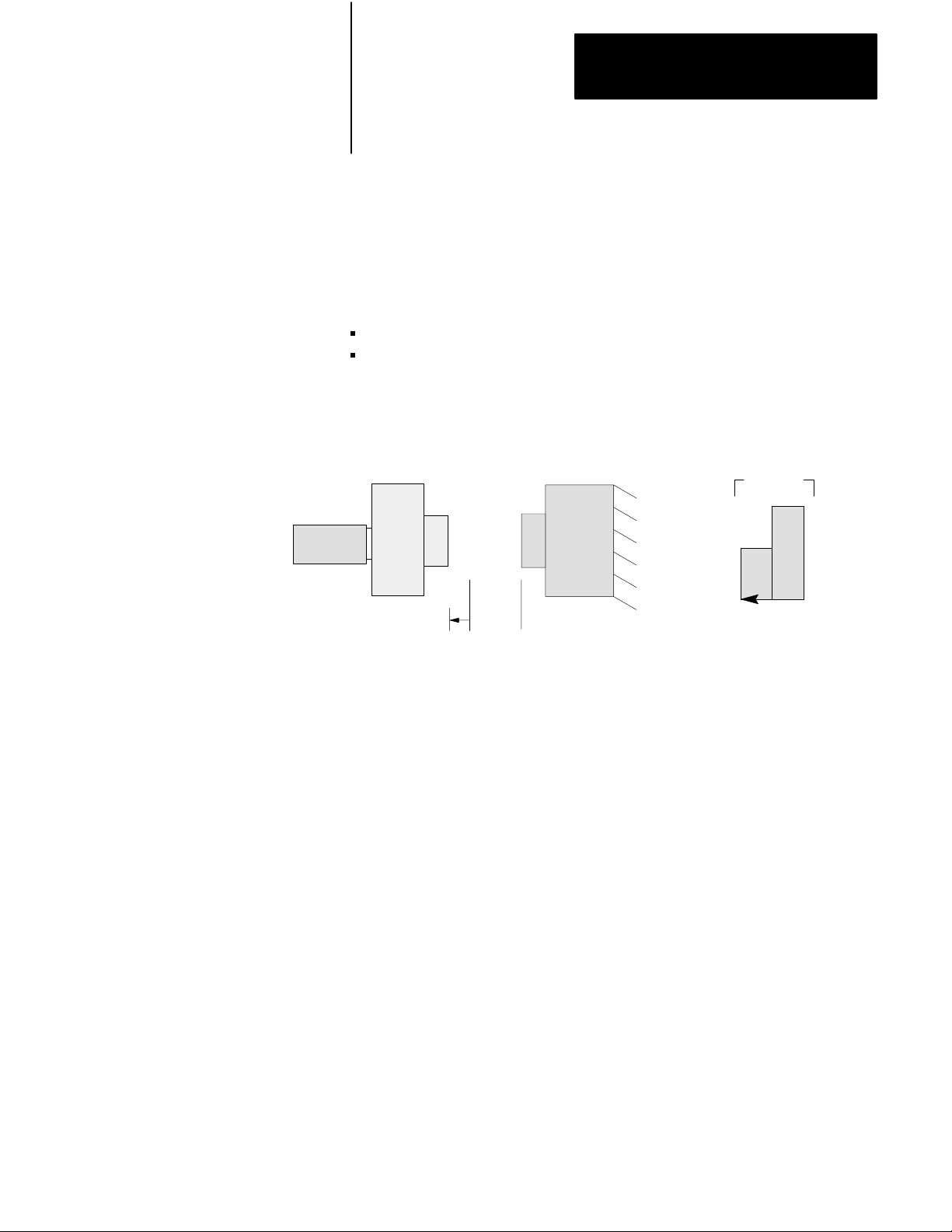

Three different close profiles have been provided to allow you to initiate

the following operations between profiles:

pick up the 3rd plate of a mold (on a floating 3-plate mold) or set cores

program other events for all valves

either automatically bridge between profiles or allow user programming

to decide when to begin the next profile

Each of these three profiles is subdivided into three position segments

(shown above each profile as in Figure 1.3). You can change clamp

velocity or pressure up to three times in each profile, or up to nine times

for the entire clamp close phase.

Clamp

Cylinder

L

Moving

Platen

Figure 1.3

Example

Clamp Close Position Segments

Stationary

Platen

0

X

11

1st

Close

Profile

Velocity

Segments

2

3

2nd

Close

Profile

Position

2

1

3

3rd

Close

Profile

2

3

Important: You may use as many or as few profiles and/or segments

within profiles as needed for your molding application. If using a single

close fast motion, use the first segment of the 1st close profile. The Low

Pressure Close Profile must follow.

After completing the last segment in each profile, the QDC module either

switches immediately to the next programmed segment of the next desired

profile or waits for a command from your PLC program to continue.

After completing the last configured close profile, the QDC module either

switches immediately to the first programmed segment of Low Pressure

Close, or waits for a command from your PLC program to continue.

1-3

Page 15

Chapter 1

Overview of the Clamp and Eject Mode

Low Pressure Close

Use the Low Pressure Close Profile to decelerate closing motion to guard

against damaging the mold halves and detect for part obstructions. The

pressure setpoint that you select to control low pressure close should

prohibit the mold from fully closing if there is an obstruction. Up to two

low pressure close profile segments may be used.

You will use the pressure vs. position control mode for low pressure close.

Clamp

Cylinder

Figure 1.4

Example

Low Pressure Close

Moving

Platen

L

0

X

Stationary

Platen

Low Pressure Close

Segments

1

2

Pressure

Position

Important: If you need only one Low Pressure Close segment, configure

the 1st segment of the Low Pressure Close Profile.

The QDC notifies your PLC program when this profile is complete and

automatically uses end-of low pressure close set-output values to build

tonnage (on a hydraulic machine) or lockup your toggle (on a toggle

machine).

1-4

Page 16

Chapter 1

Overview of the Clamp and Eject Mode

Clamp Open

You can open the mold fast with three profiles of the Clamp Open phase:

first open

second open

third open

You may select from these control modes:

velocity vs. position

pressure vs. position

Use Clamp Open to move the platen from the fully closed position (0) to

some position Y at a relatively high velocity or pressure. Y is a position

relatively close to your fully open position (L), yet far enough away to

allow deceleration into Open Slow. This is to increase positioning

accuracy at the full open position (L).

Clamp

Cylinder

Moving

Platen

Figure 1.5

Example

L0

Y

Clamp Open

Stationary

Platen

Three different open profiles have been provided to allow you to initiate

the following operations between profiles:

drop off the third plate of a mold (on a floating 3-plate mold) or pull

cores

program other events for all valves

either automatically bridge between profiles or allow user programming

to decide when to begin the next profile.

Each of these three profiles is subdivided into three position segments

(shown above each profile in Figure 1.6). You can change clamp velocity

or pressure up to three times in each profile, or up to nine times for the

entire clamp open phase.

Velocity

3rd

Open

Profile

2nd

Open

Profile

Position

1st

Open

Profile

1-5

Page 17

Chapter 1

Overview of the Clamp and Eject Mode

Clamp

Cylinder

Moving

Platen

Figure 1.6

Example

L0

Y

Clamp Open Position Segments

Stationary

Platen

33

3rd

Open

Profile

Velocity

Segments

2

1

2nd Open

Profile

Position

2

3

1

1st Open

Profile

Important: You may use as many or as few profiles and/or segments

within profiles as needed. If using a single open motion, use the first

segment of the 1st open profile. The Open Slow Profile must follow.

After completing the last segment in each profile, the QDC module either

switches immediately to the next programmed segment of the next

programmed profile or waits for a command from your PLC program to

continue.

2

1

After completing the last configured open profile, the QDC module either

switches immediately to the first programmed segment of Open Slow, or

waits for a command from your PLC program to continue.

1-6

Page 18

Chapter 1

Overview of the Clamp and Eject Mode

Open Slow

Use the Open Slow Profile to accurately position the clamp for ejecting the

part(s). You may decelerate clamp motion twice with this profile using up

to two profile segments.

You may select from these control modes:

velocity vs. position

pressure vs. position

Figure 1.7

Example

Clamp

Cylinder

Open Slow

Moving

Platen

L0Y

Stationary

Platen

Open Slow

Segments

2

Velocity

Position

Important: If you need only one open slow motion, configure only the 1st

segment of the Open Slow Profile.

1

1-7

Page 19

Chapter 1

Overview of the Clamp and Eject Mode

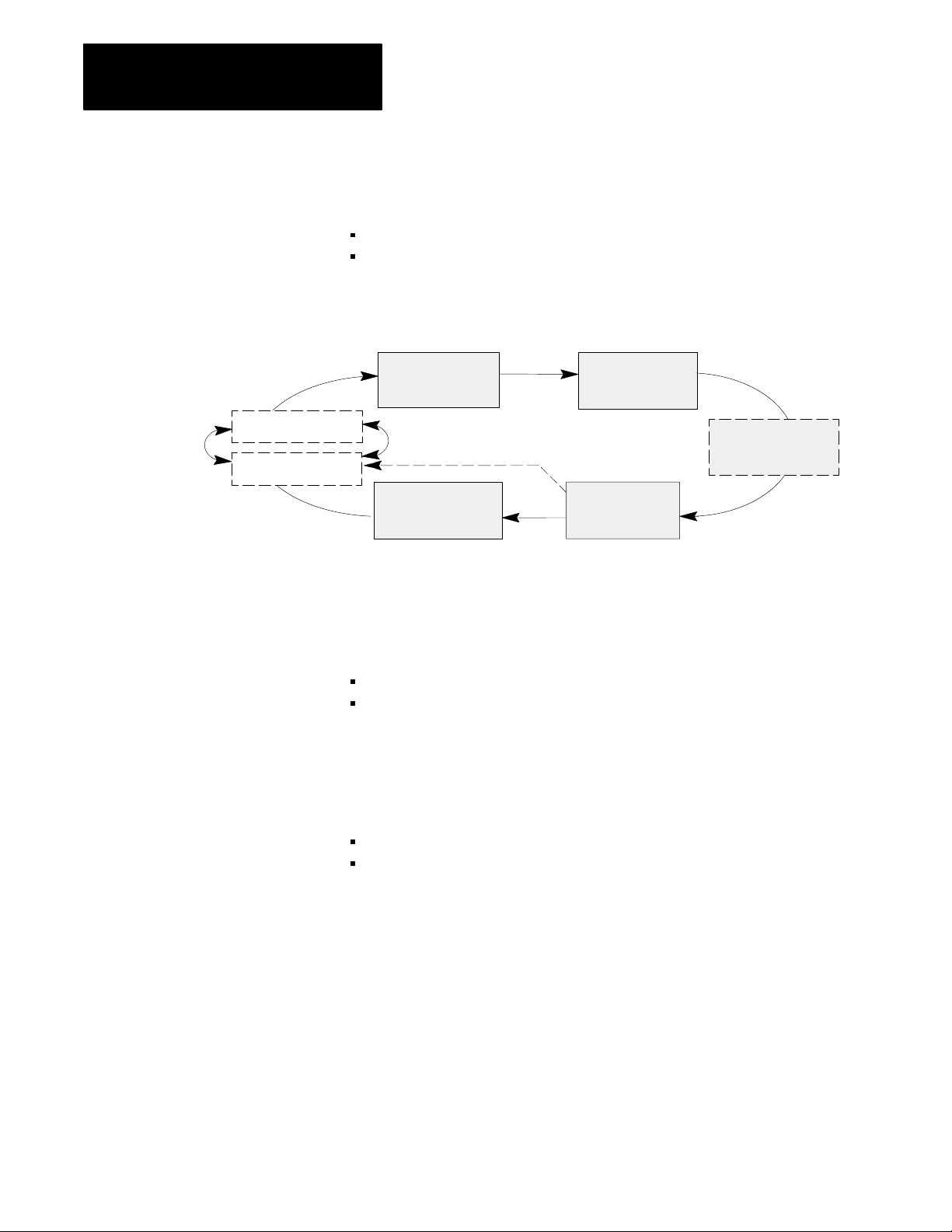

Ejector Control

Ejector retract

Ejector advance

In this section, we describe Eject operation for expelling parts from the

mold. The operation consists of:

ejector advance

ejector retract

Figure 1.8

and Eject Portion of a T

Clamp

Clamp Close

(Multiphase)

Open Slow

ypical Machine Cycle

Low Pressure

Close

Inject

Clamp Open

(Multiphase)

Ejector Advance

The QDC module starts advancing the ejector after detecting either one of

these events that you configure/program:

clamp position reaching a pre-determined setpoint

command from the user PLC program

You may advance the ejector while the clamp is still opening the mold, or

wait until the mold is fully open.

Up to three ejector advance profile segments may be used. You may select

from these control modes:

velocity vs. position

pressure vs. position

1-8

Page 20

Chapter 1

Overview of the Clamp and Eject Mode

Figure 1.9

Example

Ejector

Ejector Advance

0

Velocity

Fully Advanced Position

Ejector Advance

1

Velocity

Position

Segments

2

3

Important: If you need only one ejector advance motion, configure only

the 1st Advance segment.

Ejector Retract

After the ejector advance is completed, ejector retract is executed. Similar

to advancing the ejector, you retract it with up to three profile segments.

You may select from these control modes:

velocity vs. position

pressure vs. position

Figure 1.10

Example

Ejector

Ejector Retract

0

Velocity

Fully Advanced Position

Ejector Retract

3

Velocity

Position

Segments

2

1

1-9

Page 21

Chapter 1

Overview of the Clamp and Eject Mode

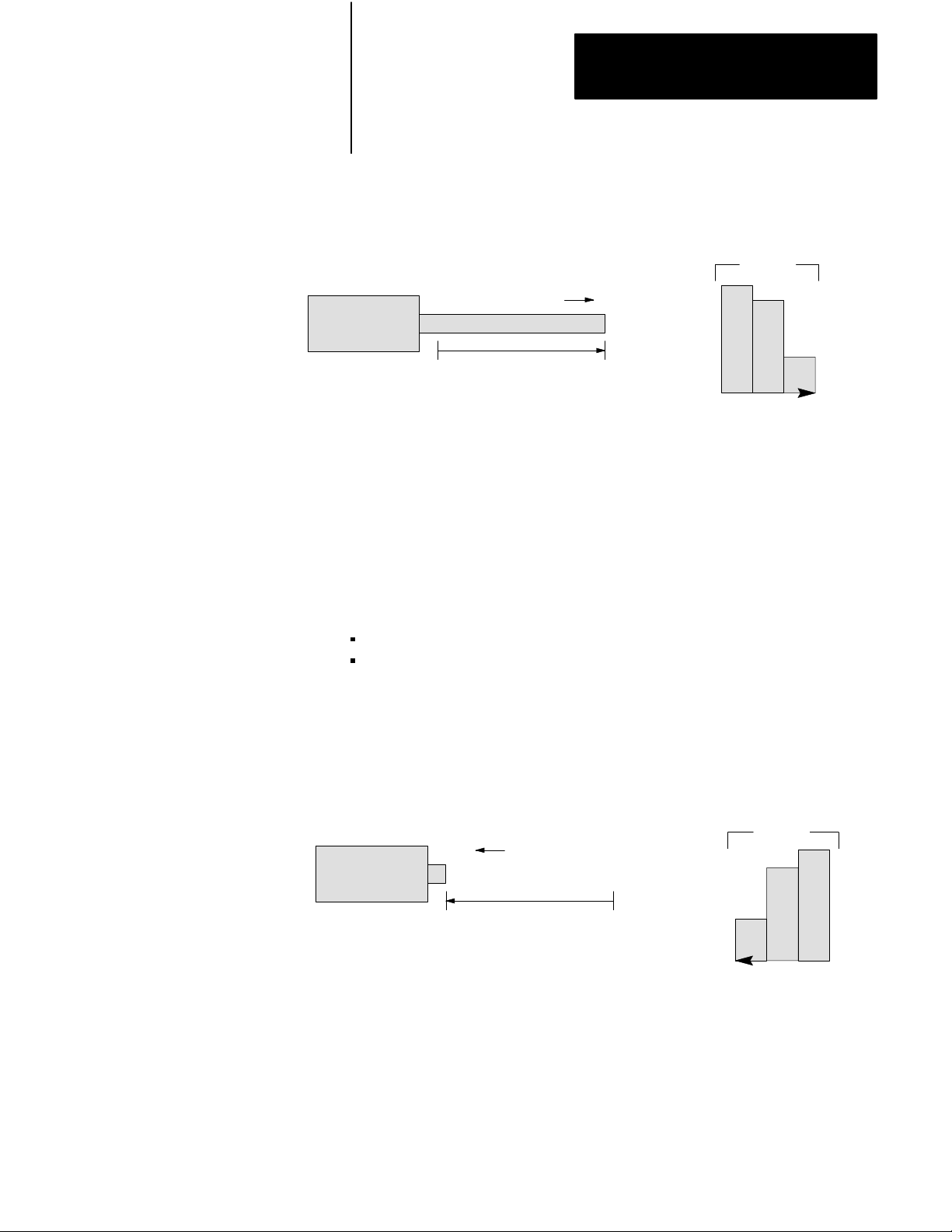

Other Eject Features

The QDC Module gives you the following additional features:

the ability to repeat the ejector cycle a number of times, changing from

advance to retract determined either automatically or by command from

your PLC program

Ejector Forward Dwell - the ability to pause after completing the first or

last ejector advance stroke. Use this feature so a robot can pick off a

part when ejectors are fully extended

Ejector “Tip” Strokes - the ability to “shake” the part off the ejector.

You may program interim single-segment advance and retract tip strokes

that occur after the first advance stroke and before the last retract stroke

Full

Retract

Figure 1.11

Advance,

First Full Advance

Tip Retract

Tip Advance

Tip Retract

Retract and T

:

:

Last Retract

Tip Strokes

1

ip Strokes

1

1

Full

Advance

= Ejector Forward Dwell

1-10

Page 22

Chapter

Install the QDC Module

2

Chapter

Objectives

Record I/O Ranges

This chapter guides you through the process of installing your QDC

module to assure reliable, safe performance. Major topics described in this

chapter include how to:

set module jumpers

key your I/O rack

install your module

wire I/O devices to your module

ground your system

plan for E-STOPs and Machine Interlocks

To match your QDC module to your I/O devices, record the I/O ranges of

your I/O devices on Worksheet 2-A. You will use this information in this

chapter for setting jumper plugs, and in chapter 3 to configure the module’s

inputs and outputs with software.

Circle or check your selections for I/O ranges on Worksheet 2-A.

Worksheet 2A

I/O Ranges

Record

I/O Connection: Voltage 1: Voltage 2: Current:

Input 1 (Ejector position) 0 to 10V dc 1 to 5V dc 4 to 20 mA

Input 2 (Ejector pressure) 0 to 10V dc 1 to 5V dc 4 to 20 mA

Input 3 (Clamp position) 0 to 10V dc 1 to 5V dc 4 to 20 mA

Input 4 (Clamp pressure) 0 to 10V dc 1 to 5V dc 4 to 20 mA

Output 1 10 to 10V dc 0 to 10V dc 4 to 20 mA

Output 2 10 to 10V dc 0 to 10V dc 4 to 20 mA

Output 3 10 to 10V dc 0 to 10V dc 4 to 20 mA

Output 4 10 to 10V dc 0 to 10V dc 4 to 20 mA

2-1

Page 23

Chapter 2

Install the QDC Module

Set Module Jumpers

Before installing the QDC module, you must use jumper plugs to configure

the I/O ranges that you selected with Worksheet 2-A.

Access and Position the Jumpers

Access the jumpers and set them as follows:

ATTENTION: To avoid damage to internal circuits, observe

handling precautions and rid yourself of any electrostatic

charge. Also, this should be done on an anti-static work station.

1. Remove the label-side cover plate by removing the four screws.

2. Remove the circuit board from the module housing by removing the

two screws located center-front at the swingarm catch.

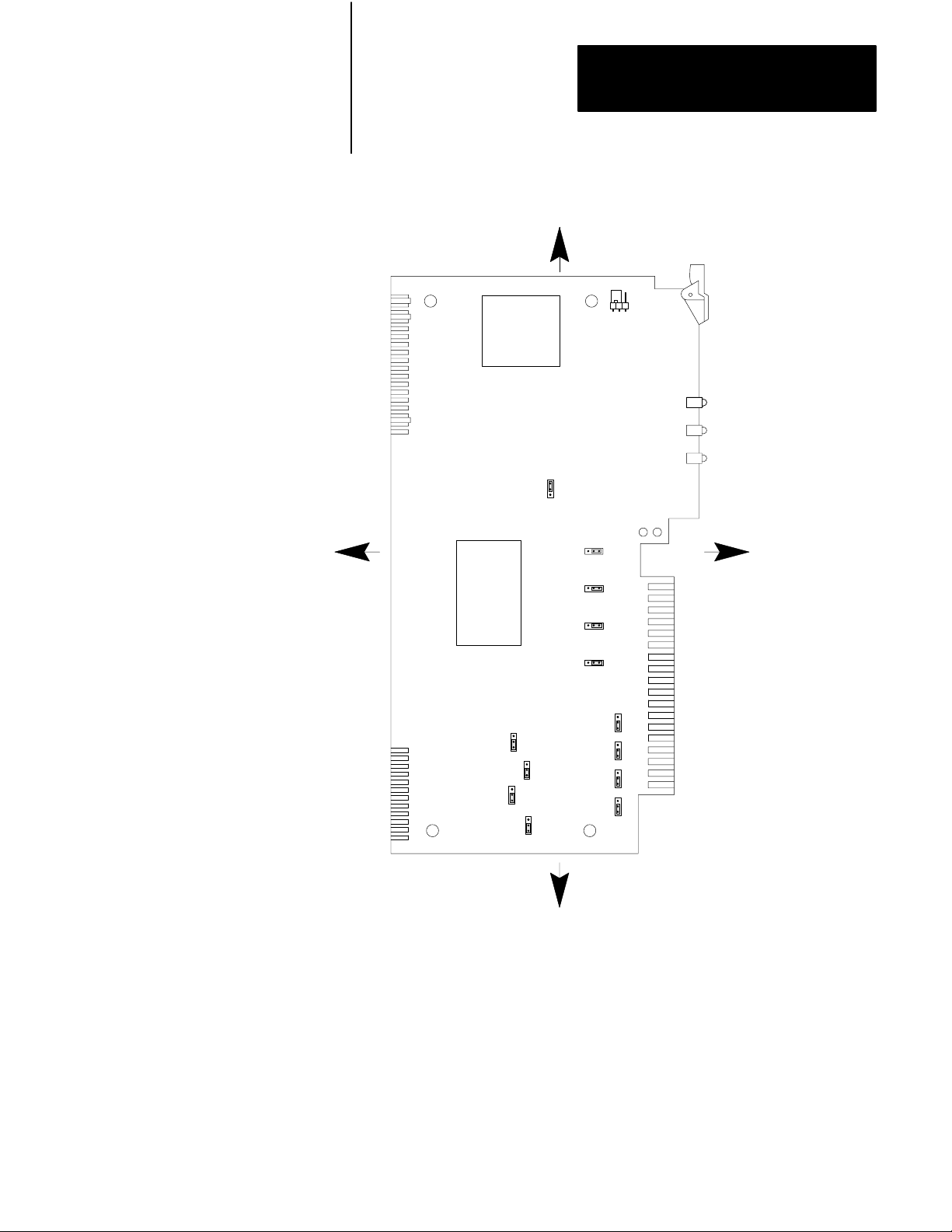

3. Carefully turn over the circuit board so it is oriented as in figure 2.1.

Handle it by the edges to avoid touching conductors or components.

4. Locate the jumpers (Figure 2.1).

5. Set the jumper plugs as shown in Table 2.A using a small needle-nose

pliers (Figure 2.1).

6. After setting the jumper plugs, re-assemble the module.

2-2

Page 24

Chapter 2

Install the QDC Module

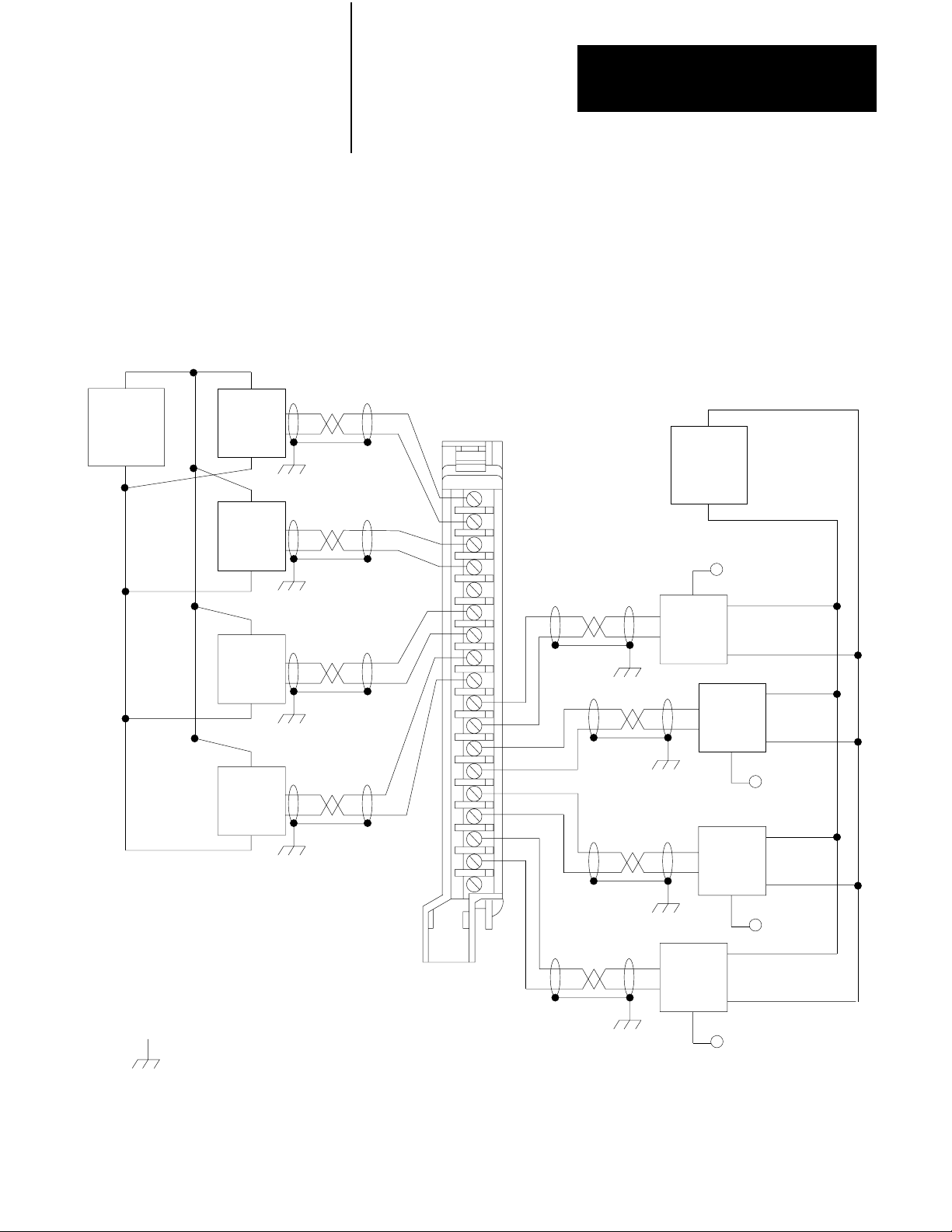

Figure 2.1

Jumper

LEFT

Locations on the QDC Module'

TOP

E5

s Circuit Board

E1

E6

RIGHT

E7

E8

E9

E10

E11

E12

E15

E16

E14

E13

E17

BOTTOM

10908I

Important: We define jumper plug positions as left, right, top, and bottom.

This represents the position of the jumper plug on the 3-pin connector

relative to the orientation of the circuit board shown above.

2-3

Page 25

Chapter 2

Install the QDC Module

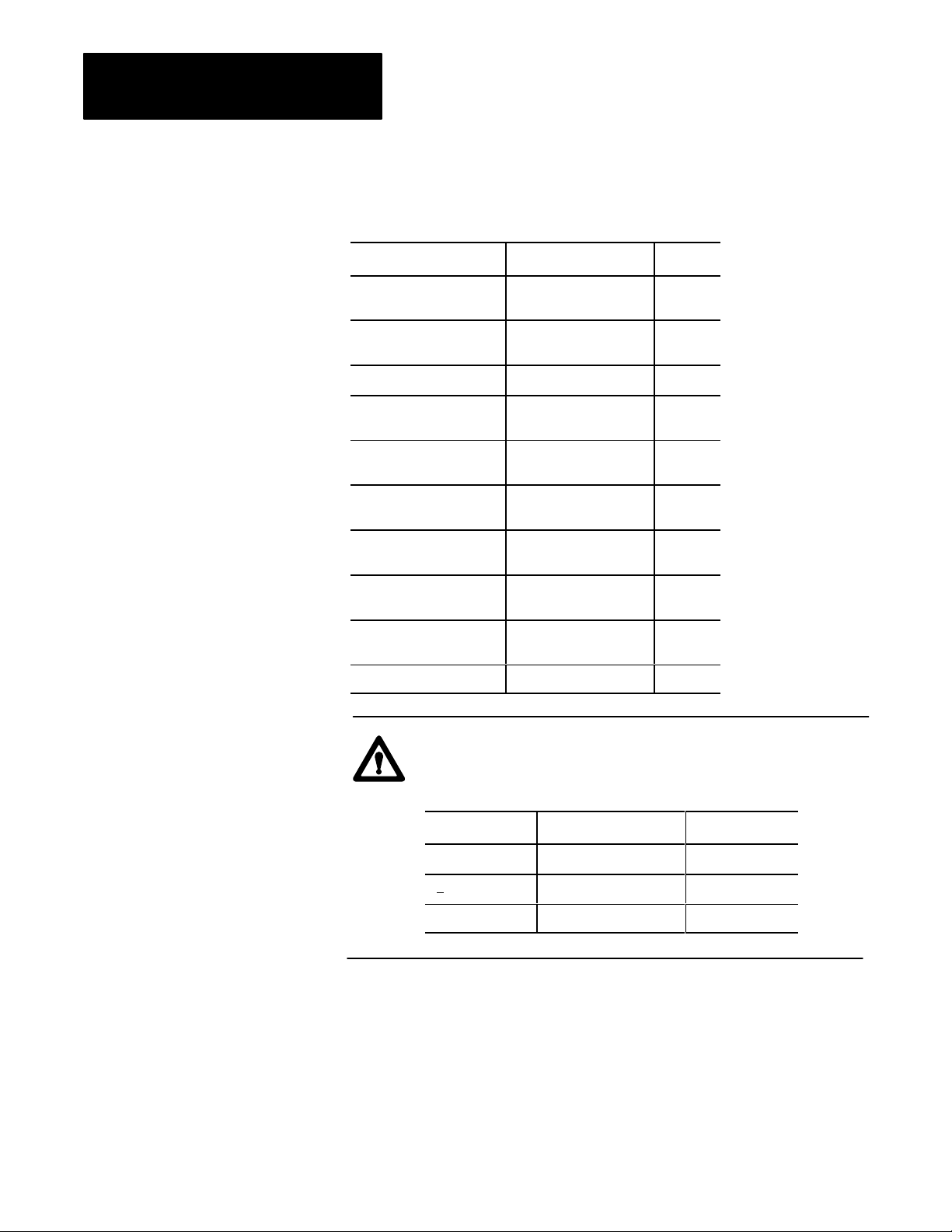

Table 2.A

Jumper

Settings

Jumper: Function: Setting:

E1 Run/Calibrate Calibrate = right

Run = left

E5 I/O Density Standard = top

Do not use bottom position

E6

E7

E8

E9

E10

E14

E13

E17

E11

E12

E15

E16

1

Factory Defaults

Input 1 (Ejector position)

Input 2 (Ejector pressure)

Input 3 (Clamp position)

Input 4 (Clamp pressure)

Output 1 (Valve 1)

Output 2 (Valve 2)

Output 3 (Valve 3)

Output 4 (Valve 4)

Output Range 1 (Valve 1)

Output Range 2 (Valve 2)

Output Range 3 (Valve 3)

Output Range 4 (Valve 4)

Voltage = right

Current = left

Current = top

Voltage = bottom

-10 to +10V dc = top

0 to +10V dc or 4 to 20mA = bottom

1

1

1

1

1

Important: If you select current output with jumper plugs E10, E14, E13,

and/or E17, then you must select the 4 to 20mA jumper position with E11,

E12, E15, and/or E16.

ATTENTION: If an output is unconnected, set the jumper

(E11, E12, E15, and/or E16) that corresponds to that output to 0

- 10V dc (bottom position). Setting the jumpers for –10 to

+10V dc and later configuring the output as “unconnected” may

cause the QDC module to output –10V dc on that channel. This

occurs when the system is stopped or when a system reset

occurs and all outputs are forced to 0% (i.e. 0% output equals

–10V dc).

2-4

Page 26

Chapter 2

Install the QDC Module

Important: Selecting –10 to +10V dc with jumper E11, E12, E15, and/or

E16 sets the QDC module for bi-directional valve operation. The

relationship to percentage output is as follows:

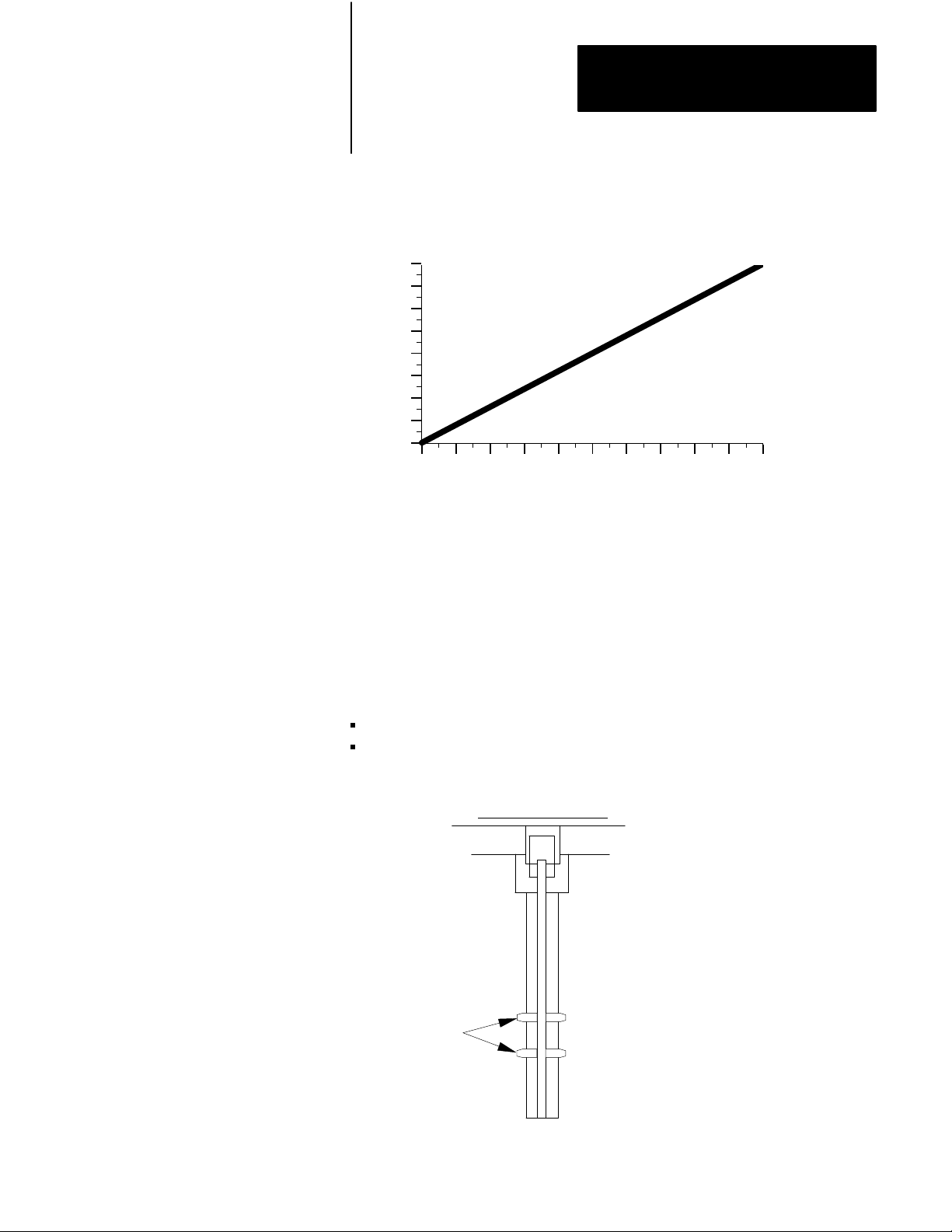

10

8

5

3

0

-3

Output Voltage

-5

-8

-10

0 102030405060708090100

%

Output Requested

Key Your I/O Chassis

Use the plastic keying bands, shipped with each I/O chassis, for keying I/O

slots to accept only one type of module. This is done to prevent the

inadvertent installation of the wrong module into the wrong slot.

The QDC module is slotted in two places on the rear edge of the circuit

board. The position of the keying bands on the backplane connector must

correspond to these slots to allow insertion of the module.

Place keying bands between the following terminal numbers labeled on the

backplane connector of your I/O chassis (see Figure 2.2):

between 20 and 22

between 26 and 28

Figure 2.2

Positions

Keying

2

4

6

8

10

12

14

16

18

20

Keying

Bands

22

24

26

28

30

32

34

36

1771QDC

12676

2-5

Page 27

Chapter 2

Install the QDC Module

Install Your QDC Module

To install your QDC module in an I/O chassis, complete the following:

1. First, turn off power to the I/O chassis.

ATTENTION: Remove power from the 1771 I/O chassis

backplane and wiring arm before removing or installing a QDC

module.

Failure to remove power from the backplane could cause injury

or equipment damage due to possible unexpected operation.

Failure to remove power from the backplane or wiring arm

could cause module damage, degradation of performance, or

injury.

2. Place the module in the plastic guides on the top and bottom of the

slot that slides the module into position.

Important: Be aware that Pro-Set 600 software expects your Clamp and

Eject QDC module to be placed in slot 1 of your I/O rack. If you choose to

install your QDC module in some other slot, some modifications to your

PLC application program may be necessary (refer to your Pro-Set 600

documentation for details).

3. Do not force the module into its backplane connector. Apply firm,

even pressure on the module to seat it properly.

4. Snap the chassis latch over the top of the module to secure it.

5. Connect the wiring arm to the module.

2-6

Page 28

Chapter 2

Install the QDC Module

Wire the QDC Module

+

Customer

PS

–

Ejector

Position

Sensor

Ejector

Pressure

Sensor

Clamp

Position

Sensor

Clamp

Pressure

Sensor

Use the swingarm (1771-WF) supplied with the QDC module to wire I/O

devices (Figure 2.3). The field wiring arm lets you install or remove the

QDC module from the I/O chassis without rewiring. Swingarm terminals

are numbered in descending order, from the top down, starting with

terminal 18 (Table 2.B).

Figure 2.3

W

iring and Grounding

I/O

+

–

+

–

+

–

+

–

Input 3

Input 4

Input 1

Input 2

–

Customer

PS

18

+

–

+

Amplifier

Valve 1

+

–

+

–

To Valve 1

+

–

Amplifier

Valve 2

Amplifier

Valve 3

+

–

To Valve 2

+

–

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Output 1

Output 2

Output 3

Earth Ground

Wiring Arm

1771WF

Output 4

+

–

Amplifier

Valve 4

To Valve 3

+

–

To Valve 4

10909I

2-7

Page 29

Chapter 2

Install the QDC Module

Table 2.B

and Eject Mode

Clamp

I/O Terminal Designations

Transducer: I/O Designation: Terminal:

Ejector position Input 1 (+)

(-)

Ejector pressure Input 2 (+)

(-)

Input common 14

Clamp position Input 3 (+)

(-)

Clamp pressure Input 4 (+)

(-)

Valve 1 Output 1 (+)

Output common

Valve 2 Output 2 (+)

Output common

Valve 3 Output 3 (+)

Output common

Valve 4 Output 4 (+)

Output common

Not used 01

18

17

16

15

13

12

11

10

09

08

07

06

05

04

03

02

2-8

ATTENTION: The QDC module has ESD protection to 20KV,

but you can damage the module by accidental application of the

wrong voltage to the I/O terminals. Do not exceed:

This voltage: On these terminals: When in:

+12V dc input (18 thru 10) any mode

+12V dc output (09 thru 02) voltage mode

+24V dc output (09 thru 02) current mode

Page 30

Chapter 2

Install the QDC Module

Ground and Shield

our I/O Devices

Y

Input Sensor

Analog inputs and outputs are sensitive to electrical noise interference.

Take care to shield them properly.

Guidelines:

Use 22-gage (or larger) twisted-pair cable, 100% shielded with drain

wire, such as Belden 8761 (or equivalent). For cable distances over

50 ft, use 18-gage cable such as Belden 8760 (or equivalent)

Ground the cable shield at one end only; generally at the sensor or

amplifier end, not at the I/O chassis (see Figure 2.4 and Figure 2.5)

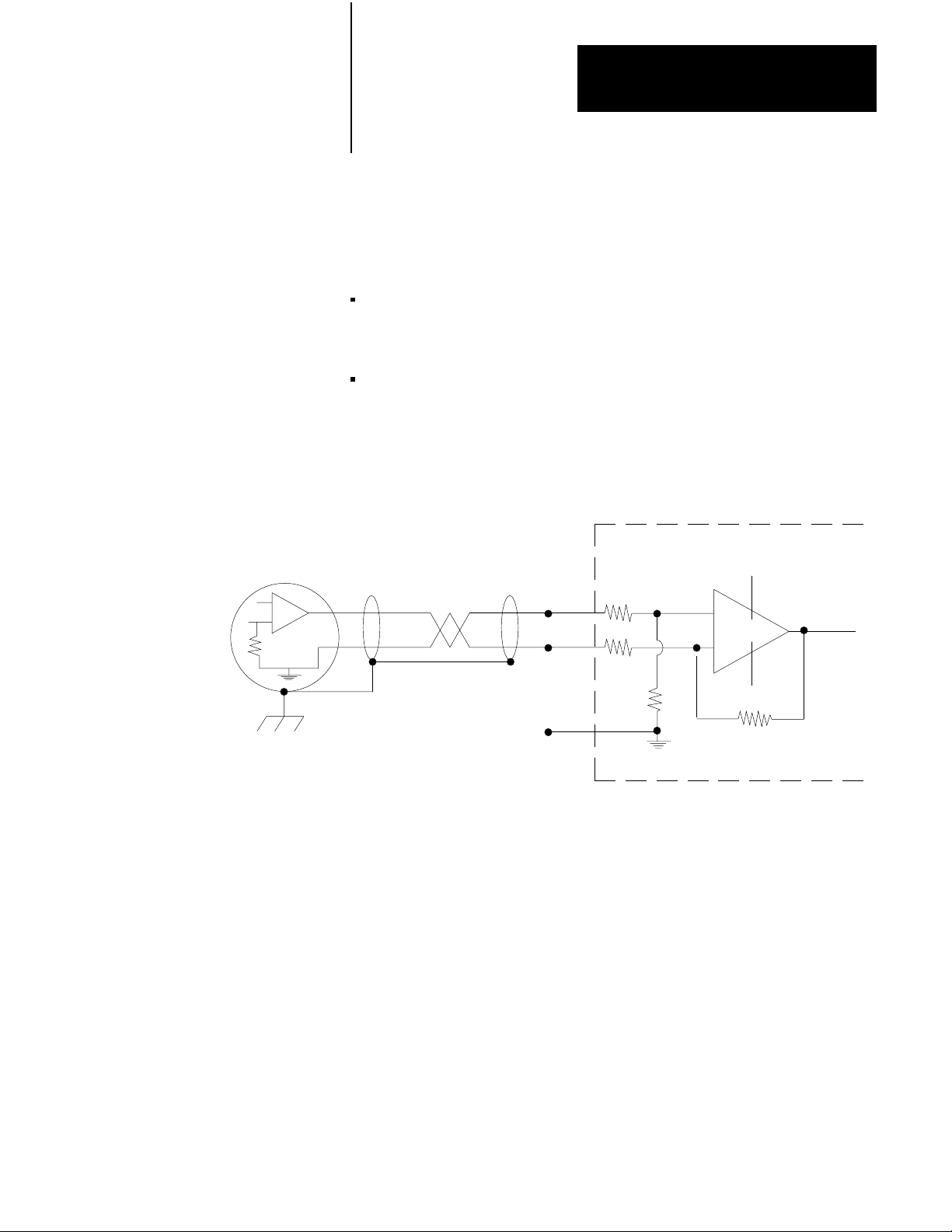

Figure 2.4

Shielding

Differential Inputs

QDC Module Input

18

17

+15V

+

–

Connect the cable shield

and case ground to earth

ground at the Input Sensor

14

No User Connections.

For Test Purposes, Only.

-15V

Input Module Common

should float

109102

2-9

Page 31

Chapter 2

Install the QDC Module

Figure 2.5

Shielding

QDC Module Output

Singleended Outputs

Customer Valve Amplifier

+

–

9

8

Connect the cable shield

to earth ground at the valve

amplifier

Input

Ground

Chassis Ground

17182

ground the cable shields to a low-impedance earth ground of less than

1/8 ohm

do not connect any ground to input common (terminal 14) except as

specified below under Grounding Exceptions

place high-voltage class A wiring and low-voltage class B wiring in

separate grounded conduits

in parallel runs, separate the class A and B conduit by at least 1 foot

where conduit runs must cross, cross them at right angles

For additional grounding recommendations, refer to the Allen-Bradley

Programmable Controller Wiring and Grounding Guidelines (pub. no.

1770-4.1).

Exceptions

If you experience unacceptable electrical noise interference, then try one or

both of the following alternative grounding connections:

connect the input cable shield to input common (terminal 14) after

disconnecting the shield from the transducer

connect the output cable shield to output common (terminal 8, 6, 4,

and/or 2) after disconnecting it from the valve amplifier

2-10

Page 32

Chapter 2

Install the QDC Module

Plan for ESTOPs and

Machine Interlocks

You must consider the installation of Emergency Stop switches and

machine interlocks when performing the following system tasks:

designing your system

assembling mechanical/hydraulic components

wiring system components

developing system ladder logic

ATTENTION: The Electrical Standard for Industrial

Machinery (NFPA 79-1987) requires an emergency stop that,

when actuated, shall de-energize all electrical power circuits

which provide electrical energy to sustain machine motion.

Maintained contact “Emergency Stop” push buttons are

recommended.

ATTENTION: The American National Standard for Plastics

Machinery -- Horizontal Injection Molding Machines -- for

Construction, Care, and Use (ANSI B151.1-1984) requires

hydraulic, mechanical, and electrical interlocks to prevent

inadvertent clamp closing with a safety gate in an open position.

In addition, we strongly recommend that the electrical

interlocks consist of redundant devices and that the control

circuit be so arranged that malfunction or improper sequencing

of either redundant device prevents further operation of the

machine.

ATTENTION: NEMA Standards Publication ICS1.1, Safety

guidelines for the Application, Installation, and Maintenance of

Solid State Control recommends that the emergency stop and

safety gate electrical interlocks should directly control their

appropriate functions through an electromechanical device

independent of the solid state logic.

The next page shows an illustration of a typical grounded PLC power

distribution circuit. For ungrounded systems or for more information on

grounding and wiring guidelines, refer to Allen-Bradley Programmable

Controller Wiring and Grounding Guidelines (pub. no. 1770-4.1) .

2-11

Page 33

Chapter 2

Install the QDC Module

Disconnect

Figure 2.6

PLC Power Distribution with Interlocks

Typical

L1

L2

L3

Incoming

AC

Use any number

of E-Stop switches

in Series

CRM

Input

Device

1FU

2FU

3FU

H

H

1

H

3

4

H

2

Step-down

Transformer

4

FUSE

X

X

1

2

Start

CRM

I/O Chassis

Power Supply

1

LN

GND

3

** See WARNING for Interlock Wiring Instructions **

2

Output

Input

Device

Module

Wiring

Arm

Output

Module

Wiring

Arm

CRM

1

5

L1

L2

L3

Back-Panel

Ground Bus

Equipment

Grounding

Conductors

CRM

To Motor

Starters

Enclosure

Wall

Grounding Electrode

Conductor to

Grounding Electrode

System

Connect

When

Applicable

User DC

Supply

+–

To DC I/O

Devices

1

To minimize EMI generation, you should connect a suppression network: for 120V AC, use Allen-Bradley

cat. no. 700-N24; for 220/240V AC, use cat. no. 599-KA04.

2

To minimize EMI generation, you should connect a suppression network: for 120V AC, use Allen-Bradley

cat. no. 599-K04; for 220/240V AC, use cat. no. 599-KA04.

3

For a power supply with a groundable chassis, this represents connection to the chassis only. For a power supply

without a groundable chassis, this represents connection to both the chassis and the GND terminal.

In many applications, a second transformer provides power to the input circuits and power supplies for isolation from the

4

output circuits.

Reference the current NEC code and ANSI B151.1 for additional wiring guidelines.

•

5

To minimize EMI generation, suppression networks should be connected across coils of electromagnetic devices.

•

2-12

10907I

Page 34

Chapter

Configure the QDC Module's

Inputs and Outputs

3

Chapter

Objectives

Your QDC module needs to know the characteristics of your clamp and

ejector sensors. In this chapter, we describe how to determine these

characteristics and download them to the QDC module. Topics include:

signal ranges from pressure and position sensors

minimum and maximum sensor signals corresponding to

minimum and maximum pressures and positions

alarm values and travel limits

We describe how to configure the QDC module in these sections:

select module parameters and I/O ranges

determine initial sensor configuration values

download configuration values to the QDC module

use the set-output operation to move the clamp and ejector

complete sensor configuration

optional sensor configurations

Important: You must properly configure the QDC module using

procedures in this chapter before attempting further configurations.

Important: If you have not already done so, install Pro-Set 600 software.

The procedures in this and the next several chapters assume that you have.

3-1

Page 35

Chapter 3

Configure the QDC Module's

Inputs and Outputs

Command and Status Blocks Used

The following table contains a list of command blocks you are to configure

throughout the course of this chapter. You may reference these command

blocks in sections 1 and 3 of the Plastic Molding Module Reference

Manual (pub. no. 1771-6.5.88).

Block: Type: Use in this Chapter: ProSet 600 Files:

Select

Module Parameters

and I/O Ranges

Module Configuration (MCC) Command Configure Module I/O

operating parameters

Module Configuration (MCC) Command Select Input Ranges for I/O B35

Module Configuration (MCC) Command Select Output Ranges for I/O B35

Module Configuration (MCC) Command Determine Initial Sensor Con

figuration values

Module Configuration (MCC) Command Determine Software Travel

Limits

Module Configuration (MCC) Command Enter Pressurealarm and

Timedelay Setpoints

B35

N41

N41

N41

You select module parameters and I/O ranges by setting configuration bits

in control words. First determine and write down correct settings using

Worksheet 3-A thru Worksheet 3-C as follows:

To Configure: In Control Word: Starting At

ProSet 600 Address:

Module Parameters MCC02 B35/528 Worksheet 3-A

Use this Worksheet:

3-2

Input Range MCC03 B35/544 Worksheet 3-B

Output Range MCC04 B35/560 Worksheet 3-C

Page 36

Worksheet 3A

Selecting Module Parameters

Chapter 3

Configure the QDC Module's

Inputs and Outputs

Control W

ProSet 600 Addr. B35/bit

ord MCC02Bxx

15 14 13 12

11 10

09 08 07 06 05 04 03 02 01 00

543 542 541 540 539 538 537 536 535 534 533 532 531 530 529 528

Value 0 0 0 0 0 0 0 0 0 0 1 0 1 0 0

Code:

0

or 1

Your value

Required initial value

loaded by ProSet 600

Select System Operation with bits 05 and 04

Clamp and Eject 1 0

Select Singleunit Operation with bit 03 = 1

(0 generates a programming error)

Select English = 0 or

metric = 1 with bit 00

Example: If you select Clamp and Eject operation with English units:

MCC02 = 00000000 00101000

Selecting I/O Ranges for your Sensors

Next, configure the QDC module’s I/O ranges to match the machine

sensors and valves. Refer to Worksheet 2-A from chapter 2 which you

filled out when setting the QDC module’s jumpers. Apply this information

to Worksheet 3-B for input ranges and Worksheet 3-C for output ranges.

Worksheet 3B

Input Ranges for your Sensors

11 10

09 08 07 06 05 04 03 02 01 00

Control W

ord MCC03Bxx

ProSet 600 Addr. B35/bit

Selecting

15 14 13 12

559 558 557 556 555 554 553 552 551 550 549 548 547 546 545 544

Value 1 1 1 1 1 1 1 1

Select Input 4 (Clamp Pressure) Range with bits 07, 06

Select Input 3 (Clamp Position) Range with bits 05, 04

Code:

0

or 1

Your value

Required initial value

loaded by ProSet 600

Select Input 2 (Ejector Pressure) Range with bits 03, 02

Select Input 1 (Ejector Position) Range with bits 01, 00

Example: If you select an input range of 4-20mA for all four inputs,

MCC03 = 11111111 10101010.

Important: Software input/output selections must match the jumper

settings for each respective input/output.

Input Range

0 - 10V dc 0 0

1 - 5V dc 0 1

4 - 20 mA 1 0

Not connected 1 1

3-3

Page 37

Chapter 3

Configure the QDC Module's

Inputs and Outputs

Worksheet 3C

Selecting Output Ranges for your V

alves

Control W

ProSet 600 Addr. B35/bit

Value 1 1 1 1 1 1 1 1

Code:

ord MCC04Bxx

0

or 1

Your value

Required initial value

loaded by ProSet 600

15 14 13 12

575 574 573 572 571 570 569 568 567 566 565 564 563 562 561 560

Select Output 4 Range with bits 07, 06

Select Output 3 Range with bits 05, 04

Select Output 2 Range with bits 03, 02

Select

Output 1 Range with bits 01, 00

11 10

09 08 07 06 05 04 03 02 01 00

Example: If you select 0-10 vdc for all four output ranges,

MCC04 = 11111111 01010101.

Important: Software input/output selections must match the jumper

settings for each respective input/output.

Output Range

-10 to +10 vdc 0 0

0 to +10 vdc 0 1

4 to 20 mA 1 0

Not connected 1 1

3-4

Page 38

Chapter 3

Configure the QDC Module's

Inputs and Outputs

Determine

Initial

Sensorconfiguration Values

To determine initial sensor configuration values, refer to Table 3.A, and to

the specifications that accompanied your sensors, valves, and cylinders.

Write down applicable values on Worksheet 3-D.

Important: You must enter floating-point numbers and percentages as

integers, so we recommend that you write them in Worksheet 3-D in the

following format: Use an assumed decimal point position that depends on

the range value. For example:

If the Range is: And You Want to

Enter this Value:

0 099.99% 75% 07500

0 99.99 inch 7.32 inch 00732

0 0999.9 mm 432.6 mm 4326

4.00 020.00 mA 16mA 01600

0 010.00 vdc 5.6 vdc 00560

0 009.99 sec 0.47 sec 00047

0 09999 PSI 321 PSI 00321

0 0999.9 Bar 222 Bar 2220

Use this

Format:

Table 3.A

Determining

Category: If: Then Use a Value Equal to:

Minimum Position

(Lines 1 and 9)

Maximum Position

(Lines 2 and 10)

Analog Signal @ Min Position your sensors are forwardacting low end of your selected range

(Line 3 and 11) your sensors are reverseacting high end of your selected range

Analog Signal @ Max Position your sensors are forwardacting high end of your selected range

(Line 4 and 12) your sensors are reverseacting low end of your selected range

Minimum Pressure

(Lines 5 and 13)

Maximum Pressure

(Lines 6 and 14)

Initial Sensorconfiguration V

N/A zero

the

mold is fully closed, the

and the ejector retract position is zero

N/A minimum range value specified by the

N/A maximum range value specified by the

alues for W

position is zero

orksheet 3D

full travel of the sensor

manufacturer

manufacturer

3-5

Page 39

Chapter 3

Configure the QDC Module's

Inputs and Outputs

Category: If: Then Use a Value Equal to:

Analog Signal @ Min Pressure your sensors are forwardacting low end of your selected range

(Lines 7 and 15) your sensors are reverseacting high end of your selected range

Analog Signal @ Max Pressure your sensors are forwardacting high end of your selected range

(Lines 8 and 16) your sensors are reverseacting low end of your selected range

T

able 3.A (continued)

Determining Initial Sensorconfiguration V

alues for W

orksheet 3D

Worksheet 3D

Determining

Initial Sensorconfiguration V

alues

Enter Your Initial Values Here

Input Control Word ProSet

1 MCC37 N41:33 0 Minimum Ejector Position Ejector Axis Measured from zero

MCC38 N41:34 Maximum Ejector Position Ejector Axis Measured from zero

MCC39 N41:35 Analog Signal @ Min Ejector Position Input Signal Range

MCC40 N41:36 Analog Signal @ Max Ejector Position Input Signal Range

2 MCC45 N41:41 0 Minimum Ejector Pressure Ejector Pressure

MCC46 N41:42 Maximum Ejector Pressure Ejector Pressure

MCC47 N41:43 Analog Signal @ Min Ejector Pressure Input Signal Range

MCC48 N41:44 Analog Signal @ Max Ejector Pressure Input Signal Range

3 MCC23 N41:19 0 Minimum Clamp Position Clamp Axis Measured from zero

MCC24 N41:20 Maximum Clamp Position Clamp Axis Measured from zero

MCC25 N41:21 Analog Signal @ Min Clamp Position Input Signal Range

MCC26 N41.22 Analog Signal @ Max Clamp Position Input Signal Range

4 MCC31 N41:27 0 Minimum Clamp Pressure Clamp Pressure

MCC32 N41:28 Maximum Clamp Pressure Clamp Pressure

MCC33 N41:29 Analog Signal @ Min Clamp Pressure Input Signal Range

MCC34 N41:30 Analog Signal @ Max Clamp Pressure Input Signal Range

1

Incremental Distance

00.00

000.0 to 999.9 Millimeters

600 Addr

to 99.99 Inches

. Value Description Units

2

Input

Signal Range

00.00 to 10.00V dc or

01.00 to 05.00V dc or

04.00 to 20.00MADC

3

2

2

3

3

2

2

2

2

3

3

2

2

Pressure

0000 to 9999 PSI

000.0 to 999.9 Bar

1

1

1

1

3-6

Page 40

Chapter 3

Configure the QDC Module's

Inputs and Outputs

Download MCC Values to the QDC Module

Use this download procedure now and later in this chapter. The procedure

requires you to complete the following general steps:

enter MCC values into the PLC-5 data table

download them to the QDC module (PLC-5 processor in run mode)

correct any data entry (programming) errors

Next we describe the general steps:

Enter MCC Values into Your PLC5 Data Table

With your programming terminal, enter values from Worksheet 3-A thru

Worksheet 3-D into your PLC-5 data table as follows:

1. Switch the PLC-5 processor to program mode.

2. Display your PLC-5 data table.

3. Locate the data file for storing the MCC block. PLC-5 data table

word addresses are listed on the worksheets.

4. Enter the value for each word and bit.

When you enter bit selections in words prefixed with file identifier B

(example: B34), the PLC-5 processor automatically switches the radix to

binary format so you can conveniently enter binary data.

Download MCC Values to the QDC Module

To download the MCC block to the QDC module, switch the PLC-5

processor from program to run mode. Pro-Set 600 software downloads the

MCC block to the QDC module for you.

Important: You can verify that the MCC block was successfully downloaded or that you made a data entry (programming) error by evaluating

the following words that Pro-Set 600 software continuously reports to the

PLC-5 processor.

If: And: Then:

SYS01B08 = 1

(B34/8)

SYS19B00 = 1

(B34/288)

N/A QDC module accepted a valid MCC.

SYS61 = 1

(ID code for MCC block

stored in N40:213)

You made a programming error in MCC.

Read the error code in SYS62 (N40:214) , and

look up the error in Section 2 of QDC Module

Reference Manual, publication 17716.5.88.

3-7

Page 41

Chapter 3

Configure the QDC Module's

Inputs and Outputs

Important: Pro-Set 600 software downloads all command blocks when

your PLC-5 processor enters run mode after a valid MCC block is

accepted. All programming errors reported in SYS62 (N40:214) are

referenced to the MCC block until SYS01-B08 = 1.

Correct Any Dataentry (Programming) Errors in MCC

Upon receipt of the MCC block, the QDC module tests data for data-entry

errors, such as a value out of range. When it detects an error, the QDC

module halts operation until you correct the error. For a complete list of

error codes to help you correct a programming error, refer to Section 2 of

the Plastic Molding Module Reference Manual, publication 1771-6.5.88.

You must correct errors by entering the changed configuration values into

your PLC-5 data table and downloading the new values to the QDC

module as outlined above. Pro-Set 600 software continues to attempt to

download the MCC block to the QDC module until an MCC block is

accepted and the QDC module returns SYS01-B08 = 1.

Important: The QDC module must receive a valid MCC block before you

can download additional blocks.

3-8

Page 42

Chapter 3

Configure the QDC Module's

Inputs and Outputs

Use the Setoutput

Operation to Move the

Clamp and Ejector

To finish configuring the QDC module, you actuate the clamp and ejector

with the QDC module’s set-output operation. Set-output applies

percentage output values to your valves to move your clamp or ejector

cylinder in a controllable fashion. You apply a percentage output signal to

each module output so you can move each actuator over its intended range.

Sensor spanning values can then be refined per the actual values monitored

by the QDC module.

ATTENTION: Do not rely on pressure valves connected to the

QDC module for pressure relief. Use them only for pressure

control below the setting of the system pressure-relief valve.

ATTENTION: A value of zero in set-output words N41:121 N41:124 does not necessarily correspond to zero pressure or

flow. If you have configured jumper E11, E12, E15, and/or E16

for bi-directional valve operation, an output of 0% gives

–10vdc, 50% gives 0vdc (see chart). Amplifier electronics or

spool-null offsets may also allow pressure or flow at zero volts

signal input. Consult your valve and amplifier specifications for

more details.

Output Voltage

-10

10

8

5

3

0

-3

-5

-8

0 102030405060708090100

%

Output Requested

3-9

Page 43

Chapter 3

Configure the QDC Module's

Inputs and Outputs

ATTENTION: As soon as you enable set-output operation, the

QDC module’s outputs drive the connected valves according to

the values you entered into DYC09 - DYC12 (Pro-Set 600

words N41:121 - N41:124). Be sure these values RESULT IN

NO MOVEMENT until you adjust them one-at-a-time with

your programming terminal in the procedures that follow.

Actuating the Clamp and Ejector with Setoutput Operation

1. Enter values that result in no motion in these DYC words:

Output: In Data Word: At ProSet 600

Address:

1 DYC09 N41:121

2 DYC10 N41:122

3 DYC11 N41:123

4 DYC12 N41:124

2. Enable set-output operation by entering a 1 in DYC01-B08 (Pro-Set

600 address B35/392). The QDC module sets outputs 1 - 4 to

percentage values that you entered in DYC09 - DYC12 respectively.

3. With your programming terminal, slowly increase the %-output value

of one output as you observe the corresponding movement.

Important: The DYC is constantly transferred to the QDC module by

Pro-Set 600 software, so changes you make to %-output values are

immediately implemented.

3-10

Page 44

Chapter 3

Configure the QDC Module's

Inputs and Outputs

Complete your Sensor Configuration

Enter Your Final Sensorconfiguration V

alues Here

Complete the procedure for configuring the QDC module to match its

sensors by spanning them over their intended range with the machine in

operation. Here we describe how you determine:

clamp position sensor values

ejector position sensor values

clamp pressure sensor values

ejector pressure sensor values

In the procedures that follow, measure and record:

minimum and maximum positions

corresponding signal values

minimum and maximum pressures

corresponding signal values

After determining these values, write them down on Worksheet 3-E.

Important: You must complete this configuration before proceeding to

any other chapters on module configuration.

Worksheet 3E

Sensorconfiguration V

Final

alues

Input Control Word ProSet 600 Addr. Value Description Units

1 MCC37 N41:33 0 Minimum Ejector Position Ejector Axis Measured from zero

MCC38 N41:34 Maximum Ejector Position Ejector Axis Measured from zero

MCC39 N41:35 Analog Signal @ Min Ejector Position Input Signal Range

MCC40 N41:36 Analog Signal @ Max Ejector Position Input Signal Range

2 MCC45 N41:41 0 Minimum Ejector Pressure Ejector Pressure

MCC46 N41:42 Maximum Ejector Pressure Ejector Pressure

MCC47 N41:43 Analog Signal @ Min Ejector Pressure Input Signal Range

MCC48 N41:44 Analog Signal @ Max Ejector Pressure Input Signal Range

3 MCC23 N41:19 0 Minimum Clamp Position Clamp Axis Measured from zero

MCC24 N41:20 Maximum Clamp Position Clamp Axis Measured from zero

MCC25 N41:21 Analog Signal @ Min Clamp Position Input Signal Range

MCC26 N41:22 Analog Signal @ Max Clamp Position Input Signal Range

4 MCC31 N41:27 0 Minimum Clamp Pressure Clamp Pressure

MCC32 N41:28 Maximum Clamp Pressure Clamp Pressure

MCC33 N41:29 Analog Signal @ Min Clamp Pressure Input Signal Range

MCC34 N41:30 Analog Signal @ Max Clamp Pressure Input Signal Range

1

Incremental Distance

00.00

to 99.99 Inches

000.0 to 999.9 Millimeters

2

Input Signal Range

00.00 to 10.00V dc or

01.00 to 05.00V dc or

04.00 to 20.00MADC

3

Pressure

0000 to 9999 PSI

000.0 to 999.9 Bar

2

2

3

3

2

2

2

2

3

3

2

2

1

1

1

1

3-11

Page 45

Chapter 3

Configure the QDC Module's

Inputs and Outputs

Determine Clamp Position Sensor Values

Important: The following procedure and subsequent set-up information

must be utilized for every different mold used on a hydraulic machine. On

a toggle clamp (with die height adjust), it must be completed only once.

ATTENTION: Incorrect values entered in DYC09 through

DYC12 may result in rapid clamp motion and potential damage

to your mold and cylinder seals. We strongly recommend

utilizing a “dummy” mold on hydraulic machines and no mold

on toggle machines.

To complete the configuration for your clamp position sensor, do the

following:

Important: If your position sensor has zero and span potentiometers to set

the zero reference and linear resolution, do so during this procedure.

1. Move the clamp forward until it reaches its mechanical close stop.

This is the zero position.

2. Remove clamp pressure and/or flow to stop clamp movement.

3. Record this position value (usually 0000) on line 9 of Worksheet 3-E

for MCC23.

4. With your programming terminal, read the signal level returned in

SYS35 (Pro-Set 600 address N41:187) from your position sensor.

You may wish to zero your position sensor at this time.

5. Record this value on line 11 of Worksheet 3-E for MCC25 (should be

at minimum signal if you zeroed your position sensor in step 4).

6. Move the clamp backward to the mechanical open stop.

7. Remove clamp pressure and/or flow to stop clamp movement.

8. Measure the distance travelled by the clamp.

3-12

9. Record this distance on line 10 of Worksheet 3-E for MCC24.

10.With your programming terminal, read the signal level returned in

SYS35 (Pro-Set 600 address N41:187) from your positioning sensor.

You may wish to span your position sensor at this time.

Page 46

Chapter 3

Configure the QDC Module's

Inputs and Outputs

11. Record this value on line 12 of Worksheet 3-E for MCC26.

You may now download your adjusted values to the QDC module using

the MCC download procedure presented earlier in this chapter.

Determine Ejector Position Sensor Values

ATTENTION: Make sure your clamp is open sufficiently to

allow full ejector travel before proceeding.

To complete the configuration for your ejector position sensor, do the

following:

Important: If your position sensor has zero and span potentiometers to set

the zero reference and linear resolution, do so during this procedure.

1. Move the ejector backward to the mechanical retract stop. This is the

zero position.

2. Remove ejector pressure and/or flow to stop ejector movement.

3. Record this position value (usually 0000) on line 1 of Worksheet 3-E

for MCC37.

4. With your programming terminal, read the signal level returned in

SYS33 (Pro-Set 600 address N41:185) from your position sensor.

You may wish to zero your position sensor at this time.

5. Record this value on line 3 of Worksheet 3-E for MCC39 (should be

at minimum signal if you zeroed your position sensor in step 4).

6. Move the ejector forward to the mechanical advance stop.

7. Remove ejector pressure and/or flow to stop ejector movement.

8. Measure the distance travelled by the ejector.

9. Record this distance on line 2 of Worksheet 3-E for MCC38.

10.With your programming terminal, read the signal level returned in

SYS33 (Pro-Set 600 address N41:185) from your positioning sensor.

You may wish to span your sensor at this time.

11. Record this value on line 4 of Worksheet 3-E for MCC40.

3-13

Page 47

Chapter 3

Configure the QDC Module's

Inputs and Outputs

12.Return your ejector to the fully retracted position.

You may now download your adjusted values to the QDC module using

the MCC download procedure presented earlier in this chapter.

Determine Values for the Clamp Pressure Sensor (if used)

To complete the configuration for your clamp pressure sensor, enter

minimum and maximum pressures and corresponding signal levels from

manufacturer’s specifications in MCC31 - MCC34. Most applications

require no further spanning. If your application requires greater accuracy,

follow the procedure below:

1. Release system pressure to obtain minimum pressure at the clamp.

2. Read the pressure gauge at the clamp.

3. Record this minimum pressure value (usually 0000) on line 13 of

Worksheet 3-E for MCC31.

4. With your programming terminal, read the signal level returned in

SYS36 (Pro-Set 600 address N41:188) from your pressure sensor.

You may wish to zero your pressure sensor at this time.

5. Record this signal level on line 15 of Worksheet 3-E for MCC33

(should be at min signal if you zeroed your pressure sensor in step 4).

ATTENTION: Use extreme caution during the next steps

because you stress the hydraulic system to its maximum rated

pressure. Loose fittings or faulty components could fail, causing

possible damage to equipment and/or injury to personnel.

6. Re-torque all hydraulic connections and joints before proceeding.

7. Boost system pressure to obtain maximum pressure at the clamp.

Max system pressure may be obtained by positioning the clamp at

full open while keeping the clamp open valve in the maximum open

position. This forces the cylinder to press against the mechanical

limits of its travel and builds max system pressure. Also, if you

wish, you may move the clamp to its full forward (mold close)

position, and allow full system pressure to force the mold closed.

3-14

8. Read the pressure gauge at the clamp (maximum system pressure

should be read at full open or full close) while the clamp is

mechanically bound from moving further.

9. Record this maximum pressure on line 14 of Worksheet 3-E for

MCC32.

Page 48

Chapter 3

Configure the QDC Module's

Inputs and Outputs

10.With your programming terminal, read the signal level returned in

SYS36 (Pro-Set 600 address N41:188) from your pressure sensor.

You may wish to span your pressure sensor at this time.

11. Record this signal level on line 16 of Worksheet 3-E for MCC34.

12.Release pressure.

You may now download your adjusted values to the QDC module using

the MCC download procedure presented earlier in this chapter.

Determine Values for the Ejector Pressure Sensor (if used)

ATTENTION: Make sure your clamp is sufficiently open to